SECTION 3B – BODY CONSTRUCTION – WAGON

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to

Section 00 CAUTIONS AND NOTES and Section 2 PRECAUTIONS in this Supplement for correct

workshop practices with regard to safety and/or property damage.

CAUTION

The Structure of the MY2003 VY & V2 Series II body shell has been developed using complex design

and development techniques. In addition to meeting all required standards, the v ehicle body is also a

critical part of the overall safety systems. It is therefore imperative the repair procedures described

here are adhered to during all vehicle body repairs.

1. GENERAL DESCRIPTION

2. BODY STRUCTURE PANELS

2.1 FRONT END & UNDERBODY

2.2 UPPERBODY STRUCTURE

2.3 BODY ASSEMBLY

3. BODY DIMENSIONS

3.1 UNDERBODY DIMENSIONS – PROJECTED

3.2 UPPERBODY DIMENSIONS – ACTUAL

FRONT

SIDE & INTERIOR

REAR

4. BODY MARGINS

5. BODY SEALING, ADHESIVES & DEADENERS

5.1 ACRYLIC SPOTWELD SEALER

5.2 JOINT SEALER

5.3 ADHESIVE – ANTI-FLUTTER

5.4 ADHESIVE – STRUCTURAL

5.5 SPRAY-ON DEADENER

5.6 DEADENER PANELS & INSULATORS

5.7 FUSIBLE REINFORCEENT PATCHES

REPLACE

5.8 DEADENER STRIP & STUFFER BLOCK

DEADENER STRIP

STUFFER BLOCK

6. CAVITY WAX

7. ROOF JOINT MOULDING

REMOVE

INSTALL

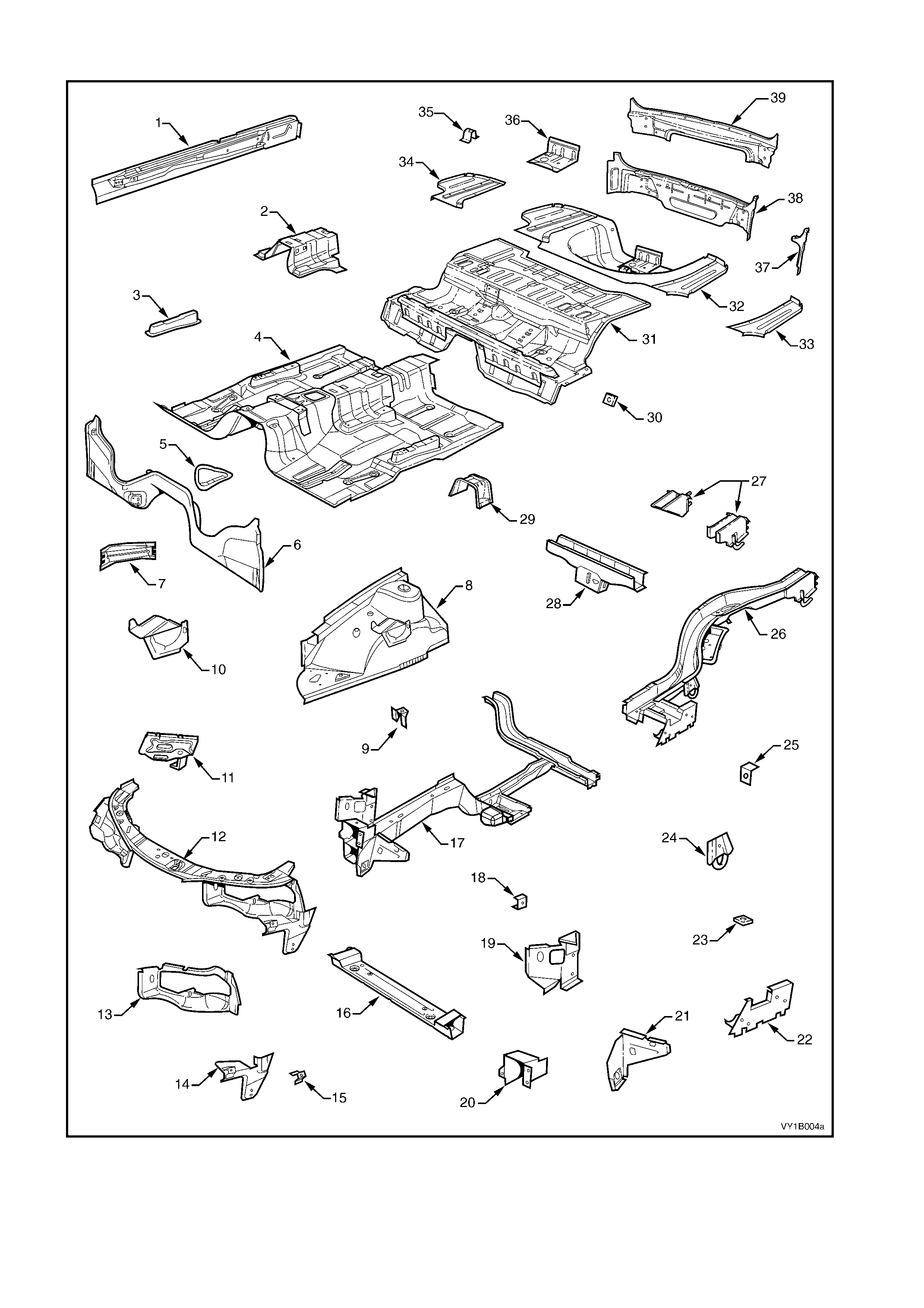

2. BODY STRUCTURE PANELS

The following tables and illustrations describe the body structure assemblies and panels that are available for

service replacement.

NOTE. Always refer to your authorised Retailer for spare parts availability configurations.

2.1 FRONT END & UNDERBODY

Legend

1. Inner Rocker Panel Assembly 21. Front Wheelhouse Panel Bracket

2. Seat Inner Bracket Assembly 22. Rear Floor Panel Outer Extension

3. Seat Outer Bracket Assembly 23. Rear Suspension Support Mount Plate

4. Front Floor Panel Assembly 24. Rear Tie Down Assembly

5. Transmission Support Bracket 25. Rear Brake Hose Bracket

6. Front Floor Panel Extension 26. Rear Side Rail Assembly

7. Front Side Rail Brace 27. Rear Bumper Impact Bar Brace Assembly, LH / RH

8. Front Wheelhouse Panel Assembly 28. Crossmember Assembly No. 2

9. Horn Bracket Assembly 29. Propeller Shaft Hanger Assembly

10. ABS Modulator Bracket Assembly 30. Rear Seat Belt Anchor Plate Assembly

11. Battery Tray Assembly 31. Rear Floor Panel Assembly

12. Front End Panel Assembly 32. Rear Compartment Floor Panel Assembly

13. Headlamp Panel 33. Rear Compartment Floor Panel Outer Extension, LH

14. Headlamp & Front Fascia Mount Bracket 34. Rear Compartment Floor Panel Outer Extension, RH

15. Fender Front Lower Bracket 35. Spare Wheel Anchor Plate Assembly

16. Radiator Lower Support Assembly 36. Fuel Tank Support Reinforcement Assembly

17. Front Side Rail Assembly 37. Rear End Panel Extension

18. Radiator Side Mounting Bracket 38. Rear End Panel Assembly

19. Front Wheelhouse Bracket Assembly 39. Rear End Lower Panel

20. Front Bumper Impact Bar Bracket

Figure 3B-1

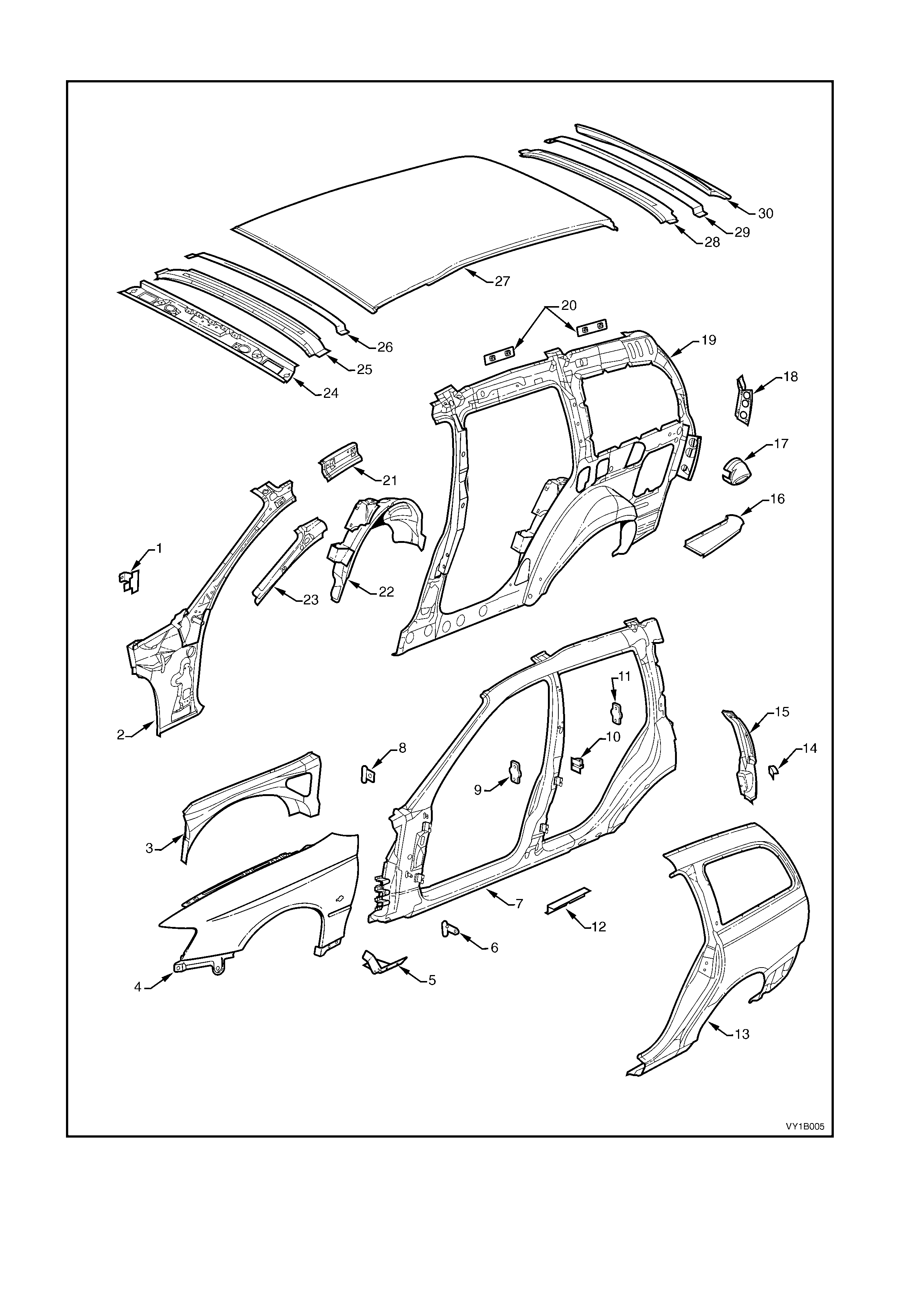

2.2 UPPERBODY STRUCTURE

Legend

1. Hinge Pillar Trim Panel Bracket 16. Quarter Outer Lower Rear Panel

2. Hinge Pillar Inner Panel Assembly 17. Fuel Filler Pipe Housing, RH

3. Front Wheelhouse Panel Upper Side Rail 18. Quarter Inner Lower Rear Extension

4. Front Fender 19. Quarter Panel Inner Assembly

5. Fender Lower Rear Bracket 20. Cargo Screen Reinforcement Assembly

6. Fender Rear Bracket 21. Quarter Panel Inner Extension

7. Door Opening Frame Assembly 22. Rear Wheelhouse Inner Panel Assembly

8. Fender Upper Rear Bracket 23. Hinge Pillar Upper Reinforcement

9. Front Door Striker Anchor Plate 24. Roof Front Header Panel

10. Rear Door Check Link Bracket 25. Roof Bow Panel No. 1

11. Rear Door Striker Anchor Plate 26. Roof Bow Panel No. 2

12. Underbody Jacking Locator 27. Roof Panel

13. Rear Quarter Panel 28. Roof Bow Panel No. 3

14. Rear Bumper Fascia Side Bracket 29. Roof Bow Panel No. 2

15. Quarter Panel Extension 30. Roof Rear Panel

Figure 3B-2

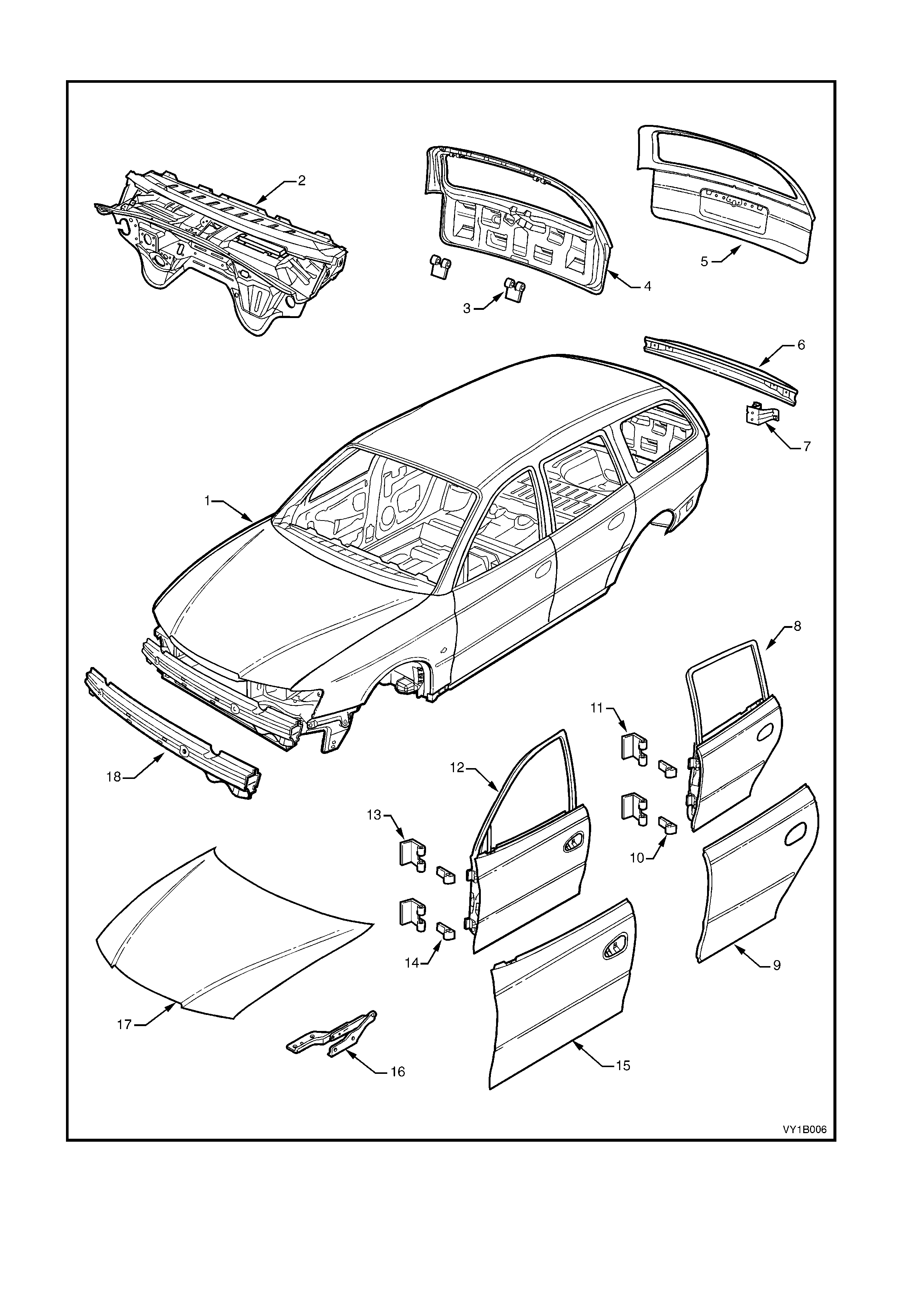

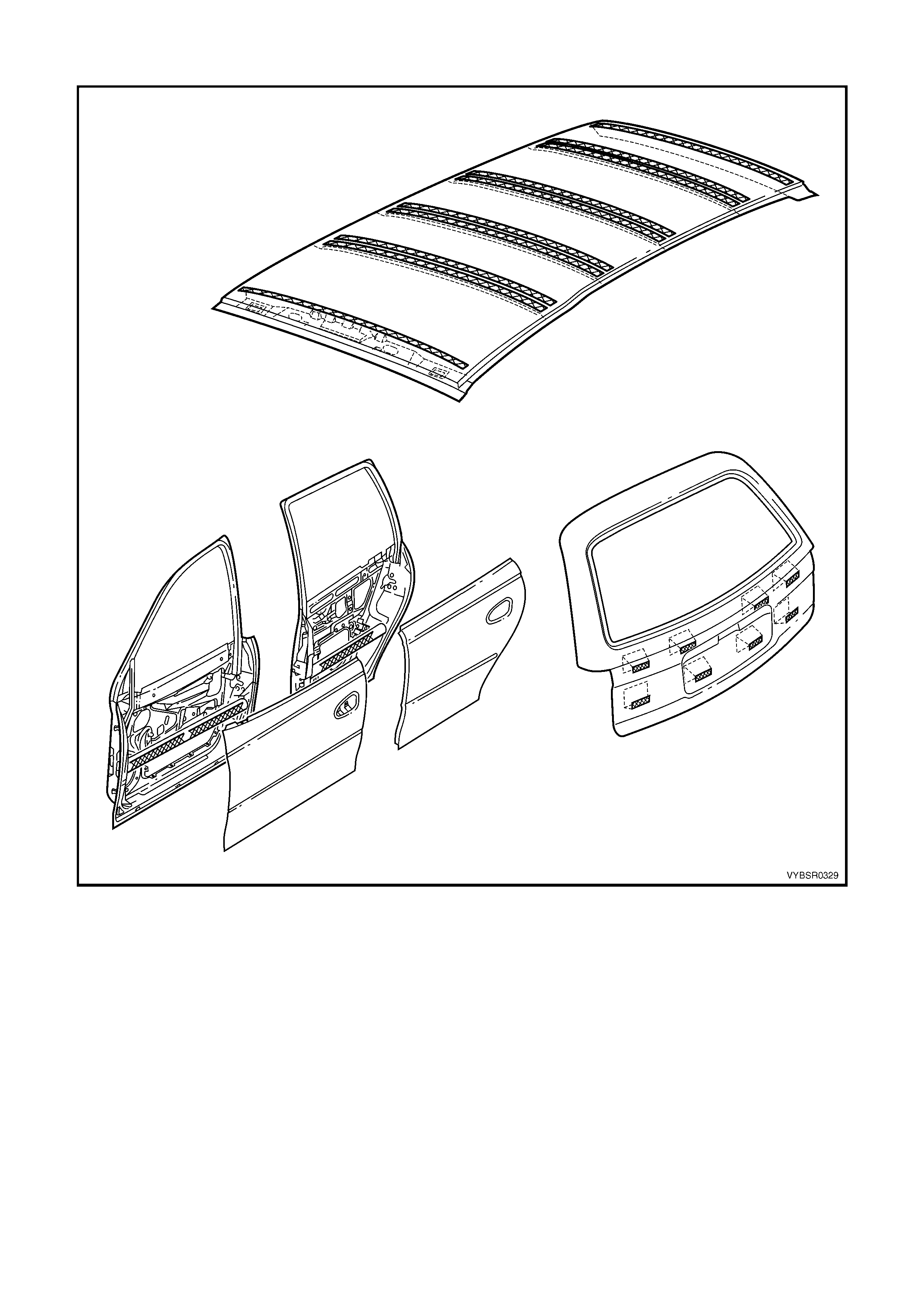

2.3 BODY ASSEMBLY

Legend

1. Body Assembly 10. Rear Door Hinge (Door Side)

2. Dash Panel Assembly 11. Rear Door Hinge (Body Side)

3. Liftgate Hinge (Liftgate Side) 12. Front Door Assembly

4. Liftgate Assembly 13. Front Door Hinge (Body Side)

5. Liftgate Outer Panel 14. Front Door Hinge (Door Side)

6. 5. Rear Bumper Impact Bar 15. Front Door Outer Panel

7. 6. Rear Bumper Impact Bar Bracket Assembly 16. Hood Hinge Assembly

8. Rear Door Assembly 17. Hood assembly

9. Rear Door Outer Panel 18. Front Bumper Impact Bar Assembly

Figure 3B-3

3. BODY DIMENSIO NS

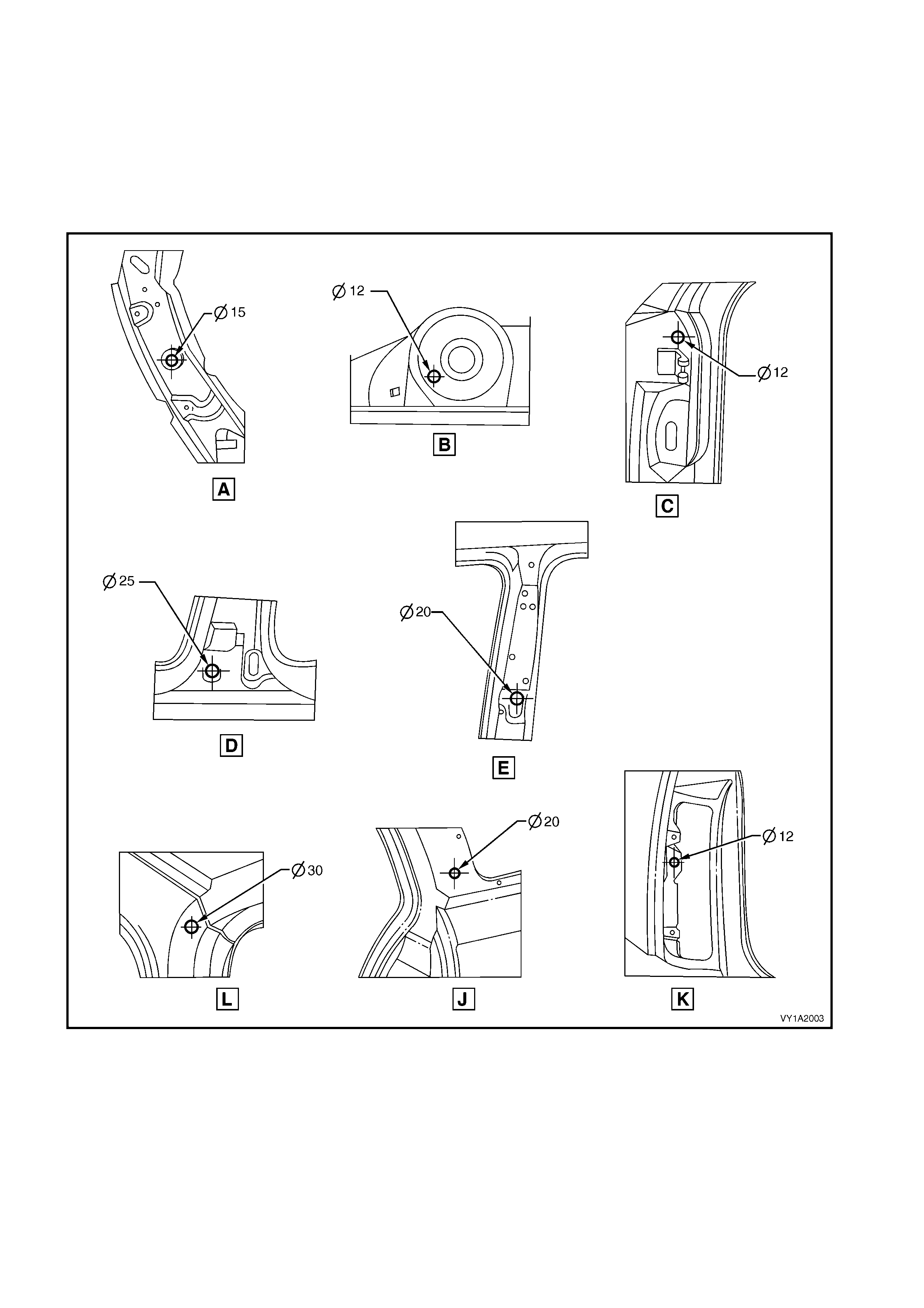

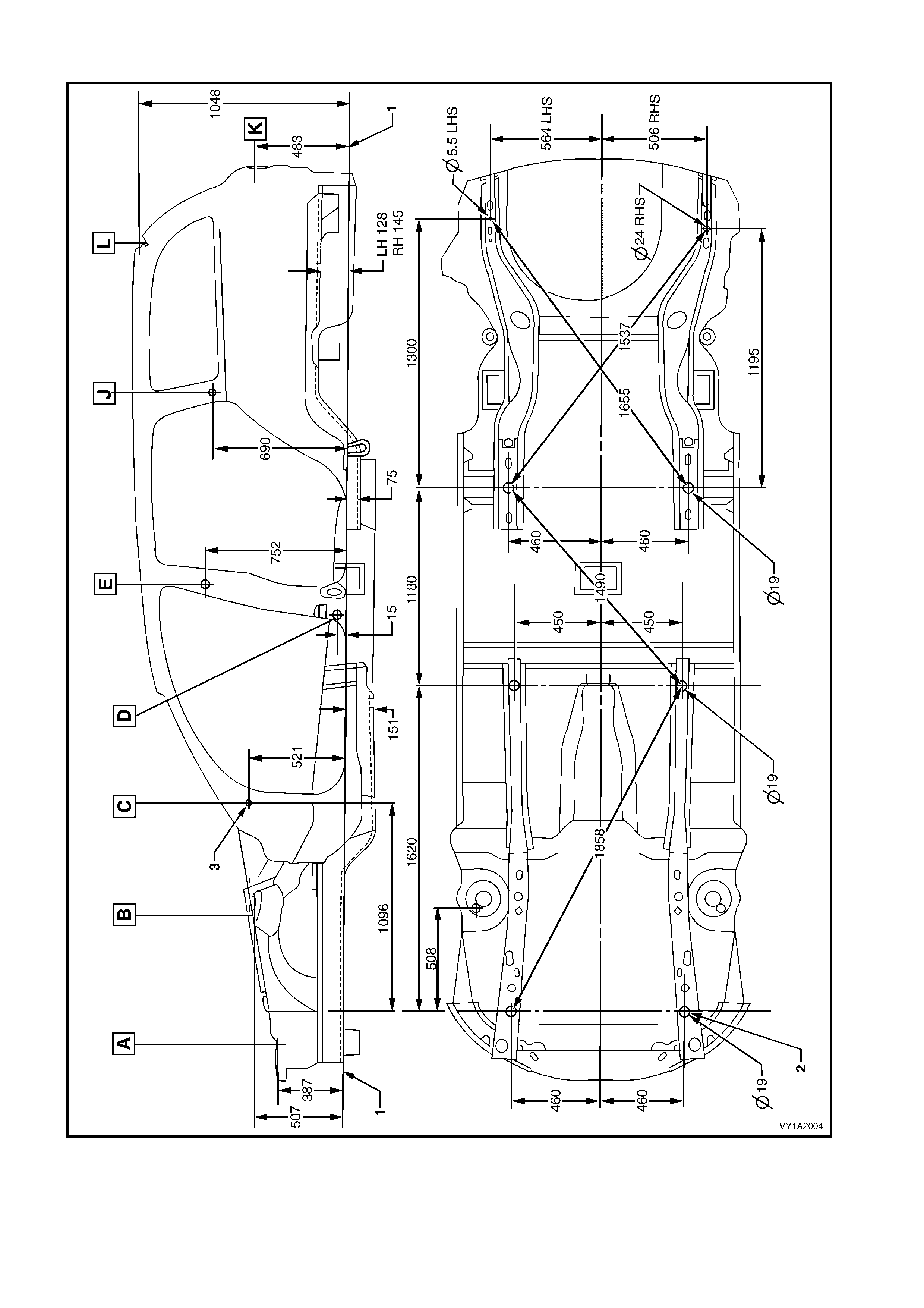

3.1 UNDERBODY DIME NSIONS – PROJECTE D

All dimensions are given in mm and are measured from the centre of holes, on the outer side of the metal surface.

The main datum surface (1) is the underside of the front side rail assembly, refer to Figure 3B-5

The main datum hole (2) is a 19 mm hole on the underside of the front side rail assembly, refer to Figure 3B-5.

The dash panel assembly attaching hole (3) in Figure 3B-5 is the datum hole also depicted at View C in

Figure 3B-4.

Figure 3B-4

Figure 3B-5

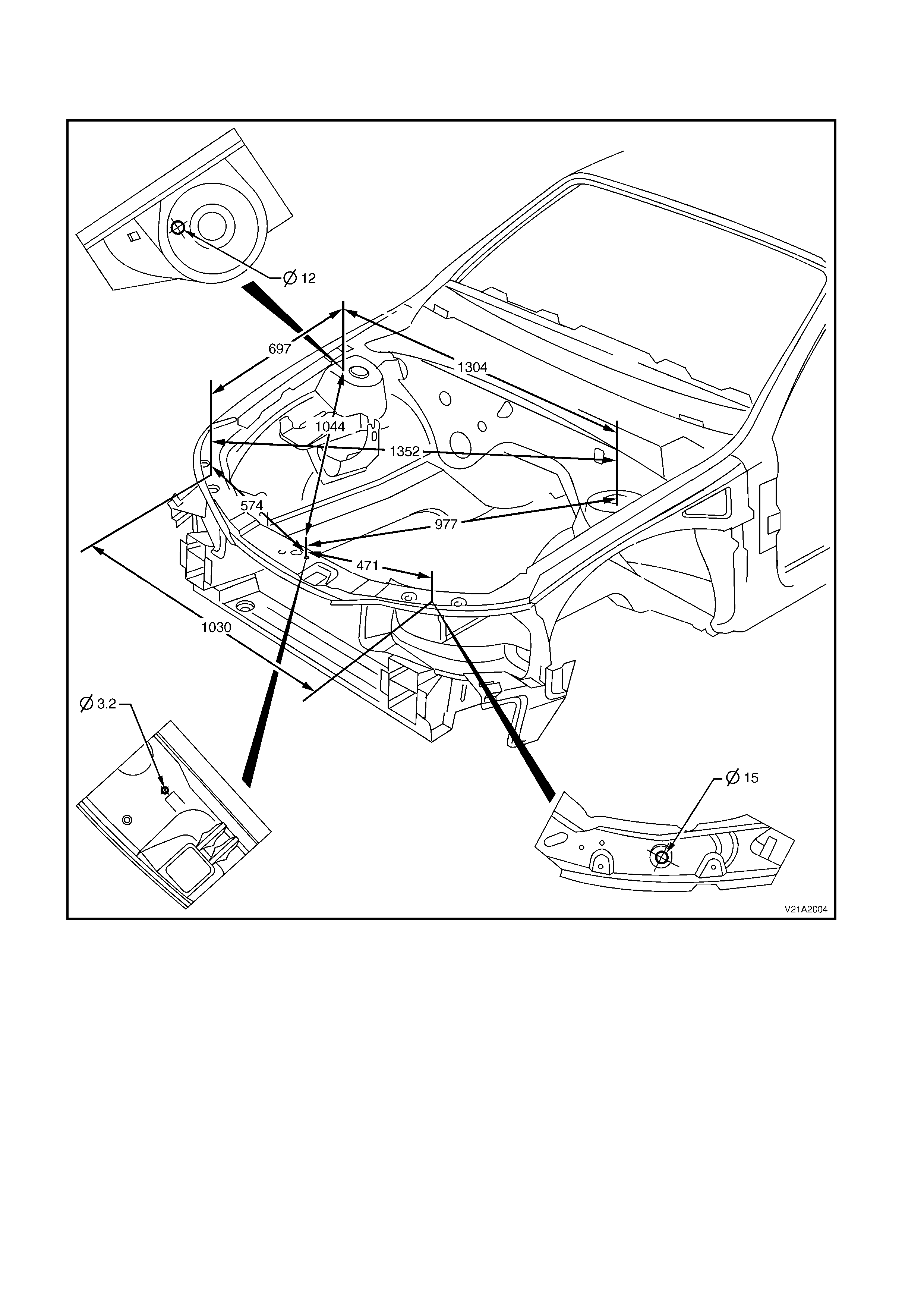

3.2 UPP ERBODY DIMENSIONS – ACTUAL

FRONT

Figure 3B-6

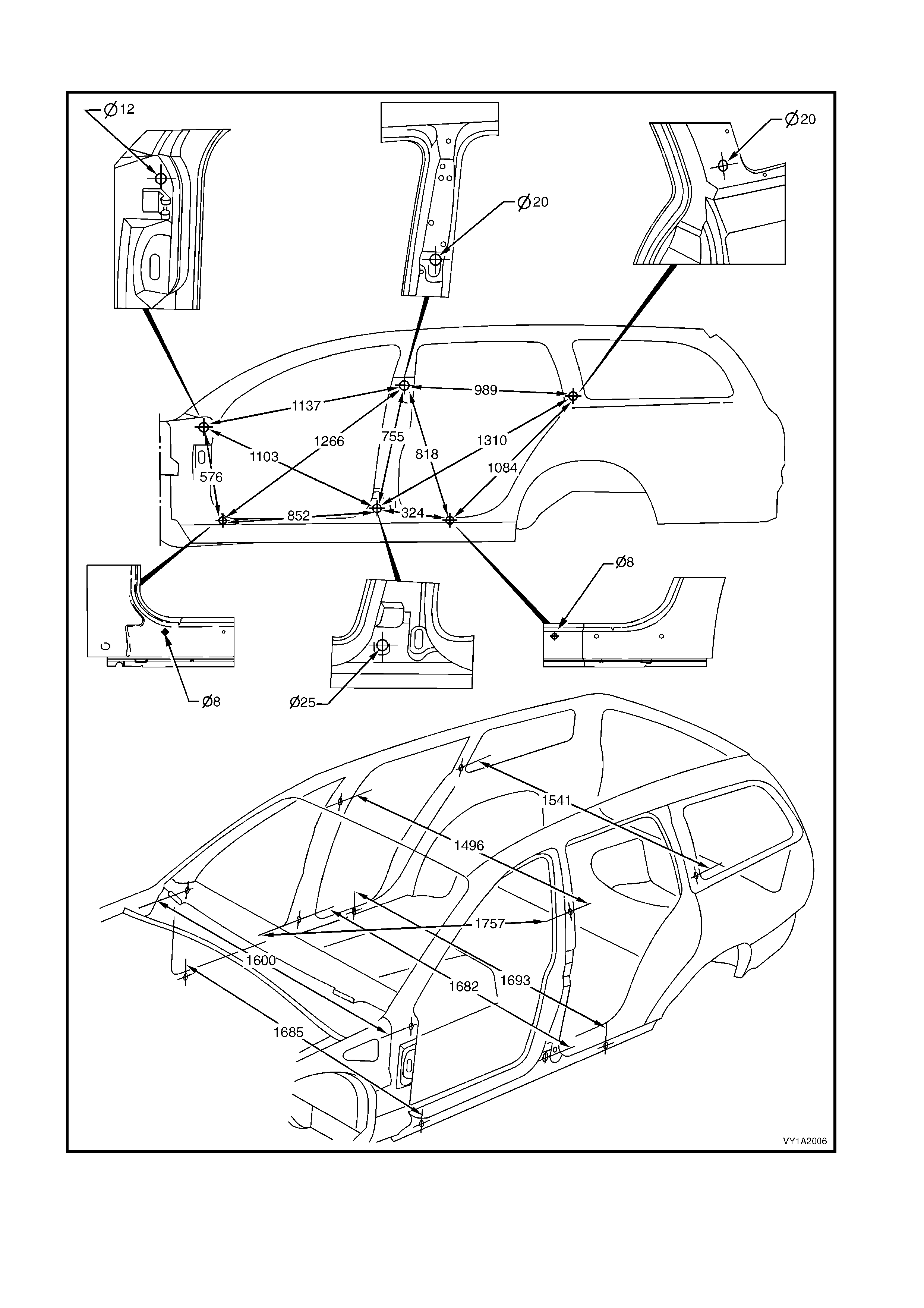

SIDE & INTERIOR

Figure 3B-7

REAR

Figure 3B-8

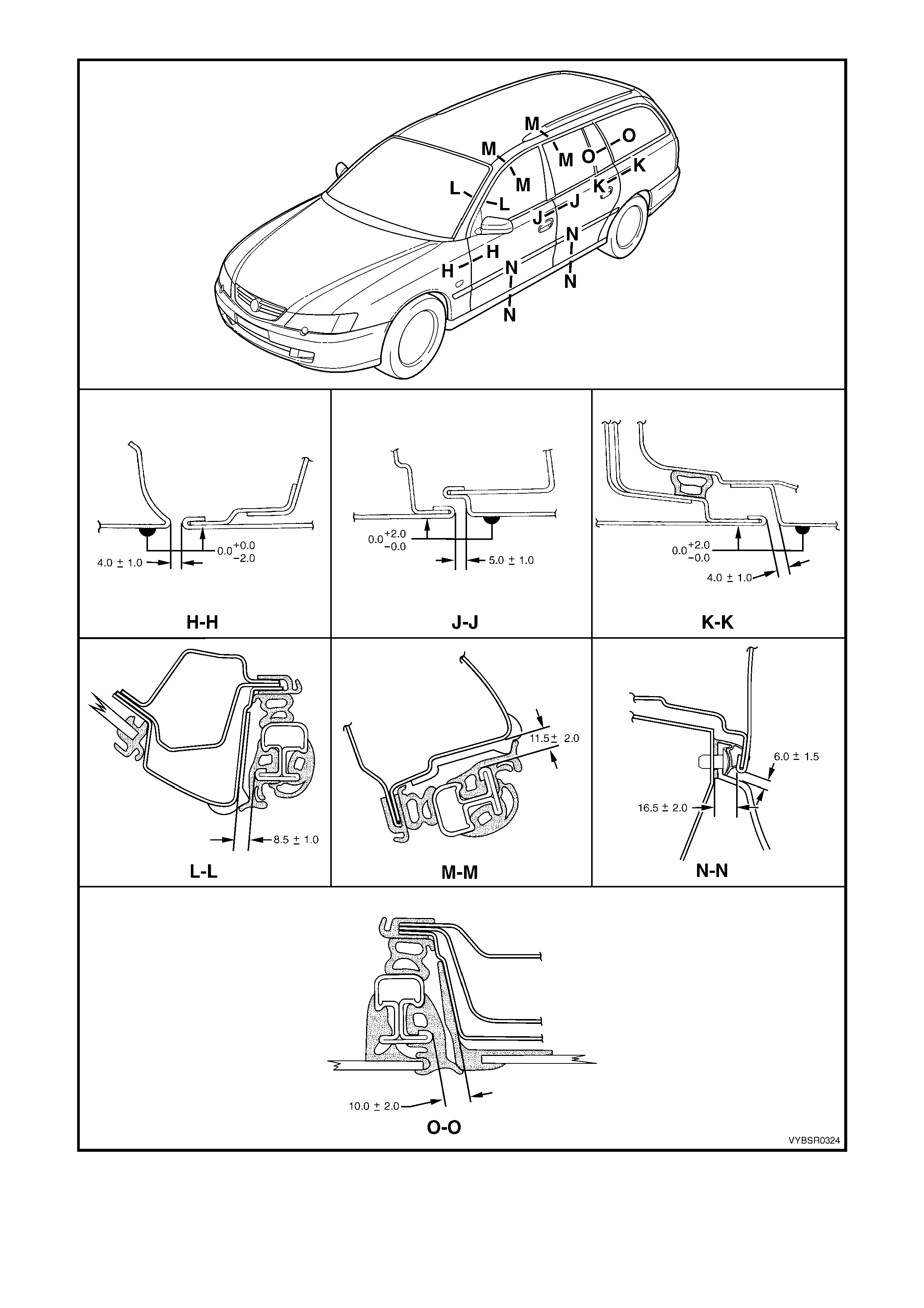

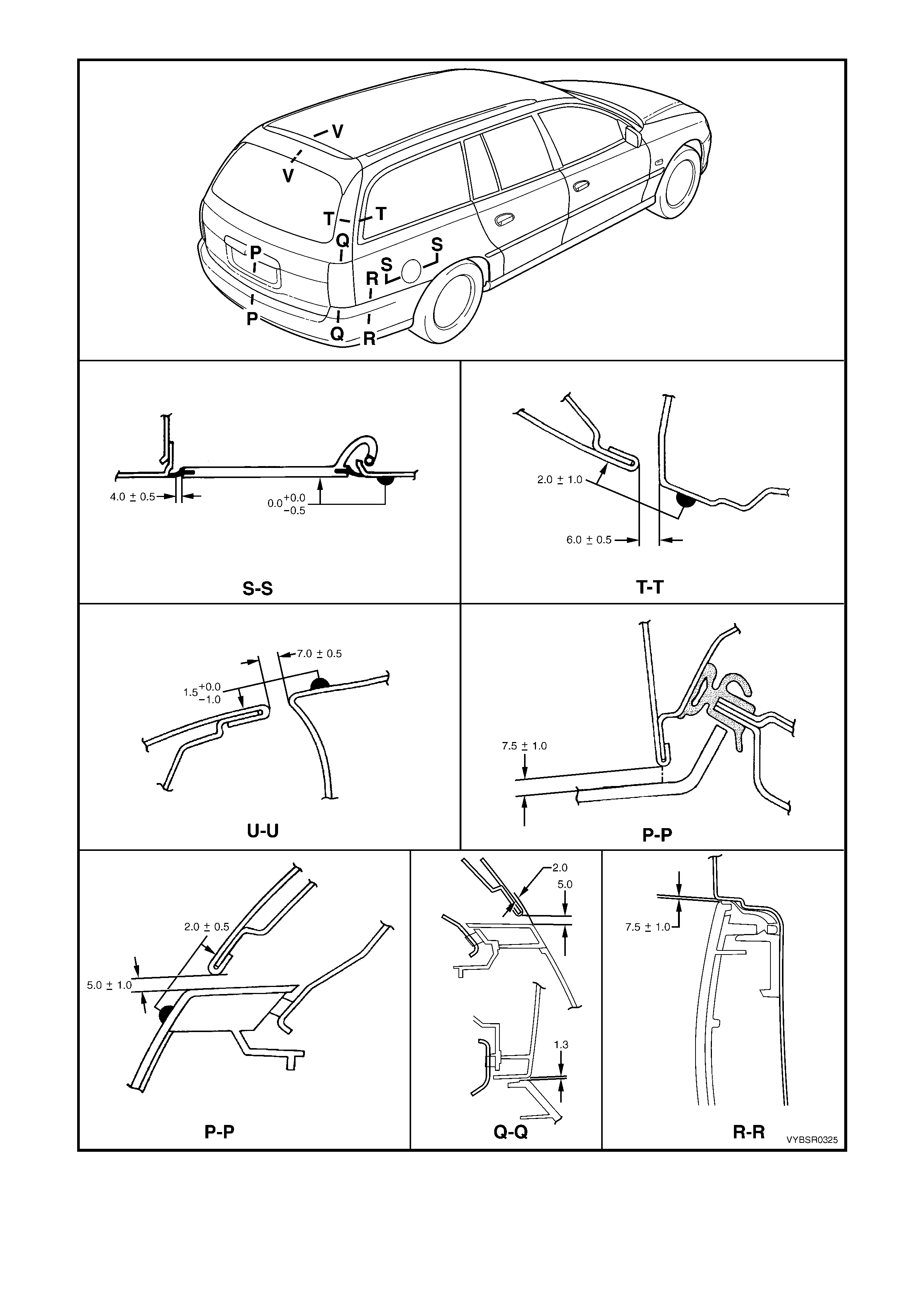

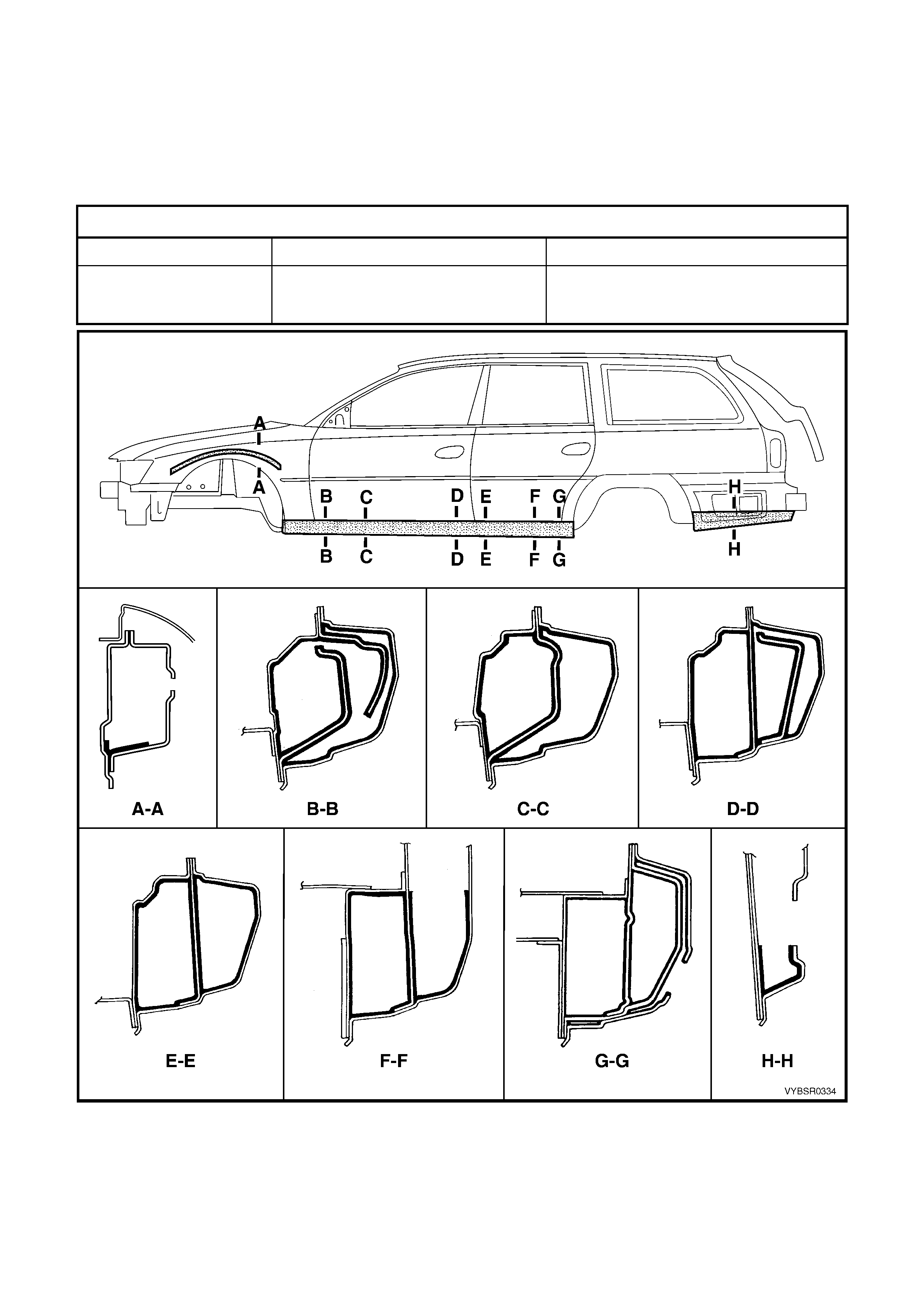

4. BODY M ARGINS

Figure 3B-9

Figure 3B-10

Figure 3B-11

5. BODY SEALING, ADHESIVES AND DEADENERS

This Section details the sealers, adhesives and deadeners used in the MY 2003 VY Series W agon body shell. It is

imperative that the correct materials are used and the directions on the product always be followed.

NOTE. When replacing any sealer, adhesive or deadener, ensure the finish meets that of the original application.

IMPORTANT: The commercially available products listed below will meet the required standards. Other products

may be available that meet the performance characteristics, however before their use, the product manufacturer

should be contacted to check its suitability.

• Weld Through Primer (Item 1)

Although not used in manufacture, W eld Through Primer is recom mended for all service repair lap and flange

joints where Ac rylic Spot Weld Sealer ( Item 2) is not used. Weld T hr ough Prim er aids in corr osion protec tion of

the joint.

• Acrylic Spot Weld Sealer (Item 2)

Used in joints that require sealing additional to Joint Sealer (Item 3). It is applied to the joint flange prior to the

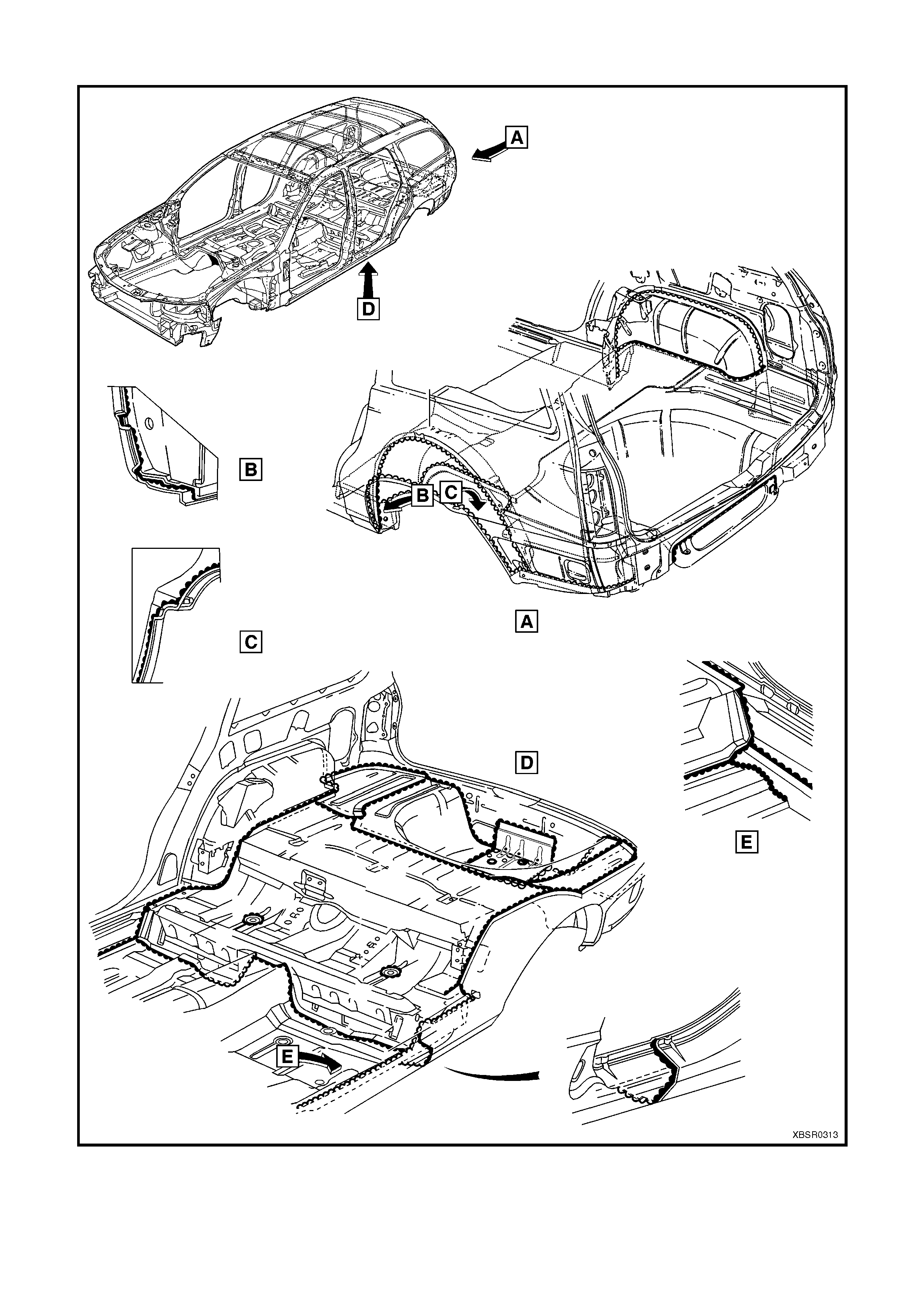

mating of panels. Refer to Figures 3B-12 & 3B-13.

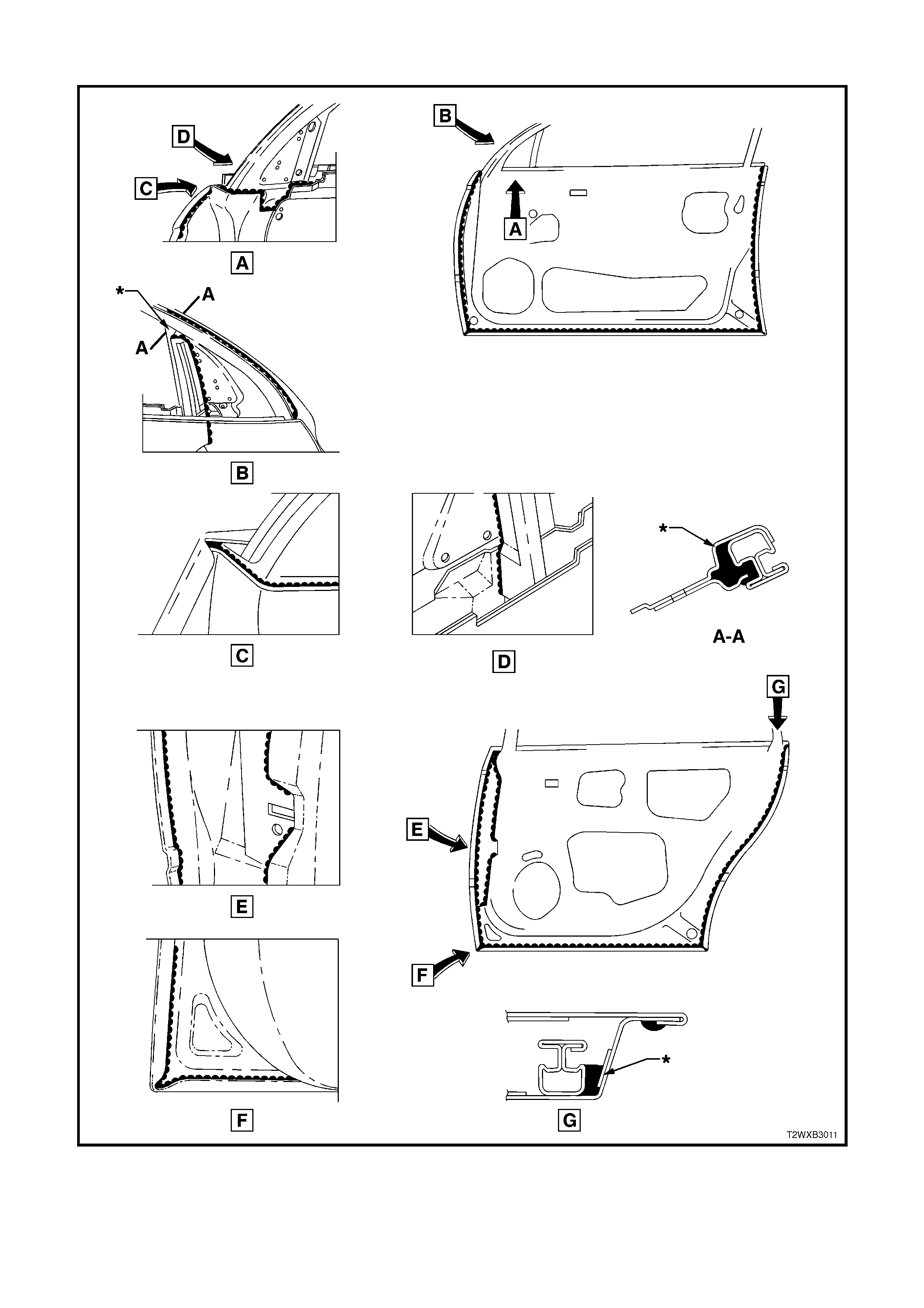

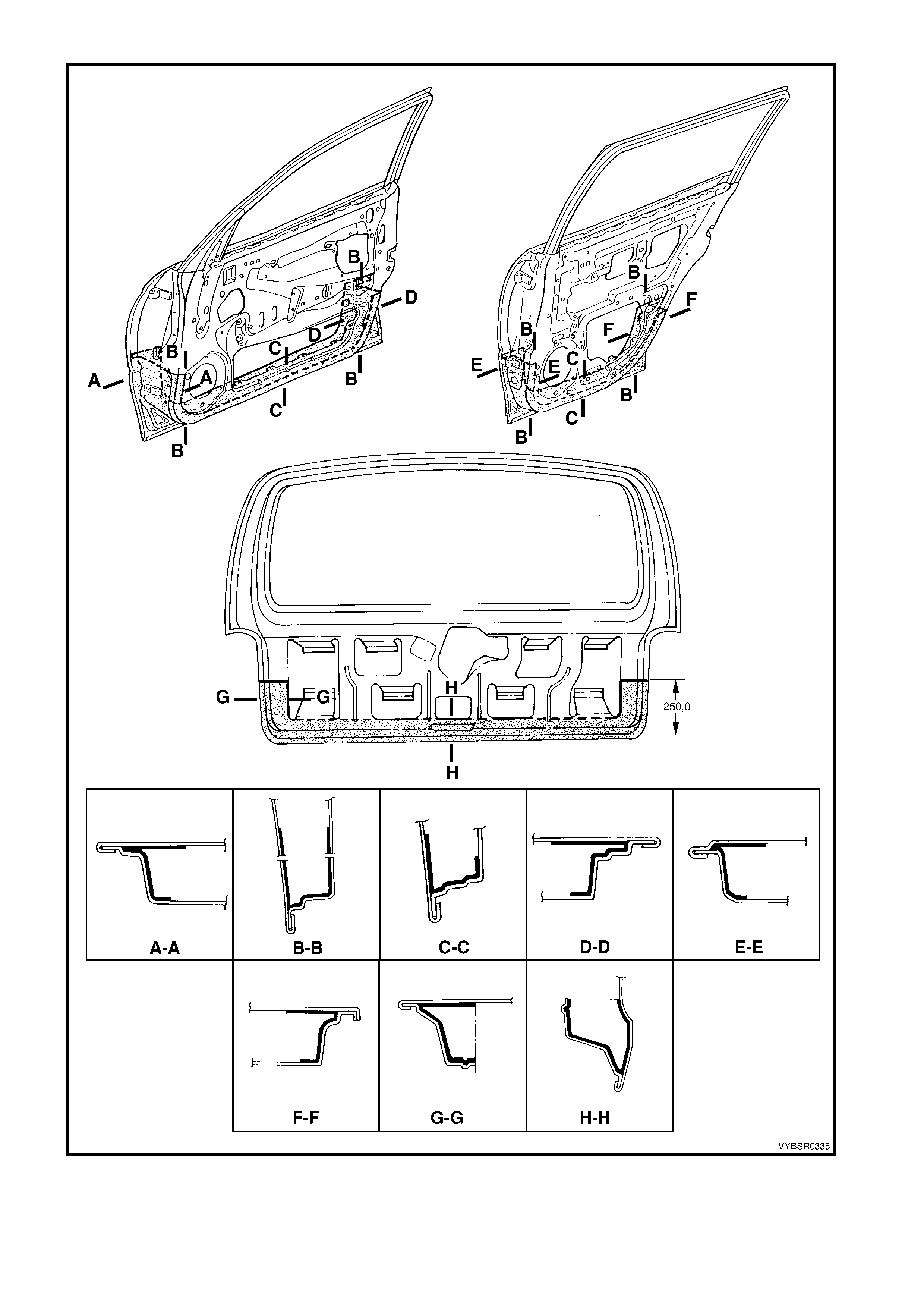

• Joint Sealer (Item 3)

Primarily used for sealing joints to achieve a watertight seal. It seals notches, cut-outs and holes. Joint sealer

should be applied after priming, prior to application of the top coat. Refer to Figures 3B-14 – 3B-19.

NOTE: Figure 3B-15, View E illustrates the underside of the spare wheel-well. Following priming, this area is

sprayed with sealer (rather than deadener) to a minimum thickness of 2.5 mm and has a rough finish. This

procedure is important due to the mounting of the fuel tank below it.

• Hand Putty (Item 4)

Hand putty, also known as caulking compound, is used in the areas marked * in Figure 3B-16.

• Adhesive - Anti-Flutter (Item 5)

While used as a filler between an inner and outer panel to reduce panel flex, Anti-Flutter adhesive also aids

rigidity and assists in dispersing loads over a larger area. Refer to Figure 3B-20 for locations.

• Adhesive - Structural (Item 6)

Critical to the strength and rigidity of the vehicle, the correct adhesive must be used for service repairs. Using

an adhesive that is too weak will reduce the performance of the joint. Using an adhesive that is too strong can

also effect the performance of the joint, compromising the vehicle’s crash performance and safety system’s

operation. This adhesive is a 2-part system. Refer to Figure 3B-21 for locations.

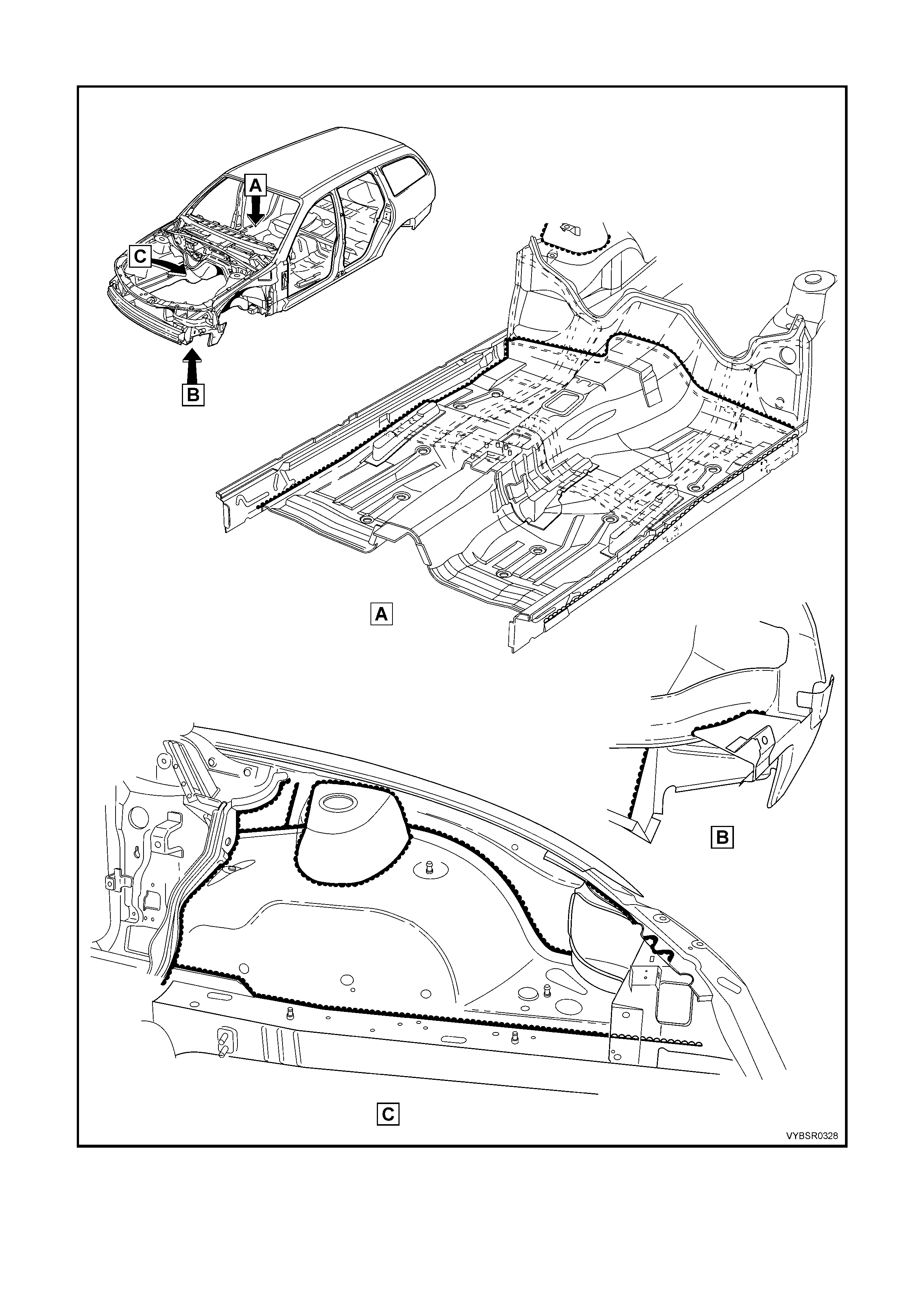

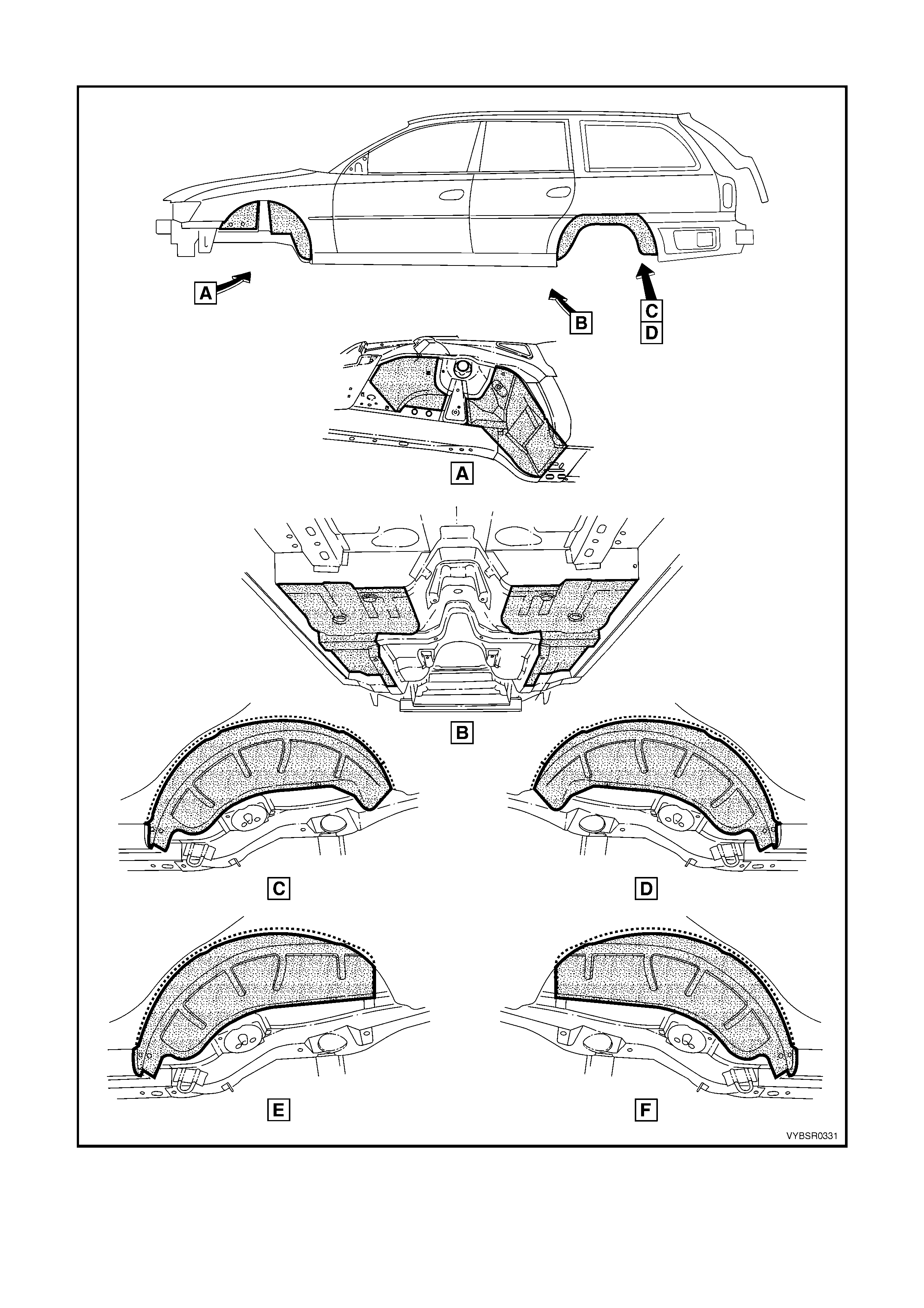

• Spray-on Deadener (Item 7)

This deadener is sprayed onto the body shell af ter painting. It is used in the wheel-wells and on the under side

of the floor pan. A minimum thickness of 1.5 mm is required in these applications. Refer to Figure 3B-22 for

locations.

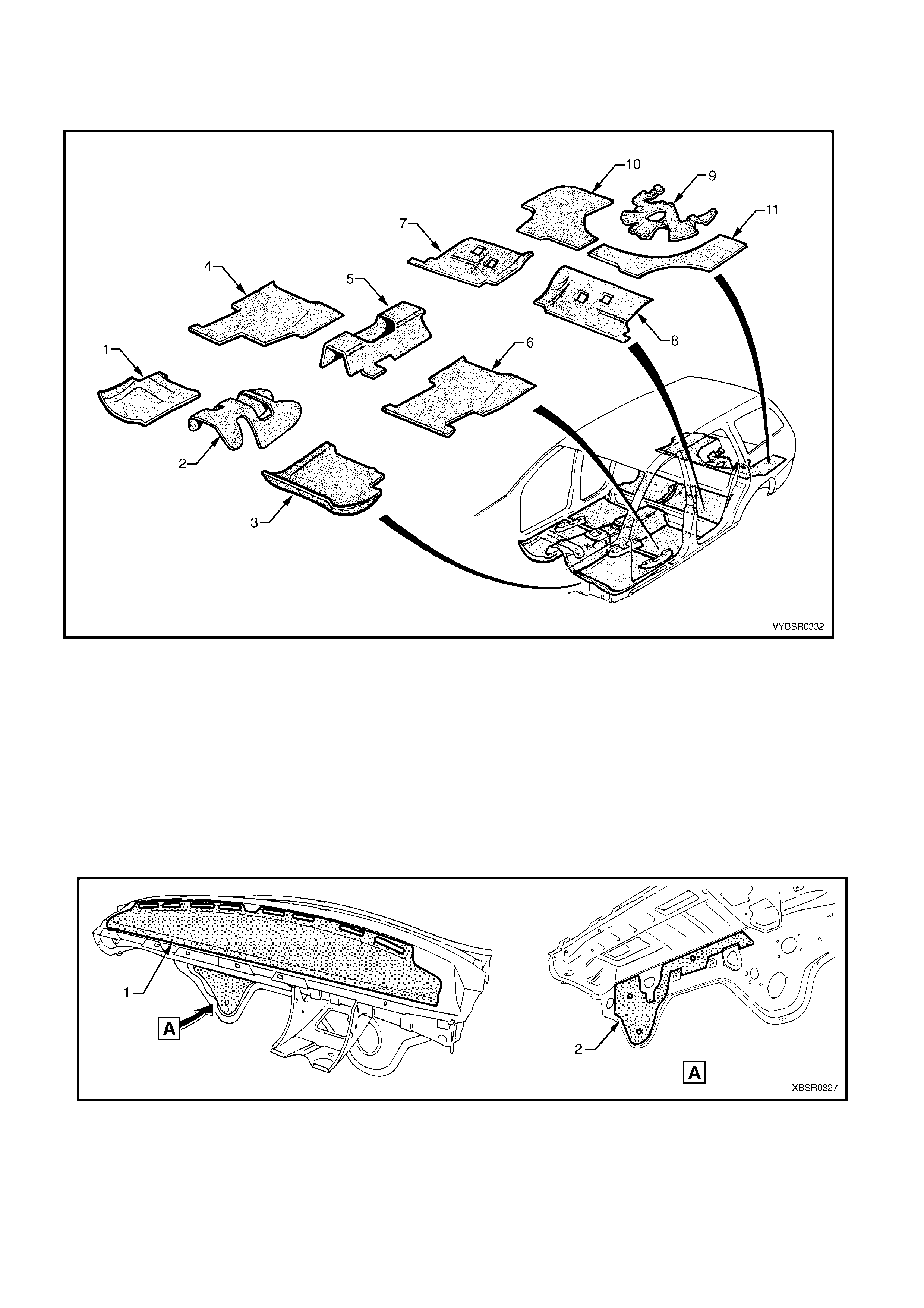

Deadener Panels

Deadener panels are sold pre-cut as Service Parts. They are installed with the coloured side up and diamond

embossed side down. The panels are installed prior to painting and some are heat fused to the body shell.

Refer to Figures 3B-23 – 3B-26 for locations.

SEALER / ADHESIVE / DEADENER

COMMERCIALLY AVAILABLE EQUIVALENTS

Item No. Item Name Manufacturer Product Name

1 Weld Through Primer Refer to supplier

2 Acrylic Spot Weld Sealer Lord (Fusor) Fusor #800 / #801

3 Joint Sealer Sprayable: Lord (Fusor)

Extruded beads: Lord (Fusor)

3M

Visible Seams

-self leveling: Lord (Fusor)

3M

-non sag: Lord (Fusor)

3M

Fusor #802

Fusor #800 / #801

Automix 8308

Fusor #122 / #125

Automix 8307

Fusor #123 / #126

Automix 8308

4 Hand Putty Lord (Fusor)

3M Fusor #800 / #801

Automix 8307

5 Adhesive - Anti Flutter Lord (Fusor) Fusor #124

6 Adhesive - Structural

(Two-Part) Lord (Fusor)

3M Fusor #108 B

Automix 8115

7 Spray-on Deadener Henkel Terophon 2000-13

NOTE: Special tools may be required to apply some materials, refer to your supplier for further information.

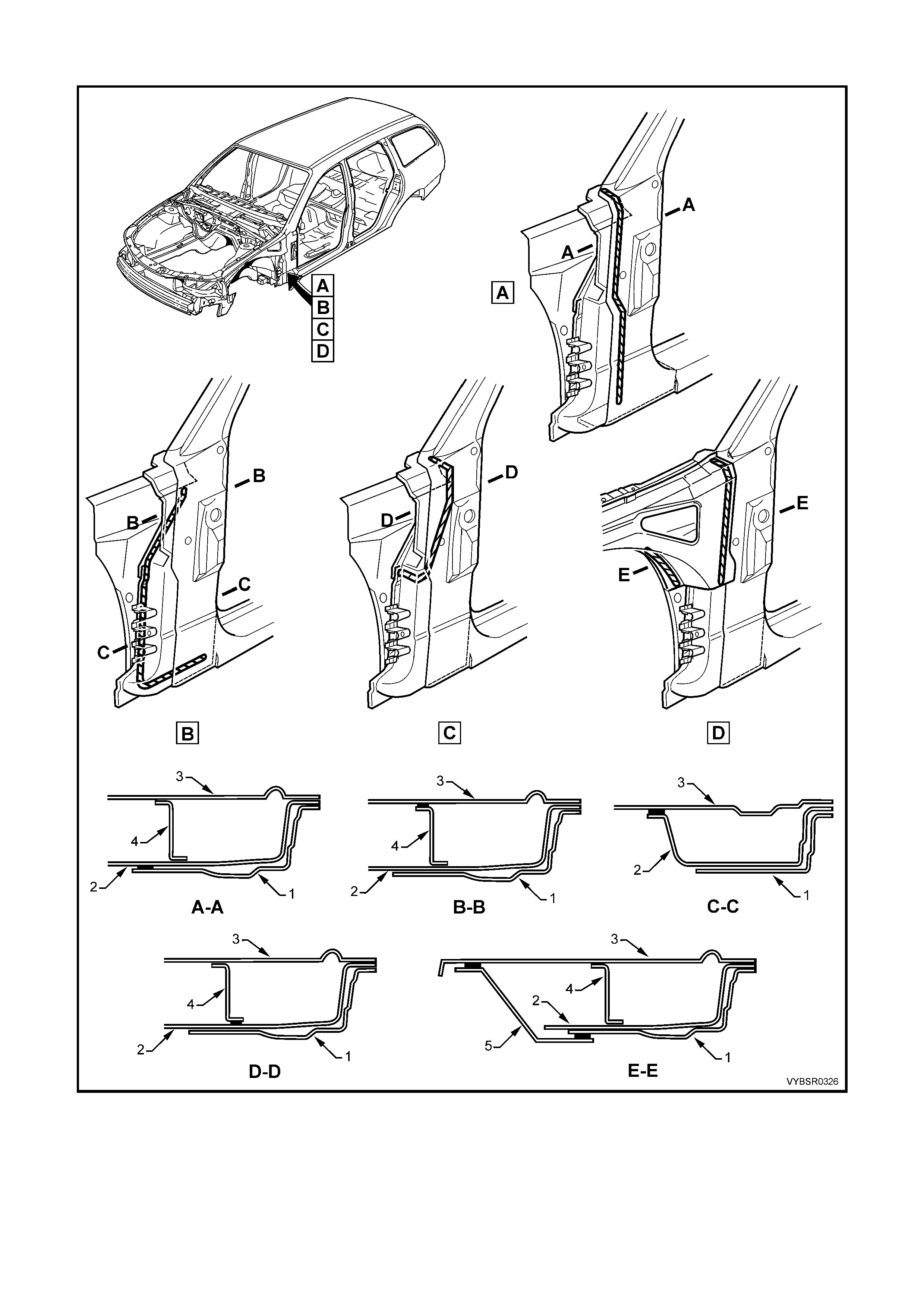

5.1 ACRYLIC SPOT WELD SEALER (ITEM 2)

Figure 3B-12

Legend

1. Door Opening Frame

2. Reinforcement - Hinge A-pillar

3. Shroud Side Panel

4. Closing Plate - A-Pillar

5. Brace - Front Wheelhouse

ACRYLIC SPOT WELD SEALER (ITEM 2) CONTINUED

Figure 3B-13

5.2 JOINT SEALER (ITEM 3)

Figure 3B-14

JOINT SEALER (ITEM 3) CONTINUED

Figure 3B-15

JOINT SEALER (ITEM 3) CONTINUED & HAND PUTTY (ITEM 4)

Figure 3B-16

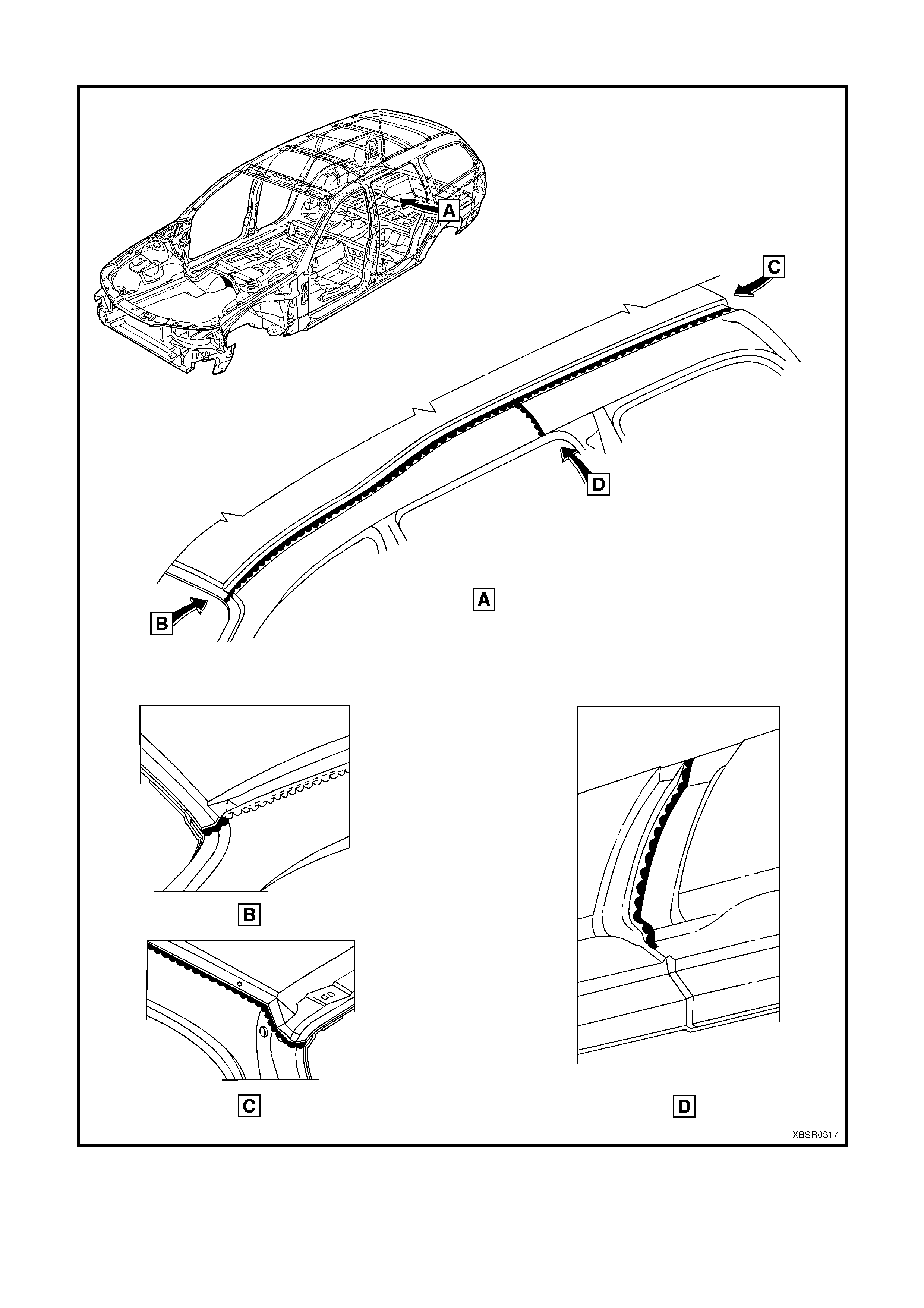

JOINT SEALER (ITEM 3) CONTINUED

Figure 3B-17

JOINT SEALER (ITEM 3) CONTINUED

Figure 3B-18

JOINT SEALER (ITEM 3) CONTINUED

Figure 3B-19

5.3 ADHESIVE – ANTI-FLUTTER (ITEM 5)

Figure 3B-20

5.4 ADHESIVE – STRUCTURAL (ITEM 6)

Figure 3B-21

5.5 SPRAY-ON DEADENER

Figure 3B-22

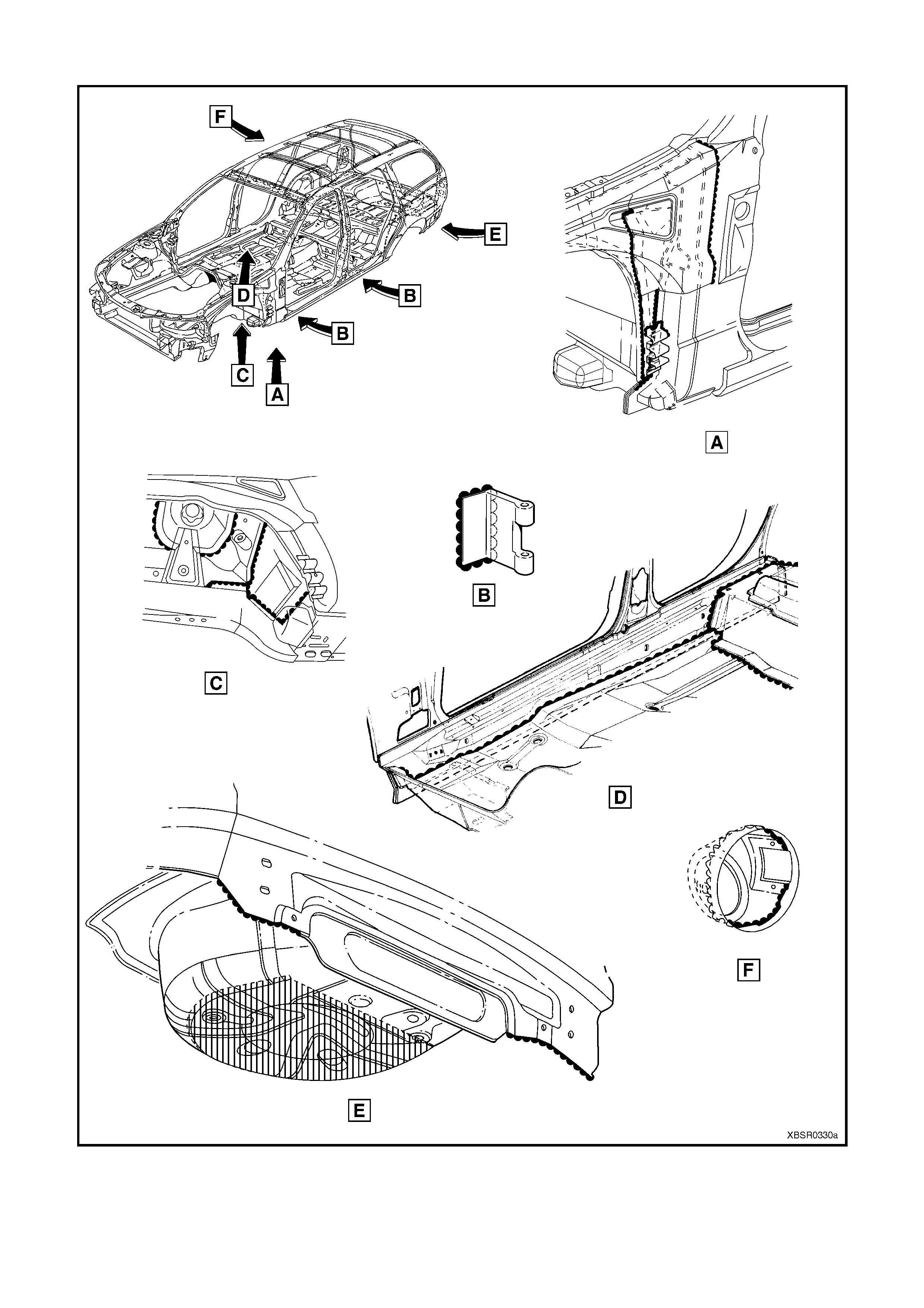

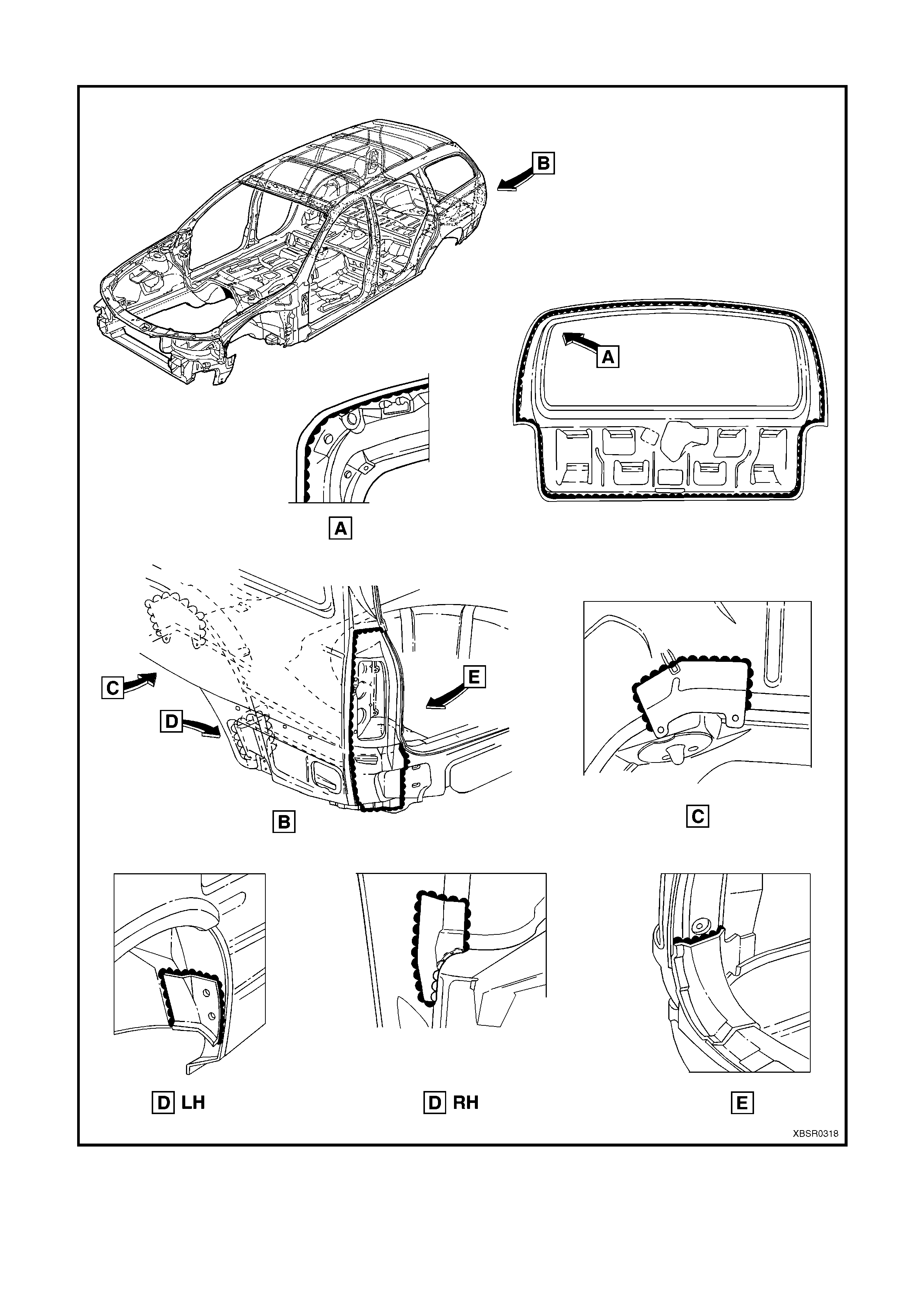

5.6 DEADENER PANELS & INSULATORS

The deadener panels shown are heat fusible type. They are to be installed with the diamond em bossed side down.

Use a heat gun, heat lamps or such to cure each deadener sheet.

Figure 3B-23

Legend

1. Deadener - Front Floor, RH

2. Deadener - Front Floor, centre

3. Deadener - Front Floor, LH

4. Deadener - Rear Floor, RH

5. Deadener - Rear Floor, Centre

6. Deadener - Floor Rear, LH

7. Deadener - Floor, Rear Seat RH

8. Deadener - Floor, Rear Seat LH

9. Deadener – Spare Wheel Well

10. Deadener – Rear Compartment, RH

11. Deadener – Rear Compartment, LH

The insulator (1) is self adhesive. To install, remove the backing paper and attach the insulator ensuring any cut-

outs align with brackets etc. Smooth the insulator firmly into position. The deadener (2) is a heat cure type and is

attached as previously described.

Figure 3B-24

Legend

1. Insulator - Dash Panel Upper

2. Deadener - Cockpit Module

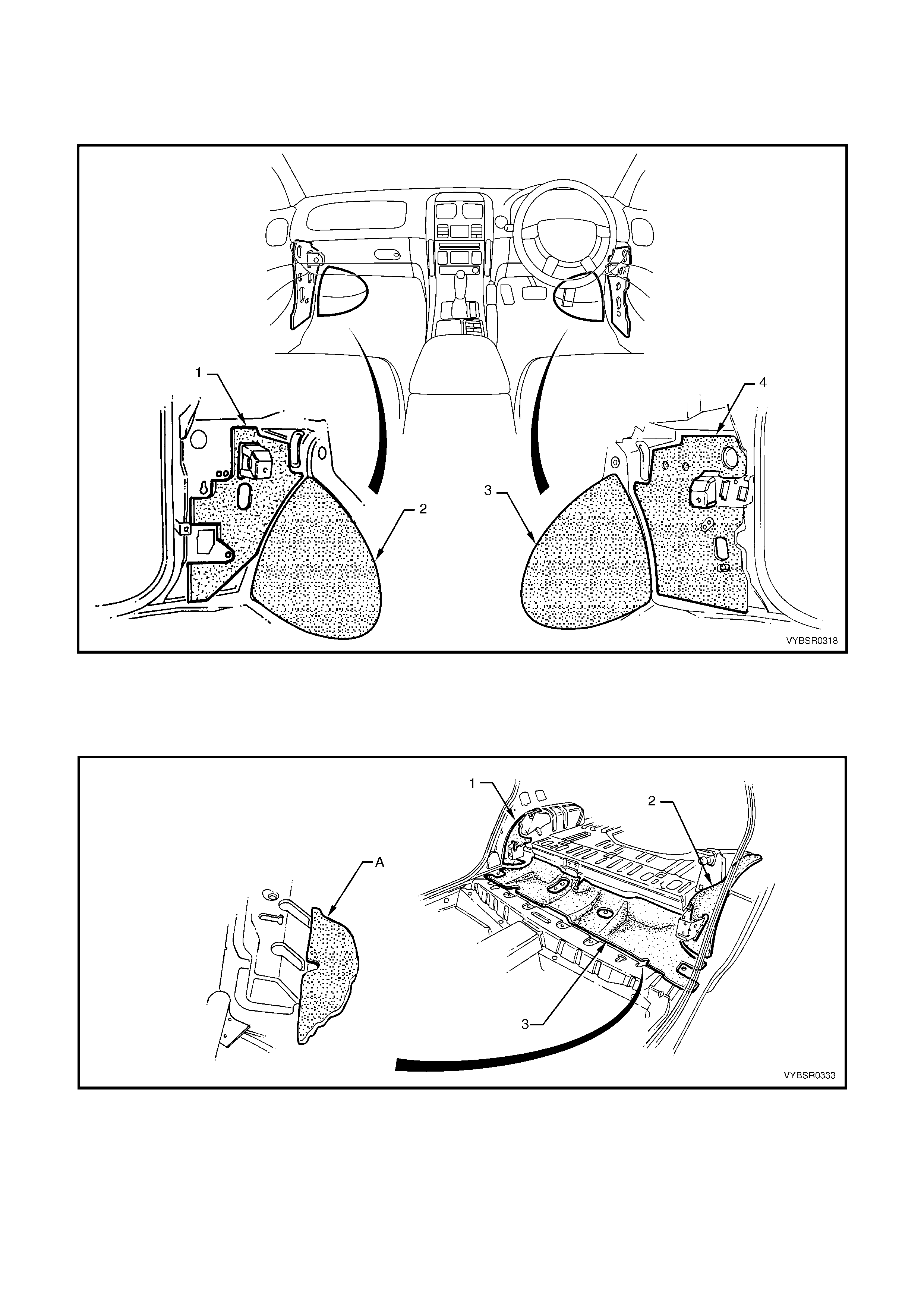

The deadeners and insulators in Figures 3B-25 & 3B-26 are self adhesive. Remove the backing paper and attach

the insulator ensuring any cut-outs align with brackets etc. Smooth the insulator firmly into position.

NOTE: Ens ure the notch in the rear seat insulators ( 3) in F igure 3B-26 is aligned with the slot in the rear seat ram p

as shown A.

Figure 3B-25

Legend

1. Insulator - Cowl Side, LH

2. Deadener - Front Floor Extension, LH

3. Deadener - Front Floor Extension, RH

4. Insulator - Cowl Side, RH

Figure 3B-26

Legend

1. Insulator - Cowl Side, LH

2. Deadener - Front Floor Extension, LH

3. Deadener - Front Floor Extension, RH

4. Insulator - Cowl Side, RH

5.7 FUSI BLE REINFORCEMENT PATCHES

Two heat fusible reinforcing patches (1) are applied to

the front f loor tunnel which provide stiffness and aid in

the reduction of Noise, Vibration & Harshness (NVH).

The sheets are pliable in their uncured state and are

applied to the vehicle prior to paint baking. The heat

required to cure and harden the sheets is

approximately 120° C, and once cured the sheets

become a structural part of the vehicle. Therefore, if

the front floor assembly is replaced, the patches must

also be replaced.

Lower curing temperature replacement patches are

available from your Autorised Dealer.

REPLACE

1. Where possible, apply the patches to the new f loor

prior to painting.

2. Ensure the surface is clean, dry and free from

weld spatter, etc.

3. Apply the patches in the locations shown ensuring

an overlap of 5-10 mm (2).

4. Using a heat gun or drying lamps , etc. evenly heat

the m aterial until it smoothes and the edges begin

to ‘soften’.

Figure 3B-27

4. Smooth the material down with a roller or like, to

ensure no air bubbles are present and to maximise

adhesion.

5. Once cooled, the material should feel hard.

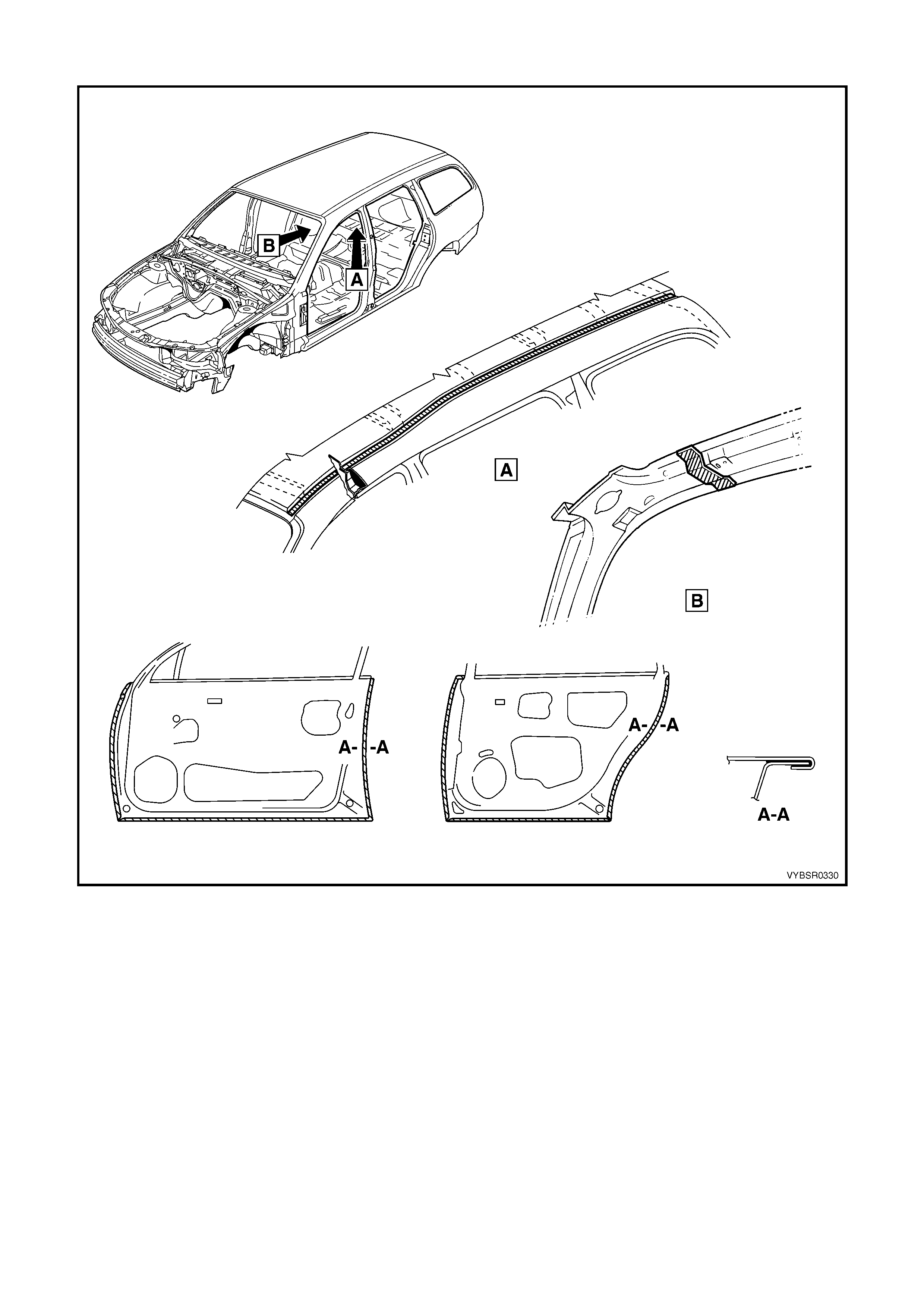

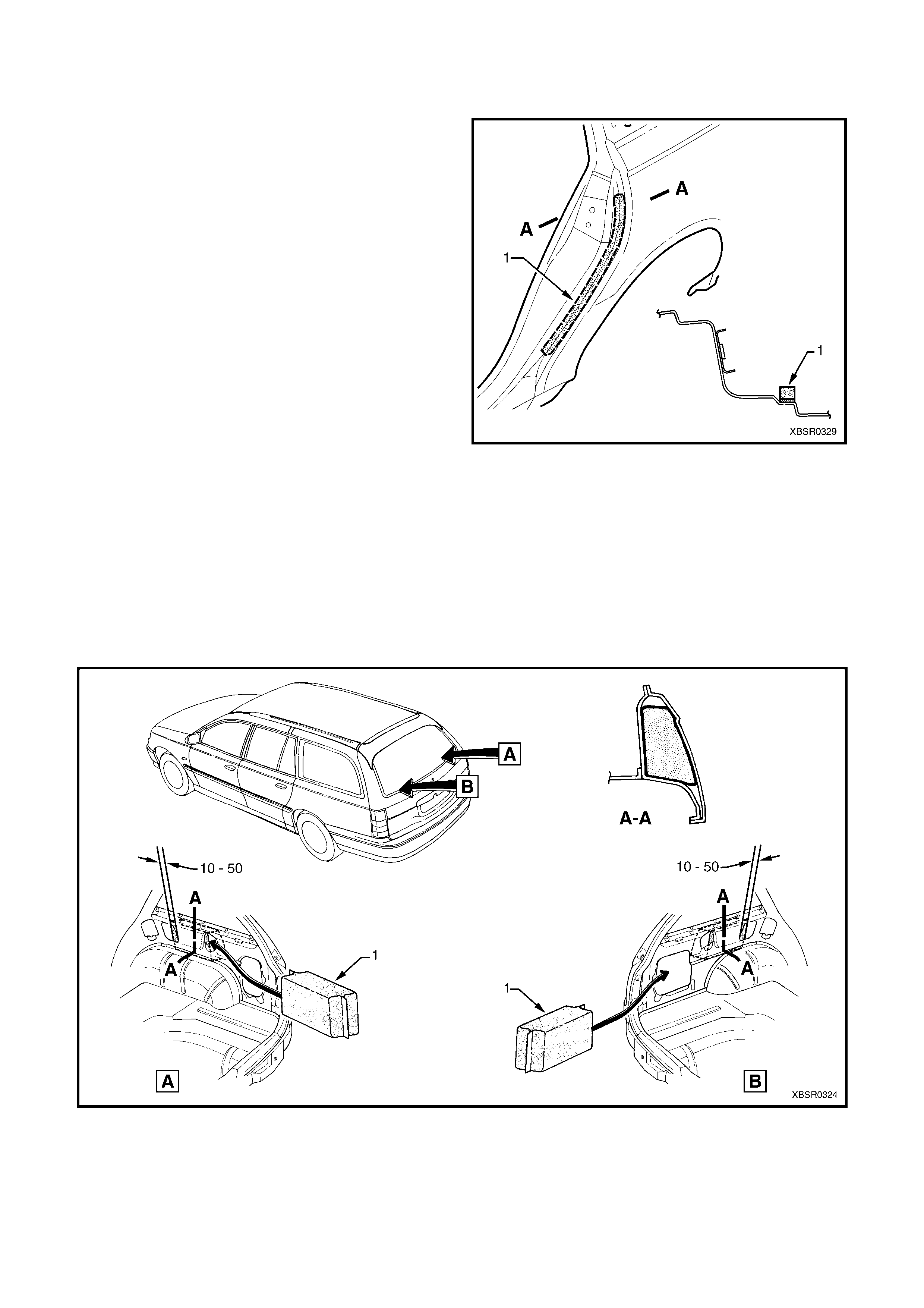

5.8 DEADENER STRIP & STUFFER BLOCK

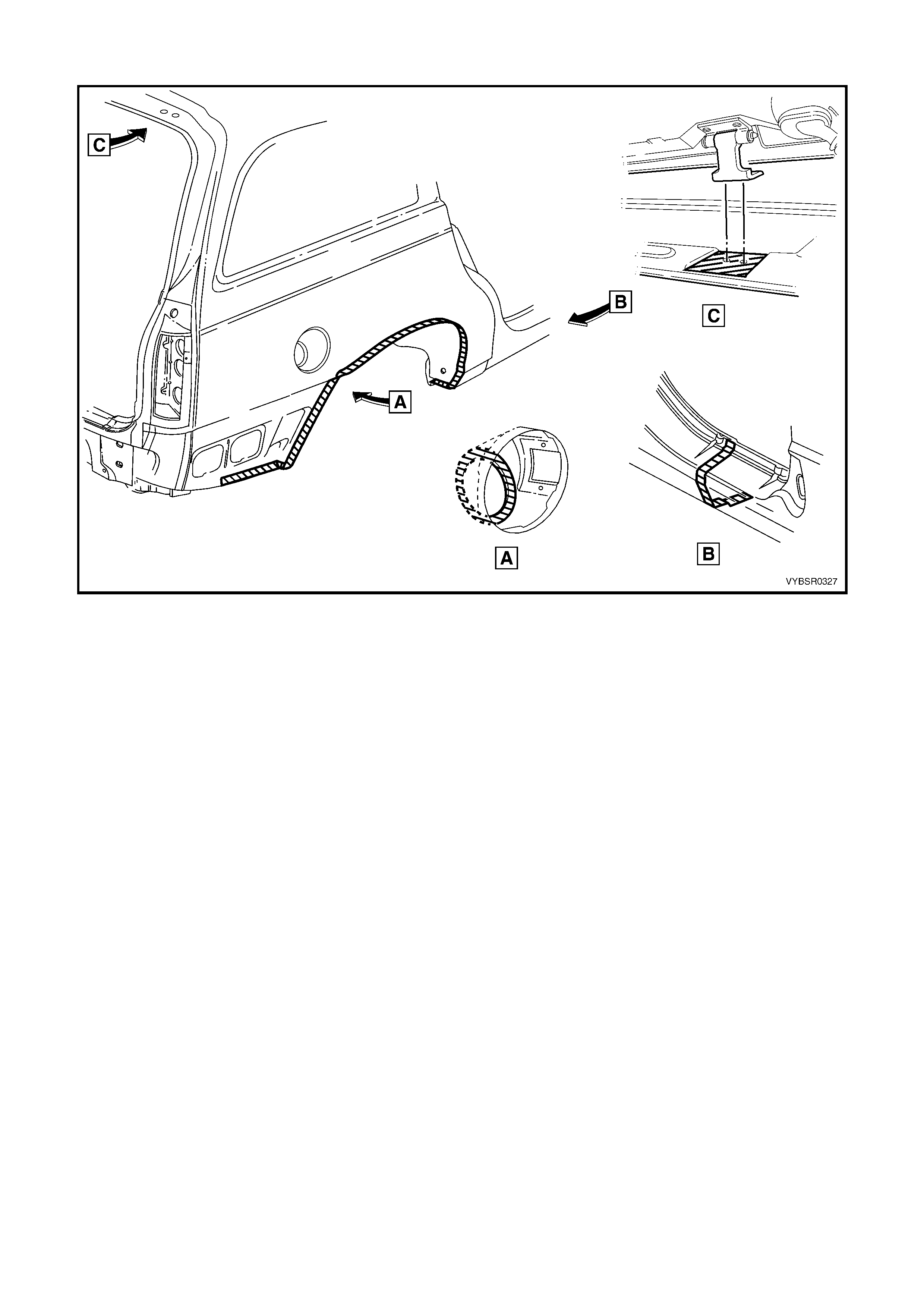

DEADENER STRIP

To improve door operation sound quality, a deadener

strip (1) is affixed within the cavity between the door

opening frame and rear quarter panel on each side of

the vehicle.

Care needs to be tak en when repair ing or welding near

these areas, as the deadener strips are not accessible

and as they are heat cured, cannot easily be removed.

The deadener strip requires 160° C to heat cure,

therefore service parts are not supplied. They are

shown here as a caution only.

STUFFER BLOCK

To aid in the reduc tion of nois e transm ittenc e, a stuff er

block (1) is inserted into the cavity between the side

panel - inner and rear quarter panel on each side of

the vehicle.

Made from high density foam, once installed they

expand naturally to close the cavity. The stuffer block

must be removed when repairing or welding as it can

easily ignite.

NOTE: Removal or installation of the RH side A is

restric ted as the f uel f iller pocket interf er es with acces s

to the c avity, therefore the block m ust be com press ed.

When installing, compress the block, tie it with string or

like, insert it in the opening above the wheelhouse and

cut the string. The block will self expand to fill the

cavity, refer Figure 3B-29.

Remove or install the LH stuffer block through the

opening in the side panel inner as shown B.

Figure 3B-28

Figure 3B-29

6. CAVITY WAX

MY 2003 VY Series Wagon body and structural panels are constructed from high quality corrosion resistant

materials. During manufacture, cavity wax is applied to the areas shown to further increase the vehicle’s anti-

corrosive properties.

Following repairs, to m aintain the anti-corrosive properties of the vehicle, once the paint is thoroughly dry apply

cavity wax to the areas shown below, and within any repaired box sections or areas inaccess ible to paint. Refer

to the table for equivalent products to those used in manufacture.

CAVITY WAX EQUIVALENTS

Item No. Equivalent Manufacturer Equivalent Product Name

8 Henkel Terotex HV 8377/65

Nox Rust Hi-Wax 100B

Terasol 800113 (Aerosol pack)

Figure 3B-30

Figure 3B-31

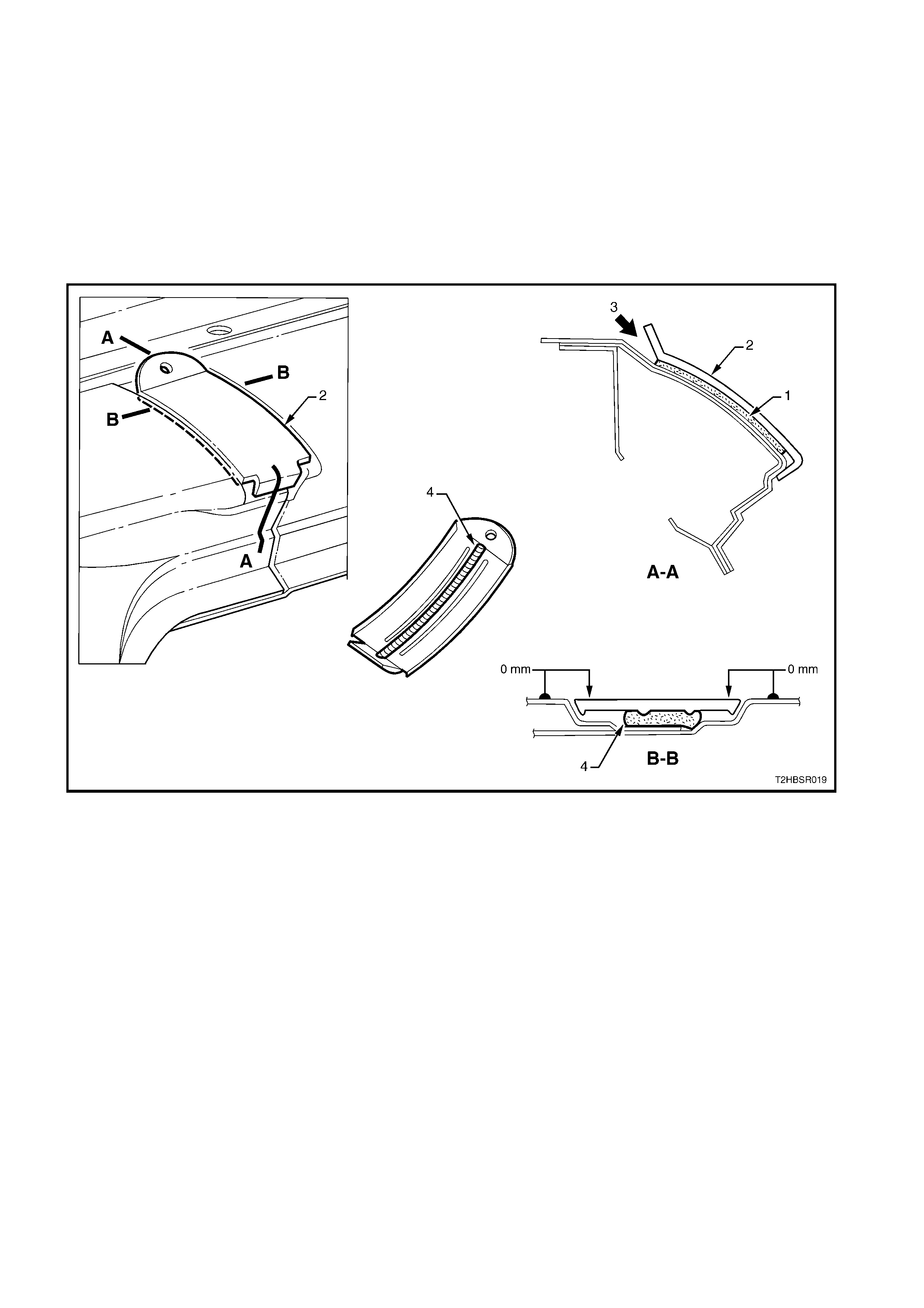

7. ROOF JOINT MOULDING

A roof joint moulding is fitted to MY 2003 VY Series Wagons at the join of the door opening frame and rear

quarter panel. The moulding is affixed with windscreen grade urethane adhesive, such as Beta-Seal 587.02 or

equivalent.

REMOVE

1. Remove the roof side rails and the door opening moulding, refer to Section 1A9, EXTERIOR

ORNAMENTAION in the MY 2003 VY & V2 Series II Service Information.

2. Carefully cut the adhesive (1) while prising the top of the m oulding ( 2) f rom the vehicle as shown 3 in Figure

3B-32.

3. Clean off residual adhesive as required.

Figure 3B-32

INSTALL

1. The surface is to be clean and painted.

2. Apply an 8 mm bead of adhesive (4) along the back of the moulding, between the ribs.

3. Fit the moulding, ensuring the outer surface is flush with the panel surfaces and the side gaps are even.

4. If required, temporarily secure moulding with tape.

5. Allow adhesive to cure overnight.