11.0~3.0 Nm

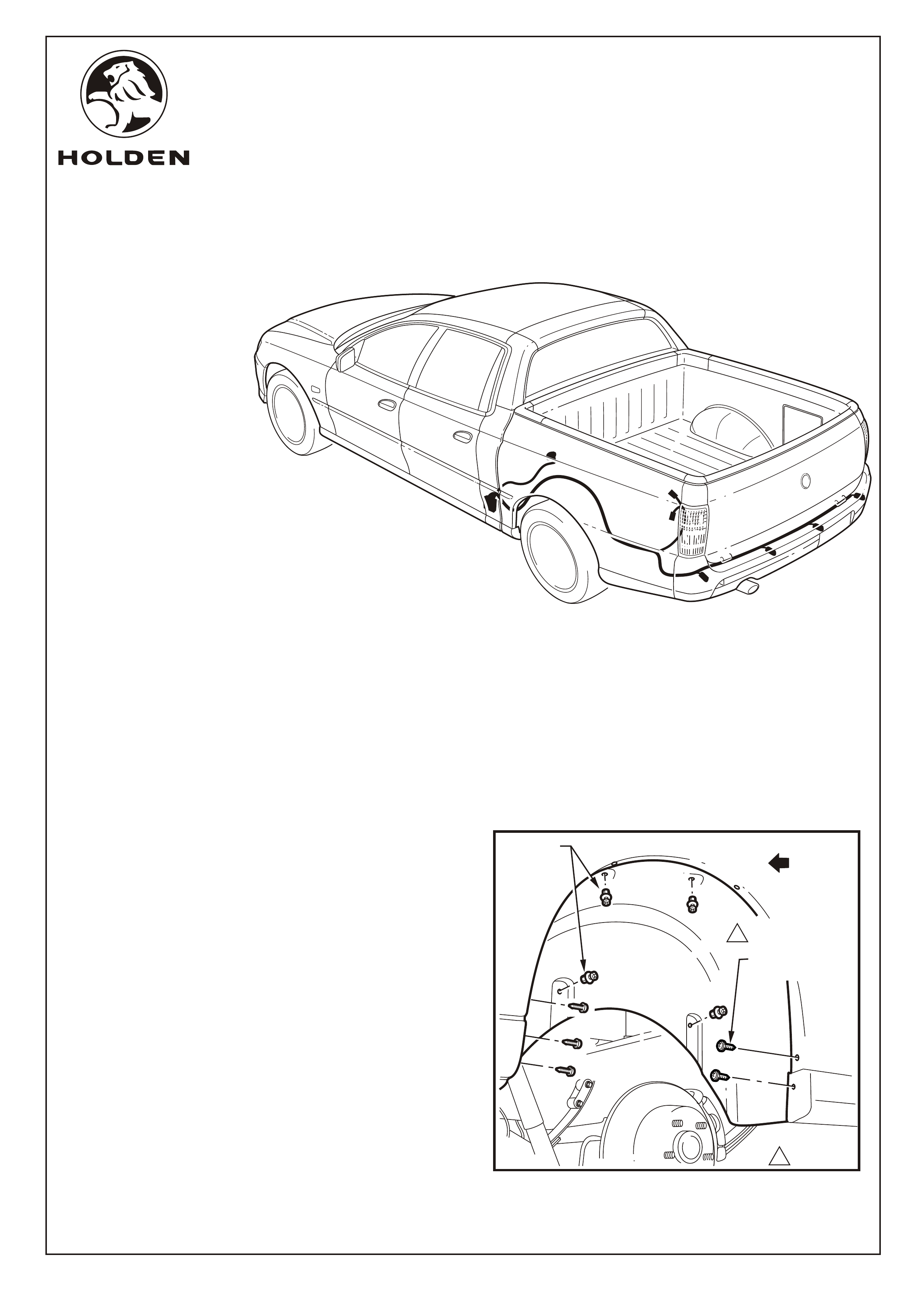

REMOVE

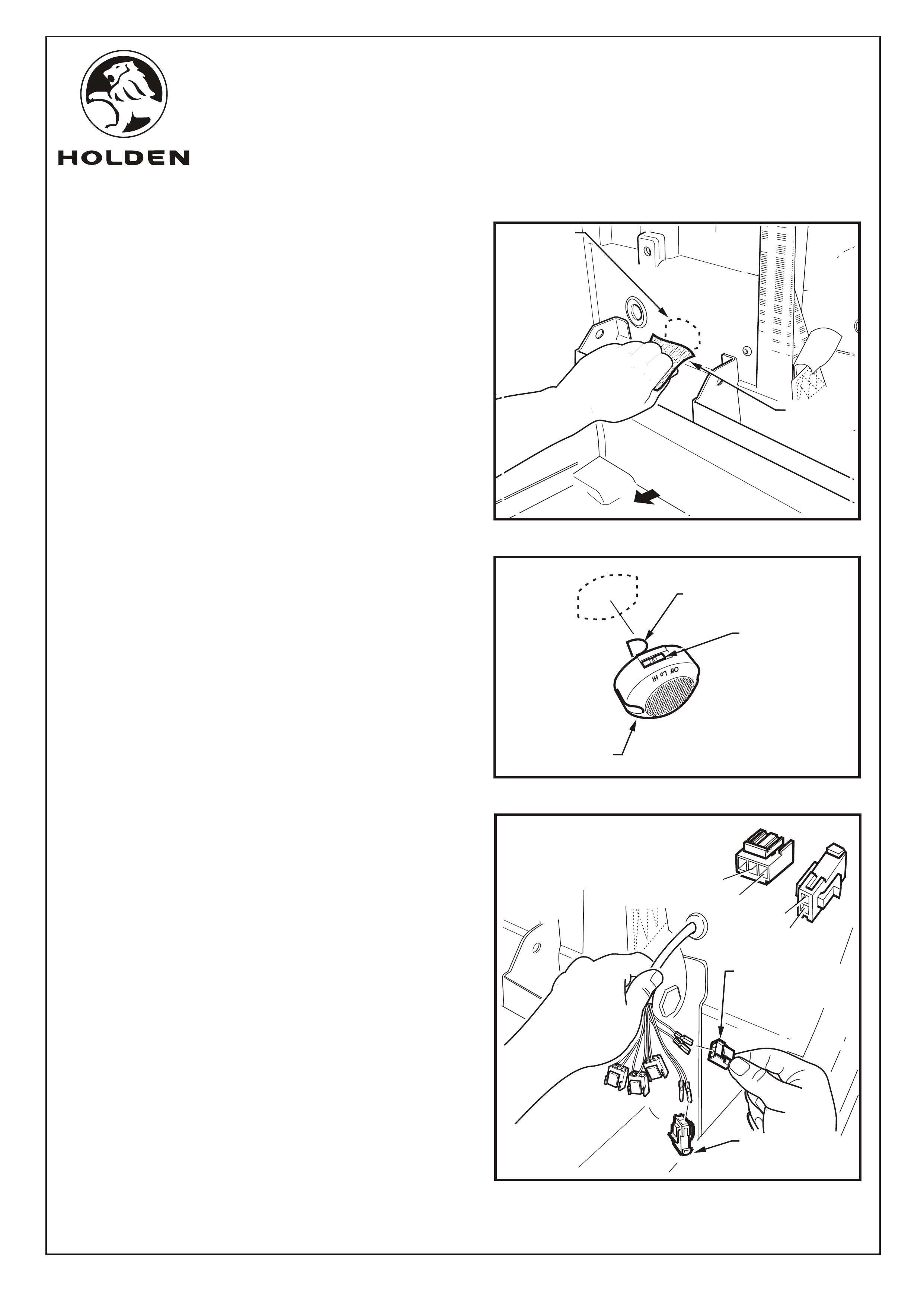

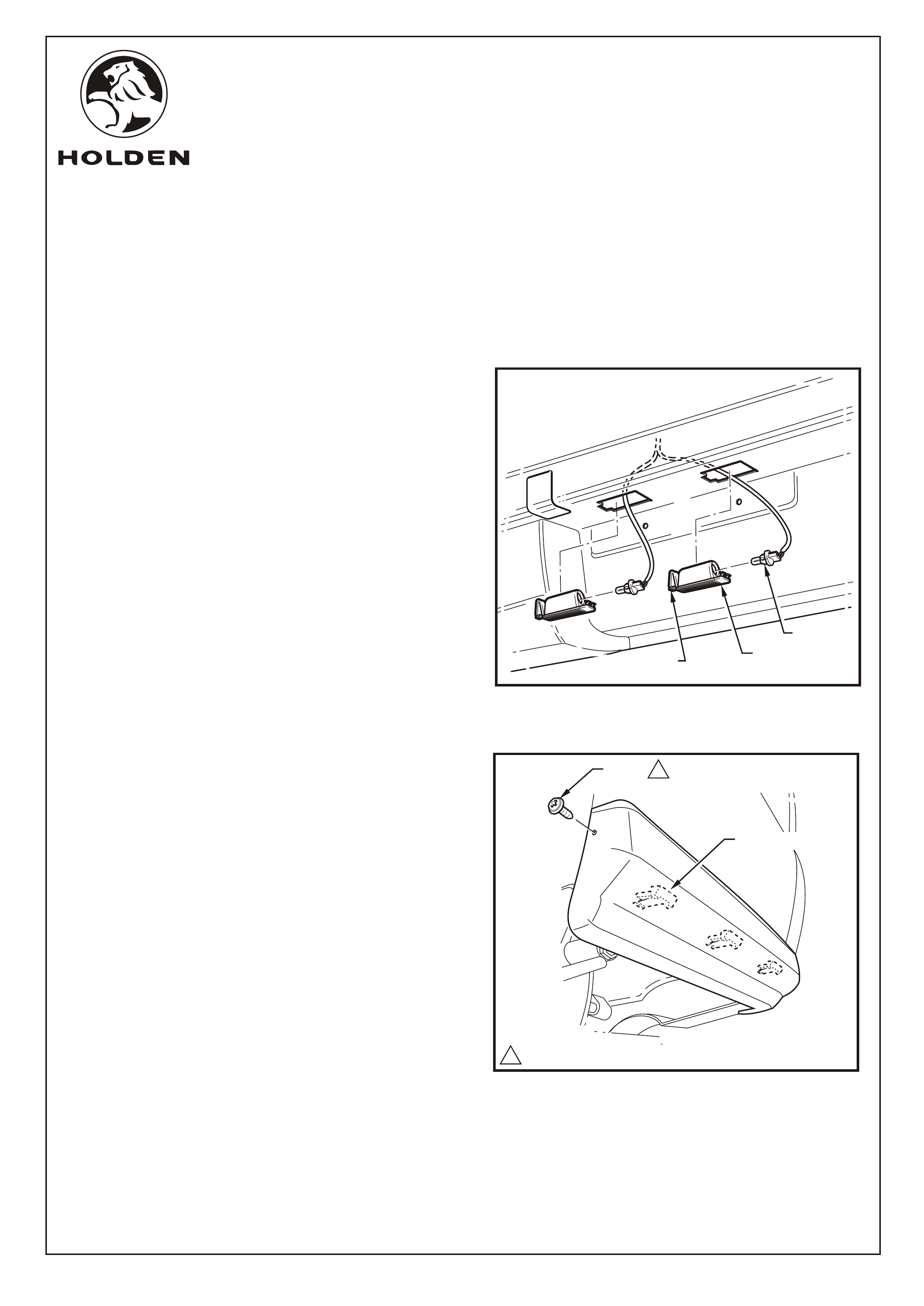

RETAINERS

(4 PLACES)

1

REMOVE

ATTACHING

SCREWS

(5 PLACES)

FRONT OF

VEHICLE

FIGURE 1

COPYRIGHT

Page 1 of 15

HOLDEN LTD

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

CREW CAB REVERSE PARKING AID SENSOR PACKAGE

Part No. 92148000

FD1166

18JULY03

FITTING INSTRUCTIONS:

1. If fitted, remove any wheel trim covering the wheel nuts

from the rear left-hand wheel and place to one side.

Loosen wheel nuts, raise vehicle and remove nuts and

wheel. Refer to vehicles owners handbook for further

information.

2. Remove the five rear left-hand side wheelhouse liner

attaching screws and the four retainers attaching the

liner to the wheelhouse panel, refer to Figure 1.

3. Manipulate the liner from behind the wheelhouse panel

and remove.

TOOLS REQUIRED:

Wheel Wrench, Philips Head Screwdriver, Flat Blade

Screwdriver, Socket Wrench and 13 mm Socket, Hoist

(Recommended), 2.0 mm Drill Bit, 22.0 mm Wood Spade

Drill Bit, Cleaning Cloth, Hi-tech Cleaning Pad (Supplied),

Guide Wire (approx. 600 mm).

COPYRIGHT

Page 2 of 15

HOLDEN LTD

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

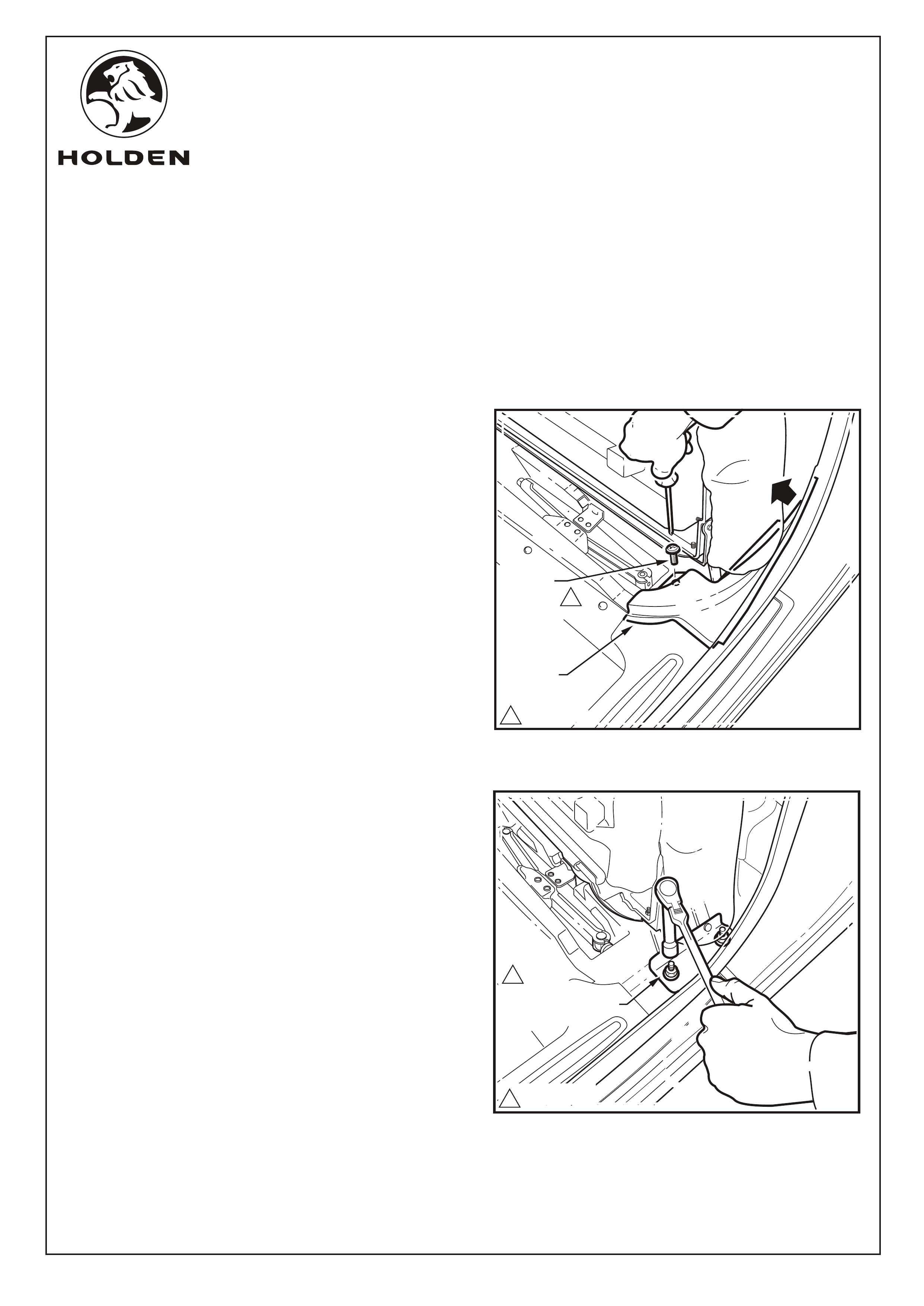

Refer to Figure 2 for the following:

4. Press the rear seat base release handle and fold and

hold the seat base in the upright position.

5. Remove attaching screw from the left-hand side interior

rocker panel extension moulding. Grasp the moulding

and pull to remove it from behind the seat cushioning

and door sill. Repeat on opposite side of vehicle.

6. Remove the two left-hand side seat bracket to floor

panel attaching nuts. Repeat on opposite side of vehicle.

Refer to Figure 3.

7. Lift the seat base up and off the floor studs and remove

from vehicle.

FITTING INSTRUCTIONS: - continued

FIGURE 2

REMOVE

FINISHER

REMOVE

ATTACHING

SCREW

REMOVE SEAT

BRACKET ATTACHING

NUT (4 PLACES)

FIGURE 3

FITTING INSTRUCTIONS FOR

CREW CAB REVERSE PARKING AID SENSOR PACKAGE

11.0~3.0 Nm

1

1

125 ~ 35 Nm

FD1166

18JULY03

FIGURE 4

COPYRIGHT

Page 3 of 15

HOLDEN LTD

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

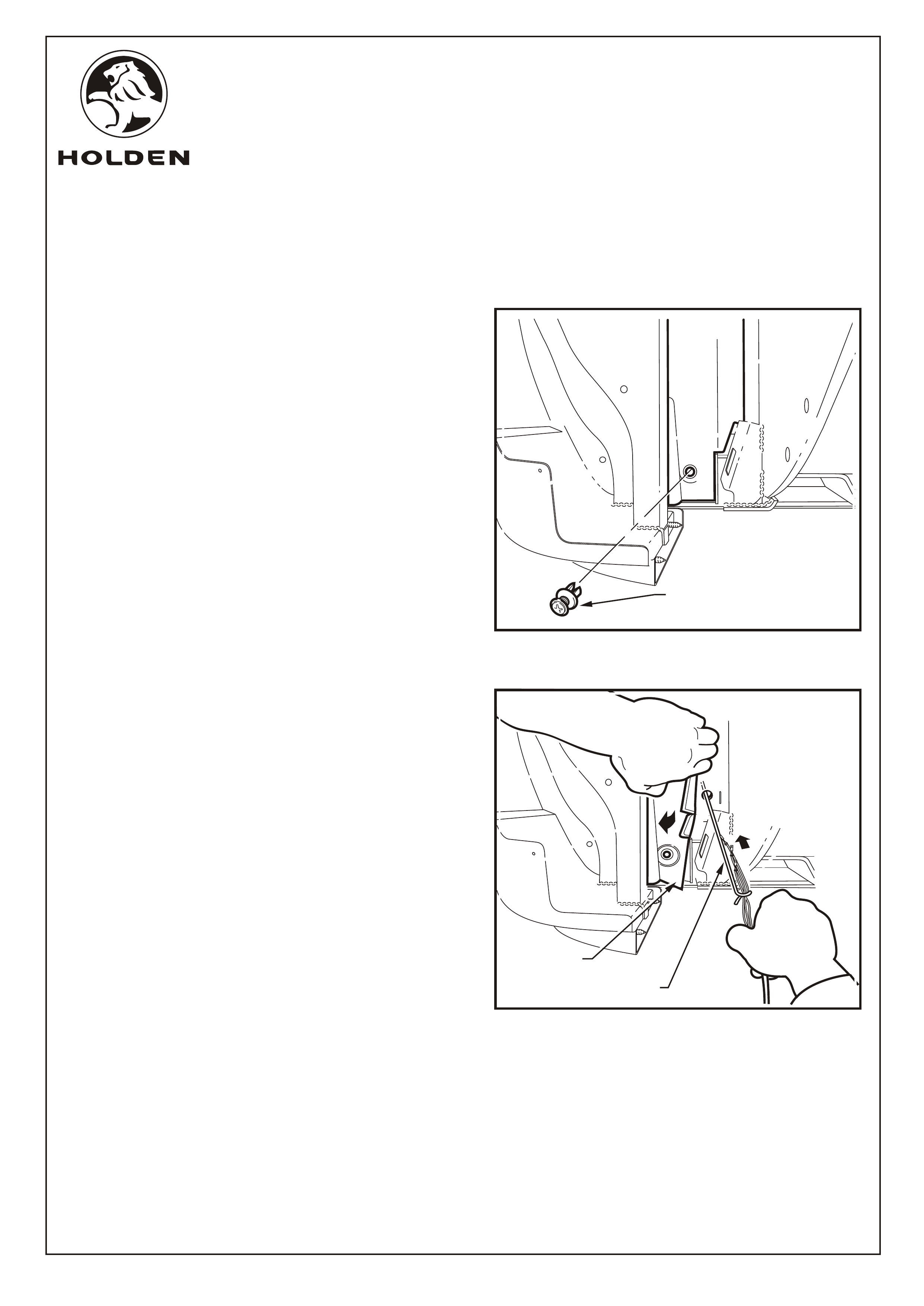

8. Remove the outer panel scrivet from the lower left-hand

side outside quarter of the cabin. Refer to Figure 4.

Refer to Figure 5 for the following:

9. Fold back the outer panel and reposition foam insulation

to allow access to the existing 12mm cabin hole.

10. Feed a guide wire through the hole.

11. Attach the main RPS harness to the guide wire with the

terminals staggered and pull harness through hole until

the RPS harness grommet meets with the hole. If

required, wrap electrical tape around guide wire and

terminals to aid installation.

12. Secure grommet into place.

NOTE: Ensure the hole surround is clean and free from

sealant or adhesive to allow the grommet to seal

correctly.

FITTING INSTRUCTIONS: - continued

FIGURE 5

REMOVE SCRIVET

GUIDE WIRE

PULL BACK

OUTER PANEL

FITTING INSTRUCTIONS FOR

CREW CAB REVERSE PARKING AID SENSOR PACKAGE

FD1166

18JULY03

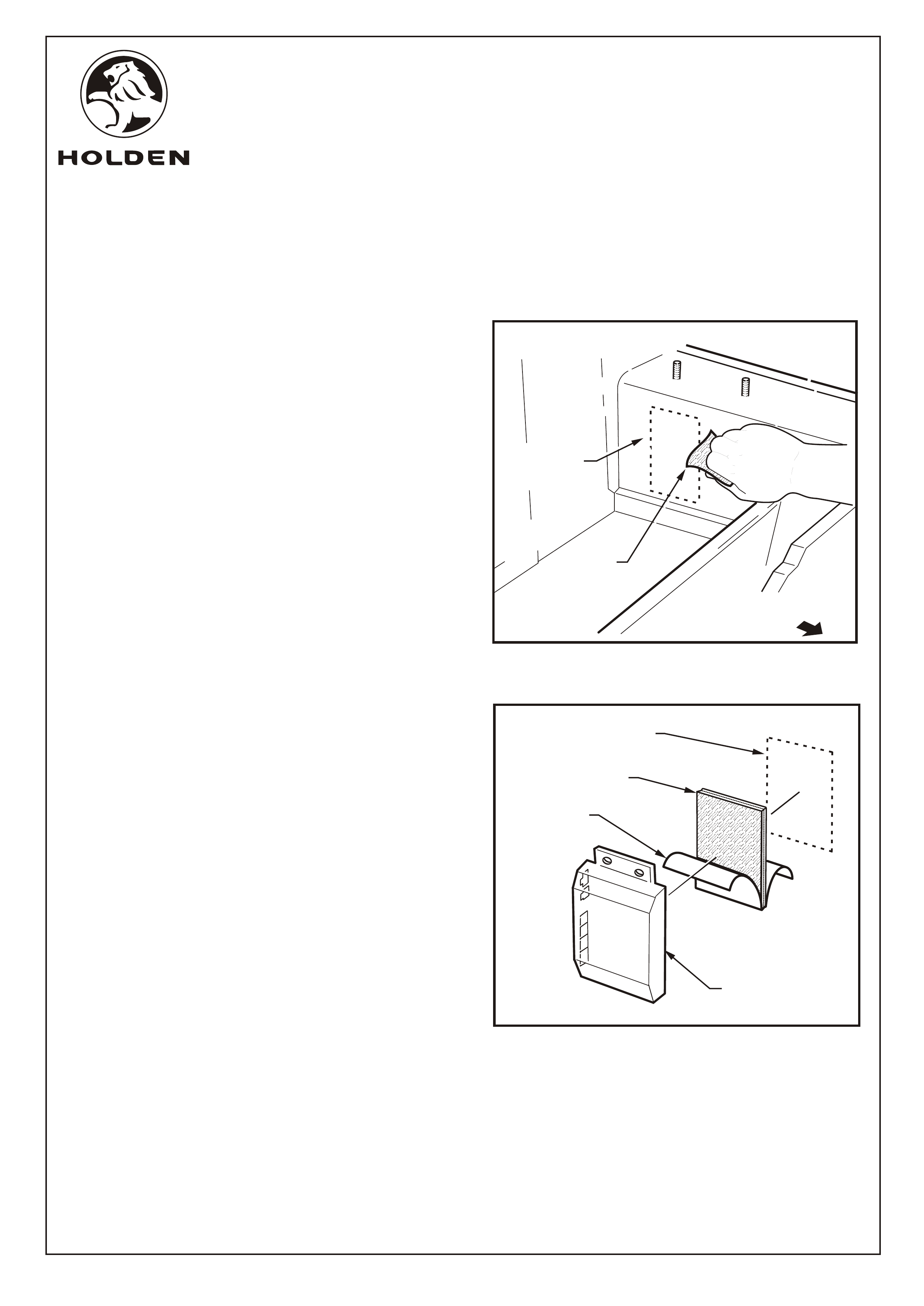

FIGURE 6

13. From inside the cabin, along the left-hand side inner sill

clean the RPS module mounting location using high-

tech cleaning pad supplied. Refer to Figure 6.

14. Wipe the back face of the RPS module using high-tech

cleaning pad.

Refer to Figure 7 for the following:

15. Peel one side of protective backing from RPS module

velcro and press fit velcro pad firmly to the back face of

the RPS module.

16. Peel backing off remaining side of the velcro pad. Press

fit the RPS module onto left hand side inner sill.

17. Apply pressure to the RPS module to ensure a secure fit

and full adhesion.

COPYRIGHT

Page 4 of 15

HOLDEN LTD

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FIGURE 7

RPS MODULE

MOUNTING

LOCATION

FITTING INSTRUCTIONS: - continued

HI-TECH

CLEANING

PAD

PROTECTIVE

BACKING

RPS MODULE

MOUNTING

LOCATION

VELCRO

PAD

RPS

MODULE

FITTING INSTRUCTIONS FOR

CREW CAB REVERSE PARKING AID SENSOR PACKAGE

FD1166

18JULY03

FRONT OF

VEHICLE

FIGURE 10

2

3

1

1

2

COPYRIGHT

Page 5 of 15

HOLDEN LTD

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FIGURE 8

18. Clean the RPS buzzer mounting location using high-

tech cleaning pad, at the location indicated, along the

lower left-hand side of the rear cabin paneling. Refer to

Figure 8.

Refer to Figure 9 for the following:

19. Attach RPS buzzer velcro pad supplied onto the existing

RPS buzzer velcro patch.

20. Peel backing from velcro pad and press fit the buzzer

onto the cabin panel as indicated, with the switch facing

up.

21. Apply pressure to the RPS buzzer unit to ensure a

secure fit and full adhesion.

Refer to Figure 10 for the following:

22. Connect tagged RPS main harness wire terminals to the

3-way female connectors supplied, according to table

below:

PIN 1 PIN 2 PIN 3

Left N/A BK/BL RD/WH

Centre Left N/A BN BL

Centre Right N/A GN WH

Right N/A GY YL

FITTING INSTRUCTIONS: - continued

RPS BUZZER

MOUNTING

LOCATION

HI-TECH

CLEANING

PAD

SET SWITCH

TO 'Hi' POSITION

RPS

BUZZER

PROTECTIVE

BACKING

FIGURE 9

FD1166

18JULY03

FRONT OF

VEHICLE

FEMALE 3-WAY

MAIN HARNESS TO

MODULE CONNECTOR

(4 PLACES)

23. Connect two remaining male terminal wires into the two

way female connector supplied, according to table

below:

PIN 1 PIN 2

Buzzer/Power BK RD

FEMALE 2-WAY

POWER SUPPLY

CONNECTOR

FITTING INSTRUCTIONS FOR

CREW CAB REVERSE PARKING AID SENSOR PACKAGE

P2

P3

P1

P2

TAPE BUNDLED

HARNESS TO

CABIN PANEL

FEED HARNESS FROM

MODULE TO BUZZER

AND CONNECT

CONNECTOR

IDENTIFICATION

POWER

SUPPLY

CONNECTOR

2-WAY

MAIN HARNESS TO

MODULE CONNECTORS

3-WAY

RPS BUZZER

CONNECTOR

4-WAY

L

CL

CR

R

COPYRIGHT

Page 6 of 15

HOLDEN LTD

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FIGURE 12

FIGURE 11

FITTING INSTRUCTIONS: - continued

Refer to Figure 11 for the following:

24. Feed the buzzer harness from the RPS module to the

RPS buzzer by running the harness underneath the

seatbelt retractor bracket. Connect the buzzer

connector to the buzzer.

Refer to Figure 12 for the following:

25. Connect all four of the 3-way main RPS harness to

module connectors into the RPS module.

26. Connect the 4-way RPS buzzer connector into the RPS

module.

27. Connect the 2-way main RPS harness power supply

female connector to the flying 2-way RPS buzzer

harness connector.

NOTE: Ensure each tagged wire and connector is

installed against its corresponding connector as marked

on the RPS module.

28. Bundle and tape excess RPS buzzer harness and

secure to the cabin paneling using suitable tape. Refer

to Figure 11.

FITTING INSTRUCTIONS FOR

CREW CAB REVERSE PARKING AID SENSOR PACKAGE

FD1166

18JULY03

MAIN RPS

HARNESS

FITTING INSTRUCTIONS: - continued

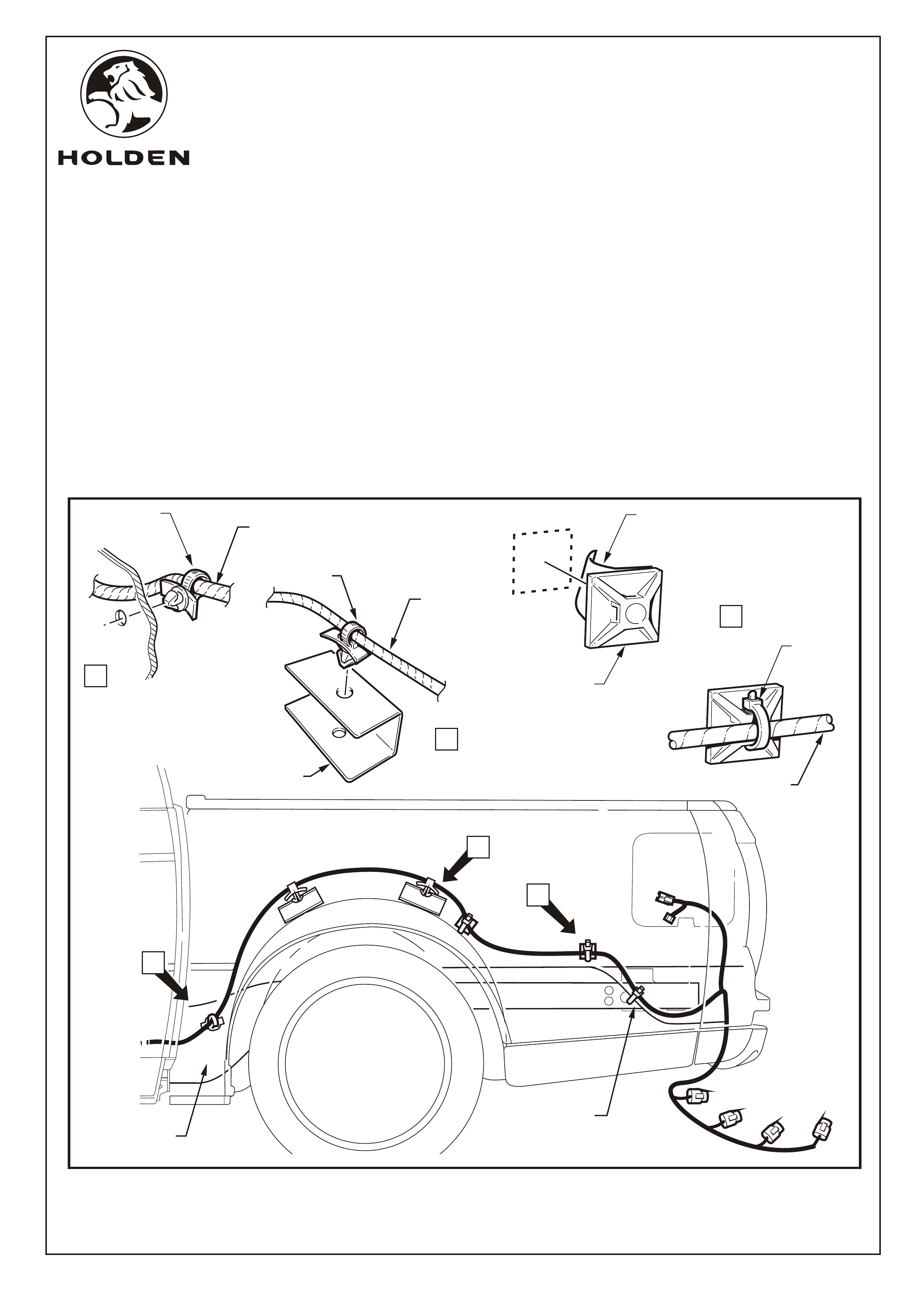

Refer to Figure 13 for the following:

29. On the left-hand underside of the vehicle, clean the vehicle surface at all securing points indicated below. Wipe

cable tie securing pad mounting surfaces with high-tech cleaning pad supplied.

30. Route harness as shown below and clip the harness by the cable tie clips to the rear body chassis rail, View A, and

the wheel arch bracket, View B.

31. Remove protective backing from cable tie attaching pads and press fit at two locations shown, refer to View C.

32. Loosely tie strap the harness to each of the securing pads as indicated, refer to View C.

33. Loosely tie strap the harness to the lower skirting of the tub paneling using the existing hole in the panel.

COPYRIGHT

Page 7 of 15

HOLDEN LTD

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

CREW CAB REVERSE PARKING AID SENSOR PACKAGE

FD1166

18JULY03

B

B

ATTACH

SECURING

PAD (2 PLACES)

REMOVE

PROTECTIVE

BACKING

A

REAR BODY

CHASSIS RAIL

TIE STRAP HARNESS

TUB PANELING LOWER

SKIRTING

CABLE

TIE

MAIN RPS

HARNESS

A

MAIN RPS

HARNESS

C

CABLE

CLIP

C

MAIN RPS

HARNESS

WHEEL ARCH

BRACKET

(2 PLACES)

CABLE

CLIP

FIGURE 13

SCREW

(8 PLACES)

COVER PANEL

1

11.0 ~ 3.0 Nm

PULL PATCH OF

RPS HARNESS

THROUGH CAVITY

COPYRIGHT

Page 8 of 15

HOLDEN LTD

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

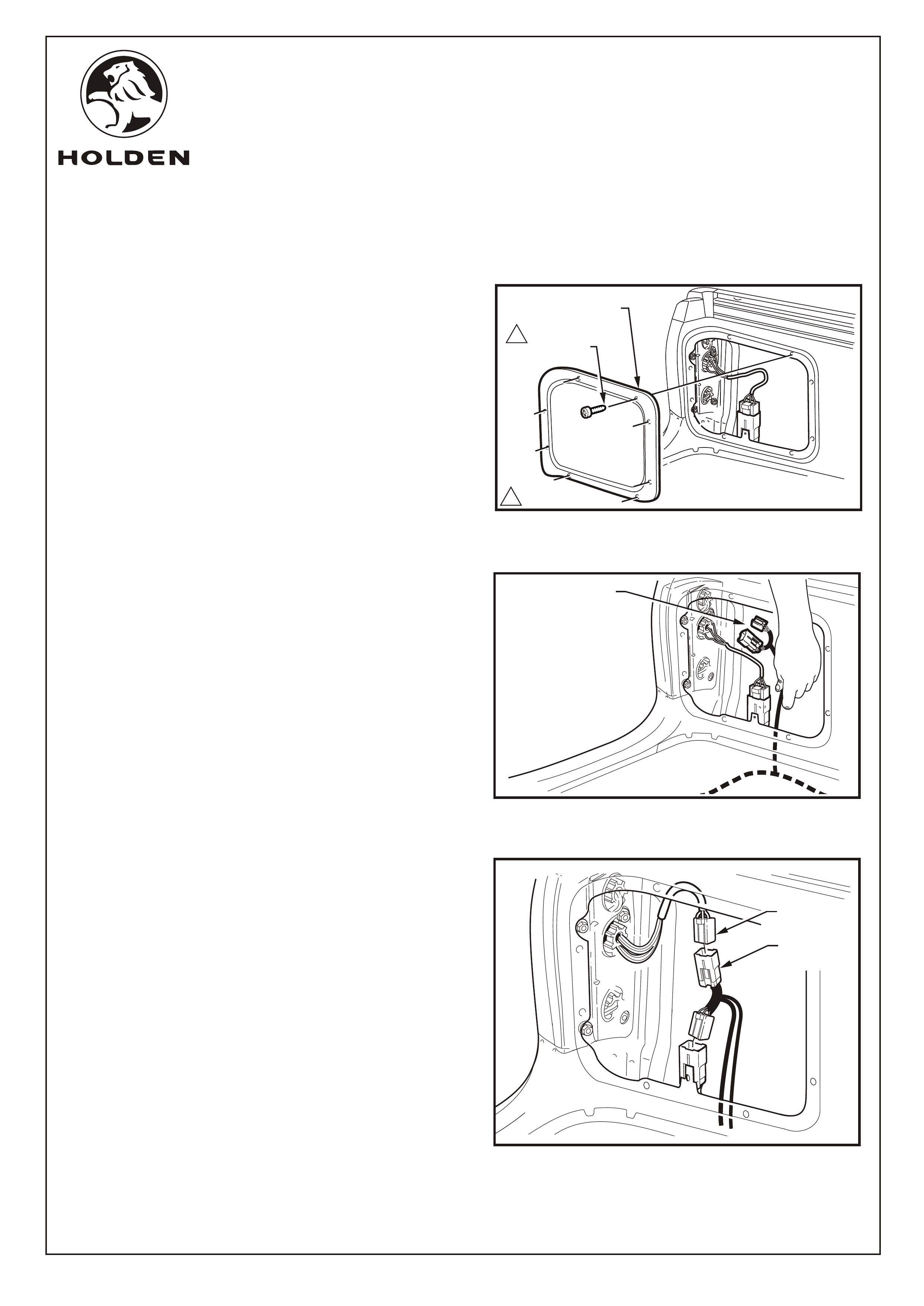

FITTING INSTRUCTIONS: - continued

34. Remove the rear inner LHS cover panel by removing

the eight attaching screws and prising the cover away

from the side panel. Refer to Figure 14.

35. Remove water proof foam from cavity and pull the RPS

patch harness branch of the main RPS harness up to

the tail lamp assembly. Refer to Figure 15.

Refer to Figure 16 for the following:

36. Disconnect the tail lamp connector from the main

harness.

37. Connect the RPS patch harness to the tail lamp and

main harness connectors.

COPYRIGHT

TAILL LAMP

CONNECTOR

PPS PATCH

CONNECTOR

FIGURE 14

FIGURE 15

FIGURE 16

FD1166

18JULY03

FITTING INSTRUCTIONS FOR

CREW CAB REVERSE PARKING AID SENSOR PACKAGE

FITTING INSTRUCTIONS: - continued

NOTE: Removal of the rear bumper fascia is necessary to

perform the rear bumper sensor hole drilling operations.

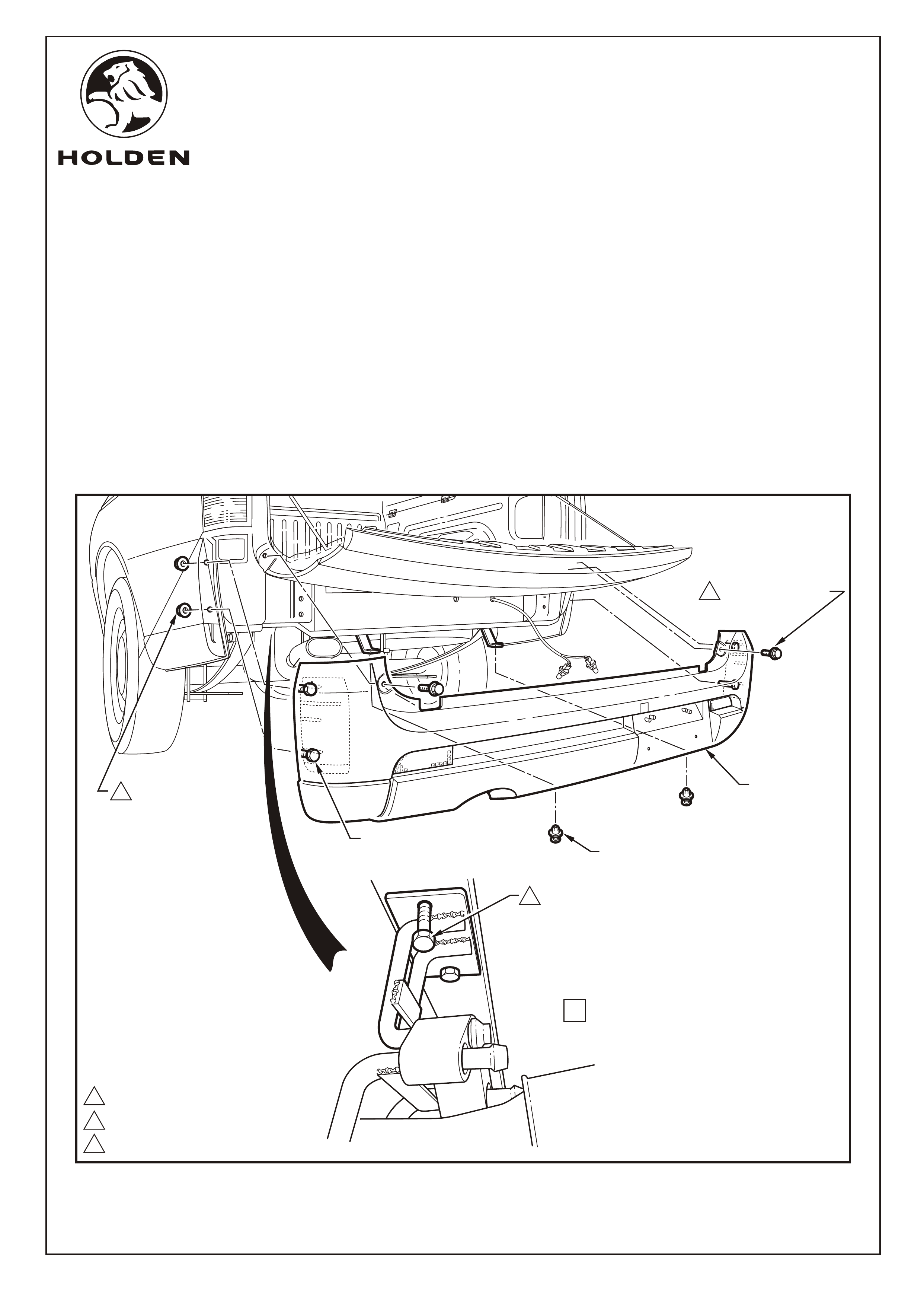

Refer to Figure 17 for the following:

38. Push the locking tang located at the end of the lamp

housing towards the lens. Pivot the lamp housing down

and remove it from the aperture.

39. Remove the bulb socket from the lamp housing and

place the lamp housing in a safe location.

40. Pass the bulb socket through the aperture in the rear

bumper fascia assembly.

41. Repeat Steps 38 to 40 for the other lamp assembly.

Refer to Figure 18 for the following:

42. For SS vehicles only:

a. Remove the rear body rear rocker moulding

attaching screw.

b. From behind the rear body panel unclip the retainer

clips in three places.

c. Repeat for the opposite side of the vehicle.

11.0 - 3.0 Nm

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

Page 9 of 15

Reproduction in whole or part

prohibited without written approval

COPYRIGHT

FIGURE 17

FIGURE 18

FD1166

18JULY03

PRESS

LOCKING TANG

LAMP

HOUSING

BULB

SOCKET

RETAINER

CLIPS

SCREW 1

FITTING INSTRUCTIONS FOR

CREW CAB REVERSE PARKING AID SENSOR PACKAGE

118.0 - 25.0 N.m

26.0 - 9.0 N.m

SCRIVET (2 PLACES)

1

2

VIEW A

FITTING INSTRUCTIONS: - continued

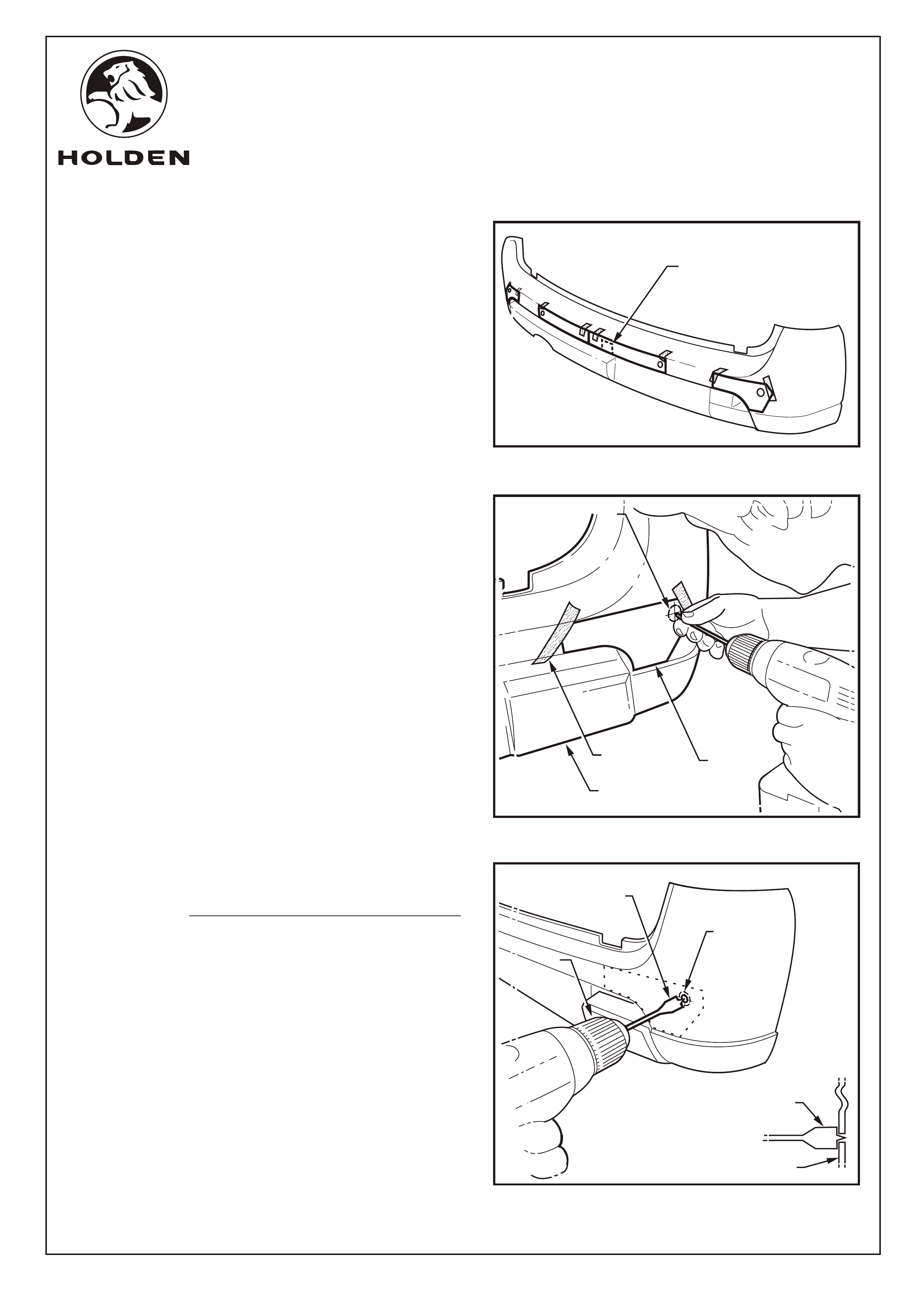

Refer to Figure 19 for the following:

43. Remove the two scrivets from beneath the lower edge of the rear bumper fascia assembly.

44. Open the endgate, remove the two screws and close the endgate.

45. Remove the nuts from the studs, two places, from inside the rear side panel, on both sides.

46. Disengage the rear bumper fascia assembly from the fascia assembly supports. To assist rear bumper fascia

removal, loosen off the exhaust assembly support bracket attaching bolts, two places, to lower the exhaust tip

clear of the bumper fascia, refer to View A.

47. With the aid of an assistant, remove the rear bumper fascia assembly from the vehicle.

345 - 50 N.m

3

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

Page 10 of 15

Reproduction in whole or part

prohibited without written approval

COPYRIGHT

FIGURE 19

FD1166

18JULY03

REAR BUMPER

FASCIA

STUD (4 PLACES)

NUT (4 PLACES)

BOLT (2 PLACES)

SCREW (2 PLACES)

FITTING INSTRUCTIONS FOR

CREW CAB REVERSE PARKING AID SENSOR PACKAGE

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

Page 11 of 15

Reproduction in whole or part

prohibited without written approval

COPYRIGHT

22

22

ENSURE DRILL BIT REMAINS

SQUARE WITH BUMPER FASCIA

BUMPER FASCIA

22

22mm DIA. WOOD

SPADE DRILL BIT

TEMPLATE

MASKING

TAPE

PILOT HOLE

2.0mm DIA

(4 PLACES)

PILOT HOLE

2.0mm DIA

(4 PLACES)

BUMPER

FASCIA

PILOT HOLE

2.0mm DIA

(4 PLACES)

SLOW

DRILL

SPEED

SLOW

DRILL

SPEED

SLOW

DRILL

SPEED

22mm DIA. HOLE

(4 PLACES)

22mm DIA. HOLE

(4 PLACES)

22mm DIA. HOLE

(4 PLACES)

ALIGN CENTRE RIGHT

TEMPLATE OVER HOIST

ACCESS TAB

FIGURE 20

FIGURE 21

FIGURE 22

FD1166

18JULY03

FITTING INSTRUCTIONS FOR

CREW CAB REVERSE PARKING AID SENSOR PACKAGE

FITTING INSTRUCTIONS: - continued

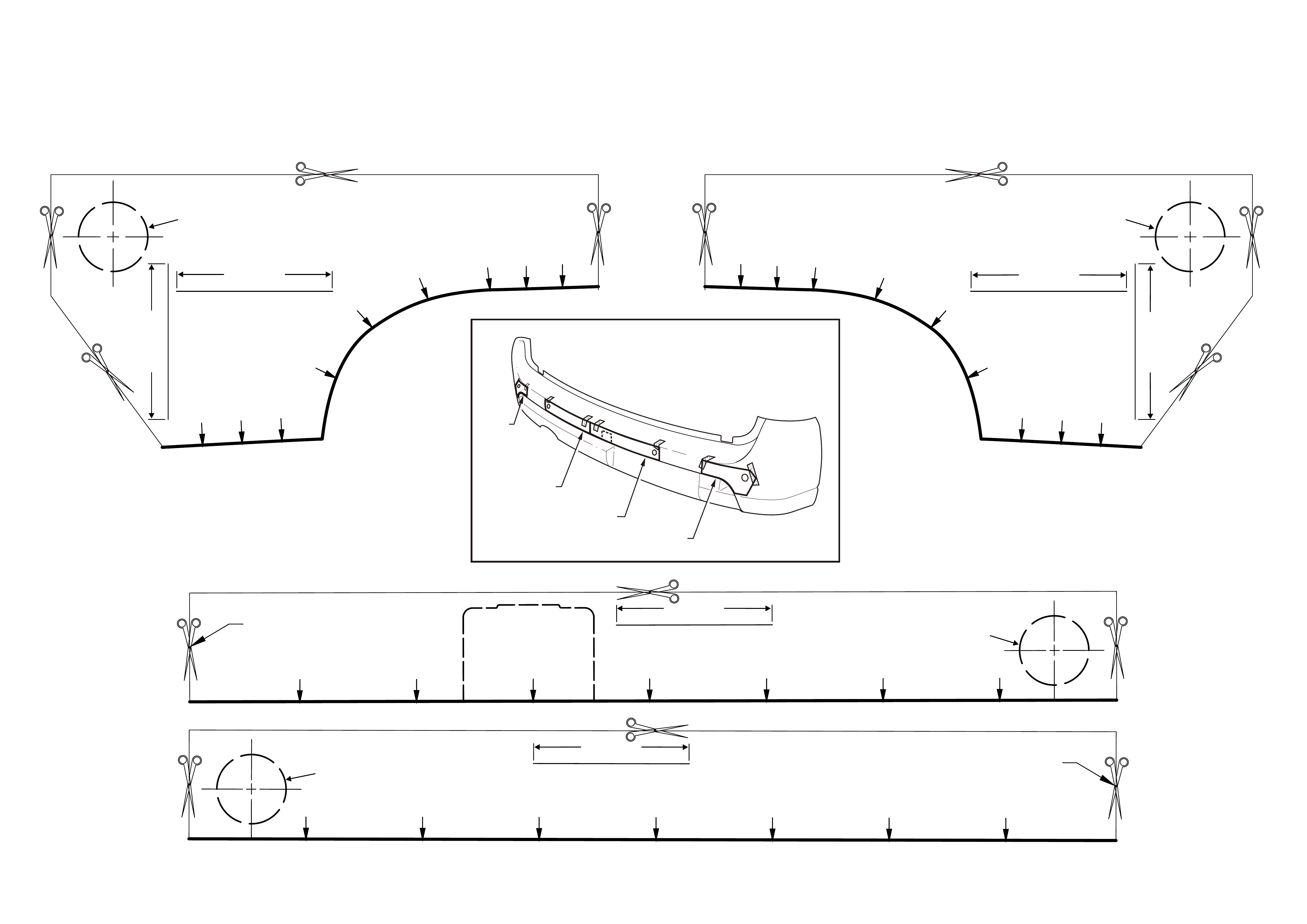

48. Cut-out the templates provided at the end of this fitting

instruction booklet. Hold the templates in position on the

bumper fascia and place masking tape on the bumper

fascia over the area to be drilled. Refer to Figure 20.

IMPORTANT: CHECK LENGTH OF THE 50mm

SCALE MARKER ON TEMPLATE TO ENSURE

TEMPLATE IS PRINTED TO CORRECT SCALE.

NOTE: Align and attache the centre right template over

the hoist access tab before attaching the centre left

template.

49. With the bumper fascia supported, drill pilot holes

through the templates and fascia (4 places) using a

2.0 mm drill bit. Refer to Figure 21.

50. Remove the templates and drill 22.0mm diameter holes

through the fascia (4 places), using a wood spade drill

bit. Refer to Figure 22.

IMPORTANT: ONLY USE A WOOD SPADE DRILL BIT.

A NORMAL DRILL BIT OR HOLE SAW WILL DAMAGE

THE BUMPER FASCIA. ENSURE THE SPADE DRILL

BIT REMAINS SQUARE WITH THE BUMPER FASCIA.

USE A SLOW DRILL SPEED ONLY TO AVOID

DAMAGING THE BUMPER FASCIA.

COPYRIGHT

Page 12 of 15

HOLDEN LTD

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS: - continued

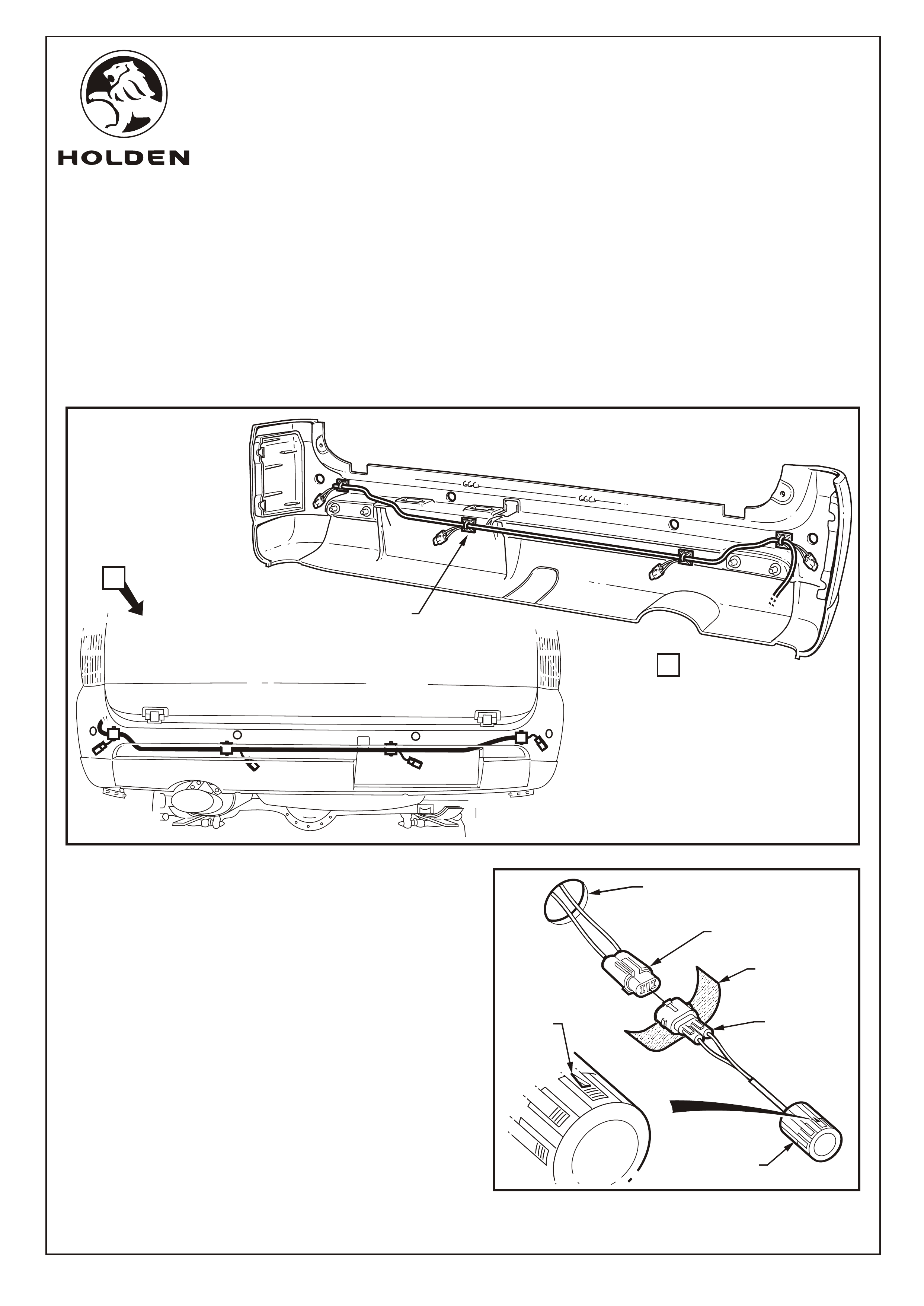

Refer to Figure 23 for the following:

51. Wipe cable tie securing pad mounting points on the inside of the bumper fascia with high-tech cleaning pad

supplied.

52. Remove protective backing from cable tie attaching pads and press fit to bumper fascia at locations shown.

53. With the aid of an assistant, hold bumper fascia assembly close to vehicle and rout harness along fascia. Loosely tie

strap harness to the securing pads, four places.

FD1166

18JULY03

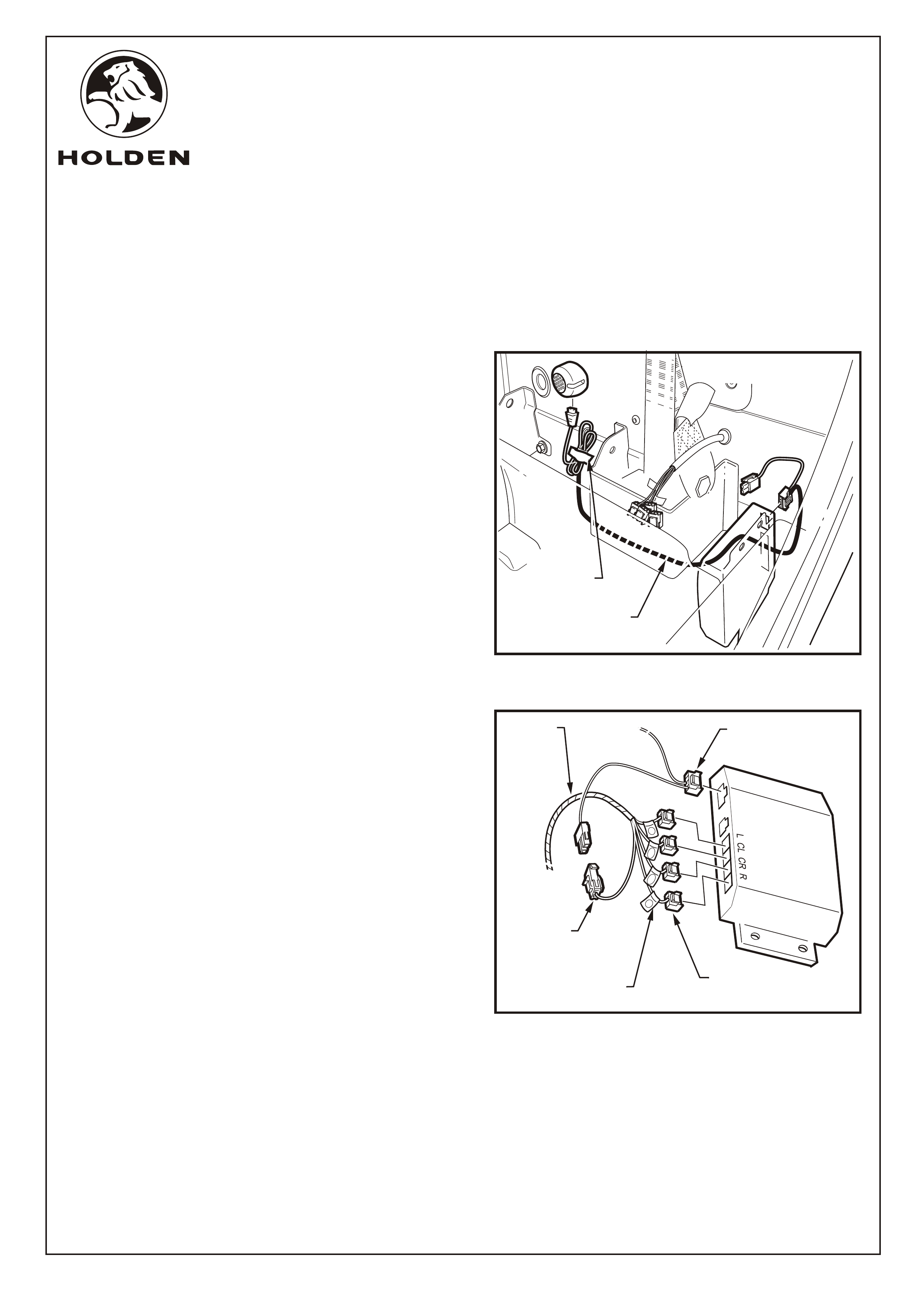

Refer to Figure 24 for the following:

54. Peel the protective backing off the foam strips supplied

and wrap firmly around each of the four sensor male

connectors.

55. Pass the male connectors with foam through the

bumper fascia holes and with the arrow on the sensor

body facing up, press fit the reverse parking sensors to

sit flush with the fascia.

SENSOR

SENSOR

CONNECTOR

FOAM STRIP

(WRAP AROUND

CONNECTOR)

RPS HARNESS

CONNECTOR

22mm DIA.

BUMPER FASCIA

HOLE

'TOP'

MARK

FIGURE 24

A

A

FIGURE 23

CABLE TIE SECURING

PAD (4 PLACES)

FITTING INSTRUCTIONS FOR

CREW CAB REVERSE PARKING AID SENSOR PACKAGE

COPYRIGHT

Page 13 of 15

HOLDEN LTD

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS: - continued

56. Fit the rear bumper fascia assembly to the vehicle and

reassemble in the reverse order to removal. Tighten all

rear bumper fascia fasteners to the specified torque.

NOTE: Ensure that the rear bumper fascia assembly

snaps and engages onto the rear bumper fascia

assembly supports.

57. Fix the caution label in a prominent position (above tyre

placard on driver’s side door).

58. Test the reverse parking sensor system for correct

operation as follows:

a. Turn the ignition to the ON position (engine not

running).

b. Place the gear lever in reverse (R). Two beeps from

the buzzer should be heard indicating the system is

activated.

c. From behind the vehicle, walk towards each sensor.

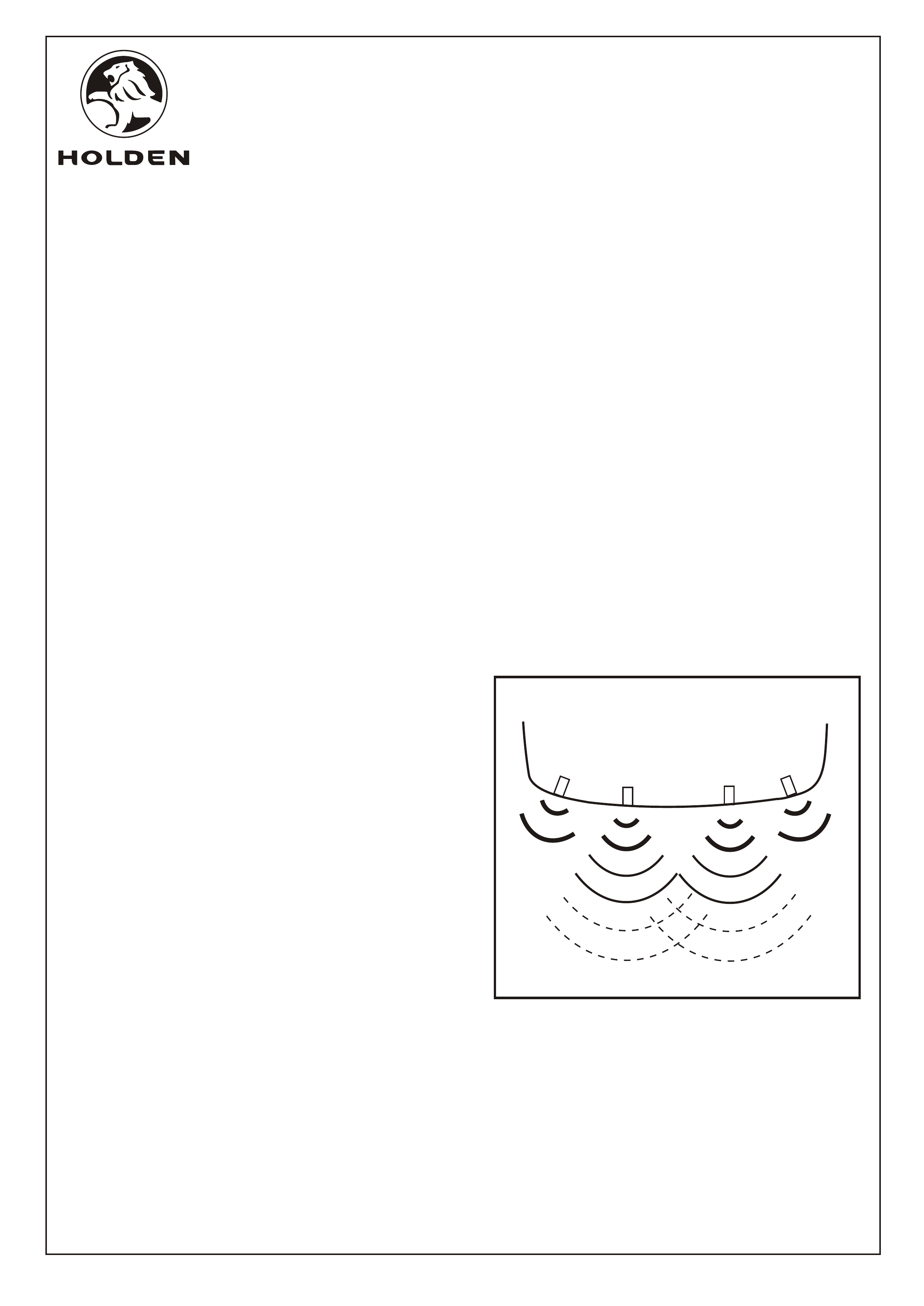

d. The two centre sensors have 3 stages.

e. The two corner sensors only have 1 stage of final

warning. Refer Figure 25.

NOTE: Refer to the owners manual for further

information and trouble shooting.

59. Refit all removed parts in the reverse order to removal

and torque fasteners to specifications.

60. Place fitting instructions in the glovebox.

IMPORTANT: DO NOT paint over the reverse parking

sensor. Ensure the reverse parking sensor remains

clean and free from road grime, mud, car polish etc.

If the sensor or the groove on the sensor surface

becomes contaminated, the performance may be

affected.

FIGURE 25

FD1166

18JULY03

FITTING INSTRUCTIONS FOR

CREW CAB REVERSE PARKING AID SENSOR PACKAGE

COPYRIGHT

Page 14 of 15

HOLDEN LTD

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

CREW CAB REVERSE PARKING SENSOR SYSTEM PACKAGE

PARTS LIST

PART NUMBER DESCRIPTION QUANTITY

92148000 REVERSE PARKING SENSOR SYSTEM PACKAGE 1

- REVERSE PARKING SENSOR MAIN HARNESS 1

- REVERSE PARKING SENSOR BUZZER/POWER HARNESS 1

- REVERSE PARKING SENSOR MAIN HARNESS TO BUZZER

HARNESS MALE 2-WAY CONNECTOR 1

- REVERSE PARKING SENSOR MAIN HARNESS TO MODULE

FEMALE 3-WAY CONNECTOR 4

- REVERSE PARKING SENSOR 4

- REVERSE PARKING BUZZER & VELCRO MOUNT PAD 1

- REVERSE PARKING SENSOR MODULE 1

- REVERSE PARKING SENSOR FOAM SEAL 4

- CABLE TIE 10

- HI-TECH CLEANING PAD 2

- VELCRO MOUNT PAD 1

- CABLE TIE MOUNT 7

INSTRUCTION MANUAL 1

FD796 PROOF OF WARRANTY CARD 1

FD 1166 FITTING INSTRUCTIONS 1

FD1166

18JULY03

FITTING INSTRUCTIONS FOR

CREW CAB REVERSE PARKING AID SENSOR PACKAGE

TEMPLATE

4 HEAD SYSTEM

IMPORTANT !!!

ALWAYS CONFIRM LENGTH OF

50mm SCALE MARKERS

BEFORE DRILLING

4 HEAD SYSTEM (RIGHT)

IMPORTANT !!! - CONFIRM LENGTH OF 50MM SCALE MARKERS BEFORE DRILLING

50mm

50mm

22.2 +0.3/ -0

IMPORTANT !!! - CONFIRM LENGTH OF 50MM SCALE MARKERS BEFORE DRILLING

50mm

50mm

22.2 +0.3/ -0

4 HEAD SYSTEM (LEFT)

RIGHT

LEFT

CENTRE LEFT

CENTRE RIGHT

Page 15 of 15

CENTRE OF

BUMPER BAR FACIA 4 HEAD SYSTEM (CENTRE LEFT)

IMPORTANT !!! - CONFIRM LENGTH OF

50MM

SCALE MARKERS BEFORE DRILLING

50mm

22.2 +0.3/ -0

CENTRE OF

BUMPER BAR FACIA

4 HEAD SYSTEM (CENTRE RIGHT)

IMPORTANT !!! - CONFIRM LENGTH OF

50MM

SCALE MARKERS BEFORE DRILLING

50mm

22.2 +0.3/ -0

ALIGN TEMPLATE

OVER SPARE WHEEL

HOIST ACCESS TAB