Body Construction, Crew Cab Page 3B–1

Page 3B–1

Section 3B

Body Construction, Crew Cab

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 2

Precautions, and Section 00 Warnings, Cautions and Notes in the MY 2004 VY Regular Cab and Crew Cab

Service Information for correct w orkshop practices with regard to safety and/or property damage.

The body structure of VY Regular Cab and

Crew Cab vehicles has been developed using

complex design and d evelopment techniques.

In addition to meeting all required standards,

the vehicle body is also a critical part of the

overall safety systems. It is therefore

imperative the repair procedures described in

this Supplement are adhered to during all

vehicle body repairs.

1 General Information ...............................................................................................................................3

2 Body Structure Panels...........................................................................................................................4

2.1 Front End & Underbody ........................................................................................................................................ 5

2.2 Upperbody Structure............................................................................................................................................. 7

2.3 Body Assembly...................................................................................................................................................... 9

2.4 Rear Tray Body Assembly .................................................................................................................................. 11

3 Body Dimensions.................................................................................................................................13

3.1 Underbody Dimensions – Projected .................................................................................................................. 13

3.2 Upperbody Dimensions – Actual........................................................................................................................ 16

Front...................................................................................................................................................................... 16

Side & Interior ...................................................................................................................................................... 17

Rear Body............................................................................................................................................................. 18

4 Body Margins........................................................................................................................................19

5 Body Sealing, Adhesives & Deadeners .............................................................................................21

5.1 Description........................................................................................................................................................... 21

Weld Through Primer (Item 1)............................................................................................................................. 21

Acrylic Spot Weld Sealer (Item 2)....................................................................................................................... 21

Joint Sealer (Item 3)............................................................................................................................................. 21

Hand Putty (Item 4).............................................................................................................................................. 21

Adhesive - Anti-Flutter (Item 5)........................................................................................................................... 21

Adhesive - Structural (Item 6)............................................................................................................................. 21

Spray-on Deadener (Item 7) ................................................................................................................................ 21

Floor Deadener Panels........................................................................................................................................ 22

Commercially Available Sealer, Adhesive and Deadener Equivalents ........................................................... 22

5.2 Acrylic Spot Weld Sealer (Item 2)....................................................................................................................... 23

Acrylic Spot Weld Sealer (Item 2) Continued .................................................................................................... 24

Acrylic Spot Weld Sealer (Item 2) Continued .................................................................................................... 25

Acrylic Spot Weld Sealer (Item 2) Continued .................................................................................................... 26

Body Construction, Crew Cab Page 3B–2

Page 3B–2

5.3 Joint Sealer (Item 3)............................................................................................................................................. 27

Joint Sealer (Item 3) Continued.......................................................................................................................... 28

Joint Sealer (Item 3) Continued.......................................................................................................................... 29

Joint Sealer (Item 3) Continued.......................................................................................................................... 30

Joint Sealer (Item 3) Continued.......................................................................................................................... 31

Joint Sealer (Item 3) Continued & Hand Putty (Item 4)..................................................................................... 32

5.4 Adhesive – Anti-Flutter (Item 5).......................................................................................................................... 33

5.5 Adhesive – Structural (Item 6) ............................................................................................................................ 34

Adhesive – Structural (Item 6) Continued.......................................................................................................... 35

5.6 Spray-on Deadener.............................................................................................................................................. 36

5.7 Deadeners & Insulators....................................................................................................................................... 37

6 Cavity Wax ............................................................................................................................................39

Cavity Wax Equivalents....................................................................................................................................... 39

Body Construction, Crew Cab Page 3B–3

Page 3B–3

1 General Information

With the following exceptions, VY Crew Cab body construction information carries over from MY 2003 VY Series vehicles

• Body structure panels

• Body dimensions

• Body margins

• Body sealing, adhesives and deadeners

• Cavity wax

For information not contained within this Section, refer to Section 3 Body Constructio n in the MY 2003 VY and V2 Series

Service Information Supplement, Bod y Structure Repair.

This Section contains body construction information specific to VY Crew Cab and AWD Crew Cab vehicles, for VY

Regular Cab Body Construction information refer to Section 3A Body Construction, Regular Cab. Described is the body

structure as a whole and provided is a detailed breakdown of the body structure comp onents, key body dimensional

measurements and body margin tolerances.

The various sealers and adhesives used throughout the body are also described as it is imperative that only the correct

materials are used for repairs.

The correct cavity wax, deadeners a nd paint refinishing techniques are also imperative if the vehicle is to be returne d to

its original condition. When re placing or repairing a part or sub-assembly, care must be taken to ensure that correct

alignment and strength of unit as a whole is maintained. In some instances, major damage to the body or frame can be

repaired more effectively and economically by replacing a part or sub-assembly with a new one, rather than repairing the

damaged part.

Body Construction, Crew Cab Page 3B–4

Page 3B–4

2 Body Structure Panels

The following tables and illustrations describe the body structure assemblies and panels that are available for service

replacement.

NOTE

Always refer to an authorised dealer for spare

parts availability configurations.

Body Construction, Crew Cab Page 3B–5

Page 3B–5

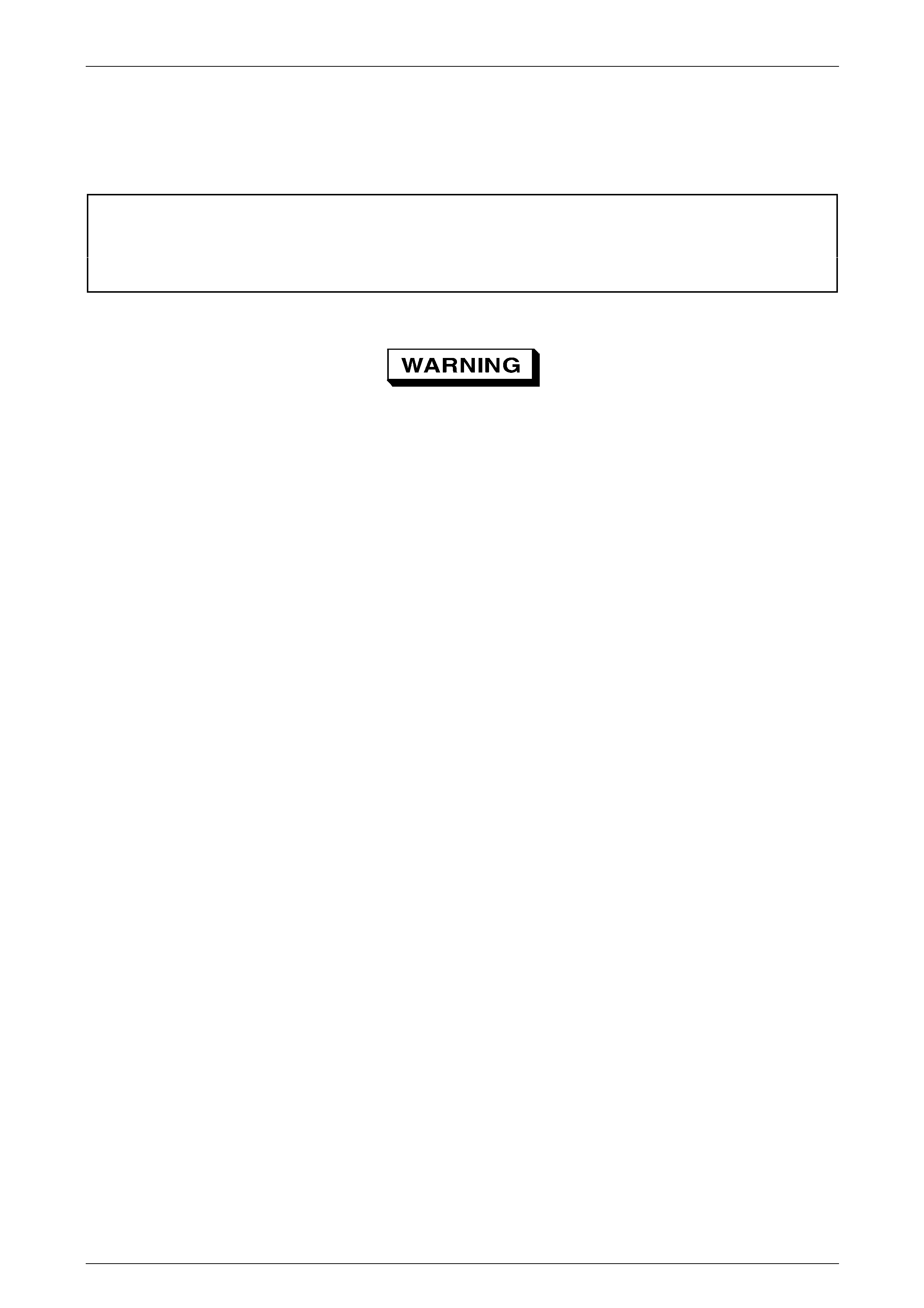

2.1 Front End & Underbody

Figure 3B – 1

Body Construction, Crew Cab Page 3B–6

Page 3B–6

Legend

1 Inner Rocker Panel Assembly, RH / LH

2 Seat Inner Bracket Assembly

3 Seat Outer Bracket Assembly, RH / LH

4 Front Floor Panel Assembly

5 Transmission Support Bracket, RH / LH*

6 Transmission Support Bracket, LH (AWD only)

7 Front Floor Panel Extension

8 Front Side Rail Brace, RH / LH

9 Front Wheelhouse Panel Assembly, RH / LH

10 Horn Bracket Assembly, LH only

11 Relay Housing Bracket, RH only

12 ABS Modulator Bracket Assembly, RH only

13 Battery Tray Assembly, RH only

14 Front End Panel Assembly

15 Headlamp Panel, LH / RH

16 Headlamp & Front Fascia Mount Bracket, LH / RH

17 Fender Front Lower Bracket, LH / RH

18 Radiator Lower Support Assembly

19 Front Side Rail Assembly, LH / RH

20 Radiator Side Mounting Bracket, LH / RH

21 Front Wheelhouse Bracket Assembly, LH / RH

22 Front Bumper Impact Bar Bracket, LH / RH

23 Front Wheelhouse Panel Bracket, LH / RH

24 Propeller Shaft Hanger Assembly

25 Rear Seatbelt Anchor Plate Assembly (3 places)

26 Floor Panel Plate Assembly (2 places), LH / RH

27 Front Floor Panel Extension Assembly

28 Rear Lower Body Panel

29 Rear Lower Body Panel Assembly, LH/ RH

* Right-hand side only for AWD vehicles

Body Construction, Crew Cab Page 3B–7

Page 3B–7

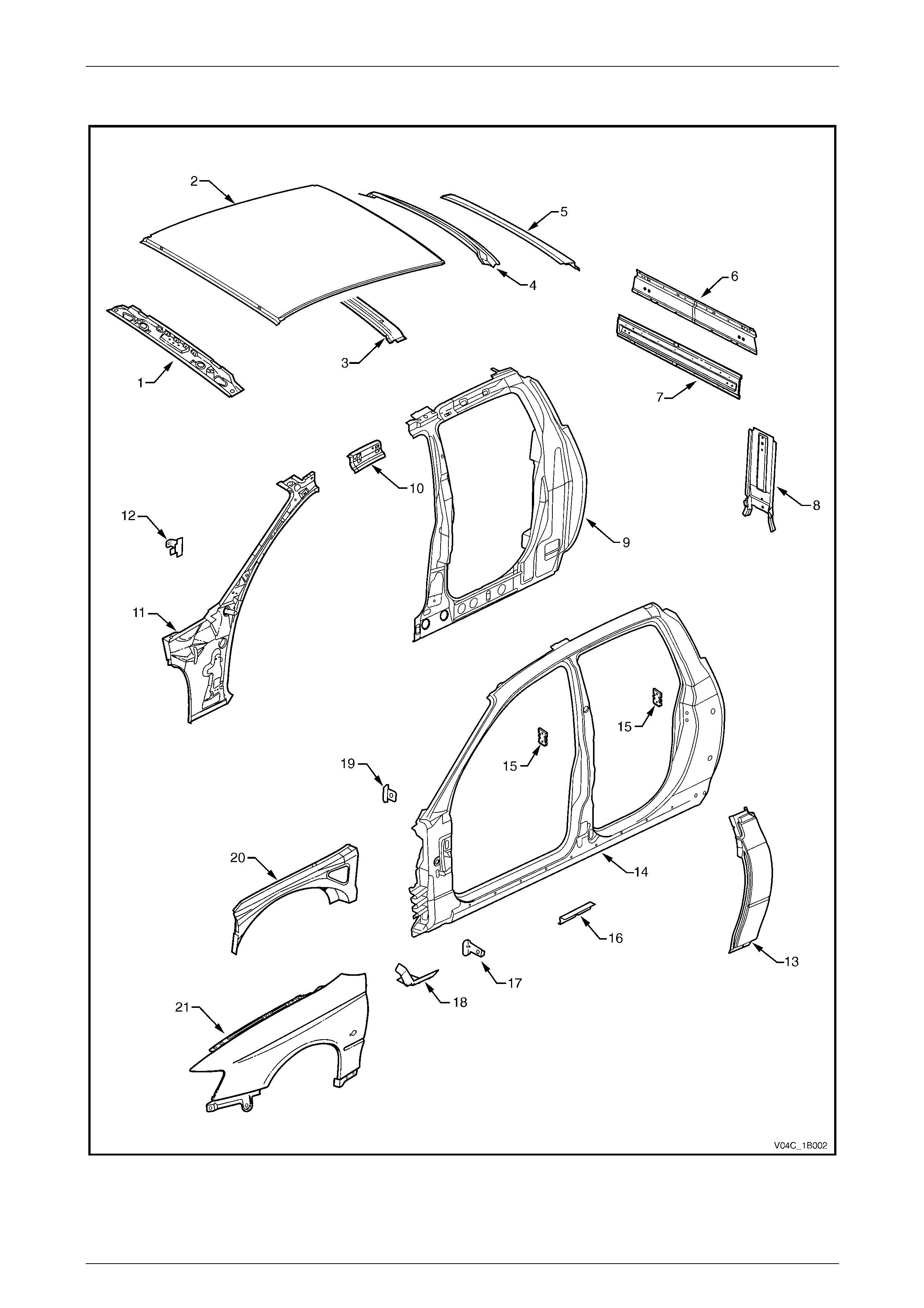

2.2 Upperbody Structure

Figure 3B – 2

Body Construction, Crew Cab Page 3B–8

Page 3B–8

Legend

1 Roof Front Header Panel

2 Roof Panel

3 Roof Bow Panel

4 Roof Rear Header Inner Panel

5 Roof Rear Header Outer Panel

6 Rear Body Upper Outer Panel Assembly

7 Rear Body Upper Inner Panel Assembly

8 Rear Body Lower Panel Assembly

9 Quarter Panel Inner Assembly, RH / LH

10 Quarter Panel Inner Extension, RH / LH

11 Hinge Pillar Inner Panel Assembly, RH / LH

12 Hinge Pillar Trim Panel Bracket, RH / LH

13 Rear Quarter Panel, RH / LH

14 Door Opening Frame Assembly, RH / LH

15 Door Striker Anchor Plate, RH / LH

16 Underbody Jacking Locator, RH / LH

17 Fender Rear Bracket, RH / LH

18 Fender Lower Rear Bracket, RH / LH

19 Fender Upper Rear Bracket, RH / LH

20 Front Wheelhouse Panel Upper Side Rail, RH / LH

21 Front Fender, RH / LH*

* The front fender for AWD vehicles is supplied with holes for the front wheelhouse opening flare.

Body Construction, Crew Cab Page 3B–9

Page 3B–9

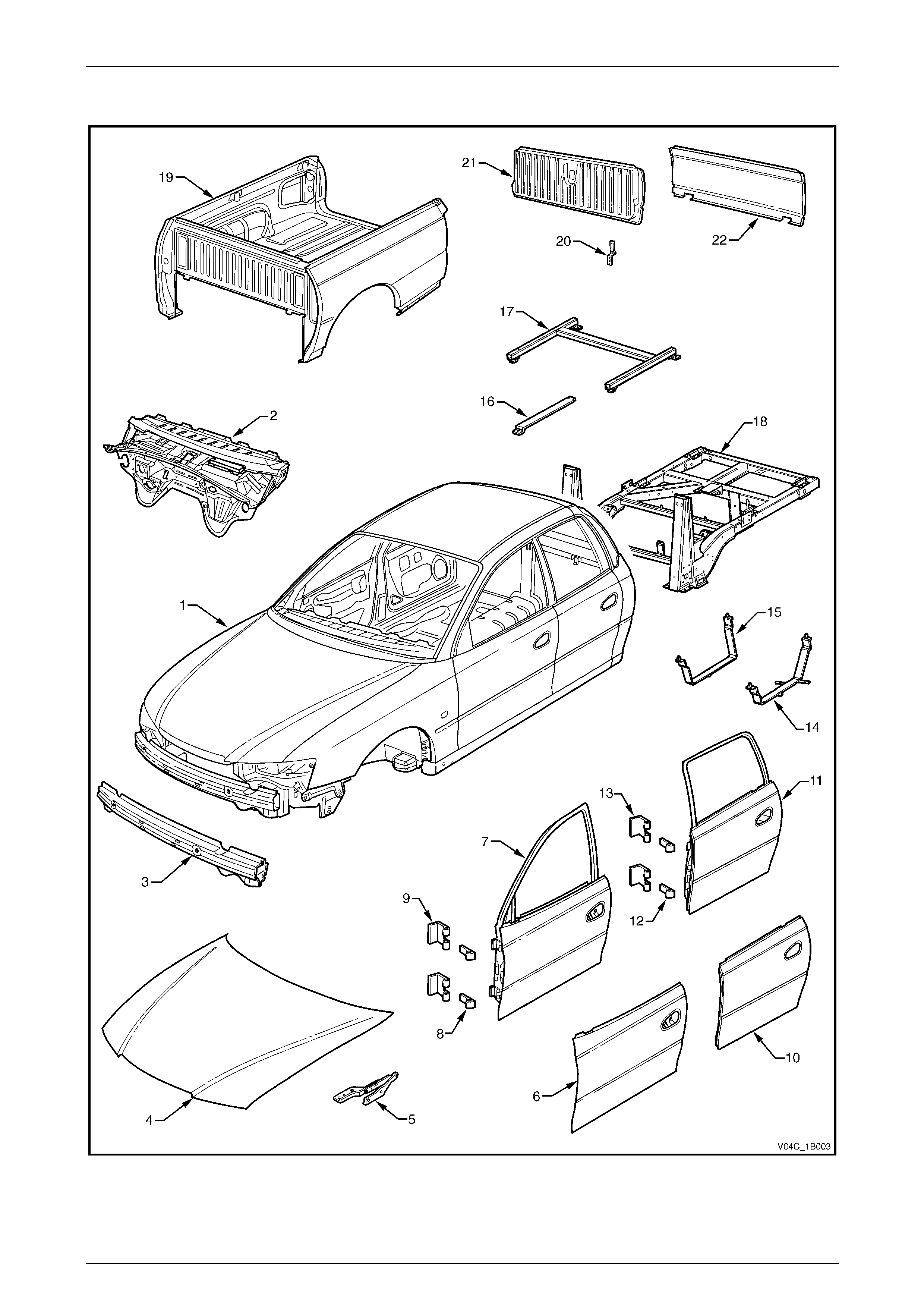

2.3 Body Assembly

Figure 3B – 3

Body Construction, Crew Cab Page 3B–10

Page 3B–10

Legend

1 Body Assembly

2 Dash Panel Assembly

3 Front Bumper Impact Bar Assembly

4 Hood Assembly

5 Hood Hinge Assembly, RH / LH

6 Front Door Outer Panel, RH / LH

7 Front Door Assembly, RH / LH

8 Front Door Hinge (door side), RH / LH

9 Front Door Hinge (body side), RH / LH

10 Rear Door Outer Panel, RH / LH

11 Rear Door Assembly, RH / LH

12 Rear Door Hinge (door side), RH / LH

13 Rear Door Hinge (body side), RH / LH

14 Fuel Tank Lower Strap, LH

15 Fuel Tank Lower Strap, RH

16 Fuel Tank Upper Strap, LH/ RH

17 Floor Support Frame

18 Subframe Assembly

19 Rear Tray Body Assembly

20 Endgate Hinge Assembly, RH / LH

21 Endgate Assembly

22 Endgate Outer Panel

Body Construction, Crew Cab Page 3B–11

Page 3B–11

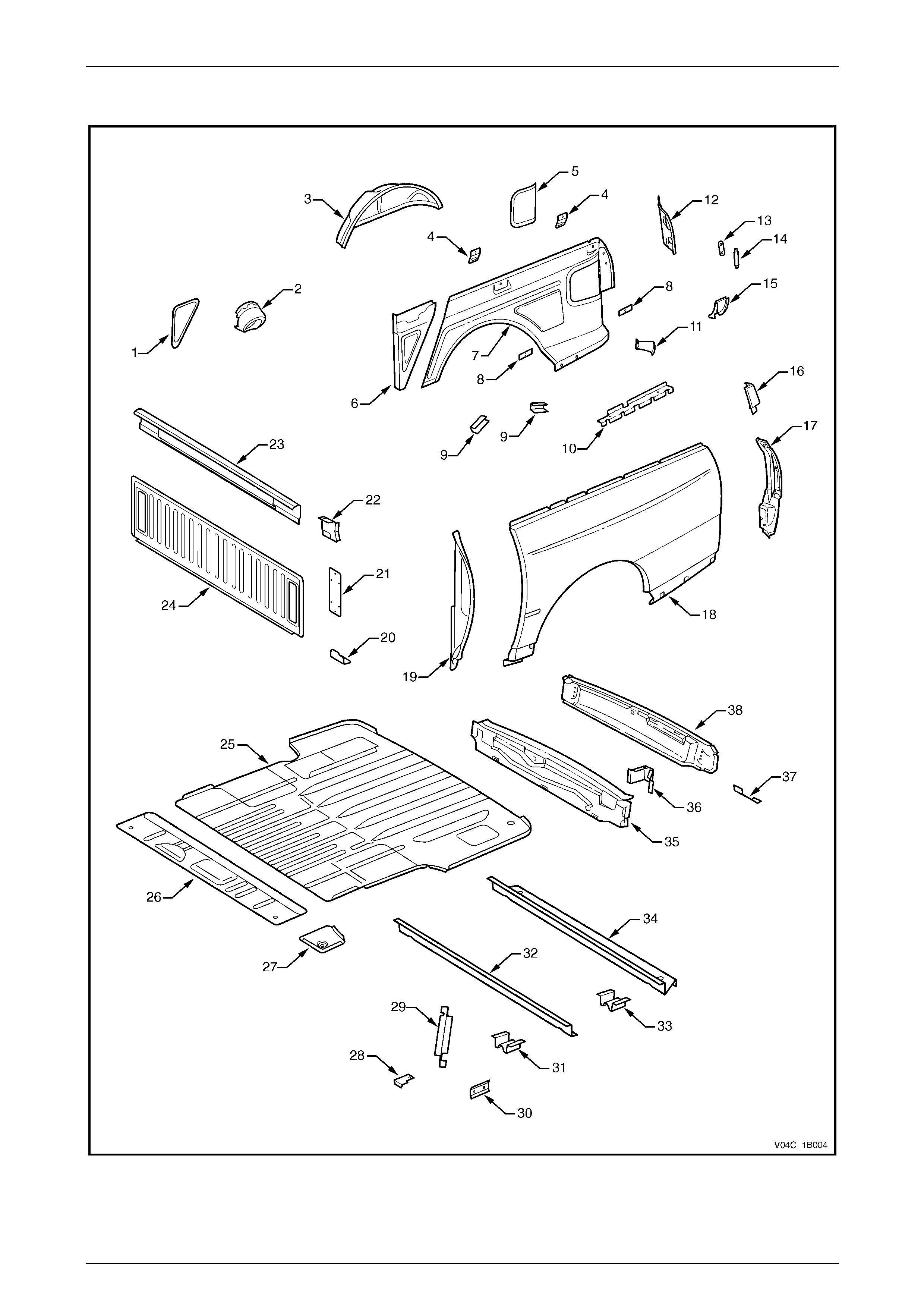

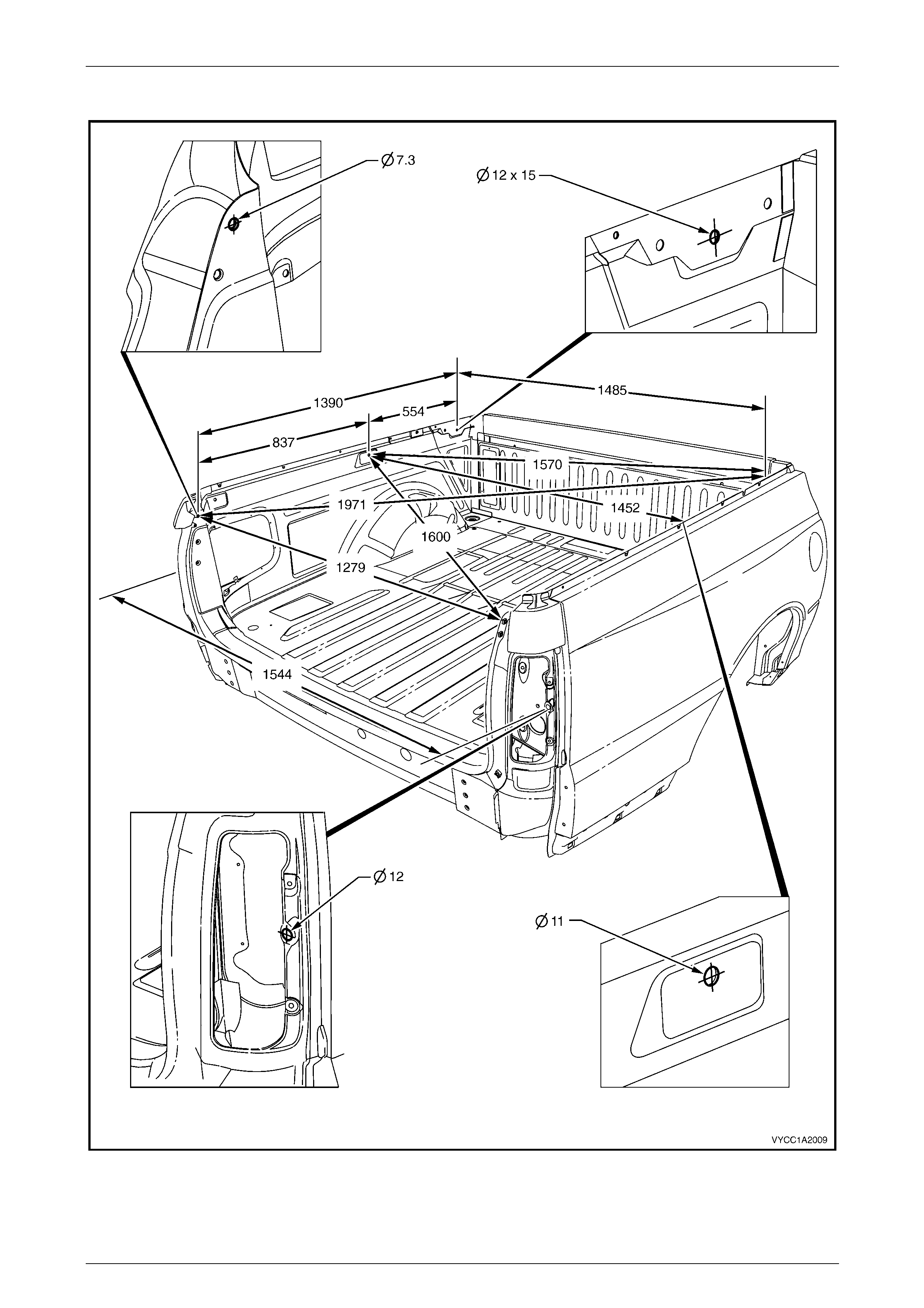

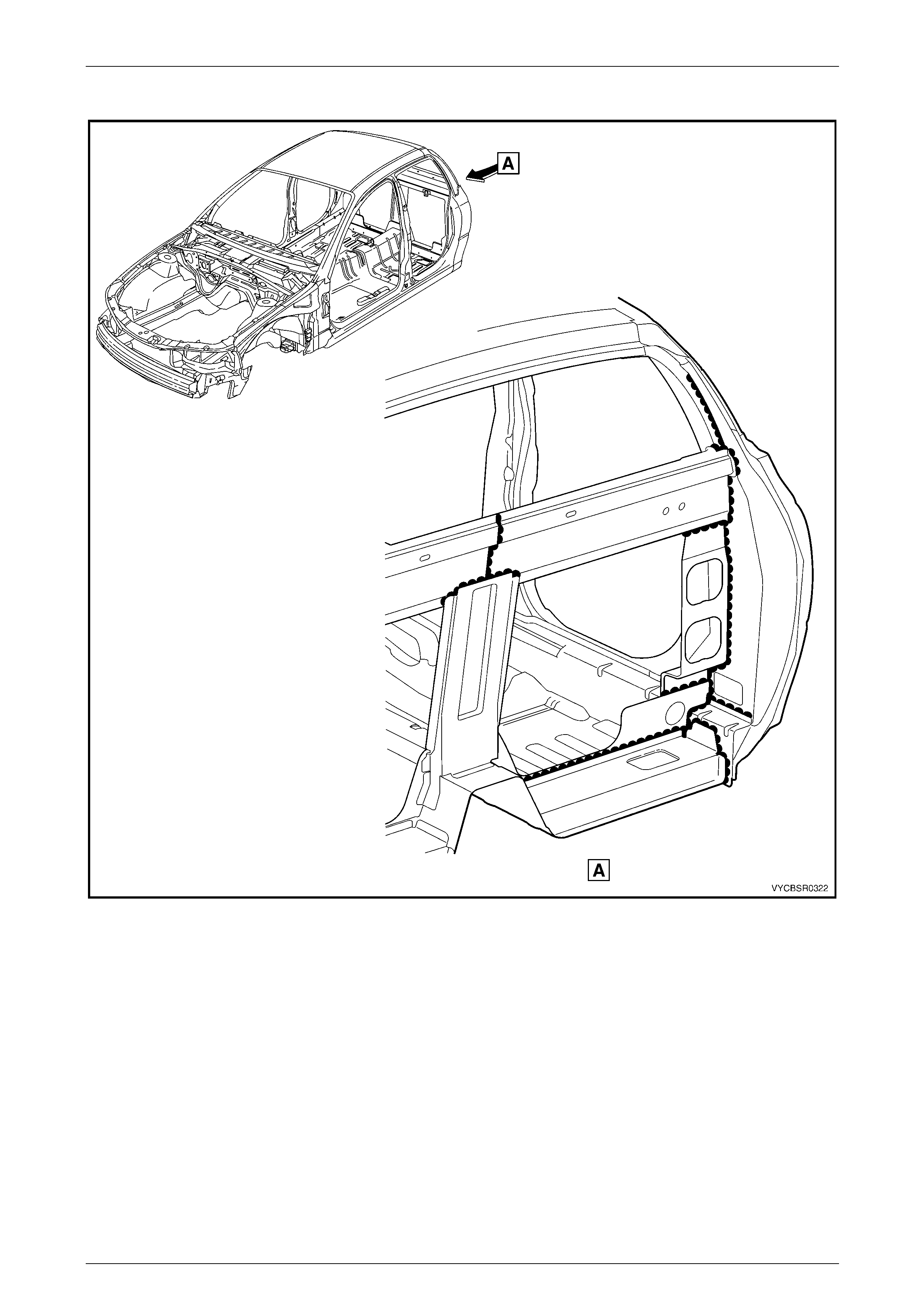

2.4 Rear Tray Body Assembly

Figure 3B – 4

Body Construction, Crew Cab Page 3B–12

Page 3B–12

Legend

1 Inner Side Panel Extension Cover, RH only

2 Fuel Filler Pipe Housing, RH only

3 Rear Wheelhouse Inner Panel, LH / RH

4 Cargo Tie Down Bracket (2 places), LH / RH

5 Rear Inner Side Panel Cover, LH / RH

6 Inner Side Panel Extension Assembly, LH / RH

7 Inner Side Panel, LH / RH

8 Cargo Tie Down Anchor Plate Assembly (2 places), LH / RH

9 Wheelhouse Filler Panel Bracket (2 places), LH / RH

10 Rear Quarter Closing Panel, LH / RH

11 Quarter Panel Rear Brace, LH / RH

12 Quarter Inner Lower Rea r Extension, LH / RH

13 Endgate Striker Anchor Plate, LH / RH

14 Endgate Striker Anchor Plate Retainer, LH / RH

15 Quarter Lower R ear Panel, LH / RH

16 Quarter Panel Upper Extension, LH / RH

17 Quarter Panel Extension, LH / RH

18 Rear Quarter Panel, LH / RH*

19 Quarter Panel Front Gusset, LH / RH

20 Rear Body Front Bracket, LH / RH

21 Front End Panel Cover, LH / RH

22 Front Cover Attachment Beam, LH / RH

23 Front End Panel Sill Assembly

24 Front End Panel

25 Load Floor Panel

26 Load Floor Front Extension

27 Load Floor Panel Front Extension, LH / RH

28 Front End Panel Locator, LH / RH

29 Load Floor Panel Support, LH / RH

30 Load Floor Panel Side Support, LH / RH

31 Load Floor Panel Locator, LH / RH

32 Load Floor Panel Front Support

33 Load Floor Panel Locator Guide, LH / RH

34 Load Floor Panel Rear Support

35 Rear End Panel

36 Endgate Hinge Reinforcement, LH / RH

37 Rear Fascia Centre Bracket, LH / RH

38 Rear End Lower Panel

* The rear quarter panel for AWD vehicles is supplied with holes for the rear wheelhouse opening flare.

Body Construction, Crew Cab Page 3B–13

Page 3B–13

3 Body Dimensions

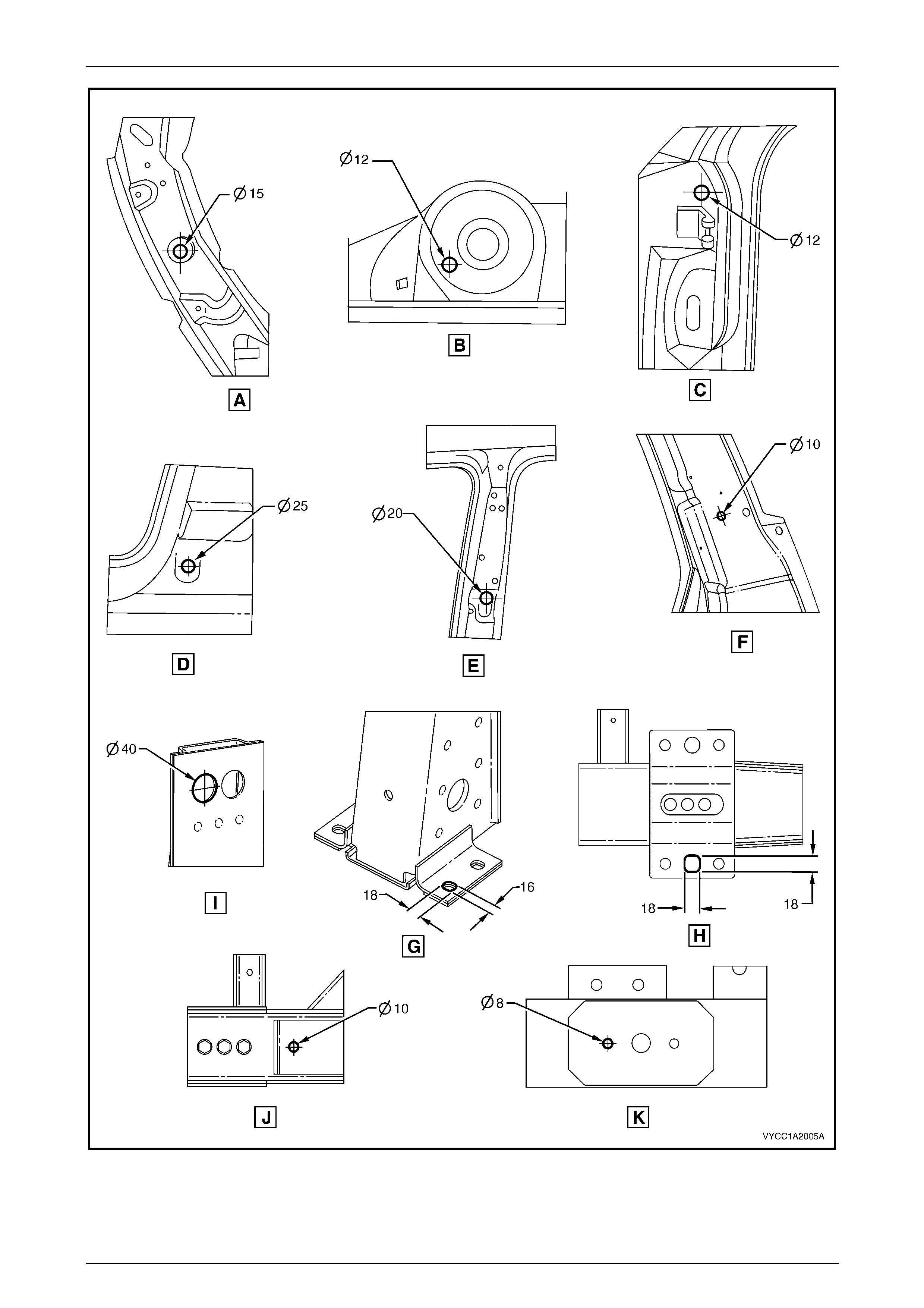

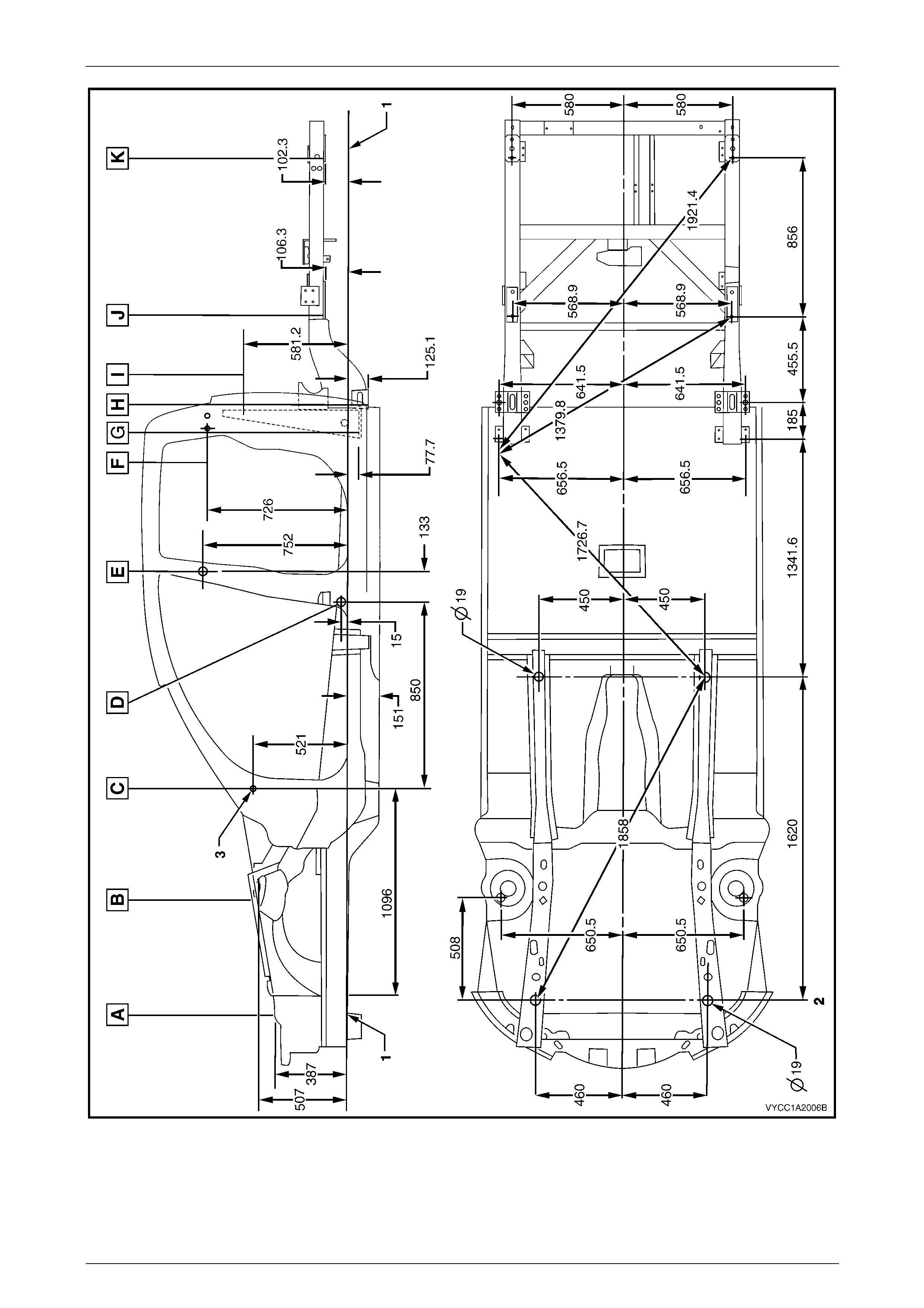

3.1 Underbody Dimensions – Projected

All dimensions are given in mm and are measured from the centre of holes, on the outer side of the metal surface.

The main datum surface (1) is the underside of the front side rail assembly, refer to Figure 3B–6.

The main datum hole (2) is a 19 mm hole on the underside of the front side rail assembly, refer to Figure 3B–6.

The dash panel assembly attaching hole (3) in Figure 3B–6 is also the same datum hole depicted at Vie w C in

Figure 3B–5.

Body Construction, Crew Cab Page 3B–14

Page 3B–14

Figure 3B – 5

Body Construction, Crew Cab Page 3B–15

Page 3B–15

Figure 3B – 6

Body Construction, Crew Cab Page 3B–16

Page 3B–16

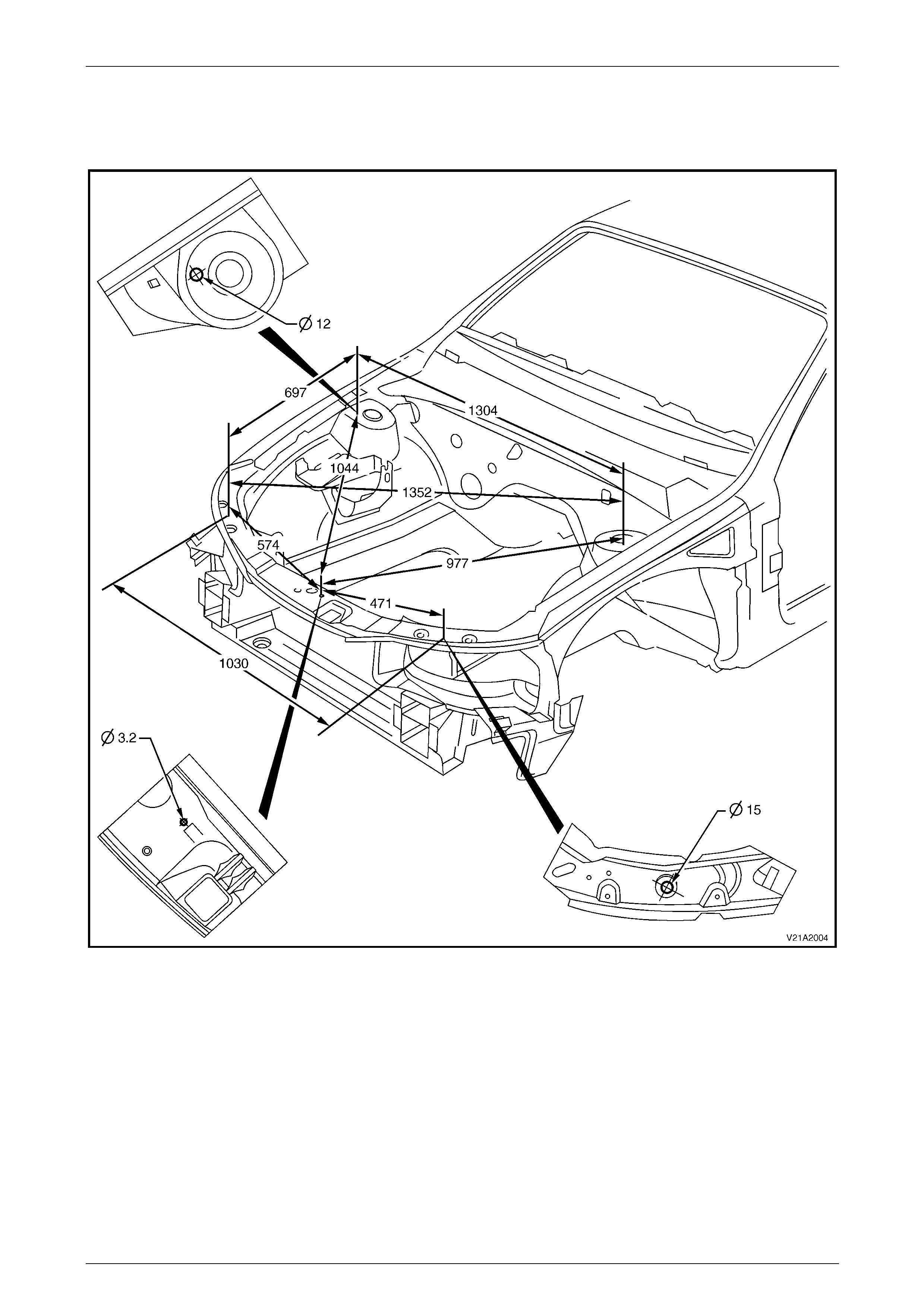

3.2 Upperbody Dimensions – Actual

Front

Figure 3B – 7

Body Construction, Crew Cab Page 3B–17

Page 3B–17

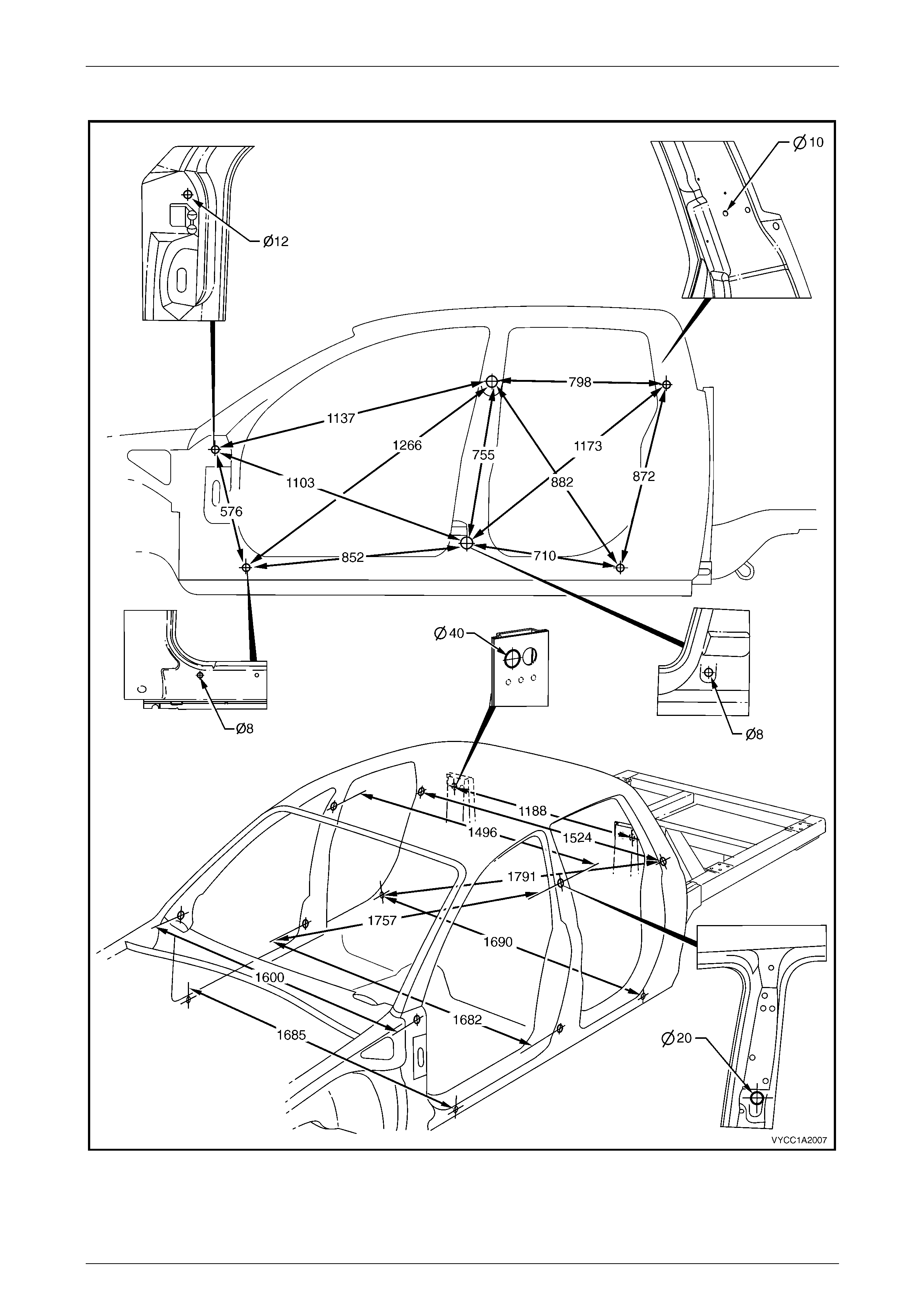

Side & Interior

Figure 3B – 8

Body Construction, Crew Cab Page 3B–18

Page 3B–18

Rear Body

Figure 3B – 9

Body Construction, Crew Cab Page 3B–19

Page 3B–19

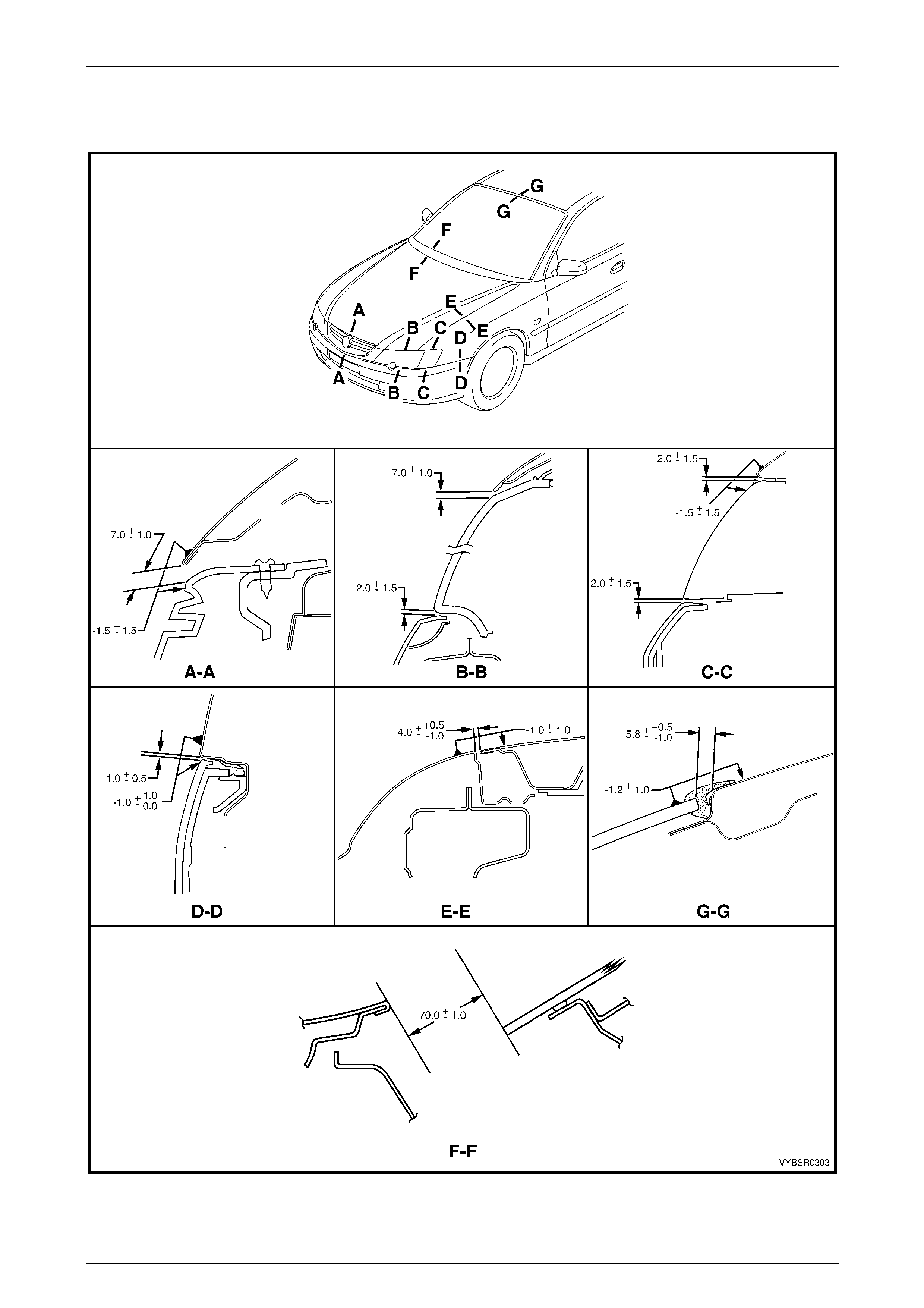

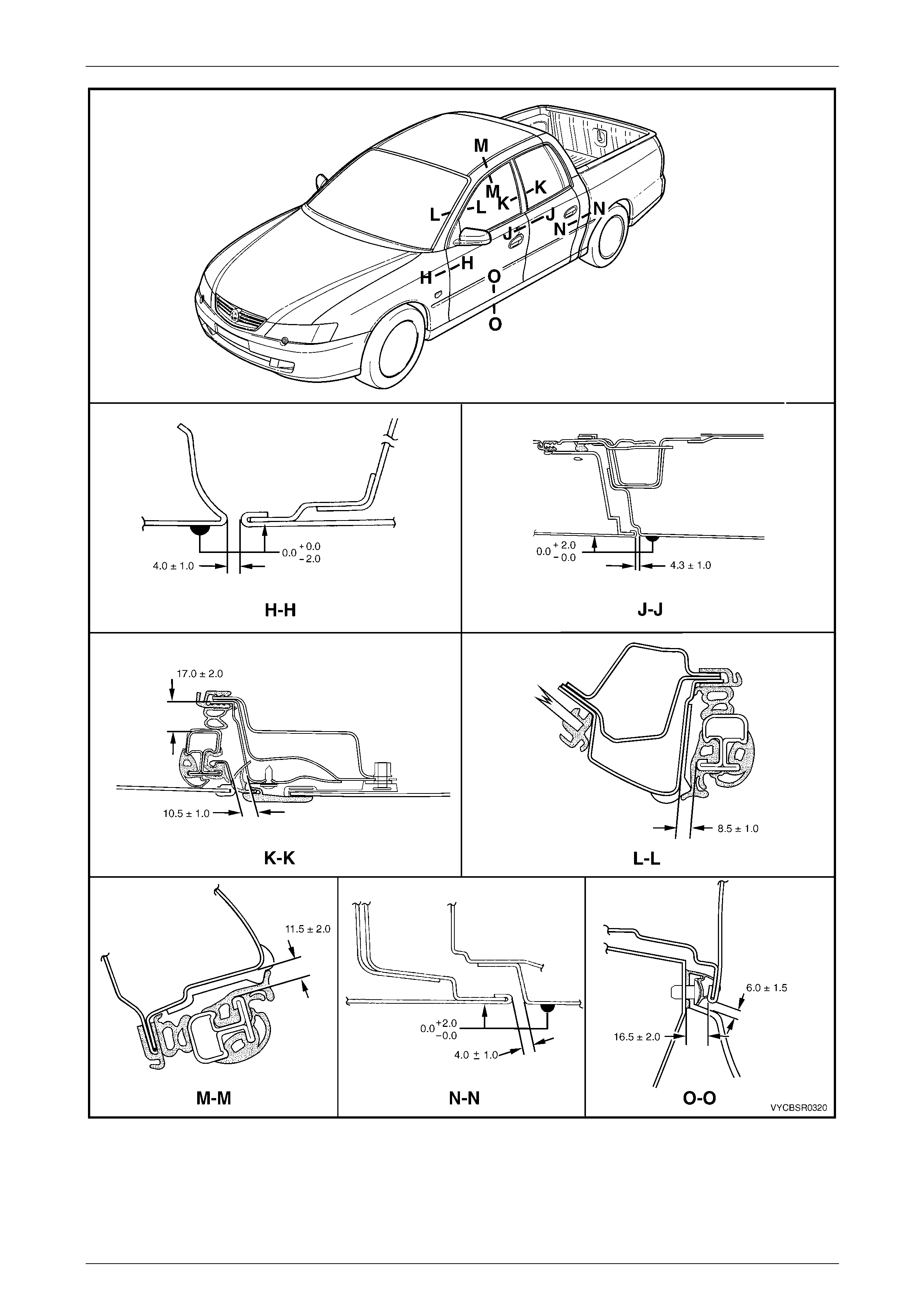

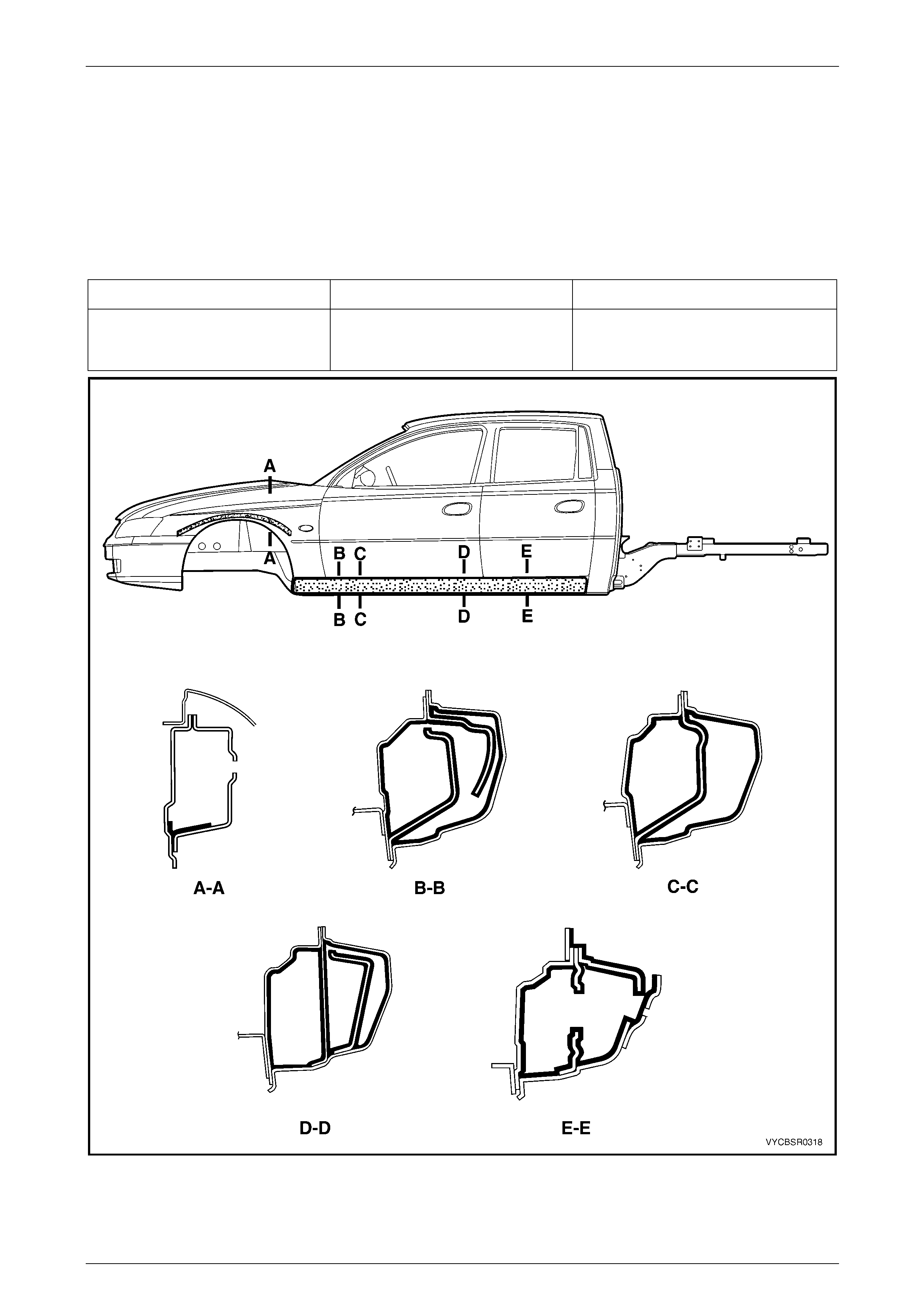

4 Body Margins

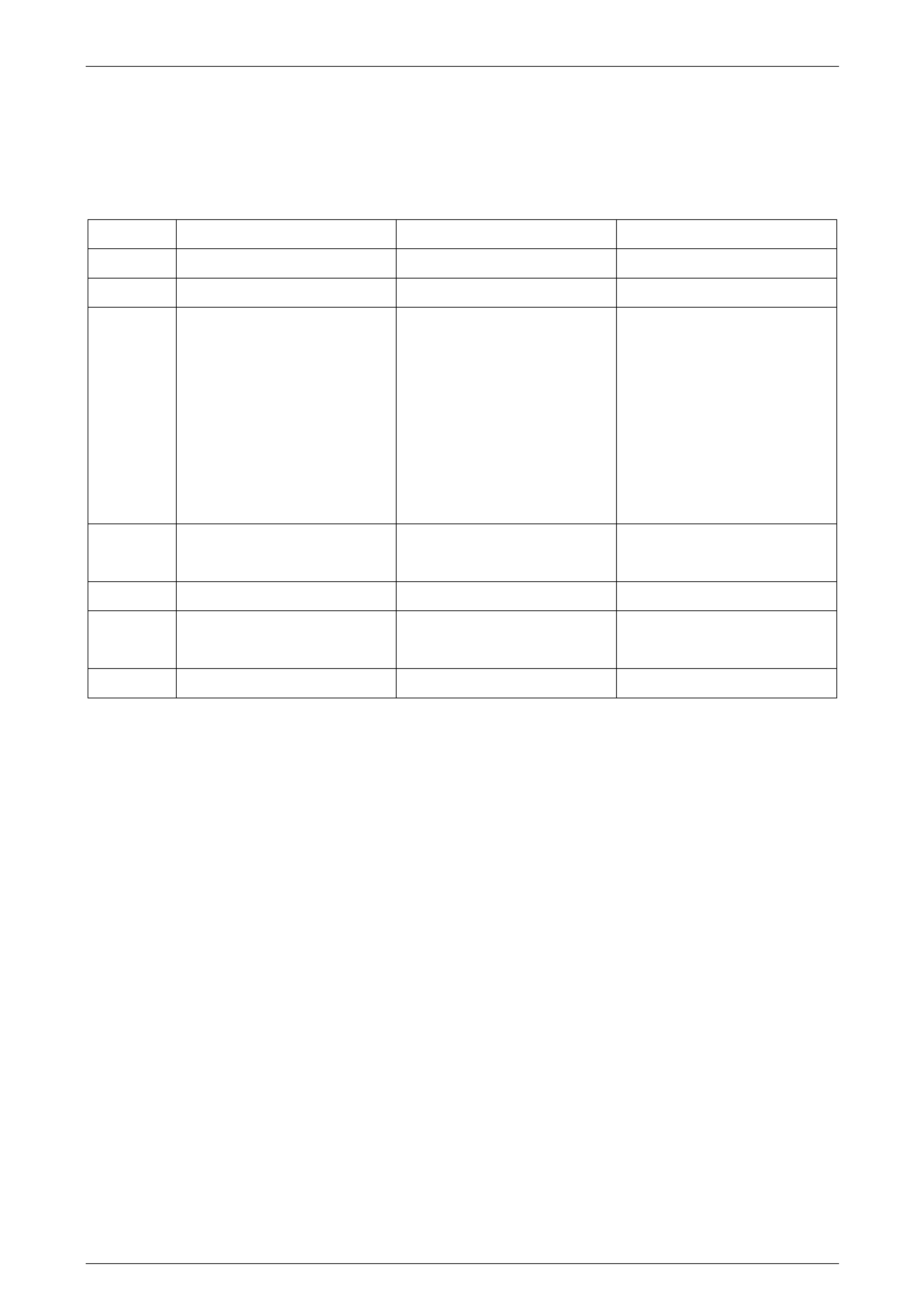

Figure 3B – 10

Body Construction, Crew Cab Page 3B–20

Page 3B–20

Figure 3B – 11

Body Construction, Crew Cab Page 3B–21

Page 3B–21

5 Body Sealing, Adhesives &

Deadeners

5.1 Description

This Section details the sealers, adhesives and deadeners used i n the VY Crew Cab body shell. It is imperative that the

correct materials are used and the directions on the product always are followed.

The commercially available products listed

below will meet the required standards. Other

products may be available that meet the

performance characteristics, however before

their use, the product manufacturer should be

contacted to check its suitability.

NOTE

When replacing any sealer, adhesive or

deadener, ensure the finish meets that of the

original applica tion.

Weld Through Primer (Item 1)

Although not used in manufacture, Weld-Through Primer is recommended for all servic e repair lap and flange joints

where Acrylic Spot Weld Sealer (Item 2) is not used. Weld Through Primer aids in corrosion protection of the joint.

Acrylic Spot Weld Sealer (Item 2)

Used in joints that require sealing additional to Joint Sealer (Item 3). It is applied to the jo int flange prior to the mating of

panels. Refer to Figure 3B–12.

Joint Sealer (Item 3)

Primarily used for sealing joints to achieve a watertight seal. It seals notches, cut-outs and holes. Joint sealer should be

applied after priming, prior to application of the top coat. Refer to Figure 3B–16 to Figure 3B–21.

Hand Putty (Item 4)

Hand putty, also known as caulking compound, is used in the areas marked * in Figure 3B–21.

Adhesive - Anti-Flutter (Item 5)

While used as a filler between an inner and outer panel to reduce panel flex, Anti-Flutter adhesive also ai ds rigidity and

assists in dispersing loads over a larger area. Refer to Figure 3B–22 for locations.

Adhesive - Structural (Item 6)

Critical to the strength and rigidity of the vehicle, the correct adhesive must be used for service repairs. Using an

adhesive that is too weak will reduc e the performance of the joint. Using an adhesive that is too strong can also effect the

performance of the joint, compromising the vehicle’s crash performance and safety system’s operation. This adhesive is

a 2-part system. Refer to Figure 3B–23 & Figure 3B–24 for locations.

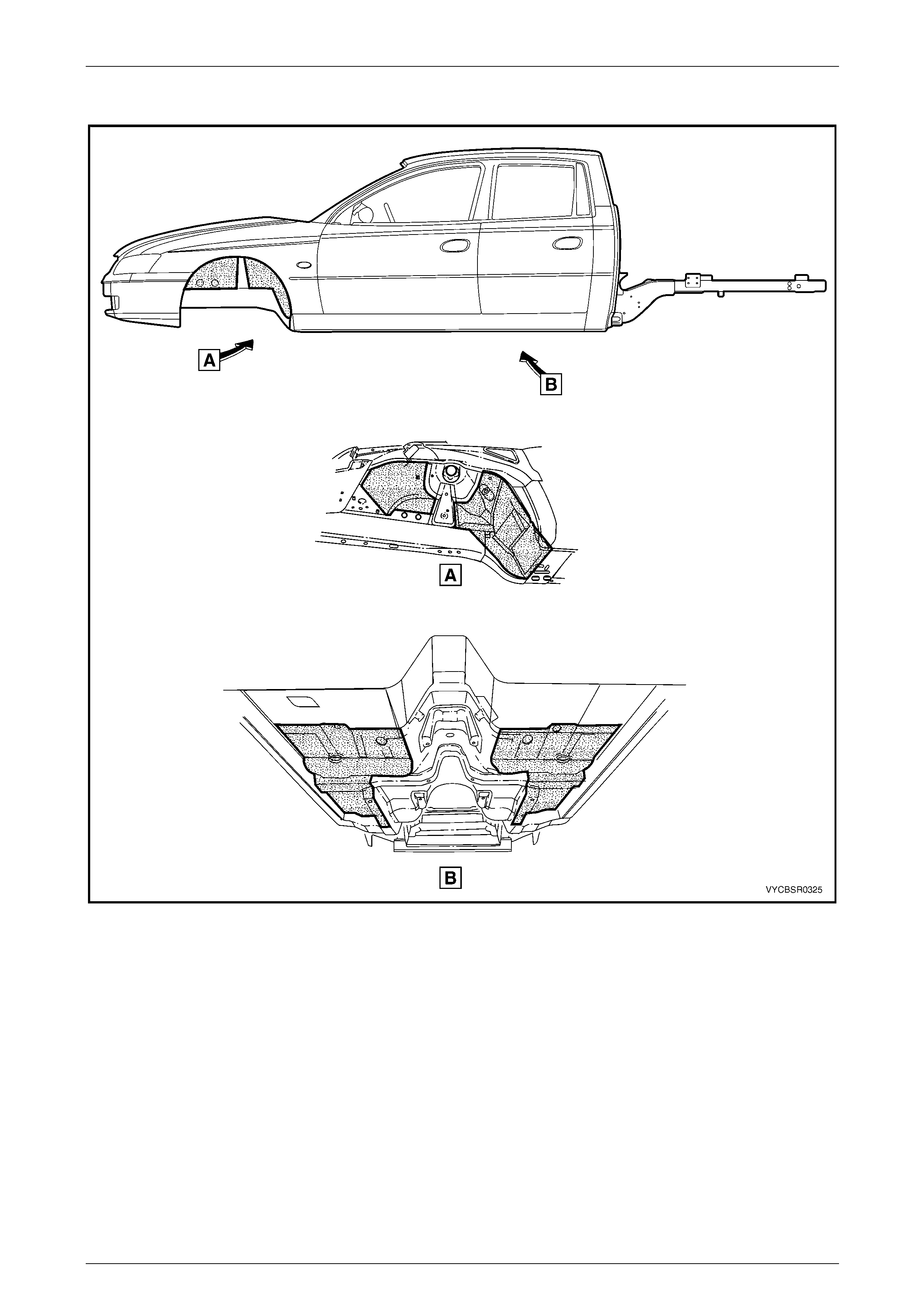

Spray-on Deadener (Item 7)

This deadener is spra yed onto the body shell after painting. It is used in the wheel-wells and on the under side of the

floor pan. A minimum thickness of 1.5 mm is required in the se applications. Refer to Figure 3B–25 for locations.

Body Construction, Crew Cab Page 3B–22

Page 3B–22

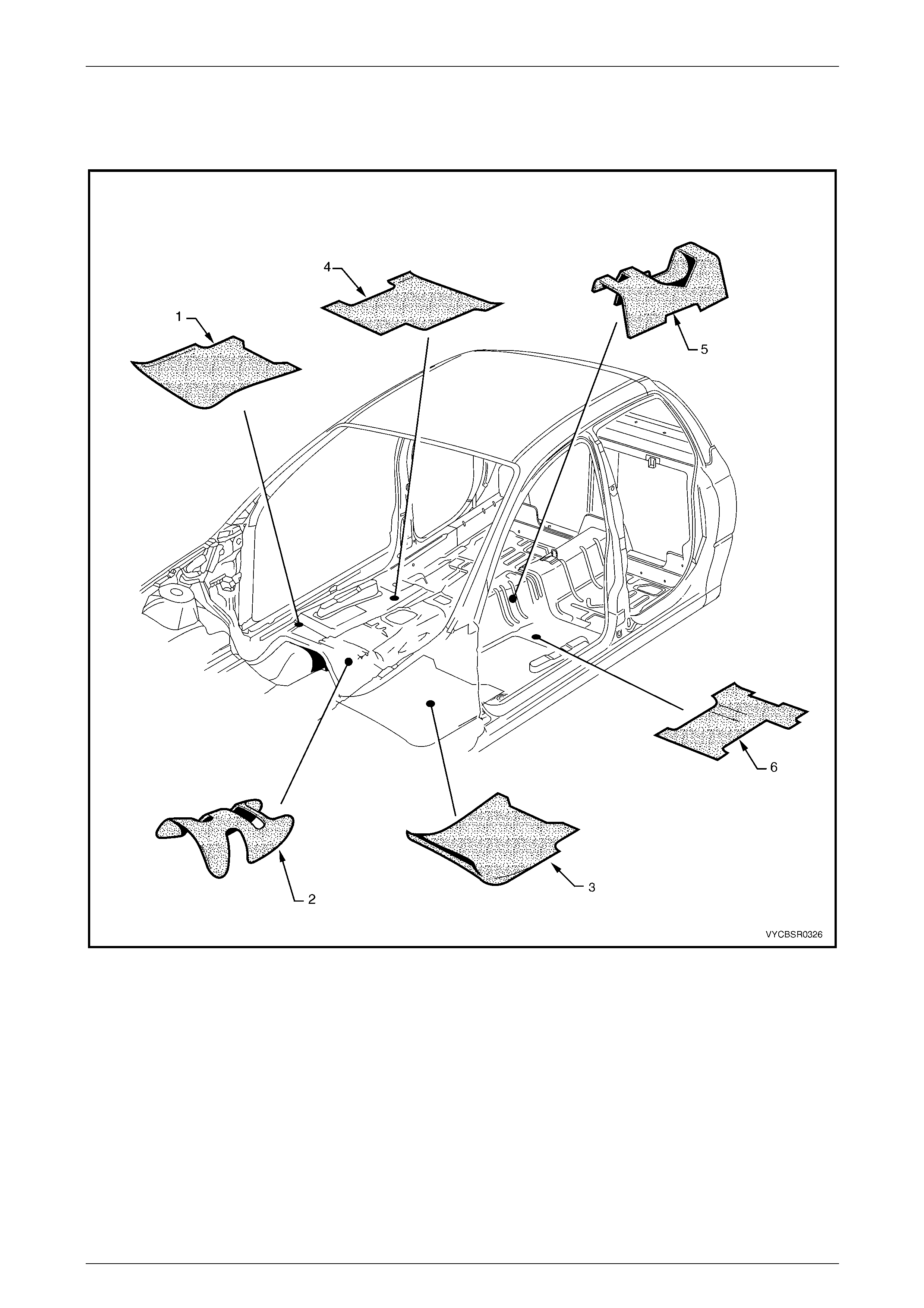

Floor Deadener Panels

Deadener panels are sold pre-cut as Service Parts. They are installed with the coloure d side up and diamond emboss ed

side down. The panels are installed prior to painting. Some are heat fused to the body sh ell. Refer to F igure 3B–26 to

Figure 3B–28 for locations.

Commercially Available Sealer, Adhesive and Deadener Equivalents

Item No. Item Name Manufacturer Product Name

1 Weld Through Primer Not Specified – Refer to supplier

2 Acrylic Spot Weld Sealer Lord (Fusor) Fusor #800 / #801

3 Joint Sealer Sprayable: Lord (Fusor)

Extruded beads: Lord (Fusor)

3M

Visible Seams

-self levelling: Lord (Fusor)

3M

-non sag: Lord (Fusor)

3M

Fusor #802

Fusor #800 / #801

Automix 8308

Fusor #122 / #125

Automix 8307

Fusor #123 / #126

Automix 8308

4 Hand Putty Lord (Fusor)

3M

Fusor #800 / #801

Automix 8307

5 Adhesive - Anti Flutter Lord (Fusor) Fusor #124

6 Adhesive - Structural (two-part) Lord (Fusor)

3M

Fusor #108 B

Automix 8115

7 Spray-on Deadener Henkel Terophon 2000-13

NOTE

Special tools may be required to apply some

materials, refer to the supplier for further

information.

Body Construction, Crew Cab Page 3B–23

Page 3B–23

5.2 Acrylic Spot Weld Sealer (Item 2)

Figure 3B – 12

Legend

1 Door Opening Frame

2 Hinge Pillar Reinforcement

3 Hinge Pillar Inner Panel

4 Hinge Pillar Closing Plate

5 Front Wheelhouse Panel Upper Side Rail

Body Construction, Crew Cab Page 3B–24

Page 3B–24

Acrylic Spot Weld Sealer (Item 2) Continued

Figure 3B – 13

Body Construction, Crew Cab Page 3B–25

Page 3B–25

Acrylic Spot Weld Sealer (Item 2) Continued

Figure 3B – 14

Body Construction, Crew Cab Page 3B–26

Page 3B–26

Acrylic Spot Weld Sealer (Item 2) Continued

Figure 3B – 15

Body Construction, Crew Cab Page 3B–27

Page 3B–27

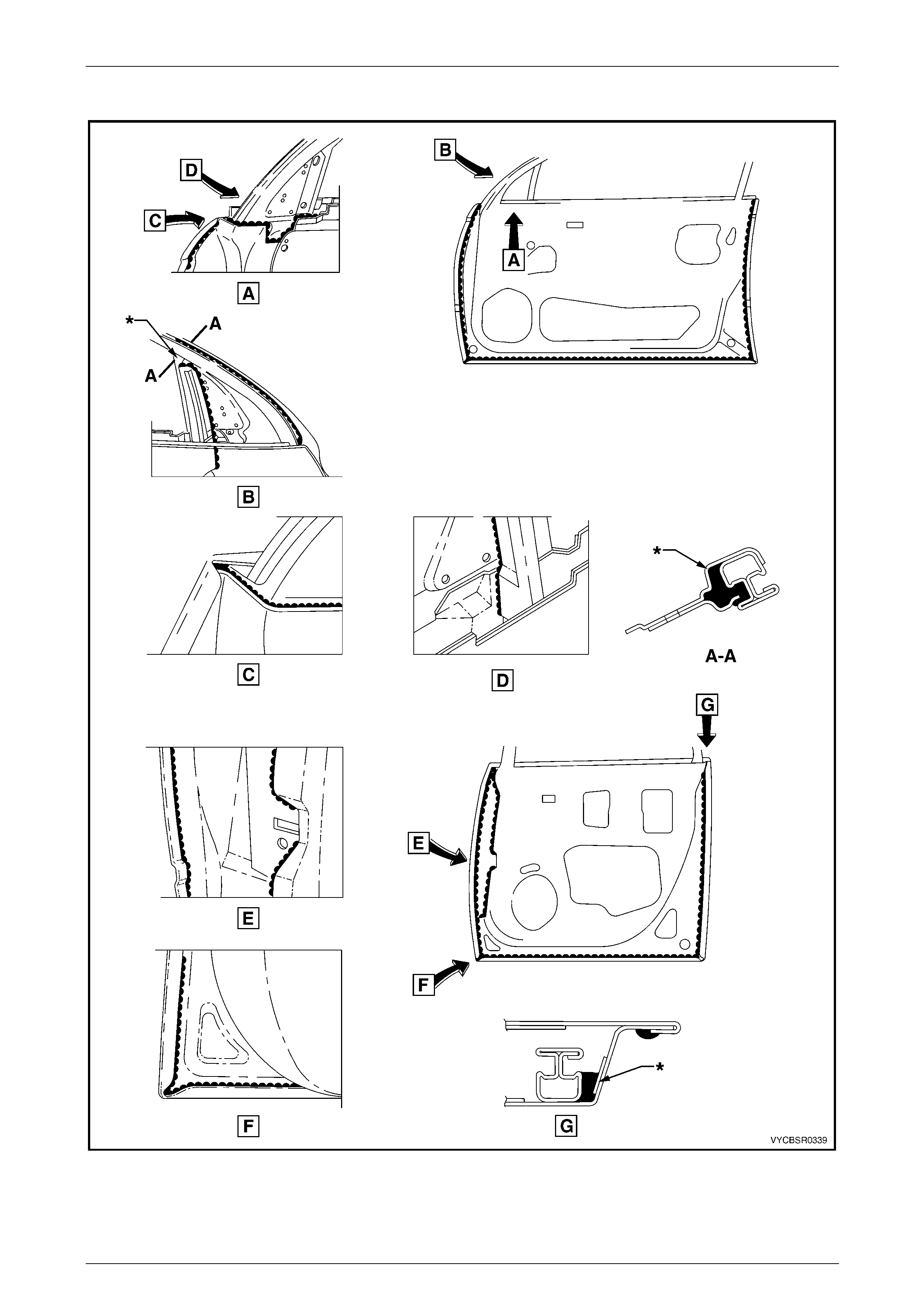

5.3 Joint Sealer (Item 3)

Figure 3B – 16

Body Construction, Crew Cab Page 3B–28

Page 3B–28

Joint Sealer (Item 3) Continued

Figure 3B – 17

Body Construction, Crew Cab Page 3B–29

Page 3B–29

Joint Sealer (Item 3) Continued

Figure 3B – 18

Body Construction, Crew Cab Page 3B–30

Page 3B–30

Joint Sealer (Item 3) Continued

Figure 3B – 19

Body Construction, Crew Cab Page 3B–31

Page 3B–31

Joint Sealer (Item 3) Continued

Figure 3B – 20

NOTE

When the inner rear body panel is installed, joint

sealer is applied around its perimeter between

the panel and body.

Body Construction, Crew Cab Page 3B–32

Page 3B–32

Joint Sealer (Item 3) Continued & Hand Putty (Item 4)

Figure 3B – 21

Body Construction, Crew Cab Page 3B–33

Page 3B–33

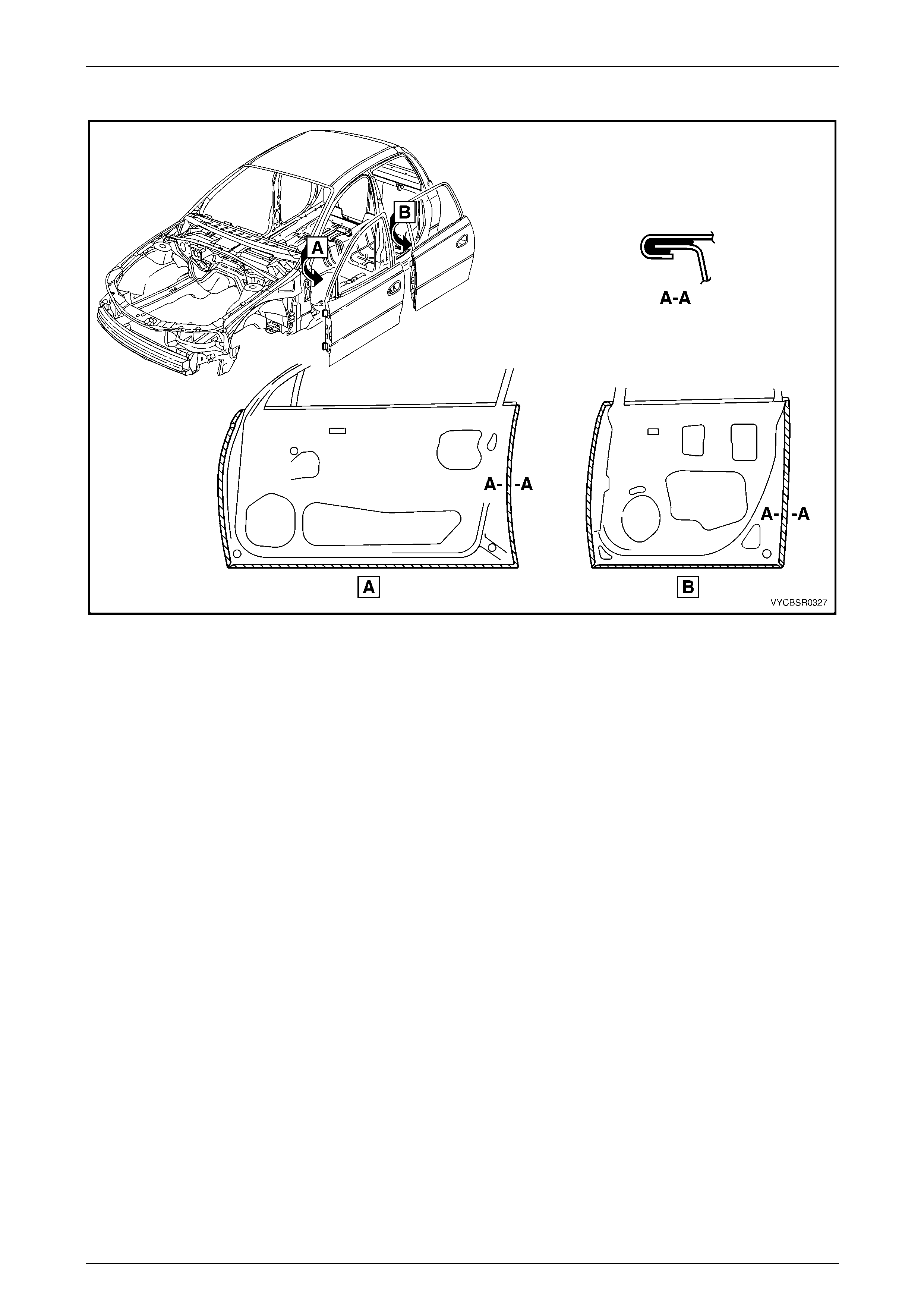

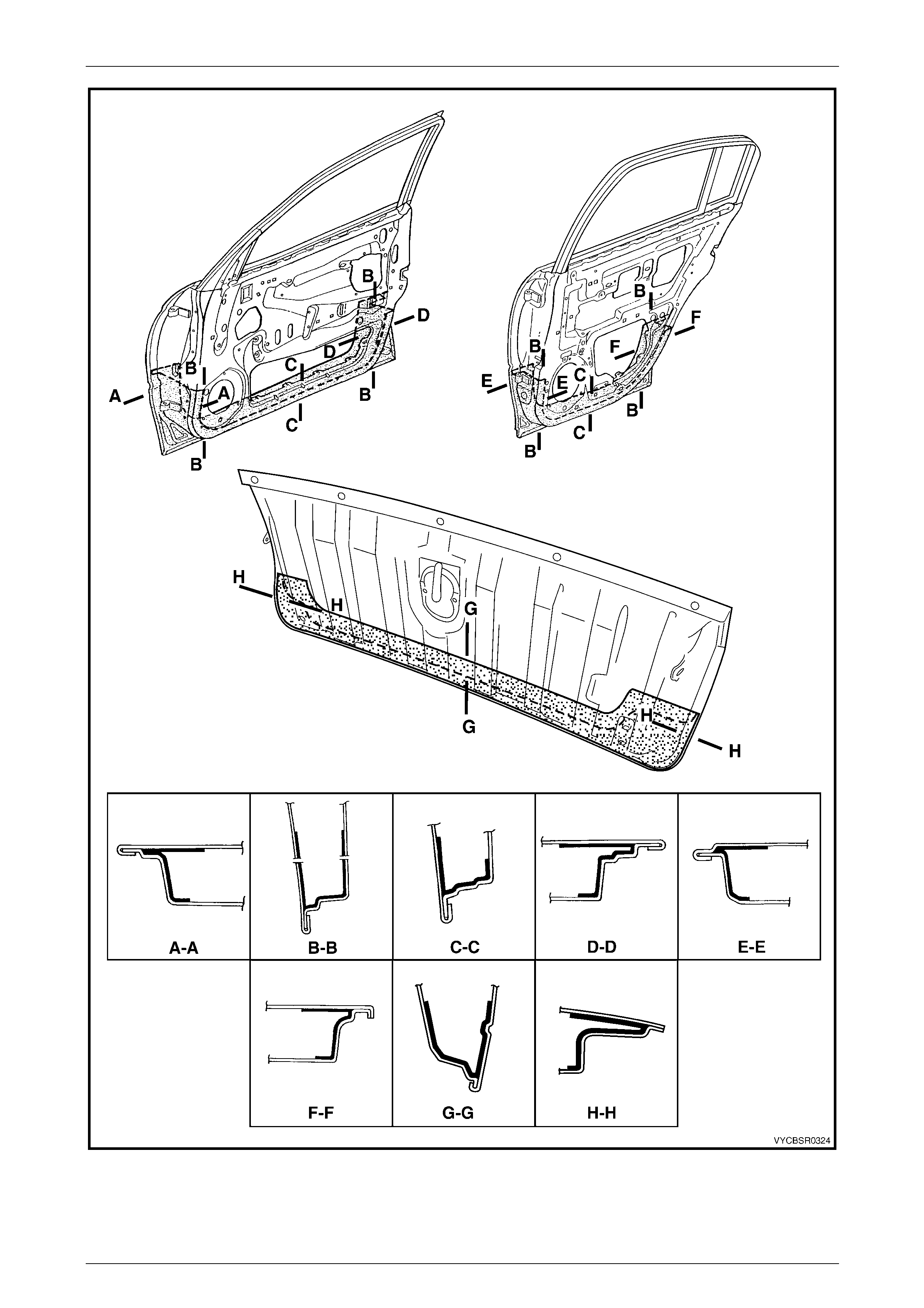

5.4 Adhesive – Anti-Flutter (Item 5)

Figure 3B – 22

Body Construction, Crew Cab Page 3B–34

Page 3B–34

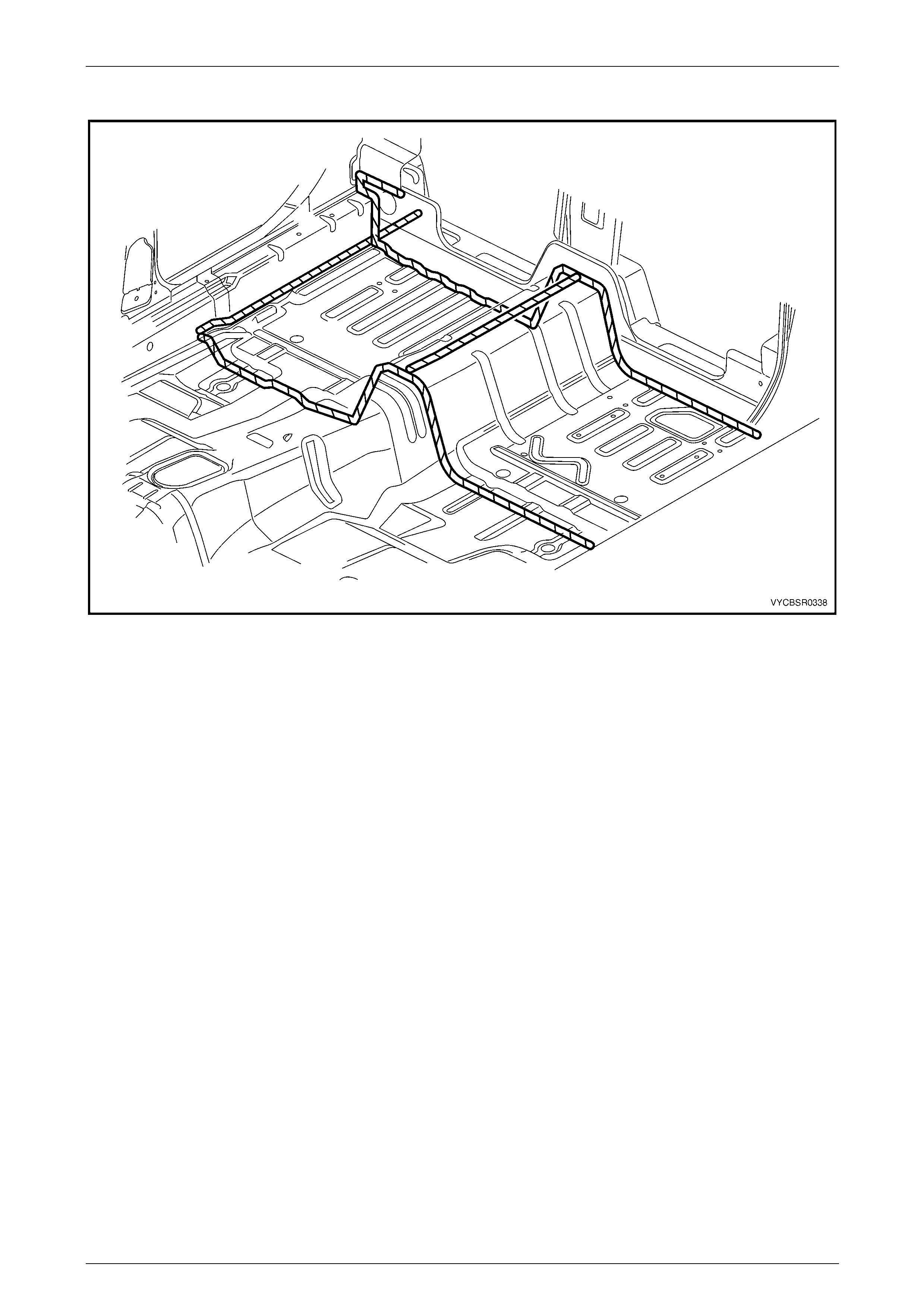

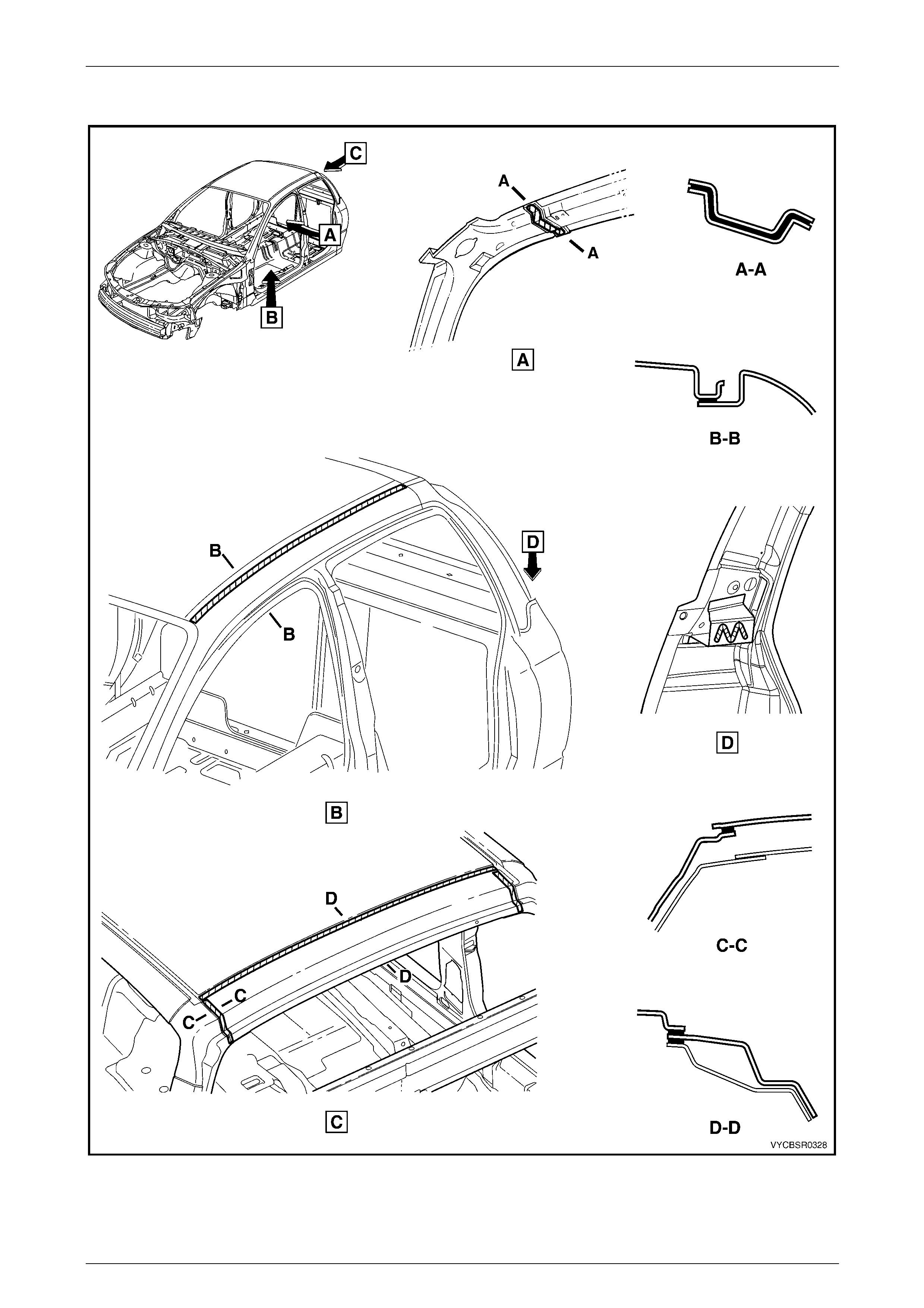

5.5 Adhesive – Structural (Item 6)

Figure 3B – 23

Body Construction, Crew Cab Page 3B–35

Page 3B–35

Adhesive – Structural (Item 6) Continued

Figure 3B – 24

Body Construction, Crew Cab Page 3B–36

Page 3B–36

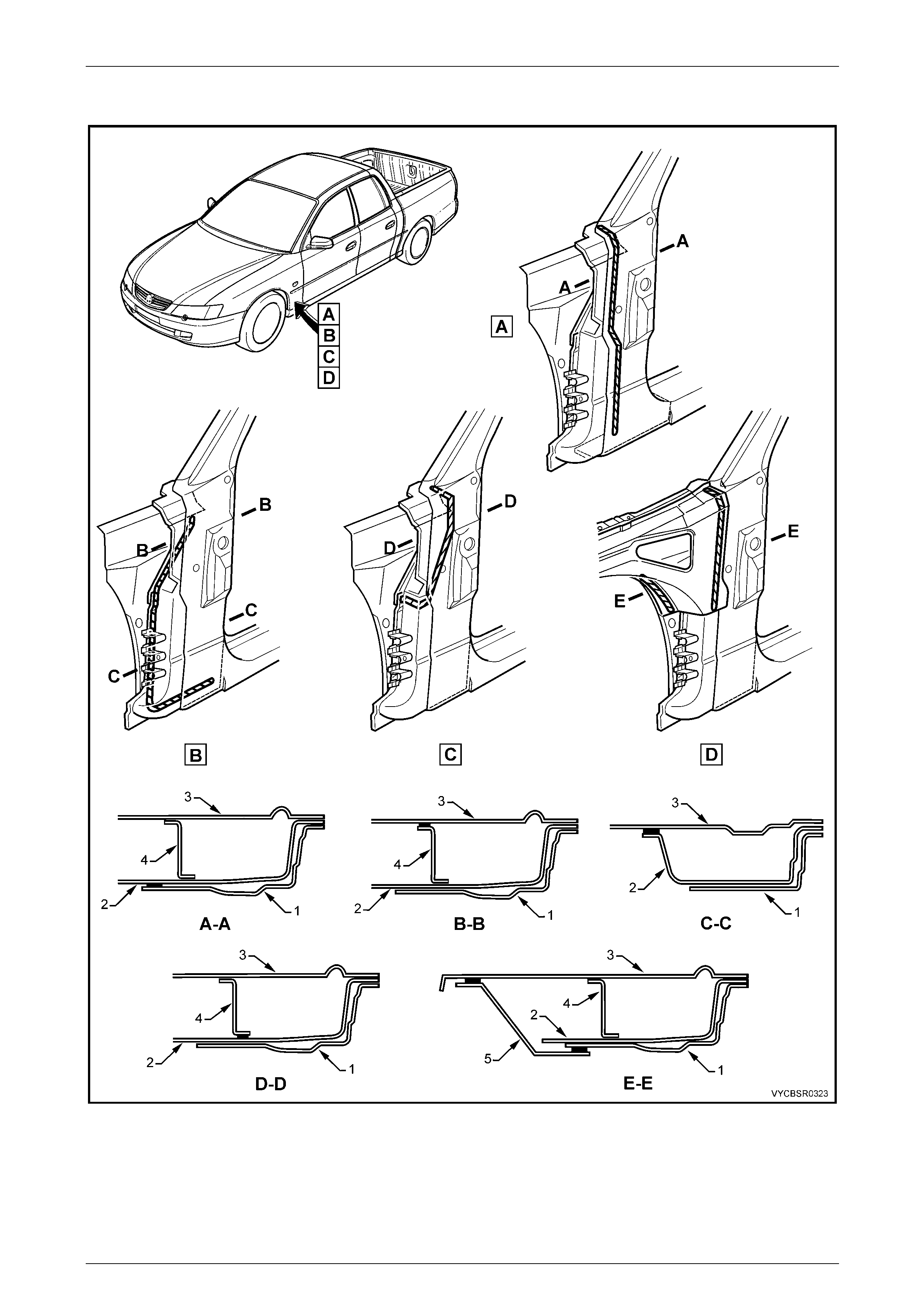

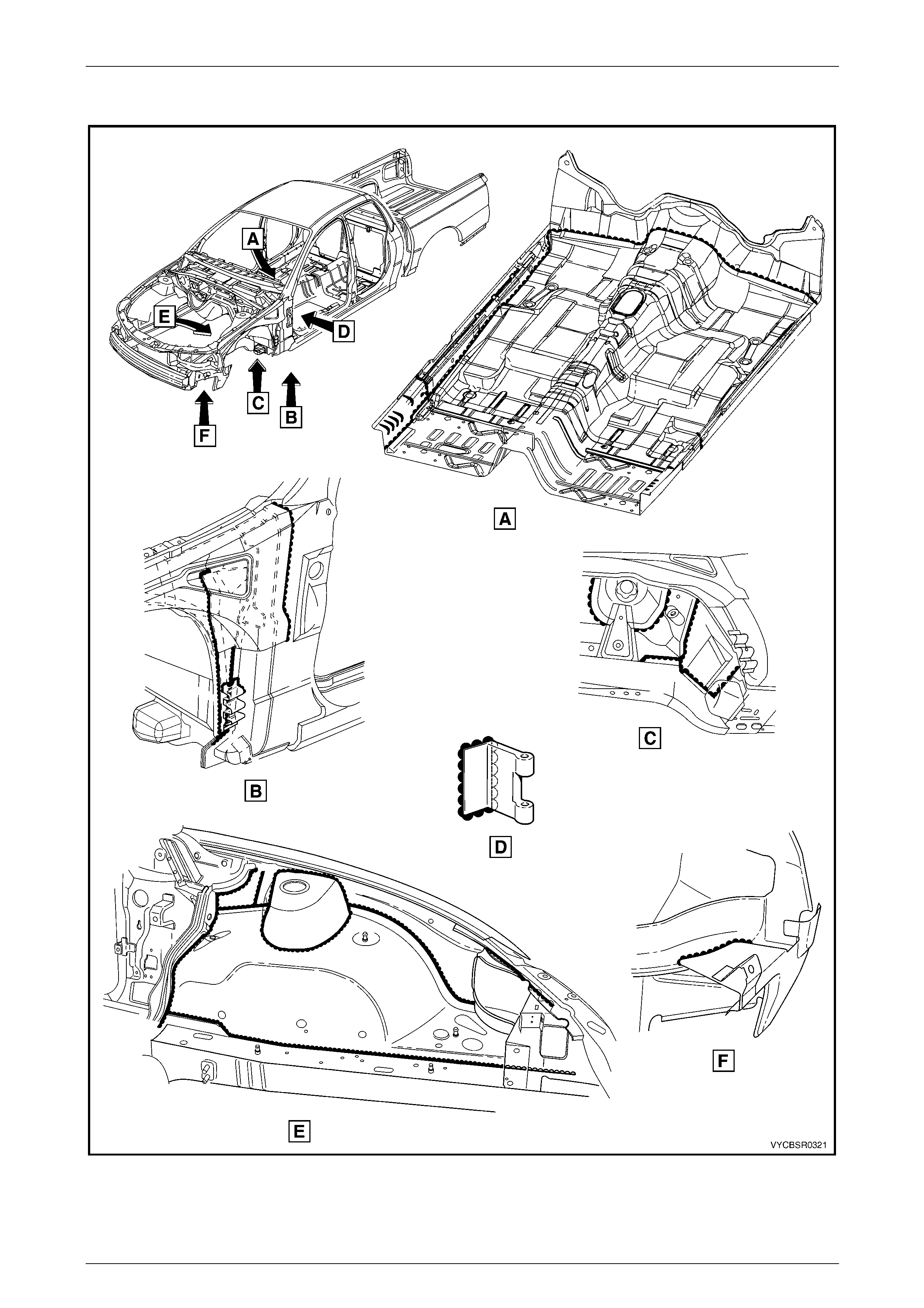

5.6 Spray-on Deadener

Figure 3B – 25

Body Construction, Crew Cab Page 3B–37

Page 3B–37

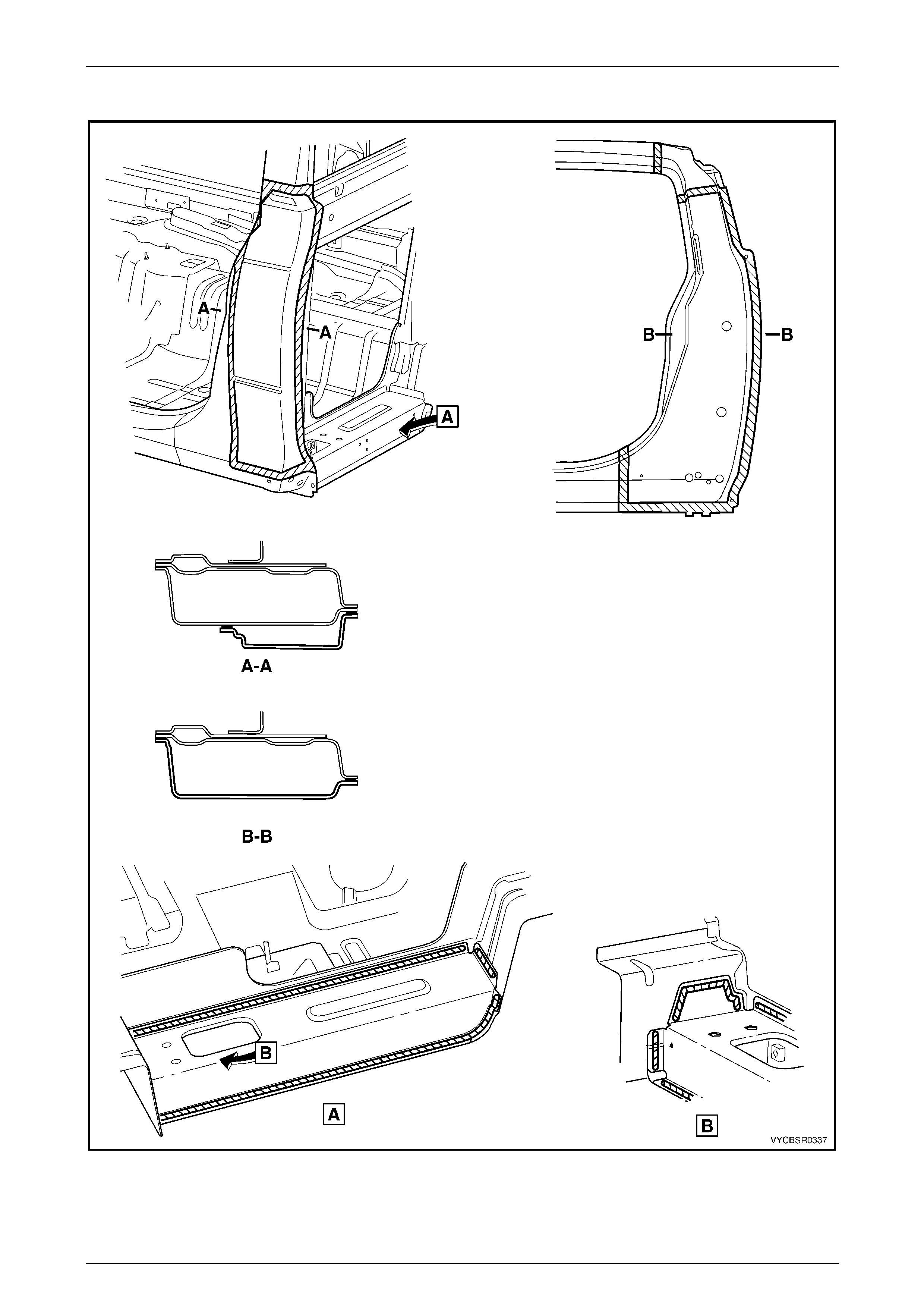

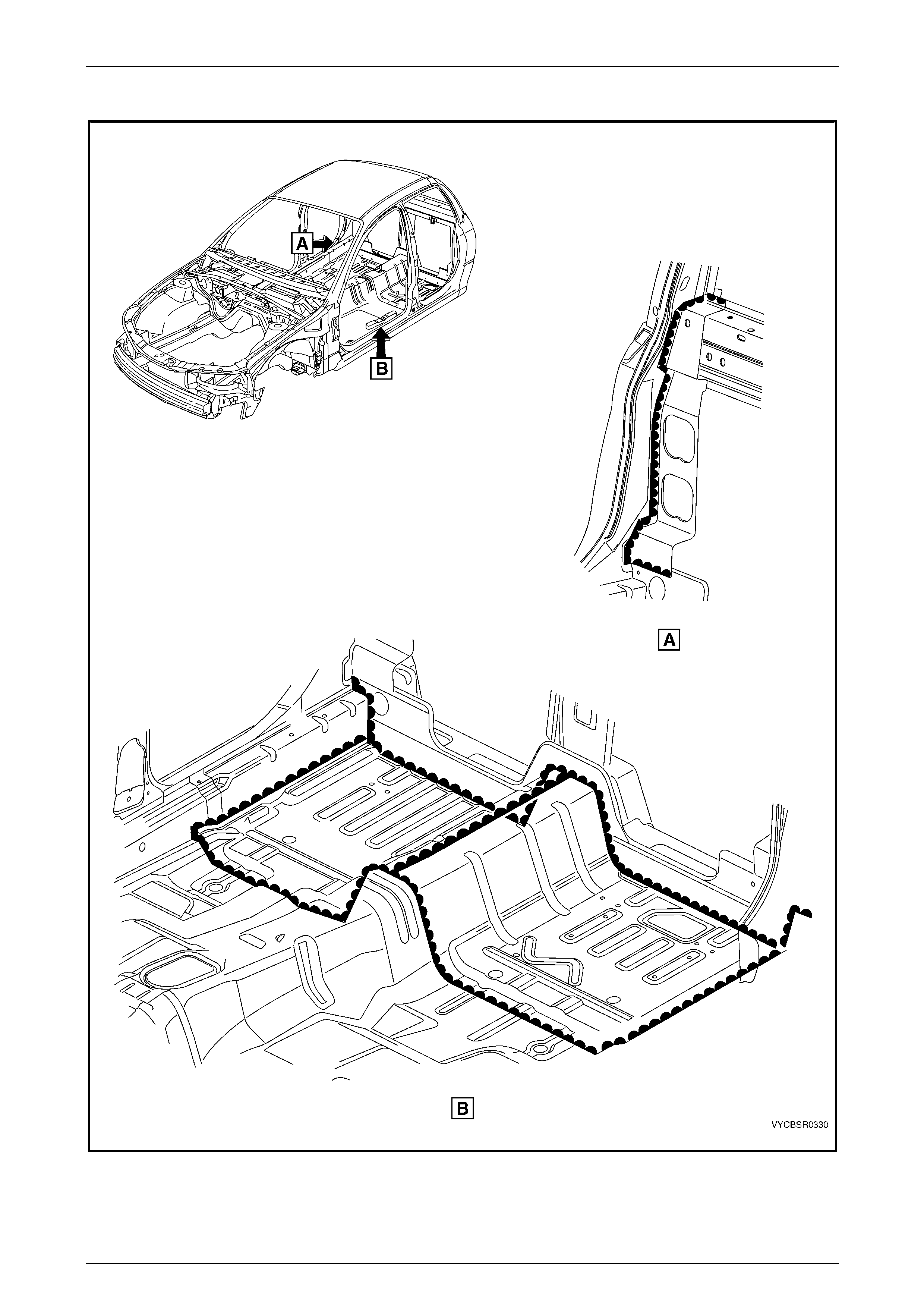

5.7 Deadeners & Insulators

The deadeners shown are heat fusible type. They are to be installed with the diamond em bossed side down. Use a heat

gun, heat lamps or such to cure each deadener sheet.

Figure 3B – 26

Legend

1 Deadener - Front Floor, RH

2 Deadener - Front Floor, Centre

3 Deadener - Front Floor, LH

4 Deadener - Rear Floor, RH

5 Deadener - Rear Floor, Centre

6 Deadener - Floor Rear, LH

Body Construction, Crew Cab Page 3B–38

Page 3B–38

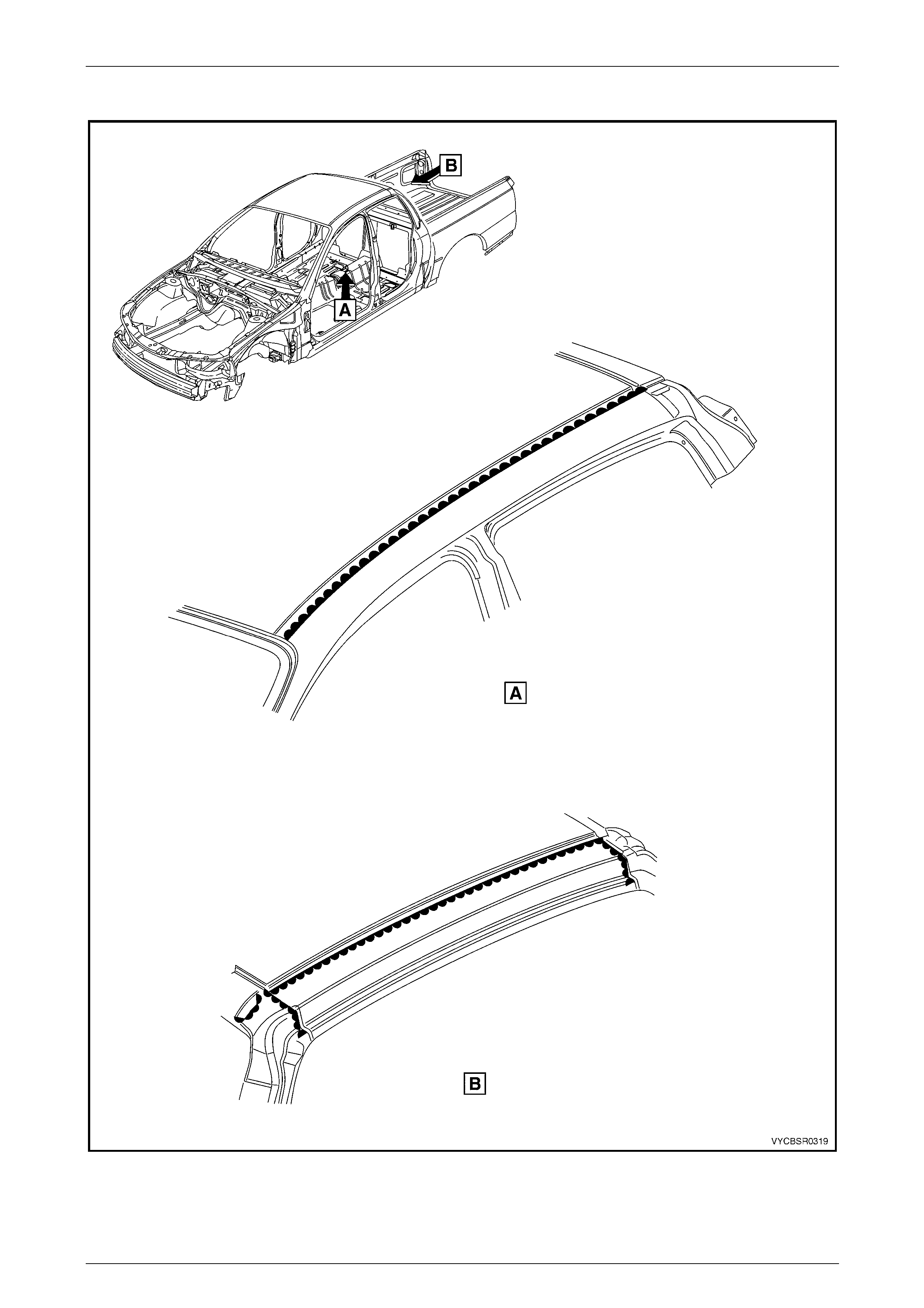

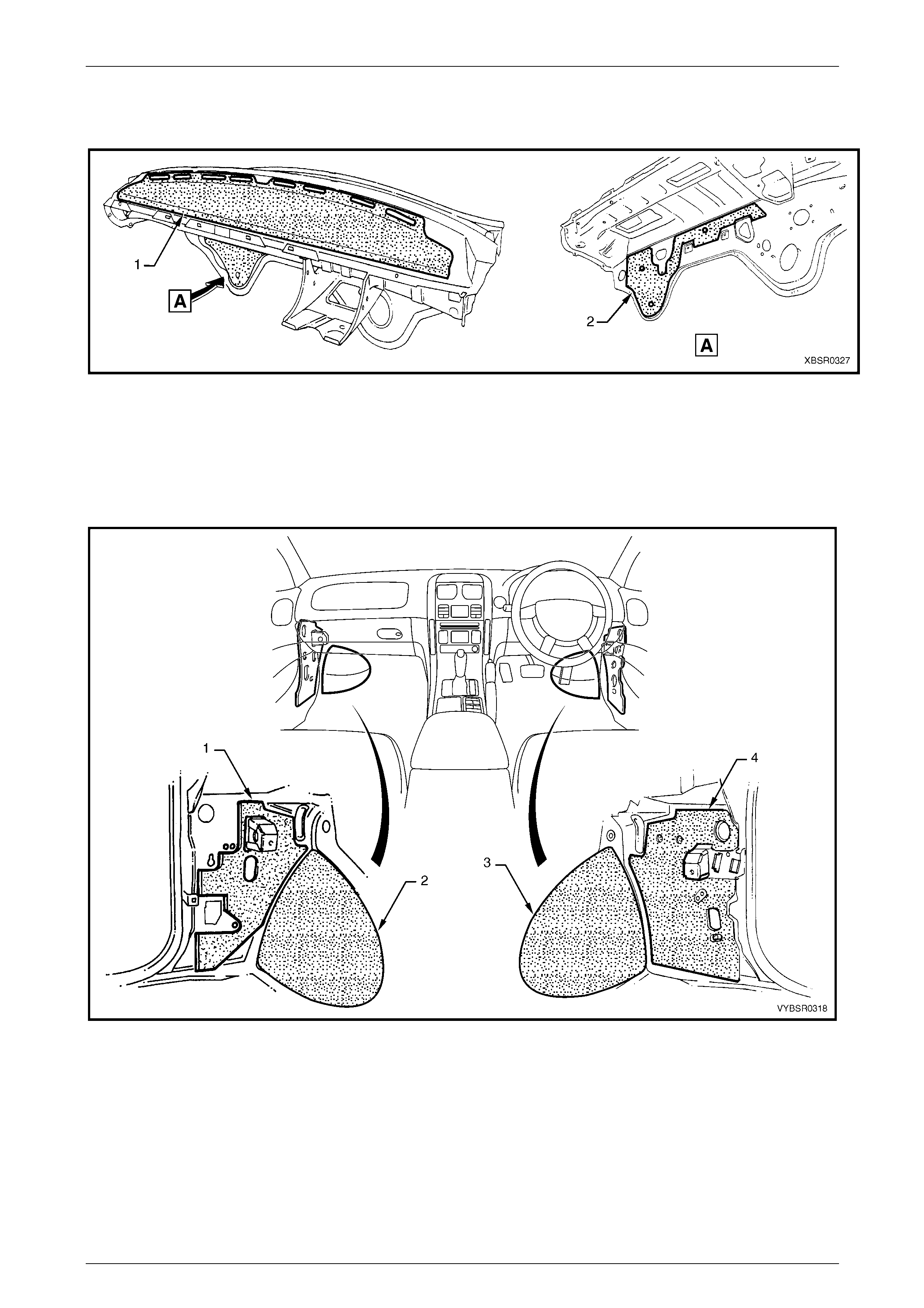

The insulator (1) is self adhes ive. To install, remove the backing paper and attach the insulator ensuring any cut-outs

align with brackets etc. Smooth the insulator firmly into position. The deadener (2) is a heat cure type and is attached a s

previously described.

Figure 3B – 27

Legend

1 Insulator - Dash Panel Upper 2 Deadener - Cockpit Module

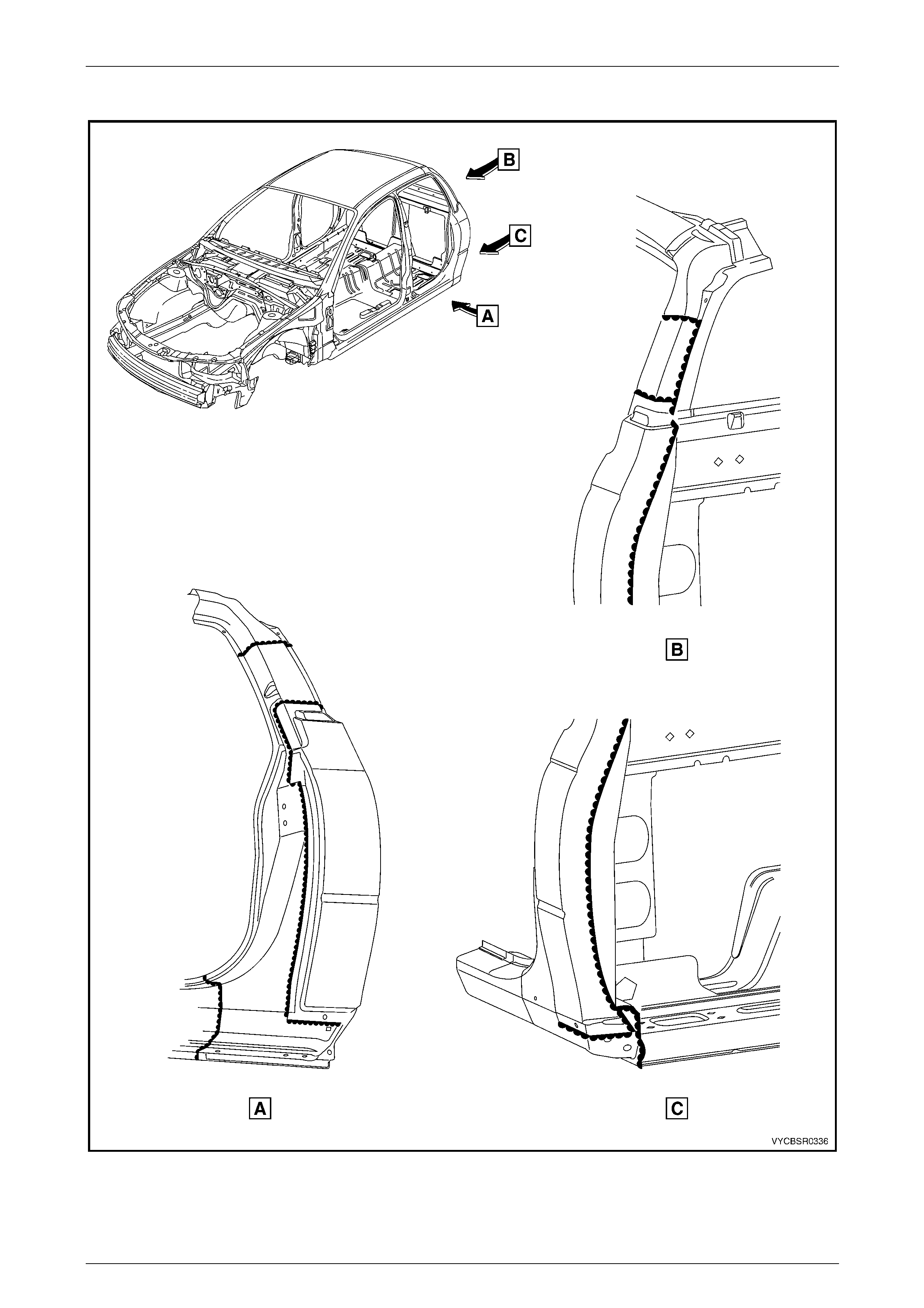

The deadeners and insulators in Figure 3B – 28 are self adh esive. Remove the backing paper and attach the insu lator

ensuring any cut-outs align with brackets etc. Smooth the insulator firmly into position.

Figure 3B – 28

Legend

1 Insulator - Cowl Side, LH

2 Deadener - Front Floor Ext ension, LH 3 Deadener - Front Floor Ext ension, RH

4 Insulator - Cowl Side, RH

Body Construction, Crew Cab Page 3B–39

Page 3B–39

6 Cavity Wax

MY 2003 VY Regular Cab body and structural panels are constructed from high quality corrosion resistant materials.

Following repairs, to maintain the anti-corrosive properties of the vehicle, once the paint is thoroughly dry apply cavity

wax within any repaired b ox sections, areas inaccessible to paint, and to the areas shown below. Refer to the table for

equivalent products to those used in man ufacture.

Cavity Wax Equivalents

Item No. Equivalent Manufacturer Equivalent Product Name

8 Henkel

Terotex HV 8377/65

Nox Rust Hi-Wax 100B

Terasol 800113 (Aerosol pack)

Figure 3B – 29

Body Construction, Crew Cab Page 3B–40

Page 3B–40

Figure 3B – 30