FD869

21DE00

COPYRIGHT

Page 1 of 6

FITTING INSTRUCTIONS FOR

TS ASTRA HATCH BACK

1000kg TOW BAR PACKAGE

Part Number 92079514

G37-01a

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

TOOLS REQUIRED:

TORX HEAD SCREW DRIVER (TORX BIT No. 20)

SCRAPER (FOR DEADENER REMOVAL)

HOT AIR GUN

DRILL

DRILL BIT, 8.0mm

METAL PRIMER

SILICONE OR BUTYL SEALER

SOCKET WRENCH

TORQUE WRENCH

SOCKETS: 10.0mm

16.0mm

TS ASTRA HATCH BACK, 1000kg TOWBAR PACKAGE

FITTING INSTRUCTIONS

G37-02a

Page 2 of 6

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

COPYRIGHT

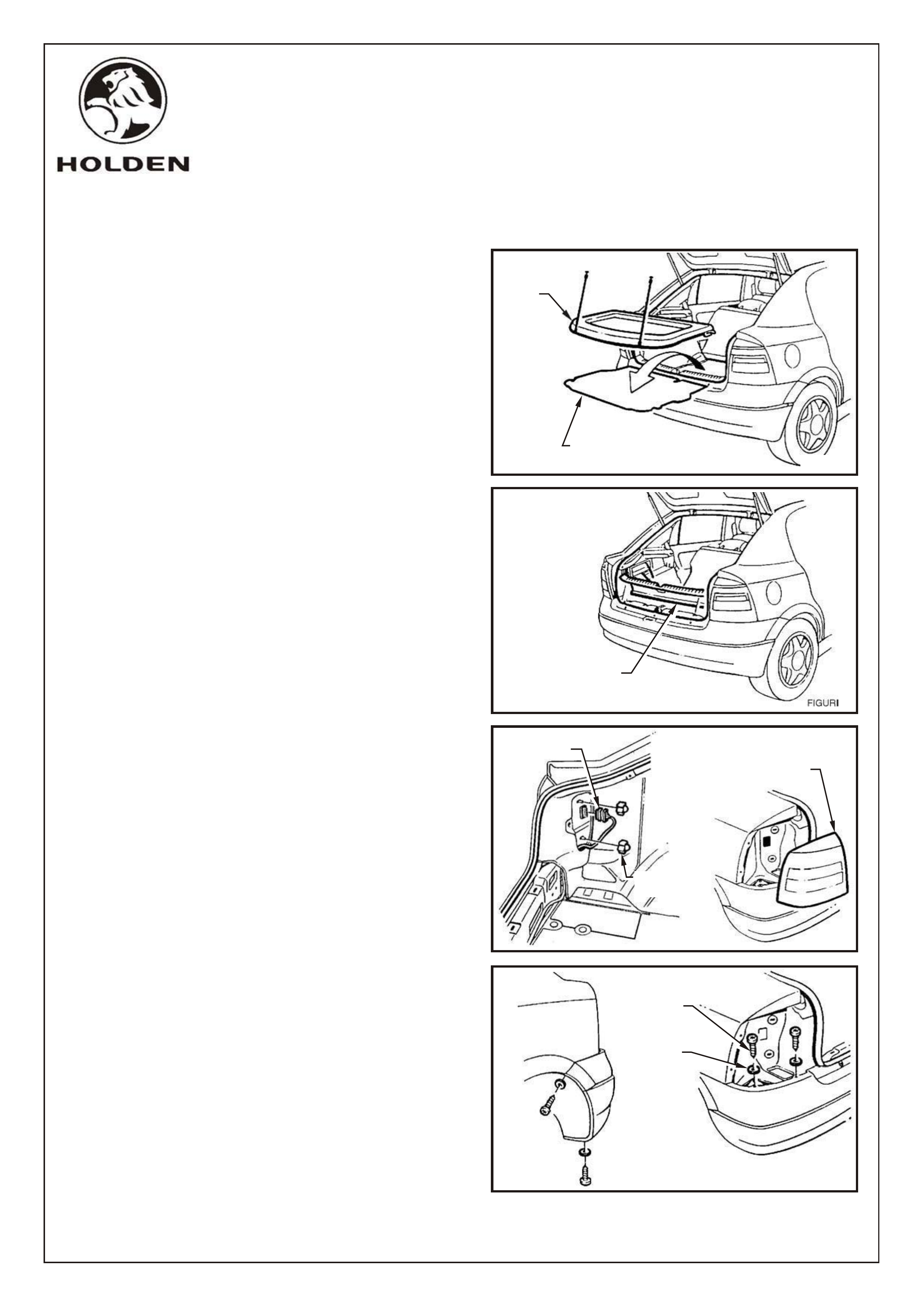

1. Open rear hatch, remove rear parcel shelf and rear

compartment floor carpet.

2. Remove back panel lower cover.

3. Open LHS and RHS tail lamp access panels and

disconnect LHS and RHS rear tail lamps

connectors.

4. Remove two plastic nuts securing each side rear tail

lamp.

5. Remove LHS and RHS rear tail lamps.

6. Remove two Torx head screws and washers

securing bumper facia at rear wheel opening and

two Torx head screws and washers at rear tail lamp

cavity, LHS of bumper facia, as shown in Figure 4.

7. Remove two Torx head screws and washers

securing bumper facia at rear wheel opening and

two Torx head screws and washers at rear tail lamp

cavity, RHS of bumper facia.

FIGURE 2

BACK PANEL

LOWER COVER

REAR

PARCEL

SHELF

REAR COMPARTMENT

FLOOR CARPET FIGURE 1

FIGURE 4

SCREW

(4 PLACES

EACH SIDE)

WASHER

(4 PLACES

EACH SIDE)

FIGURE 3

REAR TAIL LAMP

ASSEMBLY,

LHS

REAR TAIL LAMPS

CONNECTOR

PLASTIC NUT

(2 PLACES)

FD869

21DE00

G37-03a

Page 3 of 6

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

COPYRIGHT

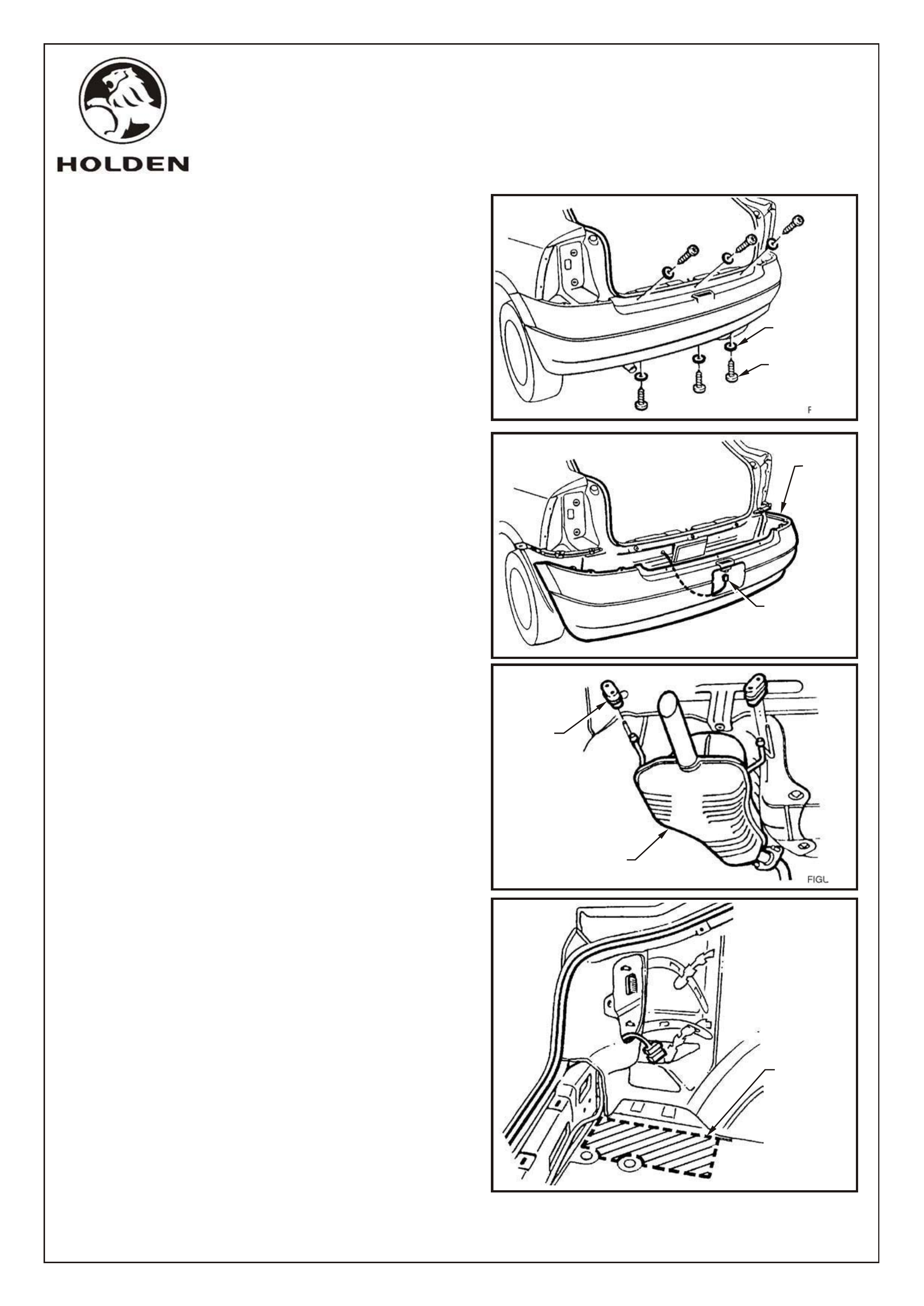

8. Remove six Torx head screws and washers from

rear bumper facia as shown in Figure 5.

9. Disconnect licence plate lamp connector and

remove rear bumper facia.

10. Disconnect two muffler hanger rubbers from rear

muffler and hanger mounts. Allow rear muffler to

hang, to provide access to LHS tow bar mounting

location.

11. Mark area on LHS of rear compartment floor where

boot plate will be fitted and scrape deadener from

this area, as shown in figure 8.

NOTE: Use a heat gun to soften deadener and aid

removal

FIGURE 5

SCREW

(6 PLACES)

WASHER

(6 PLACES)

FIGURE 6

BUMPER

FACIA

LICENCE PLATE

LAMP

CONNECTOR

FIGURE 7

REAR MUFFLER

MUFFLER

HANGER

RUBBER

(2 PLACES)

FIGURE 8

REMOVE

FLOOR

DEADENER

(LHS ONLY)

FD869

21DE00

G37-04a

Page 4 of 6

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

COPYRIGHT

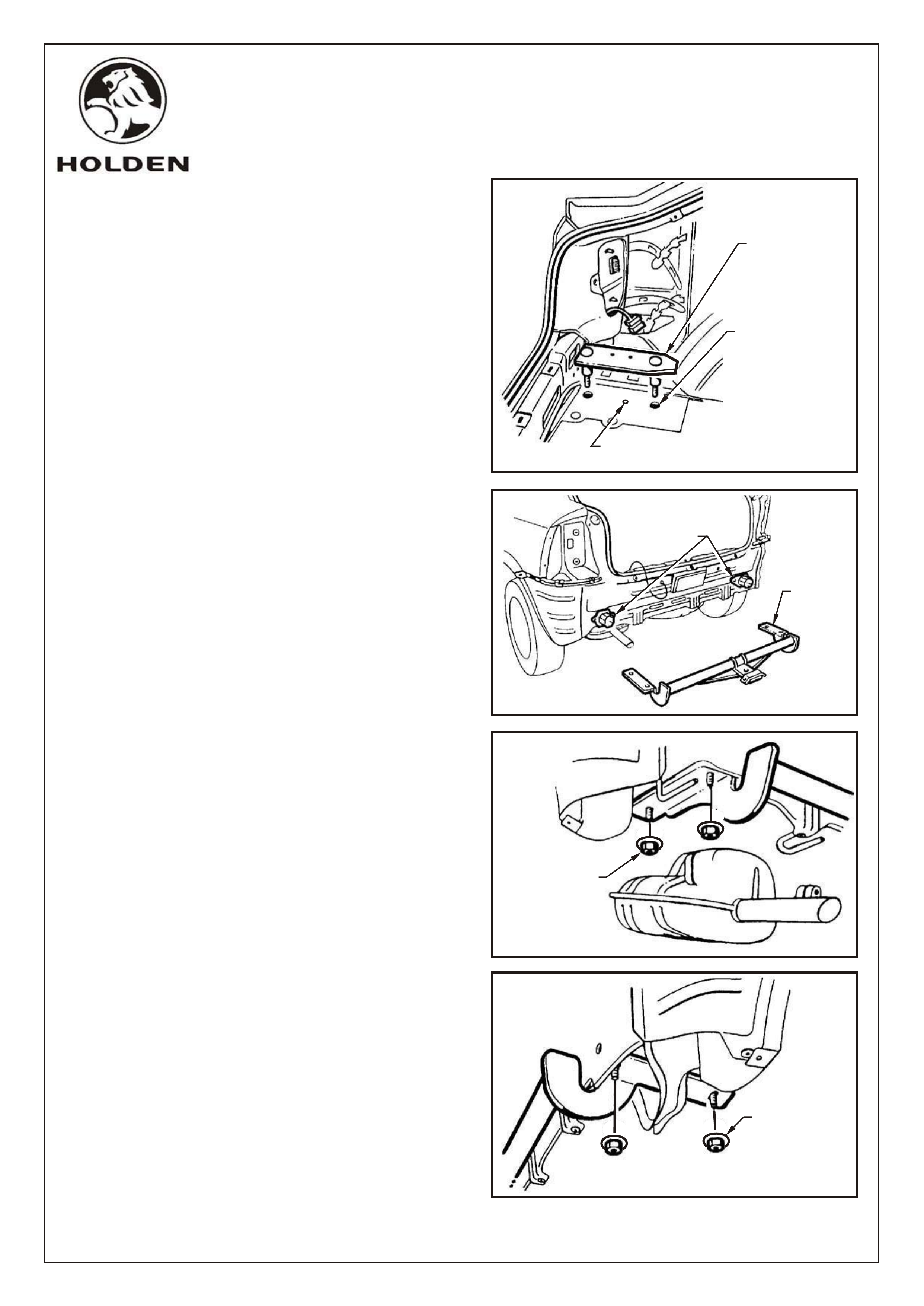

12. Drill two 20mm dia. holes(through floor panel only),

at dimple locations on LHS and RHS of rear

compartment floor.

NOTE: Do not drill centre most of three dimples .

13. Apply metal primer, around holes and to any bare

metal surfaces and allow to dry.

14. Apply silicone or butyl sealer around holes prior to

installing boot plates, for water sealing and

corrosion protection.

15. Instal spacers, boot plates and coach bolts to LHS

and RHS of rear compartment. Use two short

spacers and two 90mm coach bolts for LHS. Use

two longer spacers and two 100mm coach bolts for

RHS.

NOTE: Both boot plates must be installed with longer cut

off corner inboard, to provide correct floor coverage and

prevent boot plate fouling spare wheel well on RHS .

16. Drill off two rivets from each of two crush boxes on

rear panel. Remove and retain crush boxes to

return to customer.

17. Offer tow bar to rear of vehicle.

NOTE: Crush boxes may be refitted using rivets supplied

in package, if customer removes tow bar in the future.

18. Attach tow bar at LHS using two M10 flange nuts .

Hand tighten.

19. Attach tow bar at RHS using two M10 flange nuts.

Tighten nuts to 45Nm.

20. Tighten two M10 flange nuts at LHS to 45Nm, refer

Figure 11.

FIGURE 9

DRILL 20.0 DIA HOLE

HROUGH FLOOR

PANEL ONLY

(2 PLACES

EACH SIDE)

AT DIMPLE

LOCATIONS,

T

BOOT PLATE,

COACH BOLT,

SPACER

ASSEMBLY

FIGURE 10

TOW BAR

ASSEMBLY

FIGURE 11

FLANGE NUT, M10

(2 PLACES)

45Nm

FIGURE 12

FLANGE NUT, M10

(2 PLACES)

45Nm

REMOVE AND

RETAIN

CRUSH BOXES

DO NOT DRILL

CENTRE MOST DIMPLE

FD869

21DE00

G37-05a

Page 5 of 6

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

COPYRIGHT

21. Attach tow bar tongue using two M16 x 45.0 bolts

and spring washers. Tighten M16 x 45.0 bolts 80-

90Nm.

22. Refit rear muffler with two muffler hanger rubbers.

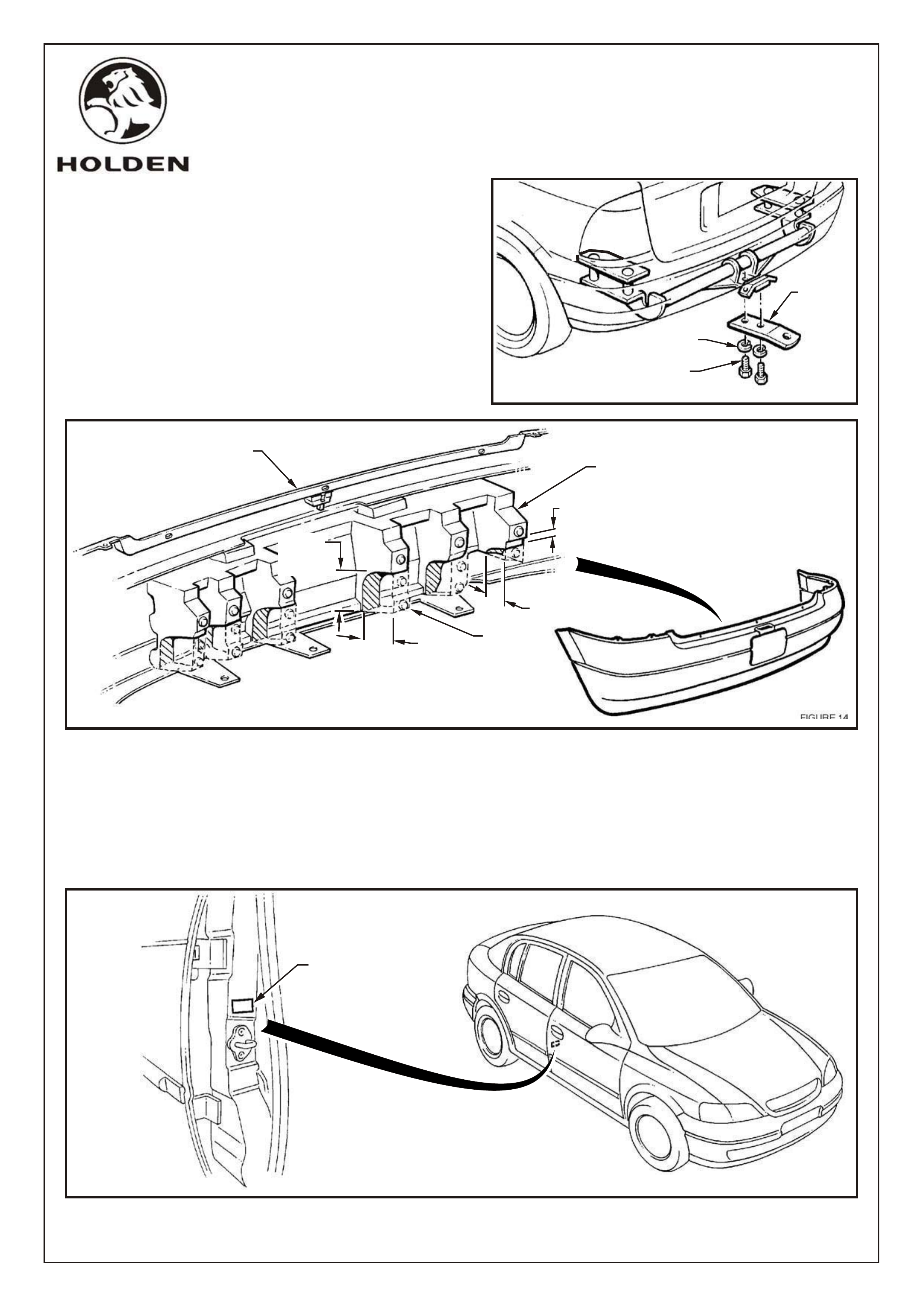

23. Before refitting rear bumper facia, the foam energy

absorber on the inner surface of the facia, must be

modified where it would otherwise interfere with the

tow bar. Cut out sections of energy absorber as

indicated in Figure 14.

TOW BAR

TONGUE

SPRING WASHER

16mm, (2 PLACES)

BOLT, M16

(2 PLACES)

80-90Nm FIGURE 13

FIGURE 15

WIPE SURFACE CLEAN

PRIOR TO APPLICATION

OF ADR LABEL

24. Refit rear bumper facia ensuring an interference free fit between the energy absorber and tow bar. Reconnect

licence plate lamp connector.

25. Refit LHS and RHS rear tail lamps.

26. Refit back panel lower cover and rear compartment floor carpet.

FIGURE 14

70mm

(TYPICAL,

5 PLACES))

20mm

70mm

70mm

(TYPICAL,

5 PLACES)

REAR BUMPER

ENERGY ABSORBER

CUT OUT

SECTIONS

AS INDICATED

REAR BUMPER FACIA

FD869

21DE00

HOLDEN SERVICE PARTS OPERATIONS

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

COPYRIGHT

Division of HOLDEN Ltd ACN 006 893 232

TS ASTRA HATCH BACK, 1000kg TOW BAR PACKAGE

Part No. 92079514

PARTS LIST

ITEM DESCRIPTION QUANTITY

92078594 TOWBAR ASSEMBLY, CONSISTS OF:

TOWBAR MAIN ASSEMBLY 1

BOOT PLATE ASSEMBLY (LHS) 1

BOOT PLATE ASSEMBLY (RHS) 1

FLANGE NUT, M10 4

92078748 TOW BAR TONGUE 1

92077203 D - SHACKLE 1

92081424 BOLT - M16 x 45, GRADE 8.8 2

92079512 SPRING WASHER - 16mm 2

ADR LABEL 1

FD796 WARRANTY CARD 1

FD869 FITTING INSTRUCTION BOOKLET 1

NOT INCLUDED IN TOW BAR PACKAGE, AVAILABLE SEPARATELY:

92078418 TRAILER WIRING HARNESS

G37-06a

Page 6 of 6

FD869

21DE00