222000000111 SSSEEERRRVVVIIICCCEEE TTTEEECCCHHHLLLIIINNNEEESSS

© 2006 GM Holden Ltd. A.B.N. 84 006 893 232

Service Department

A “HOLDEN” Product.

BRISBANE SYDNEY MELBOURNE ADELAIDE PERTH

HOLDEN SERVICE TECHLINE _____________________________________________________________JANUARY 2001

14

4JX1 INTAKE THROTTLE VALVE STICKING

DIESEL JACKAROO (UBS)

GROUP 6C TL101-6C01

Condition

Some 4JX1 engines may develop a “Hard to start” and “Lack of Engine Response” caused by the Intake

Throttle Valve sticking, the engine RPM will not increase immediately when the accelerator pedal is

depressed and the problem may disappear once the engine has warmed up. DTC 1486 (Intake throttle

position sensor high voltage) will be set. The check engine light may also illuminated.

NOTE: It is normal for the 4JX1 engine to experience some acceleration lag when cold due to oil

viscosity.

Possible Cause

Sticking butterfly valve in the Intake Throttle Valve assembly, due to an excessive build up of carbon.

Correction

After confirming the symptom and after conducting thorough investigation using the workshop manual,

Section 6 “Hesitation” it may be necessary to remove and thoroughly clean the Throttle Body.

NOTE: Do not remove or immerse the sensors into any form of cleaning agent.

AIR IN FUEL

4JX1DIESEL JACKAROO (UBS)

GROUP 6M TL101-6M01

I-GM TAS has received a large number of calls regarding air in 4JX1 fuel systems, investigations have

revealed that the fuel inlet fitting at the front of the engine was loose.

The fuel inlet has a BANJO fitting that mates to the fuel inlet pipe, the pipe has a locking nut that

tightens itself against the inlet manifold. This nut is not a locking device, it is to stop lateral movement of

the fuel pipe.

In order to check the security of the fuel pipe it is necessary to remove the cap nut and tighten the pipe

itself. However if the pipe is found to be loose replace the aluminium washer with a new one available

through HSPO. Part number 1096300830.

TORQUE SPECIFICATIONS:

FUEL PIPE: 4 Nm.

CAP NUT: 13 Nm.

BANJO FITTING: 14 Nm.

HOLDEN SERVICE TECHLINE ___________________________________________________________JANUARY, 2001

15

INJECTOR REWORK

UBS JACKAROO 4JX1 DIESEL

GROUP 6M TL101-6M02

IGM TAS continues to receive phone inquiries in regards to the Injector O – ring rework, dealers are

requested to refer to I-GM All Dealer Letter DL 04/00 for more detailed information.

Condition

Some 4JX1 engines (up to engine number 676517) may experience Diesel fuel dilution causing “Hard to

Start” and excessive smoke.

Possible Cause

The original injector O – ring hardens with age, allowing fuel to bypass and enter the crankcase.

Correction

Install the injector sealing ring kit referring to the previously released DL 04/00. From November 3rd

1999 production, engine number 676517 onwards, the material for the O - rings was changed, therefore

engines post this breakpoint should not be reworked. If an engine post this breakpoint develops fuel

dilution, a PIR should be raised.

4JX1 RAIL PRESSURE CONTROL VALVE DIAGNOSIS

DIESEL JACKAROO (UBS)

GROUP 6M TL101-6M03

Some 4JX1 engines may develop a rough idle or hesitation caused by an intermittently sticking RPCV.

An intermittently sticking RPCV is sometimes very difficult to diagnose. Therefore, to enable easier

detection of a faulty/sticking RPCV please refer to the attached graphs.

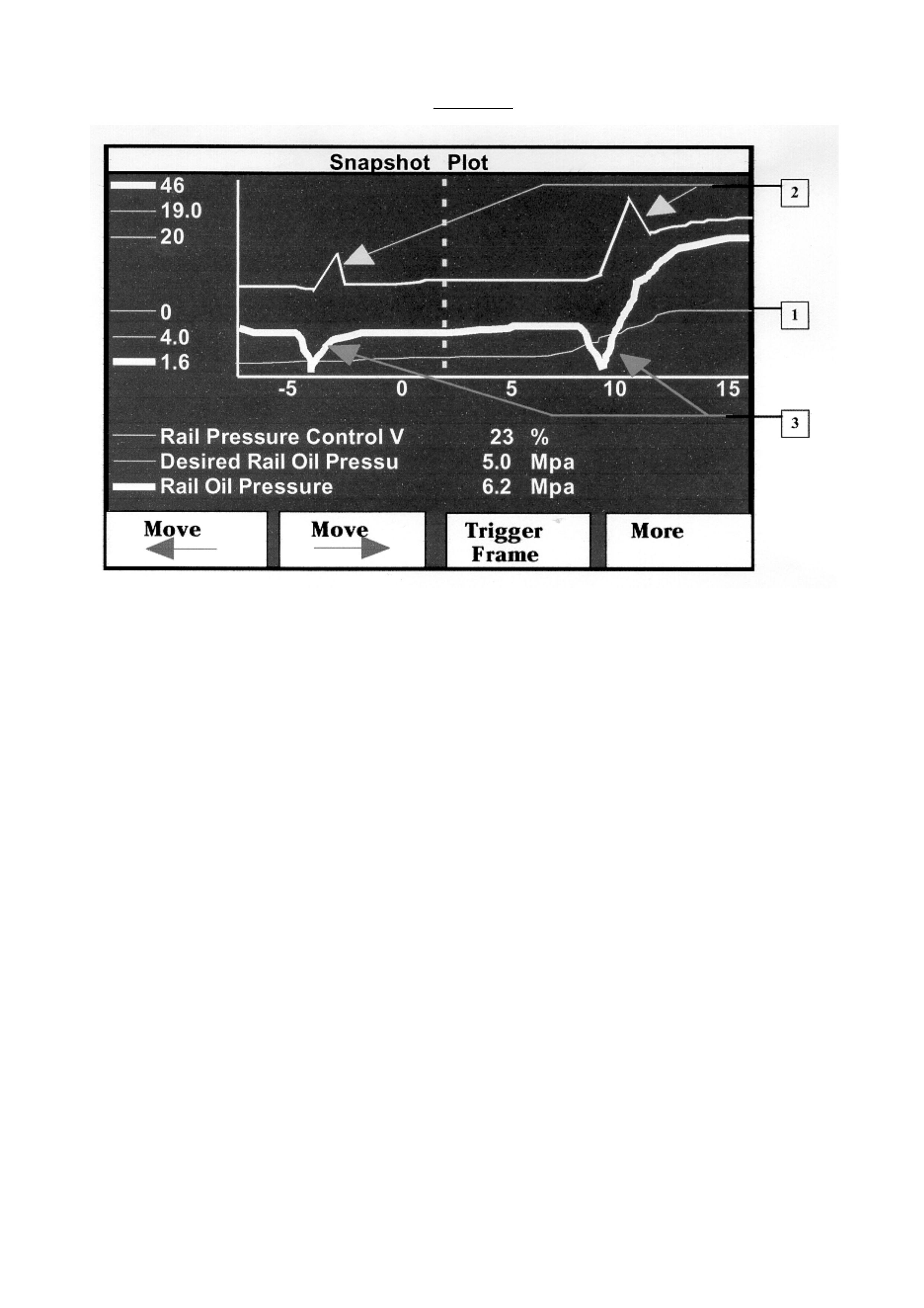

Graph 1: The graph outlines a sample of Tech 2 snapshot data that shows a faulty/sticking RPCV.

TECH 2 snapshot is most effective for checking this condition.

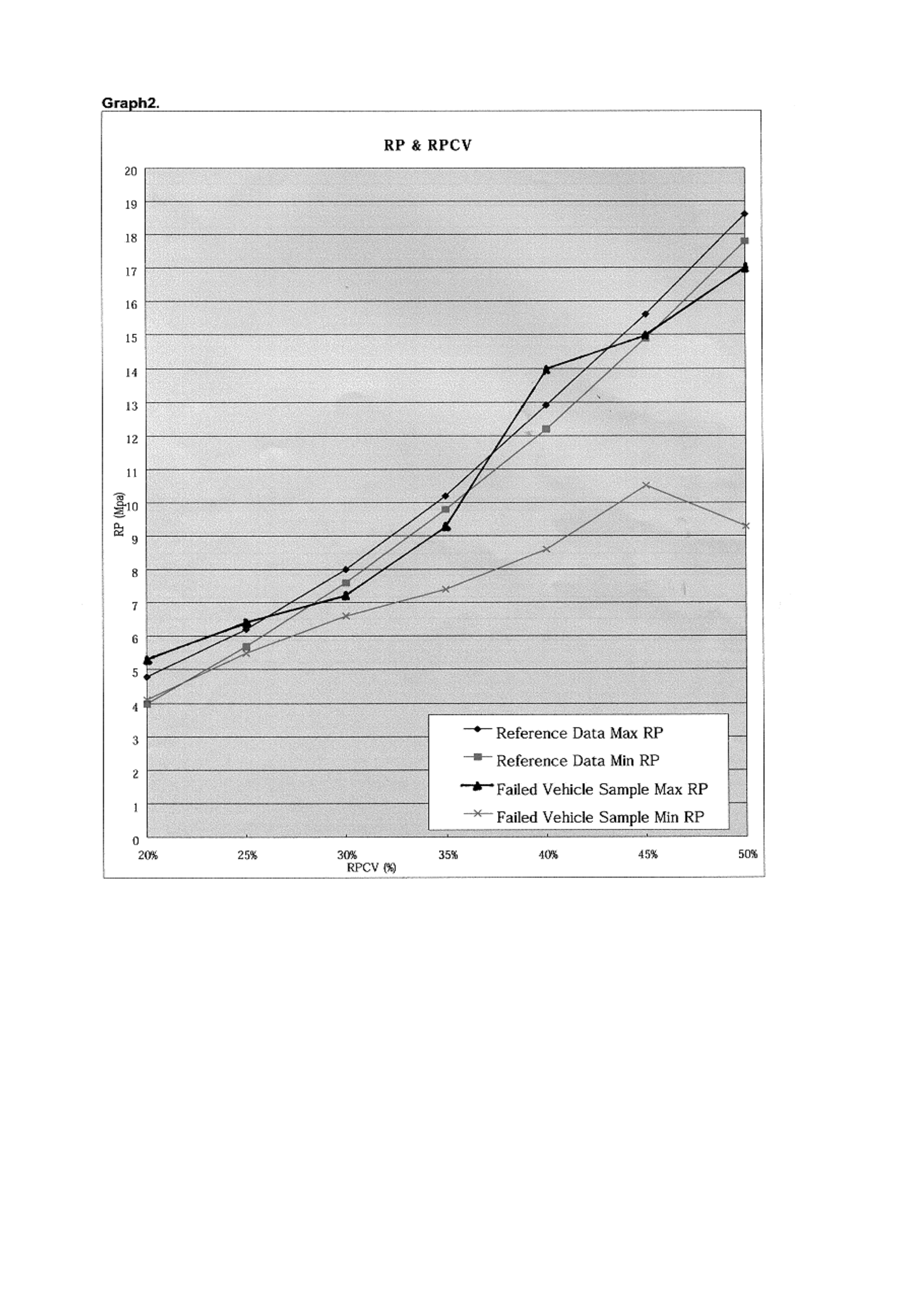

Graph 2: The graph outlines the relationship between the “Rail Oil pressure”, and the percentage of the

RPCV operating range. All of these parameters can be found using TECH 2.

NOTE: Actual pressures recorded by TECH 2 may differ slightly than those displayed on the graph; this

is due to different grades/ viscosity of engine oil and operating temperatures.

After confirming the symptom and after conducting thorough investigation using the workshop manual,

section 6 “Rough Idle”, it may be necessary to replace the RPCV, PT No: 8 97174 872 0.

HOLDEN SERVICE TECHLINE ___________________________________________________________JANUARY, 2001

16

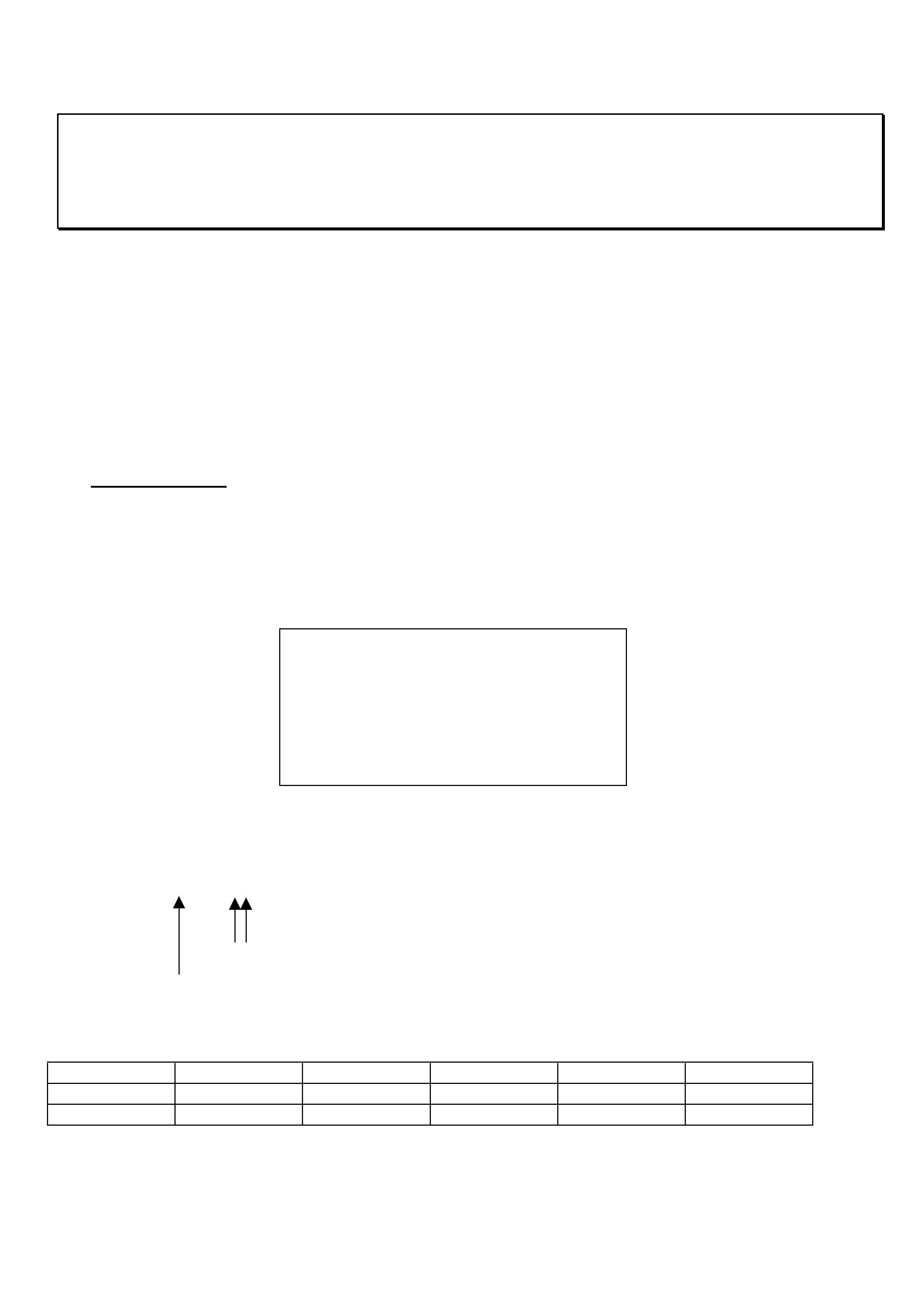

GRAPH 1.

This graph shows a sample of a Snapshot Plot Data as displayed on Tech 2.

The graph shows the relationship between the Rail Pressure Control Valve, Desired Rail Oil Pressure

and Actual Rail Oil Pressure.

Due to an intermittently sticking RPCV, the Actual Rail Oil Pressure does not meet the Desired Rail Oil

Pressure.

1. The Desired Rail Oil Pressure increases due to engine load.

2. The PCM controls the RPCV in order to meet the Desired Rail Oil Pressure. Due to the sticking

RPCV there is a delay in the movement of the RPCV.

3. The Actual Oil Pressure is not within the tolerance of the desired Rail Oil Pressure due to the

sticking RPCV. The Actual Oil Pressure drops, that can clearly be seen from the graph.

If the above condition is displayed on Tech 2, a Hesitation or rough idle could be the result of a sticking

RPCV due to contamination or an internal failure.

HOLDEN SERVICE TECHLINE ___________________________________________________________JANUARY, 2001

17

Graph 2 clearly demonstrates the rail pressure difference between a sticking (faulty) RPCV and a good

example.

HOLDEN SERVICE TECHLINE ___________________________________________________________JANUARY, 2001

18

CLUTCH PEDAL HEIGHTS

1998 & ONWARD - JACKAROO, RODEO AND FRONTERA

GROUP 7A TL101-7A01

Recent enquiries from dealerships in regard to premature clutch wear and failure has prompted

I-GM to take this opportunity to remind all Dealership Service staff of the importance of clutch pedal

adjustment in relation to clutch durability.

Correct clutch adjustment is critical to ensure clutch life and correct operation. Dealers are advised to

ensure that clutches are adjusted as per service schedules.

TF RODEO

WITH 4JB1T WITH 6VD1 WITH 4ZE1 WITH C22NE

CLUTCH PEDAL

FREEPLAY

5.0 mm -15 mm

5.0 mm -15 mm

5.0 mm -15 mm

5.0 mm -15 mm

CLUTCH PEDAL

HEIGHT

185.5 mm –

195.5 mm

216 mm –

226 mm

216 mm –

226 mm

216 mm –

226 mm

CLUTCH SWITCH

TO CLUTCH

PEDAL

CLEARANCE

(IF FITTED)

.5 mm – 1.5 mm

.5 mm – 1.5 mm

.5 mm – 1.5 mm

.5 mm – 1.5 mm

JACKAROO

WITH 4JX1TC WITH 6VE1

CLUTCH PEDAL FREEPLAY 5.0 mm -15 mm 5.0 mm -15 mm

CLUTCH PEDAL HEIGHT 231 mm –

241 mm

238.5 mm –

248.5 mm

CLUTCH SWITCH TO CLUTCH

PEDAL CLEARANCE

(IF FITTED)

.5 mm – 1.5 mm

.5 mm – 1.5 mm

FRONTERA

WITH X22SE WITH 6VD1

CLUTCH PEDAL FREEPLAY 5.0 mm -15 mm 5.0 mm -15 mm

CLUTCH PEDAL HEIGHT 178 mm –

188 mm

178 mm –

188 mm

CLUTCH SWITCH TO CLUTCH

PEDAL CLEARANCE

(IF FITTED)

.5 mm – 1.5 mm

.5 mm – 1.5 mm

HOLDEN SERVICE TECHLINE ________________________________________________________________ FEBRUARY 2001

7

LIGHT COMMERCIAL VEHICLE

INTEGRATION INTO HOLDEN

UBS, TF, UT, Suburban

(GROUP 0B) TL102-OB02

The summarised information below is

published in fuller detail in All Dealer Letters

DL 09/01 & DL 03/01.

TAS & Security Enquiries

LIGHT COMMERCIALS VEHICLES – Rodeo,

Jackaroo, Frontera, Suburban – and the

associated work that surrounds them, have been

‘integrated’ back into Holden.

Look forward to hearing more about these

vehicles from Holden Service Engineering, in

Service Techlines and All Dealer Letters, etc,

provided by Holdens Service Head Office.

From your Service Department’s point of view –

the support for these “light commercials” is now

carried out by:

HOLDEN PASSENGER & LIGHT

COMMERCIAL VEHICLE

TECHNICAL ASSISTANCE:

PHONE : 1800 033 417

(Existing Holden TAS phone No.!).

FAX : (03) 9647 2495

(Existing Holden TAS fax No.!).

In future, if you need to call TAS about any

passenger OR Light Commercial vehicles, you

just call or fax the one number!

In addition, the people in your department who

may have to request Security Numbers for these

vehicles can now contact:

HOLDEN PASSENGER & LIGHT

COMMERCIAL VEHICLE SECURITY

ENQUIRIES

FAX NUMBER: 03 9647 2865

(Existing Holden Security Enquiries Fax No.!).

TAS Procedures

With the release of All Dealer Letter 3/2001,

Nominated Contacts should now have their

copy of the TAS Procedures Manual. This

manual contains all the necessary information

required to communicate with TAS.

Please ensure that you have access to the

manual when speaking to TAS on the phone.

Nominated Contacts should also be aware that

Holden TAS now provide technical support for

Light Commercial vehicles which include

Jackaroo, Rodeo, Frontera.

Please ensure when contacting TAS that the

correct phone selections are made to reduce

your waiting times.

HOLDEN SERVICE TECHLINE ____________________________________________________________ MARCH 2001

14

AIR CONDITIONING SERVICE

TF RODEO (APPROVED IMPCO GAS

FITTED)

(GROUP 2) TL103-0201

PROBLEM DESCRIPTION

When initially charging or servicing the A/C

system when IMPCO gas has been fitted, the

positioning of the gas converter can limit

access to the low pressure service valve.

PRODUCTION RECTIFICATION

The low-pressure service valve has been

relocated. The valve is now located at the

compressor end of the low pressure hose

rather than at the dash panel end.

SERVICE RECTIFICATION

When charging or servicing the A/C system,

access to the low pressure service valve is

best obtained through the wheel arch while

the front wheels are positioned on full-lock.

REAR BRAKE SQUEAL

RODEO (4x4 and V6 4X2)

(GROUP 5) TL103-0502

PROBLEM DESCRIPTION

Excessive squeal noise emanating from rear

brakes on application.

PRODUCTION RECTIFICATION

Revised brake shoes fitted in production:

ISOVIN: Build Date:

JAATFS25HY7103377 25/01/01

JAATFS55HY7120056 25/01/01

JAATFR25HY7108590 25/01/01

* MPATFS25 TBA

* MPATFS55 TBA

* MPATFR25 TBA

* B/P’s for vehicles manufactured in

Thailand have not yet been established,

they will be included in the Breakpoint

Summary once available.

SERVICE RECTIFICATION

For pre-breakpoint vehicles the service fix

described below, which is the same as in

Dealer Letter IGM 13/99, can be applied.

I - GM has released a modified rear brake

shoe set (part number 5878317230) to

overcome the above complaint.

Before installation of the modified shoes the

rear brake assemblies should be de-dusted

and inspected for correct operation, if no

faults are observed the drums should be de-

glazed and the new shoes installed.

To effectively monitor the success of the

revised brake components, a PIR should be

submitted for any post-breakpoint vehicles

that exhibit squeal from the rear brakes.

PARTS INFORMATION

Part No.: Description: Qty:

5878317230 Brake Shoe Set 1

WARRANTY CLAIM INFORMATION

Use existing Warranty Information from SIP

as shown:

Description Shoes and Lining

Labour Op. No. H025700

Time 1.2

Failure Code 40

HOLDEN SERVICE TECHLINE ____________________________________________________________ MARCH 2001

15

RUNNING ROUGH - MISFIRE

JACKAROO (4JX1 DIESEL ENGINE)

(GROUP 6M) TL103-0601

PROBLEM DESCRIPTION

Vehicle will miss or run rough which may be

caused by a defective injector. Investigations

have shown that a manufacturing process

problem may cause the injector tip/nozzle to

crack or fracture.

PRODUCTION RECTIFICATION

A revised manufacturing process was

introduced from:

ISOVIN: Build Date:

JACUBS73GX7102072 26/02/99

Eng. 618151 -

INJ. SERIAL No. 144903 -

SERVICE RECTIFICATION

Isolate which cylinder is misfiring using the

injector isolation test on Tech 2. Once

confirmed which cylinder displays the

problem, then confirm the injector as the fault.

The easiest way to do this is to swap the

injector with one from another cylinder and

see if the misfire moves with the injector.

While swapping the suspected faulty injector

inspect the tip/nozzle for any damage. Should

the injector show signs of damage replace all

four injectors. If there is no sign of damage

continue with swapping the injectors and

replace the individual injector if required. If

the misfire does not move with the injector

then further diagnostic work is required

concentrating on the wiring loom between the

injectors and ECU.

For correct injector calibration refer to the

article in the Engine Fuel System section of

this Techline.

PARTS INFORMATION

Part No.: Description: Qty:

5873105640 Inj. Kit – Grade A Kit of 4

5873105650 Inj. Kit – Grade B Kit of 4

8972279030 Inj. Single 1

NB* When ordering a single injector individual

seals will need to be ordered separately, refer

PartFinder.

WARRANTY CLAIM INFORMATION

Use the existing information from SIP as

follows:

Description Injector, Fuel – R & R

or Replace (Diesel)

Labour Op. No. J592600

Time 1.0 hr (1 injector)

Time 1.3 hr (4 injectors)

Failure Code 05

HOLDEN SERVICE TECHLINE ____________________________________________________________ MARCH 2001

17

INJECTOR CALIBRATION

JACKAROO (4JX1 DIESEL ENGINE)

(GROUP 6M) TL103-6M01

The 4JX1 diesel engine in the 1998, and onward, model Jackaroo has injectors that are classified into 9

groups according to flow rate. The ECM is calibrated to the injectors that are fitted to the engine using

tech 2.

Injector calibration is carried out at production, but will need to be checked at pre delivery and after some

service repairs. e.g. control unit replacement, injector replacement, etc.

Incorrect injector calibration may cause unstable idle, engine vibration or excessive smoke.

When performing injector calibration difficulty may be experienced identifying the injector calibration

group. The workshop manual indicates that identification is determined by markings on the injector. This is

not always the case. Later vehicles may have the injector calibr ation number, as shown below, identified

on the top of the injector.

The only sure method for identification is to utilise the injector identification sticker. The sticker is situated

on the noise insulator cover fitted over the rocker cover, the sticker should always be update whenever

different calibration injectors are fitted. A new sticker will be provided with new injectors, if the sticker

should become unavailable then the old sticker should be updated with a permanent marker.

INJECTOR IDENTIFICATION STICKER

ENG. NO 489476 4JX1

#1 82395420 #2 83395420

#3 83365520 #4 59395920

RP SENSOR 7565

The numbers on the identification sticker are production numbers (not part numbers) used to identify

individual injectors. The 5th and 6th digits of the production number are used to classify injectors for

calibration. eg:

#1 82395420

CALIBRATION NUMBER ( 54 )

INJECTOR NUMBER (# 1)

The calibration number is used in conjunction with the following chart.

A1 20 - 26 B1 40 - 46 C1 61 - 67

A2 27 - 33 B2 47 - 53 C2 68 - 74

A3 34 - 39 B3 54 - 60 C3 75 - 80

For example: Injector number 1 has a calibration number 54. Number 54 corresponds to a B3.

HOLDEN SERVICE TECHLINE ____________________________________________________________ MARCH 2001

18

Once the injector calibration number has been established and injector category determined, the

calibration procedure in the relevant workshop manual (section 6E ) can be followed.

Since the introduction of this engine, injector group C has been deleted from HSPO and will supersede to

injector group A. Regards of the injector group calibration fitted to a vehicle from production it can be

replace by any calibration of injector providing the ECU is re-programmed to reflect the injectors fitted to

the vehicle.

HOLDEN SERVICE TECHLINE ______________________________________________________________ APRIL 2001

25

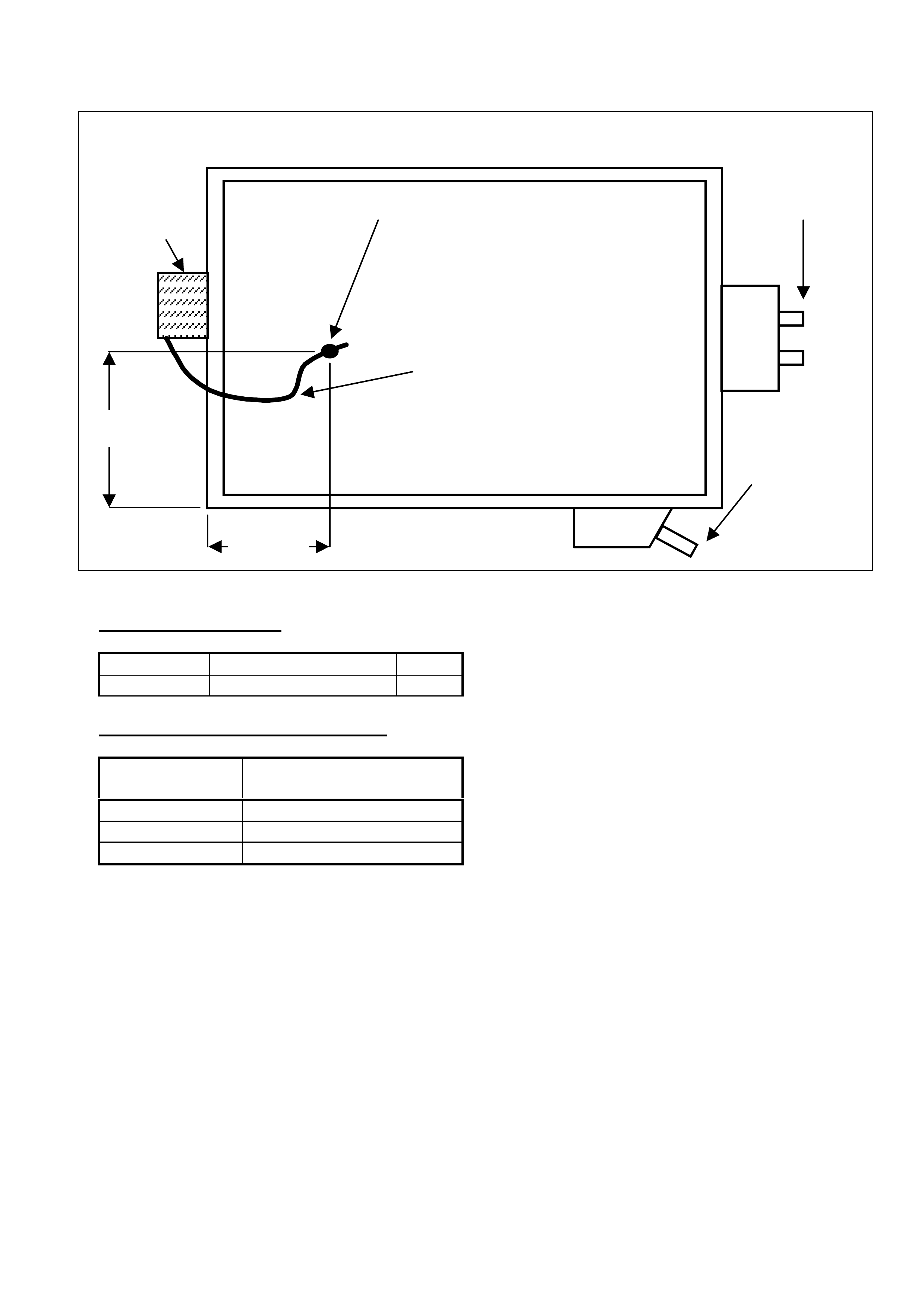

TIMING BELT INSTALLATION OR REPLACEMENT

UBS, UES, TFS – All with V6

(GROUP 6A) TL104-6A01

PROBLEM DESCRIPTION

Vehicle does not run or runs rough after timing belt replacement or installation.

Alignment marks on timing belt do not line up with alignment marks on engine during timing belt

installation.

Correction and clarification of workshop manual timing belt fitting procedures are contained in this

Techline. SIP will be updated in the next issue (July).

Relocation of alignment marks on timing belt to allow fitment as described in this Techline.

PARTS INFORMATION

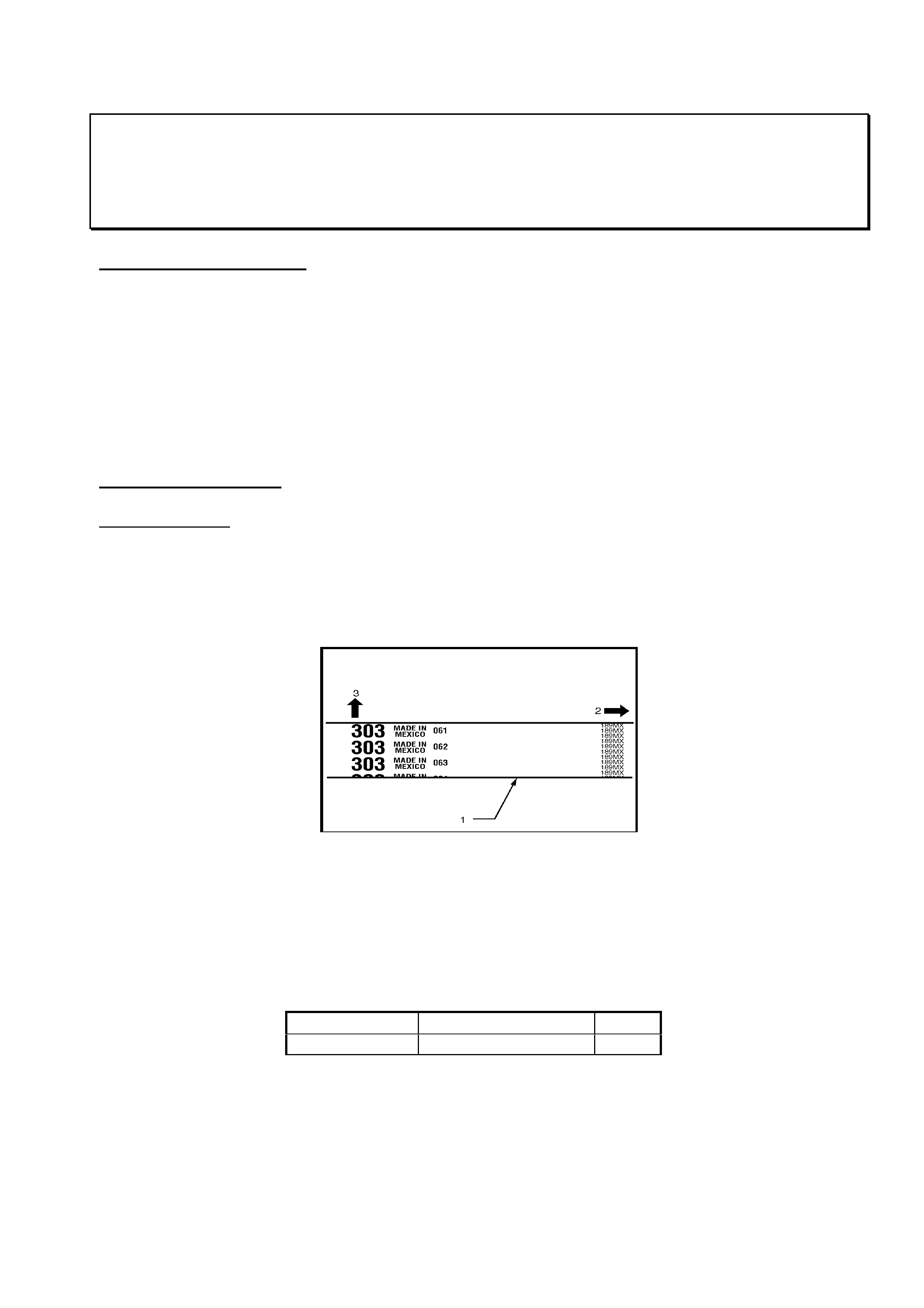

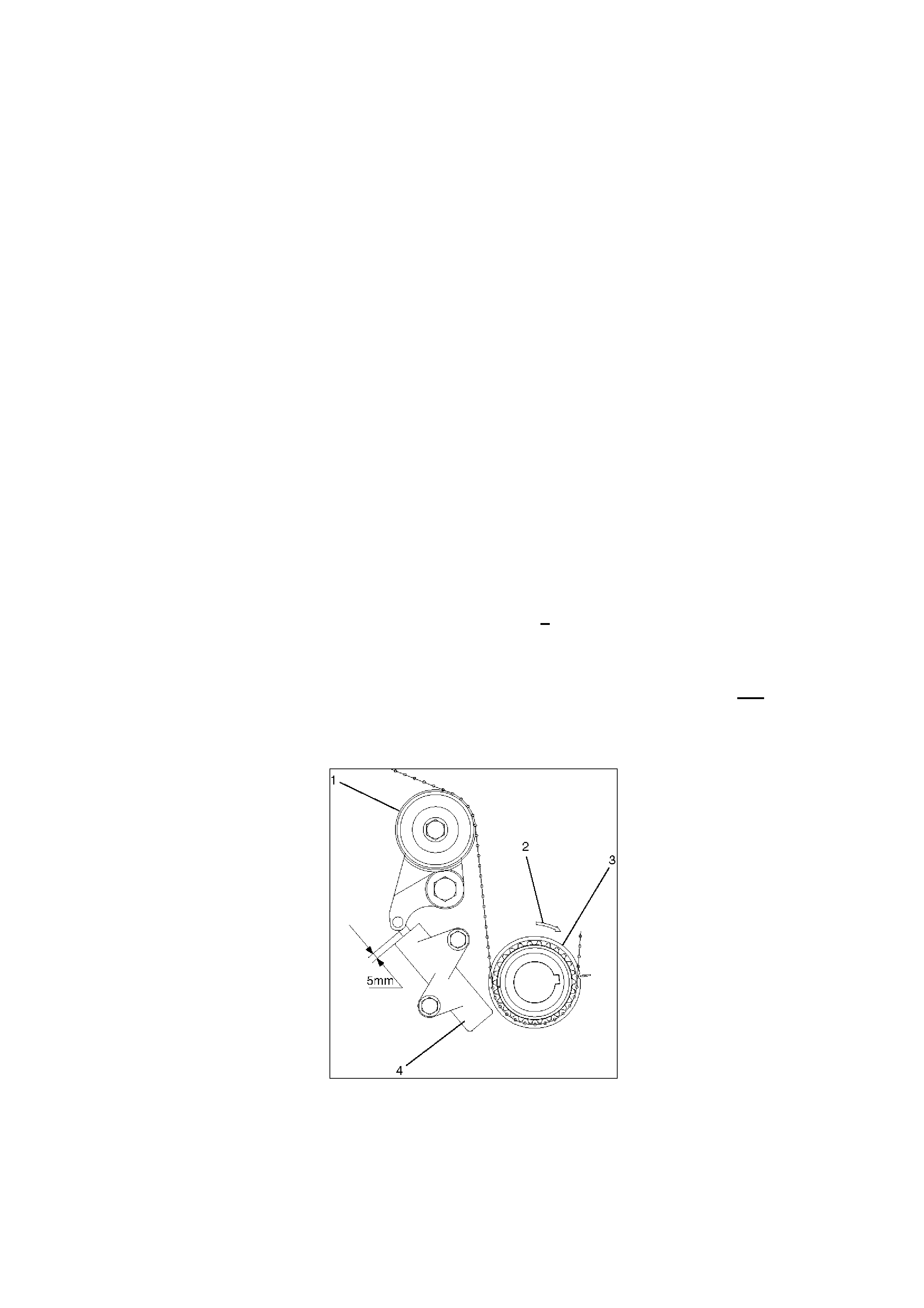

Belt Identification

The correct belt can be identified by the number 303 as shown in the diagram below. The previous

belt was marked with T200; this belt has the incorrect installation alignment marks and should not

be used.

Figure 1

LEGEND

(1) Timing Belt.

(2) Engine Rotation Direction.

(3) Cylinder Head Side.

All belts with the incorrect installation alignment mark have been removed from HSPO stock.

Part No.: Description: Qty:

8971363210 Timing Belt (303) 1

HOLDEN SERVICE TECHLINE ______________________________________________________________ APRIL 2001

26

SERVICE RECTIFICATION

SUMMARY

The procedure included in this Techline can be summarised into the following simple points. The

purpose of this summary is to provide an overview of important points required to fully understand the

following procedure.

- The V6 engine fitted to Rodeo, Jackaroo and Frontera from 98 has a cam drive system where the

reduction is partly obtained through the timing belt pulleys and partly through the cam drive gear

located in the cylinder head. The two ratios combined form a reduction ratio of 2:1.

- Due to the two-stage reduction three timing reference points are required when setting the cam

timing. They are the (1) crankshaft (2) camshaft belt pulleys (3) actual camshaft position. The

timing marks on the belt pulleys will line up every 3 crankshaft rotation while the timing marks and

actual camshaft positions will only line up every 6 crankshaft rotations.

PREPARATION PROCEDURE

Remove all components required to gain access to the timing belt as listed below:

- Battery ground;

- Air intake assembly;

- Upper radiator fan shroud;

- Serpentine belt;

- Cooling fan, cooling fan clutch and bracket

- Serpentine belt tensioner and idler pulley assemblies;

- Power steering pump assembly;

- Crankshaft pulley;

- Timing belt covers, right side first.

NOTE: If the timing belt is being replaced as part of regular servicing and there is no reason to

suspect a fault with the cam timing, follow the ‘Belt Service’ procedure.

If the timing position of the engine is unknown or in doubt ie. broken timing belt or head

removal, follow the ‘Unknown Cam Timing’ procedure.

PROCEDURE 1 - BELT SERVICE

- Rotate the engine until the notch on the crankshaft timing pulley aligns with the mark on the oil

pump housing (TDC Cyl #2, Figure 2). At the same time, the painted marks on each of the

camshaft pulleys must align with the marks on the cylinder head covers. Refer Figure 3. This

should require no more than 3 rotations of the crankshaft. The marks on the belt will not line up

with the timing marks.

HOLDEN SERVICE TECHLINE ______________________________________________________________ APRIL 2001

27

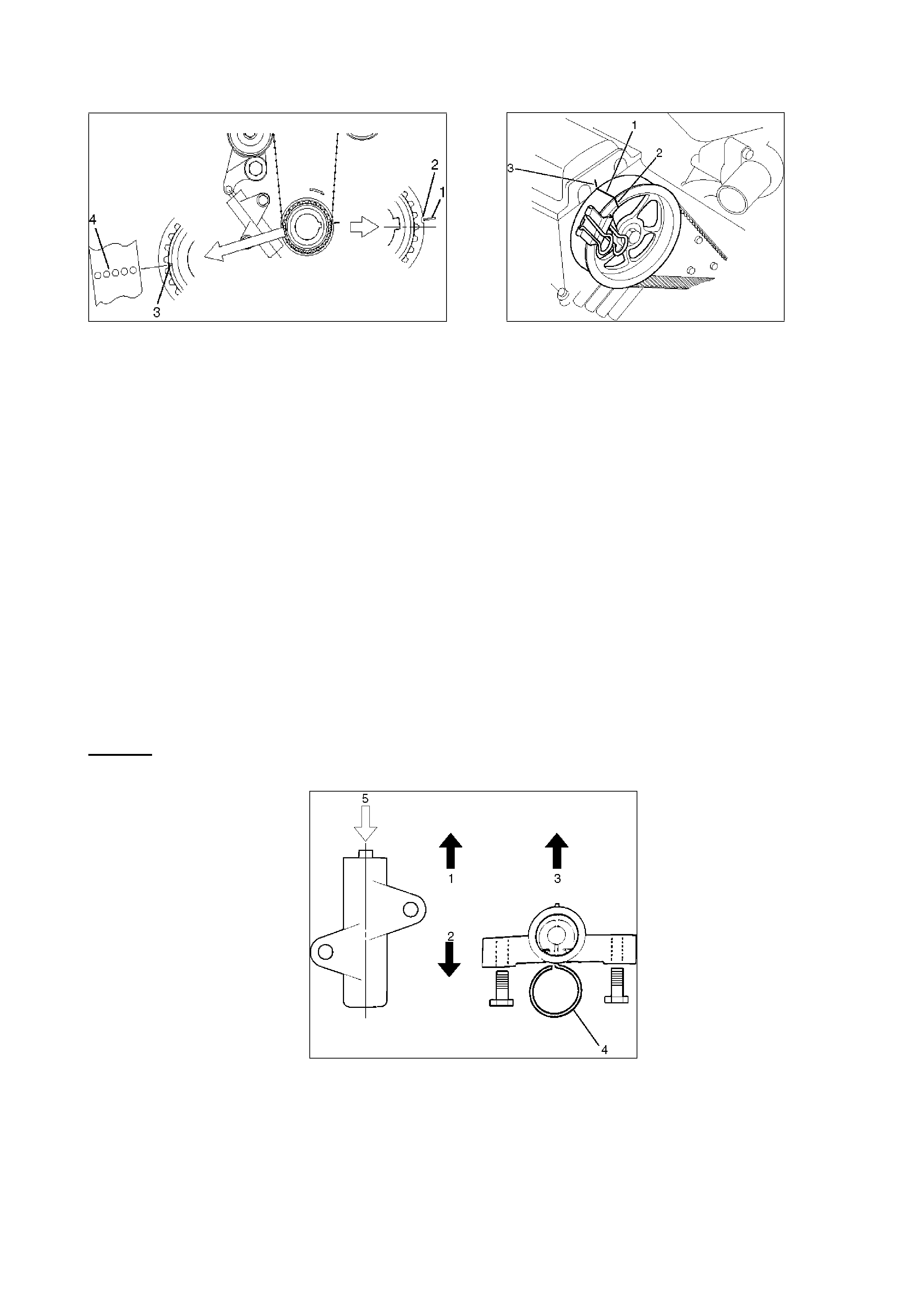

Figure 2 (Crankshaft Alignment) Figure 3 (Camshaft Alignment, mirror

image for left side)

Legend Legend

(1) Mark on oil pump (TDC Cyl #2) (1) Alignment mark on timing belt (for

(2) Notch on crankshaft timing pulley. belt installation only).

(3) Alignment mark on crankshaft timing pulley (2) Alignment mark on camshaft timing pulley

(for belt installation only). (3) Alignment mark on head cover.

(4) crankshaft alignment mark on timing belt

(for belt installation only).

- Remove the timing belt. While removing the belt be sure that the camshaft pulleys do not move.

If a camshaft pulley should move for any reason it must returned to exactly the same position ie. if

the pulley should move in a clockwise direction it must be returned to the same position by

rotating the pulley in the anti-clockwise direction and vice versa.

The camshaft will be in different position if rotated forward two revolutions. If the position of the

camshafts becomes unknown for any reason the ‘Unknown Cam Timing Procedure’ should be

used to complete the timing belt installation.

- Remove the timing belt pusher (tensioner).

Caution: To prevent air entering the oil chamber the pusher must be stored with the rod

facing upward.

Figure 4

Legend

(1) Up Side.

(2) Down Side.

(3) Direction for Installation (Engine Side).

(4) Apply force of 980Nm (220Ib) to compress the pusher (tensioner).

HOLDEN SERVICE TECHLINE ______________________________________________________________ APRIL 2001

28

BELT INSTALLATION

NOTE:

Do not bend or twist the belt otherwise, its core could be damaged. The belt should not be

bent to a radius of less than 30mm.

Do not allow oil or other chemical substances to come in contact with the belt.

Do not attempt to pry or stretch the timing belt during installation.

Store the timing belt in a cool dark place. Never expose the belt to direct sunlight or

excessive heat while in storage.

- Install the new timing belt in the direction shown in Figure 1. When installed correctly you wil be

able to read the writing on the belt during installation as seen from the front of the engine.

- Install the timing belt on the crankshaft first; align the white dotted line on the timing belt with the

alignment mark on the crankshaft pulley, refer Figure 2. Secure the belt onto the pulley using a

‘bulldog’ clip.

- Align the appropriate solid white lines on the timing belt with the respective camshaft pulleys and

secure with ‘bulldog’ clips, refer Figure 3. You may need to slightly rotate (one tooth) the L/H

camshaft pulley anticlockwise to assist with fitting the belt to the camshaft pulley, once fitted the

timing marks can then be realigned.

- Compress the belt pusher slowly in a press, be sure to maintain a light resistance on the press

handle so the hydraulic pusher is not damaged. Install an appropriate locking pin into the pusher

eg. meat skewer.

- Rotate the crank clockwise to obtain maximum belt slack for fitting the pusher.

- Install the pusher and release the locking pin.

- Remove ‘Bulldog’ clips from the crankshaft and camshaft pulleys.

NOTE: The belt installation procedure above is the same procedure as that used since 1992 on V6

Jackaroo.

- Install the crankshaft pulley and rotate the crankshaft 3 complete revolutions until the timing notch

on the crankshaft pulley again aligns with the mark on the oil pump housing, the timing marks on

the camshaft pulleys should realign with the marks on the head covers.

NOTE: The marks on the timing belt are for installation purposes only and will not realign

with the cam timing marks.

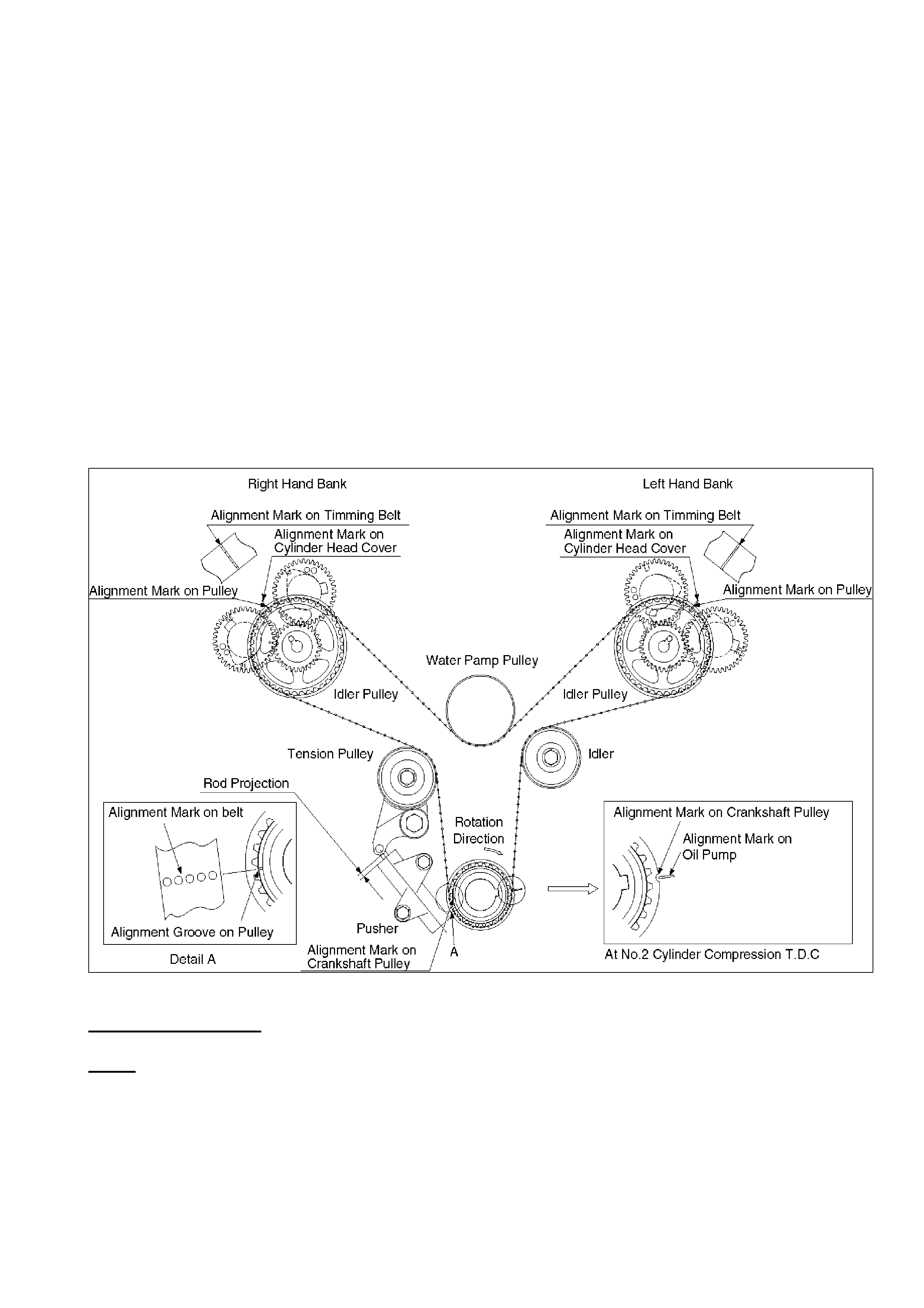

- Check that the rod projection on the timing belt tensioner is approximately 5mm (Refer Figure 5).

HOLDEN SERVICE TECHLINE ______________________________________________________________ APRIL 2001

29

Figure. 5

LEGEND

(1) Tensioner Pulley

(2) Crankshaft Direction of Rotation

(3) Crankshaft Pulley

(4) Pusher Assembly “Tensioner”

- Re-assemble the engine in the reverse order as described in the ‘Preparation Procedure’.

PROCEDURE 2 - UNKNOWN CAM TIMING

- Gain access to the front of the engine by using the ‘Preparation Procedure’ as described above.

- Remove broken belt or re-install repaired cylinder head as required. Be sure to remove any

foreign material form around the timing belt drive area.

- Remove the timing belt pusher (tensioner).

Caution: To prevent air entering the oil chamber the pusher must be stored with the rod

facing upward.

Figure 6

Legend

(1) Up Side. (2) Down Side.

(3) Direction for Installation (Engine Side). (4) Lock Pin

(5) Apply force of 980Nm (220Ib) to compress the pusher (tensioner).

HOLDEN SERVICE TECHLINE ______________________________________________________________ APRIL 2001

30

- Remove cylinder head covers.

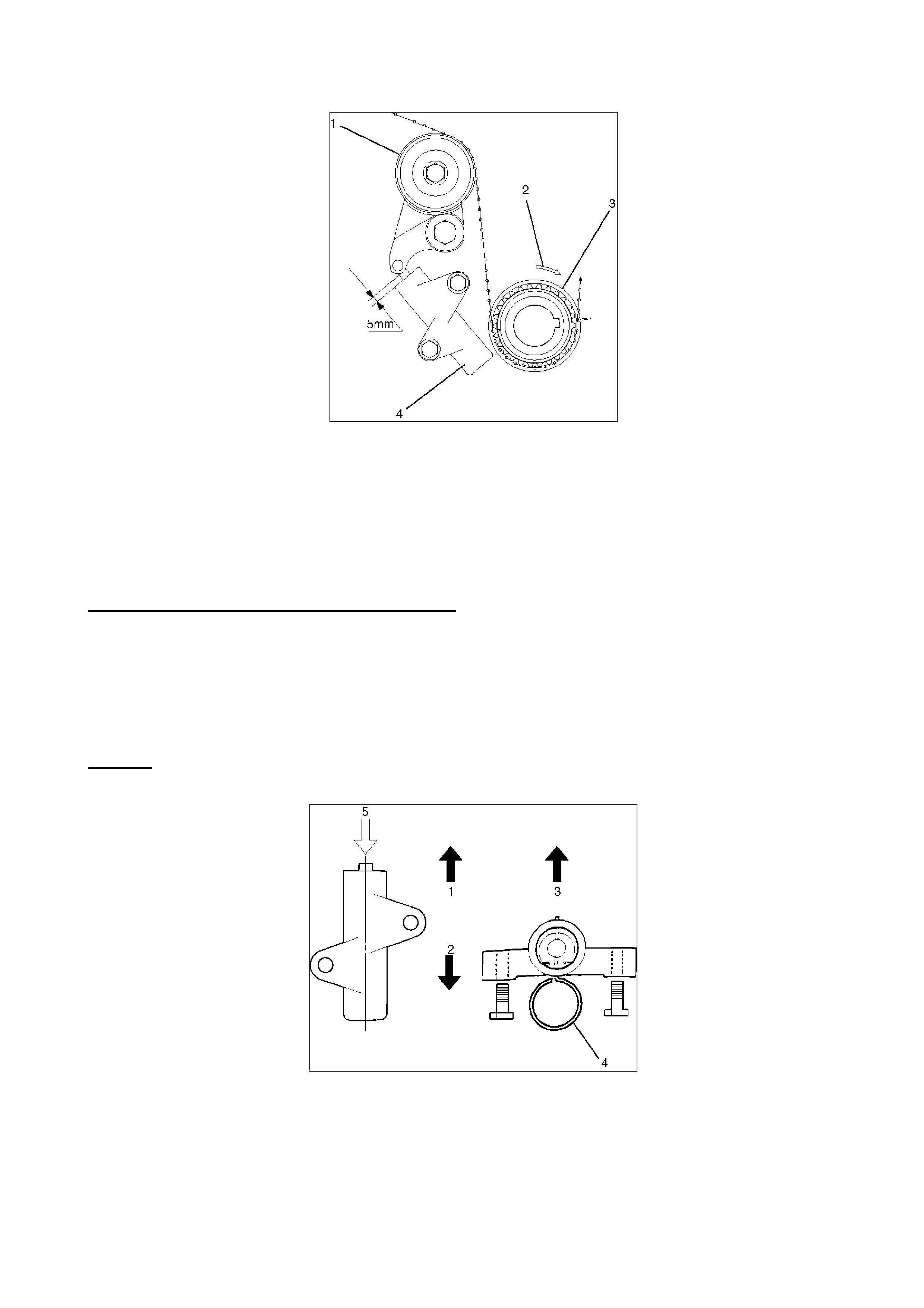

- Align the timing marks as shown in Figure 7 noting the following 3 points.

- Align the notch on the crankshaft timing pulley with the mark on the oil pump housing (TDC

Cyl#2).

- Rotate the right side camshaft pulley until the timing mark is at the 12 o’clock position relative to

the cylinder head mounting surface (Refer Figure 7). While in this position the cam lobes for

cylinder #1 (directly behind the cam pulley) must be in the position shown in Figure. 7. Up to four

rotations of the cam pulley may be required to achieve correct alignment.

- Rotate the left side camshaft pulley until the timing mark is at the 12 o’clock position relative to

the cylinder head mounting surface (Refer Figure 7). While in this position the cam lobes for

cylinder #2 (directly behind the cam pulley) must be in the position shown in Figure. 7 (Firing). Up

to four rotations of the cam pulley may be required to achieve correct alignment.

Figure. 7

BELT INSTALLATION

NOTE:

Do not bend or twist the belt otherwise, its core could be damaged. The belt should not be

bent to a radius of less than 30mm.

Do not allow oil or other chemical substances to come in contact with the belt.

Do not attempt to pry or stretch the timing belt during installation.

HOLDEN SERVICE TECHLINE ______________________________________________________________ APRIL 2001

31

Store the timing belt in a cool dark place. Never expose the to direct sunlight or excessive

heat while in storage.

- Install the new timing belt in the direction shown in Figure 1. You must be able to read the writing

on the belt during installation as seen from the front of the engine.

- Install the timing belt on the crankshaft first; align the white dotted line on the timing belt with the

alignment mark on the crankshaft pulley, refer Figure 7. Secure the belt onto the pulley using a

‘bulldog’ clip.

- Align the appropriate solid white lines on the timing belt with the respective camshaft pulleys and

secure with ‘bulldog’ clips, refer (Figure 7). You may need to slightly rotate (one tooth) the L/H

camshaft pulley anticlockwise to assist with fitting the belt to the camshaft pulley, once fitted the

timing marks can then be realigned.

- Compress the belt pusher in a press, be sure to maintain a light resistance on the press handle

so the hydraulic pusher is not damaged. Install an appropriate locking pin into the pusher eg.

meat skewer.

- Rotate the crank clockwise to obtain maximum belt slack for fitting the pusher.

- Install pusher and release the locking pin.

- Remove ‘Bulldog’ clips from the crankshaft and camshaft pulleys.

NOTE: The belt installation procedure above is same procedure as that used since 1992 on V6

Jackaroo. It is the method of positioning the cams and cam pulleys that differs.

- Install the crankshaft pulley and rotate the crankshaft 6 complete revolutions. The crank timing

pulley mark, cam timing pulley marks and cam lobe positions should return to that shown in

Figure.7.

NOTE: The marks on the timing belt are for installation purposes only and will not align again

with the cam timing marks.

- Check that the rod projection on the timing belt tensioner is approximately 5mm (Refer Figure 8).

Figure. 8

LEGEND

(1) Tensioner Pulley

(2) Crankshaft Direction of Rotation

(3) Crankshaft Pulley

HOLDEN SERVICE TECHLINE ______________________________________________________________ APRIL 2001

32

(4) Pusher Assembly “Tensioner”

- Re-assemble the engine in the reverse order as described in the ‘Preparation Procedure’.

LC6A0401.DOC

HOLDEN SERVICE TECHLINE ________________________________________________________________ MAY 2001

14

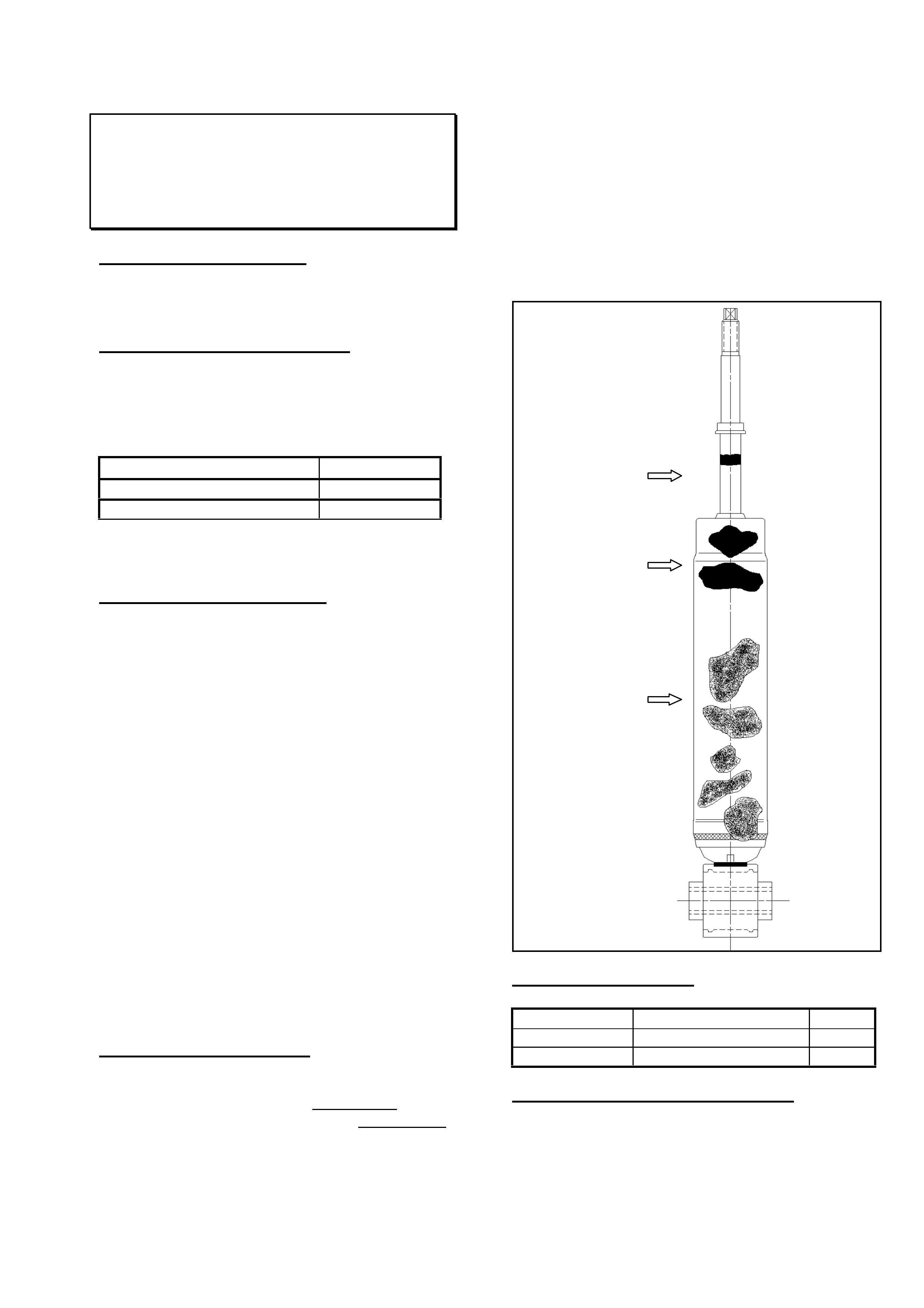

SHOCK ABSORBER LEAKAGE

UBS JACKAROO

(GROUP 3 & 4) TL105-0301

PROBLEM DESCRIPTION

Shock absorber leaks excessive oil from between

the piston rod and seal

PRODUCTION RECTIFICATION

A Teflon bush has been added in production to

reduce the amount of lateral stress placed on the

piston rod and oil seal. The seal has also been

revised to increase service life.

ISOVIN: Build Date:

JACUBS26GY7101358 (Pet) 23/02/00

JACUBS73GY7104579 (Dies) 23/02/00

Please PIR any post - breakpoint vehicles that

exhibit a leakage condition.

TECHNICAL BACKGROUND

The following information is repeated from April

2001 Passenger Techline and although it initially

referred to passenger vehicles, it can also be

applied to light commercial vehicles as a general

reference.

The normal operation of all shock absorbers

allows for a thin film of shock absorber oil to

adhere to the piston rod surface to allow for

lubrication of the seal during operation. In certain

operating environments this oil film becomes

contaminated with foreign matter such as road dirt

and sand. The seal is designed to exclude this

contaminated oil film in the compression stroke

and a build up of “sludge” results.

During the life of all shock absorbers this oily

“sludge” will create a film on the shock absorber

body. This film is normal and in no way

compromises the function of the shock absorber.

The criteria outlined below identifies the

acceptable conditions that may be observed when

inspecting shock absorbers at various times

during the life of the product.

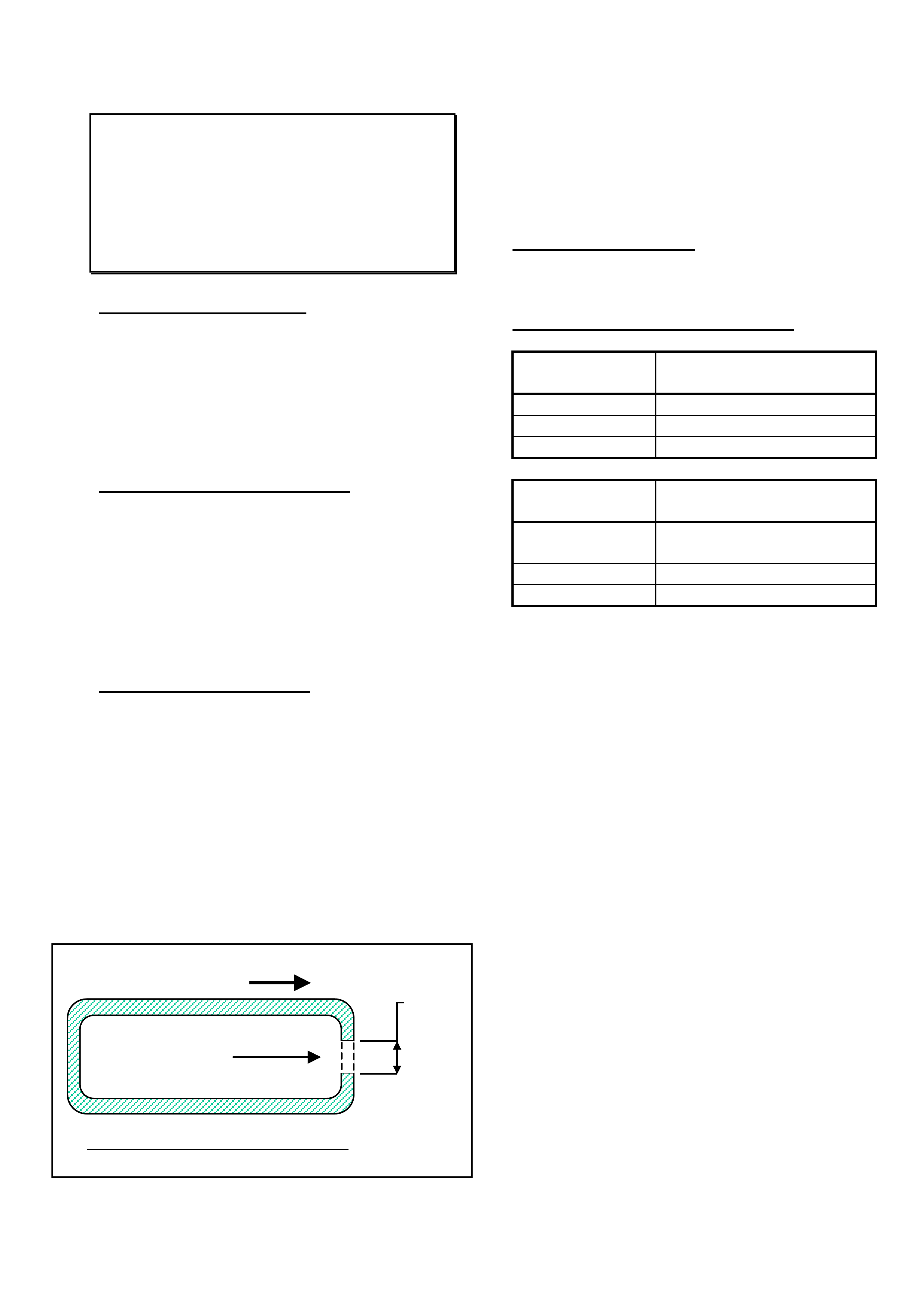

SERVICE RECTIFICATION

If a shock absorber displays worse conditions than

that shown in the drawing (ie: greater than 10mm

band of “grime” on piston rod, or greater than

40mm build up of “sludge” on body), the shock

absorber is classified as LEAKING, and should be

replaced. If the shock absorber on the other side

of the vehicle is NOT leaking, it should be left in

service.

PLEASE ALSO NOTE THAT:

In the event of a faulty shock absorber:

- the faulty unit may be replaced without replacing

a matching pair;

- faulty shock absorbers must NOT be cleaned

prior to them being returned.

PARTS INFORMATION

Part No.: Description: Qty:

8970393193 Frt Shock Absorber 1

8970438172 Rr Shock Absorber 1

WARRANTY CLAIM INFORMATION

Use existing information provided in SIP.

Oily grime build up

at end of stroke up

to 10mm wide

band

Oily “sludge”

accumulated from

normal operating

conditions to 40mm

down the body of

the shock absorber

Shock absorber body

may be discoloured

by road grease and

oil, sand and dust, but

this does not

constitute a leaking

shock absorber. In

this event the shock

absorber should be

wiped clean and

checked at the next

service

HOLDEN SERVICE TECHLINE ________________________________________________________________ MAY 2001

15

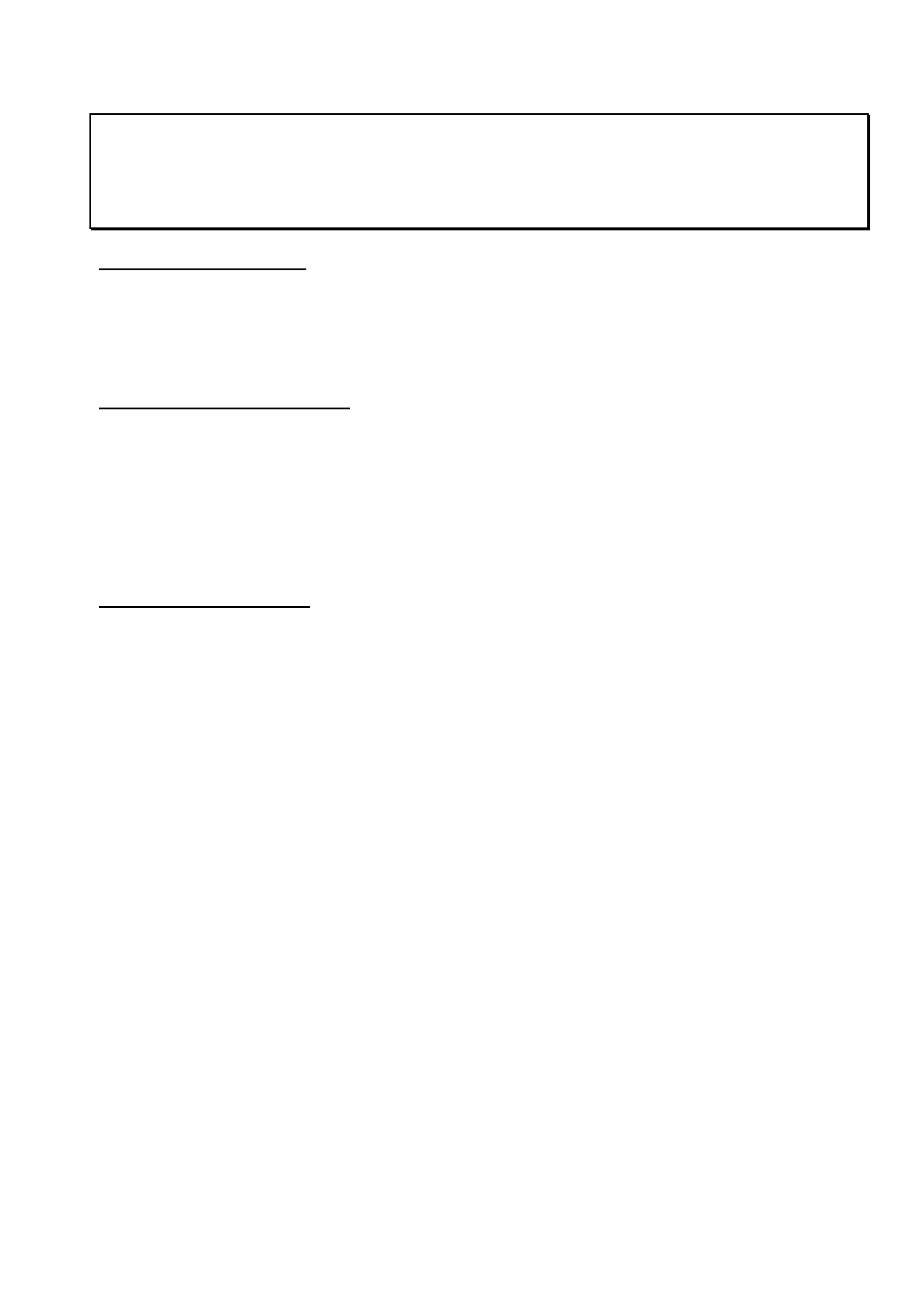

EVAPORATOR FREEZE UP

UBS JACKAROO

(GROUP 2) TL105-0201

PROBLEM DESCRIPTION

While driving with the air conditioning on for approximately two hours at highway speeds, customers

may report that the air conditioning stops working and the air flow through the vents is reduced.

Usually this occurs in areas that are experiencing humid weather. These are typical conditions that

can promote ‘evaporator freeze up’.

PRODUCTION RECTIFICATION

A revised thermistor is available, however it will not be added to production due to the low incidence.

Revised thermistors are to be fitted to vehicles on a case by case basis.

The above condition can be rectified by replacing the thermistor, a revised thermistor (refer Parts

Info. below) will cut the compressor out at approximately 1.5oC higher temperature. This

temperature difference is sufficient to prevent the air conditioning evaporator from ‘freezing up’,

while having negligible effect on the air conditioning efficiency.

SERVICE RECTIFICATION

1. Confirm the condition.

2. Recover the refrigerant.

3. Remove - The glove box

- Glove box surround

- Dash panel support

- Cooling unit assembly (disconnect harness)

4. Disassemble the evaporator case to remove the thermistor.

5. Fit the revised thermistor to the correct position as shown in Figure 1. Note: the diagram is

not to scale.

6. The clamp for the thermistor wire must be pushed fully between the evaporator cores. This will

prevent the thermistor wire from coming adrift, which will dramatically effect the air conditioning

operation.

7. Refit the cooling unit assembly in the reverse order as described in Step 3.

8. Charge the system with refrigerant as described in the air conditioning kit fitting instruction

(650 ± 50 gm).

9. Confirm air conditioning operation.

HOLDEN SERVICE TECHLINE ________________________________________________________________ MAY 2001

16

Figure 1

PARTS INFORMATION

Part No.: Description: Qty:

92144460 Thermistor 1

WARRANTY CLAIM INFORMATION:

Description Switch, thermostatic

control - Replace

Labour Op. No. D114000

Time 1.2 hr

Failure Code 26

Thermistor

46mm

Evaporator

Evaporator

Drain

Please ensure that

thermistor wire loops

down to prevent

condensation from forming

on the tip of the wire.

Clamp must be pushed fully into

the evaporator to maintain the

correct thermistor position

Refrigerant

Lines

133mm

HOLDEN SERVICE TECHLINE _______________________________________________________________ JUNE 2001

ROUGH RUNNING AND HESITATION

TF RODEO (V6 MANUAL WITH

APPROVED PARNELL LP GAS

SYSTEM FITTED)

(GROUP 6C) TL166-6C01 LCV

PROBLEM DESCRIPTION

After operating the vehicle on LPG for an

extended period, then switching to petrol, the

vehicle may run rough and hesitate under

acceleration.

Further investigation with Tech 2 will show

that the fuel trim cells have learnt fully lean

and are extremely slow to re-learn. The re-

learning process may take 1 tank (approx.) of

fuel.

This condition is the result of making

common the M/T and A/T VEHICLE ECU.

The production change occurred with the

2000 MY changes therefore, only vehicles

after the VINs listed are affected.

JAATF*25HY7100000 JAPAN Built

MPATF*HY710000000 THAILAND Built.

* Can be either S or R

Vehicle’s with a W (‘98’) or X (‘99’) in the

position Y (‘00’) highlighted above will not be

affected.

The condition is rectified by replacing the

CLS (Closed Loop System) controller of

the gas system. The revised controller has

been designed to suit the production

changes made to VEHICLE ECU.

PROBLEM RECTIFICATION

Inspect the CLS controller located behind the

RHS kick panel trim. Confirm that the

revised controller has not previously been

fitted. The earlier part has the part code

RODV66.

Revised Part

Part Code Description: Qty:

RODV67 CLS 2000 Controller 1

Parts can either be fitted by a Holden Dealer

or, your Parnell Authorised Service Agent.

Full instructions for replacing the CLS

controller are provided with the part.

PARTS INFORMATION

Parts must be ordered directly from Parnell

LP Gas Systems on 1800 679 985.

Hint Obtain warranty authorisation for any

labour charges from Parnell while ordering

the part

Ensure that you have the LPG Kit compliance

number (found on firewall in engine bay), the

vehicles registration and the odometer

reading, prior to ordering the part as this will

be required prior to the component being

despatched.

The old controller is to be returned to Parnell

within seven (7) days. Controllers that are not

returned will be invoiced to the respective

dealer.

All stock of new kits supplied by Parnell has

the revised controller included.

WARRANTY INFORMATION

Please discuss labour reimbursement with

Parnell when ordering the revised part

HOLDEN SERVICE TECHLINE ____________________________________________________________ JULY 2001

12

TURBO (SHAFT) FAILURE

UBS JACKAROO with 4JX1 DIESEL

ENGINE

(GROUP 6A) TL107-6A01

PROBLEM DESCRIPTION

The engine loses power and emits an

abnormal amount of smoke.

PRODUCTION RECTIFICATION

A revised turbocharger assembly has been

developed - revisions include:

• increased oil supply orifice diameter at

the turbo bearing;

• high speed balancing process introduced

in production to reduce the load on turbo

shaft bearings;

• finer mesh strainer used in the primary

pump oil pick-up to prevent foreign

material damaging the oil pressure relief

valve, causing a reduction in oil pressure.

This finer strainer is a product

improvement and the existing strainer

does not require replacement when a

turbo is replaced.

PRODUCTION BREAK POINT

ISOVIN: Build Date:

JACUBS73GY7106740 July 2000

SERVICE RECTIFICATION

Where a turbocharger has failed, procure a

new turbo assembly from HSPO, and fit to

the vehicle, using the following guidelines:

When fitting a new turbo you must:

§ To prevent further bearing failures,

confirm that the injector seal rework has

been carried out on the vehicle (position

C1 on the Vehicle Service History Label -

located on the drivers A pillar, between the

door hinges). Complete the injector seal

rework if required, refer All Dealer Letter

IGM 04/00.

§ Never run the vehicle before priming

the turbo bearings with oil and, never

run the vehicle with the oil supply to

the turbo disconnected.

§ Check the oil supply to and from the turbo

before fitting the new turbo assembly.

Disable the vehicle by disconnecting the

cam sensor and check oil supply at

cranking speed. Oil flow tests are easier to

complete with the failed turbo removed.

These are approximate values to use as

a guide only. Oil viscosity, temperature,

battery condition, etc, will cause results to

vary between vehicles.

ü Oil should flow from the turbo feed pipe

within approx. 17 seconds of cranking;

ü Approximately 25ml of oil should flow

from the turbo lubrication feed pipe for

every 1 second of cranking (once the

oil flow has commenced);

ü Check the oil return from the turbo to

the crank case. When oil is poured into

the return hose it should flow freely into

the crank case.

§ Prime the turbo by adding 100ml of oil to

the turbo oil lubrication inlet. Rotate the

turbo shaft slowly by hand, this will

ensure the turbo bearings are lubricated

at initial start up.

Detailed fitting instructions for removal and

installation of the turbo unit are in LCV SIP.

Once in SIP follow the path:

§ UBS Jackaro

§ Engine – 4JX1

§ Section 6A – Engine Mechanical

§ Engine Assembly

§ Turbocharger

PARTS INFORMATION

Part No.: Description: Qty:

8972503640 Turbo Assembly 1

WARRANTY CLAIM INFORMATION

Use existing warranty information in LCV SIP

as below.

Description Turbo Asm - Replace

Labour Op. No. J586300

Time 2.2 hr

Failure Code 85

Update

HOLDEN SERVICE TECHLINE ____________________________________________________________ JULY 2001

13

CLUTCH MASTER CYLINDER

LEAKAGE

RODEO (PETROL 2.2 LITRE & DIESEL

2.8 LITRE WITH M/T)

(GROUP 7A) TL107-7A01

PROBLEM DESCRIPTION

Loss of fluid from the clutch hydraulic system

through the clutch master cylinder piston

seal.

PRODUCTION RECTIFICATION

The assembly procedure has been revised to

prevent foreign material entry that could

cause damage to the cylinder surface and

piston seals at:

ISOVIN: Build Date:

JAATFR30HY7105183 DEC 2000

JAATFR55HY7119015 DEC 2000

JAATFS55HY7120096 DEC 2000

SERVICE RECTIFICATION

Replace clutch master cylinder assembly

once the leakage has been confirmed. Refer

to the applicable workshop manual for fitting,

adjusting and bleeding procedures.

PARTS INFORMATION

Part No.: Description: Qty:

8972010070 Clutch Master Cyl. 1

This part is applicable to all Rodeos with a

Diesel or Petrol 4 Cylinder engine produced

after 1988.

WARRANTY CLAIM INFORMATION

Use existing information in LCV SIP as

below:

Description Cylinder - Clutch Master,

Replace

Labour Op. No. K060000

Time 0.4

Failure Code 42

TAS CASE CLOSURES

ALL

(GROUP OB) TL107-OB01

PROBLEM DESCRIPTION

TAS personnel are concerned about a

number of Dealerships that are not making

an effort to close TAS cases, even after

repeated requests from TAS, via faxes and

phone calls.

Dealerships enlisting the assistance of TAS

are aware – via the TAS Procedures Manual

issued to dealerships - that Holden expects

TAS cases are updated or closed within a 30

day period.

This update or closure of cases is important,

not only to assist dealerships during

communications with TAS and the

dealership’s Aftersales District Managers, but

is also a vital source of stored information to

assist other dealerships who call for

information on similar problems.

The TAS Procedures Manual has been

provided to each dealership. This is a guide

to using the TAS system and allows service

departments to manage TAS cases within

their dealerships. If you are unsure of how to

use this manual or do not have a copy then

please contact TAS for direction in obtaining

one of these useful manuals.

Service Managers: Please ensure the TAS

Procedures Manual is readily available to

your Foreman and others who may be prime

TAS contacts – as there are various forms

and procedures that will be referred to by

TAS during calls.

Please Also Note:

TAS personnel will draw your attention to

your ‘open’ (non-closed) cases when you call

– please assist them in updating or closing

your outstanding cases AS SOON AS

POSSIBLE.

HOLDEN SERVICE TECHLINE ____________________________________________________________ AUGUST 2001

10

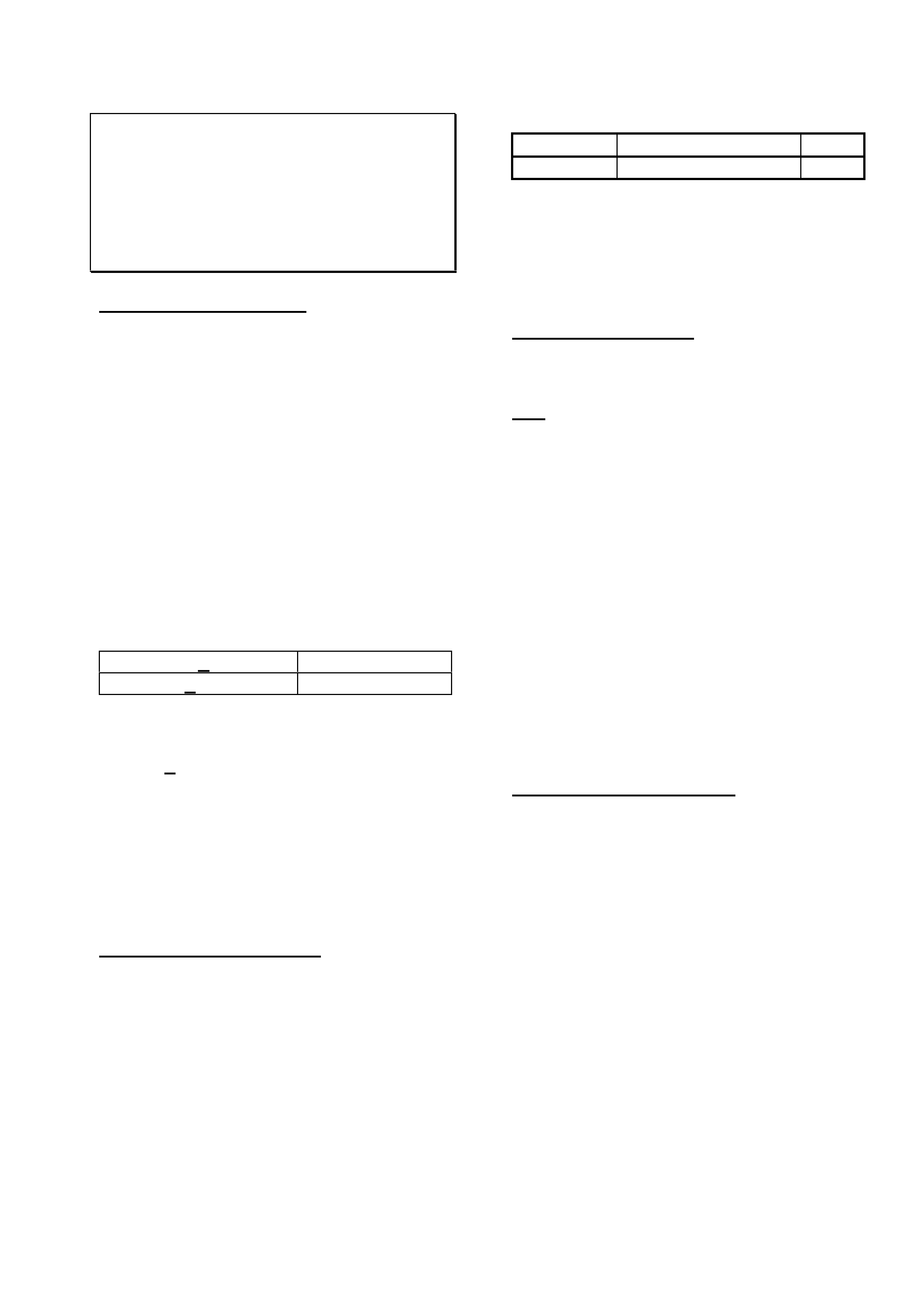

INJECTOR MISFIRE – INCORRECT

SEALANT USAGE

UBS with 4JX1TC Engine

(GROUP 6M) TL108-6M01

PROBLEM DESCRIPTION

Several instances have occurred where

technicians have been applying NYOGEL

sealant to the injector harness connectors of

the 4JX1TC diesel engine. This has resulted

in the injectors mis-firing when the engine is

placed under a medium to high load

condition.

IGM Product Campaign Bulletin 98-Z-01

advised dealers to lubricate the 4JX1 diesel

Crankshaft Position (CKP) Sensor connector

with “NYOGEL” - this is the only current

use for this sealant, and any other usage

of this sealant will be specified in future

bulletins.

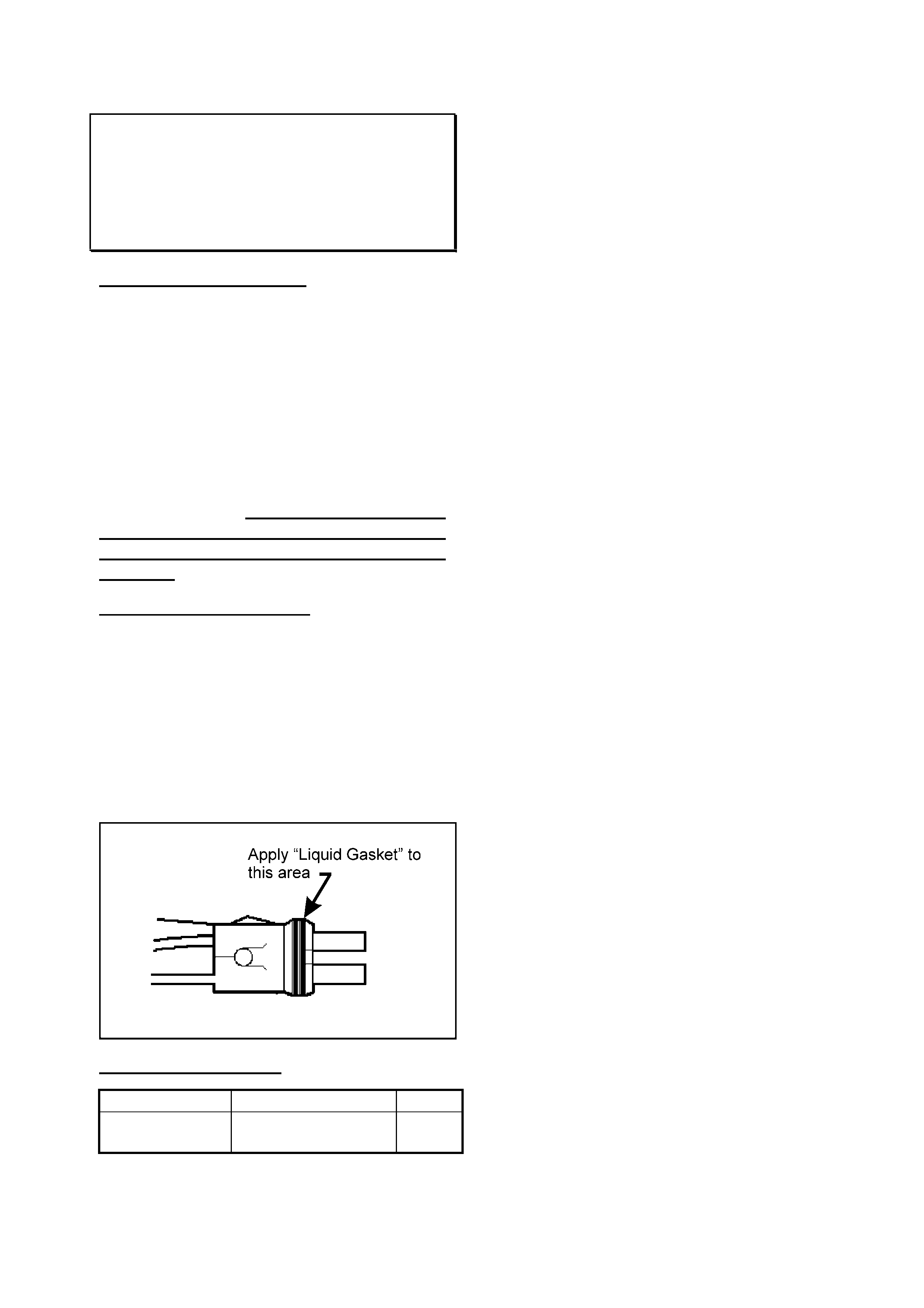

SERVICE RECTIFICATION

Technicians are advised that a thin film of

"Sealant - Liquid Gasket", Part No.

0882600080A should be applied to the

OUTER surface of the neoprene connector

sealing ring as shown in the illustration

below.

Under no circumstances must sealant be

allowed to contact the harness connector

terminals.

PARTS INFORMATION

Part No.: Description: Qty:

0882600080A Sealant - Liquid

Gasket

1

HOLDEN SERVICE TECHLINE ____________________________________________________________ AUGUST 2001

11

FRONT DOOR SNIB LOCK BUTTON

SEIZURE WHEN COLD (INTERIM

MEASURE)

TF (Rodeo)

(GROUP 1) TL108-0101

PROBLEM DESCRIPTION

On cold mornings the ignition key may not

rotate to unlock the front doors.

This condition is caused by the snib lock

guide in the interior door trim interfering with

the snib button preventing the snib button

from moving.

PRODUCTION RECTIFICATION

Corrective action has not been taken in

production to prevent this condition from

occurring.

To support the need for corrective action

in production please submit a PIR on all

vehicles that exhibit this condition.

SERVICE RECTIFICATION

Use the following procedure to rectify this

condition:

1. Remove the interior door trim.

2. Remove the snib lock guide from the front

door trim.

3. Cut a small slit through the rear of the snib

lock guide. This allows the guide to move

with temperature changes.

Insert the snib lock guide into the front door

trim with the slit facing toward the rear of the

vehicle to obscure the modification.

4. Refit the interior door trim.

PARTS INFORMATION

No parts are required.

WARRANTY CLAIM INFORMATION

Description Front Door Snib Lock

Seizure – RH Side

Labour Op. No. B000150

Time 0.7 hrs.

Failure Code 52

Description Front Door Snib Lock

Seizure – LH Side

Labour Op. No. B000153

Time 0.7 hrs.

Failure Code 52

Rear Of Vehicle

Cut a slit in

the guide to

allow guide

to flex

View from top of Lock Guide

Width of

the saw

blade

HOLDEN SERVICE TECHLINE ____________________________________________________________ AUGUST 2001

12

MISFIRE OR ‘SHUNT’ SENSATION

WITH CRUISE CONTROL ENGAGED

JACKAROO DIESEL ONLY

(ACCESSORY CRUISE FITTED)

(GROUP 6C) TL108-1201

PROBLEM DESCRIPTION

Customers may report that their vehicle has a

condition similar to a miss-fire or shunt only

with the cruise control engaged. This

condition is most likely to occur in vehicles

with an automatic transmission while driving

down a hill.

Poor earthing through the cruise control

circuit causes this condition.

SERVICE RECTIFICATION

To rectify the condition replace the Drive By

Wire (DBW) module and add an extra earth

wire as instructed below:

1. Remove the screws from the glove box hinges

and remove the glove box.

2. Remove the console that surrounds the gear

selectors. Remove any wiring attached to the

console trim e.g. telephone, heated seat

switches etc.

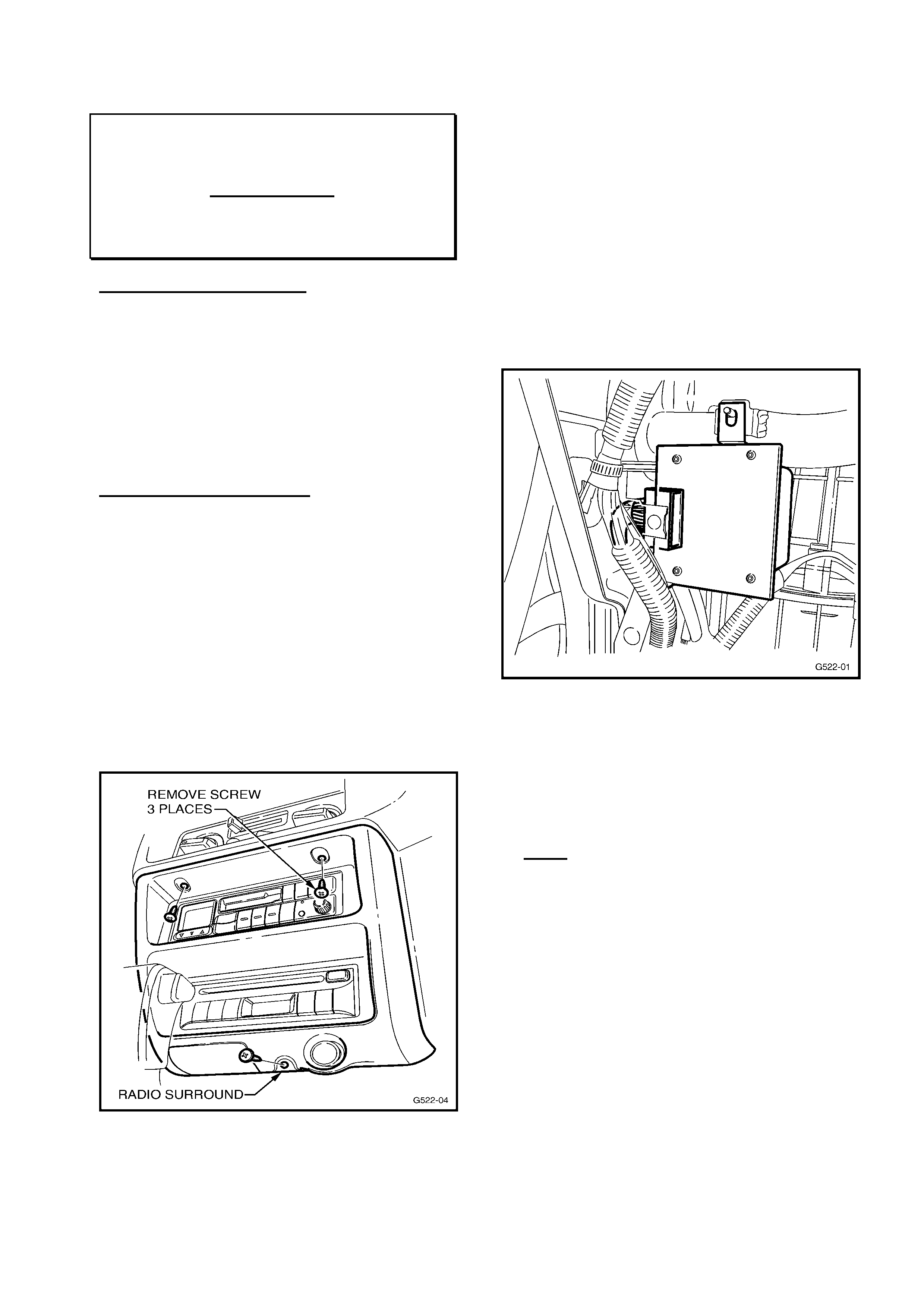

3. Remove the three attaching screws from the

radio surround. Disconnect the cigarette lighter

and ashtray illumination wiring; remove the

radio surround (Figure 1).

Figure 1

4. Remove the seven screws and two plastic

clips from the lower dash trims on the

passenger’s side. Take care not to scratch

the dash trim when removing t he plastic clip

that faces the left hand front door; remove

the lower dash trim.

5. Remove the passenger side knee bolster

reinforcement (four bolts & four nuts).

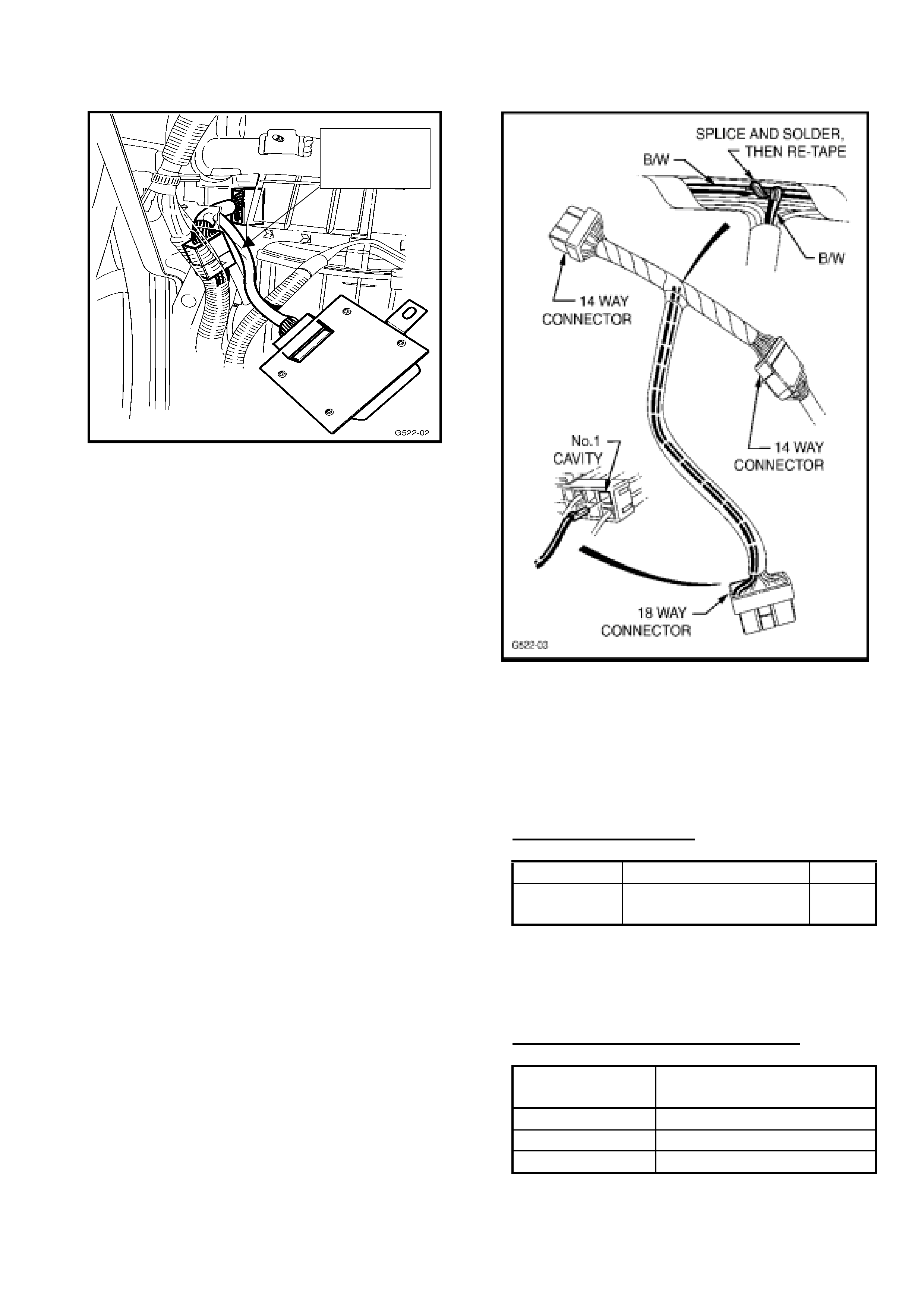

6. Remove and disconnect the existing Drive

By Wire Interface Module (Figure 2).

Figure 2.

7. Remove the module from the mounting

bracket and check the inspection date

sticker. If the module has a date sticker

prior to Oct. 2000 (or NO date sticker),

replace the DBW Module and continue to

Step 8.

Note: If the date sticker on the DBW

module is later than Oct. 2000 – the vehicle

is fitted with the latest DBW module and it

should not be replaced – do not continue

with this procedure, but contact TAS for

further diagnosis of the complaint condition.

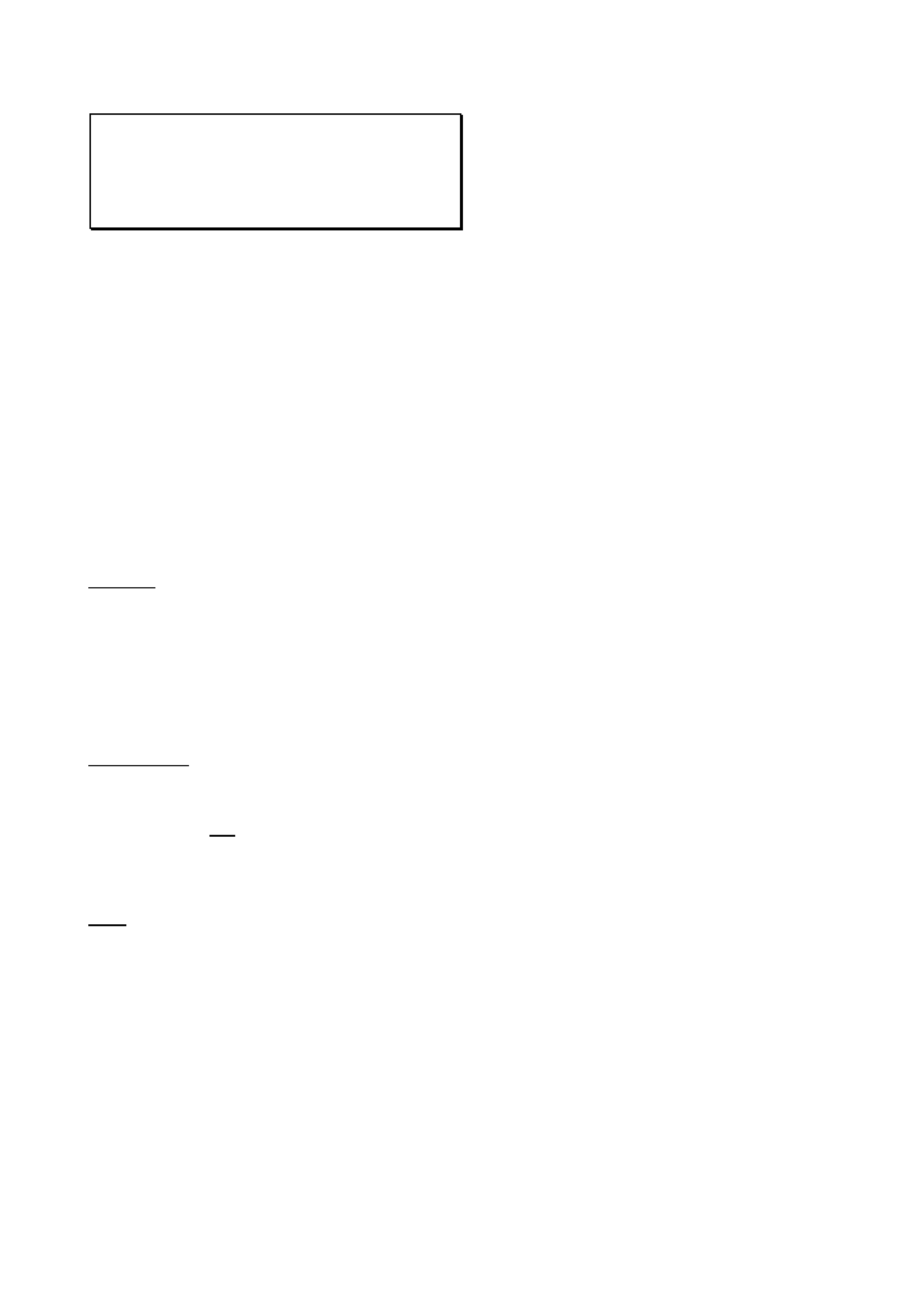

8. Disconnect the two 14 pin connectors and

the 6 pin connector of the ‘T’ shaped patch

harness; remove the harness from the

vehicle (Fig.3.).

HOLDEN SERVICE TECHLINE ____________________________________________________________ AUGUST 2001

13

Fig. 3

9. Remove the tape from the PVC tubing at the

18 way connector and the ‘T’ intersection of

the patch harness.

10. Fit the terminal of the black/white wire

(supplied with the module) to pin position 1

in the 18 pin connector (pin location is

numbered on the back of the connector).

Refer Figure 4.

11. Feed the black/white wire from the 18 pin

connector, through the PVC tubing, to the

‘T’ intersection of the patch harness.

12. Locate the black/white wire that runs

between the two 14 pin connectors, strip

sufficient insulation from this wire to make a

solder joint.

13. Cut the black/white wire from the 18 pin

connector with sufficient length to allow a

solder joint to be made with the wire

described in step 12.

14. Solder the two black/white wires at the ‘T’

intersection of the patch harness (Fig. 4).

The wire must be soldered or the cruise

control will not operate correctly. For more

details on soldering methods refer to the

VT Commodore Manual, Volume 8, 12P9 to

12P10.

Fig. 4

15. Insulate the solder joint with electrical tape

and re-tape the PVC tubing.

16. Reassemble all parts removed in the

reverse order.

PARTS INFORMATION

Part No.: Description: Qty:

92143380 DBW Module

(Earth wire included)

1

All modules and accessory kits in HSPO

stock have the revised calibration DBW

module.

WARRANTY CLAIM INFORMATION:

Description Module, Cruise Control -

Replace

Labour Op. No. R000097

Time 1.2hr

Failure Code 50

‘T’ Shaped

Harness

HOLDEN SERVICE TECHLINE _______________________________________________________SEPTEMBER, 2001

19

ENGINE OIL SPECIFICATION

JACKAROO DIESEL (4JX1 ENGINE)

(GROUP 6A) TL109-6A01

This techline supersedes all previous

information, relating to this subject,

provided in dealer letters, techlines and the

owners handbook.

This techline is to clarify and update the

required engine oil specification for the 4JX1

diesel engine as fitted to Jackaroo.

This specification should be retrospectively

applied to all vehicles, fitted with a 4JX1

engine, when being serviced by your

dealership.

Oil Specification:

Viscosity:

Preferred- 5W/30 or 10W/30

Where the preferred viscosity is not available

Use

-5W/40, 5W/50,

10W/50 or 10W/40

Classification:

API: CG-4 or CH-4

OR

ACEA: B1 or B3 (not B2)

Note: Use of the incorrect oil can cause :

• Poor cold weather starting;

• Poor idle quality;

• Excessive smoke;

• Poor performance.

This viscosity specification is consistent with

the specification outlined on the vehicle under-

bonnet stickers.

The classification on the vehicle stickers is CD

grade. This is the general export classification

specified by Isuzu and is applicable to a 5000

km oil change service interval. As Holden

specify a 10,000 km service interval the

minimum classification required is as above.

On the next page is a list of oils that meet the

required specification and are currently on the

market. The names and specification of oils

available on the market are continually

changing. To keep up to date with the latest

oils in the market please contact your oil

supplier.

……………………………..Continued next page

HOLDEN SERVICE TECHLINE _______________________________________________________SEPTEMBER, 2001

20

ENGINE OIL SPECIFICATION JACKAROO DIESEL (4JX1 ENGINE) continued….

Note: Holden does not recommend any particular brand of oil. The oils below are those within the

Holden specification range according to the information provided by the oil manufacturer. If a

particular oil manufacturer is not included in this table it does not mean that the oil manufacturer does

not produce a suitable oil. Please refer to your oil supplier to discuss oil that will meet the quoted

specification

Manufacturer

Product Name Viscosity Classification

Mobil

Mobil Delvac 1 5W/40 CH-4

Bulk Only Mobil Delvac HP-F 10W-30 CG-4

4X4 Motor Oil 10W/40 B3

Mobil 1 5W/50 B3

Mobil Delvac XP

Extra

10W/40 B3

BP

Visco 5000 5W/40 B3

Must have PLUS

in the name.

Vanellus C6 Global

Plus

10W/40 CH-4

Castrol

TXT Softec 5W/30 B3

Castrol GTX

Magnatec

10W/40 B3

FMX Magnatec 10W/30 B3

Shell

Helix Plus Eco 10 10W/30 B1

Helix Ultra 5W/40 B3

Caltex Havoline Full

Synthetic

5W/40 B3

Havoline Energy 5W/30 B1

Valvoline

Pro-Blend 10W/30 B3

Penrite

HPR5 5W/40 B3

HPR10 10W/50 B3

HOLDEN SERVICE TECHLINE___________________________________________________________OCTOBER, 2001

21

STEERING AND BODY VIBRATION

UES FRONTERA

(GROUP 01) TL0110-0103

PROBLEM DESCRIPTION

Some owners may comment on the presence

of steering wheel vibration or shimmy during

vehicle operation at medium to high speeds

Some customers may also report a knock from

the body mounts or a harsh ride.

NOTE: Depending on road conditions, some

vibration and harshness is felt through the

steering column, floor or seat when the vehicle

is driven at high speeds or in rough conditions.

POSSIBLE CAUSES:

The possible cause may be one or a

combination of the following:

1. Tyre shake and harmonic vibration

due to over-inflation or imbalance.

2. Body vibration that is transmitted

through the front body mounts

(located behind the front bumper),

due to insufficient isolation clearance

at the upper-half of the mounts.

SERVICE RECTIFICATION

Rectification for Possible Cause 1:

Test drive the vehicle to confirm the

customer’s concern.

Check if the vibration is present while driving on

a smooth surface in a straight line.

If yes inspect:

§ Tyre pressures

§ Wheel balance

§ Tyre condition for flat spots and out of

round.

Note: Tyre pressures, balance and condition

are usually not warrantable items. Wheel

balance is not warranty when the vehicle has

travelled greater than 5000 Km. Refer to the

tyre manufacturer for tyre warranty.

Rectification for Possible Cause 2.

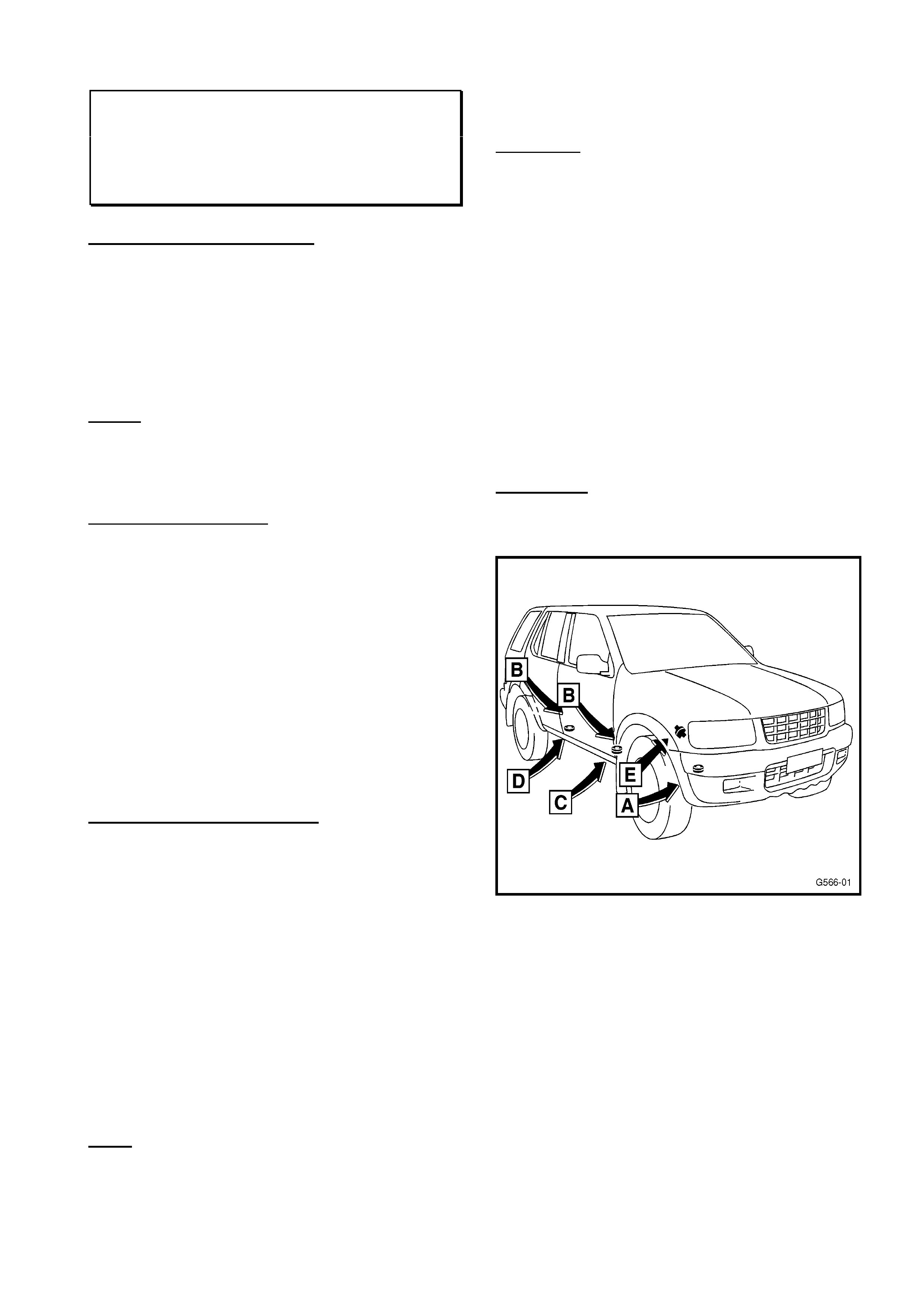

Summary:

In summary, this procedure requires the mount

clearance to be inspected at position A (fig. 1)

and, if required, adjusted according to the

outlined procedure.

The adjustment is achieved by adding two

shims between the body mount and body at

position C and one shim at position D (refer fig.

1).

As the clearance between the chassis and body

has been adjusted, the steering coupling then

requires realigning; this is inspected from

position E (refer Fig 1).

Important: The steering coupling must be

realigned after the body mount shims have

been installed.

Fig 1.

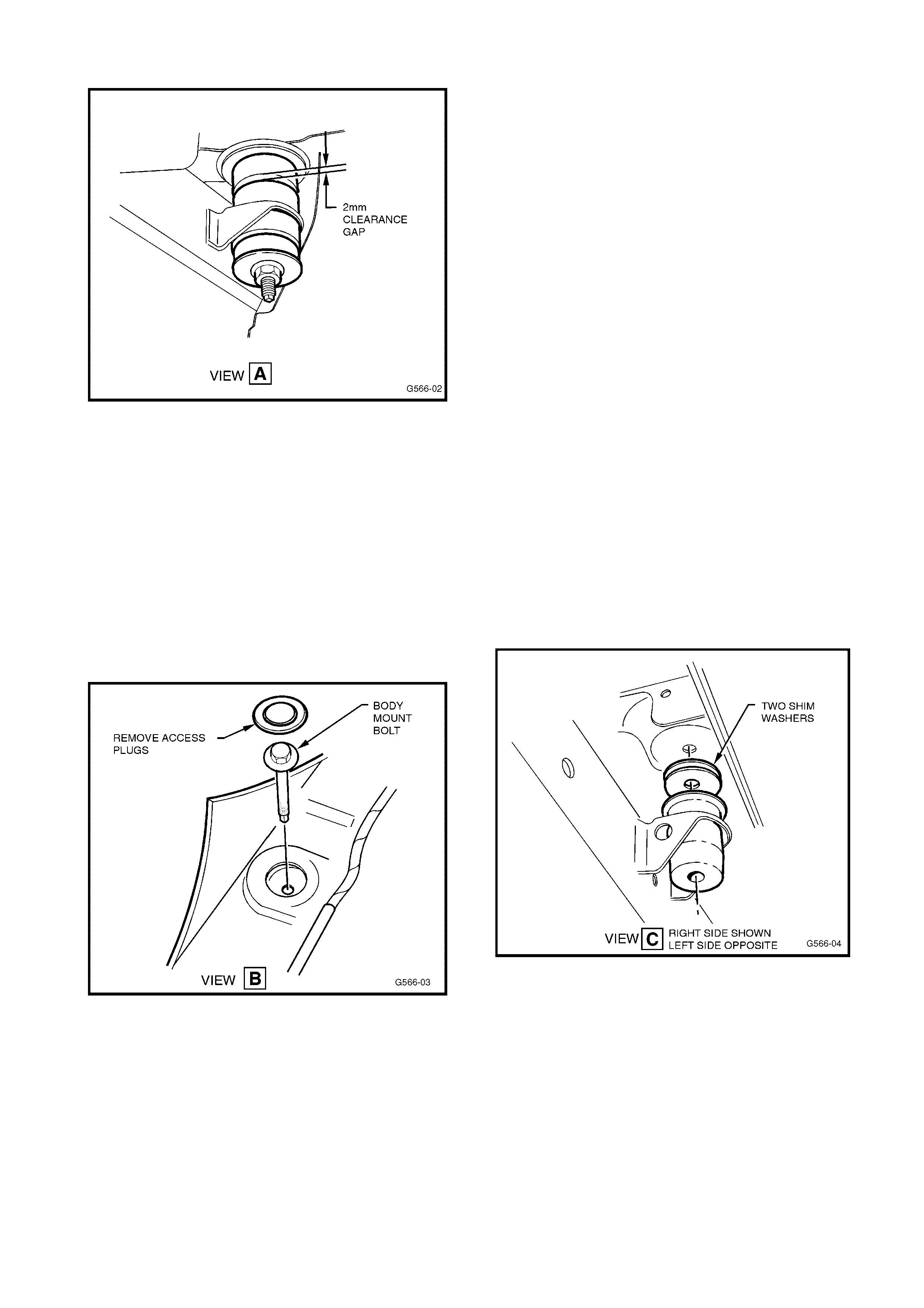

BODY MOUNT CLEARANCE-

INSPECTION AND CORRECTION.

1. Set the vehicle down on level

ground. This is necessary for the correct

reading of body mount clearances.

2. Inspect and measure the upper

clearance gap of both left and right No. 1

body mount located behind the front

bumper (refer fig. 2). View the mount

through the wheel arch; it is not

necessary to remove the bumper.

HOLDEN SERVICE TECHLINE___________________________________________________________OCTOBER, 2001

22

Fig. 2 (Refer fig. 1 for view location)

3. If the clearance gap is 2mm or more

then the body mount is within specification

and not the cause of this condition. Where

the clearance is less than 2mm proceed to

step 4.

4. Remove the front and rear plastic

doorsill kick panels, and lift the carpet.

Remove the No. 2 and No. 3 body mount

bolt access plugs (Fig. 3). Repeat this step

for the other side.

Fig. 3 (Refer fig. 1 for view location)

5. Loosen and remove the No. 2 & No. 3

body mount bolts through the access hole

along with the washer and nut underneath

the mount. Body mount No. 2 is at view C

in fig. 1 and Body mount No. 3 is at view D

in fig. 1.

6. Loosen the No. 1 body mount nut to

the end of the bolt’s thread, DO NOT

REMOVE THE NUT FROM THE BOLT.

This will provide sufficient movement of the

cab for the shims to be installed.

7. Partially lift the body away from the

chassis using a jack and suitable lifting

adaptor to protect the panel. Jack the body

sill panel at the mid-point of the front door.

Note: Only lift the body to the amount

required to install the shims. Lifting the

body an excessive amount may damage

other vehicle components.

8. Where the customer has reported a

knock emanating from the body mount

area (floor pan) the suspected mounts

should be lubricated with silicon grease.

The metal inner sleeve should be removed

from the mount and lightly coated with

rubber grease.

9. Add 2 shims to the top of No. 2 body

mount bushing (between the body and

mount); re-install the body mount bolt

through the access hole. Refit the bottom

nut making sure to hand start the nut (refer

fig. 4).

Fig. 4 (Refer fig. 1 for view location)

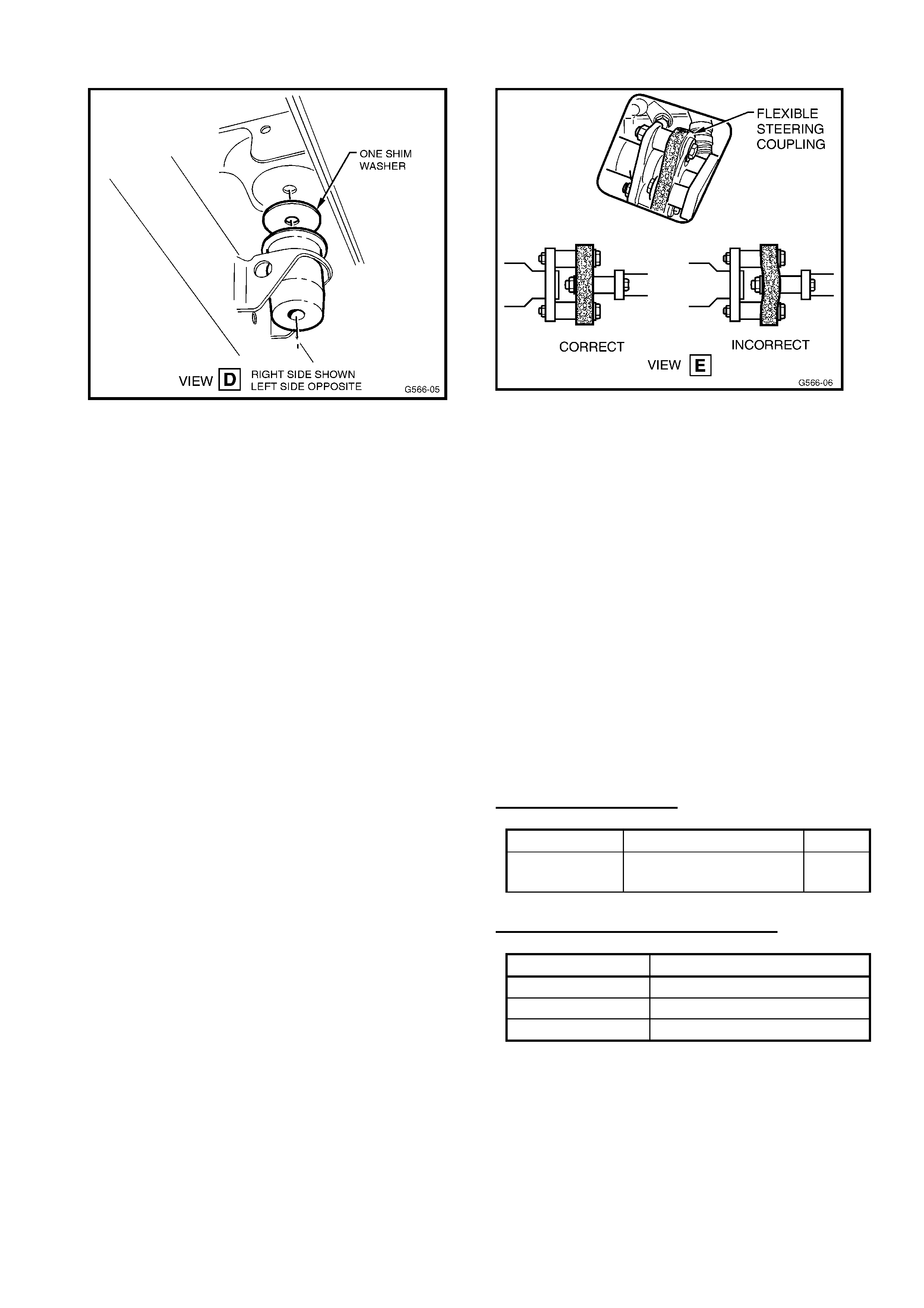

10. Add 1 shim to the top of No. 3

body mount bushing (between the

body and mount), re-install the body

mount bolt through the access hole,

refit the bottom nut making sure to

hand start the nut (Refer fig. 5).

HOLDEN SERVICE TECHLINE___________________________________________________________OCTOBER, 2001

23

Fig. 5 (Refer fig. 1 for view location)

11. Lower the body onto the chassis.

12. Torque the No. 2 and No. 3 body

mounts bolt and nut to specification: 50

N.m.

13. Re-tighten and torque the No. 1 body

mount bolt and nut to specification (50

N.m).

14. Repeat steps 5 through to 13 for the

opposite side.

15. Remove any body undercoating

residue from your hands prior to refitting

any interior parts.

16. Reinstall or secure the removed

interior access plugs , carpets and trims

on both sides

17. Verify the repair by re-measuring the

upper clearance gap of the No. 1 body

mount. Specification 2 mm or greater (Ref

step 2 & 3 on previous page).

Steering Coupling Alignment (Only

required after mount adjustment)

1. Inspect the alignment of the rubber

coupling in the second steering shaft.

The coupling can be seen in view E (fig.

6).

Fig 6 (Refer fig. 1 for view location)

An example of correct and incorrect

alignment is shown in figure 6.

2. Loosen the pinch bolt of the steering

shaft, which is under the bonnet on the

upper end of the second steering shaft

assembly.

3. Using a pry bar, through the service

cut out (View E), adjust the coupling to

the correct position.

4. Re-tighten and torque the steering

shaft pinch bolt (31 N.m).

5. Confirm the steering coupling

alignment is correct.

PARTS INFORMATION

Part No.: Description: Qty:

8970379930 Washer – Body

Mounting Washer

6

WARRANTY CLAIM INFORMATION

Description Body Mount Shims

Labour Op. No. B000156

Time 1.0 hr

Failure Code 36

HOLDEN SERVICE TECHLINE___________________________________________________________OCTOBER, 2001

14

(CRACKING)

ALL ISUZU V6 ENGINES

(GROUP 6) TL0110-0601

PROBLEM DESCRIPTION

Customers may report that the engine runs

rough or makes a “hissing sound”.

The inlet manifold to head gasket may be

cracked due to stresses caused by heat

expansion and contraction.

PRODUCTION RECTIFICATION

A revised inlet manifold has been introduced

in production from the following breakpoint.

ENGINE No.

845194

SERVICE RECTIFICATION

Replace the inlet manifold gasket as per the

appropriate workshop manual.

Note: There is no need to separate the inlet

manifold into two halves unless the common

chamber gasket is suspected to be leaking.

Please PIR any post breakpoint failures on all

vehicle models fitted with this engine.

Indicate if the vehicle is fitted with an

approved LPG system (LPG Rodeo only).

PARTS INFORMATION

Part No.: Description: Qty:

8972375380 Gasket – Inlet

Manifold to

Cylinder Head

2

WARRANTY CLAIM INFORMATION

Description Gasket, Intake - Replace

Labour Op. No. J020700

Time 1.8 hr

Failure Code 42

INLET MANIFOLD GASKET LEAKS

HOLDEN SERVICE TECHLINE________________________________________________________NOVEMBER, 2001

24

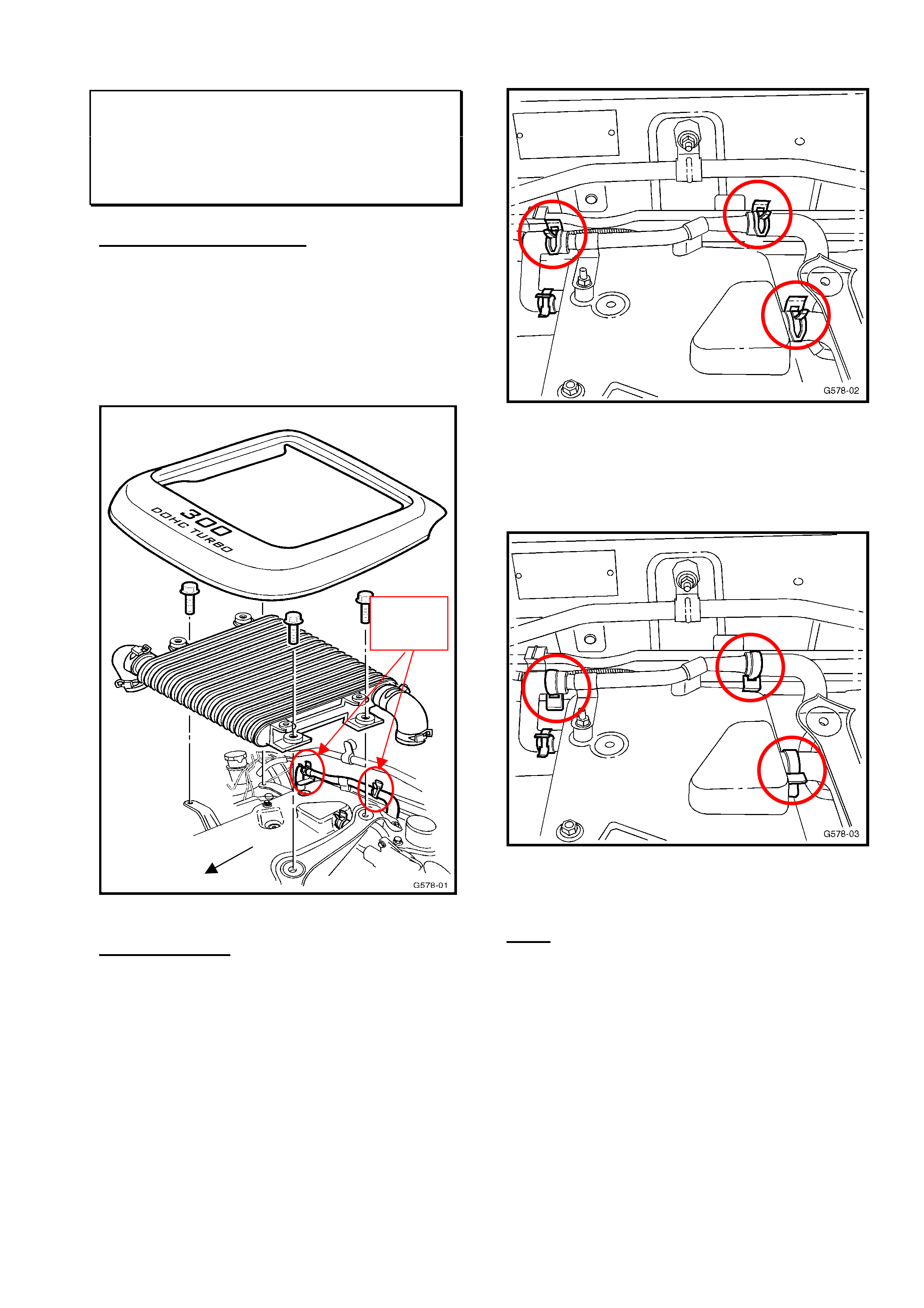

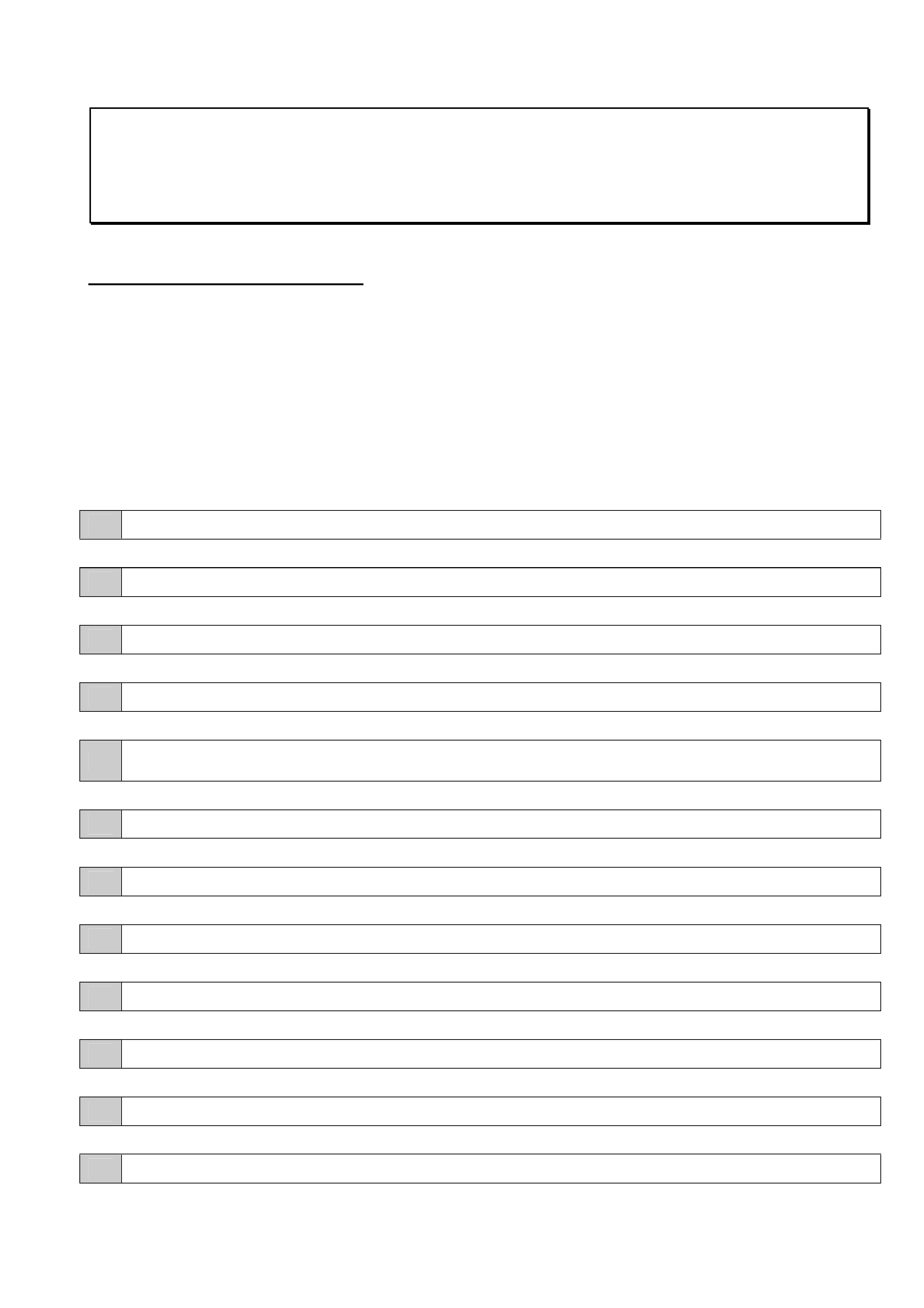

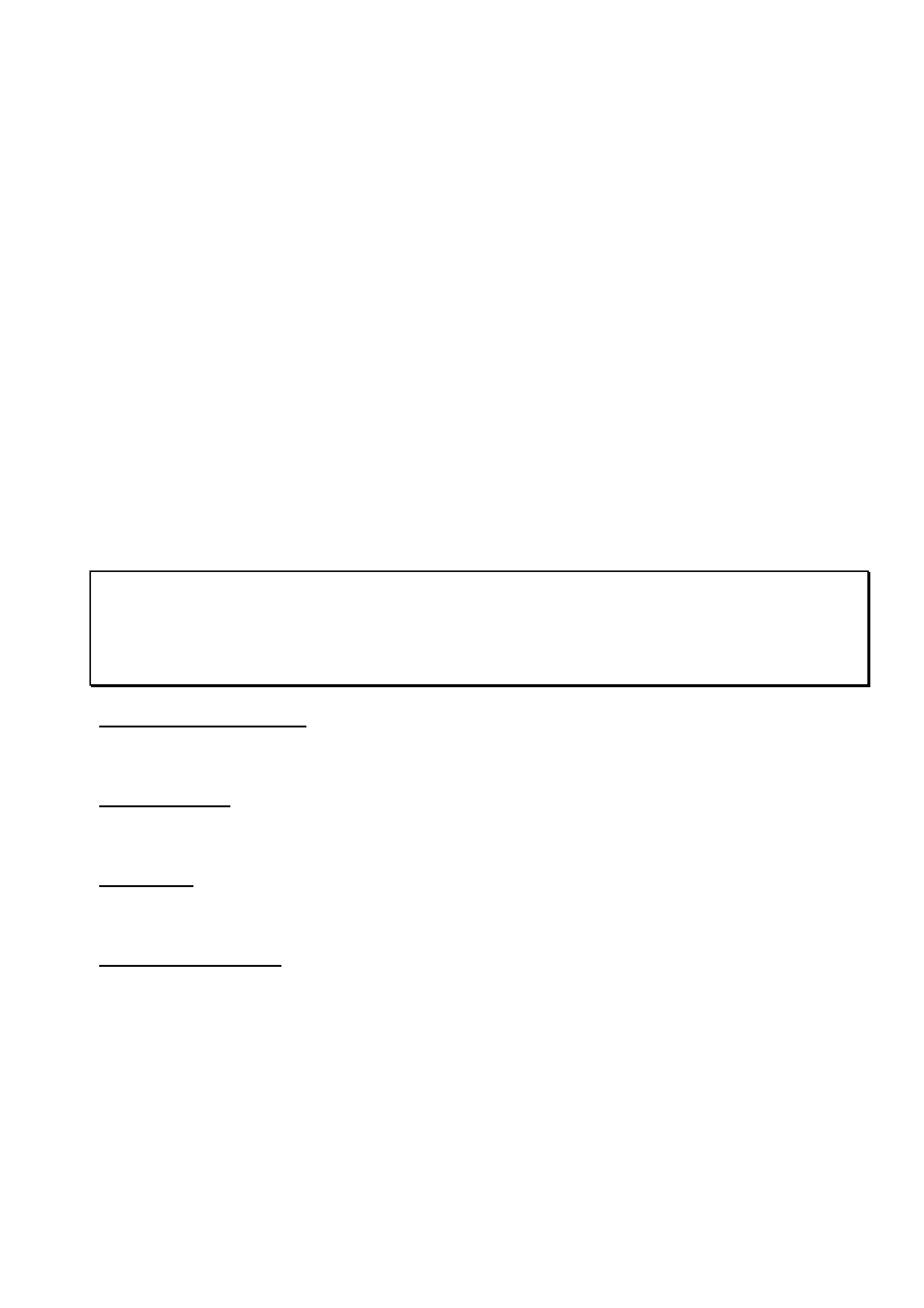

INTERCOOLER DAMAGE (Servicing)

JACKAROO DIESEL (4JX1)

(GROUP 6A) TL0111- 6A02

PROBLEM DESCRIPTION

Damage to the intercooler will occur when the

hose clamps for the engine ventilation system

are installed with the ears pointing upwards.

When installed in this position the hose clamp

ears will wear through the intercooler causing

an air leak.

Fig. 1

RECTIFICATION

When reinstalling the intercooler during

service or repairs, ensure the ears on all hose

clamps are facing downward as shown in

Fig. 3.

Fig 2.

INCORRECT CLAMP POSITION

Fig. 3.

CORRECT CLAMP POSITION

Note:

When repairing or servicing a diesel Jackaroo

do not place tools or parts on the intercooler

as the cooling fins could be damage.

A

rea of

Contact

Front

HOLDEN SERVICE TECHLINE________________________________________________________NOVEMBER, 2001

25

KEYLESS ENTRY REMOTE PROGRAMMING

FRONTERA

(GROUP 12) ‘UPDATE’ TL0111-1205

Programming Additional Keypads

• This procedure is carried out to program additional remote keypads into the system.

• The door opening and ignition key cycles should be committed to memory* before attempting this

procedure.

*It is extremely difficult to complete this procedure within the time constraints, unless the

sequence is memorised.

• A maximum of four keypads may be programmed into the system at any one time. Programming

a fifth keypad will result in the erasing of the first keypad programmed into the module.

NOTE: Steps 2 to 6 must be performed within 15 seconds

1 ENSURE all doors are closed, the key is in the ignition switch & the ignition is in the OFF position.

2 OPEN the driver door.

3 CYCLE the ignition switch from ‘OFF’ — ‘ON’ — ‘OFF’ 3 times.

4 CLOSE, then OPEN the driver door 2 times.

5 CYCLE the ignition switch from ‘OFF’ — ‘ON’ — ‘OFF’ 3 times, and remove key from the

ignition switch.

6 CLOSE, then OPEN the driver door 1 time.

7 CONFIRM a ‘LOCK’ — ‘UNLOCK’ response by watching the driver door snib button.

8 OPERATE the ‘LOCK’ and ‘UNLOCK’ buttons on the new keypad 3 times.

9 CONFIRM a ‘LOCK’ — ‘UNLOCK’ response by watching the driver’s door snib button.

10 OPERATE the ‘LOCK’ and ‘UNLOCK’ buttons on the new keypad 2 times.

11 CONFIRM a ‘LOCK’ — ‘UNLOCK’ response by watching the driver’s door snib.

12 The new keypad ID has been accepted.

HOLDEN SERVICE TECHLINE________________________________________________________NOVEMBER, 2001

26

NOTE:

• If steps 2 – 6 are not completed within the specified time, the programming procedure will fail.

• If the confirmation response is not received at Step 7, the programming procedure has failed.

• Should the door lock snib cycle 3 times at any stage of this procedure, the control unit has

aborted the programming sequence.

• Steps 1 to 12 must be performed for each individual keypad.

Hint: There are two likely causes for the system not confirming a ‘Lock’ – ‘Unlock’ at step 7, these

should be double checked before commencing with further diagnostics:

1. The programming sequence has not been completed within the specified time (confirm the time

with a stopwatch if unsure).

2. All doors (including tailgate) are not closed during the procedure as specified in step 1.

When performing the key programming procedure it is recommended that all electrical features be

switched off (dome light in the ‘door’ position).

CRUISE CONTROL SURGE

RODEO – (MY 2001)

(GROUP 12) TL0111-1206

PROBLEM DESCRIPTION

There have been a number of reports from dealers of surging when genuine accessory cruise

control is operated on a Model Year 2001 Rodeo.

RECTIFICATION

The cruise control module has been re-calibrated to be compatible to vehicles both pre and post MY

2001.

SERVICING

The updated parts/kit are also used when repairing or fitting a cruise control on a vehicle that is pre

MY 2001.

PARTS INFORMATION

The part number for the module and kit has not changed. All parts in dealer stock are being

returned to HSPO for re-calibration (Refer Parts Bulletin M556). Modules that have been re-

calibrated are fitted with a sticker denoting the module part number (92143384). Previously there

was no sticker on the module.

HOLDEN SERVICE TECHLINE________________________________________________________NOVEMBER, 2001

27

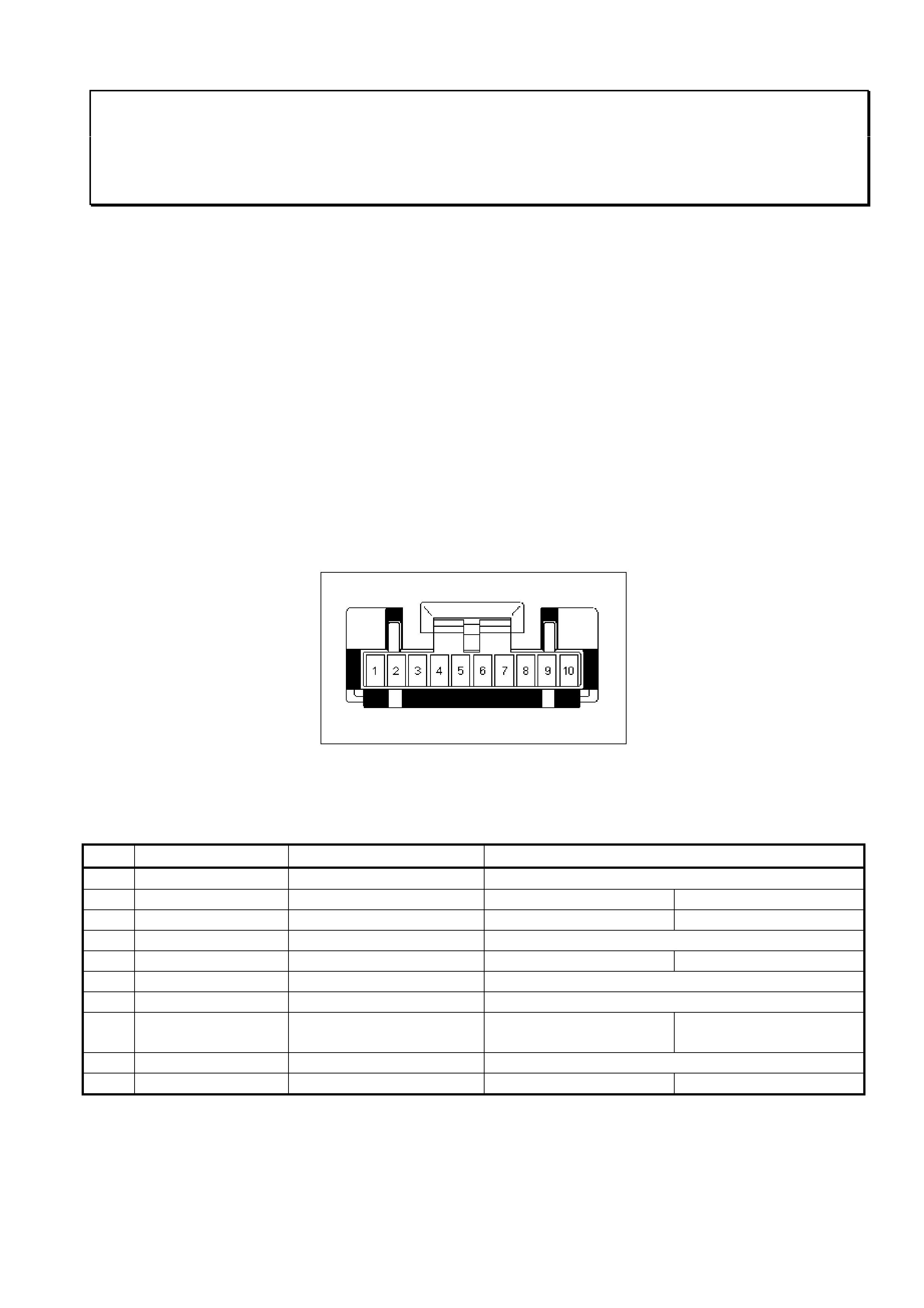

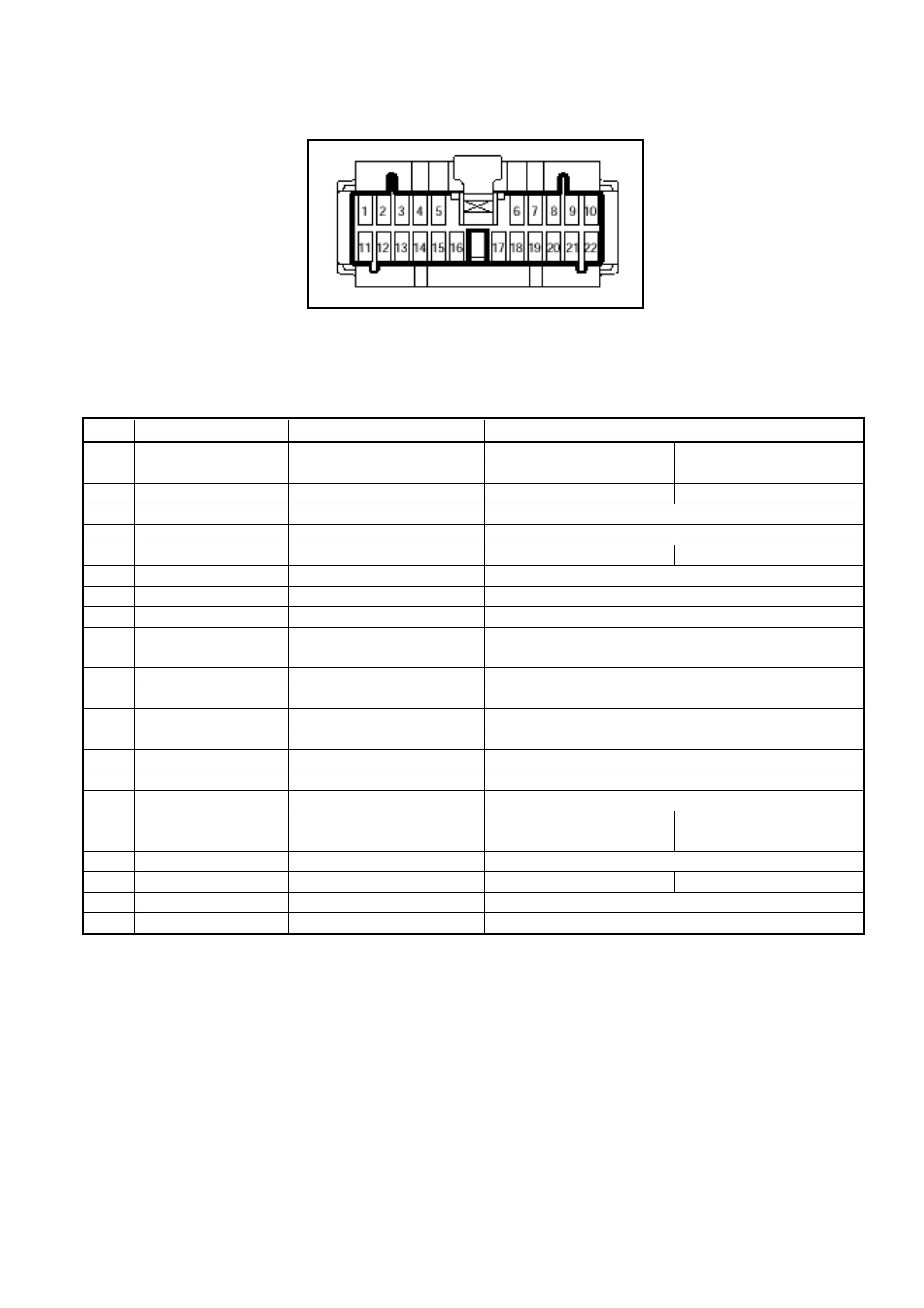

KEYLESS ENTRY - CONTROL UNIT HARNESS PINOUTS

FRONTERA (1999-2000 AND 2001-2002)

(GROUP 12) TL0111-1207

The keyless entry module harness pinouts and specifications for the 99-00 and 01-02 Frontera are

provided in this techline to assist in the diagnosis system faults.

Please refer to SIP if you are not familiar with the system of terminal numbering and connector

identification used by Isuzu.

It is recommended to use the pin location in the harness connector to identify the location of each

wire.

The keyless entry system is designed to operate with the key removed from the ignition therefore, the

following pin checks should be completed with the key removed from the ignition (except for ‘Power-

Acc’ and ‘Ignition Key Detect’).

MY1999-2000 UES Keyless Entry Harness

Keyless Entry Control Unit Harness Connector

Pinout

PIN WIRE COLOUR ITEM SPECIFICATION

1 – – –

2 Red/Green Dome Lamp Doors Open: <1.5v Doors Closed: >10v

3 Light Green Tailgate Switch Tailgate Open: 0.0v Tailgate Closed: 12v

4 Light Green/Red Door 'Lock' Switch 'UNLOCK' to 'LOCK': 0.0v-1.2v-0.0v

5 Red Door Courtesy lamps Doors Open: <1.5v Doors Closed: >10v

6 Black Ground Less than 1.0 Ohm

7 Red/Blue Door 'UnLock' Switch 'LOCK' to 'UNLOCK': 0.0v-1.2v-0.0v

8 Red/Yellow

Power - Acc. (Fuse C-

2)

Ignition Key 'OFF':

0.0v

Ignition Key 'ACC':

12v

9 Green/Yellow Power (Fuse C-19) Battery voltage at all times

10 Blue Ignition Key Detect Key in lock: 12v Key out of Lock: 0.0v

HOLDEN SERVICE TECHLINE________________________________________________________NOVEMBER, 2001

28

MY2001-2002 UES Keyless Entry Harness

Keyless Entry Control Unit Harness Connector

Pinout

PIN WIRE COLOUR ITEM SPECIFICATION

1 Red Doors Doors Open: 0.0v Doors Closed: 12v

2 – – – –

3 Blue Ignition Key Detect Key in lock: 12v Key out of Lock: 0v

4 – – –

5 Light Green/Red Door 'Lock' Switch 'UNLOCK' to 'LOCK': 0.0v-1.2v-0.0v

6 Light Green Tailgate Switch Tailgate Open: 0.0v Tailgate Closed: 12v

7 – – –

8 – – –

9 – – –

10 Light

Green/White Power (Fuse C-7) Battery voltage at all times

11 – – –

12 – – –

13 – – –

14 – – –

15 Red/Blue Door 'UnLock' Switch 'LOCK' to 'UNLOCK': 0.0v-1.2v-0.0v

16 – – –

17 Black Ground Less than 1.0 Ohm

18 Brown/White Power - Acc. (Fuse C-

19) Ignition Key 'OFF': 0v Ignition Key 'ACC':

12v

19 – – –

20 Red/Green Dome Lamp Doors Open: <1.5v Doors Closed: >12v

21 Brown Turn Indicators Indicators Operating: 0.0v-12v-0.0v

22 – – –