2

20

00

01

1

C

CA

AM

MP

PA

AI

IG

GN

N

B

BU

UL

LL

LE

ET

TI

IN

NS

S

© 2006 GM Holden LTD. A.B.N. 84 006 893 232

Service Department

A “HOLDEN” Product.

BRISBANE SYDNEY MELBOURNE ADELAIDE PERTH

For the latest and/or any missing Campaign Bulletins,

please refer to Holden Lionheart

1

PRODUCT CAMPAIGN BULLETIN

01-H-01

February 16, 2001

SUBJECT : SEAT RAIL REINFORCEMENT

MODEL: SB BARINA & COMBO

This bulletin announces the initiation of a safety related recall on some SB Barina & Combo

vehicles.

DESCRIPTION O F DEFECT

Investigation has shown that a number of vehicles in a specific batch may exhibit material fatigue

of the front seat belt buckle anchor plate on the inner seat rail runner. If this condition is present,

there is a potential risk that under extreme conditions the front seat belt buckle anchor plate may

detach f r om the seat rail r unner .

DETAILS OF AFFECTED VEHICLES

IMPORTANT NOTES:

1. The affected range is determined by the Model Year identifier (alpha) and the vehicles Serial

Number (7 digit numeric) of the ISOVIN. i.e “P” = Model Year 1993 and “4016295” is the

sequential vehicle serial number .

2. The aff ect ed rang e covers mult iple model year vehicles ie “P???????” to “ X???????” includes

model years “P”, “ R”, “S”, “ T”, “ V” ,”W” and “X” .

3. Ignore the first nine (9) characters of t he I SO VI N.

4. Affected vehicles with a drivers’ seat “height adjuster”, ONLY requires the campaign action

perf or m ed t o the Passenger Seat (seats with height adj uster are not affected)

BARINA MO DELS

Model Year 1993(“P”) to Model Year 1999(“X”) Barina Swing and City and variants including

Lambada, Joy, Gr and Prix, Cabrio and Gsi) .

The ISOVI N r ange of affected vehicles is:-

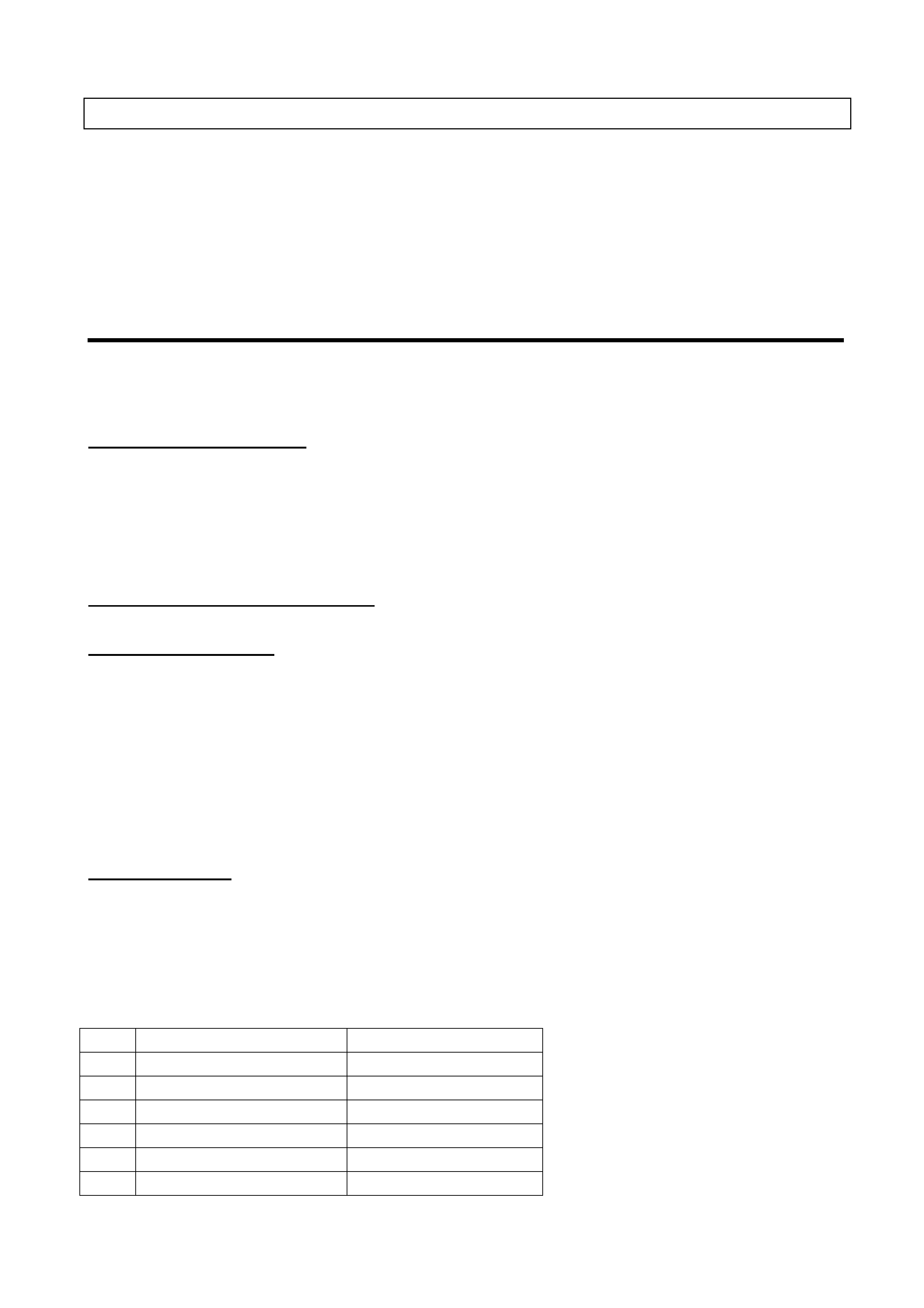

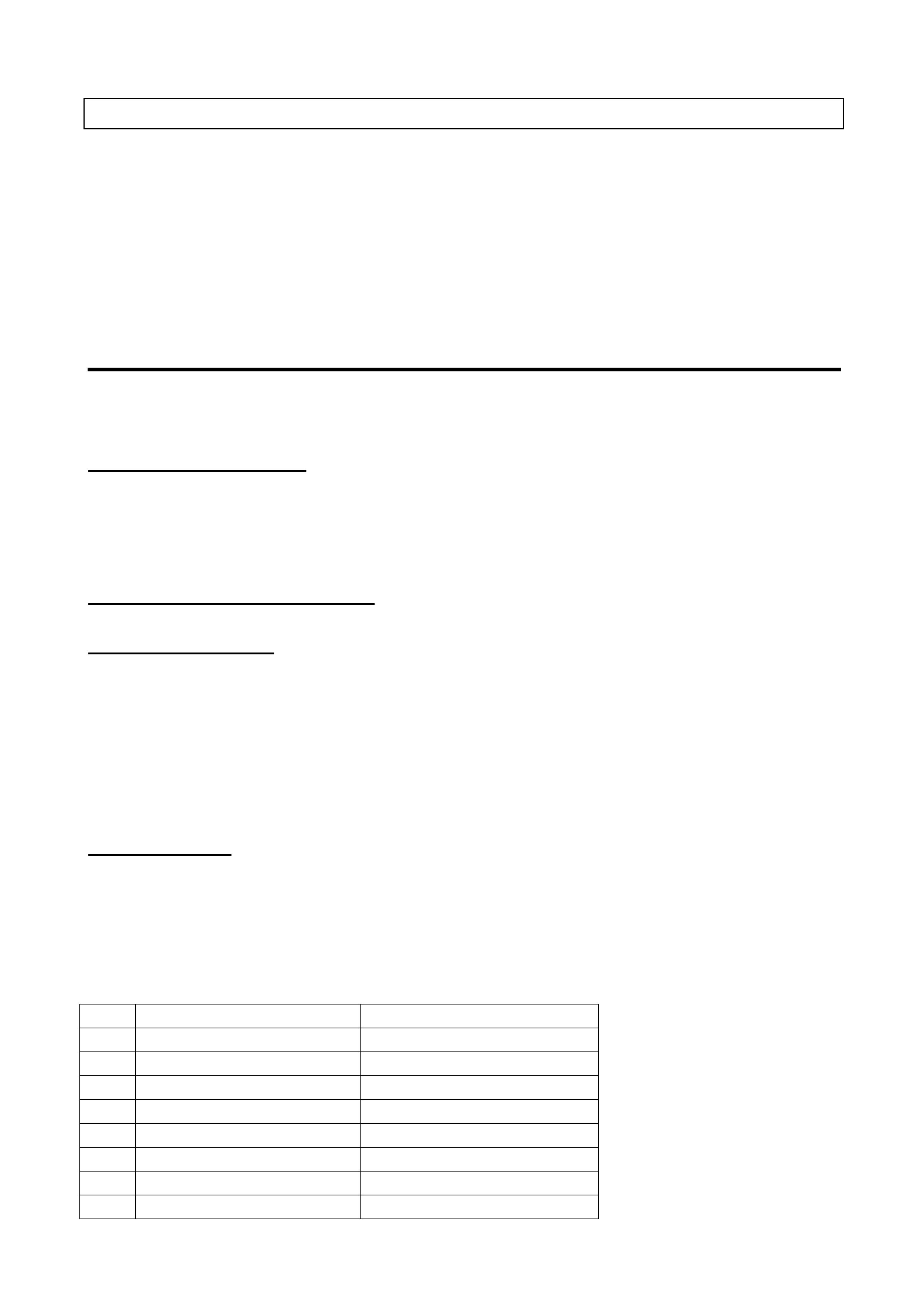

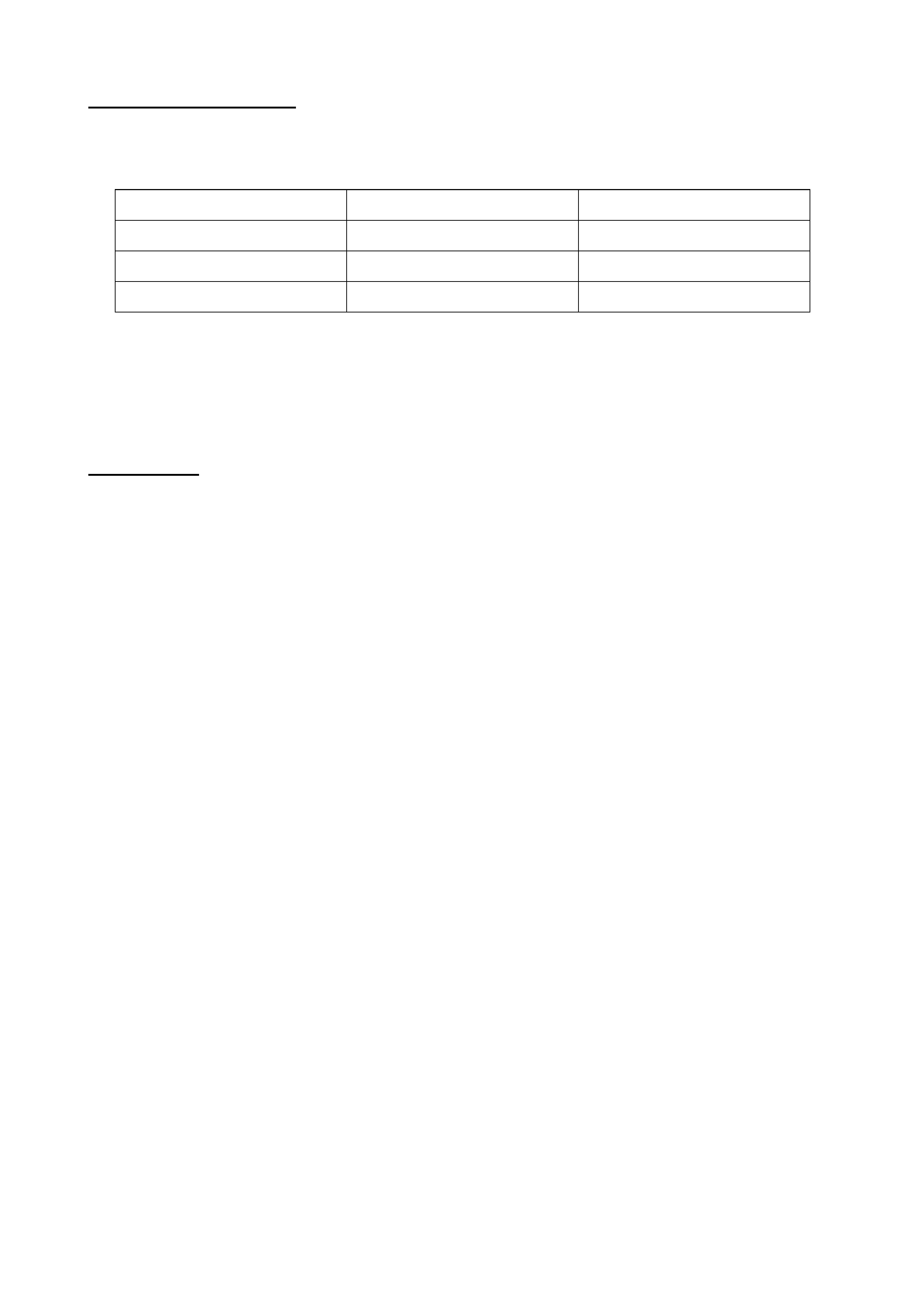

BARINA

MY FROM TO

93 P4142331* P4224948*

94 R4016295 R4380456

95 S4000435 S4429411

96 T4004684 T4429794

97 V4000062 V4438327

98 W4000079 W4444370

99 X4000134 X4424418

* Only two vehicles in model year 93 range

2

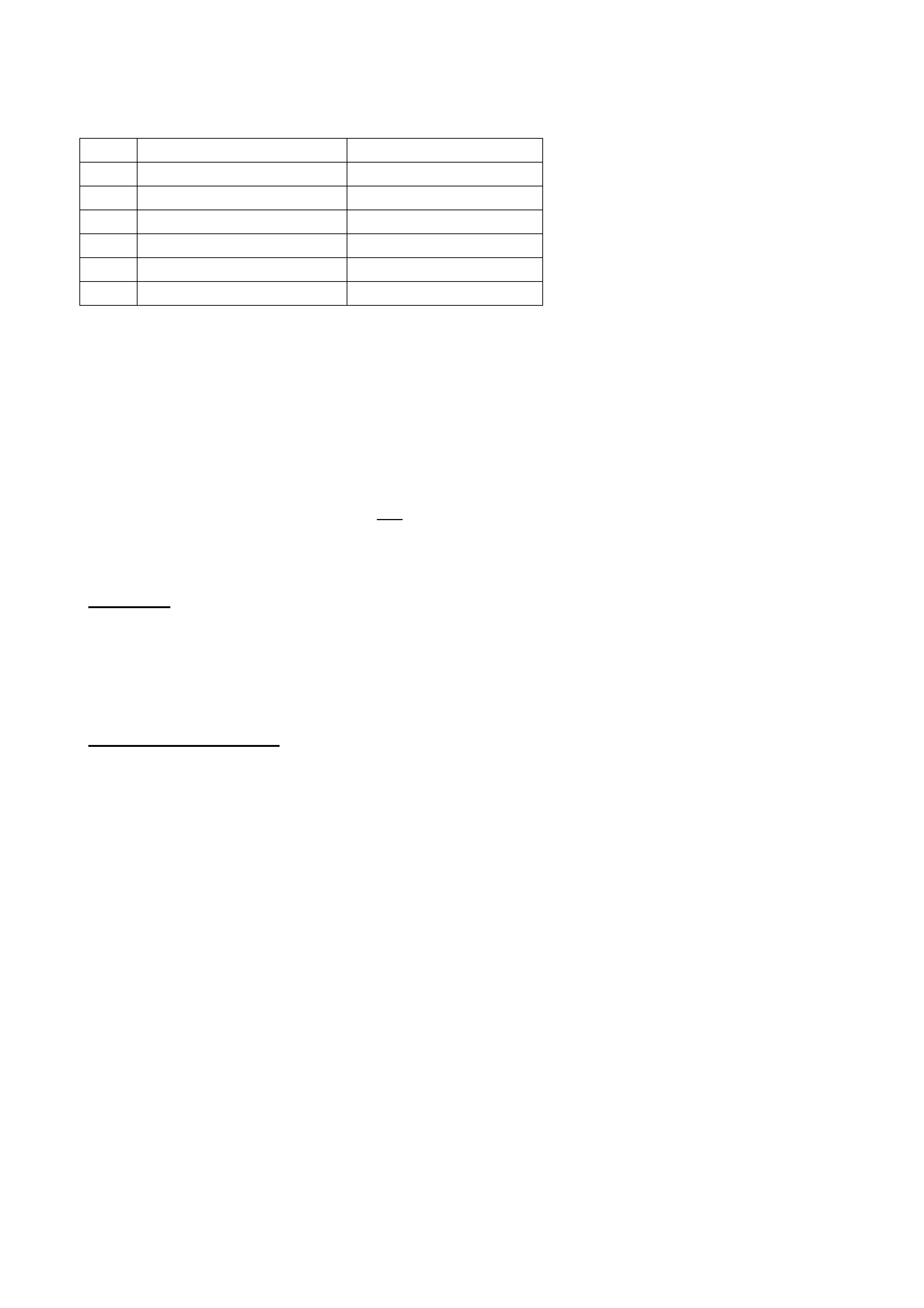

COMBO

MY FROM TO

94 R3033834# R3033834#

95 S3028384 S3028384

96 T3002006 T3053916

97 V3015334 V3056810

98 W3000695 W3059380

99 X3000201 X3059911

00 Y3006529 Y3006929

# Only one vehicle in model year 94 range

All vehicles within the affected ranges shown above are affected by this recall campaign

irrespective of whether the customer presents a customer letter or not. Dealers must check the

ISOVIN and only those vehicles within the affected r ange req uir e cam paign action.

Dealers with electronic vehicle “flagging” systems requiring a Holden Tag No. can use the

following Tag No. r anges for f lagg ing pur poses only. The I SOVIN det ermines whether t he vehicle

IS or IS NO T aff ected by this recall campaign and m ust be established f rom the pr esented vehicle

befor e com plet ing the required action O R advising the customer t hat the vehicle is not affected

From Y001593 to Y999999 and Fr om 2000000 t o 2397521

TRAINING

Due to the complex nature of the rectification, Holden will be conducting training in nominated

metropolitan and rural centres. Before commencing work, technicians performing the rectification

on vehicles aff ected by this campaign m ust com plete and pass the tr aining.

OWNER NO TIFICATION

Owners will be contacted directly by letter from Holden, providing details of the recall and

requesting them to arrange for the campaign action to be carried out. Following is a draft of the

customer letter.

Dear Holden Customer ,

At Holden we continually strive to enhance the ownership experience of our customers through

continuous product im pr ovem ent, aft er sales ser v ice and ef fective custom er com m unication.

Holden’s foremost concern is the continued safety of our customers. Accordingly the recall

campaign described below is being under t aken as a safety precaut ion.

Holden has been alerted to the fact that in a number of vehicles within a determined production

range, material fatigue on the seat belt buckle anchor plate on the inner seat rail runner in the front

seats could potentially, under extreme conditions, detach from the seat rail runner.

Our records show that your Holden vehicle was manufactured within the vehicle range which may

include this component. It is therefore necessary for you to contact a Holden dealership of your

choice as soon as possible to have a seat rail r einf orcement kit fitted to your vehicle.

3

All work w ill be carried out fr ee of charge and provided the necessary arrangements with a Holden

dealer are made in advance, your vehicle can be rectified while you wait. The required work will

take approximat ely one ( 1) hour.

Holden has initiated this action as a precautionary measure to ensure the integrity of the seat belt

buckle anchor plate.

We know that effective communication is vital to helping your understanding of the issues involved

and trust that this letter provides you with all the information you need. If you should have any

questions, please contact your dealer or call the Holden Recall Assistance Line - 1800 632 826,

where one of our operators will be pleased to assist.

Thank you for your attention to this matter. We apologies for any inconvenience this action may

cause you.

Yours Sincerely

D. McMurray

Manager Customer Assistance

DEALERSHIP ACTION REQUIRED

On presentat ion of the vehicle considered by the customer to be affected by this campaig n:

• Confirm that the vehicle is in the affected ISOVIN range – Refer to Details of Affected

Vehicles on page 1 of this bulletin.

• Determine whether anchor plate version A or version B is required (refer to laminated A4

visual instruction sheet it em A2 or B2 for criteria)

• Rework affected vehicle in accordance with the applicable Rework Instruction. Refer to

attachment (A) Rework Inst ruction 01-H-01A for anchor plate version A or attachment (B) 01-

H-01B f or anchor plate version B.

• Apply a Campaign Complet ed Identification label.

CAMPAIGN COMPLETION IDENTIFICATION

All campaigned vehicles must have a Campaign Completed identif ication label applied to the right

hand front ‘A’ pillar, between the hinges, with details of the campaign, 01-H-01, Dealership code

and date legibly entered on t he label with a perm anent ink pen.

Extra campaign ident ification labels are available free of charge f rom:

Moore Business Systems

Facsimile: (03) 9270 8900

Attention: Mr. Bob Curry

4

Quote stock No. SD 28156 on a Moore Business Systems ‘packaged goods’ order form (or

facsim ile if not available) for a box of 100 labels.

As an additional continuous improvement initiative, which was triggered by the dealer network,

Campaign Completion Identif ication will now also be included on the Vehicle Service Histor y Label

(SD 28177 available from Moore Business Systems). Place an “X” at the E-4 co-ordinate of the

Vehicle Service History Label and apply it to the inner side of t he lower instr ument panel cover.

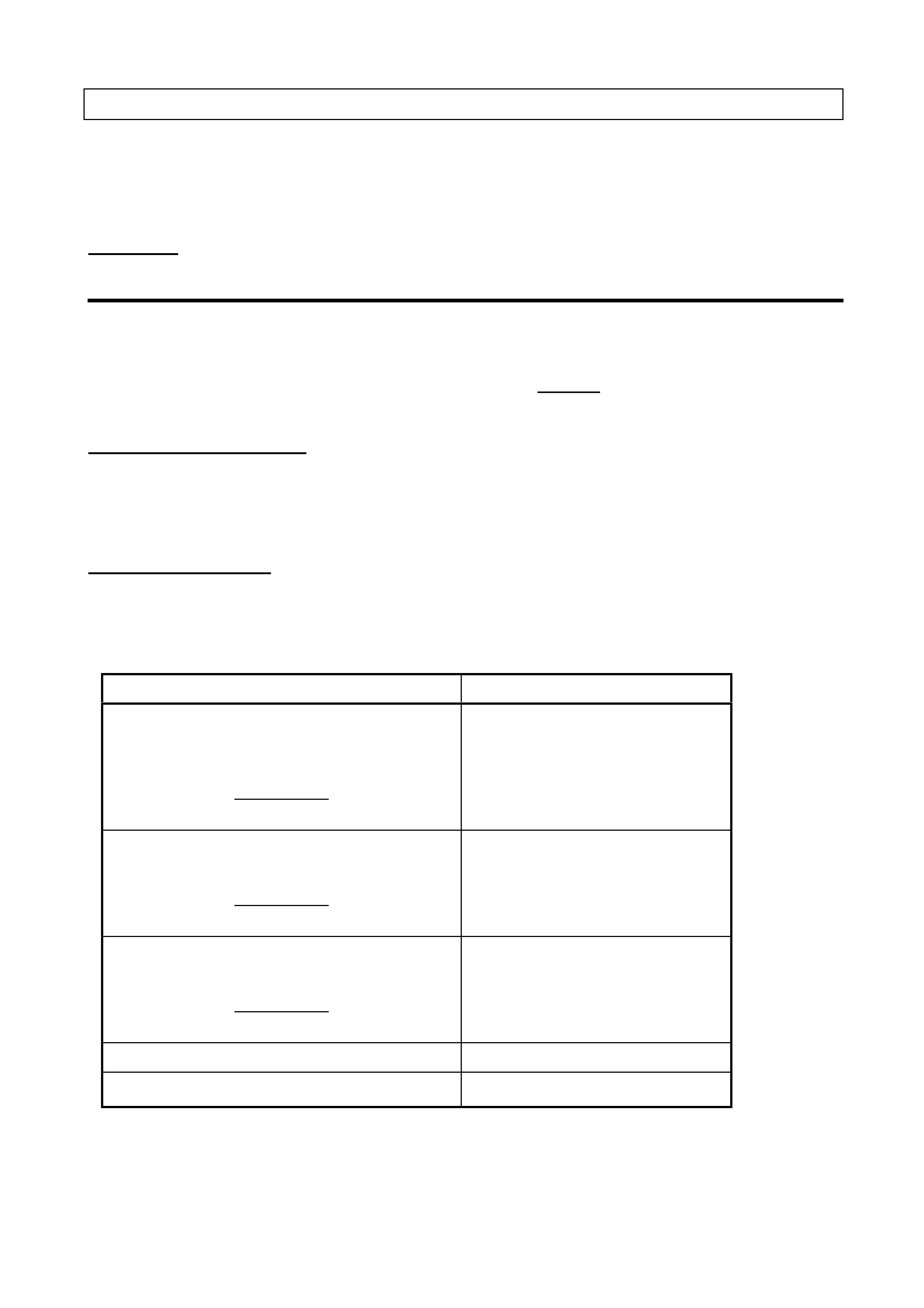

WARRANTY CLAIM INFORMATION

On completion of campaign action, dealers are requested to immediately submit a w arranty

claim.

Description:

Labour Operation No:

Standard Time:

Failure Code:

Case Type:

Fit rail reinfor cement bracket

One seat

T180501

0.3 Hours

96

08

Fit rail reinfor cement bracket

Both seats

T180502

0.4 hours

96

08

Please ensure correct vehicle details are included when submitting warranty claim information as

per the norm al warranty process.

Warranty claim submission is used to update our record of campaign completion and determines

whether furt her cust omer contact is necessary to action all affected vehicles.

Please ensure on completion of the cam paign action that a warrant y claim is submitted prom pt ly.

PARTS INFORMATION

DO NOT O RDER PARTS FOR THIS CAMPAI GN FROM HSPO

Seat Rail Reinforcement Kits for this campaign ar e available throug h SALMAT using the at tached

order form.

Controls on the quantity supplied will be enforced due to lim ited parts availability.

DO NOT campaign vehicles or order parts unnecessaril y!

Ensure the vehicle fall s within the guidelines specif i ed i n sect ion marked:

‘DETAILS OF AFFECTED VEHICLES’.

Should you require further information or clarification on the above, then please call Oliver

Mitrovski on telephone number ( 03) 9647 7619.

Joachim Burandt

General Service Manager

Attachment A: REWORK I NSTRUCTI ONS CAMPAIGN 01-H-01 VERSION A

Attachment B: REWORK INSTRUCTIONS CAMPAIGN 01-H-01 VERSION B

Attachment C: MATERIAL ORDER FORM

5

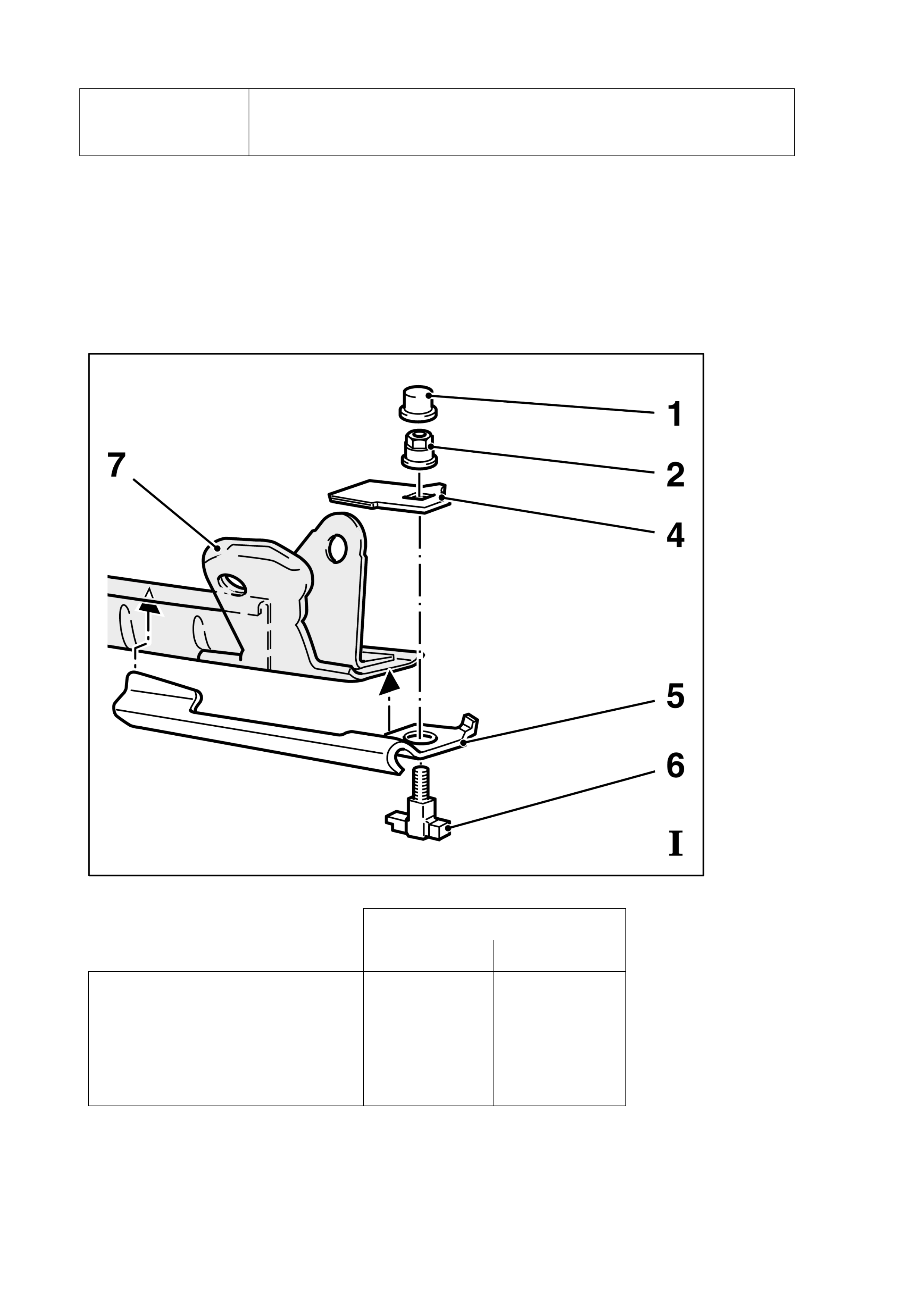

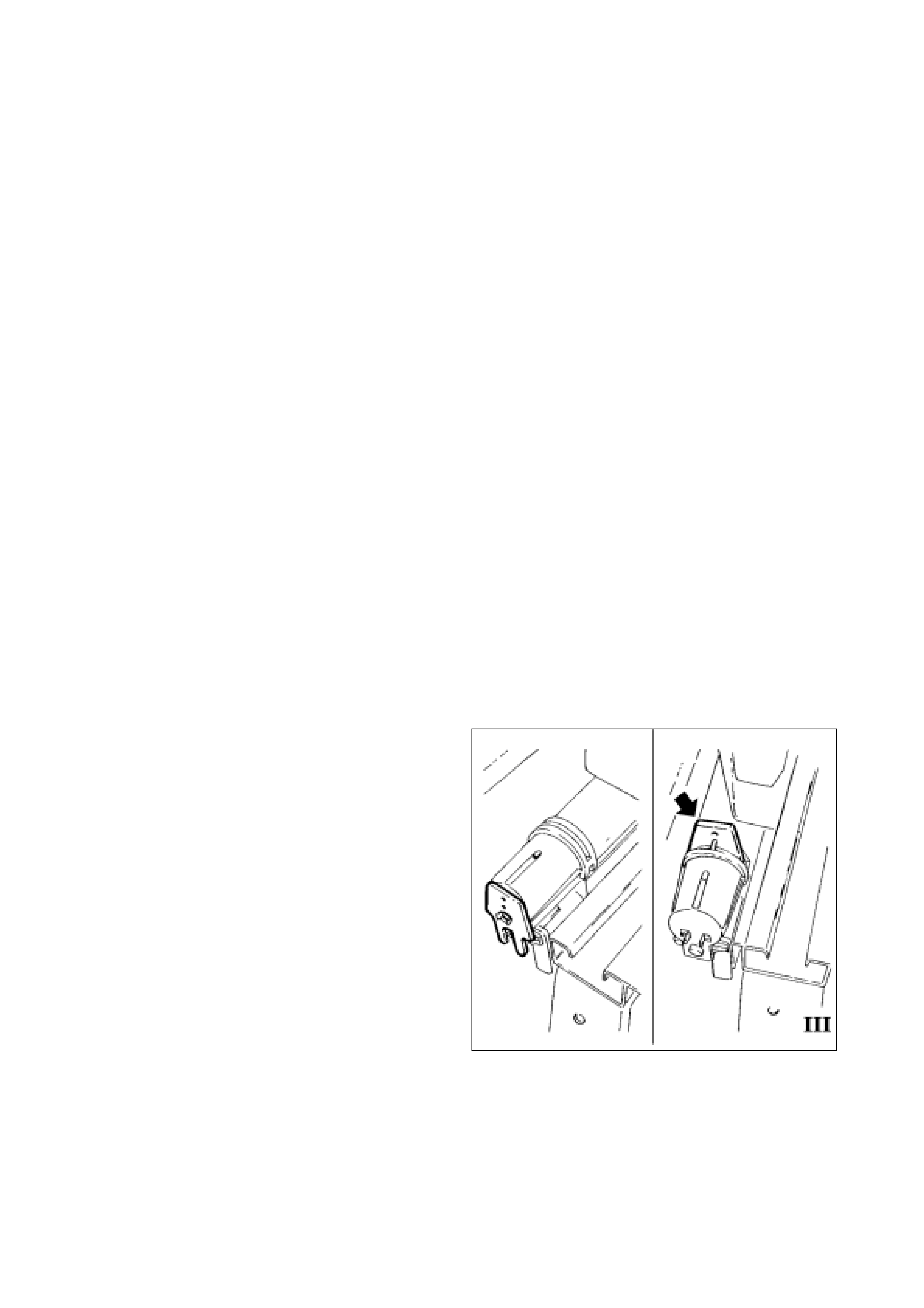

ATTACHMENT A

REWORK INSTRUCTION CAMPAIGN 01 -H-0 1 VERSION A

Rework For Seats With Anchor Plate Version “A”

The following instruction shows the rework of the right seat. The rework of the lef t seat has

to be carried out accordingly. The rework must be carried out in accordance to the rework

instruction. Only original parts of the reinforcement kit must be used.

Identification markings for

left seat right seat

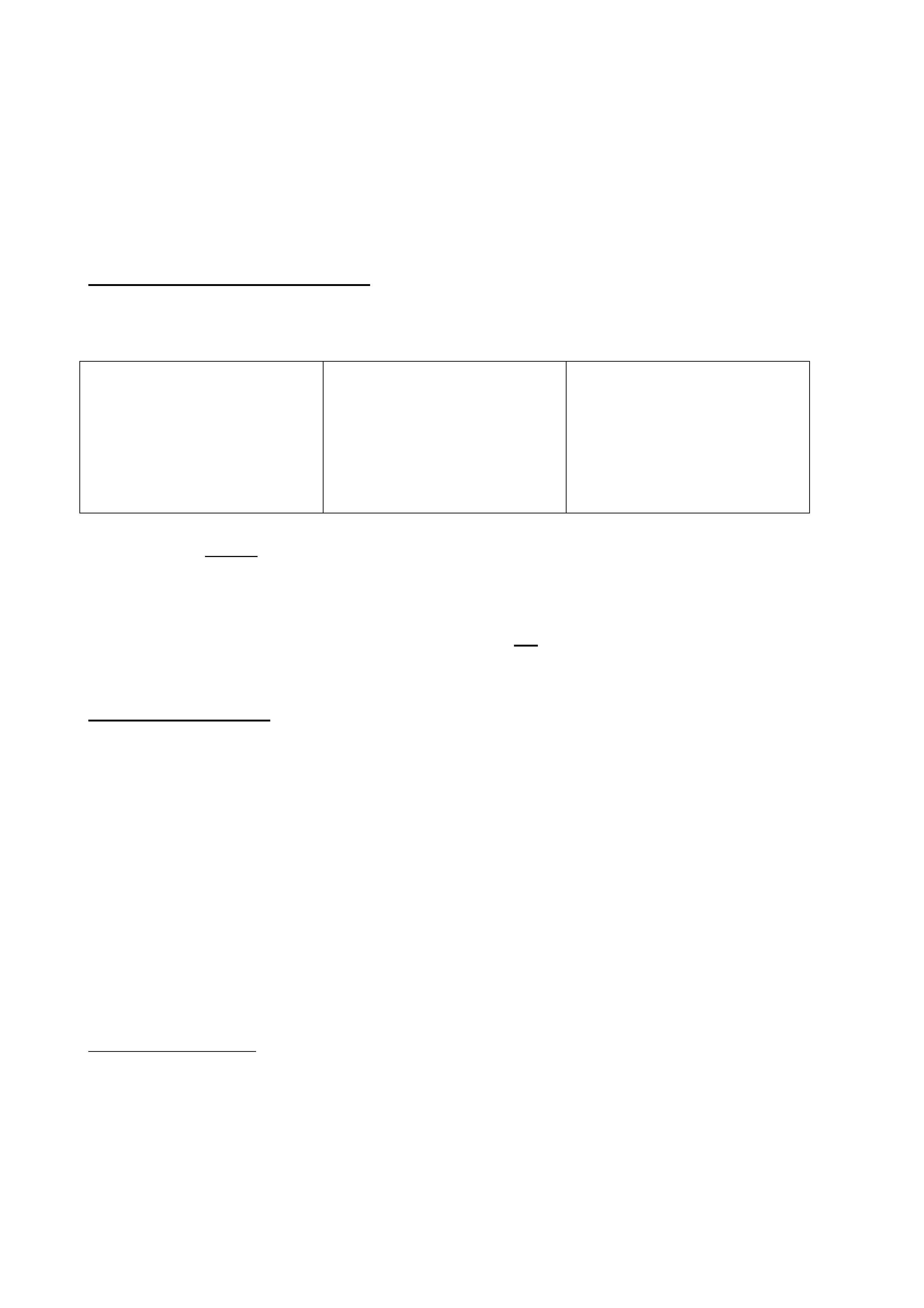

1 – Protection Cap*

2 – Shear-off Nut*

3 – Support Hook

4 – Reinforcing Plate

5 – Reinforcing Rail

6 – Hammer Screw*

7 – Seat Rail (part of the seat)

ALH

shape

ALH

ARH

shape

ARH

*) part has no marking – same part for all four types of reinforcement kits

6

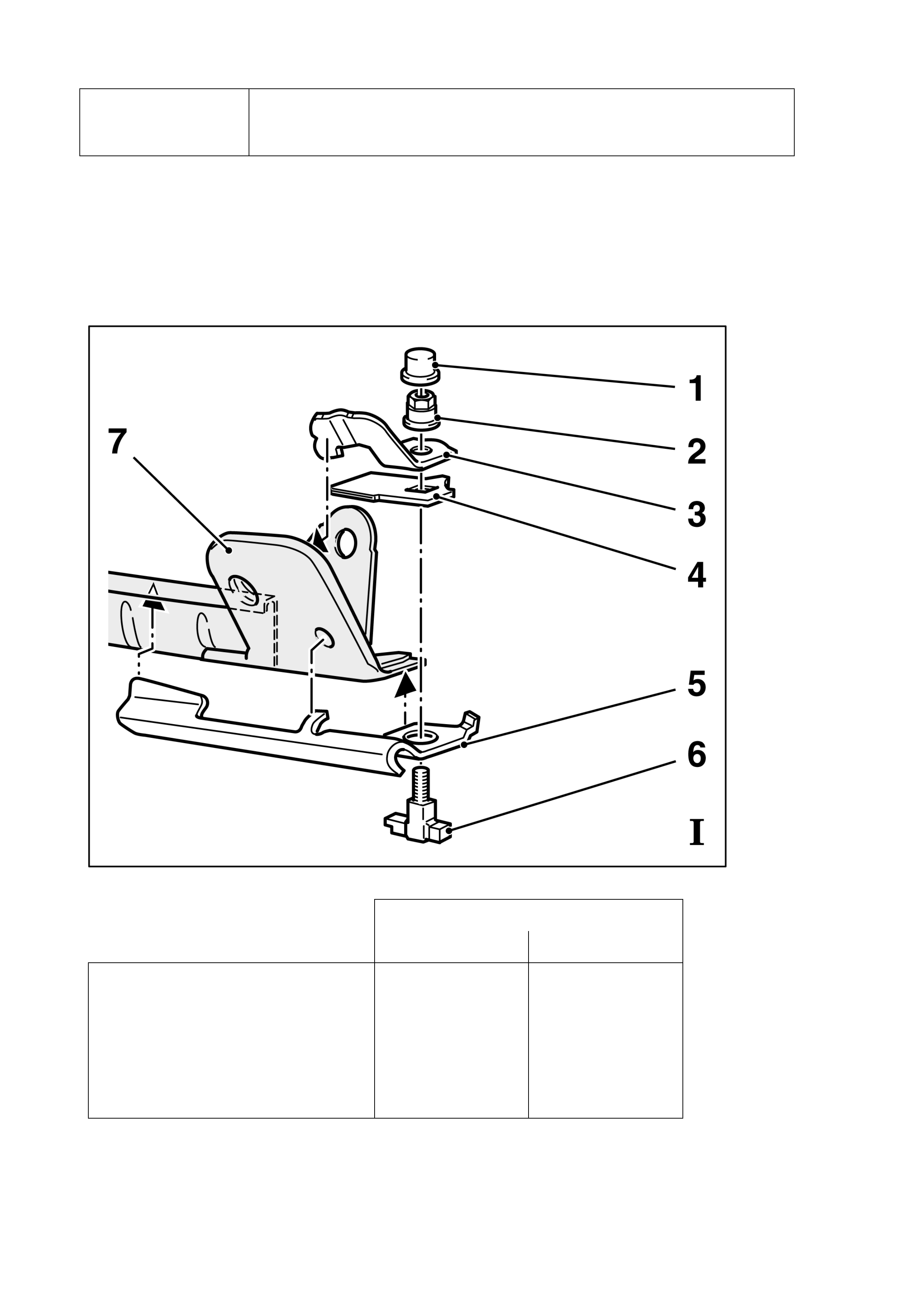

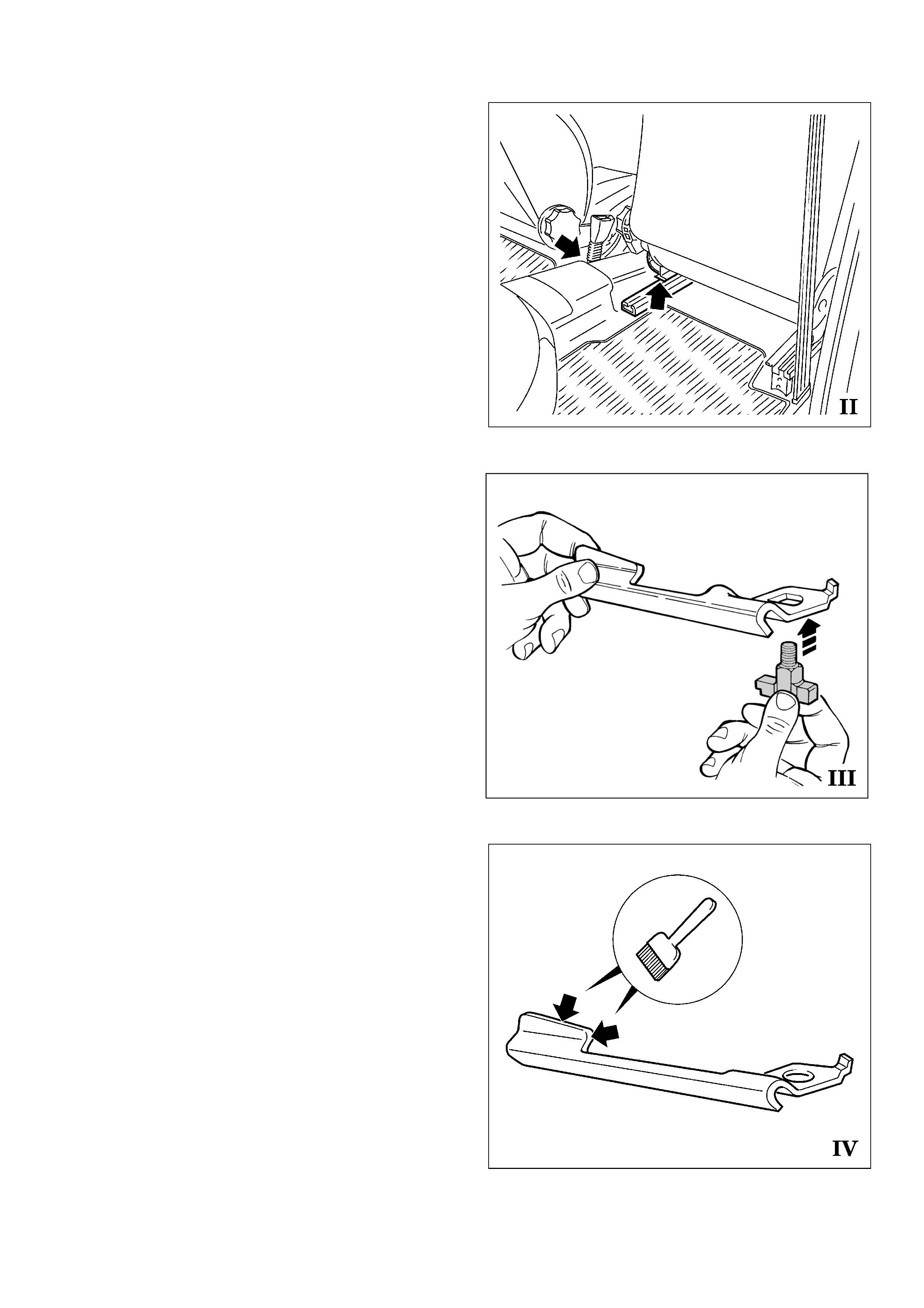

Attention:

Only seats without height adjuster are to be

reworked.

Check the anchor plate version (A or B)

Check type of rework kit.

Check completeness of reinforcement kit.

The installation of the reinforcement kit can

be carried out with the seat in all positions.

However the easiest fitting is possible when

the seat is in the rearmost position.

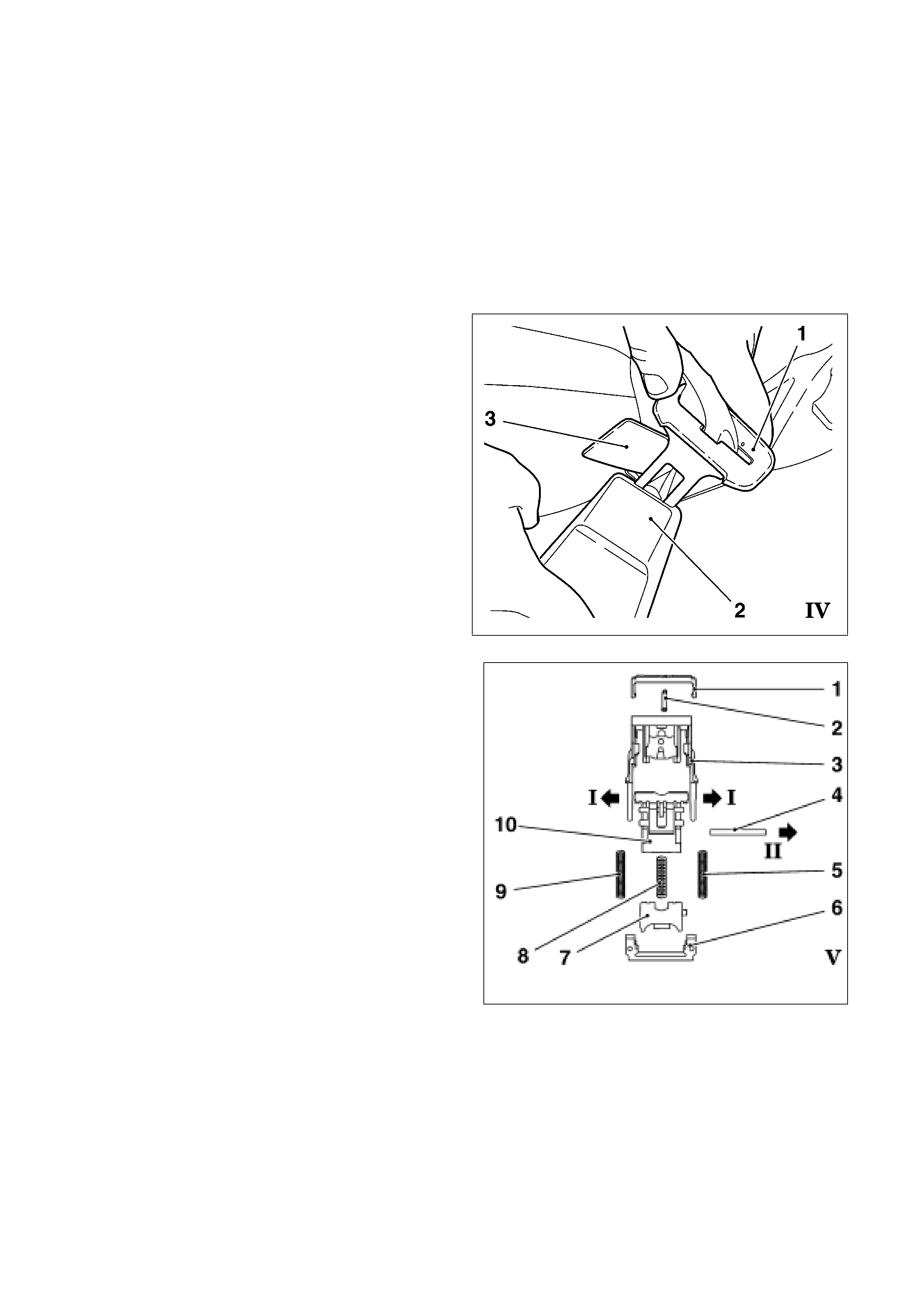

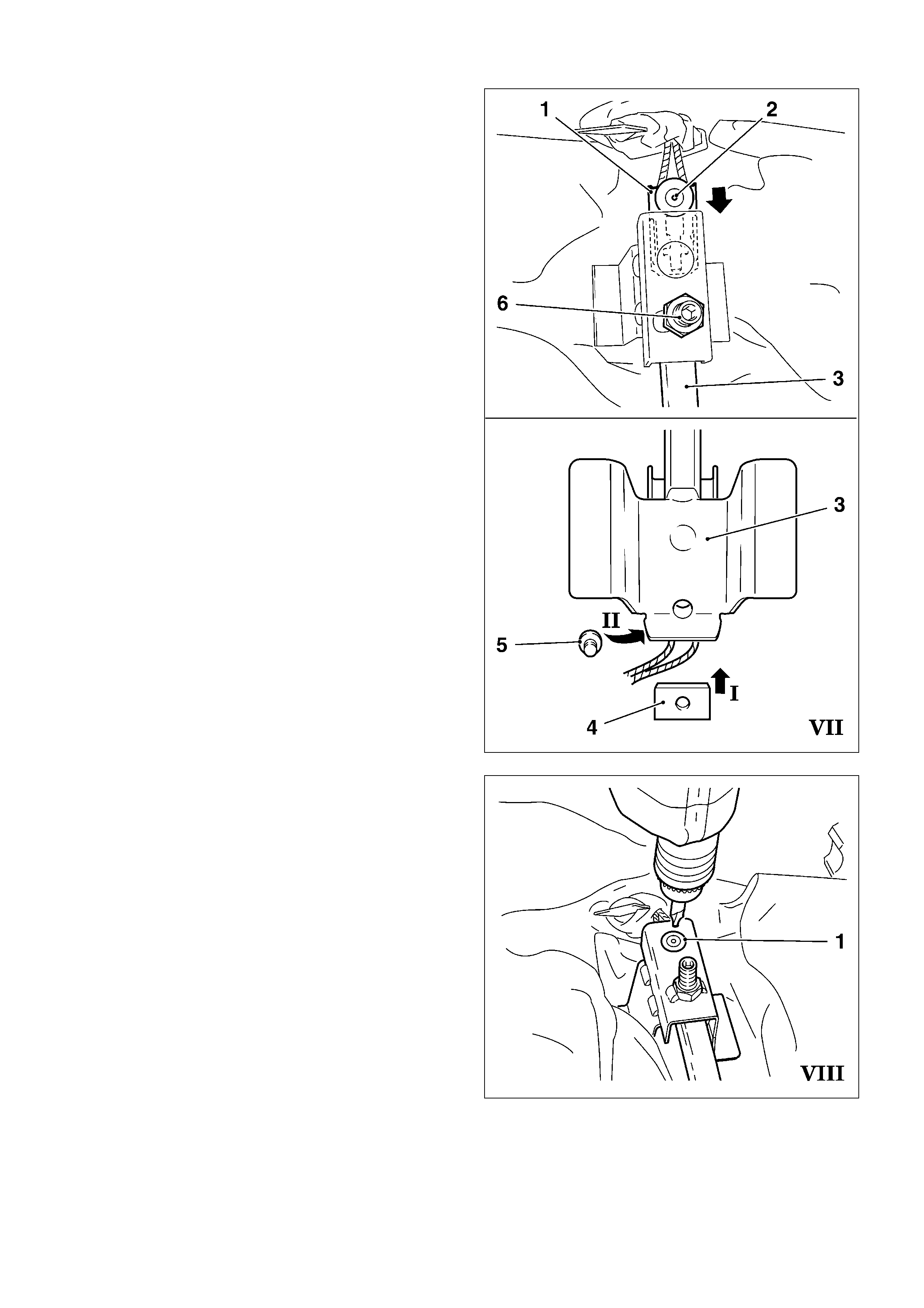

Assemble hammer screw with reinforcing

bracket as shown in figure III.

Note

When carrying out this rework for the first

time, it is recommended to apply a white paint

mark on the upper edges of the reinforcement

bracket (arrows). The white edges allow a

better check whether the reinforcement

bracket is correctly inserted into the seat rail

groove after fitting.

7

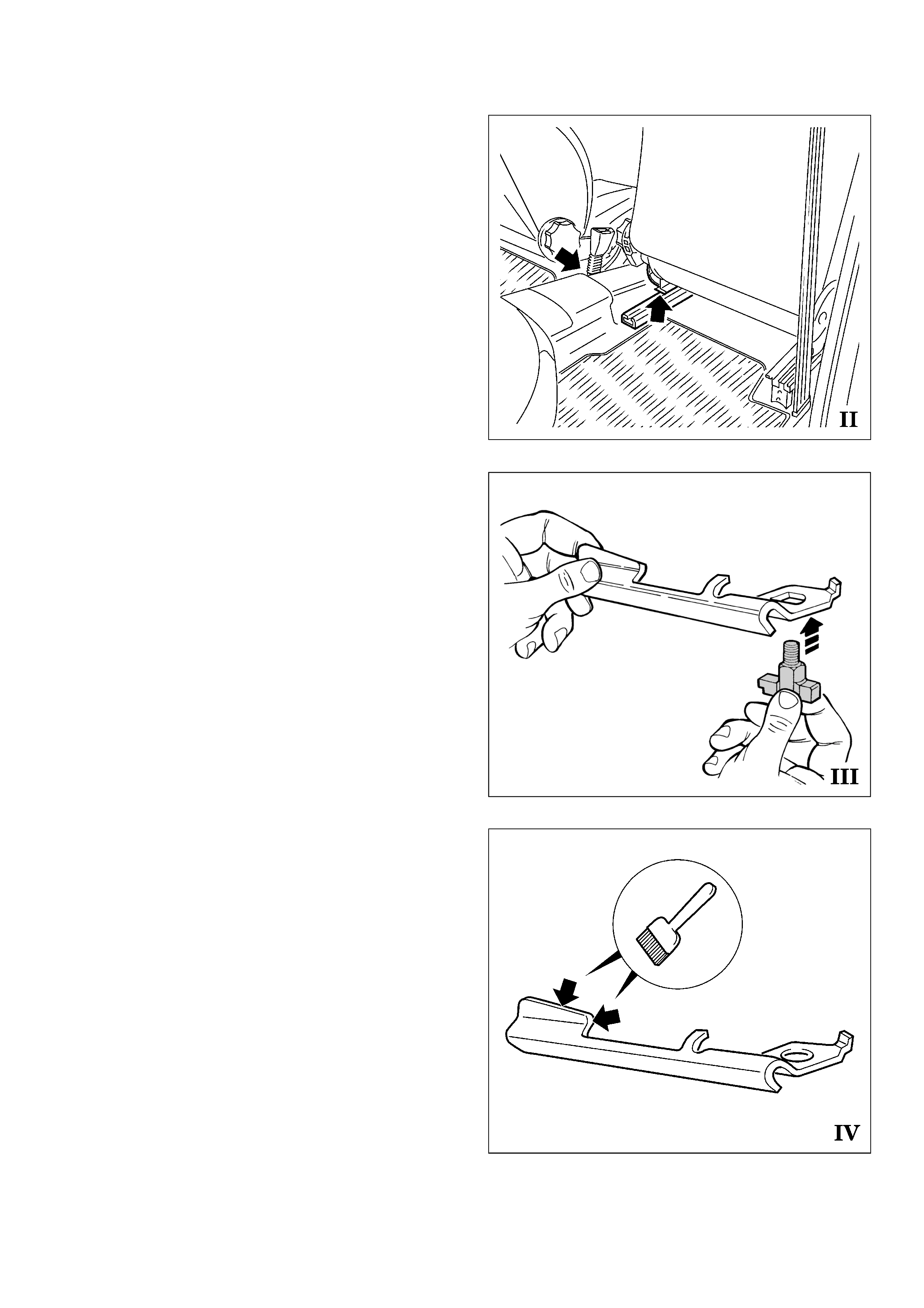

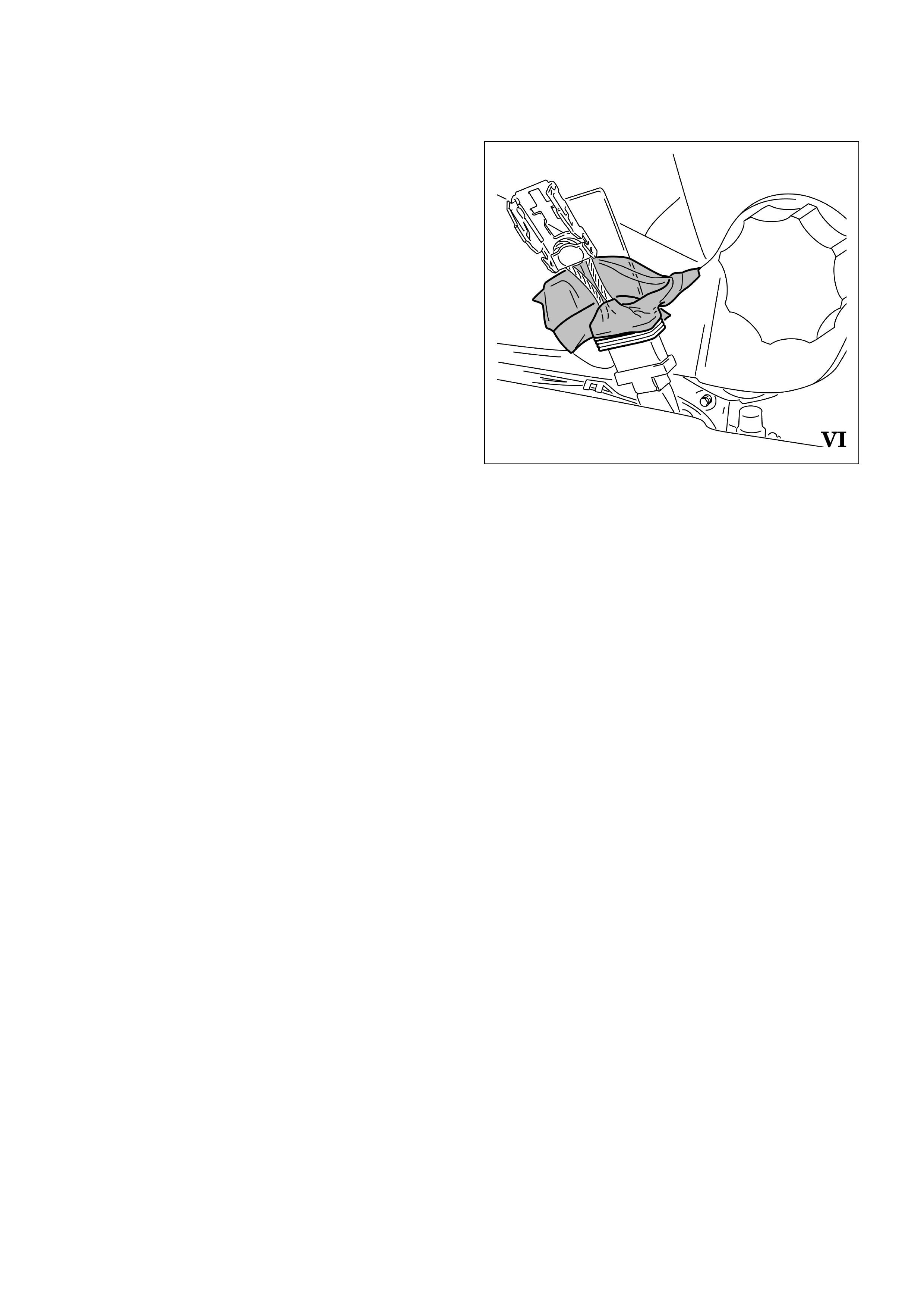

Assembly

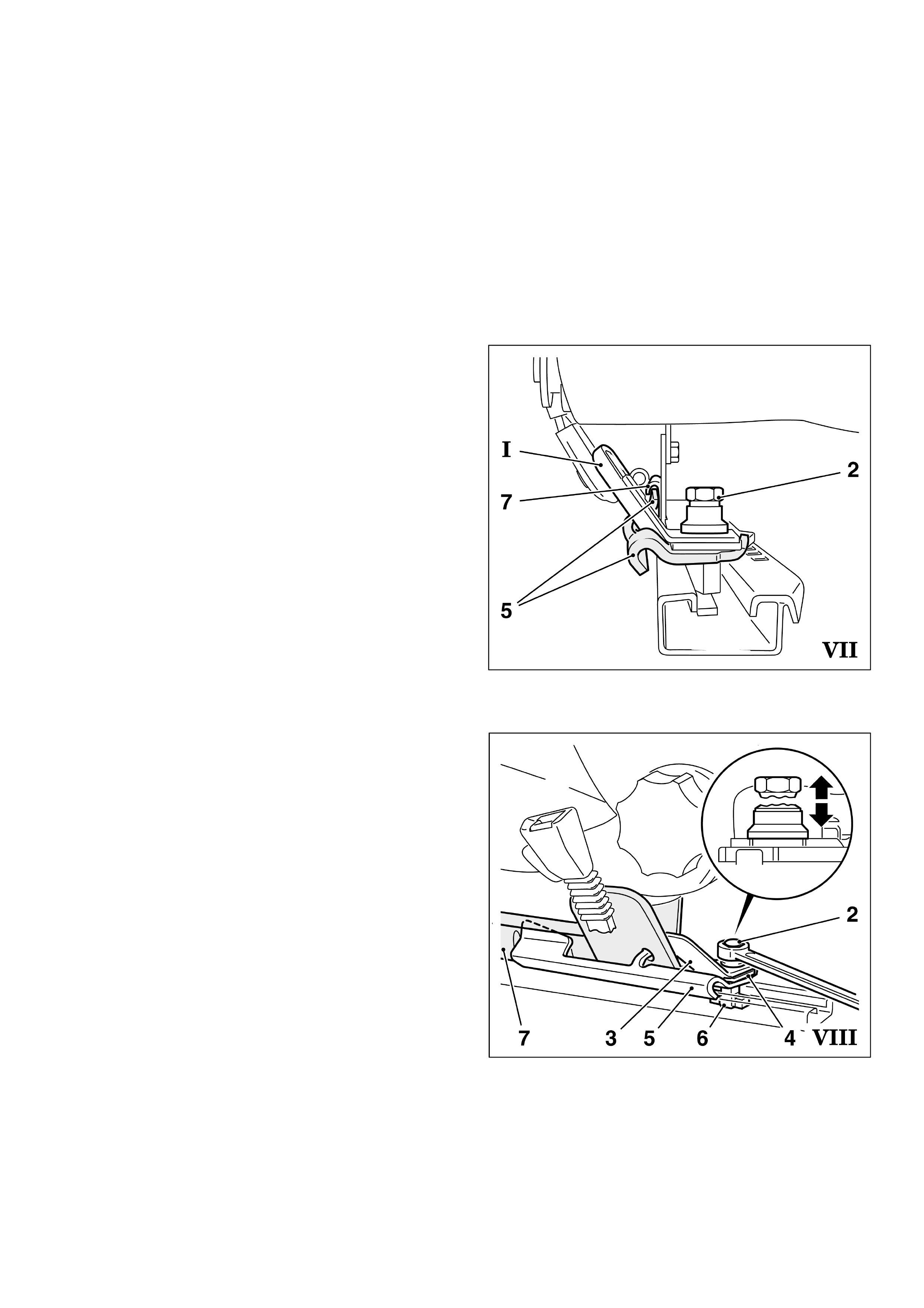

Install reinforcing bracket (5) with inserted

hammer screw (6) onto seat rail.

(Reinforcing bracket and hammer screw are

easy to insert when the seat is moved to the

rear)

Note

If the reinforcing bracket (5) can’t be

positioned correctly, the tie strap on the belt

pre-tensioner (8) has to be turned in order to

achieve more clearance for the reinforcing

bracket.

Figure VI shows the assembly of the

reinforcement kit. (Note: The pre-tensioner for

the seat belt has been removed from the

picture for a better overview)

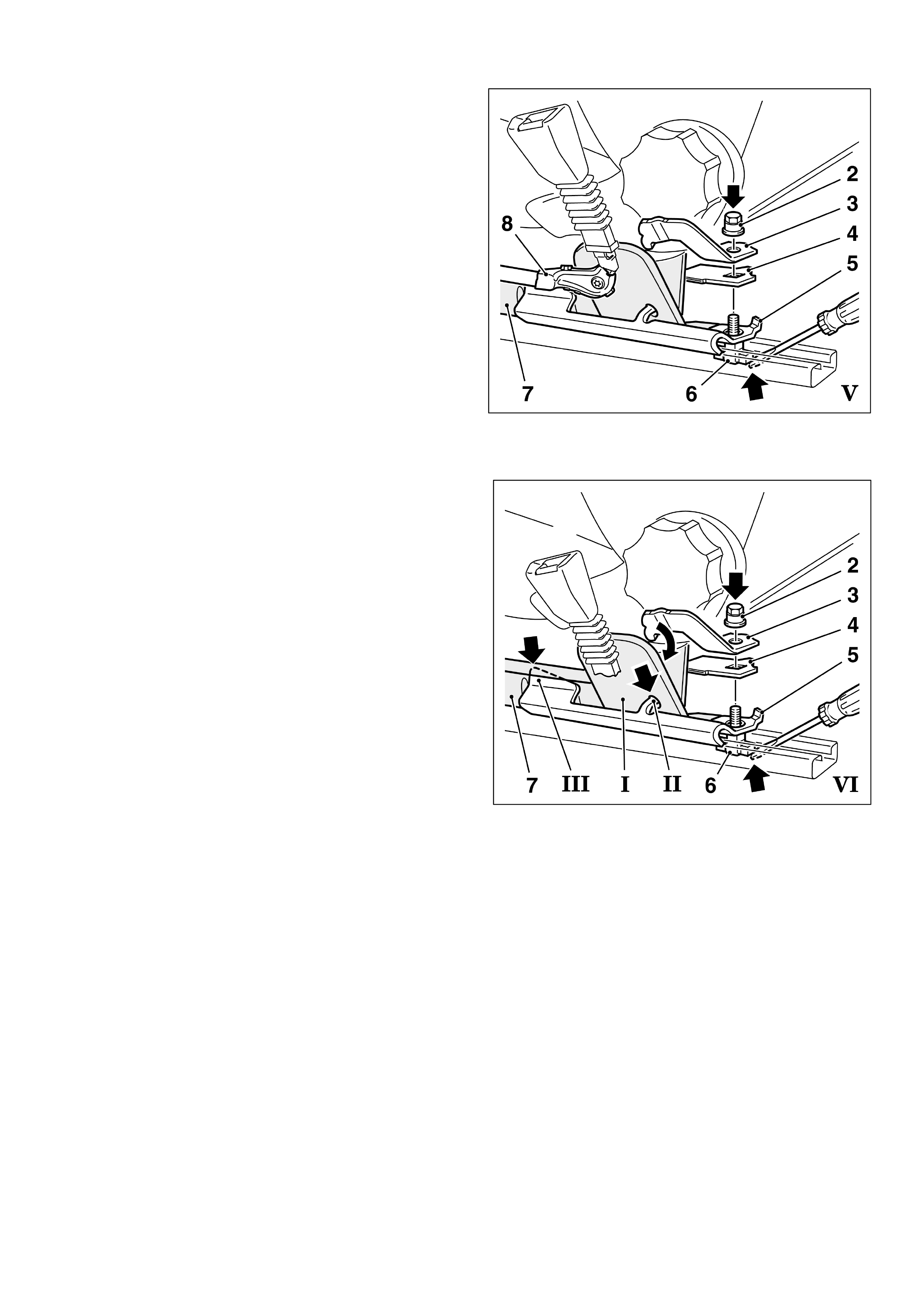

Ensure

The front upper end ( I ) of reinforcing bracket

(5) must slip into the groove of the seat rail (7)

The finger ( II ) in the centre upper area of the

reinforcing bracket (5) must slip into the bore

of the anchor plate ( I ).

Install reinforcing plate (4) Ensure that the

reinforcing plate fits correctly with hammer

screw (6) and is aligned along the seat rail (7)

Install support hook (3) Ensure that the upper

end contacts the anchor plate ( III ).

Install shear nut (2) with hexagon head

positioned upwards.

Apply LOCTITE 262 to the shear nut.

Tightening the shear nut (3) loosely with ring

wrench.

Note

On right seats (ARH) the support hook (3) has

to be hold in position during tightening by

levering with a screwdriver between hook (3)

and shear nut (2).

8

Important

Observe sequence indicated in figure (V).

It is recommended to use a screwdriver/ finger

to hold the hammer screw (6) in position

during assembling.

Important

Before the final torque is applied check

correct installation of the assembled

reinforcement kit as follow:

- Check that the seats move freely and that

the moving is not interfered by the fitted

components.

- Move seat to front most position. Look along

the reinforcing bracket with a torch and check

whether the upper end of the reinforcing

bracket (5) is inserted into seat rail groove.(7).

After correct installation, the reinforcement kit

must fit without any play.

Tighten the shear nut (2) until the nut shears

off.

Important

The head of the shear nut (2) will shear off

suddenly when reaching a torque of

approximately 40 Nm.

To prevent injuries use a ring spanner

only.

The shear nut will prevent removal of

reinforcement kit from seat rail. Therefore

make sure that the reinforcement kit is

correctly fitted before applying final torque.

If there is any problem with the reinforcement

kit after the nut head has been sheared-off,

the complete reinforcement kit must be

replaced.

9

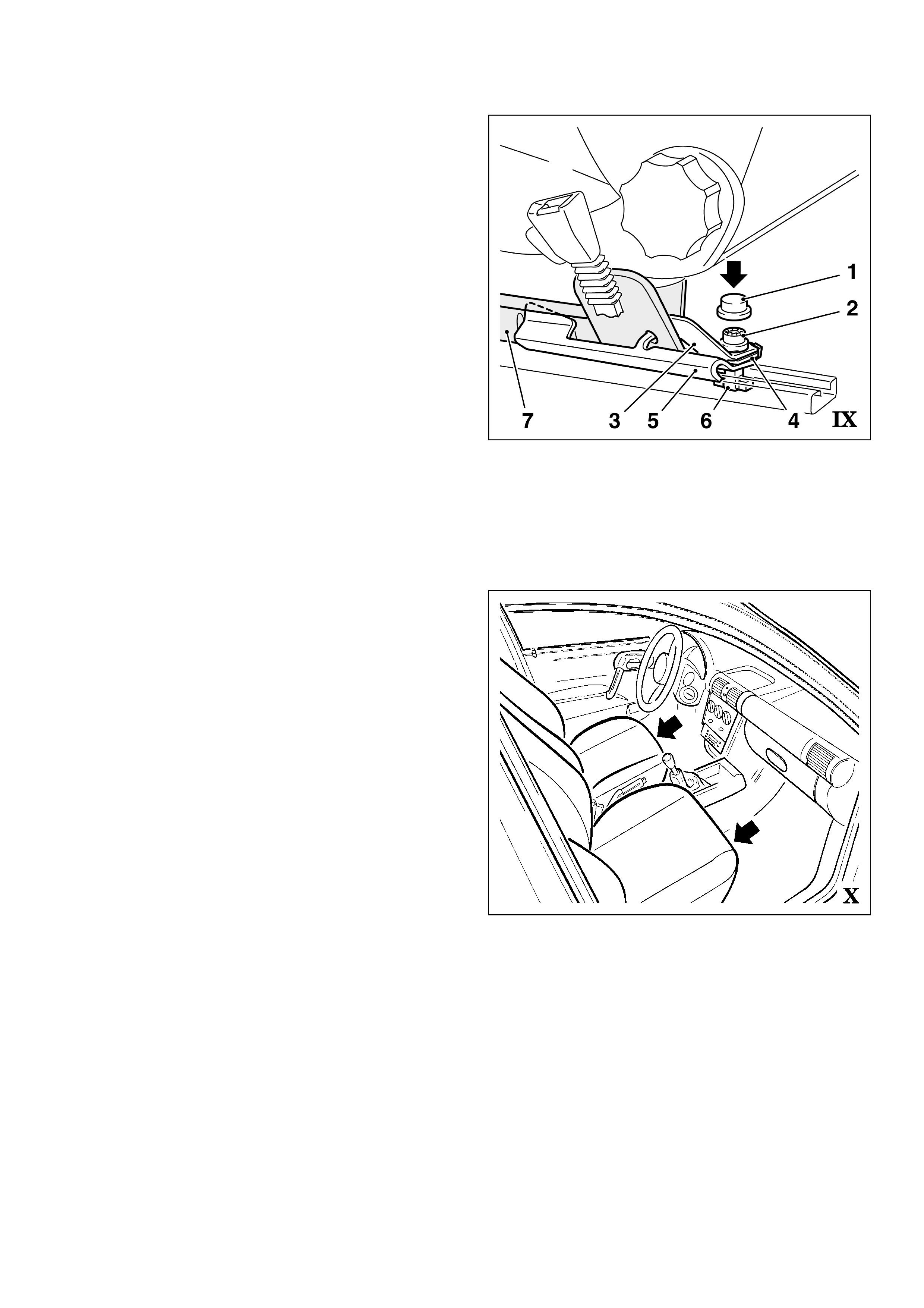

Push the protection cap (1) over the shear nut

(2) to cover the sharp edges.

Move the seats to the original position.

End.

10

ATTACHMENT B

REWORK INSTRUCTION CAMPAIGN 01-H-01 VERSION B

Rework For Seats With Anchor Plate Version “B”

The following instruction shows the rework of the right seat. The rework of the lef t seat has

to be carried out accordingly. The rework must be carried out in accordance to the rework

instruction and with the original parts of the reinforcement kit only.

Identification markings for

left seat right seat

1 – Protection Cap*

2 – Shear-off Nut*

4 – Reinforcing Plate

5 – Reinforcing Rail

6 – Hammer Screw*

7 – Seat Rail (part of the seat)

shape

BLH

shape

BRH

*) part has no marking – same part for all four types of reinforcement kits

11

Attention:

Only seats without height adjuster are to be

reworked.

Check the anchor plate version (A or B)

Check type of rework kit.

Check completeness of reinforcement kit.

The installation of the reinforcement kit can

be carried out with the seat in all positions.

However the easiest fitting is possible when

the seat is in the rearmost position.

Assemble hammer screw with reinforcing

bracket as shown in figure III.

Note

When carrying out this rework for the first

time, it is recommended to apply a white paint

mark on the upper edges of the reinforcement

bracket (arrows). The white edges allow a

better check whether the reinforcement

bracket is correctly inserted into the seat rail

groove after fitting.

12

Assembly

Install reinforcing bracket (5) with inserted

hammer screw (6) onto seat rail.

(Reinforcing bracket and hammer screw are

easy to insert when seat is moved to the rear)

Note

If the reinforcing bracket (5) can’t be

positioned correctly, the tie strap on the belt

pre-tensioner (8) has to be turned in order to

achieve more clearance for the reinforcing

bracket.

Figure VI shows the assembly of the

reinforcement kit. (Note the pre-tensioner for

the seat belt has been removed from the

picture for a better overview)

Ensure

The front upper end (I) of reinforcin g bracket

(5) must slip into the groove of the seat rail (7)

Install reinforcing plate (4) Ensure that the

reinforcing plate fits correctly with hammer

screw (6) and is aligned along the seat rail (7).

Important

Prior to installing the shear nut (2) apply a

small amount of LOCTITE 262 on the thread

of the hammer screw (6)

Install shear nut (2) with hexagon head

positioned upwards.

Tightening the shear nut (2) loosely with ring

wrench.

Important

Observe sequence indicated in figure (VI).

It is recommended to use a screwdriver/ finger

to hold the hammer screw (6) in position during

assembling.

13

Important

Before the final torque is applied check

correct installation of the assembled

reinforcement kit as follow:

- Check that the seats move freely and that

the moving is not interfered by the fitted

components.

- Move seat to front most position. Look along

the reinforcing bracket with a torch and check

whether the upper end of the reinforcing

bracket (5) is inserted into seat rail groove.(7).

After correct installation, the reinforcement kit

must fit without any play.

Tighten the shear nut (2) until the nut shears off.

Important

The head of the shear nut (2) will shear off

suddenly when reaching a torque of

approximately 40 Nm.

To prevent injuries use a ring spanner

only.

The shear nut will prevent removal of

reinforcement kit from seat rail. Therefore

make sure that the reinforcement kit is

correctly fitted before applying final torque.

If there is any problem with the reinforcement

kit after the nut head has been sheared-off,

the complete reinforcement kit must be

replaced.

14

Push the protection cap (1) over the shear nut

(2) to cover the sharp edges.

Move the seats to the original position.

End.

15

Attachment (C)

MATERIAL ORDER FORM

SAFETY RELATED RECALL 01-H-01

Fax No.: (03)-9251-6352

Attention: T. Nolan

PLEASE SUPPLY QUANTITY OF SEAT RAIL REINFO RCEMENT KIT AS NOTED BELOW.

NOTE: Only order sufficient quantities for pre-booked vehicles. Strict controls on the

quantity of parts supplied will be enforced due to limited parts availability.

RAIL KIT (ALH) Qty:

RAIL KIT (ARH) Qty:

RAIL KIT (BLH) Qty:

RAIL KIT (BRH) Qty:

From Dealer Code: ___________ Date: __________________

Dealership Name: ______________________________________

Person Ordering Parts (Contactable Person): ________________________________

(please PRINT your name)

Fax This Form To : SALMAT (03)-9251-6352

1

PRODUCT CAMPAIGN BULLETIN

01-H-02

February 16, 2001

SUBJECT : FRONT SEAT BUCKLE REPLACEMENT

MODEL: SB BARINA & COMBO

This bulletin announces the initiation of a safety related recall on some SB Barina & Combo

vehicles.

DESCRIPTION O F DEFECT

Holden has been aler ted to the f act t hat as a result of f atigue and under specif ic load conditions, the

locking spring of the front seat belt buckle mechanism may weaken. This condition can potentially

release the seat belt buckle belt latch mechanism prematurely.

DETAI L S OF AFFECTED VEHICLES

IMPORTANT NOTES:

1. The affected range is determined by the Model Year identifier (alpha) and the vehicles Serial

Number (7 digit numeric) of the ISOVIN. i.e “X” = Model Year 1999 and “4016295” is the

sequential vehicle serial number .

2. The af fect ed range covers multiple model year vehicles ie “X???????” to “Y???????” includes

vehicles built in both model years 1999 (“X”) and 2000 ( “ Y” ) .

3. Only Bar ina & Com bo vehicles with mechanical seat belt pre- tensioner devices are af fect ed by

this recall.

BARINA MO DELS

Model Year 1999(“X”) to Model Year 2000(“Y”) Barina Swing and City and variants including

Cabrio etc.

The ISOVI N r ange of affected vehicles is:-

BARINA

MY FROM TO

W0L0SBF08…….. W0L0SBF08……..

99 X4209509 X4290457

99 X4360565 X4424418

00 Y4045076 Y4304132

W0L0SBF68…….. W0L0SBF68……..

99 X4209337 X4290381

99 X4360580 X4424244

00 Y4045800 Y4304052

2

COMBO

MY FROM TO

W0L0SBF25…….. W0L0SBF25……..

99 X3031259 X3040410

99 X3050122 X3059911

00 Y3006529 Y3027005

Important Note: There are two ranges for model year 99 because there are two batches of

affected vehicles f or that m odel year.

All vehicles within the affected ranges shown above are affected by this recall campaign

irrespective of whether the customer presents a customer letter or not. Dealers must check the

ISOVIN and only those vehicles within the affected r ange req uir e campaign action.

Dealers with electronic vehicle “flagging” systems requiring a Holden Tag No. can use the

following Tag No. r anges for f lagg ing pur poses only. The I SOVIN det ermines whether t he vehicle

IS or IS NO T aff ected by this recall campaign and m ust be established f rom the pr esented vehicle

befor e com plet ing the required action O R advising the customer t hat the vehicle is not affected

From Y071063 to Y089916 and Fr om 2287358 t o 2554793

TRAINING

Due to the complex nature of the rectification, Holden will be conducting training in nominated

metropolitan and rural centres. Before commencing work technicians performing the rectification

on vehicles aff ected by this campaign m ust com plete and pass the tr aining.

SPECIAL TOOLS

There ar e t wo (2) special t ools associated with this recall.

(1) Hand Held Drill Jig

(2) Drill bit (dr ill bit life is approx. 30 vehicles – includes passenger and driver side)

Note: These tools will be supplied with the initial distribution of parts. As drill bit life is approx. 30

vehicles. Salmat will issue another drill bit once individual dealers have ordered the 20th buckle kit.

(One buck le kit contains two buckles)

OWNER NO TIFICATION

Owners will be contacted directly by letter from Holden, providing details of the recall and

requesting them to arrange for the campaign action to be carried out. Following is a draft of the

customer letter.

Dear Holden Customer ,

At Holden we continually strive to enhance the ownership experience of our customers through

continuous product im pr ovem ent, aft er sales ser v ice and ef fective custom er com m unication.

3

Holden’s foremost concern is the continued safety of our customers. Accordingly the recall

campaign described below is being under t aken as a safety precaut ion.

Holden has been alerted to the fact that in a number of vehicles within a determined production

range The locking spring of t he seat belt buckle mechanism may weaken as a result of f atigue under

specific load conditions. This condition could potentially result in the seat belt mechanism releasing

the belt latch prematurely.

Our records show that your Holden vehicle was manufactured within the vehicle range which may

include this component. It is therefore necessary for you to contact a Holden dealership of your

choice as soon as possible to have a revised seat belt buckle kit fitted to your vehicle.

All wor k w ill be car ried out f ree of charge and provided t he necessary ar rangem ents wit h a Holden

dealer are made in advance, your vehicle can be rect ified w hile you wait . The required work will take

approximately one and a half (1.5) hours.

Holden has initiated this action as a precautionary measure to ensure the integrity of the seat belt

buckle.

We know that effective communication is vital to helping your understanding of the issues involved

and trust that this letter provides you with all the information you need. If you should have any

questions, please contact your dealer or call the Holden Recall Assistance Line - 1800 632 826,

where one of our operators will be pleased to assist.

Thank you for your attention to this matter. We apologies for any inconvenience this action may

cause you.

Yours Sincerely

D. McMurray

Manager Customer Assistance

DEALERSHIP ACTION REQUIRED

On presentat ion of the vehicle considered by the customer to be affected by this campaig n:

• Confirm t hat the vehicle is in the af f e cted ISO VIN rang e – Ref er to Det ails of Af f ected Vehicles

on page 1 of this bulletin.

• Rework affected vehicle in accordance with the Rework Instructions. Refer to attachment (A)

Rework Instr uction 01-H-02.

• Apply a Campaign Completed I dentif icat ion label.

CAMPAIGN COMPLETION IDENTIFICATION

All campaigned vehicles must have a Campaign Completed identif ication label applied to the right

hand front ‘A’ pillar, between the hinges, with details of the campaign, 01-H-02, Dealership code

and date legibly entered on t he label with a perm anent ink pen.

Extra campaign ident ification labels are available free of charge f rom:

Moore Business Systems

Facsimile: (03) 9270 8900

Attention: Mr. Bob Curry

4

Quote stock No. SD 28156 on a Moore Business Systems ‘packaged goods’ order form (or

facsim ile if not available) for a box of 100 labels.

As an additional continuous improvement initiative, which was triggered by the dealer network,

Campaign Completion Identif ication will now also be included on the Vehicle Service Histor y Label

(SD 28177 available from Moore Business Systems). Place an “X” at the F-4 co-ordinate of the

Vehicle Service History Label and apply it to the inner side of t he lower instr ument panel cover.

WARRANTY CLAIM INFORMATION

On completion of campaign action, dealers are requested to immediately submit a w arranty

claim.

Description: Replace Both Front Seat Belt Buck les

Labour Operat ion No: T180601

Standard T ime: 1.1 Hours

Failure Code: 96

Case Type: 08

Please ensure correct vehicle details are included when submitting warranty claim information as

per the norm al warranty process.

Warranty claim submission is used to update our record of campaign completion and determines

whether furt her cust omer contact is necessary to action all affected vehicles.

Please ensure on completion of the cam paign action that a warrant y claim is submitted prom pt ly.

PARTS INFORMATION

DO NOT O RDER PARTS FOR THIS CAMPAI GN FROM HSPO

Front Seat Buckle Kits for this campaign are available through SALMAT using the attached order

form.

Controls on the quantity supplied will be enforced due to lim ited parts availability.

DO NOT campaign vehicles or order parts unnecessaril y!

Ensure the vehicle fall s within the guidelines specif i ed i n sect ion marked:

‘DETAILS OF AFFECTED VEHICLES’.

Should you require further information or clarification on the above, then please call Oliver

Mitrovski on telephone number ( 03) 9647 7619.

Joachim Burandt

General Service Manager

Attachment A: REW O RK INSTRUCTIONS CAMPAIGN 01-H-02

Attachment B: MATERIAL O RDER FORM

5

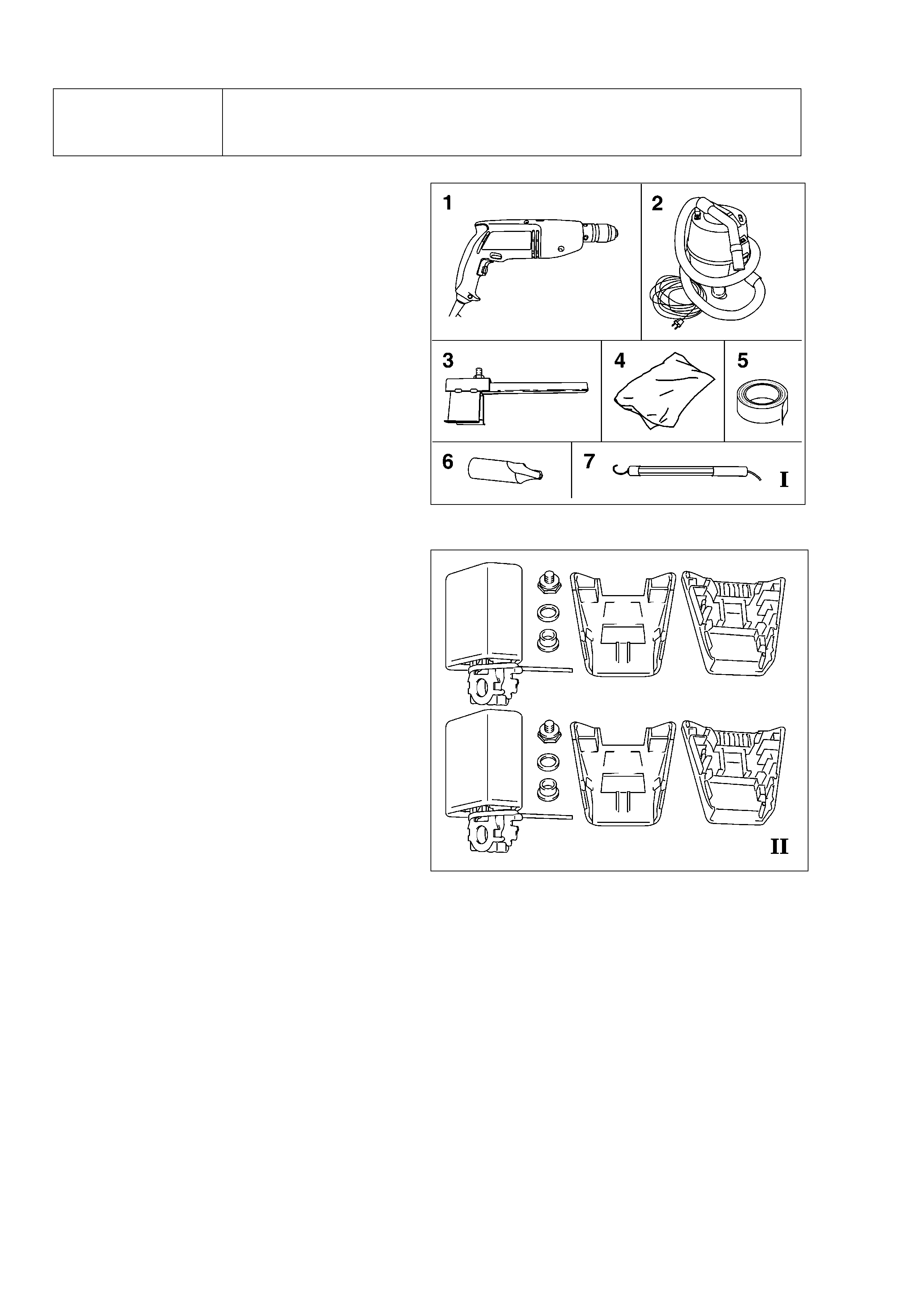

ATTACHMENT A REWORK INSTRUCTIONS CAMPAIGN 01-H-02

Tools:

Hand Held Drilling Machine(1) (13 mm Drill

Chuck)

Vacuum Cleaner(2)

Hand Held Drilling Jig (3)

Cleaning Cloth (4)

Tape (5)

Drill Bit (6)

Hand Lamp (7)

Repair Kit Seat Buckle:

2x Seat Buckle

2x Shear Bolt

2x Fixing Nut

2x Pulley

2x Seat Buckle Cap (Seat Side)

2x Seat Buckle Cap (Tunnel Side)

Rework Operation:

1. Disassembling of seat buckles

2. Drill out f ixing rivet of se at buckle frame

3. Fitting new seat buckle

4. Visual and functional check of seat buckles

6

Rework Details:

Check the vehicle for a white paint marking on the pre-tensioner, which is visible through the

aperture of the seat rail cover.

If no white paint mark is present on the pre-tensioner, both seat buckles have to be replaced in

accordance with the following instruction.

1. Disassembling of Seat Buckle:

The following Rework Instructions shows the replacement operation on the right seat buckle.

Both seat buckles have to be replaced.

Positioning of Seats

The seat to be reworked has to be moved in the rearmost position.

The other seat has to be moved in the front most position

Disassembling

Remove the seat rail cover. (4 Fixing Screws) to access seat belt pre-tensioner.

Note. Torxscrews

Securing of Pre-tensioner

The security fork has to be fitted in the

designated aperture of the pre-tensioner.

(Arrow)

Caution!

Before working on the pre-tensioner please,

observe the safety regulation for restraint

systems.

7

Note:

In the course of disassembling of the seat buckles, lock components may fall into the seat rails

or the footwell area. Use a cleaning cloth to cover the seat rails and the footwell area.

The components of the disassembled seat buckle must not be used again.

Disassembling

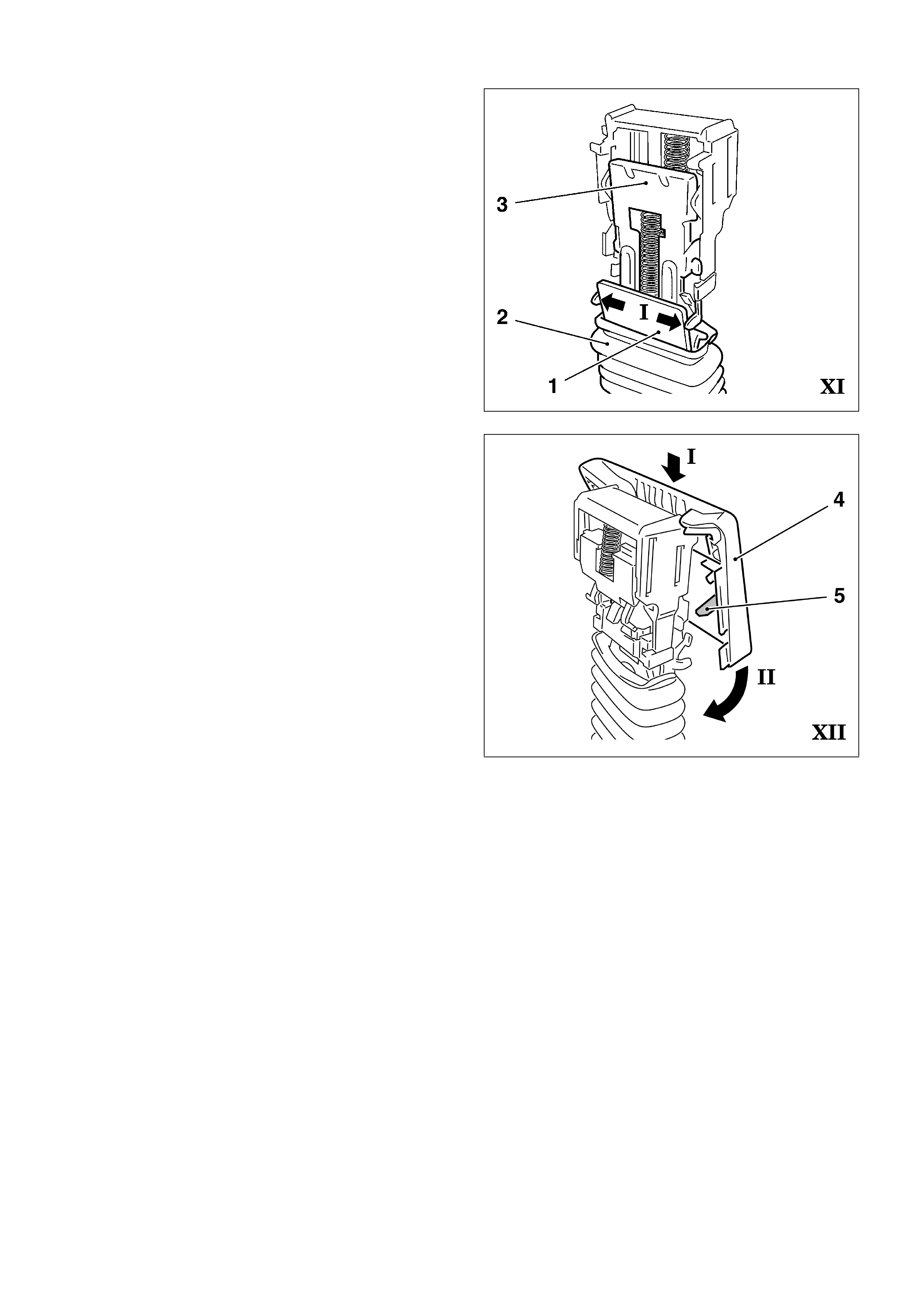

Pull out seat buckle boot by hand.

Pull out the triggering indication (3) for restraint

system from the seat buckle.

Insert the buckle latch (1) into the aperture o

f

the triggering indication of the seat buckle.

Unlatch the seat buckle caps (2) by turning the

buckle latch firmly.

Disassembling

Remove white clamp (6) and springs (5 and 9).

Clamp (1) and spring (2) remain installed.

Spread apart the spring guide (Arrow I) o

f

release butto n (3), re move the b utton b y pulling

up.

Pull out pin (4) in lat eral dire ction (A rrow II)

Remove spring element (10) with spring (8) and

guide (7).

8

2. Drill out Fixing Rivet of Seat Buckle Frame

Note

Move seat buckle boot downwards.

Fix triggering indication to the seat panel

with tape. Close the aperture of the boot with

tape as well, so no drilling swarf can ente

r

the boot.

Attention!

To achieve a correct drilling result, only the provided drill bit and hand held drilling jig must

be used.

Note:

During the drilling operation, the swarf has to be extracted with a vacuum cleaner by a

second technician.

9

Remove anti rotation block (4) from jig. Push

seat buckle frame into drilling jig (3) until the

stopper is reached and tightening the fixing

screw (6). Re install anti rotation block (4)

into drilling jig and tighten with the

designated bolt (5).

Drill out the seat buckle rivet (Picture VII, 2)

with centre bit (Picture VIII, 1) (machine

revolution – 500 rpm) – take care that the

drilling jig stands in carpet recess safely.

Important

Always wear eye protection when drilling.

10

Disassembling

Remove seat buckle frame from drilling jig – Caution: Components may be hot.

Visual check of cable for damage.

Remove cleaning cloth carefully.

Cleaning

Clean the working area using a vacuum cleaner and remove all drilling swarf.

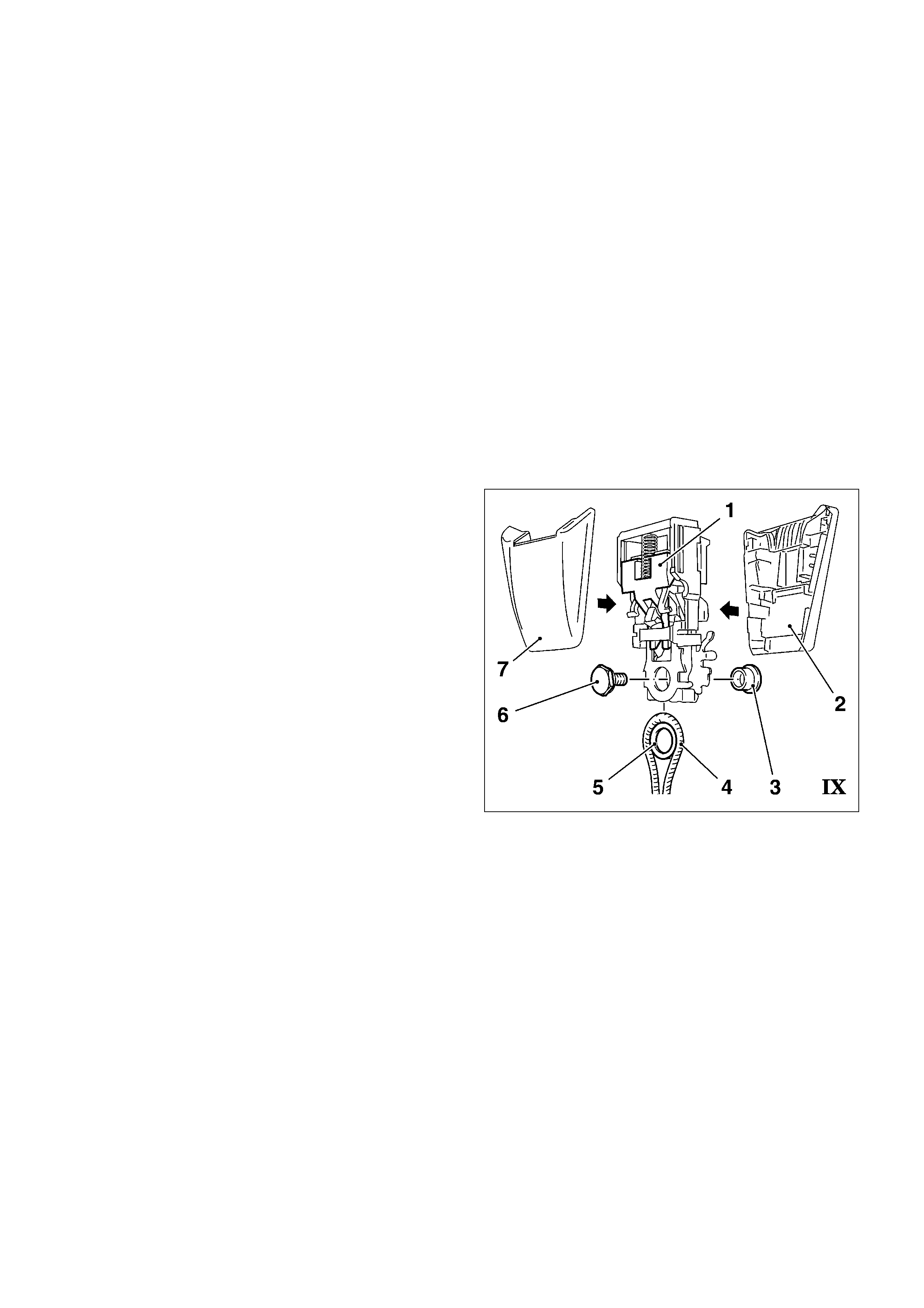

3. Installation of new Seat Buckle

Overview

1. Seat Buckle

2. Seat Buckle Cap (Seat Side)

3. Fixing Nut

4. Restraint Cable

5. Pulley

6. Shear Bolt

7. Seat Buckle Cap (Tunnel Side)

Caution !

The following operations are important for the correct function of the seat buckle.

The installation has to be carried out carefully and strictly in accordance with the

rew ork instruction.

Note

For a better overview and control of the parts which have to be used it is

recommended to put the contents of the repair kit in one box and to remove it when

needed during installation.

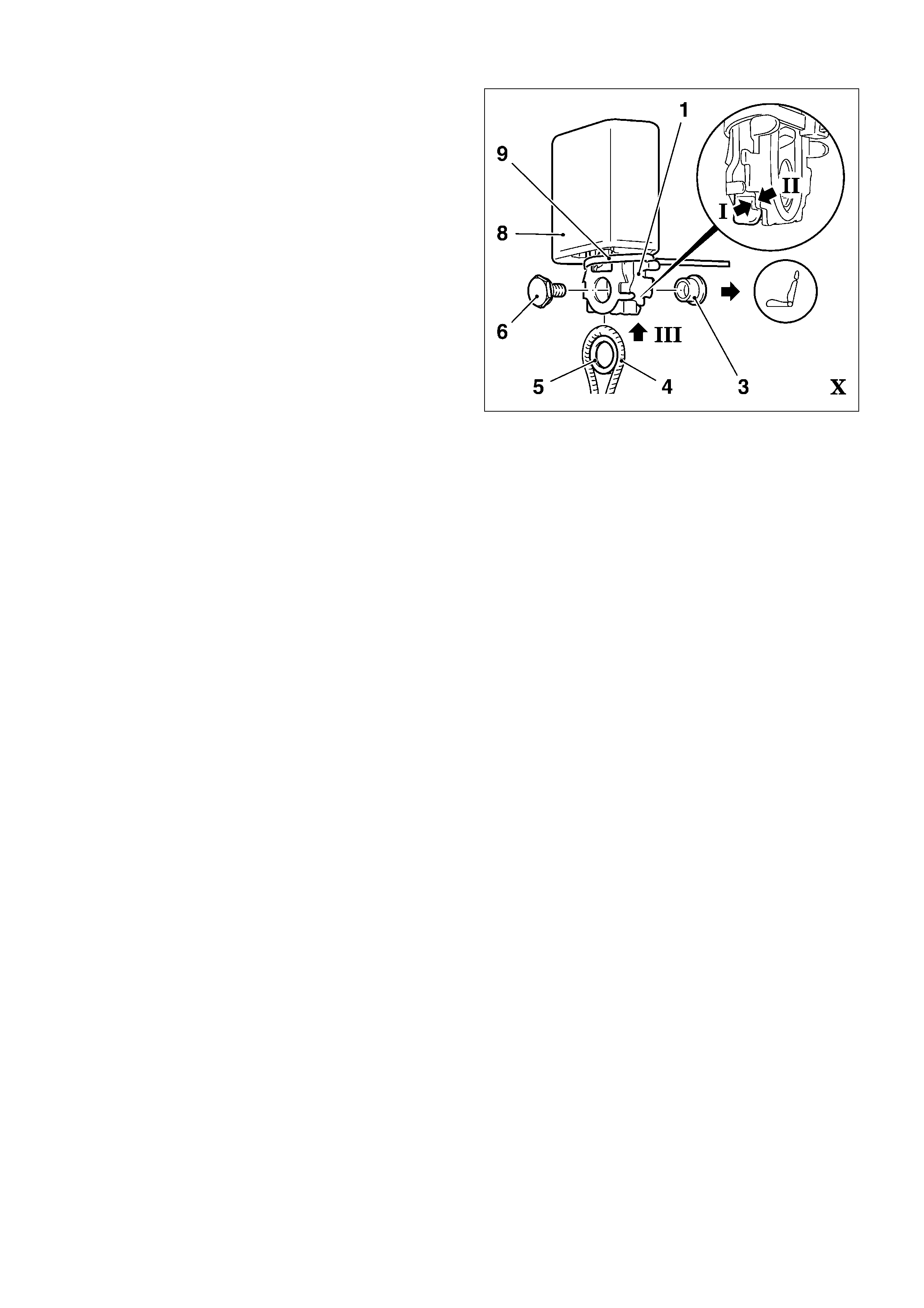

The protection cap (Picture X, 8) and the cable tie (Picture X, 9) remain installed during

fitting of the seat buckle.

11

Assembling Sequence

Insert pulley (5) and restraint cable (4) into the

seat buckle (1) (Arrow III) – Second technician

necessary.

The “black “side of the seat buckle has to

be positioned to the seat side, and the

galvanised side to the tunnel.

Insert the black fixing nut (3) through the

black side of the seat buckle and through the

pulley.

Screw in the shear bolt (6) and tightening the

bolt loosely ensuring correct location.

!! Cauti on !!

Before the bolt is sheared off the following items have to be checked:

- Seat buckle in correct position to the seat.

- Seat buckle mechanism correctly aligned (Arrow I and II, picture X )

- Pulley installed

- Alignment of seat buckle in direction to the triggering indication.

Tighten the bolt until t he screw head shears of f. Tak e care that the screw head does not fall into the

seat rails.

Remove cable tie (9) with side cutter, take care that no seat buckle components are

damaged.

Remove protection cap (8) from seat buckle.

Remove fitted tape.

Fitting the Seat Buckle Caps

Caution!

Make sure that no components of the seat buckle are damaged during fitting of the

seat buckle caps. This may result in a malfunction of the seat buckle.

In no case should any tools be used for fitting of the seat buckle caps.

12

Assembling

Insert triggering indication (1) in the guide o

f

the seat buckle. (Arrow I)

Pull up the boot (2) to the screw head and

hold the boot in position with two fingers

from the side.

Fit the seat buckle cap (seat side) from the

top to the release button until the latch of the

seat buckle side (Picture XI, 3) is located in

the seat buckle cap. (Picture XII, Arrow I )

Swing the cap to the seat buckle (Arrow II)

and locate the cap completely with lock. (5).

Make sure that the upper lip of the boot is

fully inserted in the seat buckle cap.

Fit the seat buckle cap (tunnel side) to the seat buckle and press the caps together side

by side. (No tools must be used). An audible click must be observed when the caps are

assembled together– Make sure that the boot is completely inserted in the seat buckles.

13

4. Visual and Functional Check of the Seat Buckle

Checking

Functional check of the seat buckle must be performed by assembling and releasing the

buckle latch.

Assembling

Remove security fork of pre-tensioner and place it on the designated clips on the pre-

tensioner body.

Re-install the seat rail cover (4 fixing screws).

(IMPORTANT)

Vehicle Marking

Reworked vehicles have to be marked with a white line on the pre-tensioner unit on the

drivers side visible through the aperture of the seat rail cover.

14

Attachment (C) MATERIAL ORDER FORM

SAFETY RELATED RECALL 01-H-01

Fax No.: (03)-9251-6352

Attention: T. Nolan

PLEASE SUPPLY QUANTITY OF SEAT BUCKLE KIT AS NOTED BELOW.

NOTE: Only order sufficient quantities for pre-booked vehicles. Strict controls on the

quantity of parts supplied will be enforced due to limited parts availability.

FRONT SEAT BUCKLE KIT Qty:

(Contains two buckles per kit)

From Dealer Code: ___________ Date: __________________

Dealership Name: ______________________________________

Person Ordering Parts ( Cont act abl e Person) :

________________________________

(please PRINT your name)

SALMAT USE ONLY

Cumulative buckles shipped to dealer

Fax This Form To : SALMAT (03)-9251-6352

1

PRODUCT CAMPAIGN BULLETIN

01-H-03

July 26, 2001

SUBJECT : LOW BEAM HEADLAMP - RELAY

MODEL: VT, VX and WH Series Commodore, Calai s, St atesman and Caprice

This bulletin announces the initiation of a safety related recall to replace the LOW BEAM

HEADLAMP RELAY on some Holden Commodore, Calais, Statesman and Caprice vehicles

including Holden Special Vehicles (HSV) vehicles as detailed below.

The LOW BEAM HEADLAMP component of the rework program outlined in All Dealer Letter

DL 43/01, has been upgraded to a safety related recall. Vehicles that have previously been

reworked and identified by an ‘X’ in the E-2 co-ordinate of the Vehicle Service History Label DO

NOT REQUIRE THIS CAMPAIGN ACTION.

If the Vehicle does not have an ‘X’ in the E-2 co-ordinate of the Vehicle Service History Label this

Recall Campaign act ion applies.

DESCRIPTION O F DEFECT

Investigat ion has shown that a number of vehicles in a specific batch m ay be fitted with a low beam

headlamp relay that could f ail when the low beam headlamp is switched on or selected. This would

result in the low beam headlamp not turning on.

AFFECTED VEHICLE IDENTIFICATION

Some Holden VT/VX Commodore, Calais and WH Statesman and Caprice vehicles including

Holden Special Vehicles (HSV) vehicles identified below are included in this recall.

The af fected vehicles are:

Production Serial Number (PSN) range between L545674 to L659987 inclusive, PLUS a small

number of vehicles prior to L545674 which are listed in appendix D of All Dealer Letter DL 43/ 01

(issue 3)

The (PSN) is the last 7 characters of the vehicle identification number (VIN) located at the lower

left hand corner (passenger side) of the windscreen. The PSN is commonly referred to as the

“Tag ” number.

Customer Notif i cat ion

Owners will be contacted directly by letter from Holden, providing details of the recall and

requesting the customer to organise for their vehicle to have the appropriate rectification work

carried out by a dealership of their choice.

2

Dear Holden Customer SAFETY RELATED RECALL

You may have recently received a letter from Holden requesting you book your vehicle into a

Holden dealership of your choice to replace some potentially suspect components. The low beam

headlamp relay was one of the components t hat r equir ed replacement

Holden’s forem ost concern is your continued satisfact ion and safety. On that basis, we have made

a decision to upgrade the r eplacement pr ogram of the low beam headlam p relay to a safety related

recall.

Please ensure your vehicle is rect if ied by a Holden Dealer as soon as possible.

There is potential that the low beam headlamp relay could fail which would result in the low beam

headlamps not tur ning on.

It is necessary f or you to make a service booking with a Holden dealership of your choice as soon

as possible for the r ectification work to be performed on your vehicle. This wor k will be carried out

free of char ge.

At the tim e of booking, your dealer w ill be able to conf irm the length of tim e your vehicle is required

in service.

If you should have any questions, please contact your dealer or call the Holden Recall Assistance

line on - 1800 632826, where we will be pleased to assist.

Thank you f or your attention t o this matt er. Please accept our apologies f or any inconvenience this

may cause you.

Yours Sincerely

David McMu rra y

Manager Customer Assist ance

3

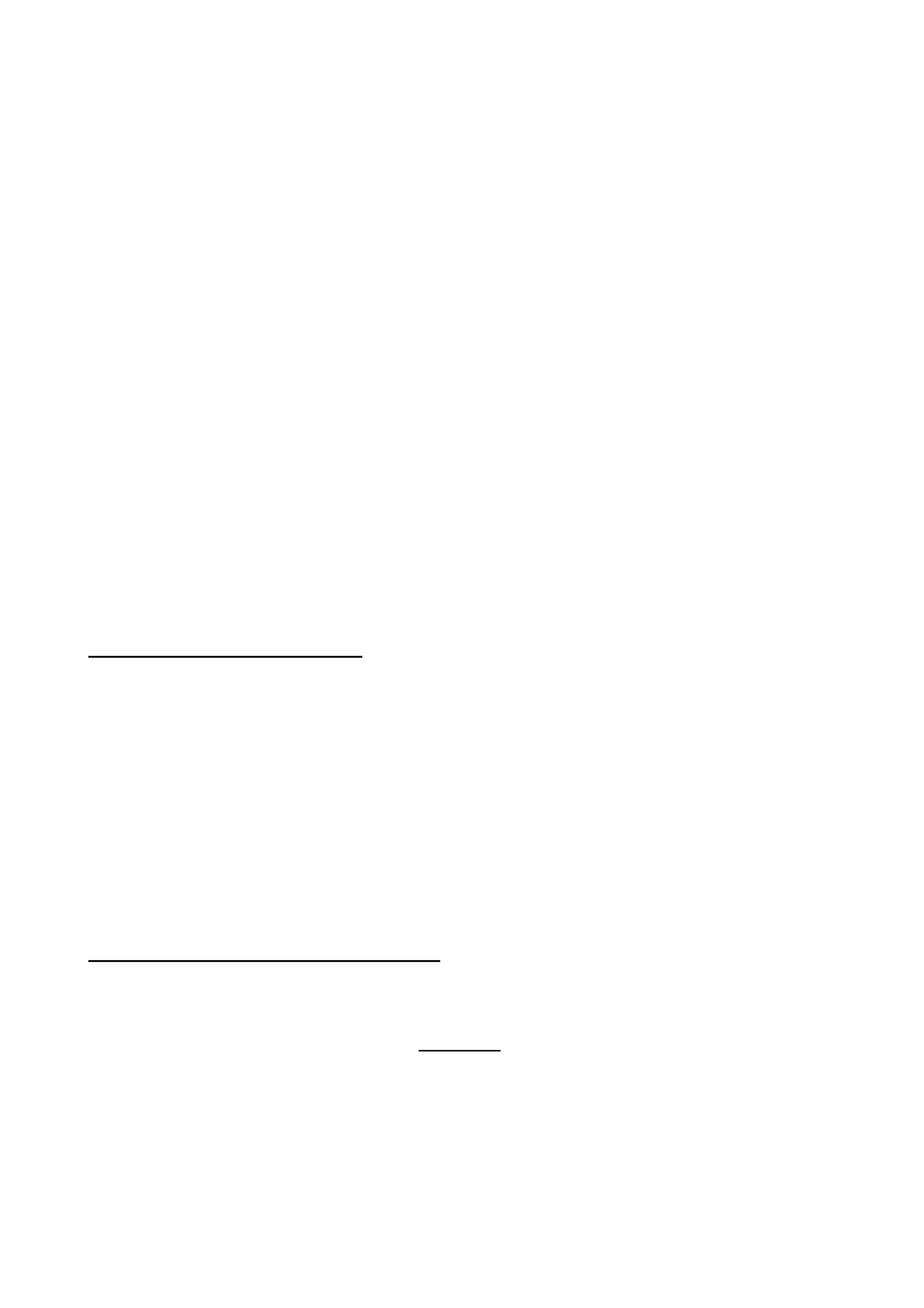

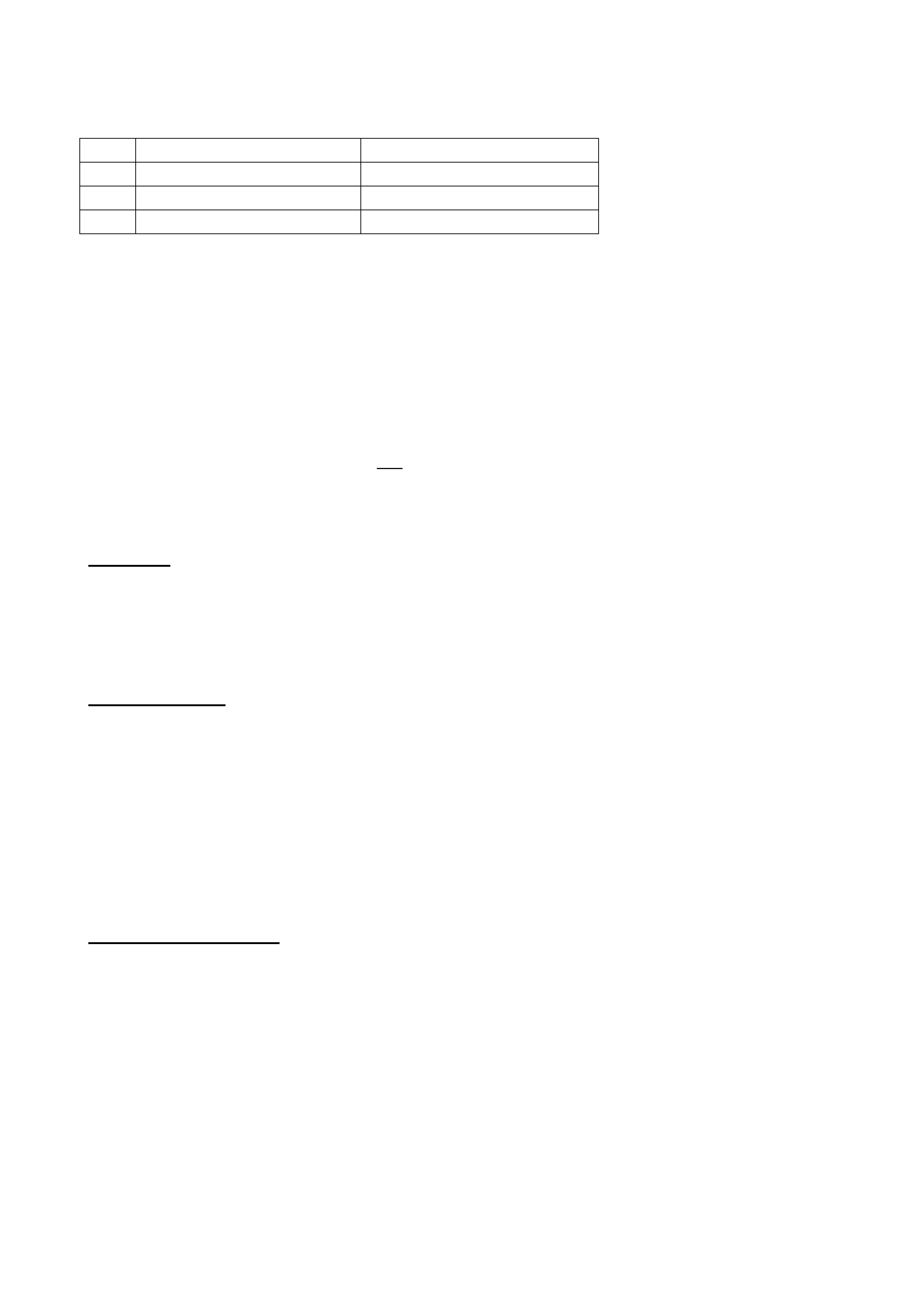

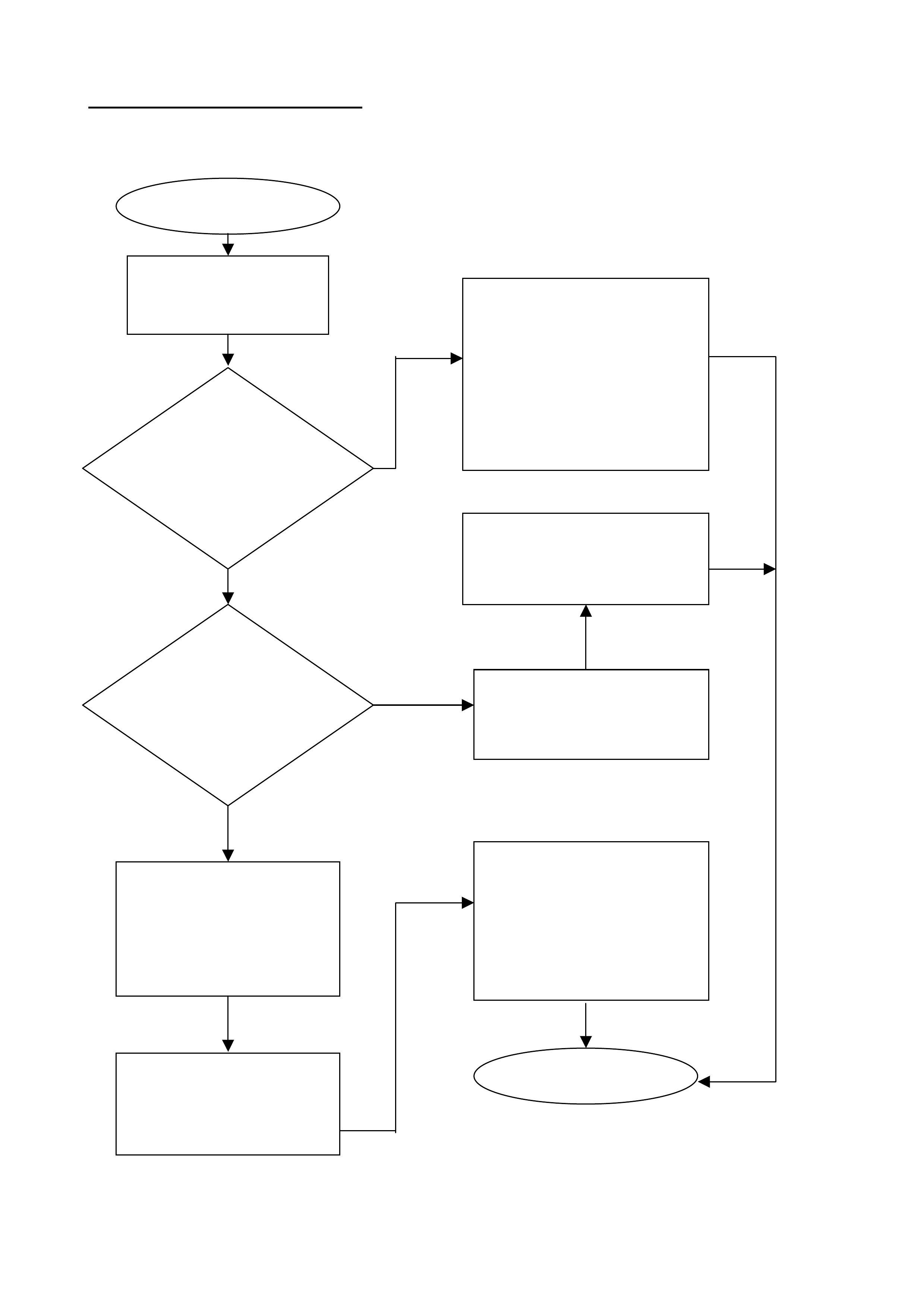

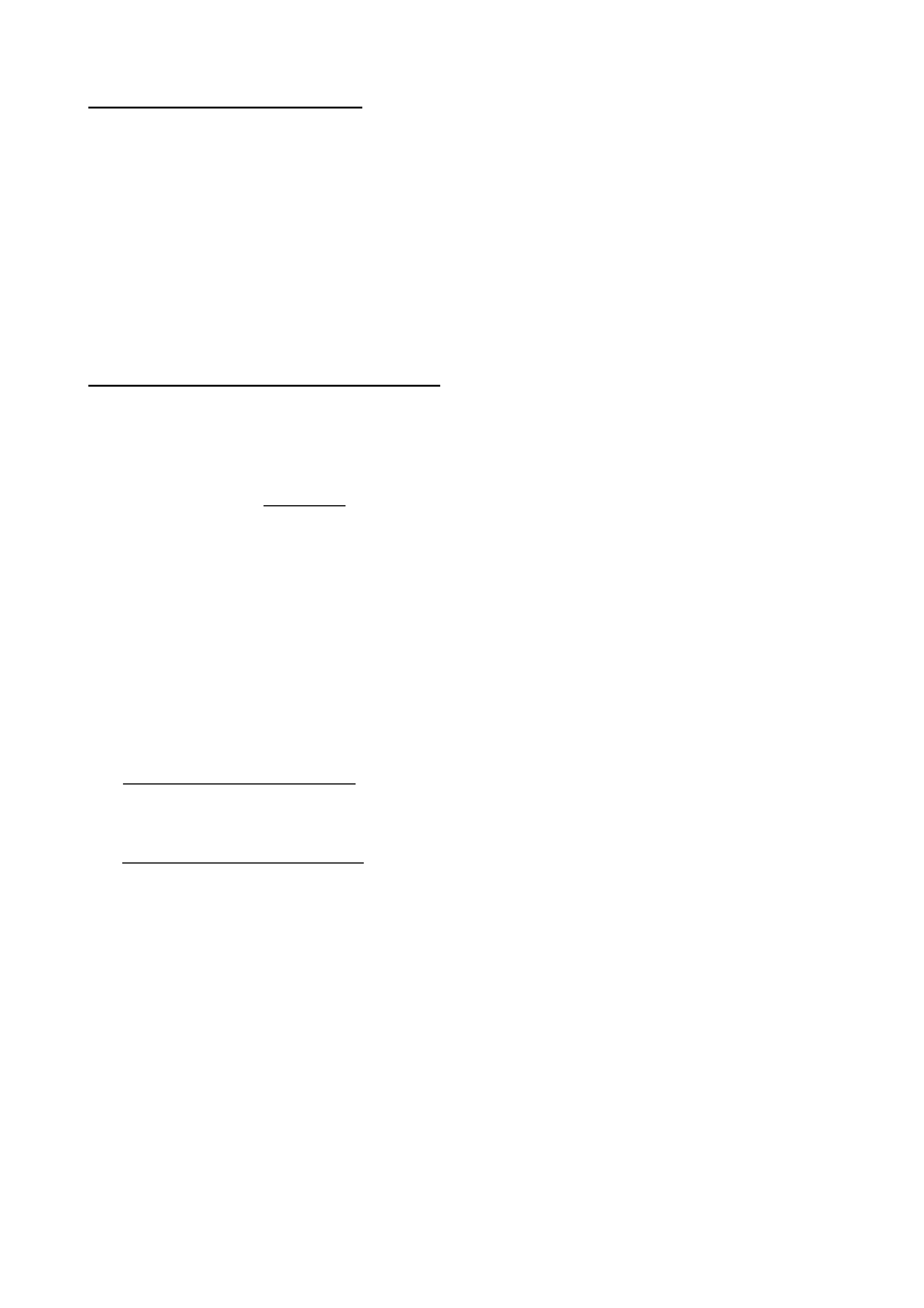

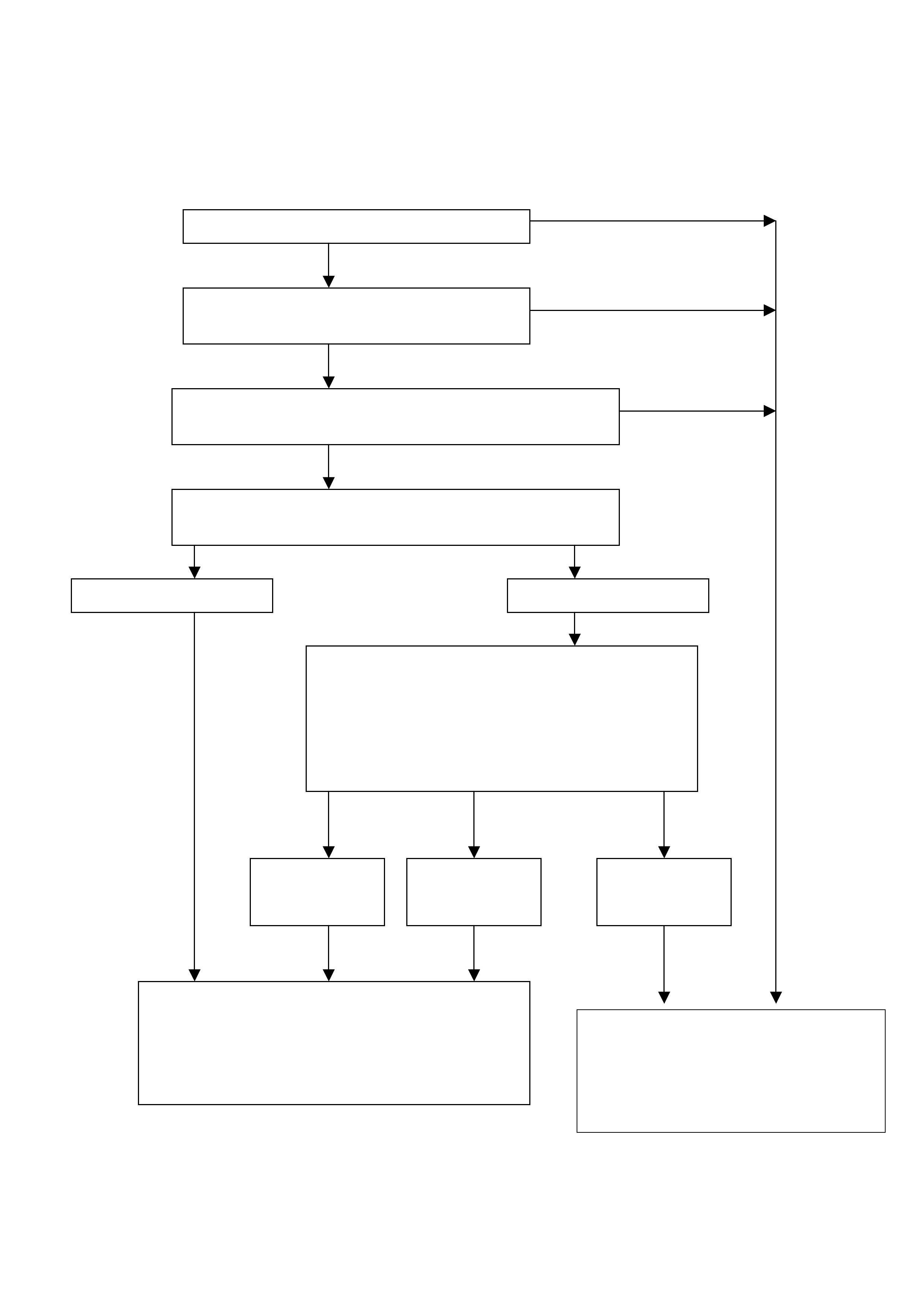

DEALERSHIP ACTION REQUIRED

On presentation of the vehicle considered by the customer to be affected by this campaign follow

the f lowchart to determine the action requir ed:

Is the

Vehicle in the affected

range or listed on appendix D?

Refer to Affected Vehicle

Identification found on

page 1 of this

document

NO

Does the

Vehicle have a

Vehicle Service History Label

with the E-2 c-ordinate

marked with

an ‘X’.

Customer Presents

vehicle for rectification

No further Recall Campaign

Action (01-H-03) is required.

Refer to DL43/01 issue 3 to

determine if hazard switch

replacement is required on this

vehicle. Mark the applicable

co-ordinate of the Vehicle

Service History Label if haz ard

switch is replaced

YES

Fit a Campaign Completion

Label and mark applicable co-

ordinates on the Vehicle Service

History Label

NO

Replace Low Beam

Headlamp Relay as per

instructions specified in

Appendix B of All Dealer

Letter DL43/01 (issue 3)

Complete all other reworks

(including fuel pump relay) in

line with guidelines specified

in All Dealer Letter DL43/01

(issue 3)

Complete and apply a

campaign completion label.

Additionally apply a Vehicle

Service History Label and

place an ‘X’ at the E-2 Co-

ordinate for relay replacement.

Mark other co-ordinates as

applicable to rework

performed

YES

START

FINISH

Complete all other reworks in

line with guidelines specified in

All Dealer Letter DL43/01

(issue 3)

4

CAMPAIGN COMPLETION IDENTIFICATION

All campaigned vehicles must have:

1. A Campaign Completed identification label applied to the right hand front ‘A’ pillar, between

the hinges, with details of the campaign, 01-H-03, Dealership code and date legibly entered

on the label with a permanent ink pen.

AND

2. For additional identification, place an “X” at the E-2 co-ordinate of a Vehicle Service History

Label and apply to the inner side of the lower instrum ent panel cover if not alr eady fitted.

Extra campaign identification and vehicle service history labels are available free of charge f r om:

Moore Business Systems

Facsimile: (03) 9270 8900

Attention: Mr. Bob Curry

For Campaign Completion Labels Quote stock No. SD 28156 on a Moore Business Systems

‘packag ed goods’ order form ( or facsimile if not available) for a box of 100 labels.

For Vehicle Service History Labels Quote stock No. SD 28177 on a Moore Business Systems

‘packag ed goods’ order form ( or facsimile if not available) for a box of 100 labels.

WARRANTY CLAIM I NFO RMATION

On complet ion of campaign action, deal ers are requested to immediatel y submit a w arranty

claim.

Refer to ALL DEALER LET TER DL 43/01 (Issue 3) for campaign claim informat ion.

Please ensure parts ar e returned in line with warranty procedure once requested by Repac

PARTS INFORMATION

DO NOT O RDER PARTS FOR THIS CAMPAI GN FROM HSPO

Important Not e:

Low Beam Headlamp Relays for this recall are the same as those already supplied to all

dealers. Additional quantities are available through SALMAT. Refer to All Dealer Letter

DL 43/01 (Issue 3) for par ts ordering inf or m ation.

DO NOT order parts unnecessarily!

Ensure the vehicle fall s within the guidel ines specifi ed i n sect i on marked:

‘AFFECTED VEHICLE IDENTIFICATION

5

CONTACT INFORMATION

For further information or clarification on this recall campaign please contact the relevant person

below.

CONTACT NAME CONTACT NUMBER

General Inquiries Oliver Mitrovski (03) 9647 7619

Parts related inqui ri es Luke Jones (Salmat) (03) 9251 6306

Warranty related inquiries Warranty Administr at ion (03) 9647 2401

J. K. Hoffman

General Service Manager

1 of 23

PRODUCT CAMPAIGN BULLETIN

01-H-04

November 30, 2001

SUBJECT: TOWBAR TONGUE REPLACEMENT

This bulletin announces the initiation of a safety-related recall to replace the TOWBAR TONGUE

on some Holden vehicles fitt ed with genuine Holden accessor y towbars.

Only genuine Holden towbars and/or r eplacement tong ues installed af t er April 1, 2000 are aff ect ed

by this recall campaig n. This installat ion dat e is not the vehicle build date.

DESCRIPTION O F DEFECT

Investigation has shown that some towbar tongues (or “goosenecks”) manufactured by Frontline

Australasia Pty Ltd, are susceptible to embrittlement that may cause the towbar tongue to break.

This embrittlement is due t o the manufacturing pr ocess of the t ongue.

AFFECTED TOWBARS

This r ecall campaign act ion is limited t o genuine Holden towbars and tongues f itted between April

1, 2000 and November 30, 2001 inclusive, The affected towbars are fitted to the models shown

below.

MODEL RATING

SEDAN

All Series VS, VT , VX & WH Commodor e,

Calais, Statesman and Caprice

INCLUDING

Holden Special Vehicles

1,590kg,

1,600kg and 2,100k g

WAGON

All Series VT, VX Commodor e

INCLUDING

Holden Special Vehicles

1,600kg and 2,100k g

UTILITY VG, VP, VR, VS & VU

INCLUDING

HSV Maloo

1,200kg, 1,590kg & 1,600kg

TF Rodeo R7 & R9 1,800kg

TS Astra 1,000kg

2 of 23

DEALERSHIP ACTION REQUIRED

On presentat ion of a vehicle f itted with a towbar tongue considered by the customer to be affect ed

by this campaign carr y out t he following procedur e.

1. Determ ine whether genuine Holden towbar (refer Appendix B).

2. Rectify as per f low chart in Appendix A.

3. Aff ix a campaig n complet ion label and a vehicle service history label as specif ied in the sect ion

titled ‘Campaign Completion I dentif icat ion’.

4. Submit a warranty claim.

Note: All st ock vehicles or vehicles presented f or r outine ser vicing should also be inspected by the

dealership.

CAMPAIGN COMPLETION IDENTIFICATION

All campaigned vehicles must have:

1. A Campaign Com p let ed identif icat ion label applied to the right hand front ‘A’ pillar , between

the hinges, with details of the cam paign, 01-H-04, Dealership code and date legibly entered

on the label with a permanent ink pen. AND

2. For additional ident ification, place an “X” at the F-1 co-ordinate of a Vehicle Service Histor y

Label and apply to the inner side of the lower instrum ent panel cover if not already fitt ed.

Extra campaign identif icat ion and vehicle service histor y labels are available f r ee of charge from:

Moore Business Systems

Facsimile: (03) 9270 8900

Phone: (03) 9270 8777

Attention: Mr. Bob Curry

For Campaign Completion Labels Quote stock no. SD 28156 on a Moore Business Systems

‘packag ed goods’ order form for a box of 100 labels.

For Vehicle Service History Labels quote stock no. SD 28177 on a Moore Business Systems

‘packag ed goods’ order form for a box of 100 labels.

3 of 23

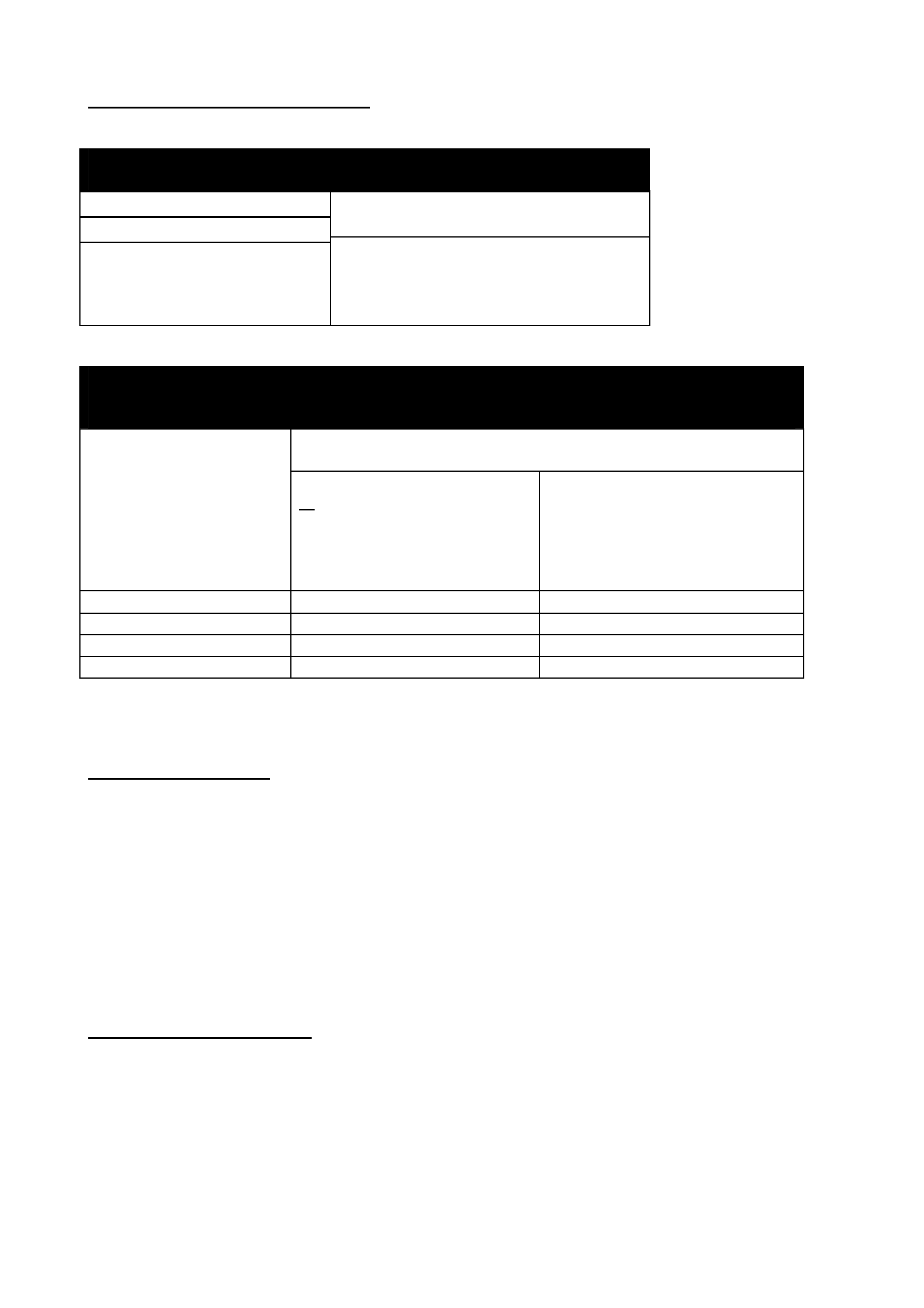

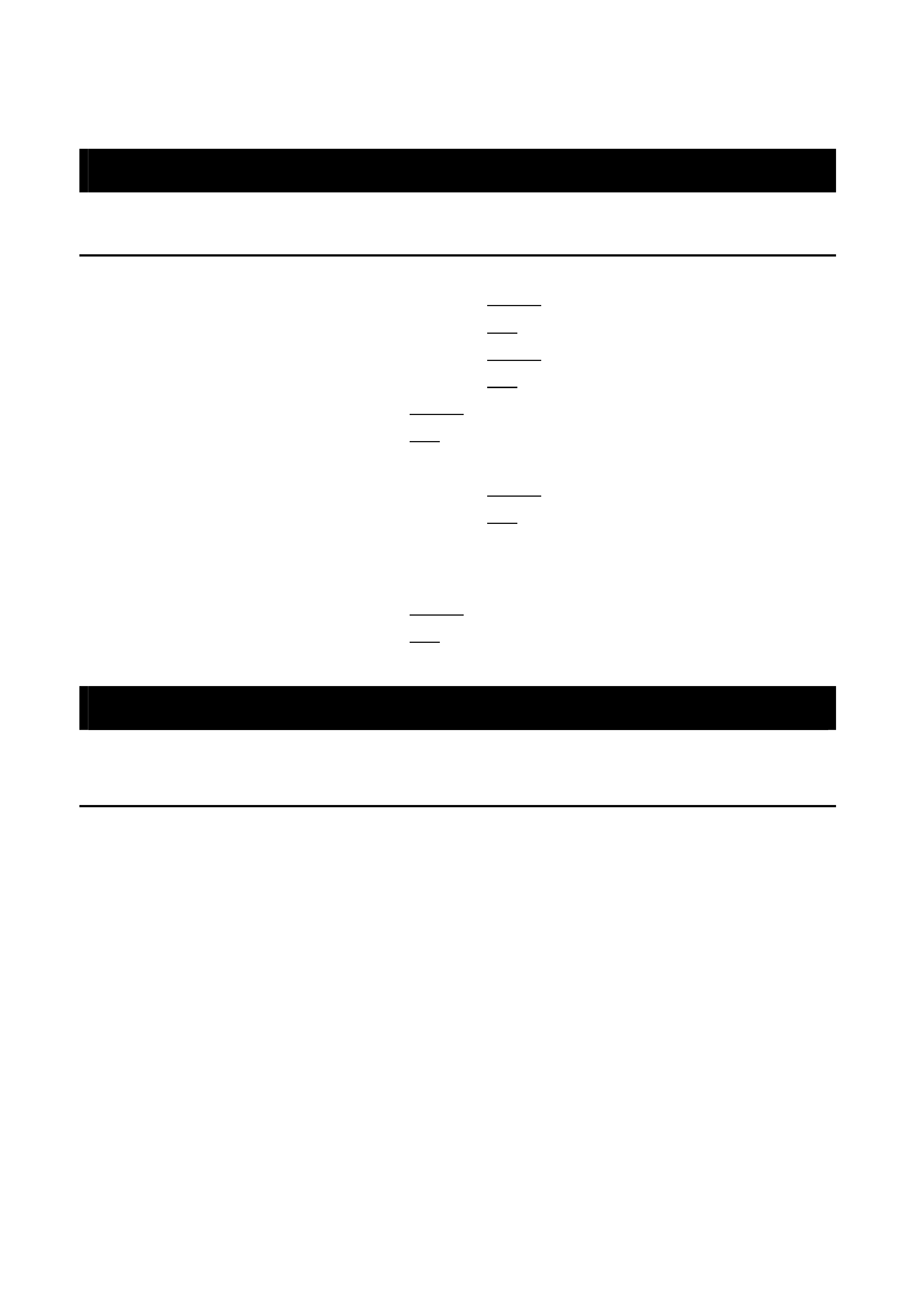

WARRANTY CLAIM INFORMATION

On completion of campaign action, dealer s ar e r equested t o im m ediately submit a warranty claim.

For Vehicles Buil t af ter 1/2/2000

(Will have received a campaign letter) :

Description:

Labour Operation No:

Standard Time:

Failure Code:

Case Type:

Fit New Level Towbar Tongue

T180801

0.4 hours

96

08

For Vehicles other t han t hose speci f ied above

(Will NOT have received a campaign letter, how ever, w ill be responding to newspaper

Safety Recall advertisement)

Fit New Level Towbar Tongue

Description:

For VG, VP & VR Utility.

or

For VS Commodor e, Calais,

Statesman, Caprice & Utility

with tag numbers from

L800000 to L999999

For all other affected vehicles

including the remaining VS

series with tag numbers from

L200000 and all VT, VU, WH

series, Astra & Rodeo built prior

to 1/2/00

Labour Operation No: R000100 R000103

Standard Time: 0.4 hr 0.4 hr

Failure Code: 95 95

Case Type: Not required Not required

Please ensure parts ar e r eturned in line with warranty procedure once req uested by Repac

PARTS INFORMATION

PARTS ARE TO BE PROCURED THRO UGH THE NORMAL HSPO

DISTRIBUTI ON CHANNELS (NOT SALMAT)

§ Order Par ts fo r t his campaign from HSPO using the nor m al HSPO ordering channels using

“RUSH” order s only.

§ Refer t o appendix B for part illustrations and part numbers.

§ Due to limited supply of part num ber s 92145225 and 92145254 or ders will only be accepted for

pre-book ed vehicles until Decem ber 10, 2001. Cust omers will not receive the recall let t er until

Friday December 7, 2001.

CUSTOMER NOTIFI CATION

Owners with vehicles built after February 2000 will be contacted directly by letter from Holden,

providing details of the recall and req uesting the custom er to organise f or their vehicle to have the

appropriate rectification work carried out by a dealership of their choice. For a draft of the

customer let ters refer t o Appendix C and D

Customers who may have purchased an af fected t owbar assembly af t er February 2000, for fitment

to an earlier built vehicle will be responding t o the newspaper advertisement.

4 of 23

CONTACT INFORMATION

For f ur t her inf or m ation or clarification on this recall campaign please cont act the relevant person

below.

CONTACT NAME CONTACT NUMBER

General enquiri es Oliver Mitrovski (03) 9647 7619

Parts related enquiri es HSPO Customer Assist ance (03) 97977332

Warranty related inquiries Warranty Administration (03) 9647 2401

J. K. Hoffman

General Service Manager

Attachments

Appendix A Dealer Inspection and Rectif icat ion Flow Chart

Appendix B Towbar Tongue Reference Char t s

Appendix C V& W carline Custom er Letter DRAFT

Appendix D TS Astra and TF Rodeo Customer Let ter DRAFT

5 of 23

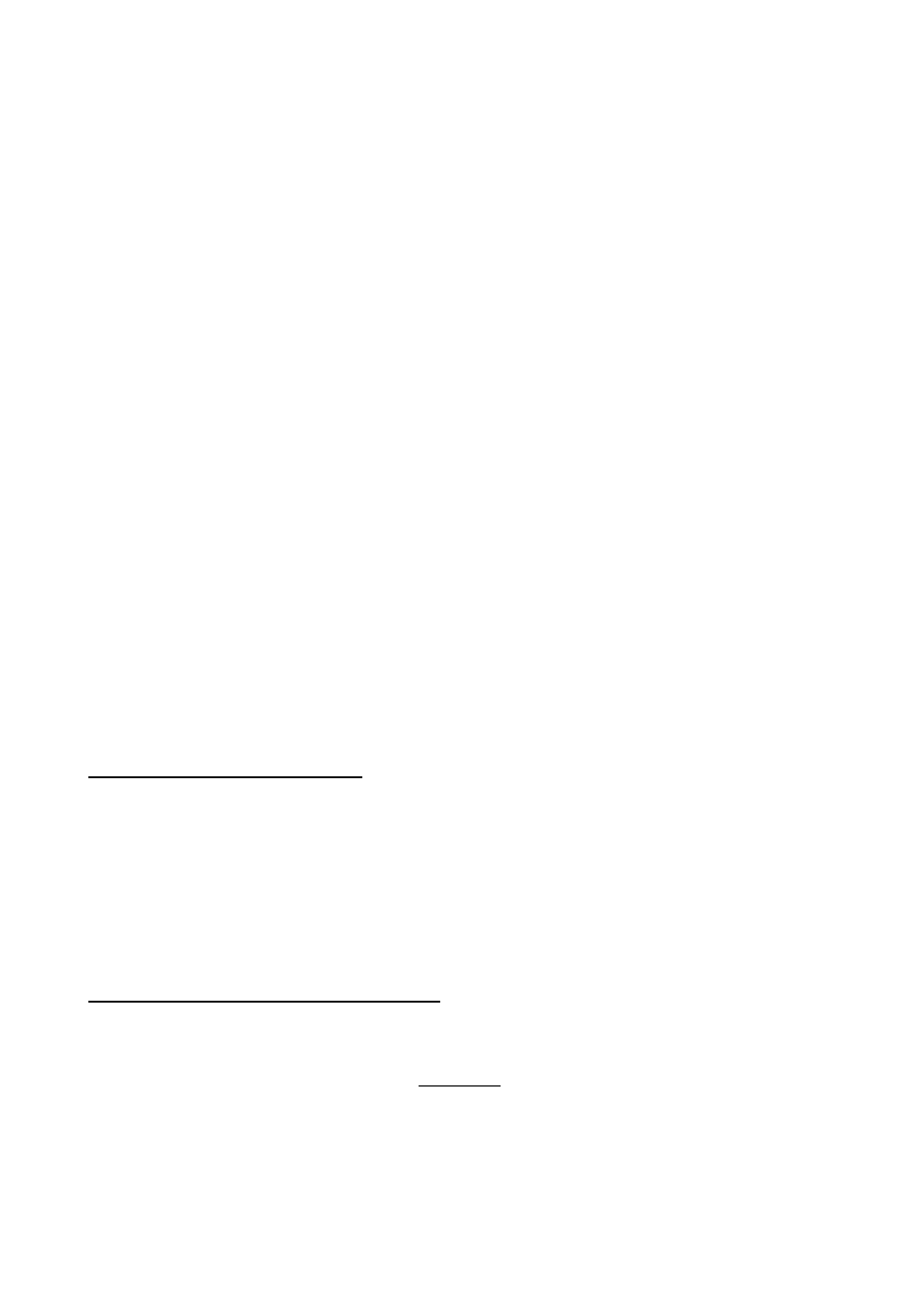

APPENDIX A

(Dealer Inspection and Rectif i cat ion Flow Chart )

IS A GENUINE TOWBAR FITTED ?

YES

NO

IS THE TOWBAR AN AFFECTED DESIGN

(REFER APPENDIX B – 16 CHARTS)

YES

NO

HAS THE VEHICLE ALREADY BEEN CAMPAIGNED?

CHECK FOR CAMPAIGN STICKER MARKED WITH 01-H-04

NO

WHAT IS THE VEHICLE BUILD DATE?

AFTER 01/02/2000

WHAT WAS THE TOWBAR ACCESSORY

FITMENT DATE?

§ ASK OWNER

or

§ CHECK VEHICLE SALES RECORDS

IF YOU ARE THE SELLING DEALER

REPLACE TOWBAR TONGUE FIT

CAMPAIGN STICKER, MARK AN ‘X’ IN

THE F-1 CO-ORDINATE OF THE

VEHICLE SERVICE HISTORY LABEL

NOT AFFECTED

If customer has a letter instruct

them to tick appropriate box and

return customer letter in reply

paid envelope

YES

ON or BEFORE 01/02/2000

DON’T KNOW

OR NOT SURE AFTER

01/04/2000 BEFORE

01/04/2000

6 of 23

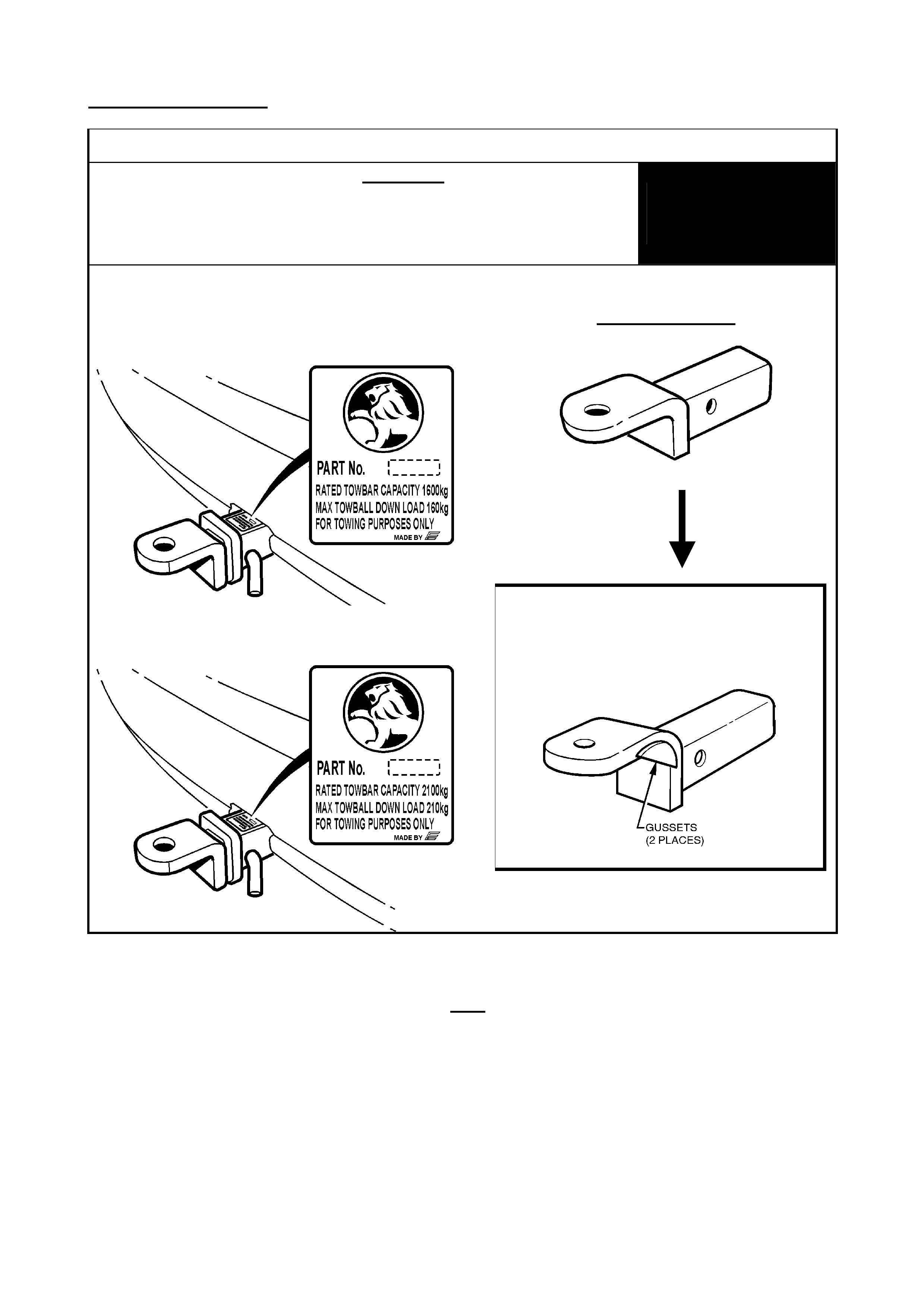

APPENDIX B (Towbar Tongue Ref e rence Chart )

Tongues AFFECTED

Model

Towbar Rating

GO TO

Diagram No.:

VT, VX, WH (I ncl. HSV)

• 1600kg & 2100kg – without Equaliser Hitch

1

• 1600kg & 2100kg – with Equaliser Hitch 2

• 1200kg & 1600kg – without Equaliser Hitch 3

VU Utility &

HSV VU Maloo Utility • 1200kg & 1600kg – with Eq ualiser Hitch 4

TF Rodeo • 1800kg – without Eq ualiser Hitch 5

• 1800kg – with Equaliser Hitch 6

TS Astra • 1000kg 7

VS Commodore & Calais

Sedans, Statesm an &

Caprice - Including HSV

(✳ NOT Utility or Wagon)

• 1590kg & 2100kg – without Equaliser Hitch

• 1590kg & 2100kg – with Equaliser Hitch 8

9

VG, VP, VR & VS Utility &

HSV Maloo Utility • 1590kg – without Eq ualiser Hitch

• 1590kg – with Equaliser Hitch 10

11

Tongues NOT AFFECTED

Model

Towbar Rating

GO TO

Diagram No.:

VS, VT, VX, WH (I ncl. HSV)

• 1200kg (s t andar d)

12

VP, VP, VR, VS Utility

• 1200kg 13

VT, VX, WH including HSV • 2100kg with Heavy Duty Equaliser Hitch

14

VS All including HSV

(✳ NOT Utility)

• 1590kg & 2100kg 15

VS Utility (I ncl. HSV)

• 1590kg 16

7 of 23

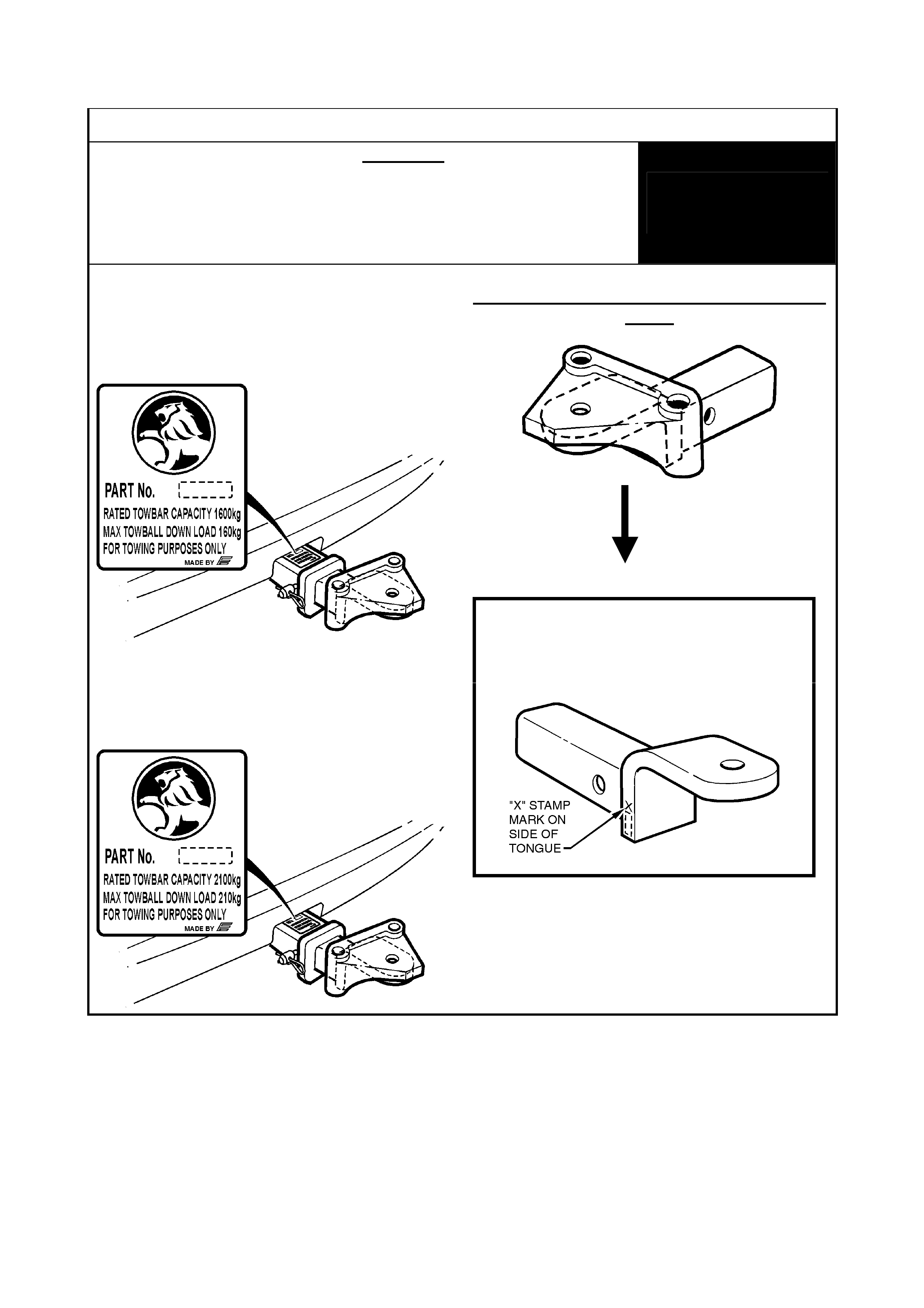

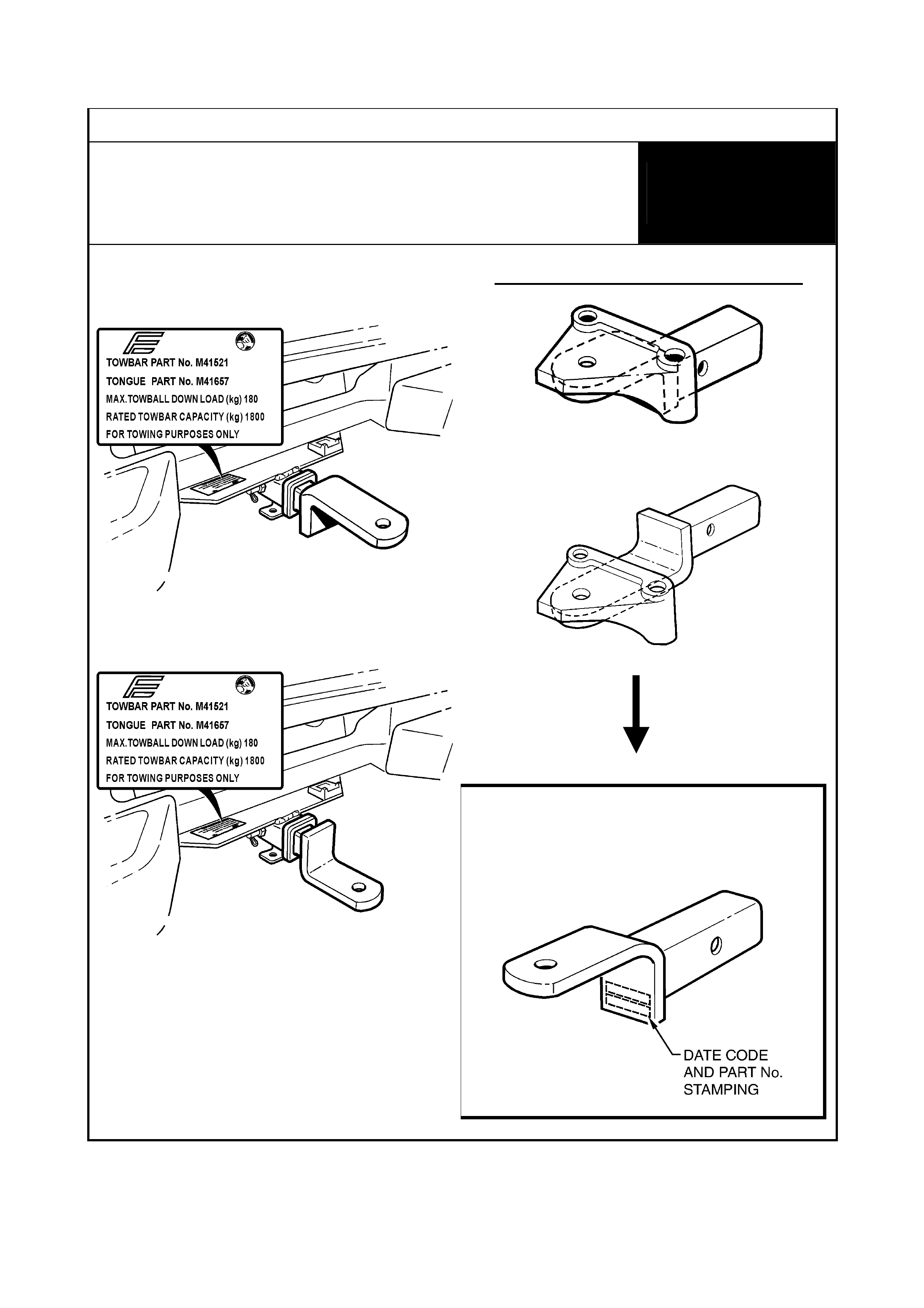

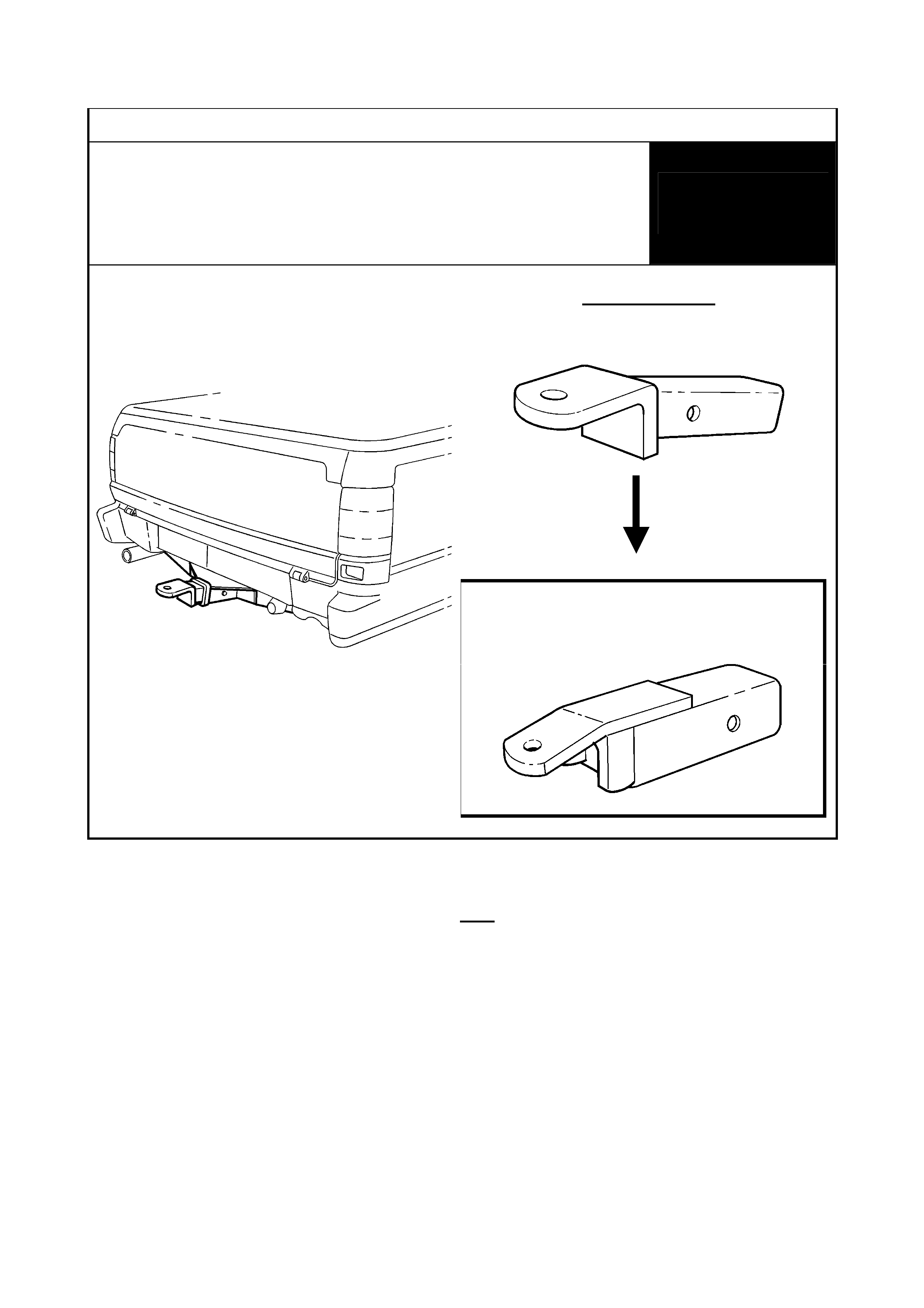

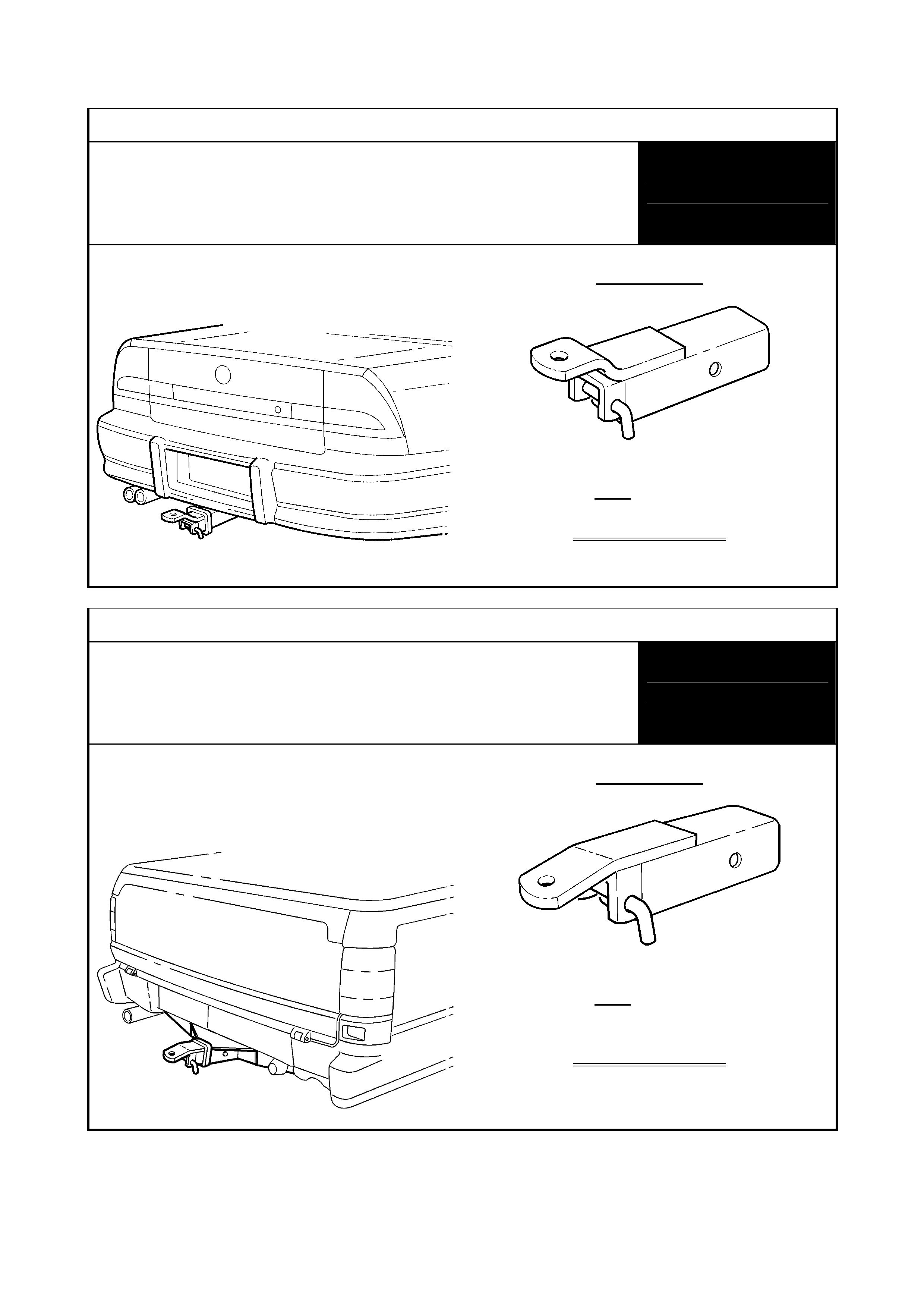

AFFECTED TONGUES

Identif i cat i on Diagram 1

VT, VX & WH - Including: HSV

1600kg & 2100kg Rating Towbars

(Equaliser Hi tch NOT used)

WITHOUT

EQUA LISER

HITCH

Genuine Holden towbar identified by label and/or

appearance:

1600kg:

OR:

2100kg:

Existing Tongue:

MUST be replaced w i t h Part Number:

92145107

(wit h gusset s)

Refer Identif i cat ion Diagram 2 - for Towbars wit h Equaliser Hitch.

Gussets (2 places) To

prevent equaliser fitm ent

8 of 23

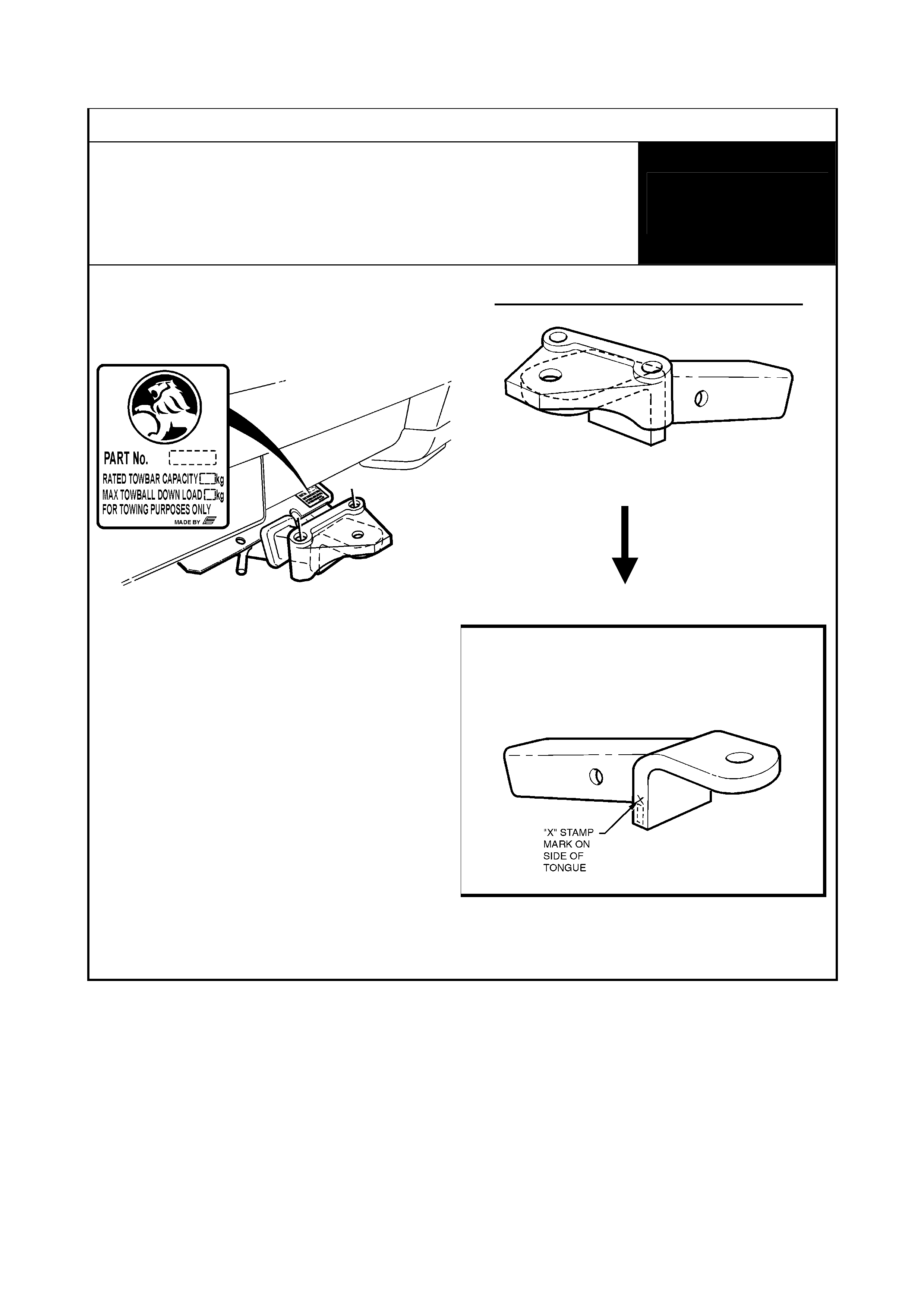

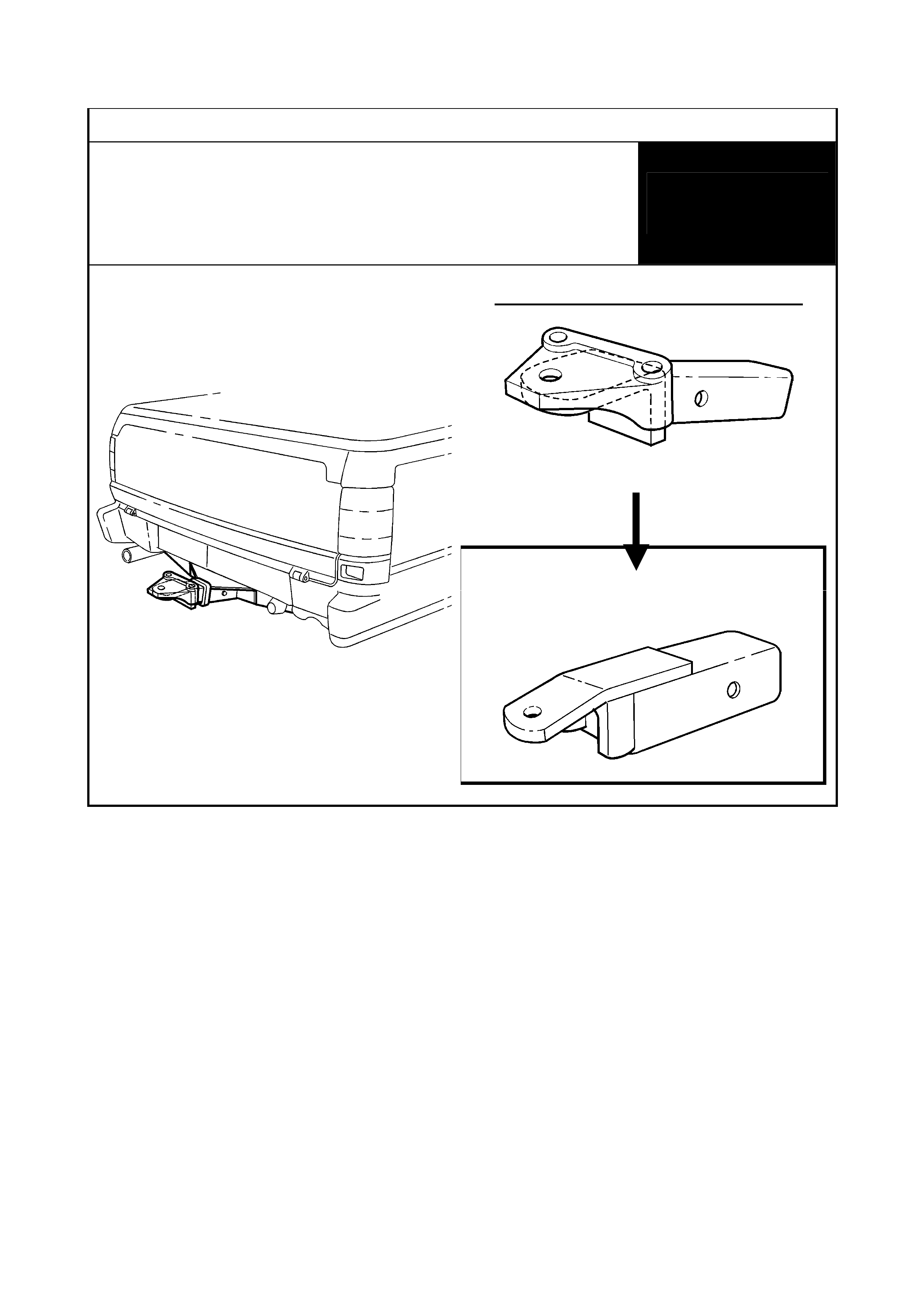

Identif i cat i on Diagram 2

VT, VX & WH - Including: HSV

1600kg & 2100kg Rating Towbars

(wit h Equal iser Hitch)

WITH

EQUA LISER

HITCH

Genuine Holden towbar identified by label

and/or appearance:

1600kg:

OR:

2100kg:

Existing Tongue wit h an exampl e Equaliser

Hitch:

MUST be replaced w i t h Part Number:

92145225

(w ith “X” mark)

9 of 23

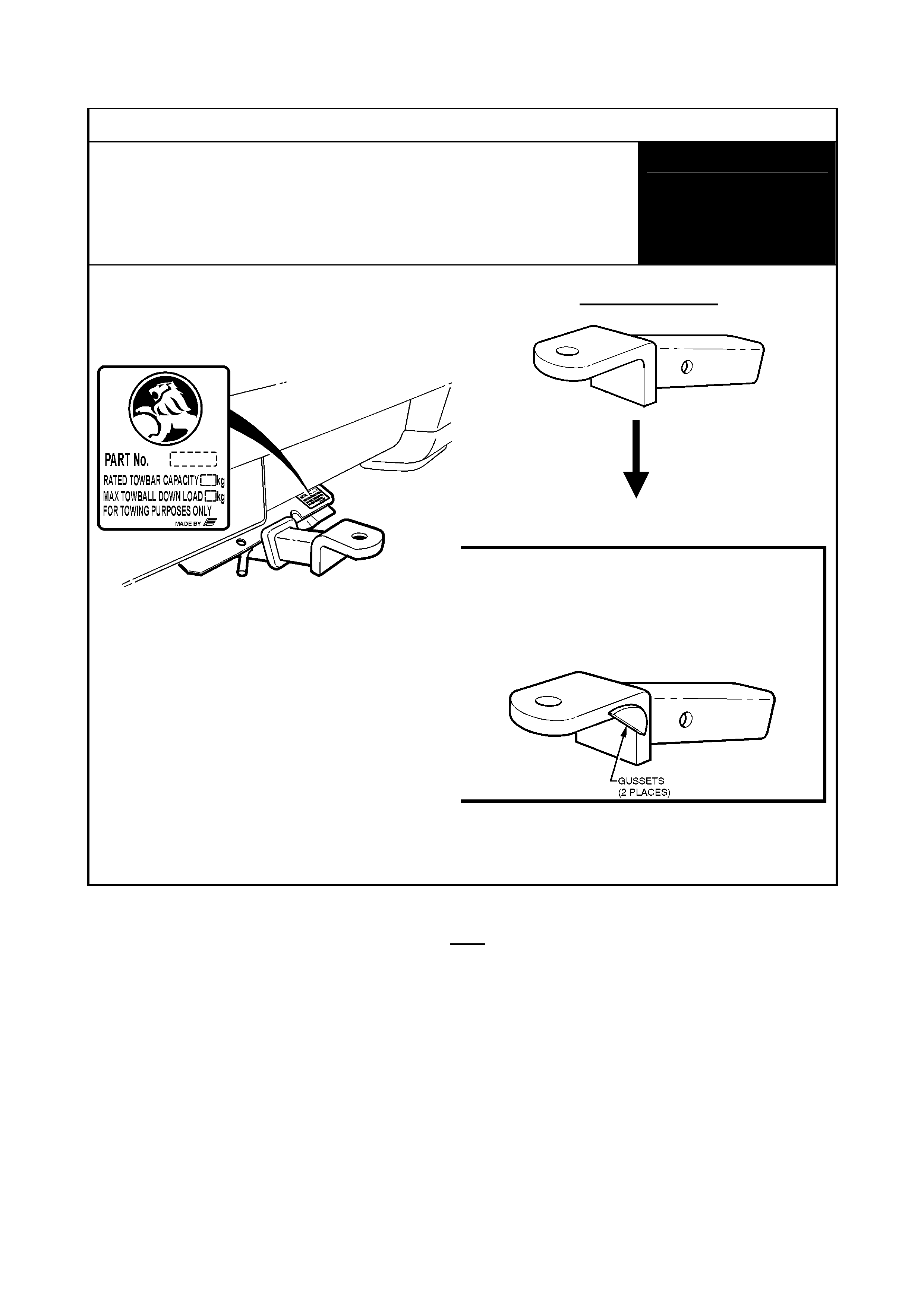

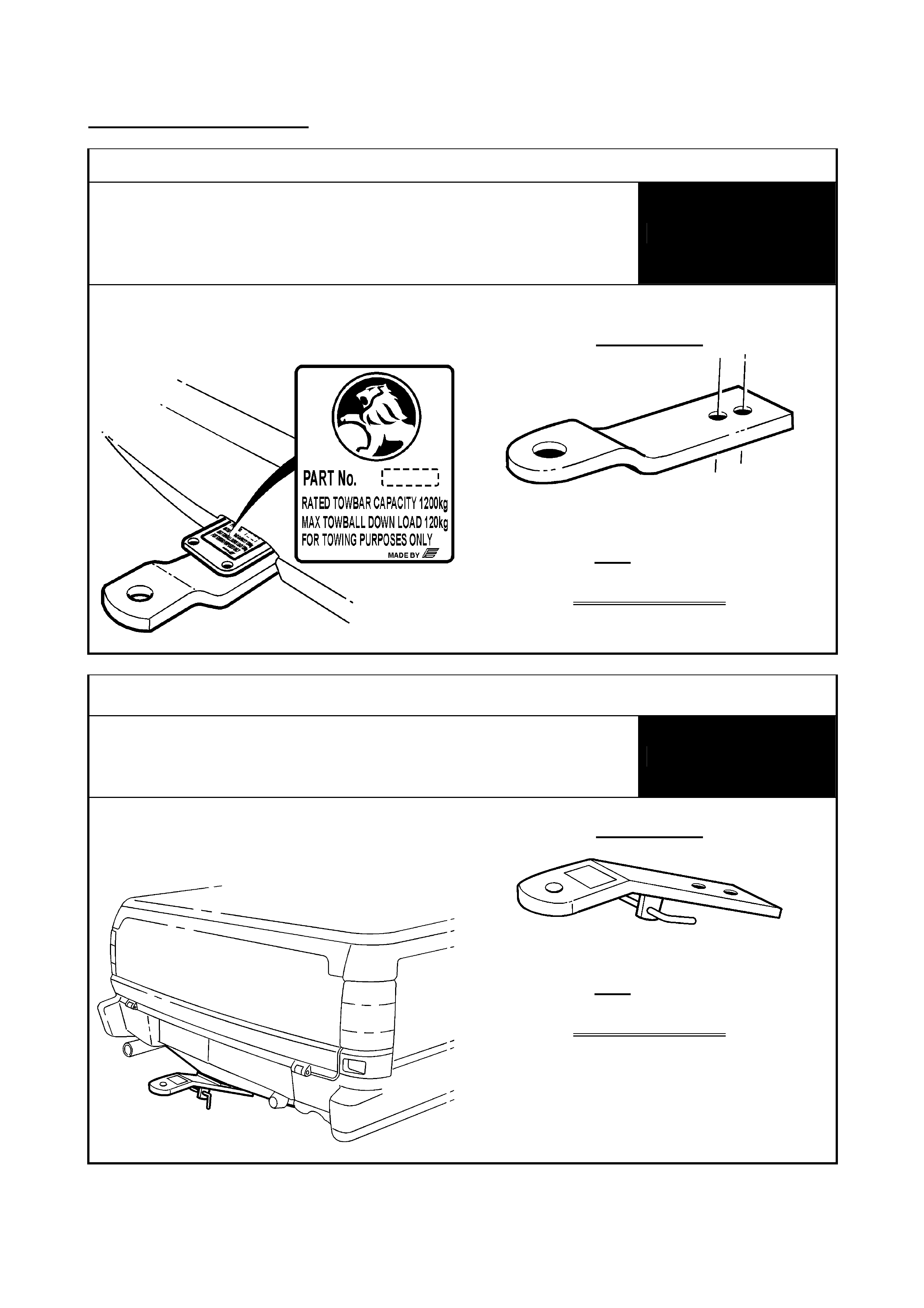

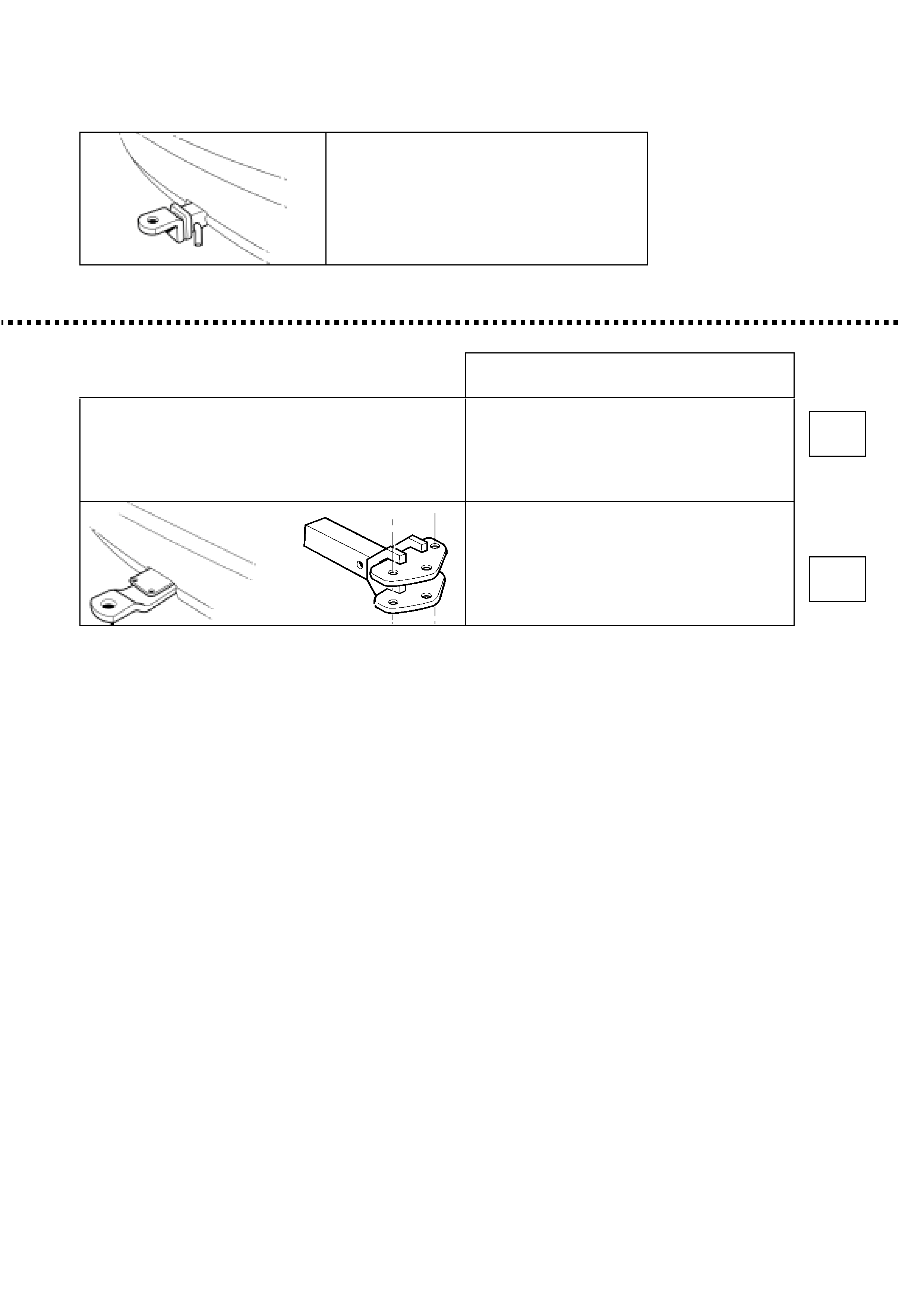

Identif i cat i on Diagram 3

VU Utility,

and HSV VU Maloo Utility

1200kg/1600kg Rating Towbars

(Equaliser Hi tch NOT used)

WITHOUT

EQUA LISER

HITCH

Genuine Holden tow bar identified by label

and/or appearance:

Existing Tongue:

MUST be replaced with HO LDEN Part No.:

92145106

(wit h gusset s)

NOTE: For HSV Maloo, Part No.: 14L-

010505 – order via normal HSV Parts

channels.

Refer Identif i cat ion Diagram 4 - for Towbars wit h Equaliser Hitch.

10 of 23

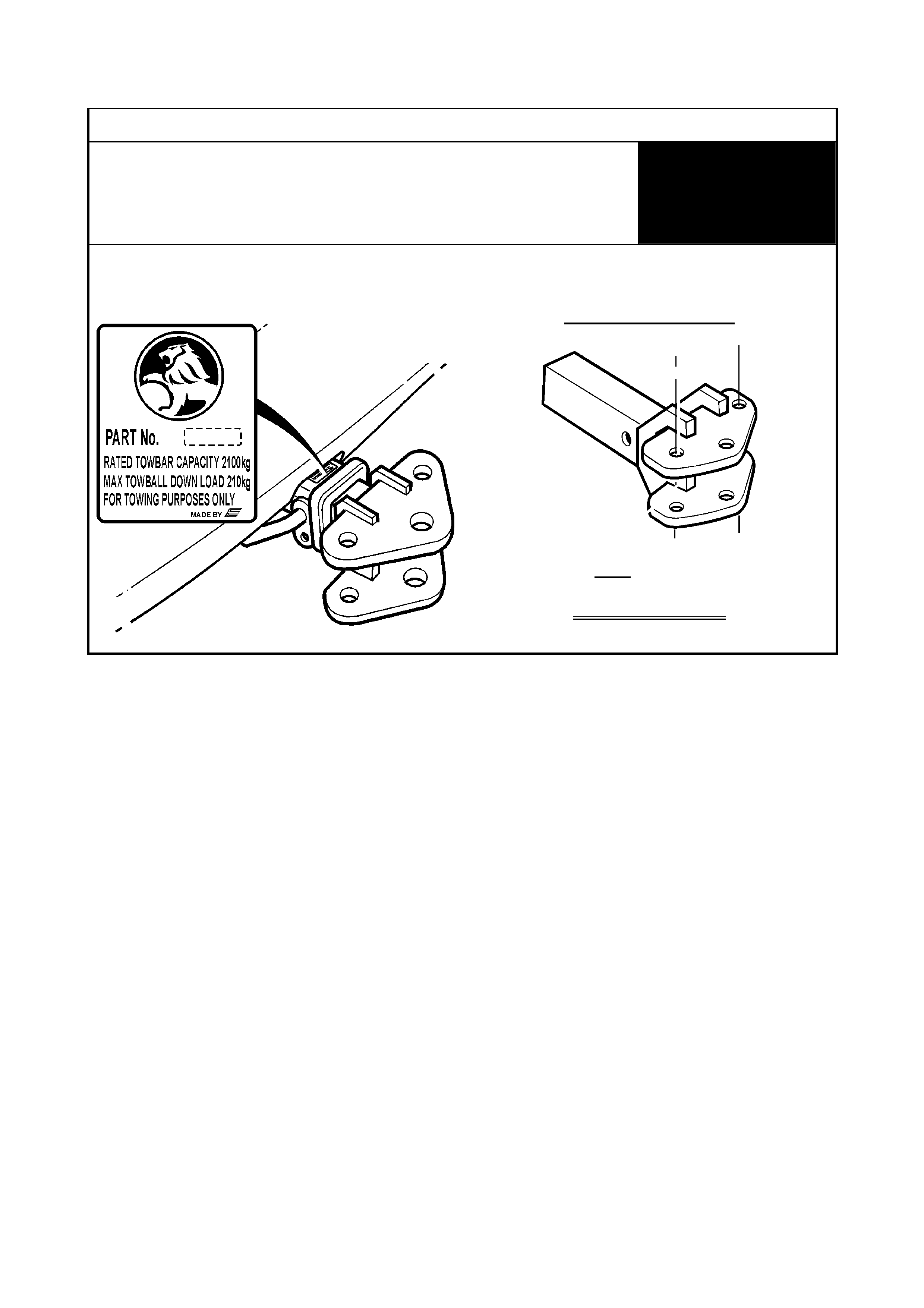

Identif i cat i on Diagram 4

VU Utility,

and HSV VU Maloo Utility

1200kg/1600kg Rating Towbars

(wit h Equal iser Hitch)

WITH

EQUA LISER

HITCH

Genuine Holden tow bar identified by label

and/or appearance:

Existing Tongue wi t h Equal iser Hitch:

MUST be replaced w i t h Part Number:

HOLDEN Part No.: 92145254

(w ith “X” mark)

NOTE: For HSV Maloo, Part No.: 14L-010505

– order via normal HSV Parts channels.

11 of 23

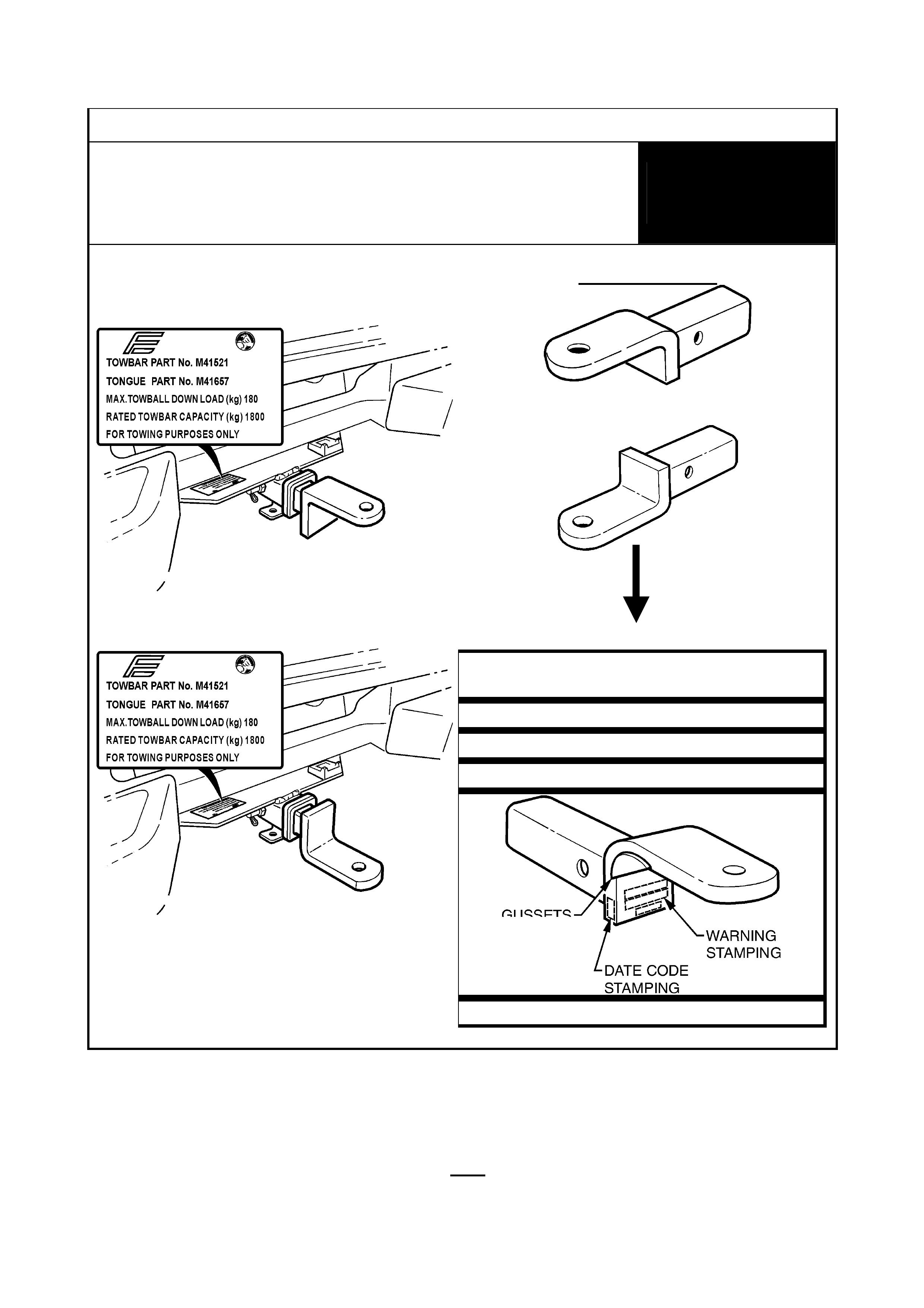

Identif i cat i on Diagram 5

TF Rodeo

1800kg Rating Towbars

(Equaliser Hi tch NOT used)

WITHOUT

EQUA LISER

HITCH

Genuine Holden tow bar identified by plate

and/or appearance:

OR:

Existing Tongue:

OR:

MUST be replaced w i t h Part Number:

92145181

(wit h gusset s)

Reinstall in applicable orientation

Refer Identif i cat ion Diagram 6 - for Towbars wit h Equaliser Hitch.

Gussets to

prevent equalis er

fitment

12 of 23

Identif i cat i on Diagram 6

TF Rodeo

1800kg Rating Towbar

(wit h Equal iser Hitch)

WITH

EQUA LISER

HITCH

Genuine Holden tow bar ident ified by plate

and/or appearance:

OR:

Existing Tongue wi t h Equal iser Hitch:

OR:

MUST be replaced w i t h Part Number:

92145223

Reinstall in applicable orientation

13 of 23

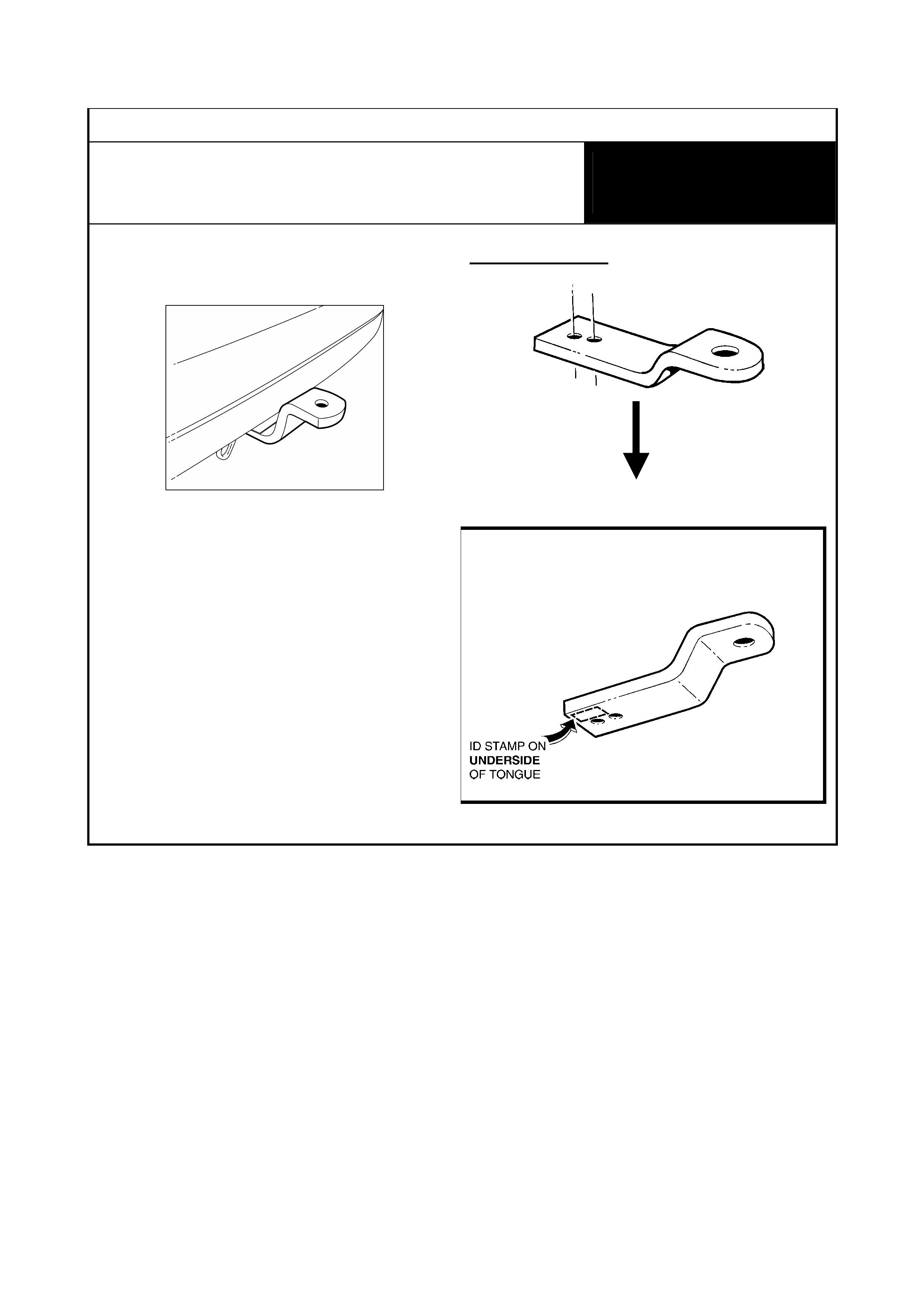

Identif i cat i on Diagram 7

TS Astra

1000kg Rating (Standard) Towbar

WITH OR WITHOUT

EQUA LISER

HITCH

Genuine Holden tow bar identified by

appearance:

Existing Tongue:

MUST be replaced w i t h Part Number:

92145222

14 of 23

Identif i cat i on Diagram 8

VS Commodore & Calais Sedans,

Statesman & Caprice

- Including HSV

(✳ NOT Utility or Wagon!)

1590kg & 2100kg Rating Towbars

(Equaliser Hi tch NOT used)

WITHOUT

EQUA LISER

HITCH

Genuine Holden towbar Identified by

appearance:

Existing Tongue:

MUST be replaced w i t h Part Number:

92145275

Refer Identif i cat ion Diagram 9 - for Towbars wit h Equaliser Hitch.

15 of 23

Identif i cat i on Diagram 9

VS Commodore & Calais Sedans,

Statesman & Caprice

- Including HSV

(✳ NOT Utility or Wagon!)

1590kg Rating Towbars

(wit h Equal iser Hitch)

WITH

EQUA LISER

HITCH

Genuine Holden towbar Identified by

appearance:

Existing Tongue wi t h Equal iser Hitch

MUST be replaced w i t h Part Number:

92145275

16 of 23

Identif i cat i on Diagram 10

VG, VP, VR & VS Utility,

Includi ng HSV

1590kg Rating Towbars

(Equaliser Hi tch NOT used)

WITHOUT

EQUA LISER

HITCH

Genuine Holden tow bar I dentified by

appearance:

Existing Tongue

MUST be replaced with HO LDEN Part

Number: 92145274

Refer Identif i cat ion Diagram 11 - for Towbars wit h Equaliser Hitch.

17 of 23

Identif i cat i on Diagram 11

VG, VP, VR & VS Utility,

Includi ng HSV

1590kg Rating Towbars

(wit h Equal iser Hitch)

WITH

EQUA LISER

HITCH

Genuine Holden tow bar I dentified by

appearance:

Existing Tongue wi t h Equal iser Hitch:

MUST be replaced with HO LDEN Part

Number: 92145274

18 of 23

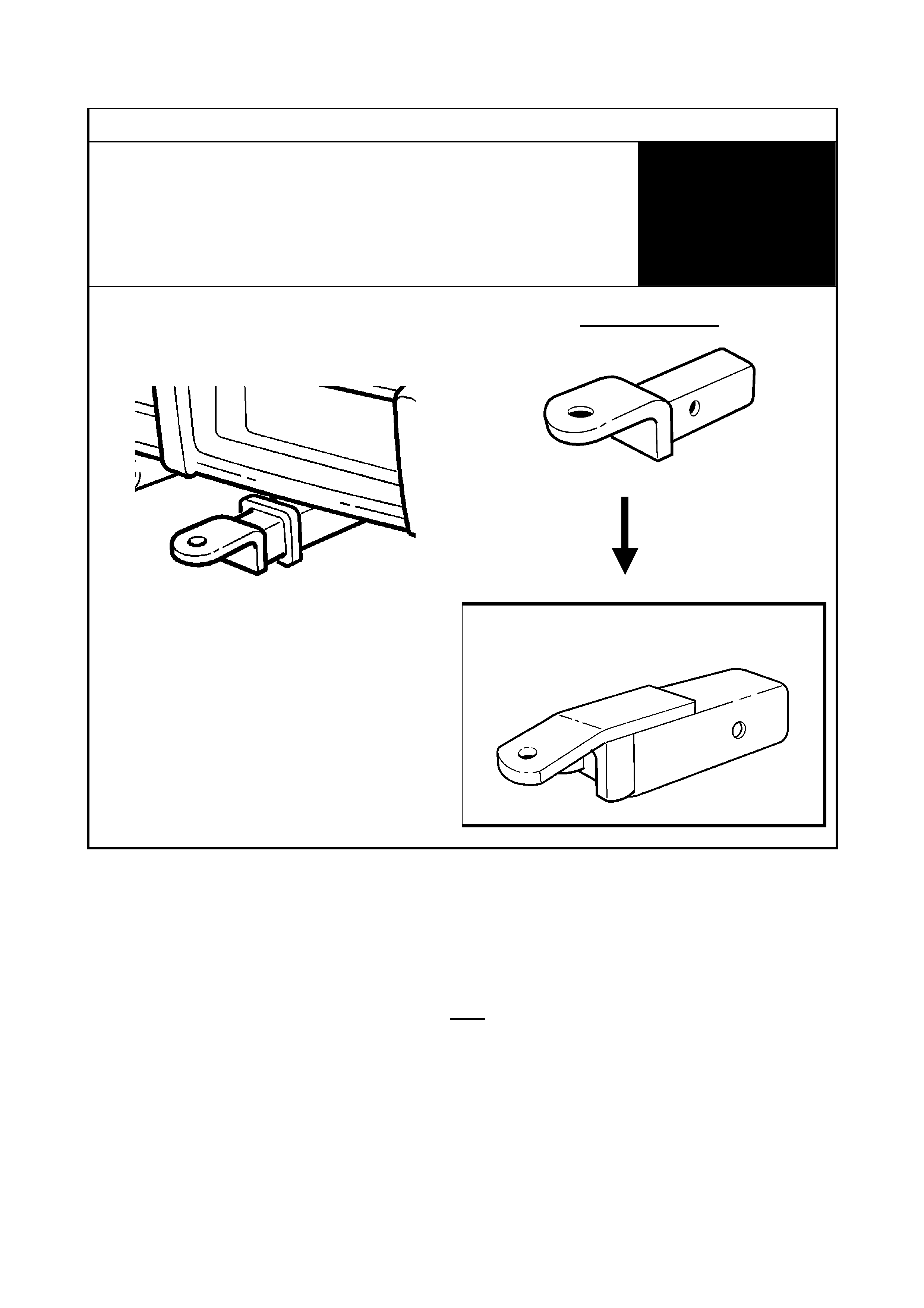

NOT AFFECTED TONGUES

Identif i cat i on Diagram 12

VS, VT, VX & WH

- Including HSV

1200kg Rating (Standard) Towbar

NOT AFFECTED

Genuine Holden towbar Identified by label

and/or appearance:

This Tongue:

IS NOT AFFECTED

DO NOT REPLACE

Identif i cat i on Diagram 13

VR, VP, VR & VS Utility - Including HSV

1200kg Rating Towbar

NOT AFFECTED

Genuine Holden towbar identified by

appearance:

This Tongue:

IS NOT AFFECTED

DO NOT REPLACE

19 of 23

Identif i cat i on Diagram 14

VT, VX & WH

- Including HSV

2100kg Rating Wit h Heavy Duty Equaliser Hi t ch

NOT AFFECTED

Genuine Holden towbar Identified by label

and/or appearance:

This Equaliser Hitch:

IS NOT AFFECTED

DO NOT REPLACE

20 of 23

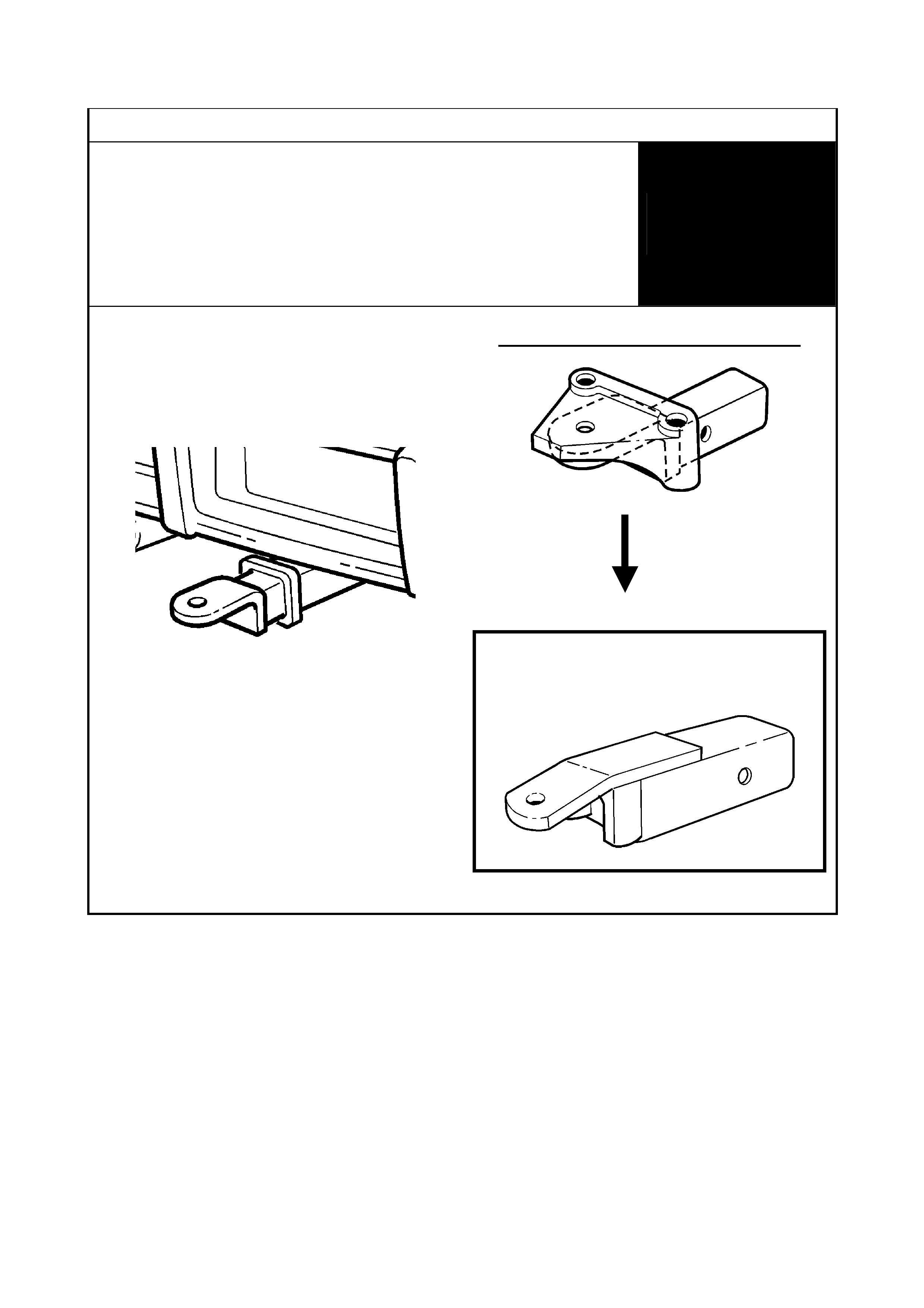

Identif i cat i on Diagram 15

VS - All Including HSV

(✳ NOT Utility!)

1590kg & 2100kg Rating Towbar

NOT AFFECTED

Genuine Holden tow bar ident ified by

appearance:

This Tongue:

IS NOT AFFECTED

DO NOT REPLACE

Identif i cat i on Diagram 16

VS Utility

- Including: HSV

1590kg Rating Towbars

NOT AFFECTED

Genuine Holden tow bar ident ified by

appearance:

This Tongue:

IS NOT AFFECTED

DO NOT REPLACE

21 of 23

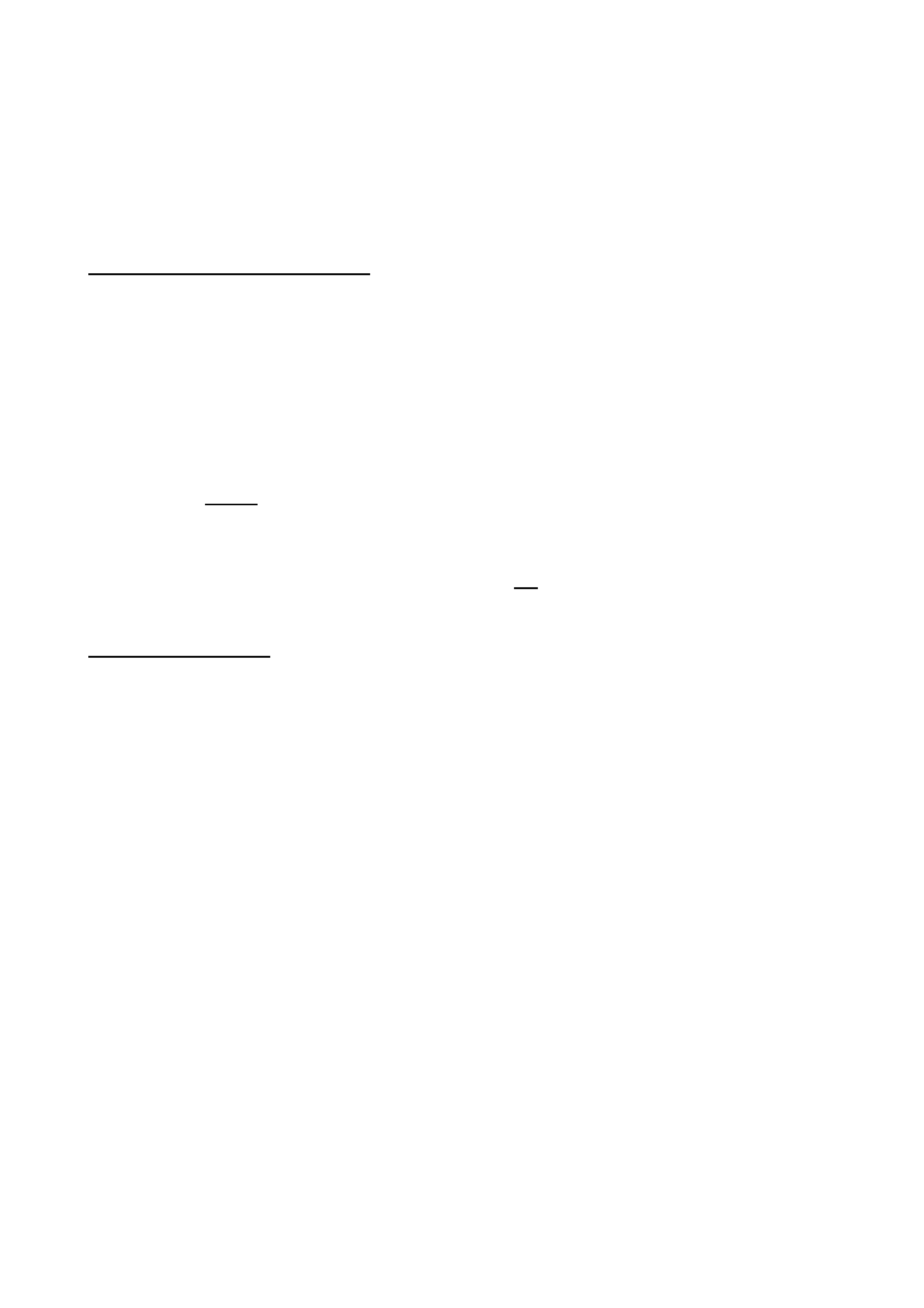

APPENDIX C

(Customer letter draft –V & W carlines)

VEHICLE TOWBAR SAFETY RECALL

Dear Holden Customer ,

As part of Holden’s ongoing commitment to your satisfaction and safety, we have initiated a safety

related recall in relation to towbar tongues manufactured by Frontline Australasia Pty Ltd from April

2000 to October 2001 which could affect your vehicle.

The towbar tongue, sometimes referred to as the ‘gooseneck’, may be susceptible to embrittlement

which may cause the tongue to break. If you have an affected towbar tongue you should cease

towing i mmedi at el y until your towbar tongue has been replaced.

Your vehicle is affect ed by this r ecall if it is f itt ed with an “ aff ected” towbar as shown in t he sketch on the

reverse of this letter. If your vehicle is affected, it is necessary for you to make a service booking as

soon as possible with a Holden dealership of your choice for a replacem ent tow bar t ongue to be fitted to

your vehicle.

If your vehicle has no t owbar or is f itted with a t owbar which is “ not affect ed”, as shown in t he sketch on

the reverse of this letter, you do not need to make a service booking. However, we ask that you

complete the det ails on the revers e of this lett er and retur n it in the reply paid envelope. This will enable

us to update our r ecor ds and avoid sending you aut om atic follow up r em inder s.

If you are in any doubt about whether your vehicle is affected, please contact a Holden dealership as

soon as possible to arrange f or an inspect ion.

All work w ill be carried out free of charge and can be performed w hile you wait, provided t he necessary

arrangement s with a Holden dealer are made in advance. The required w or k will take approxim at ely half

an hour.

If you have any questions, please contact your dealer or call the Holden Recall Hotline on – 1800

632826, where we will be pleased to assist.

Thank you for your at tention to this mat ter. Please accept our apologies for any inconvenience this may

cause you.

Yours Sincerely

David McMu rra y

Manager Customer Assist ance

22 of 23

AFFECTED

IMMEDIATELY CEASE TOWING AND

CONTACT YOUR HOLDEN DEALER

TO HAVE YOUR VEHICLE RECTIFIED

PLEASE PRESENT THIS LETTER TO

YOUR DEALERSHIP

NOT AFFECTED

CUSTOMER ACTION

NO TOWBAR OR

NON GENUINE TOWBAR FITTED TO

VEHICLE

TICK BOX AND RETURN THIS

SECTION IN REPLY PAI D ENVELO PE

NO FURTHER ACTION IS REQUIRED

TICK BOX AND RETURN THIS

SECTION IN REPLY PAI D ENVELO PE

NO FURTHER ACTION IS REQUIRED

TICK

TICK

Tongue fitted to vehicle as per illustration.

Tongue fitted to vehicle as per illustration.

OR

23 of 23

APPENDIX D

(Customer letter draf t – TS and TF)

Dear Holden Customer ,

As part of Holden’s ongoing commitment to your satisfaction and safety, we have initiated a safety

related recall in relation to genuine Holden towbar tongues manufactured by Frontline Australasia Pty

Ltd from Apr il 2000 to October 2001 which could affect your vehicle.

The towbar tongue, sometimes referred to as the ‘gooseneck’, may be susceptible to embrittlement

which may cause the tongue to break. If you have a towbar you should cease towing immediately

until your t ow bar t ongue has been repl aced.

If your vehicle is fitted with a towbar it IS affected by this recall and it is necessary for you to make a

service booking with a Holden dealership of your choice f or a replacement towbar tongue to be fit ted to

your vehicle.

If your vehicle is NOT f itted with a t owbar it is NOT affect ed by this recall. W e do, however , request t hat

you advise us by ticking the follow ing box and returning it in the r eply paid envelope. This will enable us

to update our r ecor ds and avoid sending you aut omatic follow up r eminders.

All work will be carried out free of charge and can be perfor med while you wait, provided the necessary

arrangement s w ith a Holden dealer ar e made in advance. The r equired w ork w ill take appr oximately half

an hour.

If you have any questions, please contact your dealer or call the Holden Recall Hotline on - 1800

632826, where we will be pleased to assist.

Thank you f or your att ention to this matt er. Please accept our apologies for any inconvenience this may

cause you.

Yours Sincerely

David McMurray

Manager Customer Assist ance

VEHICLE TOWBAR SAFETY RECALL

NO TOWBAR FITTED

(TICK A ND RETURN THIS WHOLE LETTER

IN REPLY PAID ENVELOPE)