FITTING INSTRUCTIONS FOR

V2 COUPE "MONARO"

1600 kg TOW BAR PACKAGE

Part Number 92144445

COPYRIGHT

Page 1 of 10

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FD1028

28OC02

G736

Page 2 of 10

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

1,0 ~ 3,0 Nm1

1600kg TOW BAR FITTING INSTRUCTIONS

REAR BUMPER FASCIA, SUPPORT BEAM & BRACKETS REMOVAL

TOOLS REQUIRED

Allen Key - 6.0 mm, Screw Driver - Philips Head & Flat Bladed, Sockets - 10mm, 17mm, 19mm, Twist Drill - 3mm,

8mm, 10mm & 12mm, Power Drill, Saw, Knife, Vacuum Cleaner, Grease, Marker Pen, Scriber.

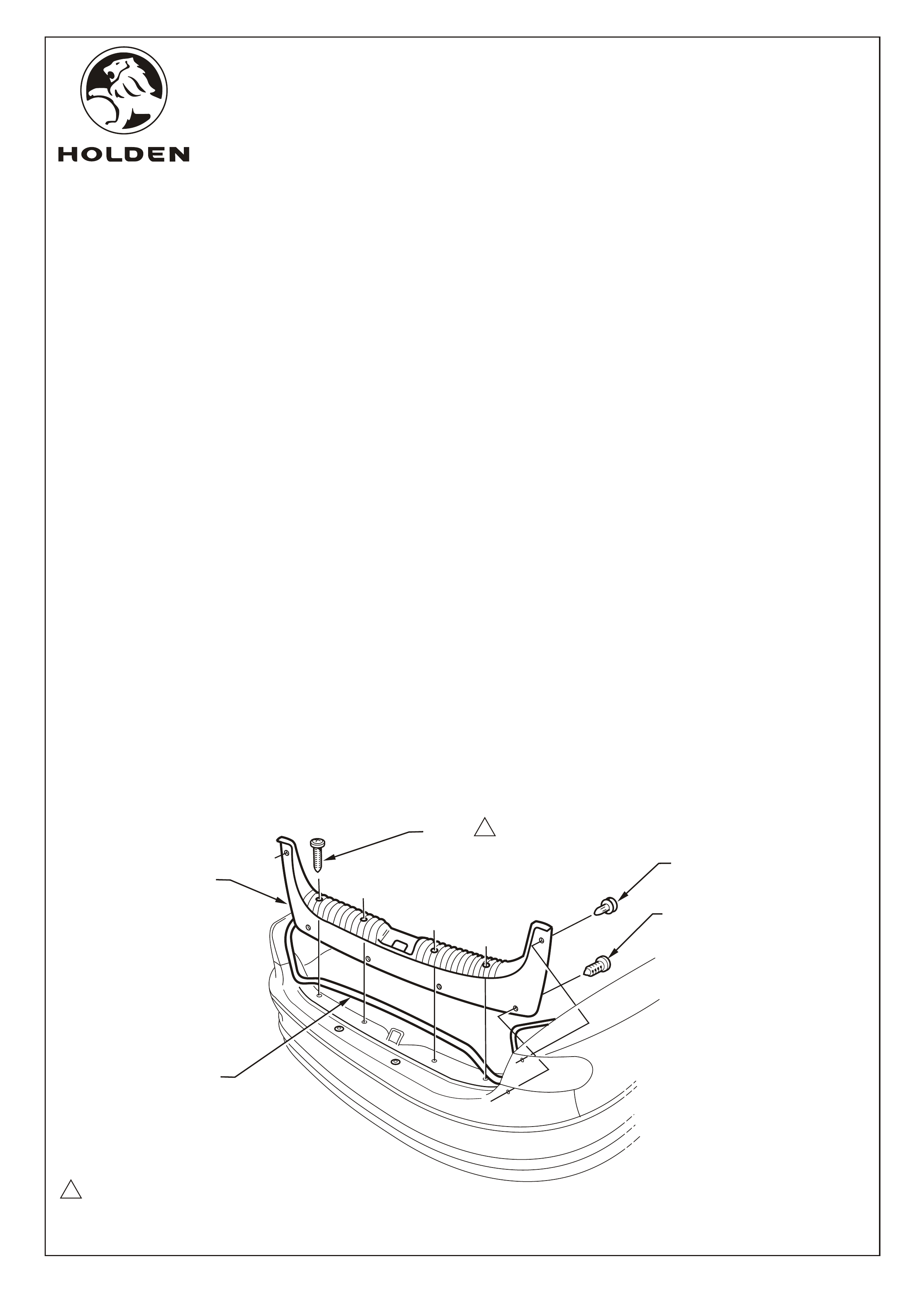

Open the rear compartment lid, lift up the floor carpet and remove the spare wheel.

Gently peel the rear compartment weatherstrip away from the opening flange to enable access to the four

bumper fascia scrivets.

Unscrew or prise out all of the fasteners retaining the rear compartment crossmember cover and remove the

cover. Refer View.

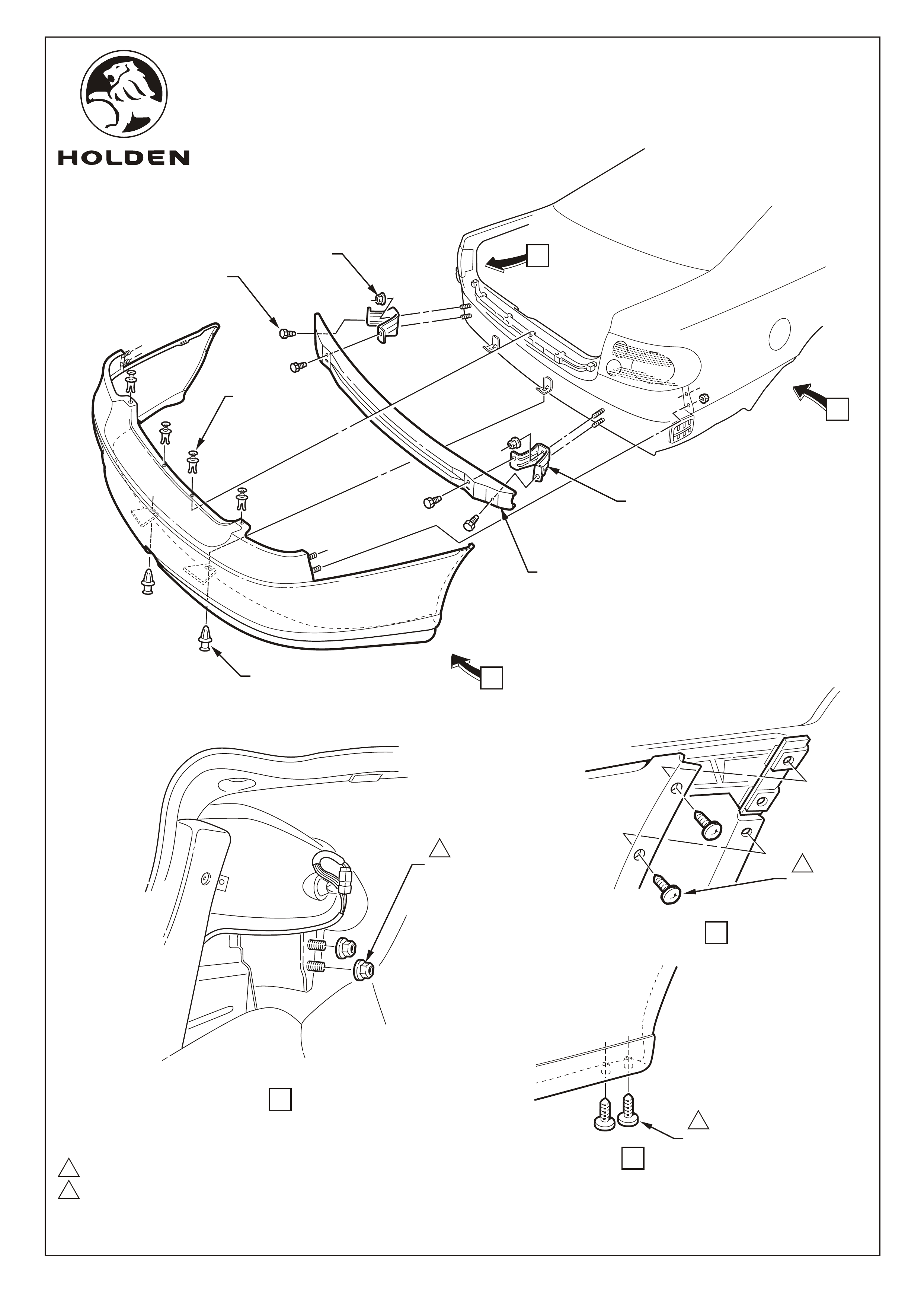

Fold the side carpet trims back from the rear corners of the rear compartment and remove the nuts (2 places

each side) securing the bumper fascia to the body. Refer View A, Page 3.

Remove the 4 scrivets on the upper edge and the 2 scrivets on the lower edge of the fascia. Refer View, Page 3.

Remove the screws, each side, fascia to the rear edge of the wheelhouse.

Refer Views B and C, Page 3.

With the fascia supported, pull the fascia sides outward disconnecting the side supports. Slide the fascia

rearwards and remove. Refer View Page 3.

Remove the bolts ( each side) securing the bumper support beam to the brackets, discard the

beam & bolts. Refer View Page 3.

Remove the nuts ( each side) securing the bumper support beam brackets to the vehicle, 2 places.

Remove the brackets and discard. Refer View Page 3. Retain the nuts for re-use.

4 places securing the

2 places

2 places

1.

2.

3.

4.

5.

6.

7.

8.

9.

1

SCREW

(4 PLACES)

SCRIVET

(2 PLACES)

WEATHERSTRIP

CROSSMEMBER

COVER

TRIM CLIP

(4 PLACES)

COPYRIGHT

G736

FD1028

28OC02

NOTE: BEFORE BEGINNING INSTALLATION CHECK VEHICLE TAG No. (Refer Page 6).

1.0 ~ 3.0 Nm

6.0 ~ 9.0 Nm

2

1

COPYRIGHT

Page 3 of 10

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

SCRIVET

(4 PLACES)

BUMPER SUPPORT

MOUNTING BRACKET

& DISCARD

REAR BUMPER

SUPPORT BEAM

& DISCARD

SCRIVET

(2 PLACES)

BOLT

(2 PLACES

R & L SIDE)

& DISCARD

NUT

(2 PLACES

R & L SIDE)

& RETAIN

2

A

B

C

VIEW B

SCREW

(2 PLACES

R & L SIDE)

VIEW A

NUT

(2 PLACES

R & L SIDE)

1

VIEW C

SCREW

(2 PLACES R & L SIDE)

1

G736

FD1028

28OC02

COPYRIGHT

Page 4 of 10

Reproduction in whole or part

prohibited without written approval

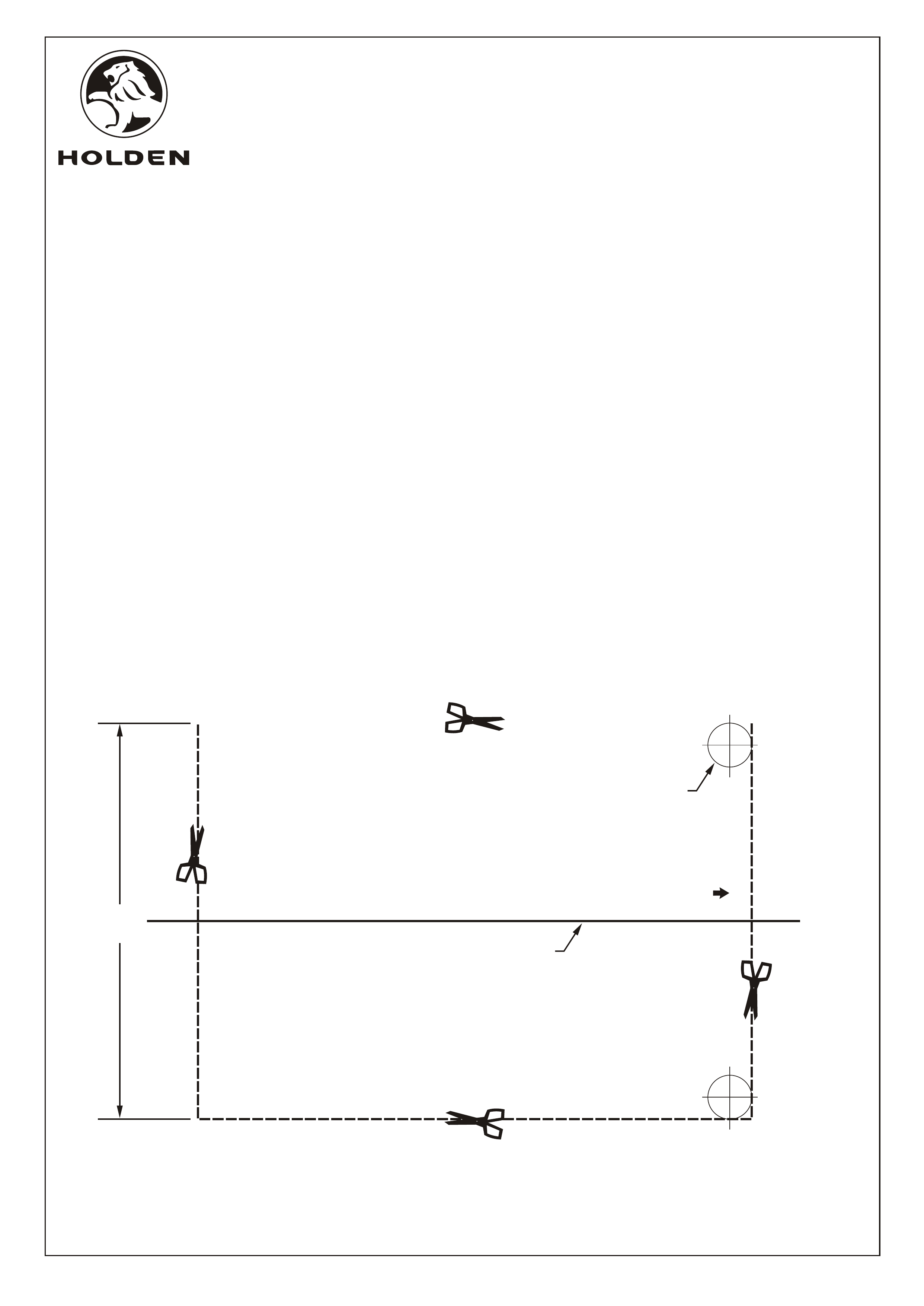

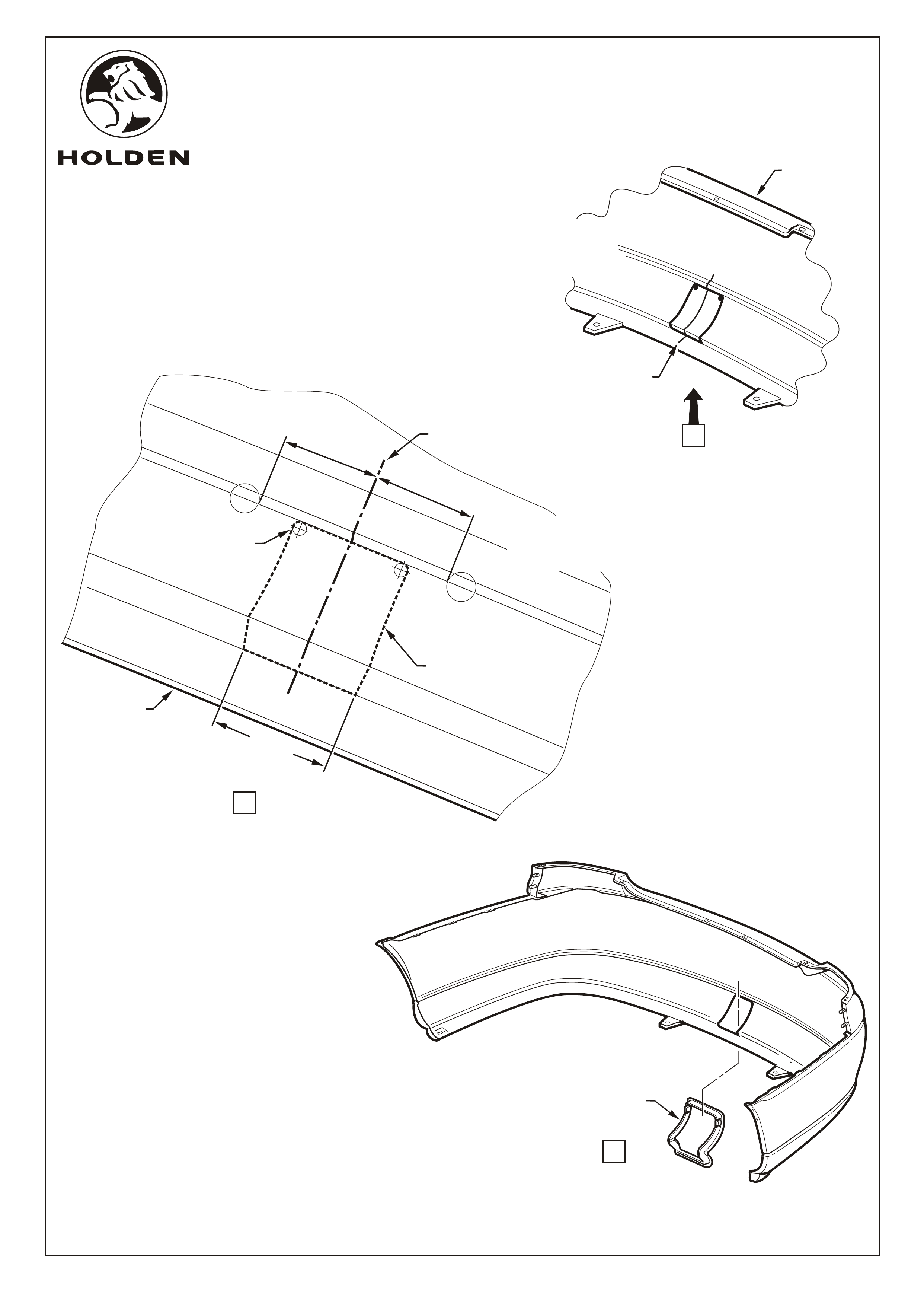

Before fascia refit, the tow bar tongue hole must be cut in the fascia

Cut out the template below, taking care to follow the perimeter line.

NOTE: The template must be 90 mm wide.

For vehicles without an embossed centre reference line, measure between the moulding injection marks

and scribe a centreline on the rear side of the fascia. Refer View A, Page 5.

Place the template on the rear side of the fascia and align the template centreline with the fascia centreline.

Refer View, Page 5.

Carefully mark the perimeter of the template on the fascia and scribe the pilot hole centre point.

Refer View, Page 5.

Drill 3.0mm dia. hole at each scribed centre point on the inside surface of the bumper fascia. Enlarge the holes

to 10.0mm. Refer View A, Page 5.

IMPORTANT: Do not drill outside the perimeter line as the surround will not cover this area.

Cut along the perimeter with a small saw or serrated knife, using care not to deviate outside the lines.

Refer View A, Page 5.

NOTE: The opening width must not exceed 90 mm.

Clean up the opening and install the tow bar surround into the fascia. Refer View B, Page 5.

10.

11.

12.

13.

14.

15.

16.

17.

HOLDEN SERVICE PARTS OPERATIONS

Division of HOLDEN Ltd ACN 006 893 232

DRILL 3.0 mm PILOT HOLES

IN FASCIA, THEN ENLARGE

TO 10.0 mm, 2 PLACES

UP

ALIGN CENTRE LINE WITH CENTRE

LINE ON FASCIA. TRANSPOSE

PERIMETER LINE TO FASCIA AND

CUT OUT TO SUIT SURROUND TRIM

CUT AROUND PERIMETER

LINE TO FORM TEMPLATE

C

L

90 mm

(REF.)

G736

FD1028

28OC02

COPYRIGHT

Page 5 of 10

Reproduction in whole or part

prohibited without written approval

HOLDEN SERVICE PARTS OPERATIONS

Division of HOLDEN Ltd ACN 006 893 232

TOWBAR SURROUND

VIEW B

CUT ALONG TEMPLATE

PERIMETER LINE

DRILL 3mm PILOT

HOLE & ENLARGE

TO 10mm.

(2 PLACES)

90mm

(REF.)

79 mm

79 mm

VIEW A

LOWER EDGE

OF FASCIA

FOR VEHICLES WITHOUT

*

EMBOSSED CENTRELINE,

MEASURE CENTRE OF INJECTION

MARKS AND SCRIBE CENTRELINE

EMBOSSED CENTRELINE

*

MARK PERIMETER OF

TEMPLATE AND SCRIBE

CENTRE OF HOLES.

BUMPER FACIA

TEMPLATE TO ALIGN

WITH CENTRELINE.

G736

A

FD1028

28OC02

COPYRIGHT

Page 6 of 10

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

TOW BAR INSTALLATION POST TAG No. L892399

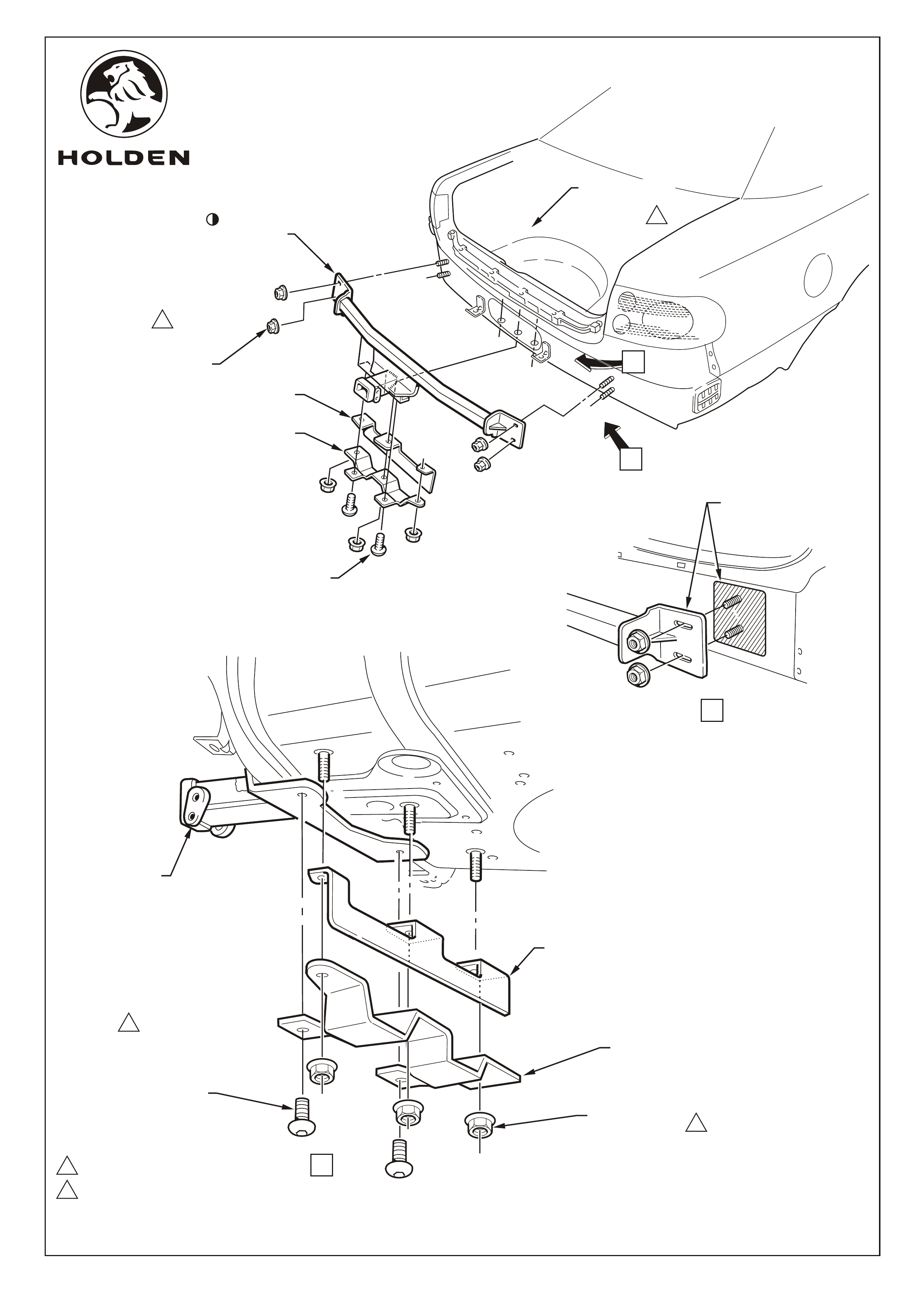

18. Scrape off any excess sealer from the body around the mounting studs where the towbar will seat. Refer

View A, Page 7.

19. Smear a thin film of grease to the bare metal exposed by removal of brackets and sealer and to the rear

face of the towbar bracket to prevent corrosion. Refer View A, Page 7.

20. Install the towbar to the four beam support studs. Centralise the towbar, fit the nuts and hand tighten,

2 places each side. Refer View A, Page 7.

21. Temporarily fit the rear bumper fascia and check that the towbar is protruding centrally through the cutout

in the fascia. Adjust the towbar as required.

22. Remove the fascia and tighten the nuts securing the tow bar to the body, 49 - 65 Nm, 2 places each side.

Refer view, Page 7.

23. Install the fuel tank shield and spare wheel well support to the spare wheel well and towbar. Fasten with the

button head socket screws (2 places), and M10 anti-rattle nuts (3 places). Tighten the spare wheel well

support nuts first, then the towbar screws to 30-40 Nm. Refer View B, Page 7.

G736

FD1028

28OC02

NOTE: Cars with TAG No.s Pre L892399 (see the last 7 characters of the VIN Number,

located behind the lower left-hand side front windscreen) require drilling holes for

fitting the spare wheel support, see separate instructions below.

Check you vehicle before starting this section.

TOW BAR INSTALLATION PRE TAG No. L892399

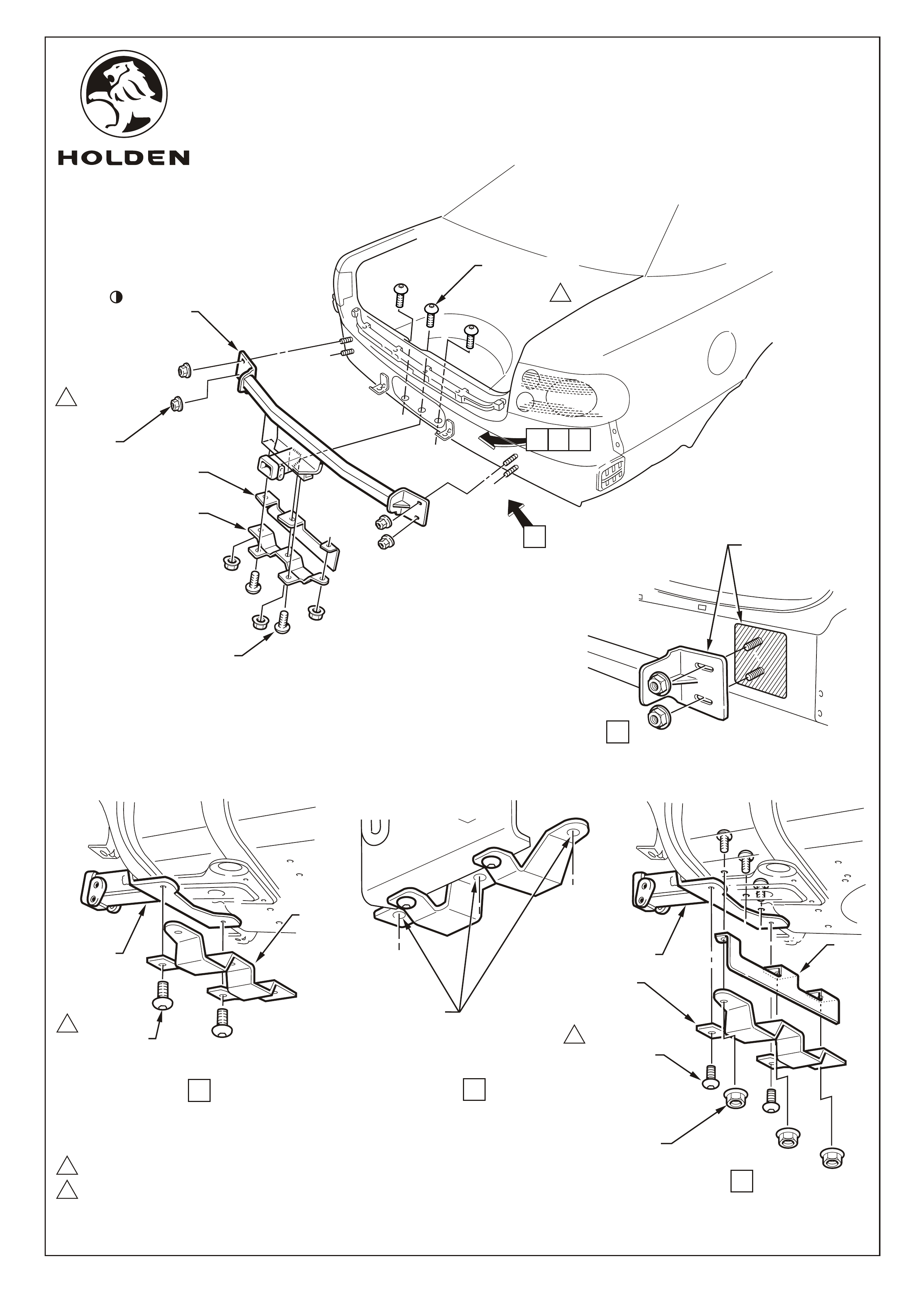

A. Attach the spare wheel support to the towbar with the button head socket screws, 2 places

and hand tighten. Refer View B, Page 8.

B. Using the spare wheel support as a template, mark the three hole centres onto

the spare wheel well. Refer View C, Page 8.

C. Remove the support and drill three 3.0mm dia. pilot holes in the spare wheel well. Enlarge

the holes to 8mm, then to 12mm. Refer View C, Page 8.

D. Deburr the holes and remove any sealer where the support will mount onto the spare wheel well.

E. Vacuum up all swarf and debris and coat the holes with corrosion protection paint.

F. Install the fuel tank shield and spare wheel well support to the spare wheel well and towbar.

Fasten with the button head socket screws, 5 places. Tighten the spare wheel well screws

first, then the towbar screws to 30-40 Nm. Refer View D, Page 8.

THIS REPLACES INSTRUCTION 23. (ABOVE) FOR CARS PRE TAG No. L892399

1

2

30.0 ~ 40.0 Nm

COPYRIGHT

Page 7 of 10

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

SCRAPE OFF EXCESS

SEALER AND COAT

SURFACES WITH

THIN FILM OF GREASE

RH SHOWN

VIEW A

G736

FD1028

28OC02

49.0 ~ 65.0 Nm VIEW B

FUEL TANK NOT SHOWN

FOR CLARITY.

SPARE

WHEEL

WELL

SUPPORT

1

SCREW-SOCKET

BUTTON HEAD (2

PLACES). TIGHTEN

SPARE WHEEL WELL

SCREWS FIRST.

TOW BAR

ASSEMBLY

FUEL

TANK

SHIELD

NUT

(2 PLACES

R &L SIDE)

2

1

SCREW-SOCKET

BUTTON HEAD

(2 PLACES)

TOW BAR

ASSEMBLY

A

SPARE WHEEL WELL

SUPPORT ASSEMBLY

FUEL TANK SHIELD

B

SCREW-SOCKET

BUTTON HEAD

(3 PLACES)

M10 ANTI-RATTLE

NUTS 1

NUT

(2 PLACES

R &L SIDE)

2

1

1

2

SCREW-SOCKET

BUTTON HEAD

(2 PLACES)

TOW BAR

ASSEMBLY

A

30.0 ~ 40.0 Nm

49.0 ~ 65.0 Nm

VIEW C

VIEW D

SPARE WHEEL WELL

SUPPORT ASSEMBLY

FUEL TANK SHIELD

COPYRIGHT

Page 8 of 10

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

C

BD

1

VIEW B

FUEL TANK REMOVED

FOR CLARITY.

FUEL TANK REMOVED

FOR CLARITY.

SCREW-SOCKET

BUTTON HEAD (5

PLACES). TIGHTEN

SPARE WHEEL WELL

SCREWS FIRST.

TOW BAR

ASSEMBLY

1

SCREW-SOCKET

BUTTON HEAD (2 PLACES)

SPARE

WHEEL

WELL

SUPPORT

SPARE

WHEEL

WELL

SUPPORT

FUEL

TANK

SHIELD

TOW BAR

ASSEMBLY

SCREW-SOCKET

BUTTON HEAD

(3 PLACES)

SCRAPE OFF EXCESS

SEALER AND COAT

SURFACES WITH

THIN FILM OF GREASE

RH SHOWN

VIEW A

MARK THREE HOLES,

REMOVE BRACKET, DRILL

3.0 mm PILOT HOLES THEN

ENLARGE TO 8.0 mm THEN

12.0 mm.

G736

FD1028

28OC02

M10 ANTI-RATTLE

NUTS

COPYRIGHT

Page 9 of 10

Reproduction in whole or part

prohibited without written approval

Reinstall the fascia, crossmember cover, weather strip and trim, which is the reversal to the removal procedure.

NOTE: Align the studs on the fascia correctly through the holes in the body, below the tail lights.

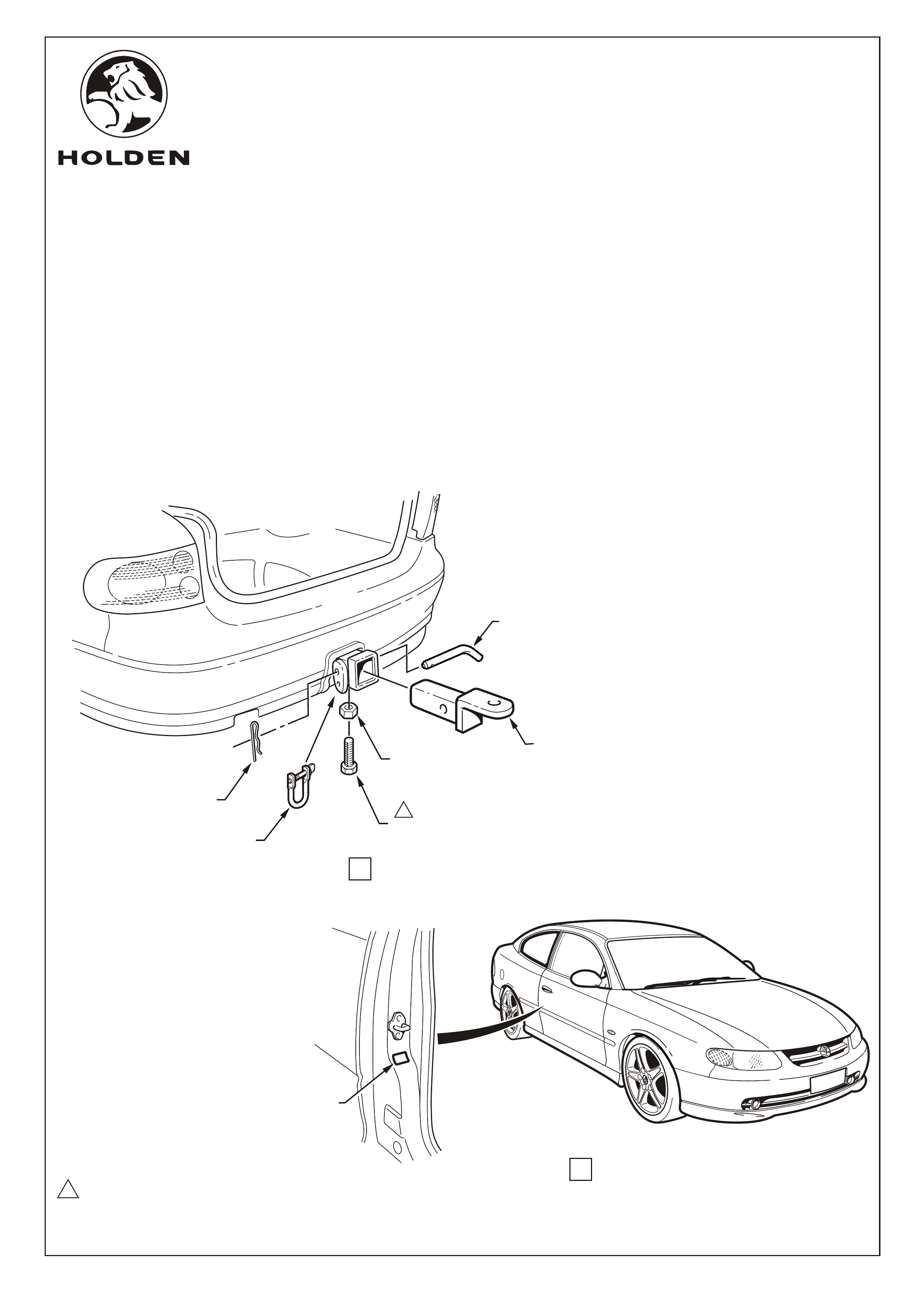

Install the towbar tongue onto the towbar assembly using the retainer pin and safety clip. Refer View A.

Install the anti-rattle bolt and nut. Tighten nut 5 - 10 Nm. Refer View A.

IMPORTANT: The anti-rattle bolt and nut must only be used when tow bar is unladen. Remove the anti-rattle

bolt and nut when the towbar is loaded.

Install the heat shield and trailer wiring harness packages as per fitting instructions included with each package.

Clean the surface of the driver's side B-pillar and apply the ADR label. Refer View B.

Once the towbar installation is complete, place the fitting instructions and warranty card in the glovebox.

24.

25.

26.

27.

28.

29.

HOLDEN SERVICE PARTS OPERATIONS

Division of HOLDEN Ltd ACN 006 893 232

SAFETY CLIP

SHACKLE

NUT M10

TOW BAR

TONGUE

ANTI -RATTLE BOLT M10 x 25

(ONLY USE WHEN UNLOADED)

1

RETAINER

PIN

VIEW A

WIPE SURFACE CLEAN

PRIOR TO APPLICATION

OF ADR LABEL

5.0 ~ 10.0 Nm

1

VIEW B

G736

FD1028

28OC02

COPYRIGHT

Page 10 of 10

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

1600kg TOW BAR KIT FOR

V2 COUPE "MONARO"

Part Number 92144445

PARTS LIST

NOT INCLUDED IN TOW BAR PACKAGE, BUT AVAILABLE SEPARATELY:

92140088 TRAILER WIRING HARNESS - FLAT 7 PIN

92140147 TRAILER WIRING HARNESS - ROUND 7 PIN (LARGE PIN)

92140148 TRAILER WIRING HARNESS - ROUND 7 PIN (SMALL PIN WITH BACKING PLATE)

92145177 PACKAGE - LOAD DISTRIBUTION HITCH (FIXED)

92140089 PACKAGE - SUPERLIFT SHOCK ABSORBERS

92140068 TOW BALL ASSEMBLY (CHROME)

92140106 TOW BALL COVER

PART NO. DESCRIPTION QUANTITY

92106900 TOW BAR MAIN ASSEMBLY 1

SCREW - SOCKET BUTTON HEAD M10 x 30 5

BOLT - ANTI-RATTLE M10 x 25 1

NUT - ANTI-RATTLE M10 4

92106902 SUPPORT ASSEMBLY - SPARE WHEEL WELL 1

92106903 SHIELD - FUEL TANK 1

92144444 SURROUND - TOWBAR 1

92077203 'D' RING SAFETY SHACKLE 1

ADR LABEL 1

FD1028 TOW BAR FITTING INSTRUCTION BOOKLET 1

FD796 WARRANTY CARD 1

92145225 PACKAGE - TOW BAR TONGUE (PAINTED) 1

92143923 PACKAGE - HEAT SHIELDS 1

- 92037805 Heat Shields - Spare Wheel Well 6

- FD974 Fitting Instruction 1

- 92143924 Heat Shield Package - Centre Bearing 1

- Bolt - Centre Bearing Heat Shield Mounting M8 2

- Washers 2

- FD1028 Fitting Instruction

G736

FD1028

28OC02