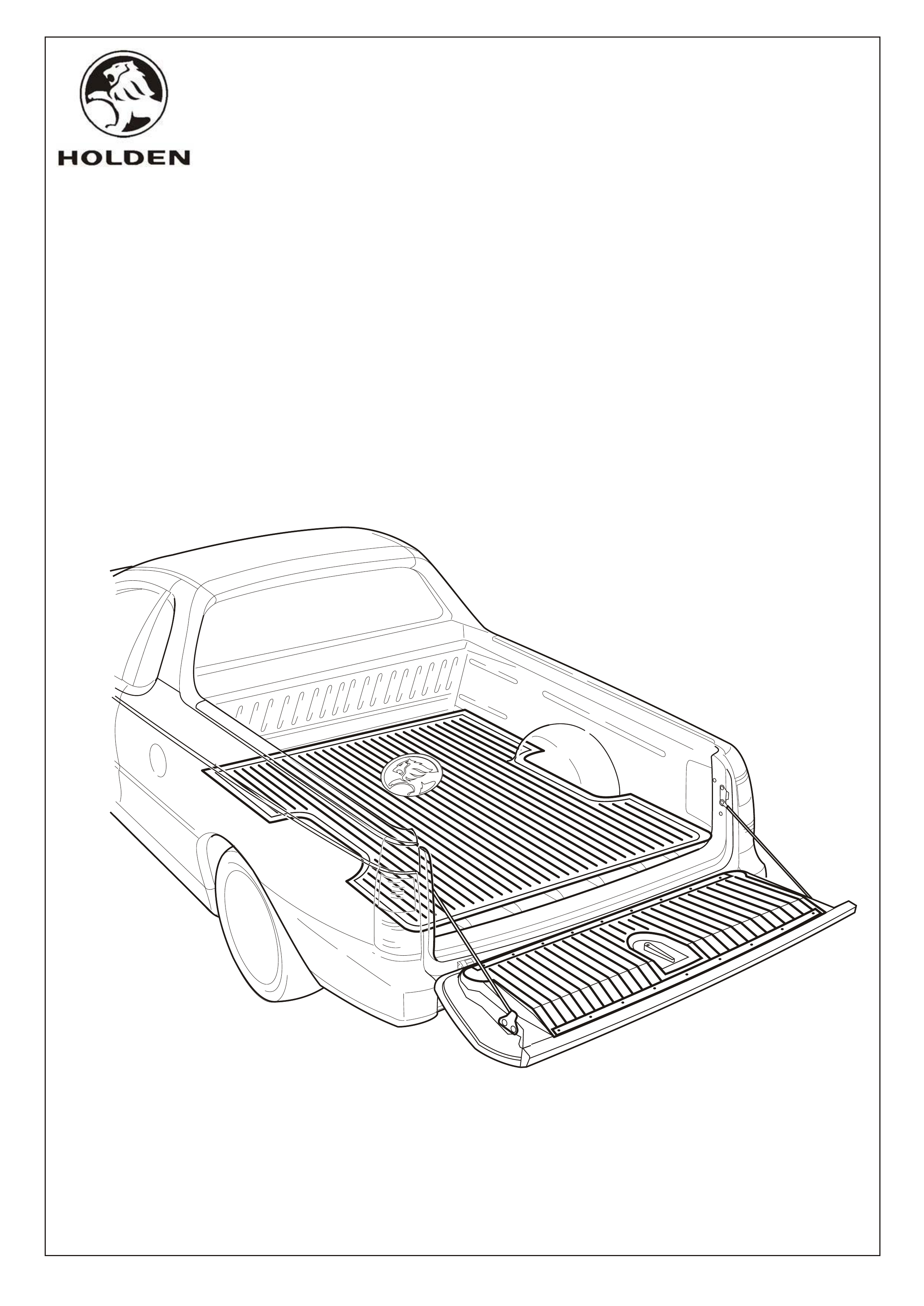

FITTING INSTRUCTIONS FOR VU UTILITY:

CARGO FLOOR PROTECTION MAT

Part Number 92142520

ENDGATE PROTECTION MAT PACKAGE

Part Number 92142519

COPYRIGHT

Page 1 of 4

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FD989-1

FD989

05JA01

COPYRIGHT

Page 2 of 4

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

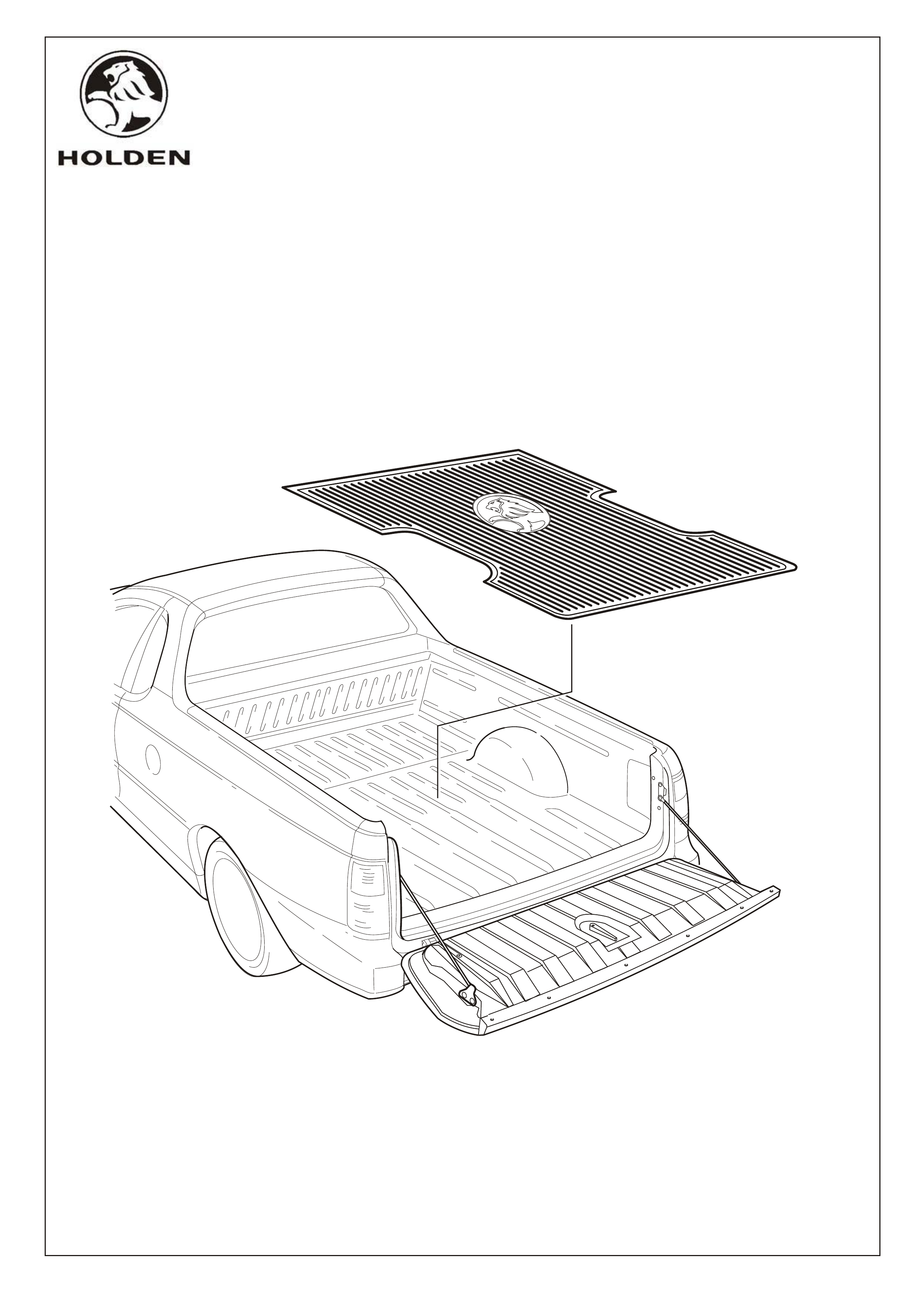

CARGO FLOOR PROTECTION MAT INSTALLATION

1. Thoroughly clean the rear compartment floor.

2. With the aid of an assistant, lift the protection mat into the tray.

3. Locate the protection mat centrally around the wheel arches.

4. Close endgate to check clearance to mat and adjust if necessary.

FD989-2

FD989

05JA01

FITTING INSTRUCTIONS

COPYRIGHT

Page 3 of 4

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

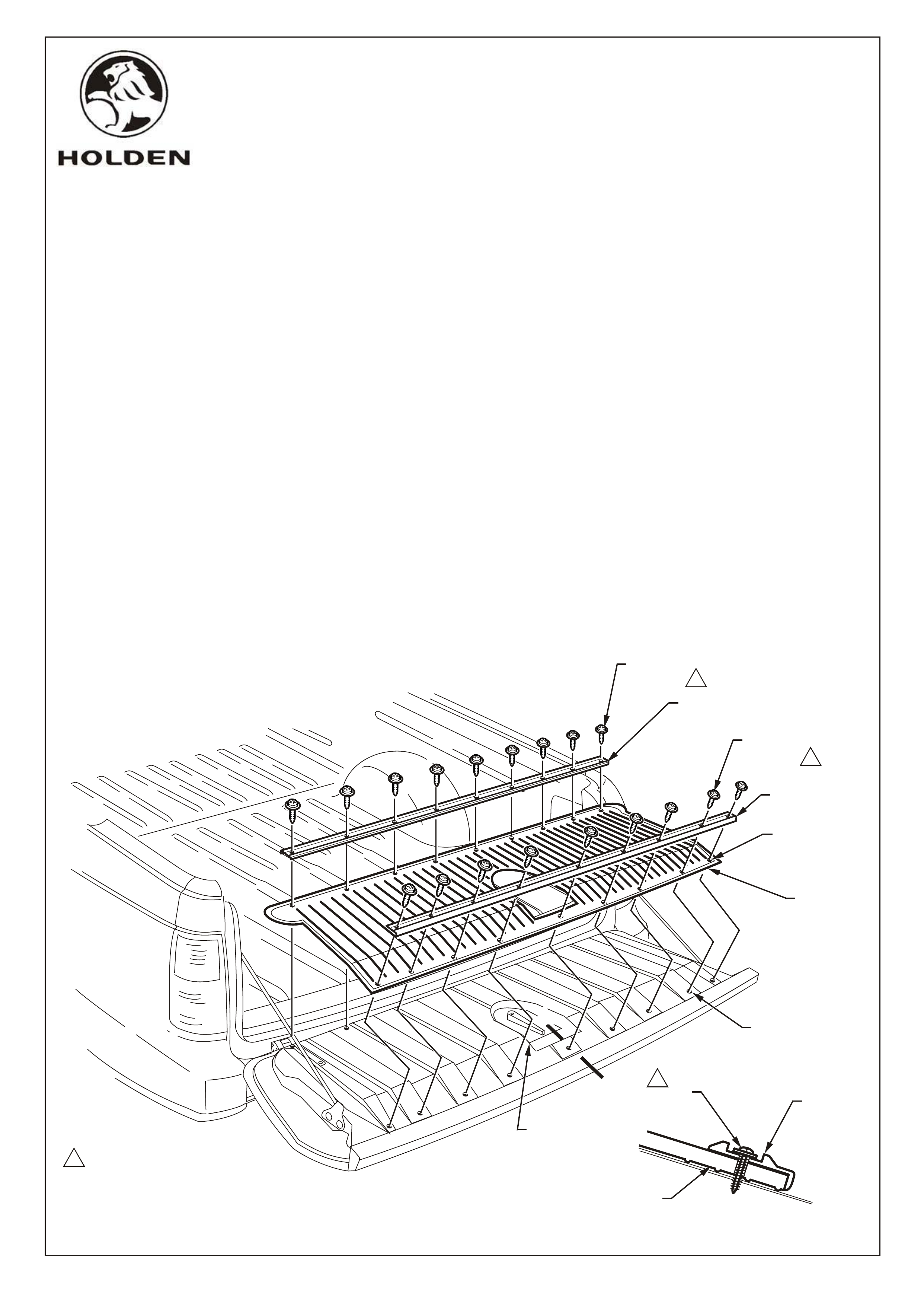

ENDGATE PROTECTION MAT

FITTING INSTRUCTIONS

TOOLS REQUIRED

1. Thoroughly clean the endgate

2. Position the endgate protection mat centrally on the vehicle endgate by aligning the opening in the

mat with the release handle recess.

3. Position the edge cover (1,210mm long) over the top edge of the mat and align the centre hole in the

edge cover with the centre line of the mat.

5. Using the centre hole in the edge cover as a template, drill a 3.0 mm dia. hole through the mat and

tailgate.

6. Temporarily fix the mat and edge cover to endgate by installing the supplied self tapping screw.

7. Drill the remaining holes through the mat and endgate using the holes in the edge cover as a

template.

8. Ensuring that the mat is aligned and flat, repeat steps 3~8 for the bottom edge cover (1,185mm long).

9. On completion of all drilling, remove the edge covers and mat. Remove all metal particles and apply

the corrosion protection compound supplied, to all drilled holes.

10. Refit the mat, instal the edge covers and fix with self tapping screws. 18 places. Tighten to specified

torque.

Electric drill, 3.0mm drill bit and a screw driver with No.2 Phillips insert bit.

FD989-3

SCREW - SELF TAPPING

9 PLACES

SCREW - SELF TAPPING

9 PLACES

SCREW

SELF

TAPPING

A

1

1

1

1

1-3 Nm

DRILL 3.0 mm DIA.

HOLES - 18 PLACES

DRILL 3.0 mm DIA.

HOLES - 18 PLACES

ENDGATE

PROTECTION

MAT

ENDGATE

RELEASE

HANDLE

RECESS

TAILGATE

PROTECTION

MAT

EDGE COVER - BOTTOM

(1,185mm LONG)

EDGE COVER - TOP

(1,210mm LONG)

EDGE

COVER

A-A

SECTION

A

FD989

05JA01

COPYRIGHT

Page 4 of 4

FD989-4

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

PART NO. DESCRIPTION QUANTITY

92142520 CARGO FLOOR PROTECTION MAT 1

92142519 ENDGATE PROTECTION MAT 1

- EDGE COVER - TOP (1,210mm LONG) 1

- EDGE COVER BOTTOM (1,185mm LONG) 1

- SCREW - SELF TAPPING 18

FD989 - FITTING INSTRUCTIONS 1

FITTING INSTRUCTIONS FOR VU UTILITY:

CARGO FLOOR PROTECTION MAT

Part Number 92142520

ENDGATE PROTECTION MAT PACKAGE

Part Number 92142519

PARTS LIST

FD989

05JA01