4 Front End Page 4-1

Page 4-1

Section 4

Front End

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

The structure of the body shell has been

developed using complex design and

development techniques. In addition to

meeting all required standards, the vehicle

body is also a critical part of the overall safety

systems. It is therefore imperative the repair

procedures described here are adhered to

during all vehicle body repairs.

1 General Description ...............................................................................................................................2

1.1 Front End Components......................................................................................................................................... 2

2 Service Operations.................................................................................................................................4

2.1 Front End Panel Assembly – Replace.................................................................................................................. 4

Remove................................................................................................................................................................... 4

Replace................................................................................................................................................................... 5

2.2 Headlamp Panel – Replace ................................................................................................................................... 8

Remove................................................................................................................................................................... 8

Replace................................................................................................................................................................. 10

2.3 Front Wheelhouse Bracket Assembly, Front Wheelhouse Bracket and Front Bumper Impact Bar Bracket

Assembly – Replace............................................................................................................................................ 12

Remove................................................................................................................................................................. 12

Replace................................................................................................................................................................. 13

2.4 Radiator Lower Support Assembly – Replace................................................................................................... 15

Remove................................................................................................................................................................. 15

Replace................................................................................................................................................................. 16

2.5 Front Wheelhouse Panel Upper Side Rail – Replace........................................................................................ 17

Remove................................................................................................................................................................. 17

Replace................................................................................................................................................................. 18

2.6 Front Wheelhouse Panel Assembly – Replace.................................................................................................. 19

Remove................................................................................................................................................................. 19

Replace................................................................................................................................................................. 20

2.7 Front Wheelhouse Panel and Front Side Rail – Partial Replace...................................................................... 22

Remove................................................................................................................................................................. 22

Replace................................................................................................................................................................. 23

2.8 Front Side Rail Assembly– Replace................................................................................................................... 25

Remove................................................................................................................................................................. 25

Replace................................................................................................................................................................. 27

2.9 Brake Pressure Modulator Bracket Assembly and Multiuse Relay Housing Bracket.................................... 29

Remove................................................................................................................................................................. 29

Replace................................................................................................................................................................. 29

Brake Pressure Modulator Bracket Assembly.................................................................................................. 30

Multiuse Relay Housing Bracket....................................................................................................................... 30

4 Front End Page 4-2

Page 4-2

1 General Description

This Section describes the replacement procedures for the front-end components of the bod y structure. Removal of bolt-

on panels and mechanical co mponents is not covered. Reference must be made to the appropriate Secti on of the

MY2005 WL Service Information.

When repairing the front end of the vehicle, care must be taken to ensure the structure is returned to its original

production configuration for th e occupant protection system to operate correctly. This is especially im portant with repairs

to the front side rails.

Incorrect repair of the front side rails could cause the seatbelt pretensioners and airbag(s) to oper ate incorrectly, affecting

the timing of deployment during a collision.

The following strategy must be used when repairing the fro nt side rai ls:

1 If minor damage has occurred to the front section of the front side rail, which does not inv olve significant creasing

or crumple of the rail, it may be straightened.

2 If significant creasing or crumple of the rail has occurred, but is restricted to the area forward of the front

suspension crossmember, the front side rail may be cut at a point between the two crossmember mounting bolts

and a partial section welded in place as described in this Section.

3 If significant creasing or crumple of the rail has occurred and continues rear ward of the front suspension

crossmember, the full front side rail assembly must be replaced.

NOTE

It is imperative the correct body adhesives,

sealers, deadeners and cavity waxes are used

when repairing the body structure of vehicle.

Refer to Section 3 Body Construction for details

of the correct materials and their commercially

available equivalents.

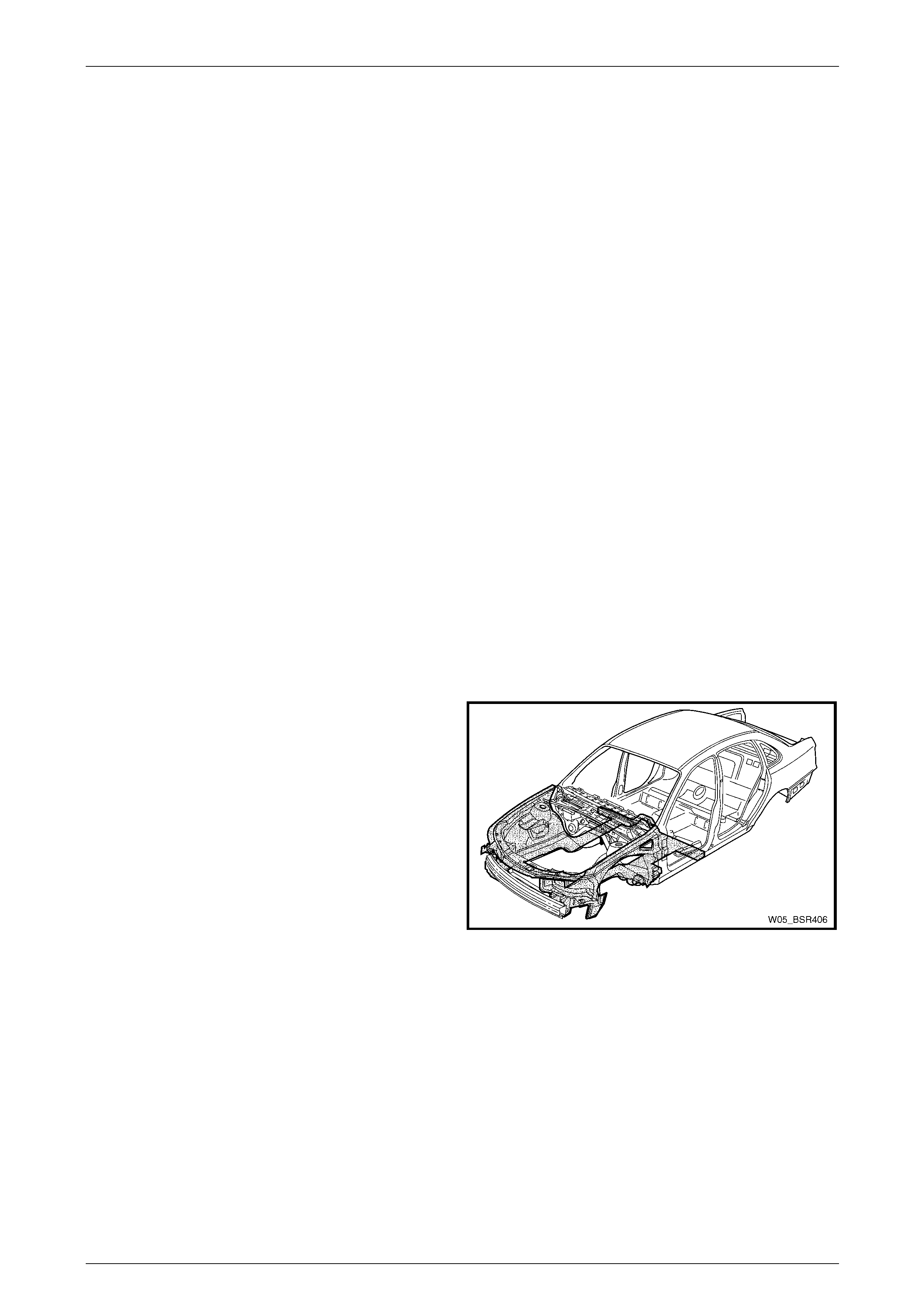

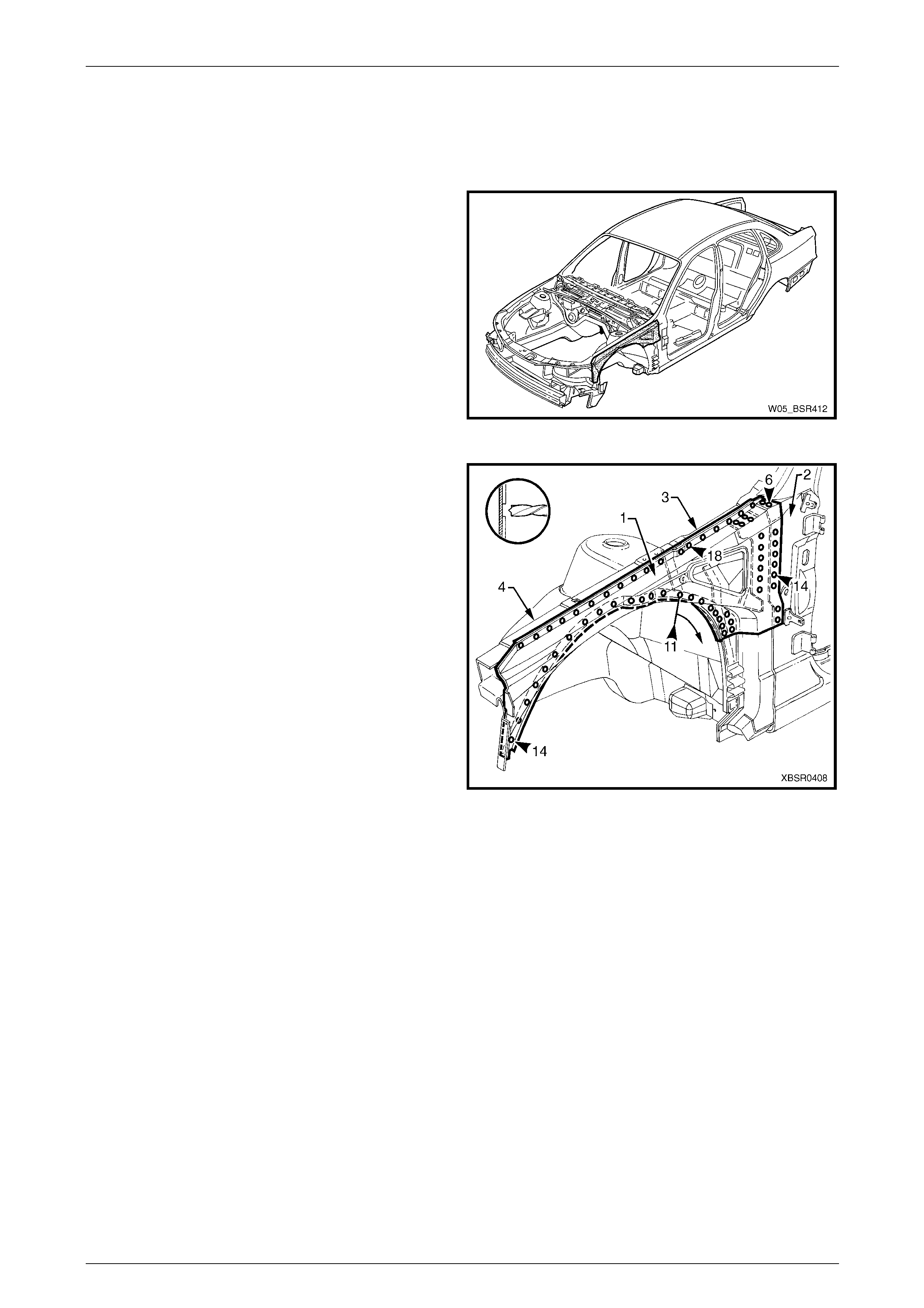

1.1 Front End Components

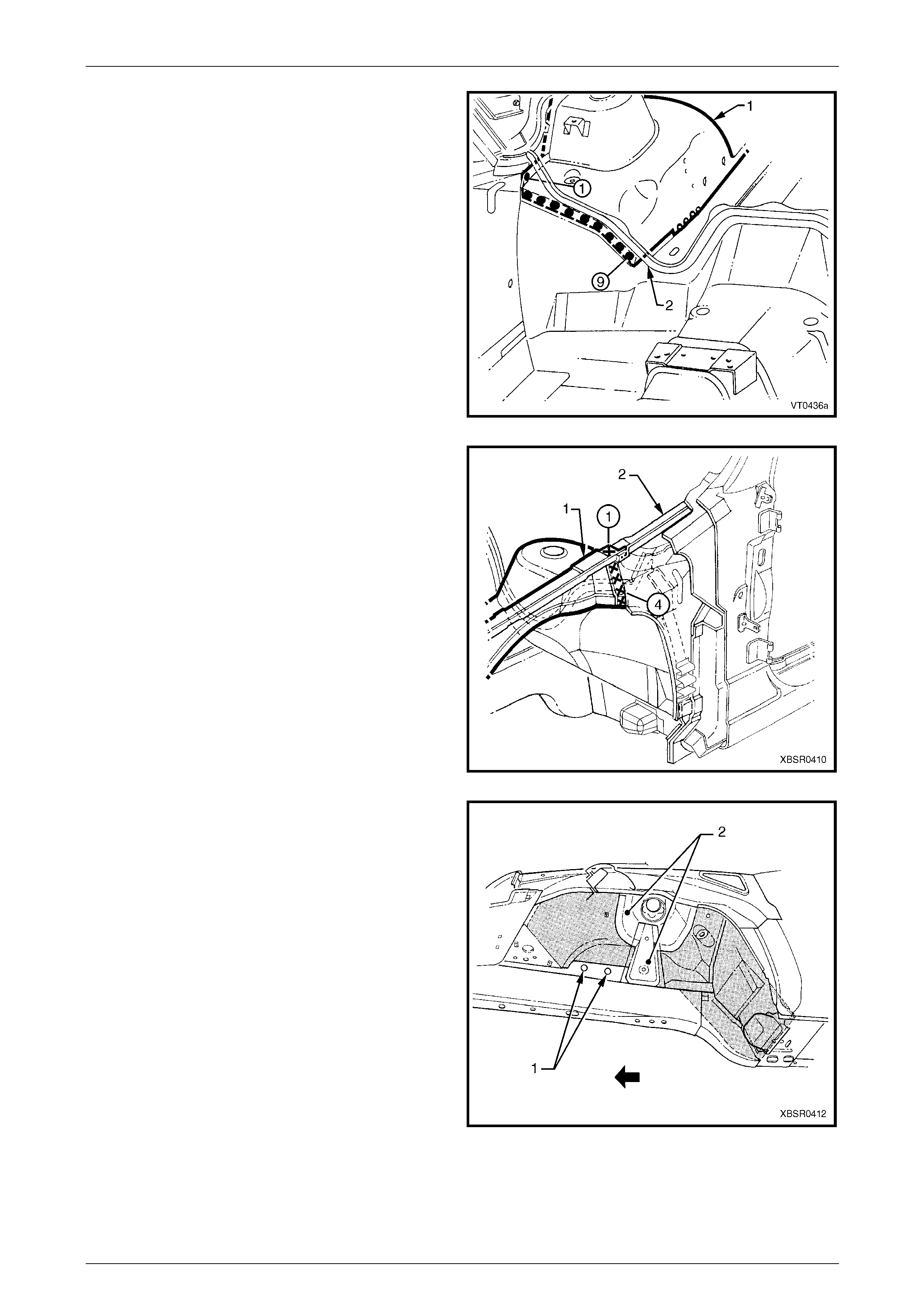

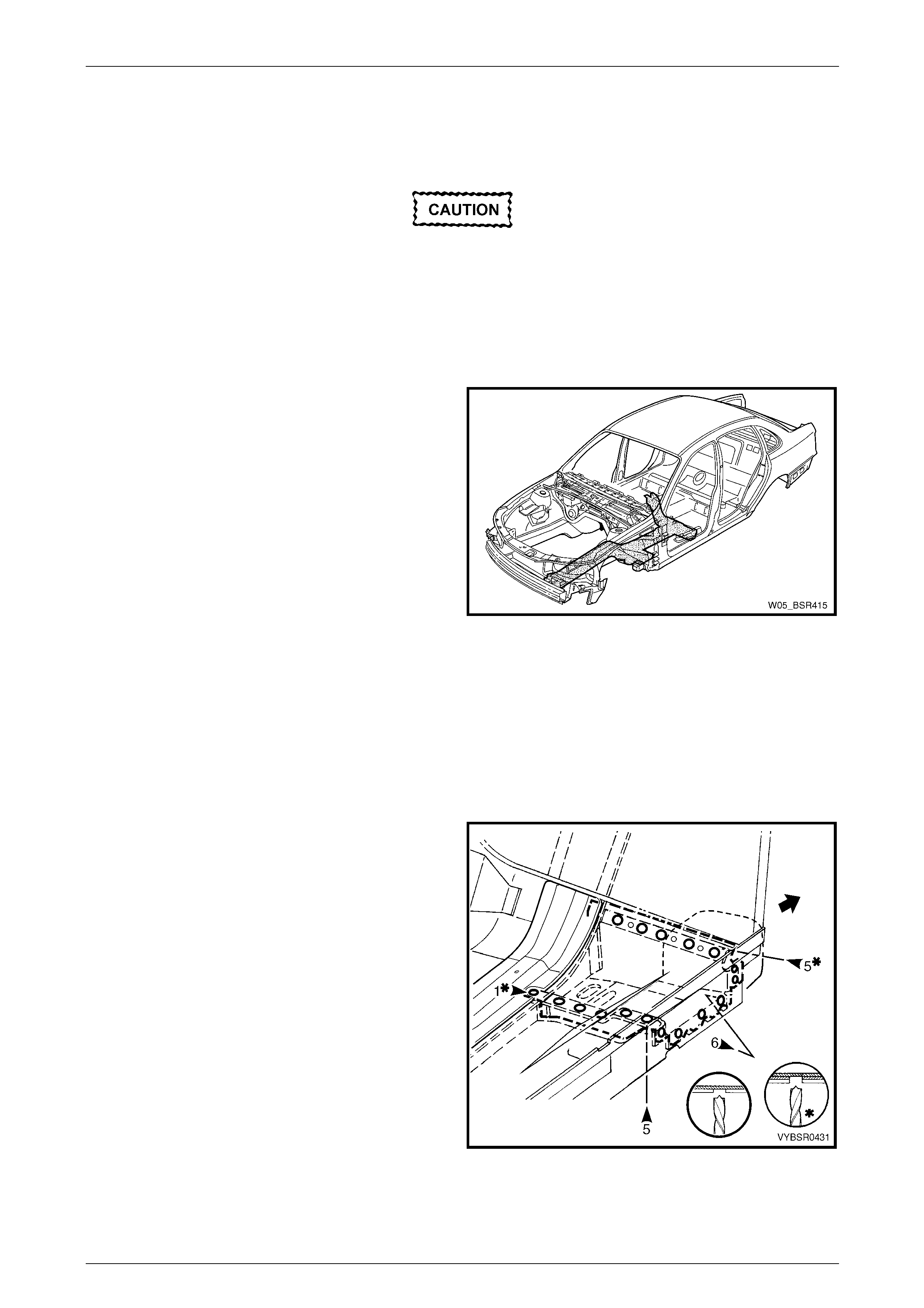

The shaded components in Figure 4 – 1 are those dealt with

in this Section.

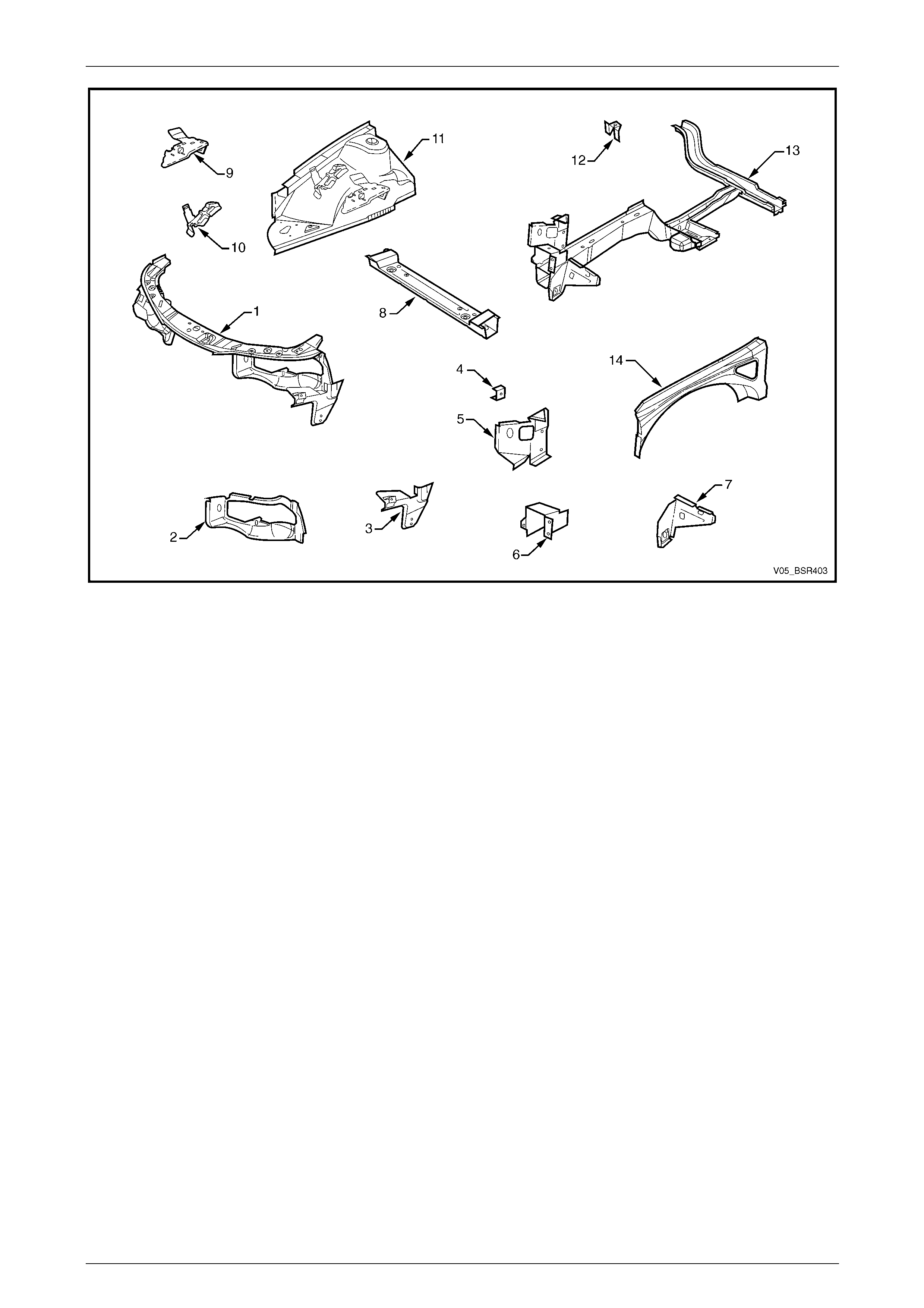

The components and assemblies shown in Figure 4 – 2 are

the serviceable parts that form the basis of the repair

procedures in this Section. For a detailed view of the body

components, refer to Section 3 Body Construction.

NOTE

Always refer to an Authorised Retailer for spare parts

availability configurations.

Figure 4 – 1

4 Front End Page 4-3

Page 4-3

Figure 4 – 2

Legend

1 Front End Panel Assembly

2 Headlamp Panel, Right-hand / Left-hand

3 Headlamp and Front Fascia Mount Bracket, Right-hand /

Left-hand

4 Radiator Side Mounting Bracket, Right-hand / Left-hand

5 Front Wheelhouse Bracket Assembly, Right-hand / Left-

hand

6 Front Bumper Impact Bar Bracket, Right-hand / Left-hand

7 Front Wheelhouse Panel Bracket, Right-hand / Left-hand

8 Radiator Lower Support Assembly

9 Brake Pressure Modulator Bracket Assembly

10 Multiuse Relay Housing Bracket

11 Front Wheelhouse Panel Assembly, Right-hand / Left-hand

12 Horn Bracket Assembly

13 Front Side Rail Assembly, Right-hand / Left-hand

14 Front Wheelhouse Panel Upper Side Rail, Right-hand / Left-

hand

NOTE

• Front end panel assembl y (1) includes parts 2

and 3.

• Front side rail assembly (13) includes parts 4,

5, 6 and 7.

4 Front End Page 4-4

Page 4-4

2 Service Operations

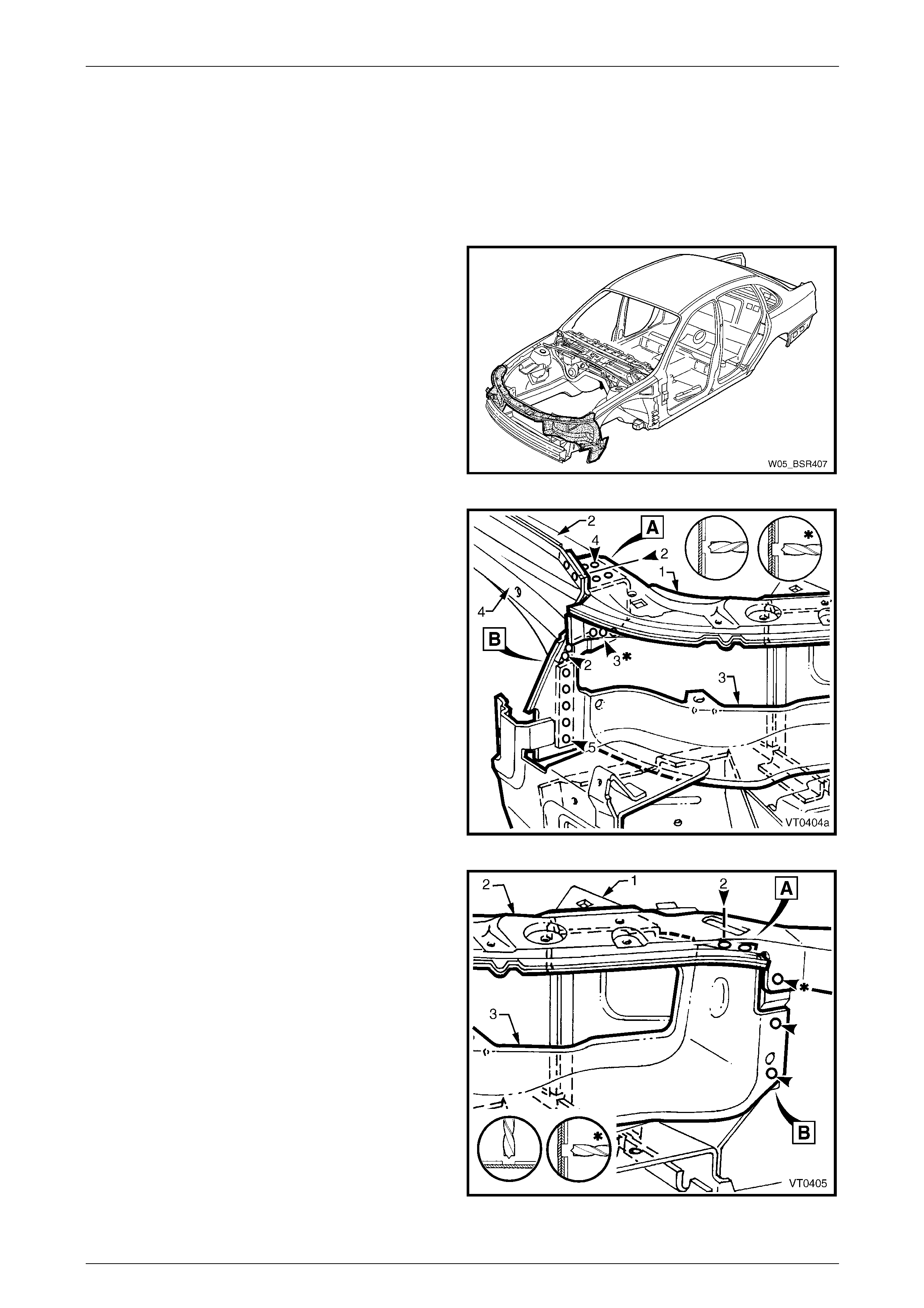

2.1 Front End Panel Assembly – Replace

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

WL Service Information.

2 Remove the front bumper impact bar assembly,

refer to Section 3 Body Construction.

3 If required, mount the vehicle on a suitable ji g or

secure an appropriate tool between the two front

wheelhouse panels to maintain correct body alignment

when the front panel is removed.

Figure 4 – 3

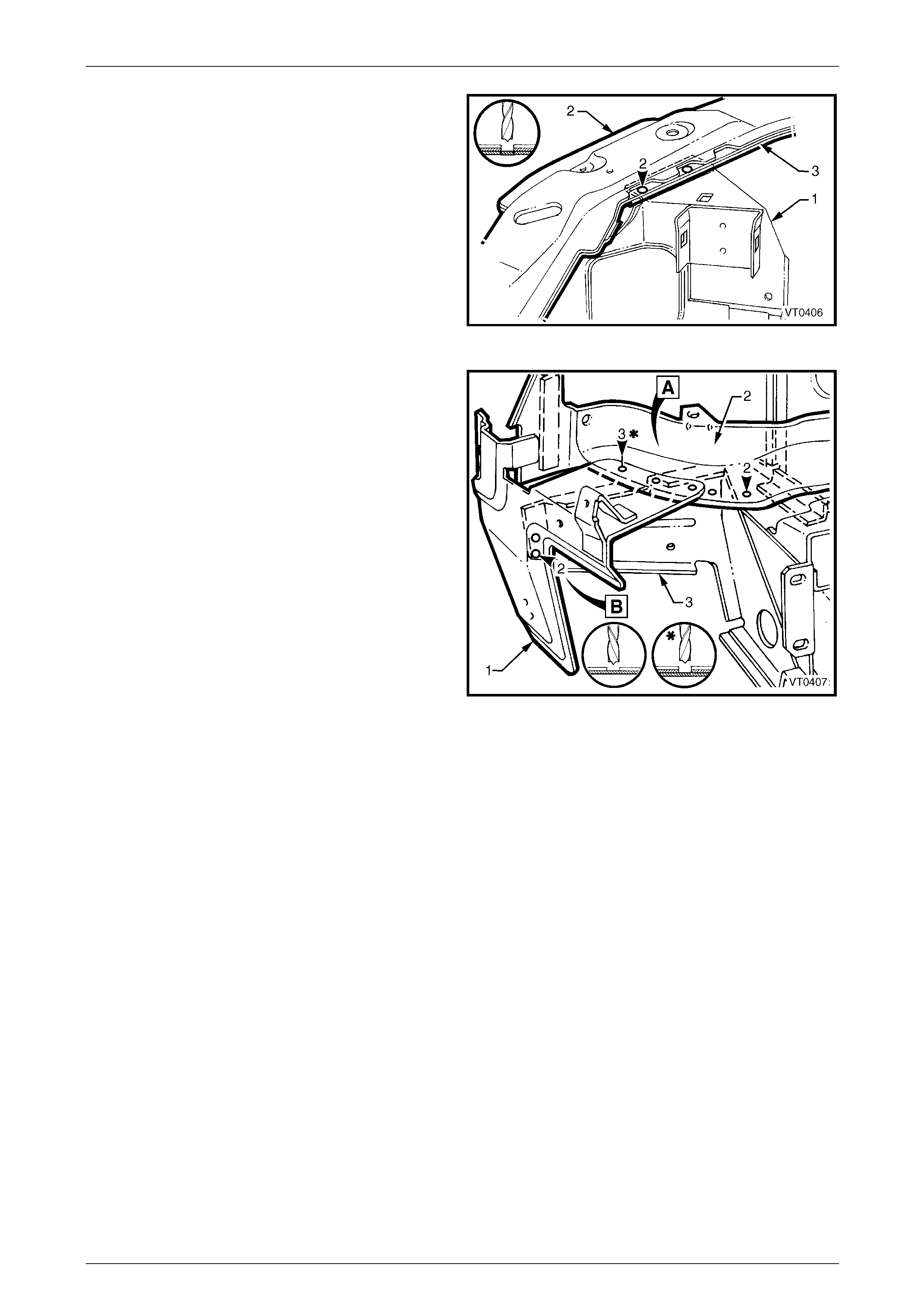

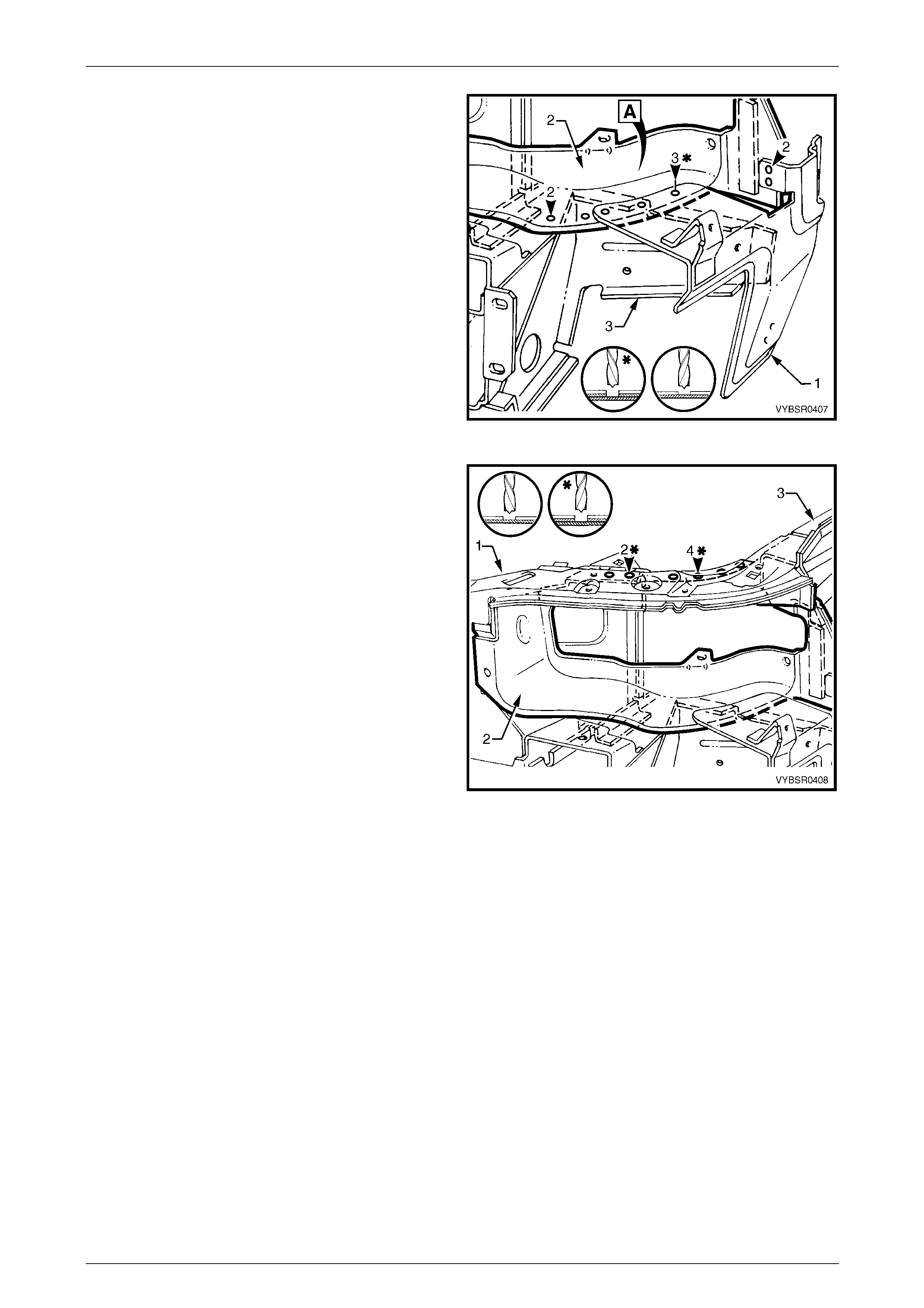

4 On each side of the vehicle, spot cut the welds

attaching the front end panel upp er (1) to the front

wheelhouse panel (2). Four welds are on the

horizontal surface and two on the vertical flange.

Refer to weld group A.

5 Spot cut a total of 10 welds on each side of the

vehicle, attaching the headlamp panel (3) to the front

wheelhouse panel (2) and to the wheelhouse upper

side rail (4). Refer to weld group B.

Figure 4 – 4

6 On each side of the vehicle, spot cut the welds

attaching the front wheelhouse bracket assembly (1)

to the front end panel upper (2) and headlamp panel

(3). Refer to weld group A.

7 On each side of the vehicle, spot cut the three welds

on the vertical flange attaching the headlamp panel

and front end panel upper to the front wheelhouse

bracket assembly. Refer to weld group B.

Figure 4 – 5

4 Front End Page 4-5

Page 4-5

8 On each side of the vehicle, spot cut the welds

attaching the front wheelhouse bracket assembly (1)

to the front end panel upper (2) and headlamp panel

(3).

Figure 4 – 6

9 On each side of the vehicle, spot cut the welds

attaching the headlamp and fr ont fascia mount bracket

(1) and headlamp panel (2) to the front wheelhouse

panel. Refer to weld group A.

10 Spot cut the two welds on each side of the vehicle

attaching the headlamp and fr ont fascia mount bracket

to the front wheelhouse panel bracket (3).

Refer to weld group B.

11 Remove the complete front end panel assembly from

the vehicle and then repair any damage to the

adjacent parts as required.

12 Check and rectify the alignme nt of the bod y as

required, refer to Section 3 Body Construction.

Figure 4 – 7

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as req uired.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as requir ed,

refer to Section 3 Body Construction.

3 Install the panel in position and secure with clamps.

4 Front End Page 4-6

Page 4-6

4 Temporarily install the fenders and hood and check

the alignment and margins.

Refer to Section 3 Body Construction. Adjust where

necessary, and then remove fenders and hood.

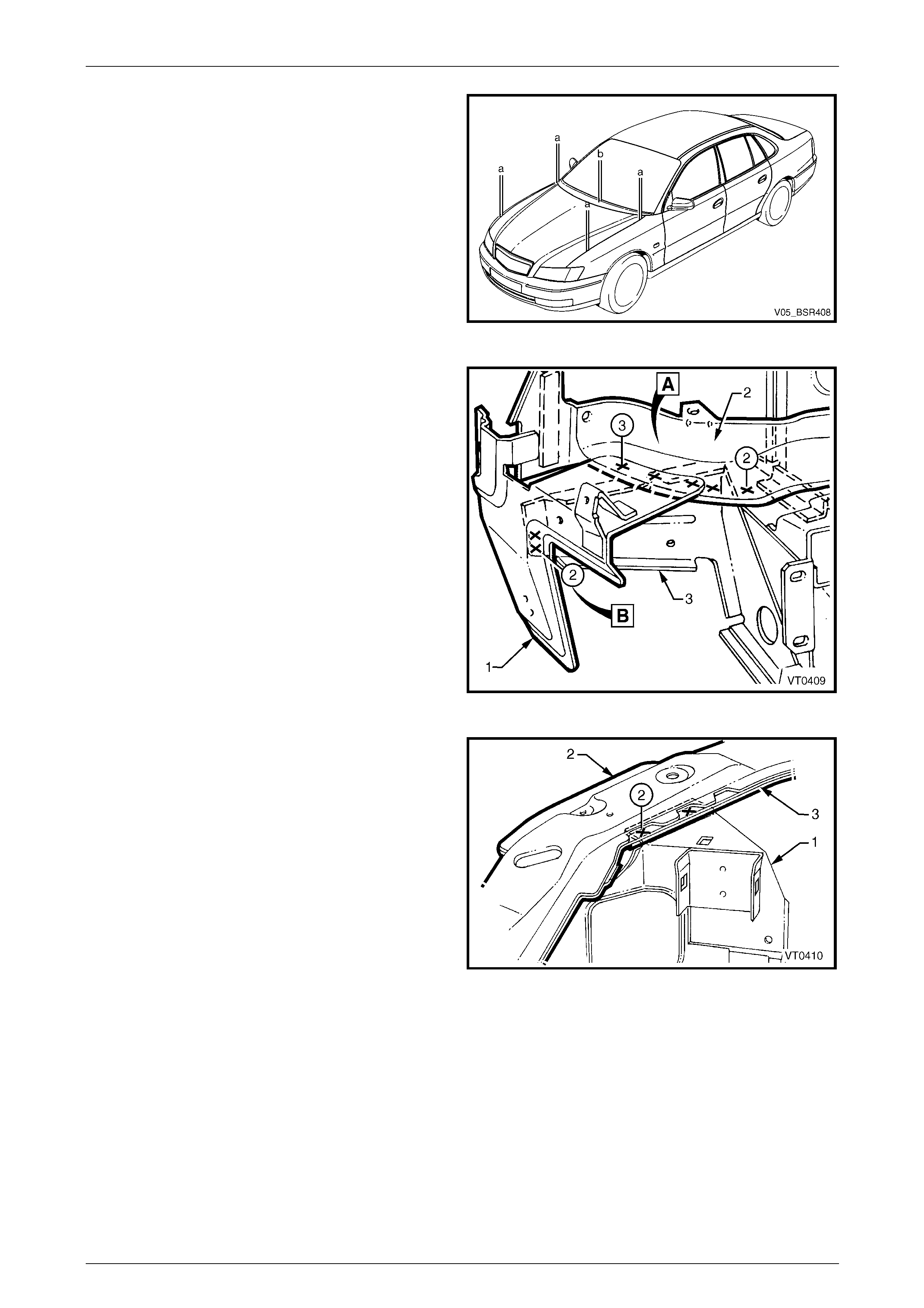

Figure 4 – 8

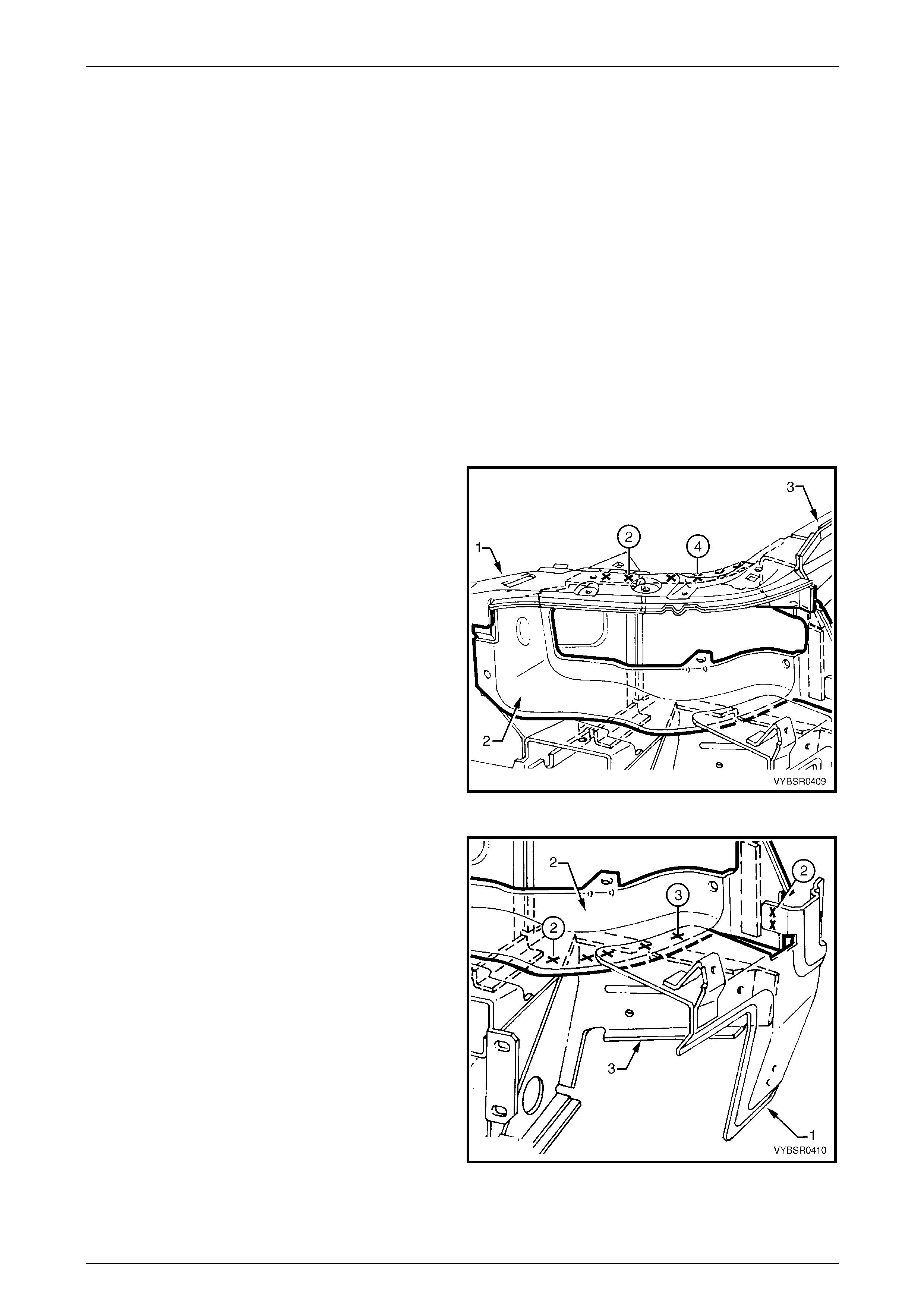

5 Spot weld the headlamp an d front fascia mount

bracket (1) and headlamp panel (2) to the front

wheelhouse panel. Refer to weld group A.

6 Spot weld the headlamp an d front fascia mount

bracket to the front wheelhouse panel bracket (3).

Refer to weld group B.

Figure 4 – 9

7 On each side of the vehicle, spot weld the front

wheelhouse bracket assembly (1) to the front end

panel upper (2) and head lamp panel (3).

Figure 4 – 10

4 Front End Page 4-7

Page 4-7

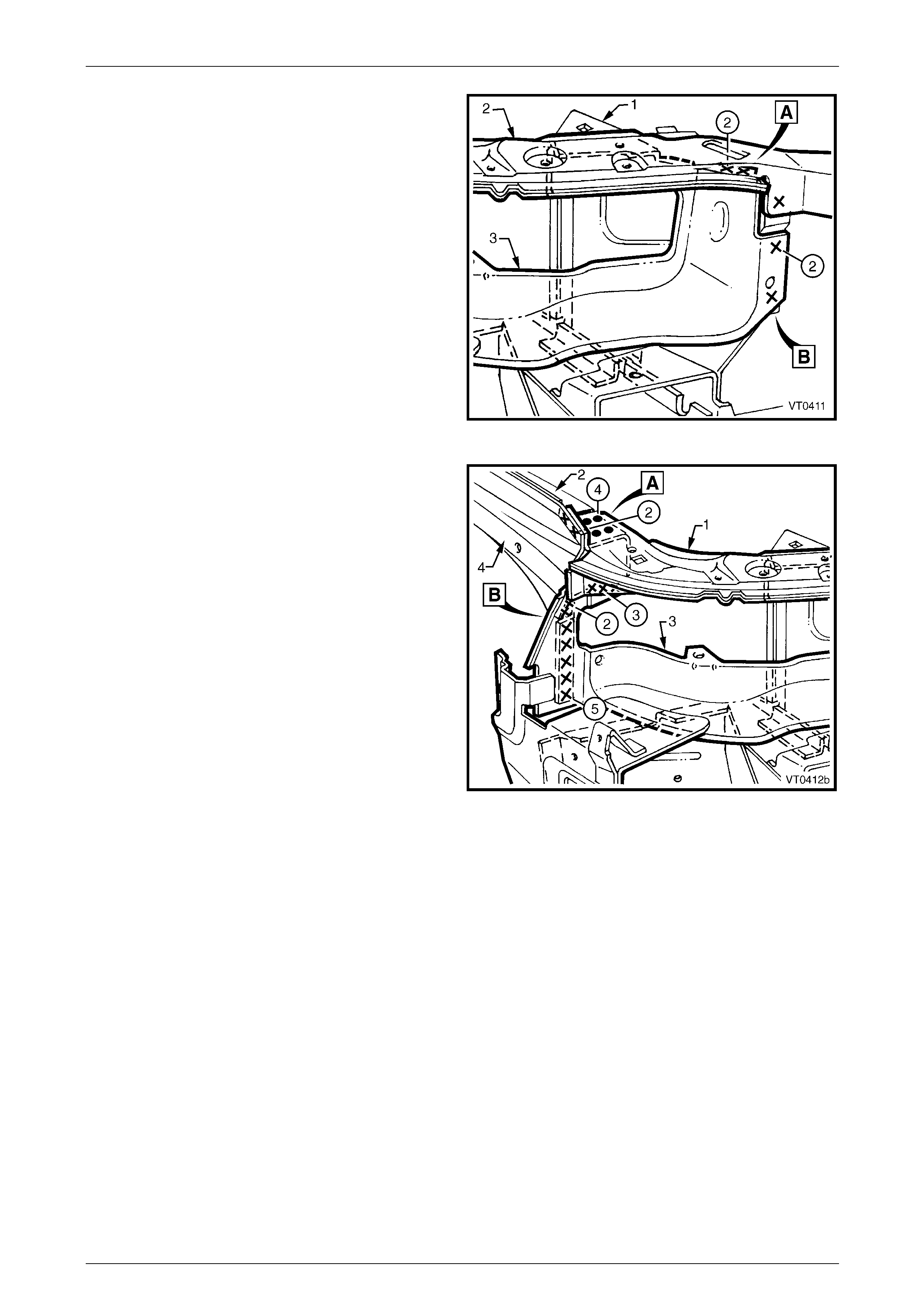

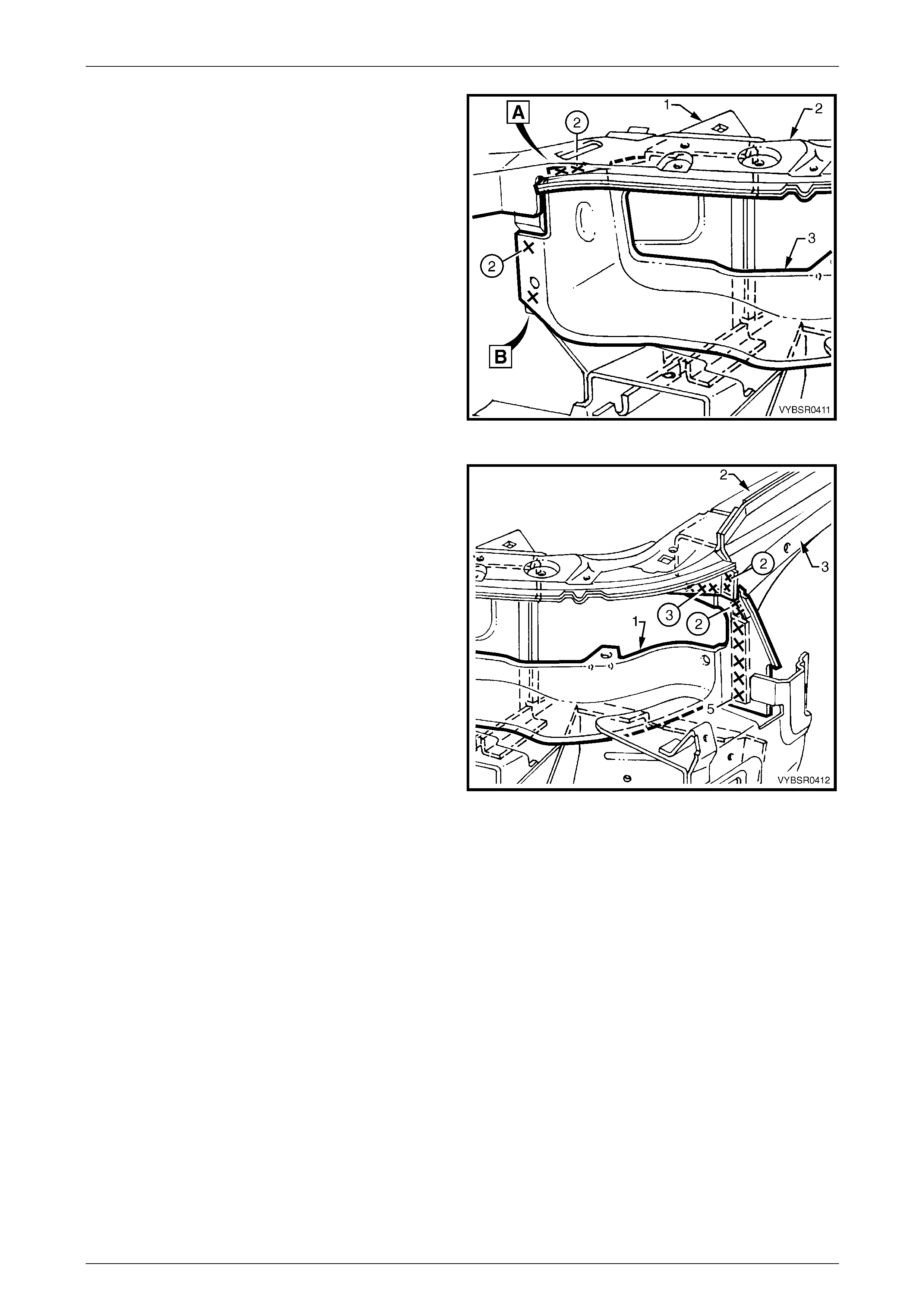

8 Spot weld in two places on each side of vehicle, the

front wheelhouse bracket assembly (1) to the front end

panel upper (2) and head lamp panel (3).

Refer to weld group A.

9 On each side of the vehicle, spot weld the headlamp

panel and the front end panel upp er to the front

wheelhouse bracket assembly. Refer to weld group B.

Figure 4 – 11

10 On each side of the vehicle, spot or plug weld the front

end panel upper (1) to the front wheelhouse panel (2).

Four welds are on the horizontal surface and two on

the vertical flange. Refer to weld group A.

11 Weld a total of 10 places on each side of vehicle, the

headlamp panel (3) to the front wheelhouse panel and

the front wheelhouse upper side rail (4).

Refer to weld group B.

12 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

13 Apply Joint Sealer (Item 3) as required.

Refer to Section 3 Body Construction.

14 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint,

refer to Section 3 Body Construction.

15 Install the front bumper impact bar assembly,

refer to Section 3 Body Construction.

16 Install the remaining components as described in the

appropriate Section of the MY2005 WL Service

Information.

Figure 4 – 12

4 Front End Page 4-8

Page 4-8

2.2 Headlamp Panel – Replace

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

WL Service Information.

2 Remove the front bumper impact bar assembly,

refer to Section 3 Body Construction.

Figure 4 – 13

3 Spot cut a total of 12 welds attaching the headlamp

panel (1) to the front wheelhouse pane l (2) and to the

wheelhouse upper side rail (3).

Figure 4 – 14

4 Spot cut the welds attaching the front wheelhouse

bracket assembly (1) to the front end panel upp er (2)

and headlamp panel (3). Refer to weld group A.

5 Spot cut the two welds on the vertical flange attachin g

the headlamp panel to the fro nt end p anel upper and

front wheelhouse bracket assembly.

Refer to weld group B.

Figure 4 – 15

4 Front End Page 4-9

Page 4-9

6 Spot cut the welds attaching the headlamp and front

fascia mount bracket (1) and headlamp pa nel (2) to

the front wheelhouse panel.

Figure 4 – 16

7 Spot cut the welds attaching the front end panel upper

(1) to the headlamp panel (2).

8 Remove the headlamp panel from the vehicle and

then repair any damage to the adjacent parts as

required.

9 Check and rectify the alignme nt of the bod y as

required, refer to Section 3 Body Construction. Repair

any damage to adjacent panels.

Figure 4 – 17

4 Front End Page 4-10

Page 4-10

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panels with drilling locations in preparation for plug welding. Drill holes as req uire d.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required,

refer to Section 3 Body Construction.

3 Clamp the headlamp panel in position.

4 Spot or plug weld the front panel upper (1) to the

headlamp panel (2) and to the front fender skirt (3).

Figure 4 – 18

5 Spot weld the headlamp an d front fascia mount

bracket (1) and headlamp panel (2) to the front

wheelhouse panel.

Figure 4 – 19

4 Front End Page 4-11

Page 4-11

6 Spot weld in two places, the front wheelhouse bracket

assembly (1) to the front end panel upper (2) and

headlamp panel (3). Refer to weld group A.

7 Spot weld the headlamp panel and the front end panel

upper to the front wheelhouse bracket assembly.

Refer to weld group B.

Figure 4 – 20

8 Spot weld a total of 12 places, the headlamp panel (1)

to the front wheelhouse panel (2) and the front

wheelhouse upper side rail (3).

9 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

10 Apply Joint Sealer (Item 3) as required.

Refer to Section 3 Body Construction.

11 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint,

refer to Section 3 Body Construction.

12 Install the front bumper impact bar assembly,

refer to Section 3 Body Construction.

13 Install the remaining components as described in the

appropriate Section of the MY2005 WL Service

Information.

Figure 4 – 21

4 Front End Page 4-12

Page 4-12

2.3 Front Wheelhouse Bracket Assembly,

Front Wheelhouse Bracket and Front

Bumper Impact Bar Bracket Assembly –

Replace

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

WL Service Information.

2 Remove the front bumper impact bar assembly,

refer to Section 3 Body Construction.

3 Remove the adjoining panels as required.

Figure 4 – 22

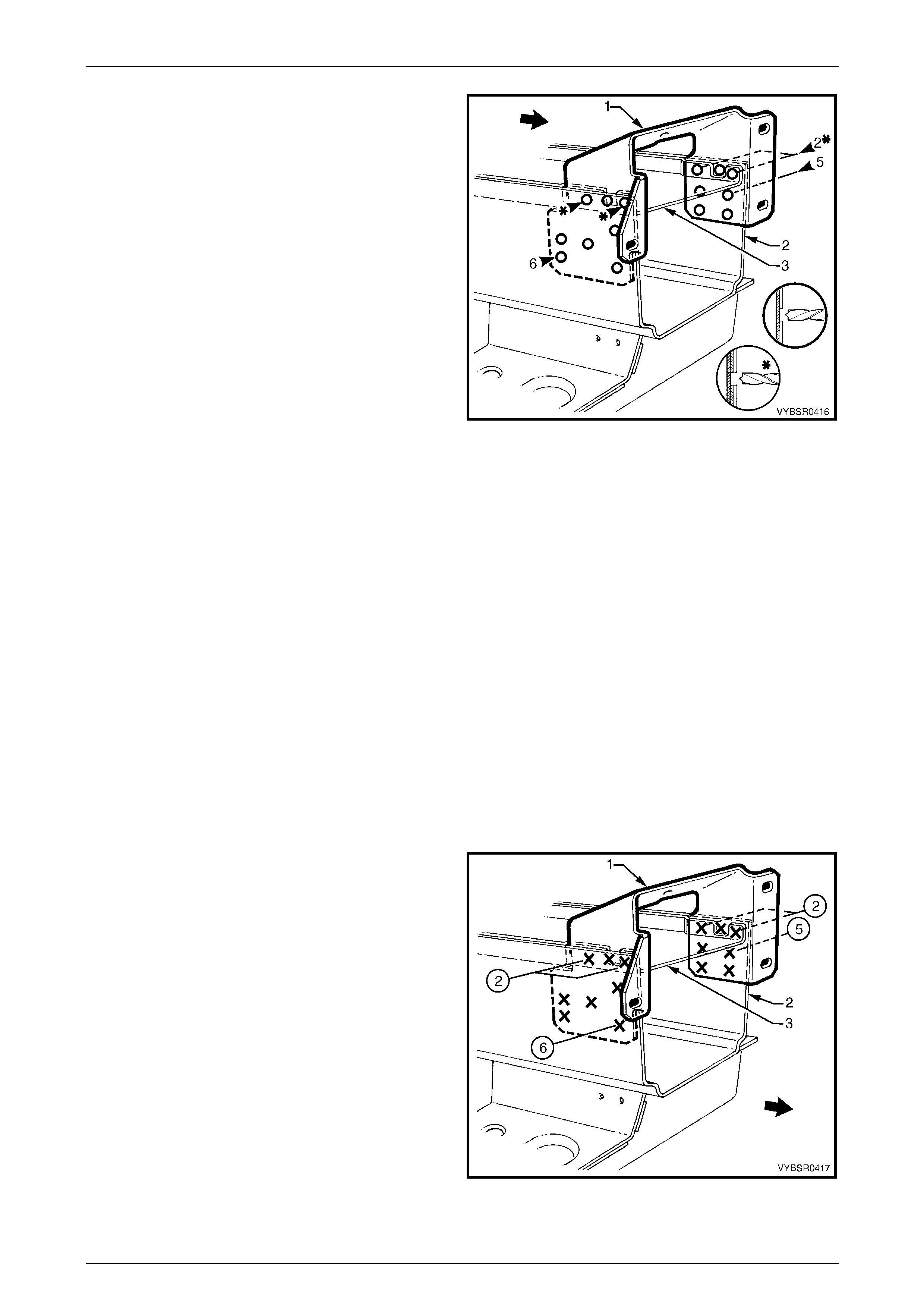

4 Spot cut the six welds attaching the front wheelhouse

bracket assembly (1) to the front side rail (2).

Refer to weld group A.

5 Spot cut the three welds attaching the front

wheelhouse bracket assembly (1) to the front bumper

impact bar bracket (3). Refer to weld group B.

6 Remove the front wheelhouse bracket assembl y.

Figure 4 – 23

7 Spot cut the welds attaching the front wheelhouse

panel bracket (1) to the front side rail (3).

Refer to weld group A.

8 Spot cut the welds attaching the front wheelhouse

panel bracket to the radiator lower support assembly

(2). Refer to weld group B.

9 Spot cut the three welds attaching the front

wheelhouse panel br acket to the front wheelhouse

panel (4). Refer to weld group C.

10 Remove the front wheelhouse panel bracket.

Figure 4 – 24

4 Front End Page 4-13

Page 4-13

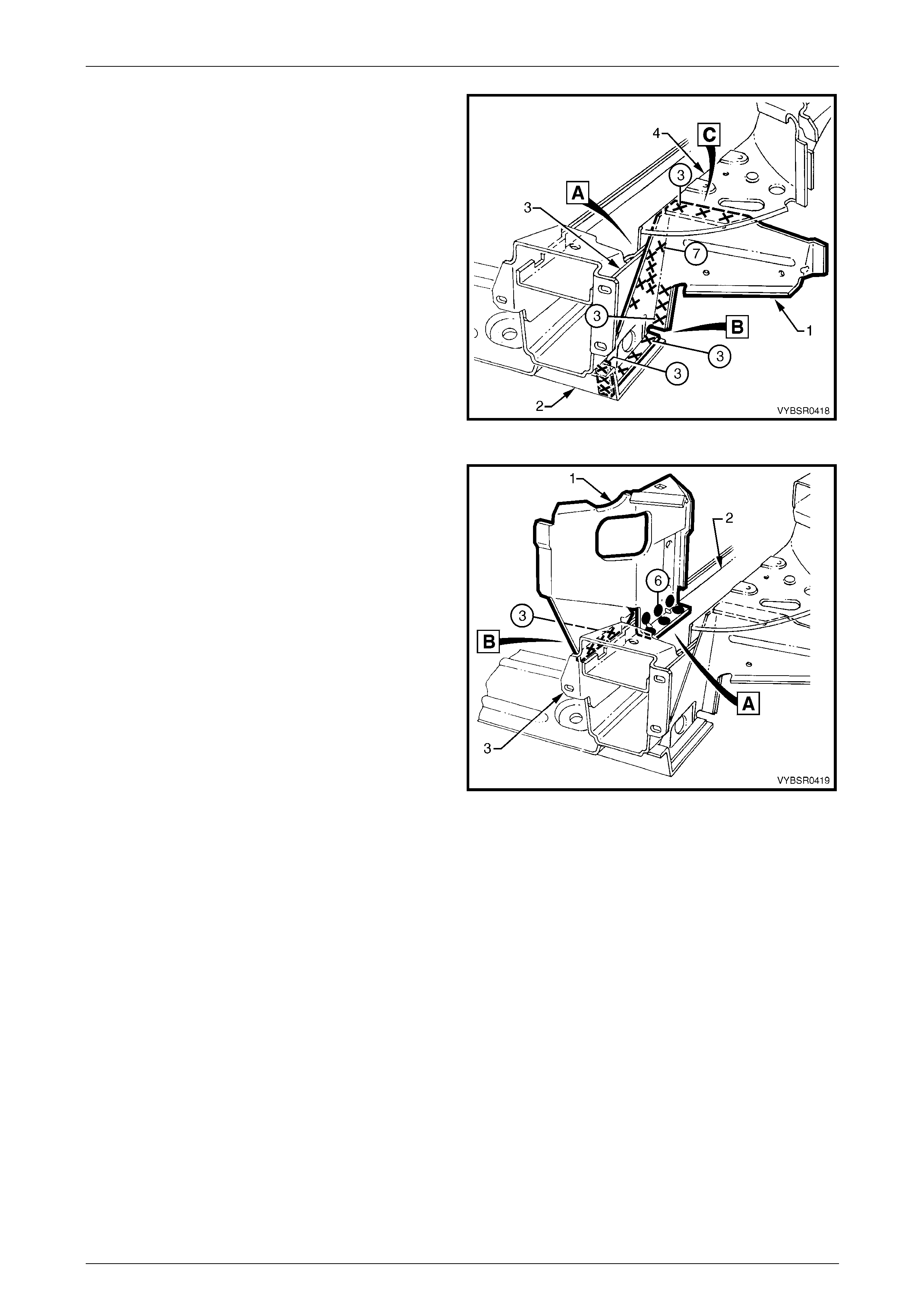

11 Spot cut the welds attaching each side of the front

bumper impact bar bracket (1) to the front side rail (2).

12 Prise front bumper impact bar bracket out from

between the front side rail and the front side rail

closing plate (3).

13 Repair any damage to adjacent panels.

14 Check and rectify the alignme nt of the bod y as

required, refer to Section 3 Body Construction.

Figure 4 – 25

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as req uired.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as requir ed,

refer to Section 3 Body Construction.

3 Clamp the panels in position and test fit the front bumper impact bar.

4 Spot weld each side of the front bumper impact bar

mounting bracket (1) to front side rail (2).

Figure 4 – 26

4 Front End Page 4-14

Page 4-14

5 Spot weld the front wheelhouse panel br acket (1) to

the front side rail (3). Refer to weld group A.

6 Spot weld the front wheelhouse panel br acket to the

radiator lower support assembly (2).

Refer to weld group B.

7 Spot weld the front wheelhouse panel br acket to the

front wheelhouse panel (4). Refer to weld group C.

Figure 4 – 27

8 Plug weld the front wheelhouse bracket asse mbly (1)

to the front side rail (2). Refer to weld group A.

9 Spot weld the front wheelhouse bracket assembly to

the front bumper impact bar bracket (3).

Refer to weld group B.

10 Replace the any removed panels as required.

11 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

12 Apply Joint Sealer (Item 3) as required.

Refer to Section 3 Body Construction.

13 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint,

refer to Section 3 Body Construction.

14 Install the front bumper impact bar assembly,

refer to Section 3 Body Construction.

15 Install the remaining components as described in the

appropriate Section of the MY2005 WL Service

Information. Figure 4 – 28

4 Front End Page 4-15

Page 4-15

2.4 Radiator Lower Support Assembly –

Replace

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

WL Service Information.

2 Remove the front bumper impact bar assembly,

refer to Section 3 Body Construction

3 If required, mount the vehicle on a suitable ji g or

secure an appropriate tool between the two front side

rails to maintain correct body alignment when the

radiator lower support assembly is remov ed.

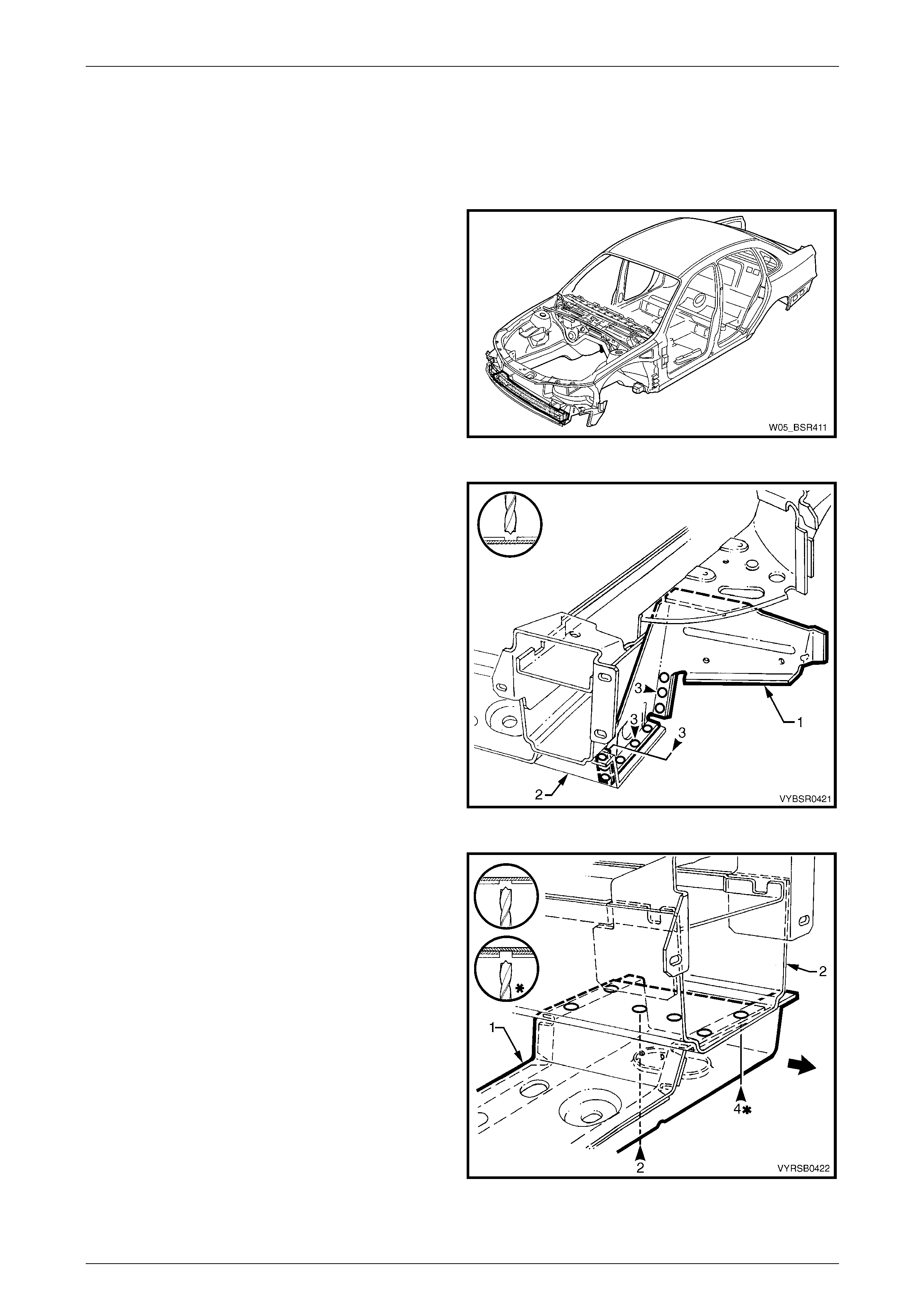

Figure 4 – 29

4 On both sides of the vehicle, spot cut nine welds

attaching the front wheelhouse panel bracket (1) to the

radiator lower support assembly (2).

Figure 4 – 30

5 From underneath the vehicle, spot cut the six welds

attaching the radiator lo wer support assembly (1) to

each front side rail (2).

NOTE

Access is available to the two centre spot welds

through the hole on the under side of the support.

6 Remove the radiator lower support assembly from the

vehicle.

Figure 4 – 31

4 Front End Page 4-16

Page 4-16

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as req uired.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as requir ed,

refer to Section 3 Body Construction.

3 Clamp the radiator lower support assembly (1) in

position on the front side rails (2) and spot or plug

weld in place.

Figure 4 – 32

4 Spot weld nine places, the front wheelhouse panel

bracket (1) to the radiator lower support assembly (2).

5 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

6 Apply Joint Sealer (Item 3) as required.

Refer to Section 3 Body Construction.

7 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint,

refer to Section 3 Body Construction.

8 Install the front bumper impact bar assembly,

refer to Section 3 Body Construction.

9 Install the remaining components as described in the

appropriate Section of the MY2005 WL Service

Information.

Figure 4 – 33

4 Front End Page 4-17

Page 4-17

2.5 Front Wheelhouse Panel Upper Side Rail

– Replace

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

WL Service Information.

2 Remove the front bumper impact bar assembly,

refer to Section 3 Body Construction.

3 As required, remove front end pane l assembly or spot

cut the welds attaching the side rail to the front end

panel assembly,

refer to 2.1 Front End Panel Assembly – Replace.

Figure 4 – 34

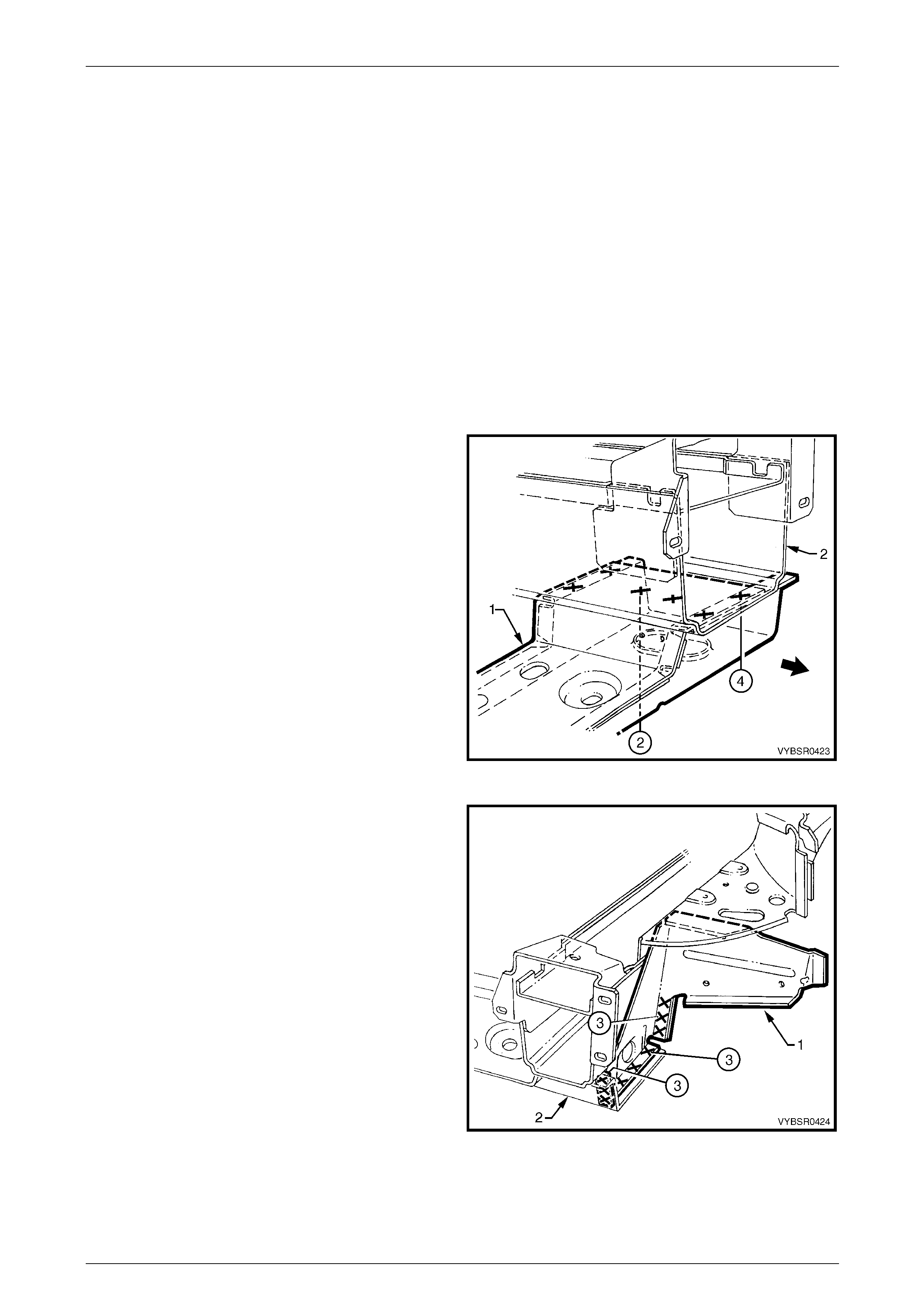

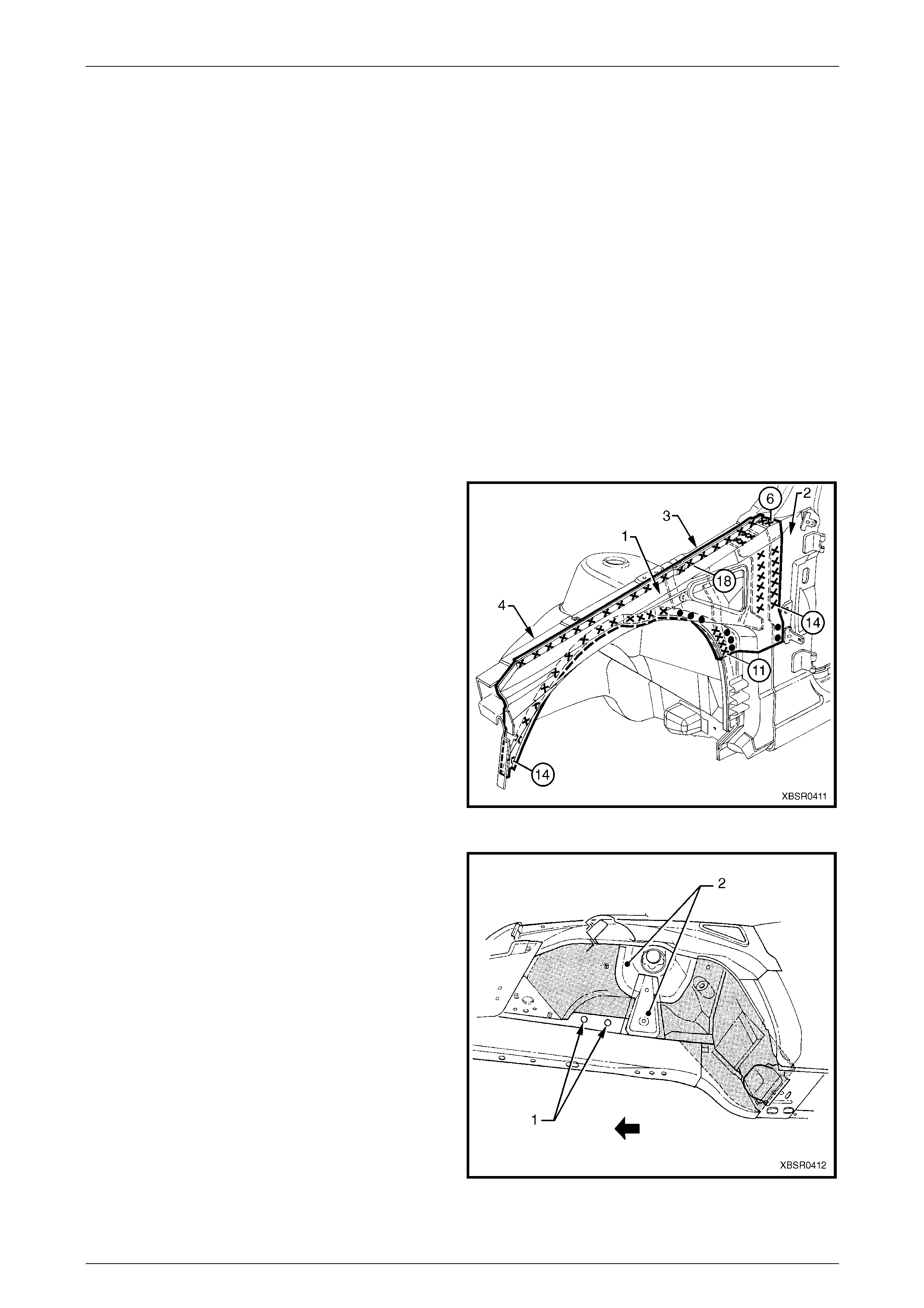

4 Spot cut the welds attaching the front wheelhouse

panel upper side rail (1) to the door ope nin g frame

assembly (2), hinge pillar inner panel assembly (3)

and front wheelhouse panel assembly (4) and remove

the upper side rail.

Figure 4 – 35

4 Front End Page 4-18

Page 4-18

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as req uired.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as requir ed,

refer to Section 3 Body Construction.

3 Clamp the front wheelhouse pane l upper side rail in position.

4 Spot or plug weld the front wheelhouse panel upper

side rail (1) to the door opening frame assembly (2),

hinge pillar inner panel assembly (3) and front

wheelhouse panel ass embly (4).

5 As required, replace the front end pan el asse mbly or

spot or plug weld the side rail to the front end panel

assembly,

refer to 2.1 Front End Panel Assembly – Replace.

6 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

7 Apply Joint Sealer (Item 3) as required.

Refer to Section 3 Body Construction

8 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint,

refer to Section 3 Body Construction).

Figure 4 – 36

9 Apply Spray-on Dea de ner (Item 7) to the wheel side of

front wheelhouse panel assembly.

Refer to Section 3 Body Construction.

NOTE

Keep the area around brake pipe holes ( 1) clear

of deadener. Overspray of deadener is

permissible on the strut tower reinforcement and

front suspension strut tower (2).

10 Install the front bumper impact bar assembly,

refer to Section 3 Body Construction.

11 Install the remaining components as described in the

appropriate Section of the MY2005 WL Service

Information.

Figure 4 – 37

4 Front End Page 4-19

Page 4-19

2.6 Front Wheelhouse Panel Assembly –

Replace

Remove

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

WL Service Information.

2 Remove the front bumper impact bar assembly,

refer to Section 3 Body Construction.

3 If required, mount the vehicle on a suitable ji g or

secure an appropriate tool between the front side rails

to maintain correct body alig nment when the front end

panel assembly is removed.

4 Remove front end panel assembly,

refer to 2.1 Front End Panel Assembly – Replace.

5 Remove the welds attaching the front wheelhouse

panel bracket to the front wheelhouse, refer to

2.3 Front Wheelhouse Bracket Assembly, Front

Wheelhouse Bracket and F ront Bumper Impact Bar

Bracket Assembly – Replace.

6 Remove the front wheelhouse pan el upper side rail,

refer to 2.5 Front Wheelhouse Panel Upper Side Rail

– Replace.

Figure 4 – 38

7 Spot cut the welds attaching the front wheelhouse

panel assembly (1) to the hinge pillar inner panel

assembly (2).

Figure 4 – 39

8 Spot cut the welds attaching the front wheelhouse

panel assembly (1) to the front floor panel extension

(2). NOTE

The dash panel assembly is not shown for

clarity.

9 Spot cut the weld attaching the front wheelhouse

panel assembly (1) to the hinge pillar inner panel

assembly.

Figure 4 – 40

4 Front End Page 4-20

Page 4-20

10 Spot cut the welds attaching the front wheelhouse

panel assembly (1) to the front side rail (2).

11 Remove front wheelhouse panel assembly and repair

any adjacent damaged panels as required.

12 Check and rectify the alignme nt of the bod y as

required, refer to Section 3 Body Construction.

Figure 4 – 41

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as req uired.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as requir ed,

refer to Section 3 Body Construction.

3 Clamp the front wheelhouse pane l assembly in position and confirm its location by checking the vehicle body

dimensions, refer to Section 3 Body Construction. Additionally, the front fender and engine hood may be fitted to

confirm margins.

4 Plug weld the front wheelhouse pan el assembly (1) to

the front side rail (2).

Figure 4 – 42

4 Front End Page 4-21

Page 4-21

5 Plug weld the front wheelhouse pan el assembly (1) to

the front floor panel extension (2) and the hinge pillar

inner panel assembly.

Figure 4 – 43

6 Spot weld the front wheelhouse panel ass embly (1) to

the hinge pillar inner panel assembly (2).

7 Replace the front wheelhouse panel upper side rail,

refer to 2.5 Front Wheelhouse Panel Upper Side Rail

– Replace.

8 Replace the front end panel assembly, refer to

2.1 Front End Panel Assembly – Replace.

9 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

10 Apply Joint Sealer (Item 3) as required.

Refer to Section 3 Body Construction.

11 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint,

refer to Section 3 Body Construction.

Figure 4 – 44

12 Apply Spray-on Dea de ner (Item 7) to the wheel side of

front wheelhouse panel assembly.

Refer to Section 3 Body Construction.

NOTE

Keep the area around brake pipe holes ( 1) clear

of deadener. Overspray of deadener is

permissible on the strut tower reinforcement and

front suspension strut tower (2).

13 Install the front bumper impact bar assembly,

refer to Section 3 Body Construction.

14 Install the remaining components as described in the

appropriate Section of the MY2005 WL Service

Information.

Figure 4 – 45

4 Front End Page 4-22

Page 4-22

2.7 Front Wheelhouse Panel and Front Side

Rail – Partial Replace

Remove

If significant creasing or crumple of the front

side rail has occurred an d continues rearw ard

of the front su spension crossmember, the fu ll

front side rail assembly must be replaced.

Refer to 1 General Description for further

information.

NOTE

The integrity of the front side rails is critical t o the

function of the occupant protection system. If the

rails are incorrectly repaired following damage, it

is possible the occupant protection system will

not function as intended, allowing incorrect

deployment.

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

WL Service Information.

2 Remove the front bumper impact bar assembly,

refer to Section 3 Body Construction.

3 Either mount the vehicle on a suitable jig or secure a n

appropriate tool between the front side rails to

maintain correct body alignment when the front end

panel assembly is removed.

4 Remove the front end panel assembly,

refer to 2.1 Front End Panel Assembly – Replace.

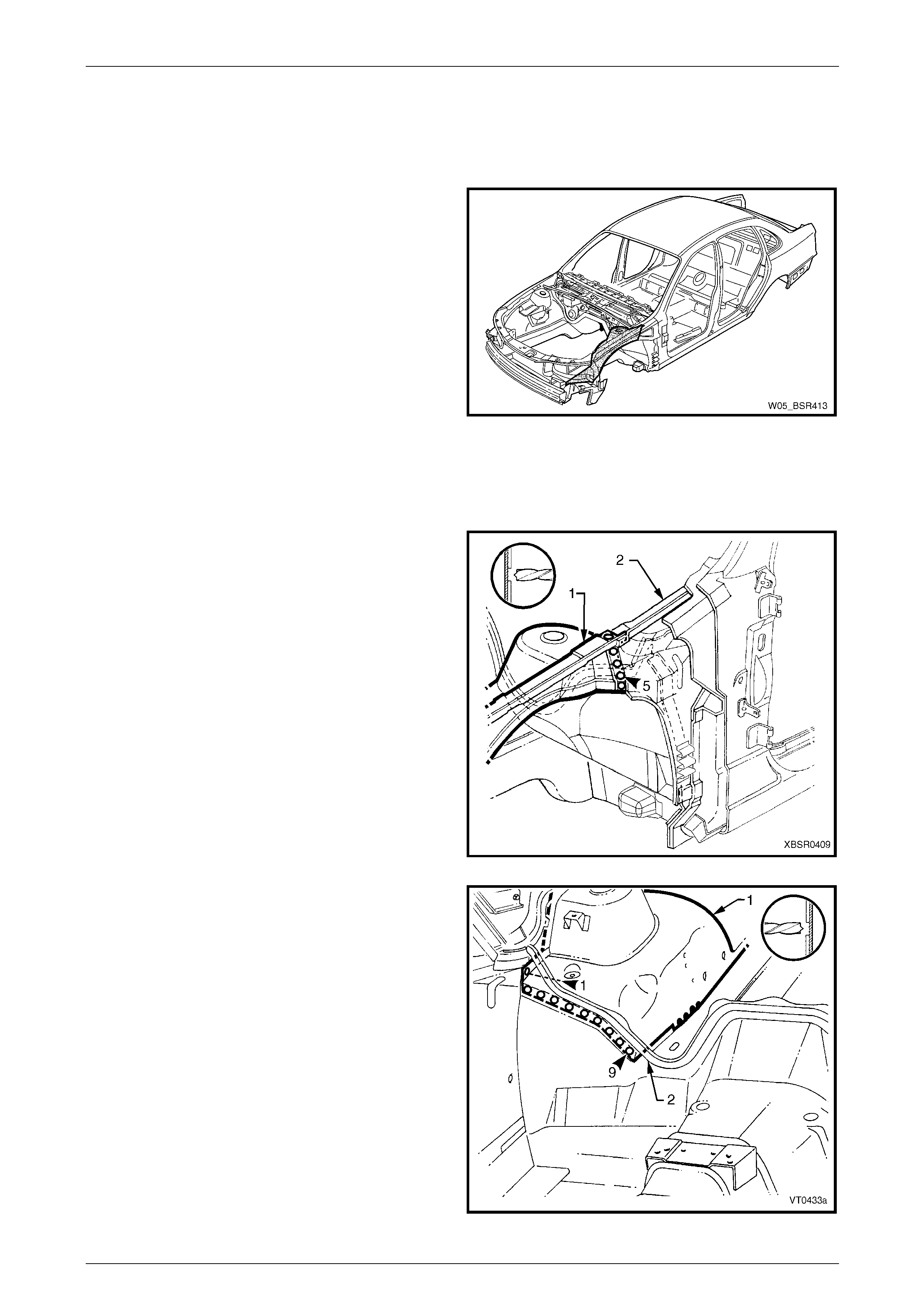

Figure 4 – 46

5 Remove the front wheelhouse pan el upper side rail on the damaged si de,

refer to 2.5 Front Wheelhouse Panel Upper Side Rail – Replace.

6 Either detach one side, or remove completely, the radiator lower support assembly,

refer to 2.4 Radiator Lower Support Assembly – Replace.

7 If the damage is on the right-hand si de of the vehicle,

the front wheelhouse panel will be cut through the

position of the multiuse relay housing bracket and

brake pressure modulator bracket assembly.

In this case, remove the brackets, refer to

2.9 Brake Pressure Modulator Bracket Assembly and

Multiuse Relay Housing Bracket.

Figure 4 – 47

4 Front End Page 4-23

Page 4-23

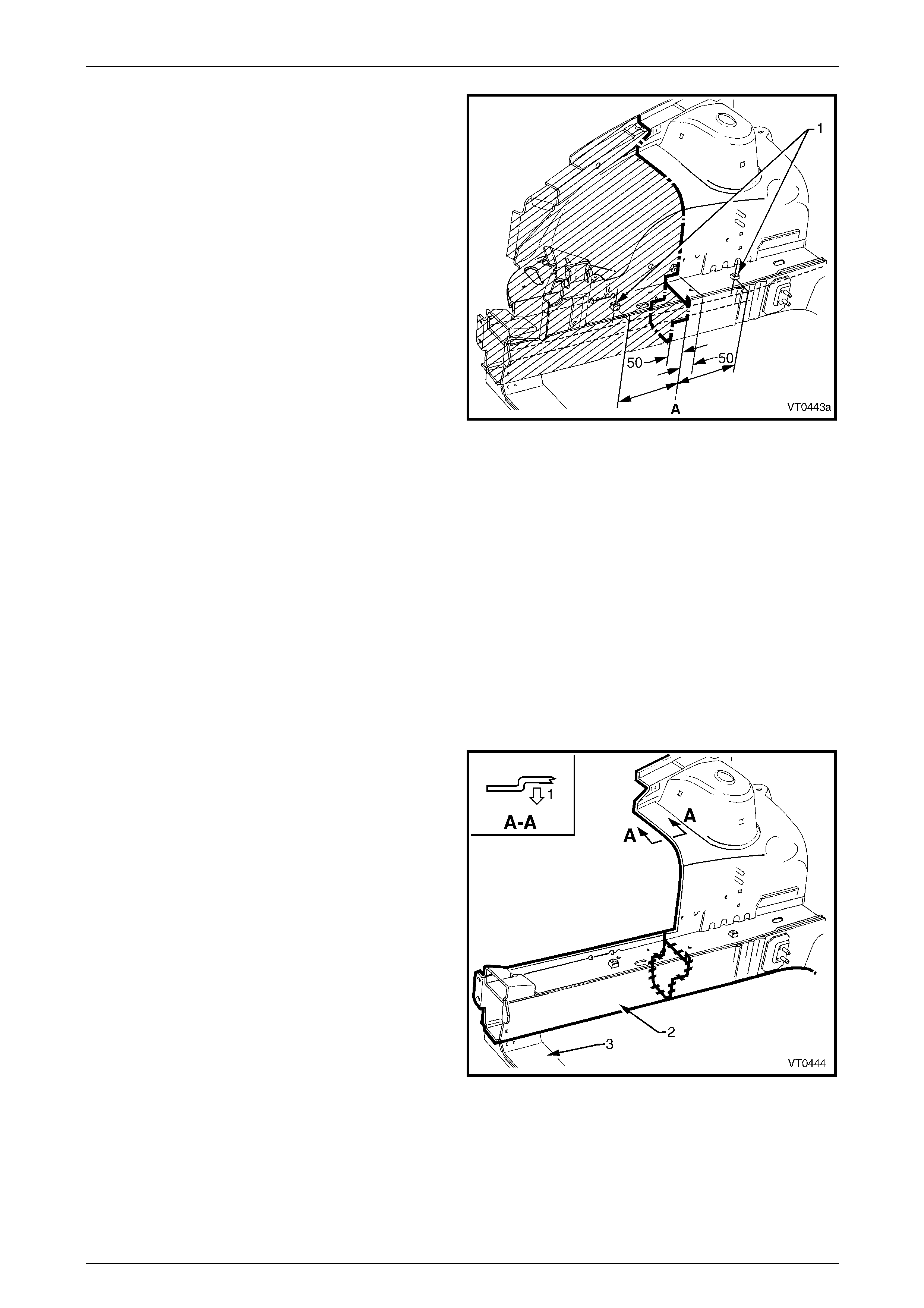

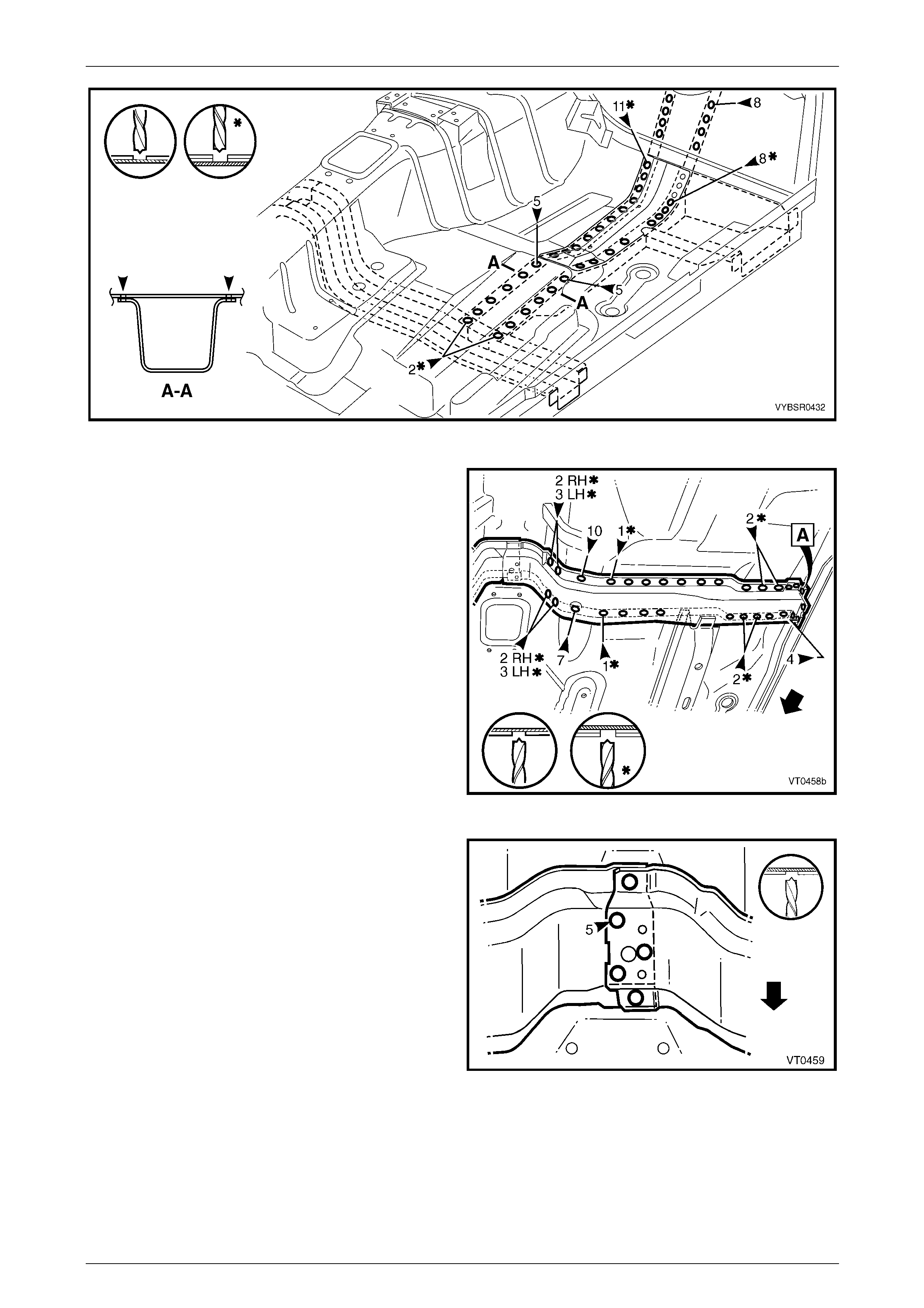

8 Rough cut the damaged front wheelh ouse panel and

front side rail, leaving enough material to allow the

final cut lines to be completed.

9 Cut the front side rail half way through its depth, mid

way between the two crossmember mounting bolt

holes shown A.

10 Step the cut forward by 50 mm as shown, so that the

load is not concentrated through a singl e lin e.

11 Accurately trim the front wheelhouse panel, 50 mm

rearward of the top front side rail cut.

12 Repair any damage to adjacent areas.

13 Check and rectify the alignme nt of the bod y as

required, refer to Section 3 Body Construction.

Figure 4 – 48

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

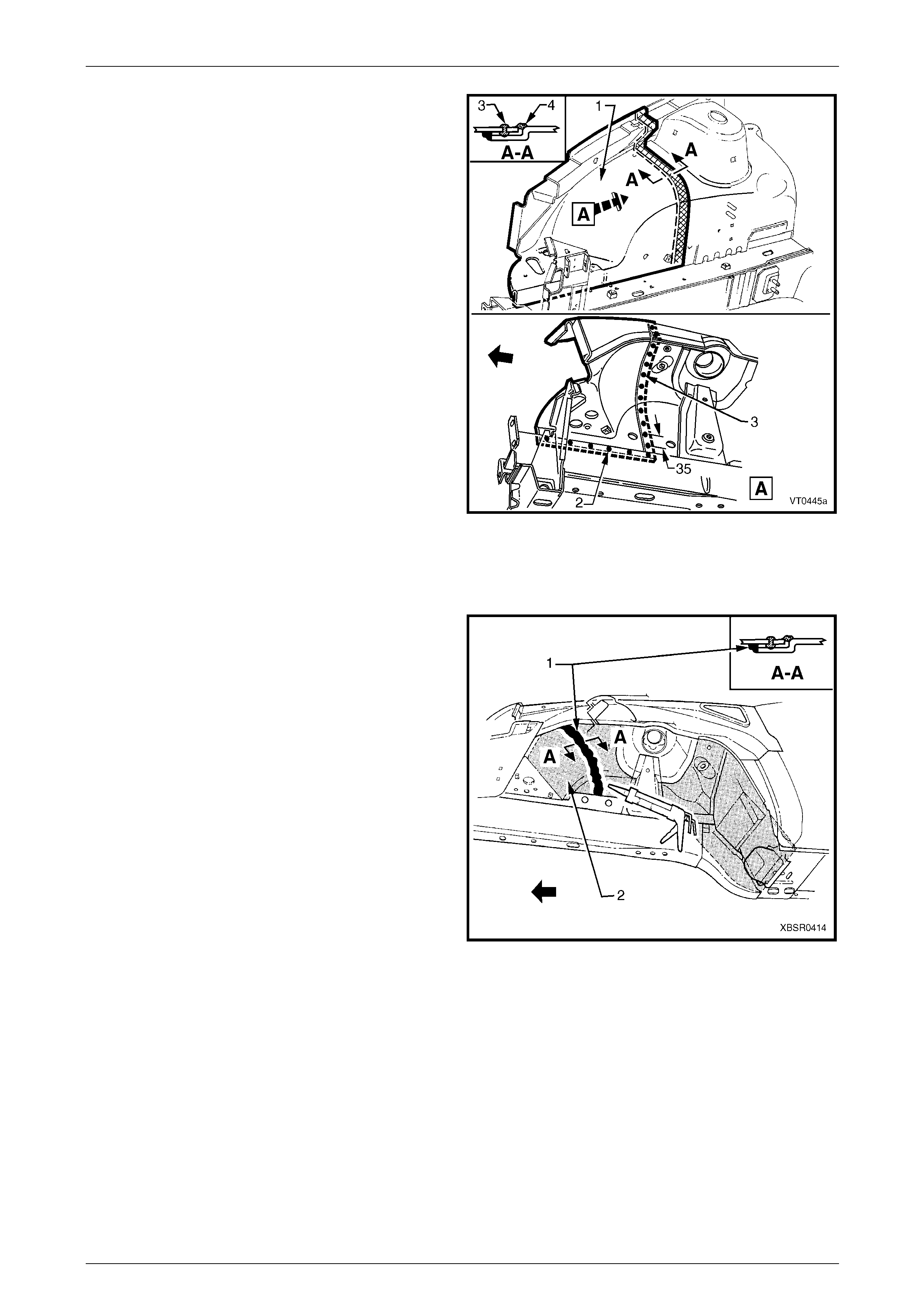

1 Using a suitable tool, modify the edge of the remaining

section of the front wheelhouse panel to form a joggle,

to facilitate lap jointing. T he joggle should be towards

the outside of the vehicle (1).

2 Accurately step cut the required section (2) from a new

front side rail assembly and clamp or tack weld the

new section in position.

3 Clamp the radiator lower support (3) in position.

Ensure the alignment of the front side rail and lower

support is correct,

refer to Section 3 Body Construction.

4 Butt-weld the stepped longitudinal sections together.

The weld should extend arou nd the entire peripher y of

the cut.

5 Spot or plug weld the radiator lower support (3) in

place. Refer to 2.4 Radiator Lower Support Assembly

– Replace.

Figure 4 – 49

4 Front End Page 4-24

Page 4-24

6 Accurately cut the required section (1) from a new

front wheelhouse panel assembly to replace the

removed section.

7 Drill the required holes in the lower edge of the front

wheelhouse panel to perm it plug welding to the front

side rail.

8 Drill holes along the lap j oint approximately every

25 mm, to accommodate plug welding of the joint.

9 Prepare all mating surfaces and treat with Weld

Through Primer (Item 1) as required,

refer to Section 3 Body Construction.

10 Clamp the modified front wheelhouse panel in position

and plug weld (2) to the front side rail.

11 Plug weld along the lap joi nt (3) throug h the previously

drilled holes.

12 Additionally, MIG (fillet) weld the front wheelhouse

panel sections together on the engine compartment

side (4).

13 Dress the welds on the engine compartment side with

a suitable grinder or sander, removing the mi nimum

amount of weld consistent with achieving an

acceptable surface finish. Figure 4 – 50

15 Install the front wheelhouse panel upper side rail, refer to 2.5 Front Wheelho use Panel Upper Side Rail – Replace.

16 Install the front end panel ass embl y, refer to 2.1 F r ont End Panel Assembly – Replace.

17 Seal the wheel side of the seam with Joint Sealer

(Item 3) (1) and apply Spray-on Deadener (Item 7) (2)

to the wheel side of the front wheelhouse panel

assembly, refer to Section 3 Body Construction.

18 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

19 Apply Joint Sealer (Item 3) as required.

Refer to Section 3 Body Construction.

Figure 4 – 51

20 Apply Cavity Wax (Item 8) as required to the inside of any box secti ons or areas inaccessible to paint,

refer to Section 3 Body Construction.

21 Install the front bumper impact bar assembly, refer to Section 3 Body Construction.

22 Install the remaining components as described in the appropriate Section of the MY2005 WL Service Information.

4 Front End Page 4-25

Page 4-25

2.8 Front Side Rail Assembly– Replace

Remove

The integrity of the front side rails is critical to

the function of the occupant protection

system. If the rails are incorrectly repaired

following damage, it is possible the occupant

protection and airbag system will not function

as intended, allowing incorrect deployment.

Refer to 1 General Description for further

information

1 Remove the adjacent bolt-on panels a nd components

as described in the appropriate Section of the MY2005

WL Service Information.

2 Remove the front bumper impact bar assembly,

refer to Section 3 Body Construction.

3 Secure the vehicle on a suitab le fixture ensuring that it

is mounted without relying on support from the front

side rail assembly(s) being replaced.

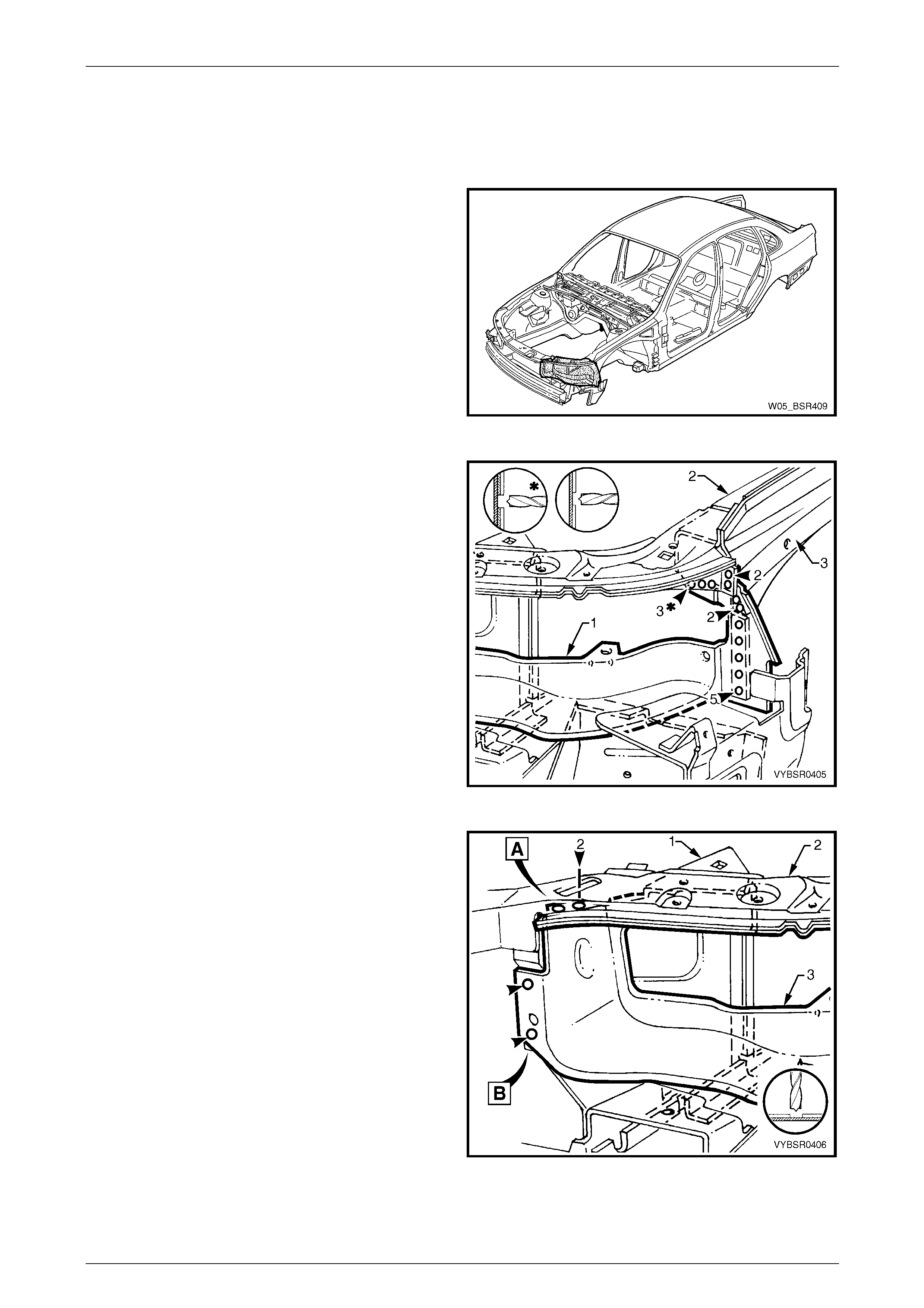

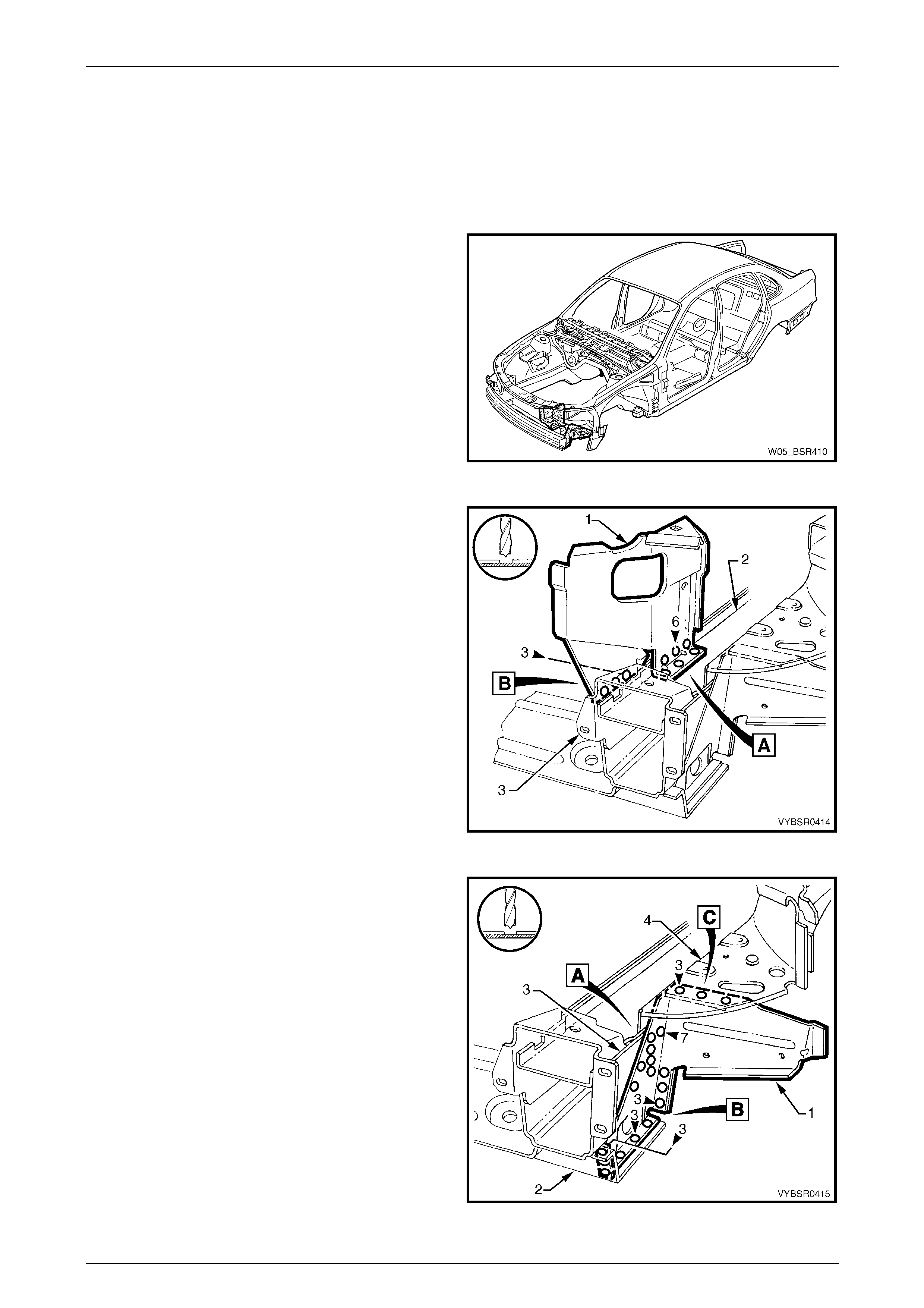

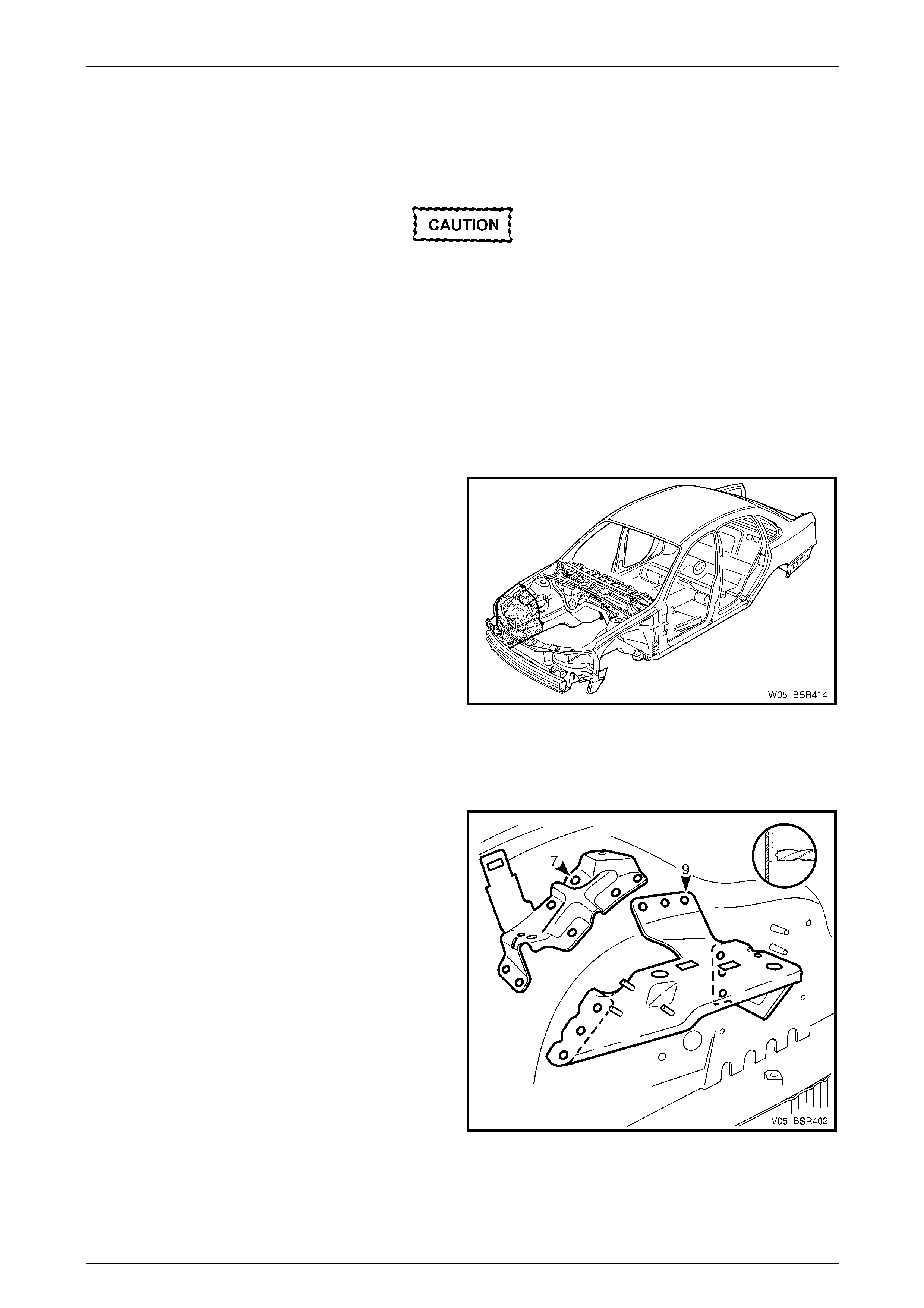

Figure 4 – 52

4 Remove the front end panel assembly as required, refer to 2.1 Front End Panel Assembly – Replace.

5 Remove the radiator lower support assembly as required,

refer to 2.4 Radiator Lower Support Assembly – Replace.

6 Remove the front wheelhouse pan el assembly as required,

refer to 2.6 Front Wheelhouse Panel Assembly – Replace.

7 Using a scraper and heat gun, remove the body sealer and deadener from the front floor and floor extension in the

front side rail attaching areas.

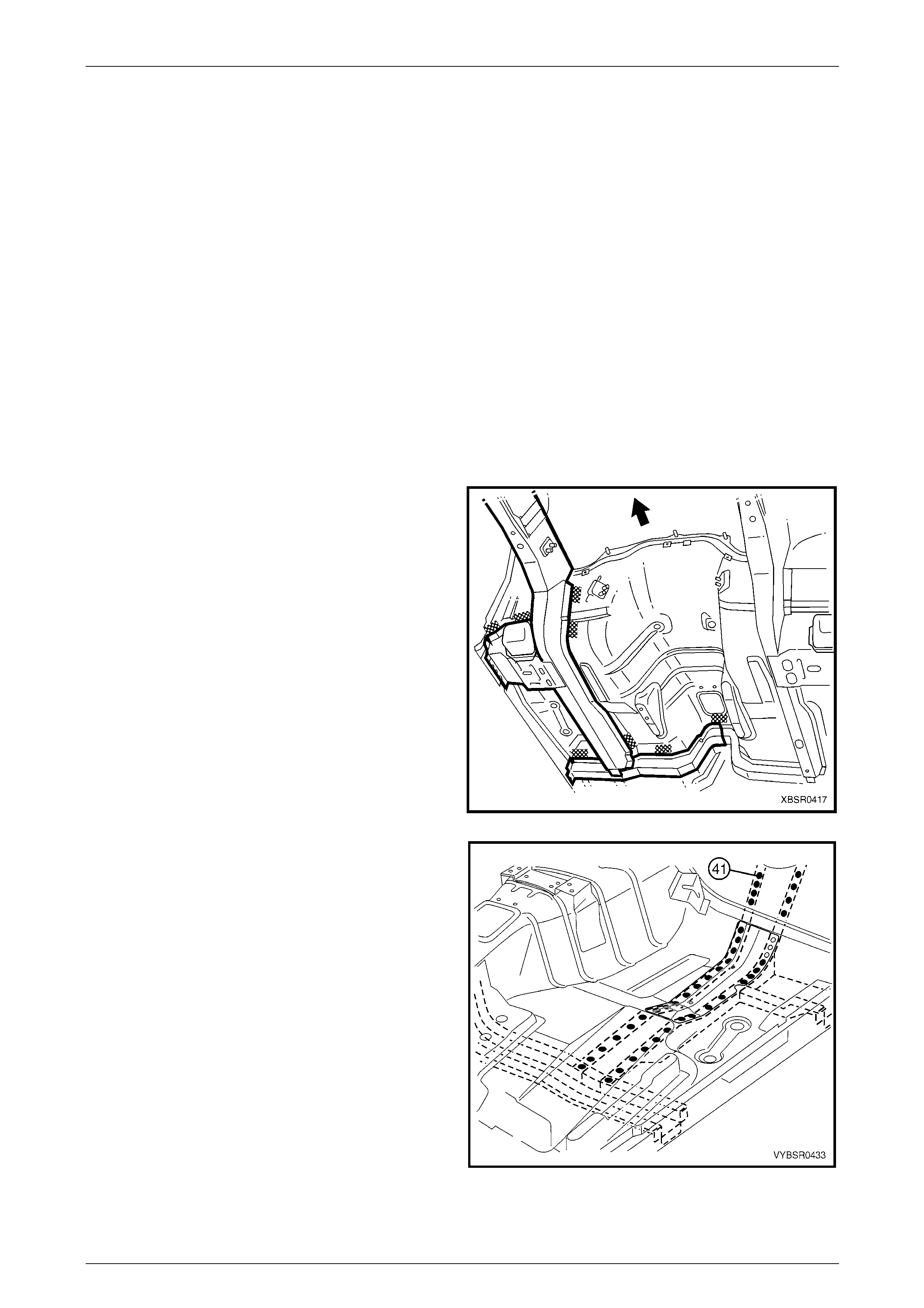

8 Spot cut the welds attaching the front floor panel

support assembly to the front floor panel and inner

rocker panel.

9 Spot cut the welds attaching the front side rail

assembly to the front floor extension panel and front

floor panel, refer to Figure 4 – 54.

Figure 4 – 53

4 Front End Page 4-26

Page 4-26

Figure 4 – 54

10 Spot cut four welds attaching the centre crossmember

to the inner rocker panel. Refer to weld group A.

11 Spot cut the welds attaching the centre crossmember

to the front floor panel and seat inner br acket

assembly.

Figure 4 – 55

12 Spot cut five welds attaching the right-hand centre

crossmember to the left-hand centre crossmember.

13 Remove the front side rail assembly from the vehicle

and repair any damage to adjoining ar eas.

14 Check and rectify the alignme nt of the bod y as

required, refer to Section 3 Body Construction.

Figure 4 – 56

4 Front End Page 4-27

Page 4-27

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

1 Dress the floor in the areas where the front side rail assemb ly will attach and mark the new assembly with drilling

locations in preparation for plug welding. Drill holes as req uired.

2 Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required,

refer to Section 3 Body Construction.

3 Secure the new front side rail assembly in positio n on the vehicle and clamp the radiator lower support assembly in

place.

4 Check the alignment of the front side rail assembl y, refer to Section 3 Bo dy Construction.

5 Lightly tack weld the front side rail assembly to the

floor in a few places, then recheck the align m ent as

above. Correct as required.

Figure 4 – 57

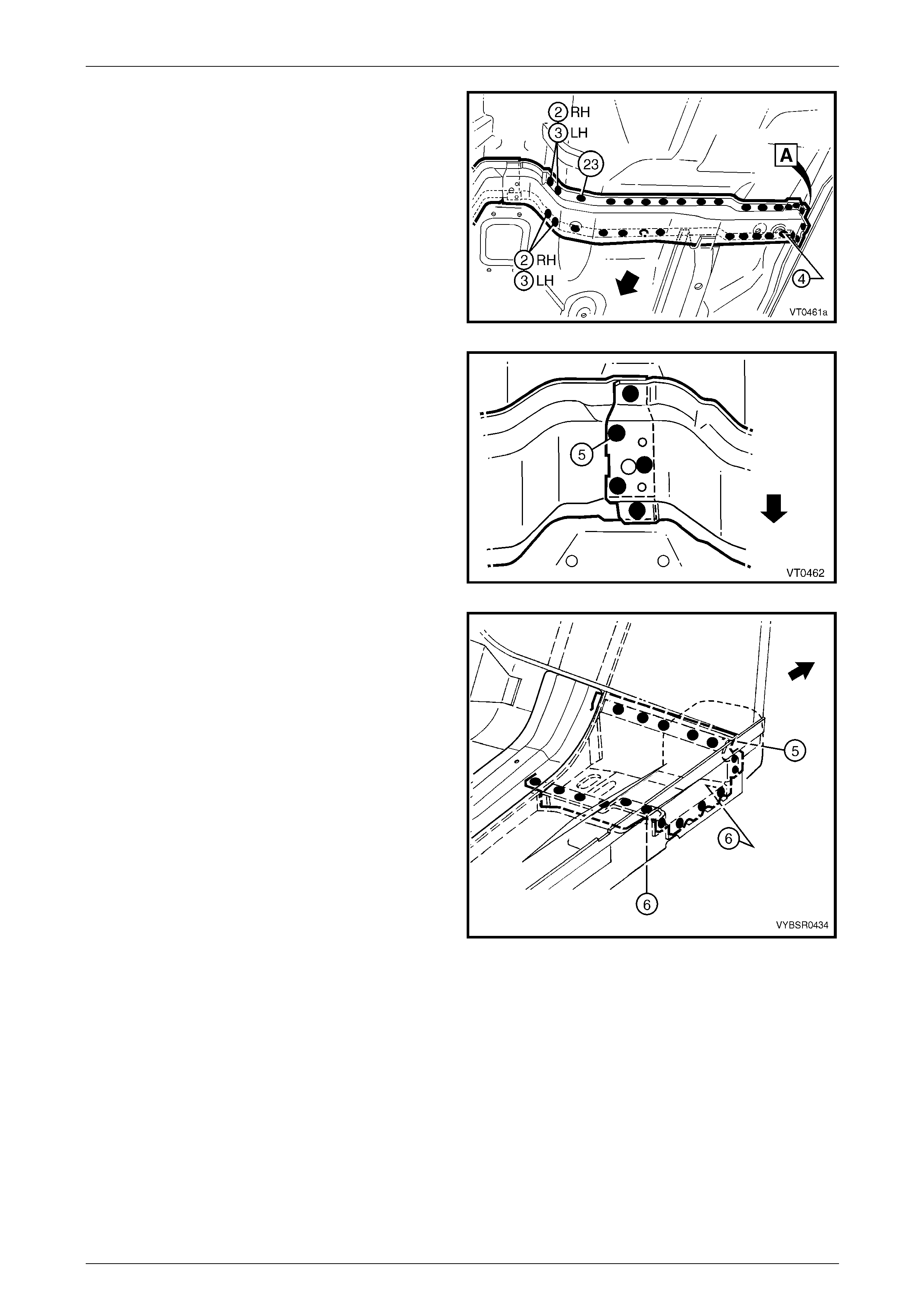

6 Plug weld the front side rail assembly to the front floor

panel extension and front floor panel.

Figure 4 – 58

4 Front End Page 4-28

Page 4-28

7 Plug weld the centre crossmember to the inner rocker

panel, refer to weld group A and to the front floor

panel.

Figure 4 – 59

8 Plug weld in four places, the right-hand centre

crossmember to the left-hand centre crossmember.

Figure 4 – 60

9 Plug or spot weld the front floor panel support

assembly to the front floor panel and inner rocker

panel.

10 Reinstall the radiator lower support assembly, refer to

2.4 Radiator Lower Support Assembly – Replace.

11 Install the front wheelhouse panel assembly, refer to

2.6 Front Wheelhouse Pane l Assembly – Replace.

12 Install the front end panel ass embl y, refer to

2.1 Front End Panel Assembly – Replace.

13 Refinish and paint panels and other components as

required. Refer to Section 3 Body Construction .

14 Apply Joint Sealer (Item 3) as required.

Refer to Section 3 Body Construction.

15 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint,

refer to Section 3 Body Construction.

16 Apply Spray-on Deadener (Item 7), after the

application of body colour.

Refer to Section 3 Body Construction. Figure 4 – 61

17 Install the front bumper impact bar assembly, refer to Section 3 Body Construction.

18 Install the remaining components as described in the appropriate Section of the MY2005 WL Service Information.

4 Front End Page 4-29

Page 4-29

2.9 Brake Pressure Modulator Bracket

Assembly and Multiuse Relay Housing

Bracket

Remove

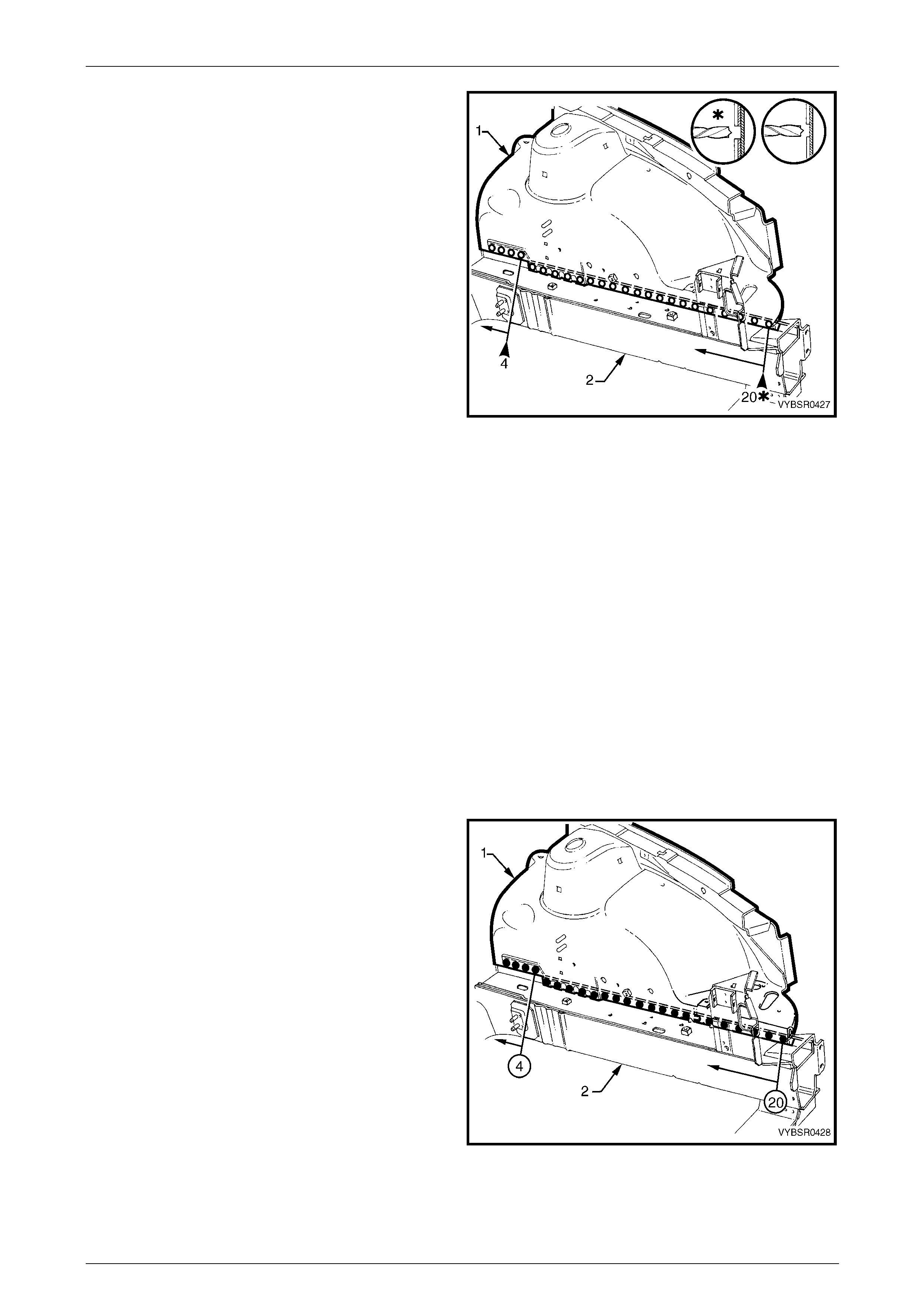

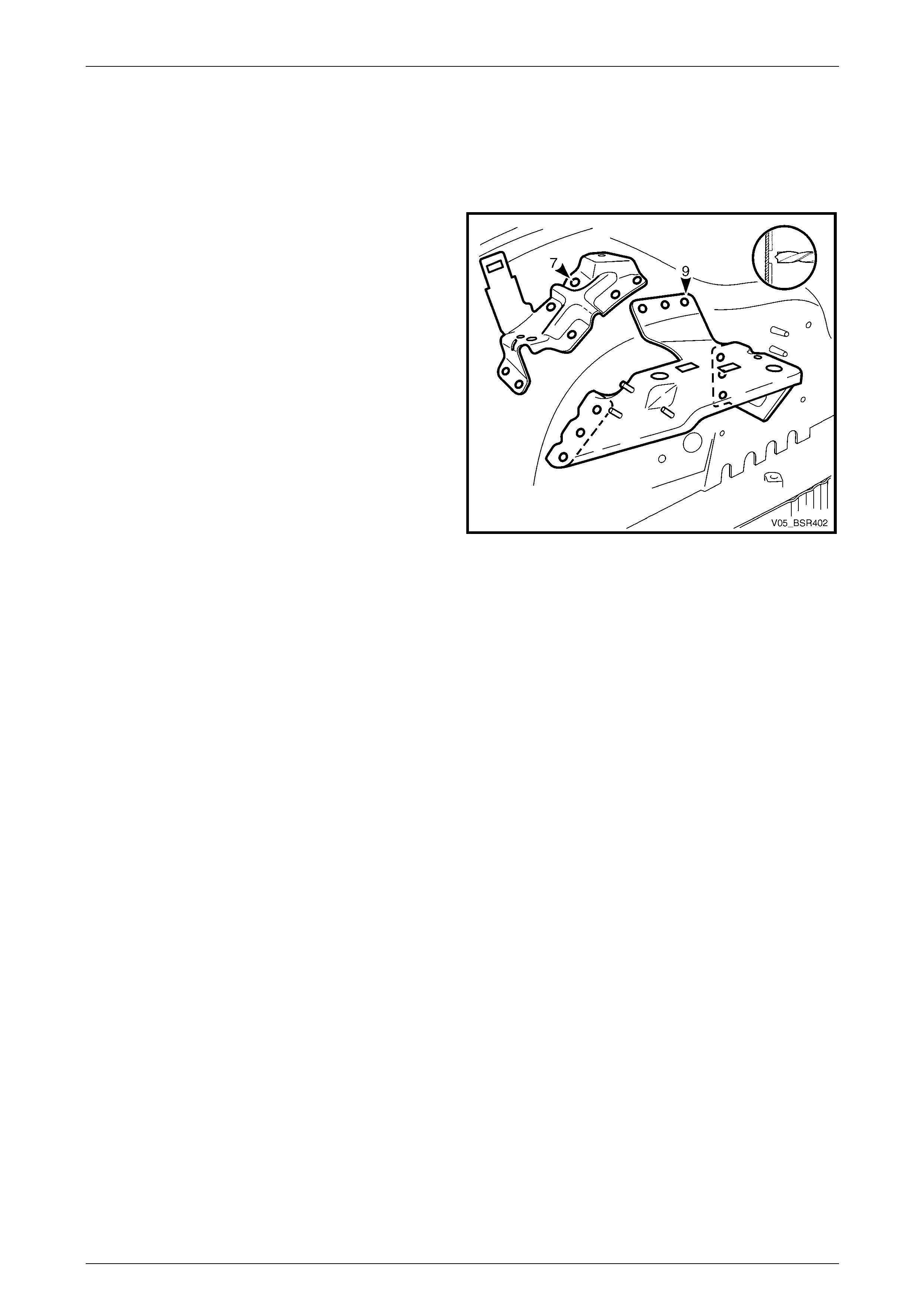

1 Spot cut the nine welds attaching the brake pressure

modulator bracket assembly or the seven welds

attaching the multiuse relay housing bracket to the

front wheelhouse panel.

Figure 4 – 62

Replace

NOTE

• Spot welding is the preferred method for

attaching of panels and should be used

whenever possible. Where the spot welding

equipment available will not access the

required weld position, a plug weld should be

performed.

• The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

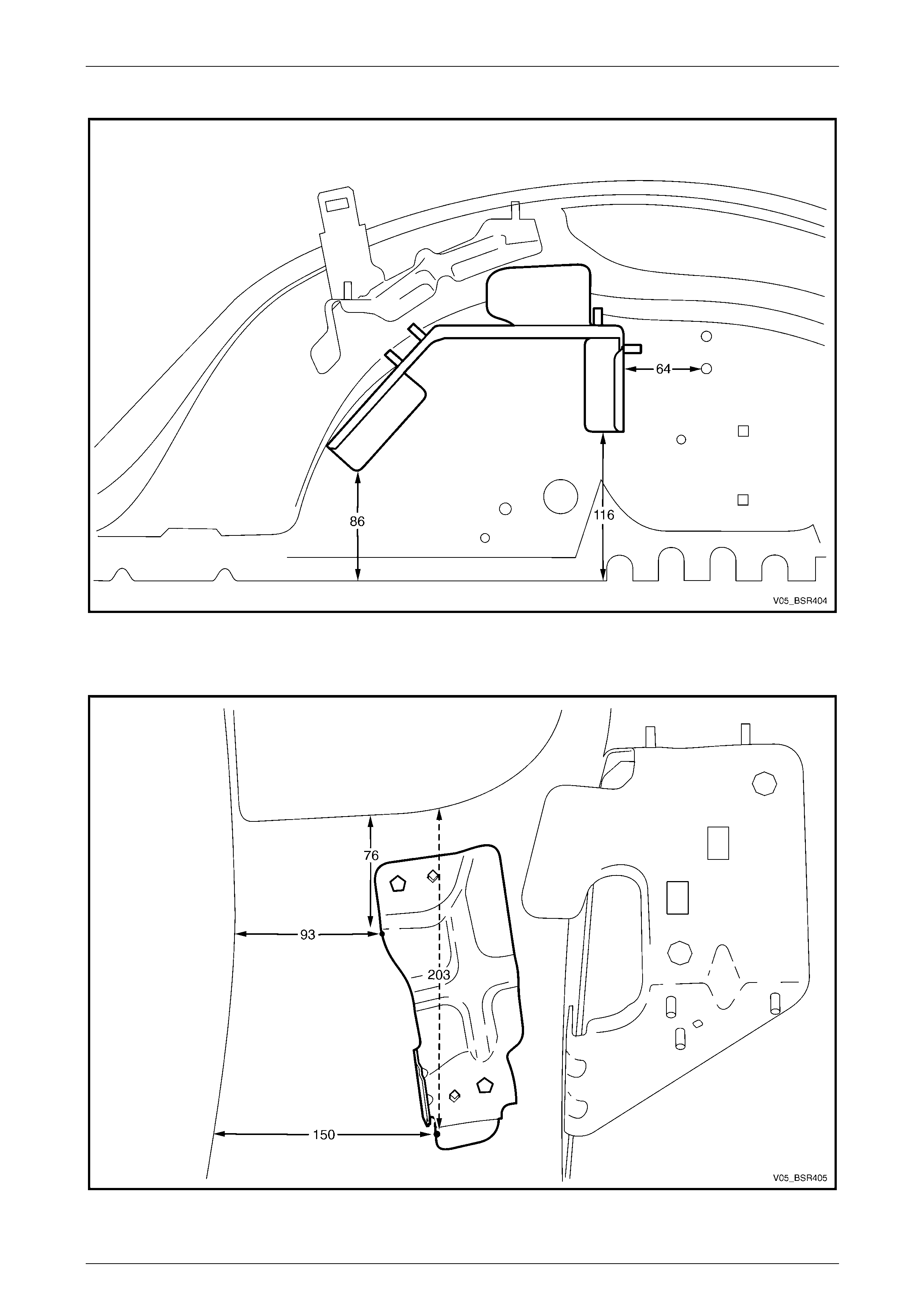

1 Place the bracket in the correct position on the wheelhouse panel, refer to Figure 4 – 6 3 or Figure 4 – 64.

2 Spot or plug weld, nine places for the brake pressure modulator bracket assembly and seven plac es for the

multiuse relay housing bracket in the positions shown, refer to Figure 4 – 62.

4 Front End Page 4-30

Page 4-30

Brake Pressure Modulator Bracket Assembly

Figure 4 – 63

Multiuse Relay Housing Bracket

Figure 4 – 64