FD822

15JL98

COPYRIGHT

Page 1 of 1

FITTING INSTRUCTIONS FOR

OIL PAN SLEEVE SEALS

Part Number M41479

G90-2-1

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

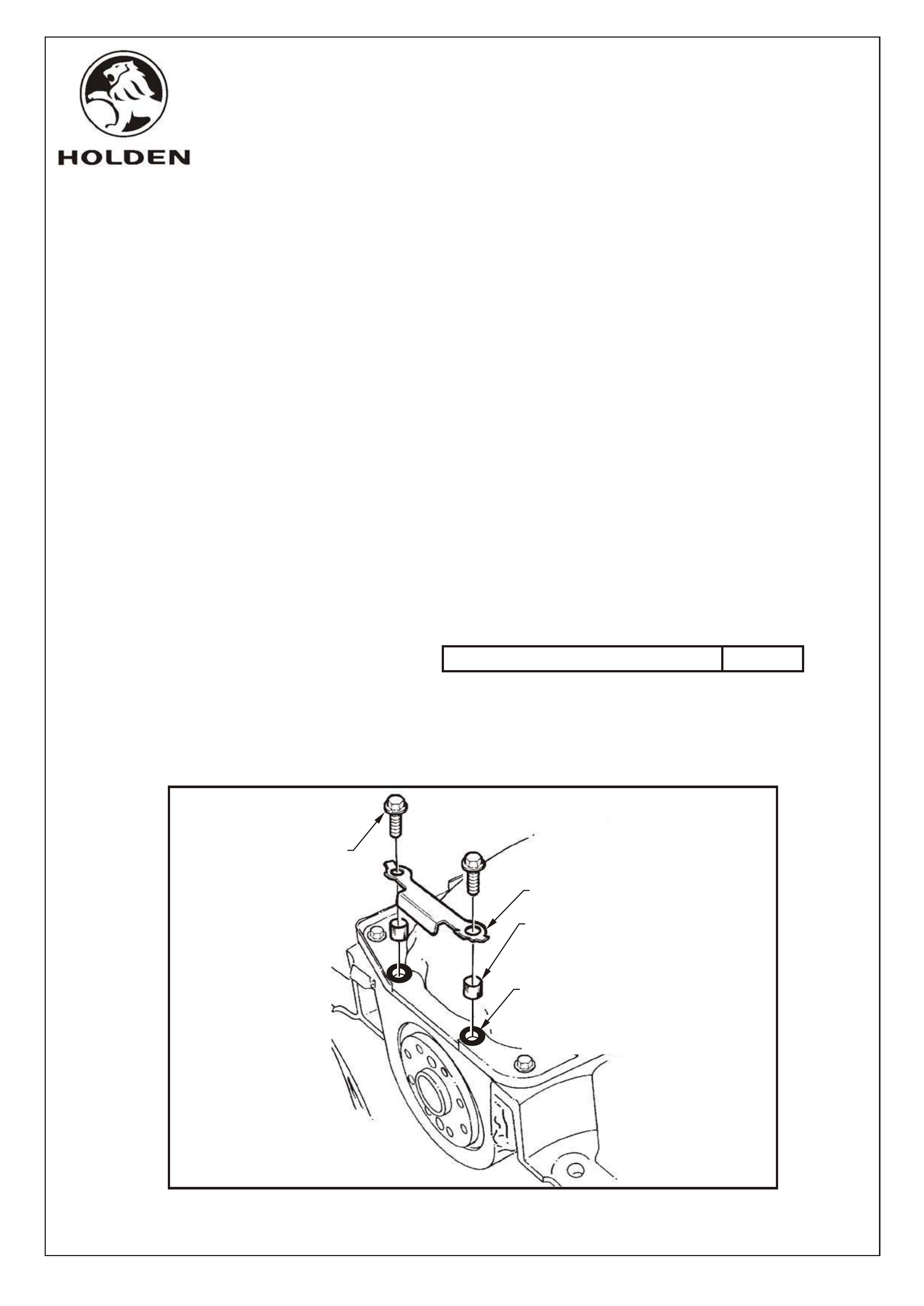

APPLY "LOCTITE 515"

TO THREADS AND

WASHER FACE OF SCREW

PRIOR TO INSTALLATION

LOCKING PLATE

APPLY "LOCTITE 515" TO THE

INSIDE OF THE TWO REAR

MOST OIL PAN SCREW HOLES

AND AROUND THE SCREW

HOLES AS SHOWN PRIOR TO

INSTALLATION OF SLEEVE

3122-08

PART NUMBER DESCRIPTION QUANTITY

92063593 SLEEVE - OIL PAN 2

24500866 GASKET - OIL PAN 1

INSTALLATION PROCEDURE:

1. Install oil pan as per Holden Dealer letter DL No. 59/96 VR V6 OIL LEAK RECTIFICATION PROCEDURE.

Refer section REINSTALL Procedures 1 to 6.

2. Carefully align the oil pan and the oil pan gasket with the two rear most oil pan bolt holes.

3. Apply Loctite 515 into and around the two rear most bolt holes.

4. Liberally apply Loctite 515 onto the inner and outer surfaces of the two rubber sleeves and carefully insert into the two rear most

bolt holes.

5. Place the lock plate into position.

6. Apply Loctite 515 on the thread and underside of the head of the two rear most oil pan bolts (yellow chromate coloured bolt) and

insert bolts into position (finger tight only)

7. Apply Loctite 515 to all remaining oil pan attaching bolt threads and insert them into position.

8. Tighten all oil pan bolts to the correct torque specification Oil pan attaching bolt/stud torque specification 8 - 12 Nm

IMPORTANT: The oil pan attaching bolts must be tightened to the correct tension. Overtightening will lead to gasket failure and

possible damage to oil pan dimples and/or front cover.

9. Bend lock plate tabs, align closest to flats on each bolt hex, over the two rear most oil pan bolt heads.

10. Refer to Procedure 15 to 17 of DL 59/96 for final installation procedures.

92063593

APPLY "LOCTITE 515"

TO SLEEVE PRIOR TO

INSTALLATION OF

SCREW AND LOCK PLATE