FD1100

16SE02

COPYRIGHT

Page 1 of 8

G681

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

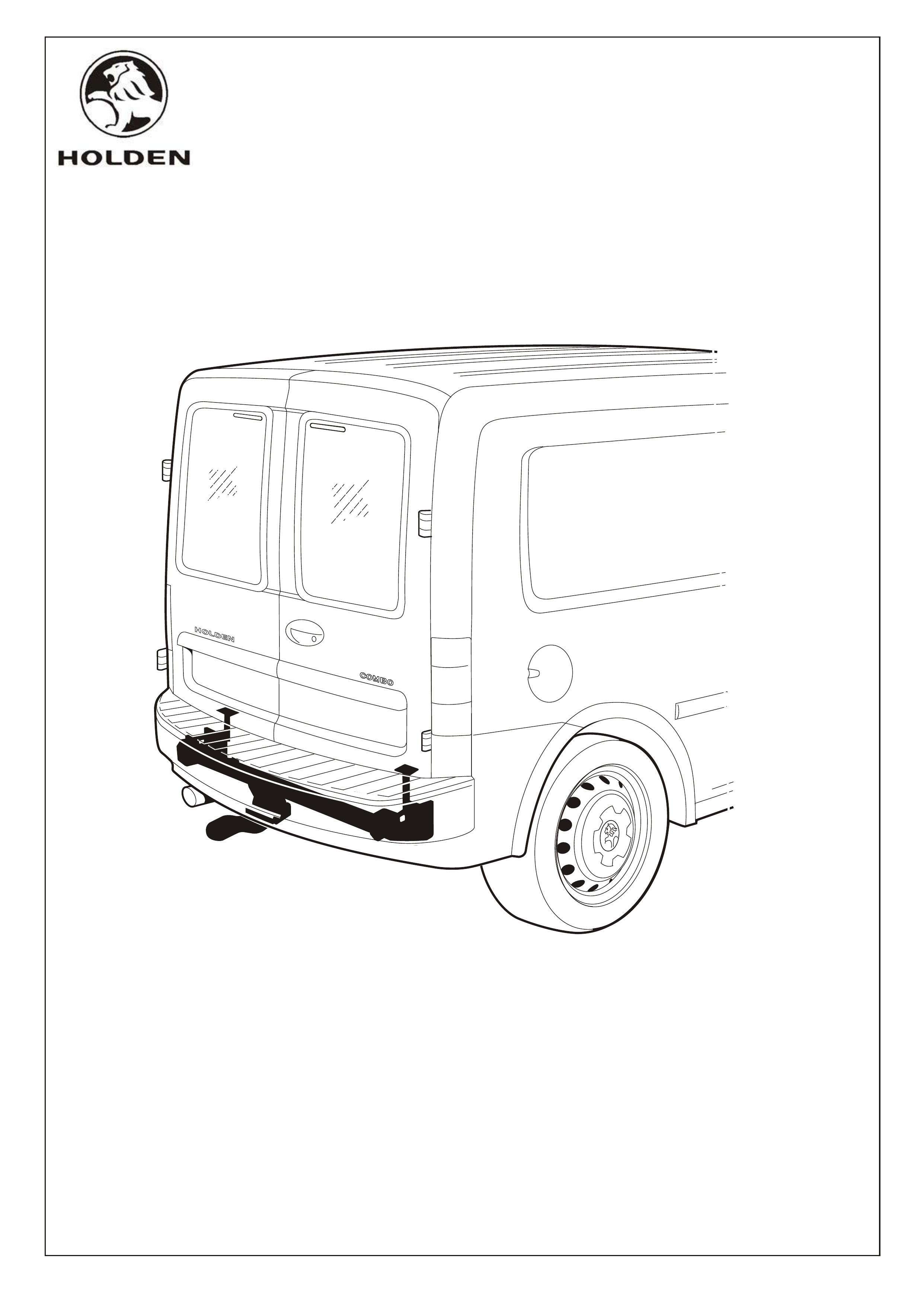

FITTING INSTRUCTIONS FOR

XC COMBO,1000kg TOWBAR PACKAGE

Part No. 92145397

FITTING INSTRUCTIONS:

NOTE: It is recommended to use a 2 post hoist, to ease

towbar assembly installation.

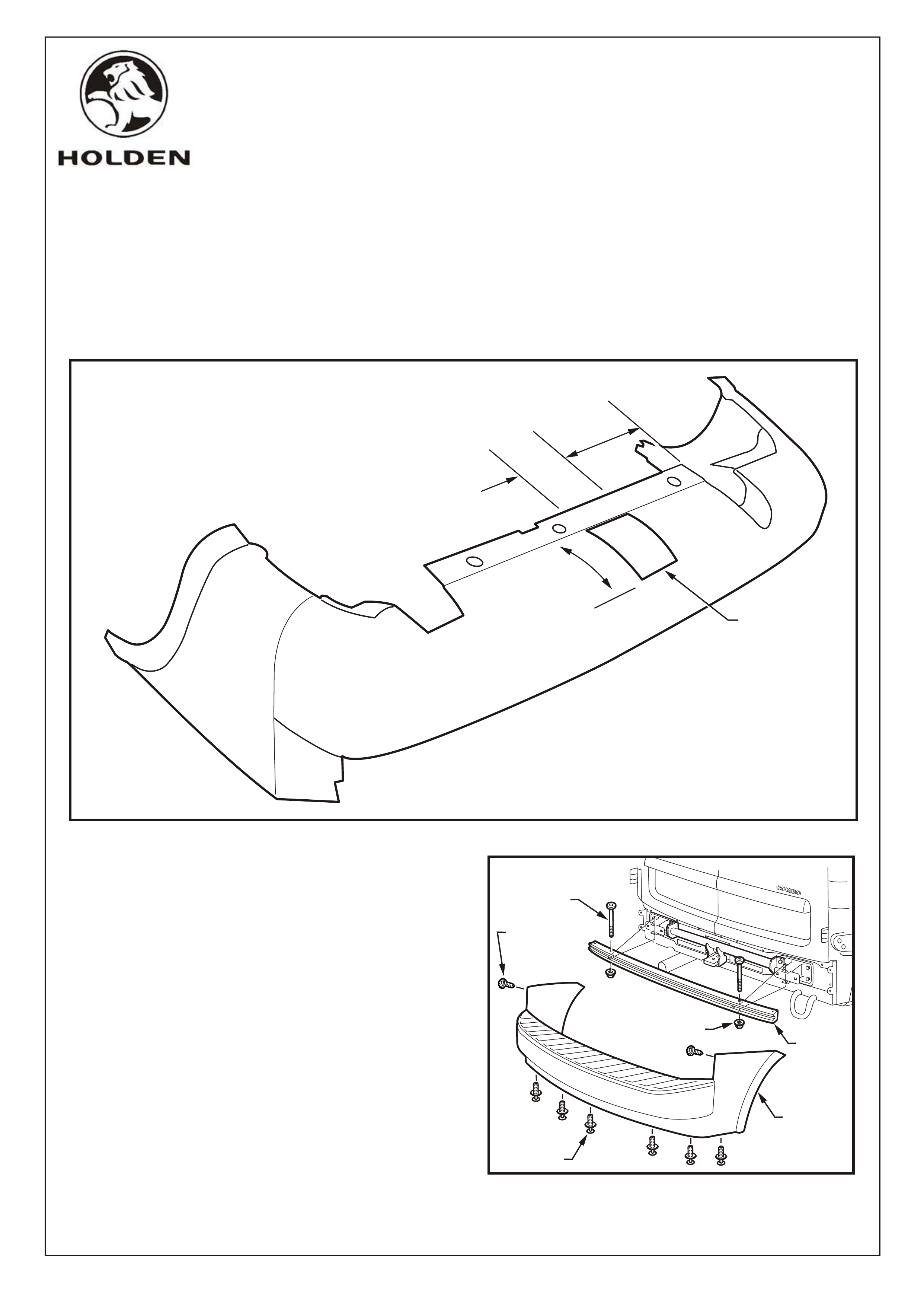

1. Place vehicle in position on hoist. Refer to owners

manual for correct jacking locations. Open the rear

cargo doors and remove the lower rear end trim panel

T25 Torx head screws - 9 places. Refer Figure 1.

Fold back the rear cargo floor carpet.

2. Unclip the rear wheel arch opening trim. Refer Figure 2.

3. Remove the rear bumper fascia, 2 screws and 6

scrivets. Refer Figure 3.

4. Remove the rear bumper fascia crash limiter (T45 x

65mm Torx head bolt and M8 nut - 2 places).

Refer Figure 3.

TOOLS REQUIRED:

2-Post Hoist, Torque Wrench, Socket Set, Spanner Set,

Torx Bit-T25, Torx Bit-T45, Power Drill, 3mm Dia. Drill Bit,

22mm Dia. Hole Saw, 11mm.Dia. Drill Bit and Rust-proof

Paint.

FITTING INSTRUCTIONS FOR

XC COMBO,1000kg TOWBAR PACKAGE

Part No. 92145397

COPYRIGHT

Page 2 of 8

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

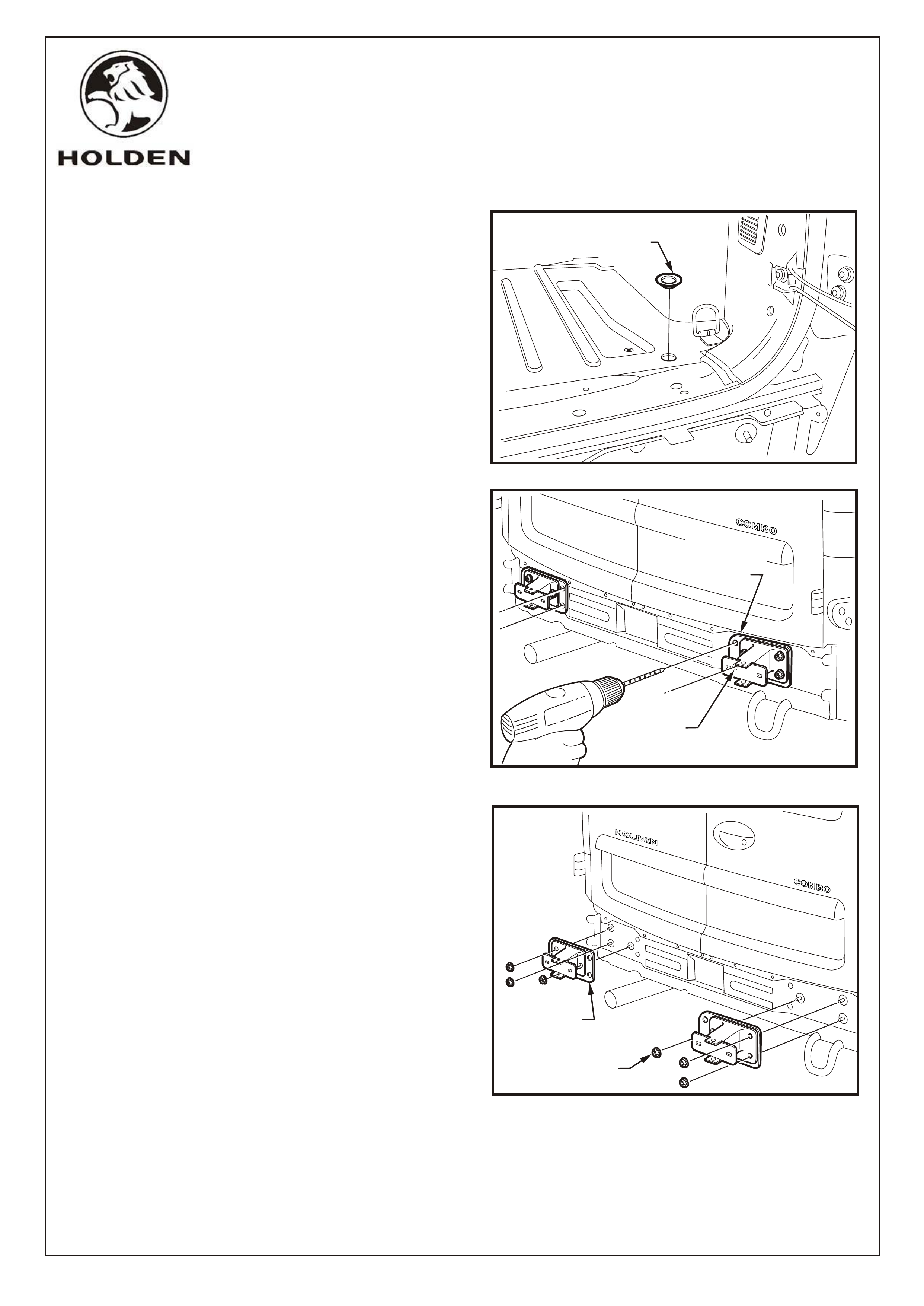

FIGURE 1

FD1100

16SE02

G681

REAR WHEEL ARCH

OPENING TRIM

FIGURE 2

FIGURE 3

REAR

BUMPER

CRASH

LIMITER

T45 x 65MM TORX

HEAD BOLT

SCREW

2 PLACES

SCRIVET

6 PLACES

M8 NUT

2 PLACES

REAR

BUMPER

FASCIA

SCREWS

9 PLACES

REAR END

TRIM PANEL

DRILL A 3.0mm

DIA HOLE 2 PLACES

R & LH SIDE

COPYRIGHT

Page 3 of 8

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FD1100

16SE02

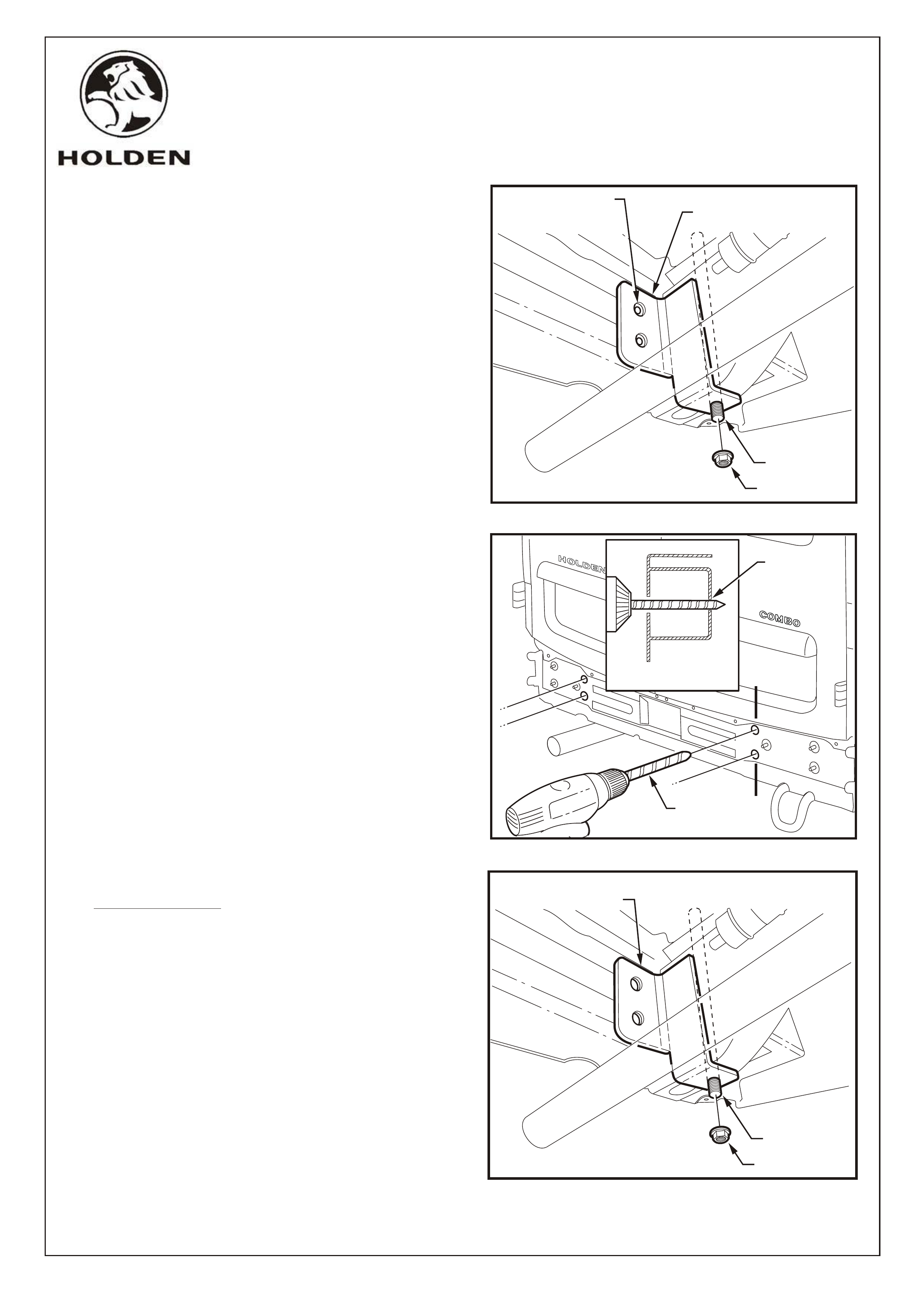

FIGURE 4

FIGURE 6

G681

FITTING INSTRUCTIONS: - continued.

5. Remove the left and right-hand side blanking

grommets from the cargo floor near the rear opening.

Refer Figure 4.

NOTE: If the XC combo trailer harness (92146212) is

being fitted, refer to fitting instructions FD1099 at this

point.

6. Using the existing bumper fascia impact absorber

brackets as templates, drill pilot holes in the rear panel

through the inner vacant holes using a 3mm Dia. drill bit

(4 places). Refer Figure 5.

7. Remove the left and right hand side bumper fascia

impact absorber brackets (3 nuts - left and right hand

side). Refer Figure 6.

FIGURE 5

BLANKING

GROMMET

IMPACT

ABSORBER

BRACKET

NUTS

3 PLACES

IMPACT

ABSORBER

BRACKET

COPYRIGHT

Page 4 of 8

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FD1100

16SE02

FIGURE 7

FIGURE 8

FIGURE 9

G681

FITTING INSTRUCTIONS: - continued.

8. Using a 22mm Dia. hole saw, enlarge the pilot holes

previously drilled (Step 6) in the rear panel (4 places).

Refer Figure 7.

IMPORTANT: When drilling across the box channel,

the 22mm Dia.hole saw is used for alignment purposes

only, DRILL A PILOT HOLE ONLY.

Ensure the drill bit remains square with the rear of the

vehicle and parallel to the cargo floor.

9. Through the holes drilled in Step 8, and with the 22mm

Dia. hole saw still fitted, drill a PILOT HOLE ONLY

through the opposite side of the box channel. Refer

Figure 8.

10. Assemble the coach bolt, cargo bracket and long

spacer tube (17.3mm OD) and fit to the existing hole in

the cargo floor (left and right-hand sides).

Refer Figure 9.

SECTION A - A A

A

PILOT

HOLE ONLY

SECTION A - A A

A

22.0 mm DIA.

HOLE ONLY

CARGO

BRACKET

COACH

BOLT

SPACER

TUBE

COPYRIGHT

Page 5 of 8

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FD1100

16SE02

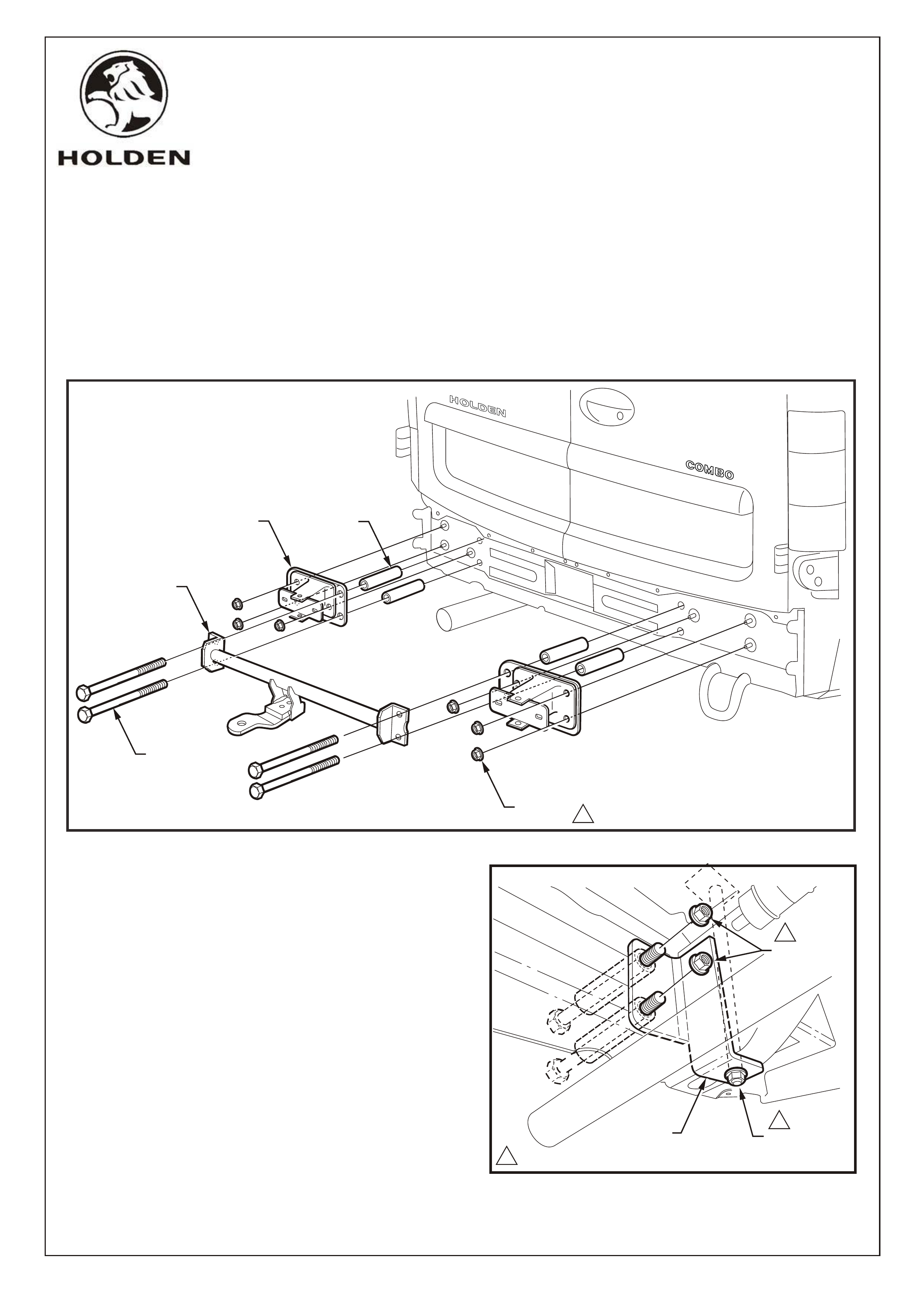

FIGURE 10

G681

FITTING INSTRUCTIONS: - continued.

11. From beneath the vehicle, temporarily install the

support bracket using M10 flange nut (left and right

hand side). Finger tighten only at this point.

Refer Figure 10.

12. Check that the pilot holes drilled in Step 9 are centred

with the towbar assembly mounting holes in the

support bracket (left and right-hand side).

Remove the support brackets.

If the pilot holes are correct, proceed with the

instructions. If the pilot holes are not correctly

positioned, adjust as necessary.

13. From the rear of the vehicle, enlarge the pilot holes

drilled in Step 11 using an 11mm Dia. drill bit.

Refer Figure 11.

14. Deburr all drilled holes and coat with rust proof paint.

15. Re-fit the support bracket (left and right hand side).

Finger tighten only. Refer Figure 12

COACH BOLT

SUPPORT

BRACKET

M10 FLANGE NUT

SECTION A - A A

A

11.0 mm DIA.

HOLE ONLY

FIGURE 12

COACH BOLT

SUPPORT

BRACKET

M10 FLANGE NUT

FIGURE 11

11.0 mm

DRILL BIT

TOWBAR ASSEMBLY

MOUNTING HOLES

& PILOT HOLES

COPYRIGHT

Page 6 of 8

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd ACN 006 893 232

FD1100

16SE02

FIGURE 14

FIGURE 13

G681

FITTING INSTRUCTIONS: - continued.

16. Assemble the towbar, the bumper fascia impact absorber brackets, the short spacers(22mm OD) and the M10 x 90

bolts.

With assistance, offer the towbar assembly up to the rear panel. Ensure the M10 x 90 bolts pass through the

support brackets fitted behind the box channel and that the impact absorber brackets mount on the original studs.

Refer Figure 13.

NOTE: Loosen the support bracket securing nuts to ease installation if necessary.

17. Reinstall the bumper fascia impact absorber bracket nuts and torque to specifications (3 places - left and right hand

side). Refer Figure 13.

18. Secure the towbar assembly to the support brackets

using M10 flange nuts, 2 places (left and right-hand

side).

Torque M10 flange nuts to specifications (6 places).

Refer Figure 14

144 Nm

IMPACT

ABSORBER

BRACKET

SHORT

SPACER

4 PLACES

M10 x 90

BOLT

4 PLACES

TOWBAR

NUT

6 PLACES 1

SUPPORT

BRACKET M10 FLANGE

NUT

M10 FLANGE

NUTS

1

1

COPYRIGHT

Page 7 of 8

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd Can 006 893 232

FD1100

16SE02

G681

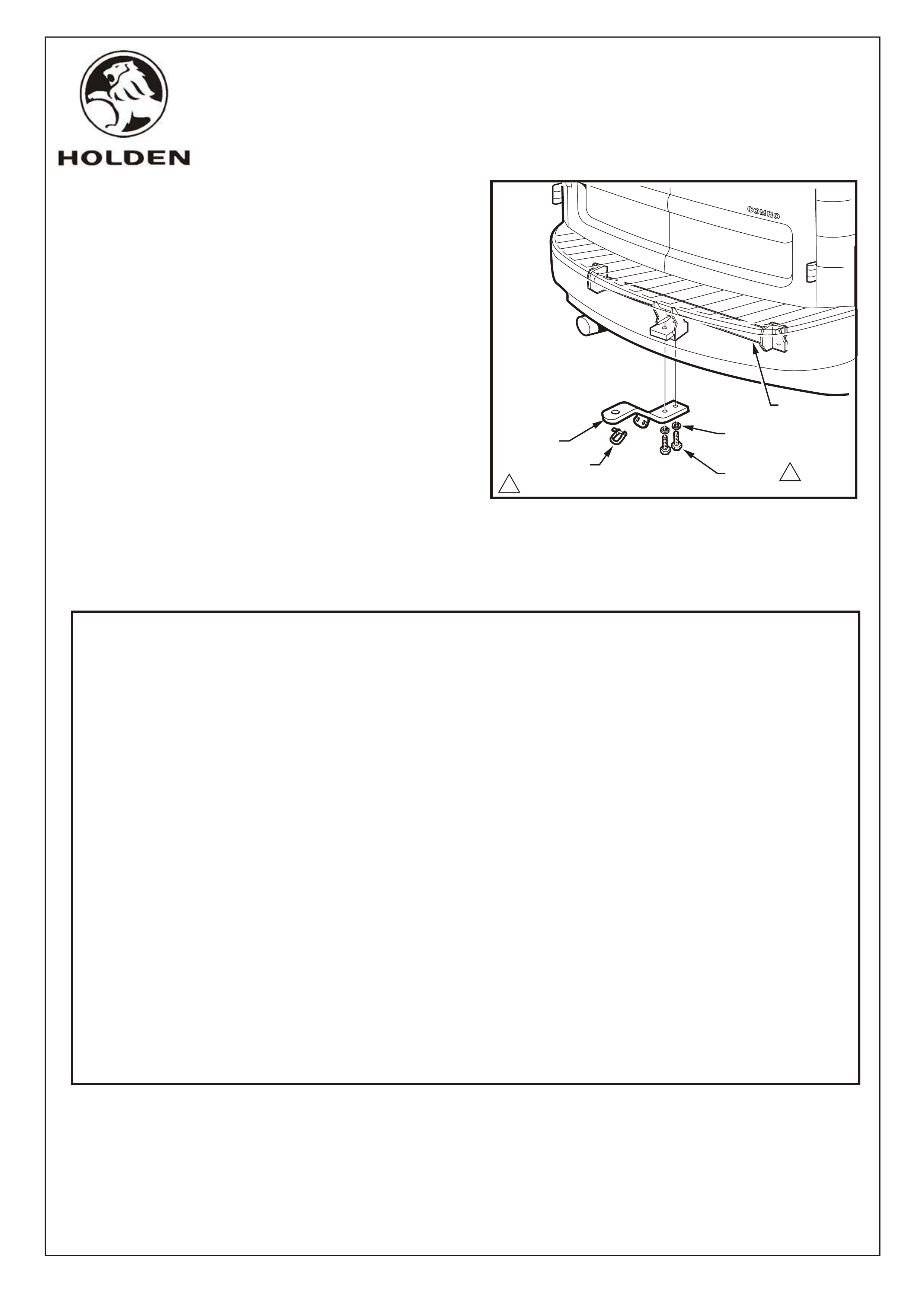

FIGURE 15

21. Reinstall the crash limiter. Torque M8 nuts to

specification.

NOTE: Ensure the trailer harness is installed before

reinstalling the bumper fascia.

Reinstall the bumper fascia.

Refer Figure 16.

120mm

260mm

140mm

CUTOUT

FIGURE 16

REAR

BUMPER

CRASH

LIMITER

T45 x 65MM TORX

HEAD BOLT

SCREW

2 PLACES

SCRIVET

6 PLACES

NUT

2 PLACES

REAR

BUMPER

FASCIA

FITTING INSTRUCTIONS: - continued.

19. Carefully mark the area of the bumper fascia to be cut out as indicated.

Refer Figure 15.

IMPORTANT: Re-check the measurements before cutting the bumper fascia.

20. Carefully cut out the marked section of the bumper fascia using a suitable saw.

NOTE: Take precautions to prevent damage to the bumper fascia.

COPYRIGHT

Page 8 of 8

HOLDEN SERVICE PARTS OPERATIONS

Reproduction in whole or part

prohibited without written approval

Division of HOLDEN Ltd Can 006 893 232

XC COMBO

1000kg TOWBAR PACKAGE (92145397)

PARTS LIST

PART NUMBER DESCRIPTION QUANTITY

TOWBAR ASSEMBLY 1

92145612 TOWBAR TONGUE 1

SUPPORT BRACKET - LHS 1

SUPPORT BRACKET - RHS 1

SPACER TUBE - 17.3 mm OD 2

SPACER TUBE - 22 mm OD 4

RUBBER HOSE SPACER 4

CARGO BRACKET 2

COACH BOLT 2

BOLT - M10 x 90 4

M10 NUT 6

HEX BOLT - M16 x 45 2

SPRING WASHER - M16 2

92077203 D-SHACKLE 1

ADR/USAGE LABEL 1

92146212 TRAILER HARNESS (INCLUDED) 1

FD1100 FITTING INSTRUCTIONS 1

FD1100

16SE02

G681

FITTING INSTRUCTIONS: - continued.

22. Fit the tongue to the towbar assembly using 2 M16 x 45

bolts and M16 spring washers. Refer Figure 17.

Torque to specifications.

23. Refit all removed parts ensuring fasteners are to

specified torques.

24. Place the fitting instructions in the vehicle glovebox.

FIGURE 17

180 - 90 Nm

TONGUE

TOW BAR

ASM.

D SHACKLE

M16 SPRING

WASHER

M16 BOLT 1