Precautions Page 2–1

Page 2–1

Section 2

Precautions

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes in the MY 2004 VY and V2 Series Service Information and Section 2

Precautions in the MY 2003 VY and V2 Series Service Information Supplement, Body Structure Repair, for

correct workshop practices with regard to safety and/or property damage.

1 General Information............................................................................................................................... 2

2 Cavity Foam............................................................................................................................................ 3

2.1 Cavity Foam – Replace..........................................................................................................................................5

Hinge Pillar..............................................................................................................................................................5

Centre Pillar............................................................................................................................................................5

Body Lock Pillar.....................................................................................................................................................6

Rocker Panel...........................................................................................................................................................6

Precautions Page 2–2

Page 2–2

1 General Information

With the following exceptions, MY 2004 VY and V2 Series Precautions information carries over from MY 2003 VY and V2

Series vehicles.

• Cavity Foam – Utility.

For information not contained within this Section, refer to Sect ion 2 Precautions in the MY 2003 VY and V2 Series

Service Information Supplement, Body Structure Repair.

Precautions Page 2–3

Page 2–3

2 Cavity Foam

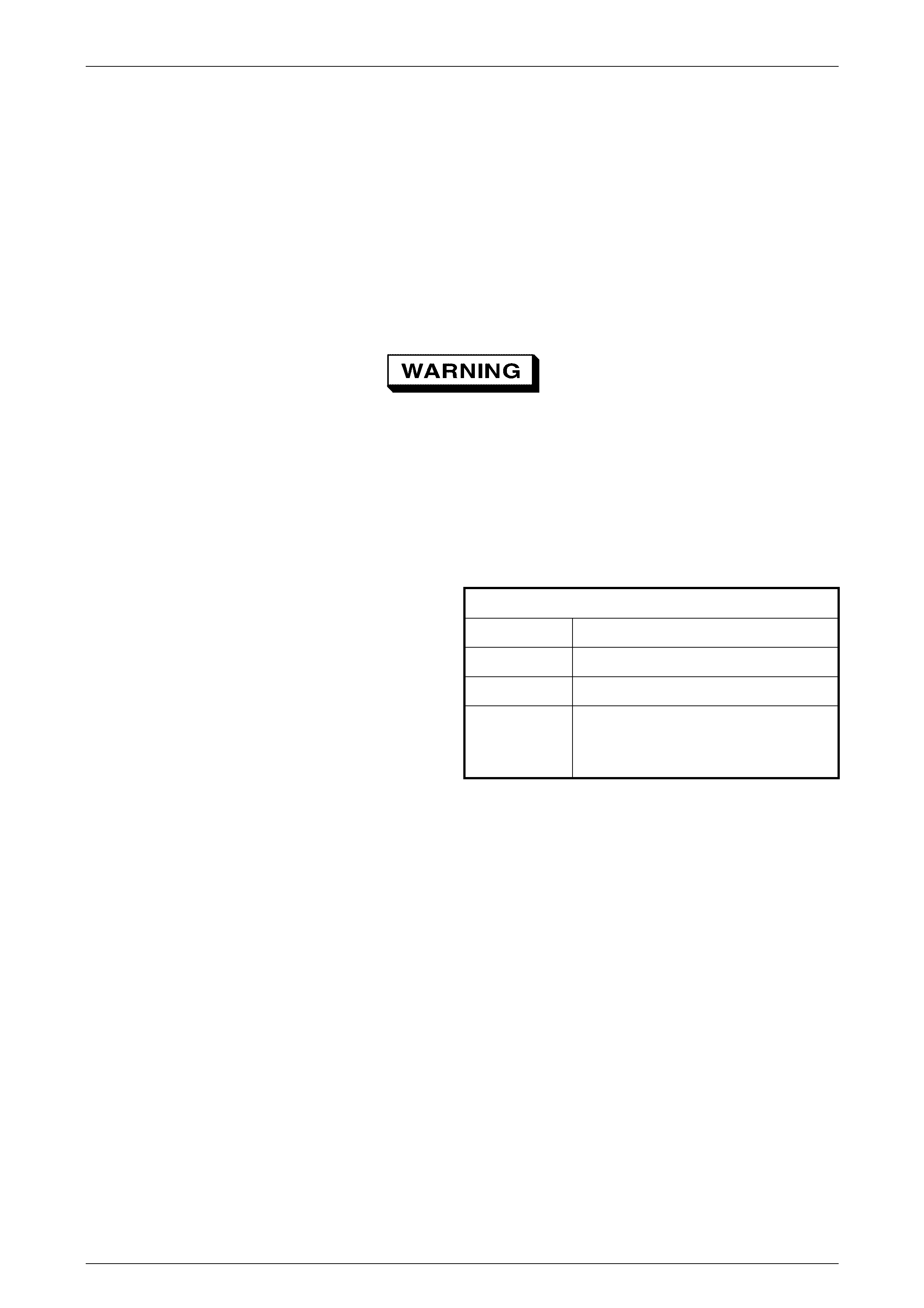

During manufacture of the vehicle, cavity foam blocks are fitted within the hinge, centre and body lock pillars, and the

rocker panel, refer to Figure 2 – 1.

NOTE

Application of cavity foam in locations C and D

will be introduced early 2004.

This foam material, when subjected to a temperature of approximately 160°C, expands up to 10 times its original size to

seal the cavity and reduce noise transmission.

The use of this material poses no health and

safety risk to a repairer, unless it is heated to

temperatures associated with using oxy /

acetylene equipment or welding, as toxic

fumes will be emitted which must not be

inhaled.

Prior to welding or heating in the areas shown, the foam must first be removed – usually by cutting it out with a knife.

If a panel or section is replaced, or repair work is performed where the foam is removed, it must be replaced with a

commercially available equivalent, such as those listed, using the following procedures prior to final trim assembly.

CAVITY FOAM EQUIVALENTS

Brand Product

Sista Multi Purpose Foam

Ramset Expandable Polyurethane Foam

NOTE

The hinge pillar inner panel assembly and

quarter panel inner assembly service parts are

supplied with uncured foam blanks. These must

not be removed as they act as a support for the

aerosol cavity foam.

Always read and follow the directions and safety

instructions with the product prior to usage.

Selleys Space invader

Precautions Page 2–4

Page 2–4

Figure 2 – 1

Legend

A Hinge Pillar C Body Lock Pillar

B Centre Pillar D Rocker Panel

Precautions Page 2–5

Page 2–5

2.1 Cavity Foam – Replace

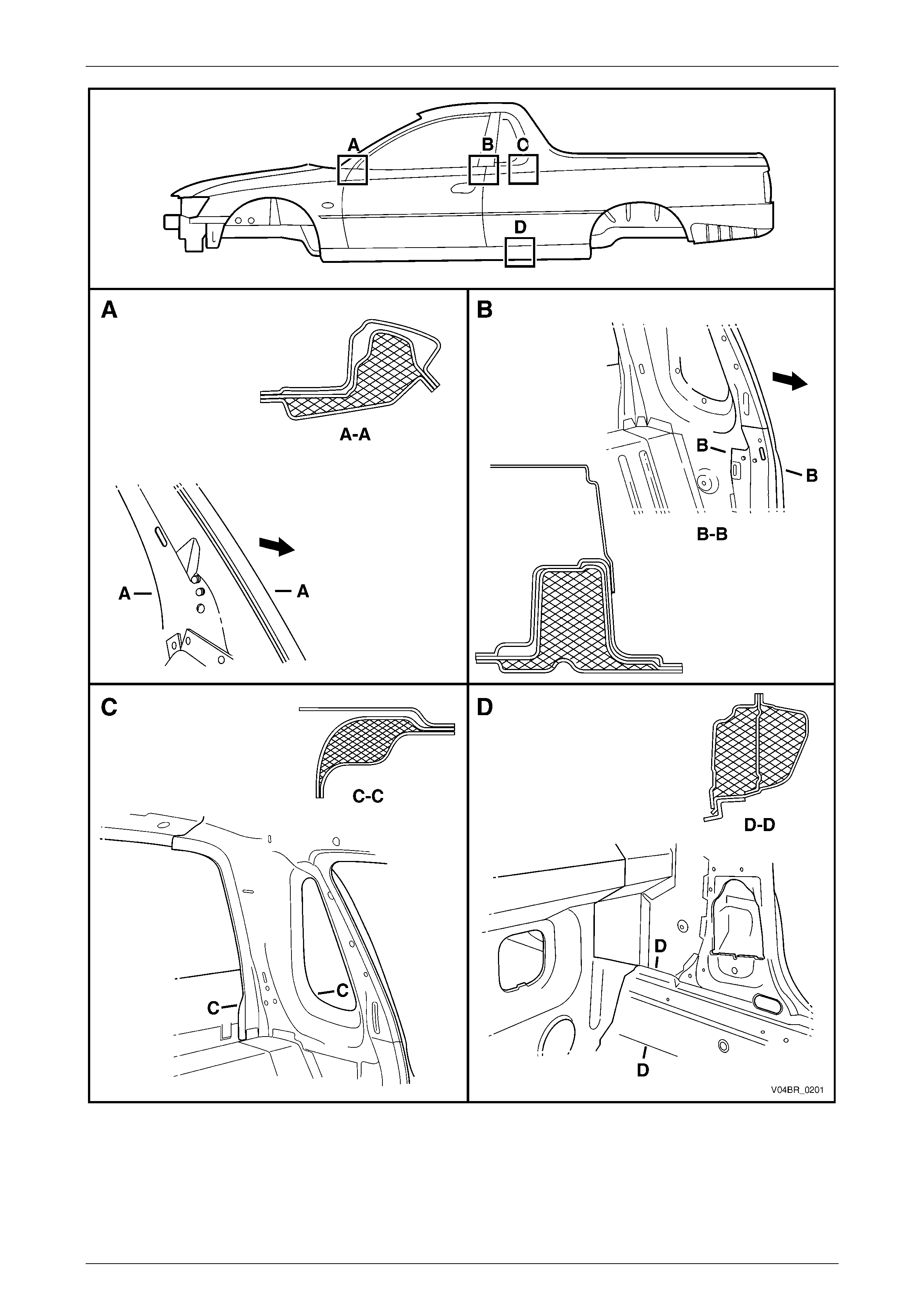

Hinge Pillar

1 For the hinge pillars, insert the nozzle of the aerosol

into the trim clip slot (1) which is above the foam

blank.

2 Spray foam into the cavity for several seconds while

drawing the nozzle out. Fill the area to a height of

approximately 50 mm.

3 Once cured, remove a small amount of foam using a

probe to enable the trim clip to seat correctly.

Figure 2 – 2

Centre Pillar

1 For the centre pillars, insert the nozzle of the aerosol

into the trim clip slot (1) which is above the foam

blank.

2 Spray foam into the cavity for several seconds while

drawing the nozzle out. Fill the area to a height of

approximately 50 mm.

3 Once cured, remove a small amount of foam using a

probe to enable the trim clip to seat correctly.

Figure 2 – 3

Precautions Page 2–6

Page 2–6

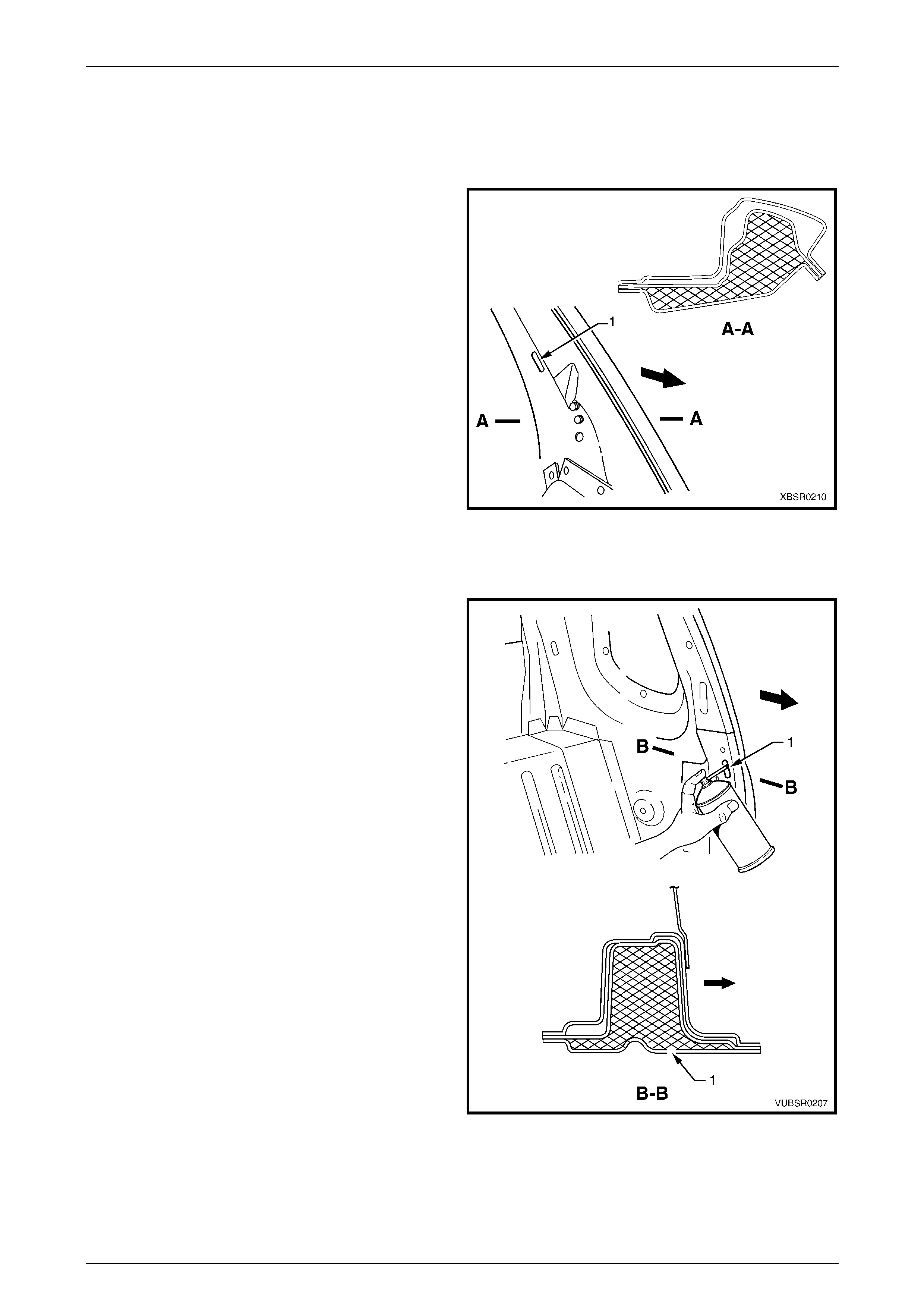

Body Lock Pillar

1 For the body lock pillars, insert the nozzle into the trim

locating hole (1) which is above the foam blank.

2 Spray foam into the cavity between the lock pillar

reinforcement and quarter panel inner for several

seconds while drawing the nozzle out. Fill the area to

a height of approximately 50 mm.

3 Once cured, remove a small amount of foam from the

locating hole using a probe to enable the trim stud to

seat correctly.

Figure 2 – 4

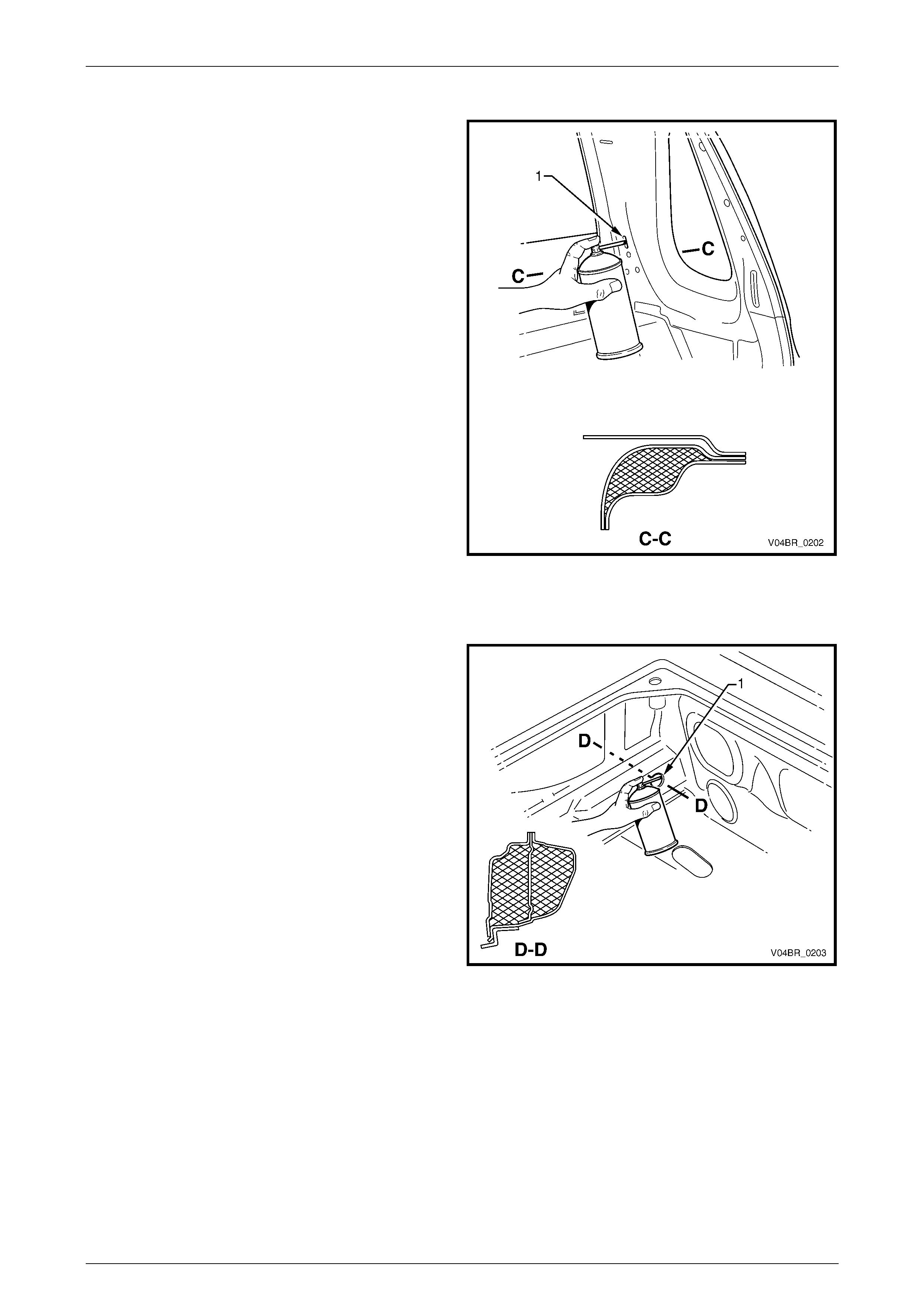

Rocker Panel

1 For the rocker panels, insert the nozzle into the inner

rocker panel hole (1) within the fuel tank cavity.

2 Spray foam into the cavity between the door opening

frame, quarter panel inner and inner rocker panel for

several seconds for a length of approximately 50 mm.

Figure 2 – 5