2

20

00

05

5

S

SE

ER

RV

VI

IC

CE

E

T

TE

EC

CH

HL

LI

IN

NE

ES

S

© 2005 GM Holden LTD. A.B.N. 84 006 893 232

Service Department

A “HOLDEN” Product.

BRISBANE SYDNEY MELBOURNE ADELAIDE PERTH

For the latest and/or any missing Techline bulletins,

please refer to Holden Lionheart

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

4

INFORMATION

Fitting Accessory Trailer Harness

ZC Model Year 2005

Group 12 Ref. No. TL0818- 0501

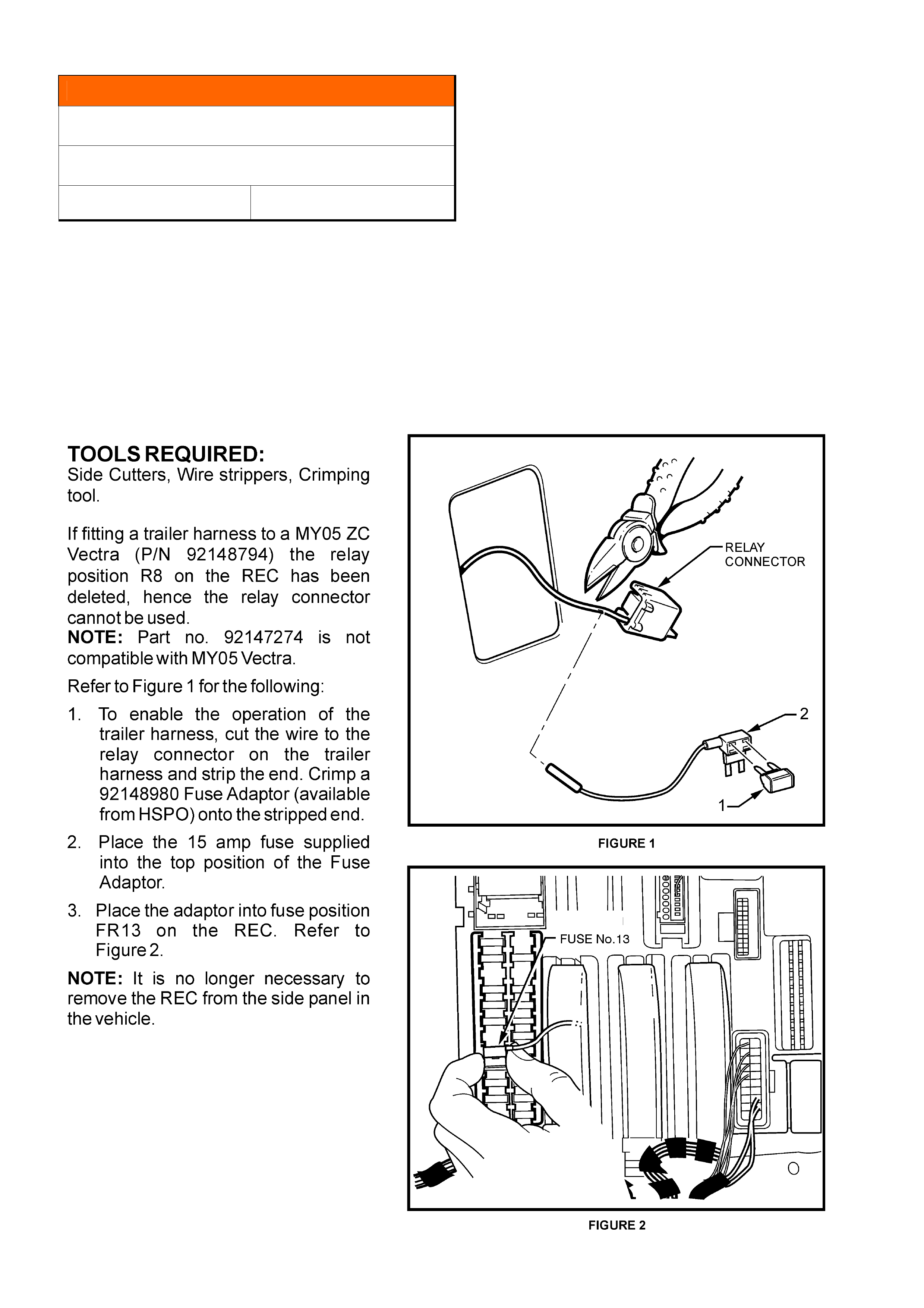

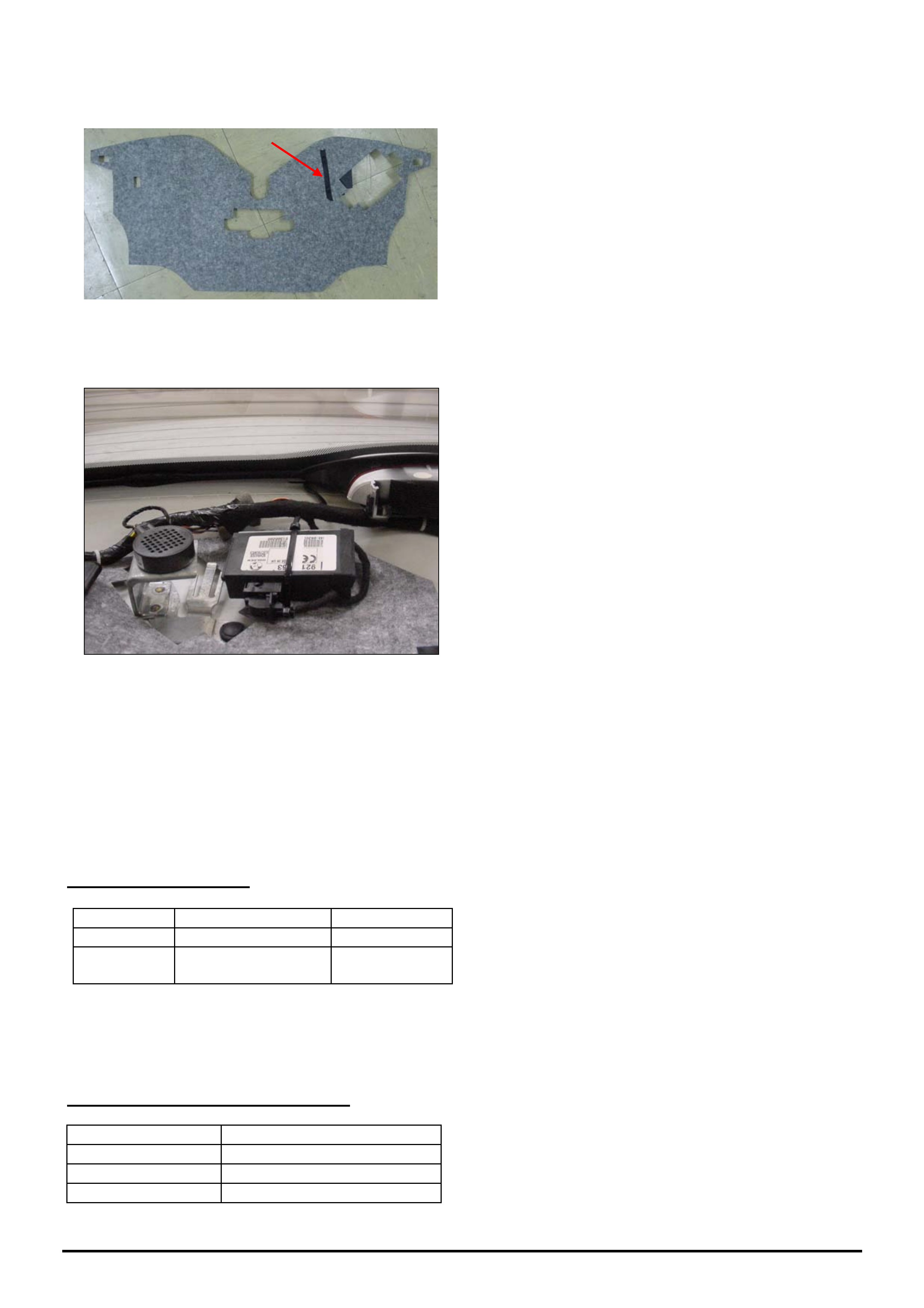

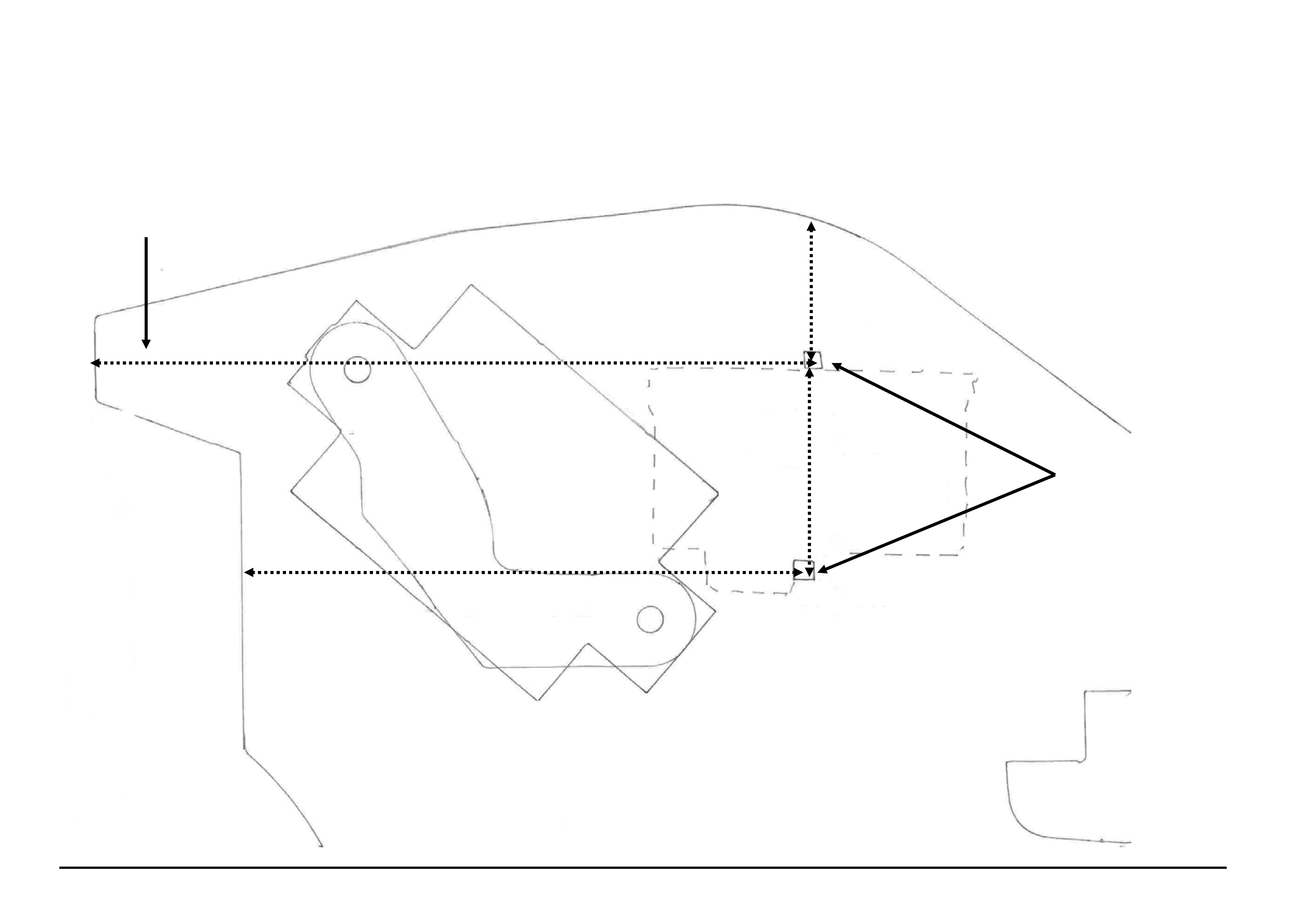

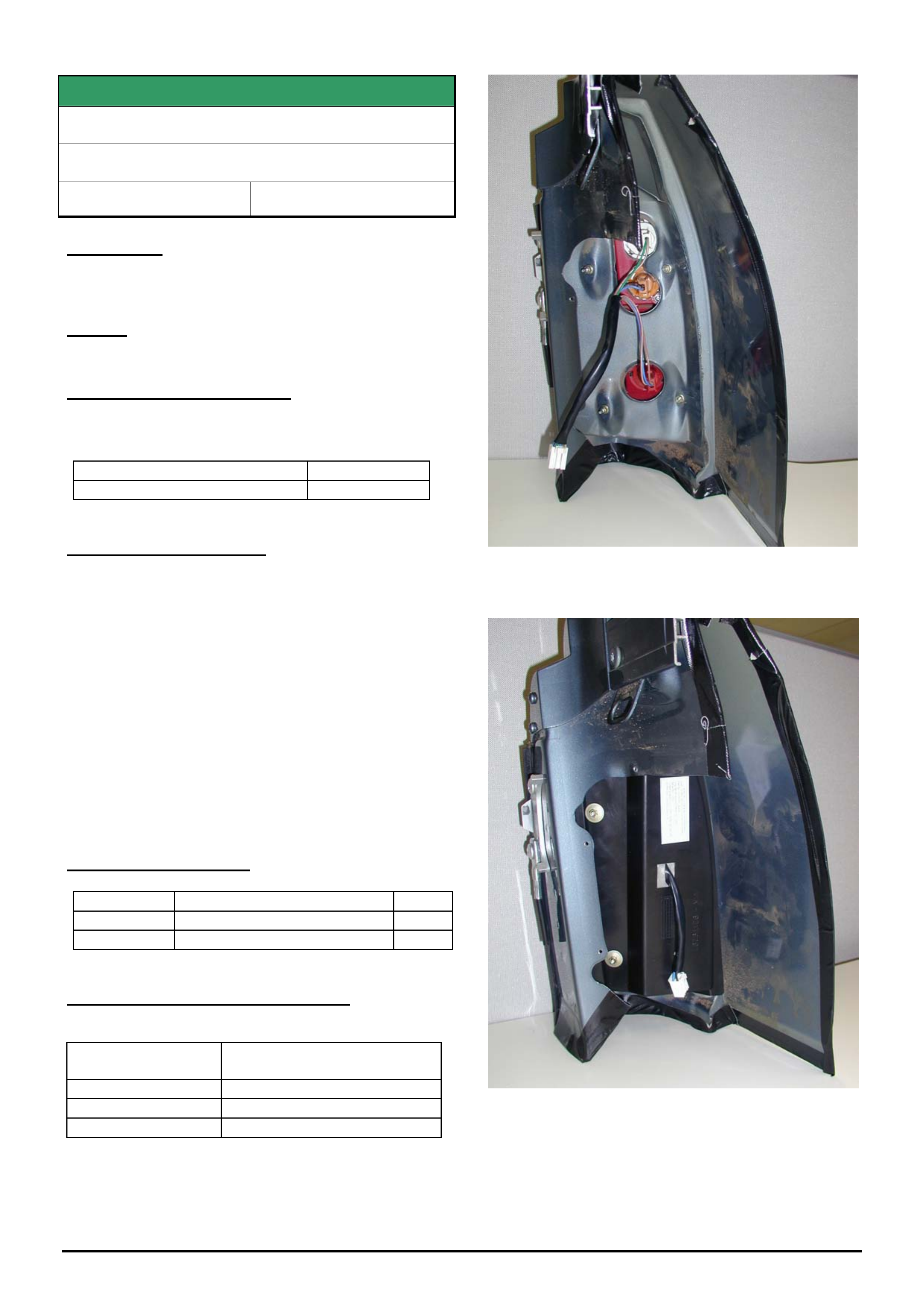

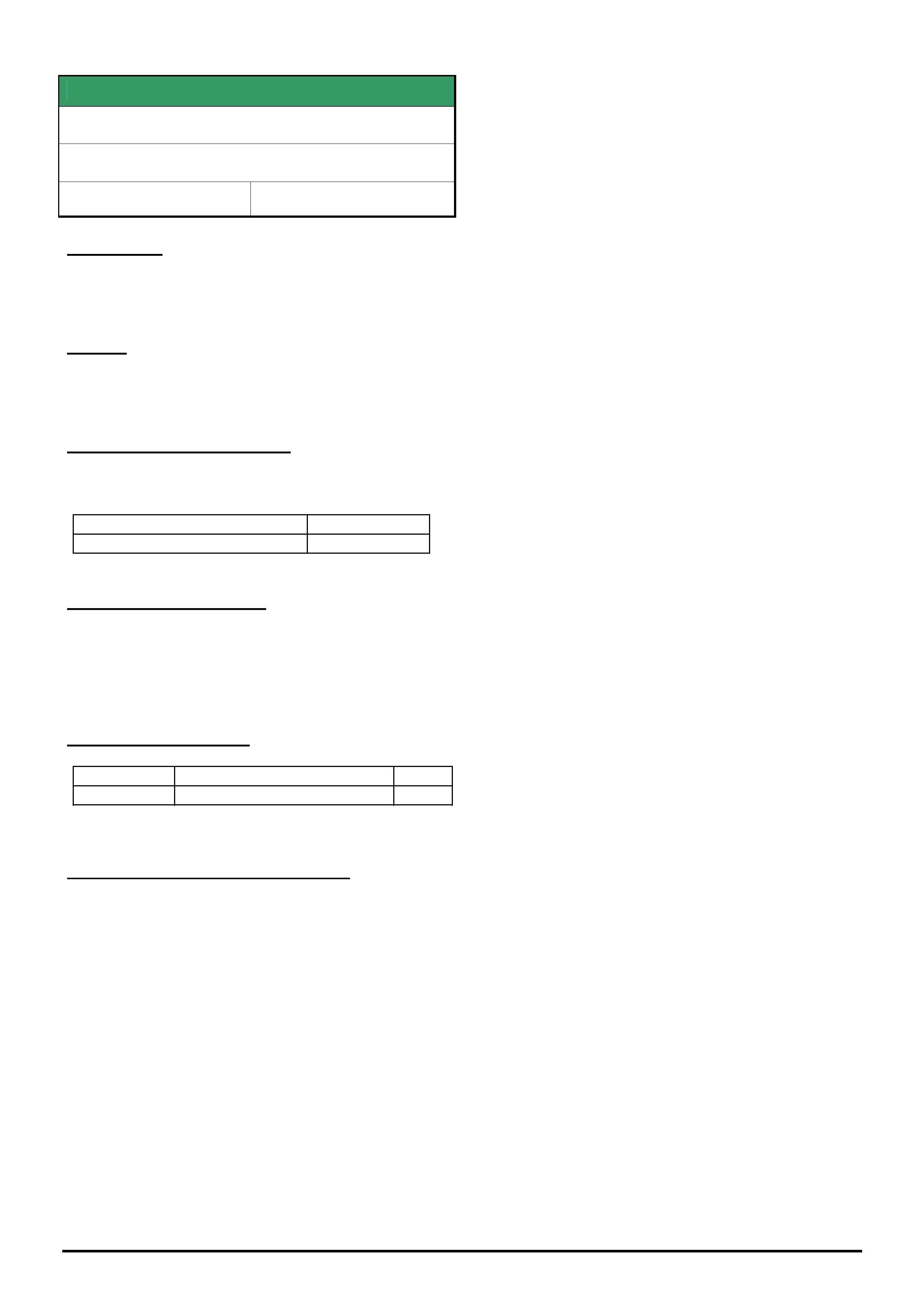

The following information is copied from HSPO Parts

Techline PT180 dated 9th Feb. 2005.

It describes the modification required when fitting a

trailer harness p/n 92148794 to a Model Year 2005 ZC

Vectra. This action is necessary due to a change to

the Rear Electrical Centre (REC) of this vehicle.

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

5

SERVICE FIX

Fuel Gauge Will Not Display Full After

Filling The Fuel Tank

VZ Gen III Ute

Group 12 Ref. No. TL0844 - 0501

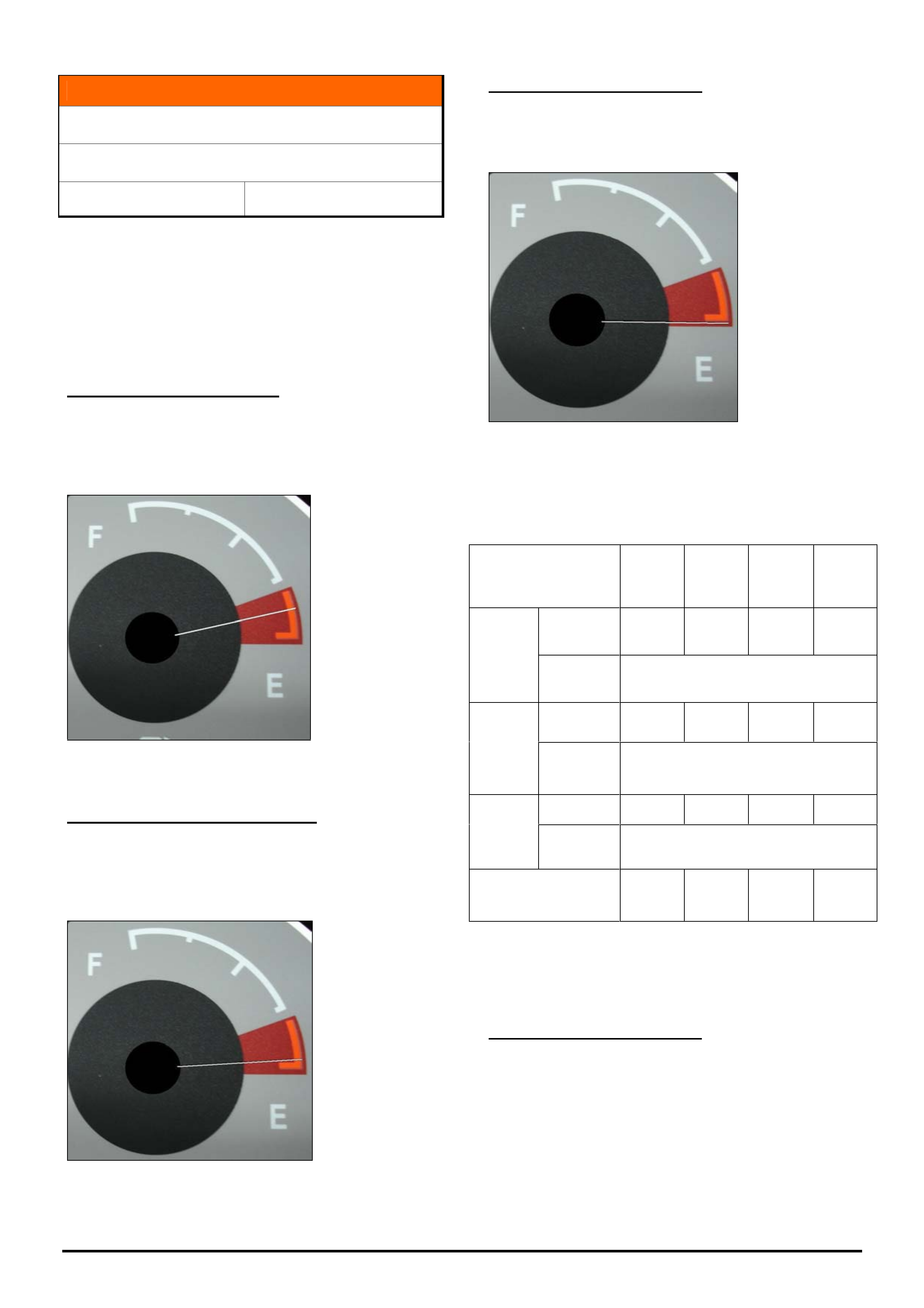

CONDITION

Reports have been received of the fuel gauge not

displaying full after refilling the fuel tank.

CAUSE

The fuel gauge section of the Engine Control Module

calibration.

CORRECTION – Production

A revised fuel gauge calibration was programmed into

vehicles in production from the following breakpoint:

ISOVIN: Built Date:

**********L390626 21/01/2005

CORRECTION – Service

To rectify this condition it will be necessary to:

1. reprogram the PCM via the standard SPS process

using TIS 2000 version 58 or later and

2. reprogram the instrument cluster fuel gauge

calibration using Tech 2 with software version

13.8.

WARRANTY CLAIM INFORMATION

Description Reprogram PCM &

Instrument cluster

Labour Op. No. N000478

Time 0.6 hr

Failure Code N0057 Registers incorrectly

SERVICE FIX

Fuel Gauge Inaccuracy

VZ / WL V6 Sedan and Wagon

Group 12 Ref. No. TL0845 - 0501

CONDITION

Reports have been received of the fuel gauge not

displaying accurately at the lower section of the gauge.

CAUSE

Variation of the fuel gauge output calculated by the

Engine Control Module (ECM).

CORRECTION – Production

A revised fuel gauge calibration was programmed into

the Engine Control Module in vehicles from the

following breakpoint:

ISOVIN: Built Date:

L382346 09/12/04

CORRECTION – Service

To rectify this condition it will be necessary to:

1. reprogram the ECM via the standard SPS process

using TIS 2000 version 58 or later and

2. reprogram the instrument cluster fuel gauge

calibration using Tech 2 with software version

13.8.

Note: In addition to the above, if the vehicle was built

prior to the 06/10/04 (L345644), refer to Service

Techline number TL0809-0410 published in issue 10,

Nov. 2004, to ensure the fuel sender float arm is not

bent.

WARRANTY CLAIM INFORMATION

Description Reprogram ECM &

Instrument

Labour Op. No. N000475

Time 0.6 hr

Failure Code N0057 Registers incorrectly

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

6

SERVICE FIX

Hill Descent Control Icon Displayed When

Shifting Gear

VZ (non AWD)

Group 12 Ref. No. TL0843 - 0501

CONDITION

Reports have been received of the Hill Descent Control

Icon being displayed in the instrument cluster when

shifting from Park to Reverse to Drive

CAUSE

Instrument cluster operating software.

CORRECTION – Production

The instrument cluster software has been revised to

rectify this condition from the following vehicle

breakpoint:

ISOVIN: Built Date:

**********L366285 10/11/04

CORRECTION – Service

To rectify this condition reprogram the instrument

cluster operating software via the standard SPS

process using Tech 2 and TIS 2000 version 57 or later.

WARRANTY CLAIM INFORMATION

Description Reprogram instrument

cluster

Labour Op. No. N312700

Time 0.3 hr

Failure Code N0057 Registers incorrectly

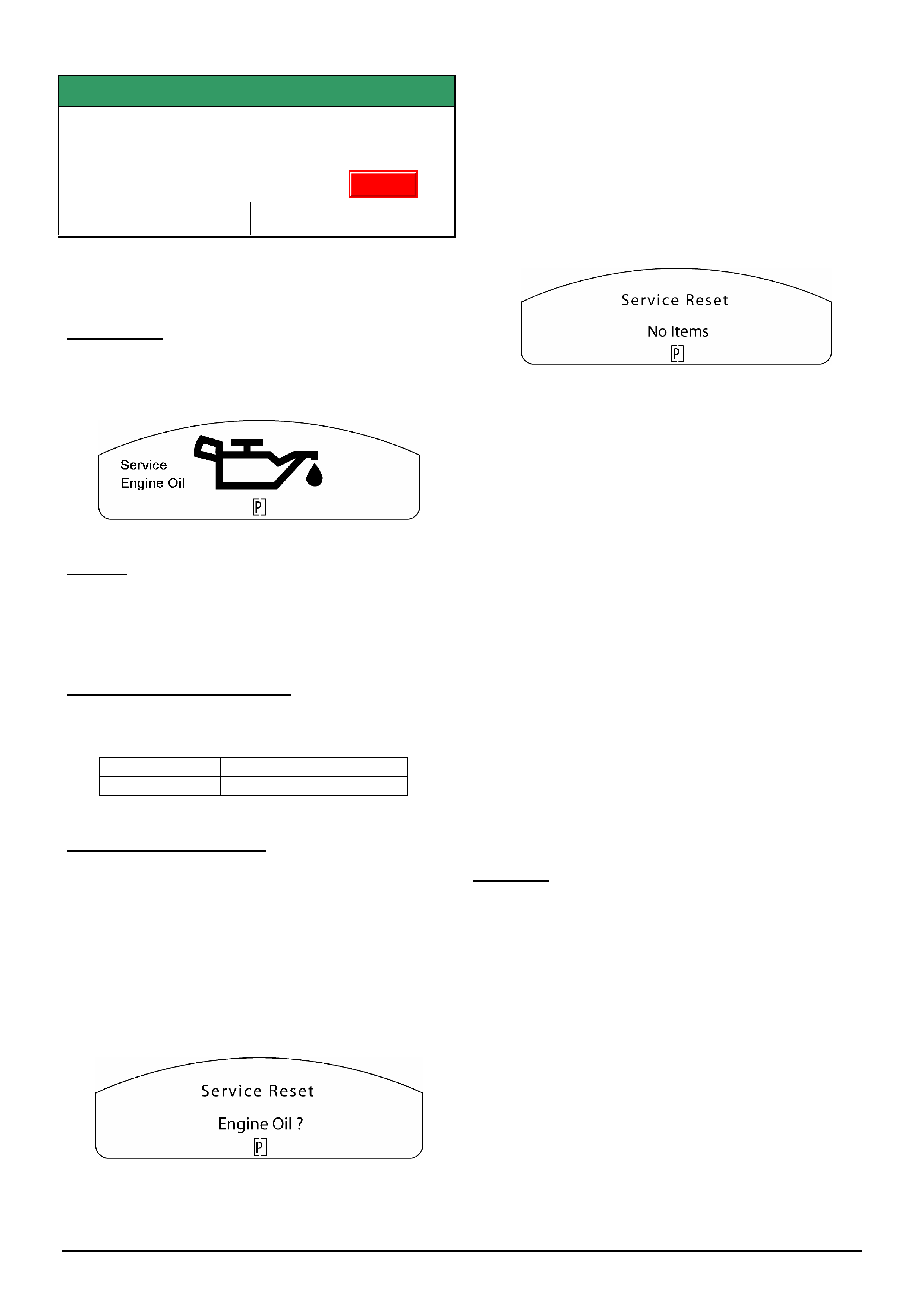

SERVICE FIX

Service Reminder Incorrect

VZ V6 Sedan, Wagon and Ute

Group 12 Ref. No. TL0831A - 0501

This Techline supercedes the previous one in Issue

11, Dec, 2004. It is revised by adding procedure for

reconfiguring instruments.

CONDITION

Reports have been received of the 10,000 km service

reminder being displayed in the instrument cluster

instead of the 15,000 km.

CAUSE

Incorrect programming of the instrument cluster during

the production process.

CORRECTION – Production

The programming process has been revised to rectify

this condition from the following vehicle breakpoints:

ISOVIN: Built Date:

Sedan **********L313609 24/11/04

Wagon **********L373979 24/11/04

Ute **********L371431 24/11/04

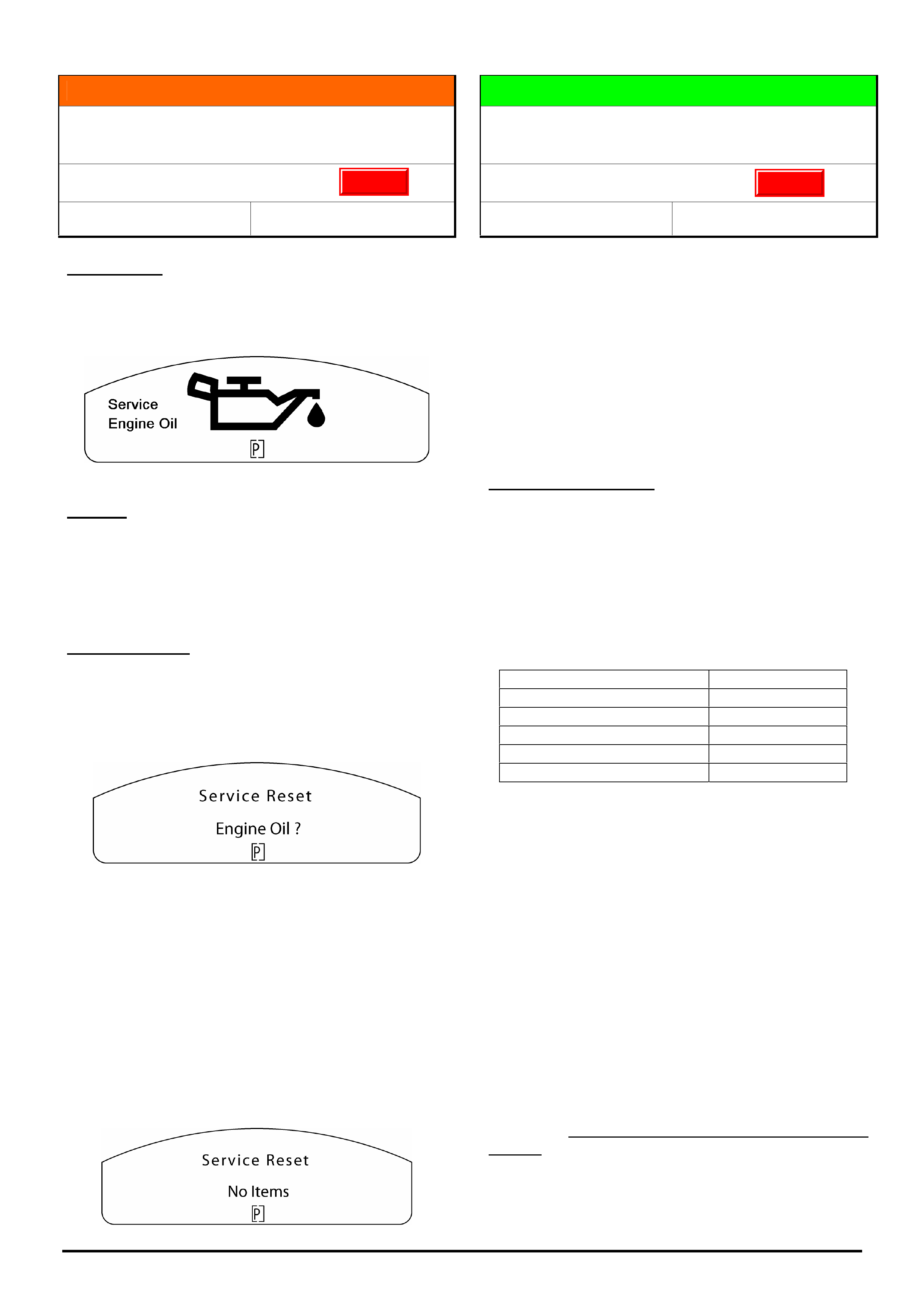

CORRECTION – Service

To rectify this condition perform the following steps;

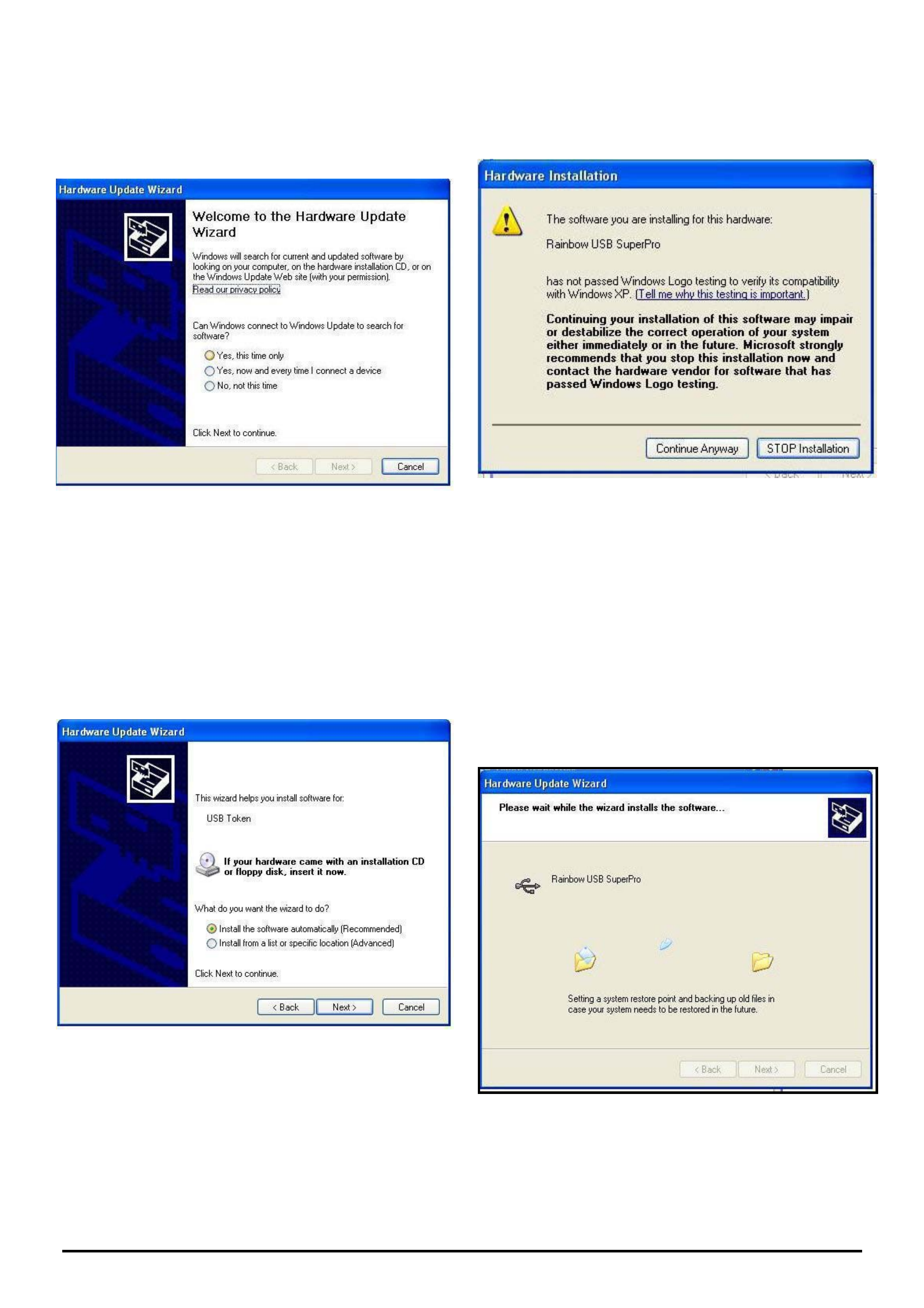

Step 1.

Using Tech 2 enter the configuration sub menu (an

example displayed below) within the instrument cluster

programming menu.

Step 2.

Scroll down to the Engine Type.

Step 3.

Select Modify and select V6.

Step 4.

Select Program.

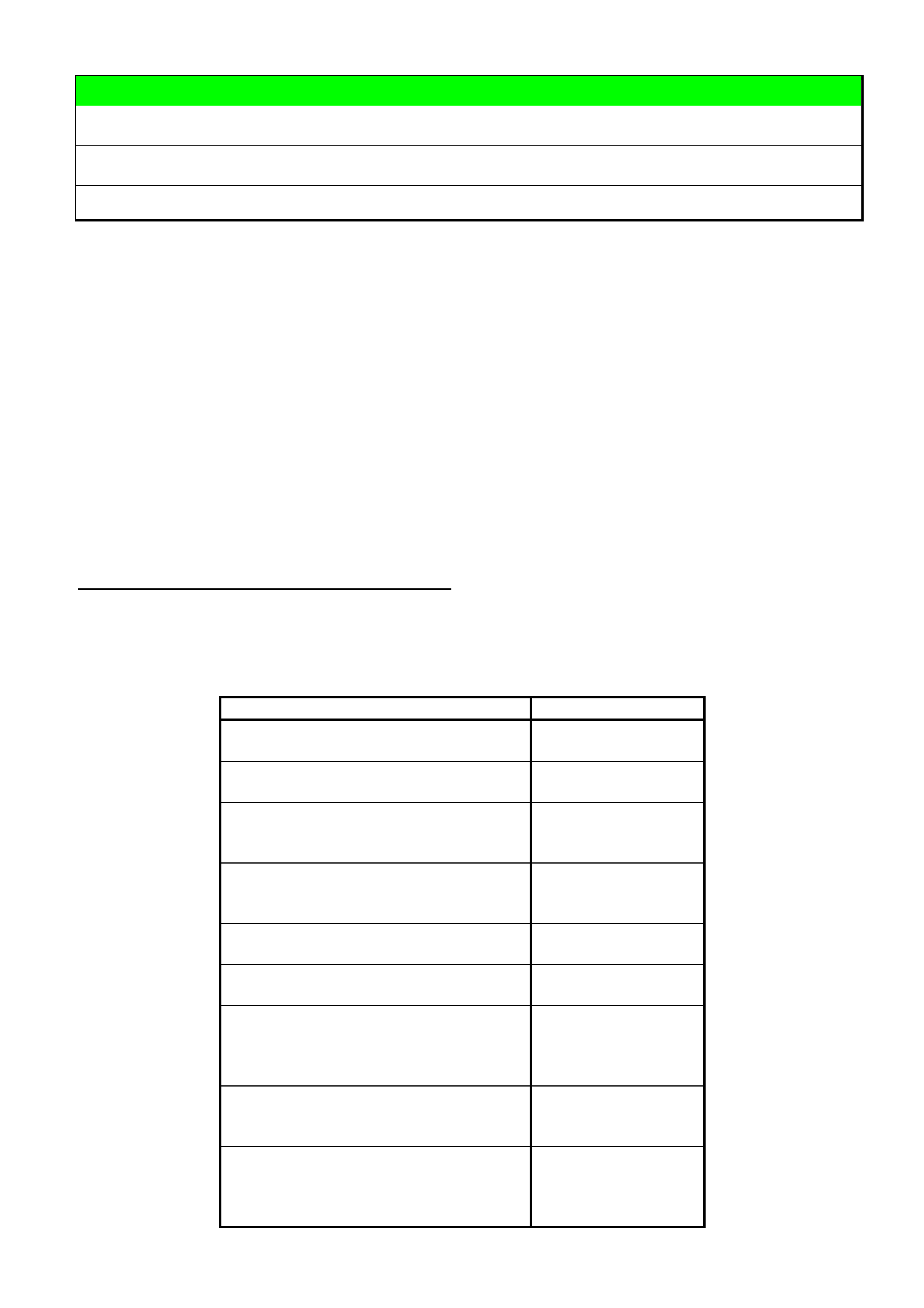

Configuration

(5) 2005 VZ and WL Series

Instrument

Country Australia/NZ

Engine Type (Select Engine)

Speedometer 6000

SRS Configuration 6 Loop SRS

Transmission Type 4 Speed Auto.

Police Mode No

Seat Belt Warning On

-----------------------------------------------1/7-------

A

bort Modify Program

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

7

Step 5.

Inspect the instrument cluster, and reset the service

interval using Tech 2 if required.

WARRANTY CLAIM INFORMATION

Description Reprogram instrument

cluster

Labour Op. No. N312700

Time 0.3 hr

Failure Code N0057 Registers incorrectly

DIAGNOSIS HINT

RH Lower Dash Panel Insulator Rattle

AH Astra

Group 1 Ref. No. TL0849- 0501

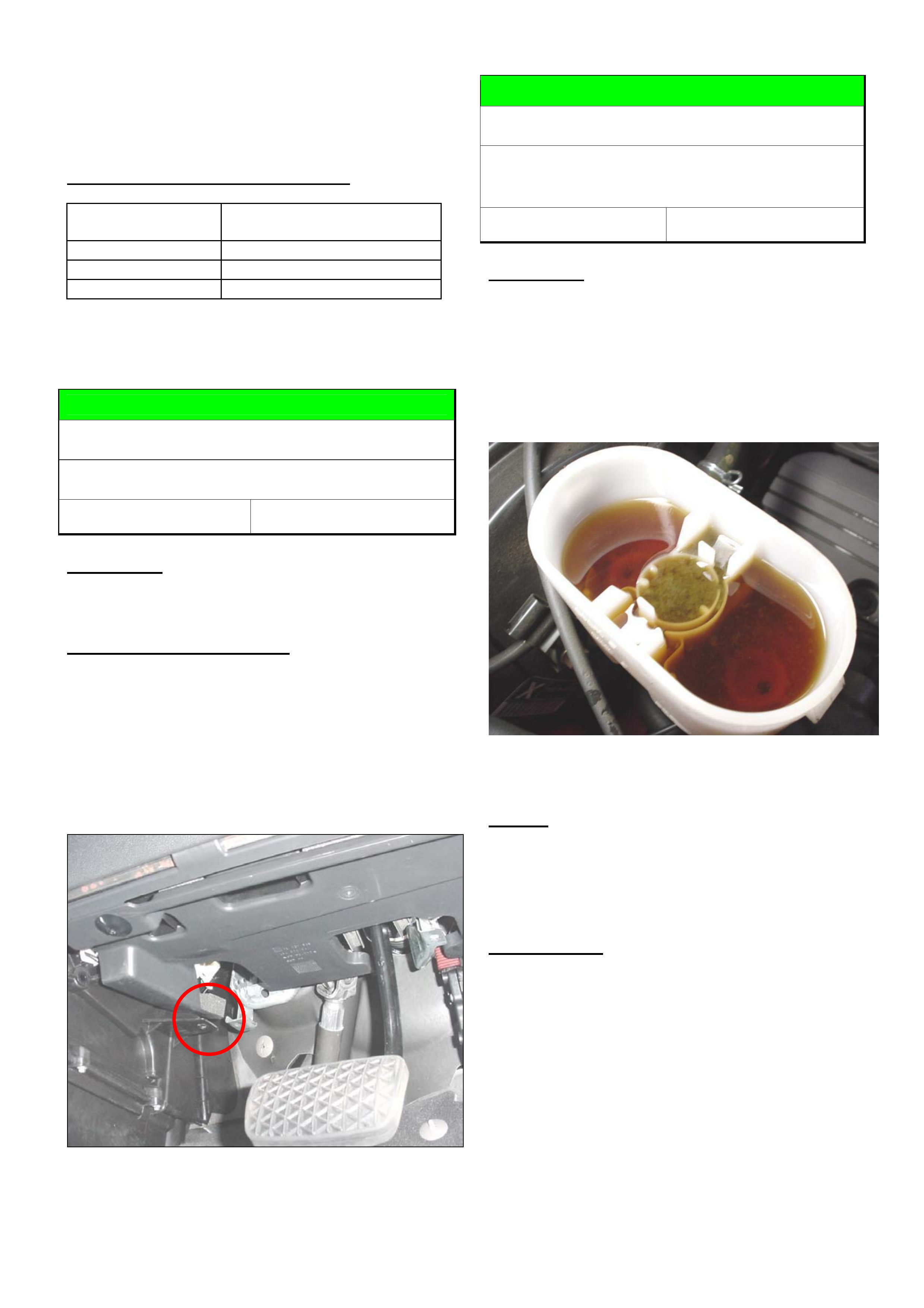

CONDITION

Rattle emanating from the RHS lower IP panel while

driving over rough roads.

POSSIBLE RECTIFICATION

Remove the insulator trim and refit with the left front

corner secured above the bracket protruding from the

HVAC casing as shown blow.

Note: An alternative is to drill a hole through the

insulator trim in line with the hole in the HVAC case

bracket. The insulator trim can then be secured using

a cable tie or an additional clip.

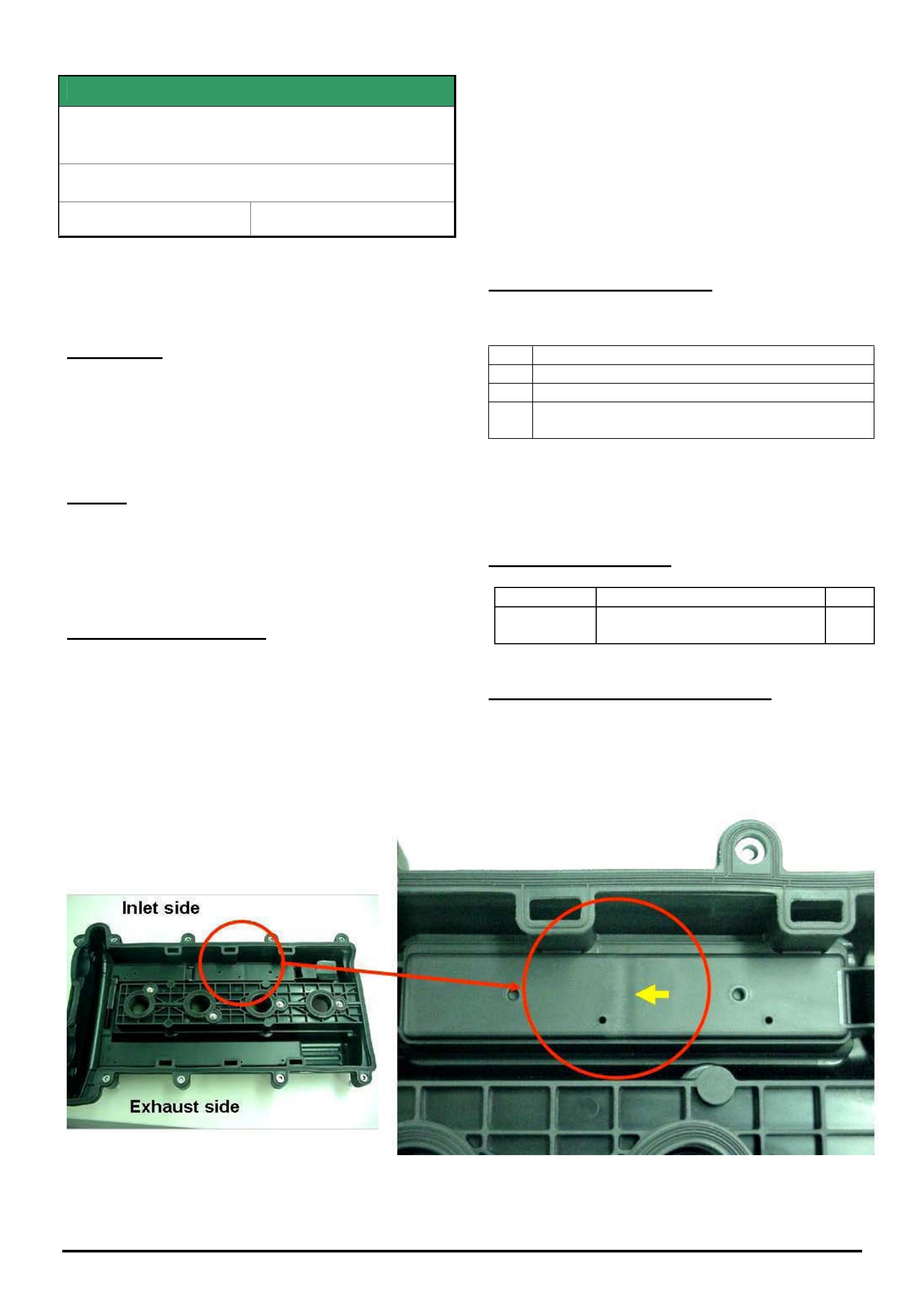

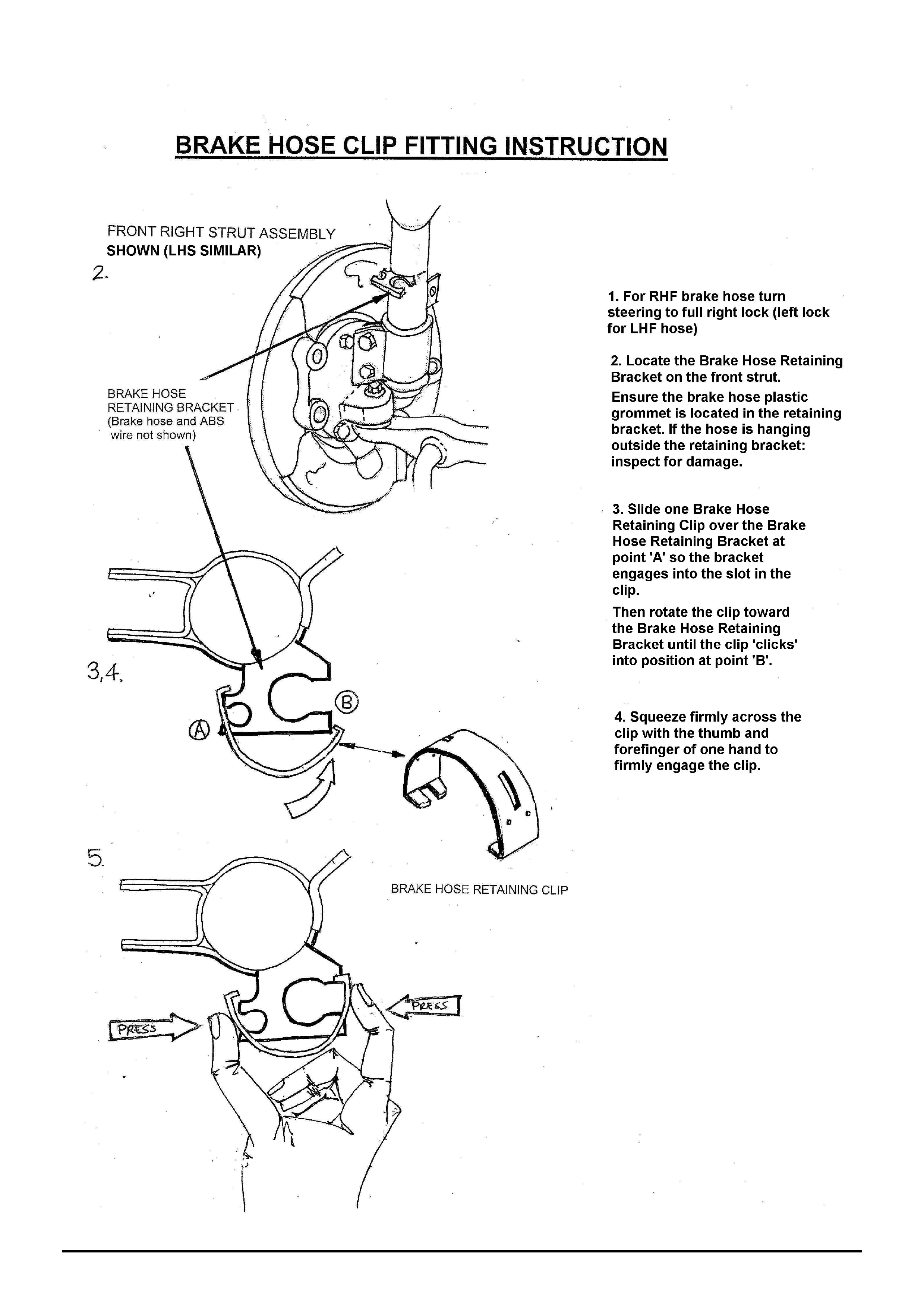

Fig 1. Shows insulator trim fitted above HVAC case

bracket.

DIAGNOSIS HINT

Brake Fluid Discoloured

VY2, WK, V2. – All with amber coloured

brake fluid

Group 5 Ref. No. TL0824- 0501

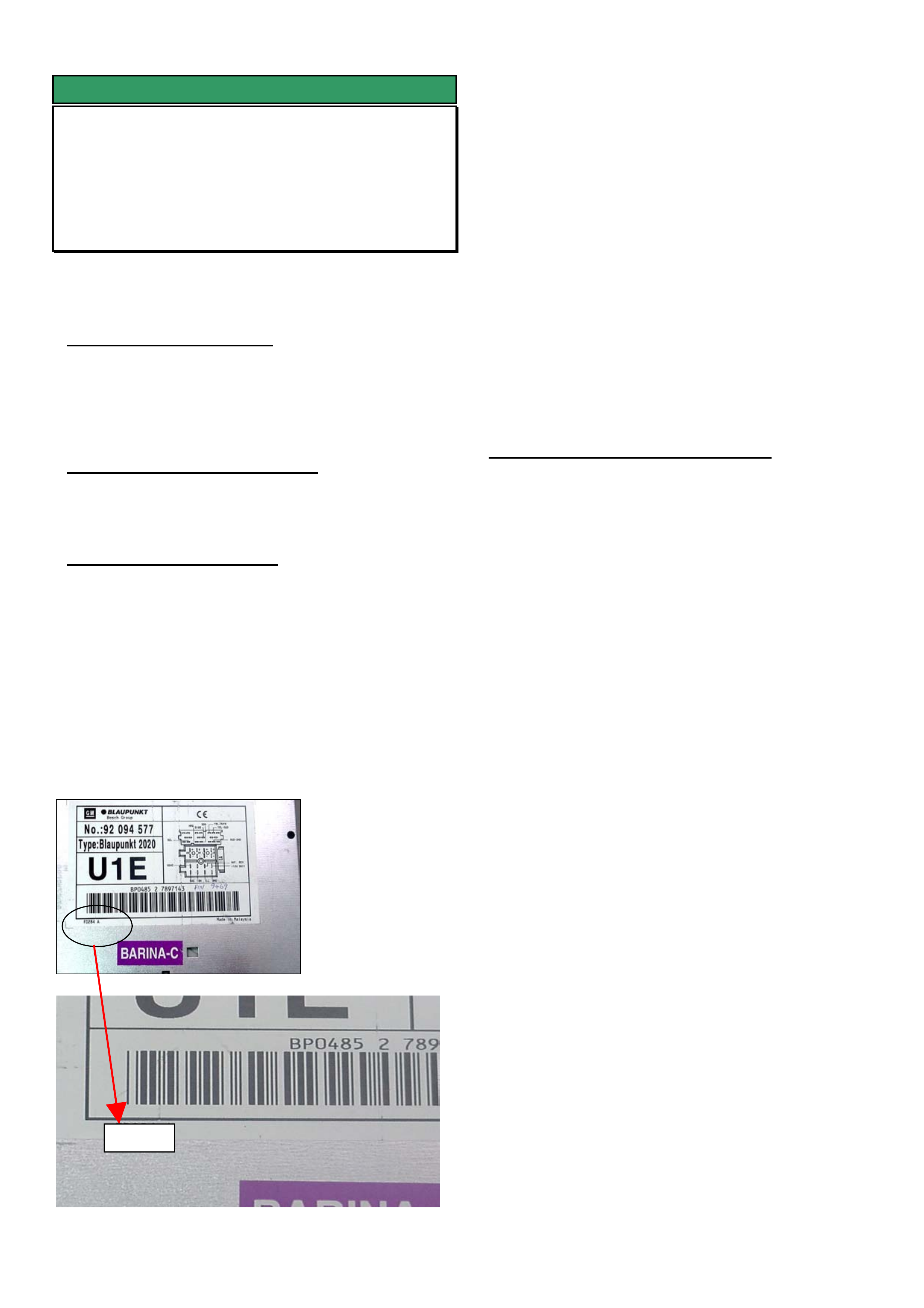

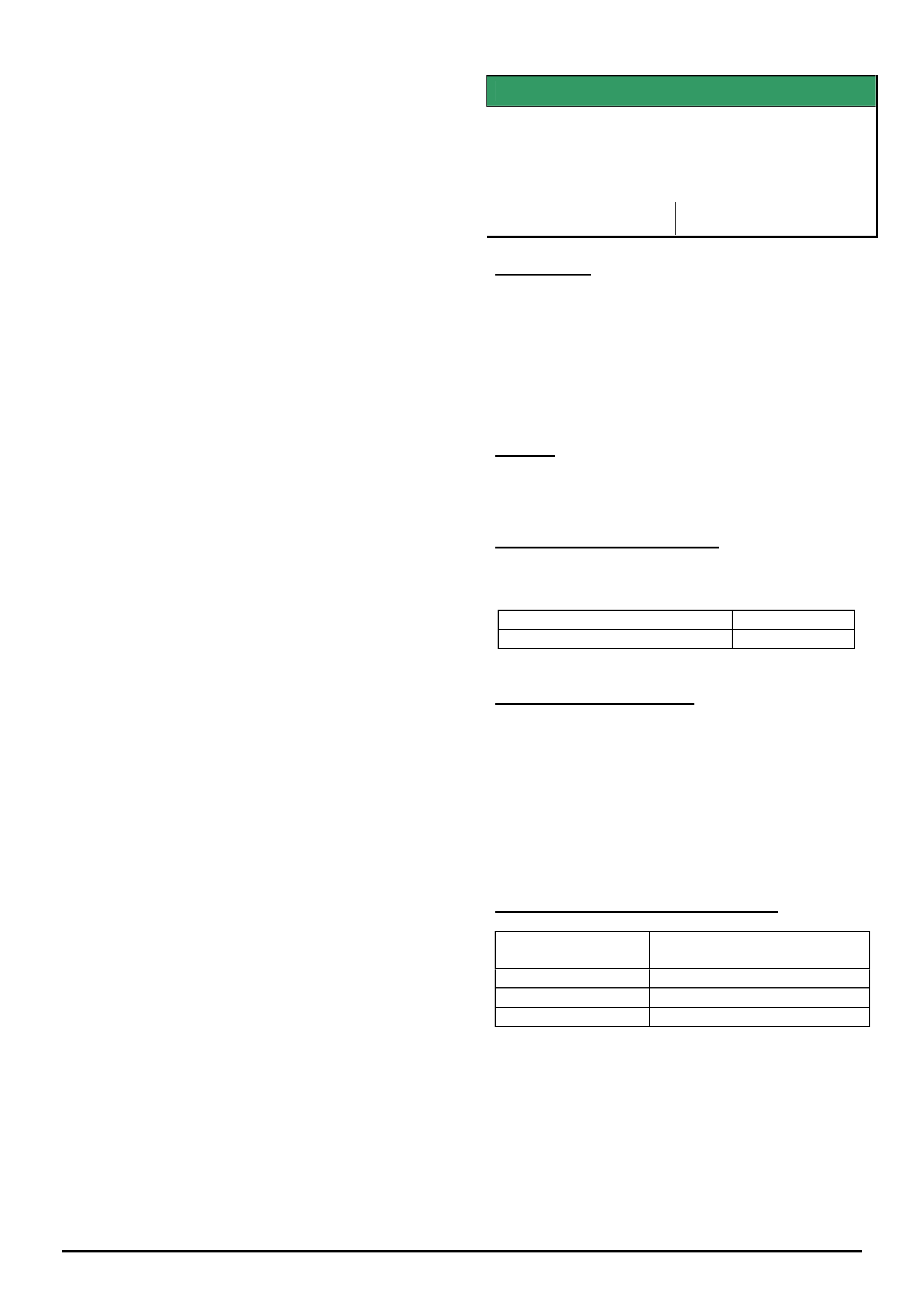

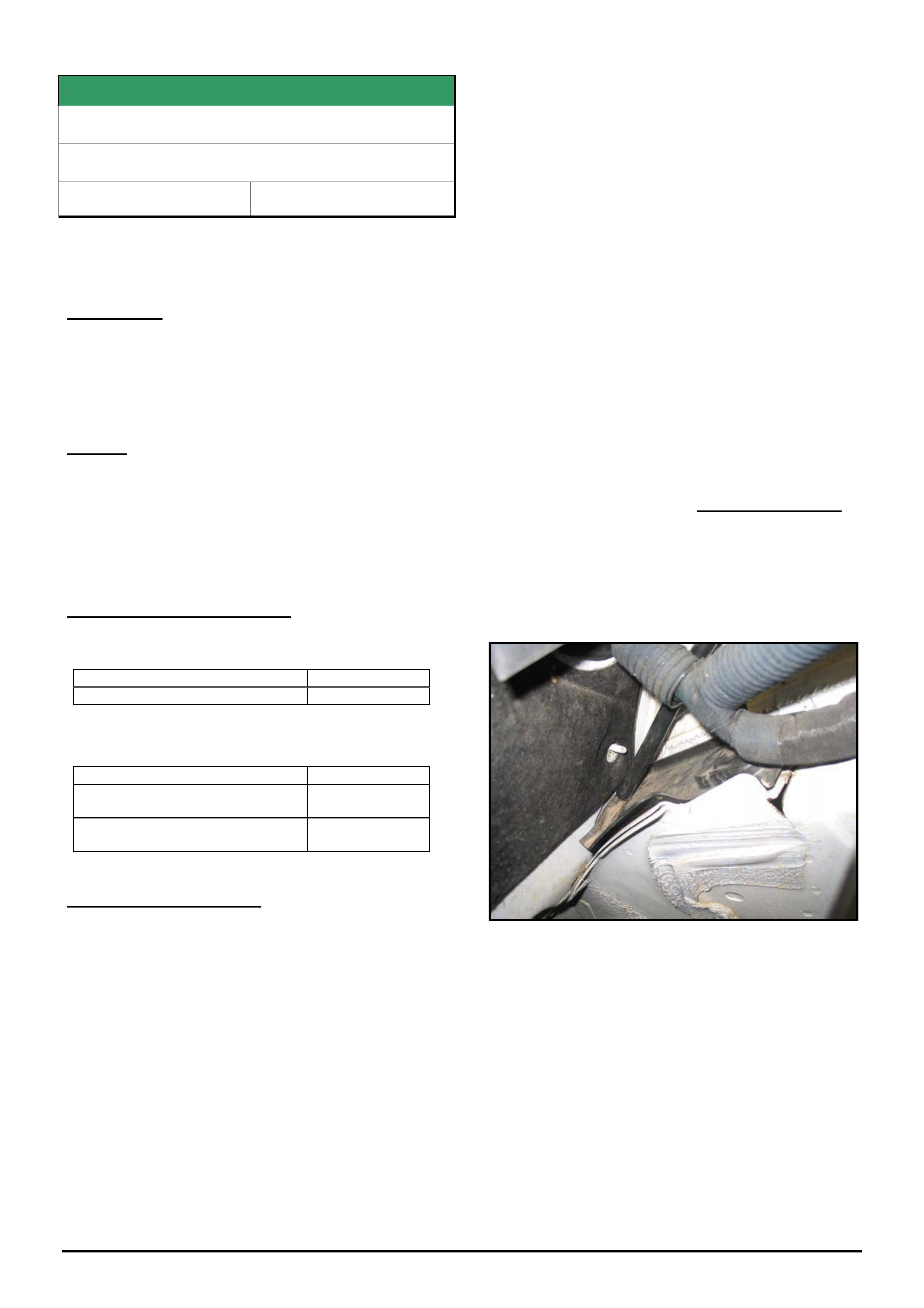

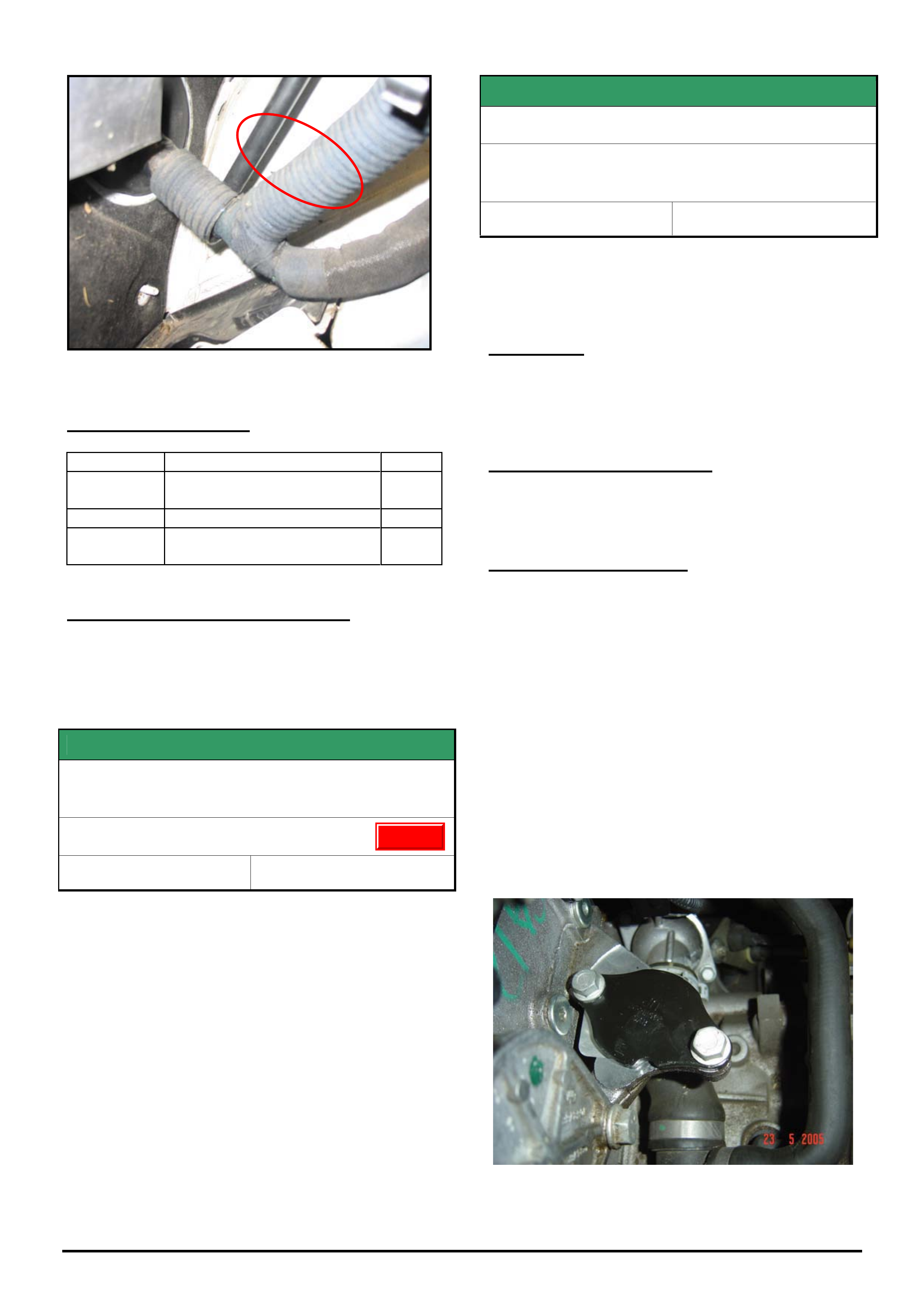

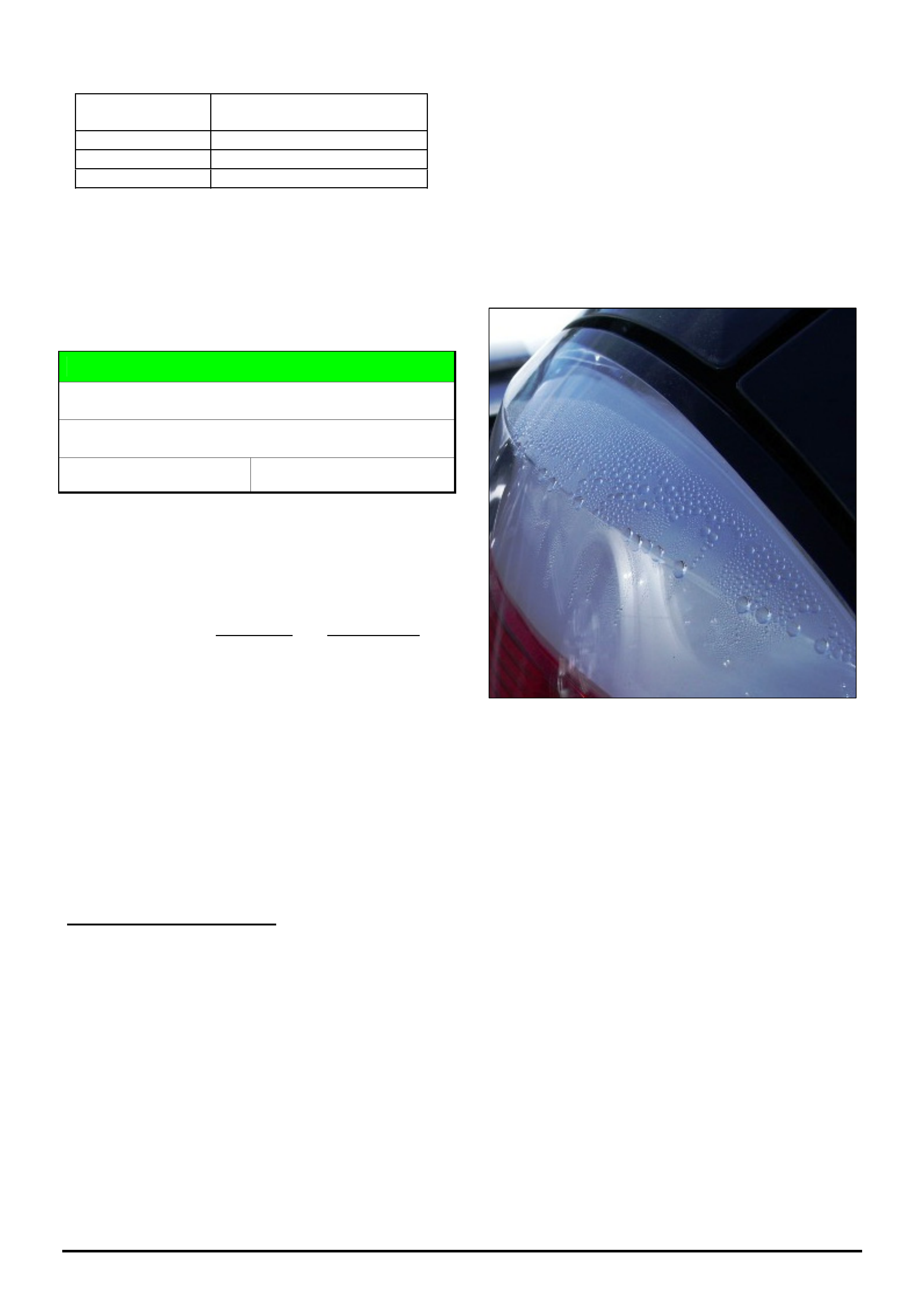

CONDITION

Some dealer PIRs describe a fungus like deposit

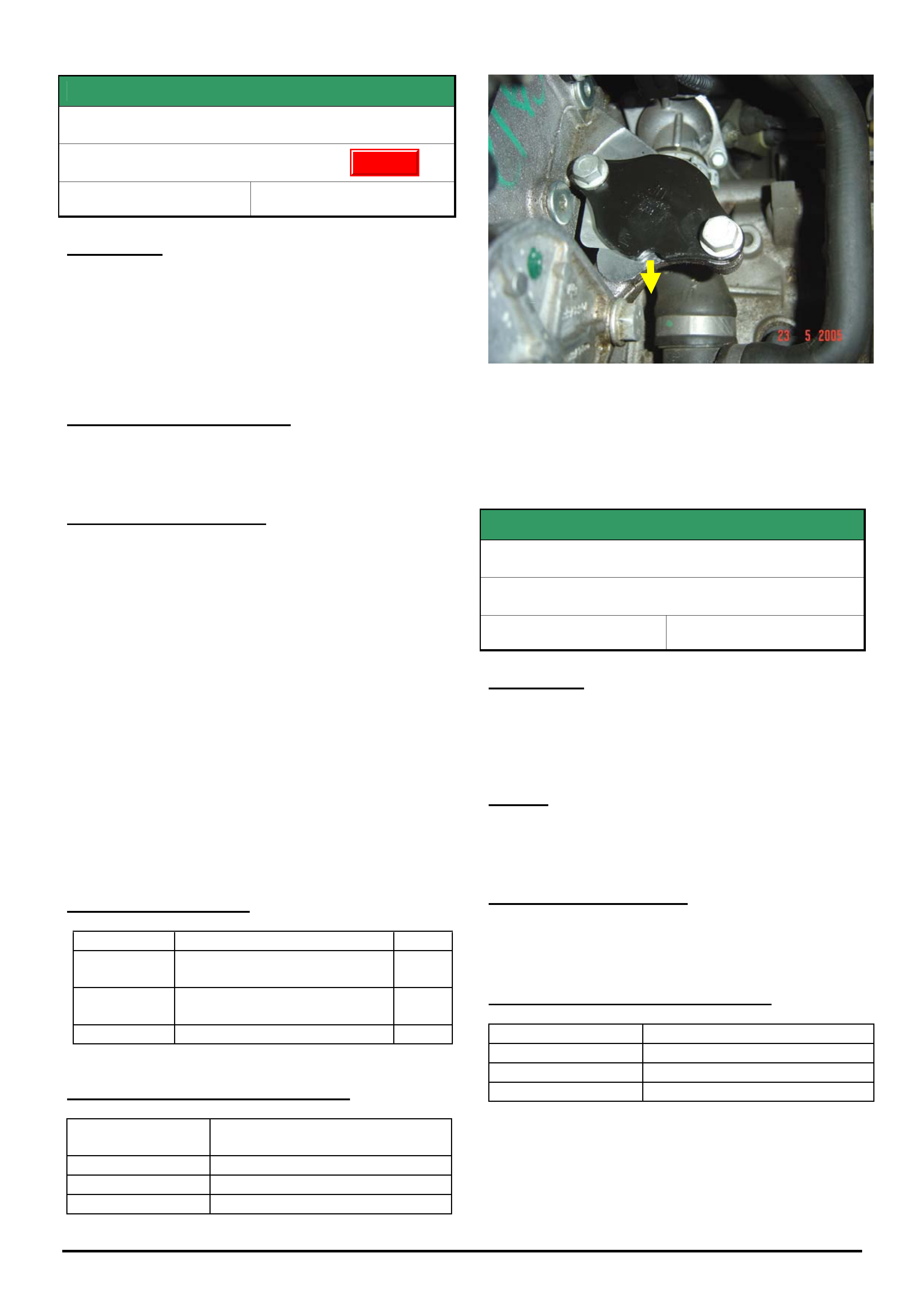

visible in the brake fluid reservoir (Refer Figure 1).

The condition has only been observed since the

introduction of the amber coloured brake fluid ( Sep

2003.)

This condition has not previously been detectable due

to the green dye which was added to the brake fluid.

Figure 1.

CAUSE

Laboratory investigations have found the deposits are

made up of small amounts of additives that have been

extracted from the reservoir cap material by the action

of the brake fluid.

CONCLUSION

It has been determined that these deposits have no

effect on the brake system performance and integrity,

therefore DO NOT flush the brake fluid lines for this

condition.

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

8

SERVICE FIX

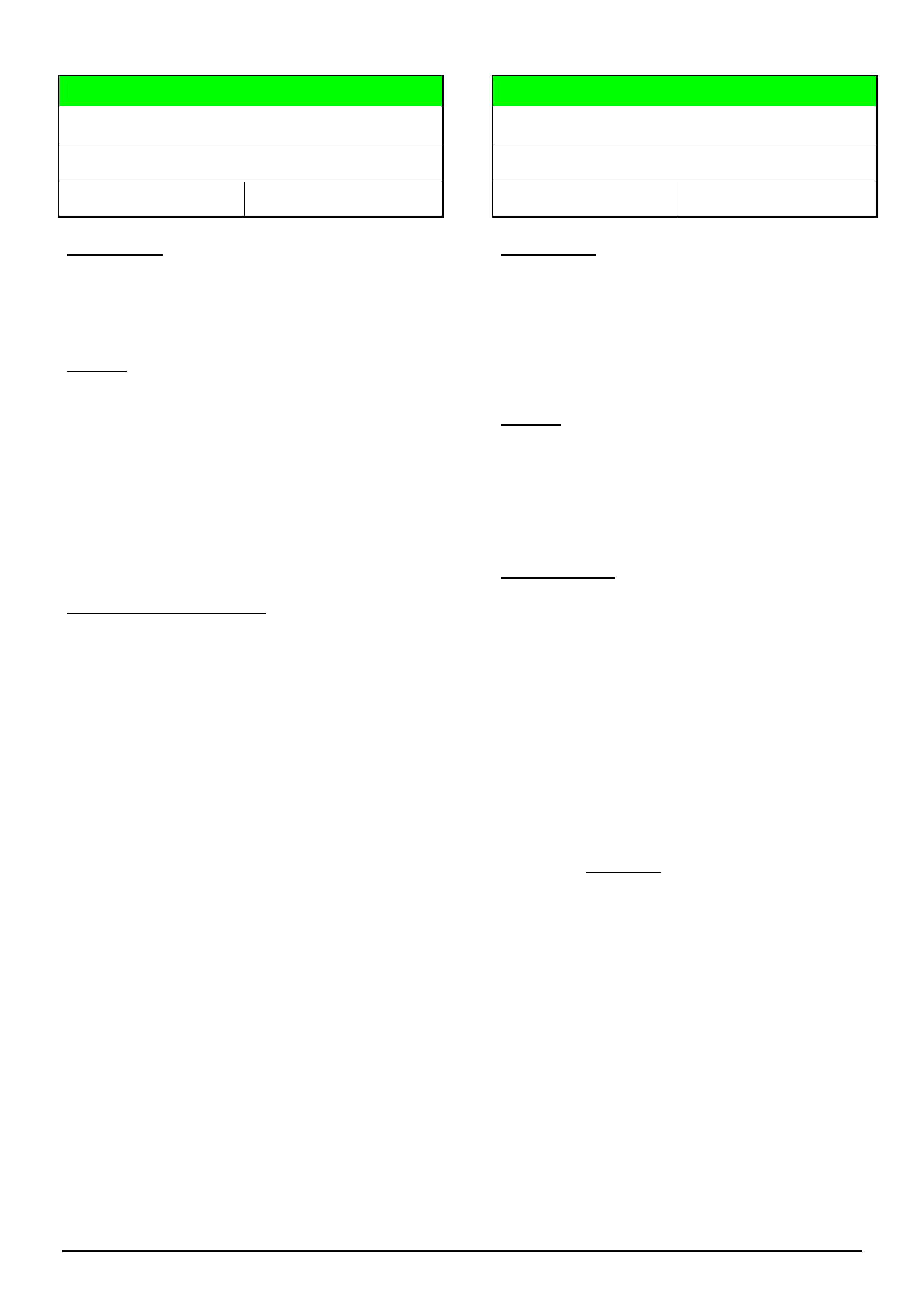

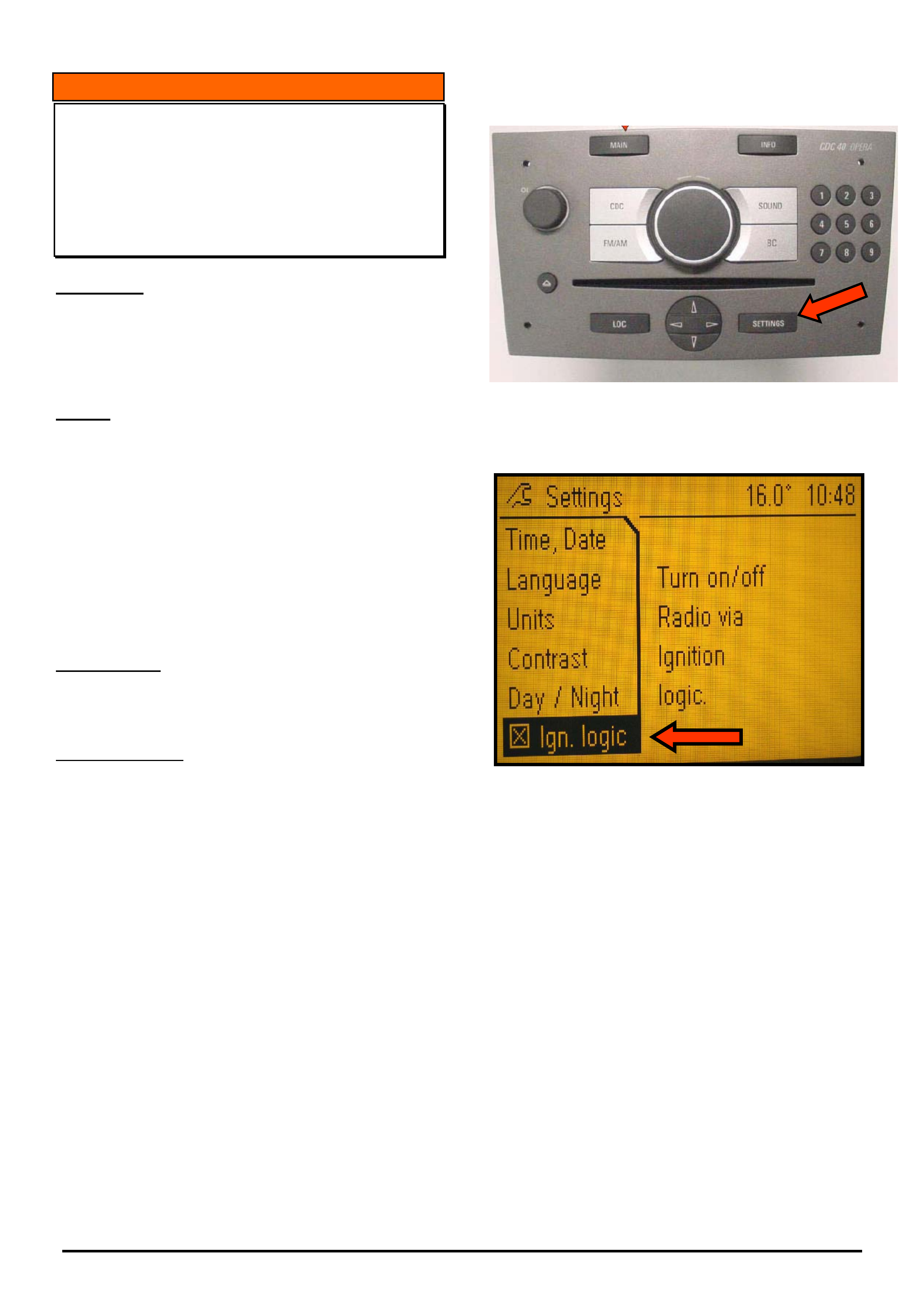

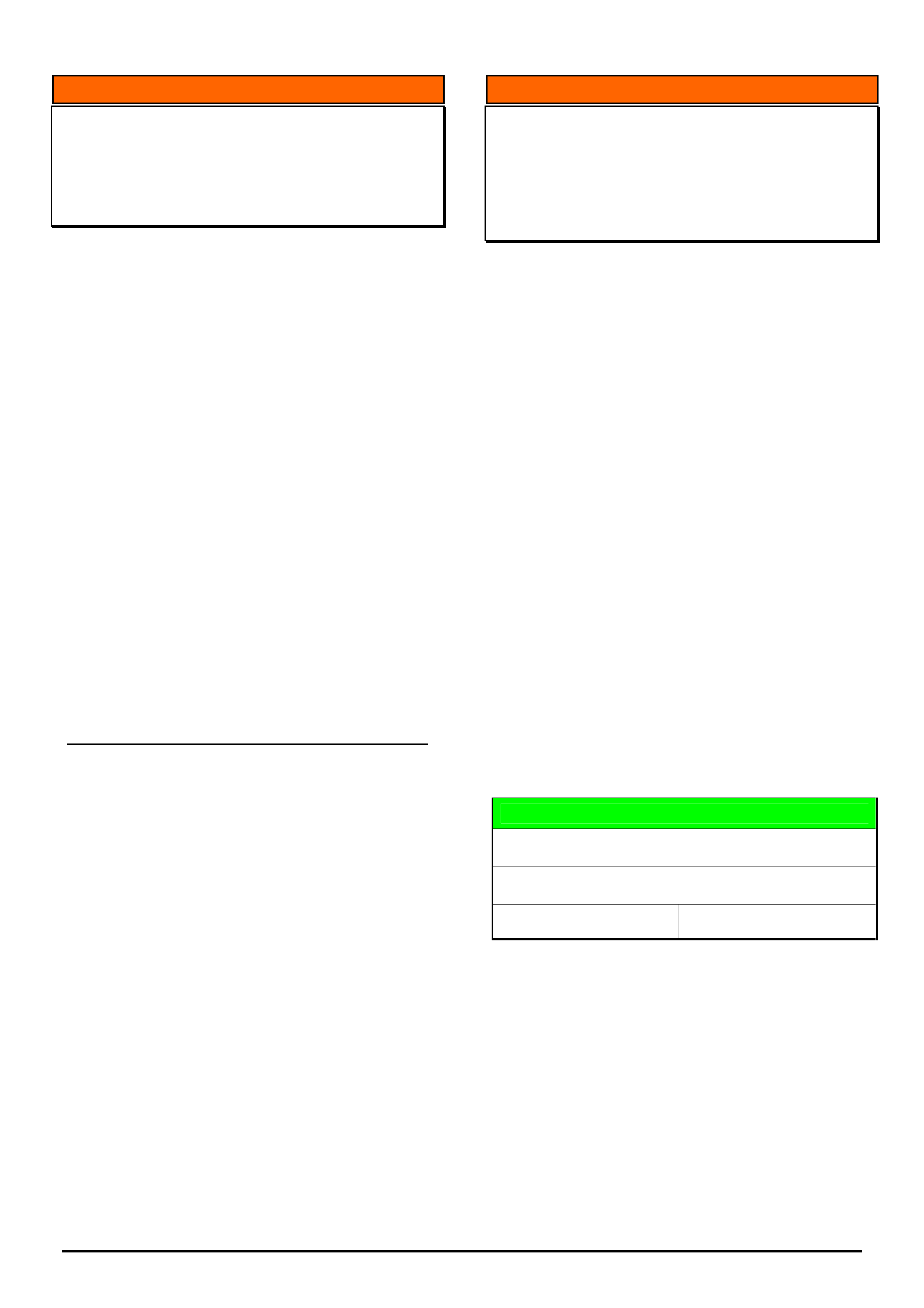

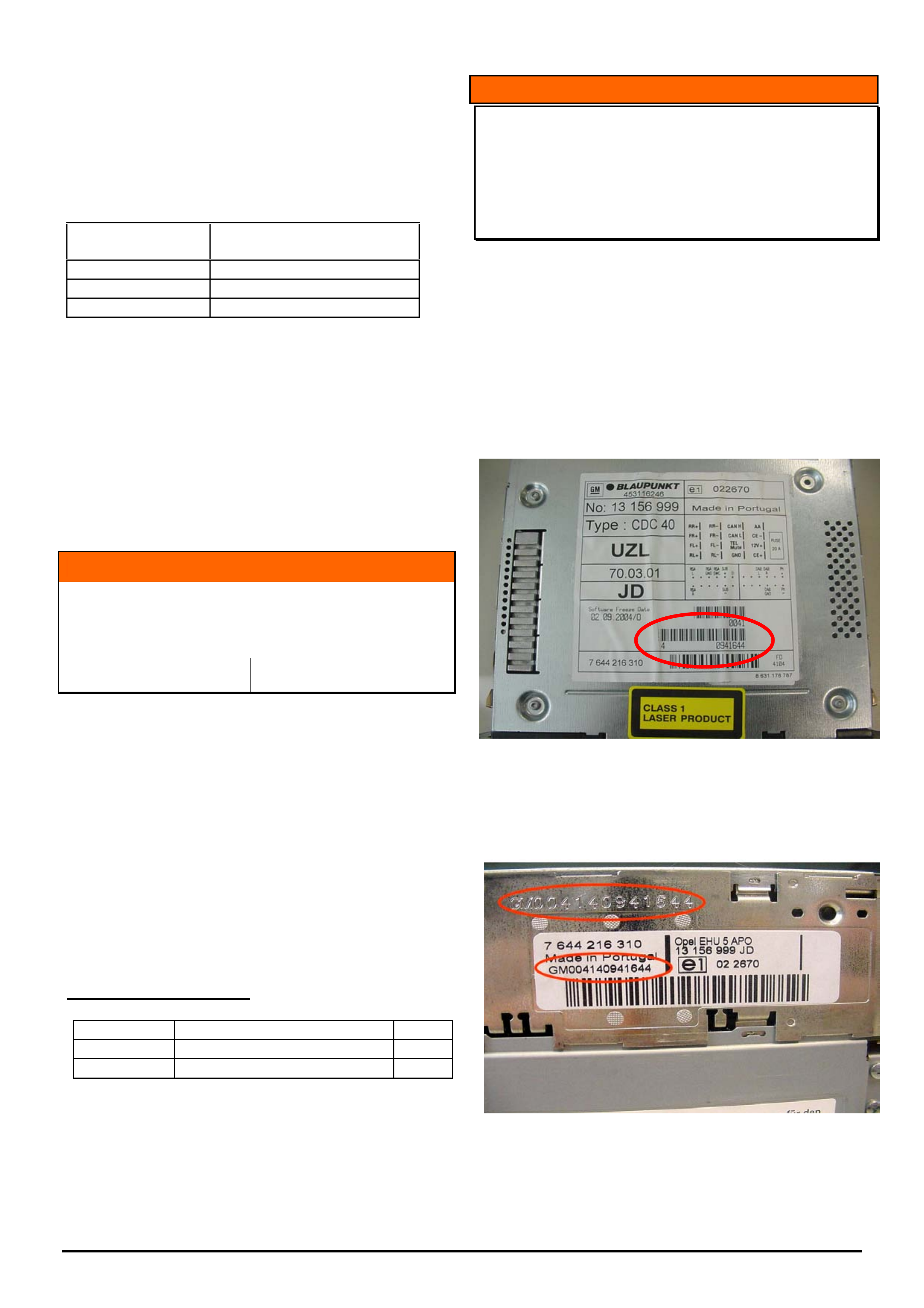

Blaupunkt 520 / 2020 CD Player

Inoperative Due To CD Not Ejecting

SB / JR / TS / TT / JS / XC /

GROUP 12 TL0479A-0501

This Techline supercedes the previous one in Issue

7,July 2003. It is reissued to revise the breakpoint (FD

reference number).

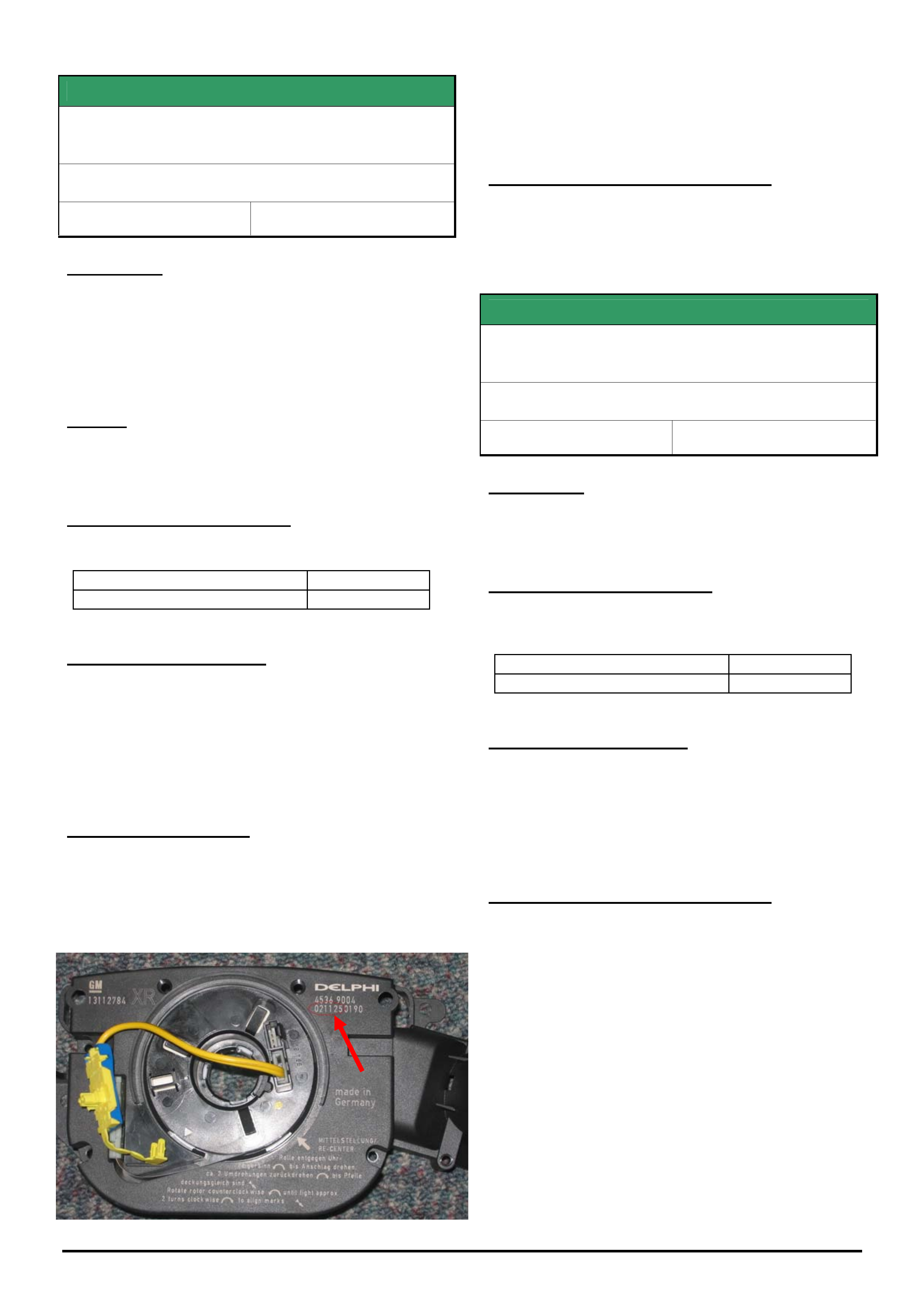

PROBLEM DESCRIPTION

Customers may complain of Blaupunkt 520 & 2020 CD

players becoming inoperative due to CD’s not ejecting.

After investigating the root cause Blaupunkt have

made a software revision to rectify this condition.

PRODUCTION RECTIFICATION

Blaupunkt implemented the software revision in all CD

players fitted to vehicles at the Port Of Entry on the 1st

of April 2004.

SERVICE RECTIFICATION

If you have a customer who presents a vehicle with the

above condition the following steps should be

performed.

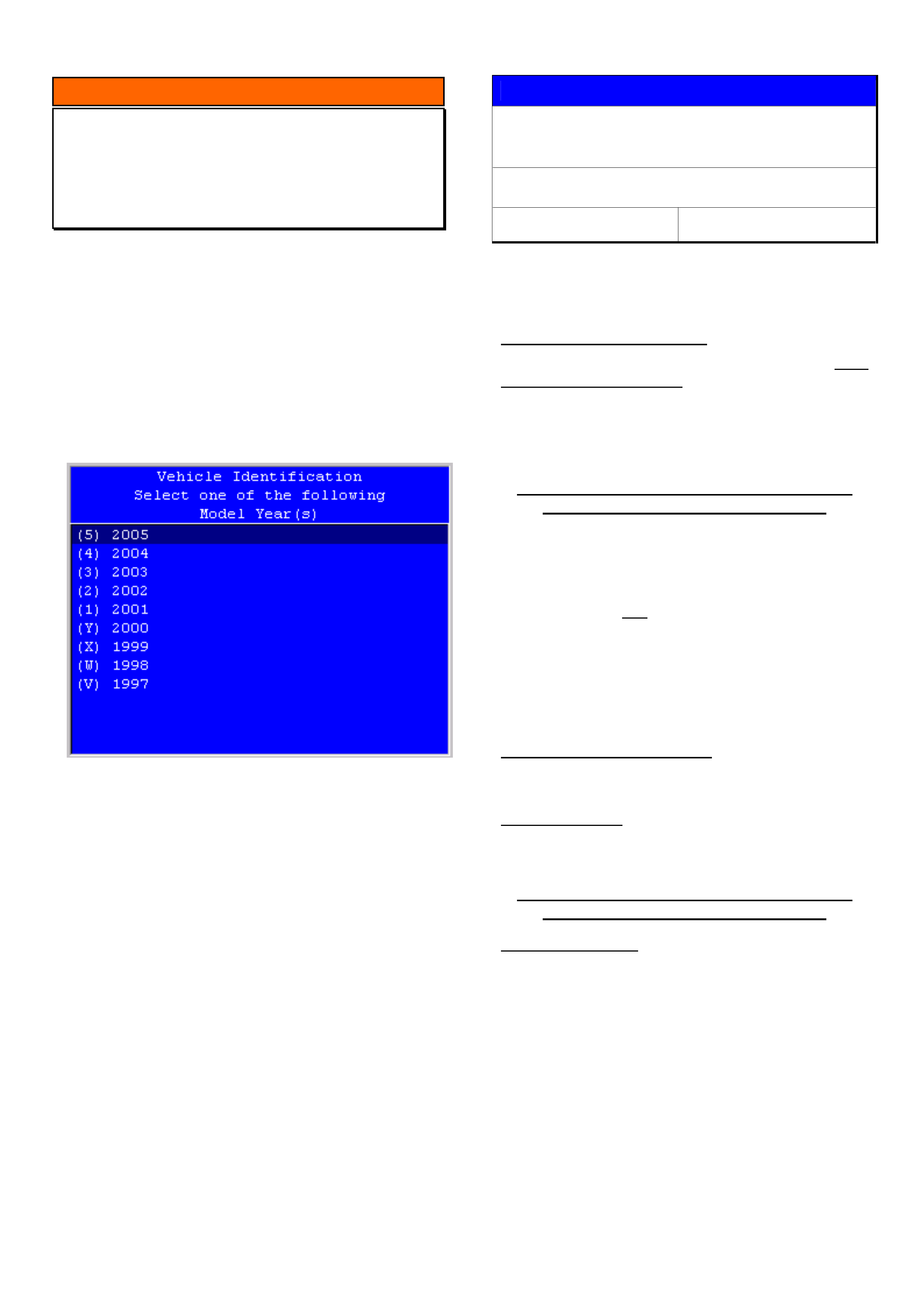

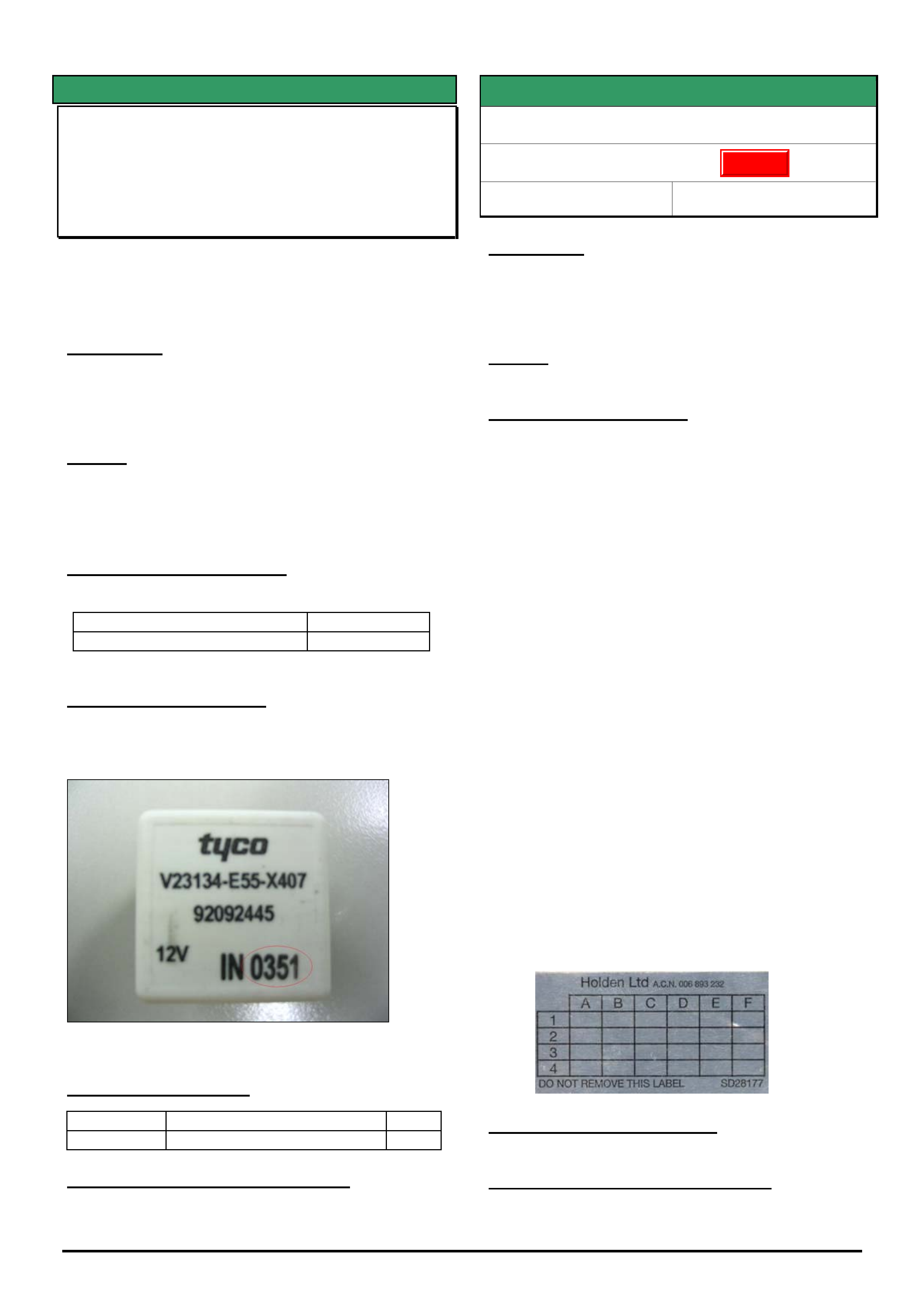

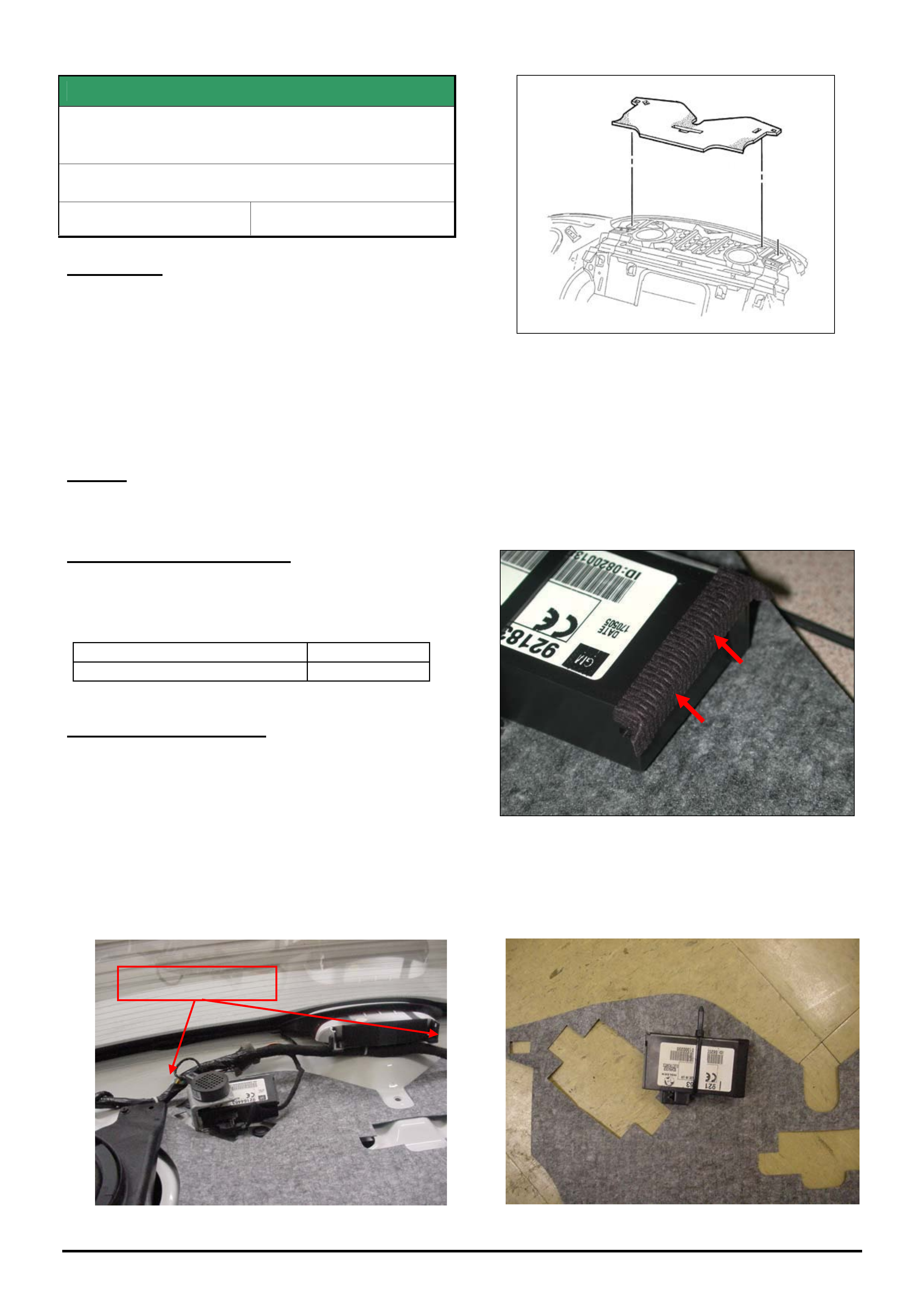

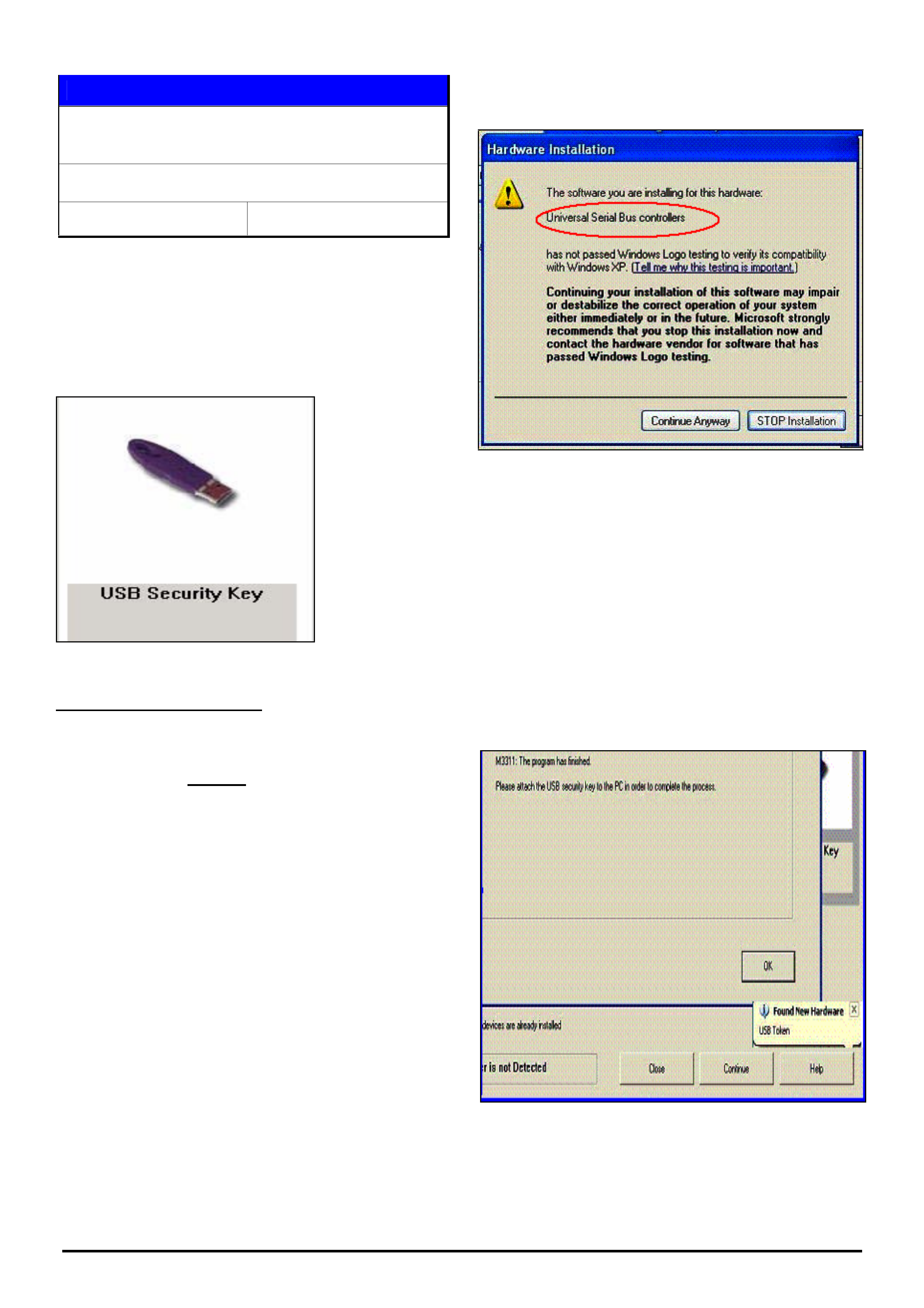

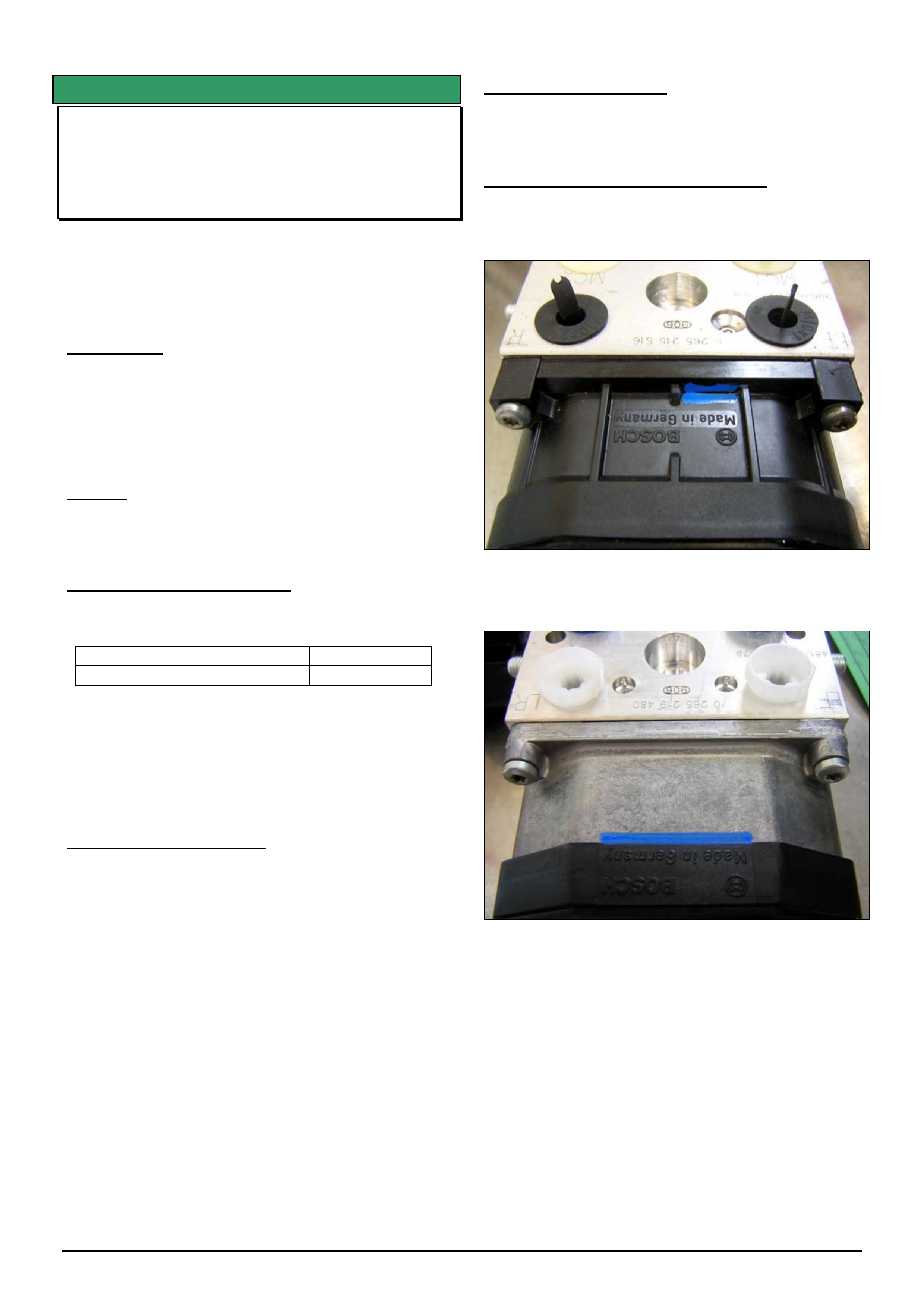

Step 1. Determine if the CD player is pre or post

break point by removing it and inspecting the bottom

left corner of the label attached to the top cover for the

FD number. Refer photographs below.

Pre breakpoint units have an FD number below

FD482. Post break point units have an FD number

FD482 or higher.

If unit is Pre breakpoint go to Step 2.

If unit is Post breakpoint go to Step 3.

Step 2. If the CD player is pre break point,

contact Blaupunkt as per the Special Warranty

Component Replacement Requirement section in

SIP and request approval to replace.

Step 3. If the CD player is post break point,

removing it from the vehicle to inspect the label will

have rectified the condition (disconnecting the power

supply).

Refit the CD player, check the operation and submit a

PIR indicating the FD number on the label and the

serial number stamped into the side of the CD player

case.

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty Information

section of current PV SIP CD

FD482

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

11

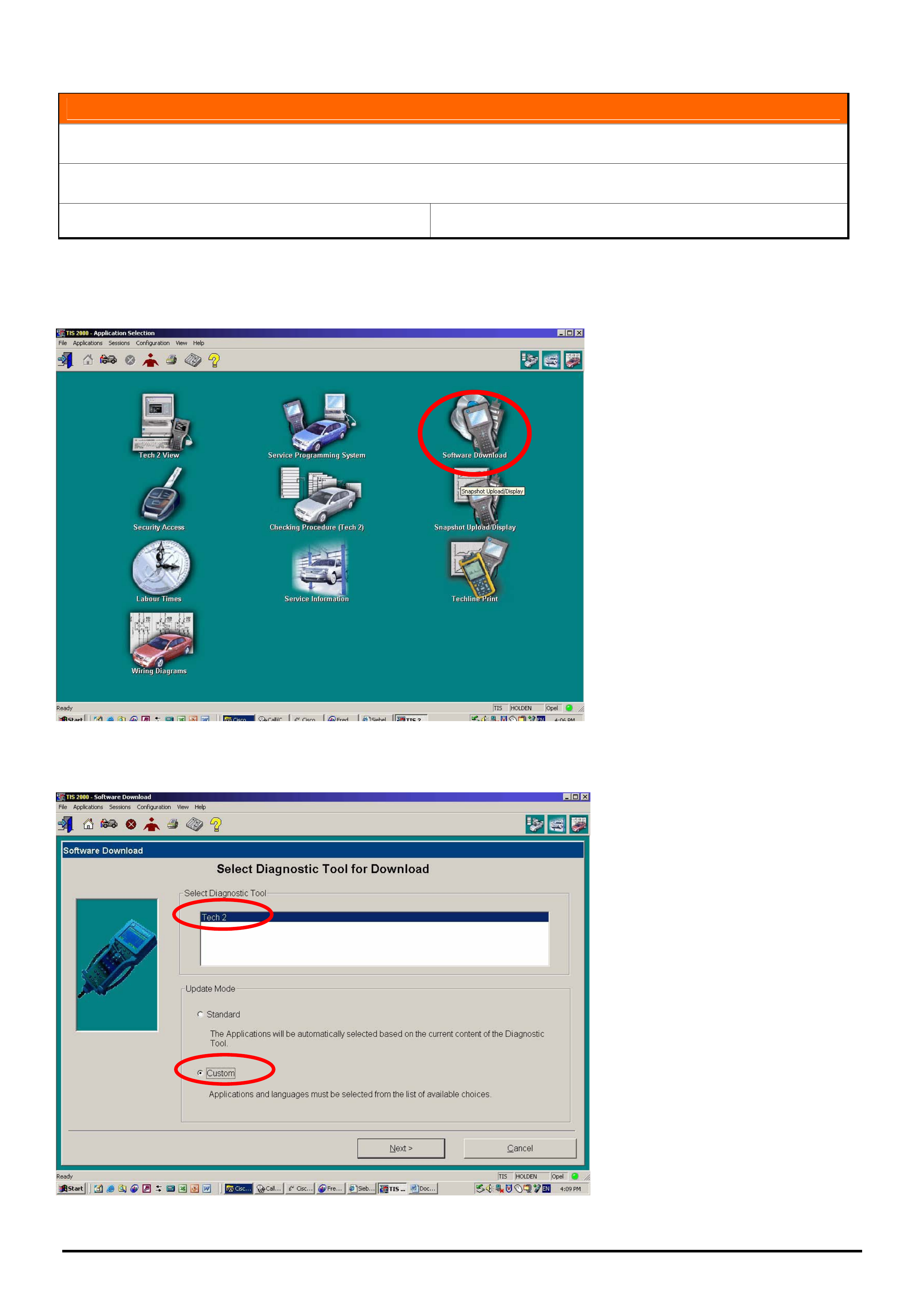

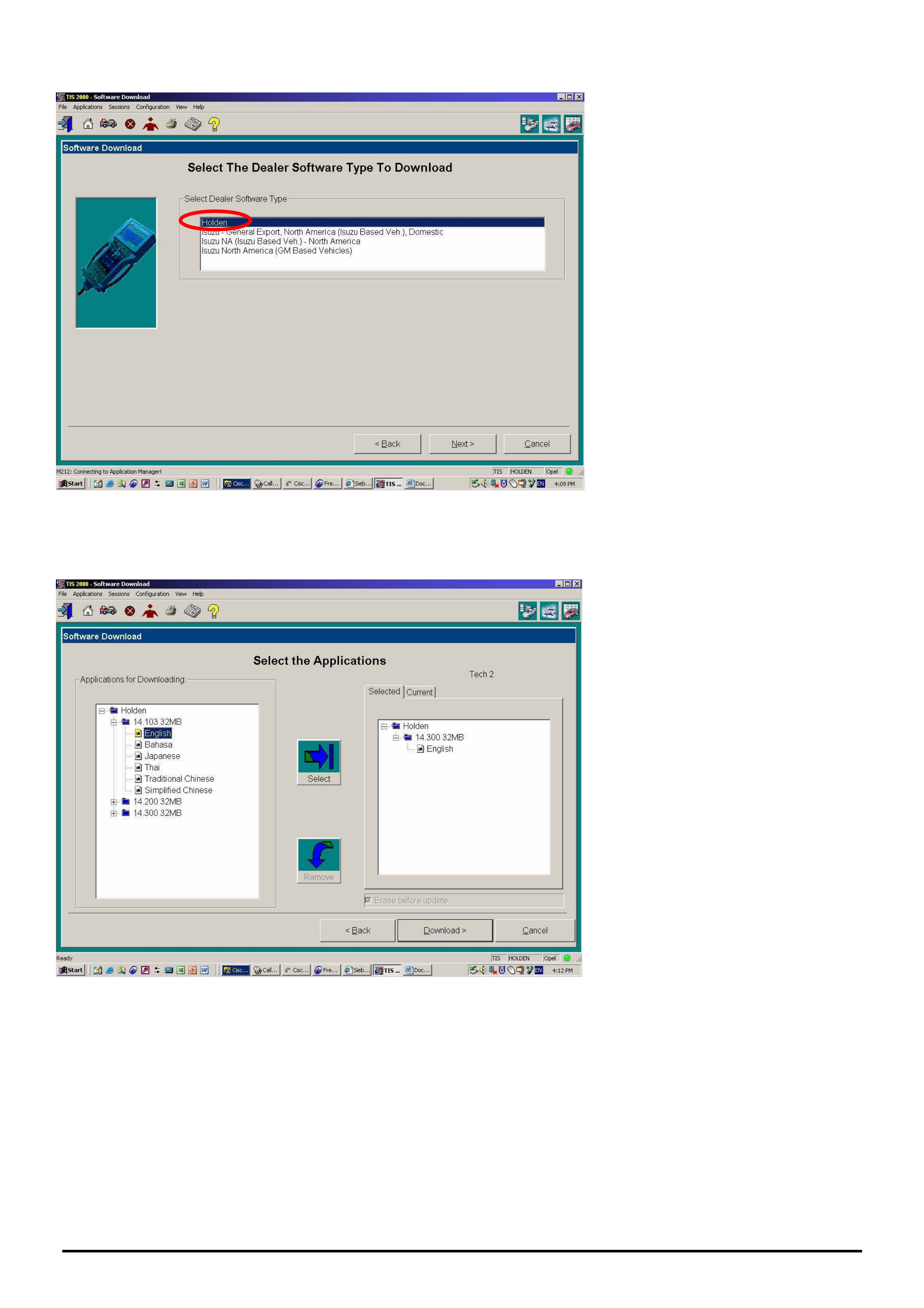

INFORMATION

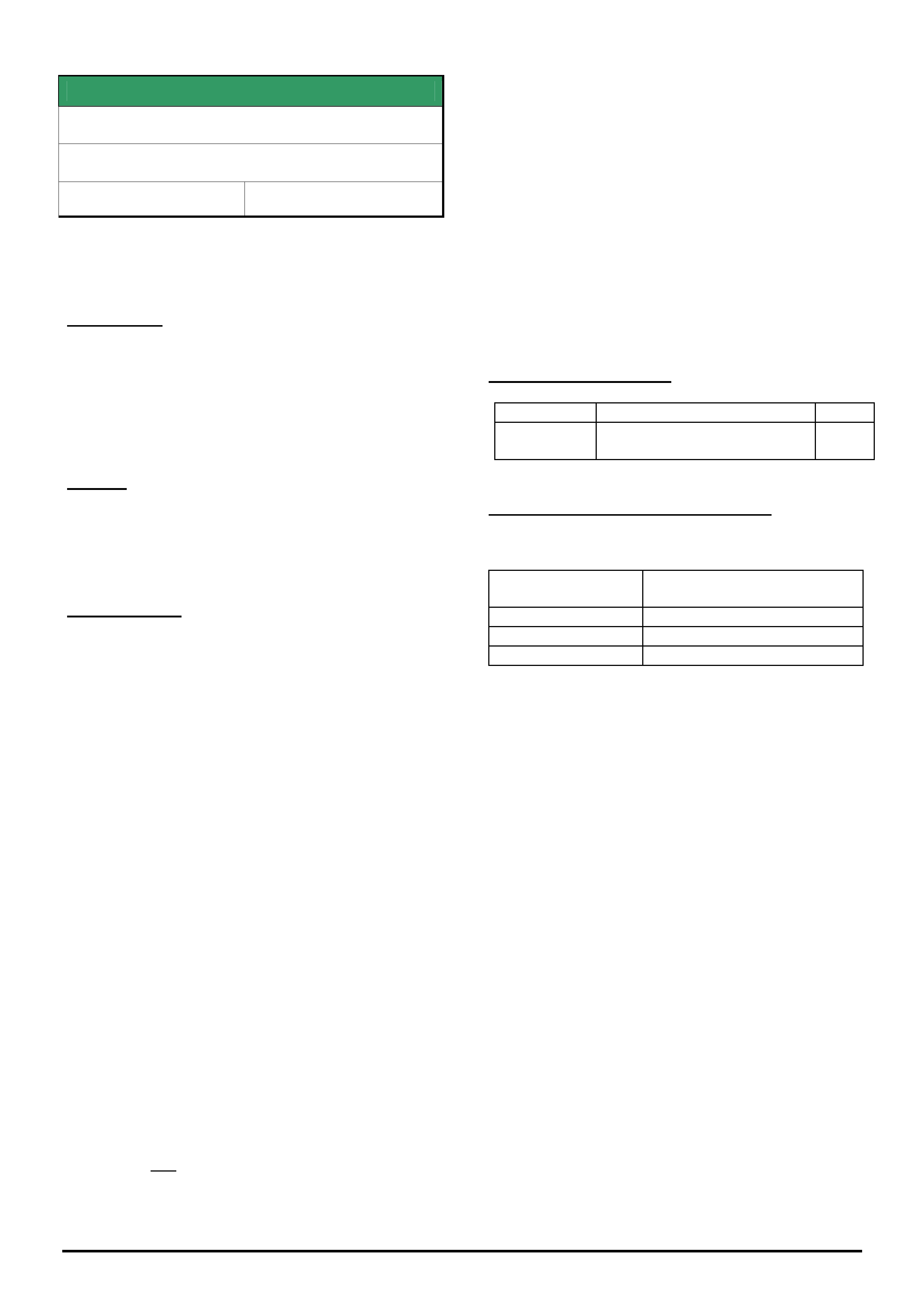

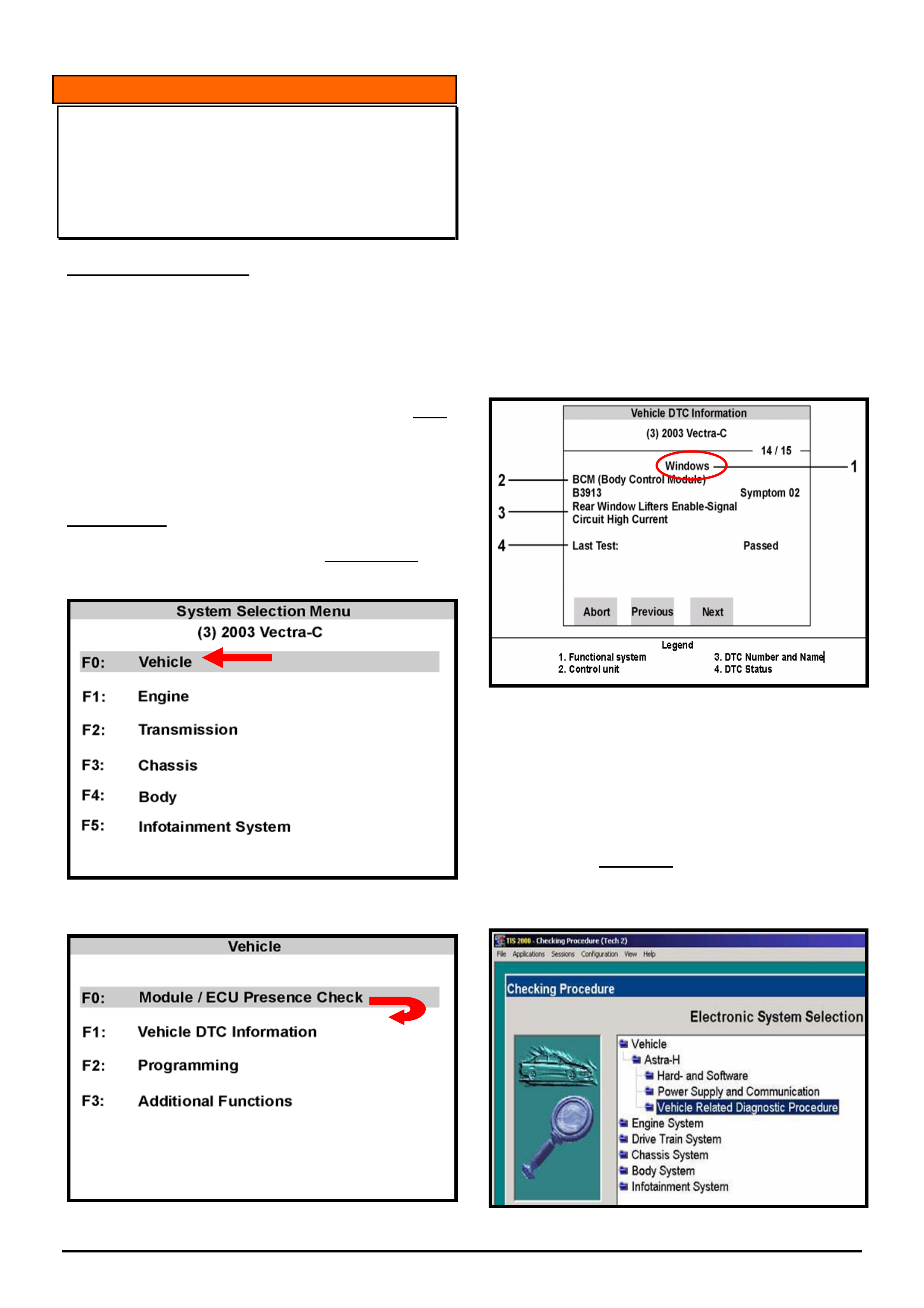

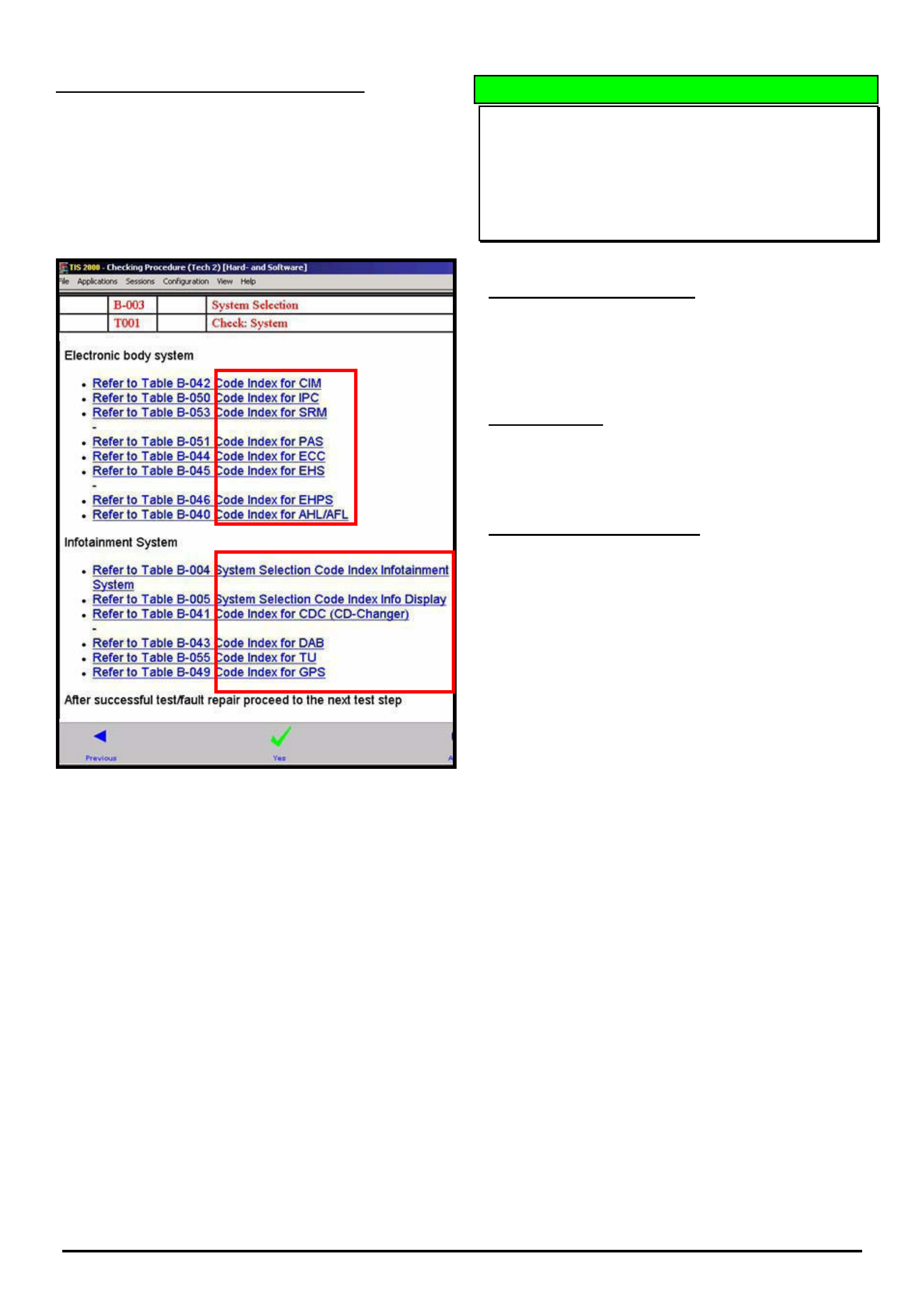

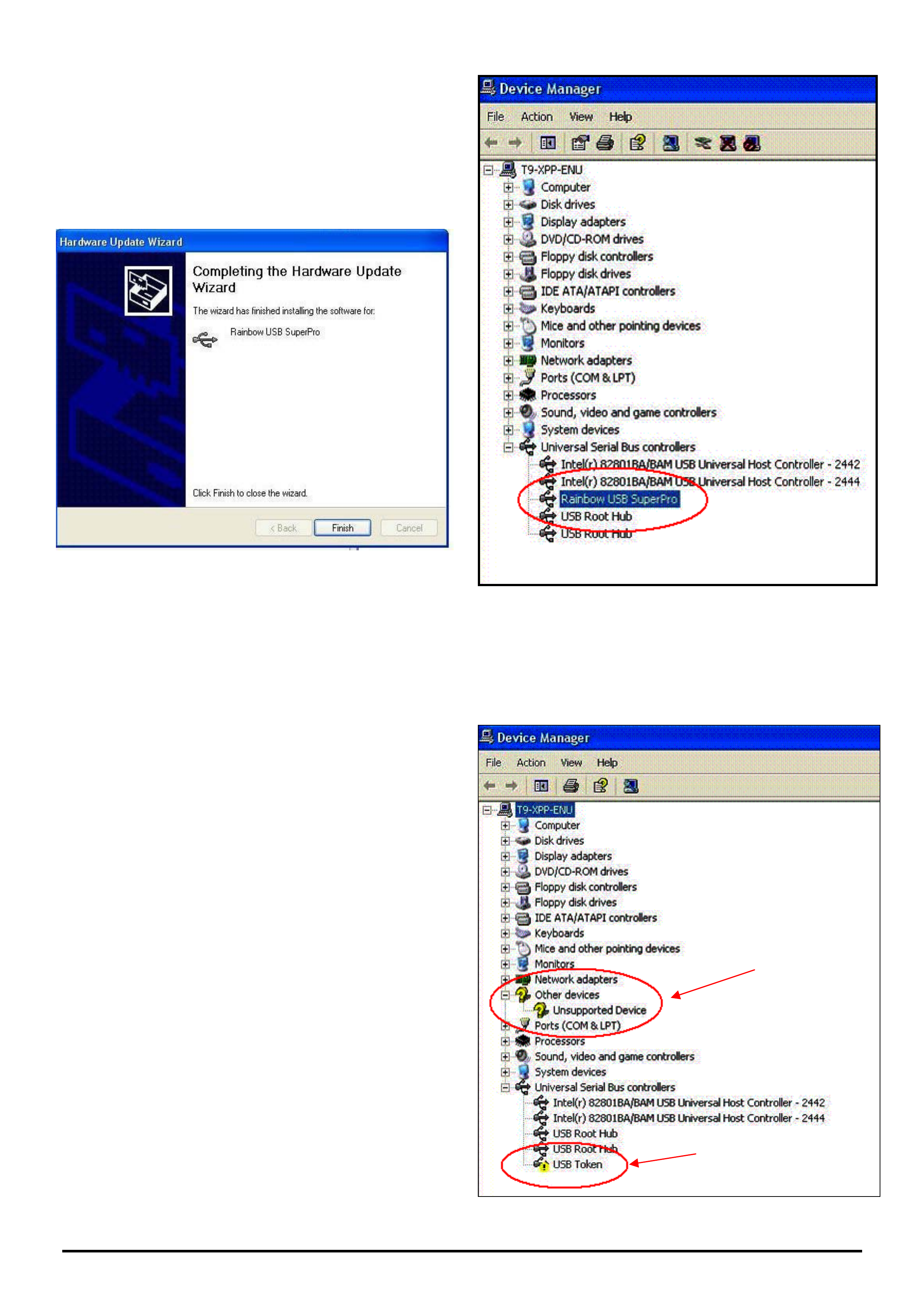

Tech 2, TIS 2000 Model Year Selection

ALL MODELS

GROUP OB TL0852-0501

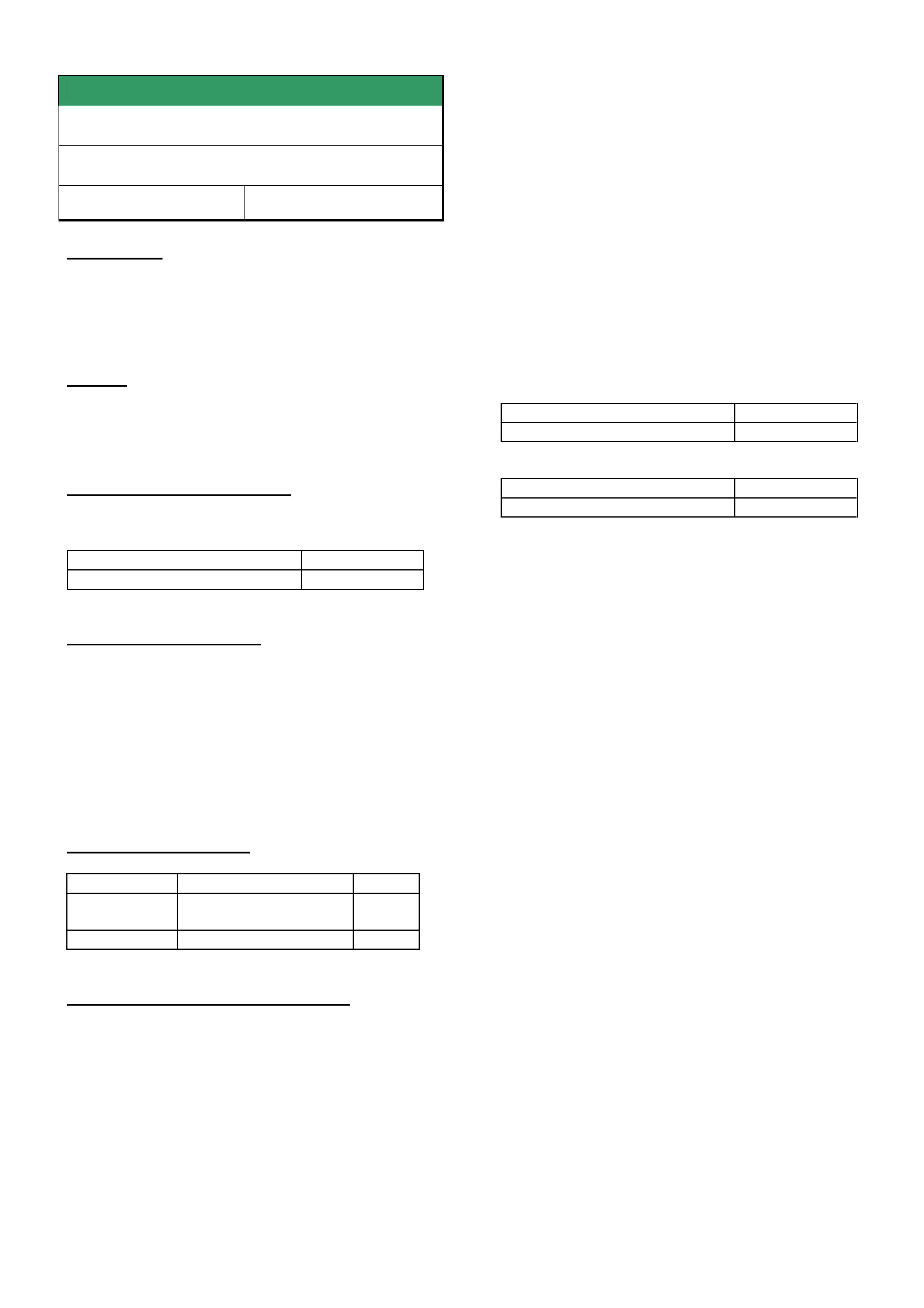

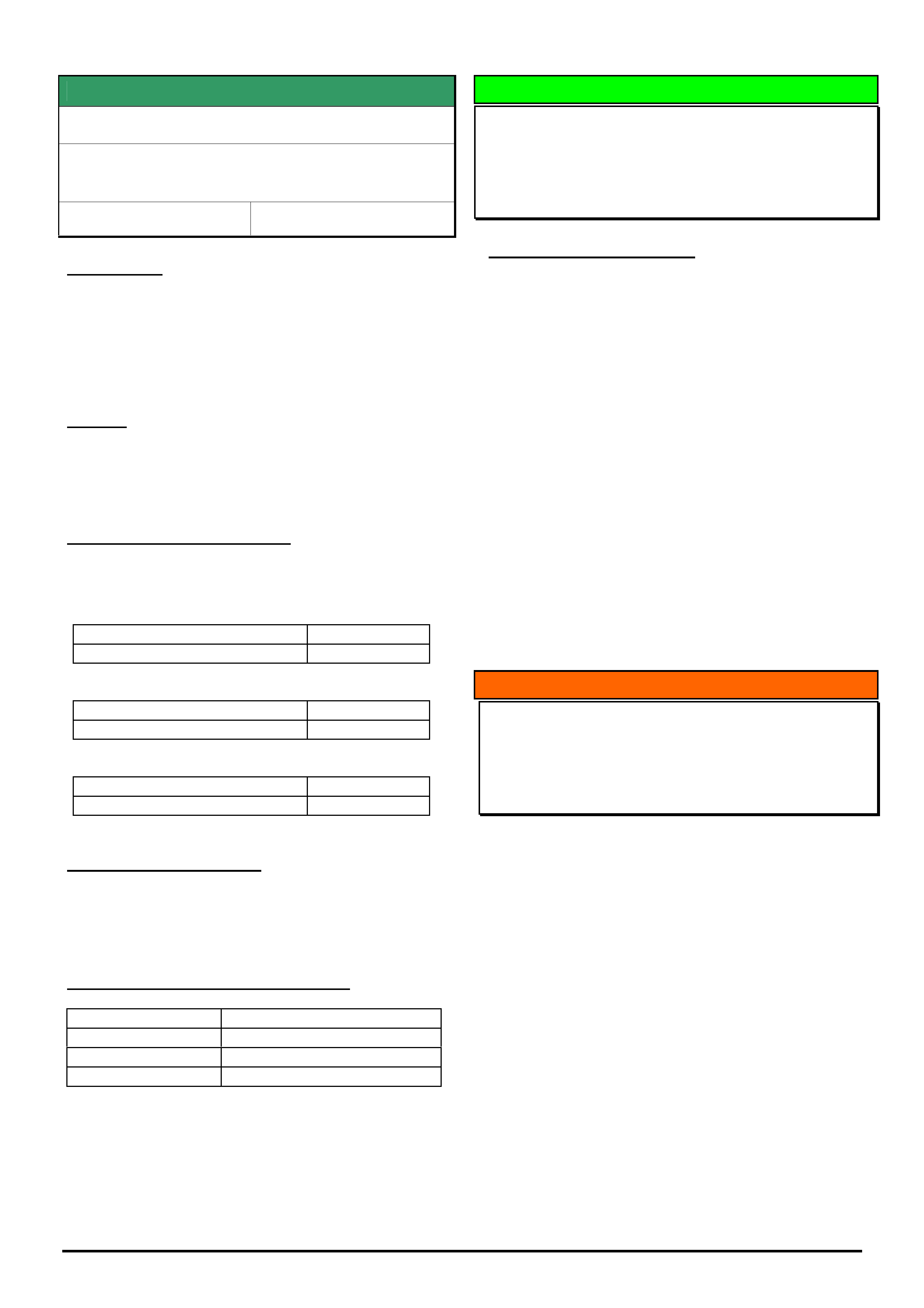

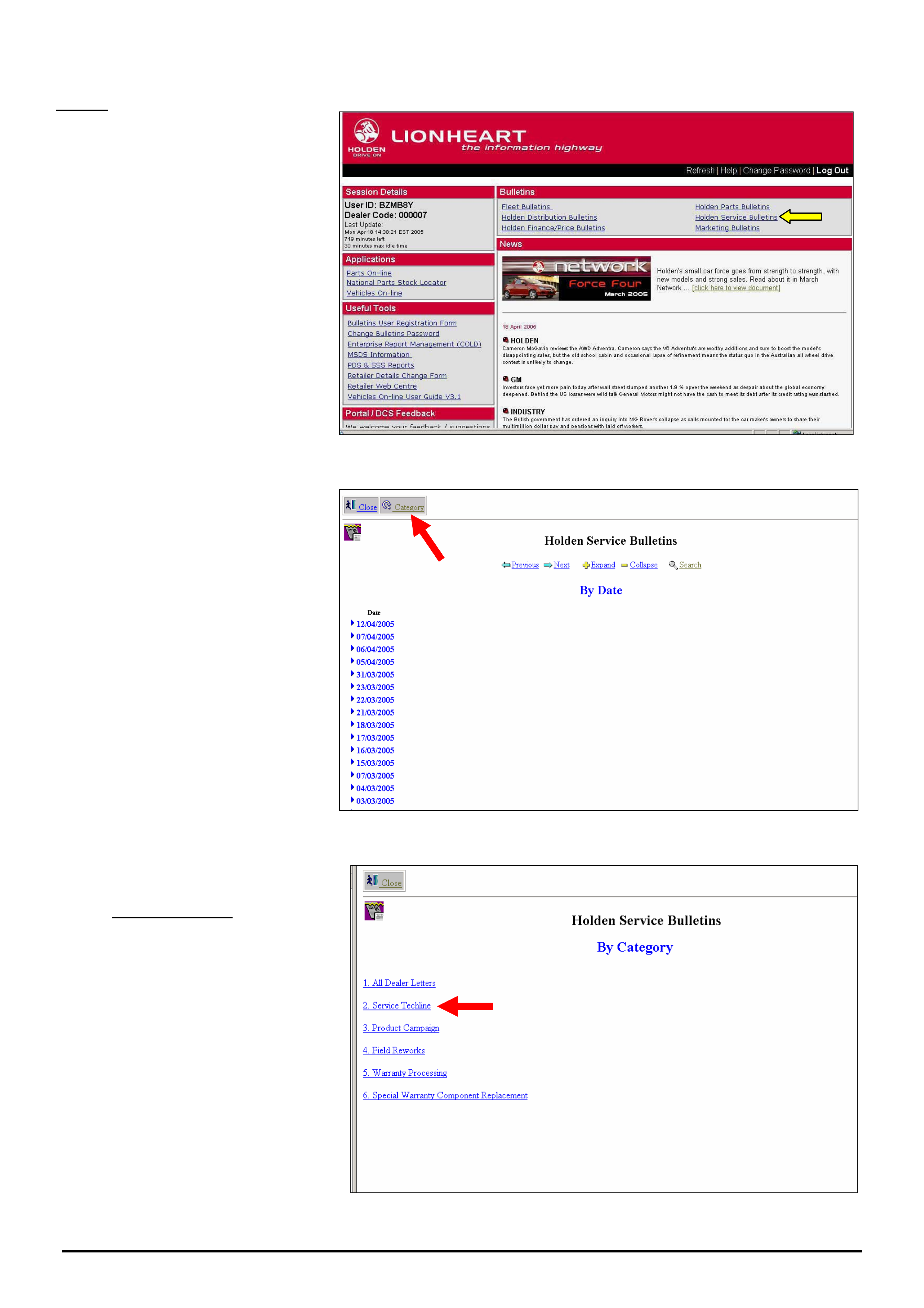

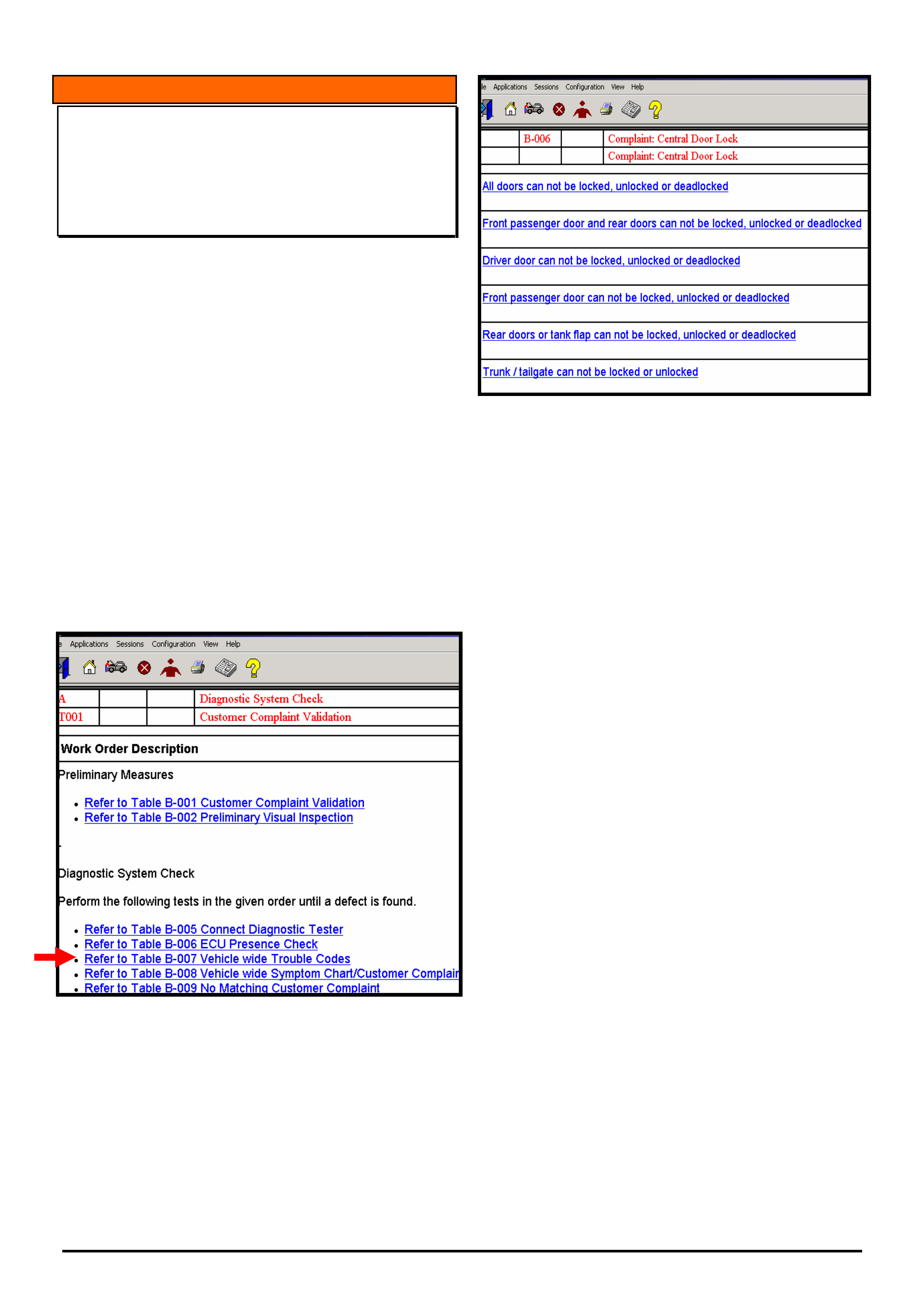

This Techline is to clarify the correct procedure for

model year selection when using Tech 2 or TIS 2000.

For many programming operations and diagnostics

carried out using Tech 2 and TIS 2000 it is critical

that the correct model year is selected. This can be

easily identified by the tenth character of the VIN.

The screen below is an example of the Tech 2 Model

Year selection screen. The Numbers and letters on

the LH side in brackets are the values of the tenth

digit of the VIN for that model Year.

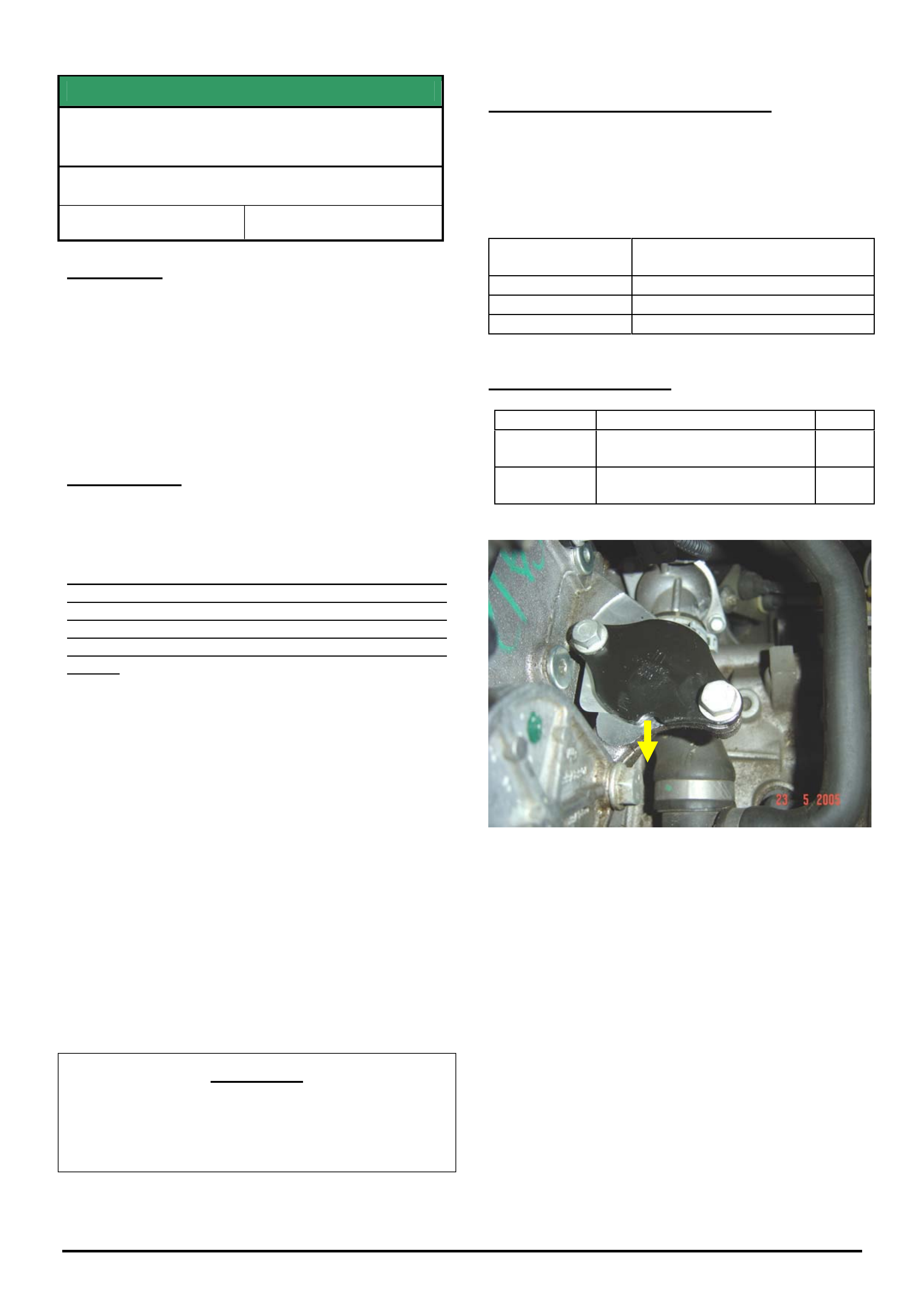

SERVICE PROCEDURE

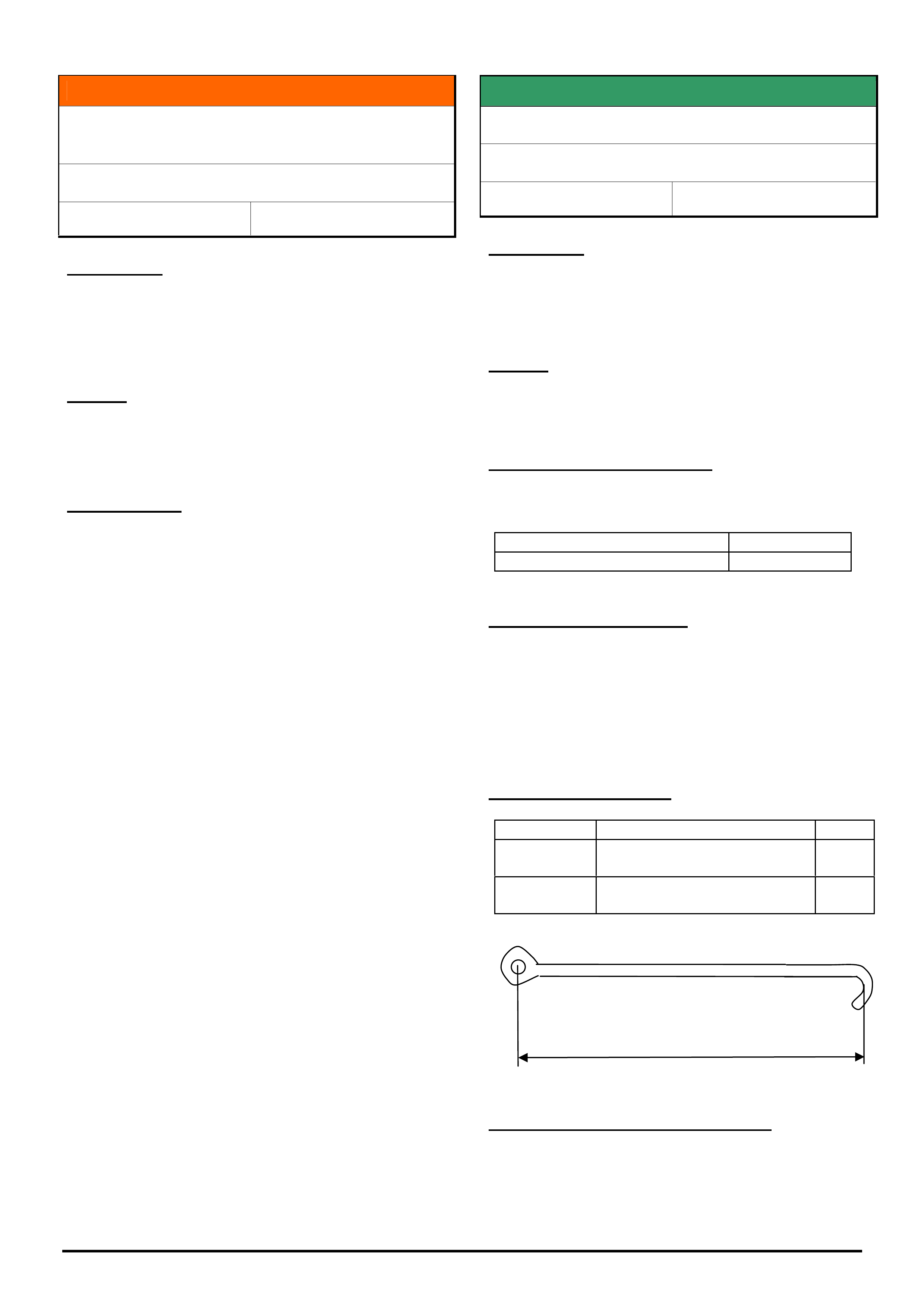

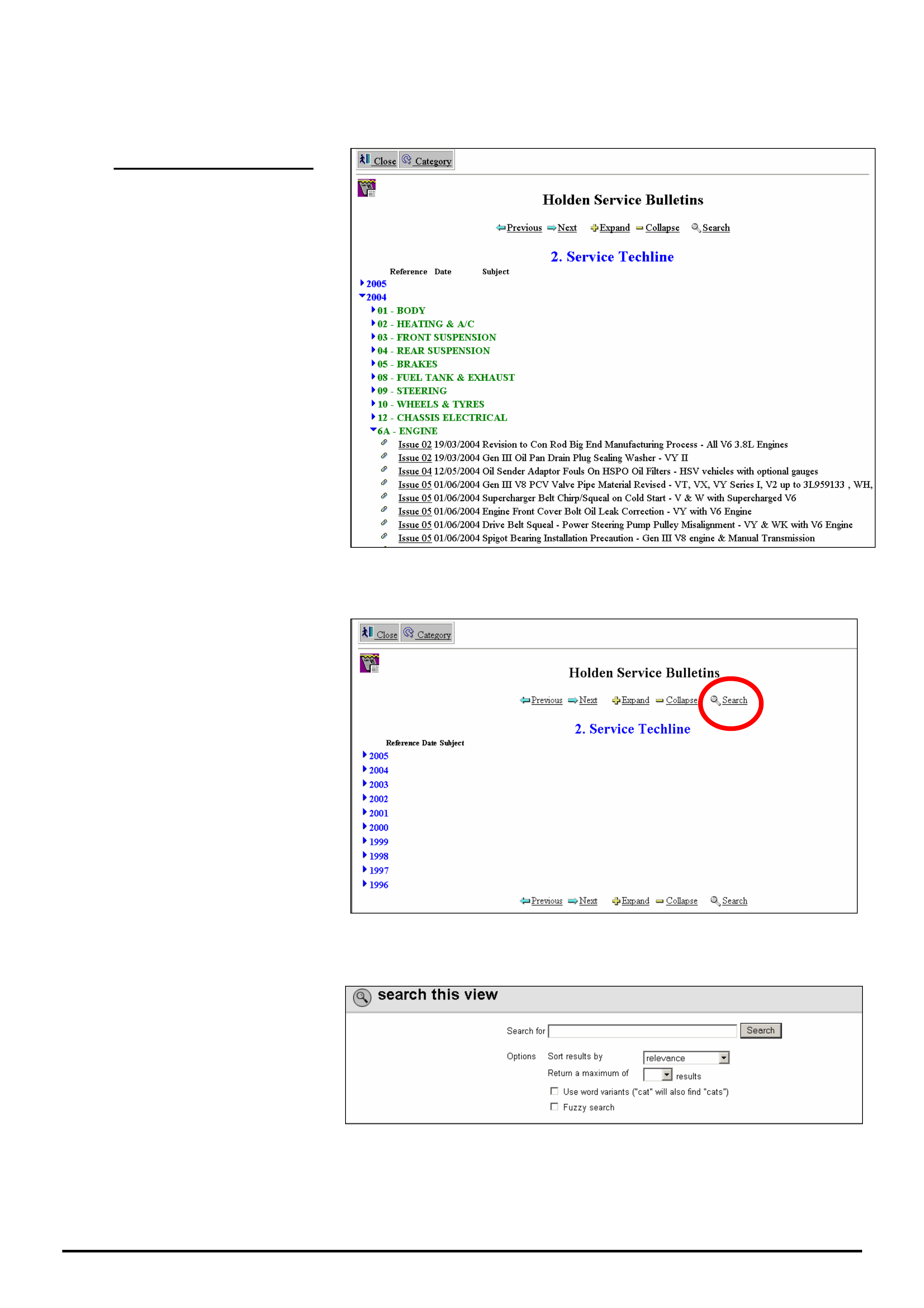

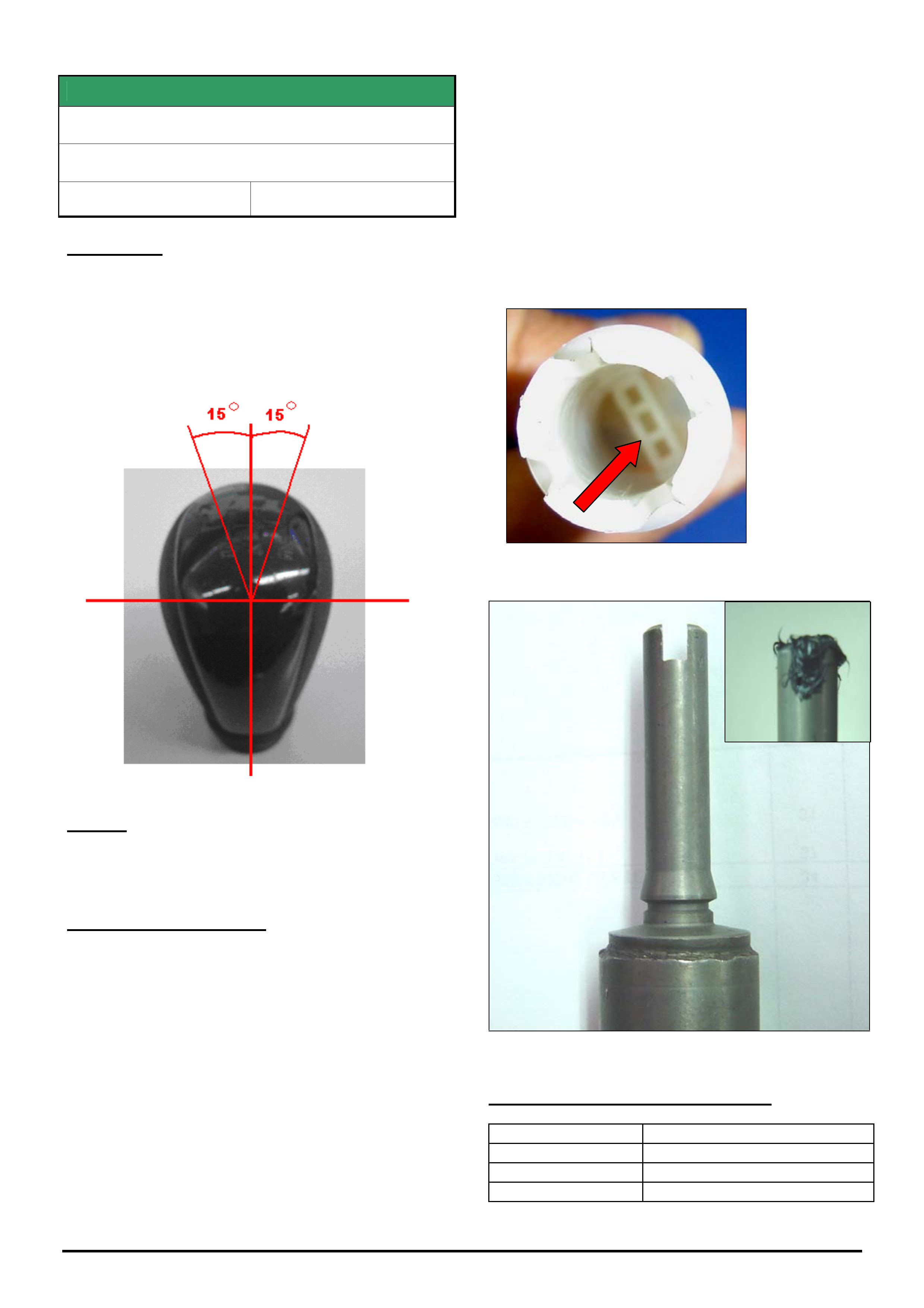

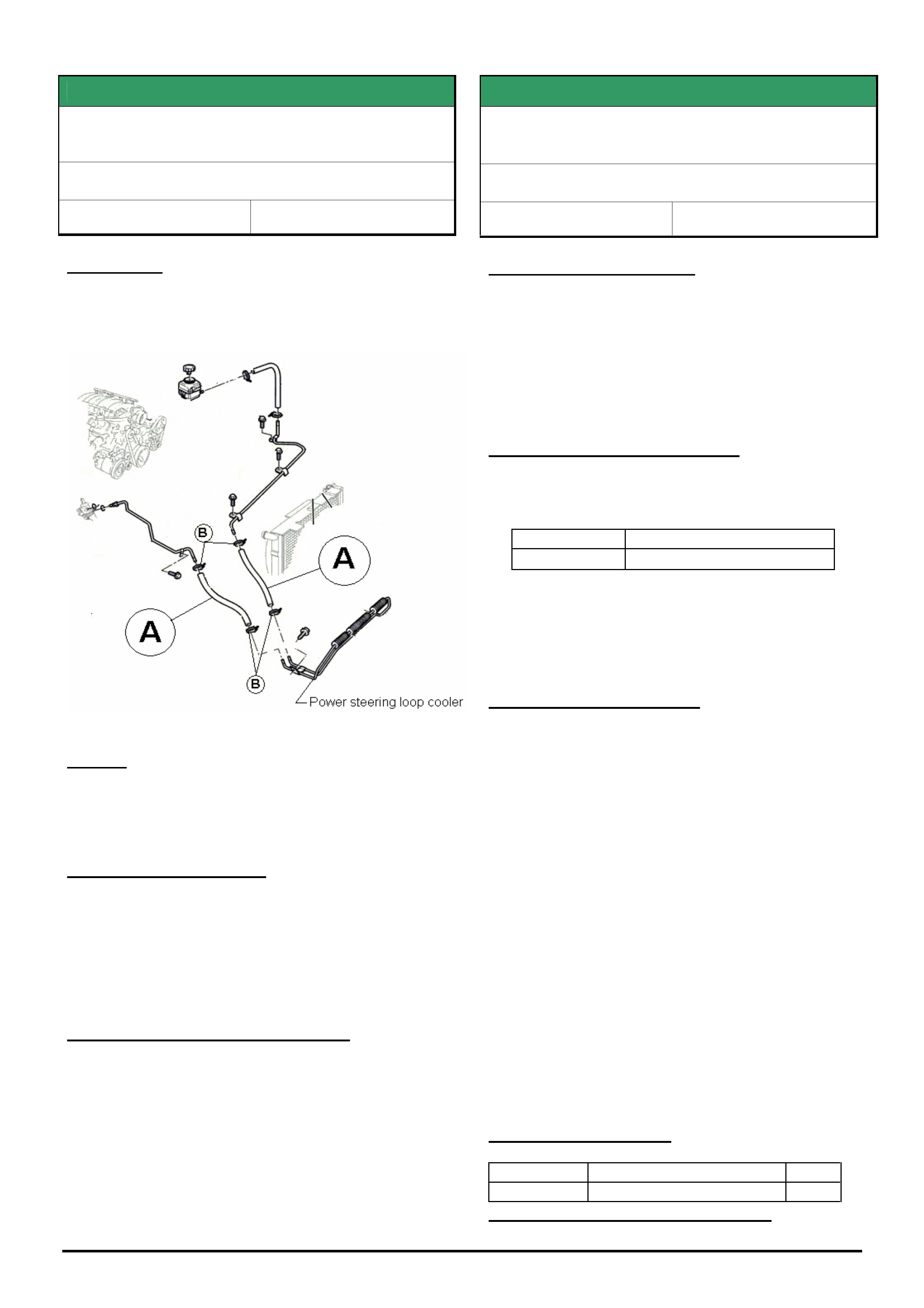

Oil Filter Cap – Care During Removal and

Replacement (Cartridge Type)

TS & XC (X18XE1 or Z18XE Engines)

Group 6A Ref. No. TL0342A - 0501

This techline is repeated from 2002 as the problem

described below continues to occur.

PROBLEM DESCRIPTION

PIR’s have reported damage to the oil filter cap used

on cartridge type oil filters.

Damage (cracking) may occur on oil filter housing

caps during removal - if the cap is over-torqued when

a filter cartridge is replaced during regular

maintenance servicing.

Ensure only 15Nm is applied to the filter cap

when an oil filter cartridge is replaced.

All X18XE engines are fitted with cartridge type oil

filters.

Z18XE1 engines are fitted with two types of oil filters:

• Cartridge type – which requires the removal of the

filter housing cap to remove and replace the filter

element;

• Screw-on type – which requires only the filter

assembly to be removed and replaced.

Screw-on type oil filters were introduced to Z18XE

engines from: engine No Z18XE20V00605

SERVICE RECTIFICATION

Summary: Adhere to correct torque specification and

ONLY use the tools recommended below.

TORQUE SPEC.:

Do NOT over-torque the oil filter cap when fitting a

new oil filter cartridge.

Ensure only 15Nm is applied to the filter cap

when an oil filter cartridge is replaced.

REMOVAL TOOLS:

When removing filter housing caps on engines with

the cartridge type filter, use ONLY a 24mm ring

spanner or socket. This fully supports the cap

material and allows removal without damage to the

cap.

TIS 2000 drawings showing the use of a ratchet

handle and square drive special tool – these are

shown ONLY for the screw-on type oil filter fitted to

engines after the breakpoint shown above.

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

12

SERVICE FIX

DTC’s P0700, P0715, P0720

ZC with V6 & A/T

Group 7B Ref. No. TL0737- 0501

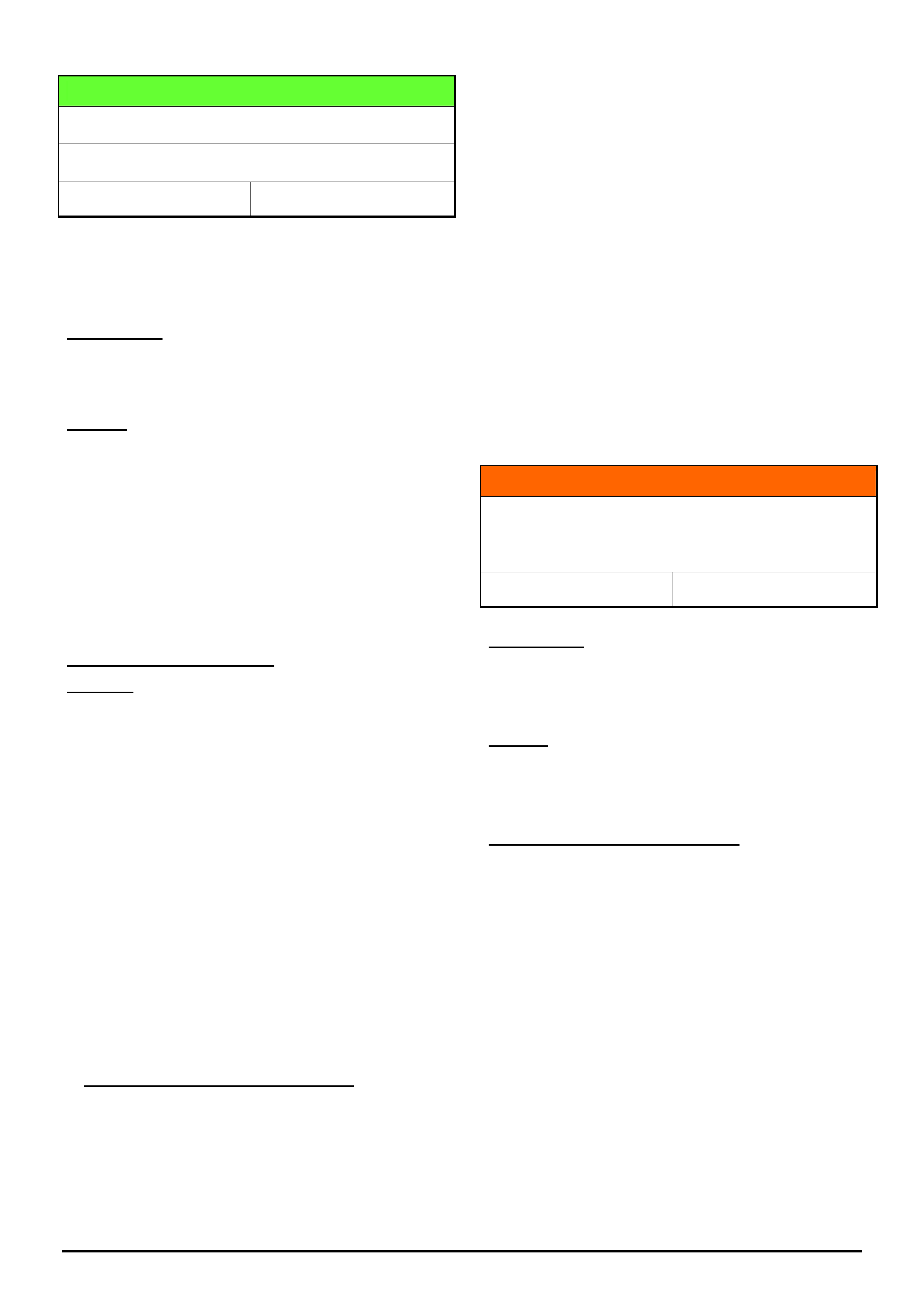

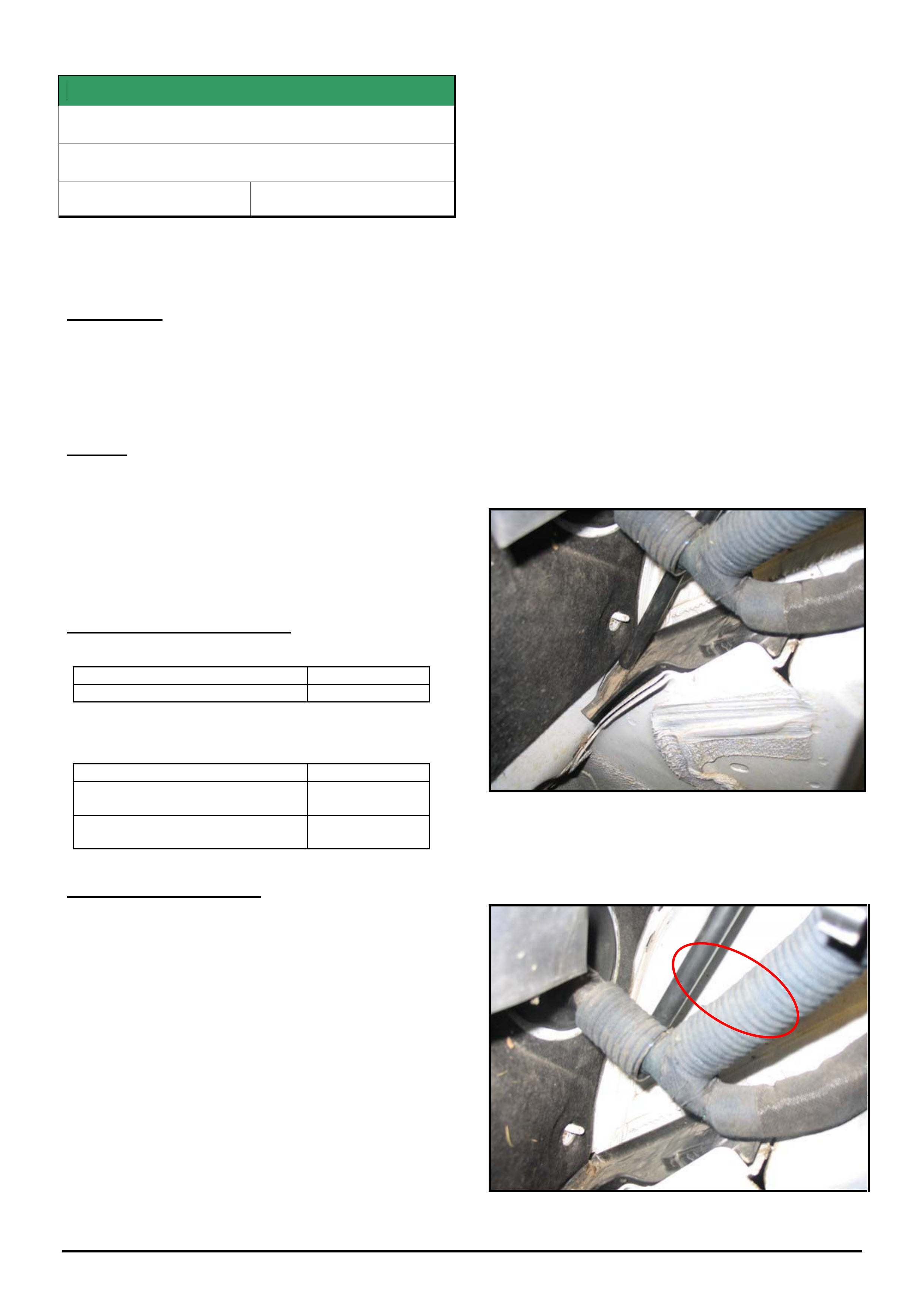

CONDITION

Customer may complain of “no shifting” or “incorrect

shifting” of transmission ratios.

DTC’s P0700, P0715 or P0720 may be stored (one

or all of the DTC’s).

CAUSE

It is possible that moisture has entered the speed

sensor connector, causing an incorrect or interrupted

signal.

CORRECTION – Production

Protective grease has been applied to speed sensors

from:

Trans. Serial No.: Built Date:

03MV735125 06/01/04

CORRECTION – Service

1. Disconnect the speed sensor connector and dry

out any moisture present.

2. If there is no evidence of corrosion or damage to

terminals apply grease 09163339 to connector to

stop future moisture entry.

3. If corrosion or damage is evident then replace

sensor. Also apply grease 09163339 to

connector to stop future moisture entry.

PARTS INFORMATION

Part No.: Description: Qty:

09163339 Grease. NYOGEL

760G 25 gm tube

1

93173888 speed sensor 1

WARRANTY CLAIM INFORMATION

Use Labour Time information in Warranty Information

section of current PV SIP CD.

NOTE: If there are re-occurences of the original

customer shift complaints together with the

above DTC’s, proceed as follows:

• Remove transmission valve body cover to

inspect for possible coolant entry to transmission

via the radiator oil cooler – which (in rare cases)

may cause the DTC’s to set.

NOTE: Remove the valve body cover

CAREFULLY and inspect for any water, or white

sediment in the cover. If water or white sediment

is evident, the radiator must be replaced, and

TAS should also be contacted for further

diagnostic information before any additional

work is carried out.

NOTE: Radiators with revised oil cooler sealing were

introduced into vehicle production from:

Ellesmere Port:

ISOVIN: Built Date:

W0L0ZCF6848035197 not available

Russelsheim:

ISOVIN: Built Date:

W0L0ZCF3541042598 not available

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

13

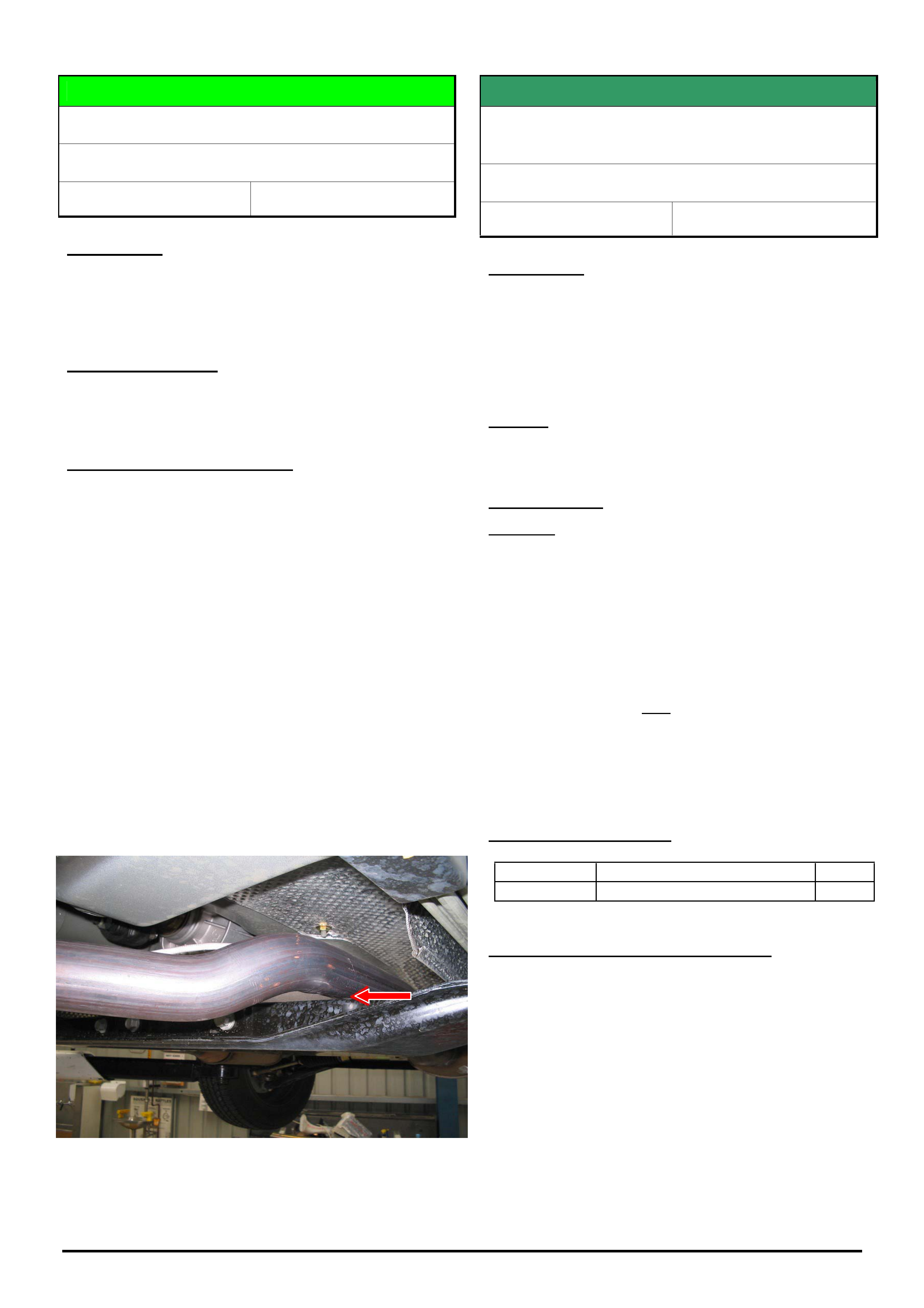

DIAGNOSIS HINT

Fluid Leak Diagnosis Using Black Light And Dye

All Models

Group: OB Ref. No. TL0837- 0501

This techline is repeated from year 2000 techlines.

The information provided in this techline is to assist Dealers in performing thorough and accurate diagnosis of

fluid leaks prior to commencing any rectification work or removing major components.

Components must NOT be replaced for “leaks” without thorough definition of leak sources.

Use of Black Light Dye and Black Light is highly recommended to trace leak sources. For extensive information

on the use of Black Light and Black Light Dye, refer to the following information repeated from a previous All

Dealer Letter.

Holden strongly recommends the use of the black light and dye method to diagnose fluid leak sources. This

method of leak detection is a proven, reliable method that identifies the specific leak source and/or location.

The black light and dye method can be used for various types of leak detection, when used with the appropriate

tracer dye it can be used for detecting engine and transmission fluid leaks, Refrigerant leaks, fuel leaks, and

coolant leaks.

The following pages provide answers to technicians’ questions about the various aspects of black light and

tracer dye, and how dealerships may use this tool to their advantage.

Black Light & Tracer Dye and Accessories

There are different types of tracer dye for different applications, plus for air-conditioning systems, an

injector is required to infuse the dye into the system. The following tracer dyes and accessories are

available from SPx Australia. Other equivalent products may be used in their place.

Contact details for SPx Australia – Ph.: (03) 9544 6222; Fax: (03) 9544 5222.

Application Part Number

Black Light Leak Detection

Lamp

16296

Replacement Black Light Bulb

AU 512

R134a Air Conditioning Tracer

Dye

(24 X 8ml bottles)

J41447

R12 Air Conditioning Tracer

Dye

(24 X 8ml bottles)

J39475

R134a Air Conditioning Injector

J41459

R12 Air Conditioning Injector

J41709

Petrol & Diesel Engine Fluid and

Transmission Fluid Tracer Dye

(24 X 1 oz bottles)

J28431-B

Coolant Tracer Dye

(24 X 1 oz bottles)

J29545-6A

Multi purpose dye

(engine oil, transmission & power

steering fluid, diesel & petrol)

16268

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

14

Black Light & Tracer Dye Useage Information

The following pages will answer most questions you may have about using Black Light and Tracer Dye.

Summary of the steps involved in detecting a fluid leak using black light and dye:

Pour specified amount of dye into the system.

Road test the vehicle under normal operating conditions, to allow the dye to mix with the host fluid/gas.

Define the leak source by directing the Black Light towards the suspect area. The fluid leak will appear as a

brightly coloured path leading to the source. Note: The colour of the dyed fluid can be checked on the dipstick,

or other component directly in contact with the host fluid/gas.

Repair fluid leak cause and recheck to ensure that leak has been rectified.

General Information

How much dye do you use? The following information is given as a guide only. Always refer to the label on the

bottle.

Engine, Transmission, Fuel

J28431-B Engine & Trans. Fluid Dye should be used as follows:

Petrol Engine Oil - 7.4ml per 3.79litres of oil (¼oz per 4-5 quarts)

Diesel Engine Oil - 7.4ml per 3.78litres of oil (¼oz per 4 quarts)

Automatic Trans. Fluid - 14.8ml per 5.68litres of fluid (2x¼oz per 6 quarts)

Manual Trans. Fluid/Oil - 7.4ml per 5.68litres of fluid (¼oz per 6 quarts)

Petrol or Diesel Fuel - 7.4ml per 7.57litres of fuel (¼oz per 2 gallons)

A/C Systems

J41447 R134a A/C Dye should be used as follows:

R134a A/C System - 7.4ml per A/C system (¼oz per system)

J39475 R12 A/C Dye should be used as follows:

R12 A/C System - 7.4ml per A/C system (¼oz per system)

Power Steering

J28431-B Engine & Trans. Fluid Dye can be used in Power Steering as follows:

Power Steering Fluid - 7.4ml per 5.68litres of fluid (¼oz per 6 quarts)

Engine Coolant Systems

J29545-6A Coolant Dye should be used as follows:

Coolant System Radiator Fluid - 7.4ml per 15.14 litres (¼oz per 16 quarts)

Note: These amounts are based on various tests - there may be occasions when good fluorescence is not

obtained with these amounts of dye, due to the condition of the host oil/fluid or the nature of certain additive

packages in the oil/fluid itself. If this occurs, use additional dye.

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

15

Q A

Do you need to use the

Fluorescent Enhancer Safety

Goggles?

Yes - they not only protect the technician, but also visually optimise the

dye fluorescence for enhanced leak detection. They are scientifically

designed to enhance fluorescence by eliminating light at wave lengths

that might interfere with the eye’s ability to view the dye’s fluorescent

light emission. Once you look at the dye with and without the goggles,

you will see the difference.

What life does the dye have

when left in coolant, ATF,

R12 and R134a refrigerant?

Indefinite - unless the ATF is “burnt” in an A/T clutch failure or if here is

an A/C compressor failure.

What life does the dye have

when left in engine oil?

Depends on how dirty the oil was when the dye was added. In clean petrol

engine oil, it will last 500+km. In diesel engine oil, it will not last as long

because of rapid carbon build-up.

Are there any adverse effects

of leaving dye in systems too

long?

None - and A/C dyes especially are very thermally stable and should last

100,000 km.

Is there a preferred method

of cleaning the dye from a

vehicle, if spilt?

IMPORTANT - Do NOT get dyes on any painted surfaces - use guard

covers when pouring dyes into any vehicle system or injecting A/C dyes. A

good cleaning solvent should clean any dye off any metal surfaces. A/C

dyes cannot be cleaned off hoses or plastic components.

What is the shelf life of the

dyes?

Indefinite, but it is recommended they be used within five years.

PETROL & DIESEL ENGINE & TRANSMISSION OIL LEAKS

Use J28431-B dye in quantities as specified in “General Information” section.

Putting dye into oil that is fairly clean will achieve the best fluorescence for le ak inspection because the greater

the carbon build-up in the oil, the more difficult to obtain good fluorescence from the dye. Therefore, if the oil

appears to be extremely dirty on the dipstick, additional dye may be required to obtain good fluorescence and

can be added without harm to the engine.

Q A

How do I know if the dilution

ratio of dye added is correct?

After adding dye at the recommended dilution ratio, operate the engine 3 to

5 minutes to allow dye to mix with oil. Then check the oil dipstick with

black light for the yellow-green fluorescent glow of the oil/dye mixture.

What is the proper procedure

for adding dye to the engine?

With the engine OFF. This will prevent possible splashing of the dye over

an area of the engine that may need inspecting.

How long does it normally

take for the dye to work?

Most leaks will appear after operating the engine 5 to 10 minutes. However,

it is recommended that the vehicle be taken for a short road test in order to

allow the dye to penetrate all leaks.

How long will it take for the

dye to penetrate very small

pinholes or porosity leaks?

To accurately detect leaks of this type, the vehicle should be operated for 1

to 3 hours under normal operating conditions. Suggestion: If such a leak is

suspected, add dye to the engine oil. Then have the vehicle owner use the

vehicle for the time recommended above. The owner should then return for

leak inspection with the black light.

Do I have to clean engine NO! Under black light, all petroleum-based products such as oil, grease, and

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

16

Q A

surfaces prior to using the

dye?

ATF will fluoresce blue. The dye will penetrate surface oil, grease and grit

to leave a yellow-green fluorescent trace (under black light) at the source of

the leak.

Do I have to clean the engine

after repairing the leak?

YES! But only at the source of the leak in order to allow the technician to

operate the engine and then re-inspect the leak repair to insure the job was

done right the first time. Suggestion: The dye/oil mixture can be removed

by using any engine degreaser or solvent-type shop cleaner.

After adding dye to the

engine oil, is it necessary to

change the oil prior to

returning the vehicle to the

customer?

NO! The dye is 100% compatible with engine oil and can remain in the

system without harm until the next oil change.

How long will it take for

ATF dye to work?

Most leaks will appear after operating the transmission for 5 to 10 minutes.

However, it is recommended that the vehicle be taken for a short road test in

order to allow ATF dye to penetrate all leaks. NOTE: All other application

and leak-detection procedures remain the same as given under the Engine

Dye Section (above). It is not necessary to clean transmission exterior

surfaces prior to using ATF dye. To detect small pinhole or porosity leaks,

the vehicle should be operated for 1 to 3 hours. The ATF dye mixture

should be cleaned from the source of the leak, and it is not necessary to

change ATF after adding dye.

How long will ATF dye be

effective in the transmission?

Because the transmission remains fairly clean internally and does not have

the carbon build-up problem present in petrol and diesel engines, the ATF

dye will be effective as long as the ATF is not changed or the ATF is not

“burnt” or discoloured by a transmission failure. Remember to check the

dipstick with the black light prior to inspecting for leaks to check

fluorescence, and do not forget to check the ATF cooler line for leaks.

BRAKE SYSTEM LEAKS

Q A

Can I use a fluorescent dye

in a brake system?

Never use any type of a fluorescent tracer dye in a brake system.

POWER STEERING LEAKS

Q A

How much dye should I use

for finding power steering

leaks?

Check the fluid capacity of the power steering system. You will probably

need to add only a small amount of dye at a dilution ratio of 7.4ml (¼ oz) to

5.68l (6 quarts) of power steering fluid. Run the system, then check the cap

or dipstick for fluorescence with the black light.

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

17

FUEL SYSTEM LEAKS

When a fuel system leak is suspected, it is recommended that the vehicle being tested have a quarter tank or less

of fuel. Trucks and larger capacity systems should be estimated as close as possible in order to keep the dye

requirement at a minimum and to keep the test procedure as economical as possible. If a difficult leak is

suspected, adding more dye than normal (a higher concentration) will produce the best results and will not harm

the system.

Q A

How do I know if enough

fuel dye has been added?

Any dipstick device that can be inserted into the filler tube can be used and

then inspected for fluorescence with the black light.

On a fuel-injected (PFI)

vehicle, can I use the fuel

rail for injecting dye?

NO! The small volume of petrol that will receive the dye is probably

insufficient for the dye to show up at an “O” ring injector leak for example.

COOLANT SYSTEM LEAKS

Q A

What is the proper procedure

for adding dye to the cooling

system?

Add dye with the engine off and radiator “cold”. This will prevent splashing

of dye and possible false readings. Also, add the coolant dye directly into

radiator and not into the reserve/surge tank found on some vehicles.

How do I clean the coolant

with dye off the radiator and

engine surfaces?

Use water with detergent and a small scrub brush.

How can I check for a

suspected coolant leak into

the engine oil?

Perform test as follows:-

Pull the engine oil dipstick and confirm the blue fluorescence of the engine

oil with the black light. (This is oil to which no dye has been added.)

With the engine off and the radiator cold, pour coolant dye into the radiator,

and operate vehicle for at least one day to allow coolant to leak into engine

oil.

With the engine off, pull engine oil dipstick and fluoresce dipstick with

black light.

If coolant is leaking into the engine oil, the dipstick should show some green

fluorescent droplets of coolant. Also, the engine oil might fluoresce a slight

whitish blue colour instead of the normal strong blue fluorescence of engine

oil.

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

18

USING DYE IN R134a or R12 A/C SYSTEMS

When dye is injected into an A/C system and the system has been operated under full pressure for 5 to 10

minutes, the dye will remain in the system even though the R134a or R12 has been evacuated for a repair. The

only time R134a or R12 dye must be replenished is when the A/C system is flushed of refrigerant oil.

Q A

How do I put R134a or R12

dye into an automotive car or

truck A/C system?

Put 7.4ml (¼ oz) of dye in the dye injector reservoir, and use a refrigerant

source to inject the dye into the A/C system.

How long will it take the

R134a or R12 dye to circulate

through the typical

automotive A/C system?

Operating the A/C system under full pressure, it will take the dye

approximately 5 to 10 minutes to circulate through most A/C systems.

However, this does not mean that the A/C leak will show up in that time

period.

How long after putting

R134a or R12 dye into the

A/C system and running the

system under full pressure

can I begin looking for the

A/C leak with the black light?

This depends on the size and location of the leak. As the refrigerant escapes

under pressure, it carries with it a very small amount of refrigerant lubricant.

This trace of lubricant is what you are looking for with the black light.

Therefore, the size of the leak will determine how long it takes for the

lubricant dye to appear and fluoresce under the black light. A hose porosity

leak would, therefore, take longer to appear than a fracture/fitting leak.

Example: A high-pressure side leak may take over a week or more to have

enough refrigerant escape to affect the cooling capacity of the A/C system,

return the car to the customer, and tell them to bring it back for leak

inspection when they again notice a lack of cooling by the A/C system. When

this car returns, the refrigerant that has escaped will leave a trace of

refrigerant lubricant with dye, which is what you will be looking for with the

black light.

How do I know if I have a

leaky service valve on the

low-pressure side if I just

used that valve to put dye into

the A/C system?

After putting the R134a or R12 dye into the A/C system through the low-

pressure service valve, clean the valve with a solvent if the refrigerant taking

the dye into the A/C system did not clean off the service valve, sufficiently to

remove all trace of dye. Do this before starting the A/C system.

How do I clean the R134a or

R12 dye off A/C components

and engine surfaces?

Use any shop degreaser or solvent to clean dye off A/C components or

engine surfaces.

Are these A/C dyes

compatible with my

refrigerant recovery and

recycle equipment?

These dyes have been tested and proven compatible by major manufacturers

of recovery and recycle equipment. When refrigerant is evacuated from an

A/C system, a small amount of compressor lubricant is also removed from

the system. The R134a or R12 dye is in solution with the system compressor

lubricant, therefore, is separated in the recovery/recycle unit along with the

compressor lubricant. Because of the small amount of compressor lubricant

removed by the recovery/recycle unit, there is no need to add additional R-

134a or R-12 dye to the A/C system for future leak detection.

How do I know if a vehicle’s

A/C system contains dye?

Remove the low-side service port sealing cap and direct the black lamp into

the valve stem area. If you do not see dye/lubricant in this area, depress the

valve stem only for an instant to help bring out some lubricant with the

refrigerant. Again direct the black light at the valve stem for traces of the

fluorescent dye/lubricant. Clean dye off service port.

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

19

Q A

How do I check for

refrigerant leaks in the

evaporator when I cannot use

the black light to see the

leak?

Use the black light to fluoresce the drain hole and see if a trace of the yellow

green dyes has washed down with the condensation. When the evaporator is

removed from the vehicle, use the black light to determine the exact location

of the leak on the evaporator. Remember to check the fittings to and from the

evaporator to be sure they are not the cause of the leak.

How do I check for the

dye/lubricant when I cannot

directly shine the black light

on all suspected leak areas?

Use a mirror to reflect the black light to the underside of a fitting, hose or

component. Also if a mirror cannot be used, a white cloth can be used to

wipe the suspected area, and then fluoresce the cloth with the black light to

check for traces of the yellow-green dye.

Can the dyes remain in the

A/C system after it has been

used for the initial leak

detection?

Dyes can safely and effectively remain in the A/C system after the initial

repair. Dyes can be used to detect future refrigerant leaks and can only be

removed from the A/C system by flushing out the system compressor

lubricant.

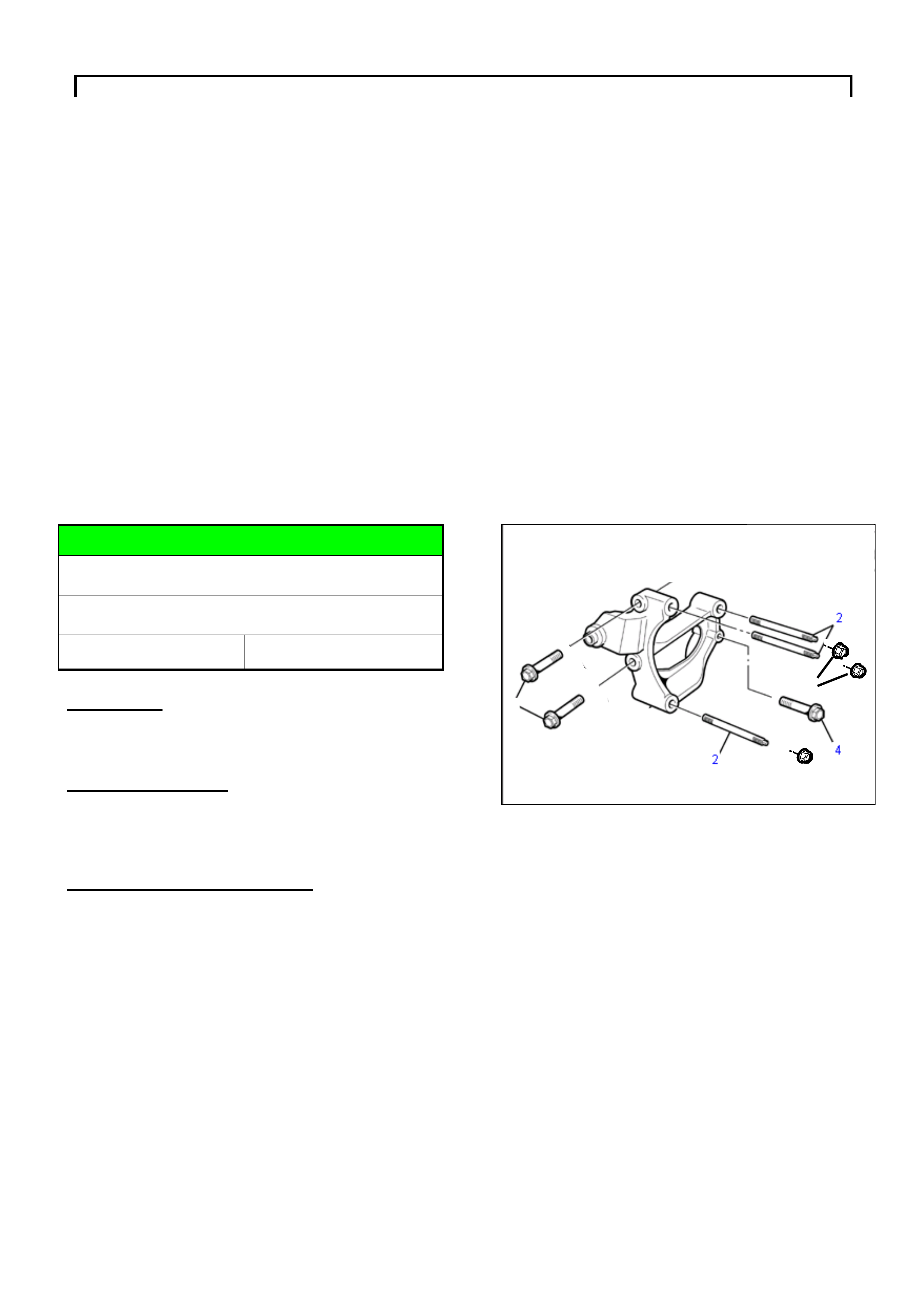

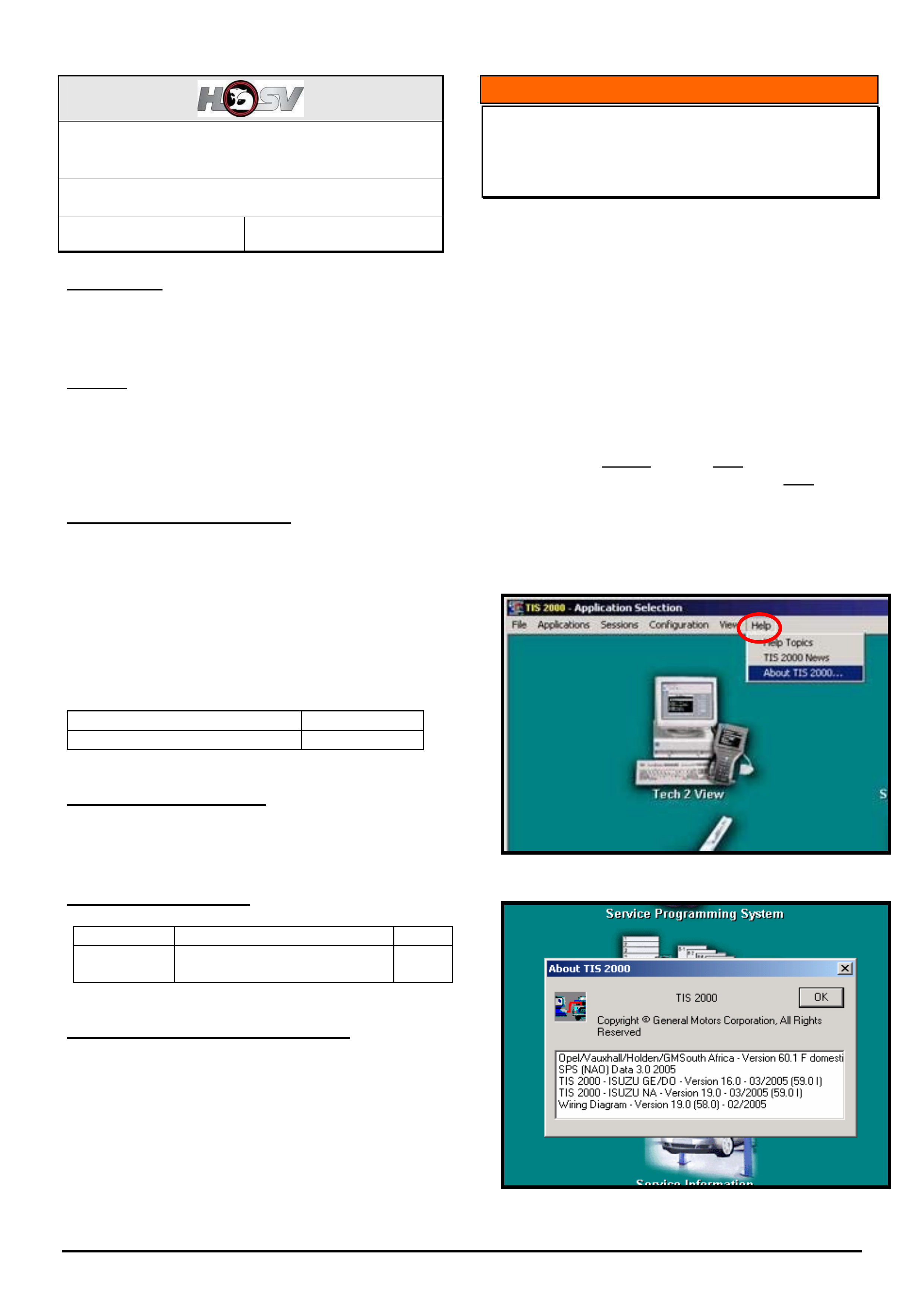

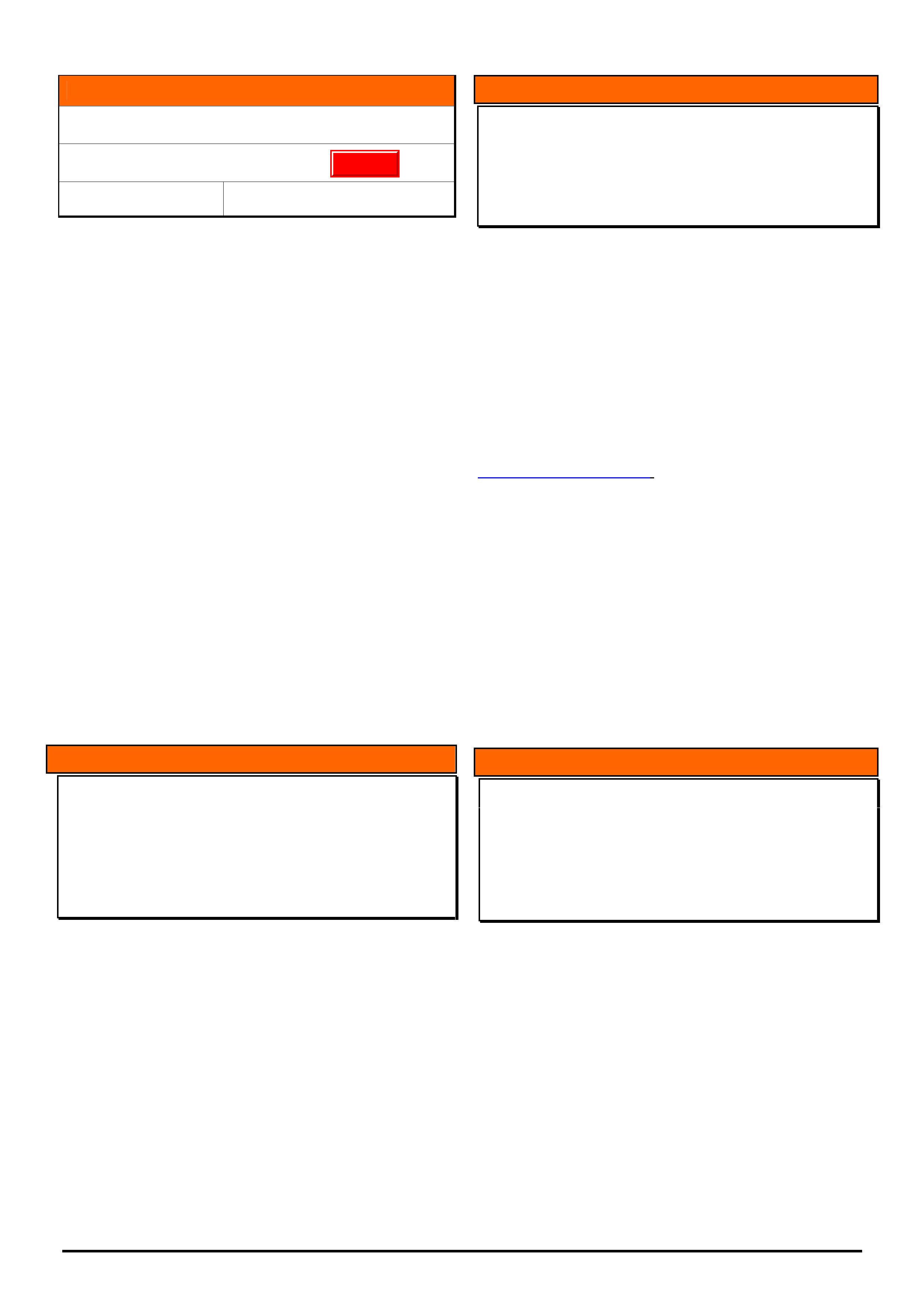

DIAGNOSIS HINT

Noise / Vibration With A/C Operating

VZ Series – V6

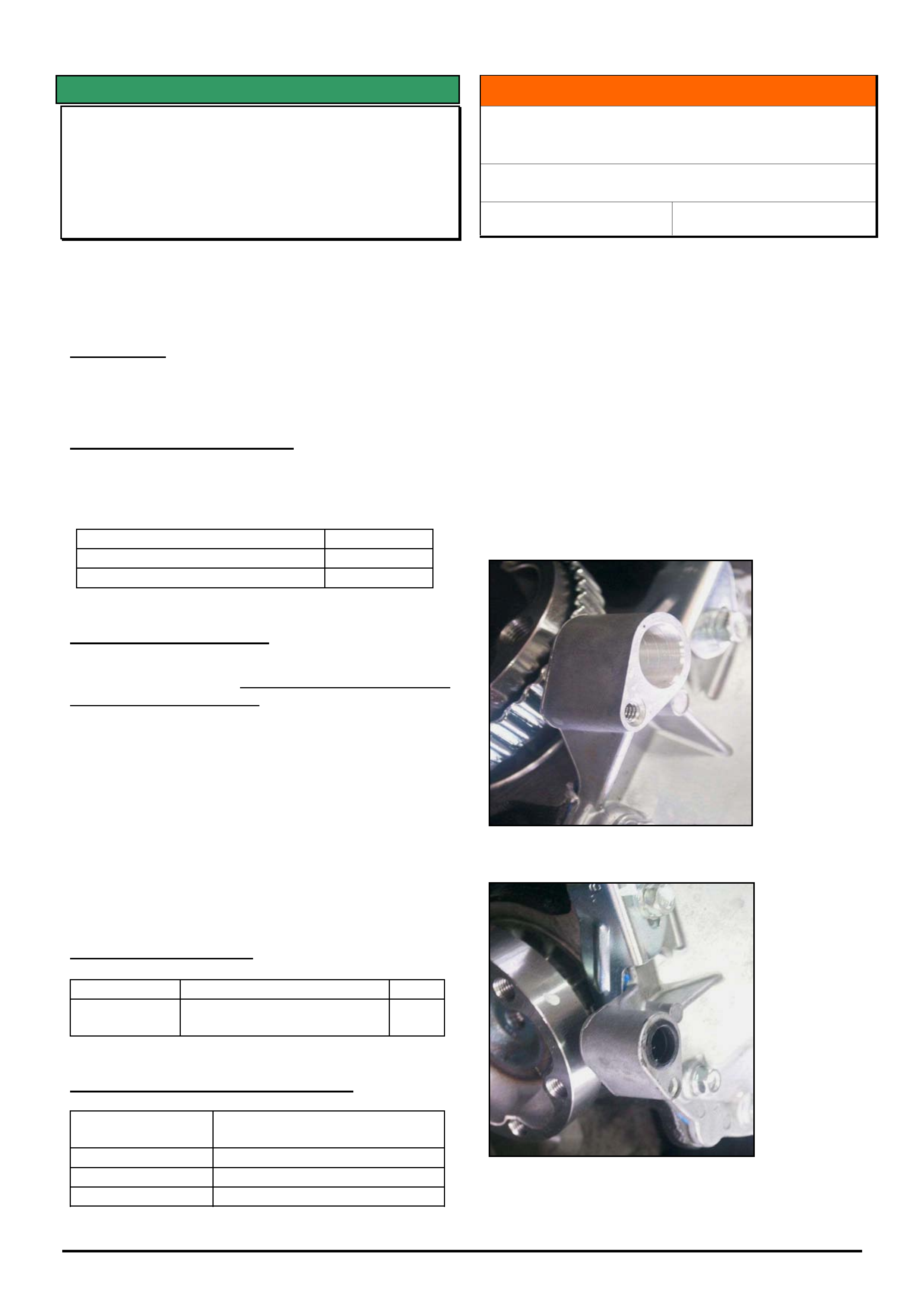

Group 2 Ref. No. TL0846- 0501

CONDITION

Any symptom of noise with the A/C operating.

POTENTIAL CAUSE

Compressor bracket mounting bolts/studs not

tensioned correctly.

SERVICE RECOMMENDATION

The compressor and compressor bracket

mounting torques must be checked before

replacing any components or commencing

further diagnostic work.

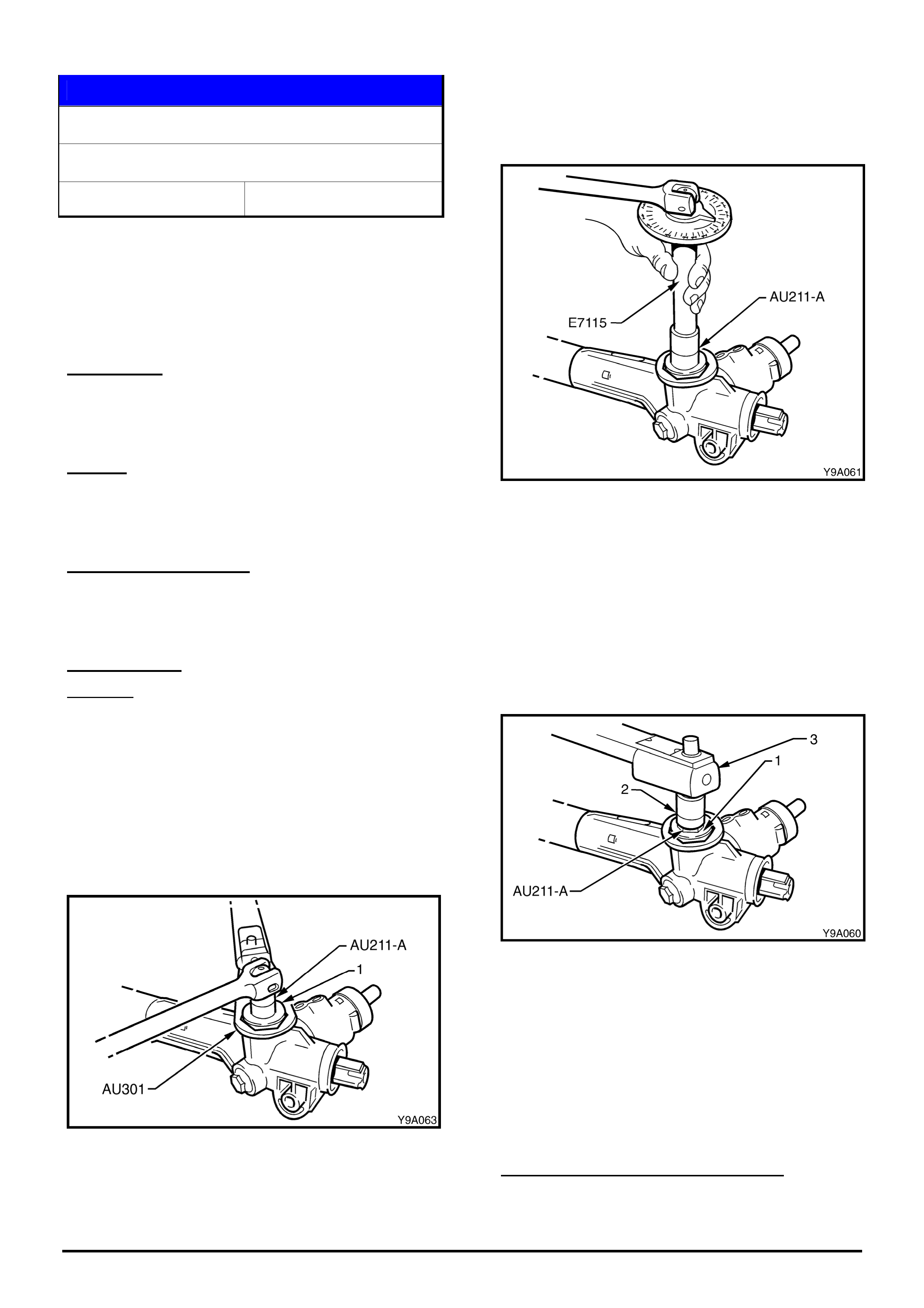

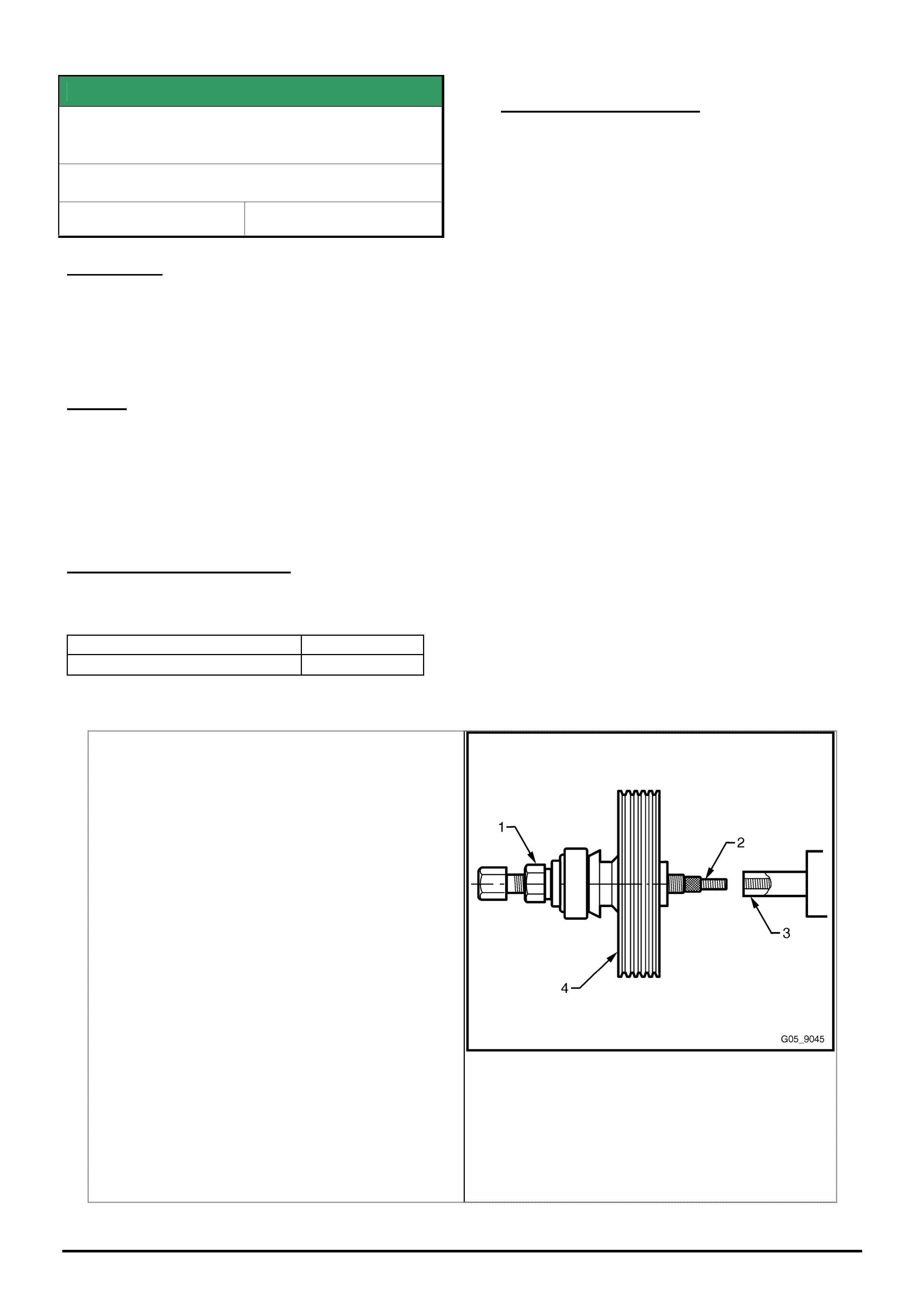

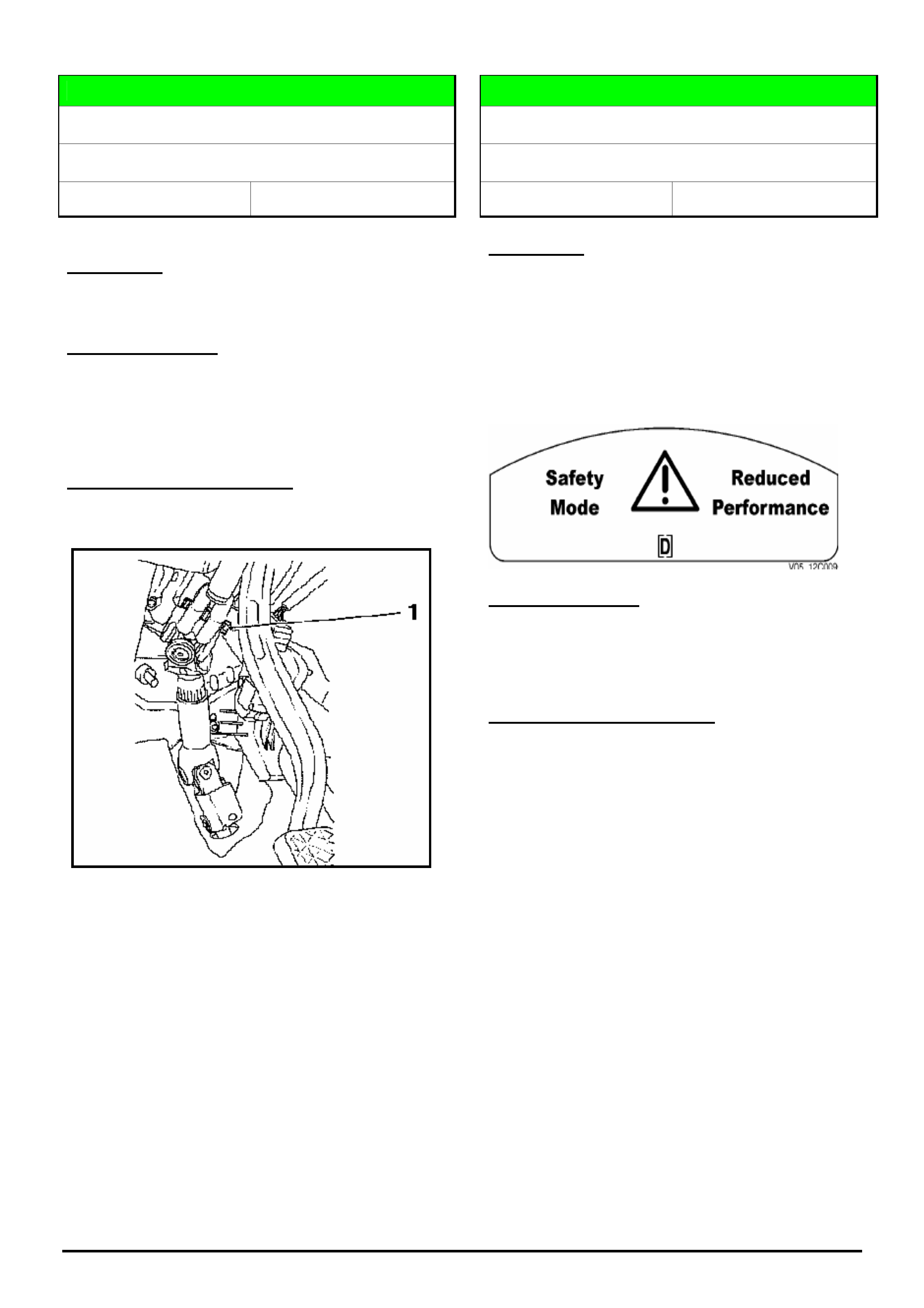

1. Torque A/C Compressor Bracket Front

Mounting Bolts (item 1 in Figure 1) - 58 +/-9

Nm.

2. Torque Studs Into Compressor Bracket

(item 2 in Figure 1) – 10 +/-2 Nm.

3. A/C Compressor To Bracket Attaching Nuts

(item 3 in Figure 1) – 22 +/-3 Nm.

4. A/C Compressor Bracket Rear Mounting

Bolt (item 4 in Figure 1) – 22 +/-3 Nm.

Figure 1. Compressor mounting bracket

3

3

1

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

20

INFORMATION

Holden Contacts and procedures

All Models

Group OB Ref. No. TL0679A- 0501

This Techline supercedes the previous one in Issue

3, April 2004. Revisions are shown in red.

This techline summarises some of the Holden

contact procedures and gives a quick reference

guide for contact numbers.

Security information.

To obtain security information for both Passenger

and LCRV vehicles the first step is to check

Lionheart. If the information is unavailable on

Lionheart then a completed security information

request form must be faxed through to the security

information department, as security information

cannot be given out by phone. Please note that

security information requests are processed by the

security information department and not TAS.

Please ensure you have the latest security

information request form, which is available on

Passenger Vehicle SIP for both Passenger and

LCRV. Contact details are listed below. There can be

up to a 4-hour turn around on requests however if the

information needs to be obtained from overseas, it

may take up to 24 hrs. Do not phone the security

information department unless you have not received

a response in the normal turn around time. For

further information please refer to ADL 63/99.

Parts inquiries and information

If any information or assistance is required in regards

to part numbers or Partfinder, please refer to the

Holden Help section in Partfinder.

Warranty Authorisation and enquiries

Warranty can only be authorised by your Aftersales

District Manager. Labour times information is

available on SIP or from the warranty department.

For any other warranty inquiries please contact

Warranty Administration.

TAS

Technical Assistance Service (TAS) is a service

provided by Holden to assist Holden Dealers in

problem resolution.

Contact to TAS must be made by a Nominated

Contact as outlined in Section 5 of the TAS

procedures manual. All techlines, dealer letters and

service information must be checked prior to

contacting TAS. The Nominated Contact must not

contact TAS until he/she has been fully involved with

the faulting vehicle and all Dealer expertise has been

exhausted. Problems should be escalated through

the Dealership to the senior technician/foreman

before contacting TAS.

TAS cases must be updated or closed within 30 days

unless a Dealer is waiting on a service fix to be

provided. It is the Dealers responsibility to update

cases. All cases should be recorded in the TAS

procedures manual, which should be referred to prior

to contacting TAS. Please note that an electronic

copy of the TAS procedures manual is also available

on passenger SIP.

All Daewoo TAS enquiries must be done by Fax.

Under no circumstances should you call TAS for

Daewoo enquiries.

Under no circumstances are TAS or other Holden

contact details to be supplied to customers or

independent repairers. TAS is a service restricted to

assisting Holden Dealer service departments.

Quick reference contact numbers

Air International Ph 1800 673 716

Australian Arrow Ph 03 9785 0792

Blaupunkt Ph 1300 307 036

Bosch Technical Assistance Ph 1800 025 462

Clarion Ph 1300 730 730

Fax 03 9551 0377

Customer Assistance Ph 1800 033 349

Dana Ph 02 9892 9237

Fax 02 9892 9310

www.spiceraxle.com.au

Delphi Ph 1800 335 777

Eurovox Ph 03 9237 0800

Fujitsu Ten Ph 03 9646 6008

Holden Assist Ph 1300 880 088

HSV Ph 03 9265 9500

Infomedia (SIP, Partfinder) Ph 1800 810 103

Panasonic Ph 02 9986 7635

PBR Diagnostic assistance Ph 1800 468 727

Petro-Ject Ph 02 9890 5701

Ph 02 9890 5244

Philips/Siemens-VDO Ph 1800 335 282

Salmat Ph 03 9358

2900

Security Information Ph 03 9647 2001

Fax 03 9647 2865

SPX Australia Ph 03 9544 6222

TAS Ph 1800 033 417

Fax 03 9647 2495

Email [email protected]

Warranty Ph 1800 033 487

Update

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

4

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

DIAGNOSIS HINT

Buzz Noise Caused By Steering Wheel

Adjusting Lever

VY, VZ, WK, WL

Group 9 Ref. No. TL0862- 0502

If an owner complains of a buzz type noise coming

from the steering column shroud area, one possible

cause for this could be the lack of clearance between

the steering column adjustment lever and the lower

plastic shroud as shown in Figure 1. Under certain

driving conditions the lever can vibrate against the

cover, resulting in a buzz noise.

To rectify, carefully bend the lever so it has clearance

to the plastic cover for all steering column positions.

i.e. from fully extended to fully retracted.

Figure 1. Shows potential area of contact

SERVICE FIX

Notchy Fore/Aft Movement on 6 & 8 Way

Front Seats

V2, VY & VZ Calais, WK, WL

Group 1 Ref. No. TL0847- 0502

CONDITION

On some vehicles fitted with 6 or 8 way power front

seats, there may be some roughness felt when moving

the seat through its full fore/aft horizontal travel.

CORRECTION - Service

After verifying that vehicle has the condition as

described above, perform the procedures A & B

shown on the following pages to both front seats.

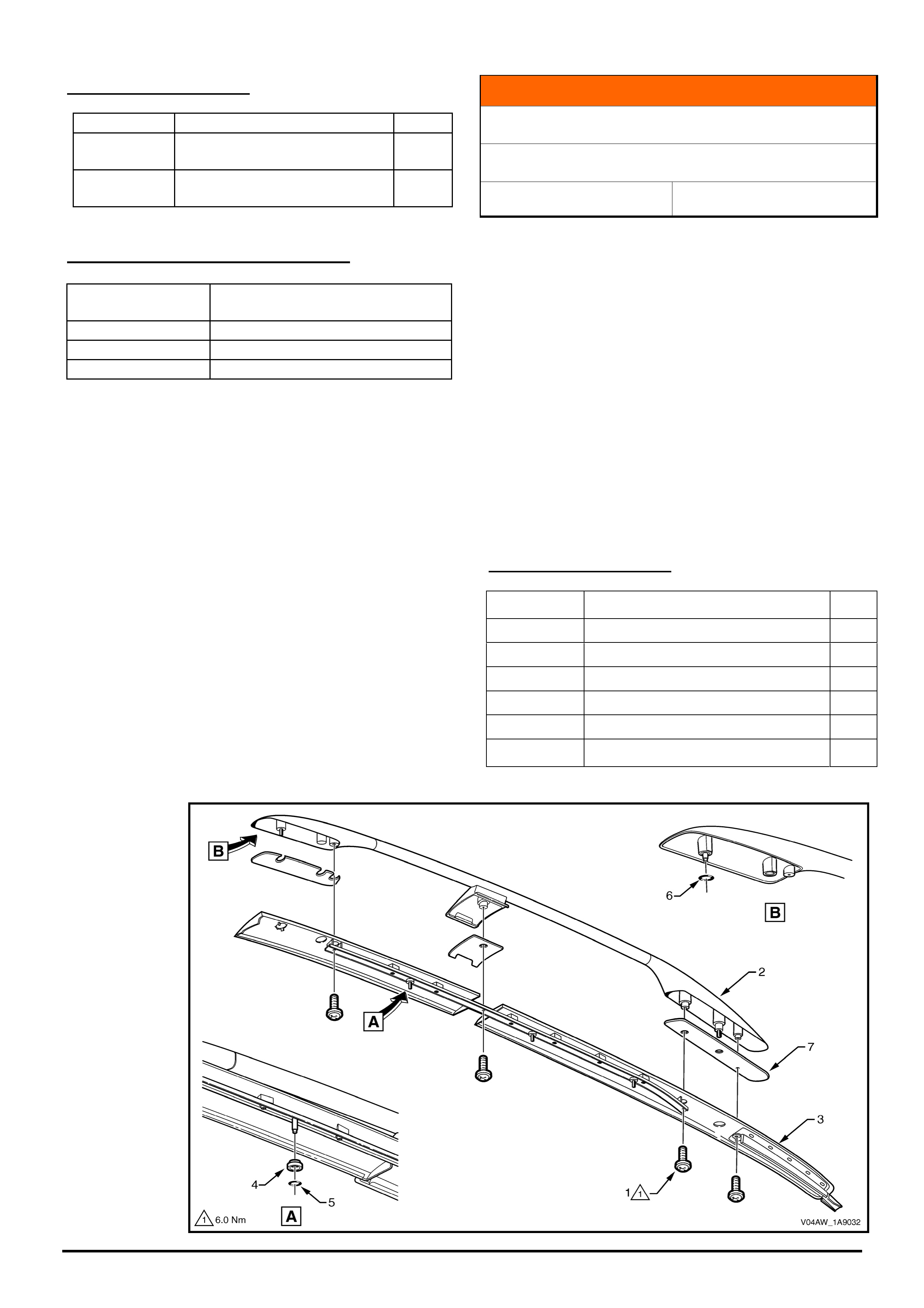

PARTS INFORMATION

Part No.: Partfinder® Name Qty:

92138926 Dampener - front seat

adjuster track

1/seat

NOTE: Each dampener consists of one steel clip and 2

nylon friction components which will need to be

assembled as shown in illustration below.

WARRANTY CLAIM INFORMATION

Description Install dampener to seat adjuster

driveshaft – both front seats

Labour Op. No. C000541

Time 0.8 hr

Failure Code C0041 chatters

CORRECTION – Production

Seats (6 & 8 way type) with dampeners fitted to

driveshafts have been installed in vehicles from:

ISOVIN: Built Date:

**********L397250 07 Feb 2005

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

5

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

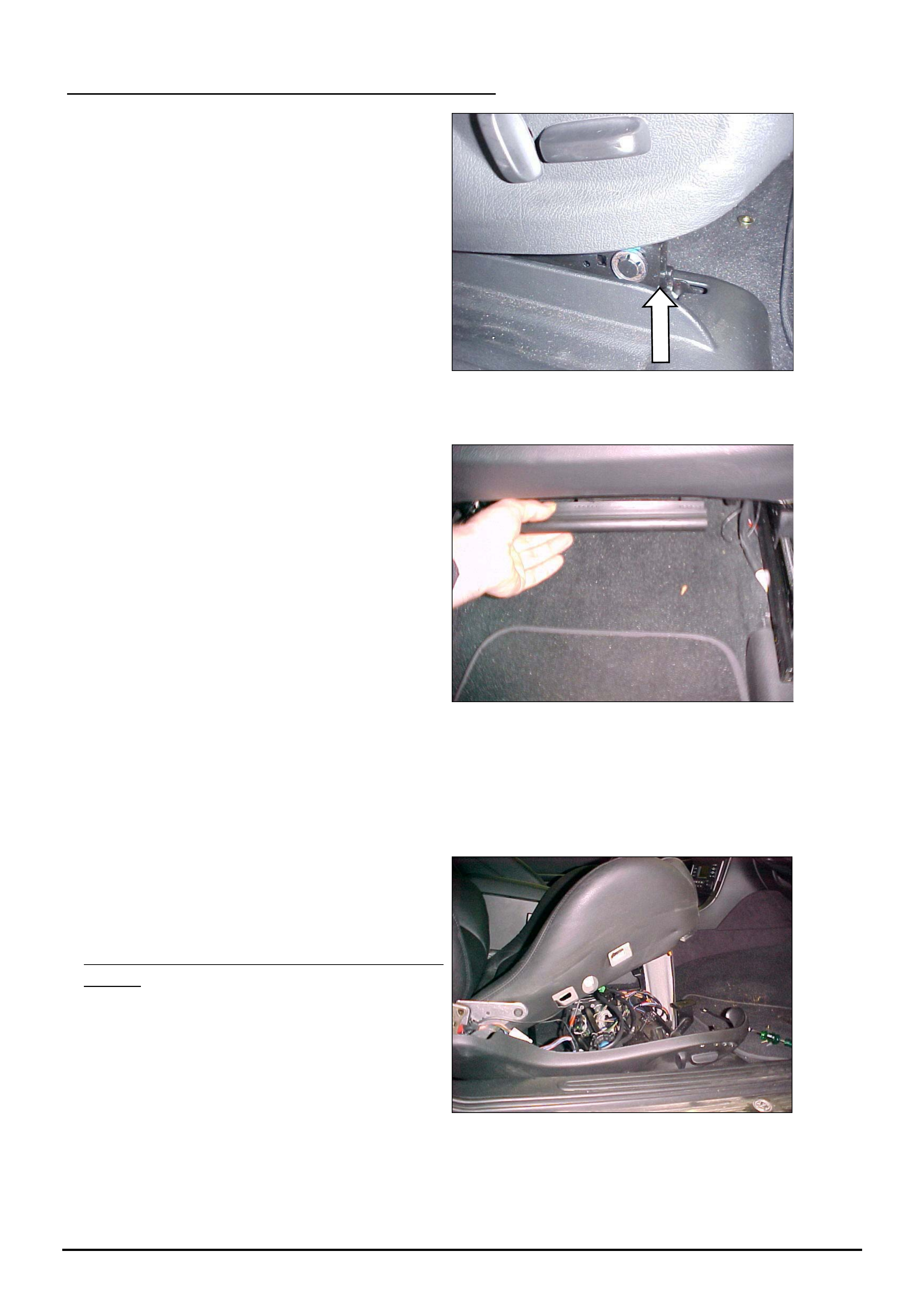

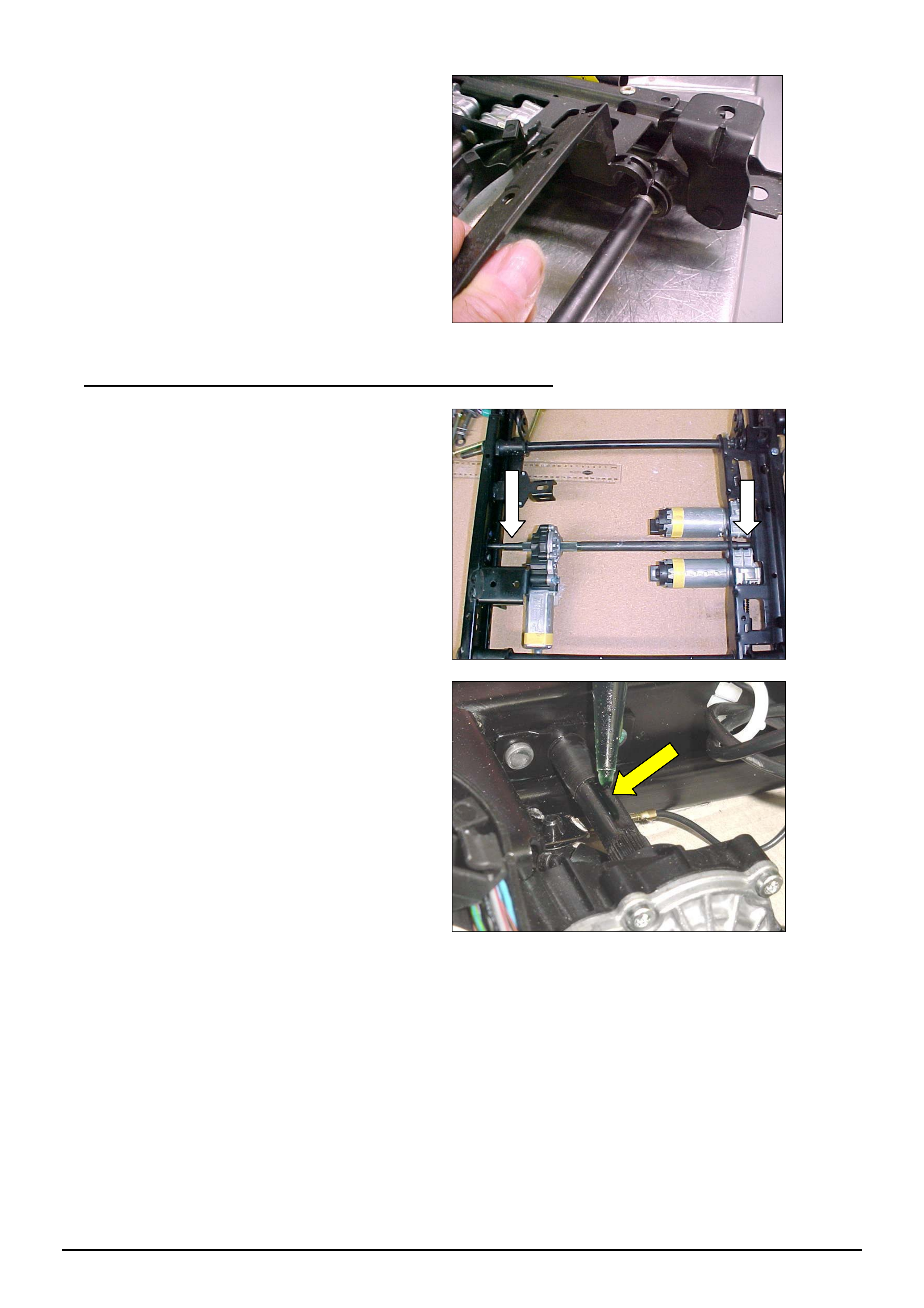

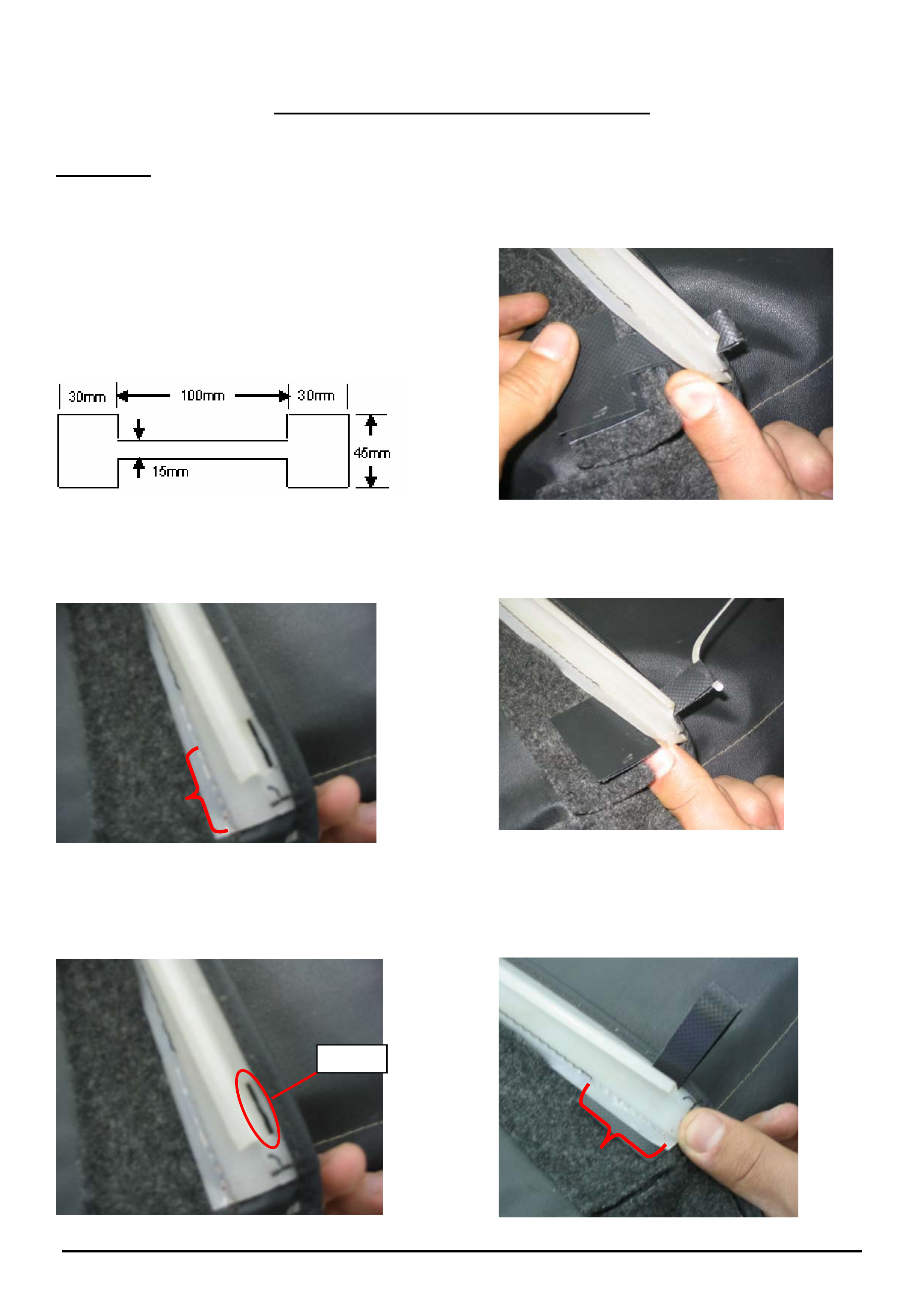

PROCEDURE A - Install dampener clip to driveshaft:

• Move seat to the mid position using seat

controls

Mid position is when the front of the track rails

are level.

• Raise seat to the full up position using seat controls

• For older vehicles that do not have the cable

tray style wiring harness – release the under

seat nappy retainer.

• Remove the side cover

• Undo the two front seat frame to cushion mounts – 13mm AF Nuts, 2 off.

• Tilt seat backward being careful not to over

stretch any of the wires.

On Older vehicles with underseat nappy

retainer:

The nappy will catch on the track assembly as

shown. It is not necessary to completely remove

the nappy as this will protect the wires from

being stretched too far.

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

6

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

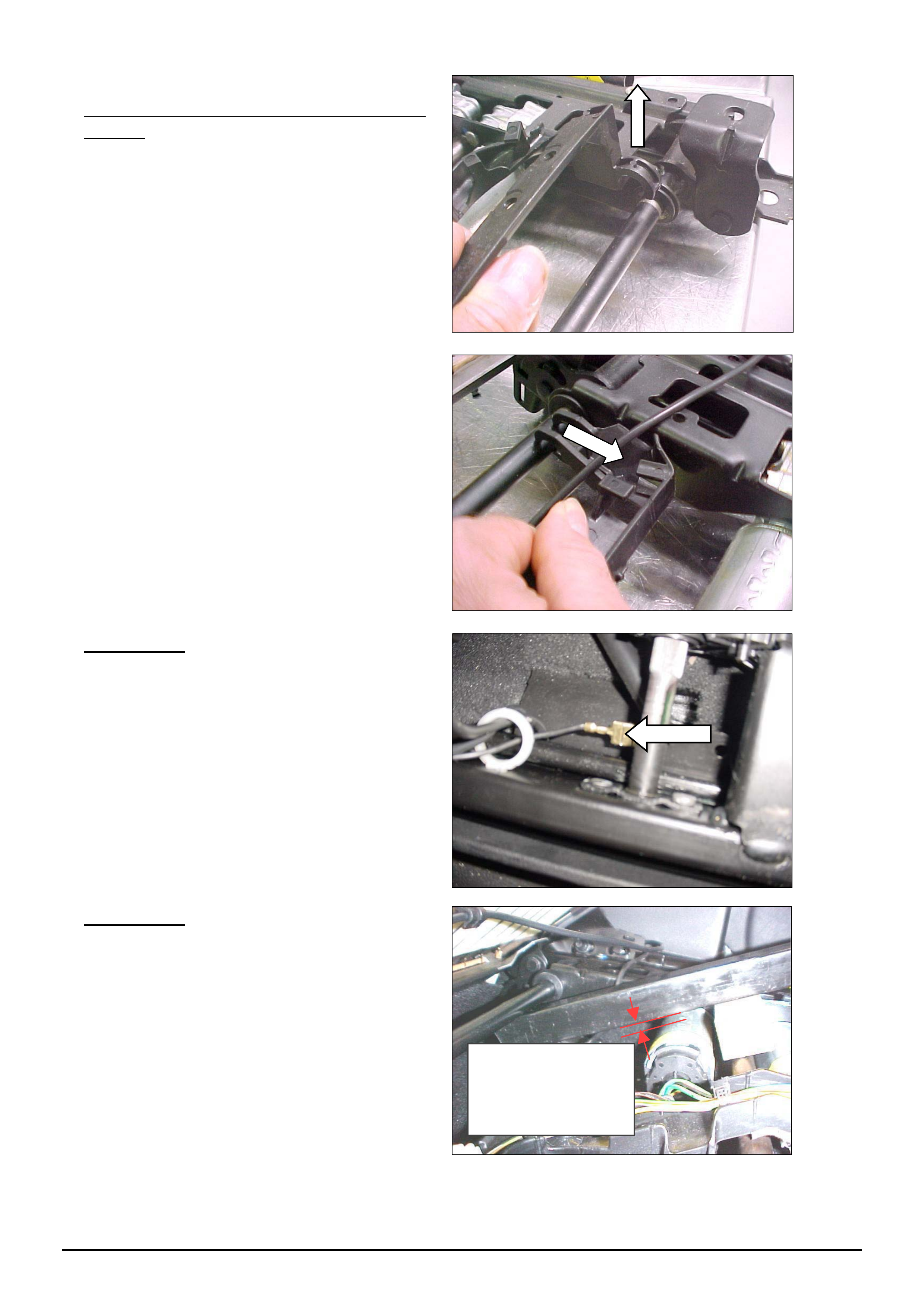

On Later vehicles with cable tray style wiring

harness:

(A). Un-clip the cable tray from the track as

shown by lifting the front clips

(B). Pull the cable tray forward to disengage

the rear clips

IMPORTANT

Ensure that the earth connection wire is

correctly connected at both ends – it should be

clipped to cushion frame and connected to the

terminal on the lower track rail.

IMPORTANT

• Obtain a length of steel tube, a tyre lever or

similar, to be used for fitting the dampener as

shown below. Hook one end of the lever under

the rear crosses shaft and place a suitable size

piece of timber in between the metal bar and

drive shaft as shown. Ensure a 5mm min. gap

is present between the metal bar and lift motor.

This will ensure that the motor is not

damaged during fitment of the dampener.

Minimum 5mm

gap between bar

and motor

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

7

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

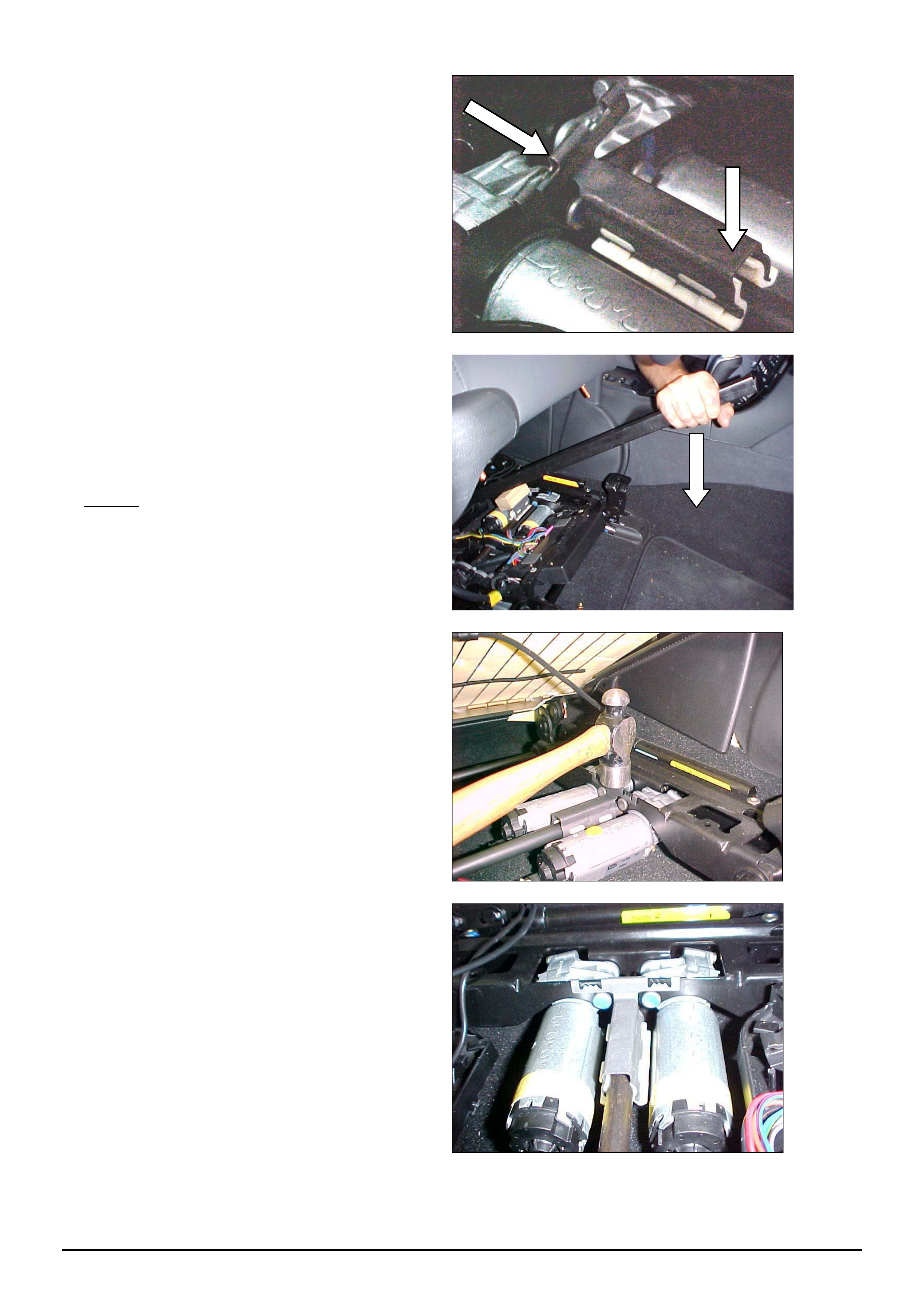

• Position the dampener by aligning the

retaining tang over the motor mount flange and

the friction pads over the drive shaft as shown.

• With the piece of wood on top of the clip to

protect the motor, push down on the lever until

the clip is pressed onto the drive shaft.

NOTE:

This photo shows the cable tray version with

cable tray disengaged and out of the way

• Tap the dampener retaining tang into place

with a hammer

This Photo shows the Dampener in final

position

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

8

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

• Refit cable tray if applicable

PROCEDURE B – Eliminate slackness in driveshaft joints.

• Move the track until the driveshaft V

grooves are in the upper position.

• Apply Loctite 680 (or equivalent) to the

groove and work into the joint under the plastic

spacer.

Be sure to place paper under the area to protect

the carpet from any drips.

• Operate the seat back and forward several times for a distance of 100mm.

After this, DO NOT operate the seat for at least 1 hour to allow the loctite to set.

NOTE The seat may be occupied during this time

• Lower seat cushion onto mounts and tighten the attaching nuts to 24-32Nm

• Reattach under seat nappy clip where applicable.

• Refit side cover.

• Repeat procedure on other front seat.

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

9

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

SERVICE FIX

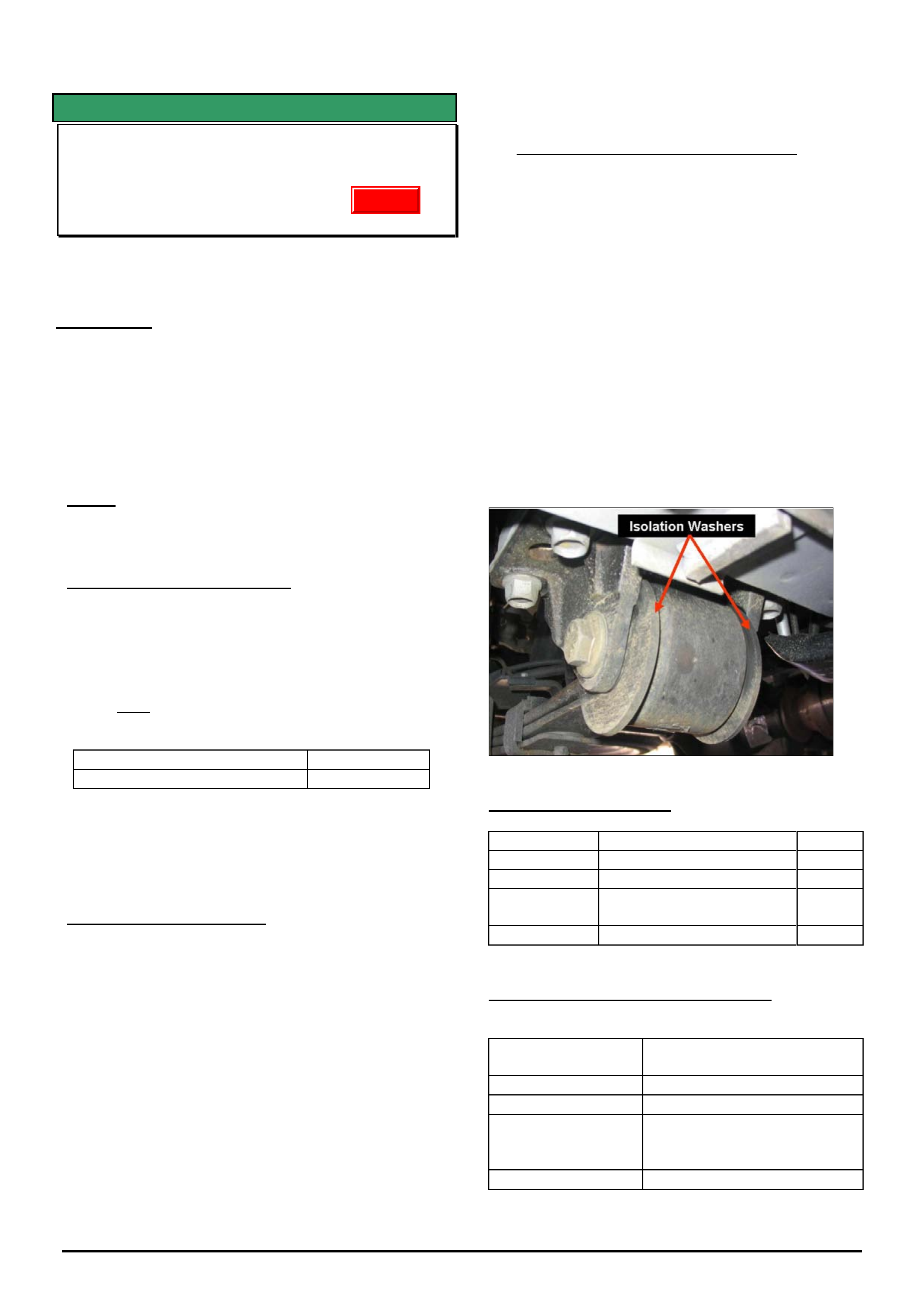

Transfer Case “Hash” Noise Reduction

VY Adventra & Cross 8

(GROUP 7B) TL0721-0502

CONDITION

It is possible for a “hash” noise (similar to a synchro

ring rattle noise) to be heard in the passenger

compartment. Reports say the condition may occur in

the range of 40 – 60 km/hr on light acceleration or

deceleration.

CAUSE

The noise heard is normal transfer case internal gear

and bearing noises which are transmitted into the

passenger compartment via the solid attachment of

the A/T shift cable to the transmission case.

CORRECTION – Service

Summary: After verifying that vehicle has symptoms

as described above, fit the new insulated shifter cable

bracket with new attaching screws.

To fit these parts, refer to Passenger SIP section 7C4

for service operation 2.2 – this procedure allows

removal of the A/T selector cable for access to the

cable bracket on the side of the transmission.

(The revised bracket is similar in appearance to the

original cable bracket – so its location and orientation

are easily defineable).

When attaching the cable bracket with the new screws

torque screws to 17±3 Nm.

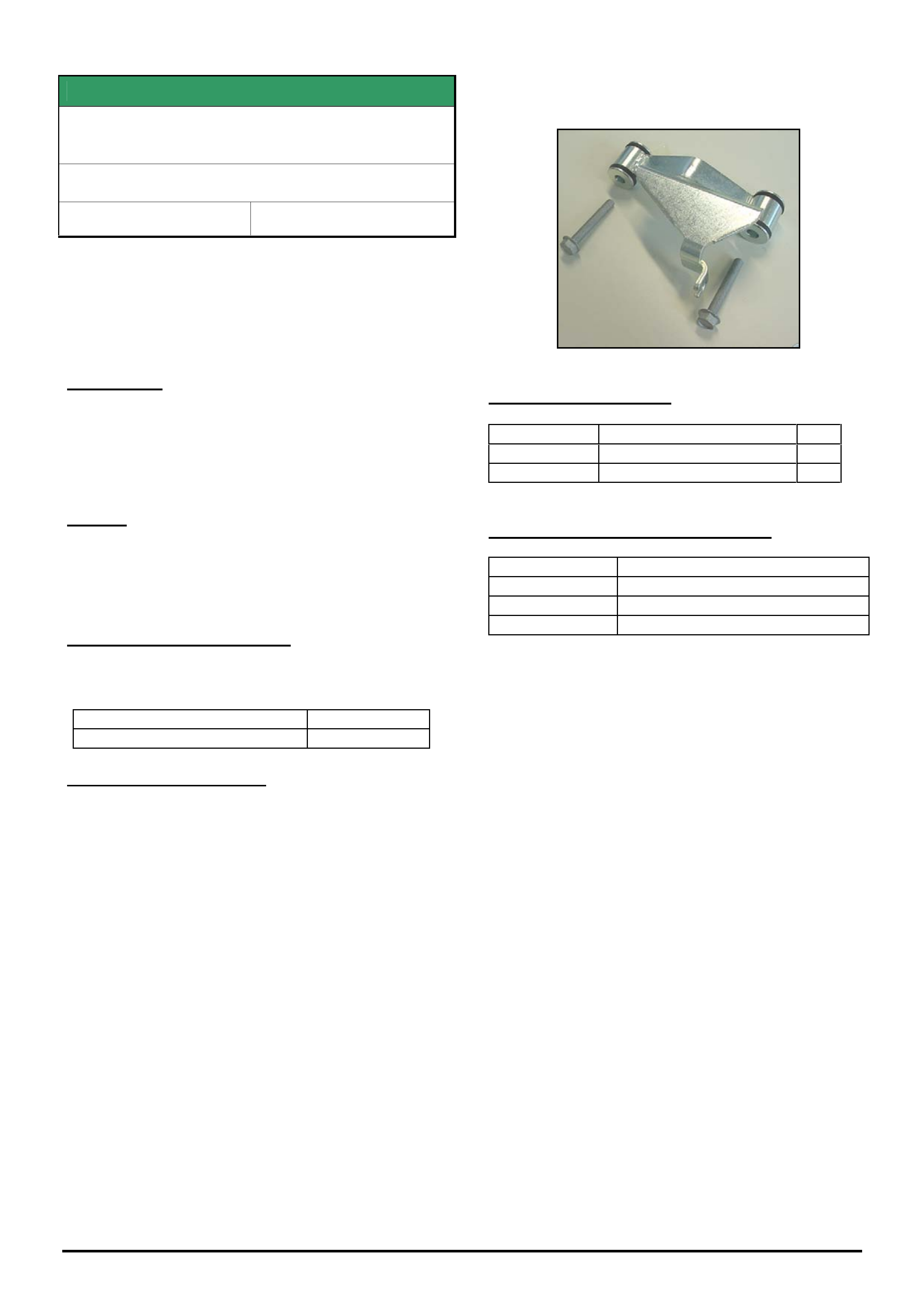

PARTS INFORMATION

Part No.: Description: Qty:

92174776 Bracket Asm., Shifter Cable 1

11098091 Screw, Bracket Mtg. 2

WARRANTY CLAIM INFORMATION

Description A/T Cable Bracket Asm. - Replace

Labour Op. No. K503100

Time 0.6 hr

Failure Code K0040 Noisy

CORRECTION – Production

The revised A/T shift cable bracket with insulating

bushes is scheduled to be fitted to vehicles in

production. Breakpoint details will be published in a

future techline.

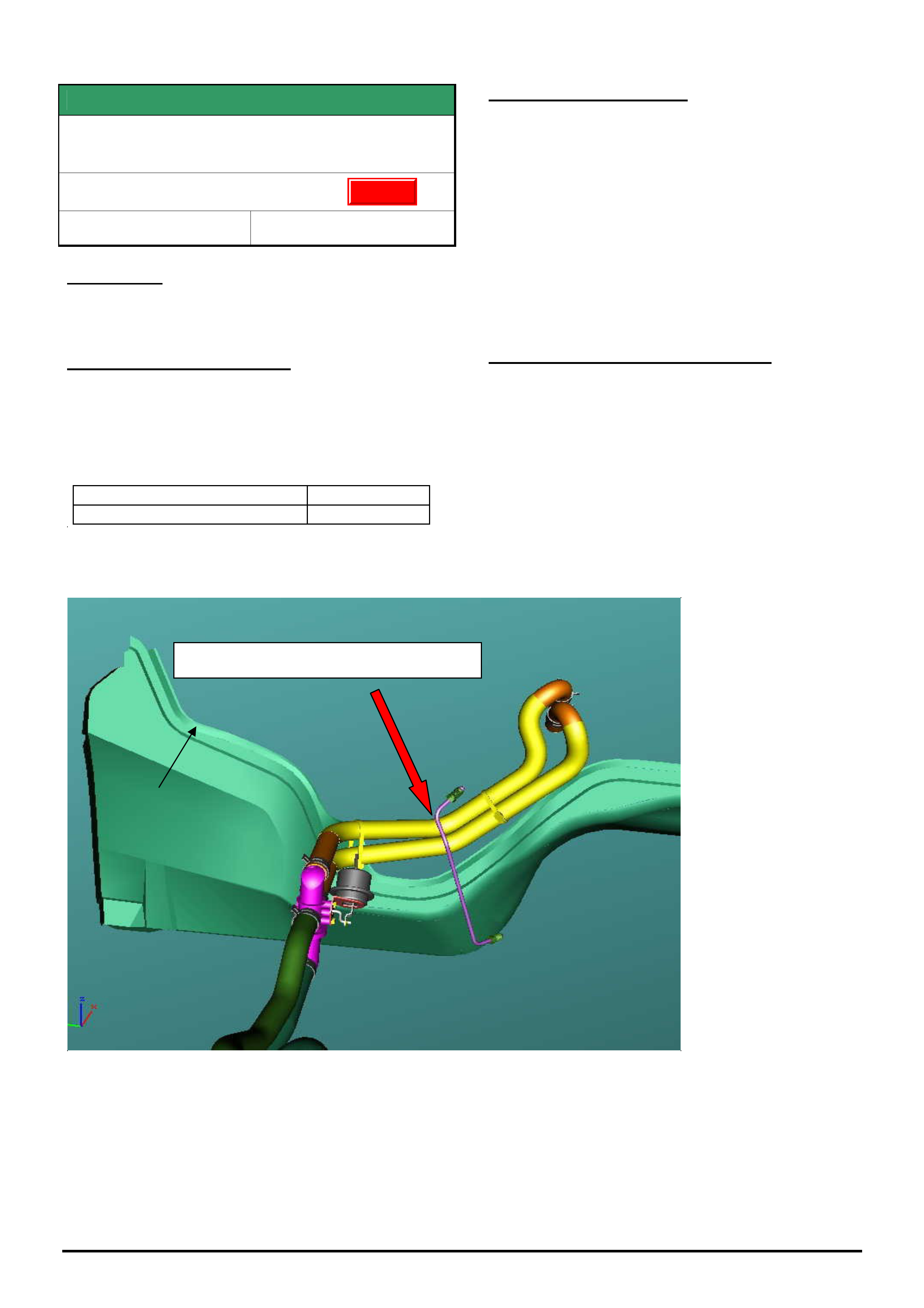

SERVICE PROCEDURE

Inlet Manifold Removal Procedure

HFV6 Engine - VZ & WL

Group 6A Ref. No. TL0868- 0502

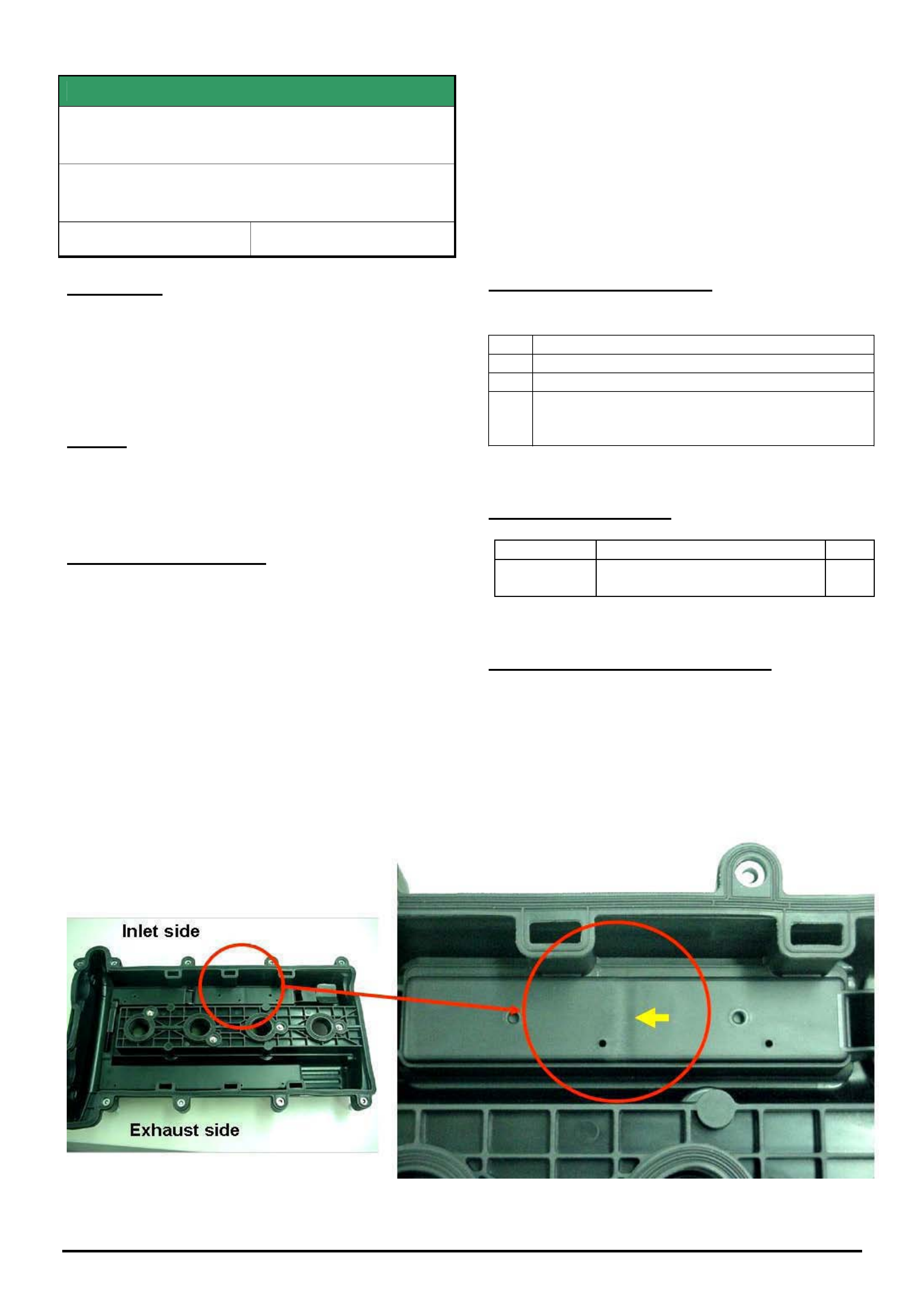

The current Passenger SIP CD advises to “split” the

inlet manifold upper and lower parts when servicing

Cylinder head/s, Fuel injector, Ignition coils and Spark

plug servicing.

It is NOT necessary to “split” the inlet

manifold for servicing of these parts!

The inlet manifold can be removed as a complete

assembly – this removes the need for the intermediate

gasket to be replaced.

In addition – the gasket between the inlet manifold

assembly and the cylinder heads is a reuseable

design which does NOT have to be replaced unless it

is damaged!

Passenger SIP CD is currently being updated to show

these revised procedures which simplify the servicing

of the manifold and related components, and negate

the need to replace any gaskets (unless damaged).

A copy of the revised procedure for Inlet Manifold

Assembly Complete (Remove & Reinstall) is available on

the Holden LIONHEART dealer website. (refer Service

Techlines, 2005, Group 6A) Please refer to this revised

procedure until the Passenger SIP CD is updated.

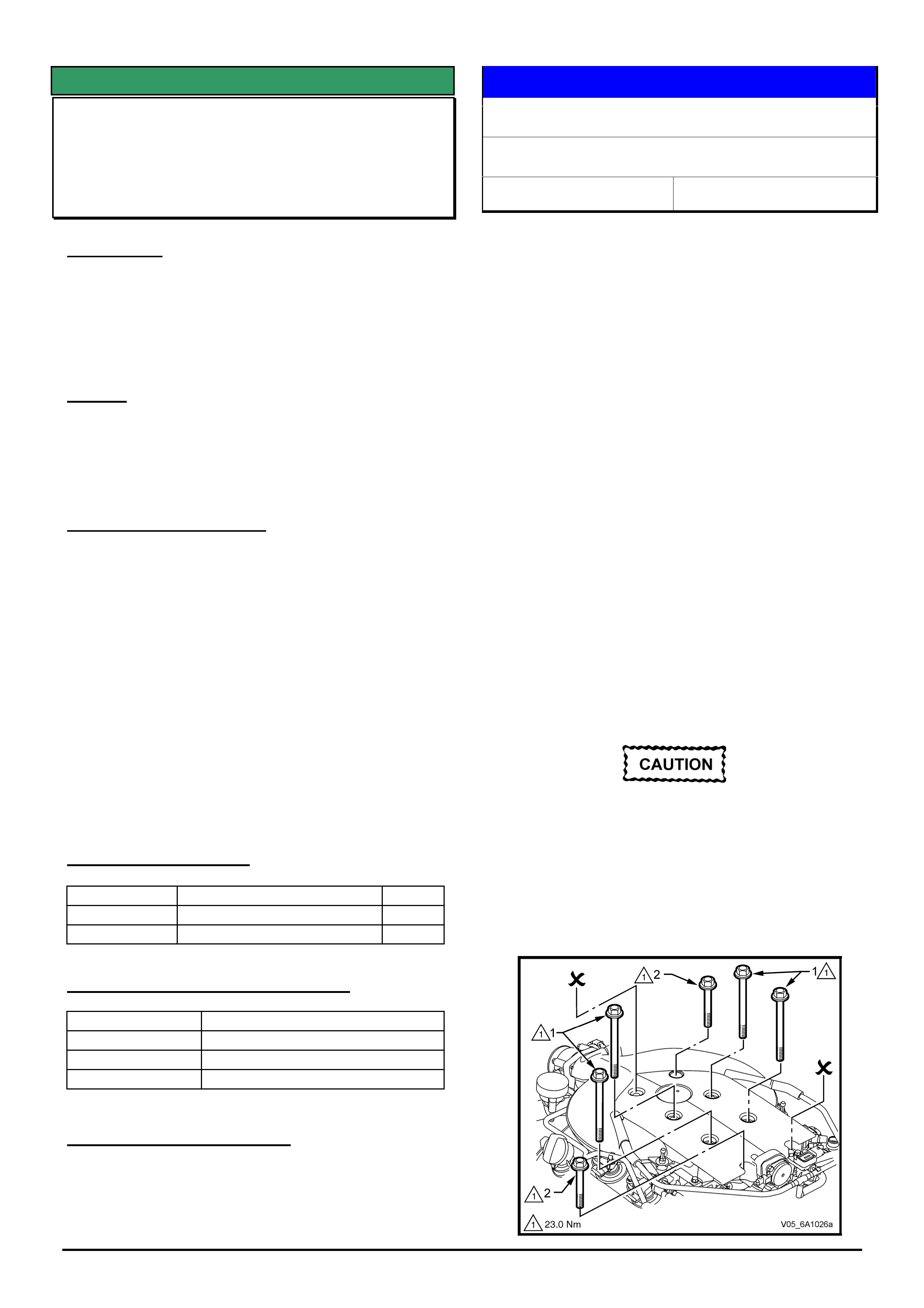

Your attention is also drawn to Figure 6A1–10 in the

revised procedure regarding the manifold mounting bolts:

Do not loosen or remove the short bolts (8)

(70 mm) holding the upper intake manifold to

the lower. These bolts are at the front left and

rear right of the upper intake manifold.

Removal of these bolts (that hold the upper and lower

manifolds together) may result in intermediate gasket

damage and subsequent engine performance concerns.

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

10

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

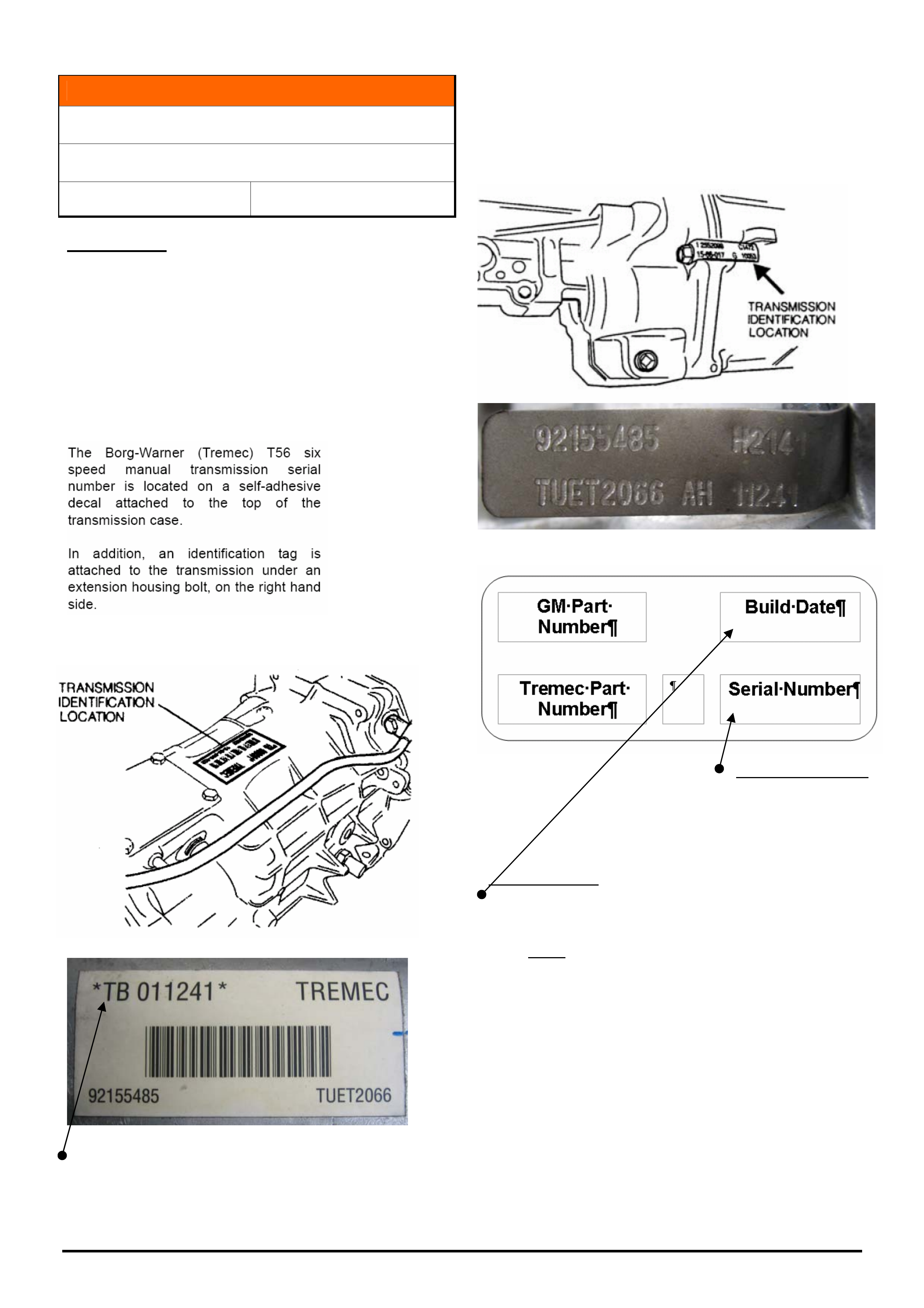

INFORMATION

M/T Fault Diagnosis

6-Speed M/T (Gen III vehicles)

Group 7A Ref. No. TL0872- 0502

Technicians should be aware of additional 6-speed

M/T diagnosis information that has been made

available in All Dealer Letter DL 06/2005.

The information allows technicians to carry out

diagnosis on specific transmission complaints, and

complaints with related components that may be

confused as transmission faults.

Please refer to this letter for diagnosis information until

the information is released in the next Passenger SIP

CD.

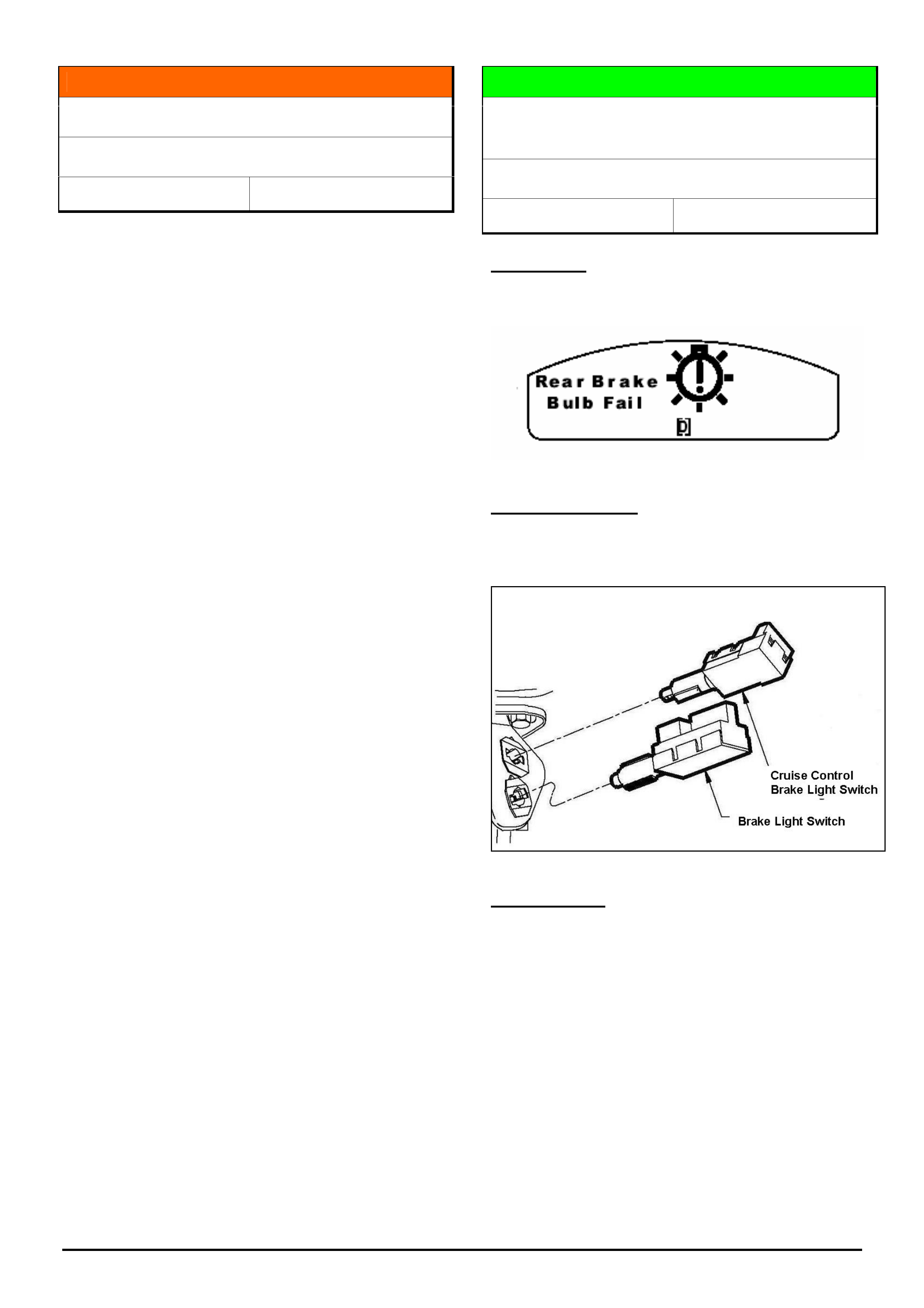

DIAGNOSIS HINT

“Rear Brake Bulb Fail” Warning Indication

Displays In Instrument Cluster

VZ, WL

Group 12 Ref. No. TL0870 - 0502

CONDITION

Rear Brake Bulb Fail warning indication displayed in

instrument cluster even though bulbs are working

POTENTIAL CAUSE

Incorrect adjustment of the cruise control brake switch

against the brake pedal.

CORRECTION

The correct switch adjustment is achieved by the

following procedure;

1. Twist the cruise control switch anticlockwise a

quarter of a turn to release the latch.

2. Push the switch until the barrel rests against the

brake pedal while the pedal is in its rest position.

3. Twist the switch clockwise to lock the barrel in

place (clearance from the barrel to the pedal

should be 0.7+ / - 0.5mm).

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

11

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

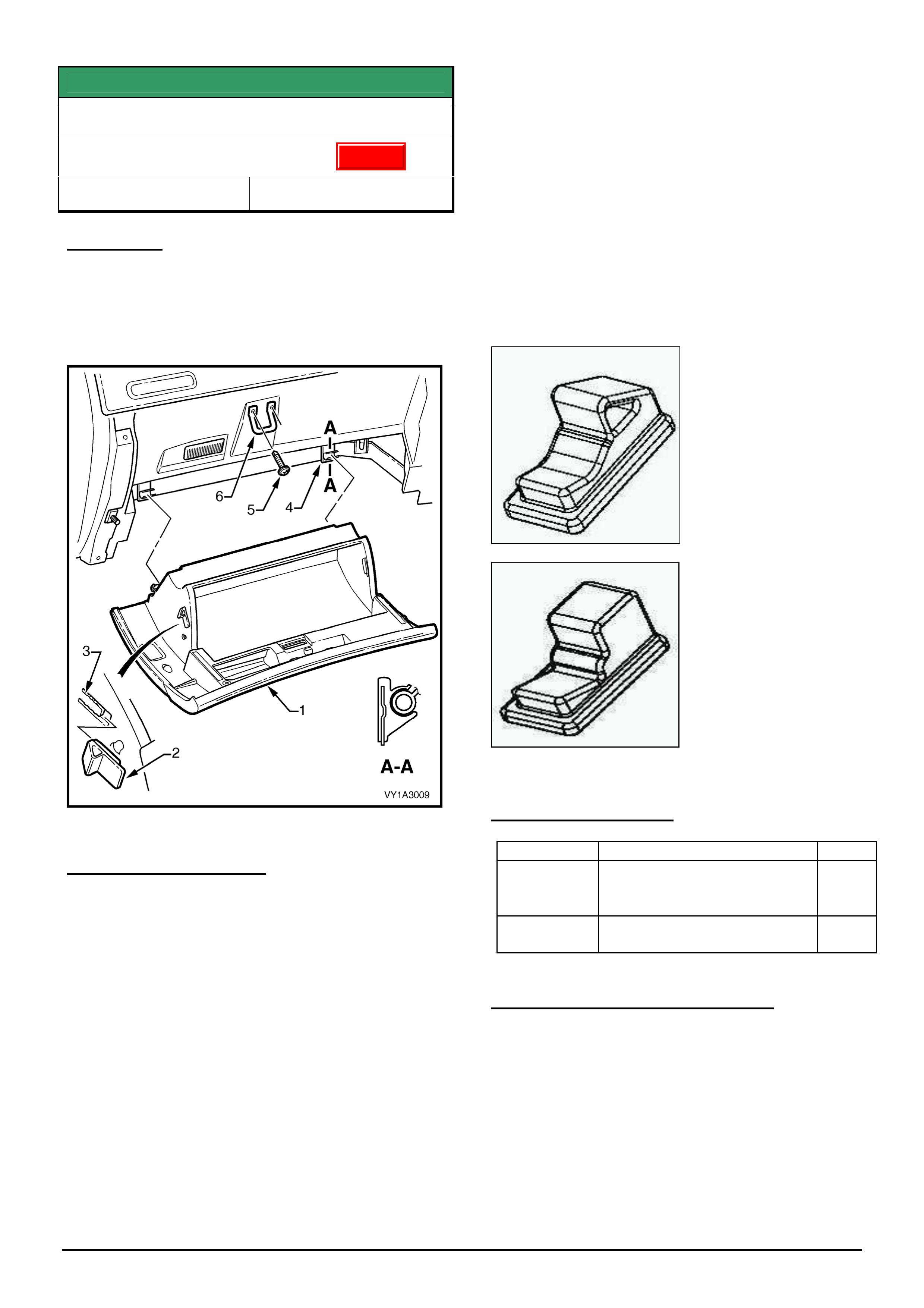

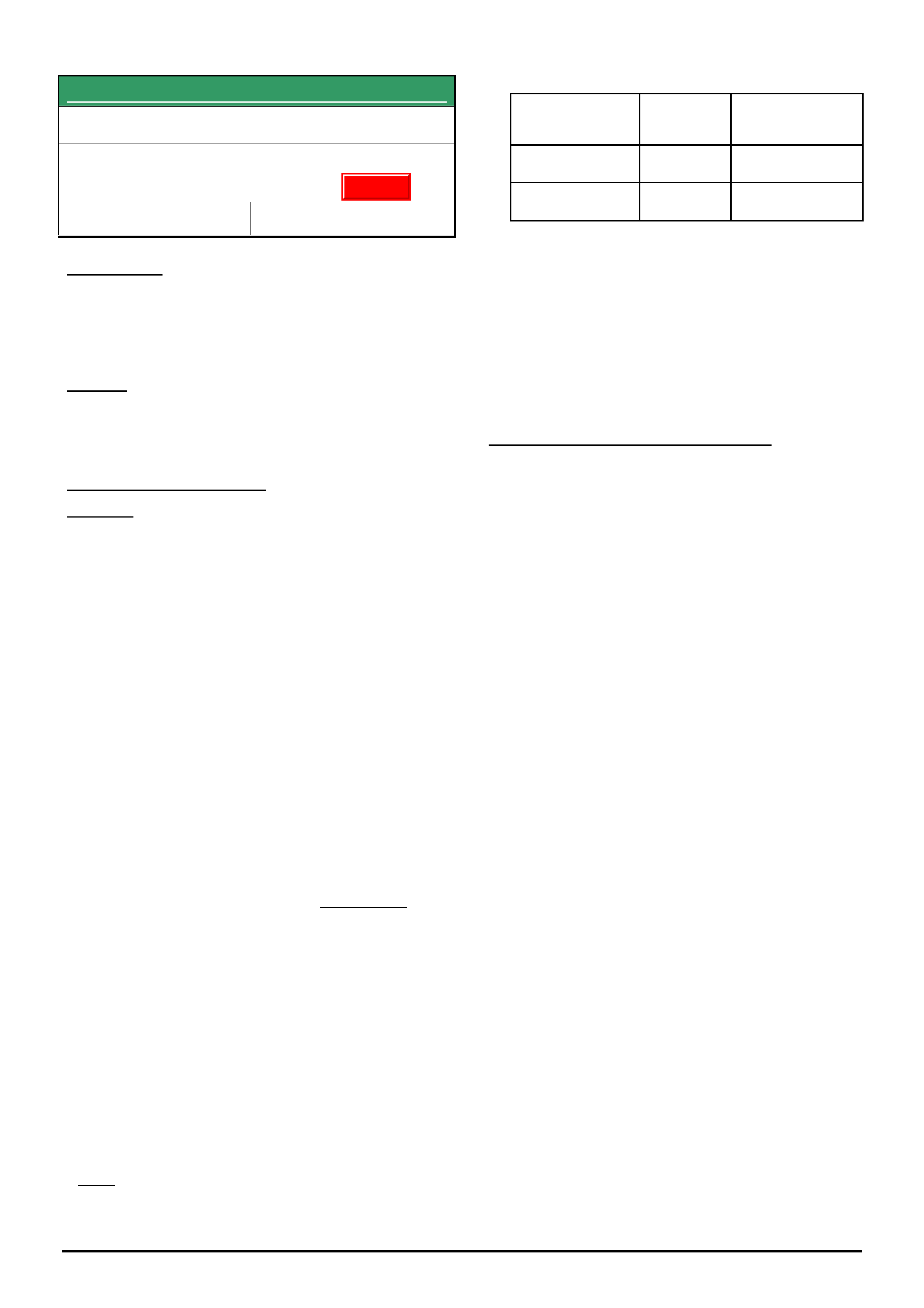

SERVICE FIX

Glove Compartment Door Opens Too Far

VY, VZ, V2 II & III, WK, WL

Group 1 Ref. No. TL0854- 0502

CONDITION

Glovebox door rubber bump stops may tear in

service. As a consequence, the glovebox

compartment swings fully downward when opened

and is not restrained by the stops.

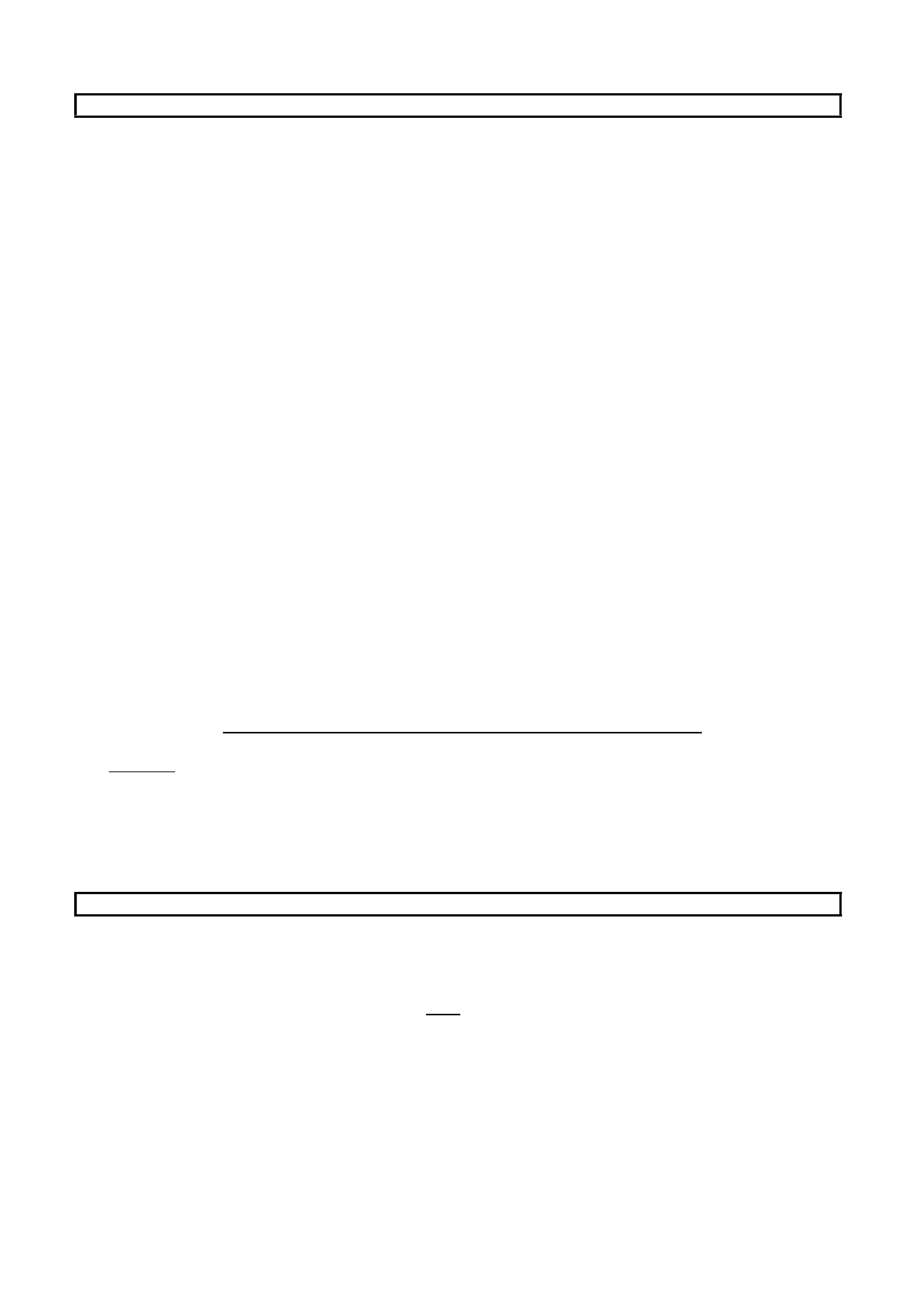

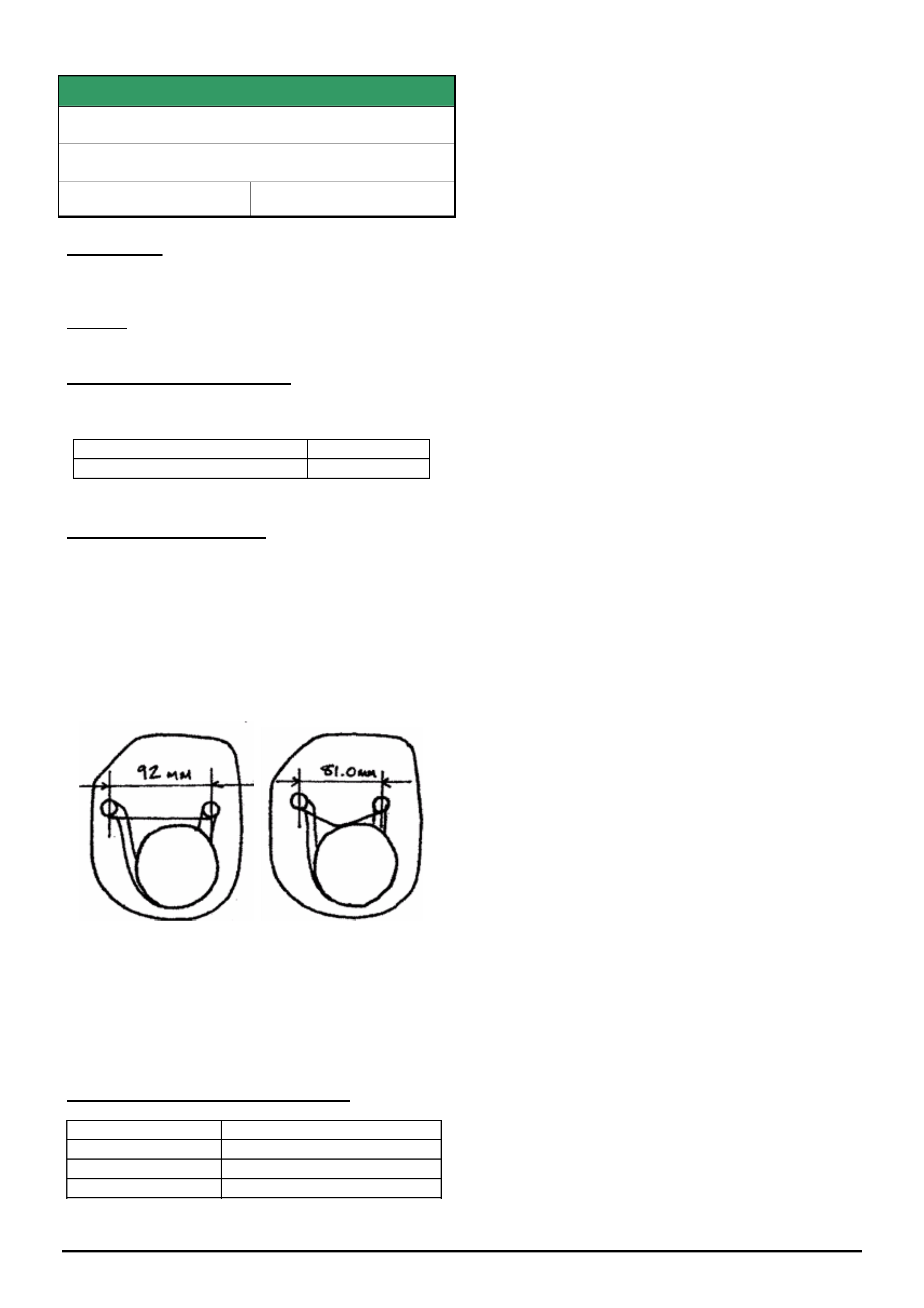

The bump stop is shown as key 2 in figure 1 below.

Figure 1.

CORRECTION – Service

1. Inspect the bump stops on both sides of the glove

compartment, to confirm whether one or both stops

are torn.

2. Remove the glove compartment following the

procedure outlined in Holden SIP Section 1A3 para

3.2, taking note to exercise particular care to avoid

damaging the glove compartment while removing

hinge pins.

3. Remove torn bump stop/s.

4. Fit new bump stops as follows:

- Fit standard bump stop (92096917) to one side of

glove compartment, and solid type bump stop

(92166561) to the other side. Figures 2 and 3

show the difference in construction of the standard

and solid bump stops

NOTE. Do not attempt to fit two of the solid type

bump stops, as the force required to fit the glove

compartment will result in damage to the glove

compartment.

5. Reinstall glovebox as follows:

- Engage lower hinge points, then rotate glove box

up into closed position whilst pushing sideways to

compress the flexible bump stop. This action is

required to provide clearance for the solid bump

stop as it wipes past the Instrument Panel structure.

NOTE: Failure to push glove box sideways as

described, may result in damage to the glovebox.

Figure 2.

Standard flexible bump

stop p/n 92096917

Figure 3.

Solid bump stop p/n

92166561

PARTS INFORMATION

Part No.: Partfinder Name Qty:

92096917 Bumper instrument panel

compartment door

(Standard)

1

92166561 Bumper instrument panel

compartment door (Solid)

1

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty Information

section of current PV SIP CD

Update

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

12

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

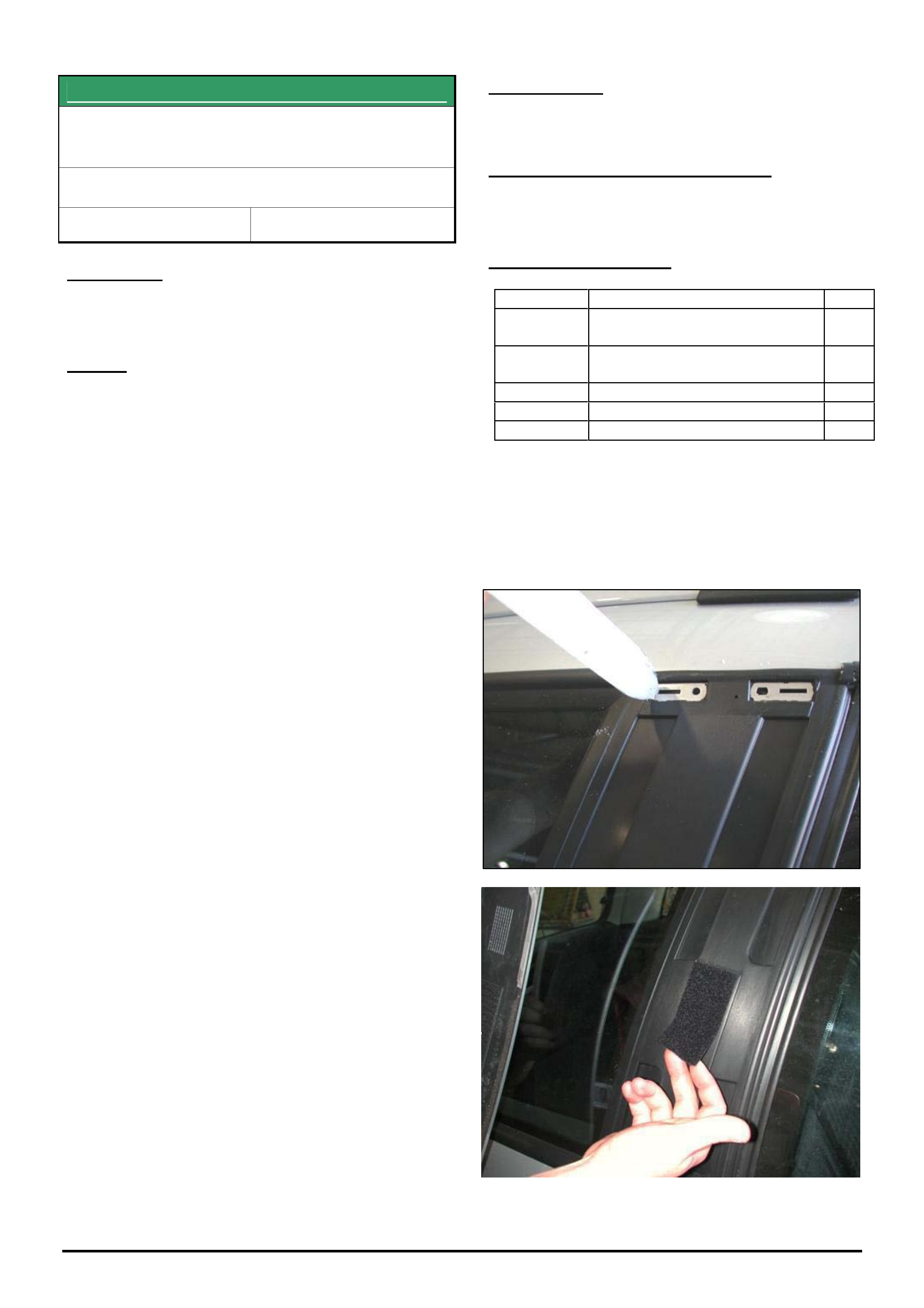

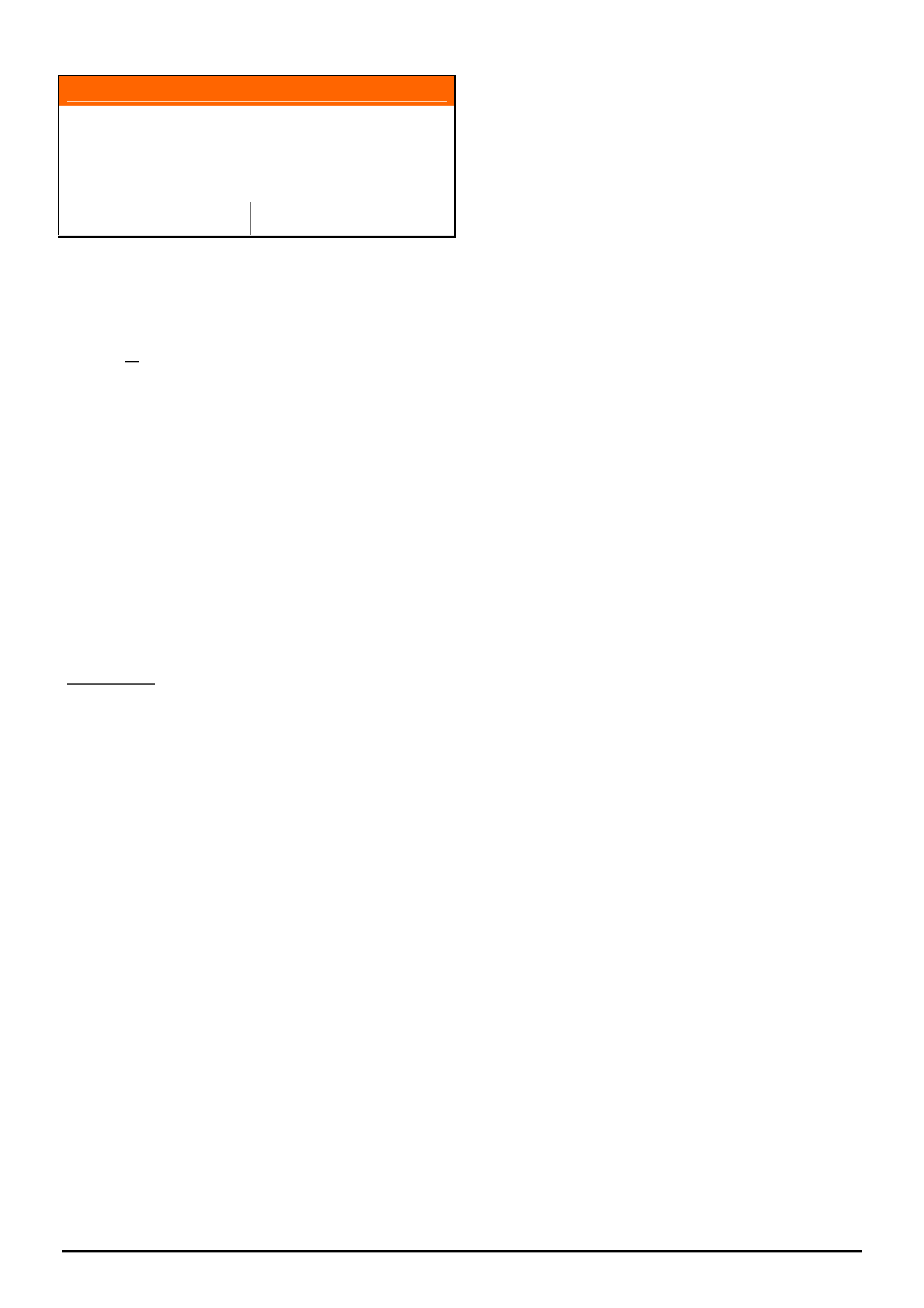

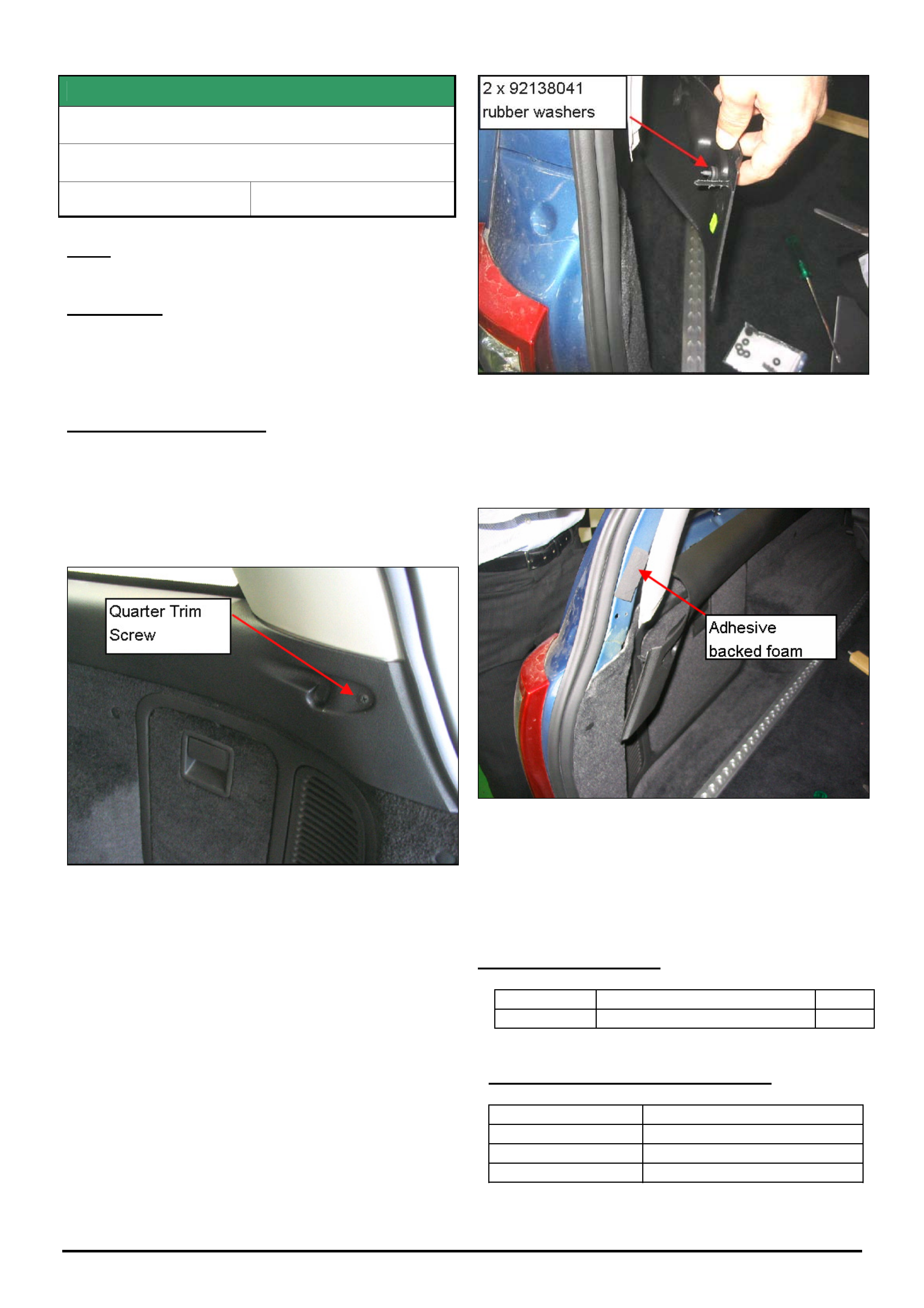

SERVICE FIX

Water Enters Cabin Over Top Of Doors

VY, V2, WK

Group 1 Ref. No. TL0770 - 0502

CONDITION

During heavy rain, water may enter the cabin over the

top of door(s).

CAUSE

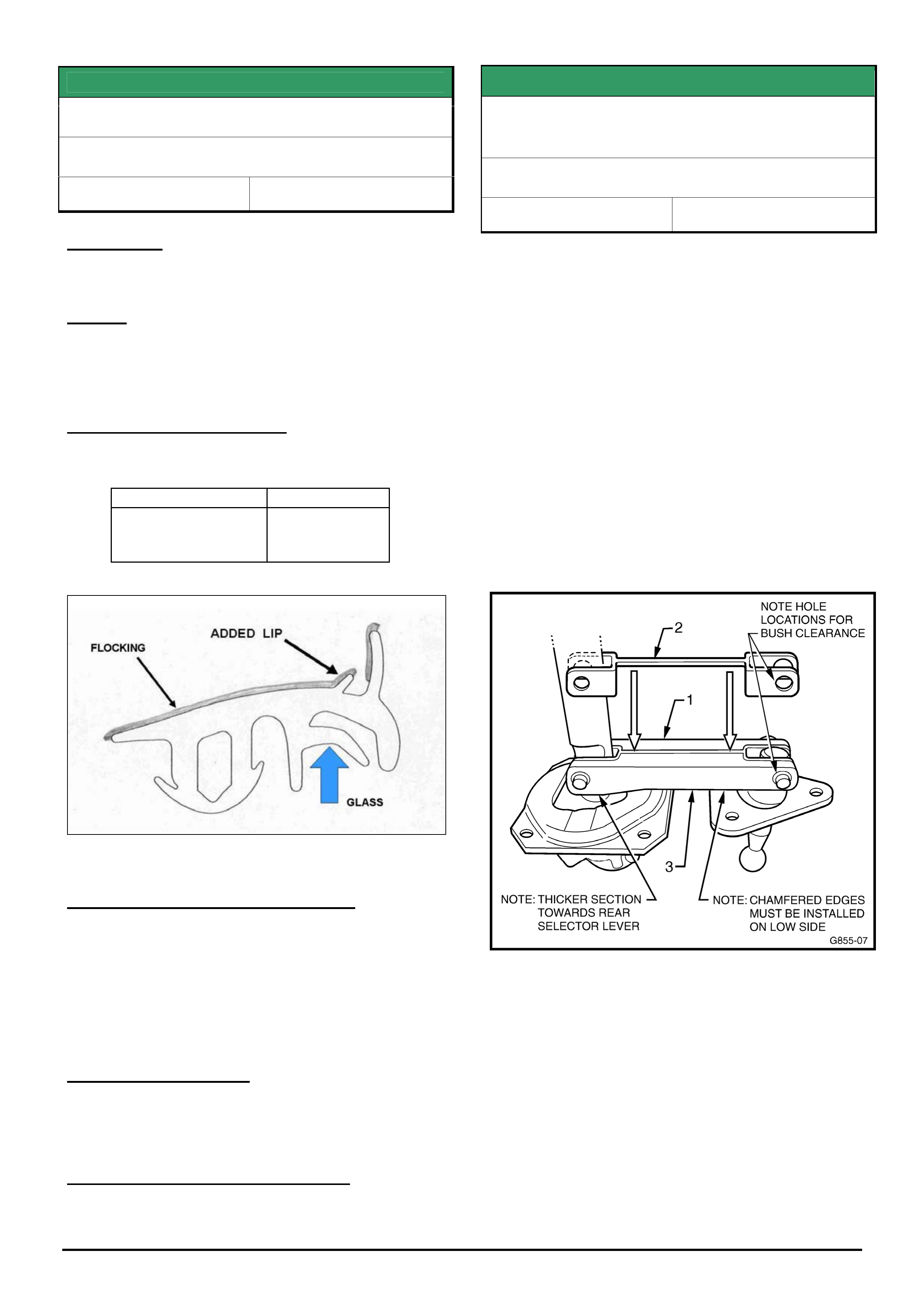

One possible cause for this condition is if the flocking

on the upper part of the door seal becomes saturated,

water may wick its way across the face of the seal and

into the cabin

CORRECTION - Production

Revised weatherstrips with a lip added as shown in

figure 1 have been fitted to vehicles from:

ISOVIN: Built Date:

WK - L283009

VY - L281359

V2 - L280361

21/05/2004

18/05/2004

18/05/2004

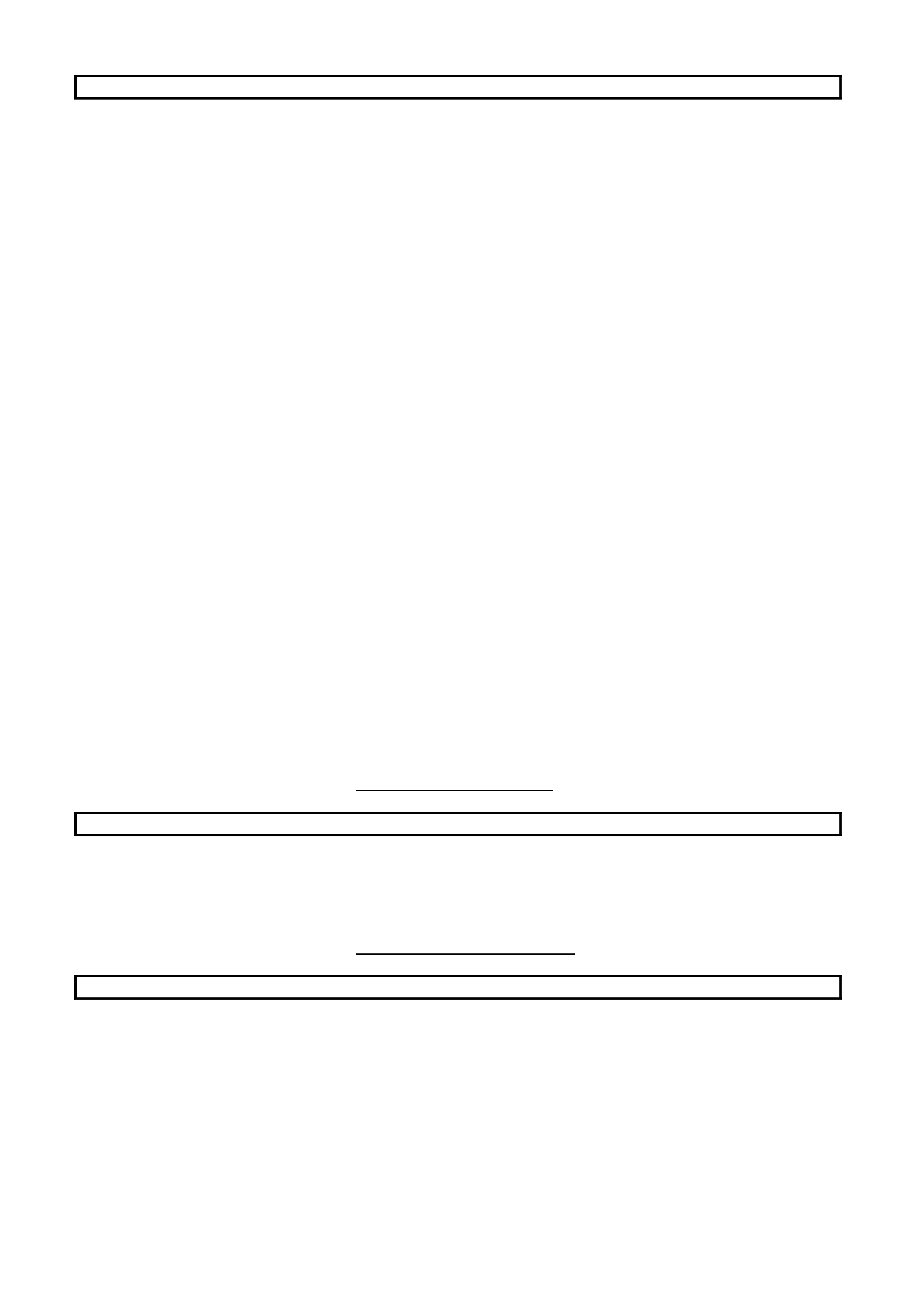

Figure 1. Shows cross section through door seal

CORRECTION – Vehicles in Service

On vehicles with the above condition, the first step in

rectification is to ensure that the door window frame is

correctly located within the body opening. If after this

first step the water leak is still present, check if the

latest design window seals are fitted. If not, then order

new seals from HSPO and install as per procedure

shown in Passenger SIP CD.

PARTS INFORMATION

Refer Partfinder for door weatherstrip assembly part

numbers. All HSPO stocks of weatherstrips are to the

revised design.

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty Information

section of current PV SIP CD

SERVICE FIX CAUTION

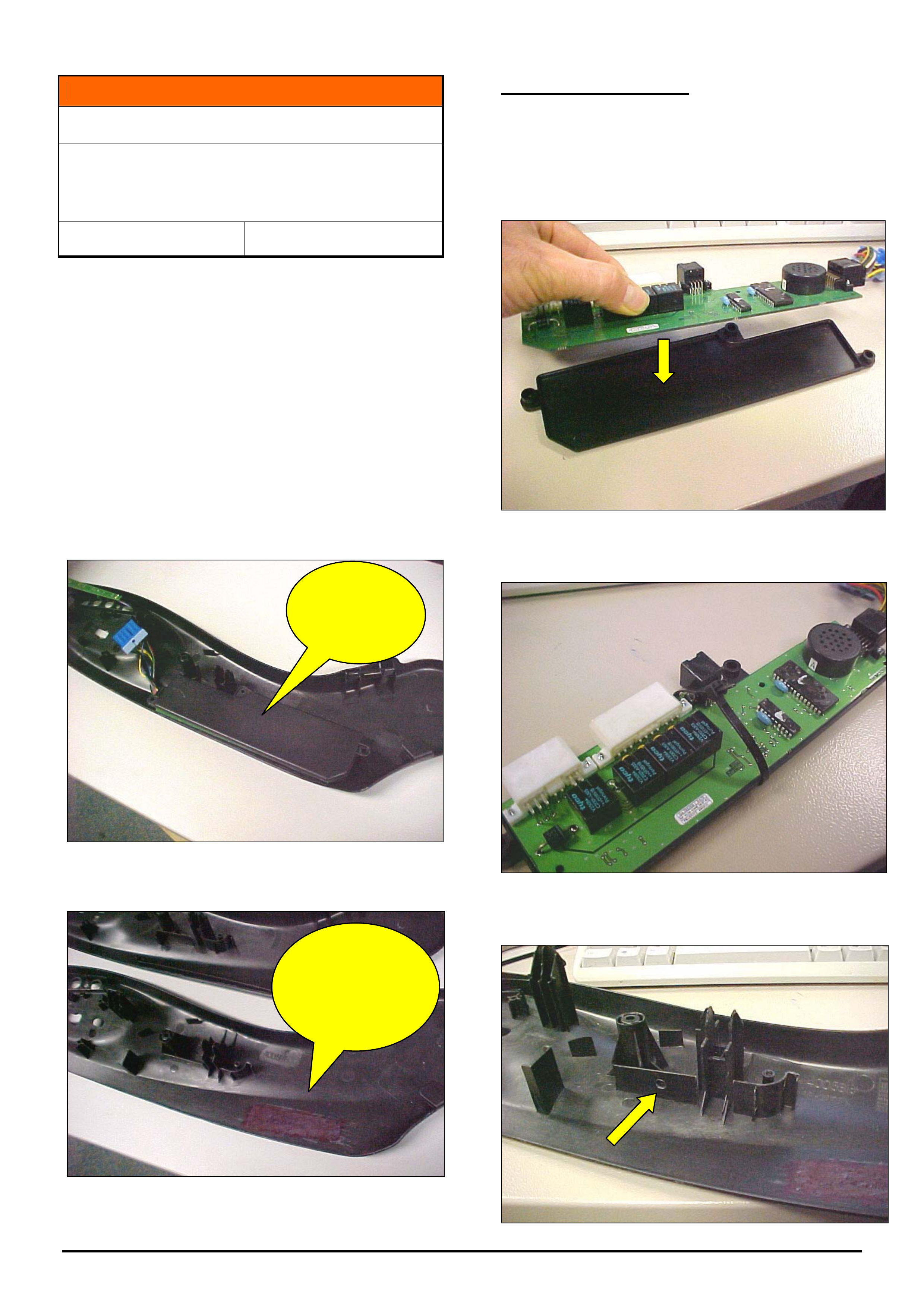

Hard To Select Gears After Rebuilding

Shifter Assembly

VTII, VX, VU, VY, V2, with Gen III & M/T

Group 7A Ref. No. TL0879-0502

Techline No. TL608A-0401 published in Feb. 2004

provided a procedure for rebuilding the gear shift

assembly to eliminate Shifter Linkage Rattle.

Since publishing this techline, the following issue has

been highlighted by the supplier of six speed Manual

Transmissions.

The supplier advises that on some transmissions

returned for gear selection complaints, the root cause

was the shifter assembly had been rebuilt incorrectly

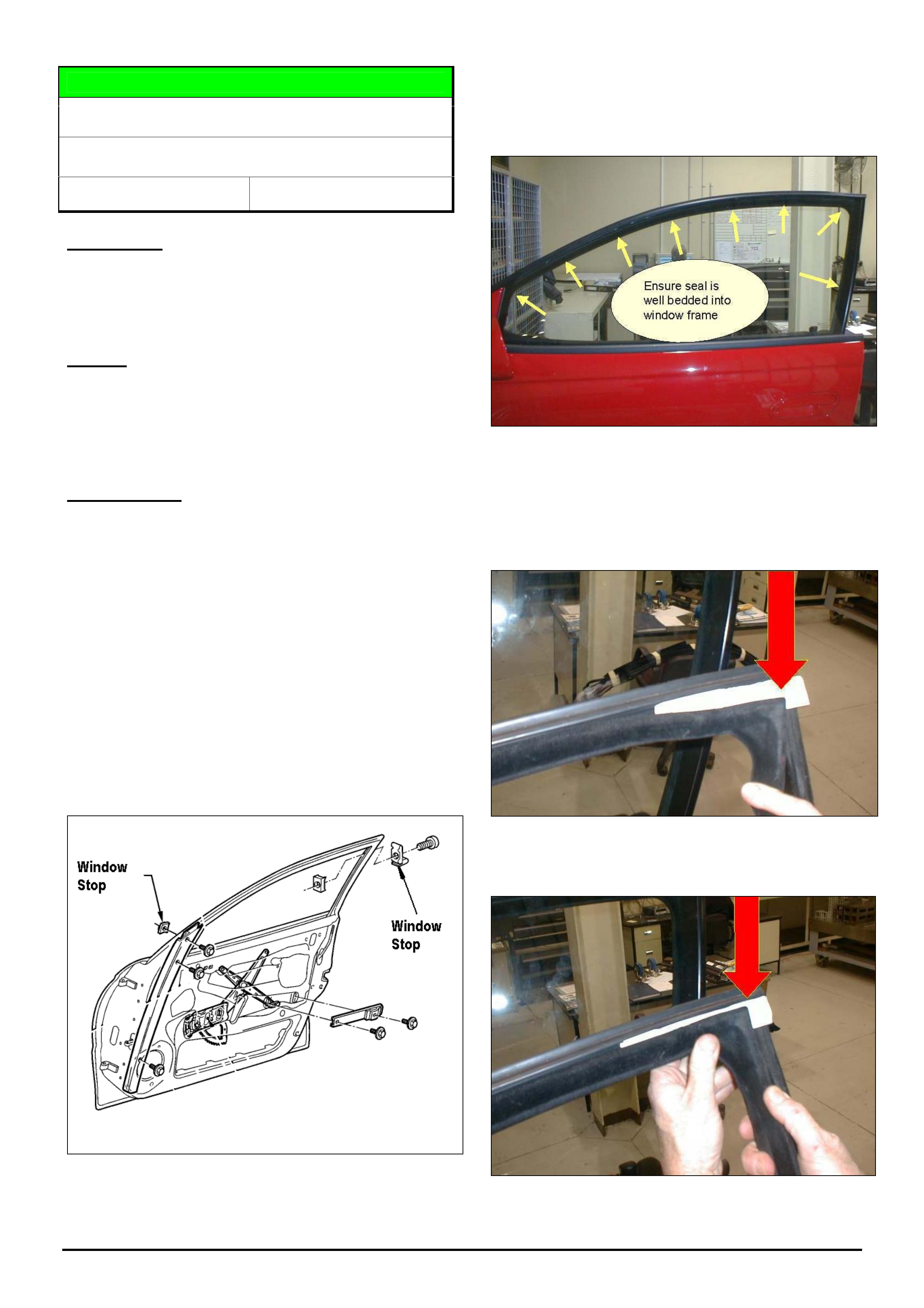

by the dealer. The bridging piece (#1 in figure below)

was installed upside down and fouled on the shifter

base.

IMPORTANT: Whenever rebuilding the shifter

assembly, ensure the bridging piece/link is installed

the correct way up as shown in figure below.

NOTE: Returned transmissions that are found to have

the above condition due to incorrect repair procedure

may not be accepted for warranty.

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

13

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

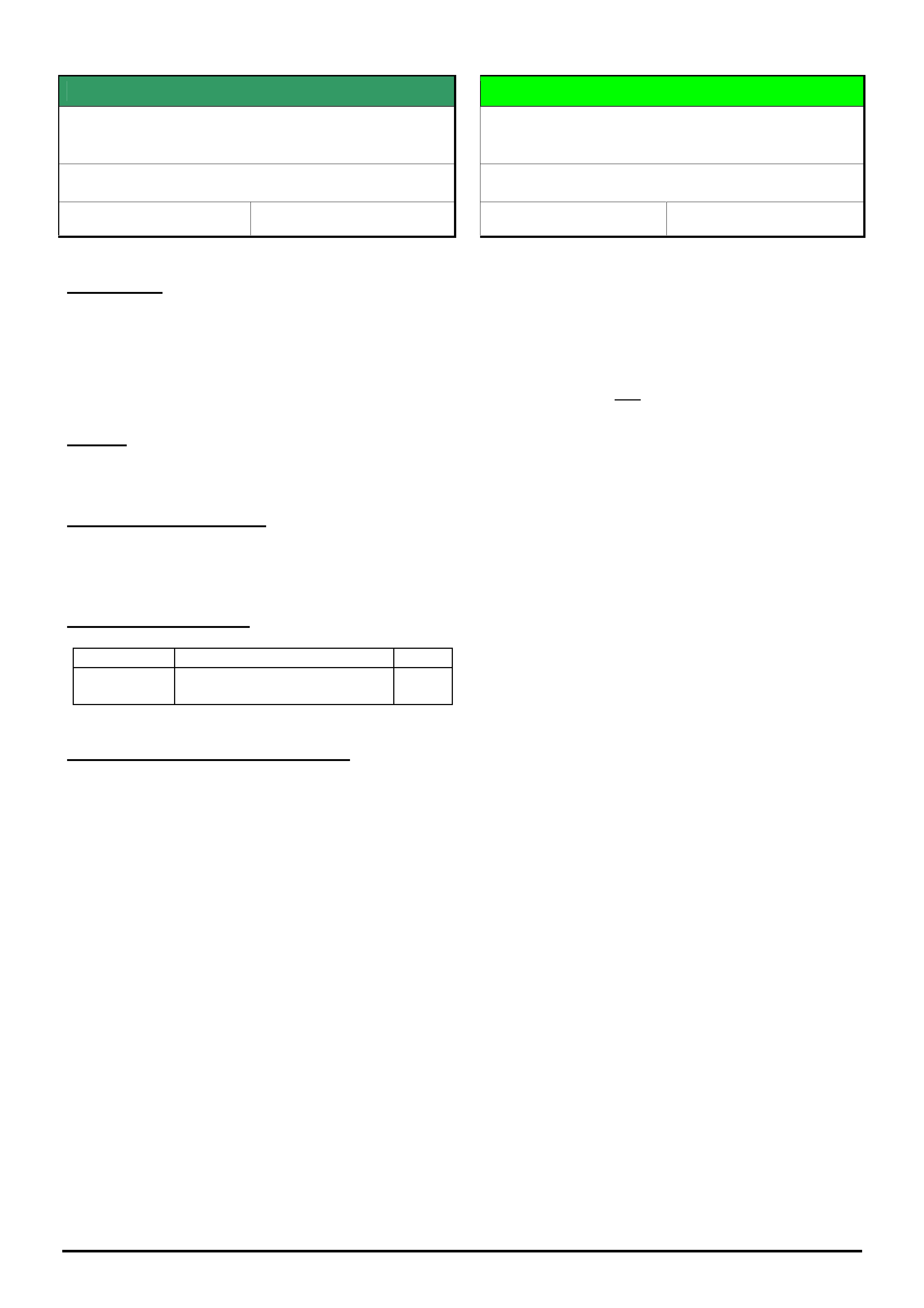

SERVICE HINT

Front Windows Will Not Close Fully

VYII, V2, WK, VZ

Group 1 Ref. No. TL0745- 0502

CONDITION

On some vehicles the Front Door Windows may not

close fully which could result in windnoise and/or water

leaks.

CAUSE

Two areas which may contribute to this condition are:

1. Window glass stops set too low

2. Window seals incorrectly installed.

CORRECTION

Reset window stops and check window seal

installation as per following procedures.

1. Window glass stops set too low.

a) Loosen window stops at front and rear of window.

Refer Figure 1.

b) Operate window into fully up position. If window

will not close completely, manually push window

up into position.

c) Tighten stops.

d) If possible, allow window to remain in closed

position for 48 hours to set seals

Figure 1. Front door window stops

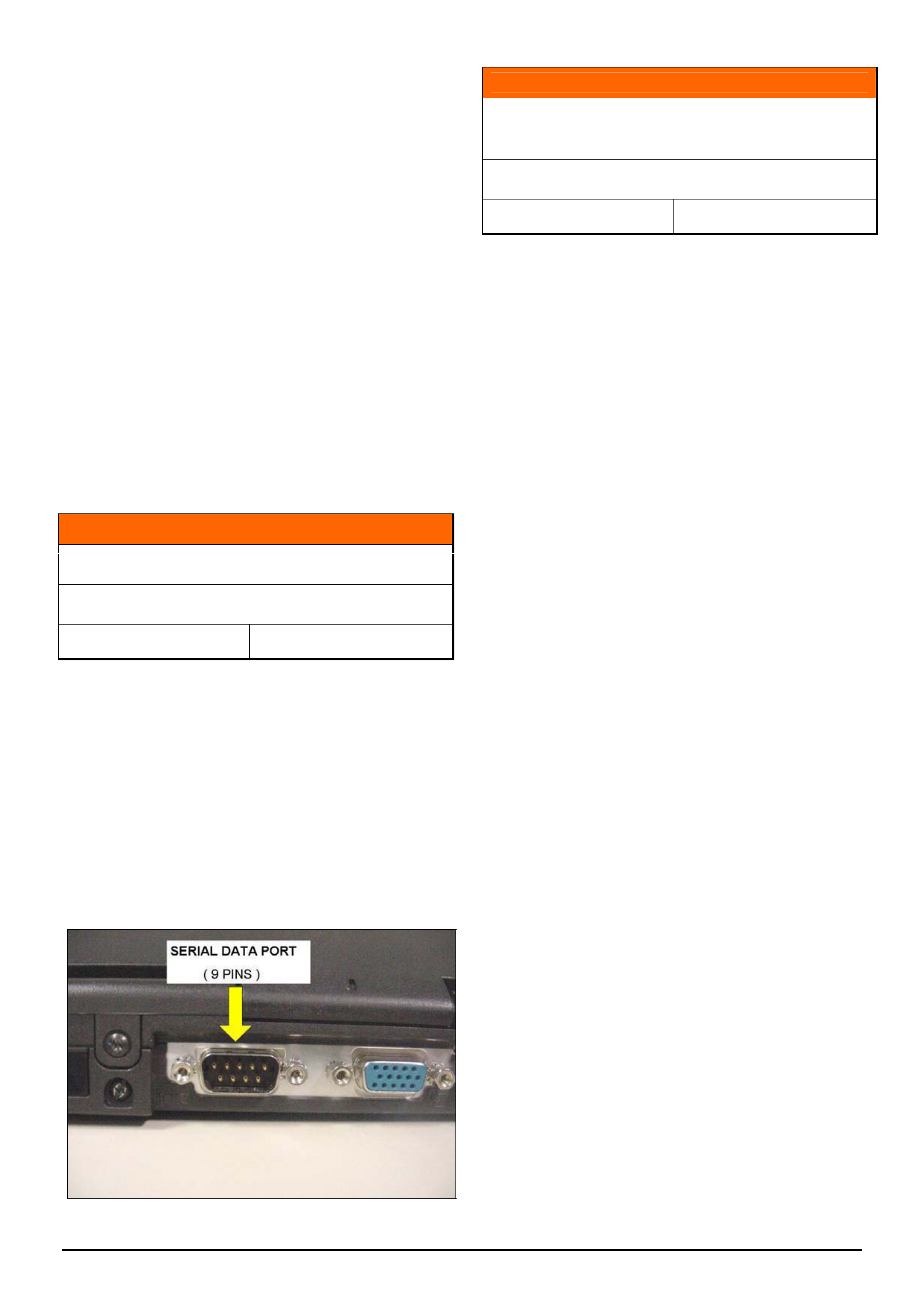

2. Window seals incorrectly installed.

a) Ensure that seals are correctly installed into the

window frames.

Figure 2.

b) Ensure that the Weather Strip Assembly rear

upper corner moulding is installed correctly. Refer

Figures 3 and 4. NOTE: the thick section of the

rear corner moulding must be located over the

corresponding depression in the doorframe.

Figure 3. Shows typical incorrect installation where

corner moulding is not fully seated into the corner of door

frame. (Paper added for clarity)

Figure 4. Corner moulding installed correctly.

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

14

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

c) Inspect window seals to ensure that they are not

damaged or twisted out of shape. If seals are

damaged or badly twisted they should be

replaced.

e) If replacing the Weather Strip Assembly – “Front

Side Door Window Upper”, drive the window up

into the Moulding and ensure that there is between

2mm and 4mm coverage of the window by the

moulding. Cycle the window up and down a

number of times to ensure that the seals are well

bedded into the door frame.

f) If possible, allow window to remain in closed

position for 48 hours to set seals

INFORMATION

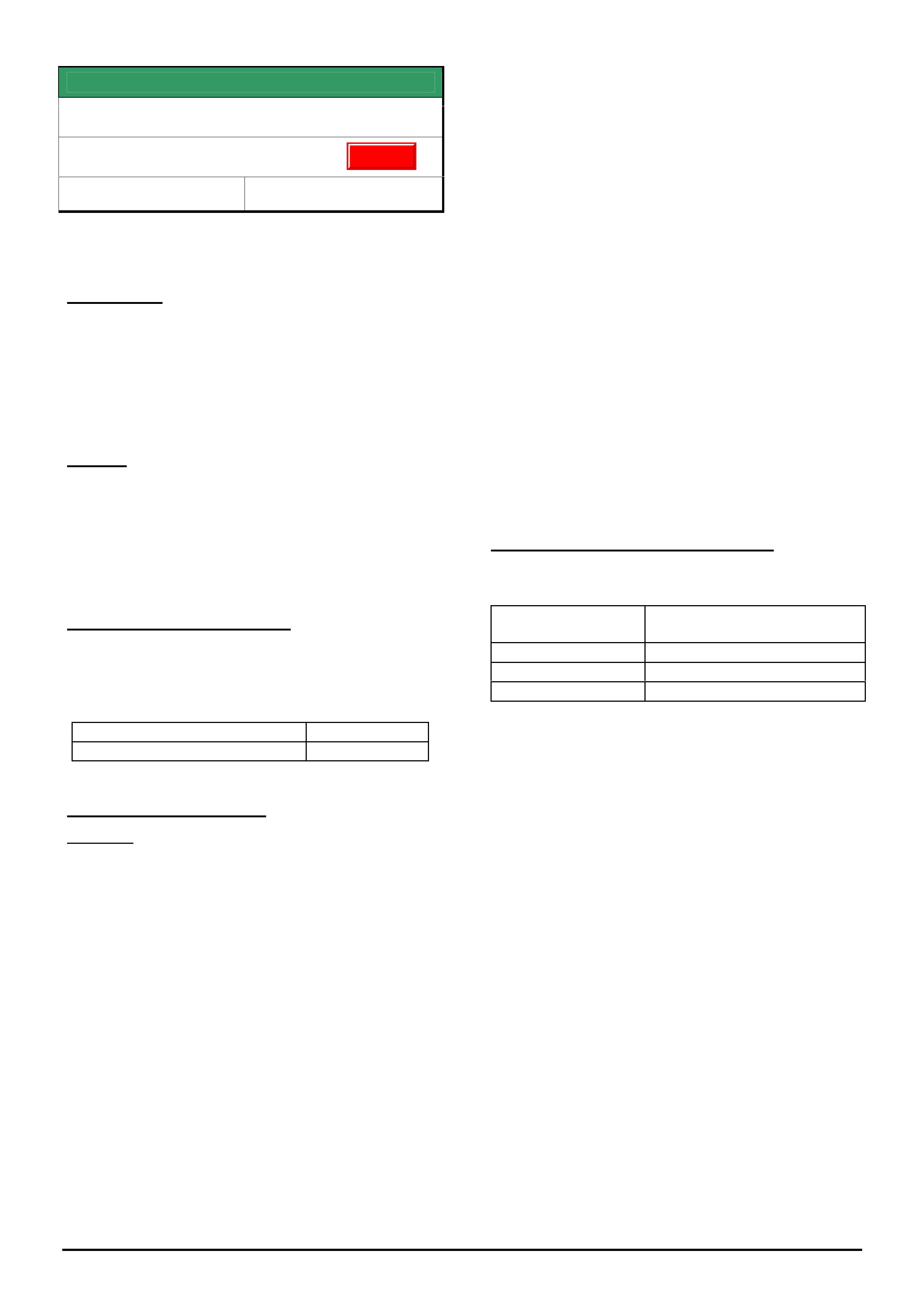

PC Serial Data Ports

All

Group OB Ref. No. TL0864 - 0502

Dealers planning to purchase a new pc or lap top,

must ensure that it has a serial data port. This is the

port which the RS 232 cable used for updating Tech 2

plugs into.

Some Dealers have purchased computers without

serial data ports on the assumption they could use a

serial data to USB adaptor, only to find that they do not

work!

Tech 2 can only be updated via the RS232 cable from

a serial data port, not a USB port.

INFORMATION

Release of Dexron III (“H” Revision)

Automatic Transmission Fluid (ATF)

All models with A/T

Group 7B Ref. No. TL0860- 0502

General Motors DEXRON III ATF specification has

been upgraded to DEXRON III (H-Revision).

Commercially available fluids labelled as “DEXRON III,

Approved for the H Specification”, can be used in any

transmission application which specifies the use of

DEXRON III, IIE, II or DEXRON.

Current stock of DEXRON III ATF can be used until

the supply is depleted.

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

15

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

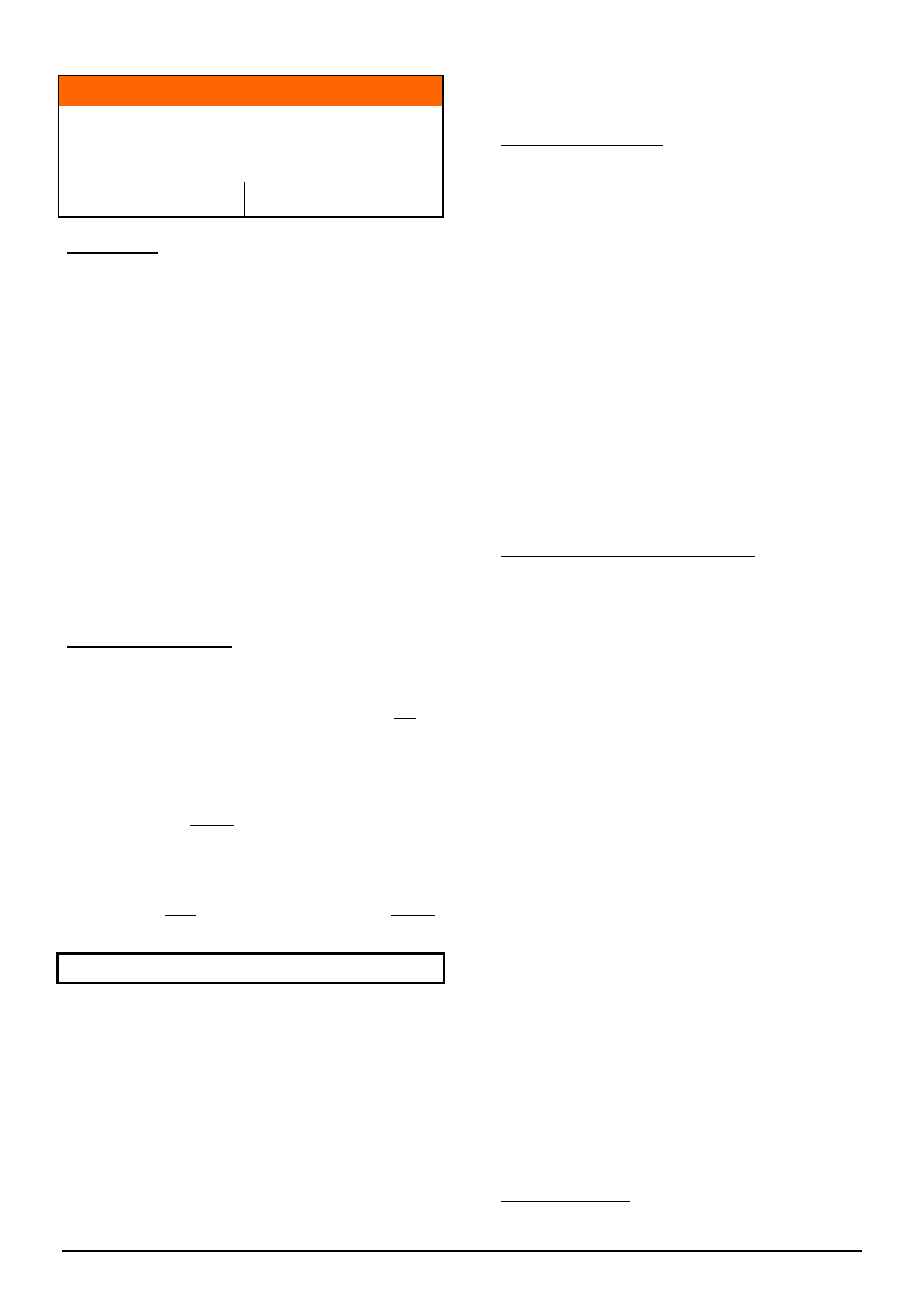

SERVICE FIX

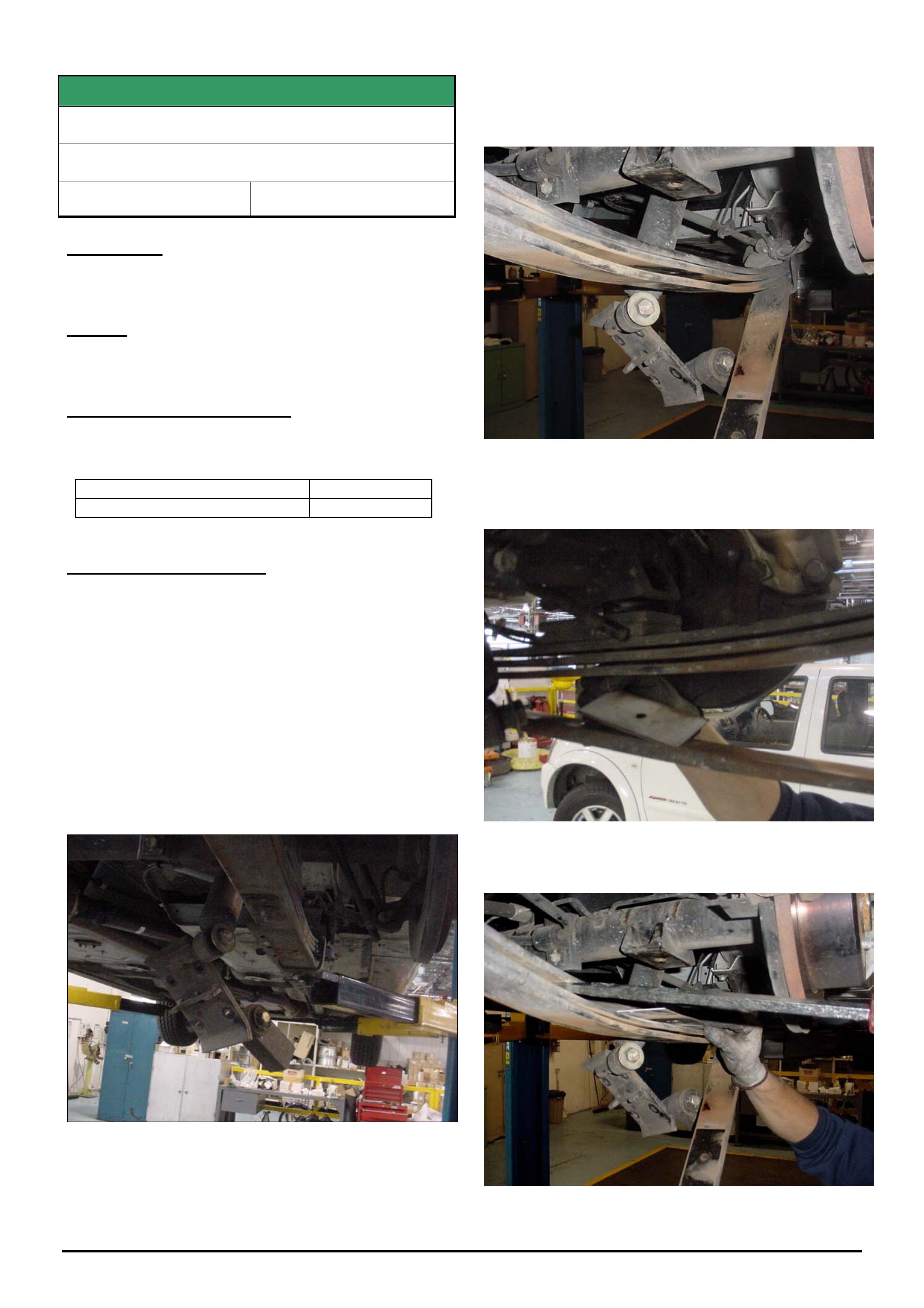

Rear Axle “Cyclic Knock” .

All V & W with IRS (non LSD)

Group 4 Ref. No. TL0602A- 0502

This Techline supercedes the previous one in Issue

11, Dec. 2004. It is revised by modifying the service

correction procedure and breakpoint information.

CONDITION

Cyclic knock noise which may occur when coasting in

speed range between 70-40km/hr whilst driving in a

straight line.

This condition is confirmed if the cyclic knock noise

disappears when the vehicle is driven in a slalom

motion.

CAUSE

Excessive axial float of the inner axle shafts within the

differential.

Problem affects V and W models (non LSD) with the

exception of cab-chassis and crew-cab vehicles (beam

axle).

CORRECTION – Production

Revised rear axle assemblies with reduced clearance

circlip grooves in the inner axle shafts were phased

into vehicle production over the last 2 weeks of Sep

2004 commencing from vehicle:

ISOVIN: Built Date:

**********L334258 16/09/2004

CORRECTION – Service

Summary: After verifying that vehicle has symptoms

as described above, proceed as follows: THIS

PROCEDURE WILL REQUIRE THE VEHICLE TO BE

LEFT IN DEALERSHIP OVERNIGHT.

Procedure.

1. Contact Dana via their website to register a case

of “cyclic knock”.

Once case is approved, Dana will send a set of

differential inner-axle assemblies with “upper

spec. spline” and reduced clearance circlip

grooves for the complaint vehicle.

2. Remove LHS and RHS driveshafts.

NOTE: mark the inner CV joints of both

driveshafts before completely removing from the

vehicle.

(Refer SIP Section 4B, 2.7 "Driveshaft Assembly”)

3. Remove LHS and RHS inner-axles from

differential.

(Refer SIP Section 4B, 2.9 "Inner Axle Shaft Seal".

Note: Diff does not need to be removed from

vehicle.)

4. Remove circlip from each inner-axle.

5. Install circlips to the new shafts supplied by Dana.

6. Clean all traces of oil from splines of the new

shafts and the matching splines in the differential.

Follow the pre-application cleaning instructions

provided on the Loctite 609 package.

7. Apply Loctite 609 to the splines on the shafts

before reassembling shafts into differential.

8. Allow Loctite to cure for 6 hours minimum before

proceeding.

9. Reverse both driveshafts before reinstalling. This

means reinstalling driveshafts with the inner CV

joint now on the outside.

WARRANTY CLAIM INFORMATION

For vehicles covered under warranty use the following

information.

Description Diff Cyclic knock noise

reduction procedure

Labour Op. No. F000200

Time 1.8 hr

Failure Code F0040 noisy

Update

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

17

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

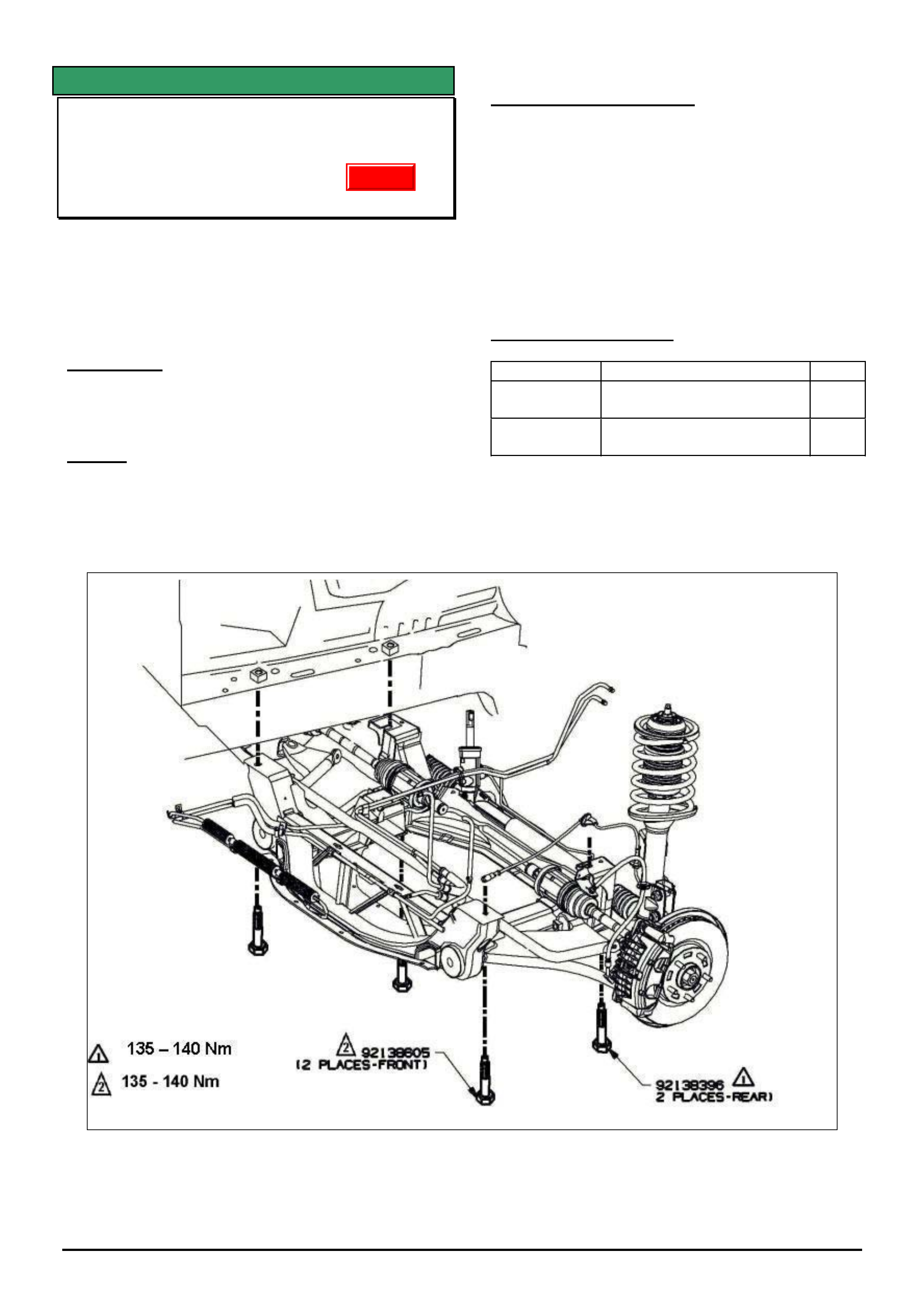

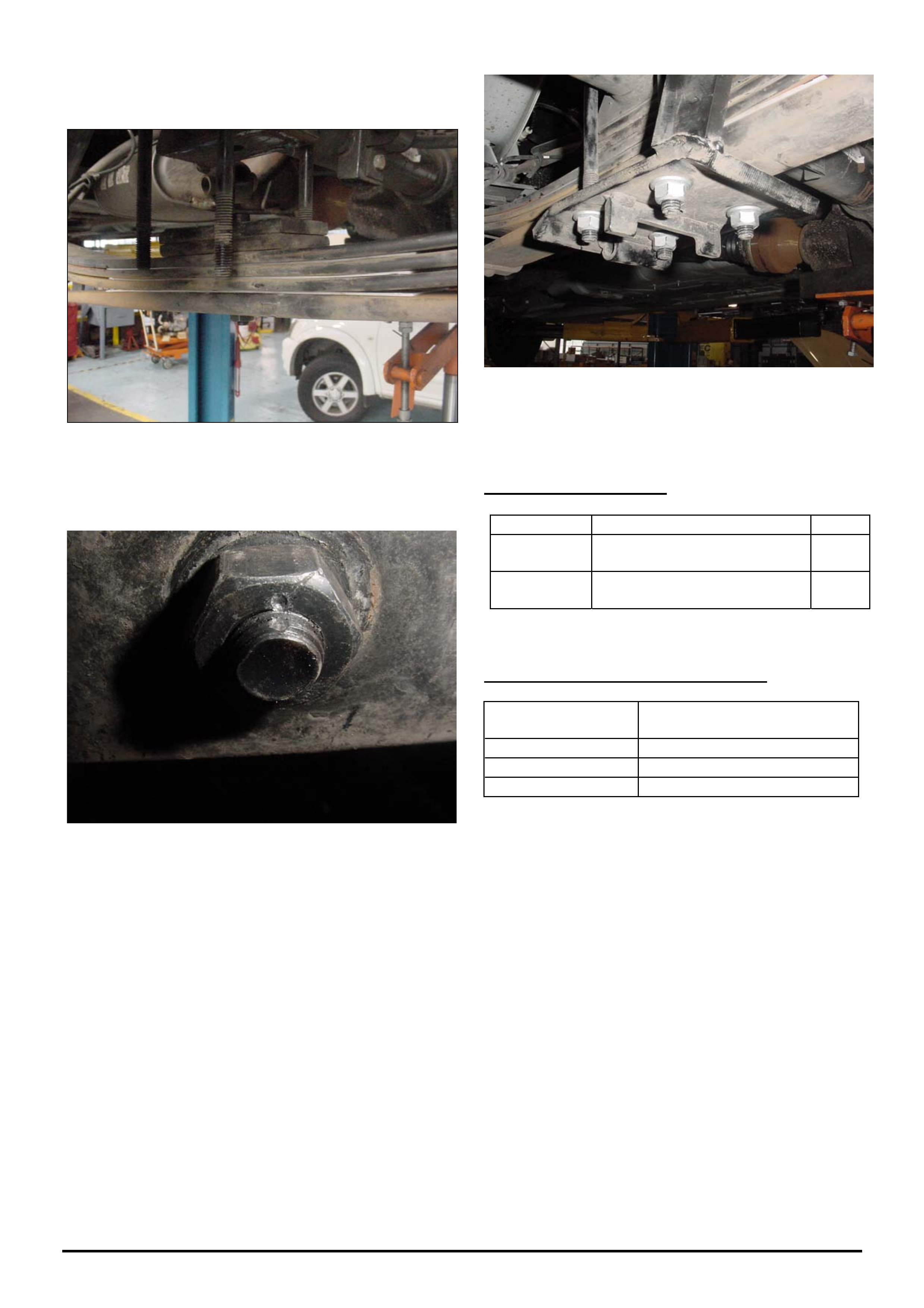

SERVICE FIX

Front Suspension Clunk (Front Subframe)

VY & VZ Adventra

GROUP 3 TL0718A-0502

This Techline supercedes the previous one in Issue 6,

July, 2004. It is revised by changing all 4 subframe

mounting bolt toques to the same value.

Also refer to Techline TL0638-0403 published in Issue

3, 2004. which gives another possible cause for front

suspension clunk

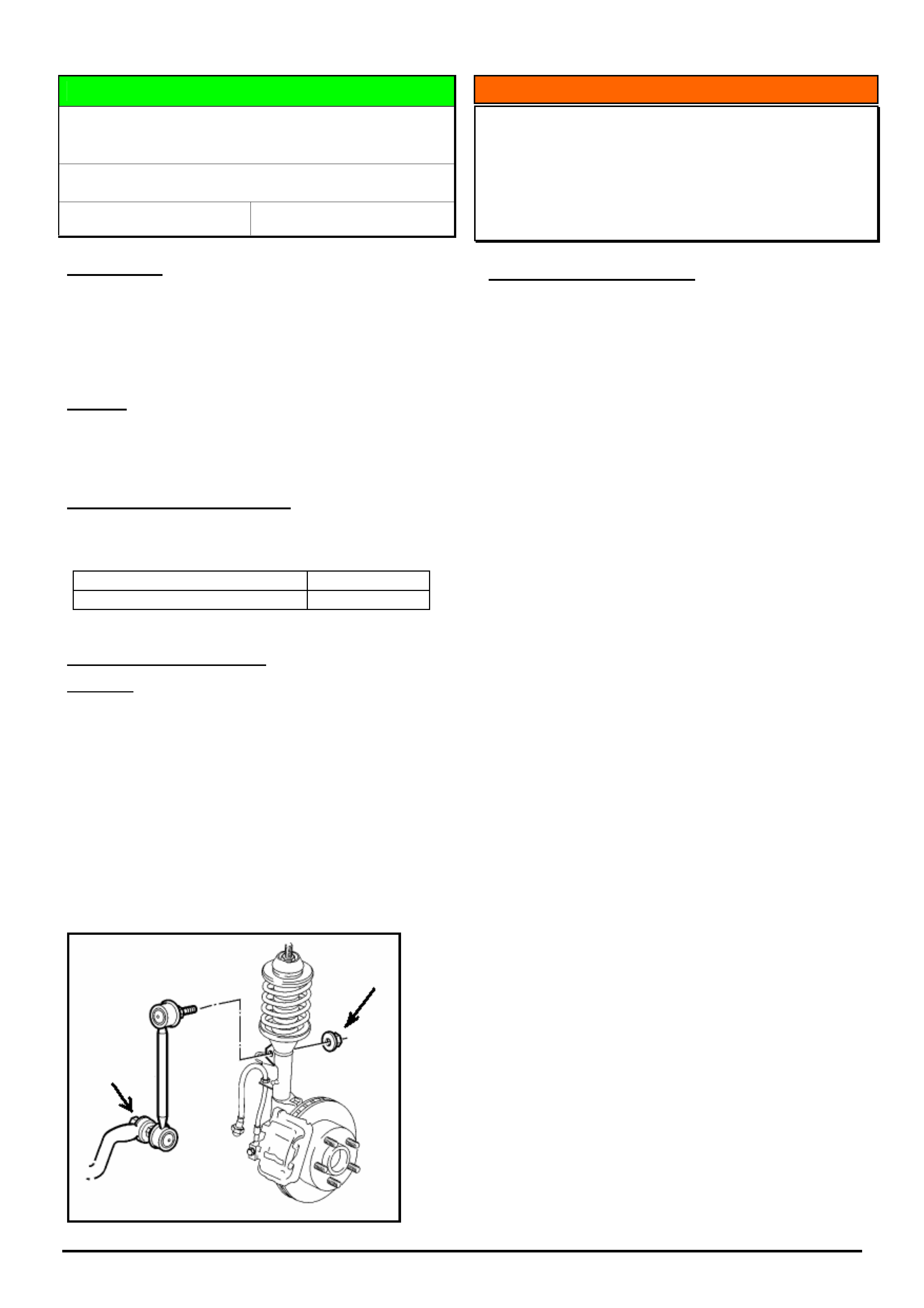

CONDITION

Loud metallic clunk noise from front suspension

usually heard when driving over pot holes or braking

over speedhumps .

CAUSE

One possible cause for this condition is fore-aft

movement of the front subframe relative to the body

due to insufficient clamp load at the attaching points.

CORRECTION – Service

On any vehicle with the symptoms as described,

ensure that all 4 subframe mounting bolts are

tightened to 135 -140 Nm.

NOTE: As these bolts are being tightened only and

not removed they do not need replacing.

If they are removed for any reason then they should be

replaced as per the standard practice for micro-

encapsulated fasteners.

PARTS INFORMATION

Part No.: Description: Qty

92138605 Bolt Front suspension

frame - front

2

92138396 Bolt Front suspension

frame - rear

2

Update

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

18

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

SERVICE PROCEDURE

Occupant Climate Control Blows Hot Air

VY, V2 II & III, WK and VZ (with OCC)

Group 2 Ref. No. TL0851- 0502

CONDITION

One or more of the following conditions may occur

intermittently:

• A/C blows hot air when cool air is selected.

• A/C blows hot air and changes mode to feet.

• ‘X ‘ appears on the OCC display

• Code 15 stored in the OCC module.

• In car temp. sensor reads –40° on Tech II.

CAUSE

A poor connection inside the in-car temperature

sensor causes an open circuit.

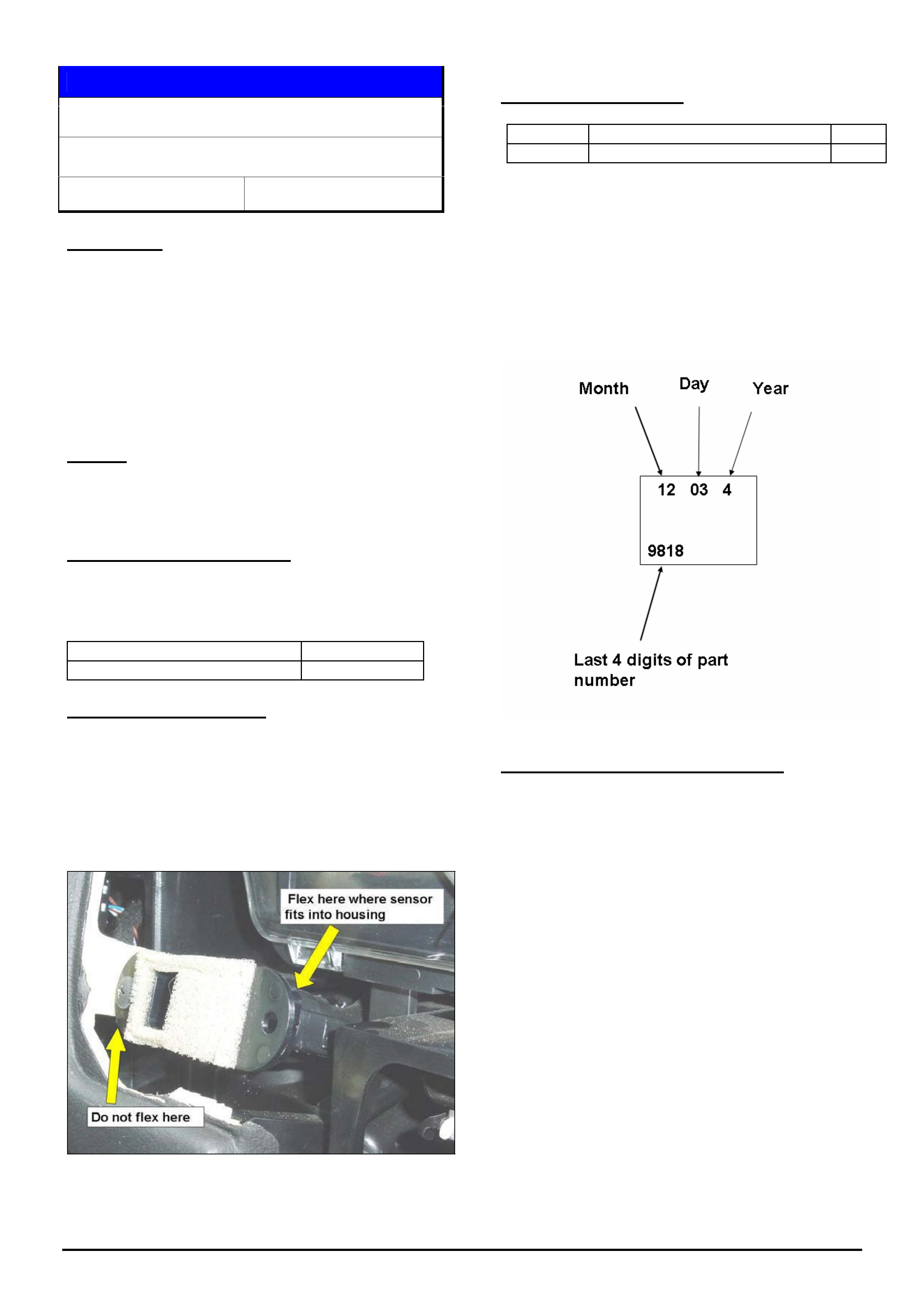

CORRECTION – Production

Production process for the manufacture of in-car

temperature sensors has been improved for vehicles

from:

ISOVIN: Built Date:

L405066 21/02/05

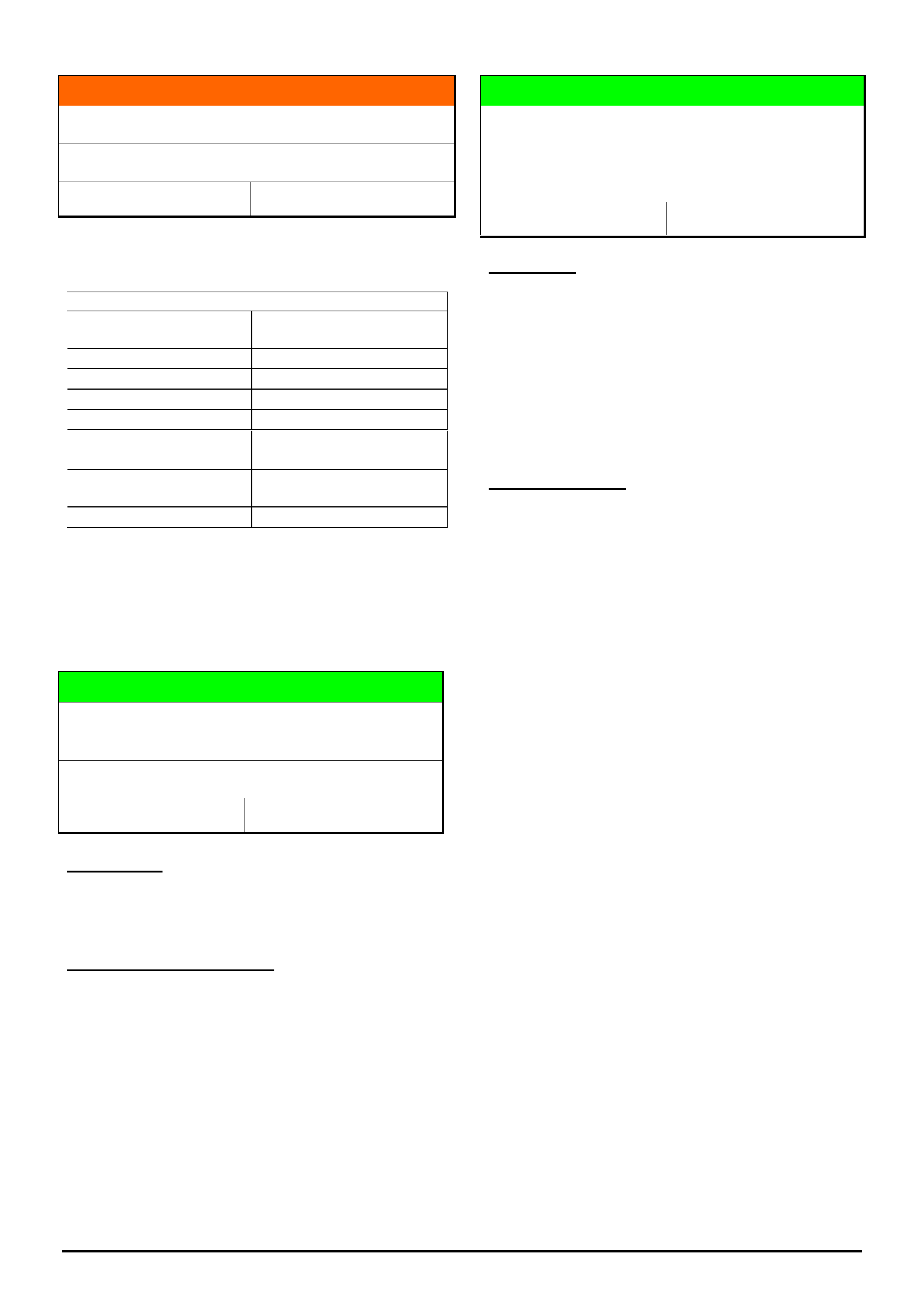

CORRECTION – Service

Perform normal SIP diagnosis.

Hint.

View the in-car temperature sensor reading on TECH

II while flexing the sensor body at the connector to

help identify an intermittently faulting sensor. Refer

Figure 1.

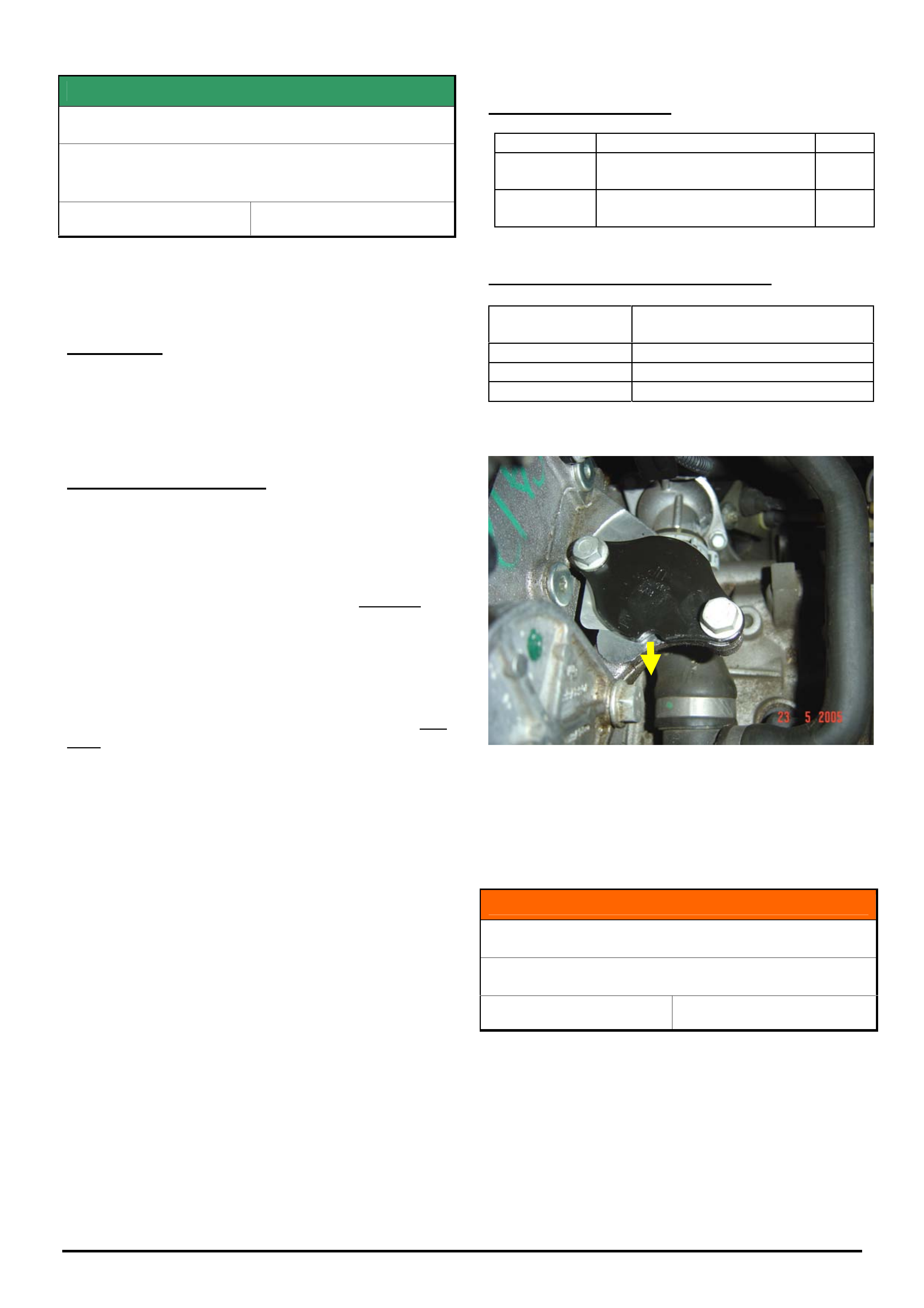

Figure 1. Shows in car temperature sensor

Replace the in-car temperature sensor if diagnosis

confirms it as faulty.

PARTS INFORMATION

Part No.: Partfinder Name Qty:

16229818 Sensor Asm. – Inside Air Temp. 1

All HSPO stock has been cleansed of suspect faulty

sensors.

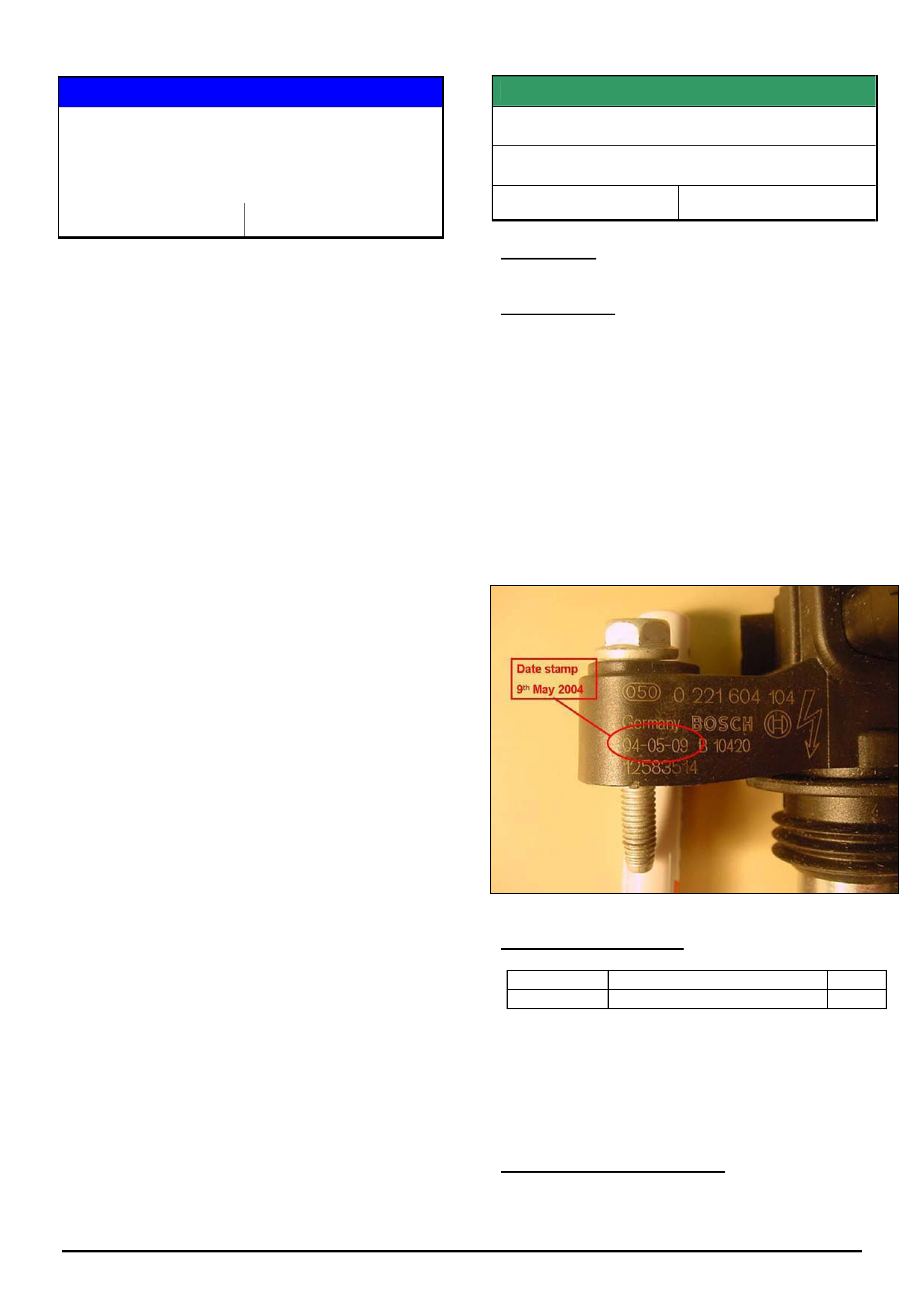

The date code breakpoint for certified stock is 12- 03 -

4 (manufactured Dec. 3rd, 2004).

The break point can be checked by inspecting the

label on the part as follows.

WARRANTY CLAIM INFORMATION

Use existing warranty information in SIP.

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

19

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

Power Steering Shudder Service Fix

Hose Contamination

VY WK with V6 engine

Group 9 Ref. No. TL0880- 0502

A contamination issue affecting some of the power

steering shudder service fix hoses was recently

identified and has now been rectified.

The contamination occurred during the hose

production process.

SERVICE ACTION

Dealers should confirm that any service fix hose to

be fitted to a vehicle is post breakpoint.

Breakpoint:

All hoses manufactured from 11 Feb 05. date code

(11B5).

All hoses supplied by HSPO warehouse from 11 Feb

05 are certified parts.

The manufacturing date code is stamped around the

metal ferrule where the hose is attached.

Date Code Explanation.

For example 11B5, 11 being the day of the month, B

being the month of the year, ie Jan = A, Feb = B, Mar

= C etc, and 5 represents the year of the decade, ie

2005.

PARTS INFORMATION

Part No.: Partfinder Name Qty:

92174786 Power Steering Hose 1

NOTE: Pre breakpoint hoses that are fitted to

vehicles do not need to be replaced with post

breakpoint hose.

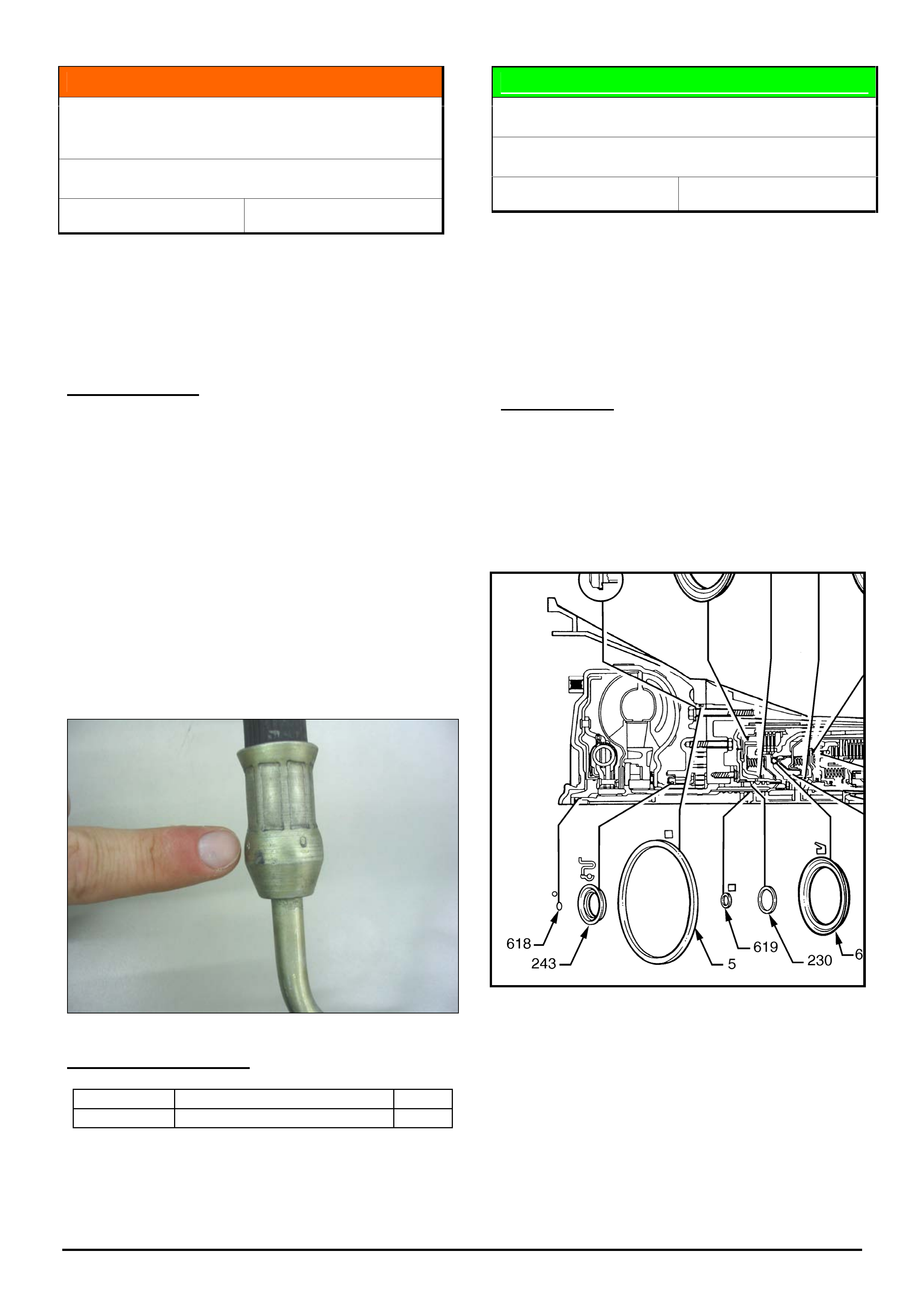

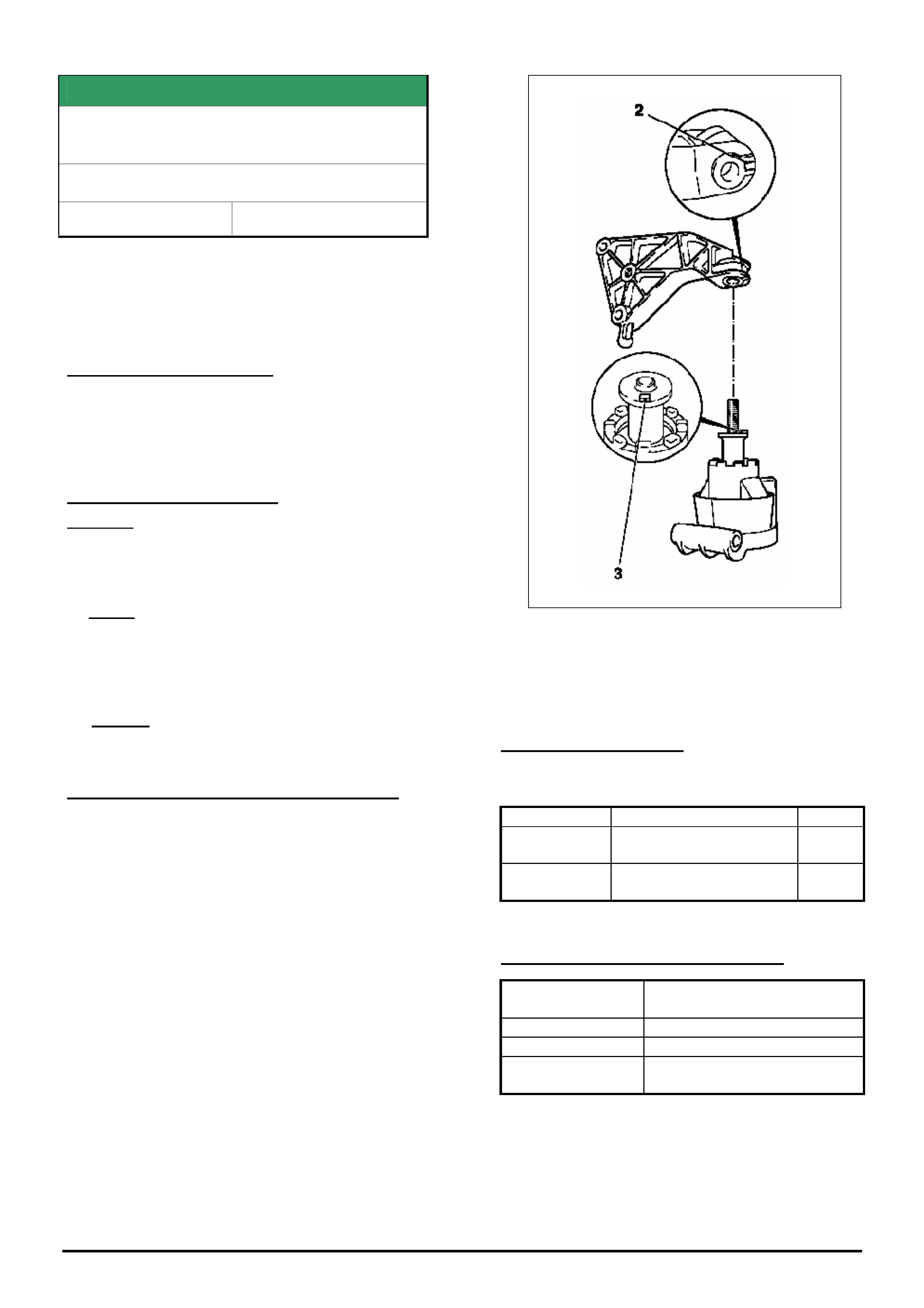

DIAGNOSTIC HINT

Transmission Slip Codes P0894, P1870

VY, VZ, WK, WL & 4L60E A/T

Group 7B Ref. No. TL0848 - 0502

The codes P0894 (VZ, WL) or P1870 (VY, WK) may

be logged causing the “check engine light“ to come

on.

Recent tear down analysis of transmissions replaced

for P0894 and P1870, reveals some instances where

the o-ring seal on the turbine shaft was either

missing or damaged. (refer Figure 1 item #618)

SERVICE HINT.

On any vehicle with the above symptoms, DO NOT

replace the transmission without first performing the

normal fault code diagnosis as per SIP. Pay

particular attention to the step which says to “check

the input shaft and housing assembly for

cut/damaged turbine shaft o-ring seal”.

Figure 1.

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

20

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

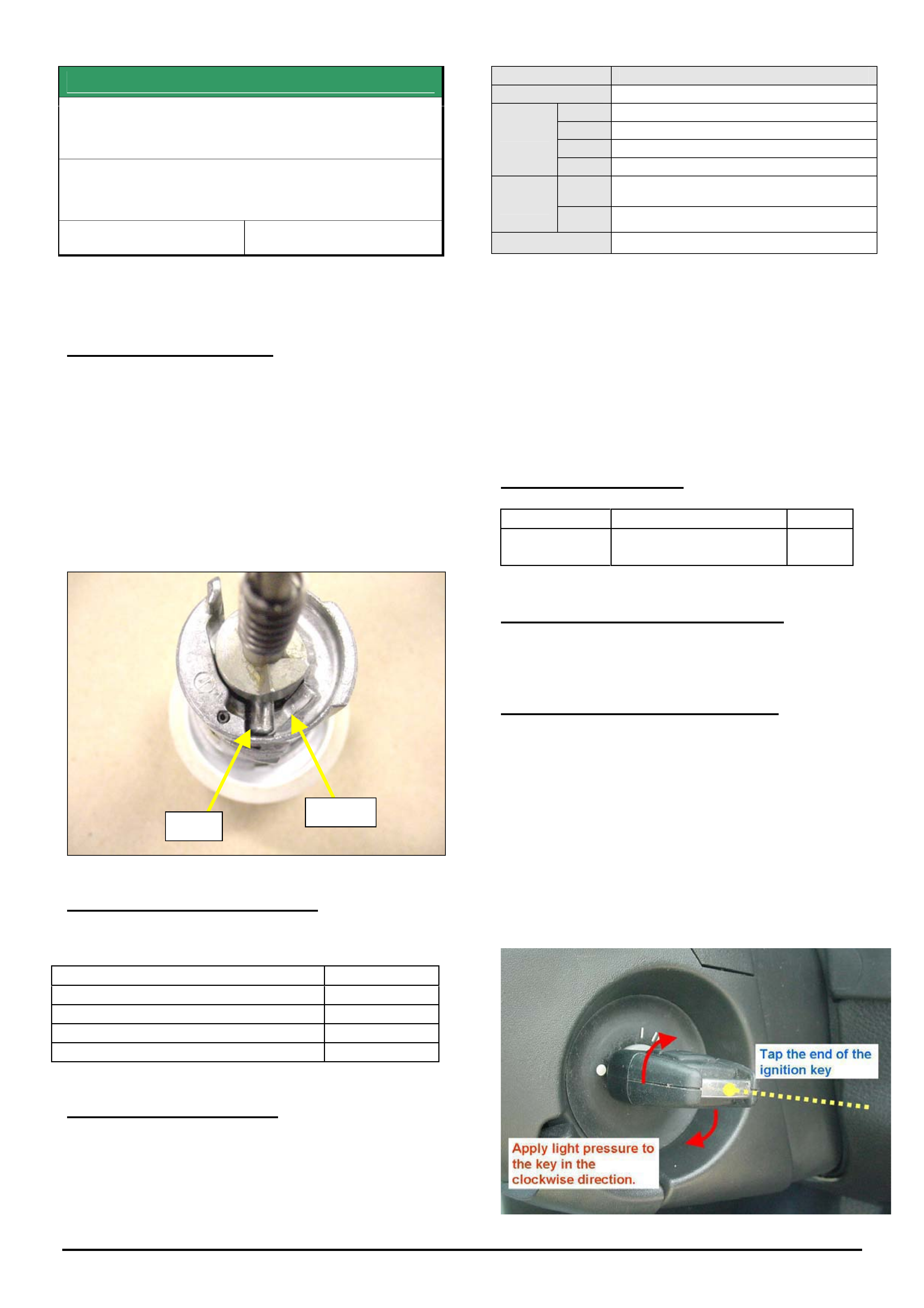

SERVICE FI

X

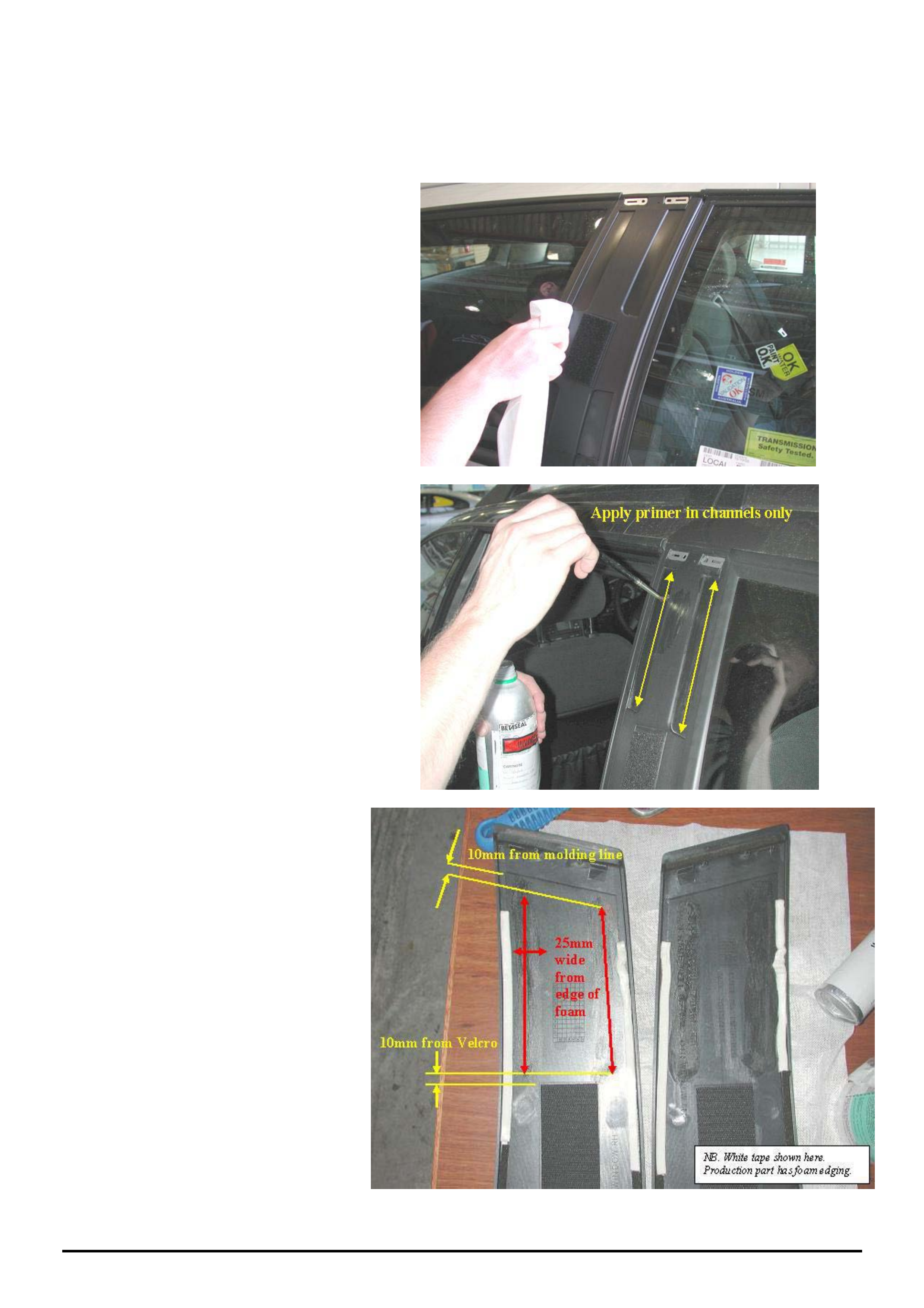

Ignition Key Jams In Off Position – Or Is

Difficult To Turn From Off Position

TS, TT, XC Barina/Combo with “S”

Profile Ignition Keys/Barrels

Group 9 Ref. No. TL421B - 0502

This Techline supercedes the previous one in Issue

3, Mar. 2003. It is revised by adding a service hint

on how to freeup a jammed ignition lock.

PROBLEM DESCRIPTION

In some vehicles the ignition key may jam in the

“OFF” position or be difficult to turn from the “OFF”

position.

This condition only affects ignition barrels/keys with

“S” profile. It does not affect those with “D” profile.

To confirm profile type refer to Part Finder TS

Catalogue, section 06-250A.

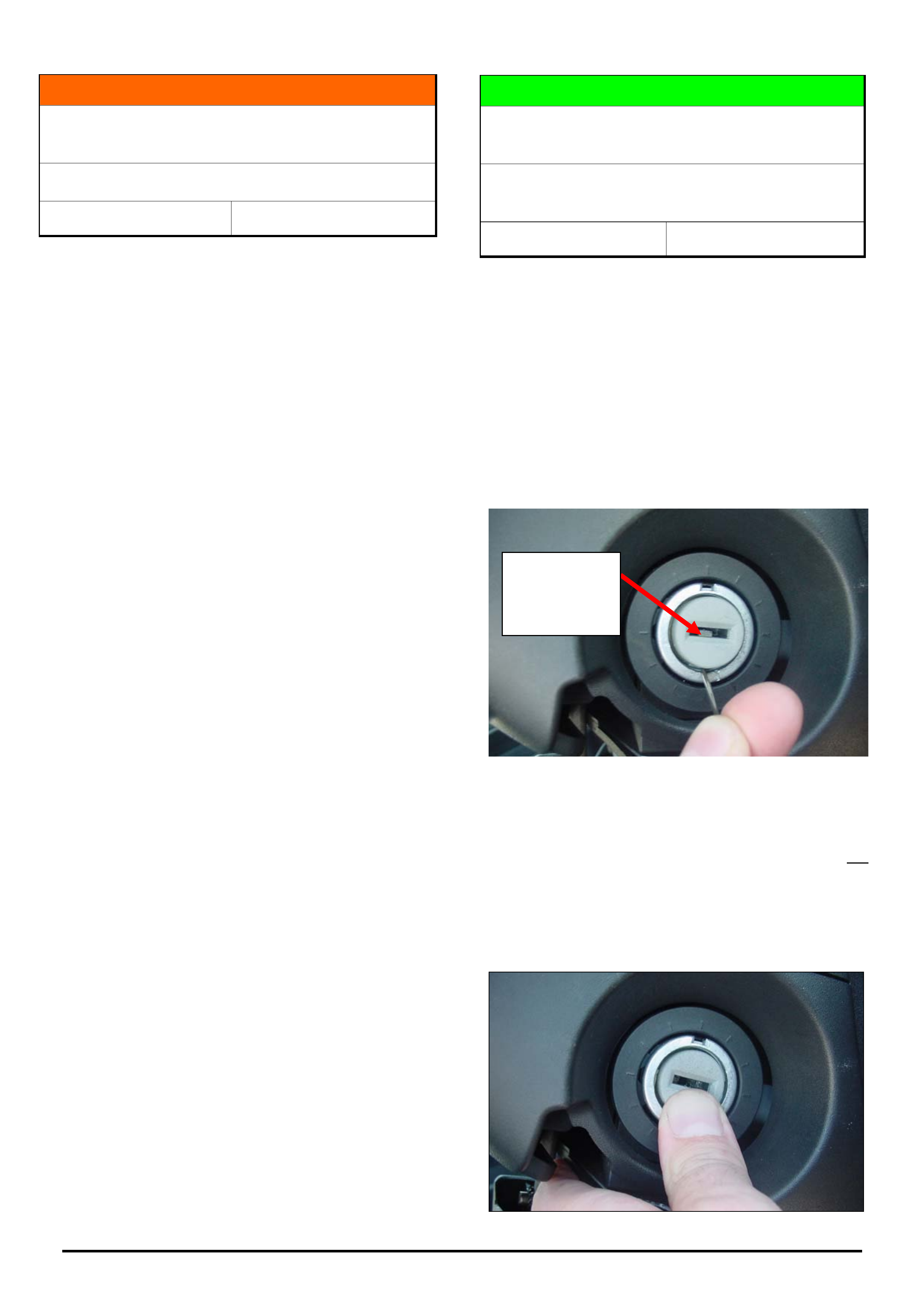

This condition results from the hard barrel pin

causing excessive wear of the soft alloy ramp section

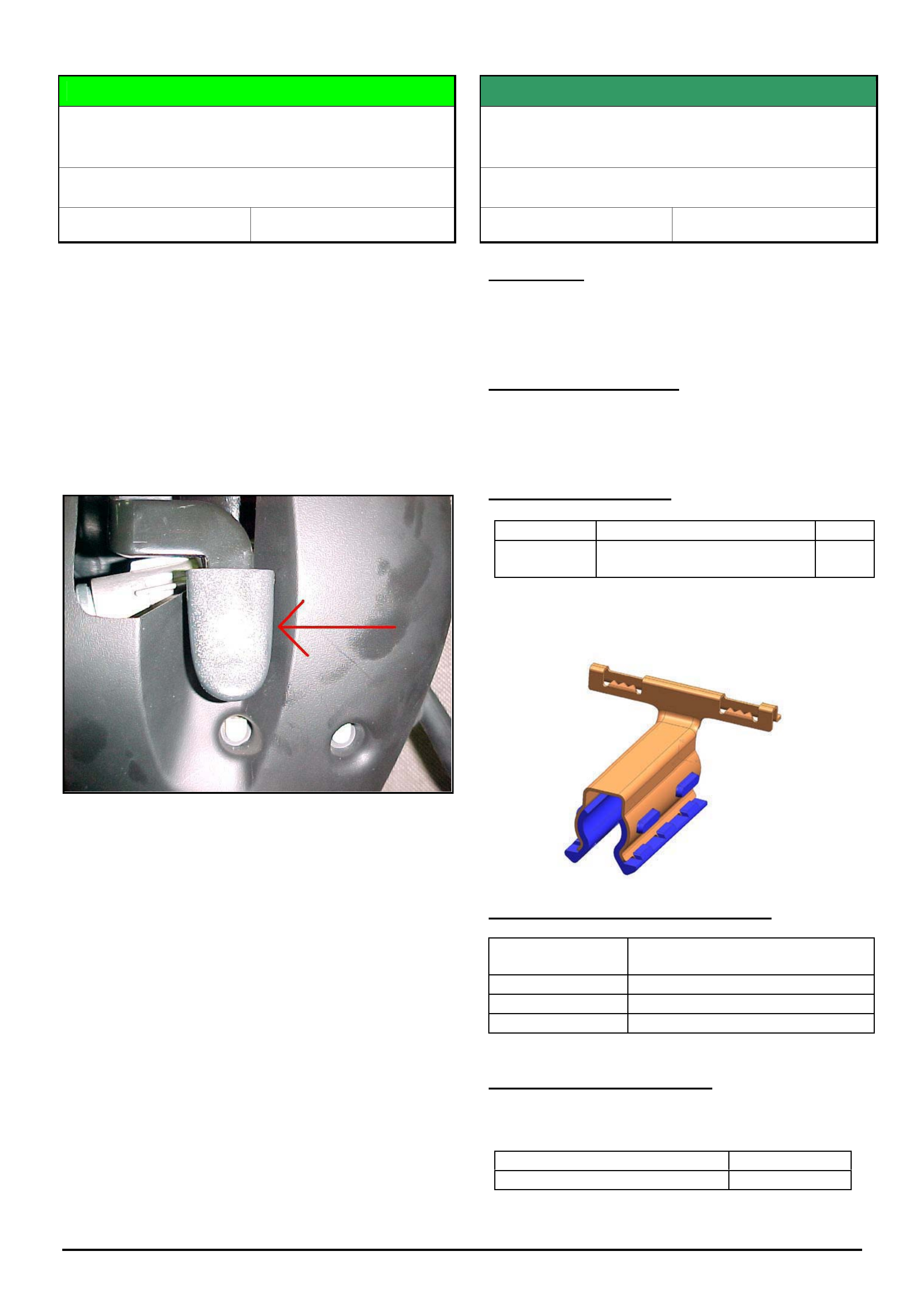

of the barrel housing. Refer Figure 1.

PIN RAMP

Figure 1.

PRODUCTION RECTIFICATION

Revised ignition barrels have been fitted to vehicles

from the following breakpoints:

ISOVIN: Build Date:

XC Barina - W0L0XCF6824246086 30/04/02

XC Combo - W0L0XCF2523030966 30/04/02

TS Astra - W0L0TGF4825195733 May 02

TT Zafira - W0L0TGF752H035990 Aug 02

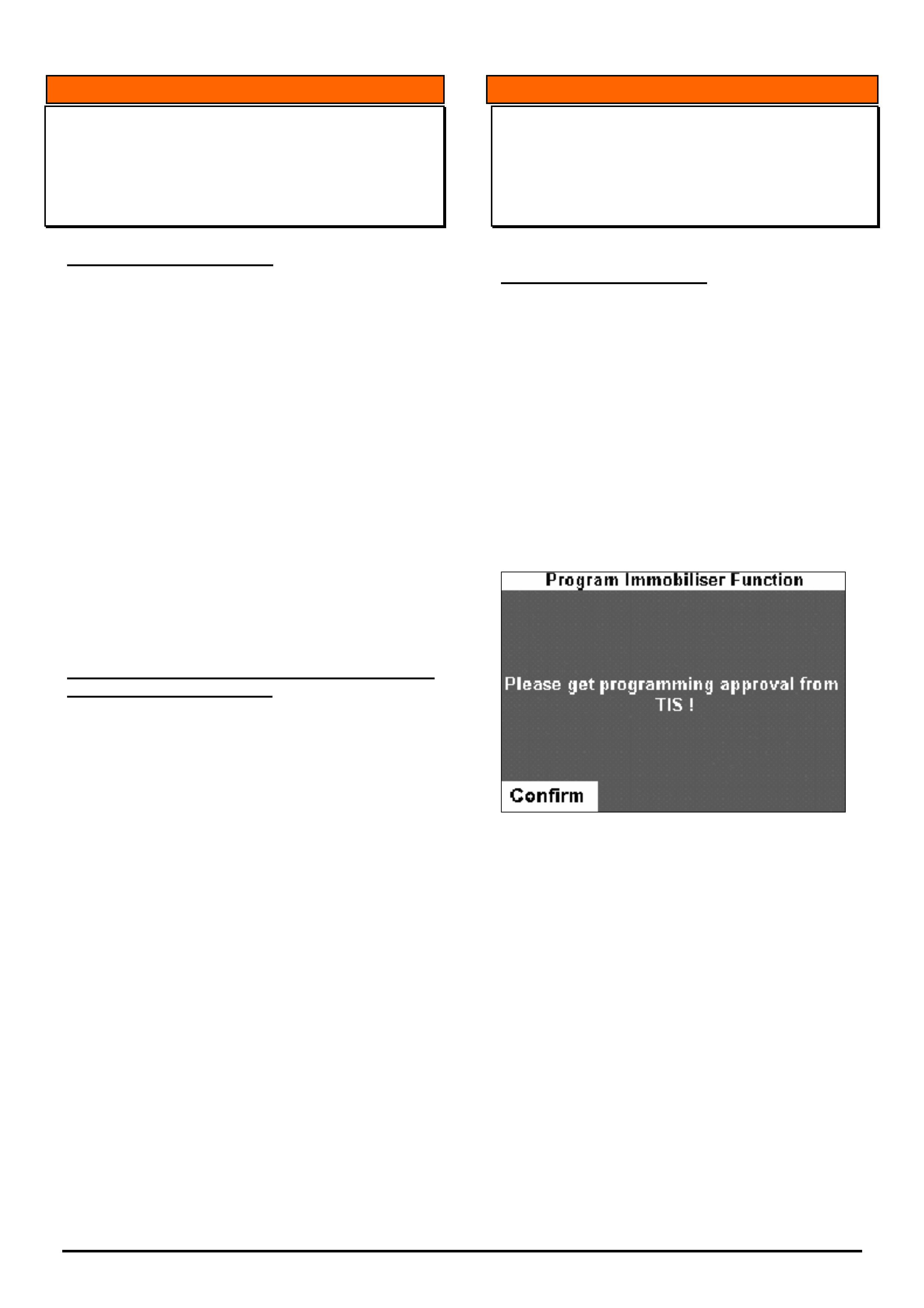

SERVICE RECTIFICATION

Summary: For complaint vehicles install a new

ignition lock cylinder and tumblers.

To Remove and Reinstall the ignition lock cylinder

refer to procedure in TIS 2000 found as follows:

TIS Screen Ð Select the following Ð

Service Information Standard Information

Model Astra G/Corsa C/Zafira

Year 2002

Eng. -

Vehicle

Data

Trans. -

Asm.

Group

- Electrical Equipment & Instruments

+Switches, Control Units, Relays, Ign Lock

Standard

Info. Applic’n Repair (Remove,Install,Adjust)

Document List Lock Cylinder for strg. & ign. lock R & R

Tumbler Replacement

The old tumblers must be replaced with the new

ones supplied in the kit. To retain the same key

coding, remove the tumblers one at a time from the

old lock shaft, read the number stamped on the

tumbler and then install a new tumbler with the same

code into the new lock shaft in the equivalent slot.

Note. There are 4 different codes of tumbler and a

total of 10 tumblers per lock cylinder.

PARTS INFORMATION

Part No.: Description: Qty:

92146450 Barrel Kit – Ignition (S

profile)

1

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty

Information section of current PV SIP CD

Hint For Freeing Up Jammed Lock

The following method may help to rotate the jammed

ignition lock preventing the need to tow a vehicle or

assist when replacing the ignition barrel assembly.

1. Apply light clockwise pressure to the key while

fitted in the ignition lock.

2. With clockwise pressure still applied, lightly tap

the end of the ignition key with a small nylon

hammer.

CAUTION: DO NOT DAMAGE THE KEY HEAD

HOLDEN SERVICE TECHLINE ________________________________________________________________________________APRIL, 2005

5

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

SERVICE FIX

Door Check Link Attaching Bolt(s) Loose

AH Astra

Group 1 Ref. No. TL0895- 0503

CONDITION

On some vehicles one or more of the door check link

attaching bolts may loosen in service.

CORRECTION – Production

Door check link bolt torques increased to 27 (+2/-1)

Nm on vehicles from:

ISOVIN: Built Date:

W0L0AHL4855006365 23/08/2004

CORRECTION – Service

On any vehicle where a door check link attaching bolt

comes loose, remove all door checklink bolts, apply a

thread locking compound to threads then retighten

bolts to 27 Nm.

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty Information

section of current PV SIP CD

INFORMATION

Oil Pan Sealant Availability and Usage

HFV6 Engine

Group 6A Ref. No. TL0888 - 0503

CONDITION

The current Passenger SIP CD specifies RTV sealant

p/n 12574611 for HFV6 engine oil pan replacement.

Unfortunately, because this sealant is not available

locally, there has been confusion over what sealant to

use in its place.

CORRECTION – Service

The sealant to be used for HFV6 engine oil pan

replacement procedures is p/n 92144969.

Future versions of Passenger SIP will be revised to

show p/n 92144969 as the replacement for 12574611.

PARTFINDER INFORMATION

PartFinder does not currently list any sealant part