2

20

00

03

3

C

CA

AM

MP

PA

AI

IG

GN

N

B

BU

UL

LL

LE

ET

TI

IN

NS

S

© 2006 GM Holden LTD. A.B.N. 84 006 893 232

Service Department

A “HOLDEN” Product.

BRISBANE SYDNEY MELBOURNE ADELAIDE PERTH

PRODUCT CAMPAIGN BULLETIN

03-H-02

October 28, 2003

SUBJECT: REPLACEMENT OF INCORRECT COMPLIANCE PLATE

MODELS AFFECTED: RA RODEO

This bulletin announces the initiation of a safety recall campaign to install

the correct compliance plate to some RA Rodeo model vehicles.

DESCRIPTION OF DEFECT

There have been some RA Rodeo vehicles retailed where the compliance

plate has incorrect information in regard to the seating capacity of the

vehicle.

To correct this situation, Holden has initiated this recall action to ensure

that every affected vehicle is updated to include the correct compliance

plate in accordance with the Australian Design Rule requirements.

AFFECTED VEHICLES

The affected vehicles are as per the list in Appendix A.

ACTION REQUIRED BY DEALERS

1.

2.

3.

4.

5.

6.

7.

8.

9.

Confirm vehicle VIN is affected by checking list as per Appendix A.

Confirm vehicle has not previously been reworked. (ie Identified by an

‘X’ in the A-2 co-ordinate of the “Vehicle Service History” label or

application of “03-H-02 Campaign Completed” label).

If vehicle has not been reworked, proceed with campaign.

Organise a vehicle booking. (Allow 5 days for shipping of the

replacement compliance plate)

Request the replacement compliance plate from SALMAT using the

Salmat Material Order Form. Note: Booking date will be required to

order a replacement compliance plate. Refer to Appendix C.

Remove originally installed compliance plate and install plate supplied

by Salmat. Refer Replacement Instruction Appendix D.

Affix a Campaign Completed Label and a Vehicle Service History Label

as specified in the section titled ‘Campaign Completion Identification’.

Return incorrectly stamped (replaced) compliance plate immediately to

Salmat in the supplied pre-paid satchel.

Submit a warranty claim. Refer “Warranty Claim Information”.

CUSTOMER NOTIFICATION

Owners of vehicles affected by this recall campaign will be contacted directly by letter from

Holden.

The letter provides details of the recall campaign and requests the customer to contact their

Holden Retailer to make a service booking to have the appropriate work carried out. Refer

to Appendix B for a draft copy of the customer letter.

CAMPAIGN COMPLETION IDENTIFICATION

All campaigned vehicles must have:

1. A Campaign Completed label applied to the right hand front ‘A’ pillar, between the

hinges, with details of the campaign, 03-H-02, Dealership code and date legibly entered

on the label with a permanent ink pen.

AND

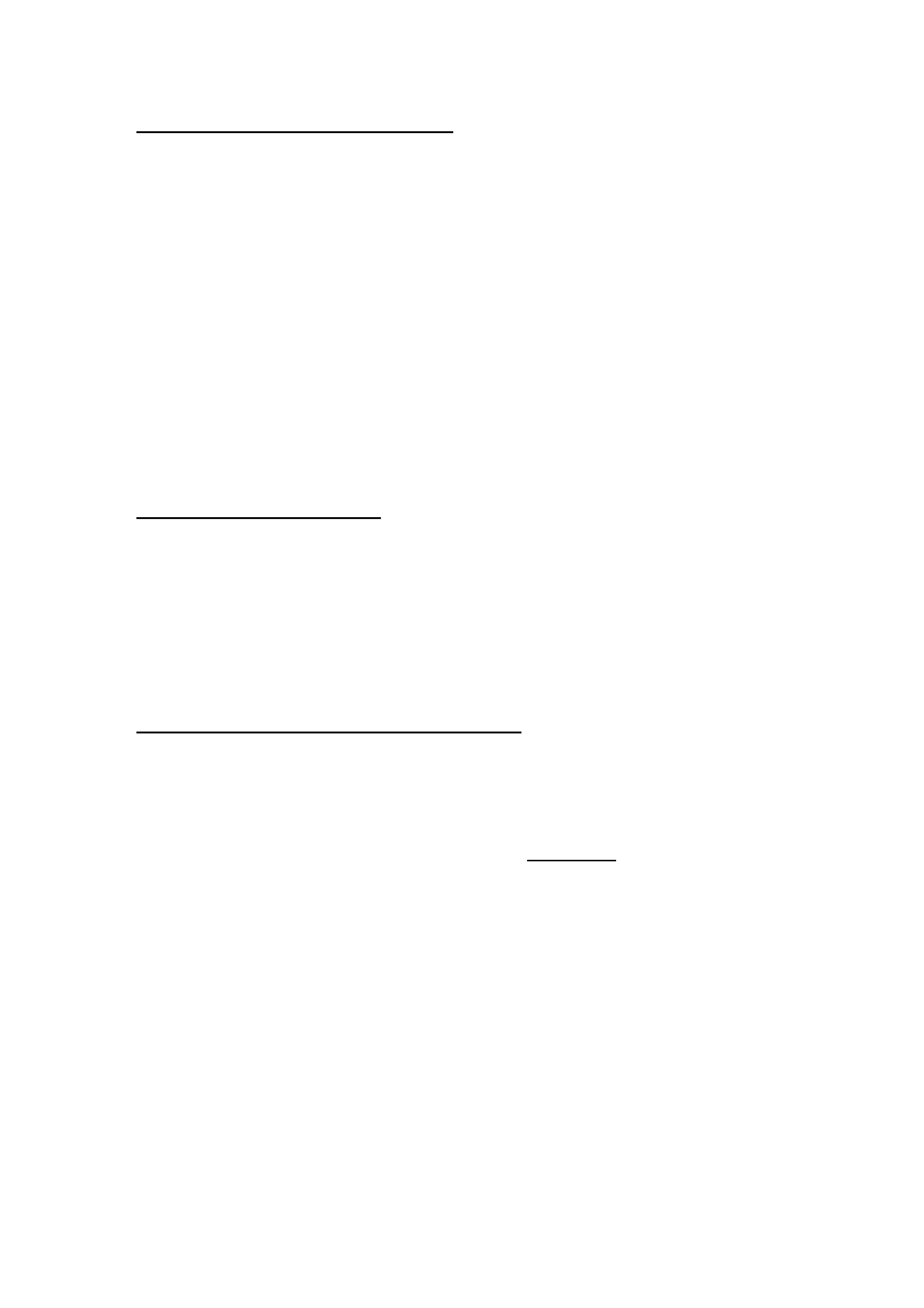

2. For additional identification, mark an “X” at the A-2 co-ordinate of a Vehicle Service

History Label and apply to the outer edge on the left-hand side of the glovebox. Refer to

Figure 2 below.

X

Figure 2

Extra Campaign Completed and Vehicle Service History labels are available free of charge

from Moore Business Systems.

• For Campaign Completed Labels Quote stock no. SD 28156 on a Moore Business

Systems ‘Packaged Goods’ order form for a pack of 100 labels.

• For Vehicle Service History Labels quote stock no. SD 28177 on a Moore Business

Systems ‘Packaged Goods’ order form for a pack of 100 labels.

Fax the order form to Moore Business Systems on Facsimile: (03) 9270 8925

Should you need to follow-up on a placed order, contact Liz Papalambidis on telephone

number (03) 9270 8788.

10/03/04

3of 7

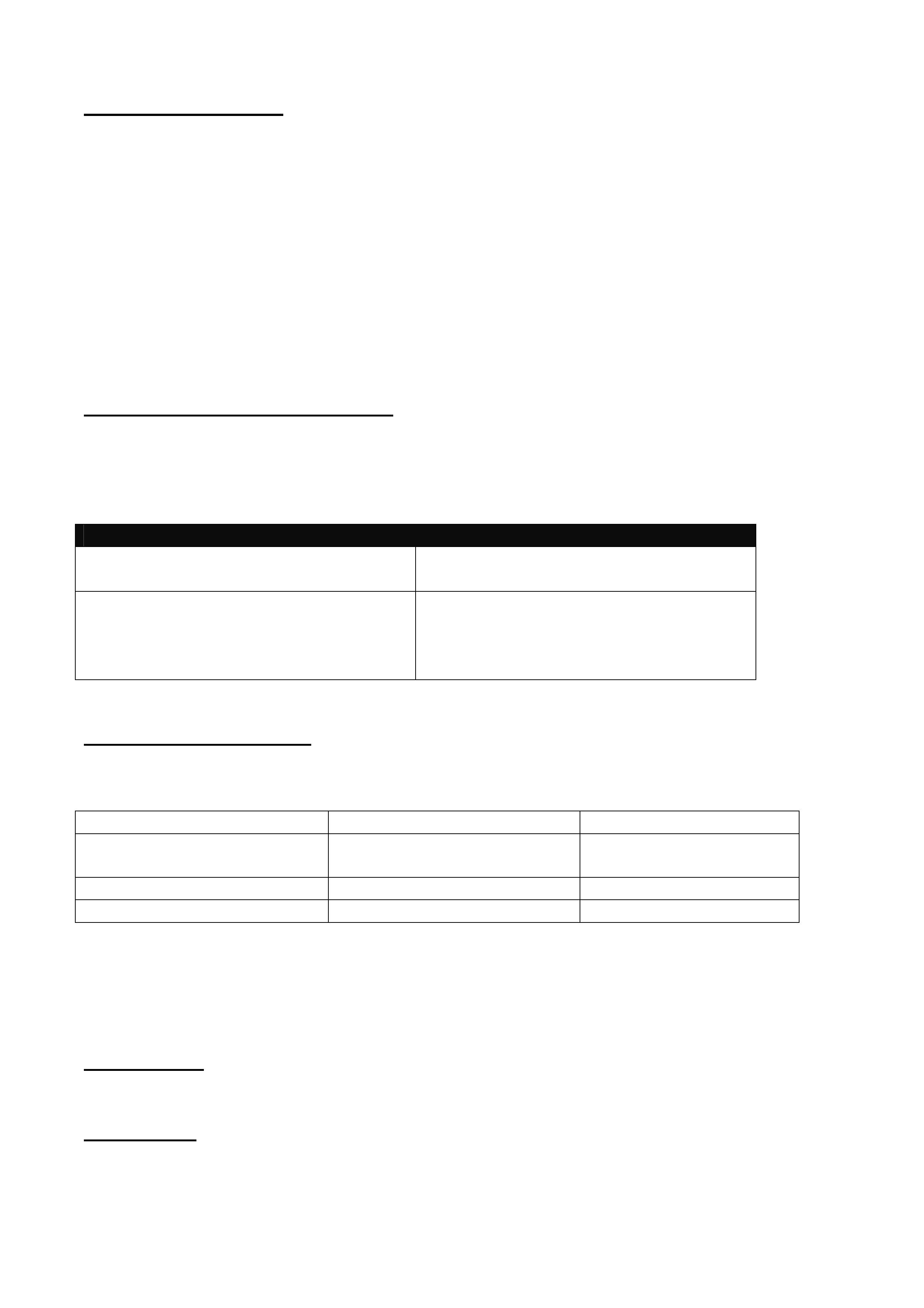

PARTS INFORMATION

A specific replacement compliance plate is available for each affected vehicle. Once a

customer booking is made, order the replacement Compliance Plate for the booked vehicle

by completing the Material Order Form, (refer to Appendix C) and faxing it to SALMAT. The

fax number is shown on the Material Order form.

The replacement compliance plate will be forwarded to your retailer premises by

“Registered Mail.” Please note that to maintain Compliance Plate security, the person

requesting the replacement plate will be required to sign for receipt of the plate at the

delivery address (retailer premises) or at the local Post Office if unavailable to sign at the

Retailer premises.

Once received, store the replacement plate in a safe and secure location to avoid loss or

damage.

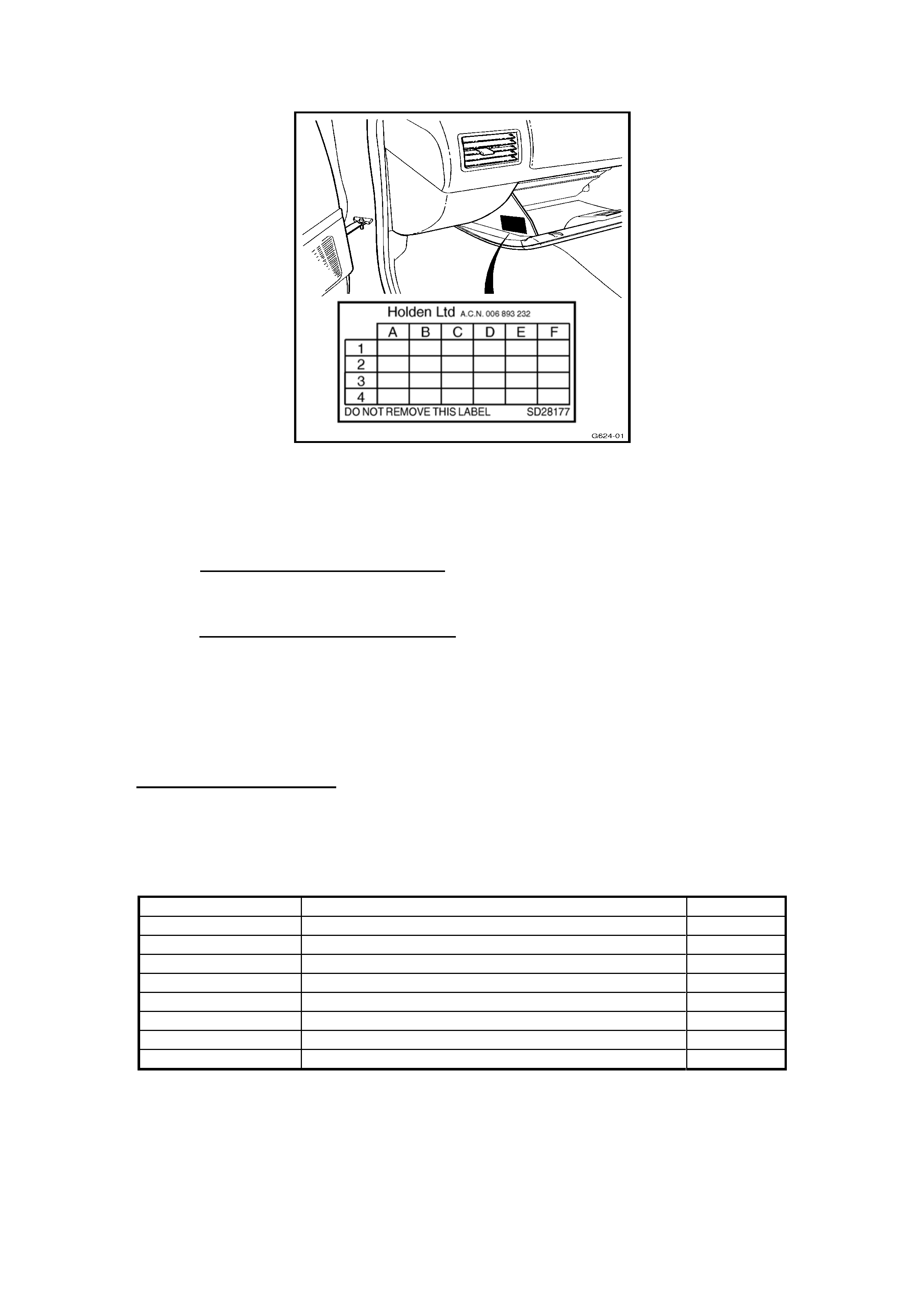

WARRANTY CLAIM INFORMATION

On completion of campaign action, retailers are requested to submit a warranty claim using

the Labour Operation Number specified below.

Warranty Claim Information

Description

Replace Compliance Plate

Labour Operation No.:

Standard Time:

Failure Code:

Case Type:

T380501

0.5 hours

96

08

CONTACT INFORMATION

For further information or clarification on this recall campaign please contact the relevant

person below.

CONTACT NAME CONTACT NUMBER

General enquiries Alex Holt

Gary Brunet

(03) 9647 7619

(03) 9647 2463

Parts related enquiries Salmat (03) 9358 2990

Warranty related enquiries Warranty Administration (03) 9647 2401

J. K. Hoffman

General Service Manager

Attachments

Appendix A Affected Vehicle List

Appendix B Customer Letter- Draft

Appendix C Material Order Form

Appendix D Replacement Instruction

10/03/04

4of 7

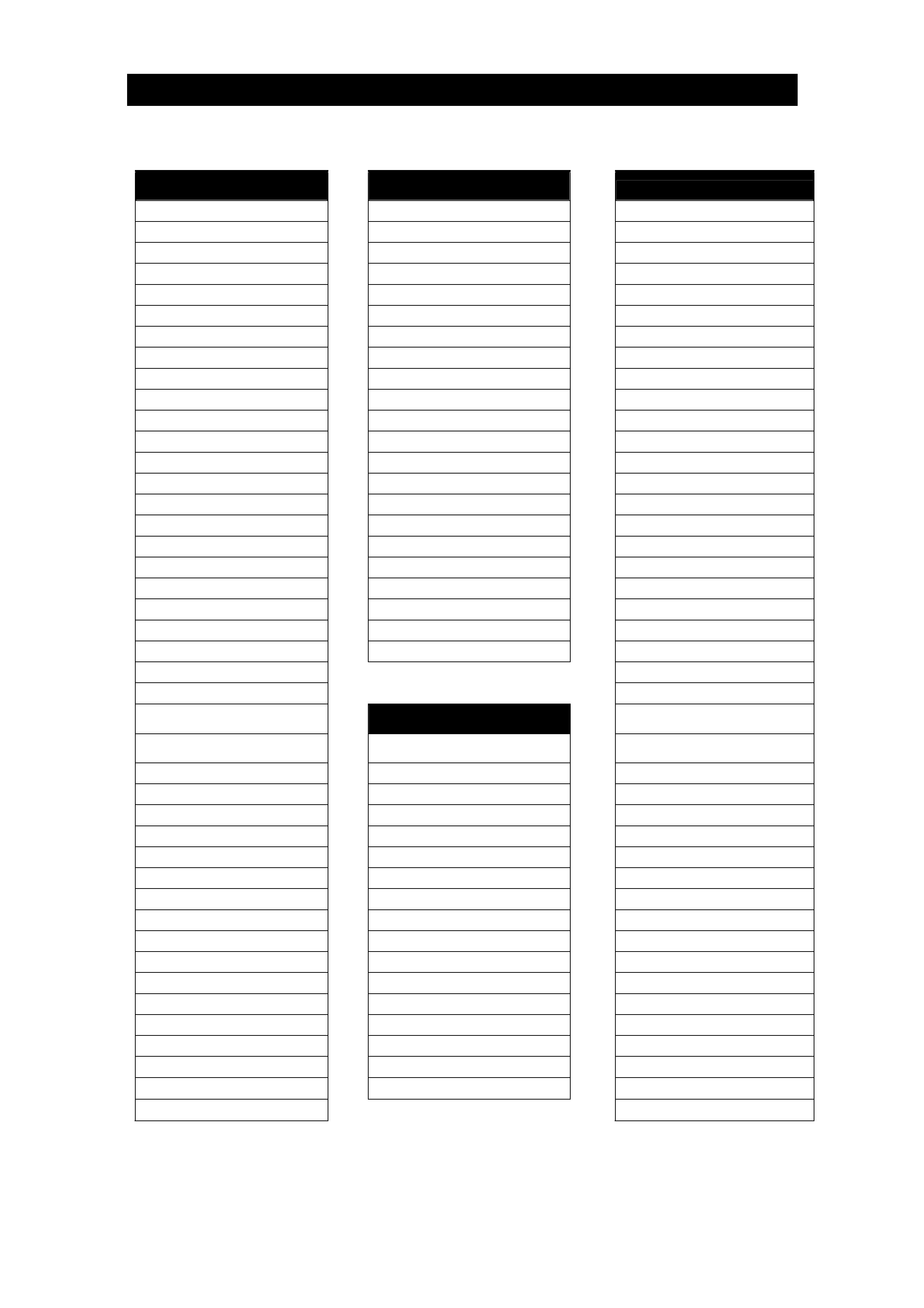

APPENDIX A – Affected Vehicle List

MPATFR32J4H500135 MPATFS77J4H500511 MPATFS77J4H503401

MPATFR26J4H500203 MPATFS77J4H500515 MPATFS77J4H503402

MPATFR26J4H500204 MPATFR26J4H500516 MPATFS77J4H503404

MPATFR26J4H500208 MPATFS77J4H500540 MPATFR26J4H503450

MPATFR26J4H500211 MPATFS77J4H500541 MPATFR26J4H503451

MPATFR26J4H500215 MPATFS77J4H500542 MPATFR26J4H503595

MPATFR26J4H500231 MPATFR26J4H500543 MPATFR32J4H503682

MPATFR26J4H500241 MPATFS77J4H500544 MPATFR32J4H503725

MPATFR26J4H500255 MPATFS77J4H500545 MPATFS77J4H503727

MPATFR26J4H500256 MPATFS77J4H500546 MPATFS77J4H503731

MPATFR26J4H500260 MPATFS77J4H500548

MPATFR26J4H500261 MPATFR26J4H500549

MPATFR26J4H500277 MPATFR26J4H500550

MPATFR26J4H500279 MPATFR26J4H500552

MPATFR26J4H500292 MPATFR26J4H500553

MPATFR26J4H500311 MPATFR26J4H500555

MPATFR26J4H500314 MPATFR26J4H500558

MPATFR26J4H500315 MPATFR26J4H502546

MPATFR26J4H500323 MPATFR26J4H502551

MPATFR26J4H500324 MPATFS26J4H502565

MPATFR26J4H500325 MPATFR26J4H502616

MPATFR26J4H500326 MPATFS26J4H502630

MPATFR26J4H500331 MPATFR26J4H502632

MPATFR26J4H500332 MPATFR26J4H502675

MPATFS77J4H500334 MPATFR26J4H502737

MPATFR26J4H500348 MPATFR26J4H502790

MPATFS77J4H500350 MPATFR26J4H502846

MPATFS77J4H500353 MPATFR26J4H502868

MPATFS77J4H500357 MPATFR26J4H502877

MPATFS77J4H500359 MPATFR26J4H502905

MPATFS77J4H500367 MPATFR26J4H502915

MPATFS77J4H500376 MPATFR26J4H502922

MPATFS77J4H500380 MPATFR26J4H502927

MPATFS77J4H500389 MPATFR26J4H502977

MPATFS77J4H500414 MPATFR26J4H503028

MPATFS77J4H500425 MPATFR77J4H503049

MPATFS77J4H500431 MPATFR26J4H503078

MPATFR26J4H500434 MPATFS77J4H503081

MPATFR26J4H500438 MPATFS77J4H503099

MPATFS77J4H500442 MPATFR26J4H503105

MPATFS77J4H500448 MPATFR26J4H503180

MPATFS77J4H500452 MPATFR26J4H503182

MPATFS77J4H500456 MPATFR26J4H503194

MPATFS77J4H500459 MPATFR26J4H503234

MPATFS77J4H500466 MPATFS77J4H503320

MPATFS77J4H500471 MPATFS77H4H503345

MPATFS77J4H500472 MPATFR77J4H503389

MPATFS77J4H500473 MPATFR26J4H503395

MPATFS77J4H500474 MPATFR26J4H503397

MPATFS77J4H500478 MPATFS77J4H503398

NOTE:

This affected vehicle listing

is sorted in serial number

sequence in ascending

order.

Read the last 6 digits to

quickly find or confirm an

affected vehicle

10/03/04

5of 7

APPENDIX B - Draft – Customer Letter

VEHICLE SAFETY RECALL

Dear Holden Customer,

As part of Holden’s ongoing commitment to customer satisfaction, we have initiated

a Vehicle Recall Campaign affecting some RA Rodeo model vehicles.

Holden has been made aware that an incorrect compliance plate has been fitted to

some of these vehicles.

In these cases the compliance plate does not specify the correct seating capacity

for the vehicle. It is an Australian Design Rule requirement that the seating

capacity information is on the compliance plate.

To ensure the compliance plate includes the correct seating capacity for your

vehicle, the compliance plate needs to be replaced.

Our records show that your Holden vehicle was manufactured with the incorrect

compliance plate. It is therefore necessary for you to make a booking, at your

convenience, with a Holden Retailer of your choice to have the correct compliance

plate fitted.

Work will be carried out free of charge and can be completed while you wait,

provided the necessary arrangements have been made with a Holden Retailer.

If you should have any questions, please contact your retailer or call the Holden Recall

and Rework Assistance Centre on 1800 632 826, where we will be pleased to assist.

Thank you for your attention to this matter. Please accept our apologies for any

inconvenience caused to you.

Yours Sincerely

David McMurray

Manager Customer Assistance

10/03/04

6of 7

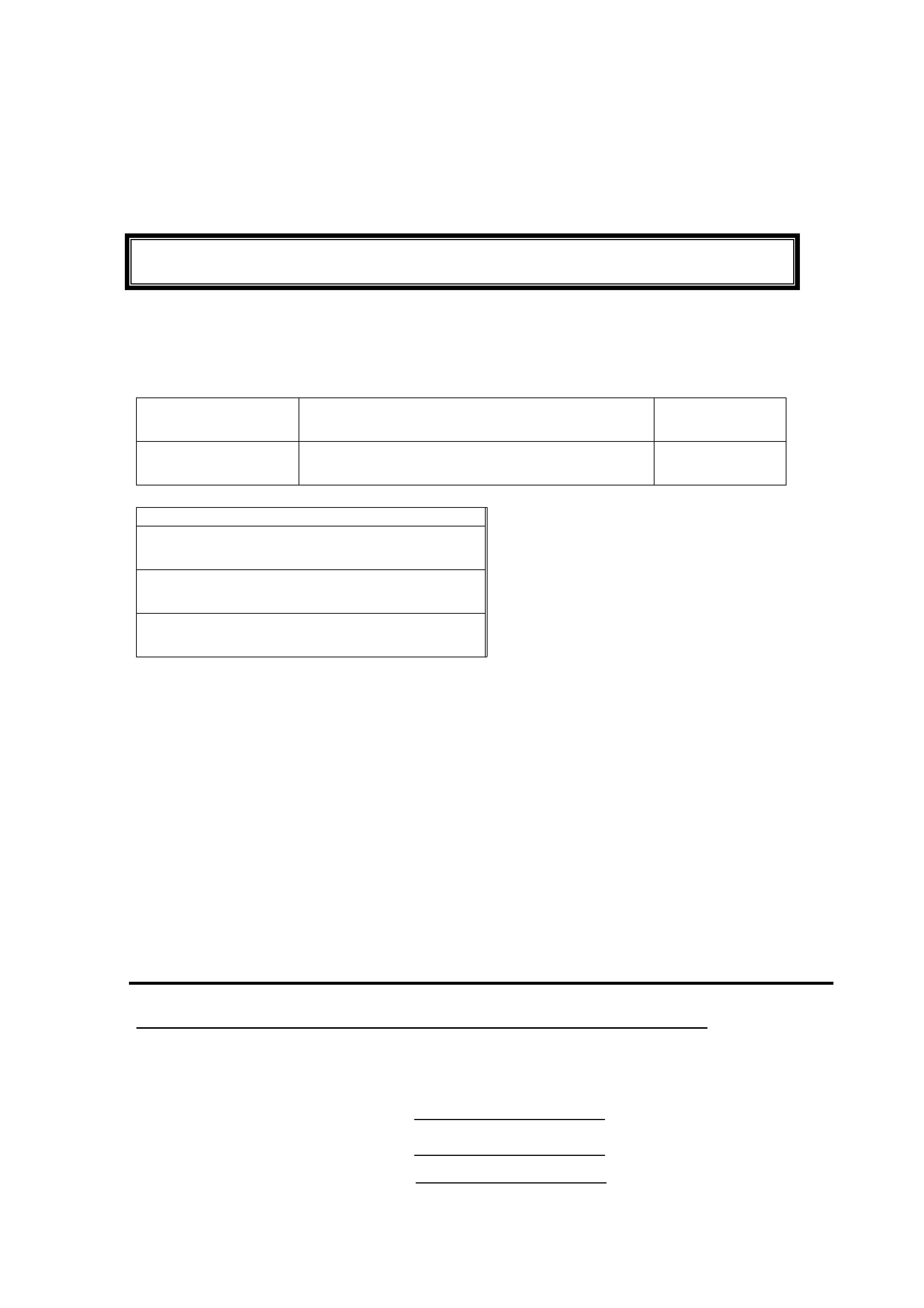

APPENDIX C – SALMAT MATERIAL ORDER FORM

RECALL CAMPAIGN 03-H-02

RA Rodeo Compliance Plate Replacement

Fax This Form To: Salmat - (03) 9358 2999

Please supply the replacement RA Rodeo Compliance Plate for the vehicle shown below

IMPORTANT: Only order parts when a customer has supplied the ISO VIN and confirmed a

booking date. ONLY 1 compliance plate can be ordered per Order Form.

Date _____________________

Retailer Code: _____________ Retailer Name:________________________

Retailer Address: _______________________________________________

Ph. No _________________________Fax No:_________________________

Name of person to receive

replacement Compliance Plate ______________________________

Via Registered Mail (Please print name clearly)

Vehicle ISOVIN Customer Booking Date

SALMAT USE ONLY

Retailer Order Acknowledgement Details (fax back to retailer same day)

Date Order Received Date Dispatched ___________________

Replacement

Compliance Plate

10/03/04

7of 7

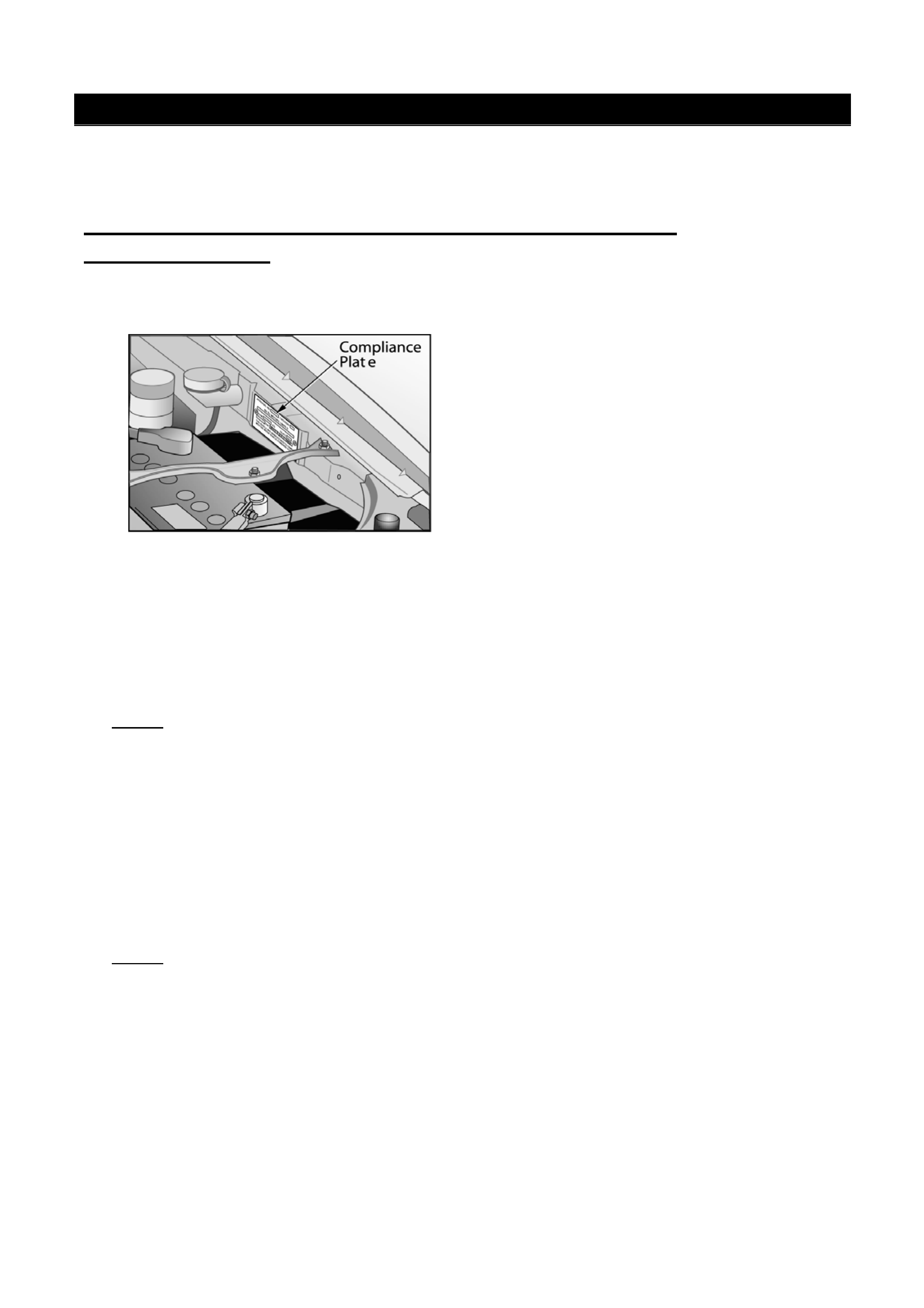

APPENDIX D – REPLACEMENT INSTRUCTION

RA RODEO COMPLIANCE PLATE REPLACEMENT

INSTRUCTIONS

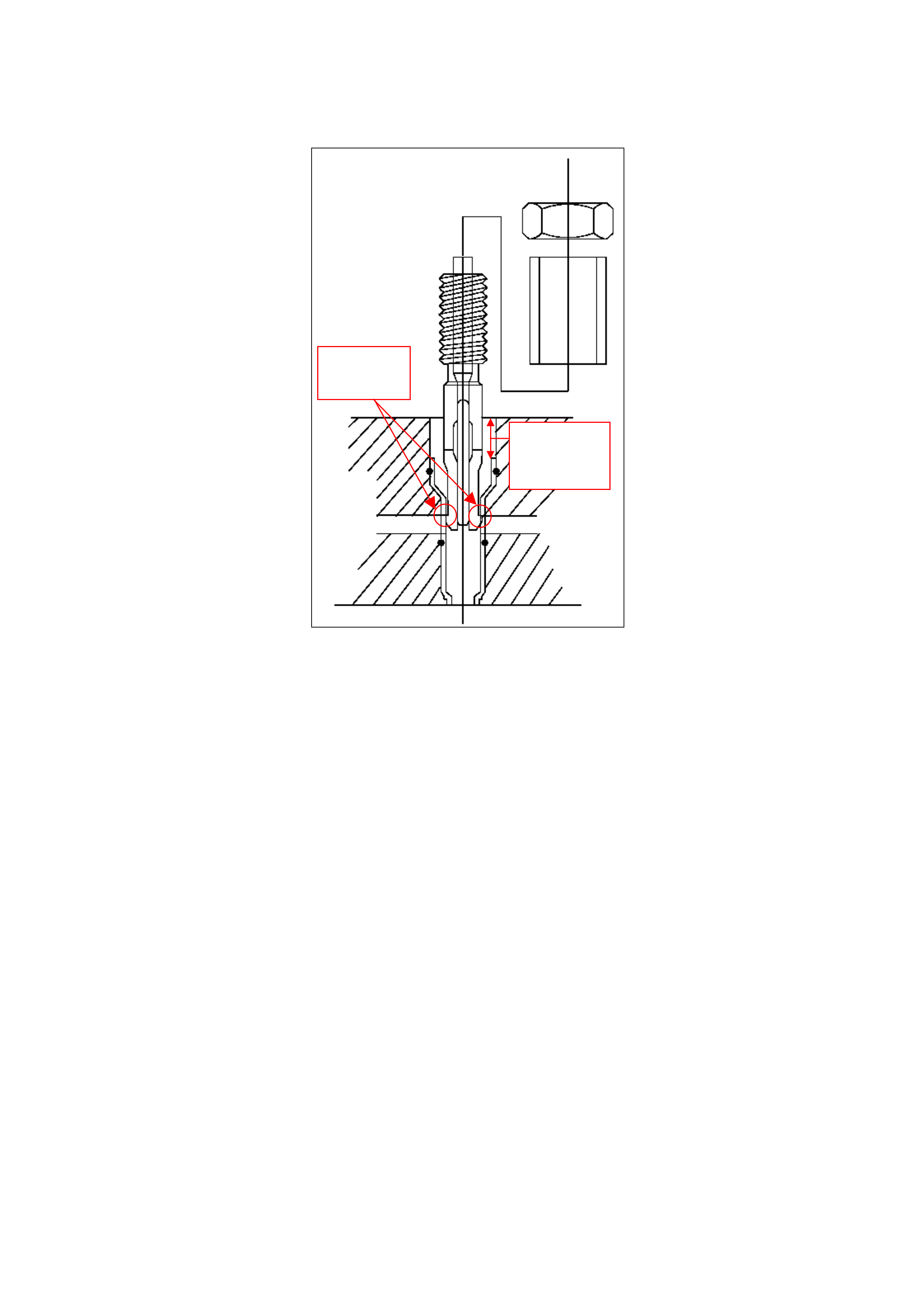

1. Locate compliance plate as per the diagram below.

COMPLIANCE PLATE

Riveted to the LH inner guard.

Displays approval numbers, category,

manufacturer’s name, model name and

code, Gross Vehicle Mass (GVM), seating

capacity, build date and V.I.N.

2.

3.

Check to confirm that the supplied replacement Compliance Plate shows the correct VIN

of the vehicle – check all 17 digits

The Compliance plate is fixed to the vehicle body inner guard by two 3.2mm rivets that

will need to be drilled out to remove the incorrectly stamped plate.

NOTE: Drill head off pop rivet only – DO NOT drill into vehicle sheet metal

4.

5.

6.

Affix the supplied replacement compliance plate with the two rivets supplied with the

replacement compliance plate ( An extra rivet is supplied as a spare in the event a rivet

does not secure correctly).

With tin snips, Cut the replaced compliance plate in two through the vertical (up and

down) - Not across the length.

Send both halves of cut compliance plate to SALMAT in the supplied pre-paid Satchel.

NOTE: Salmat has been instructed to follow-up retailers failing to return replaced plates

promptly. Please ensure that the replaced plate is returned to Salmat immediately it is

removed

PRODUCT CAMPAIGN BULLETIN

03-H-03

December 5, 2003

SUBJECT: INJECTOR SLEEVE AND O-RING REPLACEMENT

MODELS AFFECTED: 1998MY-2000MY UBS JACKAROO DIESEL

ENGINES (4JX1-TC)

This bulletin announces the initiation of a SAFETY RELATED recall campaign

to replace the injector sleeves and O-rings located in the cylinder head of the

4JX1 diesel engine.

The Sleeve Replacement Procedure discussed in Retailer letter RL72/02 has

been upgraded to a safety related recall campaign. Vehicles that have been

previously reworked via RL 72/02 procedures and are identified in Appendix

“C”, DO NOT REQUIRE THIS CAMPAIGN ACTION.

DESCRIPTION OF DEFECT

The injector sleeve sealing (O-rings) material can deteriorate and cause fuel

to leak into the crankcase.

This may result in an unintentional increase in engine speed, and possibly

vehicle speed.

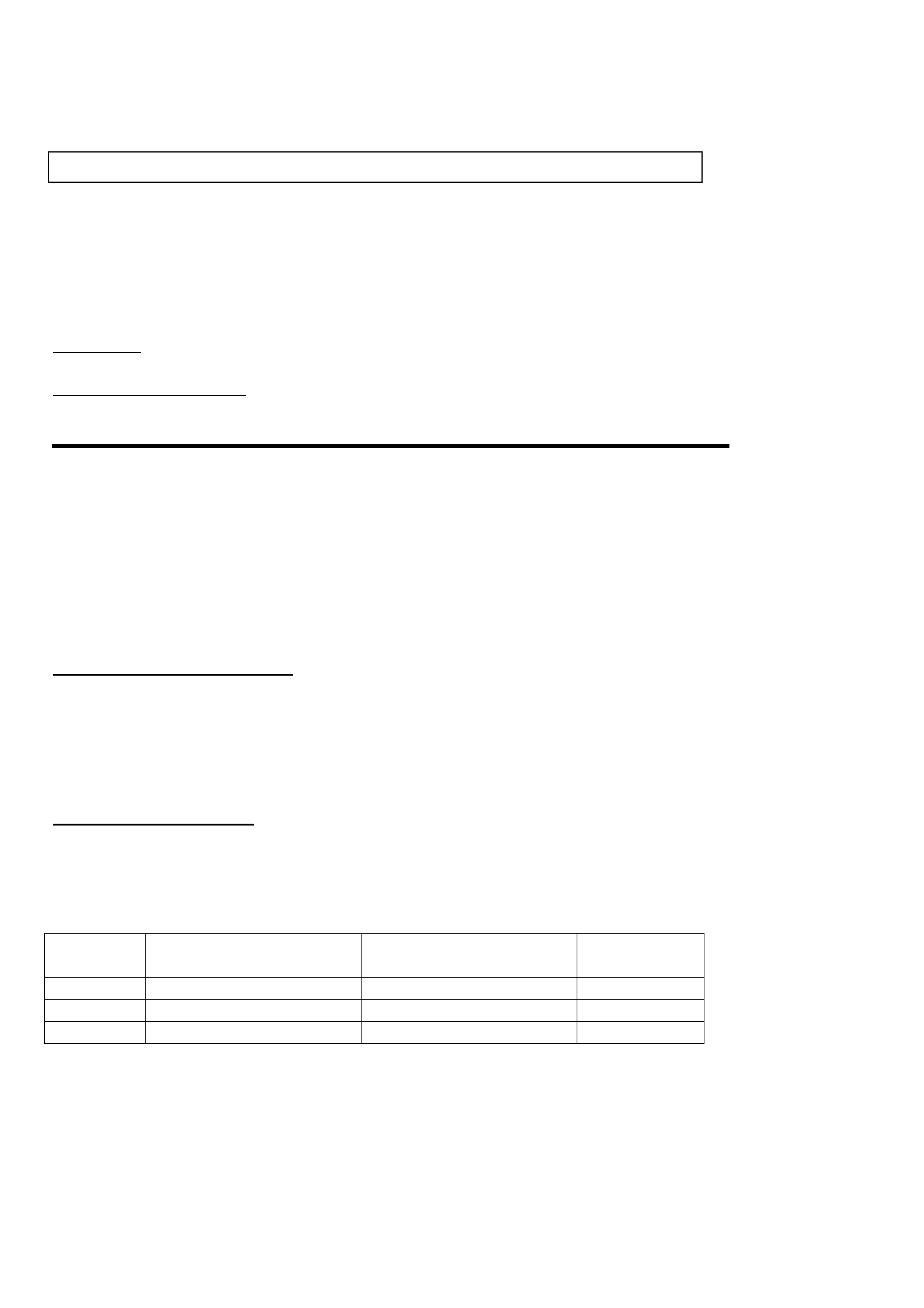

AFFECTED VEHICLES

The affected vehicles are 1998 to 2000 model year Jackaroos fitted with the

4JX1-TC diesel engine built before engine number 676517 (October 1999).

Refer to the table below for affected vehicle ISOVINS by model year.

Model

Year

From To Comments

1998 JACUBS73GW7100010 JACUBS73GW7103492 Inclusive

1999 JACUBS73GX7100566 JACUBS73GX7104876 Inclusive

2000 JACUBS73GY7100012 JACUBS73GY7102028 Inclusive

Note 1: There are 3 separate model year ranges of ISOVINS affected. Refer

to the tenth (10th) character in the ISOVIN for the model year reference i.e.

W=1998, X=1999 and Y=2000.

Page 1 of 21

Note 2: Vehicles shown on the list of previously reworked vehicles (See

Appendix C) DO NOT REQUIRE this campaign action. If the engine number is

676517 or greater then campaign action is also not required.

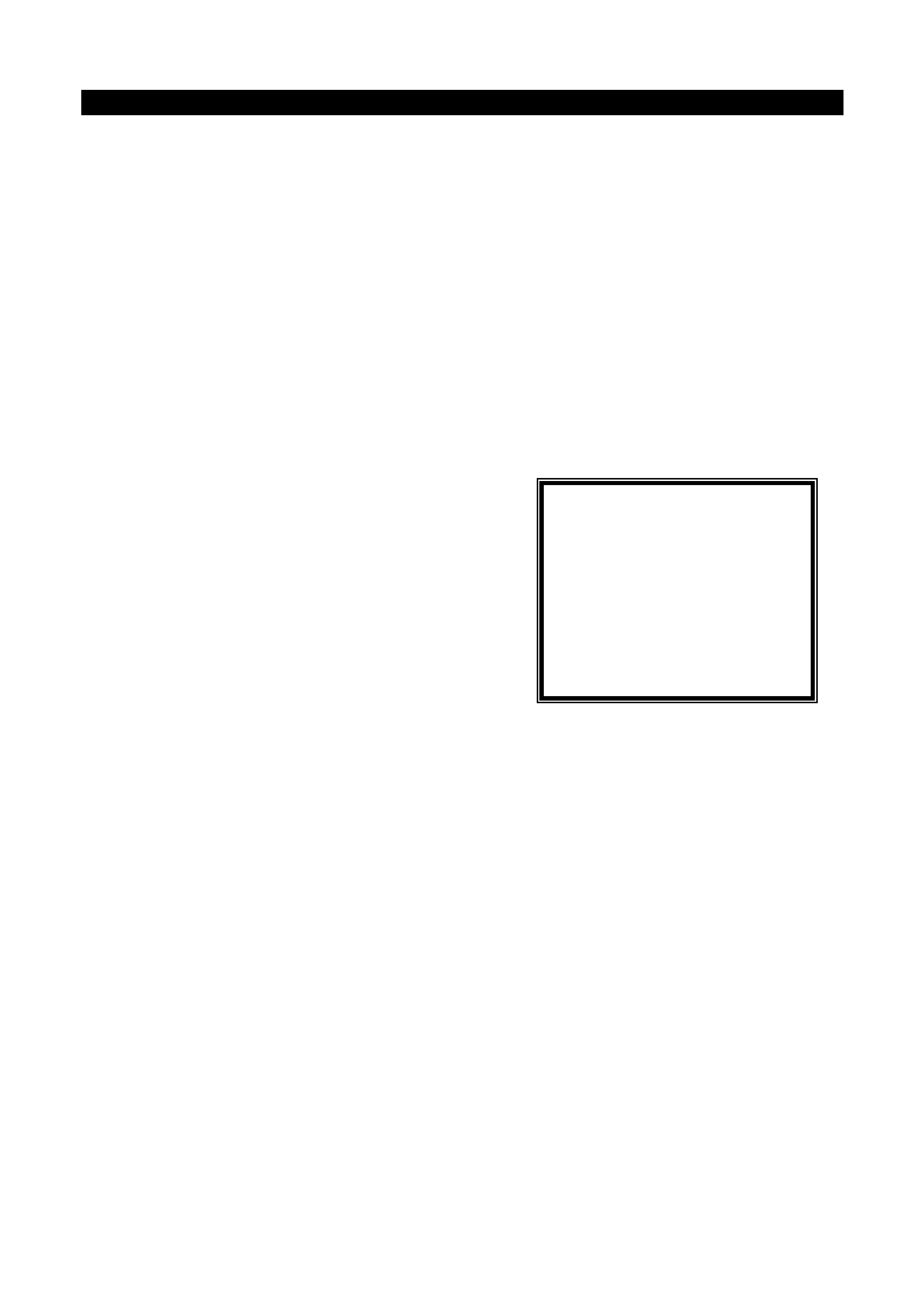

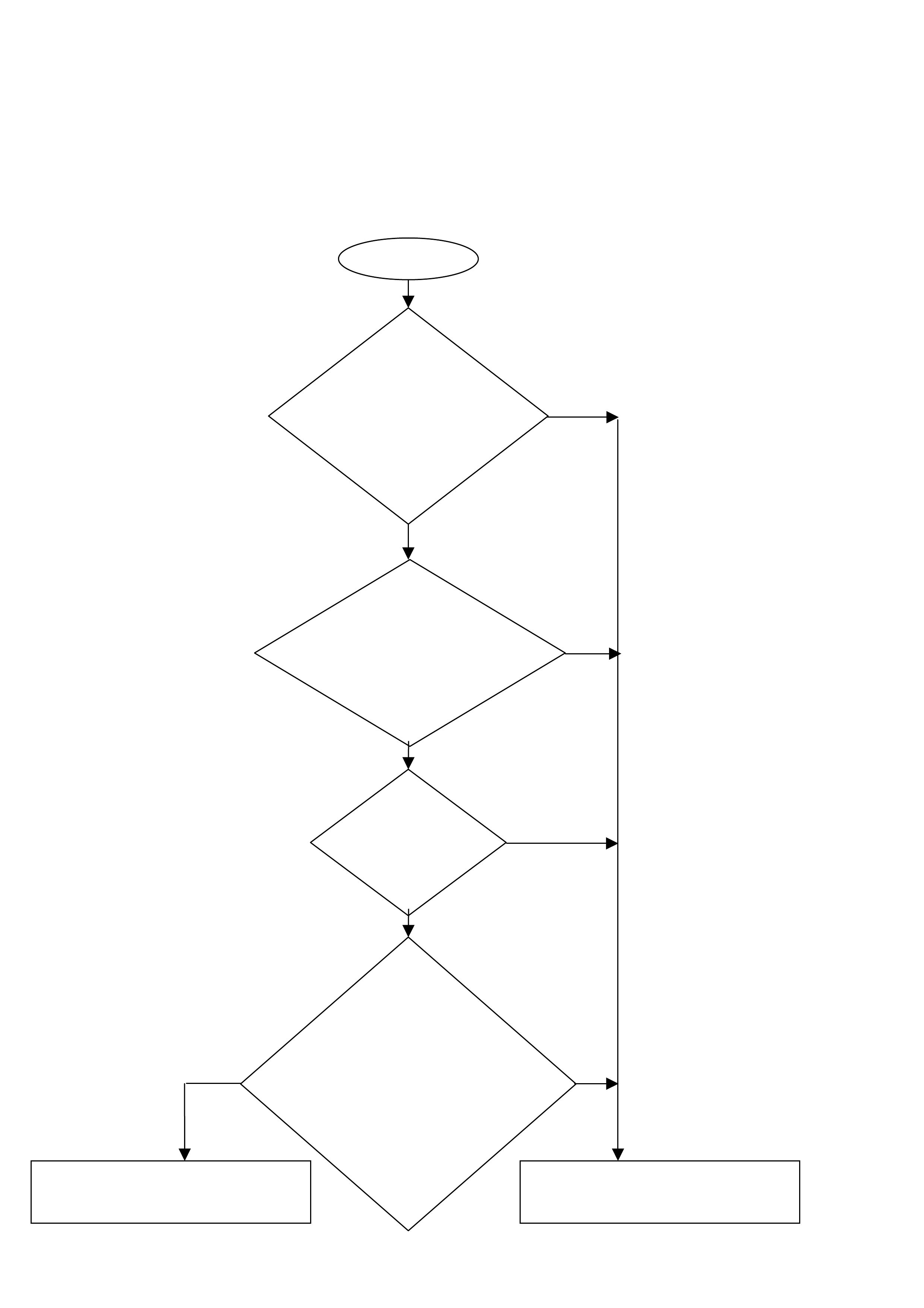

On presentation of the vehicle considered by the customer to be affected by

this campaign, follow this flow chart to determine the action required.

Page 2 of 21

Start

NO

YES

YES

NO

Is the

Vehicle on the

previous

Rework list? Refer to

Attachment C of the Product

Campaign

Bulletin.

NO

Vehicle is affected and requires

campaign action.

Vehicles not affected or have been

already reworked.

YES

NO YES

Is there a 03-H-03

Campaign Completed Label on

RH “A” pillar, and a Service History

Label with the C2 coordinate

marked with an X on

the glove box? Refer

Campaign Completion I.D.

Is the engine number

Less than 676517?

Is the

Vehicle in the affected

Range? Refer to Affected Vehicles

table on page 1 in the Product

Campaign

Bulletin.

ACTION REQUIRED BY RETAILERS

1. Check all vehicles presented to the retail premises for any reason to

identify the need for the campaign to be performed.

2. If the vehicle is affected and has not been previously campaigned

(identified by a Campaign 03-H-03 Completed Label on the RHS ‘A’Pillar),

or reworked (identified by Appendix C list) then the vehicle requires this

Recall Campaign action.

3. Proceed with campaign action as detailed in the Campaign Technical

Instructions attached. Note: A special tool is required to remove the injector

sleeves from the cylinder head. This special tool was supplied to all

retailers in 2002 with Retailer Letter RL72/02. Retailers are encouraged to

immediately locate the special tool (refer Fig 6). Note: contact Brett Fowler

on (03) 96 47 18 57 should a replacement special tool be required.

4. Apply a Campaign Completed Label and a Vehicle Service History Label as

specified in the section titled ‘Campaign Completion Identification’.

5. Submit a warranty claim. Refer Warranty Claim Information below.

CUSTOMER NOTIFICATION

Owners of vehicles affected by this recall campaign will be contacted directly

by letter from Holden. Mailing of these letters will commence mid December

2003.

The customer letter provides details of the recall and requests the customer to

contact their Holden Retailer to make a booking to have the appropriate work

carried out. Refer to Appendix A for a draft copy of the Customer Letter.

CAMPAIGN COMPLETION IDENTIFICATION

All campaigned vehicles must have:

1. A Campaign Completed label applied to the right hand front ‘A’ pillar,

between the hinges, with details of the campaign, 03-H-03, Retailer Code

and Date legibly entered on the label with a permanent ink pen.

AND

2. For additional identification, mark an “X” at the C2 –coordinate of vehicle

Service History Label and apply to the outer edge on the left-hand side of

the glovebox. Refer to Figure 2 below. Note: Check driver’s side “A” pillar

for any previous Service History label. If a Service History label is present

on the “A” pillar record information shown on it, on the new label on the

glovebox. Then remove old Service History label from the “A” pillar.

Page 3 of 21

X

Figure 2

Extra Campaign Completed and Vehicle Service History labels are available

free of charge from Moore Business Systems.

• For Campaign Completed Labels Quote stock no. SD 28156 on a Moore

Business Systems ‘Packaged Goods’ order form for a pack of 100 labels.

• For Vehicle Service History Labels quote stock no. SD 28177 on a Moore

Business Systems ‘Packaged Goods’ order form for a pack of 100 labels.

Fax the order form to Moore Business Systems on Facsimile: (03) 9270 8925

Should you need to follow-up on a placed order, contact Moore customer

service on telephone number (03) 9270 8788.

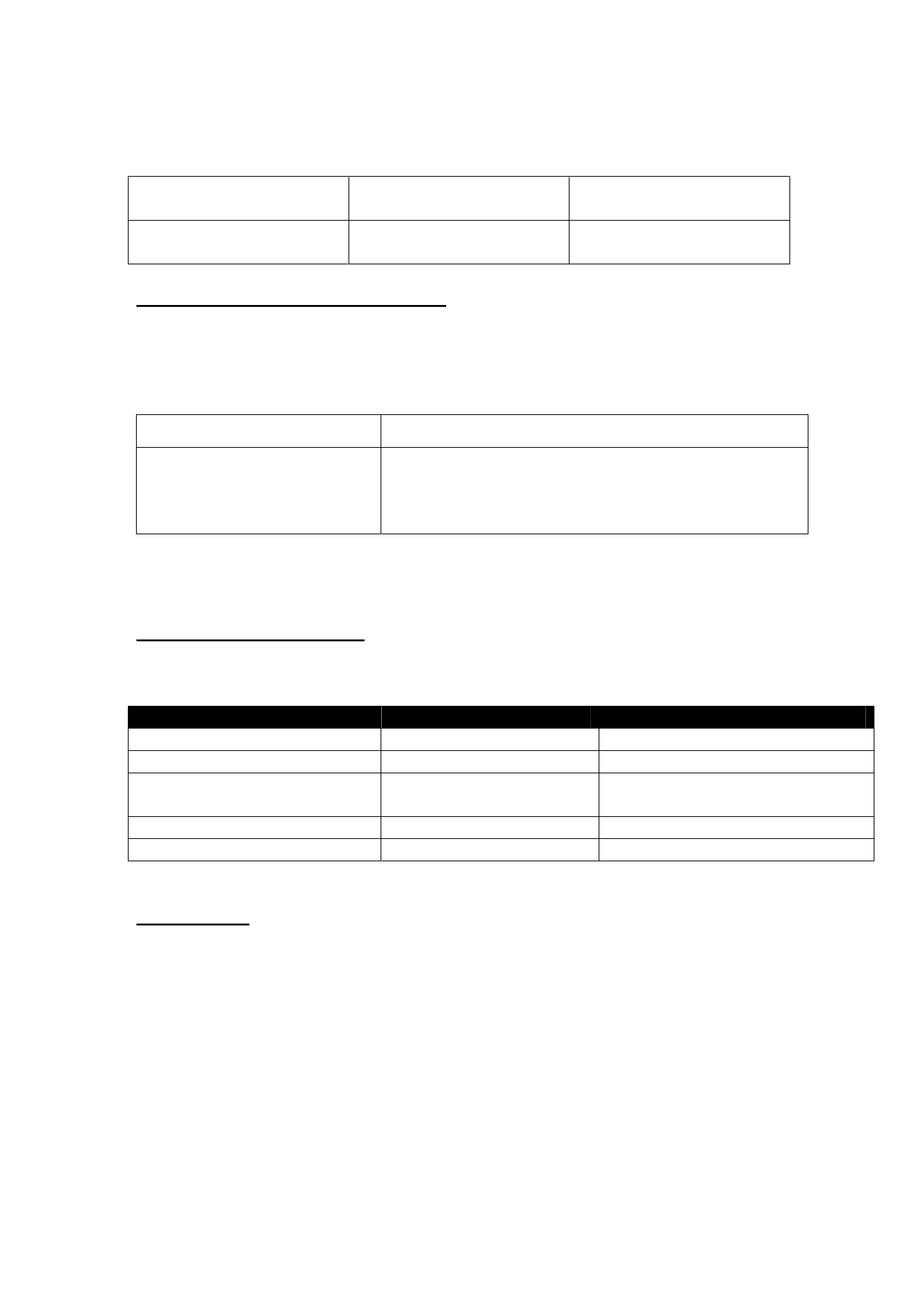

PARTS INFORMATION

Each retailer has been sent an initial quantity of 2 parts kits with this Recall

Campaign Bulletin package.

Each kit comprises of the following parts:

Part No: Description: Qty Per Kit

8971757830 Gasket – Injector Nozzle Clamp 4

8972407980 O-Ring Injector Nozzle 4

8971611092 Gasket – Injector Nozzle Clamp 4

8971842160 Gasket Oil Pipe 2

8971606721 Gasket – Cover to Cylinder Head 1

8972451850 Sleeve – Injector 4

8972229330 Gasket- Inlet Pipe 1

8971378200 Gasket – T/V 1

Additional parts kits are available free of charge from Salmat by completing

and faxing the Material Order Form. (Refer to Appendix D). Salmat will send

written confirmation acknowledging receipt of the Material Order Form plus

dispatch details within 1 working day of receipt. Confirm receipt of Material

Page 4 of 21

Order Form by Salmat if written confirmation of receipt not received within 24

hours.

Part

Number

Description Quantity

03-H-03 Injector Sleeve and Seal

kit

1

WARRANTY CLAIM INFORMATION

On completion of campaign action, retailers must IMMEDIATELY submit a

warranty claim using the applicable Recall Campaign Labour Operation

Number specified below:

Description: Injector Sleeve O-ring

Labour Operation No

Standard Time:

Failure Code:

Case Type

T380601

3.0 Hrs

96

08

Note: Additional time has been incorporated in the standard time to ensure

affected vehicles requiring this campaign action are prioritised so that vehicles

are completed and returned to customers as soon as possible.

CONTACT INFORMATION

For further information or clarification on this recall campaign please contact

the relevant person below.

CONTACT NAME CONTACT NUMBER

General enquiries Gary Brunet (03) 9647 2463

General enquiries Brett Fowler (03) 9647 1857

Technical enquiries TAS 1800 033 417

(press 2 for LCV)

Parts related enquiries Salmat (03) 9358 2990

Warranty related inquiries Warranty Administration (03) 9647 2401

Attachments

Appendix A Customer Letter- Draft

Appendix B Campaign Technical Instructions

Appendix C Affected Vehicle Listing

Appendix D Material Order Form

Page 5 of 21

APPENDIX A - Customer Letter

VEHICLE SAFETY RECALL

03-H-03

Re: Jackaroo Diesel Fuel Injector O’ring Replacement

Dear Holden Customer,

As part of Holden’s ongoing commitment to customer satisfaction and safety, we have

initiated a safety-related recall on model year 1998 to 2000 Holden Jackaroo vehicles

with Diesel Engine.

Holden has become aware that the fuel injector sealing o’rings and sleeve o’rings in

the cylinder head, may deteriorate and potentially allow fuel to leak into the engine

crank case.

In cases where a leak has developed, the vehicle may experience an unintended

increase in engine speed, and possibly vehicle speed.

Our records show your Holden vehicle was manufactured within the affected range. It

is therefore necessary for you to contact a Holden Retailer of your choice and make a

booking as soon as possible to have the affected injector seals and associated parts

replaced. The work required will be carried out free of charge.

If you have any questions regarding this recall, please contact your Holden Retailer or

call the Holden Recall and Rework Assistance Centre on 1800 632 826 and we will be

pleased to assist you further.

Thank you for your attention to this matter. Please accept our apologies for any

inconvenience caused to you.

Yours sincerely

David McMurray

Manager Customer Assistance

Page 6 of 21

APPENDIX B - Campaign Technical Instructions

The instructions provided below vary to those previously provided in SIP and Service

Techlines. Please read these instructions thoroughly to ensure the recall campaign

action is carried out precisely as intended.

1. Disconnect the battery negative (-) cable/s (ensure the radio security PIN is

available).

2. Remove the front cross member protector and drain 5 litres of coolant into a clean

container (to be reused). This prevents coolant filling the combustion chamber

when the injector sleeves are removed.

Section 1 : Remove the cylinder head cover.

3. Remove rubber intercooler surround, throttle body retaining nuts, front intercooler

bracket bolt at the engine on the left hand side and intercooler bracket bolts at the

intercooler on the right hand side.

4. Loosen the turbo to intercooler hose at the intercooler end.

5. Remove the intercooler, throttle body to intercooler hose and throttle body flange

as one assembly (Fig 1).

Figure 1

NOTE: Cover the manifold and turbo with clean rags to prevent foreign

material entry.

6. Disconnect throttle body harness connectors and remove the throttle body.

7. Remove the air intake duct mounting bolts, PCV hose (at the cylinder head),

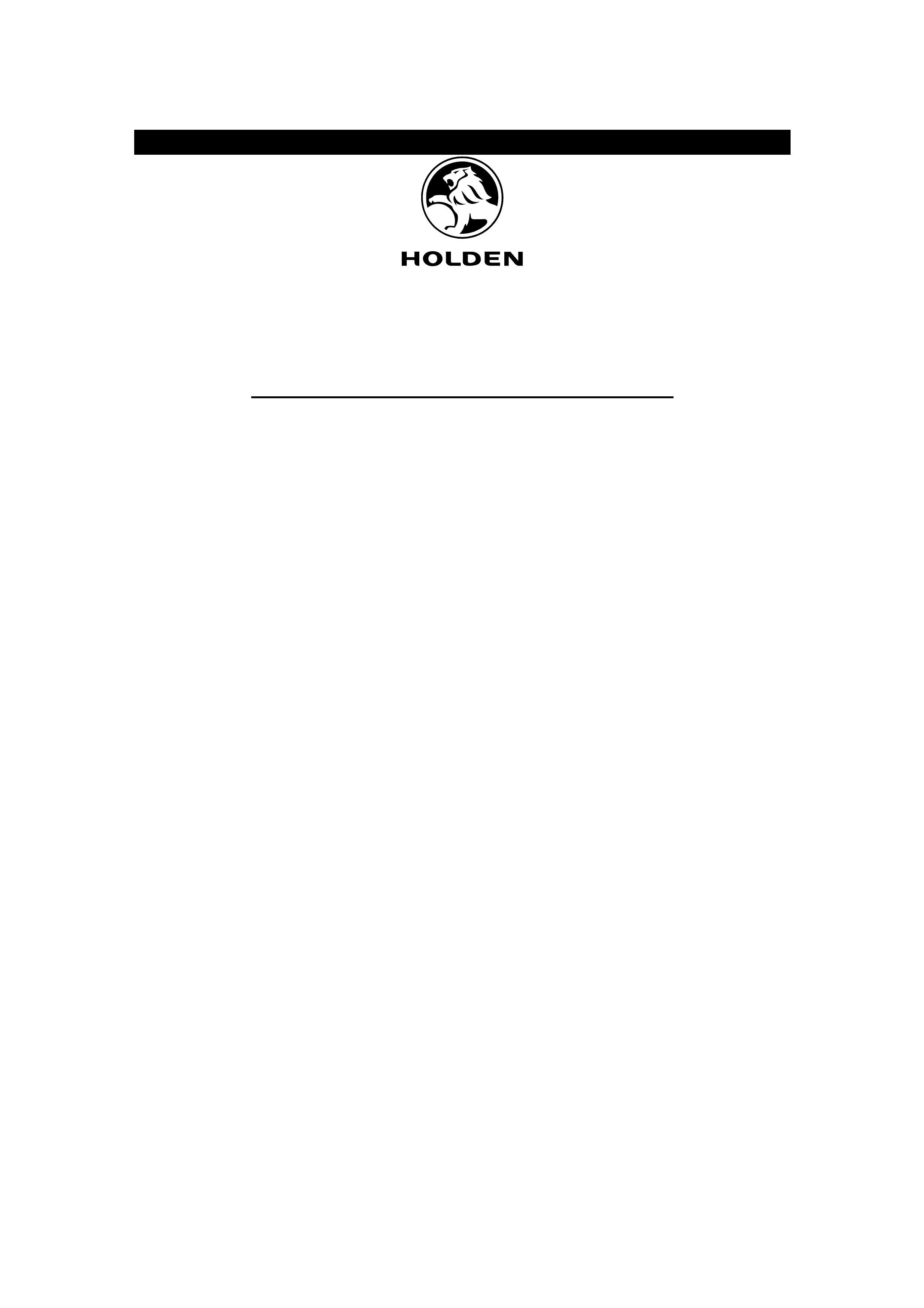

vacuum hoses, turbo clamp, air cleaner service clips and remove the air intake

duct with air cleaner element attached (Fig 2).

Page 7 of 21

Figure 2

8. Remove bolts and nuts from the cylinder head cover insulator

9. Remove PVC hose at the rear of the engine.

10. Remove the engine insulation cover and foam from the cylinder head cover and

inlet manifold. Note: Take care not to lose retaining bolt spacers when removing

the cover.

11. Place a rag around the lower high pressure oil pipe fitting and loosen,

completely remove the pipe.

NOTE: A rag must be used to restrict the escape of any residual high pressure

and to prevent oil draining onto other engine components.

12. Remove the cylinder head cover bolts and the cylinder head cover.

Section 2: Remove the injectors, oil rail and injector harness as one

assembly.

NOTE : Do not disconnect the injector harness from the oil rail or

injectors as this may cause connector breakage.

13. Remove the oil rail drain plug at the right hand front of the oil rail and allow the oil

to drain.

NOTE: Clear any drained oil from around the injector to prevent oil running

into the combustion chamber.

14. Remove bolts and nuts from the oil rail, injector H-Clamp nuts and washers and

injector harness retaining bolts.

NOTE: Carefully remove the metal retainers under the injector harness

retaining bolts.

15. Loosen the injector harness to cylinder head seal from the cylinder head and

disconnect the injector harness from the main wiring harness.

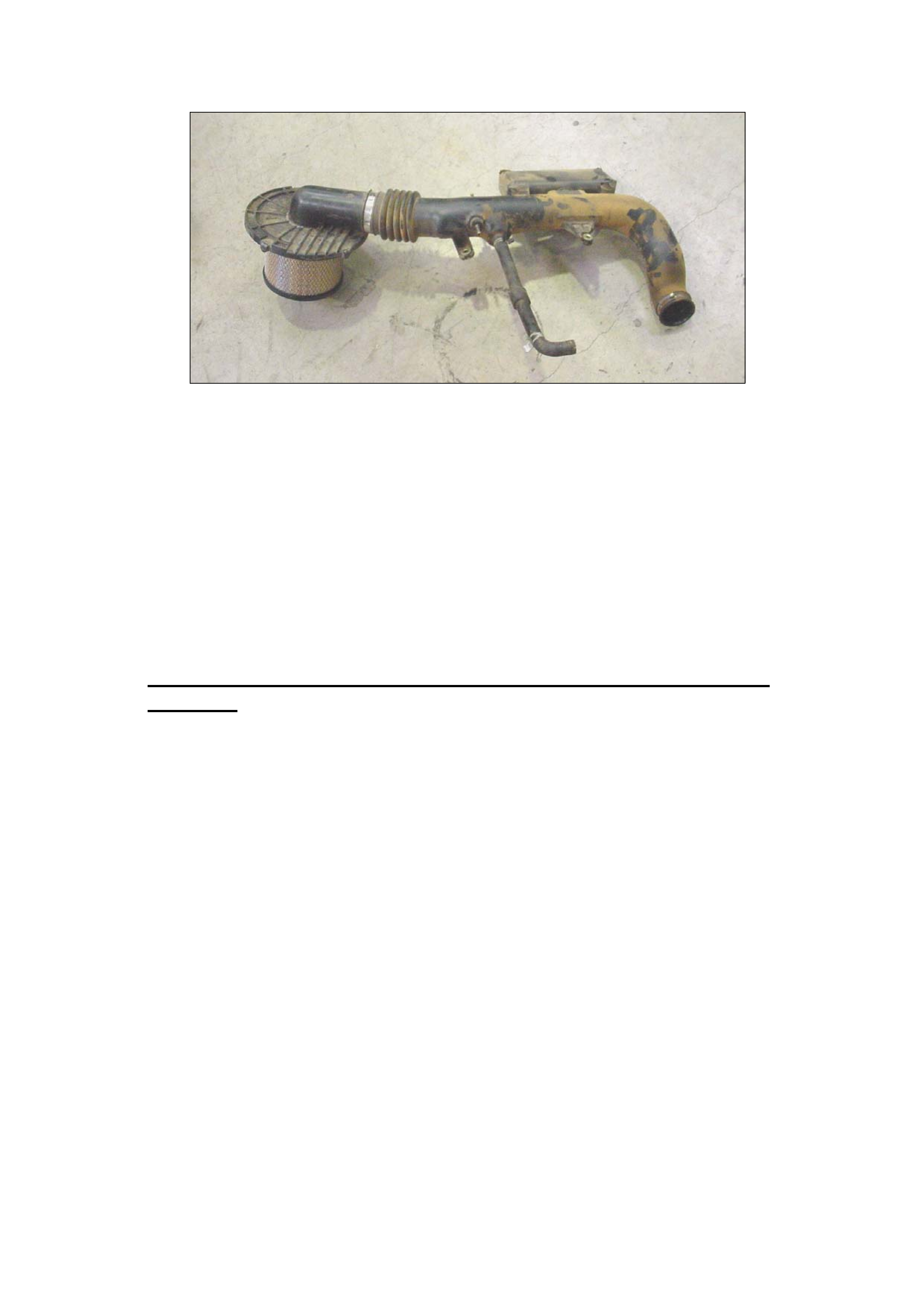

16. Remove the oil rail, injectors, injector harness and H-Clamps as one assembly

(Fig 3).

Page 8 of 21

H-Clamp

Figure 3

NOTE: Be careful not to damage the injectors when removing and reinstalling

the assembly. Have a second person assist if required.

When access is not required cover exposed combustion chambers with a rag.

Section 3: Replace Injector Sleeves and Injector Seals

NOTE: The injectors must not be swapped between cylinder positions. Since the

engine is calibrated to match the specific injectors.

17. Clean and inspect the injectors. Wipe away soot and deposits from the tip of

the nozzle with solvent and a rag.

18. Remove and discard the injector Back Up O Ring and Sleeve rework if fitted as

previously advised in IGM 04/00.

CAUTION: The use of a brush with metal bristles may damage the

injector nozzle

19. Remove the injector to oil rail mounting bolts and move the injector to access

the seal.

NOTE: There is no need disconnect the injector harness from the injector. This

will avoid the potential to break Harness connector clips.

20. Replace all injector O-rings and gaskets indicated in figure 4 on all injectors.

Lubricate only the rubber seals with engine oil.

Page 9 of 21

Figure 4 – Replace Injector Seals and Gaskets

21. Inspect the injector sleeves in the cylinder head to locate the fuel gallery holes.

Refer Figure 5.

Figure 5 – Injector Sleeve Fuel Gallery Holes

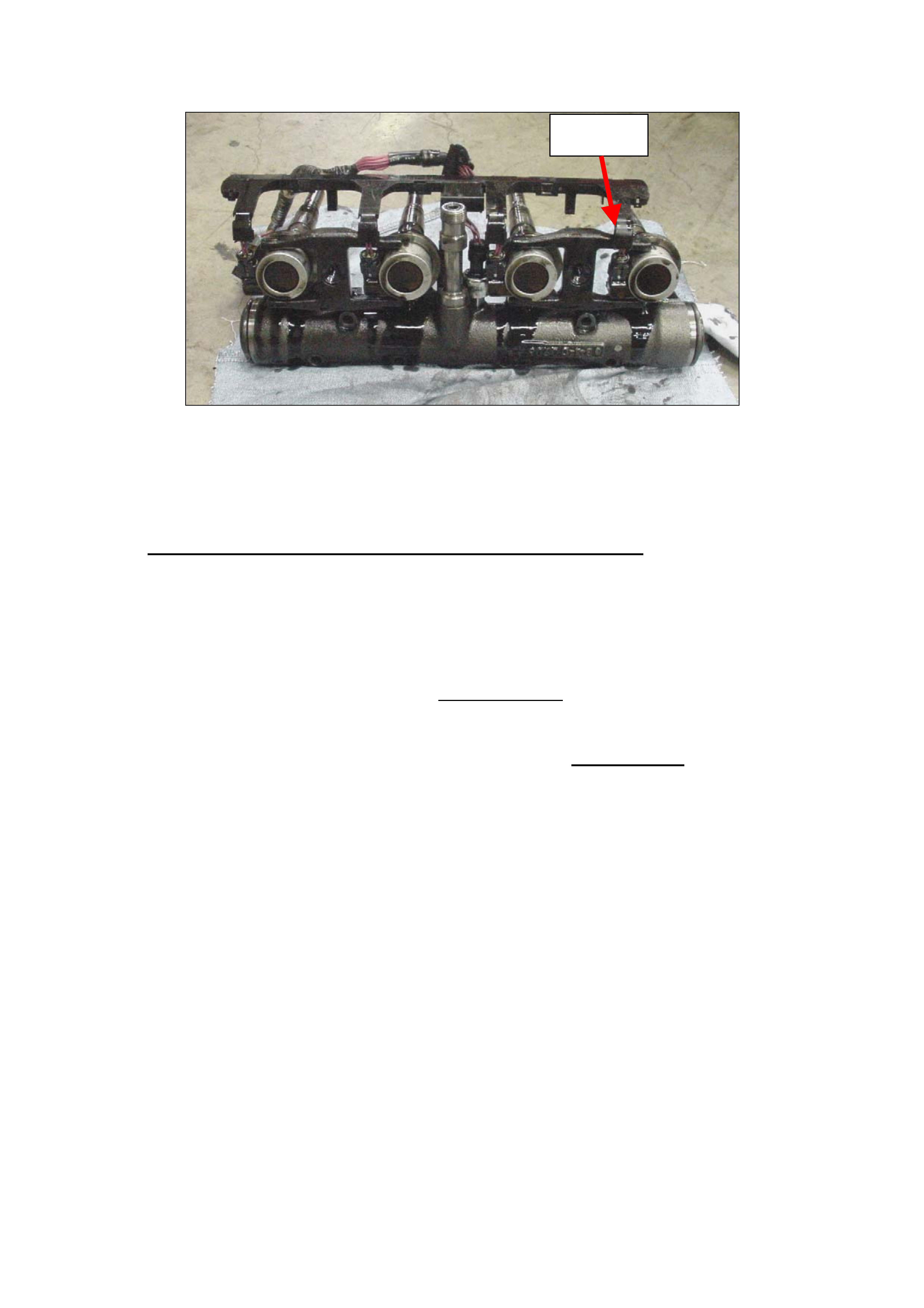

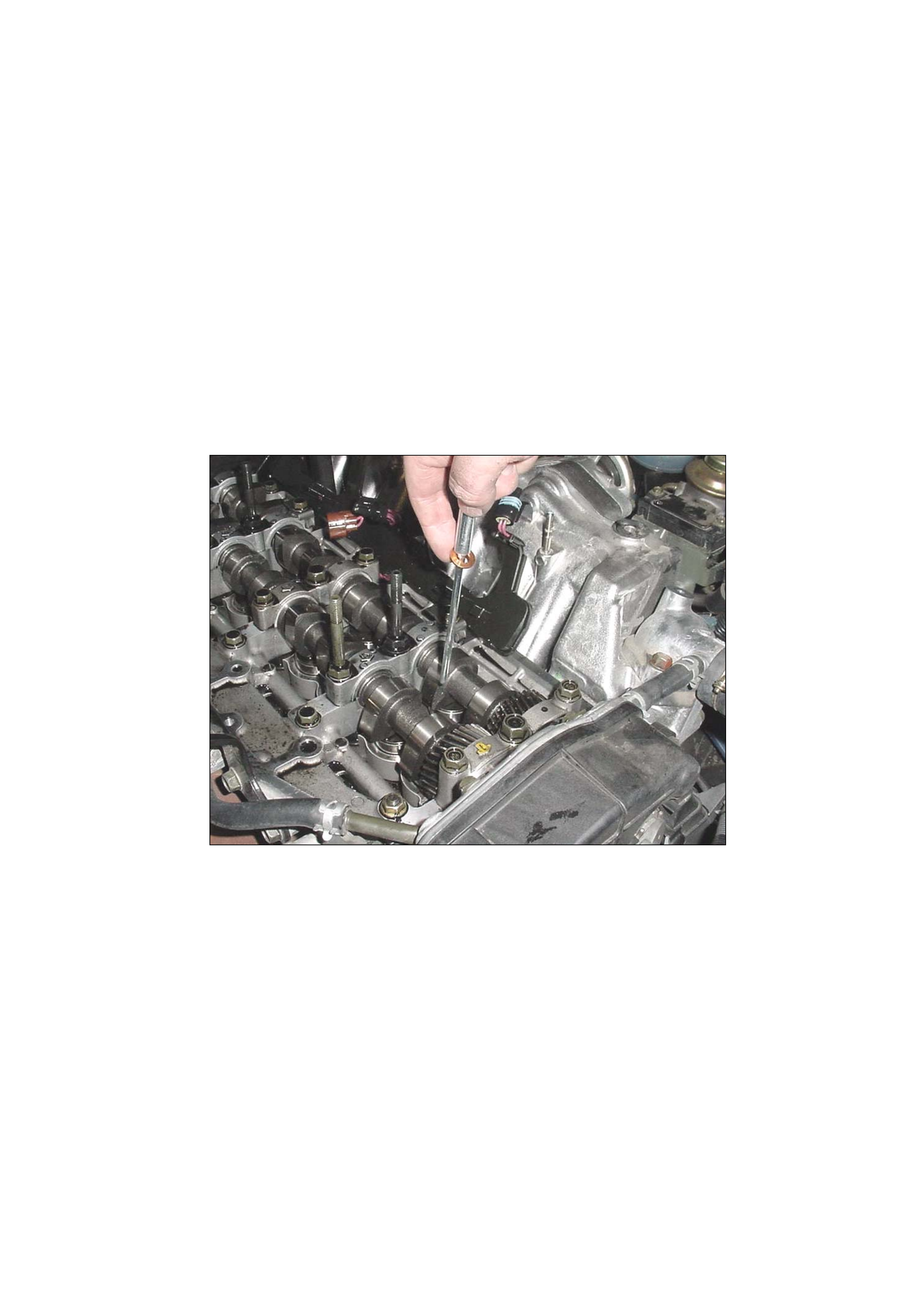

22. Orient the sleeve removal tool so the teeth will engage the fuel gallery holes

when pushed into the sleeve. Refer Figure 6.

Page 10 of 21

Figure 6 – Orienting Sleeve Removal Tool

23. Push the sleeve removal tool into the sleeve until the teeth on the tool engage

the fuel gallery holes. Twist the tool to check it is fully engaged.

24. Install the pin fully into the centre of the sleeve removal tool. If the pin does

not effortlessly seat or becomes jammed, the sleeve removal tool is not correctly

engaged in the injector sleeve and the removal tool will be damaged upon removal

(Fig 7 and 8).

25. Install the tool outer sleeve and nut.

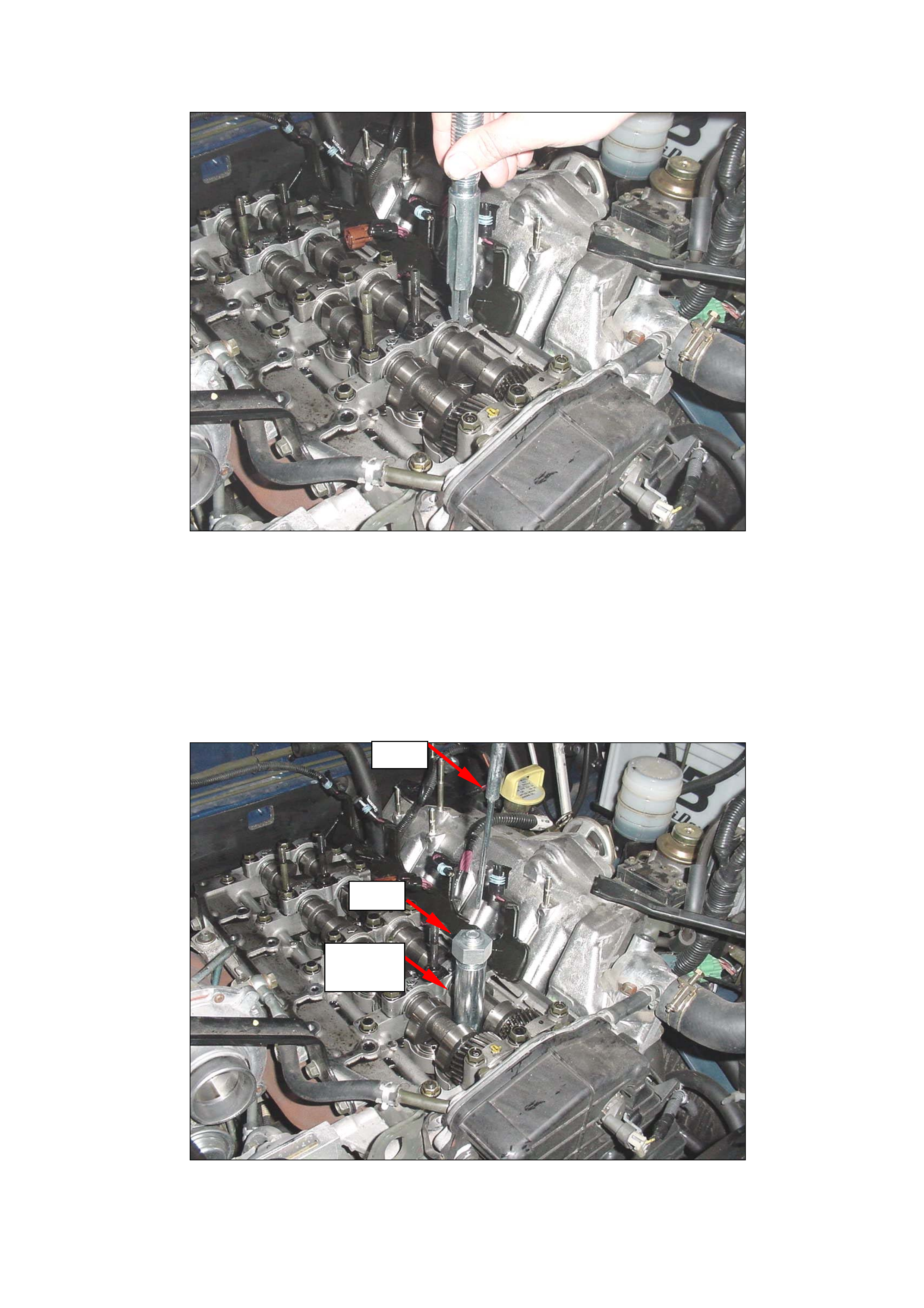

Pin

Nut

Tool

Sleeve

Figure 7 – Sleeve Removal Tool Installed

Page 11 of 21

15mm –

refer step

Prongs

Engaged

19

Figure 8 – Tool Assembly in Cylinder Head

26. Hold the flat of the threaded section of the tool with a wrench and turn the nut

clockwise to remove the sleeve from the head. Refer Figure 9.

Page 12 of 21

Figure 9 – Extracting the sleeve using the tool

27. Remove the pin from the tool. Using large pliers to compress the body of the

tool, release the teeth from the injector sleeve and remove (Fig 10).

NOTE: Do not compress the narrow teeth as damage to the tool may result.

Figure 10 – Removing the tool from the injector sleeve

Page 13 of 21

28. Repeat this process for the three remaining injector sleeves in the cylinder

head.

29. Clean the injector sleeve bores with a lint-free rag wrapped around a soft

material such as wood.

30. Prepare the new injector sleeves for installation by applying engine oil to the

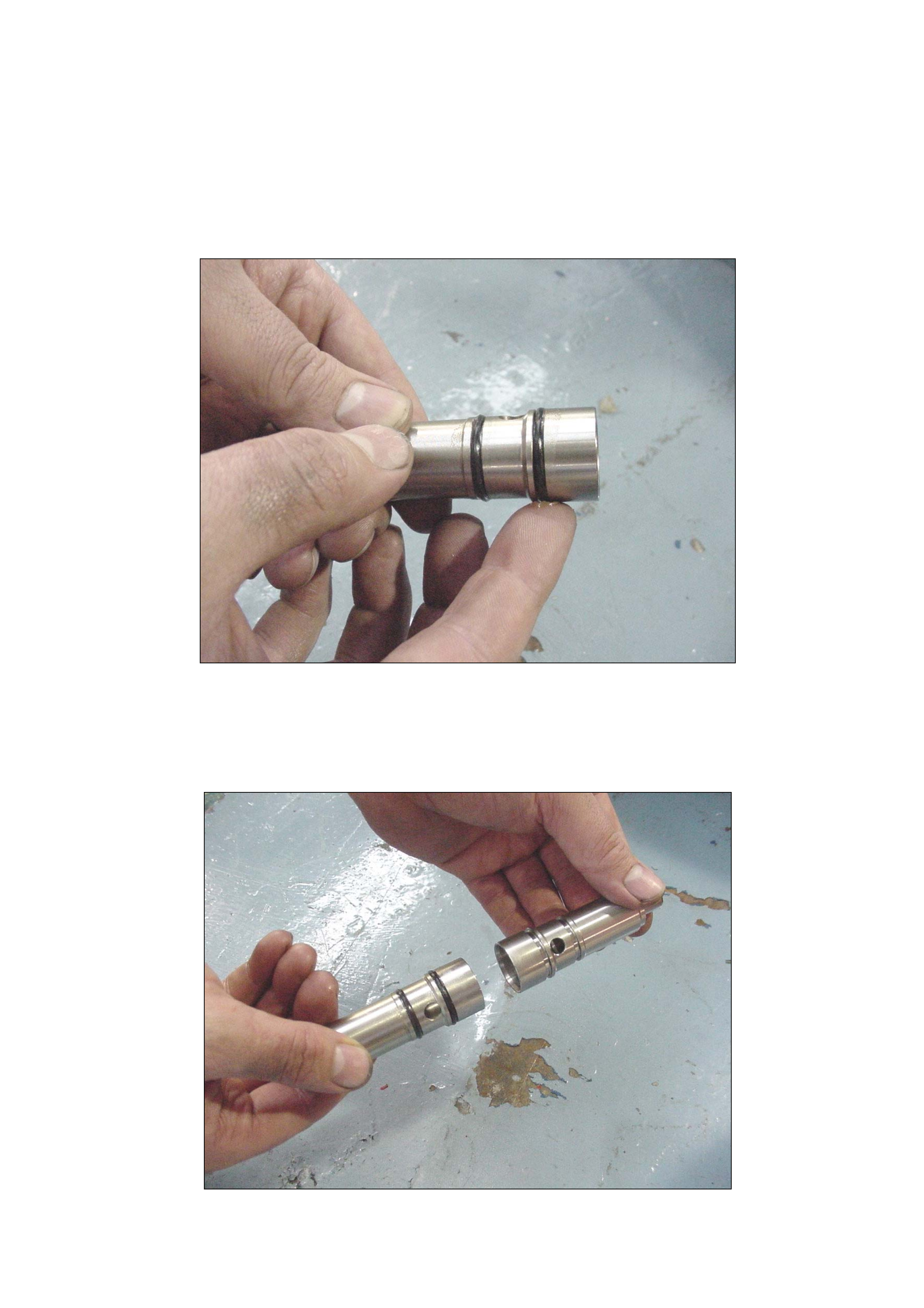

O-rings (Fig. 11).

Figure 11 – Lubricate new injector sleeve O-rings

31. Thoroughly clean an old injector sleeve to use as an installer. Remove the O-

rings in order to easily identify.

32. The old sleeve will be used, upside down, to install the new sleeve (Fig. 11).

Page 14 of 21

Figure 12 – Using old sleeve as installing tool

33. Place the new injector sleeve in the cylinder head. Align the fuel gallery holes

in the sleeve with the ports in the cylinder head (Fig 13).

Figure 13– Locating injector sleeves

34. Locate the clean, used injector sleeve upside down on the new sleeve.

35. Carefully install the new injector sleeve, using a hammer, until it is fully seated

in the cylinder head (Fig 14).

Figure 14 – Installing new injector sleeve

Page 15 of 21

NOTE: If unsure, check the injector sleeve is fully seated in the cylinder head by

measuring the depth of the sleeve in the head. The correct depth of the sleeve in

the cylinder head is 15mm (refer Figure 8). Once the sleeve is in the home

position do not continue to install the sleeve as damage may occur.

36. Repeat this procedure for the remaining three cylinder positions

37. Remove any oil or coolant that pooled in the combustion chamber with a

vacuum bleeder or syringe.

38. Insert the copper nozzle gasket into the injector sleeves taking care to ensure

the flat side faces up. Use the removal tool pin to guide the gasket into the sleeve.

Refer Figures 15 and 16.

NOTE: The surfaces of the copper gasket creates a seal and must be

clean (no visible sign of carbon, oil etc).

Do not use grease to hold the nozzle gasket on the injector during

insulation as a leak may develop.

Figure 15 – Installing the copper packing

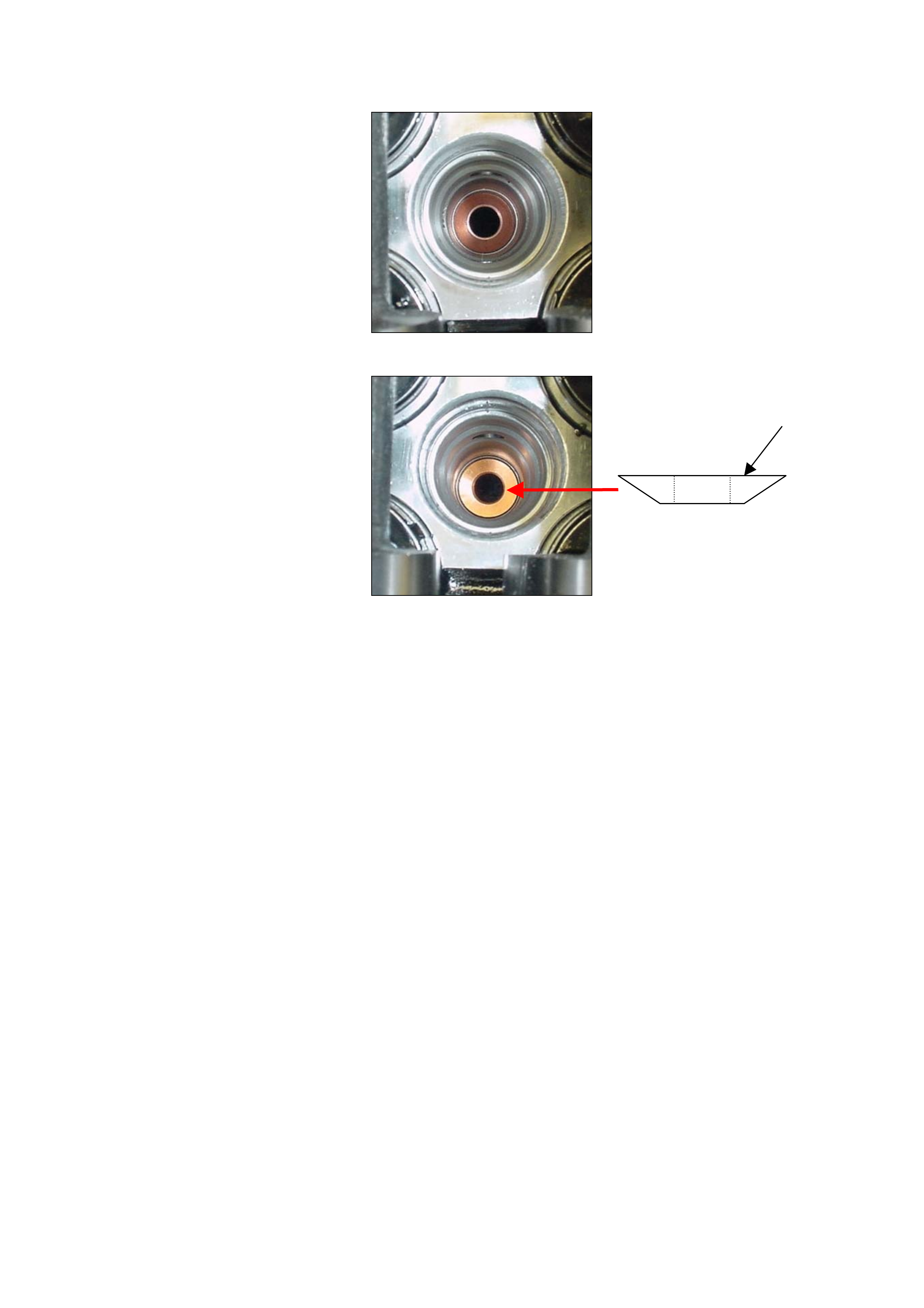

39. Inspect the copper nozzle gasket packing in the sleeve to ensure it is installed

correctly with the flat side up ( See Fig 16).

Page 16 of 21

Incorrect (upside down)

Install flat Side up

Side view of

Copper gasket

Correct

Figure 16 – Copper Gasket Inspection

40. With the H-Clamps in place, install the oil rail, injectors and injector harness

assembly.

Note: Carefully install the injectors into the sleeves. Have a second person assist

if required. Take care not to bump the injector tips since they are brittle and

could be easily damaged if accidentally knocked.

Check the oil rail drain plug is installed.

41. Install and temporarily tighten the injector to rail bolts then injector clamp

bolts.

42. Install oil rail nuts and bolts but do not torque to specification until step 46.

NOTE: Clear any drained oil from around the injector to prevent oil running

into the combustion chamber.

43. Tighten injector to oil rail bolts to the specified torque.

Torque: 6.5 Nm (0.7 kgm / 5.1 Ib ft)

44. Tighten injector H-clamp nuts to the specified torque to seat the injectors:

Torque: 30 Nm (3.1 kgm / 22 Ib ft)

45. Loosen the injector H-clamp nuts and retighten to the specified torque:

Torque: 25 Nm (2.4 kgm / 17.4 Ib ft)

46. Torque the oil rail bolts to the specified torque:

Page 17 of 21

Torque: 20 Nm (2.0 kgm / 14.5 Ib ft)

47. Reinstall the remaining components in the reverse order (steps 15 – 1) while

noting the following points:

Ensure the wiring harness at the front of the cylinder head cover is not

damaged or caught during reassembly.

Tighten the cylinder head cover bolts to specific torque 9 Nm (0.9kgm/5.8 Ib

ft)

Fit new seals to the high pressure oil pipe and tighten to specific torque 80Nm

(8.1kg.m / 57.9 Ib ft)

When installing the cylinder head cover apply liquid gasket to the mating

corners of the front cam shaft bracket, seals for the injector harness in the

head and the seal at the rear of the head

Tighten intercooler mounting bolts to specific torque 20 Nm (2.0 kg.m /

14.5Ib ft)

Refill Coolant

Engine will take approx. 15 – 20 second of cranking to start.

48. Apply a recall campaign sticker and mark position C2 on the Vehicle Service

History Label.

49. Enter radio PIN and ensure correct operation.

Page 18 of 21

Page 19 of 21

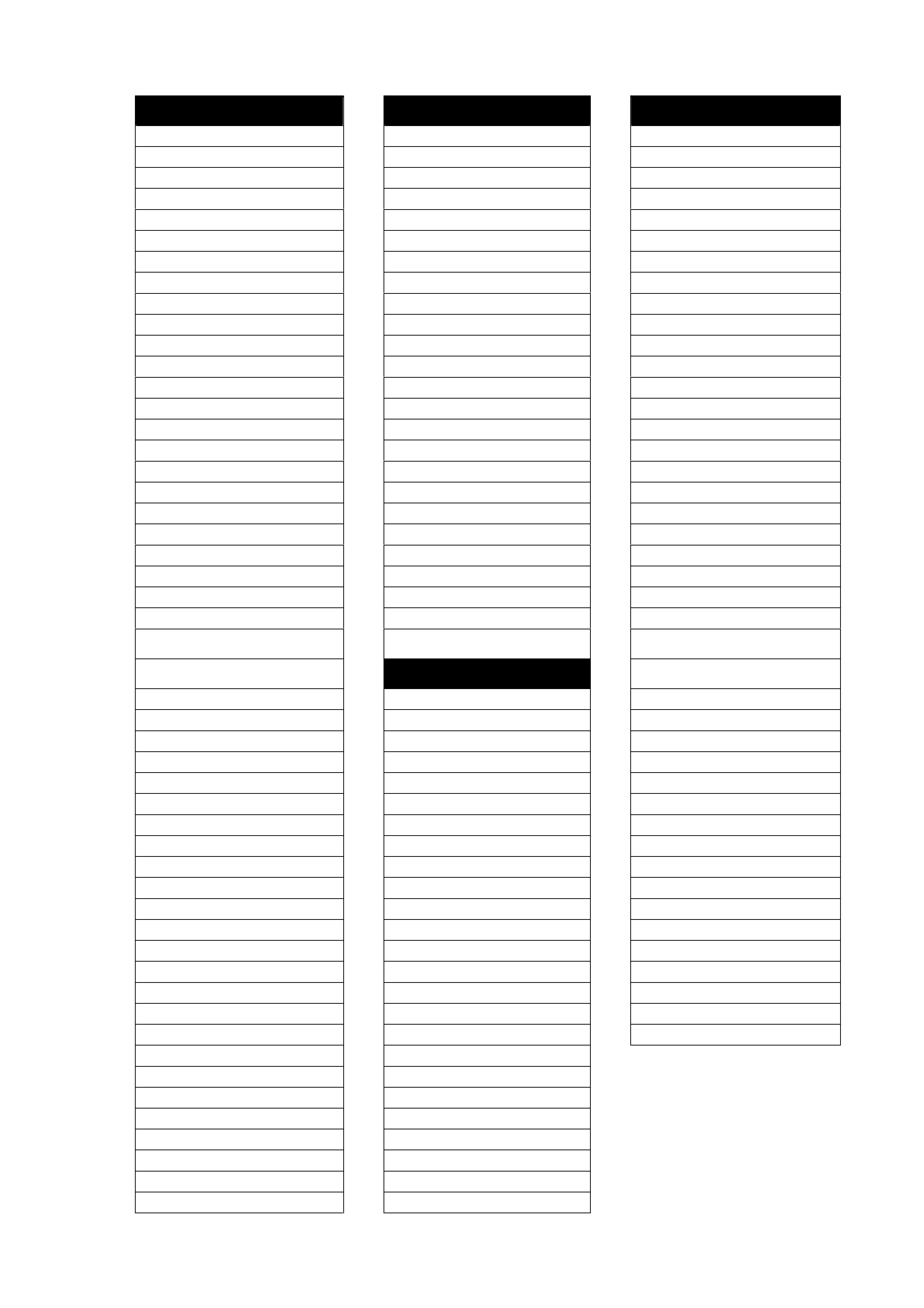

APPENDIX C – Excluded Vehicle Listing : DO NOT REWORK

This is a list of EXCLUDED vehicles due to previous rework. This list is sorted into

Model Year categories. If the vehicle is shown on the list below in the applicable

Model Year category it does not require campaign action.

1998 Model Year 1998 Model Year cont’d 1999 Model Year cont’d

JACUBS73GW7100023 JACUBS73GW7102384 JACUBS73GX7101549

JACUBS73GW7100222 JACUBS73GW7102410 JACUBS73GX7101573

JACUBS73GW7100247 JACUBS73GW7102471 JACUBS73GX7101575

JACUBS73GW7100293 JACUBS73GW7102575 JACUBS73GX7101576

JACUBS73GW7100331 JACUBS73GW7102577 JACUBS73GX7101595

JACUBS73GW7100381 JACUBS73GW7102640 JACUBS73GX7101621

JACUBS73GW7100496 JACUBS73GW7102687 JACUBS73GX7101634

JACUBS73GW7100546 JACUBS73GW7102713 JACUBS73GX7101704

JACUBS73GW7100842 JACUBS73GW7102776 JACUBS73GX7101777

JACUBS73GW7100985 JACUBS73GW7102868 JACUBS73GX7101800

JACUBS73GW7101101 JACUBS73GW7102951 JACUBS73GX7101842

JACUBS73GW7101105 JACUBS73GW7102979 JACUBS73GX7101904

JACUBS73GW7101248 JACUBS73GW7103093 JACUBS73GX7101954

JACUBS73GW7101267 JACUBS73GW7103198 JACUBS73GX7102004

JACUBS73GW7101291 JACUBS73GW7103217 JACUBS73GX7102027

JACUBS73GW7101309 JACUBS73GW7103218 JACUBS73GX7102043

JACUBS73GW7101313 JACUBS73GW7103350 JACUBS73GX7102050

JACUBS73GW7101367 JACUBS73GW7103374 JACUBS73GX7102062

JACUBS73GW7101373 JACUBS73GW7103391 JACUBS73GX7102102

JACUBS73GW7101396 JACUBS73GW7103423 JACUBS73GX7102152

JACUBS73GW7101416 JACUBS73GW7103438 JACUBS73GX7102207

JACUBS73GW7101417 JACUBS73GW7103461 JACUBS73GX7102226

JACUBS73GW7101428 JACUBS73GX7102233

JACUBS73GW7101504 JACUBS73GX7102269

JACUBS73GW7101513 1999 Model Year JACUBS73GX7102331

JACUBS73GW7101515 JACUBS73GX7100620 JACUBS73GX7102452

JACUBS73GW7101528 JACUBS73GX7100690 JACUBS73GX7102496

JACUBS73GW7101532 JACUBS73GX7100814 JACUBS73GX7102554

JACUBS73GW7101537 JACUBS73GX7100875 JACUBS73GX7102645

JACUBS73GW7101540 JACUBS73GX7100927 JACUBS73GX7102760

JACUBS73GW7101543 JACUBS73GX7100930 JACUBS73GX7102761

JACUBS73GW7101584 JACUBS73GX7100984 JACUBS73GX7102766

JACUBS73GW7101595 JACUBS73GX7101002 JACUBS73GX7103262

JACUBS73GW7101600 JACUBS73GX7101097 JACUBS73GX7103266

JACUBS73GW7101607 JACUBS73GX7101206 JACUBS73GX7103398

JACUBS73GW7101608 JACUBS73GX7101269 JACUBS73GX7103400

JACUBS73GW7101787 JACUBS73GX7101280 JACUBS73GX7103402

JACUBS73GW7101816 JACUBS73GX7101410 JACUBS73GX7103427

JACUBS73GW7101987 JACUBS73GX7101449 JACUBS73GX7103513

JACUBS73GW7102008 JACUBS73GX7101544 JACUBS73GX7103555

JACUBS73GW7102047 JACUBS73GX7101545 JACUBS73GX7103635

JACUBS73GW7102100 JACUBS73GX7101547 JACUBS73GX7103719

JACUBS73GW7102311 JACUBS73GX7103736

Continued over page

Page 20 of 21

Continued from previous page

1999 Model Year cont’d 1999 Model Year cont’d 2000 Model Year cont’d

JACUBS73GX7103898 JACUBS73GX7104750 JACUBS73GY7100998

JACUBS73GX7103909 JACUBS73GX7104765 JACUBS73GY7101000

JACUBS73GX7103953 JACUBS73GX7104774 JACUBS73GY7101002

JACUBS73GX7103963 JACUBS73GX7104777 JACUBS73GY7101009

JACUBS73GX7103982 JACUBS73GX7104779 JACUBS73GY7101022

JACUBS73GX7103984 JACUBS73GX7104780 JACUBS73GY7101038

JACUBS73GX7104005 JACUBS73GX7104781 JACUBS73GY7101060

JACUBS73GX7104076 JACUBS73GX7104786 JACUBS73GY7101070

JACUBS73GX7104078 JACUBS73GX7104800 JACUBS73GY7101071

JACUBS73GX7104128 JACUBS73GX7104812 JACUBS73GY7101083

JACUBS73GX7104147 JACUBS73GX7104813 JACUBS73GY7101092

JACUBS73GX7104174 JACUBS73GX7104820 JACUBS73GY7101127

JACUBS73GX7104218 JACUBS73GX7104822 JACUBS73GY7101140

JACUBS73GX7104259 JACUBS73GX7104827 JACUBS73GY7101180

JACUBS73GX7104288 JACUBS73GX7104836 JACUBS73GY7101181

JACUBS73GX7104322 JACUBS73GX7104839 JACUBS73GY7101226

JACUBS73GX7104382 JACUBS73GX7104844 JACUBS73GY7101233

JACUBS73GX7104399 JACUBS73GX7104845 JACUBS73GY7101287

JACUBS73GX7104400 JACUBS73GX7104852 JACUBS73GY7101290

JACUBS73GX7104419 JACUBS73GX7104854 JACUBS73GY7101294

JACUBS73GX7104436 JACUBS73GX7104860 JACUBS73GY7101299

JACUBS73GX7104450 JACUBS73GX7104861 JACUBS73GY7101362

JACUBS73GX7104464 JACUBS73GX7104863 JACUBS73GY7101376

JACUBS73GX7104480 JACUBS73GX7104864 JACUBS73GY7101384

JACUBS73GX7104481 JACUBS73GX7104872 JACUBS73GY7101389

JACUBS73GX7104483 2000 Model Year JACUBS73GY7101456

JACUBS73GX7104503 JACUBS73GY7100013 JACUBS73GY7101498

JACUBS73GX7104505 JACUBS73GY7100016 JACUBS73GY7101510

JACUBS73GX7104506 JACUBS73GY7100140 JACUBS73GY7101513

JACUBS73GX7104520 JACUBS73GY7100176 JACUBS73GY7101543

JACUBS73GX7104522 JACUBS73GY7100197 JACUBS73GY7101596

JACUBS73GX7104527 JACUBS73GY7100319 JACUBS73GY7101608

JACUBS73GX7104548 JACUBS73GY7100340 JACUBS73GY7101609

JACUBS73GX7104565 JACUBS73GY7100403 JACUBS73GY7101611

JACUBS73GX7104567 JACUBS73GY7100437 JACUBS73GY7101648

JACUBS73GX7104570 JACUBS73GY7100630 JACUBS73GY7101714

JACUBS73GX7104571 JACUBS73GY7100739 JACUBS73GY7101752

JACUBS73GX7104594 JACUBS73GY7100807 JACUBS73GY7101825

JACUBS73GX7104609 JACUBS73GY7100810 JACUBS73GY7101858

JACUBS73GX7104627 JACUBS73GY7100816 JACUBS73GY7101880

JACUBS73GX7104632 JACUBS73GY7100861 JACUBS73GY7101895

JACUBS73GX7104649 JACUBS73GY7100864 JACUBS73GY7101973

JACUBS73GX7104670 JACUBS73GY7100867 JACUBS73GY7101985

JACUBS73GX7104698 JACUBS73GY7100888

JACUBS73GX7104699 JACUBS73GY7100890

JACUBS73GX7104700 JACUBS73GY7100895

JACUBS73GX7104719 JACUBS73GY7100901

JACUBS73GX7104724 JACUBS73GY7100902

JACUBS73GX7104742 JACUBS73GY7100987

JACUBS73GX7104744 JACUBS73GY7100996

JACUBS73GY7100997

Appendix D – SALMAT MATERIAL ORDER FORM

Confirmation of parts order received by Salmat on:

Injector Seal Recall 03-H-03

Fax this form to SALMAT ON: (03) 9358 – 2999

IMPORTANT:

Only order parts after securing a vehicle booking.

The vehicle ISOVIN to be reworked must be specified below.

PART NUMBER APPLICATION

QTY

03-H-03 Injector Sleeve Recall Kit

VEHICLE ISOVIN

Contact Name: _______________________________________________

Retailer Code: _______________________ Date: ________________

Retailer Name: ______________________ Ph. No: ______________

Retailer Address: _______________________________________________

Fax No.: _______________________________________________

SALMAT USE ONLY

Retailer Order Acknowledgement faxed back to retailer within 24 hours of receiving YES / NO

QUANTITY REQUESTED DESPATCHED YES / NO (PLEASE CIRCLE APPROPRIATE

RESPONSE)

Date dispatched

FREIGHT FORWARD AGENT

Consignment Note Number

Page 21 of 21