FITTING INSTRUCTIONS FOR

WH STATESMAN & CAPRICE (5.7 V8)

2100KG TOW BAR PACKAGE

Part Number 92145285

COPYRIGHT

Page 1 of 8

FD1047-1

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FD1047

28DE01

TOOLS REQUIRED:

TORX HEAD SCREW DRIVER (TORX BIT No. 20)

SCRAPER (FOR DEADENER REMOVAL)

HOT AIR GUN

DRILL

DRILL BIT, 11.0mm

METAL PRIMER

SILICONE OR BUTYL SEALER

SOCKET WRENCH

TORQUE WRENCH

SOCKETS: 10.0mm

16.0mm

2100KG TOW BAR FITTING INSTRUCTIONS

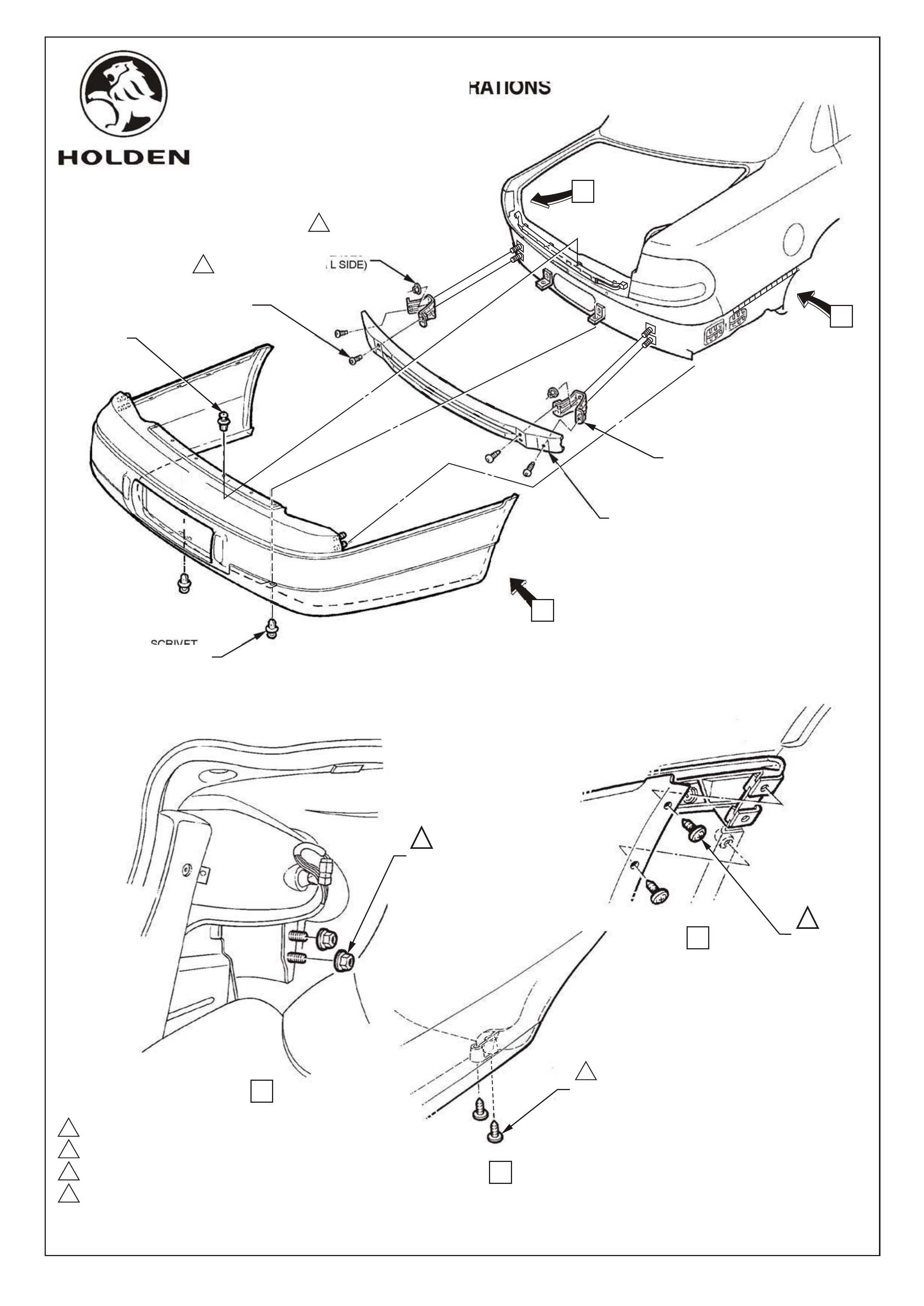

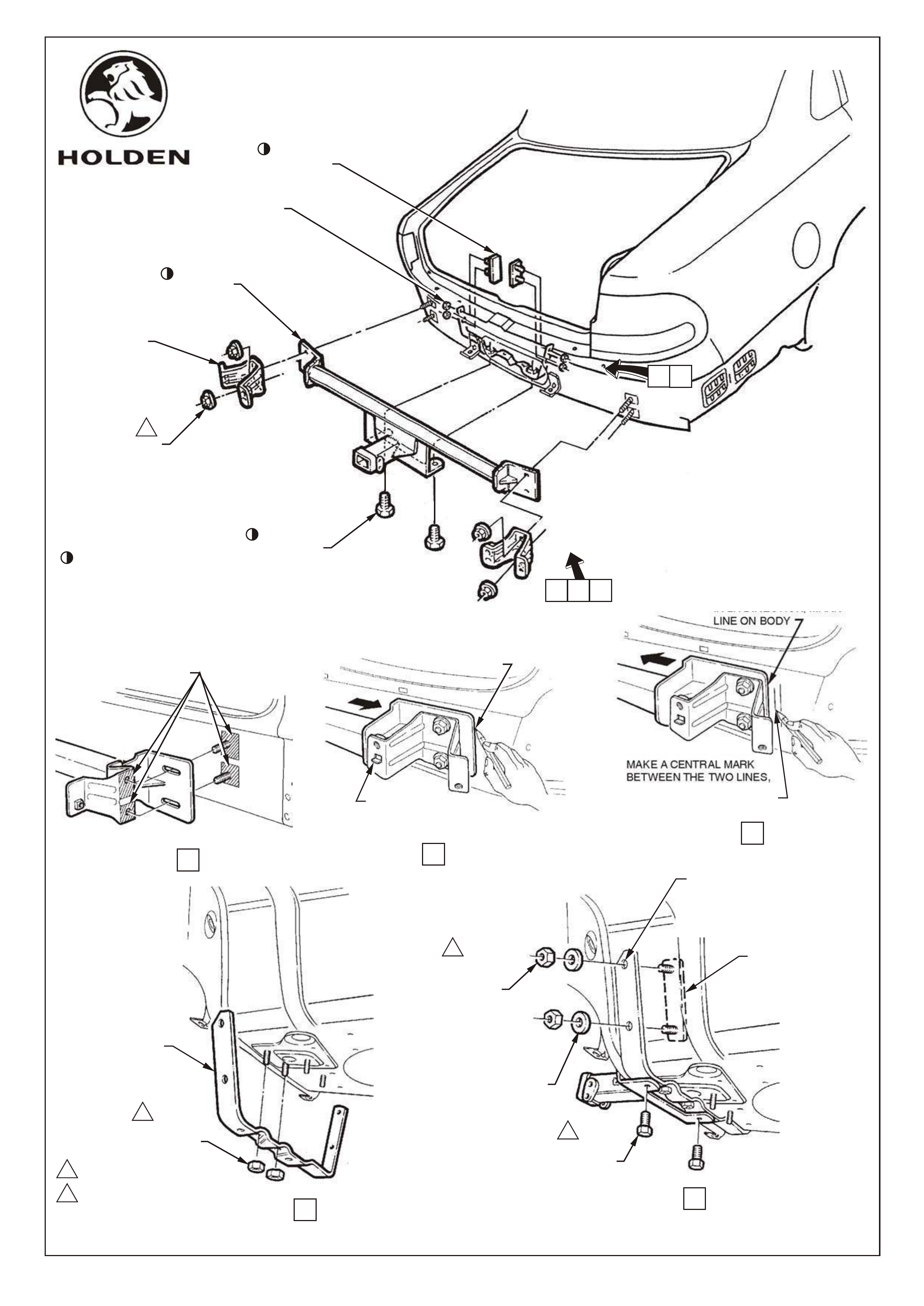

REAR BUMPER BAR SUPPORT BEAM & BRACKETS REMOVAL

Remove spare wheel cover and spare wheel from rear compartment.

Fold side carpets back from rear corners of boot compartment to access nuts securing bumper to body

refer figure 1, view A.

Remove nuts (2 places each side) refer figure 1, view A

Remove 4 scrivets at upper edge of facia, refer figure 1.

Remove 2 scrivets, lower facia edge, refer figure 1.

Remove 8 screws, facia to rear edge of wheelhouse, refer figure 1, views B and C.

With facia supported, pull facia sides outward disconnecting facia from side supports and slide rearwards

removing facia, refer figure 1.

Remove bolts securing bumper support beam to brackets. Refer figure 1.

Remove 4 nuts securing bumper support beam brackets to vehicle (4 places) and remove brackets,

refer figure 1.

1.

2.

3.

4.

5.

6.

7.

8.

9.

COPYRIGHT

Page 2 of 8

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FD1047-2

FD1047

28DE01

SMALL PARTS KIT

COVERBALL 92140106

92143024

92140068 TOW BALL ASSEMBLY (CHROME)

92140148 TRAILER WIRING HARNESS - ROUND 7 PIN (SMALL PIN WITH BACKING PLATE)

92140147 TRAILER WIRING HARNESS - ROUND 7 PIN (LARGE PIN)

92140088 TRAILER WIRING HARNESS - FLAT 7 PIN

92140101 PACKAGE - LOAD DISTRIBUTION HITCH (ADJUSTABLE)

NOT INCLUDED IN TOW BAR PACKAGE, BUT AVAILABLE SEPARATELY:

1,0 - 3,0 Nm

6,0 - 9,0 Nm

35,0 - 52,0 Nm

50,0 - 80,0 Nm

4

3

2

1

VIEW B

11

SCREW

(2 PLACES

R & L SIDE)

VIEW A

22

NUT

(2 PLACES

R & L SIDE)

Figure 1

Page 3 of 8

COPYRIGHT

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

NUT

(2 PLACES

R & L SIDE)

REAR BEAM

MOUNTING BRACKET

REAR BUMPER

SUPPORT BEAM ASM.

SCRIVET

(2 PLACES)

BOLT

(2 PLACES

R & L SIDE)

3

4

C

A

B

SCRIVET

(4 PLACES)

VIEW C

SCREW

(2 PLACES)

R & L SIDE

1

FD1047-3

FD1047

28DE01

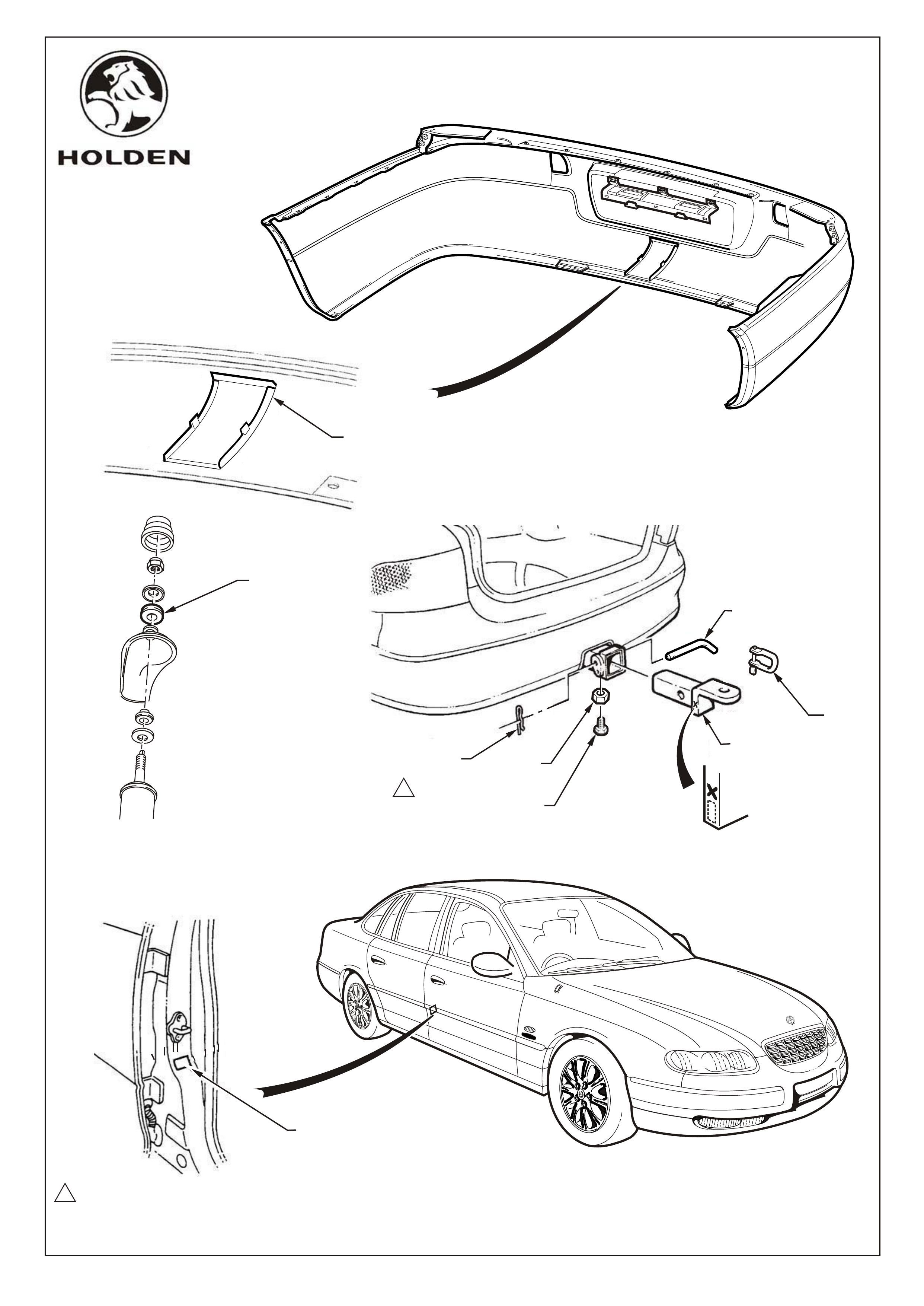

TOW BAR INSTALLATION

Smear a thin film of grease to bare metal exposed by removal of brackets, to vehicle body and rear face of

bracket to prevent corrosion, refer figure 2, view A.

Install spare wheel well brace assembly to underside of spare wheel well using two existing rearmost

weldstuds, refer figure 2, view D.

Loosely fit two M10 nuts to weld studs.

Install tow bar to 4 beam support studs, refit beam support brackets over tow bar mounting plates, fit nuts

and hand tighten (4 places).

NOTE : Brackets must be installed with tab on flange inboard of vehicle refer figure 2, view B.

Loosely fit two M10 bolts to attach tow bar main assembly to spare wheel well brace assembly.

IMPORTANT: Due to elongated holes in tow bar mounting plates, tow bar will have 10-15mm sideways

travel on rear of car. Tow bar must be accurately centralised on vehicle to ensure bumper

facia cutout aligns with tow bar tongue upon reassembly.

To centralise bar, first slide bar to extremity of travel to RH side of vehicle and mark position of edge of RH

mounting plate on body, refer figure 2, view B.

Slide bar across to extremity of travel to LH side of vehicle and mark RH mounting plate edge position

on body, refer figure 2, view C.

Make a central mark between these two lines (this will centre towbar) & reposition towbar to centre

line.

Tighten nuts securing beam support brackets and tow bar mounts to body, 50 - 80Nm (4 places),

refer figure 2.

Tighten nuts securing spare wheel well brace assembly to underbody weld studs, 30 - 40Nm,

(2 places)

Tighten bolts securing main tow bar assembly to spare wheel well brace assembly, 30 - 40Nm,

(2 places)

Use spare wheel well brace assembly as a template to drill two 10,0 dia. holes each side of spare

wheel well, refer figure 2, view E.

WARNING : Be sure spare wheel has been removed from spare wheel well before drilling holes.

Apply silicone or butyl sealer to holes for water sealing & corrosion protection purposes, 4 places.

Install two adhesive backed stud plates from inside spare wheel well, through holes in wheel well and spare

wheel well brace assembly.

From underside of vehicle attach flat washers and M10 nuts to stud plate studs,(4 places) refer figure 2,

view E.

Tighten spare wheel well brace assembly to stud plate nuts 30 - 40Nm (4 places).

Refit bumper beam, and tighten 35 - 52Nm.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

COPYRIGHT

Page 4 of 8

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FD1047-4

FD1047

28DE01

1

2

30,0 - 40,0 Nm

50,0 - 80,0 Nm

SLIDE TOW BAR TO

EXTREMITY OF TRAVEL

IN RH DIRECTION, MARK

LINE ON BODY

RH SHOWN

BRACKET MUST

BE INSTALLED

WITH TAB INBOARD

VIEW B

SLIDE TOW BAR TO

EXTREMITY OF TRAVEL

IN LH DIRECTION, MARK

LINE ON BODY

MAKE A CENTRAL MARK

BETWEEN THE TWO LINES,

ALIGN TOW BAR EDGE TO

THIS MARK TO CENTRALISE

TOW BAR

VIEW C

VIEW D

COAT BARE METAL

SURFACES WITH A

THIN FILM OF GREASE

RH SHOWN

VIEW A

NUT

(2 PLACES)

1

SPARE WHEEL

WELL BRACE

ASSEMBLY.

VIEW E

1

STUD PLATE

(2 PLACES)

FLAT

WASHER

(2 PLACES

R & L SIDE)

NUT

(2 PLACES

R & L SIDE)

1

BOLT

(2 PLACES)

USE SPARE WHEEL WELL BRACE

ASSEMBLY AS A TEMPLATE TO

DRILL 10.0 DIA. HOLES

(2 PLACES EACH SIDE)

Figure 2

COPYRIGHT

Page 5 of 8

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

REAR BUMPER

BEAM SUPPORT

BRACKET

NUT

(2 PLACES

R &L SIDE)

2

PART OF TOW BAR PACKAGE

BOLT

(2 PLACES)

NUT

(2 PLACES)

TOW BAR

ASSEMBLY

C

A B

E

D

STUD PLATE

(2 PLACES)

FD1047-5

FD1047

28DE01

Install tow bar tongue to tow bar assembly using retainer pin and safety clip, refer figure 3.

Check "X" stamp on side of tongue to verify part.

NOTE : Align studs on facia correctly through holes in body, below tail lights.

Reinstall facia in reverse to removal procedure.

hitch mounting tube, refer figure 3.

Before facia refit, knock out section in centre of bumper facia to allow protusion of bar

Clean surface of driver's side B pillar and apply ADR label, refer figure 3.

duty insulators supplied in towing package, refer figure 3.

Replace existing shock absorber top mount insulators (rubber) with yellow polyurethane heavy

Install trailer wiring harness as per fitting instructions included in trailer wiring harness package

33.

32.

31.

Install anti-rattle bolt and nut. Tighten nut 5 - 10Nm.

IMPORTANT : Anti-rattle bolt and nut must only be used when tow bar is unladen. Remove

anti-rattle bolt and nut when tow bar is loaded.

30

29.

28.

27.

COPYRIGHT

Page 6 of 8

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

NOTE: Once tow bar installation is complete, place Fitting Instruction booklet in glove box of vehicle.

FD1047-6

FD1047

28DE01

5 - 10 Nm

1

SAFETY CLIP

Figure 3

COPYRIGHT

Page 7 of 8

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

WIPE SURFACE CLEAN PRIOR

TO APPLICATION OF ADR LABEL

BUMPER FACIA

KNOCKOUT

TOW BAR

TONGUE

NUT M10

1

ANTI -RATTLE BOLT M10 x 25

(ONLY USE WHEN UNLOADED)

TOP

INSULATOR

RETAINER

PIN

FD1047-7

FD1047

28DE01

'D' RING

"X" STAMP MARK

ON SIDE OF TONGUE

2100 KG TOW BAR PACKAGE

FOR WH STATESMAN & CAPRICE (5.7 V8)

Part number 92145285

92145225 PACKAGE - TONGUE TOW BAR 1

92145220 PIN & CLIP 1

FD796 WARRANTY CARD 1

FD908 TOW BAR FITTING INSTRUCTION BOOKLET 1

ADR LABEL 1

NUT M10mm 1

BOLT ANTI RATTLE M10 x 25mm 1

BOLT M12 x 25 2

FLAT WASHER M10 8

M10 - STUD PLATE ASM. 2

BOLT M10 x 25 2

92054275 BRACE ASSEMBLY - SPARE WHEEL WELL 1

NUT M10 6

92076518 TOW BAR MAIN ASSEMBLY 1

92059988 TOW BAR PACKAGE CONSISTS OF :

SMALL PARTS KIT

COVERBALL 92140106

92143024

92140068 TOW BALL ASSEMBLY (CHROME)

92140148 TRAILER WIRING HARNESS - ROUND 7 PIN (SMALL PIN WITH BACKING PLATE)

92140147 TRAILER WIRING HARNESS - ROUND 7 PIN (LARGE PIN)

92140088 TRAILER WIRING HARNESS - FLAT 7 PIN

92140101 PACKAGE - LOAD DISTRIBUTION HITCH (ADJUSTABLE)

NOT INCLUDED IN TOW BAR PACKAGE, BUT AVAILABLE SEPARATELY:

FD1047

28DE01

COPYRIGHT

Page 8 of 8

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

PARTS LIST

92077203 'D' RING SAFETY SHACKLE 2

M40803 INSULATOR - SHOCK ABSORBER TOP MOUNTING 2

92053241 PACKAGE - HEAT SHIELD, CENTRE BEARING 1

PART NO. DESCRIPTION QUANTITY

FD1047-8

92059847 PACKAGE - HEAT SHIELDS, UNDER CARPET 1