1

19

99

99

9

C

CA

AM

MP

PA

AI

IG

GN

N

B

BU

UL

LL

LE

ET

TI

IN

NS

S

© 2006 GM Holden LTD. A.B.N. 84 006 893 232

Service Department

A “HOLDEN” Product.

BRISBANE SYDNEY MELBOURNE ADELAIDE PERTH

For the latest and/or any missing Campaign Bulletins,

please refer to Holden Lionheart

PRODUCT CAMPAIGN BULLETIN

99-H-01

February 22nd, 1999

SUBJECT : UPPER AND LOWER CONTROL ARM TO REAR SUSPENSION ARM

BOLT TORQUE CHECK & INSPECTION

MODEL : JS SERIES VECTRA

This bulletin is t o advise Holden Dealerships of the initiat ion of a saf et y relat ed cam paign t o t orq ue

check and inspect the upper and lower control arm to rear suspension arm bolts (both sides) on

JS Series Vectra vehicles.

Description of Def ect

The specified torq ue setting for the upper and lower contr ol arm to rear suspension ar m may not

have been achieved in production. In certain cir cum stances, this may result in poor and

unpredictable vehicle handling.

Details of Affected Vehicles

Vehicles requir ing this campaign action are JS Series Vect r a vehicles.

Build dates of affected vehicles fall within the r ange July 1998 to December 1998.

Vehicle Identification Numbers (VIN) L314383 to L406948 inclusive, sets the range of vehicles

affected.

2552 vehicles are involved.

Torque Check

Bolts, LH & RH

Side of Vehicle

DEALERSHIP ACTION REQUIRED

Vehicles in Dealership Stock

Perform the necessary campaign action on any JS Series Vectra vehicle that falls within the VIN

range held in Dealership Stock. These vehicles must have this campaign action completed before

retail delivery of the vehicle or transfer to another dealership.

On Presentation of Any JS Series Vectra Vehicle

On presentation of any JS Series Vectra vehicle considered by the customer to be affected by this

action, or on presentation of a JS Series Vectra vehicle for any reason, confirm that the vehicle

falls within the affected VIN range. If the vehicle requires campaign action, refer to the Detailed

Technical Instructions included at the end of this bulletin.

In summary, the rear upper and lower control arm to rear suspension arm bolts (both sides) are to

be torque checked. If the bolts are not to the specified checking torque (90Nm), the upper and

lower control arms should be inspected and replaced where necessary.

Apply a Campaign Completed identification label to the right hand front ‘A’ pillar and submit a

warranty claim using the information provided.

Vehicle Identification

All campaigned vehicles must have a Campaign Completed identification label applied to the right

hand front ‘A’ pillar, between the hinges, with details of the campaign, 99-H-01, dealership code

and date completed, legibly entered on the label with a permanent ink pen.

Extra campaign identification labels are available free of charge from:

Moore Business Systems

Facsimile: (03) 9270 8900

Attention: Mr. Bob Curry

Quote stock No. SD 28156, on a Moore Business Systems ‘packaged goods’ order form (or

facsimile if not available) for a box of 100 labels.

Vehicle Listings

Listings of affected vehicles shown in our customer name and address files are included with this

bulletin. Should dealers have any information to update the supplied listings, please update listing

and fax to:

Holden Ltd

Att: D. McMurray

Warranty Administration

Facsimile: (03) 9647 2525

Parts Information

No parts are required to complete this campaign action, except for in the unlikely event where a

vehicle has control arm damage. Parts when required can be ordered from HSPO. Refer to

PartFinderTM for specific service part numbers.

Owner Notification

Owners will be contacted directly by letter from Holden, providing details of the recall and

requesting them to arrange for the campaign action to be carried out together with the additional

field rework on applicable vehicles. Following is a draft of the cust om er letter.

Dear Holden Customer ,

At Holden we continually strive to enhance the ownership experience of our customers through

continuous product improvement, aftersales service and effective customer communication.

Holden’s foremost concern is the continued safety of our customers. Accordingly the recall

campaign described below is being under t aken as a safety precaut ion.

Holden has been alerted to the fact that within a determined production range of vehicles, the

specified torque settings may not have been achieved for attaching bolts incorporated in the rear

suspension system of your vehicle. In certain circu mstances, this may r esu lt i n poor and

unpredictable vehicle handling.

Holden has initiated this action as a precautionary measure to ensure the handling characteristics of

your vehicle are not compromised.

Our records show that your Holden Vect ra vehicle was manufact ured w ithin the det erm ined range. I t

is therefor e necessary for you to m ake a service booking w ith a H ol den dealership of your choice to

have the necessary wor k per f or m ed on your vehicle.

Some additional wor k may also be performed on your vehicle on presentation at the dealership. A

slight adjustment may be made to the routing of brake pipes located at the front of the vehicle.

This will ensure components are located correctly and prevent rubbing of the brake pipes which

may lead to paint r emoval and the potent ial f or corrosion.

All work will be carried out free of charge and can be completed while you wait, provided the

necessary arrangements have been made with the Holden dealer. The work required will take

approximately half an hour to complete.

We know that effective communication is vital to helping your understanding of the issues involved

and trust that this letter provides you with all the infor m ation you need. If you have any quest ions, t he

Holden Customer Assistance Line - 1 800 033349 would be pleased to assist.

Thank you for your at t ention to this matter. Please accept our apologies for any inconvenience that

may be caused by this action.

Yours Sincerely

I.J.MURRAY

Manager Customer Assistance

WARRANTY CLAIM INFORMATION

ON COMPLETION OF CAMPAIGN ACTION DEALERS MUST IMMEDIATELY SUBMIT A

WARRANTY CLAI M using the following data.

Description: Inspect Rear Suspensi on Control Arms

Labour Operat ion No: T980401

Standard T im e: 0.5 Hours

Failure Code: 96

Case Type: 08

In the event that components are replaced, use the appropriate labour operation number listed

below:

Description: Replace RH Lower Cont rol Arm (including inspect i on)

Labour Operat ion No: T980402

Standard T im e: 1.0 Hours

Failure Code: 96

Case Type: 08

Description: Replace LH Lower Cont rol Arm (including inspection)

Labour Operat ion No: T980403

Standard T im e: 1.0 Hours

Failure Code: 96

Case Type: 08

Description: Replace RH Upper Control Arm (including i nspection)

Labour Operat ion No: T980404

Standard T im e: 0.8 Hours

Failure Code: 96

Case Type: 08

Description: Replace LH Upper Control Arm (including i nspect i on)

Labour Operat ion No: T980405

Standard T im e: 0.8 Hours

Failure Code: 96

Case Type: 08

The range of vehicles has been identified using t he VIN number. Please ensure all vehicle details

are included when submitting warrant y claim informat ion as per t he normal warranty processes.

War ranty claim submission is used to updat e our r ecord of cam paign completion and determines

whether furt her cust omer contact is necessar y to act ion all af fected vehicles. Please ensur e on

completion of the campaig n action that a warranty claim is submitted prompt ly. I n the event that

parts ar e r eplaced, REPAC will request ret ur n of all replaced par t s via the REPAC r epor t .

DETAILED TECHNICAL INSTRUCTIONS CAMPAIGN 99-H-01

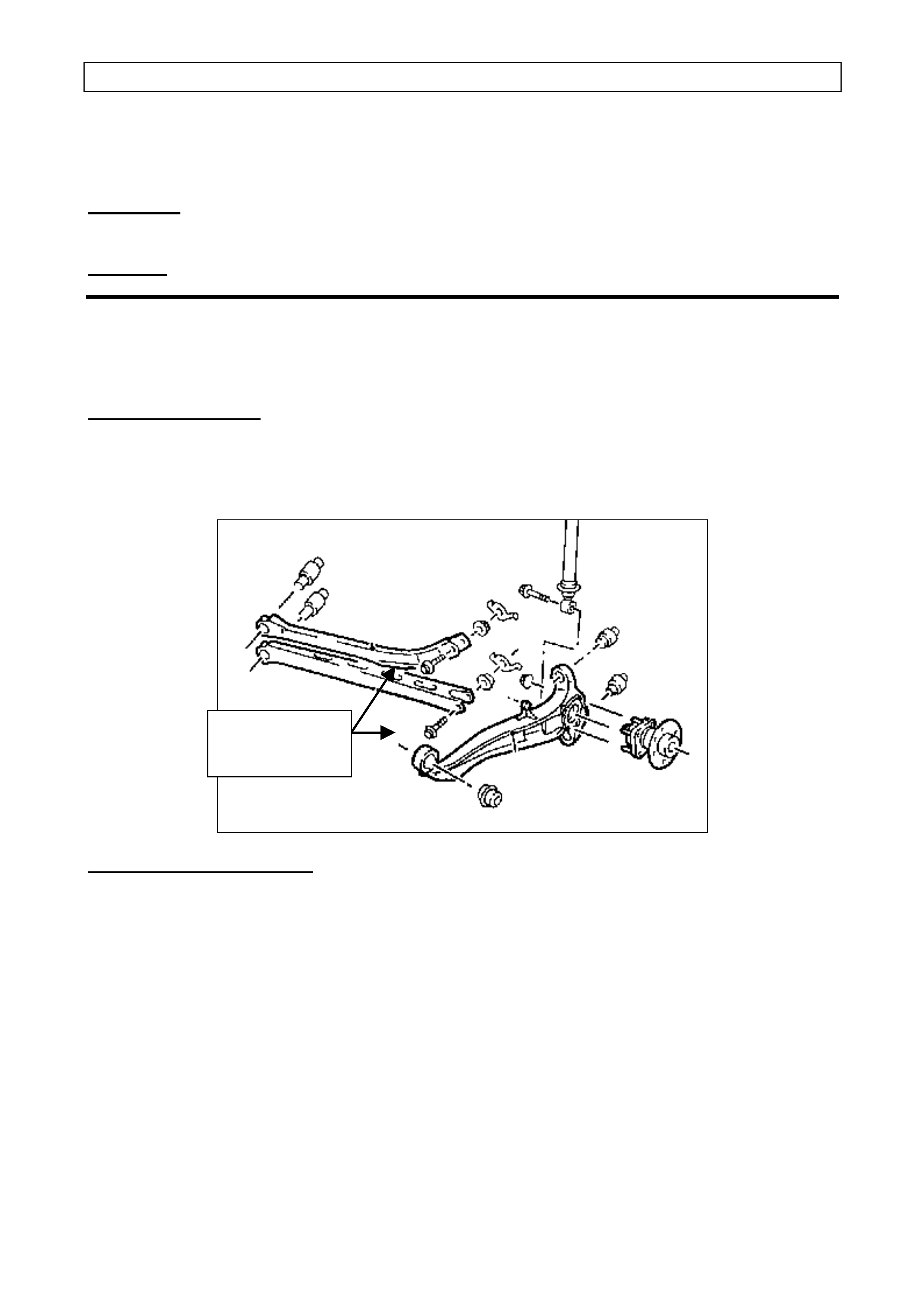

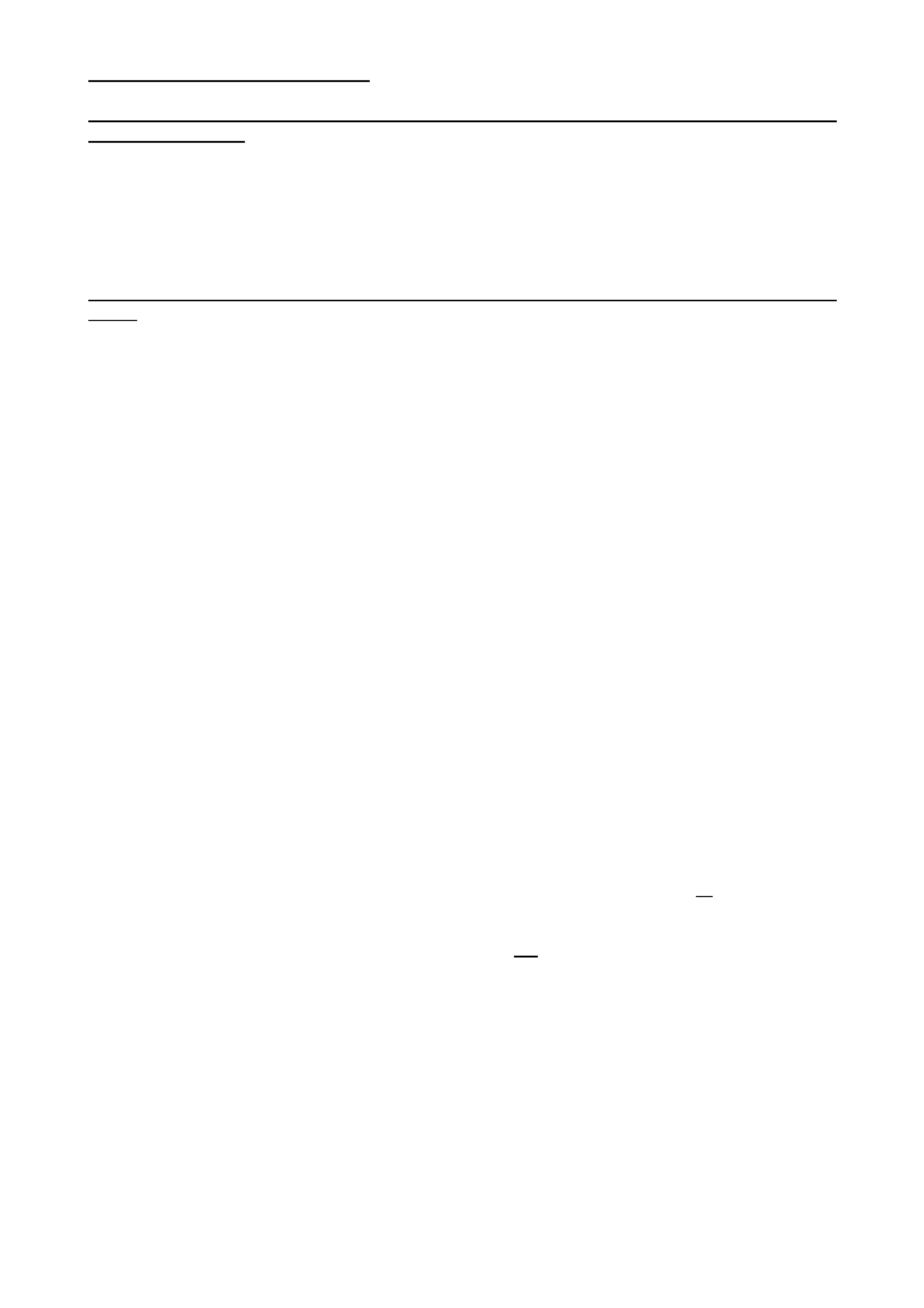

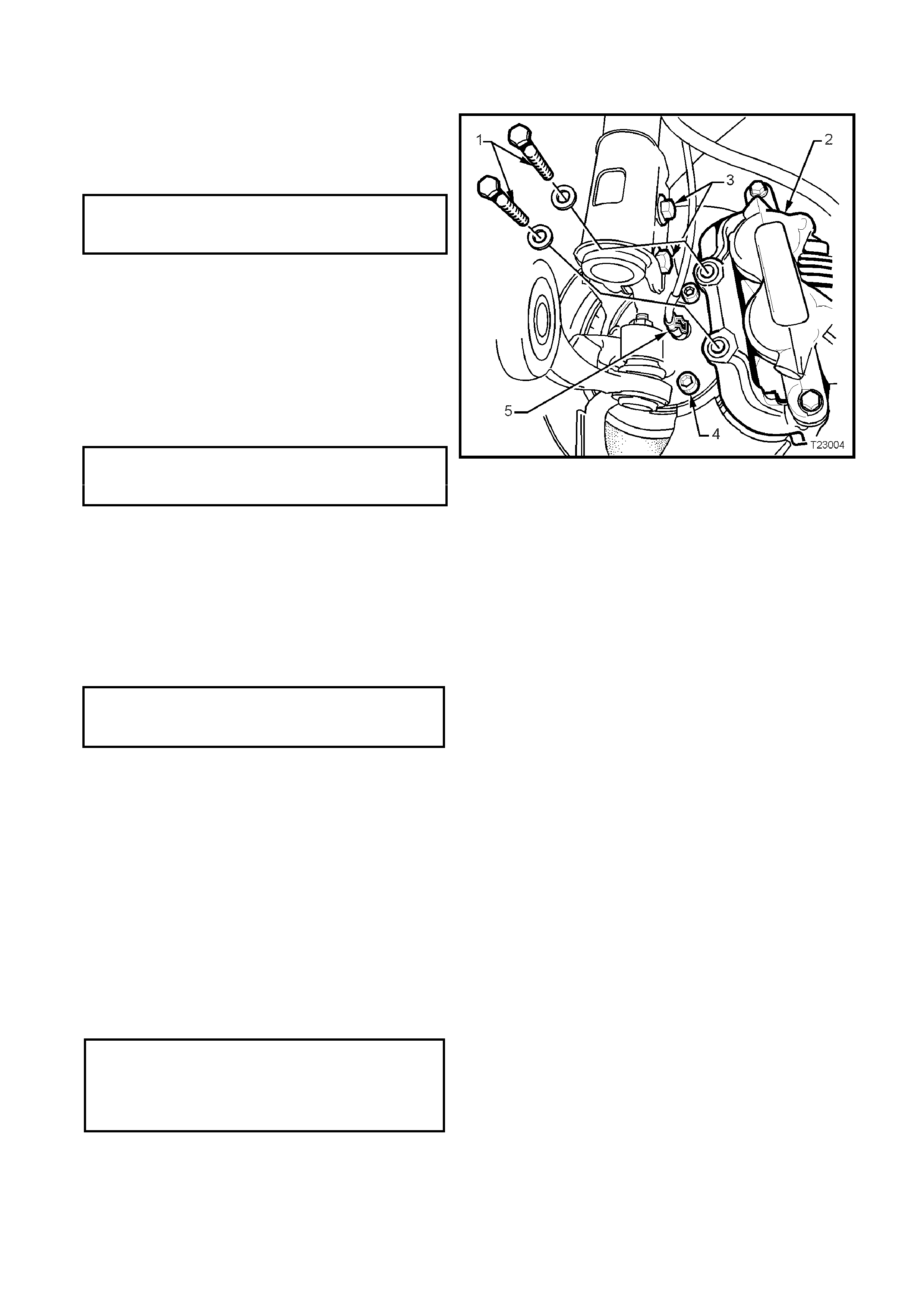

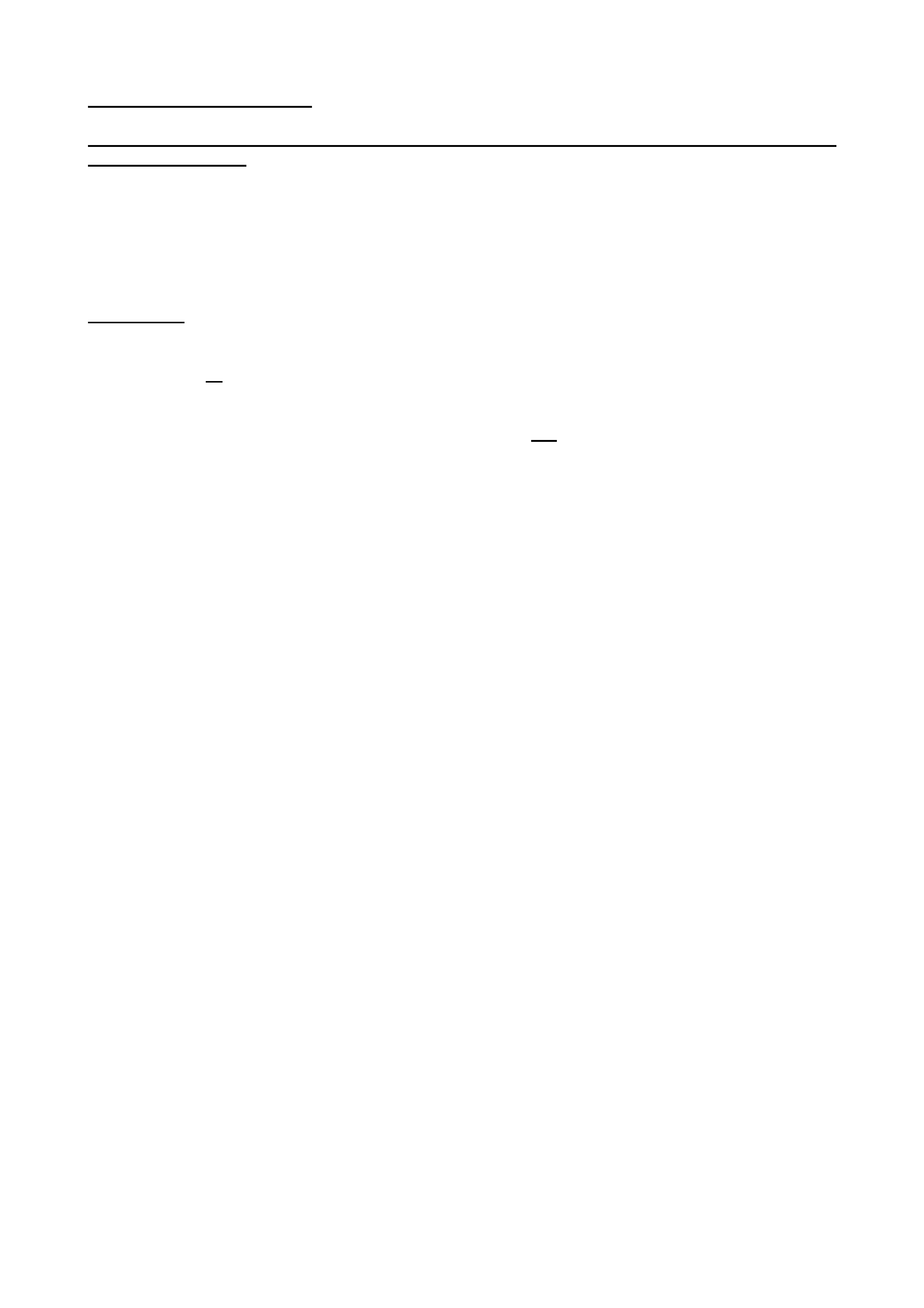

STEP 1: Raise the vehicle on a hoist and locate the upper and lower contr o l ar m bolts as

indicated in the figure below.

STEP 2: Using a tor que wrench set to 90 Nm, check t he t or que of all four ( 4) upper and

lower control arm t o r ear suspension arm bolts on bot h r ight-hand and left-hand sides of the

vehicle. The torque specif ied, 90 Nm, is the checking tor que req uir ed for t his cam paign action.

Refer t o TIS if the specific torq ue settings and pr ocedur es ar e r e quired f or component

replacement (not necessary for the checking pr ocedur es).

STEP 3: If t he upper or lower control arm bolts are found to be excessively loose, disconnect

the respective arms and inspect. Replace the arm s , bolts and other parts where necessary only if

elongation of the holes or other damag e is evident. Ensur e that service procedures ar e followed

and use the appropriat e t orque sett ings in TIS.

Important: The control ar m to suspension link fastener s ar e single use bolts only. DO NO T

remove bolts unnecessarily. Only completely remove the nut and bolt if excessively loose and

inspection of t he control arm( s) is necessar y.

Attachment “A”

FIELD REWORK: Proximity of Brake Pipes to the Automatic Transmission

Input Speed Sensor

• Corrective action applies to all JS Ser ies Vect r a vehicles with AUTOMATIC TR ANSMI SSION

and ABS built from st ar t of pr oduction L314383 to L390426.

• Ensure the vehicle f alls within the above VIN range and is equipped with autom at ic

transmission and ABS. Warranty claims subm it ted outside this r ange and without the

necessary options will not be accepted.

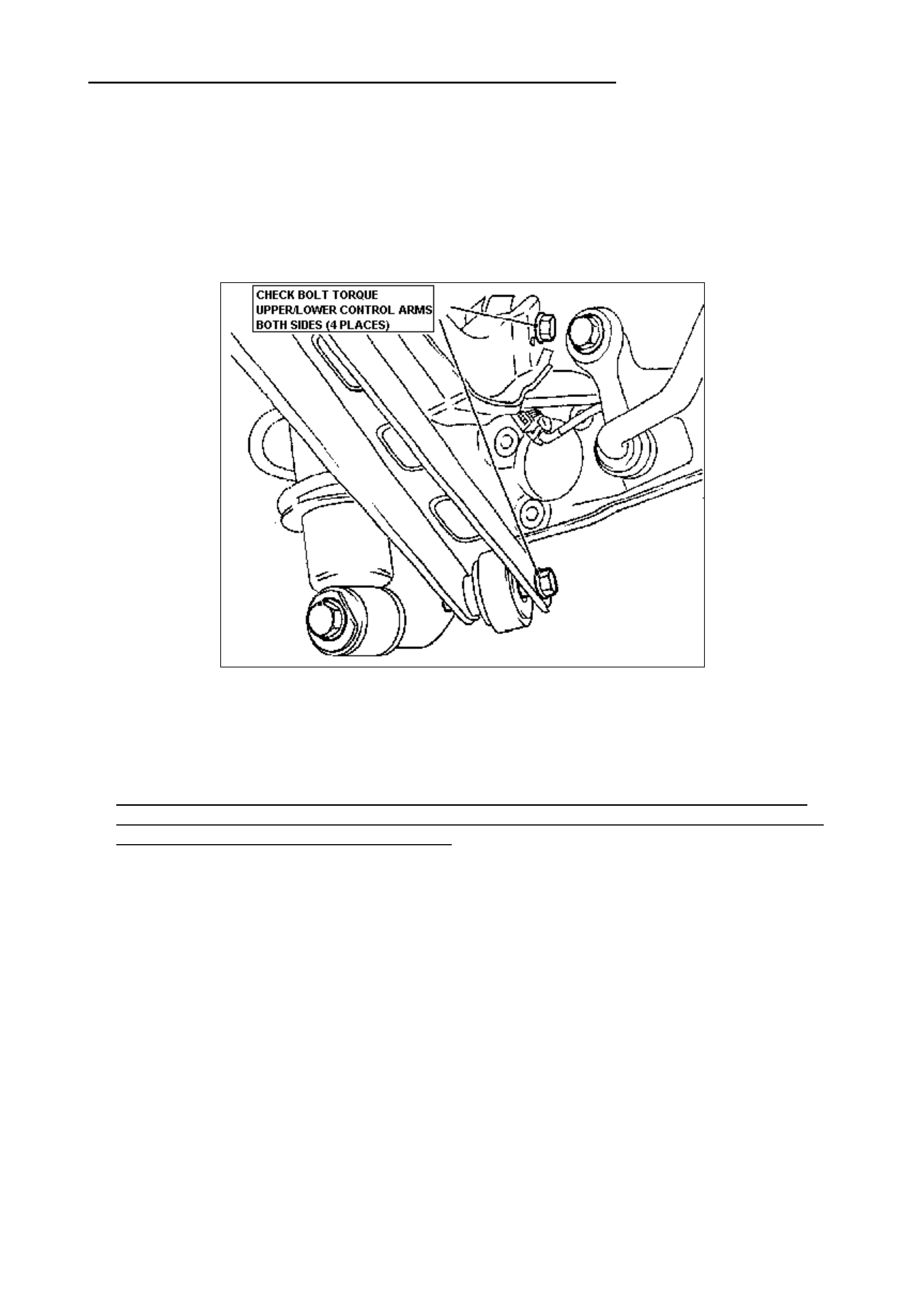

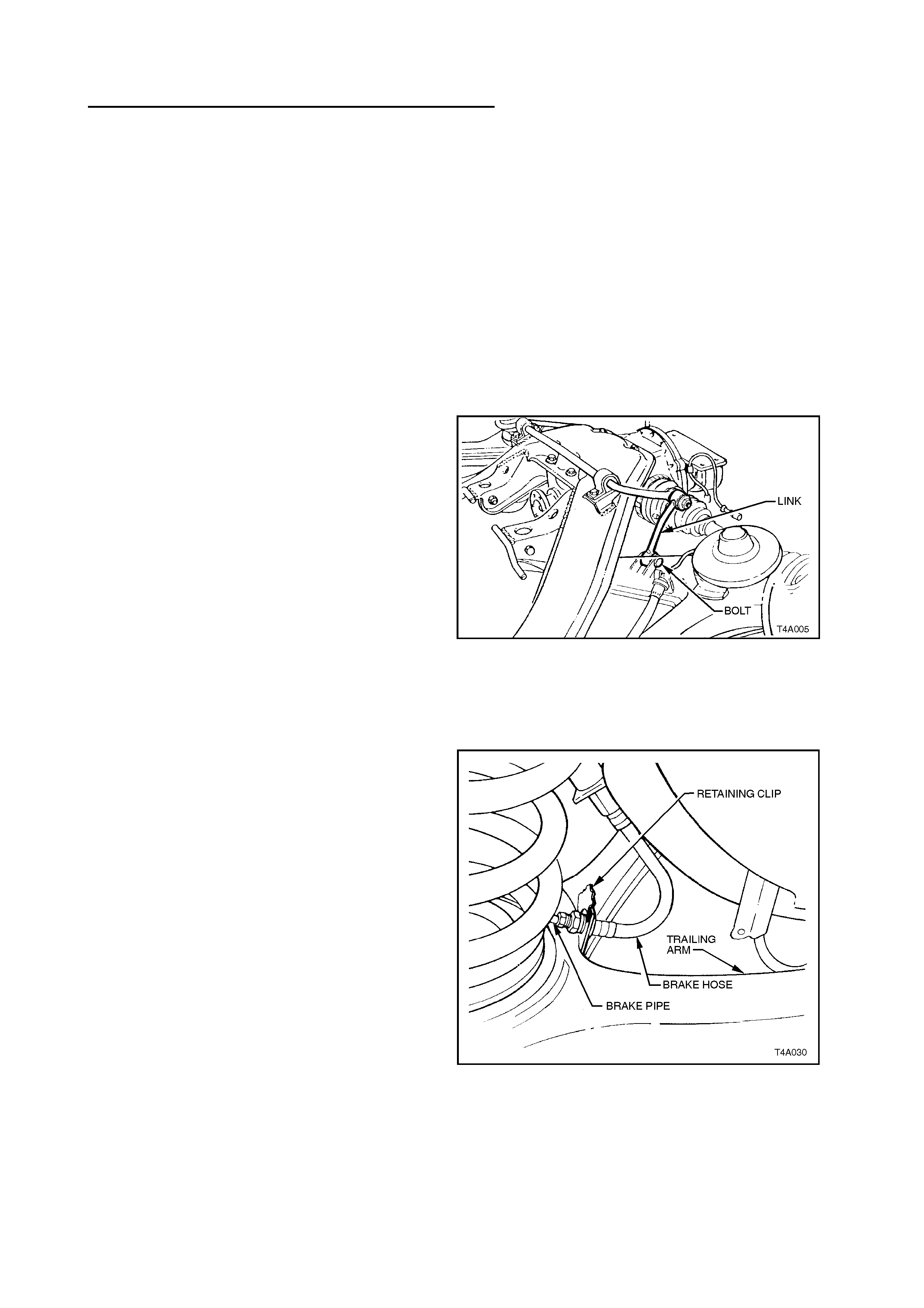

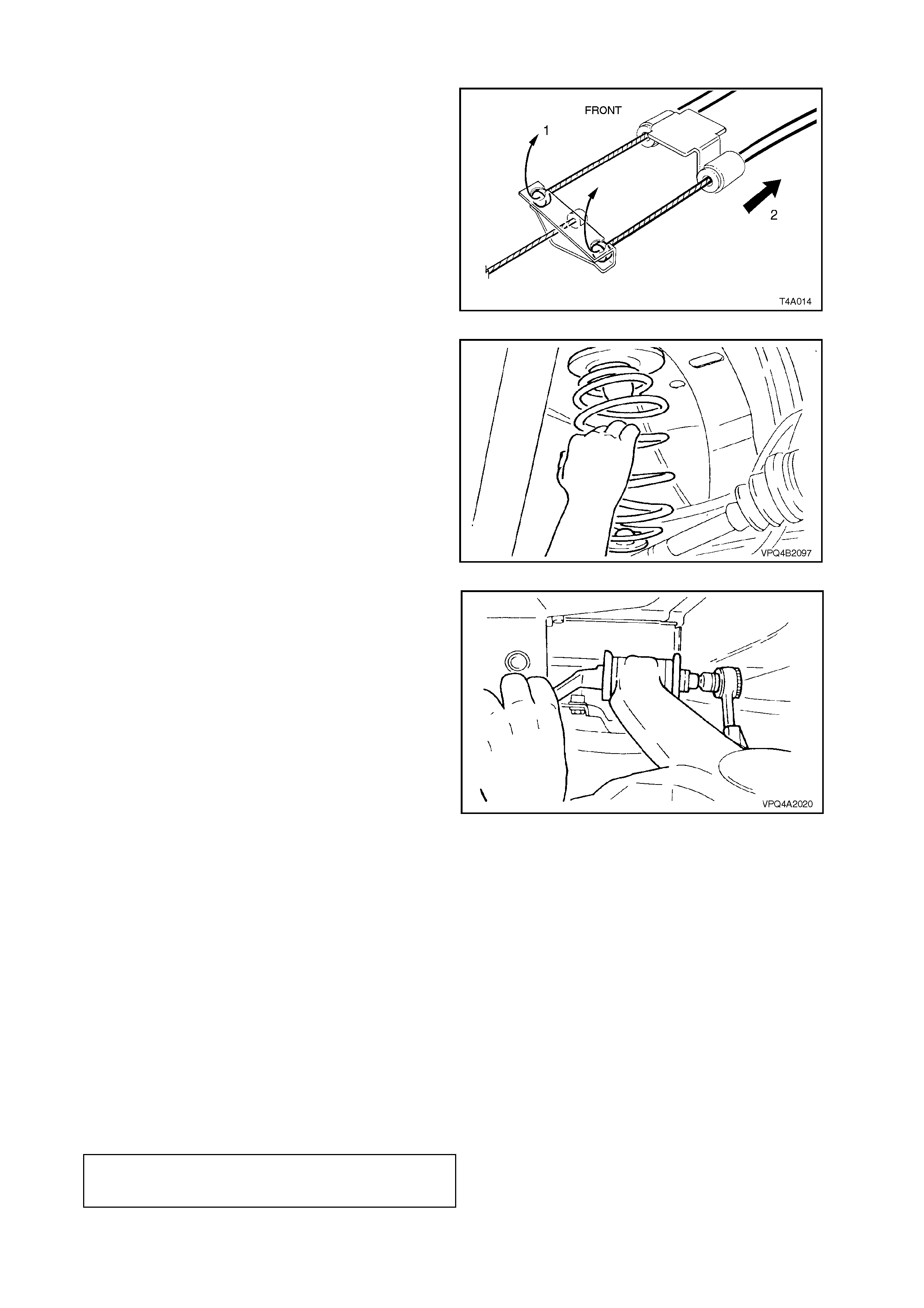

INTRODUCTION: The purpose of the field rework is to ensur e t hat the 3 brake pipes that run out

of t he ABS m odulat or and down past the top of the automatic transmission clear t he speed sensor

by at least 10mm. Under vehicle accelerat ion or traversing over bumps, a rubbing condition m ay

occur if t her e is not at least 10 mm clearance.

A minimum clear ance of 10 mm is required.

PROCEDURE:

1. Determine ther e is at least 10 mm clear ance between the brake pipes and the speed sensor

as indicated in Figur e 1 ( next page). I f ther e is 10 m m or m ore clearance, no further r ework

action is req uir ed.

2. If t her e is less than 10 mm clearance, suppor t the brake pipes using a long edgeless object

such as a wooden hammer handle positioned as indicated in Figure 1.

3. Holding the ham m er , grasp the br ake pipes near the speed sensor and with an upward and

outward gentle m ovement t owards the passenger side, slightly bend the brak e pipes to

achieve at least 10 mm clear ance. DO NOT excessively bend the pipes.

Only 10 – 15 mm clearance is required. Too much force can result in excessive clearance and

damage t o t he br ake pipes. In som e instances, it may be necessary to bend the brake pipes

individually.

4. Once the corr ect clear ance has been obtained, ensure the pipes ar e evenly spaced and

correctly engaged in the spacer br acket. The spacer brack et should be positioned as close as

possible to the bend in the br ake pipes as possible.

All vehicles requiring this r ew o r k are subject to t he ( 99- H- 01) campaign action. The vehicle

Campaign Com pleted identification label used to ident ify campaign 99-H-01 action (SD 28156)

should be used as an identif icat ion to record completion of t he above rework action. Place a “B”

on the label if t he rework has been performed.

FIGURE 1

Warranty Claim Information

Use the f ollowing informa t ion for warrant y claims:

Description : Position Brak e Pipes for Clear ance

Time : 0.3 hr

Labour Op.No. : H000213

Failure Code : 95

SUBMITTING W ARRANTY CLAIMS:

Dealers are rem inded that warranty claim submission is used to updat e our r ecor d of campaign

and rework complet ion. Please ensur e on com pletion of t he r equired action that a warranty claim

is promptly submit t ed and the replaced parts ar e r etained for return to REPAC when requested.

PRODUCT CAMPA IGN BULLETIN

99-H-02

March 1st , 1999

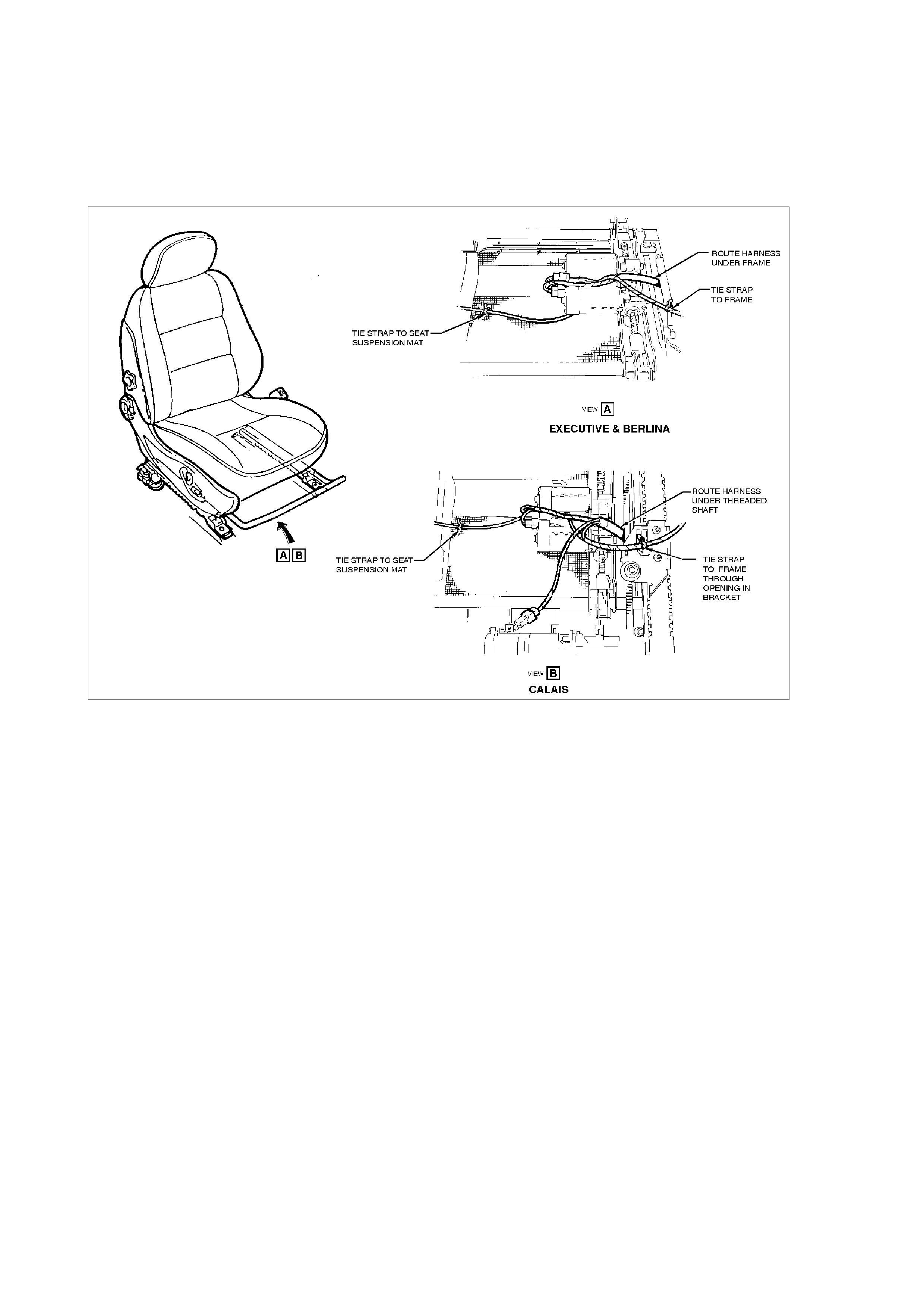

SUBJECT : PROTECTION OF WIRING HARNESS TO SEAT LIFTER MOTORS

MODEL : 1997 VT SERIES VEHICLES

This bulletin is t o advise Holden Dealerships of the init iation of a saf ety relat ed campaign on some

1997 VT Series vehicles. The wiring harness to some drivers’ (all models) and passengers’

(Calais model only) seat lifter m ot or s is t o be inspected and where necessary replaced.

Description of Def ect

Investigations have identified a batch of seats that were assembled with unprotected wiring which

is routed between the motor bracket and mat supporting the seat cushion. Under extreme

pressure, t he seat cushion may deflect enoug h to crush t he wiring harness and expose bare wires

to the motor bracket resulting in a short circuit. As a result, sufficient heat may be generated to

cause the wiring insulation at the seat to burn, however the likelihood of this happening is

extremely low.

Details of Affected Vehicles

Vehicles requiring this campaign action ar e some 1997 built VT Ser ies vehicles built f rom 24/ 06/97

to 15/08/97 inclusive.

VIN numbers L246596 to L259927 inclusive, sets the range of vehicles affected.

3691 vehicles require inspection.

Dealership Action Requi red

On presentat ion of any vehicle considered by the customer to be aff ected by this campaign, or on

presentation of a 1997 VT Series vehicle for any reason, confirm that the vehicle falls within the

affected range. Refer to the Detailed Instructions included with this bulletin (Attachment “A”) for

campaign act ion.

In summary, the wiring harness to the seat motors is to be inspected for presence of a PVC

sleeve. If the sleeve is not installed, replace t he seat harness.

Vehicle Ident ification

All campaigned vehicles must have a completed campaign identification label applied to the right

hand front ‘A’ pillar, between the hinges, with details of the campaign, 99-H-02, dealership code

and date completed, legibly entered on the label with a permanent ink pen.

Extra campaign ident ification labels ar e available free of charge from :

Moore Business Systems

Facsimile: (03) 9270 8900

Attention: Mr. Bob Curry

Quote stock No. SD 28156, on a Moore Business Systems ‘packaged goods’ order form (or

facsim ile if not available) for a box of 100 labels.

Vehicle List ings

Listings of affect ed vehicles shown in our customer nam e and addr ess files are included with this

bulletin. Should dealers have any infor m at ion to update the supplied list ings, please update listing

and fax to:

Holden Limited

Att: P. STARICK

War ranty Administration

Facsimile: (03) 9647 2525

Parts Information

Holden expects that less than 20% of the vehicles inspected will require harness replacement.

Each dealership will receive as an initial quantity of one 8VK/8VL harness and a set of tie straps

(Item 1 and 3 from below) free of charge. Use the Attached Material Order form to order

additional parts from Salmat.

Consume stock from the initial quant ity supplied and then only order replacement har nesses in line

with customer bookings.

Note: When making a booking for a VT Calais, imm ediat ely order I tem 2 and 3 f rom below in case

replacement is r equired. I f not r equired, hold in st ock f or possible fut u r e needs.

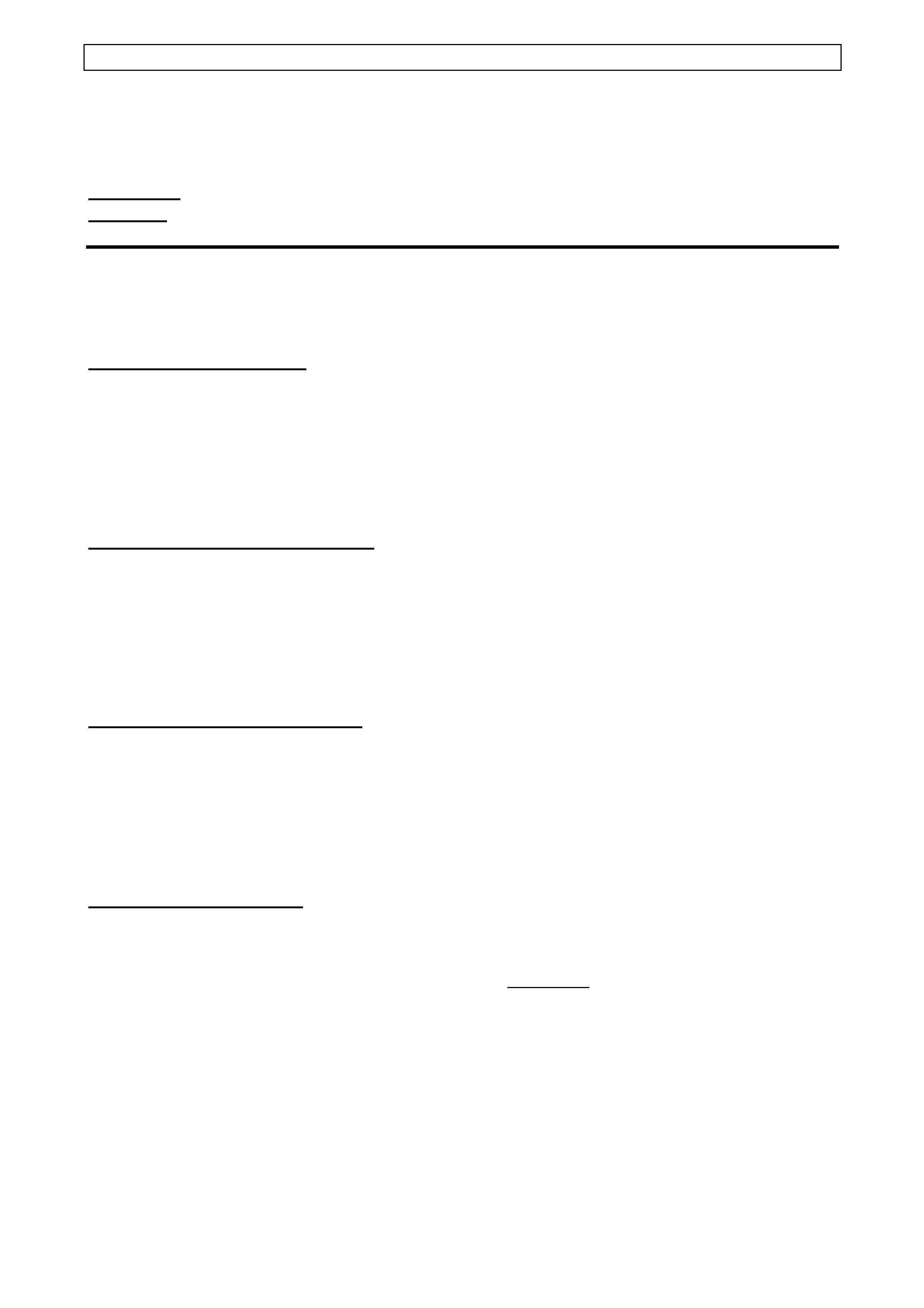

Item Part No. Description Qty/seat

1 Holden

92142707 • Right Hand 4- way seat lif t e r

harness f or dr iver seat.

8VK and 8VL models

1

2 Holden

92142714 • Right Hand 8 way seat lifter

harness f or dr iver seat

8VX models only

1

Holden

92142715 • Left Hand 8 way seat lif ter

harness passenger seat

8VX models only

1

3 92138137 • Tie straps 2

Owner Notification

Owners will be contacted directly by letter from Holden, providing details of the safety related

campaign and req uesting them to arrange f or the seat harness inspection and rectification by any

Holden dealership. T he t ext of the let ter is as follows:

Dear Holden Customer ,

At Holden we continually strive to enhance the ownership experience of our customers through

continuous product improvement, industry leading afters ales service and clear and concise cust omer

communication.

Holden’s foremost concern is the continued safety of our customers and the recall campaign

described below is being undert aken as a necessar y saf et y pr ecaut ion.

Holden has identified a small number of vehicles where the wiring to the seat lifter motors

(beneath the seat), was assembled without added protection. This may result in damage to the

wiring from the seat frame which in extreme cases may cause an electrical short circuit. As a

result, sufficient heat may be generated to cause the w iring insulation at the seat to burn, how ever

the likelihood of this happening is extremely low .

Holden has initiated a recall to inspect the harness of potentially affected vehicles. This action is

necessary to ensure that the harness is protected and free of damage.

Should an inspection reveal that the seat harness is not adequately protected a replacement seat

harness will be fitted. This action is a precautionary measure to ensure the seat operat es effectively

for the longer term.

Our records show that your Holden vehicle was manufactured within the affected range. It is

therefore necessary for you to make a service booking with a Holden dealership of your choice to

have the necessary inspection and serv ice per f or med.

This work will be carried out free of charge and can be completed while you wait, provided the

necessary arrangements have been made with your Holden dealer. If corrective action is

necessary, the work requir ed will take approximately 1 hour to complete.

We know that effective communication is vital to helping your understanding of the issues involved

and trust that this letter provides you with all the information you need. If you should have any

questions, the Customer Assistance Line - 1 800 033349, would be pleased to assist.

Thank you for your attention in this matter. Please accept our apologies for any inconvenience

which may be caused by this act ion.

Yours Sincerely

I.J.MURRAY

Manager Customer Assistance

WARRANTY CLAIM INFORMATION

ON COMPLETION OF CAMPAIGN ACTION DEALERS MUST IMMEDIATELY SUBMIT A

WARRANTY CLAI M using the following data.

Use ONE of the following Labour Operat ion Num bers for this campaign.

1. If inspect ing one or both seats:

Description: Inspect seat harness f or sl eeve fitment.

Labour Operat ion No: T980801

Standard T im e: 0.4 Hours

Failure Code: 96

Case Type: 08

2. If t he dr iver seat har ness needs r eplacing:

Description: Inspect and Replace Driver seat harness.

Labour Operat ion No: T980802

Standard T im e: 0.8 Hours

Failure Code: 96

Case Type: 08

3. If t he passenger seat har ness needs r eplacing (Calais only):

Description: Inspect and Replace Passenger seat harness.

Labour Operat ion No: T980803

Standard T im e: 0.8 Hours

Failure Code: 96

Case Type: 08

4. If bot h seat harnesses need replacing ( Calais only):

Description: Inspect and Replace both seat harnesses.

Labour Operat ion No: T980804

Standard T im e: 1.2 Hours

Failure Code: 96

Case Type: 08

The range of vehicles has been identified using t he VIN number. Please ensure all vehicle details

are included when submitting warrant y claim information as per the norm al warrant y procedur es.

War ranty claim submission is used to updat e our r ecor d of complet ion and det er m ines whether

further customer cont act is necessar y to act ion all af fected vehicles. Please ensur e on com plet ion

of t he cam paign action that a warrant y claim is subm it ted promptly.

REPAC will request re t urn of all replaced parts via the REPAC r eport.

DETAILED TECHNICAL INSTRUCTIONS CAM PAIGN 99-H- 02

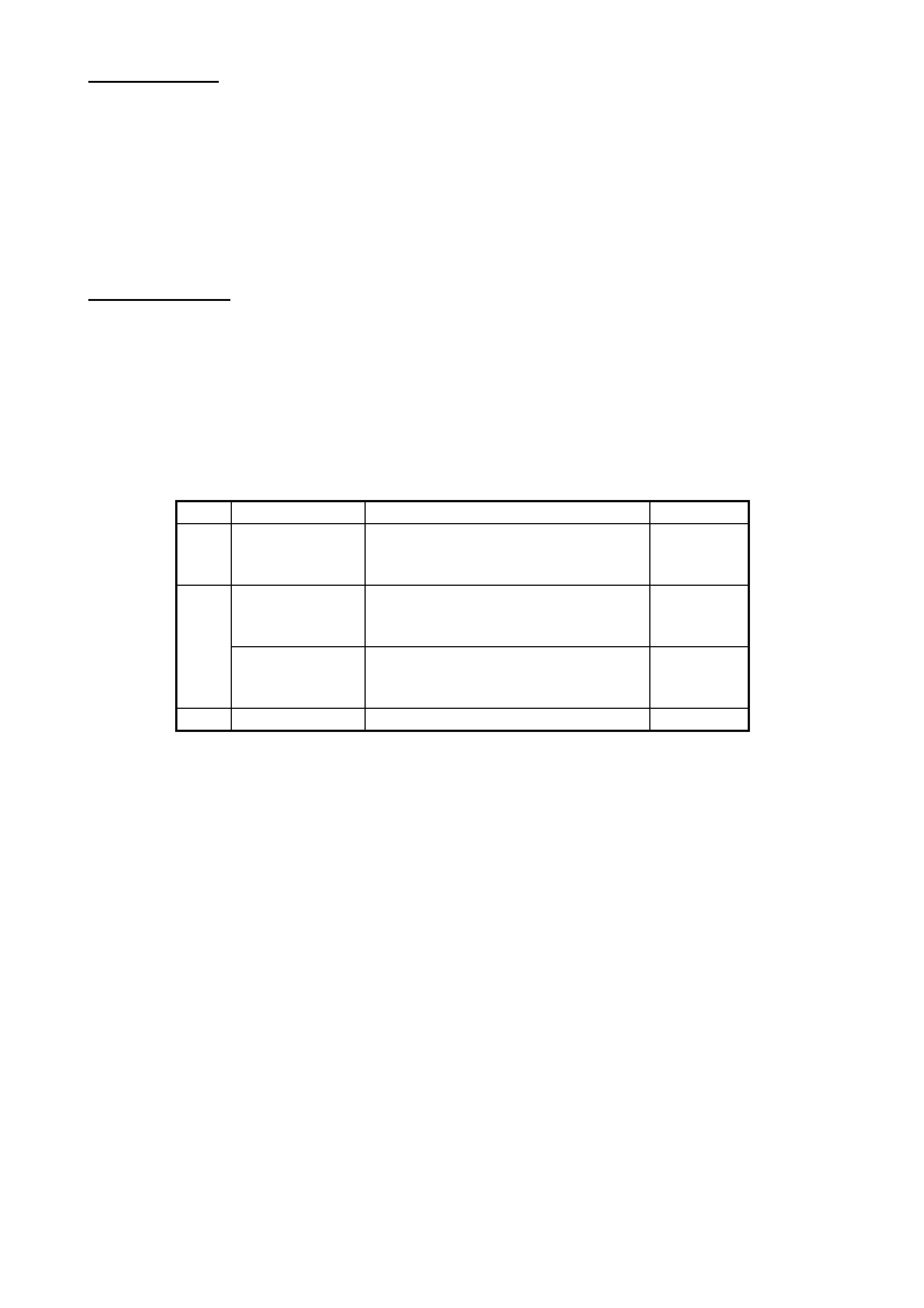

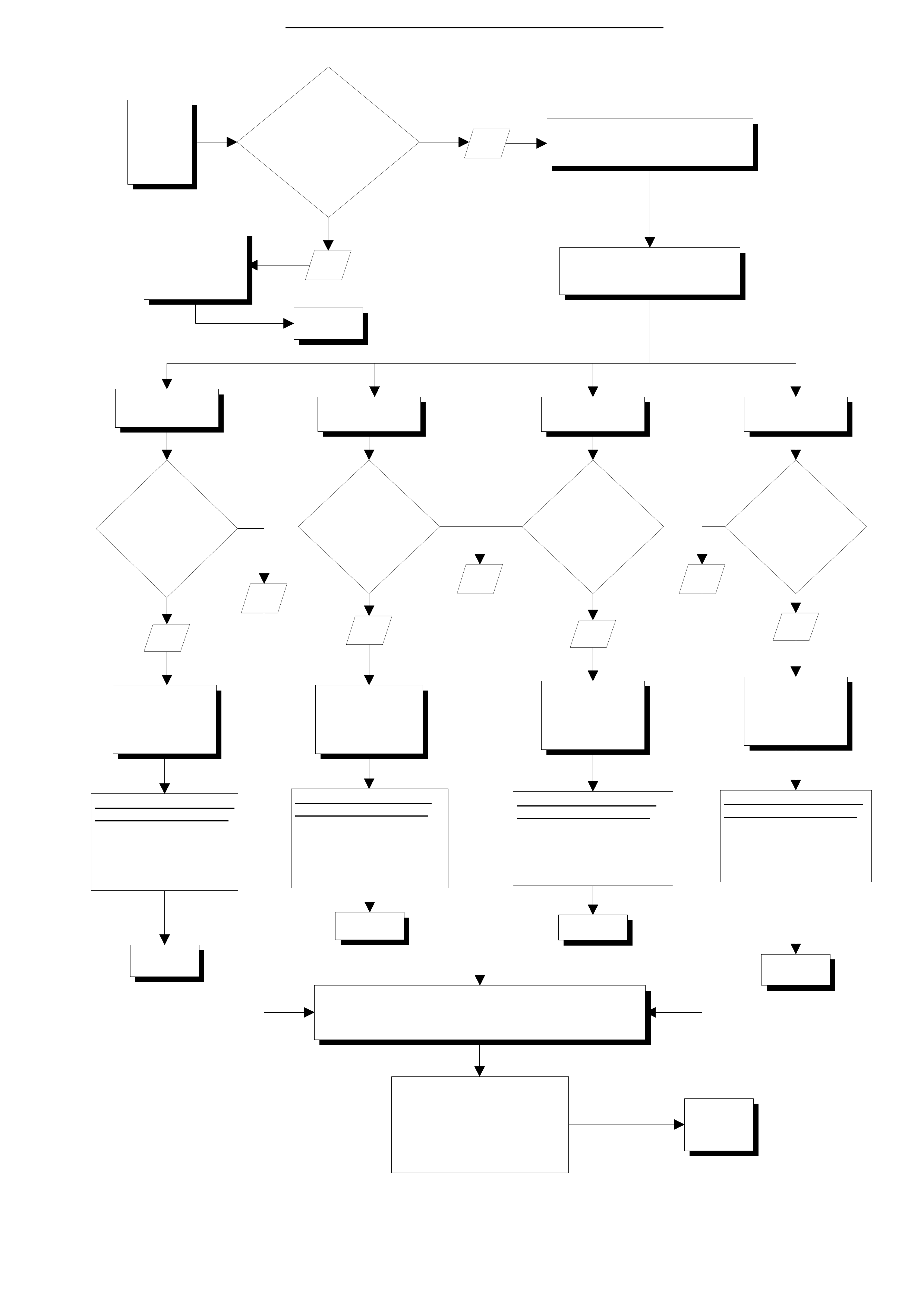

The flow chart below provides an overview of the rectification required for campaign 99-H-02.

Dealers should follow this when diagnosing affected vehicles. The procedures referred to in the

flow chart are explained further individually.

Dealers should check that the vehicle falls within the affected range before performing campaign

action.

START

Is PVC

sleeve

fitted ? R ef

to Fig 1

Replace seat harness. Ref to

Fig 2 View A for revised

routing path -Fi g 2 View B for

Calais. Follow Procedure B.

I ns pect seat har ness. Include

passenger seat for Calais.

Refer t o Proc edure A ..

Apply

Campaign

Label

Submit warranty claim

using LOp T980801.

END

Submit warranty claim using appropriate

Labour Operation number.

If drivers seat harness was only replaced,

use LOp T980802.

I f passenger se at harnes s was only

replaced used LOp T980803.

If both seat harnesses were replaced use

LOp T980804.

Apply

Campaign

Label

END

Is PSN b/w

L246596 and

L259927 incl?

A rr ange vehic l e booking and

order parts. Allow 3 days for

parts delivery.

Not involved

in Campaign

99-H-02.

Yes

No

Yes

No

Attachment A

Procedures:

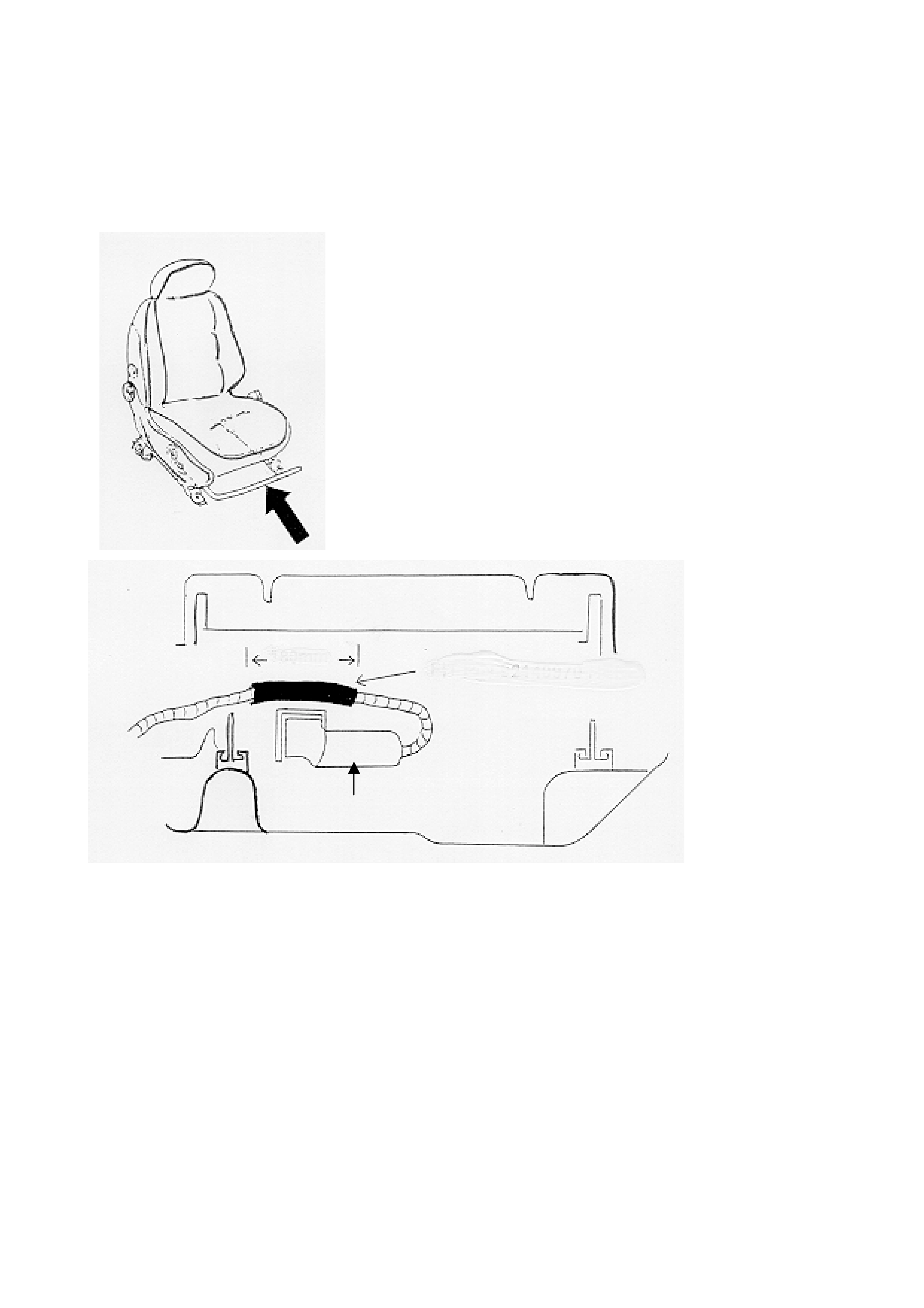

A) Check the harness for the fitment of PVC t ube.

• Position the seat fully rearward and adjust t he whole seat upward to its m aximum height

• Locate, under the seat, the harness for the seat lif ter mot or (this harness runs acr oss the top of

the seat lifter m ot or mounting bracket - ref er Figure1.)

180 mm Check for fitment of

this sleeve

Seat lifter motors

Figure 1

• If there is an existing PVC sleeve over the harness no further campaign action required,

otherwise, replace the harness- ref er to Procedure B.

B) Replace the harness for the seat lifter motor- Also applicable to passenger seat (Calais

only)

• Remove the fuse F26 for t he SRS system - this will prevent a code logging .

• Remove the driver’s seat from the vehicle (refer to 2.1 FRONT BUCKET SEAT ASSEMBLY of

the VT Ser ies I Ser vice Information)

• Remove the harness f or the seat lif ter motor. Note: mar k on the seat the position of the t wo tie

straps retaining the harness pr ior t o removing the tie str aps.

• Fit the new harness for the seat lifter motor. Refer Fig 2 View A.

• For Calais: Harness is to be routed between the threaded shaft (lead screw) and motor

mounting bracket. Refer to Fig 2 View B. Retain the harness with tie straps in the positions

previous marked. Red tape identifies the point s on t he har ness which are to be r etained.

• Plug in the connectors for the seat lif ter motors (white and black connectors). If f itting harness

to a Calais model connect t o the horizontal slide motor (red). Refer t o Fig 2 View B.

• Install the pr et ensioner connector clip.

• Reinstall the seat to the vehicle (refer to 2.1 FRONT BUCKET SEAT ASSEMBLY of the VT

Series I Service Information)

• Reinstall fuse F26 for t he SRS system

• Check seat elect r ical functions for corr ect oper ation

• Apply Campaign completed label

• Submit warranty claim

Figure 2

Attachment to Campaign Bulletin (Following)

SALMAT

MATERIAL ORDER FORM

Holden VT Series

Seat Harness and Tie Strap

Fax No.: (03)-9251-6352

Attention: N. Kennedy

This dealership wishes to order additional Seat Harness/s and Tie Straps for completion of

recall Campaign 99-H-02.

Please dispatch the parts detailed below, to this dealership, as soon as possible.

__________________________________________________________________________

Item Part Number Amount

1 92142707 (Drivers seat -RH 4 way

8VK and 8VL models)

2 92142714 (Drivers seat -RH 8 way

8VX models)

92142715 (Passengers seat - LH 8

way 8VX models)

3 92138137 in packs of 5

___________________________________________________________________________

From Dealer Code: ___________ Date:_____________________

Dealership Name: ______________________________________

Dealership Service Manager: _____________________________________

(please PRINT your name)

Fax This Form To : SALMAT (03)-9251-6352

PRODUCT CAMPAIGN BULLETIN

99-H-03

April 21, 1999

SUBJECT : JS VECTRA CHILD RESTRAINT ANCHORAGES

MODEL : JS SERIES VECTRA (IMPORT, HATCH ONLY)

This bulletin is t o advise Holden Dealerships of the init iat ion of a saf et y r elated campaign t o rework

the rear child r est r aint anchorage br ackets on JS Series Vect r a ( hatch only) vehicles.

Description of Def ect

Insuf ficient weld penetration of the spot weld that at taches the child anchorag e br acket to the rear

panel.

Details of Affected Vehicles

Vehicles requir ing this campaign action are impor ted JS Series Vectra ( hatch ONLY) vehicles.

A list of all affected vehicles, ‘Attachment A’, is included with this bulletin. The broad range of

affected vehicles falls within the tag range Y067450 to Y076366 (build date as per the Australian

Compliance Plate, August 1998 to February 1999). Dealers must verify that the vehicle to be

reworked is on the affected vehicle listing provided with this bulletin.

267 vehicles within the above rang e are involved.

DEALERSHIP ACTION REQUIRED

Vehicles in Dealership Stock

Perform the necessary campaign action on any JS Series Vectra (hatch) vehicle that falls within

the Tag number range held in Dealership Stock. These vehicles must have this campaign action

completed before ret ail delivery of the vehicle or transfer to anot her dealership.

On Presentati on of Any JS Series Vectra Vehicle

On presentation of any JS Series Vectr a vehicle considered by the customer to be af f ected by this

action, or on presentation of a JS Series Vectra vehicle for any reason, confirm that the vehicle

falls within the broad affected Tag number range. If the vehicle falls within the broad affected tag

range and is on the affected vehicle listing (Attachment A) provided with this bulletin, rework the

vehicle.

If the vehicle requires campaig n action, ref er to the Detailed T echnical Instructions included at the

end of t his bulletin.

In summary, the three child anchorage brackets located behind the rear inner panel trim and rear

bumper facia, are to be reworked by drilling 2 holes in each anchorage (3 anchorage’s, 6 holes in

total) and fastening with a screw and nut assembly.

Apply a Campaign Completed identification label to the right hand front ‘A’ pillar and submit a

warranty claim using t he inform at ion pr ovided.

Vehicle Ident ification

All campaigned vehicles must have a Campaign Completed identif ication label applied to the rig ht

hand front ‘A’ pillar, between the hinges, with details of the campaign, 99-H-03, dealership code

and date completed, legibly entered on the label with a permanent ink pen.

Extra campaign ident ification labels ar e available free of charge from :

Moore Business Systems

Facsimile: (03) 9270 8900

Attention: Mr. Bob Curry

Quote stock No. SD 28156, on a Moore Business Systems ‘packaged goods’ order form (or

facsim ile if not available) for a box of 100 labels.

Vehicle List ings

Two listings are included with this bullet in:

1. A summarised list ing of all vehicles affe ct ed by this cam paign action (Attachment ‘A’) .

2. Listing of af fected vehicles shown in our customer nam e and addr ess files.

Should dealers have any informat ion t o updat e the supplied listings, please updat e listing and fax

to:

Holden Ltd

Att: P. Starick

War ranty Administration

Facsimile: (03) 9647 2525

Parts Information

Parts required to complete this campaign action are tabulated below. Parts are available from

HSPO.

Part No.: Description: Qty

Req’d:

92138175 (SP3836) SCREW 6

11094423 NUT 6

11035613 WASHER 6

Owner Notification

Owners will be contacted directly by letter from Holden, providing details of the recall and

requesting them to arrange for the campaign action to be carried out. Following is a draft of the

customer letter.

Dear Holden Customer ,

At Holden we continually strive to enhance the ownership experience of our customers through

continuous product improvement, aftersales service and effective customer communication.

Holden’s foremost concern is the continued safety of our customers. Accordingly the recall

campaign described below is being under t aken as a safety precaut ion.

Holden has been alerted to the fact that within a determined production range of vehicles, the spot

weld that secures the rear child seat anchorage brackets to the rear panel may not have had

sufficient penetration causing possible weaknesses in the restraint anchorage system.

To improve the st r ength of the anchorage system, your Holden dealer will modif y t he anchorage

by fitting additional f ast ener s.

Holden has initiated this action as a precautionary measure to ensure the anchorage brackets are

sufficiently secured and that the safety of all passengers is not compromised.

Our records show that your Holden Vect ra vehicle was manufact ured w ithin the det erm ined range. I t

is therefor e necessary for you to m ake a service booking w ith a H ol den dealership of your choice to

have the necessary wor k per f or m ed on your vehicle.

All work will be carried out free of charge and can be completed while you wait, provided the

necessary prior arrangements have been made with your Holden dealer. The work required will

take approximat ely one hour to complete.

We know that effective communication is vital to helping your understanding of the issues involved

and trust that this letter provides you with all the infor m ation you need. If you have any quest ions, t he

Holden Customer Assistance Line - 1 800 033349 would be pleased to assist.

Thank you for your at t ention to this matter. Please accept our apologies for any inconvenience that

may be caused by this action.

Yours Sincerely

D.McMurray

Manager Customer Assistance

WARRANTY CLAIM INFORMATION

ON COMPLETION OF CAMPAIGN ACTION DEALERS MUST IMMEDIATELY SUBMIT A

WARRANTY CLAI M using the following data.

Description: Rework Child Restraint Anchorage on Hat c h Models

Labour Operat ion No: T980901

Standard T im e: 1.1 Hours

Failure Code: 96

Case Type: 08

The range of vehicles has been identified using the Tag number. Please ensure all vehicle details

are included when submitting warrant y claim informat ion as per t he normal warranty processes.

War ranty claim submission is used to updat e our r ecord of cam paign completion and determines

whether furt her cust omer contact is necessar y to act ion all af fected vehicles. Please ensur e on

completion of the campaig n action that a warranty claim is subm it t ed promptly.

DETAILED TECHNICAL INSTRUCTIONS CAMPAIGN 99-H-03

1. Remove rear bumper facia as per t he ser vice instructions.

2. Remove the inner tr im panel t hat covers the child rest r aint anchors.

3. Place a piece of cardboard or dropsheet i n t he hat ch t o cat ch any swarf from the

drilling operation.

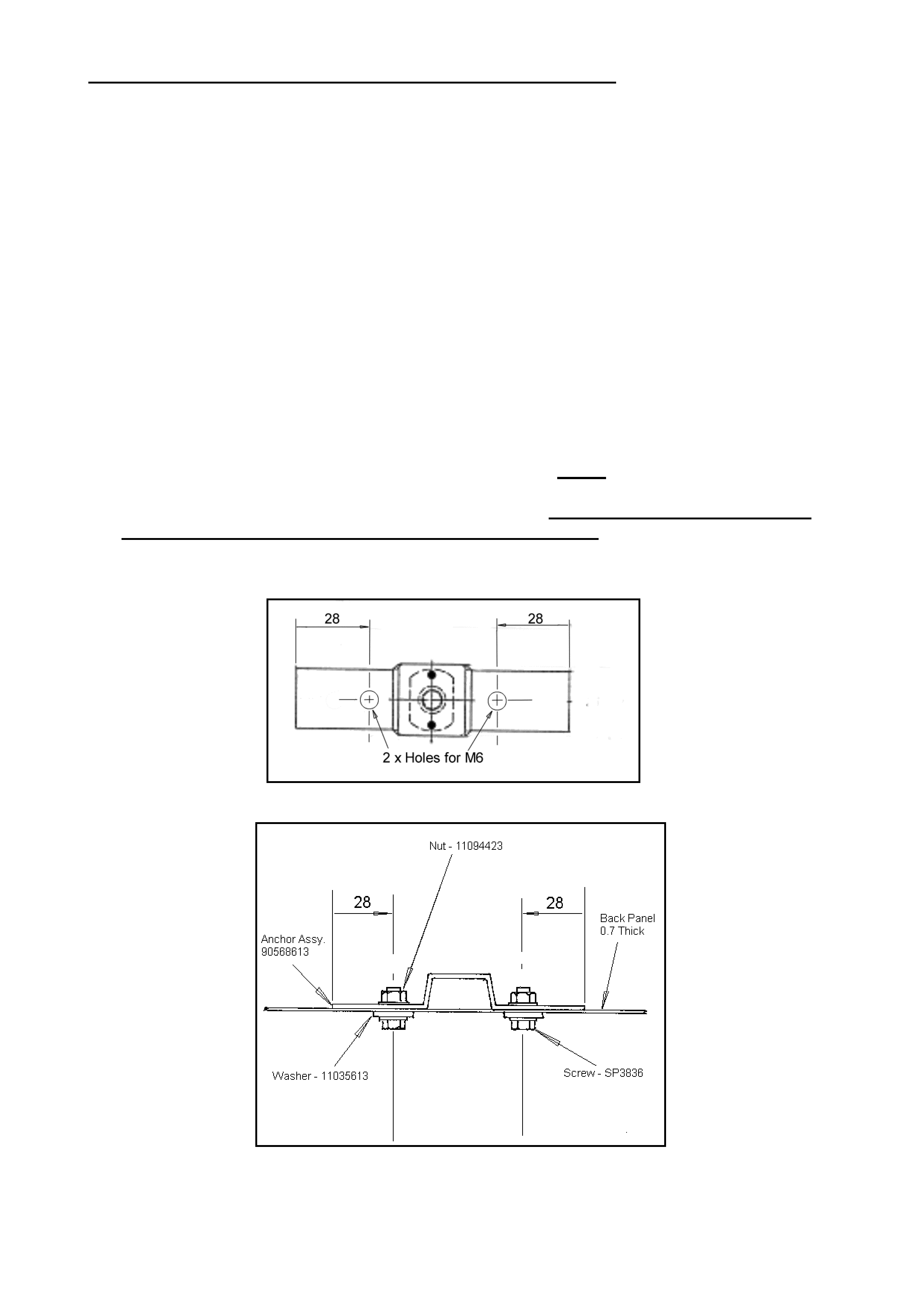

4. As per Figur e 1& 2 below, drill 6. 0m m diameter holes for M6 screw’s with centres 28 mm from

the outer end of the 3 anchor s as shown. Mark, centre punch and drill carefully throug h the

anchor assembly and the back panel from inside t he hatch.

5. Apply a bead of silicon sealer (92140051) ar ound the head of each scr ew, under t he nut

flang e and on t he outer panel surface under the scr ew head.

6. Place 18mm washers (11035613) onto t he scr ews.

7. Insert scr ews (92138175) int o each hole with head outboard.

8. Place nuts (11094423) ont o each scr ew and torque each screw to 12Nm.

9. Ensure all 3 anchors are secur ed and t or qued correct ly. Ensure al l swarf is cleaned from

the inside of t he vehicle, including in the spare wheel wel l.

10. Refit the inner trim panel and rear bumper facia assembly.

Figure 1: View f rom within hatch looking rearward.

Figure 2

92138175

Page 1 99-H-03

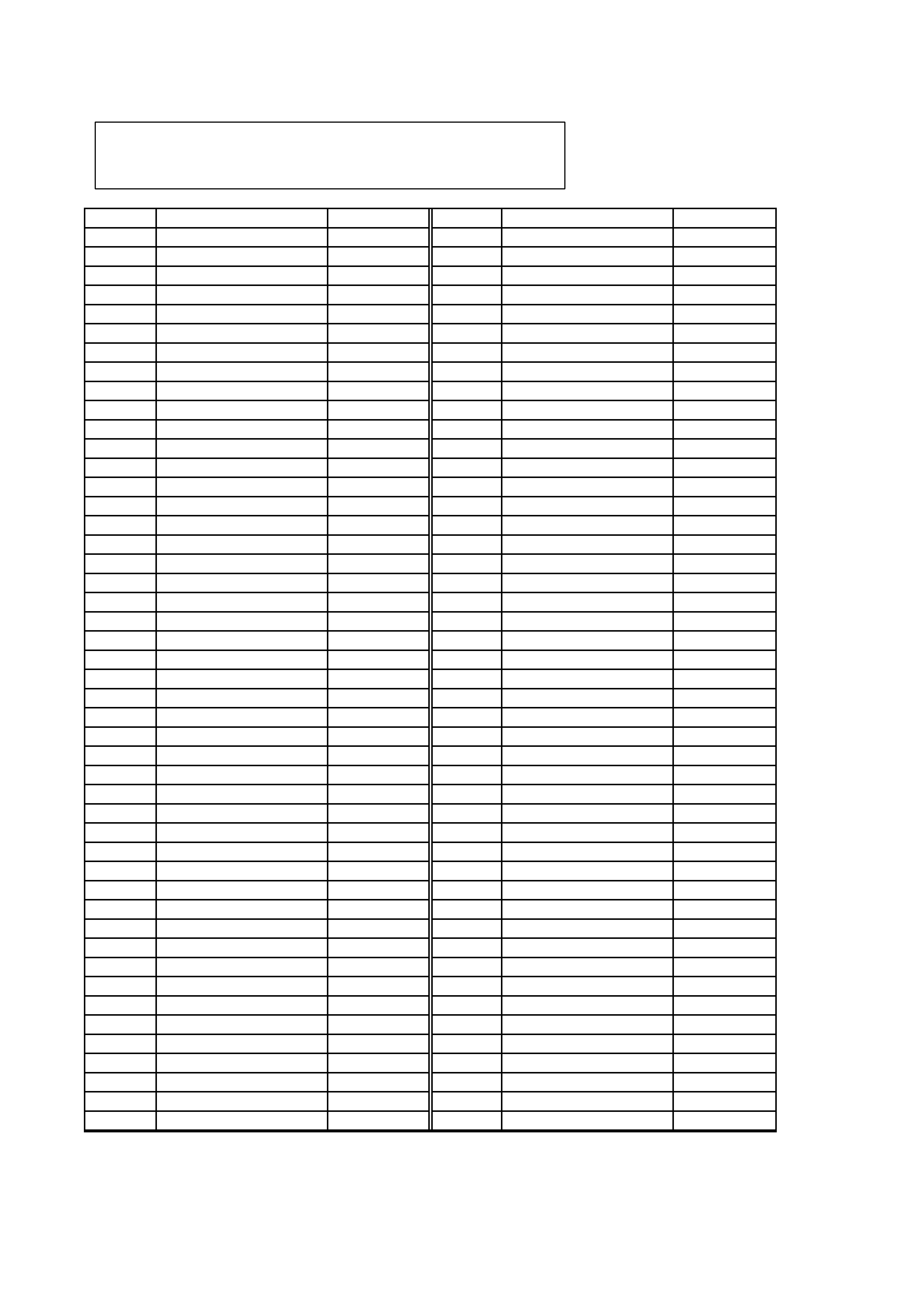

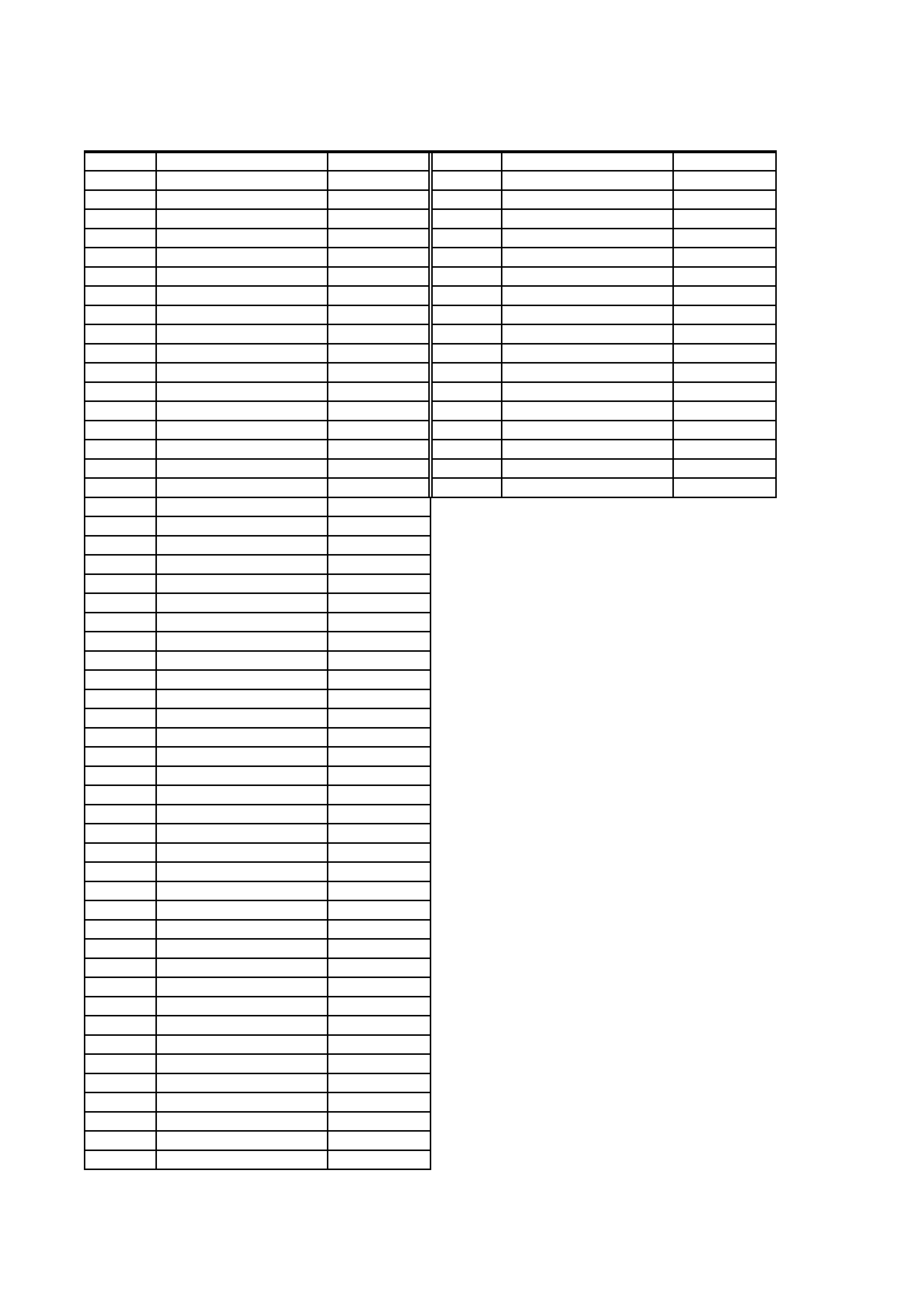

TAG #

ISOVIN #

W/SALE D/C

TAG #

ISOVIN #

W/SALE D/C

Y067450 W0L0JBF68W7137415 269 Y072635 W0L0JBF68W7156553 415

Y067451 W0L0JBF68W7137499 603 Y072636 W0L0JBF68W7156864 300

Y067452 W0L0JBF68W7137583 603 Y072637 W0L0JBF68W7156892 706

Y067453 W0L0JBF68W7137680 406 Y072638 W0L0JBF68W7159262 706

Y067454 W0L0JBF68W7138217 124 Y072640 W0L0JBF68W7159424 434

Y067456 W0L0JBF68W7138374 452 Y072641 W0L0JBF68W7159520 280

Y067457 W0L0JBF68W7138480 438 Y072642 W0L0JBF68W7159557 376

Y071345 W0L0JBF68W7156689 385 Y072643 W0L0JBF68W7159847 126

Y071346 W0L0JBF68W7156209 435 Y072644 W0L0JBF68W7159898 107

Y071347 W0L0JBF68W7156301 862 Y072645 W0L0JBF68W7159922 437

Y071348 W0L0JBF68W7156423 724 Y072646 W0L0JBF68W7159946 865

Y071349 W0L0JBF68W7156493 888 Y072647 W0L0JBF68W7159959 562

Y071350 W0L0JBF68W7156738 367 Y072648 W0L0JBF68W7161874 630

Y071441 W0L0JBF68W7156096 455 Y072649 W0L0JBF68W7162069 300

Y071442 W0L0JBF68W7156381 700 Y072650 W0L0JBF68W7162087 368

Y071443 W0L0JBF68W7157017 502 Y072651 W0L0JBF68W7162524 166

Y071550 W0L0JBF68W7155735 107 Y072750 W0L0JBF68W7156545 663

Y071551 W0L0JBF68W7155843 502 Y072751 W0L0JBF68W7156772 452

Y071552 W0L0JBF68W7156534 603 Y072752 W0L0JBF68W7156811 353

Y071553 W0L0JBF68W7156731 374 Y072753 W0L0JBF68W7159906 764

Y071589 W0L0JBF68W7156246 368 Y072754 W0L0JBF68W7161935 706

Y071591 W0L0JBF68W7156278 445 Y072755 W0L0JBF68W7161941 422

Y071592 W0L0JBF68W7156316 435 Y072756 W0L0JBF68W7162203 895

Y071593 W0L0JBF68W7156564 502 Y072757 W0L0JBF68W7162305 610

Y071594 W0L0JBF68W7156783 512 Y072758 W0L0JBF68W7162487 300

Y071595 W0L0JBF68W7156836 659 Y072759 W0L0JBF68W7162576 412

Y071638 W0L0JBF68W7156411 616 Y072760 W0L0JBF68W7162759 369

Y071639 W0L0JBF68W7156463 434 Y072761 W0L0JBF68W7162788 124

Y071640 W0L0JBF68W7156583 343 Y072762 W0L0JBF68W7162839 376

Y071725 W0L0JBF68W7156204 773 Y072763 W0L0JBF68W7162849 526

Y071726 W0L0JBF68W7156221 434 Y072764 W0L0JBF68W7162913 126

Y071727 W0L0JBF68W7156263 858 Y072765 W0L0JBF68W7163121 520

Y071728 W0L0JBF68W7156401 300 Y072766 W0L0JBF68W7163131 124

Y071729 W0L0JBF68W7156724 822 Y072767 W0L0JBF68W7163136 727

Y071730 W0L0JBF68W7156905 435 Y072768 W0L0JBF68W7163163 888

Y071731 W0L0JBF68W7157251 800 Y072769 W0L0JBF68W7163168 124

Y071732 W0L0JBF68W7157315 603 Y072770 W0L0JBF68W7163363 502

Y071733 W0L0JBF68W7157661 616 Y072771 W0L0JBF68W7163806 343

Y071734 W0L0JBF68W7158564 502 Y072772 W0L0JBF68W7164368 437

Y071735 W0L0JBF68W7158604 455 Y072925 W0L0JBF68W7156637 631

Y071796 W0L0JBF68W7156526 313 Y072926 W0L0JBF68W7162347 381

Y071798 W0L0JBF68W7157074 342 Y072927 W0L0JBF68W7162424 141

Y071799 W0L0JBF68W7159182 438 Y072928 W0L0JBF68W7162621 502

Y071800 W0L0JBF68W7159569 612 Y072929 W0L0JBF68W7164130 163

Y072632 W0L0JBF68W7156329 435 Y072930 W0L0JBF68W7164260 700

Y072633 W0L0JBF68W7156416 362 Y072931 W0L0JBF68W7164592 455

Y072634

W0L0JBF68W7156451

605

Y072932

W0L0JBF68W7164762

616

ATTACHMENT 'A'

99-H-03 - AFFECTED VEHICLE LISTING

Page 2 99-H-03

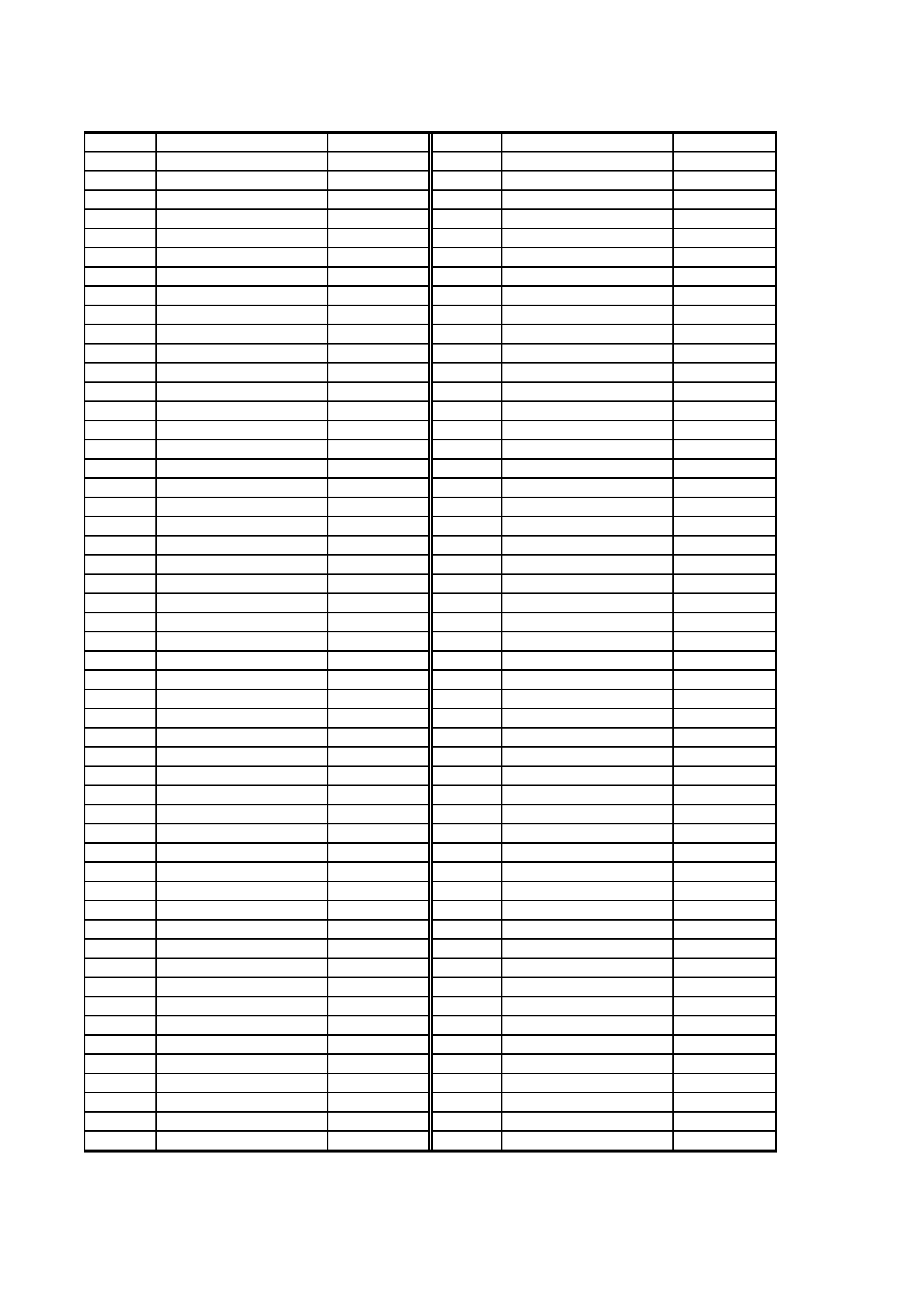

TAG #

ISOVIN #

W/SALE D/C

TAG #

ISOVIN #

W/SALE D/C

Y072933 W0L0JBF68W7164961 107 Y073413 W0L0JBF68W7170409 581

Y072948 W0L0JBF68W7162326 484 Y073570 W0L0JBF68W7164374 141

Y072949 W0L0JBF68W7162782 124 Y073571 W0L0JBF68W7167016 422

Y072950 W0L0JBF68W7164292 166 Y073572 W0L0JBF68W7170422 376

Y072951 W0L0JBF68W7165250 435 Y073573 W0L0JBF68W7170851 338

Y072995 W0L0JBF68W7162678 381 Y073574 W0L0JBF68W7171807 141

Y072996 W0L0JBF68W7163092 603 Y073617 W0L0JBF68W7170320 802

Y072997 W0L0JBF68W7163357 166 Y073618 W0L0JBF68W7170649 415

Y072998 W0L0JBF68W7164239 739 Y073620 W0L0JBF68W7170900 706

Y072999 W0L0JBF68W7164280 636 Y073622 W0L0JBF68W7171505 413

Y073000 W0L0JBF68W7164917 706 Y073623 W0L0JBF68W7171594 547

Y073174 W0L0JBF68W7161862 376 Y073638 W0L0JBF68W7162156 565

Y073175 W0L0JBF68W7162529 373 Y073640 W0L0JBF68W7170185 252

Y073176 W0L0JBF68W7162668 610 Y073641 W0L0JBF68W7170719 616

Y073177 W0L0JBF68W7163313 486 Y073642 W0L0JBF68W7171464 124

Y073178 W0L0JBF68W7164286 603 Y073643 W0L0JBF68W7171599 434

Y073179 W0L0JBF68W7165188 124 Y073644 W0L0JBF68W7171675 564

Y073180 W0L0JBF68W7165302 320 Y073645 W0L0JBF68W7171820 894

Y073181 W0L0JBF68W7165344 124 Y073646 W0L0JBF68W7171849 166

Y073183 W0L0JBF68W7166889 512 Y073647 W0L0JBF68W7171887 129

Y073184 W0L0JBF68W7166942 636 Y073648 W0L0JBF68W7171947 434

Y073185 W0L0JBF68W7167000 50 Y073649 W0L0JBF68W7171983 339

Y073186 W0L0JBF68W7167155 368 Y073650 W0L0JBF68W7172472 434

Y073187 W0L0JBF68W7167222 354 Y073651 W0L0JBF68W7172703 461

Y073188 W0L0JBF68W7167228 438 Y073680 W0L0JBF68W7162534 895

Y073189 W0L0JBF68W7167239 438 Y073681 W0L0JBF68W7163156 413

Y073190 W0L0JBF68W7167495 502 Y073682 W0L0JBF68W7164865 437

Y073191 W0L0JBF68W7167531 455 Y073683 W0L0JBF68W7165468 343

Y073192 W0L0JBF68W7167680 438 Y073684 W0L0JBF68W7170657 437

Y073256 W0L0JBF68W7162118 434 Y073685 W0L0JBF68W7171826 354

Y073257 W0L0JBF68W7162296 437 Y073686 W0L0JBF68W7171832 636

Y073258 W0L0JBF68W7164234 658 Y073687 W0L0JBF68W7172228 163

Y073259 W0L0JBF68W7164298 437 Y073688 W0L0JBF68W7172416 437

Y073260 W0L0JBF68W7165202 124 Y073689 W0L0JBF68W7172616 574

Y073261 W0L0JBF68W7166766 313 Y073690 W0L0JBF68W7172634 124

Y073333 W0L0JBF68W7162194 437 Y073691 W0L0JBF68W7172862 374

Y073334 W0L0JBF68W7162463 811 Y073692 W0L0JBF68W7172890 376

Y073335 W0L0JBF68W7163391 875 Y073693 W0L0JBF68W7173081 434

Y073336 W0L0JBF68W7163438 126 Y073694 W0L0JBF68W7173086 563

Y073337 W0L0JBF68W7164870 437 Y073695 W0L0JBF68W7173474 438

Y073338 W0L0JBF68W7165143 124 Y073708 W0L0JBF68W7163188 129

Y073339 W0L0JBF68W7166852 124 Y073709 W0L0JBF68W7165038 616

Y073340 W0L0JBF68W7167184 376 Y073710 W0L0JBF68W7170621 369

Y073341 W0L0JBF68W7170192 435 Y073712 W0L0JBF68W7173274 498

Y073405 W0L0JBF68W7162582 875 Y073713 W0L0JBF68W7173484 565

Y073406 W0L0JBF68W7163149 631 Y073714 W0L0JBF68W7173686 435

Y073407 W0L0JBF68W7163173 313 Y073716 W0L0JBF68W7174032 354

Y073408 W0L0JBF68W7165462 124 Y073753 W0L0JBF68W7163114 412

Y073409 W0L0JBF68W7166794 438 Y073797 W0L0JBF68W7163244 435

Y073410 W0L0JBF68W7167213 320 Y073798 W0L0JBF68W7172478 435

Y073411 W0L0JBF68W7167692 445 Y073799 W0L0JBF68W7173495 437

Y073412

W0L0JBF68W7169862

676

Y073801

W0L0JBF68W7173749

300

Page 3 99-H-03

TAG #

ISOVIN #

W/SALE D/C

TAG #

ISOVIN #

W/SALE D/C

Y073802 W0L0JBF68W7173888 445 Y075861 W0L0JBF68W7183572 616

Y073803 W0L0JBF68W7174215 635 Y075862 W0L0JBF68W7183577 902

Y073840 W0L0JBF68W7164874 512 Y075864 W0L0JBF68W7185014 512

Y073841 W0L0JBF68W7171754 888 Y075870 W0L0JBF68W7180656 622

Y073842 W0L0JBF68W7172589 141 Y075871 W0L0JBF68W7181772 616

Y073843 W0L0JBF68W7174389 173 Y075873 W0L0JBF68W7183903 434

Y074012 W0L0JBF68W7172724 280 Y075874 W0L0JBF68W7184242 888

Y074126 W0L0JBF68W7173691 320 Y075875 W0L0JBF68W7184314 622

Y074127 W0L0JBF68W7176332 636 Y075879 W0L0JBF68W7184890 809

Y074491 W0L0JBF68W7176244 888 Y075881 W0L0JBF68W7185215 502

Y074492 W0L0JBF68W7176616 630 Y075978 W0L0JBF68W7183257 368

Y074493 W0L0JBF68W7176622 647 Y075979 W0L0JBF68W7183667 435

Y074495 W0L0JBF68W7176852 561 Y076239 W0L0JBF68W7190319 857

Y074496 W0L0JBF68W7176970 381 Y076250 W0L0JBF68W7191695 100

Y074498 W0L0JBF68W7163179 706 Y076291 W0L0JBF68W7191489 100

Y074499 W0L0JBF68W7165480 420 Y076297 W0L0JBF68W7191886 502

Y074500 W0L0JBF68W7170249 636 Y076366 W0L0JBF68W7190618 857

Y074503 W0L0JBF68W7176867 561

Y074506 W0L0JBF68W7177227 631

Y074507 W0L0JBF68W7177286 894

Y074571 W0L0JBF68W7177117 598

Y074572 W0L0JBF68W7177278 124

Y074573 W0L0JBF68W7177696 486

Y074574 W0L0JBF68W7177851 445

Y074575 W0L0JBF68W7179447 562

Y074660 W0L0JBF68W7177619 616

Y074773 W0L0JBF68W7176916 794

Y074872 W0L0JBF68W7179453 706

Y074874 W0L0JBF68W7179664 435

Y075440 W0L0JBF68W7176787 434

Y075443 W0L0JBF68W7179809 875

Y075449 W0L0JBF68W7180369 875

Y075455 W0L0JBF68W7180984 888

Y075532 W0L0JBF68W7179689 562

Y075536 W0L0JBF68W7179796 107

Y075538 W0L0JBF68W7180036 434

Y075539 W0L0JBF68W7180041 892

Y075541 W0L0JBF68W7180215 435

Y075542 W0L0JBF68W7180228 455

Y075545 W0L0JBF68W7180644 616

Y075548 W0L0JBF68W7180741 107

Y075626 W0L0JBF68W7176628 163

Y075628 W0L0JBF68W7179579 896

Y075630 W0L0JBF68W7180298 896

Y075631 W0L0JBF68W7180304 875

Y075632 W0L0JBF68W7180334 455

Y075634 W0L0JBF68W7180841 300

Y075635 W0L0JBF68W7182027 700

Y075856 W0L0JBF68W7177138 616

Y075857 W0L0JBF68W7179466 434

Y075858 W0L0JBF68W7180222 124

Y075859 W0L0JBF68W7180375 810

1

PRODUCT CAMPA IGN BULLETIN

99-H-04

21st April, 1999

SUBJECT : AIRBAG SENSING & DIAGNOSTIC MODULES

MODEL : 1998 VT SERIES VEHICLES

This bulletin is t o advise Holden Dealerships of the init iation of a saf ety relat ed campaign on some

1998 VT Series vehicles in order to identify and replace suspect Sensing and Diagnostic Module

(SDM) located under the centr e console assembly.

DESCRIPTION O F DEFECT

The Sensing and Diagnostic Module is part of the Supplemental Restraint System (SRS) with its

prime function to sense crash events and discriminate between non-deployment and required

deployment events.

Investigations have identified that certain batches of SDMs were manufactured with potentially

faulty microprocessors. As a consequence, the module may sense inaccurate information and

impede the behaviour of the Supplemental Restraint System.

DETAILS OF AFFECTED VEHICLES

Vehicles requiring this campaign action are 1998 built VT Series vehicles within the following Tag

No. rang e. From L367025 built (24/8/98) t o L413138 built (11/12/ 98) inclusive.

A total of 30,700 vehicles require inspection in order t o locate 19,300 suspect modules.

Only those modules whose serial number falls within an affected batch r equire replacement.

DEALERSHIP ACTION REQUIRED

On presentat ion of any vehicle considered by the customer to be aff ected by this campaign, or on

presentation of a 1998 VT Series vehicle for any reason, confirm that vehicle falls within the

affected range. For campaign action on vehicles within the affected range refer to

“Attachment A flow chart”.

In summary, the SDM module is to be inspected to determine whether its’ serial number falls

within an aff ected batch. I f so, t he m odule will need to be replaced.

VEHICLE IDENTIFICATION

All campaigned vehicles must have a completed campaign identification label applied to the right

hand front ‘A’ pillar, between the hinges, with details of the campaign, 99-H-04, dealership code

and date completed, legibly entered on the label with a permanent ink pen.

Extra campaign ident ification labels ar e available free of charge from :

Moore Business Systems

Facsimile: (03) 9270 8900

Attention: Mr. Bob Curry

Quote stock No. SD 28156, on a Moore Business Systems ‘packaged goods’ order form (or

facsim ile if not available) for a box of 100 labels.

2

VEHICLE LISTINGS

Listings of affected vehicles shown in our customer name and address files are included with this

bulletin. Should dealers have any information to update t he supplied listings, please update listing

and fax to:

Holden Limited

Att: P. STARICK

War ranty Administration

Facsimile: (03) 9647 2525

PARTS INFORMATION

Each dealership will receive an initial quantity of modules representing approximately 30% of the

total affected parts free of charge.

Use the Attached Material Order form to order additional parts from Salmat. Ensure your

dealership stock is frequently replenished.

Part No. Description Qty.

92057981 • SDM version 6. 2

Driver air bag 1

92057980 • SDM version 6. 2

Driver and Passenger air bags

1

92057976

• SDM version 8. 1

Driver, Passeng er and Side air bags

1

92053352

• SDM version 6. 2

No air bags fitted- Not installed to

Australian use vehicles – “EXPORT

ONLY”

1

OWNER NO TIFICATION

Owners will be contacted directly by letter from Holden, providing details of the safety related

campaign and requesting them to arrange for the module inspection and rectification by any

Holden dealership. T he t ext of the let ter is as follows:

Dear Holden Customer ,

At Holden we continually strive to enhance the ownership experience of our customers through

continuous product improvement, industry leading afters ales service and clear and concise cust omer

communication.

Holden’s foremost concern is the continued safety of our customers and the recall campaign

described below is being undert aken as a necessar y saf et y pr ecaut ion.

Holden has identified a number of vehicles where the control module for the Supplemental

Restraint System (Air bag & Seat belt pre-tensioners) may malfunction. This control module is

provided by an external supplier .

This may result in the warning light coming on and in very rare cases t his may cause the syst em to

be activated. Should your vehicles’ Supplemental Restraint System warning light illuminate prior

to the inspection for this campaign, it is important that the vehicle not be driven and you contact

your Holden dealer.

Holden has initiated a recall to inspect, and if necessary replace the control module. This action is

necessary to ensure that the Supplemental Restraint System will function correctly when required.

3

Our records show that your Holden vehicle was manufactured within the production range of

vehicles with a potentially affected control module. It is theref or e necessar y f or you to make a service

booking with a Holden dealership of your choice to have the control module inspected and if

necessay replaced.

This work will be carried out free of charge and can be completed while you wait, provided the

necessary arrangements have been made with your Holden dealer. The work required will take

approximately 1 hour t o complete.

We know that effective communication is vital to helping your understanding of the issues involved

and trust that this letter provides you with all the information you need. If you should have any

questions, please contact your dealer or call the Holden Customer Assistance Line - 1 800 632826,

and our operators will be pleased to assist.

Thank you for your attention in this matter. Please accept our apologies for any inconvenience

that may be caused by t his act ion.

Yours Sincerely

D.J.McMURRAY

Manager Customer Assistance

A single campaign notice will appear in the major metropolitan and regional daily newspapers, on

Tuesday 27th April, 1999 advising owners of the requirement for this rectification.

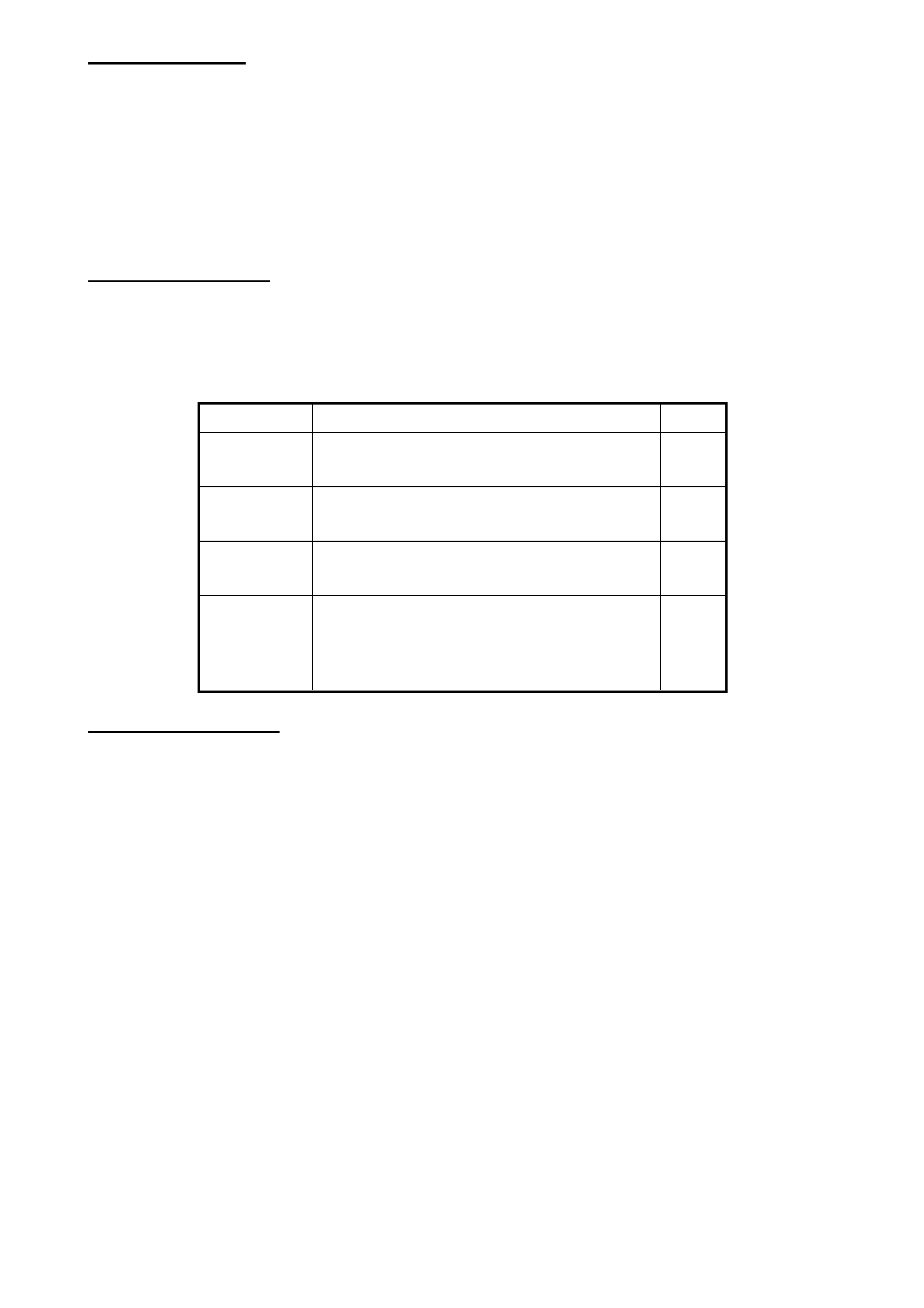

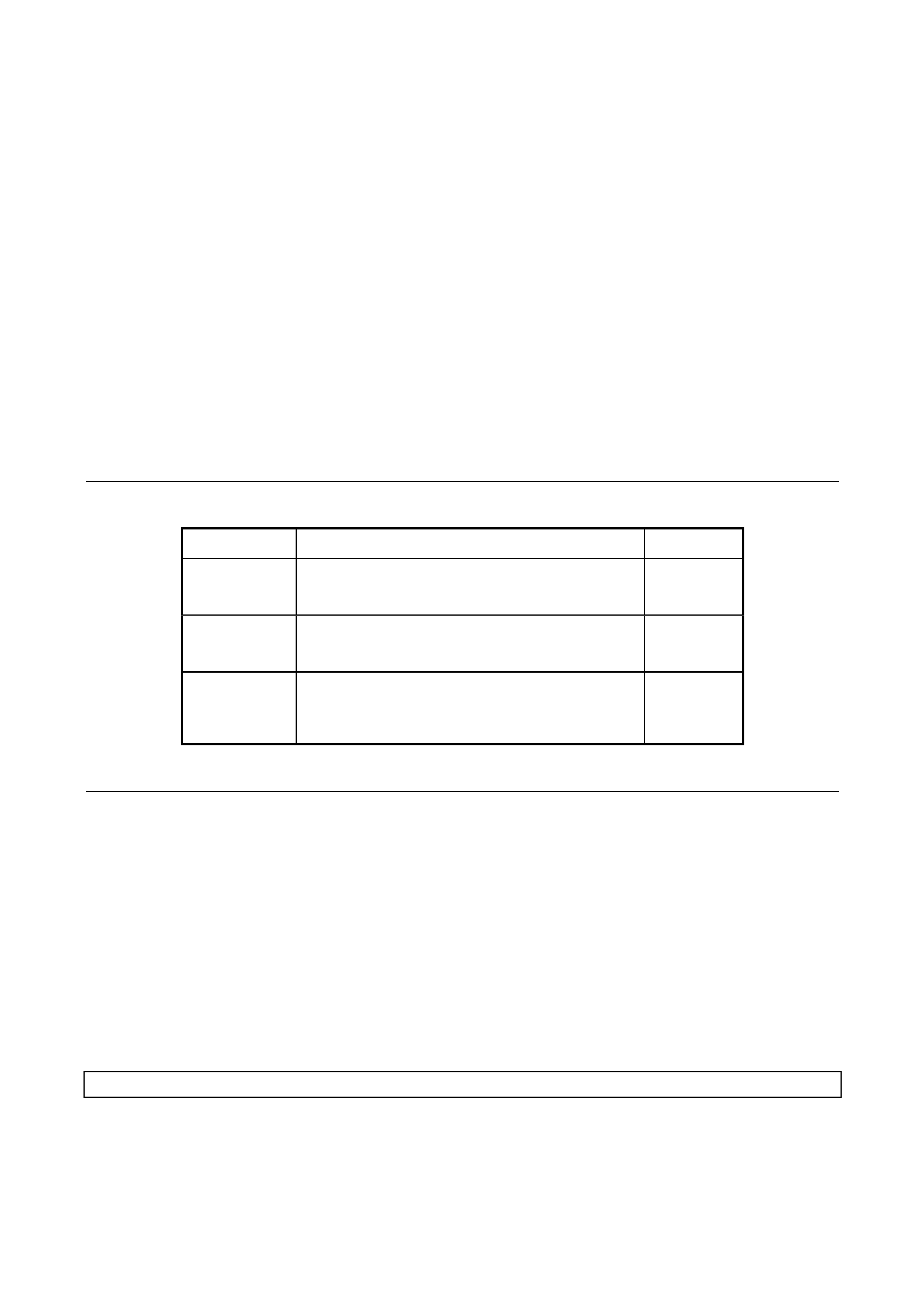

WARRANTY CLAIM INFORMATION

On completion of campaign action, dealers are requested to immedi ately submit a w arranty

claim using O NE of the Labour Operation Numbers as shown i n Attachment A, Flow chart.

Warranty claim submission is used to update our record of completion and determines whether

further customer cont act is necessar y to act ion all af fected vehicles.

Once again, please ensure on completion of the campaign action that a warranty claim is

submitted pr omptly.

REPAC will request re t urn of all replaced parts via the REPAC r eport.

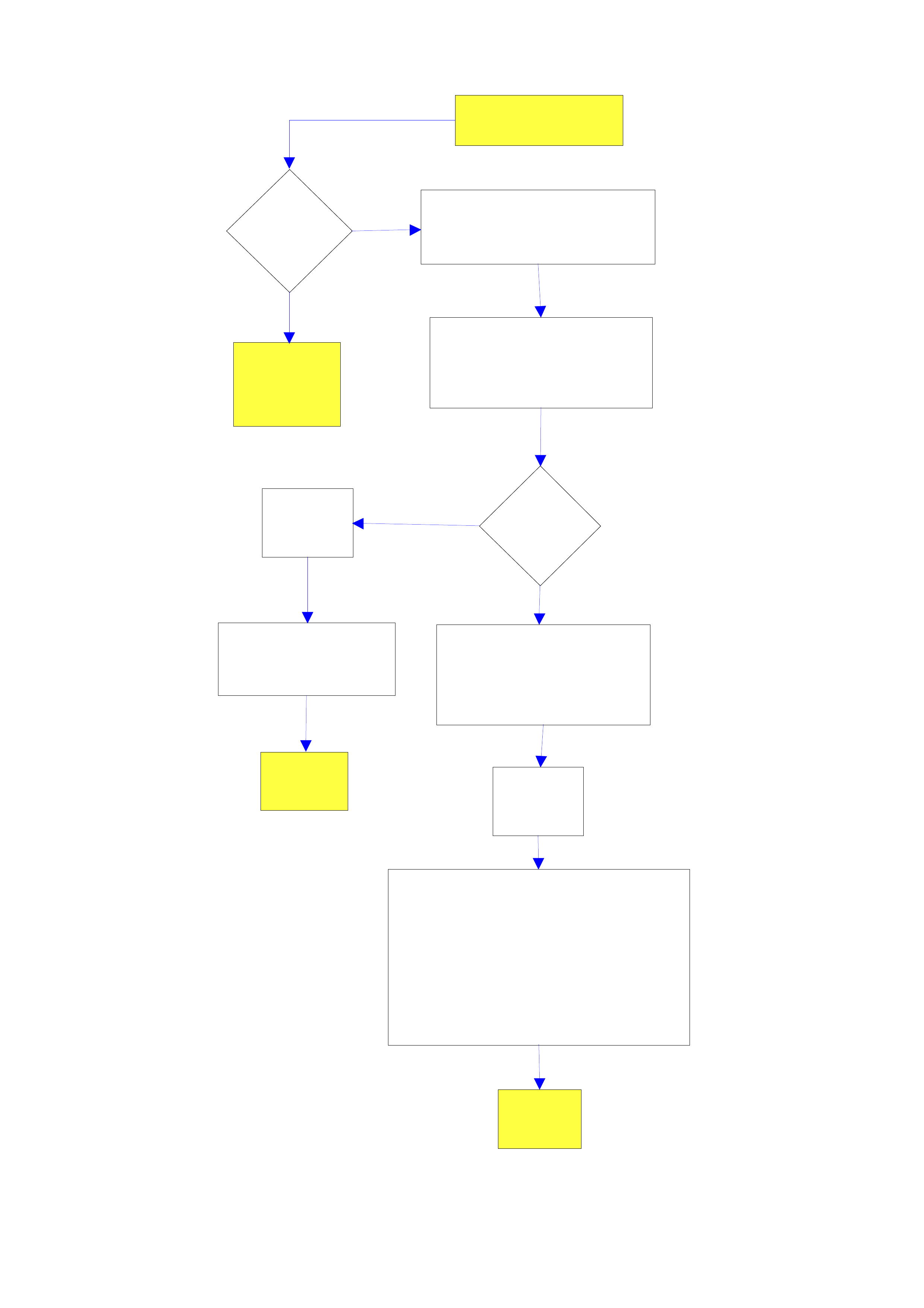

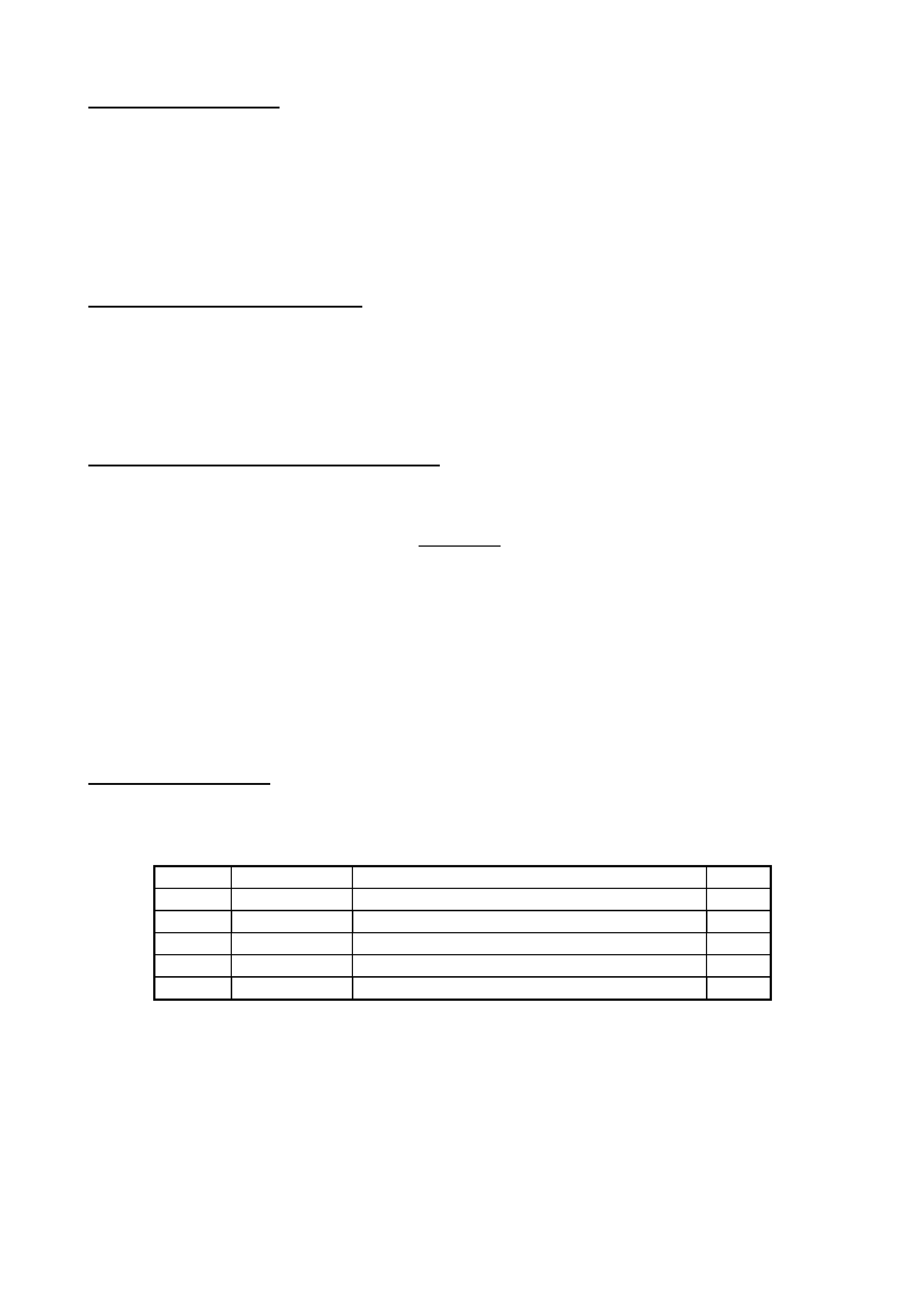

DETAILED TECHNICAL INSTRUCTIONS CAM PAIGN 99-H- 04

Not all vehicles will need to have the Sensing and Diagnostic Module (SDM) r eplaced. Only those

modules whose serial number f alls within an affect ed batch requir e replacement.

The flow chart on Attachment A will guide dealers to identify the affected modules. Refer to the

following procedur es for the inspection and where, necessary replacement of the module.

STEP 1. REMOVE T HE CENTRE CONSO LE ASSEMBLY

• Remove four screws securing centre console to transmission tunnel and slide front seats

forward to gain access to rear screws.

• Remove screws securing centre facia side extensions and remove centre facia side

extensions. Note there ar e three screws for the left-hand side extension and two screws for t he

right- hand side extension.

• Open centre console bin and pull rubber insert out from console bin. Remove two retaining

nuts.

4

• For vehicles with manual transmission, remove gearshift knob by rotating counter clockwise.

Prise gear shift boot from centre console.

• Remove rubber cap from transmission console and remove two screws from transmission

console. Prise out t r ansm ission console, disconnect ing power window harness where fitted.

• Remove two screws attaching storag e com par t ment to instr um ent console and r em ove st or age

compartm ent . Remove four screws attaching centre console t o inst r um ent panel.

• Partially remove centre console and disconnect wiring harness to centr e console. Fully remove

centre console by lifting rear end up and pulling assembly out.

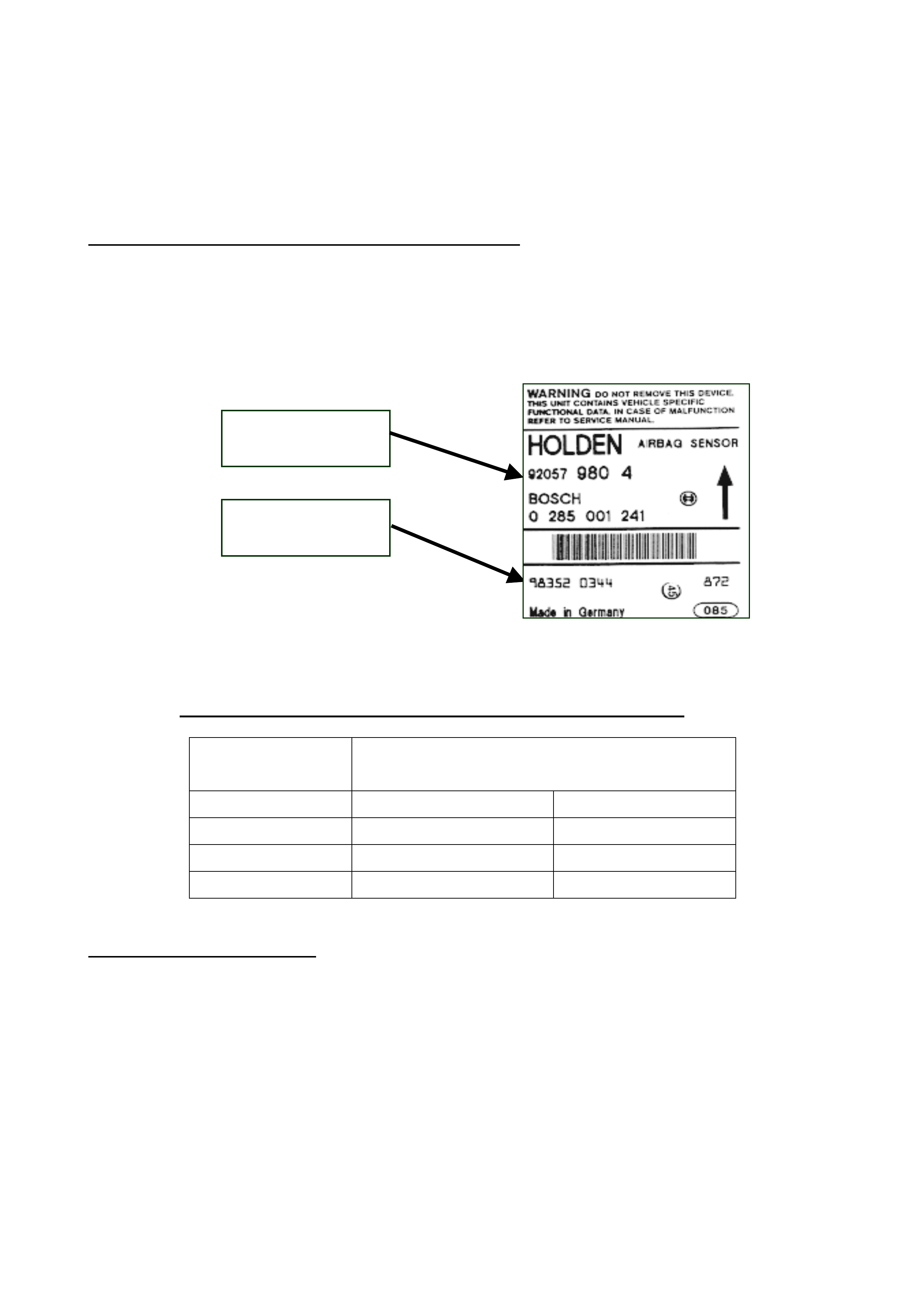

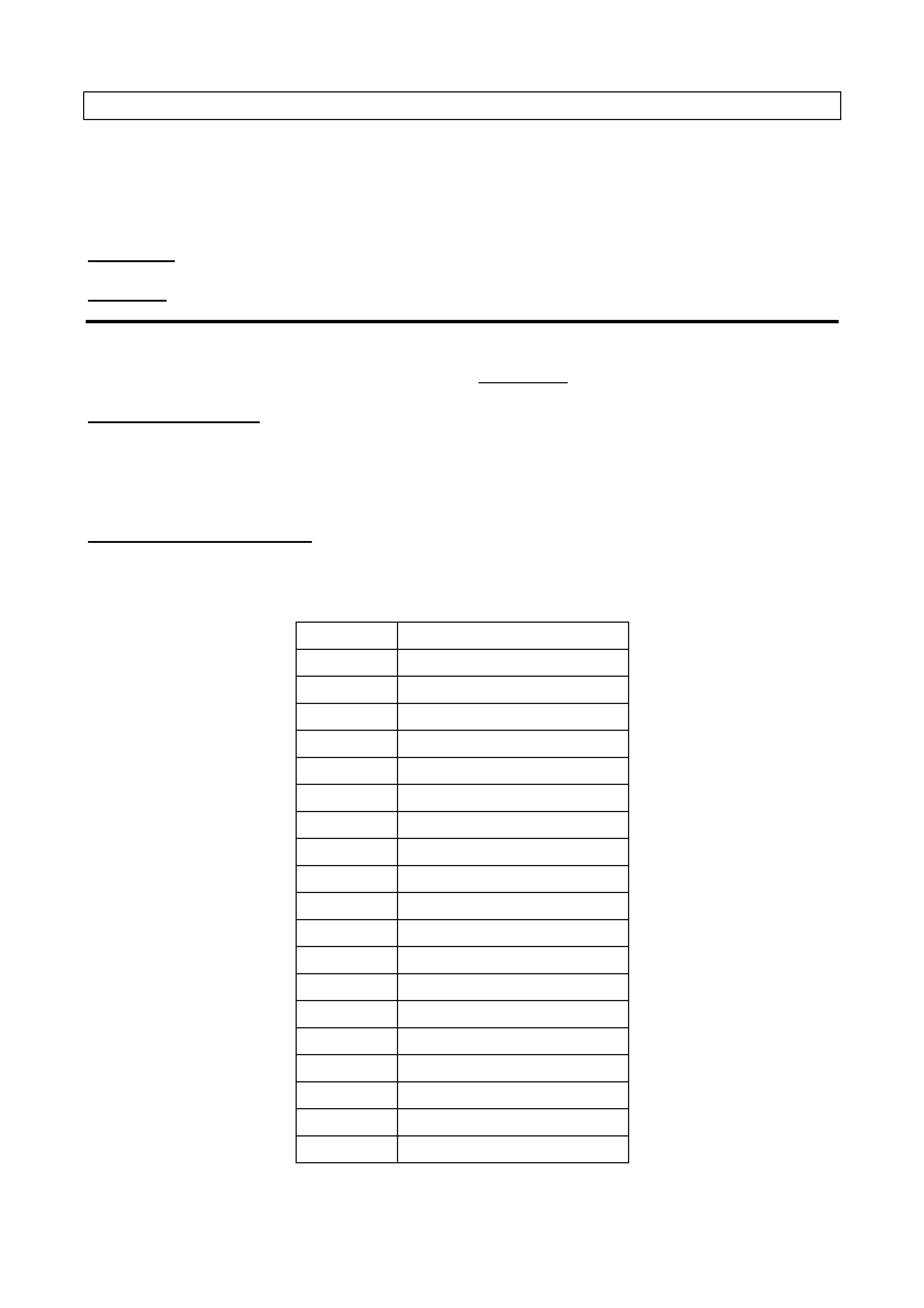

STEP 2. INSPECTIO N OF SDM SERIAL NUMBER

• Check the SDM part number and serial number as shown in Figure 1 below. If the ser ial

number falls within the affected range of ser ial numbers shown for that par t number (refer t o

Table 1 on the next pag e) , then the SDM must be replaced with a new one. Proceed to step

3. If the SDM serial number does not fall within the af fected r ange proceed to St ep 6.

Figure 1

• Table 1- Af f ect ed bat ches of SDM seri al numbers for each part number

SDM Part Number

Affected SDM Serial Numbers

From To

92075492

982510001

982880542

92075493

982400001

982930028

92075494

982450001

982940183

92057976

981920001

982930003

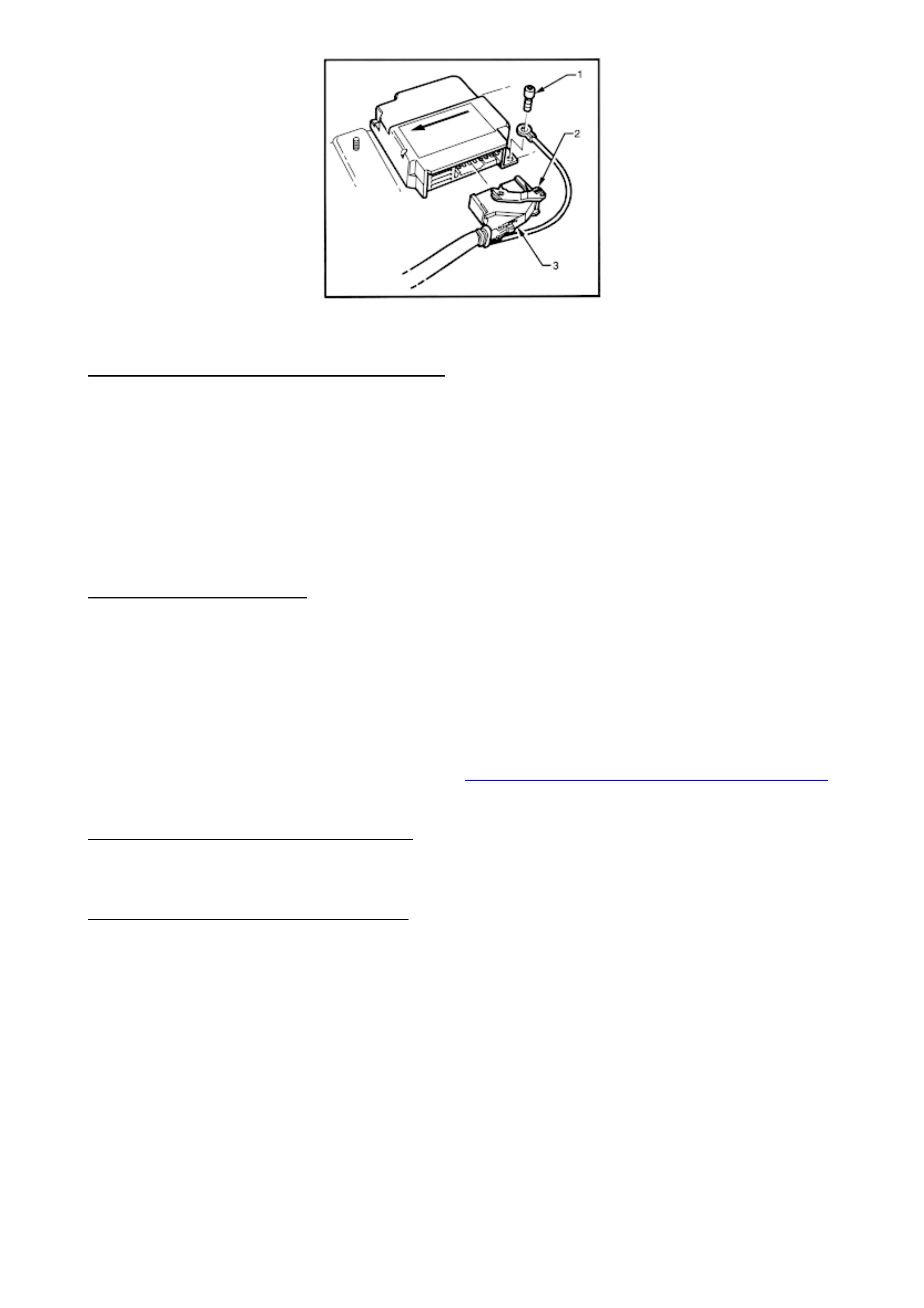

STEP 3. REMOVE SDM

• Disable the SRS system by disconnecting bot h t he battery earth and power leads and wait at

least 10 seconds bef or e per form ing any work on the vehicle.

CAUTION: T he SDM can maintain sufficient voltage t o cause SRS deployment for up t o 10

seconds aft er t he ignition switch is turned O FF or t he battery is disconnected.

• Using a number T30H Torx bit, Tool No. ETX30H and suitable holder such as Tool No.

J25359-8, loosen and rem ove the SDM to f loor attaching scr ew (1) with the earth lead attached

to it. Refer Figure 2 below.

• Lift up SRS wiring harness connector locking lever (2) and pull harness connector (3) out of

SDM. Refer Fig 1 below.

• Using the number T30H Torx bit, Tool No. ETX30H and suitable holder such as Tool No.

J25359-8, loosen and rem ove the r em aining two SDM to floor attaching screws.

• Remove SDM.

Holden Part Number

First 8 digits

SDM Serial Number

First 9 digits

5

Figure 2

STEP 4. INSTALL REPLACEMENT SDM

Installation of the new SDM is the reverse of r em oval procedur es, noting the following points:

• Ensure that the dir ectional arr ow on the SDM identificat ion label is point ing t owards the f r ont of

the vehicle.

• Install the SRS wiring har ness earth lead to t he left hand r ear SDM retaining screw.

• Using a number T30H Torx bit, Tool No. ETX30H and suitable holder such as Tool No.

J25359-8, tig hten SDM to floor att aching screws between 7-11 Nm.

• Connect the SRS wiring harness connector, ensuring that the connector is fully seated into

SDM module and the locking lever is locked down.

STEP 5. ENABLE SRS

• Reconnect both the bat tery power and earth leads.

• Switch ignition on, and observe the SRS warning lamp in the instrument cluster. The warning

lamp should be illuminated f or approximately 5 seconds. During this period the SDM performs

a wiring and self check .

• If no system faults ar e detected, t he SRS warning lam p will be switched off.

• If the warning lamp remains illuminated and an audible alarm chimes, or the warning lamp

illuminates 2 seconds after it was originally switched off , an SRS fault is present. Ref er to the

relevant volume of the VT Service Manual, 12M SUPPLEMENTAL RESTRAINT SYSTEM,

3 - DIAGNOSTICS.

STEP 6. REFIT CENTRE CONSOLE

• Reverse of r em oval procedur e.

STEP 7. APPLY CAMPAIGN LABEL

• Apply a ‘Campaign Completion’ label on the RHF door ‘A’ pillar between the door hinges and

submit a warranty claim.

6

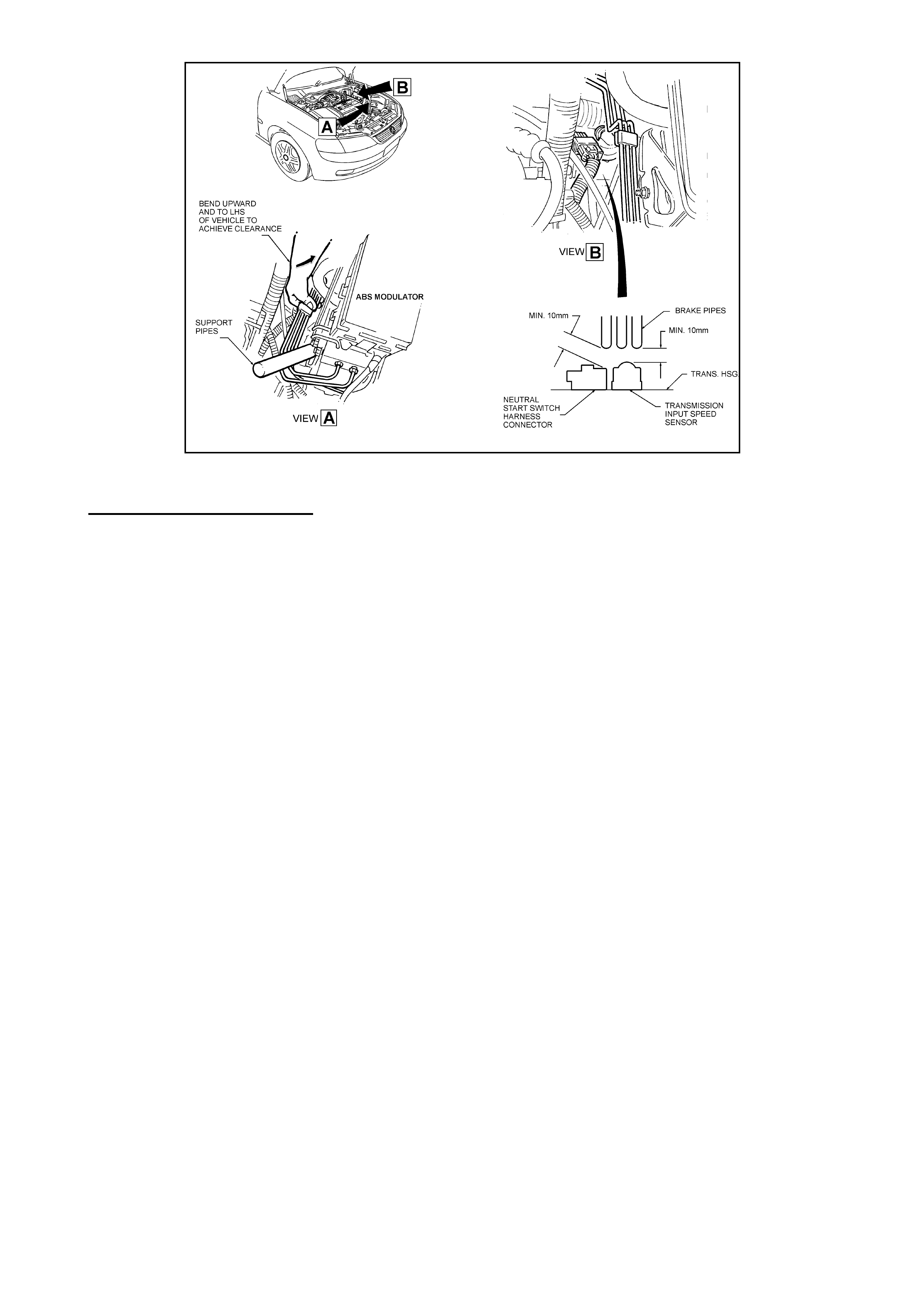

START

VEHICLE IS NOT

AFFECTED

(RETURN T O

CUSTOMER

REMO V E CE NT RE CONSOLE TO

DETERMINE SDM PART NUMBER AND

SERIAL NUMBER

SENSING & DIAGNOSTIC MODULE

(SDM) PART NUMBER

92075492 92075493 92075494 92057976

REPLACE SDM

WITH P ART

NUMBE R

92053352

REPLACE SDM

WITH P ART

NUMBE R

92057981

REPLACE SDM

WITH P ART

NUMBE R

92057980

APP LY CAMP AIGN L ABE L &

SUBMIT WARRANTY CLAIM

Lab our Op. : T 981002

Std Time : 1.0 Hrs

F/C : 96

Case T ype : 08

REPLACE SDM

WITH P ART

NUMBE R

92057976

IS SDM

SERIAL N U M BER

BETWEEN

982510001

AND

982880542

INCLUSIVE

IS

VEHICLE TAG

NUMBE R WIT HI N TAG

RANGE

L367025 TO L413138

INCLUSIVE?

IS SDM

SERIAL N U M BER

BETWEEN

982400001

AND

982930028

INCLUSIVE

IS SDM

SERIAL N U M BER

BETWEEN

982450001

AND

982940183

INCLUSIVE

IS SDM

SERIAL N U M BER

BETWEEN

981920001

AND

982930003

INCLUSIVE

APP LY CAMP AIGN L ABE L &

SUBMIT WARRANTY CLAIM

Lab our Op. : T 981002

Std Time : 1.0 Hrs

F/C : 96

Case Type : 08

APP LY CAMP AIGN L ABE L &

SUBMIT WARRANTY CLAIM

Lab our Op. : T 981002

Std Time : 1.0 Hrs

F/C : 96

Case Type : 08

APP LY CAMP AIGN L ABE L &

SUBMIT WARRANTY CLAIM

Lab our Op. : T 981002

Std Time : 1.0 Hrs

F/C : 96

Case Type : 08

SDM SERIAL NUM BER IS NOT IN THE AFFECTED RANGE

VEHICLE IS NOT AFFECTED -

DO NOT REPLACE SDM - Reinstall console

APPLY CAMPAIGN LABEL &

SUBMIT WARRANTY CLAIM

Labour Op. : T981001

Std Time : 0.8 Hrs

F/C : 96

Case Ty pe : 08

FINISH

FINISH

FINISH

FINISH

FINISH

YES YES

YES YES

NO

NO NO

NO

YES

FINISH

Attacmnent A - 99-H-04 SDM IDENTIFICATION PROCESS FLOW CHART

7

Attachment to Campaign Bulletin 99-H-04

SALMAT

MATERIAL ORDER FORM

Holden VT Series

Sensing and Diagnostic Modules

Fax No.: (03)-9251-6352

Attention: Kelly Sherriff

This dealership wishes to order additional Sensing and Diagnostic Modules for completion

of recall Campaign 99-H-04.

Please dispatch the parts detailed below, to this dealership, as soon as possible.

Part No. Description Amount

92057981

SDM version 6.2

Driver air bag

92057980

SDM version 6.2

Driver and Passenger air bags

92057976

SDM version 8.1

Driver, Passenger and Side air

bags

From Dealer Code: ___________ Date:_____________________

Dealership Name: ______________________________________

Dealership Service Manager: _____________________________________

(please PRINT your name)

Fax This Form To : SALMAT (03)-9251-6352

PRODUCT CAMPAIGN BULLETIN

99-H-05

July 9, 1999

SUBJECT : INSPECTION OF STEERING GEAR ASSEMBLY

MODEL : VT SERIES II – ALL LEVEL 1 & 2 VEHICLES

This bulletin is to advise Holden Dealerships of the initiation of a safety related campaign to

inspect the steering gear assembly on VT Series II, Level 1 & 2 vehicles (excluding Calais).

Description of Def ect

During assembly of the steering gear at the supplier, the rackbar and the inner ball joint housing

are staked (crimped) af ter the correct attaching torque has been achieved. It has been brought to

Holden’s attention that on a small number of steering gear assemblies, the final attaching torque

may not have been achieved and subsequent staking has not occurred.

Details of Affected Vehicles

Vehicles requiring this campaign action are VT Series II, Level 1 & 2 (excluding Calais) vehicles.

Vehicles requir ing this campaign action are all 1999 built VT Series II vehicles built bet ween

27/05/99 to 22/06/99 inclusive.

Vehicle Identification Numbers (VIN) L464495 to L473691 (6H8VTK35HXL464495 to

6H8VTK69HXL473691) inclusive, sets the range of vehicles affected.

5941 vehicles require inspection.

DEALERSHIP ACTION REQUIRED

Vehicles in Dealership Stock

Perform the necessary campaign action on any VT Series II vehicle held in Dealership stock that

falls within the affected VIN range. These vehicles must have this campaign action completed

befor e r etail delivery of the vehicle, or transf er to another dealer ship.

On Presentati on of Any VT Series I I Vehicle

On presentation of any VT Series II vehicle considered by the customer to be affected by this

action, or on presentation of a VT Series II vehicle for any reason, confirm that the vehicle falls

within the affected VIN range. If the vehicle requires campaign action, refer to the Detailed

Technical Inst r uctions included at the end of this bulletin.

In summary, the steering gear needs to be visually inspected to ensure that staking has occurred

which validates that the inner ball joint housing has been

torqued correctly into the rackbar. Both sides are staked simultaneously, so to prove the process,

only the left-hand side needs to be inspected as it is easier to access. If the inspection fails to

validate the process, the steering gear must be replaced. Upon replacing the steering gear, carry

out a f r ont-end alignm ent.

Aft er ‘inspection’ or ‘inspect ion and replacement’, apply a Campaig n Com pleted identif ication label

to the right hand front ‘A’ pillar and subm it a warranty claim using t he inform ation provided.

Vehicle Ident ification

All campaigned vehicles must have a Campaign Complet ed identification label applied to t he right

hand front ‘A’ pillar, between the hinges, with details of the campaign, 99-H-05, dealership code

and date completed, legibly entered on the label with a permanent ink pen.

Extra campaign ident ification labels ar e available free of charge from :

Moore Business Systems

Facsimile: (03) 9270 8900

Attention: Mr. Bob Curry

Quote stock No. SD 28156, on a Moore Business Systems ‘packaged goods’ order form (or

facsim ile if not available) for a box of 100 labels.

Vehicle List ings

Listings of affect ed vehicles shown in our customer nam e and addr ess files are included with this

bulletin. Should dealers have any infor m at ion to update the supplied list ings, please update listing

and fax to:

Holden Ltd

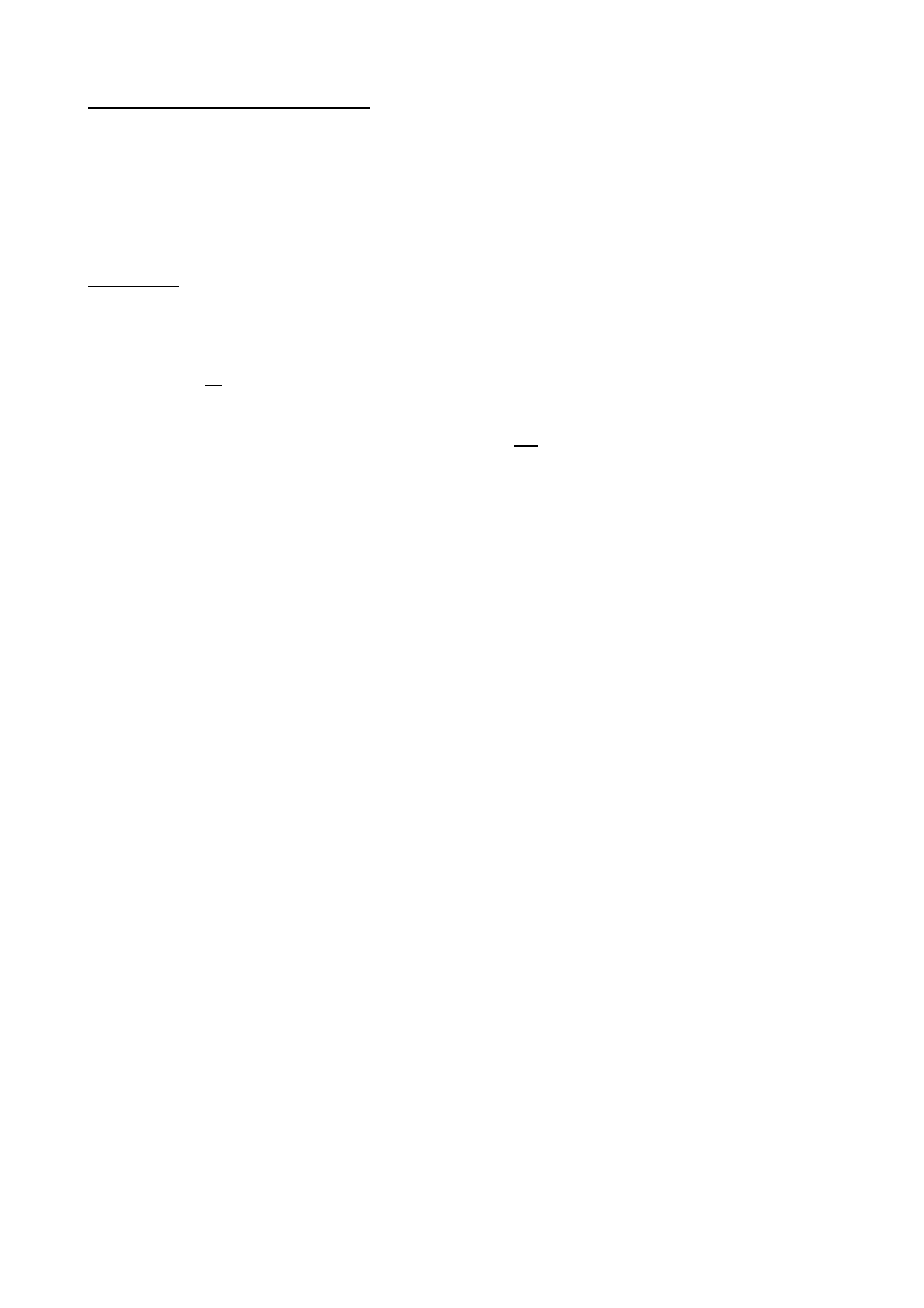

Att: P. Starick

War ranty Administration

Facsimile: (03) 9647 2525

Parts Information

Required par t s ar e to be ordered from HSPO.

The single part required to complete the inspection is the Inner Bellows Strap – Holden P/N

92140017.

In the unlikely event that a vehicle fails the inspection, the steering gear assembly must be

replaced. Replacement steering gears – Holden P/N 92057321 m ust be ordered through DCS via

the Emergency Order Process. Only order steering gear assemblies when a defective steering

gear has been ident ified.

Under no circumstances is a vehicle that fails the steering gear inspection to be returned to the

customer unt il a r eplacem ent steering gear assembly has been f it ted.

Owner Notification

Owners will be contacted directly by letter from Holden, providing details of the recall and

requesting them to arrange for the campaign action to be carried out. Following is a draft of the

customer letter.

Dear Holden Customer ,

At Holden we continually strive to enhance the ownership experience of our customers through

continuous product improvement, aftersales service and effective customer communication.

Holden’s foremost concern is the continued safety of our customers. Accordingly the recall

campaign described below is being under t aken as a safety precaut ion.

Holden has been alerted to the fact that in a limited number of vehicles within a determined

production range, a steering system component supplied to Holden may not have been

manufactur ed to the correct specification. In cert ain circumst anc es, this m ay resul t in poor or

unpredictable steer ing r esponse.

Our records show that your Holden VT Series II vehicle was manufactured within the vehicle range

which may include this component. It is therefore necessar y for you to contact a H olden dealership

of your choice as soon as possible to have your vehicle inspected and any necessary work

performed.

All work w ill be car ried out free of charge and your vehicle can be inspected w hile you w a it ,

provided the necessary ar r angem ents are made in advance w ith a Holden dealer . If on inspect ion

it is determined that your st eering syst em component requires replacement, the dealership w ill

endeavour to minimise any inconvenience t o you.

Holden has initiated this action as a precautionary measure to ensure the steering system of your

vehicle is functioning correctly.

We know that ef fect ive communicat ion is vital t o helping your under standing of the issues involved

and trust that this letter provides you with all the information you need. If you should have any

questions, please contact your dealer or call the Holden Recall Assistance Line - 1800 632 826,

and our operator s w ill be pleased to assist.

Thank you for your at t ention to this matter. Please accept our apologies for any inconvenience t hat

may be caused by this action.

Yours Sincerely

D. McMurray

Manager Customer Assistance

WARRANTY CLAIM INFORMATION

ON COMPLETION OF CAMPAIGN ACTION DEALERS MUST IMMEDIATELY SUBMIT A

WARRANTY CLAI M using the following data.

Description: Inspect Steering Gear

Labour Operat ion No: T981201

Standard T im e: 0.5 Hours

Failure Code: 96

Case Type: 08

In the event that t he steering gear is replaced:

Description: Inspect, Replace Steering Gear & Wheel Align

Labour Operat ion No: T981202

Standard T im e: 2.5 Hours

Failure Code: 96

Case Type: 08

The range of vehicles has been identified using t he VIN number. Please ensure all vehicle details

are included when submitting warrant y claim informat ion as per t he normal warranty processes.

War ranty claim submission is used to updat e our r ecord of cam paign completion and determines

whether furt her cust omer contact is necessar y to act ion all af fected vehicles. Please ensur e on

completion of the campaig n action that a warranty claim is submitted prompt ly. I n the event that

parts ar e r eplaced, REPAC will request ret ur n of all replaced par t s via the REPAC r epor t .

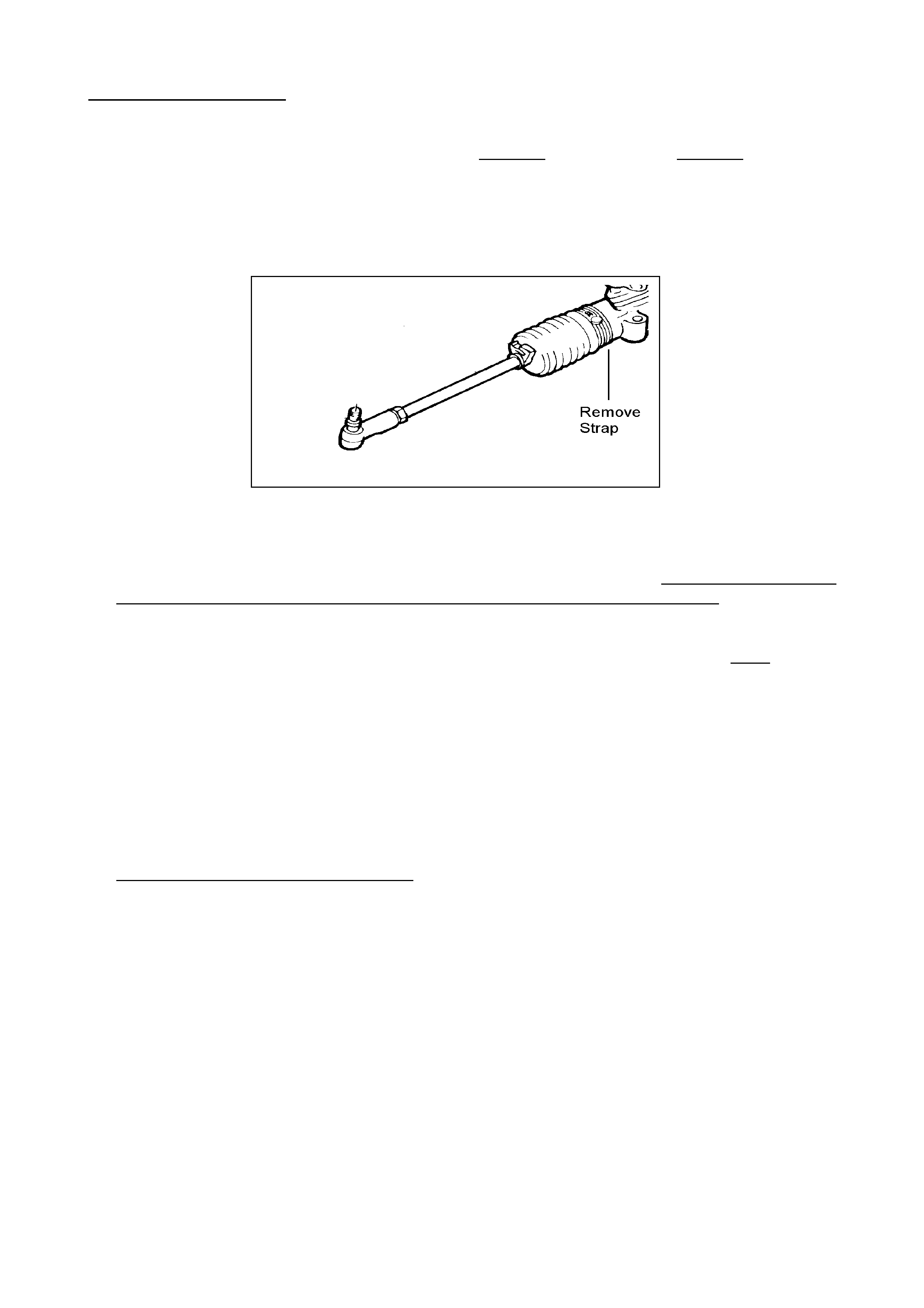

DETAILED TECHNICAL INSTRUCTIONS CAMPAIGN 99-H-05

The purpose of the inspection is t o locate a stak e m ar k that signif ies that the inner ball joint to

rackbar t or queing and subseq uent staking process was achieved by the supplier. The stak e m ark

is located in the k e yway type slot and located slightly above the normal field of view, made visible

by removing the tie rod inner bellows. T he st ake def or ms (crimps) the mating t hr eads, which aids

in preventing t he inner ball joint from r ot ating.

INSPECTION PROCESS:

1. Ensure the vehicle is a VT Series II, Level 1 or 2 vehicle (non-variatronic) and the vehicle is

within the affected ISO VI N r ange 6H8VTK35HX L464495 t o 6H8VTK69HXL473691.

2. Raise the vehicle on a hoist and remove the inner left steering gear inner bellows strap that

secures the bellows to the steering gear main housing as indicated in Figure 1. Slide the

bellows outboard, off the steering rack housing, exposing the inner steering gear ball joint

housing. O nly the left side of the steering g ear needs to be inspected.

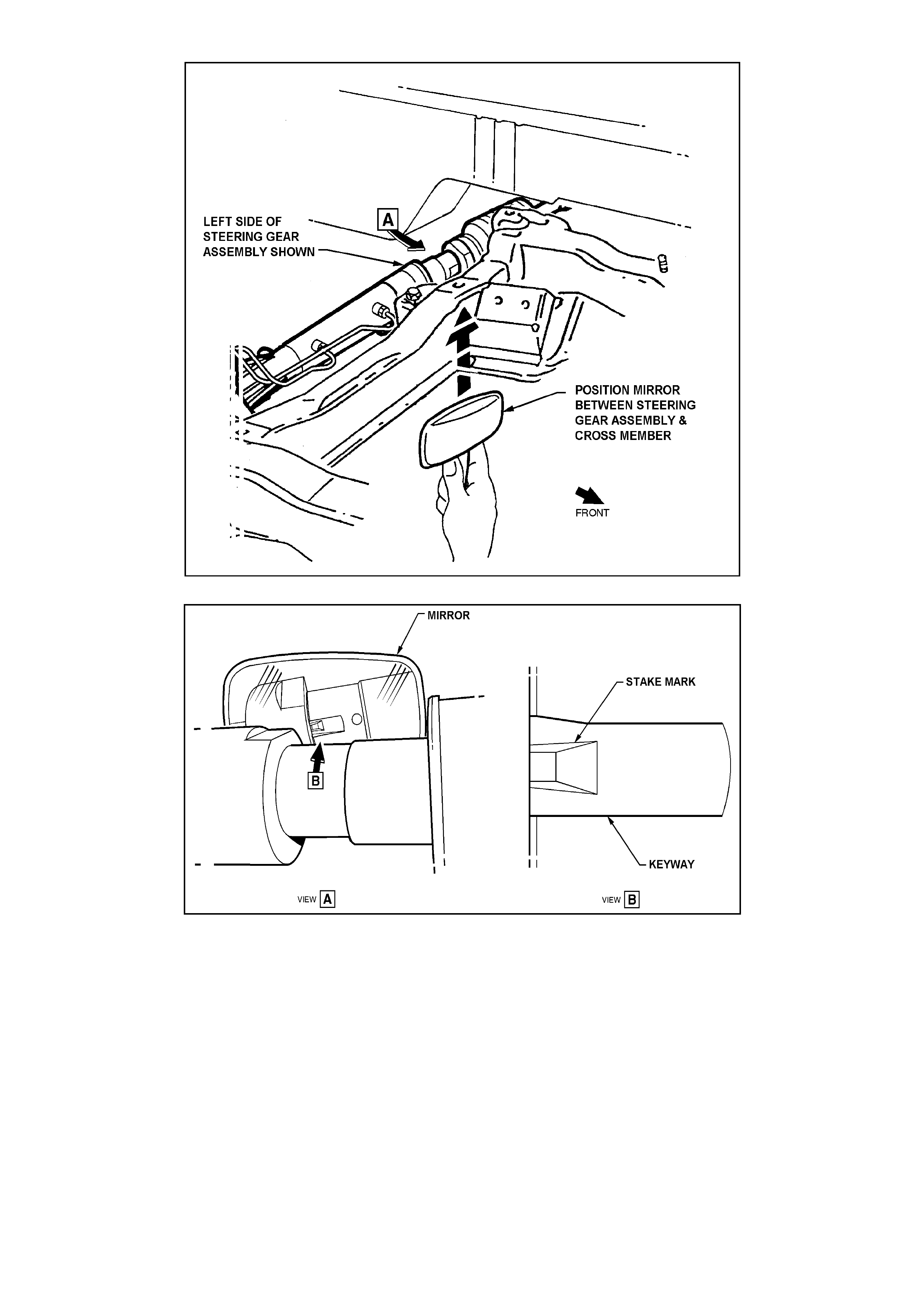

Figure 1

3. Locate the milled keyway on the rackbar by standing at the front of the vehicle and feeling for

the milled slot. The keyway is slightly above the normal field of view at the joining of the inner

ball joint housing and the rack bar. To inspect for the staking mark, a mirror and light source

must be used to locate the keyway otherwise proper inspection is not possible as indicated in

Figure 2 on t he following page.

4. Once this milled keyway has been located, the technician must identify a small surface

indentation in the keyway. Now move and stand behind the steering gear. Place the mirror

forward of the inner ball joint. From this position angle the mirror to enable a clear view of the

milled keyway. Refer Figure 2 and 3.

5. The stake indentation is approximately of rectangular shape in the milled keyway close to the

connection of the inner ball joint housing onto the rackbar. The dimensions of the stake mark

may vary slightly from gear to gear. The process has been completed if there is a definitive

surf ace ‘mark up’ within the keyway. Figure 3 is r epresentative (mir rored ref lection) of what the

technician will see.

Information Regarding the Stake Mark: During the manufacturing process, the tie rod / inner

ball joint assembly is attached to the rack bar via the threaded stud protruding from the inner

ball joint housing. Once the inner ball joint housing has been torqued correctly, the rackbar is

staked in the keyway area which deforms the mating threads increasing the screw friction of

the assembly.

NOTE: If during the tightening process the inner ball joint housing to rackbar attaching torque

is not reached, no st aking occur s , and t here will be no surface ‘mar k up’ of any kind evident. If

the surface at the base of the keyway is a smooth machined surface, then no staking has

taken place and t he r ack f ails the inspection.

Figure 2

Figure 3 – Example of mirrored stake mark (may vary slightly between gears)

VEHICLES PASSING INSPECTION

• If the stake mark is positively observed and there is a definite change in the surface

characteristics of the r ackbar k eyway as indicated in Figure 3, t he vehicle passes inspection.

• Using part num ber 92140017 – Strap Bellows Inner, r eat t a ch t he bellows to t he st eer ing gear .

• Apply a Campaign Completed identification label to the right hand front ‘A’ pillar and submit a

warranty claim using the inform ation provided.

VEHICLES THAT FAIL INSPECTION

• If the stake mark is not positively observed and there is no definitive change in the surface

characteristics of the rackbar keyway, the steering gear must be replaced. After replacing the

steering gear, Holden P/ N 92057321, perf orm a f ront-end alig nment.

• Apply a Campaign Complet ed identification label to the r ight hand front ‘A’ pillar and submit a

warranty claim using the inform ation provided.

1

PRODUCT CAMPAIGN BULLETIN

99-H-06

November 4, 1999

SUBJECT : STEERING KNUCKLE

MODEL : 1999 VT SERIES II VEHICLES

This bulletin announces t he initiation of a safety relat ed cam paign on eig hty ( 80) 1999 VT Series II

vehicles in order to replace bot h St eer ing Knuckles.

DESCRIPTION O F DEFECT

Investigation has shown that a small number of Steering Knuckles may have been manufactured

in a specific batch where the casting operation may have caused casting defects to occur. This

may potentially comprom ise t he dur abilit y of the k nuckle.

DETAI L S O F AFFECTED VEHICLES

A total of eighty (80) vehicles are affected and require BOTH knuckle assemblies to be replaced.

These vehicles are identified in Table 1 below:

List of Affected Vehicles

L477764 L481425 L481557 L481589

L477999 L481426 L481561 L481592

L480047 L481427 L481562 L481593

L480858 L481428 L481563 L481595

L481194 L481461 L481564 L481596

L481342 L481513 L481566 L481597

L481365 L481538 L481567 L481599

L481402 L481540 L481569 L481600

L481404 L481542 L481570 L481603

L481406 L481543 L481571 L481604

L481408 L481544 L481572 L481605

L481410 L481545 L481574 L481609

L481411 L481547 L481576 L481610

L481412 L481548 L481578 L481611

L481413 L481550 L481579 L481613

L481415 L481551 L481580 L481614

L481416 L481552 L481583 L481620

L481419 L481553 L481585 L481621

L481420 L481555 L481587 L481622

L481421 L481556 L481588 L481630

Table 1

2

OWNER NO TIFICATION

A Holden representative has contacted each owner affected by this campaign by phone and

provided details of t he safety related cam paign. Your dealership has been nom inated to carry out

the campaig n r ect ification work and a booking dat e and time has been arranged.

Your cooperation and assistance in complying with the customer’s request via Holden CAS is

specifically requested so that customer inconvenience is minimised and the required action is

completed on all vehicles as quickly as possible.

DEALERSHIP ACTION REQUIRED

On presentation of the vehicle considered by the customer to be affected by this campaign,

confir m that the vehicle is listed in T able 1.

If the vehicle is listed in Table 1, both knuckles must be replaced. Refer to “Detailed Technical

Instruct ions Campaign 99-H- 06” .

CAMPAIGN COMPLETION IDENTIFICATION

All campaigned vehicles must have a Campaign Completed identif ication label applied to the rig ht

hand front ‘A’ pillar, between the hinges, with details of the campaign, 99-H-06, dealership code

and date legibly entered on t he label with a perm anent ink pen.

Extra campaign ident ification labels ar e available free of charge from :

Moore Business Systems

Facsimile: (03) 9270 8900

Attention: Mr. Bob Curry

Quote stock No. SD 28156 on a Moore Business Systems ‘packaged goods’ order form (or

facsim ile if not available) for a box of 100 labels.

PARTS INFORMATION

All requir ed parts (as listed below) will be supplied directly f rom Holden (via Salmat) in a pack age.

Parts will be shipped so they arrive prior to t he vehicle arr iving for this cam paign action.

Item Part No. Description Qty.

1 92078263 • Left Hand Steer ing Knuckle Ass. 1

2 92078262 • Rig ht Hand Steering Knuckle Ass. 1

3 11090821 • Bolt- St eer ing knuckle to str ut 4

4 92138205 • Nut- St eering k nuckle to str ut 4

5 92138554 • Nut- Ball joint to Steering knuckle 2

3

WARRANTY CLAIM INFORMATION

On completion of campaign action, dealers are requested to immedi ately submit a w arranty

claim.

Description: Replace Front Suspension Steer ing Knuckle (bot h sides)

Labour Operat ion No: T981301

Standard T im e: 2.5 Hours (includes Wheel Alignment)

Failure Code: 96

Case Type: 08

Please note that the fr ont wheel alignment check included in the repair procedur e is included in the

Standard T im e.

Also note that a 0.5 hrs bonus is included in the Standard Time to cover miscellaneous activities

associated with priority booking of customer s.

Please ensure all vehicle details are included when submitting warranty claim information as per

the normal warranty process.

Warranty claim submission is used to update our record of campaign completion and determines

whether furt her cust omer contact is necessar y to act ion all af fected vehicles.

Please ensure on completion of the campaign action that a warrant y claim is submitted promptly.

On completion of the campaign action ensure a defective material tag is attached to the steering

knuckle.

REPAC will request return of all replaced part s via the REPAC r epor t.

4

DETAI L ED TECHNICAL INSTRUCTIONS CAMPAIGN 99-H-06

Vehicles requiring this campaign action are eighty (80) 1999 built VT Series 2 vehicles listed in

Table 1.

DO NOT REPLACE THE STEERING KNUCKLES UNLESS THE TAG NUMBER IS LISTED ON

TABLE 1 AND YOU HAVE RECEIVED A CUSTOMER BOO KI NG DETAIL FORM .

STEERING KNUCKLE

REMOVE

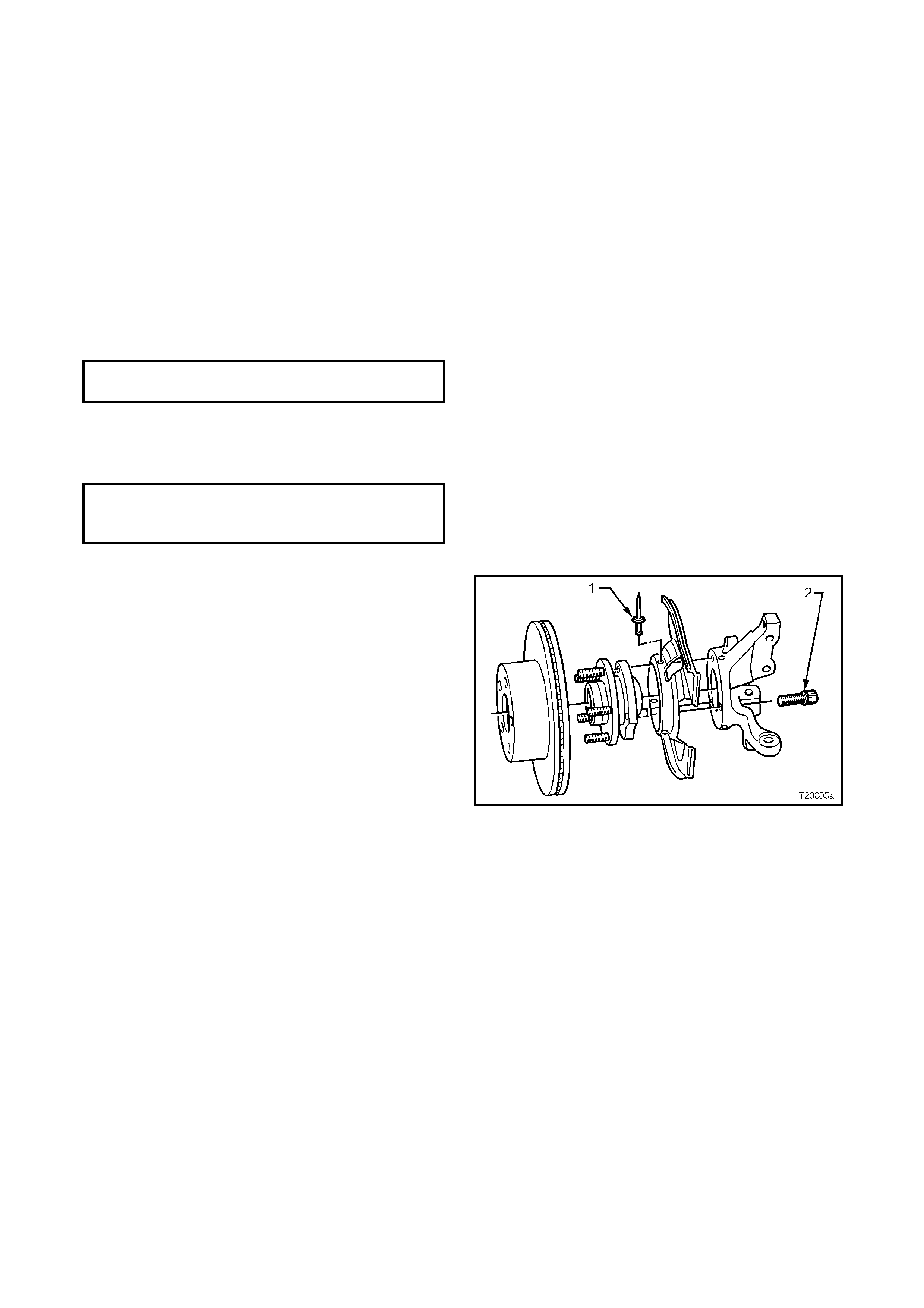

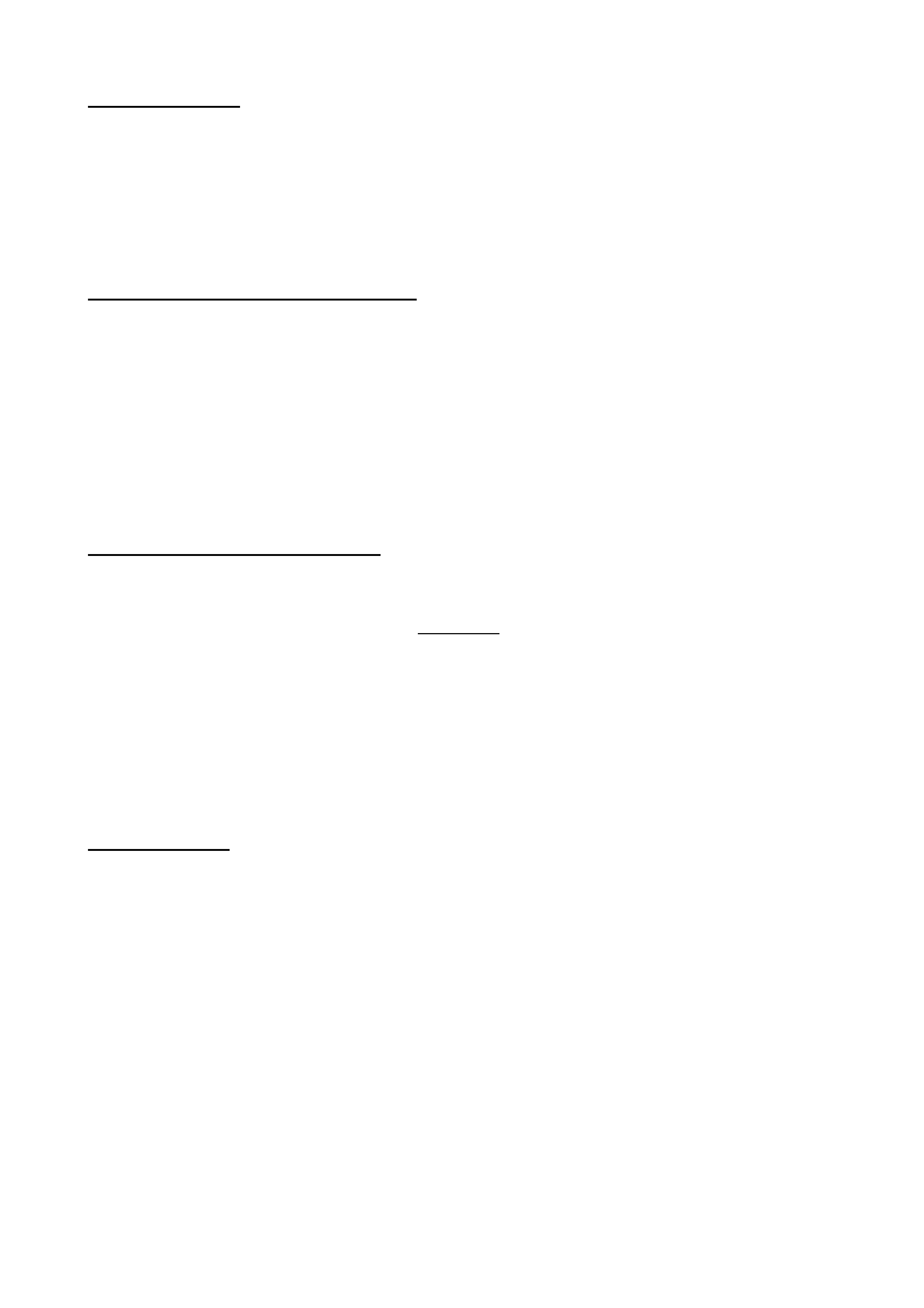

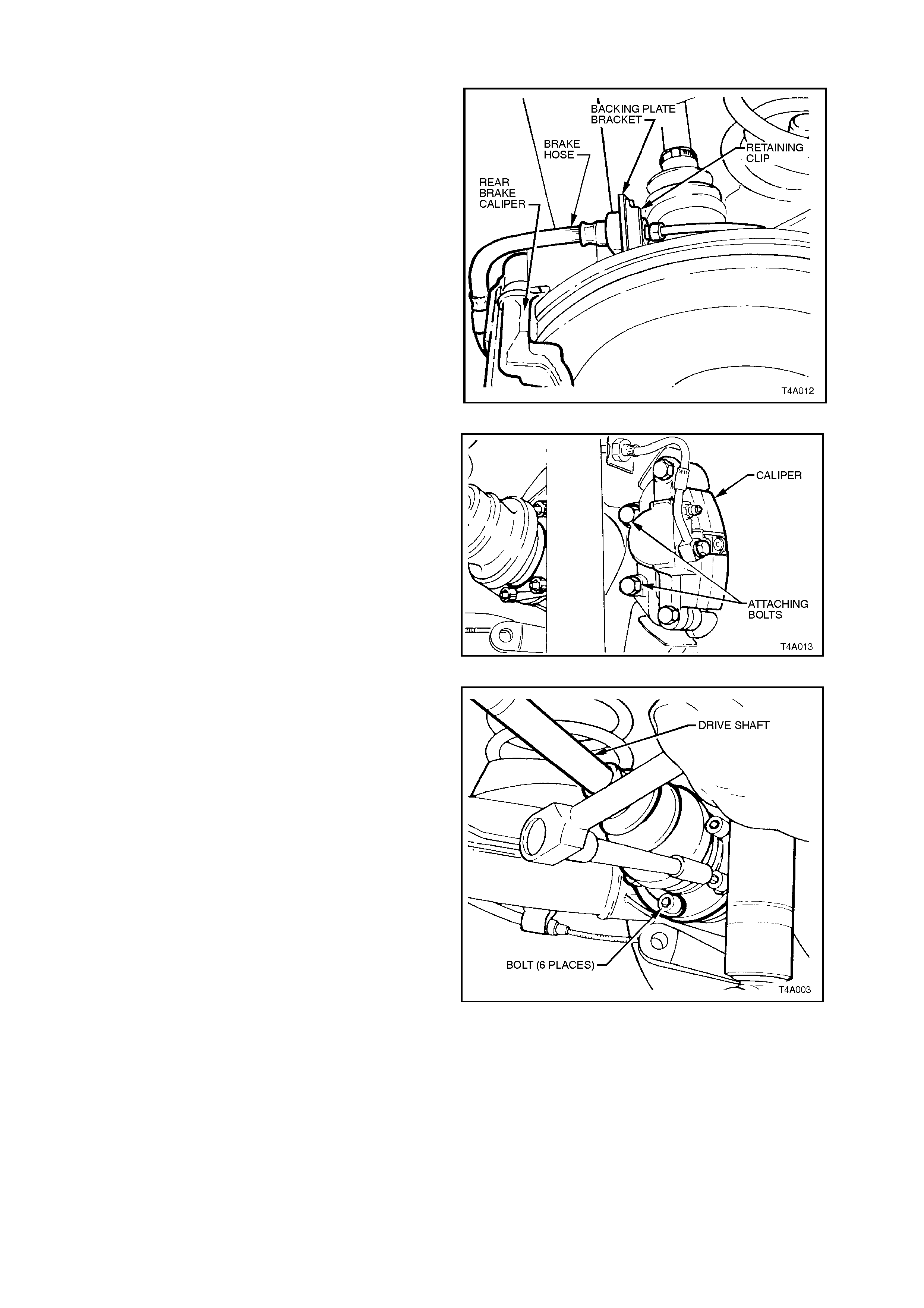

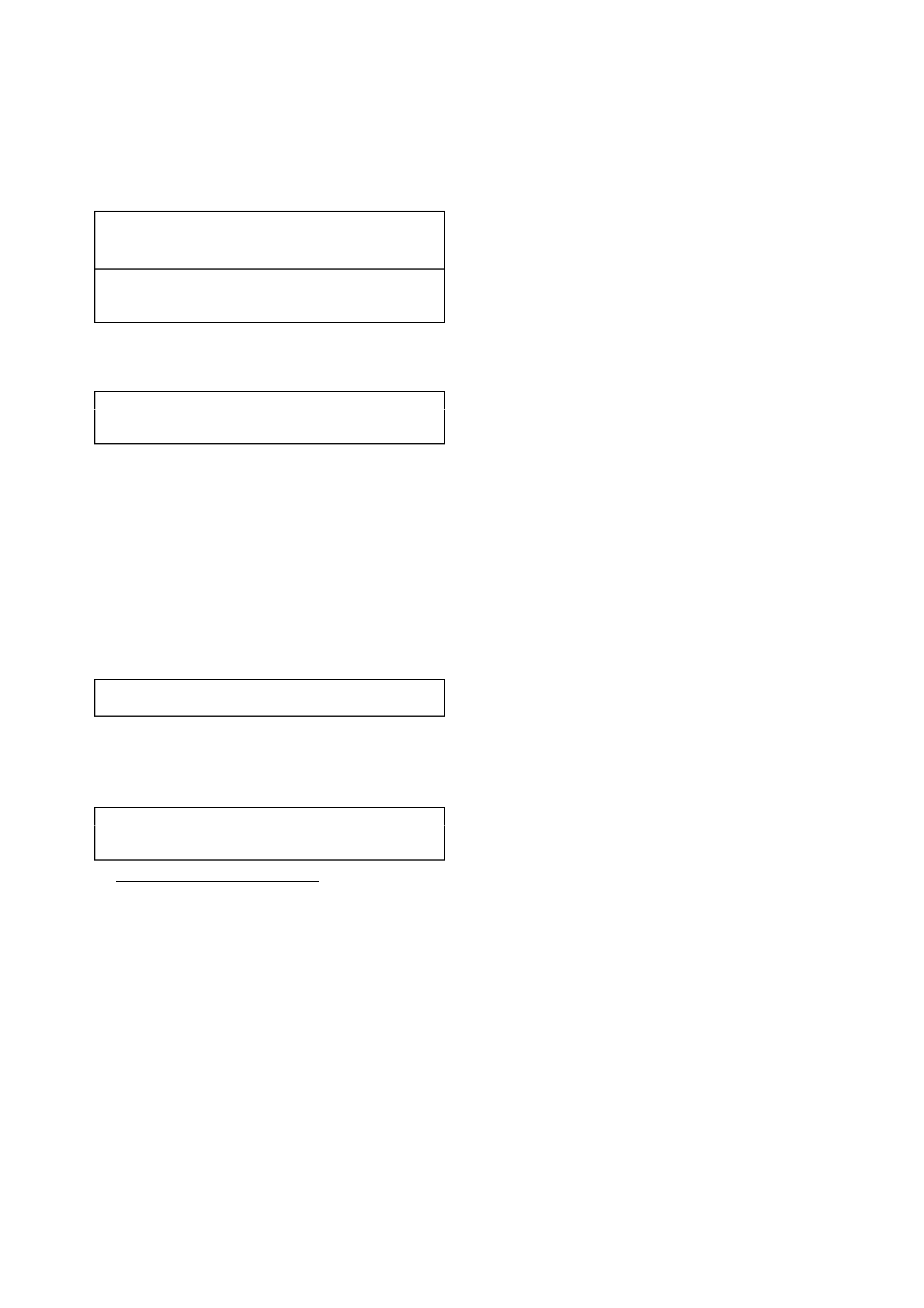

1. Remove wheel cover (steel wheels) or centre

cap (alloy wheels).

2. Mark relationship of front road wheels to hub

and brake disc. Loosen then remove road

wheel attaching nuts. Remove the road wheels.

3. Remove brake caliper anchor plate retaining

bolts and washers (1), lift caliper assembly (2)

from brake disc. Position caliper (2) in such a

way that no strain is placed on the brake hose.

If necessary, tie caliper to the suspension

spring with a piece of wire. THE CALIPER IS

NOT TO HANG BY BRAKE HOSE.

4. While the brake disc to hub location is marked

in production, ensure that the disc to hub

position is carefully marked.

NOTE: This is necessary to overcome the

possibility of inducing a brake shudder condition

after reassembly.

5. Remove brake disc from the wheel bearing

hub.

NOTE: For vehicles equipped with ABS, disconnect

the wheel speed sensor connector (5) from the hub

sensor connector, by lifting the connector locking

tab and pulling on the connector to disconnect.

6. Using a commercially available 10 mm Allen

key socket and a suitable socket bar, loosen

each of the three bolts (4) holding the hub to

the steering knuckle.

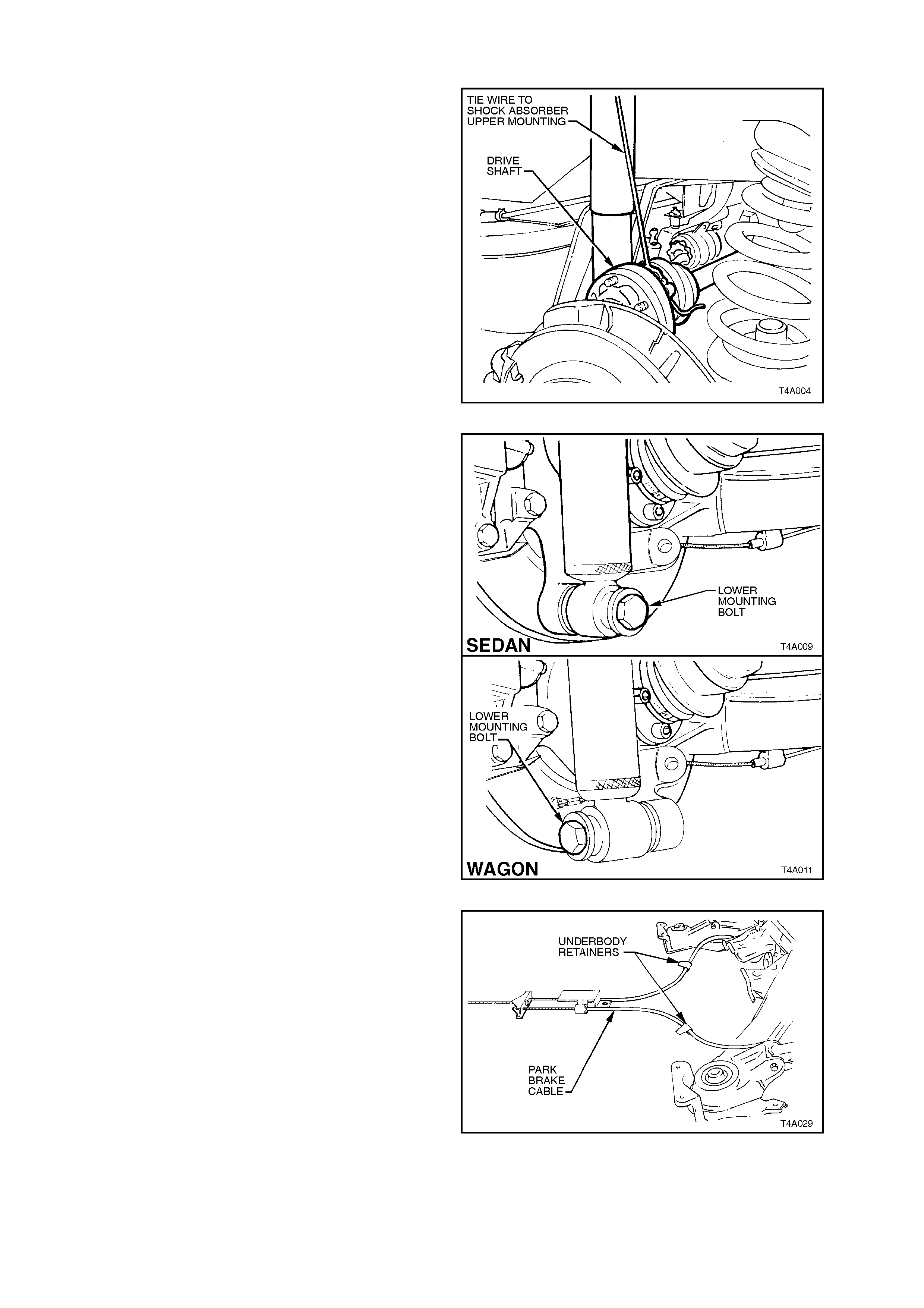

NOTE 1: If the Allen key socket is too long to fit into

the front, upper hub bolt, then the lower strut to

steering knuckle nut (and bolt) will need to be

loosened and removed. Discard the removed bolt

and nut, as they must be replaced on reassembly.

NOTE 2: For the front lower hub bolt, turn wheel

outwards to provide sufficient clearance.

Figure 1

7. If the hub is a tight fit to the knuckle, it may be

necessary to loosen the three loosened bolts

and tap on the heads. DO NOT STRIKE THE

HUB.

8. Remove the three bolts and then the hub from

steering knuckle.

9. To remove the brake shield from the steering

knuckle, drill the heads from the three rivets

securing the shield to the steering knuckle.

NOTE: While the next series of illustrations show

the brake caliper, disc and shield still installed, the

service oper ations described ar e unaffec ted by this

background.

5

10. Remove the tie rod end s plit pin and loosen the

castellated nut (1) until the nut is flush with the

end of the tie rod ball joint stud.

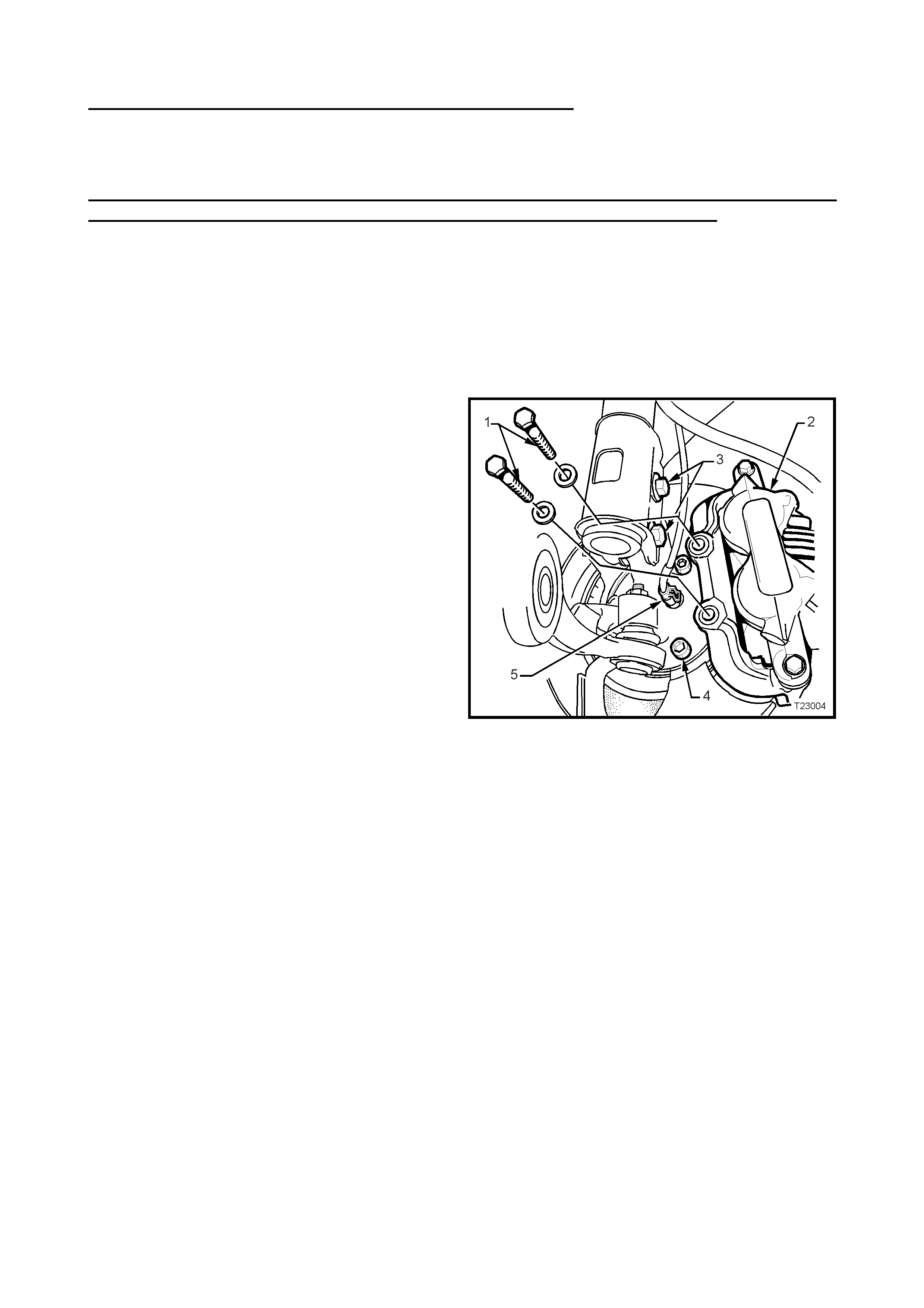

11. Install T ool No. 7311 as shown, then us e a ring

spanner (2) to press stud out from steering

knuckle.

12. Fully remove the castellated nut to free the tie

rod end completely.

Figure 2

13. Loosen, rem ove and disc ar d the two lower strut

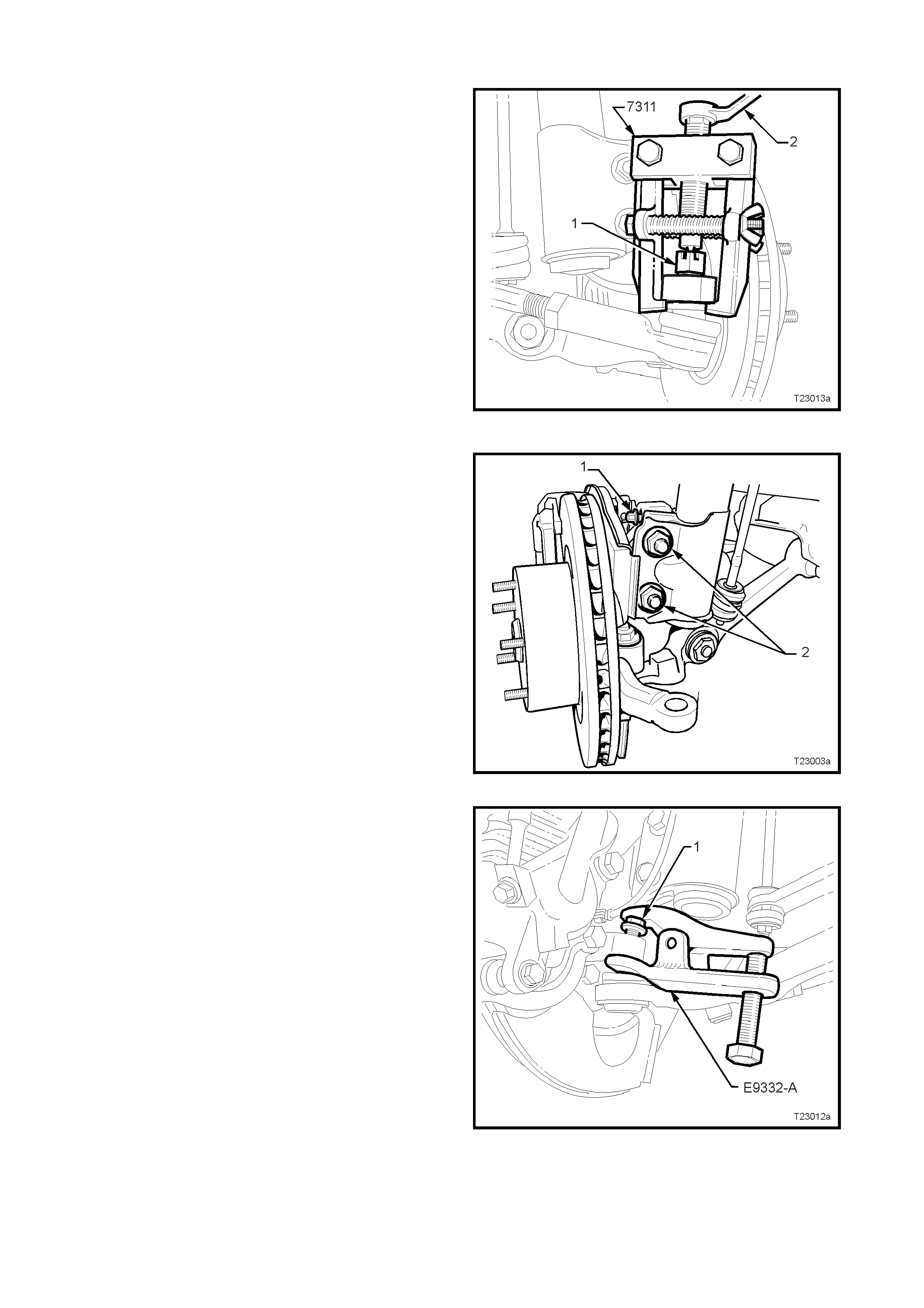

attaching nuts (2).

14. Remove the camber adjusting bolt (1) from the