6C Cabin Floor and Seatback Assembly – Utility Page 6C-1

Page 6C-1

Section 6C

Cabin Floor and Seatback Assembly – Utility

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 2

Precautions in this Supplement and Section 00 Warnings, Cautions and Notes in the MY2005 VZ Service

Information for correct workshop practices with regard to safety and/or property damage.

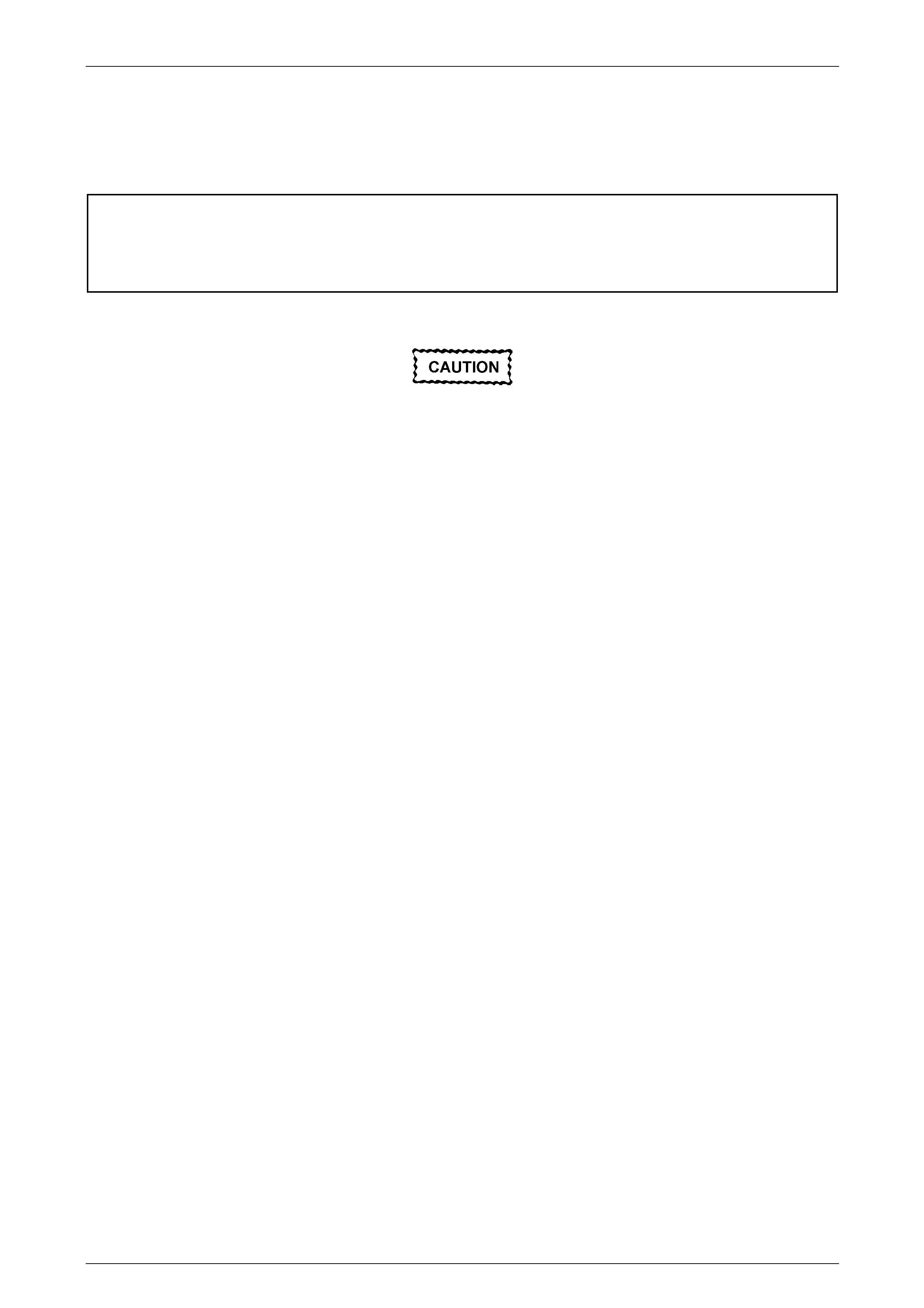

The structure of the body shell has been

developed using complex design and

development techniques. In addition to

meeting all required standards, the vehicle

body is also a critical part of the overall safety

systems. It is therefore imperative the repair

procedures described here are adhered to

during all vehicle body repairs.

1 General Description ...............................................................................................................................2

1.1 Cabin Floor and Seatback Assembly Components ............................................................................................ 2

2 Service Operations.................................................................................................................................4

2.1 Front Floor Panel Assembly – Replace................................................................................................................ 4

Remove................................................................................................................................................................... 4

Replace................................................................................................................................................................... 6

2.2 Inner Rocker Panel Assembly – Replace............................................................................................................. 8

Remove................................................................................................................................................................... 8

Replace................................................................................................................................................................... 9

2.3 Load Compartment Extension Outer Panel and Bracket – Replace................................................................ 11

Remove................................................................................................................................................................. 11

Replace................................................................................................................................................................. 12

2.4 Front Seatback Panel Outer – Replace .............................................................................................................. 14

Remove................................................................................................................................................................. 14

Replace................................................................................................................................................................. 16

2.5 Front Seatback Panel – Replace......................................................................................................................... 18

Remove................................................................................................................................................................. 18

Replace................................................................................................................................................................. 20

2.6 Front Floor Rear Extension Assembly – Replace............................................................................................. 22

Remove................................................................................................................................................................. 22

Replace................................................................................................................................................................. 24

6C Cabin Floor and Seatback Assembly – Utility Page 6C-2

Page 6C-2

1 General Description

With the following exceptions the Utility Cabin Floor and Seatback assembly informatio n carries over from Sedan

vehicles. For information not covered in this Section,

refer to Section 6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon, Wagon, Coupe and AWD Wagon.

• Front Floor Panel Assembly

• Inner Rocker Panel Assembly

• Load Compartment Extension Outer Panel and Bracket.

• Front Seatback Panel Outer.

• Front Seatback Panel.

• Front Floor Rear Extension Assembly.

Removal of bolt-on panels and mecha nica l components is not covered. For information on the removal of these parts,

reference must be made to the appropriate Section of the MY2005 VZ Service Information.

• When repairing the cabin floor of the vehicle,

care must be taken to ensure the structure is

returned to its original production

configuration.

• It is imperative that the correct body

adhesives, sealers, deadeners and cavity

waxes are used when repairing the body

structure. Refer to Section 3C Body

Construction – Utility for details of the correct

materials and their commercially available

equivalents.

1.1 Cabin Floor and Seatback Assembly

Components

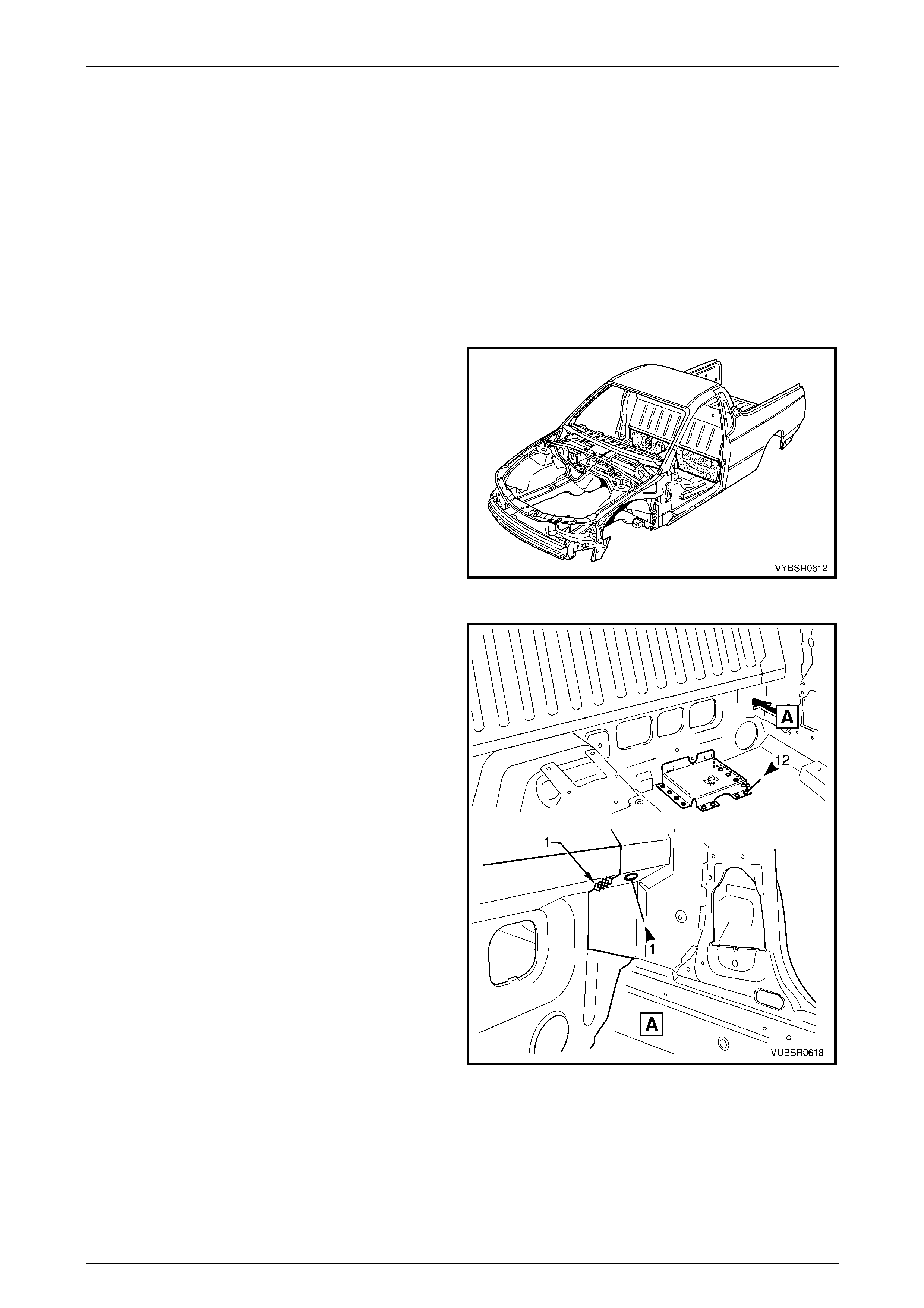

The shaded components in Figure 6C – 1 are the cabin floor

and seatback assembly components fitted to vehicles dealt

with in this Section. The Service Operations not covered in

this section, refer to Section 3A Body Construction – Sedan.

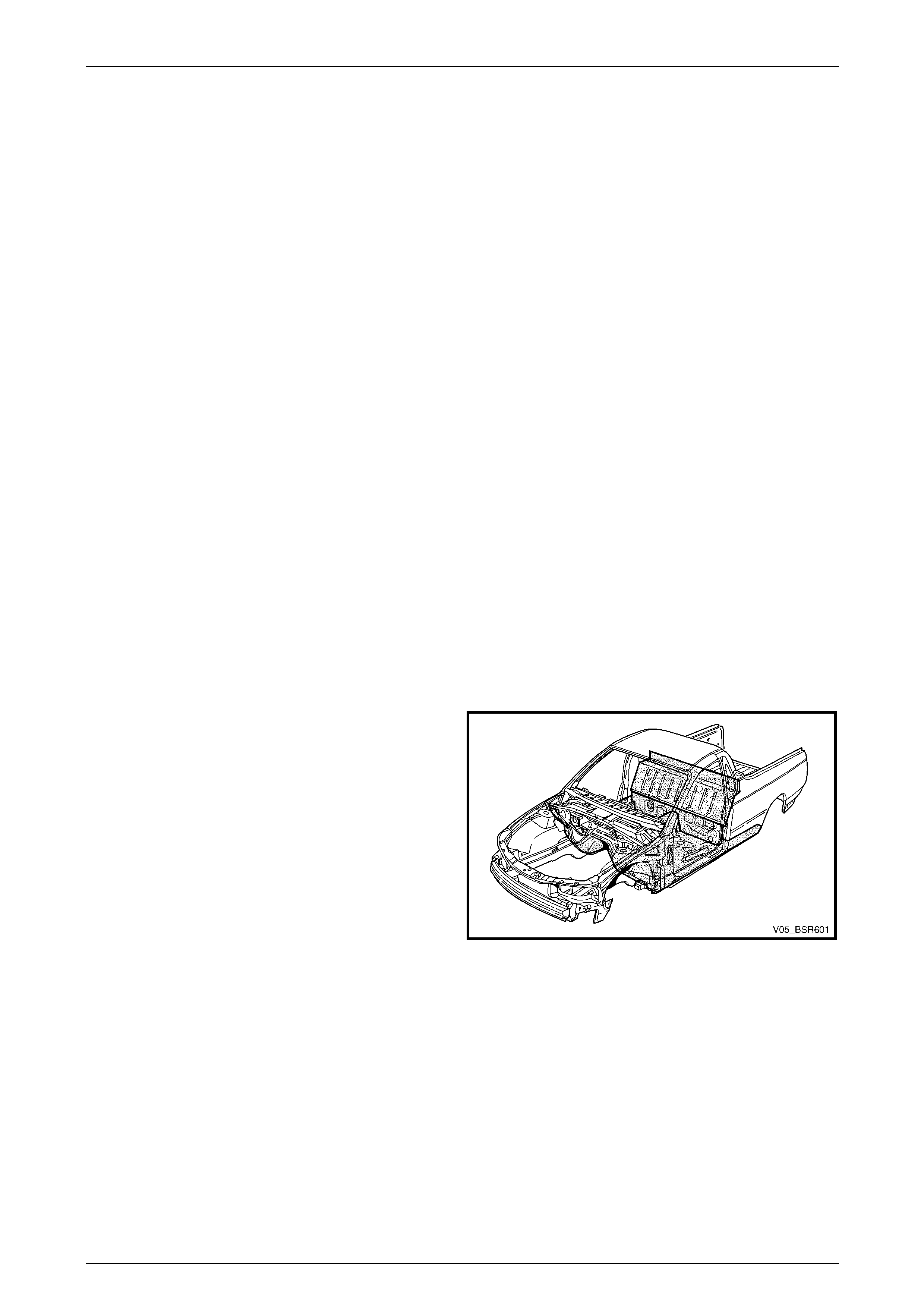

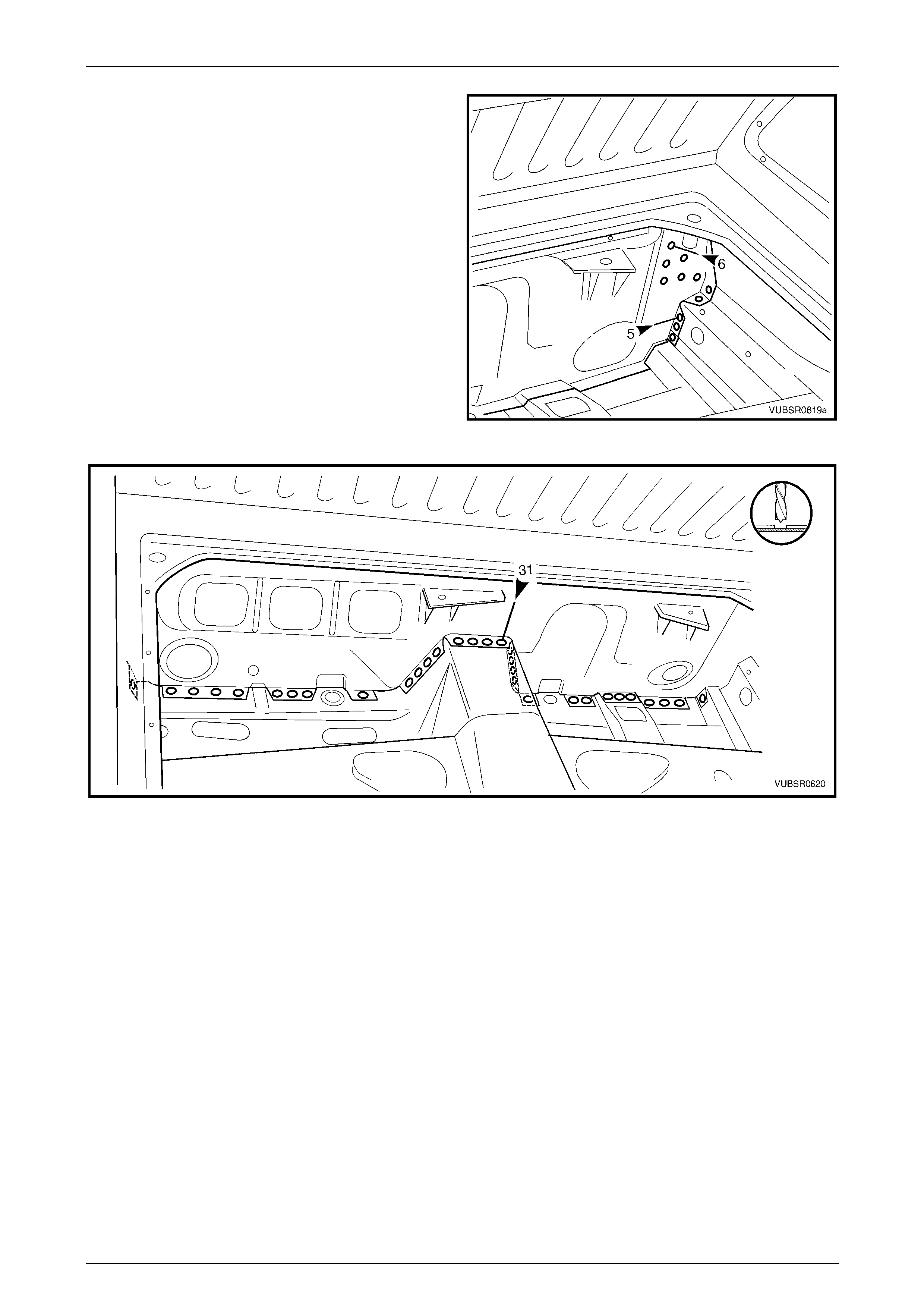

The components and assemblies shown in Figure 6C – 2

and are the serviceable parts that form the

basis of the repair procedures in this Sectio n.

For a detailed view of the body components,

refer to Section 3C Body Construction – Utility.

NOTE

Always refer to an Authorised Retailer for spare

parts availability configurations.

Figure 6C – 1

6C Cabin Floor and Seatback Assembly – Utility Page 6C-3

Page 6C-3

Figure 6C – 2

Legend

1 Front Floor Rear Extension Assembly

2 Front Floor Rear Extension Reinforcement

3 Fuel Tank Bracket Assembly

4 Jack Stowage Bracket

5 Front Tie Down Bracket, Left-hand / Right-hand

6 Front Seatback Panel Outer, Left-hand / Right-hand

7 Load Compartment Extension Outer Panel

8 Load Compartment Extension Panel Bracket, Right-hand

9 Front Seatback Panel

10 Inner Rocker Panel Assembly, Left-hand / Right-hand

11 Front Floor Panel Assembly

6C Cabin Floor and Seatback Assembly – Utility Page 6C-4

Page 6C-4

2 Service Operations

2.1 Front Floor Panel Assembly – Replace

Care must be taken to avoid cutting the fuel,

brake or emission control pipes.

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

VZ Service Information.

2 Remove the adjoining panels as required, refer to the

relevant Section in this Supplement.

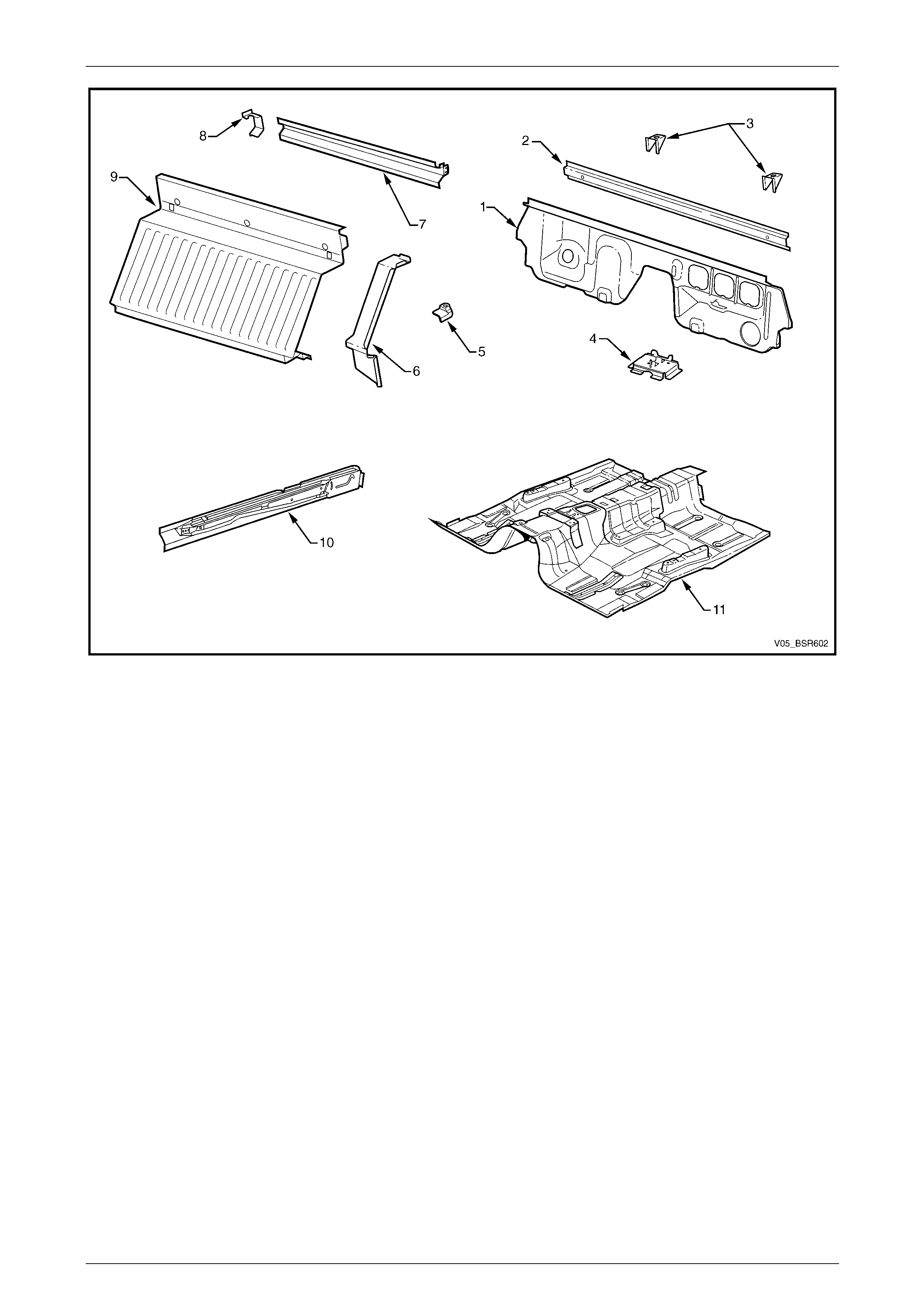

3 Secure the vehicle on a suitable fixture. As a

minimum, support the structural sections of the vehicle

on safety stands.

4 Using a scraper and heat gun, remove the body sealer

and deadener from the front floor attaching areas.

5 Spot cut the welds attaching the front floor rear

extension to the front floor panel assembly, refer to

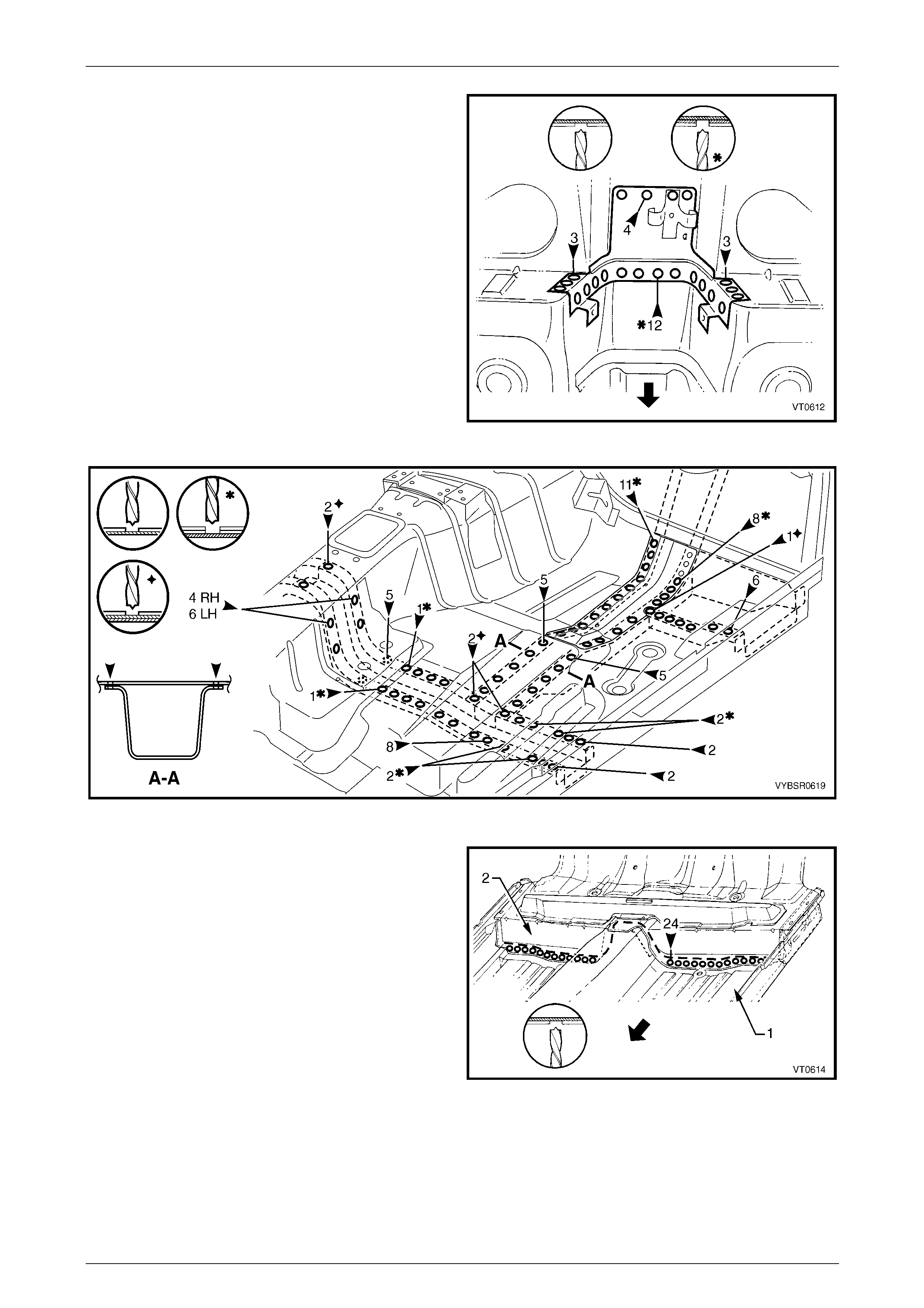

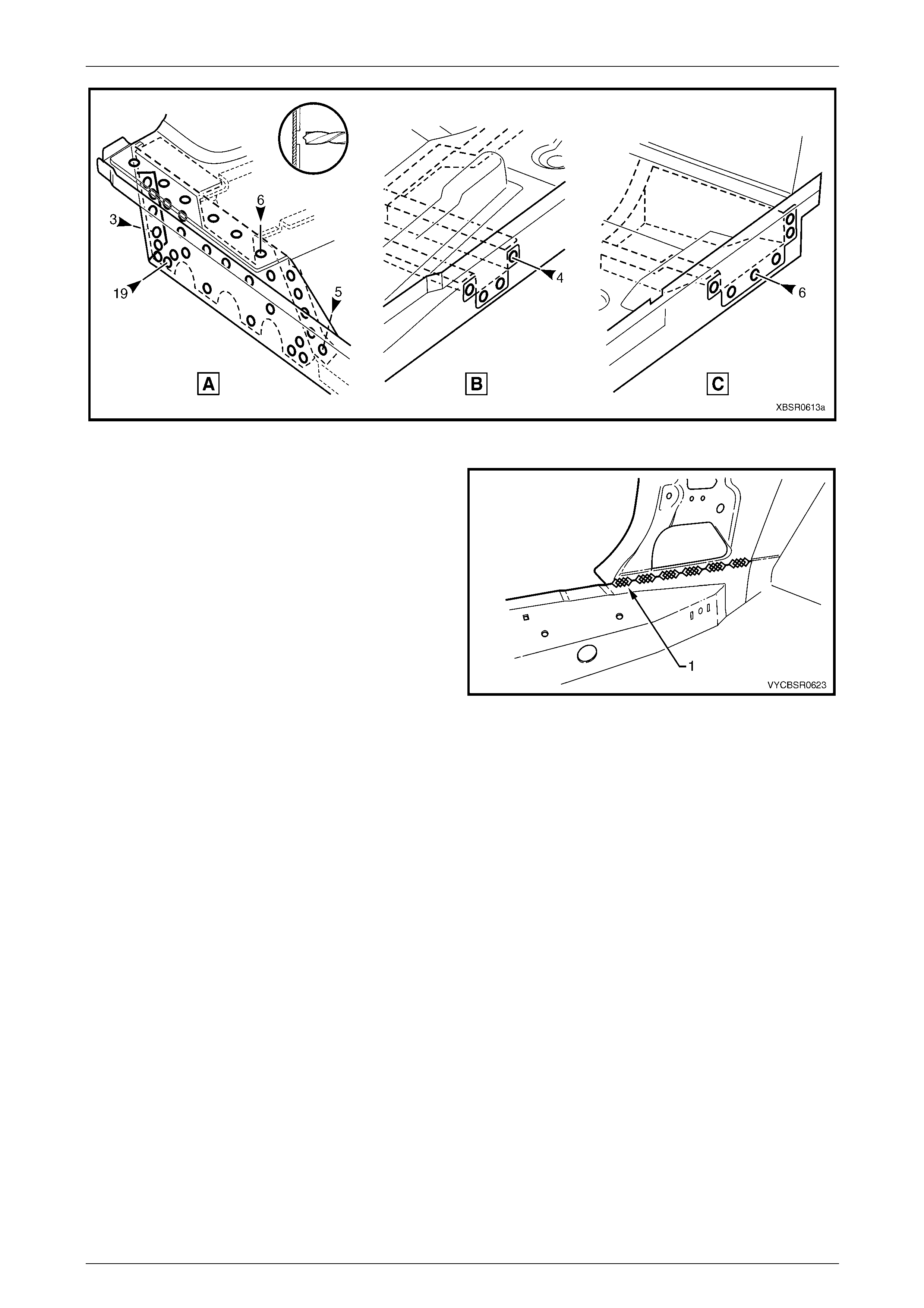

2.6 Front Floor Rear Extension Assembly – Replace. Figure 6C – 3

6 Spot cut the welds attaching the front floor panel extension to the front floo r panel assembly,

refer to Section 6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon, Wagon, Coupe and AWD Wagon.

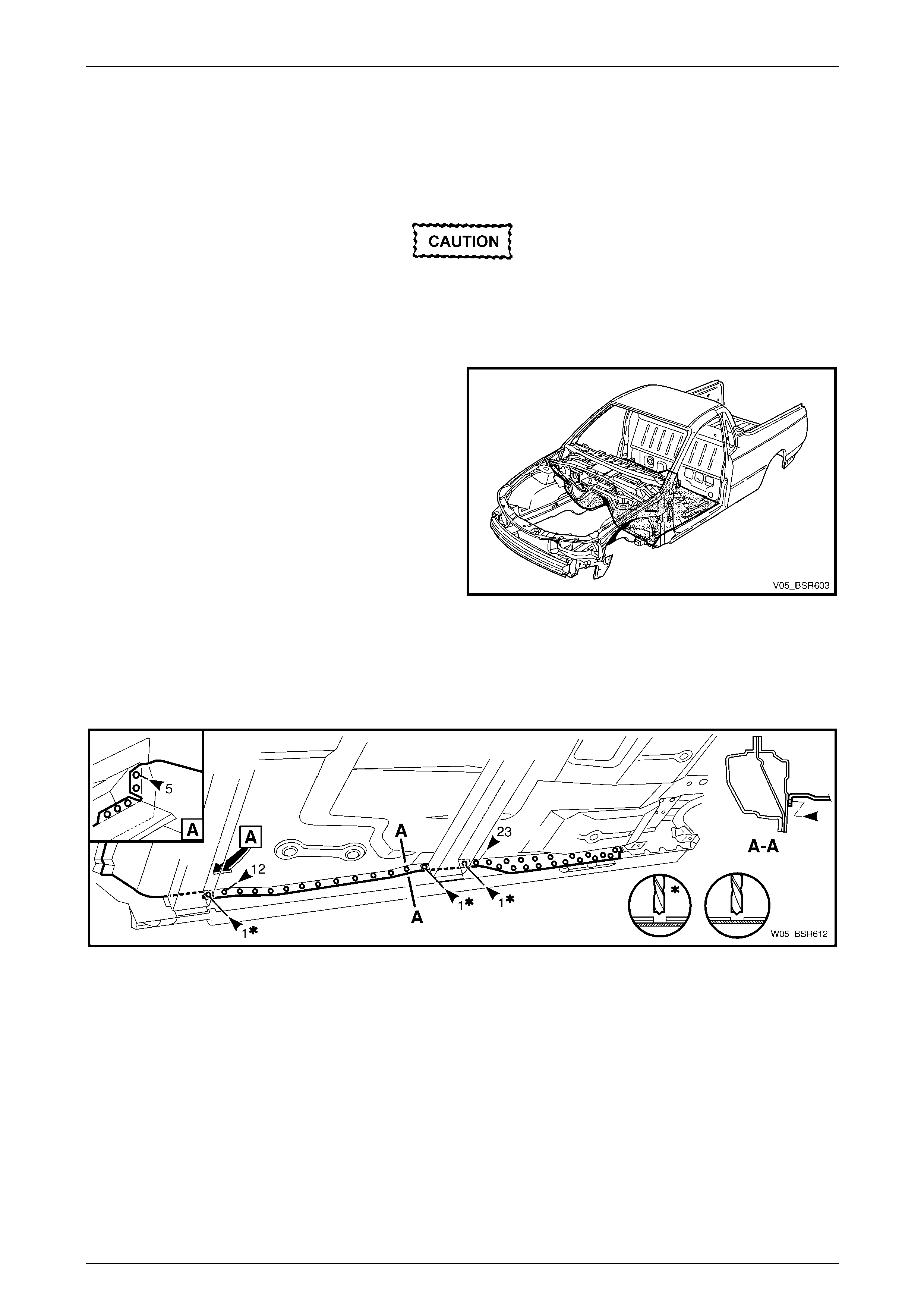

7 From underneath the vehicle, spot cut the welds attaching the front floor panel assembly to the inner rocker panel

assembly, refer to Figure 6C – 4.

Figure 6C – 4

6C Cabin Floor and Seatback Assembly – Utility Page 6C-5

Page 6C-5

8 From underneath the vehicle, spot cut the welds

attaching the park brake cable bracket to the rear floor

panel assembly.

9 On each side of the vehicle, spot cut the welds

attaching the front floor panel assembly to the front

side rail assemblies, refer to Figure 6C – 6.

Figure 6C – 5

Figure 6C – 6

10 Spot cut the welds attaching the front floor panel

assembly (1) to the rear floor panel assembly (2).

11 Remove the front floor assembly from the vehicle and

repair any damage to adjacent panels as required.

12 Check and rectify the alignme nt of

the body as required,

refer to Section 3C Body Construction – Utility.

Figure 6C – 7

6C Cabin Floor and Seatback Assembly – Utility Page 6C-6

Page 6C-6

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as requir ed,

refer to Section 3C Body Construction – Utility.

3 Secure the front floor panel assembly (1) in position

and make several tack welds around its

circumference. Plug weld to the rear floor panel

assembly (2).

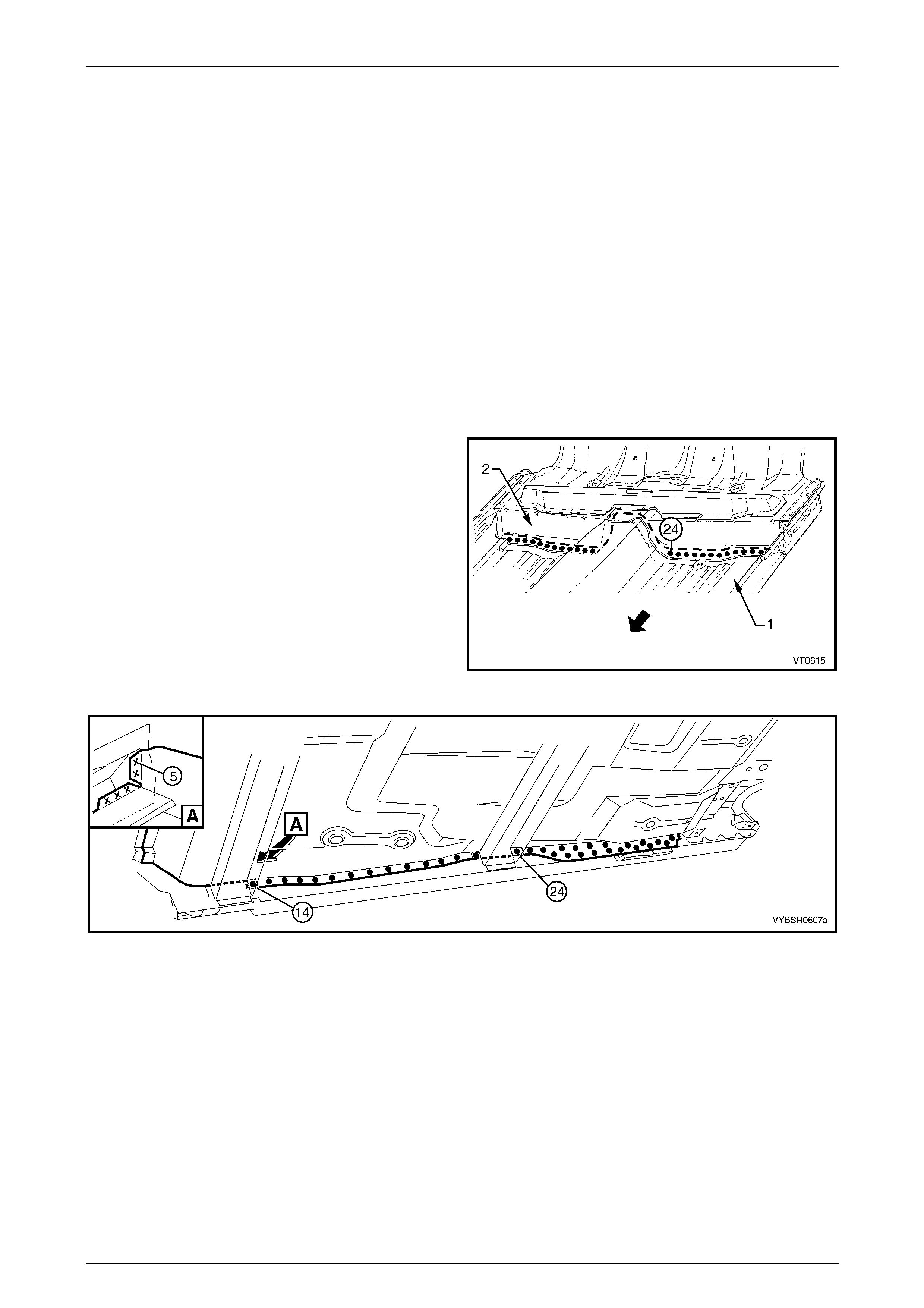

4 From underneath the vehicle, spot or plug weld the

front floor assembly to the inner rocker panel

assembly, 14 places forward of the crossmember and

24 places rear of the crossmember. From inside the

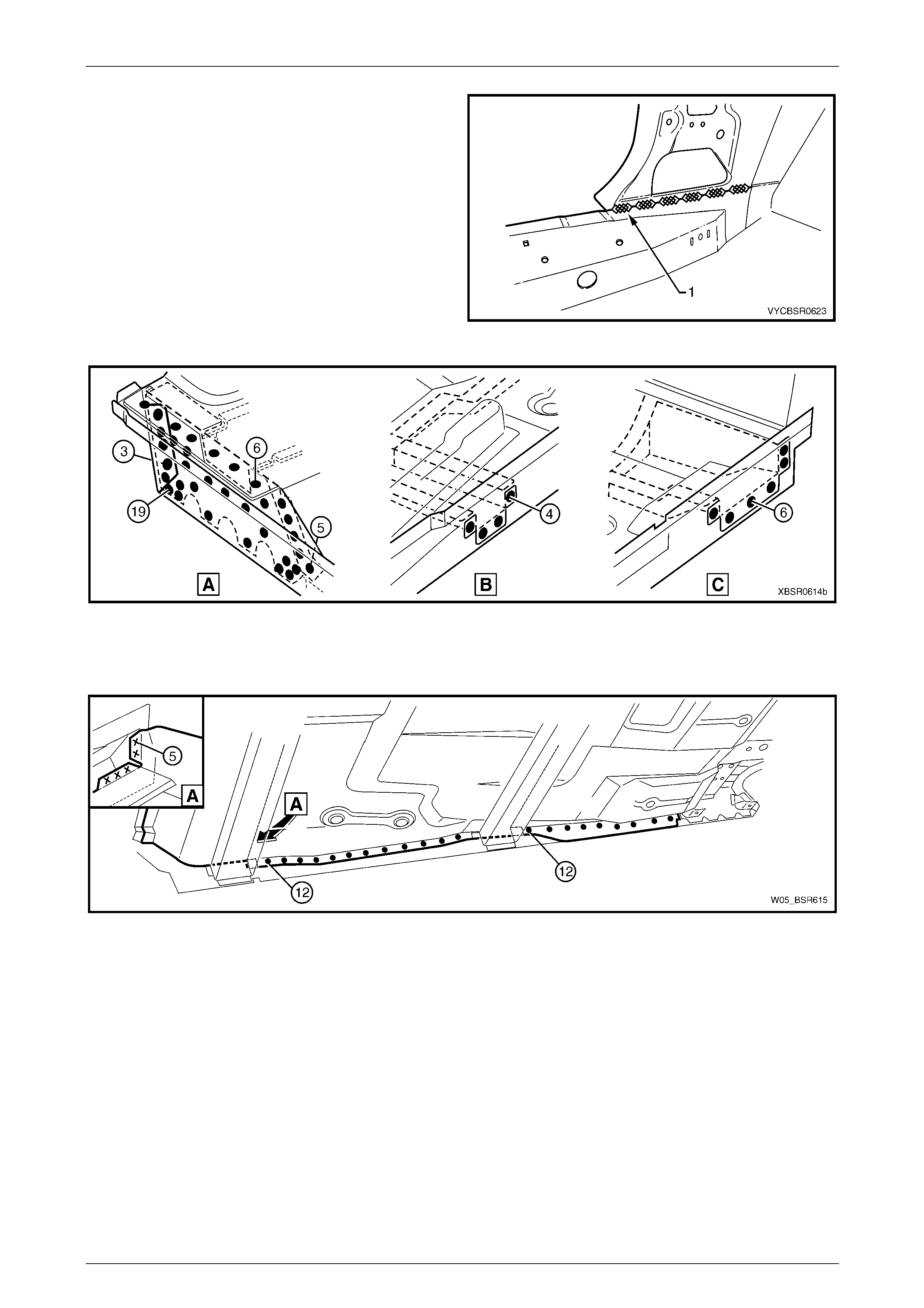

vehicle, also spot weld, five places. Figure 6C – 9.

Figure 6C – 8

Figure 6C – 9

5 Replace the front floor panel extension, or weld the extension to the front floor panel assembly,

refer to Section 6A Cabin Floor – Sedan, Wagon, Coupe and AWD Wagon .

6 On each side of the vehicle, plug weld the front floor panel assembly to the front side rail assemblies,

refer to Figure 6C – 10.

6C Cabin Floor and Seatback Assembly – Utility Page 6C-7

Page 6C-7

Figure 6C – 10

7 Plug weld the front floor rear extension to the front floor panel assembly,

refer to 2.6 Front Floor Rear Extension Assembly – Repl ace.

8 Reinstall the park brake cable bracket to the rear floor

panel assembly.

9 Replace any other remov ed panels as required, refer

to the relevant Section in this Supplement.

10 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

11 Apply Joint Sealer (Item 3) as required.

Refer to Section 3C Body Construction – Utility.

12 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint,

refer to Section 3C Body Construction – Utility.

13 Apply floor deadeners as required,

refer to Section 3C Body Construction – Utility.

14 Apply Spray-on dea dener (Item 7) as required to the

underside of the floor,

refer to Section 3C Body Construction – Utility.

15 Reinstall the remaining bolt-on panels and

components as required, refer to the appropriate

Section of the MY2005 VZ Service Information.

Figure 6C – 11

6C Cabin Floor and Seatback Assembly – Utility Page 6C-8

Page 6C-8

2.2 Inner Rocker Panel Assembly – Replace

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

VZ Service Information.

2 Secure the vehicle on a suitable fixture. As a

minimum, support the structural sections of the vehicle

on safety stands.

3 Remove the adjacent panels as required, refer to the

relevant Section in this Supplement.

4 Spot cut the welds attaching the front floor panel

assembly to the inner rocker panel as required.

Refer to Figure 6C – 13.

Figure 6C – 12

Figure 6C – 13

5 Spot cut the welds attaching the inner rocker panel

assembly to the front floor rear extension assembly.

6 Spot cut the welds attaching the inner rocker panel

assembly to the rear floor panel outer extension (A),

centre crossmember (B), and front floor panel support

(C), refer to Figure 6C – 15.

Figure 6C – 14

6C Cabin Floor and Seatback Assembly – Utility Page 6C-9

Page 6C-9

Figure 6C – 15

7 Remove the MIG welds (1) attaching the inner rocker

panel to the hinge pillar inner assembly.

8 Remove the inner rocker panel from the vehicle and

repair any damage to adjacent panels as required.

9 Check and rectify the alignme nt

of the body as required,

refer to Section 3C Body Construction – Utility.

Figure 6C – 16

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as requir ed,

refer to Section 3C Body Construction – Utility.

3 Clamp the inner rocker panel in positi on, noting to ensure it fits behind the hinge pillar inn er assemb ly.

6C Cabin Floor and Seatback Assembly – Utility Page 6C-10

Page 6C-10

4 Make six MIG welds (1) to attach inner rocker panel

assembly to the hinge pillar inner assembly.

5 Plug weld the inner rocker pa nel to the rear floor panel

outer extension (A), centre crossmember (B) and front

floor panel support (C), refer Figure 6C – 18.

Figure 6C – 17

Figure 6C – 18

6 Spot or plug weld the front floor panel assembly to the inner rocker panel, undern eath and inside.

Refer to Figure 6C – 19.

Figure 6C – 19

7 Replace the adjoining removed panels as required, refer to the relevant Section in this Supplement.

8 Refinish and paint panels and other components as required. Refer to Section 3 Body Construction.

9 Apply Joint Sealer (Item 3) as required. Refer to Section 3C Body Construction – Utility.

10 Apply Cavity Wax (Item 8) as required to the inside of any box secti ons or areas inaccessible to paint,

refer to Section 3C Body Construction – Utility.

11 Reinstall the remaining bolt-on panels and components as required, refer to the appropriate Section of the MY2005

VZ Service Information.

6C Cabin Floor and Seatback Assembly – Utility Page 6C-11

Page 6C-11

2.3 Load Compartment Extension Outer

Panel and Bracket – Replace

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

VZ Service Information.

2 Remove the rear window, refer Section 1A6 Stationary

Windows in the MY2005 VZ Service Information.

3 Remove the adjacent panels as required, refer to the

relevant Section in this Supplement.

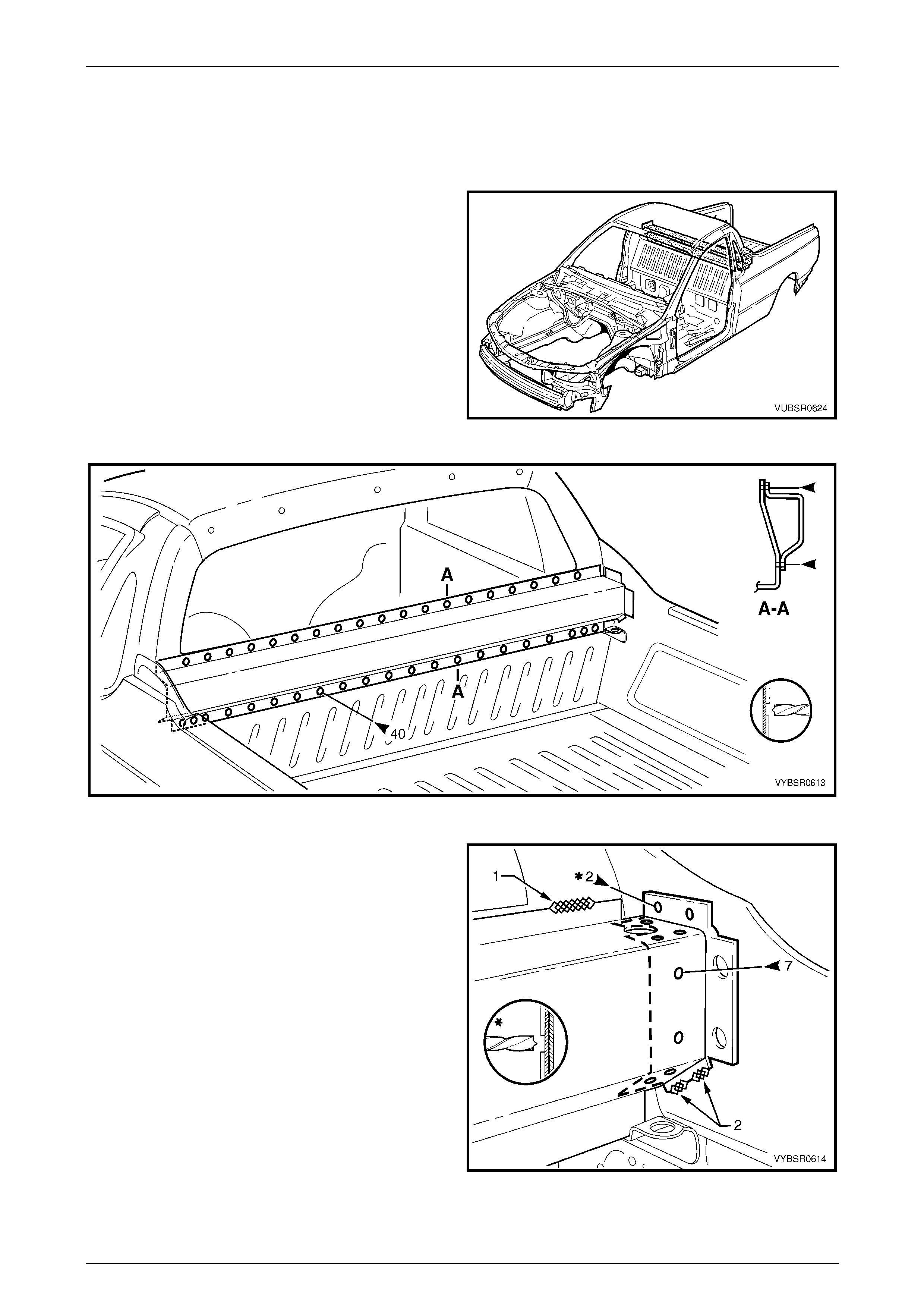

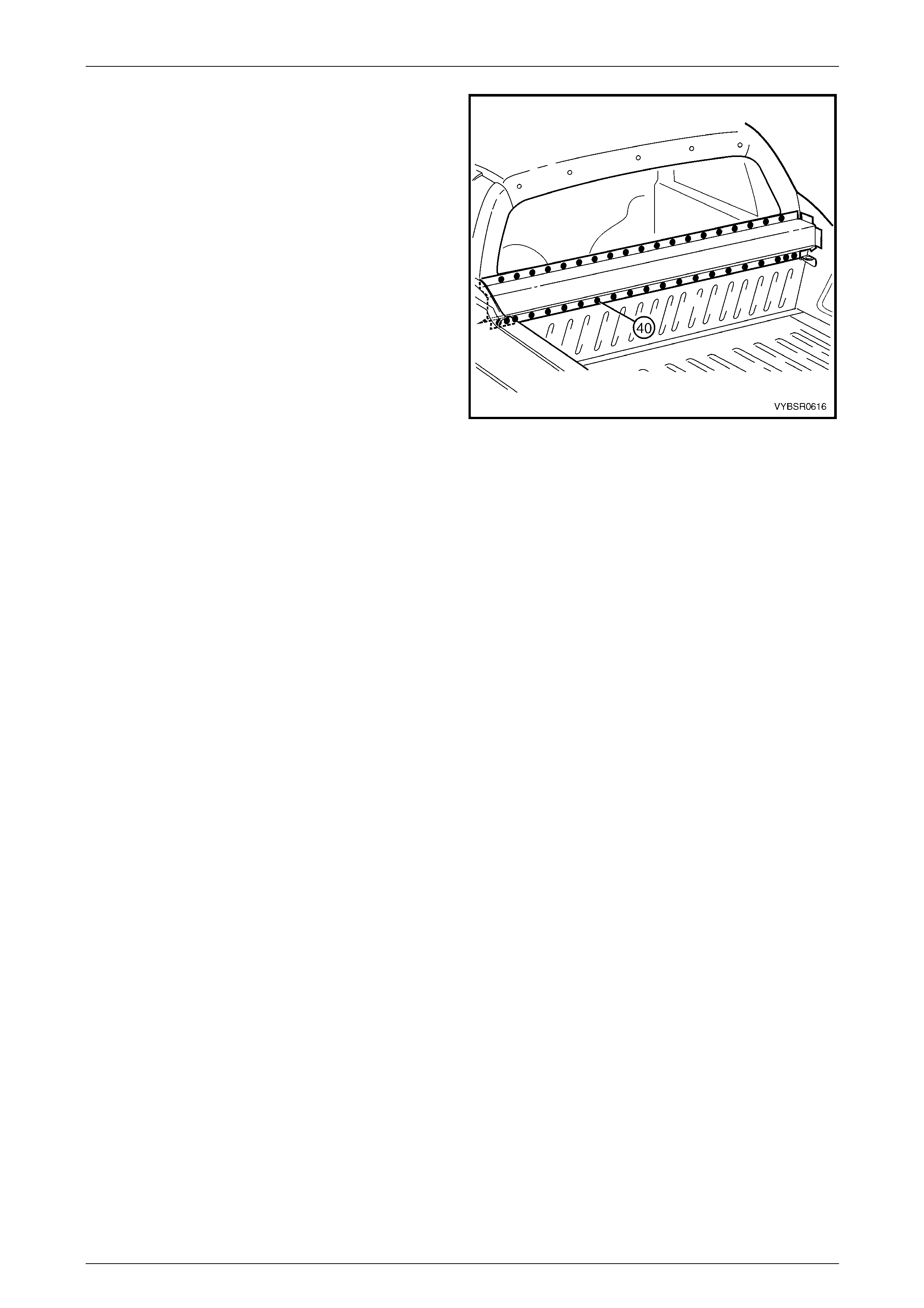

4 Spot cut the 40 welds attaching the load compartment

extension outer pane l to the front seatback panel,

refer to Figure 6C – 21.

Figure 6C – 20

Figure 6C – 21

5 For the right-hand side either:

a spot cut the two welds and grind off the three

MIG welds (1) and (2) attaching the load

compartment extension outer panel and load

compartment extension panel bracket, or

b spot cut the seven welds attaching the load

compartment extension outer panel to the load

compartment extension panel bracket and grind

off the MIG weld (1).

6 For the left-hand side, spot cut the t wo welds and

grind off the three MIG welds attaching the load

compartment extension outer panel.

7 Remove the panel from the vehicle and re pair any

damage to adjacent panels.

8 Check and rectify the alignme nt of the

body as required,

refer to Section 3C Body Construction – Utility. Figure 6C – 22

6C Cabin Floor and Seatback Assembly – Utility Page 6C-12

Page 6C-12

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as requir ed,

refer to Section 3 Body Construction.

3 Clamp the panel and bracket (if removed) i n positi on.

NOTE

Ensure the two holes through the load

compartment extension outer panel and side

panel inner upper are aligned.

4 For the right-hand side:

a spot or plug weld seven places, the load

compartment extension outer panel to the load

compartment panel bracket.

b MIG weld one place (1) 25 mm, the load

compartment extension outer panel to the side

inner upper front panel.

If the load compartment panel bracket was removed

also:

a Spot or plug weld two places, the load

compartment panel bracket to the side panel

inner upper and rear quarter panel.

b MIG weld 20 mm two places (2), the load

compartment panel bracket to the side inner

upper panel.

5 For the left-hand side:

• Spot or plug weld two places, the load

compartment extension outer panel to the side

panel inner upper and rear quarter panel.

• MIG weld 20 mm two places (2), the load

compartment extension outer panel to the side

inner upper panel and one place (1) 25 mm, the

side inner upper front panel.

Figure 6C – 23

6C Cabin Floor and Seatback Assembly – Utility Page 6C-13

Page 6C-13

6 Spot or plug weld 40 places, the load com pa rtment

extension outer pane l to the front seatback panel.

7 Replace the adjoining removed panels as required,

refer to the relevant Section in this Supplement.

8 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

9 Apply Joint Sealer (Item 3) as required.

Refer to Section 3C Body Construction – Utility.

10 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint,

refer to Section 3C Body Construction – Utility.

11 Install the rear window, refer to Section 1A6 Stationary

Windows in the MY2005 VZ Service Information.

12 Install the remaining components as described in the

MY2005 VZ Service Information.

Figure 6C – 24

6C Cabin Floor and Seatback Assembly – Utility Page 6C-14

Page 6C-14

2.4 Front Seatback Panel Outer – Replace

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

VZ Service Information.

2 Remove the rear window, refer Section 1A6 Stationary

Windows in the MY2005 VZ Service Information.

3 Secure the vehicle on a suitable fixture. As a

minimum, support the structural sections of the vehicle

on safety stands.

4 Remove the adjacent panels as required, refer to the

relevant Section in this Supplement.

5 Grind off the two MIG welds (1) and spot cut the welds

attaching the front tie down bracket to each side of the

vehicle, refer to Figure 6C – 26. Figure 6C – 25

Figure 6C – 26

6C Cabin Floor and Seatback Assembly – Utility Page 6C-15

Page 6C-15

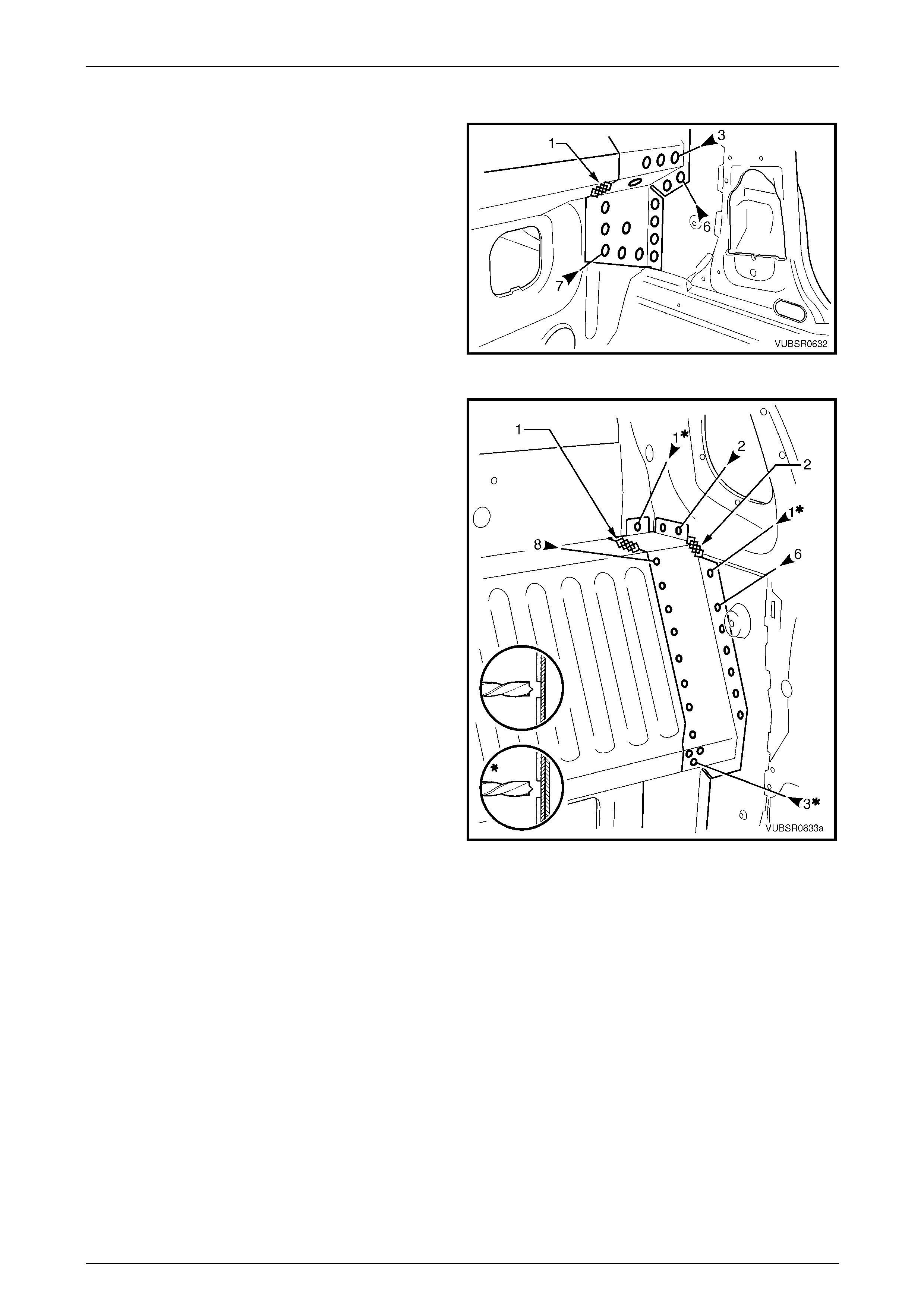

6 Spot cut the welds attaching the front seatback panel

outer to the:

• front floor rear extension assembly, seven

places,

• side inner upper panel, six places,

• load floor panel outer extension, three places.

7 Grind off the MIG weld (1) attaching the front floor rear

extension asse mbly to the front seatback panel outer.

Figure 6C – 27

8 Spot cut the welds attaching the front seatback panel

outer to the:

• front seatback panel, eight places,

• side inner upper front panel and side inner upper

front panel, one place,

• side inner upper front panel, two places,

• side inner upper front panel and side inner upper

panel, one place,

• side inner upper panel, six places,

• front seatback panel and front floor rear

extension asse mbly, three places.

9 Grind off the MIG welds (1) and (2) attaching the front

seatback panel outer to the front seatback panel and

side inner upper front panel.

10 Remove the panel(s) from the vehicle and repair any

damage to adjacent panels a s required.

11 Check and rectify the alignme nt of

the body as requir ed,

refer to Section 3C Body Construction – Utility.

Figure 6C – 28

6C Cabin Floor and Seatback Assembly – Utility Page 6C-16

Page 6C-16

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as requir ed,

refer to Section 3C Body Construction – Utility.

3 Clamp the front seatback panel outer in pos ition.

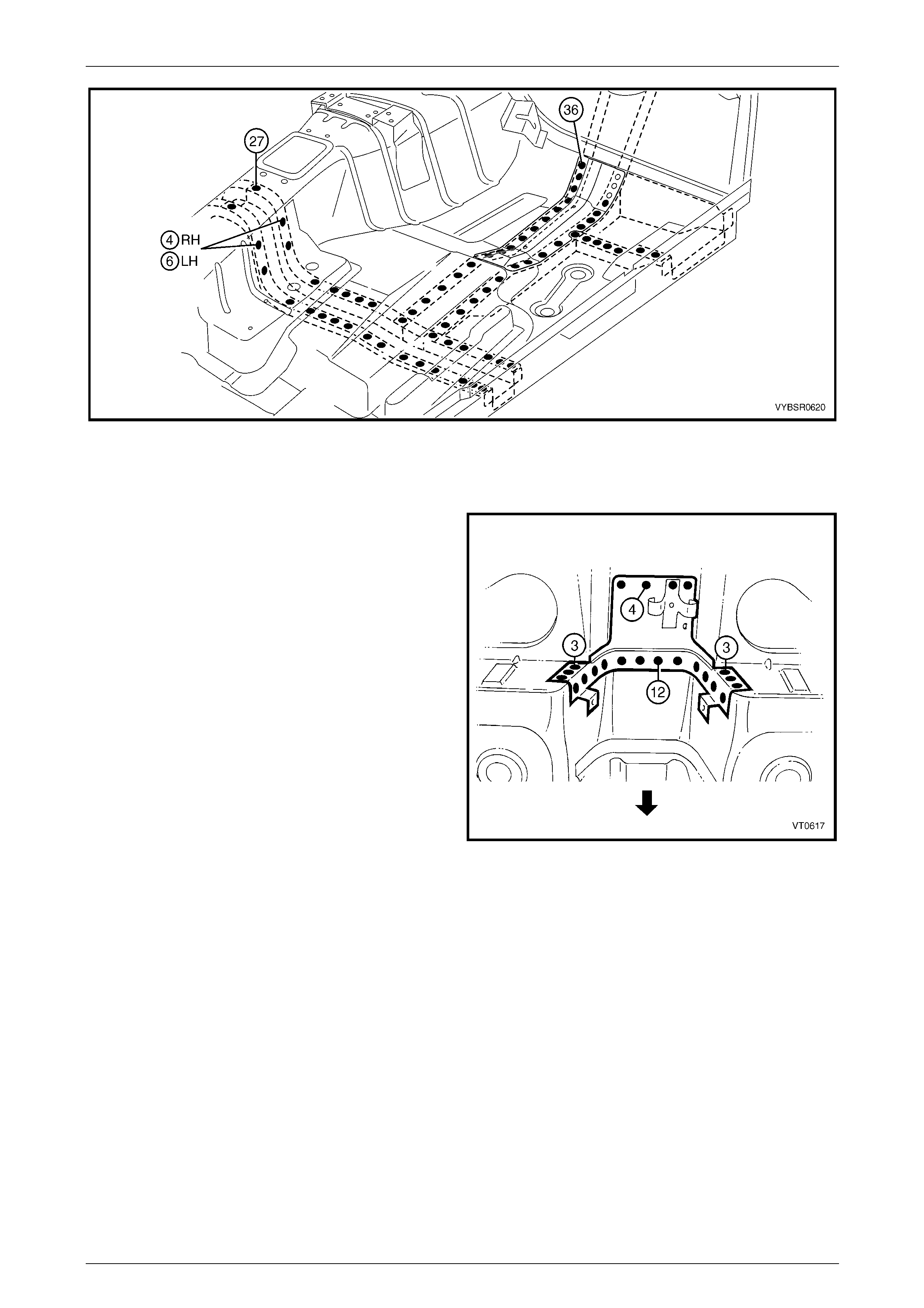

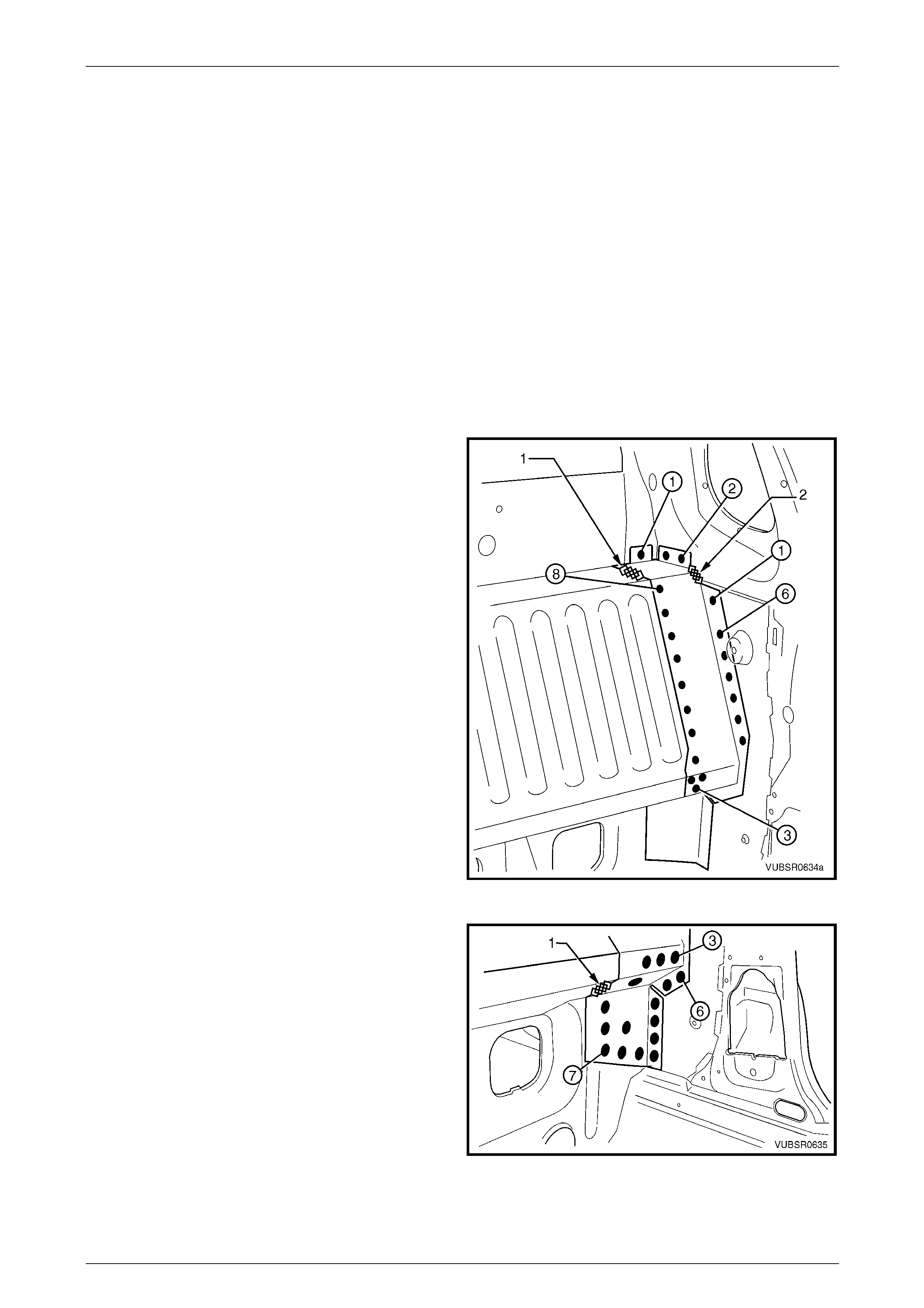

4 Spot or plug weld the front seatback panel outer to

the:

• front seatback panel, eight places,

• side inner upper front panel and side inner upper

front panel, one place,

• side inner upper front panel, two places,

• side inner upper front panel and side inner upper

panel, one place,

• side inner upper panel, six places,

• front seatback panel and front floor rear

extension asse mbly, three places.

5 MIG weld the front seatback panel outer (1) 50 mm to

the front seatback panel and (2) 25 mm to the side

inner upper front panel.

Figure 6C – 29

6 Spot or plug weld the front seatback panel outer to

the:

• front floor rear extension assembly, seven

places,

• side inner upper panel, six places,

• load floor panel outer extension, three places.

7 MIG weld (1) 25 mm the front floor rear extension

assembly to the front seatback panel outer.

8 MIG weld (1) two places and spot or plug weld the

front tie down bracket, each side of the vehicle,

refer to Figure 6C – 31. Figure 6C – 30

6C Cabin Floor and Seatback Assembly – Utility Page 6C-17

Page 6C-17

Figure 6C – 31

9 Replace the adjoining removed panels as required, refer to the relevant Section in this Supplement.

10 Refinish and paint panels and other components as required. Refer to Section 3 Body Construction.

11 Apply Joint Sealer (Item 3) as required. Refer to Section 3C Body Construction – Utility.

12 Apply Cavity Wax (Item 8) as required to the inside of any box secti ons or areas inaccessible to paint,

refer to Section 3C Body Construction – Utility.

13 Install the rear window, refer to Section 1A6 Stationary Windows in the MY200 5 VZ Service Information.

14 Install the remaining compon ents as descr ibed in the MY2005 VZ Service Information.

6C Cabin Floor and Seatback Assembly – Utility Page 6C-18

Page 6C-18

2.5 Front Seatback Panel – Replace

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

VZ Service Information.

2 Remove the rear window, refer Section 1A6 Stationary

Windows in the MY2005 VZ Service Information.

3 Secure the vehicle on a suitable fixture. As a

minimum, support the structural sections of the vehicle

on safety stands.

4 Remove the adjacent panels as required, refer to the

relevant Section in this Supplement.

5 Spot cut the welds attaching the front seatback panel

to the front floor rear extension assembly and front

seatback panel outer, refer to Figure 6C – 33.

6 Grind off the MIG welds (1) attaching the front

seatback panel to the front seatback panel outer and

side inner upper front panel, refer to Figure 6C – 33.

Figure 6C – 32

Figure 6C – 33

6C Cabin Floor and Seatback Assembly – Utility Page 6C-19

Page 6C-19

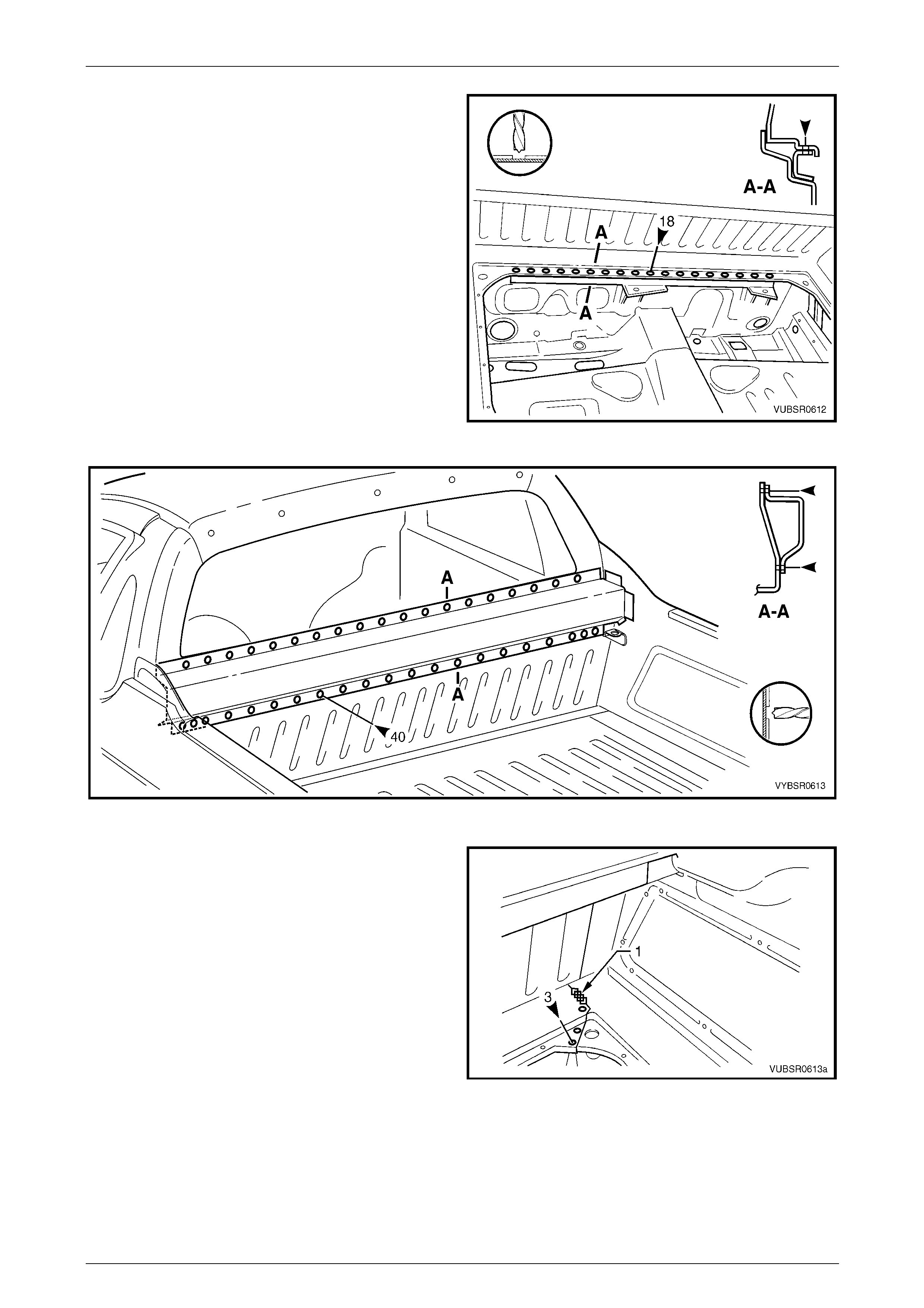

7 Spot cut the 18 welds attaching the front seatback

panel to the front floor rear extension reinforc ement.

8 Spot cut the 40 welds attaching the front seatback

panel to the load compartment extensio n outer panel,

refer to Figure 6C – 35.

NOTE

If the load compartment extension outer panel is

also being removed, this procedure is not

required.

Figure 6C – 34

Figure 6C – 35

9 Spot cut the three welds and grind off the MIG weld (1)

attaching the front seatback panel to the load floor

panel outer extension.

10 If the load compartment extension outer panel is also

being removed, refer to 2.3 Load Compartment

Extension Outer Panel and Bracket – Repla c e .

11 Remove the panel from the vehicle and re pair any

damage to adjacent panels a s required.

12 Check and rectify the alignme nt of

the body as requir ed,

refer to Section 3C Body Construction – Utility.

Figure 6C – 36

6C Cabin Floor and Seatback Assembly – Utility Page 6C-20

Page 6C-20

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as requir ed,

refer to Section 3C Body Construction – Utility.

3 Clamp the front seatback panel in position.

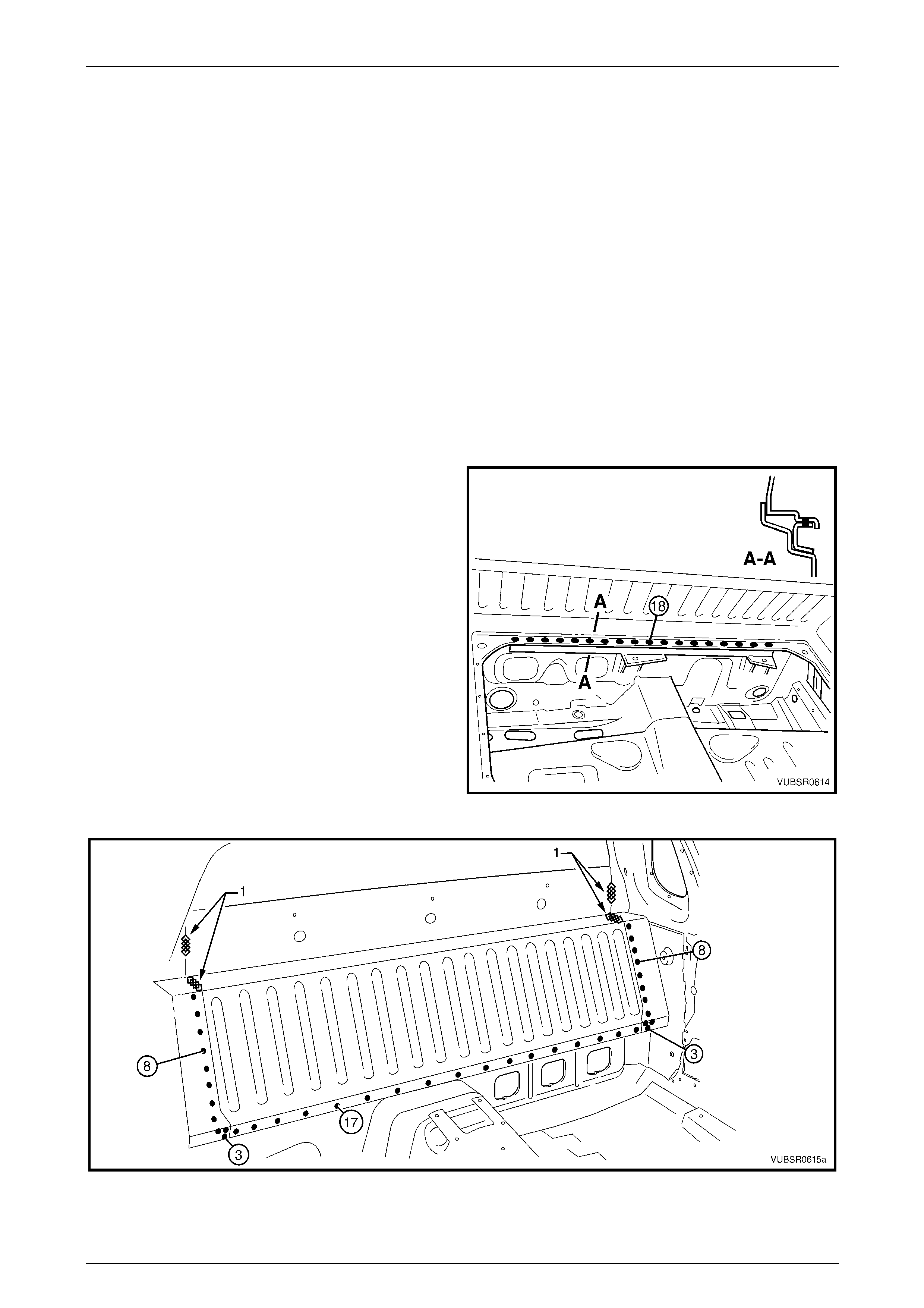

4 Spot or plug weld the front seatback panel to the front

floor rear extension reinforcement.

5 Spot or plug weld the front seatback panel to the front

floor rear extension assembly and front seatback

panel outer, refer to Figure 6C – 38.

6 MIG weld 50 mm two places each side (1), the front

seatback panel to the and front seatback panel outer

and side inner upper front pan el,

refer to Figure 6C – 38.

Figure 6C – 37

Figure 6C – 38

6C Cabin Floor and Seatback Assembly – Utility Page 6C-21

Page 6C-21

7 If the load compartment extension outer panel upper

was not removed, spot or plug weld the front seatback

panel 40 places.

Figure 6C – 39

8 Spot or plug weld three places and MIG weld 25 mm

one place (1), the front seatback panel to the load floor

panel outer extension.

9 Replace the adjoining removed panels as required,

refer to the relevant Section in this Supplement.

10 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

11 Apply Joint Sealer (Item 3) as required.

Refer to Section 3C Body Construction – Utility.

12 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint,

refer to Section 3C Body Construction – Utility.

13 Install the rear window, refer to Section 1A6 Stationary

Windows in the MY2005 VZ Service Information.

14 Install the remaining components as described in the

MY2005 VZ Service Information.

Figure 6C – 40

6C Cabin Floor and Seatback Assembly – Utility Page 6C-22

Page 6C-22

2.6 Front Floor Rear Extension Assembly –

Replace

NOTE

This procedure describes r emoving the front floor

rear extension, front floor rear extension

reinforcement and front fuel tank brackets as an

assembly. As the parts are serviced separately,

their installation is described as they would be

replaced.

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

VZ Service Information.

2 Secure the vehicle on a suitable fixture and support

the structural sections of the vehicle on safety stands.

3 Remove the adjacent panels as required, refer to the

relevant Section in this Supplement.

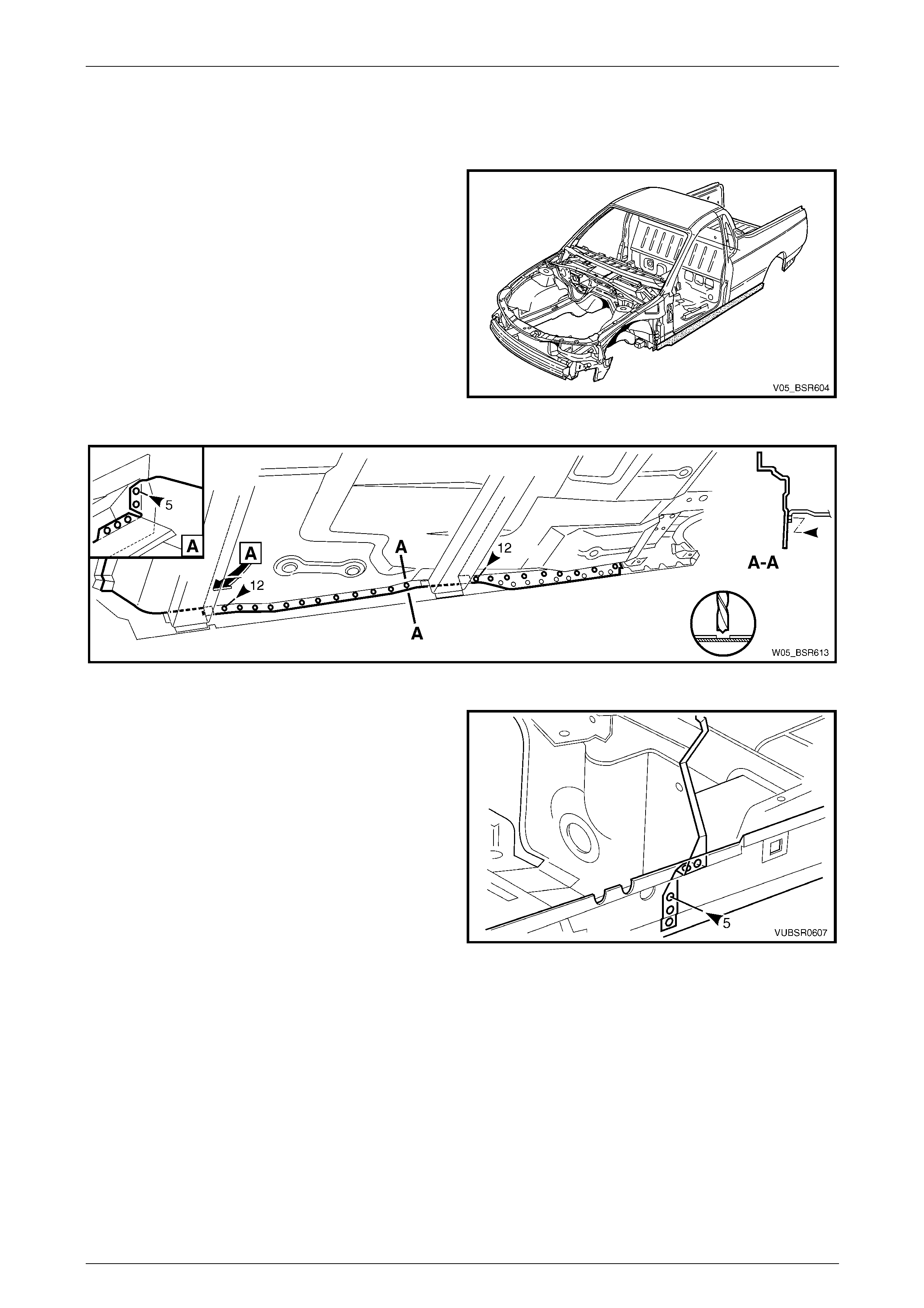

Figure 6C – 41

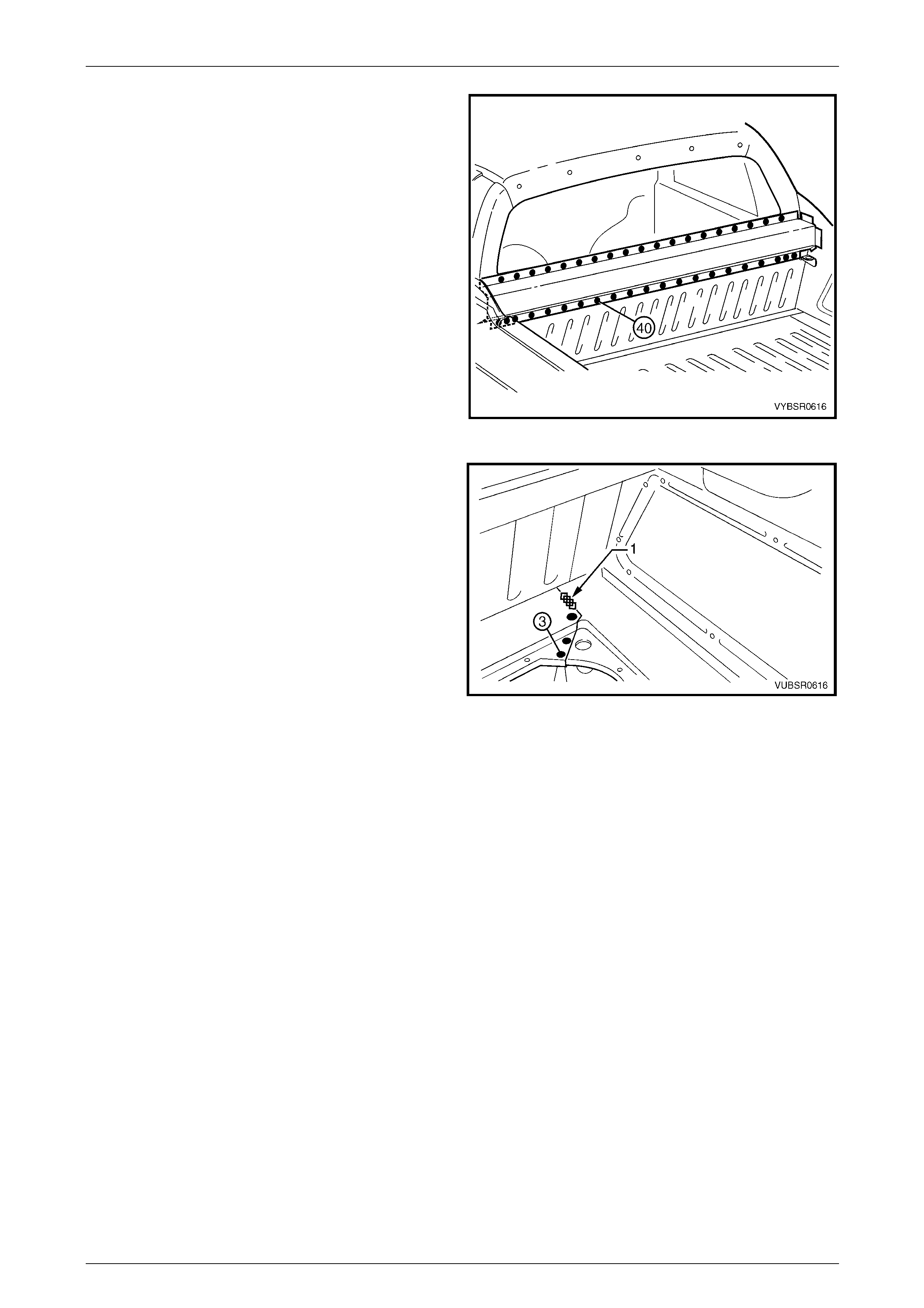

4 If required, spot cut the 12 welds attaching the jack

stowage bracket to the floor.

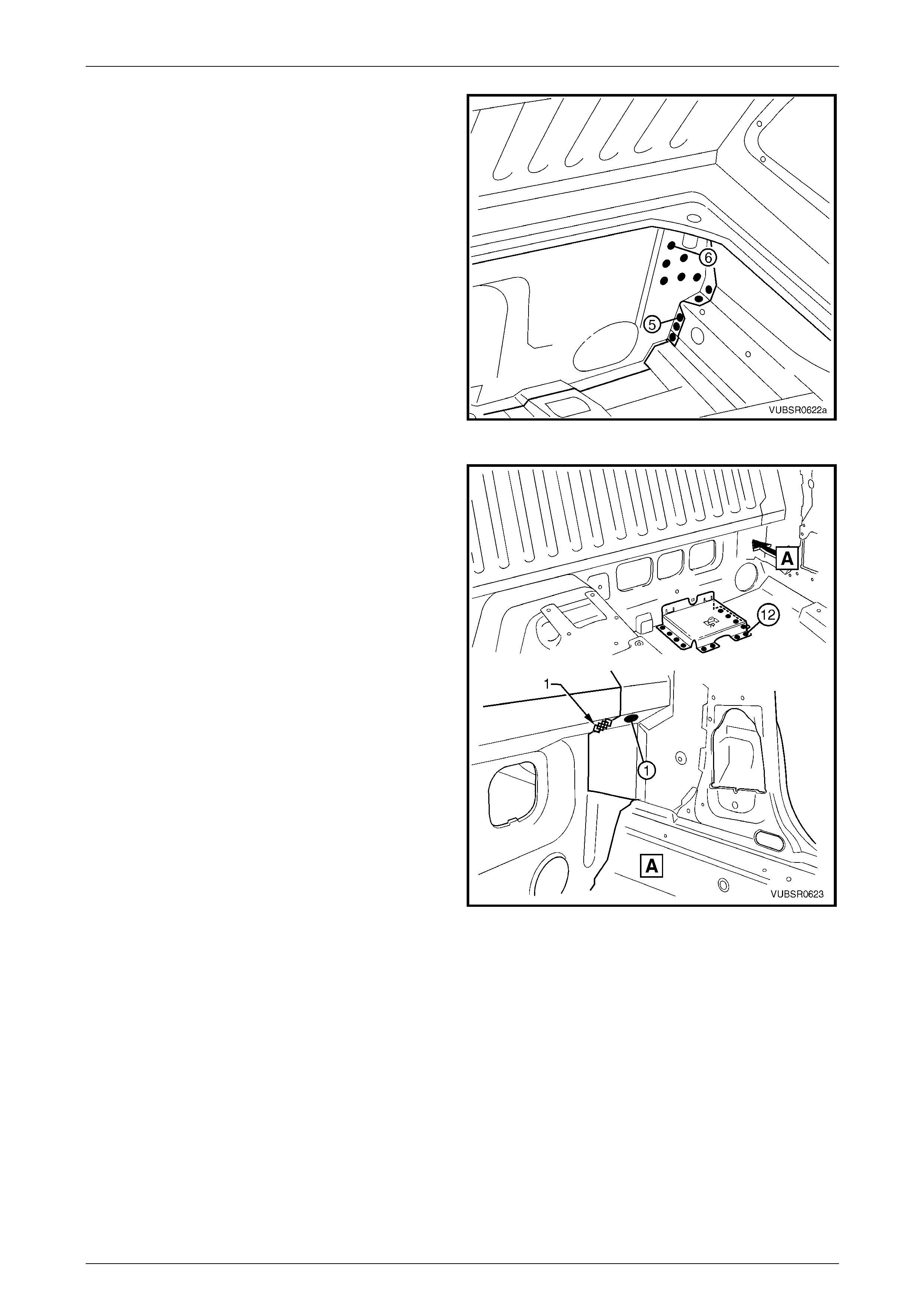

5 Spot cut the weld and grind off the MIG weld (1) each

side, attaching the front floor rear extension to the

front seatback panel outer, refer to View A.

6 If the front seatback panel has not been remo ved,

remove the welds attaching it to the front floor rear

extension, refer 2.5 Front Seatback Panel – Replace

in this Section.

Figure 6C – 42

6C Cabin Floor and Seatback Assembly – Utility Page 6C-23

Page 6C-23

7 Spot cut the welds attaching the front floor rear

extension to the:

a front seatback panel outer, six places each side,

b inner rocker panel, five places each side,

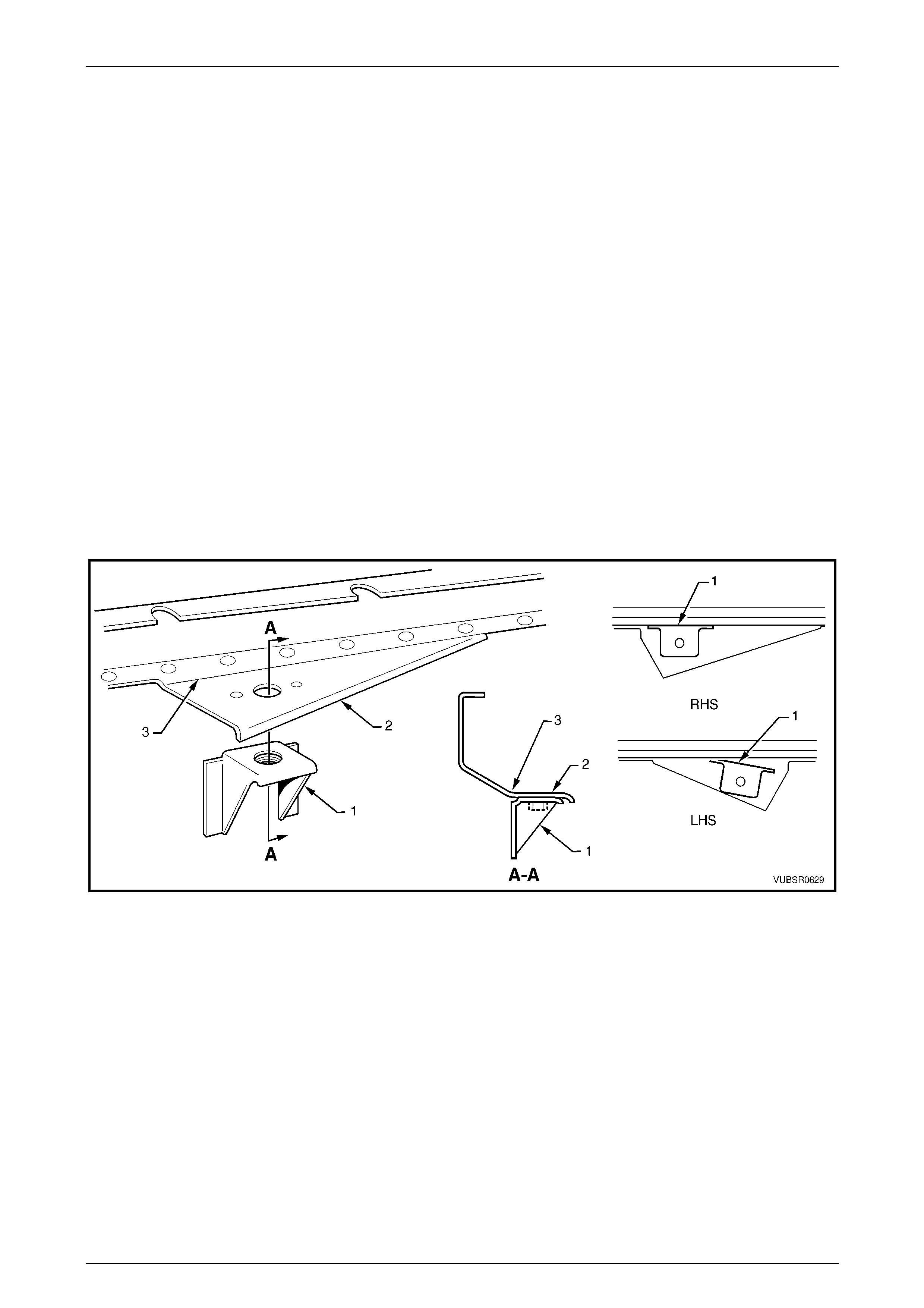

8 Spot cut the 31 welds attaching the front floor rear

extension to the to front floor panel,

refer to Figure 6C – 44.

9 Remove the front floor rear extension assembly from

the vehicle and repair any damage to adjacent panels.

10 Check and rectify the alignme nt of

the body as requir ed,

refer to Section 3C Body Construction – Utility.

Figure 6C – 43

Figure 6C – 44

6C Cabin Floor and Seatback Assembly – Utility Page 6C-24

Page 6C-24

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panels with drilling locations in preparation for plug welding. Drill holes as required.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required,

refer to Section 3C Body Construction – Utility.

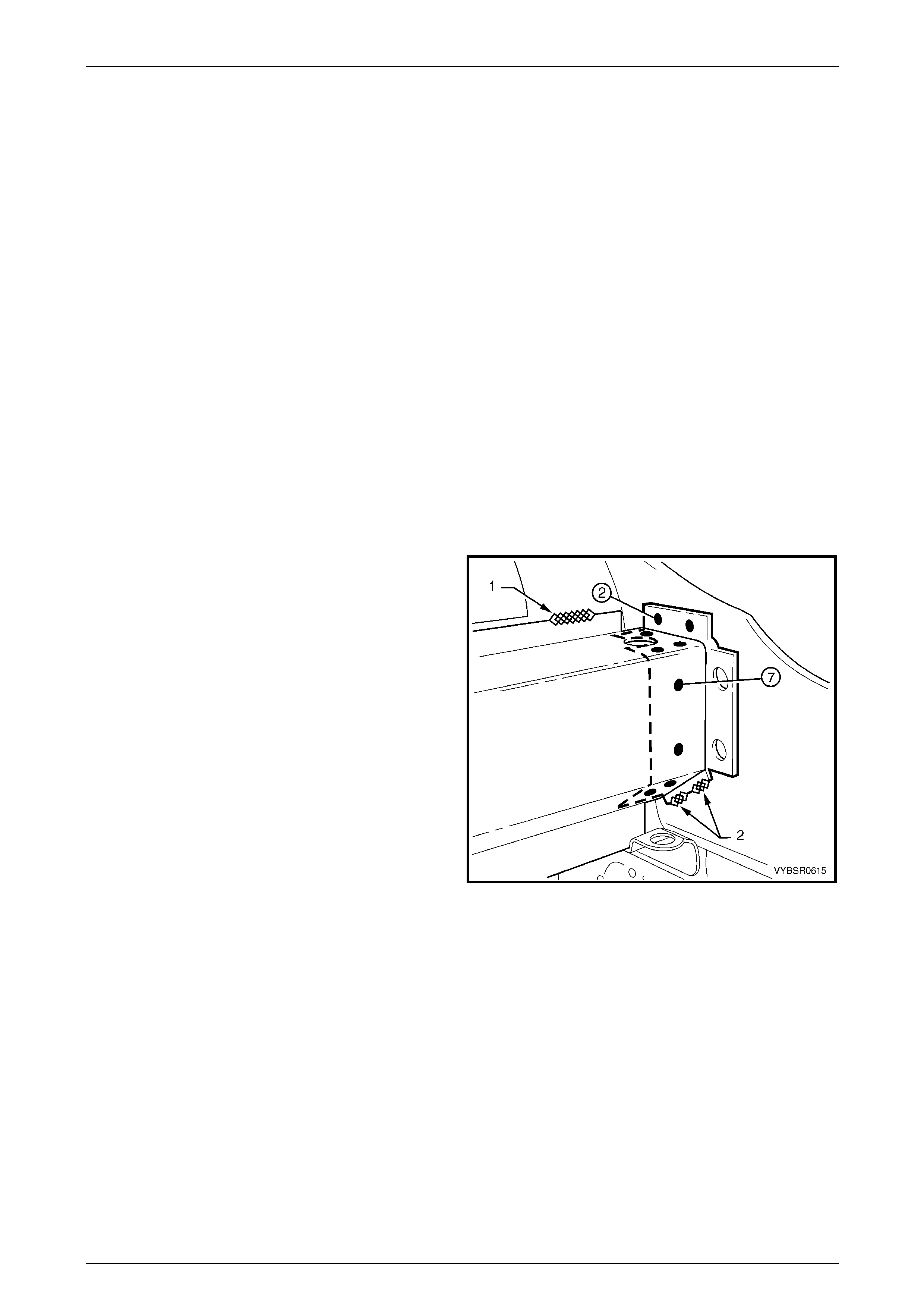

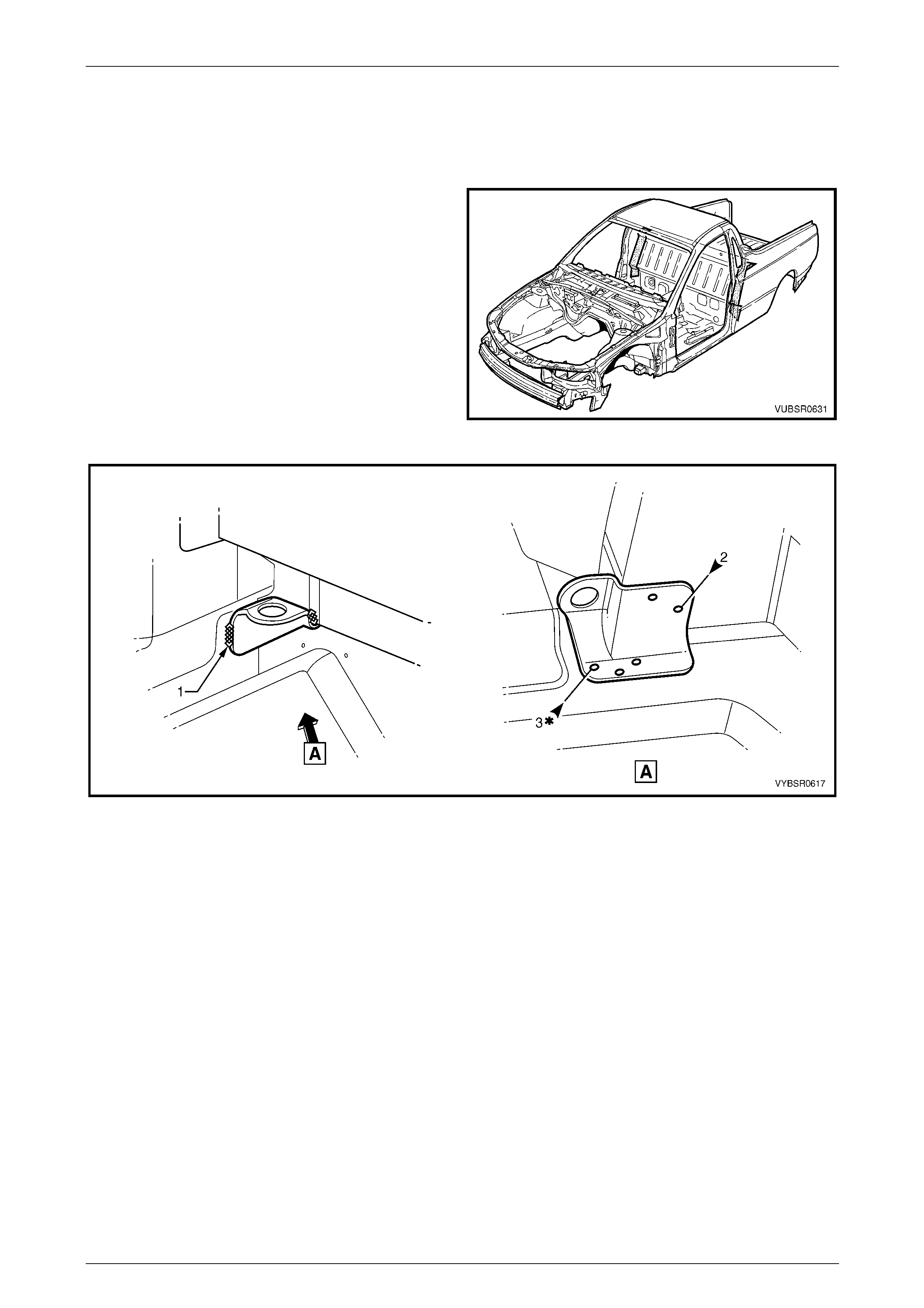

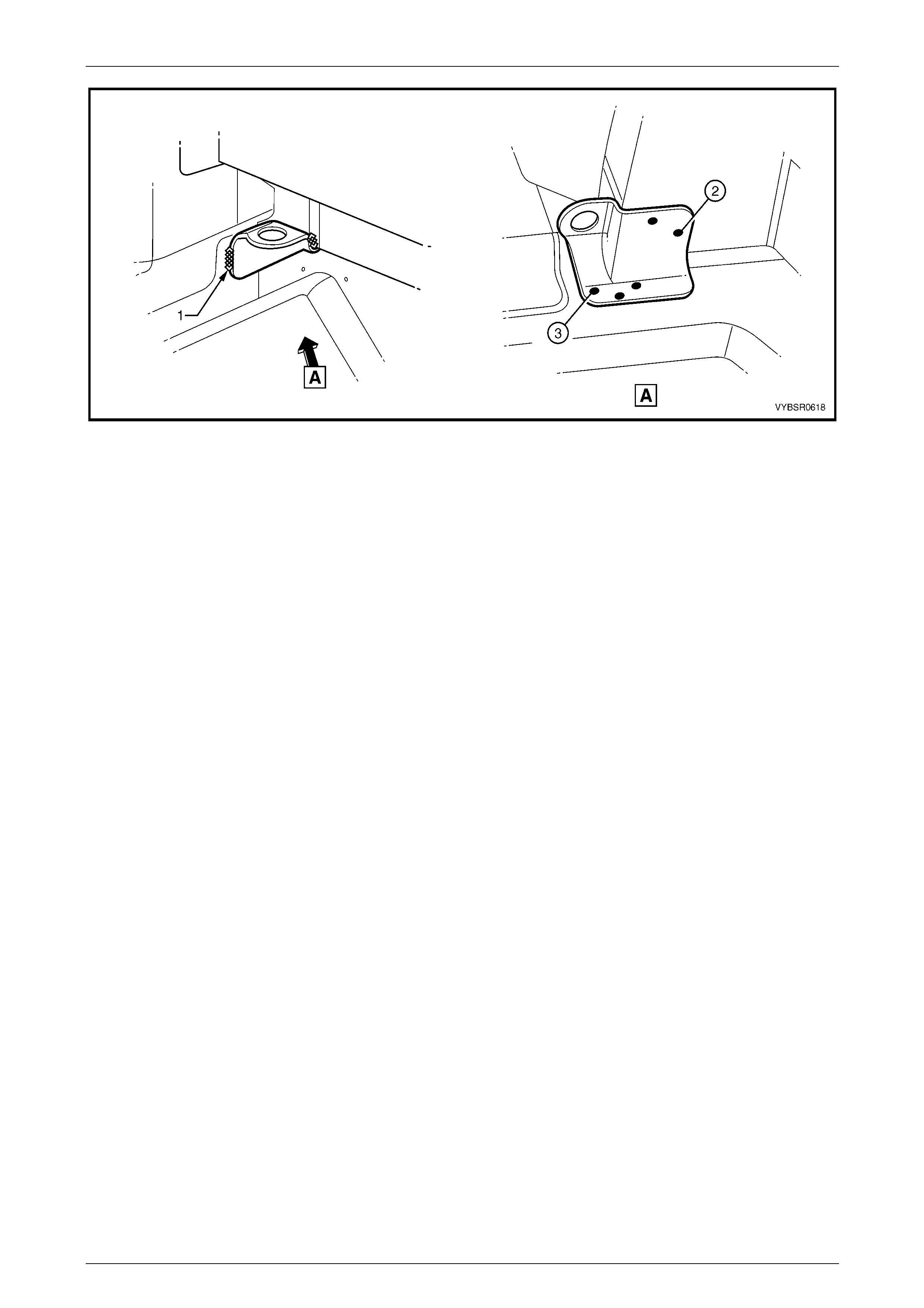

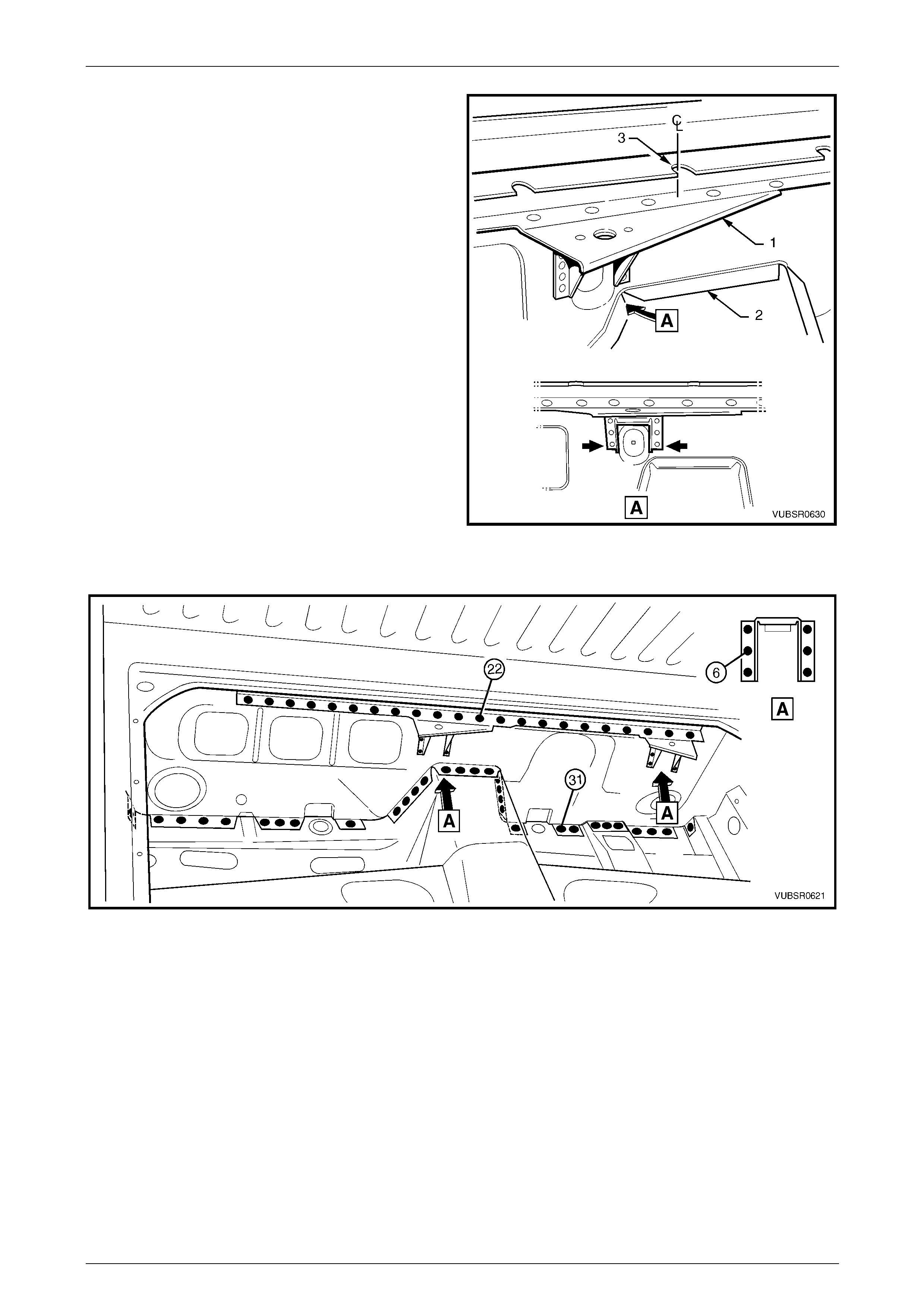

3 Prior to installing the front floor rear extension, fit the left-hand fuel tank bracket (1) on to the front floor rear

extension reinforcement (2) as shown, aligning the fuel tank mounting stud within the reinforcement hole. The

bracket is to be parallel to the fold (3), refer to Figure 6C – 45. Tack weld in position.

4 Repeat for the right-hand fuel tank bracket, noting that it does not sit parallel. Temporarily fit the reinforcement onto

the front floor rear extension to obtain the correct angl e while ensuring the fuel tank mounting stud hole remains

aligned within the reinforcement hole.

Figure 6C – 45

6C Cabin Floor and Seatback Assembly – Utility Page 6C-25

Page 6C-25

5 Fit the reinforcement and fuel tank bracket assembly

(1) on to the front floor rear extension (2). Position the

left-hand fuel tank bracket over the rib in the front floor

rear extension as shown A. Tack weld the

reinforcement in position.

NOTE

Check the notch in the reinforcement (3) is

central on front floor rear extension assembly.

6 Install and clamp the front floor rear extensi on

assembly in position.

NOTE

Test fit the front seatback panel if it is not

installed, to ensure it seats correctly with the

reinforcement. Also test fit the fuel tank to

ensure it aligns with the mounting studs.

7 Spot or plug weld 31 places, the front floor rear

extension to the floor panel, refer to Figure 6C – 47.

8 Spot or plug weld 22 places, the front floor rear

extension reinf orceme nt to the front floor rea r

extension, refer to Figure 6C – 47.

9 Spot or plug weld six places each, the fuel tank

brackets to the front floor rear extension,

refer to Figure 6C – 47.

Figure 6C – 46

Figure 6C – 47

6C Cabin Floor and Seatback Assembly – Utility Page 6C-26

Page 6C-26

10 Spot or plug weld six places each side, the front floor

rear extension to the to the front seatback panel o uter.

11 Spot or plug weld five places each side, the front floor

rear extension to the to inner rocker panel.

Figure 6C – 48

12 Spot or plug weld one place each side, the front floor

rear extension to the to the front seatback panel outer,

refer to View A.

13 MIG weld 25 mm long, the front floor rear extension to

the to the front seatback panel outer, refer to View A.

14 Spot or plug weld the jack stowage bracket to the floor

panel, if it was removed.

15 Install the front seatback panel if removed,

refer to 2.5 Front Seatback Panel – Replace.

16 Replace the adjoining removed panels as required,

refer to the relevant Section in this Supplement.

17 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

18 Apply Joint Sealer (Item 3) as required.

Refer to Section 3C Body Construction – Utility.

19 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint,

refer to Section 3C Body Construction – Utility.

20 Install the remaining components as described in the

MY2005 VZ Service Information.

Figure 6C – 49