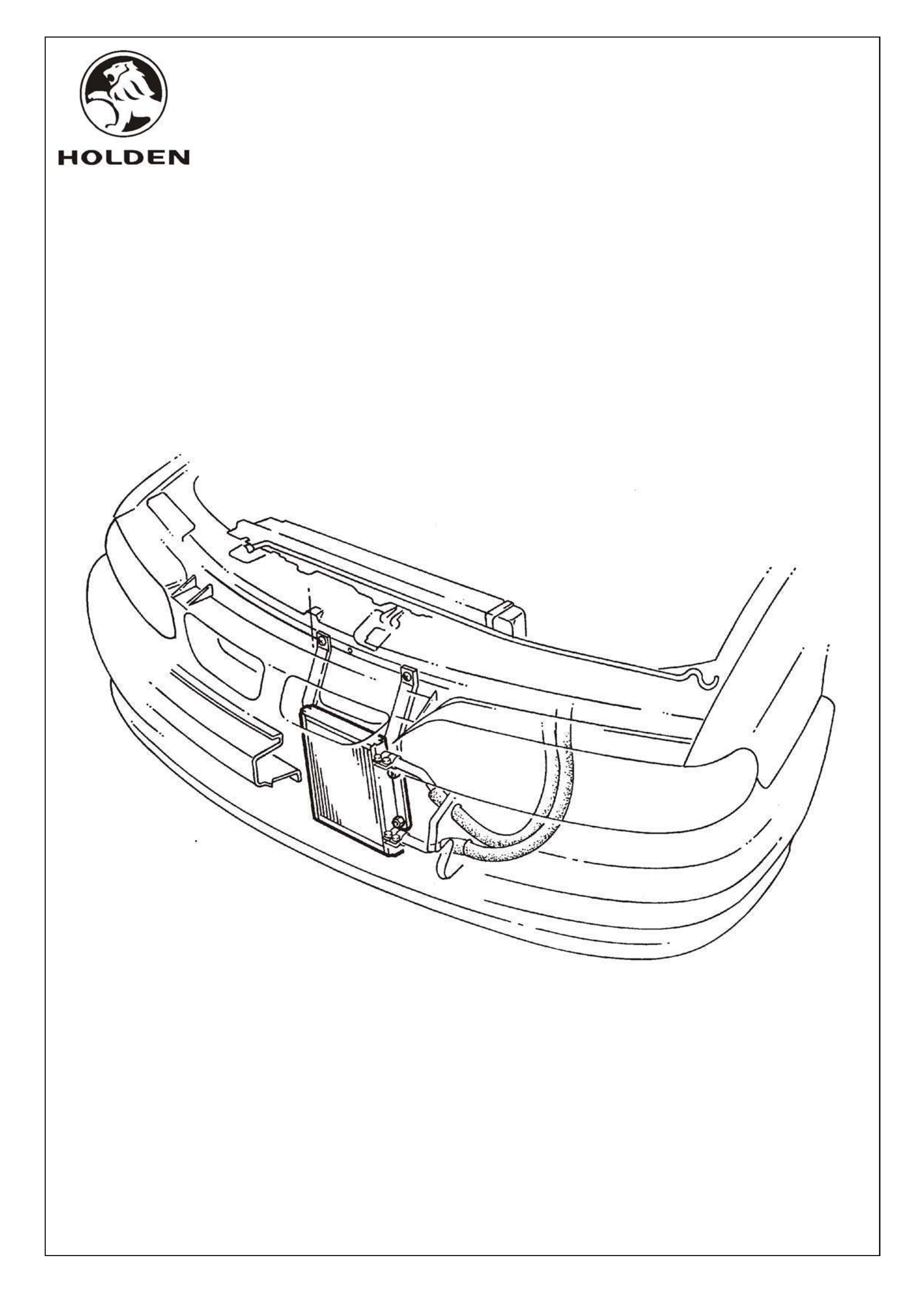

FITTING INSTRUCTIONS FOR

VS TRANSMISSION OIL COOLER PACKAGE (V8)

Part Number M41535

FD824

15JL98

COPYRIGHT

Page 1 of 4

3207a-01

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

1

25,0 - 12,0Nm

1,0 - 3,0Nm

A

VIEW

DRILL 3.9 DIA. HOLE

(2 PLACES)

SCREW

SP2058

(2 PLACES)

NUT

11065574

(4 PLACES)

OIL COOLER

92041215

RELOCATE

BRACKET

EXISTING MOUNTING

BRACKET HOLES

NOTE: CLEAN ALL

CONTAMINANTS, OIL

AND DIRT AROUND

UNUSED HOLES.

APPLY METAL PRIMER,

DULUX EPOXY PRIMER

SURFACER (DEPS)

410-39790 (BLACK), OR

EQUIVALENT NEATLY

AROUND HOLES.

80.5

112.0

2

1

A-A

SECTION

FRONT

BUMPER

SUPPORT

GRILLE

FRONT MEMBER ASM.

- LOWER

FRONT

AIR DAM

A

C

L

A

A

C

L

OF

CAR

TIGHTEN THIS CLAMP FIRST

4,0 MAX

(BETWEEN TABS

AFTER

TIGHTENING)

TIGHTEN THIS CLAMP SECOND

VIEW B

1,0 - 2,0

B

CLAMP

11093191

(4 PLACES)

FD824

15JL98

COPYRIGHT

Page 2 of 4

3207a-02

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

V8 TRANSMISSION OIL COOLER PACKAGE

FITTING INSTRUCTIONS

1. Disconnect battery negative terminal.

2. Remove grille and front air dam, refer VS Service Manual Volume 1.

3. Mark screw hole locations for new position of inboard transmission oil cooler bracket,

one hole in front panel upper and one hole in front member lower, refer view A, and drill

3.9mm dia. holes.

4. Disconnect both oil cooler hoses from existing external tranmission oil cooler. Plug

or cover hose ends, to prevent loss of transmission oil.

NOTE: Do not allow contaminants to enter cooler hoses while detached from oil cooler.

5. Remove existing oil cooler from two mounting brackets.

6. Remove inboard mounting bracket. Fix bracket at new location using self tapping

screws (SP2058) and torque screws 1,0 - 3,0Nm.

NOTE: Outboard oil cooler bracket does not require removal.

7. Clean all contaminants, oil and dirt from around holes left from previous oil cooler

inboard mounting bracket screws. Apply metal primer, Dulux Epoxy Primer Surfacer

(DEPS) 410-39790 (Black) or equivalent neatly around holes.

8. Fit new larger oil cooler (92041215) to mounting brackets with nuts (11065574).

Torque nuts 5,0 - 12,0Nm.

9. Reconnect oil cooler hoses to new oil cooler using two new clamps (11093191) on each

hose end. Position the two clamps together 1,0 - 2,0mm from end of hose and tighten

in correct sequence, refer view B. Clamp furthest from hose end is to be tightened first.

After tightening, clamps must have less than 4,0mm between tabs, refer view B.

10. Check transmission oil level (cold) before starting engine.

11. Reconnect battery negative terminal.

12. Run engine, select all gears through transmission. Check oil cooler hose connections

to oil cooler for leaks. Check transmission oil level when at operating temperature,

top up if neccessary.

NOTE: Transmission should require top up of oil due to new larger capacity oil cooler.

13. Reinstall grille and front air dam, refer VS Service Manual Volume 1.

FD824

15JL98

COPYRIGHT

Page 3 of 4

3207a-03

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

V8 TRANSMISSION OIL COOLER PACKAGE

PARTS LIST

PART NUMBER DESCRIPTION QUANTITY

92041215 TRANSMISSION OIL COOLER 1

SP2058 SELF TAPPING SCREW 2

11065574 NUT 4

11093191 CLAMP 4

FD824

15JL98 Figure x

COPYRIGHT

Page 4 of 4

3207a-04

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232