2006 SERVICE TECHLINES

© 2006 GM Holden LTD. A.B.N. 84 006 893 232

Service Department

A “Holden” Product

BRISBANE SYDNEY MELBOURNE ADELAIDE PERTH

For the latest and/or any missing Techline bulletins,

please refer to Holden Lionheart

HOLDEN SERVICE TECHLINES___________________________________________________________________________FEBRUARY, 2006

4

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

Introduction of DVD for TIS 2000

All

Group OB Ref. No. TL1025A - 0601

This Techline supercedes the previous one in Issue 10,

Nov, 2005. It is revised by adding a note on setup of the

DVD drive.

From January 2006 the previous CD-ROMs for TIS

2000 will be replaced by a DVD.

The major growth in data in recent years has made

this change necessary.

Please ensure that your TIS 2000 PC has a DVD

drive by 1.1.2006 at the latest.

Advantages of changing to DVD.

• The previous data set of 4 CDs will be replaced by

one DVD

• Simpler updates, without having to change the CD

several times

• Quicker updates

• Improved quality graphics

• Use of digital photos

• Conventional CD-ROMs can also be read by DVD

drives

Important Note - DVD Setup

To guarantee a smooth update for TIS 2000, it is

essential that any new DVD drive to be used for TIS

2000 DVD’s is allocated to the letter previously used

by the CD drive. If this is not done, TIS 2000 must be

uninstalled and the DVD drive set up as a new

installation.

For more information refer to Dealer Letter 25/05 and

the TIS 2000 Newsletter available on TIS 2000 CD66.

INFORMATION

Tag Number Identification Plate

RA Rodeo

Group OB Ref. No. TL1040 - 0601

On imported vehicles the Tag Identification Plate is

normally fitted to the radiator support panel at Port Of

Entry.

This plate is no longer fitted to the following imported

models:

RA Rodeo.

Tag plate no longer fitted as from Friday 21/10/05.

JF Viva and TK Barina.

Tag plate not fitted commencing from model

introduction.

NOTE: The 17 digit Vehicle Identification Number

(ISOVIN) remains as the main identification number

for all vehicles.

HOLDEN SERVICE TECHLINES___________________________________________________________________________FEBRUARY, 2006

6

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

Electronic Odometer Programming

RA Rodeo,

UBS Jackaroo MY1998 onwards,

UES Frontera MY2001 onwards

Group 12 Ref. No.TL0481A-0601

This Techline supercedes the previous one in Issue 5,

2003. It is revised by adding TK & JF models.

When a replacement instrument cluster is installed

into one of the above models it is a requirement to

program the odometer to the value of the one

removed.

If your Service Department does not know of any

instrument repairers who are capable of performing

this operation on the above models, below are some

contacts of instrument repairers currently being used

by other Dealers.

Victoria

Automotive Instrument Repairs

59 C Glenvale Crescent,

Mulgrave, Victoria 3170

Phone (03) 9561 2366

Fax (03) 9561 9134

NSW

Macarthur Instruments

P.O. Box 3016

Narellan Delivery Centre, NSW, 2567

fax (02) 4659 7294

Mobile (0416) 241 903

QLD

Future Auto Instruments

113 Turpin Rd,

Labrador, QLD 4215

Mobile (0414) 518 766

New Zealand

Robinson Instruments

19 Fale Street

Freeman's Bay

Auckland

Phone (09) 3771565

Fax (09) 3580573

HOLDEN SERVICE TECHLINES___________________________________________________________________________FEBRUARY, 2006

13

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

A/C Compressor Noise, Replacement

Guidelines

RA Rodeo

Group 2 Ref. No. TL1068 - 0601

A high rate of A/C compressors returned to REPAC for

noisy operation have been vehicle and bench tested

with No Fault Found.

Further investigation has found that if the A/C system

is over or undercharged, compressor noise will

become evident. The tests indicate that if the charge

level was as low as 600 grams or as high as 800

grams, noise was introduced to the A/C system that

could result in customer complaint.

Prior to replacing an A/C compressor the following

steps must be followed:

• Check that the A/C system is fitted as per the

fitting instruction ensuring that all plumbing is

routed correctly and not contacting body or

engine components.

• Recharge the A/C system with the correct

weight of gas (measure the gas removed and

note in the warranty claim). If the gas charge

was low then check for leaks.

If the compressor is going to be replaced the

warranty claim 3C’s must describe the exact

customer complaint, when the noise occurs

including operating environment and the type of

noise. This information will help to identify any

compressor problems and avoid chargebacks.

The following points should be observed when

replacing A/C system components:

• High and low side pressures should be

allowed to equalise prior to degassing.

• Fast gas recovery draws more oil from the

system. Initially the low side tap should be

opened gradually to slow the gas recovery rate

which reduces the amount of oil removed with

the gas.

• Spare parts are supplied dry (except

compressor) and an appropriate amount of oil

should be added when replacing components

(See table 1).

• When a compressor is replaced, an oil balance

test must be performed.

• Charging procedure is detailed in the fitting

instructions.

Table 1

Component Replaced Oil To Be Added To System

Evaporator 30mls

Condenser 30mls

Receiver Drier 15mls

Any Pipe 5mls

Compressor Oil Balance Required.

SERVICE FIX

Check Engine Light On – DTC P0502 Sets

RA Rodeo - 4 Cyl. Petrol Engine

Group 6C Ref. No. TL1073 - 0601

CONDITION

Check Engine Light (CEL) illuminates intermittently,

DTC P0502 is found during diagnosis.

CAUSE

Incomplete starting procedure - IE: cranking and not

holding key on long enough for engine to start – has

been defined as the most likely cause of the DTC

setting. The DTC only sets and illuminates the CEL

when this occurs on two consecutive ‘key on’ cycles,

thus the intermittent nature of CEL and code setting.

CORRECTION – Service

Summary: SPS vehicles using LCRV TIS 2000 CD 19

or later (delivered to Dealers in January, 2006).

On vehicles with the above complaint, reprogram the

engine electronic control unit via the standard Service

Programming System using LCRV TIS 2000 CD No.

19 or later.

WARRANTY CLAIM INFORMATION

Use Existing Labour Times information in Warranty

Information section of current LCV SIP CD as follows:

Description Engine Diagnostic Trouble

Code P0502

Labour Op. No. J900502

Time ST

Failure Code K0057 Registers incorrectly

HOLDEN SERVICE TECHLINES______________________________________________________________________________MARCH, 2006

6

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

DIAGNOSIS HINT

Whistle / Squeal Noise From Engine Turbo

Under Acceleration

RA RODEO Diesel 4JH1

Group 6A Ref. No. TL1075 - 0602

PROBLEM DESCRIPTION

Owner may complain of whistle or squealing noise

from the engine when under acceleration. May also be

referred to as loud Turbo Charger whistle noise

SERVICE RECTIFICATION

Whistle and squealing noises can be generated by air

leaks in the intake or exhaust system on a turbo

charged engine. The noise can be generated when

high pressure air or exhaust gas is escaping from a

leaking gasket or hose clamp.

If an RA Rodeo 4JH1 diesel is presented with the

above complaint, the following checks should be

performed

• Ensure that all intake hoses, ducting and clamps

are tight and leak free.

• Check the exhaust system (manifold & gaskets) for

signs of leaking.

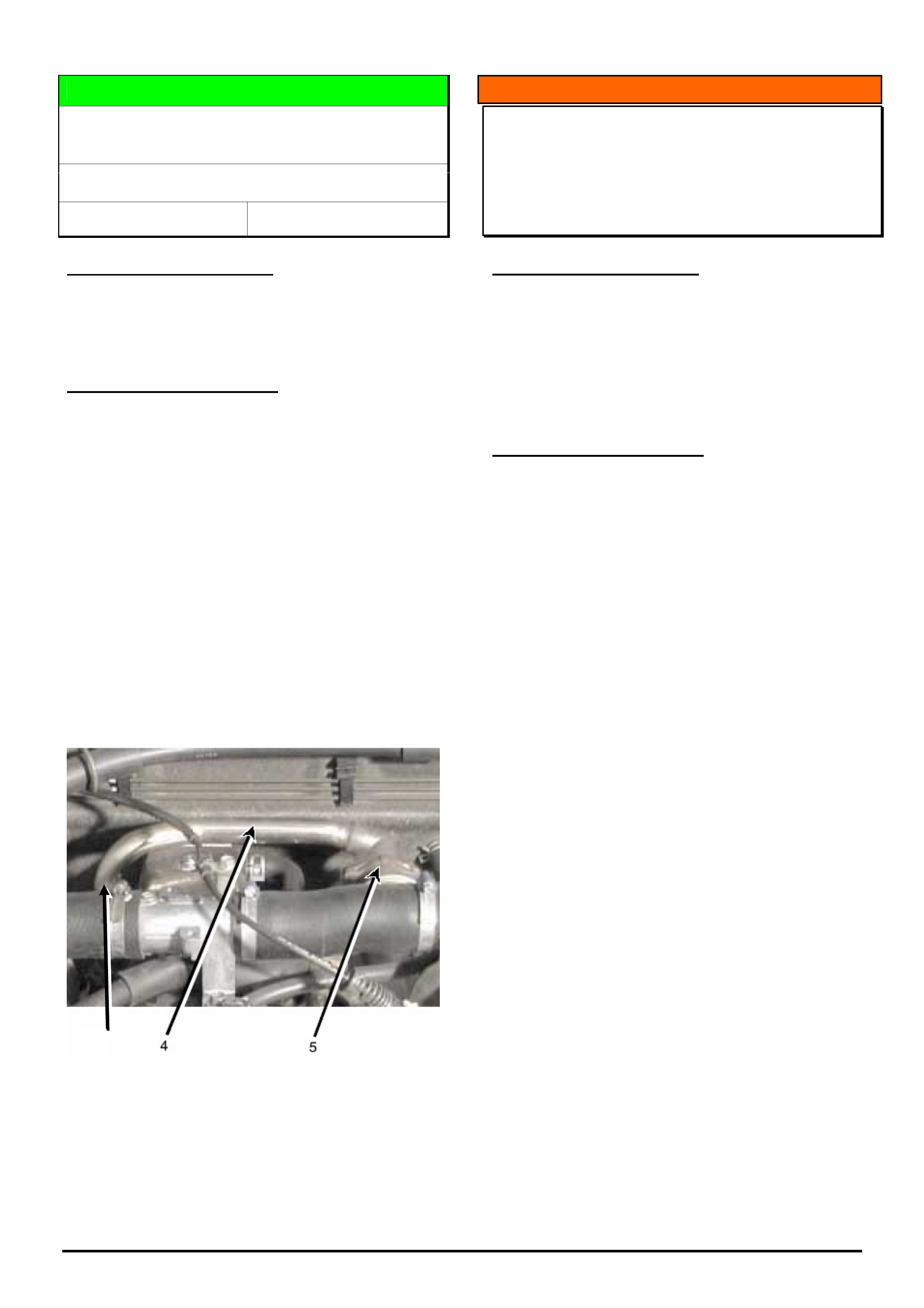

• Check the EGR crossover pipe (4) and associated

gaskets (5 & 6) for leaking as shown in picture

below.

DO NOT REPLACE TURBO CHARGERS FOR THE

ABOVE COMPLAINT

Contact TAS if the above checks fail to resolve the

complaint.

6

INFORMATION

Accessory Cruise Control Inoperative After

Fitment

RA Rodeo with 3.6 HFV6

(GROUP 12) TL1086-0602

PROBLEM DESCRIPTION

Dealers may find that after fitting accessory cruise

control to an RA Rodeo “HFV6 engine,” the cruise

control may not operate.

The PIM will only “Auto Detect” that the cruise control

switch has been fitted after a “Power Down” situation.

SERVICE RECTIFICATION

Dealers are reminded that the battery negative cable

must be disconnected during fitment of the cruise

control kit. Upon reconnection, the PIM should

automatically detect that cruise control is now fitted

and will function correctly.

If Cruise Control has been fitted without disconnecting

the battery and is not operating, disconnect the

negative battery cable for at least 30 seconds. Then

reconnect the cable and check for correct cruise

operation

HOLDEN SERVICE TECHLINES______________________________________________________________________________MARCH, 2006

14

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

Holden Contacts and procedures

All

Group OB Ref. No. TL0679B-0602

This Techline supercedes the previous one (TL0679A-0501) in

Issue 1, Feb 2005. It contains UPDATED information.

This techline summarises some of the Holden contact

procedures and gives a quick reference guide for

contact numbers.

Security information.

To obtain security information for both Passenger and

LCRV vehicles the first step is to check the New Online

Warranty system (NOW). If the information is

unavailable on NOW then a completed security

information request form must be faxed through to the

Vehicle Security Information Centre, as security

information cannot be given out by phone. Please note

that security information requests are processed by the

Vehicle Security Information Centre and not TAS.

To ensure you have the latest security information

request form always refer to Service Forms in the

Service Bulletin section of the Holden Lionheart Portal.

Fax completed forms to the Vehicle Security

Information Centre on fax 03-96472865.

There can be up to a 4-hour turn around on requests,

however if the information needs to be obtained from

overseas, it may take up to 24 hrs. Do not phone the

security information department unless you have not

received a response in the normal turn around time.

For further information please refer to ADL 42/05.

Accessories and parts inquiries

If any information or assistance is required in regards

to Microcat, part numbers, Holden accessories or if

you need to contact HSPO Customer Assistance,

please refer to the Holden Help section in Microcat.

Warranty Authorisation and enquiries

Warranty can only be authorised by your Aftersales

District Manager. Labour times information is available

on SIP or from the warranty department. For any other

warranty inquiries please contact Warranty

Administration.

TAS

Technical Assistance Service (TAS) is a service

provided by Holden to assist Holden Dealers in

problem resolution.

Contact to TAS must be made by a Nominated Contact

as outlined in Section 5 of the TAS procedures

manual. All techlines, dealer letters and service

information must be checked prior to contacting TAS.

The Nominated Contact must not contact TAS until

he/she has been fully involved with the faulting vehicle

and all Dealer expertise has been exhausted.

Problems should be escalated through the Dealership

to the senior technician/foreman before contacting

TAS.

TAS cases must be updated or closed within 30 days

unless a Dealer is waiting on a service fix to be

provided. It is the Dealers responsibility to update

cases. All cases should be recorded in the TAS

procedures manual, which should be referred to prior

to contacting TAS. Please note that an electronic copy

of the TAS procedures manual is also available on

passenger SIP.

Under no circumstances are TAS or other Holden

contact details to be supplied to customers or

independent repairers. TAS is a service restricted to

assisting Holden Dealer service departments.

Quick reference contact numbers

Autostrada Ph 1800 634 343

Air International Ph 1800 673 716

Australian Arrow Ph 03 9785 0792

Blaupunkt Ph 1300 307 036

Bosch Technical Assistance Ph 1800 025 462

Clarion Ph 1300 730 730

Fax 03 9551 0377

Customer Assistance Ph 1800 033 349

Dana Ph 02 9892 9237

Ph 02 9892 9343

Fax 02 9892 9310

www.spiceraxle.com.au

HBD DVD support (Delphi) Ph 03 8558 8313

Eurovox Ph 03 9237 0800

Fujitsu Ten Ph 03 9646 6008

Holden Assist Ph 1300 880 088

Hollandia/Webasto sunroof Ph 02 9540 4811

Fax 02 9540 4316

HSV Ph 03 9265 9500

Impco Ph 03 9584 5644

Infomedia (SIP, Partfinder) Ph 1800 810 103

Lumen Ph 03 8787 1000

Panasonic Ph 02 9986 7635

PBR Diagnostic assistance Ph 1800 468 727

Petro-Ject Ph 02 9890 5701

Ph 02 9890 5244

Philips/Siemens-VDO Ph 1800 335 282

Salmat Ph 03 9358 2900

Security Information Ph 03 9647 2001

Fax 03 9647 2865

SPX Australia Ph 03 9544 6222

TAS Ph 1800 033 417

Fax 03 9647 2495

Email [email protected]

Triple M Ph 1800 773 030

Warranty Ph 1800 033 487

HOLDEN SERVICE TECHLINES______________________________________________________________________________MARCH, 2006

15

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

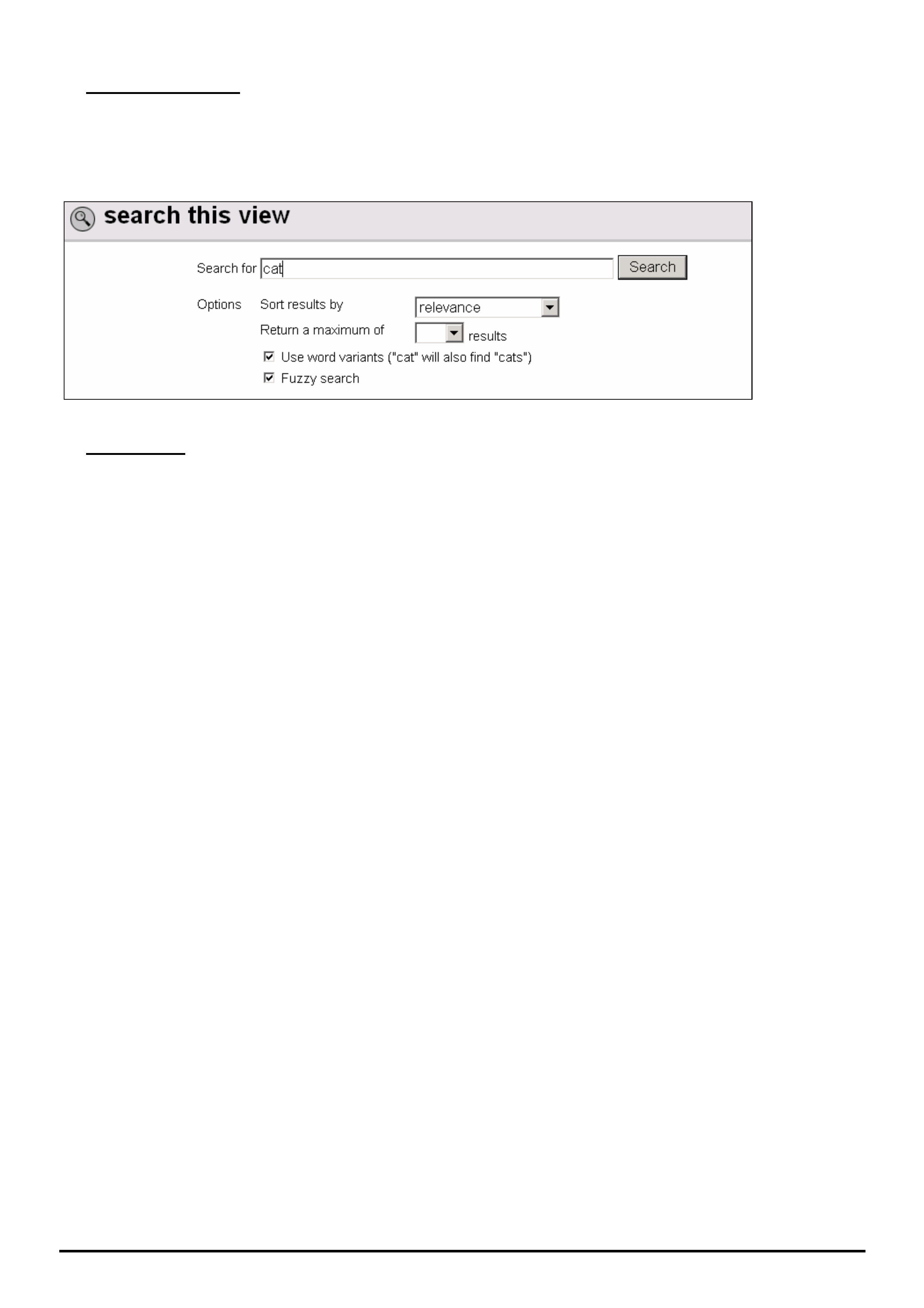

DIAGNOSIS HINT

HVAC Temperature Control Not Working – Air

Mix Cable Incorrectly Installed

RA Rodeo

(GROUP 2) TL0587A-0602

This Techline is REPEATED (from Issue 11/2003) as this

problem is still being reported from the field.

PROBLEM DESCRIPTION

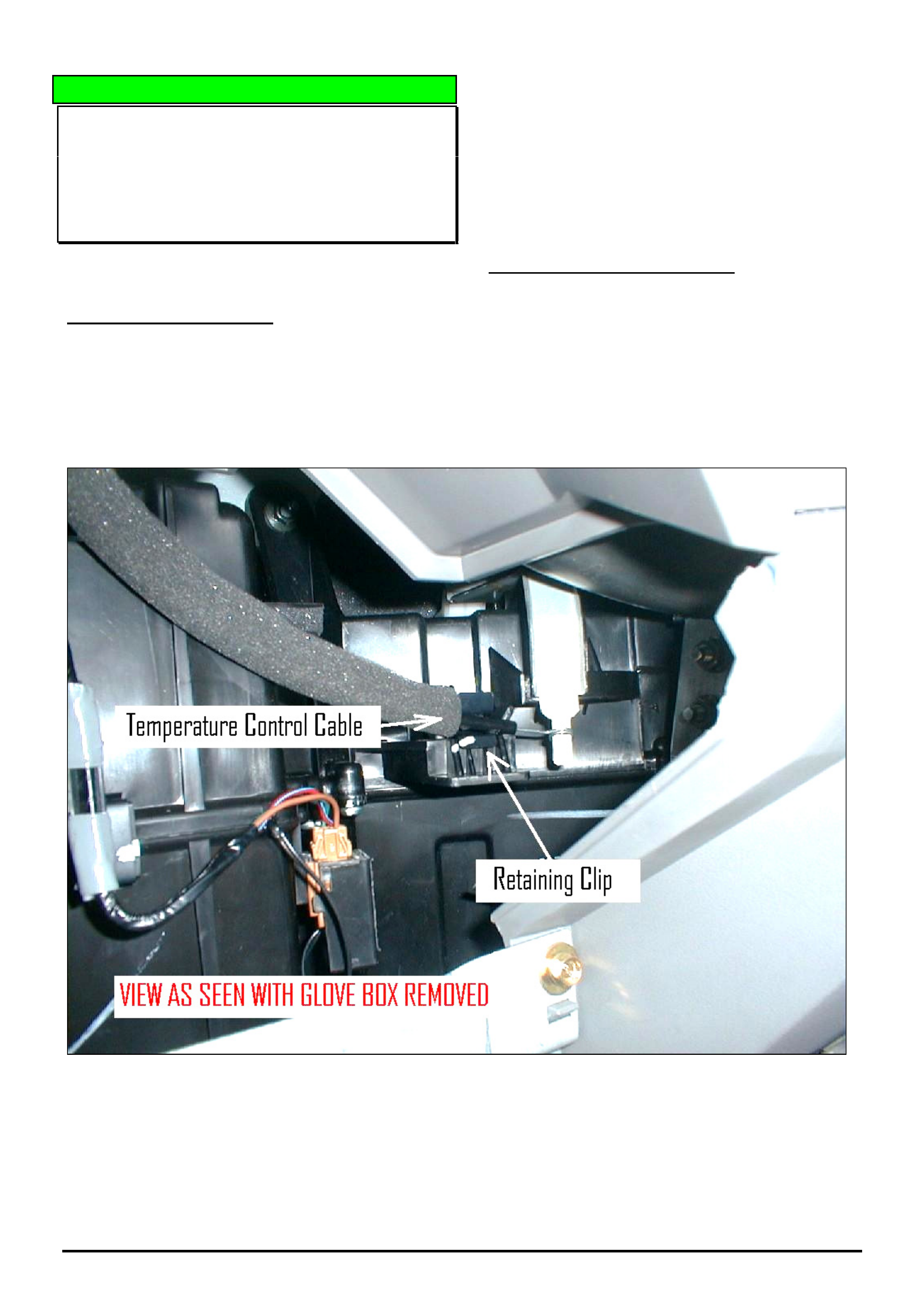

There have been reports of the HVAC temperature

control (air mix dial) not working.

Investigation of complaint vehicles shows this problem

is due to the air mix cable not being held in the

retaining clip. This results in the outer cable moving,

which in turn causes the inner cable to dislodge from

the air mix door control lever.

In most cases, the cause of the above problem is the

cables have not been placed correctly into the

retaining clips when air conditioning has been originally

fitted to the vehicle.

SERVICE RECOMMENDATION

When installing air conditioning (or re-installing the

cable for any reason) it is important to pay special

attention to the correct installation of the air mix cable.

After installing the cable in the retaining clip, ensure

the full range of hot/cold adjustment can be achieved

with the control dial.

Figure 1. Shows Temperature control cable correctly retained in clip on side of HVAC case.

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

6

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

DIAGNOSIS HINT

TECH 2 Usage

RA RODEO – HFV6

(GROUP OB) TL1100-0603

Some technicians are encountering a problem when

using Tech 2 on the above model where it keeps

returning to the base menu’s when this is not

commanded.

When navigating the menu’s on Tech 2, it is vital that

the “CONFIRM” “softkey” is used when Tech 2

prompts this input.

DO NOT use the “ENTER” key instead of the

“CONFIRM” key.

SERVICE FIX

SRS Light On DTC B0022 or B0016 Squib

Circuit Low Resistance

RA Rodeo

Group 12 Ref. No. TL1060 - 0603

CONDITION

Customers may advise the SRS (air bag) light

illuminates.

When Tech 2 is connected, DTC B0022 Drivers Squib

Circuit Low Resistance and/or B0016 Passengers

Squib Circuit Low Resistance codes set in the airbag

module.

CAUSE

This condition may be caused by a poorly formed SDM

connector causing the shorting pins not to disengage.

CORRECTION – Production

A revised SDM has been fitted in production from the

following breakpoint

ISOVIN: Built Date:

MPATFR77H6H525256 29/11/05

CORRECTION – Service

1. Confirm the above DTC’s are set (as ether current

or history).

2. Perform a visual inspection of the SRS harness to

ensure no obvious circuit damage.

3. Replace the SDM with the revised part as per the

standard LCV SIP procedure.

4. Using Tech 2, clear DTC’s in the SDM.

PARTS INFORMATION

Part No.: Description Qty:

8980326260 Revised SDM 1

WARRANTY CLAIM INFORMATION

.

Use Labour Times information in Warranty Information

section of current LCV SIP CD

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

10

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

Searching for Service Information on Holden Dealer Portal - “Lionheart”

(GROUP OB) TL0921A-0603

( This Techline supercedes the previous one in Issue 5, June 2005. It is UPDATED with the latest procedure. )

This Techline describes how to find the following Service Information on the Holden Dealer Portal - “Lionheart”.

• Service Techlines

• All Dealer Letters

• Campaign Bulletins

• Field reworks

• Warranty Processing

• Special Warranty Component Replacements

• Service Forms.

PROCEDURE.

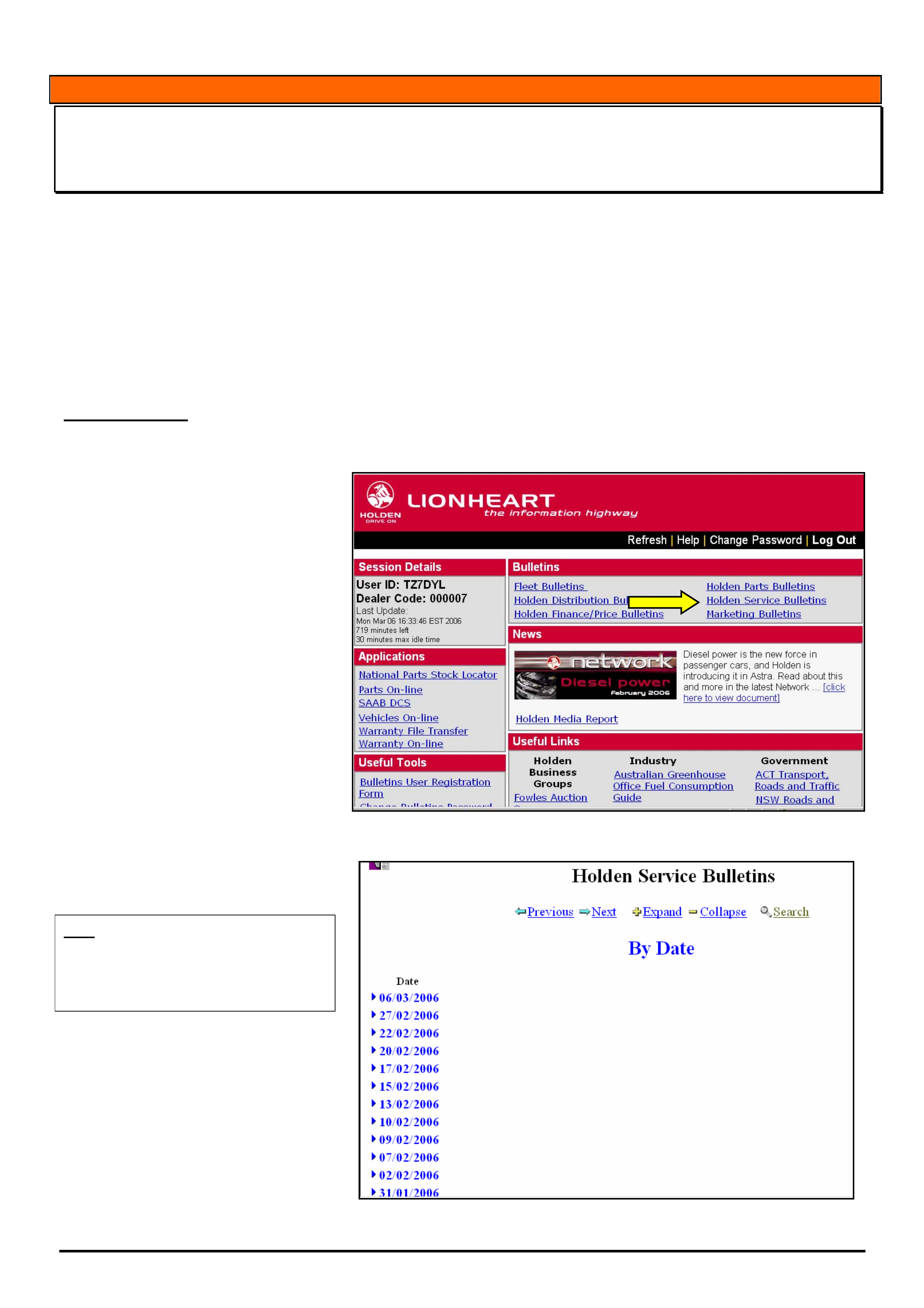

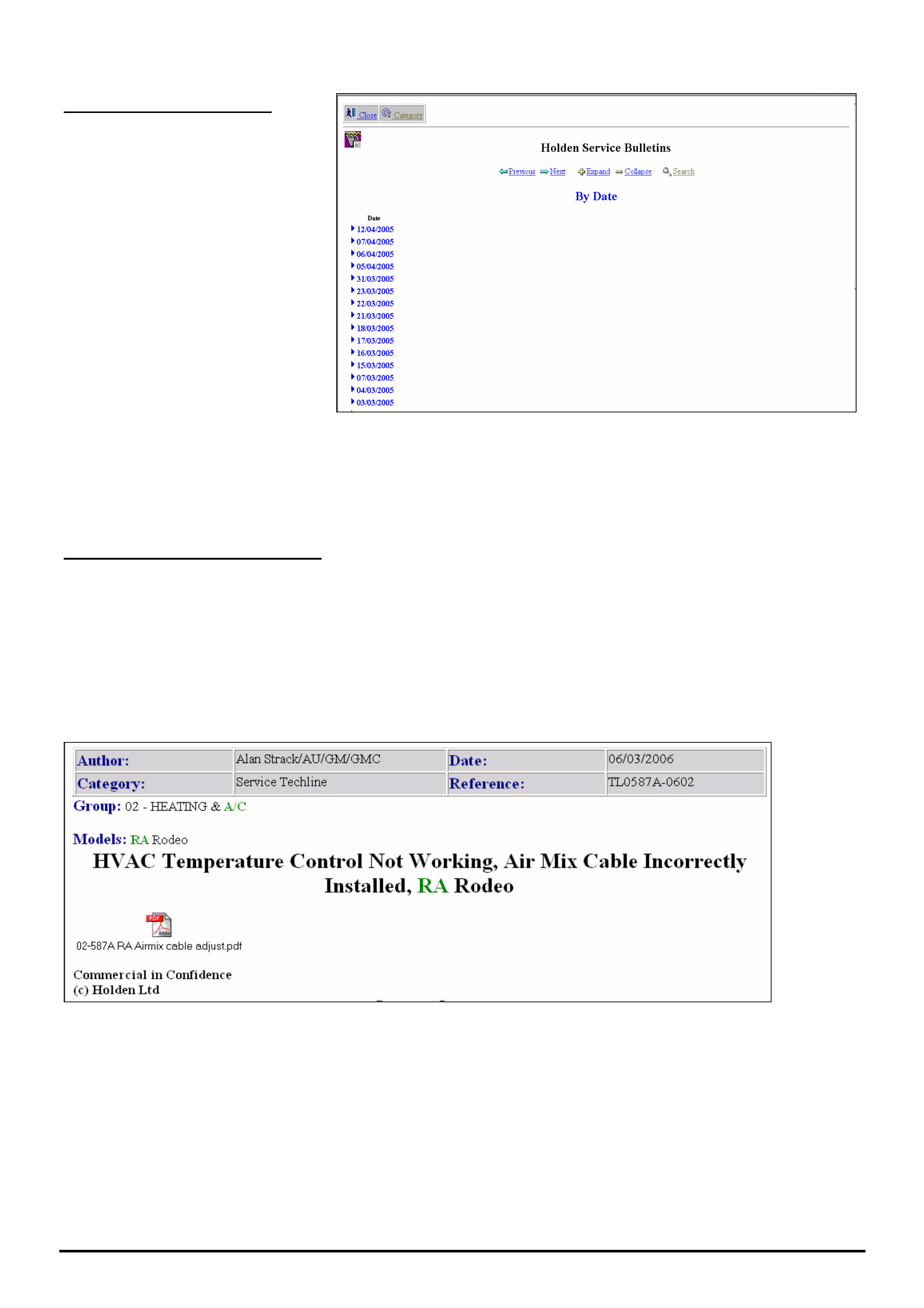

When you logon to the Holden Portal the Lionheart Home page will appear as shown in Figure 1.

Now select “Holden Service Bulletins”

as indicated by yellow arrow.

.

Figure 1

The next screen to appear is shown in

Figure 2.

HINT: This screen should be thought of as

an email inbox.

You should check this screen everyday to

view the latest information issued by

Holden Service Department.

The date at the top of the list is when

the newest bulletins were posted onto

Lionheart. In the example in Figure 2

this date is 06/03/2006.

Figure 2.

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

11

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

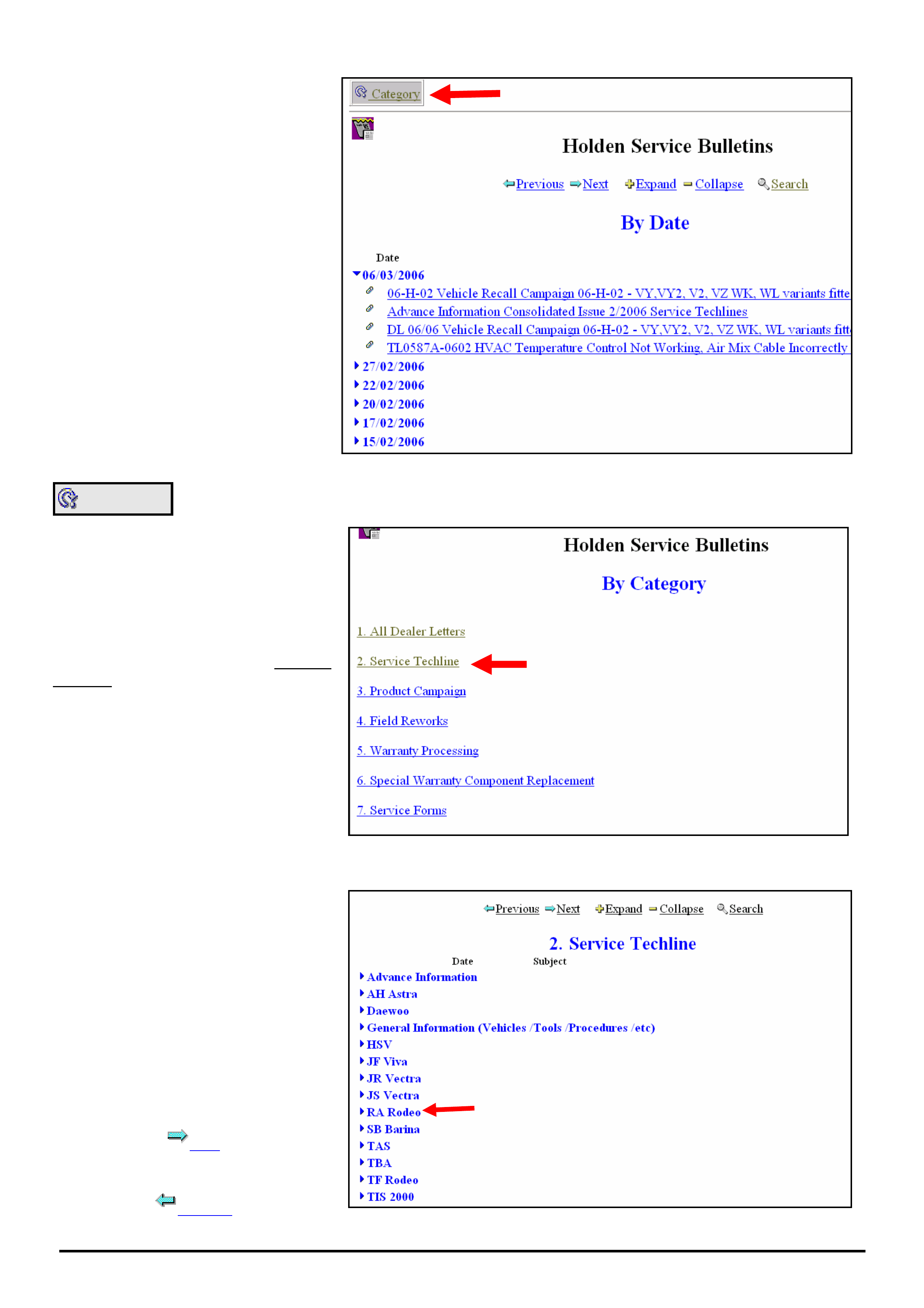

To view the bulletins for the 06/03/2006,

click on the “►” symbol next to the date

and a list of bulletins will appear as

shown in Figure 3.

To view any bulletin click on it.

Figure 3.

Category

If you select the “Category” button as

indicated by the red arrow in Figure 3

the screen shown in Figure 4 will

appear.

Now select the category you want.

As an example, select “Service

Techline”

The next screen to appear is shown in

Figure 5.

Figure 4

From this screen you select the model

you are interested in.

For example, click on the “►” next to

RA Rodeo

The next screen to appear is shown in

Figure 6.

NOTE: To view the full list of models

you will need to turn over to the next

page by clicking on the “next” arrow at

the top or bottom of the screen

Next

To go back a screen, press “previous”

Previous

Figure 5

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

12

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

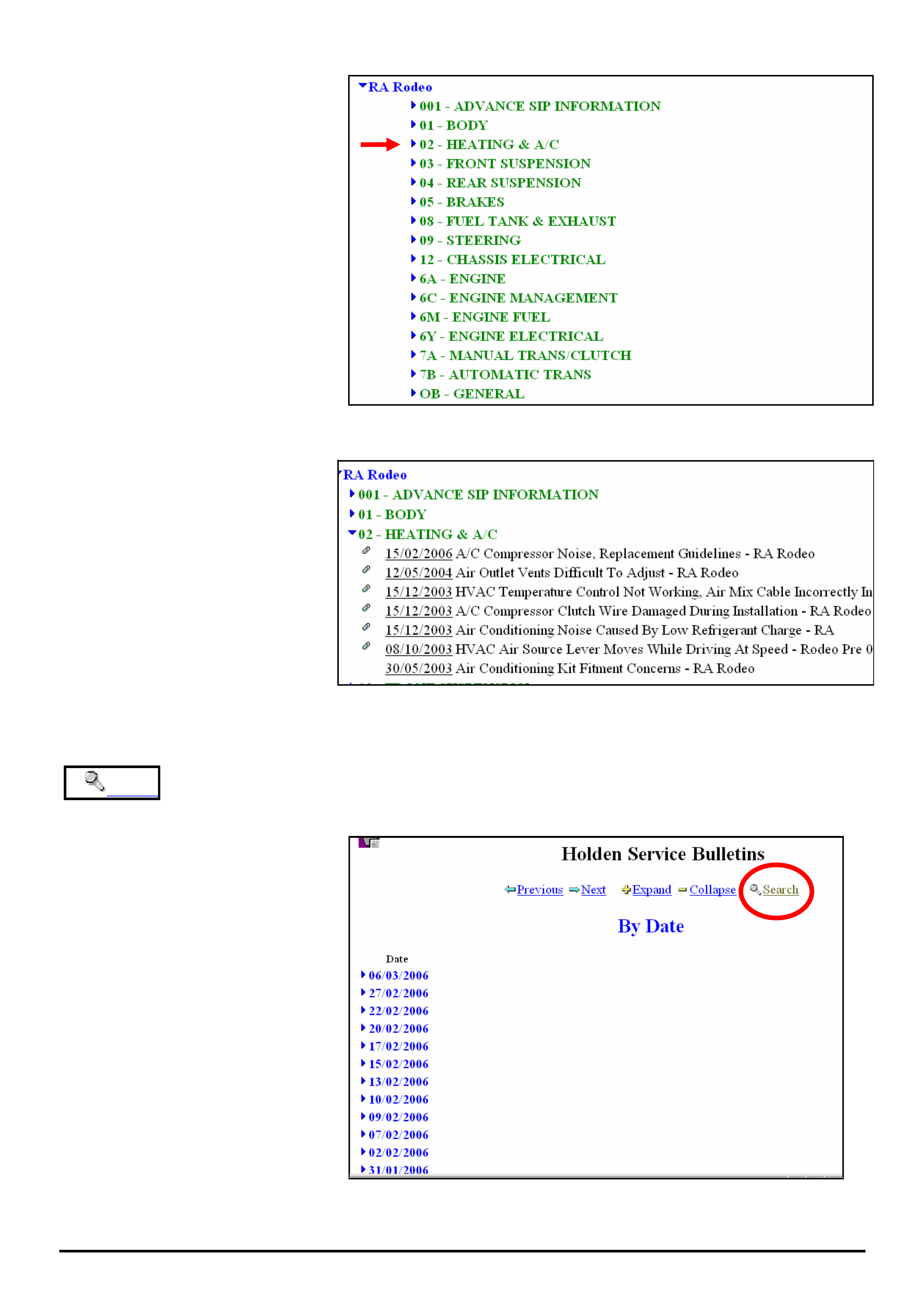

Now select the Group you are interested

in.

Example - select 02-HEATING & A/C

The next screen to appear is shown in

Figure 7.

Figure 6.

Now look through the list of Techlines

to find the one you are interested in.

NOTE: Techlines are arranged in

order of date with the newest at top of

list.

Figure 7.

Search USING THE SEARCH METHOD TO FIND INFORMATION ON LIONHEART

If you select the SEARCH function

from the screen in Figure 8 it will

search through all the Service

Information Categories as follows:

• Service Techlines

• All Dealer Letters

• Campaign Bulletins

• Field reworks

• Warranty Processing

• Special Warranty Component

Replacements

• Service Forms.

To shorten the search process, select

the SEARCH function only after you

are in the particular category you are

interested in.

Following, is a description of how to

search for Service Techlines.

Figure 8

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

13

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

Searching for Service Techlines

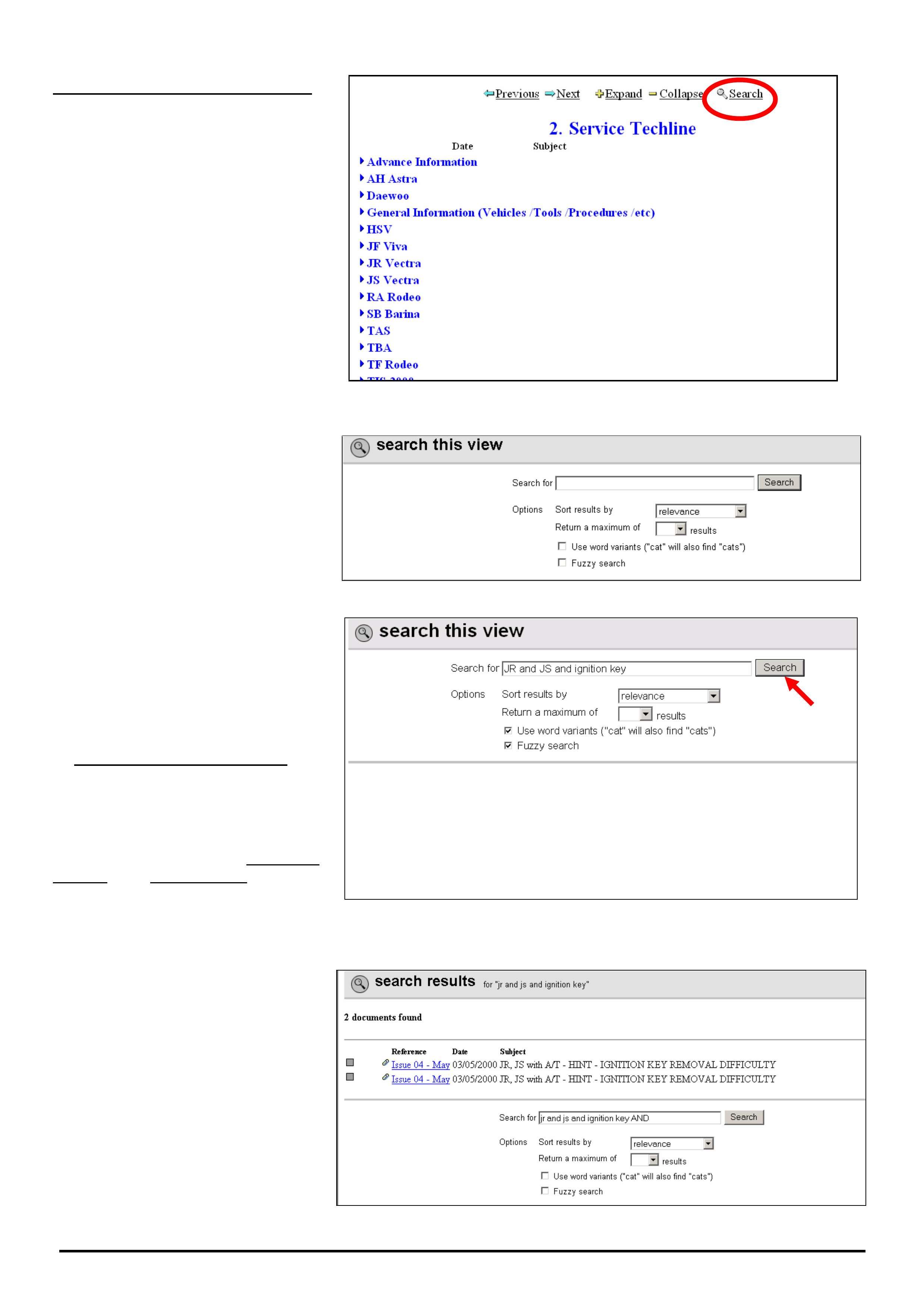

From the screen shown in Figure 9

click on the “Search” key. This will

bring up the screen shown in Figure

10.

Figure 9

This is the search screen used for

entering “keywords” to search for.

It is important to enter the right words

here in order to find what your looking

for.

Figure 10

As an example (Figure 11) try

searching for Techlines related to JR

& JS Vectra Ignition Barrel

Jamming.

In the top window, type in the following

“search string” exactly as shown.

“JR and JS and Ignition key”.

Don’t touch the next 2 boxes titled

“Sort results by” or,

“Return a maximum of”.

Tick the last 2 boxes i.e. Use Word

variants and Fuzzy search. Refer to

later explanations of these terms.

Now click the “Search” button. Shown

with the red arrow.

Figure 11

The search result is 2 documents as

shown in Figure 12.

Click on the hot-key section (in blue)

to view the techlines.

Figure 12.

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

14

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

Notes on choosing “Keywords”

for searching

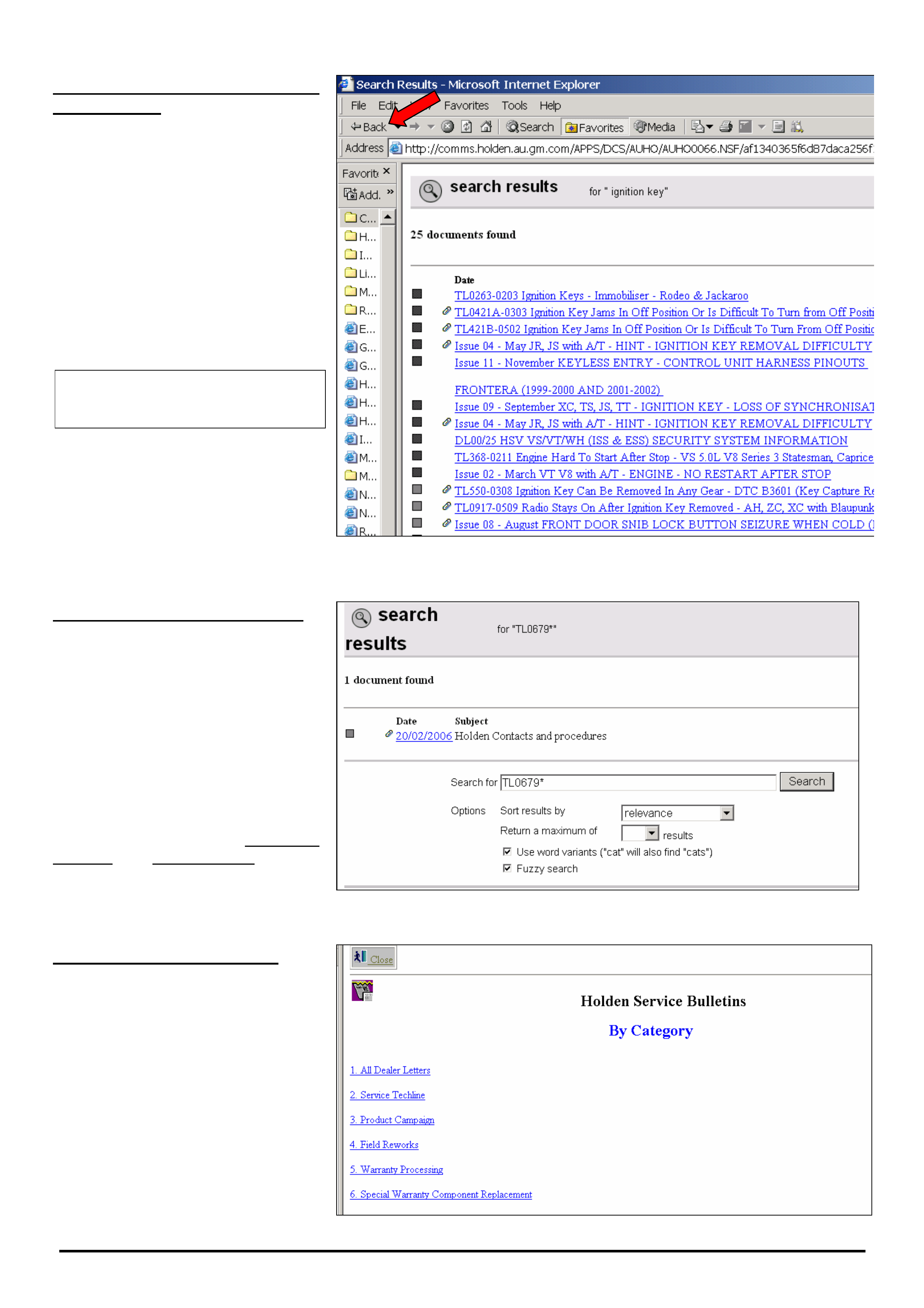

If we had only entered “ignition key”

without any model descriptor, this

would have located 25 items as shown

in Figure 13.

If we had only entered “ignition”, the

search would have located 86 items.

This demonstrates the importance of

selecting the right “keywords” to

search with so you don’t end up with

large numbers of items to read

through.

Rule of thumb: - The less

information in the “search window”

the more information comes back.

HINT: If at anytime you wish to go

back to the “Search” function press

the “Back” arrow in the top left side of

the toolbar. Refer red arrow in Figure

13.

Figure 13.

Searching by Techline Number

Use this procedure if you have an

existing techline and you want to

check to see if there is a later version

on Lionheart.

Example. - Search for the latest issue

of techline TL0679.

Type “TL0679*” in the search window

as shown in Figure 14.

Tick the last 2 boxes - “Use Word

variants” and “Fuzzy search”.

The latest version found will be

TL0679B-0602.

Figure 14

Searching Other Categories

The search procedure described

above for Service Techlines may also

be used for Dealer Letters, Campaign

Bulletin, Field rework, Warranty

Bulletin, etc. You must first select the

category you want from the Category

screen (Figure 15) before proceeding

with search.

Use the same procedure as that

described for a Service Techline.

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

15

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

Figure 15.

Doing a “General” search.

To find ALL published information on

a particular subject, select “Search”

from screen shown in Figure16.

As an example, enter “Daewoo” in

the search field

This “search” will give you everything

that contains the word “Daewoo” .eg.

Dealer letters, Techlines, Recalls,

Warranty etc.

Figure 16

General Notes On Searching.

• If you perform a search and the results are not what you were looking for; to conduct another search, you will need

to hit the “← Back” arrow as shown in Figure 13. This will bring up the “active” search window. Delete the current

search keywords then enter some new keywords and press “search” again.

• The search engine cannot search any “attached” files for keywords. For example, in Figure 17, the search engine

will search through every word that actually appears on the screen as shown. It cannot search through the

attached file, viz “02-587A RA Airmix cable adjust.pdf”.

Figure 17

HOLDEN SERVICE TECHLINES________________________________________________________________________________APRIL, 2006

16

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

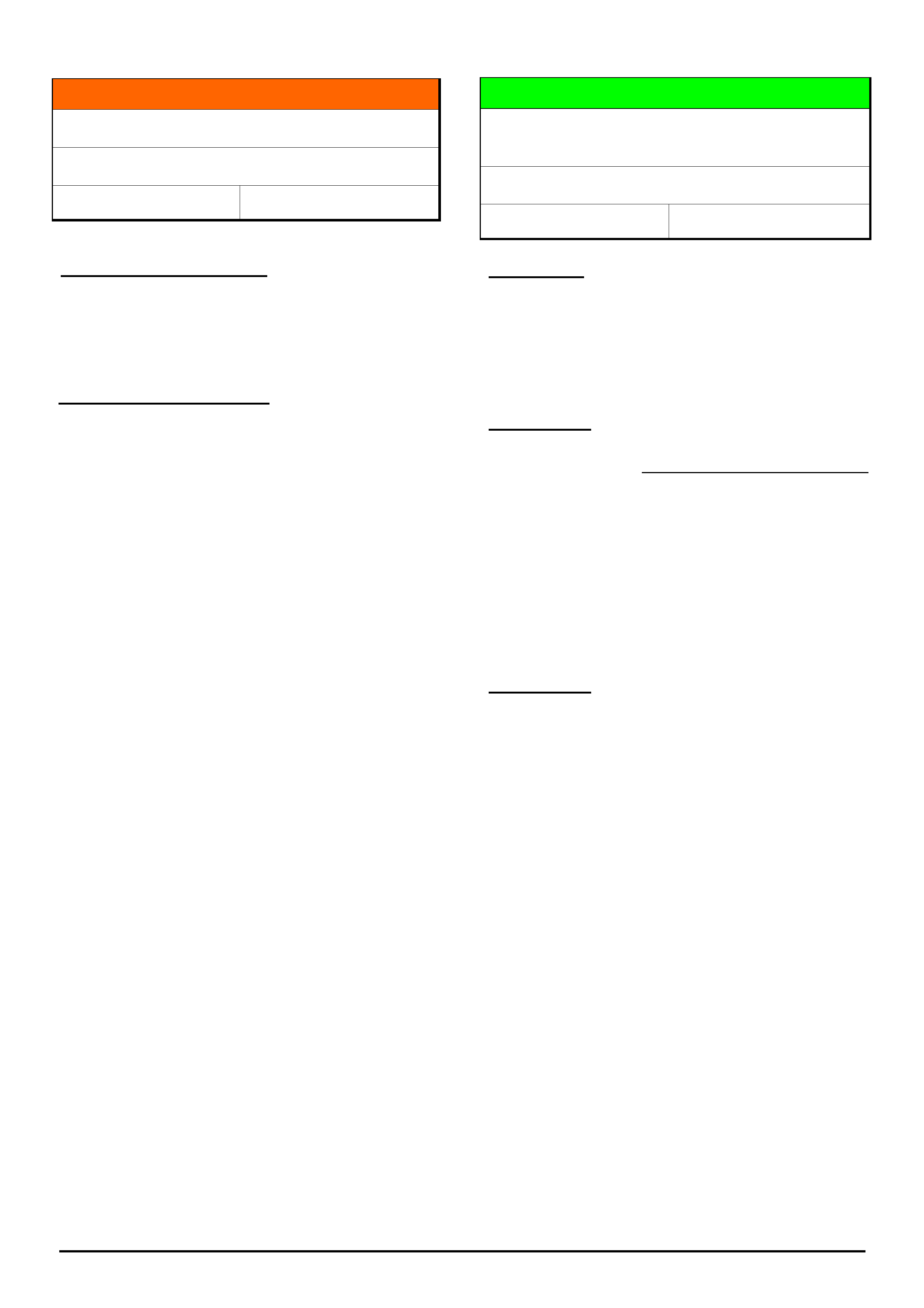

• “Use Word Variants”

If you tick this box in the search panel (refer Figure 18) and type in “cat” in the “Search For” window, the search

engine will find every word that has cat in it, eg. catalytic, category, cats, etc. This is useful if you cannot remember

the exact spelling of a word or you forget the “s” when the word is plural.

Figure 18.

• Fuzzy Search

EXAMPLE 1. - Search for techlines with DTC P0335 in the Subject title.

If you accidentally type in DTCP0335 without a space between C and P, and do a Fuzzy search, the search engine

will still bring up all techlines containing “DTC P0355”.

EXAMPLE 2. - Search for techlines containing 4JX1 in the subject title.

If you type in 4JX, a fuzzy search will still find all techlines with 4JX1 in the title.

NOTE: this feature doesn’t work if you forget to enter the first letter. In this example, doing a Fuzzy search on JX1 will

not find anything.

HOLDEN SERVICE TECHLINES_________________________________________________________________________________MAY, 2006

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

DTC P0532 Set After Fitting A/C

RA Rodeo with HFV6

Group 2 Ref. No. TL1111 - 0604

PROBLEM DESCRIPTION

DTC P0532 (Air Conditioner Pressure Low) is logged

in the ECM as either a Present or Not Present DTC

after fitting Air Conditioning.

SERVICE RECTIFICATION

Ensure that a DTC check is carried out after fitting,

servicing, or charging the Air Conditioning system.

It is quite normal for the DTC to log while the Air

Conditioner is being “charged”.

Once the DTC is “cleared” with Tech 2, any further

occurrence of the DTC needs to be addressed in the

normal manner. Refer to LCRV SIP and Strategy

based diagnostics.

DIAGNOSIS HINT

Check Engine Light On, DTC P1520 (B)

Neutral Switch Off Error

RA Rodeo 4JH1 diesel & M/T

Group 6C Ref. No. TL1122 - 0604

CONDITION

Check Engine Light (CEL) is illuminated and Tech 2

shows DTC P1520 B logged.

On any vehicle with the above symptoms, the following

procedure is recommended.

Check No.1.

Using Tech 2, select Engine Data Display / Neutral

switch. Ensure the neutral switch data parameter

changes state from Off to On when changing gear.

• If the data parameter does not change state, follow

the diagnostic flow charts associated with DTC

P1520 (A) or P1520 (B) as per LCV SIP to perform

wiring checks.

• If the data parameter does change state as the

gears are changed - proceed to check 2.

Check No. 2

Using Tech 2, select Engine Data display / Vehicle

speed. While driving vehicle, ensure Tech 2 is

showing vehicle speed.

If there is no vehicle speed showing in Tech 2, use the

Diagnostic flow charts associated with DTC P0500 in

LCV SIP to perform the wiring checks for the speed

sensor circuit.

Do Not swap ECU or replace any parts if the wiring

checks fail to locate the problem. Contact TAS for

further assistance.

HOLDEN SERVICE TECHLINES_________________________________________________________________________________MAY, 2006

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

SERVICE PROCEDURE

Inspection/Cleaning of Radiator and A/C

Condensor at Maintenance Services

RA Rodeo

Group 6K Ref. No. TL1105 - 0604

As part of routine servicing, the radiator and A/C

condenser must be inspected every 20,000km to

ensure air flow is not restricted.

Vehicles that operate under specific conditions or

within specific regions may be more prone to radiator

and A/C condenser blockage.

When a vehicle or region has a history of radiator and

A/C condenser blockage due to excessive mud or

grass etc, it is good work practice to check for this

condition at every service.

This service requirement is essential to ensure that

engine operating temperatures (both coolant and

engine oil) are maintained within safe operating limits.

This is most critical on turbo charged diesel engines.

Vehicles that do not have the radiator/condenser and

air cleaner maintained during service can suffer from

reduced engine performance and longevity.

When debris is removed from the condenser/radiator

core, advise the customer of the type of material found

so that exposure to this material can be minimised or

avoided. The customer should also be reminded to

clean the insect screen regularly to ensure proper air

flow.

Note 1: Vehicles that have grass seeds blocking the

condenser and radiator air flow could possibly have

grass seeds blocking the air filter. The air filter must

also be cleaned or replaced as per the service

schedule (extreme operating condition schedule must

be followed when required. Refer owners handbook).

Note 2: Inspection of the radiator and A/C condenser

is part of the standard service schedule. However, any

work performed to clear the components is an

additional retail cost.

SERVICE PROCEDURE

HFV6 Timing Cover Removal

RA Rodeo

Group 6A Ref. No. TL1110 - 0604

When performing any work on a HFV6 engine that

requires removal of the front timing cover, technicians

must ensure that they are following the procedure

outlined in SIP.

Particular attention needs to be paid to draining the

coolant prior to removal of the timing cover.

Failure to do this may result in coolant entering the oil

pan and contaminating the oil. This may lead to

incorrect diagnosis of a perceived engine problem (e.g.

head gasket) or damage to the engine.

Refer to Passenger Vehicle SIP section 6A1 for the

correct procedure.

HOLDEN SERVICE TECHLINES_________________________________________________________________________________JUNE, 2006

8

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

DIAGNOSIS HINT

Preliminary Checks for Complaint of Low

Power

RA Rodeo with 4JH1 diesel engine

Group 6C Ref. No. TL1056A-0605

This Techline supercedes the previous one (TL1056-1105) in

Issue 11, Dec 2005. It is UPDATED by clarifying/expanding

some of the check items. Please destroy all copies of the

old techline.

If an owner has concerns of low power output from

their vehicle, validate the customer concern and

determine if the vehicle is, or isn’t operating normally.

If the vehicle is low on power, and before calling TAS,

do strategy based diagnosis with particular emphasis

on the following items .

• Air intake system. - Check for partial restriction.

Check air element and Pre-cleaner if fitted and all

ducting. NOTE - The intercooler is part of the air

intake and should be checked for restrictions.

Earth points. – Check: C-2, C-36, C-109, P-6 and

E-10. Refer to earth circuit wiring diagrams in SIP

for locations. Perform voltage drop measurements

across each earth circuit to battery negative post at

all 5 earth points. (Less than 0.2 Volt is required)

• Fuel supply. - Check fuel filter and gauze strainer in

Banjo Bolt (inlet hose of Injector Pump), Water trap.

Fit clear plastic hose to injector pump inlet and

check for air in the fuel (a very small amount of air is

acceptable)

• Fuel Quality. – Ensure that only good quality diesel

fuel is being used.

• Throttle Position Sensor (TPS) adjustment.

Adjust as per LCV SIP instructions. NOTE: this

adjustment is critical to correct engine operation.

Incorrectly adjusted TPS can cause the MAF

reading to be significantly lower than the desired

value as shown on TECH 2 with engine speeds

above idle.

• Mass Air Flow Meter readings on TECH 2.

The M.A.F. should read very close to the desired

value shown on Tech 2. If the reading is approx. ½

of the desired reading this could indicate a partially

restricted exhaust system such as catalytic

convertor or muffler or pipe. Refer to previously

published Techline on MAF contamination. (issue 3,

2004 group 6C)

• EVRV. Refer Techline in issue 3, 2004 group 6C.

• EGR Valve.

The EGR valve may be mechanically “stuck” open.

Ensure that the EGR is fully closed by inspecting the

“seating” area of the valve. NOTE: The EGR will

need to be removed to perform this inspection.

For diagnostic purposes only, it is permissible to

temporarily blank off the EGR valve between the

inlet manifold and EGR valve with a blanking plate.

• Valve clearances should be set to the specifications

in LCV SIP. NOTE: Engine must have been

allowed to “stand” for at least 5-6 hours PRIOR to

setting valve clearances. This is to allow the engine

sufficient time to adequately cool down.

• Engine condition. Eg. Compression Test.

• Injector Pump Internal fault (TAS case required).

HOLDEN SERVICE TECHLINES_________________________________________________________________________________JUNE, 2006

10

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

SERVICE FIX

Electrolyte Leak From Battery Caps

RA Rodeo

Group 12 Ref. No. TL1104 - 0605

CONDITION

Evidence of a slight electrolyte leak from around the

vehicle battery caps.

Dealer finds the charge rate is normal and there is no

sign of battery cells being overfilled.

CAUSE

Design of battery caps.

CORRECTION – Vehicles in Production

Revised battery caps are scheduled to be fitted to

vehicles in mid June 2006. Breakpoint to be advised.

ISOVIN: Built Date:

TBA TBA

CORRECTION – Vehicles in Service

1. After verifying that vehicle has condition as

described above, replace all six caps with new

style caps. Refer parts information below.

2. When replacing caps, special care must be taken

to clean the sealing surface to ensure a good seal.

The top of the battery and any other affected areas

should be cleaned to remove any trace of

electrolyte or foreign material.

3. Do not overtighten new caps as this may damage

the seal and thread. A suggested method of

tightening is to turn cap by hand very lightly until

the cap stops rotating (i.e. seal is seated) Then

tighten cap a further 45 degrees.

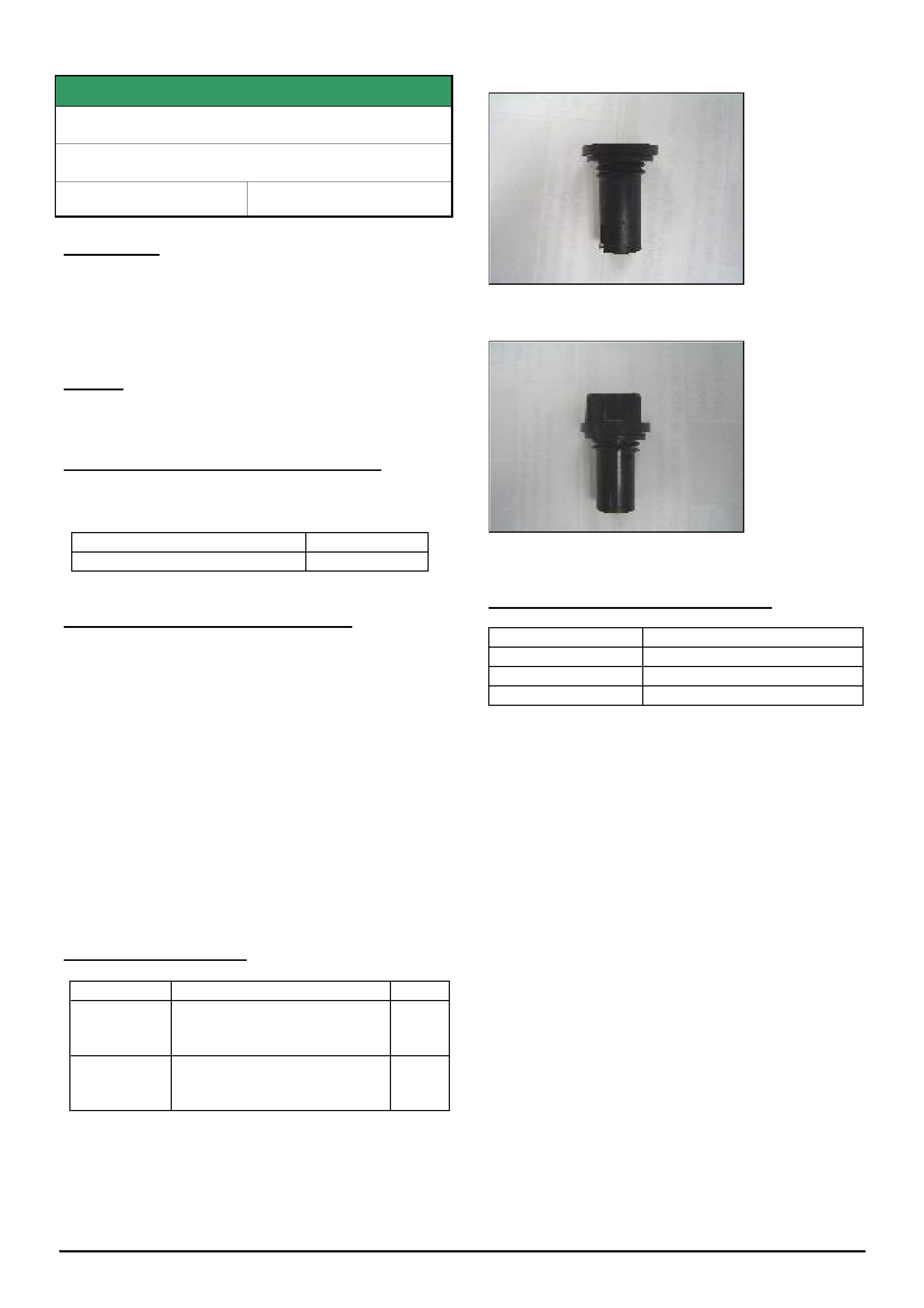

PARTS INFORMATION

Part No.: Description Qty:

898043986

0

Battery cap

C24SE

6

898043987

0

Battery cap

HFV6, 6VE1, 4JH1TC

6

Old style cap

New style cap

WARRANTY CLAIM INFORMATION

Description Replace battery caps

Labour Op. No. N000502

Time 0.2 hr

Failure Code N0042 Leaks

HOLDEN SERVICE TECHLINES_________________________________________________________________________________JUNE, 2006

14

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

INFORMATION

Diesel Engine RPM Control

TF Rodeo, RA Rodeo, UBS Jackaroo

(GROUP 6C) TL1134 - 0605

Background

Some dealer technicians have difficulty diagnosing

diesel engine problems due to an inadequate

understanding of how these engines increase/decrease

RPM.

Following is a very brief explanation of how the speed

of a diesel engine is controlled in the above models.

A Brief Explanation of Diesel Engine Speed Control

Unlike a petrol fuelled engine, a diesel engine DOES

NOT use the throttle butterfly as a means to control

engine speed.

In a diesel, engine speed is controlled by the amount of

fuel injected into the combustion chamber.

In a diesel, air to support combustion is supplied on

demand and in whatever quantity is required. The air

supply is not controlled as it is in a petrol engine.

In early models the accelerator pedal is connected

mechanically to the injector pump by linkages or a

cable.

Examples are: TF Rodeo, Jackaroo 4JG2 engine and

Suburban.

In later models (e.g. RA Rodeo 4JH1 engine) the

accelerator pedal is “connected” to the injector pump

(where fitted) by an electrical circuit. A Throttle

Position Sensor (TPS) located on the end of the throttle

shaft, provides accelerator pedal position and rate of

change to the ECM.

Depressing the accelerator pedal causes the injector

pump (where fitted) to increase the amount of fuel

delivered to the injectors at a pre-determined pressure

and the injectors then deliver the fuel to the engine for

combustion.

In the Hydraulic Electronic Unit Injector (HEUI) system,

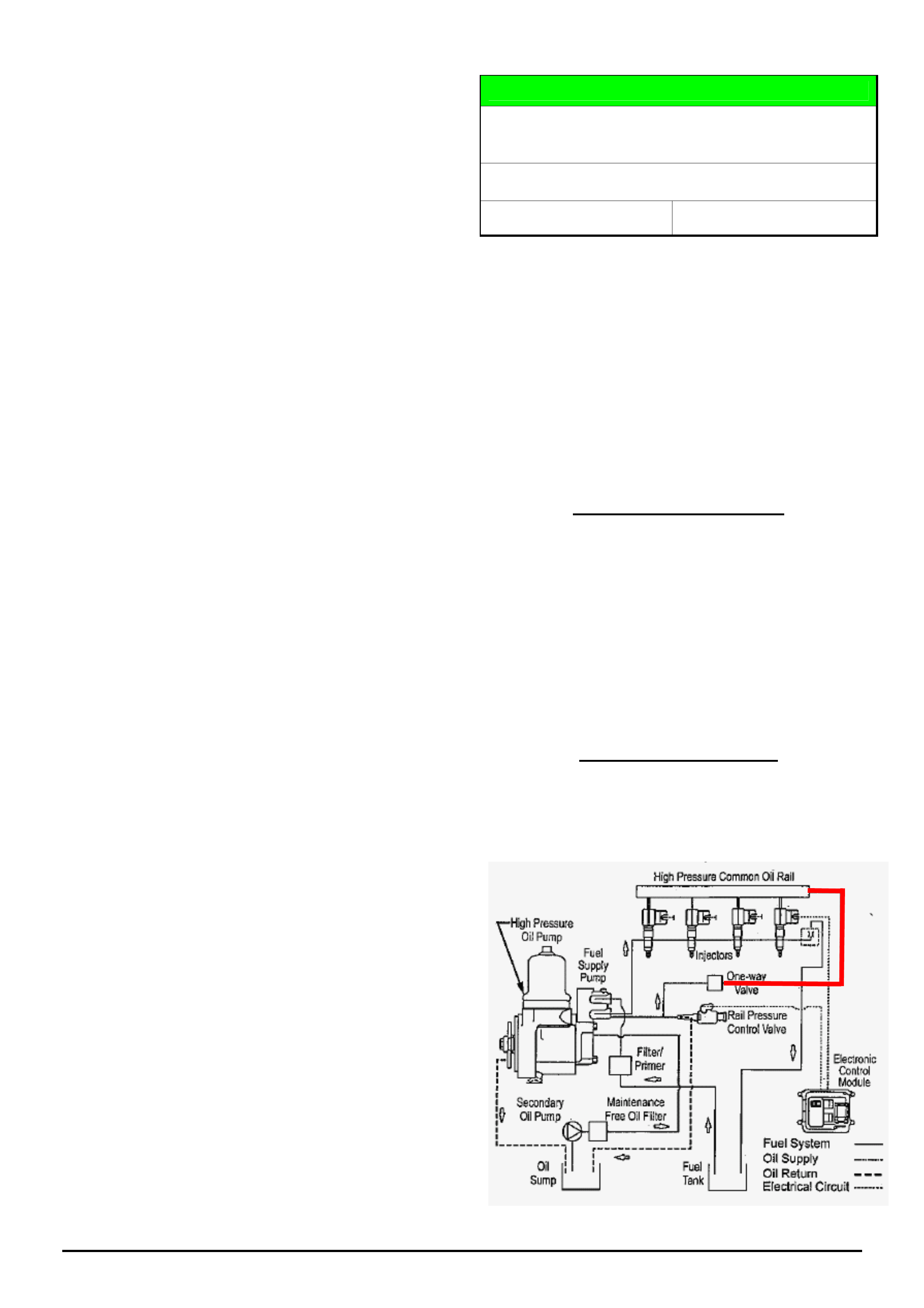

such as 4JX1-TC engine in Jackaroo, there is no

injector pump to deliver the fuel. Basically this is

achieved by a system where high pressure engine oil

and electronic control (via ECM) are combined to

control the injection of fuel for each cylinder over the

entire engine operating range.

What is the purpose of the throttle butterfly on

current diesel engines?

As already stated, a diesel engine DOES NOT use the

throttle butterfly as a means to increase and decrease

engine rpm.

The throttle butterfly on current diesel engines is mainly

there for EGR purposes.

On older diesel engines (pre EGR controls) there was

no throttle butterfly fitted. For example: 4JB1-TC and

4JH1-TC engines in TF Rodeo.

Suggested Reading.

For further information related to the content of this

techline refer to previous Technicians Guild articles

such as:

2000/Issue 6 – 4JX1-TC engine in Jackaroo

2002/Issue 2 – 4JH1-TC in 2002 TF Rodeo

2003/Issue 1 – 4JX1-TC engine changes for Euro 3

2004/Issue 6 – Direct Injection Fuel System

HOLDEN SERVICE TECHLINES_________________________________________________________________________________JULY, 2006

7

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

DIAGNOSIS HINT

Unable To Select Low Range (4WD only) and

PRNDL Indicators Not Operating On Cluster

(2WD & 4WD)

RA Rodeo HFV6 Alloytec & A/T

Group 7C & 12 Ref. No. TL1144 - 0606

PROBLEM DESCRIPTION

4WD Model - Low range cannot be selected and

PRNDL Auto Shift Indicators not operating on the

instrument cluster.

2WD Model - PRNDL Auto Shift Indicators not

operating on the instrument cluster.

Problem happens after the PIM is reset and then linked

to ECM, or the PIM is replaced and linked after vehicle

repair.

SERVICE RECTIFICATION

Summary: Ensure PIM is programmed correctly

whenever it is replaced.

This is a reminder to technicians that whenever

replacing a PIM in a HFV6 Rodeo, the PIM must be

configured to the correct transmission type, otherwise

the 4WD Low range and the PRNDL indicators will not

operate. This is because during the PIM / ECU linking

process the transmission type has not been set so it

defaults to INVALID.

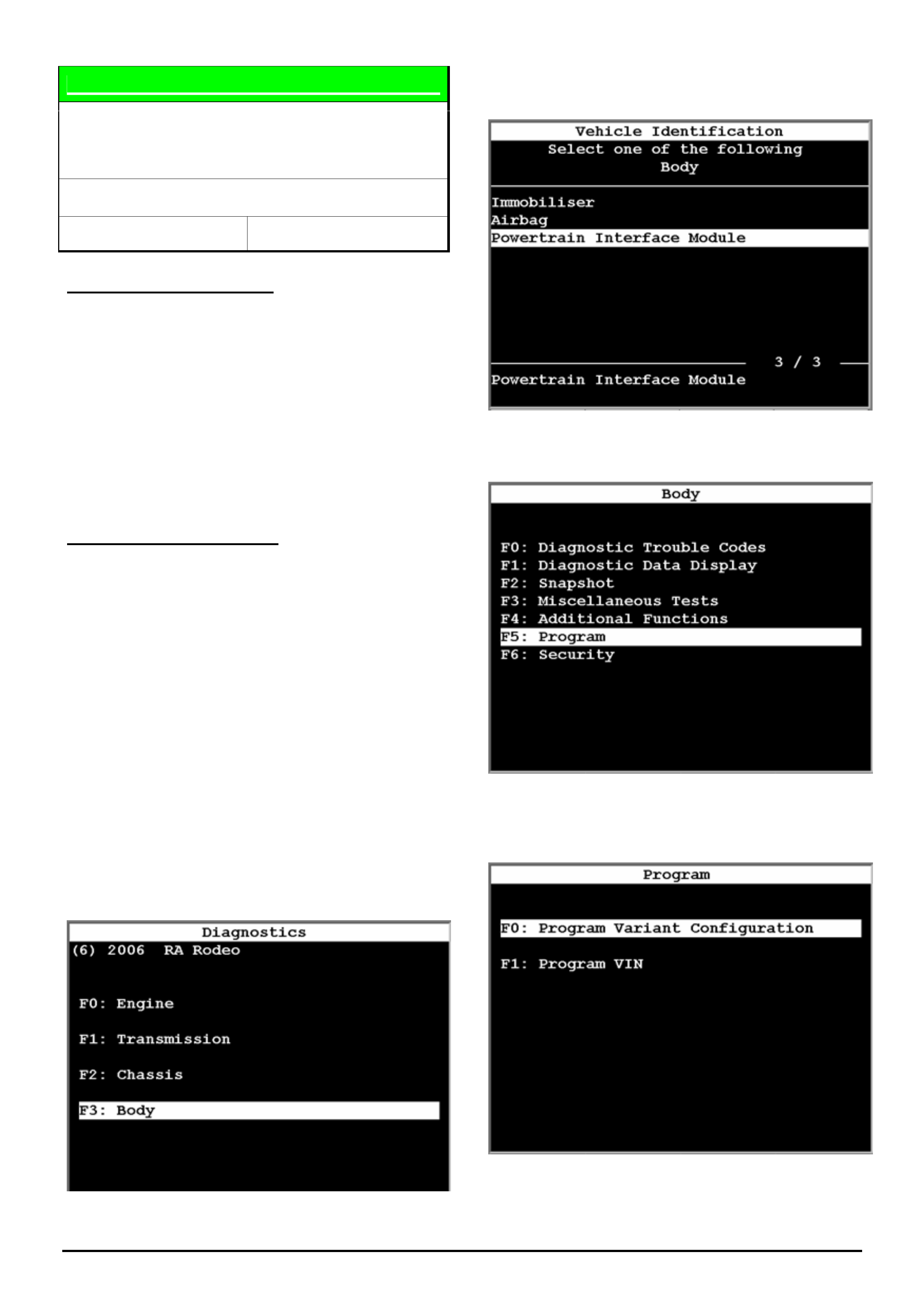

The procedure to re-configure the PIM

transmission type is shown below. This procedure

is also found in SIP Section 6E1 / 11.3 - PIM

Configuration

1 After selecting the vehicle type (RA Rodeo) and

model year, select the Body Option as shown

below.

2 Select the Powertrain Interface Module as

shown below.

3 Select the Program Option as shown below.

4 Select the Program Variant Configuration as

shown below.

HOLDEN SERVICE TECHLINES_________________________________________________________________________________JULY, 2006

8

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

5 The following screen will then show. Now press the

“Modify” soft key

6 Select the appropriate transmission type then

press confirm

7 The following screen will now show. Press the

“Program” soft key

8 The following screen will now show. This is the

end of the programming process. Clear all DTC and

confirm operation of 4WD Low range and the PRNDL

Indicator lights.

HOLDEN SERVICE TECHLINES_________________________________________________________________________________JULY, 2006

10

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

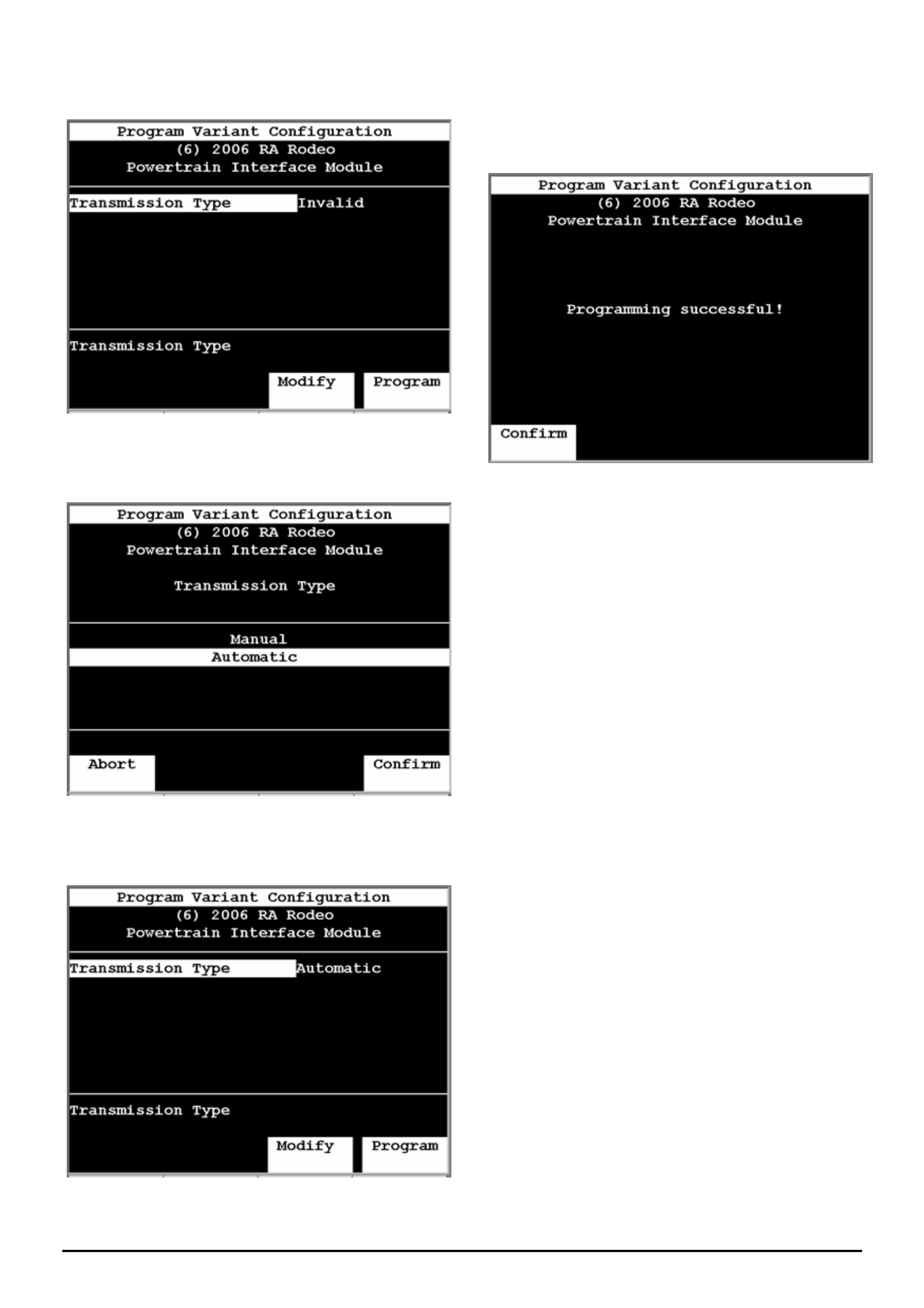

SERVICE PROCEDURE

Correct A/T Identification for SRTA Requests

VY, VZ, WL, V2, RA, VE, WM

Group 7B Ref. No. TL1148 - 0606

CONDITION

Incorrect SRTA exchange transmissions are being

received at Dealerships from SRTA.

CAUSE

Incorrect identification of transmission type requested

by Dealership personnel via incomplete/incorrect

information on SRTA TRANSMISSION ORDER FORM.

NOTE: Transmission serial numbers no longer carry

serial numbers that coincide with vehicle build date or

model year.

CORRECT PROCEDURE

(1). Vehicles with Original Equipment (OE)

Transmission:

The transmission serial number as read

off the transmission case must be

provided to SRTA to ensure that a correct

exchange transmission will be supplied.

The following diagram shows the location of the

transmission serial number – for recording on the

SRTA TRANSMISSION ORDER FORM:

(2). Vehicles fitted with a SRTA Transmission:

Transmission ID/Serial number location For

SRTA Transmissions ONLY

SRTA transmissions are identified by a GREEN plate

attached to the RH side of the transmission case with

the word “Hydramatic” at the top of the plate.

For Reference only: ACDelco® remanufactured

transmissions are identified by a BLUE plate attached to the

RH side of the transmission case with the word ACDelco at

the top of the plate.

Both of these plates “over-ride” the O.E. number

stamped on the trans. case, and include: Model

Identifier, Julian Date and Individual Transmission

Serial No. (as mentioned above).

This information MUST be used where a SRTA

transmission suffers a failure requiring replacement of

the unit. Warranty acceptance on such a unit is

defined by distance travelled, or date of fitting the unit

to date of failure (24 month/50000km parts warranty

applies).

NOTE: Both SRTA and ACDelco remanufactured

transmissions are painted silver and OE transmissions

are unpainted, plain cast alloy.

SRTA Action

SRTA will no longer supply exchange transmissions

based solely on either model or ISOVIN numbers

supplied on a SRTA TRANSMISSION ORDER FORM.

Forms supplied without serial numbers from the

transmission – as noted above - will not be honoured

and the Dealer will be requested to arrange for the

serial number – RECORDED FROM THE VEHICLE -

to be supplied.

To avoid customer inconvenience, ensure

that the transmission serial number is

recorded when the transmission is first

diagnosed as requiring replacement.

Serial No.

Serial No.

HOLDEN SERVICE TECHLINES_________________________________________________________________________________JULY, 2006

11

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

SERVICE PROCEDURE

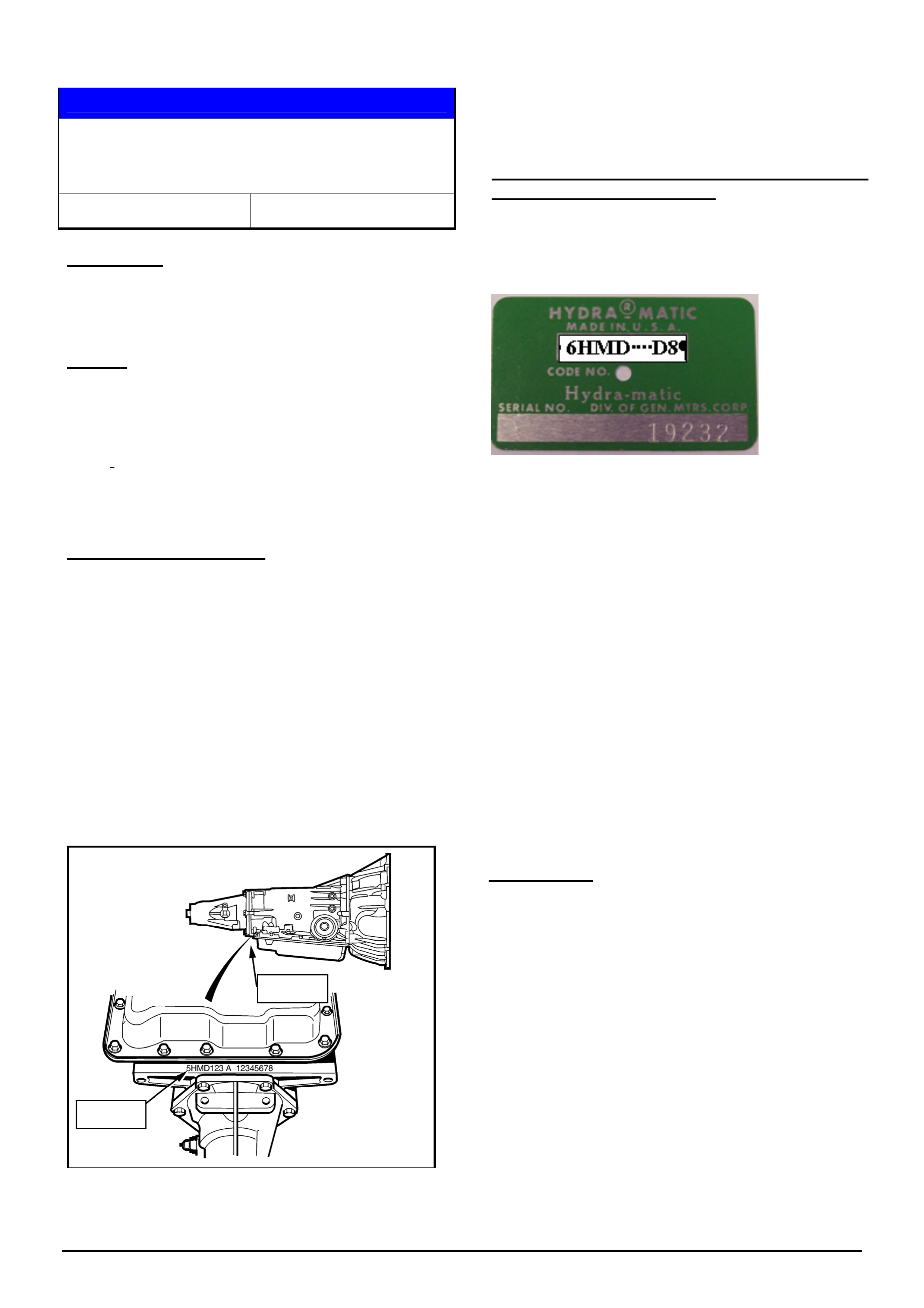

Installing New A/C Compressor - Oil Balance

Procedure

All

Group 2 Ref. No. TL1106 - 0606

A new compressor contains a complete A/C system oil

charge.

Therefore, whenever a compressor is replaced, the

following procedure must be performed in order to

maintain the correct amount of compressor lubricant in

the system.

DO NOT install a new compressor without first

performing the oil balance procedure.

OIL BALANCE PROCEDURE

STEP 1. Drain and measure (and record) the quantity

of oil removed from the old compressor.

STEP 2. Drain the oil from the new compressor into a

clean measuring container.

STEP 3. Refill the new compressor with the new oil

removed in step 2, but using the same quantity as

drained from the old compressor in step 1.

NOTE: In cases where a refrigerant hose has blown or

a compressor housing is cracked, the complete A/C

system will have to be flushed to remove all traces of

oil and foreign material. The new compressor can then

be installed with no oil balance check required.

Step 1.

Drain, measure, and record

the quantity of oil removed

from the old compressor.

Step 2.

Drain the oil from the new

compressor into a clean

measuring container.

Step 3.

Refill the new compressor with

the new oil removed in step 2,

but using the same quantity as

drained from the old compressor

in step 1.

HOLDEN SERVICE TECHLINES_____________________________________________________________________________AUGUST, 2006

13

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

DIAGNOSIS HINT

High Pressure Oil System - Pressure

Diagnosis

UBS Jackaroo, 4JX1-TC Diesel Engine

Group 6A Ref. No. TL1141 - 0607

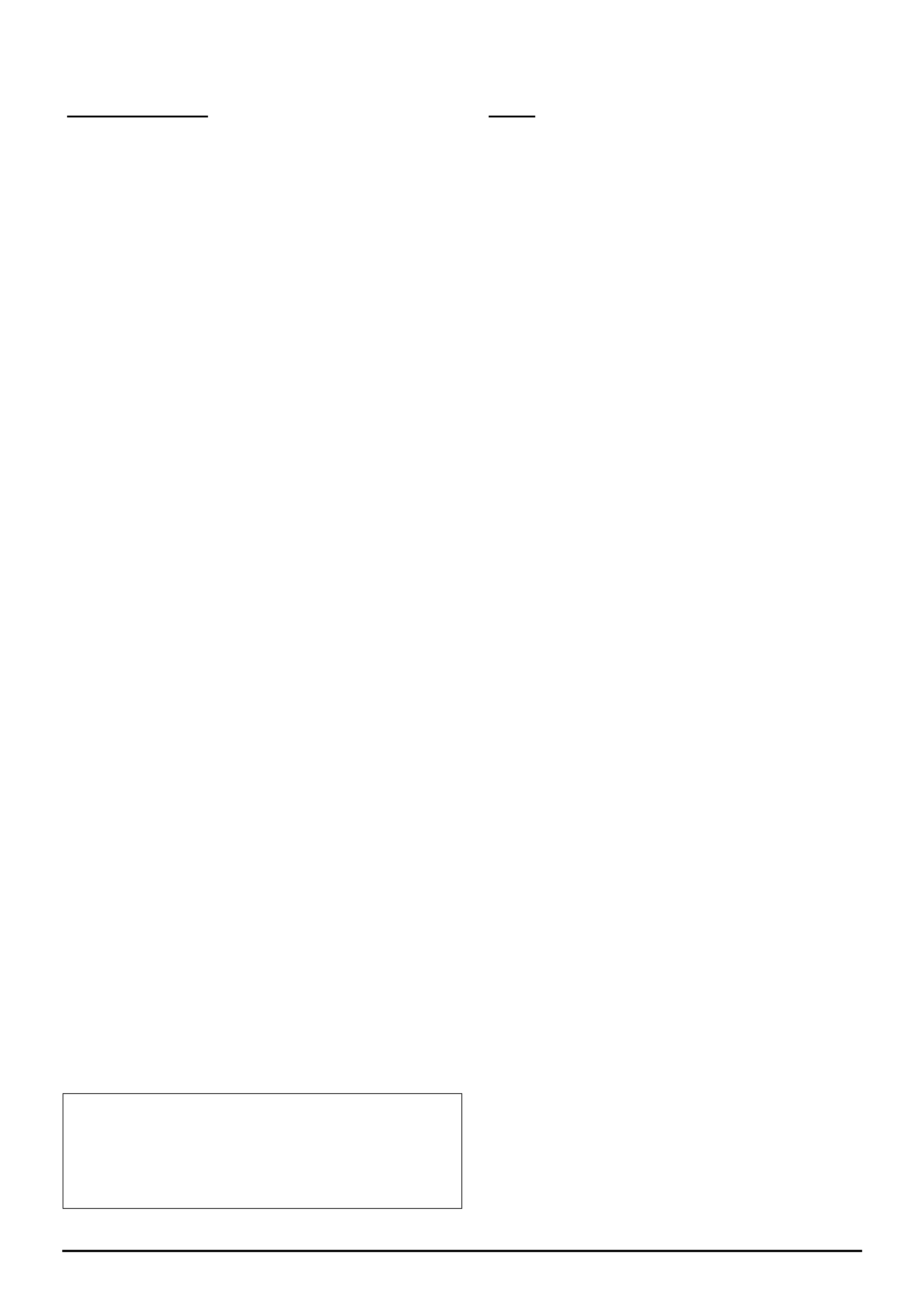

This techline contains details of a test tool (refer Figure

2) to aid in the diagnosis of pressure faults in the High

Pressure Oil System in 4JX1-TC engines.

Using this test tool in accordance with the test

procedure, will help technicans to correctly identify

any leaks or defective components in the “high

pressure oil system”.

High Pressure Oil System componentry consists of oil

pump, common oil rail (manifold), rail pressure control

valve, rail pressure sensor, one way valve and

associated piping.

Manufacture of test tool

Figure 2 contains sketch plans for a test tool which is

to be installed into the High Pressure Oil System for

diagnosis purposes only.

Due to the high pressures this tool is subjected to,

the manufacture of this tool SHOULD be

outsourced to a company which has expertise in

hydraulic hoses and fittings.

All components used must be able to handle oil

pressure up to 5000 psi (35 MPa).

Installation of test tool

The tool is to be installed between the High Pressure

Common Oil Rail and the one way valve located on the

left hand side of engine. (refer red line in diagram

below. This will require removal of the existing steel oil

pipe in this location.

Figure 1. Install Test tool at location of red line

HOLDEN SERVICE TECHLINES_____________________________________________________________________________AUGUST, 2006

14

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

Test Procedure.

STEP 1. Test Tool Installation.

The test tool must be installed in the orientation as

shown in Figure 2. When installed, the tap must be

located between the oil pressure gauge and the tappet

cover as shown.

After installation, proceed to Step 2.

STEP 2 - TAP OPEN. (engine stationary and engine

cranking)

These tests enable the Oil Rail Pressure Sensor to be

checked for accuracy by comparing the reading

obtained with Tech 2 to the reading on the oil pressure

gauge.

NOTE: The procedure for obtaining a reading with

Tech 2 is contained in SIP under 4JX1 engine

diagnostics.

With the Engine NOT cranking - the Rail Oil

Pressure should be 0 +/- 0.2 Mpa – on Tech2

If the above specification is NOT met, check the

injector harness connector (near oil dipstick tube) for

oil ingress to the connector.

If “flooded” with oil, the Rail Pressure Sensor and

Injector Harness will require replacing.

With the Engine cranking - compare the reading

obtained with Tech 2 to the reading on the oil pressure

gauge. If the readings are similar then the Oil Rail

Pressure Sensor is okay. If they differ greatly then the

sensor should be replaced.

For those cases where the Oil Rail Pressure Sensor

and the pressure gauge on the “test tool” show very

little or no oil pressure, proceed to the “Tap Closed”

procedure as follows.

STEP 3. - TAP CLOSED.

Close the tap on the test tool then crank the engine

over. Monitor the Rail Pressure Control Valve % on

Tech2. This should go to 98% after a few seconds of

cranking.

This test checks the integrity of the oil system prior to

tap - i.e. from the tap back to the high pressure pump.

If the system is able to develop high pressure with the

tap closed, the cause of any pressure loss being

investigated will be AFTER the tap - (i.e somewhere

under the rocker cover).

CAUTION: The engine MUST NOT be cranked any

longer than necessary to confirm if high pressure is

obtainable. It is possible the oil pressure could

exceed 4000psi or 28 bar. The starter motor will

begin to “labour” when high pressure is reached.

Hints

• The actual rail oil pressure must be in excess of 3.5

Mpa for the injectors to enable. This can be seen on

Tech 2 data.

• Snapshots are recorded at 2 frames per second.

When conducting a snapshot try and capture data in

a “block” of 10 seconds.

Achieving these blocks of constant information

makes “reading” snapshot data on TIS 2000 much

easier.

E.g. Key on, engine off 10 Seconds

Cranking 10 Seconds

Idle 10 seconds

Full throttle 10 seconds.

If any further assistance is required please contact

TAS LCV group.

HOLDEN SERVICE TECHLINES______________________________________________________________________________________________________________________AUGUST, 2006

15

UBS Jackaroo 4JX1 - High Pressure Oil System - Test Tool

Figure 2.

Fitting A

- attached to one way (non-return)

valve on LH side of Engine.

Oil Gauge

0 to 5000

p.s.i. /

35 MPA

In-line tap. Must

be able to handle

5000psi/ 35000kpa

CHECKING PROCEDURE: (Refer

to page 1 for complete details)

- Tap open checks accuracy of the

Rail Sensor.(check against reading

with Tech 2)

- Tap closed checks system integrity

prior to tap.

If high pressure is achievable then

leak is after tap (under the Tappet

Cover).

Fitting B

– Attached to Oil Rail

NOTE:

This Test Tool assembly fits in place of the

steel pipe part number 8972091980.

It is recommended to purchase 8972091980

from spare parts and then have the gauge and

tap fitted into the line.

HOLDEN SERVICE TECHLINES_____________________________________________________________________________AUGUST, 2006

17

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

DIAGNOSIS INFORMATION

Subject: HARD START or NO START

Model: RA RODEO Petrol & Diesel

Group: 6C Ref. No. TL0955A - 0607

This Techline supercedes the previous one TL0955-0506 in Issue 6, July 2005. It is Revised by changing to a Flow Chart

format. A customer questionaire has also been added.

IMPORTANT

• Despite all the previous techlines published on this subject, many

immobilisers are being replaced unnecessarily for the above

condition.

• Please note that from publication of this techline, any immobiliser

that is replaced unnecessarily will not be accepted under warranty.

• TO AVOID THE UNNECESSARY REPLACEMENT OF IMMOBILISERS

the “Recommended Procedure” shown in the box below should be

followed.

►►►►► RECOMMENDED PROCEDURE ◄◄◄◄◄◄

1. A set of questions relevant to the correct diagnosis of the immobiliser have been

developed and assembled into a Customer Questionnaire. It is recommended that

your Service Advisor complete the questionnaire with the customer when booking

vehicle in.

2. Customer Questionnaire to be attached to the Repair Order for technician’s

reference as a “tool” to assist with correct diagnosis of the immobiliser.

3. Technician to proceed with problem diagnosis commencing with flow Chart 1.

NOTE: Below is a list of previous techlines published in relation to this subject. These may be used for

reference, however, all the information in them has been consolidated into this techline.

TL0955-0506 Group 6C - July 2005 Hard Start or No Start (summary of previous information)

TL0826-0411 Group 6C - Dec 2004 Intermittent Crank but No Start (ECU revised software)

TL0813-0410 Group 12 - Nov 2004 Engine difficult to start, cranks, starts, stalls (battery voltage low)

TL0693-0404 Group 12 - May 2004 Immobiliser VIN programming

TL 0541A-0404 Group 12 - May 2004 Intermittent No Crank or No Start. (Immobiliser related)

HOLDEN SERVICE TECHLINES_____________________________________________________________________________AUGUST, 2006

18

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

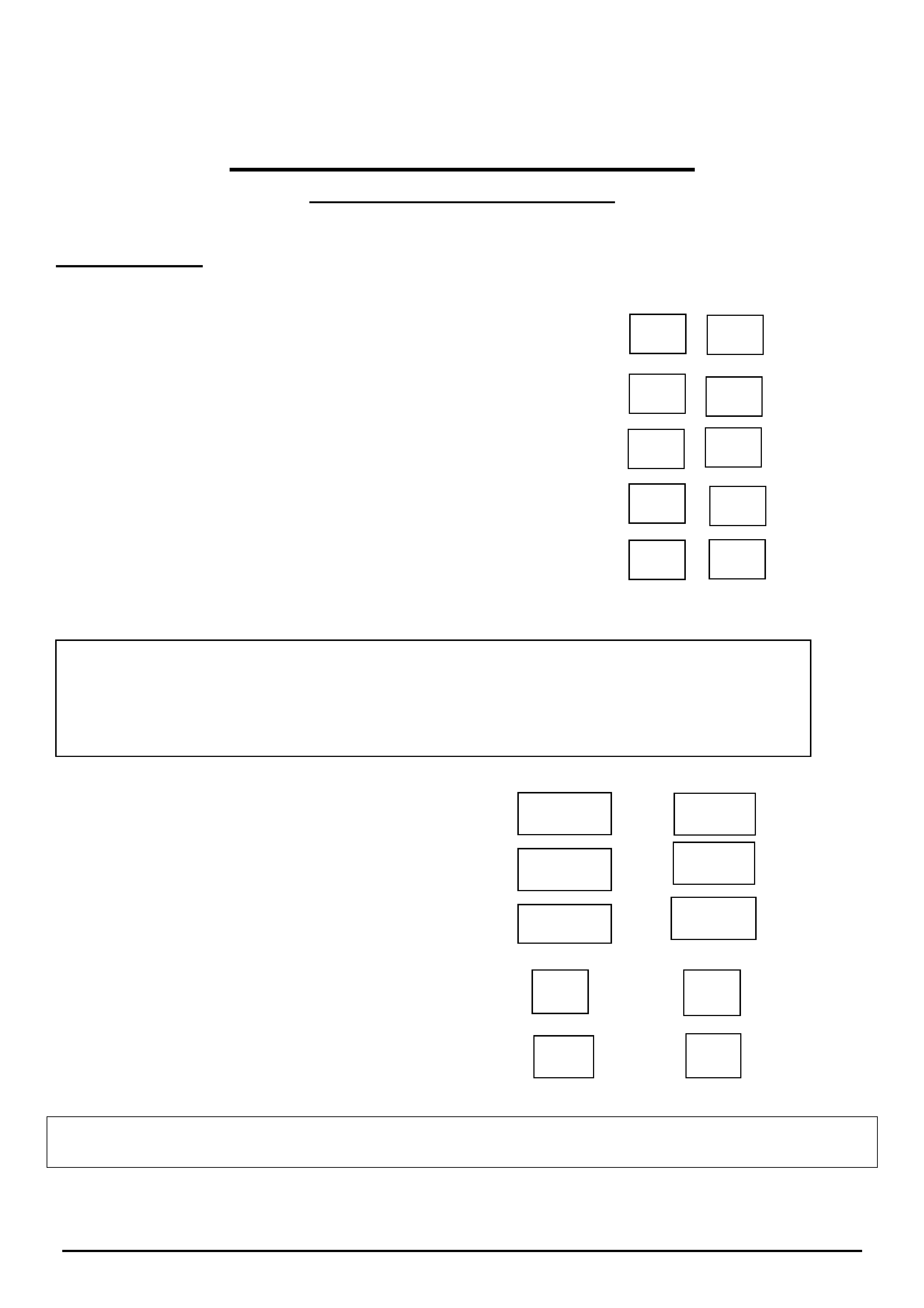

RA Rodeo Hard to Start

CUSTOMER QUESTIONAIRE

(To be filled in by Service Advisor)

Service Advisor to ask customer the following questions at time of vehicle book-in.

Circle correct answer

1/ Does the vehicle ALWAYS Crank over when trying to start?

2/ Does the Check Engine Light flash while attempting to crank engine?

3/ Does the Engine start then stall?...........................................................................................

4/ Does the Engine Crank but Check Engine Light stays off?

5/ Is the fault present with BOTH Ignition Keys?

6/ Get the customer to describe how they normally reproduce the fault?

7/ How often does the fault occur? Frequency No. of times

8/ Customer asked to bring in BOTH ignition keys when

presenting vehicle for repairs.

9/ Customer informed on how to re-start Engine AFTER

turning ignition off and waiting 20 Seconds.

When completed, attach this sheet to the Repair Order for the Technician’s information.

Yes No

Yes No

Yes No

Yes No

Yes No

Daily

Weekly

Monthly

Yes No

Yes No

HOLDEN SERVICE TECHLINES_____________________________________________________________________________AUGUST, 2006

19

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

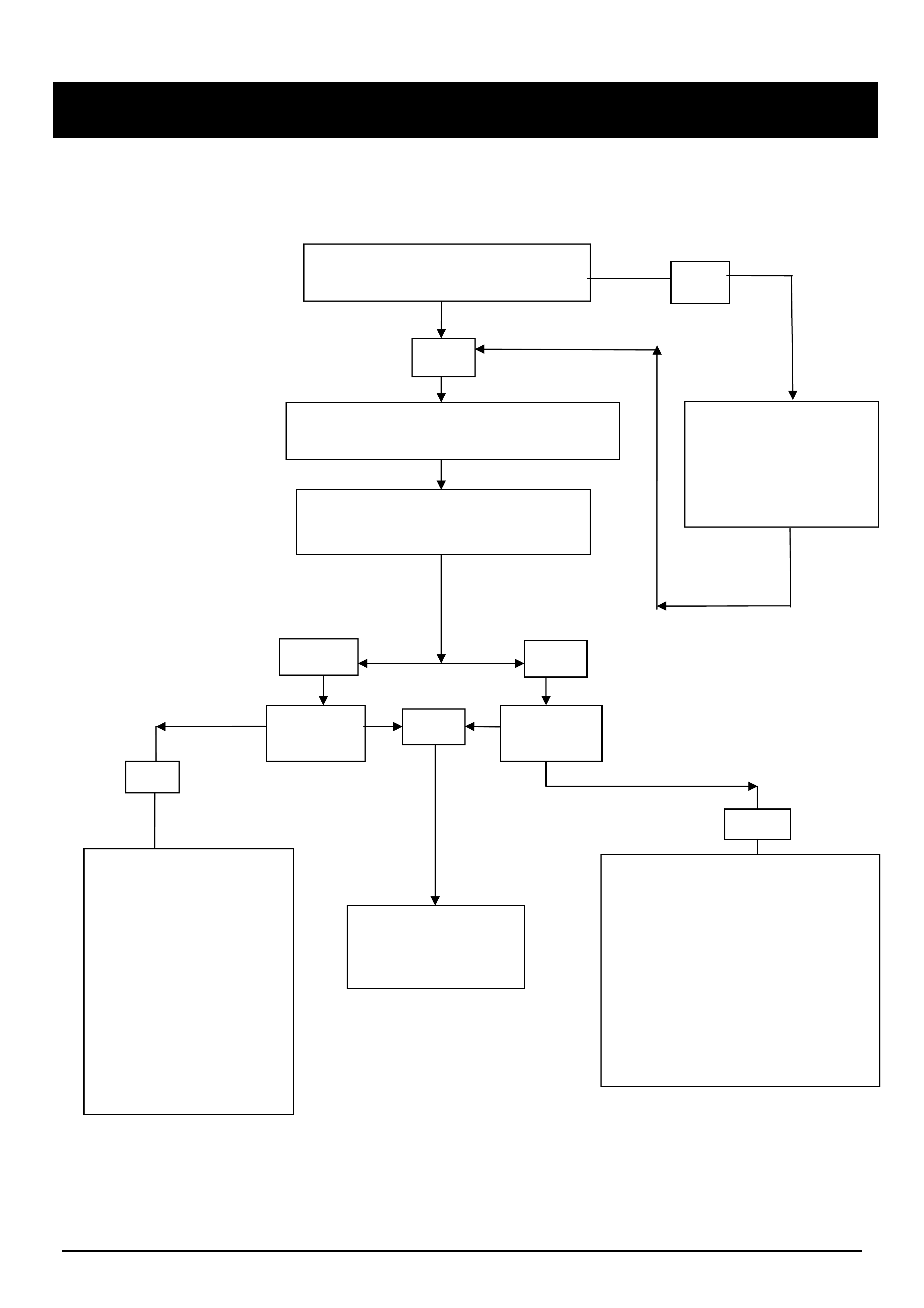

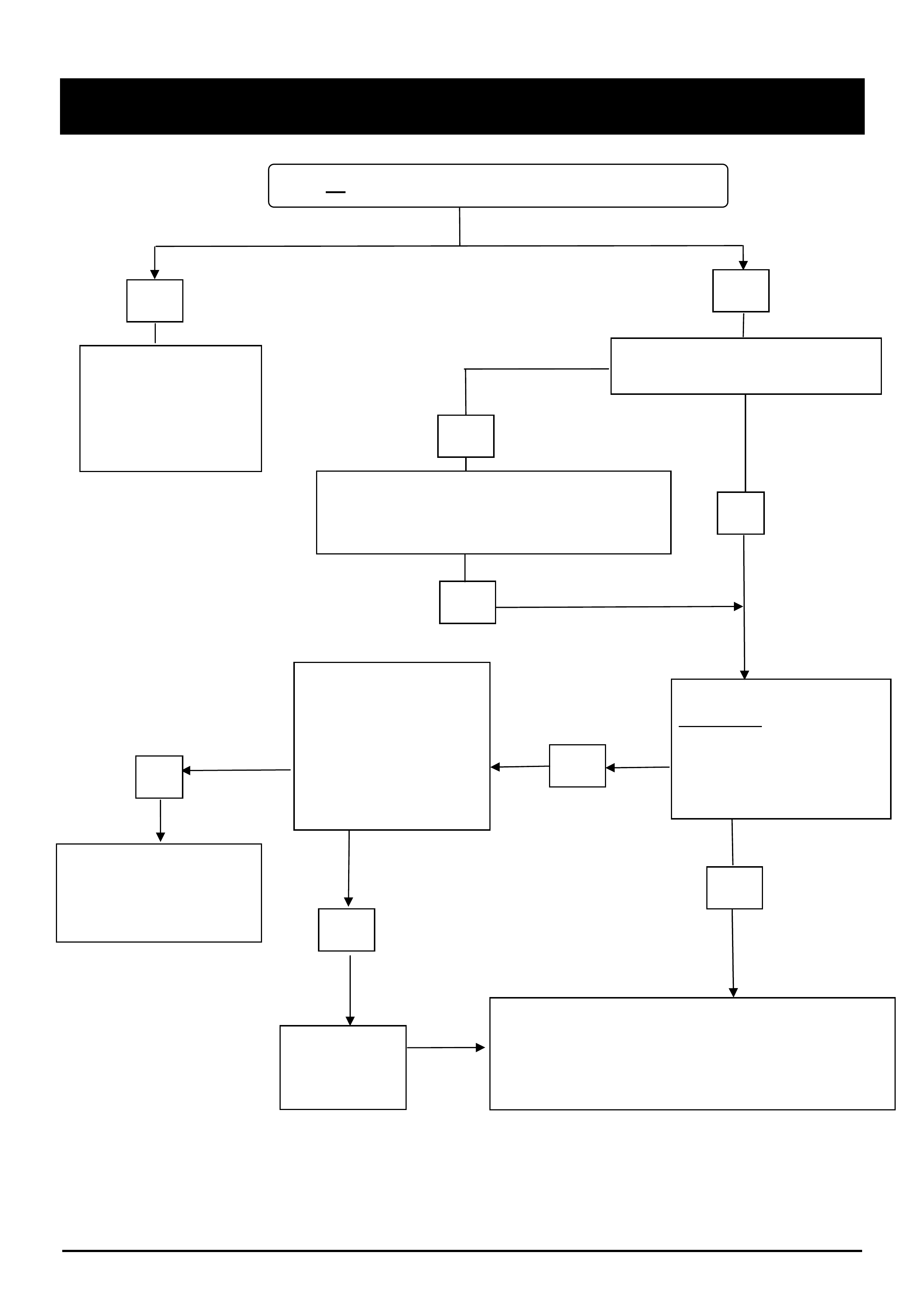

Chart 1 RA Rodeo Hard Start

YES NO

Does the engine ALWAYS Crank

when trying to start the Engine.

Is the C.E.L

Flashing ?

Is the C.E.L

Flashing ?

No

Fault is NOT in the

Immobiliser system.

Refer to “Cranks won’t

run” chart in LCRV SIP in

the Engine and

Driveability Section of

applicable engine, under

Symptom Diagnosis.

If further Assistance is

required contact TAS

Proceed to

Preliminary

Checks

Yes

No

Fault is NOT in the

Immobiliser system.

Refer to Starting and Charging in

LCRV SIP under Electrical –

System Repair - 8A of Symptom

Diagnosis.

Do not replace Immobiliser.

If further Assistance required contact

TAS.

.

Do you have a completed copy of

the Customer Questionaire? No

Yes

Use information gathered from Customer

to answer following flow chart questions.

Obtain a completed

questionaire from the

Service Advisor.

Do you now have a

completed form ?

HOLDEN SERVICE TECHLINES_____________________________________________________________________________AUGUST, 2006

20

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

PRELIMINARY CHECKS

► THE FOLLOWING MUST BE COMPLETED ON ALL VEHICLES PRIOR TO PROCEEDING TO CHART 2 ◄

1. Battery Check.

The Battery MUST be checked with a Hydrometer and a load tester. The cranking voltage should be above 10.5

Volts.

2. DTC Checks.

• Are there any DTC’s logged in the engine ECU or the Immobiliser ICU? If so, what are they? Include the

fault code number and Tech 2 descriptions.

• If Present DTC’s are shown, perform the relevant flow chart diagnosis for the DTC’s SEE NOTE A

• If History DTC’s are shown, the DTC charts can still be used to identify and check the relevant circuits and

wiring associated with the DTC.

• NOTE A. DTC B8007 can be set falsely by cycling the Ignition key from On – Off – On within 30 seconds.

Do not diagnose by this code if this is the case.

• NOTE B. If there are no DTC’s in the engine or Immobiliser ICU, the problem is probably NOT Immobiliser

related. In this case, perform usual engine no start / hard start diagnosis, E.G. fuel pressure, fuses, power

& earth supplies, etc. Use Tech 2 typical data values to help in diagnosis.

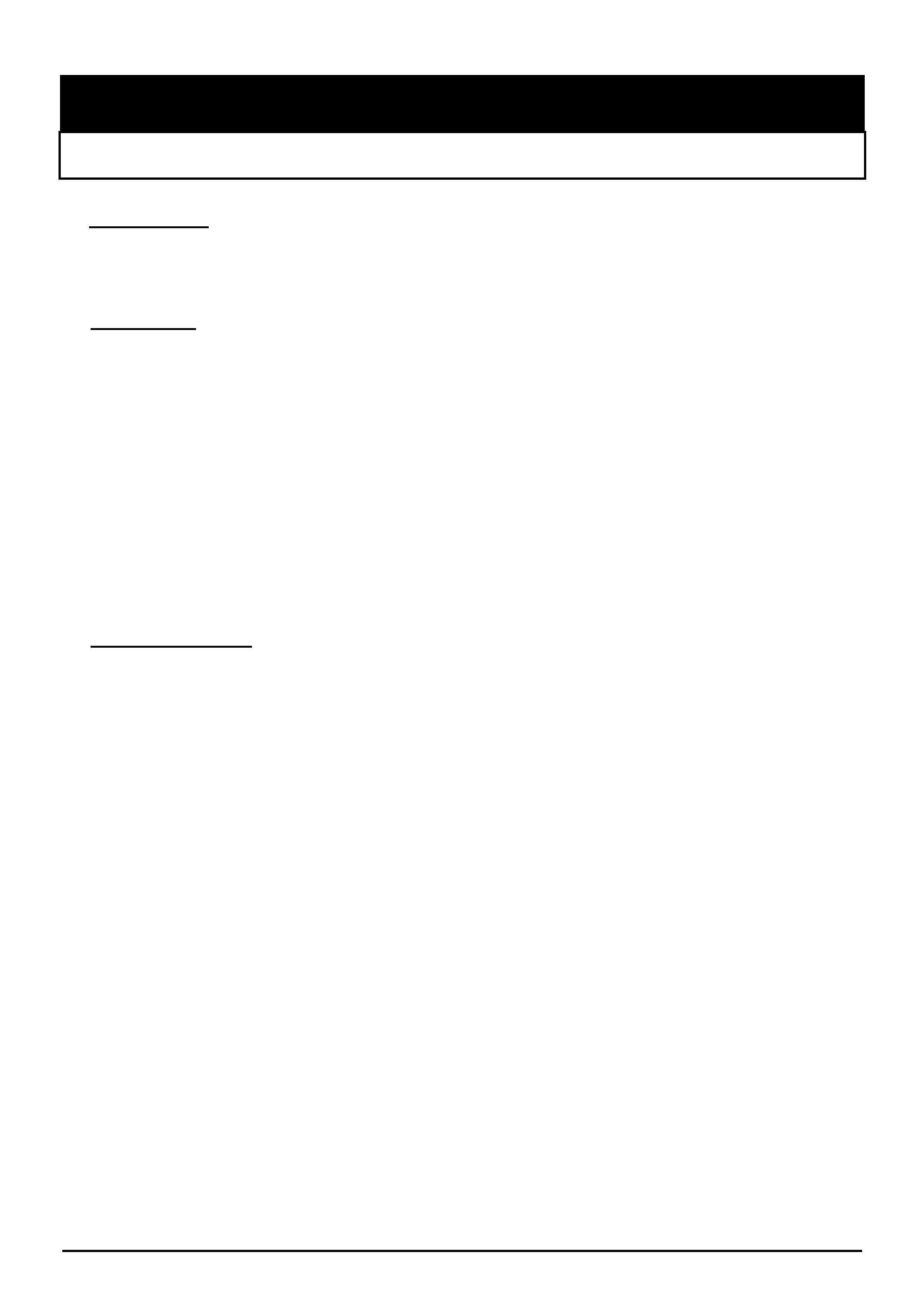

3. Body Earth Checks.

IMPORTANT: It is critical that the following checks and cleaning are carried out properly.

VOLT DROP CHECKS. - These checks are necessary to identify any poor earths which need rectification.

Volt drop checks should be done with an electrical load applied by turning on all

lights, heater fan, demister etc. with engine idling if possible.

1. Check for voltage drop across each earth circuit to battery negative post at all 5 earth points (shown

below) and record. Volt drop must be less than 0.2 Volt. Use a digital multimeter with at least 10 Mega

ohm input impedance (tool J39200 or equivalent).

2. If volt drop is above 0.2 Volt then rectify/repair cause of excessive volt drop.

3. Please report any excessive volt drops (including location) to Holden on a PIR.

• Earth P-5. Location – Battery negative terminal.

Ensure the terminal is clean and tight.

• Earth P-6. Location - Battery tray.

Paint to be cleaned from between Earth terminal and Battery Tray. Terminal to be cleaned.

NOTE -This earth point is the only link the earthing system has between the fully rubber mounted

cabin and the battery.

• Earth C-2 Location - R.H. inner guard.

Paint to be cleaned from between Earth terminal and Battery Tray. Terminal to be cleaned.

• Earth C-36 Location - L.H. inner guard.

Paint to be cleaned from between Earth terminal and Battery Tray. Terminal to be cleaned.

• Earth C-109. Location - Under LH front seat.

Paint to be cleaned from between Earth terminal and Battery Tray. Terminal to be cleaned.

HOLDEN SERVICE TECHLINES_____________________________________________________________________________AUGUST, 2006

21

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

The earth points C2, C36,

and C109 all earth to the

cabin.

4. Engine Earth Check

All Engine Earths are to be cleaned.

Refer to SIP /Eng. and Driveability /Ground Points - to view an “Earth” block diagram to assist in locating where

each light, module, switch, etc. is Earthed to for a better understanding of the Earthing system in RA Rodeo

vehicles.

5. Terminal Checks.

Check terminal retention from the Key Antennae to

the Immobiliser, via Patch Harness.

HINT. This can be done by removing a male

terminal from the Antenna / Key reader Patch

harness and use this terminal to test retention of

female terminals. Resize terminals if required to

increase retention.

6. ECM Software

The ECM must have latest calibration installed. Please request Info. via SPS on Tech 2 and check if new ECM

software is available. Update ECM via SPS on TIS 2000 if newer Software available.

If the vehicle is a 3.5 V6 built before engine number 240817, program engine ECU with the latest TIS software.

NOTE: revised engine ECU software was fitted in production from engine number 240817

7. Accessories.

Non genuine electrical accessories that are wired into the vehicle are a major contributor to hard start problems,

and must be removed before proceeding with diagnosis.

NOTE: There is a genuine accessory “Patch Harness” available for Cellular Phones. (Refer to Techline TL0922-

0504 May 2005).

8. Proceed To Chart 2.

C-2

C-109

C-36

P-6

P-5

HOLDEN SERVICE TECHLINES_____________________________________________________________________________AUGUST, 2006

22

Holden Techlines are written to inform technicians of conditions that may occur on some vehicles, and to provide information that could assist in the

proper service fix of a vehicle. If a condition is described, do not assume the service fix applies to a vehicle or that the vehicle will have that condition.

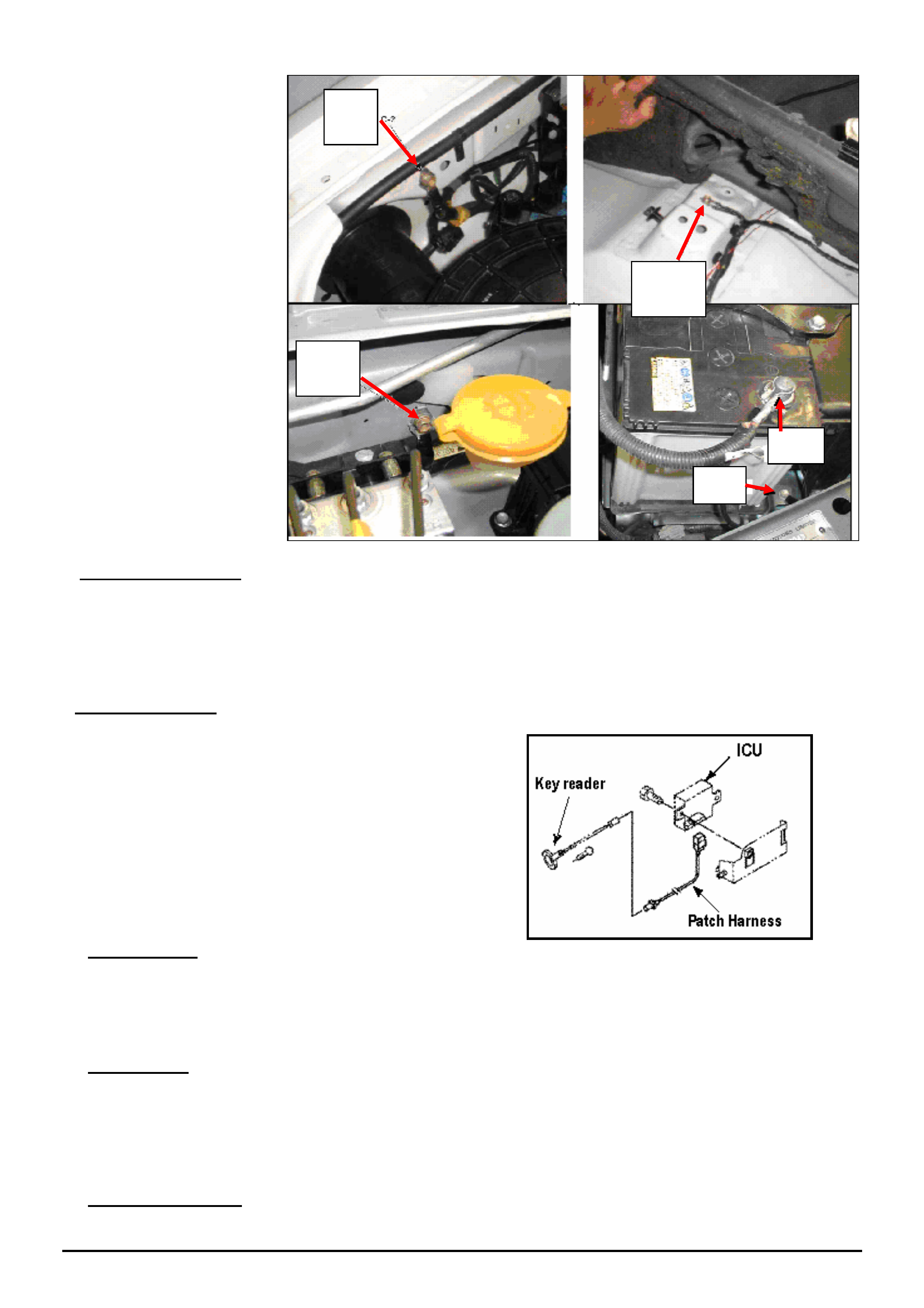

Chart 2 Engine Cranks with CEL Flashing

Check the part number on

the Immobiliser Control

Unit.

Petrol 8973773230

Diesel 8973773240

Is the Part number

correct?

No

Replace Immobiliser with

part Number

Petrol 8973773230

Diesel 8973773240

Yes

Is the VIN earlier than

Breakpoint VIN below?

4JH1 -

MPATFS77J4H536880

6VE1 -

Fill in TAS case management form and contact TAS

Light Commercial for further assistance.

Have Service Advisors sheet and this chart attached to

case Management form prior to calling TAS.

No

Do NOT

replace

Immobiliser

The Preliminary

checks are to be fully

completed. Please

complete prior to

proceeding

Yes

Yes

Does the vehicle have any Non-

genuine Accessories Fitted?

Have all of the PRELIMINARY checks been completed?

No Yes

Yes

No

Accessories MUST be wired to Battery Positive

and Negative. Refer to Preliminary Checks

Are accessories correctly wired to Battery?

HOLDEN SERVICE TECHLINES__________________________________________________________________________ SEPTEMBER, 2006

7

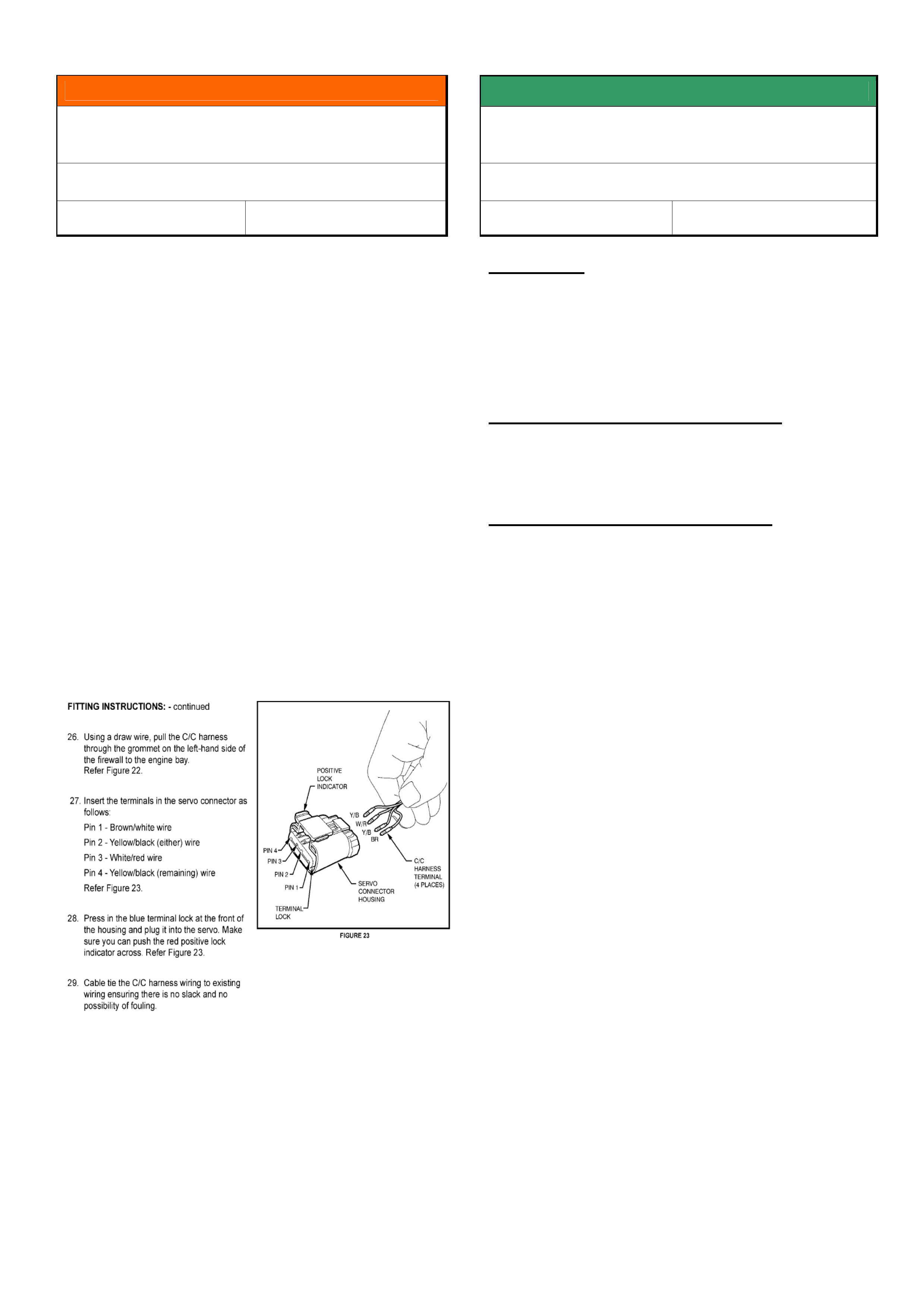

INFORMATION

Cruise Control Inoperative after Fitment

RA Rodeo 6VE1 Petrol & 4JH1 Diesel

Group 12 Ref. No. TL1178 – 0608

This techline is issued to inform technicians of a

problem that may be encountered when fitting the

accessory cruise control kit to the above model.

The technician may find that when test driving the

vehicle after fitting cruise control, the vehicle will not

maintain the set speed even though the cruise set light

is illuminated on the cluster.

Almost all cases of the above complaint have found to

be caused by the cruise control actuator wiring being

incorrectly fitted into the Servo Connector Housing.

Therefore, when the terminals are fitted to this

connector, take the utmost care to ensure that the

male terminals are correctly engaging with the

corresponding female terminals in the connector. If not

enough care is taken, it is possible for the male

terminals to “push over” to the side causing poor or no

contact with the corresponding female terminal.

Shown below is page 13 of the cruise control

accessory fitting instructions for reference

SERVICE FIX

Fuel Gauge Drops To Empty & DTC P0460

Sets In The Engine ECU

RA, all with HFV6 MY06

Group 12 Ref. No. TL1164 - 0608

CONDITION

Customers may advise their fuel gauge drops to empty

and the low fuel light comes on or “Fuel Gauge Error”

message displayed in instrument cluster.

DTC P0460 "Fuel Level Sender range / performance"

sets in the engine ECU

CORRECTION – Vehicles In Service

On any vehicle with the above condition reprogram the

engine ECU as per the standard SPS process using

Tech 2 and TIS 2000 version 74 or later.

WARRANTY CLAIM INFORMATION

Use standard Labour Times found in the Warranty

Information section of the current PV SIP disc.