222000000000 SSSEEERRRVVVIIICCCEEE TTTEEECCCHHHLLLIIINNNEEESSS

© 2006 GM Holden Ltd. A.B.N. 84 006 893 232

Service Department

A “HOLDEN” Product.

BRISBANE SYDNEY MELBOURNE ADELAIDE PERTH

100mm

150mm

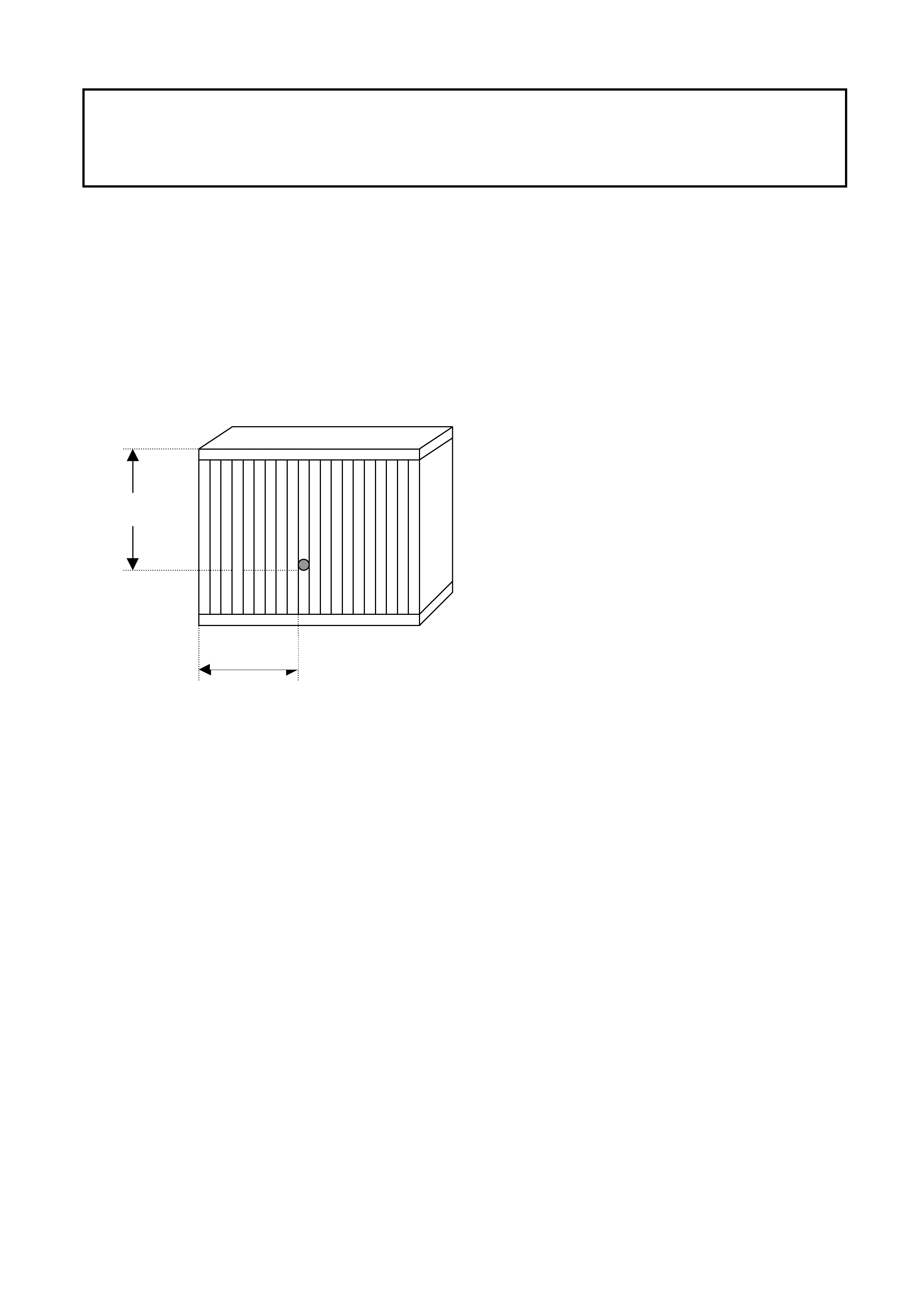

REVISED EVAPORATOR THERMISTOR POSITION (February 2000)

TF RODEO V6

GROUP 2

Information from the field has revealed that V6 Rodeo vehicles may experience evaporator ice –

up on 100km+ distance trips. Evaporator ice up is usually described as poor blower fan output

with large quant it ies of water draining f r om the evaporator when the vehicle is stationary.

Air International has developed a revised thermistor position to prevent the evaporator

temperature dropping below zero degrees which causes the condensation on the evaporator to

freeze.

Refer to the diagram below for the revised thermistor position, and disregard any prior bulletins

referring to this subject.

Note- Evaporator viewed from the air

off side. Thermistor tip location

should be 150 mm from the upper

side and 100 mm (10 fins) from the

left side of the core.

The thermistor clip is approx. 20mm

from the plotted sensor tip point.

CRANKSHAFT PULLEY BOLT (February 2000)

RODEO with 4JB1T

GROUP 6A

From engine number: 586429 (build - December 99), the crankshaft front pulley bolt tension for

the 4JB1- T engine has been increased to 24+/- .5kg.m (174+/- 4lb.ft, 235+/-5N.m) from 21+/- 2

kg . m (152+/- 14lb. ft, 206+/ - 20 N.m).

All relevant workshop manuals should be chang ed accor dingly.

Dealers aware of any failed or loose bolts in engines manufactured after the above breakpoint

should notif y I-GM TAS immediately. (PH: 1800 032 608 )

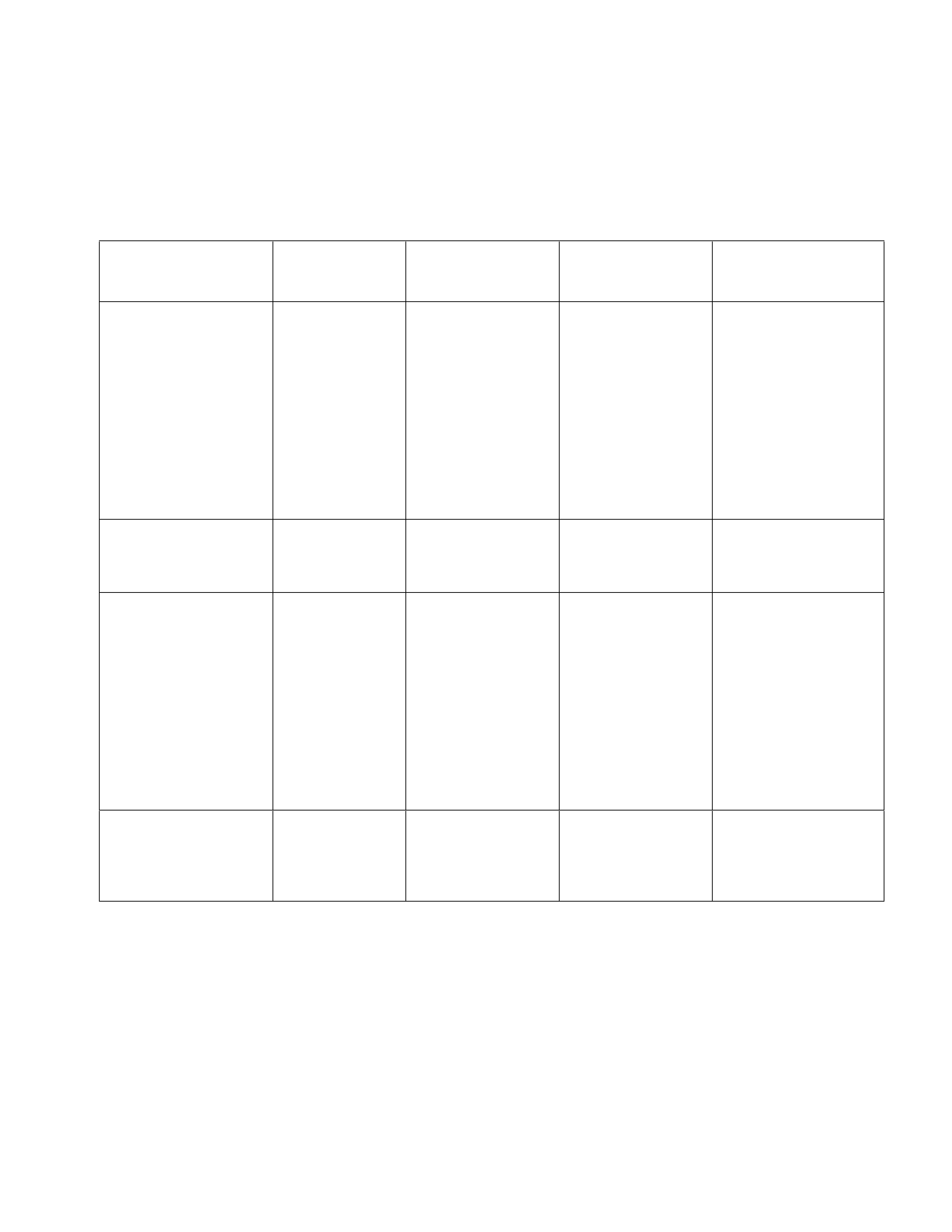

COOLANT SPECIFICATIONS (June 2000)

ALL IGM MODELS

(GROUP 6K)

The attached table is a reference guide to coolant specifications for all Isuzu vehicles.

Vehicle Model Factory Fill

Spec Recommended

Change at Alternative

Replacement

Coolant Spec

Recommended

Change at

~1998, R7 Rodeo

~1997, L5 Jackaroo

1996, UT Frontera

~1996, Isuzu Truck

HN2043

2 Years / 40 000

HN2217

Or

GM6277m

5 Years / 100 000

(Max)

5 Years / 100 000

(Min)

1997~, Isuzu Truck

HN2217

2 Years / 40 000

GM6277m

5 Years / 100 000

(Min)

1999~, R9 Rodeo

1998~, U8 Jackaroo

1997, UT Frontera

MX, Frontera

HN2217

5 Years / 100 000

(Max)

GM6277m

5 Years / 100 000

(Min)

Suburban

GM6277m

(Dexcool)

5 Years / 100 000

(Min)

Note – An inspection of cooling system components for corrosion should be carried out prior to

refilling with new coolant. Failure to identify a problem at this point may be a costly experience at a

later date. When using an alternative to the factory fill coolant the cooling system must be

thoroughly flushed prior to refilling.

ANTI THEFT/KEYLESS ENTRY DIAGNOSIS (June 2000)

JACKAROO

(GROUP 12)

The charts below are quick reference material that is intended to be used in conjunction with the

relevant workshop manual section (8H) and wiring diagrams (8D – 242) in the current Jackaroo

workshop manual.

DOOR SWITCH DIAGNOSIS

Front Door Key Swit ch

Detect Switch Circuit - Open

FUNCTION OPERATION

Anti – Theft LED No effect

Remote Locking No effect

Mechanical Locking No effect

Alarm System ( Arming ) Mechanical key will not arm system

Alarm System ( Disarm ) Mechanical key will not arm system

Note Unlocking the door with the mechanical key will activate the alarm system.

Detect Switch Circuit – Short to Ground

FUNCTION OPERATION

Anti – Theft LED No effect

Remote Locking No effect

Mechanical Locking No effect

Alarm System ( Arming ) No effect – (see below)

Alarm System ( Disarm ) No effect – (see below)

Note Locking / Unlocking the door with the snib button will arm / disarm the alarm

system

Tamper Switch Circuit - Open

FUNCTION OPERATION

Anti – Theft LED No effect

Remote Locking No effect

Mechanical Locking No effect

Alarm System ( Arming ) No effect

Alarm System ( Disarm ) No effect

Note Open circuit is the normal state for this switch. Forcing the lock will not activate the alarm

when this condition exists

Tamper Switch Circuit – Short to Ground

FUNCTION OPERATION

Anti – Theft LED Flashes at constant 2Hz with doors closed

Remote Locking Inoperative

Mechanical Locking No effect

Alarm System ( Arming ) Inoperative

Alarm System ( Disarm ) Inoperative

Door Lock Key Switch

Door Lock Key Switch - Open

FUNCTION OPERATION

Anti – Theft LED No effect

Remote Locking No effect

Mechanical Locking No central locking from failed door

Alarm System ( Arming ) No effect

Alarm System ( Disarm ) No effect

Note Central locking is still available from arm – rest master switch

Door Lock Key Switch (Lock) – Short to Ground

FUNCTION OPERATION

Anti – Theft LED No effect

Remote Locking Remote unlock only

Mechanical Locking No central locking from failed door

Alarm System ( Arming ) No effect

Alarm System ( Disarm ) No effect

Note Central locking is still available from arm – rest master switch

Door Lock Key Switch (Unlock) – Short To Ground

FUNCTION OPERATION

Anti – Theft LED No effect

Remote Locking Remote lock only

Mechanical Locking No effect

Alarm System ( Arming ) No effect

Alarm System ( Disarm ) No effect

Hood & Dome Lamp Switches

Hood Switch Circuit - Open

FUNCTION OPERATION

Anti – Theft LED No effect

Remote Locking No effect

Mechanical Locking No effect

Alarm System ( Arming ) No effect

Alarm System ( Disarm ) No effect

Note Open circuit is the normal state for this switch. Forcing the hood will not activate the

alarm when this condition exists

Hood Switch Circuit – Short to Ground

FUNCTION OPERATION

Anti – Theft LED Normal operation with doors open, but off when

doors locked

Remote Locking No effect

Mechanical Locking No effect

Alarm System ( Arming ) Inoperative

Alarm System ( Disarm ) Inoperative

Dome Lamp Switch ( Door Sw.) Circuit - Open

FUNCTION OPERATION

Anti – Theft LED No effect

Remote Locking No effect

Mechanical Locking No effect

Alarm System ( Arming ) No effect

Alarm System ( Disarm ) No effect

Note Open circuit is the normal state for this switch. The dome lamp will not activate when the

door is opened

Dome Lamp Switch (Door Sw.) Circuit – Short to Ground

FUNCTION OPERATION

Anti – Theft LED See note below

Remote Locking Inoperative

Mechanical Locking No effect

Alarm System ( Arming ) Inoperative

Alarm System ( Disarm ) Inoperative

Note The Anti – theft LED will flash at 2Hz for 30 secs. After a remote keypad button is

depressed, then go out. The LED will remain on continuously while the unlock button is

depressed on the keypad.

REVISED FUEL FILTER ASSEMBLY (June 2000)

JACKAROO 4JX1 DIESEL

(GROUP 6M)

When used in cold conditions (Below 0°C) some 4JX1 Jackaroo vehicles may experience fuel flow

difficulties through the filter assembly upon cold start up.

The restriction is due to trapped air freezing on the filter element creating a barrier through which the

fuel is unable to flow. To overcome this concern, Isuzu has released a revised filter assembly that has

improved air breathing/bleeding abilities.

The part number for the revised filter assembly is 8972245600.

ISUZU-GM SERVICE TECHLINE _________________________________________________________________ AUGUST 2000

12 12

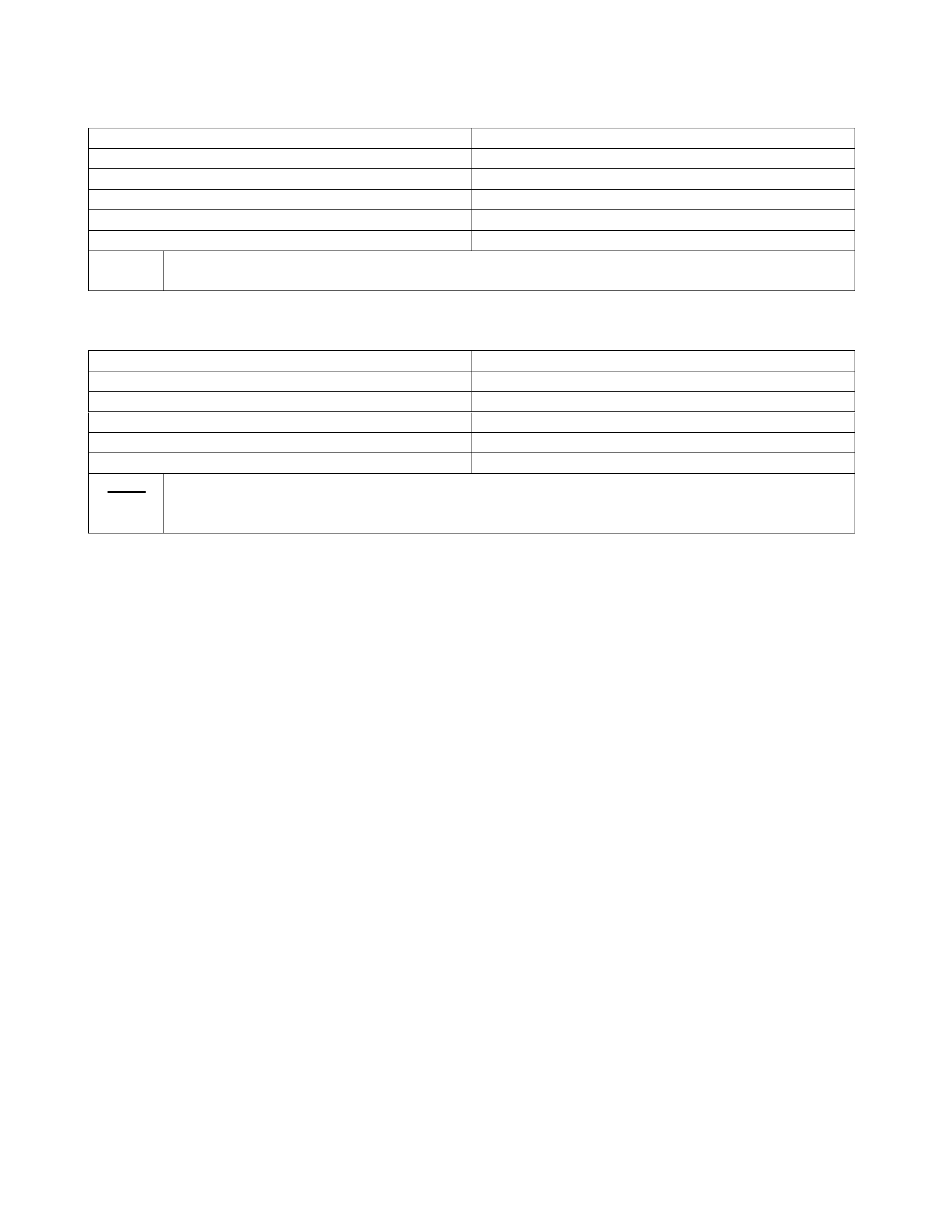

RIDE HEIGHT SPECIFICATIONS

RODEO & JACKAROO GROUP 3

Detailed below are the ride height specifications for Jackaroo (UBS) and Rodeo (TF). For details

on adjustment refer to the relevant workshop manual ( Section 3 ).

Note- All measurements should be made when the vehicle is at curb weight and with bump stops

in good condition. (Curb weights can be found in the relevant owners handbook)

Current model Rodeo

Front- There are two settings, one for TFS (4x4) and TFR25 (4x2, V6), the other for TFR (4x2).

There is a simpler method that requires the construction of a measuring tool. The tool can then be

placed between the bump stop and the lower control arm to indicate the trim height. The diameter

of the tool for 4x2 excluding V6 is 45mm, for 4x4 and V6 17mm (refer below)

Note- this method can only be used if the vehicles bump stops are in good condition.

Z =56 mm

TFR (4x2) EXCLUDING V6

ENGINE

Z=130mm

TFS (4x4) & TFR V6 (4X2 WITH

V6 ENGINE

)

TFS & TFR V6 TFR EXCLUDING V6

17 mm 45mm

ISUZU-GM SERVICE TECHLINE _________________________________________________________________ AUGUST 2000

13 13

Rear- The ride height is measured as a clearance between the bump stop and the top of the

axle(refer below)

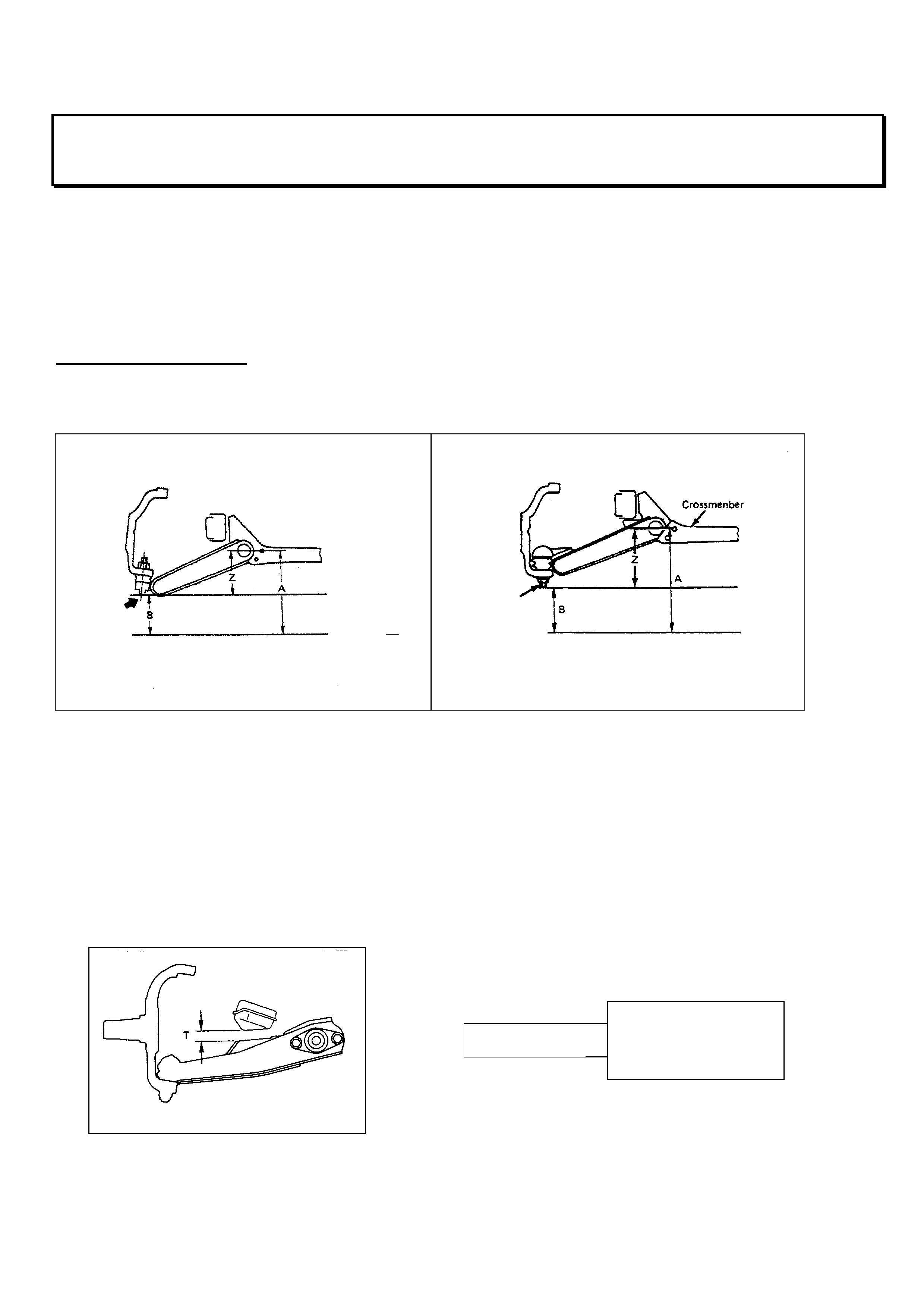

Current model Jackaroo

Jackaroo trim height is 139 +/- 5mm (refer below).

The trim height can also be checked by placing a tool between the bump stop and the lower

control arm. The Jackaroo tool diameter is 24mm.(refer below)

The ride height for TFS (4x4) and TFR25 (4x2 V6) is 95mm, and for

TFR (4x2)is 90mm

Z = 13 9mm +/- 5 mm

T= 24mm

ISUZU-GM SERVICE TECHLINE _________________________________________________________________ AUGUST 2000

14 14

INTERCOOLER/AIR DUCT OIL CONTAMINATION

DIESEL JACKAROO & RODEO GROUP 6A

I-GM has recently received a large number of inquiries regarding acceptable oil contamination on

4JX1 and 4JB1 engine air intake systems.

It should be noted that crankcase ventilation may cause a light coating of oil throughout the intake

ducting as part of normal engine operation, however it is not normal to have oil collecting or

pooling.

If confronted with an engine that has excessive oil contamination in the intake system, it is

suggested that thorough examination be undertaken to determine the origin of the oil, e.g.

crankcase breather or turbo seal. If not immediately obvious, the contaminated parts should be

cleaned and the vehicle monitored at short intervals.

CHECK ENGINE LIGHT ILLUMINATING

V6 LPG RODEO GROUP 6C

Rodeo vehicles fitted with approved LPG kits may experience a situation where the check engine

light is illuminated and DTC P0171 is present in the ECM. When confronted with the above

situation, please refer to the relevant information below.

PARNELL SUPPLIED KITS.

1) The Parnell system will set a lean code after the vehicle has been operated until the LPG

cylinder is empty. During this running period the engine is operating on vapor only, as the liquid

has been consumed and all that remains is indeed vapor. This scenario is a function of the

ECM performing correctly as the engine has experienced a lean condition (as it would when

running out of petrol) and has recorded the appropriate DTC.

Customers should be informed of the above condition and advised not to run on LPG empty.

2) Parnell systems fitted with the CLS2000 processor (located behind the drivers kick panel) may

need a software upgrade, to version V65 (printed on the processor). The upgraded processor

will be supplied by Parnell on a change over basis.

IMPCO

The impco system sets a lean code as a direct result of set operating parameters. This code is

apparent mainly on automatic TF's, it normally sets during coast or when the system is leaning off.

At this stage there is no repair for this condition, Impco are investigating the concern and IGM will

advise when a field fix is developed.

Dealers are advised to confirm if the code sets on petrol. If the code sets while the vehicle is on

petrol, normal diagnosis should be performed. However if the code does not set on petrol the car

should be released, the owner advised and rebooked when a repair is advised.

ISUZU-GM SERVICE TECHLINE _________________________________________________________________ AUGUST 2000

15 15

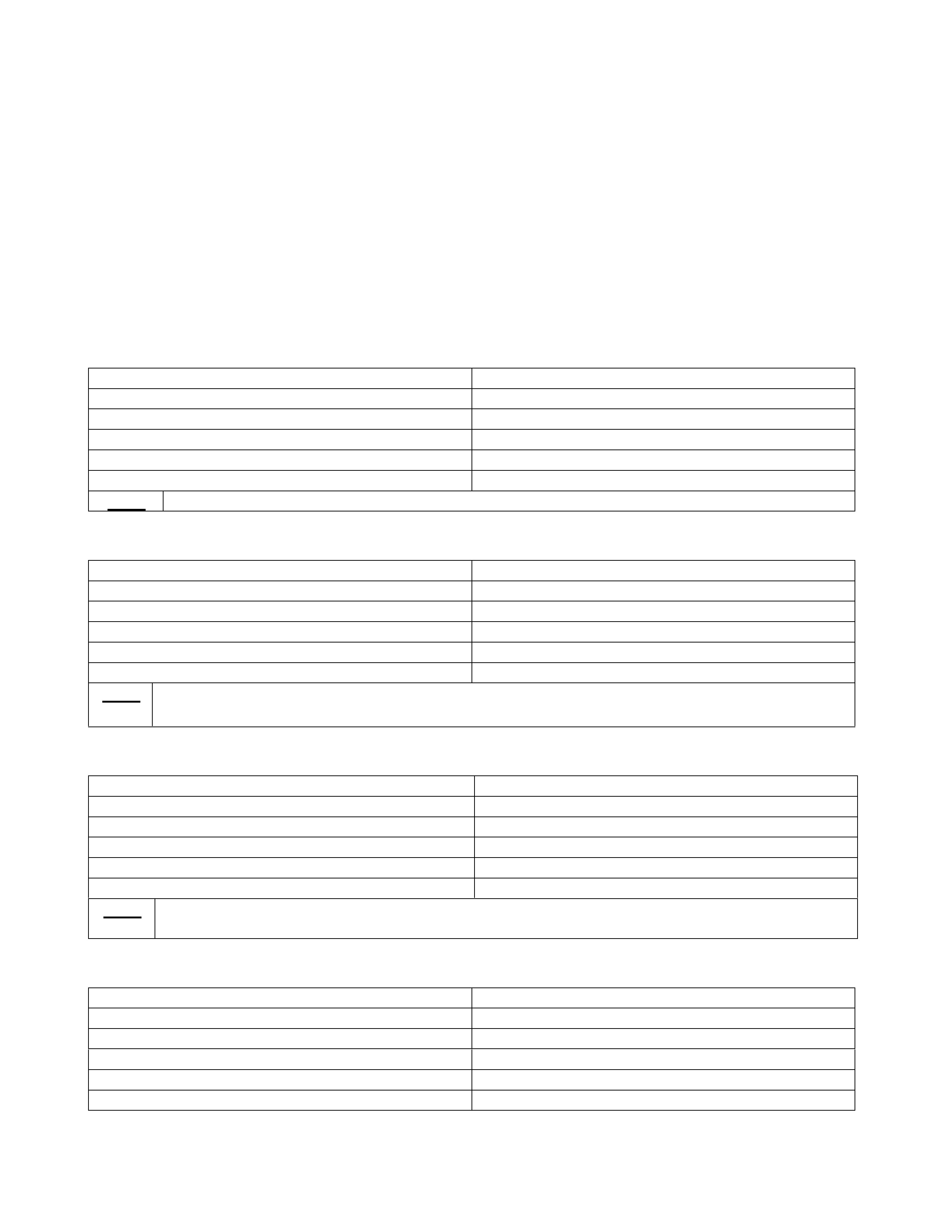

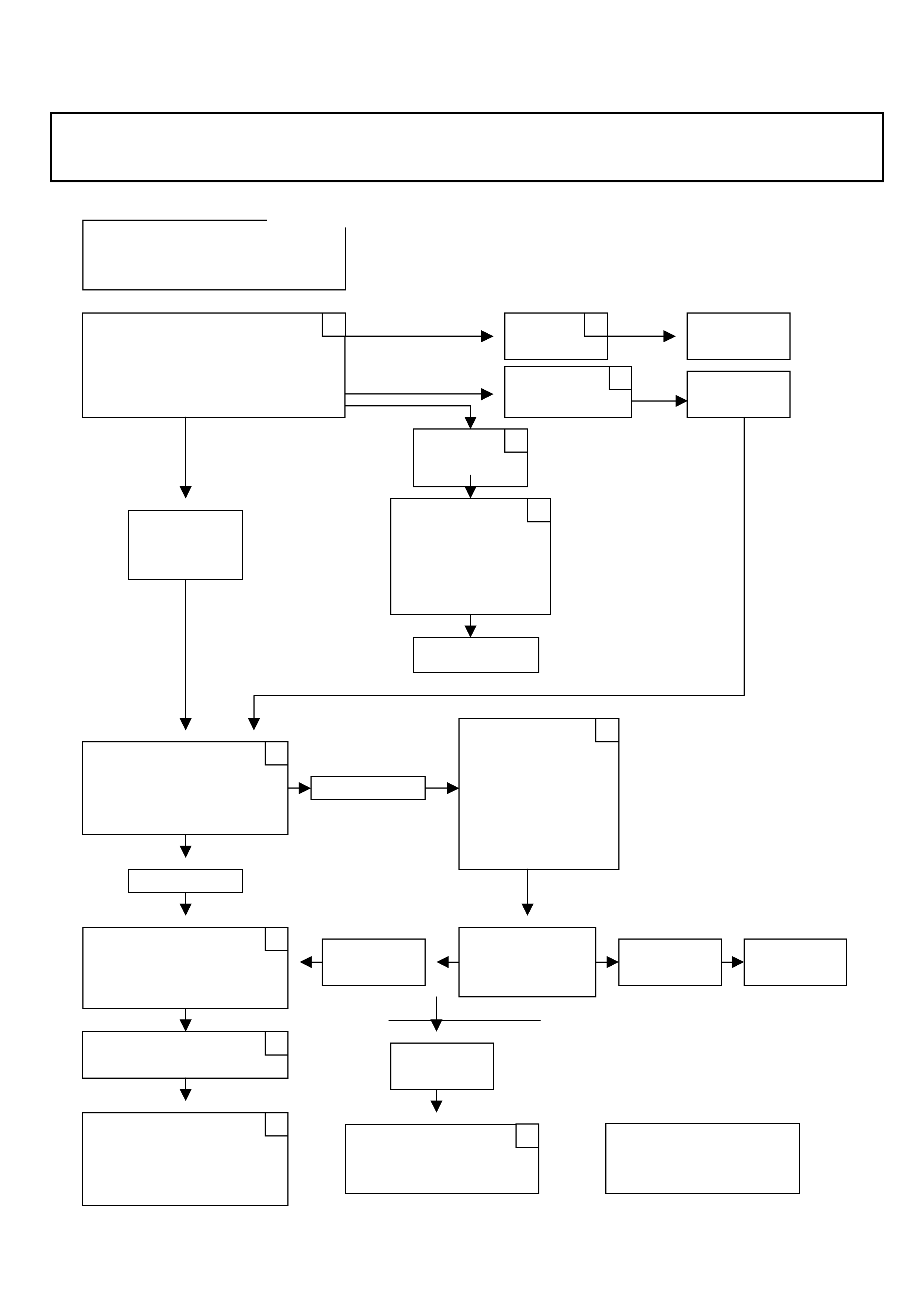

4JX1 DIFFICULT S TART PRE – CHECK

DIESEL JACKAROO GROUP 6C

IDENTIFY OIL

VISCOSIT

Y

GRADE

MANUFACTURER

OPERATE FUEL

PRIMING PLUNGER

UNTIL FIRM.

CRANK VEHICLE

DEFINE CRANK

Time: secs.

Engine crank RPM:

LOCATE SOURCE OF

AIR AND REPAIR AS

PER SHEET No. 2

HIGHER

THAN

10 SECS.

TURN ON IGNITION

WAIT FOR GLOW INDICATOR

TO GO OUT.

STARTS O.K.

O.K.

DRAIN / FILL

WITH CORRECT

SPEC. (2 TIMES)

REPLACE BOTH

OIL FILTERS

VERIFY

CHECK BATTERY

RE-CHARGE

CHECK TERMINALS

REPLACE AS

NECESSARY

O.K.

CONFIRM

START

O.K.

NO START

OBD1

SYSTEM CHECK

AS PER MANUAL

BELOW

10 SECS.

MORE THAN

100 RPM

LESS

THAN 100 RPM

INCORRECT

NO START BELOW

5 SECS.

CORRECT

INSTRUCTIONS

COMPLETE

RING - TAS.

Note- Copy this sheet and mark the box in the

top right corner as each step is completed.

4JX1

–

DIFFICULT START PRE - CHEC

K

ISUZU-GM SERVICE TECHLINE _________________________________________________________________ AUGUST 2000

16 16

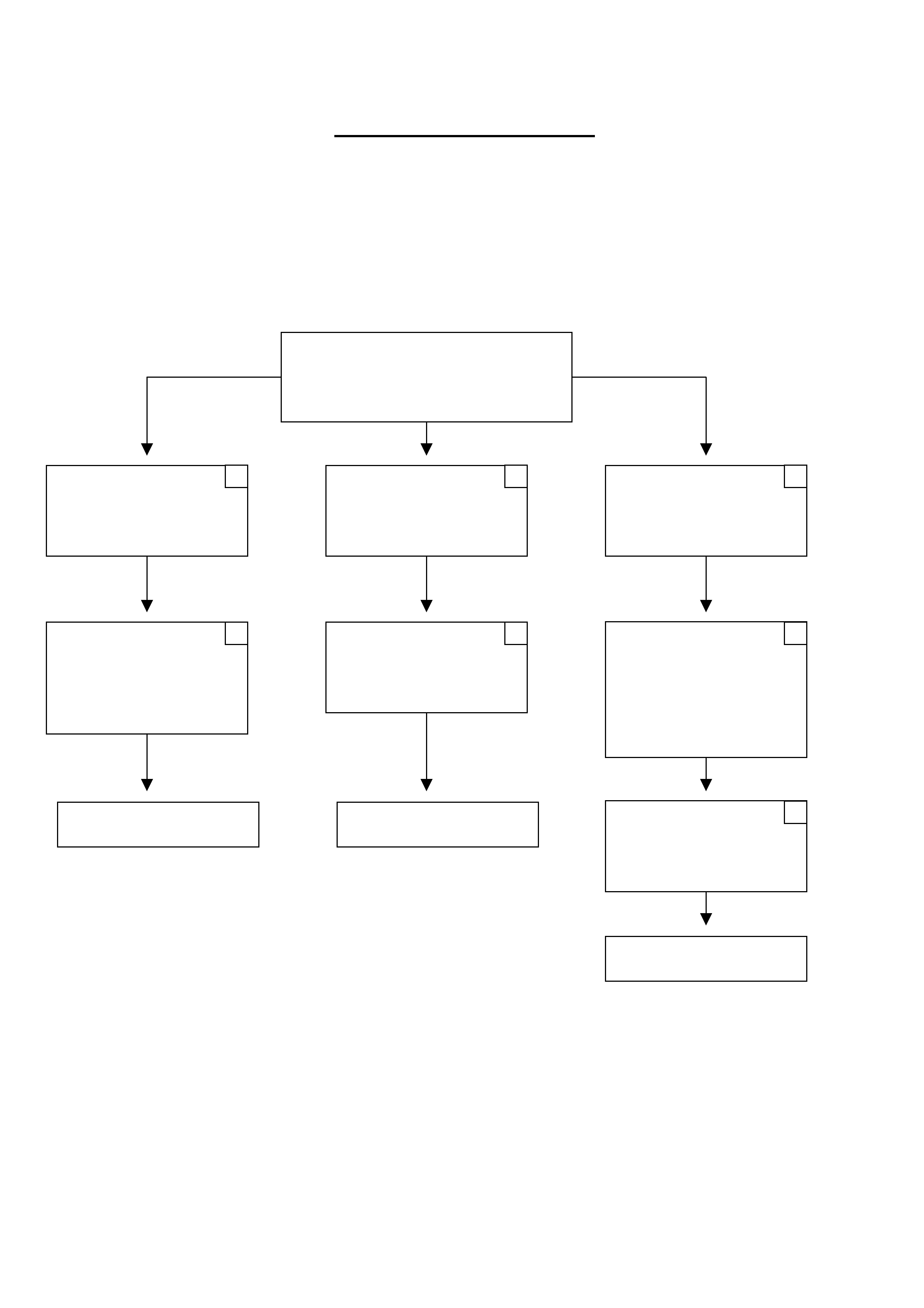

4JX1 - DIFFICULT START

(Sheet 2)

Step 1) Fit clear hose between filter housing outlet and lift pump.

Step 2) Fit clear hose on Tank return at rear of head.

Step 3) Fit clear hose between tank & filter housing inlet.

CONFIRM FILTER SEAL

CONFIRM FUEL FILTER

HOUSING (JUNE T/L )

PRODUCTION CHANGE

VERIFY REPAIR

INSPECT FUEL PIPES

FOR LEAKS AND

REPAIR

INSPECT INLET

FITTING TO HEAD FOR

TIGHTNESS AND

LEAKS.

CONFIRM INJECTOR

"O" RING

REWORK AS PER ADL

AIR OR OIL IN

SYSTEM AT THE

TANK RETURN

AIR IN SYSTEM

BETWEEN TANK AND

FILTER HOUSING

AIR IN SYSTEM

BETWEEN

FILTER HOUSING AND

LIFT PUMP

AIR IN FUEL

VERIFY REPAIR

CHECK INJECTOR

COPPER SEALS,

"O" RINGS AND

RE-TORQUE

VERIFY REPAIR