HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FD1105

03DE04

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

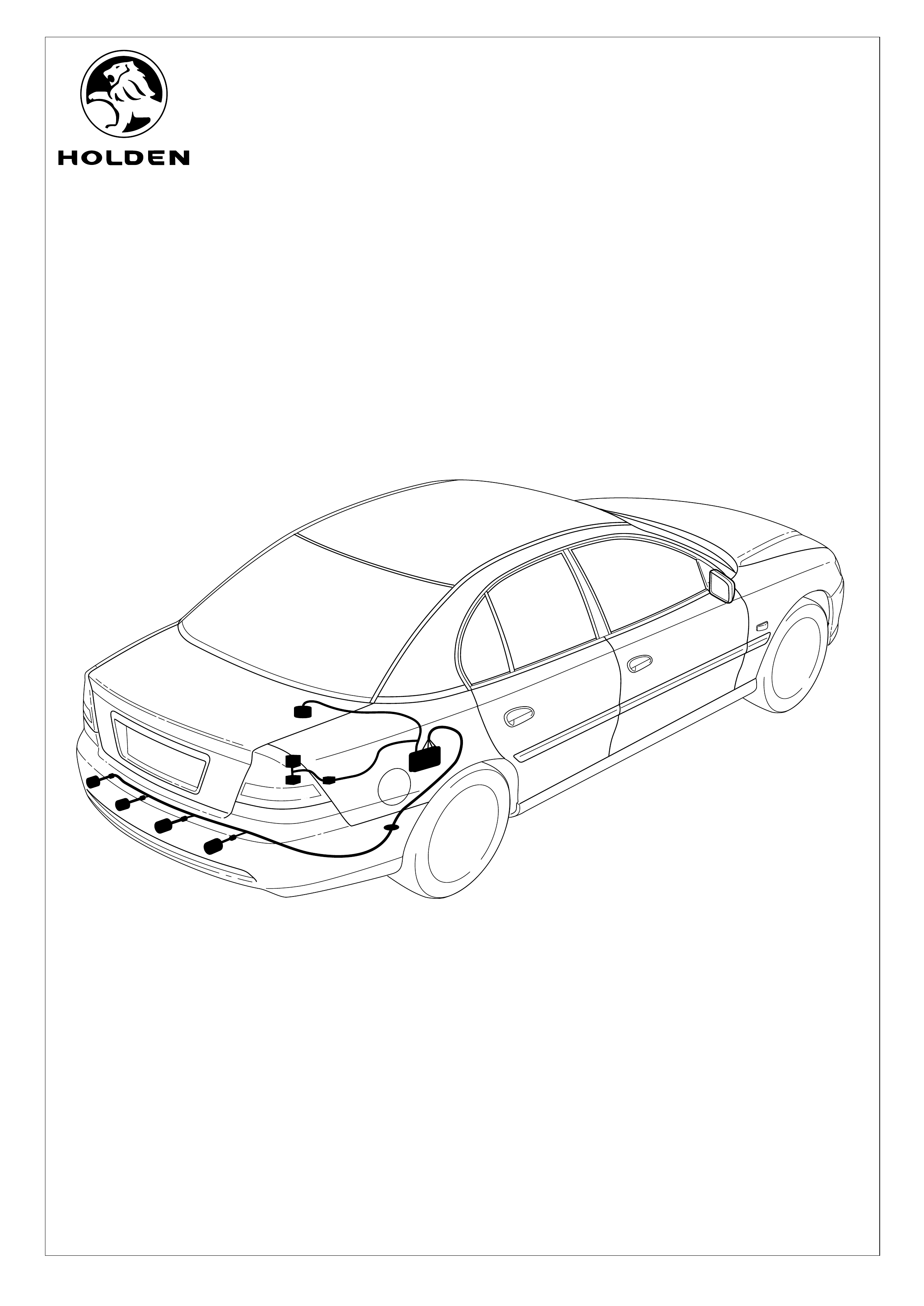

FITTING INSTRUCTIONS FOR

REVERSE PARKING SENSOR SYSTEM

MODELS VT, VX SEDANS,

VX BERLINA/CALAIS SEDANS,

VY SEDANS, VZ SEDANS

& WL SEDANS

Page 1 of 18

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FD1105

03DE04

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

TOOLS REQUIRED:

Flat-blade Type Screwdriver, Phillips Head Screwdriver,

Hammer, metal Plug, 2.0 mm Drill Bit, Lumen Spade Drill Bit

(P/N 92147946), Cleaning Cloth, Hi-tech Cleaning Pad

(Supplied), Guide Wire (approx. 600 mm).

FITTING INSTRUCTIONS:

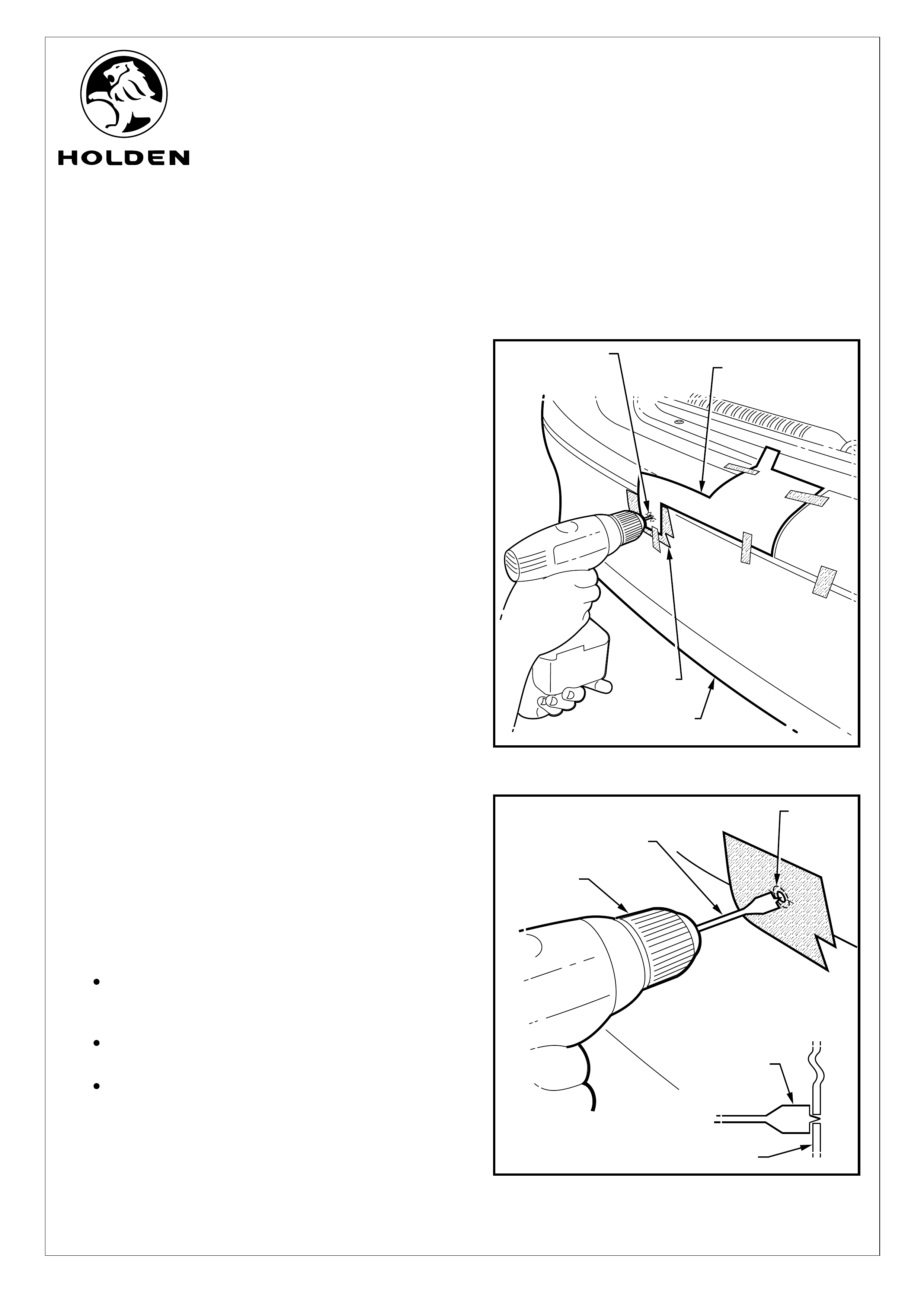

1. Copy and cut-out the required templates on pages 9-

18. Check that the scale on the copied template is

correct. Fit the templates on the vehicles as indicated:

L - Left - Template 1 - Page 9, VT, VX Exec.

Template 5 - Page 11, VX Berlina/Calais.

Template 9 - Page 13, VY Sedan.

Template 13 - Page 15, VZ Sedan.

Template 17 - Page 17, WL Sedan

CL - Centre Left - Template 2 - Page 9, VT, VX Exec.

Template 6 - Page 11, VX Berlina/Calais.

Template 10 - Page 13, VY Sedan.

Template 14 - Page 15, VZ Sedan.

Template 18 - Page 17, WL Sedan.

CR - Centre Right - Template 3 - Page 10, VT, VX Exec.

Template 7 - Page 12, VX Berlina/Calais.

Template 11 - Page 14, VY Sedan.

Template 16 - Page 16, VZ Sedan.

Template 20 - Page 18, WL Sedan.

R - Right - Template 4 - Page 10, VT, VX Exec.

Template 8 - Page 12, VX Berlina/Calais.

Template 12 - Page 14, VY Sedan.

Template 15 - Page 16, VZ Sedan.

Template 19 - Page 18, WL Sedan.

Place masking tape over the area of the bumper fascia

to be drilled. Refer to Figure 1.

2. Drill pilot holes through the templates and fascia (4

places) using a 2.0 mm drill bit. Refer to Figure 1.

3. Remove the templates and drill 22.2mm dia. holes

through the fascia (4 places), using the Lumen spade

drill bit. Refer to Figure 2.

IMPORTANT:

Use only the Lumen spade drill bit as a normal

drill bit or hole saw may damage the bumper

fascia.

Ensure the spade drill bit remains square with

the bumper fascia.

Use 1,500 - 2,000 RPM (slow speed) drill speed

only to avoid damaging the bumper fascia.

Ÿ

Ÿ

Ÿ

FIGURE 1

FITTING INSTRUCTIONS FOR

REVERSE PARKING SENSOR SYSTEM

FIGURE 2

PILOT HOLE

2.0mm DIA

(4 PLACES)

MASKING

TAPE

TEMPLATE

BUMPER

FASCIA

(4 PLACES)

LUMEN SPADE

DRILL BIT

ENSURE DRILL

BIT REMAINS

SQUARE WITH

BUMPER FASCIA

BUMPER FASCIA

1,500 - 2,000 RPM

DRILL SPEED

Page 2 of 18

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FD1105

03DE04

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

FITTING INSTRUCTIONS FOR

REVERSE PARKING SENSOR SYSTEM

FITTING INSTRUCTIONS: - continued.

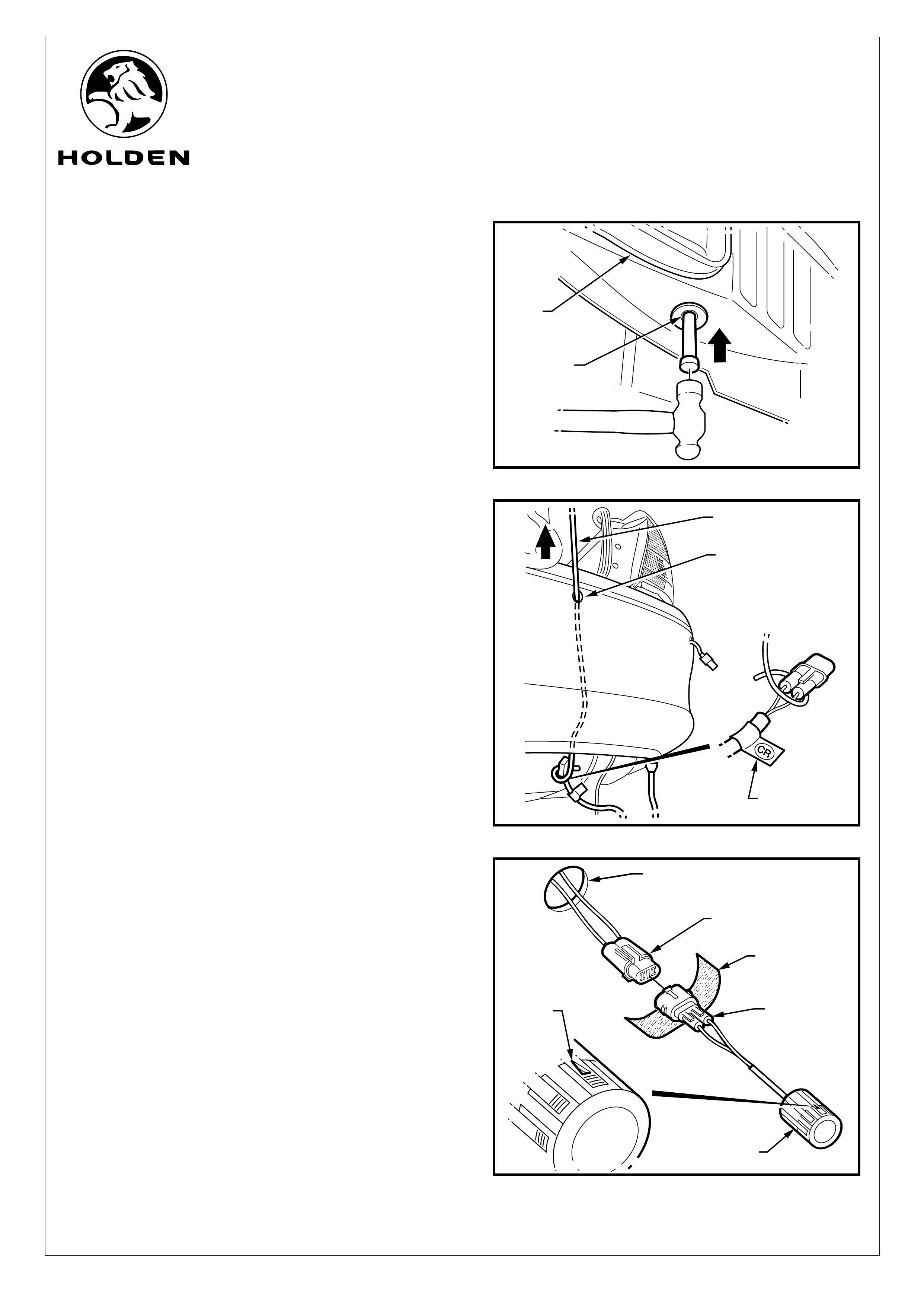

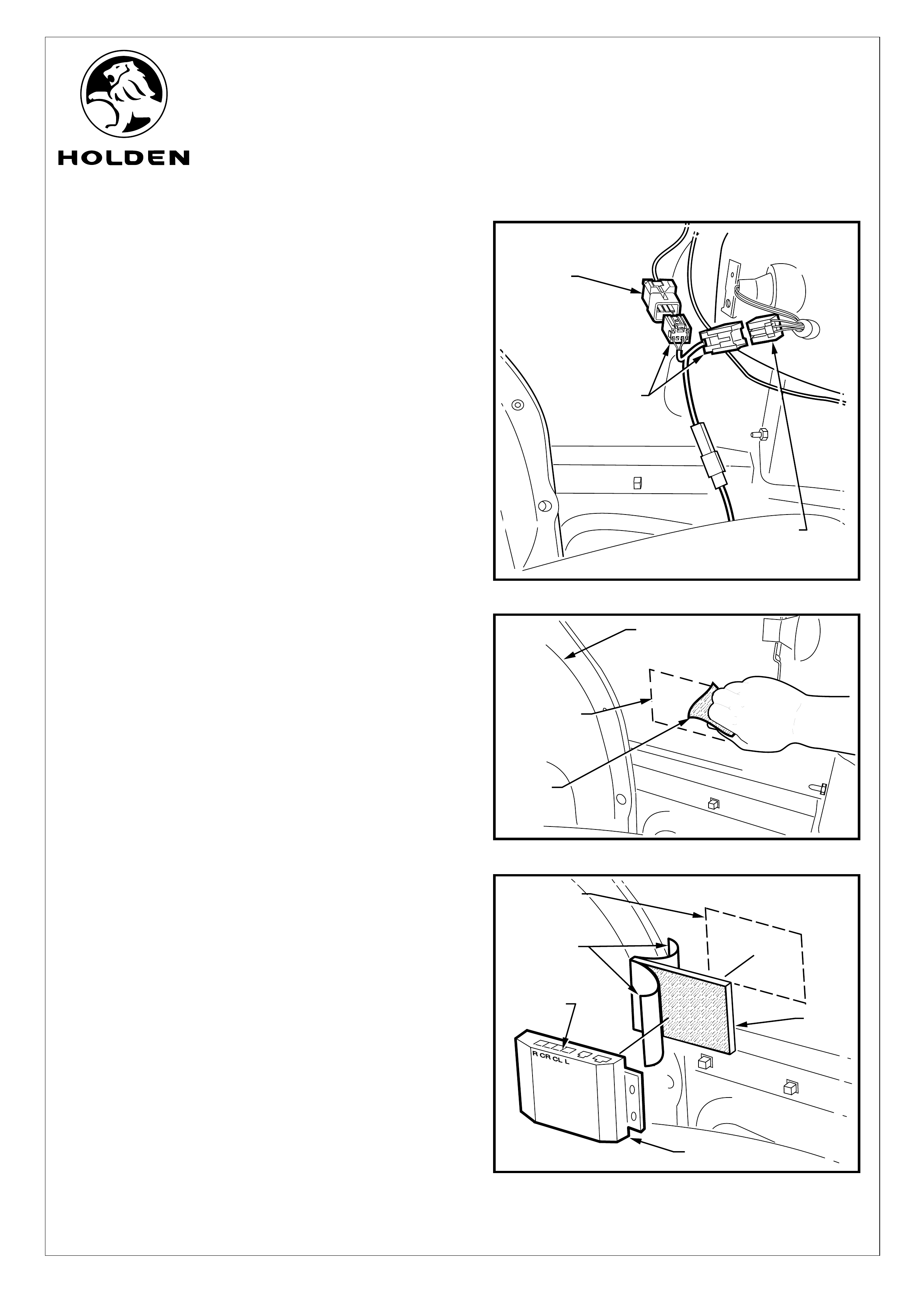

4. Remove the metal plug from behind the right-hand side

wheel arch below the air extraction vent, by knocking out

from beneath the vehicle. Refer to Figure 3.

5. From inside the rear compartment, clean sufficient

sealant from around the metal plug hole to allow the new

harness grommet to seal securely.

6. Feed the reverse parking sensor (RPS) harness

connectors through the bumper fascia as follows:

Pass a piece of guide wire through the right-hand side

fascia hole, down between the bumper fascia and the

bumper reinforcement.

Fix the right hand side connector (R) to the wire and

pull back through the hole.

Use care when feeding the connector between the

fascia and bumper reinforcement.

Repeat for the centre-right (CR), the centre left (CL)

and the left (L) connectors.

NOTE: Ensure the harness connectors correspond to

the position of the sensors. This is indicated by a label

situated behind the harness connector as follows:

L- Left

CL - Centre Left

CR - Centre Right

R- Right

Refer to Figure 4.

7. Peel the protective backing off the foam strip and wrap

firmly around the sensor connectors. Refer to Figure 5.

8. Connect the sensors to the RPS harness connectors.

Refer to Figure 5.

9. Pass the connectors back through the holes then press

fit the reverse parking sensors (4 places) into the holes

drilled in the fascia.

IMPORTANT: Ensure the arrow on the sensor body

faces the top of the fascia. Refer to Figure 5.

FIGURE 3

FIGURE 4

FIGURE 5

PULL CONNECTOR

THROUGH HOLE

GUIDE

WIRE

CONNECTOR

IDENTIFICATION

SENSOR

SENSOR

CONNECTOR

FOAM STRIP

(WRAP AROUND

CONNECTOR)

HARNESS

CONNECTOR

RPS HARNESS

CONNECTOR

22mm DIA.

BUMPER FASCIA

HOLE

'TOP'

MARK

METAL

PLUG

AIR

EXTRACTION

VENT

Page 3 of 18

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FD1105

03DE04

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

FITTING INSTRUCTIONS FOR

REVERSE PARKING SENSOR SYSTEM

FITTING INSTRUCTIONS: - continued.

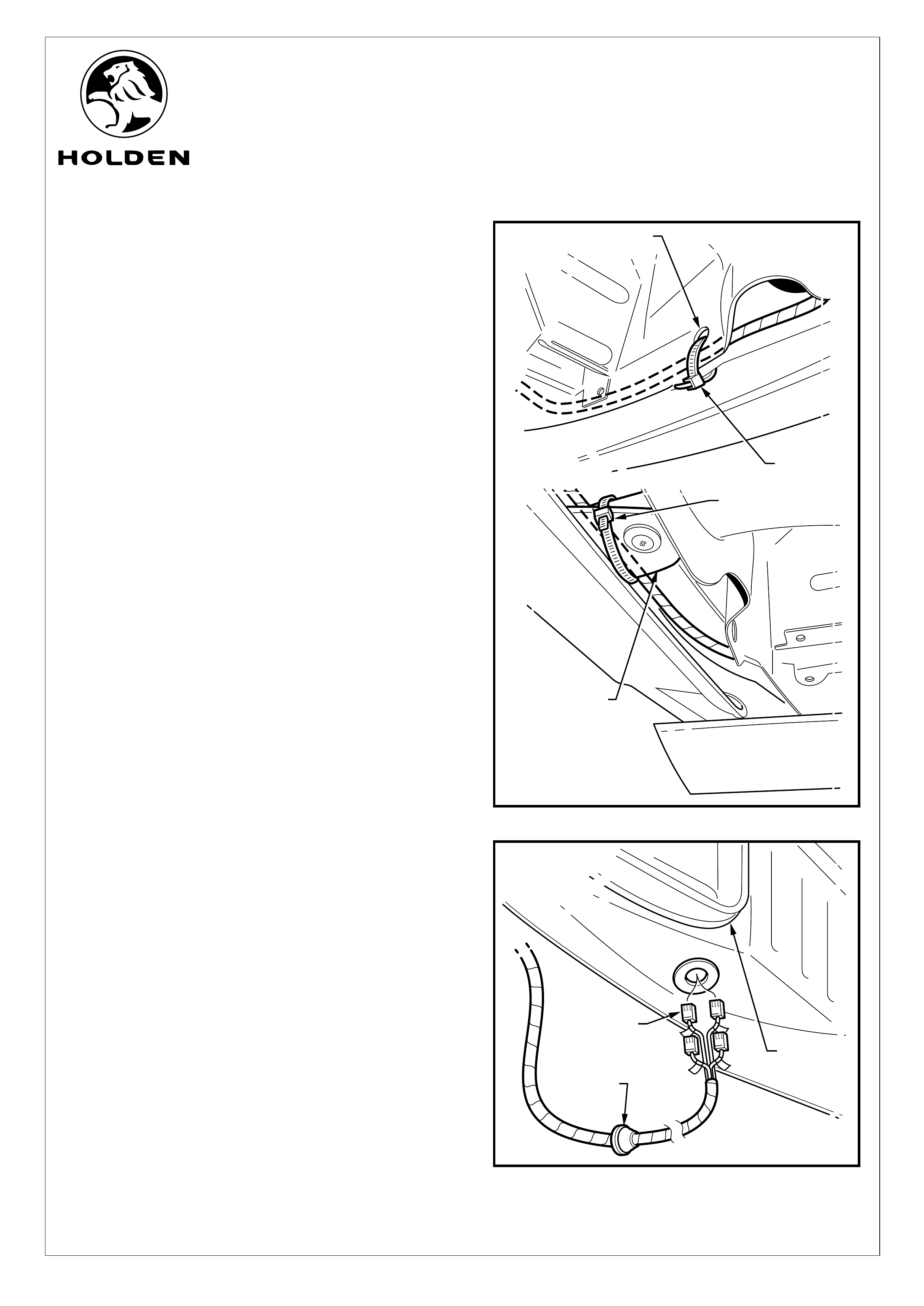

Refer to Figure 6 for the following:

10. Tie strap the RPS harness (2 places) as follows:

a. Tie strap securely to the hole on the right-hand side

of the lower rear panel.

b. Tie strap loosely to the left-hand side bumper fascia

support bracket.

11. Feed the RPS harness module connectors through the

hole behind the right-hand side rear wheel arch below

the air extraction vent, and fit the grommet securely in

position. Refer to Figure 7.

NOTE: Ensure the grommet mounting hole surround is

clean and free from sealant to allow the grommet to seal

securely.

AIR

EXTRACTION

VENT

FIGURE 6

FIGURE 7

CABLE TIE

BUMPER FASCIA

SUPPORT BRACKET

(LEFT-HAND SIDE

CABLE TIE

LOWER REAR HOLE

(RIGHT-HAND SIDE)

GROMMET

RPS HARNESS

MODULE

CONNECTORS

Page 4 of 18

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FD1105

03DE04

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

FITTING INSTRUCTIONS FOR

REVERSE PARKING SENSOR SYSTEM

FITTING INSTRUCTIONS: - continued.

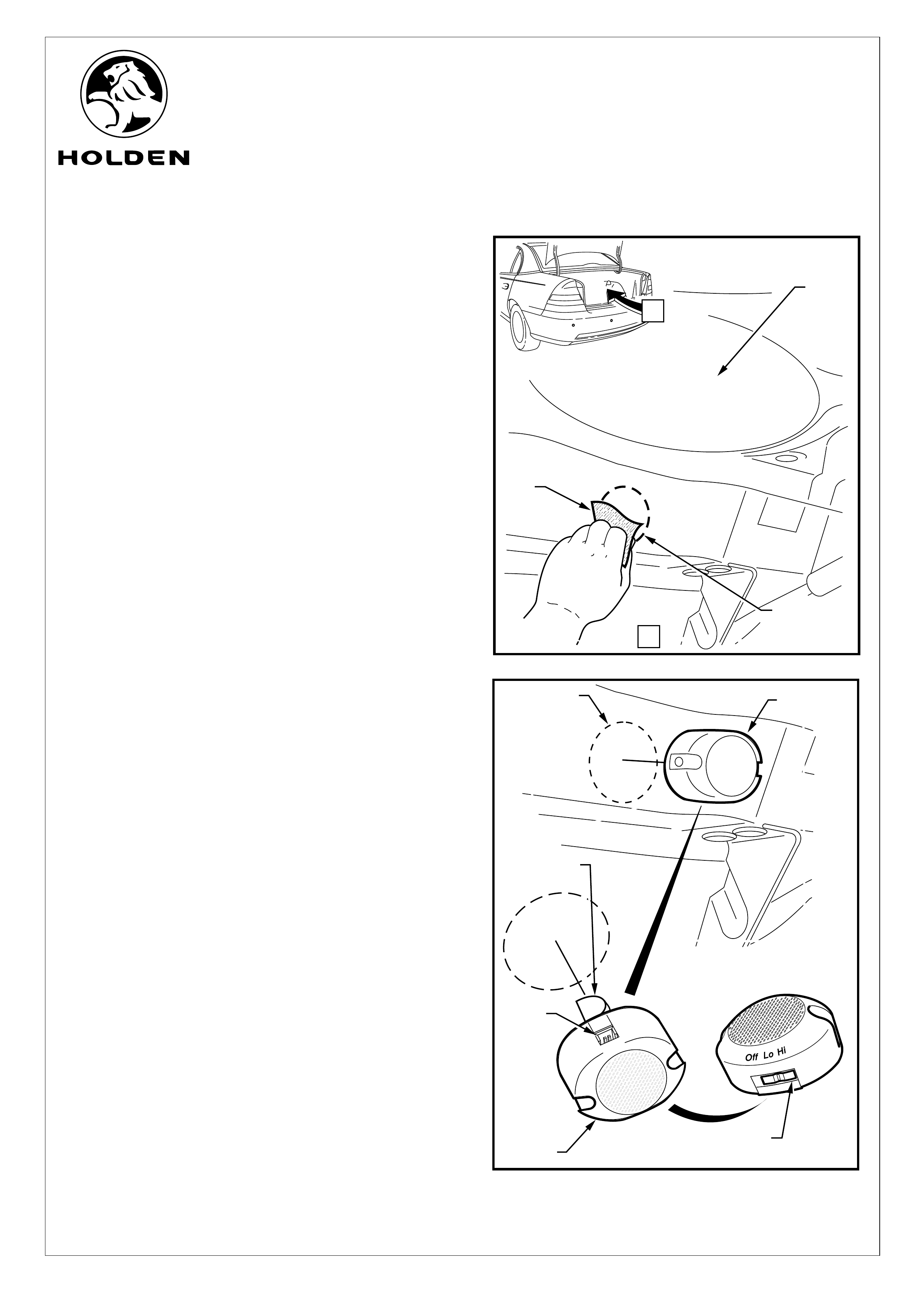

12. Unclip the rear compartment liner from the right-hand

side rear quarter panel and parcel shelf area.

Disconnect the existing right-hand side rear

compartment tail light connector. Refer to Figure 8.

13. Fit the corresponding connectors on the RPS main

wiring harness between the connectors on the right-

hand side rear compartment tail light harness.

Refer to Figure 8.

14. The RPS module mounts on the inside of the right-hand

side rear quarter panel behind the wheel arch as

indicated.

NOTE: Before fitting the module, clean the mounting

area then wipe with the hi-tech cleaning pad supplied

(retain pad for later use). Also wipe the back of the RPS

module. Refer to Figure 9.

15. Peel the backing off one side of the RPS module velcro

mounting pad and press fit firmly to the back of the RPS

module. Refer to Figure 10.

16. Peel the backing off the remaining side of the velcro

mounting pad and press fit the RPS module onto the

inner rear quarter panel in the position indicated,

ensuring the WIRING CONNECTOR SOCKETS FACE

"UP". Apply pressure to the RPS module unit to ensure

a secure fit. Refer to Figure 10.

FIGURE 8

EXISTING

RIGHT-HAND

SIDE TAIL LAMP

CONNECTOR

RPS MAIN

WIRING HARNESS

CONNECTORS

EXISTING

RIGHT-HAND

SIDE TAIL LAMP

CONNECTOR

FIGURE 9

RPS MODULE

MOUNTING

LOCATION

HI-TECH

CLEANING

PAD

RIGHT-HAND SIDE

REAR WHEEL ARCH

PROTECTIVE

BACKING

RPS MODULE

MOUNTING

LOCATION

RPS MODULE

VELCRO

PAD

FIGURE 10

WIRING

SOCKETS

Page 5 of 18

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FD1105

03DE04

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

SWITCH SET

TO 'Hi' POSITION

FIGURE 11

FIGURE 12

FITTING INSTRUCTIONS FOR

REVERSE PARKING SENSOR SYSTEM

FITTING INSTRUCTIONS: - continued.

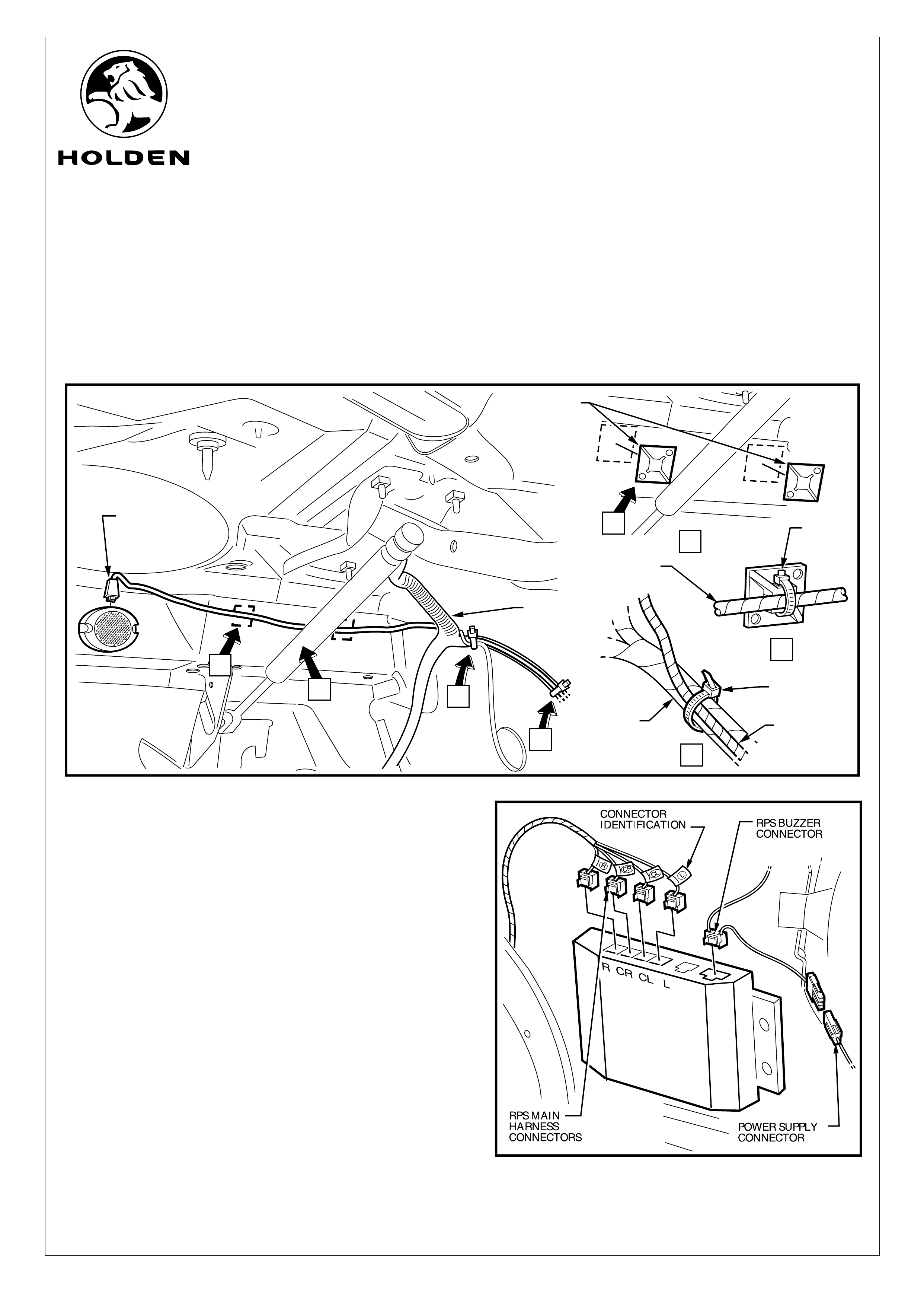

17. The RPS buzzer mounts in the rear compartment under

the rear parcel shelf as indicated. Clean the mounting

area then wipe with the hi-tech cleaning pad supplied

(retain pad for later use). Refer to Figure 11.

Refer to Figure 12 for the following:

18. Peel the protective backing off the RPS buzzer and

press fit in the position indicated ensuring the WIRING

SOCKET FACES "UP". Apply pressure to the buzzer

unit to ensure a secure fit.

NOTE: Prior to fitting the buzzer, ensure the switch is set

to 'Hi'. Refer to Figure 12.

REAR

PARCEL

SHELF

RPS BUZZER

MOUNTING

LOCATION

HI-TECH

CLEANING

PAD

RPS BUZZER

RPS BUZZER

MOUNTING

LOCATION

RPS

BUZZER

WIRING

SOCKET

PROTECTIVE

BACKING

A

Page 6 of 18

VIEW A

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FD1105

03DE04

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

CABLE TIE

SECURING

PADS

FIGURE 13

FITTING INSTRUCTIONS FOR

REVERSE PARKING SENSOR SYSTEM

21. Connect the RPS buzzer harness connector to the

RPS module. Refer to Figure 14.

22. Connect the four RPS harness connectors into the RPS

module. Ensure the harness connectors correspond to

the positions in the module. This is indicated by a label

situated behind the connectors and on the front face of

the RPS module as follows:

L- Left

CL - Centre Left

CR - Centre Right

R- Right

Refer to Figure 14.

23. Connect the RPS power supply harness connector to

the corresponding RPS main wiring harness connector.

Refer to Figure 14.

FITTING INSTRUCTIONS: - continued.

19. Connect the RPS buzzer harness connector to the buzzer and route to the right-hand side of the parcel shelf and

follow the existing vehicle harness to the RPS module. Tie strap the RPS buzzer harness to the existing vehicle

harness in two places. Refer to Figure 13 (View C).

20. Clean the underside of the rear parcel shelf in the positions indicated (2 places) and wipe with the high-tech cleaning

pad supplied. Press fit the two cable tie securing pads in the positions indicated (View A). Secure the RPS buzzer

harness to the parcel shelf at these two locations with cable ties. Refer to Figure 13 (View B).

A

B

C

A

B

C

RPS BUZZER

HARNESS

CONNECTOR

C

RPS BUZZER

HARNESS

EXISTING

VEHICLE

HARNESS

CABLE TIE

CABLE

TIE

RPS BUZZER

HARNESS

EXISTING

VEHICLE

HARNESS

B

FIGURE 14

Page 7 of 18

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FD1105

03DE04

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

FITTING INSTRUCTIONS FOR

REVERSE PARKING SENSOR SYSTEM

VT, VX, VY & WL REVERSE PARKING SENSOR SYSTEM

PARTS LIST

FITTING INSTRUCTIONS: - continued.

24. Neatly cable tie excess wiring harness.

25. Fix the caution label in a prominent position (above tyre

placard on drivers side door).

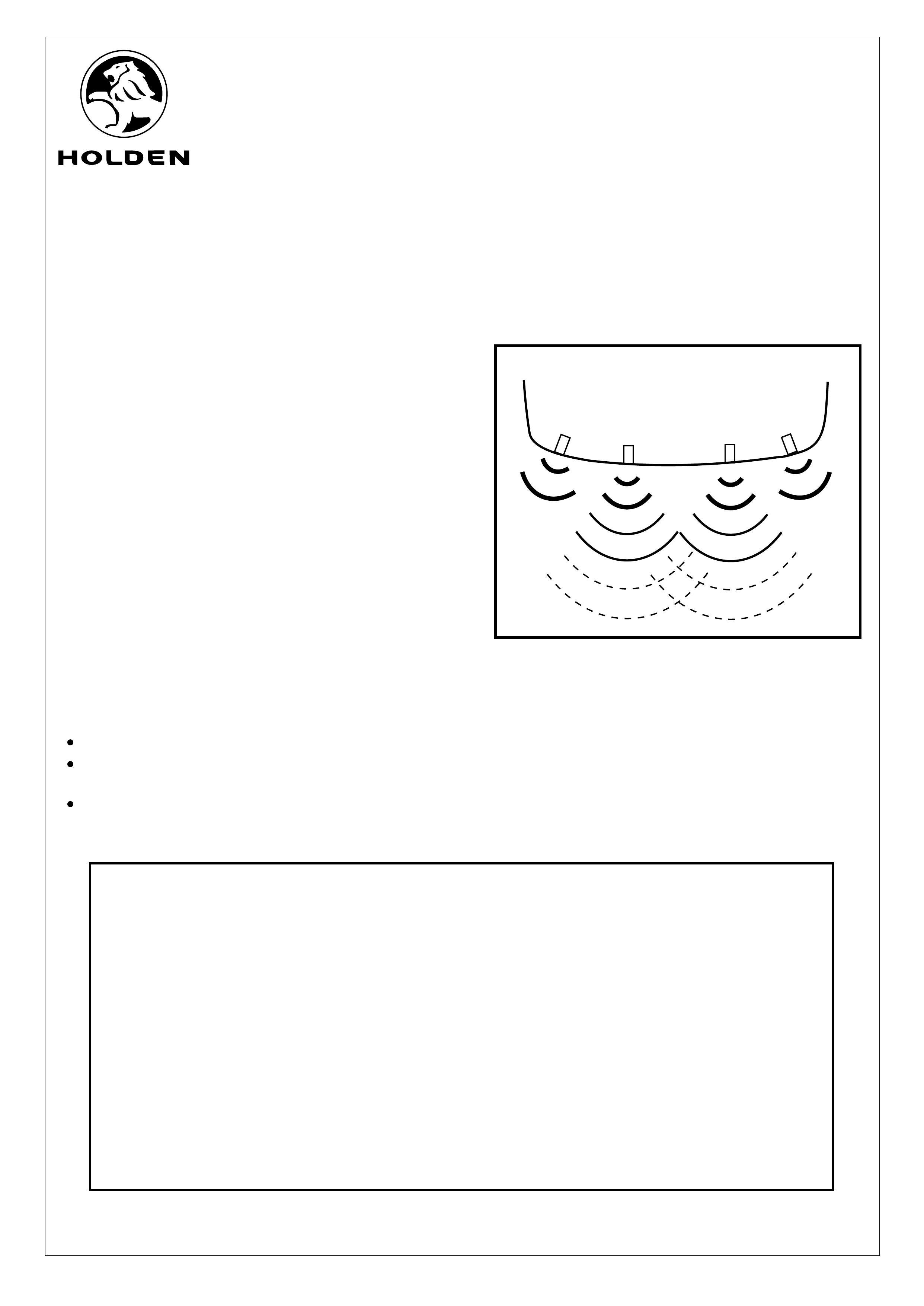

26. Test the reverse parking sensor system for correct

operation as follows:

Turn the ignition to the "ON" position (engine not

running).

Place the gear lever in reverse (R).

From behind the vehicle, walk towards each sensor.

The two centre sensors have 3 stages.

The two corner sensors only have 1 stage of final

warning. Refer to Figure 15.

Refer to the owners manual for further information

and trouble shooting.

Turn the ignition to the "OFF" position.

27. Refit all removed parts and torque fasteners to

specifications.

28. Place fitting instructions in the glovebox.

IMPORTANT:

DO NOT paint over the reverse parking sensor.

Ensure the reverse parking sensor remains clean

and free from road grime, mud, car polish etc.

If the sensor or the groove on the sensor surface

becomes contaminated, the performance may be

affected.

Ÿ

Ÿ

Ÿ

PART NUMBER DESCRIPTION QUANTITY

92144863 REVERSE PARKING SENSOR SYSTEM

REVERSE PARKING SENSOR MAIN HARNESS 1

REVERSE PARKING SENSOR HARNESS 1

REVERSE PARKING SENSOR BUZZER HARNESS 1

REVERSE PARKING SENSOR 4

REVERSE PARKING BUZZER 1

REVERSE PARKING SENSOR MODULE VELCRO MOUNTING PAD 1

REVERSE PARKING SENSOR FOAM SEAL 4

REVERSE PARKING SENSOR BUZZER HARNESS ADHESIVE PADS 2

CABLE TIE 10

HI-TECH CLEANING PAD 1

INSTRUCTION MANUAL 1

FD 1105 FITTING INSTRUCTIONS 1

FIGURE 15

Page 8 of 18