FITTING INSTRUCTIONS FOR

VS SEDAN, 2100 KG TOW BAR PACKAGE.

V6 & V8, 5 LINK REAR SUSPENSION &

AUTOMATIC TRANSMISSION

Part Number 92053228

NOT INCLUDED IN TOW BAR PACKAGE, BUT MANDATORY TO FIT

PACKAGE - SUPA LIFT SHOCK ABSORBERS

PACKAGE - POWER STEERING FLUID COOLER

PACKAGE - SEDAN REAR QUARTER BRACE

PACKAGE - HEAVY DUTY EQUALISER HITCH

TOWING PATCH HARNESS (FLAT 7 PIN), or

TOWING PATCH HARNESS (ROUND 7 PIN)

HEAVY DUTY RADIATOR (V6 ONLY)

SYNTHETIC REAR AXLE OIL (V6 ONLY)

OIL IDENTIFICATION TAG (V6 ONLY)

92038038

92053149

M41155

M40742

92034465

M39838

92057296

HN2040

VS20589

FD809

15JL99

COPYRIGHT

Page 1 of 12

FD809-1a

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

HSPO2-SH.CDR

M41536

M41535

PACKAGE - AUTO TRANS FLUID COOLER (V6), or

PACKAGE - AUTO TRANS FLUID COOLER (V8)

MANDATORY TO FIT FOR VS SERIES 1 ONLY,

IF EXTERNAL AUTO TRANS FLUID COOLER IS NOT ALREADY FITTED:

Disconnect battery negative terminal.

Remove rear bumper bar, refer VS Service Manual Volume 1 Section 1D

Remove rear bumper support beam, refer Figure 3 view E and VS Service Manual Volume 1 Section 1D.

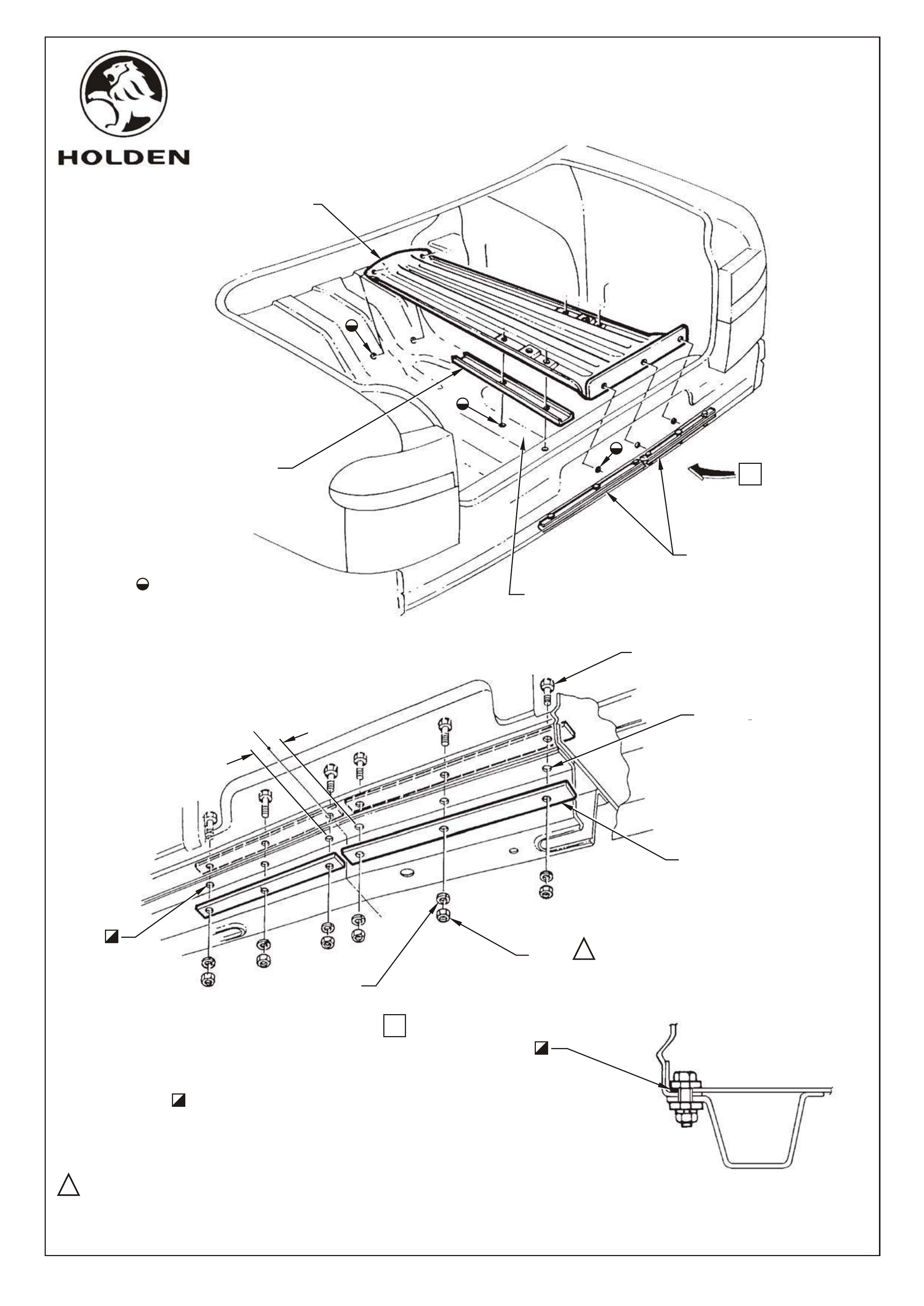

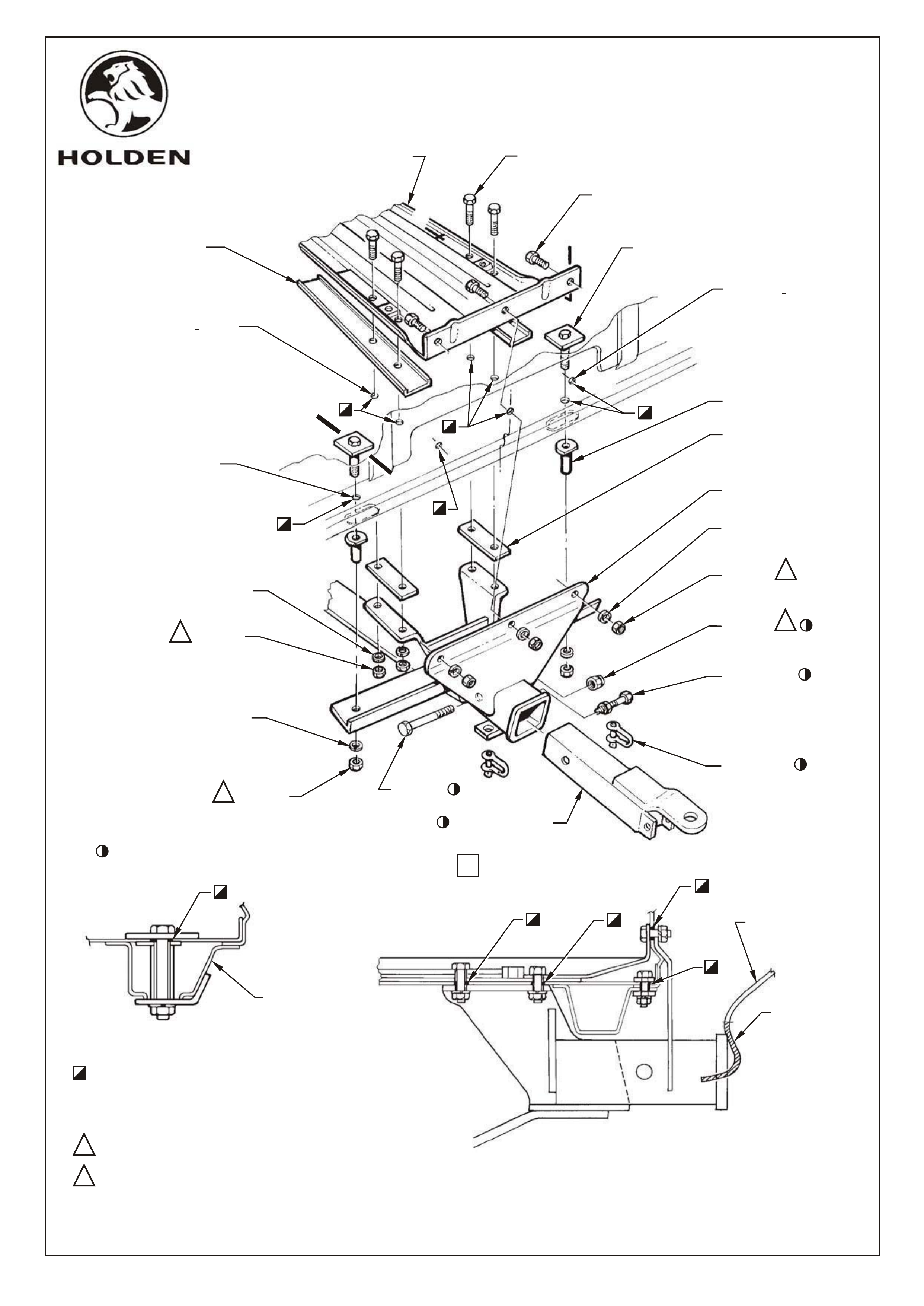

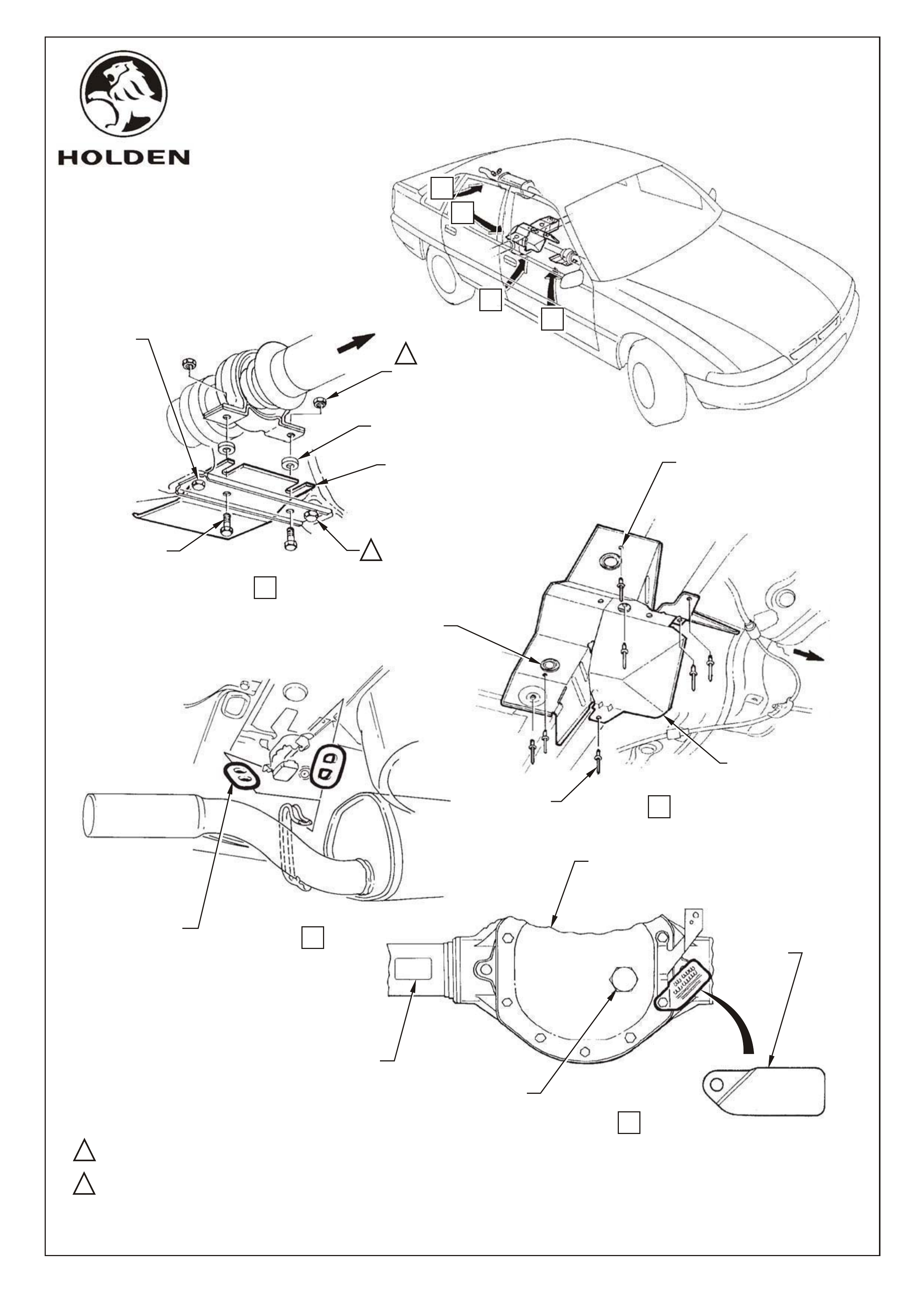

Position seam bracing plates 25mm each side of centre line of rear compartment, refer Figure 1 view A and

section A-A. Using bracing plates as templates, mark and drill six 8.5mm dia. holes.

Ensure surfaces to be coated are free from contaminents, oil and dirt. Apply metal primer, Dulux Epoxy

Primer Surfacer (DEPS) 410-39790 Black, or equivalent and allow 10 - 15 minutes to dry, then caulking

compound, Dulux Fill and Seal Putty, 409-19000 to any bare metal and around holes (6 places).

Install seam bracing plate, retaining bolts, (M8 x 20mm, 6 off) washers and nuts and tighten to correct

torque specification.

For ease of fitment it is essential the seam backing plates are located and secured before

fitment of the tow bar upper part assembly.

2100 KG TOW BAR FITTING INSTRUCTIONS (5 LINK)

SEAM BRACING PLATES

SEAM BRACING PLATE RETAINING NUT TORQUE SPECIFICATION 17 - 23Nm.

NOTE:

1.

2.

3.

4.

5.

6.

TOW BAR

WARNING: EXERCISE CARE WHEN DRILLING HOLES IN REAR COMPARTMENT FLOOR

IN VICINITY OF THE FUEL TANK.

NOTE:

NOTE:

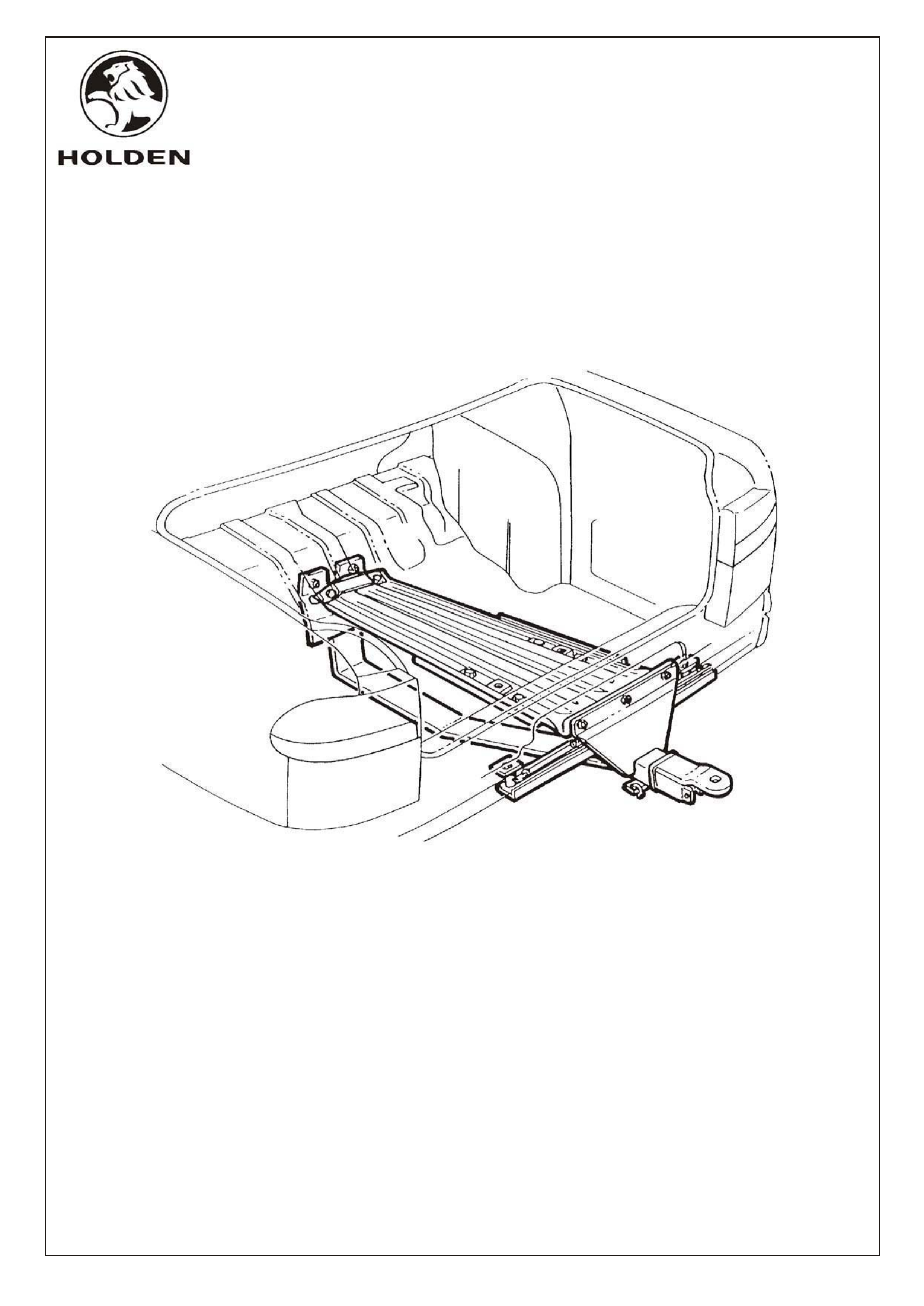

Position the upper part assembly on the centre of the rear compartment floor, refer Figure 1. Mark rear

compartment floor where upper part assembly comes into contact with floor and remove deadener from

marked area of rear compartment floor, refer Figure 1.

Loosen fuel tank retaining strap rear retaining nut and bolt (DO NOT REMOVE) and slightly lower rear of fuel

tank to allow easier installation of tow bar.

Position 'U' channel strengthening plates and upper part assembly on centre line of rear compartment floor,

align holes in strengthening plates with those in upper part assembly.

It is essential that 'U' channel strengthening plate be located under the upper part assembly

when marking hole locations, to ensure correct height of bolt holes.

Using upper part assembly as a template mark the 9 retaining hole centres, refer Figure 1. Remove upper

part assembly.

Do not mark through welded nut on upper part assembly.

1.

2.

3.

4.

FD809

15JL99

COPYRIGHT

Page 2 of 12

FD809-2a

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

HSPO2-SH.CDR

MARK HOLES 9 PLACES REMOVE DEADENER FROM

CONTACTING SURFACES OF

REAR FLOOR

SEAM BRACING PLATES

BOLT M8

(6 PLACES)

SEAM BRACING PLATE

(4 PLACES)

WASHER M8

(6 PLACES)

'U' CHANNEL

STRENGTHENING

PLATES

UPPER PART ASSEMBLY

A

A

VIEW

A-A

SECTION

11

NUT M8

(6 PLACES)

11

C

L25,0

25,0

17 - 23 Nm

CLEAN SURFACES OF CONTAMINENTS, OIL AND DIRT, THEN APPLY

METAL PRIMER, DULUX EPOXY PRIMER SURFACER (DEPS) 410-39790

BLACK AND ALLOW 10 - 15 MINUTES TO DRY, THEN APPLY CAULKING

COMPOUND, DULUX FILL AND SEAL PUTTY 409-19000.

(TYPICAL 6 PLACES)

DRILL 8,0 DIA.

+0,5

0,0

6 HOLES USING

BRACING PLATE

AS TEMPLATE

(6 PLACES)

(6 PLACES)

FD809

15JL99 Figure 1

COPYRIGHT

Page 3 of 12

FD809-3a

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

HSPO2-SH.CDR

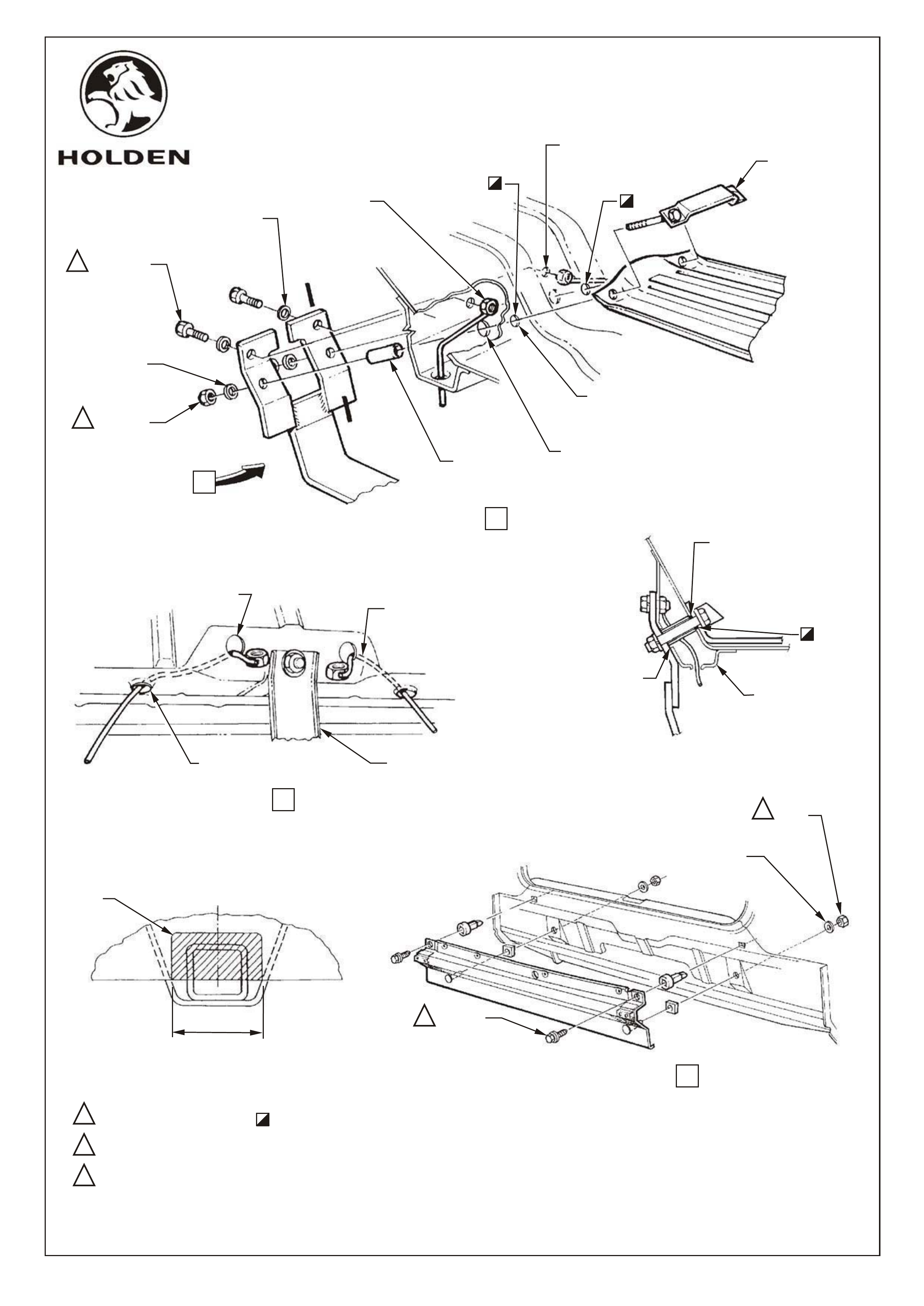

Drill four 12.5mm dia. holes in rear compartment floor, refer Figure 2 view B.

Drill three 12.5mm dia. holes in back panel lower, refer Figure 2 view B.

Drill two 12.5mm dia. holes in front of rear compartment floor, refer Figure 3 view C.

Ensure surfaces to be coated are free from contaminents, oil and dirt. Apply metal primer, Dulux Epoxy

Primer Surfacer (DEPS) 410-39790 Black, or equivalent and allow 10 - 15 minutes to dry, then caulking

compound, Dulux Fill and Seal Putty, 409-19000 to any bare metal and around holes (9 places),

refer Figure 2 view B and Figure 3 view C.

Place 'U' channel strengthening plates and upper part assembly onto rear compartment floor.

Install bracket assembly through upper part assembly, 'U' channel and rear compartment floor.

Install spacers with welded washers into oval pressed holes in rear boxed section, refer Figure 2 section C-C.

Remove corresponding grommets from inside of rear compartment and remove deadener from area around

existing hole. Install the two bolts with welded washers (M10 x 80, 2 off), into existing holes in rear boxed

section and through spacers with welded washers. refer Figure 2 view B & section C-C.

Ensure surfaces to be coated are free from contaminents, oil and dirt. Apply metal primer, Dulux Epoxy

Primer Surfacer (DEPS) 410-39790 Black, or equivalent and allow 10 - 15 minutes to dry, then caukling

compound, Dulux Filll and Seal Putty, 409-19000 to any bare metal and around holes,

refer Figure 2 view B ,section B-B and section C-C.

Place nut with wire attached, wire end first through 19mm hole in crossmember outer panel at front of rear

floor. Pass wire through 10mm flared hole in lower face of crossmember, refer Figure 3 view D.

Install tow bar lower part assembly and retain by installing spring washers and nuts to bolts with square

plates, previously fitted (2 places).

Insert rear lower spacer plates between tow bar lower part assembly and underbody, refer Figure 2 view B.

From inside of rear compartment install upper part assembly to lower part assembly retaining bolts

(M10 x 35mm, 3 off) through the rear face of the lower part assembly, body and lower part assembly. From

outside of vehicle install spring washers and retaining nuts and hand tighten, refer Figure 2 view B and

section B-B.

Install upper part assembly to lower part assembly retaining bolts (M10 x 35mm, 4off) through upper part

assembly, rear compartment floor, 'U' channel strengthening plate, rear lower spacer plates and lower part

assembly, install spring washers and retaining nuts and hand tighten, refer Figure 2 view B and section B-B.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

FD809

15JL99

COPYRIGHT

Page 4 of 12

FD809-4a

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

HSPO2-SH.CDR

C

B

B

C

B

VIEW

C-C

SECTION

B-B

A

SECTION

11

11

11

11

22

22

40 - 55Nm

70 - 90Nm

ENSURE SURFACES TO BE COATED ARE FREE FROM CONTAMINENTS,

OIL AND DIRT. APPLY METAL PRIMER, DULUX EPOXY PRIMER SURFACER

(DEPS) 410-39790 BLACK, OR EQUIVALENT, AND ALLOW 10 - 15 MINUTES

TO DRY, THEN CAULKING COMPOUND, DULUX FILL AND SEAL PUTTY,

409-19000 TO ANY BARE METAL AND AROUND HOLES.

REAR BUMPER FACIA

REMOVE

REFER FIGURE 3

CROSSMEMBER-BACK

PANEL LOWER

UPPER PART

ASSEMBLY

BOLT M10

(4 PLACES)

BOLT M10

(3 PLACES)

'U' CHANNEL

STRENGTHENING

PLATE

(2 PLACES)

M10 BOLT-

WELDED PLATE

(2 PLACES)

SPACER

(2 PLACES)

REAR LOWER

SPACER PLATE

(2 PLACES)

LOWER PART

ASSEMBLY

WASHER M10

(3 PLACES)

NUT M10

(3 PLACES)

NUT M16

(NYLOC)

ANTI-RATTLE

BOLT ASSEMBLY

M10

'D' SHACKLE

(2 PLACES)

TOW BAR TONGUE

BOLT M16

NUT M10

(2 PLACES)

WASHER M10

(2 PLACES)

NUT M10

(4 PLACES)

WASHER M10

(4 PLACES)

EXISTING HOLE

DISCARD GROMMET

(2 PLACES)

PART OF TOW BAR TONGUE PACKAGE

4 HOLES IN REAR

FLOOR

CAUTION: EXERCISE

CARE WHEN DRILLING

IN VICINITY OF PETROL

TANK

3 HOLES IN BACK

PANEL LOWER

DRILL 12,0 DIA.

+0,5

0,0

DRILL 12,0 DIA.

+0,5

0,0

DETAIL

FD809

15JL99 Figure 2

COPYRIGHT

Page 5 of 12

FD809-5a

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

HSPO2-SH.CDR

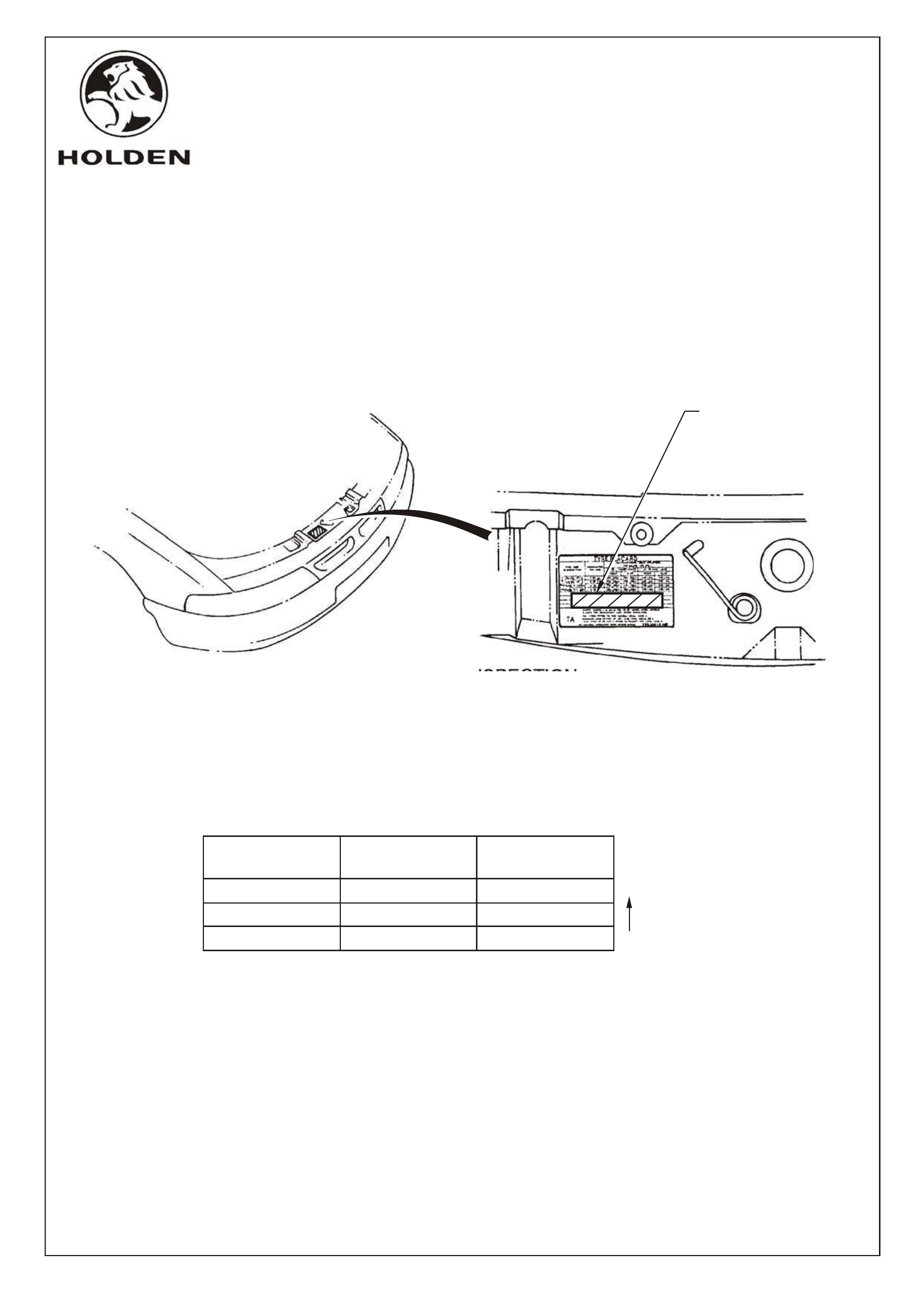

From underneath the vehicle, install spacers over bracket assembly bolts, install lower part assembly

bracing strap onto bracket assembly bolts, install spring washers and nuts and hand tighten, refer

Figure 3 view C and section D-D.

Initially tighten all bolts to 20Nm.

NOTE: This is important to ensure correct location of the bracing strap bolt.

Using bracing strap as template drill two 10.5mm dia. holes in crossmember, refer Figure 3 view C.

Install bolt (10 X 35, 2 off) and retain using nut with wire attached which have previously been inserted

into crossmember, refer Figure 3 view D.

Tighten all M10 bolts and nuts to correct torque specification(11 off).

M10 BOLT AND NUT TORQUE SPECIFICATION 40 - 55Nm.

Tighten fuel tank strap retaining bolt and nut to the correct torque specification.

FUEL TANK STRAP RETAINING BOLT AND NUT TORQUE SPECIFICATION 15 - 25Nm

Mark and cut rear bumper, refer Figure 3 detail A, to allow reinstallation of rear bumper bar.

Reinstall rear bumper support beam, refer Figure 3 view E and VS Service Manual Volume 1 Section 1D.

Reinstall rear bumper, refer VS Service Manual Volume 1 Section 1D.

Install tow bar tongue into tow bar assembly, install tow bar tongue retaining bolt flat washer and

nyloc nut. Install tow bar tongue anti rattle bolt (M10 x 35mm), spring washer and nut and tighten

to correct torque specification.

TOW BAR TONGUE RETAINING BOLT AND NUT TORQUE SPECIFICATION 80 - 90Nm.

TOW BAR TONGUE ANTI RATTLE BOLT AND NUT TORQUE SPECIFICATION 40 - 55Nm.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

FD809

15JL99

COPYRIGHT

Page 6 of 12

FD809-6a

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

HSPO2-SH.CDR

D

D

D

D

VIEW

E

VIEW

C

VIEW

D-D

SECTION

A

DETAIL

DRILL 10,0 DIA. HOLES

NUT M10

(2 PLACES)

WASHER M10

(2 PLACES)

BOLT M10

(2 PLACES)

WASHER M10

(2 PLACES)

NUT M10

(2 PLACES)

SPACER

(2 PLACES)

EXISTING HOLE

(2 PLACES)

DRILL 12,0 DIA. HOLES

IN REAR FLOOR

(2 PLACES)

BRACKET ASM.

FEED WIRE END FIRST

THROUGH 19,0 DIA. HOLE

NUTS M10 WITH WIRE

(2 PLACES)

10,0 DIA. FLARED HOLE FUEL TANK STRAP

EXISTING HOLE

PANHARD ROD

BRACKET

CROSSMEMBER

ASM

11

11

22

33

33

1,5 - 3,0Nm

2210 - 25Nm

3340 - 55Nm

100

C

LOF VEHICLE

BEFORE INSTALLATION

OF TOW BAR, REMOVE

SHADED AREA SHOWN

FROM REAR BUMPER

FACIA

NUT

(2 PLACES)

WASHER

(2 PLACES)

SCREW

(2 PLACES)

ENSURE SURFACES TO BE COATED ARE FREE FROM CONTAMINANTS,

OIL AND DIRT. APPLY METAL PRIMER, DULUX EPOXY PRIMER SURFACER

(DEPS) 410-39790 BLACK, OR EQUIVALENT AND ALLOW 10 - 15 MINUTES

TO DRY, THEN CAULKING COMPOUND, DULUX FILL AND SEAL PUTTY,

409-19000 TO ANY BARE METAL AND AROUND HOLES.

+0,5

-0,0

+0,5

-0,0

12,0 DIA. HOLE

+0,5

-0,0

IN PANHARD ROD BRACKET

CROSS MEMBER

(2 PLACES)

FD809

15JL99 Figure 3

COPYRIGHT

Page 7 of 12

FD809-7a

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

HSPO2-SH.CDR

CENTRE BEARING HEAT SHIELD

Loosen centre bearing carrier to underbody retaining bolts, DO NOT REMOVE BOLTS.

Select correct heat shield: V6 - 92053241, or V8 - 92047132 (discard shield which is not required)

Slide centre bearing heat shield on top of centre bearing carrier and tighten to correct torque specification,refer Figure 4

view A.

CENTRE BEARING TO LOWER CUP GUIDE

RETAINING BOLT TORQUE SPECIFICATION 20 - 25Nm

HEAT SHIELD INTERMEDIATE MUFFLER

Disconnect intermediate exhaust pipe from catalytic converter and allow exhaust to hang on mounts, refer VS Service

Manual Volume 4 Section 8B1.

WARNING: BEFORE REMOVAL OF PROPELLER SHAFT, PAINT A MARK ON THE PROPELLER SHAFT AND PINION

FLANGE SO THAT THEY CAN BE LINED UP ON REASSEMBLY.

Remove propeller shaft from vehicle, refer VS Service Manual Volume 2 Section 4C.

Position heat shield centrally over pressed holes in crossmember assembly rear, refer Figure 4 view B. Using shield

as template mark the seven retaining hole centres and drill 4.0mm holes in floor pan where marked.

Secure the heat shield to floor pan using SP3878 rivets (7 places).

Install propeller shaft, refer VS Service Manual Volume 2 Section 4C.

Reconnect intermediate exhaust pipe to catalytic converter and tighten to correct torque specification, refer VS Service

Manual Volume 4 Section 8B1.

INTERMEDIATE EXHAUST PIPE TO CATALYTIC CONVERTER

ATTACHING BOLT TORQUE SPECIFICATION 30 - 50 Nm.

SILICONE EXHAUST SUPPORT RINGS

Remove and discard rear muffler support rings.

Install silicone support rings to rear muffler (2 places), refer Figure 4 view C.

REAR AXLE LUBRICANT CHANGE (V6 ONLY)

Due to high differential loads when towing 2100kg, it is essential that a synthetic (High Performance) differential oil is

used

All V8 Commodores, and V6 Commodores with Limited Slip Differential (LSD) and or Anti Lock Braking System (ABS),

are supplied standard with synthetic oil. Differentials filled with synthetic oil may be easily identified via a metal tag

stating "HIGH PERFORMANCE, USE APPROVED LUBRICANT ONLY". Refer Figure 4 view D.

For differentials not identified with this tag, a mineral based oil has been used. Before undertaking 2100kg towing it is

essential that the oil be changed to synthetic differential oil, Mobillube SHC, SAE 80W-140 (ID) product code 51107 or

equivalent to Holden's specification number HN2040. Refer to Owner's Manual Volume No. 2 Section 4B1 for correct

oil change procedure.

NOTE: Lowest retaining bolt on rear axle housing cover may be used for draining of oil.

Ensure that after the oil has been replaced, the axle is identified with the correct "HIGH PERFORMANCE,

USE APPROVED LUBRICANT ONLY" tag: P/No. VS20589. This will prevent incorrect oil being used during service

operations.

1.

2.

3.

1.

2.

3.

4.

5.

6.

1.

2.

1.

2.

3.

4.

FD809

15JL99

COPYRIGHT

Page 8 of 12

FD809-8a

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

HSPO2-SH.CDR

LOOSEN CENTRE BEARING

CARRIER BOLTS. RETIGHTEN

AFTER INSTALLATION OF

HEAT SHIELD

FRONT OF

VEHICLE

NUT - EXISTING

(2 PLACES)

SPACER - EXISTING

(2 PLACES)

BOLT - EXISTING

(2 PLACES)

HEAT SHIELD -

CENTRE BEARING

92053241 (V6)

92047132 (V8)

DRILL 4,0 DIA.

(7 HOLES)

FRONT

OF

VEHICLE

SHIELD-

INTERMEDIATE

MUFFLER

92053240

POP RIVET

SP3878

(7 PLACES)

TO LOCATE SHIELD.

POSITION CENTRALLY

OVER FLANGED HOLES

IN REAR CROSSMEMBER

ASSEMBLY

A

VIEW

B

VIEW

B

A

HIGH

PERFORMANCE

USE APPROVED

LUBRICANT ONLY

BROADCAST CODE

FILLER PLUG

OIL IDENTIFICATION

TAG

VS20589

REAR AXLE

HOUSING

COVER

D

VIEW

REPLACE EXISTING

EXHAUST SUPPORT

RINGS WITH

SILICONE EXHAUST

SUPPORT RINGS

92049407

(2 PLACES)

C

VIEW

C

D

11

11

22

22

20 - 25Nm

20 - 35Nm NOTE: WHERE OIL IDENTIFICATION TAG IS NOT FITTED,

DIFFERENTIAL OIL MUST BE CHANGED TO

SYNTHETIC DIFFERENTIAL OIL, MOBILLUBE SHC,

SAE 80W - 140 (ID) PRODUCT CODE 51107 OR

EQUIVALENT TO HN2040, THEN ATTACH OIL

IDENTIFICATION TAG VS20590.

FD809

15JL99 Figure 4

COPYRIGHT

Page 9 of 12

FD809-9a

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

HSPO2-SH.CDR

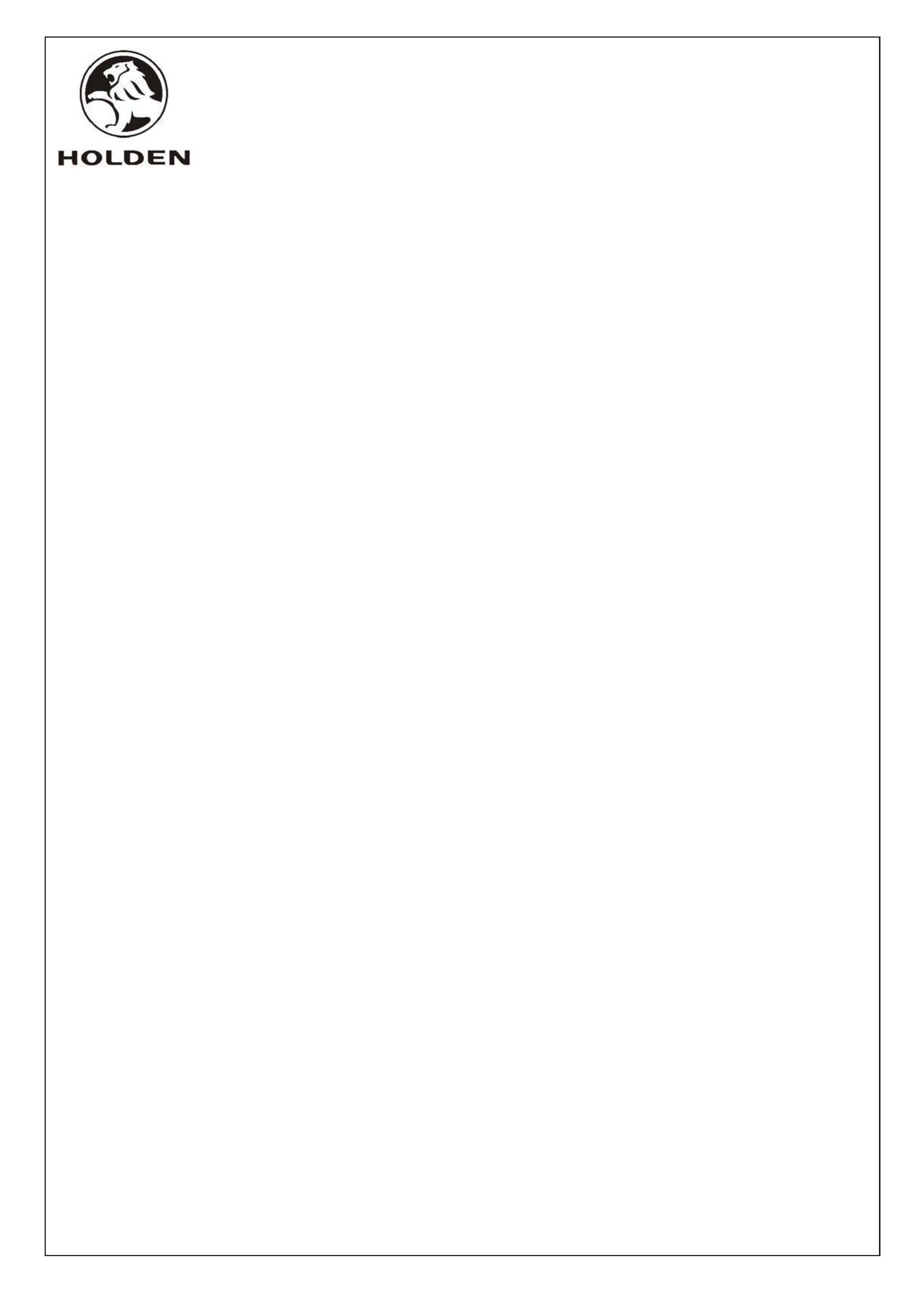

Remove backing from Owner's Manual sticker.

Place sticker on front cover of Owner's Manual.

Open bonnet.

Remove backing from Tyre Placard sticker.

Place sticker in vacant area on original Tyre Placard.

NOTE: Do not cover any information on the original Tyre Placard.

Raise the front of vehicle, refer VS Service Manual Volume 1 Section 0A.

Remove front wheels, refer VS Service Manual Volume 5 Section 10.

NOTE : I nspect front and rear pads to ensure the same brake pad material is fitted front

and rear. Friction material markings are visible with wheels removed and calipers

still fitted to vehicle. The following materials may be used with this towing package

(in order of preference) :

If front brake pads differ from rear brake pads, replace whichever is least

preferred (refer chart) to match other pad type.

Remove front brake calipers, refer VS Service Manual Volume 2 Section 5A.

Remove front hub/brake discs, refer VS Service Manual Volume 2 Section 5A.

Remove front brake shields and discard, refer VS Service Manual Volume 12 Section 3.

Reinstall front hub/brake discs, refer VS Service Manual Volume 2 Section 5A.

Reinstall front calipers, refer VS Service Manual Volume 2 Section 5A.

Reinstall front wheels, refer VS Service Manual Volume 5 Section 10, and lower vehicle.

Reconnect battery negative terminal.

Most

Preferred

1.

2.

3.

1.

2.

3.

4.

5.

6.

7.

8.

9.

OWNER'S MANUAL STICKER

1.

2.

TYRE PLACARD STICKER

FRONT BRAKE SHIELD REMOVAL AND PAD INSPECTION

PLACE TYRE PLACARD

STICKER (M40752),

IN VACANT AREA ON

EXISTING TYRE

PLACARD STICKER.

Pad

Marking

Part No.

Front

Part No.

Rear

BM962 92055692 92055693

BMT6100 VS19504 VS19505

BM826 92046580 92046581

FD809

15JL99

COPYRIGHT

Page 10 of 12

FD809-10a

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

HSPO2-SH.CDR

NOT PART OF TOW BAR PACKAGE, BUT MANDATORY TO FIT *

SUPA LIFT SHOCK ABSORBERS *

AUTOMATIC TRANSMISSION COOLER *

(FOR VS SERIES 1 ONLY, IF AUTO TRANS FLUID COOLER IS NOT ALREADY FITTED)

Install supa lift shock absorbers in accordance with the fitting instructions contained in supa lift

shock absorber package.

Install automatic transmission cooler in accordance with the fitting instructions contained in

automatic transmission cooler package.

Install power steering cooler in accordance with the fitting instructions contained in the power

steering cooler package.

Install rear quarter panel brace in accordance with the fitting instructions contained in the rear

quarter brace package

Install rear heavy duty equaliser hitch in accordance with the fitting instructions contained in the

heavy duty equaliser hitch package.

Install towing patch harness in accordance with the fitting instructions contained in towing patch

harness package.

Install heavy duty radiator in accordance with procedure outlined in VS Service Manual, Volume 1,

Section 6B1 (V6 only).

SUPA LIFT SHOCK ABSORBER PACKAGE

POWER STEERING COOLER *

REAR QUARTER BRACE *

HEAVY DUTY EQUALISER HITCH *

TOWING PATCH HARNESS *

HEAVY DUTY RADIATOR *

AUTOMATIC TRANSMISSION OIL COOLER PACKAGE (V6)

or

AUTOMATIC TRANSMISSION OIL COOLER PACKAGE (V8)

POWER STEERING COOLER PACKAGE

REAR QUARTER BRACE PACKAGE

HEAVY DUTY EQUALISER HITCH PACKAGE

TOWING PATCH HARNESS (FLAT 7 PIN)

or

TOWING PATCH HARNESS (ROUND 7 PIN)

HEAVY DUTY RADIATOR PACKAGE

92038038

M41536

M41535

92053149

M41155

M40742

92034465

M39838

92057296

FD809

15JL99

COPYRIGHT

Page 11 of 12

FD809-11a

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

HSPO2-SH.CDR

PACKAGE - SUPA LIFT SHOCK ABSORBERS

PACKAGE - POWER STEERING FLUID COOLER

PACKAGE - SEDAN REAR QUARTER BRACE

PACKAGE - HEAVY DUTY EQUALISER HITCH

TOWING PATCH HARNESS (FLAT 7 PIN) or

TOWING PATCH HARNESS (ROUND 7 PIN)

HEAVY DUTY RADIATOR (V6 ONLY)

OIL IDENTIFICATION TAG (V6 ONLY)

SYNTHETIC REAR AXLE OIL, EG. MOBILLUBE SHC, SAE 80W - 140,

OR EQUIVALENT LUBRICANT TO HOLDEN'S SPECIFICATION HN2040 (V6 ONLY).

NOT INCLUDED IN TOW BAR PACKAGE, BUT MANDATORY TO FIT :

92038038

92053149

M41155

M40742

92034465

M39838

92057296

VS20589

HN2040

2100 KG TOW BAR PACKAGE FOR 5 LINK (92053228)

PARTS LIST

PART NO. DESCRIPTION QUANTITY

TOW BAR ASSEMBLY

CONSISTS OF:

UPPER PART ASSEMBLY

LOWER PART ASSEMBLY

'U' CHANNEL STRENGTHENING PLATE

BRACKET ASSEMBLY

SPACER - BRACKET ASM. TO LOWER PART ASM.

NUT - M10

SPRING WASHER - 10mm

SPACER WITH WASHER

BOLT - M10 x 80 WITH SQUARE PLATE

NUT - M10

SPRING WASHER - 10mm

PLATE - REAR LOWER SPACER

BOLT - M10 x 25mm

NUT - M10

SPRING WASHER - 10mm

BOLT - M10 x 35mm

NUT - M10

SPRING WASHER - 10mm

BOLT - M10 x 25mm

NUT - M10

SPRING WASHER - 10mm

SEAM BRACING PLATE

BOLT - M8 x 20mm

NUT - M8

SPRING WASHER - 8,0mm

TOW BAR TONGUE PACKAGE (CHROME)

CONSISTS OF:-

TOW BAR TONGUE

BOLT - M16 x 85mm

NUT - M16 (NYLOC)

FLAT WASHER 16mm

BOLT M10 x 35mm

NUT - M10mm

'D' SHACKLE

HEAT SHIELD - INTERMEDIATE MUFFLER

RIVET - BLIND 4,0 x 13,2mm

SILICONE EXHAUST RING

BOOKLET FITTING INSTRUCTIONS

CHART - 2100KG TOWING SYSTEMS

STICKER - TYRE PLACARD

STICKER - OWNER'S HANDBOOK

HEAT SHIELD - CENTRE BEARING(V6/V8, DISCARD SHIELD

WHICH IS NOT REQUIRED).

92053240

SP3878

92049407

FD809

FD825

M40752

92053241/92047132

1

1

2

1

2

2

2

2

2

2

2

2

3

3

3

4

4

4

2

2

2

4

6

6

6

1

1

1

1

1

1

1

2

1

7

2

1

1

1

1

1/1

M40964

FD809

15JL99

COPYRIGHT

Page 12 of 12

FD809-12a

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

HSPO2-SH.CDR

M41536

M41535

PACKAGE - AUTO TRANS FLUID COOLER (V6) or

PACKAGE - AUTO TRANS FLUID COOLER (V8)

MANDATORY TO FIT FOR SERIES 1 ONLY,

IF EXTERNAL AUTO TRANS FLUID COOLER IS NOT ALREADY FITTED :