IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all motor vehicles.

The service procedures recommended by HOLDEN Ltd A.C.N. 006 893 232 and

described in this publication are effective methods for performing service operations.

Some of these service operations require the use of tools specially designed for the

purpose. The special tools should be used when and as recommended.

It is important to note that some warnings against the use of specific service methods that

can damage the vehicle or render it unsafe are stated in this publication. It is important to

understand these warnings are not exhaustive HOLDEN Ltd could not possibly know,

evaluate and advise the service trade of all conceivable ways in which service might be

done or of all the possible hazardous consequences of each way. Consequently HOLDEN

Ltd has not undertaken any such broad evaluation. Accordingly, anyone who uses a

service procedure or tool which is not recommended HOLDEN Ltd, must first be

thoroughly satisfied that neither personal safety nor vehicle safety will be jeopardised by

the service method selected.

HOLDEN

VX SERIES COMMODORE AND CALAIS

V6 SEDAN AFTERSALES LPG KIT

INSTALLATION INSTRUCTIONS

FOREWORD

The information in these installation instructions, when

used in conjunction with the VX Series Service Information

will provide installation procedures for the HOLDEN Ltd

approved aftersales LPG kit for VX Series vehicles with V6

engine and automatic transmission.

THE INSTALLATION INSTRUCTIONS AND SERVICE

PROCEDURES DETAILED IN THIS BOOKLET ARE

BASED ON USING THE APPROVED HOLDEN QUALITY

REPLACEMENT PARTS AVAILABLE FROM

AUTHORISED HOLDEN PARTS OUTLETS.

The Table of Contents on this page enables the user to

locate the numeric identifier for each Section. In addition,

numeric identifiers are used to signify the individual

operations within the Sections.

A list of installation tools, where required, is also included

in Sections 5.

Installation Tools, unless otherwise specified, are available

from:

IMPCO TECHNOLOGIES.

1 - 3 Taunton Drive

Cheltenham, Vic 3192

All correspondence to:

PO Box 45,

Cheltenham, Vic 3192

Telephone: (03) 9584 5644

Fax. (03) 9583 0696

HOLDEN Ltd does not endorse, prefer, or assume

responsibility for the products of this firm nor for any such

items which may be available from other makers.

All information, illustrations and specifications contained in

this Booklet are based on the latest product information

available at the time of publication approval. The right is

reserved to make changes at any time without notice.

ISSUED: FEBRAURY 2001

PRINTED IN AUSTRALIA

TABLE OF CONTENTS

1 LPG INSTALLATION

INSTRUCTIONS

2 LPG LEAK TESTING

3 TECH 2 LPG SET-UP & ENABLE

PROCEDURES

4 LPG AFTER INSTALLATION

CHECK

5 LPG INSTALLATION TOOLS

6 PARTS LIST

HOLDEN Ltd A.C.N. 006 893 232

SERVICE DEPARTMENT

COPYRIGHT - HOLDEN Ltd

Reproduction in whole or in part prohibited without written approval

NOTES

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

LPG INSTALLATION INSTRUCTIONS 1-1

SECTION 1

CAUTION:

This vehicle is equipped with a Supplemental Restraint System (SRS). A SRS will consist of either seat belt pre-

tensioners and a driver’s side airbag, seat belt pre-tensioners and a driver’s and front passenger’s airbags or

seat belt pre-tensioners, a driver’s, front passenger’s and left and right hand side airbags for the front

occupants. Refer to CAUTIONS, Section 12M, in the VX Series Service Information before performing an y service

operation on or around SRS components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible personal injury or unnecessary SRS system repairs.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is disturbed during Service

Operations, it is vital that the complete ABS or ABS/ETC system is checked, using the procedure as detailed in 4

DIAGNOSIS, ABS or ABS/ETC FUNCTION CHECK, in Section 12L ABS & ABS/ETC, in the VX Series Service

Information.

LPG INSTALLATION INSTRUCTIONS

CONTENTS

Ref. Subject Page Ref. Subject Page

1.1 GENERAL INFORMATION............................ 1-1

1.2 SAFETY PRECAUTIONS............................... 1-2

1.3 SEQUENCE OF INSTALLATION................... 1-3

1.4 COMPONENT REMOVAL.............................. 1-3

1.5 REAR COMPARTMENT PREPARATION...... 1-4

1.6 ENGINE BAY PREPARATION....................... 1-5

1.7 LPG HARNESS INSTALLATION................... 1-6

1.8 LPG HARNESS INTERIOR ROUTING &

FUEL MODE SWITCH INSTALLATION ........ 1-7

1.9 LPG CYLINDER INSTALLATION.................. 1-9

1.10 FILLER INSTALLATION................................ 1-12

1.11 INTERMEDIATE SERVICE LINE

INSTALLATION.............................................. 1-13

1.12 FRONT SERVICE LINE INSTALLATION ...... 1-14

1.13 CONVERTOR INSTALLATION...................... 1-16

1.14 COOLANT HOSE INSTALLATION ................1-17

1.15 MIXER INSTALLATION..................................1-18

1.16 AIR CLEANER INSTALLATION.....................1-20

1.17 EMERGENCY DECKLID RELEASE CABLE

EXTENSION ...................................................1-21

1.18 REAR SPRING INSTALLATION ....................1-22

1.19 COMPLIANCE PLATES & ID. LABELS –

INSTALLATION..............................................1-22

1.20 LEAK TEST ....................................................1-24

1.21 TECH 2 LPG SET-UP & ENABLE

PROCEDURES...............................................1.24

1.22 COMPONENT REINSTALLATION.................1-24

1.23 AFTER INSTALLATION CHECK....................1-24

1.24 ENABLE THE SRS & AUDIO SYSTEMS.......1-24

1.1 GENERAL INFORMATION

LPG INSTALLATION INSTRUCTIONS 1-1

The following Liquefied Petroleum Gas (LPG) installation

instructions apply to the Holden approved Aftersales LPG

Installation Kit, which can be fitted to all VX Series sedans

with V6 engine and automatic transmission.

This LPG kit must be fitted in accordance with these

installation instructions if the vehicle is to conform to

Australian Standard AS 1425 - 1999 and ADR 44/02.

Automotive LPG is a hydrocarbon fuel and consists primarily

of propane (60% - 90%) and butane (40% - 10%). The

propane to butane mix varies depending on the source and

manufacturing location. This gives LPG an octane rating of

approximately 110 RON.

Pure LPG is colourless, odourless and tasteless, however

commercial LPG has a pungent odour to enable LPG to be

detected by a human. This pungent odour is achieved by

adding a chemical to the LPG to enable a human to detect the

LPG at concentrations of LESS than 0.5% by volume in air.

LPG boils at approximately -40°C at atmospheric pressure,

this means that the LPG must be pressurised to

approximately 750 kPa to maintain it in a liquid state.

1-2 LPG INSTALLATION INSTRUCTIONS

1.2 SAFETY PRECAUTIONS

• DO NOT smoke or allow naked flames, or any

ignition source near the vehicle.

• LPG must NEVER be allowed to come in contact

with any part of the body. Due to the very low

boiling point of LPG, it readily absorbs heat from

its surroundings, or any surface it comes into

contact with when released into the atmosphere.

LPG can cause severe frostbite if it is allowed to

come into contact with the human body.

• When working on the LPG system, suitable

protective clothing including gloves and safety

goggles MUST be worn to prevent personal injury.

• LPG in the vapour form is highly flammable and in

the interests of safety, the LPG system should be

leak tested and isolated by turning “OFF” the

manual service valve and draining service lines of

LPG before any service work is carried out on the

vehicle.

• During servicing, the man ual service valve must be

turned “OFF” at all times and the service lines

drained of LPG, except w hen th e gas is required to

be available for servicing or testing of the LPG

system.

• Any servicing or testing of the LPG system must

be performed by accredited personnel in a

“Specialist Gas Workshop” in accordance with

Australian Standards AS 2746 - 1985 and AS 1425 -

1989.

• Never disconnect the battery from the vehicle's

electrical system while the engine is running.

• Never disconnect or connect the SDM connector

with the ignition turned on.

• Disconnecting the battery WILL NOT immediately

deactivate the SRS. A residual energy reserve in

the SDM is incorporated to enable the pre-

tensioners and air bag/s to deploy in the event of a

battery failure. The SDM has the power to deploy

the air SRS for up to 10 seconds after the battery

has been disconnected or the ignition turned o ff.

• The SDM can maintain sufficien t voltage to cause a

deployment for up to 10 seconds after the ignition

switch is turned OFF or the battery is

disconnected. Many of the service operations

require disconnection of the battery to avoid an

accidental deployment of the pre-tensioners or air

bag/s.

1.3 SEQUENCE OF INSTALLATION

The following sequence is suggested for the LPG installation:

1. Component Removal: All components must be removed as

required to allow access to the various parts of the vehicle for the

LPG conversion.

2. Body Panel Modification: Holes are drilled or cut in preparation for

running the filler and service lines, vent tubes and the new wiring

harness.

3. The LPG wiring harness is installed in the vehicle.

4. Fuel Mode Switch fitted to instrument panel facia.

5. LPG Tank and Service Line Installation: The LPG tank is bolted-in

and the filler and service lines installed.

6. Engine Compartment Installation: Components such as the

convertor, mixer, fuel control valve and air cleaner are fitted into

the engine compartment to complete the LPG system.

7. Emergency decklid release cable extension is installed.

8. Rear Springs Installation: The new rear springs are fitted which

allow for the increased weight at the rear.

9. Labels and Plates Installed: The required labels and ID plates are

fitted.

10. Leak Test: The system is checked for gas leaks.

11. TECH 2 LPG set-up & enable procedures are performed.

12. Component Replacement: All removed components are replaced

on the vehicle.

13. Post Installation Check: The checklist is completed.

LPG INSTALLATION INSTRUCTIONS 1-3

1.4 COMPONENT REMOVAL

1. Disconnect both the battery earth and power leads and wait at

least 10 seconds before performing any work on the vehicle. This

operation disables the SRS.

2. Remove engine dress cover.

(Refer Section 6A1-1 in the VX Series Service Information)

3. Remove intake airflow duct and mass air flow sensor.

(Refer Section 6A1-1 in the VX Series Service Information)

4. Remove air cleaner assembly and discard. Retain mounting bolts.

(Refer Section 6C1-3 in the VX Series Service Information)

5. Remove audio system.

NOTE: The PIN security code wil be required.

(Refer Section 12D in the VX Series Service Information)

6. Remove transmission console.

(Refer Section 1A3 in the VX Series Service Information)

7. Remove instrument panel lower cover, RHS.

(Refer Section 1A3 in the VX Series Service Information)

8. Remove LH and RH centre facia side extension trims.

(Refer Section 1A3 in the VX Series Service Information)

9. Remove instrument panel compartment, (LHS).

(Refer Section 1A3 in the VX Series Service Information)

10. Remove instrument panel facia.

(Refer Section 1A3 in the VX Series Service Information)

11. Remove instrument cluster.

(Refer Section 12C in the VX Series Service Information)

12. Remove rear seat cushion and rear seat back.

(Refer Section 1A7 in the VX Series Service Information)

13. Remove rocker panel cover, RHS.

(Refer Section 1A1 in the VX Series Service Information)

14. Remove shroud lower trim assembly, LHS and RHS.

(Refer Section 1A1 in the VX Series Service Information)

15. Remove lower B-pillar trim assembly, RHS.

(Refer Section 1A8 in the VX Series Service Information)

16. Remove rear compartment carpet and wheelhouse trim RHS.

(Refer Section 1A1 in the VX Series Service Information)

17. Remove fuel filler door.

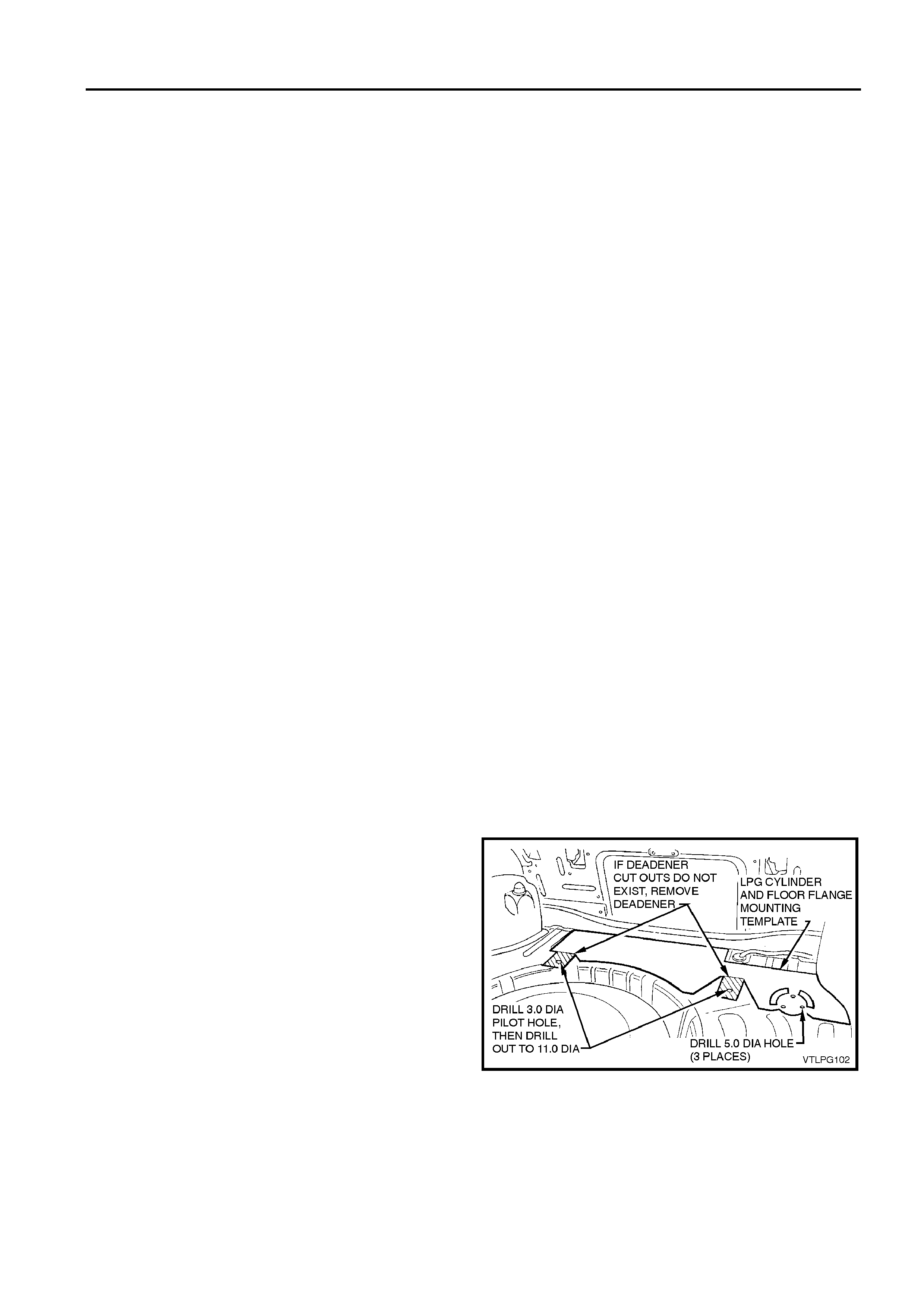

1.5 REAR COMPARTMENT

PREPARATION

1. Where required, remove deadener from floor panel

using the template supplied to determine correct

location.

NOTE: Heat and soften deadener with a hot air gun to aid

removal.

2. Locate the dimples in the floor for positions of the two

tank mounting holes. Drill two 3.0 mm pilot holes

through the panel, and then drill each hole out to

11.0 mm.

NOTE 1: Care must be taken when drilling the RHS tank

mounting hole in the rear floor as there is a wiring loom

located directly beneath the drilling location. Use a drill

spacer or other means to limit the depth of the drill travel.

NOTE 2: If dimples do not exist, use template to mark two

tank mounting hole positions.

3. Apply anti-corrosion compound meeting HOLDEN Ltd

Specification HN1071 around perimeter of all holes

drilled in rear floor panel and allow to cure.

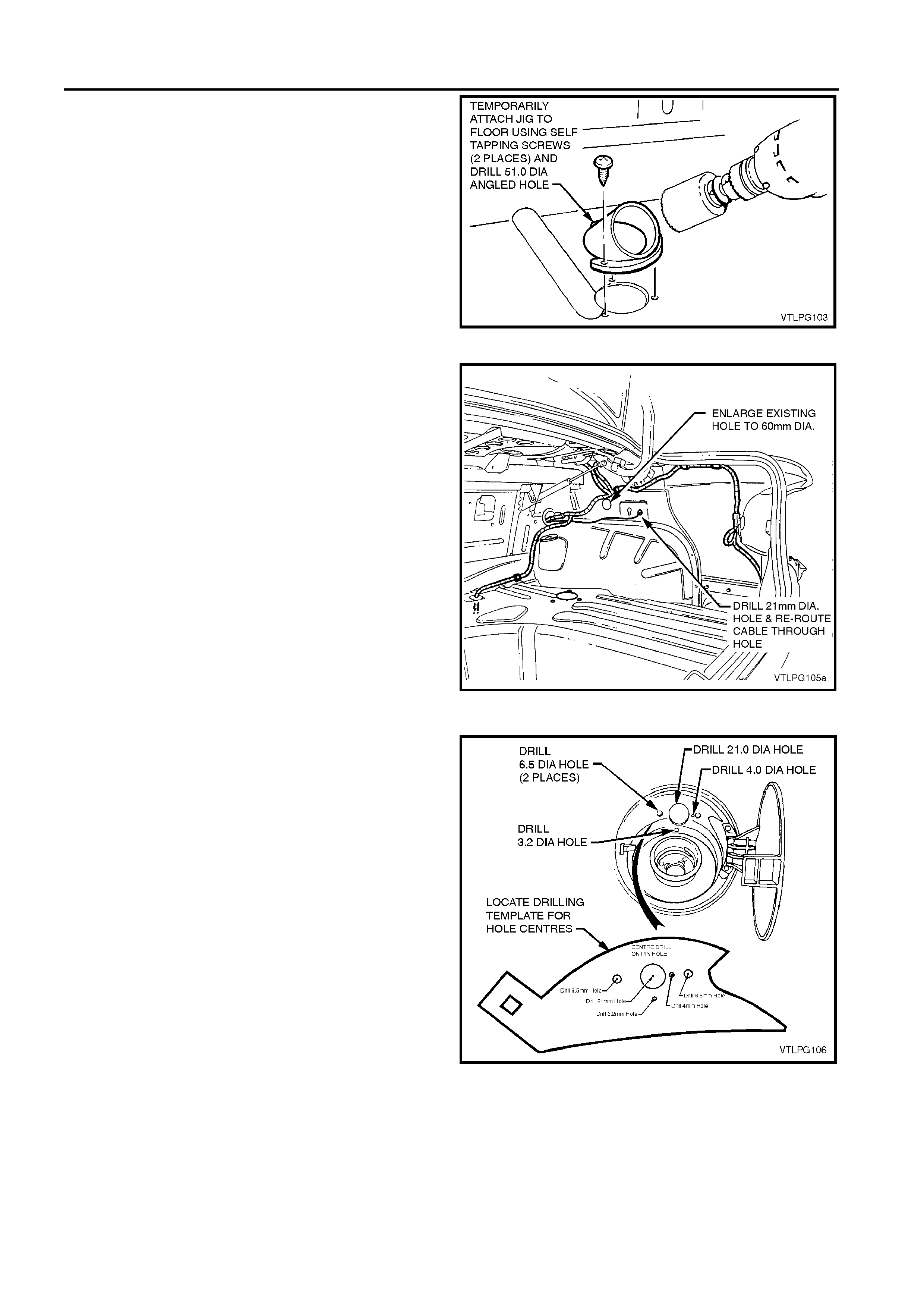

Figure 1-1

1-4 LPG INSTALLATION INSTRUCTIONS

4. Mark and drill three 5.0mm holes for mounting floor

flange. Use template to determine position.

5. Using drilling jig special tool, drill the 51.0 mm angled

hole in the rear floor panel.

6. Apply anti-corrosion compound meeting HOLDEN Ltd

Specification HN1071 around perimeter of all holes

drilled in rear floor panel and allow to cure.

Figure 1-2

7. Drill 21.0 mm hole in side panel as shown. Location is

determined by the existing marking on panel.

8. Remove fuel filler door remote cable from existing hole

and re-route through new hole.

9. Enlarge existing hole in side panel (formerly used for

fuel filler door cable) as shown, to 60.0 mm.

10. Apply anti-corrosion compound meeting HOLDEN Ltd

Specification HN1071 around perimeter of all holes

drilled in rear side panel and allow to cure.

NOTE: Limit drilling depth when drilling the 60.0mm hole

through inner side panel to avoid damage to outer side

panel.

Figure 1-3

11. Using template to determine the locations, drill holes in

top of fuel filler pocket as shown.

12. Apply anti-corrosion compound meeting HOLDEN Ltd

Specification HN1071 around perimeter of all holes

drilled in fuel filler pocket and allow to cure.

Figure 1-4

LPG INSTALLATION INSTRUCTIONS 1-5

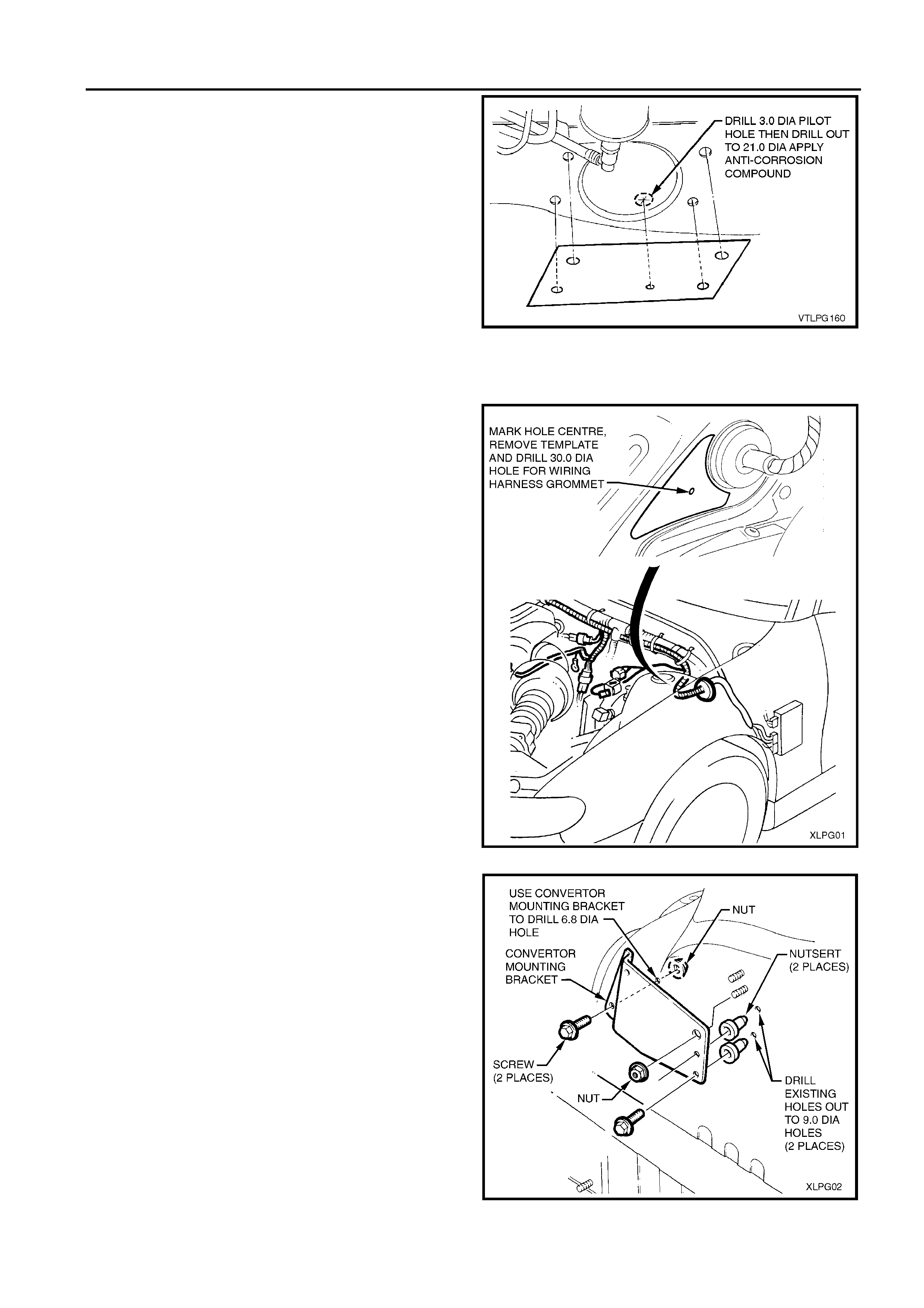

13. Using template supplied, mark position of rear service

line hole in chassis rail, and drill 3.0mm pilot hole. Drill

out to 21.0mm using hole saw.

14. Apply anti-corrosion compound meeting HOLDEN Ltd

Specification HN1071 around perimeter of holes.

Figure 1-5

1.6 ENGINE BAY PREPARATION

1. Locate template provided on dash panel, on LHS of

engine bay and drill 6.0 mm pilot hole. Cut hole out to

30.0 mm with hole saw as shown.

2. Remove body deadener from inner side of dash panel

and apply anti-corrosion compound meeting Holden

Specification HN1071 around perimeter of hole. Allow to

cure.

Figure 1-6

3. Enlarge two existing holes in wheelhouse, as indicated,

by drilling out to 9.0 mm. Fit supplied nutserts to holes.

4. Using the convertor bracket as a template, drill 6.8 mm

hole as shown.

5. Apply anti-corrosion compound meeting HOLDEN Ltd

Specification HN1071 around perimeter of all holes

drilled in wheelhouse and allow to cure.

Figure 1-7

1-6 LPG INSTALLATION INSTRUCTIONS

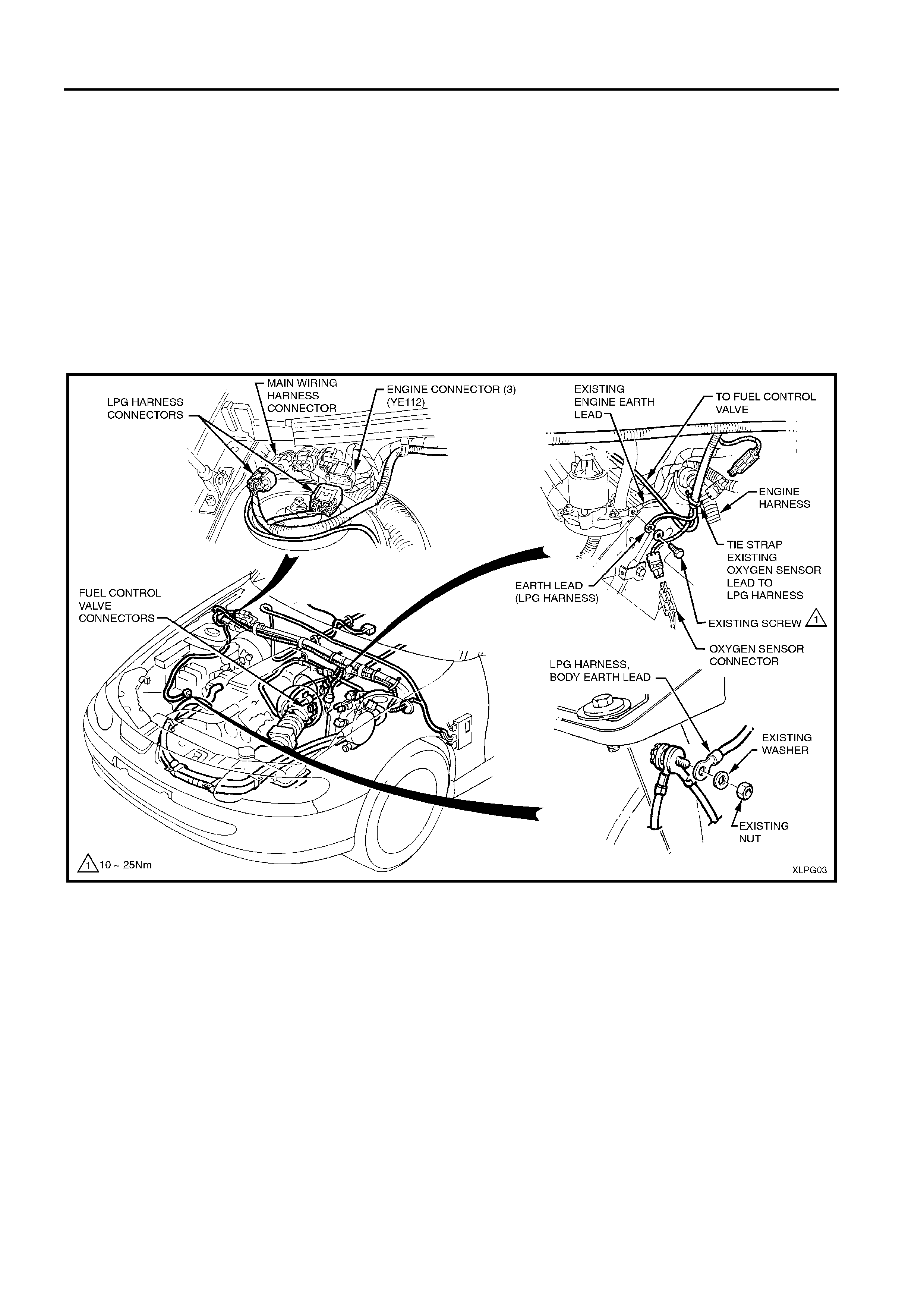

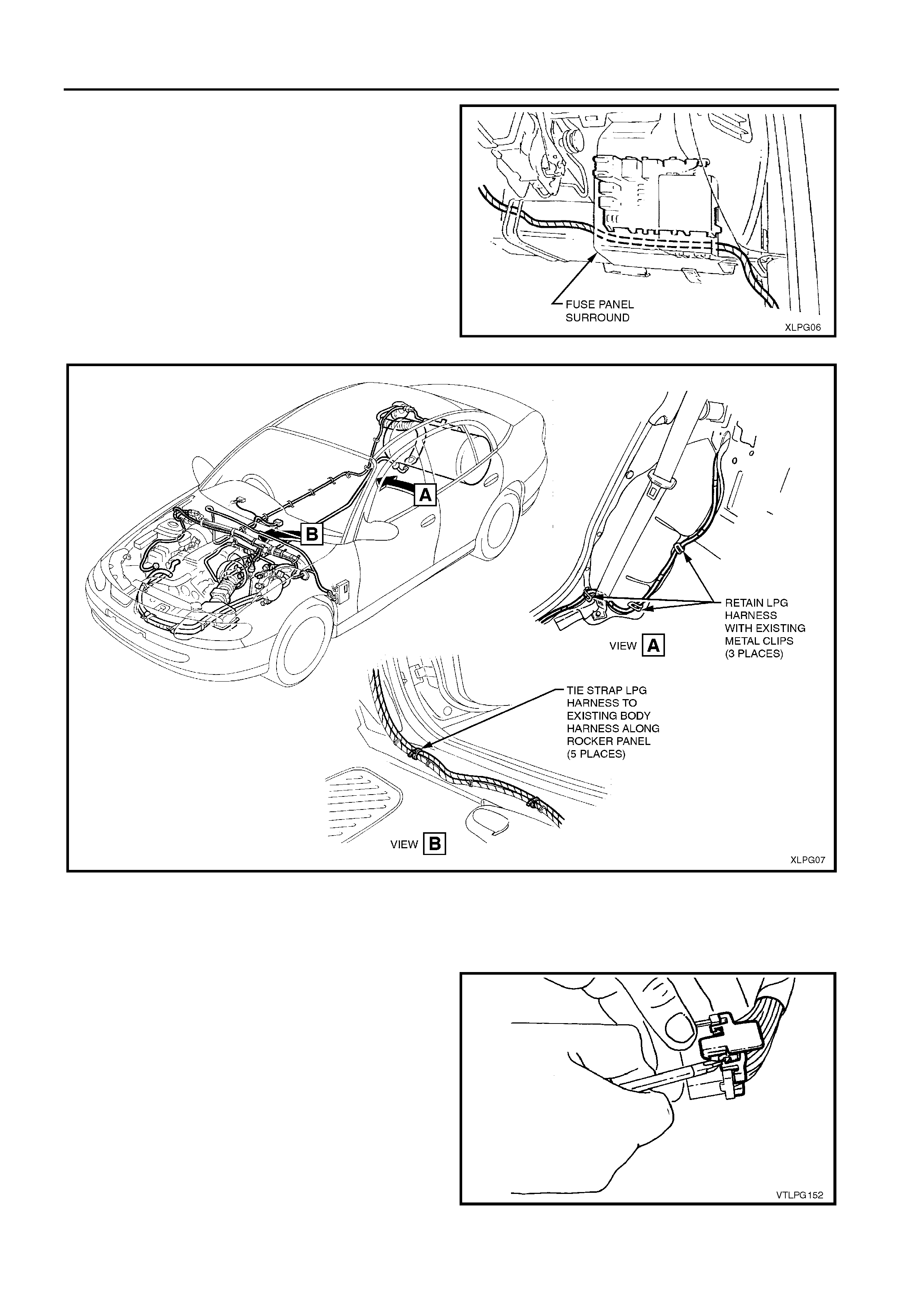

1.7 LPG HARNESS INSTALLATION

1. Insert the interior section of the LPG harness through

30mm hole in dash panel from engine compartment

side. Install harness grommet into dash panel.

2. Route the engine compartment section along the top

edge of the cockpit module, underneath existing main

wiring harness.

3. Insert the LPG harness to existing wiring harness clips

on RHS (2 places) and tie strap to existing harness LHS

(3 places) as shown in Figure 1-8.

4. Install the LPG engine earth lead to the existing harness

earth lead at the rear of the LH cylinder head. Tighten

retaining bolt to 10 – 25 Nm.

5. Disconnect LH oxygen sensor connector and connect

LPG harness connector into LH oxygen sensor harness

connector and engine harness connector, route harness

and install cable ties as shown in Figure 1-8.

6. Route LPG harness fuel control valve connector to fuel

control valve location ready for connection.

7. Disconnect engine harness connector from main wiring

harness. Connect LPG harness connectors into main

harness connector and engine harness connector as

shown in Figure 1-8.

8. Route LPG harness body earth lead between RH strut

tower and wiring harness former, and around under side

of former to existing body earth point on the ABS

mounting bracket as shown in Figure 1-8.

Figure 1-8

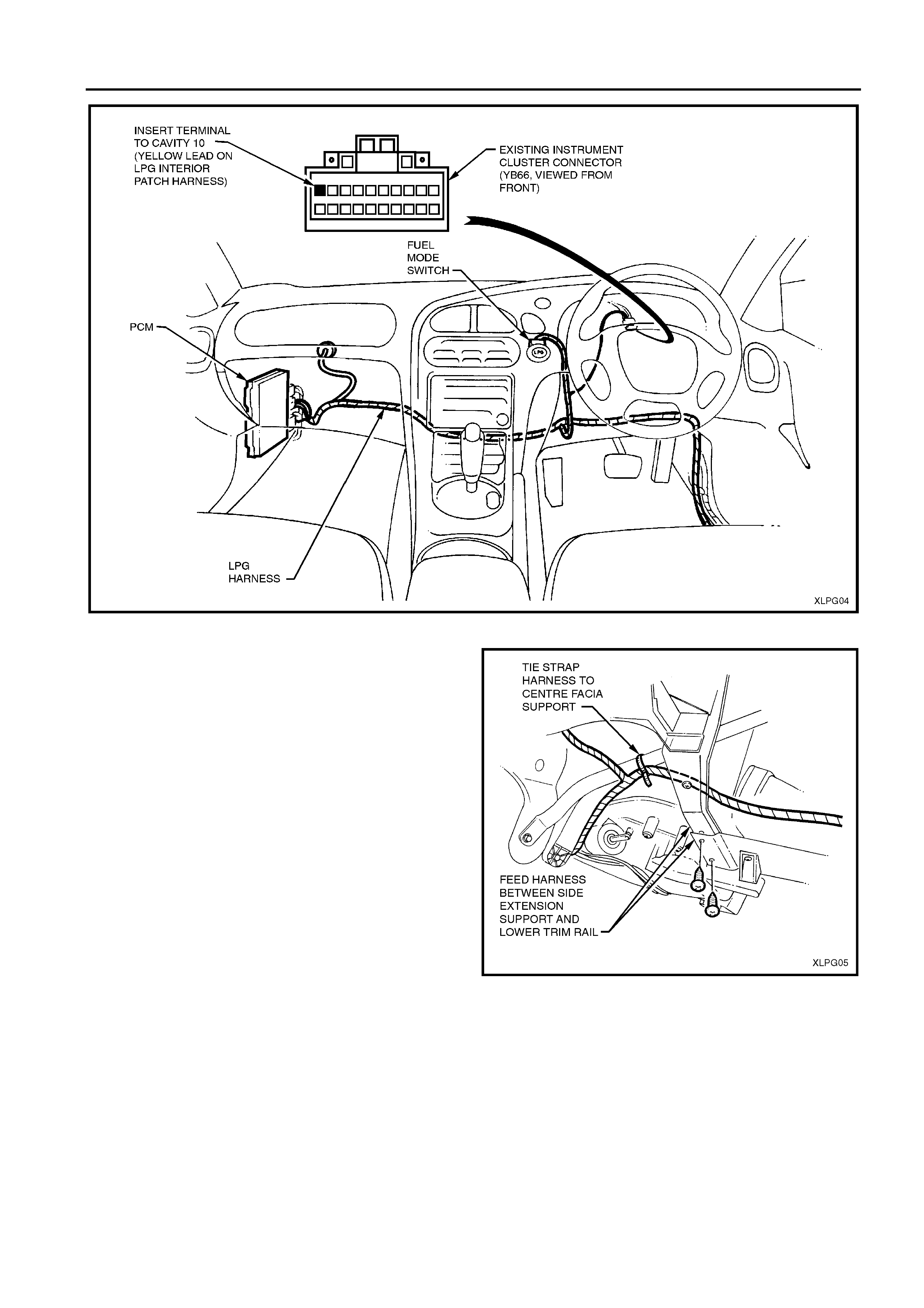

1.8 LPG HARNESS INTERIOR ROUTING

& FUEL MODE SWITCH INSTALLATION

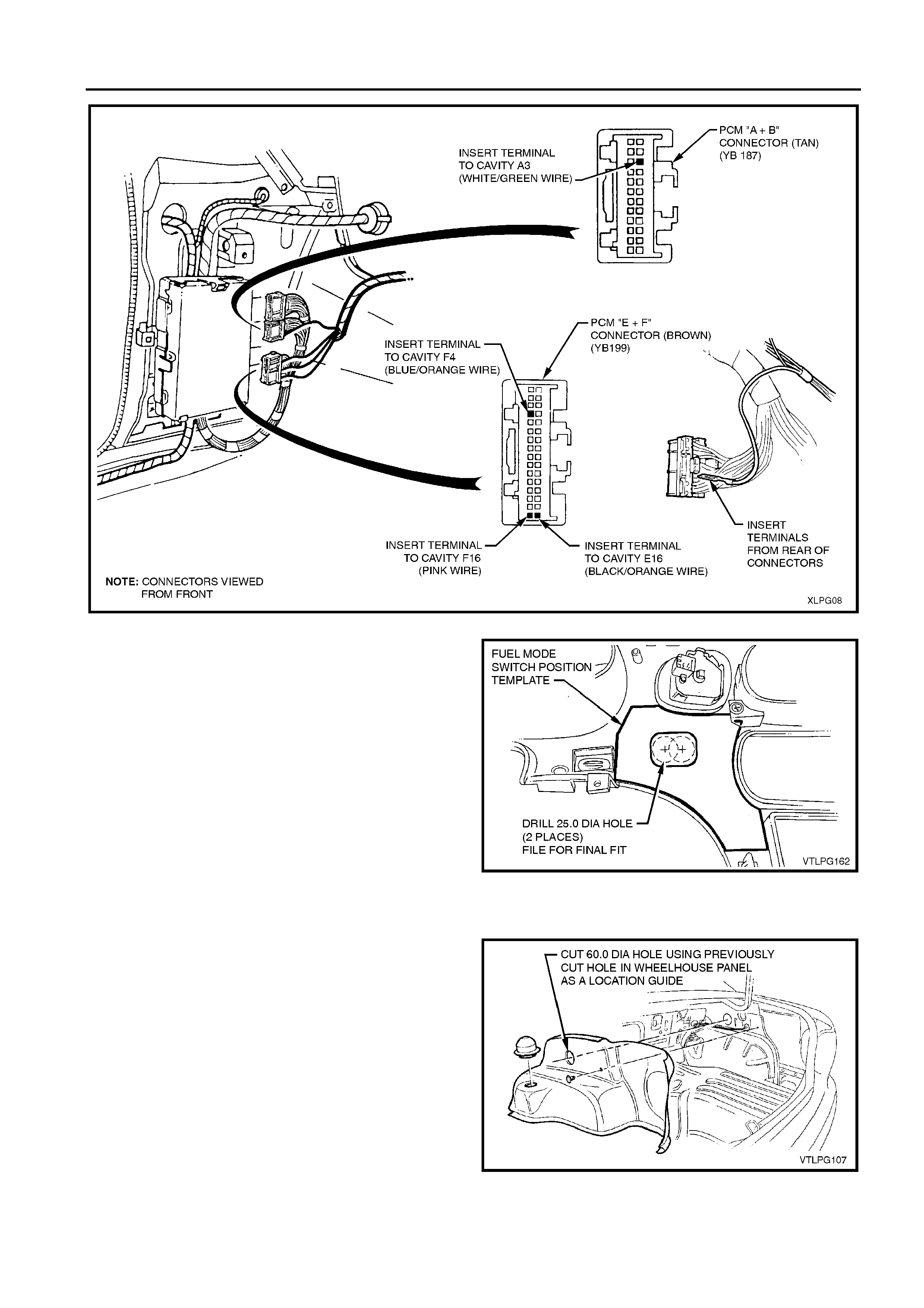

1. Install the interior section of the LPG harness from PCM

connections (behind LHF lower side trim) towards RHF

lower side trim, routing behind centre console.

2. Feed fuel mode switch connector and yellow lead, up

through centre facia, refer illustration.

3. Connect yellow wire to instrument cluster connector in

the No. 10 cavity.

LPG INSTALLATION INSTRUCTIONS 1-7

Figure 1-9

4. Remove two screws securing lower trim rail to centre

facia side extension support.

5. Feed the harness between lower trim rail and centre

facia side extension support and position behind centre

facia side extension support as shown in Figure 1-10.

Tie strap the harness to centre facia support.

Figure 1-10

1-8 LPG INSTALLATION INSTRUCTIONS

6. Route the harness behind the fuse block, until protective

sleeve locates behind fuse block.

7. Route the harness behind RHF lower side trim, along

RH rocker panel and around inner wheel arch, through

existing body harness retaining clips, as shown in Figure

1-12.

8. Cable tie the harness to the existing body harness,

(along rocker panel).

9. Feed the harness through the large hole in body, into

the rear compartment as shown in Figure 1-12, ready for

connection to the LPG cylinder anti-theft harness.

Figure 1-11

Figure 1-12

10. Make any necessary adjustments to the LPG harness

positioning, then return to PCM location for connections

to PCM.

11. Remove the PCM and disconnect wiring connectors.

12. Remove covers from ‘E & F’ connector, (tan).

13. Remove covers from ‘A & B’ connector, (brown).

Figure 1-13

LPG INSTALLATION INSTRUCTIONS 1-9

Figure 1-14

18. Position Fuel Mode Switch Template on rear side of

instrument panel facia and mark area to be cutout.

19. Drill pilot hole and trim instrument panel facia carefully

to suit Fuel Mode Switch. Use Fuel Mode Switch to test

fitment.

NOTE: Use extreme caution when trimming instrument panel

facia as the visual surface of instrument panel facia can be

easily damaged.

Figure 1-15

1.9 LPG CYLINDER INSTALLATION

1. Refit wheelhouse trim in position, and using the existing

60.0mm hole in side panel as a guide, mark hole onto

trim. Remove trim and cut hole. Install grommet into

inner panel.

2. Refit wheelhouse trim.

Figure 1-16

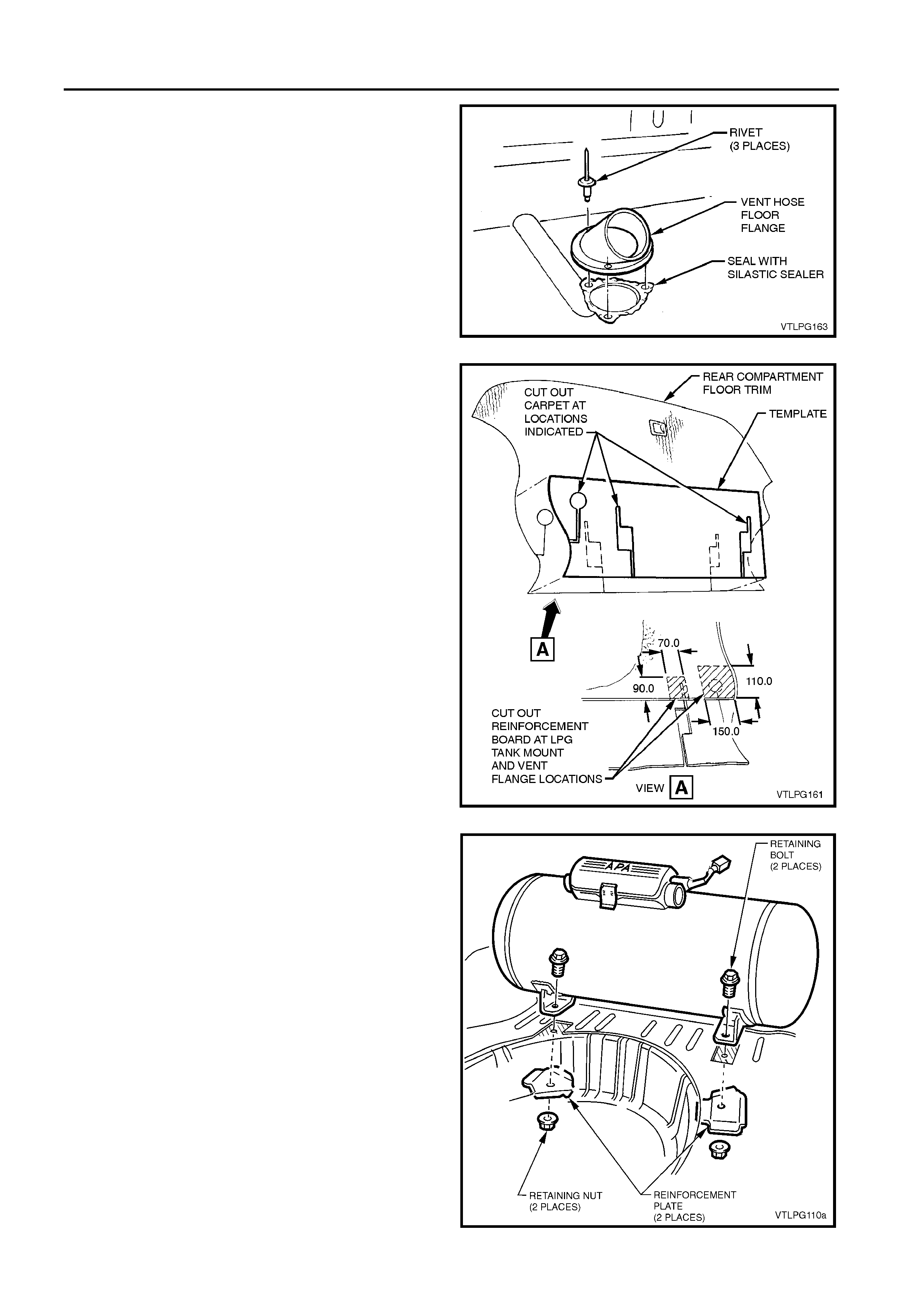

1-10 LPG INSTALLATION INSTRUCTIONS

3. Apply a bead of silicone sealer meeting HOLDEN Ltd

Specification HN1886 around the base of vent hose

flange.

4. Attach vent hose floor flange in position on RHS of rear

compartment floor using three rivets.

Figure 1-17

5. Position rear floor trim template onto rear floor trim,

mark and trim carpet as shown in Figure 1-18.

6. From back side of trim, cut backing board away at tank

and vent hose floor flange locations as shown in Figure

1-18, View A.

7. Refit rear floor trim.

Figure 1-18

8. Place the LPG cylinder in position on rear compartment

floor panel and install the two rear cylinder retaining

bolts.

Figure 1-19

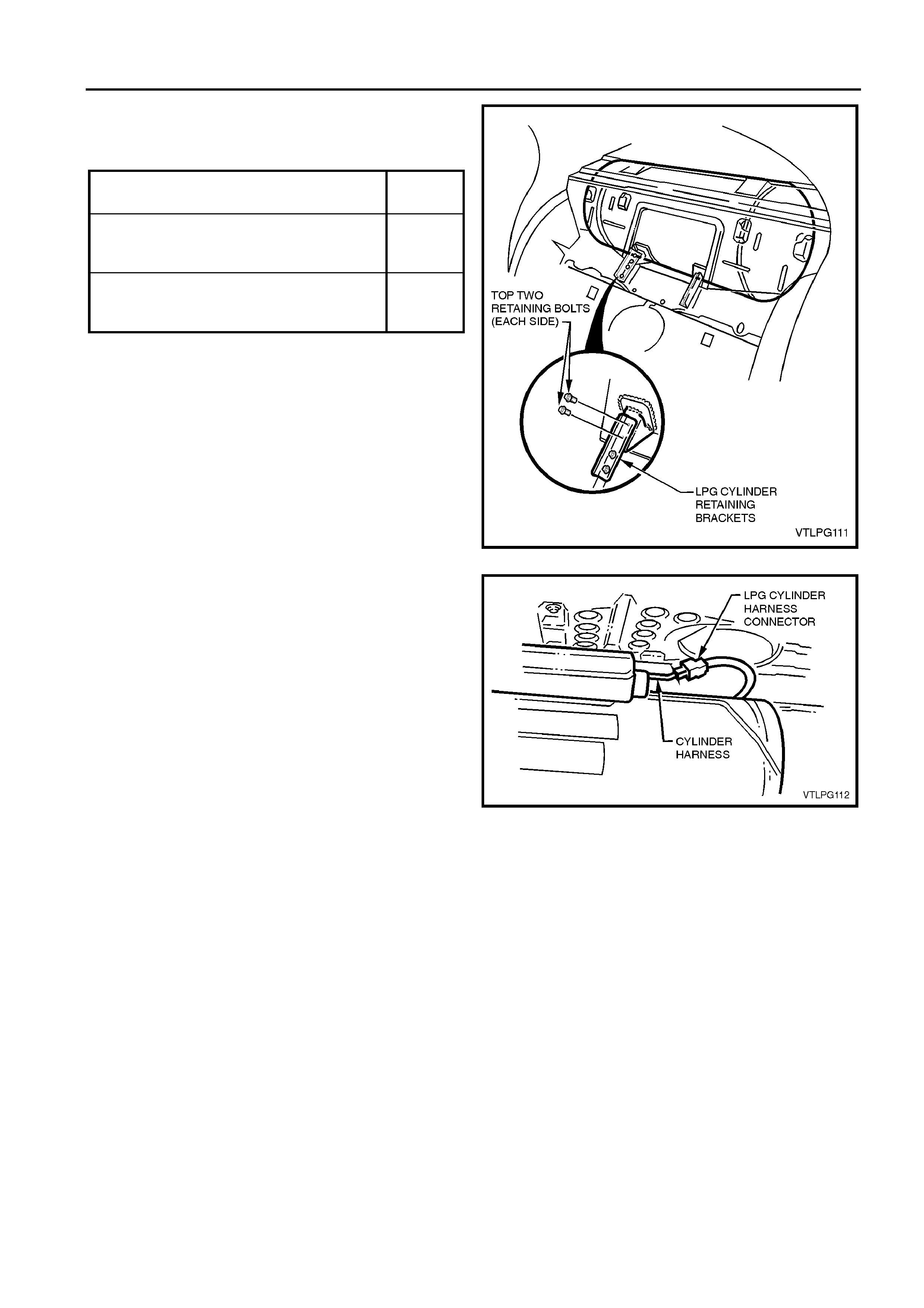

LPG INSTALLATION INSTRUCTIONS 1-11

9. Install two front brackets as shown.

10. Tighten all LPG cylinder mounting bolts to the specified

torques.

Figure 1-20

11. Connect LPG cylinder anti-theft wiring harness to the

LPG harness.

Figure 1-21

LPG CYLINDER REAR RETAINING NUT

TORQUE SPECIFICATION 70 - 90

Nm

TANK BRACKET TO REAR FLOOR

RETAINING BOLT

TORQUE SPECIFICATION 25 - 35

Nm

TANK BRACKET TO LPG TANK

RETAINING BOLT

TORQUE SPECIFICATION 10 - 12

Nm

1-12 LPG INSTALLATION INSTRUCTIONS

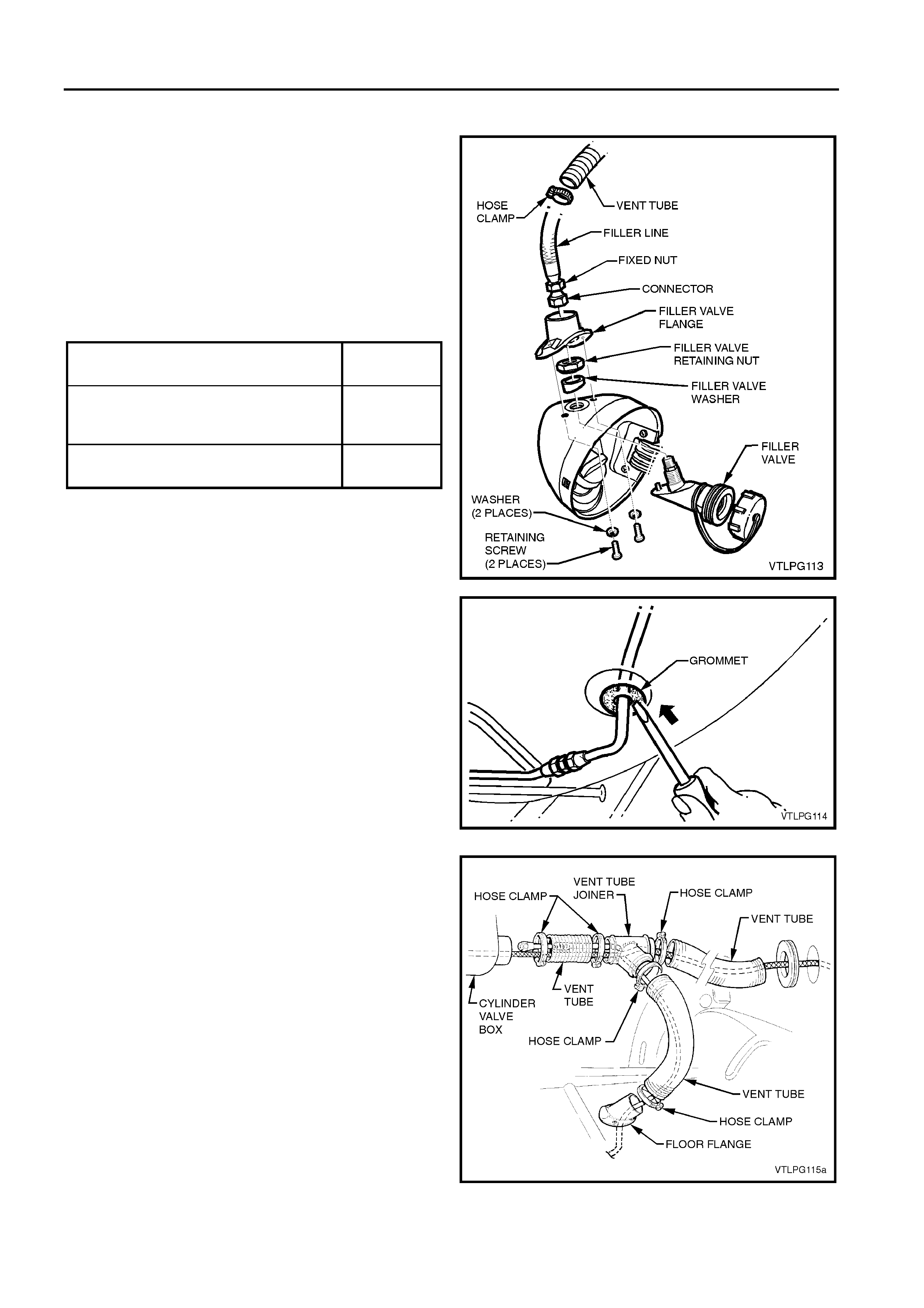

1.10 FILLER INSTALLATION

1. Install filler valve through hole in fuel filler pocket and

secure with nut and tapered spacer. Tighten nut to

specified torque.

2. Apply a bead of silicone sealer meeting HOLDEN Ltd

Specification HN1886 to the base of vent tube flange.

3. Install the filler vent tube flange to the fuel filler pocket.

Tighten the attaching screws to the specified torque.

4. Apply Loctite 577 sealant to filler valve threads and

attach the filler tube, tightening the fitting to the specified

torque.

5. Feed the filler tube through to the rear compartment.

Figure 1-22

6. Install service line through vent hose flange and feed

through hole in rear longitudinal.

7. Refit service line grommet from underneath vehicle.

Figure 1-23

8. Install the vent tubes, clamps and joiner, piece by piece,

over the service line and filler tube, drawing the service

line and filler tube through into the cylinder valve box.

Figure 1-24

FILLER VALVE NUT

TORQUE SPECIFICATION 50 - 60 Nm

FILLER VENT TUBE FLANGE

RETAINING SCREW

TORQUE SPECIFICATION

25 - 35 Nm

FRONT SERVICE LINE CONNECTOR

TORQUE SPECIFICATION 10 - 12 Nm

LPG INSTALLATION INSTRUCTIONS 1-13

9. Apply Loctite 577 sealant to the AFL valve threads and

the filler valve

10. Ensuring the flared surfaces are free of sealer and

contaminates, attach the service line and the filler line,

tightening them to the correct torque specifications.

Figure 1-25

11. Tighten vent tube hose clamps to the correct torque

specification.

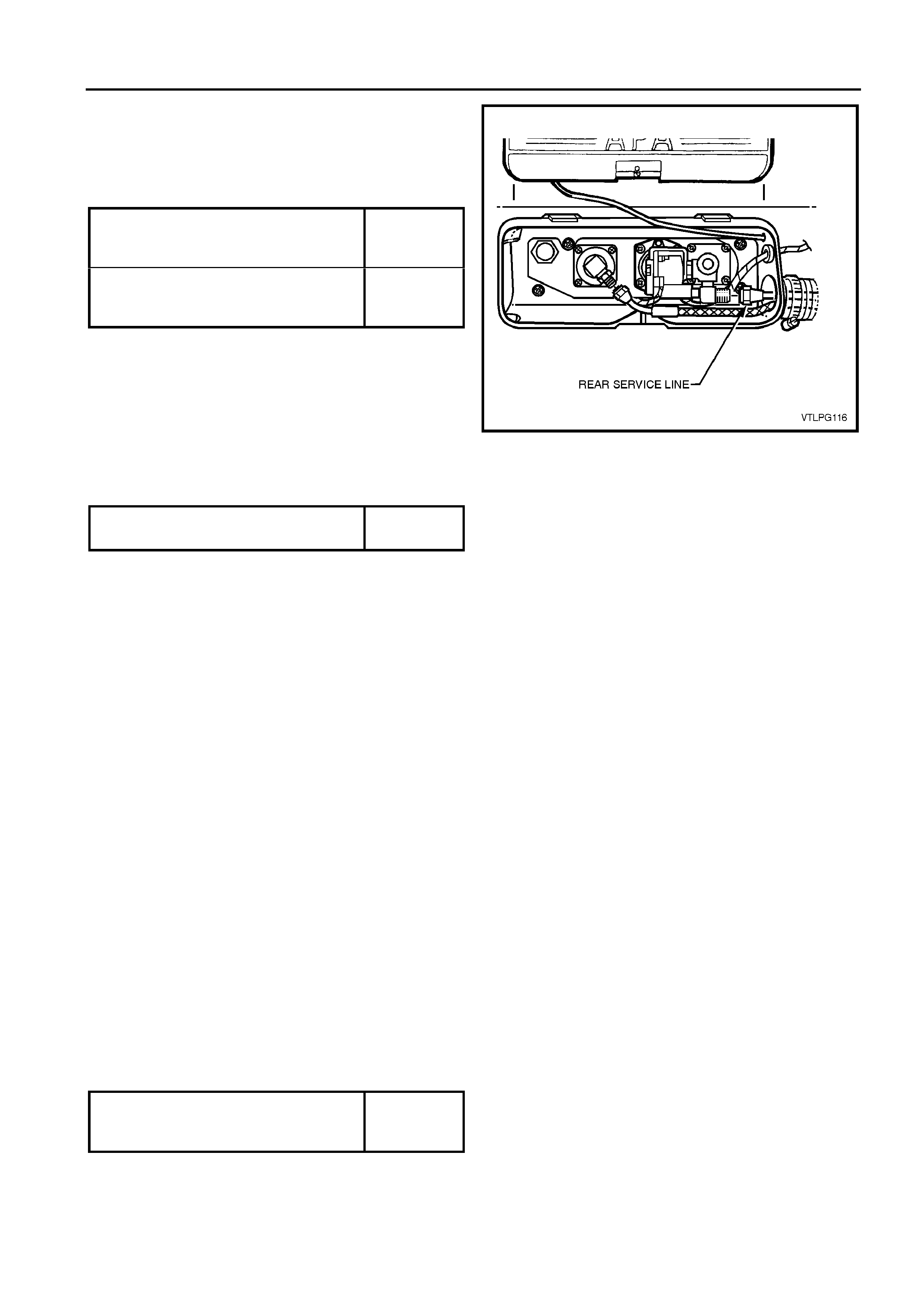

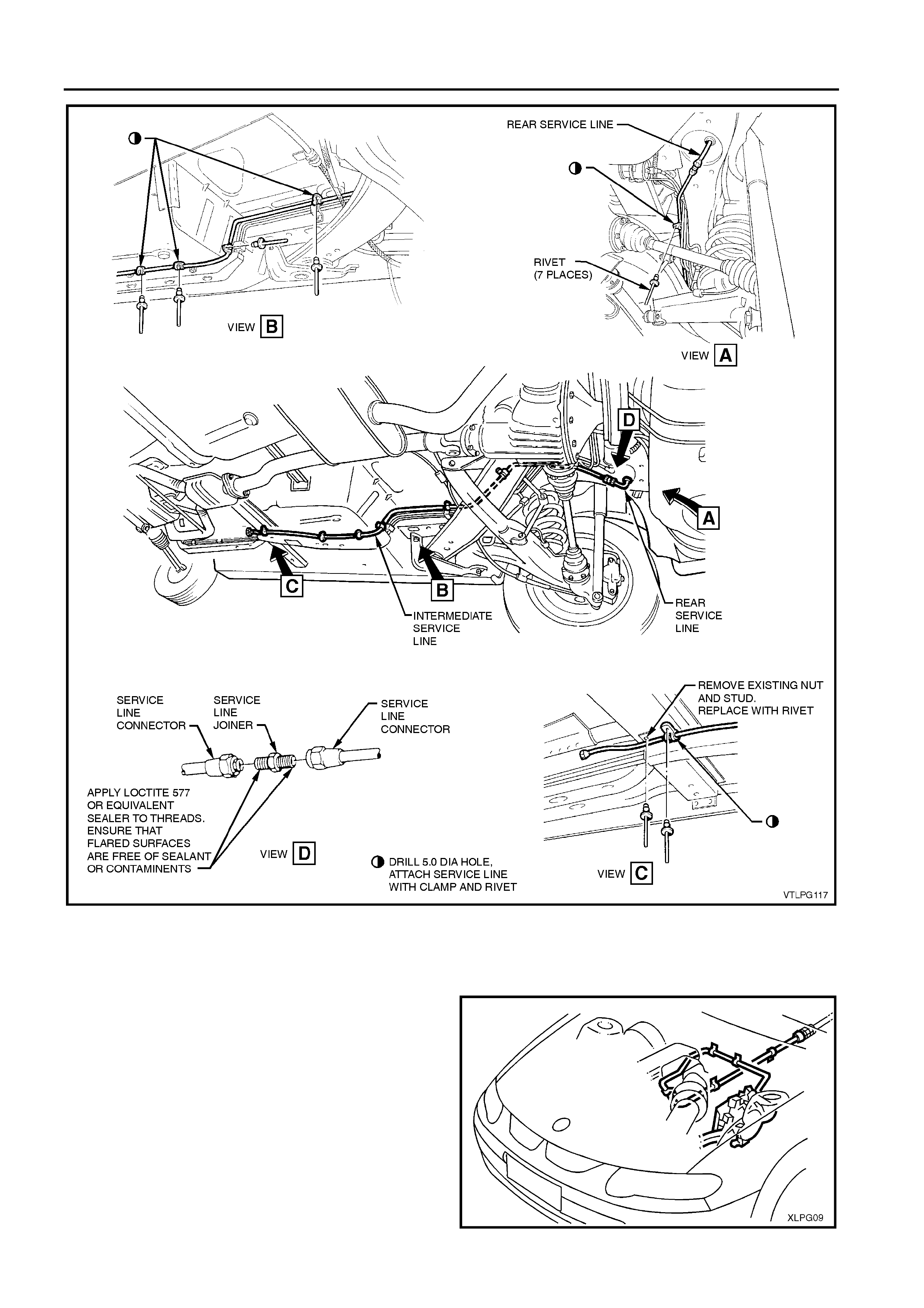

1.11 INTERMEDIATE SERVICE LINE

INSTALLATION

1. From underneath the vehicle, place the intermediate

service line in position, feeding the line from the front,

over the handbrake cable, rear suspension and axle

assembly.

2. Attach temporarily to rear service line as shown in View

A, Figure 1-26.

3. Attach service line to floor with mounting clamps

supplied. Drill 5 mm holes and rivet to rear floor in a

position as shown in View A, Figure 1-26.

4. Attach to rear floor in two places and alongside stone

shield in two places using clamps and rivets supplied, as

shown in View B, Figure 1-26.

5. Remove front inner nut and stud from stone shield and

replace with pop rivet to alleviate clearance problem

with service line. Attach service line to crossmember

with clamp and pop rivet as shown in View C, Figure

1-26.

6. Disconnect intermediate service line from rear service

line at coupling.

7. Disconnect intermediate service line from rear service

line at coupling.

8. Apply Loctite 577 sealant to the intermediate to rear

service line joiner threads, ensuring the flared surfaces

are free of sealant and contaminants, refer View D,

Figure 1-26.

9. Reassemble the connections and tighten to the correct

torque specifications.

FILLER LINE TO AFL VALVE

CONNECTION

TORQUE SPECIFICATION

12 - 18 Nm

REAR SERVICE LINE TO TANK

SERVICE VALVE

TORQUE SPECIFICATION

12 - 18 Nm

VENT TUBE HOSE CLAMP

TORQUE SPECIFICATION 1.0 - 3.0 Nm

INTERMEDIATE SERVICE LINE TO

REAR SERVICE LINE

TORQUE SPECIFICATION

12 - 18 Nm

1-14 LPG INSTALLATION INSTRUCTIONS

Figure 1-26

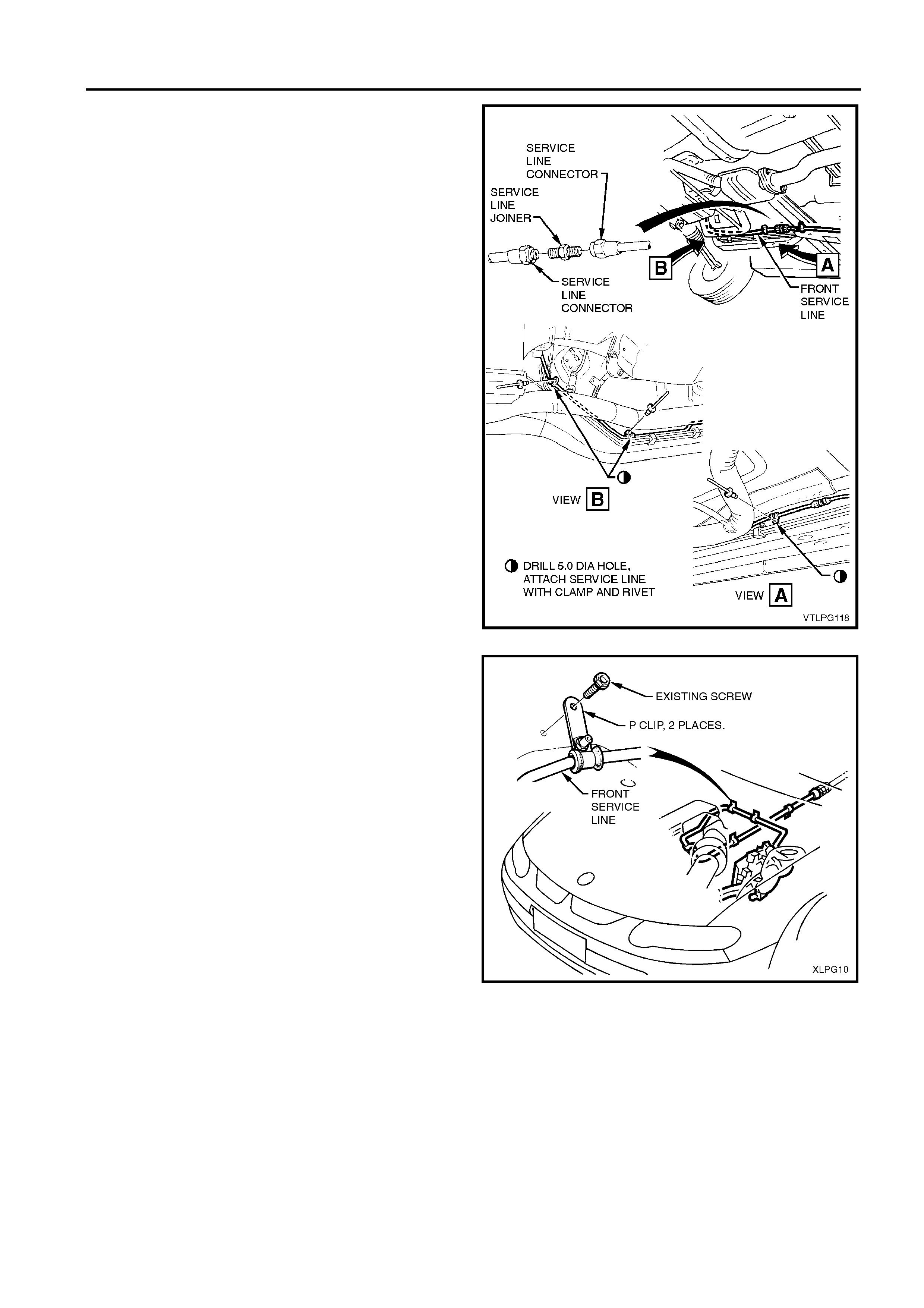

1.12 FRONT SERVICE LINE

INSTALLATION

1. Remove longitudinal brace. Refer VX Series Service

Information.

2. From under the vehicle, feed the front service line into

the engine compartment.

3. From above, position the front service line across the

rear of the engine compartment, to the LH side of the

engine compartment.

Figure 1-27

LPG INSTALLATION INSTRUCTIONS 1-15

4. From under the vehicle, temporarily attach the front

service line to the intermediate line.

5. Attach the line to the longitudinal in two places and to

the front floor extension in one place as shown, using

clamps and pop rivets supplied.

Figure 1-28

6. Attach the front service line to the firewall in two places

as shown, using clips supplied and existing hardware.

Figure 1-29

1-16 LPG INSTALLATION INSTRUCTIONS

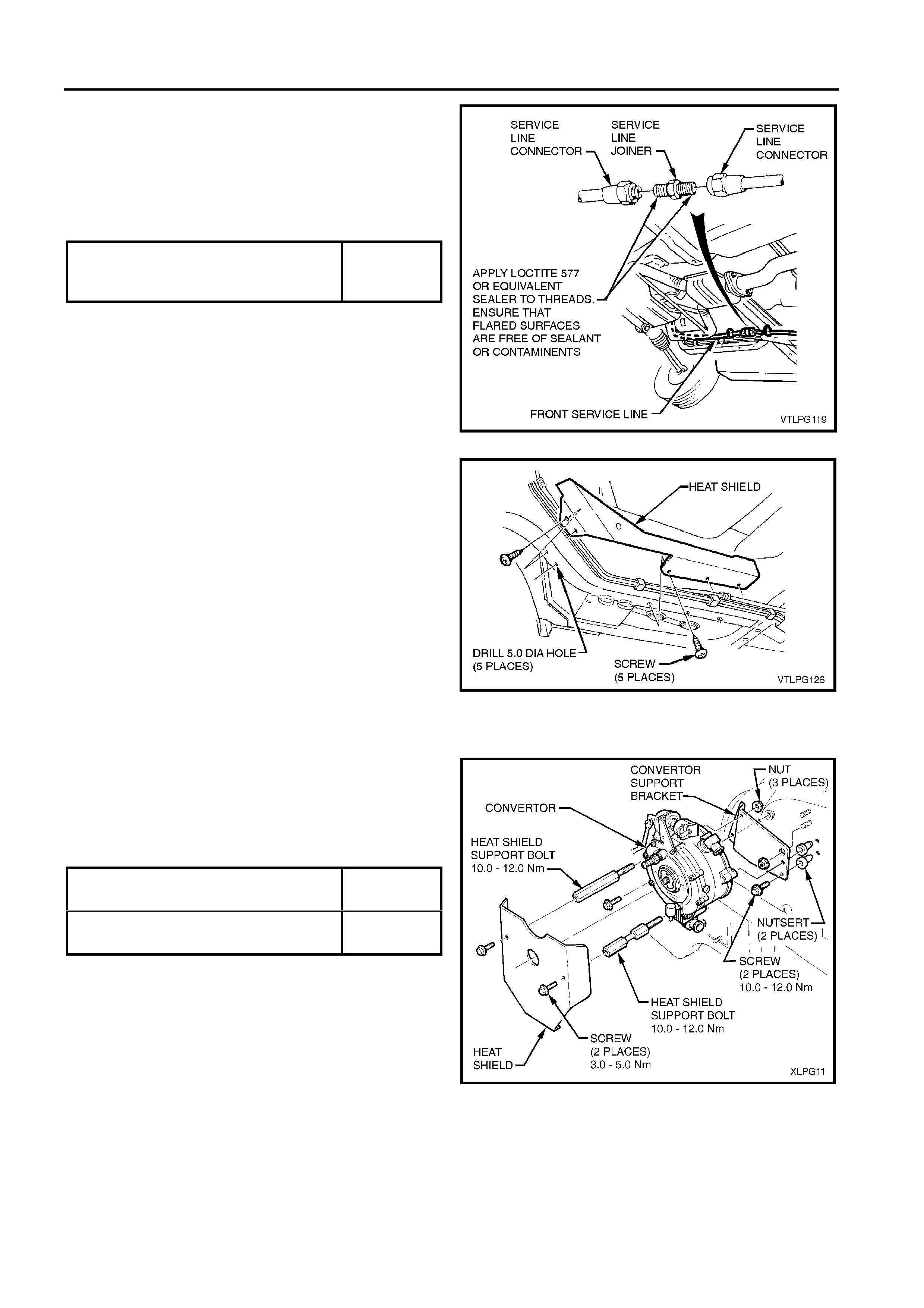

7. Disconnect front service line from intermediate service

line.

8. Apply Loctite 577 sealant to the front to intermediate

service line joiner threads, ensuring the flared surfaces

are free of sealant and contaminates.

9. Reconnect and tighten the connections to the correct

torque specifications.

Figure 1-30

10. Position heat shield on vehicle as shown and mark

locations of mounting holes. Refer Fig. 1-31.

11. Drill 3.5mm holes where marked.

12. Attach heat shield with screws as shown.

Figure 1-31

1.13 CONVERTOR INSTALLATION

1. Assemble convertor mounting bracket and convertor to

wheelhouse as shown.

2. Tighten all bolts and nuts to the specified torque.

3. Attach convertor heat shield as shown and tighten the

two mounting bolts to the specified torque.

Figure 1-32

FRONT SERVICE LINE TO

INTERMEDIATE SERVICE LINE

TORQUE SPECIFICATION

12 - 18 Nm

CONVERTOR MOUNTING BOLTS

TORQUE SPECIFICATION 10 - 12 Nm

HEAT SHIELD MOUNTING BOLTS

TORQUE SPECIFICATION 3.0 - 5.0 Nm

LPG INSTALLATION INSTRUCTIONS 1-17

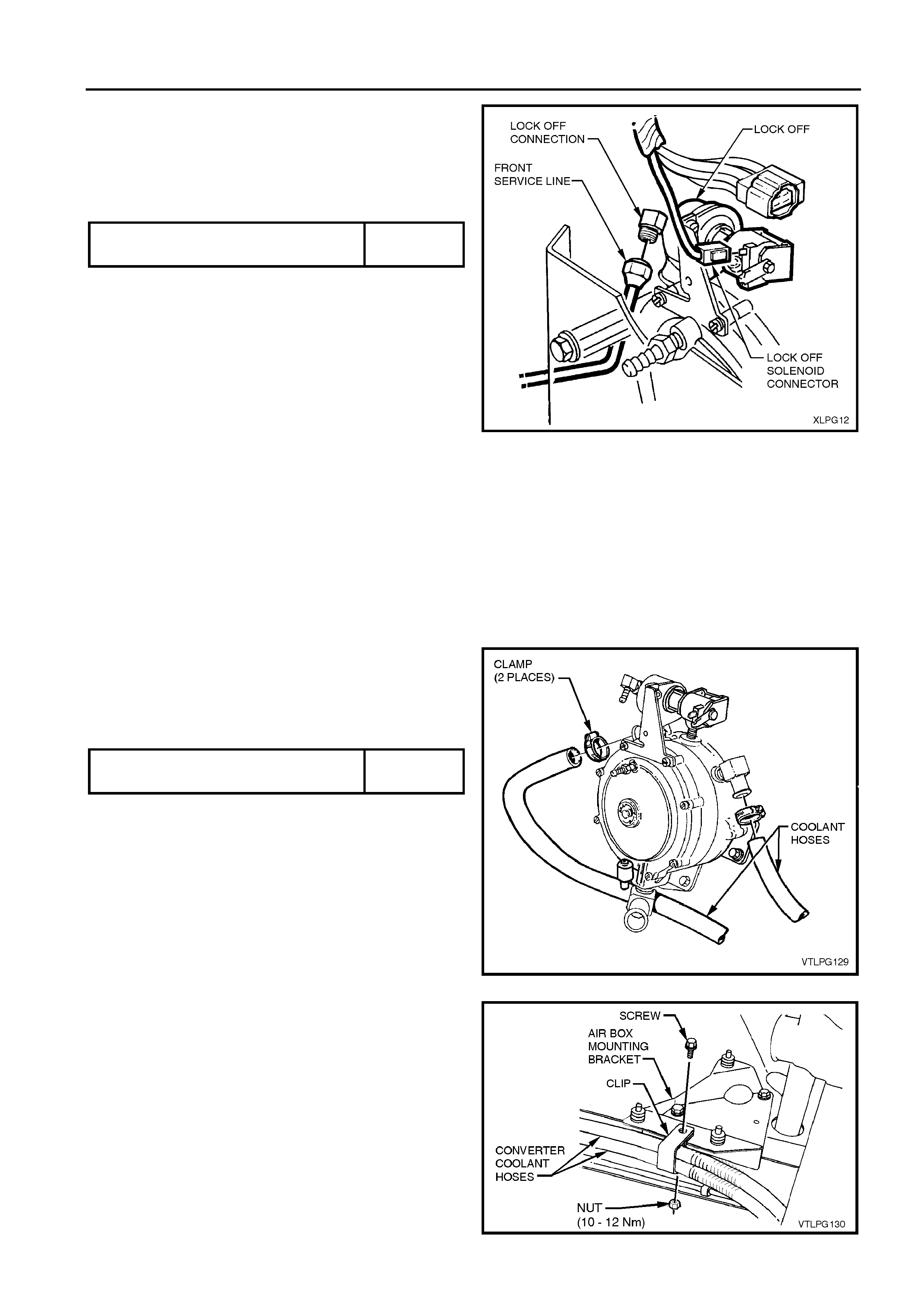

4. Apply Loctite 577 sealant to the front service line joiner

and lock-off valve inlet threads, ensuring the flared

surfaces are free of sealant and contaminates.

5. Tighten the connections to the correct torque

specifications.

6. Attach wiring harness connector to lock-off solenoid.

Figure 1-33

1.14 COOLANT HOSE INSTALLATION

1. Allow cooling system to cool to ambient temperature

(less than 50°c), then remove radiator cap.

CAUTION: DO NOT REMOVE RADIATOR CAP WHILE

THE ENGINE COOLANT TEMPERATURE IS ABOVE

50°C, AS PERSONAL INJURY MAY RESULT.

2. Place drain tray beneath vehicle.

3. Remove and discard coolant hose from heater valve to

engine coolant inlet.

4. Route coolant hoses from LPG convertor. Route one

hose to engine coolant inlet and the other to heater

valve.

5. Fit hose clamps to the coolant hoses and tighten to the

correct torque specification.

Figure 1-34

6. Install the coolant hose with retaining bracket to existing

hole in the air cleaner mounting bracket using bolt and

nut provided. Refer Figure 1-35. Tighten nut to the

specified torque. Note convoluted protector shields on

coolant hoses.

NOTE: For this step to be completed, installation of the air

cleaner mounting bracket is required. Refer to

Operation 1.16 in this Section.

Figure 1-35

COOLANT HOSE CLAMP TORQUE

SPECIFICATION 3.0 - 4.0 Nm

FRONT SERVICE LINE TO LOCK-OFF

VALVE TORQUE SPECIFICATION 10 - 12 Nm

1-18 LPG INSTALLATION INSTRUCTIONS

7. Mark the two coolant hose bracket retaining bolt hole

centres below the radiator in the front crossmember.

Each hole is located 150 mm from the centreline

(denoted by a hole in the crossmember). Drill two 3.5

mm holes at these points.

8. Attach hoses, including convoluted protector shields as

shown. Screw brackets to front crossmember with self-

tapping screws, tightening to specified torque.

Figure 1-36

9. Position coolant hoses in retaining bracket on the RHF

longitudinal in the position shown. Refer Fig. 1-37. Drill

3.5 mm hole in longitudinal and attach retaining bracket

with self-tapping screw as shown. Tighten screw to the

correct torque specification. Note convoluted protector

shields on coolant hoses.

Figure 1-37

10. Check coolant hose routing to ensure hoses do not foul.

11. Fill, bleed and pressure test cooling system. Refer to

Section 6B1-1 ENGINE COOLING - V6 ENGINE, in the

VX Series Service information.

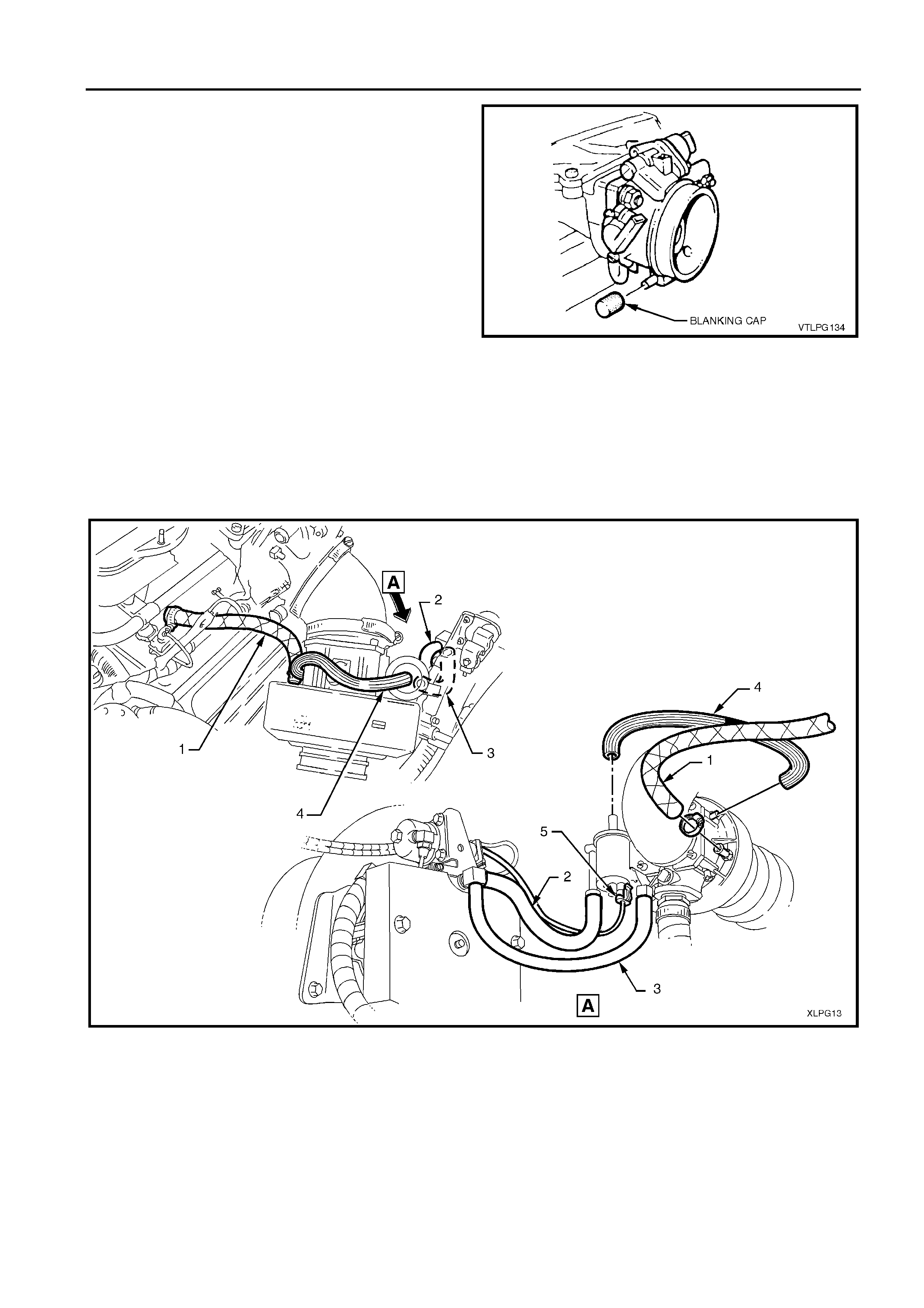

1.15 MIXER INSTALLATION

1. Install the adaptor hose to the throttle body, aligning

arrow with casting mark on the throttle body. Install hose

clamp and tighten to specified torque.

2. Attach mixer to adaptor hose with vapour inlet facing

down. Install adaptor hose clamp and tighten so mixer

may still be rotated.

3. Place hose clamp over air duct boot and install air duct

boot to mixer assembly. Tighten hose clamp to the

correct torque specification.

4. Install vapour hose shield to vapour hose.

5. Position hose clamps on vapour hose, install vapour

hose onto mixer vapour inlet and convertor vapour outlet

and tighten hose clamps.

6. Rotate mixer to obtain maximum clearance between

vapour hose and exhaust manifold, without kinking

vapour hose, so vapour inlet becomes approximately

10° off vertical.

Figure 1-38

ADAPTOR HOSE AND AIR DUCT BOOT

HOSE CLAMPS

TORQUE SPECIFICATION

3.0 - 4.0 Nm

VAPOUR HOSE CLAMPS

TORQUE SPECIFICATION 3.0 - 4.0 Nm

COOLANT HOSE BRACKET TO FRONT

CROSS MEMBER RETAINING SCREW

TORQUE SPECIFICATION

3.0 - 4.0 Nm

COOLANT HOSE BRACKET TO

LONGITUDINAL RETAINING SCREW

TORQUE SPECIFICATION

3.0 - 4.0 Nm

LPG INSTALLATION INSTRUCTIONS 1-19

7. Remove crankcase breather from throttle body and

install blanking cap as shown.

Figure 1-39

8. Referring to Fig. 1-40:

- Utilising the existing breather hose clamps, attach

the hose (1) between the mixer port and crankcase

breather port.

- Fit the vacuum hose between the FCV and convertor

(2) and between the convertor and mixer (3).

- Fit the balance hose (4) between FCV and mixer.

- Connect the FCV wiring connector (5).

Figure 1-40

1-20 LPG INSTALLATION INSTRUCTIONS

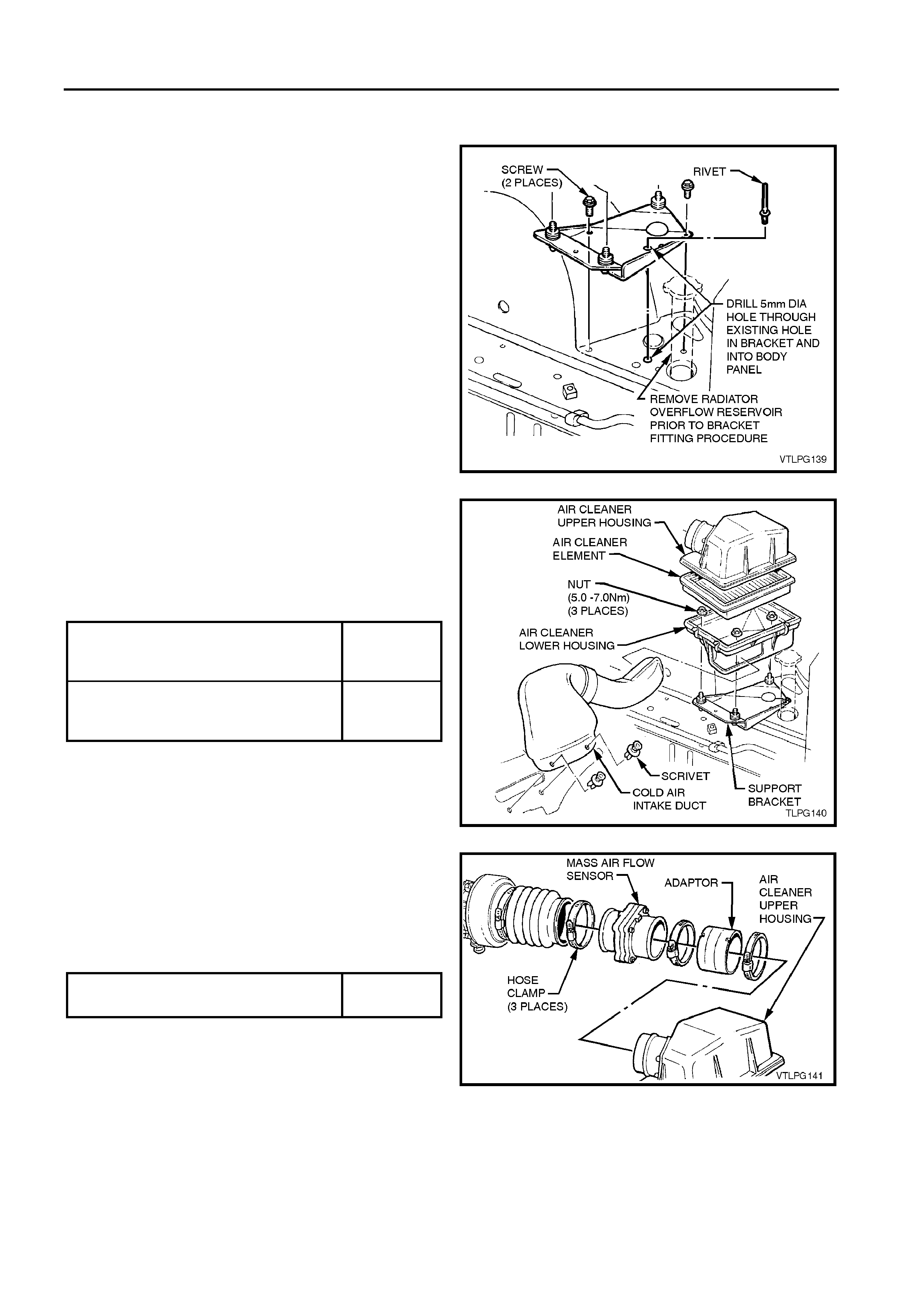

1.16 AIR CLEANER INSTALLATION

1. Attach air cleaner mounting bracket in place with

mounting bolts as shown, tightening to specified torque.

2. Drill 5.0 mm hole through existing hole in air cleaner

mounting bracket and into body panel as shown.

3. Install pop rivet in newly drilled 5.0 mm hole.

Figure 1-41

4. Install air cleaner lower housing as shown, tightening

retaining nuts to the specified torque.

5. Replace element in lower housing and clip the upper

housing in place.

6. Install cold air intake duct as supplied in kit. Attach in

two places with scrivets.

Figure 1-42

7. Assemble the air duct adaptor and mass airflow sensor,

tightening the hose clamp to the specified torque.

8. Place hose clamps on the adaptor and air duct boot and

install the mass airflow sensor between the air cleaner

and air duct boot.

9. Tighten the hose clamps to the specified torque.

Figure 1-43

AIR CLEANER MOUNTING BRACKET

RETAINING BOLTS

TORQUE SPECIFICATIONS.

3.0 - 5.0 Nm

AIR CLEANER BASE

RETAINING NUTS

TORQUE SPECIFICATION

5.0 - 7.0 Nm

AIR FLOW DUCT RETAINING HOSES

TORQUE SPECIFICATION 3.0 - 4.0 Nm

LPG INSTALLATION INSTRUCTIONS 1-21

1.17 EMERGENCY DECKLID RELEASE

CABLE EXTENSION

As the LPG tank installation hinders access to the

emergency decklid release from within the rear

compartment, by law an extension must be added to provide

access to the release.

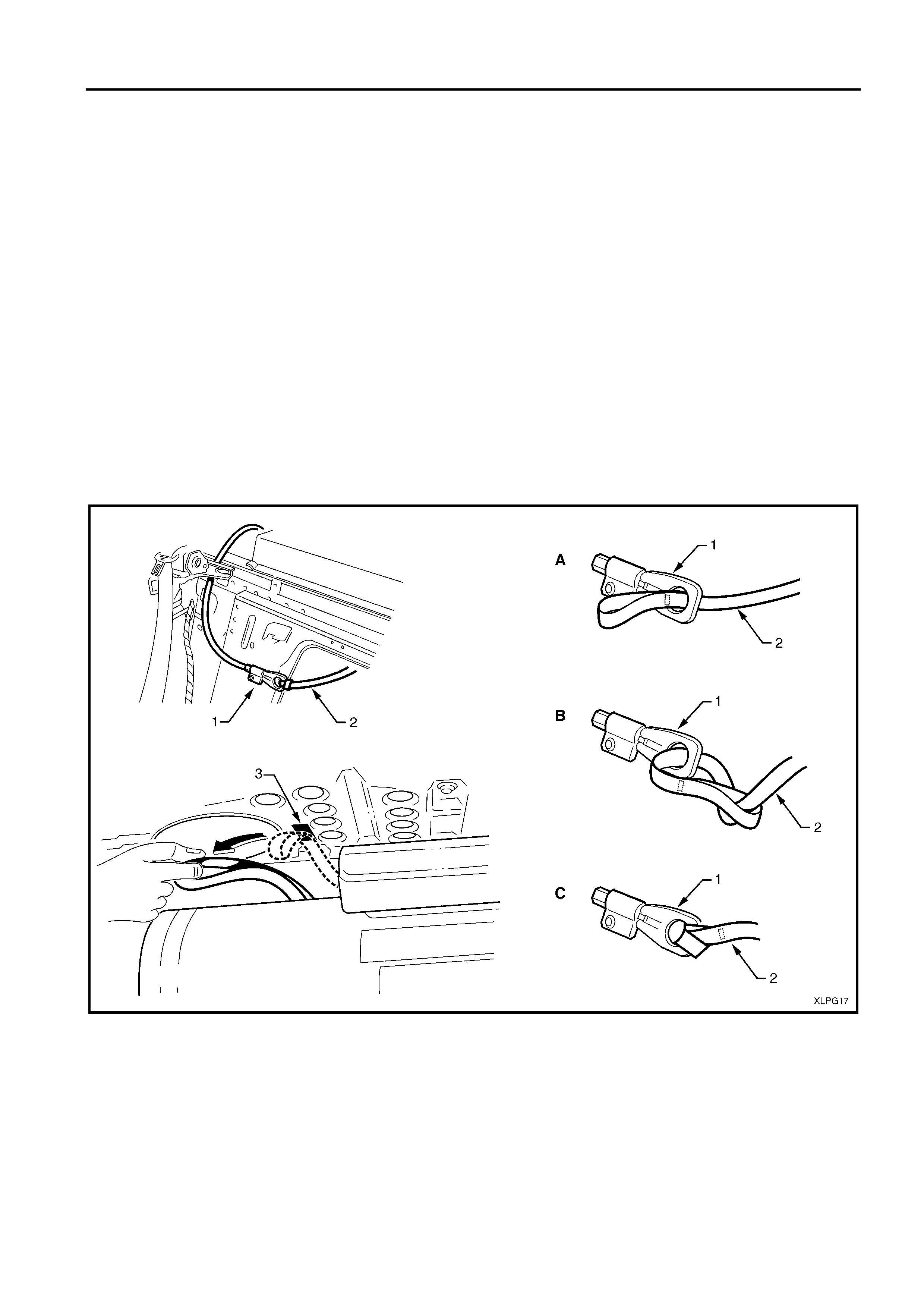

Referring to Fig.1-44:

1. Locate the emergency decklid release cable end (1).

2. Pass one end of the extension (2) through the hole in

the cable end as shown A.

3. Pass the other end of the extension through the loop

and tighten as shown B & C.

4. Route the extension over the LPG tank.

5. From inside the rear compartment, apply the self-

adhesive Velcro strip (3) to the underside of the back

panel - upper.

6. Attach the extension to the Velcro strip.

7. Check the operation of the release by unattaching the

extension and pulling it to the LH side.

8. Reattach the extension to the Velcro strip.

Figure 1-44

Legend

1. Emergency decklid release cable assembly

2. Emergency decklid release cable extension

3. Velcro strip

1-22 LPG INSTALLATION INSTRUCTIONS

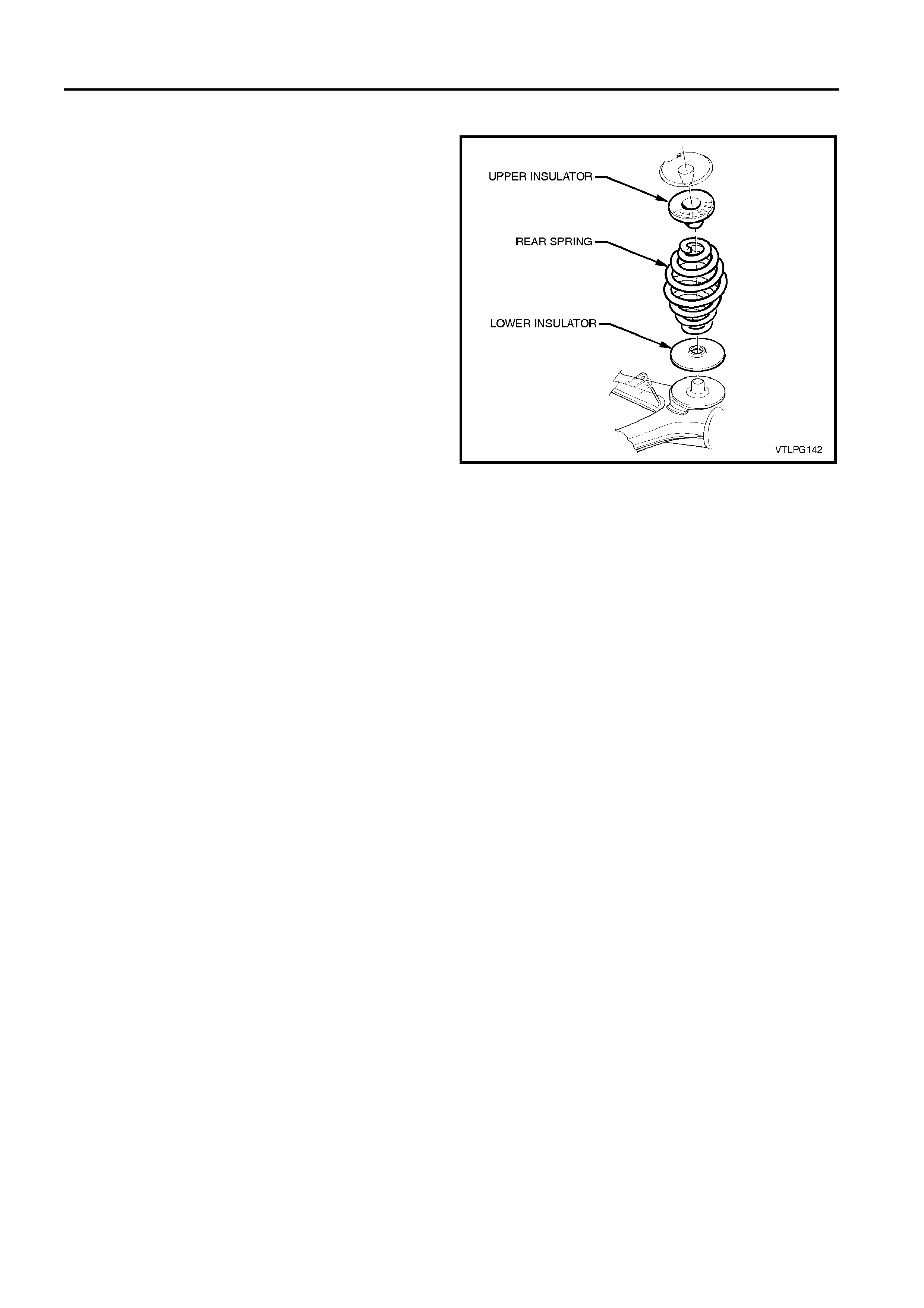

1.18 REAR SPRING INSTALLATION

Remove the rear springs and replace with the new springs

provided in the kit. Refer VX Series Service Information.

Figure 1-45

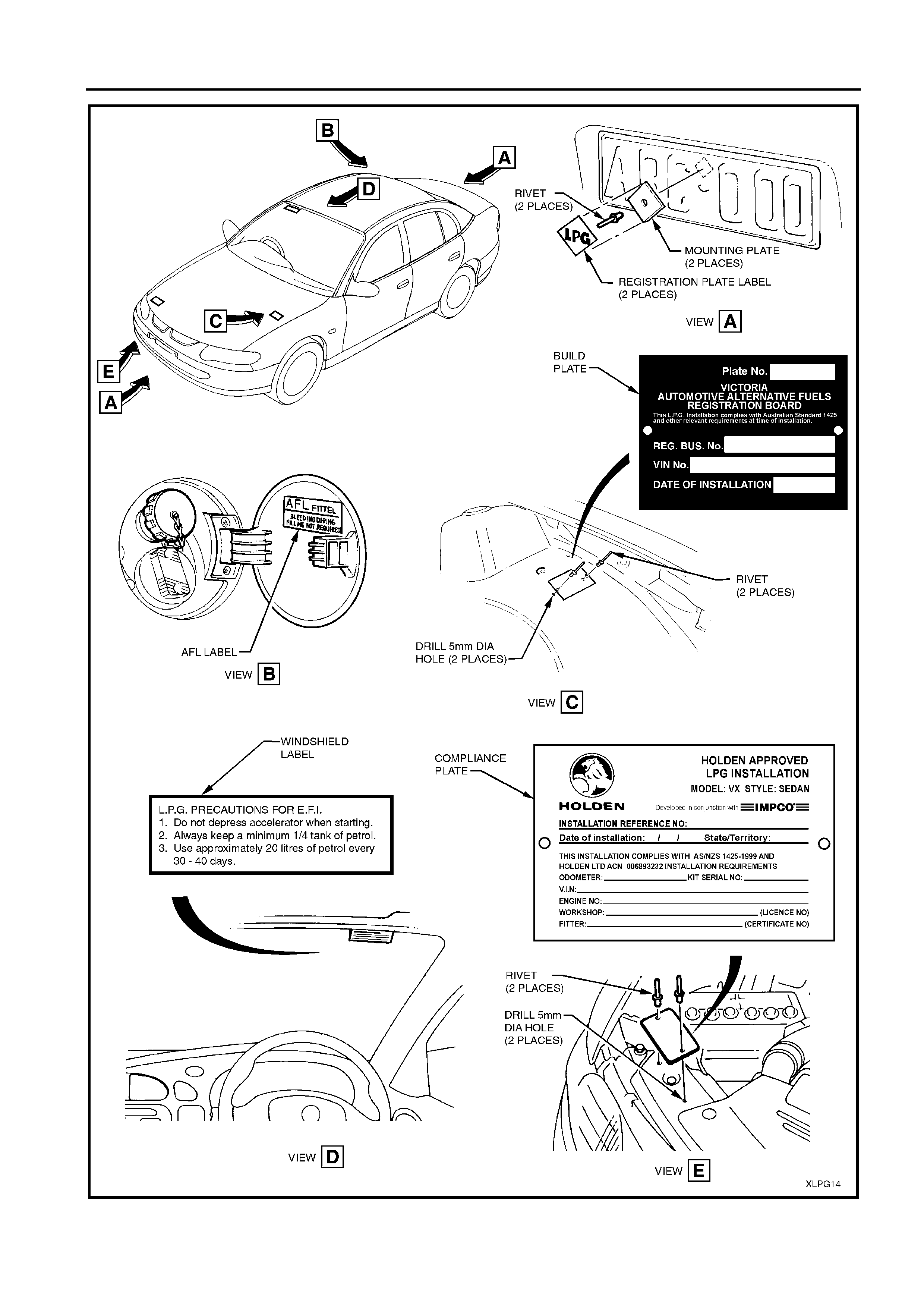

1.19 COMPLIANCE PLATES & ID.

LABELS – INSTALLATION

Referring to Fig. 1-46, affix:

- “LPG PRECAUTIONS FOR EFI” label to windscreen.

- LPG Automatic Fill Limiter (AFL) label to inside of fuel

filler cover door.

- Mounting plate & LPG label to middle of both front and

rear registration plates.

- “HOLDEN APPROVED LPG INSTALLATION” plate to

upper front panel using the template supplied

- Compliance plate to LHF wheelhouse panel using the

template supplied.

NOTE: If the vehicle has not been registered, place the

registration plate mounting plates and labels in the glove box

with the warranty card and owners manual supplement.

LPG INSTALLATION INSTRUCTIONS 1-23

Figure 1-46

1-24 LPG INSTALLATION INSTRUCTIONS

1.20 LEAK TEST

Perform the LPG leak test as described in Section 2 of these

installation instructions.

1.21 TECH 2 LPG SET-UP & ENABLE

PROCEDURES

Perform the procedures described in Section 3 of these

installation instructions to programm the PCM for LPG and

enable the instrument cluster LPG lamp.

1.22 COMPONENT REINSTALLATION

Reinstall all other components removed in accordance with

the procedures outlined in the appropriate Sections in the VX

Series Service Information.

1.23 AFTER INSTALLATION CHECK

To ensure that the LPG installation has been carried out in

accordance with these installation instructions, an After

Installation Check MUST be performed.

The checklist is to be completed by the authorised fitting

technician and filed by the authorised fitting dealer. Refer to

Section 4 of these installation instructions.

1.24 ENABLE THE SRS & AUDIO

SYSTEMS

The vehicle is equipped with SRS (Air Bag), to enable the

system, refer to "ENABLING THE SRS" in 2.2 SYSTEM

DISABLING AND ENABLING PROCEDURE in Section 12M

of the VX Service Information.

Following the procedure in the vehicle owner’s manual,

reprogram the audio system the the four digit security PIN

code.

LPG LEAK TESTING 2-1

SECTION 2

CAUTION:

This vehicle is equipped with a Supplemental Restraint System (SRS). A SRS will consist of either seat belt pre-

tensioners and a driver’s side airbag, seat belt pre-tensioners and a driver’s and front passenger’s airbags or

seat belt pre-tensioners, a driver’s, front passenger’s and left and right hand side airbags for the front

occupants. Refer to CAUTIONS, Section 12M, in the VX Series Service Information before performing an y service

operation on or around SRS components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible personal injury or unnecessary SRS system repairs.

LPG LEAK TESTING

CONTENTS

Ref. Subject Page

2.1 GENERAL INFORMATION...................................2-1

2.2 COMBUSTIBLE GAS DETECTORS ....................2-2

2.3 FOAM....................................................................2-2

2.4 LEAK TEST PROCEDURE...................................2-3

2.1 GENERAL INFORMATION

The following leak test procedure is to be carried out on the

LPG system high pressure components and is to be

performed as part of the LPG installation. It is also to be

performed as part of each normal maintenance service.

For safety reasons the leak test must be carried out in the

open air, in a well ventilated area and PRIOR to bringing the

vehicle into the workshop after filling with LPG.

2-2 LPG LEAK TESTING

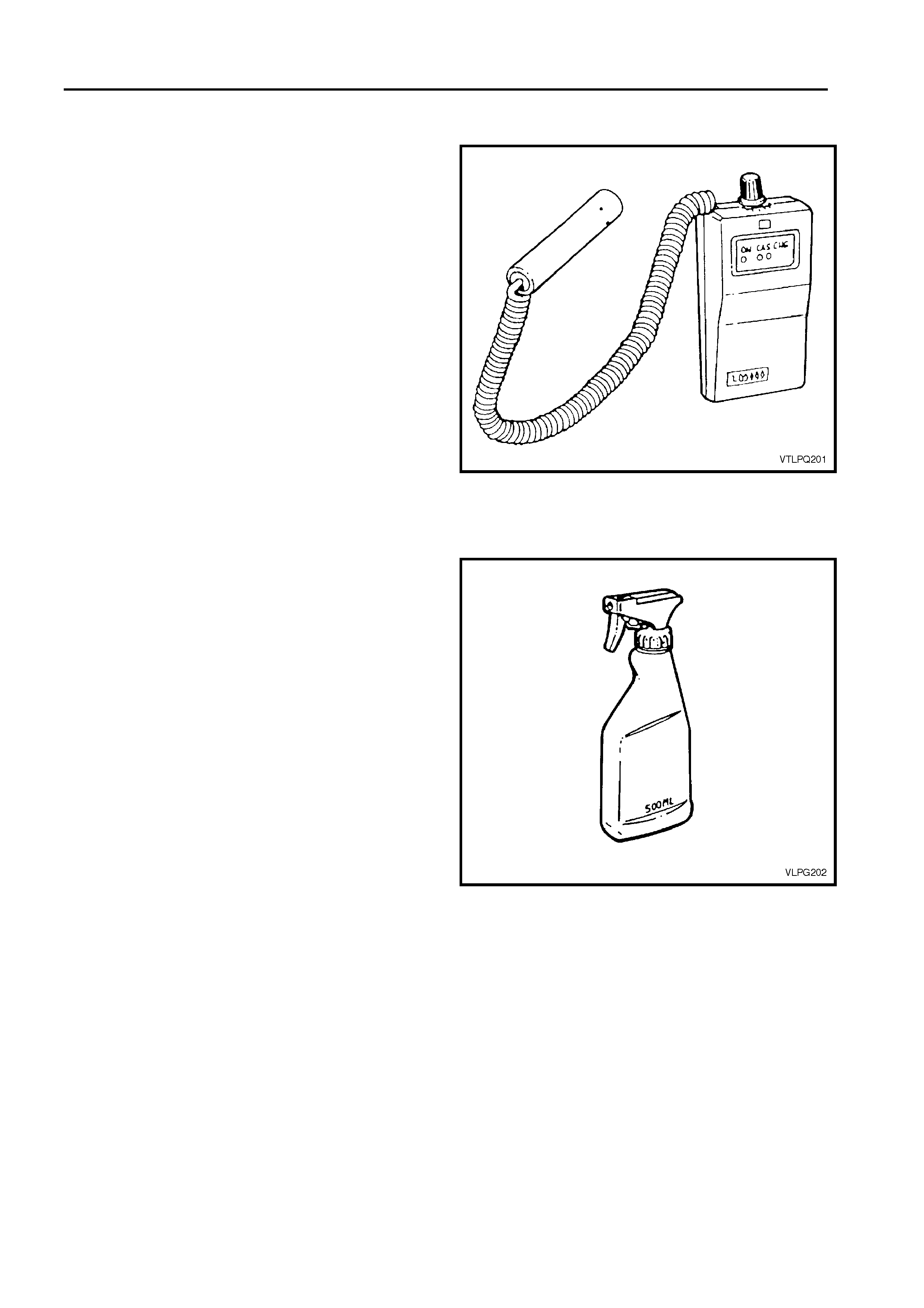

2.2 COMBUSTIBLE GAS DETECTORS

If a combustible gas detector, such as an LD-9001 LP Gas

leak detector or equivalent, is to be used for leak testing of

the LPG system, the combustible gas detector should be

capable of detecting 25 parts per million (PPM) of LPG in air.

A detector such as a LD-9001 LP Gas Leak Detector or

equivalent is recommended.

Whichever leak detector is used, it is important to follow the

manufacturer's instructions in regard to adjustment and

setting of the instrument prior to conducting the leak test.

Care in interpretation is necessary, as the detector can

respond to the presence of any of several vapours that are

combustible, some of which may not be LPG, such as oil

smears, joining compounds, etc. It may also detect residual

LPG vapours that are present for reasons other than

leakage, and which must be cleared before a valid test for

leakage can be made.

If a leak is present, a detector will signal its existence but not

its size. The detector will indicate its general location, but

may not be able to locate it exactly, so a follow up or proving

check with foam is often desirable. Figure 2-1

2.3 FOAM

If foam is to be used, the foaming agent should be a

proprietary leak test solution, formulated specifically for the

purpose such as Gameco Leak Check ™ or a similar

solution. The solution should be fresh and the whole of the

area to be tested should be coated. Time should be allowed

for bubbles to form. All areas under test must be able to be

observed during the leak test.

Whichever foaming agent is used, it is important to follow the

manufacturer's instructions.

Foam testing is more effective for small leaks. Large leaks

tend to blow the solution away from the leak without forming

a bubble, so care in application is necessary.

The leak test is performed by directing a spray of solution at

each of the possible leak points in the high pressure side of

the system.

After the solution is applied, the area should be watched

carefully for no less than 15 seconds.

A leak is indicated by the presence of gas bubbles (foaming)

in the solution at the leak source.

NOTE: LPG is heavier than air, so testing should be carried

out thoroughly below all components and fittings.

If a leak is detected at a joint, the relevant component/s must

be removed as described in the appropriate component

service operation. Refer to Section 2, SERVICE

OPERATIONS in the VX Series Service Information. All

mating threads should be cleaned, then resealed using the

specified sealant and tightened to the specified torque. Once

installed, thoroughly leak test the components again.

At the completion of each test, the leak test area of foaming

agent should be dried with low pressure compressed air or

shop cloths and the immediate area sprayed with a water

dispersing agent such as WD40, RP7 etc.

Figure 2-2

LPG LEAK TESTING 2-3

2.4 LEAK TEST PROCEDURE

With 3 litres of LPG in the LPG cylinder, leak test the complete LPG

system following the instructions below

1. Park the vehicle in a dry, well ventilated area.

CAUTION: Do not smoke or allow naked flames or any ignition

source near the vehicle during the testing operations.

2. Ensure the vehicle is operating on LPG and run the engine for at

least 30 seconds to fully pressurise the system, then stop the

engine.

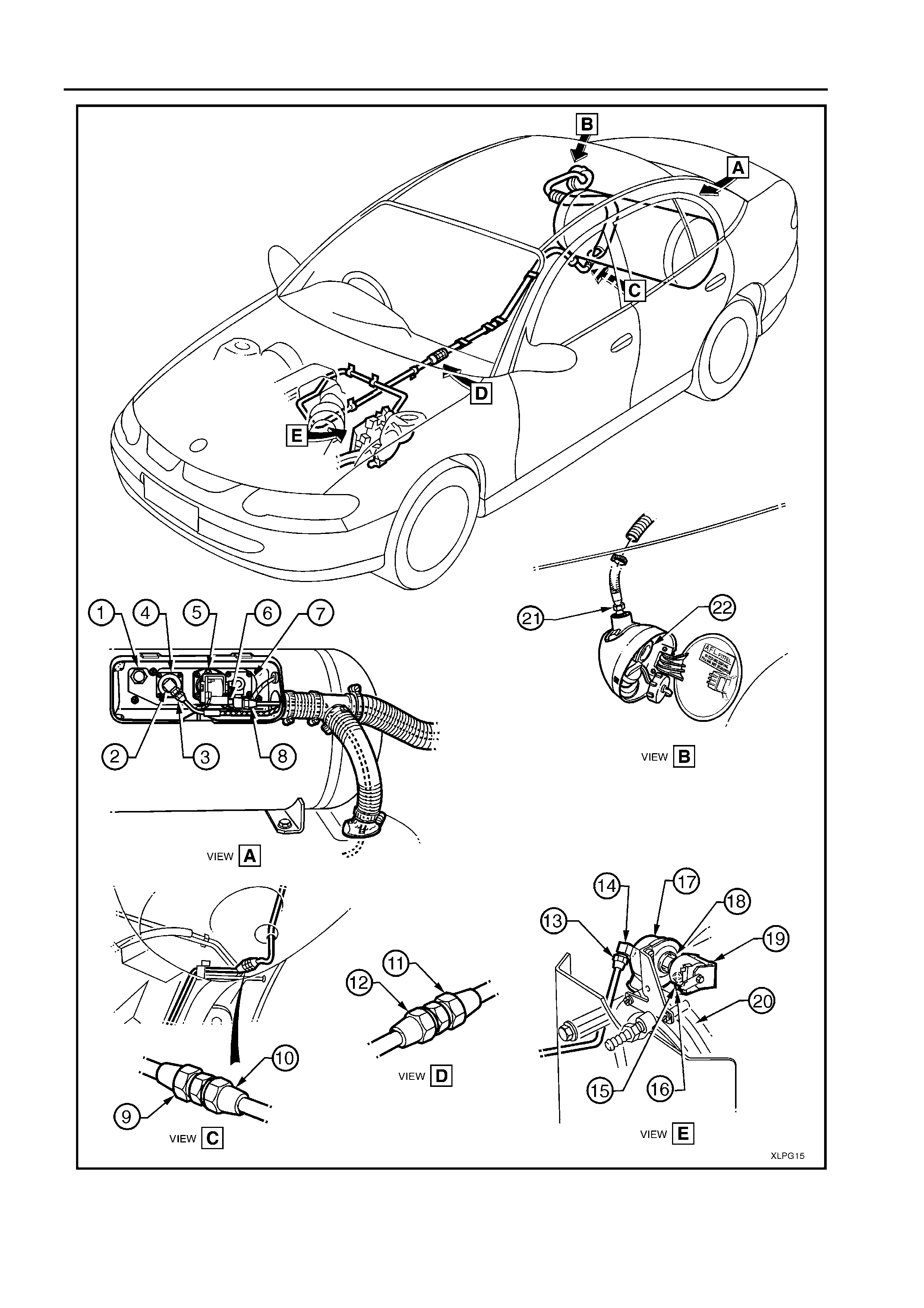

3. The recommended sequence of testing is as follows:

A. Refer to F igure 2-3, View A. Open rear compartment lid, remove

the valve box cover and leak test at and around the following:

- Pressure relief valve (1).

- AFL inlet elbow to AFL (2).

- Rear service line to AFL inlet elbow connection (3).

- AFL to LPG cylinder (4).

- Cylinder fuel gauge assembly (5).

- Solenoid and manual service valve assembly (6).

- Solenoid and manual service valve assembly to LPG

cylinder (7).

- Rear service line to solenoid and manual service valve

assembly connection (8).

B. Refer to F igure 2-3, View B.

Open filler box door and leak test at and around the filler valve

check ball (22).

Remove the rear compartment carpet from the right side

wheelhouse to gain access to the inner side of the filler valve

assembly. Refer to Section 1A1 BODY in the VX Series Service

Information. Leak test at and around the filler line to filler valve

connection.

C. Refer to Figure 2-3, View C. Raise rear of vehicle and support

on jack stands. Refer to Section OA GENERAL INFORMATION

in the VX Service Information for the location of jacking points.

Leak test at and around the following:

- Rear service line to intermediate service line joiner

connection (9).

- Intermediate service line to rear service line joiner

connection (10).

D. Refer to Figure 2-3, View D. With vehicle still raised on stands,

leak test at and around the following:

- Intermediate service line to front service line joiner

connection (11).

- Front service line to intermediate service line joiner

connection (12).

E. Refer to F igure 2-3, View E. Leak test in the engine

compartment, at and around the following:

- Front service line to lockoff inlet connection (13).

- Lockoff inlet connection to lockoff (14).

- Lockoff (17,18, 19)

- Lockoff to lockoff outlet connection (15).

- Lockoff outlet connection to convertor (16).

- Convertor mounting faces (20).

NOTE: The vehicle cannot be operated on LPG in the workshop, unless

the workshop is a 'Specialist Gas Workshop", refer Australian Standard

AS 2746 - 1985.

4. At the completion of the leak test, close the manual service valve,

start the engine and run the engine until all LPG in the service lines

is exhausted. With the engine stopped, switch to "petrol", and start

the engine.

5. The vehicle can now be driven into the workshop.

2-4 LPG LEAK TESTING

Figure 2-3

TECH 2 LPG SET-UP & ENABLE PROCEDURES 3-1

SECTION 3

CAUTION:

This vehicle is equipped with a Supplemental Restraint System (SRS). A SRS will consist of either seat belt pre-

tensioners and a driver’s side airbag, seat belt pre-tensioners and a driver’s and front passenger’s airbags or

seat belt pre-tensioners, a driver’s, front passenger’s and left and right hand side airbags for the front

occupants. Refer to CAUTIONS, Section 12M, in the VX Series Service Information before performing an y service

operation on or around SRS components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible personal injury or unnecessary SRS system repairs.

TECH 2 LPG SET-UP & ENABLE PROCEDURES

CONTENTS

Ref. Subject Page

3.1 PCM SERVICE PROGRAMMING WITH LPG CALIBRATION................. 3-1

3.2 INSTRUMENT CLUSTER LPG LAMP ENABLE PROCEDURE.............. 3-4

3.2 PCM SET-UP PROCEDURE.................................................................... 3-6

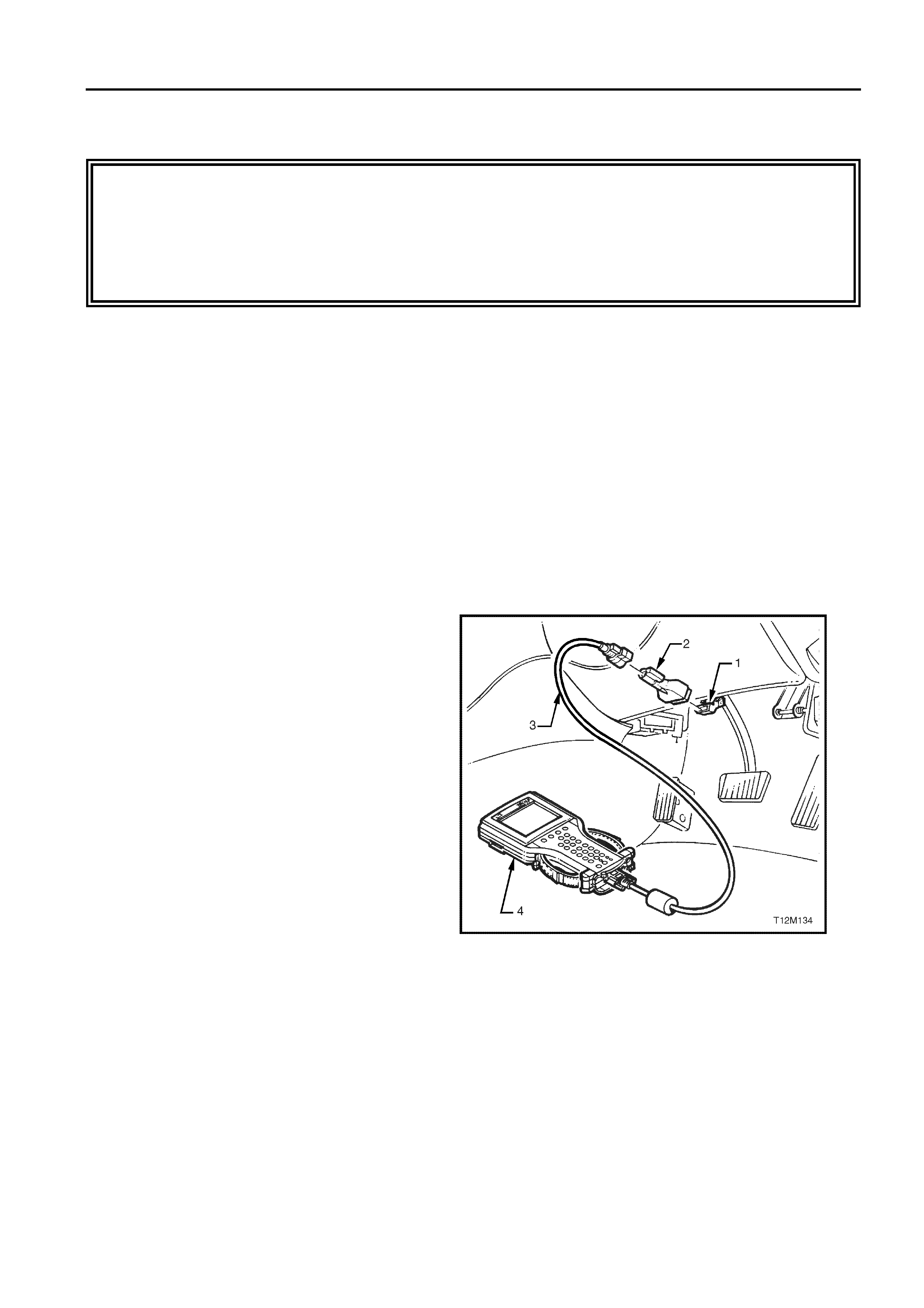

The following procedures are required to enable the

vehicle to operate on LPG and are best performed in the

order they they appear in this Section.

Prior to beginning, connect TECH 2 to the data link

connector (DLC).

1. DLC

2. DLC Adaptor

3. DLC Cable

4. TECH 2

Figure 3-1

3.1 PCM SERVICE PROGRAMMING

WITH LPG CALIBRATION

NOTE: T he following PCM service programming must be

performed following LPG system installation or when a

PCM has been replaced.

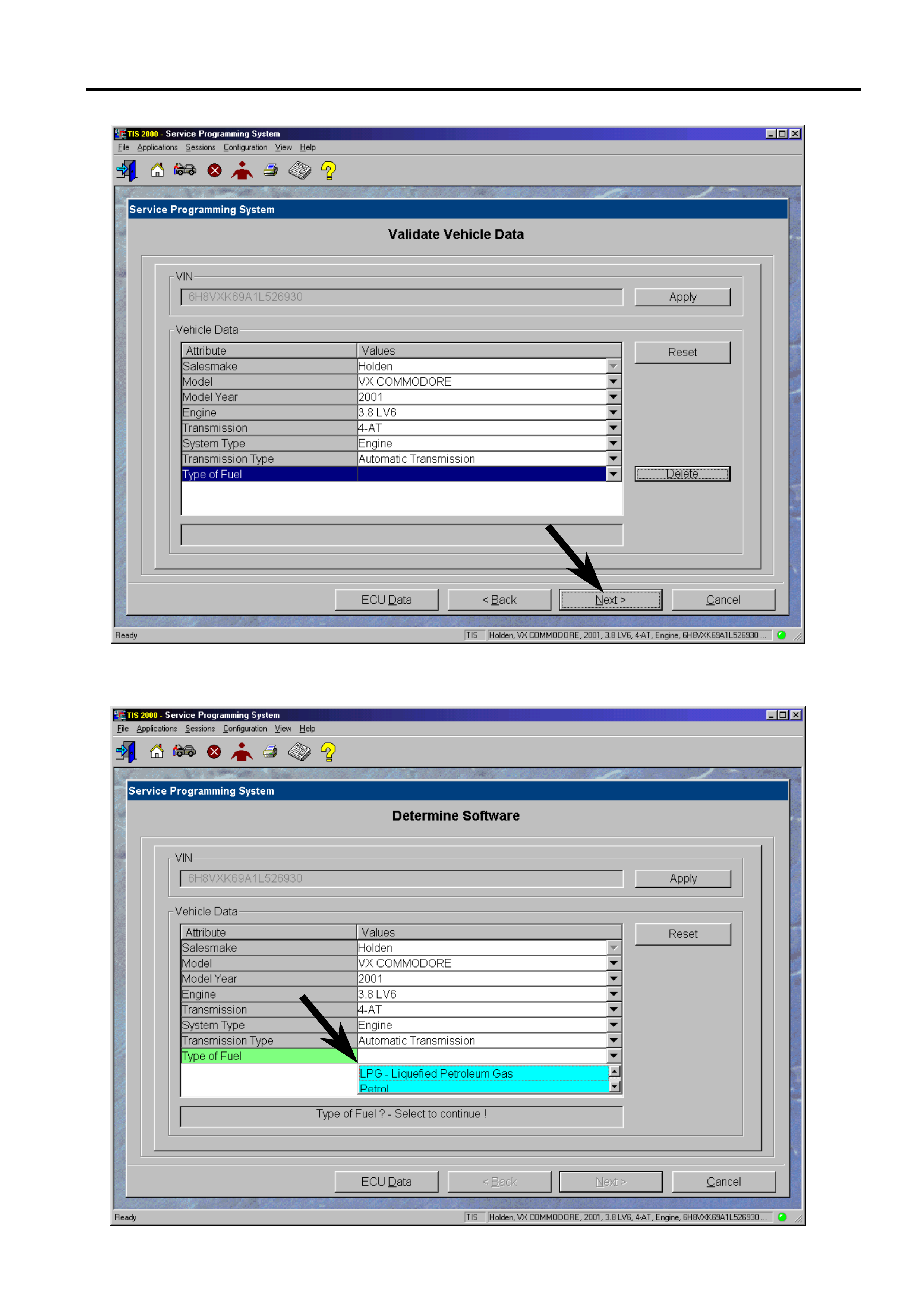

1. Connect Tech 2 as previously described.

2. Refer to the VX Series Service Information Package

(SIP) CD-ROM and follow procedure 4.2 SPS

PROCESS in Section OC – TECH 2 until the

Validate Vehicle Data screen is displayed, refer

Fig. 3-2.

3-4 TECH 2 LPG SET-UP & ENABLE PROCEDURES

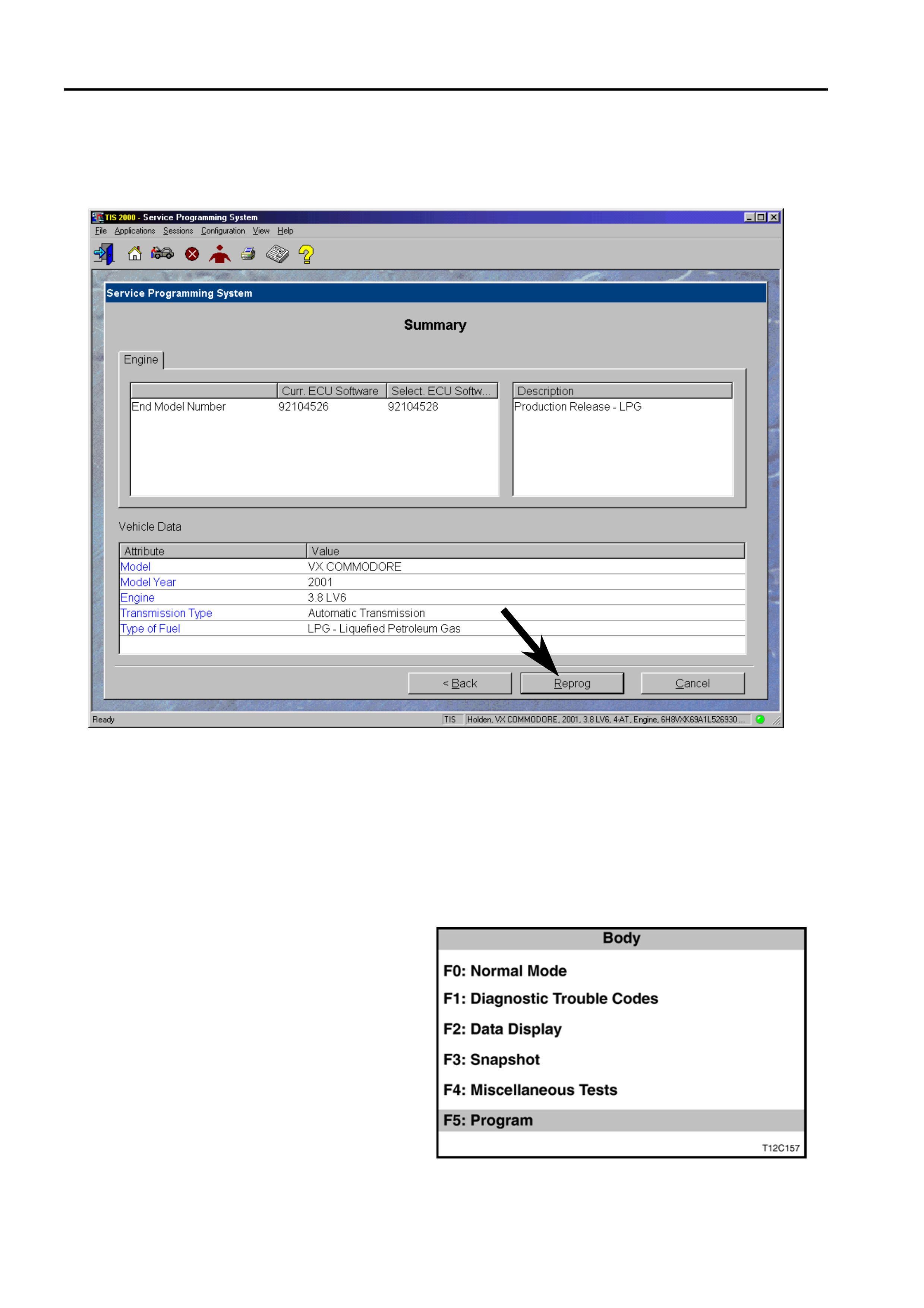

7. Once selected a summary screen will then be

displayed allowing the details to be confirmed, refer

Fig. 3-6.

8. Select the REPROG button.

9. Continue the steps in 4.2 SPS PROCESS procedure

on the SIP CD-ROM.

Figure 3-6

3.2 INSTRUMENT CLUSTER LPG LAMP

ENABLE PROCEDURE

NOTE: The following instrument cluster LPG lamp

enable procedure must be performed following LPG

system installation or when an instrument cluster has

been replaced.

1. Ensure the ignition is off.

2. Connect Tech 2 as previously described.

3. Navigate through the Tech 2 menus to display the

Body / Instruments application menu.

4. Select F5: Program.

Figure 3-7

TECH 2 LPG SET-UP & ENABLE PROCEDURES 3-5

5. From the Program Menu, select F1: Options.

Figure 3-8

6. At the Options Menu, press the NEXT soft key and

scroll through the following series of screens to the

LPG Lamp screen:

- Rear Lamp Failure,

- Traction Control Off Lamp,

- LPG Lamp,

- Cruise On Lamp,

- Police Mode,

- Low Coolant Lamp,

- High Temperature Lamp,

- Program Options Confirm.

Figure 3-9

7. At the LPG Lamp screen, press the MODIFY soft

key to change Disabled to Enabled.

8. Use the NEXT key to scroll to the Program Options

Confirm screen.

Figure 3-10

9. At the Program Options Screen, ensure the LPG

Lamp is Enabled.

10. Press the ABORT soft key to abandon the process

or press the PROGRAM soft key to confirm the

parameters.

11. Press the CONFIRM soft key when the

programming is completed.

Figure 3-11

3-6 TECH 2 LPG SET-UP & ENABLE PROCEDURES

3.3 PCM SET-UP PROCEDURE

NOTE: The following LPG Set-up Procedure must be

performed following LPG system installation and when

any LPG system component (mixer, converter, FCV or

PCM) has been replaced, overhauled, reprogrammed, or

when the engine assembly has been replaced or

overhauled.

The LPG Set-up procedure allows adjustment of the idle

mixture under the following controlled conditions:

- Short and Long-Term Fuel Trim Cells set to zero.

- Fixed Spark advance.

- Fixed idle air control valve steps.

- Fuel control valve duty cycle fixed at 40%.

1. Connect TECH 2 as previously described.

2. Switch the vehicle to LPG mode, if not already done

so.

3. Start the engine and allow it and the oxygen sensors

to reach operating temperature, with no load on the

engine, air conditioning off (if fitted), all electrical

consumers turned off and park position selected.

4. On Tech 2 Select: Diagnostics / Appropriate Model

Year ((1) 2001) / VX Commodore / Engine / V6 /

Function Tests/ LPG Set-up.

During the set-up procedure, Tech 2 ensures the

follow engine operating conditions are met and

maintained:

- Engine Coolant Temperature greater than 91°C

- Operating in closed loop.

- Right hand oxygen sensor is ready.

- The engine cooling fan is off (engine coolant

temperature less than 104°C).

Once all the preconditions have been met, Tech 2

will display the Right O2 Sensor Voltage and Status.

Engine

LPG Setup

Right O2 Sensor

Right O2 Status

500 mV

Rich

VXLPG001

Confirm

Figure 3-12

5. Adjust the idle mixture screw until the right hand

oxygen sensor voltage is as close to 500 mV as

possible and the status of the right O2 Sensor is

constantly toggling between rich and lean.

Oxygen sensor voltages greater than 500 mV

indicates a rich mixture, turn the idle mixture screw

anti-clockwise to lean off the mixture.

Oxygen sensor voltages less than 500 mV indicates

a lean mixture, turn the idle mixture screw clockwise

to richen the mixture.

If the engine coolant temperature exceeds 104°C,

the engine cooling fan will be turned on and Tech 2

will suspend the set-up procedure. When the engine

cools down and the cooling fan is turned off, Tech 2

will continue with the set-up procedure.

Figure 3-13

LPG AFTER INSTALLATION CHECK 4-1

SECTION 4

CAUTION:

This vehicle is equipped with a Supplemental Restraint System (SRS). A SRS will consist of either seat belt pre-

tensioners and a driver’s side airbag, seat belt pre-tensioners and a driver’s and front passenger’s airbags or

seat belt pre-tensioners, a driver’s, front passenger’s and left and right hand side airbags for the front

occupants. Refer to CAUTIONS, Section 12M, in the VX Series Service Information before performing an y service

operation on or around SRS components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible personal injury or unnecessary SRS system repairs.

LPG AFTER INSTALLATION CHECK

CONTENTS

Ref. Subject Page Ref. Subject Page

4.1 GENERAL INFORMATION ............................... 4-1

4.2 UNDERBODY.................................................... 4-2

4.3 REAR COMPARTMENT.................................... 4-3

4.4 VEHICLE INTERIOR ......................................... 4-4

4.5 UNDER BONNET..............................................4-5

4.6 LEAK CHECK AND FILLING ............................4-6

4.7 FILLING .............................................................4-7

4.8 COMMISSIONING OF VEHICLE.......................4-7

4.1 GENERAL INFORMATION

LPG AFTER INSTALLATION CHECK 4-1

On completion of the LPG installation, it is a requirement of

HOLDEN Ltd (A.C.N. 006 893 232) that the copy of the

following check list, supplied in the LPG Kit, must be

completed and filed by the fitting dealer to ensure a high

quality installation standard. Be advised that HOLDEN Ltd

reserves the right at any time to audit any after installation

check sheet.

All items in this checklist must be checked to ensure they have been installed, adjusted or reinstalled as outlined in the

Installation Instructions, or applicable Service Information.

DATE:................................................... VEHICLE:..................................................................................................

VIN No. REGISTRATION No. ..................................................... REGISTRATION No..........................................

Kit No............................................................................................................................................................................

AUTHORISED DEALER:............................................................. LICENCE No:.....................................................

FITTER:....................................................................................... LICENCE No:.....................................................

4-2 LPG AFTER INSTALLATION CHECK

4.2 UNDERBODY

(Tick the appropriate box)

CHECK OK REPAIR

1. Rear service line and intermediate service line

connected to joiner (near grommet in rear longitudinal)

and connectors tightened to correct torque specification.

2. Front and intermediate service lines connected to joiner

just forward of brake/fuel pipe harness cover and

connectors tightened to correct torque specification.

3. Front and intermediate service lines are not chafing or in

contact with the brake, petrol or evaporative lines, body,

or any other components.

4. Front and intermediate service lines correctly routed and

retaining clips installed.

5. LPG cylinder correctly installed and attaching nuts

tightened to correct torque specifications (4 locations).

6. Rear springs installed and rear shock absorber

mounting bolts tightened to correct torque

specifications.

7. Drive shaft and constant velocity joint to trunnion flange

attaching bolts are tightened to correct torque

specifications.

LPG AFTER INSTALLATION CHECK 4-3

4.3 REAR COMPARTMENT

(Tick the appropriate box)

CHECK OK REPAIR

1 Floor flange installed and silicone sealer applied.

2 Service line vent tube installed to floor flange and

retaining clamps tightened.

3 Service line vent tube installed, joiner and retaining

clamp tightened.

4 Filler connected to joiner and LPG cylinder high-

pressure inlet elbow and filler line connectors tightened

to the correct torque specification.

5 Filler plate installed correctly and retaining cap screws

tightened to the correct torque specifications.

6 Filler lid operates without binding and shuts flush, AFL

label is affixed to inside of filler lid.

7 Rear service line connected to solenoid and manual

service valve assembly and connector tightened to the

correct torque specification.

8 LPG cylinder level sender and smart unit harness

connector is connected to LPG body harness connector.

9 LPG body harness is correctly routed and retained to

existing harness with cable ties (five places).

10 Emergency decklid release cable extension has been

installed and operates correctly.

11 Rear compartment carpet and quarter trim carpet have

been reinstalled and are positioned correctly.

4-4 LPG AFTER INSTALLATION CHECK

4.4 VEHICLE INTERIOR

(Tick the appropriate box)

CHECK OK REPAIR

1 All of the following LPG body harness connections are

installed:

a. LPG body harness fuel mode switch connector to

fuel mode switch.

b. LPG body harness single lead PCM terminals are

inserted to PCM connector as follows:

- White / Green lead into A3,

- Black / Oran

g

e lead into E16

,

2 LPG harness routed along rocker panel from RHF

shroud lower trim (kick panel) and tie strapped to

3 Rear seat and RHR seat back reinstalled.

4 RH rocker panel cover reinstalled.

5 RHF instrument panel lower trim assembly and

instrument panel facia reinstalled with fuel mode switch

itlld d

tdt LPG i h

6 LPG harness routing not impairing heater valve.

O

p

erate the heater controls to ensure that the harness

7 PCM connectors are installed correctly.

8 LH & RH lower side trim assemblies and rocker panel

cover installed.

9 All instrument panel controls, including the LPG lamp

function correctly.

LPG AFTER INSTALLATION CHECK 4-5

4.5 UNDER BONNET

(Tick the appropriate box)

CHECK OK REPAIR

1 All the following LPG engine harness connections are

installed and routed correctly:

a. LPG engine harness 8 pin connectors are

connected to main harness and engine harness

connectors (YE112) located near RH strut tower.

b. Earth lead is installed to rear of LH cylinder head

and retaining bolt is tightened to the correct torque.

c. LPG engine harness oxygen sensor connectors are

connected to vehicle engine harness and oxygen

sensor connectors (YE97).

d. LPG engine harness lockoff connector is connected

to LPG lockoff.

e. LPG engine harness fuel control valve connectors

connected to fuel control valve.

2 Oxygen sensor wiring correctly routed and cable tie

installed.

3 The vapour line to mixer and vapour line to convertor

retaining clamps are installed and tightened.

4 The vapour line and vacuum hoses are connected and

routed correctly.

5 Convertor and convertor bracket installed and retaining

bolts are tightened to the correct torque specification.

6 Coolant pipe hose clamps fitted and tightened. Coolant

and vapour hoses correctly routed to avoid contact with

engine or body parts.

7 Fuel control valve (FCV) installed.

8 Air intake tube installed, clamps and mounting screw

tightened to the correct torque specification.

9 Air cleaner assembly and MAF sensor installed.

10 Front service line 'P' clamps installed on cockpit module

and tightened to the correct torque specification.

4-6 LPG AFTER INSTALLATION CHECK

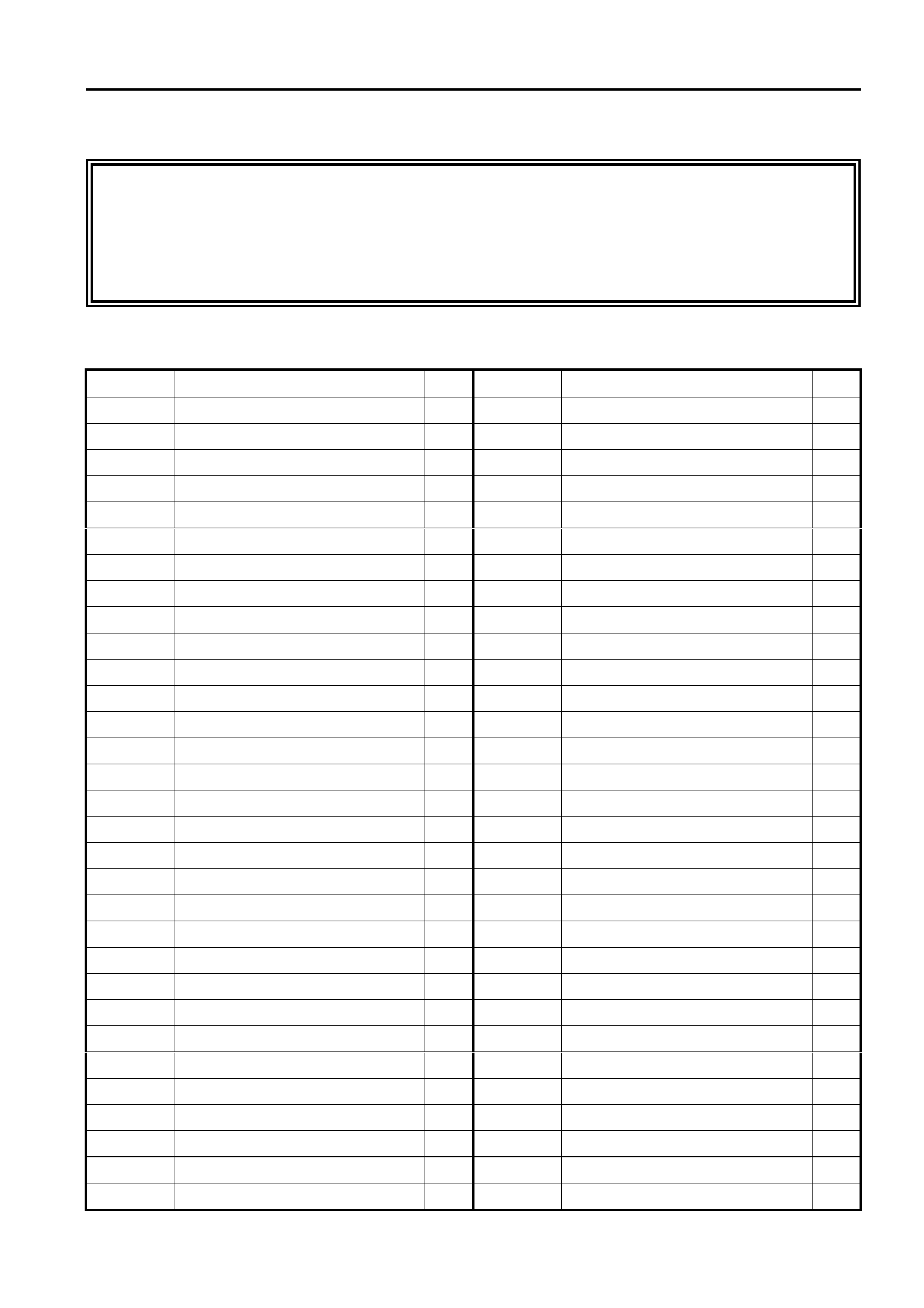

4.6 LEAK CHECK AND FILLING

With approximately three litres of LPG in the cylinder, leak

test the complete LPG system as outlined in the leak test

procedure in Section 2 of the installation instructions. The

following 19 points must have been tested.

(Tick the appropriate box)

CHECK OK REPAIR

1 Pressure relief valve.

2 Solenoid and manual service valve assembly to LPG

cylinder.

3 Solenoid and manual service valve assembly.

4 Rear service line to solenoid and manual service valve

assembly connector.

5 LPG cylinder fuel gauge assembly.

6 AFL inlet elbow to LPG cylinder.

7 Rear service line to AFL inlet elbow connector.

8 AFL to LPG cylinder.

9 Filler valve to filler line.

10 Filler valve check ball.

11 Rear service line to intermediate service line joiner

connection.

12 Intermediate service line to rear service line joiner

connection.

13 Intermediate service line to front service line joiner

connection.

14 Front service line to intermediate service line joiner

connection.

15 Front service line to LPG lockoff inlet straight nipple

connection.

16 LPG lockoff inlet connection to LPG lockoff.

17 LPG lockoff.

18 LPG lockoff to LPG lockoff outlet connection.

19 LPG lockoff outlet connection to convertor.

LPG AFTER INSTALLATION CHECK 4-7

4.7 FILLING

After the leak test has been completed and there are NO

LEAKS, fill the LPG cylinder and record the number of litres

taken.

NOTE: Don’t forget the three litres you put into the LPG

cylinder to conduct the Leak Test.

The LPG cylinder capacity of 74 litres is the 'fillable' capacity.

Automatic Fill Limiter (AFL) operation.

Total Litres Taken.

______________________________ Litres

4.8 COMMISSIONING OF VEHICLE

(Tick the appropriate box)

CHECK OK REPAIR

1 Glove box installed, key and lock operate correctly.

2 PCM has been reprogrammed with LPG calibration.

3 LPG idle mixture has been set according to the PCM

Set-up procedure.

4 Vehicle’s fuel changeover operation.

5 Registration plate LPG mounting bracket & labels

affixed.

6 LPG compliance plate affixed.

7 Windscreen label affixed.

8 Owner handbook LPG supplement.

9 Road test vehicle.

10 Warranty card filled out.

4-8 LPG AFTER INSTALLATION CHECK

NOTES

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

LPG INSTALLATION TOOLS 5-1

SECTION 5

CAUTION:

This vehicle is equipped with a Supplemental Restraint System (SRS). A SRS will consist of either seat belt pre-

tensioners and a driver’s side airbag, seat belt pre-tensioners and a driver’s and front passenger’s airbags or

seat belt pre-tensioners, a driver’s, front passenger’s and left and right hand side airbags for the front

occupants. Refer to CAUTIONS, Section 12M, in the VX Series Service Information before performing an y service

operation on or around SRS components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible personal injury or unnecessary SRS system repairs.

LPG INSTALLATION TOOLS

TOOL PURPOSE

Drilling Jig

Used for drilling floor flange hole in rear floor panel

Leak Tester:

Combustible-gas detector

LD-9001 or equivalent

LPG system leak testing

Spray bottle & foaming agent.

Gameco Leakcheck™ or

equivalent

LPG cylinder location drilling jig LPG cylinder

Convertor support bracket drilling jig Convertor support bracket

Rivet gun Self closing pop rivets

10mm right angle (90°) drill Drilling holes

Hole saws: 60mm Vent hose flange and fuel filler

51mm Fuel filler

30mm Dash panel

21mm Fuel filler

Drill bits: 11.0mm LPG cylinder

6.5mm & 9.0mm LPG convertor

5.0mm Rivets

4.2mm (short) Vent hose flange / compliance plate

3.5mm Fuel filler locating pin

3.0mm Pilot holes / registration plate label mounting plate

3mm letter punch & number punch sets Compliance Plate

Loctite 577 sealant Gas tight connection threads

Anti-corrosion compound meeting Holden Specification HN1071 Bare metal surfaces

Silicone sealer meeting Holden Specification HN1886 Floor flange

5-2 LPG INSTALLATION TOOLS

NOTES

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

PARTS LIST 6-1

SECTION 6

CAUTION:

This vehicle is equipped with a Supplemental Restraint System (SRS). A SRS will consist of either seat belt pre-

tensioners and a driver’s side airbag, seat belt pre-tensioners and a driver’s and front passenger’s airbags or

seat belt pre-tensioners, a driver’s, front passenger’s and left and right hand side airbags for the front

occupants. Refer to CAUTIONS, Section 12M, in the VX Series Service Information before performing an y service

operation on or around SRS components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible personal injury or unnecessary SRS system repairs.

PARTS LIST

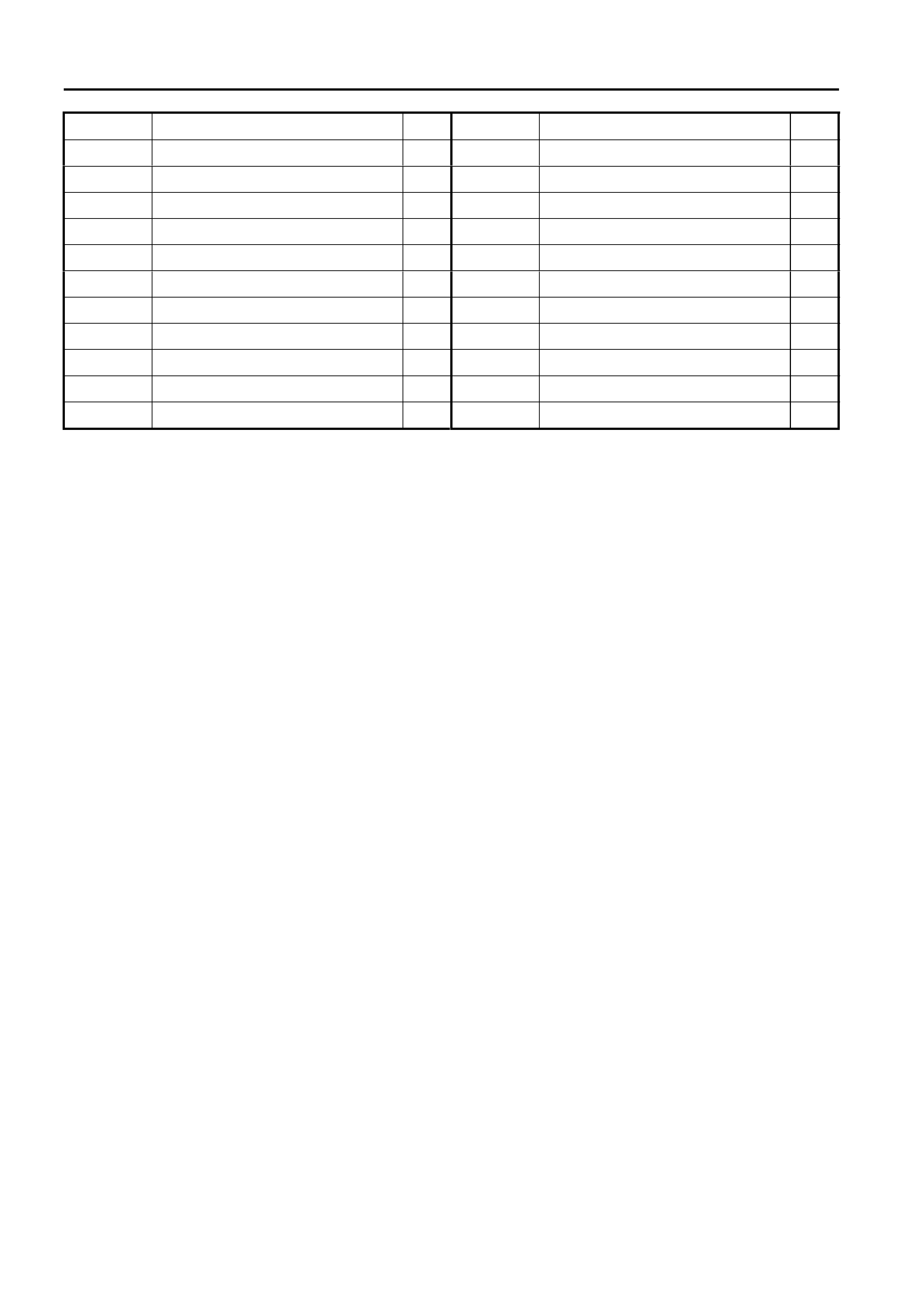

PART NO DESCRIPTION QTY PART NO DESCRIPTION QTY

92041796 Element Assembly – Air Cleaner 1 92056798 Bracket – Air Cleaner 1

92049209 Body – Air Cleaner Upper Complete 1 92056801 Joiner – Vent Tube 1

92052498 Clamp – Induction Tube 2 92057558 Hose – Crankcase Vent 1

92052506 Duct Assembly 1 92057565 Joiner 2

92053006 Housing – Air Cleaner Bottom 1 92057566 Clamp – Hose 2

92053315 Duct – Air Cleaner 1 92057573 Grommet – Throttle Body 1

92055702 Induction Tube 1 92058200 Grommet – Vent Hose 1

92055703 Hose – Inlet Air Mass Meter 1 92058201 Pocket Flange – Fuel 1

92055705 Hose – Heater Water Valve to Conv. 1 92058202 Washer – Filler Valve 1

92055706 Hose – Convertor to Engine 1 92058203 Nut – Filler Valve 1

92055707 Clamp – Hose to Body 4 92077227 Fuel Cap Asm. – LPG 1

92055708 Convoluted Tube – Hose Protector 5 92081206 Bracket – Convertor 1

92055714 Heat Shield – LPG Supply Pipe 1 92081623 Shield – Convertor heat 1

92055723 Label – LPG 2 92083934 Hose – Convertor to FCV 1

92055724 Label – LPG Instruction 1 92083935 Hose – Mixer to FCV 1