2006 SERVICE TECHLINES

© 2006 GM Holden LTD. A.B.N. 84 006 893 232

Service Department

A “Holden” Product

BRISBANE SYDNEY MELBOURNE ADELAIDE PERTH

For the latest and/or any missing Techline bulletins,

please refer to Holden Lionheart

HOLDEN SERVICE TECHLINES___________________________________________________________________________FEBRUARY, 2006

4

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

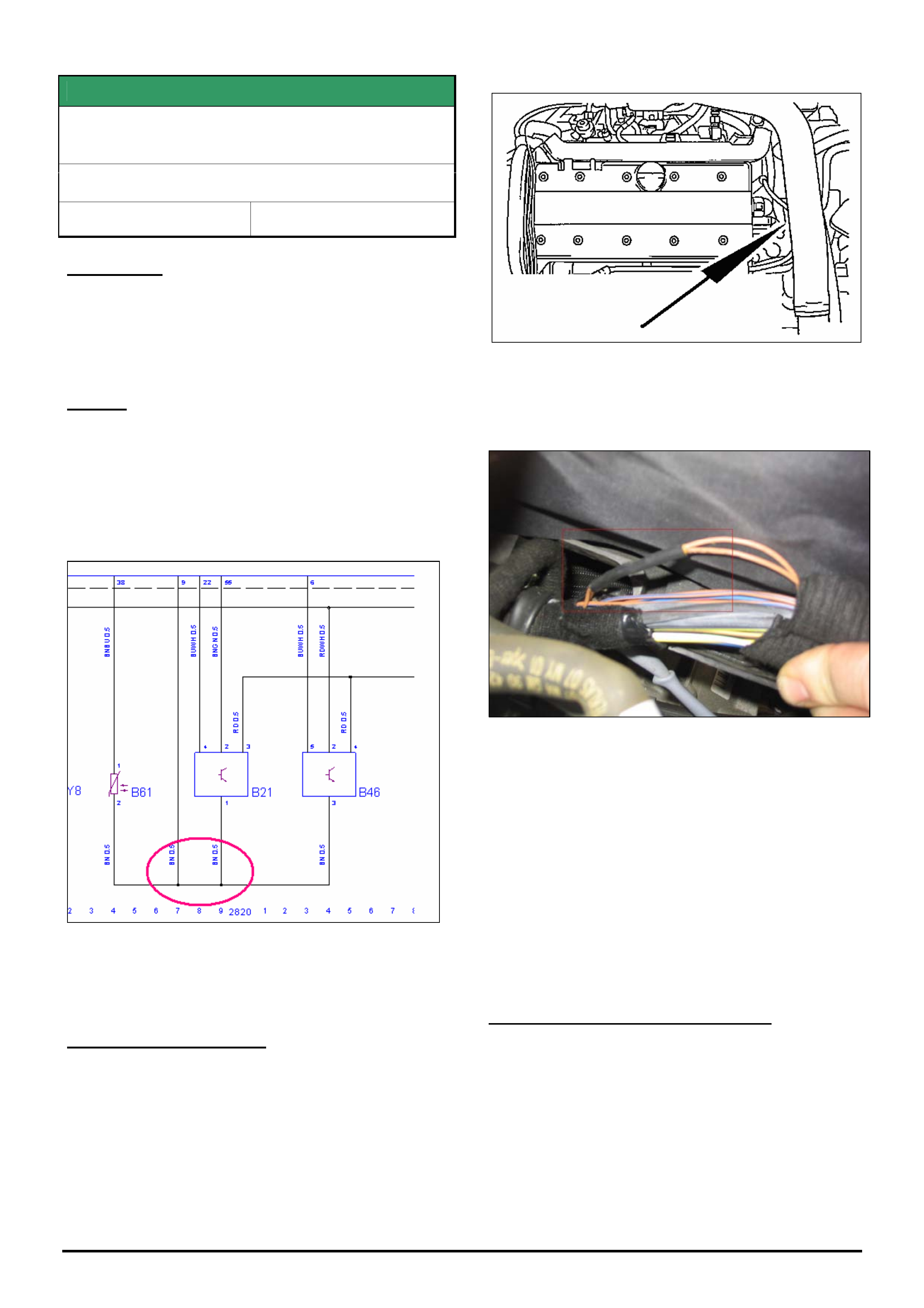

DIAGNOSIS HINT

P1483 DTC stored in ECU

AH Astra with M/T

Group 6C & 12 Ref. No. TL1069 - 0601

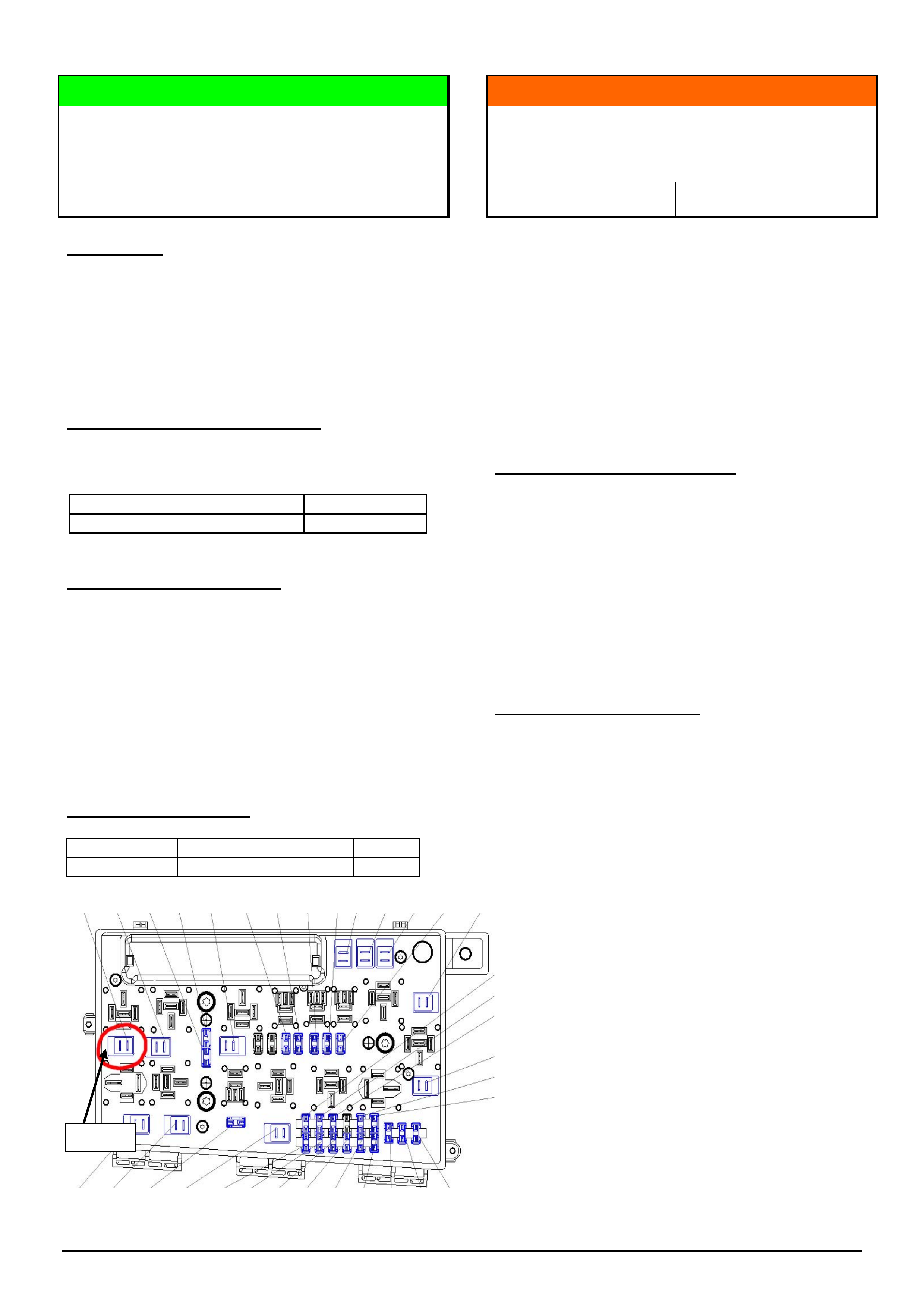

CONDITION

Some Model Year 2005.5 vehicles may be presented

with an Engine Check Lamp on and DTC P1483 (Fan

Control 3 Circuit Low Voltage) stored in the engine

ECU. Vehicles with this condition may have been

incorrectly built with fuse 5 missing from the UEC

(Underhood Electrical Centre).

CORRECTION in PRODUCTION

This condition was rectified as of the following

breakpoint:

ISOVIN: Built Date:

W0L0AHL4855122854 12/01/05

CORRECTION in SERVICE

To rectify the condition described above, install a 30A

fuse into location 5 of the UEC as shown on the

attached diagram.

Note: If fan speed 3 is commanded by Tech 2 using

the Functional Test in a vehicle with manual

transmission, it is possible that a DTC P1483 will set.

This is a normal condition and no further work will be

required.

PARTS INFORMATION

Part No.: Description: Qty:

13133860 FUSE 1

INFORMATION

Introduction of DVD for TIS 2000

All

Group OB Ref. No. TL1025A - 0601

This Techline supercedes the previous one in Issue 10,

Nov, 2005. It is revised by adding a note on setup of the

DVD drive.

From January 2006 the previous CD-ROMs for TIS

2000 will be replaced by a DVD.

The major growth in data in recent years has made

this change necessary.

Please ensure that your TIS 2000 PC has a DVD

drive by 1.1.2006 at the latest.

Advantages of changing to DVD.

• The previous data set of 4 CDs will be replaced by

one DVD

• Simpler updates, without having to change the CD

several times

• Quicker updates

• Improved quality graphics

• Use of digital photos

• Conventional CD-ROMs can also be read by DVD

drives

Important Note - DVD Setup

To guarantee a smooth update for TIS 2000, it is

essential that any new DVD drive to be used for TIS

2000 DVD’s is allocated to the letter previously used

by the CD drive. If this is not done, TIS 2000 must be

uninstalled and the DVD drive set up as a new

installation.

For more information refer to Dealer Letter 25/05 and

the TIS 2000 Newsletter available on TIS 2000 CD66.

Fuse 5

HOLDEN SERVICE TECHLINES___________________________________________________________________________FEBRUARY, 2006

5

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

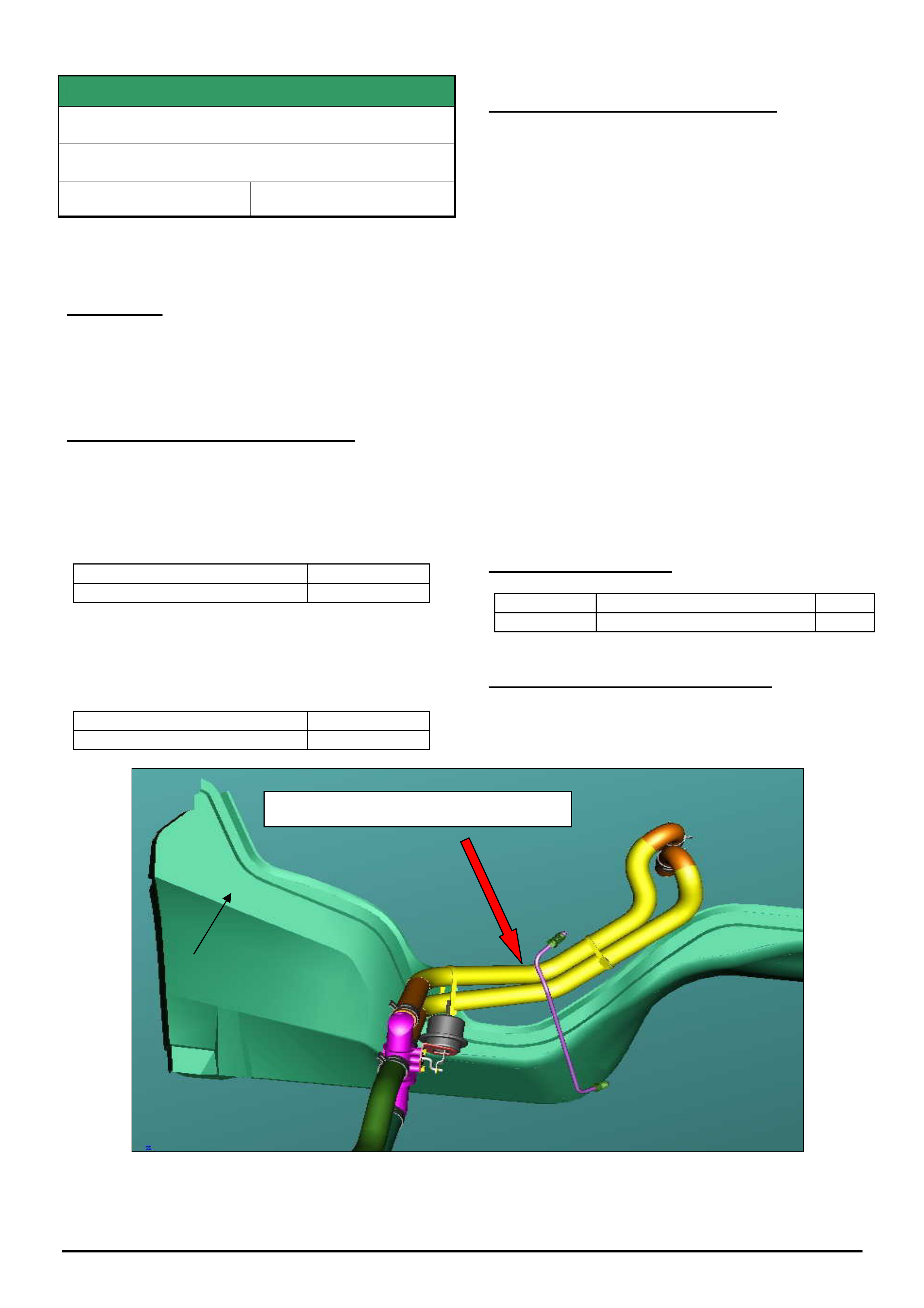

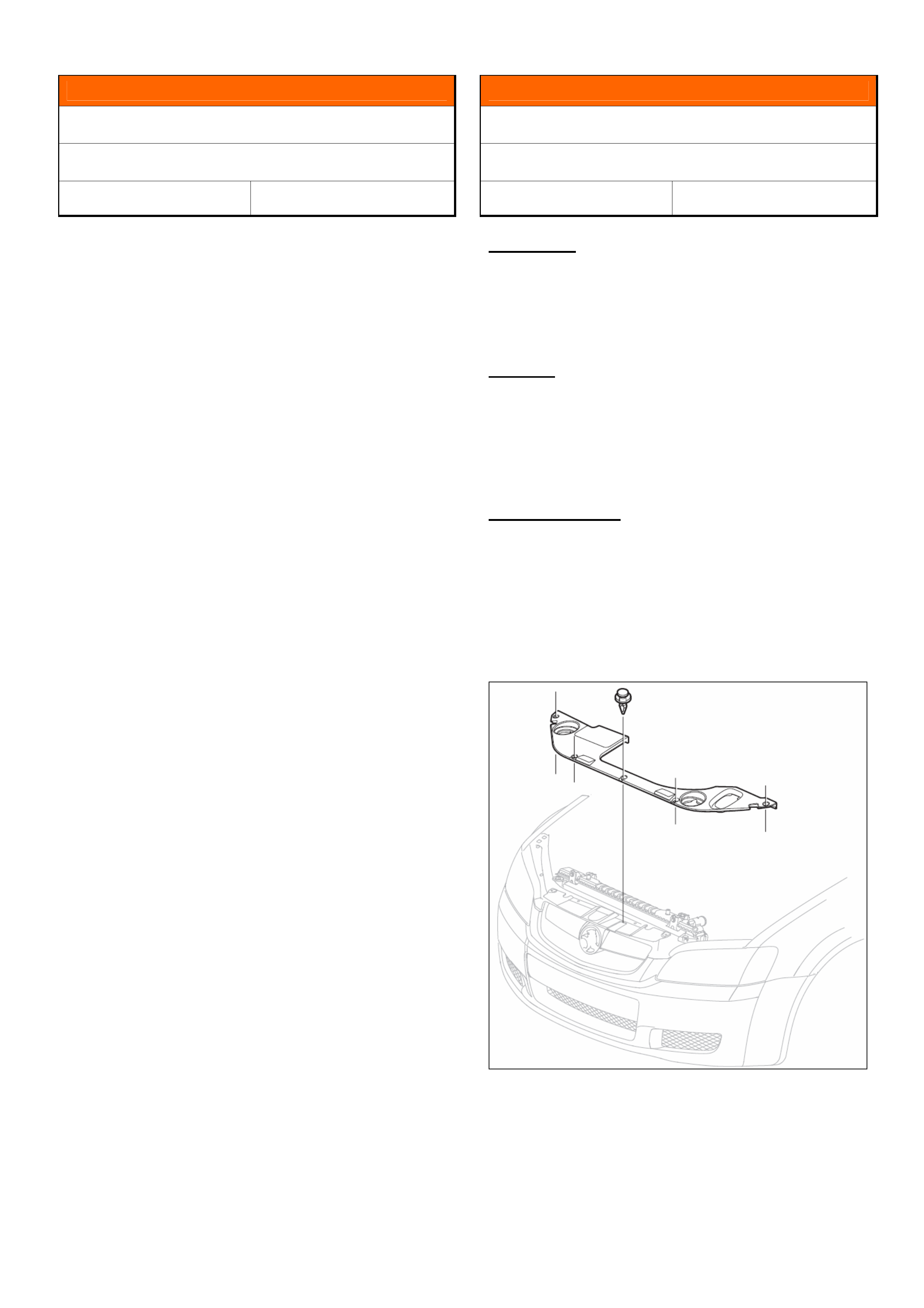

Common Upper Radiator Shroud.

VZ & WL

Group 6K Ref. No. TL1006 - 0601

Service technicians should be aware that the upper

radiator shroud for V6 and V8 engine vehicles has

been made common from the Tag numbers listed

below (detailed in Microcat).

Model Tag

VZ L438762

WL L438092

Important Service Note

The removable access panel above the radiator cap

has been deleted on V8 vehicles therefore it is now

necessary to remove the upper radiator shroud to

access the radiator cap.

All replacement radiator shrouds have superseded to

the latest part (92183569). The “Cover - Radiator

Filler” (92175359) has also superseded to the latest

shroud assembly (92183569).

SERVICE FIX

“Distance To Empty” Or “Average Fuel

Consumption” Information Incorrect/Inaccurate

VZ with LPG

Group 12 Ref. No. TL1064 - 0601

CONDITION

Customer advises that the “distance to empty” or

“average fuel consumption” information displayed in

their instrument cluster is incorrect or inaccurate.

CAUSE

During programming at the VAP (vehicle assembly

plant) some instrument clusters were not configured

for LPG operation.

When configured for LPG, the “Average Fuel

Consumption” and “Distance To Empty” are removed

from the trip computer display for both LPG & Petrol

operation.

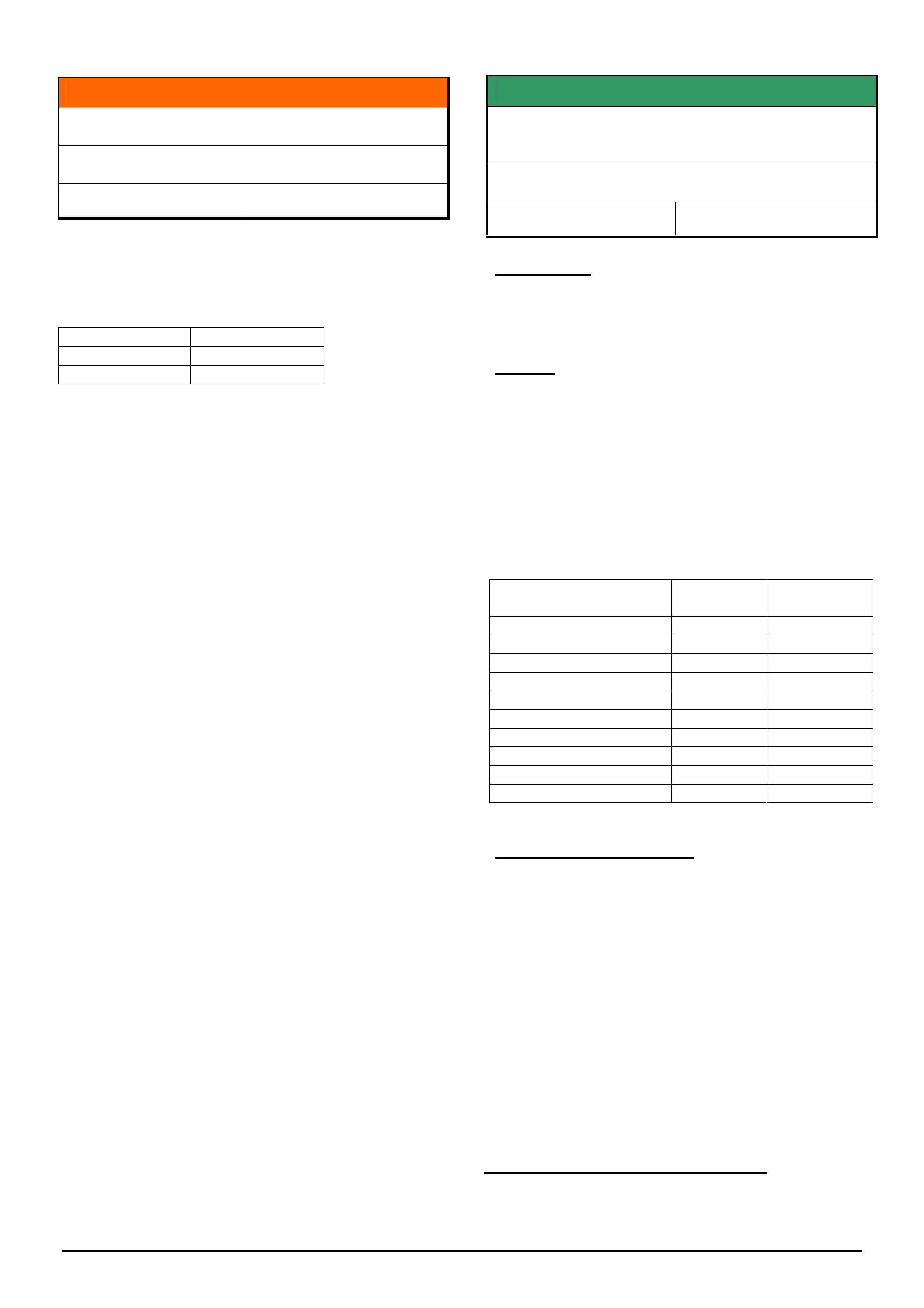

The table below gives an example of the information

displayed in the instrument cluster.

Petrol

Only

Petrol / LPG

(Dual fuel)

Digital speedometer 3 3

Stop watch 3 3

Odometer 3 3

Trip meter 3 3

Distance to go 3 3

Time to go 3 3

Distance to Empty 3 2

Average Speed 3 3

Average Fuel 3 2

Overspeed presets 3 3

CORRECTION – Service

After verifying that vehicle has the above condition,

re-configure the instrument cluster using Tech 2 via

the following steps,

1. F0: Diagnostic / Model Year / Vehicle Type / F4:

Body / Instrument / F5: Program / F1:

Configuration.

2. Scroll through the list to the engine, select the

modify soft key then select V6.

3. Scroll through the list to LPG Fitted, select the

modify soft key then select Yes.

4. Select the program soft key.

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty Information

section of current PV SIP CD

HOLDEN SERVICE TECHLINES___________________________________________________________________________FEBRUARY, 2006

6

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

SERVICE FIX

Turn signal / Hazard Lamps Stay Illuminated

VZ, WL

Group 12 Ref. No. TL1067 - 0601

CONDITION

Customer advises that intermittently the turn signal /

hazard lamps may stay illuminated without the switch

being activated.

CORRECTION – Production

Revised body control modules (BCM) have been fitted

to vehicles in production from the 10/08/05.

CORRECTION – Service

If a customer presents a vehicle with the above

condition, request a changeover BCM from Australian

Arrow using the standard process which is found in

SIP or on Lionheart.

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty

Information section of current PV SIP CD

INFORMATION

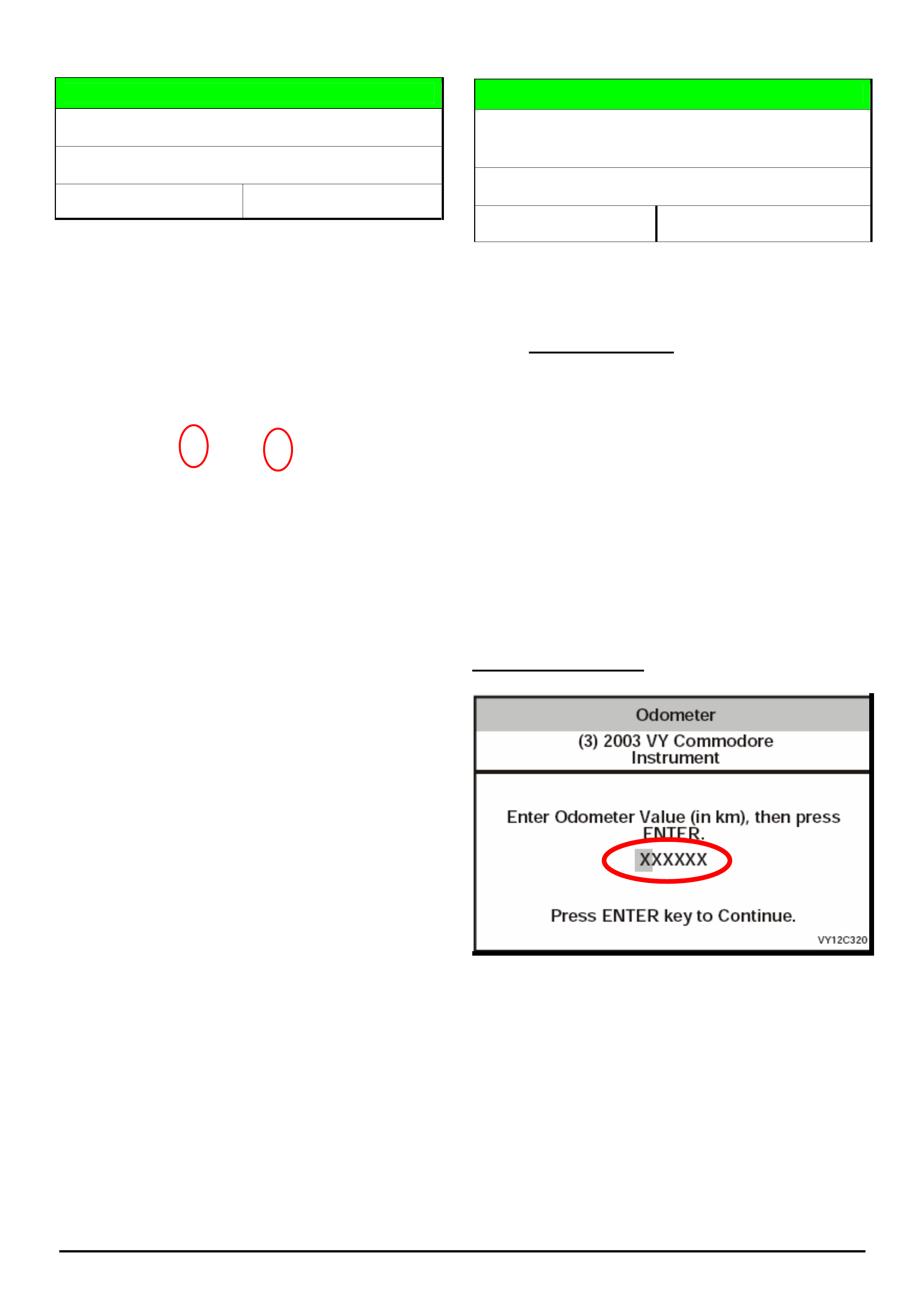

Electronic Odometer Programming

TK Barina, JF Viva,

Group 12 Ref. No.TL0481A-0601

This Techline supercedes the previous one in Issue 5,

2003. It is revised by adding TK & JF models.

When a replacement instrument cluster is installed

into one of the above models it is a requirement to

program the odometer to the value of the one

removed.

If your Service Department does not know of any

instrument repairers who are capable of performing

this operation on the above models, below are some

contacts of instrument repairers currently being used

by other Dealers.

Victoria

Automotive Instrument Repairs

59 C Glenvale Crescent,

Mulgrave, Victoria 3170

Phone (03) 9561 2366

Fax (03) 9561 9134

NSW

Macarthur Instruments

P.O. Box 3016

Narellan Delivery Centre, NSW, 2567

fax (02) 4659 7294

Mobile (0416) 241 903

QLD

Future Auto Instruments

113 Turpin Rd,

Labrador, QLD 4215

Mobile (0414) 518 766

New Zealand

Robinson Instruments

19 Fale Street

Freeman's Bay

Auckland

Phone (09) 3771565

Fax (09) 3580573

HOLDEN SERVICE TECHLINES___________________________________________________________________________FEBRUARY, 2006

7

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

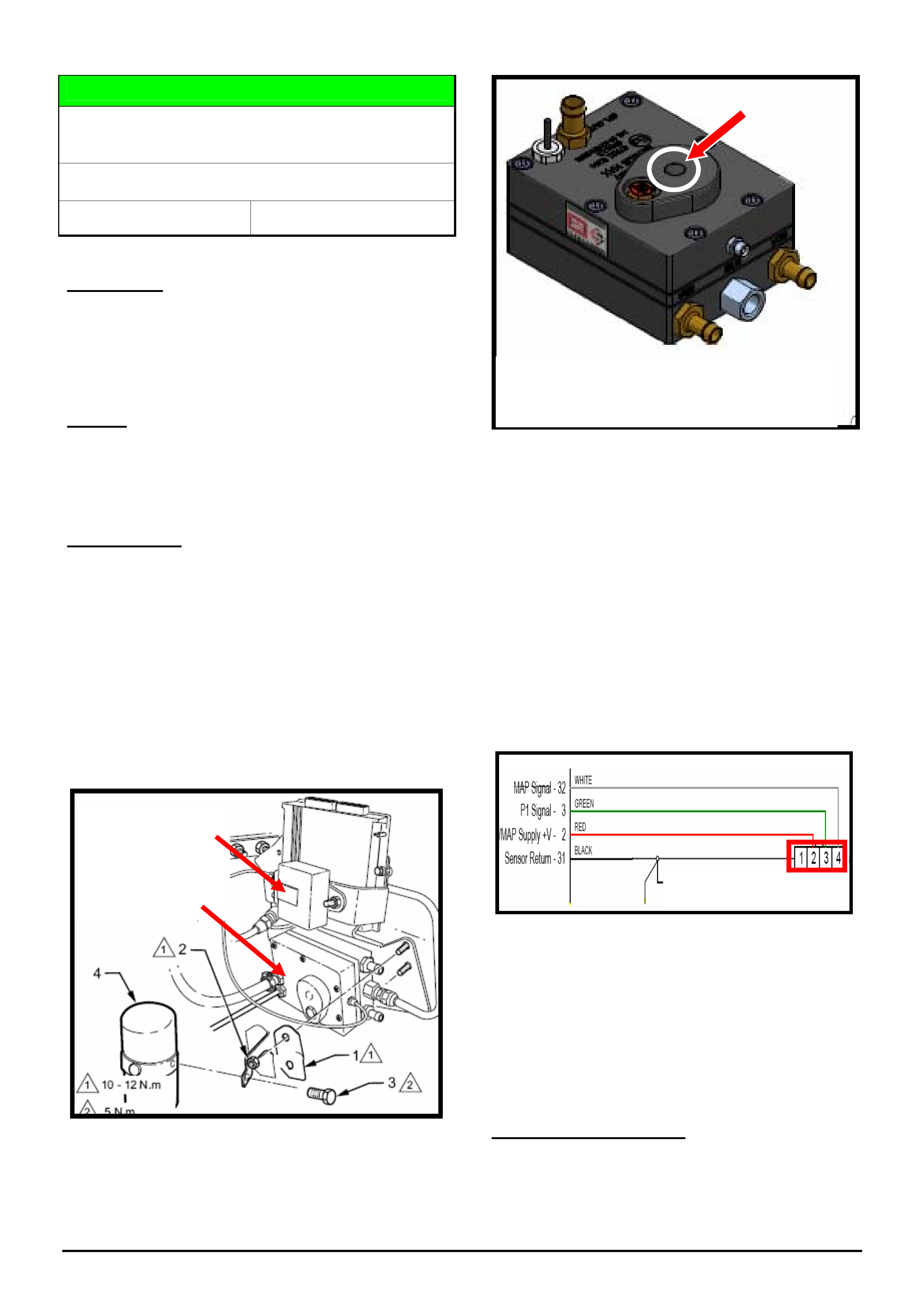

SERVICE FIX

Engine RPM Flare During Upshift &

Hesitation/Flat Spot at 90 km/h

(Reprogram with Scan 100 and R-Card)

DAEWOO LACETTI with M/T

Group 6C Ref. No. TL1065 – 0601

CONDITION

Engine RPM flares or RPM “hangs-on” during gear

upshift.

Vehicle may also exhibit a hesitation or flat spot while

driving at approx. 90km/h.

NOTE: Only Manual Transmission Vehicles are

affected.

CORRECTION - Service

On complaint vehicles the ECM will need to be

reprogrammed with revised software using a Scan

100 tool and a Daewoo R-Card.

Contact your Aftersales District Manager for access to

a Scan 100 tool (if you don’t have one).

A Daewoo “Lacetti” R-card will need to be obtained

via TAS and will require a TAS case to be loaded

prior to dispatch of the R-card.

Note: this R-card contains different software to the

one for DTC 35 high idle as quoted in Service

Techline TL0978-0509 (refer Issue 9/2005) .

REPROGRAMMING PROCEDURE

Preliminary Checks.

A. Ensure battery is fully charged and all power

consuming devices are turned off.

B. Vehicle to be at full operating temperature.

IMPORTANT

The following procedure for using the “R-Card”

must be strictly adhered to.

Failure to do so may result in the irrecoverable

loss of the ECM.

Procedure

1. Ensure Scan 100 has the re-program card

inserted in the lower card slot.

Note, the main Scan 100 card is in the slot closest to

the screen of Scan100 and the re-program card is in

the lower slot. Both cards must be in the Scan 100.

2. Ensure the external 240 volt power supply is

connected to the Scan 100 unit.

3. Connect the Scan 100 to the vehicle via the data

lead and correct adaptor to the diagnostic link of the

particular vehicle. Check workshop manual for the

location of the diagnostic link connector.

4. Turn ignition on. Do not start the engine. Ignition

lights on dash illuminated.

5. Turn Scan 100 tool on.

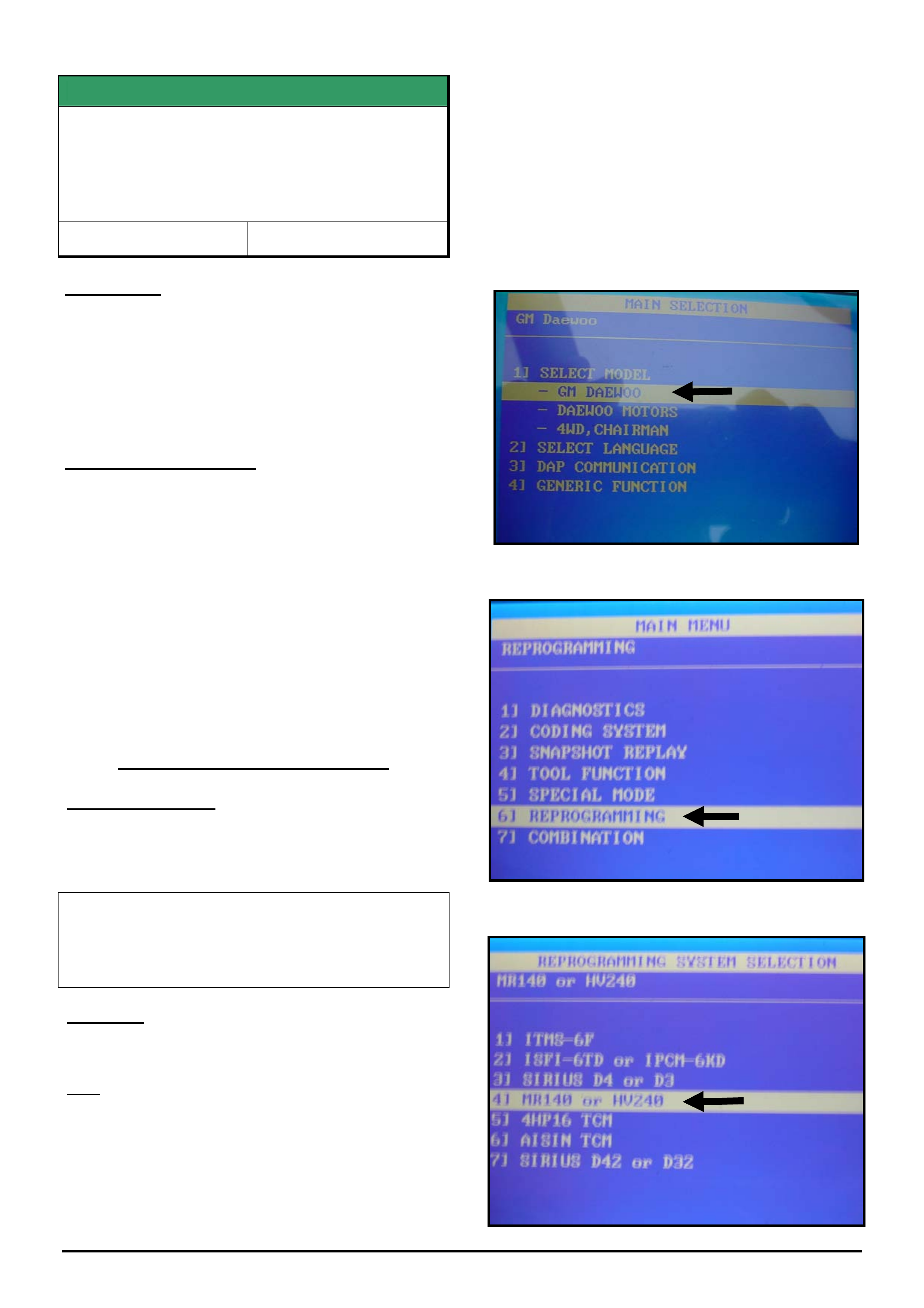

6. Select GM DAEWOO then press enter.

7/ select (6) RE-PROGRAMMING then press ENTER.

8. select (4) MR140 or HV240 then press ENTER.

HOLDEN SERVICE TECHLINES___________________________________________________________________________FEBRUARY, 2006

8

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

9. Select (1) ECM REPROGRAM (SCAN 100 --> ECM)

There will now be two available “files” to choose from

and they MUST be loaded in the following order.

(FIRST) LACETTI 1.8 DOHC M/T

2003-10-20 File Name: 96491309.

This file will update the ECM to avoid flat spotting /

hesitation.

(SECOND) LACETTI 1.8 DOHC M/T

2005-03-23 File Name 96491309

This file will reprogram the ECM to avoid engine

rpm “flare” between gears.

NOTE: Both files have the same file name -

”96491309”.

10. Select (01) LACETTI 1.8 DOHC M/T

2003-10-20 File Name: 96491309.

then press ENTER

Should the following message appear, then the

Calibration you are attempting, has already been

installed and you should go to step 13.

If this message does not appear then proceed to step 11.

11. A message should appear stating

“DO YOU START REPROGRAM OF ECM ?”.

Select “YES”

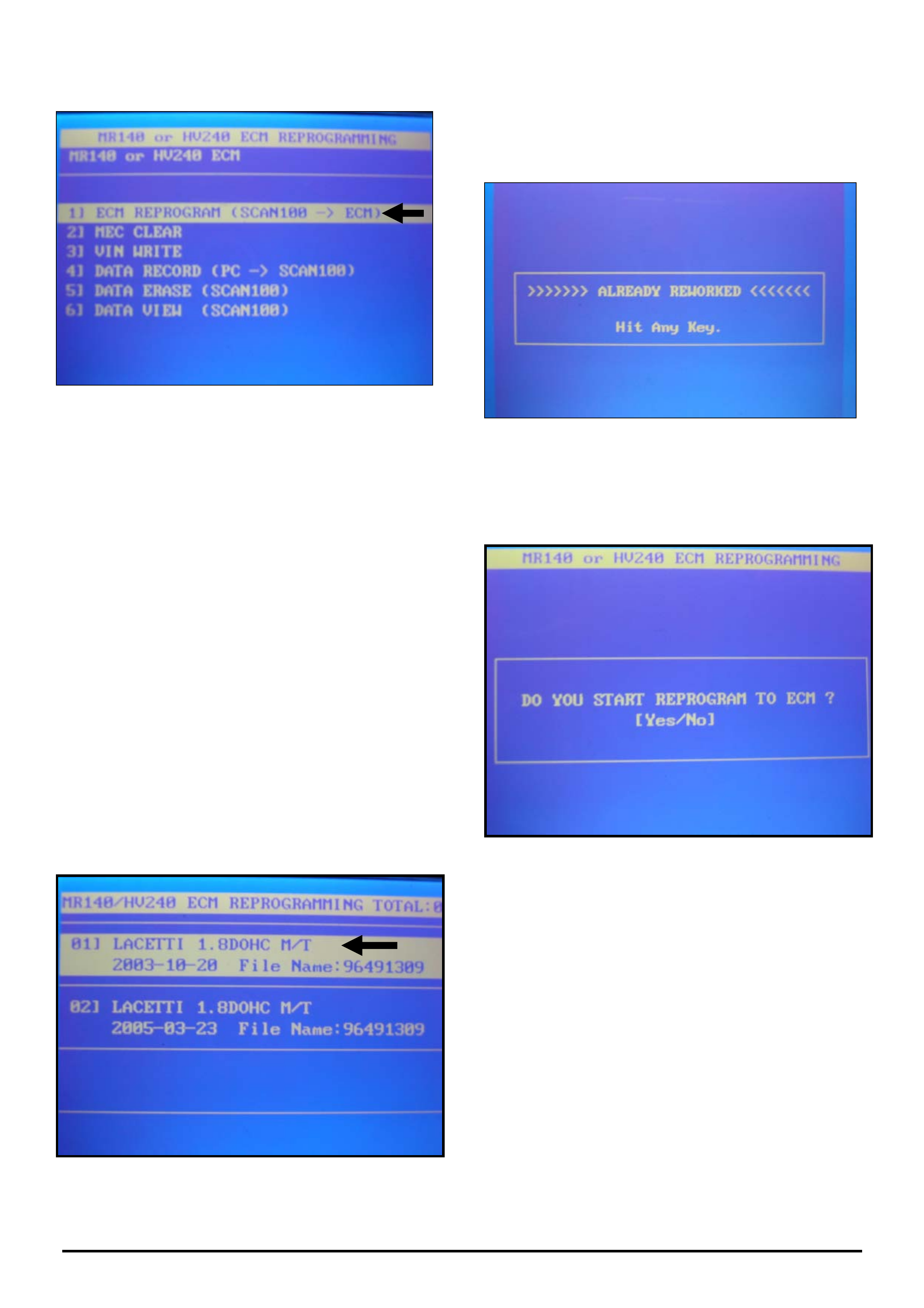

12. Wait for programming to finish.

A message stating that “REPROGRAM SUCCESSFUL

(GOOD)” will appear.

HOLDEN SERVICE TECHLINES___________________________________________________________________________FEBRUARY, 2006

9

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

13. Turn ignition switch to the “off” position for 20

seconds. Turn ignition switch to “on” then start

engine.

14. Press “esc”. several times to return to the main

screen.

15. Repeat Steps 6 to 9.

16. Select (02) Lacetti 1.8 DOHC M/T

2005-03-23 File Name 96491309.

Press ENTER and repeat steps 11 to 14 as above.

Should the following message appear, then the

Calibration you are attempting, has already been

installed and no further action is required.

Should either of the 2 messages below appear, contact

TAS prior to disconnecting or exiting procedure with

Scan 100.

HOLDEN SERVICE TECHLINES___________________________________________________________________________FEBRUARY, 2006

10

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

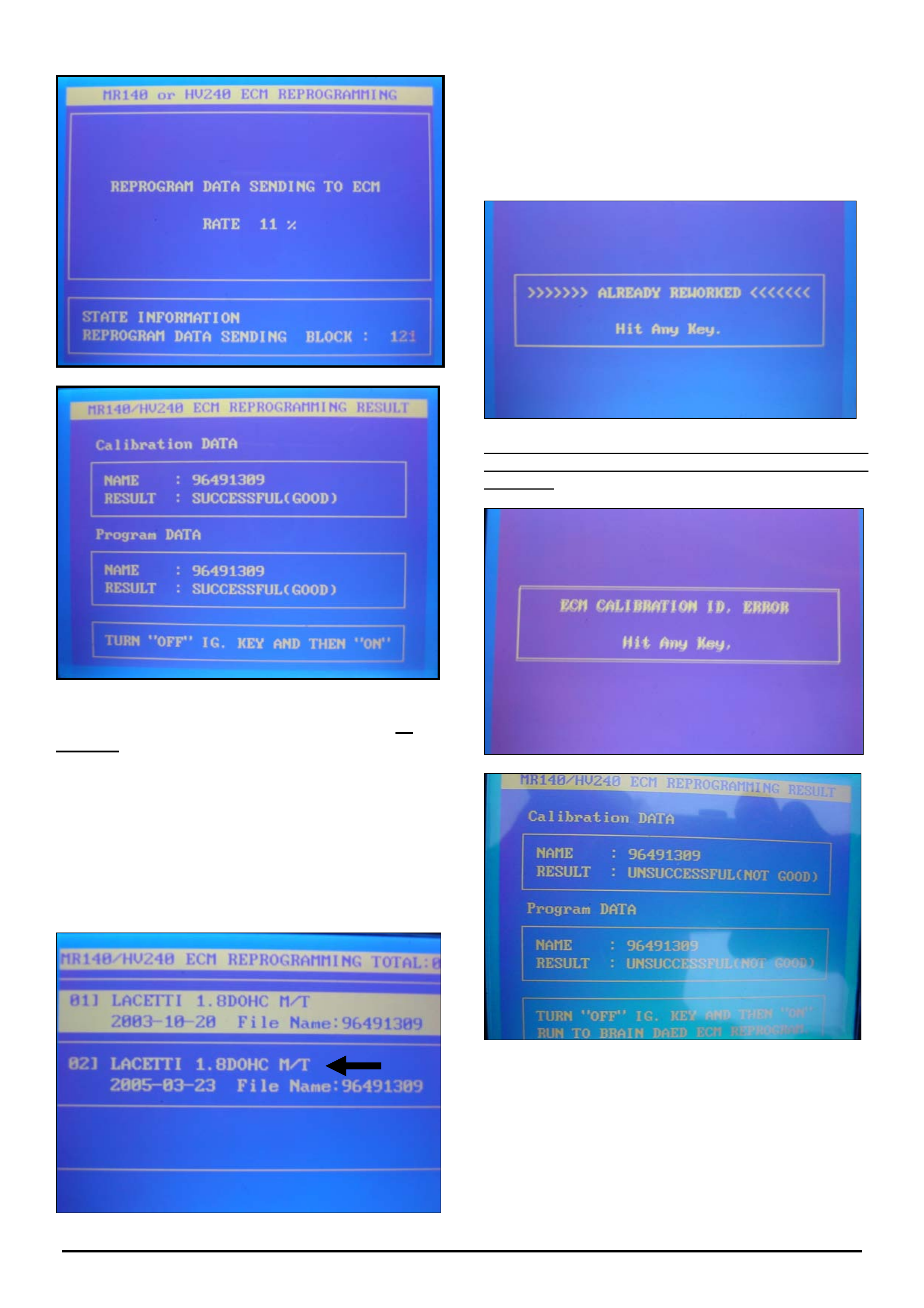

SERVICE FIX

Glove Compartment Door Opens Too Far

VY, VZ, V2 II & III, WK, WL

Group 1 Ref. No. TL0854A-0601

This Techline supercedes the previous one (TL0854-0502)

in Issue 2, Mar, 2005. It is revised as both previous bump

stops have been superseded by a new part number.

CONDITION

Glove compartment door rubber bump stops may

tear in service. As a consequence, the glove

compartment swings fully downward when opened

and is not restrained by the stops.

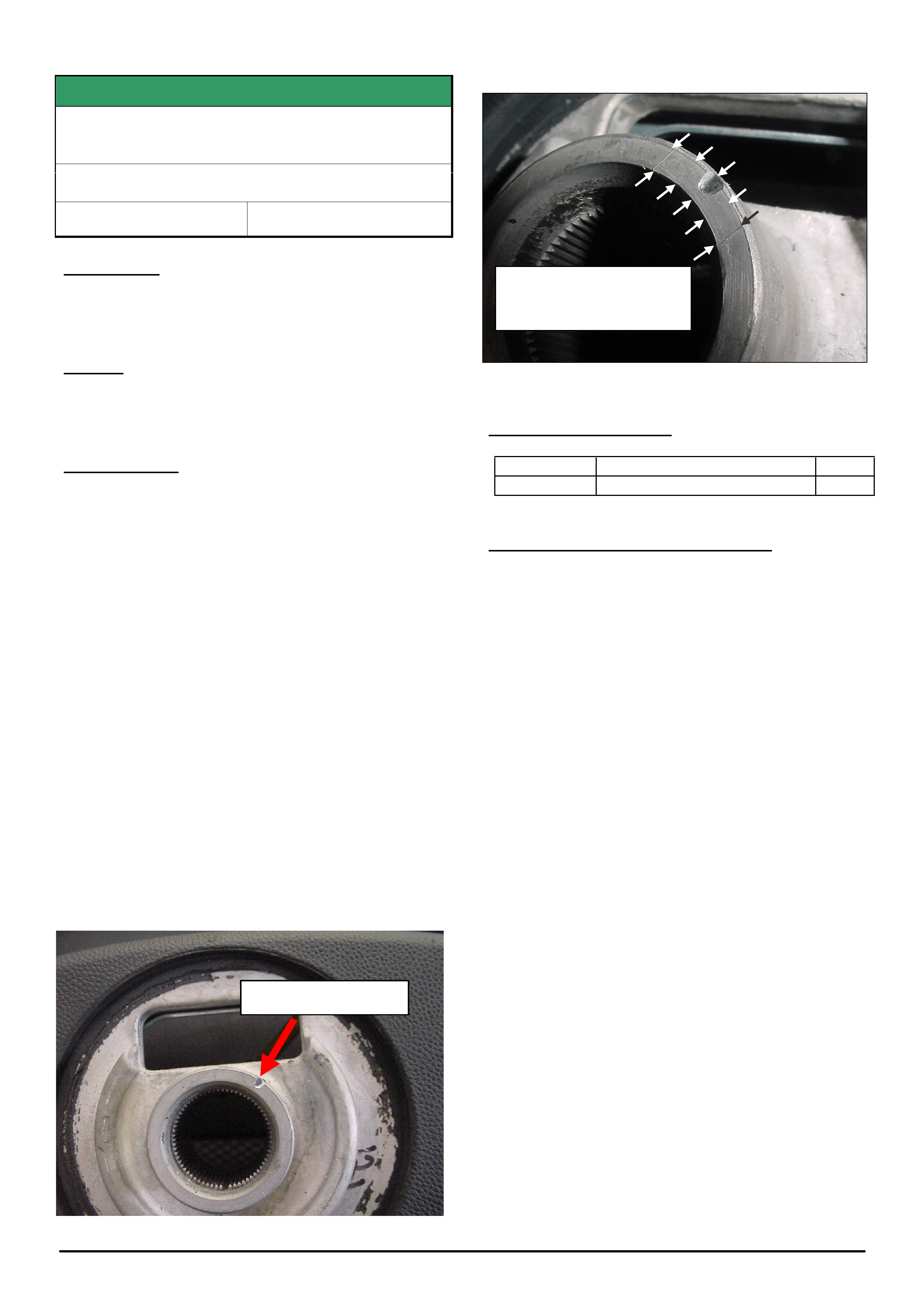

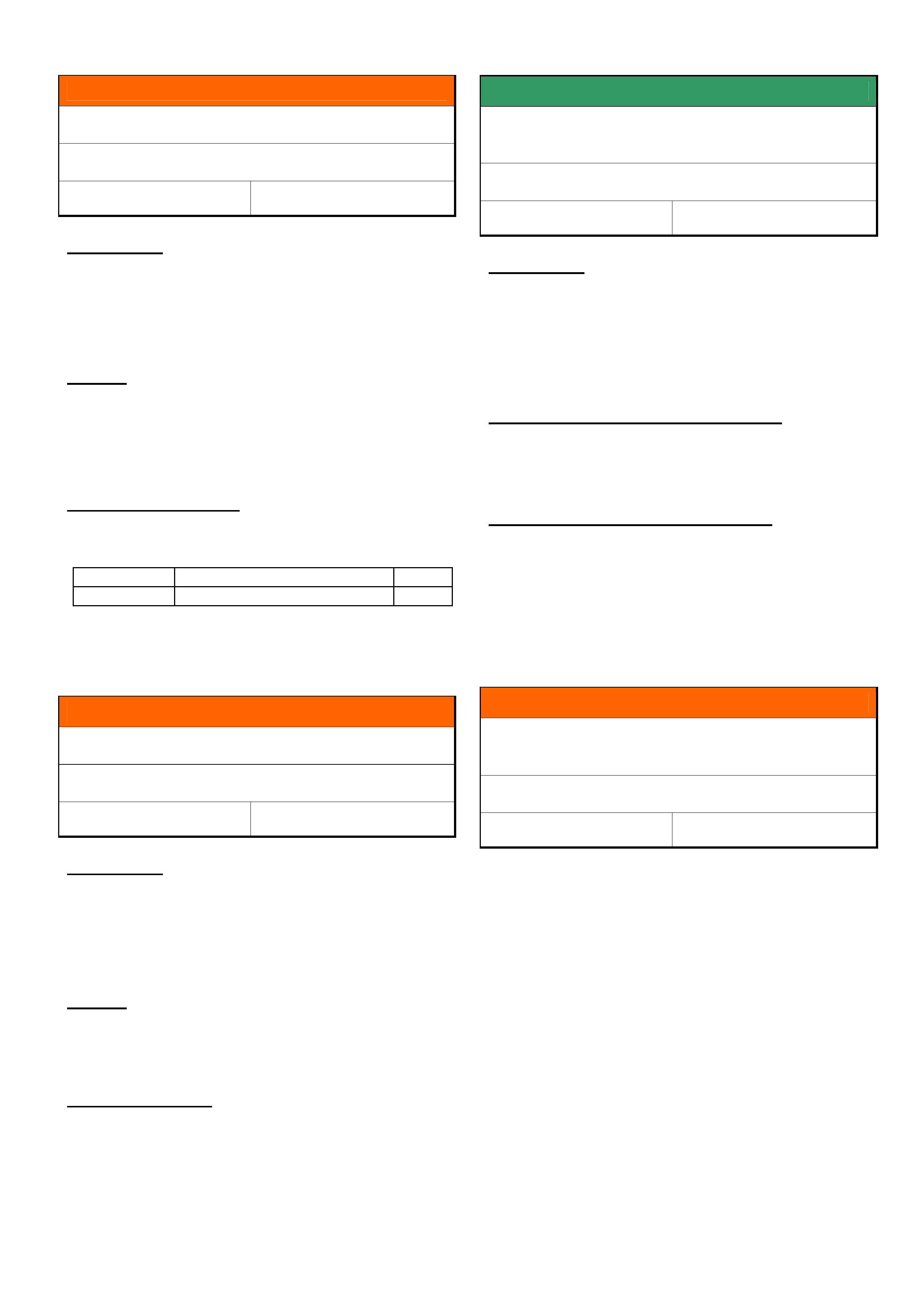

The bump stop is shown as key #2 in figure below.

Figure 1.

CORRECTION – Production

Revised bumpstops have been fitted to vehicles from:

ISOVIN: Built Date:

0000000000L486687 3rd AUG 2005

CORRECTION – Service

1. Inspect the bump stops on both sides of the glove

compartment, to confirm whether one or both stops

are torn.

2. Remove the glove compartment using the

procedure outlined in Holden SIP Section 1A3 para

3.2, taking care to avoid damaging the glove

compartment while removing hinge pins.

3. Remove damaged bump stop/s.

4. Fit new bump stops 92186491.

5. Reinstall glove compartment as follows:

Engage lower hinge points, then rotate glove

compartment up into closed position whilst pushing

sideways to compress one of the bump stops. This

action is required to provide clearance for the other

bump stop as it slides over the Instrument Panel

structure.

PARTS INFORMATION

Part No.: Partfinder Name Qty:

92186491 Bumper instrument panel

compartment door

1

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty

Information section of current PV SIP CD

HOLDEN SERVICE TECHLINES___________________________________________________________________________FEBRUARY, 2006

11

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

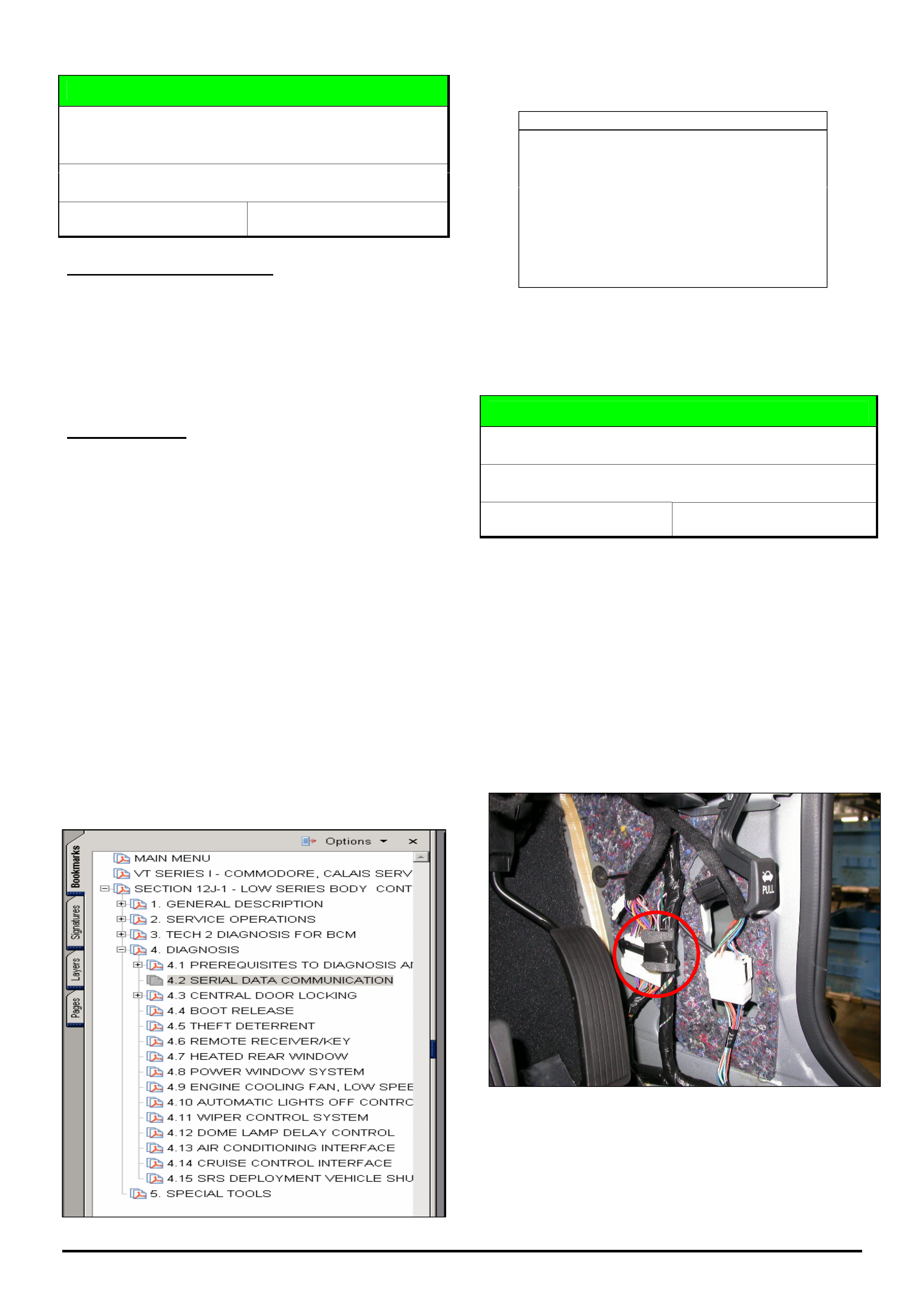

DIAGNOSIS HINT

CAN-bus Configuration Mismatch DTC’s

AH Astra, ZC Vectra

Group 12 Ref. No. TL1050 - 0601

CONDITION

Trouble codes (DTC’s) may be stored after replacing

modules that communicate on the CAN-bus network.

These DTC’s may be stored in multiple modules if the

configurations are different.

The configurations in these modules must all be

programmed the same, otherwise the following DTC will

set.

“CAN-bus Configuration Mismatch”

This highlights the importance of ALWAYS starting

diagnosis with a “Module / ECU Presence Check” as

shown in the following screen from Tech2.

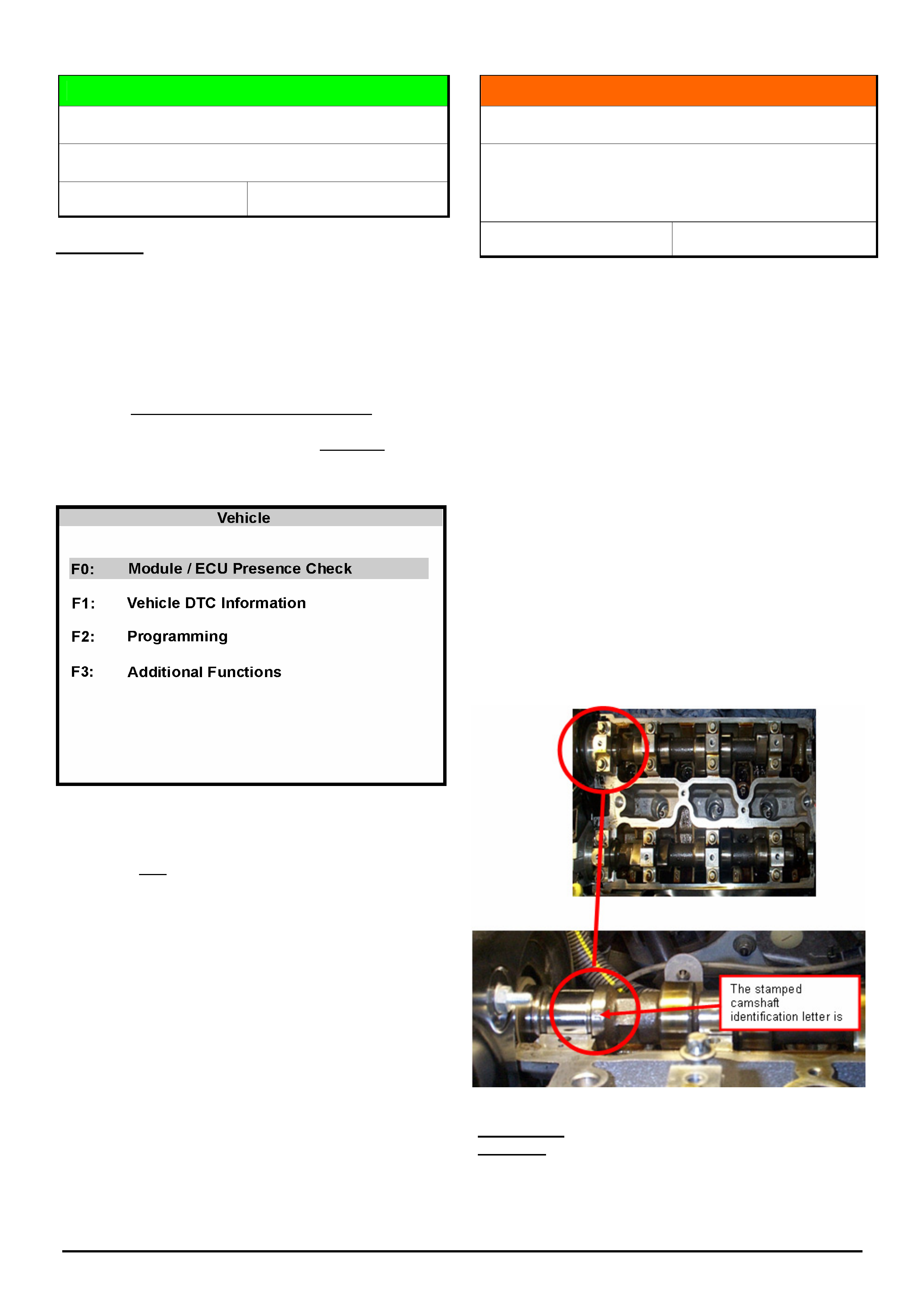

Figure 1

This “Presence Check” not only checks the modules are

present and communicating on the CAN-bus, but also

checks that ALL the modules are configured the same.

If a mismatch is detected, Tech 2 will display the

module(s) concerned then automatically prompt you

through the configuration process.

This procedure saves time by not having to check and

reprogram each module individually.

INFORMATION

Camshaft identification

SB Barina,

TR / TS / AH Astra,

JR / JS / ZC Vectra

Group 6A Ref. No. TL1063-0601

When performing cylinder head repairs on the twin

cam engines fitted to the above models (see list of

engines below) some technicians have had difficulty

with identification of camshafts.

C18SEL, C16XE, C20SE, C22SE

X16XE, X18XE1, X20XEV, X25XE, Z18XE

Z20LET, Z22SE

Y26SE

Most camshafts can be identified by the following

markings which are located near the first cam bearing

or cam drive gear end.

The letter "H" or "C" or "Z" = inlet

The letter " I “ or "T" or "Y" = exhaust

Z32SE Engine has the following identification:

G = Inlet Camshaft

J = Exhaust camshaft

Location of Z32SE markings is as follows:

↑

Gear end of

camshaft

HOLDEN SERVICE TECHLINES___________________________________________________________________________FEBRUARY, 2006

12

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

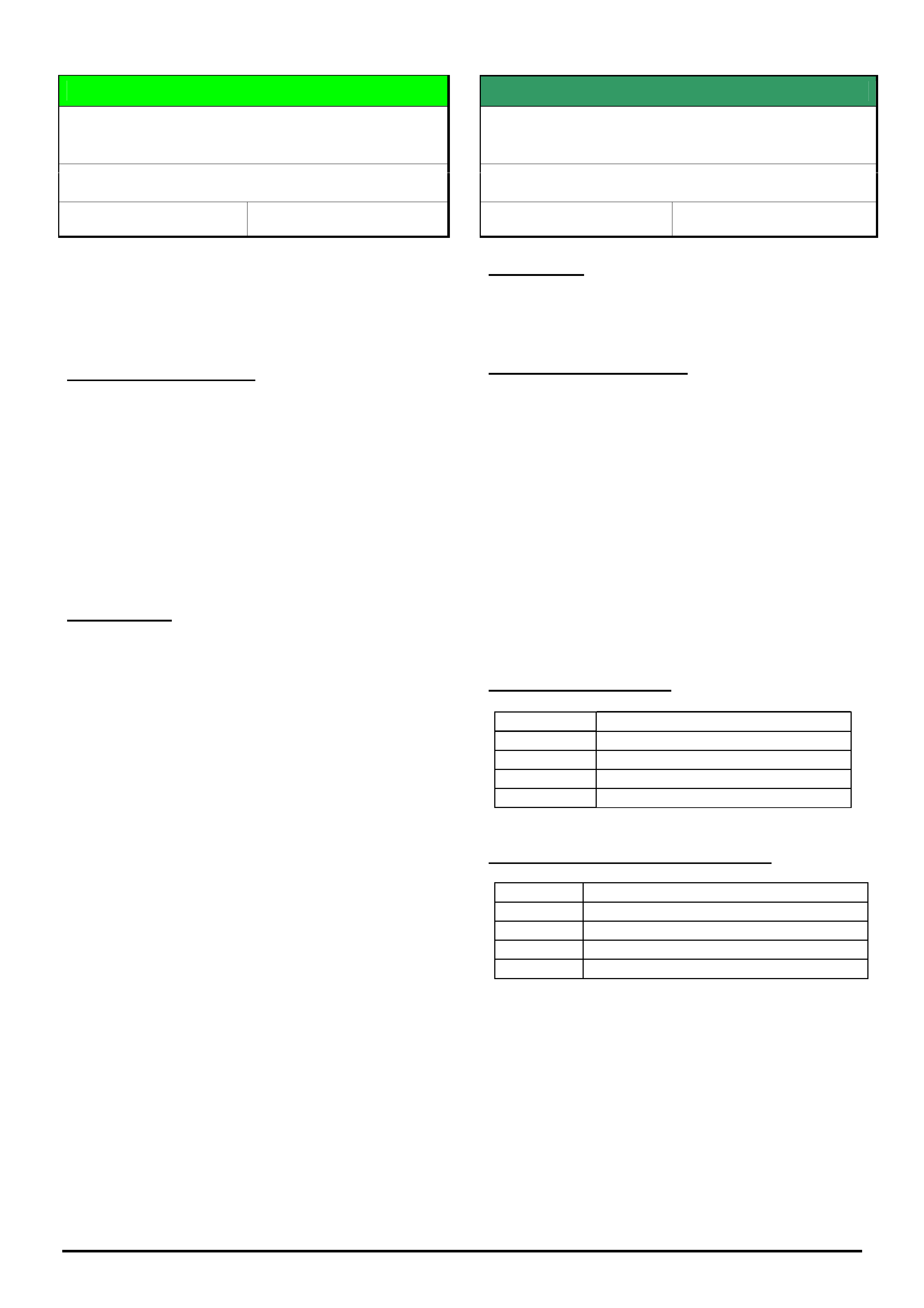

SERVICE FIX

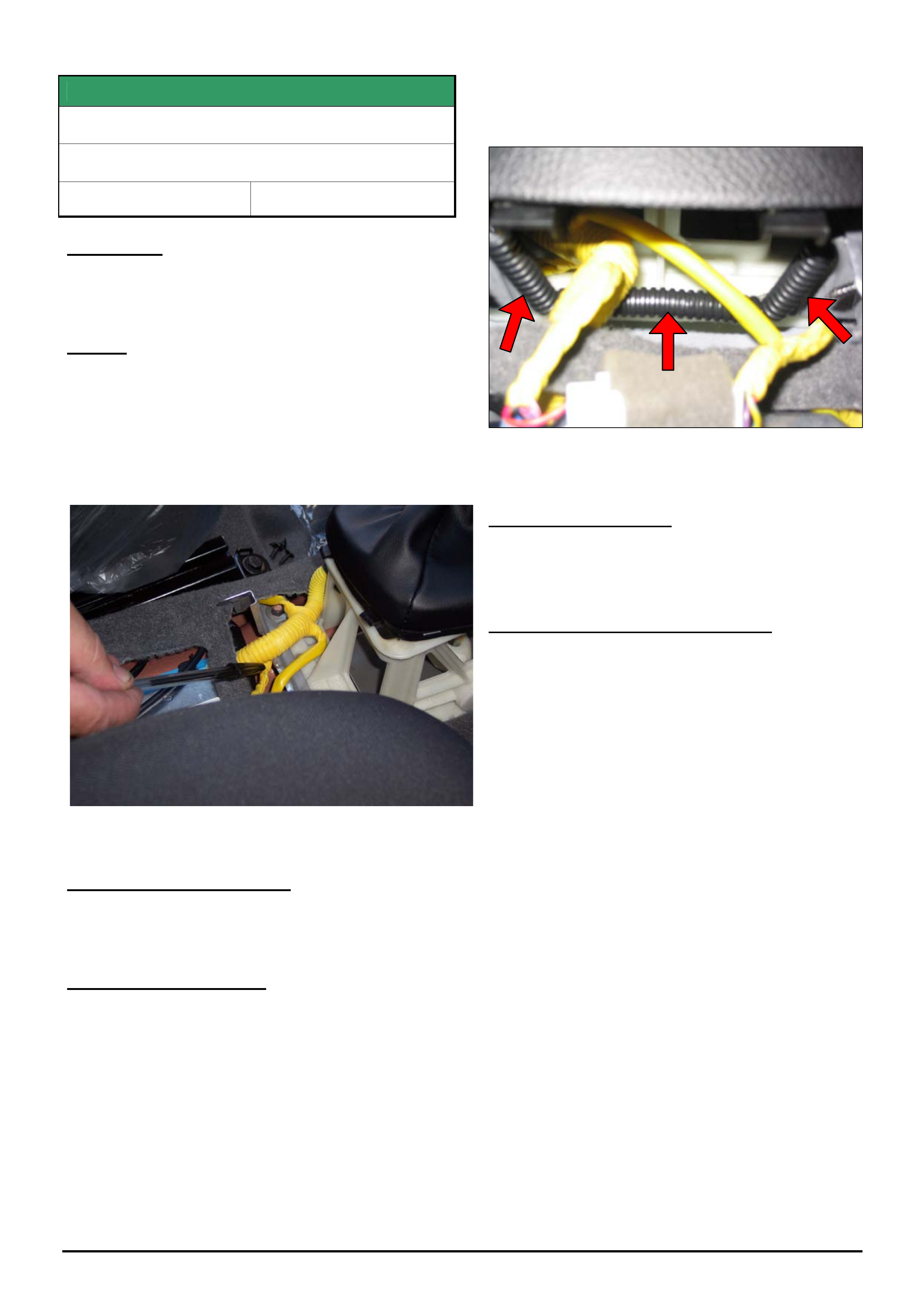

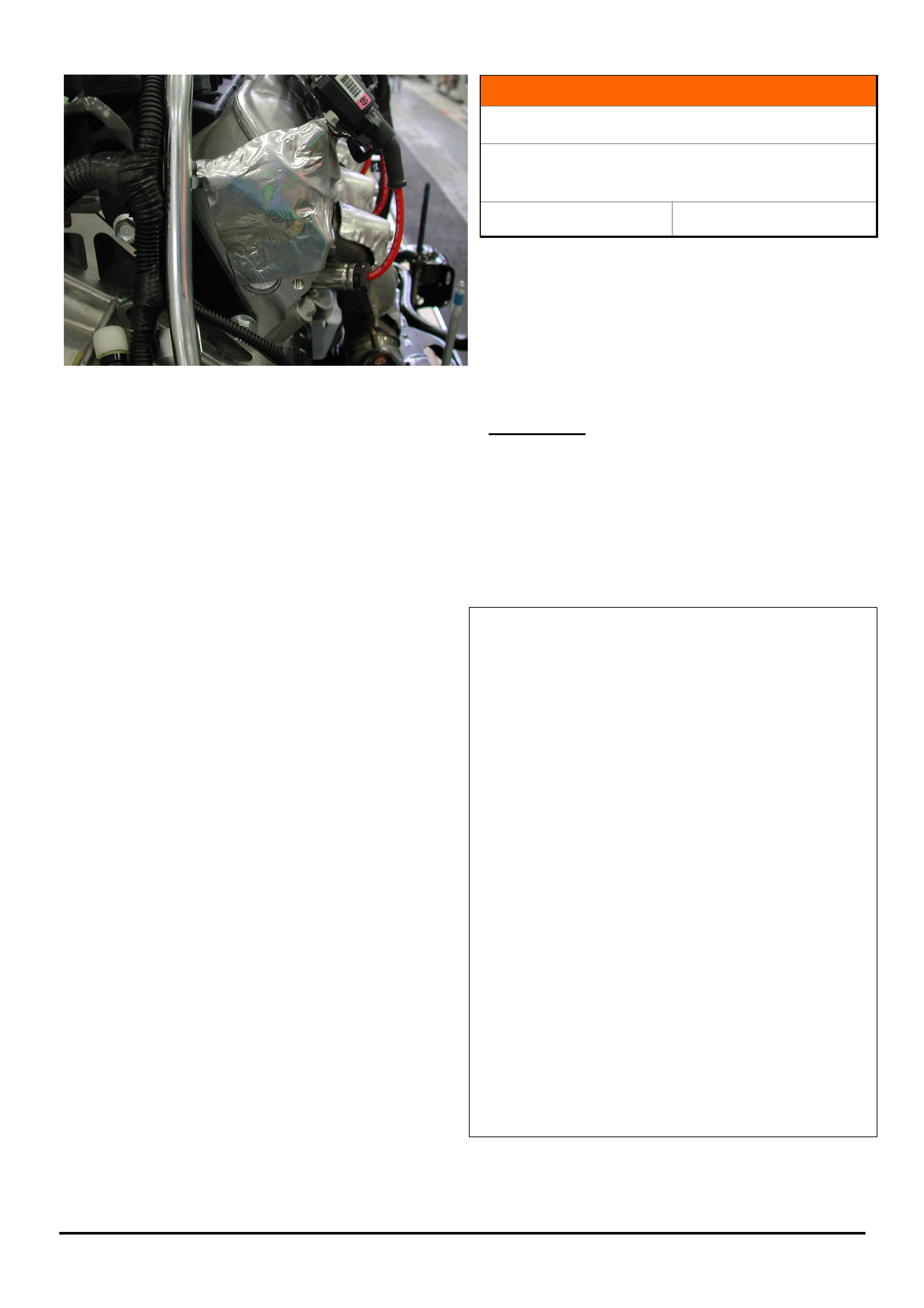

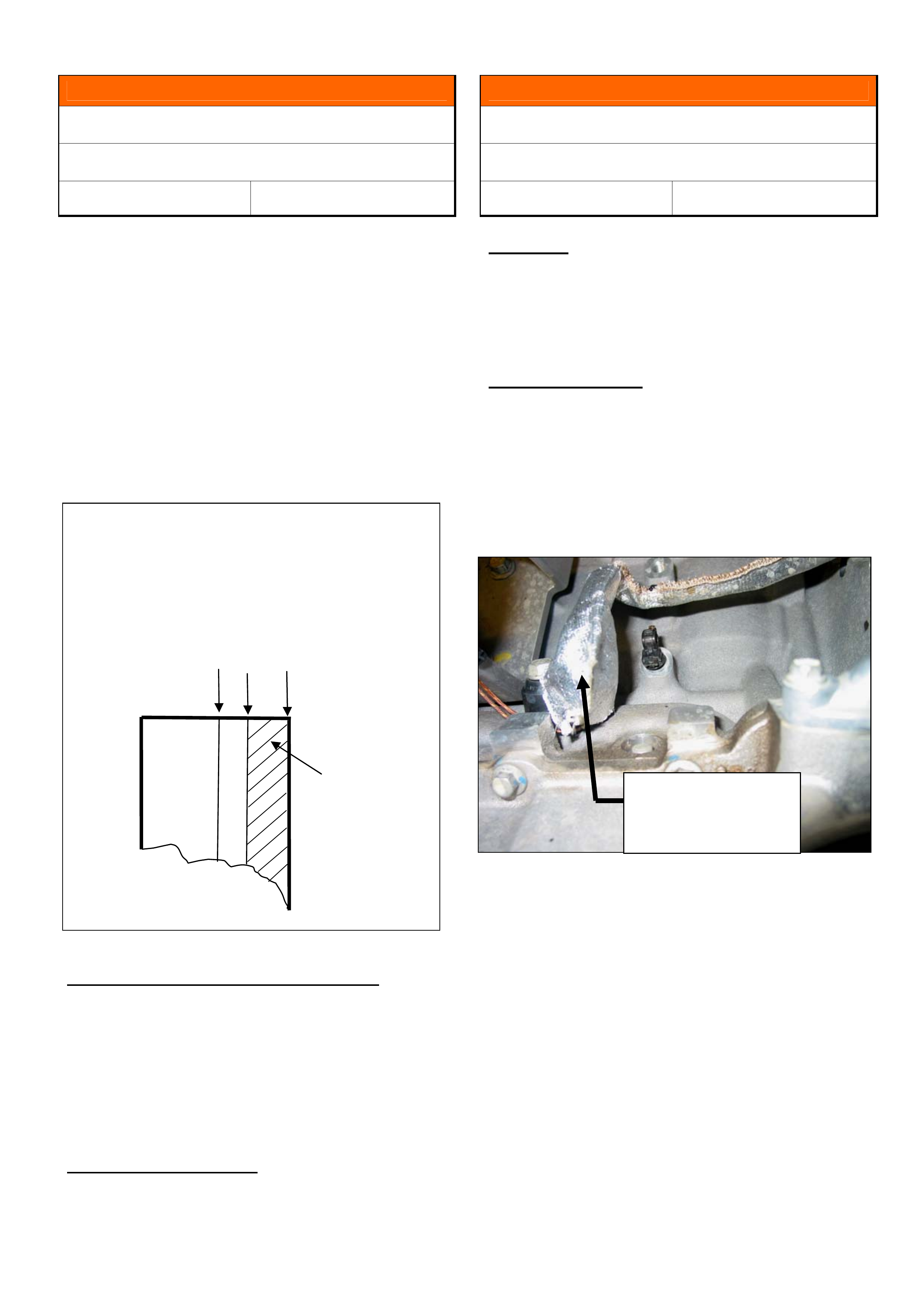

SRS light Illuminates

JF Viva

Group 12 Ref. No. TL1045 - 0601

CONDITION

SRS light may be illuminated in the instrument cluster

with various SRS circuit DTC’s set in the SDM.

CAUSE

The SRS wiring harness under the centre console

between the SDM and the transmission shifter may

have been damaged by a sharp metal edge, causing a

short to ground and various DTC’s to set.

Damage may occur to any of the circuits contained

within this harness resulting in a variety of different

DTC’s.

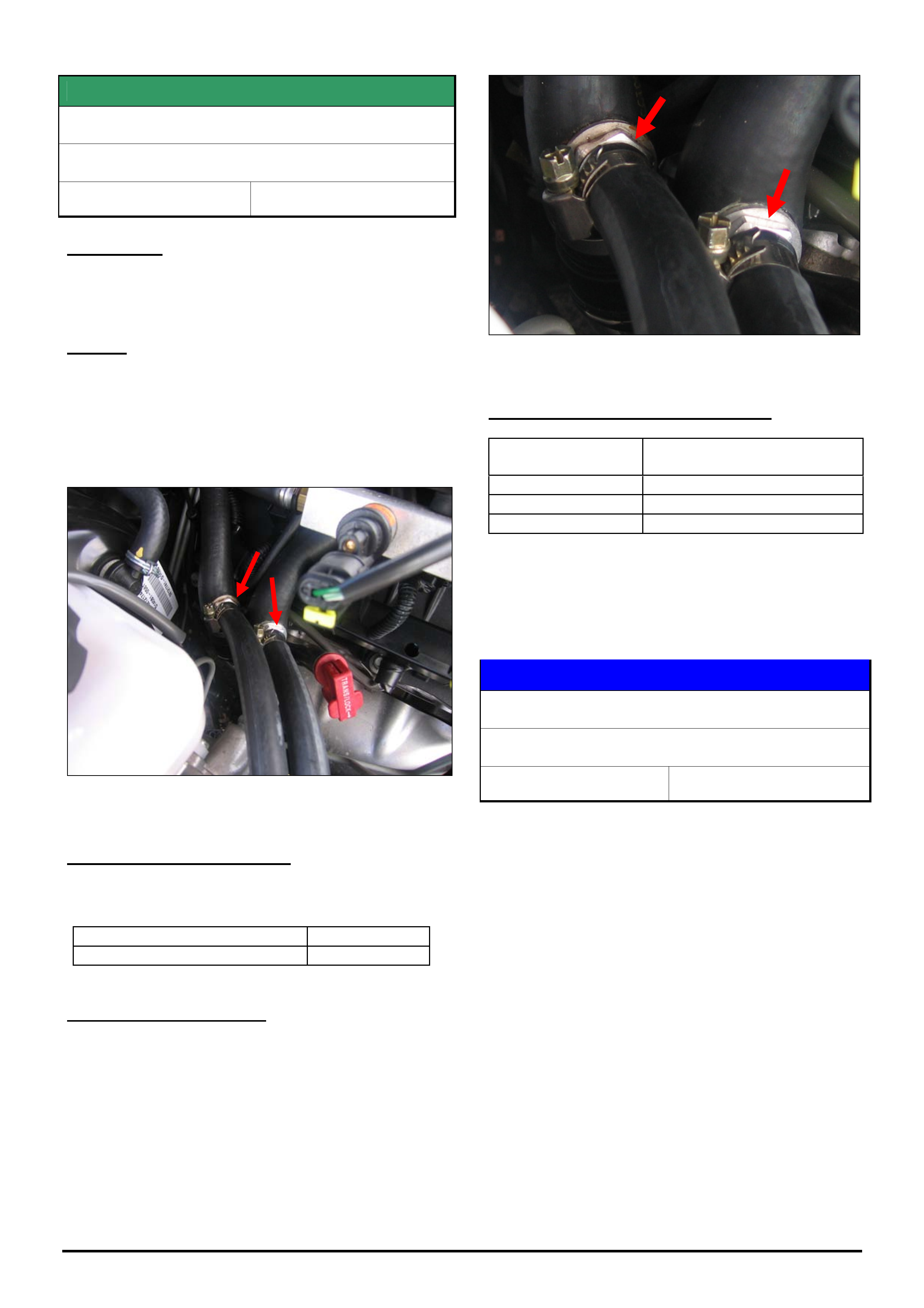

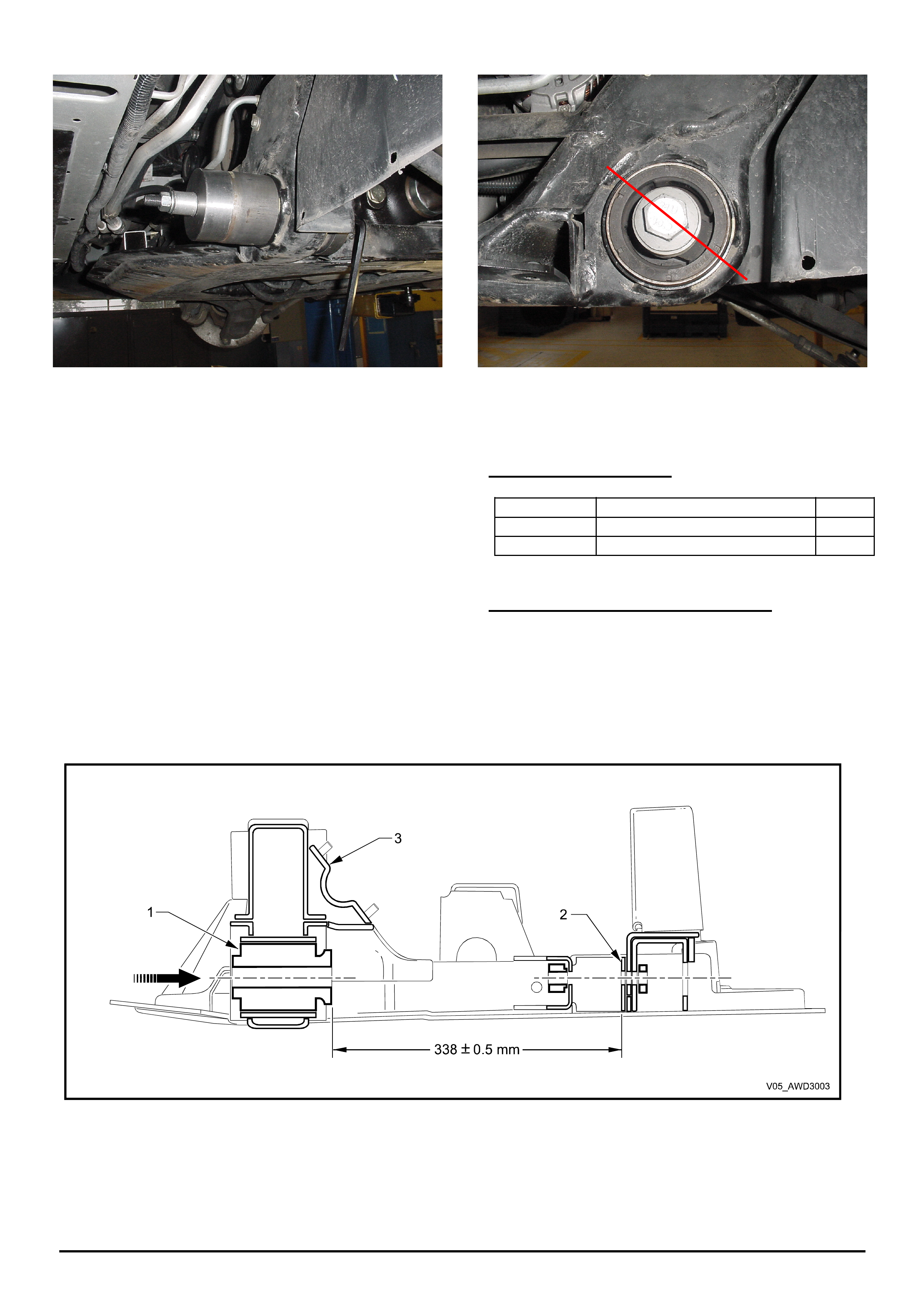

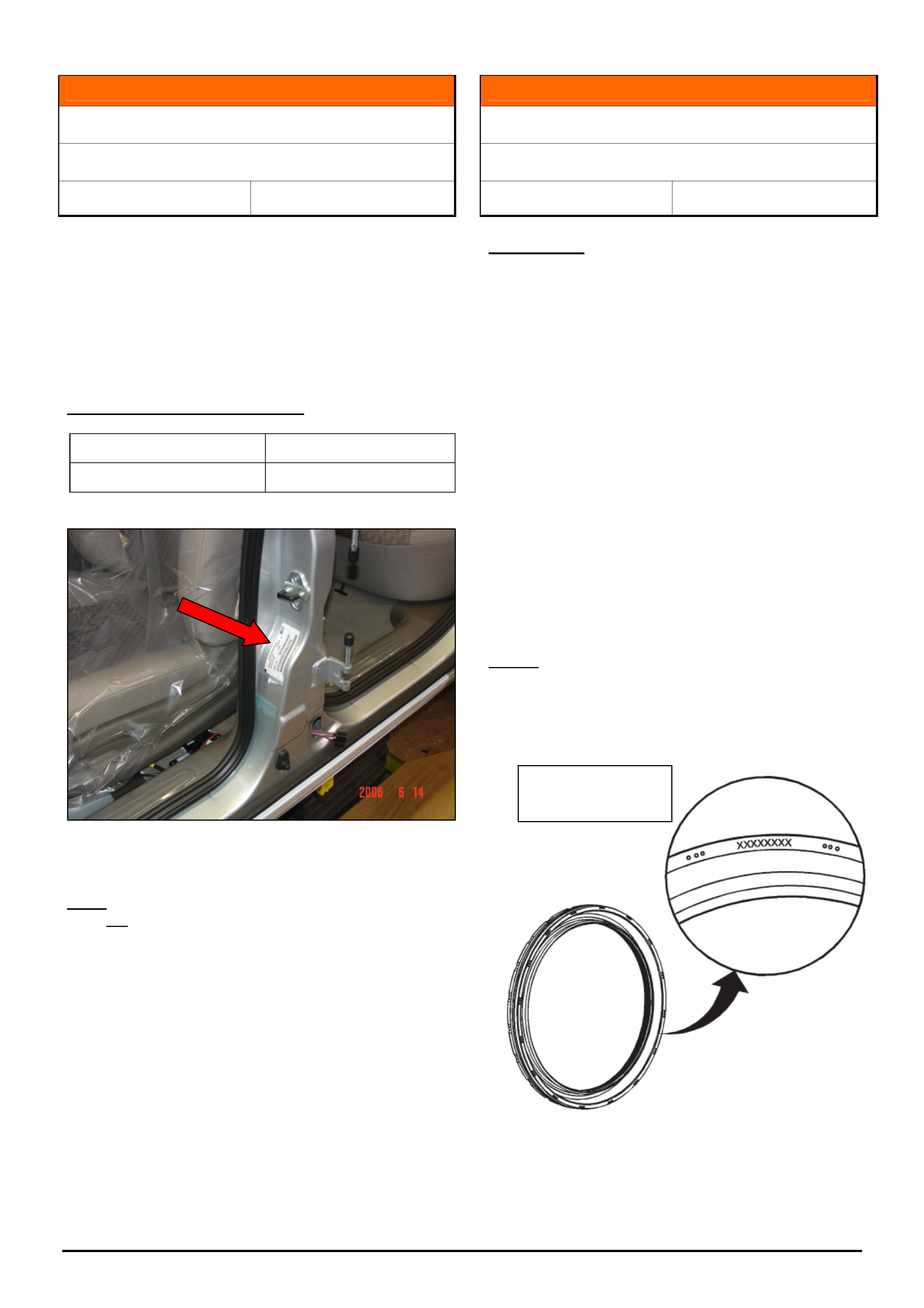

Figure 1 Shows location of damage

CORRECTION – Production

Vehicle’s shipped from POE (Port Of Entry) after the

14/11/05 have been inspected for this condition.

CORRECTION – Service

If presented with a vehicle shipped from POE prior to

14/11/05 with the SRS light on, perform the following

steps:

1. Carefully inspect the SRS harness in the

location described above.

2. If wiring damage is discovered, repair and re-

insulate.

3. Ensure the sharp edge on the metal bracket

shown below is covered with a piece of

convoluted tube to prevent further damage.

Figure 2. Shows convoluted tubing placed over sharp

edge.

PARTS INFORMATION

Use any commercially available convoluted tubing of

approx. 9mm diameter.

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty Information

section of current PV SIP CD for wiring repairs.

HOLDEN SERVICE TECHLINES___________________________________________________________________________FEBRUARY, 2006

14

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

SERVICE PROCEDURE

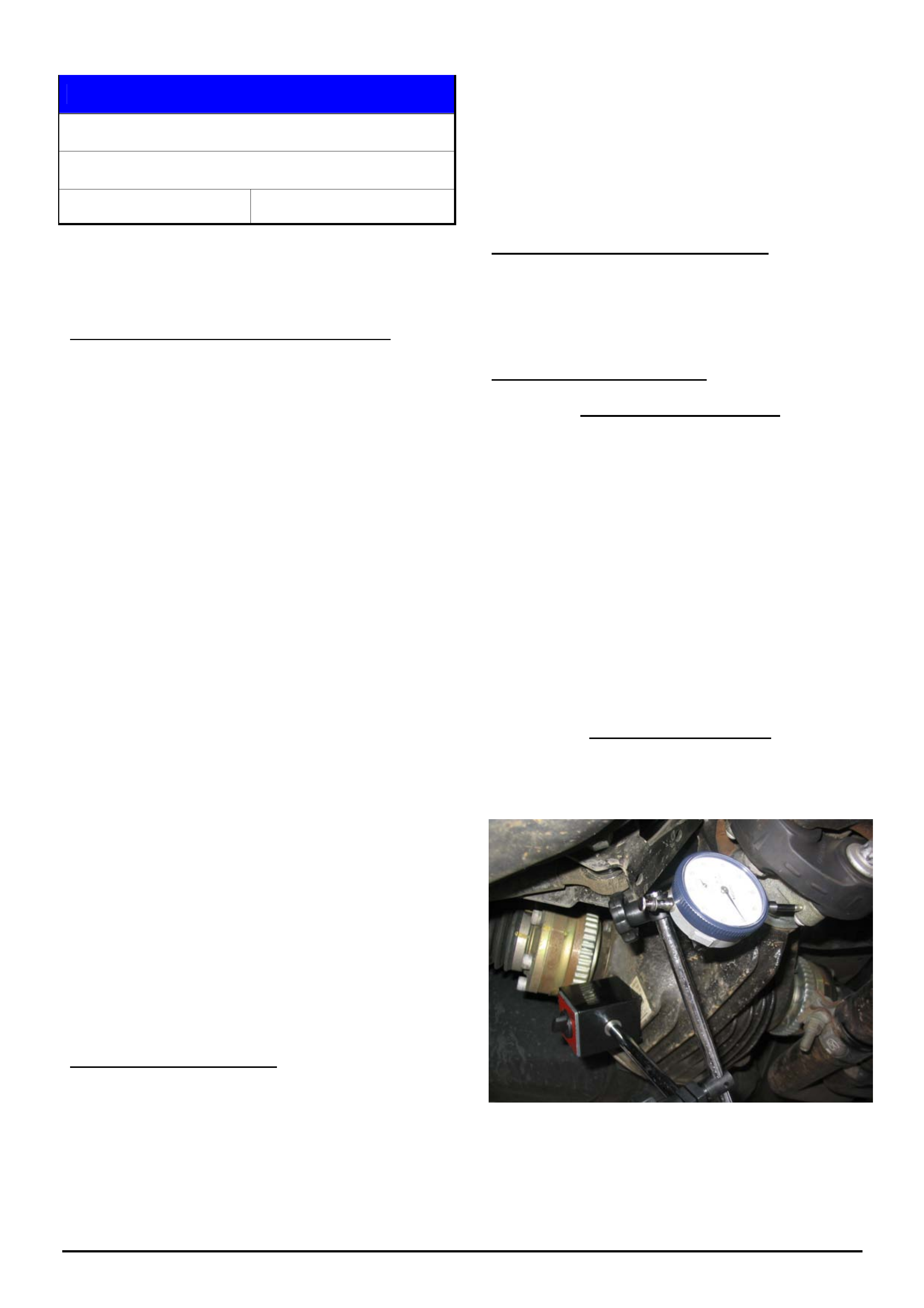

Driveline Clunk/Backlash from Rear Axle

VZ (with IRS or Beam Axle)

Group 4 Ref. No. TL0853 - 0601

This Techline provides a Lash Check procedure for IRS

Rear Axle Assemblies and supersedes the previous bulletin

(TL0815-0410) on VY/VZ Differential Clunk Noise in Issue

10, Nov. 2004.

IMPORTANT BACKGROUND INFORMATION

Before commencing the procedures provided in this

Techline and to ensure that unnecessary

measurements or repairs are not conducted,

Technicians and Service Advisors must be aware of

and have read the following Service Techlines:

- Explanation of Driveline Clunk or backlash Noise –

refer July 2005 (Issue 6, page 16).

- Suspected Clunk from Driveline - refer October

2005 (Issue 9, page 10 – spare wheel related).

Service Advisors in particular need to ensure that they

clearly understand the reported condition so that the

condition can be reproduced by the dealership

technician and so that customers can be immediately

advised of those conditions that are normal drivetrain

related operating noises.

DO NOT proceed any further if the clunk noise is

confirmed as a normal or characteristic driveline

system operating noise.

Various components in the driveline system can

produce noise as a result of the application and

release of torque through the driveline. This Techline

provides the procedures to be followed to determine

whether the cause of abnormal “Clunk” noise is

caused by excessive clearance within the differential

unit.

The procedures below provide a structured and

accurate method of measuring combined differential

assembly backlash in both Beam axle assemblies and

IRS final drive units when the noise is classified as

abnormal or excessive when compared to other

equivalent specification vehicles. This measurement

procedure will also ensure that components are not

replaced unnecessarily

A. Evaluation of Concern

- Road test the vehicle to repeat the customer

reported concern

- Use the Driveline Noise Definition Worksheet

attached to record details of the complaint condition.

- This worksheet will also record the necessary

information for the Dana Website Request Form

should a replacement diff be required.

- It is essential that the driving conditions, when the

reported concern occurs, is recorded.

- It is also important that the condition is compared

to an equivalent specification vehicle to assist

determining whether the concern is a normal or

characteristic noise or is abnormal.

- If an equivalent vehicle is not available to

compare against and you are unsure whether the

noise level is normal or abnormal, then proceed to

Step B. Otherwise, no further action is required.

B. Vehicle set up for measurement

- Prepare vehicle for measurement by accelerating

forward and then reverse with moderate throttle.

- Drive vehicle onto a four post hoist.

- Apply handbrake firmly

- Raise vehicle

C. Differential Lash Check

For Beam Axle Assemblies

Perform a rear axle backlash check using the

procedure described in PV SIP found as follows:

Section 4B2 – Rear Final Drive and Live Axle

2 – Minor Service Operations

2.6 – Combined Rear Axle Backlash Check

Should the measured backlash be greater than 3.0mm

– the measured backlash dimension MUST be

included in the Dana request application.

The combined backlash specification for the Beam

Rear Axle Assembly is 3.0 mm

DO NOT request a replacement axle if backlash is less

than 3.0mm.

For IRS Final Drive Units

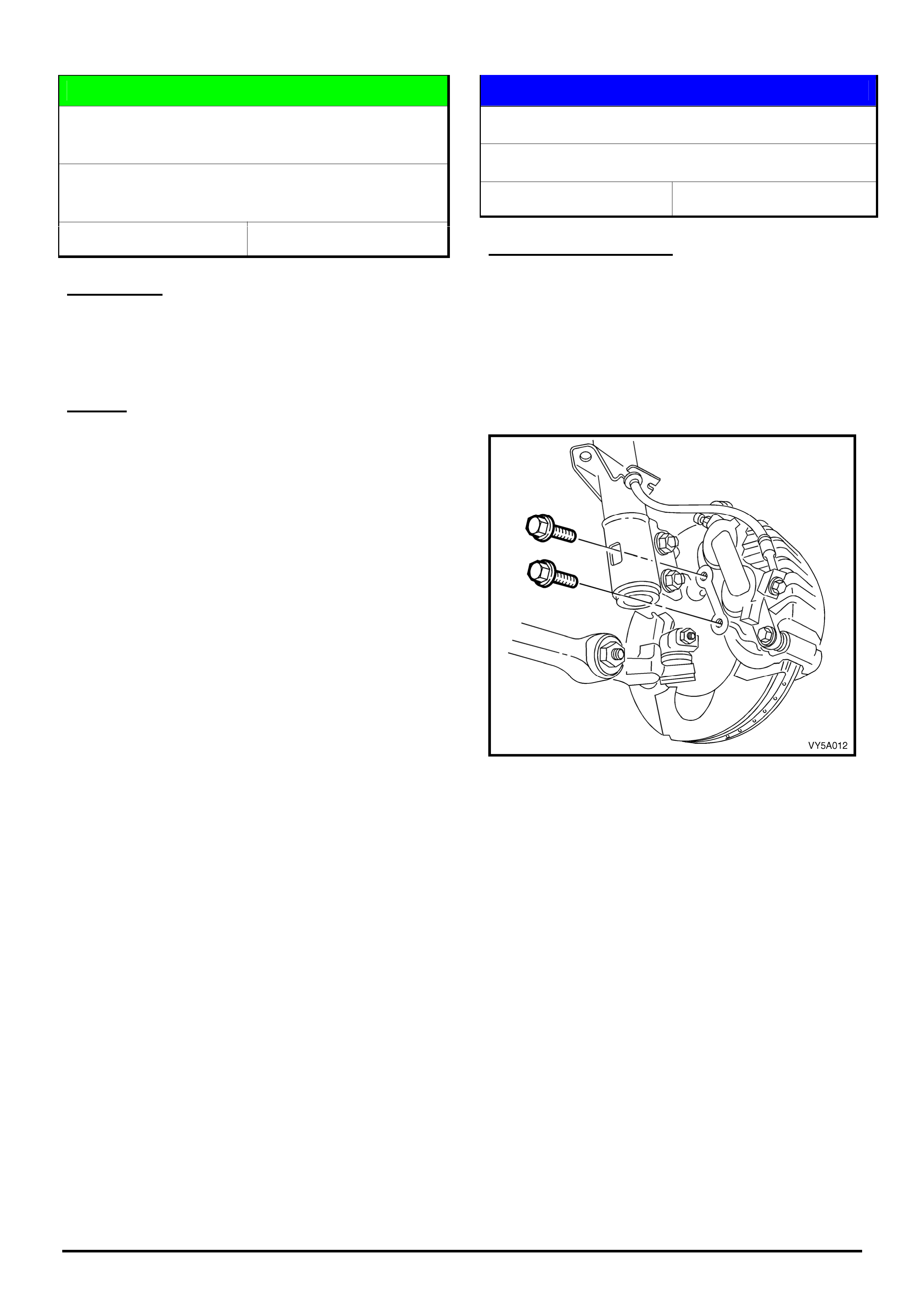

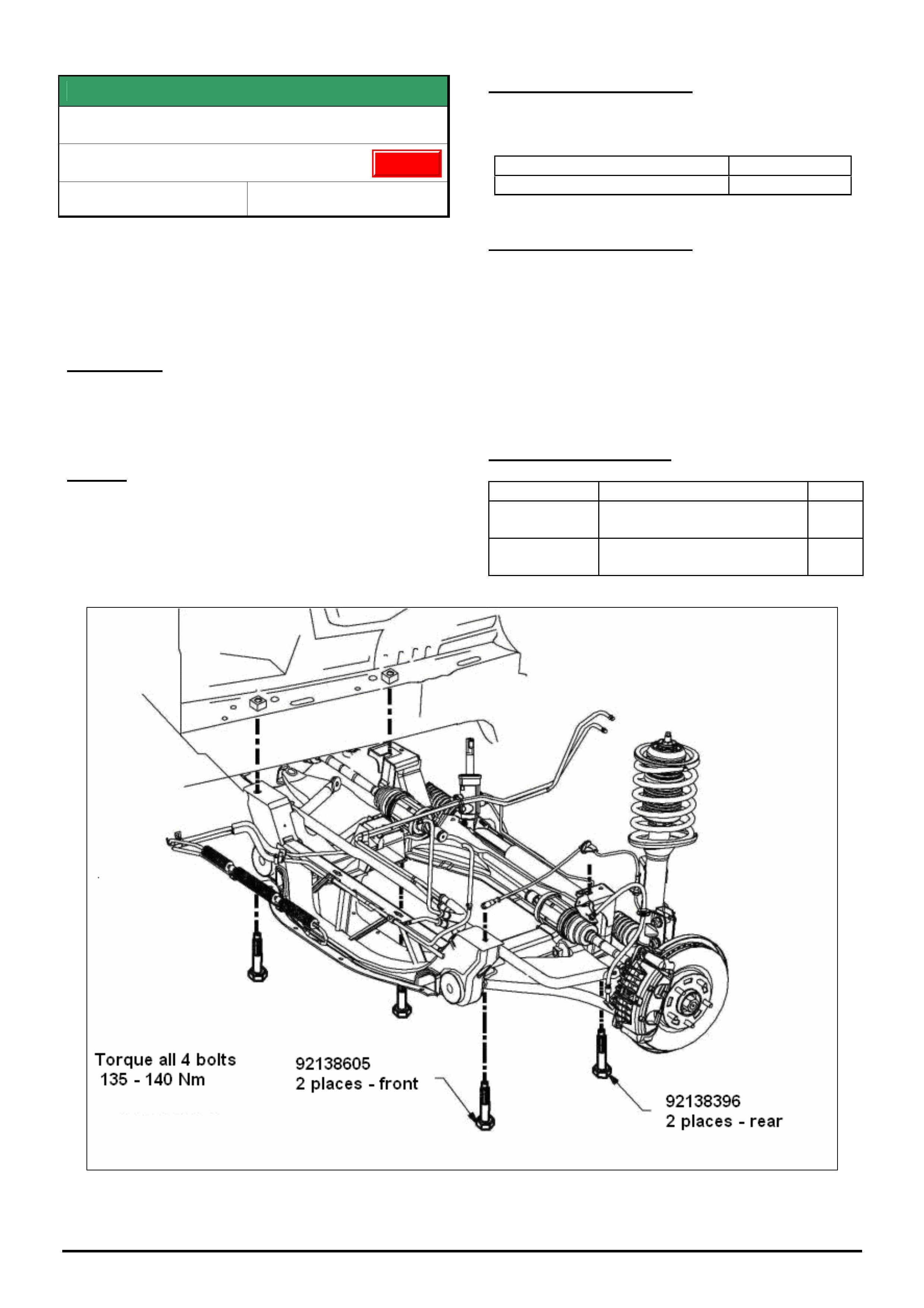

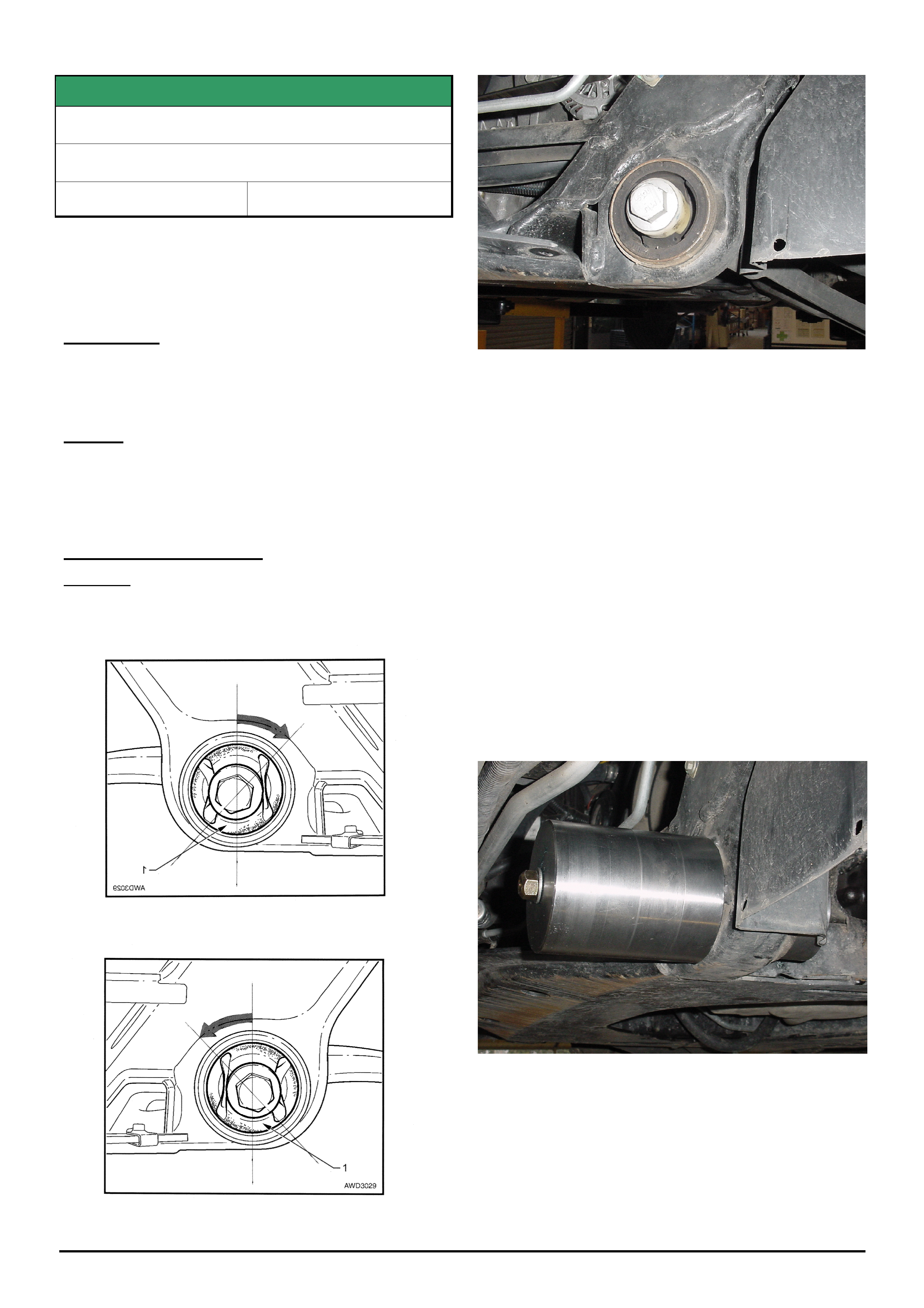

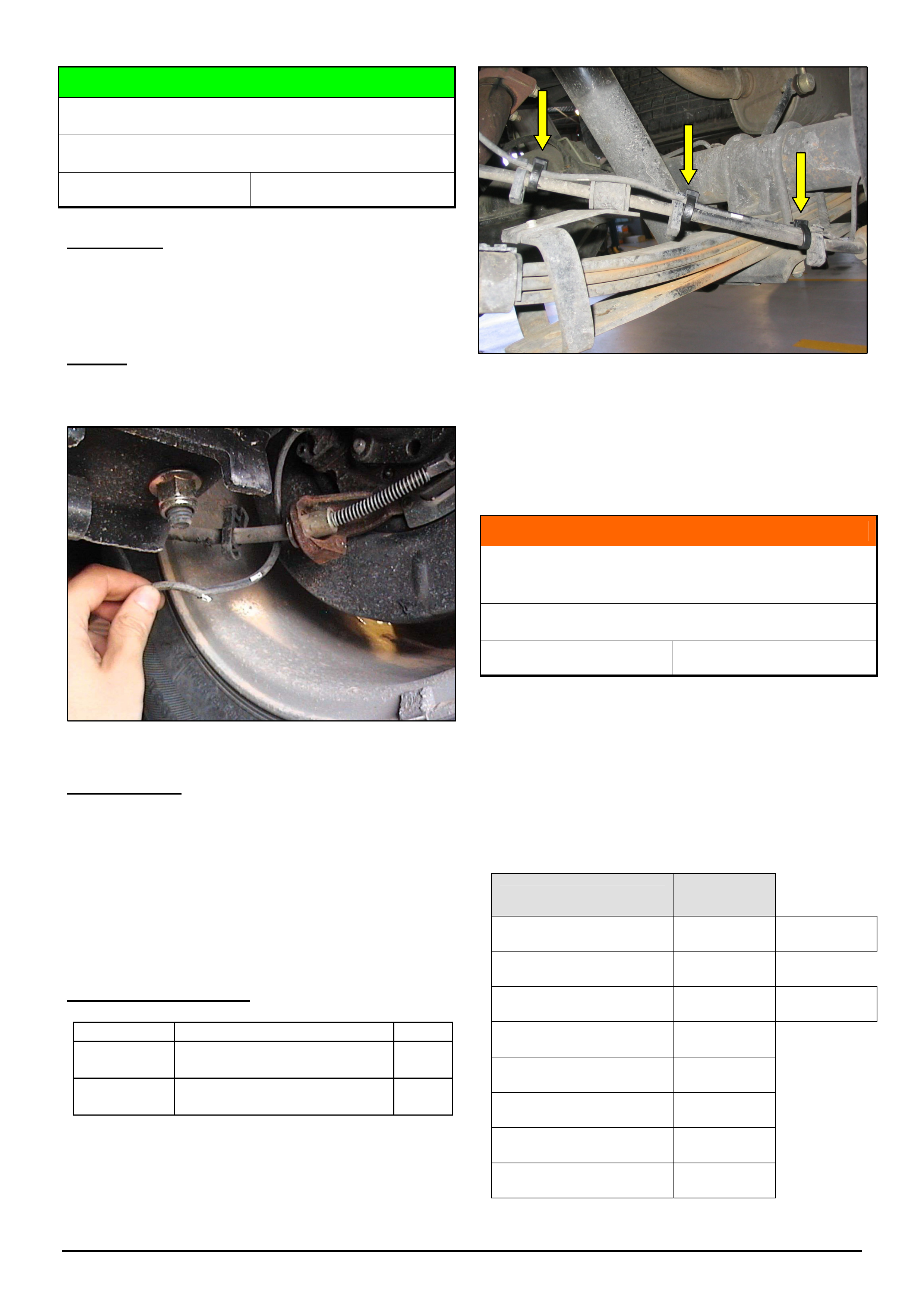

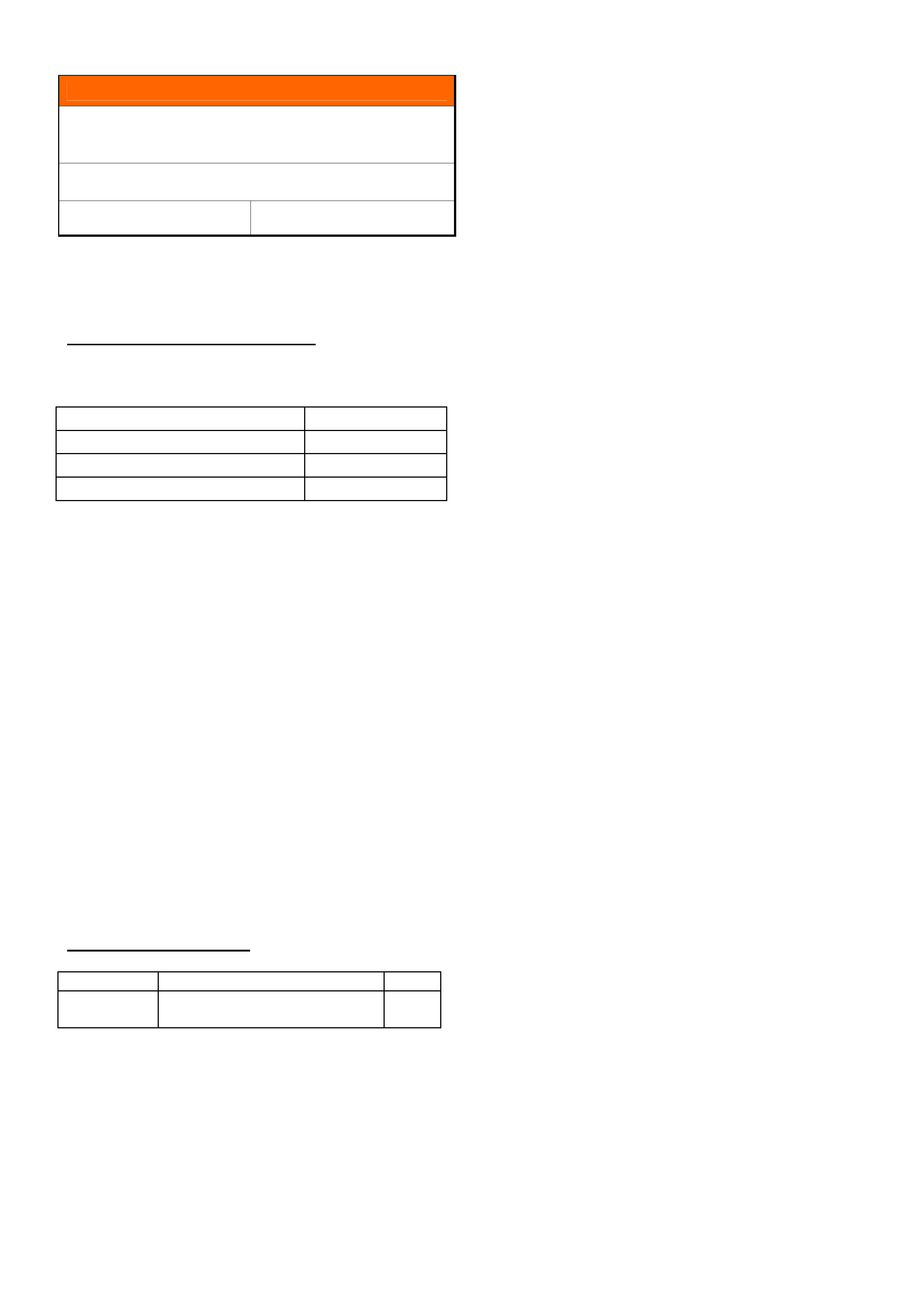

1. Attach magnetic dial indicator base to the diff

housing and probe the pinion flange as shown in

Photo 1 below.

Photo 1: Diff pinion flange measurement.

2. Have an assistant TWIST both inner driveshaft

CV’s in the same direction against the applied

handbrake and HOLD in this position.

HOLDEN SERVICE TECHLINES___________________________________________________________________________FEBRUARY, 2006

15

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

3. Rotate the propshaft with hand torque in one

direction and set the dial indicator to zero.

4. Rotate the propshaft with hand torque in the

opposite direction and take a reading of the travel.

5. Provided a rotational movement is applied to the

propshaft and even torque is applied in both

directions, then the measurement taken

represents the lash within the differential unit.

6. Repeat the measurement procedure above with

both the inner driveshaft CV’s twisted in the

opposite direction to step 5 above, to confirm an

accurate and repeatable lash measurement.

7. The combined backlash specification for the IRS

Differential unit is 3.0 mm.

8. Record both measurements taken and the

specification value on the Repair Order.

D. Service Correction

When the lash check shows that the differential lash

reading is within specification then the differential unit

is not the cause of the abnormal clunk noise condition.

When the lash check shows a lash measurement of

greater than 3.0 mm then request a replacement

beam axle or IRS Diff unit from Dana – refer to your

Zone Aftersales representative in case approval is

required.

HOLDEN SERVICE TECHLINES___________________________________________________________________________FEBRUARY, 2006

16

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

Attachment to Service Techline TL0853-0601

Driveline Noise Definition Worksheet Date: _____________________

Dealership: _____________________________________ Dealer Code: _____________________

Completed by: __________________________________ Return Fax No.: ______________________

ISOVIN No.: ___________________________________________

Axle Serial No. _______________________

Axle Part No.: _______________________

Vehicle Type: VY VZ

Crewman (Beam) 1-Tonner (Beam) Sedan/Wagon/Ute (IRS)

Engine: V6 V8

* Confirm the customer complaint via road test THEN describe it using the chart below:

Circle comments as required.

Noise Description (Circle)

CLUNK WHINE SQUEAK GRIND

For CLUNK – Backlash Measured is: _______ mm

Affected Speed Range:

10 20 30 40 50 60 70 80 90 100 110

Gear: Automatic

(Circle Lever Position):

D 4 3 2 N R

Gear: Manual

(Circle Gear Selected):

1 2 3 4 5 6 R

Accelerator Applied:

OR When at Coast:

Light Medium Heavy Cruise

Yes No

Dealer Action: Order new axle from Dana

Have axle rebuilt * Supply Sub-Let Report with PIR

Nothing

Other: Define: ___________________________

Zone Authorisation Number: ______________________________ (For use on Dana Website Request)

Additional Comments:

Dana WERN No. (if supplied): ____________________________

HOLDEN SERVICE TECHLINES______________________________________________________________________________MARCH, 2006

5

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

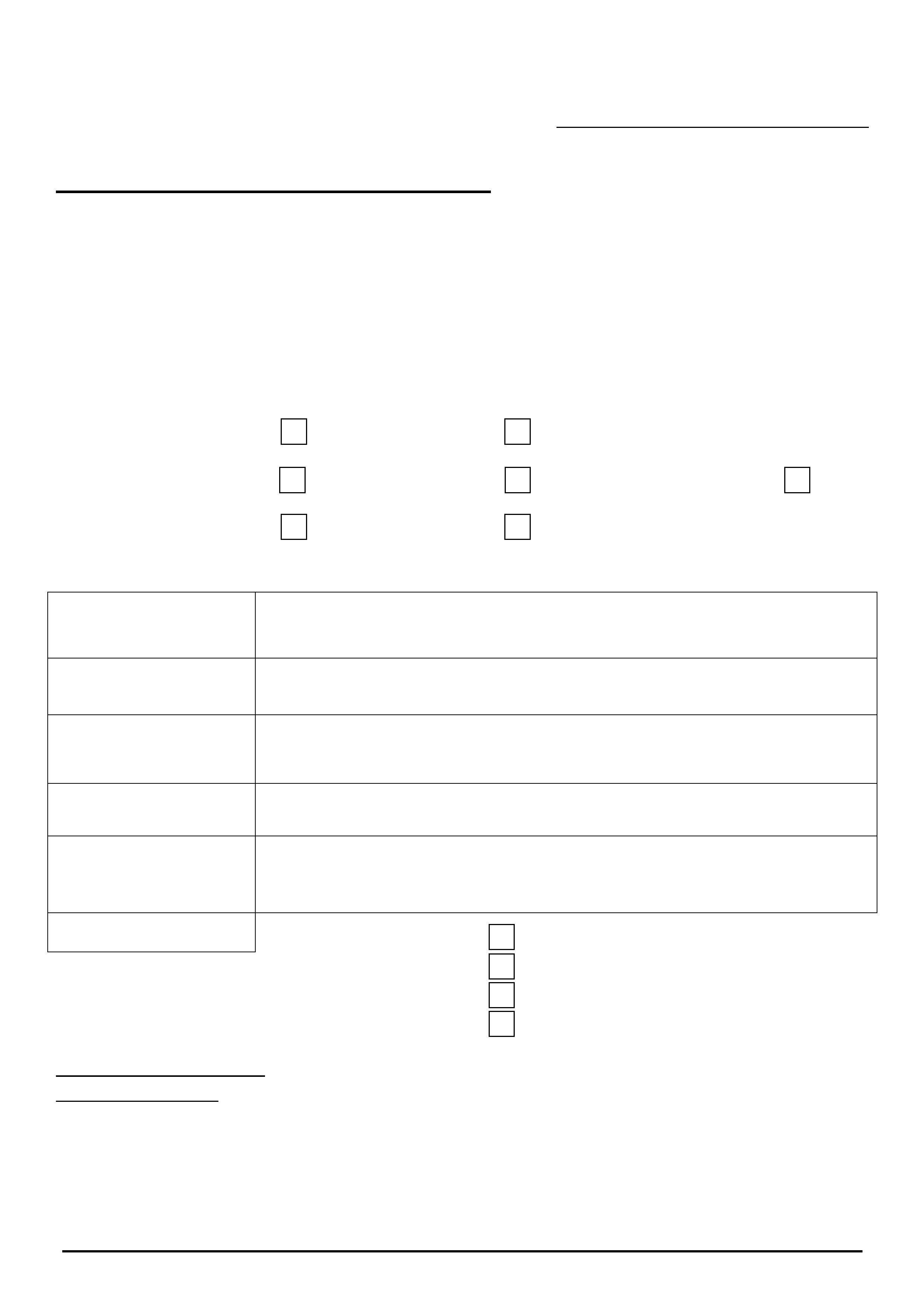

DIAGNOSIS HINT

A/C Compressor not working

AH Astra & ZC Vectra fitted with ECC

(Electronic Climate Control)

Group 2 Ref. No. TL1077-0602

CONDITION

Air conditioning is not cold, or A/C compressor does not

operate on vehicles fitted with ECC after vehicle

delivery.

DIAGNOSIS HINT

As a result of ECC settings being unintentionally

changed by the user, the A/C compressor can be

permanently turned off via the A/C selection menu in the

information display.

When the A/C compressor is set to off, “ECO”

(Economy) is displayed as shown in the following screen

which is from an early type ZC Vectra.

(ZC Vectra, early type – shows A/C off).

CORRECTION

Customers should be educated on how to set the ECC

so that the compressor is set to “on”.

The procedure for doing this is as follows.

Press the main ECC control button to enter the A/C

Menu screen. From the options which are displayed,

ensure the A/C compressor is switched on by placing

the “X” in the box. Refer picture below.

1. Air Distribut.

2. A/C

3. Autom. blower

(AH Astra-shows A/C on)

Note. Warranty claims must not be submitted for this

condition as this is an ECC setting issue only.

X

A/C

Menu

A/C

Menu

HOLDEN SERVICE TECHLINES______________________________________________________________________________MARCH, 2006

6

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

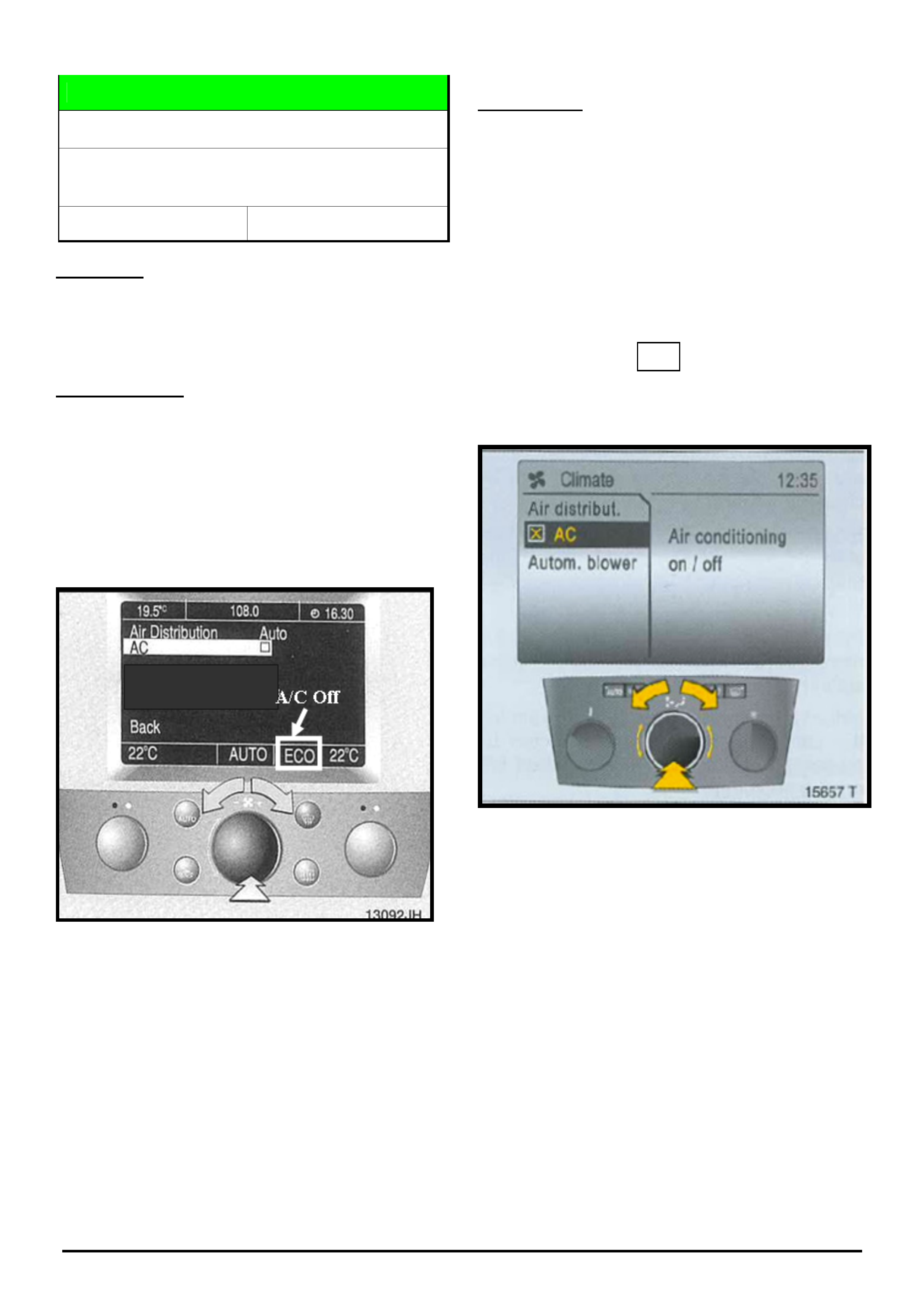

SERVICE PROCEDURE

Yaw Rate Sensor Orientation

VZ, WL, with ESP (Electronic Stability

Program)

Group 12 Ref. No. TL1078-0602

This techline is written to inform technicians of the

correct orientation of the Yaw Rate sensor as fitted to

the above models as it has been proven possible to

reinstall it in the opposite direction.

Please refer to the attached diagram which is taken

from Passenger Vehicle SIP.

It is important to note the orientation in relation to the

front of the vehicle and also the electrical connector

into the sensor. The attaching nut torque is 7-11 Nm.

HOLDEN SERVICE TECHLINES______________________________________________________________________________MARCH, 2006

7

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

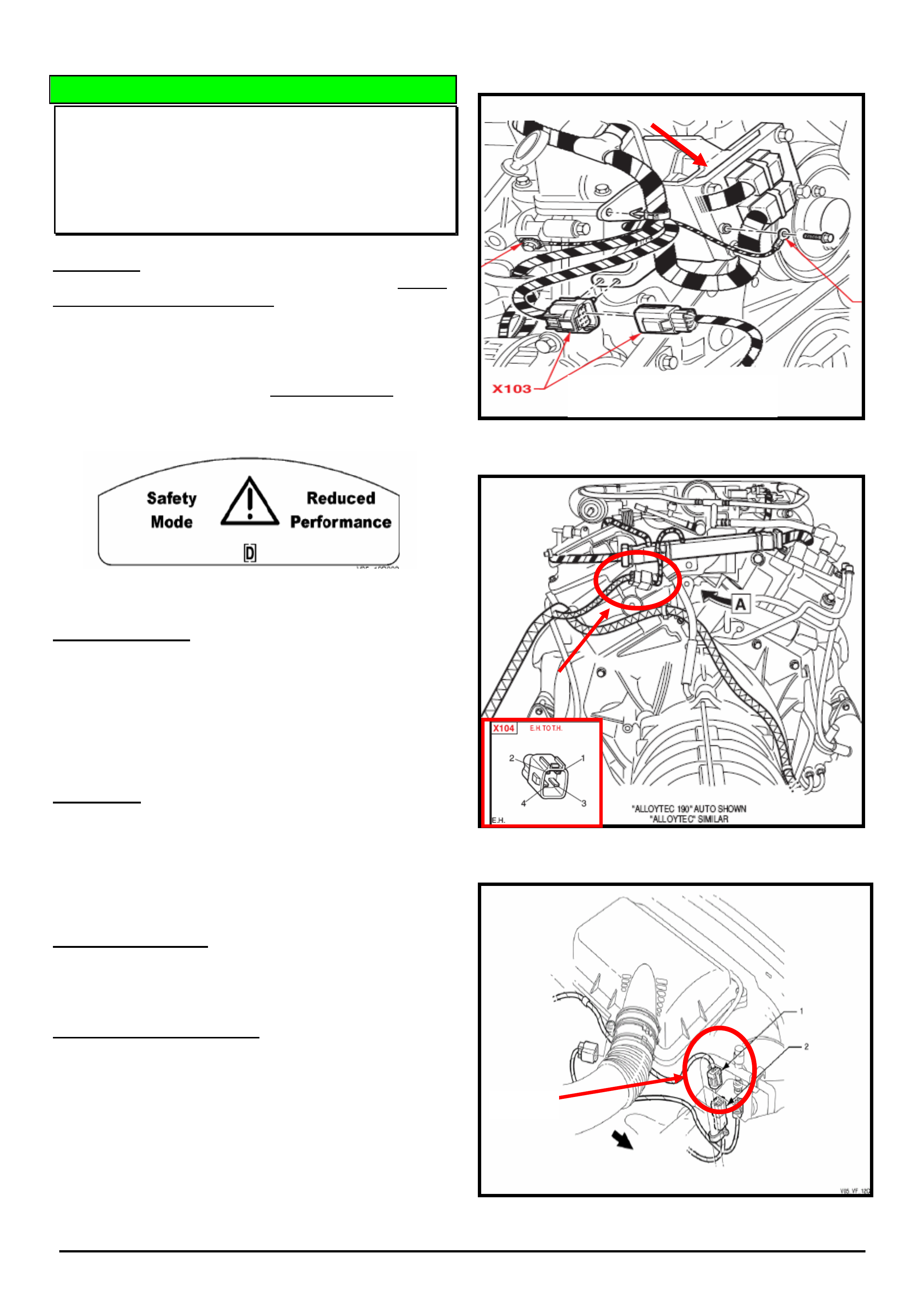

DIAGNOSIS HINT

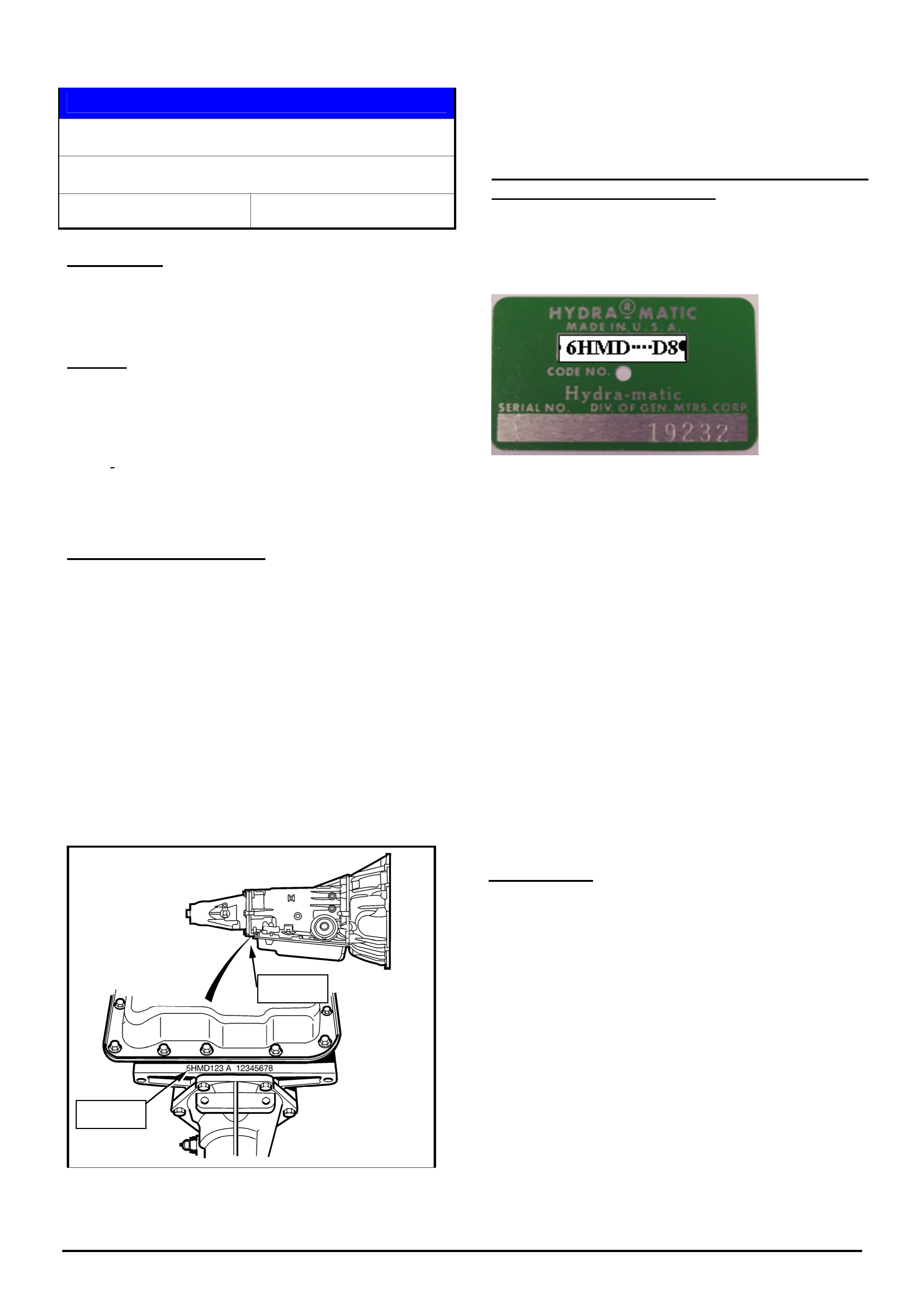

A/T Malfunction or Shift Problems, Various

DTC’s set.

V & W models with 4L60E or 4L65E A/T

Group 7B Ref. No. TL1076 - 0602

CONDITION

Customer may report various symptoms that suggest

incorrect shifts, changes or deterioration in the

transmission functions, and the Powertrain lamp may

be “on”.

Tech 2 may show various DTC’s are set.

DIAGNOSIS HINT

First - Define if the transmission is definitely NOT

functioning correctly – Refer to Information Techline

(TL0887-0504) in May, 2005, Issue 4, page 13.

If the transmission features information detailed in this

techline does not explain the customer’s concern, then

proceed as follows:

A possible cause for the above symptoms is a “poor”

harness connection to the transmission. Therefore it is

essential when performing any A/T related diagnostics,

to include checking the harness connection to the

transmission as follows.

1. Unplug the connection at the transmission.

2. Visually inspect for any damaged terminals. (bent

or burnt)

3. Replace harness if burnt, and/or attempt to

restraighten any bent terminals using fine nose

pliers.

4. Reconnect harness plug firmly.

5. Road test vehicle for original complaint.

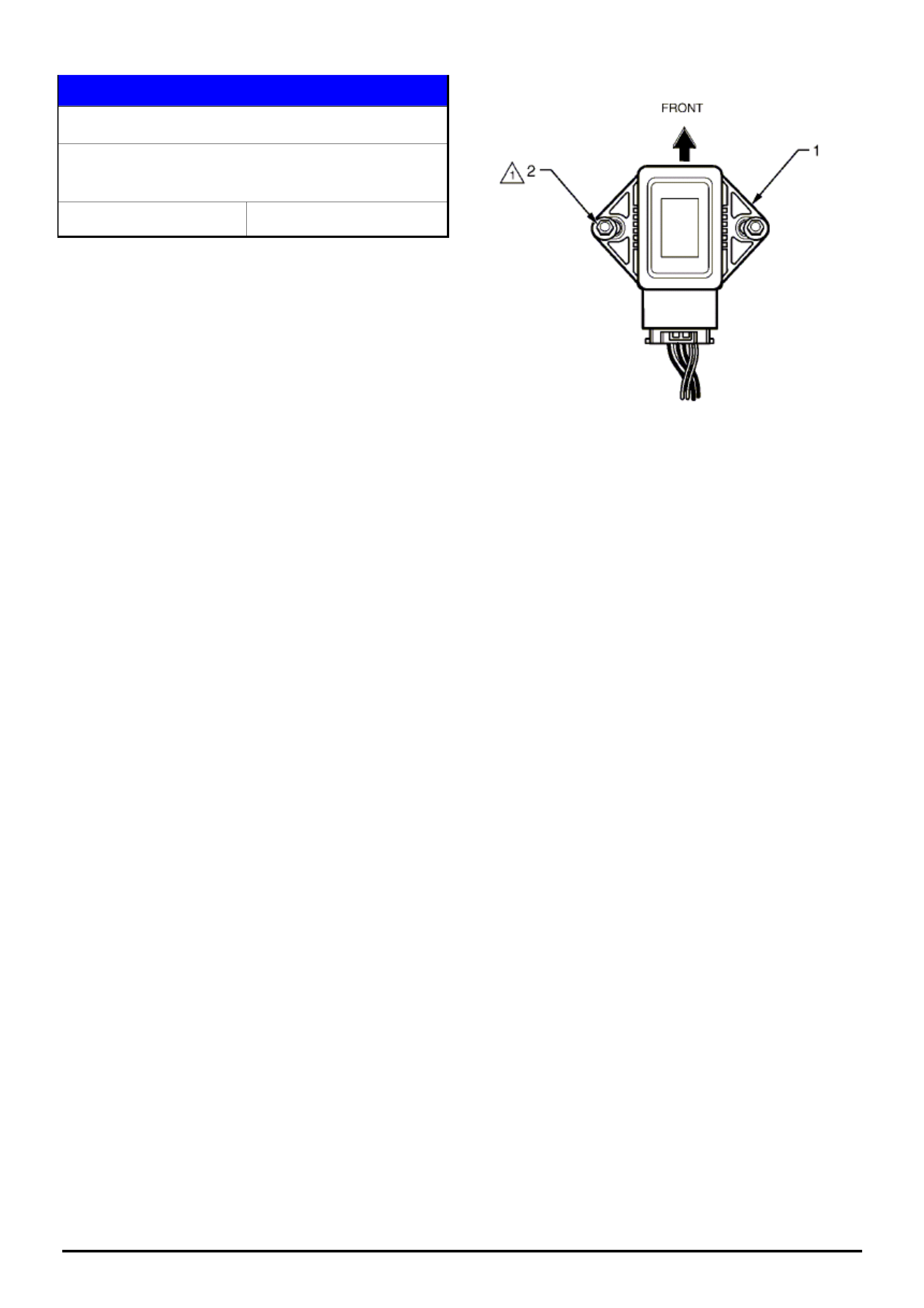

SERVICE FIX

Front Lower Control Arm Bush Squeak

XC Barina

Group 3 Ref. No. TL0994 - 0602

CONDITION

On some vehicles a creak noise may be heard coming

from the front suspension control arm bush when

travelling over speed bumps.

CORRECTION – Service

After verifying vehicle has the condition as described

above, fit revised bushes (part number 93188303) to

the front lower control arms.

These revised bushes have been developed to

overcome the creak condition.

Revised bushes should be fitted to both front lower

control arms as per procedure in TIS.

PARTS INFORMATION

Part No.: Description Qty:

93188303 Lower control arm bush 2

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty Information

section of current PV SIP CD

HOLDEN SERVICE TECHLINES______________________________________________________________________________MARCH, 2006

8

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

DIAGNOSIS HINT

Rear Park Assist (RPA) Behaves Erratically

With Trailer Attached

VY,VZ (wagon, sedan, coupe) WK,WL,V2 with

Factory Fitted RPA

Group 12 Ref. No. TL0991 - 0602

CONDITION

Customer complains that their vehicle’s Rear Park

Assist (RPA) system behaves erratically when they

hook up a trailer.

CAUSE

The above condition may be caused by fitment of the

wrong trailer harness, or an incorrectly fitted harness.

Notes:

The correct harness for use on VZ and WL models

fitted with RPA is part number 92144494. (Flat 7 pin ).

There are two other harnesses available for the above

models which are for vehicles without RPA (option

code UD7). Ensure that neither of these harnesses is

fitted.

The correct harness 92144494 must be installed as

per the procedure shown in the fitting instructions. A

copy of these instructions (p/n FD1095) may be found

in Passenger Vehicle SIP under “Accessories Fitting

Instructions”.

If your trailer has a round plug, you must use one of

the adapter harnesses as specified in Microcat.

SERVICE PROCEDURE

Front Brake Caliper Anchor Bolts

VT, VU, VX, V2, VY, VZ, WH, WK, WL

Group 5 Ref. No. TL1070 - 0602

IMPORTANT REMINDER

The front caliper anchor bolts are a “single use” only

bolt which means they must be replaced after removal.

(Also refer to PV SIP)

Also, these bolts must be tightened using the torque

turn method. (refer SIP for torque specification)

Front caliper attaching bolts.

HOLDEN SERVICE TECHLINES______________________________________________________________________________MARCH, 2006

9

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

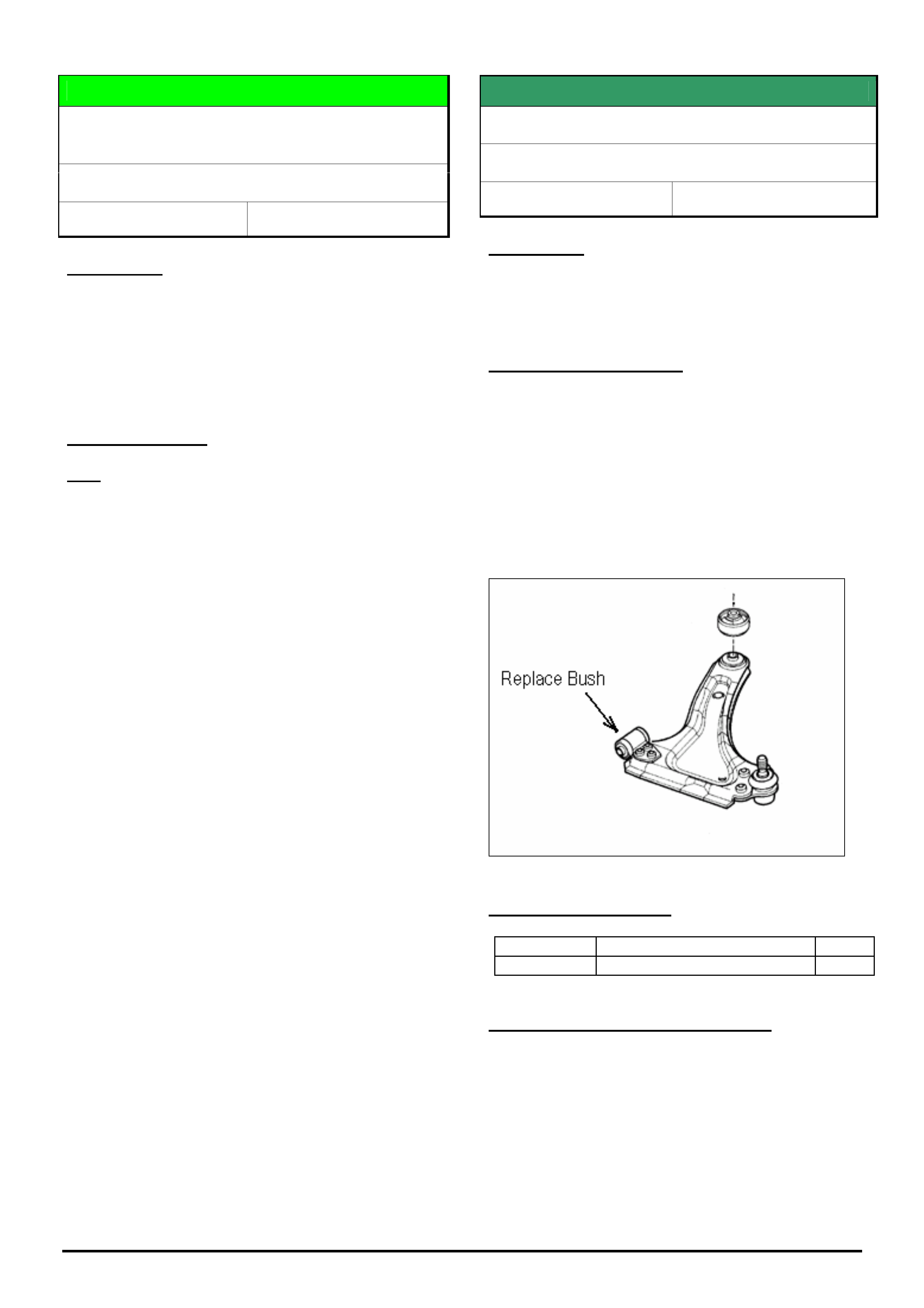

SERVICE FIX

Diff. Period Whine, 80 – 110 km/h

VY & VZ – One Tonner & Crewman

Group 4 Ref. No. TL0631C-0602

This Techline supersedes the previous one in Issue 11, Dec.,

2005. It is UPDATED by adding V6 M/T to the models which

can now be fitted with the revised pinion flange (2-spoke).

CONDITION

Some vehicles may experience an unacceptable

period whine noise from the differential at

approximately 80 - 110 km/h at light to medium throttle

cruising.

A certain level of rear axle assembly noise is normal

and to be expected on these light commercial type

vehicles due to their cab chassis structure and

associated load carrying requirements.

NOTE: This noise must not be confused with noises

resulting from possible faulty differential bearings or

gears.

CORRECTION – Production

Two countermeasures have been introduced into

production on the specific models as listed:

• A softer rubber bush in the front eye of the leaf

spring. – Crewman V8 (A/T & M/T), (RWD & AWD)

• A 2-spoke pinion flange – Crewman V8 A/T (RWD

only)

Breakpoint for both countermeasures in Crewman is:

ISOVIN: Built Date:

**********L218227 09/03/2004

CORRECTION – Service

Summary: After verifying that complaint vehicle has

condition as described above, fit revised bushes in

front eye of rear springs of ALL vehicles. Also, for V8

& V6( M/T) Rear Wheel Drive ONLY - fit a 2-spoke diff

pinion flange.

Procedure. (For specific procedures not covered in detail

refer to latest PV SIP.)

1. Remove rear springs.

2. Press out existing front eye bush from each spring.

3. Press in new eye bush p/n 92148815.

4. Reinstall spring assemblies.

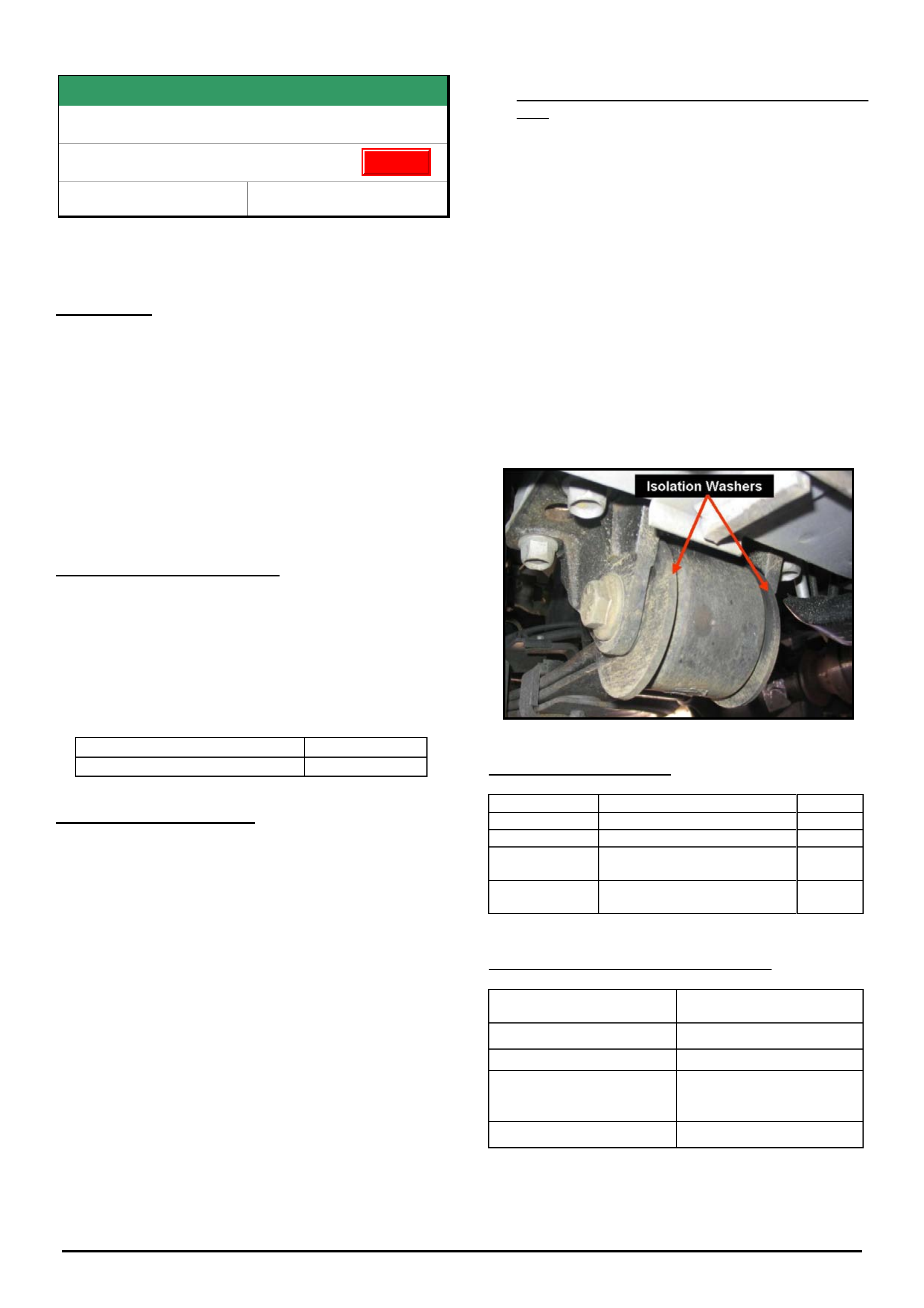

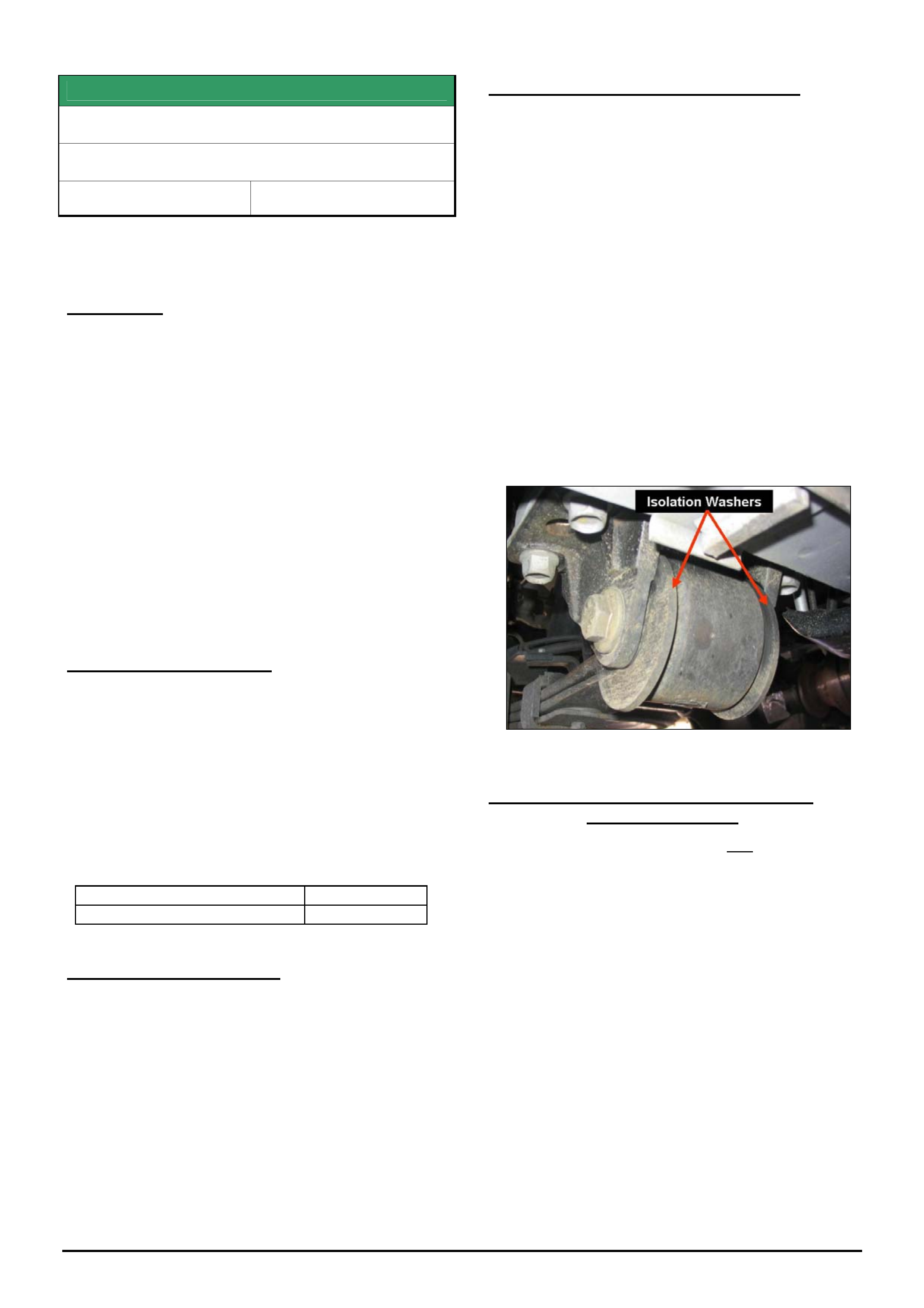

NOTE: There are four large washers p/n 92175916

that need to be fitted – one on each side of the front

spring eye bush as spacers/locators. These washers

are only fitted to vehicles with the revised spring eye

bushes.

5. For V8 (A/T & M/T) and V6(M/T) Rear Wheel Drive

Only: Revised pinion flange p/n 92176653 should

be fitted with a new nut p/n 92146565 exactly as

per procedure found in PV SIP:

Section 4B – Final Drive & Drive Shafts,

2. Minor Service Operations,

2.11 Pinion Flange / Replace using old seal.

CAUTION: Overtightening of the pinion nut may

result in excessive bearing preload and bearing

damage.

6. The alternative to Dealers doing step 5 is to

have a sublet repairer (diff specialist) fit the

flange. Any such repairer must use a torque

reading tension wrench to ensure the pre-load

before and after is the same - otherwise,

preload related noise/failure may occur at a

later date.

PARTS INFORMATION

Part No.: Description: Qty:

92148815 Bush Rr Spring Front 2

92175916 Washer 4

92176653 Pinion Flange

V8, and V6 (M/T only)

1

92146565 Flange Nut

V8, and V6 (M/T only)

1

WARRANTY CLAIM INFORMATION

Description Replace Bush, Leaf Spring

Front Eye – Both Sides

Labour Op. No. F000197

Time 1.6 hr.

Add for V8 & V6(M/T) Rear

Wheel Drive Only - Fitting

of revised Pinion Flange

0.5 hr.

Failure Code F0040 noisy

A/T – automatic transmission. RWD – Rear wheel drive

M/T – manual transmission AWD – All wheel drive

Update

HOLDEN SERVICE TECHLINES______________________________________________________________________________MARCH, 2006

10

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

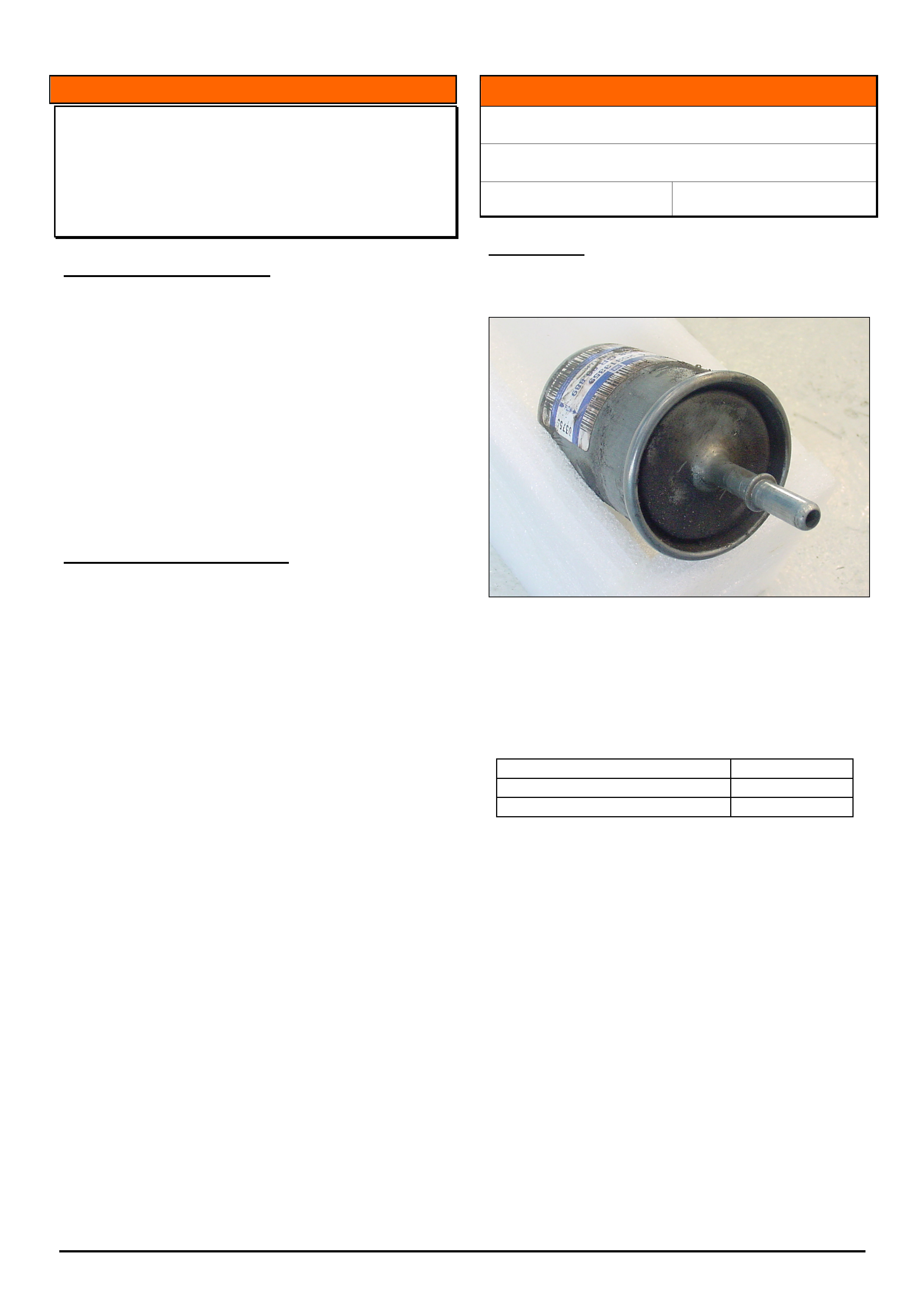

SERVICE FIX

Exhaust drone at 2500rpm

TT Zafira, TS Astra – Z22SE engine

Model Year 2003 & 2004

(GROUP 8) TL1085-0602

CONDITION

Customers may complain of an exhaust boom, drone

or resonance noticed at 2500rpm with the engine

under load.

CORRECTION - SERVICE

On customer complaint vehicles only, install a new

front engine pipe 55558954 which includes a revised

flex element. This will reduce the noise which arose on

model year 2003 and later vehicles when the exhaust

system was revised.

PARTS INFORMATION

Part No.: Description: Qty:

55558954 Exhaust Front Pipe 1

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty Information

section of current PV SIP CD

SERVICE FIX

PCM, ECU, TCM, SPS Programming &

Instrument Cluster programming

All HSV models as follows -

VTII VX VY V2 VZ WH WK WL

Group 12 Ref. No. TL1084-0602

Please be aware that when replacing a PCM, ECU, TCM

or Instrument Cluster in the above mentioned HSV

models, the initial programming needs to be completed

by HSV.

Note that this only applies to NEW modules and NOT for

software updates, as TIS 2000 will allow updates once

the initial software is loaded by HSV.

To minimise the logistics of this procedure, contact HSV

on (03) 9265 9500 for their Technical Liaison personnel

to arrange for prompt parts programming and delivery.

HOLDEN SERVICE TECHLINES______________________________________________________________________________MARCH, 2006

11

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

SERVICE FIX

“Engine Oil Life” Reset

VZ & WL HSV Gen 4 (LS2)

Group 12 Ref. No. TL1083 - 0602

When servicing any HSV vehicle fitted with an LS2

engine the “engine oil life” must be reset in the

engine control module using Tech 2 when the engine

oil is changed.

Failure to reset the engine oil life may result in the

following warning being displayed in the instrument

cluster when the ignition is cycled.

CORRECTION – Service

Summary

If this icon is displayed in the instrument cluster it will

be necessary to perform the following two procedures:

Instrument Cluster Service Engine Oil reset & Engine

Control Module “Engine Oil Life” reset.

If the vehicle is presented for scheduled servicing and

the “Service Engine Oil” icon is not displayed on the

instrument cluster it will only be necessary to perform

the Engine Control Module “Engine Oil Life” reset.

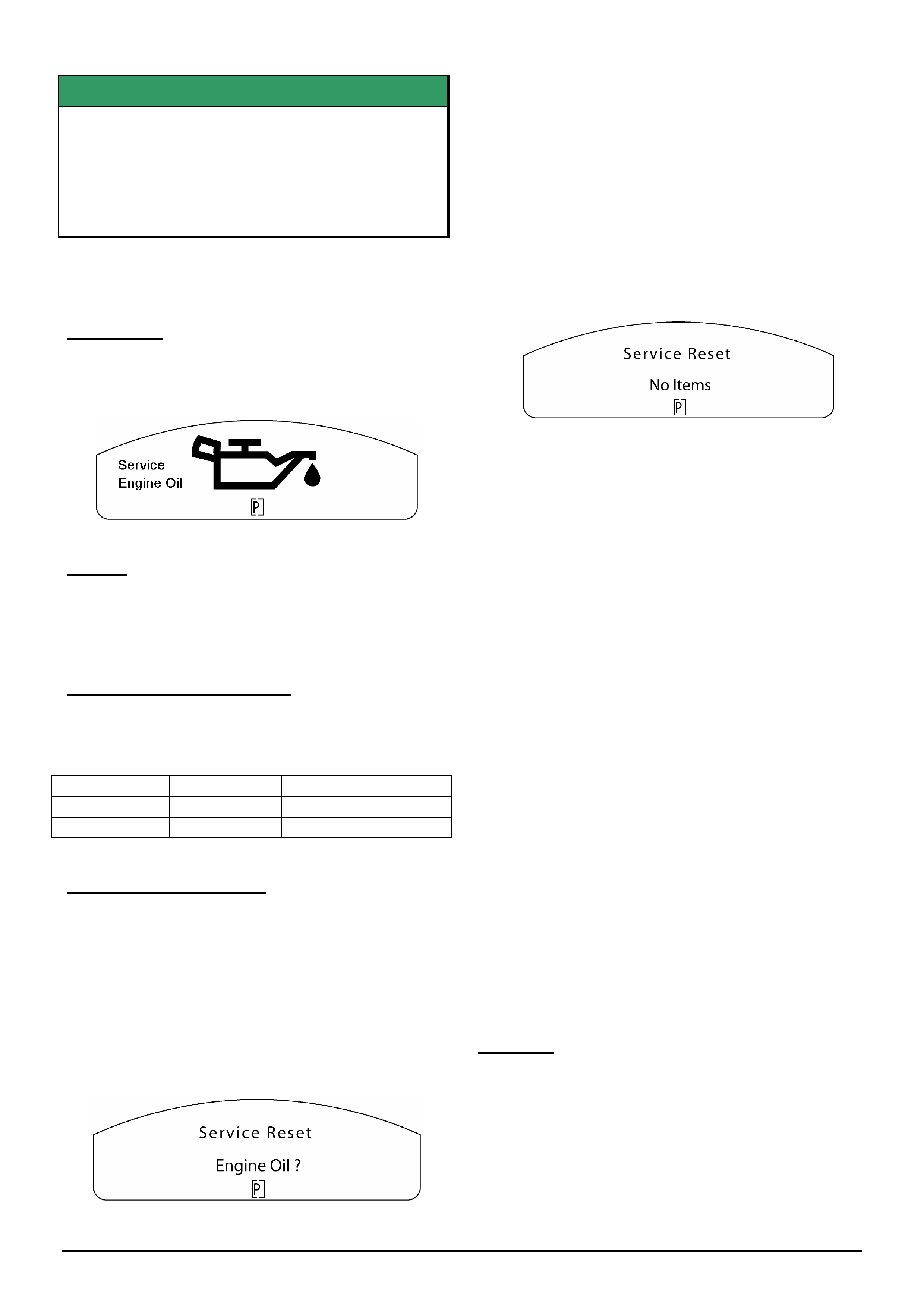

Instrument Cluster Service Engine Oil reset

procedure

If the above warning icon displays, the following

instrument cluster reset procedure must be performed.

1. Press and hold the up and down buttons on the

trip computer mode switch while turning the ignition

key on until a beep is heard, the following will be

displayed.

2. Press the set button on the trip computer mode

switch until a beep is heard (approx 8-10 seconds)

to reset the service item.

The display will then revert back to the start up

sequence.

If more than one service items are set, the next

service item will be displayed.

Press the set button on the trip computer mode

switch to reset the next service item if required.

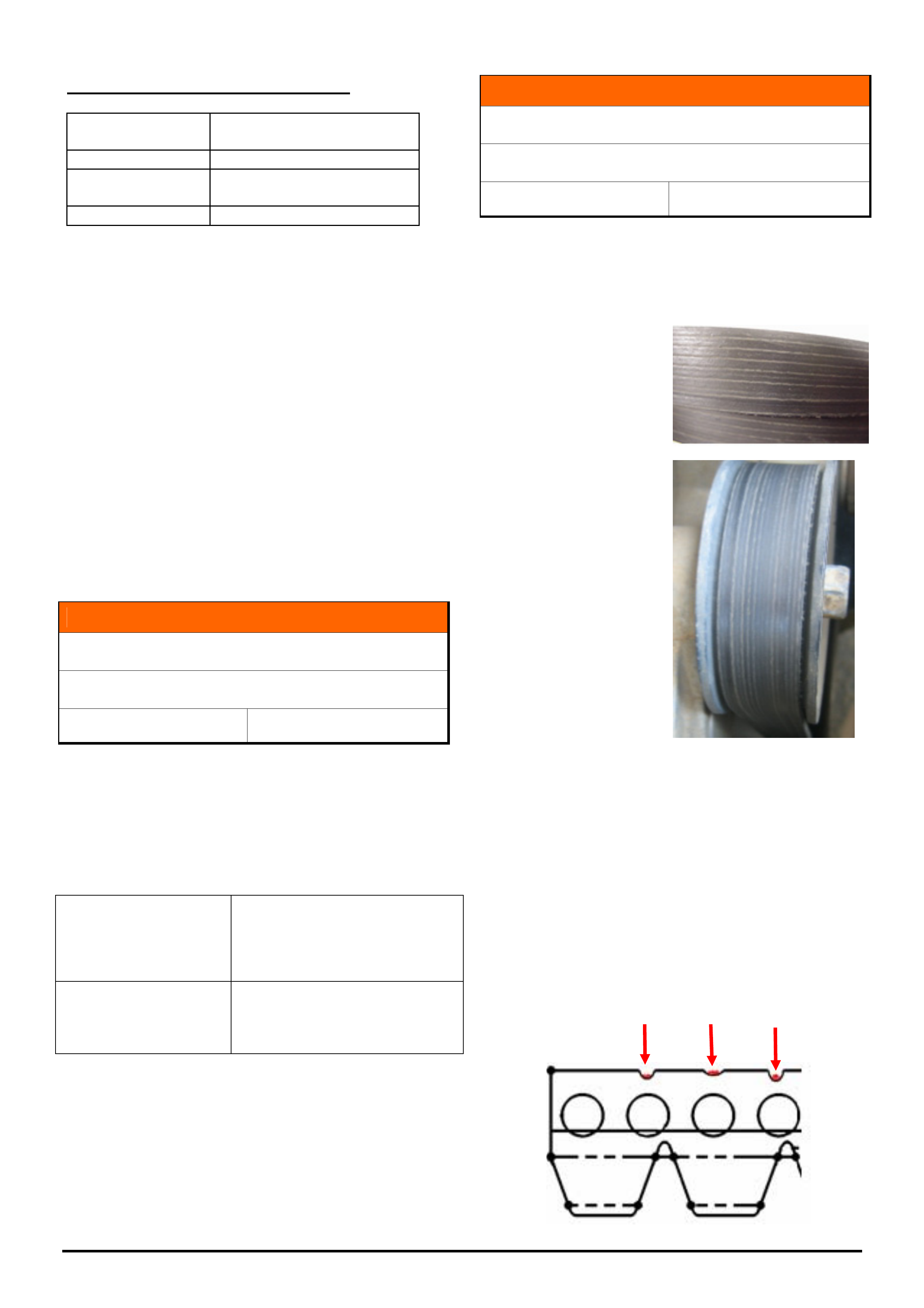

3. The following will then be displayed.

Engine Control Module “Engine Oil Life” reset

procedure

1. Connect Tech 2 to the vehicle and make the

following selections,

F0: Diagnostics / Model Year / Vehicle Type /

F1: Engine / V8 Gen IV / F6: Programming /

F2: Reset Engine Oil Life

Select the “Yes” soft key

Select the “Confirm” soft key

SERVICE ADVISORS NOTE

If the “Service Engine Oil” icon appears between

scheduled services on a HSV Gen 4 (LS2) (and it

has been reset at the previous service) it may

indicate the vehicle is being used under extreme

conditions.

It may be necessary to discuss with your

customer the need for additional servicing.

For additional service requirements please refer

to the vehicle service booklet.

HOLDEN SERVICE TECHLINES______________________________________________________________________________MARCH, 2006

12

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

SERVICE FIX

Service Engine Oil Warning Displays in the

Instrument Cluster.

VZ & WL excluding HSV Gen 4 (LS2)

Group 12 Ref. No. TL0890B - 0602

This Techline supersedes TL0890A-0503 in Issue 10, November

2005. It is UPDATED by adding new information for Service

Correction and Warranty Claims.

CONDITION

On some vehicles the “Service Engine Oil” warning

icon may display in the instrument cluster when the

ignition is cycled.

CAUSE

The “Service Engine Oil” feature which is not available

for the local market, has been inadvertently enabled in

the engine calibration.

CORRECTION – Production

Revised engine calibrations were introduced over a

one week period ending in the production breakpoint

below.

Engine Type Build Date: ISO VIN:

Gen III (LS1) 05/10/2005 6G1ZK14F96L516298

HFV6 2/12/2005 **********L535578

CORRECTION – Service

The following solution applies only to Gen III & HFV6

vehicles. The solution for HSV Gen 4 is published in

Techline # TL1083 – 0602 .

If the above warning icon displays, the following reset

procedure must be performed.

4. Press and hold the up and down buttons on the

trip computer mode switch while turning the ignition

key on until a beep is heard, the following will be

displayed.

5. Press the set button on the trip computer mode

switch until a beep is heard (approx 8-10 seconds)

to reset the service item.

The display will then revert back to the start up

sequence.

If more than one service items are set, the next

service item will be displayed.

Press the set button on the trip computer mode

switch to reset the next service item if required.

6. The following will then be displayed.

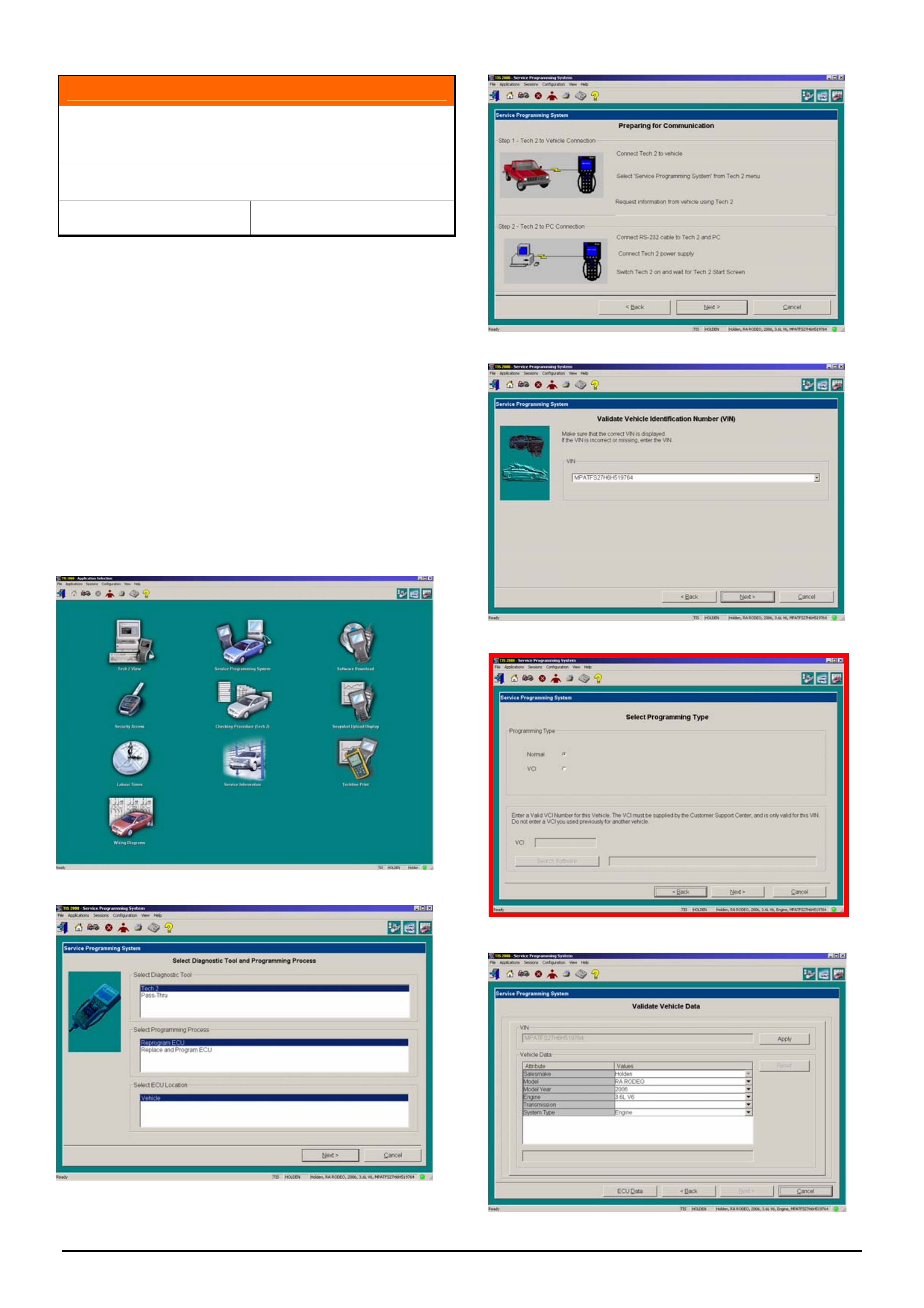

7. Re-program the ECU or PCM (engine or

powertrain control module) as per the standard SPS

(Service Programming System) process using Tech 2

and TIS 2000 version 69 or later.

NOTE: For detailed instruction on this process refer

to Holden Lionheart portal, Service Techlines,

Section OD – TIS, “Reprogramming Procedure –

Engine ECU / PCM SPS”.

8. Re-program the Instrument cluster as per the

standard SPS (Service Programming System) process

using Tech 2 and TIS 2000 version 65 or later.

NOTE: For detailed instruction on this process refer

to Holden Lionheart portal, Service Techlines,

Section OD – TIS, “Reprogramming Procedure –

Instrument Cluster SPS”.

9. Re-program the Fuel Gauge Calibration in the

instrument cluster using Tech 2 software version

14.502 or later from TIS 2000 version 65 or later.

NOTE: For detailed instruction on this process refer

to Holden Lionheart portal, Service Techlines,

Section OD – TIS, “Reprogramming Procedure –

Instrument Cluster Fuel Gauge calibration”.

CAUTION:

Software downloaded from TIS 2000 CD 65 or later is

not compatible with old instrument cluster software,

old engine ECU / PCM software or old fuel gauge

calibration from earlier releases of TIS 2000.

Therefore these three files must be used as a set

whenever programming an engine control module,

instrument cluster or fuel gauge calibration.

HOLDEN SERVICE TECHLINES______________________________________________________________________________MARCH, 2006

13

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

WARRANTY CLAIM INFORMATION

Description Service Engine Oil

Warning

Labour Op. No. J000791

Time V8 - 0.4 hrs

V6 - 0.5 hrs

Failure Code J0057

NOTE: Labour operation number and time covers

instrument cluster, ECU / PCM and fuel gauge re-

programming.

INFORMATION

Coolant Usage/Replenishment Precaution

JF Viva & TK Barina

Group 6K Ref. No. TL1088 - 0602

Technicians should be aware of the possible coolant

colours and specifications for these models.

When replacing coolant, refer to the Vehicle Owner

Handbook information.

(Refer to TK Barina handbook information as follows)

Coolant specification

(if coolant is ORANGE/RED)

50%Clean water and 50% Extended life

anti-freeze Coolant (orange) conforming

to Holden Spec.GM6277M

Part Number 92145527(5 litre)

Coolant specification

(if coolant is BLUE)

50% Clean water and 50% Silicate

Coolant(green), conforming to

Holden Spec HN 2217

When replacing or replenishing coolants please note

the following:

- Orange & Red coolant can be mixed;

- Blue & Green coolants can be mixed.

DO NOT mix any other combinations of these coolants

or cooling system damage may result.

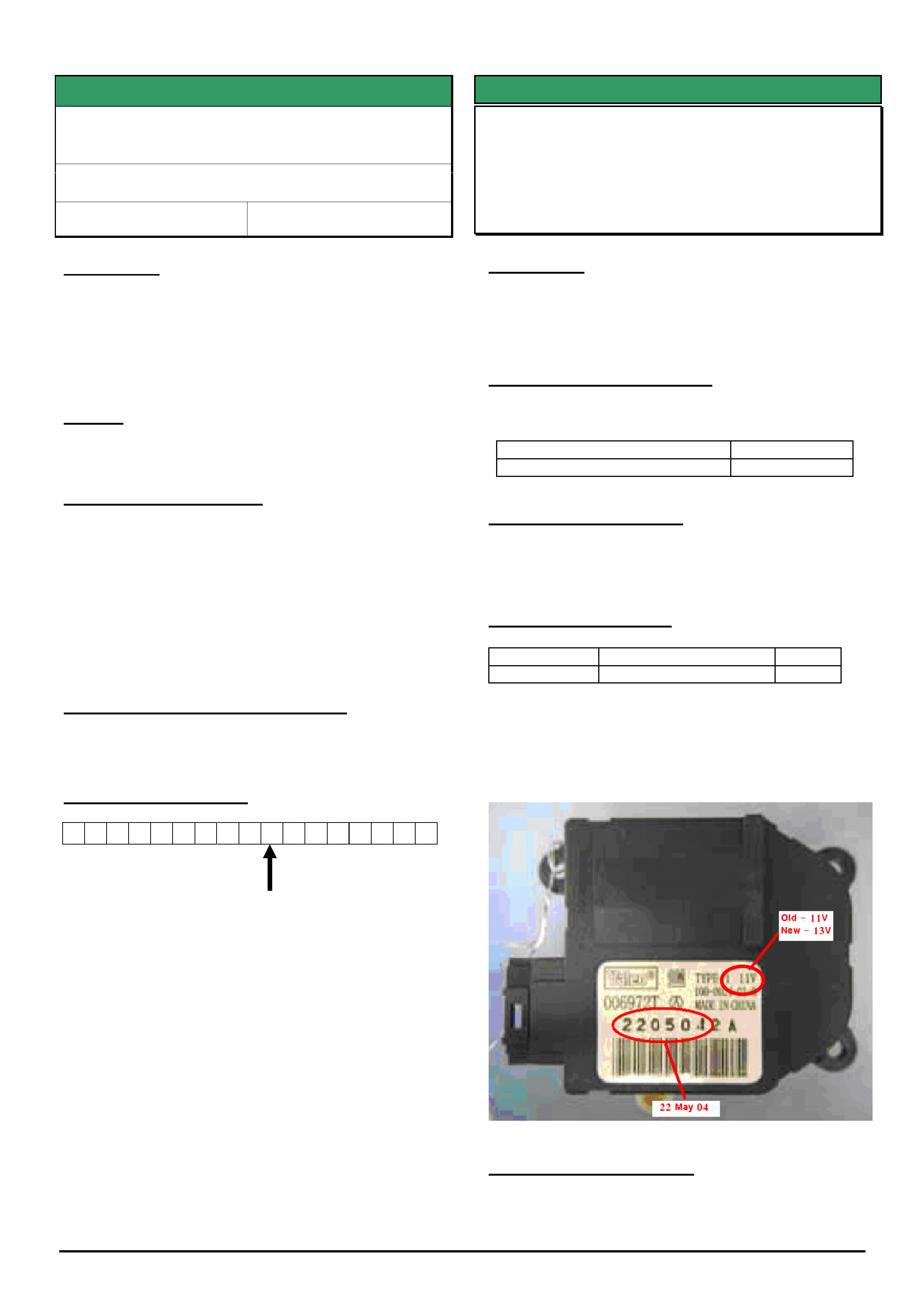

INFORMATION

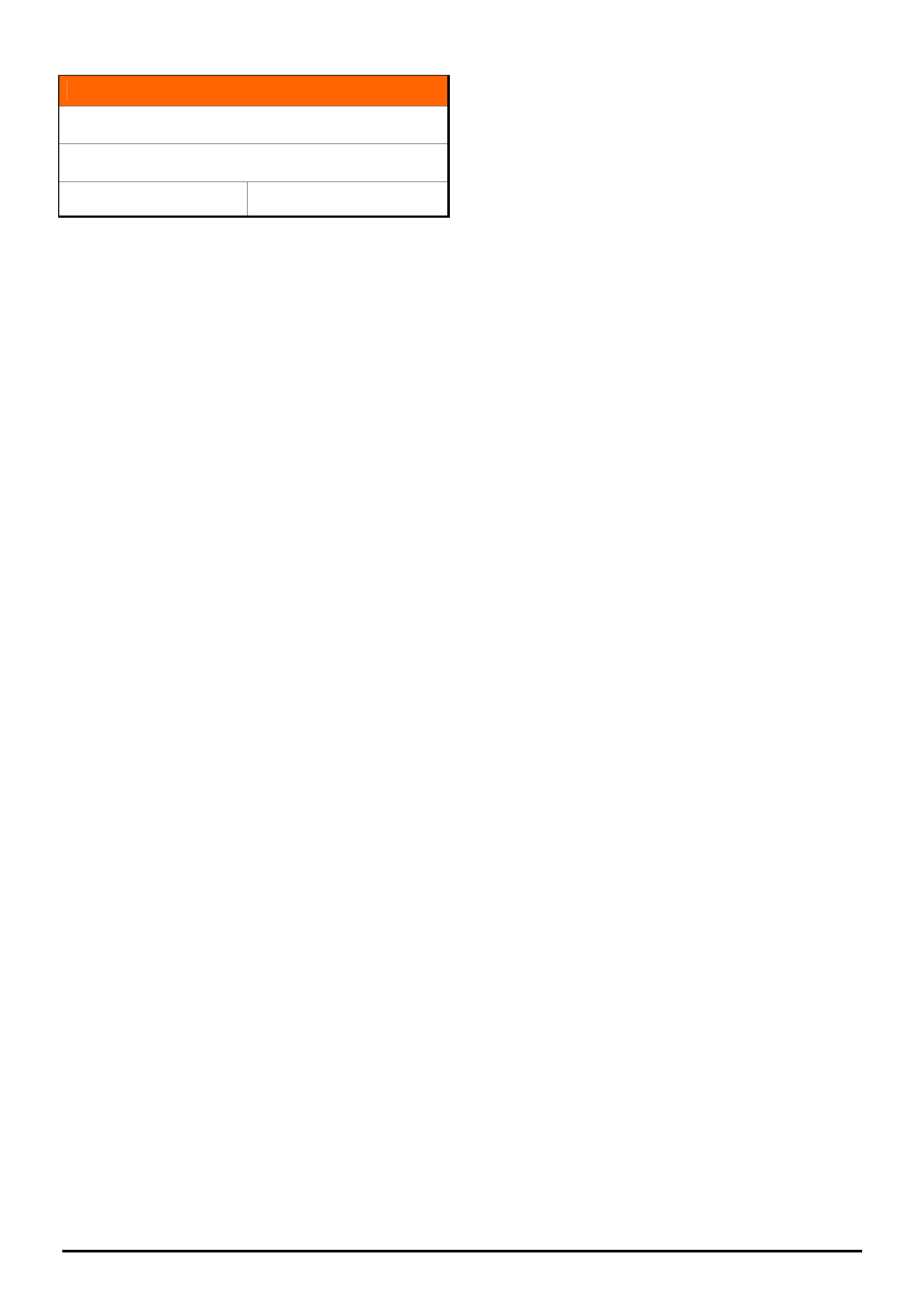

Drive Belt “Excessive Wear” Appearance

VZ & WL with LS1 or LS2 V8

Group 6A Ref. No. TL1043 - 0602

Technicians (or customers) may believe that drive

belts are “excessively worn” when the belt backing

discolours or develops “stripes” or “lines” - evident at

the back of the belt as shown below:

On belt surface:-

On belt, as fitted to

an engine:

DO NOT replace belts because of this discoloration or

the “lines” or “stripes” that are evident

This is normal wear and tear from dust being trapped

between the back of the belt and idler pulleys, etc. –

and may occur more rapidly when a vehicle is driven in

dusty areas.

Discoloration is from imbedded dirt which also

increases the visibility of the back side indentations

which are inherent in the construction of this type of

belt. The “lines” coincide with pressure points created

by the belt inner reinforcing cords as in this sketch:

HOLDEN SERVICE TECHLINES______________________________________________________________________________MARCH, 2006

14

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

Holden Contacts and procedures

All

Group OB Ref. No. TL0679B-0602

This Techline supercedes the previous one (TL0679A-0501) in

Issue 1, Feb 2005. It contains UPDATED information.

This techline summarises some of the Holden contact

procedures and gives a quick reference guide for

contact numbers.

Security information.

To obtain security information for both Passenger and

LCRV vehicles the first step is to check the New Online

Warranty system (NOW). If the information is

unavailable on NOW then a completed security

information request form must be faxed through to the

Vehicle Security Information Centre, as security

information cannot be given out by phone. Please note

that security information requests are processed by the

Vehicle Security Information Centre and not TAS.

To ensure you have the latest security information

request form always refer to Service Forms in the

Service Bulletin section of the Holden Lionheart Portal.

Fax completed forms to the Vehicle Security

Information Centre on fax 03-96472865.

There can be up to a 4-hour turn around on requests,

however if the information needs to be obtained from

overseas, it may take up to 24 hrs. Do not phone the

security information department unless you have not

received a response in the normal turn around time.

For further information please refer to ADL 42/05.

Accessories and parts inquiries

If any information or assistance is required in regards

to Microcat, part numbers, Holden accessories or if

you need to contact HSPO Customer Assistance,

please refer to the Holden Help section in Microcat.

Warranty Authorisation and enquiries

Warranty can only be authorised by your Aftersales

District Manager. Labour times information is available

on SIP or from the warranty department. For any other

warranty inquiries please contact Warranty

Administration.

TAS

Technical Assistance Service (TAS) is a service

provided by Holden to assist Holden Dealers in

problem resolution.

Contact to TAS must be made by a Nominated Contact

as outlined in Section 5 of the TAS procedures

manual. All techlines, dealer letters and service

information must be checked prior to contacting TAS.

The Nominated Contact must not contact TAS until

he/she has been fully involved with the faulting vehicle

and all Dealer expertise has been exhausted.

Problems should be escalated through the Dealership

to the senior technician/foreman before contacting

TAS.

TAS cases must be updated or closed within 30 days

unless a Dealer is waiting on a service fix to be

provided. It is the Dealers responsibility to update

cases. All cases should be recorded in the TAS

procedures manual, which should be referred to prior

to contacting TAS. Please note that an electronic copy

of the TAS procedures manual is also available on

passenger SIP.

Under no circumstances are TAS or other Holden

contact details to be supplied to customers or

independent repairers. TAS is a service restricted to

assisting Holden Dealer service departments.

Quick reference contact numbers

Autostrada Ph 1800 634 343

Air International Ph 1800 673 716

Australian Arrow Ph 03 9785 0792

Blaupunkt Ph 1300 307 036

Bosch Technical Assistance Ph 1800 025 462

Clarion Ph 1300 730 730

Fax 03 9551 0377

Customer Assistance Ph 1800 033 349

Dana Ph 02 9892 9237

Ph 02 9892 9343

Fax 02 9892 9310

www.spiceraxle.com.au

HBD DVD support (Delphi) Ph 03 8558 8313

Eurovox Ph 03 9237 0800

Fujitsu Ten Ph 03 9646 6008

Holden Assist Ph 1300 880 088

Hollandia/Webasto sunroof Ph 02 9540 4811

Fax 02 9540 4316

HSV Ph 03 9265 9500

Impco Ph 03 9584 5644

Infomedia (SIP, Partfinder) Ph 1800 810 103

Lumen Ph 03 8787 1000

Panasonic Ph 02 9986 7635

PBR Diagnostic assistance Ph 1800 468 727

Petro-Ject Ph 02 9890 5701

Ph 02 9890 5244

Philips/Siemens-VDO Ph 1800 335 282

Salmat Ph 03 9358 2900

Security Information Ph 03 9647 2001

Fax 03 9647 2865

SPX Australia Ph 03 9544 6222

TAS Ph 1800 033 417

Fax 03 9647 2495

Email [email protected]

Triple M Ph 1800 773 030

Warranty Ph 1800 033 487

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

4

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

Convex Mirrors On Driver’s Side

XC Tigra, TK Barina sedan,

Group 1 Ref. No. TL1098 - 0603

Some dealers report they are seeing new models such

as the above, being delivered with convex** type

external mirrors on the drivers side.

NOTE: A recent change in Australian Design Rules

(ADR’s) has now made it possible for new vehicles to

be built with “convex” mirrors on both sides of the

vehicle.

Therefore, DO NOT REPLACE the drivers side mirror

on these new vehicles thinking that they have not been

built to specification.

** Convex mirror – Objects viewed in this type of mirror

are actually closer than they appear.

DIAGNOSIS HINT

Replacement Body Control Modules (BCM)

sourced from HSPO

All V & W cars

(GROUP 12) TL1103-0603

TAS continue to receive many calls from dealers who

say they are unable to link a new replacement BCM to

the PCM/PIM.

This problem will occur if the BCM has been sourced

from HSPO and the dealer is still using the original

remotes. It is a mandatory requirement that both

remotes are replaced whenever the BCM is

sourced from HSPO.

TIP: If Tech 2 asks you to “disarm the theft deterrent

with a programmed remote key”, this is an indication

that you have not replaced the remotes or

programmed them first.

If the BCM is obtained under warranty through the

changeover program, the original remotes are to be

used (unless specified otherwise).

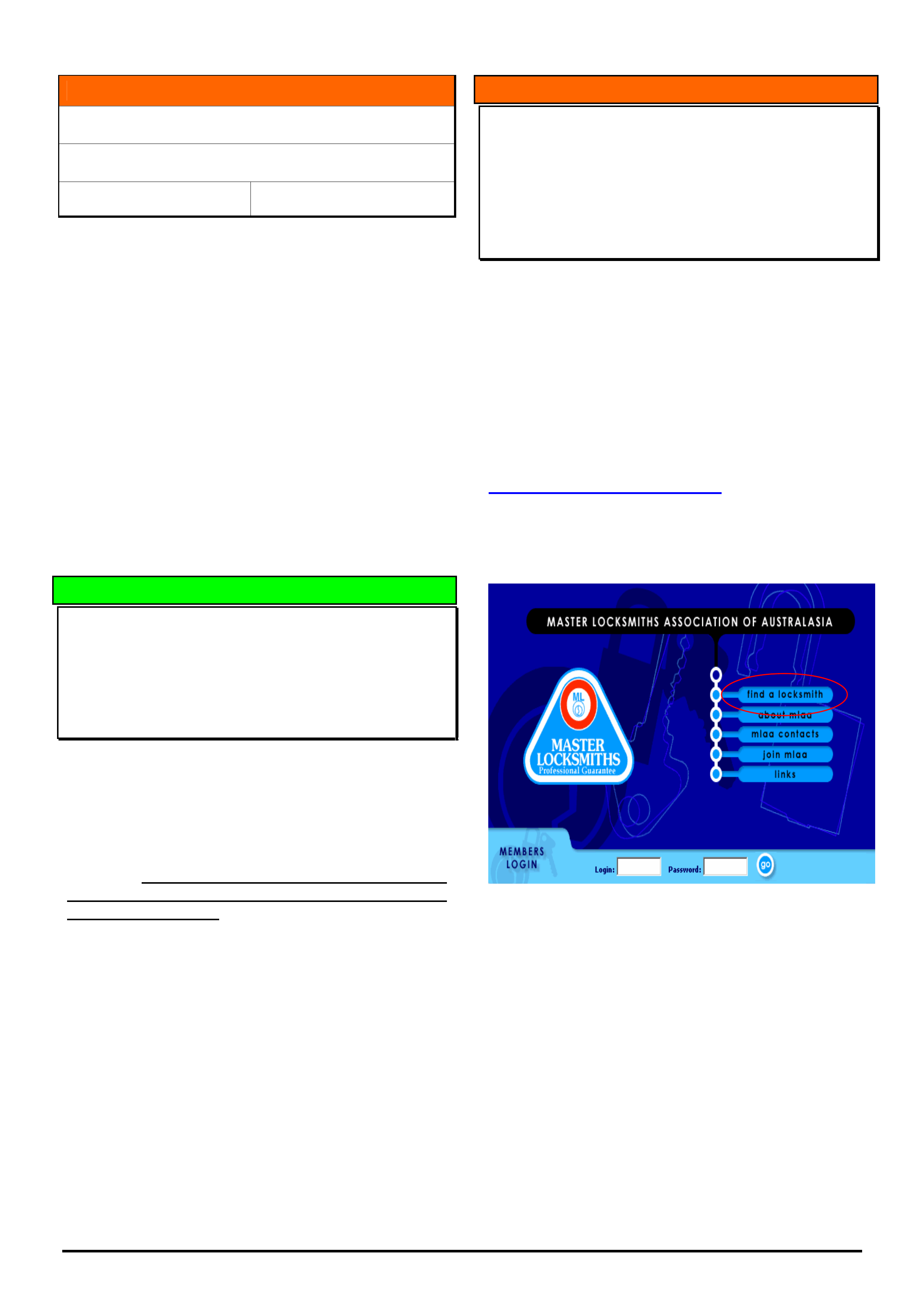

INFORMATION

Finding Locksmiths to cut ‘Z’ (snake) profile

keys

MY 2005 onwards – XC Barina, TS Astra, AH

Astra, ZC Vectra, TIGRA

(GROUP OB) TL1089-0603

As of model year 2005, some of our imported vehicles

have what is called a ‘Z’ or ‘snake’ style door/ignition

key profile.

As specialised equipment is required to cut this type of

key, some locksmiths may not be able to do this.

Following, is one example of a web site link that may

assist dealers to contact a locksmith in their area to

ensure they can cut this type of key.

www.masterlocksmiths.com.au

From the home page as shown, select ‘find a

locksmith’, choose Australia or New Zealand as

required and follow the prompts.

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

5

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

SERVICE PROCEDURE

Keyless Entry Remote Key Programming

Daewoo Leganza With Factory Fitted Keyless

Entry System

(GROUP 12) TL1096-0603

To program the remote key for the keyless entry system

you will need a Scan 100 tool.

Dealers who do not possess a Scan 100 tool will need to

obtain one on loan from their Zone office.

NOTE: There is no option on Tech 2 to program the

remote key for the keyless entry system on this model

as this function has not been written into the Tech 2

Software.

Programming Procedure using SCAN-100

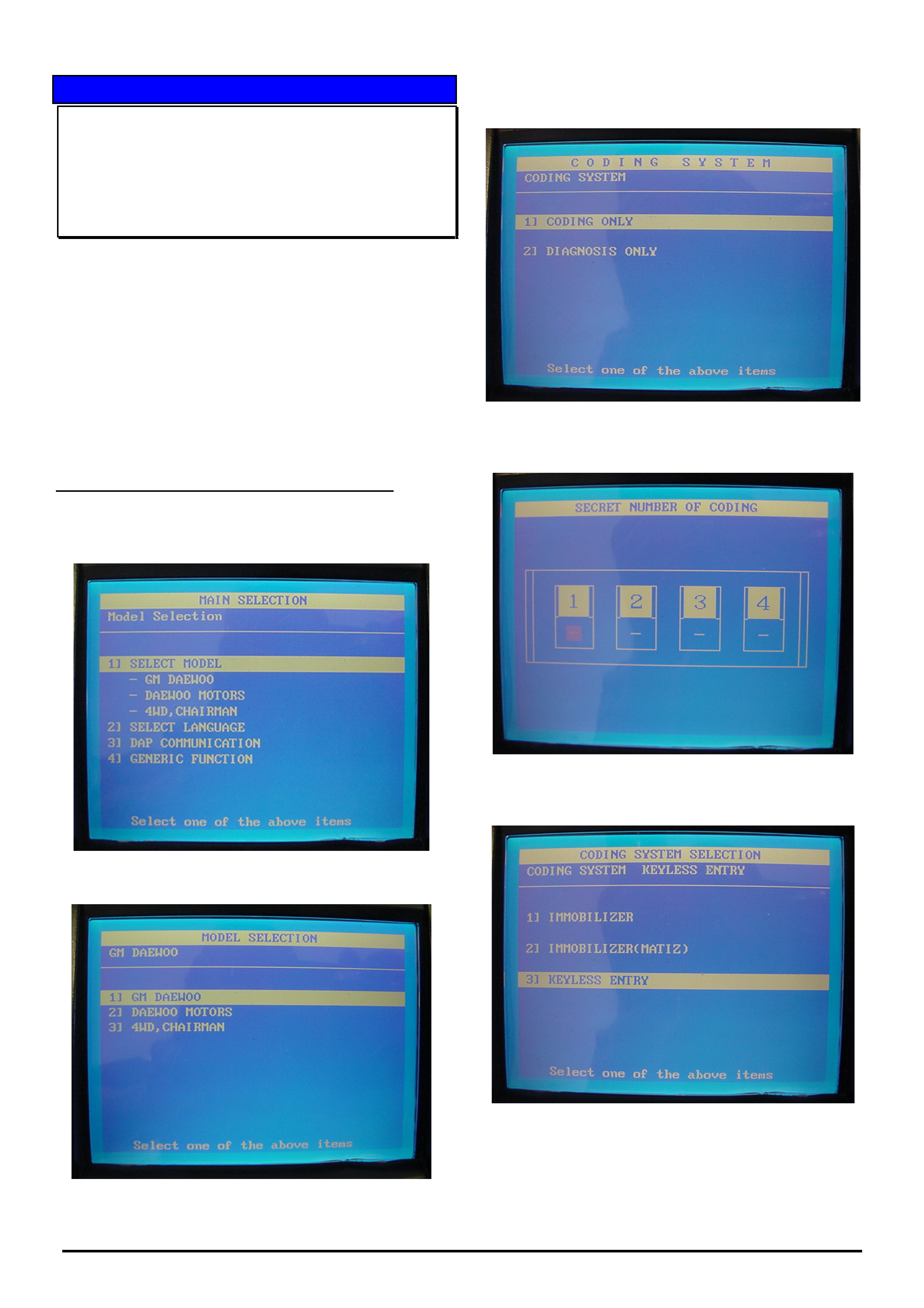

1. From the Model Selection screen select

“GM DAEWOO” then press enter

2. From the Coding System screen select “CODING

ONLY” then press enter

3. Enter the “secret number” using 0 0 0 0

4. Select “KEYLESS ENTRY” then press enter

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

6

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

5. Select Lanos, Leganza, Matiz, Tacuma, Kalos

then press enter

6. After selection of this screen continue to follow the

prompts as shown on the Scan 100.

DIAGNOSIS HINT

Instruments Customisation Mode Options

Missing

VY,VZ, WK,WL

(GROUP 12) TL1090-0603

Condition

Customer advises that when selecting the

customisation mode within the multi function display

(MFD) of the Instrument cluster, some features as

described in the Owners Handbook are no longer

available.

Cause

TAS cases have shown this symptom occurs after the

customer has fitted an aftermarket accessory radio.

Because the genuine (factory fitted) radio

communicates on the serial data bus, it needs to be

present in order to display all of the audio features

within the MFD. Therefore, the genuine radio must be

refitted to display ALL previous options.

If this is not possible, it must be explained to the

owner/installer that the serial data circuit must remain

open with nothing connected to it or other

communications issues may arise.

NOTE: Any faults which arise as a result of fitting

aftermarket (non genuine) accessories as described

above are not covered under warranty.

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

7

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

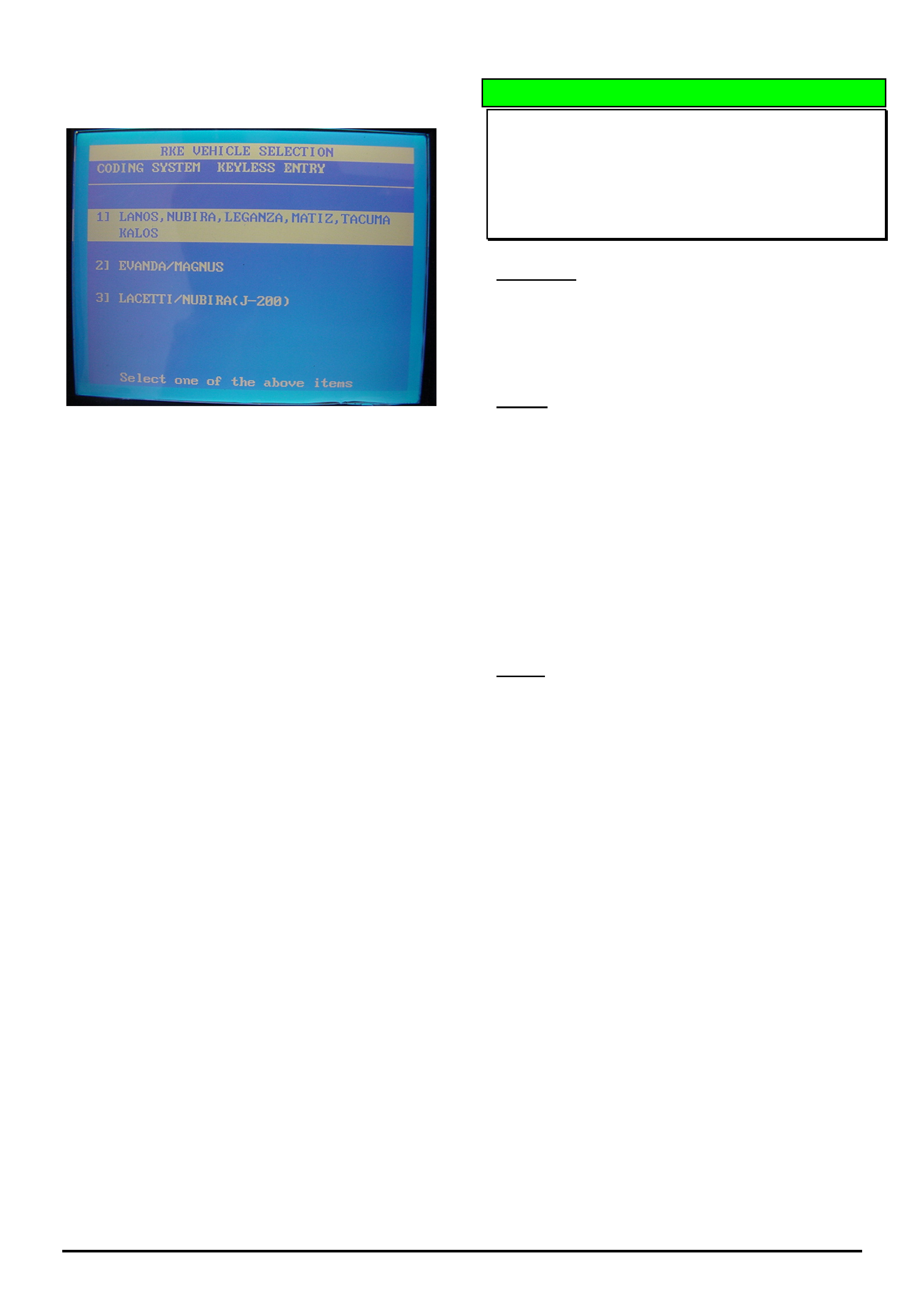

INFORMATION

HSPO Replacement Seat Base Assemblies

VZ, WL

Group 1 Ref. No. TL1097- 0603

Some replacement HSPO front seat base assemblies

may have an earth lead attached to the inner seat

track as shown in Figure 2.

Situation A. - Existing seat base has an earth lead

attached.

If you are supplied with a replacement seat base with

an earth lead attached which is replacing a seat base

that already has an earth lead attached, then simply

replace the seat base and reattach the earth lead to

the location provided in the seat cushion frame as

shown in Figure 1.

Figure 1

Situation B. Existing seat base DOES NOT have an

earth lead

If you are supplied with a replacement seat base with an

earth lead attached which is replacing a seat base that

does not have an earth lead attached proceed as

follows:

1. Remove the earth lead by cutting the wire as close

to the inner track as possible as shown in Figure 2.

(DO NOT ATTEMPT TO DRILL OUT THE RIVET)

2. Replace the seat base as per PV SIP instructions.

3. After installation of the seat base assembly, fit a

seat base to seat frame earth spring (Part No.

92190159), as per Product Campaign 06-H-02.

NOTE: On vehicles where the campaign has

previously been completed, ensure the earth

spring is reinstalled correctly. Refer to product

campaign 06-H-02 bulletin for details of correct

fitment.

Figure 2.

INFORMATION

Use Of Accessory Cargo Barrier With Factory

Fitted LPG

VZ Wagon

Group OB Ref. No. TL1101 - 0603

The genuine Holden accessory cargo barrier cannot

be fitted on vehicles with factory fitted LPG (option

code LW2).

When the spare wheel is relocated it intrudes into the

space that the cargo barrier would normally occupy.

Microcat is currently being updated to show that the

cargo barrier cannot be fitted on vehicles with factory

fitted LPG.

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

8

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

DIAGNOSIS HINT

Intermittent Loss of Sound from the Audio

System

WK, WL, Caprice

Group 12 Ref. No. TL1102 - 0603

Customers may advise the sound from the audio

system intermittently drops out.

The following information has been received via dealer

PIR’s and is published to minimise diagnosis time

when investigating problems related to the above

symptom.

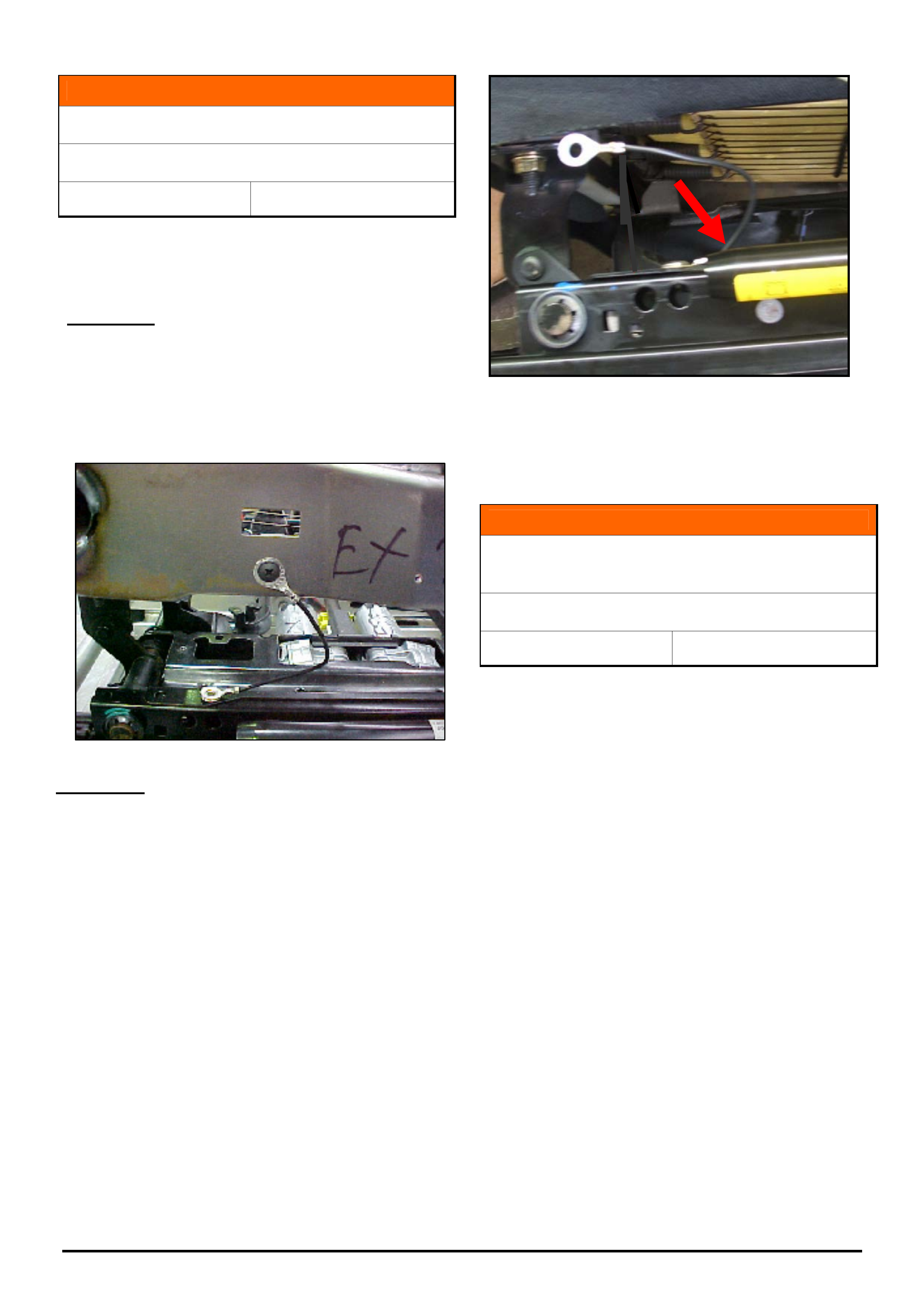

Inspect the wiring in the right hand rear quarter panel

next to the premium sound amplifier for wiring damage

(short to ground) in the location highlighted in figure 1

and figure 2.

Figure 1

Figure 2

If damage is discovered, repair the damaged circuits

and re-insulate to avoid a repeat failure.

See Figure 2

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

9

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

SERVICE FIX

DTC P1106 “Boost Pressure Control Device

Malfunction”

TS Astra Z20LET

Group 12 Ref. No. TL1099 - 0603

CONDITION

Customers may advise the CEL light illuminates.

When Tech 2 is connected DTC P1106 “Boost

Pressure Control Device Malfunction” is set in the

engine ECU.

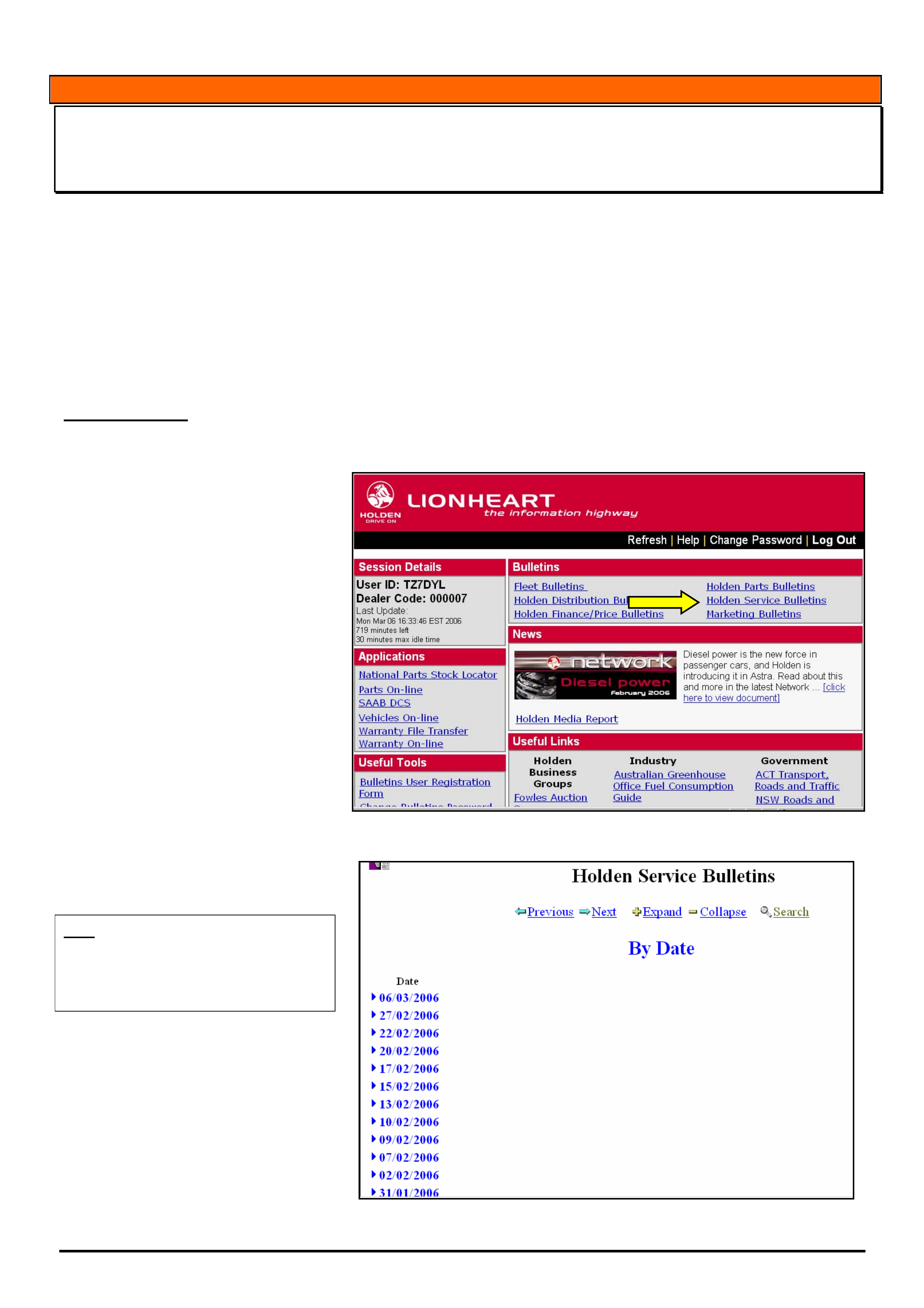

CAUSE

The cause of this condition may be a poor connection

in an earth splice joint within the engine harness (refer

circuit diagram in figure 1).

This splice joint provides an earth for the Coolant

Temp Sensor (B61), Intake Manifold Absolute

Pressure Sensor (B21) and the Air Mass Meter (B46).

Figure 1

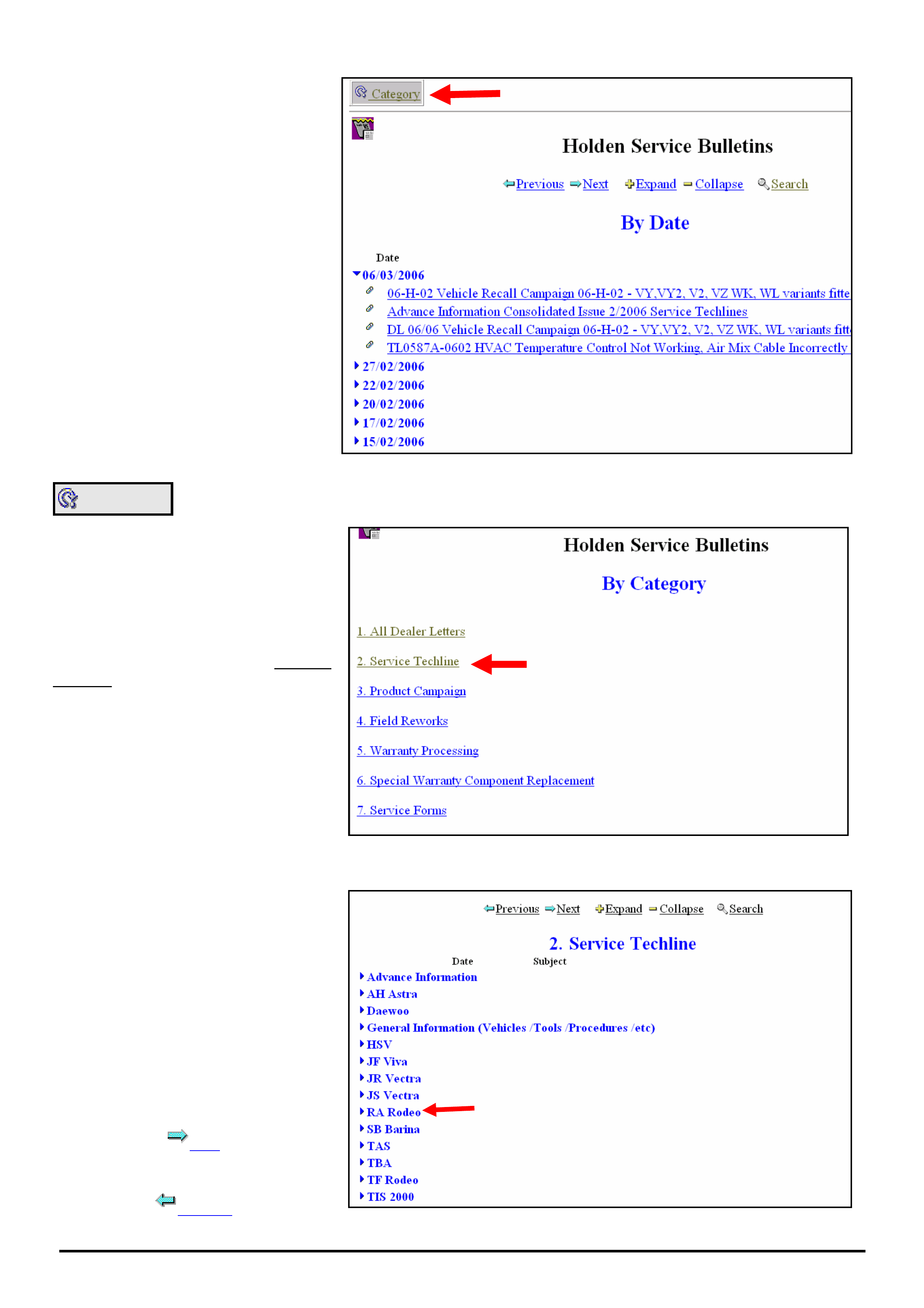

CORRECTION – Service

Confirm DTC P1106 is set in the engine ECU either

history or present.

5. Locate the section of the engine harness indicated

in figure 2, on the passenger’s side of the engine

bay under the intake hose, next to the battery.

Figure 2.

6. Remove the tape from this section of the engine

harness and locate the splice joint shown in figure 3.

Figure 3

7. Remove the suspect splice joint (under the black

heat shrink in figure 3, from the harness and

renew the splice joint. Reconnect the four earth

circuits.

Note: If unsure of the approved method of wiring

repair refer to PVSIP VZ / Wiring Diagrams / Section

12P / 5. Wiring Repair Procedure / 5.3 Splicing Wiring

Using Spice Clips.

8. Re-insulate the splice joint after repair and re-tape

the engine harness.

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty Information

section of current PV SIP disc.

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

10

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

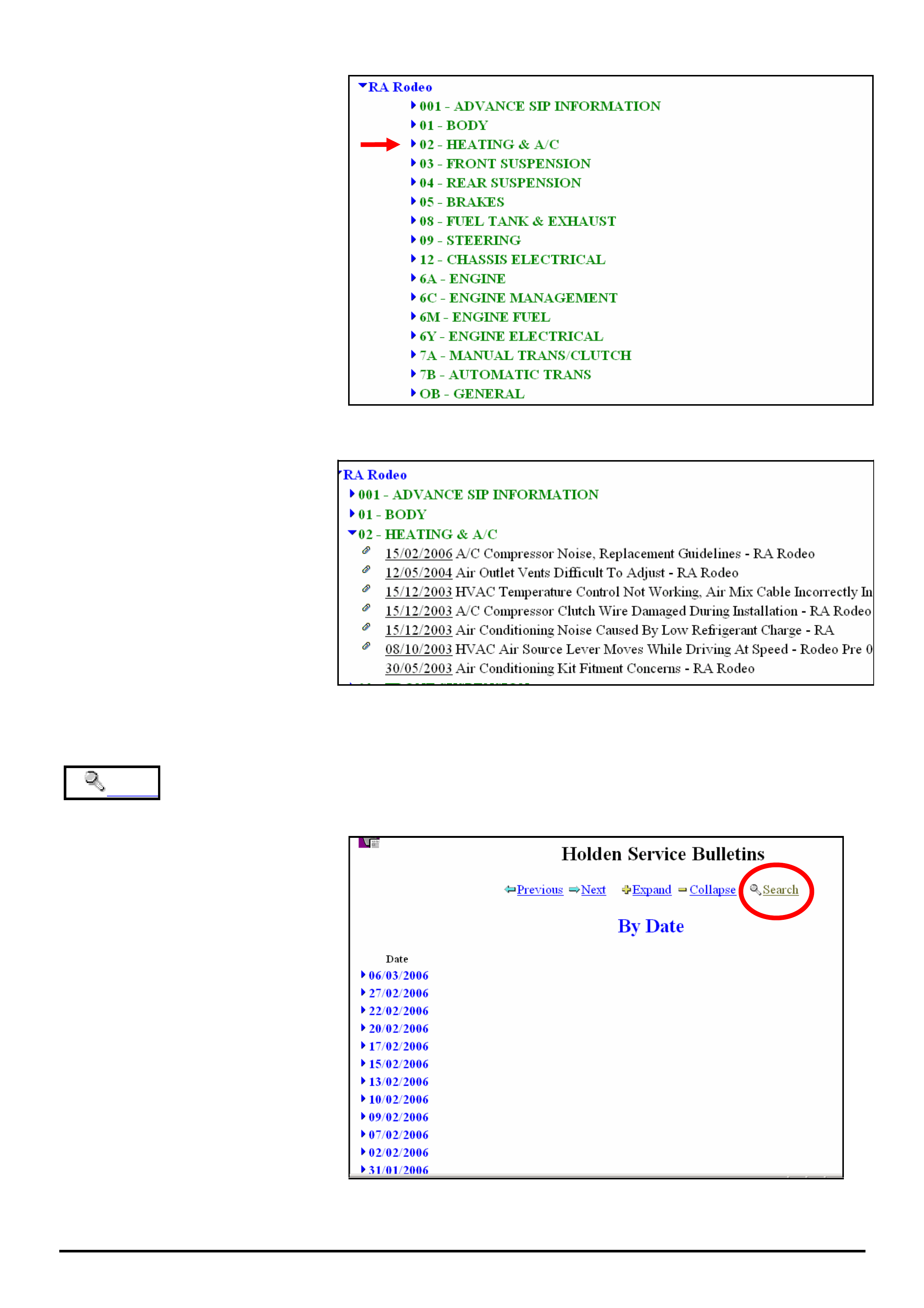

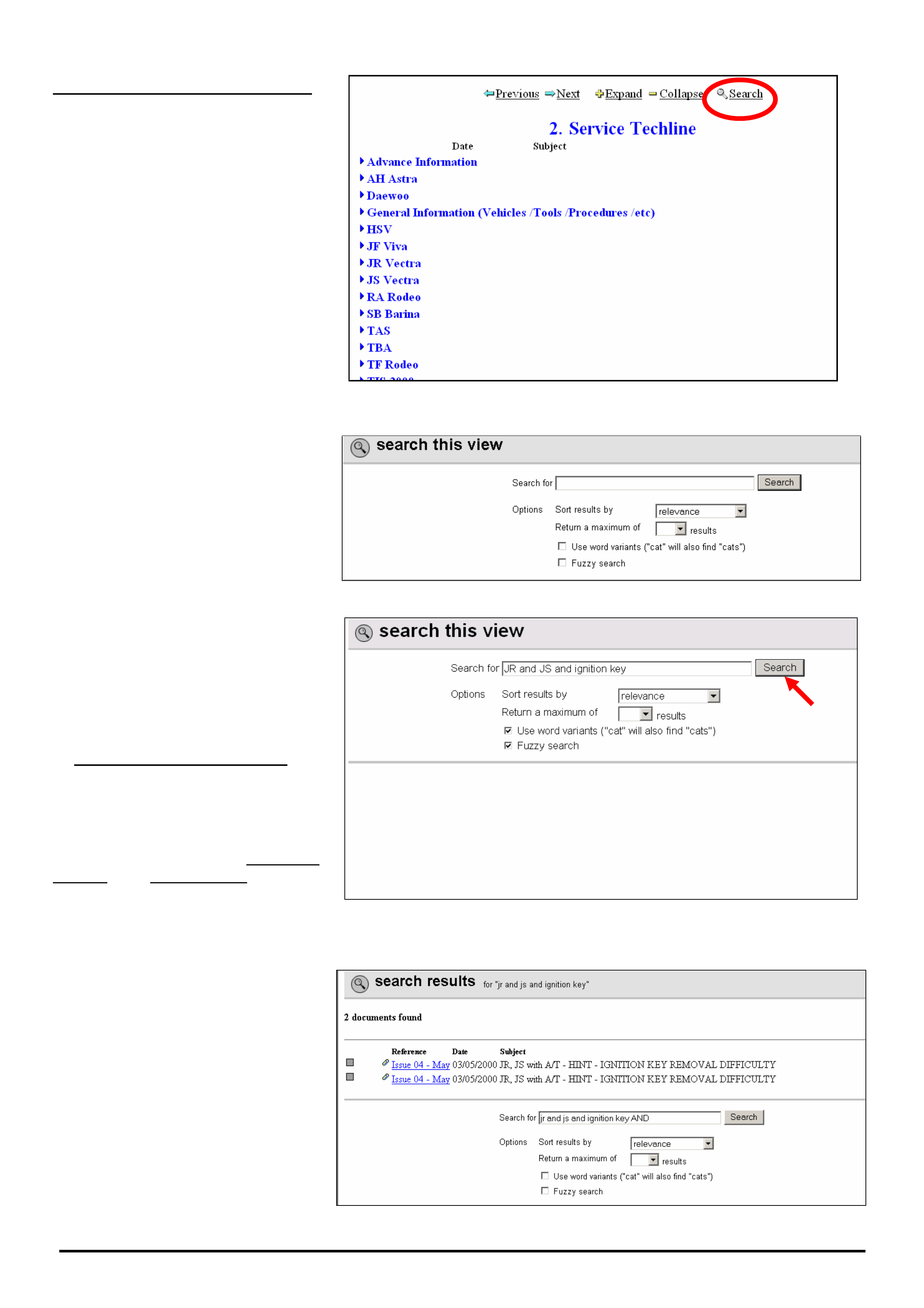

INFORMATION

Searching for Service Information on Holden Dealer Portal - “Lionheart”

(GROUP OB) TL0921A-0603

( This Techline supercedes the previous one in Issue 5, June 2005. It is UPDATED with the latest procedure. )

This Techline describes how to find the following Service Information on the Holden Dealer Portal - “Lionheart”.

• Service Techlines

• All Dealer Letters

• Campaign Bulletins

• Field reworks

• Warranty Processing

• Special Warranty Component Replacements

• Service Forms.

PROCEDURE.

When you logon to the Holden Portal the Lionheart Home page will appear as shown in Figure 1.

Now select “Holden Service Bulletins”

as indicated by yellow arrow.

.

Figure 1

The next screen to appear is shown in

Figure 2.

HINT: This screen should be thought of as

an email inbox.

You should check this screen everyday to

view the latest information issued by

Holden Service Department.

The date at the top of the list is when

the newest bulletins were posted onto

Lionheart. In the example in Figure 2

this date is 06/03/2006.

Figure 2.

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

11

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

To view the bulletins for the 06/03/2006,

click on the “►” symbol next to the date

and a list of bulletins will appear as

shown in Figure 3.

To view any bulletin click on it.

Figure 3.

Category

If you select the “Category” button as

indicated by the red arrow in Figure 3

the screen shown in Figure 4 will

appear.

Now select the category you want.

As an example, select “Service

Techline”

The next screen to appear is shown in

Figure 5.

Figure 4

From this screen you select the model

you are interested in.

For example, click on the “►” next to

RA Rodeo

The next screen to appear is shown in

Figure 6.

NOTE: To view the full list of models

you will need to turn over to the next

page by clicking on the “next” arrow at

the top or bottom of the screen

Next

To go back a screen, press “previous”

Previous

Figure 5

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

12

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

Now select the Group you are interested

in.

Example - select 02-HEATING & A/C

The next screen to appear is shown in

Figure 7.

Figure 6.

Now look through the list of Techlines

to find the one you are interested in.

NOTE: Techlines are arranged in

order of date with the newest at top of

list.

Figure 7.

Search USING THE SEARCH METHOD TO FIND INFORMATION ON LIONHEART

If you select the SEARCH function

from the screen in Figure 8 it will

search through all the Service

Information Categories as follows:

• Service Techlines

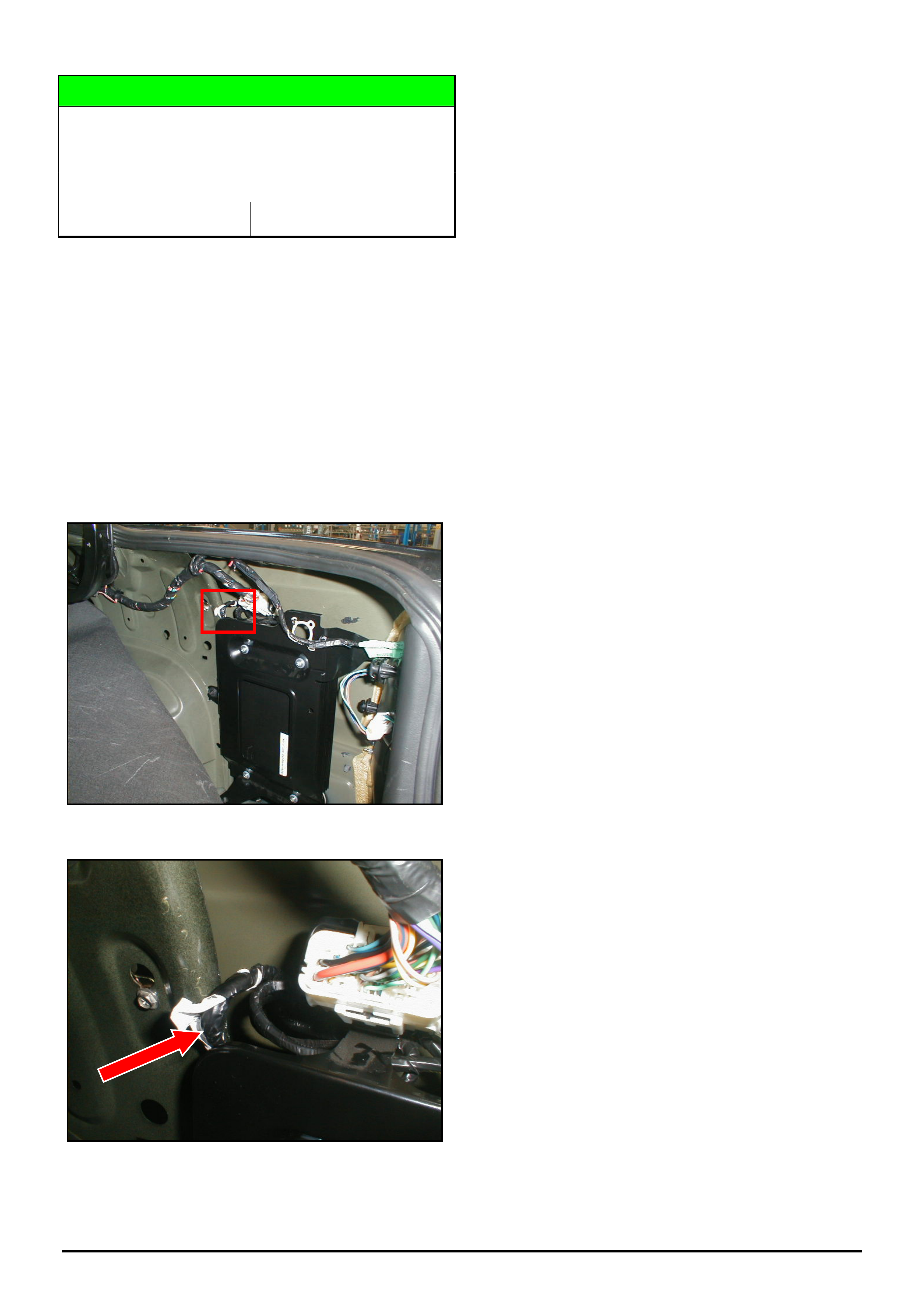

• All Dealer Letters

• Campaign Bulletins

• Field reworks

• Warranty Processing

• Special Warranty Component

Replacements

• Service Forms.

To shorten the search process, select

the SEARCH function only after you

are in the particular category you are

interested in.

Following, is a description of how to

search for Service Techlines.

Figure 8

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

13

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

Searching for Service Techlines

From the screen shown in Figure 9

click on the “Search” key. This will

bring up the screen shown in Figure

10.

Figure 9

This is the search screen used for

entering “keywords” to search for.

It is important to enter the right words

here in order to find what your looking

for.

Figure 10

As an example (Figure 11) try

searching for Techlines related to JR

& JS Vectra Ignition Barrel

Jamming.

In the top window, type in the following

“search string” exactly as shown.

“JR and JS and Ignition key”.

Don’t touch the next 2 boxes titled

“Sort results by” or,

“Return a maximum of”.

Tick the last 2 boxes i.e. Use Word

variants and Fuzzy search. Refer to

later explanations of these terms.

Now click the “Search” button. Shown

with the red arrow.

Figure 11

The search result is 2 documents as

shown in Figure 12.

Click on the hot-key section (in blue)

to view the techlines.

Figure 12.

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

14

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

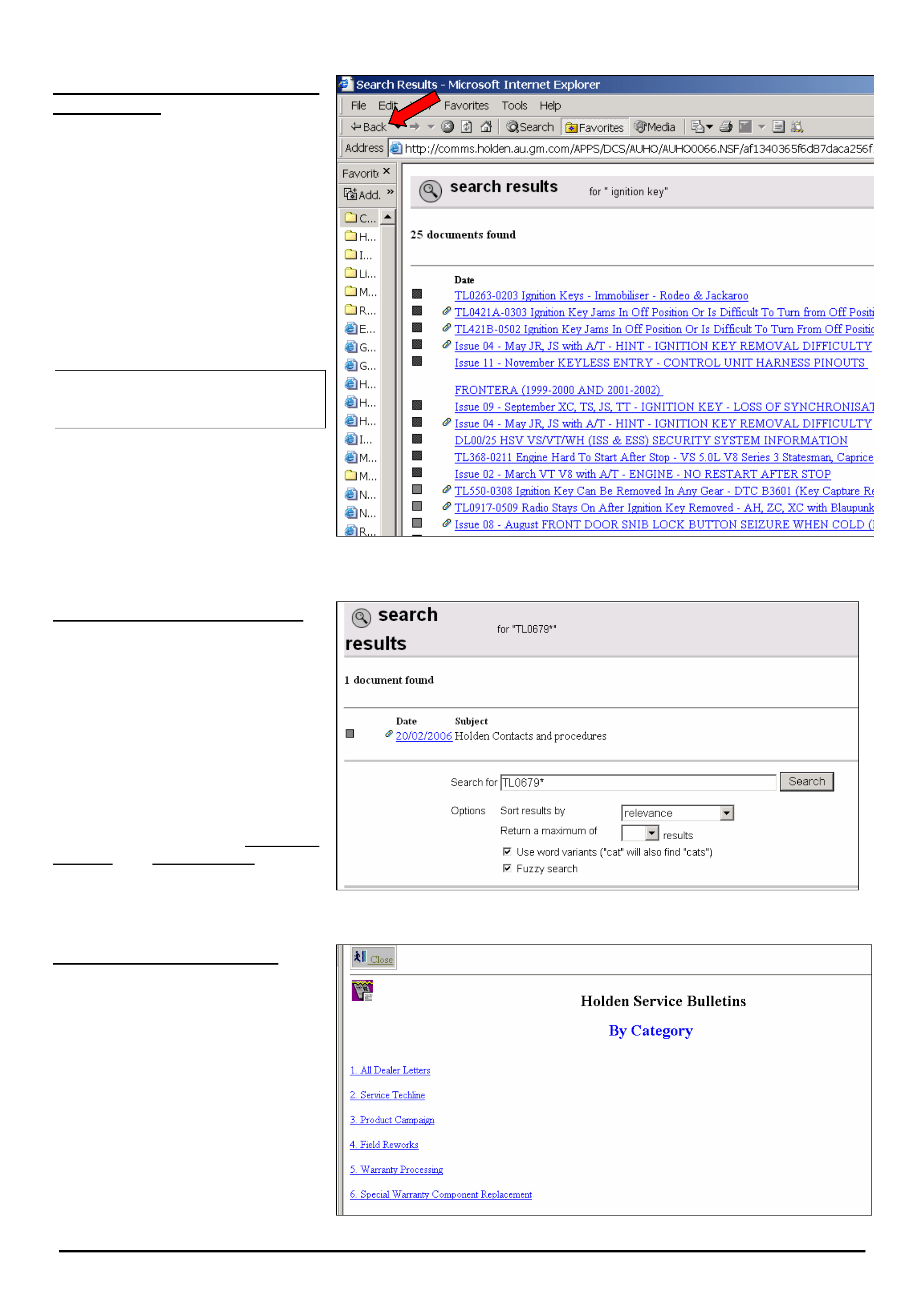

Notes on choosing “Keywords”

for searching

If we had only entered “ignition key”

without any model descriptor, this

would have located 25 items as shown

in Figure 13.

If we had only entered “ignition”, the

search would have located 86 items.

This demonstrates the importance of

selecting the right “keywords” to

search with so you don’t end up with

large numbers of items to read

through.

Rule of thumb: - The less

information in the “search window”

the more information comes back.

HINT: If at anytime you wish to go

back to the “Search” function press

the “Back” arrow in the top left side of

the toolbar. Refer red arrow in Figure

13.

Figure 13.

Searching by Techline Number

Use this procedure if you have an

existing techline and you want to

check to see if there is a later version

on Lionheart.

Example. - Search for the latest issue

of techline TL0679.

Type “TL0679*” in the search window

as shown in Figure 14.

Tick the last 2 boxes - “Use Word

variants” and “Fuzzy search”.

The latest version found will be

TL0679B-0602.

Figure 14

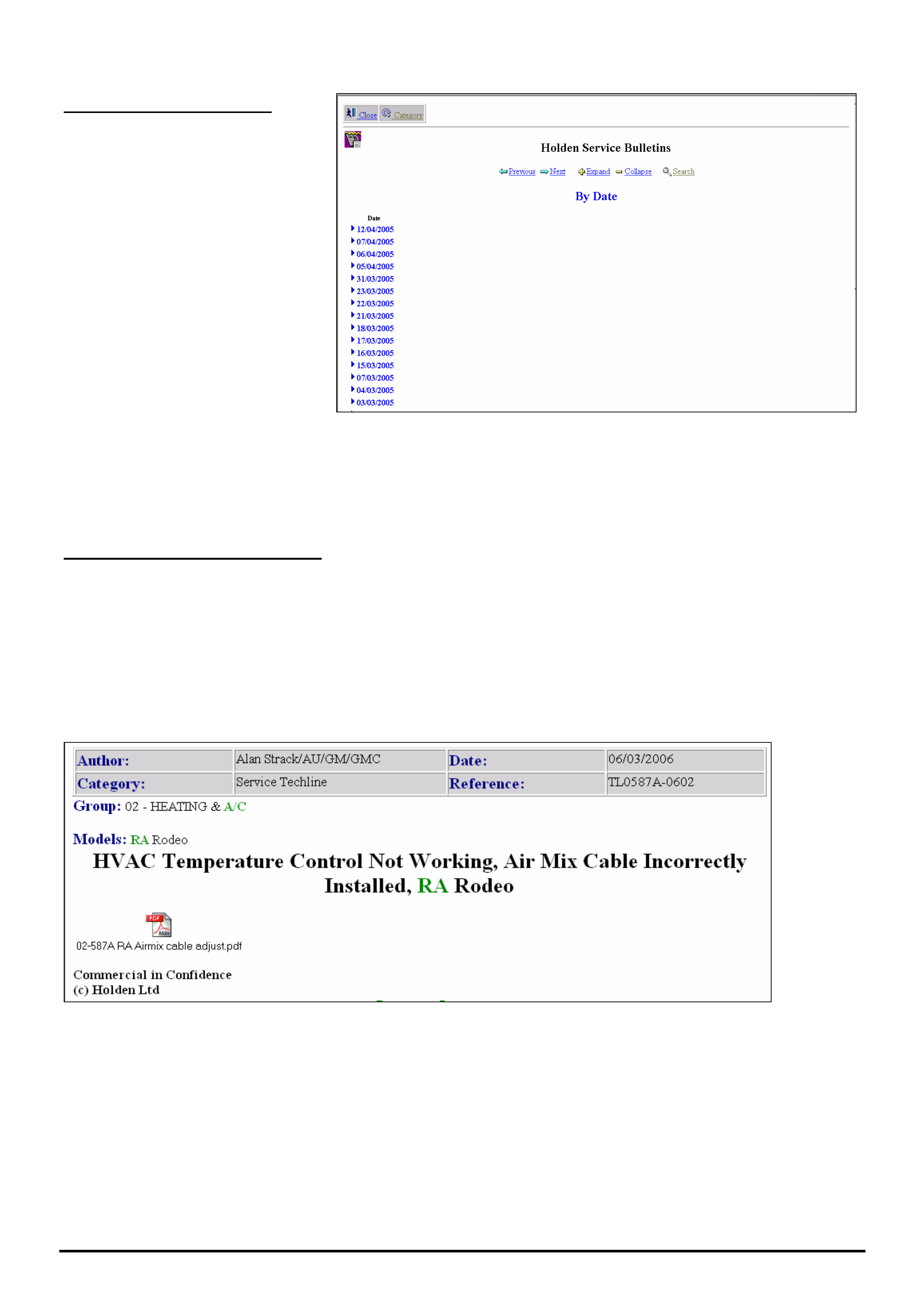

Searching Other Categories

The search procedure described

above for Service Techlines may also

be used for Dealer Letters, Campaign

Bulletin, Field rework, Warranty

Bulletin, etc. You must first select the

category you want from the Category

screen (Figure 15) before proceeding

with search.

Use the same procedure as that

described for a Service Techline.

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

15

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

Figure 15.

Doing a “General” search.

To find ALL published information on

a particular subject, select “Search”

from screen shown in Figure16.

As an example, enter “Daewoo” in

the search field

This “search” will give you everything

that contains the word “Daewoo” .eg.

Dealer letters, Techlines, Recalls,

Warranty etc.

Figure 16

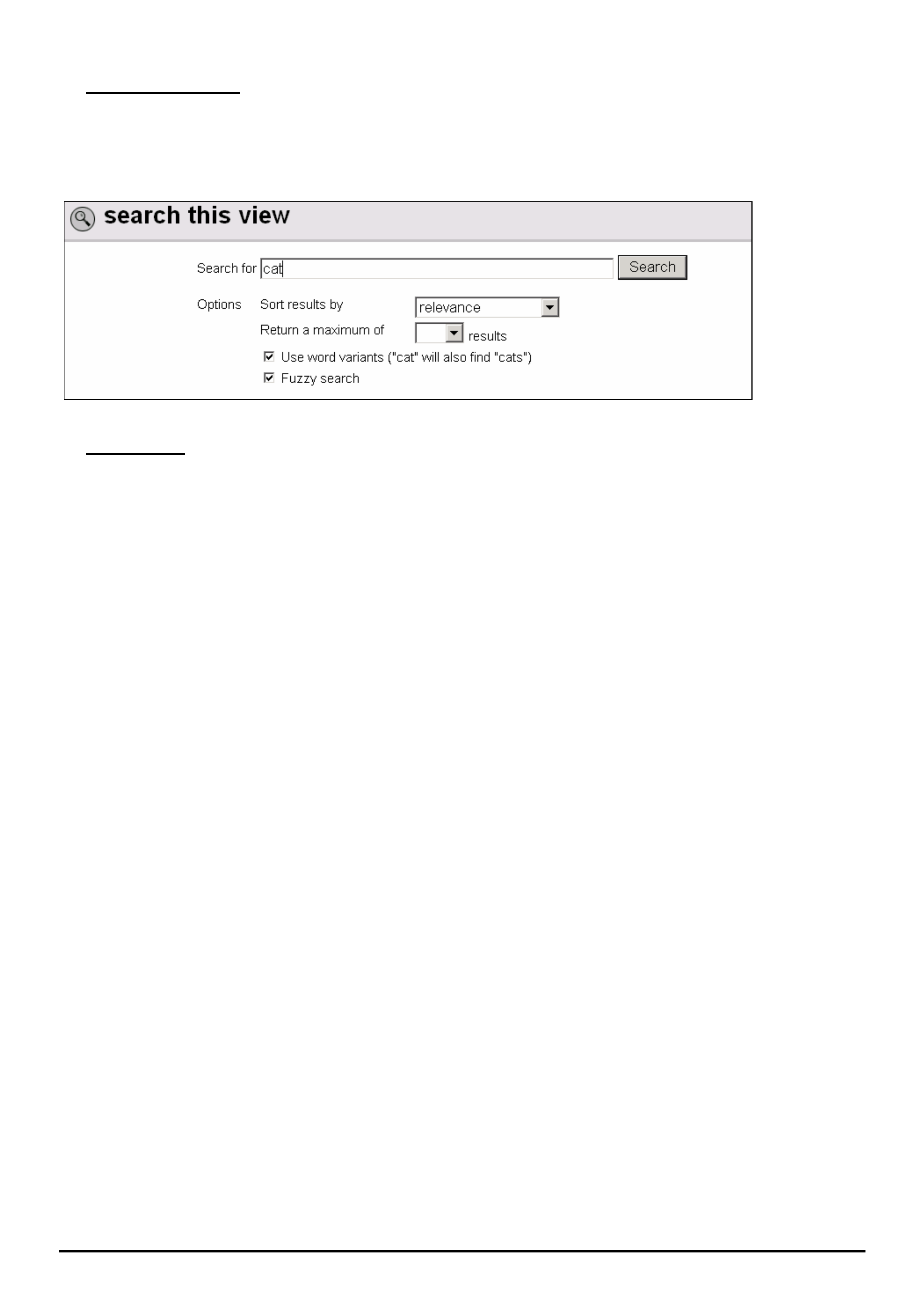

General Notes On Searching.

• If you perform a search and the results are not what you were looking for; to conduct another search, you will need

to hit the “← Back” arrow as shown in Figure 13. This will bring up the “active” search window. Delete the current

search keywords then enter some new keywords and press “search” again.

• The search engine cannot search any “attached” files for keywords. For example, in Figure 17, the search engine

will search through every word that actually appears on the screen as shown. It cannot search through the

attached file, viz “02-587A RA Airmix cable adjust.pdf”.

Figure 17

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

16