6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-1

Page 6A-1

Section 6A

Cabin Floor – Sedan, Wagon, Coupe and AWD

Wagon

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 2

Precautions in this Supplement and Section 00 Warnings, Cautions and Notes in the MY2005 VZ Service

Information for correct workshop practices with regard to safety and/or property damage.

The structure of the body shell has been

developed using complex design and

development techniques. In addition to

meeting all required standards, the vehicle

body is also a critical part of the overall safety

systems. It is therefore imperative the repair

procedures described here are adhered to

during all vehicle body repairs.

1 General Description ...............................................................................................................................2

1.1 Cabin Floor Components...................................................................................................................................... 2

2 Service Operations.................................................................................................................................4

2.1 Front Floor Panel Extension – Replace ............................................................................................................... 4

Remove................................................................................................................................................................... 4

Replace................................................................................................................................................................... 5

2.2 Front Floor Panel Extension – Partial Replace.................................................................................................... 7

Remove................................................................................................................................................................... 7

Replace................................................................................................................................................................... 8

2.3 Front Floor Panel Assembly – Replace.............................................................................................................. 10

Remove................................................................................................................................................................. 10

Replace................................................................................................................................................................. 12

2.4 Inner Rocker Panel Assembly – Replace........................................................................................................... 14

Remove................................................................................................................................................................. 14

Replace................................................................................................................................................................. 15

2.5 Right-hand Transmission Support Bracket – Replace ..................................................................................... 17

Remove................................................................................................................................................................. 17

Replace................................................................................................................................................................. 17

2.6 Seat Inner Bracket Assembly – Replace............................................................................................................ 19

Remove................................................................................................................................................................. 19

Replace................................................................................................................................................................. 20

2.7 Seat Outer Bracket Assembly – Replace........................................................................................................... 21

Remove................................................................................................................................................................. 21

Replace................................................................................................................................................................. 22

2.8 Propeller Shaft Hanger Assembly – Replace..................................................................................................... 23

Remove................................................................................................................................................................. 23

Replace................................................................................................................................................................. 24

2.9 Left-hand Transmission Support Bracket – Replace........................................................................................ 25

Remove................................................................................................................................................................. 25

Replace................................................................................................................................................................. 26

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-2

Page 6A-2

1 General Description

This Section describes the replacement procedures for the cabin floor component s of the body structure.

For the servicing of the rear floor components refer to:

• Section 10A Body Rear – Sedan

• Section 10B Body Rear - Wagon and AW D Wagon

• Section 10D Body Rear - Coupe

Removal of bolt-on panels and mecha nica l components is not covered. For information on the removal of these parts,

reference must be made to the appropriate Section in the MY2005 VZ Service Information.

NOTE

• When repairing the cabin floor of the vehicle,

care must be taken to ensure the structure is

returned to its original production

configuration.

• It is imperative that the correct body

adhesives, sealers, deadeners and cavity

waxes are used when repairing the body

structure. Refer to Section 3 Body

Construction for details of the correct

materials and their commercially available

equivalents.

1.1 Cabin Floor Components

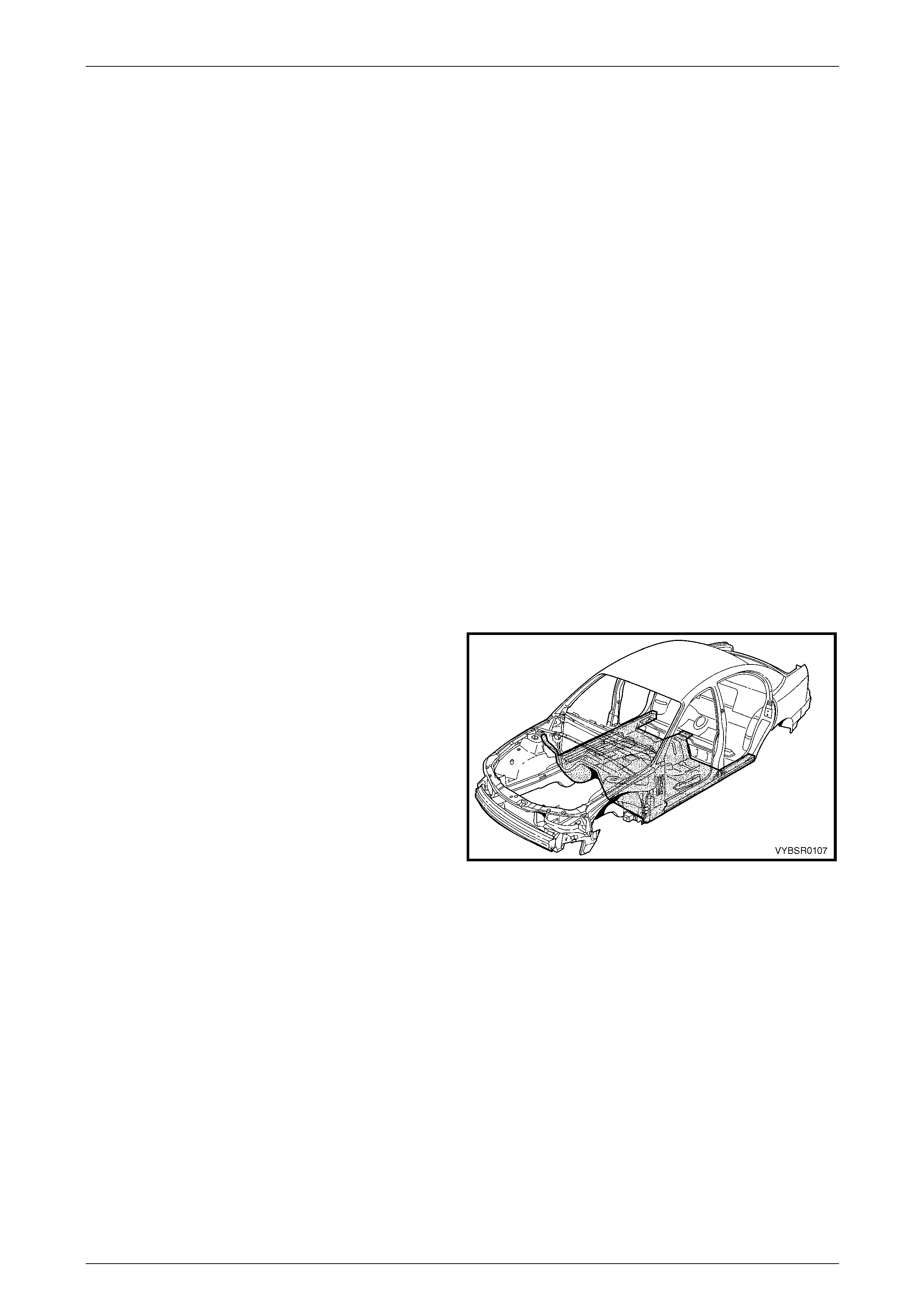

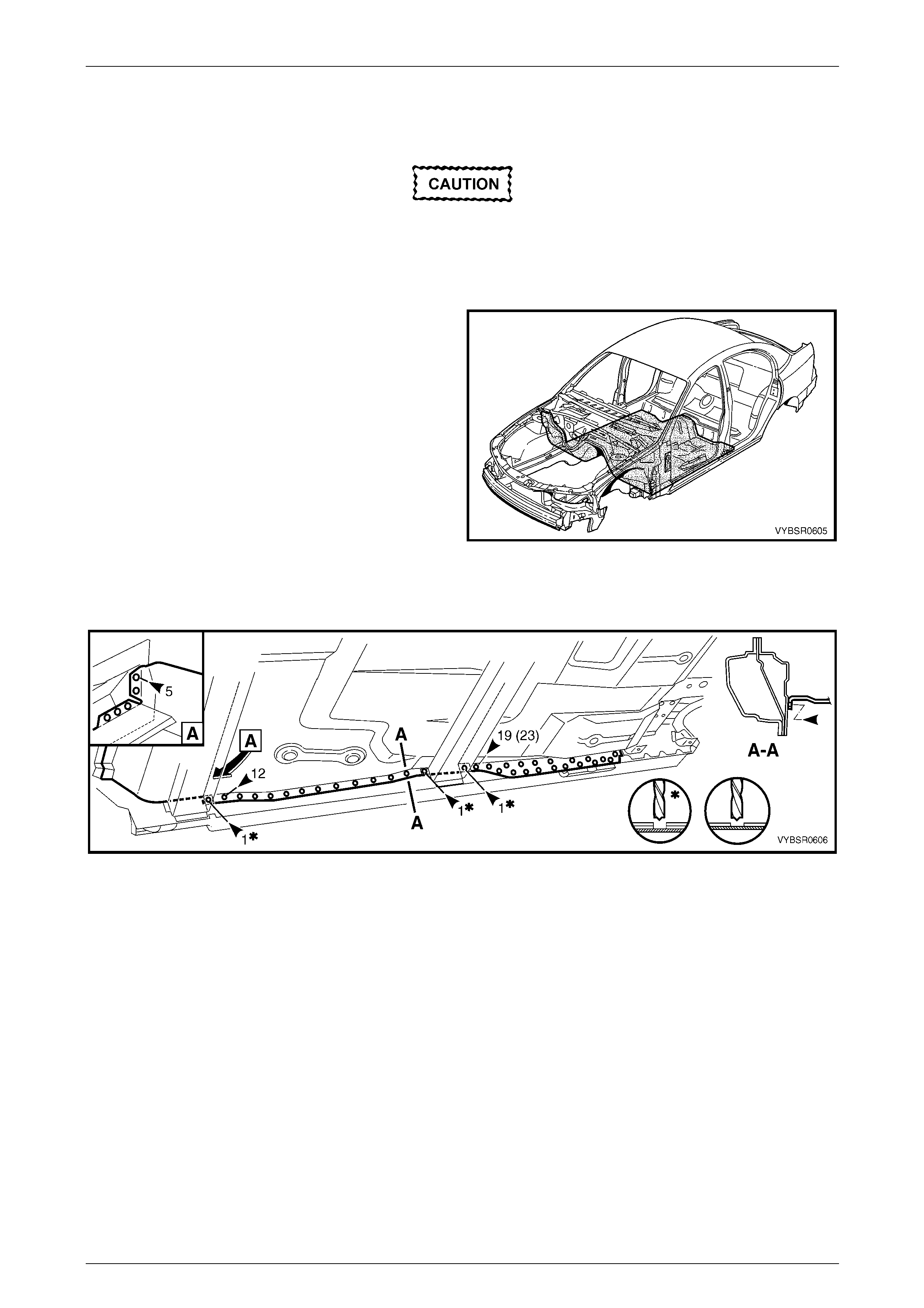

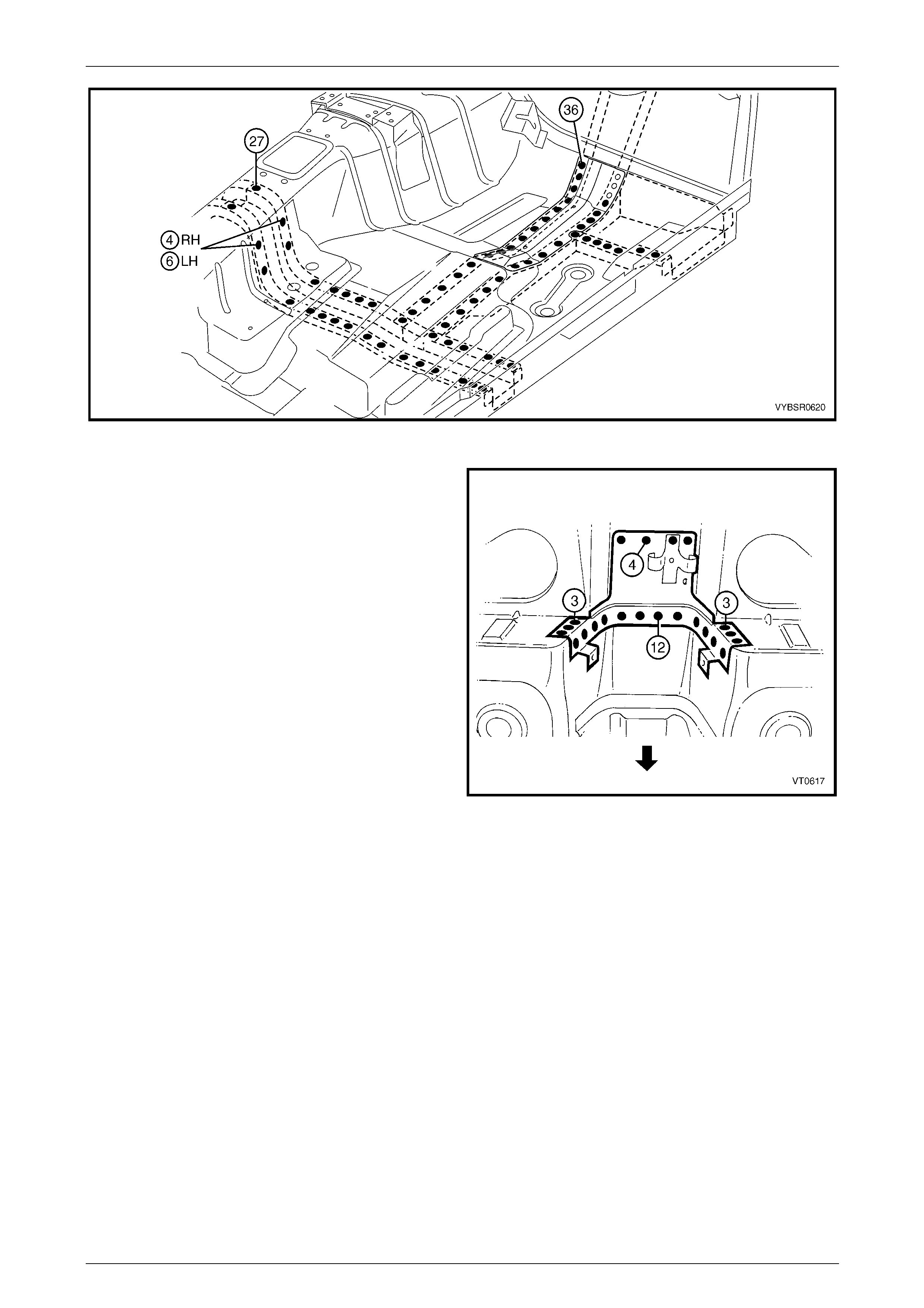

The shaded components in Figure 6A – 1 are the cabin floor

components dealt with in this Section.

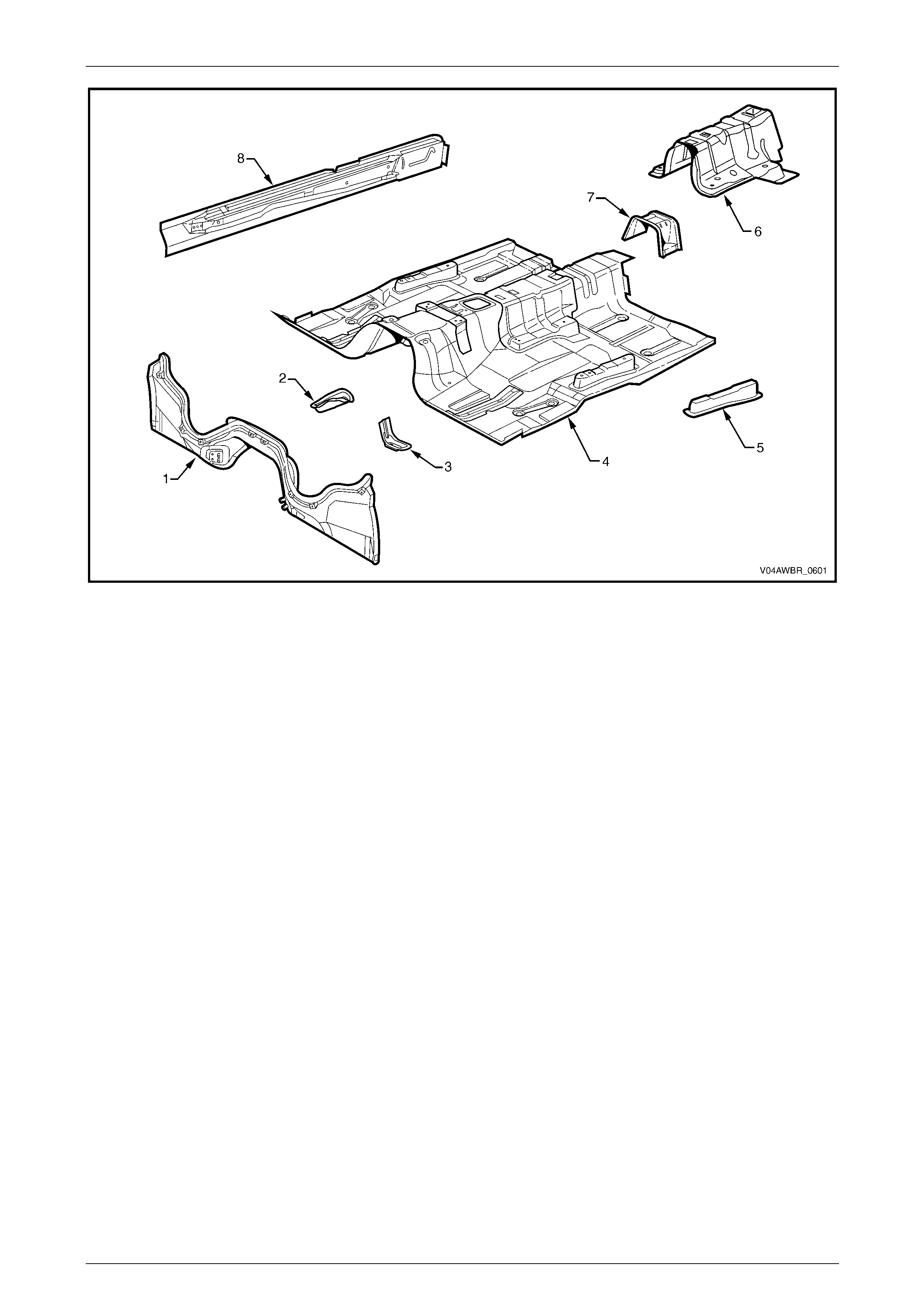

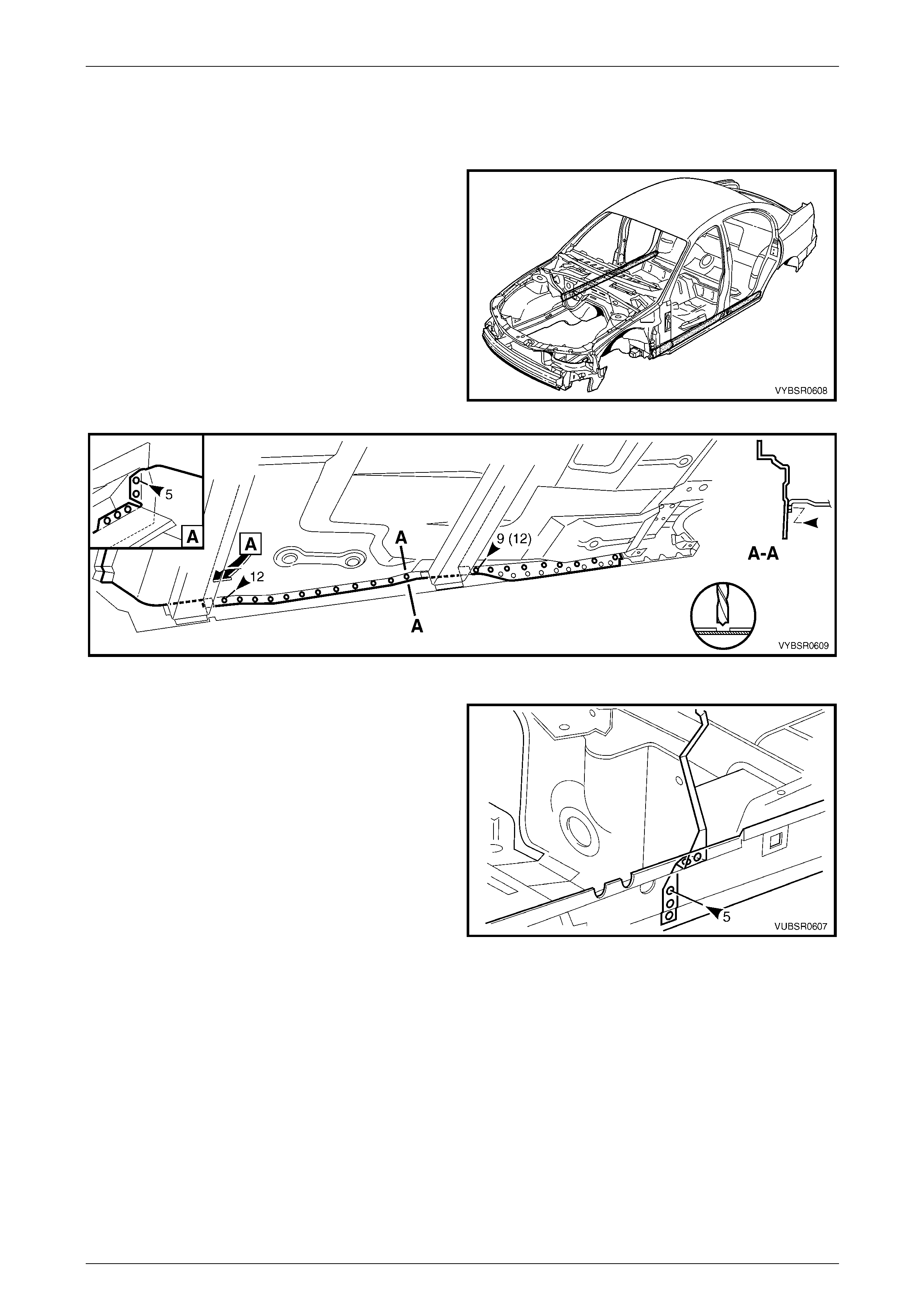

The components and assemblies shown in Figure 6A – 2

and are the serviceable parts that form the basis of the

repair procedures in this Section. For a detailed view of the

body components, refer to Section 3 Body Construction.

NOTE

Always refer to an Authorised Retailer for spare

parts availability configurations.

Figure 6A – 1

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-3

Page 6A-3

Figure 6A – 2

Legend

1 Front Floor Panel Extension

2 Transmission Support Bracket, Right-hand / Left-hand

(except AWD)

3 Transmission Support Bracket, Left-hand (AWD Only)

4 Front Floor Assembly

5 Seat Outer Bracket Assembly, Right-hand / Left-hand

6 Seat Inner Bracket Assembly

7 Propeller Shaft Hanger Assembly

8 Inner Rocker Panel Assembly, Right-hand / Left-hand

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-4

Page 6A-4

2 Service Operations

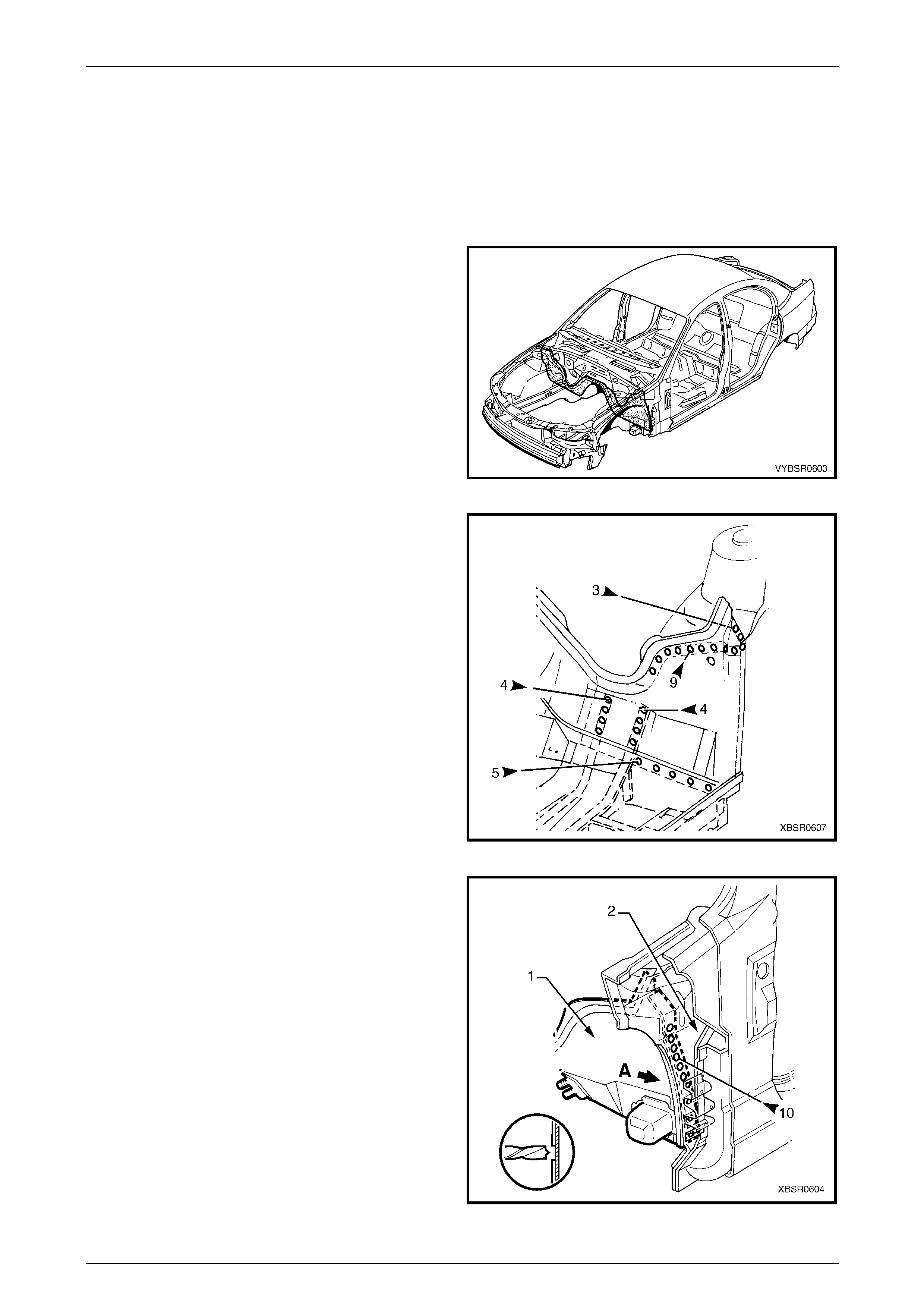

2.1 Front Floor Panel Extension – Replace

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

VZ Service Information.

2 Secure the vehicle on a suitable fixture. As a

minimum, support the appropriate structural s ections

of the vehicle on safety stands.

3 Remove the dash panel asse mbly,

refer to Section 5 Cockpit Module.

4 Remove the adjoining panels as required, refer to the

relevant Section in this Supplement.

5 Using a scraper and heat gun, remove the body sealer

and deadener from the front floor and floor extension

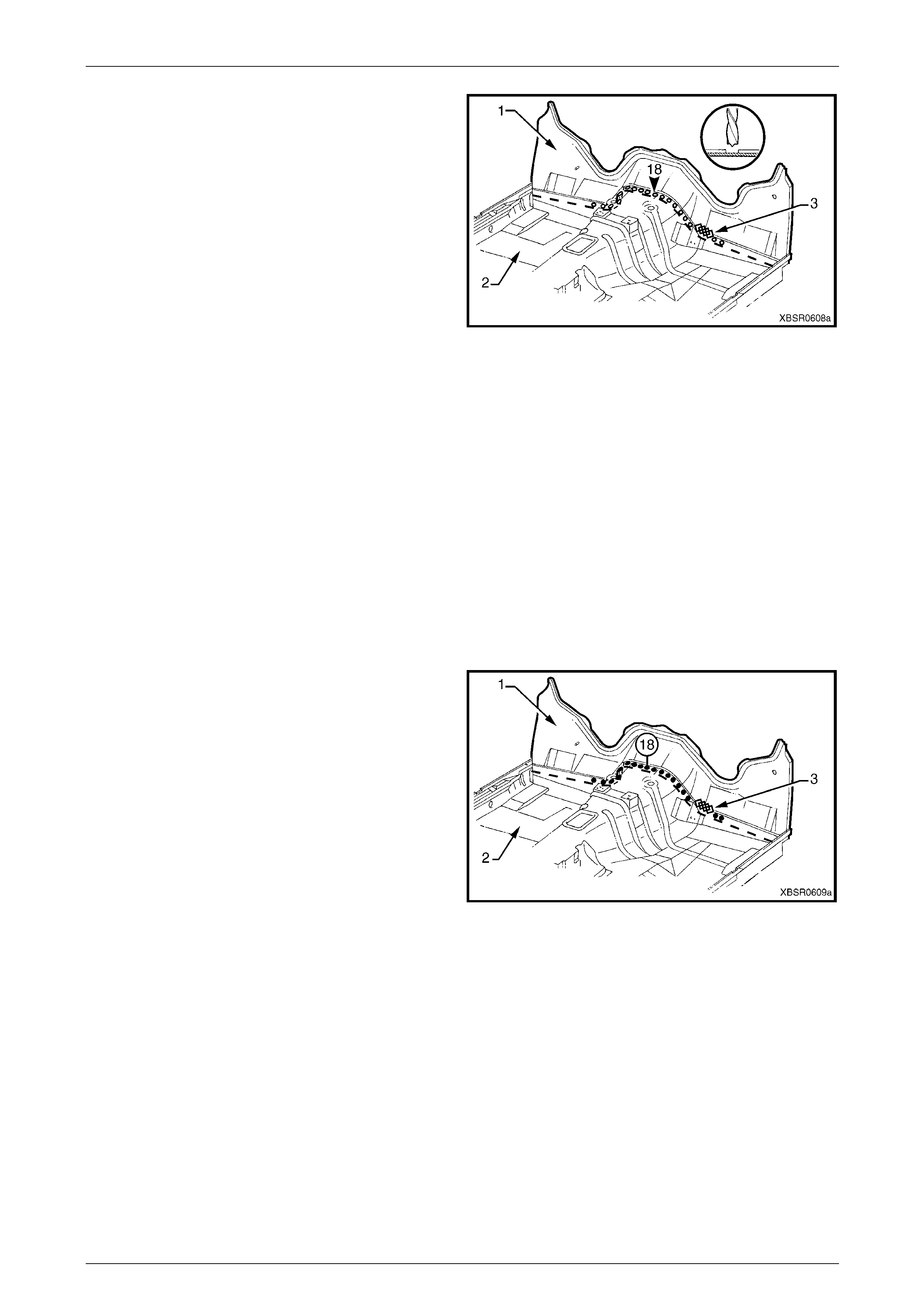

attaching areas. Figure 6A – 3

6 Spot cut the welds on each side of the vehicle,

attaching the front floor panel extension to the front

side rail assembly, front wheelhouse panel assembly

and front floor panel assembly.

Figure 6A – 4

7 Spot cut the welds on each side of the vehicle,

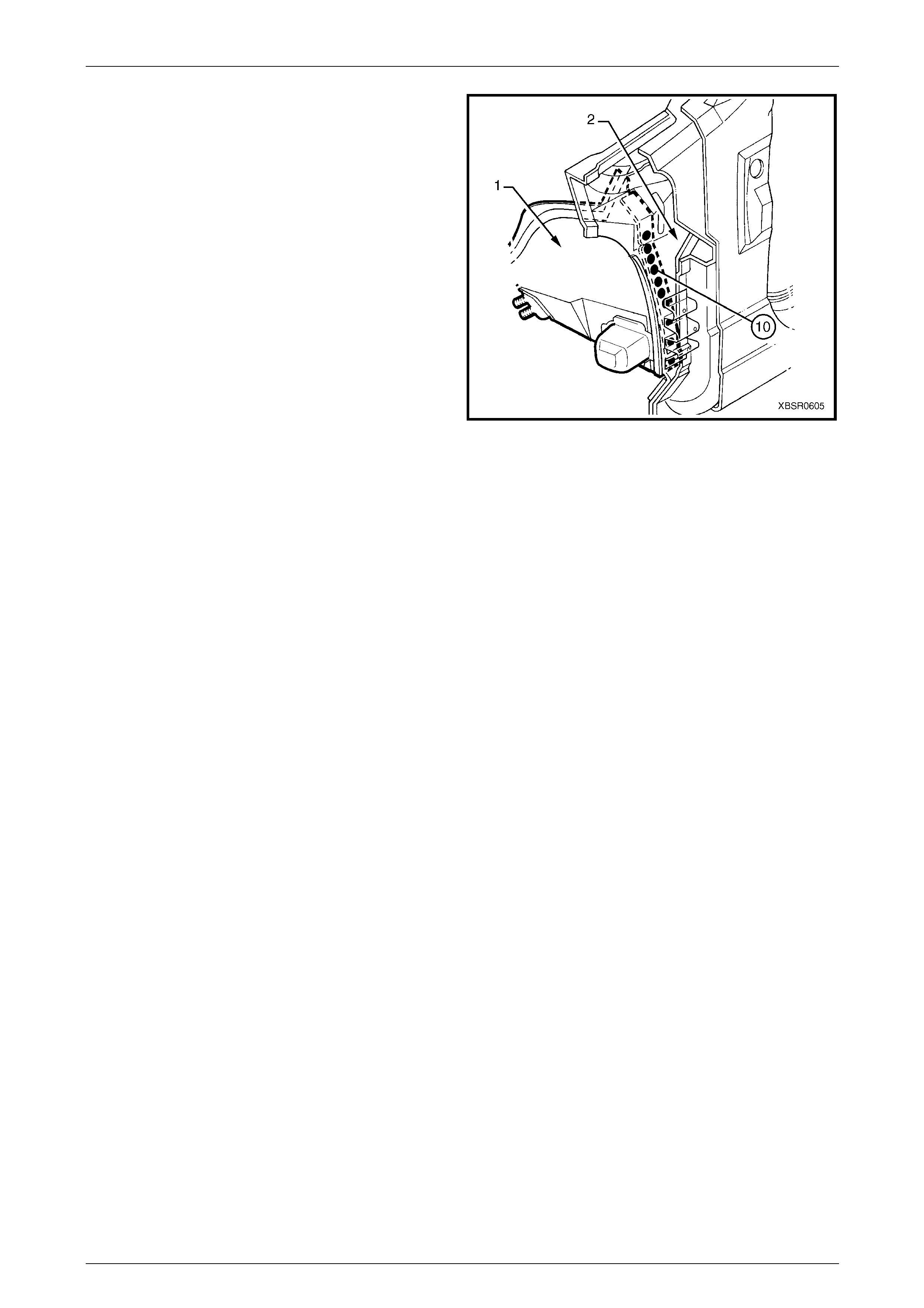

attaching the front floor panel extension (1) to the

hinge pillar inner panel (2) fro m the direction shown A.

Figure 6A – 5

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-5

Page 6A-5

8 Spot cut the welds attaching the front floor panel

extension (1) to the front floor pane l assembly (2).

9 Remove the MIG weld (3) from near the footrest

bracket.

NOTE

Some models may not have this weld.

10 Remove the front floor panel extension from the

vehicle, then repair any damage to adjacent parts as

required.

11 Check and rectify the alignme nt of the bod y as

required, refer to Section 3 Body Construction. Figure 6A – 6

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

NOTE

The new front floor panel extension (1) may be

plug welded in position from above, utilising the

holes cut in the front floor panel assembly (2)

during removal.

2 Prepare all mating surfaces and treat with Weld

Through Primer (Item 1) as required,

refer to Section 3 Body Construction.

3 Clamp the new panel in position in the vehicle.

4 Plug weld the front floor panel extension to the front

floor panel assembly.

5 Make a MIG weld (3) near the footrest bracket. Figure 6A – 7

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-6

Page 6A-6

6 On each side of the vehicle, spot or plug weld the front

floor panel extension to the front side rails, front

wheelhouse panel ass embly and front floor panel.

Figure 6A – 8

7 Spot or plug weld the front floor panel extension (1) to

the hinge pillar inner panel (2).

8 Replace any other remov ed panels as required, refer

to the relevant Section in this Supplement.

9 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

10 Apply Joint Sealer (Item 3) as required.

Refer to Section 3 Body Construction.

11 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint,

refer to Section 3 Body Construction.

12 Apply floor deadeners as required,

refer to Section 3 Body Construction.

13 Replace the dash panel ass embly,

refer to Section 5 Cockpit Module.

14 Reinstall the remaining bolt-on panels and

components as required, refer to the appropriate

Section of the MY2005 VZ Service Information. Figure 6A – 9

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-7

Page 6A-7

2.2 Front Floor Panel Extension – Partial

Replace

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

VZ Service Information.

2 Secure the vehicle on a suitable fixture. As a

minimum, support the appropriate structural s ections

of the vehicle on safety stands.

3 Remove the dash panel asse mbly,

refer to Section 5 Cockpit Module.

4 Remove the adjoining panels as required, refer to the

relevant Section in this Supplement.

5 Using a scraper and heat gun, remove the body sealer

and deadener from the front floor and floor extension

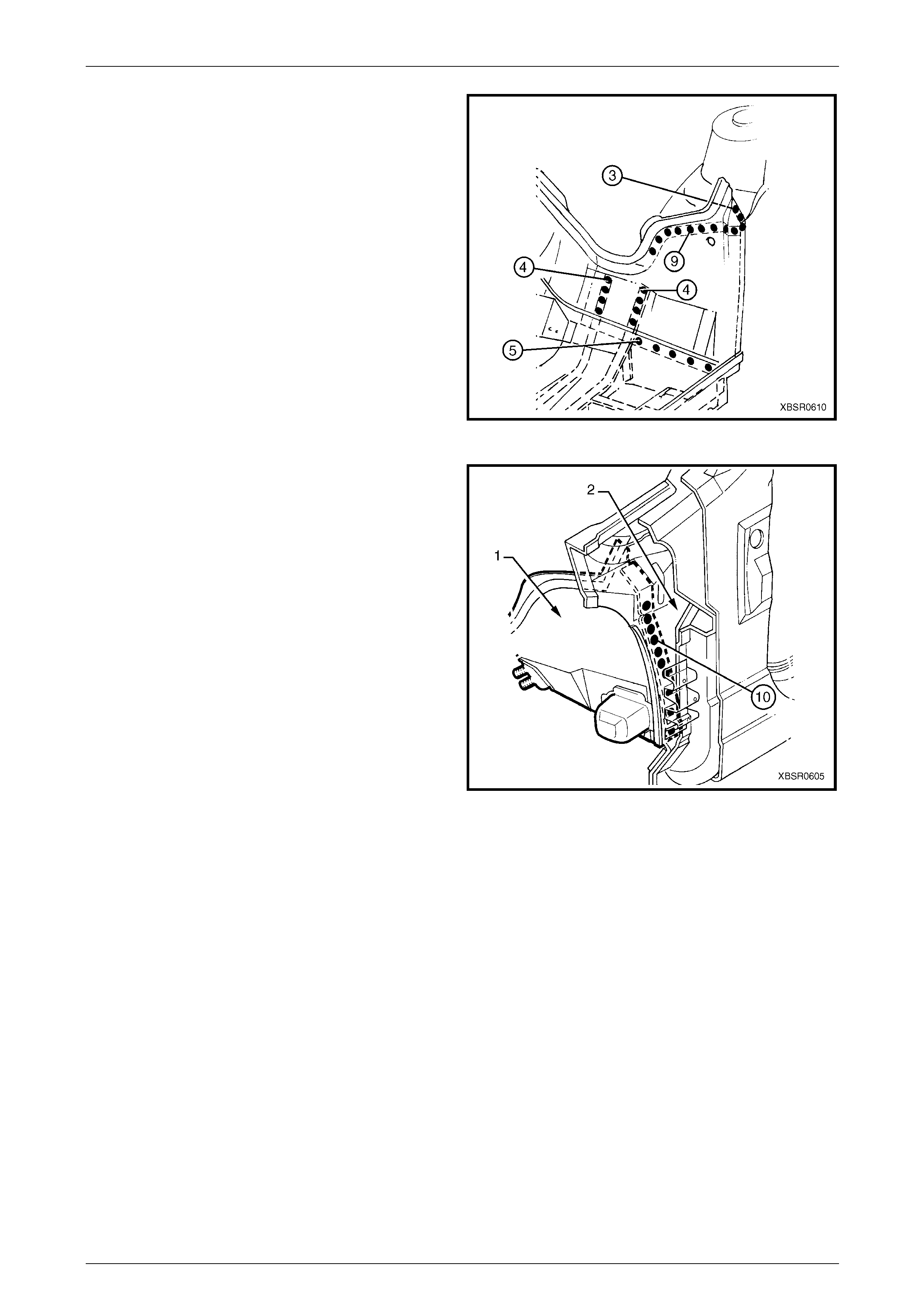

attaching areas. Figure 6A – 10

6 Mark the front floor panel extension for cutting as

shown. Cut the panel 30 mm inboard from the front

side rail flange.

7 Spot cut the welds attaching the partial front floor

panel extension to the front side rail assembly, front

wheelhouse panel ass embly and front floor panel

assembly.

Figure 6A – 11

8 Spot cut the welds attaching the front floor panel

extension (1) to the hinge pillar inner panel (2) from

the direction shown A.

9 Remove the partial front floor panel e xtension and

repair any damage to adjacent panels as required.

10 Check and rectify the alignme nt of the bod y as

required, refer to Section 3 Body Construction.

Figure 6A – 12

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-8

Page 6A-8

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

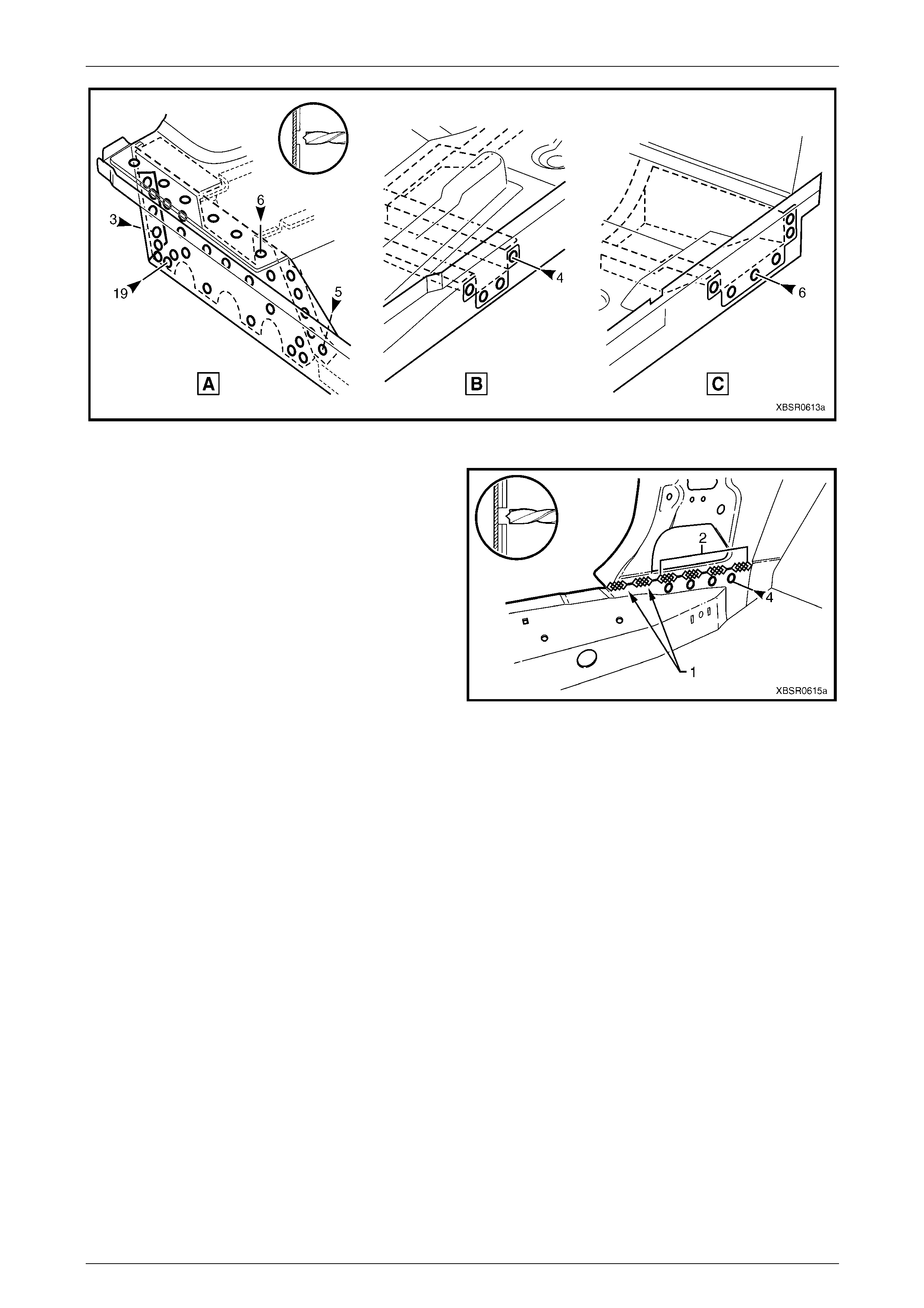

1 Accurately cut the required section from a new panel, allowing approximately 15 mm overlap for the lap joint.

2 On the new section, trim the glue track back 15 mm to

allow butting against the section on the vehicle.

3 Flange the new section of front floor panel extensio n

(1) using a suitable tool to for m a joggle (2) to facilitate

the lap joint. The joggle shoul d be towards the interior

of the vehicle.

4 Ensure that the old and new glue tracks (3) align, to

allow installation of the dash panel assembly. The glue

tracks need not be butt welded.

5 As required, mark the new panel with drilling locations

in preparation for plug welding. Drill holes as required.

6 Prepare all mating surfaces and treat with Weld

Through Primer (Item 1) as required,

refer to Section 3 Body Construction.

7 Spot or plug weld (4) the lap joint at a minimum

spacing of 35 mm along the join, then MIG weld along

the engine compartment side of the panels. Figure 6A – 13

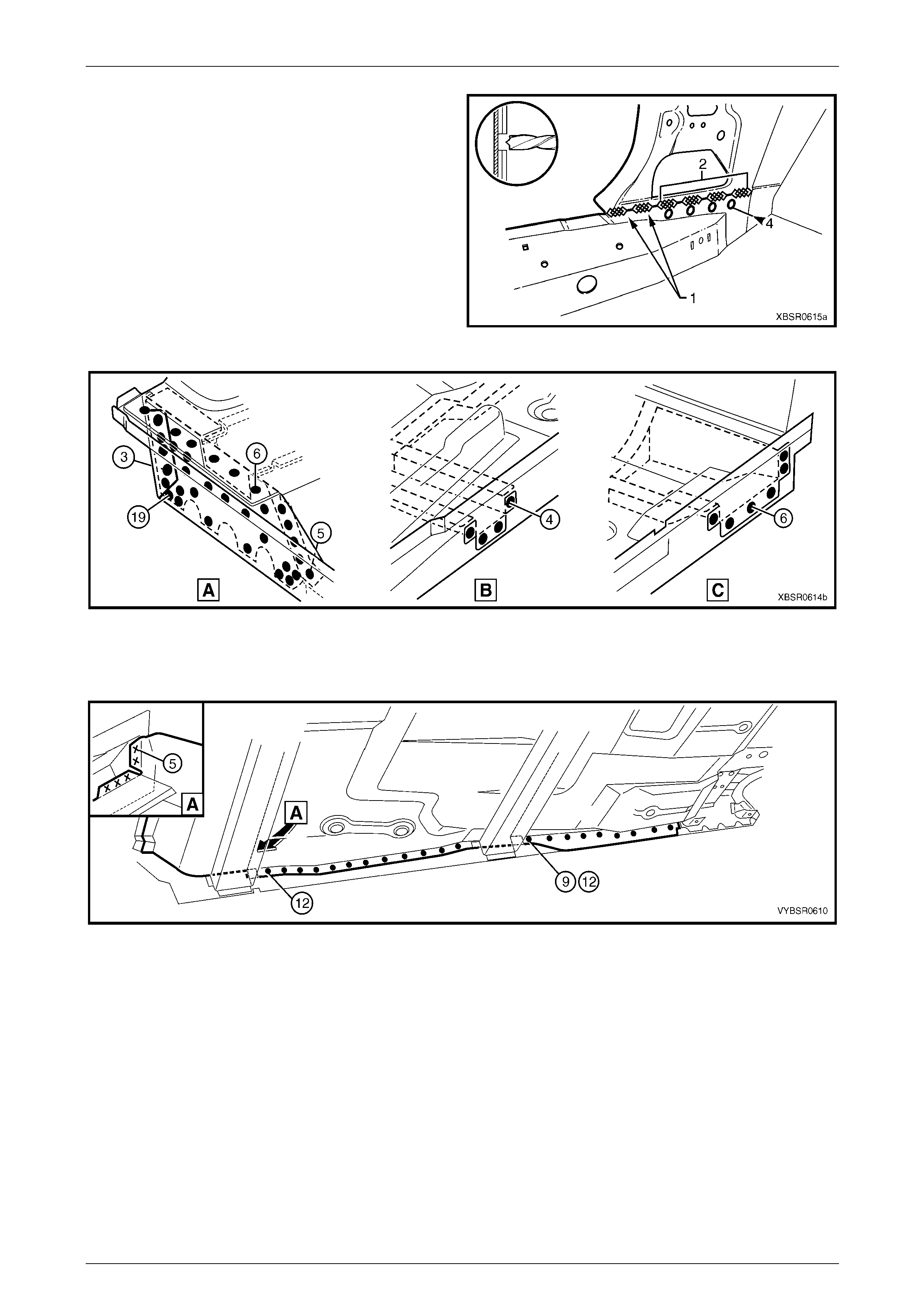

8 Spot or plug weld the partial floor panel extension to

the front side rails, front wheelhouse panel assembly

and front floor panel.

Figure 6A – 14

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-9

Page 6A-9

9 Spot or plug weld the front floor panel extension (1) to

the hinge pillar inner panel (2).

10 Replace any other remov ed panels as required, refer

to the relevant Section in this Supplement.

11 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

12 Apply Joint Sealer (Item 3) as required.

Refer to Section 3 Body Construction.

13 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint,

refer to Section 3 Body Construction.

14 Apply floor deadeners as required,

refer to Section 3 Body Construction.

15 Replace the dash panel ass embly,

refer to Section 5 Cockpit Module.

16 Reinstall the remaining bolt-on panels and

components as required, refer to the appropriate

Section of the MY2005 VZ Service Information. Figure 6A – 15

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-10

Page 6A-10

2.3 Front Floor Panel Assembly – Replace

Care must be taken to avoid cutting the fuel,

brake or emission control pipes.

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

VZ Service Information.

2 Remove the adjoining panels as required, refer to the

relevant Section in this Supplement.

3 Secure the vehicle on a suitable fixture. As a

minimum, support the structural sections of the vehicle

on safety stands.

4 Using a scraper and heat gun, remove the body sealer

and deadener from the front floor attaching areas.

5 Spot cut the welds attaching the front floor panel

extension to the front floor panel assembly, refer to

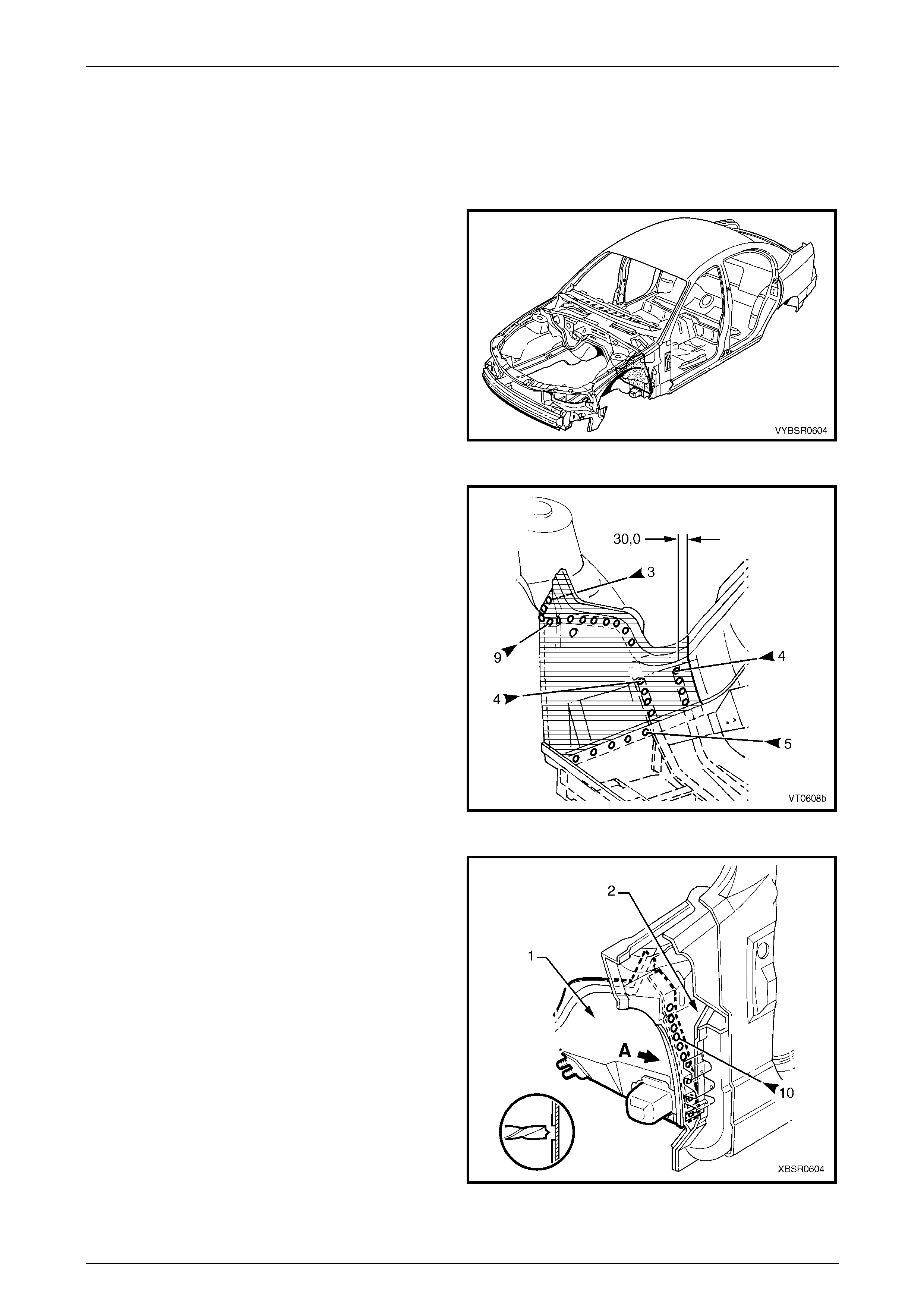

2.1 Front Floor Panel Extension – Replace. Figure 6A – 16

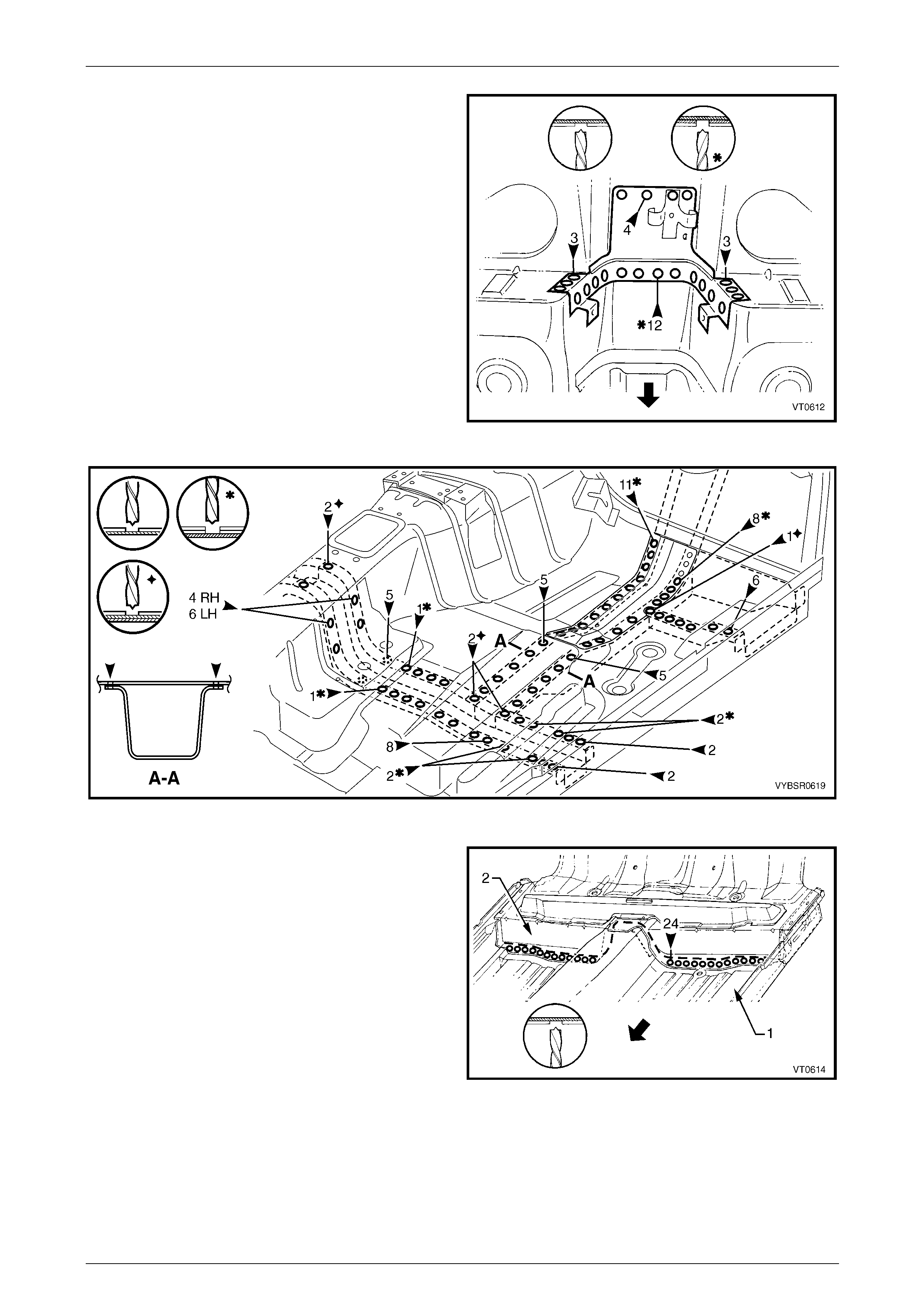

6 From underneath the vehicle, spot cut the welds attaching the front floor panel assembly to the inner rocker panel

assembly, refer to Figure 6A – 17.

Figure 6A – 17

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-11

Page 6A-11

7 From underneath the vehicle, spot cut the welds

attaching the park brake cable bracket to the rear floor

panel assembly.

8 On each side of the vehicle, spot cut the welds

attaching the front floor panel assembly to the front

side rail assemblies, refer to Figure 6A – 19.

Figure 6A – 18

Figure 6A – 19

9 Spot cut the welds attaching the front floor panel

assembly (1) to the rear floor panel assembly (2).

10 Remove the front floor assembly from the vehicle and

repair any damage to adjacent panels as required.

11 Check and rectify the alignme nt of the bod y as

required, refer to Section 3 Body Construction.

Figure 6A – 20

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-12

Page 6A-12

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as requir ed,

refer to Section 3 Body Construction.

3 Secure the front floor panel assembly (1) in position

and make several tack welds around its

circumference. Plug weld to the rear floor panel

assembly (2).

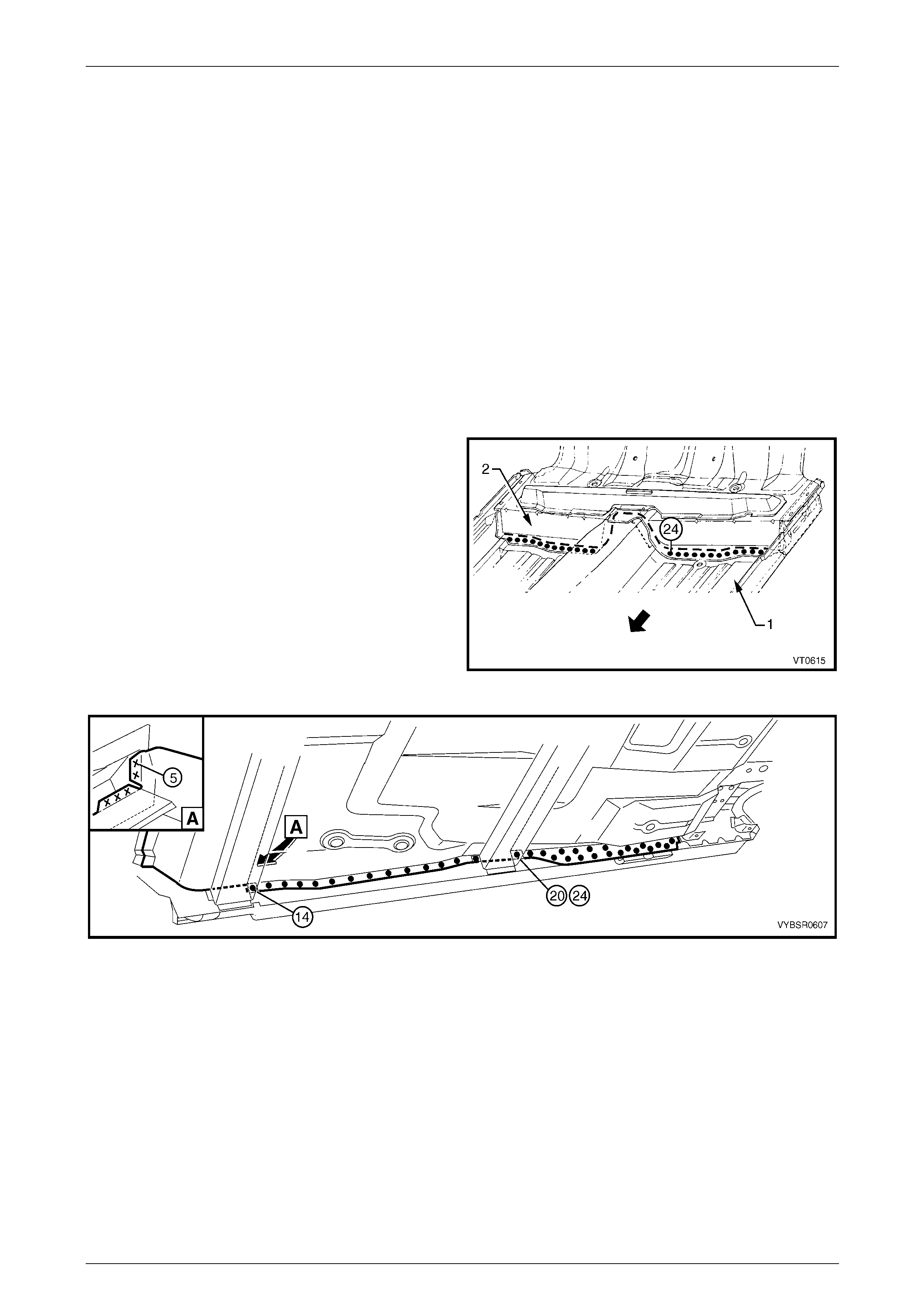

4 From underneath the vehicle, spot or plug weld the

front floor assembly to the inner rocker panel

assembly, 14 places forward of the crossmember and

20 places for Sedan and Coupe vehicles or 24 places

for Wagon vehicles rear of the crossmember. F r om

inside the vehicle, also spot weld, five places, refer to

Figure 6A – 22.

Figure 6A – 21

Figure 6A – 22

5 Replace the front floor panel extension, or weld the extension to the front floor panel assembly,

refer to 2.1 Front Floor Panel Extension – Replace.

6 On each side of the vehicle, plug weld the front floor panel assembly to the front side rail assemblies,

refer to Figure 6A – 23.

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-13

Page 6A-13

Figure 6A – 23

7 Reinstall the park brake cable bracket to the rear floor

panel assembly.

8 Replace any other remov ed panels as required, refer

to the relevant Section in this Supplement.

9 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

10 Apply Joint Sealer (Item 3) as required.

Refer to Section 3 Body Construction.

11 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint,

refer to Section 3 Body Construction.

12 Apply floor deadeners as required,

refer to Section 3 Body Construction.

13 Apply Spray-on dea dener (Item 7) as required to the

underside of the floor,

refer to Section 3 Body Construction.

14 Apply fusible reinforcement patches,

refer to Section 3 Body Construction.

15 Reinstall the remaining bolt-on panels and

components as required, refer to the appropriate

Section of the MY2005 VZ Service Information.

Figure 6A – 24

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-14

Page 6A-14

2.4 Inner Rocker Panel Assembly – Replace

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

VZ Service Information.

2 Secure the vehicle on a suitable fixture. As a

minimum, support the structural sections of the vehicle

on safety stands.

3 Remove the adjacent panels as required, refer to the

relevant Section in this Supplement.

4 Spot cut the welds attaching the front floor panel

assembly to the inner rocker panel as required.

Refer to Figure 6A – 26.

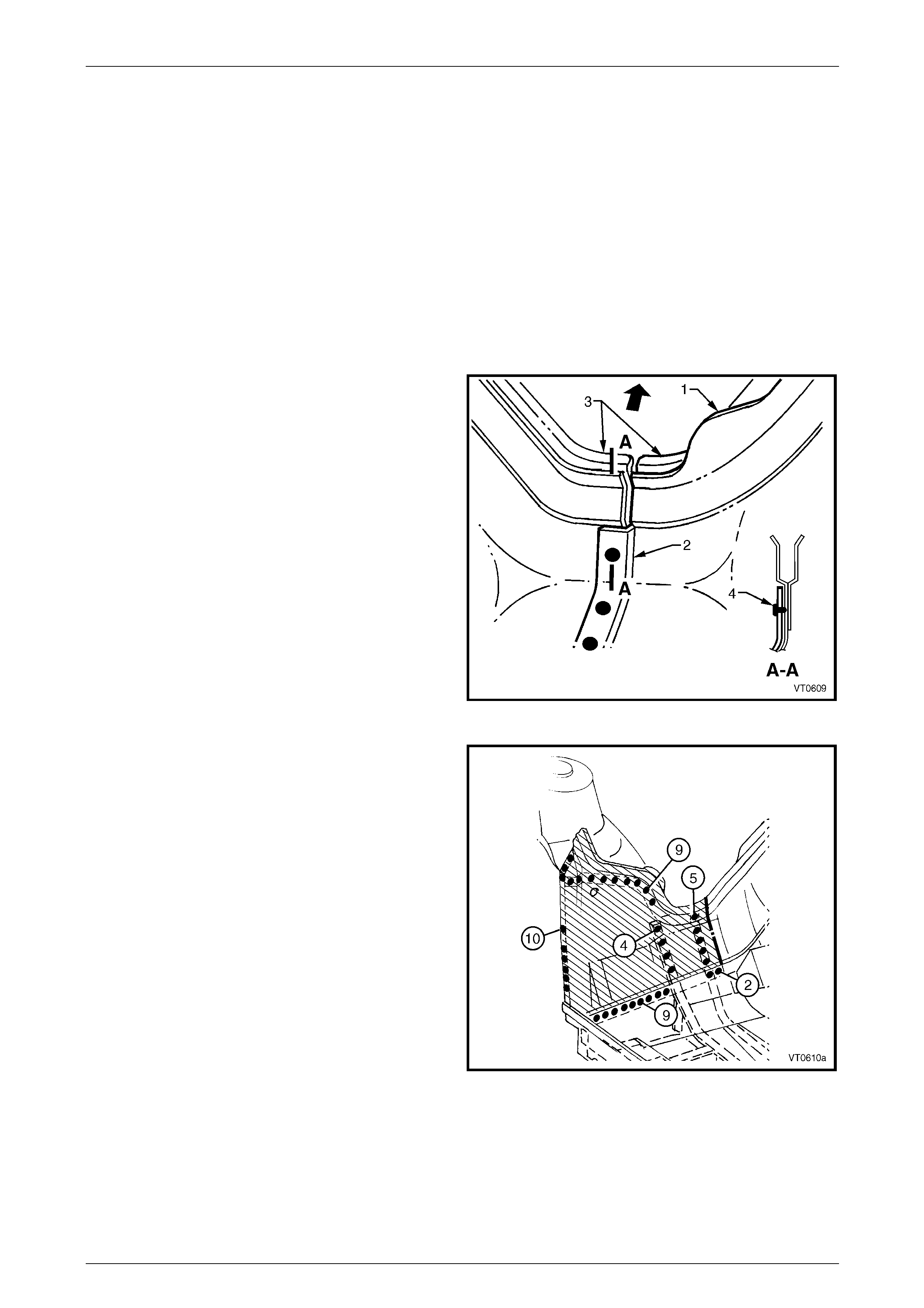

Figure 6A – 25

Figure 6A – 26

5 Spot cut the welds attaching the inner rocker panel

assembly to the rear floor panel outer extension (A),

centre crossmember (B), and front floor panel support

(C), refer to Figure 6A – 28.

Figure 6A – 27

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-15

Page 6A-15

Figure 6A – 28

6 Remove the two MIG welds (1) attaching the inner

rocker panel to the hinge pillar inner assembly.

7 If not already done so, remove the four spot welds, or

for some models four MIG welds (2), attaching the

inner rocker panel to the hinge pillar in ner assembly

and rocker panel reinforcement.

8 Remove the inner rocker panel from the vehicle and

repair any damage to adjacent panels as required.

9 Check and rectify the alignme nt of the bod y as

required, refer to Section 3 Body Construction.

Figure 6A – 29

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as requir ed,

refer to Section 3 Body Construction.

3 Clamp the inner rocker panel in positi on, noting to ensure it fits behind the hinge pillar inn er assemb ly.

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-16

Page 6A-16

4 Make two MIG welds (1) and if removed, four MIG

welds (2), to attach inner rocker panel to the hinge

pillar inner assembly.

NOTE

If removed, the four plug welds are to be made

once the door opening frame assembly is

installed.

5 Plug weld the inner rocker pa nel to the rear floor panel

outer extension (A), centre crossmember (B) and front

floor panel support (C), refer Figure 6A – 31 .

Figure 6A – 30

Figure 6A – 31

6 Spot or plug weld the front floor panel assembly to the inner rocker panel, undern eath and inside,

refer to Figure 6A – 32.

Figure 6A – 32

7 Replace the adjoining removed panels as required, refer to the relevant Section in this Supplement.

8 Refinish and paint panels and other components as required. Refer to Section 3 Body Construction.

9 Apply Joint Sealer (Item 3) as required. Refer to Section 3 Body Construction.

10 Apply Cavity Wax (Item 8) as required to the inside of any box secti ons or areas inaccessible to paint,

refer to Section 3 Body Construction.

11 Reinstall the remaining bolt-on panels and components as required, refer to the appropriate Section of the MY2005

VZ Service Information.

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-17

Page 6A-17

2.5 Right-hand Transmission Support

Bracket – Replace

Remove

1 Remove the adjacent bolt-on panels and components as described in the appropriate Section of the MY2005 VZ

Service Information.

2 Using a scraper and heat gun, remove the body sealer and deadener from the front floor attaching areas.

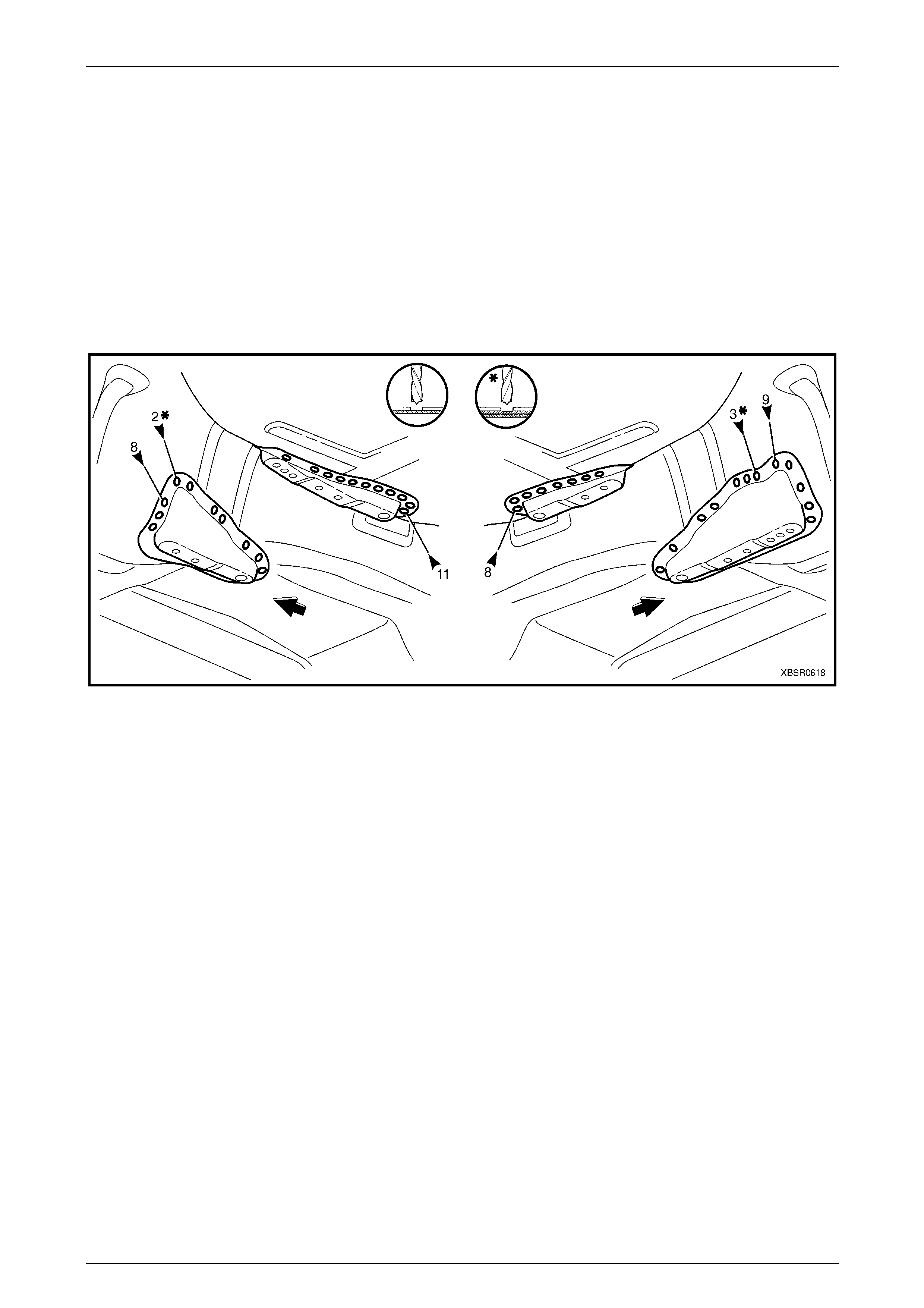

3 Spot cut the 18 welds for the right-hand side or 23 welds for the left-hand side attaching the transmissi on support

bracket to the front floor panel assembly as required, refer to Figure 6A – 33.

4 Remove the transmission support bracket from the vehicle and repair an y damage to the adjacent area as

required.

Figure 6A – 33

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as requir ed,

refer to Section 3 Body Construction.

NOTE

Positioning of the transmission support brac ket is

critical to driveline orientation. Incorrect location

can cause driveline vibrations.

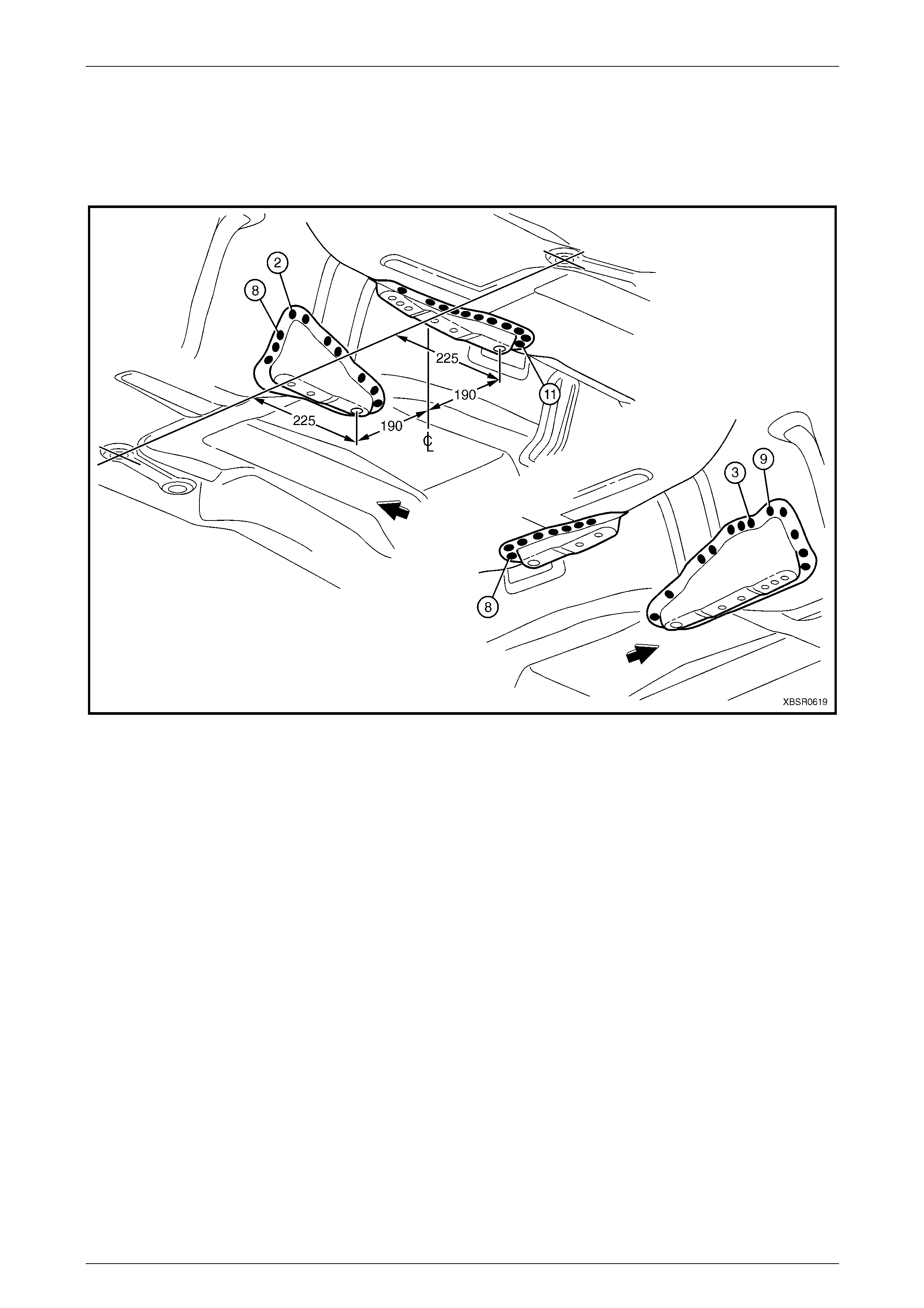

3 Position the transmission support bracket so that the rear tooling hole centre is 190 mm from the vehicle centre and

225 mm rearward of the datum hole centres in the floor, refer to Figure 6A – 24.

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-18

Page 6A-18

4 Temporarily bolt the transmission crossmember in position to help locate the mount. Check the crossmember for

correct orientation to the vehicle.

5 Clamp or tack weld the mount in position and recheck positioning.

6 Spot or plug weld the mount assembl y to the floor, 18 places for the right-han d side or 22 places for the left-hand

side, refer to Figure 6A – 24.

Figure 6A – 34

7 Refinish and paint panels and other components as required. Refer to Section 3 Body Construction.

8 Apply Joint Sealer (Item 3) as required. Refer to Section 3 Body Construction.

9 Apply Cavity Wax (Item 8) as required to the inside of any box secti ons or areas inaccessible to paint,

refer to Section 3 Body Construction.

10 Apply floor deadeners as req uired, refer to Section 3 Body Construction.

11 Apply Spray-on dea dener (Item 7) as required to the underside of the floor, refer to Section 3 Body Construction.

12 Reinstall the remaining bolt-on panels and components as required, refer to the appropriate Section of the MY2005

VZ Service Information.

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-19

Page 6A-19

2.6 Seat Inner Bracket Assembly – Replace

Remove

1 Remove the adjacent bolt-on panels and components as described in the appropriate Section of the MY2005 VZ

Service Information.

2 As required, use a scraper and heat g un to remove the body sealer and deadener from the front floor and floor

extension attachin g areas.

3 Lower the transmission rear mount and propeller shaft centre bearing assembly to avoid damage from heat, refer to

the appropriate section of the MY2005 VZ Service Information.

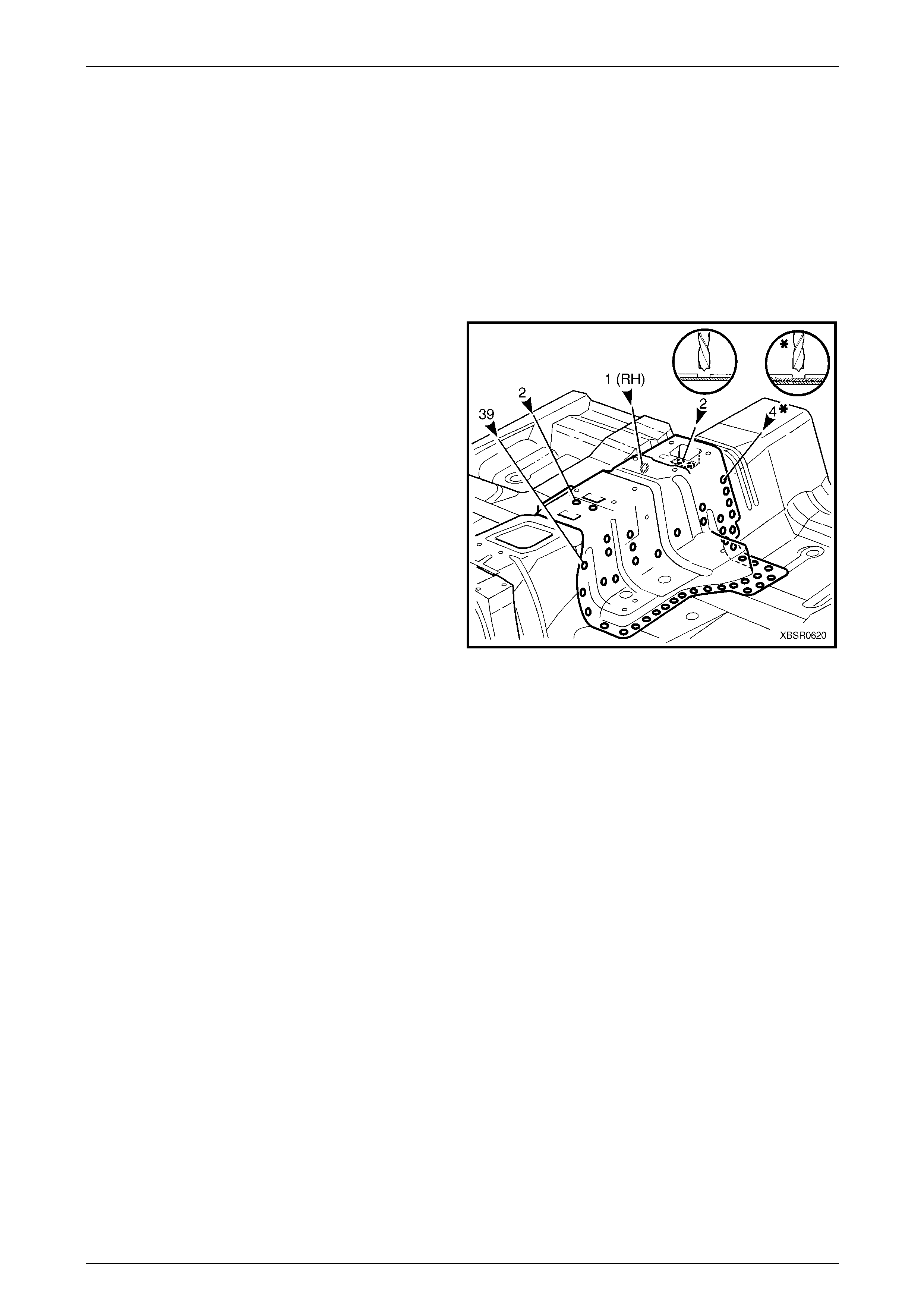

4 Spot cut the 39 welds each side attaching the seat

inner bracket assembly to the floor.

5 Spot cut the four welds each side attaching the

bracket assembly to the floor and propeller shaft

hanger assembly.

6 Spot cut the two welds front and rear attaching the top

of the bracket assembly to the floor.

7 Spot cut the weld attaching the right-hand side of the

bracket assembly to the floor.

8 Remove the bracket assembly from the vehicle and

repair any damage to the adjacent area as required.

Figure 6A – 35

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-20

Page 6A-20

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required,

refer to Section 3 Body Construction.

3 Install the seat inner bracket assembly in position and

check that the seat mount holes will align with the

seat.

4 Spot or plug weld the bracket assembl y to the floor

(and propeller shaft hanger assembly if required) as

shown.

5 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

6 Apply floor deadeners as required,

refer to Section 3 Body Construction.

7 Reinstall the transmission re ar mount, refer to

Section 7 Manual Transmissi on or

Section 7 Automatic Transmission i n the MY200 5 VZ

Service Information.

8 Reinstall the propeller sh aft centre bearing assembly,

refer to Section 4C1 Rear Propeller Shaft and

Universal Joint in the MY2005 VZ Service Information.

9 Reinstall the remaining b olt-on panels and

components as required, refer to the appropriate

Section of the MY2005 VZ Service Information.

Figure 6A – 36

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-21

Page 6A-21

2.7 Seat Outer Bracket Assembly – Replace

Remove

1 Remove the adjacent bolt-on panels and components as described in the appropriate Section of the MY2005 VZ

Service Information.

2 Using a scraper and heat gun, remove the body sealer and deadener from the front floor attaching areas.

3 From the underside of the floor, remove deadener in the area of the reinforcement.

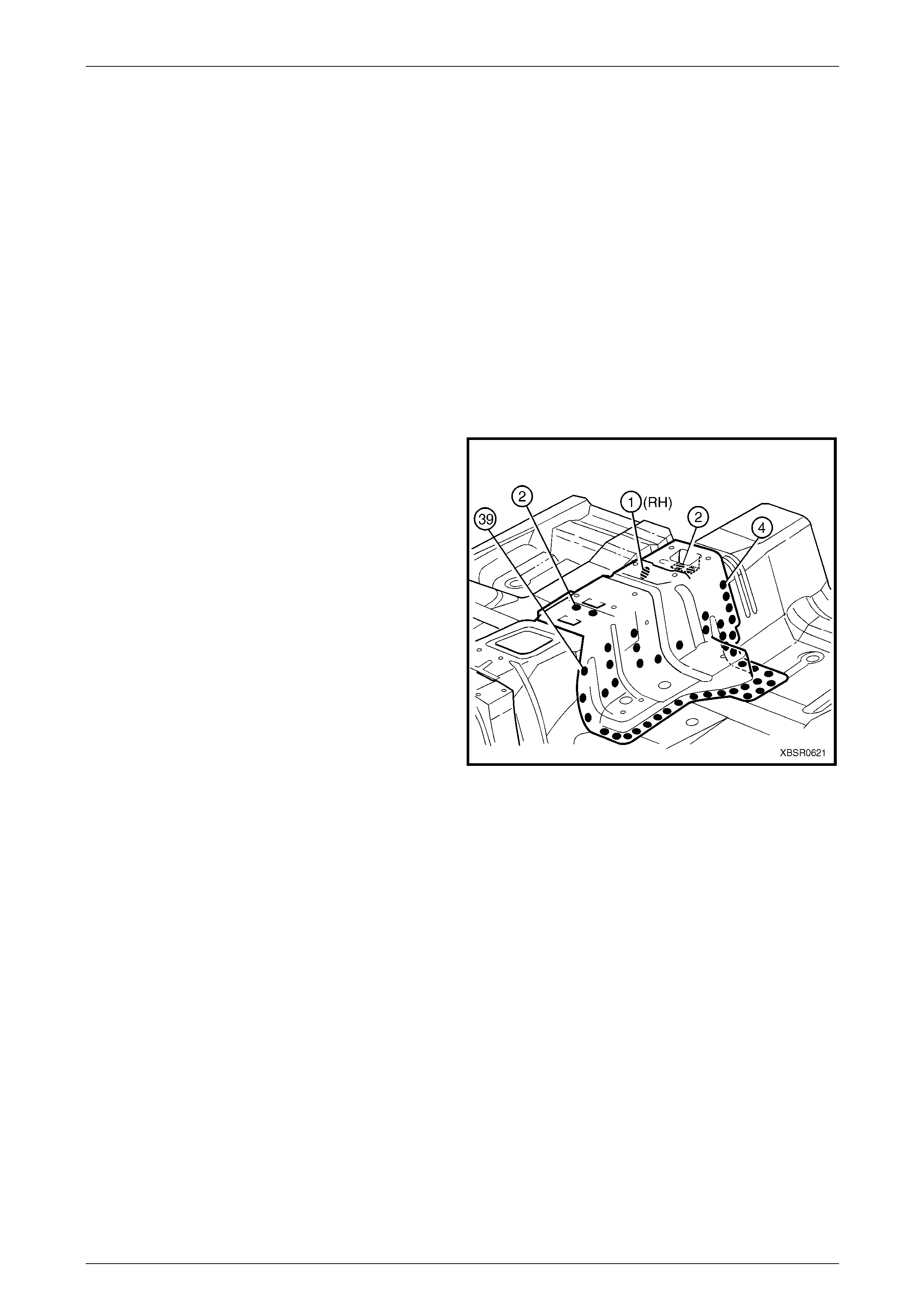

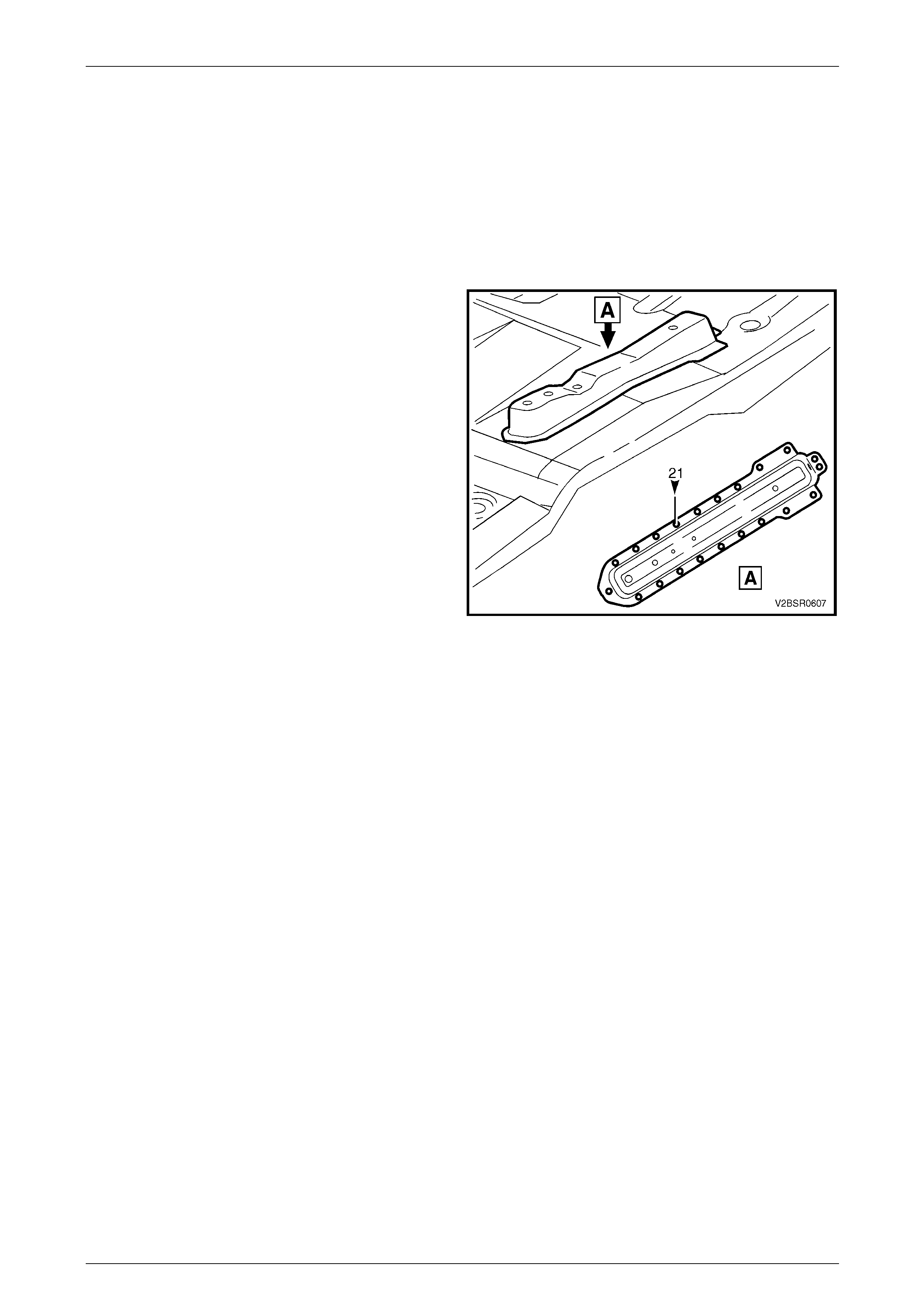

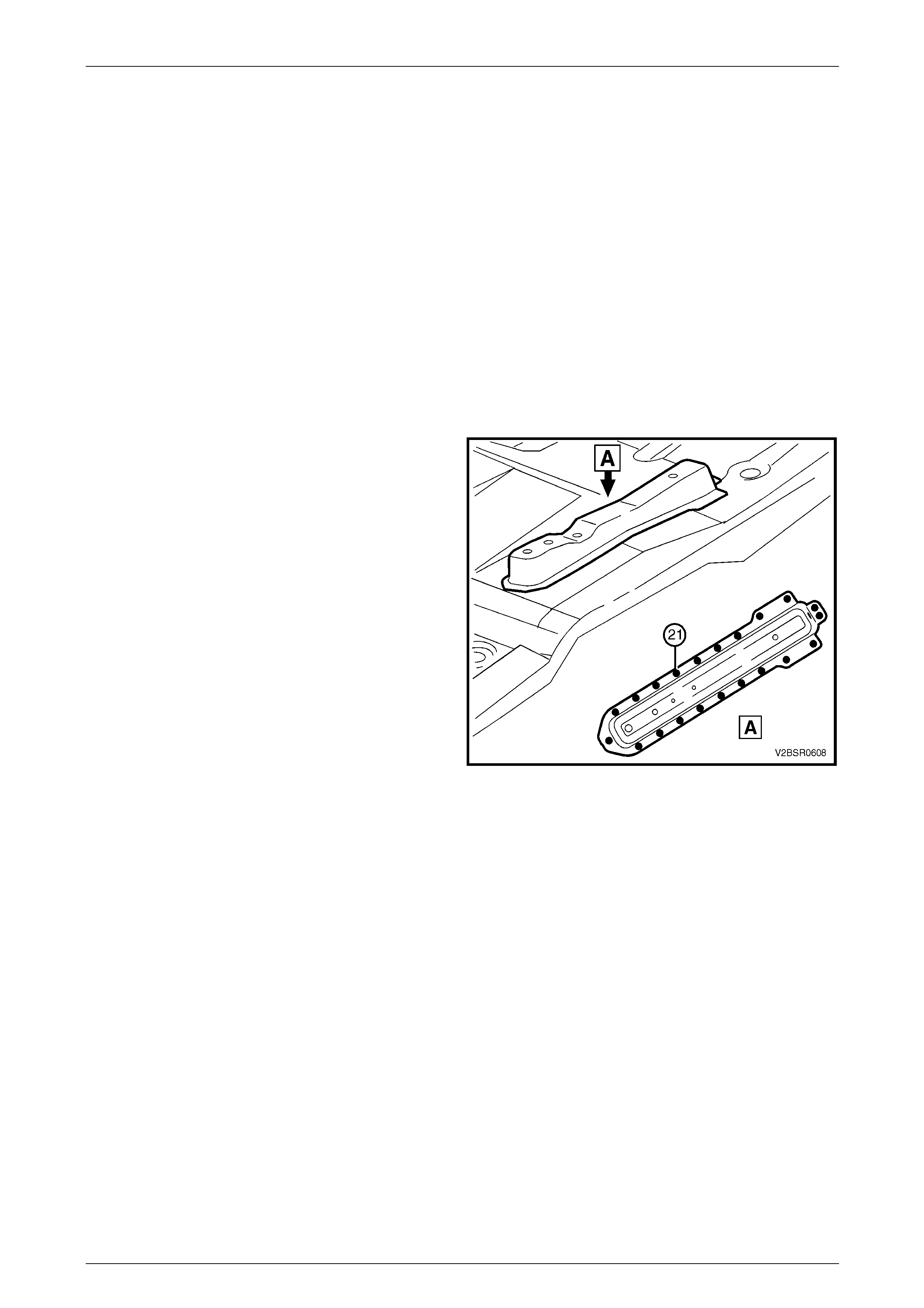

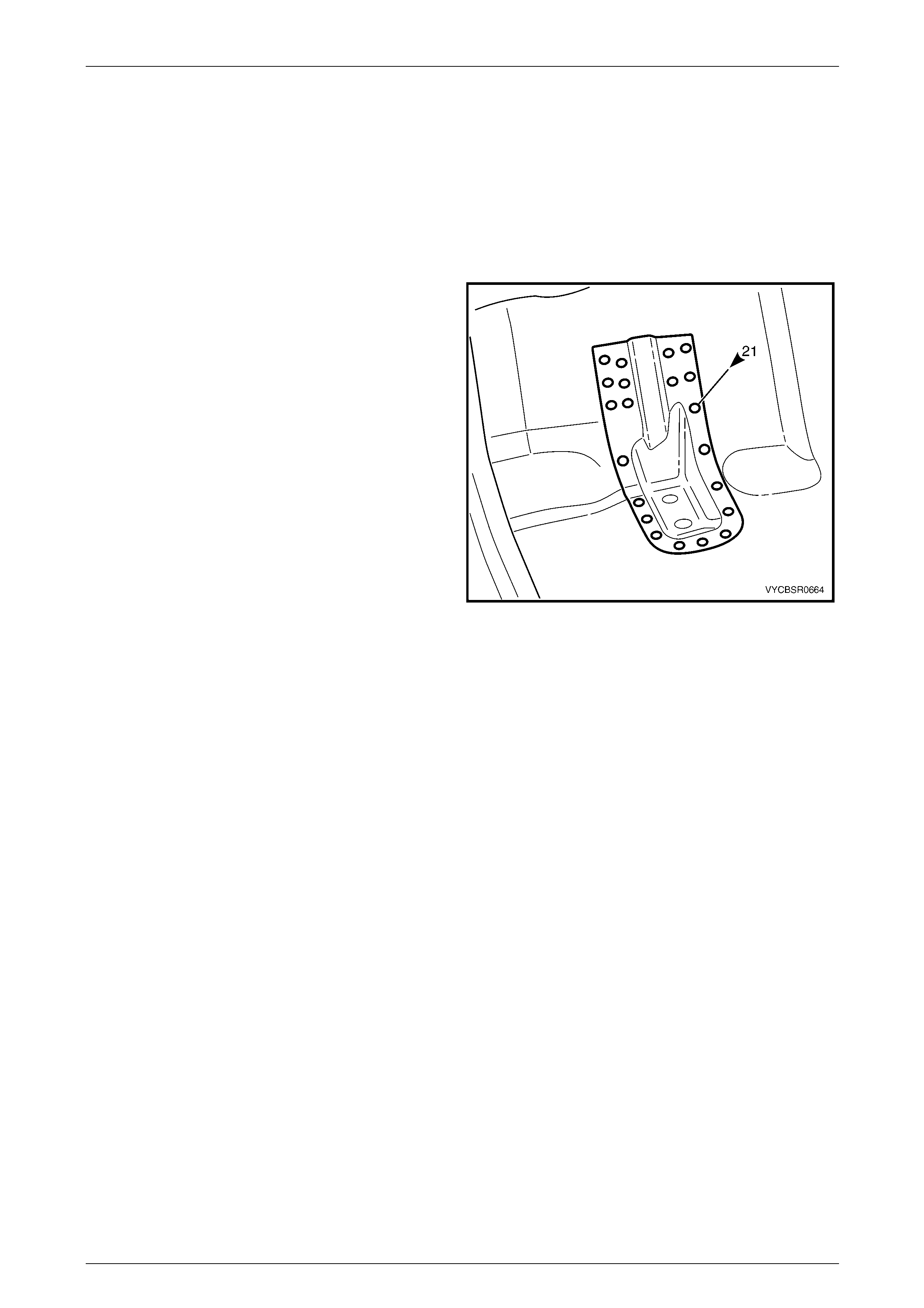

4 Spot cut the 21 welds attaching the seat outer bracket

assembly to the floor.

5 Remove the bracket assembly from the vehicle and

repair any damage to the adjacent area as required.

Figure 6A – 37

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-22

Page 6A-22

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as requir ed,

refer to Section 3 Body Construction.

3 Install the seat outer bracket assembly in position and

check that the seat mount holes will align with the

seat.

4 Spot or plug weld the bracket assembl y to the floor,

21 places as shown.

5 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

6 Apply Spray-on dea dener (Item 7) as required to the

underside of the floor,

refer to Section 3 Body Construction.

7 Apply floor deadeners as required,

refer to Section 3 Body Construction.

8 Reinstall the remaining b olt-on panels and

components as required, refer to the appropriate

Section of the MY2005 VZ Service Information.

Figure 6A – 38

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-23

Page 6A-23

2.8 Propeller Shaft Hanger Assembly –

Replace

Remove

1 Remove the adjacent bolt-on panels and components as described in the appropriate Section of the MY2005 VZ

Service Information.

2 Remove the propeller shaft and centre b earing assembly,

refer to Section 4C1 Rear Propeller Shaft and Universal Joint in the MY2005 VZ Service Information.

3 Using a scraper and heat gun, remove the body sealer and deadener from the front floor attaching areas.

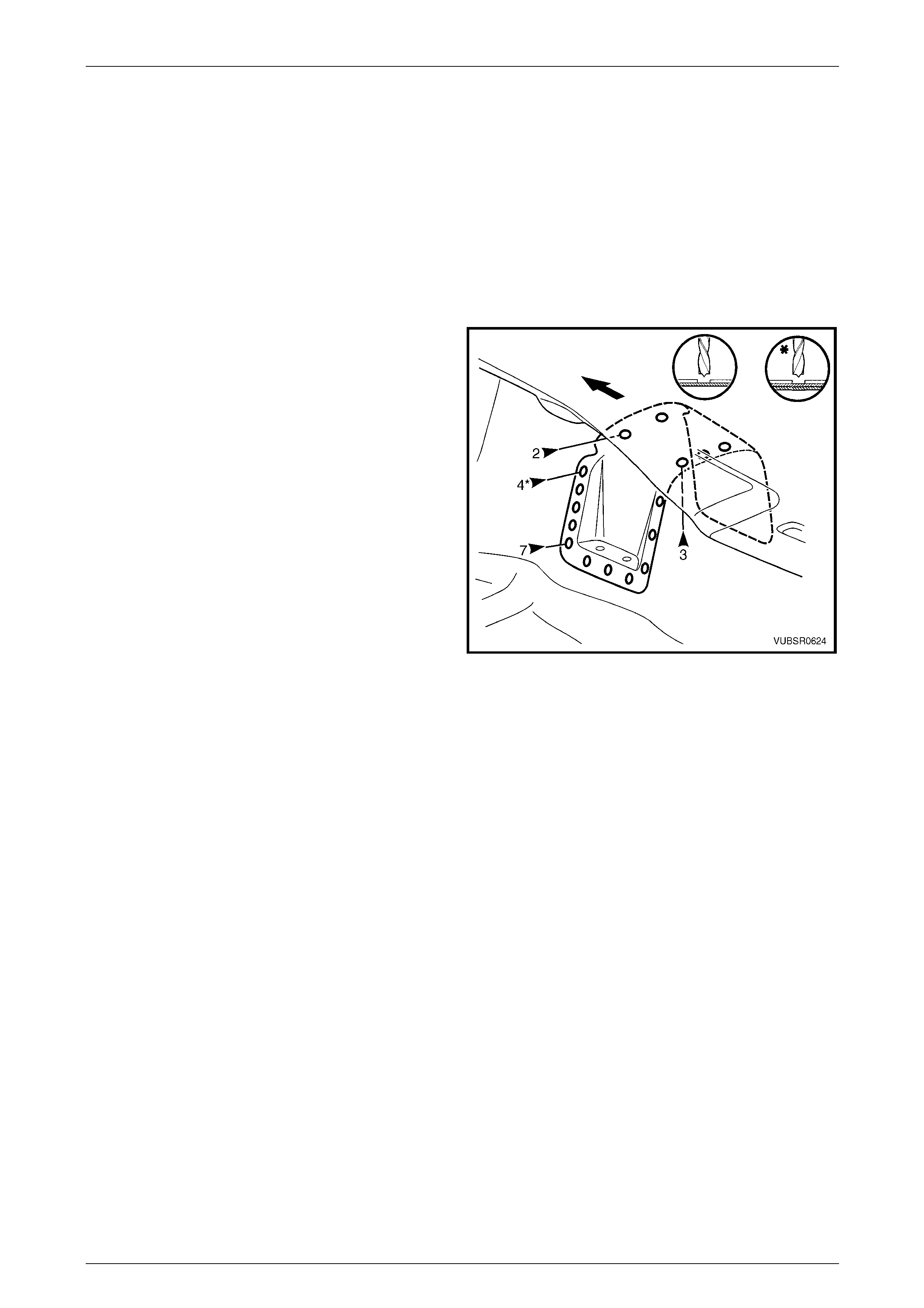

4 Spot cut the two welds front and three welds rear

attaching the propeller shaft hanger assembly to the

floor.

5 Spot cut the seven welds each side attaching the

hanger assembly to the floor.

6 Spot cut the four welds each side attaching the hang er

assembly to the floor and seat inner bracket assembly.

7 Remove the hanger assembly from the vehicle and

repair any damage to the adjacent area as required.

Figure 6A – 39

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-24

Page 6A-24

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as requir ed,

refer to Section 3 Body Construction.

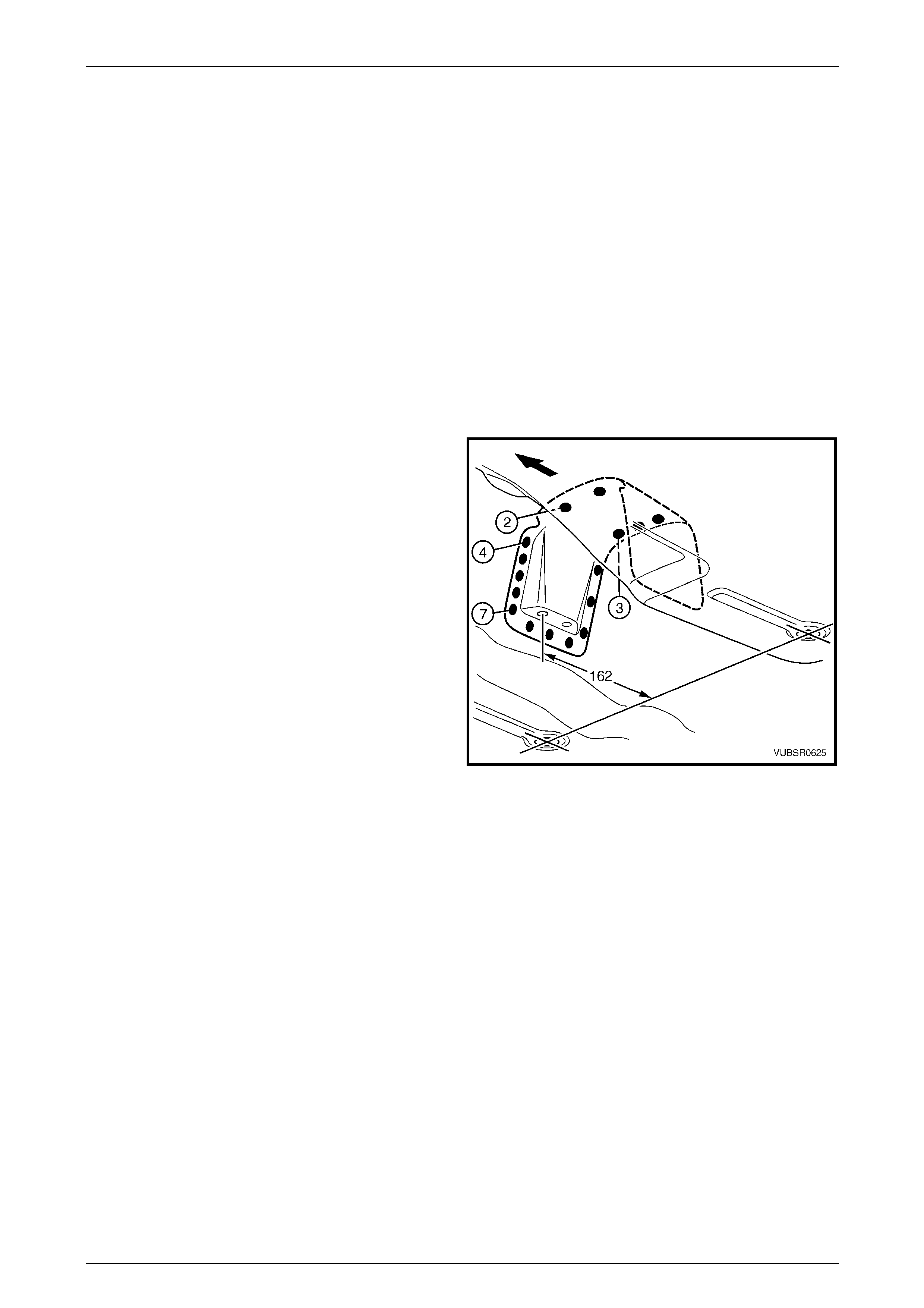

3 Install the propeller shaft hanger assem bly, positioning

each front datum hole 162 mm forward of the datum

hole centres in the floor.

4 Spot or plug weld the hanger assembly to the floor,

two places front and three places rear.

5 Spot or plug weld the hanger assembly to the floor,

seven places each side.

6 Spot or plug weld the hanger assembly to the floor and

seat inner bracket assembly, four places each side.

7 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

8 Apply Spray-on dea dener (Item 7) as required to the

underside of the floor,

refer to Section 3 Body Construction.

9 Apply floor deadeners as required,

refer to Section 3 Body Construction.

Figure 6A – 40

10 Install the propeller shaft and centre be aring assembly,

refer to Section 4C1 Rear Propeller Shaft and Universal Joints in the MY2005 VZ Servic e Information.

11 Reinstall the remaining bolt-on panels and components as required, refer to the appropriate Section of the MY2005

VZ Service Information.

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-25

Page 6A-25

2.9 Left-hand Transmission Support Bracket

– Replace

Remove

1 Remove the adjacent bolt-on panels and components as described in the appropriate section of the MY2005 VZ

Service Information.

2 Using a scraper and heat gun, remove the body sealer and deadener from the front floor attaching areas.

3 Spot cut the welds attaching the transmission support

bracket to the vehicle.

4 Remove the transmission support bracket from the

vehicle and repair any damag e to the adjacent area as

required.

Figure 6 – 41

6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon Page 6A-26

Page 6A-26

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as requir ed,

refer to Section 3 Body Construction.

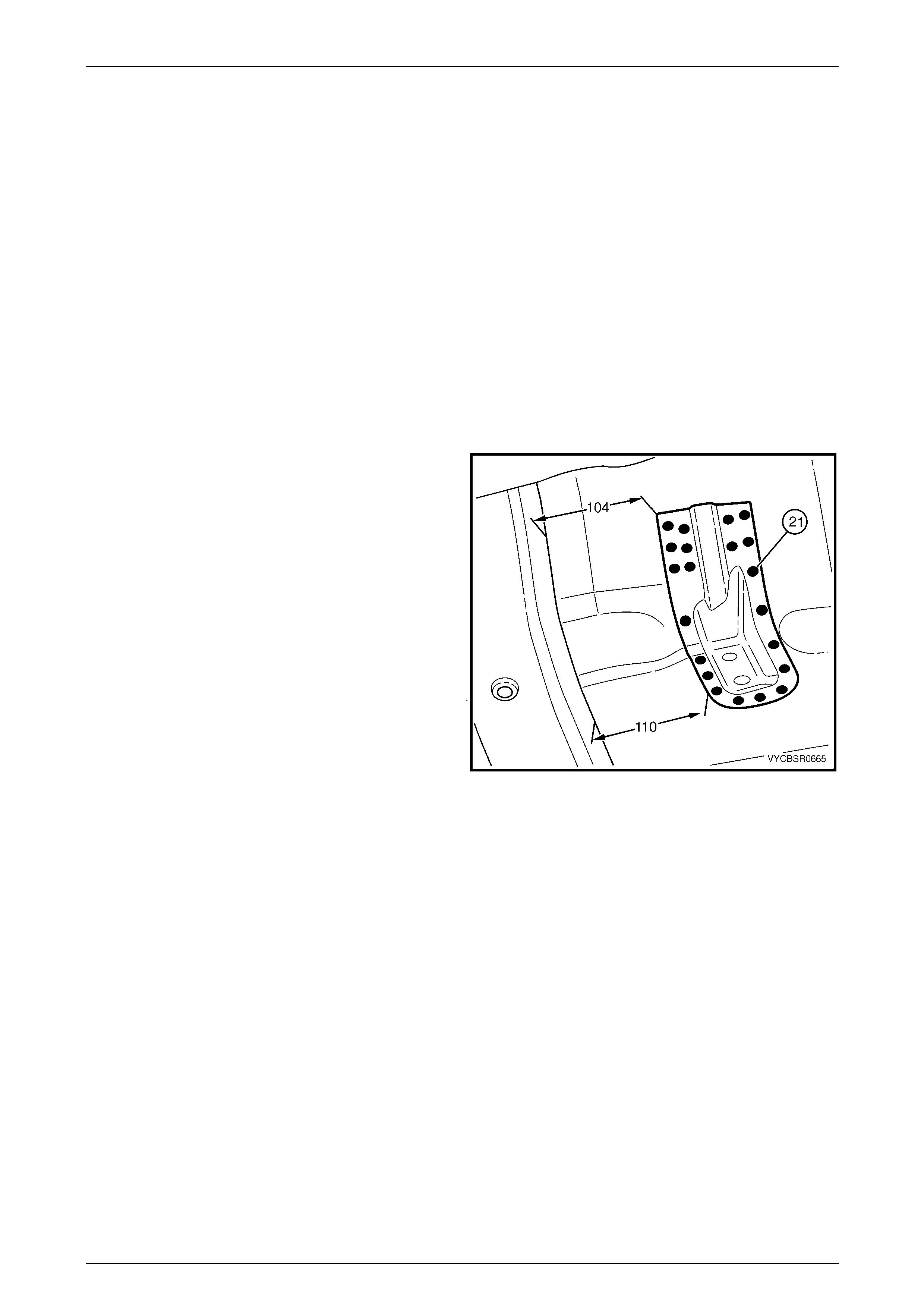

3 Position the transmission support bracket to the

dimensions shown, measuring from the front edge of

the crossmember flange.

NOTE

Positioning of the transmission support bracket is

critical to driveline orientati on.

4 Temporarily bolt the transmission crossmember in

position to help locate the mount.

5 Spot or plug weld the transmission supp ort bracket to

the front floor panel assembly.

6 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

7 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint,

refer to Section 3 Body Construction. Figure 6 – 42

8 Apply floor deadeners as req uired, refer to Section 3 Body Construction.

9 Apply Spray-on Deadener (Item 7) as required to the under side of the floor, refer to Section 3 Body Construction.

10 Reinstall the remaining bolt-on panels and components as required, refer to the appropriate Section of the MY2005

VZ Service Information.