2

20

00

04

4

C

CA

AM

MP

PA

AI

IG

GN

N

B

BU

UL

LL

LE

ET

TI

IN

NS

S

© 2006 GM Holden LTD. A.B.N. 84 006 893 232

Service Department

A “HOLDEN” Product.

BRISBANE SYDNEY MELBOURNE ADELAIDE PERTH

For the latest and/or any missing Campaign Bulletins,

please refer to Holden Lionheart

Technical Instructions

Technical Instructions

XC Combo

Campaign 04-H-01

Concern

The steering wheel may loosen

on the steering column

diminishing driver control.

Cause

The screw fastening the steering

wheel to steering column may be

below the required torque

specification.

Solution

Replace centre torx screw and

torque to 30 Nm.

Method

Models : MY 2003 – 2004 XC Combo

Part Required :

Quantity Part No. Part Description

1 24 454 509 Torx Screw

Special Tool Required

1 M15 x 1.5 thread tap

Affected Vehicle ISOVIN:

W0L0XCF2543006613

STEP 1

Disconnect negative lead from battery. Wait 1 minute

unit the capacitor has discharged.

Note: Ensure radio PIN number is available before

disconnecting the battery.

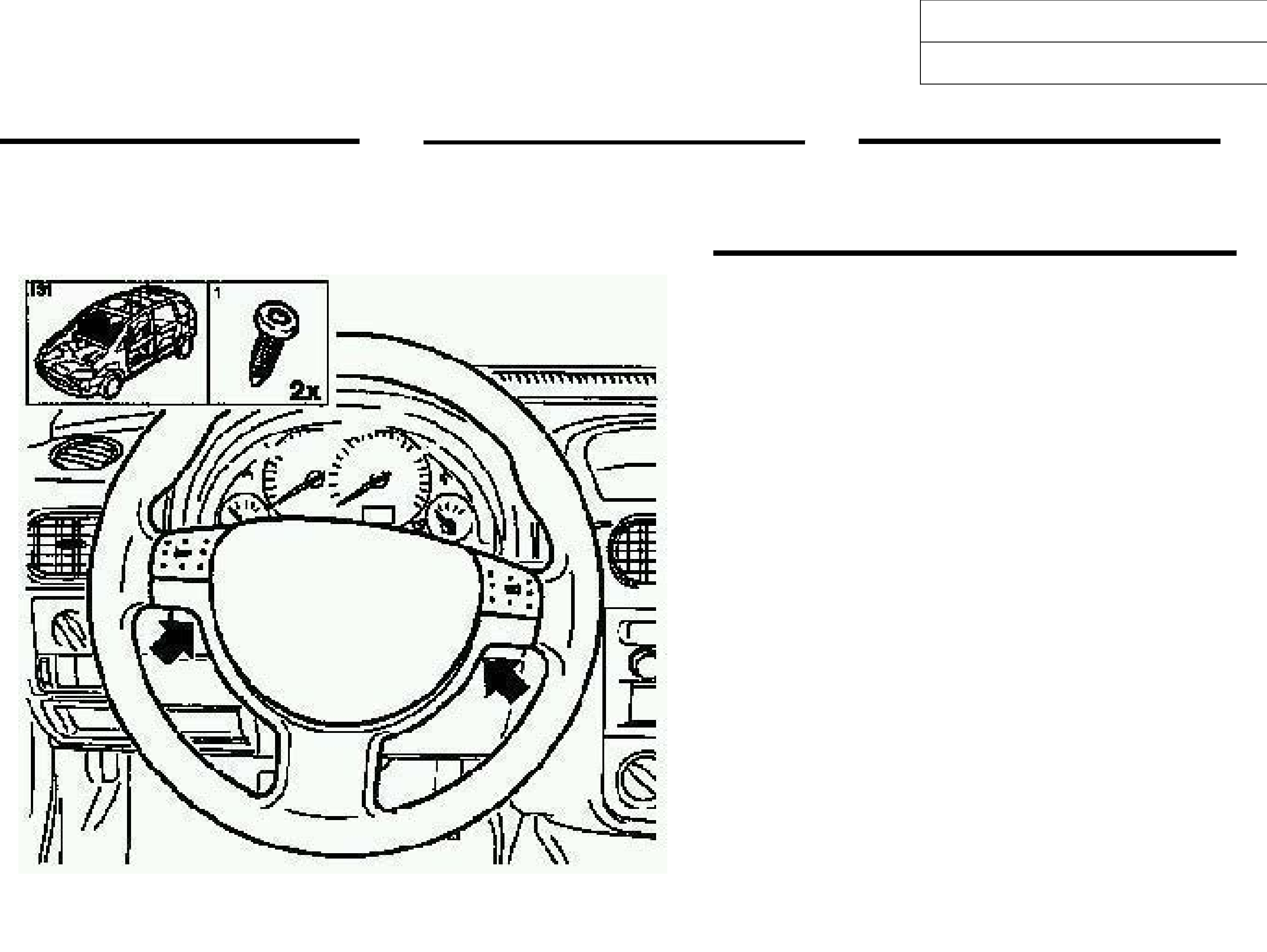

STEP 2

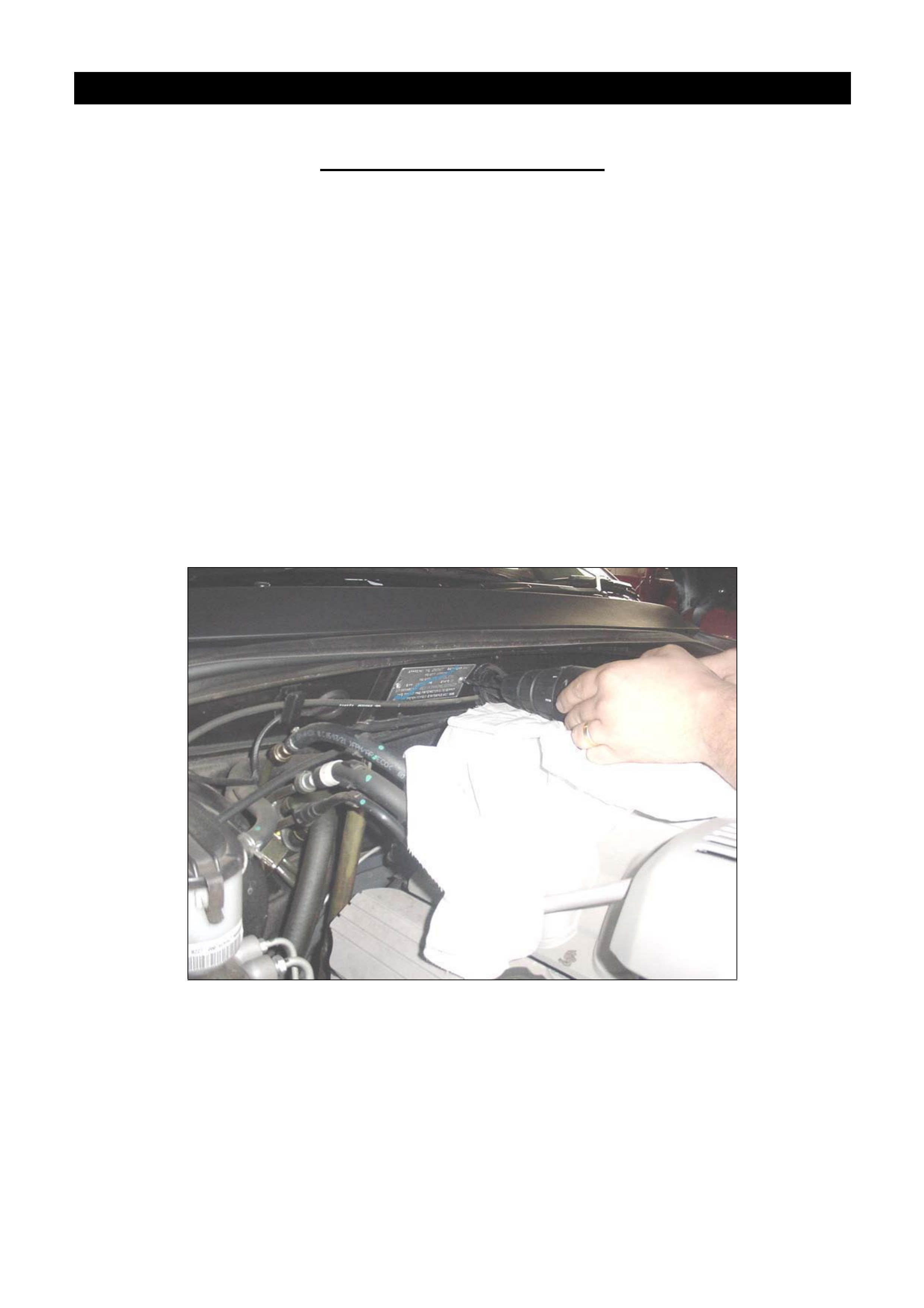

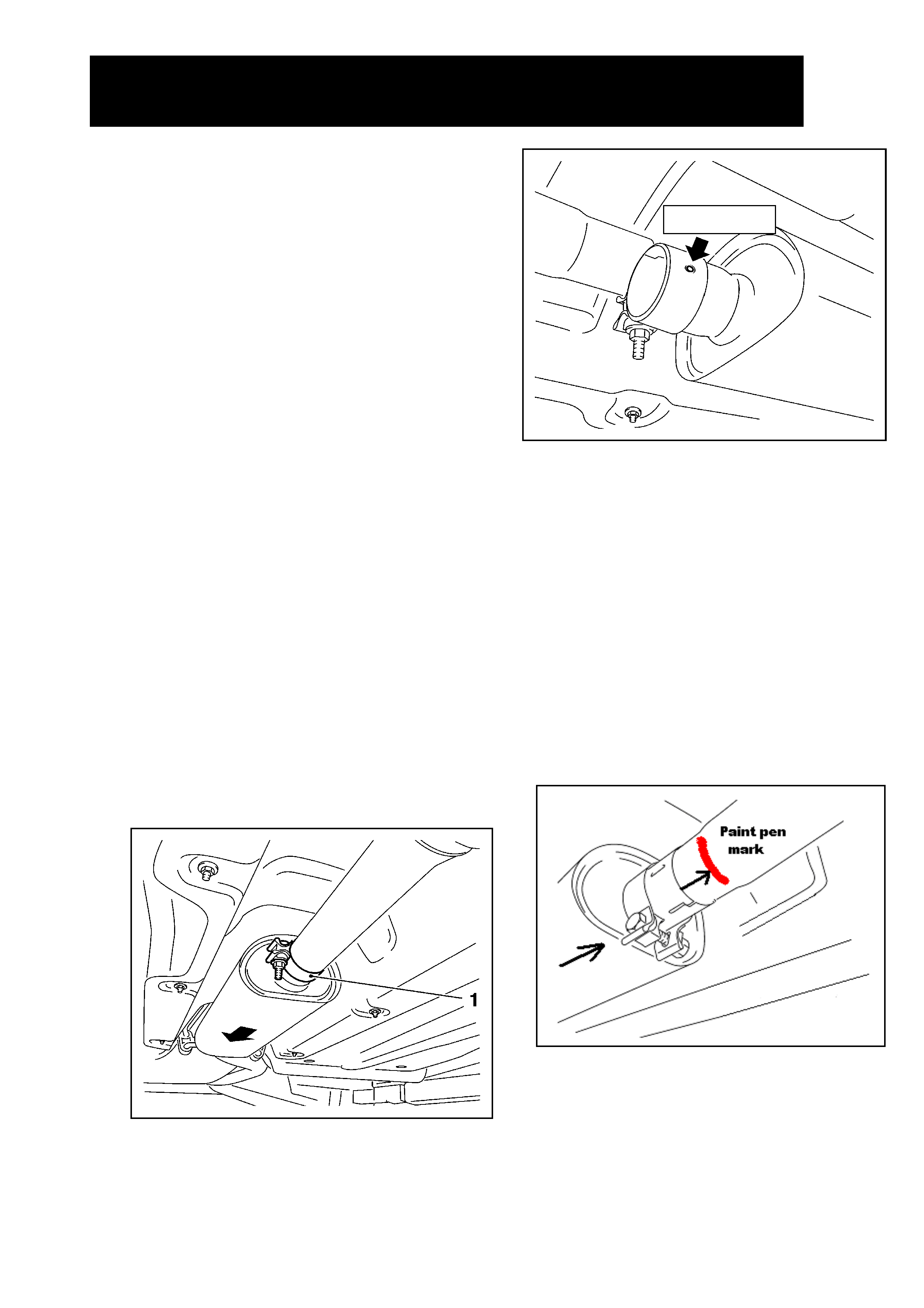

Dis-assemble two M6 x 20 torx screws from the rear

of the steering wheel assembly (Refer to Figure 1).

STEP 3

Carefully lift airbag unit, noting the wiring harness

route for reinstallation later. Release airbag wiring

harness plug and detach.

NOTE: Always set aside airbag unit with padded

side upwards.

Figure 1

XC Combo

Campaign 04-H-01

Method

STEP 4

Turn steering wheel to straight-ahead position,

remove ignition key and allow steering lock to

engage.

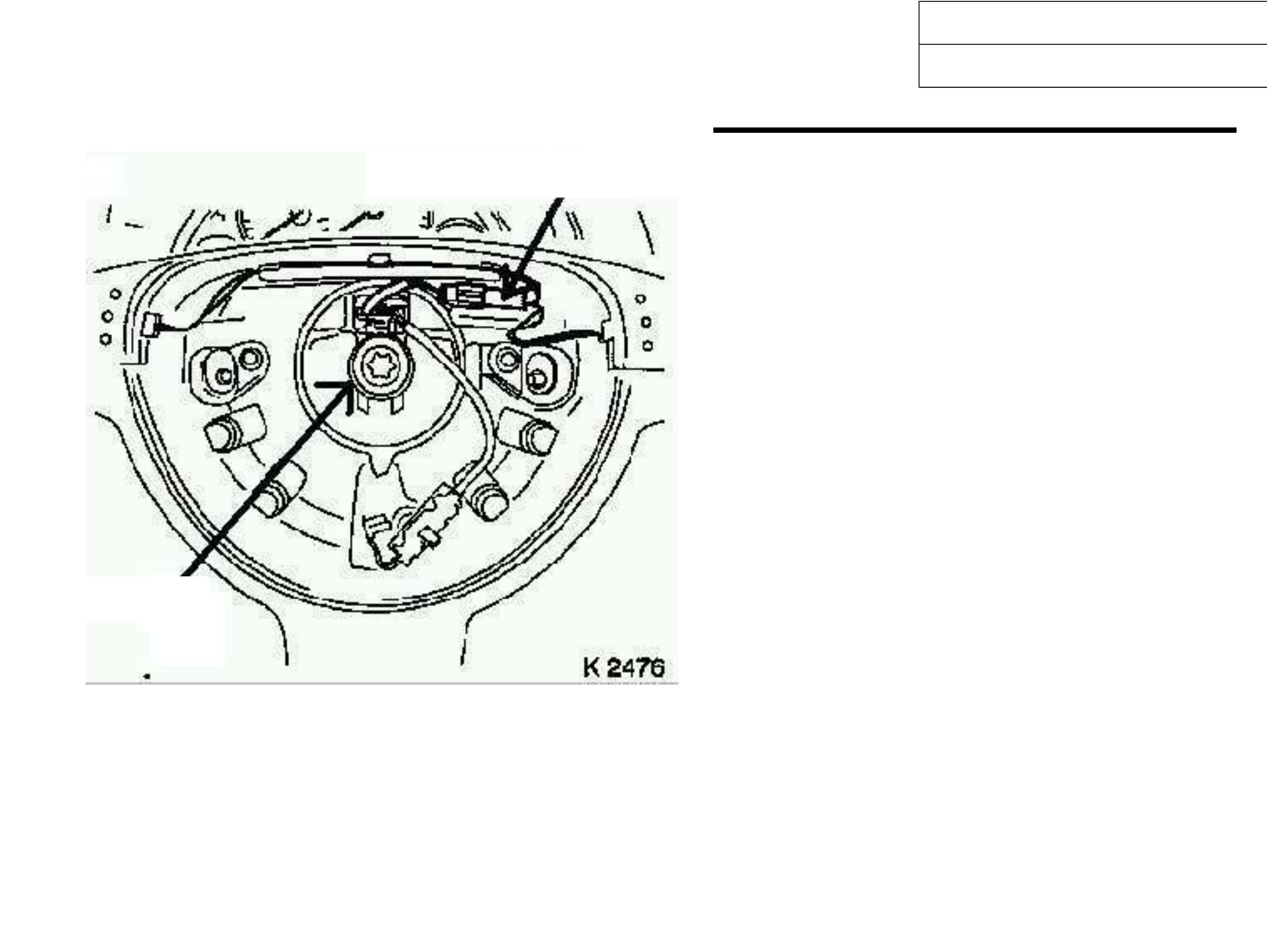

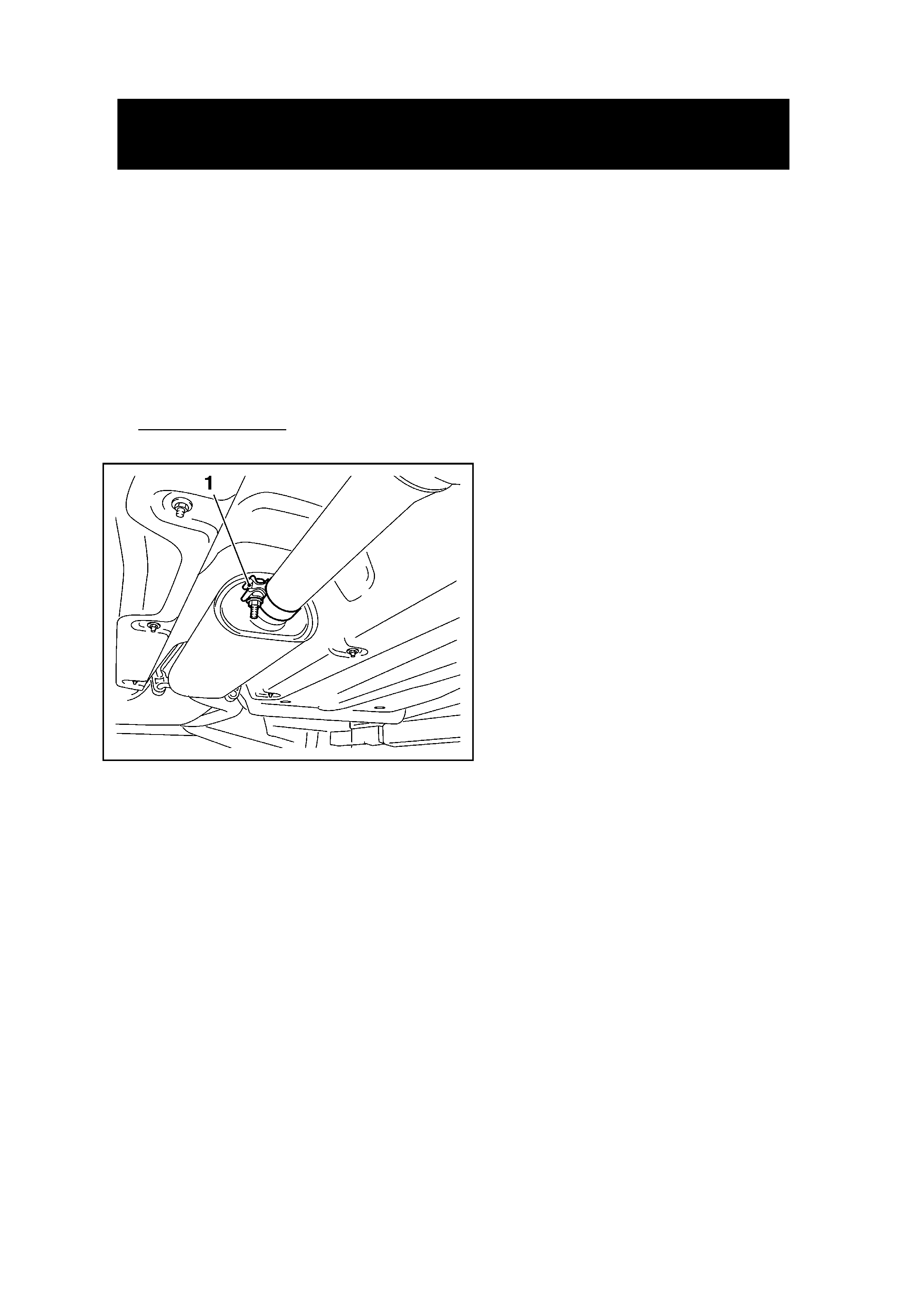

STEP 5

Remove horn wiring harness connector from steering

wheel bracket and disengage connector (Refer to

Figure 2).

STEP 6

Loosen and remove the M15 x 20 steering wheel

attaching torx screw (Refer to Figure 2). Retain this

M15 screw for return to Repac when requested via

Repac Report.

STEP 7

Use the Ø M15 x 1.5 thread tapping tool, to clean the

locking compound from the steering shaft thread (no

metal should be cut during this step). Run the tap

carefully down the thread. Never force the tap it

should rotate easily. To avoid breaking the tap, be

prepared to stop rotating clockwise once the tap

reaches the bottom of the hole.

NOTE: This step must be performed as it

will clean from the thread existing locking

compound.

Figure 2

Technical Instructions

Technical Instructions

Torx screw

Wiring harness connector

XC Combo

Campaign 04-H-01

Method

STEP 8

Assemble new M15 x 20 steering wheel attaching

torx screw and carefully tighten to 30 Nm with a

torque wrench (Refer to Figure 2).

Note: Tightening to 30Nm with a torque wrench in

this application is important.

STEP 9

Engage horn wiring harness connector and clip into

the bracket on the steering wheel. Route the wiring

harness as previously observed at step 3 (Refer to

Figure 2).

STEP 10

Assemble airbag wiring harness plug to airbag unit.

STEP 11

Assemble airbag unit to steering wheel using the two

original M6 x 20 torx screws and tighten to 8 Nm

(Refer to Figure 1).

Technical Instructions

Technical Instructions

STEP 12

Connect negative lead to battery and ensure radio

PIN is re-entered and radio operates correctly.

Campaign completed Identification:

Apply a Recall Campaign Label to the right hand

front “A” pillar between the hinges, with details of the

campaign, 04-H-01, Retailer code and Date legibly

entered on the label with a permanent ink pen.

Additionally, mark position C-1on the Vehicle Service

History Label and apply it to the inner side of the

lower instrument panel cover.

Warranty claim information

Description Replace torx screw

Labour Opern number T480801

Standard time 0.5 hr

Failure Code 96 (NOW J0096)

04-H-01 Contact Information

General

enquiries

Brett Fowler (03) 9647 1857

Technical

enquiries

TAS 1800 033 417

Warranty

enquiries

Warranty

Administration

(03) 9647 2401

21/04/04

1of 7

PRODUCT CAMPAIGN BULLETIN

04-H-02

April 20, 2004

SUBJECT: REPLACEMENT OF INCORRECT COMPLIANCE PLATE

MODELS AFFECTED: VY ONE TONNER & CREWMAN

This bulletin announces the initiation of a safety recall campaign to install the correct

compliance plate to some VY One tonner & Crewman model vehicles.

DESCRIPTION OF DEFECT

Since the start of VY One tonner & Crewman vehicle production the compliance

plate has displayed technically incorrect information in regard to the model

designation and approval number of the vehicle.

To correct this situation, Holden has initiated this recall action to ensure that every

affected vehicle is updated to include the correct compliance plate in accordance

with the Australian Motor Vehicle Standards Act 1989.

Correct VY One tonner compliance plates will display the following model

designation:

• Holden VY Utility (Since One tonner was certified under the “Utility”

compliance submission).

Correct VY Crewman compliance plates will display the following model

designation and approval number:

• Holden VY Utility (Since Crewman was also certified under the “Utility”

compliance submission).

• 24567

AFFECTED VEHICLES

Affected Build Date Range

Body Style

From To

Cab Chassis 05/05/2003 09/10/2003

Crew Cab 15/05/2003 09/10/2003

Note: For reference and vehicle flagging purposes in Retailer management systems

use the following Tag numbers:

L112322 to L182309

plus

L985274, L985304, L988652, L988664, L988686, L988688.

ACTION REQUIRED BY RETAILERS

1. Confirm vehicle Build date is within the range shown in the “Affected Vehicles”

table.

2. Confirm vehicle has not previously been reworked i.e:

Identified by an ‘X’ in the B-1 co-ordinate of the “Vehicle Service History”

label

Application of “04-H-02 Campaign Completed” label.

3. If vehicle has not been reworked, proceed with campaign.

21/04/04

2of 7

4. Organise a vehicle booking. (Allow 5 full days for shipping of the replacement compliance plate)

5. Immediately request the replacement compliance plate from SALMAT using the Salmat Material

Order Form attached. Note: Booking date will be required to order a replacement compliance

plate. Refer to Appendix C.

6. Double check that the VIN number on the supplied new plate matches the vehicle VIN number.

7. Remove originally installed compliance plate and install plate supplied by Salmat. Refer

Replacement Instruction Appendix B.

8. Affix a Campaign Completed Label and a Vehicle Service History Label as specified in the

section titled ‘Campaign Completion Identification’.

9. Return incorrectly stamped (replaced) compliance plate immediately to Salmat in the supplied

pre-paid satchel (after cutting into 2 pieces).

10. Submit a warranty claim. Refer “Warranty Claim Information”.

CUSTOMER NOTIFICATION

Owners of vehicles affected by this recall campaign will be contacted directly by letter from Holden.

The letter provides details of the recall campaign and requests the customer to contact their Holden

Retailer to make a service booking to have the appropriate work carried out. Refer to Appendix A

for a draft copy of the customer letter.

CAMPAIGN COMPLETION IDENTIFICATION

All campaigned vehicles must have:

1. A Campaign Completed label applied to the right hand front ‘A’ pillar, between the hinges, with

details of the campaign, 04-H-02, Dealership code and date legibly entered on the label with a

permanent ink pen.

AND

2. For additional identification, mark an “X” at the B-1 co-ordinate of a Vehicle Service History

Label and apply to the inner side of the lower instrument panel cover if not already fitted.

Extra Campaign Completed and Vehicle Service History labels are available free of charge from

Moore Business Systems.

• For Campaign Completed Labels Quote stock no. SD 28156 on a Moore Business Systems

‘Packaged Goods’ order form for a pack of 100 labels.

• For Vehicle Service History Labels quote stock no. SD 28177 on a Moore Business Systems

‘Packaged Goods’ order form for a pack of 100 labels.

Fax the order form to Moore Business Systems on Facsimile: (03) 9270 8925

Should you need to follow-up on a placed order, contact Moore customer service on telephone

number (03) 9270 8788.

21/04/04

3of 7

PARTS INFORMATION

A specific replacement compliance plate is available from Salmat for each affected vehicle. Once a

customer booking is made, immediately order the replacement Compliance Plate for the booked

vehicle by completing the Material Order Form attached, (refer to Appendix C) and fax it to

SALMAT. The fax number is shown on the Material Order form.

The replacement compliance plate will be forwarded to your retailer premises by “Registered Mail.”

Please note that to maintain Compliance Plate security, the person requesting the replacement

plate will be required to sign for receipt of the plate at the delivery address (retailer premises), or at

the local Post Office if unavailable to sign at the Retailer premises. The person requesting the plate

is also responsible for ensuring it is correctly fitted to the vehicle.

Once received, store the replacement plate in a safe and secure location to avoid loss or damage.

Please note that if compliance plates are lost or misplaced replenishment is not possible.

Two special pop rivets will be supplied to secure the compliance plate to the vehicle, these rivets

must be used.

WARRANTY CLAIM INFORMATION

On completion of campaign action, retailers are requested to submit a warranty claim using the

Labour Operation Number specified below.

Warranty Claim Information

Description

Replace Compliance Plate

Labour Operation No.:

Standard Time:

Failure Code:

Case Type:

T480901

0.5 hours

96 (NOW J0096)

08

CONTACT INFORMATION

For further information or clarification on this recall campaign please contact the relevant person

below.

CONTACT NAME CONTACT NUMBER

General enquiries Brett Fowler

(03) 9647 1857

Parts related enquiries Salmat (03) 9358 2990

Warranty related enquiries Warranty Administration (03) 9647 2401

J. K. Hoffman

General Service Manager

Attachments

Appendix A Customer Letter- Draft

Appendix B Replacement Instruction

Appendix C Material Order Form

21/04/04

4of 7

APPENDIX A - Draft – Customer Letter

Dear Holden Customer,

As part of Holden’s ongoing commitment to customer satisfaction, we have initiated

a Vehicle Recall Campaign affecting some One Tonner and Crewman model

vehicles.

Holden has become aware that an incorrect compliance plate has been fitted to

some of these vehicles.

In these cases the compliance plate does not specify the correct model designation

and, - in the case of the Crewman- approval number. It is a requirement under the

Australian Motor vehicle Standards Act (1989) C’th requirement that the

compliance plate information of a vehicle is correct.

To ensure the compliance plate includes the correct model designation and

approval number, the compliance plate needs to be replaced.

Our records show that your Holden vehicle was manufactured with the incorrect

compliance plate. It is therefore necessary for you to make a booking, at your earliest

convenience, with a Holden Retailer of your choice to have the correct compliance

plate fitted. Please allow the Holden Retailer at least 5 days to receive the specific

replacement compliance plate for your vehicle.

Work will be carried out free of charge, and provided the necessary arrangements

have been made with a Holden Retailer, can be completed while you wait.

If you have any questions, please contact your Holden retailer or call the Holden

Recall and Rework Assistance Centre on 1800 632 826, where we will be pleased to

assist.

Thank you for your attention to this matter. Please accept our apologies for any

inconvenience that may be caused to you.

Yours Sincerely

David McMurray

Manager Customer Assistance

VEHICLE SAFETY RECALL

21/04/04

5of 7

APPENDIX B – REPLACEMENT INSTRUCTION

Technical Procedure

1. Inspect the new Safety Compliance Plate supplied by SALMAT to confirm the VIN

corresponds with the VIN of the vehicle.

2. Mark a permanent line through the centre of the Safety Compliance Plate currently fitted to

the centre of the dash panel, prior to removal to allow easy identification of the old plate.

3. Drill out the rivet heads of the Safety Compliance Plate – do not drill into the vehicle sheet

metal - and remove without damaging the dash panel or paint.

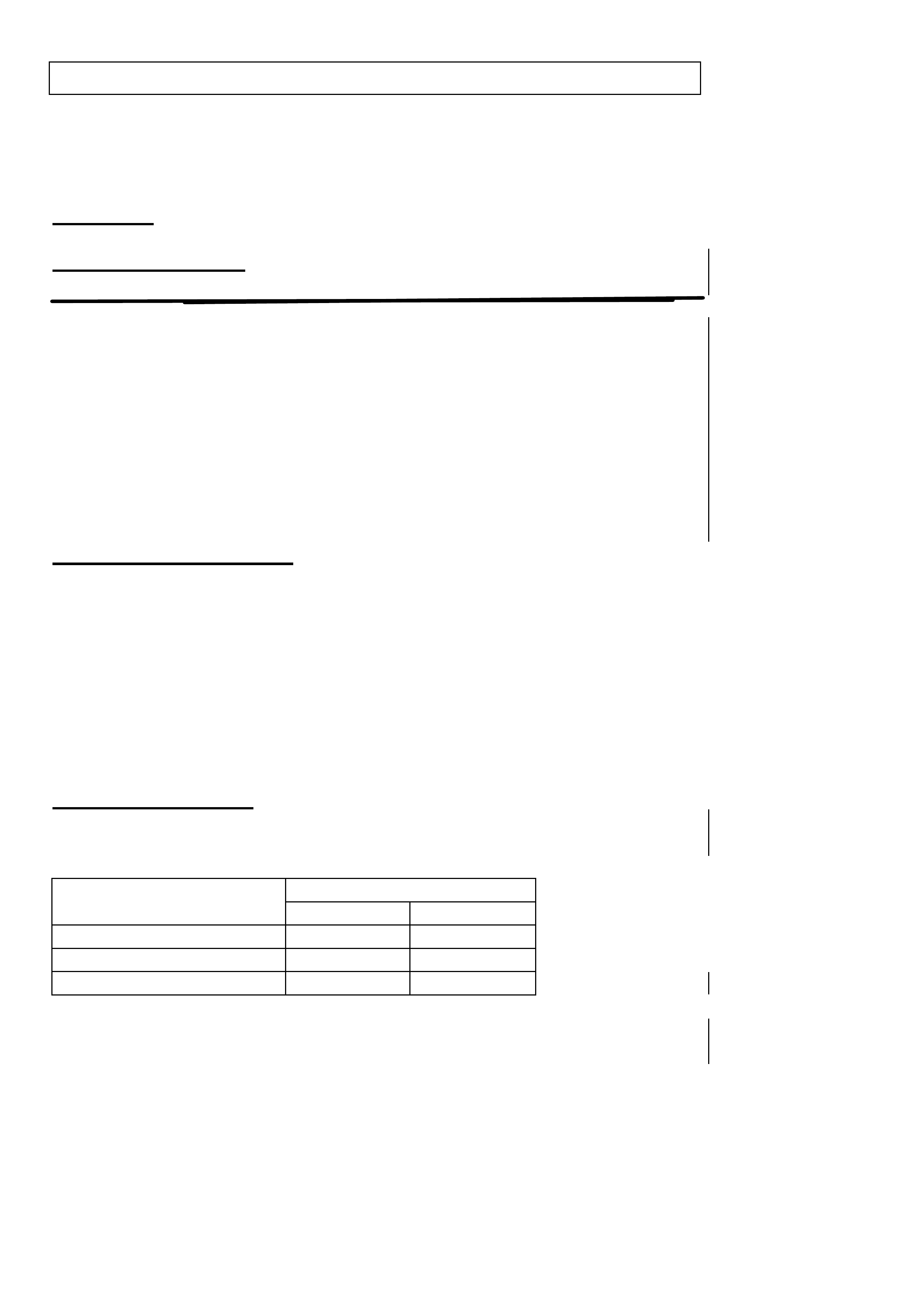

Note 1: Due to the angle of the dash panel and engine location (V6 and V8) the rivet must be

approached from an angle as shown in figure 1. With a 6mm drill bit run the drill at high speed

before coming in contact the rivet head. Hold the drill position firmly and slowly drill out the rivet

head.

Note 2: Starting the drill while in contact with the rivet head will cause the drill to move and possibly

scratch the vehicle paint.

Figure 1

4. Fit the new Safety Compliance Plate in the existing locating holes in the dash panel using

the flower head rivets provided with the new Safety Compliance Plate.

Note: Three flower head rivets are provided with the replacement plate. One is a spare and can be

used if required however, if not required the third rivet must be returned with old plate.

5. Confirm the identification of the old Safety Compliance Plate by the line marked through the

centre, then cut the plate in half.

21/04/04

6of 7

6. Place the two Safety Compliance Plate pieces and spare rivet, if unused, in the provided

return envelope and post to the return address.

7. Apply a Campaign Completed sticker to the right a-pillar between the door hinges. Mark

location B1 on the Vehicle Service History Label located on the inside of the lower instrument

panel cover.

21/04/04

7of 7

APPENDIX C – SALMAT MATERIAL ORDER FORM

RECALL CAMPAIGN 04-H-02

VY CREWMAN & ONE TONNER Compliance Plate

Replacement

Fax This Form To: Salmat - (03) 9358 2999

Please supply the replacement Compliance Plate for the vehicle shown below

IMPORTANT: Only order parts when a customer has supplied the ISO VIN and confirmed a

booking date. ONLY 1 compliance plate can be ordered per Order Form.

Date _____________________

Retailer Code: _____________ Retailer Name:________________________

Retailer Address: _______________________________________________

Ph. No _________________________Fax No:_________________________

Name of person to receive

replacement Compliance Plate ______________________________

Via Registered Mail (Please print name clearly)

Vehicle ISOVIN (17 digits) Vehicle Registration Number Customer Booking Date

SALMAT USE ONLY

Retailer Order Acknowledgement Details (fax back to retailer same day)

Date Order Received Date Dispatched ___________________

Replacement

Compliance Plate

1 of 9

PRODUCT CAMPAIGN BULLETIN

04-H-03 (ISSUE 2)

May 26, 2004

SUBJECT: POWER STEERING COOLER HOSE REPLACEMENT

MODELS AFFECTED: VY,WK, and HSV VARIANTS INCLUDING

HSV COUPE SERIES II

This bulletin has been re-issued to clarify the vehicles affected by a safety recall

campaign, to replace the power steering cooler hose(s) fitted to VY,WK and

HSV models operating with V6 or V8 engines as first declared in RL 15/04

The main points of this revised issue are:

q HSV Coupe series II added.

q What to do if presented with a vehicle fitted with a low speed steering

shudder fix.

Revisions to issue 1 are indicated by an adjacent line in the right hand

margin of the page.

DESCRIPTION OF DEFECT

The material within the power steering cooler hose has inadequate strength in

the return side of the power steering system, consequently the power steering

cooler hose(s) may rupture during hard cornering operation.

To correct this situation, Holden has initiated this recall action to ensure that

every affected vehicle is fitted with a new improved power steering cooler

hose(s).

V6 engines have 1 power steering cooler hose.

V8 engines have 2 power steering cooler hoses.

AFFECTED VEHICLES

The Holden Monaro is not affected, but the HSV Coupe series II models are

affected by campaign 04-H-03.

Affected Build Date Range Model

From To

VY 26/08/2002 02/09/2003

WK 20/03/2003 02/09/2003

V2 II (HSV) 13/01/2003 02/09/2003

Note: The build date referred to in the above tables is shown on the vehicle

compliance plate not the I.D plate for HSV vehicles.

For VY

L899955 to L166789

For WK

L986609 to L167139

However the Build date shown on the compliance plate is the absolute indicator

for this recall campaign. Tag numbers are to be used for reference only.

2 of 9

VEHICLES FITTED WITH LOW SPEED STEERING SHUDDER FIXES.

Some V6 vehicles arriving for this recall may have a full length flexible return hose fitted from

the steering rack to the cooler instead of the normal rigid pipe and suspect hose. The fitting of

the flexible return hose was part of an early containment steering shudder service fix. Vehicles

inspected and found to be fitted with the full length flexible return hose do not require

replacement of the power steering cooler hose.

There is also a later release low speed steering shudder production fix which involves a

revised high pressure hose only between the pump and steering gear. This fix does not involve

the return side of the power steering system, therefore the power steering cooler hose still

requires replacement under campaign 04-H-03 on these vehicles.

ACTION REQUIRED BY RETAILERS

1. Confirm vehicle model is within the range shown in the “Affected Vehicles” table.

2. Confirm vehicle Build date is within the range shown in the “Affected Vehicles” table.

3. Confirm vehicle has not previously been reworked i.e:

q Identified by an ‘X’ in the A-4 co-ordinate of the “Vehicle Service History” label

q Application of “04-H-03 Campaign Completed” label.

4. Inspect for a flexible return hose fitted from steering rack to cooler as explained above

in “VEHICLES FITTED WITH LOW SPEED STEERING SHUDDER FIX ES”. If a

flexible hose is fitted go to step 6.

5. If vehicle has not been reworked or had a flexible hose installed from the rack to the

cooler, proceed with campaign and replace hoses as per Appendix B.

6. Affix a Campaign Completed Label and a Vehicle Service History Label as specified

in the section titled ‘Campaign Completion Identification’.

7. Submit a warranty claim. Refer “Warranty Claim Information”.

CUSTOMER NOTIFICATION

Owners of vehicles affected by this recall campaign, will be contacted directly by letter from

Holden sent to their recorded address. Also a recall notice will appear in major newspapers.

The letter and recall notice provide details of the recall campaign and request the customer to

contact their Holden Retailer to make a service booking to have the appropriate work carried

out. Refer to Appendix A for a draft copy of the customer letter.

CAMPAIGN COMPLETION IDENTIFICATION

All campaigned vehicles must have:

1. A Campaign Completed label applied to the right hand front ‘A’ pillar, between the hinges,

with details of the campaign, 04-H-03, Dealership code and date legibly entered on the

label with a permanent ink pen.

AND

2. For additional identification, mark an “X” at the A-4 co-ordinate of a Vehicle Service

History Label and apply to the inner side of the lower instrument panel cover if not already

fitted.

27/05/04 3of 7

Extra Campaign Completed and Vehicle Service History labels are available free of charge

from Moore Business Systems.

• For Campaign Completed Labels Quote stock no. SD 28156 on a Moore Business

Systems ‘Packaged Goods’ order form for a pack of 100 labels.

• For Vehicle Service History Labels quote stock no. SD 28177 on a Moore Business

Systems ‘Packaged Goods’ order form for a pack of 100 labels.

Fax the order form to Moore Business Systems on Facsimile: (03) 9270 8925

Should you need to follow-up on a placed order, contact Moore customer service on telephone

number (03) 9270 8788.

PARTS INFORMATION

PARTS ARE TO BE PROCURED THROUGH THE NORMAL HSPO DISTRIBUTION

CHANNELS (NOT SALMAT). NORMAL HSPO PRICEING WILL APPLY.

The new improved power steering cooler hoses will display P/N 92209162 on their exterior.

Parts required for each vehicle

Quantity per vehicle

Parts V6 V8

92209162

Hose power steering

1 2

WARRANTY CLAIM INFORMATION

On completion of campaign action, retailers are requested to submit a warranty claim using the

Labour Operation Number specified below.

Warranty Claim Information

Description

Replace Power Steering Cooler Hose(s)

Labour Operation No.:

Standard Time:

Failure Code:

T481001

0.5 hours

96 (NOW T0096)

Parts are to be claimed as per the normal Warranty process.

CONTACT INFORMATION

For further information or clarification on this recall campaign please contact the relevant

person below.

CONTACT NAME CONTACT NUMBER

(03) 96 47 18 57

General enquiries Brett Fowler

or

Alex Holt (03) 96 47 76 19

Technical enquiries TAS 1800 033 417

Parts related enquiries HSPO (03) 97 97 73 41

Warranty related enquiries Warranty Administration 1800 033 487

J. K. Hoffman

27/05/04 4of 7

General Service Manager

Attachments

Appendix A Customer Letter- Draft

Appendix B Replacement Instruction

27/05/04 5of 7

APPENDIX A - Draft – Customer Letter

Dear Holden Customer,

As part of Holden’s ongoing commitment to customer safety, we have initiated a

Vehicle Recall Campaign affecting the following models: Commodore (All variants),

Calais, Utility, Crewman, One Tonner, Statesman, and Caprice vehicles manufactured

from August 2002 to September 2003 including Holden Special Vehicles (HSV).

Our records indicate that your Holden vehicle was manufactured within the affected

range.

Holden is aware that a power steering cooler hose may rupture during cornering,

which could impact your vehicle control.

It is therefore necessary for you to contact a Holden Dealer of your choice, and make

a booking to have the power steering cooler hoses replaced as soon as possible.

Work will be carried out free of charge. At the time of booking, your Dealer will be able

to advise you how long your vehicle will be required for the work to be completed.

If you have any questions, please contact your Holden Dealer or call the Holden Recall

and Rework Assistance Centre on 1800 632 826, where we will be pleased to assist.

Thank you for your attention to this matter. Please accept our apologies for any

inconvenience that may be caused to you.

Yours sincerely

David McMurray

Manager Customer Assistance

VEHICLE SAFETY RECALL

27/05/04 6of 7

APPENDIX B – REPLACEMENT INSTRUCTION

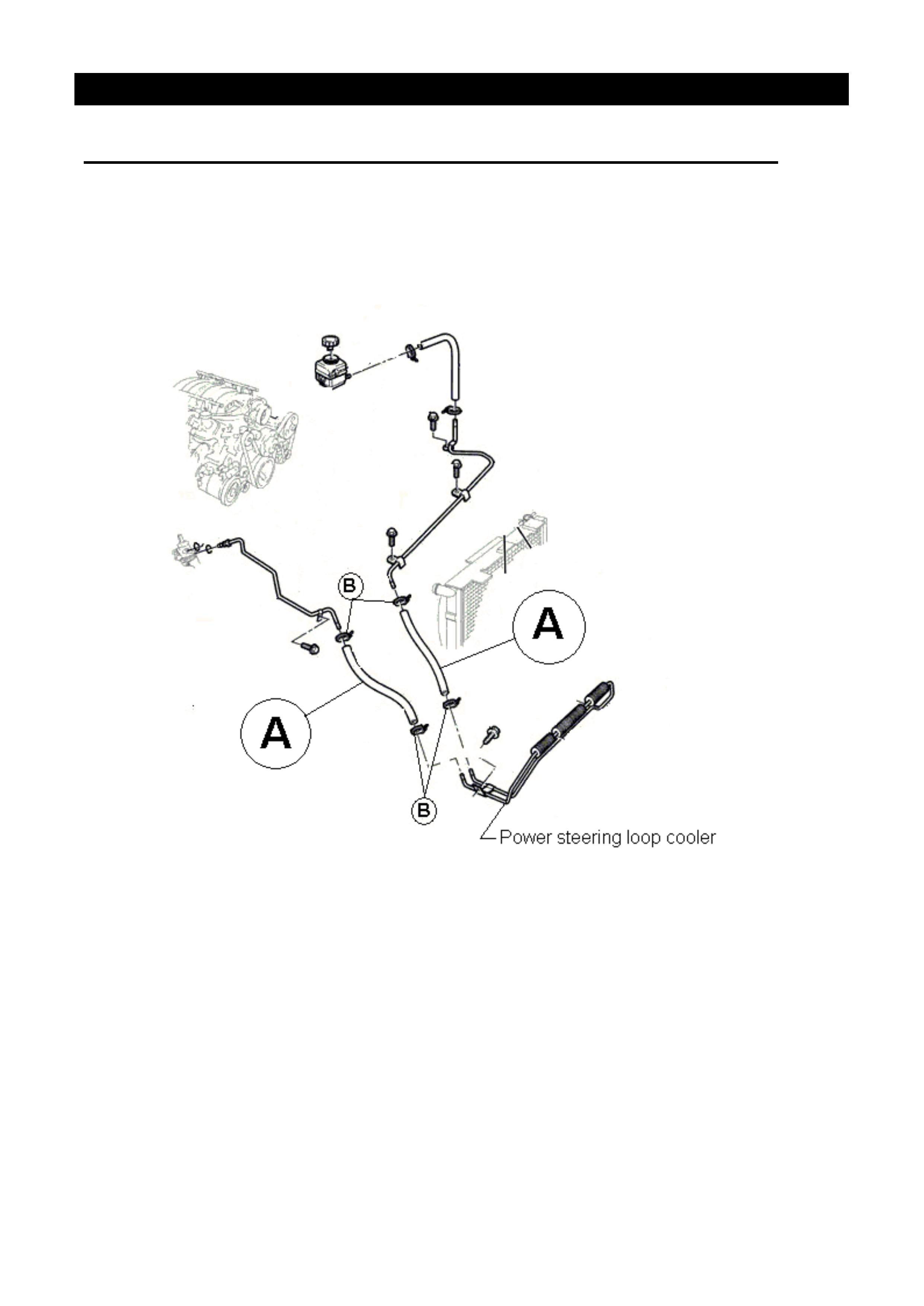

VY & WK POWER STEERING COOLER HOSE REPLACEMENT INSTRUCTIONS

1. Determine vehicle engine type:

Gen III V8 will require the two rubber connecting hoses (Item A) to the inlet and outlet of the

power steering cooler to be replaced. Refer Figure 1.

Figure 1. V8 power steering hoses requiring replacement

27/05/04 7of 7

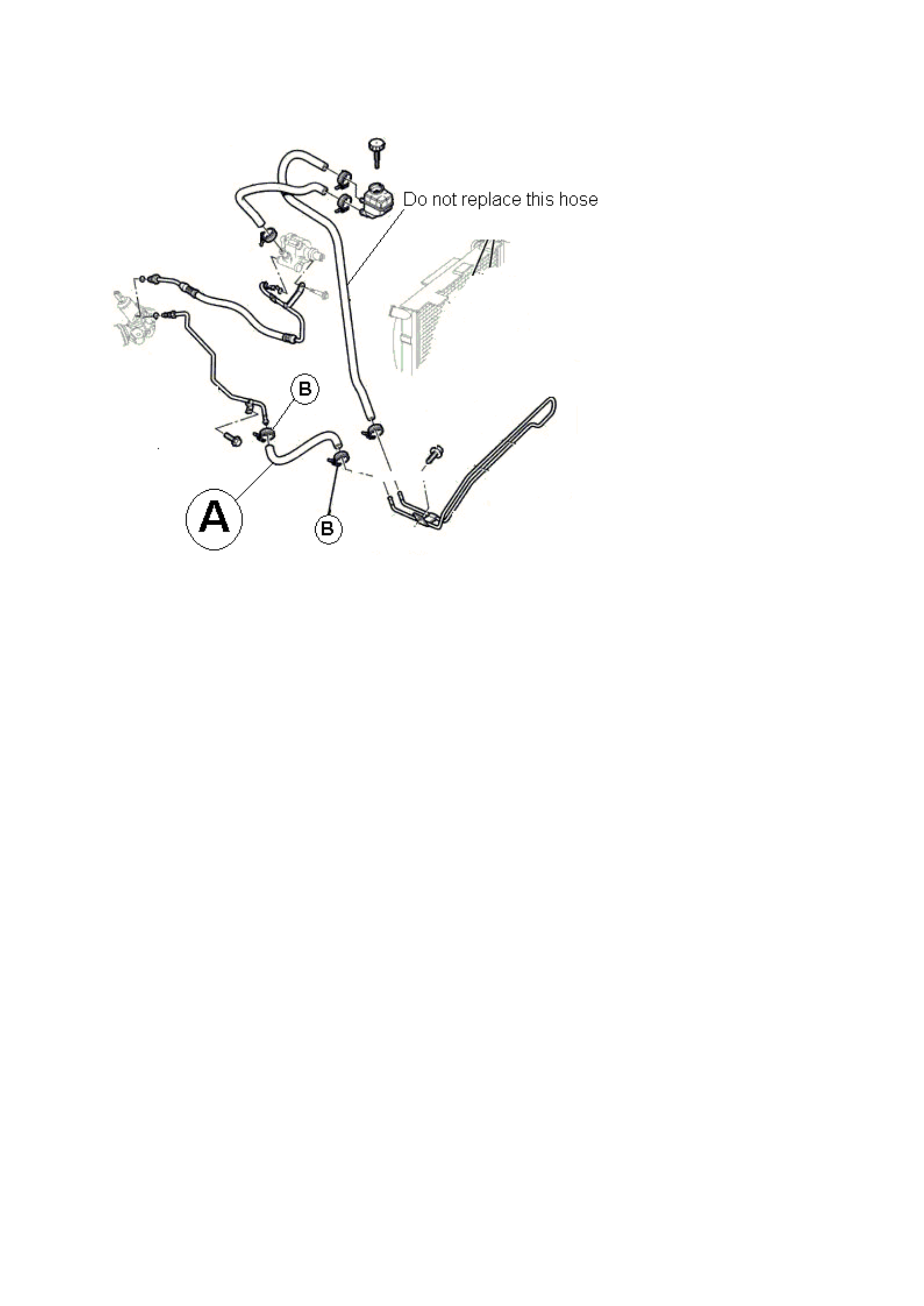

The V6 and V6 supercharged will require only the inlet connecting hose (Item A) to the power

steering cooler to be replaced . Refer Figure 2

Figure 2. V6 power steering hose to be replaced.

2. The hose(s) to be replaced are located at the bottom right hand corner of the engine bay.

3. Place vehicle on hoist observing all safety precautions associated with vehicles on hoists.

4. Loosen the two/four hose clamps (Items B) which secure the hose(s) between the power

steering cooler and the rigid pipe.

5. Place drain tray underneath hose(s) and remove hose from the vehicle. Note: Power

steering fluid may be HOT from vehicle operation.

6. Wipe any oil from the exterior of the rigid pipes.

7. Install new hose p/n 92209162

8. Use existing hose clamps (Item B) unless damaged when removed. If damaged replace

with p/n 11088301. Torque to 2-3 Nm.

9. Top up power steering reservoir.

10. Bleed power steering system as per the procedure in SIP as follows:

a) Raise the front of the vehicle and place on safety stands.

b) With the engine not running, add the power steering fluid to reservoir to the maximum mark

(or greater if it is known that the steering gear is empty).

27/05/04 8of 7

c) Start the engine and allow to run for only 2-3 seconds. Do not turn the steering wheel at this

point.

d) Continue with steps b and c until the power steering fluid level remains constant.

e) Start and run the engine at idle speed, turning the steering wheel from lock to lock, without

holding at the full lock positions (this will build up high pressures, atomising any entrapped air).

Repeat this procedure from six to eight times. Stop the engine, check the power steering fluid

level and top up to the maximum level, as required.

f) Start and run the engine at idle speed. Again turn the steering wheel from lock to lock but

now slowly build up the pressure levels by holding against the full lock position for 1-2 seconds.

Repeat this procedure from four to six times. Stop the engine and top up the power steering

fluid level to the maximum mark, as required.

Note: while the majority of entrapped air will be removed by the above process, a small

amount may remain, which can only be removed by alternate circulation and settling of the

power steering fluid for a prolonged period. This is usually achieved automatically after two to

three days, with daily driving and settling overnight.

g) Turn the steering wheel to the straight-ahead position, lower vehicle to the ground and turn

ignition “OFF”

11. Check for leaks and rectify if necessary.

9 of 9

1 of 9

PRODUCT CAMPAIGN BULLETIN

04-H-04

June 4, 2004

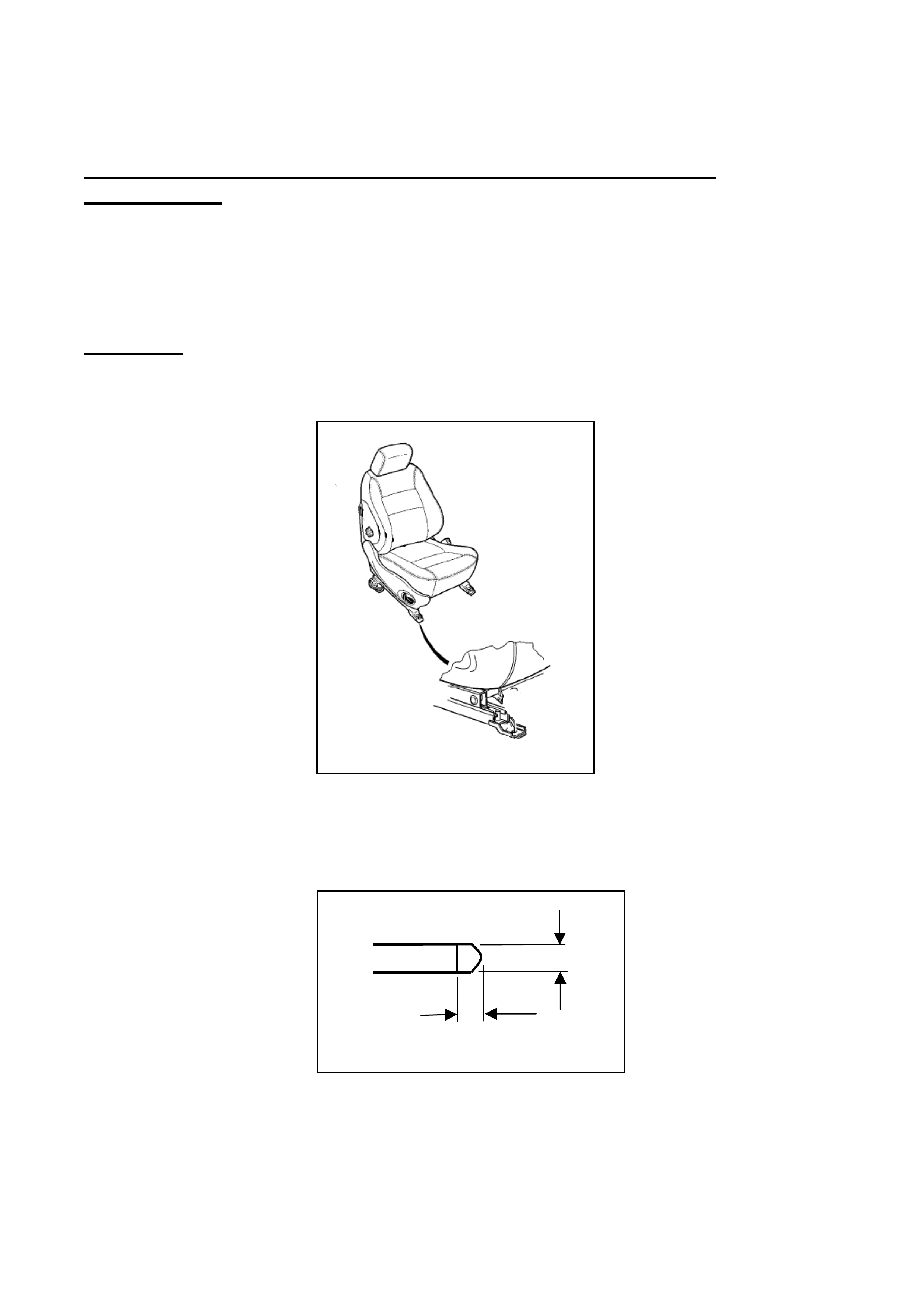

SUBJECT: VYII DRIVER’S SEAT ASSEMBLY.

MODELS AFFECTED: VY Series II

This bulletin announces the initiation of a safety recall campaign to inspect

and possibly replace the driver’s seat Track and Height Adjuster Asm fitted to

VY series II models. The intention of this campaign is to inspect the driver’s

seat track for correct mounting foot attachment and if found defective to

replace the Track and Height Adjuster Asm.

DESCRIPTION OF DEFECT

Due to a vendor equipment failure some driver’s seats may have been

manufactured with incomplete riveting and welding between the seat track

and the mounting foot. If the riveting and welding is incomplete between the

seat track and foot, occupant safety maybe compromised in a vehicle

accident condition.

AFFECTED VEHICLES

Only VY vehicles as listed in Appendix A, which were built during the first two

weeks of May 2004 are affected.

ACTION REQUIRED BY RETAILERS

1. Confirm vehicle Tag number is affected by checking list on Appendix A.

2. Confirm vehicle has not previously been inspected i.e:

Identified by an ‘X’ in the C-1 co-ordinate of the “Vehicle Service

History” label

Application of “04-H-04 Campaign Completed” label.

3. If vehicle has not been inspected, proceed with campaign instructions as

per Appendix B.

4. Affix a Campaign Completed Label and a Vehicle Service History Label as

specified in the section titled ‘Campaign Completion Identification’.

5. Submit a warranty claim. Refer “Warranty Claim Information”.

2 of 9

CUSTOMER NOTIFICATION

Owners of vehicles affected by this recall campaign, will be contacted directly by letter from

Holden sent to their recorded address. The letter provides details of the recall campaign

and requests the customer to contact their Holden Dealer to make a service booking to

have the appropriate work carried out. Refer to Appendix C for a draft copy of the customer

letter.

CAMPAIGN COMPLETION IDENTIFICATION

All campaigned vehicles must have:

1. A Campaign Completed label applied to the right hand front ‘A’ pillar, between the

hinges, with details of the campaign, 04-H-04, Dealership code and date legibly entered

on the label with a permanent ink pen.

AND

2. For additional identification, mark an “X” at the C-1 co-ordinate of a Vehicle Service

History Label and apply to the inner side of the lower instrument panel cover if not

already fitted.

Extra Campaign Completed and Vehicle Service History labels are available free of charge

from Moore Business Systems.

• For Campaign Completed Labels Quote stock no. SD 28156 on a Moore Business

Systems ‘Packaged Goods’ order form for a pack of 100 labels.

• For Vehicle Service History Labels quote stock no. SD 28177 on a Moore Business

Systems ‘Packaged Goods’ order form for a pack of 100 labels.

Fax the order form to Moore Business Systems on Facsimile: (03) 9270 8925

Should you need to follow-up on a placed order, contact Moore customer service on

telephone number (03) 9270 8788.

PARTS INFORMATION

If a defective driver’s Track and Height Adjust Asm is found, contact TAS immediately to

report the identification of a defective assembly and for availability of a replacement part.

When you receive the replacement part confirm its condition is OK by performing the

procedure in Appendix B.

Please return the defective part to REPAC when requested by the REPAC report.

Replacement part information:

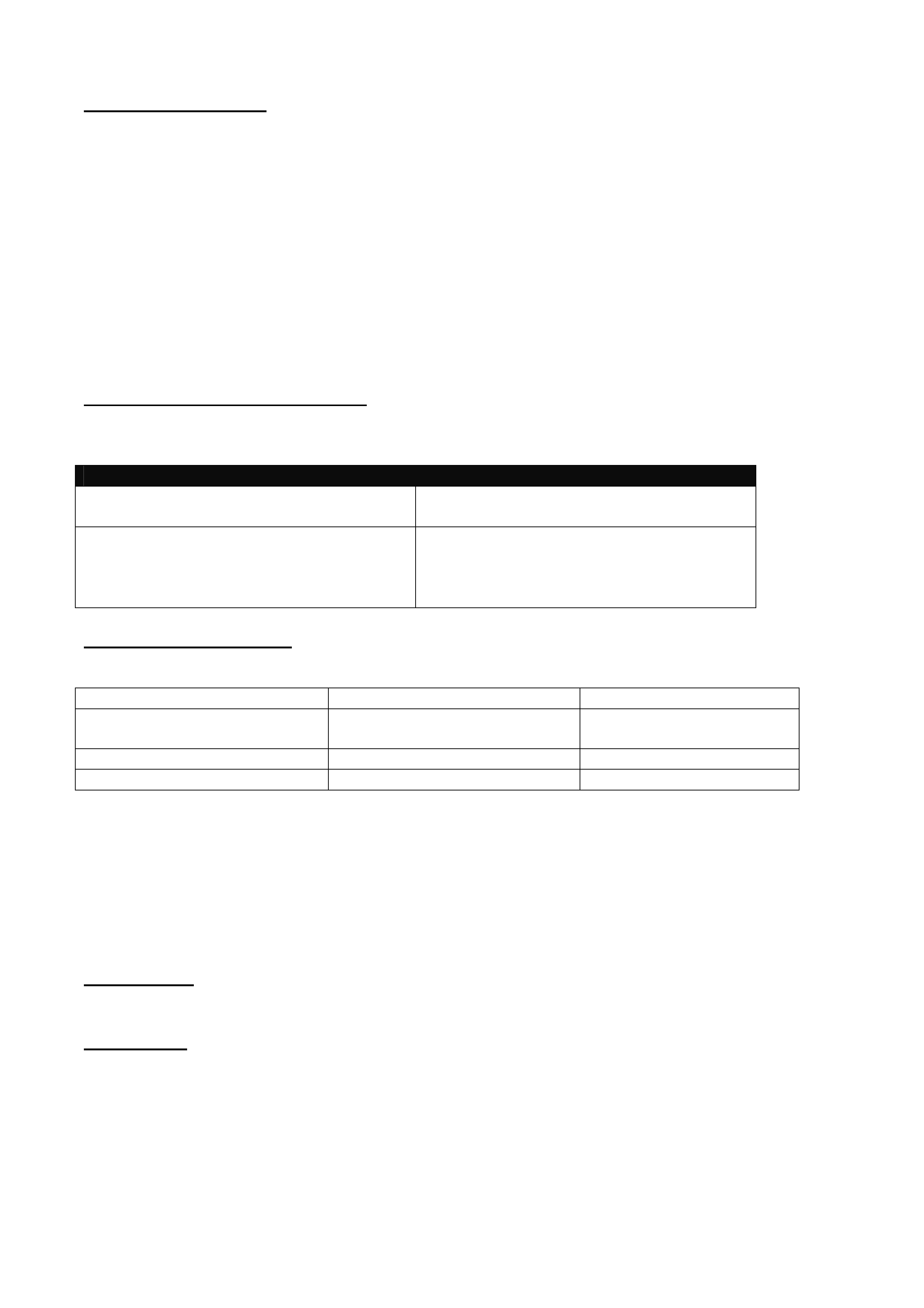

Part Number Description

92146645 Track and Height Adjust Asm

– 2 Way RH

92146648 Track and Height Adjust Asm

– 4 Way RH

2 Way seats have only fore and aft adjustment. 4 Way seats have fore,aft and height

adjustment.

WARRANTY CLAIM INFORMATION

Page 3 of 9

On completion of campaign action, retailers are requested to submit a warranty claim using

the Labour Operation Numbers specified below.

Warranty Claim Information

Description

Inspect Track and Height

Adjust Asm

Replace Track and Height

Adjust Asm (includes

inspection)

Labour Operation No.:

Standard Time:

Failure Code:

T481101

0.5 hours

96 (NOW T0096)

T481102

1.3 hours

96 (NOW T0096)

CONTACT INFORMATION

For further information or clarification on this recall campaign please contact the relevant

person below.

CONTACT NAME CONTACT NUMBER

(03) 96 47 18 57

General enquiries Brett Fowler

or

Daniel Coburn (03) 96 47 15 24

Technical enquiries TAS 1800 033 417

Parts related enquiries TAS 1800 033 417

Warranty related enquiries Warranty Administration 1800 033 487

J. K. Hoffman

General Service Manager

Attachments

Appendix A Affected vehicle list

Appendix B Inspection Procedure

Appendix C Customer Letter- Draft

4 of 9

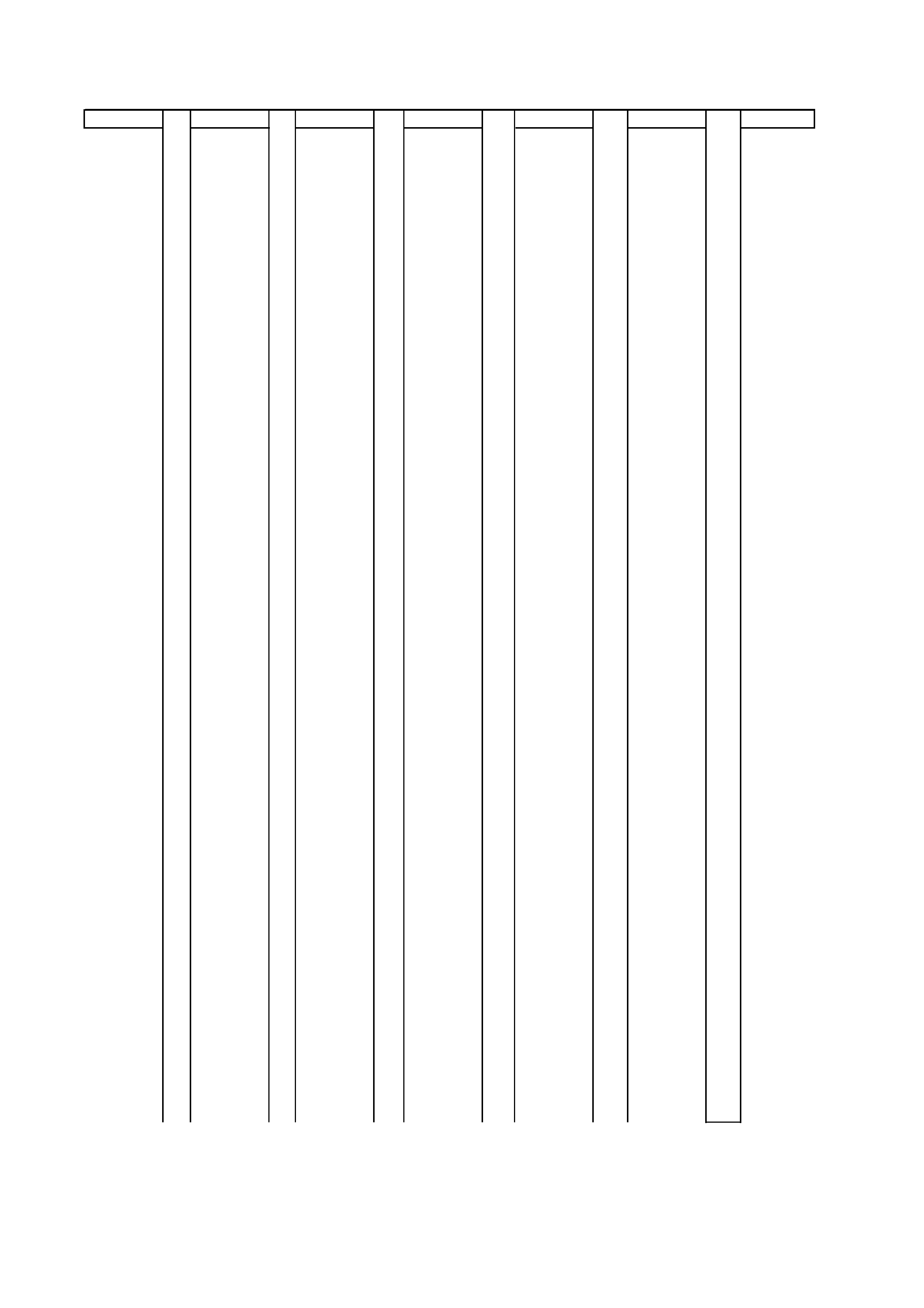

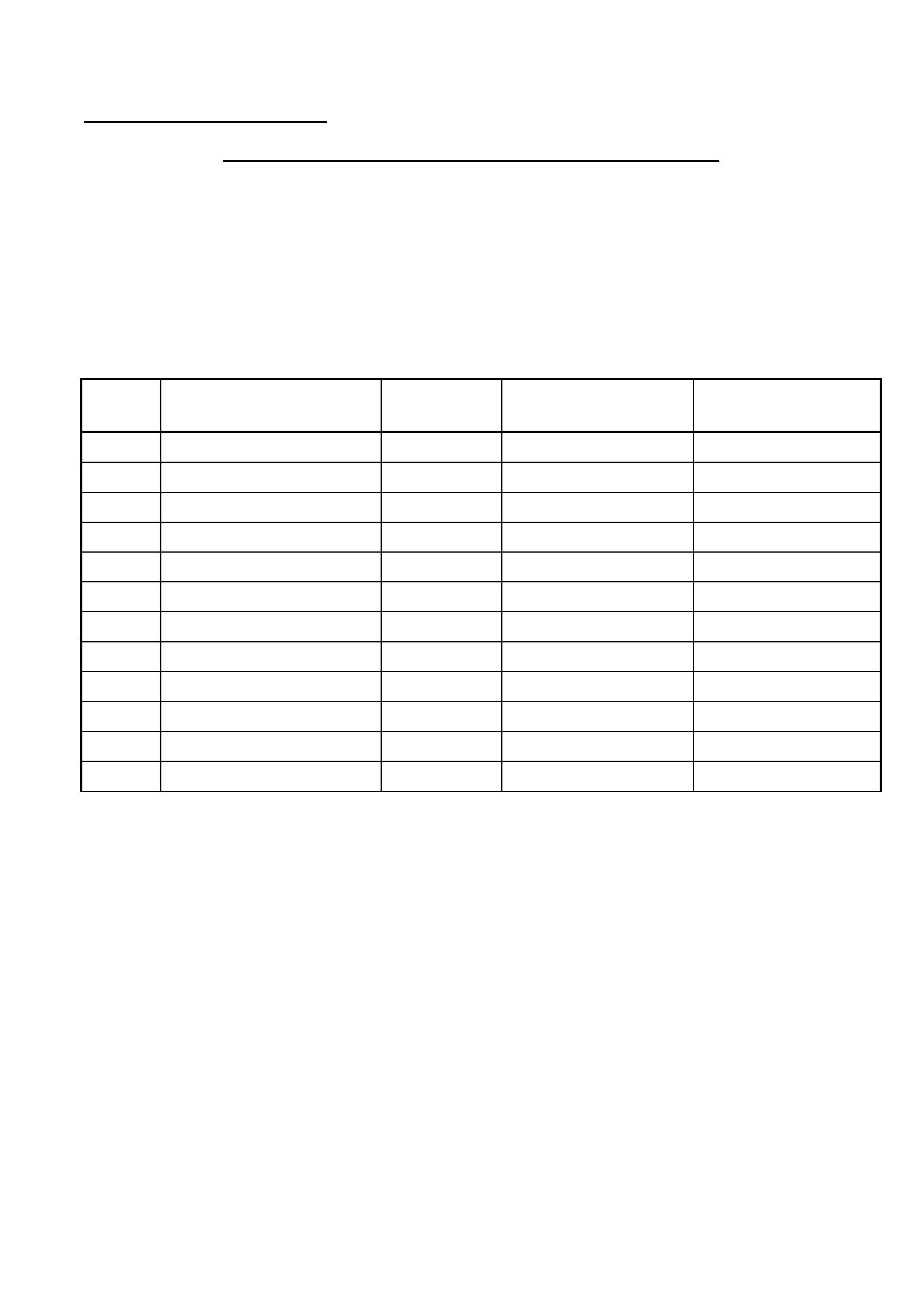

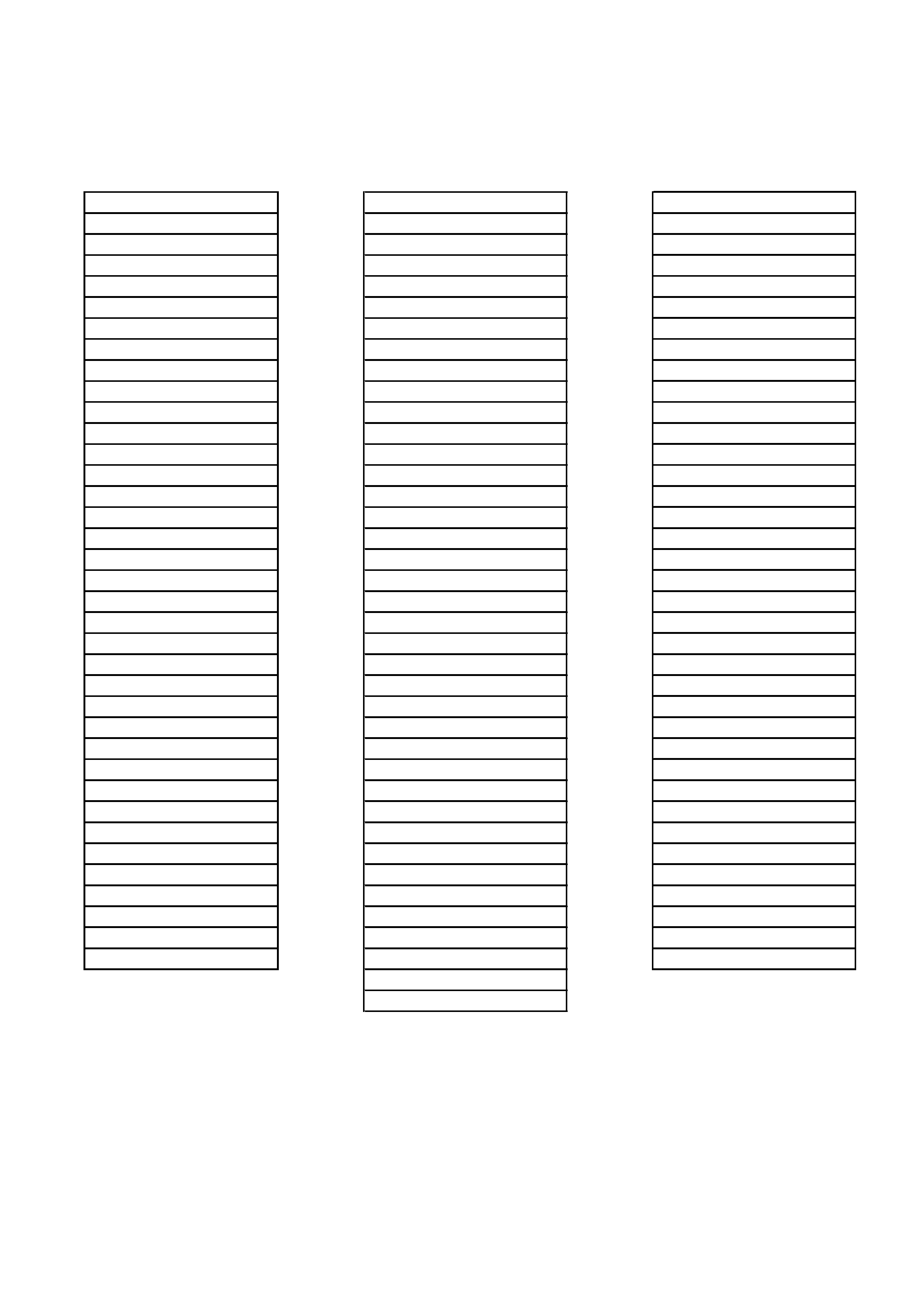

APPENDIX A

AFFECTED VEHICLE LISTING

Tag No. Tag No. Tag No. Tag No. Tag No. Tag No. Tag No.

L241701 L271617 L273951 L274325 L274556 L274770 L275002

L243248 L271619 L273962 L274326 L274559 L274773 L275003

L243900 L271620 L274004 L274329 L274560 L274783 L275005

L248879 L271621 L274018 L274331 L274561 L274786 L275006

L251817 L271624 L274024 L274335 L274562 L274791 L275011

L254051 L271628 L274036 L274343 L274563 L274794 L275017

L254060 L271629 L274040 L274375 L274565 L274797 L275019

L262286 L271637 L274078 L274376 L274566 L274808 L275021

L267604 L272302 L274079 L274379 L274569 L274809 L275022

L267959 L272303 L274091 L274388 L274573 L274811 L275023

L268740 L272304 L274095 L274391 L274576 L274812 L275027

L268743 L272307 L274100 L274392 L274580 L274813 L275032

L268745 L272308 L274112 L274403 L274587 L274816 L275036

L269422 L272309 L274120 L274404 L274590 L274824 L275039

L269430 L272311 L274130 L274406 L274594 L274830 L275040

L269439 L272312 L274143 L274411 L274607 L274831 L275041

L269455 L272313 L274148 L274412 L274612 L274832 L275043

L269477 L272315 L274155 L274426 L274615 L274841 L275048

L269481 L272321 L274158 L274427 L274619 L274852 L275049

L269483 L272323 L274166 L274432 L274621 L274855 L275051

L270199 L272327 L274167 L274435 L274622 L274857 L275052

L270200 L272328 L274174 L274445 L274624 L274860 L275053

L270204 L272333 L274175 L274453 L274631 L274865 L275055

L270836 L272335 L274178 L274466 L274635 L274867 L275056

L270838 L272339 L274180 L274467 L274636 L274869 L275060

L270844 L272973 L274188 L274475 L274638 L274873 L275061

L270851 L272989 L274189 L274478 L274642 L274874 L275066

L270864 L272990 L274193 L274479 L274649 L274877 L275183

L270870 L273019 L274195 L274487 L274666 L274878 L275185

L270872 L273027 L274197 L274510 L274668 L274880 L275186

L270882 L273036 L274203 L274511 L274672 L274882 L275188

L270890 L273047 L274205 L274512 L274684 L274900 L275191

L270891 L273054 L274208 L274513 L274688 L274908 L275192

L270892 L273580 L274213 L274516 L274689 L274911 L275193

L270894 L273590 L274221 L274517 L274697 L274912 L275195

L270897 L273596 L274234 L274519 L274698 L274931 L275198

L271571 L273607 L274237 L274520 L274704 L274932 L275199

L271582 L273611 L274243 L274522 L274707 L274934 L275200

L271583 L273620 L274249 L274523 L274714 L274938 L275202

L271584 L273637 L274250 L274524 L274719 L274940 L275203

L271585 L273639 L274253 L274526 L274720 L274944 L275205

L271588 L273644 L274257 L274527 L274728 L274945 L275207

L271590 L273648 L274259 L274528 L274733 L274947 L275208

L271591 L273653 L274264 L274530 L274736 L274952 L275209

L271594 L273660 L274266 L274531 L274744 L274955 L275210

L271595 L273686 L274268 L274532 L274745 L274965 L275211

L271599 L273702 L274269 L274533 L274747 L274970 L275212

L271601 L273705 L274275 L274535 L274752 L274972 L275214

L271603 L273708 L274277 L274537 L274754 L274980 L275217

L271604 L273716 L274290 L274538 L274755 L274985 L275218

L271605 L273724 L274292 L274545 L274761 L274987 L275219

L271608 L273725 L274312 L274546 L274762 L274988 L275220

L271609 L273727 L274313 L274551 L274766 L274989 L275221

L271610 L273732 L274314 L274552 L274768 L274994 L275222

L271613 L273946 L274322 L274553 L274769 L274998 L275223

5 of 9

Tag No. Tag No. Tag No. Tag No. Tag No. Tag No. Tag No.

L275224 L275437 L275559 L275705 L275924 L276122 L276231

L275226 L275441 L275562 L275706 L275925 L276123 L276236

L275228 L275442 L275567 L275707 L275927 L276126 L276238

L275229 L275443 L275570 L275709 L275930 L276127 L276241

L275300 L275446 L275574 L275711 L275934 L276128 L276244

L275301 L275448 L275581 L275712 L275935 L276129 L276245

L275302 L275450 L275584 L275716 L275937 L276131 L276246

L275304 L275451 L275586 L275717 L275938 L276133 L276249

L275307 L275454 L275590 L275718 L275940 L276137 L276251

L275311 L275456 L275593 L275720 L276035 L276140 L276254

L275313 L275458 L275597 L275722 L276036 L276144 L276261

L275315 L275459 L275602 L275725 L276039 L276145 L276263

L275325 L275466 L275606 L275728 L276040 L276148 L276264

L275326 L275471 L275607 L275729 L276043 L276149 L276266

L275327 L275474 L275609 L275734 L276044 L276150 L276269

L275329 L275475 L275610 L275736 L276047 L276152 L276270

L275330 L275476 L275612 L275737 L276048 L276154 L276273

L275334 L275478 L275613 L275739 L276050 L276155 L276274

L275335 L275480 L275614 L275741 L276051 L276163 L276277

L275338 L275481 L275620 L275742 L276055 L276164 L276279

L275339 L275483 L275621 L275745 L276056 L276167 L276283

L275342 L275484 L275622 L275746 L276058 L276169 L276286

L275345 L275487 L275625 L275747 L276060 L276171 L276287

L275347 L275490 L275626 L275748 L276061 L276172 L276289

L275348 L275492 L275629 L275750 L276062 L276177 L276291

L275351 L275494 L275630 L275751 L276063 L276178 L276292

L275353 L275495 L275633 L275753 L276066 L276181 L276294

L275355 L275497 L275634 L275759 L276067 L276182 L276295

L275356 L275499 L275635 L275762 L276070 L276184 L276296

L275359 L275500 L275639 L275764 L276072 L276185 L276298

L275363 L275501 L275640 L275766 L276074 L276186 L276302

L275368 L275504 L275645 L275767 L276076 L276190 L276303

L275370 L275505 L275646 L275768 L276081 L276191 L276304

L275382 L275507 L275647 L275770 L276082 L276194 L276308

L275384 L275508 L275649 L275771 L276083 L276195 L276309

L275387 L275510 L275650 L275775 L276085 L276198 L276313

L275388 L275518 L275651 L275777 L276086 L276199 L276314

L275389 L275519 L275656 L275778 L276087 L276203 L276315

L275390 L275520 L275657 L275781 L276090 L276204 L276317

L275392 L275522 L275658 L275782 L276091 L276205 L276319

L275393 L275523 L275663 L275785 L276094 L276207 L276322

L275395 L275524 L275669 L275787 L276095 L276208 L276324

L275398 L275525 L275670 L275788 L276096 L276209 L276326

L275403 L275527 L275673 L275791 L276097 L276211 L276329

L275405 L275531 L275674 L275796 L276099 L276215 L276330

L275410 L275532 L275675 L275797 L276100 L276217 L276331

L275412 L275535 L275682 L275799 L276102 L276218 L276332

L275417 L275536 L275686 L275800 L276104 L276219 L276334

L275419 L275546 L275687 L275804 L276108 L276220 L276335

L275422 L275548 L275688 L275805 L276109 L276221 L276336

L275426 L275550 L275691 L275918 L276112 L276223 L276340

L275432 L275551 L275694 L275919 L276113 L276224 L276342

L275433 L275552 L275698 L275920 L276114 L276227 L276343

L275434 L275554 L275699 L275921 L276119 L276229 L276344

L275435 L275555 L275702 L275922 L276120 L276230 L276346

6 of 9

Ta

g

No. Ta

g

No. Ta

g

No. Ta

g

No. Ta

g

No. Ta

g

No.

L276350 L276454 L276844 L276984 L277118 L277238

L276353 L276457 L276846 L276985 L277119 L277241

L276357 L276460 L276849 L276986 L277124 L277243

L276359 L276461 L276851 L276989 L277125 L277245

L276360 L276462 L276852 L276990 L277126 L277246

L276361 L276464 L276853 L276994 L277128 L277247

L276365 L276465 L276855 L276997 L277129 L277248

L276366 L276466 L276856 L277000 L277130 L277250

L276368 L276468 L276858 L277001 L277132 L277251

L276370 L276470 L276861 L277004 L277135 L277254

L276371 L276471 L276867 L277006 L277136 L277259

L276372 L276474 L276872 L277010 L277137 L277260

L276373 L276475 L276874 L277012 L277138 L277264

L276375 L276477 L276876 L277015 L277141 L277265

L276380 L276478 L276878 L277017 L277142 L277267

L276381 L276479 L276881 L277018 L277143 L277269

L276384 L276482 L276888 L277019 L277145 L277271

L276386 L276483 L276891 L277025 L277147 L277272

L276389 L276486 L276894 L277026 L277150 L277275

L276391 L276488 L276896 L277027 L277152 L277277

L276392 L276489 L276897 L277029 L277154 L277282

L276394 L276492 L276901 L277035 L277156 L277283

L276396 L276493 L276904 L277038 L277157 L277287

L276399 L276496 L276906 L277039 L277160 L277290

L276400 L276497 L276909 L277045 L277162 L277293

L276403 L276500 L276910 L277047 L277163 L277295

L276406 L276502 L276913 L277050 L277165 L277302

L276409 L276506 L276915 L277052 L277166 L277305

L276411 L276511 L276917 L277053 L277169 L277312

L276413 L276512 L276919 L277054 L277173 L277316

L276414 L276514 L276922 L277056 L277174 L277323

L276415 L276515 L276923 L277060 L277177 L277324

L276418 L276517 L276926 L277062 L277179 L277334

L276419 L276518 L276927 L277065 L277180 L277339

L276420 L276520 L276929 L277066 L277182 L277343

L276423 L276521 L276931 L277068 L277183 L277350

L276424 L276523 L276932 L277072 L277184 L277377

L276425 L276524 L276940 L277073 L277186 L277389

L276427 L276658 L276943 L277074 L277188 L277895

L276428 L276803 L276946 L277078 L277195 L277900

L276429 L276806 L276947 L277081 L277199 L277902

L276430 L276807 L276950 L277082 L277200 L277903

L276432 L276809 L276956 L277091 L277203 L277906

L276434 L276811 L276958 L277092 L277205 L277907

L276435 L276813 L276959 L277094 L277208 L277908

L276437 L276814 L276962 L277100 L277209 L277909

L276438 L276818 L276963 L277101 L277211 L277911

L276440 L276820 L276964 L277104 L277214 L277915

L276442 L276823 L276966 L277107 L277220 L277920

L276443 L276826 L276968 L277108 L277221 L277930

L276444 L276828 L276971 L277109 L277225 L277940

L276447 L276833 L276976 L277110 L277226

L276448 L276837 L276977 L277112 L277229

L276452 L276838 L276979 L277113 L277230

L276453 L276842 L276981 L277116 L277237

7 of 9

APPENDIX B

SEAT TRACK AND HEIGHT ADJUST ASM FOOT INSPECTION

PROCEDURE

VY Series II – R/H/S Track and Height Adjust Asm on Driver’s Seat,

applicable to vehicles listed in Appendix A:

Inspection:

1. Adjust the front R/H seat fore/aft adjustment to the rear most position.

2. Mark a line on a 1.00mm thick feeler gauge 3mm from the end as shown in figure

2.

3. With line facing up, try and place the 1mm feeler gauge between the front of the

mounting foot and outer rail track as shown in figure 3 & 4.

3mm

Fig 2

Max. 13 mm

Fig 1

8 of 9

4. The feeler gauge should NOT travel any further than 3 mm into the gap. The

indicator line on feeler gauge must remain visible as shown in figure 3.

5. If feeler gauge travels further than 3 mm, covering the indicator line (shown in

figure 4), then the Track and Height Adjust Asm must be replaced. This

condition indicates the part has excessive clearance due to incorrect riveting.

Refer to SIP for instructions regarding the replacement of the Track and Height

Adjust Asm.

6. Inspect the inside of the right hand rail to check that the weld has been located

to weld the metal of the rail to the metal of the rail foot as shown by the “weld

location” arrow in fig 5.

7. If the weld is not in the correct position contact TAS for further instructions.

8. Fit a completed campaign sticker to vehicle.

Note: The seat assembly needs to pass both feeler

gauge check and weld location check to be in “OK”

condition.

Fig 5 Foot

Rail

Weld

Location

Fig 3 Fig 4

OK

Not OK

9 of 9

APPENDIX C - Draft – Customer Letter

Dear Holden Customer,

As part of Holden’s ongoing commitment to customer safety, we have initiated a Vehicle

Recall Campaign for Holden vehicles manufactured during the first two weeks of May

2004. This includes Executive, Acclaim, S, SS, SV8, Berlina, One Tonner, Crewman,

Adventra, and VY series II based HSV models.

Our records indicate that your Holden vehicle was manufactured within the affected range.

Holden’s seat supplier has advised that, some driver’s seats may have been manufactured

with incomplete riveting and welding between the seat track, and the mounting foot on the

front right hand side. If the riveting and welding is incomplete between the seat track and

foot, occupant safety maybe compromised in a vehicle accident.

It is therefore necessary for you to contact a Holden Dealer of your choice, and make a

booking to have the driver’s seat inspected as soon as possible.

Work will be carried out free of charge. At the time of booking, your Dealer will be able to

advise you how long your vehicle will be required for the work to be completed.

If you have any questions, please contact your Holden Dealer or call the Holden Recall and

Rework Assistance Centre on 1800 632 826, where we will be pleased to assist.

Thank you for your attention to this matter. Please accept our apologies for any

inconvenience that may be caused to you.

Yours sincerely

David McMurray

Manager Customer Assistance

VEHICLE SAFETY RECALL

Page 1 of 7

PRODUCT CAMPAIGN BULLETIN

04-H-07

November 5, 2004

SUBJECT: EXHAUST PIPE CLAMP REPLACEMENT

MODELS AFFECTED: ZC VECTRA MODEL YEAR 2004, Z22SE & Z32SE ENGINES

This bulletin announces the initiation of a Safety Recall to replace the centre exhaust pipe

clamp fitted to a specific range of ZC Vectra MY 04 vehicles.

DESCRIPTION OF DEFECT

The clamp used to secure the middle muffler to the front exhaust pipe may loosen during

operation due to incorrect material selection of the clamp.

Eventually the pipes may come apart and cause damage to the fuel tank and hand brake

cable.

AFFECTED VEHICLES

Model Year Body Style From VIN To VIN

2004 Hatch W0L0ZCF6841126554 W0L0ZCF6848108687

2004 Sedan W0L0ZCF6941019511 W0L0ZCF6941132955

ACTION REQUIRED BY DEALERS

1. Confirm vehicle VIN number is within the range shown in the “Affected Vehicles” section

(above). Affected vehicles will be flagged in NOW system for recall action. Affected

Stock vehicles must also be reworked prior to customer delivery or dealer transfer.

2. Confirm vehicle has not previously been reworked ie:

Identified by an ‘X’ in the B-1 co-ordinate of the “Vehicle Service History” label

Application of “04-H-07 Campaign Completed” label.

Confirm campaign status in NOW vehicle search.

3. Determine the clamp part number to be replaced.

Some Sedan vehicles with VINs prior to W0L0ZCF6941038081 (inclusive) are fitted with

a smaller clamp. These specific vehicles will need to be reworked using the smaller

diameter replacement clamp. Refer to Parts Information section on page 2.

Rework the other vehicles by fitting the larger clamp.

4. In the event the exhaust pipes have separated, call Holden’s Technical Assistance

Centre (TAS) for next step advice.

Page 2 of 7

In summary, TAS will clarify the dealers findings, fax next step repair instructions and

send replacement parts. A TAS case will also be opened. If necessary, the vehicle will

be quarantined with alternative transport to be arranged for the customer.

Holden will close the TAS case as soon as the replaced parts arrive at Repac.

5. Replace the affected exhaust pipe clamp in accordance with the Technical Instructions.

Refer Appendix B.

6. Affix a Campaign Completed Label and a Vehicle Service History Label as specified in

the section titled ‘Campaign Completion Identification’ to signify campaign completion.

7. Return replaced part/s to Repac when requested via the Repac Report.

8. Submit a warranty claim. Refer “Warranty Claim Information”.

CUSTOMER NOTIFICATION

Owners of vehicles affected by this recall campaign, will be contacted directly by letter to

their recorded address. The letter provides details of the recall campaign and requests the

customer to contact a Holden Dealer and make a service booking to have the appropriate

work carried out. Refer to Appendix A for a draft copy of the customer letter.

CAMPAIGN COMPLETION IDENTIFICATION

All campaigned vehicles must have:

1. A Campaign Completed label applied to the right hand front ‘A’ pillar, between the

hinges, with details of the campaign, ie

• Campaign No. “04-H-07”

• Dealer Code

• Date legibly entered on the label with a permanent ink pen.

AND

2. For additional identification, mark an “X” at the B-1 coordinate of vehicle service history

label and apply to the passenger side fuse box cover.

Extra Campaign Completed and Vehicle Service History labels are available free of charge

from Moore Business Systems. Fax your order to: (03) 9270 8925.

• For Campaign Completed Labels Quote stock no. SD 28156 on a Moore Business

Systems ‘Packaged Goods’ order form for a pack of 100 labels.

• For Vehicle Service History Labels quote stock no. SD 28177 on a Moore Business

Systems ‘Packaged Goods’ order form for a pack of 100 labels.

PARTS INFORMATION

Each dealer has been sent an initial quantity of three exhaust pipe clamps with this Recall

Campaign Bulletin package, comprising of:

• 2 x Part number 13205242

• 1 x Part number 13212335

Page 3 of 7

Additional clamps are available free of charge from Salmat by completing and faxing the

Material Order Form, Refer to Appendix C. Follow up Salmat to confirm receipt of Material

Order Form if written confirmation of receipt from Salmat is not received within 2 working

days.

Replacement part information:

Part Number Description Quantity

13205242 Clamp – 55 mm 1

*13212335 (Refer Note) Clamp – 50 mm 1

Note: *Only 20 vehicles will need to be fitted with the 50mm clamp. Therefore do not order

additional quantities unless the part number (13212335) supplied is used to rework an

affected vehicle.

WARRANTY CLAIM INFORMATION

On completion of campaign action, dealers are requested to submit a warranty claim using

the Labour Operation Numbers specified below:

Warranty Claim Information

Description

Replace exhaust pipe clamp.

Labour Operation No.:

Standard Time:

Failure Code:

Claim Type:

T481401

0. 5

T0096

08

CONTACT INFORMATION

For further information or clarification on this recall campaign please contact the relevant

person below:

ENQUIRY TYPE CONTACT NAME CONTACT NUMBER

(03) 9647 1857

General enquiries Martha Kostidis

or

Brett Fowler (03) 9647 5698

Technical enquiries TAS 1800 033 417

Parts related enquiries Salmat (03) 9358 2990

Warranty related enquiries Warranty Administration 1800 033 487

J. K. Hoffman

General Service Manager

Attachments

Appendix A Customer Letter- Draft

Appendix B Technical Procedure

Appendix C Material order form

Page 4 of 7

APPENDIX A - Draft Customer Letter

Dear Holden Customer,

As part of Holden’s ongoing commitment to customer safety, we have initiated

a vehicle safety recall campaign on some model year 2004 ZC Vectra vehicles.

The clamp holding the front exhaust pipes together may expand and allow

the pipes to come apart.

Driving in this condition for over fifteen minutes can cause damage to the

fuel tank and hand brake cable.

Our records indicate that your Holden vehicle was manufactured within the

affected range.

It is therefore necessary for you to contact a Holden Dealer of your choice, and

make a booking to have the clamp replaced with the upgraded design as soon

as possible.

Work will be carried out free of charge. At the time of booking, your Dealer will

be able to advise you how long your vehicle will be required for the work to be

completed.

If you have any questions, please contact your Holden Dealer or call the Holden

Recall and Rework Assistance Centre on 1800 632 826, where we will be pleased

to assist.

Thank you for your attention to this matter. Please accept our apologies for any

inconvenience that may be caused to you.

Yours sincerely

David McMurray

Manager, Customer Assistance

VEHICLE SAFETY RECALL

04-H-07

Page 5 of 7

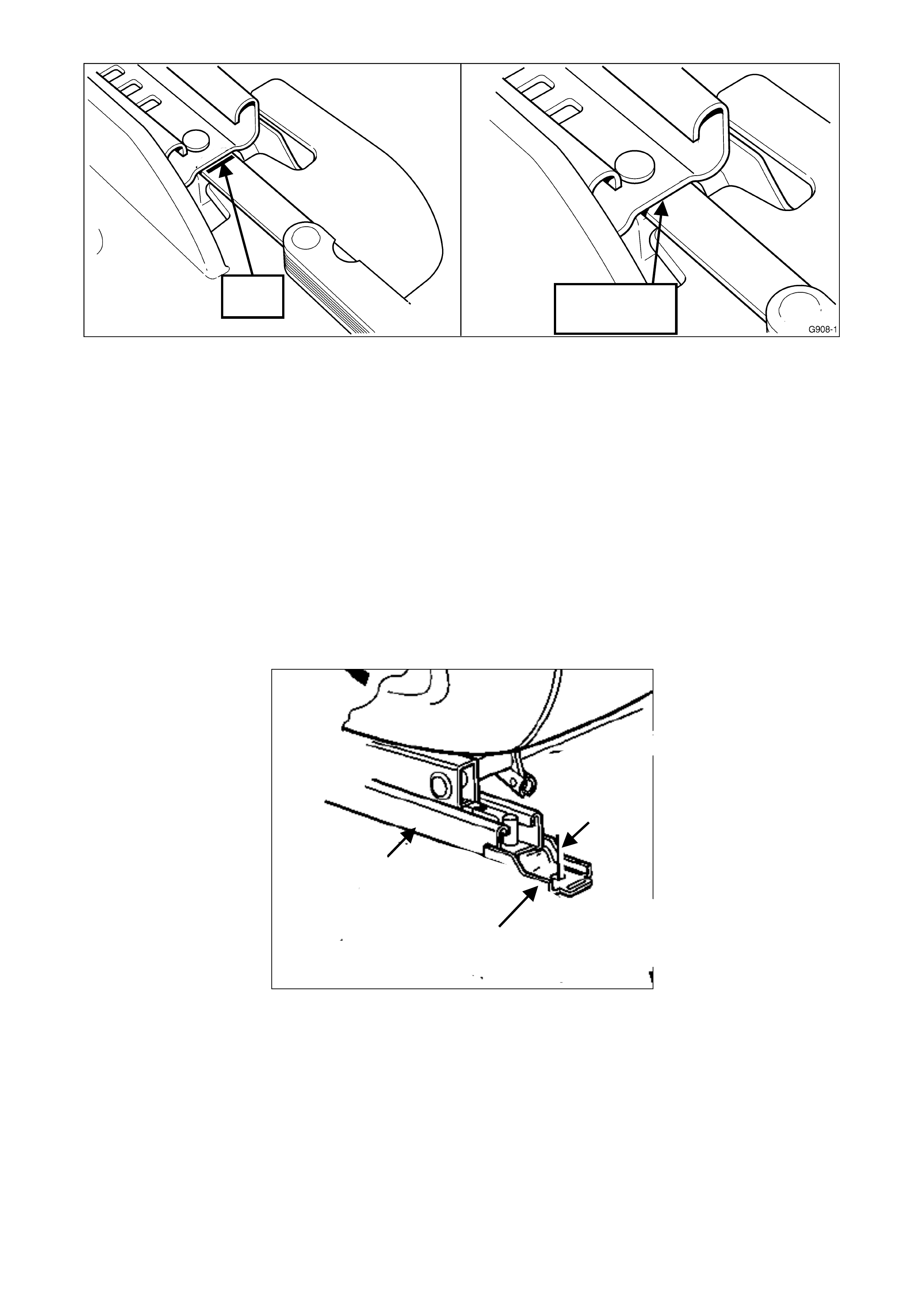

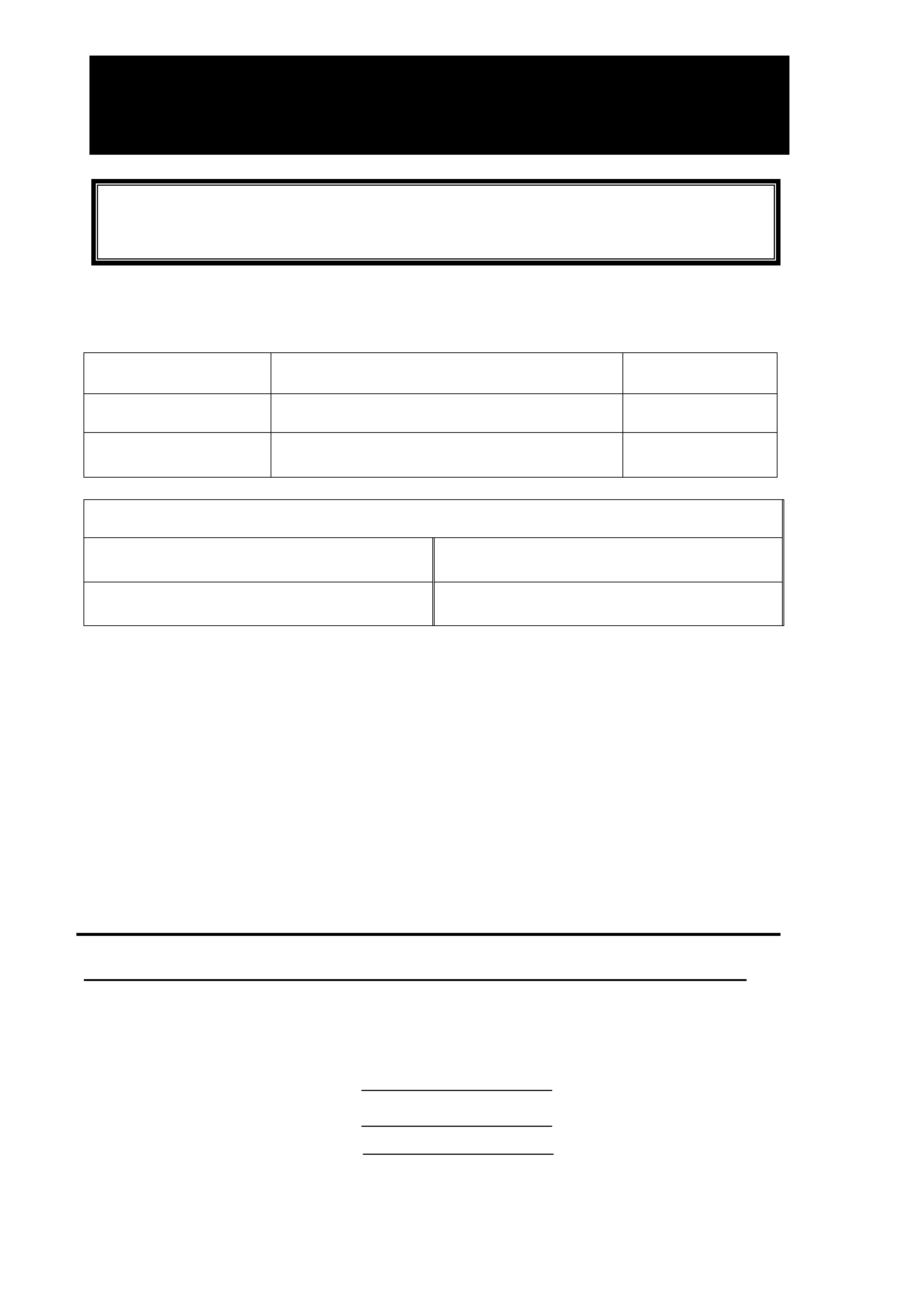

1. Raise vehicle onto hoist.

2. In the event the exhaust pipes have

completely separated, immediately

contact Holden Technical Assistance

Centre TAS for next step advice.

IMPORTANT NOTE

Contact with Holden Technical

Assistance must be in line with the

standard TAS operating procedure

(nominated TAS contacts only).

3. If exhaust pipes are connected,

proceed to remove the centre

exhaust clamp.

a) Using a ratchet and 15 mm

socket, loosen clamp (1). Refer

Fig 1.

b) Prior to separating exhaust pipe,

mark the join with a paint pen.

This will help identify the point at

which it is required to be re-fitted.

c) Carefully push the middle muffler

to the rear as shown by the arrow

until parts are apart. Refer Fig 1.

d) Remove clamp from middle

muffler by prising the clamp open.

In doing this, the spot weld should

also break. Refer Fig 2.

Hint: If necessary, a small cold

chisel can be used.

Figure 1

Figure 2

4. Install new clamp.

a) Slide new clamp over pipe.

b) Slide middle muffler to front

exhaust pipe.

c) Push middle muffler up to the paint

pen marking on the front exhaust

pipe as indicated by arrow in Fig 3.

Note: Spot weld only used for initial

assembly. Not necessary for service

replacement.

Figure 3

Mould heat shrink tubing using heat gun or

Hot water

APPENDIX B – TECHNICAL INSTRUCTIONS FOR CAMPAIGN 04-H-07 ZC VECTRA

EXHAUST CLAMP REPLACEMENT.

S

p

ot weld

Page 6 of 7

5. Align clamp horizontally as shown in

Fig.4 (1).

6. Torque to 45 Nm.

7. Check exhaust system for leaks.

8. Affix a Campaign Completed label and

a Vehicle Service history label as

specified in the section titled

‘Campaign Completion Identification’.

End of procedure.

Figure 4

APPENDIX B – TECHNICAL INSTRUCTIONS FOR CAMPAIGN 04-H-07 ZC

VECTRA EXHAUST CLAMP REPLACEMENT.

Page 7 of 7

Fax this order form to SALMAT ON: (03) 9358 – 2999

IMPORTANT:

The vehicle ISOVIN to be reworked must be specified below.

Part Number Description Quantity

13205242 Clamp – 55 mm

13212335 Clamp – 50 mm

VEHICLE ISOVIN

Contact Name: _______________________________________________

Dealer Code: _______________________ Date: ________________

Dealer Name: ______________________ Ph. No: ______________

Dealer Address: _______________________________________________

Fax No.: _______________________________________________

SALMAT USE ONLY

Dealer Order Acknowledgement faxed back to Dealer within 2 working days of receiving YES / NO

Confirmation of parts order received by Salmat on:

QUANTITY REQUESTED DESPATCHED YES / NO (PLEASE CIRCLE APPROPRIATE RESPONSE)

Date despatched

FREIGHT FORWARD AGENT

Consignment Note Number

APPENDIX C – SALMAT MATERIAL ORDER FORM FOR

CAMPAIGN 04-H-07

ZC VECTRA EXHAUST CLAMP REPLACEMENT.

Page 1 of 3

FAX COMMUNICATION

To: From:

Service Manager

Fax: Fax: (03) 9647 2525

Phone: Phone: (03)

PRODUCT CAMPAIGN BULLETIN

04- H- 09

December 2004

SUBJECT: LEFT HAND REAR DOOR REPLACEMENT

MODELS AFFECTED: VZ COMMODORE AND WL STATESMAN

This bulletin announces the initiation of a safety related recall to replace the left hand rear door fitted

to selected (few) VZ and WL Holden vehicles.

Further to the telephone conversation with a representative from your Service Department, the vehicle

shown against your Dealer Code in Attachment 1, MUST be Quarantined and reworked as per the

instructions below. Alternatively, if the vehicle against your Dealer Code has been delivered to a

customer, you will need to contact the customer and make arrangements for rework action.

1. Vehicle Affected is shown against your Dealer Code and listed on Attachment 1.

2. Description of Defect: Advice received from the vehicle assembly plant that some doors were

manufactured with defective spot welds. This condition may affect the structural integrity of the

doors and potentially affect occupant protection in the event of a side impact collision.

3. Rework Action required is to replace the Left Hand Rear Door. Refer to SIP CD, section VY-1A5:

Front & Rear Door Assembly, part 3.18: Rear Door Assembly.

4. Replacement parts will be sent to your dealership, following confirmation of customer booking

date by the Service Manager. Secure booking dates after Friday 17th December allowing enough

time for parts to arrive. Parts will be attentioned to the Service Manager, comprising of:

• 1 x fully trimmed left hand rear door

• 1 x belt line moulding

5. Campaign Completion Identification

All campaigned vehicles must have:

A Campaign Completed label applied to the right hand front ‘A’ pillar, between the hinges, with details

of the campaign, ie

• Campaign No. “04-H-09”

• Dealer Code

• Date legibly entered on the label with a permanent ink pen.

AND

For additional identification, mark an “X” at the B-2 coordinate of Vehicle Service History label and

apply to the inner side of the lower instrument panel cover.

Extra Campaign Completed and Vehicle Service History labels are available free of charge from

Moore Business Systems. Fax your order to: (03) 9270 8925.

Page 2 of 3- Recall Campaign 04-H-09

• For Campaign Completed Labels Quote stock no. SD 28156 on a Moore Business Systems

‘Packaged Goods’ order form for a pack of 100 labels.

• For Vehicle Service History Labels quote stock no. SD 28177 on a Moore Business Systems

‘Packaged Goods’ order form for a pack of 100 labels.

6. Warranty Claim Information

WARRANTY CLAIM INFORMATION

Description

Replace Left Hand Rear Door.

Labour Operation No:

Standard Time:

Failure Code:

Case Type:

T481601

2.0 hours

T0096

08

7. Sign and Fax Vehicle Rework Completed Confirmation Sheet – Refer to Attachment 1.

Prior to sending the fax ensure all items on the checklist below have been completed:

• Affected components MUST have been replaced as per Rework Instructions

• Campaign Completed Label and Vehicle Service History Label filled out.

• Warranty claim MUST have been submitted

8. Replaced (defective) components MUST be returned to Repac marked to the attention of Brett

Fowler. Use the same packaging the revised door was shipped in.

9. For Further Information or clarification on the above, then please contact Brett Fowler on

telephone number (03) 9647-1857 or Daniel Coburn on (03) 9647 1524.

J. K. Hoffman

General Service Manager

ATTACHMENTS

• Attachment 1 – Affected Vehicle List and Rework Completed Confirmation

Page 3 of 3 – Recall Campaign 04-H-09

Attachment 1

ATTENTION: BRETT FOWLER

04-H-09 Recall Campaign - Left Hand Rear Door Replacement

AFFECTED VEHICLES

AND

REWORK COMPLETED CONFIRMATION

1. The vehicle shown against your Dealer Code is affected by this Campaign Action.

2. Please complete all work mentioned in section 7 above.

3. Enter rework date, print Service Manager’s name and have Service Manager sign to confirm

Rework Completion.

4. Fax to Holden on 03 9647 2525.

Dealer

Code

ISOVIN AFFECTED DATE

REWORKED

SERVICE MANAGER

NAME (please print)

SERVICE MANAGER

Signature

573 6G1ZK54785L342707

636 6G1ZK52785L343181

636 6G1LY54785L348365

230 6G1ZK52B75L348439

895 6G1ZX54715L348480

438 6G1ZX54735L349288

449 6G1LY54715L349325

230 6G1ZK52B45L349385

336 6G1ZL54B05L349538

562 6G1ZK52B75L349591

422 6G1ZK52715L349601

230 6G1ZK52BX5L349603

FAX THIS REWORK COMPLETED CONFIRMATION to : (03) 9647 2525

Page 1 of 6

PRODUCT CAMPAIGN BULLETIN

04-H-11

March 15, 2005

SUBJECT: TYRE BEAD DAMAGE.

MODELS AFFECTED: VZ and WL

Note: This Campaign Bulletin supersedes ADL 53/04 that was released on

December 3, 2004.

This bulletin expands the safety recall campaign initiated by ADL 53/04 to increase the

affected range of vehicles, and also allow Dealers to self manage the sourcing of the five

replacement tyres required for affected vehicles listed in Appendix A.

DESCRIPTION OF DEFECT

There is a possibility that the tyre bead may have been damaged during tyre and wheel

assembly at the Vehicle Assembly Plant (VAP).

AFFECTED VEHICLES

Only VZ and WL vehicles as listed on Appendix A, and flagged in the NOW system.

ACTION REQUIRED BY RETAILERS

1. Confirm vehicle is affected by checking the list at Appendix A.

2. Confirm vehicle has not previously been reworked i.e:

Identified by an ‘X’ in the C-1 co-ordinate of the “Vehicle Service History” label

Application of “04-H-11 Campaign Completed” label.

Confirm campaign status in NOW vehicle search.

3. If vehicle has not been previously reworked, proceed with campaign instructions as per

Appendix B.

4. Affix a Campaign Completed Label and a Vehicle Service History Label as specified in

the section titled ‘Campaign Completion Identification’.

5. Submit a Warranty Claim. Refer “Warranty Claim Information”.

6. Replaced tyres must be returned to REPAC.

Page 2 of 6

CUSTOMER NOTIFICATION

Owners of vehicles affected by this recall campaign will be contacted directly by letter from

Holden sent to their recorded address. The letter provides details of the recall campaign

and requests the customer to contact their Holden Dealer to make a service booking to

have the appropriate work carried out. Refer to Appendix C for a draft copy of the customer

letter.

CAMPAIGN COMPLETION IDENTIFICATION

All campaigned vehicles must have:

1. A Campaign Completed label applied to the right hand front ‘A’ pillar, between the

hinges, with details of the campaign, 04-H-11, Dealership code and date legibly entered

on the label with a permanent ink pen.

AND

2. For additional identification, mark an “X” at the C-1 co-ordinate of a Vehicle Service

History Label and apply to the inner side of the lower instrument panel cover if not

already fitted.

Extra Campaign Completed and Vehicle Service History labels are available free of charge

from Moore Business Systems.

• For Campaign Completed Labels Quote stock no. SD 28156 on a Moore Business

Systems ‘Packaged Goods’ order form for a pack of 100 labels.

• For Vehicle Service History Labels quote stock no. SD 28177 on a Moore Business

Systems ‘Packaged Goods’ order form for a pack of 100 labels.

Fax the order form to Moore Business Systems on Facsimile: (03) 9270 8925

Should you need to follow-up on a placed order, contact Moore customer service on

telephone number (03) 9270 8788.

PARTS INFORMATION

Initially some replacement tyres were despatched to Dealers directly from the Vehicle

Assembly Plant. Tyres will no longer be despatched to Dealers from the Vehicle Assembly

Plant. Dealers requiring replacement tyres for affected vehicles should source identical

replacements for the original tyres from an Authorised Bridgestone Agent. To claim costs

incurred see Warranty Claim Information.

Note: Often the spare tyre will be a different size and specification to the road wheel tyres,

so ensure the exact same tyre is fitted to the spare as originally fitted.

Replaced tyres must be returned to REPAC when requested by the REPAC report.

Page 3 of 6

WARRANTY CLAIM INFORMATION

On completion of campaign action, Dealers are requested to submit a Warranty Claim using

the Labour Operation Number specified below.

WARRANTY CLAIM INFORMATION

Description

Replace Five Tyres

Labour Operation No.:

Standard Time:

Failure Code:

Case Type:

T481501

0.5 hours + sublet (fitting and tyres)

1.5 In house fitting+ sublet (tyres only

)

T0096

08

CONTACT INFORMATION

For further information or clarification on this recall campaign please contact the relevant

person below.

CONTACT NAME CONTACT NUMBER

(03) 9647 1857

General enquiries Brett Fowler / Rob Davies

or

Alex Holt (03) 9647 7619

Technical enquiries TAS 1800 033 417

Warranty related enquiries Warranty Administration 1800 033 487

J. K. Hoffman

General Service Manager

Attachments

Appendix A Affected vehicle list

Appendix B Tyre fitting Instructions

Appendix C Customer Letter- Draft

Note: All tyres

must be

invoiced as a

sublet.

Page 4 of 6

APPENDIX A

AFFECTED VEHICLE LISTING

This is a list of vehicles that require all five tyres to be replaced due to possible damage.

Before replacing tyres confirm vehicle has not previously been reworked.

ISOVIN ISOVIN ISOVIN

6G1LY54F05L363191 6G1LY54755L371957 6G1ZK43B45L373842

6G1LY54795L365515 6G1ZK54B35L372041 6G1ZK43B65L373843

6G1ZK42B45L369047 6G1ZK43B25L372219 6G1ZK43B75L373852

6G1ZK43B85L369809 6G1ZK43B95L372248 6G1ZK42B65L373861

6G1ZK43B15L369814 6G1ZK43B45L372254 6G1LY54705L374202

6G1ZK43B35L369815 6G1ZK43B35L372259 6G1LY54795L374229

6G1ZK42F15L369817 6G1ZK42B55L372264 6G1ZK43B05L374700

6G1ZK43B35L369829 6G1ZK43B05L372266 6G1LY54725L374959

6G1ZK43B15L369831 6G1ZK43B65L372269 6G1LY54765L375046

6G1ZK43B25L369837 6G1ZK43B45L372271 6G1LY54735L375084

6G1ZK43B95L369852 6G1ZK43B85L372273 6G1LY54715L375214

6G1LY54735L370290 6G1ZK43B75L372281 6G1LY54755L375300

6G1LY54F85L370342 6G1ZK43B95L372282 6G1LY54745L375322

6G1ZK43B65L370599 6G1LY54735L372332 6G1LY54745L375756

6G1ZK42B75L370600 6G1ZK52785L372387 6G1LY54725L375867

6G1LY54F75L370977 6G1LY54795L372402 6G1LY54705L375883

6G1LZ54F65L370997 6G1LY547X5L372425 6G1LY54795L375901

6G1LY54F35L371172 6G1ZK54B75L372446 6G1LY54725L375979

6G1LY54715L371177 6G1ZL84B05L372478 6G1LY54715L376007

6G1ZK52B75L371557 6G1ZK52B75L372479 6G1LY54715L376055

6G1ZK52B55L371573 6G1ZK34F65L372980 6G1LY54755L376169

6G1ZX54715L371581 6G1ZK03F15L373017 6G1LY54725L376193

6G1LY54F65L371604 6G1ZK43B15L373040 6G1LY54795L376224

6G1LY54725L371625 6G1ZK43B35L373041 6G1LY54F15L376578

6G1ZX54F75L371642 6G1ZK42B75L373044 6G1LY54F75L376648

6G1ZK527X5L371659 6G1ZK43B35L373055 6G1LY54F55L376843

6G1LY54F65L371666 6G1ZK43B55L373056 6G1LY54FX5L376885

6G1ZK52B15L371697 6G1ZK43B75L373060 6G1LY54F25L377464

6G1ZK52725L371705 6G1ZK43B05L373062 6G1LY54765L377511

6G1ZX54F55L371719 6G1ZK43B95L373075 6G1LY54745L377765

6G1ZK54F35L371734 6G1ZK43B15L373085 6G1LY54795L377776

6G1LY547X5L371744 6G1ZK43B65L373096 6G1LY54795L377793

6G1ZK54B85L371788 6G1ZK43B85L373102 6G1LY547X5L378273

6G1LY54F75L371918 6G1ZK43BX5L373103 6G1LY54F75L378304

6G1ZK84B45L371921 6G1ZK43B35L373105 6G1LY54F15L378329

6G1LY547X5L371923 6G1ZK43B65L373132 6G1LY54725L378459

6G1ZK43B15L373829

6G1ZK43B95L373836

NOTE: A further 73 vehicles have already been reworked.

Page 5 of 6

APPENDIX B

Tyre Fitting Instructions.

1. Five (includes the spare tyre) identical replacement tyres must be sourced from an

Authorised Bridgestone Agent.

2. Replacement tyres must be exactly the same as those originally fitted, including the

spare tyre which is often a different size and specification to the road tyres.

3. When fitted, check that the replacement tyres have been inflated to the correct

pressure as per the vehicles Tyre Placard.

4. Road test the vehicle to ensure it does not vibrate abnormally.

5. If the vehicle does vibrate have the wheel balance re-checked.

6. Apply a Campaign Completed label to the right hand front ‘A’ pillar, between the

hinges, with details of the campaign, 04-H-11, Dealership code and date legibly

entered on the label with a permanent ink pen.

And:

mark an “X” at the C-1 co-ordinate of a Vehicle Service History Label and apply to

the inner side of the lower instrument panel cover if not already fitted.

7. Ensure that replaced tyres are returned to REPAC.

8. Submit a Warranty Claim.

Page 6 of 6

APPENDIX C - Draft – Customer Letter

Dear Holden Customer,

As part of Holden’s ongoing commitment to customer safety, we have initiated a Vehicle

Recall Campaign on a small number of Holden vehicles manufactured from October 28,

2004 to November 22, 2004 inclusive.

Our records indicate that this Vehicle Recall Campaign affects your Holden vehicle.

There is a possibility that the tyre bead may have been damaged during tyre and wheel

assembly at the Vehicle Assembly Plant. This damage may lead to loss of tyre air

pressure.

It is therefore necessary for you to contact a Holden Dealer of your choice, and make a

booking to have your vehicle’s tyres replaced as soon as possible.

Work will be carried out free of charge. At the time of booking, your Dealer will be able to

advise you how long your vehicle will be required for the work to be completed.

If you have any questions, please contact your Holden Dealer or call the Holden Recall and

Rework Assistance Centre on 1800 632 826, where we will be pleased to assist.

Thank you for your attention to this matter. Please accept our apologies for any

inconvenience that may be caused to you.

Yours sincerely

David McMurray

Manager Customer Assistance

VEHICLE SAFETY RECALL