HOLDEN SERVICE TECHLINE_____________________________________________________ __________JANUARY, 2003

4

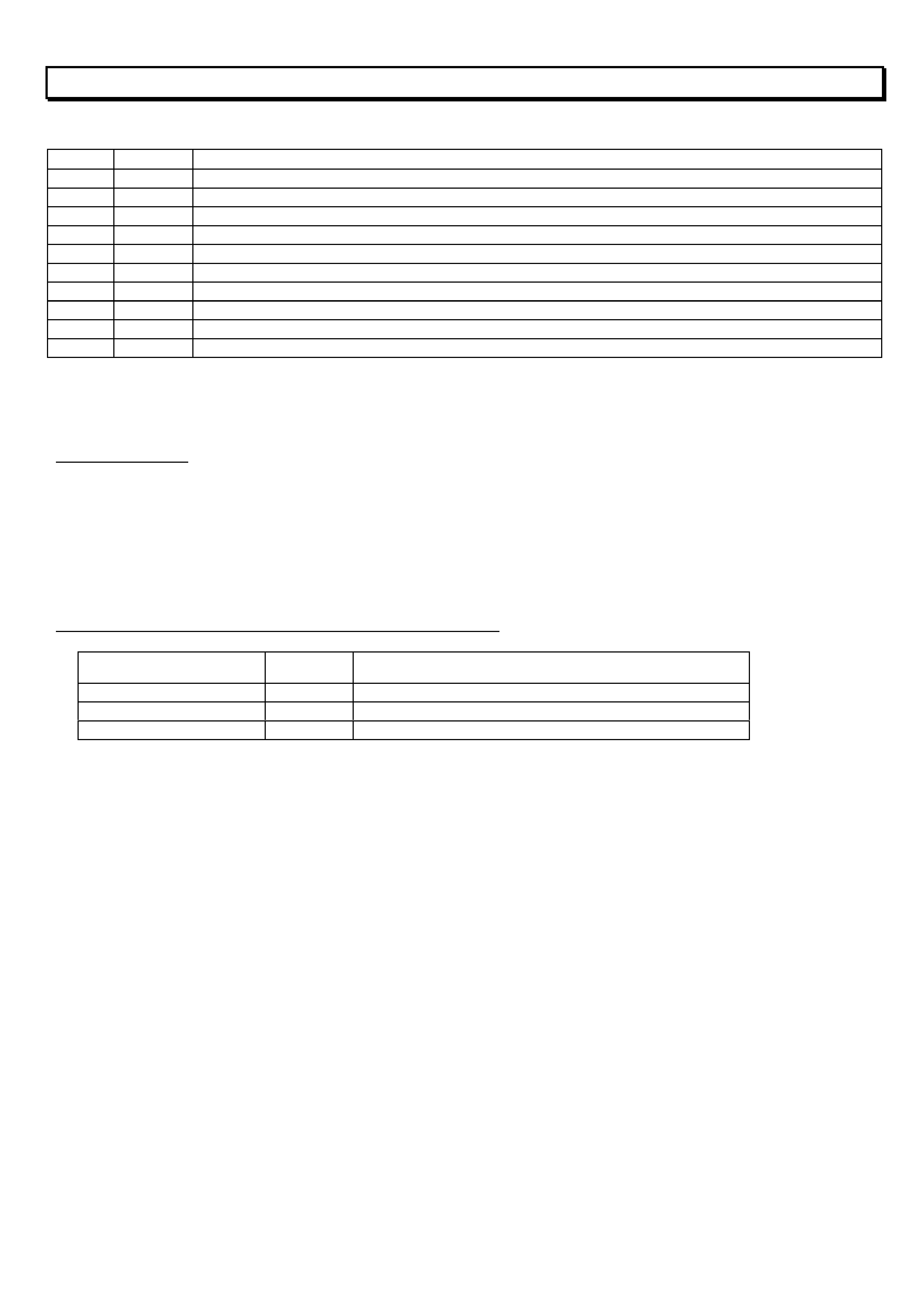

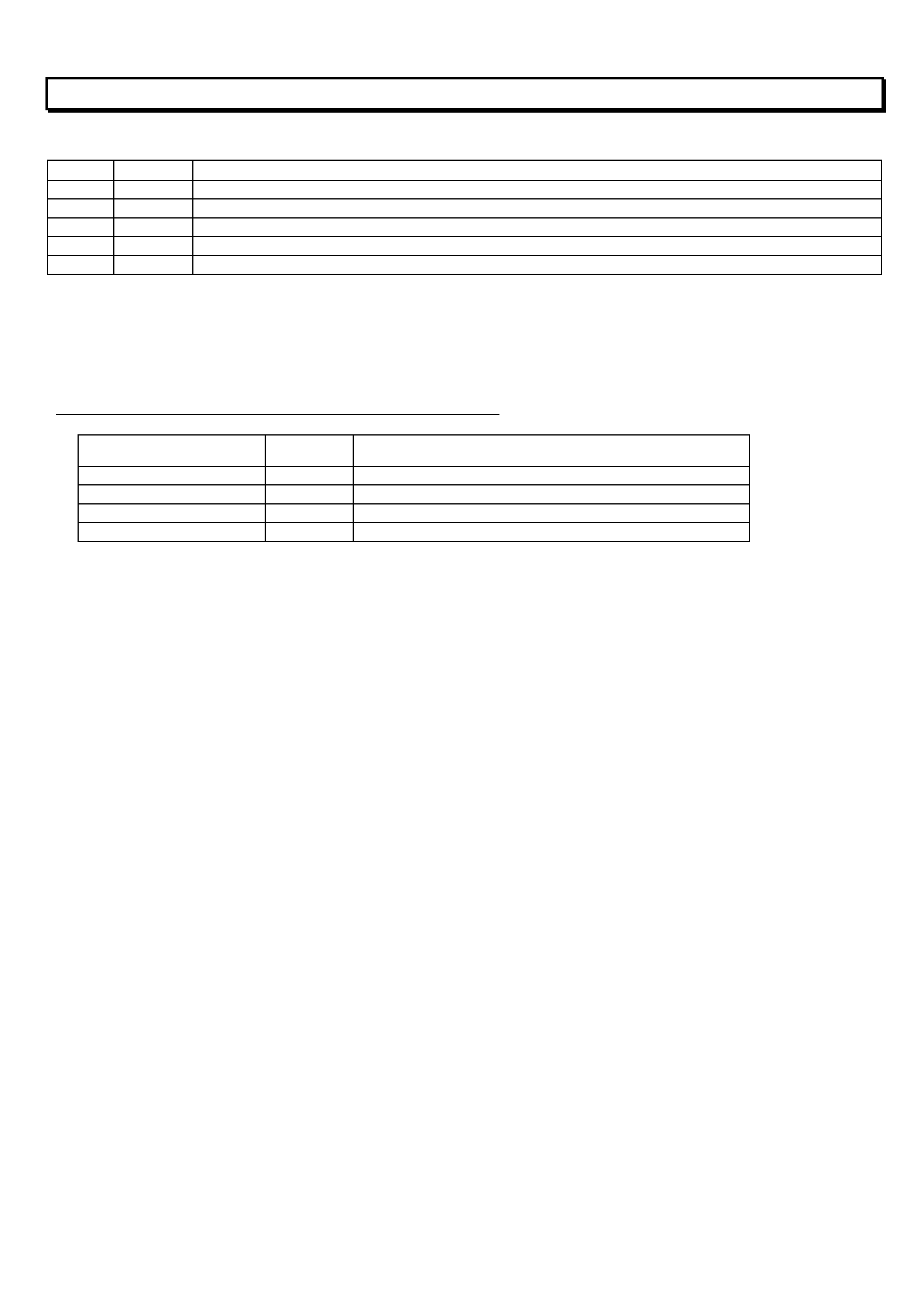

ALL HOLDEN RETAILER LETTER SUMMARY – 2003

All Holden Retailer Letters issued since the last Techline issue are as follows:

DL No. Date Title

89/02 TBA

90/02 19/12/02 Christmas Closedown Arrangements

91/02 19/12/02 Distribution Of TIS2000 CD ROM version 37.0B

92/02 20/12/02 Holden Customer Satisfaction Incentive Program

93/02 23/12/02 Distribution Of Holden PV SIP CD ROM version 5.1

i/03 20/1/03 Field Rework – VY Police Packs, Speedometer Calibration

2/03 24/1/03 Astra Owner Handbook Towing Information

3/03 29/1/03 Technicians Guild Enrolment Forms & Tax Invoice Details - 2003

Monthly Hints!

JS VECTRA - M/T 1st & 2nd LOW SPEED GEAR RATTLE

Some customers may complain of rattle noise emanating from the transmission at low speed, in 1st or 2nd gear.

Holden has a transm is sion change over program es tablished to addres s this concer n specific ally. If you get a c ustom er

report of this, verify the concern and speak with a TAS Consultant. They will confirm the symptoms and arrange a

change over transmission to be despatched accordingly.

Your Latest Electronic Service Information CD is:

Package: Version: Date Issued:

Passenger SIP 5.2 Feb 2003 RL TBA

Light Commercial SIP 3.3 Oct 2002 Refer RL 69/02

TIS 2000 38.0B Feb 2003 RL TBA

HOLDEN SERVICE TECHLINE____________________________________________________________FEBRUARY, 2003

5

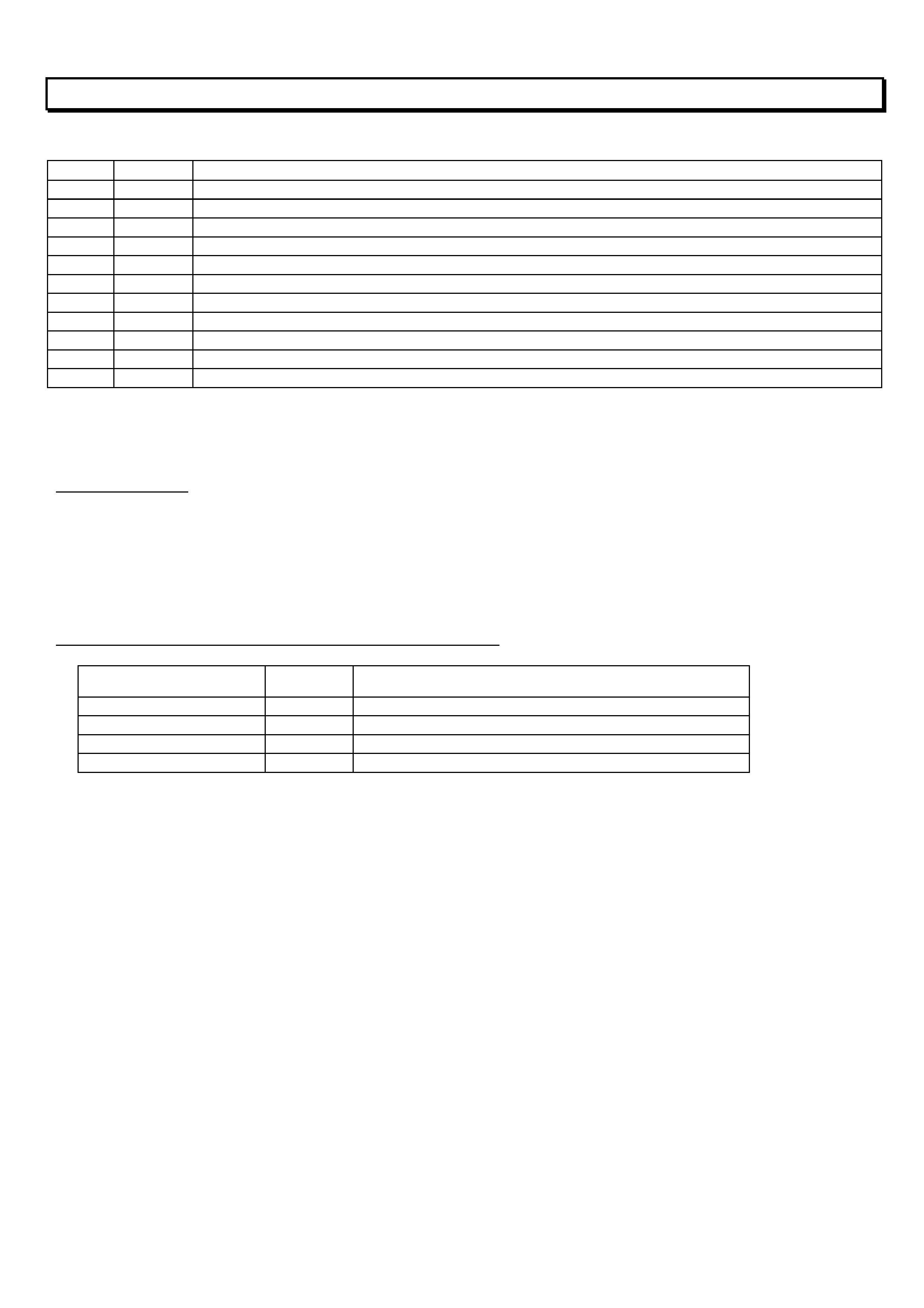

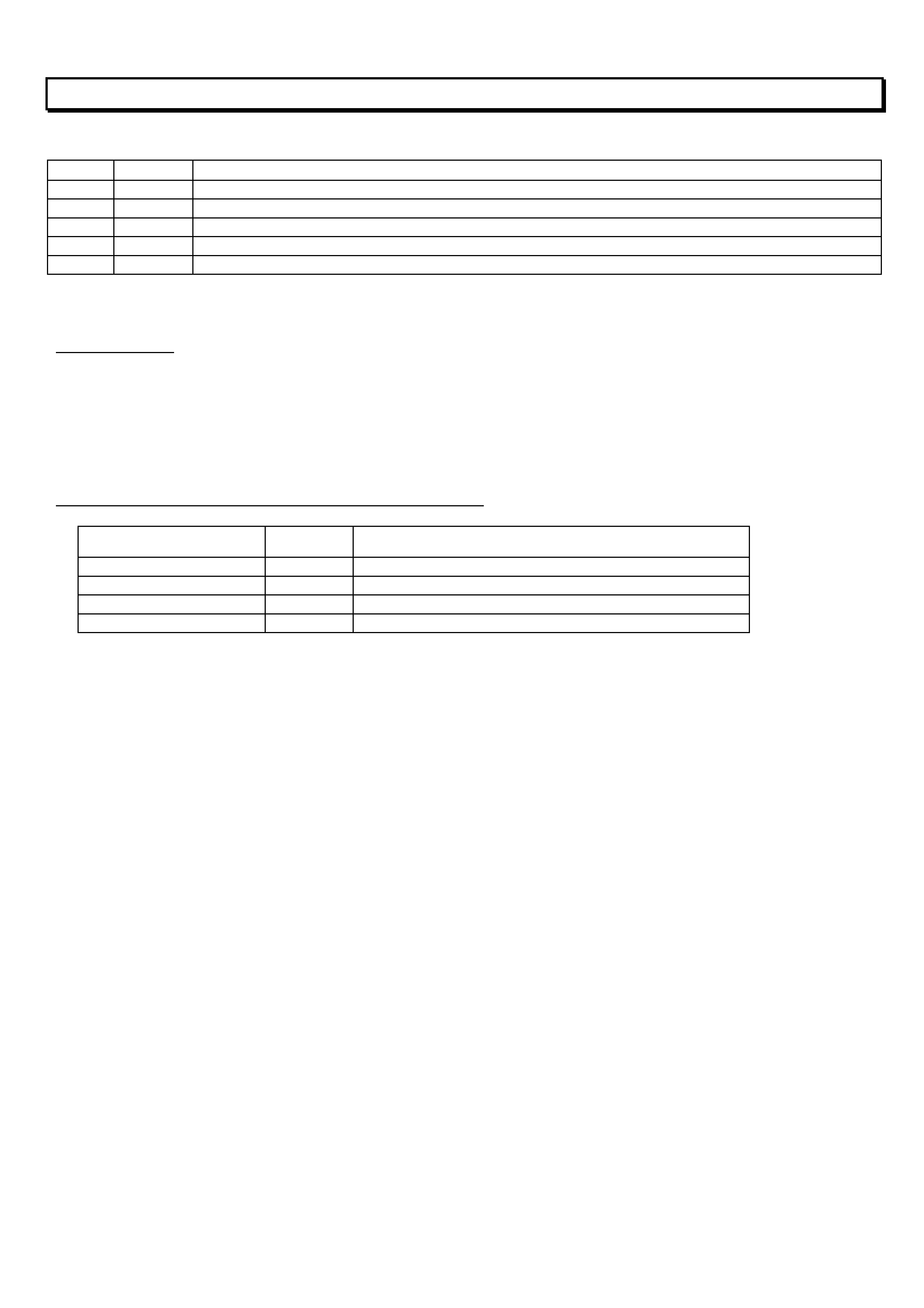

ALL HOLDEN RETAILER LETTER SUMMARY – 2003

All Holden Retailer Letters issued since the last Techline issue are as follows:

DL No. Date Title

4/03 3/2/03 V&W Models, Gen 3 V8 Engine Piston Revision

5/03 5/2/03 Distribution Of PV SIP 5.2 & TIS 2000 38.0B CDROMS

6/03 5/2/03 Service Readiness – TF Rodeo (MY03)

7/03 CANCELLED

8/03 25/2/03 Warranty Replacement Procedures for Blaupunkt Audio Head Unit – VY & V2 SeriesII Monaro

9/03 17/2/03 MY2003 TF Rodeo - Special Service Tools

10/03 TBA

11/03 20/2/03 Warranty Replacement Procedures for Fujitsu Ten Audio Head Unit – MY 2003 TF Rodeo (RA model)

12/03 19/2/03 Distribution of Light Commercial & Recreational SIP CDROM Version 4.1

13/03 25/2/03 ZC Vectra Owner Handbook Traction Control & Power Steering Fluid Check Information

14/03 26/2/03 Distribution of LCRV TIS 2000 #8.0B CDROM

Monthly Hints!

VY Instrument Configuration for LPG.

The ins trum ent conf iguration f or LPG on VY is dif fer ent from VX. T o enable the LPG gauge with Tech 2, you need first

to select V6 engine and then select V6 LPG.

Your Latest Electronic Service Information CD is:

Package: Version: Date Issued:

Passenger SIP 5.3 Mar 2003 refer RL TBA

Light Commercial SIP 4.1 Feb 2003 refer RL 12/03

TIS 2000 39.0B Mar 2003 refer RL TBA

LCRV TIS 2000 8.0B Feb 2003 refer RL 14/03

HOLDEN SERVICE TECHLINE__________________________________________________________________MARCH, 2003

5

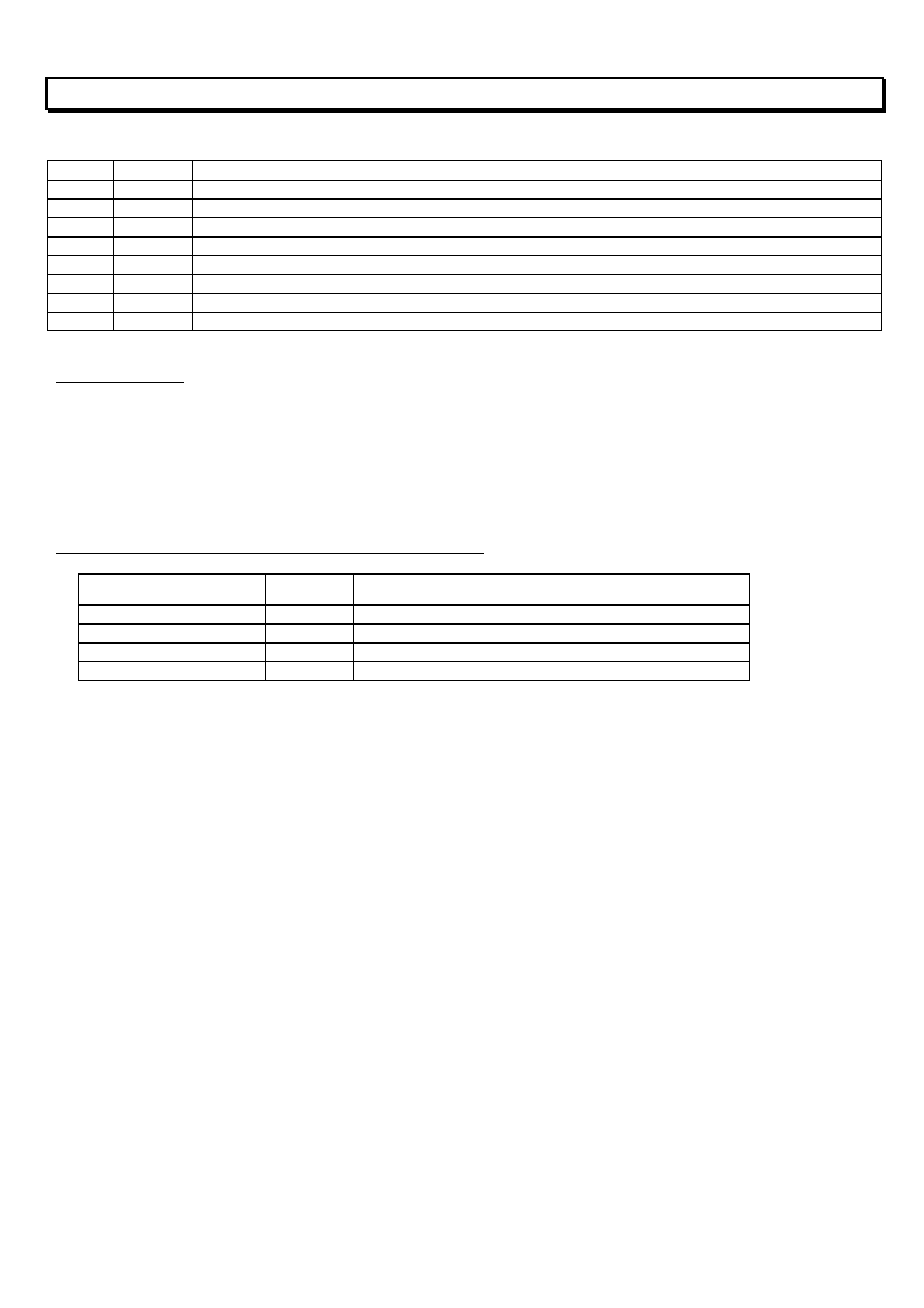

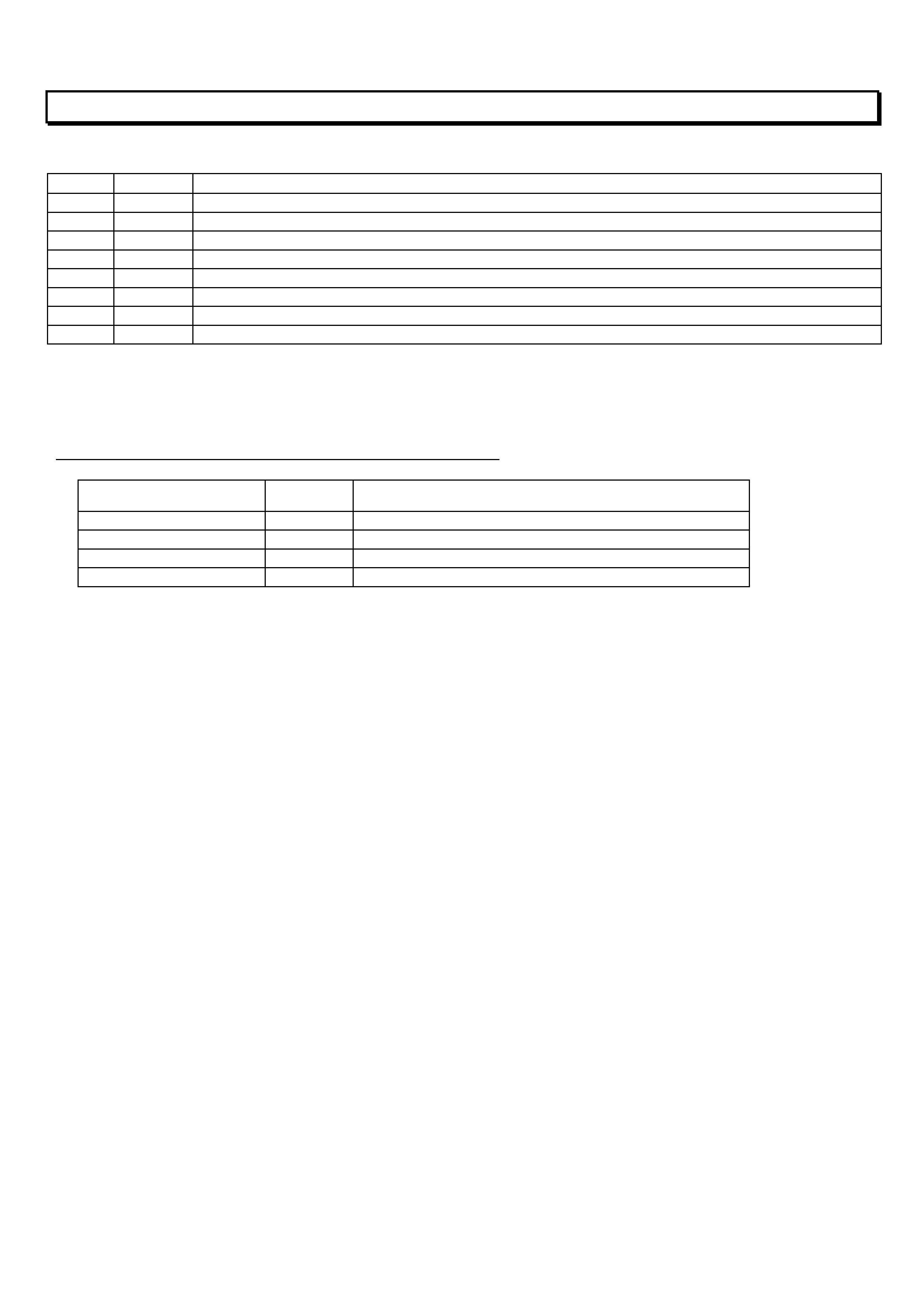

ALL HOLDEN RETAILER LETTER SUMMARY – 2003

All Holden Retailer Letters issued since the last Techline issue are as follows:

DL No. Date Title

15/03 3/3/03 Distribution of Holden TIS 2000 CDROM 39.0B

16/03 4/3/03 VX,WH,V2,VY -Holden Assist Clarification Of Modes Of Operation -

17/03 4/3/03 RA Rodeo Early Warning Program

18/03 11/3/03 Distribution Of PV SIP 5.3 CDROM

19/03 18/3/03 Distribution Of ZC Vectra Mandatory Special Service Tools

20/03 19/3/03 VY & LPG, Sedan & Ute – Default to LPG On Startup

21/03 20/3/03 RA Rodeo – Incorrect Thermistor Connector

22/03 20/3/03 RA Rodeo – A/C Fitting Instruction Corrections

Monthly Hints!

Service Techlines “O n- Li ne”.

For inf ormation about viewing Service T echlines “On Line” on your Retailers PCs make s ure you r ead pages 9 and 10

of this iss ue. This allows you to get the inf orm ation well in advance of rec eiving the printed version via the T echnicians

Guild or the copy your Service manager receives in the mail.

Your Latest Electronic Service Information CD is:

Package: Version: Date Issued:

Passenger SIP 5.3 Mar 2003 refer RL 18/03

Light Commercial SIP 4.1 Feb 2003 refer RL 12/03

TIS 2000 39.0B Mar 2003 refer RL 15/03

LCRV TIS 2000 8.0B Feb 2003 refer RL 14/03

HOLDEN SERVICE TECHLINE_________________________________________________________________ APRIL, 2003

5

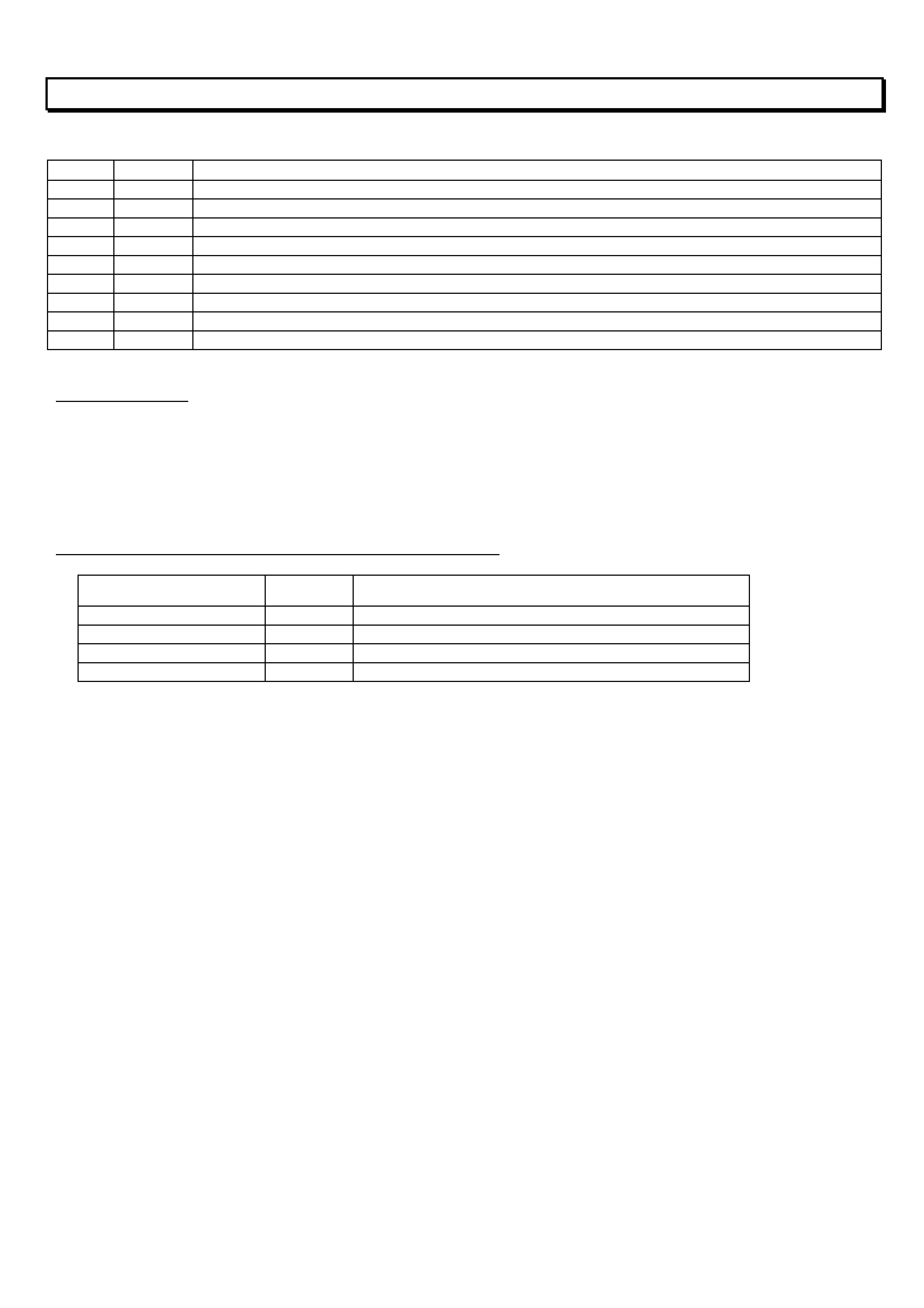

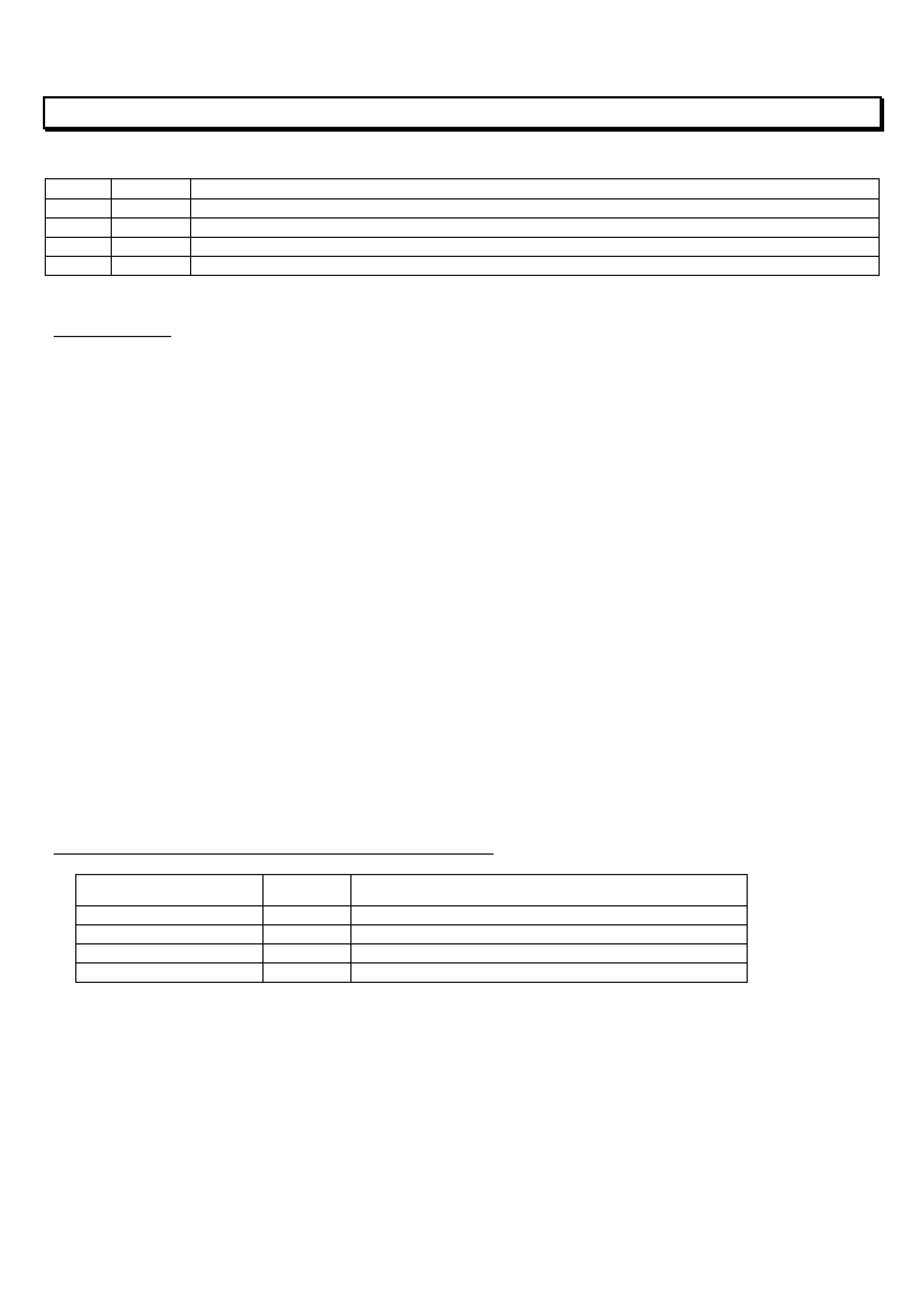

ALL HOLDEN RETAILER LETTER SUMMARY – 2003

All Holden Retailer Letters issued since the last Techline issue are as follows:

DL No. Date Title

23/03 4/4/03 Service Readiness – WK Statesman & Caprice

24/03 4/4/03 SSS Service consultant and technician reporting

25/03 7/4/03 Distribution of PV SIP 5.4 & TIS 2000 #40.0B CD ROMS

26/03 7/4/03 Warranty replacement procedures for Clarion audio head unit – YG Cruze

27/03 4/03 ZC Vectra owners handbook – CAN Bus interference warning stickers

28/03 23/4/03 Service Readiness – ZC Vectra

29/03 22/4/03 Warranty replacement procedures for Siemens VDO Sat. Nav. System components – VY,V2, WK

30/03 TBA

31/03 30/4/03 Distribution of LCRV SIP 4.2 and LCRV TIS2000 9.0

Monthly Hints!

Service Techlines are now “O n- Line”.

For information about viewing Service Techlines “On Line” at your Retailership read pages 9 and 10 of the previous

techline issue 3/2003. This allows you to get the information well in advance of receiving the printed version.

Your Latest Electronic Service Information CD is:

Package: Version: Date Issued:

Passenger SIP 5.4 Apr 2003 refer RL 25/03

Light Commercial SIP 4.2 Apr 2003 refer RL 31/03

TIS 2000 40.0B Apr 2003 refer RL 25/03

LCRV TIS 2000 9.0B Apr 2003 refer RL 31/03

HOLDEN SERVICE TECHLINE___________________________________________________________________ MAY, 2003

5

ALL HOLDEN RETAILER LETTER SUMMARY – 2003

All Holden Retailer Letters issued since the last Techline issue are as follows:

DL No. Date Title

30/03 5/05/03 Warranty replacement procedures for Panasonic DVD system components – WK Caprice

31/03 30/4/03 Distribution of LCRV SIP 4.2 and LCRV TIS2000 9.0

32/03 9/05/03 Distribution of PV SIP 5.5, TIS 2000 41.0B and VY Wiring Manual update pages

33/03 27/05/03 Service Readiness – VY Cab Chassis

34/03 28/05/03 Special Service Tools – RA Rodeo and VY Regular Cab Chassis

Your Latest Electronic Service Information CD is:

Package: Version: Date Issued:

Passenger SIP 5.5 May 2003 refer RL 32/03

Light Commercial SIP 4.2 Apr 2003 refer RL 31/03

TIS 2000 41.0B May 2003 refer RL 32/03

TIS 2000 LCRV 9.0B Apr 2003 refer RL 31/03

HOLDEN SERVICE TECHLINE________________________________________________________________ JUNE, 2003

5

ALL HOLDEN RETAILER LETTER SUMMARY – 2003

All Holden Retailer Letters issued since the last Techline issue are as follows:

DL No. Date Title

35/03 6/6/03 TS Astra Z18XE Revised Engine Calibration for DTC P0335

36/03 13/6/03 New Repairer for Tech 2 & Candi Module

37/03 19/6/03 Distribution of Passenger Vehicle Service Information for June.

38/03 24/6/03 Distribution of TIS 2000 #42.0 CDROM

39/03 24/6/03 Distribution of Light Commercial & Recreational Service Information Package 4.3

Monthly Hint!

Service Techlines now “O n- Line”.

For information about viewing Service Techlines “On Line” at your Retailership read pages 9 and 10 of Service Techline

Issue 3/2003. Us ing this method allows you to get Service Techlines approx imately 2 week s in advance of receiving the

printed version.

Your Latest Electronic Service Information CD is:

Package: Version: Date Issued:

Passenger SIP 5.6 June 2003 refer RL 37/03

Light Commercial SIP 4.3 June 2003 refer RL 39/03

TIS 2000 42.0 June 2003 refer RL 38/03

TIS 2000 LCRV 9.0B Apr 2003 refer RL 31/03

HOLDEN SERVICE TECHLINE___________________________________________________________JULY, 2003

3

ALL HOLDEN RETAILER LETTER SUMMARY – 2003

All Holden Retailer Letters issued since the last Techline issue are as follows:

DL No. Date Title

40/03 27/6/03 03-H-01 SAFETY RECALL CAMPAIGN – V2 Monaro Series II CV8 and V2 Series II HSV Coupe

41/03 3/7/03 Gen III Engine Product Information

42/03 7/7/03 Fujitsu Ten Change Of Address – RA Rodeo Audio System

43/03 TBA

44/03 17/7/03 TECH 1 Repairs

45/03 18/7/03 Holden By Design (HBD) Product Information

46/03 22/7/03 CAUTION – Do Not Reprogram VY V6 Cab Chassis PCM With TIS 2000 CD 42 and 43

Your Latest Electronic Service Information CD is:

Package: Version: Date Issued:

Passenger SIP 5.6 June 2003 refer RL 37/03

Light Commercial SIP 4.3 June 2003 refer RL 39/03

TIS 2000 42.0 June 2003 refer RL 38/03

TIS 2000 LCRV 9.0B Apr 2003 refer RL 31/03

HOLDEN SERVICE TECHLINE______________________________________________________________SEPTEMBER, 2003

3

ALL HOLDEN RETAILER LETTER SUMMARY – 2003

All Holden Retailer Letters issued since the last Techline issue are as follows:

DL No. Date Title

50/03 TBA

51/03 26/8/03 Distribution of TIS 2000 44.0 CDROMS

52/03 10/9/03 VY Reg Cab – Insufficient clearance between Tow ball & Number Plate Support OnTriple M Trays

53/03 22/9/03 VY Reg Cab – Rear Disc Brake Scraping Noise

Monthly Hint!

VY Gear Lever Boot Replacement Made Easy

There have been a few concerns raised about fitting new gear lever boots to VY 6-speed shifters. The Pass. SIP

procedure is OK – but some boots may be hard to ‘stretch’ over the base of the shift lever! In these cases – there are

existing small cuts in the shifter boot material between the four stitched ends at the lever hole – just increase the depth

of the each cut by 2mm and the boot will more readily stretch over the lever.

V & W Car – Pinion Seal Oil “Weeps” or “Leaks”?

A small amount of oil “weepage” may be found near the rear axle pinion seal - at pre-delivery or first service.

Note that assembly oil is applied to the pinion seal during manufacture to ensure good bed-in, as when the axle is in

service, the seal is lubricated by the internal diff oil. Trials conducted at the supplier show that up to 8mL of oil can be

drained "off" the housing following the current oiling process!

This could be the source of the "weep" and the perceived "leaks" reported by Retailers.

An alternative lubrication method is being tested so that this perceived weep or leak does not occur in future.

Please do not replace pinion seals before cleaning the pinion nose/seal area and assessing for actual leakage.

Gen III Engine Replacement

When fitting a GenIII V8 “G3A” engine – the engine supplied may carry a different oil sender; or valley cover (2004

engines carry internal PCV components). If these parts on the new engine differ from the old engine - ensure you

exchange the parts – do not attempt to upgrade the old engine to the new engine’s PCV system.

Gen III Engine - Head Bolt Fitting

When replacing Gen III V8 head bolts for any reason – the following process is recommended: Blow out the head bolt

holes with compressed air to remove and dry out coolant residue/oil/etc; using a DRY tap - clean out old sealant

residue from threads; blow out the holes to remove the resultant sealant debris. Failure to carry out this process may

result in thread damage or cracking of the cylinder block.

Your Latest Electronic Service Information CD is:

Package: Version: Date Issued:

Passenger SIP 5.9 Sep 2003

Light Commercial SIP 4.3 June 2003 refer RL 39/03

TIS 2000 44.0 Aug 2003 refer RL 51/03

TIS 2000 LCRV 9.0B Apr 2003 refer RL 31/03