FITTING INSTRUCTIONS FOR

XC BARINA

FRONT MUD FLAPS

Part No. 92144464

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of General Motors - Holden's Automotive Limited ACN 006 893 232

FD1009

COPYRIGHT

Page 1 of 3

FD1009

05MY01

COPYRIGHT

Page 2 of 3

HOLDEN SERVICE PARTS OPERATIONS

prohibited without written approval

Reproduction in whole or part

Division of HOLDEN Ltd ACN 006 893 232

FD1009

05MY01

FD1009

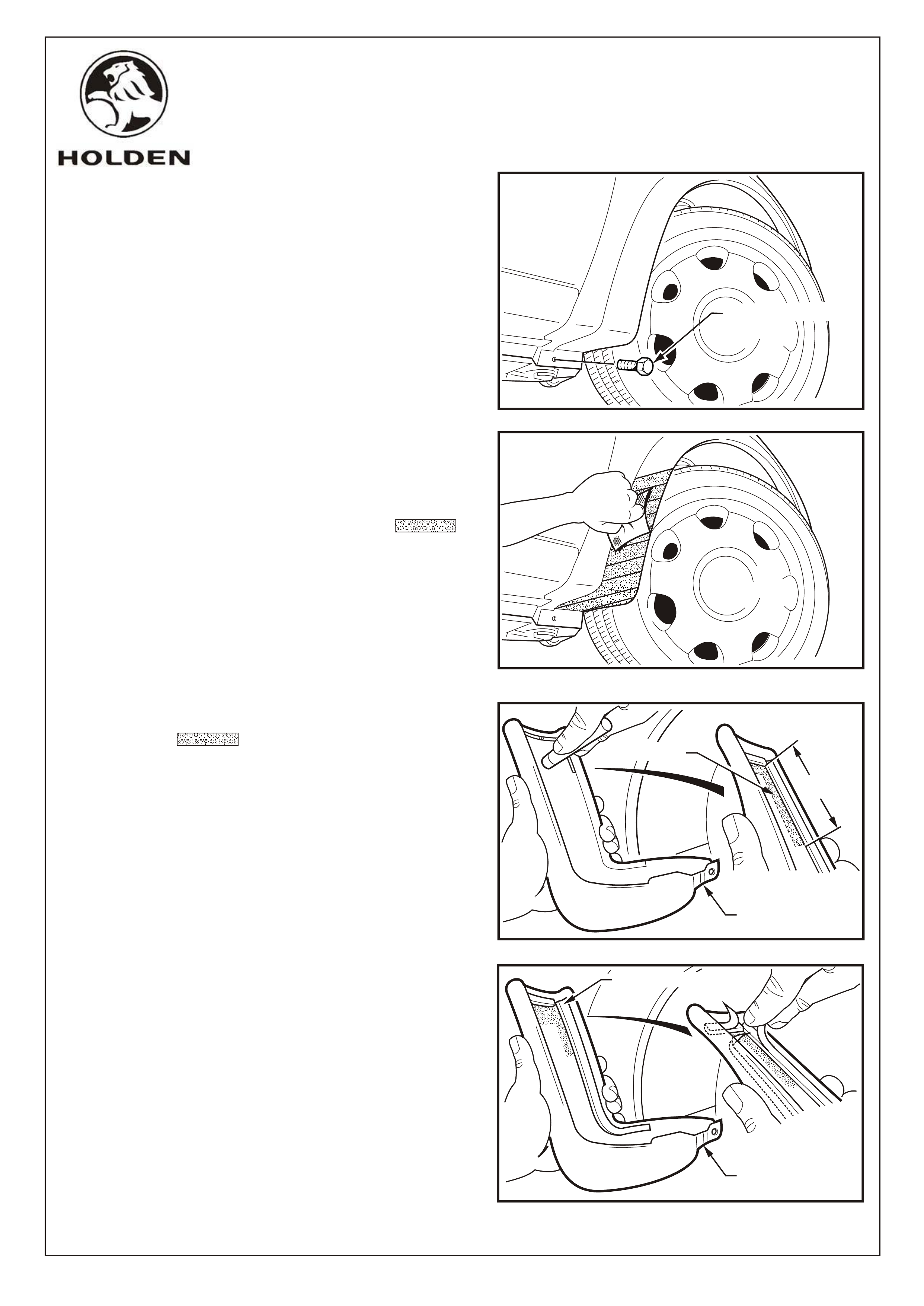

FIGURE 1

FIGURE 2

FIGURE 3

FIGURE 4

MUD FLAP

75mm

3M

PRIMER

MUD FLAP

PROTECTIVE

TAPE

REMOVE EXISTING

SCREW

FITTING INSTRUCTIONS

1. Remove screw from lower rear facia and discard.

Refer Figure1.

2. Thoroughly clean any road grime from the mating

surface of the wheel arch to which the mud flap

attaches. Using the alcohol wipe supplied in the

package, wipe the contact area shown

on the wheel arch to prepare the surface for the

adhesive application. Refer Figure 2.

3. Prepare surface area of adhesive application

shown on the mud flap, by using the

3M Primer 94 as supplied in the package. Refer

Figure 3.

4. Peel a small amount of protective backing tape

from the adhesive strips on the mud flap. Refer

Figure 4

NOTE: The warranty is void, if the above

processes are not carried out.

TOOLS REQUIRED

Spanner 13mm, Screw Driver Philips Head, Betaseal

55402 polyurethane adhesive (P/N 92143609) &

Cleaning Cloth.

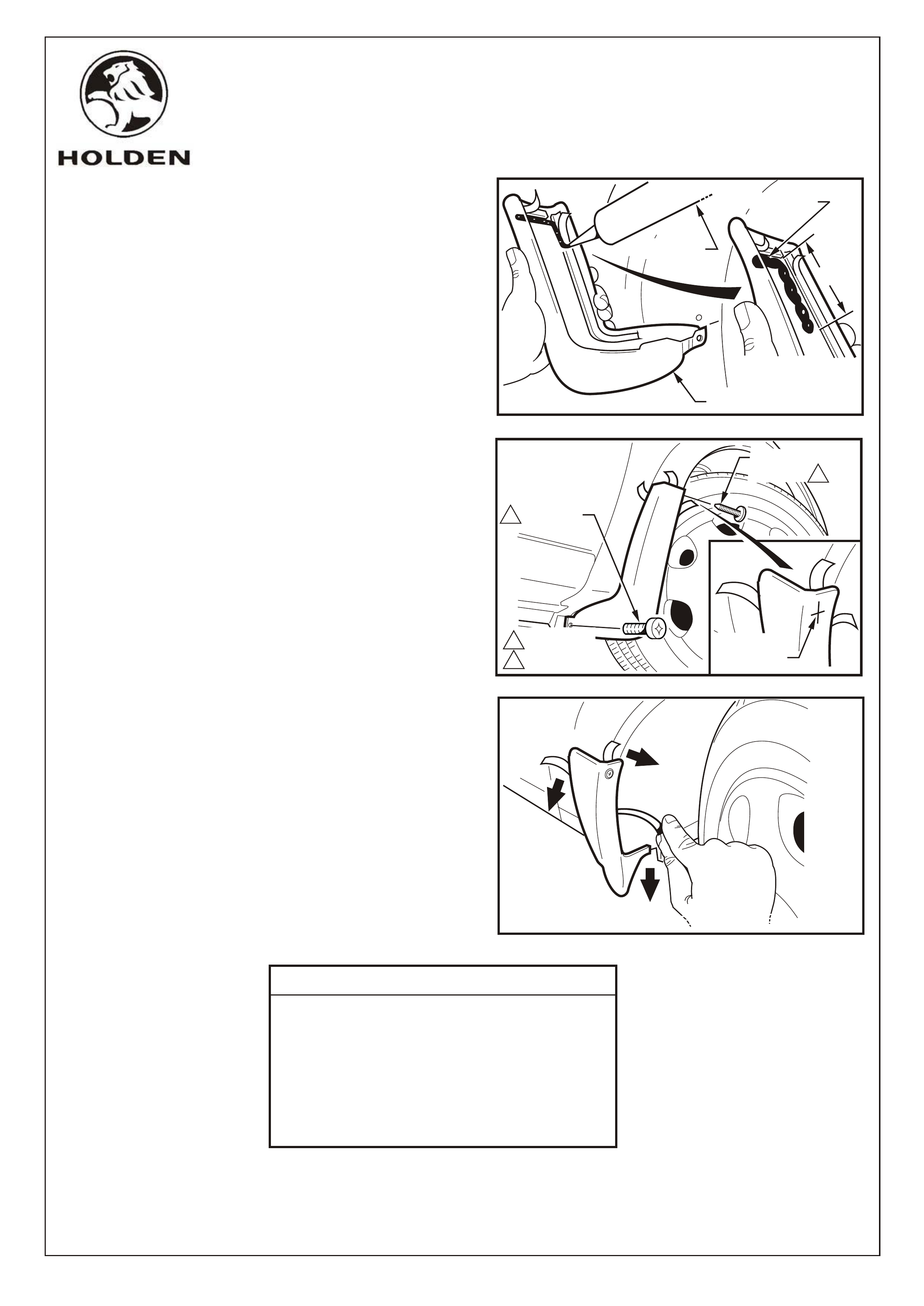

MUD FLAP

ADHESIVE

75mm

4mm DIA. BEAD

5.0 - 8.0 Nm

1

SELF-TAPPING

SCREW

SCREW

COPYRIGHT

Page 3 of 3

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FD1009

FIGURE 5

FIGURE 6

FIGURE 7

DESCRIPTION QUANTITY

MUDFLAP RH 1

MUDFLAP LH 1

3M PRIMER 94 1

ALCOHOL WIPE 2

SCREW SELF TAPPING 2

SCREW-MACHINE 2

FITTING INSTRUCTIONS-FD1009 1

PARTS LIST

SCREW

LOCATION

FITTING INSTRUCTIONS...continued

5. Apply a 4.0mm dia. bead of polyurethane adhesive

Betaseal 55402 over area as indicated on the

contact surface of the mud flap. Refer Figure 5.

6. Fit the mud flap to the vehicle and fix by installing

the self tapping screw and the machine screw

supplied in the package. Tighten to specified

torque. Refer Figure 6.

7. Pull the exposed backing strips from the adhesive

strips and apply pressure for to ensure permanent

adhesion. Allow 24 hours to attain full adhesion.

Refer Figure 7

8. Repeat fitting process to opposite side of the

vehicle.

9. Place fitting instructions in the vehicles glove box.

1.0 - 3.0 Nm

2

2

1

FD1009

05MY01