Instruction No. 9214 5080

A.I. Instruction No. 09-17385

AS-37-GR40P

Air Conditioning Fitting Instructions (4JH1-TC & 4JB1T Models)

2001 Rodeo

Turbo Diesel - Engine 4JB1

Turbo Intercooled Diesel - Engine 4JH1-TC

(Including LT Sport)

Kit No. 92144690 15/11/2001

Division of GM Holden Ltd

ABN 84 006 893 232

CONTENTS

PREPARATION

POINTS TO CHECK

INSTALLATION PRECAUTIONS

LABELS

SPECIFICATIONS

TIGHTENING TORQUES

BOLT MEASURE

PARTS TO BE REMOVED (INTERIOR)

AIR CONDITIONER SWITCH INSTALLATION

EVAPORATOR INSTALLATION

EVAPORATOR DRAIN HOSE INSTALLATION

PARTS TO BE REMOVED (ENGINE COMPARTMENT)

COMPRESSOR AND MOUNT INSTALLATION - 4JB1 ENGINE

COMPRESSOR AND MOUNT INSTALLATION - 4JH1-TC ENGINE

CONDENSER FITMENT

FDR BRACKET, FDR AND

PRESSURE SWITCH WIRING INSTALLATION

HOSES & TUBES - LIQUID TUBE (A)

HOSES & TUBES - LIQUID TUBE (B)

HOSES & TUBES - SUCTION TUBE

HOSES & TUBES - DISCHARGE TUBE

COMPRESSOR RELAY

WIRING DIAGRAM

EVACUATION AND CHARGING PROCEDURE

Preparation

Before starting the installation, read these

fitting instructions through, then follow the

sequence from Page 1 through to the

evacuation and charging.

Points to check

a. Check and note any damage to the

vehicle interior or exterior.

b. Check and note operation of all

accessories, horn, lights, etc.

c. Check operation of engine cooling

system.

d. Inspect the kit for damaged parts

before starting the installation.

Installation Precautions

a. This system has been designed to suit

standard wiring by the vehicle manufac-

turer, the wiring of non-approved

accessories could result in malfunction

of the unit or damage to the vehicle.

b. Disconnect the negative lead from

the battery.

c. Route all refrigerant hoses, tubes

and wiring harnesses to avoid fouling.

d. To prevent entry of moisture or foreign

material into the system do not remove

shipping plates or plugs until

immediately before installation of

components.

SIZE TUBE THREAD TORQUE

O.D. -UNF N.M.

No. 5 5/16 9/16-18 13-15.0

No. 6 3/8 5/8-18 11.0-16.0

No. 8 1/2 3/4-16 18.0-23-0

No. 10 5/8 7/8-14 24.0-30.0

No.12 3/4 1-1/6-12 30.0-38.0

Note: This system uses a

specific Lubricating oil-

Polyalkylene Glycol (PAG). This oil

is highly hygroscopic, adhere

to Step D

e. O-Rings do not require lubrication as

they are pre-fitted to most tubes/hoses

and pre-lubricated with silicon at the

manufacturer.

f.

Use two spanners when tightening fittings.

g. Use torques specified.

h. As this R134a Air Conditioning system

uses no sightglass in the filter drier,

refrigerant must be filled by weight

scales or dial-a-charge to the specified

amount only quoted in the rear section

of these instructions.

i. Use only specific R134a charging

equipment and leak detector.

Torque Chart - Hose & Tube Fittings

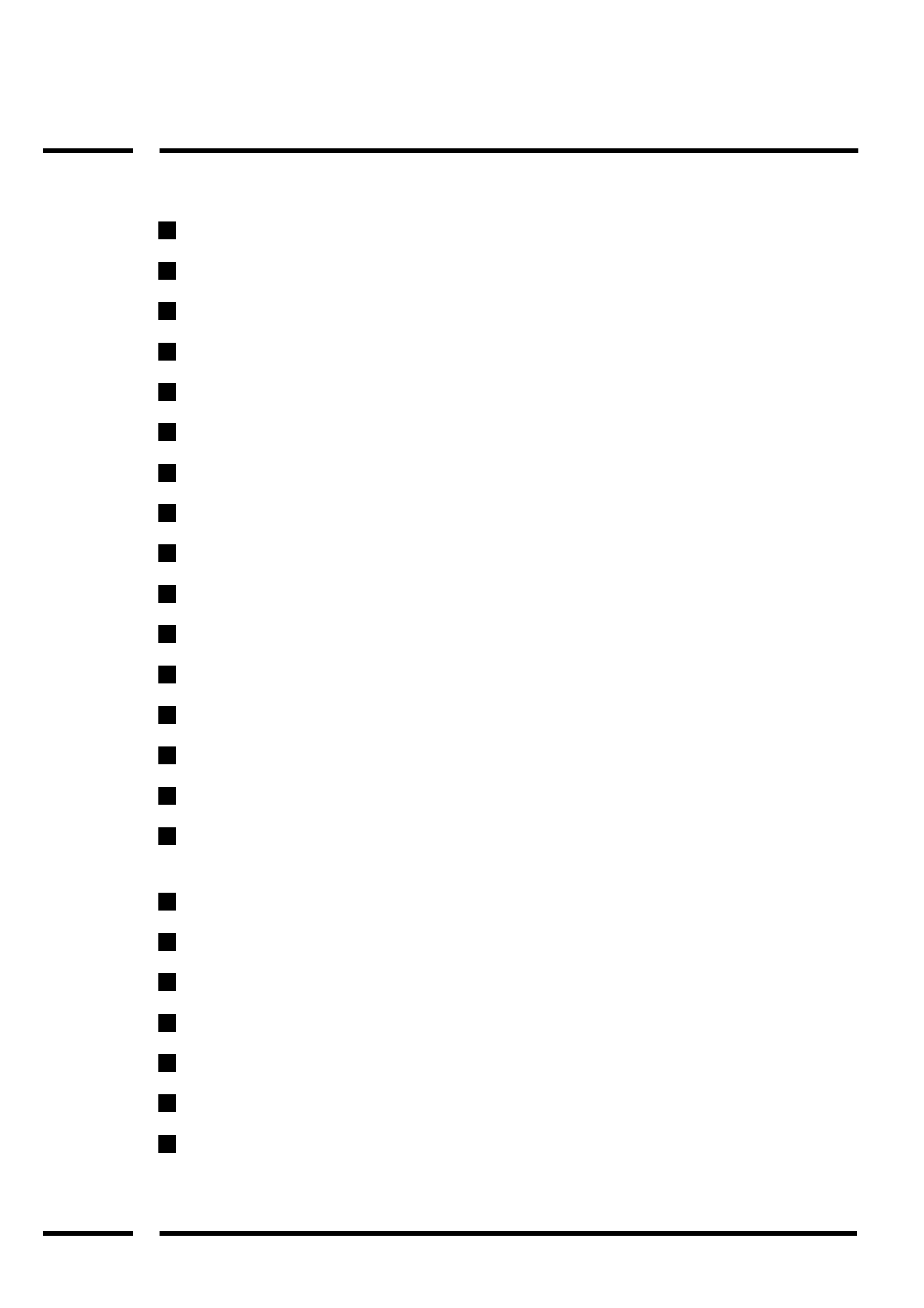

Labels

A/C Kit Part

Number:

Location —

Glove box

interior (The kit

number on this

label is to be

used for

reference when ordering A/C spare parts.

Warning

Label:

Location —

Radiator

support

Panel.

Warranty

Plate:

Location —

1 x Owners

Manual

1 x Firewall

(Use ball

point

pen-mark label with relative information).

Refrigerant

Label:

Location —

Radiator

support panel

- top LH side.

Specifications

Compressor — Delphi SP 10 (10 Piston).

Clutch — 12 Volt, Double A groove.

A/C Belt Size — Length 39".

Condenser — Dual Pass Serpentine.

Evaporator — Laminated plate and fin design.

TX Valve — 1.5 ton externally equalised with charcoal dampening.

Pressure Switch — High Pressure Compressor Off 2940 ± 196kpaG.

Low Pressure Compressor Off 205 ± 19.6kpaG.

Refrigerant Capacity — R134a 750 ± 25 grams.

Filter Drier Receiver (FDR) — XH9 Desiccant - No sight glass.

Lubricating Oil — SP10.

‘O’ Ring Material — HNBR Colour - Green.

Compressor Oil Charge

(when first installed new) — 150 ±10cc (total system capacity).

Tightening Torques

Condenser Pad Fitting Bolts — 7-10NM

Filter Drier Pipe Connections — 13 - 15NM

Liquid Tube to Evaporator Pipe Connection — 13 - 15NM

Suction Tube to Evaporator Pipe Connection — 24 - 30NM

Suction Hose to Compressor Pad Fitting Bolt — 20 - 30NM

Discharge Hose to Compressor Pad Fitting Bolt — 20 - 30NM

Compressor Mount Bracket to Engine Bolts — 40 - 50NM

Compressor Mounting Bolts — 40 - 50NM

Wheel Nuts (Aluminium Wheels) — 125NM

Wheel Nuts (Steel Wheels) — 125NM

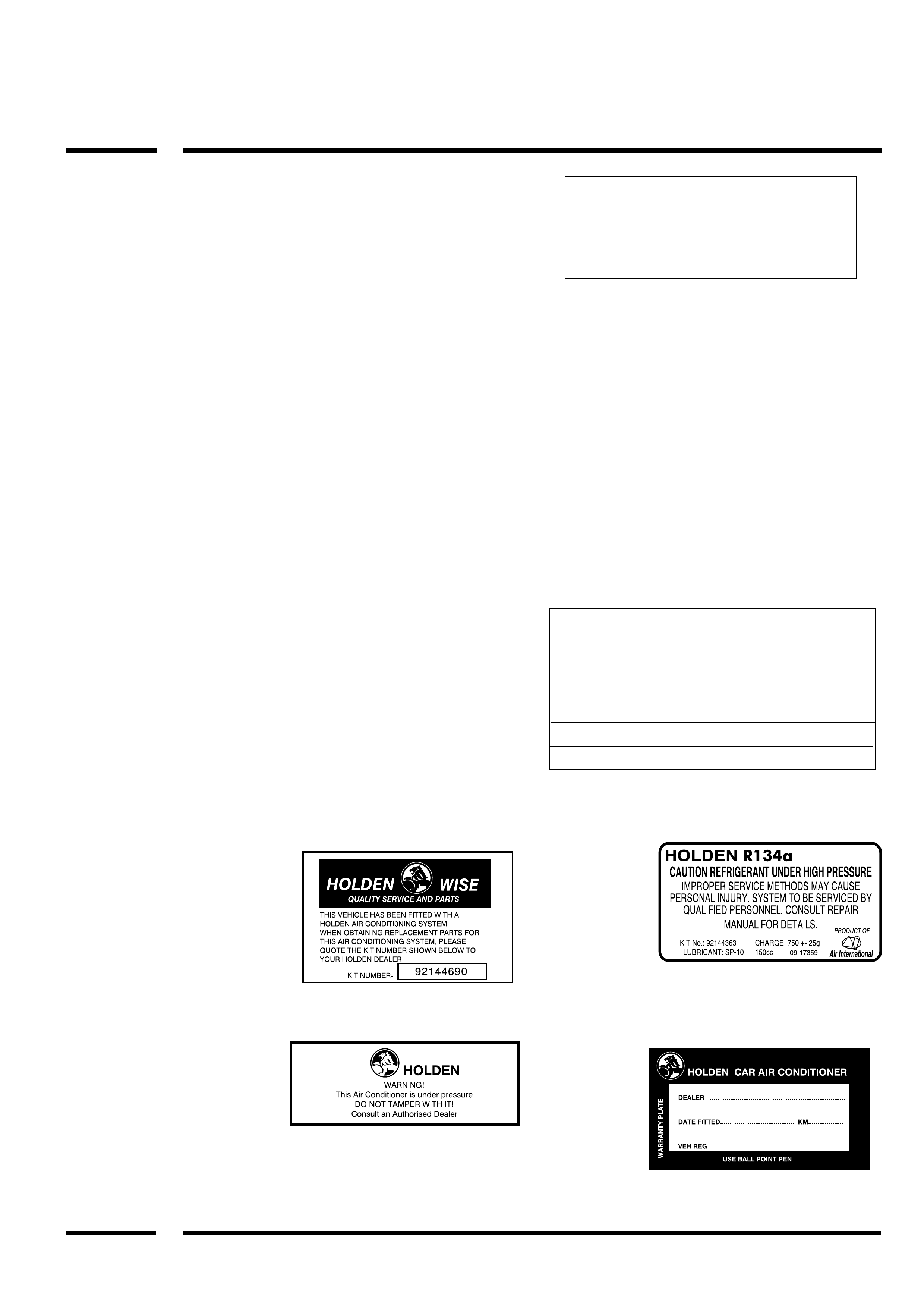

1Parts to be Removed (Interior)

a. Glove box (2 screws).

b. Glove box support (2 bolts).

c. Upper glove box panel (4 screws).

d. Duct (unclip).

e. Resistor (discard transfer duct, metal

resistor backing plate and 2 screws).

f. Remove and discard rubber plugs from

firewall.

g. Remove plastic wire retainer from R/H

lower 6mm stud.

h. Upper dash surround (7 screws, 2

plugs).

Heater Bezel

Knobs

Plugs

Resistor

Discard

Air

Transfer

Duct

Glove Box

2Air Conditioner Switch Installation

a. Unclip heater control bezel and knobs

and push out and discard the A/C

blanking plug from the heater control

bezel.

b. Clip air conditioner switch into vacant

position in dash.

c. Reinstall heater control bezel and

knobs (4).

A/C

Switch

Heater

Control Bezel

Upper Glove

Box Panel

Glove Box

Support

Upper Dash Surround

;;;

;;;

;;;

;;;

;;;

;;

;;

;;

3

4

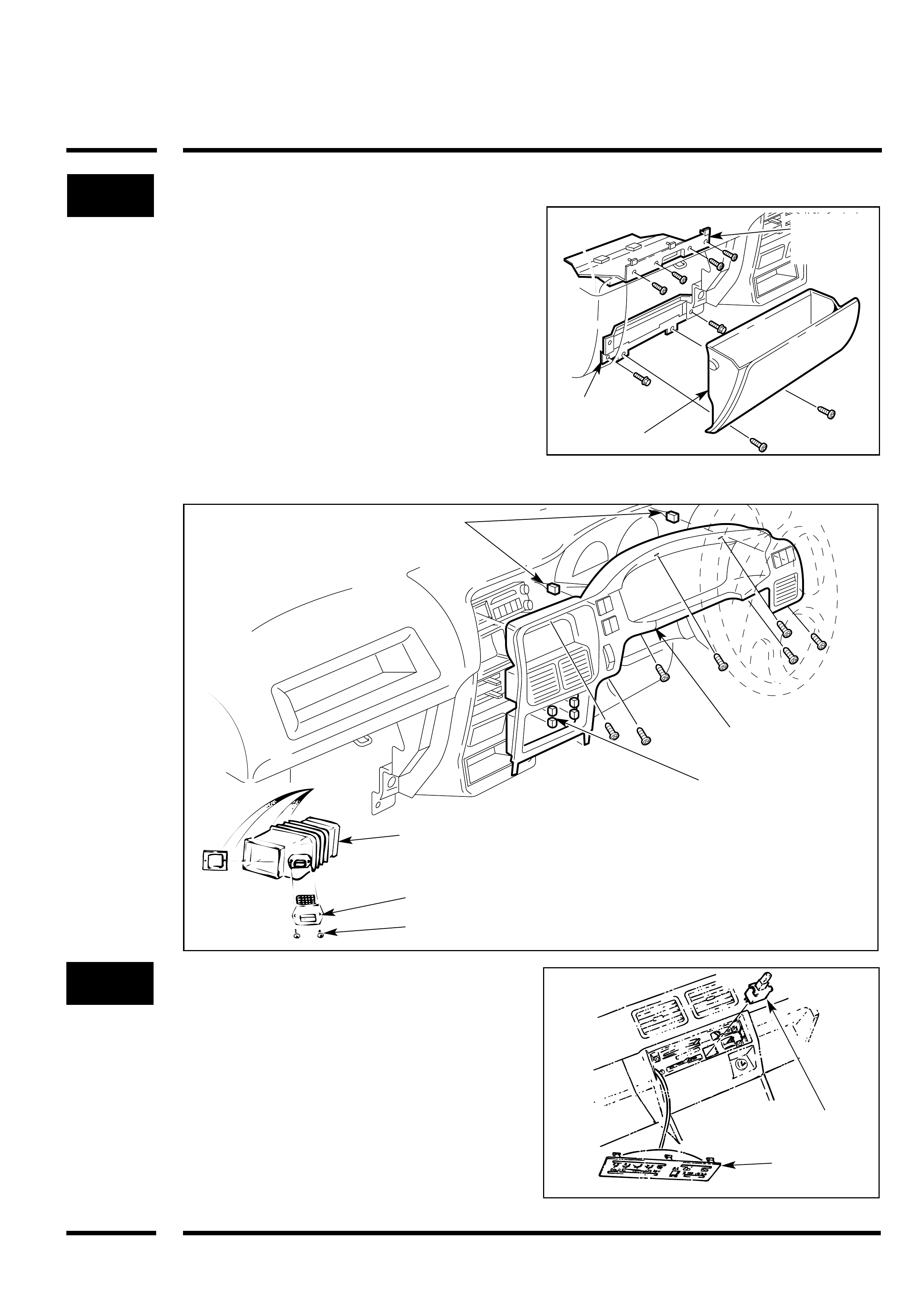

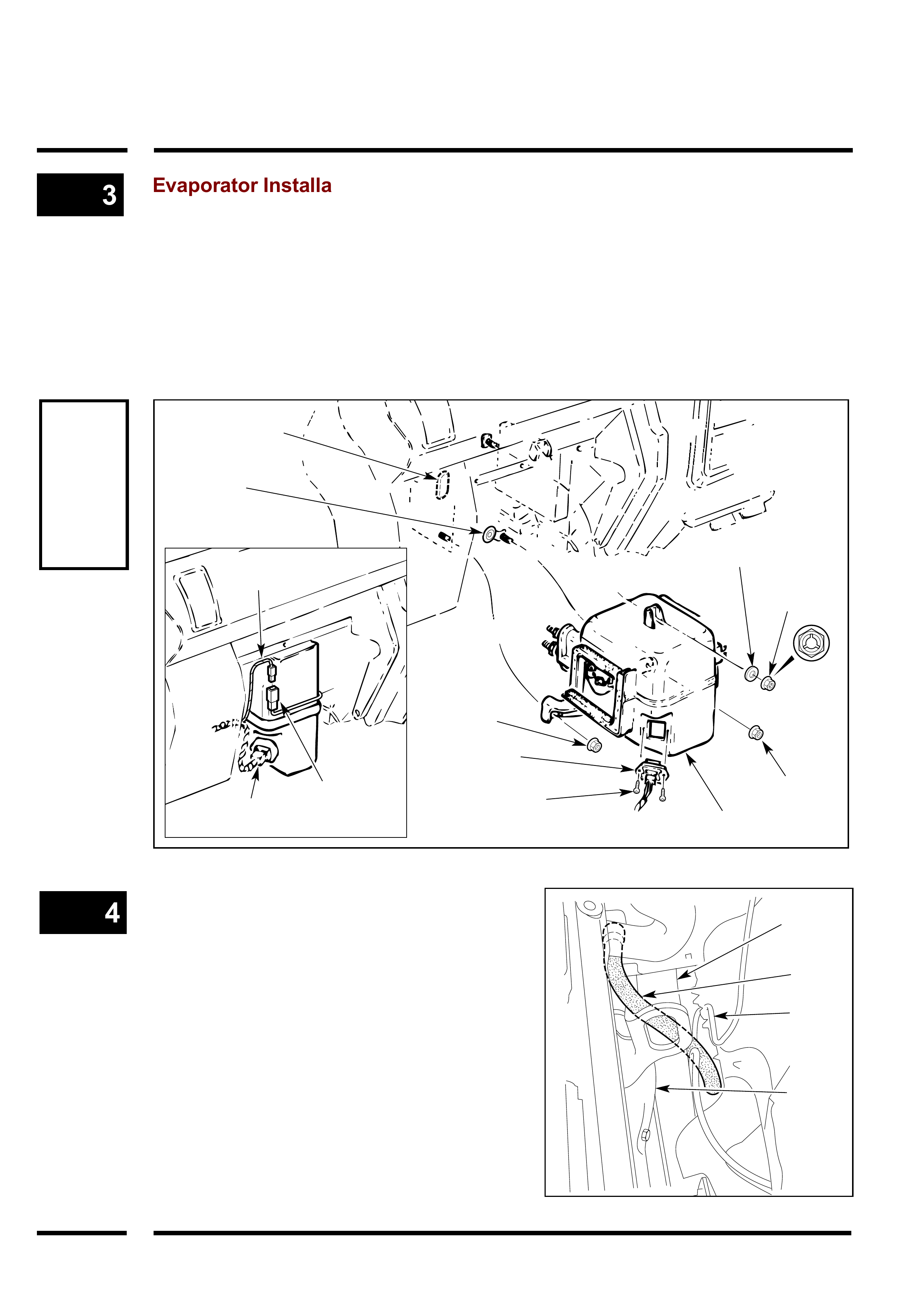

Evaporator Installation

a. Remove and discard (2) firewall rubber

blanking plugs.

b. Fit the original blower resistor to evaporator

case with (2) new self tapping screws.

c. Remove right lower blower case 6mm

nut and retain.

d. Install evaporator assembly into position

and retain with (1) supplied 6mm nut, (1)

Evaporator Drain Hose Installation

a. From the engine bay install the drain hose

to the evaporator drain tube. Route drain

hose away from the exhaust manifold and

behind the brake tube as shown.

b. Re-install all parts.

CAUTION

Do not

overtighten

evaporator

mounting

nuts as stud

damage will

occur.

original 6mm nut and (1) 6mm PAINT

STRIPPING nut and 7mm flat washer for

the upper mounting.

NOTE: Care should be taken when

installing evaporator assembly as the

fresh/recirc cable could become

dislodged.

e. Connect evaporator wiring electrical plug

to original harness in vehicle, then

reconnect blower resistor electrical plug.

(2) Self

Tapping

Screws

Blower

Resistor

(1) 6mm Nut

(1)

Original

6mm Nut

Evaporator

(1) 7 x 25mm

Flat Washer

(1) 6mm Paint

Stripping Nut

Original

Harness

Evaporator Pipe

Blanking Grommet

Evaporator Drain

Hose Plug

Evaporator

Wiring Plug

Blower

Resistor Plug

Brake

Tube

Drain

Hose

Chassis

Rail

Exhaust

Manifold

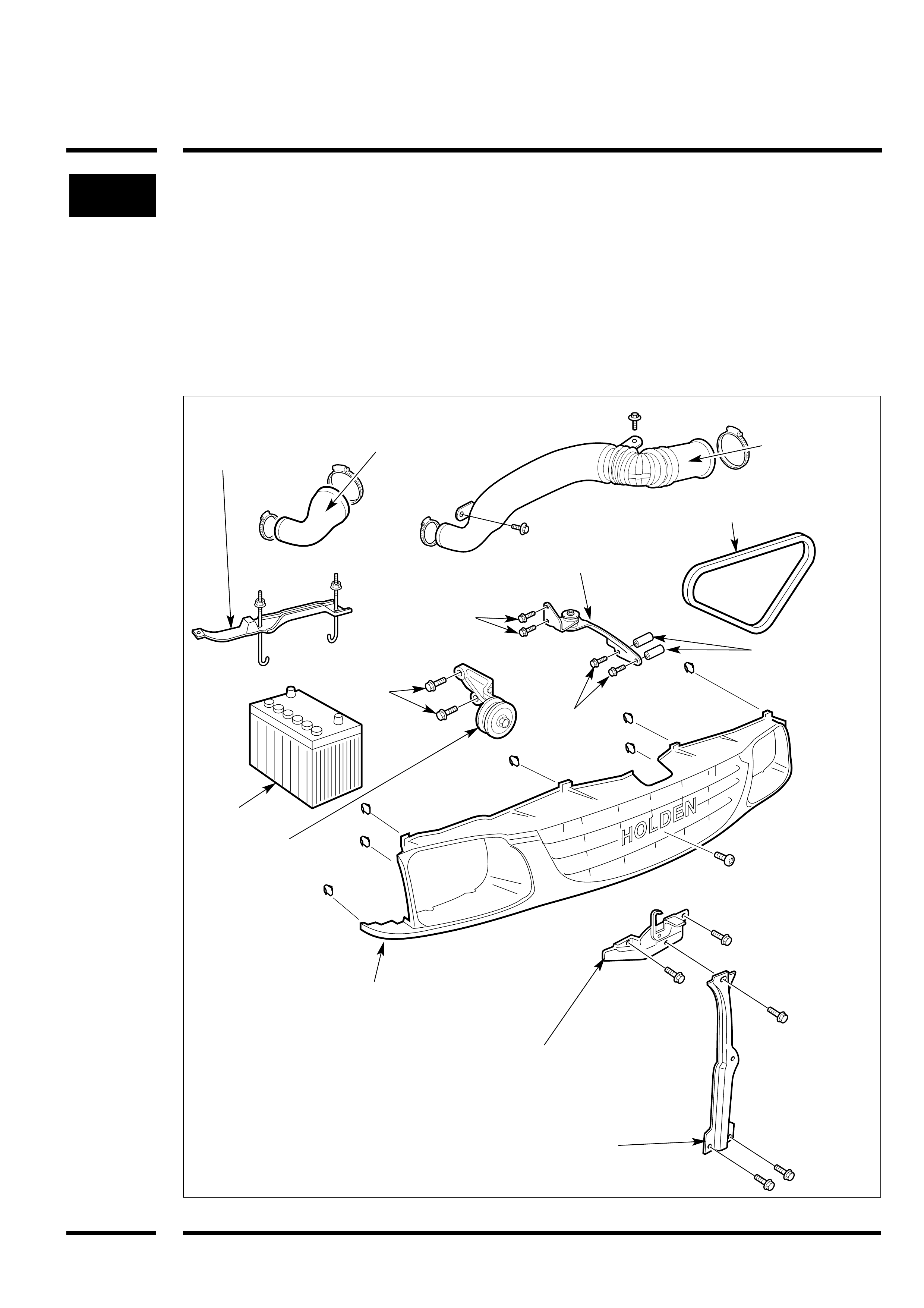

5Parts to be Removed

(Engine Compartment)

a. Grille (8) clips and (1) screw.

b. Unclip wiring harness from battery

retaining rod.

c. Battery and clamp.

d. Bonnet lock support (3) bolts.

e. Bonnet catch (2) bolts.

f. Idler pulley (2) bolts (discard).

g. Belt (discard).

4JH1-TC Engine Only

h. Air intake tube (2) clamps and (4JH1-TC)

(2) bolts.

i. Intercooler mounting bracket (2) bolts

(retain), (2) bolts (discard) and (2)

spacer tubes (discard).

Grille

Bonnet

Lock

Support

Bonnet

Catch

Battery

Idler Pulley

(Discard)

Belt

(Discard)

(2) Bolts

(Discard)

(2) Bolts

(Discard)

4JHI-TC Engine

(2) Bolts (Retain)

(2) Spacer Tubes

(Discard)

4JHI-TC Engine

Intercooler

Mounting Bracket

(Retain)

6

CAUTION

Co-ordinate

top radiator

hose

clamp at

thermostat

housing to

eliminate the

possibility of

belt contact.

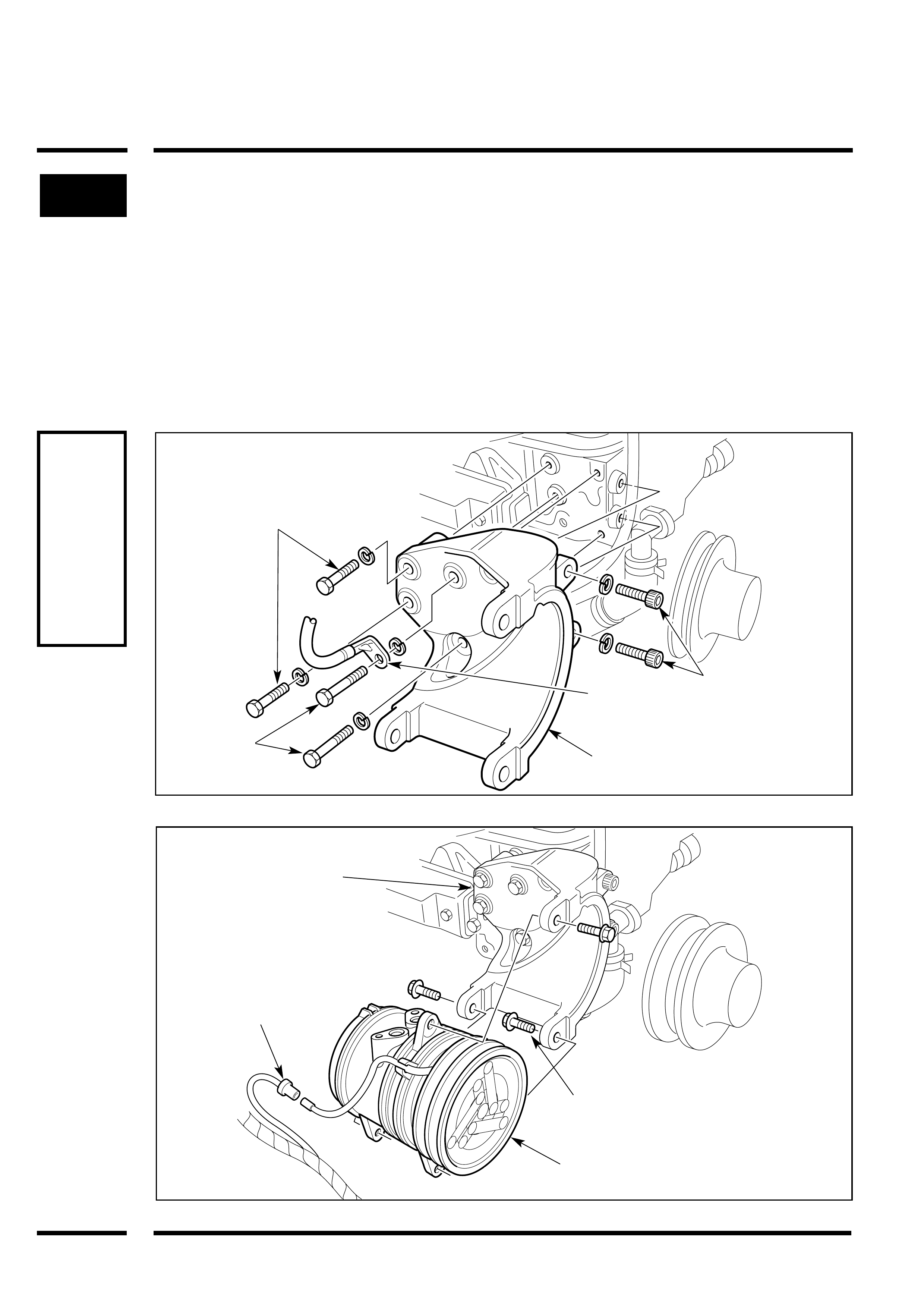

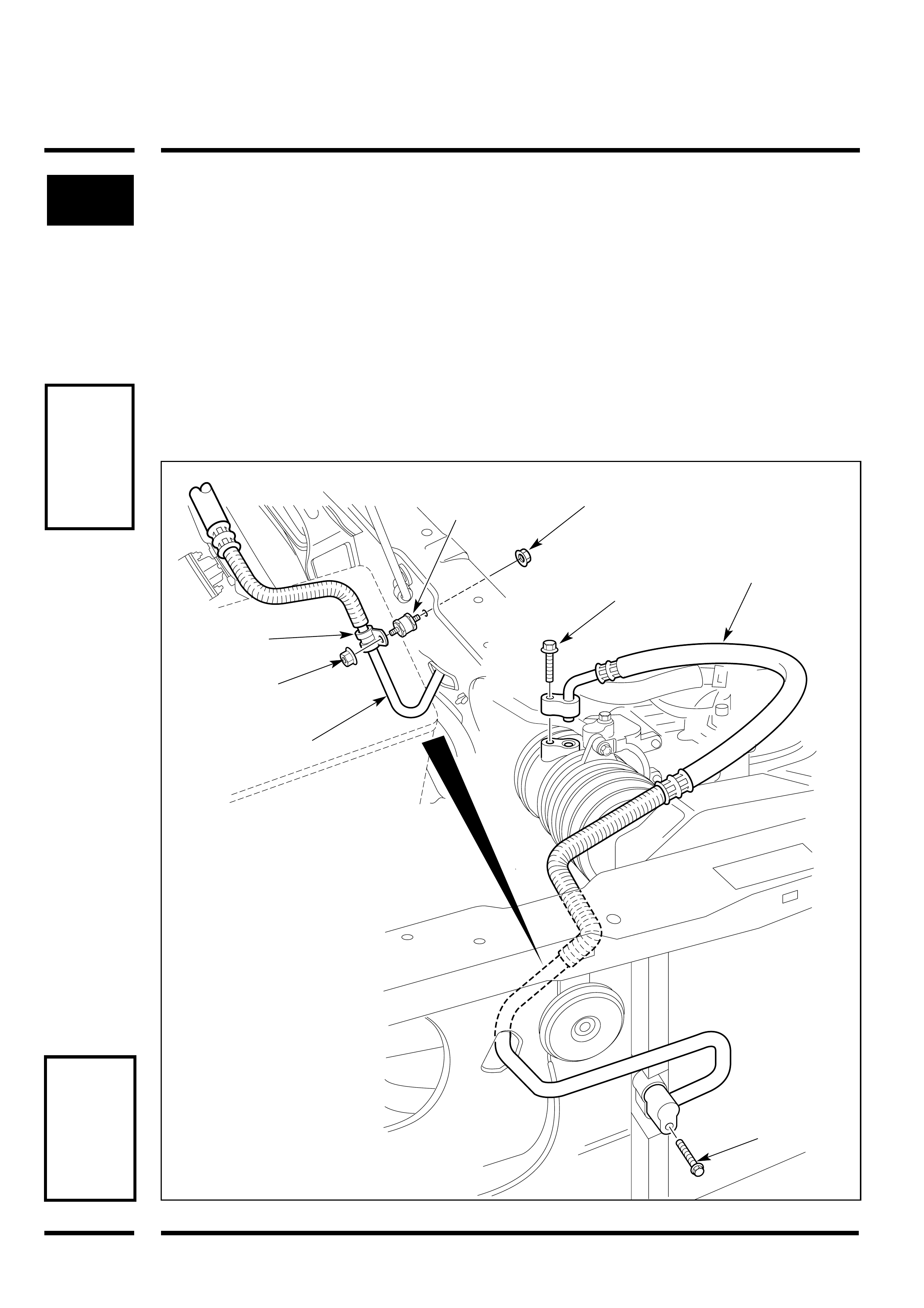

Compressor and Mount Installation

4JB1 Engine

a. Remove (2) existing bolts in the

thermostat housing and discard.

Note: Fit negative battery cable to mounting

as indicated below.

b. Install compressor mounting bracket to

engine using (2) M8 x 40mm, (2) M10 x

45mm bolts and (4) spring washers and

(2) M8 x 40mm capscrews and (2) spring

washers in positions indicated below.

c. Install compressor to upper mounting

bracket first, using (1) M8 x 30 washer

faced bolt then swing compressor

downwards and fit the lower mounts

using (2) M8 x 30mm washer faced bolts.

d. Loosen power steering pump, install A/C

belts and tension to 50kg (see caution).

e. Connect compressor clutch wire to

vehicle loom (green wire at thermostat

housing).

(2) M8 x 40mm

Bolts & Spring

Washers

(3) M8 x 30mm

Washer Faced

Bolts

(2) M8 x40mm

Cap Screws &

Spring Washers

(2)

M10 x 45mm

Bolts & Spring

Washers

Negative

Battery Lead

Vehicle Harness

Connector

(Green Wire

Compressor

Mounting Bracket

Compressor

Mounting Bracket

Compressor

CAUTION

Co-ordinate

top radiator

hose

clamp at

thermostat

housing to

eliminate the

possibility of

belt contact.

(2)

Original

Bolts

(1) M8 x 45mm

Bolt & Spring

Washer

(1) M8 x 40mm

Bolt & Spring

Washer

(1) M10 x 50mm

Bolt & Spring

Washer

(2) M8 x40mm

Cap Screws &

Spring Washers

(1) M10 x 45mm

Bolt & Spring

Washer

Negative

Battery Lead

Compressor

Mounting Bracket

(3) M8 x 30mm

Washer Faced

Bolts

Vehicle Harness

Connector

(Green Wire

Compressor

Mounting Bracket

Compressor

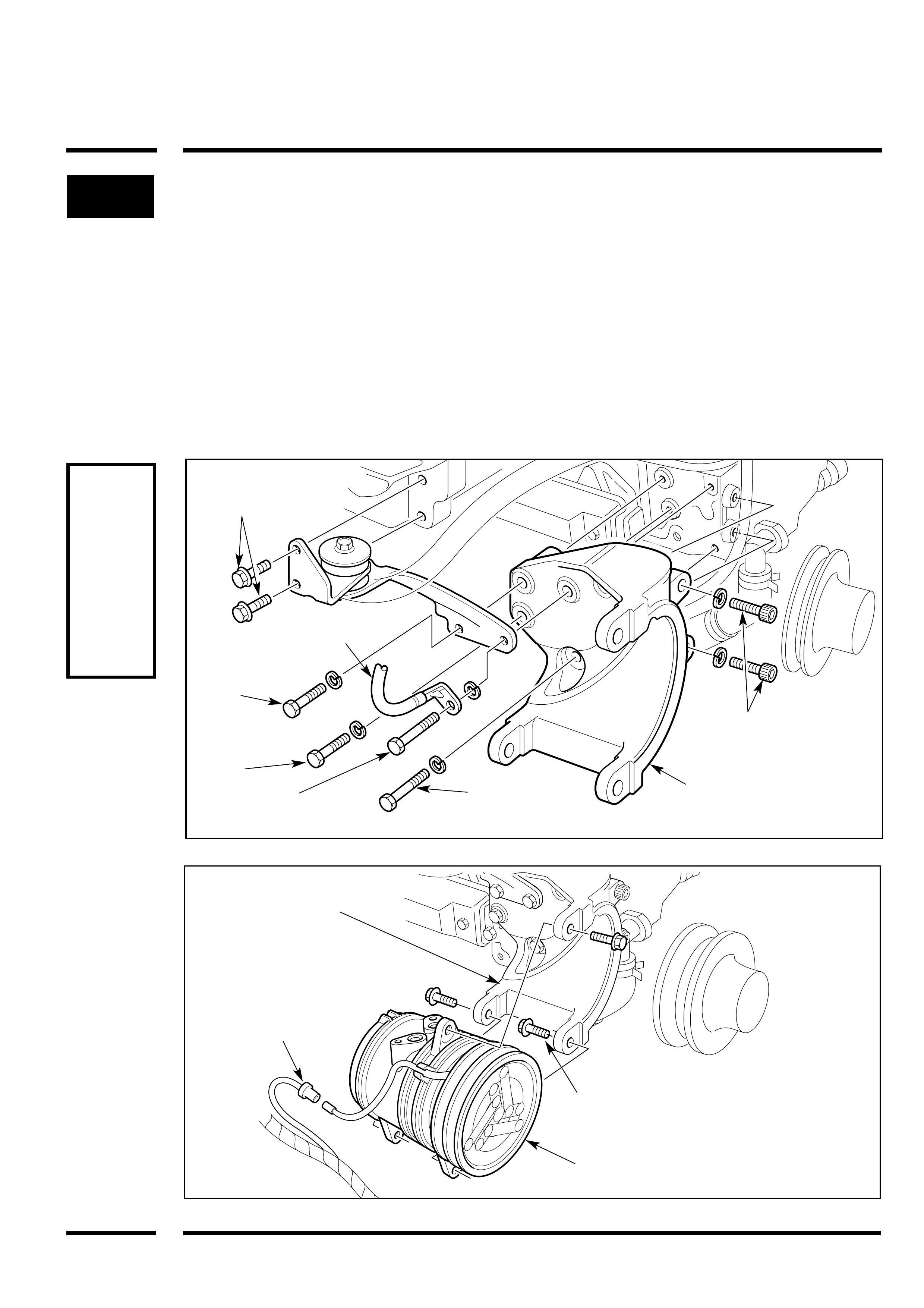

7Compressor and Mount Installation

4JH1-TC Engine

a. Remove (2) existing bolts in the

thermostat housing and discard.

b. Secure compressor mounting bracket to

engine by installing the lower mounting

bolts (1) M10 x 45 bolt, (1) M8 x 40 bolt

and (2) spring washers.

Note: Fit negative battery cable to mounting

as indicated below.

c. Install the intercooler mounting bracket

(previously removed) to the upper position

of the compressor mount. Secure with (1)

M10 x 50 bolt, (1) M8 x 45 bolt, (2) spring

washers and (2) original bolts.

d. Install compressor to upper mounting

bracket first, using (1) M8 x 30 washer

faced bolt then swing compressor

downwards and fit the lower mounts

using (2) M8 x 30mm washer faced bolts.

e. Loosen power steering pump, install A/C

belts and tension to 50kg (see caution).

f. Connect compressor clutch wire to vehicle

loom (green wire at thermostat housing).

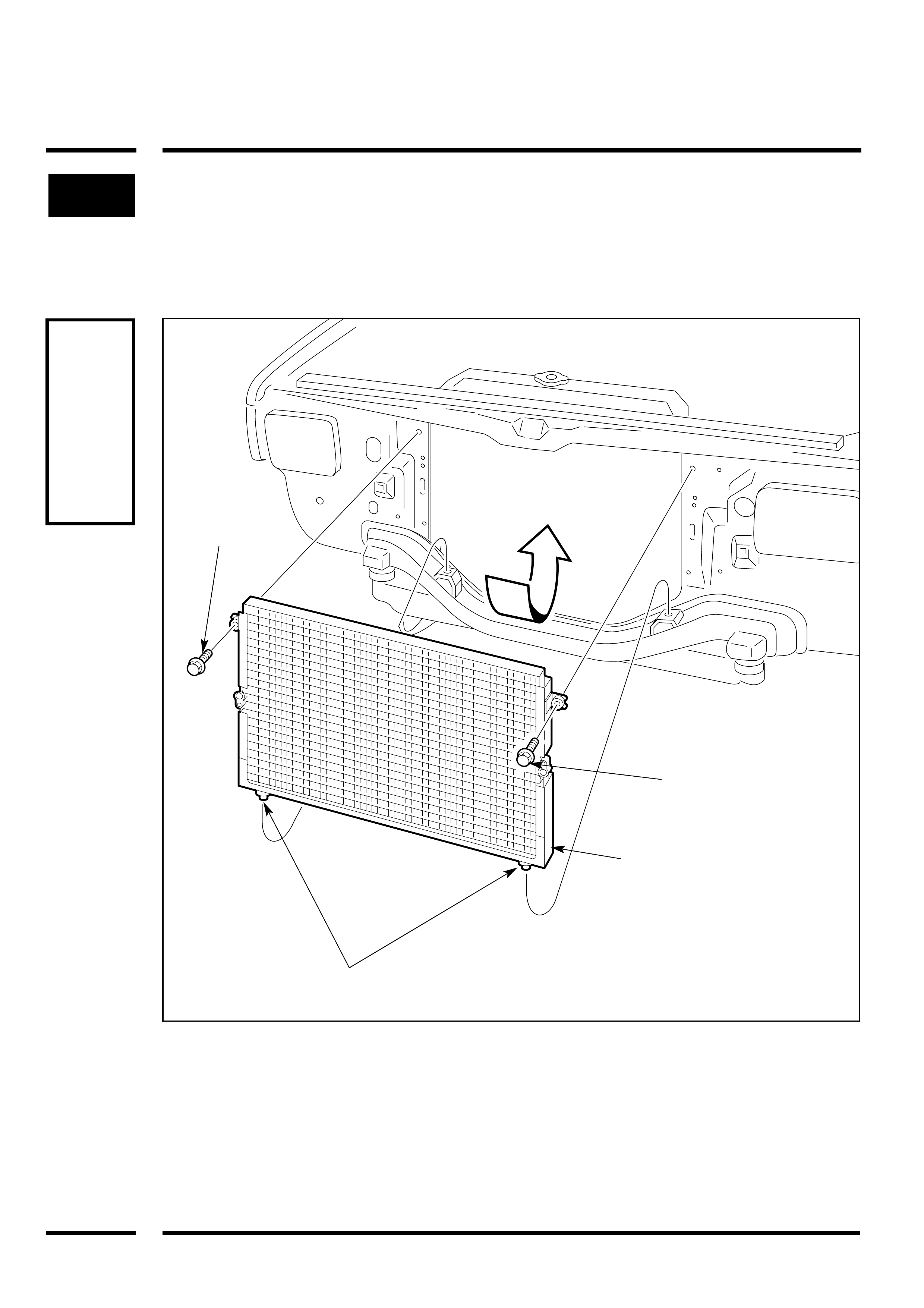

8Condenser Fitment

a. Insert condenser into front panel radiator

opening ensuring that the mounting

cushions are in position and secure with

(2) M6 x 30mm washer faced bolts in the

position shown.

CAUTION

Be careful

not to

cause

radiator

face

damage

when

installing

condenser

Condenser

Mounting Cushions

M6 x 30mm

Washer

Faced Bolt

M6 x 30mm

Washer

Faced Bolt

Hoses & Tubes - Liquid Tube (A)

a. Fit liquid tube (A) loosely to FDR and

secure to condenser pad fitting using (1)

M6 x 60 washer faced bolt.

b. Tighten FDR mount clamping bolt to

specified torque.

9

10

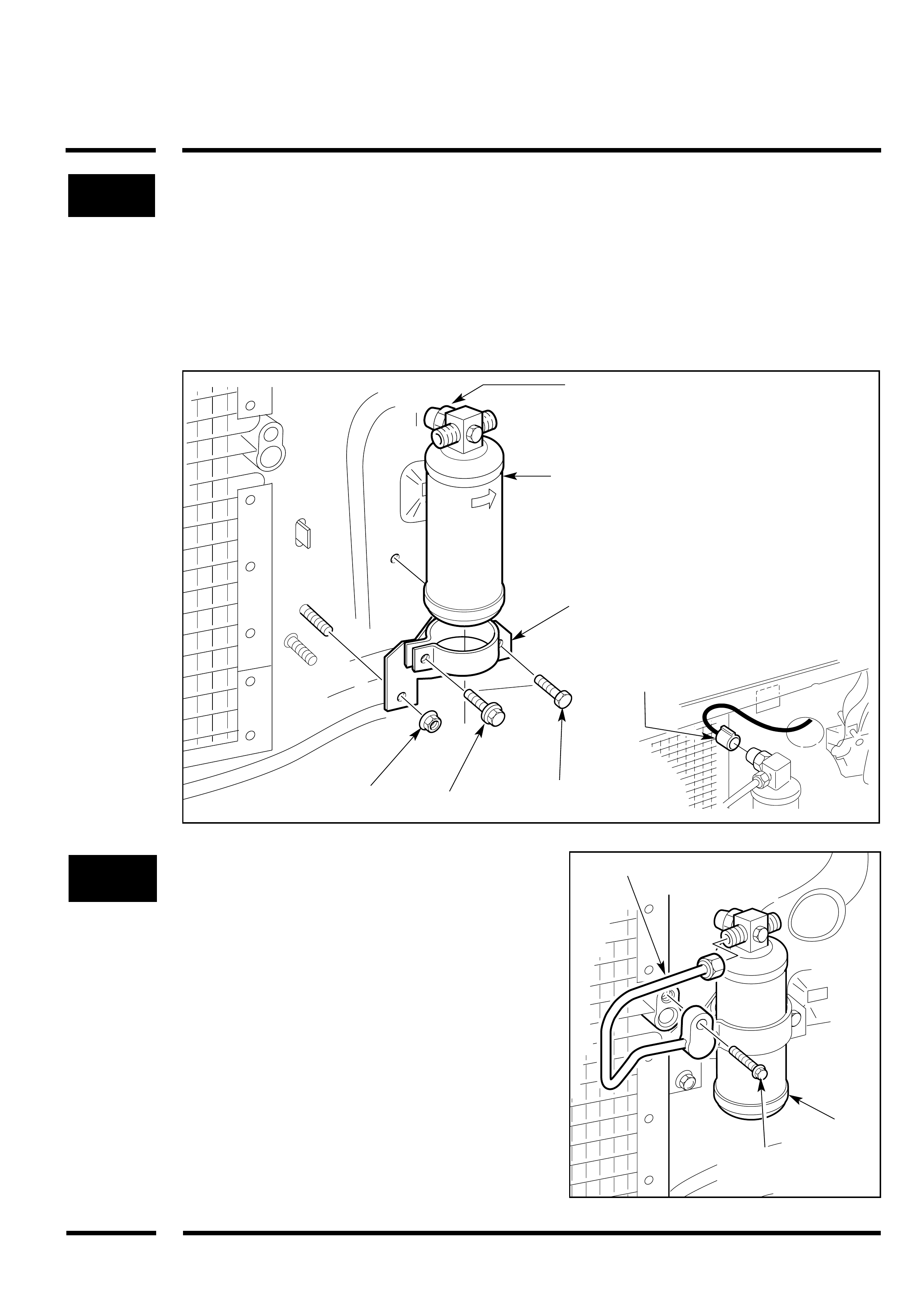

FDR Bracket, FDR and Pressure

Switch Wiring Installation

a. Fit FDR bracket to radiator support panel

using (1) M6 x 12mm bolt and (1)

existing 8mm washer faced nut.

b. Insert filter drier into bracket, position as

indicated below and fit clamping bolt

(1) M6 x 30mm.

NOTE: Do not tighten mounting bolt at this

stage

c. Connect pressure switch to loom plug.

NOTE: Ensure that the filter drier is fitted

with the pressure switch facing back

towards the engine.

FDR

FDR

Bracket

Existing Nut M6 x 30mm Bolt

Liquid Tube (A)

FDR

M6 x 12mm

Bolt

Pressure Switch

Plug

(Facing Back

Towards Engine)

(1) M6 x 60

Washer Faced Bolt

Pressure Switch

Connection

IN

OUT

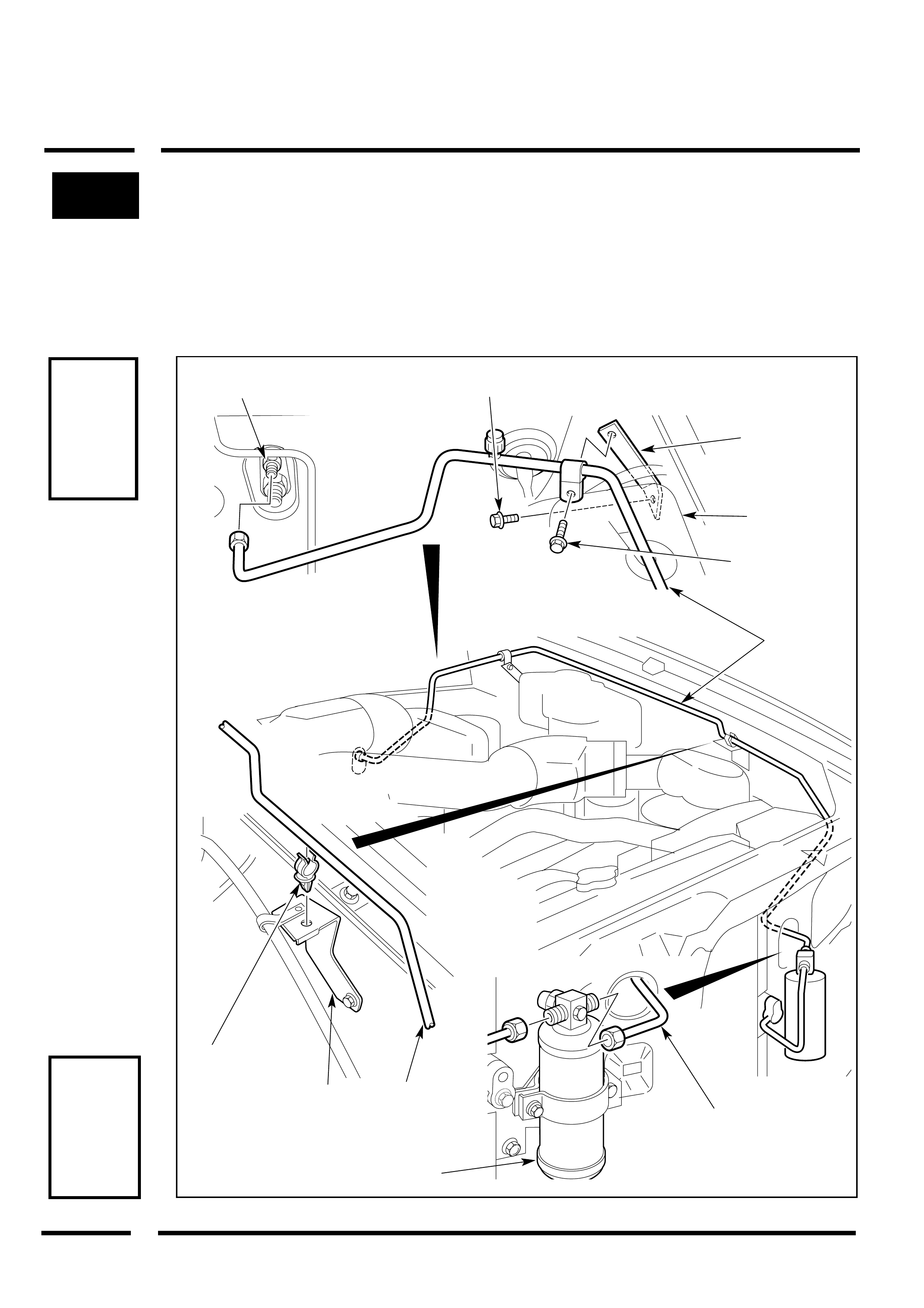

11 Hoses & Tubes - Liquid Tube (B)

a. Install liquid tube (B) through radiator

support panel.

b. Secure liquid tube (B) to evaporator inlet

tube and filter drier outlet.

c. Fit the liquid tube support bracket

behind the washer bottle lug using

NOTE

Tube

tightening

torques as

indicated

on Page 3

Liquid Tube

Retaining

Bracket

Existing Bolt

Evaporator

Inlet Tube

(1) M6 x 12mm

Washer Faced

Bolt

Washer

Bottle

Liquid

Tube (B)

Liquid

Tube (B)

Liquid

Tube (B)

Existing

Bracket

existing bolt. Secure liquid tube (B) to

mounting bracket using (1) M6 x 12

washer faced bolt and clamp.

d. Fit the plastic retaining clip into the

existing bracket on the LH side inner

guard to secure liquid tube (B).

e. Torque fittings to specifications.

NOTE

All ‘O’ Rings

are pre

lubricated at

the

manufactur

er

FDR

Plastic

Clip

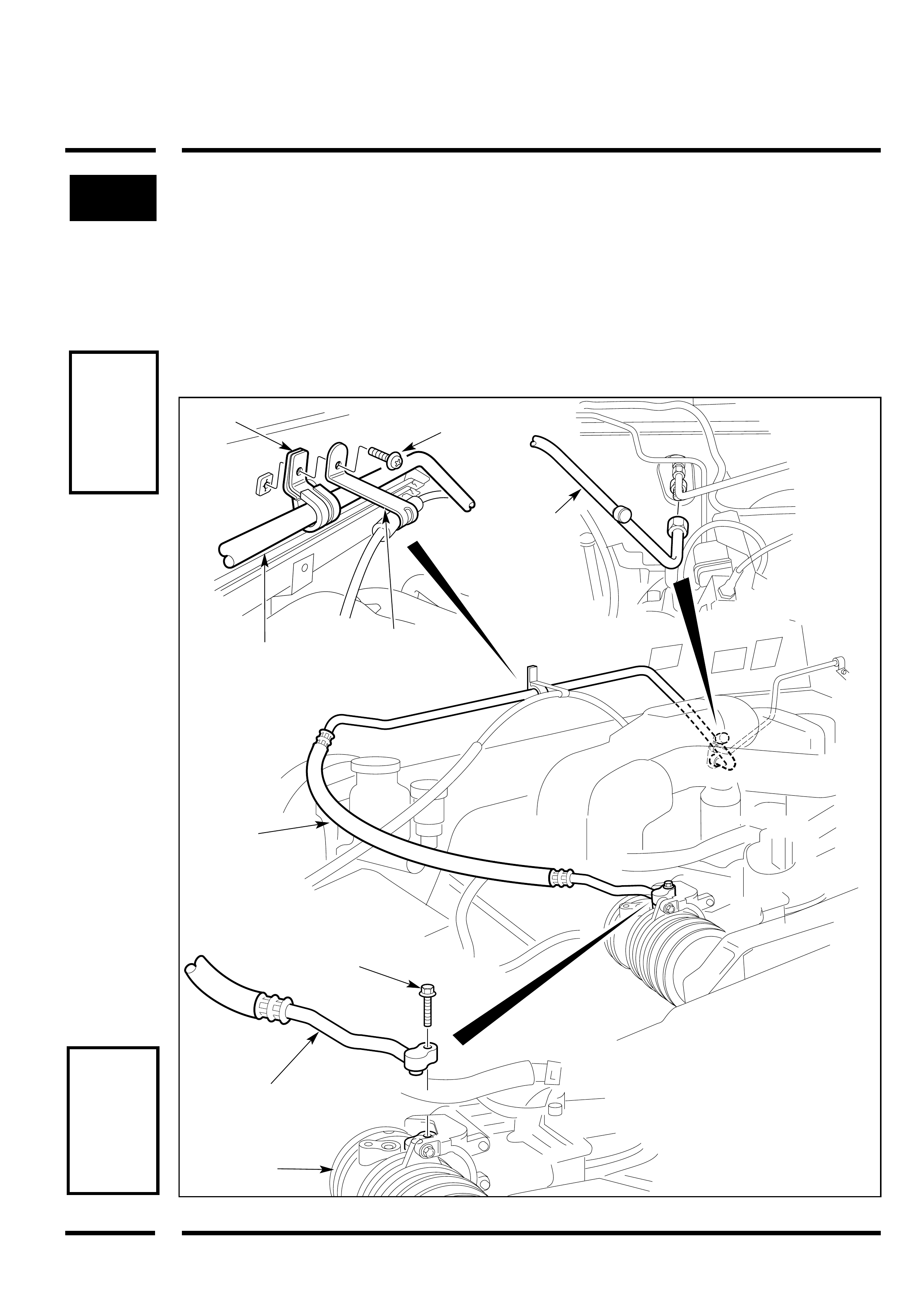

12 Hoses & Tubes - Suction Tube

a. Route suction tube/hose assembly from

evaporator to compressor. Torque fitting

to specification (see page 1).

b. Install suction hose pad fitting to

compressor using (1) M8 x 30 bolt and

torque to 20-30Nm.

c. Remove screw from accelerator cable

retaining bracket at firewall.

Self Tapping

Screw

Clamp

Accelerator Cable

Retaining Bracket

(4JB1 Only)

Suction

Tube

Suction

Tube

Compressor

Suction

Tube

Suction

Tube

(1) M8 x 30

Washer

Faced Bolt

d. Install clamp (stamped 09-74729) to

suction tube. Secure the clamp behind

the accelerator cable retaining bracket

(4JB1) or the clamp on its own (4JH1-TC)

using (1) self tapping screw (found in the

mount and drive carton).

NOTE

All ‘O’ Rings

are pre

lubricated at

the

manufactur

er

NOTE

Tube

tightening

torques as

indicated

on Page 3

13 Hoses & Tubes - Discharge Tube

a. Feed discharge tube through radiator

support panel and connect to condenser

pad fitting using (1) M6 x 60mm washer

faced bolt.

b. Remove shipping plate and bolts from

compressor and discard. Install discharge

hose pad fitting to compressor using (1)

M8 x 30 bolt and torque to 20-30Nm.

c. Secure discharge tube to radiator

support panel (engine side) using (1)

insulator mount, (1) clamp and (2) M6

washer faced nuts.

LT SPORT ONLY

d. Remove the bolt and nut from the upper

RH headlamp mounting and discard.

e. Insert rubber insulator stud through the

radiator support panel and headlamp

mounting. Secure with (1) M6 washer

faced nut.

f. Secure discharge tube to the rubber

insulator stud, using (1) clamp and (1) M6

washer faced nut.

Torque to specifications (See page 1).

NOTE

All ‘O’ Rings

are pre

lubricated at

the

manufactur

er

NOTE

Tube

tightening

torques as

indicated

on Page 3

Discharge

Tube

Discharge

Tube

Insulator

Mount

Clamp

M6 Washer

Faced Nut

M6 Washer

Faced Nut

(1)

M6 x 60mm

Washer

Faced Bolt

(1) M8 x 30

Washer

Faced Bolt

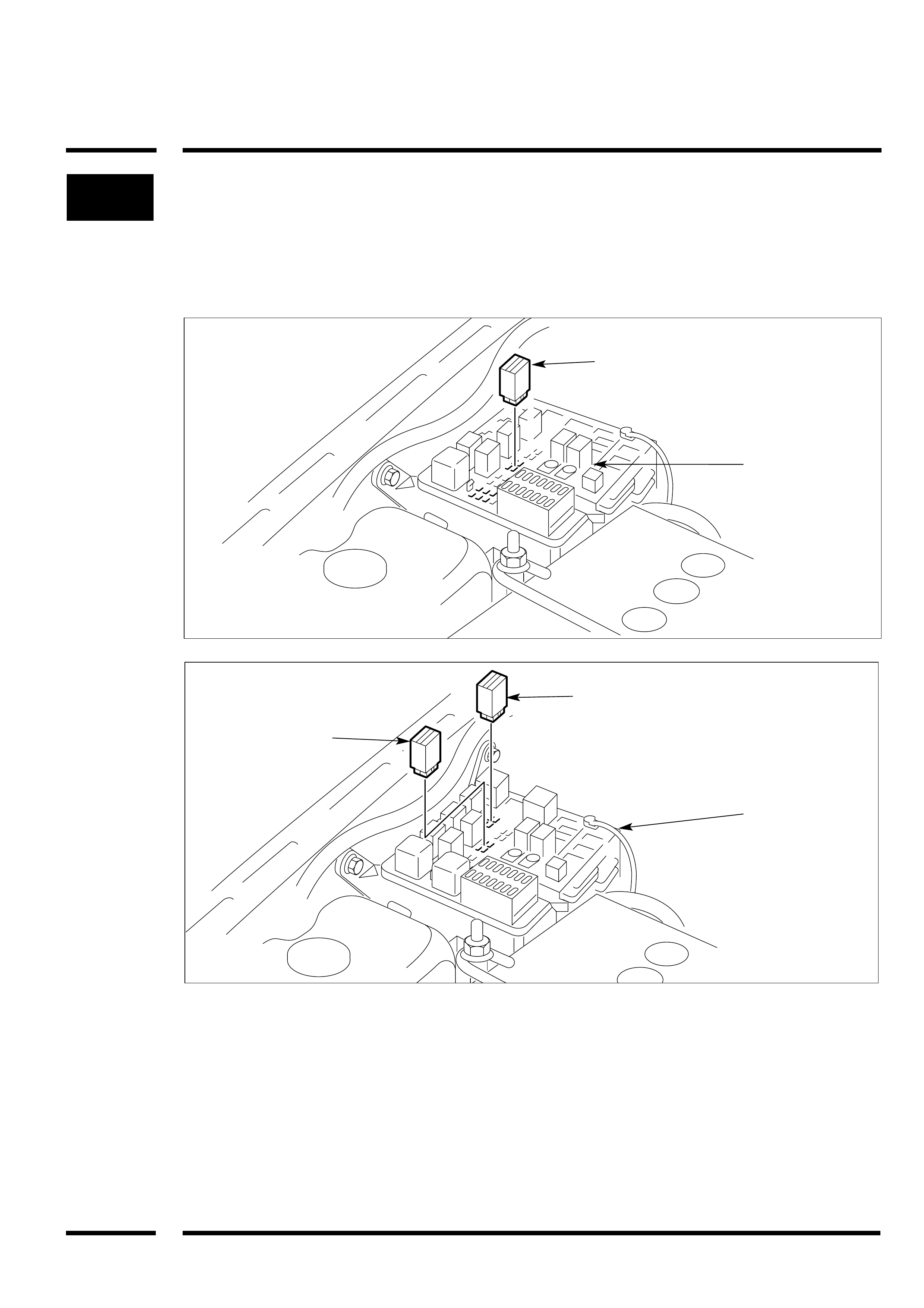

14 Compressor Relay

a. Locate fuse and relay panel, RH side

inner guard, remove cover and fit (1)

micro relay (4JB1) or (2) micro relays

(4JH1-TC) supplied to position(s) shown.

b. Reinstall all parts previously removed.

Fuse/Relay

Panel

Relay

4JB1

Fuse/Relay

Panel

A/C

Compressor

Relay

A/C Thermo

Relay

4JH1-TC

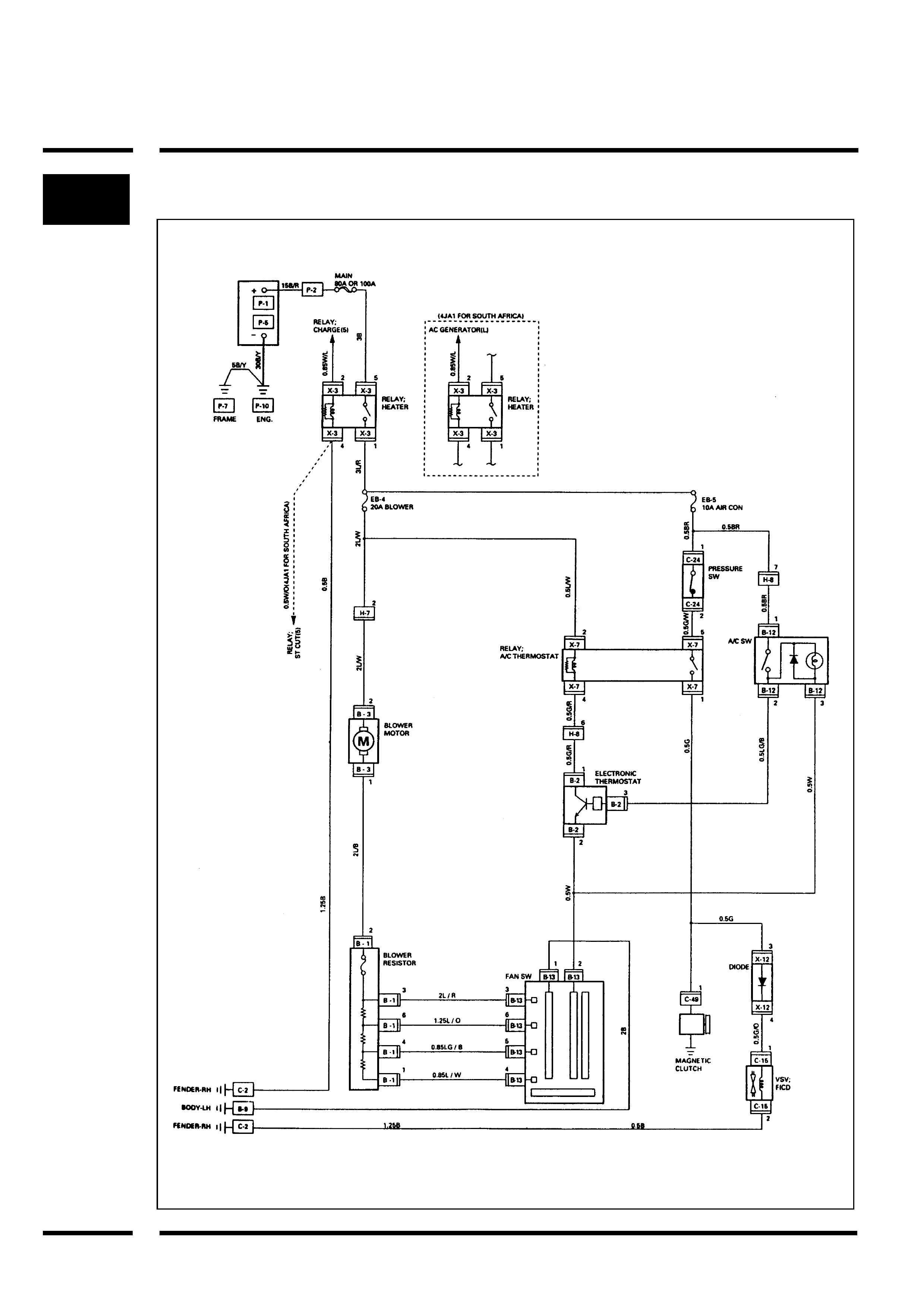

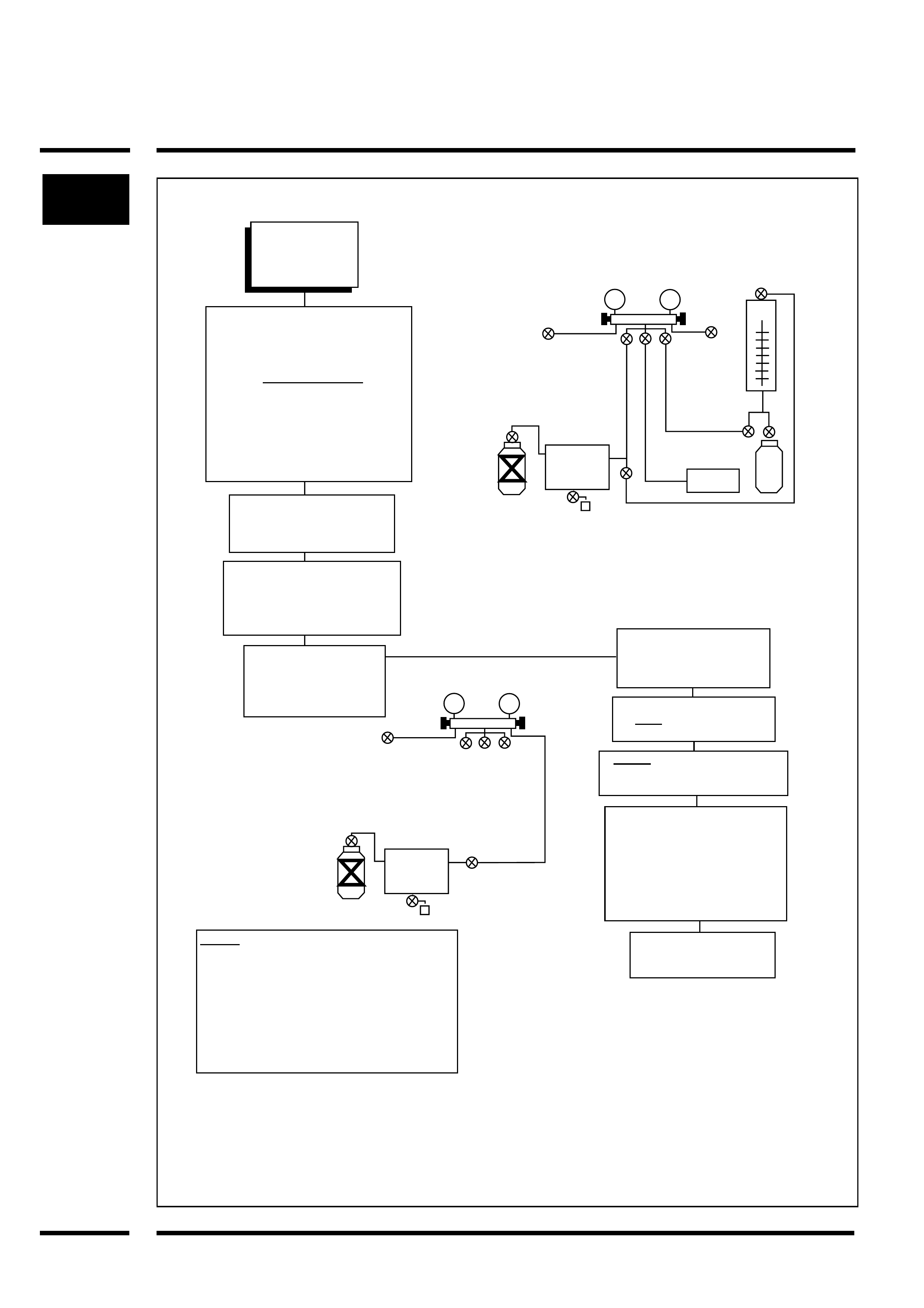

15 Wiring Diagram

CEFG

AB

D

H

LOW HIGH

REFRIGERANT

RECOVERY

UNIT VACUUM

PUMP

SPECIFIED CHARGE 750 +/- 25 GRAMS

NOTE: 1. Gloves and safety glasses

must be warn.

2. Work in a well ventilated

area.

3. Do not smoke near

refrigerant.

4. Aviod PAG oil contacting

paint work. Wash off

immediatly.

5. Do not smoke near

refrigerant.

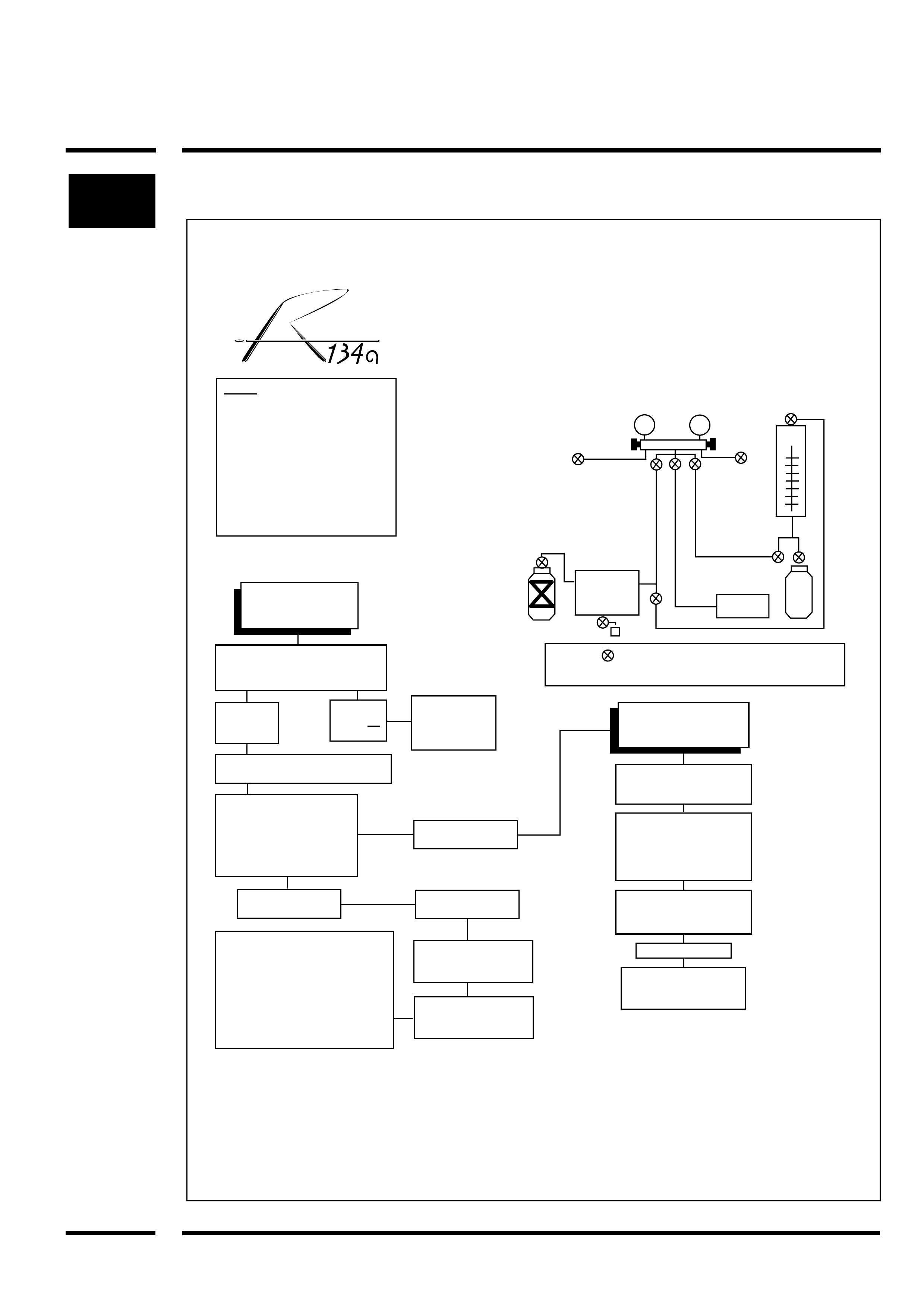

Start vacuum pump, open valve F,

open valves A & C low pressure

filling hose.

High side

gauge reads

below zero

High side

gauge not

below zero

Blockage or leak

evident in system.

find cause and

rectify.

Leave valves A, C, & F open. Slowly

open high side valves B & D.

Evacuate system to 6 kpa

absolute.

Close valves A, B & F.

System must maintain 6 kpa

-absolute for a minimum

of 15 mins.

Low pressure gauge

needle steady

Recover refrigerant from

system, open valves A, B, C,

D, E and H. After the recovery

procedure close valve E. Open

valve F and continue the evacuation

procedure for a minimum of 15 mins

then close valves A, B & F. Turn

pump off. (Refer Fig. 1)

Low pressure gauge

needle rises.

Continue evacuation

for 15 mins.

Partially charge system

with 200 grams of

refrigerant

Partially charge system with

200 grams of refrigerant

through high filling hose.

Locate leakage using an

electrical leak detector.

Check on the underside of

all fittings and components

Recover refrigerant from

system open valves A, B, C,

D, E, & H. (Refer Fig. 1)

Repair leak source

Continue with evacuation

and charging procedure

as per steps 1-3

NOTE: Indicates stop tap or valve-fit these

whenever a hose has to be removed

Fig. 1

Check for leakage using

an electronic leak

detector

STEP 1

EVACUATION

STEP 2

LEAK TESTING

16

Evacuation and Charging Procedure

C

EFG

A

B

D

H

LOW

HIGH

REFRIGERANT

RECOVERY

UNIT

VACUUM

PUMP

C

A

B

D

H

LOW

HIGH

REFRIGERANT

RECOVERY

UNIT

First Aid: In the event of R134a contacting the

eye, carry out the folllowing procedure:-

1. Do not rub eye

2. Splash large quantities of water into the eye to

raise the temperature.

3. Continue to irrigate the eye for 15-20 mins.

4. Take patient without delay to hospital or

physician.

5. Do not attempt to treat yourself.

Start engine set to fast idle.

Activate A/C switch. Set

controls to maximum cooling

and high fan speed.

Open low side valves, A & C

slowly and complete the

charging process (If required).

Caution: do not allow more than

275 kpa to register on the low

side gauge during charging.

Close all valves and taps.

Remove high and low filling hoses,

make sure valves C & D are closed.

Connect high side filling hose to

recovery unit inlet side. Open valves

A, B & D. Switch on recovery machine

and remove all refrigerant in filling

hoses. (Refer Fig. 3)

Carry out performance testing.

Refer appropriate workshop

manual for specifications.

Fig. 3

Fig. 2

Warning: Never run compressor

without refrigerant in

system as the compressor

relies on refrigerant/oil flow.

Any oil displaced during the

refrigerant recovery process

must be replaced in the

system before charging can

commence. The R134a

system uses P.A.G. (poly-

alkaline glycol) lubricating

oil. Use specified oil type.

Warning: Never charge system

through the high side

with the compressor

running.

Open high side valves B, D & G.

Allow as much refrigerant as

possible to enter system, but

do not let more than the specified

amount enter the system.

Close valves B & D. rotate

compressor front plate 12

revolutions to ensure no

liquid is trapped in the

compressor.

STEP 3

CHARGING

SYSTEM

17