7E Body Side – Regular Cab Page 7E–1

Page 7E–1

Section 7E

Body Side – Regular Cab

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 2

Precautions in this Supplement and Section 00 Warnings, Cautions and Notes in the MY2005 VZ Service

Information for correct workshop practices with regard to safety and/or property damage.

The structure of the body shell has been

developed using complex design and

development techniques. In addition to

meeting all required standards, the vehicle

body is also a critical part of the overall safety

systems. It is therefore imperative the repair

procedures described here are adhered to

during all vehicle body repairs.

1 General Information ...............................................................................................................................2

1.1 Body Side Components ........................................................................................................................................ 2

2 Service Operations.................................................................................................................................4

2.1 Rear Quarter Panel Assembly – Replace............................................................................................................. 4

Remove................................................................................................................................................................... 4

Replace................................................................................................................................................................... 5

2.2 Rear Quarter Panel Reinforcement – Replace..................................................................................................... 7

Remove................................................................................................................................................................... 7

Replace................................................................................................................................................................... 8

2.3 Door Opening Frame Assembly – Replace.......................................................................................................... 9

Remove................................................................................................................................................................... 9

Replace................................................................................................................................................................. 13

2.4 Door Opening Frame Assembly – Partial Replace, Hinge Pillar...................................................................... 18

Remove................................................................................................................................................................. 18

Replace................................................................................................................................................................. 21

2.5 Door Opening Frame Assembly – Partial Replace, Centre Pillar..................................................................... 26

Remove................................................................................................................................................................. 26

Replace................................................................................................................................................................. 28

2.6 Quarter Panel Inner Assembly – Replace.......................................................................................................... 32

Remove................................................................................................................................................................. 32

Replace................................................................................................................................................................. 34

7E Body Side – Regular Cab Page 7E–2

Page 7E–2

1 General Information

This Section describes the replacement procedures for the body side com ponents of the Regular Cab body structure.

Removal of bolt-on panels and mecha nica l components is not covered. For information on the removal of these parts,

reference must be made to the appropriate Section in the MY 2005 VZ Service Information.

With the following exceptions, Regular Cab body side information carries ov er from Utility body side,

refer to Section 7C Body Side – Utility.

• Body side components

• Rear quarter panel assembly

• Rear quarter panel reinforce ment

• Door opening frame assembl y

• Quarter panel inner assembly

This Section includes door opening frame assembly partial r eplacement procedures for the hinge p illar, centre pillar and

rocker panel. These procedures must be followed carefully, as they can involve hidden reinforcement panels. The cutting

locations specified are the only places allowable.

NOTE

• When repairing the body side of the vehicle,

care must be taken to ensure the structure is

returned to its original production

configuration. This is especially important to

maintain side impact standards.

• It is imperative the correct body adhesives,

sealers, deadeners and cavity waxes are

used when repairing the body structure.

Refer to Section 3E Body Construction –

Regular Cab.

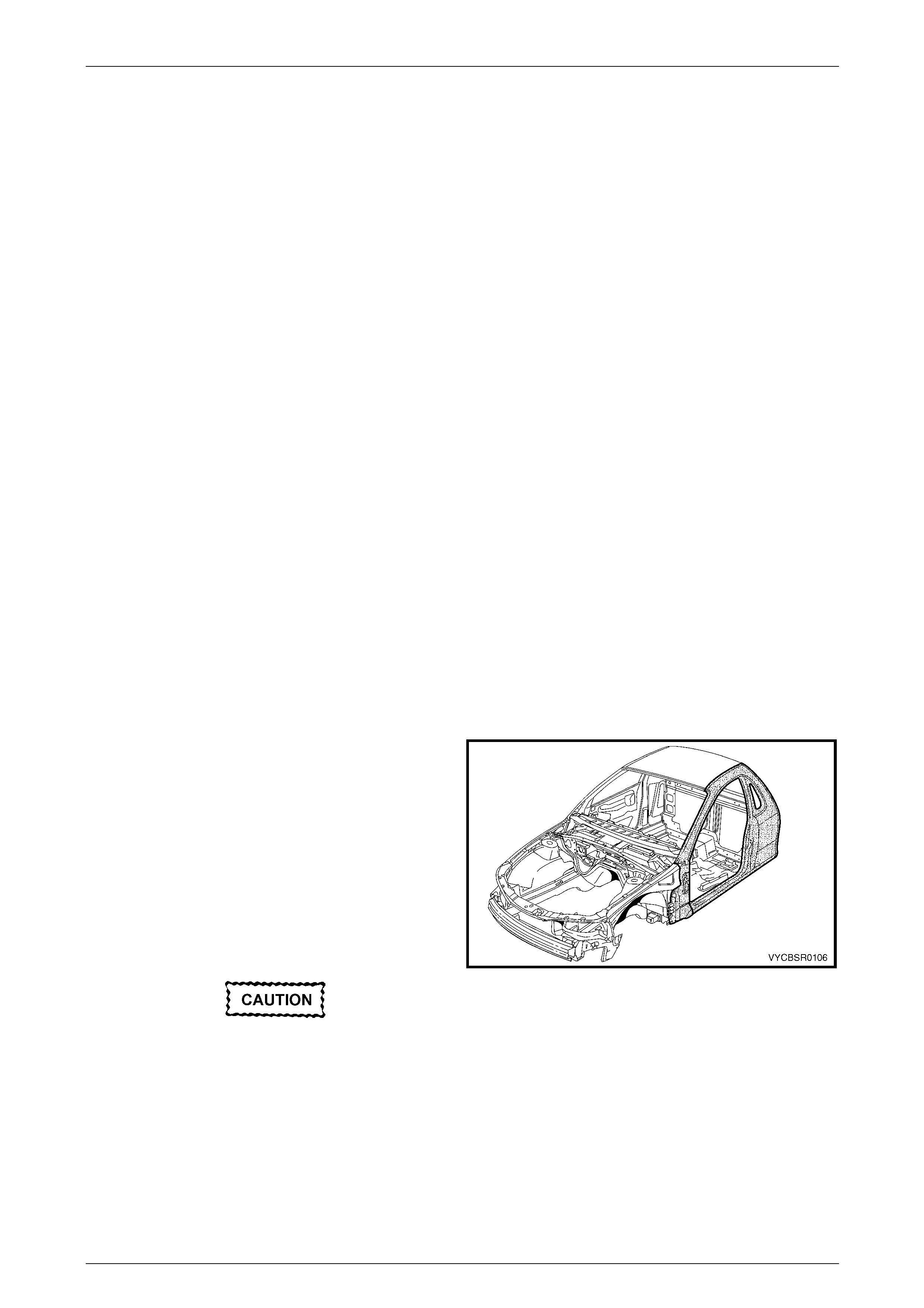

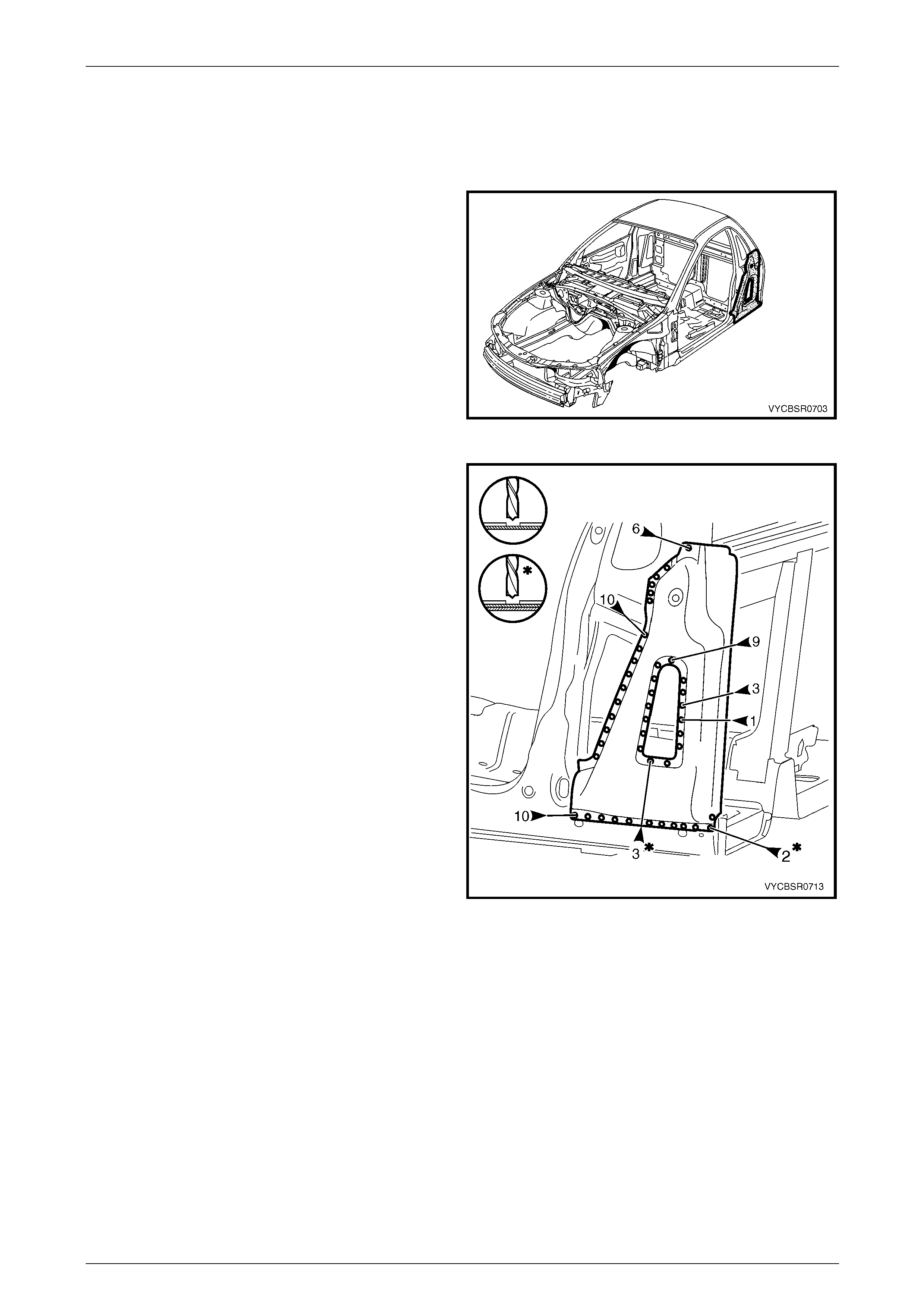

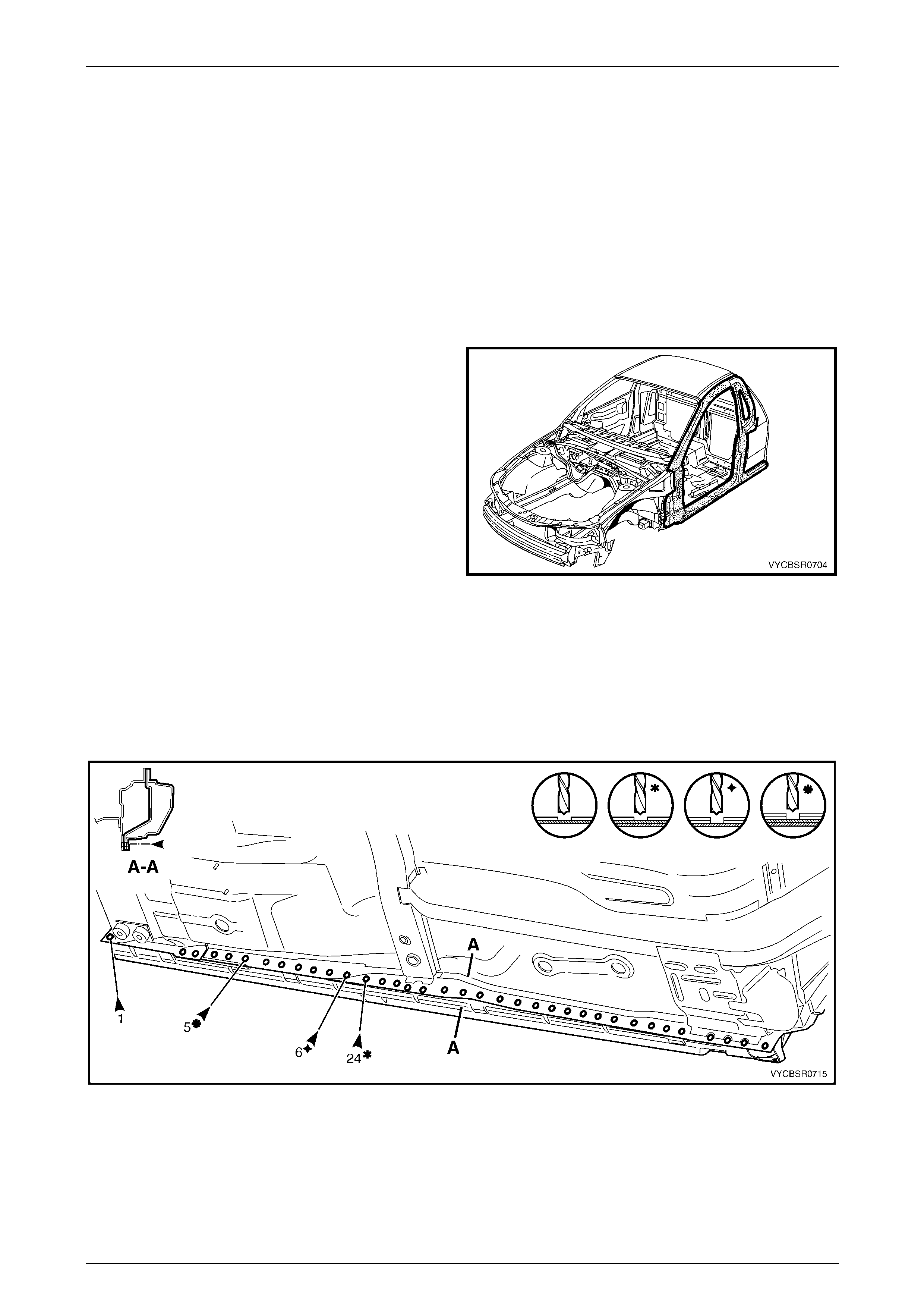

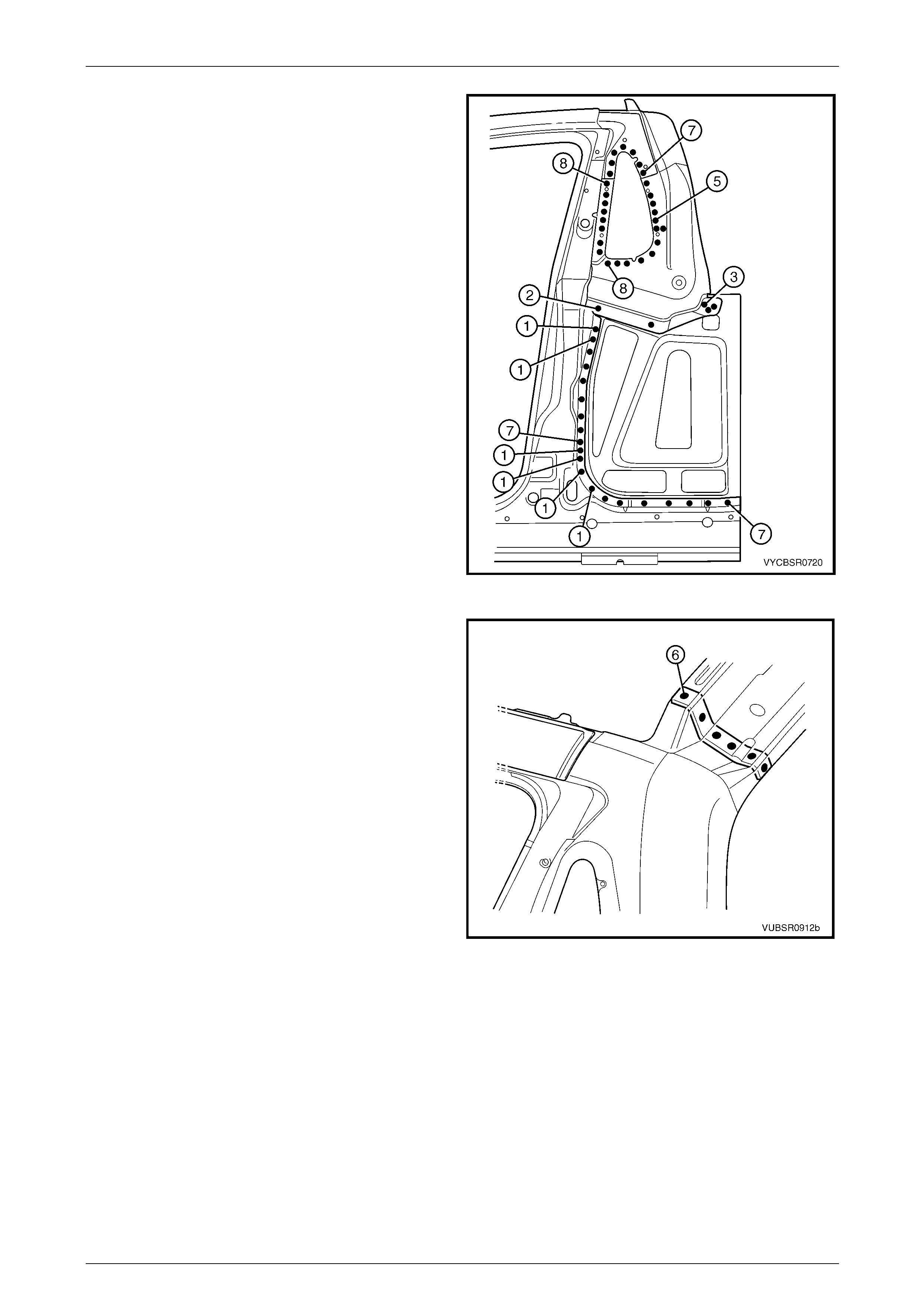

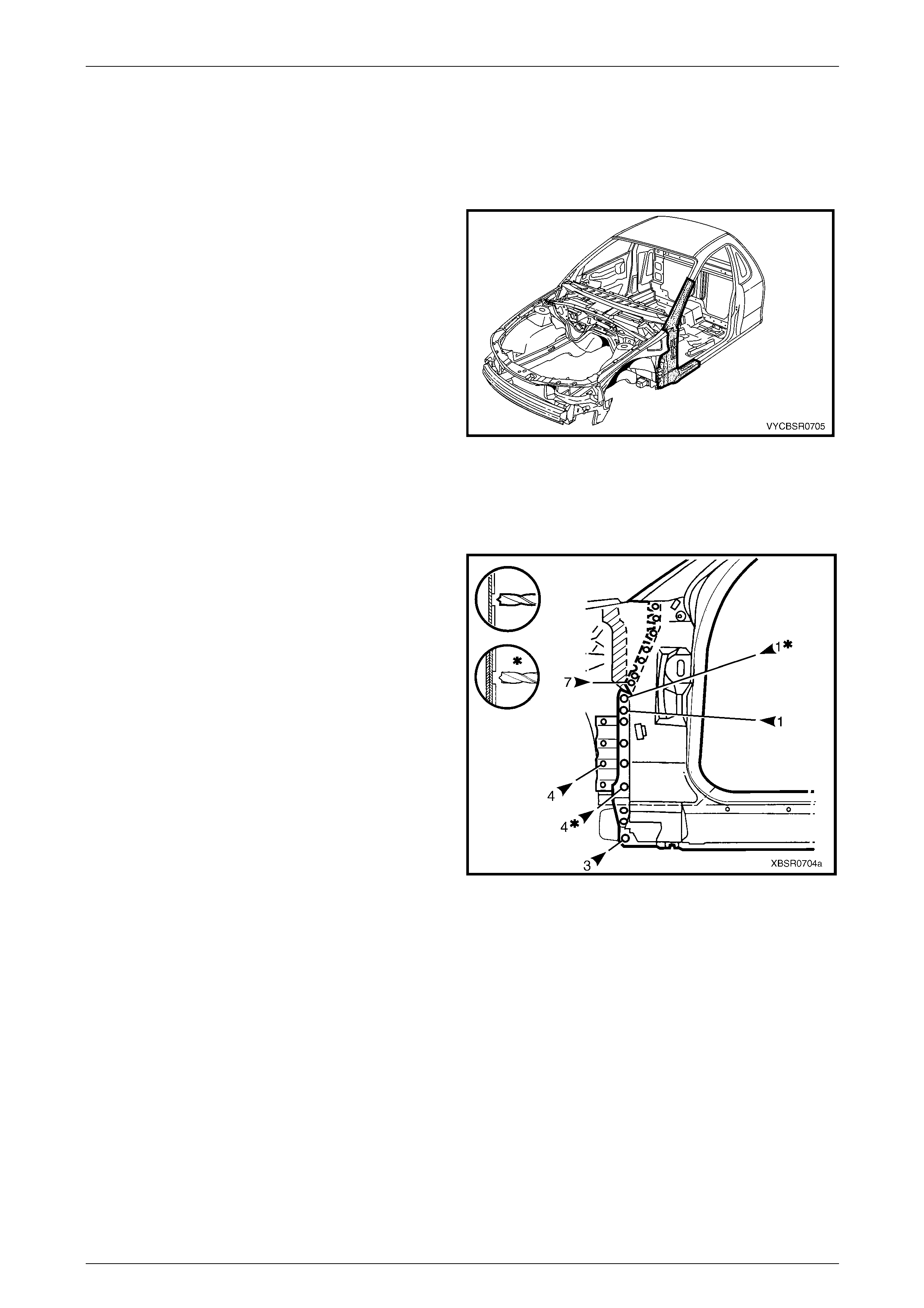

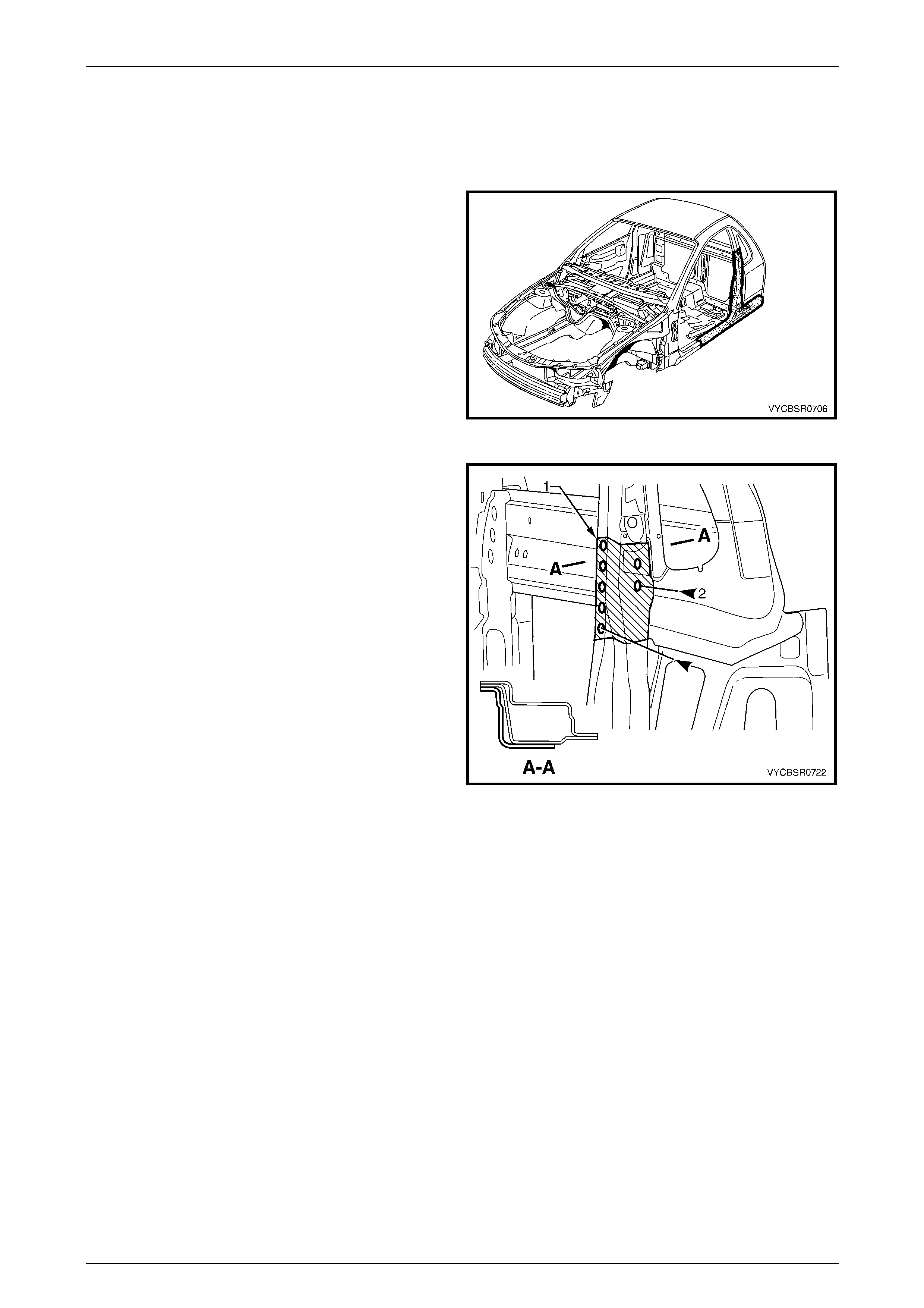

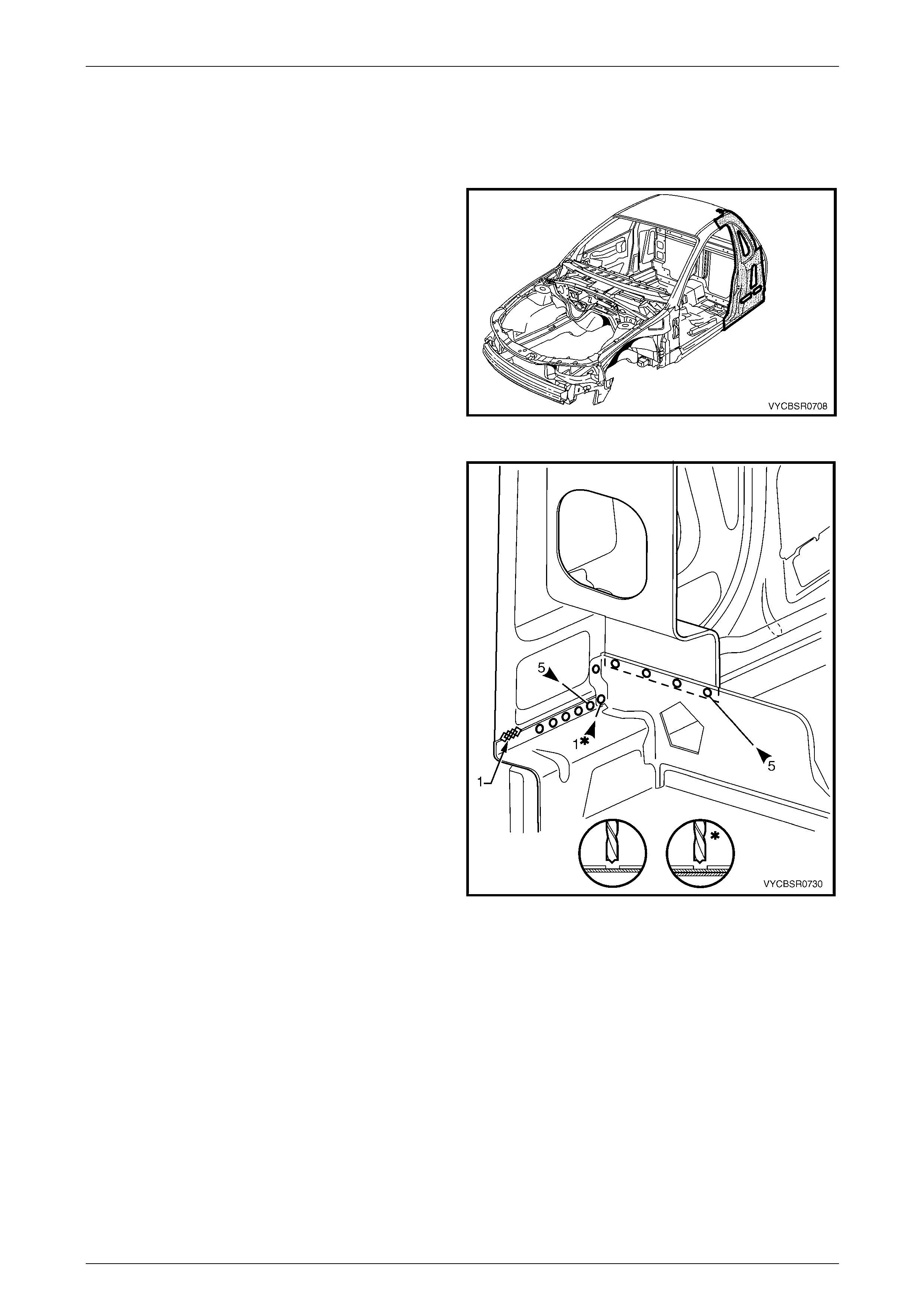

1.1 Body Side Components

The shaded components shown are the body side

components dealt with in this Section.

The components and assemblies shown in

Figure 7E – 2 are the serviceable parts that form the basis

of the repair procedures in this Section.

For a detailed view of the body components,

refer to Section 3E Body Construction – Regular Cab.

NOTE

Always refer to an Authorised Retailer for spare

parts availability configurations.

Cavity foam may be used within the hinge,

centre and lock pillars. Care needs to be

taken when repairing the vehicle in these

areas, refer to Section 2 Precautions prior to

beginning any work for further information

regarding the use of cavity foam.

Figure 7E – 1

7E Body Side – Regular Cab Page 7E–3

Page 7E–3

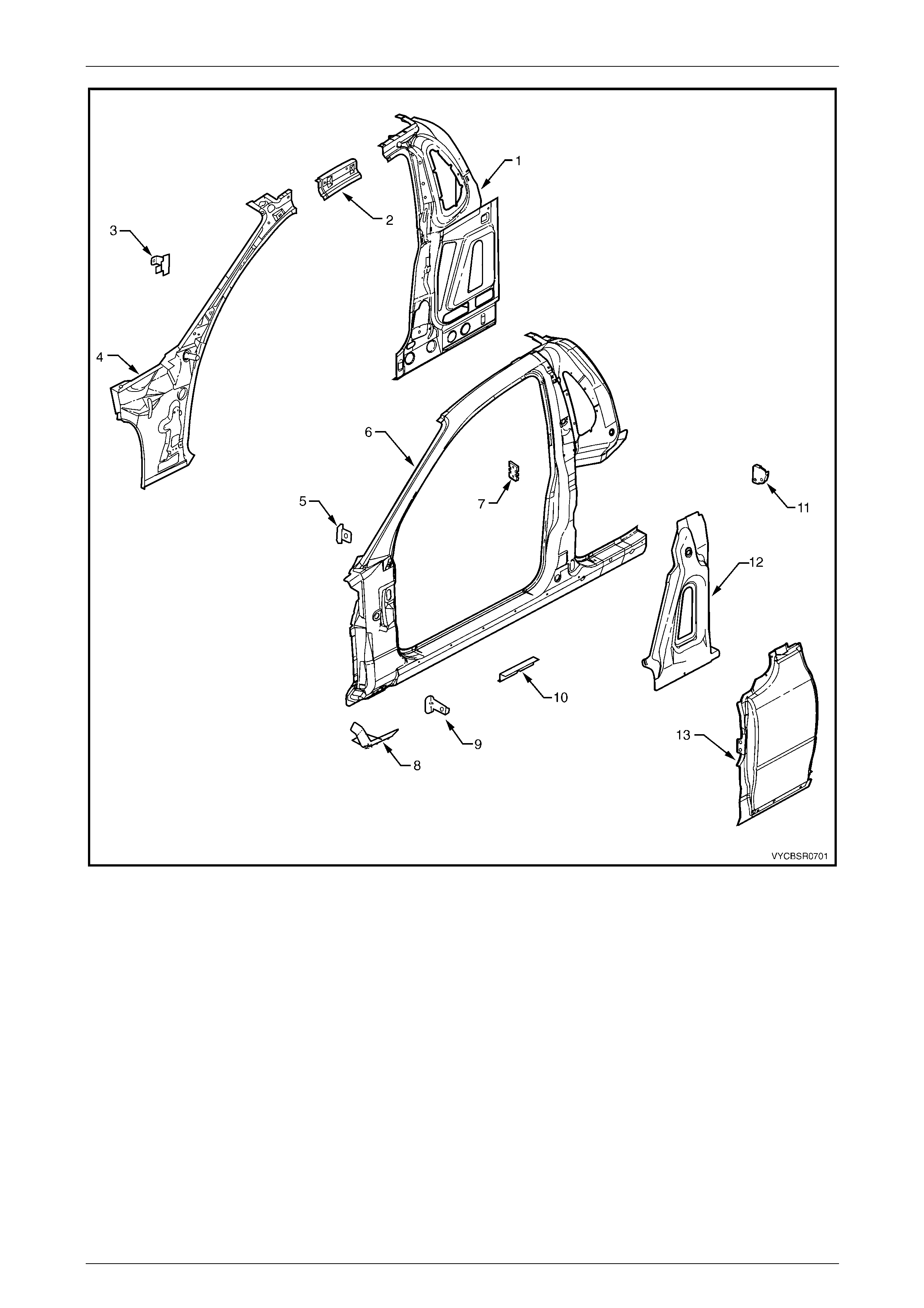

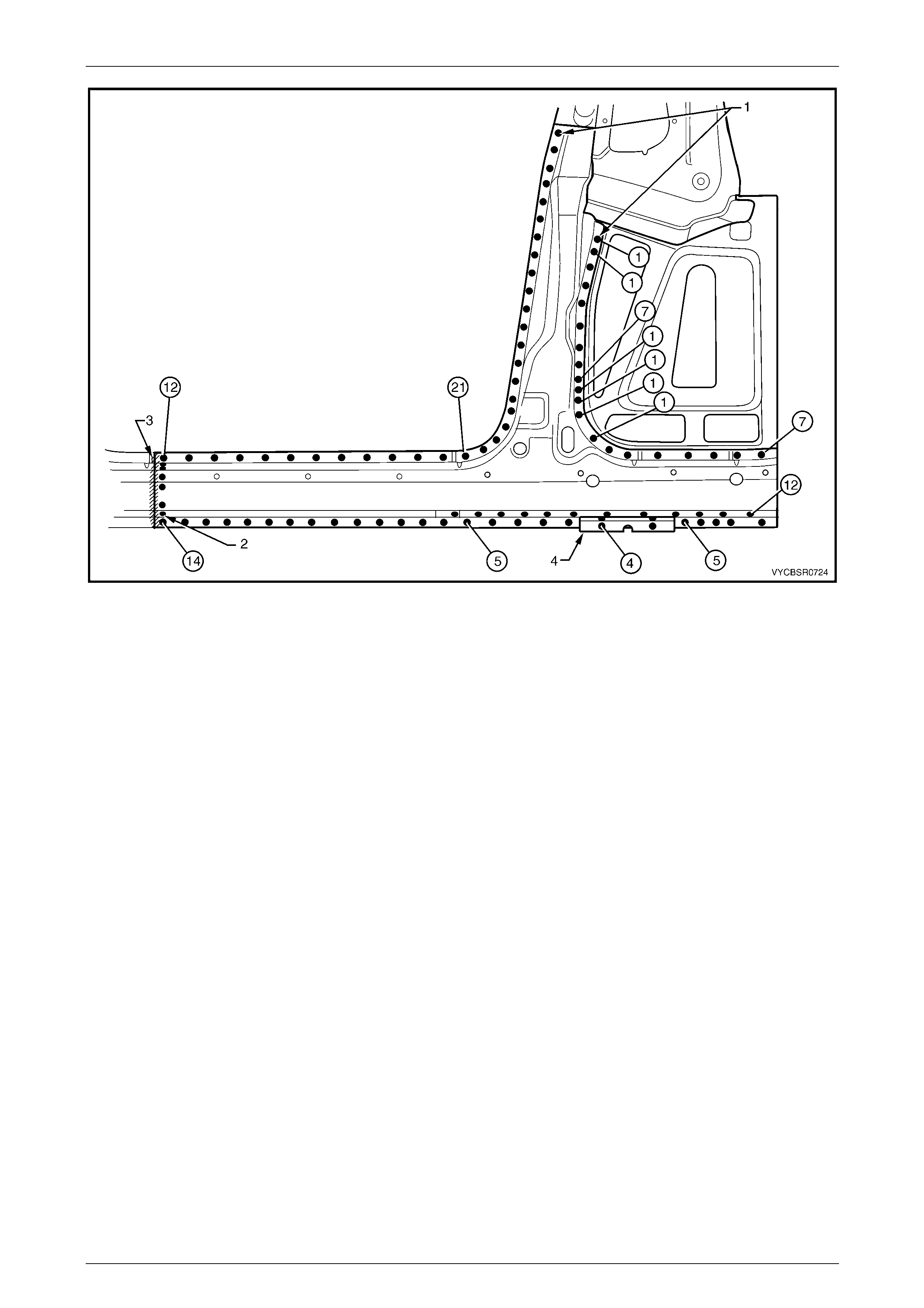

Figure 7E – 2

Legend

1 Quarter Panel Inner Assembly, Left-hand / Right-hand

2 Quarter Panel Inner Extension *, Left-hand / Right-hand

3 Hinge Pillar Trim Panel Bracket *, Left-hand / Right-hand

4 Hinge Pillar Inner Panel Assembly *, Left-hand / Right-hand

5 Fender Upper Rear Bracket, Left-hand / Right-hand

6 Door Opening Frame Assembly, Left-hand / Right-hand

7 Door Striker Anchor Plate, Left-hand / Right-hand

8 Fender Lower Rear Bracket, Left-hand / Right-hand

9 Fender Rear Bracket, Left-hand / Right-hand

10 Underbody Jacking Locator, Left-hand / Right-hand

11 Inner Rocker Panel Filler Left-hand/ Right-hand, Left-hand /

Right-hand

12 Rear Quarter Panel Reinforcement, Left-hand / Right-hand

13 Rear Quarter Panel Assembly, Left-hand / Right-hand

NOTE

• The door opening frame assembly (6)

includes parts 5, 7, 8, 9, 10 and 11.

• * For replacement procedures refer to

Section 7C Body Side – Utility.

7E Body Side – Regular Cab Page 7E–4

Page 7E–4

2 Service Operations

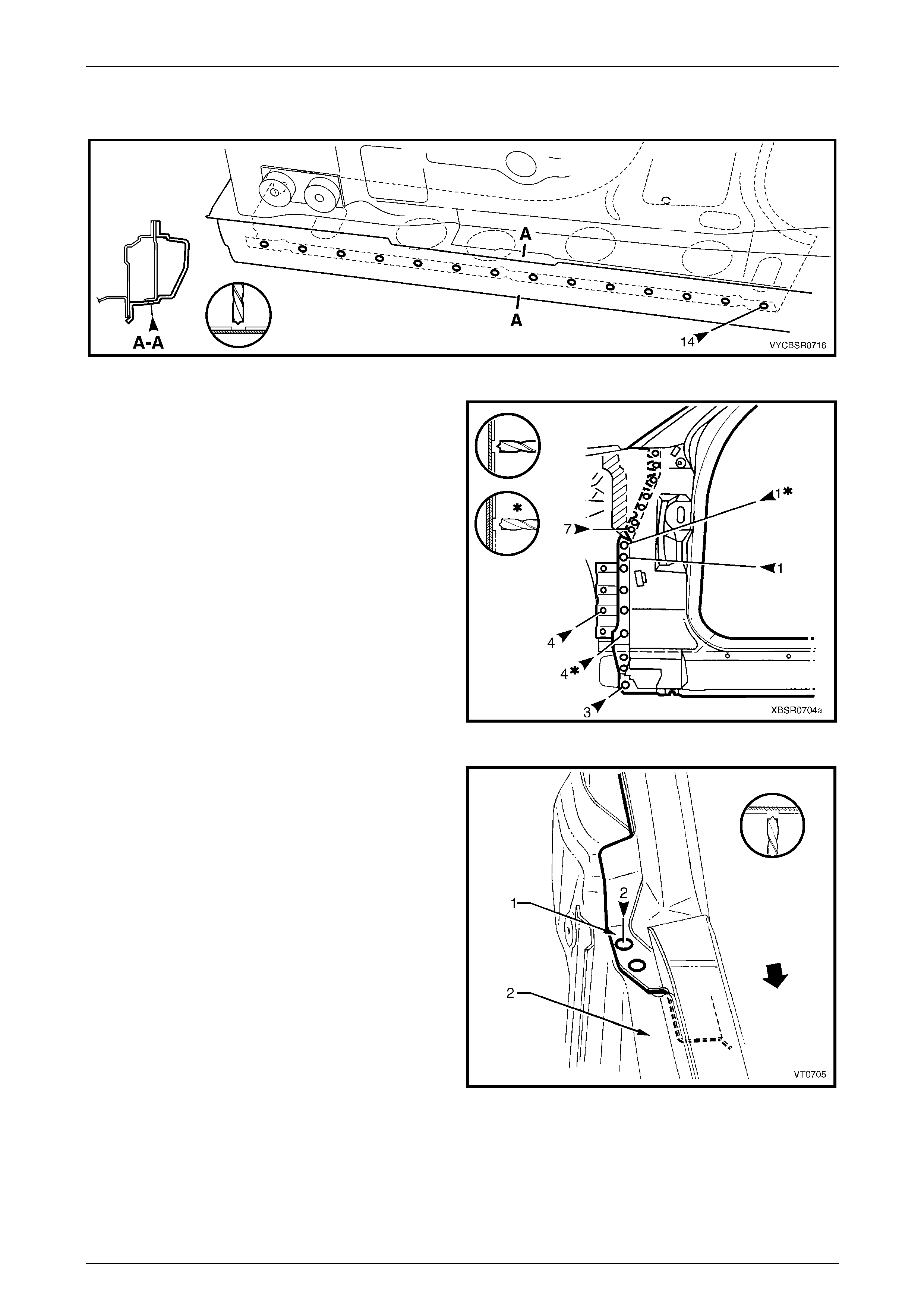

2.1 Rear Quarter Panel Assembly – Replace

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of th e MY

2005 VZ Service Information.

2 Remove the rear and quarter windows, refer to

Section 1A6 Stationary Windows in the MY 2 005 VZ

Service Information.

3 Remove other adjacent pane ls as required, refer to the

relevant Section in this Supplement.

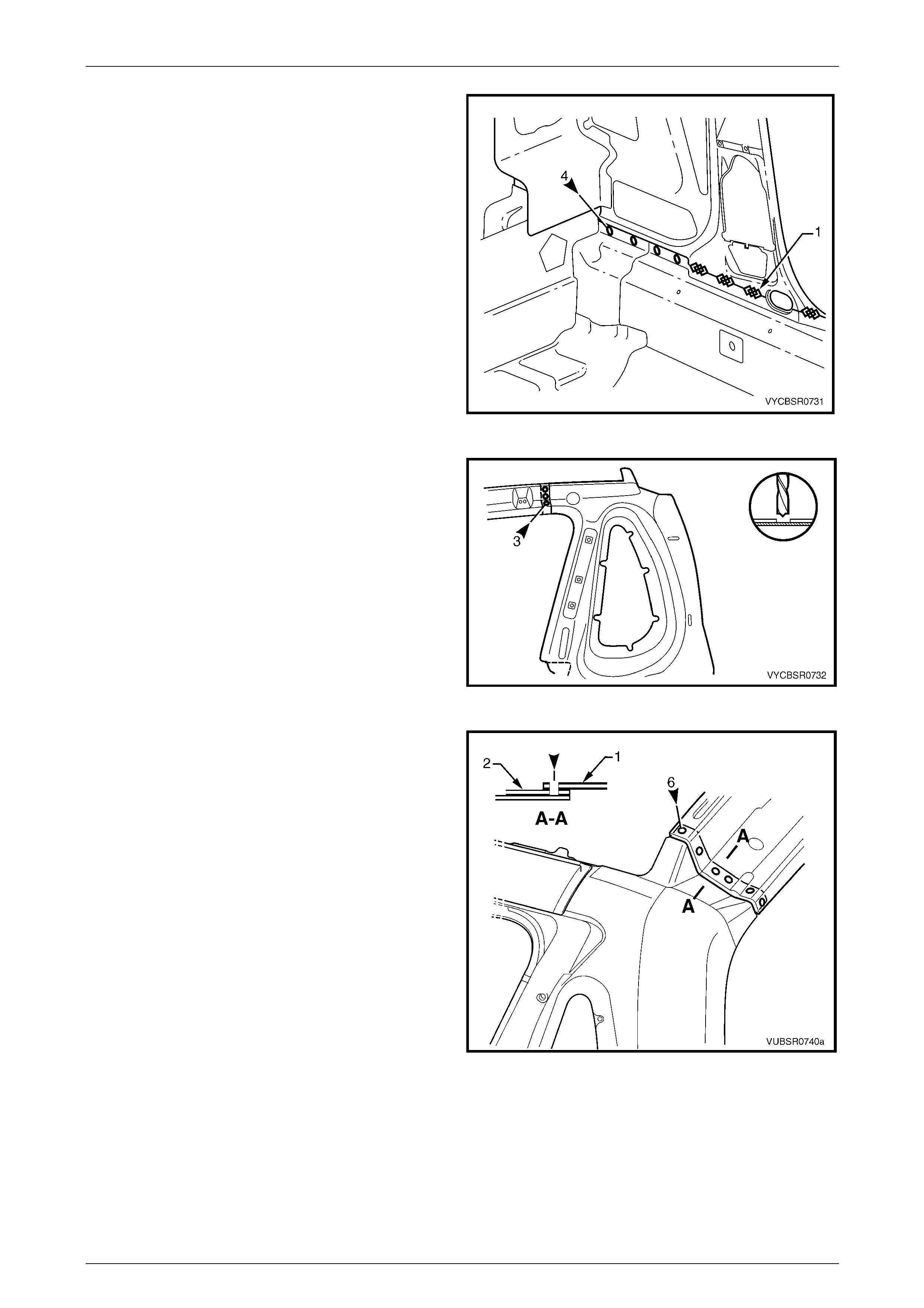

Figure 7E – 3

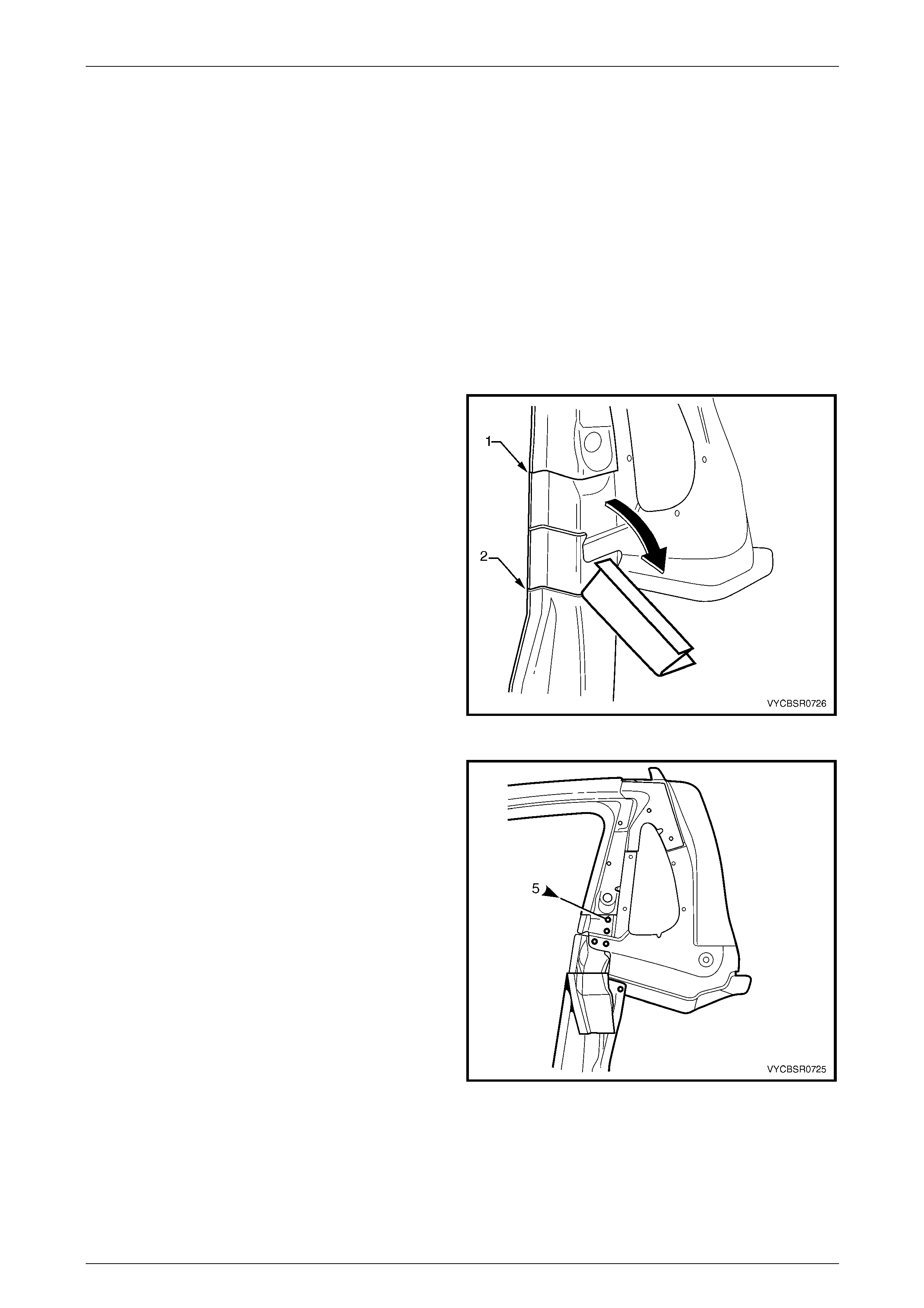

4 Spot cut the welds attaching the rear quarter panel

assembly to the door opening frame.

Figure 7E – 4

7E Body Side – Regular Cab Page 7E–5

Page 7E–5

5 Spot cut the welds attaching the rear quarter panel

assembly to the door opening frame assembly.

6 Remove the rear quarter panel assembl y from the

vehicle and repair any damag e to adjacent parts as

required.

NOTE

Acrylic spot weld sealer is used in many of the

joints which may require prisi ng apart.

7 Check and rectify the alignme nt of

the body as requir ed,

refer to Section 3E Body Construction – Regular Cab.

Figure 7E – 5

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment will not access the required weld

position, a plug weld should be performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2 Prepare all mating surfaces and treat with weld through primer (Item 1) as required,

refer to Section 3E Body Construction – Regular Cab.

3 Apply Acrylic Spot Weld Sealer (Item 2), refer to Section 3E Body Construction – Regular Cab.

4 Clamp the rear quarter panel assemb ly in position.

7E Body Side – Regular Cab Page 7E–6

Page 7E–6

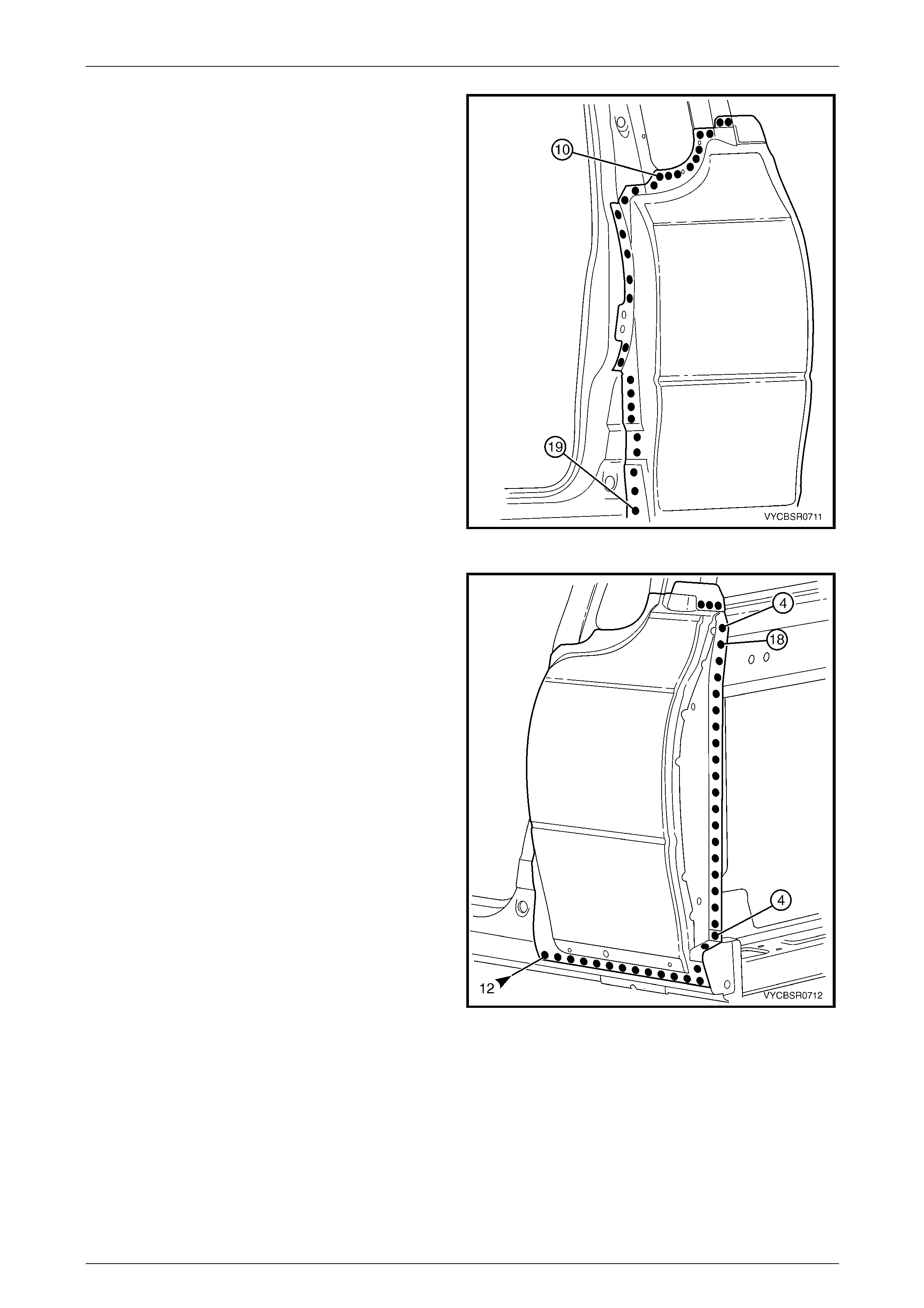

5 Spot or plug weld the rear quarter panel ass embl y to

the door opening frame assembly.

Figure 7E – 6

6 Spot or plug weld the rear quarter panel ass embl y to

the door opening frame assembly.

7 Replace the adjoining removed panels as required,

refer to the relevant Section in this Supplement.

8 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

9 Apply Joint Sealer (Item 3) as required.

Refer to Section 3E Body Construction – Regular Cab.

10 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint,

refer to Section 3E Body Construction – Regular Cab.

11 Replace the rear and quarter wind ows, refer to

Section 1A6 Stationary Windows in the MY 2 005 VZ

Service Information.

12 Install the remaining components as described in the

appropriate Section in the MY 2005 VZ Service

Information.

Figure 7E – 7

7E Body Side – Regular Cab Page 7E–7

Page 7E–7

2.2 Rear Quarter Panel Reinforcement –

Replace

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of th e MY

2005 VZ Service Information.

2 Remove the rear quarter panel,

refer to 2.1 Rear Quarter Panel Assembly – Replace.

3 Remove other adjacent pane ls as required, refer to the

relevant Section in this Supplement.

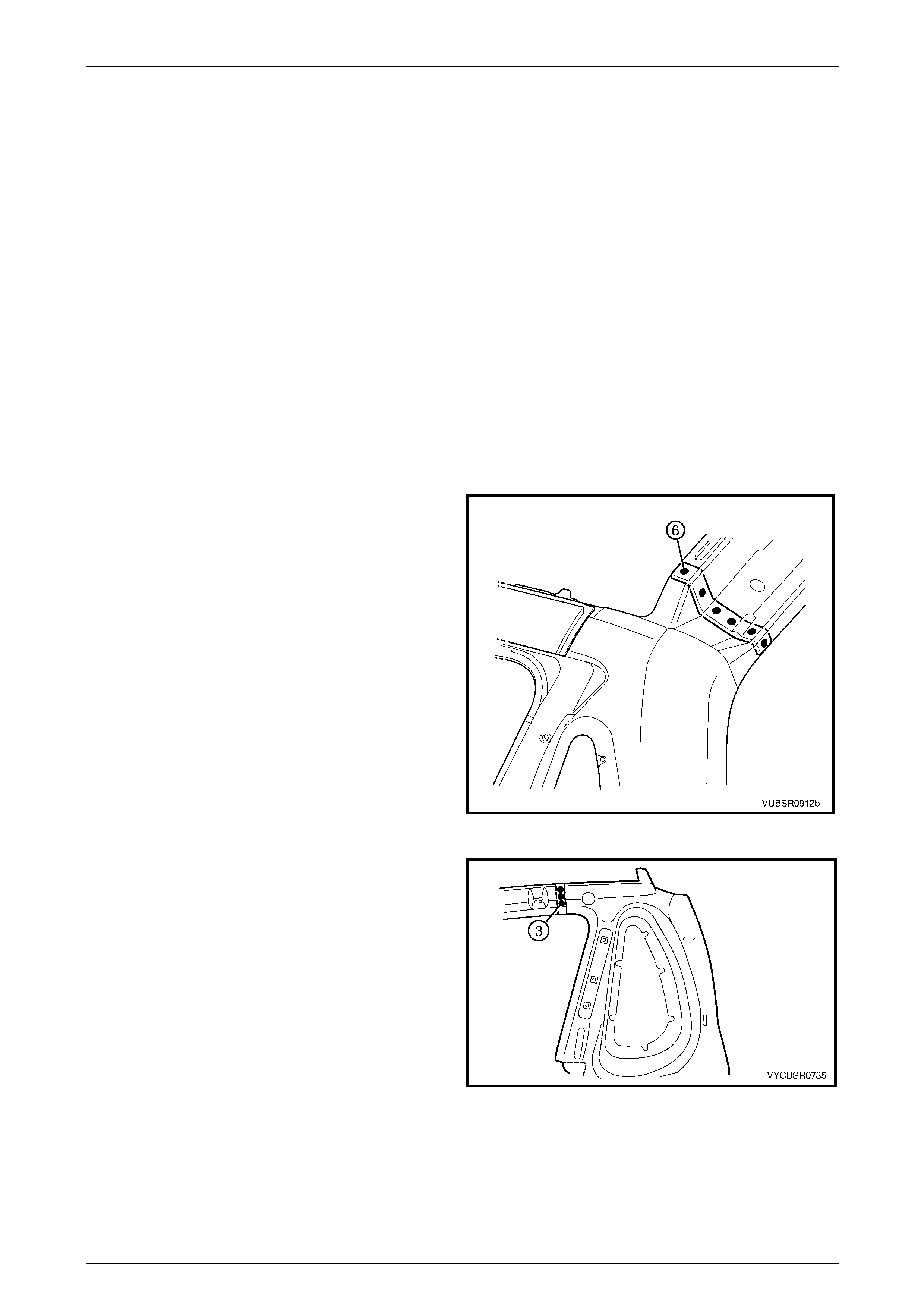

Figure 7E – 8

4 Spot cut the welds attaching the rear quarter panel

reinforcement to the door opening frame ass embl y

and quarter panel inner ass embly.

NOTE

Remove any additional welds not previously

removed with adjacent panels as required.

5 Remove the rear quarter panel reinforcement from the

vehicle and repair any damag e to adjacent parts as

required.

6 Check and rectify the alignme nt of

the body as requir ed,

refer to Section 3E Body Construction – Regular Cab.

Figure 7E – 9

7E Body Side – Regular Cab Page 7E–8

Page 7E–8

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment will not access the required weld

position, a plug weld should be performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations

in preparation for plug welding. Drill holes as required.

2 Prepare all mating surfaces and treat with Weld

Through Primer (Item 1) as required,

refer to Section 3E Body Construction – Regular Cab.

3 Apply Acrylic Spot Weld Sealer (Item 2),

refer to Section 3E Body Construction – Regular Cab.

4 Clamp the panel in position.

5 Spot or plug weld the rear quarter panel reinforcement

to the door opening frame assembly and q ua r ter panel

inner assembly.

6 Replace the adjoining removed panels as required,

refer to the relevant Section in this Supplement.

7 Replace the adjoining removed panels as required,

refer to the relevant Section in this Supplement.

8 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

9 Apply Joint Sealer (Item 3) as required.

Refer to Section 3E Body Construction – Regular Cab.

10 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint,

refer to Section 3E Body Construction – Regular Cab. Figure 7E – 10

11 Install the remaining components as described in the appropriate Section in the MY 2005 VZ Service Information.

7E Body Side – Regular Cab Page 7E–9

Page 7E–9

2.3 Door Opening Frame Assembly –

Replace

NOTE

This procedure requires the removal of the roof

panel. As an alternative, the door opening frame

assembly can be separated at the upper pillar

sections by following the procedures in Door

Opening Frame Assembly – Partial Replace,

Hinge Pillar and Centre Pillar in this Sectio n.

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of th e MY

2005 VZ Service Information.

2 Remove the front door assembly,

refer to Section 8 Doors, Liftgate and Endgat e.

3 Remove the windshield, quarter window and rear

window, refer to Section 1A6 Stationary Windows

Service Information.

4 Remove the dash panel retaining bolt from the hinge

pillar.

5 Remove the roof panel, refer to Section 9C Roof.

6 Remove the rear quarter panel,

refer to 2.1 Rear Quarter Panel Assembly – Replace. Fig ure 7E – 11

7 Remove the rear quarter panel reinforcement, refer to 2.2 Rear Quarter Panel Reinforcement – Replace.

8 Remove the front wheelhouse panel upper side rail, refer to Section 4 Front End.

9 Remove other adjacent pane ls as required, refer to the relevant Section in this Supplement.

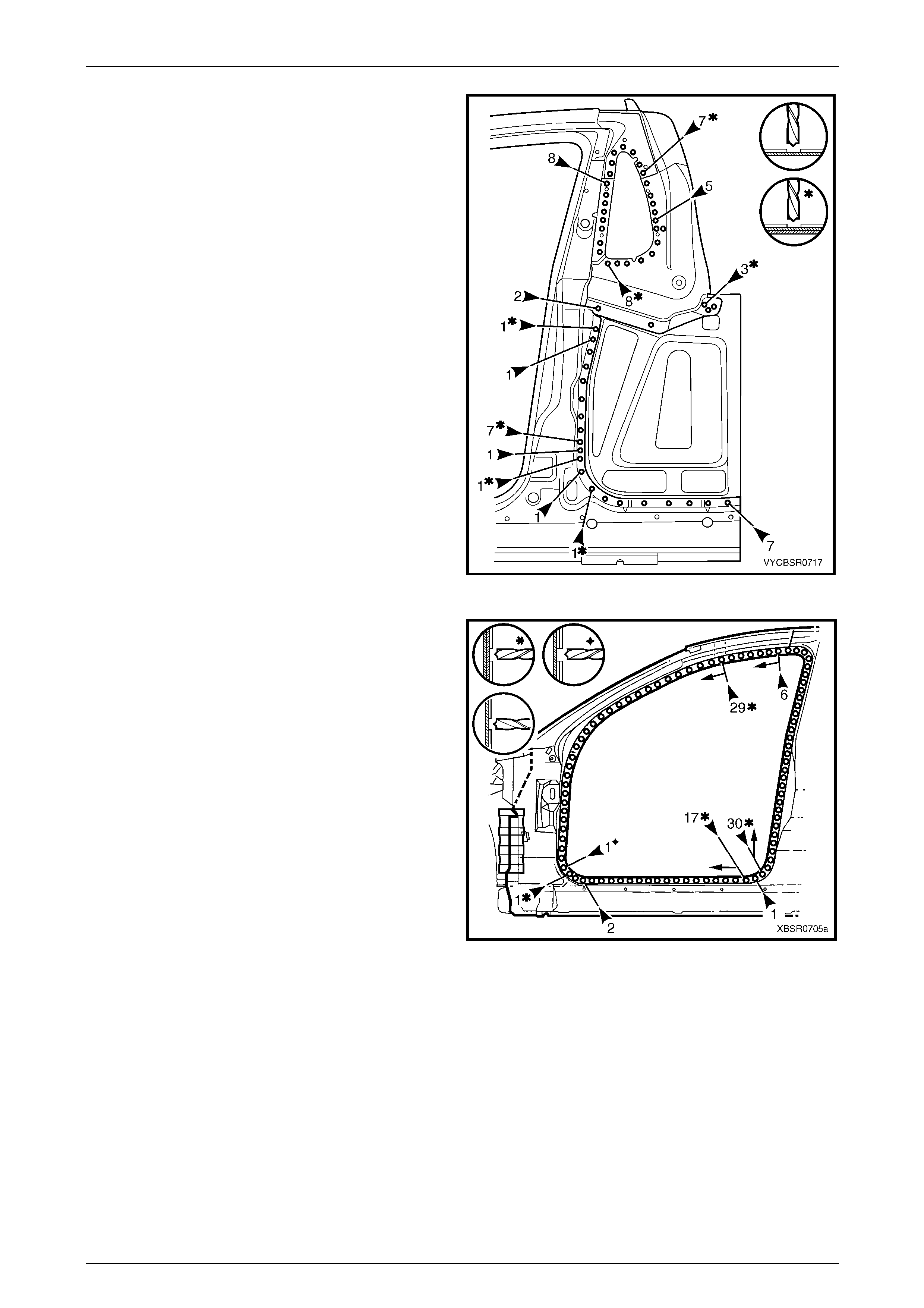

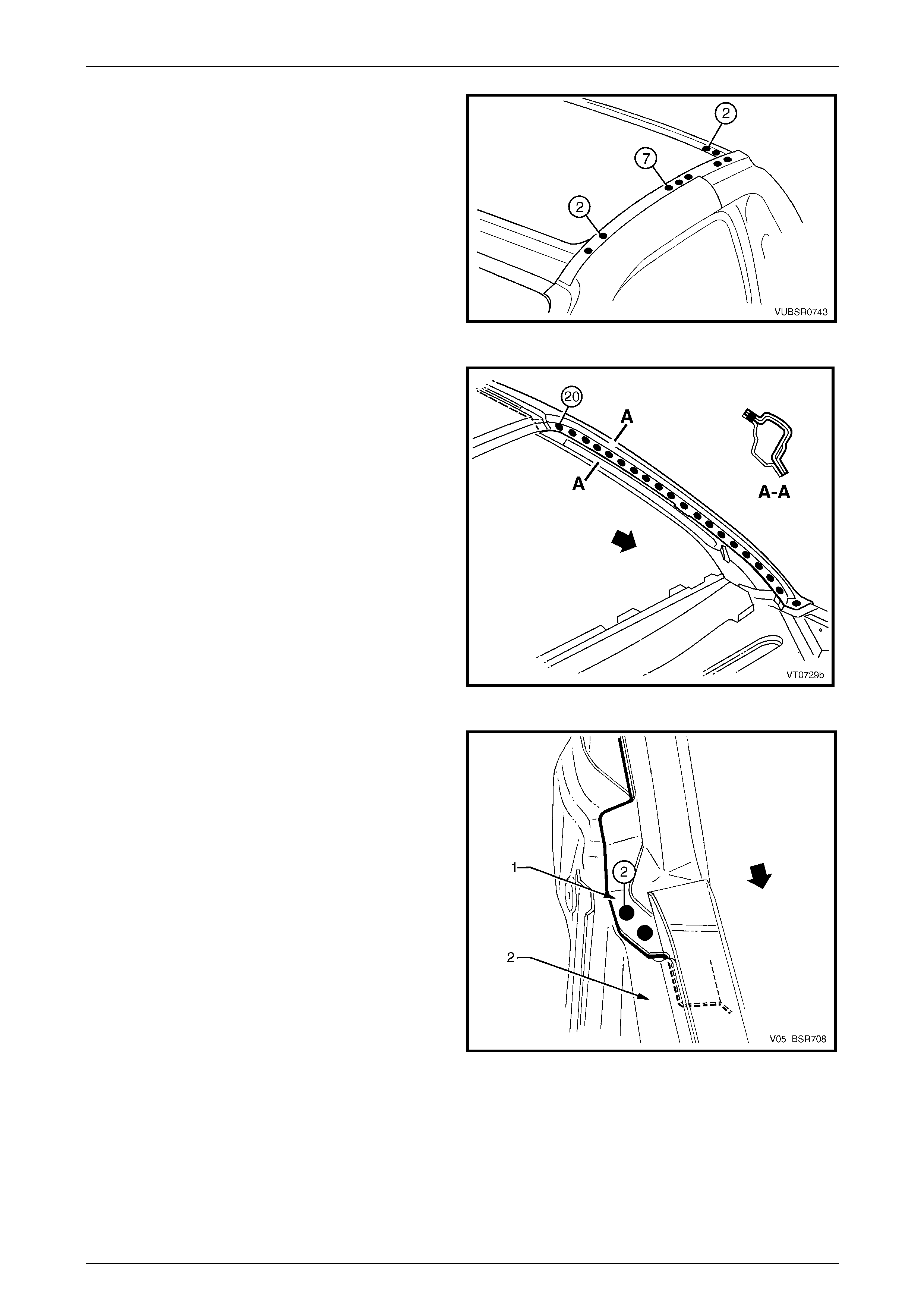

10 Spot cut along the vertical flange below the rocker panel to separate the door opening frame assembly from the

inner rocker panel, refer to Figure 7E – 12.

Figure 7E – 12

7E Body Side – Regular Cab Page 7E–10

Page 7E–10

11 Spot cut from below, up into the rocker panel, the welds attaching the door opening frame assembly to the quarter

panel inner assembly, refer to Figure 7E – 13.

Figure 7E – 13

12 Spot cut the welds attaching the door openin g frame

assembly to the inner rocker panel and to the hin ge

pillar inner panel assembly.

NOTE

In order to spot cut the uppermost of these welds

it may be necessary to cut and peel back the

section of hinge reinforcement panel covering

the welds, to gain the required access.

Figure 7E – 14

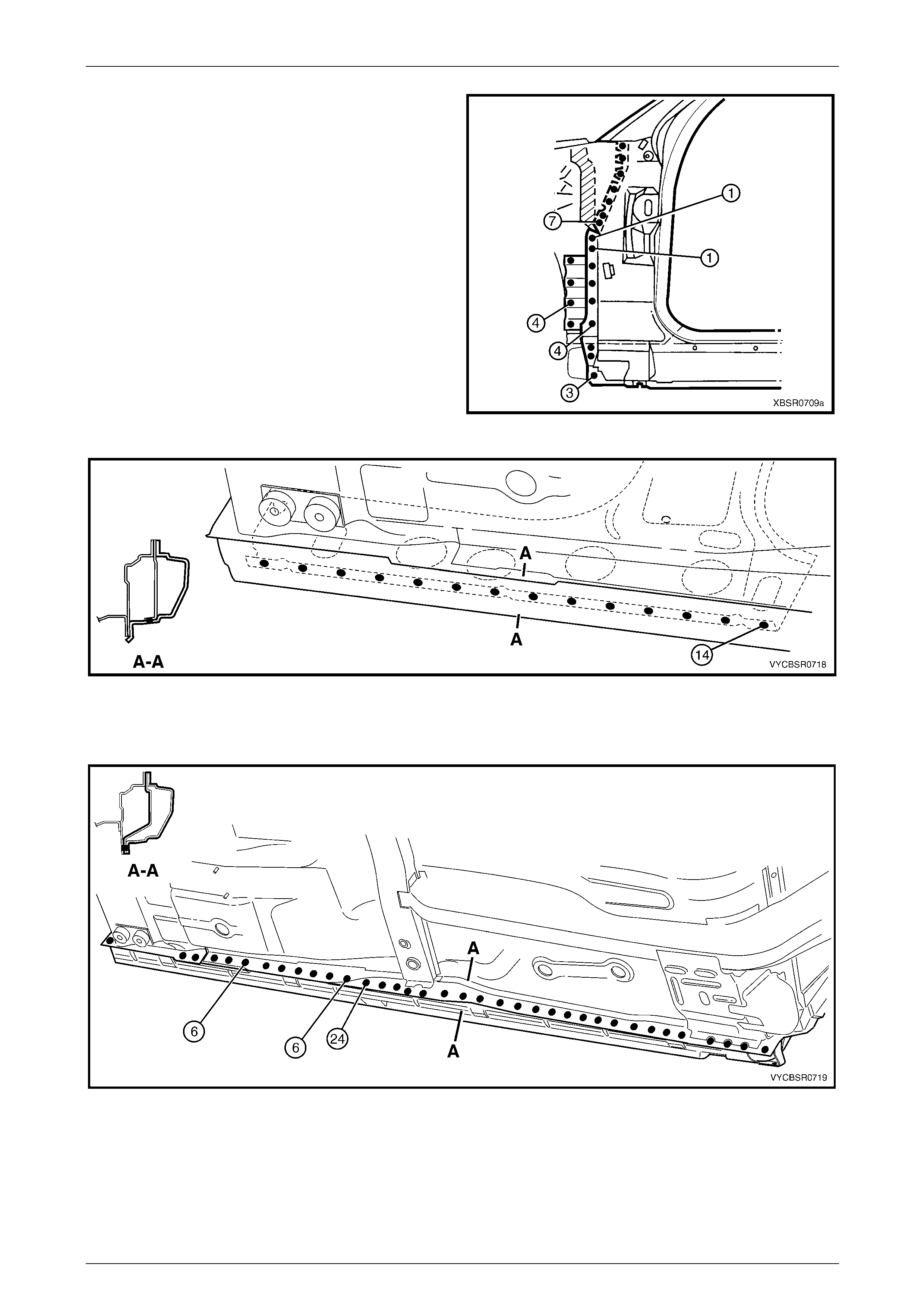

13 Spot cut the two welds at the base of the hinge pillar,

attaching the door opening frame assembly (1) to the

hinge pillar inner panel assembly (2).

Figure 7E – 15

7E Body Side – Regular Cab Page 7E–11

Page 7E–11

14 Spot cut the welds on the windshield side flange,

attaching the door opening frame assembly (1) to the

hinge pillar inner panel assembly (2).

Figure 7E – 16

15 As required, spot cut the welds along the roof flange.

NOTE

Many of these welds may have been removed

with the roof panel.

Figure 7E – 17

16 Spot cut the welds attaching the door openin g frame

assembly to the roof rear panel.

Figure 7E – 18

7E Body Side – Regular Cab Page 7E–12

Page 7E–12

17 Spot cut the welds attaching the door openin g frame

assembly to the side inner upper front panel, side

inner upper panel and quarter panel inner assembl y.

Figure 7E – 19

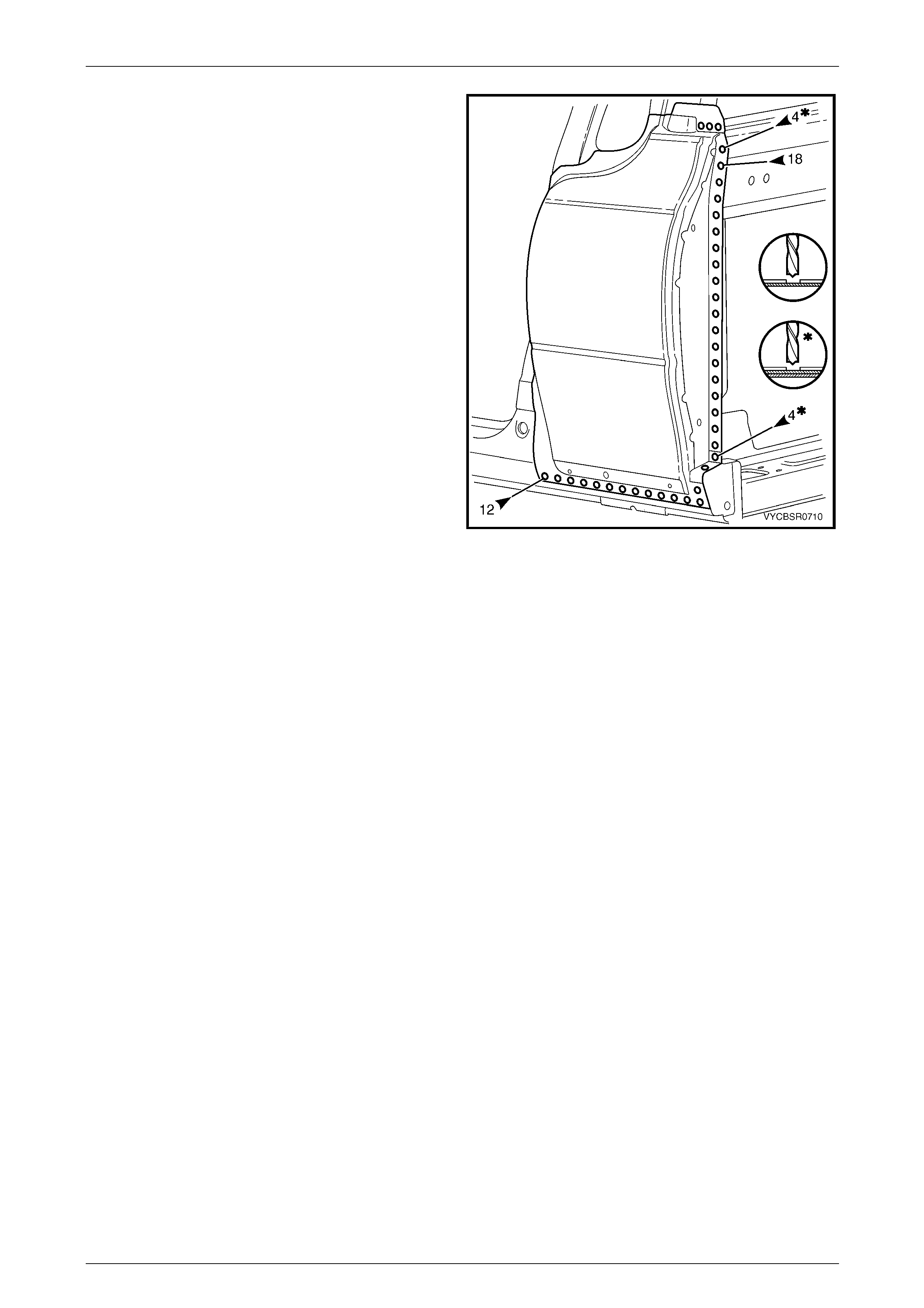

18 Spot cut the welds on the flange surrounding the front

door opening, attaching the door op ening frame

assembly to the hinge pillar inner assembly, inner

rocker panel and quarter panel in ner assembly.

19 Remove the door opening fram e assembly and repair

any damage to adjacent parts as required.

20 Check and rectify the alignme nt

of the body as required,

refer to Section 3E Body Construction – Regular Cab.

Figure 7E – 20

7E Body Side – Regular Cab Page 7E–13

Page 7E–13

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment will not access the required weld

position, a plug weld should be performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as requir ed,

refer to Section 3E Body Construction – Regular Cab.

3 Apply Acrylic Spot Weld Sealer (Item 2), refer to Section 3E Body Construction – Regular Cab.

4 Securely clamp the door openin g frame assembly in position on the vehicle body.

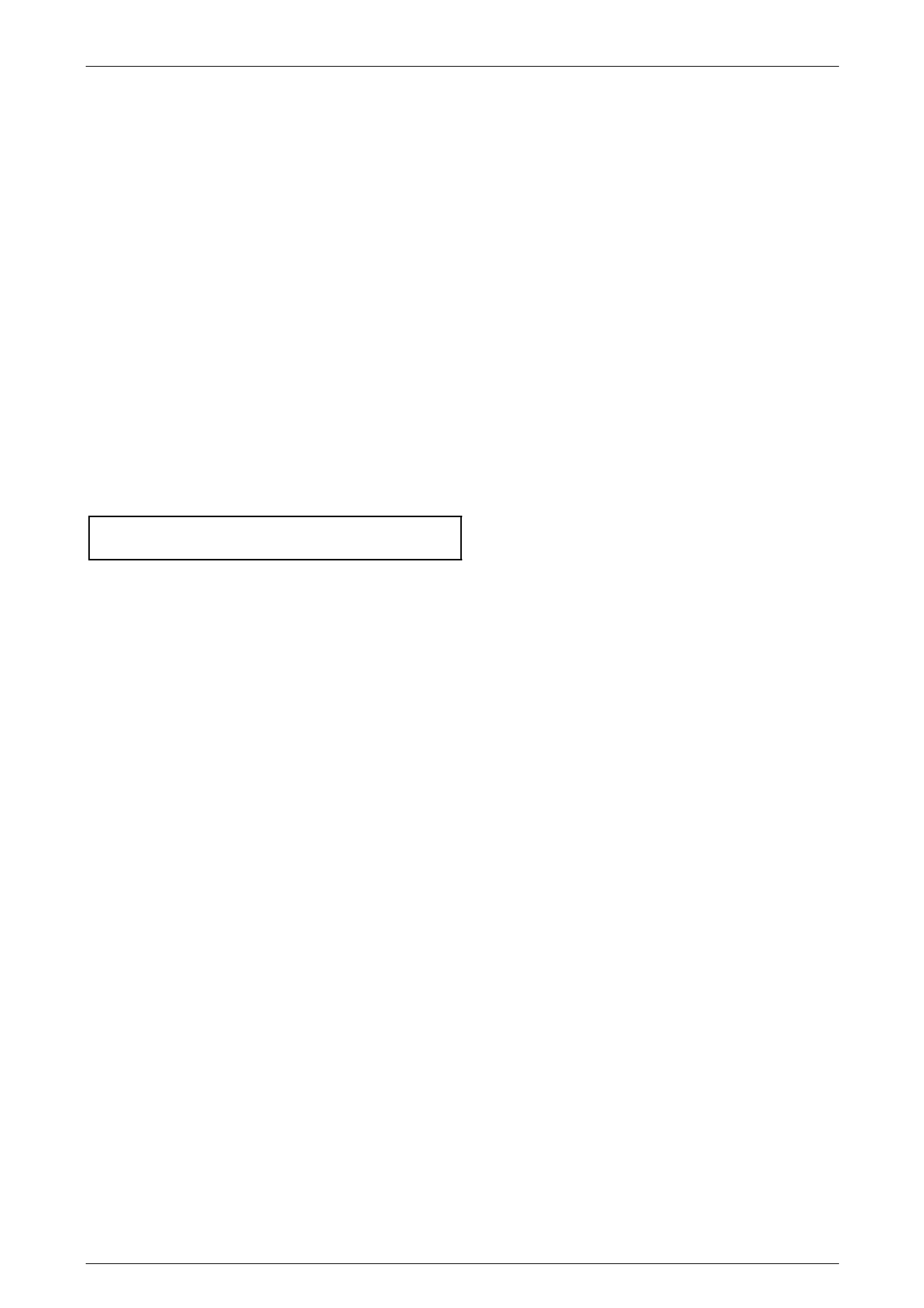

5 Spot or plug weld around the front door opening

flange.

Figure 7E – 21

7E Body Side – Regular Cab Page 7E–14

Page 7E–14

6 Spot or plug weld the door opening frame assembly to

the side inner upper front panel, side inner u pper

panel and quarter pane l inner assembly.

Figure 7E – 22

7 Spot weld the door opening frame assembly to the

roof rear panel.

Figure 7E – 23

7E Body Side – Regular Cab Page 7E–15

Page 7E–15

8 Spot or plug weld the door opening frame assembly

along the roof flange.

NOTE

The remaining welds are made when the roof

panel is installed.

Figure 7E – 24

9 Spot weld along the windshield flange, attaching the

door opening frame assembly to the hinge pillar inner

panel assembly.

Figure 7E – 25

10 Spot weld in two places at the base of the hinge pillar,

attaching the door opening frame assembly (1) to the

hinge pillar inner panel assembly (2).

Figure 7E – 26

7E Body Side – Regular Cab Page 7E–16

Page 7E–16

11 Spot or plug weld the door opening frame assembly to

the inner rocker panel and to the hinge pillar inner

panel assembly.

NOTE

If the sheet metal was modified to allow access

to these welds, it should be repaired to its

original configuration.

12 Plug weld up through the rocker panel to attach the

door opening frame assembly to the quarter p anel

inner assembly, refer to Figure 7E – 28.

Figure 7E – 27

Figure 7E – 28

13 Spot weld the door opening frame assembly along the vertical flange below the rocker panel,

refer to Figure 7E – 29

Figure 7E – 29

7E Body Side – Regular Cab Page 7E–17

Page 7E–17

14 Replace the front wheelhouse panel upper side rail, refer to Section 4 Front End.

15 Replace the roof panel, refer to Section 9C R oof.

16 Replace the rear quarter panel reinforceme nt, refer to 2.2 Rear Quarter Panel Reinforcement – Replace.

17 Replace the rear quarter panel, refer to 2.1 Rear Quarter Pane l Assembly – Replace.

NOTE

Refinish and prime any bare metal as required

prior to replacing these panel s.

18 Install the door hinges, refer to Section 8 Do ors, Liftgate and Endgate.

19 Replace other adjoining removed pa nels as required, refer to the relevant Section in this Supp lement.

20 Refinish and paint panels and other components as required. Refer to Section 3 Body Construction.

21 Apply Joint Sealer (Item 3) as required. Refer to Section 3E Body Construction – Regular Cab.

22 Apply Cavity Wax (Item 8) as required to the inside of any box secti ons or areas inaccessible to paint,

refer to Section 3E Body Construction – Regular Cab.

23 Apply Spray-on Dea dener (Item 7) where applicab le, refer to Section 3E Body Construc tion – Regular Cab.

24 Install the dash panel retaining bolt throu gh the hinge pil lar and tighten to the specified torque.

Dash panel retaining b olt

torque specification.........................................35.0 – 45.0 Nm

25 Replace the windshield, quarter glass and rear window, refer to Section 1A6 Stationary Glass in the MY 2005 VZ

Service Information.

26 Insert Cavity Foam into the hinge and centre pillars as required, refer to Section 2 Precautions.

27 Install the remaining components as described in the appropriate Section in the MY 2005 VZ Service Information.

7E Body Side – Regular Cab Page 7E–18

Page 7E–18

2.4 Door Opening Frame Assembly – Partial

Replace, Hinge Pillar

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of th e MY

2005 VZ Service Information.

2 Remove the front door assembly,

refer Section 8 Doors, Liftgate and Endgate.

3 Remove the windshield, refer to

Section 1A6 Stationary Windows in the MY 2 005 VZ

Service Information.

4 Remove the dash panel retaining bolt from the hinge

pillar.

5 Remove the front wheelhouse pan el upper side rail,

refer to Section 4 Front End.

6 Remove other adjacent pane ls as required, refer to the

relevant Section in this Supplement.

7 Secure an appropriate tool between the front door

opening flanges to maintain correct bod y alignment.

Figure 7E – 30

8 Spot cut the welds attaching the door openin g frame

assembly to the inner rocker panel and to the hin ge

pillar inner panel assembly.

NOTE

In order to spot cut the uppermost of these welds

it may be necessary to cut and peel back the

section of hinge reinforcement panel covering

the welds, to gain the required access.

Figure 7E – 31

7E Body Side – Regular Cab Page 7E–19

Page 7E–19

9 Spot cut the two welds at the base of the hinge pillar,

attaching the door opening frame assembly (1) to the

hinge pillar inner panel assembly (2).

Figure 7E – 32

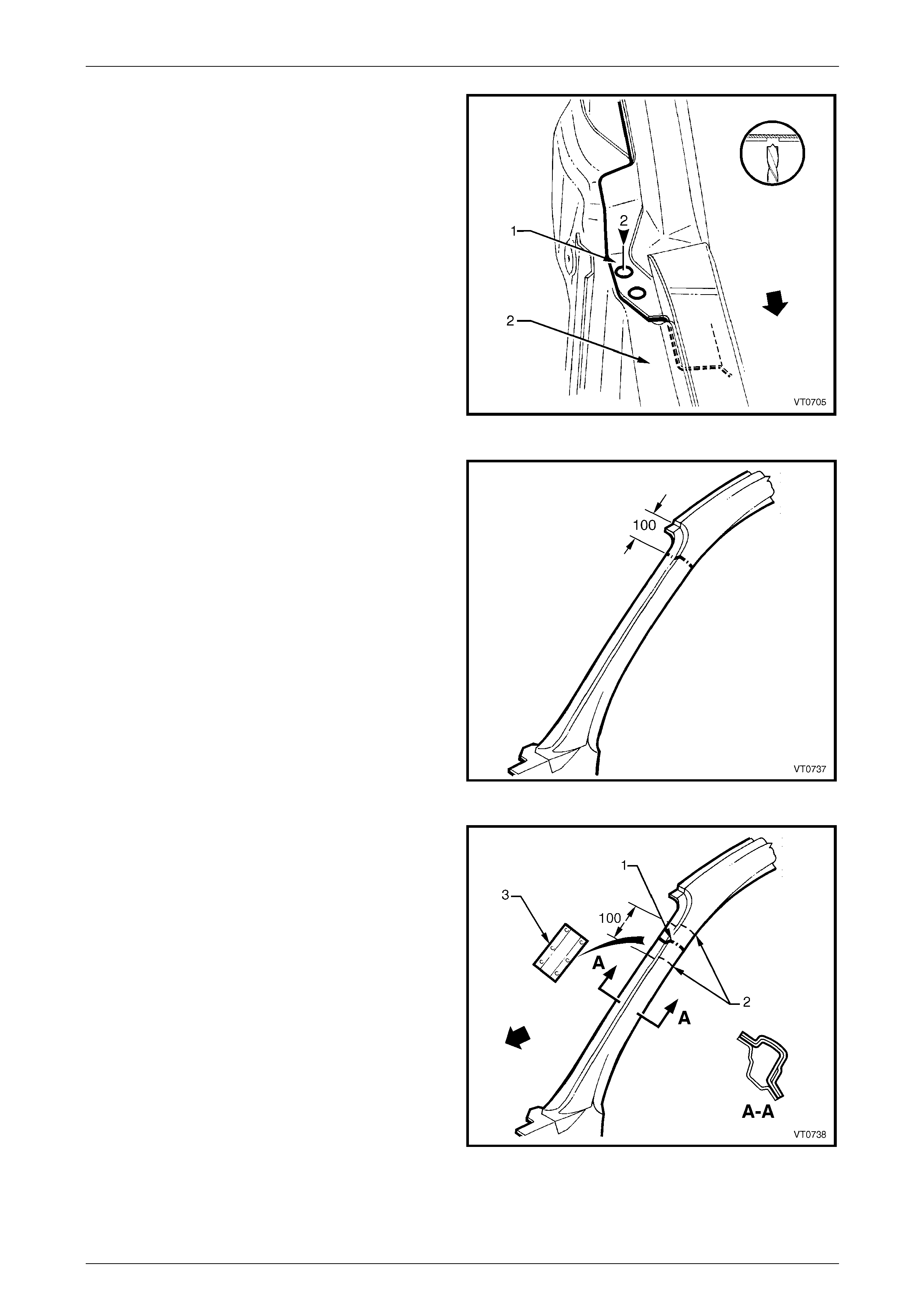

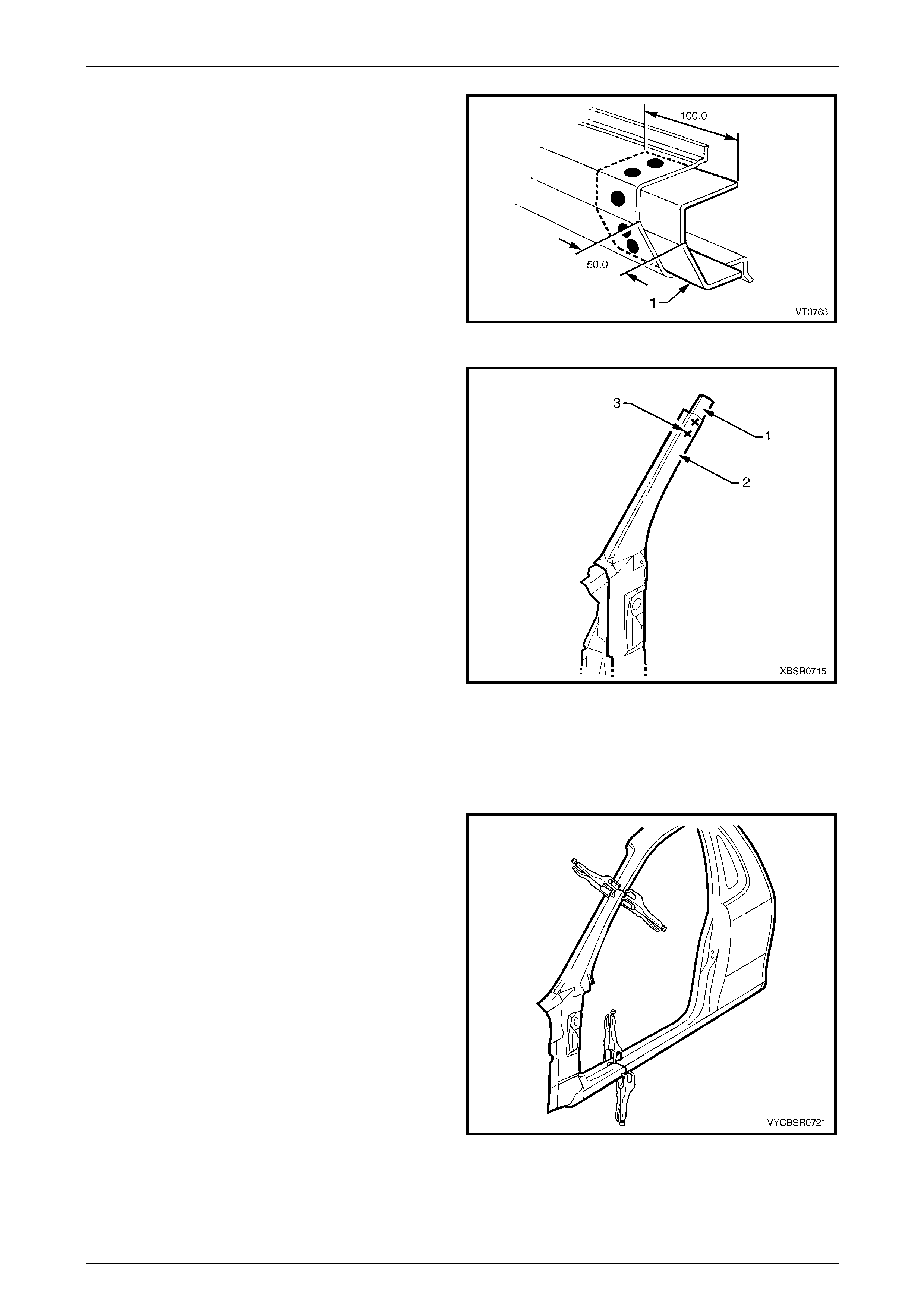

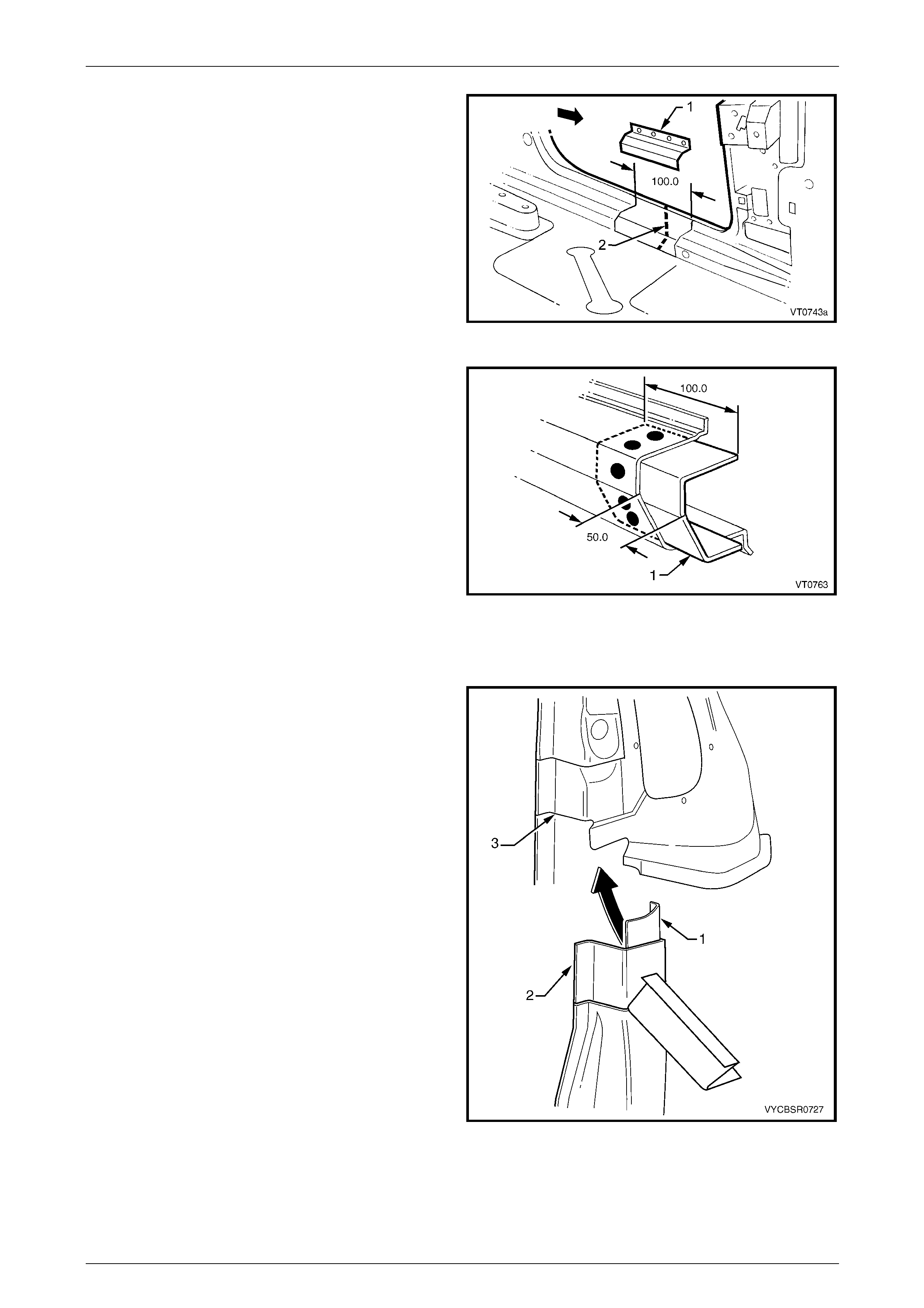

10 Select a cutting point on the hinge pillar. This cut point

should be within the region specified.

Figure 7E – 33

11 At the selected point (1), cut through the outer and

reinforcement panels, leaving the inner panel intact.

12 Mark the inner panel at points 50 mm either side of the

cut line on the outer panel and cut the inner panel at

these two points (2). Spot cut the welds and remove

the 100 mm section of inner panel (3).

Figure 7E – 34

7E Body Side – Regular Cab Page 7E–20

Page 7E–20

13 Spot cut the welds on the windshield side flange, up to

the point of the cut.

Figure 7E – 35

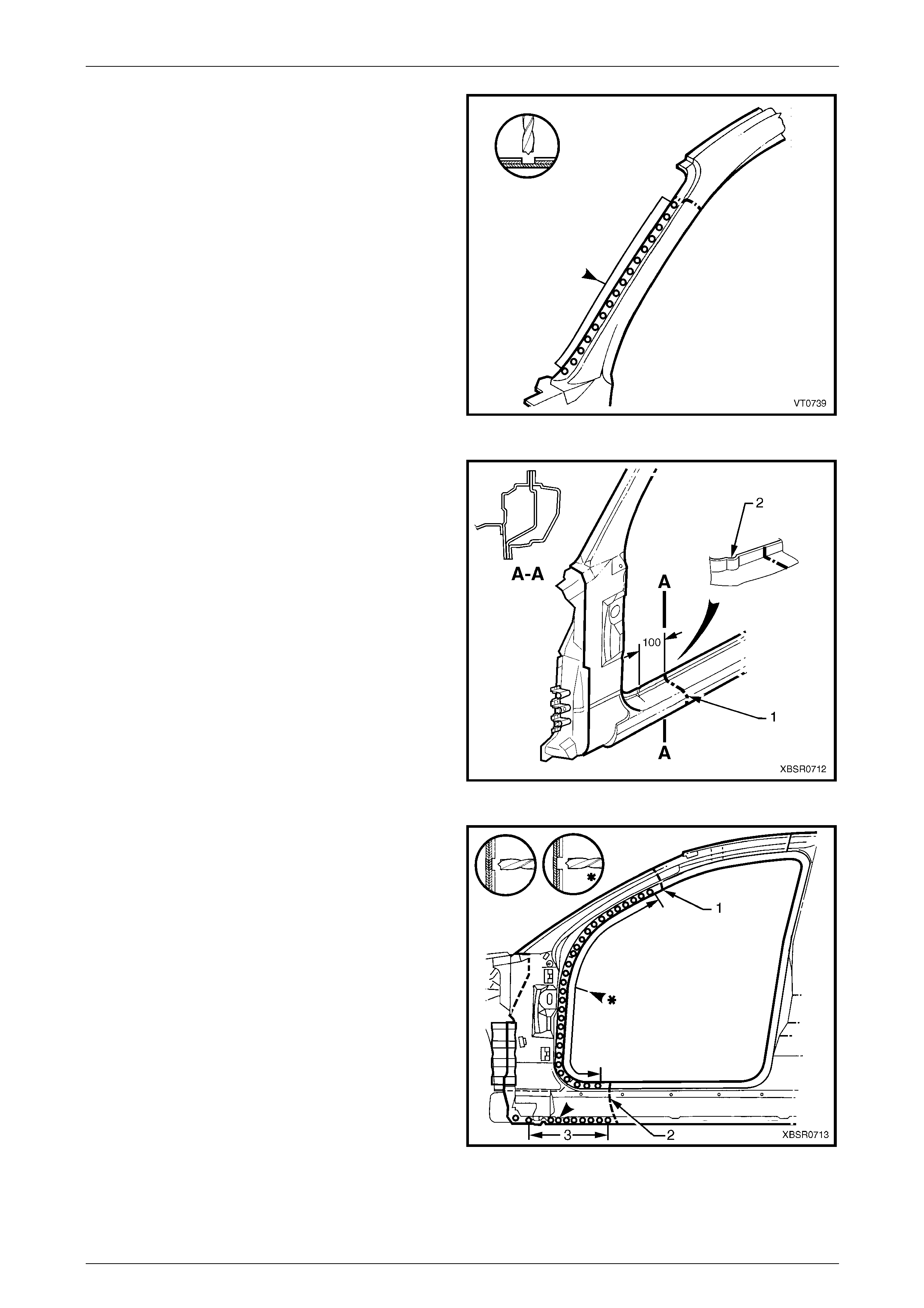

14 Cut through the rocker panel section of the door

opening frame assembly. The cut point (1) sh ould be

approximately 100 mm from the dimple (2) on the

flange. Cut through both the outer pane l and the

reinforcement panel.

Figure 7E – 36

15 Spot cut the welds on the flange along the front door

opening, from the cut near the top of the hinge pill ar

(1) to the cut in the rocker panel (2).

16 Spot cut the welds along the flange (3) below the

rocker panel (to the point of the cut), separ ating the

door opening frame assembly from the inner rocker

panel.

17 Remove the partial hinge p illar from the vehicle, then

repair any damage to adjacent parts.

18 Check and rectify the alignme nt of

the body as required, refer to

Section 3E Body Construction – Regular Ca b.

Figure 7E – 37

7E Body Side – Regular Cab Page 7E–21

Page 7E–21

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment will not access the required weld

position, a plug weld should be performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

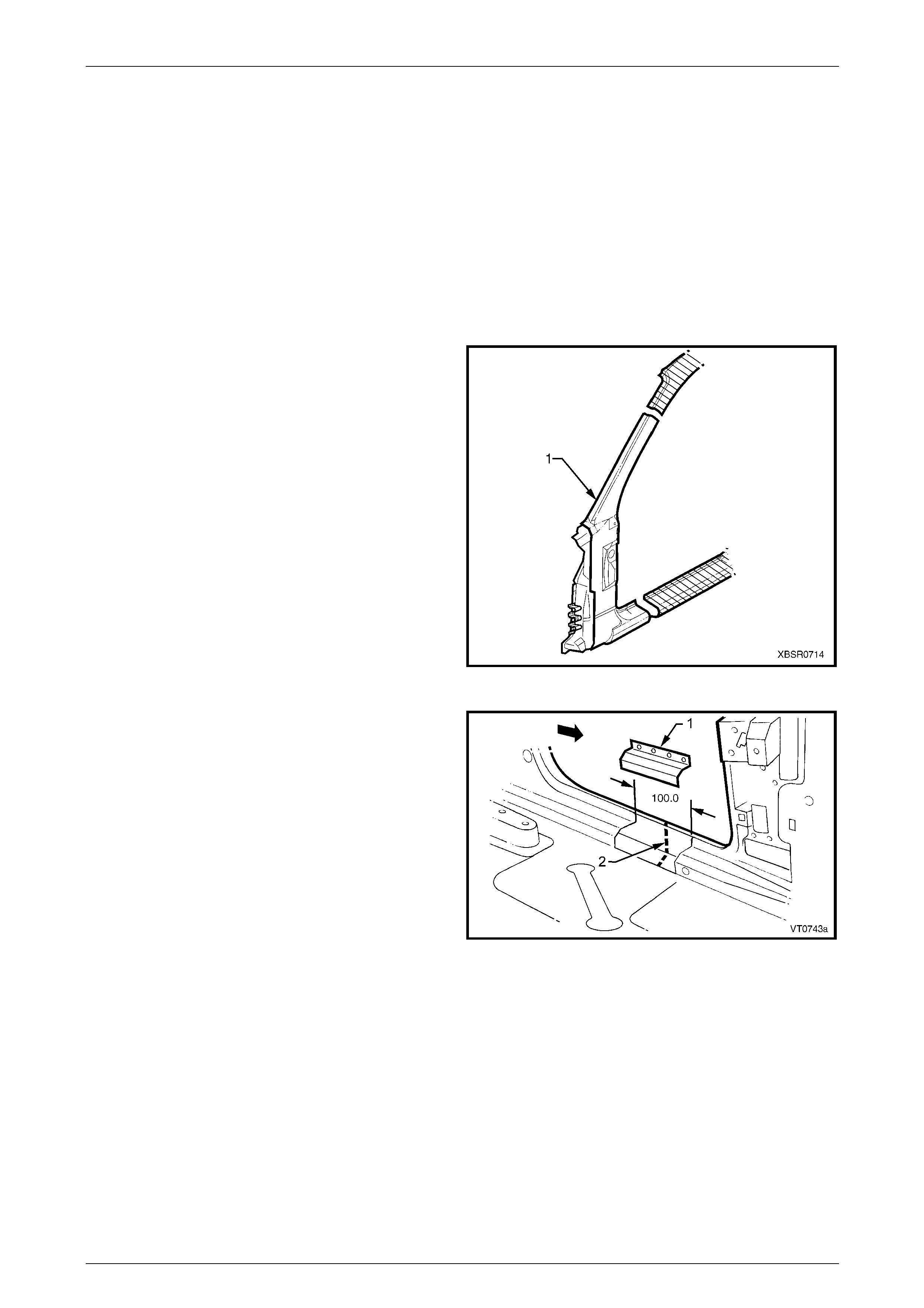

1 Cut a replacement panel section (1), accurately

measuring the position of cuts to match the section

removed.

Figure 7E – 38

2 Remove a section of inner rocker panel (1), cut 50 mm

each side of the cut in the rocker panel (2). This all ows

access for welding the rocker panel reinf orcement.

Figure 7E – 39

7E Body Side – Regular Cab Page 7E–22

Page 7E–22

3 Either manufacture a new section or cut an existing

length of surplus rocker panel section, to form a

reinforcement (1), approximately 100 mm in length.

4 Prepare the mating surfaces and treat with Weld

Through Primer (Item 1) as required, refer to

Section 3E Body Construction – Regular Ca b.

5 Clamp this reinforcement firmly behind the cut section

of rocker panel on the vehicle and spot or plug weld in

place. Position welds at a maximum spacing of 35 mm

apart.

Figure 7E – 40

6 Using a similar technique, ma nufacture or cut a

section of reinforcement panel (1) (appro xim ately

60 mm long) to fit on the inside of the replacement

hinge pillar out er panel (2) at the point of the cut.

NOTE

Remove the flanges from this reinforcement

panel.

7 Prepare the mating surfaces and treat with Weld

Through Primer (Item 1) as required, refer to

Section 3E Body Construction – Regular Ca b.

8 Clamp the reinforcement panel firmly behind the cut

section of the hinge pillar outer and spot weld (3) in

place.

9 Mark the new hinge pillar pan el with drilling locations

in preparation for plug welding where required. Drill

holes as marked.

10 Prepare the mating surfaces and treat with Weld

Through Primer (Item 1) as required, refer to

Section 3E Body Construction – Regular Ca b.

11 Apply Acrylic Spot Weld Sealer (Item 2), refer to

Section 3E Body Construction – Regular Ca b.

Figure 7E – 41

12 Clamp the replacement panel in position on the

vehicle and check the door opening dimensions,

refer to Section 3E Body Construction – Regular Cab.

Adjust position as required.

Figure 7E – 42

7E Body Side – Regular Cab Page 7E–23

Page 7E–23

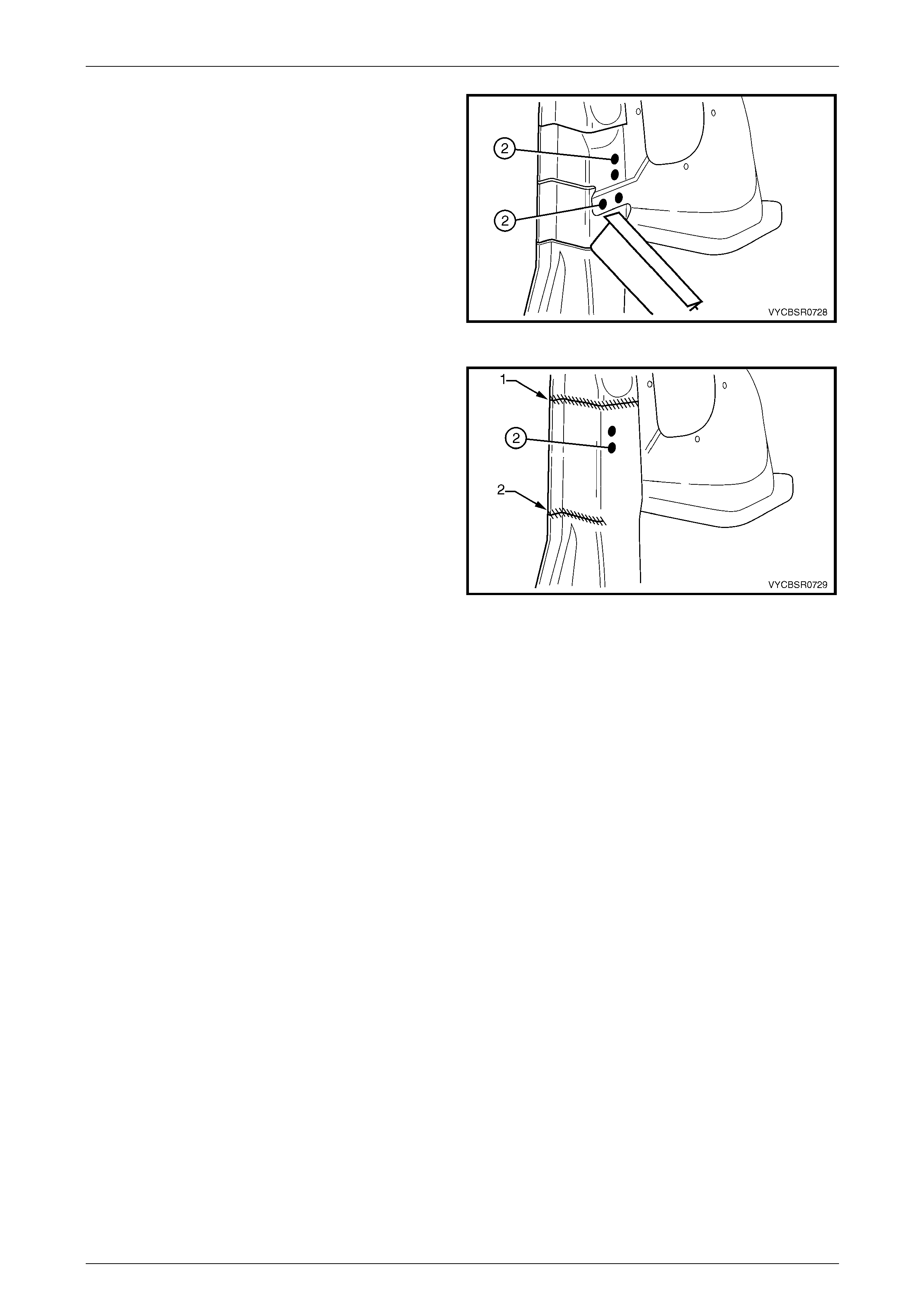

13 Plug weld (1) the top of the pillar to the manufactured

reinforcement, then MIG butt weld (2) the two sections

together.

Figure 7E – 43

14 Plug weld (1) the new panel in the rocker panel region,

then MIG butt weld (2) the two sections together.

Figure 7E – 44

15 Gaining access through the removed sectio n of inner

panel, MIG butt weld (1) the reinforcement panel

together.

16 Butt weld the removed access panel (2) in position.

Replace the spot welds with the same number that

was removed.

Figure 7E – 45

7E Body Side – Regular Cab Page 7E–24

Page 7E–24

17 Spot weld (1) the pillar along the door op ening flange.

18 Spot weld (2) the flange beneath the rocker pan el,

attaching the new panel to the inner rocker panel.

Figure 7E – 46

19 Spot weld (1) the pillar along the windshield opening

flange.

Figure 7E – 47

20 Spot or plug weld the door opening frame assembly

(1) to the hinge pillar inner panel assembly (2) at the

base of the hinge pillar.

Figure 7B – 48

7E Body Side – Regular Cab Page 7E–25

Page 7E–25

21 Spot or plug weld the door opening frame assembly to

the inner rocker panel and to the hinge pillar inner

panel assembly.

NOTE

If the sheet metal was modified to allow access

to these welds, it should be repaired to its

original configuration.

Figure 7E – 49

22 Gaining access through the section of removed in ner

rocker panel, MIG butt weld (1) the new section of

rocker panel reinforcement to the existing section.

23 Replace the removed section of inner rocker panel (2)

by MIG butt welding it in place and spot welding it

along the door opening flange. Replace the spot welds

with the same number of as were removed.

24 Replace the front wheelhouse panel upper side rail,

refer to Section 4 Front End.

25 Install the door hinges,

refer to Section 8 Doors, Liftgate and Endgat e.

26 Replace other adjoining removed pa nels as required,

refer to the relevant Section in this Supplement.

27 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

Figure 7E – 50

28 Apply Joint Sealer (Item 3) as required. Refer to Section 3E Body Construction – Regular Cab.

29 Apply Cavity Wax (Item 8) as required to the inside of any box secti ons or areas inaccessible to paint,

refer to Section 3E Body Construction – Regular Cab.

30 Install the dash panel retaining bolt throu gh the hinge pil lar and tighten to the specified torque.

Dash panel retaining b olt

torque specification.........................................35.0 – 45.0 Nm

31 Replace the windshield, refer to Section 1A6 Stationary Glass in the MY 2005 VZ Service Information.

32 Insert Cavity Foam into the hinge pillar as required, refer to Section 2 Precautions.

33 Reinstall the front door assembly, refer to Section 8 Doors, Liftgate and Endgate.

34 Install the remaining components as described in the appropriate Section of the MY 2005 VZ Service Informatio n.

7E Body Side – Regular Cab Page 7E–26

Page 7E–26

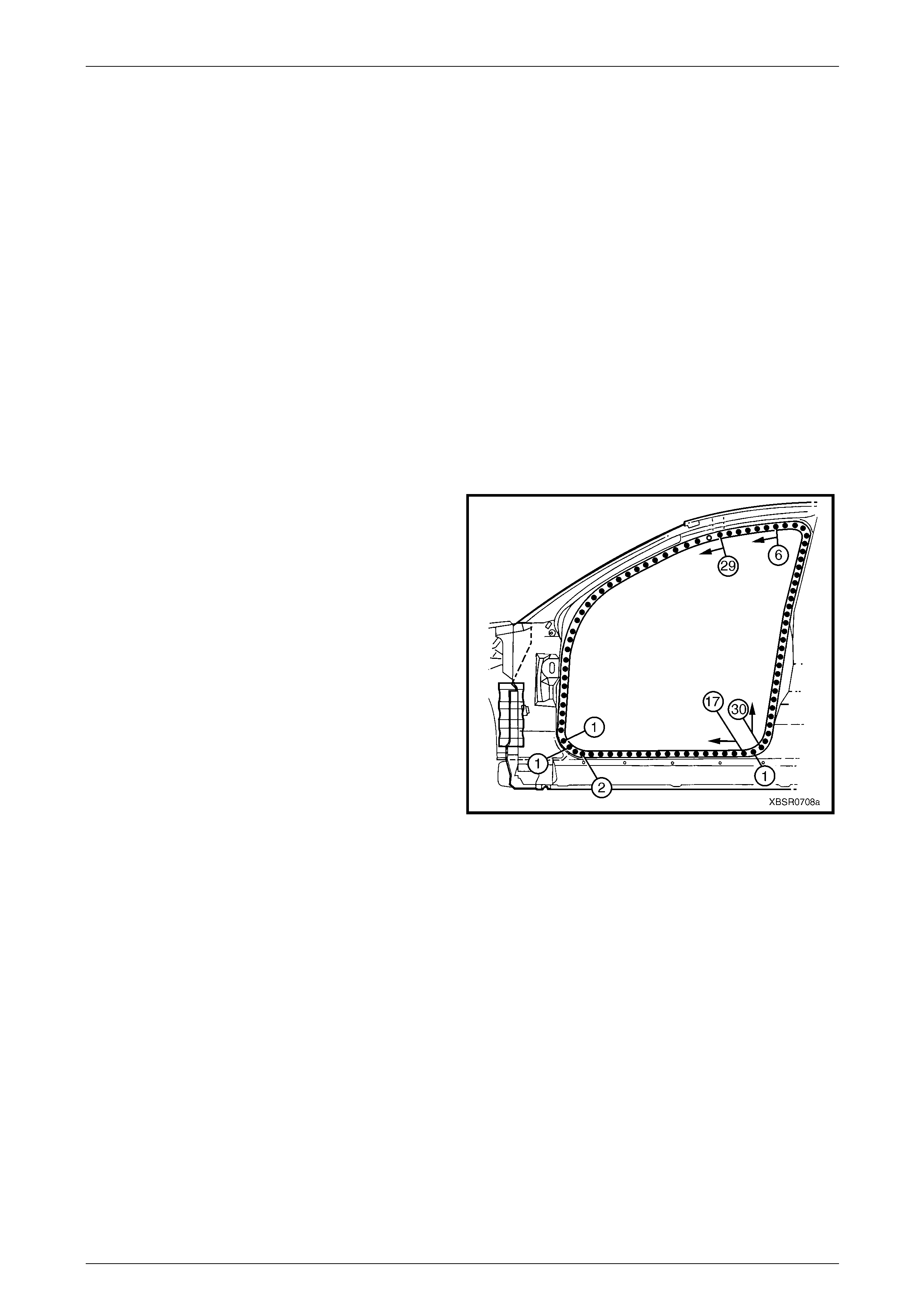

2.5 Door Opening Frame Assembly – Partial

Replace, Centre Pillar

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of th e MY

2005 VZ Service Information.

2 Secure the vehicle on a suitable fixture. As a

minimum, support the appropriate structural s ections

of the vehicle on safety stands. Secure a suitable tool

between the front door openi ng flanges to maintain

alignment.

3 Remove the rear quarter panel,

refer to 2.1 Rear Quarter Panel Assembly – Replace.

4 Remove the rear quarter panel reinforcement, refer to

2.2 Rear Quarter Panel Reinforcement – Re place.

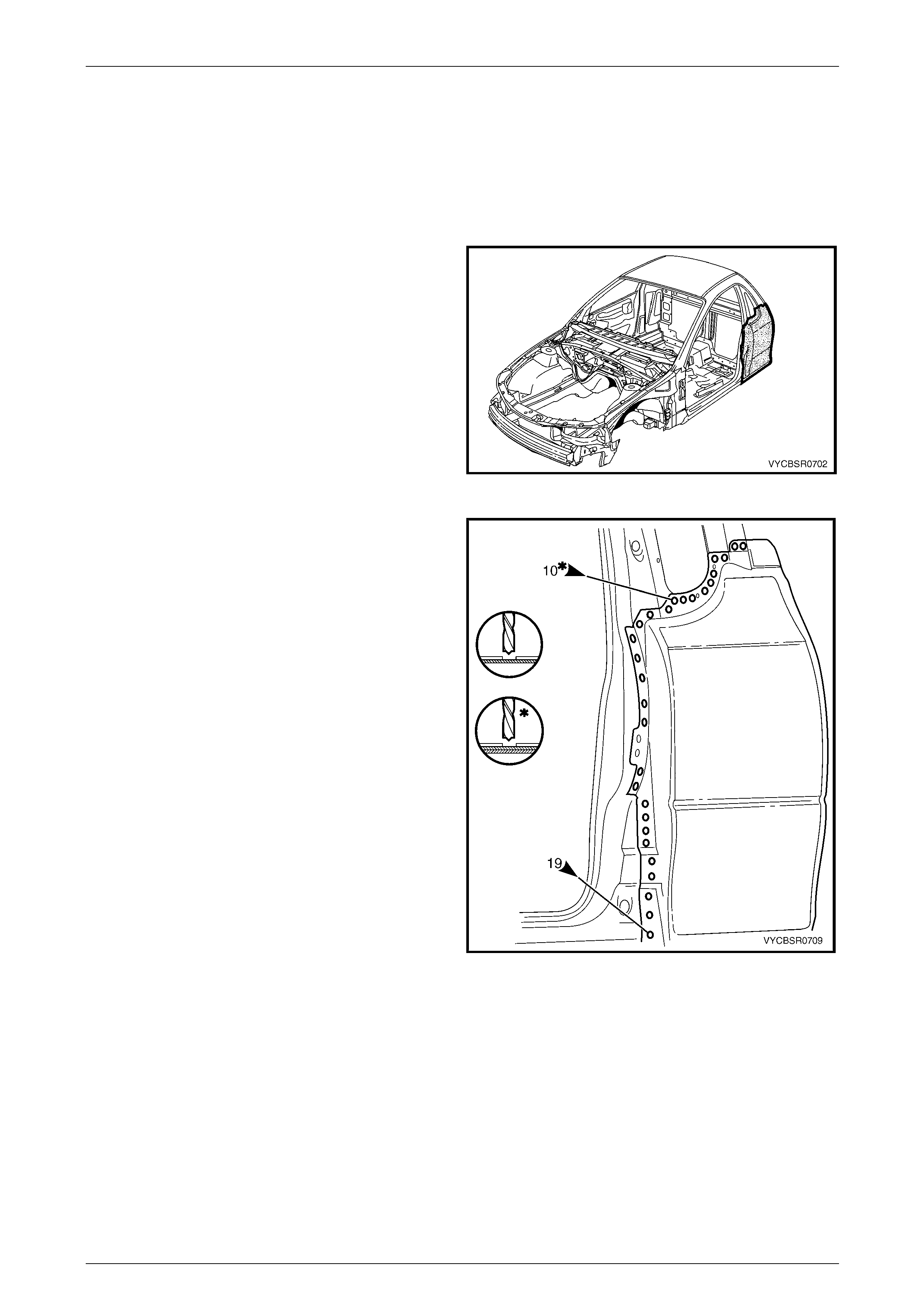

Figure 7E – 51

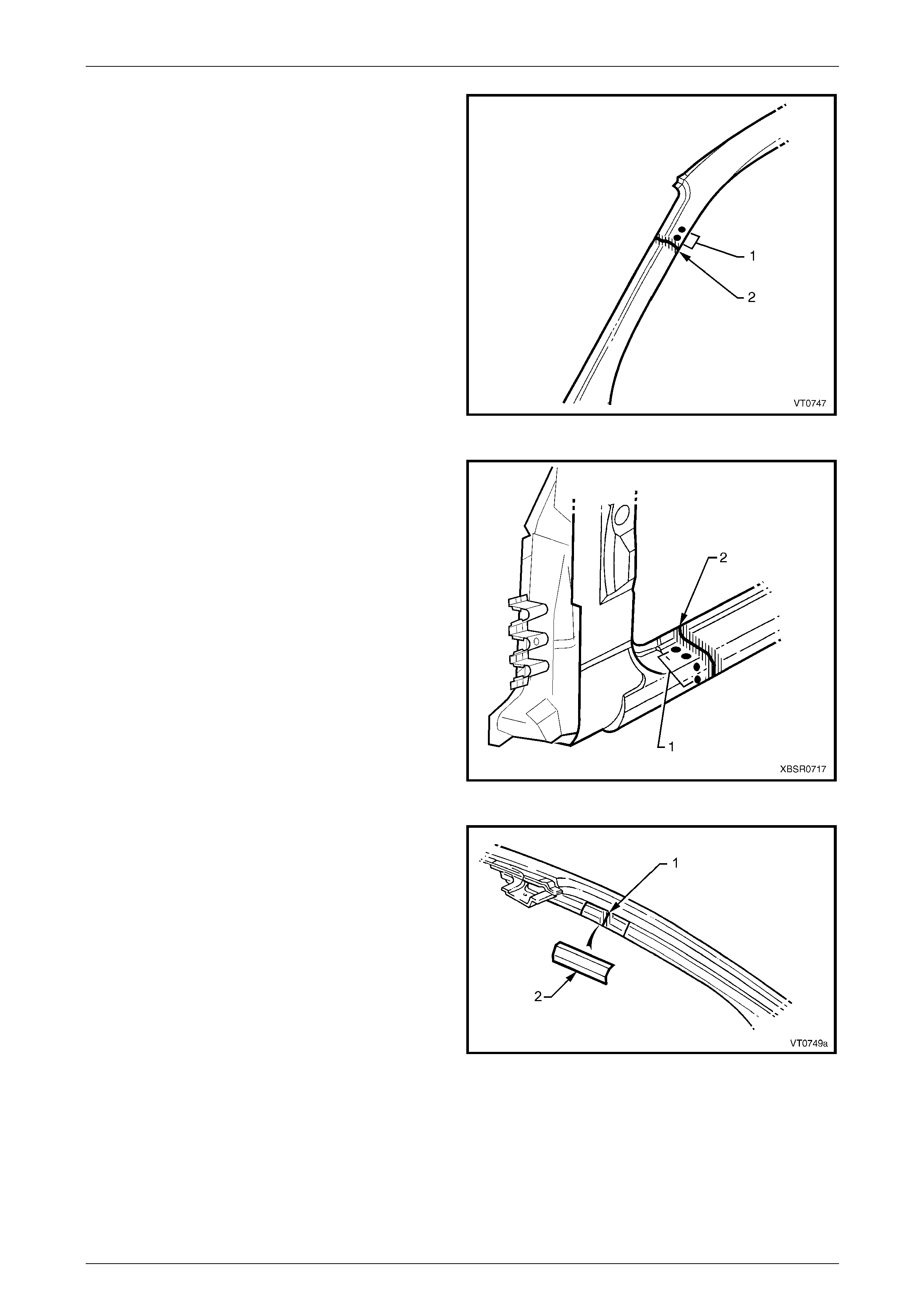

5 Cut the door opening frame a ssembly (1) as shown.

NOTE

The upper cut is just below the recess and the

lower cut is approximately level with the centre

pillar upper reinforcement.

6 Spot cut the two welds attaching door opening frame

assembly to the centre pillar reinforcement.

7 Spot cut the welds attaching the door openin g frame

assembly to the quarter panel inner assembly.

Figure 7E – 52

7E Body Side – Regular Cab Page 7E–27

Page 7E–27

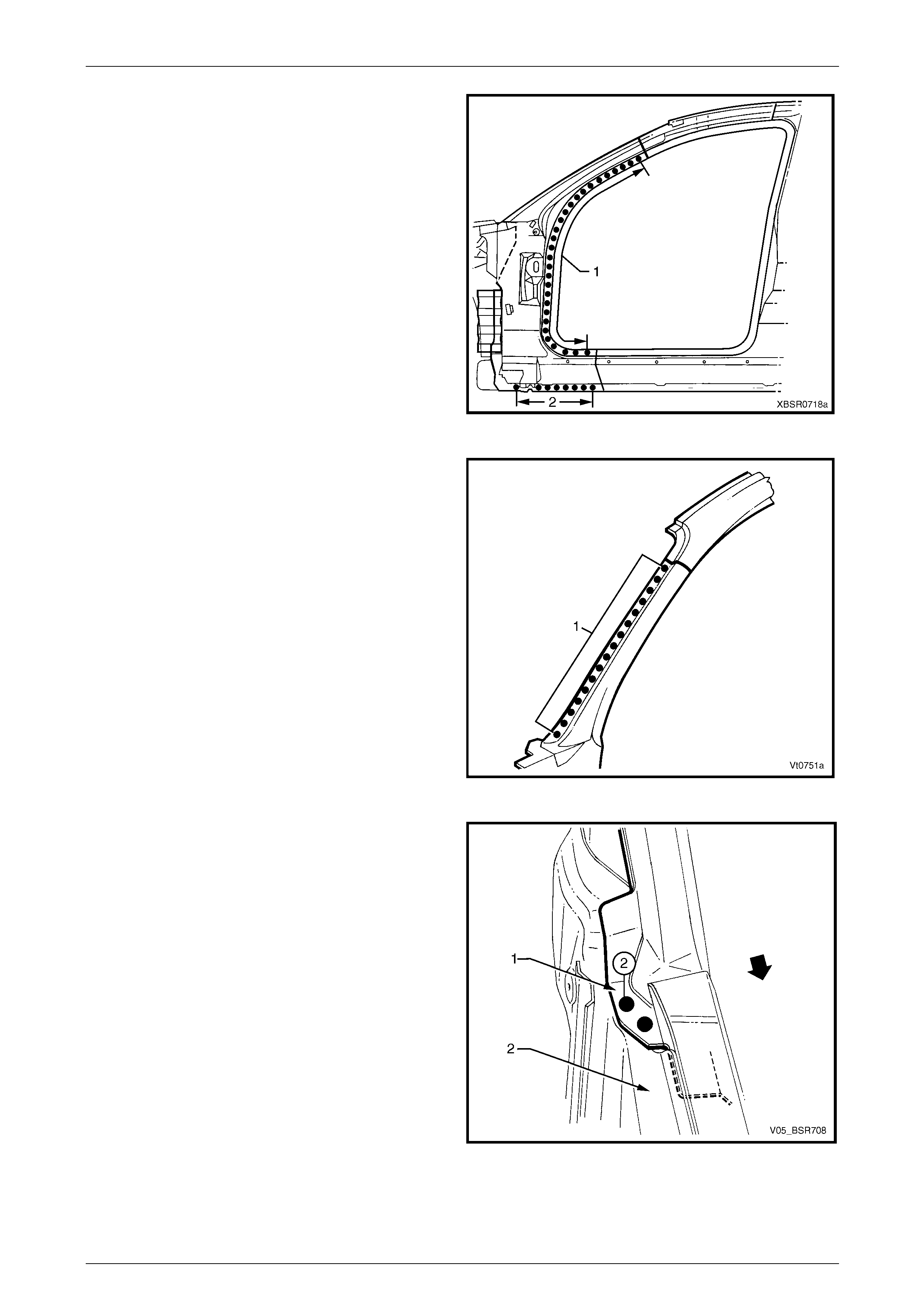

8 Cut through the rocker panel section of the door

opening frame assembly. The cut point (1) sh ould be

approximately 100 mm from the dimple (2) on the

flange. Cut through both the outer pane l and the

reinforcement panel.

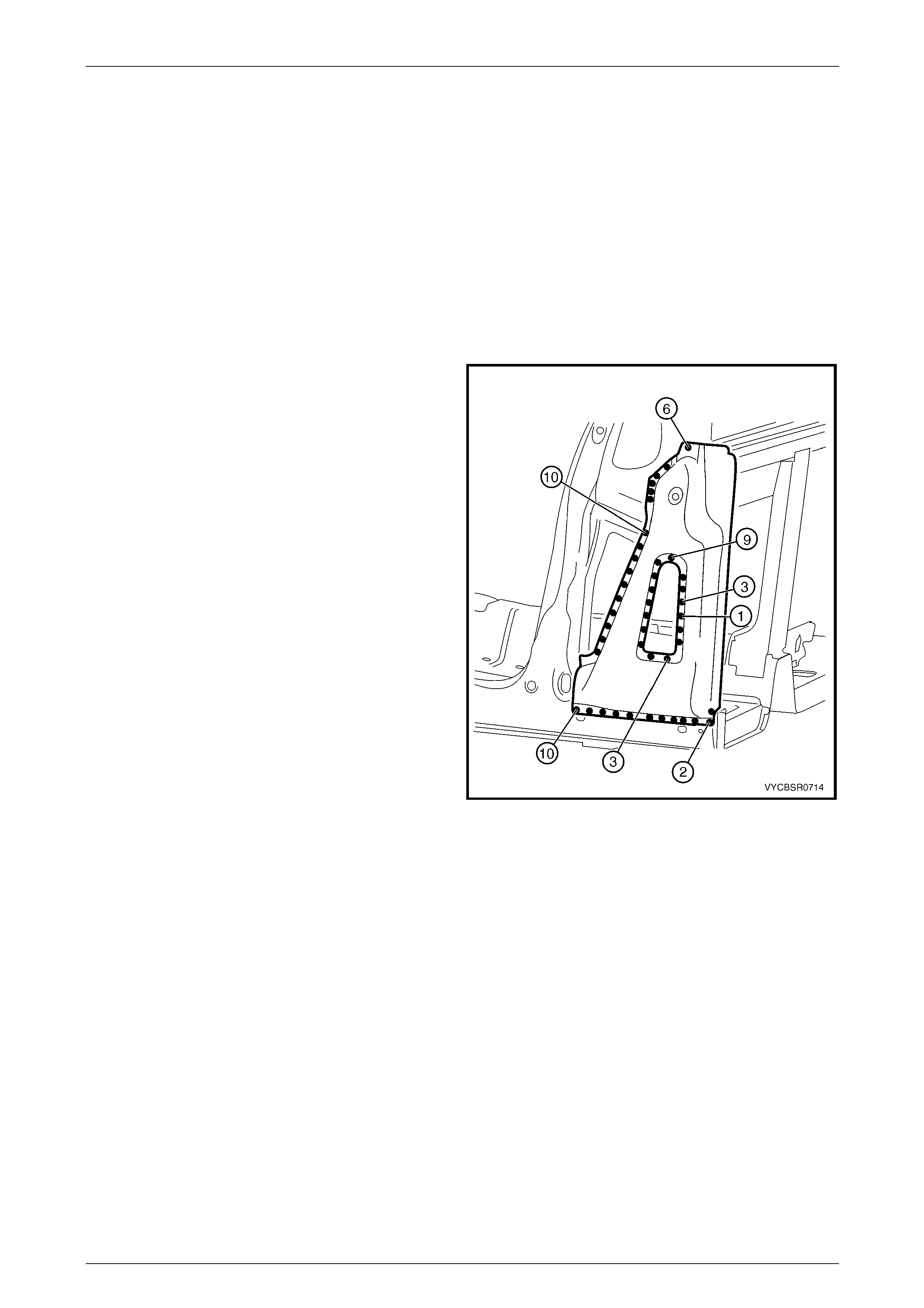

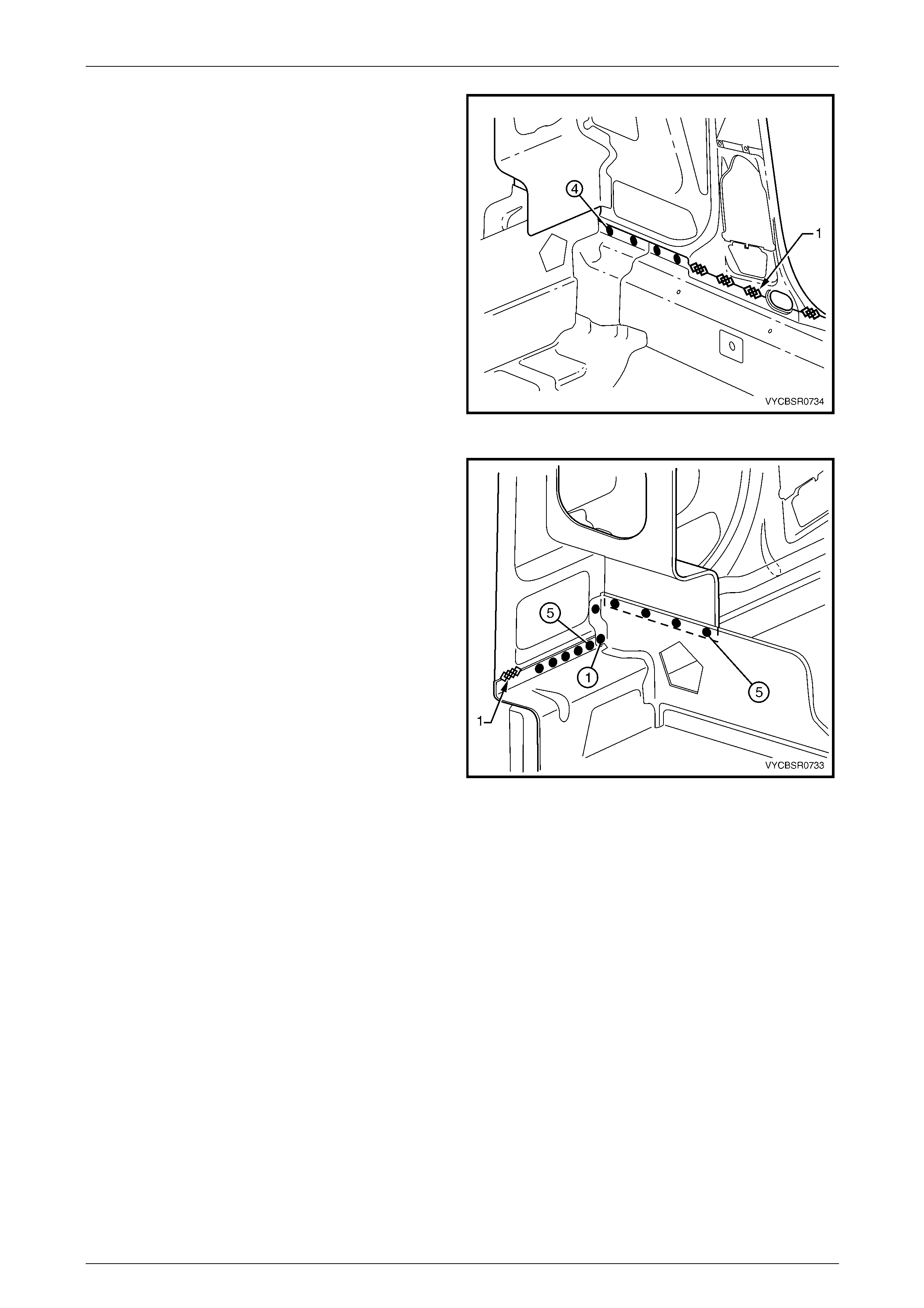

9 Spot cut the welds attaching the underbod y jacking

locator (1) and remove, refer to Figure 7E – 53.

10 Spot cut the welds attaching the front and rear sides of

the door opening frame assembly to the quarter panel

inner assembly.

NOTE

The number of welds will vary depending on the

cut locations.

11 Spot cut the 12 welds attaching lower edge of the

quarter panel inner assembly to the door opening

frame.

12 Spot cut the four welds attaching the centre pillar

upper reinforcement to the centre pillar reinforcement.

13 Remove the centre pillar section from the vehicle.

14 Repair any damage to adjacent parts as required.

Figure 7E – 53

Figure 7E – 54

7E Body Side – Regular Cab Page 7E–28

Page 7E–28

Replace

NOTE

Spot welding is the preferred method for

attaching of panels and should be used whenever

possible. Where the spot welding equipment will

not access the required weld position, a plug

weld should be performed.

The same number and position of spot welds (or

plug welds) should be used when replacing the

panel, as was used during manufacture, in order

to maintain the original structural strength of the

vehicle.

1 Cut the replacement door opening frame assembly through rocker section. Accurately measure the position of cuts

to match the removed panel section.

2 Cut the replacement door opening frame assembly

below the recess to match the removed section from

the vehicle (1).

NOTE

Cut through the outer panel onl y.

3 Make a second cut approximately level with the centre

pillar upper reinforcement (2).

NOTE

Cut through the flange and front side onl y.

4 Cut the required spot welds and carefull y bend the

outer panel down to expose the spot welds attaching

the centre pillar upper reinforc ement to the centre

pillar reinforcement.

Figure 7E – 55

5 On the replacement panel, spot cut the five welds

attaching the centre pillar lower section to the centre

pillar upper reinforcement and remove the s ection.

Figure 7E – 56

7E Body Side – Regular Cab Page 7E–29

Page 7E–29

6 Remove a section of inner rocker panel (1), cut 50 mm

each side of the cut in the rocker panel (2). This all ows

access for welding the rocker panel reinf orcement.

Figure 7E – 57

7 Cut two sections from surplus rocker panel pieces, or

manufacture new sections (1), each ap proximately

100 mm in length.

8 Prepare the mating surfaces and treat with Weld

Through Primer (Item 1) as required, refer to

Section 3E Body Construction – Regular Ca b.

9 Clamp these sections firmly behi nd both the cut faces

of rocker panel on the vehicle and spot or plug weld in

place. Perform the welds at a maximum spacing of

35 mm apart.

10 Mark the new panel with drilling locations in

preparation for plug welding where required. Drill holes

as marked.

11 Prepare the mating surfaces and treat with Weld

Through Primer (Item 1) as required, refer to

Section 3E Body Construction – Regular Ca b.

Figure 7E – 58

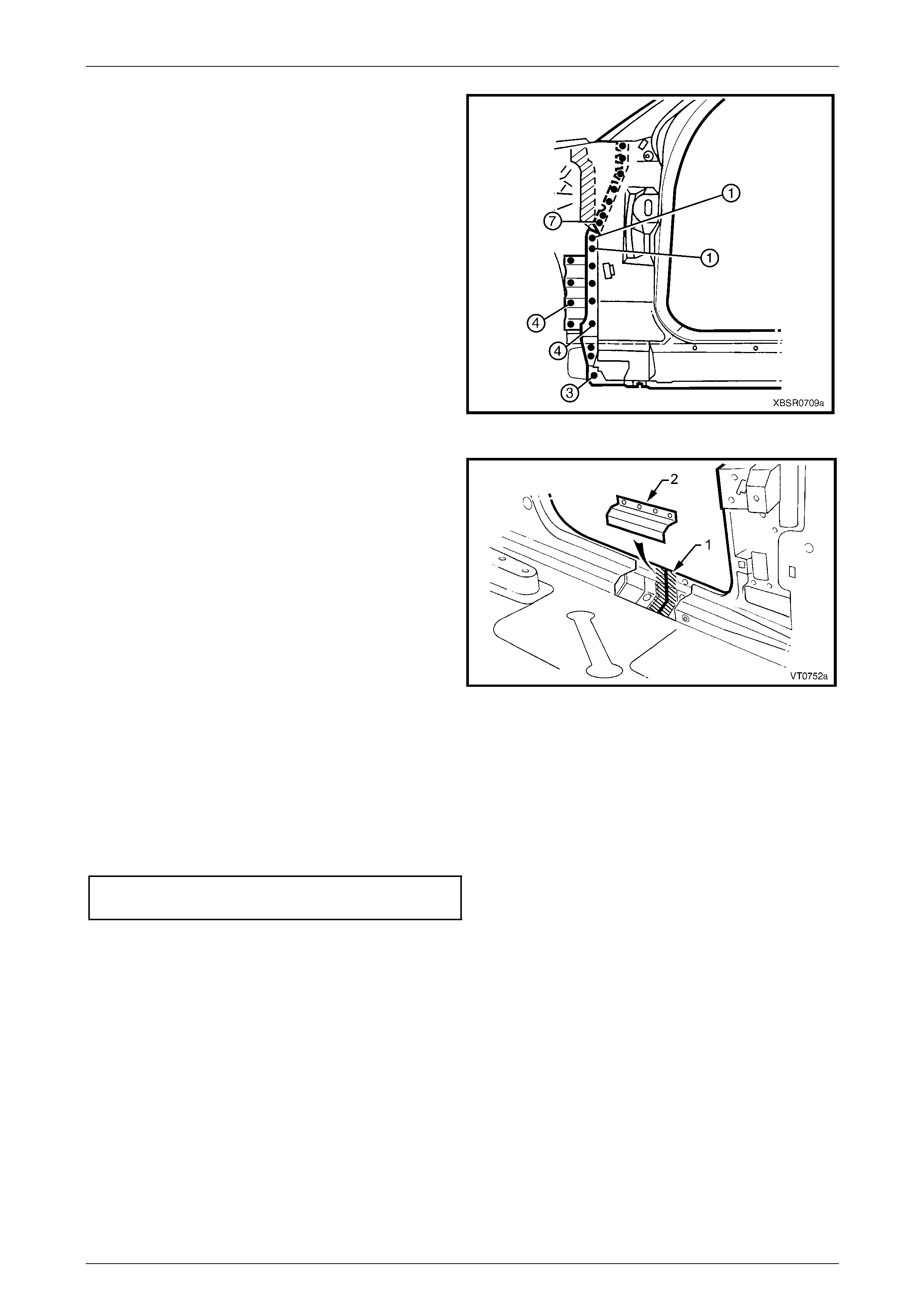

12 Install the replacement panel i n position, sliding the

centre pillar reinforcement (1) and the centre pillar

lower reinforcement (2) behind the centre pillar upper

reinforcement (3), until the front edge of the lo wer

reinforcement butts against the front edge of the upper

reinforcement.

13 Manipulate the rocker panel section in position,

inserting the front first, then the rear and clamp the

assembly in place.

Figure 7E – 59

7E Body Side – Regular Cab Page 7E–30

Page 7E–30

14 Plug weld the centre pillar upper reinforcement to the

centre pillar lower reinforcement, two places and the

centre pillar reinforcement two places.

Figure 7E – 60

15 Bend the outer panel back in position and MIG butt

weld the sections together as shown (1) and (2).

16 Plug weld the outer panel, centre pillar up per

reinforcement and centre pillar reinforcement two

places.

17 Plug weld (1) the front and rear sides of the door

opening frame assembly to the quarter panel inner

assembly, refer to Figure 7E – 62.

NOTE

The number of welds will vary depending on the

cut locations.

18 Plug weld (2) the front and rear sides of the door

opening frame assembly to the rocker panel

reinforcement.

Figure 7E – 61

19 Plug weld on the underside of the rocker panel, the centre pillar section to the quarter panel i nner assembly and

the rocker panel, refer to Figure 7E – 62.

20 Plug weld the lower edge of the qu arter panel inner assembly to the door ope ning frame.

21 MIG butt weld (3) each join across the rocker panel.

22 Plug weld the underbody jacking locator (4) in place.

7E Body Side – Regular Cab Page 7E–31

Page 7E–31

Figure 7E – 62

23 Dress the welds by grinding or sanding, ensuring sufficient material remains to guarantee the strength of the weld.

Finish the area using an appropriate technique.

24 Replace the adjoining removed panels as required, refer to the relevant Section in this Supplement.

25 Refinish and paint panels and other components as required.

Refer to Section 3E Body Construction – Regular Cab.

26 Apply Joint Sealer (Item 3) as required. Refer to Section 3E Body Construction – Regular Cab.

27 Apply Cavity Wax (Item 8) as required to the inside of any box secti ons or areas inaccessible to paint,

refer to Section 3E Body Construction – Regular Cab.

28 Insert Cavity Foam into the centre pillar as required, refer to Section 2 Precautions.

29 Install the remaining components as described in the appropriate Section of the MY 2005 VZ Service Information.

7E Body Side – Regular Cab Page 7E–32

Page 7E–32

2.6 Quarter Panel Inner Assembly – Replace

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of th e MY

2005 VZ Service Information.

2 Remove the rear quarter panel, refer to

2.1 Rear Quarter Panel Assembly – Replace.

3 Remove the rear quarter panel reinforcement, refer to

2.2 Rear Quarter Panel Reinforcement – Re place.

4 Remove the door opening frame assembly, refer to

2.3 Door Opening Frame Assembly – Repl ace.

Figure 7E – 63

5 Grind off the MIG weld (1) attaching the quarter panel

inner assembly to the inner rocker panel assembly.

6 Spot cut the welds attaching the quarter panel inner

assembly to the rear lower body panel and the inner

rocker panel assembly.

Figure 7E – 64

7E Body Side – Regular Cab Page 7E–33

Page 7E–33

7 Spot cut the welds attaching the quarter panel inner

assembly to the inner rocker panel.

8 Grind the four MIG welds (1) from the inside of the

quarter panel inner assembly, joining the inner rocker

panel.

Figure 7E – 65

9 Spot cut the welds attaching the quarter panel inner

assembly to the quarter panel inner extension.

Figure 7E – 66

10 Spot cut the welds attaching the door openin g frame

assembly to the roof rear header panel.

11 Remove the quarter panel inner assembly and repair

any damage to adjacent parts as required.

12 Check and rectify the alignme nt of

the body as required, refer to

Section 3E Body Construction – Regular Ca b.

Figure 7E – 67

7E Body Side – Regular Cab Page 7E–34

Page 7E–34

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment will not access the required weld

position, a plug weld should be performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 Mark the new panel and drill holes in preparation for plug welding where required.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required,

refer to Section 3E Body Construction – Regular Cab.

3 Apply Acrylic Spot Weld Sealer (Item 2), refer to Section 3E Body Construction – Regular Cab.

4 Clamp the new panel in position on the vehicle.

5 Plug or spot weld the door opening frame assembly to

the roof rear header panel.

Figure 7E – 68

6 Plug or spot weld the quarter panel inner assembly to

the quarter panel inner extension.

Figure 7E – 69

7E Body Side – Regular Cab Page 7E–35

Page 7E–35

7 Plug or spot weld the quarter panel inner assembly to

the inner rocker panel.

8 MIG weld four places, the quarter panel inner

assembly to the inner rocker panel (1).

Figure 7E – 70

9 Plug or spot weld the quarter panel inner assembly to

the rear lower body pan el and the inner rocker panel

assembly.

10 MIG weld (1) the quarter panel inner assembl y to the

inner rocker panel assembly.

11 Clean up welds and prime any bare metal.

12 Replace the door opening fra me assembly, refer to

2.3 Door Opening Frame Assembly – Repl ace.

13 Replace the rear quarter panel reinforceme nt, refer to

2.2 Rear Quarter Panel Reinforcement – Re place.

14 Replace rear quarter panel, refer to

2.1 Rear Quarter Panel Assembly – Replace.

15 Replace other adjoining removed pa nels as required,

refer to the relevant Section in this Supplement.

16 Refinish and paint panels and other

components as required.

Refer to Section 3E Body Construction – Regular Cab.F i gure 7E – 71

17 Apply Joint Sealer (Item 3) as required. Refer to Section 3E Body Construction – Regular Cab.

18 Apply Cavity Wax (Item 8) as required to the inside of any box secti ons or areas inaccessible to paint,

refer to Section 3E Body Construction – Regular Cab.

19 Apply Spray-on Deadener (Item 7) to the wheel side of the rear wheelhouse,

refer to Section 3E Body Construction – Regular Cab.

20 Install the remaining components as described in the appropriate Section of the MY 2005 VZ Service Informatio n.