FD1069

11MA03

COPYRIGHT

Page 1 of 19

G673

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

VY CRUISE CONTROL PACKAGE,

V6 & SUPERCHARGED V6,

Part No. 92145711

FITTING INSTRUCTIONS:

NOTE: This Cruise Control Package is suitable for

vehicles fitted with traction control.

1. Disconnect the vehicle battery.

IMPORTANT: Disconnecting the vehicle battery may

impact or damage electrical systems in the vehicle - Body

Control Module, Entertainment System, Electric Sunroof,

etc unless correct instructions are followed. Please

contact your Holden Retailer for further information.

NOTE: To reinstate the audio system, the security code

will be required.

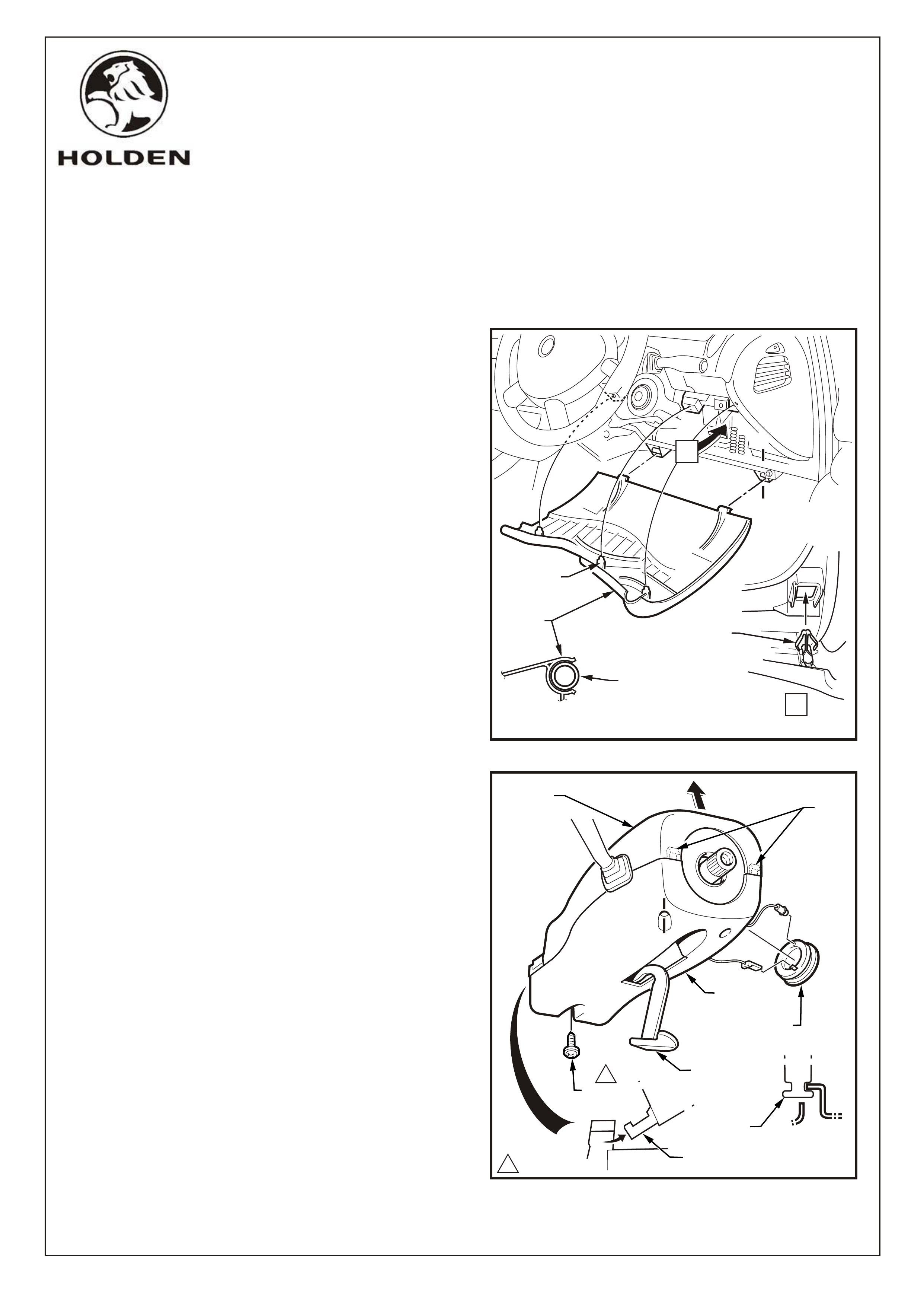

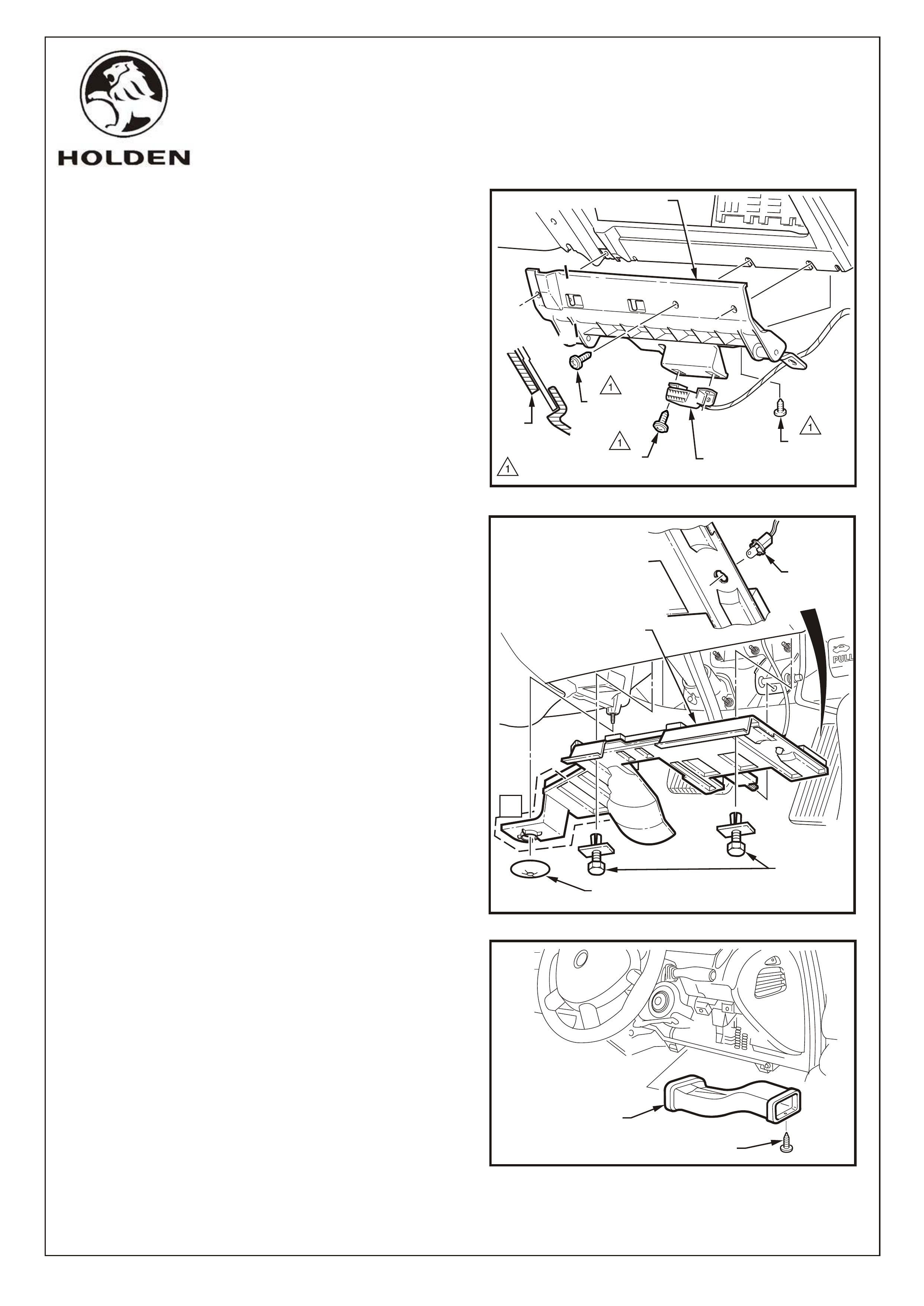

2. Remove the instrument panel, lower trim panel

assembly as follows:

Adjust steering wheel to upper most position.

Grasp the upper edge of the instrument panel

lower trim panel assembly and pull outwards to

disengage the three retaining clips.

Swing the panel assembly open.

Holding each side of the panel assembly pull

rearwards to disengage it from the instrument

panel lower trim panel retainer (two places).

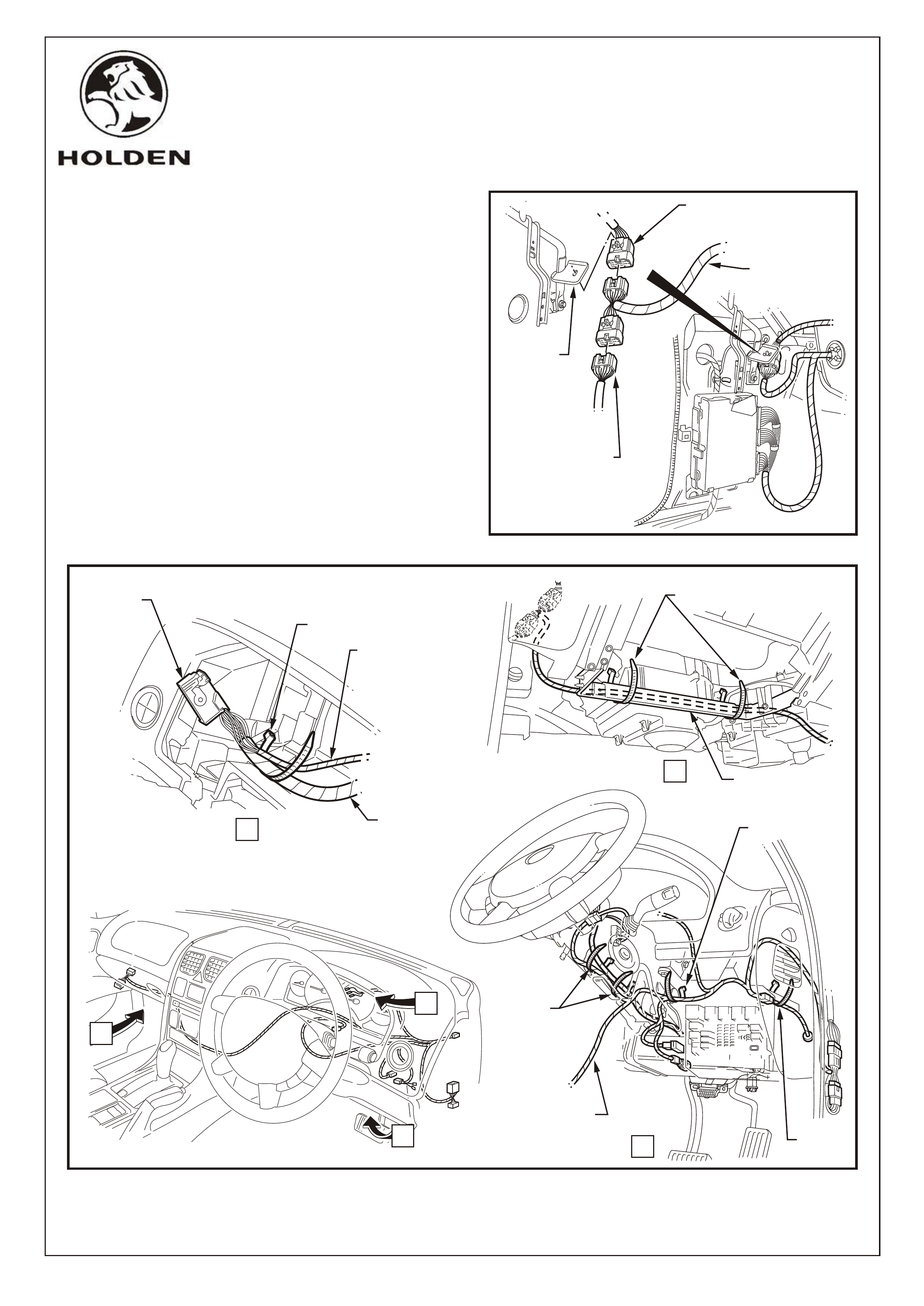

Refer Figure 1.

3. Remove the upper and lower steering column covers

as follows:

Release the steering column adjustment lever and

move the column to its lowest position.

NOTE: The steering wheel does not need to be

removed. It is not shown for clarity only.

From below the steering column, remove the screw

attaching the lower cover.

Depress the face of the lower cover inwards to

disengage the tabs and lift the steering column

upper cover.

Raise the upper cover as high as possible to

disengage the lugs and remover the cover.

Remove the theft deterrent receiver assembly from

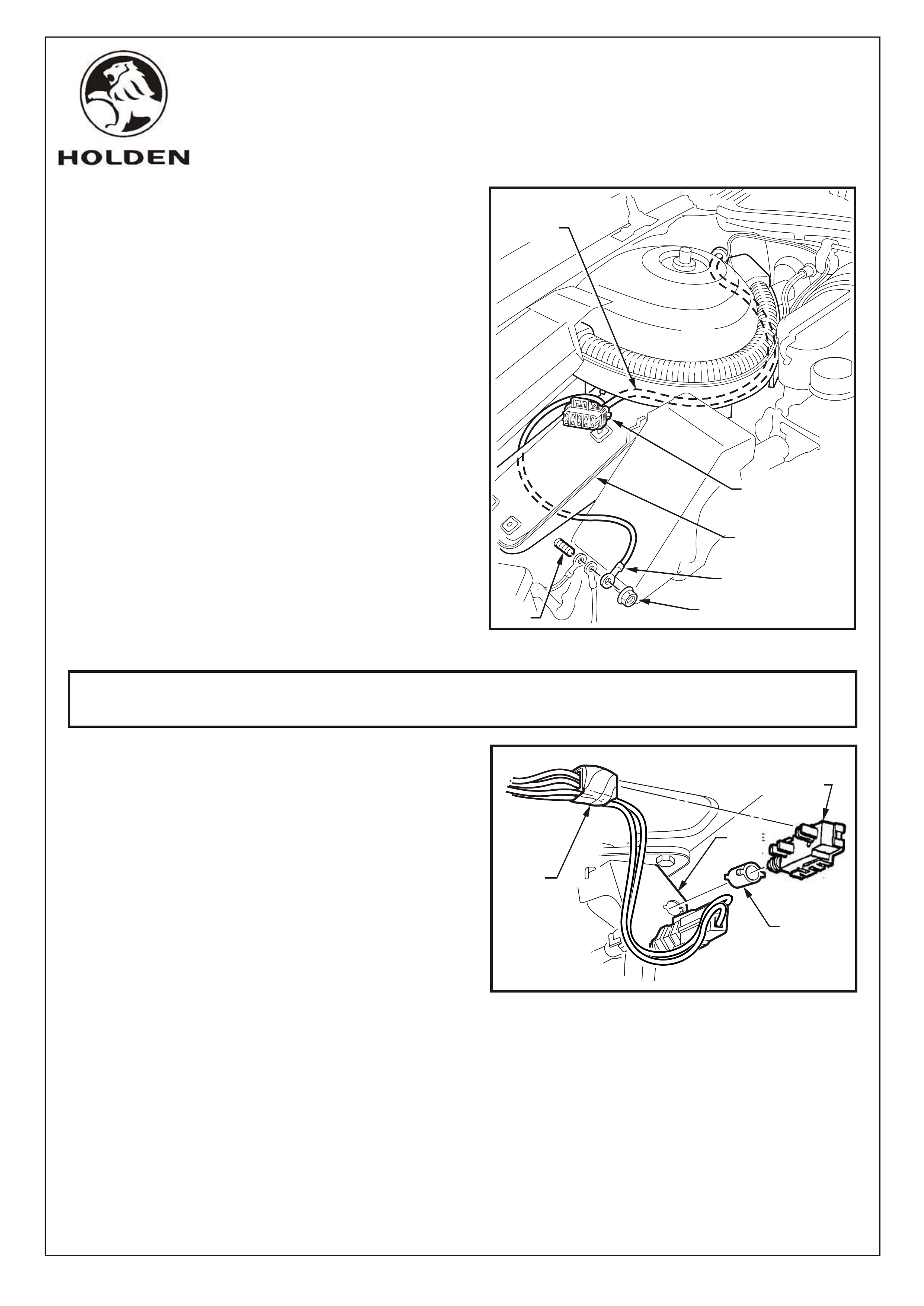

the steering column lower cover.

Disconnect the wiring connector and globe socket

from the receiver assembly.

Slide the lower cover rearward to disengage it form

the lugs and remove the cover.

Refer Figure 2.

TOOLS REQUIRED:

Hole saw (20mm), Centre Punch, Phillips Head Screw Driver, Flat Blade Screwdriver, 10mm Socket,

Torx Bit T25 Corrosion Protection Paint.,

FITTING INSTRUCTIONS FOR

VY CRUISE CONTROL PACKAGE, V6 & SUPERCHARGED V6,

Part No. 92145711

COPYRIGHT

Page 2 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FIGURE 1

LOWER

TRIM

PANEL

A-A

A

A

A

A

RETAINING

CLIP

RETAINING

CLIP

(3 PLACES)

LOWER TRIM

PANEL

RETAINER

(2 PLACES)

UPPER

COVER

SCREW

ADJUSTMENT

LEVER

A-A

A

A

10.5 - 2.0 Nm

FIGURE 2

LOWER

COVER

TABS

THEFT DETERRENT

RECEIVER

LUGS

LUGS

1

G673

FD1069

11MA03

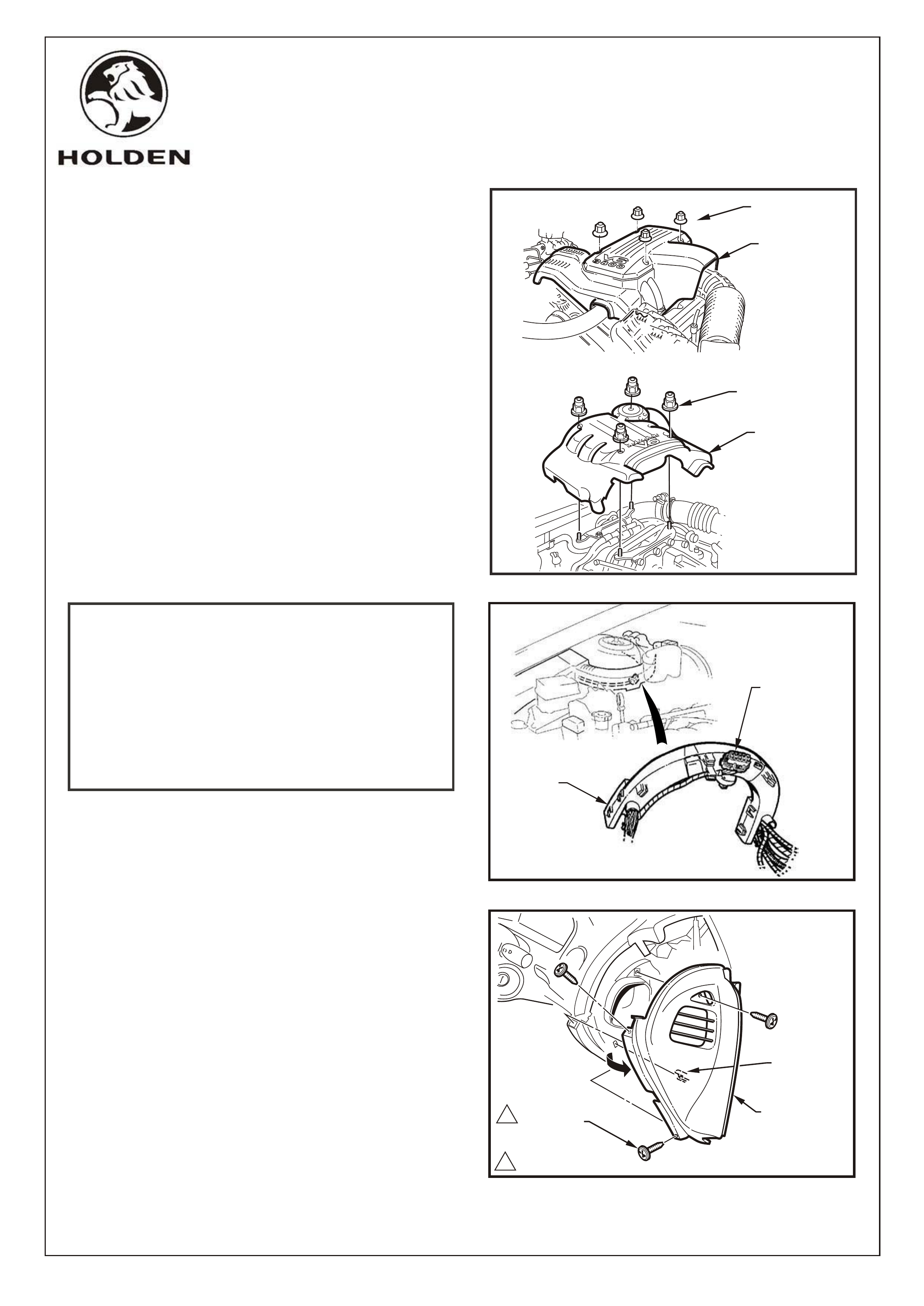

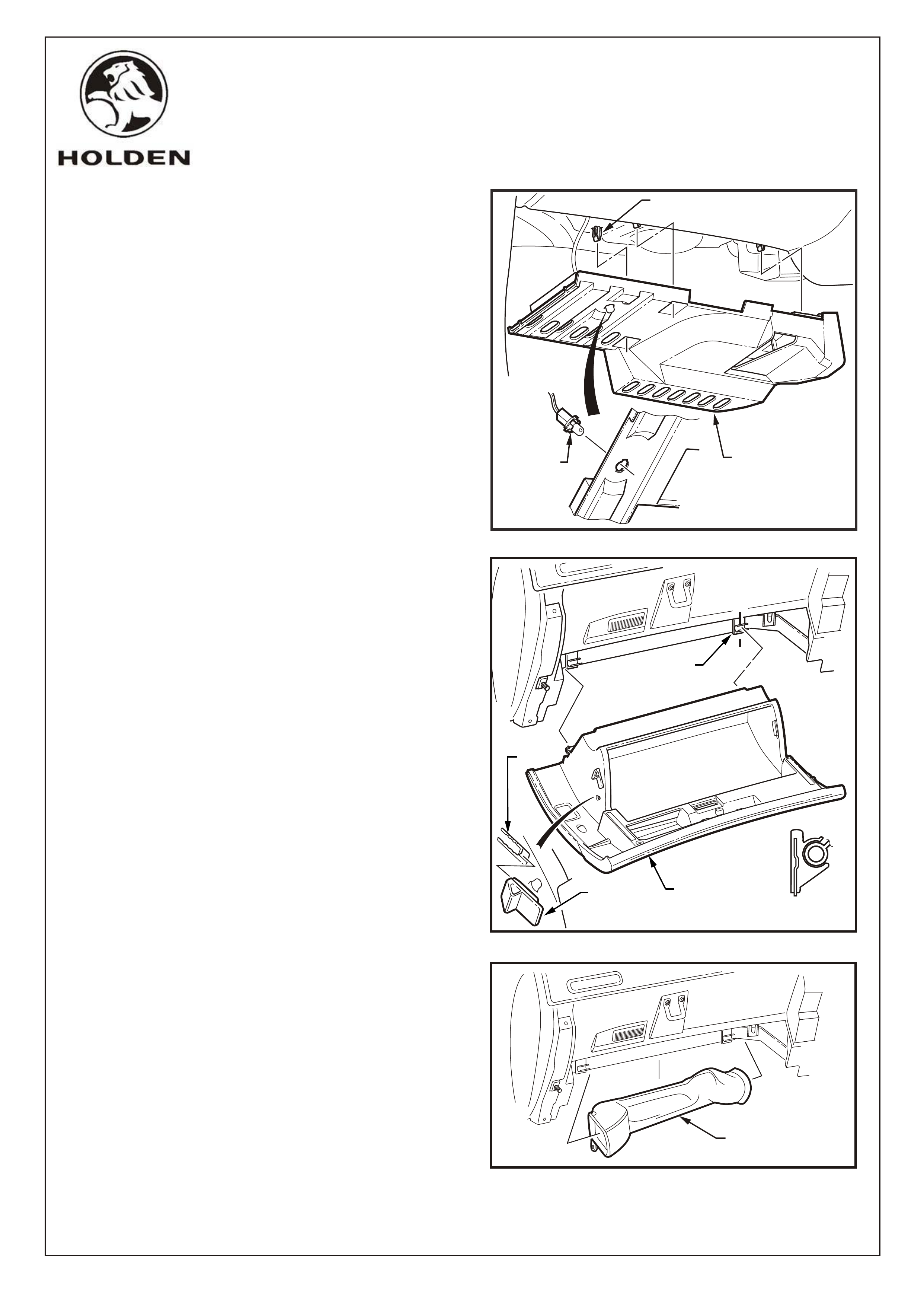

4. Remove the four dome nuts securing the engine

dress cover and remove cover. Refer Figure 3.

NOTE: For MANUAL TRANSMISSION vehicles also

refer to page 18 of these instructions for additional

procedures.

IMPORTANT: Check if the stepper motor connector

is clipped to the underside of the strut tower former, as

part of the original wiring harness. Refer Figure 4.

If connector exists, go to Step 50.

If connector does not exist, continue installation as

described below.

5. Remove the right and left-hand instrument panel

outer covers as follows:

Remove the three screws attaching the right and

left-hand instrument panel outer covers to the

instrument panel.

Remove the cover by rotating outward to

disengage the retaining clip and the ventilation

ducts.

Refer Figure 5 (right-hand side shown).

COPYRIGHT

Page 3 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

STEPPER

MOTOR

CONNECTOR

STRUT

TOWER

FORMER

FIGURE 3

FIGURE 4

FIGURE 5

11.0 - 3.0 Nm

1SCREW

(3 PLACES) INSTRUMENT

PANEL OUTER

COVER

RETAINING

CLIP

G673

V6

SUPERCHARGED V6

DOME NUTS

(4 PLACES)

ENGINE DRESS

COVER

ASSEMBLY

ENGINE DRESS

COVER

ASSEMBLY

DOME NUTS

(4 PLACES)

FD1069

11MA03

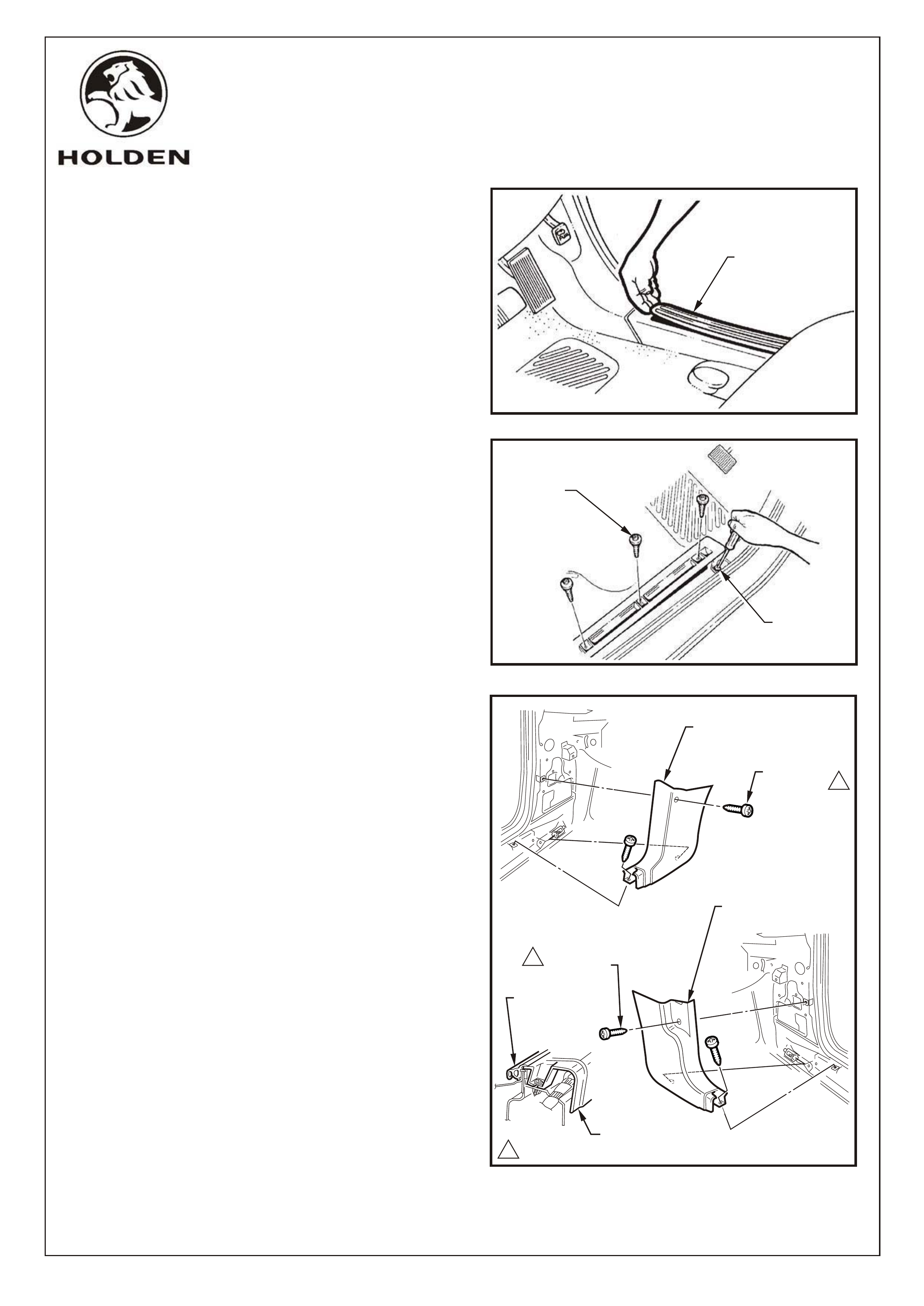

6. Remove the right and left-hand side rocker panel

cover inserts.

Refer Figure 6.

7. Remove the front three TORX head screws and

loosen the rear most screw with TORX bit T25 on the

right and left-hand sides. Refer Figure 7.

8. Lift the front of the inner rocker panel cover to gain

access to the screw securing the hinge pillar trim

assembly to the rocker panel. Refer Figure 7.

9. Remove the right and left-hand side hinge pillar trim

assemblies as follows:

Remove the two attaching screws from the hinge

pillar trim assembly.

Disengage the hinge pillar trim clip by pulling the

lower edge of the hinge pillar trim assembly up and

away from the sheet metal.

NOTE: When refitting, ensure the outer edge of the

hinge pillar trim assembly engages the door

opening weatherstrip.

Refer Figure 8.

COPYRIGHT

Page 4 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

TORX HEAD

SCREW

(3 PLACES)

SCREW

ROCKER PANEL

COVER INSERT

FIGURE 6

FIGURE 7

SCREW

(2 PLACES)

1

1

1

0.7 - 1.0 Nm

FIGURE 8

RIGHT-HAND SIDE

HINGE PILLAR TRIM

SCREW

(2 PLACES)

LEFT-HAND SIDE

HINGE PILLAR TRIM

HINGE PILLAR TRIM

DOOR OPENING

WEATHERSTRIP

G673

FD1069

11MA03

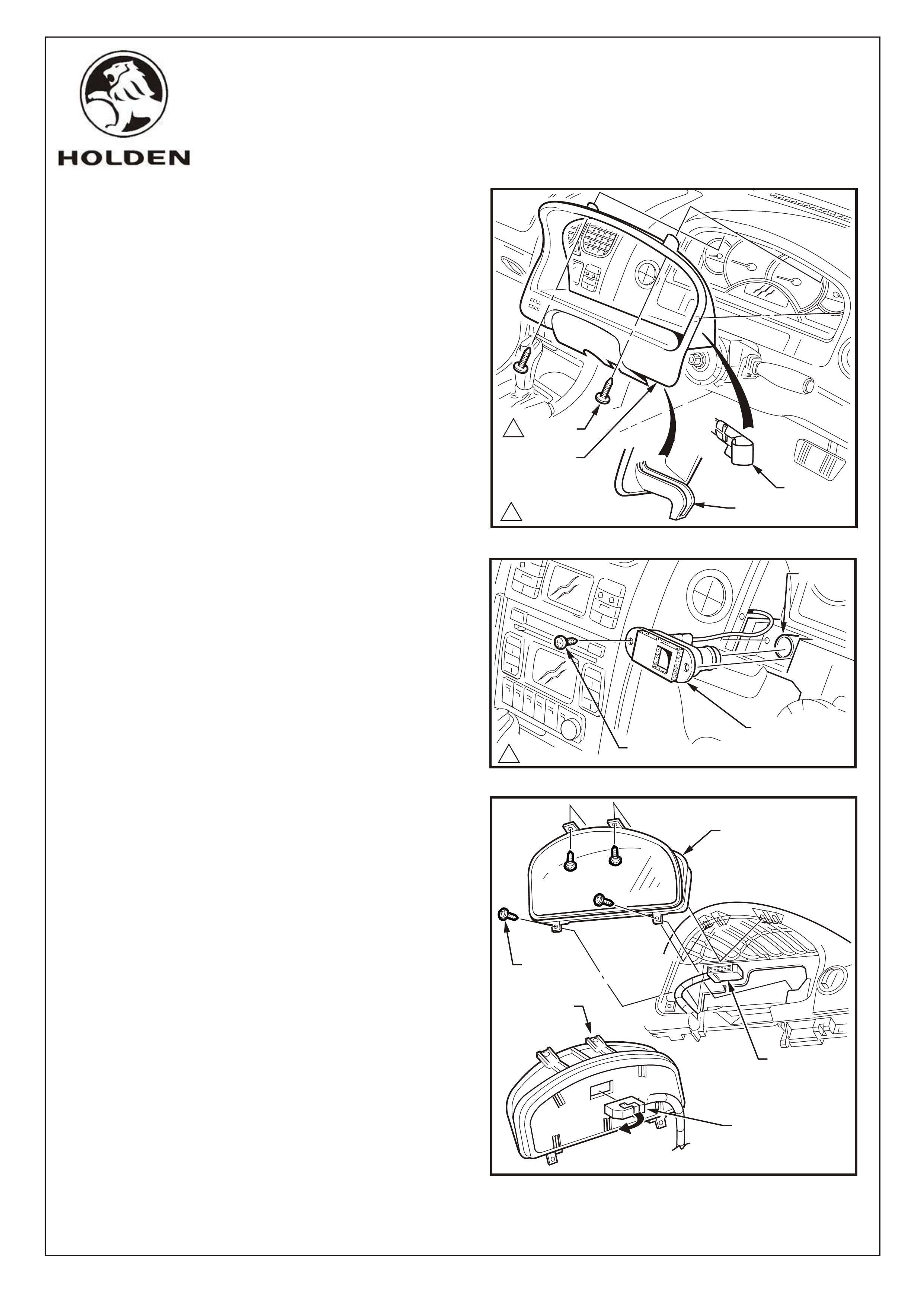

10. Remove the 2 screws attaching the data link

connector to the instrument panel lower trim panel

retainer. Refer Figure 9.

11. Remove the instrument panel lower trim panel

retainer as follows:

Remove the screw attaching the retainer to the air

duct.

Remove the three screws attaching the retainer to

the instrument panel assembly and the instrument

panel.

Slide the retainer downward to disengage the two

lugs from the instrument panel assembly as shown

at Section A-A and remove the retainer.

Refer Figure 9.

12. Remove the right-hand side instrument panel lower

trim plate assembly as follows:

Remove the retainer attaching the instrument

panel lower trim plate assembly to the HVAC unit

(Automatic Transmission Vehicles only).

NOTE: The area shown A is not present on Manual

Transmission vehicles.

Loosen the screw and remove the retainer (2

places) attaching the plate assembly to the

instrument panel.

Lower the plate assembly slightly and withdraw the

lug from the pedal bracket.

If fitted, remove the stepwell lamp by rotating the

socket and removing from the plate assembly.

Remove the plate assembly.

Refer Figure 10.

13. Remove right-hand side ventilation duct.

Refer Figure 11.

COPYRIGHT

Page 5 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FIGURE 9

FIGURE 10

RETAINER (AUTOMATIC

TRANSMISSION VEHICLES ONLY)

A

RETAINER

(2 PLACES)

INSTRUMENT PANEL

LOWER TRIM PLATE

ASSEMBLY

STEPWELL

LAMP

FIGURE 11

RIGHT-HAND SIDE

VENTILATION DUCT

SCREW

G673

1.0 - 3.0 Nm

A

A

A-A DATA LINK

CONNECTOR

SCREW

(2 PLACES)

SCREW

(AIR DUCT)

SCREW

(3 PLACES)

LUG

LOWER TRIM PANEL RETAINER

FD1069

11MA03

COPYRIGHT

Page 6 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

14. Remove the left-hand side instrument panel lower

trim plate assembly as follows:

Grasp the instrument panel lower trim plate

assembly and carefully pull downward to

disengage the retaining clips (3 places).

Lower the plate assembly slightly and if fitted

remove the stepwell lamp by rotating the socket

and removing from the plate assembly.

Remove the plate assembly.

Refer Figure 12.

15. Remove the instrument compartment assembly as

follows:

Open the instrument compartment assembly.

Using a fine flat-blade screwdriver, flatten the

instrument panel compartment bumper stop each

side and carefully open the compartment assembly

fully.

From the inside of the compartment assembly,

push outwards on the bumper stop and slide the

bumper from the lug. Repeat for the opposite side.

Close the compartment assembly half way and

grasping each side pull rearward to disengage the

compartment assembly from each instrument

panel compartment hinge.

Refer Figure 13.

NOTE: Take care when disengaging the hinges as

removing the compartment assembly on the wrong angle

may cause damage.

16. Remove right-hand side ventilation duct.

Refer Figure 14.

FIGURE 12

STEPWELL

LAMP

LEFT-HAND SIDE

INSTRUMENT PANEL

LOWER TRIM PLATE

CLIP

(3 PLACES)

A-A

A

FIGURE 13

A

INSTRUMENT

PANEL

COMPARTMENT

HINGE

BUMPER

STOP

LUG

LEFT-HAND SIDE

VENTILATION DUCT

FIGURE 14

G673

FD1069

11MA03

3

SCREWS

(4 PLACES)

INSTRUMENT

CLUSTER

17. Remove the instrument cluster trim panel assembly

as follows:

NOTE: The steering wheel is not shown for clarity, the

cluster trim can be removed with the steering wheel

installed.

Release the steering column adjustment lever and

move the steering column to its lowest position.

Remove the two screws attaching the instrument

cluster trim assembly to the instrument panel.

Depress the top of the trim assembly slightly and tilt

the top of the trim assembly out of the instrument

panel pad, disengaging the retaining clips (3

places) each side.

Unhook each lug from the instrument panel pad.

Remove the trim assembly.

Refer Figure 15

in-car air

temperature sensor

19. Remove the instrument cluster as follows:

Remove the four screws attaching the instrument

cluster to the instrument panel.

Roll the top of the instrument cluster from its cavity.

Using a fine flat blade screwdriver, open the wiring

connector locking tab on the back of the cluster.

Remove the cluster assembly.

Refer Figure 17.

NOTE: When reinstalling the instrument cluster,

tighten the screws in the sequence indicated.

Refer Figure 17.

18. Remove the screw attaching the

to the instrument panel. Extract

the sensor assembly from the cavity and disconnect

the air tube. Refer Figure 16.

COPYRIGHT

Page 7 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

11.0 - 3.0 Nm

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

IN-CAR

TEMPERATURE

SENSOR

FIGURE 16

SCREW

FIGURE 15

11.0 - 3.0 Nm

1SCREWS

CLIPS

(3 PLACES

EACH SIDE)

LUG

INSTRUMENT

CLUSTER

TRIM ASSEMBLY

2

4

1

INSTRUMENT

CLUSTER

WIRING

CONNECTOR

WIRING

CONNECTOR

FIGURE 17

AIR TUBE

G673

FD1069

11MA03

COPYRIGHT

Page 8 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FIGURE 18

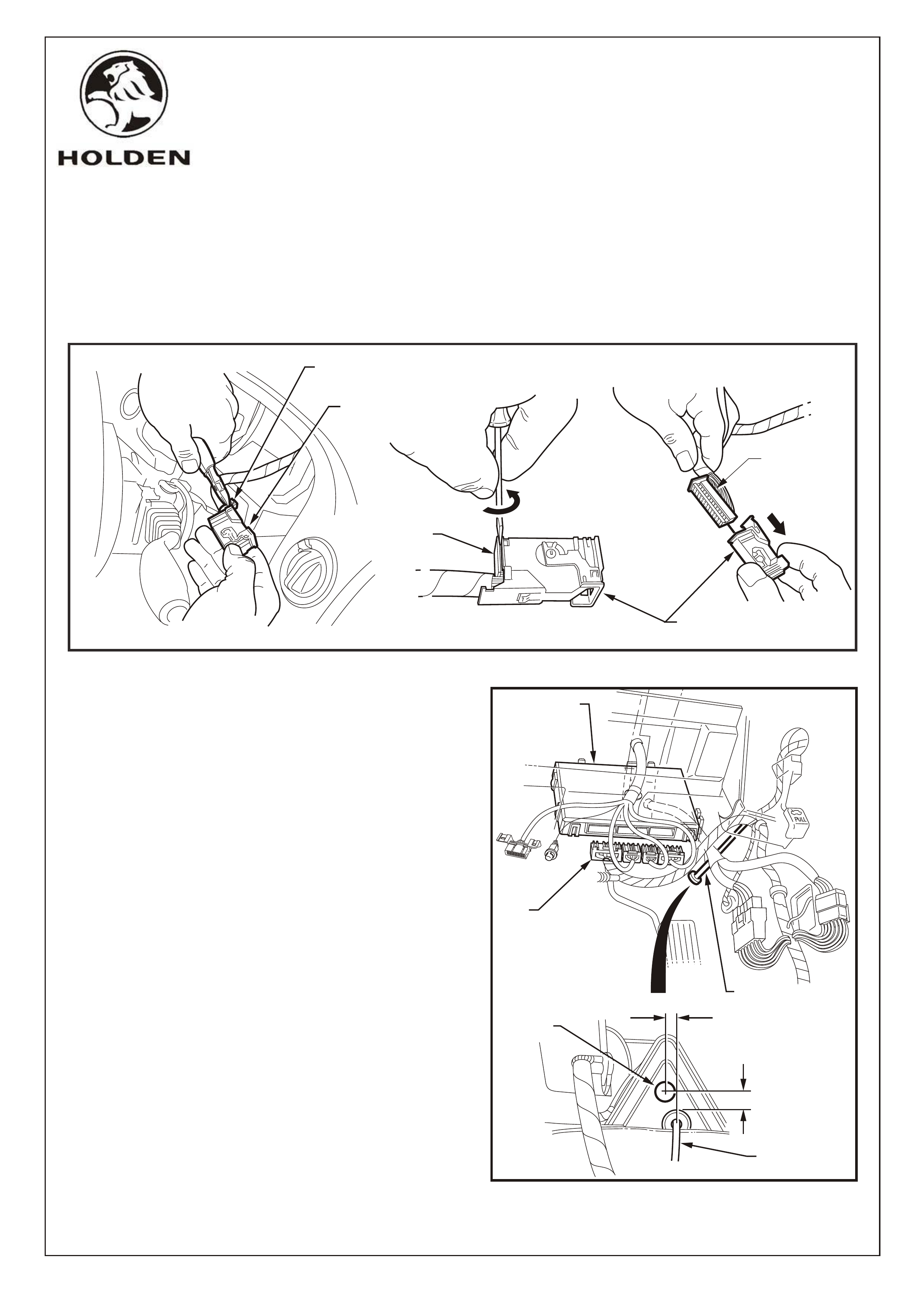

20. Cut the cable tie securing the instrument cluster

connector housing to the wiring harness.

Refer Figure 18.

21. Place a small flat blade screwdriver between the front

edge of the connector housing and the inner

connector. Twist as shown to release the housing and

withdraw from the inner connector. Refer Figure 18.

INSTRUMENT CLUSTER

WIRING CONNECTOR

CUT CABLE TIE

CONNECTOR

HOUSING

INNER

CONNECTOR

INNER

CONNECTOR

TWIST TO

RELEASE

20.0

5.0

BONNET

RELEASE CABLE

DRILL

20.0 mm DIA

HOLE

FIGURE 19

REMOVE BCM

FROM MOUNT

BONNET

RELEASE

CABLE

22. Detach the BCM from its mount, disconnect the wiring

connectors and remove the BCM. Refer Figure 19.

23. Mark and centre punch the hole location on the

firewall, above the bonnet release cable. Refer

Figure 19.

NOTE: Prior to drilling, cover the carpet to protect

from iron filings.

24. Drill a 20mm dia. hole with a hole saw. Deburr and

coat the bare metal with anti-corrosion primer.

25. From the engine compartment, insert the cruise

control engine bay patch harness (part number

92066684) through the drilled hole and seat the

grommet in the hole securely.

26. Refit the BCM and reconnect the wiring connectors.

BCM

WIRING

CONNECTORS

G673

FD1069

11MA03

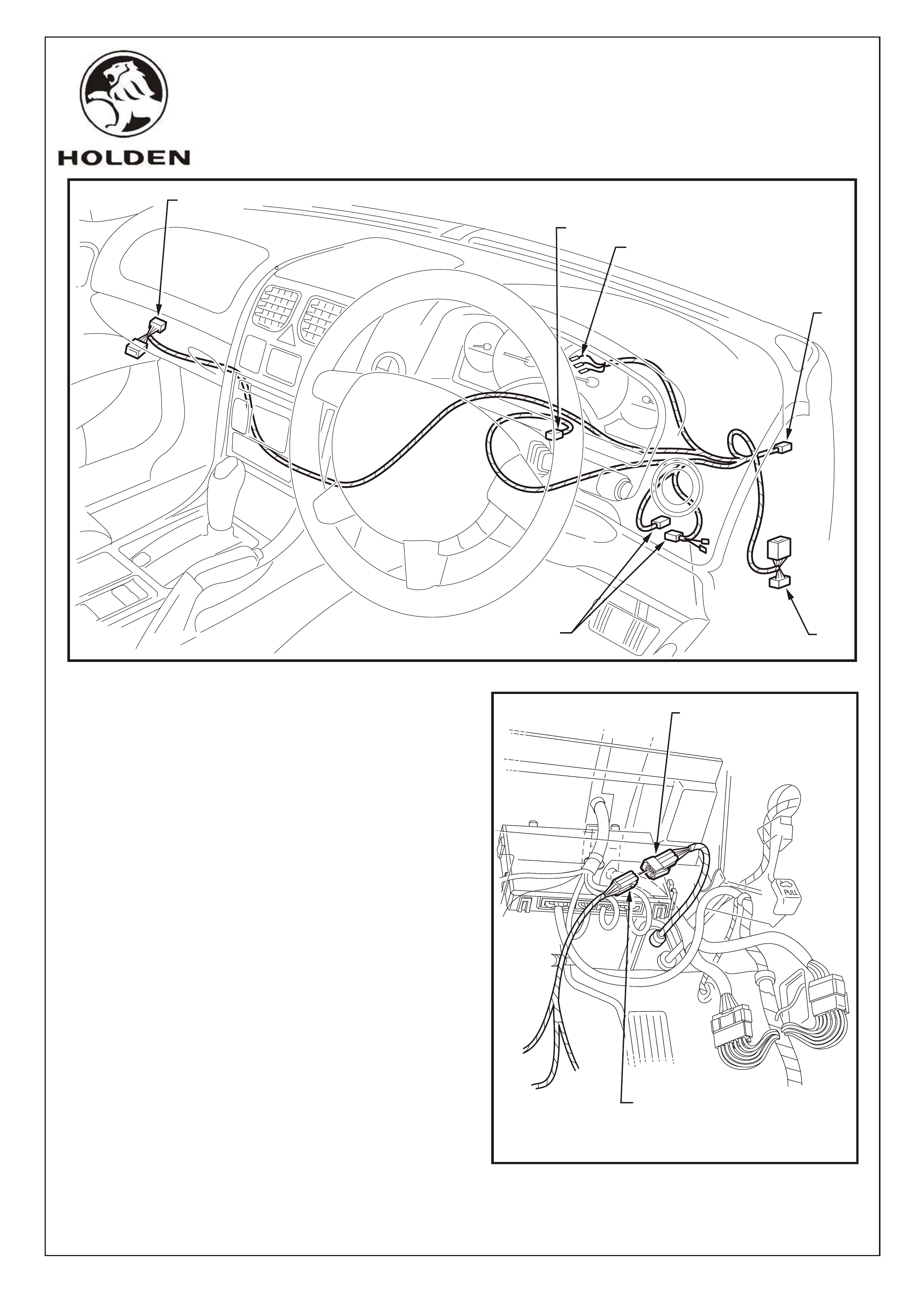

27. Connect the cruise control cabin patch harness 9

Pin connector to the corresponding cruise control

engine bay harness 9 Pin connector previously

installed (1) and route through the dash framework

above the fuse panel.

Refer Figures 20 & 21.

COPYRIGHT

Page 9 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FIGURE 20

GENERAL CRUISE CONTROL CABIN PATCH HARNESS ROUTING

(2)

(6)

FIGURE 21

CRUISE CONTROL

ENGINE BAY PATCH

HARNESS CONNECTOR

CRUISE CONTROL

CABIN PATCH

HARNESS CONNECTOR

(4)

(3)

(1)

(5)

G673

FD1069

11MA03

COPYRIGHT

Page 10 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

BODY

HARNESS

CONNECTOR

MAIN WIRING

HARNESS

CONNECTOR

CRUISE CONTROL

CABIN PATCH

HARNESS

CONNECTORS

FIGURE 22

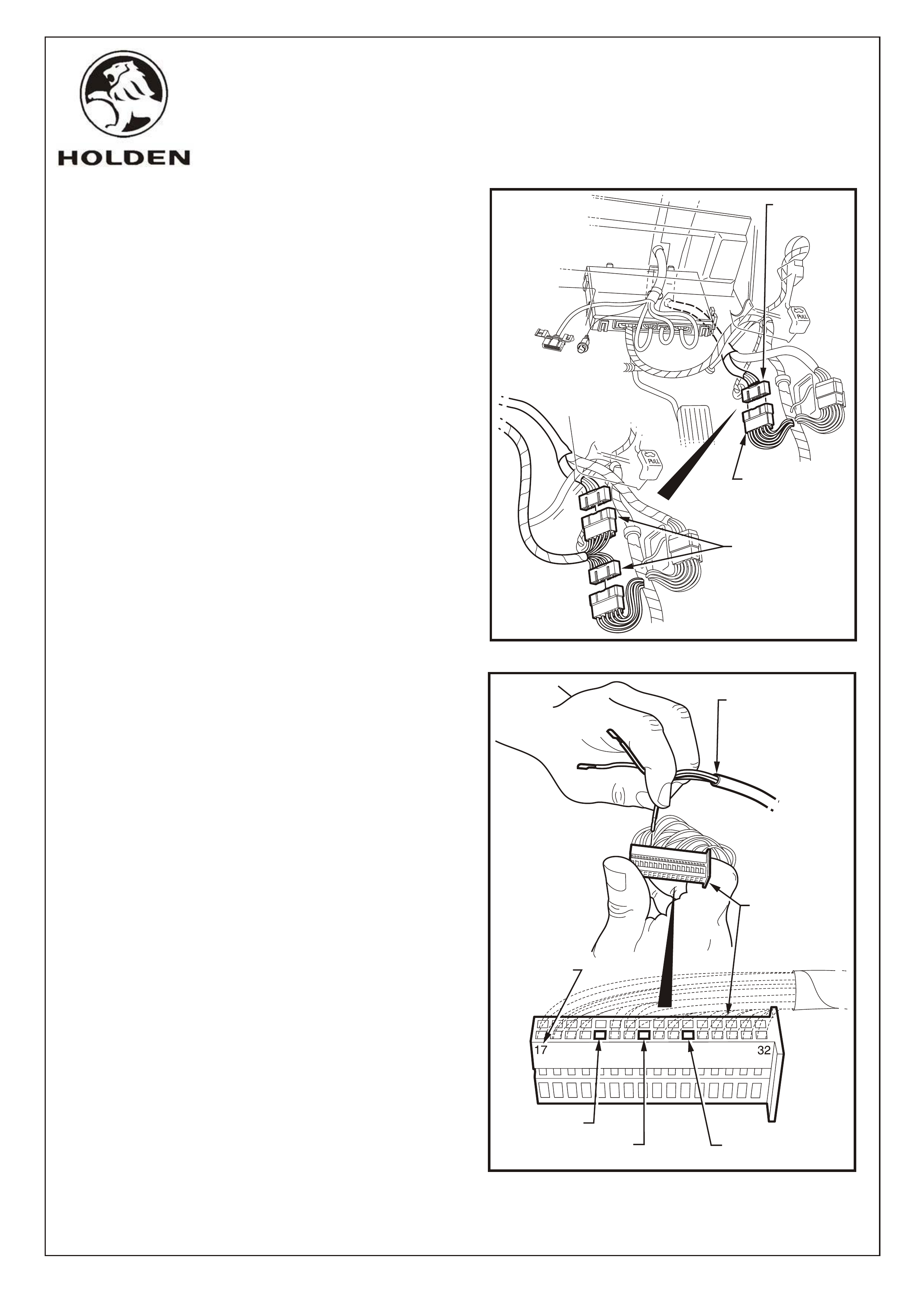

28. Route the two, 22 Pin connectors through the dash

framework to the right-hand side kick panel (2).

Refer Figure 21.

29. Disconnect the main wiring harness 22 Pin

connector and the body harness 22 Pin connector

and connect the corresponding connectors from the

cruise control cabin patch harness.

Refer Figure 22.

30. Route the section of the harness with the three

exposed wires over the steering column bracket,

back through the hole in the panel and alongside

the existing harness to the instrument cluster

connector (3). Refer Figure 20.

31. Determine the pin numbering sequence on the

inner connector (stamped on the side of the

connector body) and insert the cruise control cabin

patch harness wires as follows:

WHITE WIRE - PIN 21

YELLOW/RED WIRE - PIN 24 (Refer Note*)

GREY WIRE - PIN 27

*NOTE: Some vehicles may already have a

Yellow/Red wire at pin location 24. If present,

remove the wire, insulate, tape back and insert the

cruise control patch harness Yellow/Red wire.

Ensure the wires are securely fitted then

reassemble the inner connector to the housing

connector and secure with a cable tie.

Refer Figure 23.

32. Reconnect the instrument cluster connector and

reinstall the instrument cluster.

Refer Figures 17 &18.

21 - WHITE

24 - YELLOW/RED

REFER TO NOTE*, STEP 31

27 - GREY

PIN

NUMBERS

INSTRUMENT

CLUSTER

INNER

CONNECTOR

CRUISE

CONTROL CABIN

PATCH HARNESS

FIGURE 23

G673

FD1069

11MA03

COPYRIGHT

Page 11 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

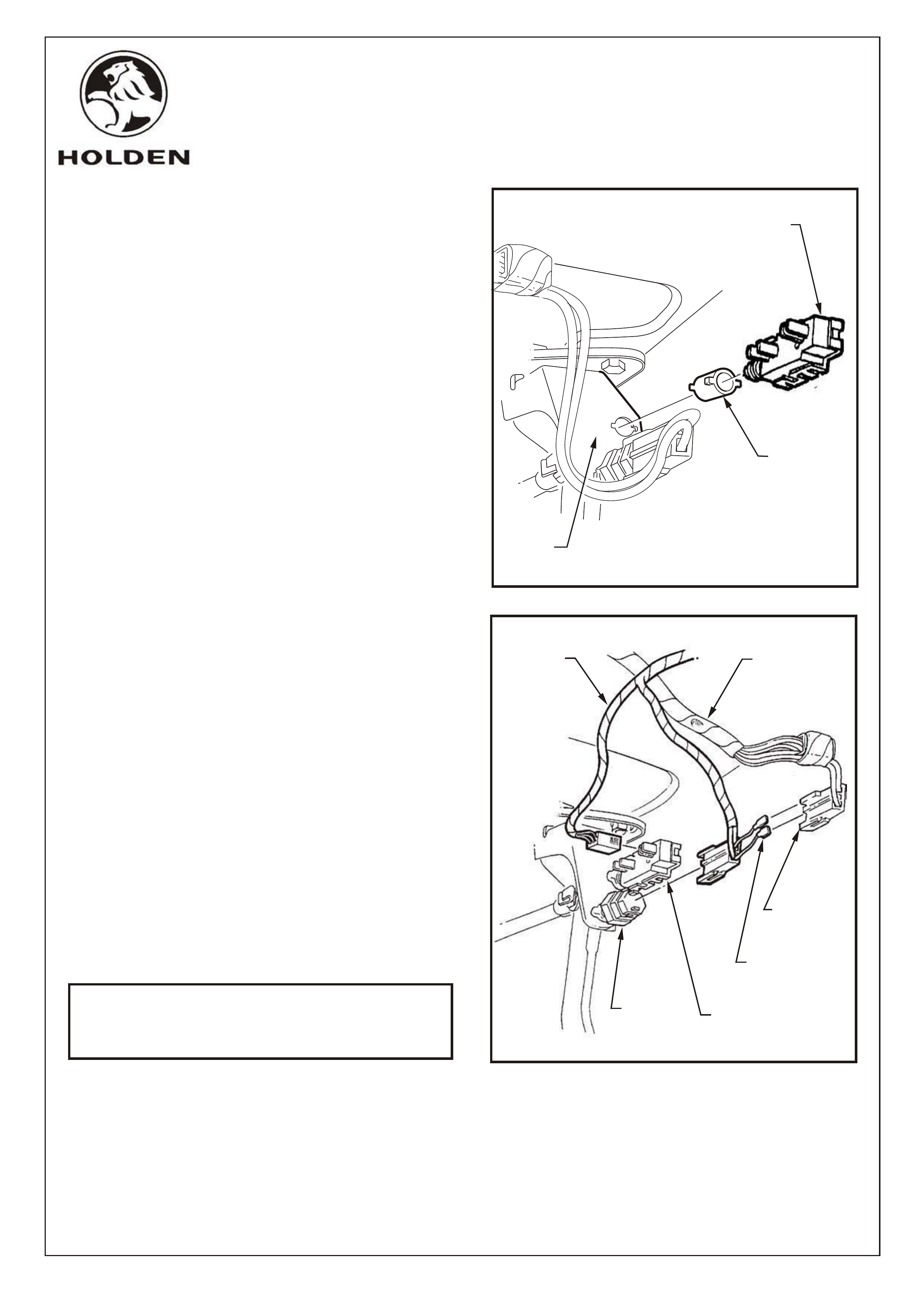

33. Route the brake switch connector and cruise

control release switch connector above the steering

column to the top of the brake pedal (4).

Refer Figure 20 & 24.

34. Fit the cruise control release switch to the mounting

hole in the brake pedal support as follows:

Fit the clip from the cruise control package to the

mounting hole.

Holding the brake pedal in its depressed position,

install the switch into the tubular clip. Push the

switch forward until the switch body locates in the

clip. Refer Figure 24.

NOTE: Audible ‘clicks’ will be heard as the threaded

portion of the switch assembly is pushed into the

tubular clip toward the brake pedal. Pull the brake pedal

fully against the stop until audible ‘click’ sounds can no

longer be heard. (Switch assembly is pushed back out

from the clip to provide correct switch position

adjustment). Depress the brake pedal again and repeat

the above procedure to ensure that the switch

adjustment is correct (no ‘click sounds).

Refer Figure 24.

35. Disconnect the brake switch connector from the

brake switch. Refer Figure 25.

36. Connect the cruise control cabin patch harness

brake switch connector to the brake switch. Refer

Figure 25.

37. Insert the blade terminals into the vehicle brake

switch connector (ensure wire colours are correctly

matched). Refer Figure 25.

38. Insulate the blade terminals into the connector

housing with electrical tape.

39. Attach the cruise control cabin patch harness

release switch connector to the cruise control

release switch. Refer Figure 25.

NOTE: For MANUAL TRANSMISSION vehicles

also refer to Page 18 of these instructions for

additional procedures.

FIGURE 24

CRUISE CONTROL

RELEASE SWITCH

BRAKE

PEDAL

SUPPORT

CLIP

CRUISE

CONTROL

PATCH

HARNESS

EXISTING

WIRING

HARNESS

BLADE

TERMINALS

BRAKE

SWITCH

BRAKE

SWITCH

CONNECTOR

FIGURE 25

CRUISE CONTROL

RELEASE SWITCH

G673

FD1069

11MA03

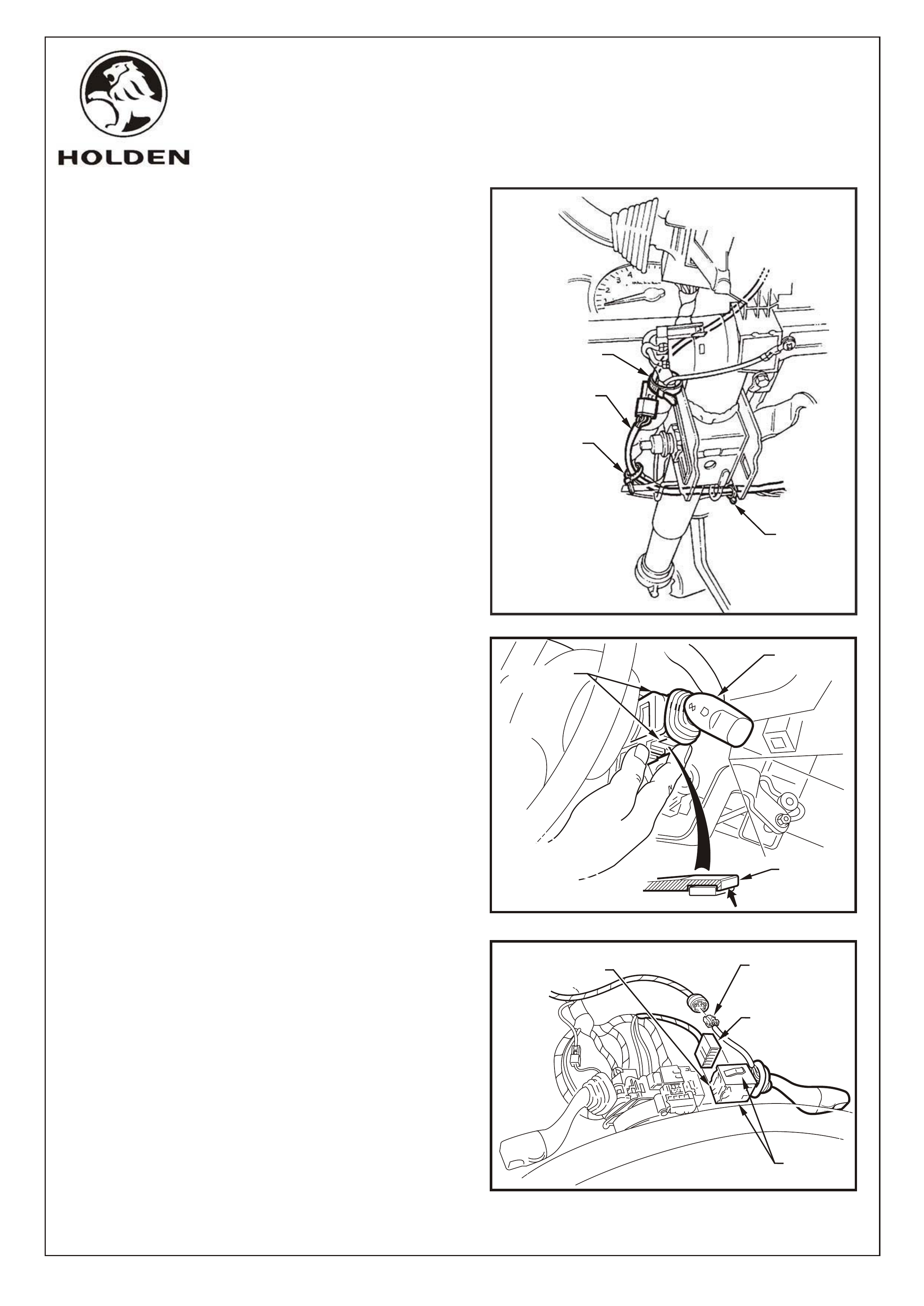

40. Route the cabin patch harness up alongside the

steering column wiring harness to the indicator stalk

switch (5). Refer Figures 26 & 28.

41. Depress the retaining tangs on the turn switch stalk

assembly and pull the assembly away from the

steering column. Refer Figure 27.

42. Depress the wiring harness connector tangs and

pull the connector from the switch assembly.

Remove the turn signal assembly and replace with

the cruise control/indicator switch assembly from

the cruise control package.

Connect the cruise control patch harness connector

and indicator switch connector to the cruise control/

indicator switch assembly.

Refer Figure 28.

43. Secure patch harness from fuse panel to stalk

switch with supplied tie straps. Refer Figure 28.

COPYRIGHT

Page 12 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

CRUISE CONTROL

PATCH HARNESS

TIE STRAP

TIE STRAP

TIE STRAP

FIGURE 26

FIGURE 28

RH INDICATOR

SWITCH

CONNECTOR

CRUISE CONTROL

STALK

CONNECTOR

SWITCH

RETAINING

TANGS

FIGURE 27

RETAINING

TANGS

RETAINING

TANG

SWITCH

ASSEMBLY

RH INDICATOR

SWITCH ASSEMBLY

G673

FD1069

11MA03

COPYRIGHT

Page 13 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

44. Route the remaining section of the cruise control

cabin harness (two 24 pin connectors) over the

steering column, behind the centre console, beneath

the HVAC unit, to the left-hand side kick panel.

45. Unclip the main wiring harness connector from the

retaining bracket and disconnect from the power train

harness connector. Refer Figure 29.

46. Connect the corresponding connectors on the cruise

control cabin patch harness to the main wiring harness

connector and the powertrain harness connector.

Refer Figure 29.

47. Clip the main wiring harness connector back into the

retaining bracket. Refer Figure 29.

48. Cable tie cruise control cabin patch harness securely

as indicated below. Refer Figure 30.

FIGURE 29

POWERTRAIN

HARNESS

CONNECTOR

MAIN WIRING

HARNESS

CONNECTOR

RETAINING

BRACKET

CRUISE CONTROL

CABIN PATCH

HARNESS

FIGURE 30

POWERTRAIN

HARNESS

CONNECTOR

CABLE TIE

INSTRUMENT

CLUSTER

HARNESS

INSTRUMENT

CLUSTER

CONNECTOR

GLOVEBOX SUPPORT

PANEL

CABLE TIE

CRUISE CONTROL

CABIN PATCH

HARNESS

CABLE TIE

CABLE TIE

CRUISE CONTROL

CABIN PATCH

HARNESS

CABLE TIE

A

B

C

B

C

A

G673

FD1069

11MA03

COPYRIGHT

Page 14 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FIGURE 31

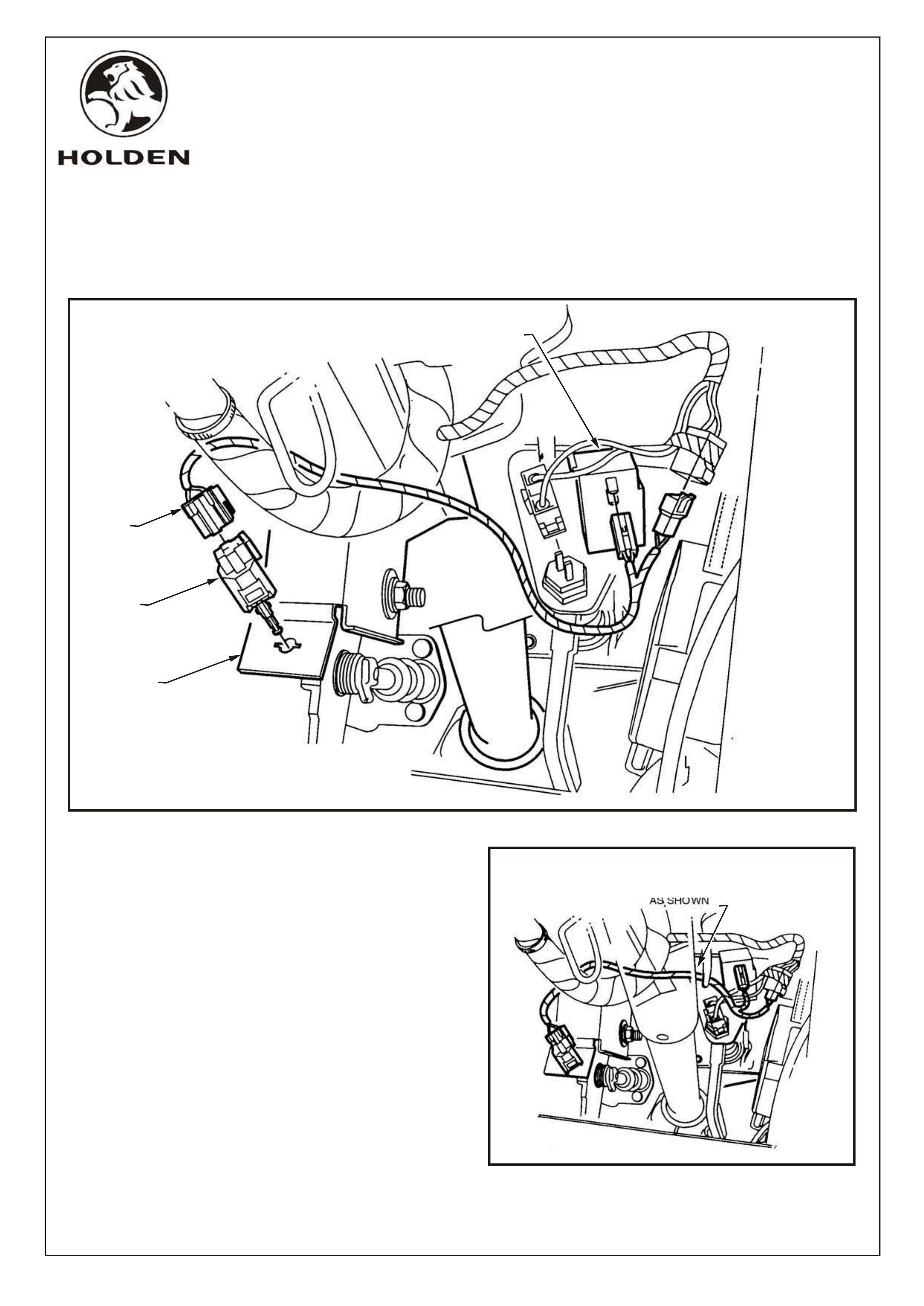

49. Route the cruise control engine bay patch harness

from the firewall around the strut tower, under the

vehicle harness former to the stepper motor bracket.

Route the earth lead between the stepper motor

bracket and inner fender, to existing body earth stud.

Attach cruise control earth terminal to the body earth

stud with existing terminals and nut.

Refer Figure 31.

Proceed to Step 55.

EARTH TERMINAL

EXISTING NUT

CRUISE CONTROL

STEPPER MOTOR

CONNECTOR

STEPPER MOTOR

BRACKET

CRUISE CONTROL

ENGINE BAY

HARNESS

STUD

IMPORTANT: Steps 50 to 54 apply only to vehicles which have cruise control wiring incorporated in the

existing vehicle wiring as determined by the presence of an existing stepper motor connector. Refer Figure 4.

CLIP

ATTACH

CONNECTOR

TO CRUISE

CONTROL

RELEASE

SWITCH

BRAKE

PEDAL

CRUISE CONTROL

RELEASE SWITCH

FIGURE 32

50. Fit the clip from the cruise control package to the

mounting hole of the brake pedal support. Refer

Figure 32.

51. Untape the connector from the wiring harness and

connect to the cruise control release switch.

52. Holding the brake pedal in the depressed position,

install the switch into the tubular clip. Push the

switch forward until the switch body locates in the

clip.

Refer Figure 32.

NOTE: Audible 'clicks' will be heard as the threaded

portion of switch assembly is pushed into the tubular

clip toward the brake pedal. Pull brake pedal fully

against stop until audible 'click' sounds can no longer

be heard. (Switch assembly is pushed back out from

the clip to provide correct switch position adjustment).

Depress the brake pedal again and repeat above

procedure to ensure that the switch adjustment is

correct (no 'click' sounds).

G673

FD1069

11MA03

COPYRIGHT

Page 15 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

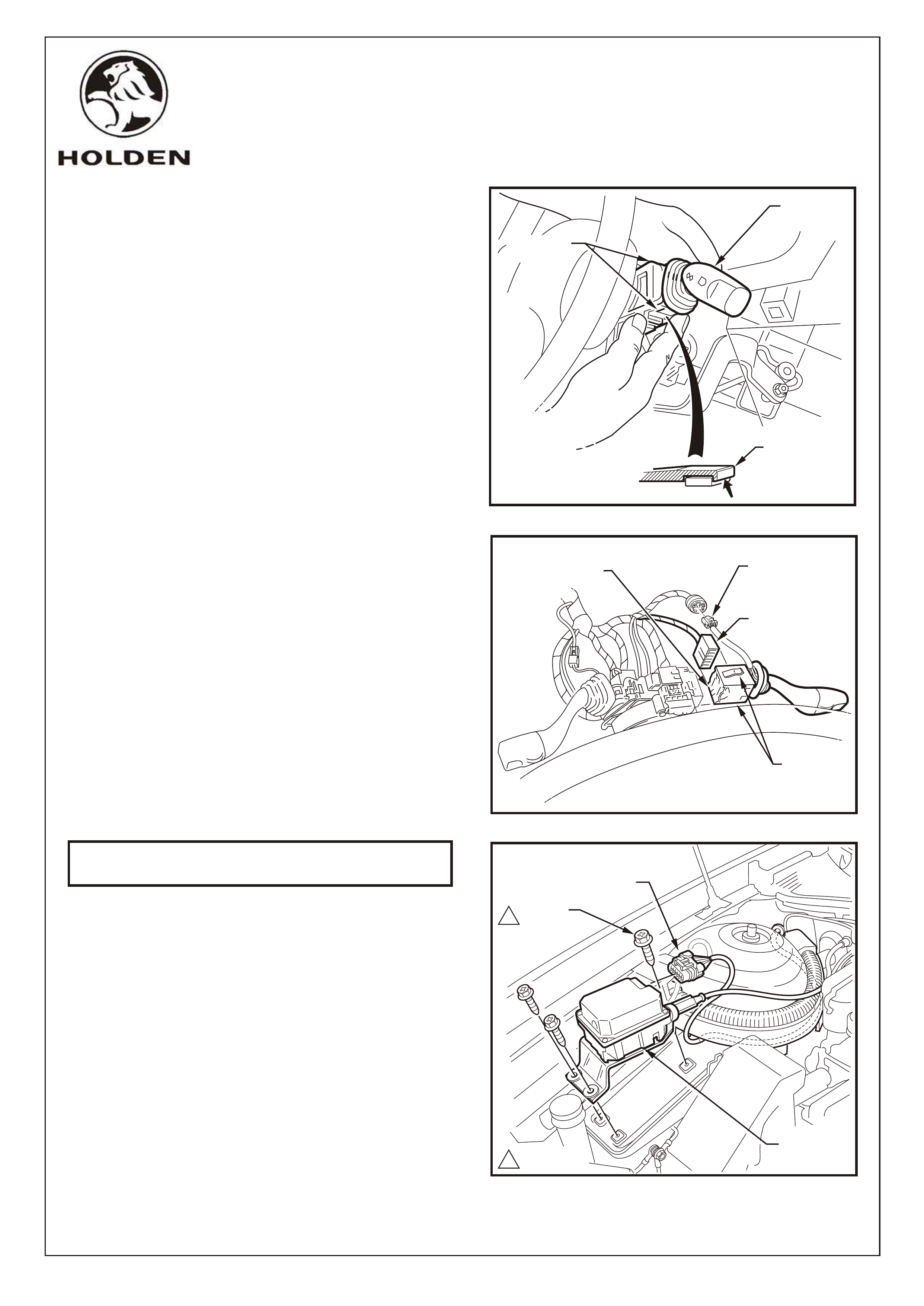

53. Depress the retaining tangs on the switch assembly

and pull the assembly away from the steering column.

Refer Figure 33.

54. Depress the wiring harness connector tangs and

pull the connector from the switch assembly.

Remove the turn signal assembly and replace with

the cruise control/indicator switch assembly from

the cruise control package.

Connect the cruise control patch harness connector

and indicator switch connector to the cruise control/

indicator switch assembly.

Refer Figure 34.

IMPORTANT: Steps 55 onwards applies to all

vehicles.

55. Install the stepper motor to the stepper motor

mounting bracket using the 3 screws supplied

and tighten to specified torque.

Refer Figure 35.

56. Attach the connector from the cruise control engine

bay patch harness or the existing harness to the

stepper motor. Refer Figure 35.

RH INDICATOR

SWITCH ASSEMBLY

RH INDICATOR

SWITCH

CONNECTOR

CRUISE CONTROL

STALK

CONNECTOR

SWITCH

RETAINING

TANGS

FIGURE 34

FIGURE 33

RETAINING

TANGS

RETAINING

TANG

SWITCH

ASSEMBLY

FIGURE 35

STEPPER

MOTOR

SCREW

(3 PLACES)

EXISTING OR

ENGINE BAY PATCH

HARNESS CONNECTOR

12.0 - 5.0 Nm

1

G673

FD1069

11MA03

COPYRIGHT

Page 16 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FIGURE 36

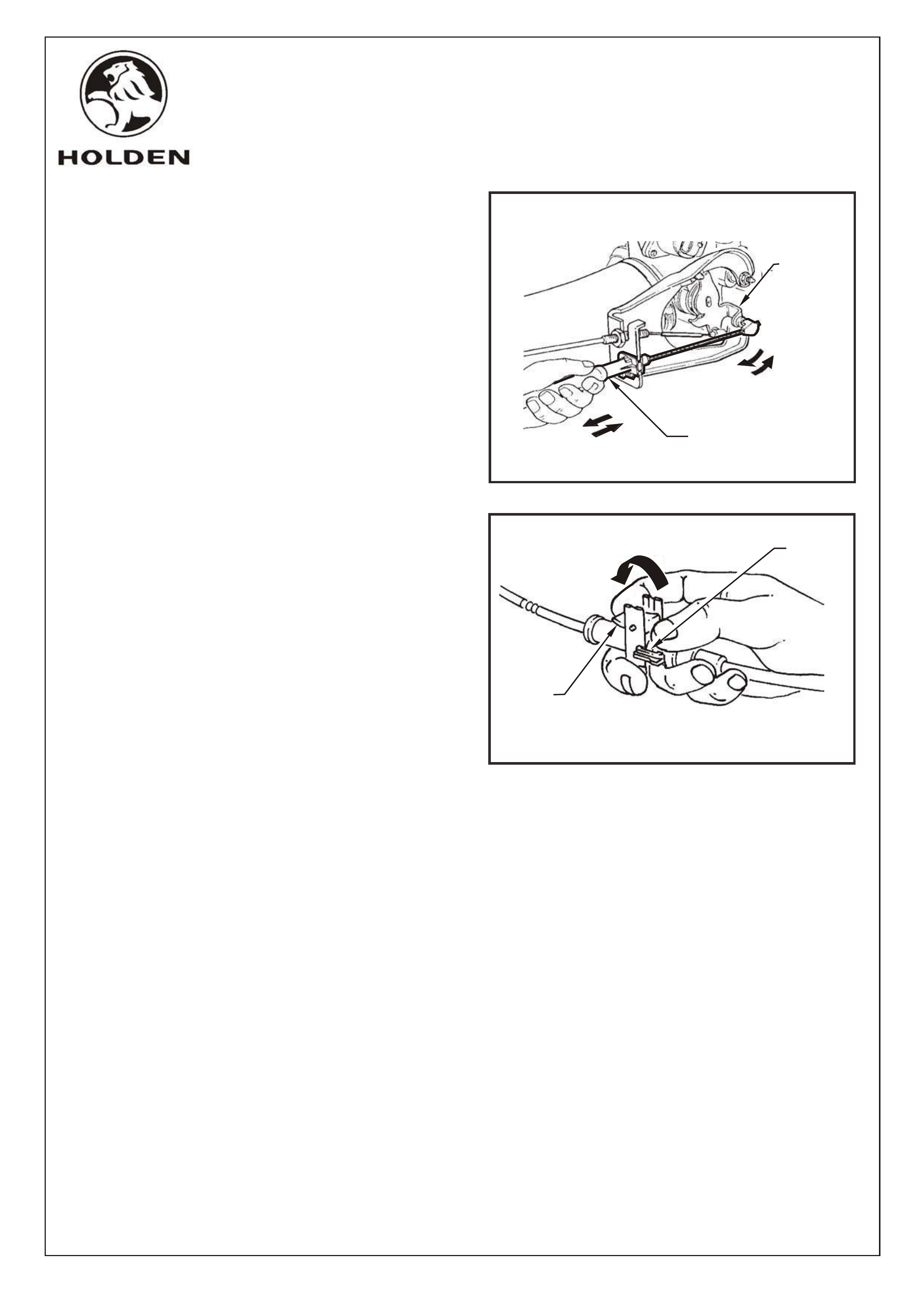

57. Attach the cable to the rear of the stepper motor,

route cable below harness former (fit in existing

clip) and behind brake booster then attach to

engine harness retention clips along edge of

firewall (3 places). Refer Figure 36.

58. Cable to be routed from the last retention clip on

dash panel to the throttle cable bracket in smooth

arc in alignment with the throttle cable.

Refer Figure 36.

59. Unlock cable adjustment locking lever. Refer

Figure 37.

FIGURE 37

G673

CRUISE

CONTROL

CABLE

THROTTLE

CABLE

A-A

SECTION

(1 PLACE)

WIRING

HARNESS

RETENTION

CLIP

WIPER

MOTOR

HARNESS

(M.W.H.)

POWERTRAIN

WIRING

HARNESS

CRUISE

CONTROL

CABLE

THROTTLE

CABLE

REAR

WASHER

HOSE

(WAGON

ONLY)

(2 PLACES)

B-B

SECTION

WIRING

HARNESS

RETENTION

CLIP

THROTTLE

CABLE

POWERTRAIN

WIRING

HARNESS

REAR

WASHER

HOSE

(WAGON

ONLY)

CRUISE

CONTROL

CABLE

A

A

B

B

B

C

(SERIES II - 1 PLACE)

C-C

SECTION

THROTTLE

CABLE

POWERTRAIN

WIRING HARNESS

CRUISE

CONTROL

CABLE

TIE STRAP

CABLE LOCK

C

BTHROTTLE

CABLE

BRACKET

OUTER

CABLE

LOCK

LOCKING

LEVER

PULL UP

FD1069

11MA03

60. Connect inner cable end to throttle stud then slide

outer cable into throttle bracket. Refer figure 38

COPYRIGHT

Page 17 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd Can 006 893 232

FIGURE 38

G673

THROTTLE

BODY

VALV E

LEVER

OUTER CABLE

FIGURE 39

OUTER

CABLE

LOCK

LOCKING

LEVER

PUSH DOWN

61. Ensure throttle is in closed position, adjust cruise

control cable, using adjuster, to achieve minimum

slack. Flip adjustment lever to lock cable in

position. Refer figure 39

62. Refit all removed parts noting torques if specified.

63. Re-connect the battery negative lead.

64. Reinstate the audio system by entering the security

code, refer owners manual.

65. Place fitting instructions in the glove box of vehicle.

NOTE: After installation, check operation of cruise

control, (including lamps in instrument panel) in

accordance with Section 12C, Instruments, in VY

Service Information Package (SIP). Any problems may

be corrected using this section of the SIP.

FD1069

11MA03

66. Adjust the steering column to the upper position.

67. While depressing the clutch pedal, install the clutch

switch. Refer Figure 40.

68. Rotate the switch 90 degrees to secure in position.

69. Fit the patch harness to the clutch switch. Refer

Figure 40.

70. Route the patch harness over the main wiring harness

and steering column. Refer Figure 41.

71. Fit the patch harness connectors to the cruise control

release switch and main wiring harness connector.

Refer Figure 41.

FITTING INSTRUCTIONS FOR VY

CRUISE CONTROL PACKAGE, MANUAL TRANSMISSION

CLUTCH SWITCH (92077936) AND PATCH HARNESS (92075048)

COPYRIGHT

Page 18 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd Can 006 893 232

CRUISE CONTROL

RELEASE SWITCH

PATCH

HARNESS

CLUTCH

SWITCH

CLUTCH

PEDAL

BRACKET

PARTIAL STEERING COLUMN

SHOWN FOR CLARITY

ENSURE PATCH HARNESS

IS ROUTED OVER MAIN WIRING

HARNESS AND STEERING COLUMN

AS SHOWN

FIGURE 40

FIGURE 41

G673

FD1069

11MA03

PART NUMBER DESCRIPTION QUANTITY

FITTING INSTRUCTIONS

VY CRUISE CONTROL PACKAGE (92145711),

V6 & SUPERCHARGED V6

PARTS LIST

25336986 STEPPER MOTOR & CABLE ASSEMBLY 1

92138364 BOLT - STEPPER MOTOR TO WHEELHOUSE 3

92066684 PATCH HARNESS - ENGINE BAY 1

92066647 PATCH HARNESS - CABIN 1

92089543 SWITCH - TURN SIGNAL/CRUISE 1

09794682 SWITCH - BRAKE 1

92138622 CLIP - C/CONTROL BRAKE SWITCH MOUNT 1

7436769 STRAP - 220MM 5

SP3516 STRAP - 180MM 7

FD1069 FITTING INSTRUCTIONS BOOKLET 1

FD796 WARRANTY CARD

NOT INCLUDED IN CRUISE CONTROL PACKAGE, BUT MANDATORY TO FIT

TO VEHICLES WITH MANUAL TRANSMISSION (REFER PAGE 18):-

92077936 SWITCH - CLUTCH 1

92075048 PATCH HARNESS - CLUTCH SWITCH 1

COPYRIGHT

Page 19 of 19

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd Can 006 893 232

G673

FD1069

11MA03