3 Body Construction Page 3-1

Page 3-1

Section 3

Body Construction

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 2

Precautions in this Supplement and Section 00 Warnings, Cautions and Notes in the MY2005 VZ Service

Information for correct workshop practices with regard to safety and/or property damage.

The structure of the body shell has been

developed using complex design and

development techniques. In addition to

meeting all required standards, the vehicle

body is also a critical part of the overall safety

systems. It is therefore imperative the repair

procedures described here are adhered to

during all vehicle body repairs.

1 General Description ...............................................................................................................................2

1.1 Body Structure Part Refinishing........................................................................................................................... 2

1.2 Anti-Corrosive Treatment...................................................................................................................................... 3

1.3 Paint Refinishing.................................................................................................................................................... 4

Panel Refinishing................................................................................................................................................... 4

Paint Code.............................................................................................................................................................. 4

2 Bumper Impact Bar Assemblies...........................................................................................................5

2.1 Front........................................................................................................................................................................ 5

Remove................................................................................................................................................................... 5

Reinstall.................................................................................................................................................................. 5

2.2 Rear......................................................................................................................................................................... 6

Remove................................................................................................................................................................... 6

Reinstall.................................................................................................................................................................. 6

3 Special Tools ..........................................................................................................................................7

4 Torque Wrench Specifications..............................................................................................................8

3 Body Construction Page 3-2

Page 3-2

1 General Description

This Section contains general body construction information relative to all body styles. Information specific to a body style

has been divided into sub-sections for each body style.

Each sub-section describes the body structure as a whole and prov ides a detailed break down of the body structure

components, key body dimensional measurements and body margin tolerances.

The various sealers and adhe sives used throughout the body are also described, as it is imperative that only the correct

materials are used for repairs.

The correct cavity wax, deadeners a nd paint refinishing techniques are also imperative if the veh icle is to be returned to

its original condition.

When replacing or repairin g a part or sub-assembly, care must be taken to ensure that correct alignment and strength of

unit as a whole is maintained. In some instances, major damage to the body or frame can be repaired more effectively

and economically by replacing a part or sub-assembly with a new one, rather than repairing the damaged part.

1.1 Body Structure Part Refinishing

The vehicle body structure is designed to meet or exceed many regulations, including crash performance and occupant

protection, etc. When replacing or repairin g a part or sub-assembly, care must be taken to ensure that correct alignment

and strength of unit as a whole is maintained.

In some instances, major damage to the body structure can be repaired more effectively and economically by replacing a

part or sub-assembly with a new one, rather than repairing the damaged part.

Spot welding is used extensiv ely for joining panels or assemblies, however special adhesives are playing an ever

increasing role in the joini ng of body structure components, either on their own or together with spot welds. Where

repairs are performed, it is imperative that effective rust proofing techniques, as outlined in the following paragraphs, be

observed.

It is for these reasons that qualified persons with suitable tr aining and qualificatio ns only perform the repair or

replacement of body structure components.

3 Body Construction Page 3-3

Page 3-3

1.2 Anti-Corrosive Treatment

Precoated and galvanised steel is used extensively for vari ous body structure components for increased corrosion

protection. Body panels such as the engin e hoo d, door and decklid outer panels are precoated on the inner surface of

the metal to improve corrosion protection. Other bod y structure members have complete double-sided galvanised

protection.

In addition, a rust preventative material (cavity wax) is sprayed after paint application to areas such as the interior

surfaces of doors, etc.

Any repair or replacement of panels, assemblies, etc. that disturb this anti-corrosive treatment must be resealed and

should be included as part of the repair or replacement operation.

Anti-corrosive compounds used for repairs should be light bodi ed materials designed to penetrate b etween metal-to-

metal surfaces such as pinch weld flanges and integral panel attaching poi nts.

All bare metal surfaces must be treated with metal conditioner and primed. These operations need to be carried out prior

to the application of sealers, waxes and sound deadeners. Attaching points of new replacement panels should be

resealed. The hemming flanges of replacement doors, liftgates, endgates and rear compartment lids will require

resealing.

Open joins that require bridging of the sealer to close a gap should be sealed with a heavy-b odied caulking material.

When colour applicatio n is required to restore repaired areas to original appearance, conventional refinishing

preparation, undercoat build-u p and colour application techniques should be employed.

When deadeners are disturbe d during damage repair, or a panel has been replaced, the deadener material must b e

replaced with an equivalent material. The location and pattern for replacement material can be determined by observing

the original deadener application outlines.

3 Body Construction Page 3-4

Page 3-4

1.3 Paint Refinishing

Panel Refinishing

Metal service replacement parts (or assembl ies) are p ainted with a black, high bake factor y primer. To ensure sound

adhesion of colour coats in service, the following refinish steps are necessary.

1 Clean part with a wax and grease remov ing solvent such as Prepsol.

2 Scuff-sand panel lightly with wet and dry number 400 pa per and water. Avoid cut throughs . Re-clean part, and then

apply sealer to entire part.

3 If the factory primer coat has been cut through, apply metal conditioner to the exposed bare metal. Follo w the

directions on container label.

4 Apply primer-surfacer to the entire part; allow to dry thoroughly before sandin g.

5 Sand primer-surfacer using wet and dry number 400 paper and water. Do not sand sealer.

6 Re-clean part.

7 Apply colour coats to parts as directed on the contain er la bel.

8 Follow directions on cont ainer label for dryin g time before compounding.

9 Compound part by hand or with power equipment.

10 Non-sealing polish may be applied after rub-out if desired. Waxes however, should not b e app lied until the paint

finish has aged for at least two months. NOTE

Always follow the paint manufacturer’s

recommendations to ensure a high quality

durable finish is achieved.

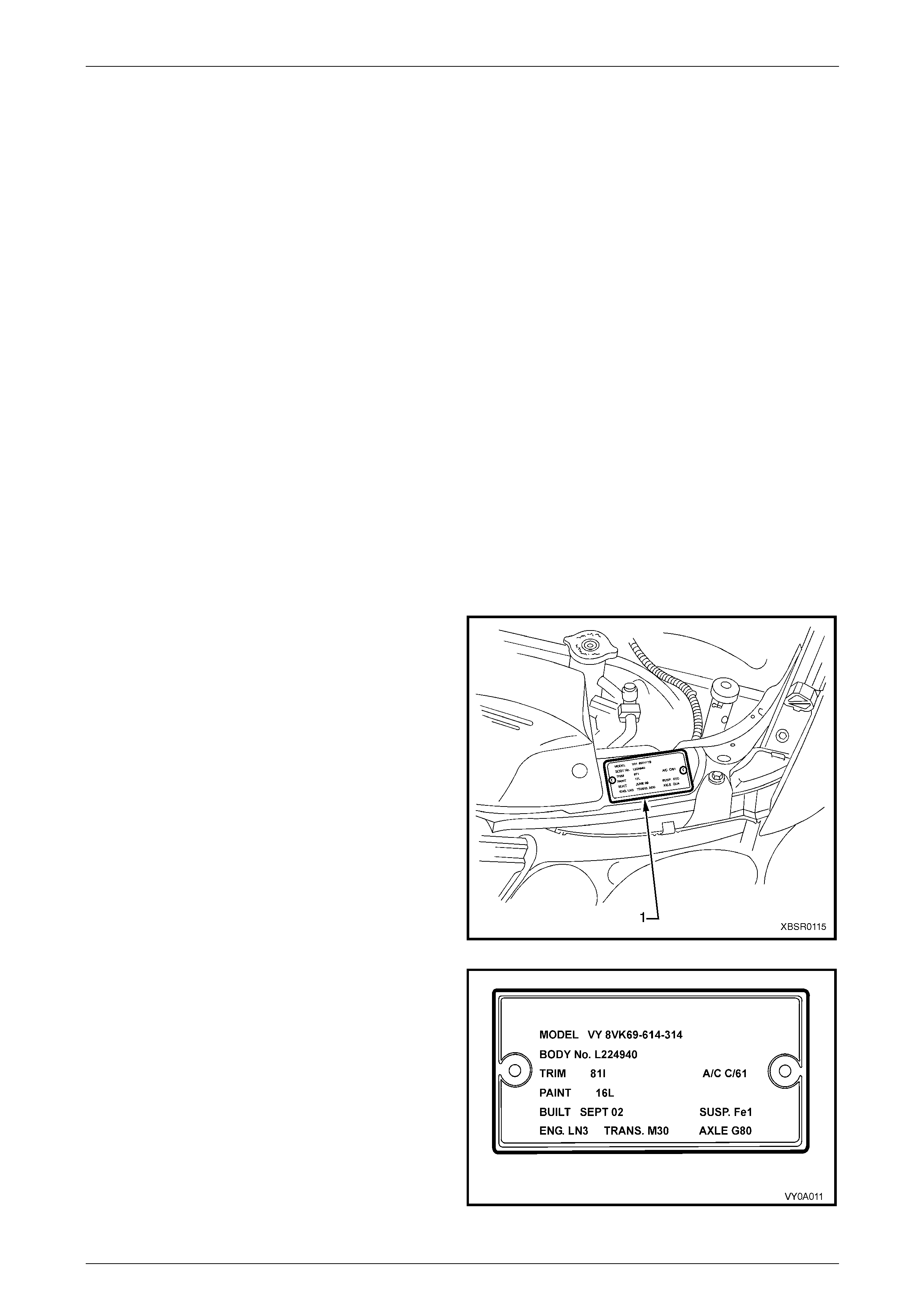

Paint Code

The Paint Code for the vehicle can be found on the Body

and Option Identification Plate (1).

Figure 3 – 1

The Paint Code enables a refinish paint to be matched with

the original paint colour. NOTE

The paint on the vehicle may not exactly match

the original colour due to fade, in which case

paint colour matching will be required. As this is

an acquired skill, it is a task that must be

performed by qualified individuals.

Figure 3 – 2

3 Body Construction Page 3-5

Page 3-5

2 Bumper Impact Bar Assemblies

The bumper impact bar assemblies not only act as a mount and support for the bumper fascias, but are also critical in

the dispersion of crash energ y. Hence, the y play an inte gral role in the operation of the vehicle’s safety systems. Repair

of the bar assemblies should be limited to replacement, as straightening and/or heating can weaken a bar assembly,

potentially resulting in incorrect airbag and se atbelt pretensioner operation.

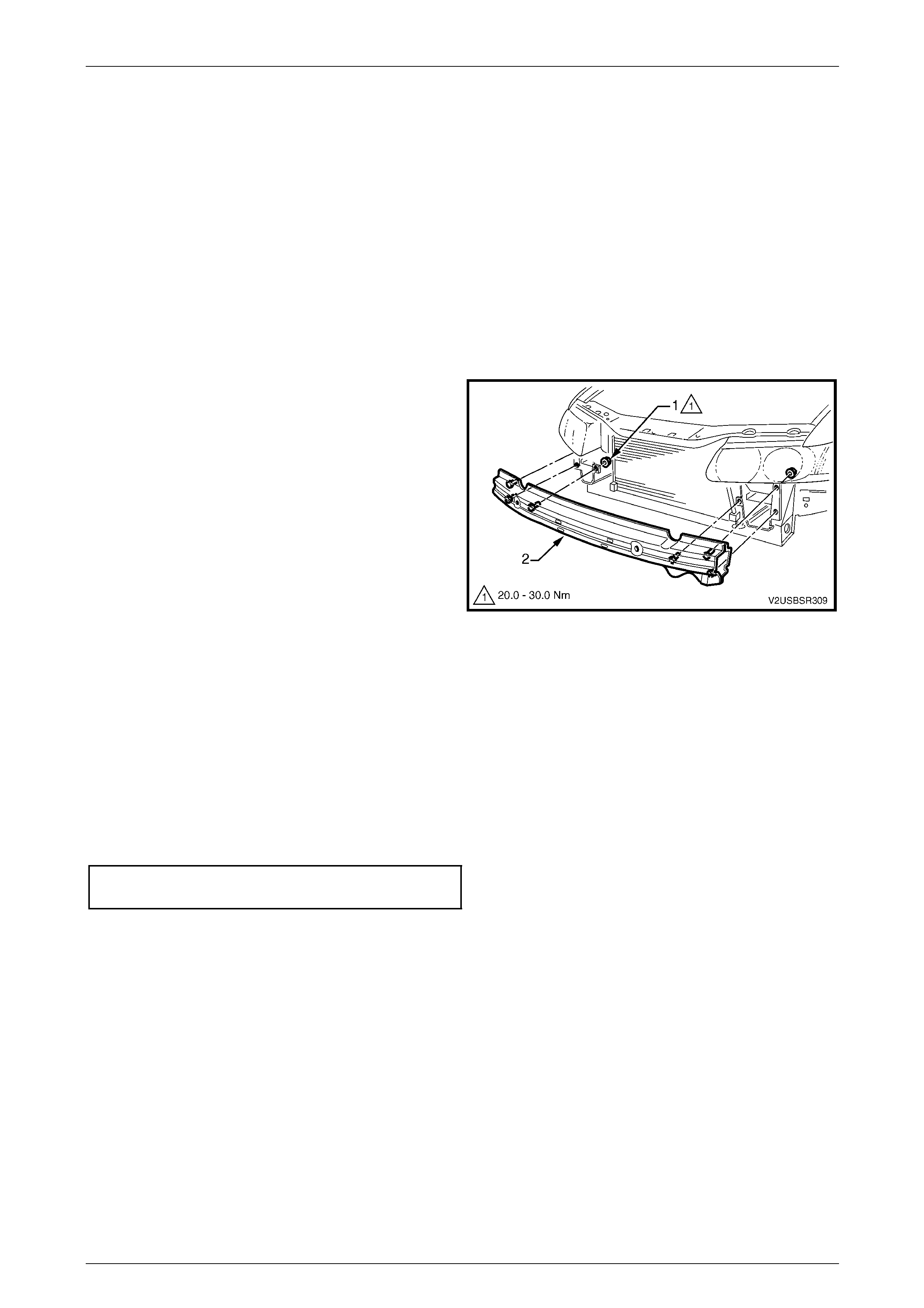

2.1 Front

Remove

1 Remove the front bumper fascia assembly, refer to Section 1D Bumper Bars in the Service Information.

2 If fitted, remove the radiator air lower baffle, refer to Section 6B1 Engine Cooling in the Service Information.

3 Remove the nuts (1), three places each side, attaching

the bar assembly (2) to the vehicle.

4 Remove the bar assembly.

Figure 3 – 3

Reinstall

NOTE

Check the vehicle’s front body dimensions as

required to ensure correct alignment, refer to

Section 1A2 Body Dimensions.

1 Fit the bar assembly in position and attach each nut. Do n ot tighten.

2 Ensure the bar assembly is correctl y pos itioned centrally and tighten the nuts to the specified torque.

Front bumper impact bar assembly

attaching nut torque specification............20.0 – 30.0 Nm

3 Refit the front bumper fascia assembly, refer to Section 1D Bumper Bars in the Service Information.

3 Body Construction Page 3-6

Page 3-6

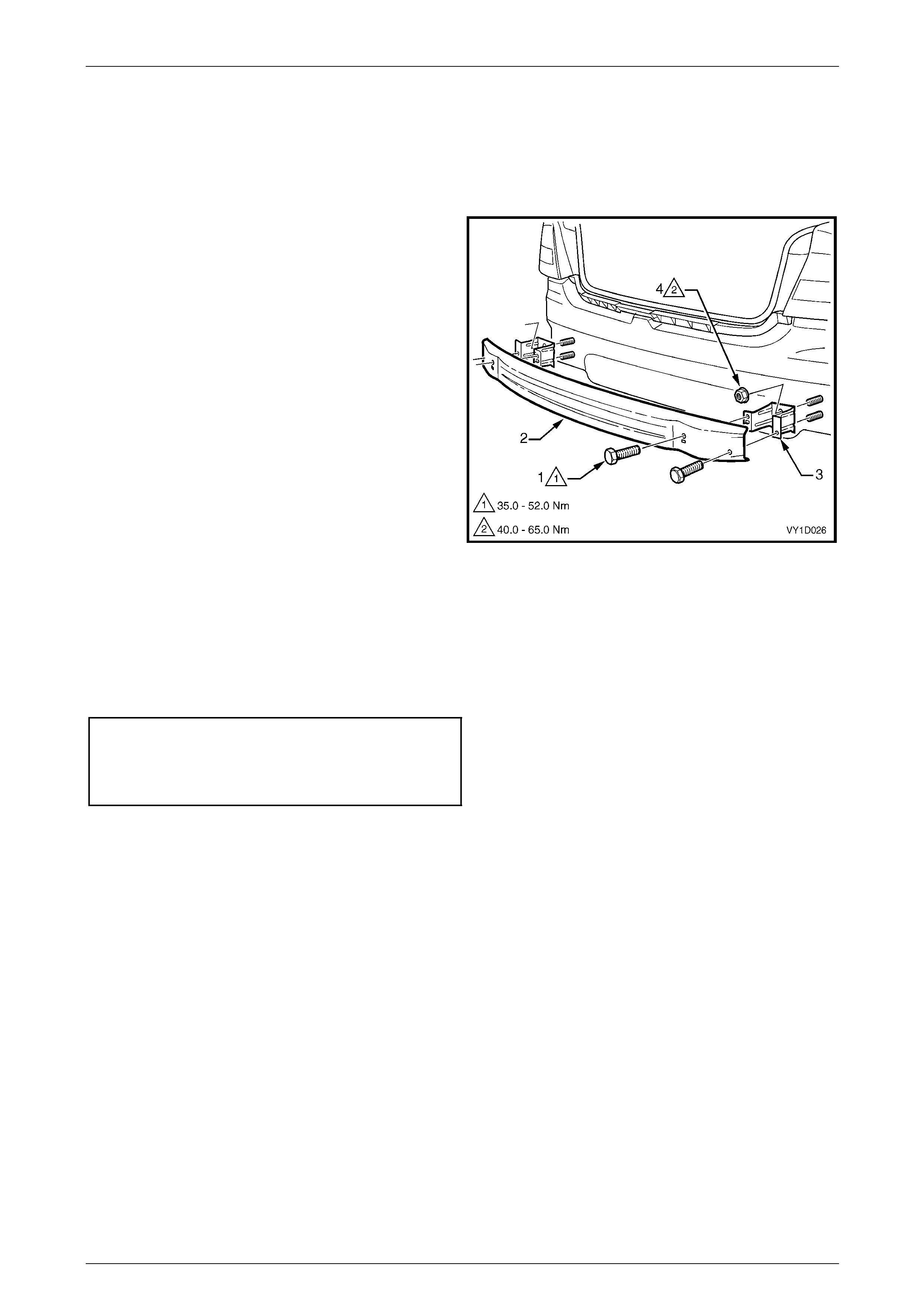

2.2 Rear

Remove

1 Remove the rear bumper fascia assembly, refer to Section 1D Bumper Bars Service Information.

2 Remove the screws (1), two places each side,

attaching the rear bumper im pact bar (2) to the rear

bumper impact bar bracket assembly (3).

3 Remove the bar.

4 If required, remove the two nuts (4), attaching the

bracket assembly to the vehicle and remove the

bracket.

Figure 3 – 4

Reinstall

1 Fit the bracket assemblies in position and attach the nuts. Tighten to the specified torque.

2 Fit the bar to the bracket assemblies and fit each screw. Do not tighten.

3 When all screws are installed, check the bar is centralised. Tighten the bolts to the specified torque.

Rear bumper impact bar bracket assembly

attaching nut torque specification............49.0 – 65.0 Nm

Rear bumper impact bar attaching

screw torque specification.......................35.0 – 52.0 Nm

3 Body Construction Page 3-7

Page 3-7

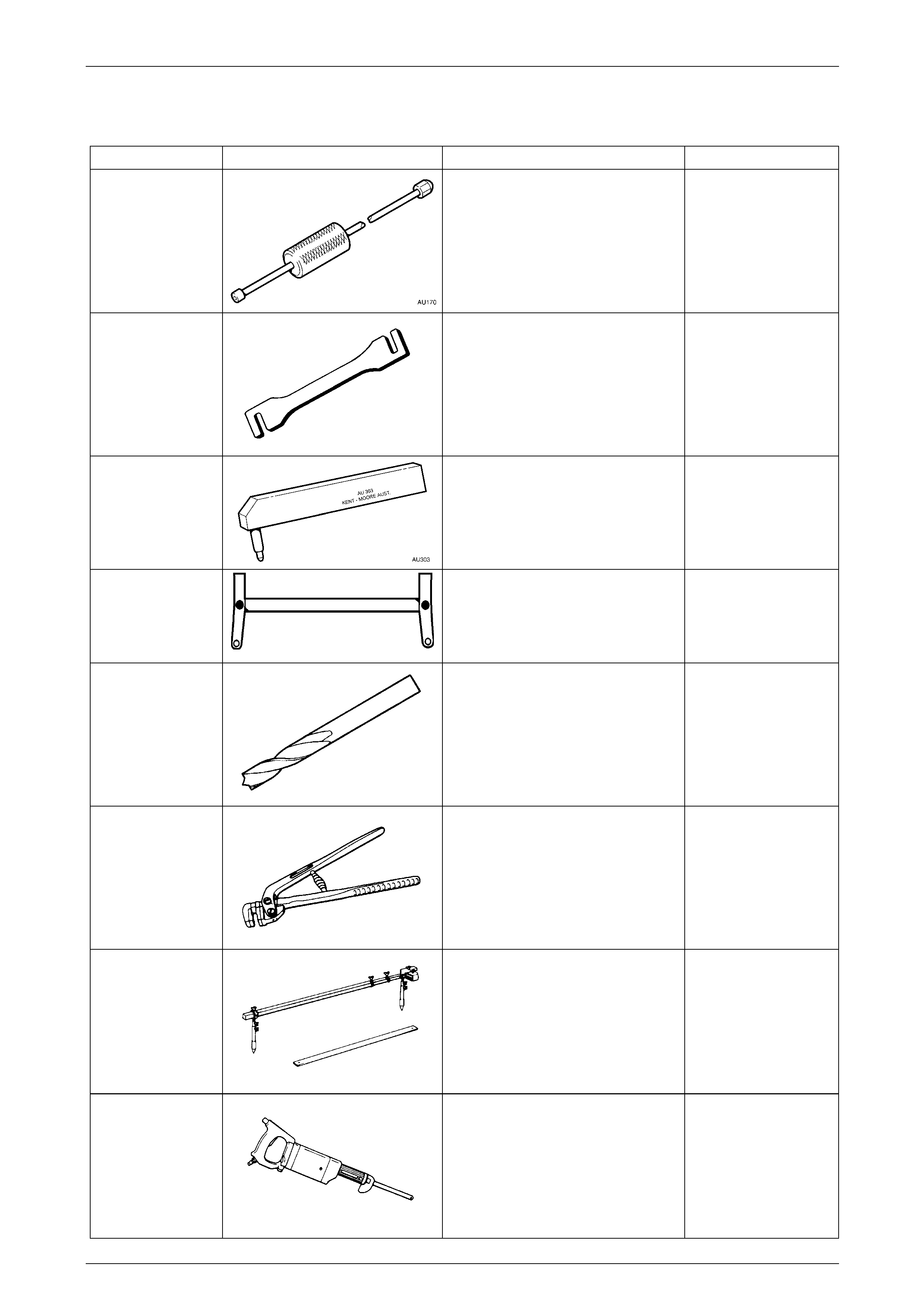

3 Special Tools

Tool Number Illustration Description Tool Classification

AU170 Door Hinge Sleeve Remover

Used for removing door hinge pivot

sleeves

AU184 Door Hinge Setting Tool

Used to adjust door alignment.

AU303

Door Hinge Sleeve Installer

Used to install door hinge piv ot

sleeves

AU458

Rear Crossmember Centring Tool

Used when any servic e operation

requires removal / reinstallation of

rear suspension frame assembly, or

when checking rear end alignment.

N/A Spot Cutting Tool

Commercially available

Used for separating spot welds

N/A Flanging Tool

Commercially available

Used for making a joggle to form a lap

joint on overlapping panels.

N/A Tracking Gauge

Commercially available

Used for measuring body dimensions

N/A Power Saw

Commercially available

Used for cutting panels. An angle

grinder may also be used when

deemed more appropri ate for the task

3 Body Construction Page 3-8

Page 3-8

4 Torque Wrench Specifications

Front Bumper Impact Bar Assembly Attaching Nut...................20.0 – 30.0 Nm

Rear Bumper Impact Bar Bracket Assembly Attaching Nut.......49.0 – 65.0 Nm

Rear Bumper Impact Bar Attaching Screw................................35.0 – 52.0 Nm