2 Precautions Page 2-1

Page 2-1

Section 2

Precautions

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes in the MY2005 WL Service Information for correct workshop practices with

regard to safety and/or property damage.

The structure of the body shell has been

developed using complex design and

development techniques. In addition to

meeting all required standards, the vehicle

body is also a critical part of the overall safety

systems. It is therefore imperative the repair

procedures described here are adhered to

during all vehicle body repairs.

1 General Description ...............................................................................................................................3

2 Personal Safety Precautions.................................................................................................................4

2.1 Protective Gear ...................................................................................................................................................... 4

2.2 Flammable Materials.............................................................................................................................................. 5

2.3 Fuel Tank................................................................................................................................................................ 6

2.4 Workshop Precautions.......................................................................................................................................... 7

2.5 Vehicle Stability Precautions................................................................................................................................ 8

2.6 Dash Panel Precautions........................................................................................................................................ 9

2.7 Air-conditioning System ..................................................................................................................................... 10

3 General Precautions ............................................................................................................................11

3.1 Cutting Locations ................................................................................................................................................ 11

3.2 Dash Panel Assembly.......................................................................................................................................... 12

3.3 Steering System................................................................................................................................................... 13

3.4 Discharging The Fuel Lines................................................................................................................................ 14

4 Occupant Protection System Precautions ........................................................................................15

4.1 Repairs To Vehicle Structure.............................................................................................................................. 16

4.2 Repairs And Inspections Required After A Collision ....................................................................................... 17

4.3 System Disabling And Enabling Procedure ...................................................................................................... 18

Disabling the OPS................................................................................................................................................ 18

Enabling the OPS................................................................................................................................................. 18

4.4 OPS Safety Precautions...................................................................................................................................... 19

5 Electrical Precautions..........................................................................................................................20

5.1 Electronic Devices............................................................................................................................................... 20

5.2 Before Repairing The Vehicle............................................................................................................................. 21

Paint Ovens.......................................................................................................................................................... 21

Welding................................................................................................................................................................. 21

2 Precautions Page 2-2

Page 2-2

6 Jacking Precautions ............................................................................................................................22

7 Towing Precautions .............................................................................................................................23

7.1 Towing On Four Wheels...................................................................................................................................... 23

7.2 Towing On Two Wheels....................................................................................................................................... 24

8 Plastic Components.............................................................................................................................25

Exterior............................................................................................................................................................. 25

Interior.............................................................................................................................................................. 28

8.1 Plastic Types........................................................................................................................................................ 30

9 Special Steel Precautions....................................................................................................................31

9.1 Pre-Coated Steel.................................................................................................................................................. 31

9.2 Re-phosphorised Steel........................................................................................................................................ 32

9.3 High Strength Low Alloy Steel............................................................................................................................ 33

10 Cavity Foam..........................................................................................................................................34

Replace................................................................................................................................................................. 35

2 Precautions Page 2-3

Page 2-3

1 General Description

This Section contains important information regarding the precautions that are to be observed when performing repair

work.

The reasons for these precaut ions are threefold:

• Firstly, it is important the safety of those repairing the vehicle is not compromised.

• Secondly, it must be ensured that inadverte nt damage is not caused to the vehicle during the preparation for, or

during the performance of, repairs to that vehicle.

• Finally, it must be ensured that any relevant Federal an d State legislation is abided by.

2 Precautions Page 2-4

Page 2-4

2 Personal Safety Precautions

2.1 Protective Gear

Protective clothing should be worn at all times when automotive body repa ir work is being carried out. The appropriate

safety gear will vary in accordance with the work being performed an d includes:

• work overalls,

• dust mask,

• safety shoes,

• work gloves,

• welding mask,

• ear muffs,

• safety glasses and

• leather apron.

2 Precautions Page 2-5

Page 2-5

2.2 Flammable Materials

It is extremely important to keep the work areas clear of flammable materials. Flammable materials such as adhes ives,

solvents and paints are regularly used in the repair i ndustry. T heir proximity creates a problem where ignition sources

such as grinding sparks and welding flames and sparks are regularly present.

All flammable chemicals shoul d be kept i n appropriate storage cabinets.

Be sure to abide by local law s and regulations

regarding the storage of hazardous materials.

2 Precautions Page 2-6

Page 2-6

2.3 Fuel Tank

Keep all naked flames and sparks away from

the vehicle if you can smell fuel vapour.

Extreme care must be exercised when using

an oxy/acetylene to rch.

Welding, grinding or drilling near the fuel tank is dangero us. If a vehicle ha s been involved in a collision, fuel may be

leaking from the tank, lines or unions.

If repairing the underbody, or any rear p art of the vehicl e, the fuel tank sh ould first be removed to avoid fire and possible

personal injury.

Be aware that grinding or cutting the fuel pipes may cause fire. For the procedure to discharge the fuel lines

refer to 3.4 Discharging The Fuel Lines.

2 Precautions Page 2-7

Page 2-7

2.4 Workshop Precautions

The process of welding produces fumes which if inhaled may have short or long term he alth effects.

Welding metals containing certain alloys, are galvanised, or are specially treated may increase the health risk.

While the risks to the body repairer are slight, it is imperative that any welding is performed in a well-ventilated area.

Where it is not possible to ensure good ve ntilation, a suitable respirator should be worn.

The body structure of consists of metal compone nts made from:

• mild steel,

• mild steel with Galvaneal coating – 2 sides,

• mild steel with Zinc coating – 2 sides, and/or

• mild steel with Zinc-nickel coating – 1 and 2 sides.

2 Precautions Page 2-8

Page 2-8

2.5 Vehicle Stability Precautions

To avoid personal injury occurring, the following precautions should be observed:

• Secure the vehicle on safety stands; never work below a vehicle supported only by jacks.

• Frame straightening e quipment can be dangerous; always use in strict ac cordance with the manufacturer’s

recommendations.

2 Precautions Page 2-9

Page 2-9

2.6 Dash Panel Precautions

The silicone adhesiv e used in the glue track, once cured, requires no special precautions. However, when mixing the

adhesive compound with the catalyst, the precautions listed below should be observed.

• The catalyst is a toxic substance and must not be swallowed. Keep the catalyst out of reach of children.

• Wear safety glasses to avoid contact with the eyes. If eye contact occurs, wash the area in clean water only, and

seek immediate medical advice.

• Wear protective gloves when handing the adhesiv e and catalyst as they can cause skin irritation.

• If irritation occurs, wipe the adhesive/catalyst off using a clean cloth and then wash the affected area thoroughl y in

clean water.

• As the vapour produced by the catalyst may cause breathin g difficulties, use only in a well ventilated area.

• Since the catalyst is combustible, keep it a way from sparks and flame.

2 Precautions Page 2-10

Page 2-10

2.7 Air-conditioning System

NOTE

As an environmental m easure, Federal and State

legislation requires air-conditioning systems be

discharged in accordance with certain

regulations. It is recommended that you be

acquainted with the requirements.

Care should be taken when discharging th e air-conditioning s ystem to ensure that the refrigerant is not released to the

atmosphere, but recaptured for recycling. Environment friendly refrigera nt R134a is not an ozone depleting substance

but its release would add to the greenhouse warming effect. It is therefore essential that the refrigerant be recovered

using a Refrigerant Recover y Unit (RRU).

Refer to Section 2B HVAC Climate Control – Servicing and Diagnosis in the MY2005 WL Service Information for

comprehensive procedures o n discharging and refilling the air-conditioning system.

NOTE

R134a and R12 are not compatible and must

never be mixed.

Frostbite will be caused if the refrigerant liquid contacts skin. Always wear safety gloves and goggles and stay clear of

any discharge.

If R134a enters the eye, freezing of the eye could occur a nd could result in blindness. If this situation oc curs, the

following procedure is suggested:

1 Keep calm.

2 Do not rub eyes.

3 Splash large quantities of cool water into the eyes to raise the temperature.

4 Tape a sterile patch in place to prevent dirt from entering the eye.

5 Go immediately to a doctor or hospital.

Do not attempt to treat the condition yourself.

2 Precautions Page 2-11

Page 2-11

3 General Precautions

3.1 Cutting Locations

Do not cut the body structure at any point

other than specified in this Supplement.

The vehicle body structures are designed to meet or exceed all relevant Statutory Regulations. Cutting anywhere other

than specified may compromise the strength of the vehicle and therefore occupant protec tion system operation and

occupant safety.

2 Precautions Page 2-12

Page 2-12

3.2 Dash Panel Assembly

To avoid fire, do not attempt to burn the

remaining sealant from the glue track using

an oxy/acetylene to rch.

The dash panel assembly must be bonded to the body with the correct two-part, fast cure silicone adhesive. It is

important that the dash panel is ready for installation and has been trial fitted before the adhesive is mixed, as the

working time is less than 20 minutes.

Ensure that preparation of the pan el surfac e is completed prior to mixing the adhesive. T his should include painting of

the surrounding areas and thorough cleaning of the glue track.

After installation, the dash panel should not be disturbed until the ad hesive is fully cured (about 3 hours).

Refer to Section 5 Cockpit Module for a full description of the installation procedure for the dash pa nel assembly.

2 Precautions Page 2-13

Page 2-13

3.3 Steering System

Vehicles involved in collisions resulting in major body or sheet metal damage, or where the steering column has been

impacted, may also have a damaged or misa ligned steering column. Refer to Section 9 Steering in the MY2005 W L

Service Information.

2 Precautions Page 2-14

Page 2-14

3.4 Discharging The Fuel Lines

The fuel rail on the engine may contain up to

one litre of fuel under pressure.

Disconnecting the fuel lines at any point

without relieving the pressure will cause

petrol to be expelled and may cause fire or

injury.

To discharge the fuel lines:

1 Apply the parking brak e.

2 Remove the fuel pump fuse from the engine compartme nt fuse an d relay panel.

3 With the throttle closed, crank the engine.

NOTE

The engine may start and idle, until the fuel

supply remaining in the lines is exhausted.

4 When the engine stops, engage the starter again for a further 10 seconds to ensure dissipation of any remaining

pressure.

5 Turn the ignition switch to the OFF position.

6 Disconnect the fuel lines from the fuel tank, allowing any remaining fuel to drain, and then seal the apertures with

suitable plastic plugs.

7 Drain the contents of the fuel tank.

NOTE

The fuel tank may contain up to 82 litres of petrol.

9 Remove the tank from the vehicle, refer to Section 8A1 Fuel System in the MY2005 W L Service Information.

10 Seal the fuel tank filler with a plug. Do not use a rag.

2 Precautions Page 2-15

Page 2-15

4 Occupant Protection System

Precautions

The Occupant Protection System (OPS) provides protection additional to the driver and front passenger seatbelts in

three ways:

1 By activating seatbelt pretensioners which tighten the seatbelt during a collision, restricting the occupant’s forward

movement.

2 By deploying a front driver inflatable restraint from the centre of the steering wheel and a front passenger inflatable

restraint from the top left side of the instrument panel pad assembly, dur ing certain frontal collisions.

3 By deploying a side inflatable restraint (where fitted) for the front occupants to offer additiona l protection for the

driver or front passenger during certain side impact collisions.

The Sensing and Diagnostic Module (SDM), located under the front floor conso le, contro ls inflatable restraint and

seatbelt pretensioner deployment. The SDM has the ability to deploy the seatbelt pretensioners only, the pretensioners

and front inflatable restraint or a side inflatable restraint on the side of the vehicle which an impact occurs .

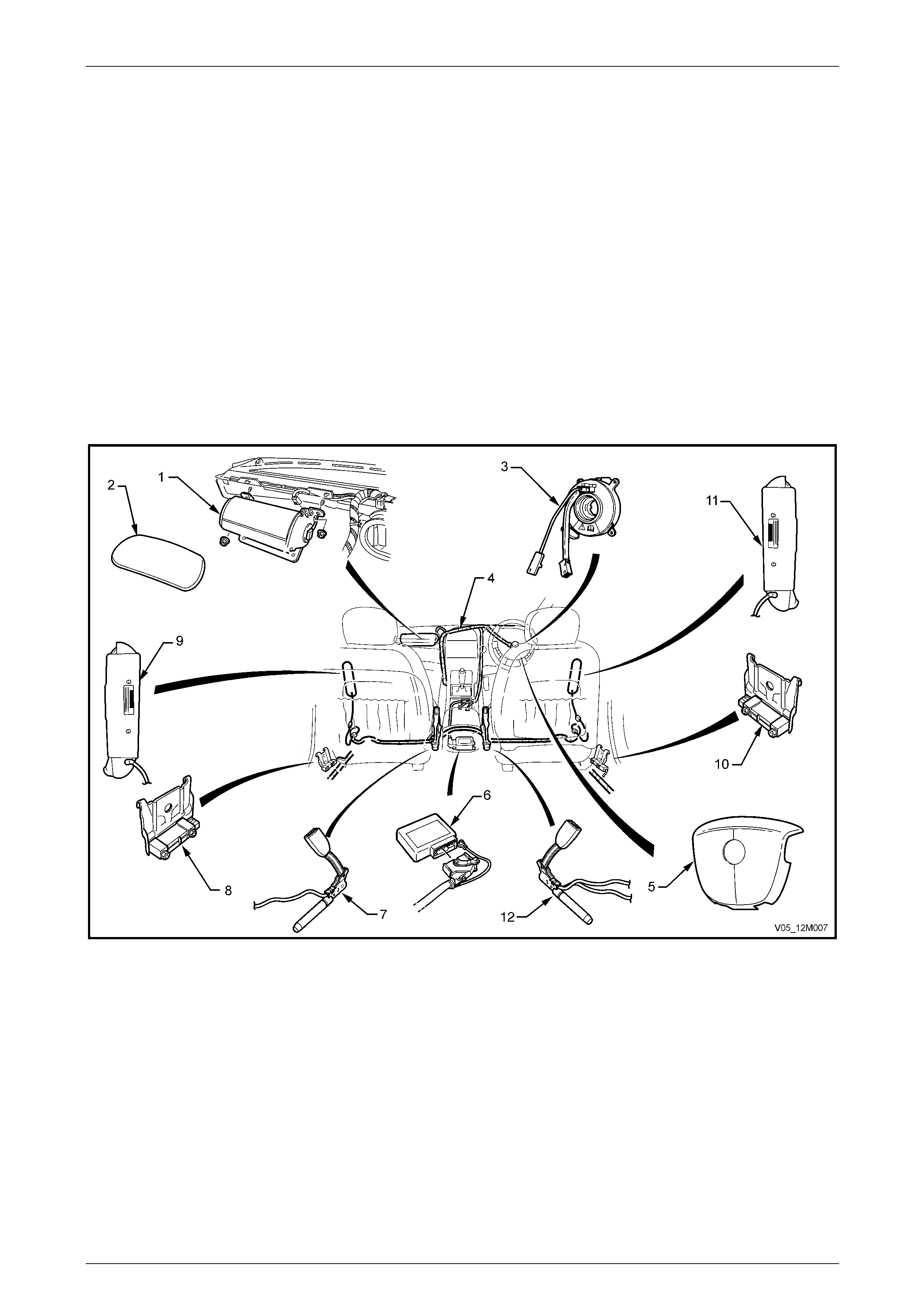

Refer to Figure 2 – 1 for occupant protection system component locations.

Figure 2 – 1

Legend

1 Instrument Panel Inflatable Restraint (passenger airbag)

Assembly

2 Instrument Panel Inflatable Restraint Opening Trim Cover

3 Clock Spring Coil Assembly

4 OPS Wiring Harness (part of front body wiring harness)

5 Steering Wheel Inflatable Restraint (driver airbag) Assembly

6 Sensing and Diagnostic Module (SDM)

7 Left-hand Seat Belt Pretensioner Assembly

8 Left Side-impact Sensor (peripheral acceleration sensor)

9 Left Side-impact Inflatable Restraint (side-impact airbag)

Assembly

10 Right Side-impact Sensor (peripheral acceleration sensor)

11 Right Side-impact Inflatable Restraint (side-impact airbag)

Assembly

12 Right-hand Seat Belt Pretensioner Assembly

2 Precautions Page 2-16

Page 2-16

• Accessory type or after-market bull-bars

or such devices not approved and fitted to

a vehicle with OPS may adversely affect

the vehicle’s desired threshold

characteristics for deployment.

• Accessory and after-market seat covers

must not be fitted to a vehicle with side

inflatable restraints unless approved by

the vehicle manufacturer. Seat covers that

are not approved could greatly inhibit the

performance of the side inflatable

restraint, compromising the occupant’s

safety in the event of side inflatable

restraint deployment.

• Accessory or after-market instrument

panel covers, or the like, must not be

installed. This would greatly inhibit the

performance of the front passenger

inflatable restraint and reduce front

passenger’s safety in the event of an

inflatable restraint deployment.

• Fitting of accessories such as drink

holders, cassette / CD racks, additional

mirrors, etc. are not permitted in the

immediate deployment area of the front

passenger’s inflatable restraint as these

may be propelled towards the occupants

when the airbag is deployed.

4.1 Repairs To Vehicle Structure

Correct operation of the Occupant Protection

System (OPS) requires that any repairs to the

vehicle structure must return it to its original

production configuration.

The procedures to achieve this are in line with those detailed in the rel eva nt Section of th is Supplement.

The integrity of the front side rail assembl ies is critical to the function of the OPS. If the front side rail assemblies are

damaged, or incorrectly repaired following damage, it is possible the OPS will not function as intended, resulting in

incorrect deployment timing and placing the occupant(s) at increased risk of injury.

The following strategy should be used when repairing the front side rail assemblies:

1 If minor damage has occurred to the front of the front side rail assembl y which does not involve significant creasing

or crumple, it may be straightened.

2 If significant creasing or crumple of the front side rail assembly has occurred, but is restricted to the area forward of

the front suspension crossmember, the front side rail assembly may be cut at a point b etween the two

crossmember mounting bolts and a ne w partial section welded in place. For informatio n o n the recomme nded cut

point, refer to Section 4 Front End.

3 If significant creasing or crumple of the front side rail assembly has occurred and continues rearward of the front of

the front suspension crossmember, the full front side rail assembly should be replaced.

2 Precautions Page 2-17

Page 2-17

4.2 Repairs And Inspections Required After

A Collision

Below is listed the components that must be replaced if deployment occurs under the conditions listed. If any OPS

components are damaged, they must be replaced with new parts. If OPS component mounting points are dama ge d, the y

must be repaired or replaced.

NOTE

Never use OPS components from another

vehicle.

The steering wheel must be dimensionally in spected, whether deployment has occurred or not.

Refer to Section 9 Steering, in the MY2005 WL Service Information.

A collision severe Enough to deploy the seatbelt pretensioners but not the Inflatable Restr aints(s).

Replace the follo wing compo nents:

• Any seatbelt worn during the collision,

• Seatbelt pretensioner/s,

• Front seat guide rail and adjuster assembly (where the seat was occupied in the collision),

• Sensing and Diagnostic Module.

A collision where the seatbelt pretens ioners and front inflatable restraint(s) has deployed.

Replace the components as above in addition to:

• Driver inflatable restraint module,

• Steering wheel,

• Clock spring coil,

• Steering column,

• Instrument panel inflatable restraint module (where fitted),

• Instrument panel pad assembly,

• Instrument panel inflatable rest raint opening trim cover,

• Instrument panel inflatable restraint bracket,

• Instrument panel lower bracket.

A collision where a side inflatable restra int has deployed.

Replace the follo wing compo nents:

• Any seatbelt worn during the collision,

• Relevant side front seat assembly (including the side inflatable restraint module),

• Relevant side impact sensor,

• Sensing and Diagnostic Module.

2 Precautions Page 2-18

Page 2-18

4.3 System Disabling And Enabling

Procedure

Disabling the OPS

The SDM can maintain sufficient voltage to

cause SRS deployment for up to 10 seconds

after the ignition switch is turned off or the

battery is disconnected.

NOTE

Disconnection of the battery affects certain

vehicle electronic systems. Refer to

Section 00 Warnings Cautions and Notes in the

MY2005 WL Service Information before

disconnecting the batter y.

1 Disconnect both the battery earth and p ower leads and wait at least 10 seconds before performing a ny work on the

vehicle.

Enabling the OPS

NOTE

Ensure all wiring harness connectors are

connected before reconnecting the batter y leads.

1 Reconnect both the battery power and earth leads.

2 Switch ignition on and observe the OPS (SRS) warning indicator in the inst rument cluster. The warning indicator

should be illuminated for approximately five seconds. During this period the SDM performs a wiring and self-check.

3 If no system faults are detected, the warning indicator will be switched off. If the warning indicator remains

illuminated and an audible alarm chimes, or the warning indicator illuminate s two seconds after it was originally

switched off, an OPS fault is present. Refer to Section 12M Occupant Protection System in the MY2005 WL

Service Information.

2 Precautions Page 2-19

Page 2-19

4.4 OPS Safety Precautions

• Do not use a fast battery charger for starting the vehicle.

• Never disconnect the battery from the vehicle’s electrical s ystem while the engine is running.

• Disconnect the battery from the vehicle’s electrical system before fast battery charging.

• Never disconnect or connect the SDM connector with the ignition turned on.

• After an accident, always replace the individual OPS components.

Refer to 4.2 Repairs And Inspections Required After A Collision.

NOTE

Damaged or defective components must always

be replaced with new parts.

• Always reinstall fasteners in the same location from which they were removed, using the correct tightening torque

where given. If the fastener needs replacing, replace it with the correct part number.

• Because the strength of the windshie ld and its urethane adhesive is critical to the correct deplo yment of the air bag,

always replace these items with parts complying to the correct specification, refer to

Section 1A6 Stationary Windows in the MY2 005 WL Service Information.

• Failure to use the correct product may result in poor retention of the glass. For vehicles with a front passenger

airbag, the windshield must be replaced correctl y to ensure the occupant protection provided by the OPS is

maintained as the windshield supports the passenger airbag during deployment.

• Take care when handling the side impact sensor. Never strike or jar the sensor or adjacent body structure in a

manner which could cause deployment of the side airbag . Never carry a peripher al acceleration sensor b y the

wiring harness leads.

• If a side impact sensor is dropped from a hei ght greater than one metre, it must be replaced.

• Take care when handling the SDM. Never strike or jar the modu le or body structure adjacent to the module in a

manner which could cause deployment of the pretensio ners or inflatable restraints.

• When carrying a live (undeployed) inflatabl e restraint module, ensure that it is al ways pointed away from you. In

case of an accidental deplo ym ent, the likelihood of injury from the airbag is minimised.

• When placing a live inflatable restraint module on a bench or other surface, always face the assembly up. This will

provide free space for the inflatable restraint to expand in case of accident al deployment. Also, never place

anything on top of the inflatable restraint module.

• Never carry the pretensioners, driver’s inflatable restraint modu le, front passenger inflatable restraint module or

side inflatable restraints module by their wiring harness leads.

• Do not apply po wer to a module except as s pecified in the MY2005 WL Service Information.

• Do not attempt to make any repairs or modifications to a module or sensor. A damaged or defective horn bar and

driver airbag inflator module, front passeng er airbag inflator module or side airbag inflat or module must only be

replaced with new parts.

• Always wear gloves and safet y gl asses when handling a deployed pretensioner or inflatable restraint module. The

surface of these components may contain chemicals (e.g. sodium hydroxide) as a result of the gas gen erated

during combustion. T his can irritate the skin. W ash hands with mild soap and water after handling.

• Refer to Section 12M Occupant Protection System in the MY2005 W L Service Informatio n for detailed service

procedures and precautions.

2 Precautions Page 2-20

Page 2-20

5 Electrical Precautions

5.1 Electronic Devices

The vehicle is equipp ed with many electronic devices as standard equipment to monitor and control various vehicle

functions.

These electronic devices are susceptible to damage from severe shock, transient volta ge and high temperatures.

Refer to Section 12O Fuses, Relays and Wir ing Harnesses for descriptions and illustrations of the location of electronic

devices.

2 Precautions Page 2-21

Page 2-21

5.2 Before Repairing The Vehicle

Disconnection of the battery affects certain

vehicle electronic systems. Refer to

Section 00 Warnings, Cautions and Notes in

the MY2005 WL Service Information before

disconnecting the battery.

1 Disconnect both the negative and positive cables from the battery terminals.

2 Check the area adjacent to the damage for electronic devices, particularl y behind trim panels and under the

dashboard.

3 Remove any units that may have been damaged in the impact or may be damaged during repairs.

Paint Ovens

The high temperatures produced in a paint

oven can damage the electronic control

devices and some trim items in the vehicle.

Remove all electronic devices, plastic or

fabric trim items and the dashboard

assembly, before placing the vehicle in a

paint oven that will achieve temperatures

above 70°C.

Welding

MIG or arc welding produces transient voltages that may damage the electronic control devices unless t he following

precautions are observed:

• Always disconnect both terminals of the battery.

• Ensure that the earth clamp is located as close as possible to the welding site.

• Check behind the panels being welded for wiring harnesses. Reposition a ny harness to avoid damage.

• In the vicinity of the repairs, disconnect the wiring harness body earth points.

• Remove any electronic control devices from areas near the damage.

2 Precautions Page 2-22

Page 2-22

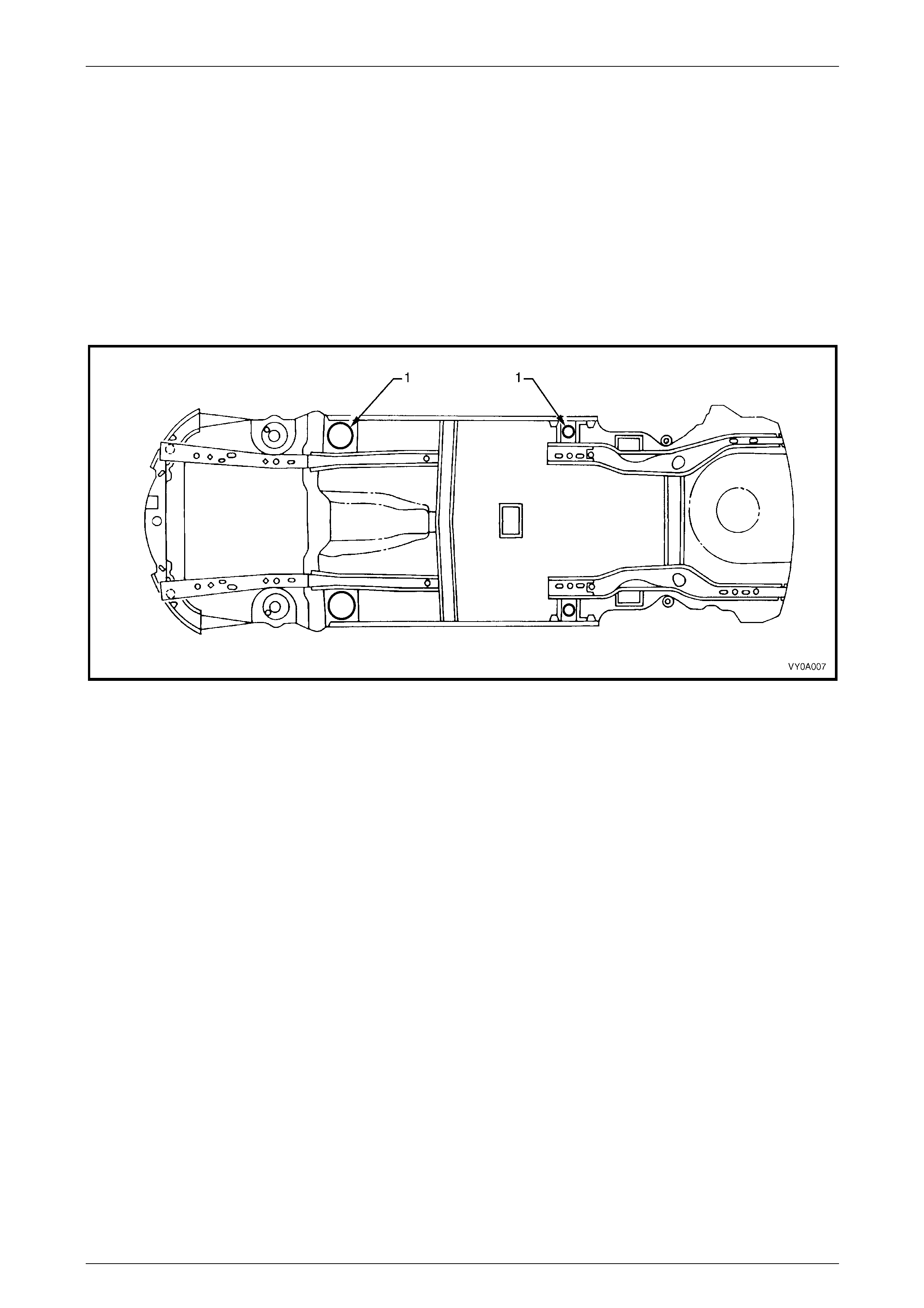

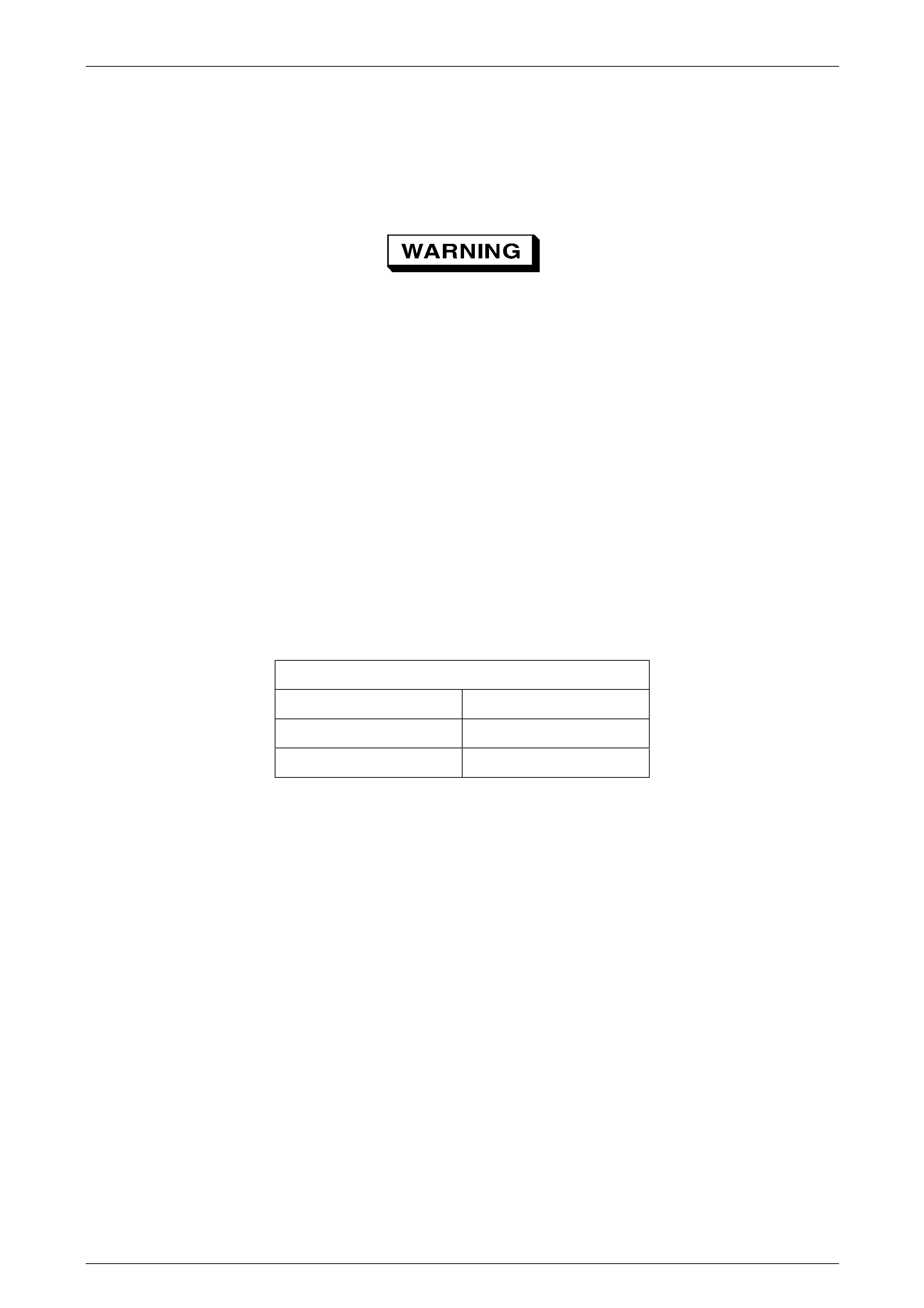

6 Jacking Precautions

NOTE

• When using a trolley jack to raise the vehicle,

it is important that the jack be positioned

under the suspension crossmember or hoist

pad locations (1). Refer to Figure 2 – 2.

• Do not jack under the suspension control

arms. The vehicle should always be

supported by jack stands at the hoist pad

locations when raised.

Figure 2 – 2

2 Precautions Page 2-23

Page 2-23

7 Towing Precautions

The correct lifting or towing equipment is necessary when lifting or towing the vehicle to prevent damage during an y

towing operation.

The preferred method for towing the vehic le is on a vehicle transporter (tilt- t ray, etc.) or with a vehicle and equipment that

has the ability to raise all wheels off the ground. If these methods are not available, then the following can be performed

providing the following preca utions are taken.

NOTE

Towing the vehicle is th e sole responsibilit y o f the

individual tow truck operator and is at his/her

discretion as to the appropriate method of towing

a vehicle in each instance. State and Local laws

must be obeyed at all times.

7.1 Towing On Four Wheels

If unavoidable, the vehicle may be towed on all four wheels taking note of the following precautions:

• Switch the ignition key to the ACC position to free the steering lock.

• Ensure that the transmission is in Neutral position.

• Remove the propeller shaft if the transmission is damaged.

If it is not possible to following these precautions, then the vehicle must be transported on a special vehicle transporter.

NOTE

• Vehicles must not be towed at a speed over

55 km/h unless the propeller shaft is remove d.

• Do not attach towing equipment to the

bumper bars or brackets.

• Only one person (to steer the vehicle) is

permitted in the towed vehicle; passengers

are not allowed.

2 Precautions Page 2-24

Page 2-24

7.2 Towing On Two Wheels

Vehicles must not be towed on the driven

wheels at a speed over 55 km/h unless the

appropriate propeller shaft is removed.

If unavoidable, the vehicle may be towed with two wheels off the ground under the following conditions:

• If towing the vehicle from the rear, do not use the steering lock to lock the front wheels in the straight ahead

position. The steering lock must be free, as the steering lock mechanism a nd ignition switch may be damage d if

used to prevent the steering from moving while towing. Use other appropriate means of securing the steering in the

straight ahead position.

• Take care not to foul the brake pip es. Do not use suspension components as lifting points.

• Ensure the transmission is in the Neutral position.

If it is not possible to following these precautions, then the vehicle must be transported on a special vehicle transporter.

2 Precautions Page 2-25

Page 2-25

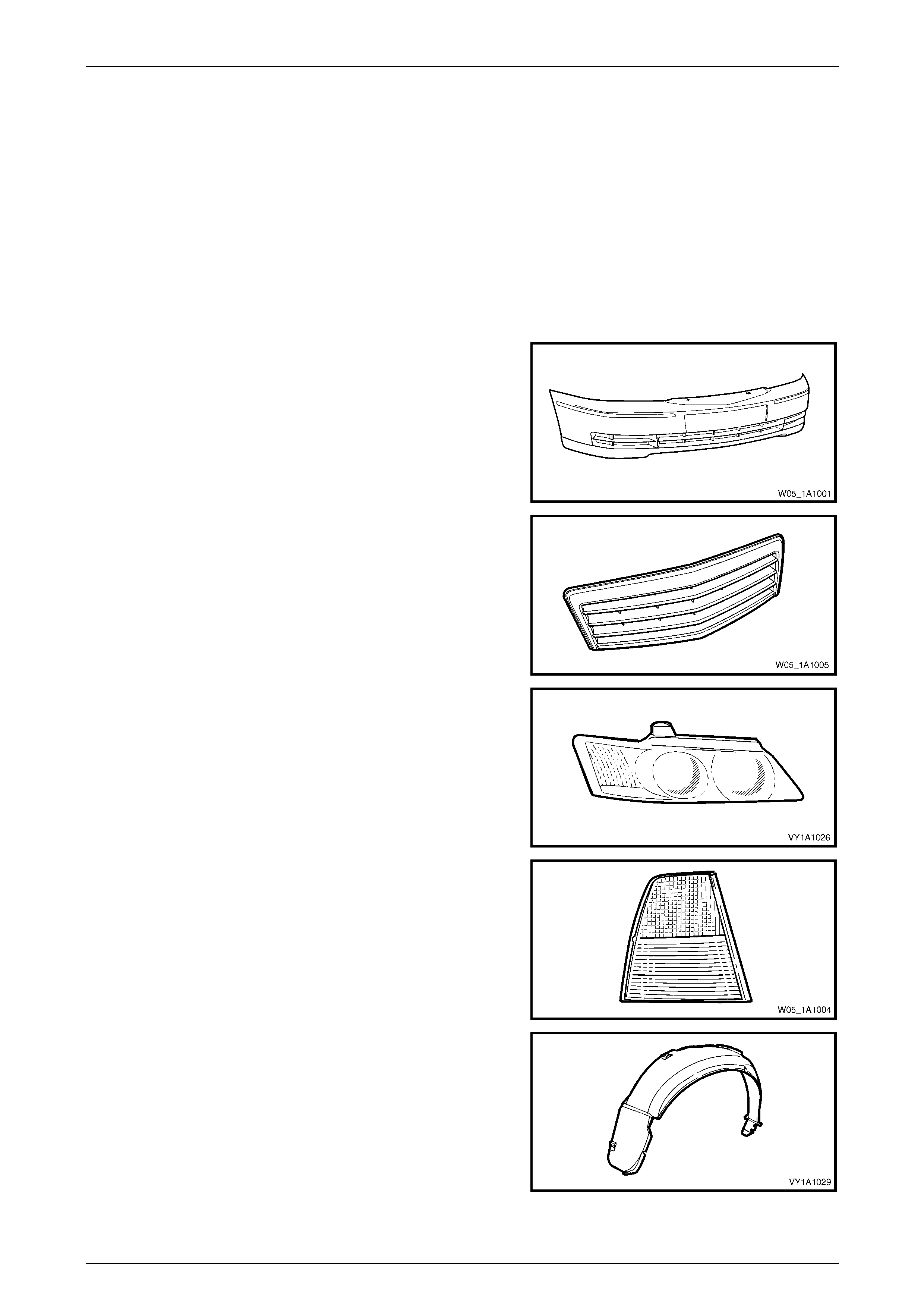

8 Plastic Components

Plastic components are used throughout the vehicl e. The following table is included to ass ist with the identification and

composition of common comp onents. refer to 8.1 Plastic Types for a description of handling procedures for each

different plastic composition.

NOTE

Most components are also identified with the

material code in an incons picuous location.

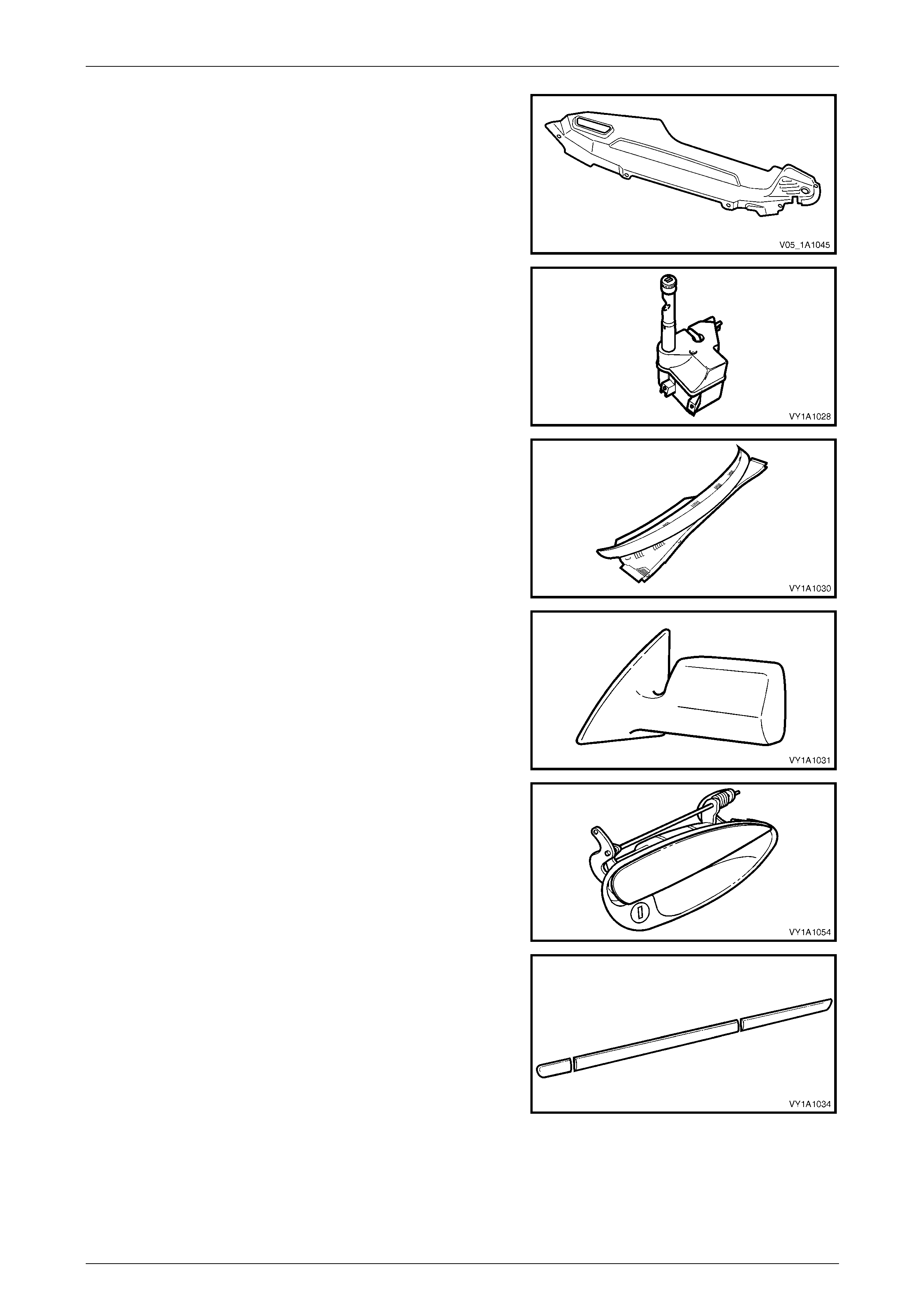

Exterior

Front Bumper Fascia

Material: PP

Radiator Grille Assembly

Material: Painted – ABS, Unpainted – ASA

Headlamp Assembly

Material: Lens – PC, Housing – PP/T30

Tail lamp Assembly

Material: Lens - PMMA, Housing – ABS

Wheelhouse Li ner

Material: PP

2 Precautions Page 2-26

Page 2-26

Upper Radiator Air Baffle

Material: PP

Radiator Overflow Reservoir Assembly

Material: PP

Plenum Cover Assembly

Material: PP

Outside Rear View Mirror Housing

Material: Painted – ABS, Unpainted - ASA / PC

Door Handle Assembly

Material: PA 66

Body Side Moulding

Material: ASA

2 Precautions Page 2-27

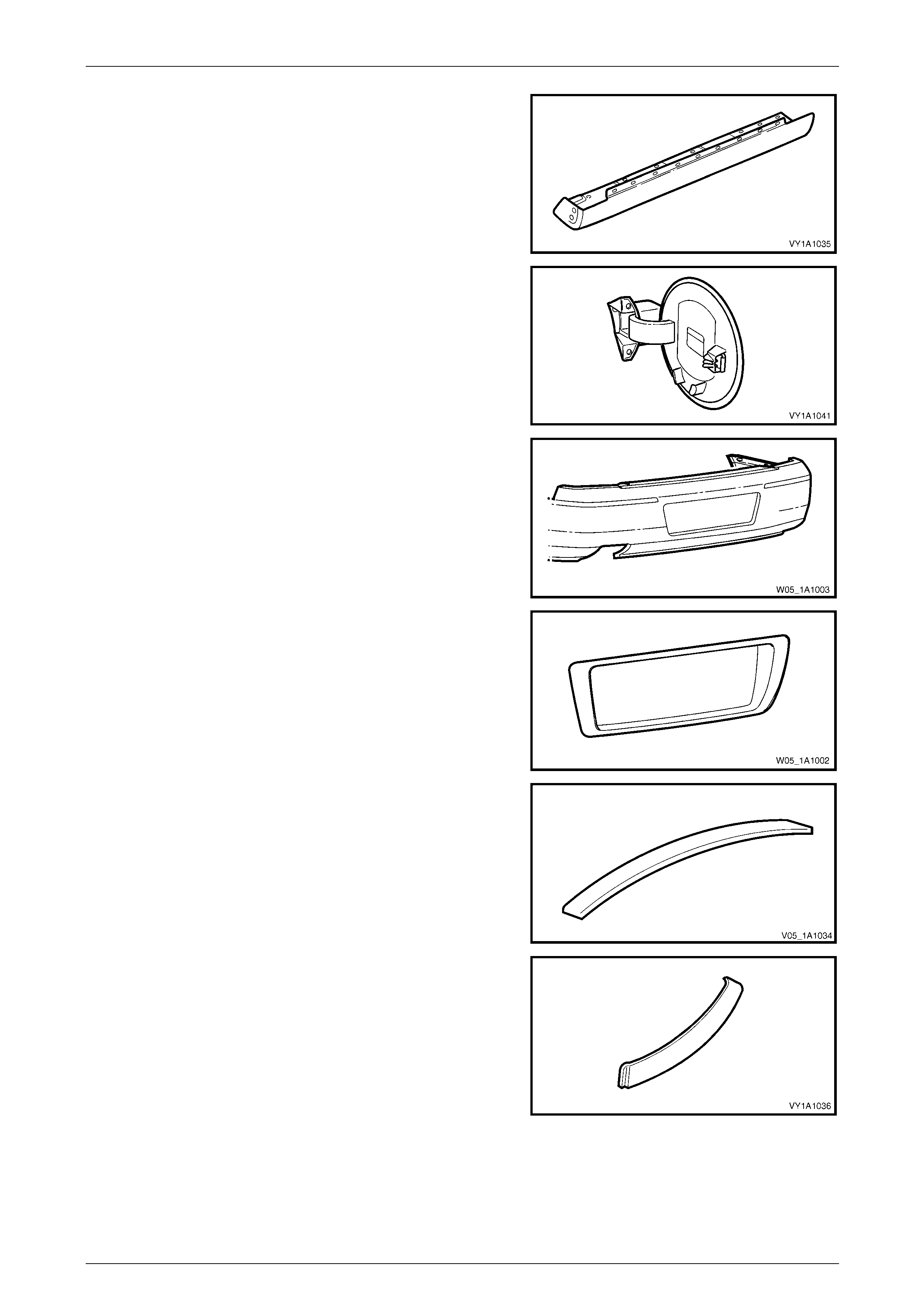

Page 2-27

Rocker Panel Moulding Assembly

Material: PP

Fuel Filler Door

Material: PPE / PA

Rear Bumper Fascia

Material: PP

Rear Licence Plate Surround

Material: ABS

Roof Panel Joint Moulding Assembly

Material: PVC

Quarter Panel Belt Moulding

Material: PPE/PA-M20

2 Precautions Page 2-28

Page 2-28

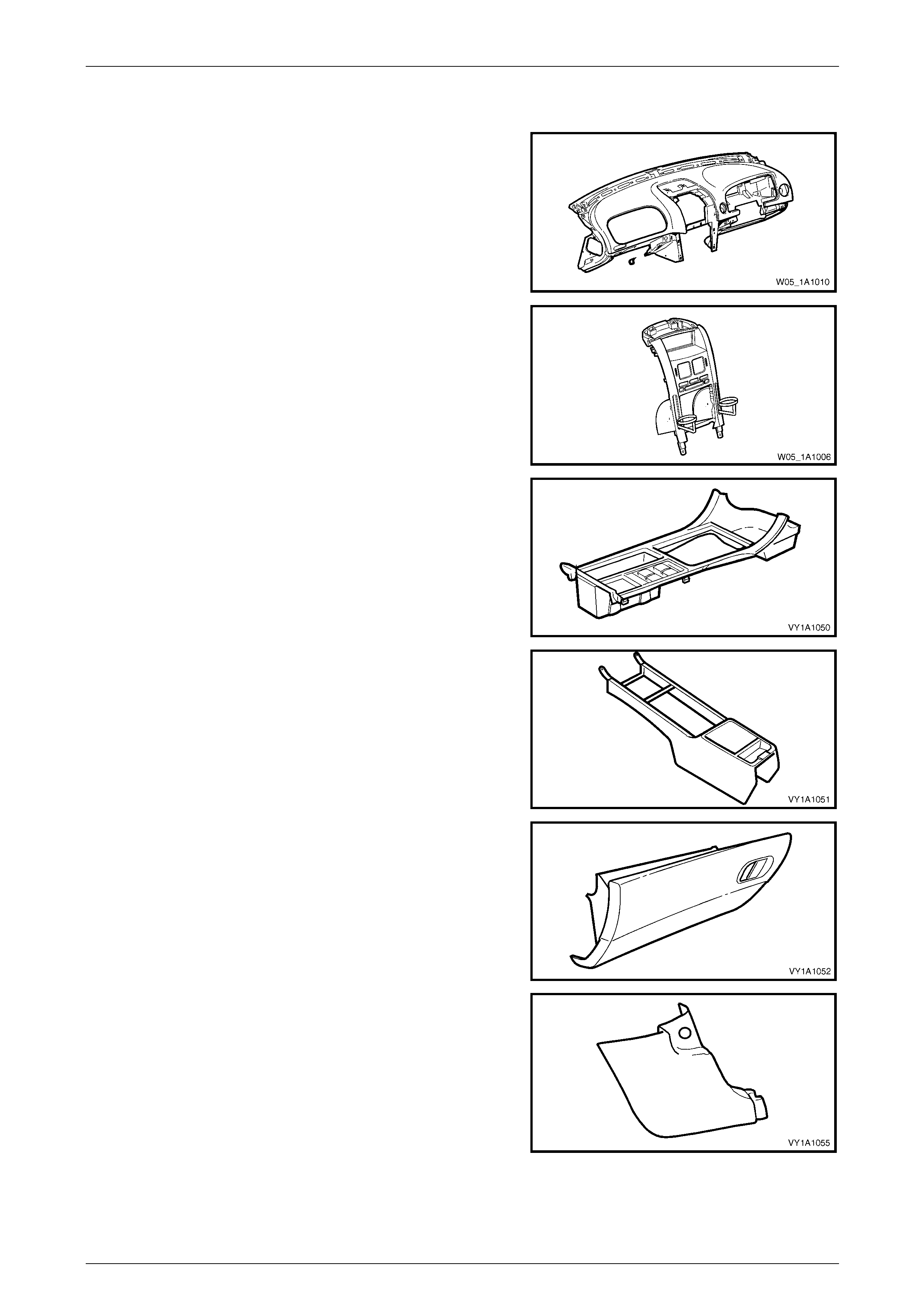

Interior

Instrument Panel Pad Assembly

Material: Carrier – ABS, Pad Substrate – PP, Foam – PVC, Skin - ABS

Instrument Panel Centre Trim Assembly

Material: PC/ABS

Floor Console Cover Assembly

Material: PC/ABS

Front Floor Console

Material: PP

Instrument Panel Compartment

Material: PP

Hinge Pillar Trim

Material: PP

2 Precautions Page 2-29

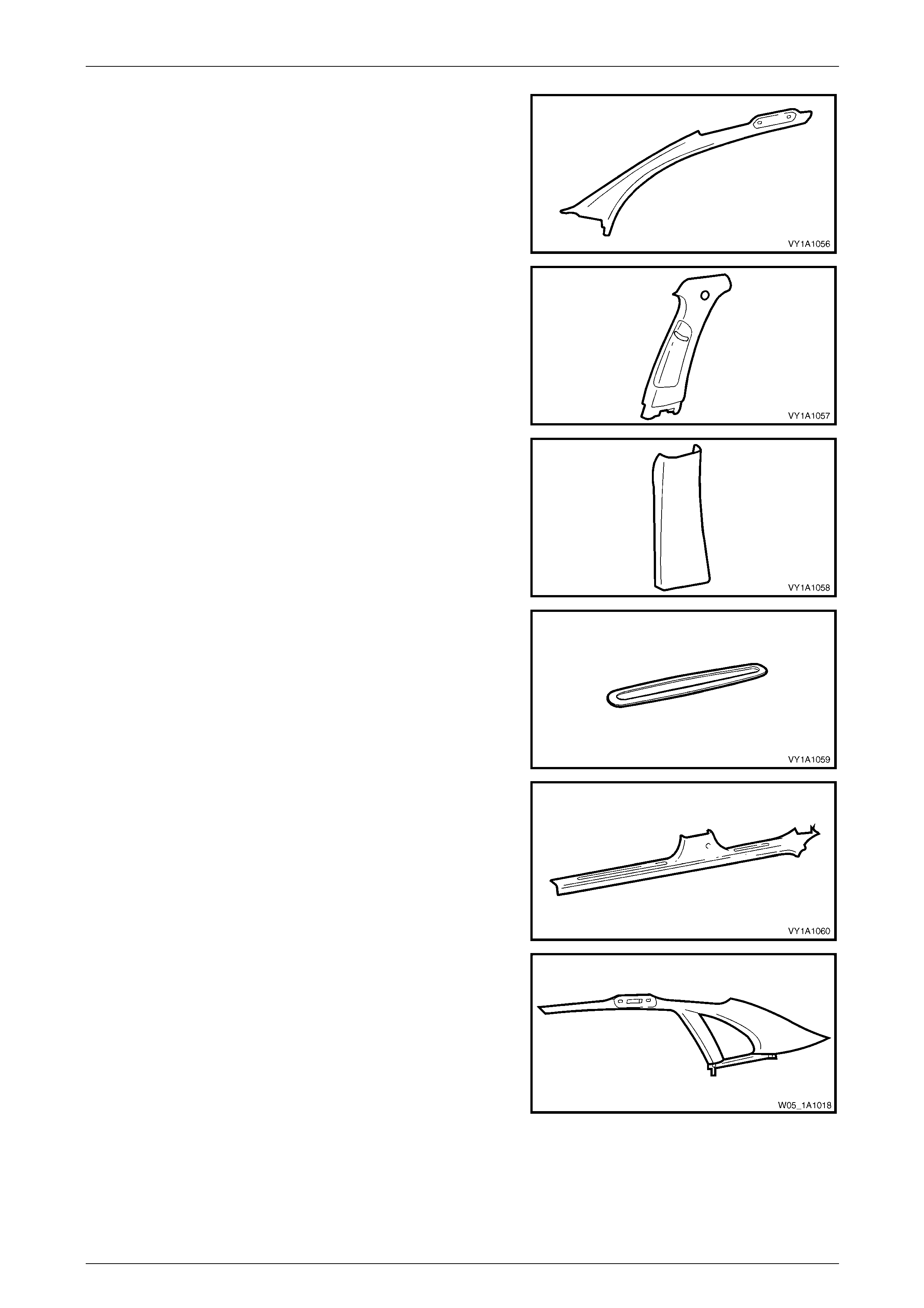

Page 2-29

Windscreen Side Garnish

Material: PP

Centre Pillar Upper Trim

Material: PP

Centre Pillar Lower Trim

Material: PP

Side Sill Trim Plate

Material: PP

Side Sill Trim

Material: PP

Body Lock Pillar Garnish

Material: PP

2 Precautions Page 2-30

Page 2-30

Rear End Trim Panel

Material: PP

8.1 Plastic Types

The repair procedure for plastic body parts must conform with the type of plastic material.

Precautions to be taken with plastic parts are detailed in the following chart:

Code Material Name Heat Resisting

Temp* °C Resistance to

Alcohol or Gasoline NOTES

ABS Acrylonitrile

Butadiene Styrene

Resin

80 Alcohol is harmless if applied only

for short time in small amounts (i.e.

quick wiping to remove grease).

Avoid gasoline and organic

or aromatic solvents.

ASA Acrylate Styrene

Acrylonitrile 80 Alcohol is harmless if applied only

for short time in small amounts (i.e.

quick wiping to remove grease).

Avoid gasoline and organic

or aromatic solvents.

PC Polycarbonate 120 Alcohol is harmless. Avoid gasoline, brake fluid,

wax, wax removers and

organic solvents.

PMMA Polymethyl

Methacrylate 80 Alcohol is harmless if applied only

for short time in small amounts. Avoid dipping or immersing

in alcohol, gasoline,

solvents, etc.

PE Polyethylene 80 Alcohol and gasoline are harmless. Most solvents are harmless.

PP /

PP67 Polypropylene 80 Alcohol and gasoline are harmless. Most solvents are harmless.

PPE Polyphenylene

Ether 100 Alcohol and gasoline are h armless if

applied only for a short time in small

amounts (i.e. quick wiping to remove

grease).

Avoid dipping or immersing

in alcohol, gasoline,

solvents, etc.

PU Polyurethane

Foam 100 Alcohol and gasoline are h armless if

applied only for a short time in small

amounts (i.e. quick wiping to remove

grease).

Avoid dipping or immersing

in alcohol, gasoline,

solvents, etc.

PVC Polyvinyl Chloride 80 Alcohol and gasoline are h armless if

applied only for short time in small

amounts. (i.e. quick wiping to

remove grease).

Avoid dipping or immersing

in alcohol, gasoline,

solvents, etc.

TPO Thermoplastic

Olefin 80 Alcohol is harmless.

Gasoline is harmless if applied only

for short time in small amounts.

Most solvents are harmless

but avoid dipping or

immersing in alcohol,

gasoline, solvents, etc.

PPE/

PA-M20 Modified

Polypropylene

Ether and

Polyamide Alloy

190 Alcohol and gasoline are h armless if

applied only for a short time in small

amounts (i.e. quick wiping to remove

grease).

Avoid dipping or immersing

in alcohol, gasoline,

solvents, etc.

2 Precautions Page 2-31

Page 2-31

9 Special Steel Precautions

A number of different types of steel are used for the panels and b od y structure of vehicles. These are as follows.

9.1 Pre-Coated Steel

In the steel manufacturing process, a corrosi on protection layer of zinc-nickel alloy, galvaneal or zinc ric h coating, is

applied to one or both of the surfaces. This layer is very thin and can easily be burnt or eroded away under repair

conditions.

Most repairs such as sanding, grinding or welding will remove the protective layer. To maintain the corrosio n protection

of the vehicle after repairs, both sides of the panel should be painted with a zinc rich primer, primer surfacer and topcoat

of refinish paint where possible.

NOTE

If it is not possible to cover the inside surface of

the panel with pai nt, cavit y wax should be used to

prevent premature corrosion. Refer to

Section 3 Body Construction in this Supplement.

2 Precautions Page 2-32

Page 2-32

9.2 Re-phosphorised Steel

Re-phosphorised steels are used in many areas for their high strength properties, but can be repaired and welded in the

same manner as conventional low carbon steels.

2 Precautions Page 2-33

Page 2-33

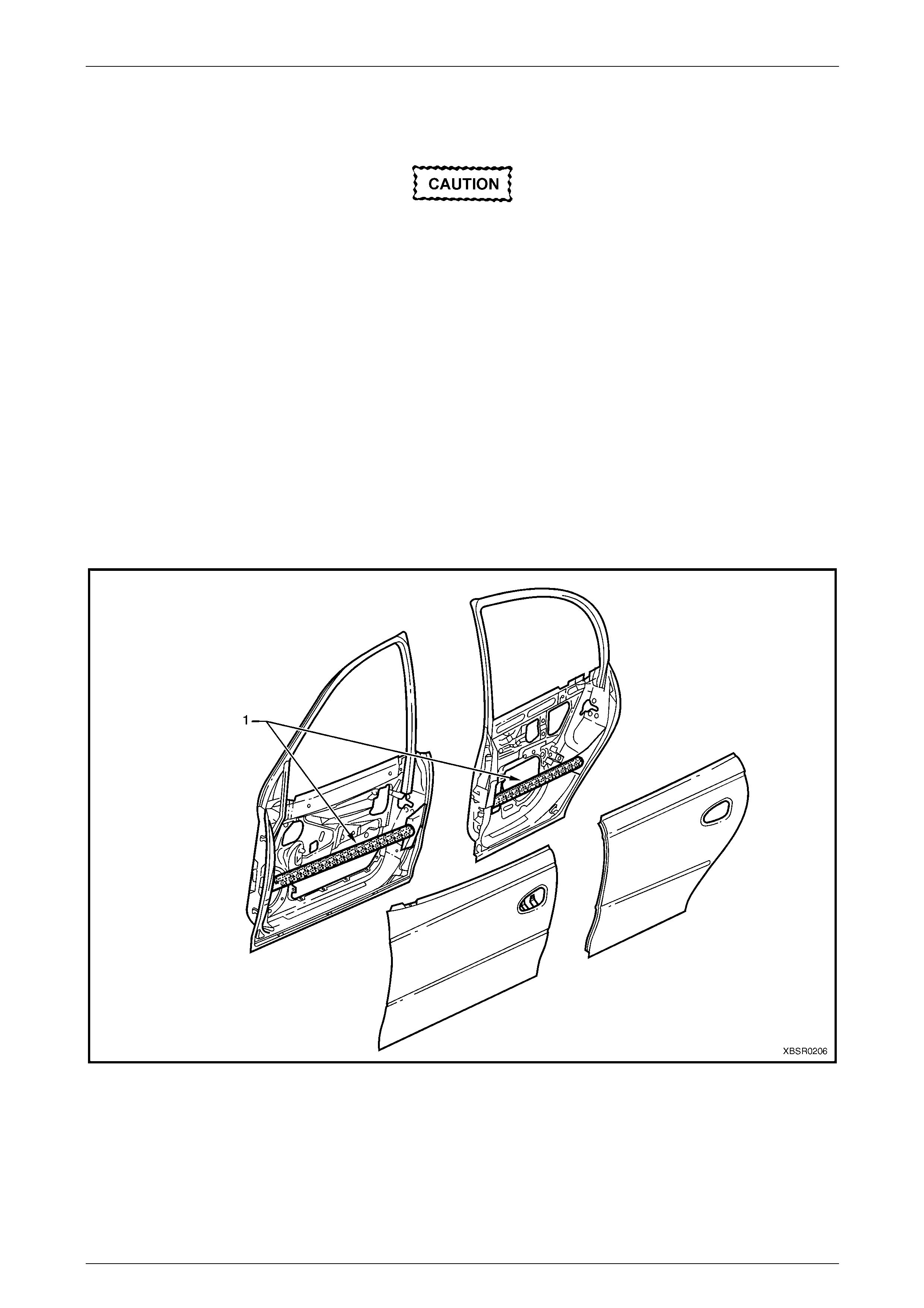

9.3 High Strength Low Alloy Steel

Components manufactured from high

strength low alloy (HSLA) steel must not be

heated, welded or straightened in any way. If

a door anti-intrusion beam or rear side rail

reinforcement is damaged, the only

acceptable practice is to re place the complete

door assembly.

High strength low alloy (HSLA) steels are used in the primar y structure of the v ehicle because of their high strength

properties. Many are readily repairable and weldable using MIG or Arc welding equipment, however some must not be

heated or repaired at all.

Heat sensitivity and repair ability of the material is dependent on the chemical composition of the specific HSLA grade

and/or level of cold work in the manufacture of the part.

The further application of heat may anneal (soften) the material, while cold repair can fatigue and weaken it, leadin g to

failure.

The door anti-intrusion beams (1) fitted within all doors are critical to driver/passen ger safety in side impact

displacements, refer to Figure 2 – 3.

Figure 2 – 3

2 Precautions Page 2-34

Page 2-34

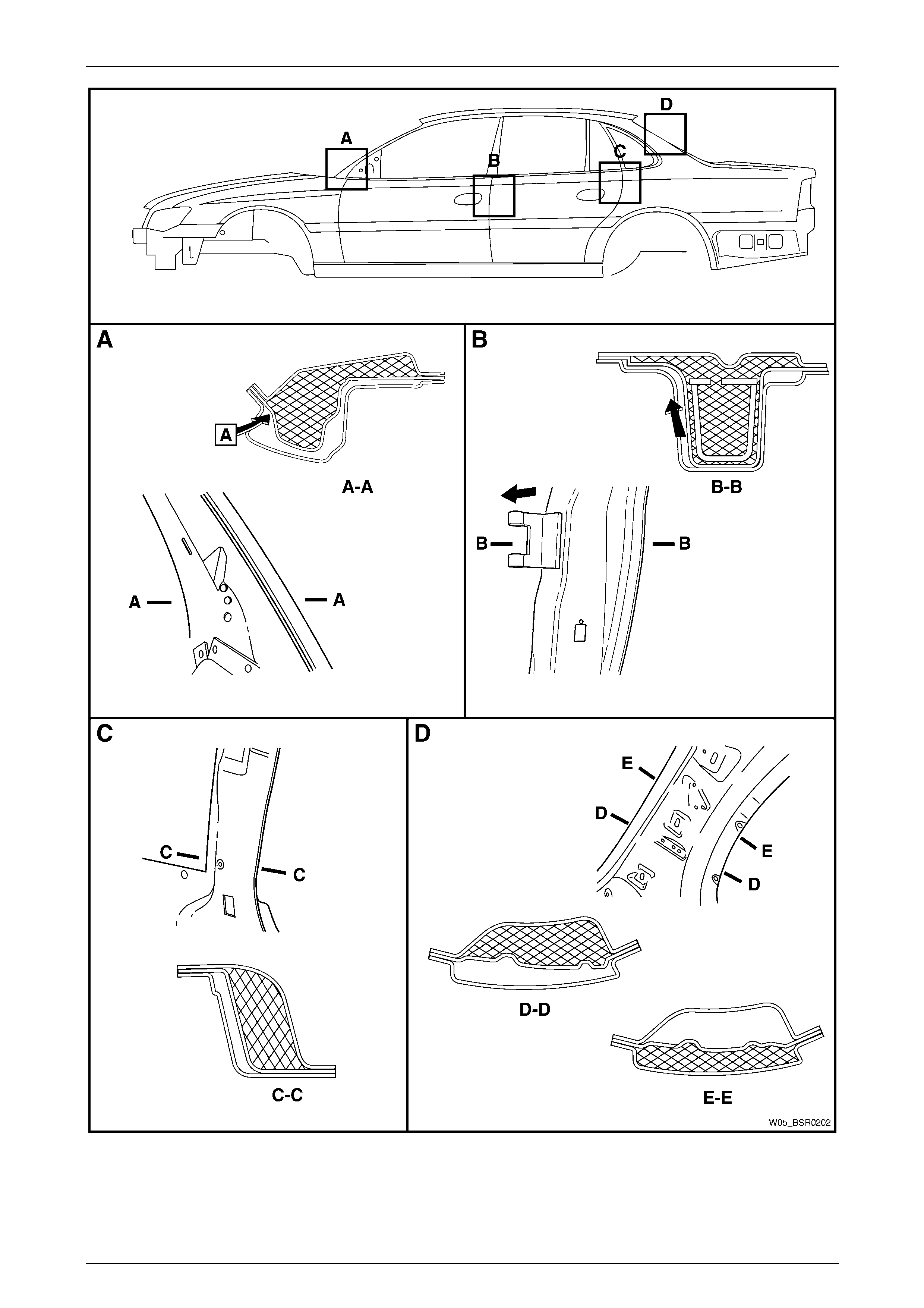

10 Cavity Foam

During manufacture of the vehicle, cavity foam blocks are placed in the hi nge, centre, lock and rear lock pillars. This

material, when subjected to a temperatur e of approximately 160°C, expands up to 10 times its original size to seal the

cavity.

The use of this material poses no health and

safety risk to a repairer, unless it is heated to

temperatures associated with using oxy /

acetylene equipment or welding, as toxic

fumes will be emitted which must not be

inhaled.

Prior to welding or heating in the areas shown, the foam must first be removed, usually by cutting it out with a knife.

If a panel or section is replaced or repair work is carried out where the foam is removed, it must be replaced with a

commercially availabl e equivalent, such as those listed, using the following procedure.

NOTE

• The hinge pillar inner panel assembly and

quarter panel inner assembly service parts

are supplied with unc ured fo a m bl anks. T hes e

must not be removed as they act as a support

for the aerosol cavity foam.

• Always read and follow the directions and

safety instructions with the product prior to

usage.

Cavity Foam Equivalents

Brand Product

Sista Multi Purpose Foam

Selleys Space Invader

2 Precautions Page 2-35

Page 2-35

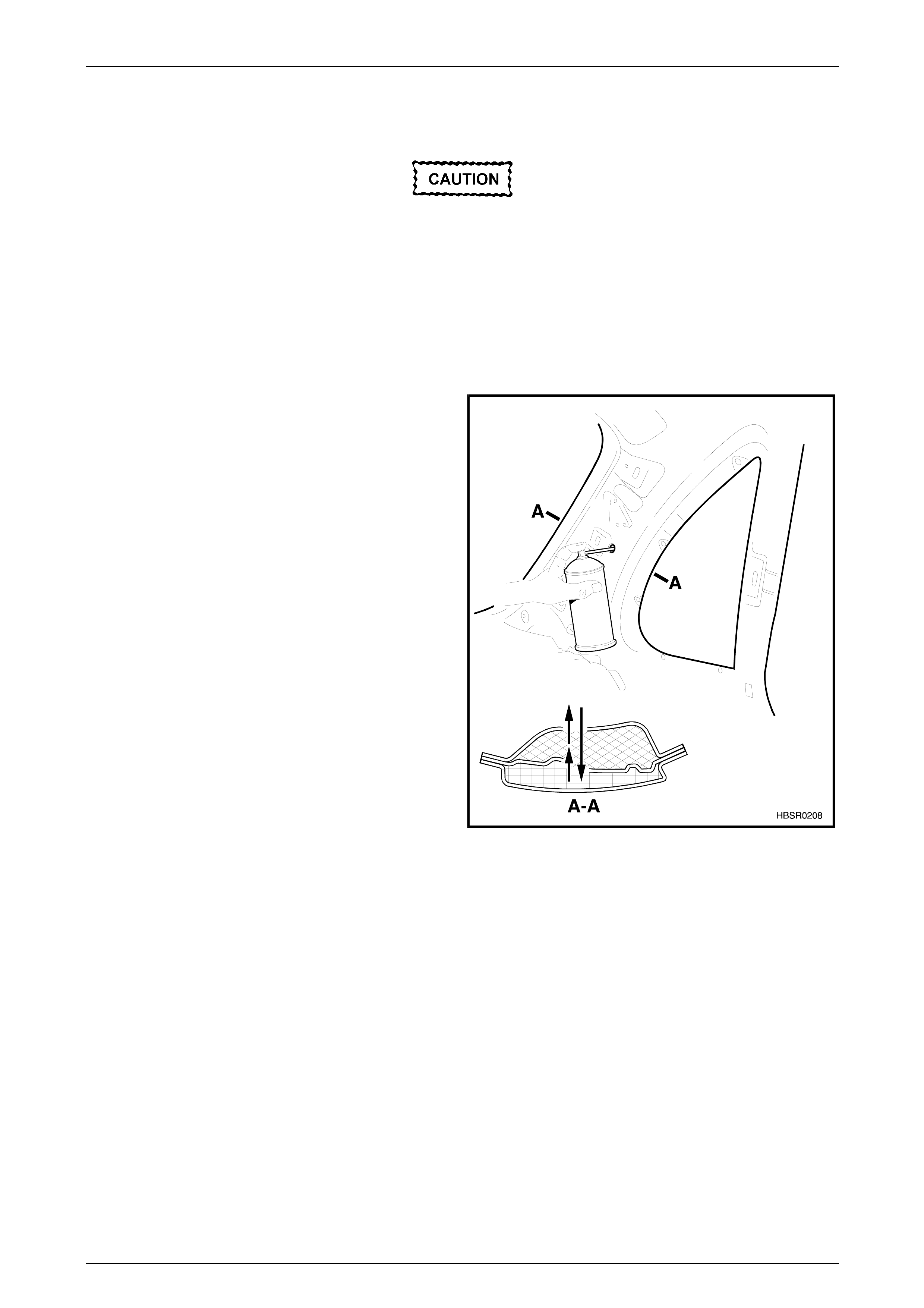

Replace

Take care not to drill into the outer panel.

1 For the hinge, centre and lock pillar, drill a h ole in the quarter panel inner assembl y at the section areas, refer to

Figure 2 – 5, as required. The hole size should be similar to the diameter of the nozzle sup plie d with the

replacement foam.

2 Insert the nozzle into the drilled hol e and spray foam into the cavity for several seconds to fill the area to a height of

approximately 50 mm.

3 For the rear lock pillar, two cavity blocks are installed, refer to D, Figure 2 – 5. Drill a hole in the quarter panel inner

assembly at Section D–D and carefull y continue drilling a further hole thro ugh the back lock pillar reinforcement.

4 Insert the nozzle into the drilled hol e through the

quarter panel inner assembly and back lock pillar

reinforcement and spra y foam into the cavity between

the outer panel and back lock pillar reinforcement for

several seconds to a height of approximately 50 mm.

5 Retract the nozzle into the cavity between the back

lock pillar reinforcement and quarter panel inner

assembly and spray foam to fill this cavity for several

seconds to a height of approximately 50 mm.

Figure 2 – 4

2 Precautions Page 2-36

Page 2-36

Figure 2 – 5