2

20

00

05

5

S

SE

ER

RV

VI

IC

CE

E

T

TE

EC

CH

HL

LI

IN

NE

ES

S

© 2006 GM Holden Ltd. A.B.N. 84 006 893 232

Service Department

A “HOLDEN” Product.

BRISBANE SYDNEY MELBOURNE ADELAIDE PERTH

For the latest and/or any missing Techline bulletins,

please refer to Holden Lionheart

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

9

DIAGNOSIS PROCEDURE

Leak Testing Injectors in 4JX1 Engine

UBS Jackaroo & Monterey

Group 6M Ref. No. TL0832- 0501

On any engine that shows an increase of oil level, and

fuel dilution is suspected, the following procedure will

assist in identifying if leaking injectors are the cause of

this condition.

Equipment required:

1. UV Dye – e.g. SPX Multipurpose Dye, P/N 16268

2. UV light source – e.g. Kent Moore 12 Volt Leak

Detection Lamp, P/N J42220

3. Fuel safe container to mix dye and diesel.

4. Compressed air supply.

5. Pressure gauge (optional)

6. Tyre inflator.

7. Fuel pipe P/N 8971371924 or suitable banjo fitting

8. Flexible fuel hose (approx 5/16” diameter, same as

EFI pressure hose.)

9. Hose clamps (various, to suit)

10. One person brake bleeding kit - e.g. MightyVAC

Procedure:

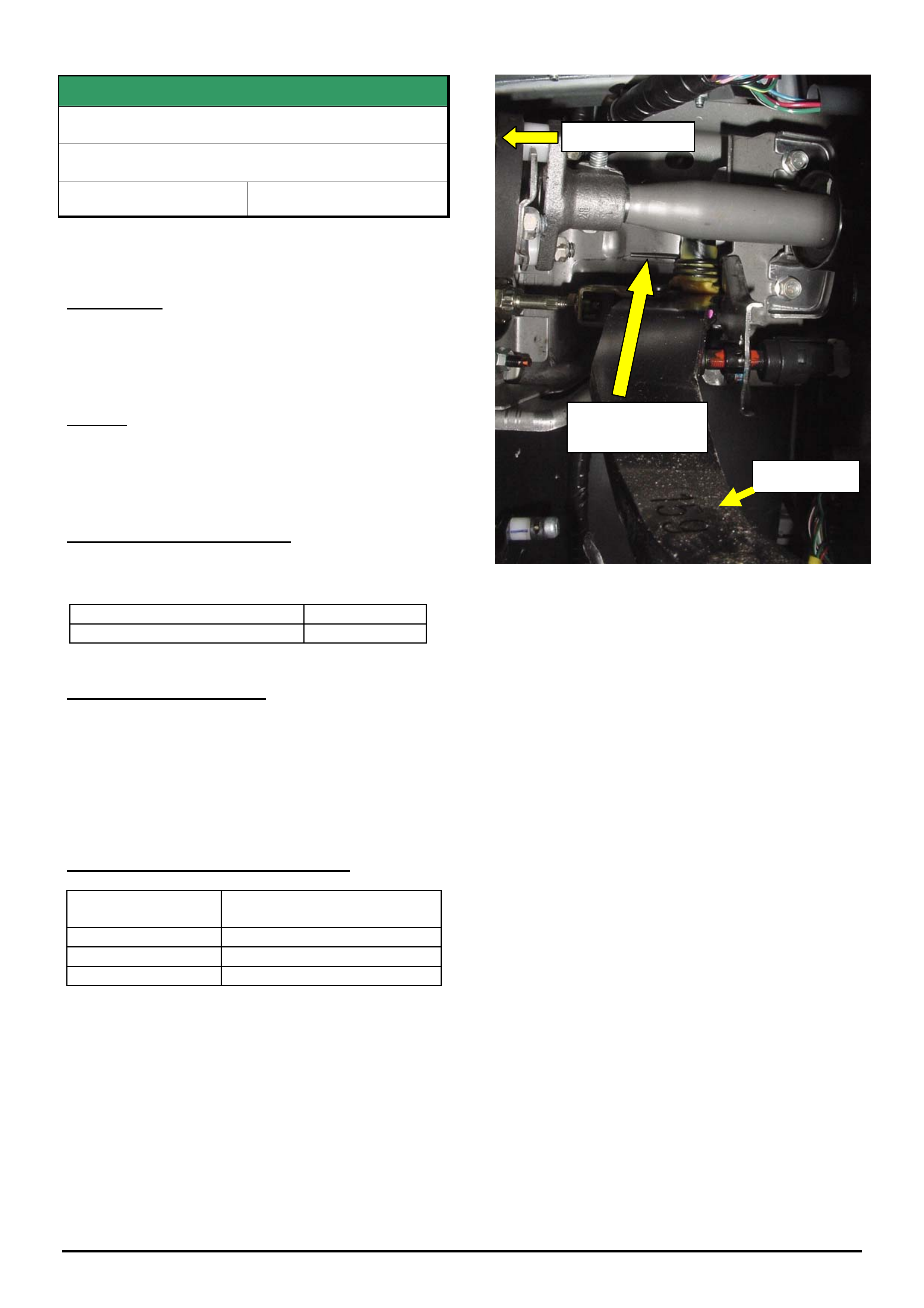

Step 1. Remove engine tappet cover.

Step 2 – Create a fitting for the front of the fuel gallery

as follows:

Cut the large banjo fitting from the end of the fuel pipe

(P/N 8971371924) as pictured below. The end may

need to be adapted to whatever size hose you are

using.

Figure 1. Shows fuel pipe prior to modifying

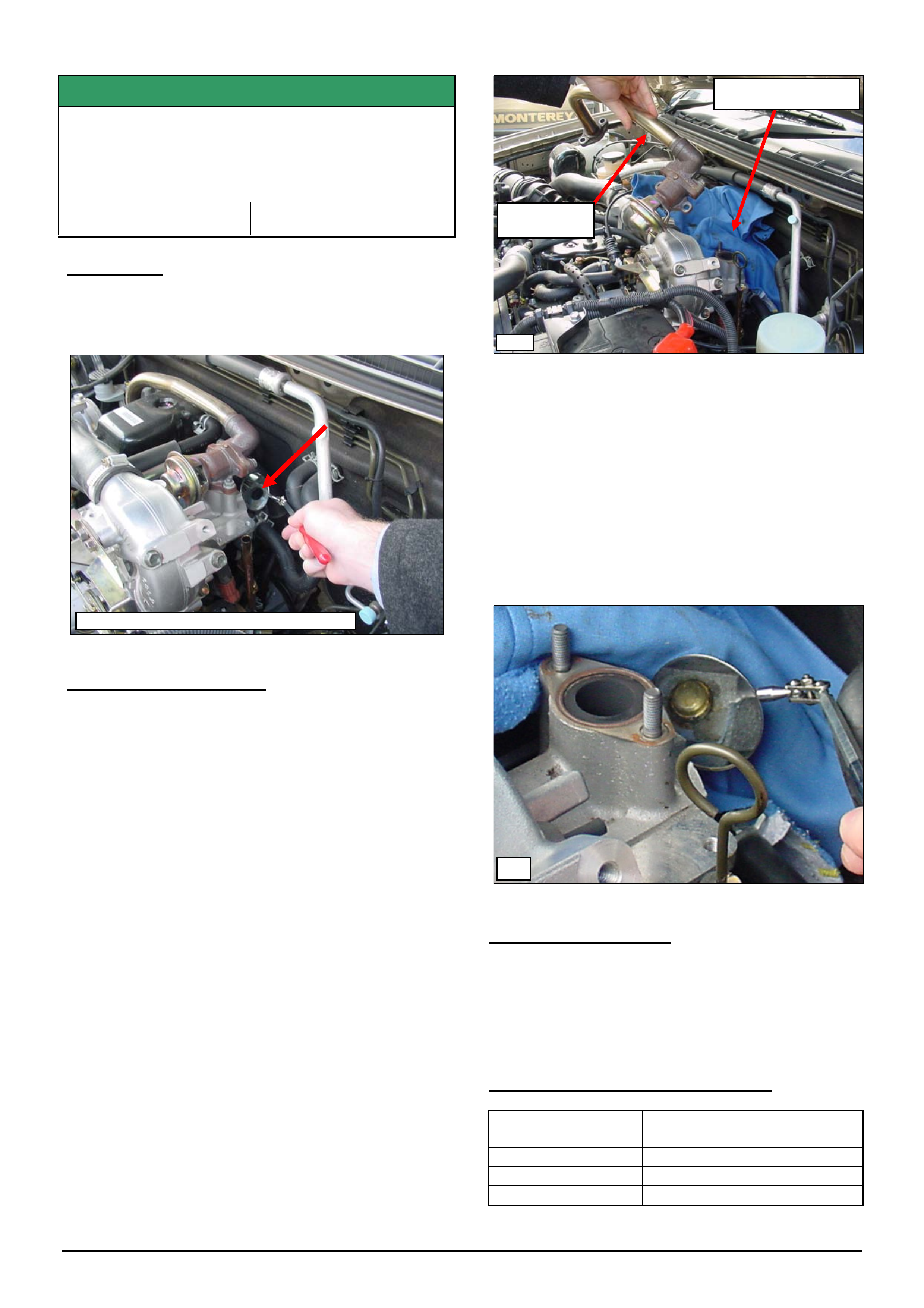

Step 3. - Remove vehicles fuel pipe (P/N

8971371924). from front of the head, then install the

modified fuel pipe or banjo fitting using the original nut

and two fibre washers. Refer Figure 2.

Figure 2.

Step 4 – Introduce fuel/dye into injectors.

Mix the dye with a suitable quantity of diesel, as per

the instructions included with the dye. Use a fuel safe

container.

Plumb in the Mighty-VAC as shown in figure 3 (next

page). Connect a hose from the modified fuel pipe to

the container with the diesel and dye. Remove the fuel

return hose from the chassis rail and attach to the

Mighty-VAC.

Pump the Mighty-VAC steadily until the diesel / dye

mix has been pulled all the way through the fuel lines.

Step 5. Pressurise the fuel/dye mixture.

Clamp off the return line to the Mighty-VAC with

suitable pipe clamps.

Remove the Mighty-VAC.

Remove the hose from the fuel pipe on the front of the

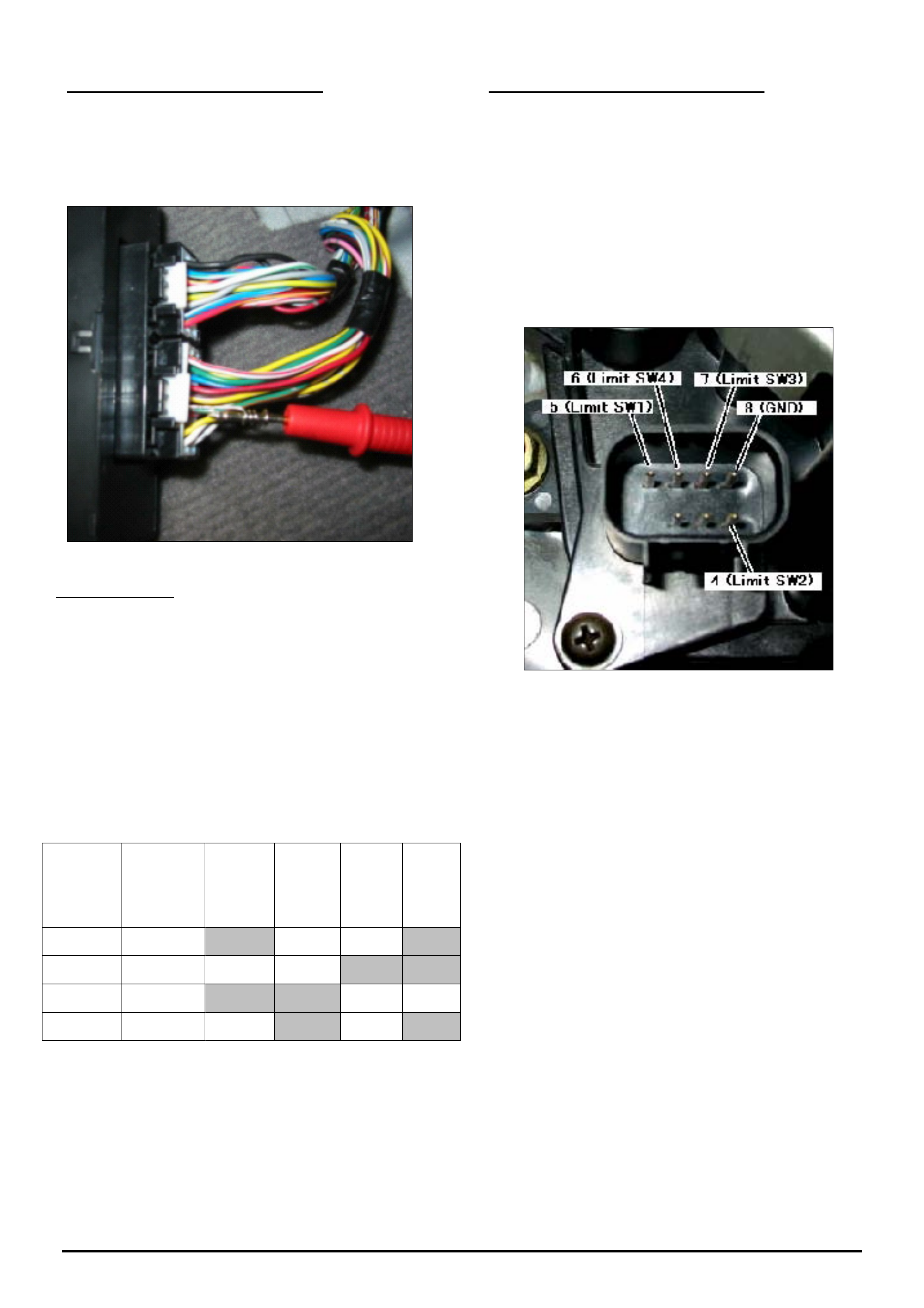

head and attach inflator hose using hose clamp. An

inflator hose can be made by cutting the end from a

standard tubeless valve stem and inserting into 5/16”

hose. Use a hose clamp to secure valve stem. Screw a

standard Schroeder valve into valve stem. Refer to

figure 4.

Inflate fuel system to 650KPa using a tyre inflator.

Check with a gauge to make sure the pressure is

holding.

Figure 4. Inflator fitting

CUT HERE

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

10

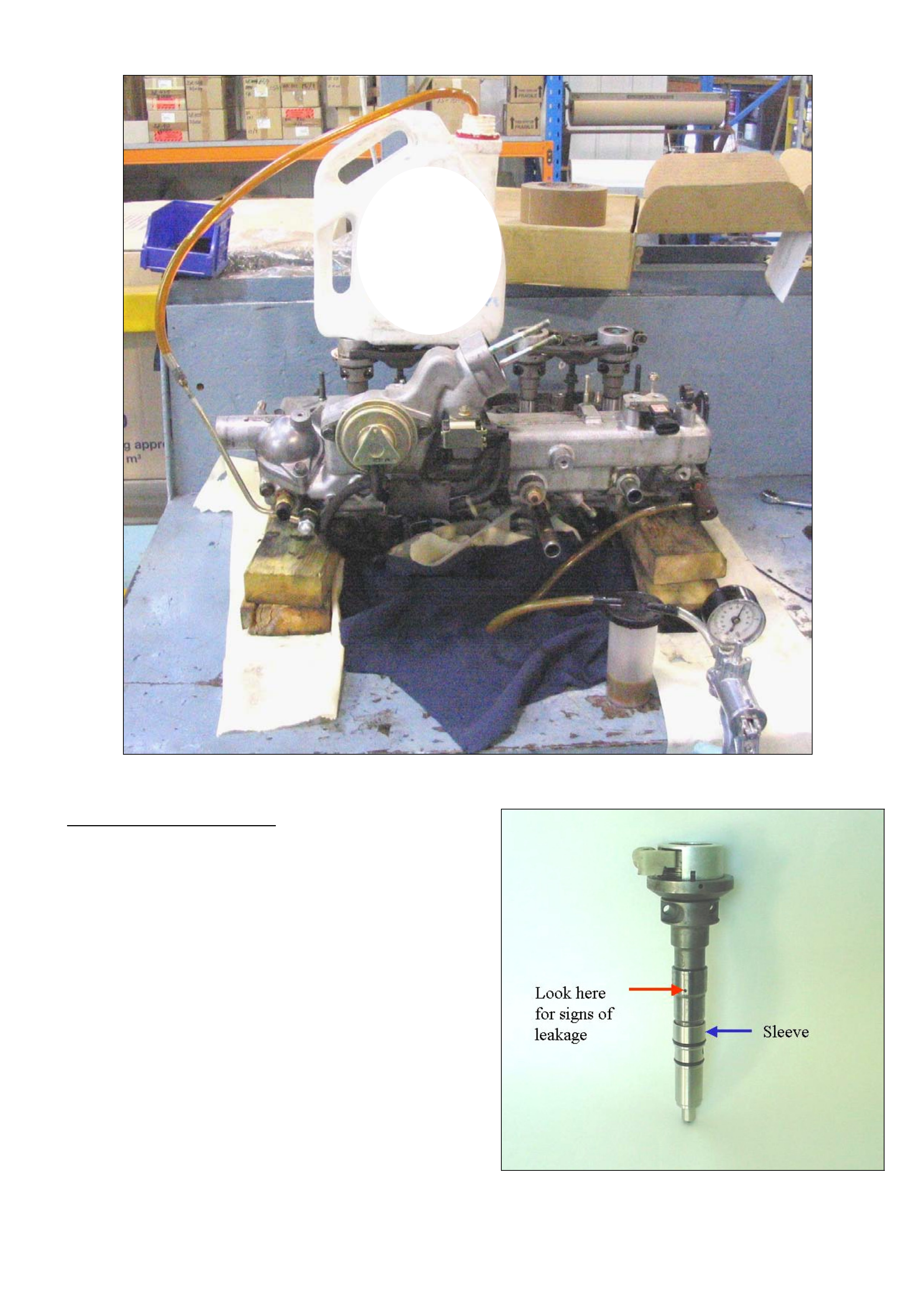

Figure 3. Leak testing setup on bench for demonstration purposes only.

Step 6 – Inspect with UV light.

IMPORTANT: Use supplied goggles. DO NOT look

at UV light with naked eye.

Shine the UV light around the injectors looking for

leaks. Leaks will glow a bright colour which can vary

with the type of dye used. The most common place a

leak will be found will be from the vent holes on the

sides of the injectors. Refer Figure 5. It may take 5 -

10 minutes for a leak to appear.

Note: The dye can run from the injector vent holes to

fill the area around the top of the sleeve as shown in

Figure 6. This can make it look like the sleeve o-ring

has failed. However, in all the post BP engines

recently tested in REPAC, none have had sleeve o-

ring failure.

If a leak is detected, replace injector(s) as required.

To retest the system, all the diesel and dye will have

to be flushed and cleaned from the system.

Figure 5.

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

11

Figure 6.

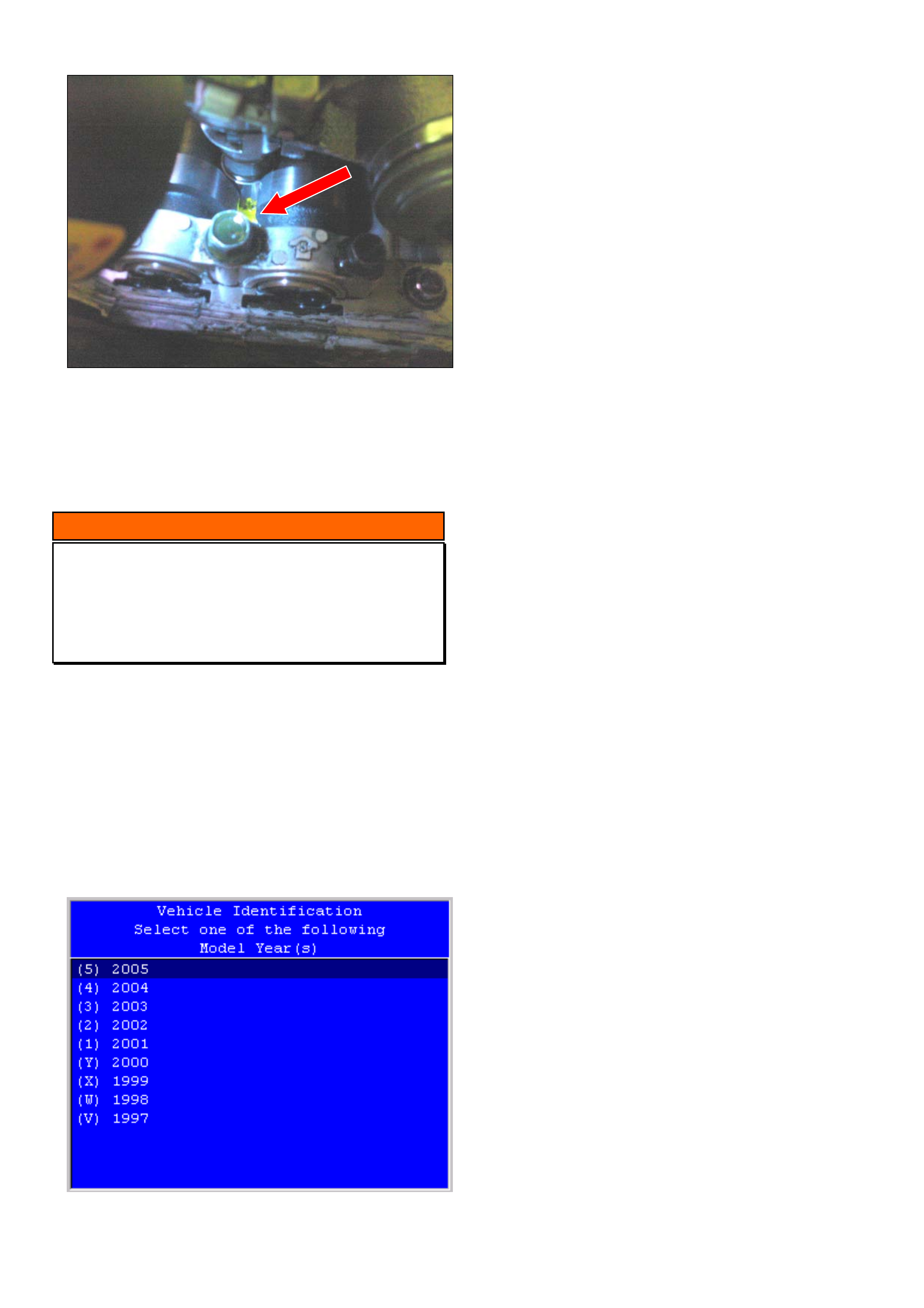

INFORMATION

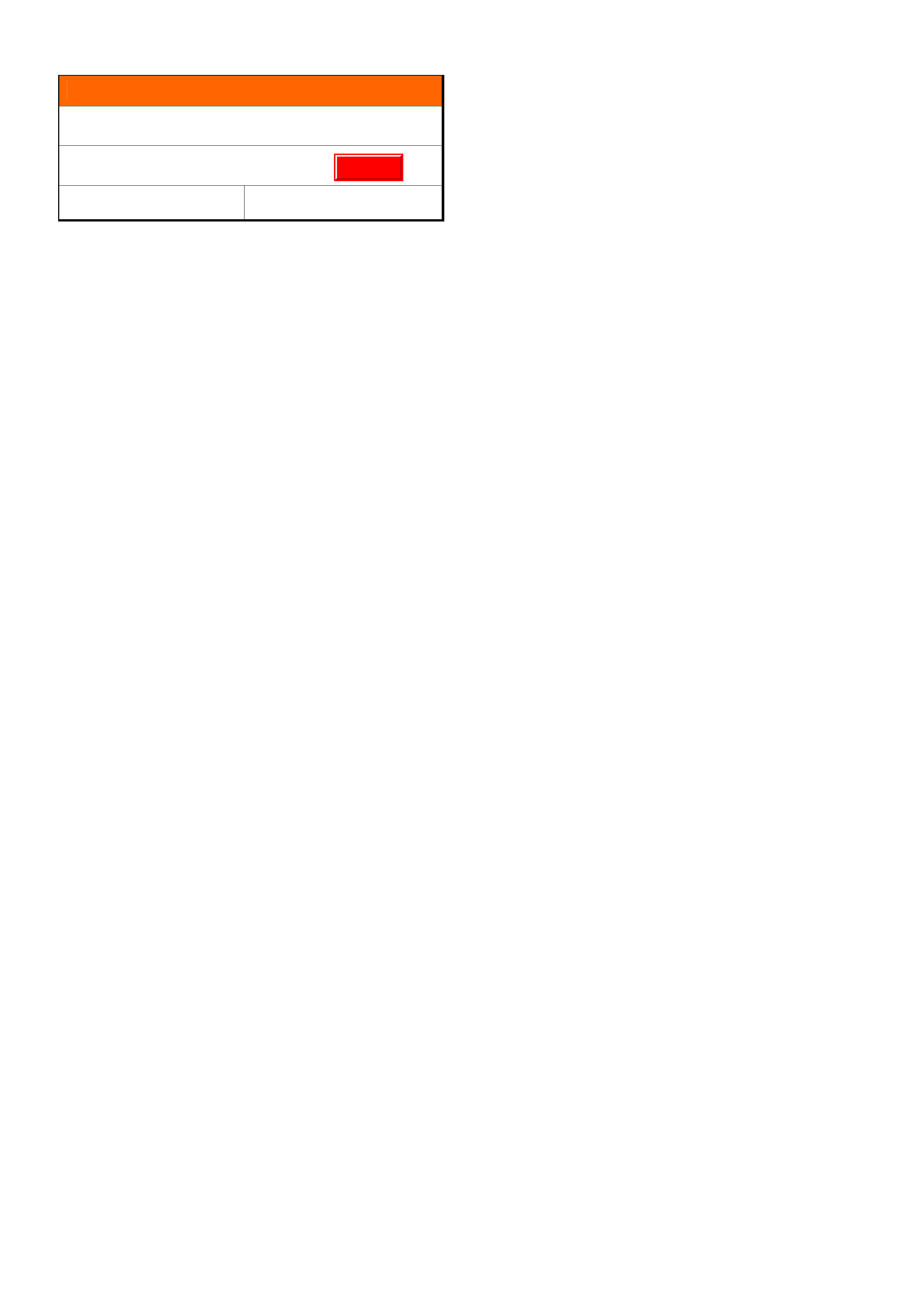

Tech 2, TIS 2000 Model Year Selection

ALL MODELS

GROUP OB TL0852-0501

This Techline is to clarify the correct procedure for

model year selection when using Tech 2 or TIS 2000.

For many programming operations and diagnostics

carried out using Tech 2 and TIS 2000 it is critical

that the correct model year is selected. This can be

easily identified by the tenth character of the VIN.

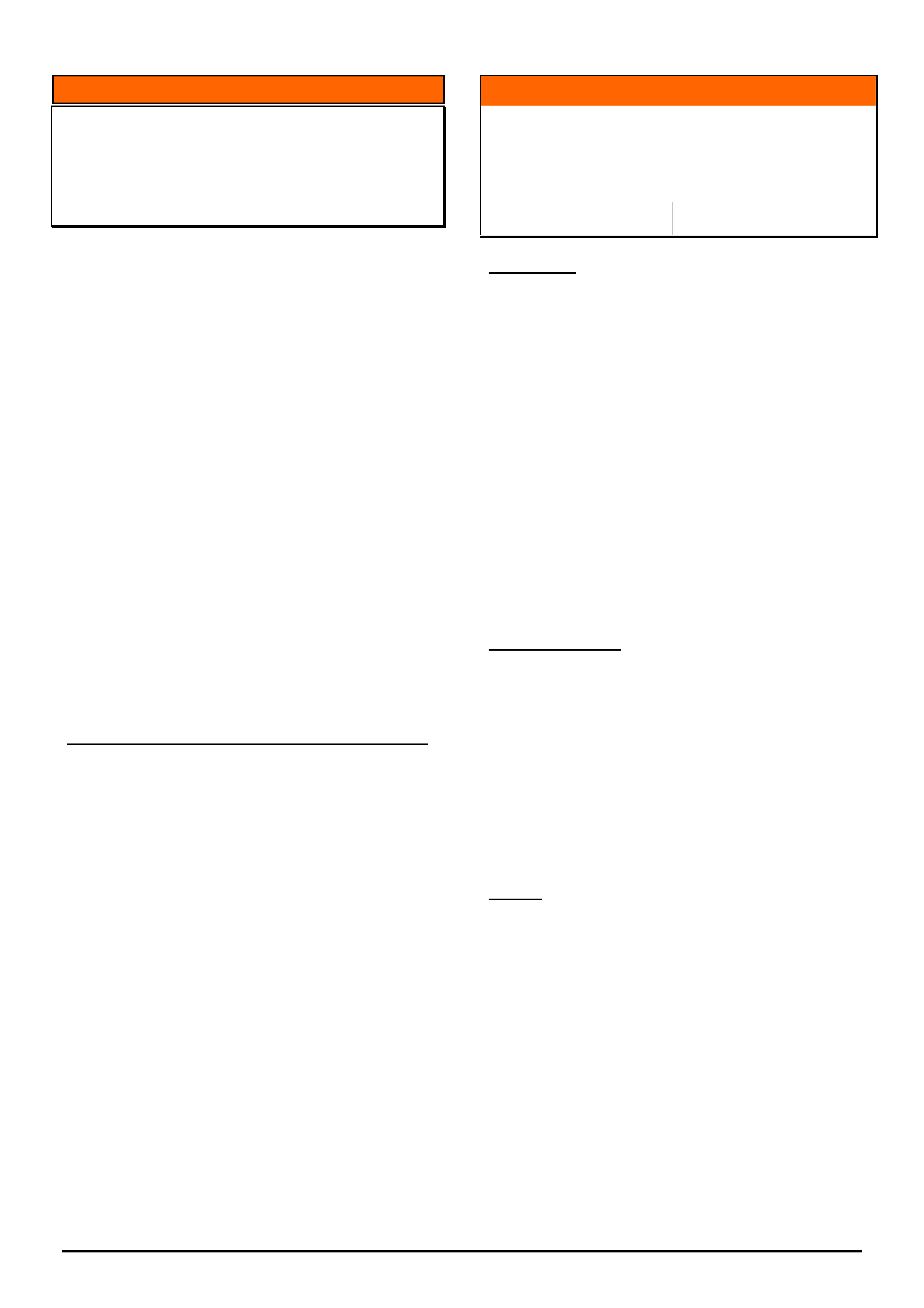

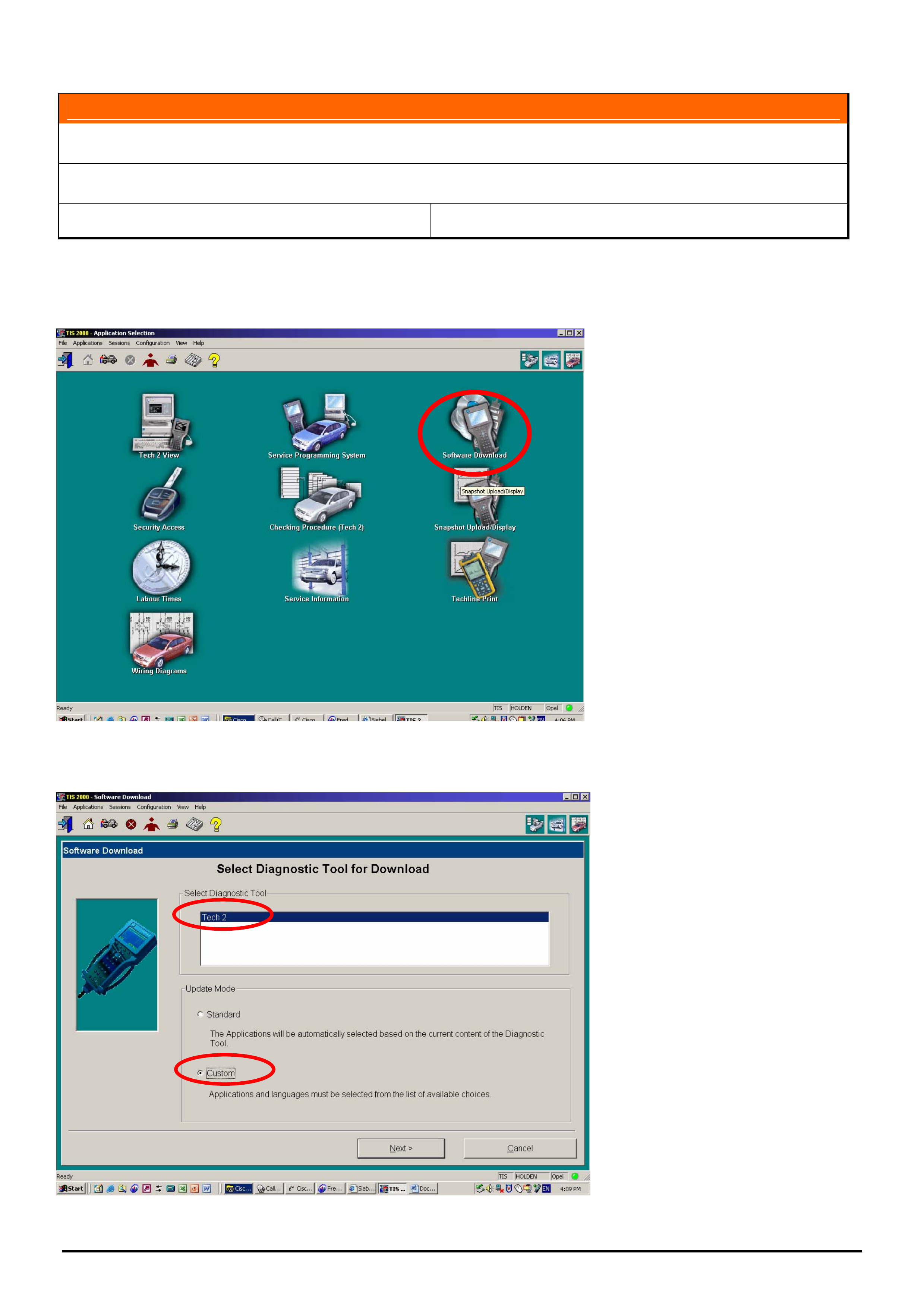

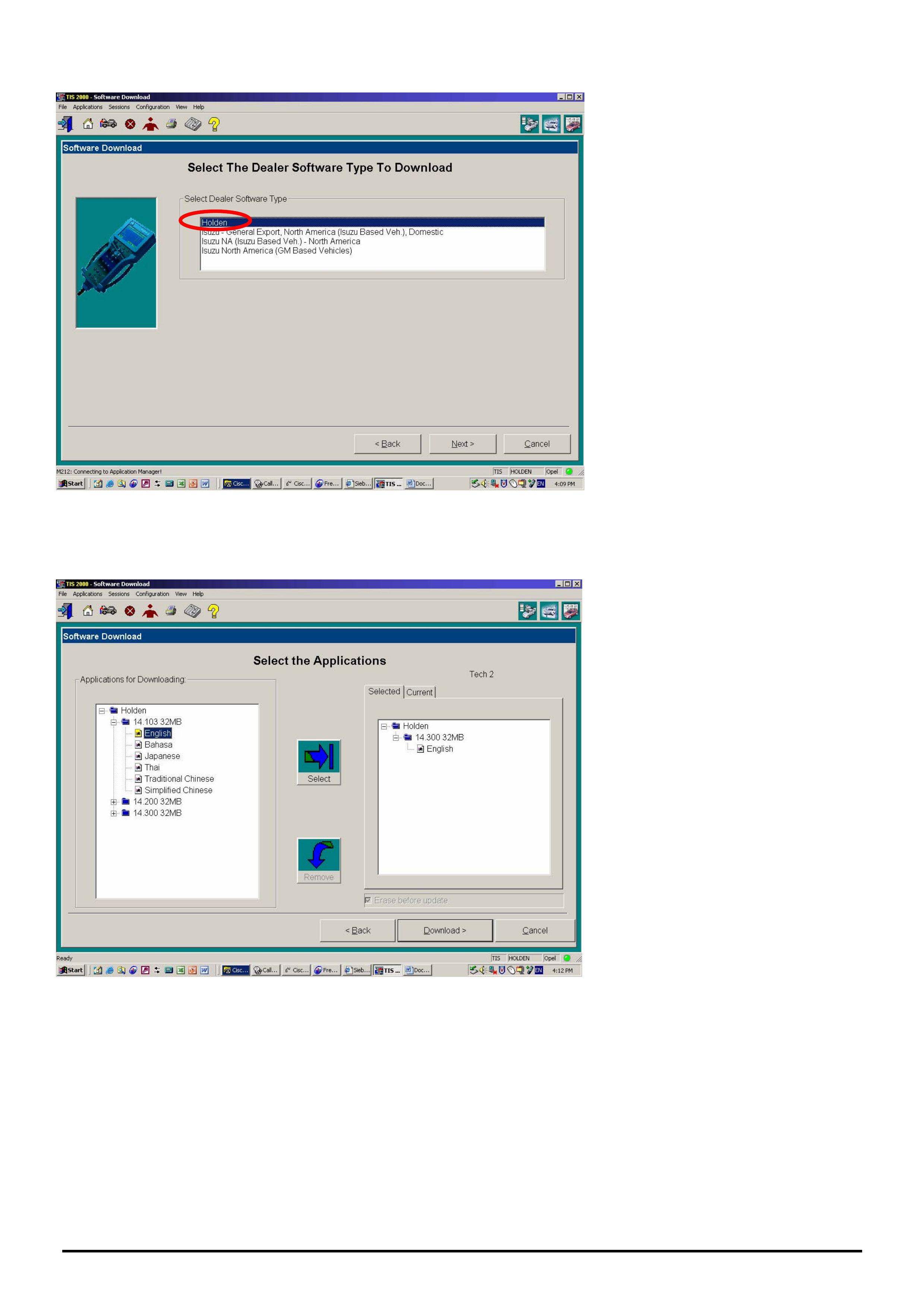

The screen below is an example of the Tech 2 Model

Year selection screen. The Numbers and letters on

the LH side in brackets are the values of the tenth

digit of the VIN for that model Year.

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

13

DIAGNOSIS HINT

Fluid Leak Diagnosis Using Black Light And Dye

All Models

Group: OB Ref. No. TL0837- 0501

This techline is repeated from year 2000 techlines.

The information provided in this techline is to assist Dealers in performing thorough and accurate diagnosis of

fluid leaks prior to commencing any rectification work or removing major components.

Components must NOT be replaced for “leaks” without thorough definition of leak sources.

Use of Black Light Dye and Black Light is highly recommended to trace leak sources. For extensive information

on the use of Black Light and Black Light Dye, refer to the following information repeated from a previous All

Dealer Letter.

Holden strongly recommends the use of the black light and dye method to diagnose fluid leak sources. This

method of leak detection is a proven, reliable method that identifies the specific leak source and/or location.

The black light and dye method can be used for various types of leak detection, when used with the appropriate

tracer dye it can be used for detecting engine and transmission fluid leaks, Refrigerant leaks, fuel leaks, and

coolant leaks.

The following pages provide answers to technicians’ questions about the various aspects of black light and

tracer dye, and how dealerships may use this tool to their advantage.

Black Light & Tracer Dye and Accessories

There are different types of tracer dye for different applications, plus for air-conditioning systems, an

injector is required to infuse the dye into the system. The following tracer dyes and accessories are

available from SPx Australia. Other equivalent products may be used in their place.

Contact details for SPx Australia – Ph.: (03) 9544 6222; Fax: (03) 9544 5222.

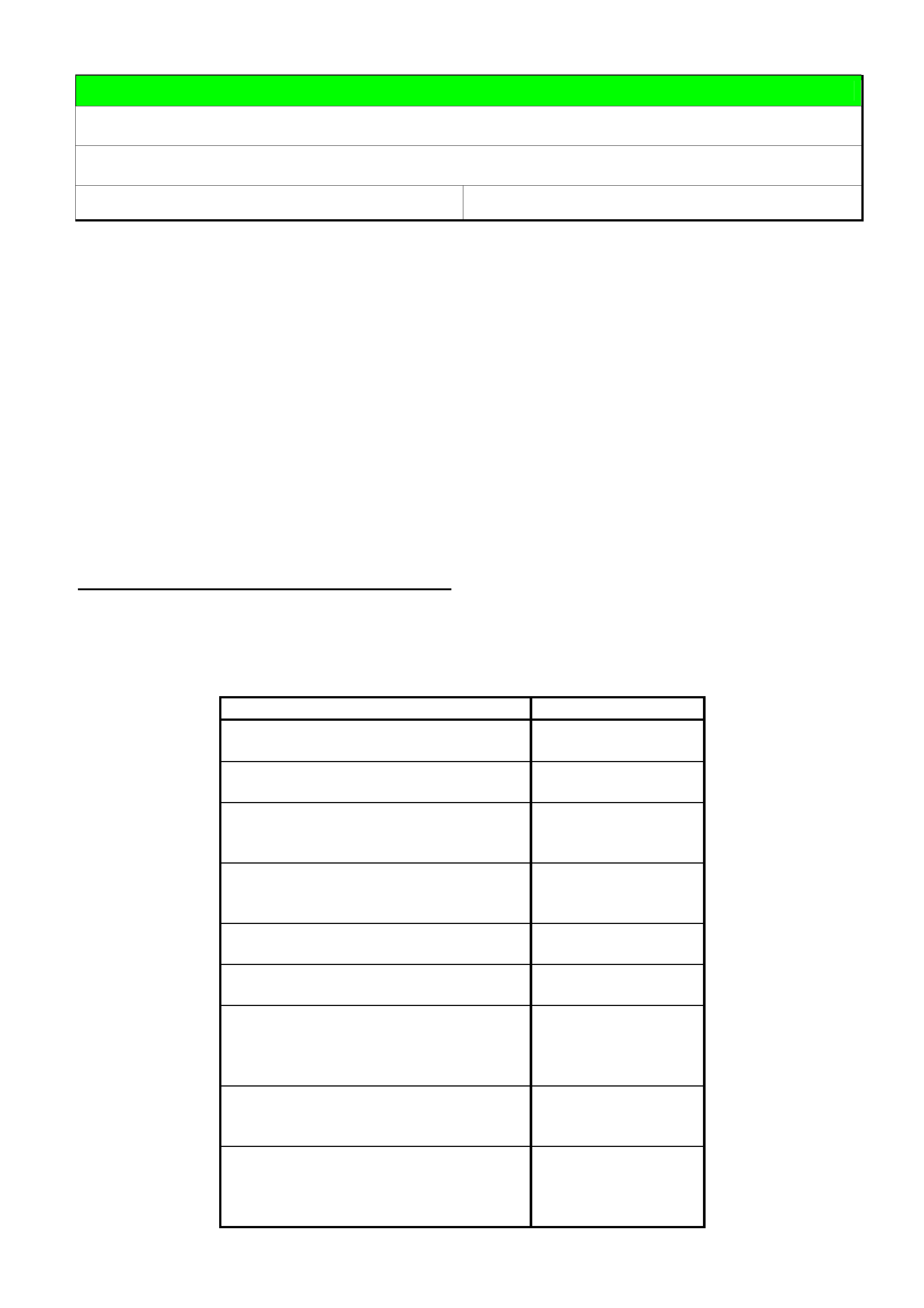

Application Part Number

Black Light Leak Detection

Lamp

16296

Replacement Black Light Bulb

AU 512

R134a Air Conditioning Tracer

Dye

(24 X 8ml bottles)

J41447

R12 Air Conditioning Tracer

Dye

(24 X 8ml bottles)

J39475

R134a Air Conditioning Injector

J41459

R12 Air Conditioning Injector

J41709

Petrol & Diesel Engine Fluid and

Transmission Fluid Tracer Dye

(24 X 1 oz bottles)

J28431-B

Coolant Tracer Dye

(24 X 1 oz bottles)

J29545-6A

Multi purpose dye

(engine oil, transmission & power

steering fluid, diesel & petrol)

16268

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

14

Black Light & Tracer Dye Useage Information

The following pages will answer most questions you may have about using Black Light and Tracer Dye.

Summary of the steps involved in detecting a fluid leak using black light and dye:

Pour specified amount of dye into the system.

Road test the vehicle under normal operating conditions, to allow the dye to mix with the host fluid/gas.

Define the leak source by directing the Black Light towards the suspect area. The fluid leak will appear as a

brightly coloured path leading to the source. Note: The colour of the dyed fluid can be checked on the dipstick,

or other component directly in contact with the host fluid/gas.

Repair fluid leak cause and recheck to ensure that leak has been rectified.

General Information

How much dye do you use? The following information is given as a guide only. Always refer to the label on the

bottle.

Engine, Transmission, Fuel

J28431-B Engine & Trans. Fluid Dye should be used as follows:

Petrol Engine Oil - 7.4ml per 3.79litres of oil (¼oz per 4-5 quarts)

Diesel Engine Oil - 7.4ml per 3.78litres of oil (¼oz per 4 quarts)

Automatic Trans. Fluid - 14.8ml per 5.68litres of fluid (2x¼oz per 6 quarts)

Manual Trans. Fluid/Oil - 7.4ml per 5.68litres of fluid (¼oz per 6 quarts)

Petrol or Diesel Fuel - 7.4ml per 7.57litres of fuel (¼oz per 2 gallons)

A/C Systems

J41447 R134a A/C Dye should be used as follows:

R134a A/C System - 7.4ml per A/C system (¼oz per system)

J39475 R12 A/C Dye should be used as follows:

R12 A/C System - 7.4ml per A/C system (¼oz per system)

Power Steering

J28431-B Engine & Trans. Fluid Dye can be used in Power Steering as follows:

Power Steering Fluid - 7.4ml per 5.68litres of fluid (¼oz per 6 quarts)

Engine Coolant Systems

J29545-6A Coolant Dye should be used as follows:

Coolant System Radiator Fluid - 7.4ml per 15.14 litres (¼oz per 16 quarts)

Note: These amounts are based on various tests - there may be occasions when good fluorescence is not

obtained with these amounts of dye, due to the condition of the host oil/fluid or the nature of certain additive

packages in the oil/fluid itself. If this occurs, use additional dye.

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

15

Q A

Do you need to use the

Fluorescent Enhancer Safety

Goggles?

Yes - they not only protect the technician, but also visually optimise the

dye fluorescence for enhanced leak detection. They are scientifically

designed to enhance fluorescence by eliminating light at wave lengths

that might interfere with the eye’s ability to view the dye’s fluorescent

light emission. Once you look at the dye with and without the goggles,

you will see the difference.

What life does the dye have

when left in coolant, ATF,

R12 and R134a refrigerant?

Indefinite - unless the ATF is “burnt” in an A/T clutch failure or if here is

an A/C compressor failure.

What life does the dye have

when left in engine oil?

Depends on how dirty the oil was when the dye was added. In clean petrol

engine oil, it will last 500+km. In diesel engine oil, it will not last as long

because of rapid carbon build-up.

Are there any adverse effects

of leaving dye in systems too

long?

None - and A/C dyes especially are very thermally stable and should last

100,000 km.

Is there a preferred method

of cleaning the dye from a

vehicle, if spilt?

IMPORTANT - Do NOT get dyes on any painted surfaces - use guard

covers when pouring dyes into any vehicle system or injecting A/C dyes. A

good cleaning solvent should clean any dye off any metal surfaces. A/C

dyes cannot be cleaned off hoses or plastic components.

What is the shelf life of the

dyes?

Indefinite, but it is recommended they be used within five years.

PETROL & DIESEL ENGINE & TRANSMISSION OIL LEAKS

Use J28431-B dye in quantities as specified in “General Information” section.

Putting dye into oil that is fairly clean will achieve the best fluorescence for le ak inspection because the greater

the carbon build-up in the oil, the more difficult to obtain good fluorescence from the dye. Therefore, if the oil

appears to be extremely dirty on the dipstick, additional dye may be required to obtain good fluorescence and

can be added without harm to the engine.

Q A

How do I know if the dilution

ratio of dye added is correct?

After adding dye at the recommended dilution ratio, operate the engine 3 to

5 minutes to allow dye to mix with oil. Then check the oil dipstick with

black light for the yellow-green fluorescent glow of the oil/dye mixture.

What is the proper procedure

for adding dye to the engine?

With the engine OFF. This will prevent possible splashing of the dye over

an area of the engine that may need inspecting.

How long does it normally

take for the dye to work?

Most leaks will appear after operating the engine 5 to 10 minutes. However,

it is recommended that the vehicle be taken for a short road test in order to

allow the dye to penetrate all leaks.

How long will it take for the

dye to penetrate very small

pinholes or porosity leaks?

To accurately detect leaks of this type, the vehicle should be operated for 1

to 3 hours under normal operating conditions. Suggestion: If such a leak is

suspected, add dye to the engine oil. Then have the vehicle owner use the

vehicle for the time recommended above. The owner should then return for

leak inspection with the black light.

Do I have to clean engine NO! Under black light, all petroleum-based products such as oil, grease, and

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

16

Q A

surfaces prior to using the

dye?

ATF will fluoresce blue. The dye will penetrate surface oil, grease and grit

to leave a yellow-green fluorescent trace (under black light) at the source of

the leak.

Do I have to clean the engine

after repairing the leak?

YES! But only at the source of the leak in order to allow the technician to

operate the engine and then re-inspect the leak repair to insure the job was

done right the first time. Suggestion: The dye/oil mixture can be removed

by using any engine degreaser or solvent-type shop cleaner.

After adding dye to the

engine oil, is it necessary to

change the oil prior to

returning the vehicle to the

customer?

NO! The dye is 100% compatible with engine oil and can remain in the

system without harm until the next oil change.

How long will it take for

ATF dye to work?

Most leaks will appear after operating the transmission for 5 to 10 minutes.

However, it is recommended that the vehicle be taken for a short road test in

order to allow ATF dye to penetrate all leaks. NOTE: All other application

and leak-detection procedures remain the same as given under the Engine

Dye Section (above). It is not necessary to clean transmission exterior

surfaces prior to using ATF dye. To detect small pinhole or porosity leaks,

the vehicle should be operated for 1 to 3 hours. The ATF dye mixture

should be cleaned from the source of the leak, and it is not necessary to

change ATF after adding dye.

How long will ATF dye be

effective in the transmission?

Because the transmission remains fairly clean internally and does not have

the carbon build-up problem present in petrol and diesel engines, the ATF

dye will be effective as long as the ATF is not changed or the ATF is not

“burnt” or discoloured by a transmission failure. Remember to check the

dipstick with the black light prior to inspecting for leaks to check

fluorescence, and do not forget to check the ATF cooler line for leaks.

BRAKE SYSTEM LEAKS

Q A

Can I use a fluorescent dye

in a brake system?

Never use any type of a fluorescent tracer dye in a brake system.

POWER STEERING LEAKS

Q A

How much dye should I use

for finding power steering

leaks?

Check the fluid capacity of the power steering system. You will probably

need to add only a small amount of dye at a dilution ratio of 7.4ml (¼ oz) to

5.68l (6 quarts) of power steering fluid. Run the system, then check the cap

or dipstick for fluorescence with the black light.

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

17

FUEL SYSTEM LEAKS

When a fuel system leak is suspected, it is recommended that the vehicle being tested have a quarter tank or less

of fuel. Trucks and larger capacity systems should be estimated as close as possible in order to keep the dye

requirement at a minimum and to keep the test procedure as economical as possible. If a difficult leak is

suspected, adding more dye than normal (a higher concentration) will produce the best results and will not harm

the system.

Q A

How do I know if enough

fuel dye has been added?

Any dipstick device that can be inserted into the filler tube can be used and

then inspected for fluorescence with the black light.

On a fuel-injected (PFI)

vehicle, can I use the fuel

rail for injecting dye?

NO! The small volume of petrol that will receive the dye is probably

insufficient for the dye to show up at an “O” ring injector leak for example.

COOLANT SYSTEM LEAKS

Q A

What is the proper procedure

for adding dye to the cooling

system?

Add dye with the engine off and radiator “cold”. This will prevent splashing

of dye and possible false readings. Also, add the coolant dye directly into

radiator and not into the reserve/surge tank found on some vehicles.

How do I clean the coolant

with dye off the radiator and

engine surfaces?

Use water with detergent and a small scrub brush.

How can I check for a

suspected coolant leak into

the engine oil?

Perform test as follows:-

Pull the engine oil dipstick and confirm the blue fluorescence of the engine

oil with the black light. (This is oil to which no dye has been added.)

With the engine off and the radiator cold, pour coolant dye into the radiator,

and operate vehicle for at least one day to allow coolant to leak into engine

oil.

With the engine off, pull engine oil dipstick and fluoresce dipstick with

black light.

If coolant is leaking into the engine oil, the dipstick should show some green

fluorescent droplets of coolant. Also, the engine oil might fluoresce a slight

whitish blue colour instead of the normal strong blue fluorescence of engine

oil.

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

18

USING DYE IN R134a or R12 A/C SYSTEMS

When dye is injected into an A/C system and the system has been operated under full pressure for 5 to 10

minutes, the dye will remain in the system even though the R134a or R12 has been evacuated for a repair. The

only time R134a or R12 dye must be replenished is when the A/C system is flushed of refrigerant oil.

Q A

How do I put R134a or R12

dye into an automotive car or

truck A/C system?

Put 7.4ml (¼ oz) of dye in the dye injector reservoir, and use a refrigerant

source to inject the dye into the A/C system.

How long will it take the

R134a or R12 dye to circulate

through the typical

automotive A/C system?

Operating the A/C system under full pressure, it will take the dye

approximately 5 to 10 minutes to circulate through most A/C systems.

However, this does not mean that the A/C leak will show up in that time

period.

How long after putting

R134a or R12 dye into the

A/C system and running the

system under full pressure

can I begin looking for the

A/C leak with the black light?

This depends on the size and location of the leak. As the refrigerant escapes

under pressure, it carries with it a very small amount of refrigerant lubricant.

This trace of lubricant is what you are looking for with the black light.

Therefore, the size of the leak will determine how long it takes for the

lubricant dye to appear and fluoresce under the black light. A hose porosity

leak would, therefore, take longer to appear than a fracture/fitting leak.

Example: A high-pressure side leak may take over a week or more to have

enough refrigerant escape to affect the cooling capacity of the A/C system,

return the car to the customer, and tell them to bring it back for leak

inspection when they again notice a lack of cooling by the A/C system. When

this car returns, the refrigerant that has escaped will leave a trace of

refrigerant lubricant with dye, which is what you will be looking for with the

black light.

How do I know if I have a

leaky service valve on the

low-pressure side if I just

used that valve to put dye into

the A/C system?

After putting the R134a or R12 dye into the A/C system through the low-

pressure service valve, clean the valve with a solvent if the refrigerant taking

the dye into the A/C system did not clean off the service valve, sufficiently to

remove all trace of dye. Do this before starting the A/C system.

How do I clean the R134a or

R12 dye off A/C components

and engine surfaces?

Use any shop degreaser or solvent to clean dye off A/C components or

engine surfaces.

Are these A/C dyes

compatible with my

refrigerant recovery and

recycle equipment?

These dyes have been tested and proven compatible by major manufacturers

of recovery and recycle equipment. When refrigerant is evacuated from an

A/C system, a small amount of compressor lubricant is also removed from

the system. The R134a or R12 dye is in solution with the system compressor

lubricant, therefore, is separated in the recovery/recycle unit along with the

compressor lubricant. Because of the small amount of compressor lubricant

removed by the recovery/recycle unit, there is no need to add additional R-

134a or R-12 dye to the A/C system for future leak detection.

How do I know if a vehicle’s

A/C system contains dye?

Remove the low-side service port sealing cap and direct the black lamp into

the valve stem area. If you do not see dye/lubricant in this area, depress the

valve stem only for an instant to help bring out some lubricant with the

refrigerant. Again direct the black light at the valve stem for traces of the

fluorescent dye/lubricant. Clean dye off service port.

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

19

Q A

How do I check for

refrigerant leaks in the

evaporator when I cannot use

the black light to see the

leak?

Use the black light to fluoresce the drain hole and see if a trace of the yellow

green dyes has washed down with the condensation. When the evaporator is

removed from the vehicle, use the black light to determine the exact location

of the leak on the evaporator. Remember to check the fittings to and from the

evaporator to be sure they are not the cause of the leak.

How do I check for the

dye/lubricant when I cannot

directly shine the black light

on all suspected leak areas?

Use a mirror to reflect the black light to the underside of a fitting, hose or

component. Also if a mirror cannot be used, a white cloth can be used to

wipe the suspected area, and then fluoresce the cloth with the black light to

check for traces of the yellow-green dye.

Can the dyes remain in the

A/C system after it has been

used for the initial leak

detection?

Dyes can safely and effectively remain in the A/C system after the initial

repair. Dyes can be used to detect future refrigerant leaks and can only be

removed from the A/C system by flushing out the system compressor

lubricant.

HOLDEN SERVICE TECHLINE _______________________________________________________________FEBRUARY, 2005

20

INFORMATION

Holden Contacts and procedures

All Models

Group OB Ref. No. TL0679A- 0501

This Techline supercedes the previous one in Issue

3, April 2004. Revisions are shown in red.

This techline summarises some of the Holden

contact procedures and gives a quick reference

guide for contact numbers.

Security information.

To obtain security information for both Passenger

and LCRV vehicles the first step is to check

Lionheart. If the information is unavailable on

Lionheart then a completed security information

request form must be faxed through to the security

information department, as security information

cannot be given out by phone. Please note that

security information requests are processed by the

security information department and not TAS.

Please ensure you have the latest security

information request form, which is available on

Passenger Vehicle SIP for both Passenger and

LCRV. Contact details are listed below. There can be

up to a 4-hour turn around on requests however if the

information needs to be obtained from overseas, it

may take up to 24 hrs. Do not phone the security

information department unless you have not received

a response in the normal turn around time. For

further information please refer to ADL 63/99.

Parts inquiries and information

If any information or assistance is required in regards

to part numbers or Partfinder, please refer to the

Holden Help section in Partfinder.

Warranty Authorisation and enquiries

Warranty can only be authorised by your Aftersales

District Manager. Labour times information is

available on SIP or from the warranty department.

For any other warranty inquiries please contact

Warranty Administration.

TAS

Technical Assistance Service (TAS) is a service

provided by Holden to assist Holden Dealers in

problem resolution.

Contact to TAS must be made by a Nominated

Contact as outlined in Section 5 of the TAS

procedures manual. All techlines, dealer letters and

service information must be checked prior to

contacting TAS. The Nominated Contact must not

contact TAS until he/she has been fully involved with

the faulting vehicle and all Dealer expertise has been

exhausted. Problems should be escalated through

the Dealership to the senior technician/foreman

before contacting TAS.

TAS cases must be updated or closed within 30 days

unless a Dealer is waiting on a service fix to be

provided. It is the Dealers responsibility to update

cases. All cases should be recorded in the TAS

procedures manual, which should be referred to prior

to contacting TAS. Please note that an electronic

copy of the TAS procedures manual is also available

on passenger SIP.

All Daewoo TAS enquiries must be done by Fax.

Under no circumstances should you call TAS for

Daewoo enquiries.

Under no circumstances are TAS or other Holden

contact details to be supplied to customers or

independent repairers. TAS is a service restricted to

assisting Holden Dealer service departments.

Quick reference contact numbers

Air International Ph 1800 673 716

Australian Arrow Ph 03 9785 0792

Blaupunkt Ph 1300 307 036

Bosch Technical Assistance Ph 1800 025 462

Clarion Ph 1300 730 730

Fax 03 9551 0377

Customer Assistance Ph 1800 033 349

Dana Ph 02 9892 9237

Fax 02 9892 9310

www.spiceraxle.com.au

Delphi Ph 1800 335 777

Eurovox Ph 03 9237 0800

Fujitsu Ten Ph 03 9646 6008

Holden Assist Ph 1300 880 088

HSV Ph 03 9265 9500

Infomedia (SIP, Partfinder) Ph 1800 810 103

Panasonic Ph 02 9986 7635

PBR Diagnostic assistance Ph 1800 468 727

Petro-Ject Ph 02 9890 5701

Ph 02 9890 5244

Philips/Siemens-VDO Ph 1800 335 282

Salmat Ph 03 9358

2900

Security Information Ph 03 9647 2001

Fax 03 9647 2865

SPX Australia Ph 03 9544 6222

TAS Ph 1800 033 417

Fax 03 9647 2495

Email [email protected]

Warranty Ph 1800 033 487

Update

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

12

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

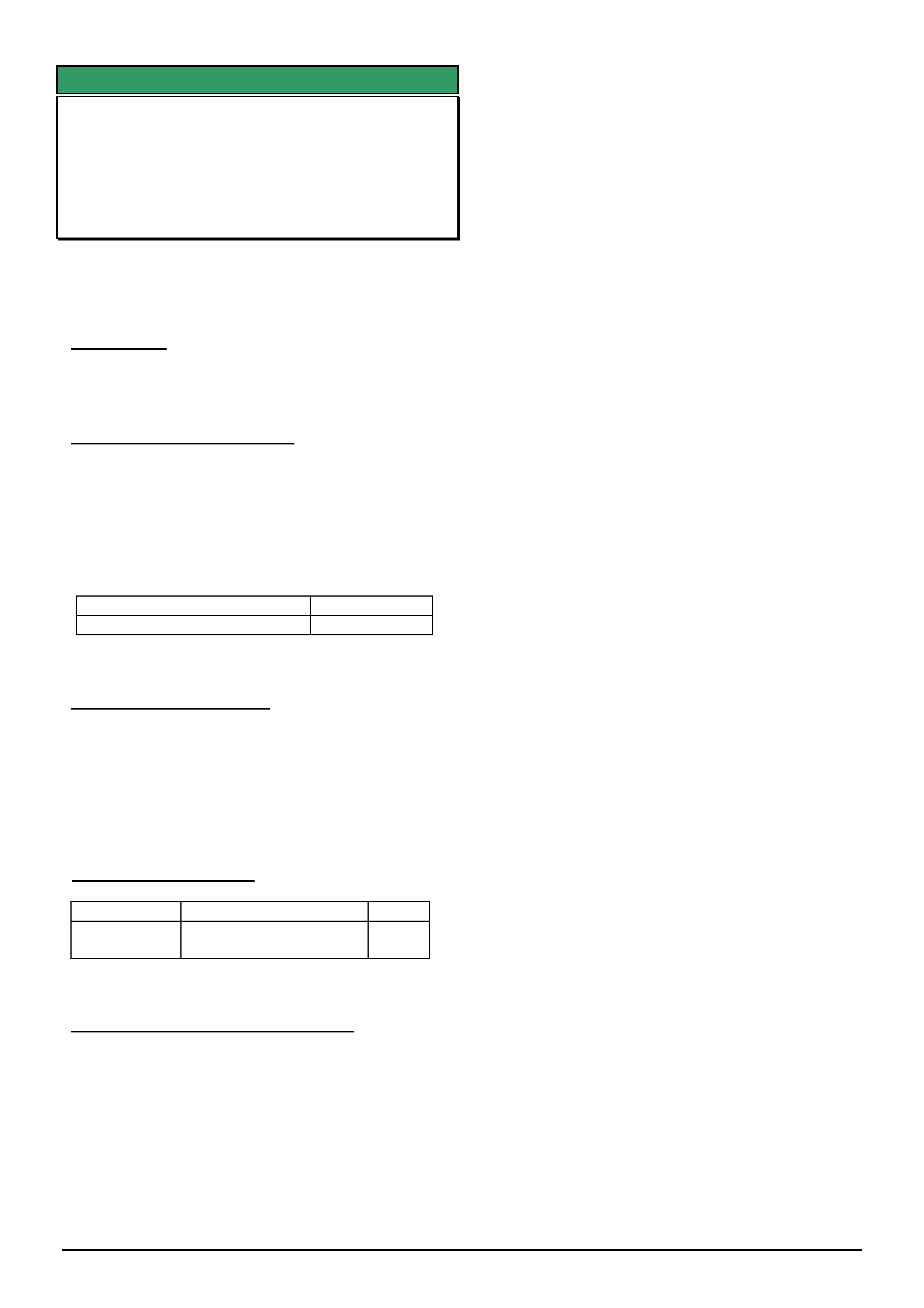

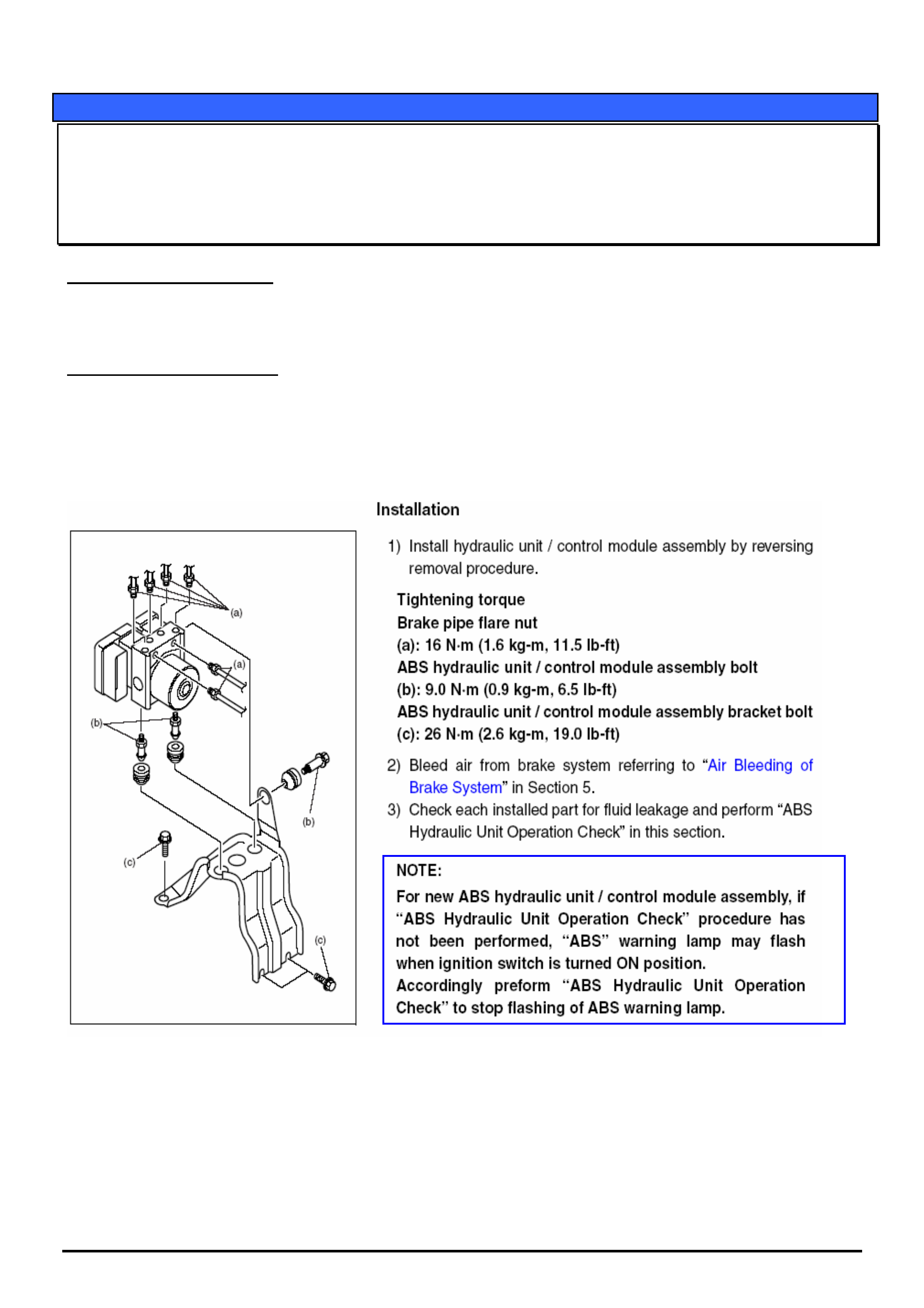

SERVICE FIX

Manual Transmission Front Countershaft

Roller Bearing Noisy

RA Rodeo with M/T

(GROUP 7A) TL0683A-0502

This Techline supercedes the previous one in Issue 5,

June,2004. It is revised by correcting the Production

Breakpoint Information. (Shown in red)

CONDITION

Transmission countershaft bearing noise evident due

to premature failure of front countershaft roller bearing.

CORRECTION – Production

Revised design (wider) front countershaft roller

bearings have been fitted to all transmissions from

Trans Serial No. 38215353 (Date 21/8/2003)

Transmissions with revised design (wider) front

countershaft roller bearings have been fitted to

vehicles from:

ISOVIN: Built Date:

MPATFR26J4H510242 30/9/2003

CORRECTION – Service

Where evaluation of the complaint noise is consistent

with a countershaft bearing noise (evident in all

forward gears except 4th) inspect the front countershaft

roller bearing for signs of wear. Fit a new bearing as

required, as per the procedure outlined in Light

Commercial SIP CD.

PARTS INFORMATION

Part No.: Description: Qty:

8970296004 Bearing Roller

Countershaft Front

1

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty Information

section of current Passenger Vehicle SIP CD

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

14

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

DIAGNOSIS HINT

Engine Surge or Low Power After Engine

or Gearbox Repair

RA Rodeo 3.5 L 6VE1

Group 6C Ref. No. TL0873- 0502

PROBLEM DESCRIPTION

Vehicle may surge or flat spot when under partial load

(E.G. half acceleration). Vehicle will perform normally

when accelerator is pressed to wide open position.

The problem usually occurs after repairs that have

required the engine or gearbox to be removed from

the vehicle.

Fault codes related to rich or lean condition MAY be

logged in ECU

SERVICE RECTIFICATION

Check O2 sensor operation with Tech 2; Check short

term and long term fuel trims, to see if there is a big

variance from Bank 1 to Bank 2 .

E.G. (Bank 1 STFT –30% Bank 2 STFT +30 %)

If there is a large variation, the problem is most likely

due to the O2 sensor wires having been crossed from

side to side when the wiring has been refitted.

In this case, check the correct O2 sensors are

connected to the correct plug. If a problem is found,

correct the wiring and clear fuel trim cells with Tech 2

and retest vehicle operation.

INFORMATION

Release of Dexron III (“H” Revision)

Automatic Transmission Fluid (ATF)

All models with A/T

Group 7B Ref. No. TL0860- 0502

General Motors DEXRON III ATF specification has

been upgraded to DEXRON III (H-Revision).

Commercially available fluids labelled as “DEXRON III,

Approved for the H Specification”, can be used in any

transmission application which specifies the use of

DEXRON III, IIE, II or DEXRON.

Current stock of DEXRON III ATF can be used until

the supply is depleted.

HOLDEN SERVICE TECHLINE ________________________________________________________________________________MARCH, 2005

16

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

Finding D.T.C’s on LCV SIP

All LCV Models

Group OB Ref. No. TL0874- 0502

The Light Commercial Vehicle (LCV) group in TAS

receives many calls from Dealers unable to locate

Diagnostic Trouble Code (D.T.C.) information for

LCV models.

The following instructions provide a step by step

procedure for locating this information.

ALL MODELS except YG Cruze

1. Open L.C.V. S.I.P. program from Desktop (double

click icon).

2. Select “Service Information” (single click)

3. Select Vehicle type eg., RA Rodeo, UE Frontera,

UBS Jackaroo (single click)

4. Select Engine type fitted to the vehicle and “single

click” “+” to expand menu.

5. From the selections available, select the title with

the words “Engine Driveability and

Emissions”(or similar)

6. From the list of topics under “Engine Driveability

and Emissions” look for the title “ECM Diagnostic

Trouble codes” or “PCM Diagnostic Trouble

Codes”. The DTC’s are contained in these

sections.

NOTE: In some instances, the DTCs will also

appear in the menu of topics on the LHS of the

screen.

YG Cruze

1. Open L.C.V. SIP program from Desktop (double

click icon).

2. Select YG Cruze (single click)

3. Expand “Engine” as mentioned above.

4. Select Section 6 Engine General Information

5. Open Section 2 Engine Diagnosis

6. DTC information starts at Section 2.13

HOLDEN SERVICE TECHLINE ________________________________________________________________________________APRIL, 2005

8

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

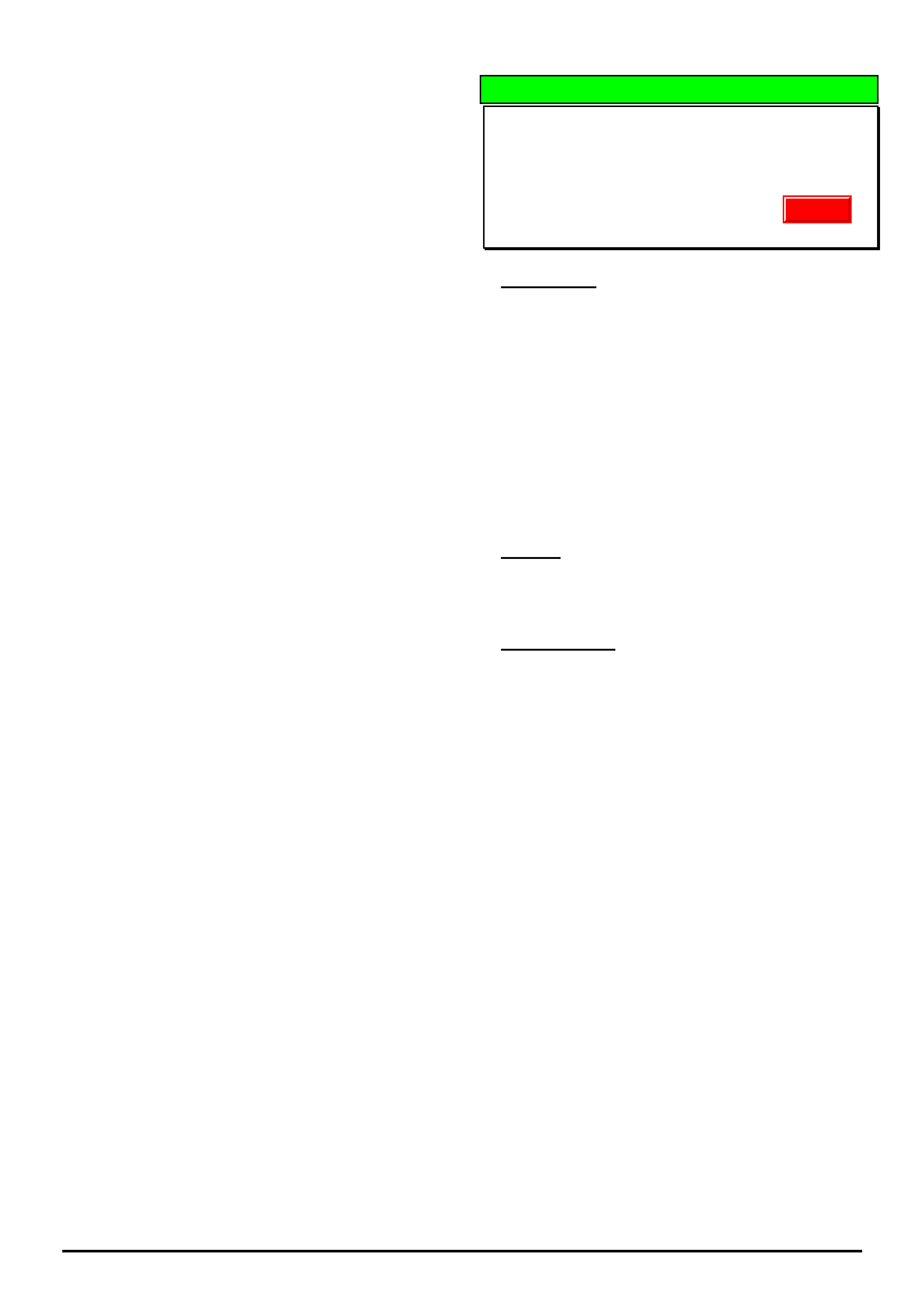

TIS 2000 Security Access and SPS Issues Due

To Hardware Key Incompatibility With New PC

All Models

Group OB Ref. No. TL0896- 0503

CONDITION

After installation of a new PC, Dealers may report

problems accessing security information or service

programming system (SPS). An error message may

appear. The problem may be intermittent.

CAUSE

New PC’s with a processor speed which is 2.0 Ghz or

greater are not compatible with older style “dongle”

hardware keys.

CORRECTION

To overcome this, a new “superpro” hardware key kit

(Parallel or USB) will need to be purchased through

SPX.

Please note: New hardware keys will need to be

registered before they will work.

The above information was explained in All Dealer

Letter 14/04

INFORMATION

Tis 2000 and Tech 2 ECU Programming

Terminology

GROUP OB TL0902-0503

When trying to reset or program modules with TIS

2000 or Tech 2, “reset ECU” or “program ECU” is often

displayed. Many Dealers assume ECU stands for

Engine Control Unit. This techline is to clarify that

ECU stands for “Electronic control unit” not “engine

control unit” and therefore applies to the module you

are dealing with.

For example - If you are resetting a CIM and tech 2

displays “reset ECU” it is referring to the CIM because

that is the module you are resetting and have

accessed with tech 2.

HOLDEN SERVICE TECHLINE ________________________________________________________________________________APRIL, 2005

10

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

DIAGNOSIS HINT

First Steps In Electrical Problem Diagnosis

(Check Earth Points)

RA Rodeo (and other models)

Group 12 Ref. No. TL0892- 0503

TAS receives numerous calls on varying Electrical

faults on the above models.

Some of these are DTC’s and SPS related problems.

A potential cause of these problems could be poor

electrical contact at Earth points. e.g. loose

attachments, dirt or paint between Terminal and

body.

SERVICE HINT

Prior to contacting TAS for help with diagnosis of any

electrical fault, it is strongly recommended that you

check/clean all the Earth points first.

The Earth Points in LCV SIP are located by the

following path:

Service Information/ RA / Engine type / 6E - “Engine

driveability and emissions” / Ground Point Chart /

Location.

This leads to photographs showing the exact location

of earth points.

If, after checking/cleaning earth points, the problem

is still present, contact TAS using the standard

procedure.

SERVICE FIX

Accelerator sensitivity at slow speeds and

over rough terrain.

RA Rodeo 4JH1-TC Diesel with Manual

transmission

Group 6C Ref. No. TL0865- 0503

CONDITION

Some owners may complain that the vehicle throttle

control is too sensitive. When driven at slow speed

or on rough terrain with low range or a low gear

selected, this sensitivity can create a jerking or

hopping motion.

CAUSE

Insufficient resistance in accelerator system.

CORRECTION – Service

(1) Adjust the throttle position sensor so that the

throttle position % (on Tech II) begins to increase

from 0 % as soon as the throttle butterfly starts to

move from the idle position.

Note: The throttle position sensor must still read 0%

when the vehicle is at idle.

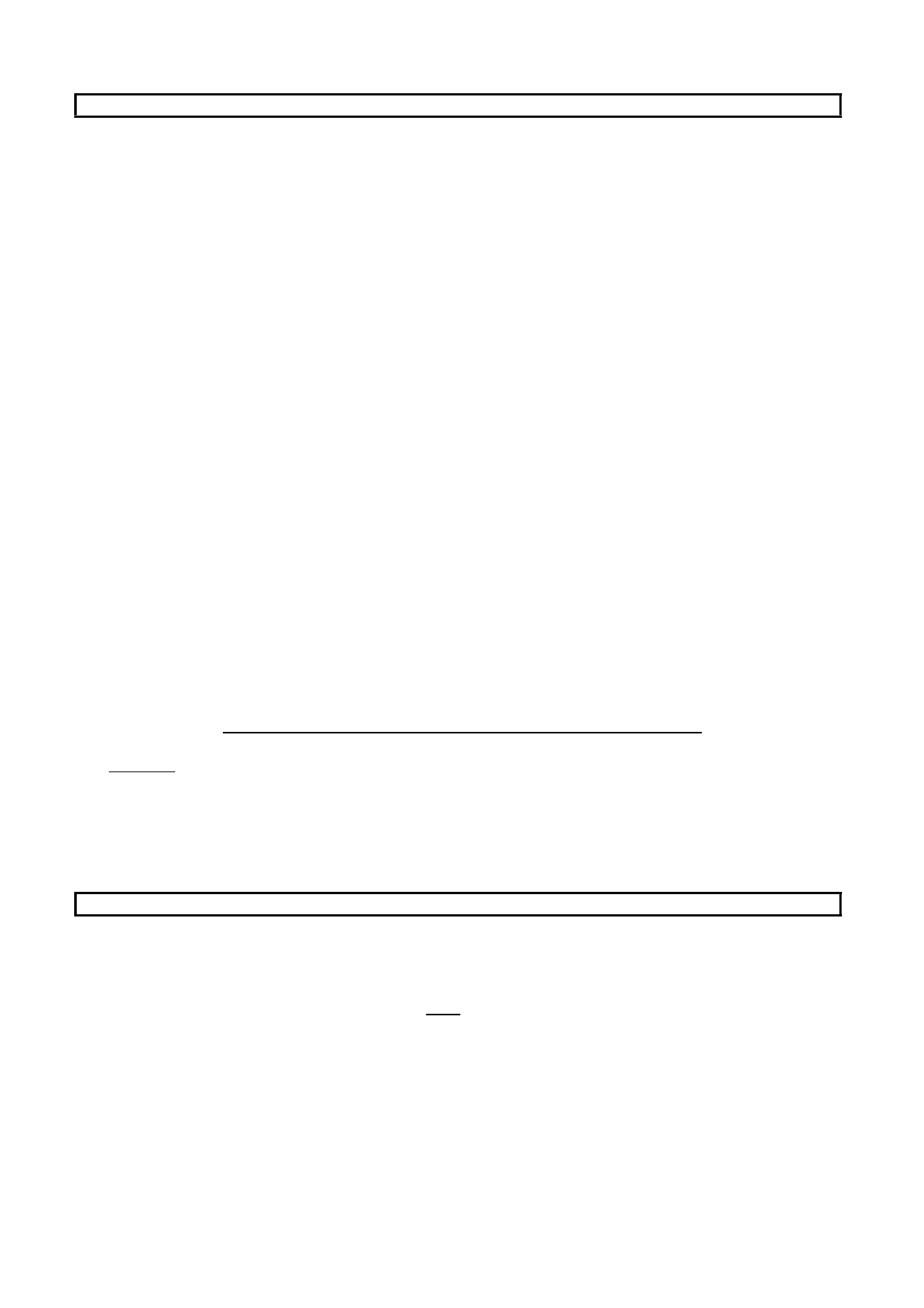

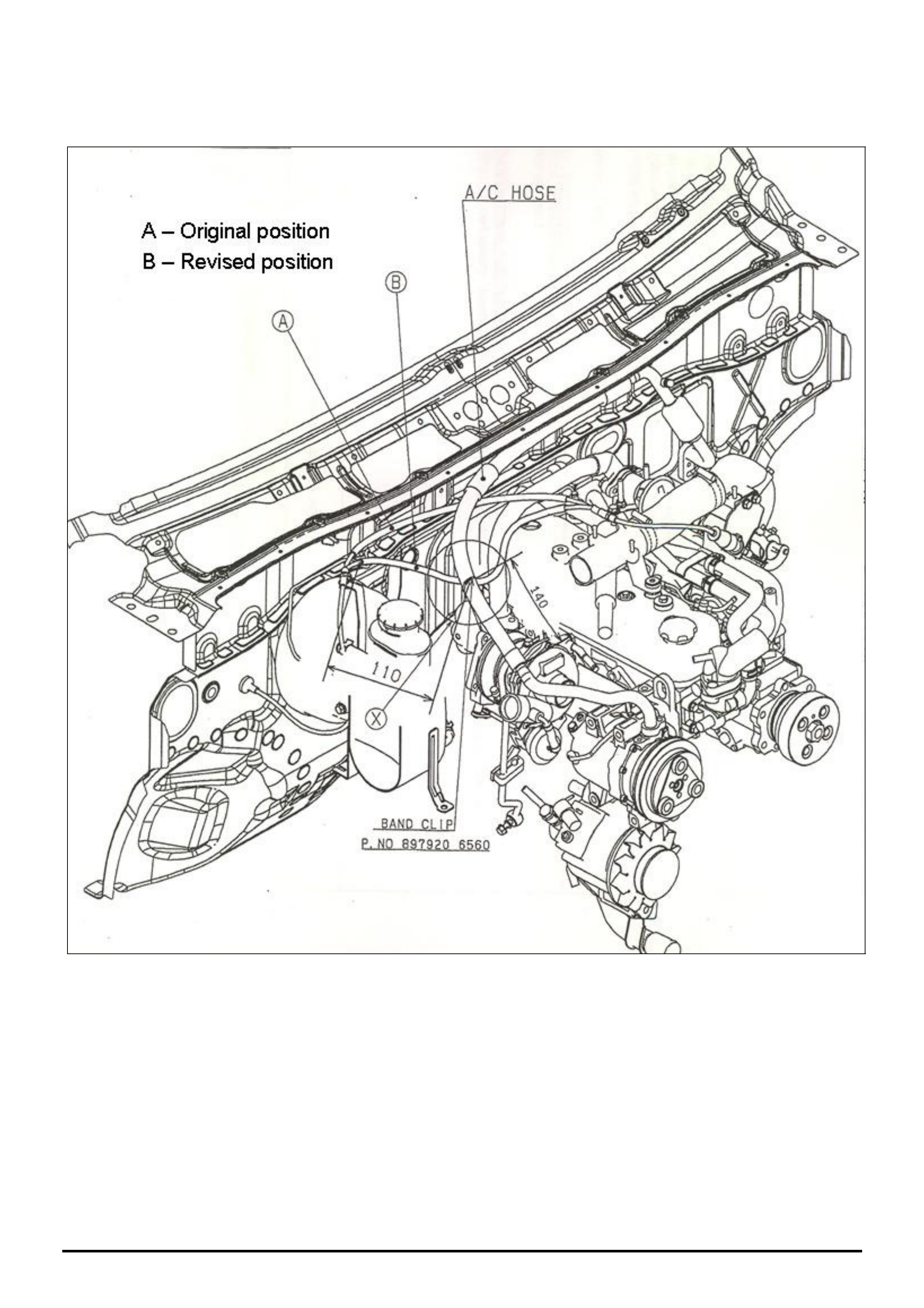

(2) Re-route accelerator cable as shown in Figure 1

using a cable tie as shown in Parts Information.

Ensure that the accelerator cable has no extreme

bends and operates correctly but with increased

effort.

NOTE: The accelerator cable can only be re-rerouted

on those vehicles where an accessory A/C kit has

been fitted.

PARTS INFORMATION

Part No.: Partfinder Name Qty:

8979206560 Clip band (cable tie) 1

WARRANTY CLAIM INFORMATION

Description Adjust TPS & reroute

accelerator cable

Labour Op. No. J000770

Time 0.3 hr

Failure Code J0033

HOLDEN SERVICE TECHLINE ________________________________________________________________________________APRIL, 2005

11

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

Figure 1. Shows accelerator cable rerouted from position A to B

HOLDEN SERVICE TECHLINE __________________________________________________________________________________MAY, 2005

6

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

Seat Belts Replaced For Complaint Of

Not Extending

UES Frontera, YG Cruze, RA Rodeo

(GROUP 1) TL253B-0504

This Techline is repeated from Issue 4, April 2003

as dealers continue to replace seat belts for this

condition which is not a fault

PROBLEM DESCRIPTION

Numerous seat belts returned through the warranty

system cannot be faulted. The reason for

replacement of these belts is given as "seat belt will

not extend" or "seat belt jamming".

It appears that customers and Retailer staff may be

unaware of the Auto Locking Ratchet (ALR) system.

Refer to following for explanation of ALR.

Automatic Locking Ratchet (ALR) Mechanism.

The rear outer seat belts (all rears on RA Rodeo) and

left hand front seat belt have an Automatic Locking

Ratchet (ALR) mechanism. When this mechanism is

activated it will only allow the belt to retract. When

the mechanism is de-activated the belt can be

extended or retracted as normal.

To activate the ALR mechanism, extend the seat

belt to its maximum length.

To de-activate the ALR mechanism, allow the seat

belt to retract fully.

The ALR function may be useful as an additional

means of locating a child seat, when used in

conjunction with the approved child restraint anchor

points.

Note: It is always better to install a child restraint in

the rear seat.

SERVICE RECOMMENDATION

To avoid mis-diagnosis of seat belts, Holden Retailer

frontline staff should familiarise themselves with the

operation of the ALR system . They will then be able

to explain this feature to any customers who

complain that their seat belts “will not extend” or are

“jamming”.

NOTE: Seat belts replaced unnecessarily for

complaint of “not extending” will not be accepted as

warranty.

INFORMATION

TIS Approval with Tech 2

All Vehicle Types

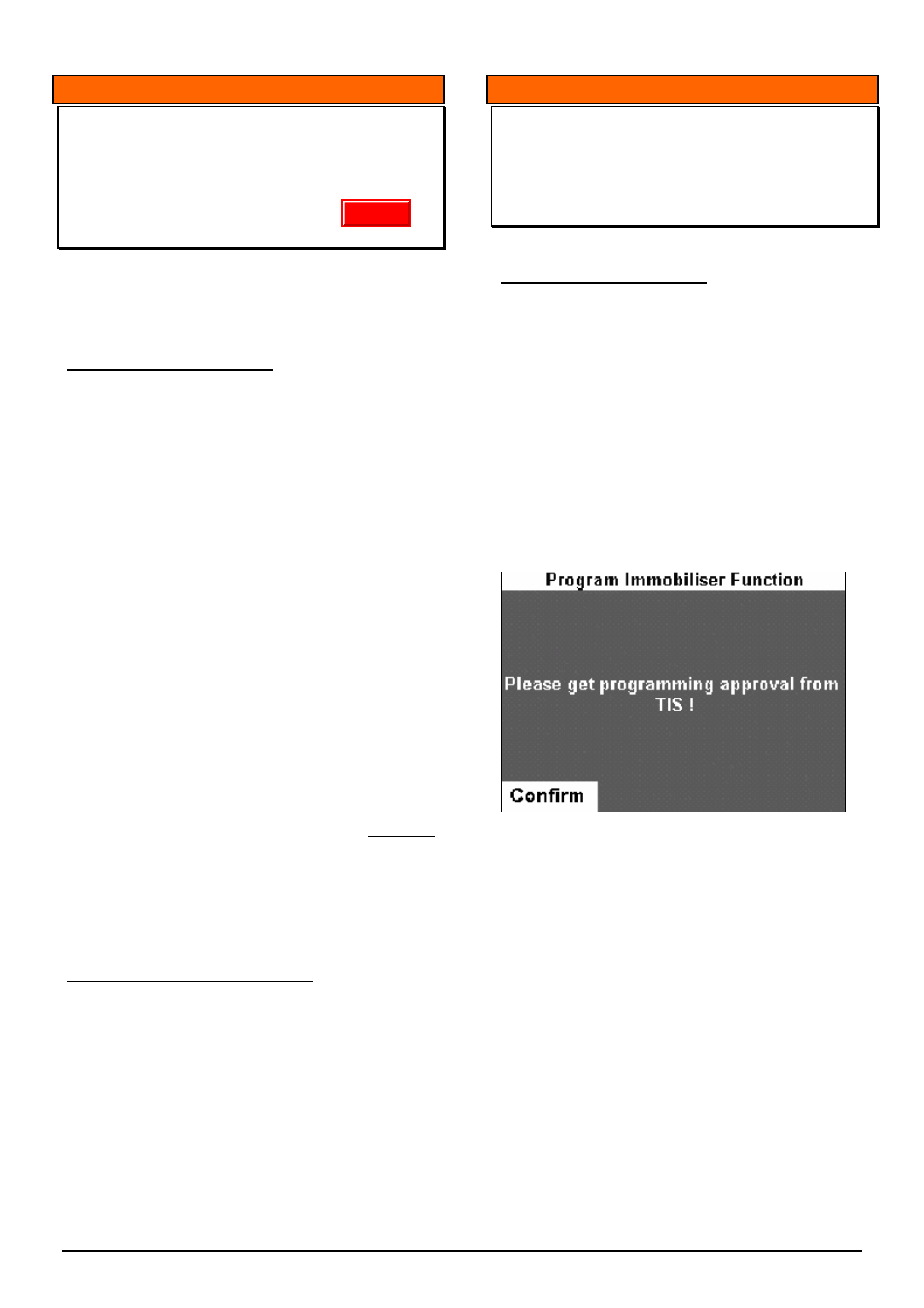

(GROUP OB) TL0903-0504

PROBLEM DESCRIPTION

Programming difficulties when trying to link

immobilizers or program keys, may be attributed to

the incorrect process of obtaining TIS Approval on

Tech 2.

Some programming difficulties have occurred when

technicians have got TIS Approval on Tech 2 before

going to the vehicle. THIS IS NOT THE CORRECT

PROCEDURE

Dealers are reminded that the correct procedure for

obtaining TIS Approval is to only connect the Tech 2

to TIS, AFTER the following message is displayed on

the Tech 2 screen when Tech 2 is connected to the

vehicle.

Failure to follow this procedure may result in

programming failures or unnecessary parts

replacements.

Update

HOLDEN SERVICE TECHLINE __________________________________________________________________________________MAY, 2005

7

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

DIAGNOSIS INFORMATION

Manual Transmission Rattle Noise in

Neutral at Idle

RA 4JH1 Diesel with M/T

(GROUP 7A) TL0910-0504

CONDITION

The vehicle may develop a “rattle” or “chatter” type

noise from the gearbox when the engine is at idle

and the gearbox is in neutral and foot is off the clutch

pedal.

The noise will go away when driven, or if the engine

RPM is increased.

The noise will go away when the clutch pedal is

depressed.

The noise may be intermittent.

CAUSE

The cause of the noise is currently under

investigation.

CORRECTION

If a vehicle is presented with the above complaint DO

NOT attempt any gearbox or clutch repairs - contact

TAS for further diagnostic assistance.

Update

HOLDEN SERVICE TECHLINE __________________________________________________________________________________MAY, 2005

8

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

SERVICE FI

X

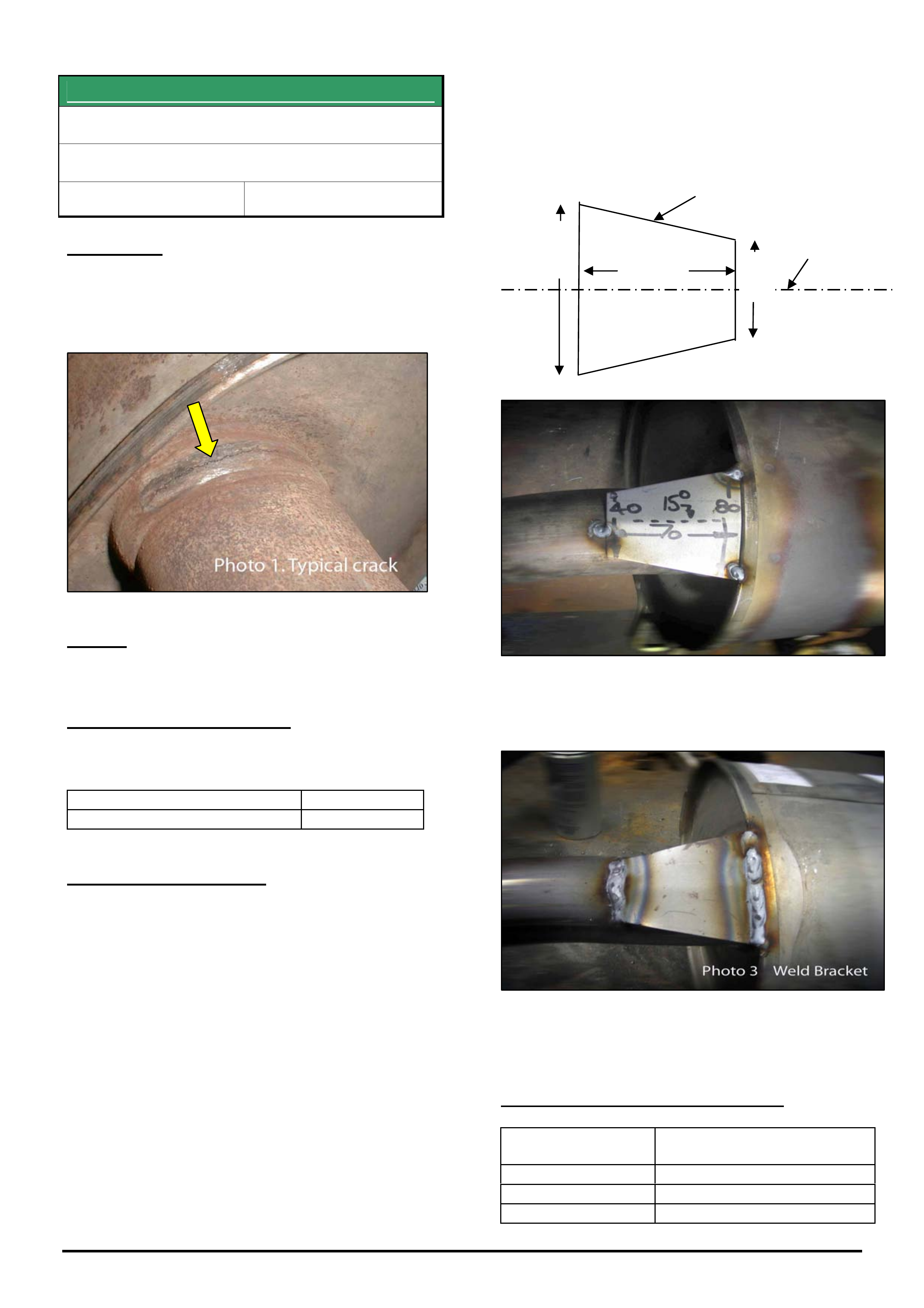

Muffler Cracks at inlet and outlet pipes.

RA Rodeo V6 Petrol Engine

Group 8 Ref. No. TL0876- 0504

CONDITION

Cracks form at the inlet and/or outlet pipe of the

muffler where the pipe joins to the muffler. Refer

Photo 1.

CAUSE

Insufficient integrity of weld.

CORRECTION – Production

Mufflers manufactured with improved welding

process have been fitted to vehicles from:

ISOVIN: Built Date:

MPATFR26H5H538834 20/01/05

CORRECTION – Service

Step 1. Re-weld crack/s at inlet and/or outlet pipe.

If weld is cracked or damaged beyond repair then

replace the muffler.

Step 2, Fabricate two support brackets as per

sketch below. Even if both pipes are not cracked, a

support bracket is required at both inlet and outlet

pipe.

Step 3. Fillet weld fabricated brackets to

muffler inlet and outlet pipes as per Photo 3 below.

Step 4. Paint brackets and welded surfaces with

Zinc Rich Primer or similar.

WARRANTY CLAIM INFORMATION

Description Muffler - repair crack and

weld on brackets

Labour Op. No. L000251

Time 0.8 hr

Failure Code L0002 weld broken

80mm

70mm

40mm

2mm steel

plate

Bend 15° along

centre line

Bend 15° along

centre line

HOLDEN SERVICE TECHLINE __________________________________________________________________________________MAY, 2005

16

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

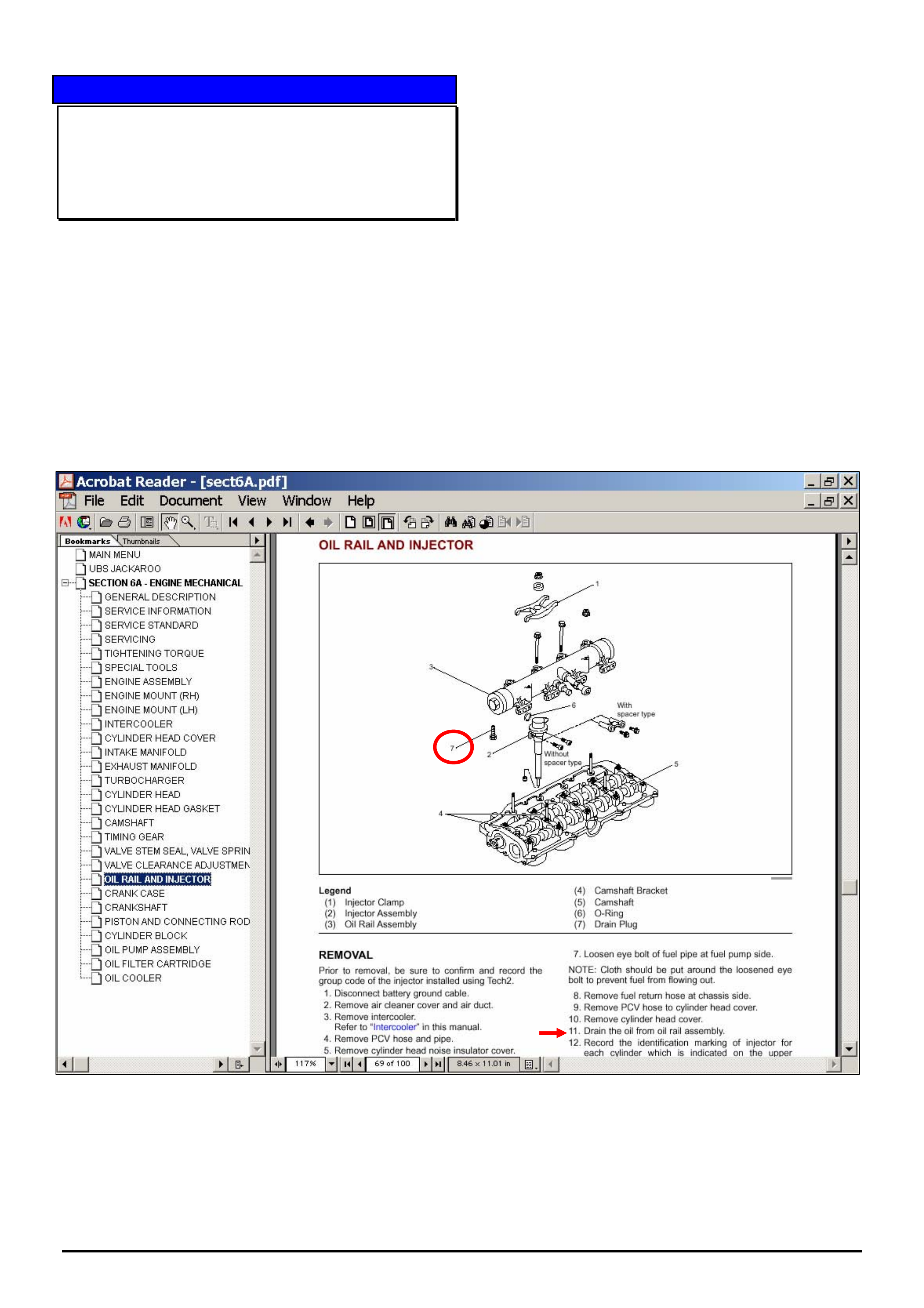

Checking TIS 2000 Version Number

GROUP OB TL0924-0504

The latest version of TIS (and other service

information Cd’s) is published at the beginning of

each Techline Issue under the heading:-

‘Your Latest Electronic Service Information’.

To confirm which version of TIS2000 is loaded on

your PC proceed as follows.

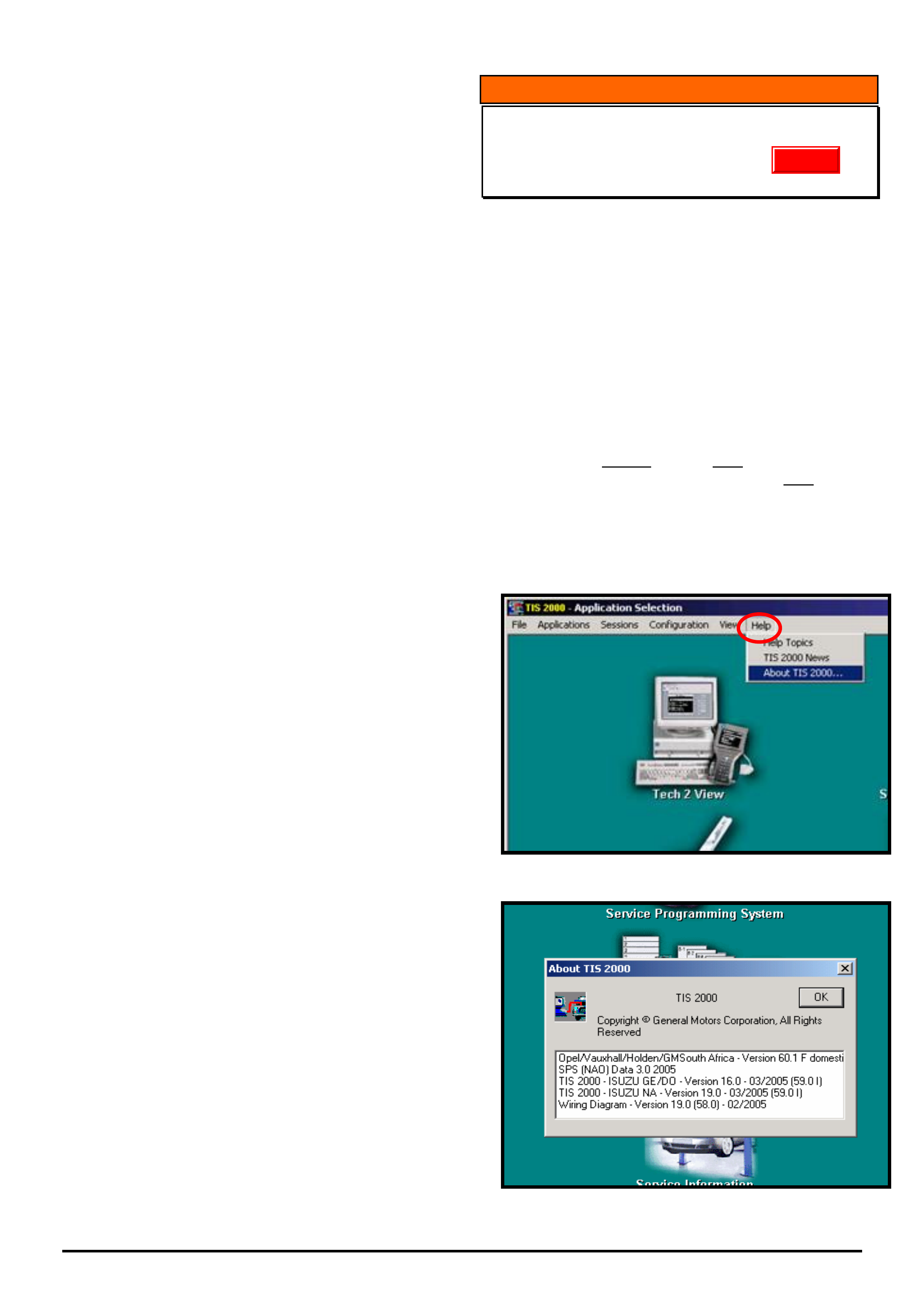

From the TIS main screen click ‘Help’ from the top

menu bar, then click ‘About TIS 2000’ refer Figure 1.

In the ‘pop up’ is the current version of service

information installed. Refer figure 2.

In this example the current version is:

Opel/Vauxhall/Holden/Version 60.1 Domestic.

TIS 2000 – Isuzu GE/DO Version 16.0 (Isuzu

General Export Domestic)

Wiring Diagram – Version 19.0

Note: For instructions on how to download TIS 2000

Isuzu software into Tech 2, refer Techline Issue 2

March 2004.

Figure 1.

Figure 2.

Update

HOLDEN SERVICE TECHLINE __________________________________________________________________________________MAY, 2005

18

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

Location of Mobile Phone Wiring

Connector

RA Rodeo

(GROUP 12) TL0922-0504

PROBLEM DESCRIPTION

TAS receive calls on electrical problems with RA

models that are the result of incorrect wiring of

mobile phones into the vehicles electrical system.

This highlights the fact that many installers of

aftermarket mobile phones are unaware of the

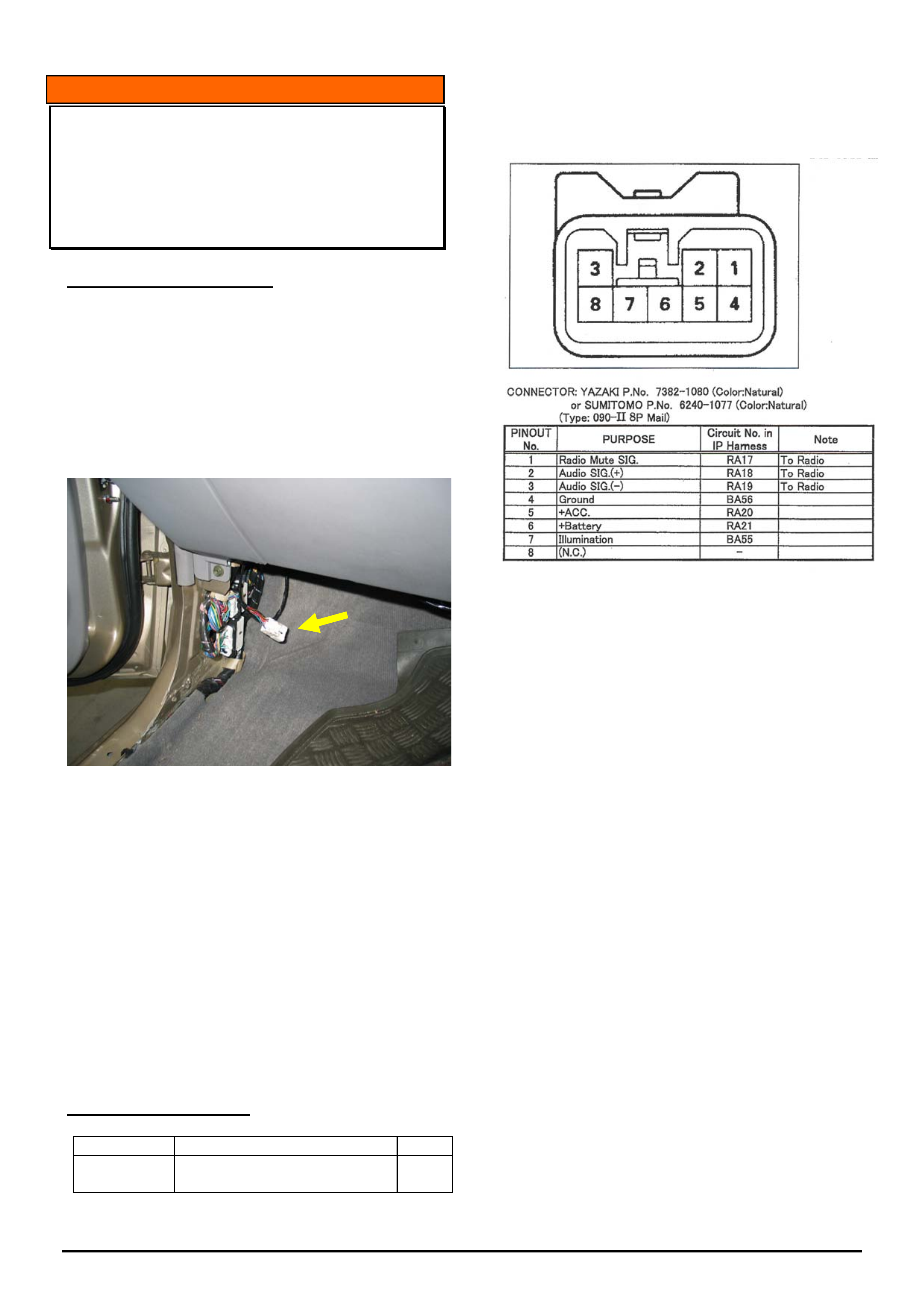

location of the cellular phone connector which is

located in the LH kick panel area as shown in Figure

1.

Figure 1.

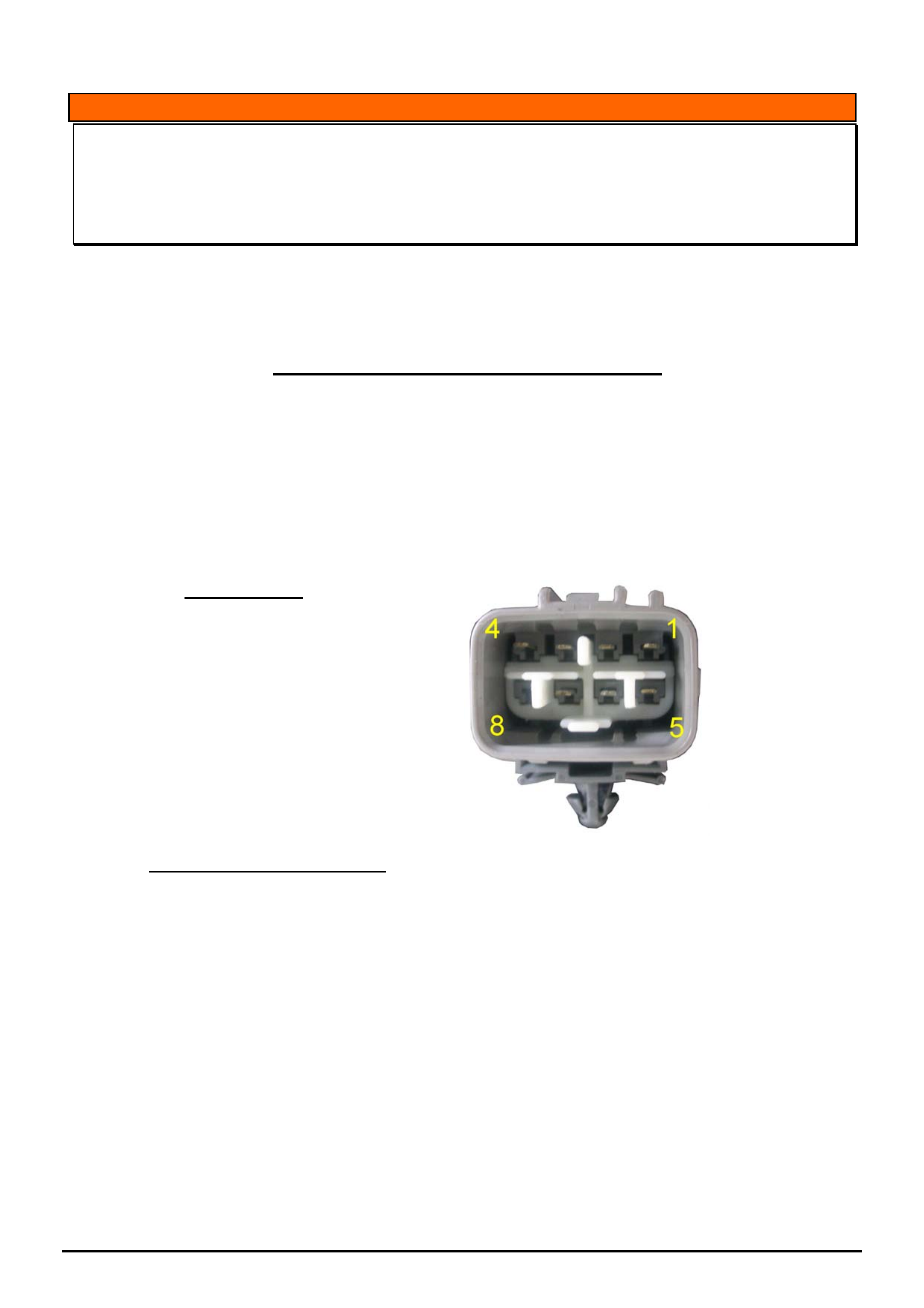

The pin configuration for this connector is shown in

Figure 2.

At the time of publication of this Techline it is

confirmed that pins 2 and 3 do NOT work in

conjunction with the standard Audio Units fitted to

these Vehicles.

In addition, pin 4 is not “Ground” and may NOT be

used.

NOTE: A mobile phone patch harness is available for

this connector from H.S.P.O.

For part number refer to Partfinder / RA Rodeo/

Accessories / Telephone Fittings.

PARTS INFORMATION

Part No.: Partfinder Name Qty:

92147932 Harness Patch Mobile Phone

1

Mobile Phone Connector

(IP Harness side)

Figure 2.

HOLDEN SERVICE TECHLINE __________________________________________________________________________________JUNE, 2005

5

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

TECHLINE CORRECTION

“Fuel Gauge Reads Empty With 25 Litres Left

In The Tank – RA Diesel”

Published in Issue 4, May 2004, Page 16.

Ref. No. TL0576-0404

Please correct your copy of the above Techline as

follows:

In the breakpoint table, alter the date for the 2x4 model

to read 10/11/03 as shown.

ISOVIN: Built Date:

MPATFR77H4H514631 (2 X 4) 10/11/04 03

MPATFS77H4H515657 (4 X 4) 19/11/03

INFORMATION

Searching for Techlines, Dealer Letters etc. on

Holden Lionheart (Portal)

(GROUP OB) TL0921-0504

This Techline describes two methods for locating

Techlines, Dealer Letters, Campaign Bulletins etc. on

Holden Lionheart.

• CONVENTIONAL method

• SEARCH ENGINE method.

The CONVENTIONAL method is similar to looking up

information in a text book. You commence by looking

in the Table Of Contents at the front of the book then

looking up the page reference then scanning down the

page until you find the section you’re looking for.

The “SEARCH ENGINE” method involves entering

your search criteria in a Search window and then

letting the search engine find the techlines

automatically.

HOLDEN SERVICE TECHLINE __________________________________________________________________________________JUNE, 2005

14

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

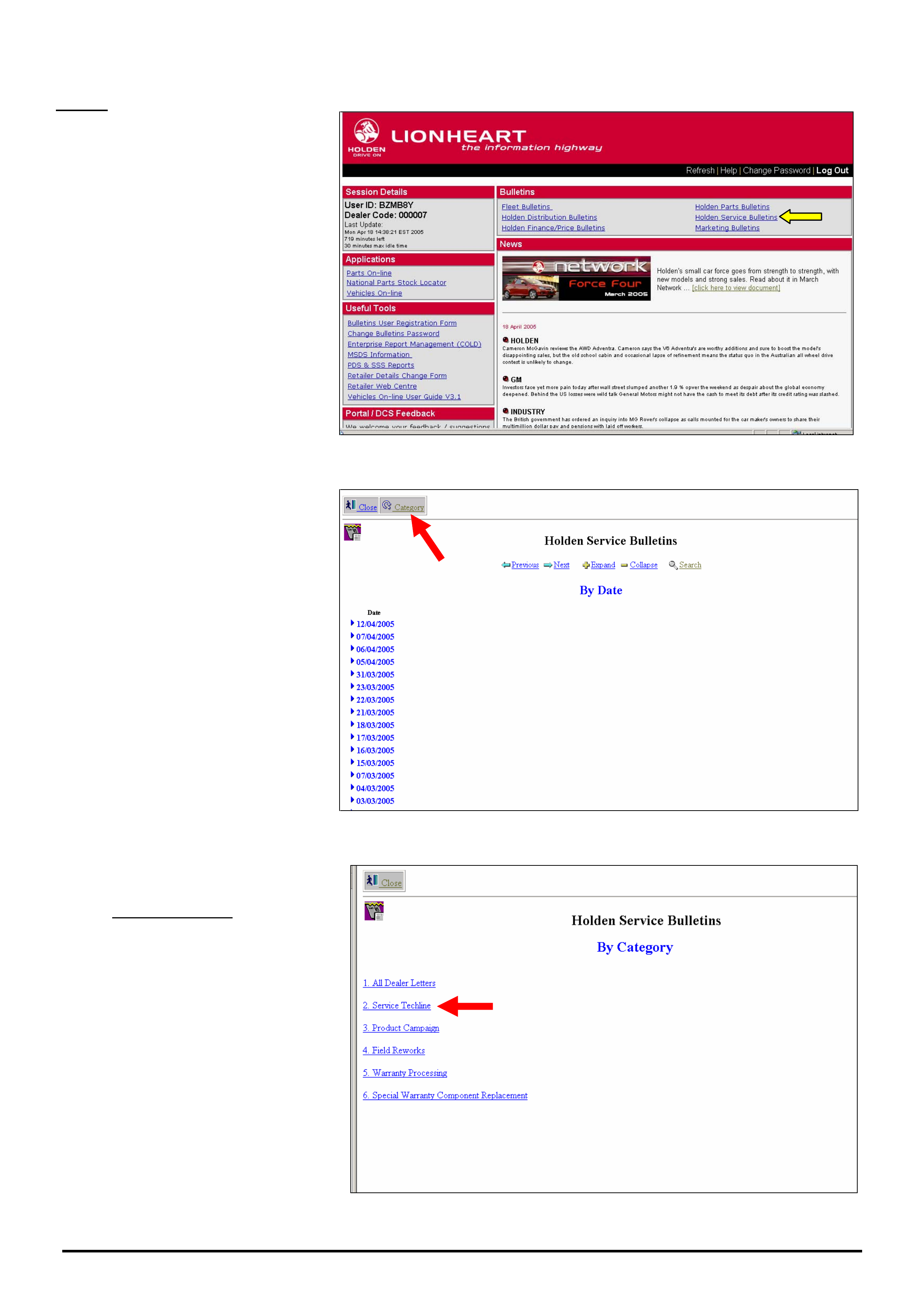

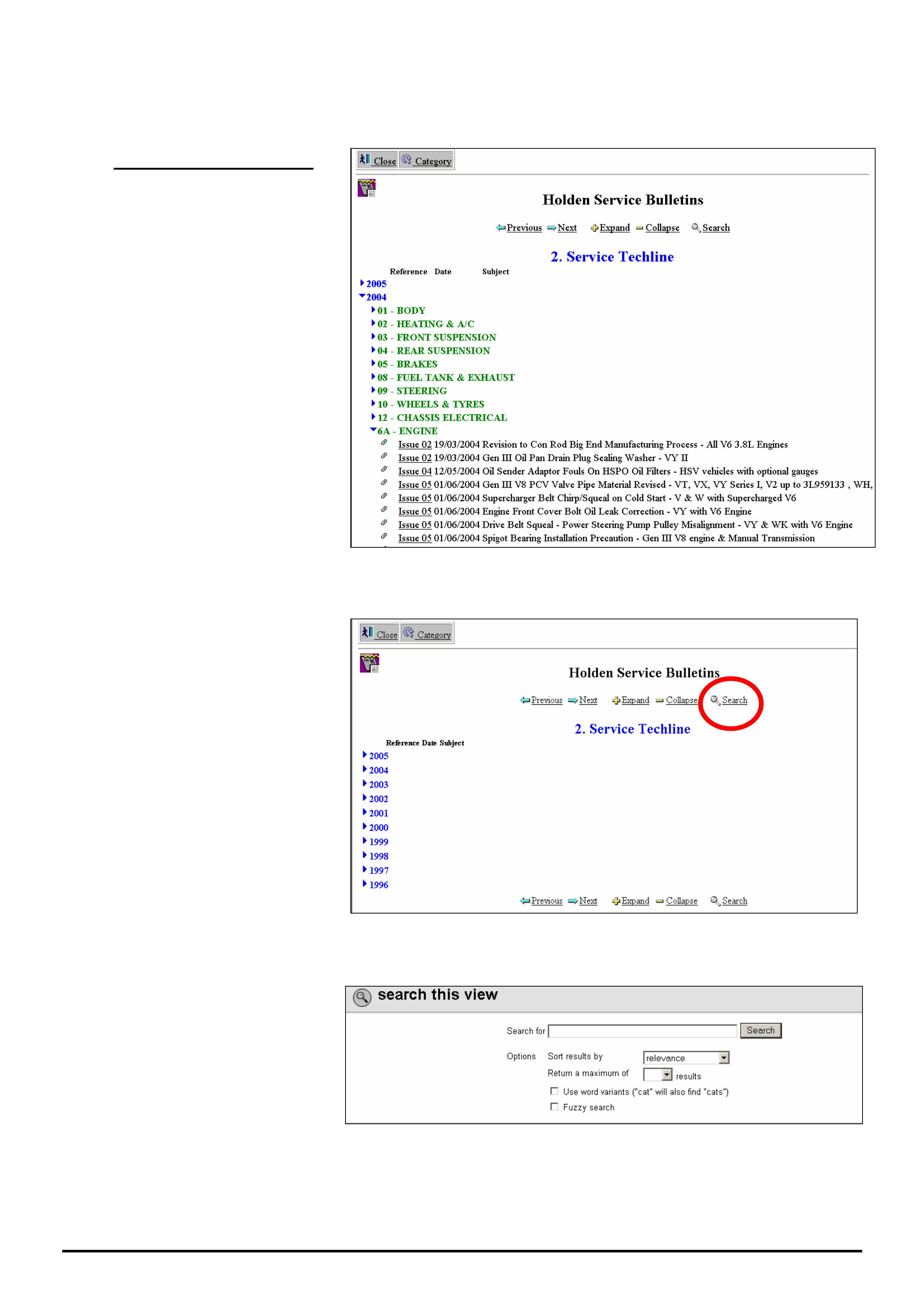

START

1. After logging onto Holden

Lionheart select “Holden Service

Bulletins” as indicated by yellow

arrow.

Figure 1.

2. The next screen to appear shows

all items in the Holden Service

Bulletin Database arranged by Date.

The most recent items are on the top

of the list. To view the item, click on

the ►next to the date.

HINT: Check this screen everyday

to view the latest information

issued by Holden Service

Department.

If you select the “Category” button as

indicated by red arrow, the screen

shown in Figure 3 will appear.

Figure 2

3. In this example we will show how

to locate a Service Techline. Now

select “Service Techline” from the list

shown.

The next screen to appear is shown

in Figure 4 on next page.

Figure 3.

HOLDEN SERVICE TECHLINE __________________________________________________________________________________JUNE, 2005

15

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

Following is a description of how to locate information by the conventional method or by using the search

function.

4 (A). Conventional Method.

As an example, we will look for a

techline on

V

Y V6 oil leak from

engine front cover.

Choosing the right year and the right

Group to look in are the keys to

finding a techline quickly.

As VY was produced from 2002 to

2004 you should commence looking

in 2004. Choose group 6A – Engine

and look through list of techlines until

you find the right one, which in this

example was published in Issue

05/2004

The drawback with this

“Conventional” method is knowing

which year and group to look in. It

can also be time consuming

scanning through long lists of

techlines.

Figure 4

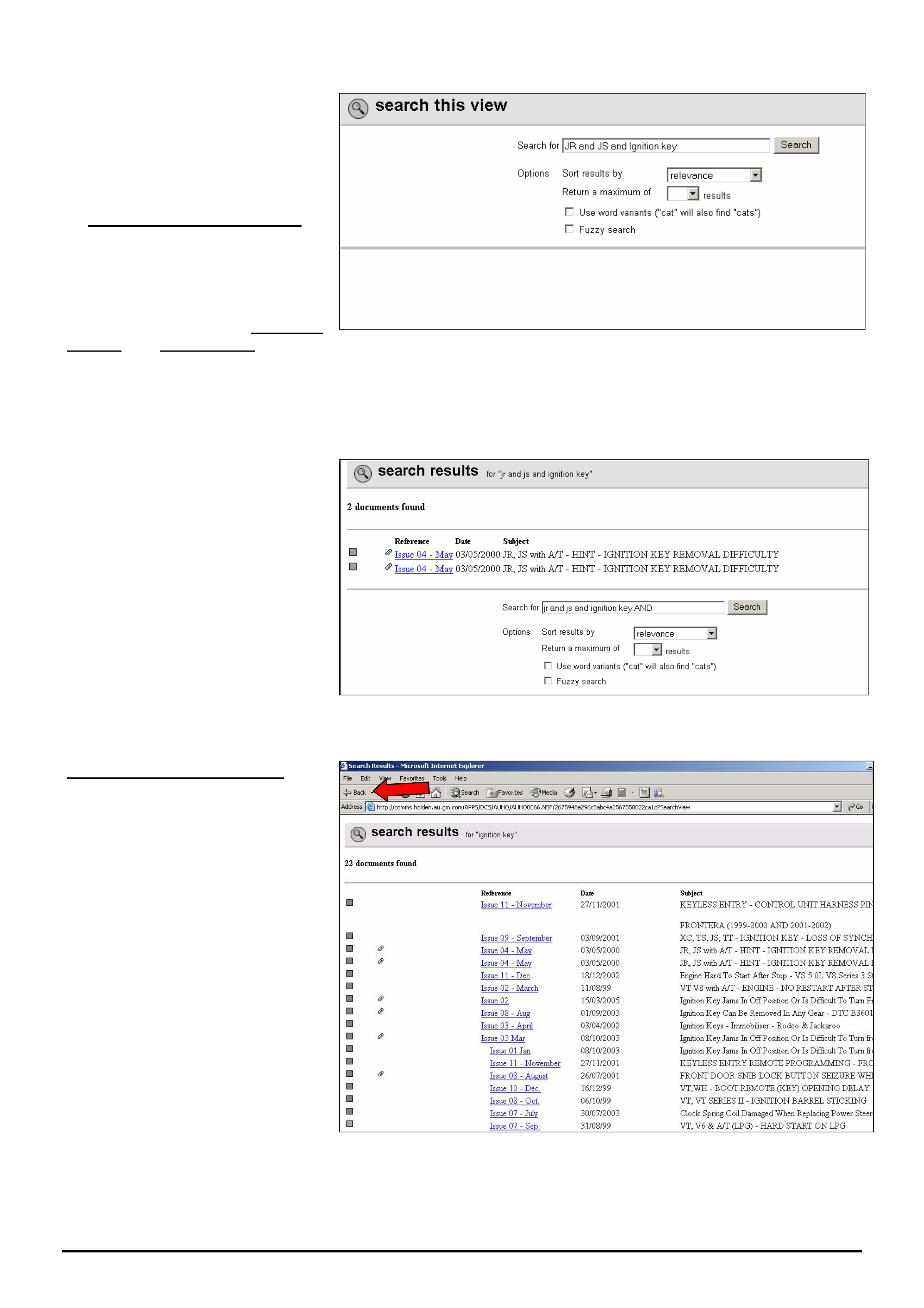

4 (B). SEARCH-Function

Method

From the screen shown in Figure 5,

click on the “Search” key. This will

bring up the screen shown in Figure

6.

Figure 5

This is the search screen we use for

entering our search criteria (i.e. an

accurate summary of what we are

searching for)

Figure 6

HOLDEN SERVICE TECHLINE __________________________________________________________________________________JUNE, 2005

16

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

As an example we will search for

techlines related to JR & JS Vectra

Ignition Barrel Jamming.

In the “Search for” window, type in

the following “search string”.

“JR and JS and Ignition key”.

Don’t touch the next 2 boxes titled

“Sort results by” or “Return a

maximum of”.

Tick the last 2 boxes i.e. Use Word

variants and Fuzzy search. Refer to

later explanations of these terms.

Now click the “Search” button.

Figure 7

The search result is 2 documents as

shown in Figure 8.

Click on the hot-key section (in blue)

to view the techlines.

Figure 8.

Defining Your Search Criteria

If we had entered only “ignition key”

in the search window the search

engine would have located 22

techlines as shown in Figure 8.

If we had entered only “ignition”, the

search engine would have located

85 techlines.

So you can see the importance of

defining your search criteria as

accurately as possible so you don’t

end up with huge numbers of items

to read through.

Rule of thumb: the less information

in the “search window” the more

information comes back.

If at anytime you wish to go back to

the “Search” function press the

“Back” arrow in the top left side of

the toolbar. Refer red arrow.

Figure 9.

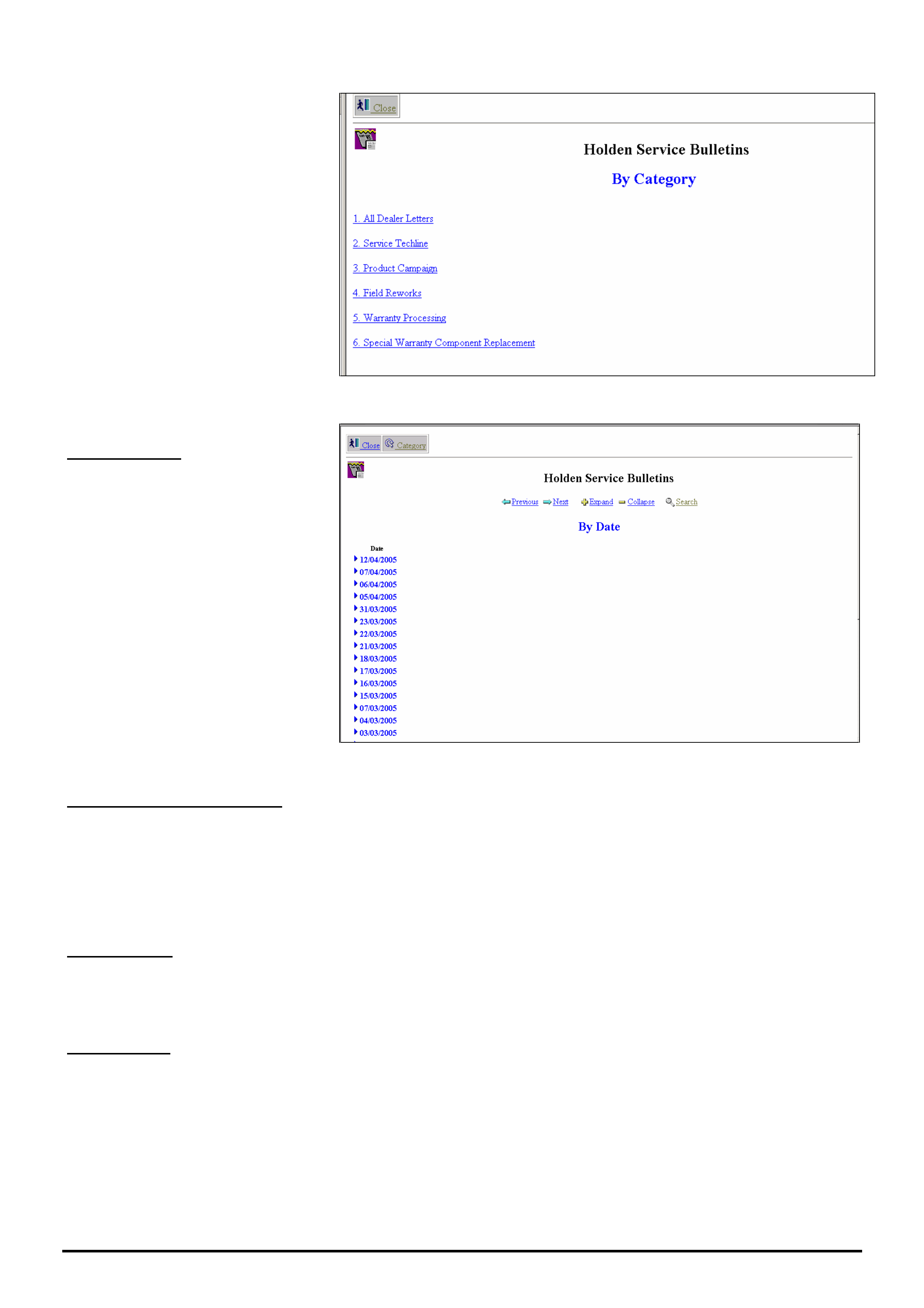

HOLDEN SERVICE TECHLINE __________________________________________________________________________________JUNE, 2005

17

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

To search for a Dealer Letter,

Campaign Bulletin, Field rework or

Warranty Bulletin, use the same

procedure as that described for a

Service Techline.

IMPORTANT: You must first select

the category you want from the

Category screen (Figure 10) before

proceeding with search.

Figure 10.

General Search.

To find ALL published information on

a subject, select “Search” from

screen shown in Figure11.

As an example, enter “Daewoo” in

the search field

This “search” will give you everything

that contains the word “Daewoo” .eg.

Dealer letters, Techlines, Recalls,

Warranty etc.

Figure 11

General Notes On Searching.

• If you perform a search and the results are not what you were looking for; to conduct another search, you will

need to hit the “← Back arrow” in the Microsoft Internet Explorer menu at top left of page. This will bring up a

new search window that you can enter new search criteria into after deleting the previous search criteria.

• The search engine cannot search any “attached” files such as Word, Excel, Pdf, on Holdens database. It can only

search for words that appear on the viewing page for each individual item.

Word Variants

If you tick this box in the search panel, and type in “cat” in the “Search For” window, the search engine will find every

word that has cat in it, eg. catalytic, category, cats, etc. This is useful if you cannot remember the exact spelling of a

word or you forget the s when the word is plural.

Fuzzy Search.

EXAMPLE 1. Search for techlines with DTC P0335 in the Subject title.

If you accidentally type in DTCP0335 without a space between C and P, and do a Fuzzy search, the search engine

will still bring up all techlines containing “DTC P0355”.

EXAMPLE 2. Search for techlines containing 4JX1 in the subject title.

If you accidentally type in 4JX, a fuzzy search will still find all techlines with 4JX1 in the title. This feature doesn’t

seem to work if you forget to enter the first letter. in this example, doing a Fuzzy search on JX1 will not find anything.

HOLDEN SERVICE TECHLINE __________________________________________________________________________________JULY, 2005

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

DIAGNOSIS INFORMATION

Hard Start or No start

RA RODEO Petrol & Diesel

(GROUP 6C) TL0955-0506

This techline is written to assist in diagnosis of

any RA Rodeo with a complaint of hard start or

intermittent no start.

A vehicle can be difficult to start for many reasons.

Attempting to diagnose a hard start / no start condition

without all the relevant information may lead to wrong

diagnosis and unnecessary parts replacement.

If the fault is intermittent and cannot be reproduced in the

workshop, then the owner must be questioned to get the

relevant information to allow the fault to be reproduced.

THE FOLLOWING INFORMATION IS REQUIRED AS A

MINIMUM BEFORE ATTEMPTING TO DIAGNOSE A

HARD/NO START CONDITION.

Owner Questions should include the following.

1. Does the engine - Crank / Not crank / Crank Partially /

Start & then Stall ?

2. Does the Engine Check Light (MIL) flash when the

vehicle won’t start?

3. How does the owner get car started?

4. Are there any electrical accessories fitted to the

vehicle at the time of hard start? E.G. UHF radio, phone

charger, either hard wired or plug in type, service lights

ETC, If so where are these accessories wired to ?.

NOTE: Electrical accessories that are incorrectly wired

into the vehicle can cause hard start problems, and must

be fixed before further diagnosis.

After the above information is determined, continue with

the following workshop checks.

Workshop Checks

1 What is the open circuit voltage & cranking voltage of

the vehicle battery ?

Cranking voltage should be above 10.5 Volts.

2 Are there any DTC’s logged in the engine ECU or

the Immobiliser ICU? If so, what are they? Include the

fault code number & Tech 2 descriptions ?

If Present DTC’s are shown, perform the relevant flow

chart diagnosis for the DTC’s SEE NOTE A

If History DTC’s are shown, the DTC charts can still be

used to identify & check the relevant circuits & wiring

associated with the DTC.

NOTE A. DTC B8007 can be set falsely by cycling the

Ignition key from On – Off – On within 30 seconds. Do

not diagnose by this code if this is the case.

NOTE B. If there are no DTC’s in the engine or

Immobiliser ICU, the problem is probably NOT

Immobiliser related. In this case, perform usual engine

no start / hard start diagnosis, E.G. fuel pressure, fuses,

power & earth supplies, etc. Use Tech 2 typical data

values to help in diagnosis.

3 Remove & clean Earth points C-2 & C-109, Refer

LCRV SIP – System Electrical – Electrical Body &

Chassis - Grounding Point

4 Is the vehicle built after the following breakpoints for

the revised type immobiliser ?

V6 MPATF*26*4H539342

L4 MPATFR32J4H540437

DIESEL MPATF*77*4H536880

Vehicles built after the above VIN Numbers will already

have the revised type immobiliser fitted therefore go to

step 6

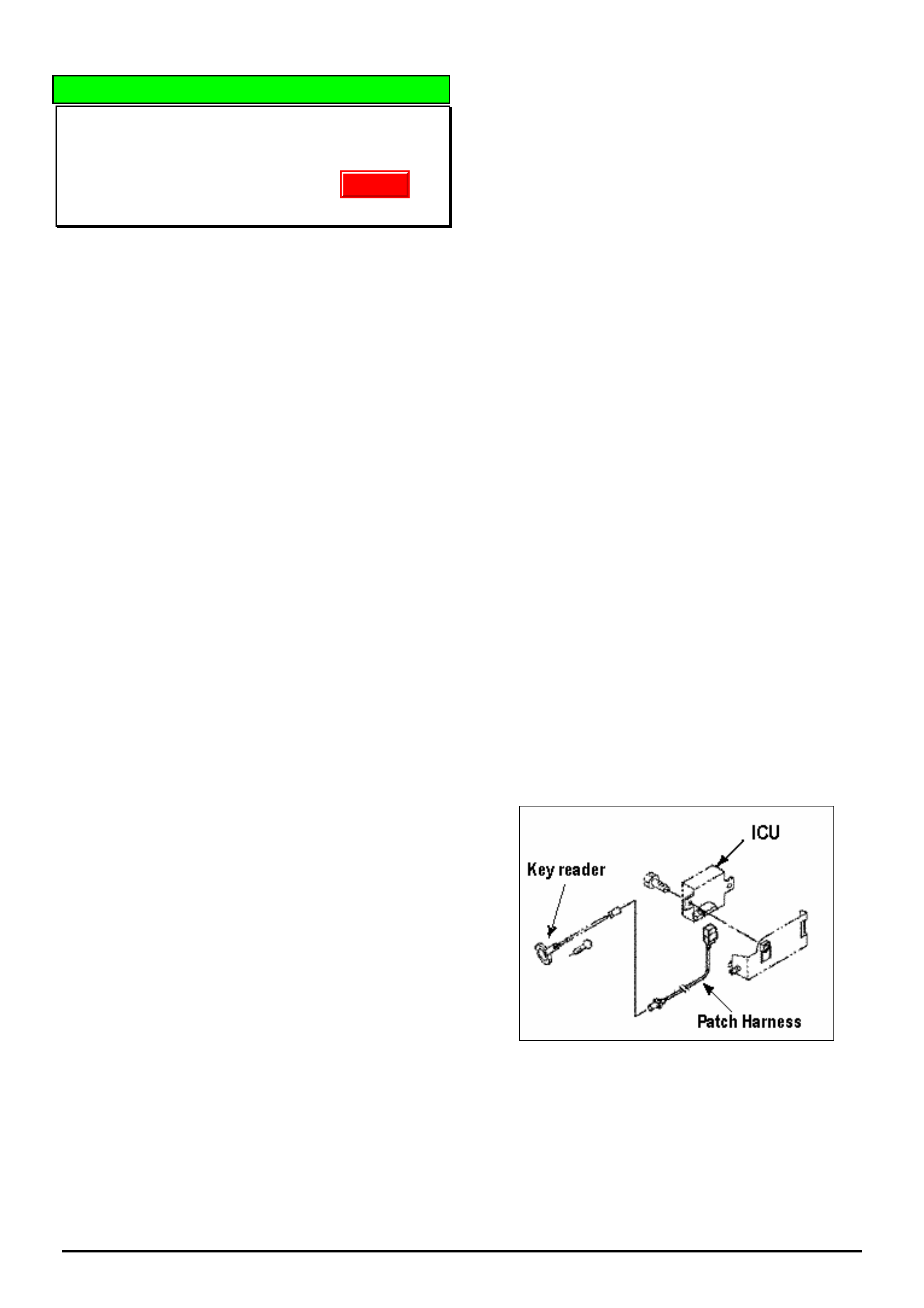

5 What is the Part Number of the Immobiliser ICU fitted

to the vehicle ? This can be read off the sticker on the

ICU. The Part Number should be as follows:

Petrol Engines - 8973773230

Diesel Engines - 8973773240

If ICU Part Number is different to above, replace the ICU

(With Zone Approval), following the relevant Reset &

Programming Procedures in LCRV Sip

6 Check the Immobiliser ICU & Antenna Connector

terminal retention of all terminals.

HINT. This can be done by removing a male terminal

from the Antenna / Key reader Patch harness and use

this terminal to test retention of female terminals.

7 If the vehicle is a V6 before engine number 240817,

program engine ECU with the latest TIS software.

This should be, 97389275 – 2750. SPS if required

NOTE Revised engine ECU software was fitted in

production from engine number 240817

If all above checks do not resolve the problem,

contact TAS for further diagnosis assistance.

Update

HOLDEN SERVICE TECHLINE __________________________________________________________________________________JULY, 2005

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

SERVICE FIX

Brake Light Stays On

RA Rodeo

Group 5 Ref. No. TL0918 - 0506

This Techline is provided as an interim service fix

to be applied until further notice.

CONDITION

Customer complains that the brake lights stay on after

leaving the vehicle or that the brakes appear to be

dragging or sticking on.

CAUSE

Booster internal components not to specification

resulting in insufficient force in the system to return

the brake pedal to the “fully off” position.

CORRECTION – Production

Boosters with internal revisions to overcome the

above condition have been fitted to vehicles from:

ISOVIN: Built Date:

MPATFS77J5H517613 20/10/04

CORRECTION – Service

On complaint vehicles, the condition can be rectified

by increasing the tension of the brake pedal return

spring as follows.

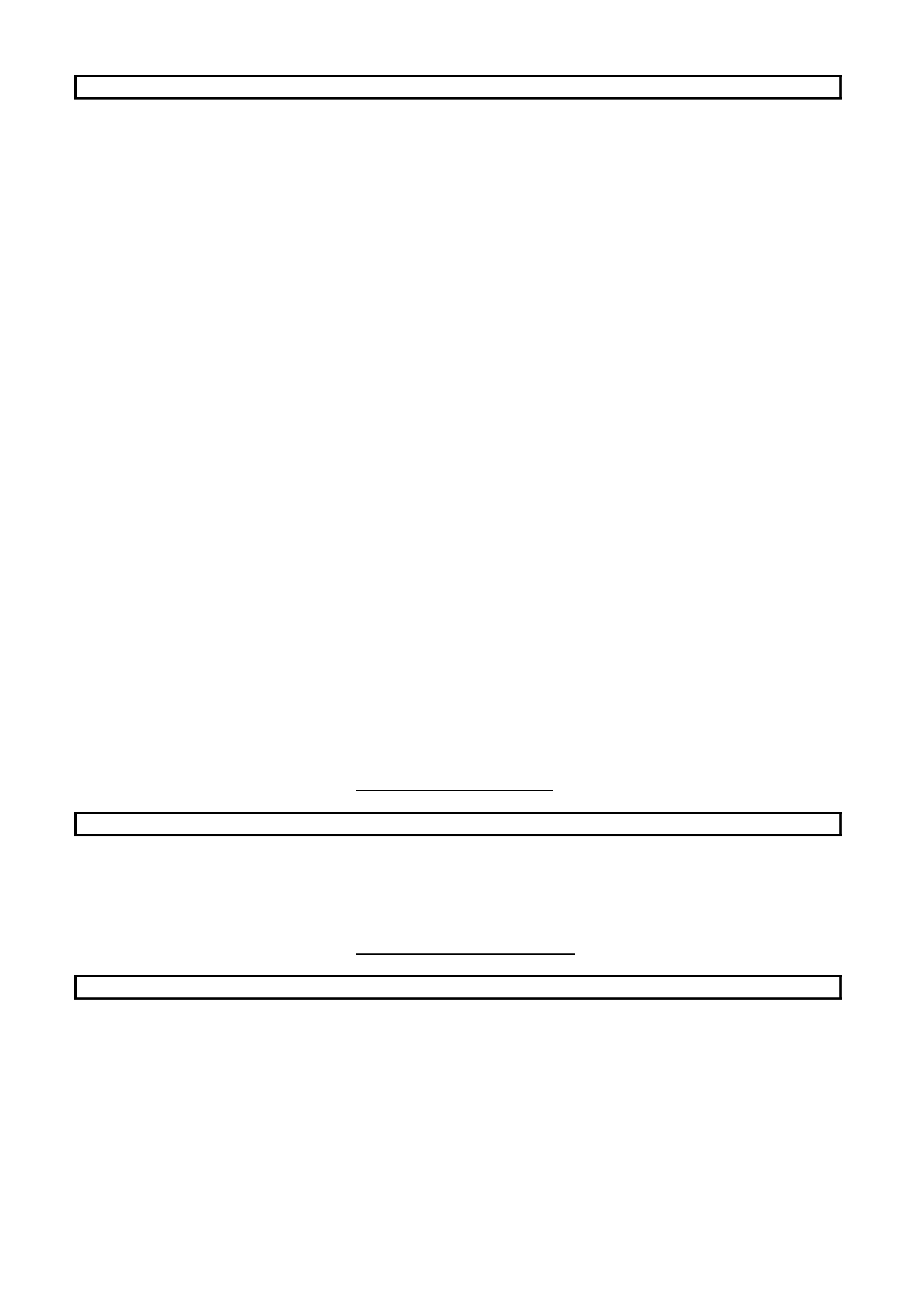

Add a 10mm (min) thick rubber pad under the leg of

the spring as shown in Figure 1.

WARRANTY CLAIM INFORMATION

Description Add spacer to brake pedal

return spring

Labour Op. No. H000266

Time 0.2 hr

Failure Code H0033 weak

Figure 1.

Place spacer

under spring leg

Brake Pedal

Front of vehicle

HOLDEN SERVICE TECHLINE __________________________________________________________________________________JULY, 2005

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

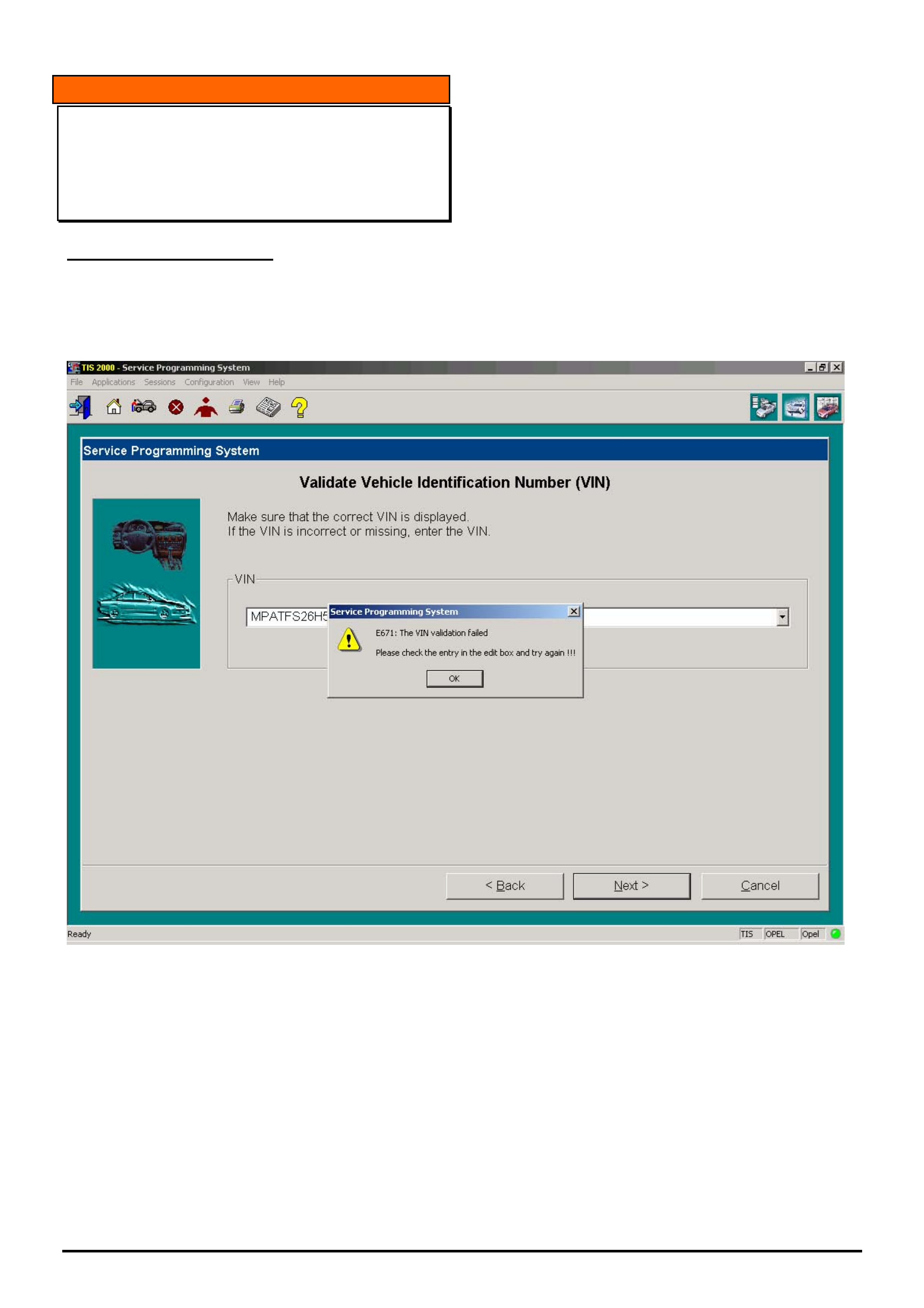

INFORMATION

TIS 2000 VIN validation failed message

LCRV TIS 2000

(GROUP OB) TL0951-0506

PROBLEM DESCRIPTION

When trying to carry out service programming (SPS)

on an LCRV product the message shown below may

appear.

One of the reasons for this message occurring is that

the LCRV TIS 2000 disc may not be loaded. This

may have been as a result of TIS 2000 being installed

on a new PC or if TIS 2000 was uninstalled and

reinstalled for some reason but the LCRV disc was

not loaded.

The Service Techline in Issue 4, 2005 (page 16)

describes how you can determine which discs are

loaded.

Note also that if the LCRV disc is not loaded then the

main TIS page will not have the “tech 2 view” icon as

it is loaded from the LCRV TIS disc.

HOLDEN SERVICE TECHLINE __________________________________________________________________________________JULY, 2005

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

Explanation of Driveline “Clunk” or “Backlash

Noise”

All Rear Drive Vehicles

Group 4 Ref. No. TL0956 - 0506

Some owners of rear wheel drive vehicles may

comment that the vehicle exhibits a “clunk” noise while

driving when the accelerator is depressed and then

released.

Similarly, owners of vehicles equipped with either

manual or auto transmissions may comment that the

vehicle exhibits a “clunk” noise when shifting between

Park & Drive, Park & Reverse or Drive & Reverse.

Whenever two or more gears interact with one another,

there must be a certain amount of clearance between

those gears in order for the gears to operate properly.

This clearance or freeplay (backlash) can translate into

a clunk noise whenever the gear is loaded and

unloaded quickly, or whenever the direction of rotation

is reversed.

The more gears/components you have in a system, the

more freeplay the total system will have.

The clunk noise that owners sometimes hear may be

the result of a stackup of freeplay (backlash) between

the components in the driveline.

For example: The potential for a driveline clunk would

be greater in a 4WD or AWD vehicle than in a 2WD

vehicle.

This is because in addition to the freeplay from the rear

axle gears, the drive shaft joints, and the transmission

(common to all vehicle types), the 4WD transfer case

and front drive shaft/s (and their associated

clearances) add additional freeplay to the driveline.

In service, dealers are discouraged from attempting to

repair driveline clunk conditions for the following

reasons:

• Driveline clunk is almost never the result of one

individual component with excessive freeplay, but

rather the result of the cumulative effect of

freeplay (backlash/lash) that is present in all of the

driveline components.

Because all of the components in the driveline

have a certain amount of freeplay (backlash) by

design, changing driveline components may not

result in a satisfactory freeplay (or driveline clunk)

reduction.

• While some owners may find the clunk noise

objectionable, this will not adversely affect the

durability or performance of the vehicle or its

components.

HOLDEN SERVICE TECHLINE _______________________________________________________________________________AUGUST, 2005

7

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

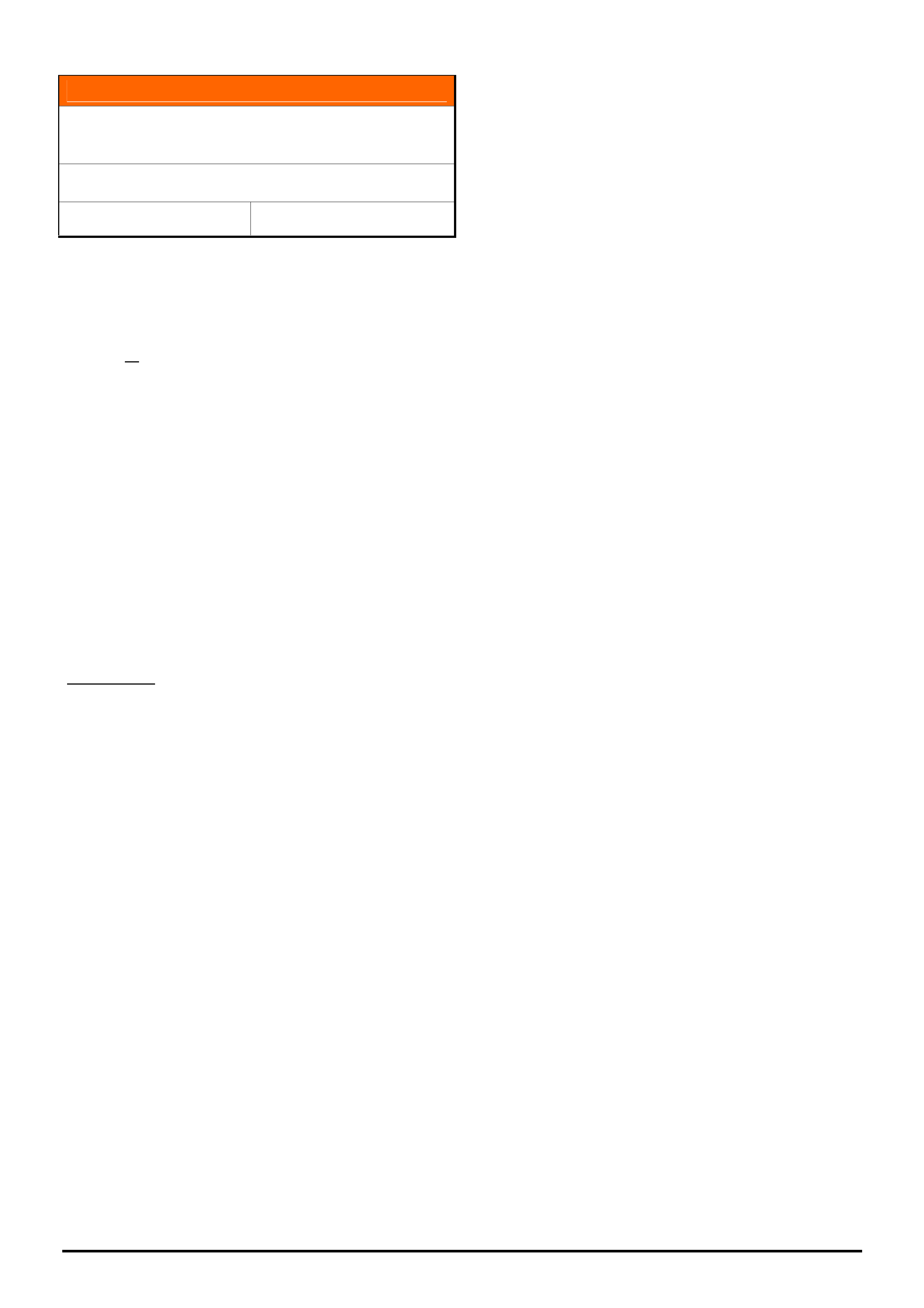

DIAGNOSIS HINT

Erratic Tachometer Operation, and/or 4WD Not

Operating (if fitted)

RA Petrol or Diesel

(GROUP 12) TL0649A-0507

This Techline supercedes the previous one in Issue 2,

March, 2004. It is revised by adding a picture of the

location of the suspect fuse.

CONDITION

Erratic tacho or speedo operation and/or no 4WD

operation (if 4wd equipped).

CAUSE

This condition may be caused by a blown or missing

fuse located at Fuse No. C-2 in the interior fuse box.

To locate fuse C-2 refer to following diagram.

CORRECTION

Verify that the ABS fuse at C-2 in interior fuse box isn’t

blown or missing.

NOTE: Vehicles without ABS require this fuse to be in

place for correct instrument cluster and 4WD

operation.

HOLDEN SERVICE TECHLINE _______________________________________________________________________________AUGUST, 2005

8

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

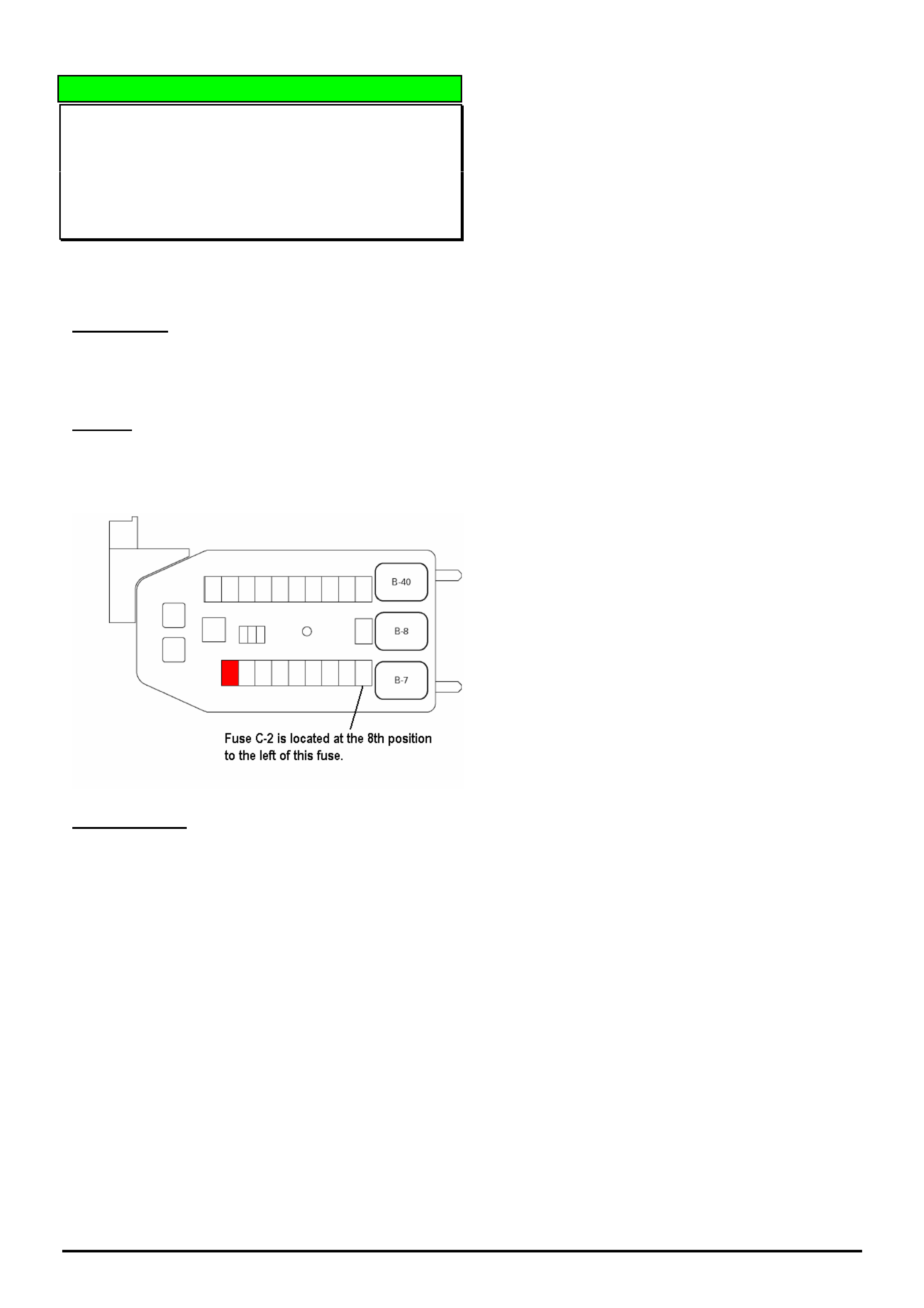

DIAGNOSIS HINT

Engine Vibration / Drone Noise at 2500-3000

RPM

RA RODEO Diesel 4JH1 With A/C

(GROUP 6A) TL0962-0507

PROBLEM DESCRIPTION

A vibration may be felt through the cabin of the vehicle

or a drone noise can be heard when engine RPM is

between 2500 - 3000 RPM. Complaint can be

reproduced in the workshop by revving the engine.

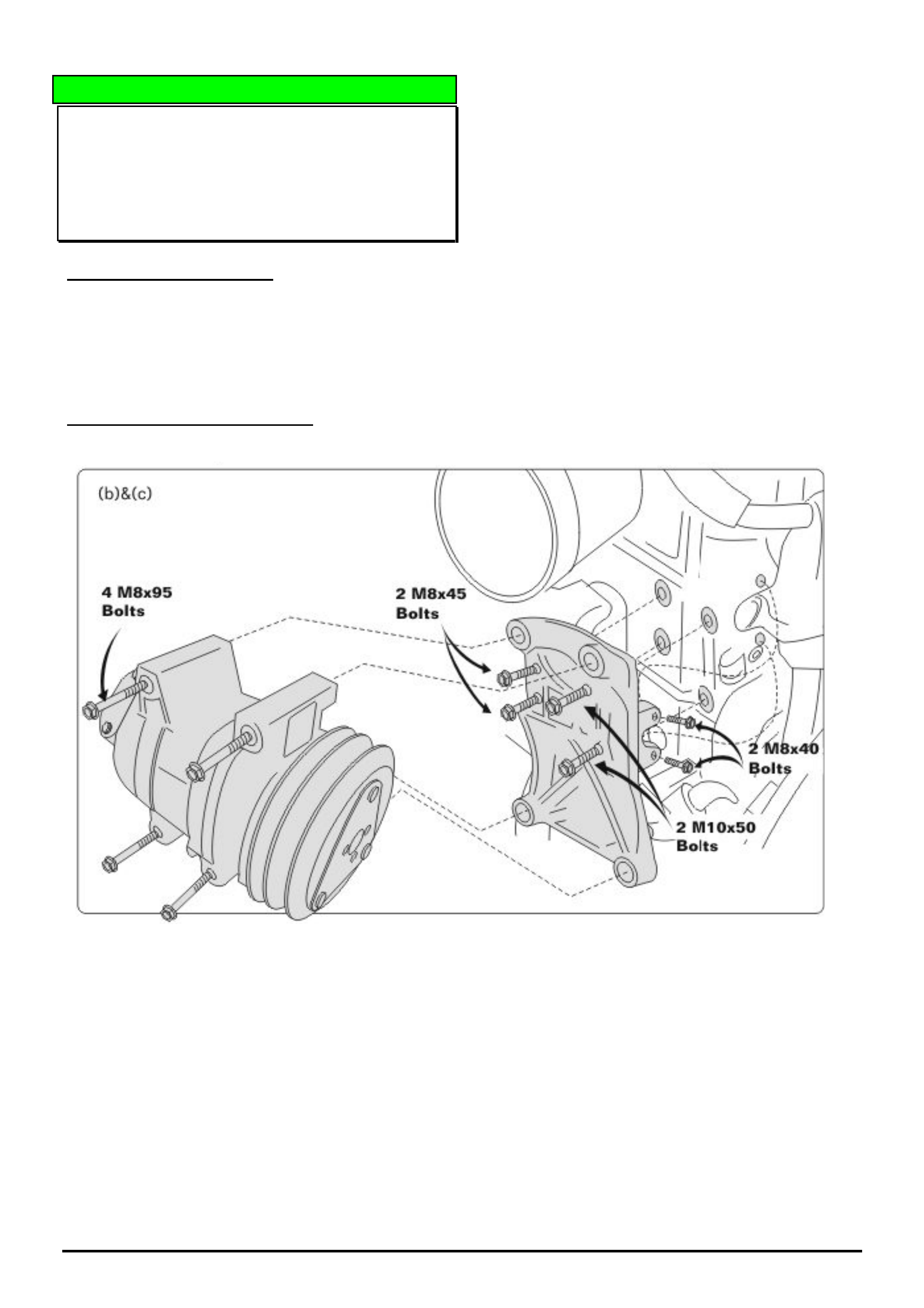

SERVICE RECOMMENDATION

Remove the A/C Compressor bracket mounting bolts

that hold the bracket to the engine as shown.

Note: There is no need to evacuate the A/C system.

Check the ends of the threads of M8 x 45 and M10 x

50 bolts for signs that the threads have bottomed out in

the threads of the engine (may be seen as 2 end

threads of the bolts are shiny) If it looks like the bolts

have bottomed out, place 2 mm flat washers under the

head of the bolts and retighten.

Note: Loosen the two front M8X40 bolts prior to

tensioning the four side bolts, then tension the front

bolts.

Refit compressor, adjust drive belt and retest to verify

that the vibration has been repaired.

HOLDEN SERVICE TECHLINE _______________________________________________________________________________AUGUST, 2005

9

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

TAS Vehicle Call Groups

Group OB Ref. No. TL0963 - 0507

TAS receive many calls where the caller has selected the incorrect group on the phone system for the vehicle model

they are enquiring about. Please refer to the following dialling options (numbers) when navigating through the TAS

phone system.

Introductory Message

HOLDEN dial 1 SAAB dial 2

Bulletin Board

- dial 1

LCV & Daewoo vehicles

- dial 2

• Jackaroo

• Frontera

• Cruze

• Rodeo

• ALL DAEWOO

badged vehicles.

Holden Passenger vehicles

- dial 3

• Commodore / sedan /

wagon / ute / 1 tonner /

crewman / AWD

• Statesman, Caprice

• Monaro

• Zafira

• Astra

• Vectra

• Barina

HOLDEN SERVICE TECHLINE ___________________________________________________________________________SEPTEMBER, 2005

7

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

SERVICE FIX

Poor Engine Performance After Driving

Through Water or Washing Engine.

RA with 3.0L 4JH1 Diesel Engine

Group 6C Ref. No. TL0677A - 0508

This Techline supercedes TL0677-0404 published in

Issue 3, 2004. It is revised by including service fix

information.

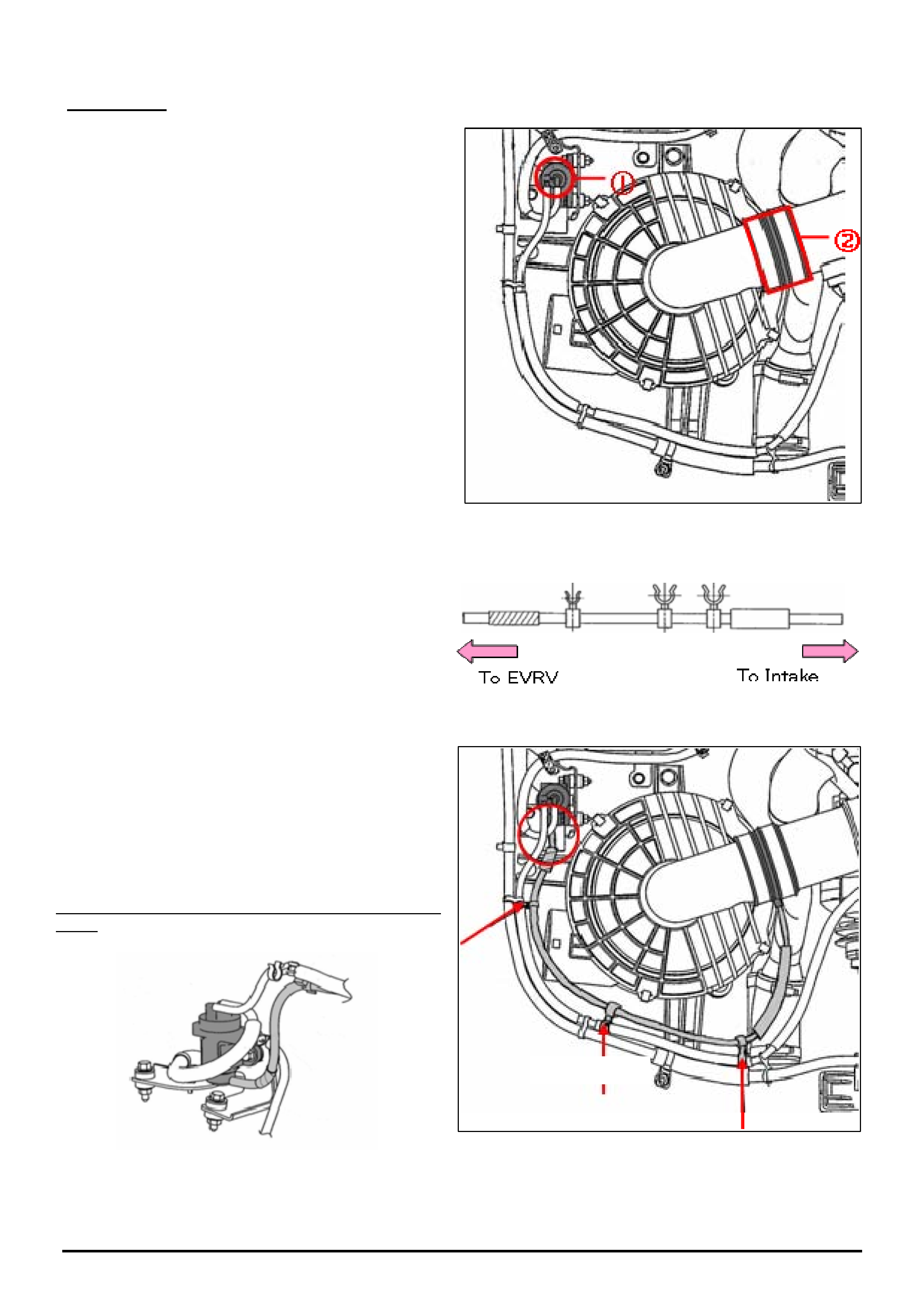

CONDITION

Poor engine performance or lack of power after driving

through water or washing the engine.

CAUSE

This can be caused by dust in the Electrical Vacuum

Regulating Valve (EVRV) getting wet and blocking the

filter in the valve.

NOTE: The EVRV is located in the engine

compartment on the RHS guard area and its function is

to control the operation of the EGR valve.

CORRECTION – Production

A revised EVRV system was fitted to vehicles from:

ISOVIN: Built Date:

MPATFS77H5H581779 04/07/05

CORRECTION – Service

When diagnosing for the above condition, the vacuum

line to the EGR valve can be removed and plugged for

the duration of a test drive to confirm if it is the EGR

system that is causing the low performance.

THIS HOSE MUST BE RECONNECTED AFTER THE

TEST.

If the EGR valve is not operating correctly, remove the

EVRV, and visually inspect for dust or water entry to

the valve. If the valve is found to be contaminated it

must be replaced and new hose and duct fitted as

detailed on next page.

PARTS INFORMATION

Part No.: Partfinder Name Qty:

897374971

0

EGR Vacuum Valve 1

898009671

0

Hose EVRV to intake duct

(incl 3 clips)

1

898009695

0

Duct; Aircleaner to MAF (incl

2 clamps)

1

WARRANTY CLAIM INFORMATION

Description Install EVRV filtered air Kit

Labour Op. No. J000785

Time 0.3 hr

Failure Code J0012 foreign material

DIAGNOSIS HINT

Turbocharger Diagnosis / Oil Seep From

Intake Ducts

RA Rodeo – 4JH1 TC, UBS Jackaroo 4JX1

Group 6A Ref. No. TL0976 - 0508

This techline supersedes TL0731-0408 published in

Issue 8, 2004, titled Turbocharger Oil Leak Diagnosis.

Most of the turbochargers replaced under warranty for

engine oil consumption complaints cannot be faulted

when tested through REPAC.

Possible explanations for these Turbochargers being

replaced unnecessarily are:

1. Dealers may have incorrectly assumed that the

oil they are seeing in the intake ducts* is excessive and

is coming from the turbocharger seal.

2. The excessive oil consumption complaint may be

caused by another condition e.g. blocked air cleaner or

excessive engine blow by.

* - Why is there oil in the intake?

Turbochargers may “appear” to be leaking oil from the

impellor shaft in some cases when they are not. There

will be minimal oil residue on the intake side of the

turbocharger and oil wetness in the ducting after the

turbocharger. This occurs because atomised oil exits the

PCV system and collects in the intake, predominantly in

and after the turbocharger. Usually turbocharger failures

can be detected by noise and, in some cases, white

smoke.

Complaint Prevention:

Some complaints of leaking intake ducts may be

prevented by checking the hoses and clamps for the

intake ducting during service. It is good practice to

check the tension of intake duct hose clamps while

performing the under bonnet checks.

Leaking Duct Complaints:

The intake ducts should be resealed where possible.

Parts that appear to have a visual fault should be

replaced.

Oil Consumption Complaints:

No action should be taken for vehicles with an oil

consumption complaint until the sealing of the intake

duct has been checked and rectified when required. A

standard oil consumption test must be performed prior to

any major repairs. Where any components are replaced

for oil consumption the consumption rate must be

quoted in the 3C’s and TAS case where applicable.

Replacement Guidelines.

As a general rule, turbochargers should not be replaced

unless they are noisy or, in some cases, if the vehicle is

blowing white smoke.