Precautions Page 2–1

Page 2–1

Section 2

Precautions

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to this Section,

and Section 00 Warnings, Cautions and Notes in the MY 2004 VY Regular Cab and Crew Cab Service

Information for correct workshop practices with regard to safety and/or property damage.

The body structure of VY Regular Cab and

Crew Cab vehicles has been developed using

complex design and d evelopment techniques.

In addition to meeting all required standards,

the vehicle body is also a critical part of the

overall safety systems. It is therefore

imperative the repair procedures described in

this Supplement are adhered to during all

vehicle body repairs.

1 General Information ...............................................................................................................................2

2 Electrical Precautions............................................................................................................................3

2.1 Electronic Devices................................................................................................................................................. 3

2.2 Before Repairing The Vehicle............................................................................................................................... 4

Radio and Audio Equipment................................................................................................................................. 4

Instrumentation...................................................................................................................................................... 4

Cellular Mobile Phones .........................................................................................................................................4

Paint Ovens............................................................................................................................................................ 4

Welding................................................................................................................................................................... 4

Location Of Electronic Control Devices .............................................................................................................. 5

3 Jacking Precautions ..............................................................................................................................8

3.1 Regular Cab............................................................................................................................................................ 8

3.2 Crew Cab ................................................................................................................................................................ 9

4 Plastic Components.............................................................................................................................10

4.1 Plastic Component Precautions......................................................................................................................... 10

4.2 Plastic Component Identification – Regular Cab .............................................................................................. 11

4.3 Plastic Component Identification – Crew Cab................................................................................................... 13

Precautions Page 2–2

Page 2–2

1 General Information

This Section, along with Section 00 Cautions

& Notes in the MY 2004 VY Regular Cab and

Crew Cab Service Information should be

thoroughly read and understood before any

repair work is commenced on VY Regular Cab

and Crew Cab vehicles.

With the following exceptions, VY Regu lar Cab and Crew Cab Precautions I nformation carries over from MY 2003 VY

Series vehicles.

• Electrical Precautions

• Jacking Precautions

• Plastic Components

For information not contained within this Section, refer to Section 2 Precautions in the MY 2003 VY and V2 Series

Service Information Supplement, Body Structure Repair.

This Section contains important information regarding the precautions that are to be observed when performing repair

work on VY Regular Cab and Crew Cab vehicles.

The reasons for these precaut ions are threefold.

Firstly, it is important that the safety of those repairing the vehicle is not compromised.

Secondly, it must be ensured that inadvertent damage is not caused to the vehicle during the preparation for, or during

the performance of, repairs to that vehicle.

Finally, it must be ensured that any relevant Federal an d State legislation is abided by.

Precautions Page 2–3

Page 2–3

2 Electrical Precautions

2.1 Electronic Devices

VY Regular Cab and Crew Cab vehicles are equipped with many electronic devices as standard equipment to monitor

and control various vehicle functions.

These electronic devices are susceptible to damage from severe shock, transient voltage and high temperatures.

Particular note should be taken of the

Powertrain Control Module (PCM), which is

located on the left-hand hinge pillar panel.

Heat, or transient voltage produced by spot,

MIG or arc welding techniques will cause

damage to the electrical components within

the PCM. Always disconnect the battery and

unplug and remove the PCM before repairing

the vehicle.

NOTE

It is worth noting that other equipment, such as

instruments, radios, mobile telephones and

various aftermarket accessories are also

controlled by electronics and are therefore

subject to similar precautions. Refer to

Figure 2–1 to Figure 2–3 for the electronic

devices and their locations.

Precautions Page 2–4

Page 2–4

2.2 Before Repairing The Vehicle

Disconnection of the battery affects certain

vehicle electronic systems. Refer to Section

00, 5 Battery Disconnectio n Procedures in the

MY 2003 VY Regular Cab Service Information

before disconnecting the battery.

1 Disconnect both the negative and positive cables from the battery terminals.

2 Unplug the harnesses and re move the Powertrain Control Module (PCM) from the left side hinge pillar panel.

3 Check the area adjacent to the damage for electronic devices, particularly behind trim panels and under the

instrument panel.

4 Remove any units that may have been damaged in the impact or may be damaged d uring repairs.

Radio and Audio Equipment

Radios and other forms of audio equipment should be treated with due care. Before removing the equipment or

commencing repairs to the vehicle, consult the radio operator’s manual accompanying the vehic le for precautionary

details. Always disconnect both the negative and positiv e ca bles from the battery terminals. Never have the radio

operating while repairi ng the vehicle.

Instrumentation

The instruments can be damaged by impact or temperatures above 80°C. Always remove the instrument cluster before

subjecting the vehicle to temperatures above 80°C.

Cellular Mobile Phones

Transient voltage and magnetic pulses can easily damage mobil e phones and other communications equipment. Such

communications equipment sometimes has the control unit mounted in the luggage compartment or in other out of sight

areas. Refer to the operator’s instructions ac companying the particular unit for precautions.

Paint Ovens

The high temperatures prod uced in a paint oven can damage the electronic control devices and some trim items in the

vehicle.

Remove all electronic devices, plastic or

fabric trim items and the instrument panel

assembly, before placing the vehicle in a

paint oven that will achieve temperatures

above 70°C.

Welding

MIG or arc welding produces transient voltages that may damage the electronic control devices unless the following

precautions are observed:

• Always disconnect the battery and disconnect the PCM before repairing any part of the vehicle.

• Ensure that the earth clamp is located as close as possible to the welding site.

• Check behind the panels being welded for wiring harnesses. Reposition an y harness to avoid damage.

• In the vicinity of the repairs, disconnect the wiring harness Body Earth Points.

• Remove any electronic control devices from areas near the damage, refer to Figure 2 – 1 to Figure 2 – 3.

Precautions Page 2–5

Page 2–5

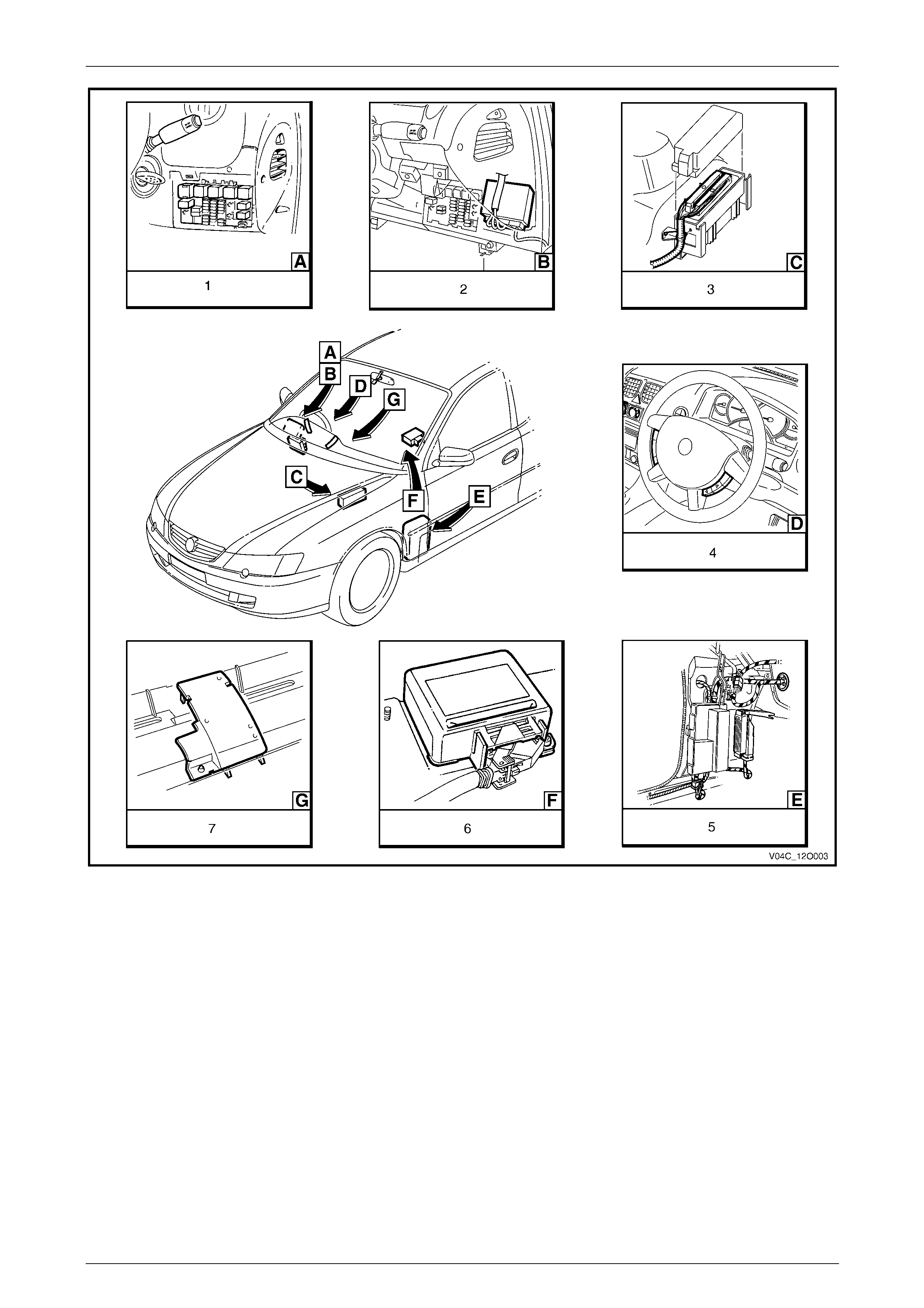

Location Of Electronic Control Devices

Figure 2 – 1

Legend

1 Fusible Links

2 Climate Control module

3 Relays & Fuses – Engine Compartment

4 Cruise Control Module

5 Powertrain Control Module (PCM) – V6 Engine

6 Direct Ignition System (DIS) Module – V6 Engine

7 ABS Hydraulic Modulator

Precautions Page 2–6

Page 2–6

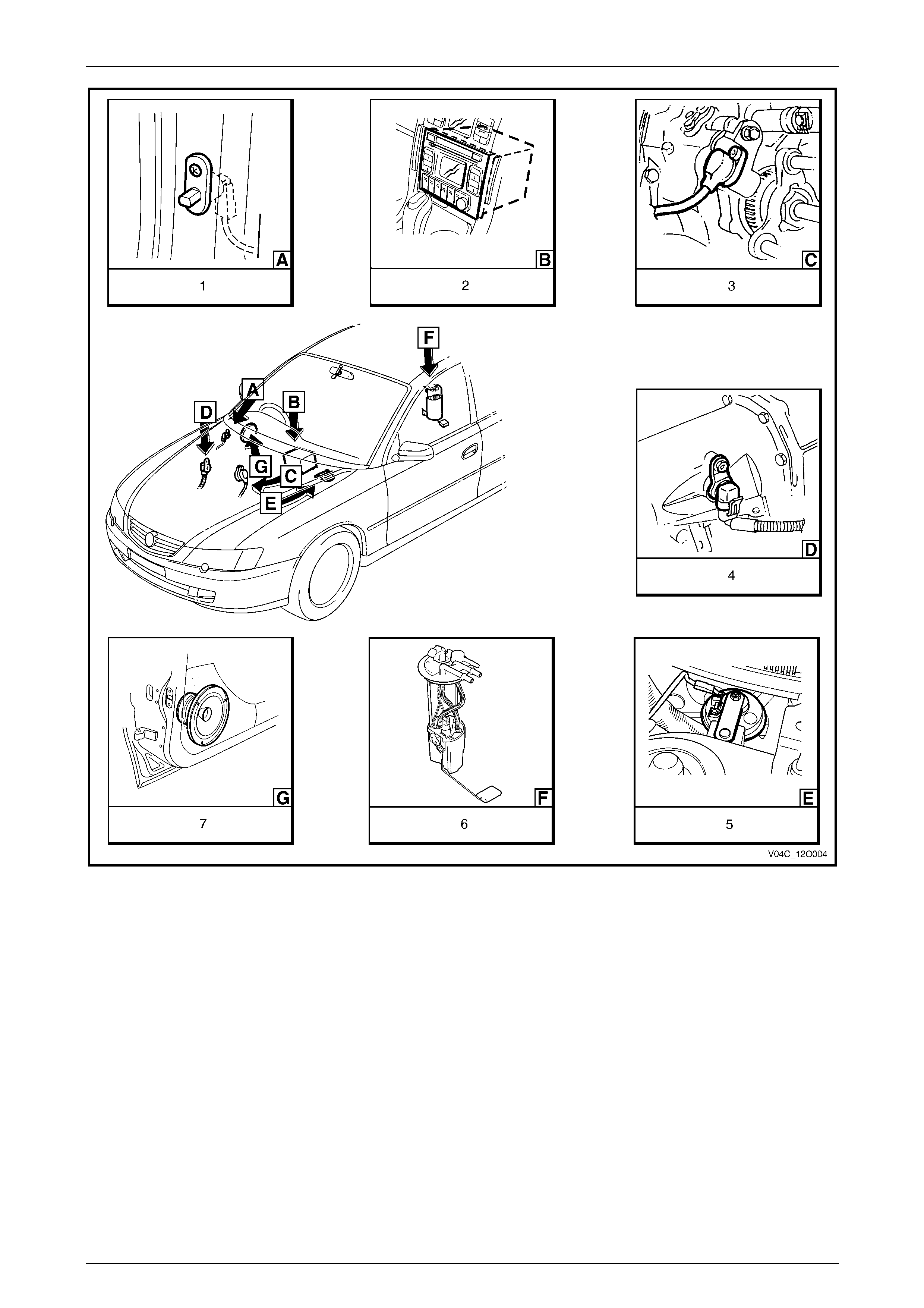

Figure 2 – 2

Legend

1 Relays & Fuses – Instrument Panel

2 Body Control Module

3 Powertrain Control Module – Gen III V8 Engine

4 Steering Wheel Radio & CD Player Controls

5 Powertrain Interface Module (PIM) – GEN III V8 Engine

6 Sensing & Diagnostic Module – Occupant Protection System

7 Remote Key Receiver and Ambient Light Sensor

Precautions Page 2–7

Page 2–7

Figure 2 – 3

Legend

1 Door Ajar Warning Switch

2 Radio Assembly

3 Vehicle Speed Sensor – Manual Transmission

(V6 shown, V8 similar)

4 Vehicle Speed Sensor – Automatic Transmission

5 Anti-theft Horn

6 Modular Fuel Pump & Sender Assembly

7 Front Door Speaker Assembly

Precautions Page 2–8

Page 2–8

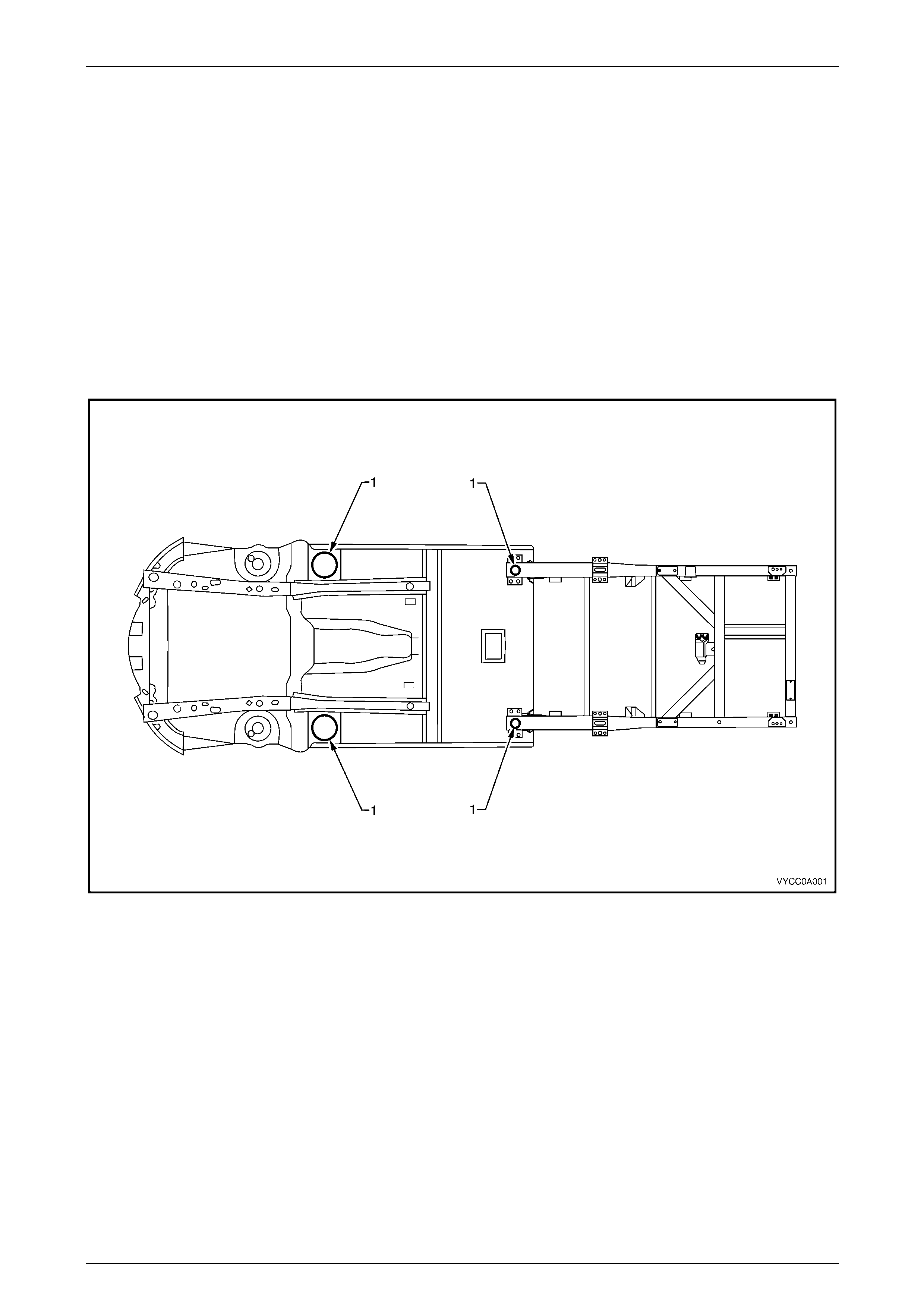

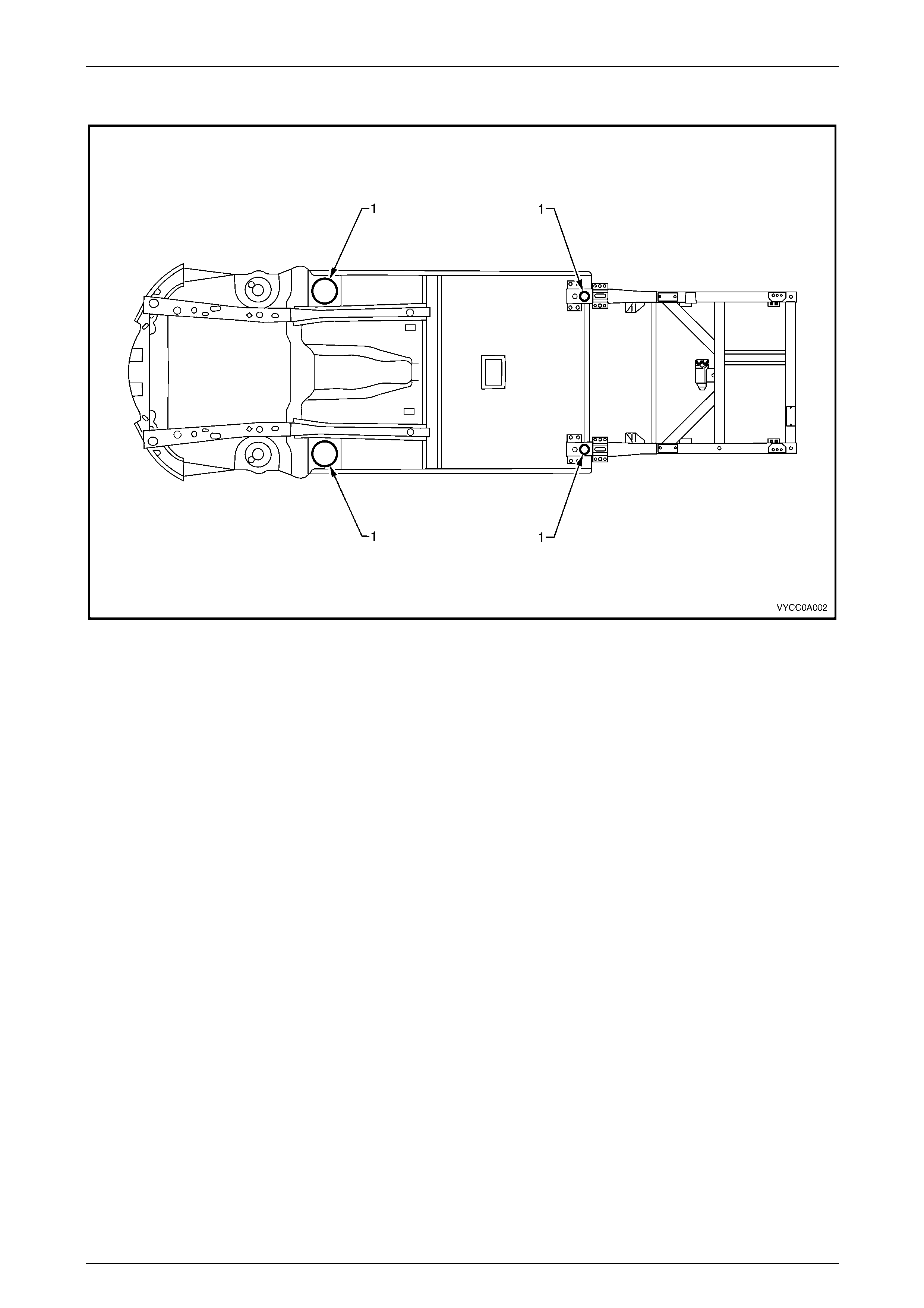

3 Jacking Precautions

NOTE

When using a trolley jack to raise the veh icle, it is

important that the jack be positioned under the

suspension crossmember or hoist pad locations

(1). Refer to Figure 2 – 4 for Regular Cab or

Figure 2 – 5 for Crew Cab.

Do not jack under the suspension control arms.

The vehicle should always be supported by jack

stands at the hoist pad locations when raised.

3.1 Regular Cab

Figure 2 – 4

Precautions Page 2–9

Page 2–9

3.2 Crew Cab

Figure 2 – 5

Precautions Page 2–10

Page 2–10

4 Plastic Components

4.1 Plastic Component Precautions

Plastic components are used throughout the vehicl e. The following chart is included to assist with the characteristics and

precautions to be taken with the most common types. The repair procedure for plastic bo dy parts must conform to the

type of plastic material.

Refer to 4.2 Plastic Component Identification for a listing of the main plastic components used throughout the vehicle and

the material from which they are made.

NOTE

Most components are also identified with the

material code in an incons picuous place.

Code Material Name

Heat Resisting

Temp* °C Resistance to Alcohol

or Gasoline Notes

ABS Acrylonitrile

Butadiene Styrene

Resin

80 Alcoh ol is harmless if applied

only for short time in small

amounts (i.e. quick wiping to

remove grease)

Avoid gasoline and organic

or aromatic solvents.

PC Polycarbonate 120 Alcohol is harmless. Avoid gasoline, brake fluid,

wax, wax removers and

organic solvents.

PP Polypropylene 80 Alcohol and gasolin e are

harmless. Most solvents are harmless.

UP Unsaturated

polypropylene 200 Alcohol and gasolin e are

harmless. Most solvents are harmless.

* Temperatures higher than those listed here may result in material deformation.

Precautions Page 2–11

Page 2–11

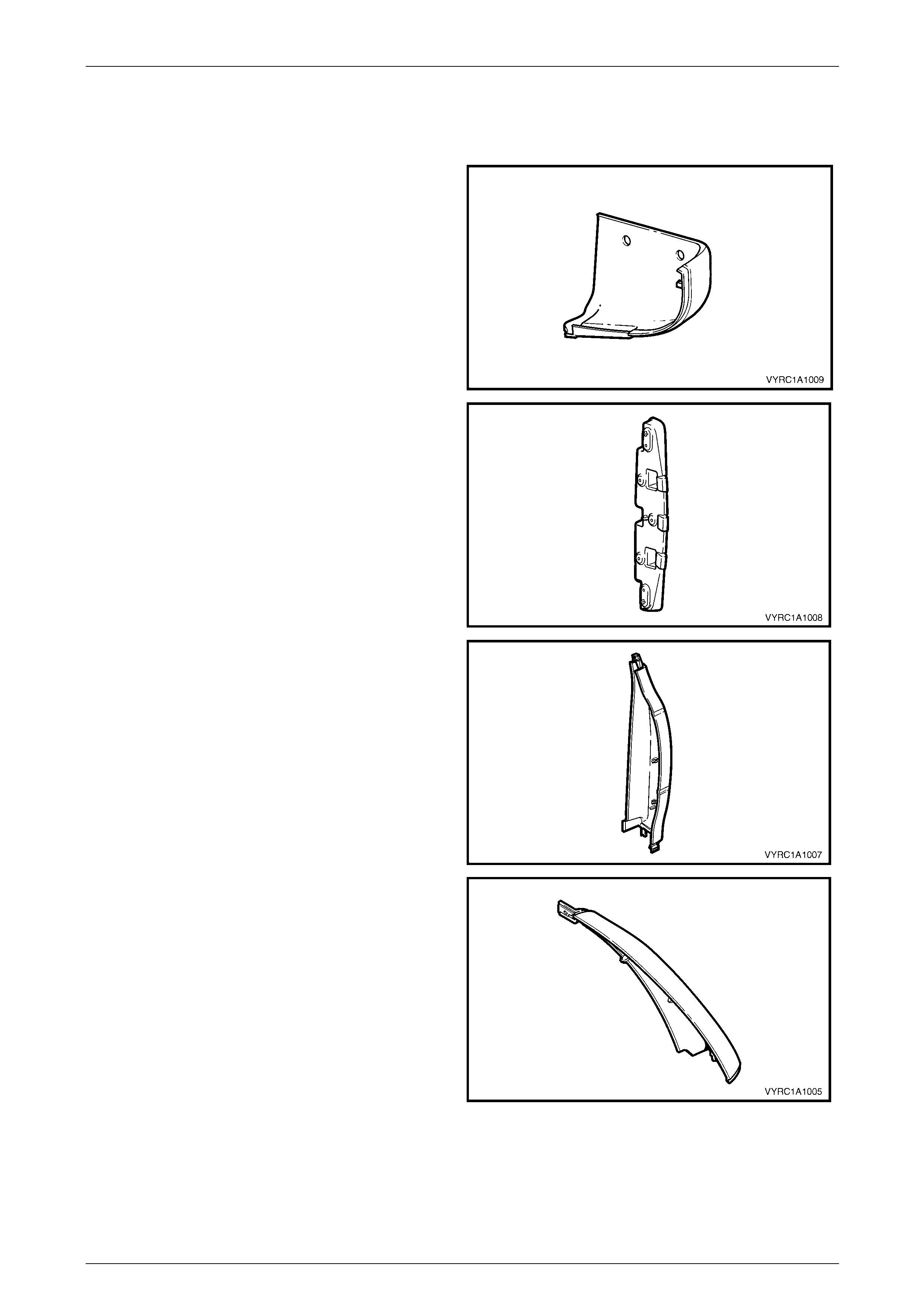

4.2 Plastic Component Identification –

Regular Cab

Rocker Panel Rear Moulding Assembly

Material:

PP

Body Side Rear Trim Panel Bracket

Material:

Nylon

30% F/Glass

Body Side Rear Trim Panel

Material:

ABS / PC

Rear Quarter Window Side Moulding Assembly

Material:

ABS / PC

Precautions Page 2–12

Page 2–12

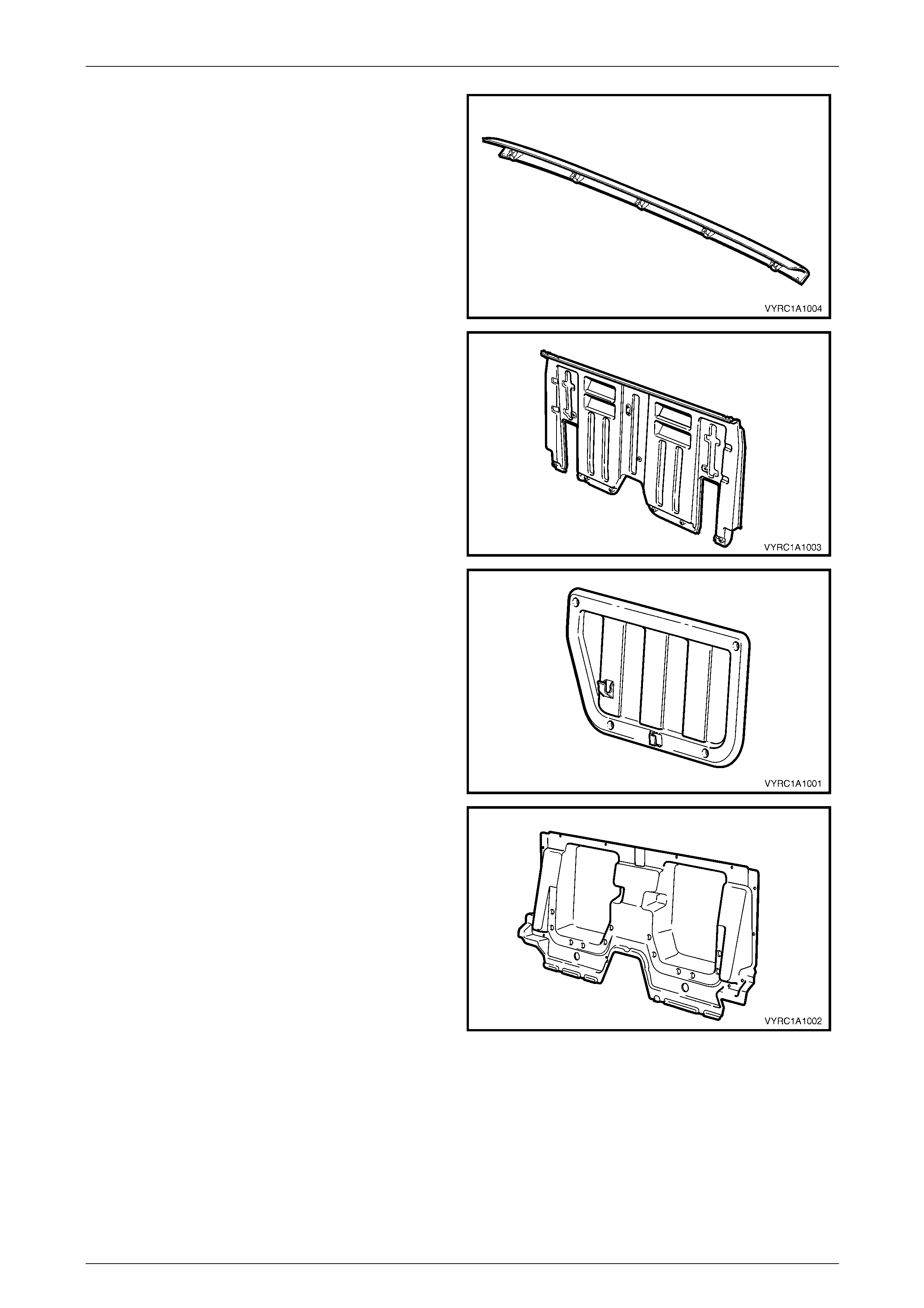

Rear Quarter Window Upper Mould ing Assembly

Material:

ABS / PC

Body Rear Outer Panel Assembly

Material:

PP

Rear Seatback Body Panel Trim Panel Asse mbly

Material:

PP

Body Rear Inner Panel

Material:

UP

Precautions Page 2–13

Page 2–13

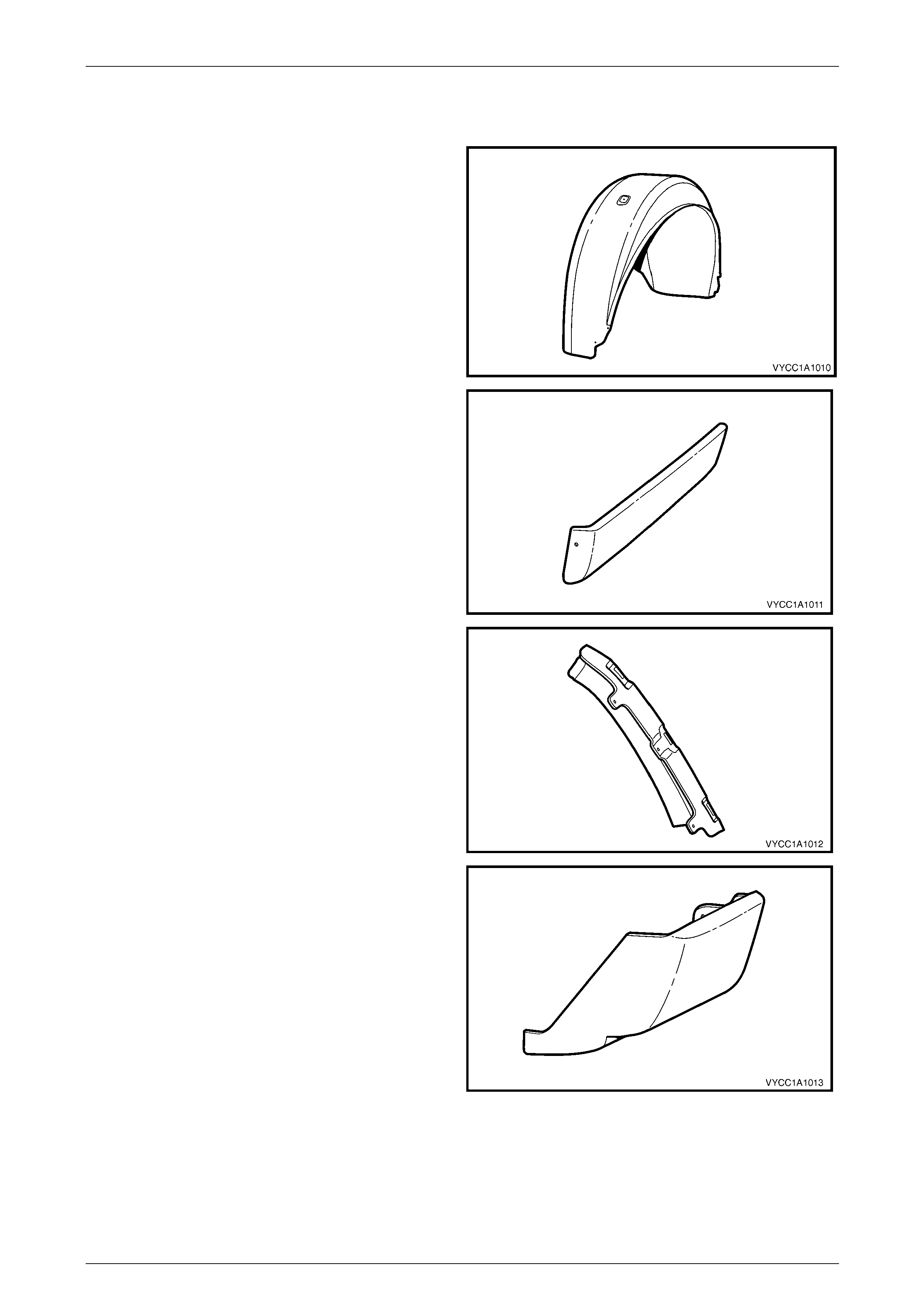

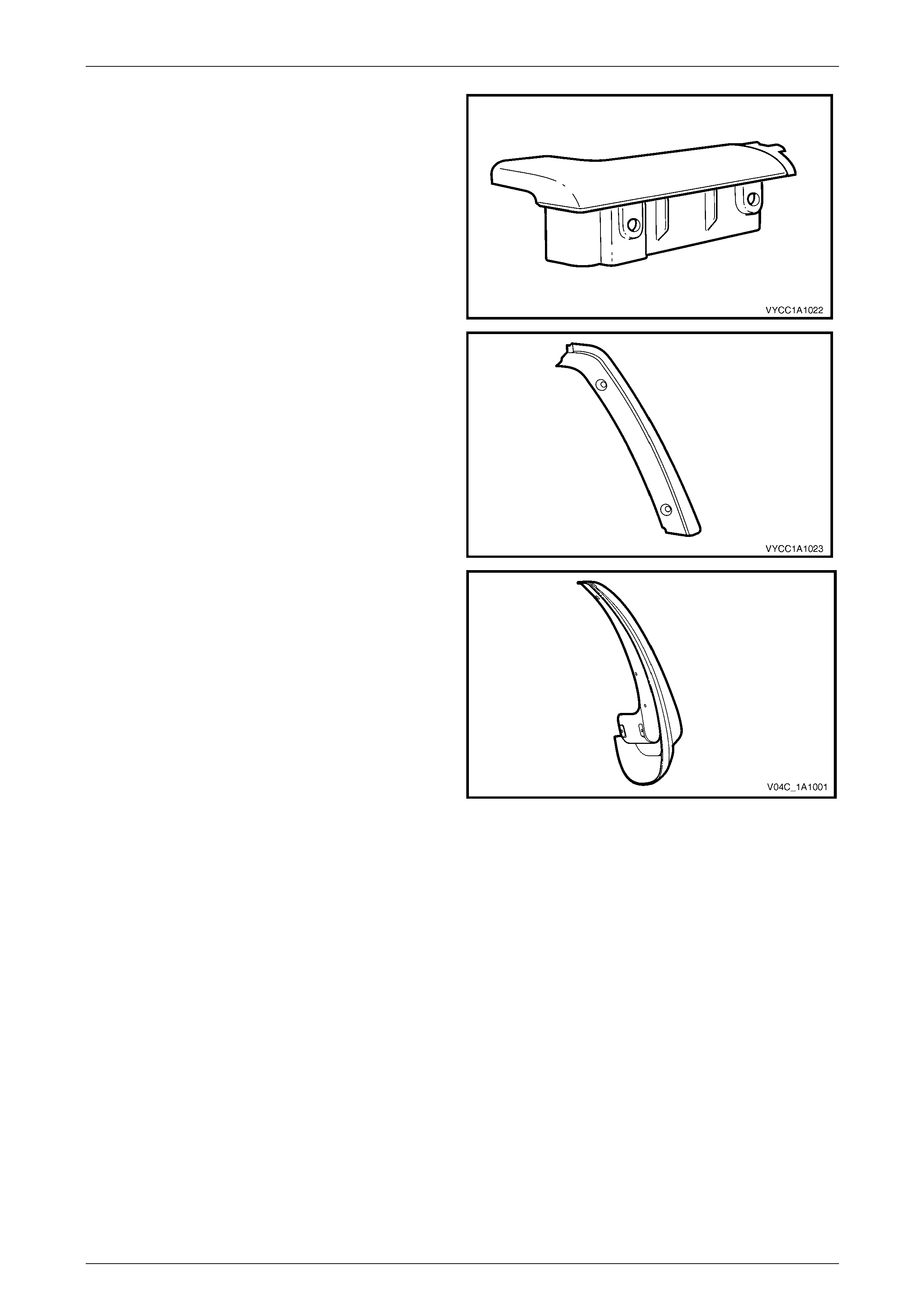

4.3 Plastic Component Identification – Crew

Cab

Rear Wheelhouse Liner

Material:

PP

Rear Body Rear Rocker Moulding

Material:

PP

Body Lock Pillar Trim Retainer Moul ding

Material:

PP

Rear Body Front Rocker Moulding

Material:

PP

Precautions Page 2–14

Page 2–14

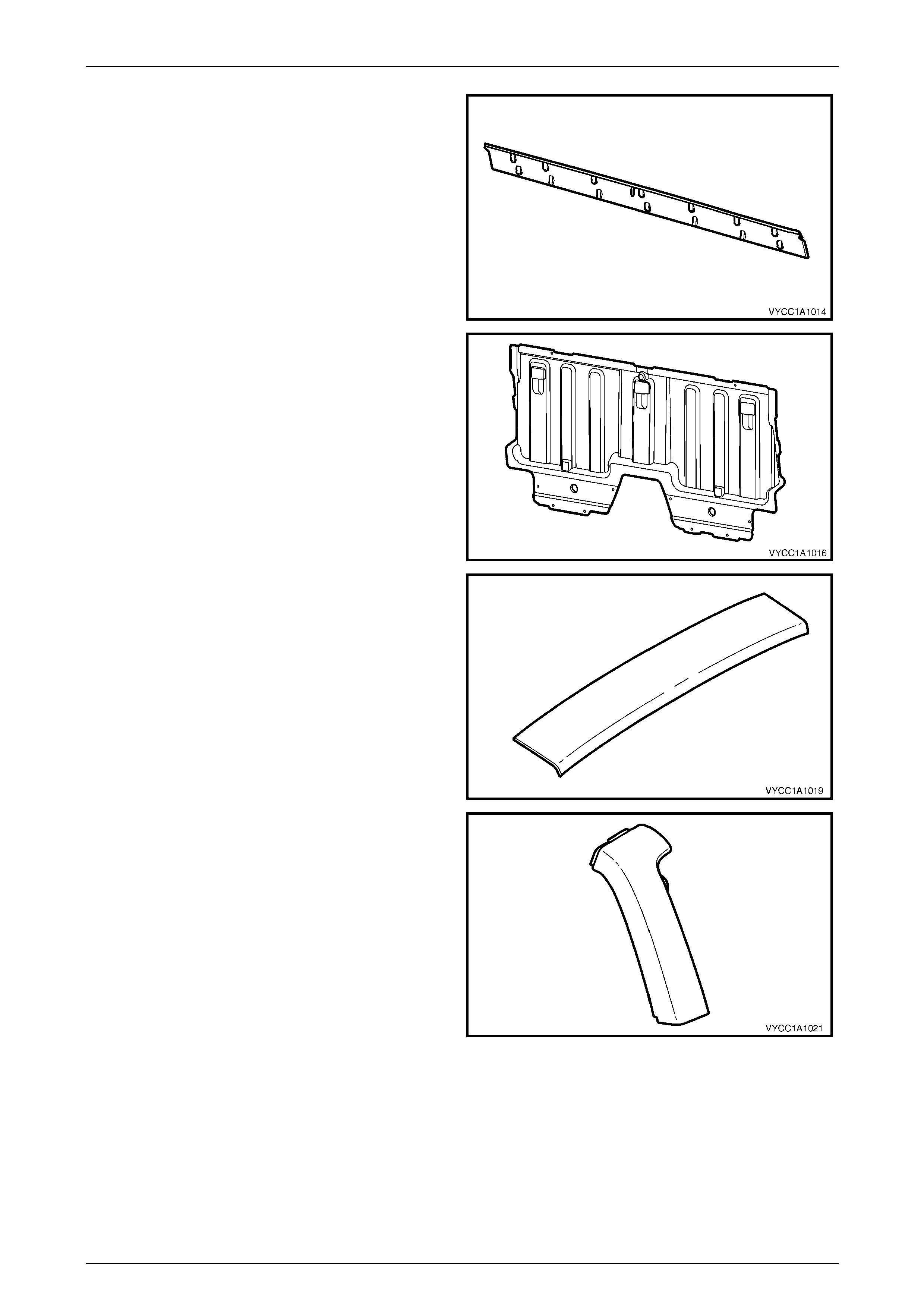

Rear Window Lower Finisher

Material:

ABS / PC

Inner Rear Body Panel

Material:

UP

Rear Header Trim Assembly

Material:

ABS / PC

Body Lock Pillar Trim

Material:

ABS / PC

Precautions Page 2–15

Page 2–15

Rear Body Front Rail Cover

Material:

PP

Body Lock Pillar Door Finisher

Material:

ABS / PC

Rear Mudflap

Material:

PP