HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

Reproduction in whole or part

prohibited without written approval

COPYRIGHT

FD1237

29JUN04

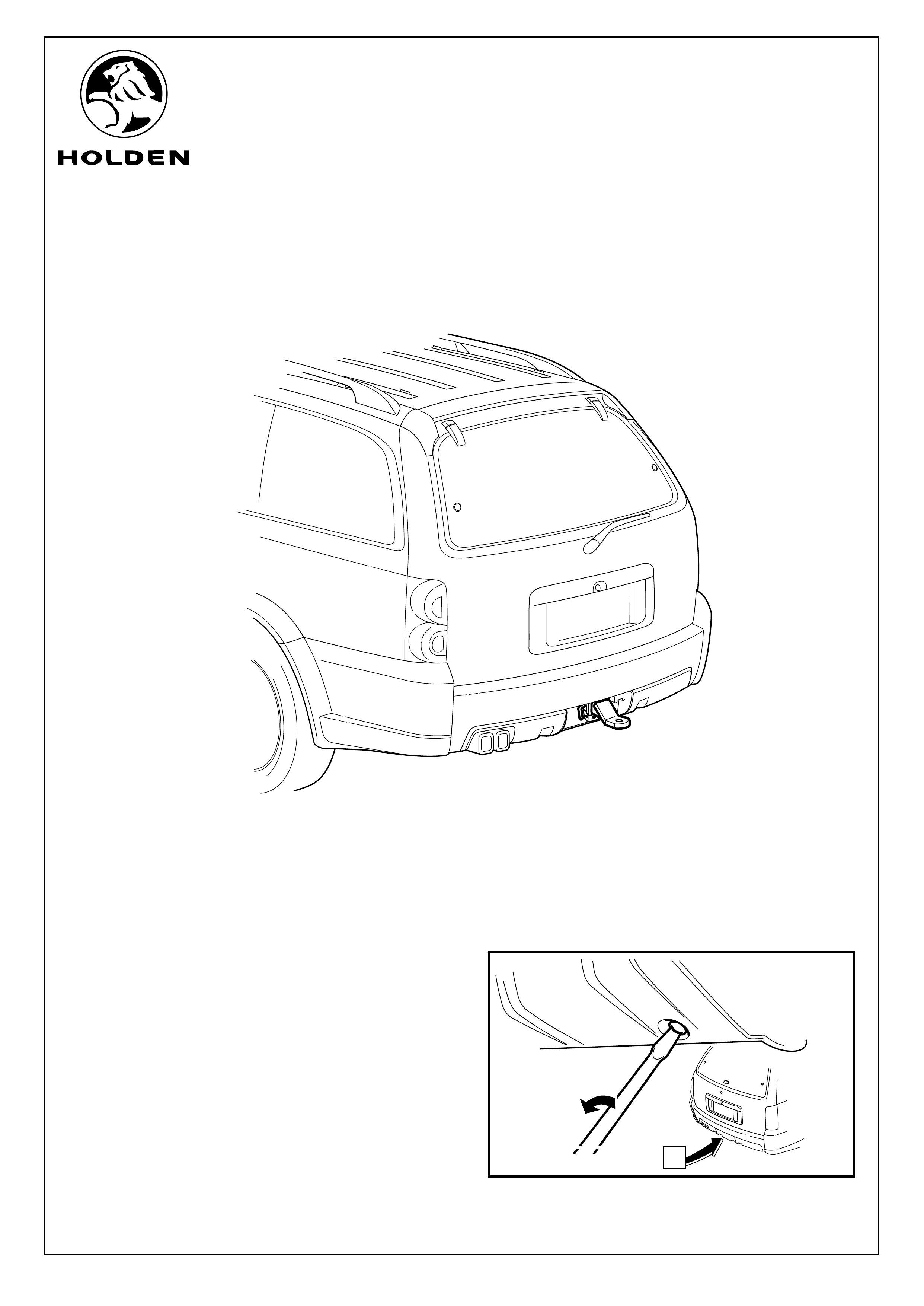

FITTING INSTRUCTIONS FOR

AWD WAGON TOW BAR TONGUE PACKAGE

Page 1 of 6

Part No. 92171071 (1600 KG)

92171073 (2100 KG)

FIGURE 1

A

TOOLS REQUIRED:

Flat Blade Screwdriver, Drill, Torque Wrench, Ratchet,

10mm and 12mm Sockets, 12.5mm Drill Bit, 1/8” Drill Bit,

Rivet Gun and Rivets.

FITTING INSTRUCTIONS:

To install towbar tongue:

1. Turn rear fascia tow bar cover fastener, (2 places), a

quarter turn anti-clockwise to unlock, using a flat blade

screwdriver. Refer to Figure 1.

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

Reproduction in whole or part

prohibited without written approval

COPYRIGHT

FD1237

29JUN04

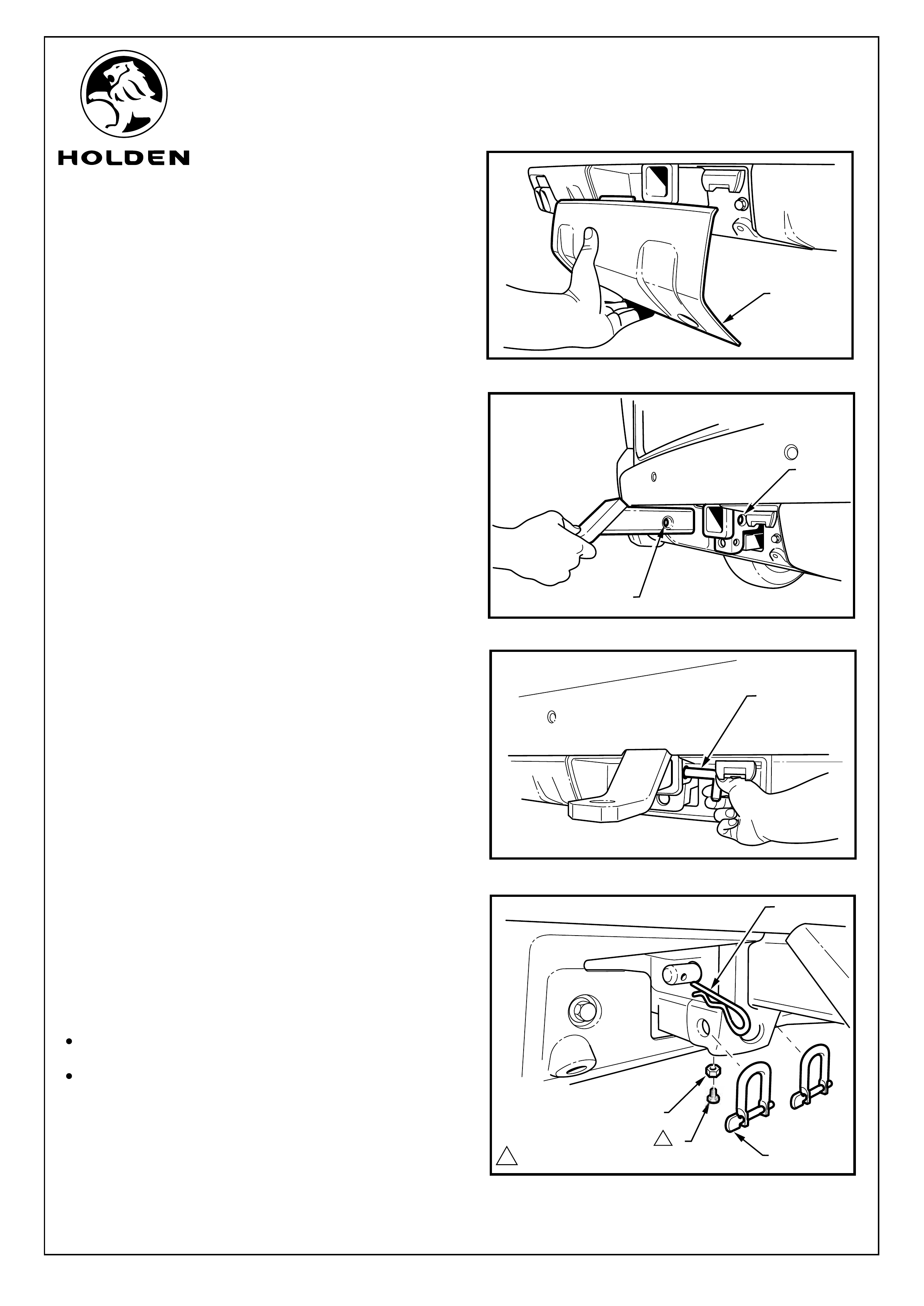

2. Grasp the bottom edge of rear fascia tow bar cover (1)

and pull to remove. Refer to Figure 2.

3. Slide tongue into the tow bar throat so that the tongue

hole (1) and the throat hole (2) are aligned. Refer to

Figure 3.

4. Insert the securing pin (1) through the throat hole and

tongue hole. Refer to Figure 4.

Refer to Figure 5 for the following:

5. Insert the retaining clip (1) into the hole in the securing

pin.

6. Attach the D-shackle (2) (2 places) onto the tow bar as

required.

NOTE:

ŸThe M10 nut (3) and M10x25 anti-rattle bolt (4)

SHOULD BE installed when the towbar is not in use.

ŸThe M10 nut and anti-rattle bolt MUST BE removed

when the towbar is in use.

7. Fit spare wheel well butyl patch heat shield in package

number 92037805 supplied. Refer to fitting instructions

supplied with the package.

Page 2 of 6

1

2

FIGURE 2

FIGURE 3

FIGURE 4

1

FITTING INSTRUCTIONS: - continued

1

FIGURE 5

1

2

3

4

1

40.0 - 50.0 Nm

1

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

Reproduction in whole or part

prohibited without written approval

COPYRIGHT

FD1237

29JUN04

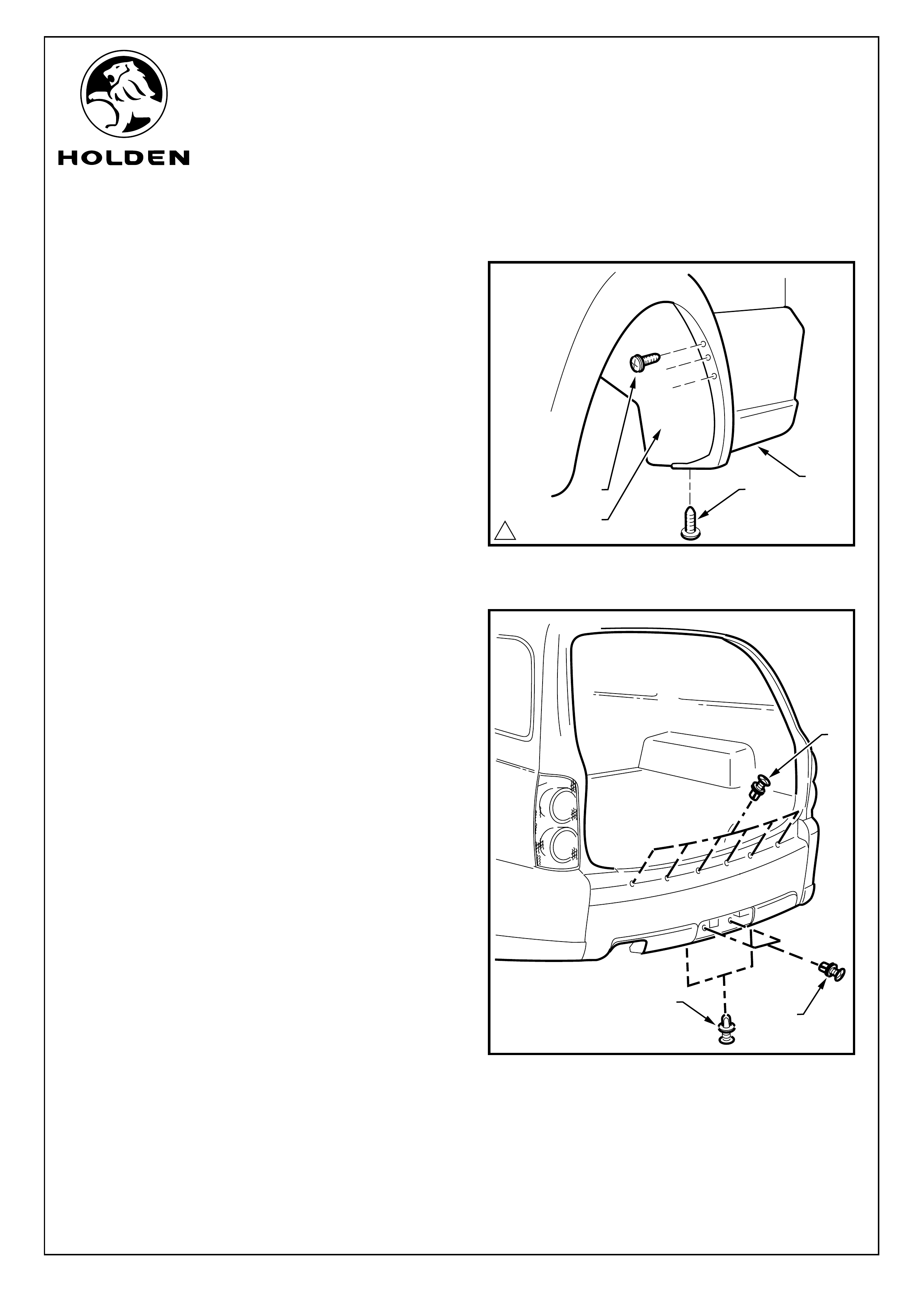

To upgrade tow bar to 2100kg rating:

10. Remove the scrivets (1) (2 places) from either side of the

towbar opening.

13. Unhook the bumper fascia from the wheelhouse liner.

Refer to Figure 6 for the following:

8. Remove the screw (1) (1 place each side of the vehicle)

attaching the rear bumper fascia assembly (2) to the

rear wheelhouse liner (3).

9. Remove the screw (4) (3 places each side of the vehicle)

attaching the rear bumper fascia assembly to the rear

wheelhouse liner (3).

Refer to Figure 7 for the following:

11. Remove the scrivets (2) (2 places) from below the rear

bumper fascia assembly.

12. Remove the scrivets (3) (6 places) from across the

liftgate opening.

FITTING INSTRUCTIONS: - continued

FIGURE 7

Page 3 of 6

FIGURE 6

1

4

2

3

1

2

3

11.0 - 3.0 Nm

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

Reproduction in whole or part

prohibited without written approval

COPYRIGHT

FD1237

29JUN04

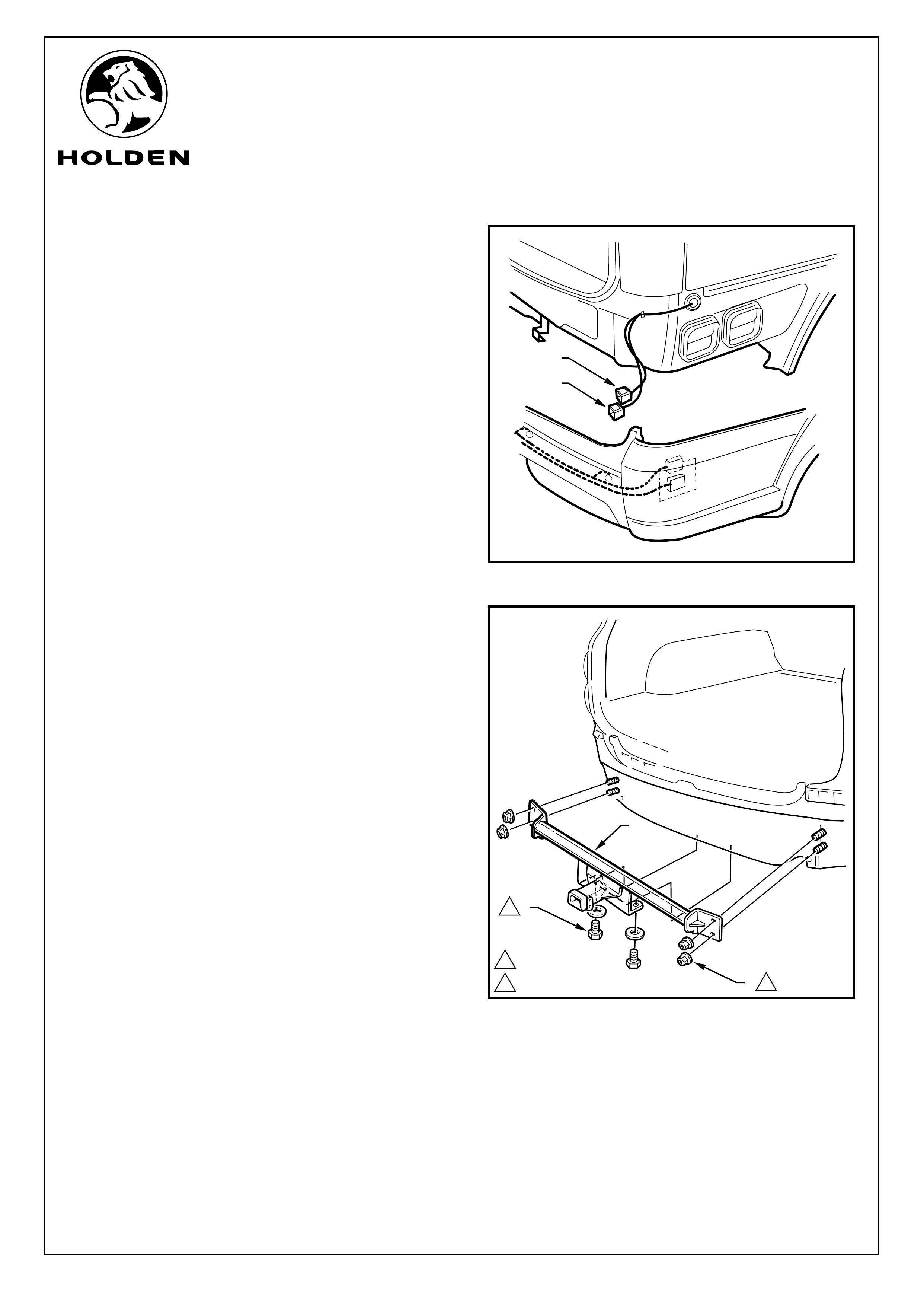

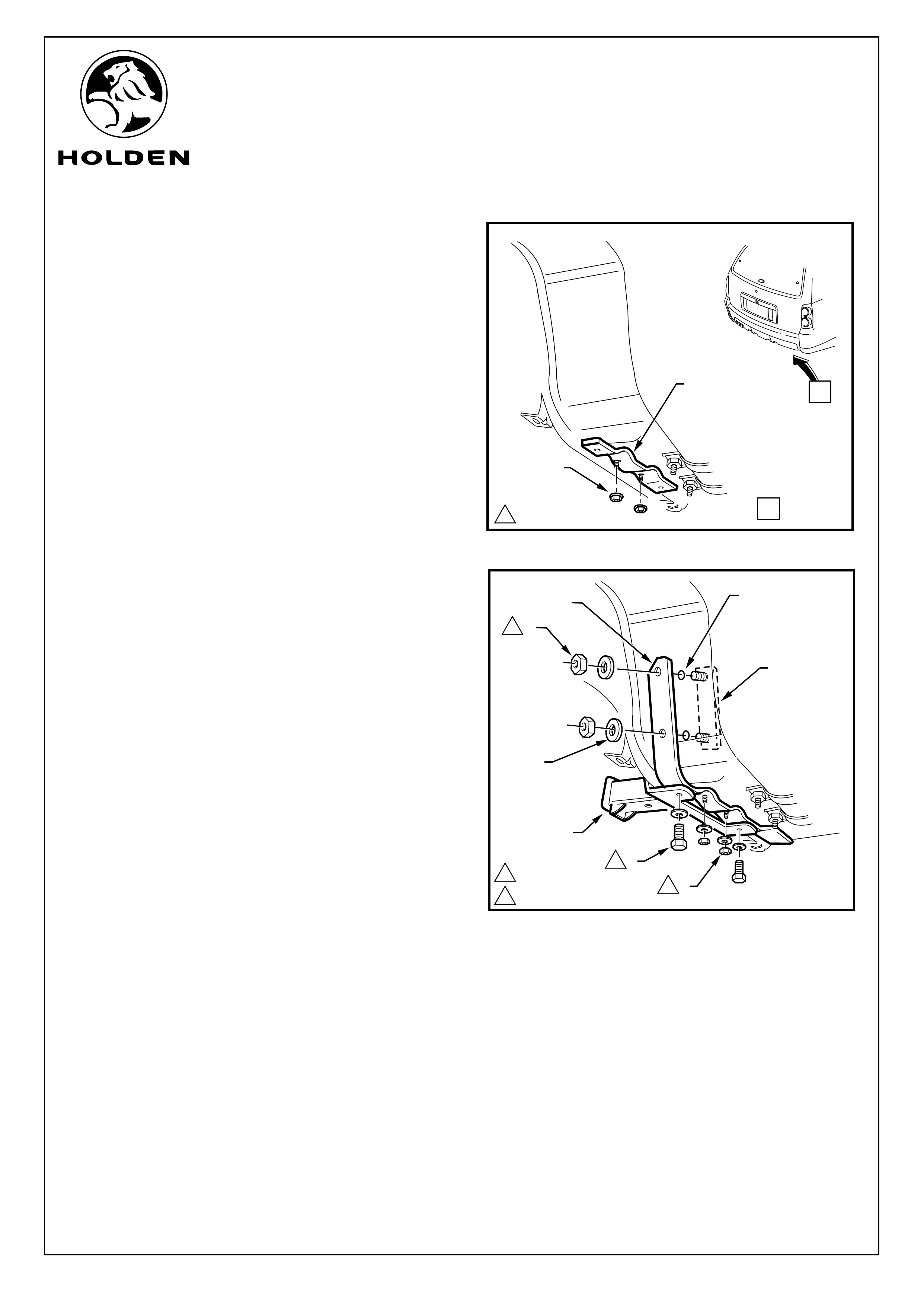

Refer to Figure 8 for the following:

15. With the aid of an assistant, remove the bumper from the

vehicle far enough to access the wiring connectors.

16. Disconnect the towbar wiring harness connector (1).

17. Disconnect the reverse parking aid wiring connector (2).

18. Remove the rear bumper fascia assembly by sliding it

rearward.

Refer to Figure 9 for the following:

19. Remove the bolt (1) (2 places) at the bottom of the

towbar assembly (2).

20. Remove the nuts (3) (2 places each side of the vehicle)

attaching the towbar assembly to the vehicle.

21. Remove the towbar assembly (2).

14. Carefully unclip each side of the bumper fascia

assembly from the guide assembly by grasping and

pulling the upper end of the bumper fascia assembly

until the fascia assembly comes away from the vehicle.

FITTING INSTRUCTIONS: - continued

FIGURE 8

COPYRIGHT

Page 4 of 6

32

1

2

1

FIGURE 9

140.0 - 50.0 Nm

250.0 - 80.0 Nm

1

2

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

Reproduction in whole or part

prohibited without written approval

COPYRIGHT

FD1237

29JUN04

Page 5 of 6

Refer to Figure 10 for the following:

22. Remove M10 flanged nuts (1) (2 places) securing the

existing spare wheel well brace (2) to the underbody

weld studs.

Refer to Figure 11 for the following:

24.

Install M10 nuts and washers (2) (2 places) securing the

new spare whee

o drill two 12.5 dia. holes

(5) in each side through the spare wheel well.

31. Apply silicone or butyl sealer to holes for water sealing &

corrosion protection purposes, (4 places).

32. Remove the backing tape from the two adhesive backed

stud plates (6). Install the

from the inside of the spare wheel well, through holes in

wheel well and spare wheel well brace assembly.

33. From the underside of the vehicle, attach flat washers

(7) and M12 nuts (8) to the studs on the stud plates, (4

places), and tighten to specified torque.

34. Drill out rivets holding existing ADR Load Specification

Plate onto tow bar using 1/8” drill bit and replace plate

with new 2100kg ADR load specification plate supplied.

Rivet the new plate through existing holes to attach.

23. Remove the spare wheel well brace.

Install the new extended spare wheel well brace (1).

25.

l well brace to the wheel well underbody

weld studs and tighten to the specified torque.

26. Reinstall the towbar assembly (3).

27. Install M10 bolts and washers (4) (2 places) securing the

towbar assembly to the new spare wheel brace and

tighten to the specified torque.

28. Reinstall the nuts (3) (2 places each side of the vehicle)

attaching the towbar assembly to the vehicle and tighten

to the specified torque. Refer to Figure 9.

29. Open the tailgate and remove the rear floor and spare

wheel.

30. From the underside of the vehicle, use the new spare

wheel well brace as a template t

CAUTION: Spare wheel must be removed before

performing drilling operations.

adhesive backed stud plates

35. Reinstall the spare wheel and rear floor.

36. Reinstall the rear bumper fascia assembly.

FITTING INSTRUCTIONS: - continued

VIEW A

140.0 - 50.0 Nm

2

FIGURE 10

A

1

FIGURE 11

275.0 - 85.0 Nm

7

6

5

14

3

140.0 - 50.0 Nm

28

12

1

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

Reproduction in whole or part

prohibited without written approval

COPYRIGHT

FD1237

29JUN04

AWD WAGON TOW BAR TONGUE PACKAGE (1600KG)

PARTS LIST

PART NUMBER DESCRIPTION QUANTITY

92171071 TOWBAR TONGUE PACKAGE - AWD 1600KG 1

- TOWBAR TONGUE 1

92077203 "D" SHACKLE - TOW BAR 2

- PIN & CLIP - TOW BAR 1

- BOLT - ANTI RATTLE. M10X25 1

- NUT - M10 1

92143923 - HEAT SHIELD PACKAGE - SPARE WHEEL WELL 1

FD1237 FITTING INSTRUCTIONS 1

FD796 PROOF OF WARRANTY CARD 1

Page 6 of 6

AWD WAGON TOW BAR TONGUE PACKAGE (2100KG)

PART NUMBER DESCRIPTION QUANTITY

92171073 TOWBAR TONGUE PACKAGE - AWD 2100KG 1

92171071 TOWBAR TONGUE PACKAGE - AWD (CONTENTS AS PER ABOVE) 1

- ADR LOAD SPECIFICATION PLATE (2100KG) 1

- ADR COMPLIANCE LABEL (2100KG) 1

92054275 BRACE ASSEMBLY - TOW BAR 1

92143965 SMALL PARTS KIT 1

- BOLT - M10X25 2

- NUT - M10 2

- WASHER - M10 BRIGHT 4

- STUD PLATE - 2100KG 2

- NUT - M12 4

- WASHER - M12 BRIGHT 4

- RIVET - 1/8” 2

FIGURE 12

WIPE SURFACE CLEAN

PRIOR TO APPLICATION

OF ADR LABEL

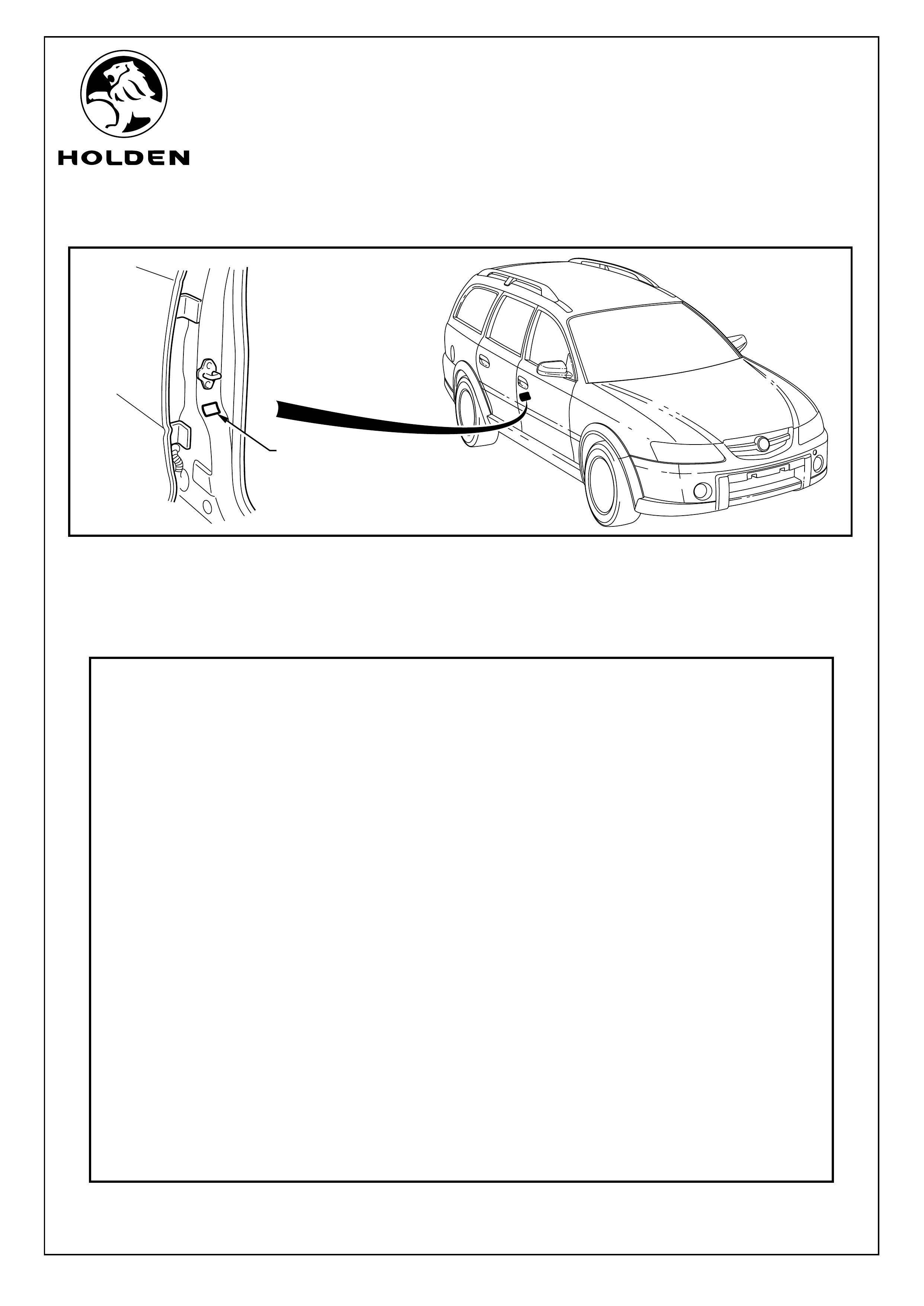

37. Clean the surface of the driver's side B-pillar and apply ADR label supplied. Refer to Figure 12.

FITTING INSTRUCTIONS: - continued

For both 1600kg and 2100kg towbar tongue packages:

38. Place fitting instructions in vehicles glove box.