SECTION 8 – DOORS, LIFTGATE & ENDGATE

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to

Section 00 CAUTIONS AND NOTES and Section 2 PRECAUTIONS in this Supplement for correct

workshop practices with regard to safety and/or property damage.

CAUTION

The Structure of the M Y 2003 VY & V2 Series II body shell has been developed using complex design

and development techniques. In addition to meeting all required standards, the v ehicle body is also a

critical part of the overall safety systems. It is therefore imperative the repair procedures described

here are adhered to during all vehicle body repairs.

1. GENERAL DESCRIPTION

1.1 DOORS, LIFTGATE & ENDGATE

COMPONENTS

2. SERVICE OPERATIONS

2.1 FRONT DOOR ASSEMBLY – REPLACE

REMOVE

REINSTALL

ADJUST

2.2 REAR DOOR ASSEMBLY – REPLACE

REMOVE

REINSTALL

ADJUST

2.3 DOOR HINGE (BODY SIDE) – REPLACE

REMOVE

REINSTALL

2.4 FRONT DOOR OUTER PANEL – REPLACE

REMOVE

REPLACE

2.5 REAR DOOR OUTER PANEL – REPLACE

REMOVE

REPLACE

2.6 LIFTGATE ASSEMBLY – REPLACE

REMOVE

REINSTALL

ADJUST

2.7 LIFTGATE OUTER PANEL – REPLACE

REMOVE

REPLACE

2.8 ENDGATE ASSEM BLY – REPLACE

REMOVE

REINSTALL

ADJUST

2.9 ENDGATE OUTER PANEL – REPLACE

REMOVE

REPLACE

3. SPECIAL TOOLS

1. GENERAL DESCRIPTION

This Section describes the repair and replacement procedures for the doors, Wagon liftgate and Utility endgate.

The procedures are limited to the replacement the door, liftgate or endgate assembly or the outer panel, which is

attached to the inner panel assembly by way of a folded hem flange and structural adhesive. Removal of bolt-on

trim and hardware components is not covered in this Supplement. Reference must be made to the appropriate

Sections in the MY 2003 VY & V2 Series II Service Information.

The front and rear door assemblies are supplied with the door hinge flaps that are MIG welded to the frame

assembly - door opening.

IMPORTANT: The door impact beams must not be heated, welded or straightened in any way, due to their critical

role in driver/passenger safety. Damage to the impact beams will necessitate the replacement of the entire door

assembly.

NOTE: It is imperative that the correct body adhesives, sealers, deadeners and cavity waxes are used when

repairing the body structure of MY 2003 VY & V2 Series II vehicles. Refer to Section 5. BODY SEALING,

ADHESIVES & DEADENERS and Section 6. CAVITY WAX in Section 3A (Sedan), 3B (Wagon), 3C (Utility) or

3D (Coupe) for details of the correct materials and their commercially available equivalents.

1.1 DOORS, LIFTGATE & ENDGATE COMPONENTS

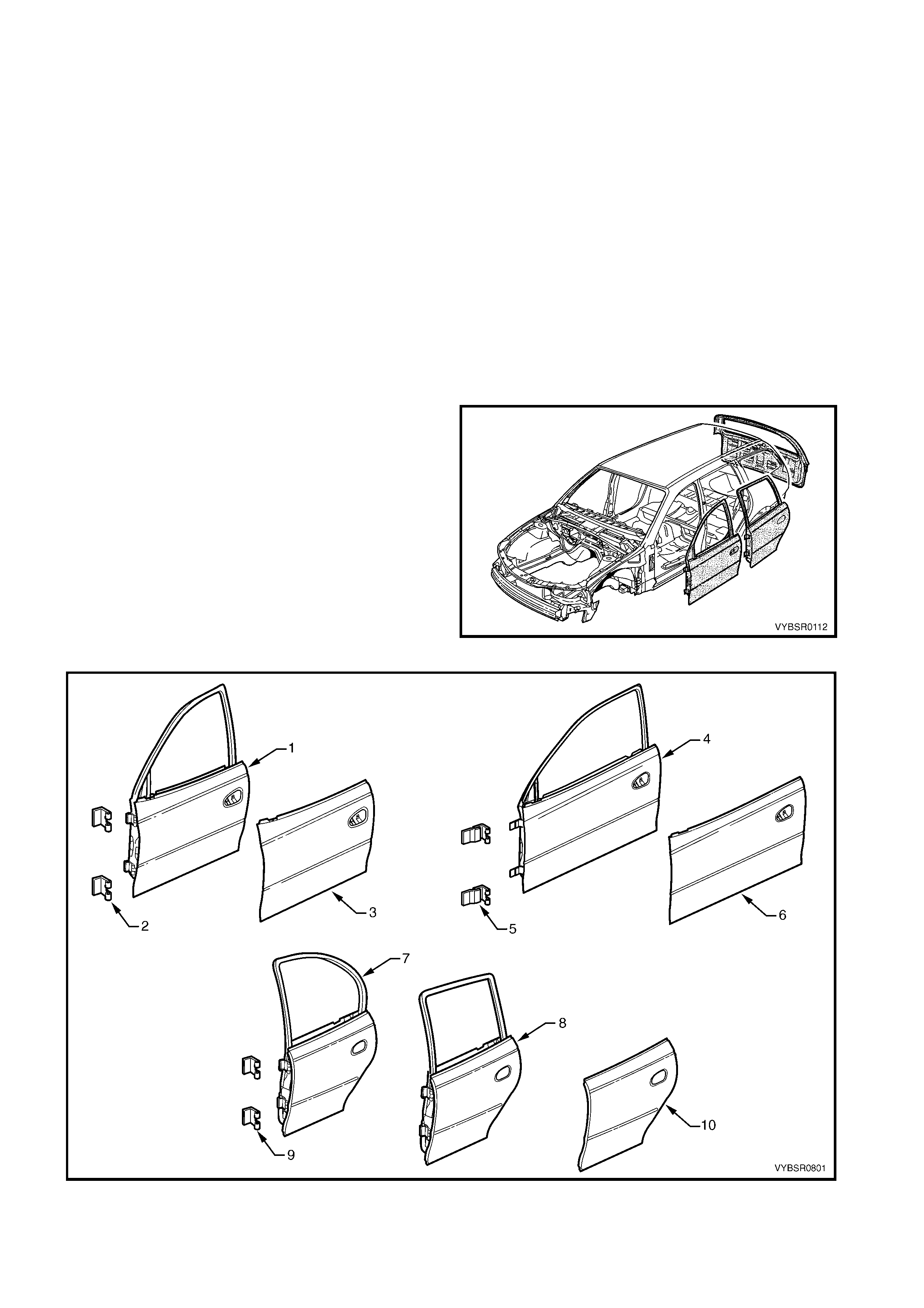

The shaded components in Figure 8-1 are those dealt

with in this Section.

The components and assemblies shown in Figure 8-2

and 8-3 are the parts serviced for MY 2003 VY & V2

Series II vehicles which form the basis of the repair

procedures in this Section. For a detailed view of the

body components, refer to Section:

3A BODY CONSTRUCTION – SEDAN,

3B BODY CONSTRUCTION – WAGON,

3C BODY CONSTRUCTION – UTILITY or

3D BODY CONSTRUCTION – COUPE.

NOTE: Always refer to your Authorised Retailer for

spare parts availability configurations. Figure 8-1

Figure 8-2

Legend (Figure 8-2)

1. Front Door Assembly, excluding Coupe

2. Front Door Hinge (Body Side), excluding Coupe

3. Front Door Outer Panel, excluding Coupe

4. Front Door Assembly, Coupe

5. Front Door Hinge (Body Side), Coupe

6. Front Door Outer Panel, Coupe

7. Rear Door Assembly, Sedan

8. Rear Door Assembly, Wagon

9. Rear Door Hinge (Body Side)

10. Rear Door Outer Panel

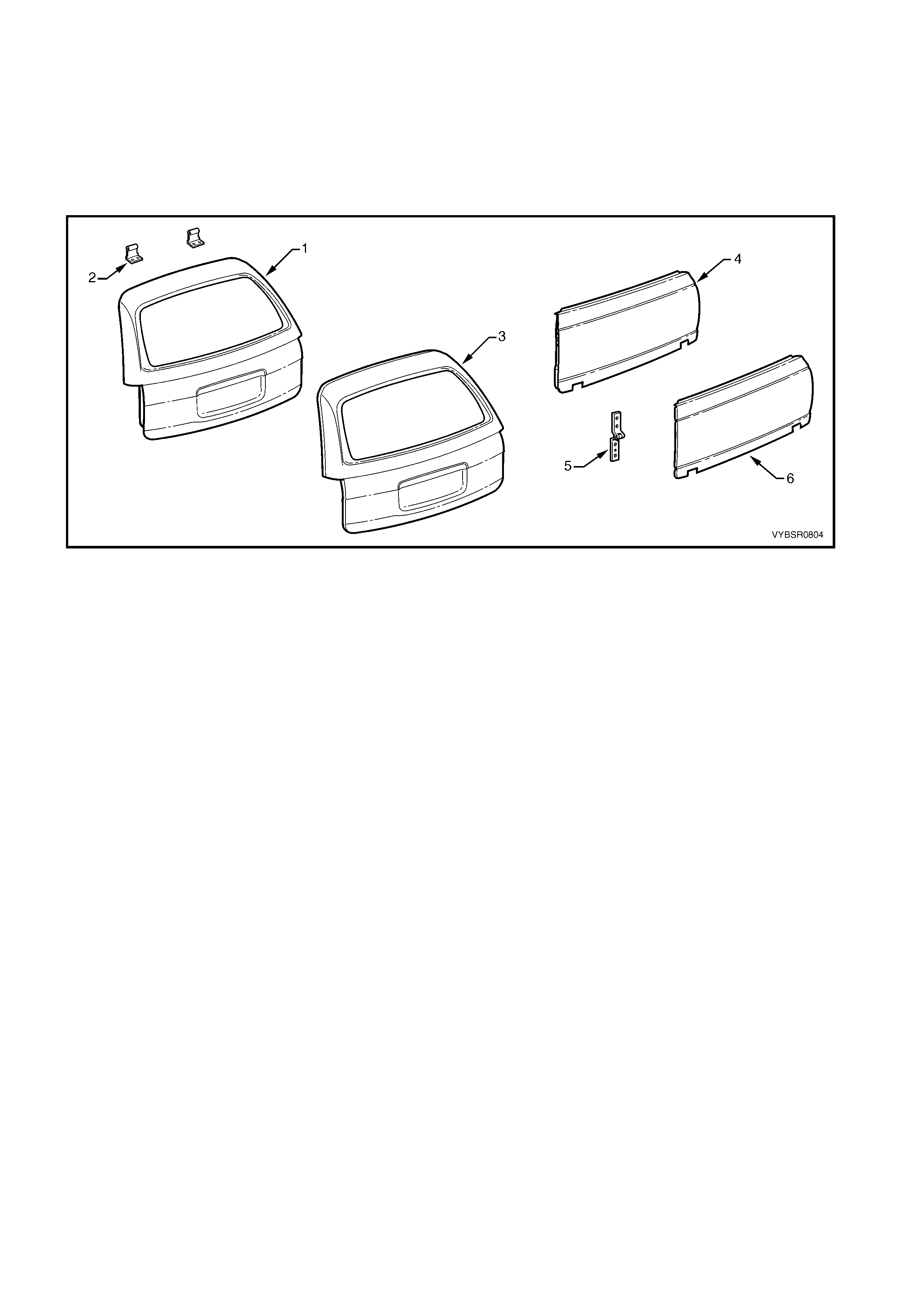

Figure 8-3

Legend

1. Liftgate Assembly

2. Liftgate Hinge (Body Side)

3. Liftgate Outer Panel

4. Endgate Assembly

5. Endgate Hinge Assembly

6. Endgate Outer Panel

2. SERVICE OPERATIONS

2.1 FRONT DOOR ASSEMBLY – REPLACE

REMOVE

NOTE: Disass emble the door trim and har dware as required. Refer to Section 1A5 FRO NT AND REAR DOOR

ASSEMBLIES in the MY 2003 VY & V2 Series II Service Information.

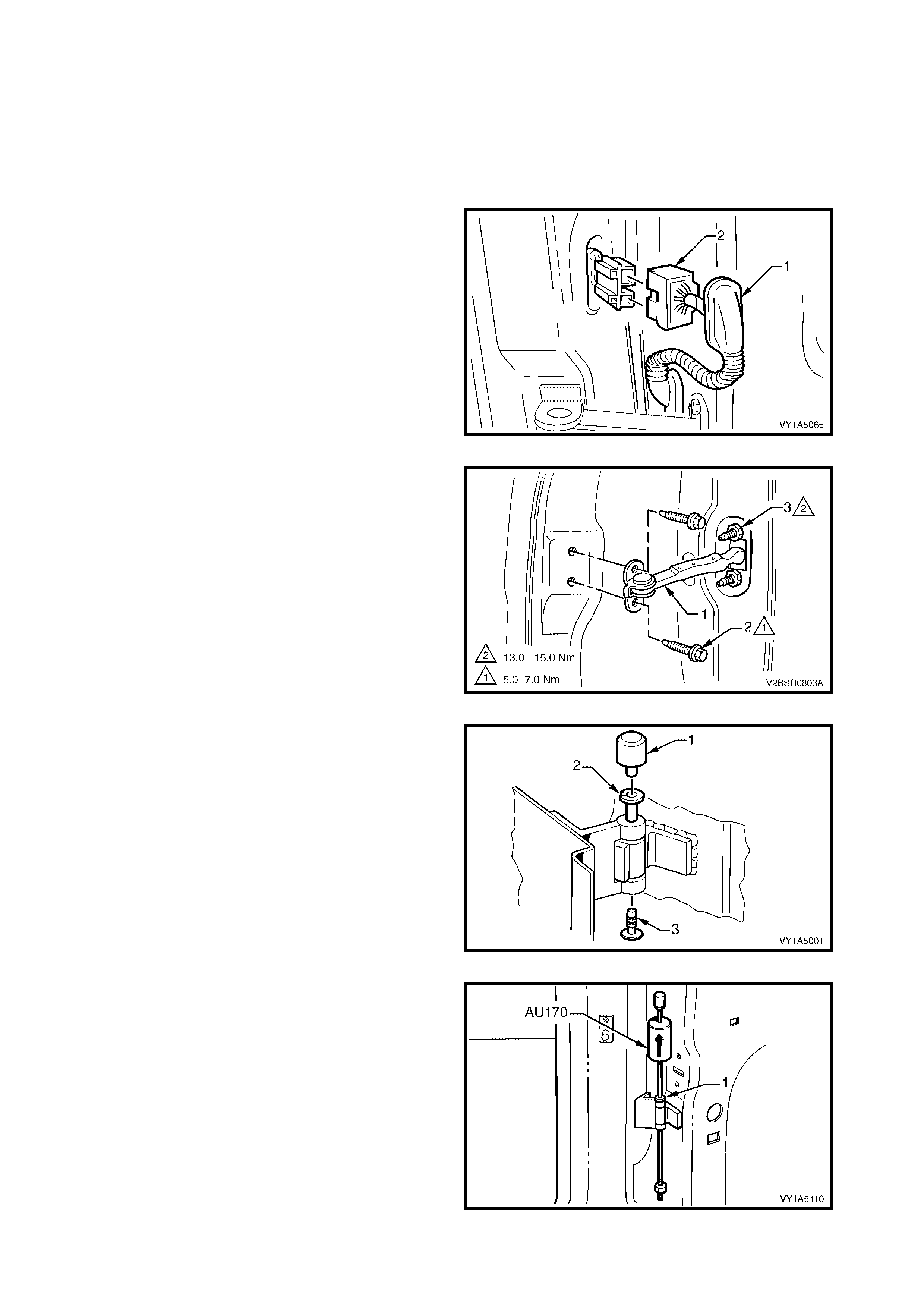

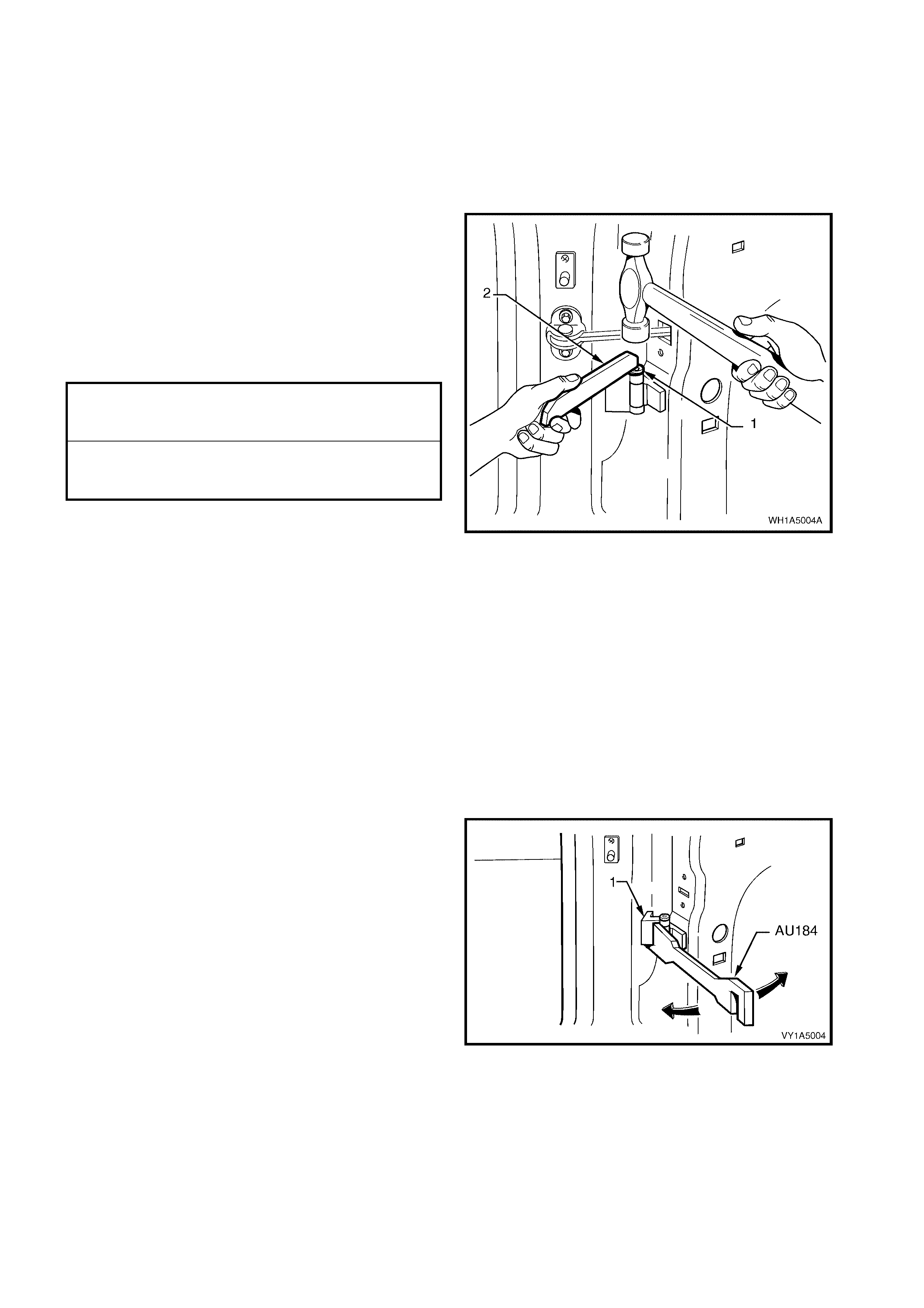

1. Remove the grommet (1) from the door wiring

harness connector plug (2).

2. Remove the connector plug from the pillar by

pushing tabs and gently pulling on the wiring

harness and then disconnect.

Figure 8-4

3. Disconnect the check assembly (1) from the

vehicle by removing the two screws (2).

NOTE 1: If required, remove the two nuts (3),

attaching the check assembly to the door, allowing

access to the hinge pins.

NOTE 2: Ensure the door cannot swing freely causing

damage.

Figure 8-5

4. Remove the front hinge pin cap (1) and the front

hinge plug (3) from the front hinge pin (2) on the

upper and lower hinges.

5. Have an assistant support the door or support the

base of the door on a wooden block and a trolley

jack.

Figure 8-6

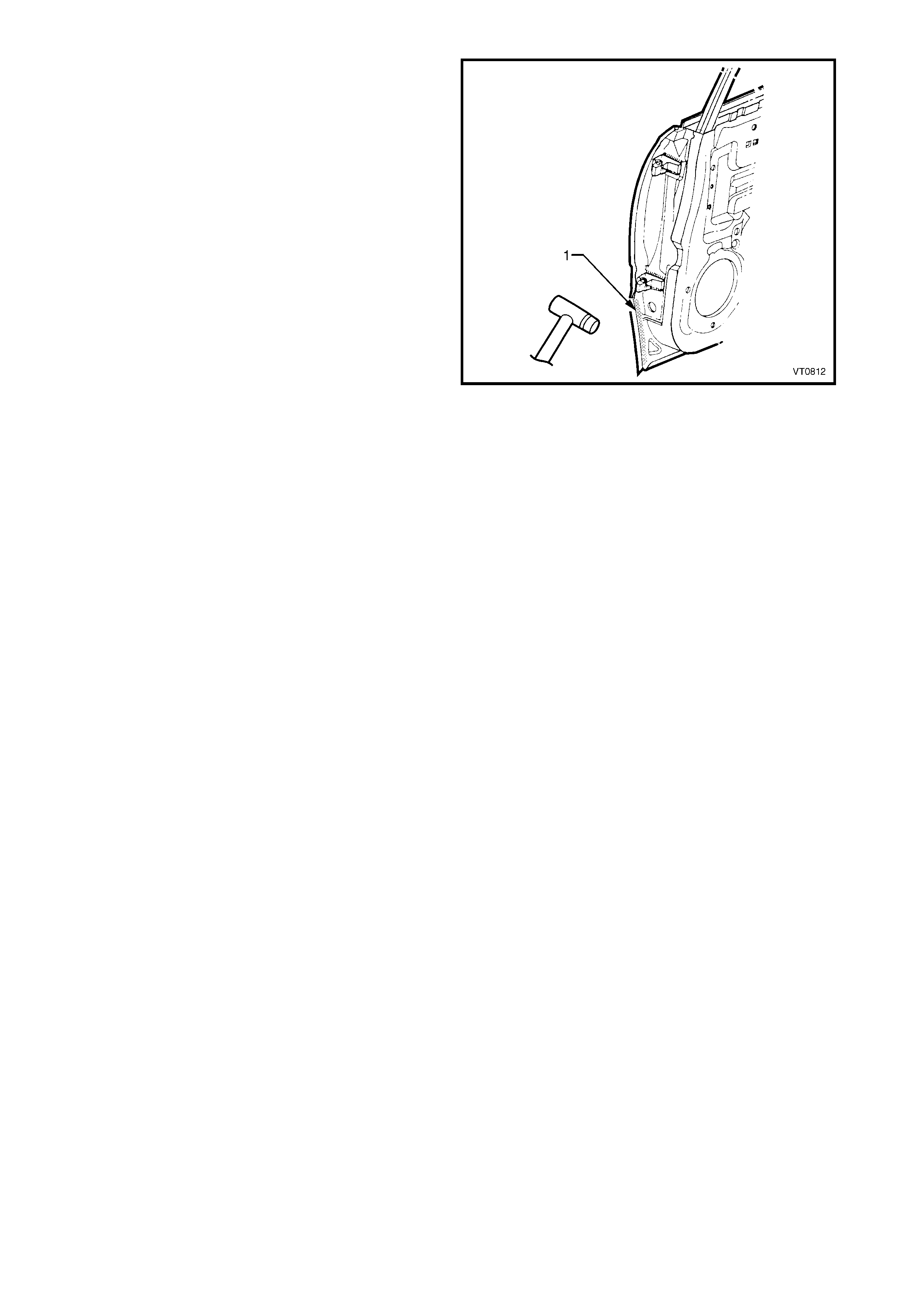

6. Using the Tool No. AU170, drive the lower and

then the upper hinge pivot sleeves (1) from the

hinges.

7. Remove the door assembly.

Figure 8-7

REINSTALL

IMPORTANT: If installing a new door panel assembly it must be prepared to maintain original manufacturer

specifications. This includes the application of joint sealer, hand putty and cavity wax. Refer to 5. BODY

SEALING, ADHESIVES & DEADENERS in Section 3A (Sedan), 3B (Wagon), 3C (Utility) or 3D (Coupe).

Reinstallation of the front door assembly is the reverse of the removal procedure, noting the following:

1. Apply a Lithium base greas e NLGI No. 1 (with 9 % zinc oxide) or equivalent, to the hinge pivot sleeves prior

to installation.

2. Use Tool No. AU303 (2), to install the hinge pivot

sleeves (1).

3. Check the fit of the door and adjust as required,

referring below.

NOTE: Make allowances in the adjustment if the trim

and hardware are not installed.

4. Tighten all retaining screws to the correct torque

specification.

5. Reinstall the trim and hardware as required.

6. Connect and install the door wiring harness

connector to the body wiring harness and refit the

grommet.

7. Refit the hinge pivot sleeve dust caps, refer to

Figure

8-6.

Figure 8-8

ADJUST

Attention should be given to unifor m m argins and alignm ent between the door and surr ounding parts when door

adjustments are being carried out.

Uniform margins and alignment of the doors in relation to the body opening can be achieved by setting the

appropriate door hinge. Refer to 4. BODY MARGINS in Section 3A (Sedan), 3B (Wagon), 3C (Utility) or

3D (Coupe).

It is sound prac tice to rem ove the door lock strik er as sem bly and allow the door to hang fr ee on the hinges. Set

the hinges as necessary to achieve correct alignment and uniform margins, then reinstall and adjust the striker.

Use Tool No AU184 to set door hinges by slightly

bending the front door hinge (1) noting the following:

1. Take care when adjusting the doors not to

misalign the hinge pins. Any significant

mis alignment will cause the pins to s hear when the

door is opened or closed.

2. Ex c es sive bending or levering of the window frame

will cause damage.

3. F inal adjus tment must take place when all the door

components and seals are installed.

IMPORTANT: Adjust the doors with the striker

assembly removed. The striker assembly should only

be fitted once satisfactory alignment is achieved. It

must NOT be used to pull the door into the correct

position.

Figure 8-9

CHECK ASSEMBLY TO PILLAR

RETAINING SCREW

TORQUE SPECIFICATION 5.0 – 7.0 Nm

CHECK ASSEMBLY TO DOOR

RETAINING NUTS

TORQUE SPECIFICATION 13.0 – 15.0

2.2 REAR DOOR ASSEMBLY – REPLACE

REMOVE

1. Remove the grommet and door wiring harness

connector plug assembly (1).

2. Remove the connector plug from the pillar by

gently pulling on the wiring harness and then

disconnect.

Figure 8-10

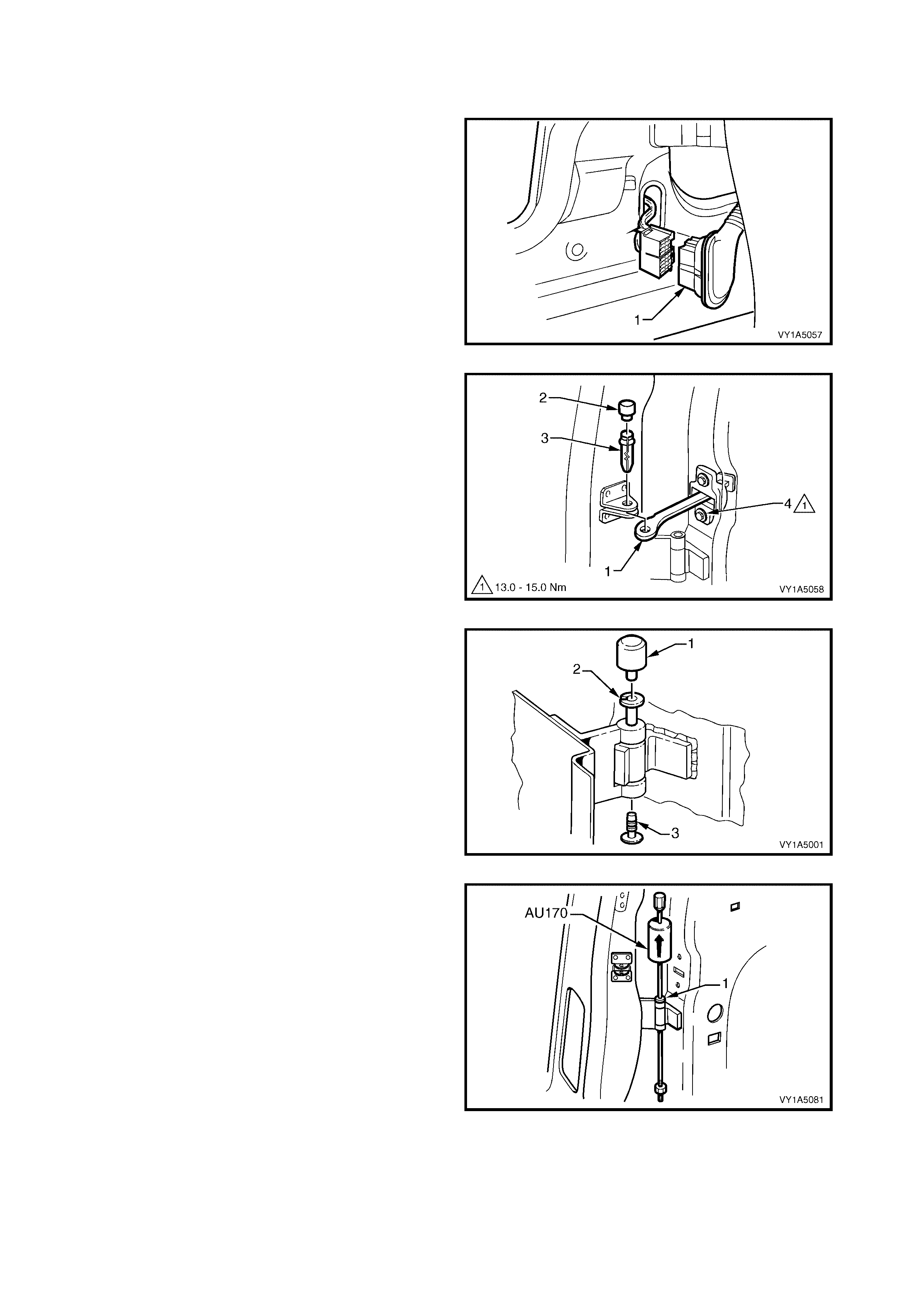

3. Disconnect the rear door check assembly (1) from

the vehicle, by removing the rear door check link

brack et cover (2) and then the rear door check link

pin (3).

NOTE 1: If required, remove the two screws (4)

attaching the check-link assembly to the door to allow

access to the hinge pins.

NOTE 2: Ensure the door cannot swing freely causing

damage.

Figure 8-11

4. Remove the rear hinge pin cap (1) and the rear

hinge plug (3) from the rear hinge pin (2) on the

upper and lower hinges.

5. Have an assistant support the door or support the

base of the door on a wooden block and a trolley

jack.

Figure 8-12

6. Using Tool No. AU170, drive the lower and then

the upper hinge pivot sleeves (1) from the hinges.

7. Remove the door assembly.

Figure 8-13

REINSTALL

IMPORTANT: If installing a new door panel assembly it must be prepared to maintain original manufacturer

specifications. This includes the application of joint sealer, hand putty and cavity wax. Refer to 5. BODY

SEALING, ADHESIVES & DEADENERS in Section 3A (Sedan), 3B (Wagon), 3C (Utility) or 3D (Coupe).

Reinstallation of the rear door assembly is the reverse of the removal operation, noting the following:

1. Apply a Lithium base greas e NLGI No. 1 (with 9 % zinc oxide) or equivalent, to the hinge pivot sleeves prior

to installation.

2. Use Tool No. AU303 (2), to install the hinge pivot

sleeves (1).

3. Check the fit of the door and adjust as required,

referring below.

NOTE: Make allowances in the adjustment if the trim

and hardware are not installed.

4. Tighten all retaining screws to the correct torque

specification.

5. Reinstall the trim and hardware as required.

6. Connect and install the door wiring harness

connector to the body wiring harness and refit the

grommet.

7. Refit the hinge pivot sleeve dust caps, refer to

Figure 8-12 Figure 8-14

ADJUST

Attention should be given to unifor m m argins and alignm ent between the door and surr ounding parts when door

adjustments are being carried out.

Uniform margins and alignment of the doors in relation to the body opening can be achieved by setting the

appropriate door hinge. Refer to 4. BODY MARGINS in Section 3A (Sedan), 3B (Wagon), 3C (Utility) or

3D (Coupe).

It is sound prac tice to rem ove the door lock strik er as sem bly and allow the door to hang fr ee on the hinges. Set

the hinges as necessary to achieve correct alignment and uniform margins, then reinstall and adjust the striker.

Use Tool No AU184 to set door hinges by slightly

bending the door hinge flaps (1) noting the following:

1. Take care when adjusting the doors not to

misalign the hinge pins. Any significant

mis alignment will cause the pins to s hear when the

door is opened or closed.

2. Ex c es sive bending or levering of the window frame

will cause damage.

3. F inal adjus tment must take place when all the door

components and seals are installed.

IMPORTANT: Adjust doors with striker plates

removed. Striker plates should only be fitted once

satisfactory alignment is achieved. They must NOT be

used to pull the door into the correct position. Figure 8-15

CHECK ASSEMBLY TO DOOR

RETAINING SCREW

TORQUE SPECIFICATION 13.0 – 15.0

2.3 DOOR HINGE (BODY SIDE) – REPLACE

REMOVE

1. Remove the appropriate door from vehicle as previously described.

2. Carefully grind the MIG weld from around the hinge flap.

3. Remove the hinge and grind any remaining MIG weld as required.

NOTE: Do not cut into the door opening frame panel.

REINSTALL

1. Rem ove any trim and co m ponents fr om behind the pillar area as required. Ref er to the appropr iate Sections

in the MY 2003 VY & V2 Series II Service Information.

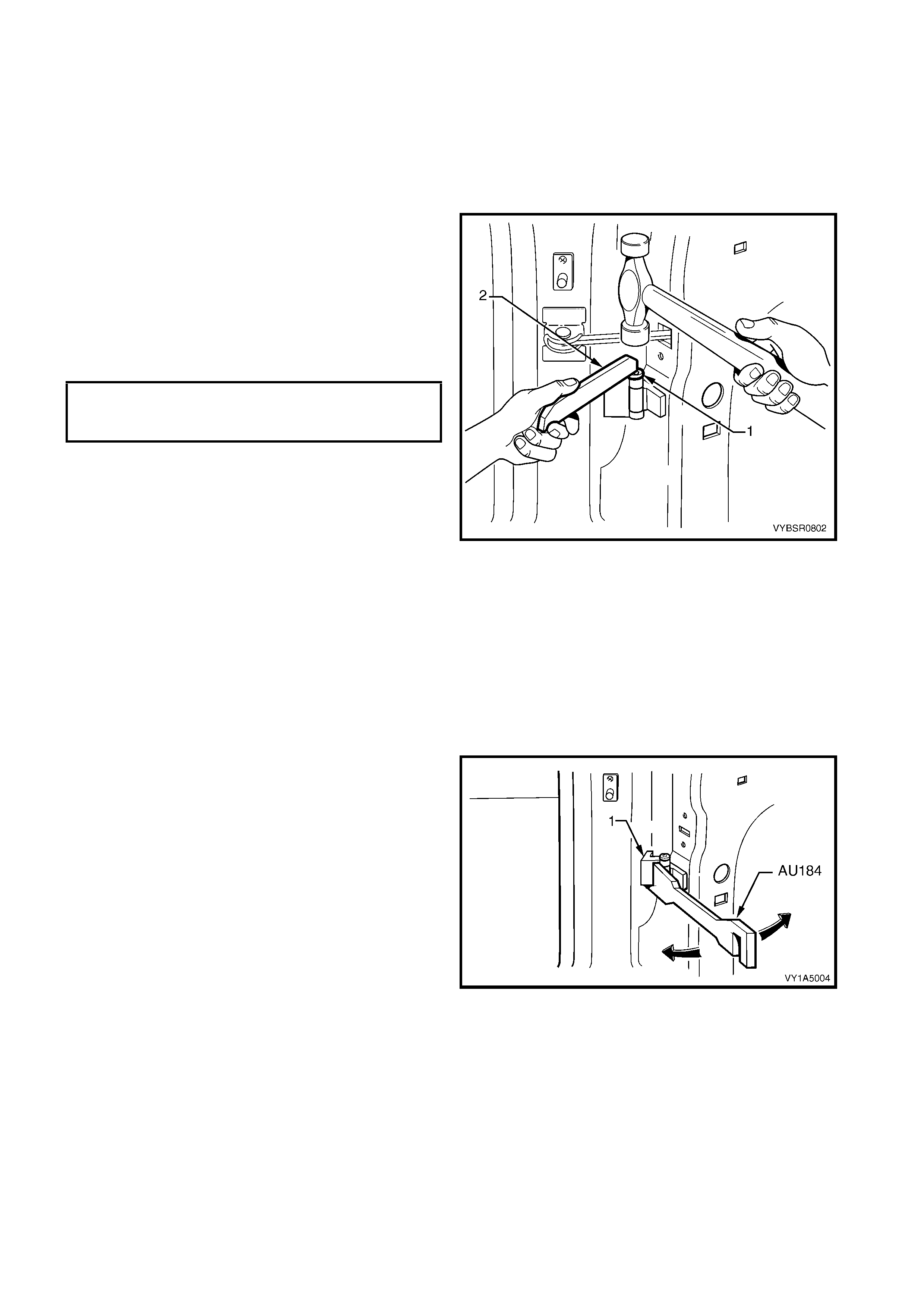

2. Construct two spacers (1) from timber, 10 mm

thick.

3. Tape the spacers in the positions shown near the

dimples in the flange of the r ocker panel, either for

the front or rear doors.

NOTE: If both front and rear door hinge flaps require

replacing, begin with the rear door.

4. If not already done so, fit the hinge flaps onto the

door assembly.

5. With the aid of an assistant, place the door

assembly in position on the vehicle and adjust its

position with shims as required. Refer to 4. BODY

MARGINS in Section 3A (Sedan), 3B (Wagon),

3C (Utility) or 3D (Coupe) for specifications.

NOTE: Position the rear of the door approximately 3

mm higher than specified to allow for the additional

weight of the door hardware and trim components.

6. Tack weld the upper and lower hinge flaps to the

door opening frame assembly .

7. Rem ove the spac er block s and shim s and recheck

the door alignment. Rectify as required.

8. Complete welding the hinge flap, refer to 8-17,

A – except Coupe, or B – Coupe.

Figure 8-16

Figure 8-17

9. Remove the door assembly from the hinge as previously described.

10. Grind or sand the weld to provide a smooth finish.

11. Refinish and paint the hinge flaps and surrounding area as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

12. Apply a smooth bead of Joint Sealer (Item 3) around all sides of the flap before the top paint coats to

maintain corrosion protection under the flap, refer to 5. BODY SEALING, ADHESIVES & DEADENERS in

Section 3A (Sedan), 3B (Wagon), 3C (Utility) or 3D (Coupe).

13. Apply Cavity W ax (Item 8) as required to the ins ide of any box s ections or areas inacces sible to paint, refer

to 6. CAVITY WAX in Section 3A (Sedan), 3B (Wagon), 3C (Utility) or 3D (Coupe).

2.4 FRONT DOOR OUTER PANEL – REPLACE

CAUTION: The door impact beams must not be heated, welded or straightened in any way, due to their

critical role in driver/passenger safety. If the door impact beams are damaged, the complete door must

be replaced.

NOTE: The pr ocedure for replacem ent of the f ront door outer panel is the s ame f or all m odels, even though the

Coupe front door is longer.

REMOVE

1. Disassemble the door trim and hardware as required. Refer to Section 1A5 FRONT AND REAR DOOR

ASSEMBLIES in the MY 2003 VY & V2 Series II service information.

2. Remove the front door from the vehicle, refer to 2.1 FRONT DOOR ASSEMBLY – REPLACE.

3. Remove the edge of the hem by grinding or

sanding, along the front, rear and lower edges of

the door.

Figure 8-18

4. Soften the adhesive between the door outer panel

and the door impact beam using a heat gun in the

areas (1).

5. Separate the door outer panel from the door inner.

Figure 8-19

6. Remove the hemming strip from the door inner

panel by grinding or chiselling away the metal and

the adhesive.

7. Repair any damage to the door inner panel as

required. Remove any residual adhesive from the

hem and door impact beam.

8. Prepare and prime and bare metal.

9. Test fit the door inner panel onto the vehicle.

Figure 8-20

REPLACE

1. Apply five equally spaced beads (1) of Anti-flutter

Adhesive (Item 5) to the impact beam, refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3A (Sedan), 3B (Wagon), 3C (Utility)

or 3D (Coupe).

Figure 8-21

2. Apply Structural Adhesive (1) (Item 6) to the

mating s urfaces ar ound the hem on the door inner

panel, refer to 5. BODY SEALING, ADHESIVES

& DEADENERS in Section 3A (Sedan),

3B (Wagon), 3C (Utility) or 3D (Coupe).

3. Clam p the outer panel in pos ition and fold over the

hemming to attach the outer panel firmly to the

inner shell.

NOTE: This procedure must be performed carefully to

avoid damaging the panel surface. The use of body

filler around the outer edges of the door outer panel to

rectify hammering damage is considered

unacceptable.

4. Test fit the door onto the vehicle and ensure the

panel margins are within specification, refer to

4. BODY MARGINS in Section 3A (Sedan),

3B (Wagon), 3C (Utility) or 3D (Coupe).

5. Remove the door.

6. Refinish and paint the door as required. Refer to

Section 3, 1.3 PAINT REFINISHING.

Figure 8-22

7. Apply Joint Sealer (Item 3) as required. Refer to 5. BODY SEALING, ADHESIVES & DEADENERS in

Section 3A (Sedan), 3B (Wagon), 3C (Utility) or 3D (Coupe)

8. Apply Cavity W ax (Item 8) as required to the inside of any box sections or areas inac cessible to paint, ref er

to 6. CAVITY WAX in Section 3A (Sedan), 3B (Wagon), 3C (Utility) or 3D (Coupe).

9. Install the door onto the vehicle and adjust as required, refer to 2.1 FRONT DOOR ASSEMBLY –

REPLACE.

10. Replace the door trim and hardware as required. Refer to Section 1A5 FRONT AND REAR DOOR

ASSEMBLIES in the MY 2003 VY & V2 Series II service information.

2.5 REAR DOOR OUTER PANEL – REPLACE

CAUTION: The door impact beams must not be heated, welded or straightened in any way, due to their

critical role in driver/passenger safety. If the door impact beams are damaged, the complete door must

be replaced.

REMOVE

1. Disassemble the door trim and hardware as required. Refer to Section 1A5 FRONT AND REAR DOOR

ASSEMBLIES in the MY 2003 VY & V2 Series II service information.

2. Remove the rear door from the vehicle, refer to 2.2 REAR DOOR ASSEMBLY – REPLACE.

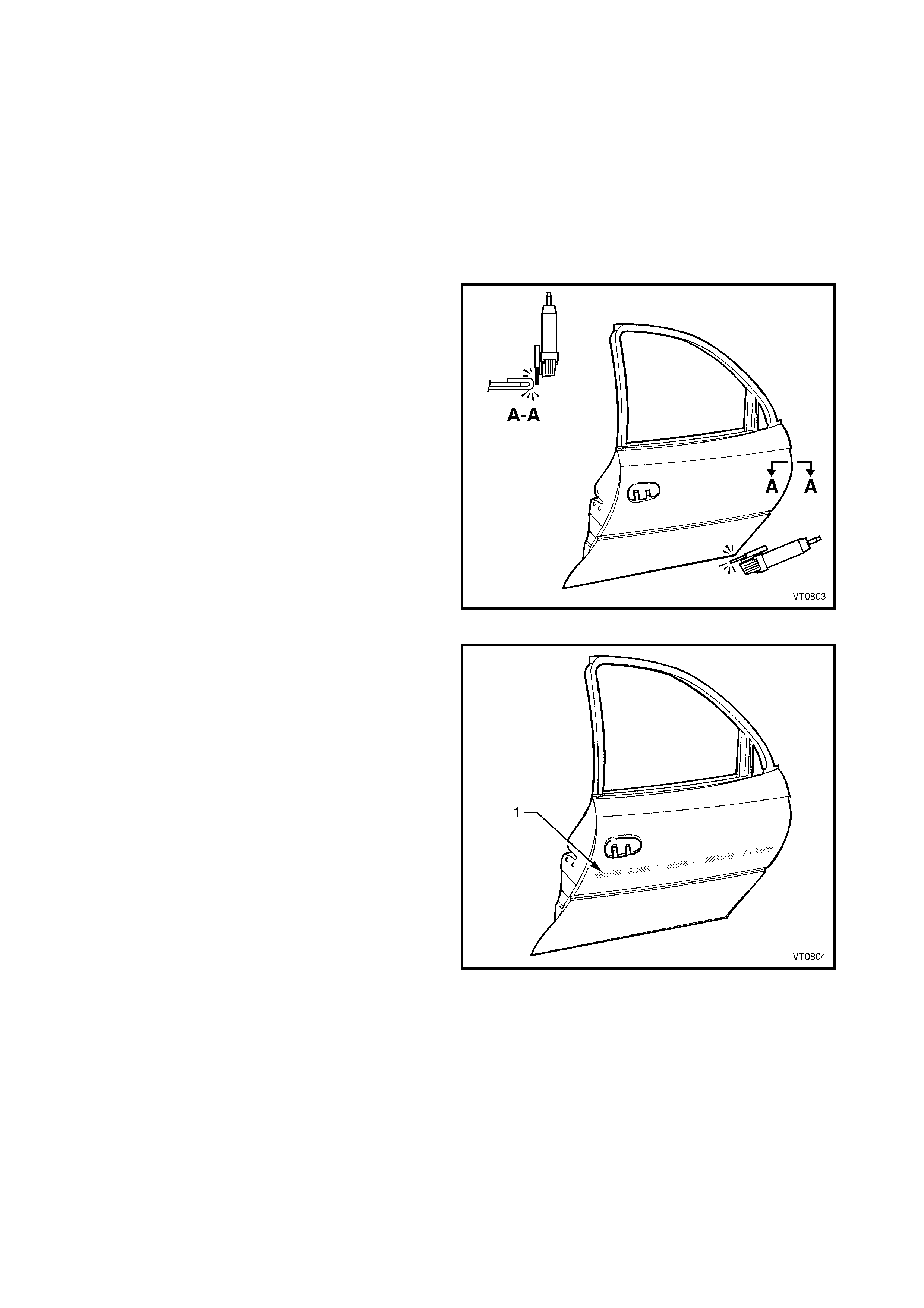

3. Remove the edge of the hem by grinding or

sanding, along the front, rear and lower edges of

the door.

Figure 8-23

4. Soften the adhesive between the door outer panel

and the door impact beam using a heat gun in the

areas (1).

5. Separate the door outer panel from the door inner.

Figure 8-24

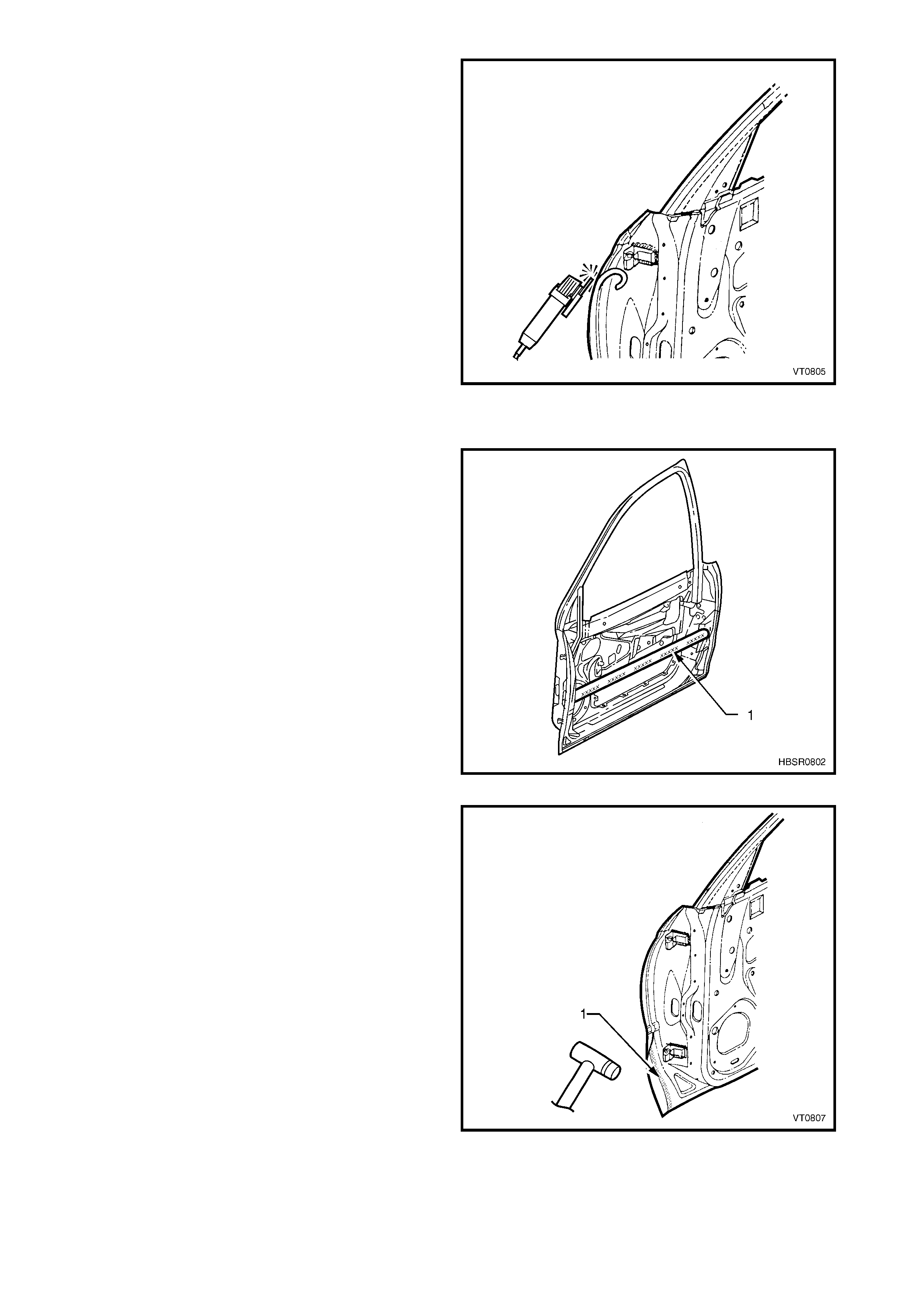

6. Remove the hem ming str ip ( 1) from the door inner

panel by gr inding or chiselling away the metal strip

and the adhesive.

NOTE: There are two tack welds (2) attaching the

hemming to the door inner panel on the front edge of

the rear door. These welds must be ground off to

remove the hemming from this area.

7. Repair any damage to the door inner panel as

required. Remove any residual adhesive from the

hem and door impact beam.

8. Prepare and prime and bare metal.

9. Test fit the door inner panel onto the vehicle.

Figure 8-25

REPLACE

1. Apply five equally spaced beads (1) of Anti-flutter

Adhesive (Item 5) to the impact beam, refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3A (Sedan) and 3B (Wagon).

Figure 8-26

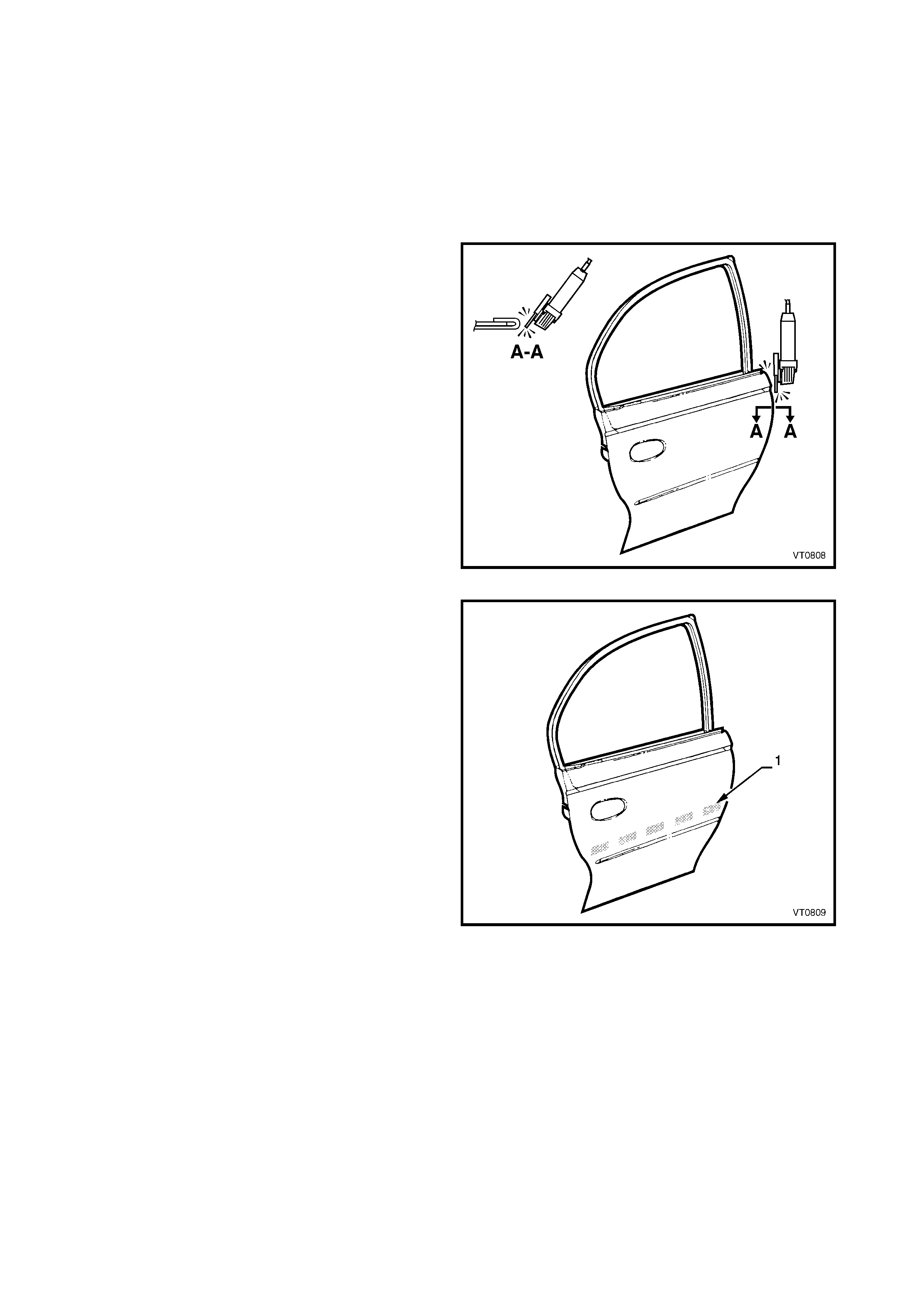

2. Apply Structural Adhesive (1) (Item 6) to the

mating s ur f ac es ar ound the hem on the door inner,

refer to 5. BODY SEALING, ADHESIVES

& DEADENERS in Section 3A (Sedan) and

3B (Wagon).

3. Clam p the outer panel in pos ition and fold over the

hem to attach the outer panel firmly to the inner

panel.

NOTE: This procedure must be performed carefully to

avoid damaging the panel surface. The use of body

filler around the outer edges of the door outer panel to

rectify hammering damage is considered

unacceptable.

4. Test fit the door onto the vehicle and ensure

the panel margins are within specification, refer to

4. BODY MARGINS in Section 3A (Sedan) and

3B (Wagon).

5. Remove the door.

6. Place two MIG tack welds attaching the front

hemming to the door inner panel.

NOTE: Place several wet rags on the surrounding

surface and the outer panel to minimise heat distortion.

7. Refinish and paint the door as required. Refer to

Section 3, 1.3 PAINT REFINISHING.

Figure 8-27

8. Apply Joint Sealer (Item 3) as required. Refer to 5. BODY SEALING, ADHESIVES & DEADENERS in

Section 3A (Sedan) and 3B (Wagon).

9. Apply Cavity W ax (Item 8) as required to the inside of any box sections or areas inac cessible to paint, ref er

to 6. CAVITY WAX in Section 3A (Sedan) and 3B (Wagon).

10. Install the door onto the vehicle and adjust as required, refer to 2.2 REAR DOOR ASSEMBLY – REPLACE.

11. Install the door trim and hardware as required. Refer to Section 1A5 FRONT AND REAR DOOR

ASSEMBLIES in the MY 2003 VY & V2 Series II service information.

2.6 LIFTGATE ASSEMBLY – REPLACE

REMOVE

1. Disassemble the tailgate trim and hardware as required, refer to Section 1A4 HOOD, REAR

COMPARTMENT LID, LIFTGATE & ENDGATE in the MY 2003 VY & V2 Series II service information.

2. Remove the lif tgate window, refer to Section 1A6 STAT IONARY WINDOWS in the MY 2003 VY & V2 Series

II service information.

3. Partially remove the right-hand quarter inner trim

upper refer to Sectio n 1A8, 3.8 QUAR T ER INNER

TRIM UPPER in the MY 2003 VY & V2 Series II

service information.

4. Partially remove the right-hand body rear corner

garnish, refer to Section 1A8, 3.9 BODY REAR

CORNER GARNISH in the MY 2003 VY & V2

Series II service information.

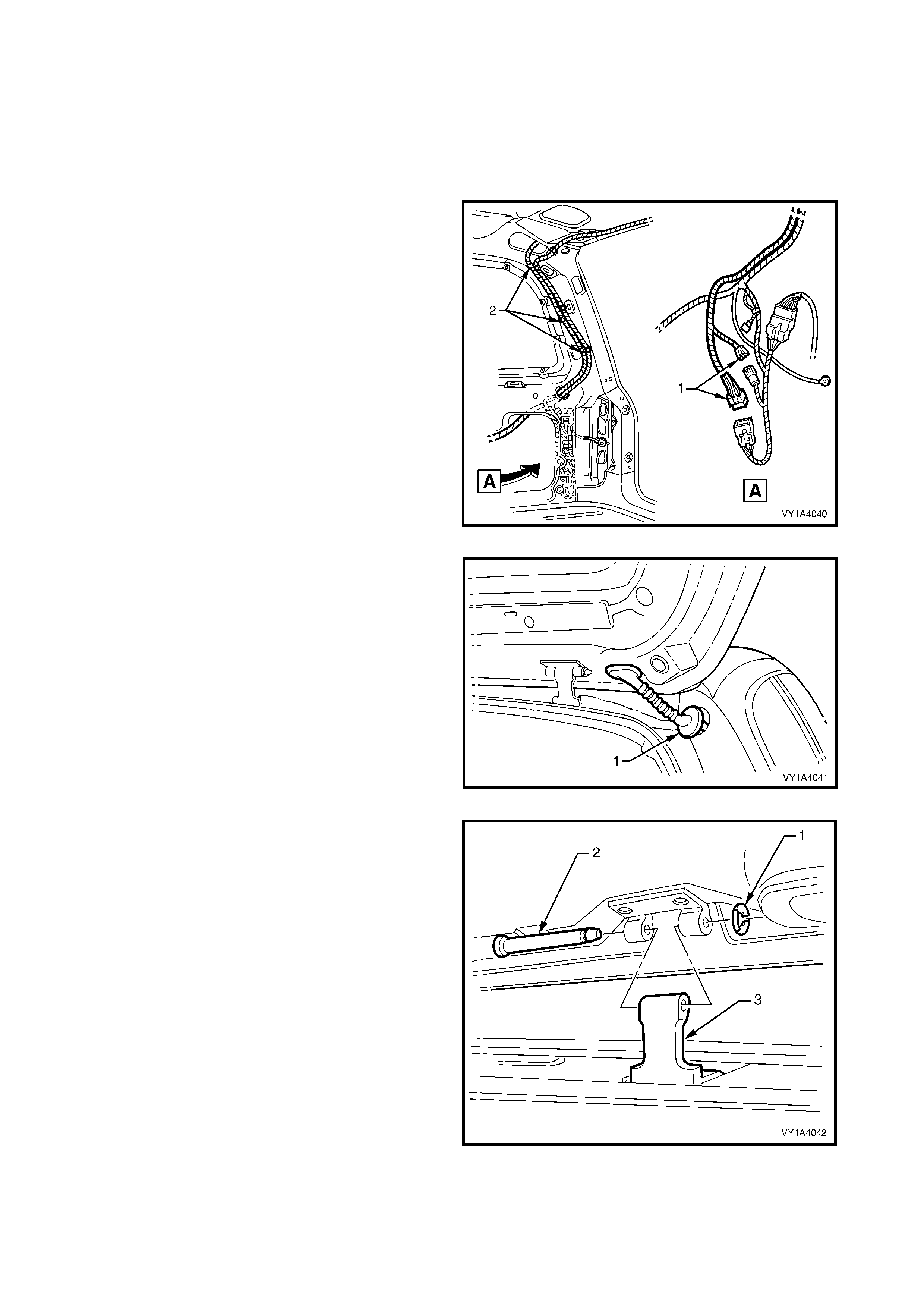

5. Disconnect the two liftgate assembly wiring

harness connectors (1).

6. Unclip the liftgate harness, three places (2).

Figure 8-28

7. Remove the right-hand grommet (1) from the

vehicle and withdraw the harness from the pillar

cavity.

8. Remove the left-hand grommet from the liftgate

and withdraw the washer hose through the liftgate

cavity.

Figure 8-29

9. Remove the liftgate hinge pin retainer (1) from

each side of the vehicle.

10. Have an as s istant hold the other side of the lif tgate

and withdraw each liftgate hinge pin (2).

11. Remove the liftgate assembly leaving the liftgate

hinge (body side) (3) in position.

Figure 8-30

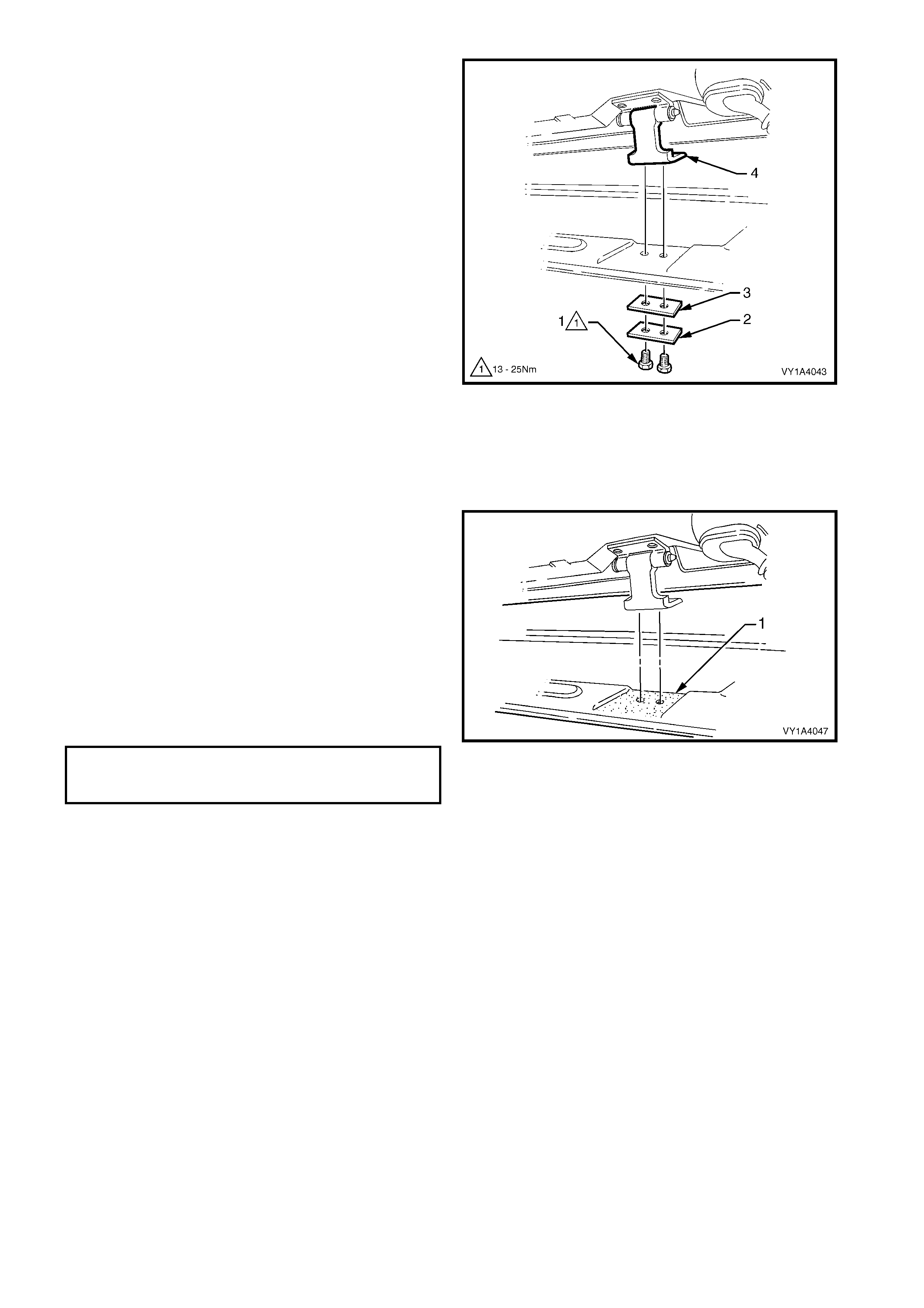

NOTE: As an alternative:

12. Remove the rear window upper garnish, refer to

Section 1A8, HEADLING & TRIM in the MY 2003

VY & V2 Series II service information.

13. Remove the two screws (1), plate (2) and seal (3).

14. Remove the liftgate assembly with the liftgate

hinge (body side) (4).

Figure 8-31

REINSTALL

Installation is the reverse of removal noting the following.

1. If the liftgate was removed from the liftgate hinge pin, lubricate the pin with lithium based grease prior to

installation.

2. If the liftgate was removed with the liftgate hinge

(body side), apply s ealer such as Lord Fus or #800

or #801 or equivalent to the area shown (1).

3. Set the two bumpers to the full-in position then

adjust to achieve the required alignment of the

liftgate, refer to the following adjustment

procedure.

4. Test the operation of the wiper, washer, high

mount stop lam p, r ear com par tm ent courtesy lamp

switch and lock mechanism before installing the

trim panels.

5. Tighten all screws to the specified torque.

Figure 8-32

ADJUST

Correct alignment of the liftgate is critical to its operation and to the aesthetics of the vehicle. The following

components allow adjustment of the liftgate:

• Liftgate bumper: Provides adjustment at the outer area of the liftgate assembly.

• Liftgate hinge (body side) screws: Provide forward, rearward and skew adjustment of the liftgate assembly.

• Liftgate striker assembly: Provides vertical and sideways adjustment of the liftgate assembly.

Whenever alignment is required, perform adjustment in the following order.

1. If fitted, remove the liftgate striker assembly.

2. Ensure the liftgate weatherstrip assembly is installed and the liftgate bumpers are fitted and set fully in.

3. Carefully close the liftgate, watching the top and each side does not contact the vehicle.

4. Check the alignment of the liftgate for width and consistency of gap to the roof panel, quarter panel each

side, tail lamps and rear bumper fascia, refer to 4. BODY MARGINS in Section 3B for specifications.

LIFTGATE HINGE (BODY SIDE)

ATTACHING SCREW

TORQUE SPECIFICATION 13.0 – 25.0 Nm

5. If the gap between the lif tgate and roof panel is not

within specification and/or is not parallel to the

quarter panel each side, open the liftgate and

adjust the position of the liftgate hinge(s):

• Remove the rear window upper garnish if not

already done, refer to Section 1A8, 3.10

REAR WINDOW UPPER GARNISH in the

MY 2003 VY & V2 Series II service

information.

• Loosen the two screws (1) attaching the

liftgate hinge (2).

• Lift the hinge away from the body and apply

sealer such as Lord Fusor #800 or #801 or

equivalent to the area shown (3).

• Adjust the position of the hinge, tighten the

screws and recheck the liftgate alignment.

NOTE: Do not make all adjustments at once. Perform

one adjustment, carefully close the liftgate, check its

position and make further adjustments until correct

alignment is achieved.

6. If the gap between the liftgate and roof panel is

within specific ation and the liftgate is parallel to the

quarter panel each side, open the liftgate and

adjust the liftgate bumpers to provide a slightly

greater gap at the lower edge of the liftgate above

each tail lamp. This allows f or the s triker to pull the

liftgate in slightly when closed.

Figure 8-33

7. Install the liftgate striker assembly.

8. Close the liftgate, watching that the striker does

not pull the liftgate to one side, changing the panel

gaps. If it does, move the striker as required.

9. Tighten all screws to their specified torque.

LIFTGATE HINGE (BODY SIDE)

ATTACHING SCREW

TORQUE SPECIFICATION 13.0 – 25.0 Nm

2.7 LIFTGATE OUTER PANEL – REPLACE

REMOVE

1. Rem ove the tailgate from the vehicle as described

in 2.6 LIFTGATE ASSEMBLY – REPLACE in this

Section.

2. Spot cut the welds around the window flange

attaching the lif tgate outer panel to the inner panel

assembly.

Figure 8-34

3. Grind or sand the hem from around the edges of

the liftgate.

Figure 8-35

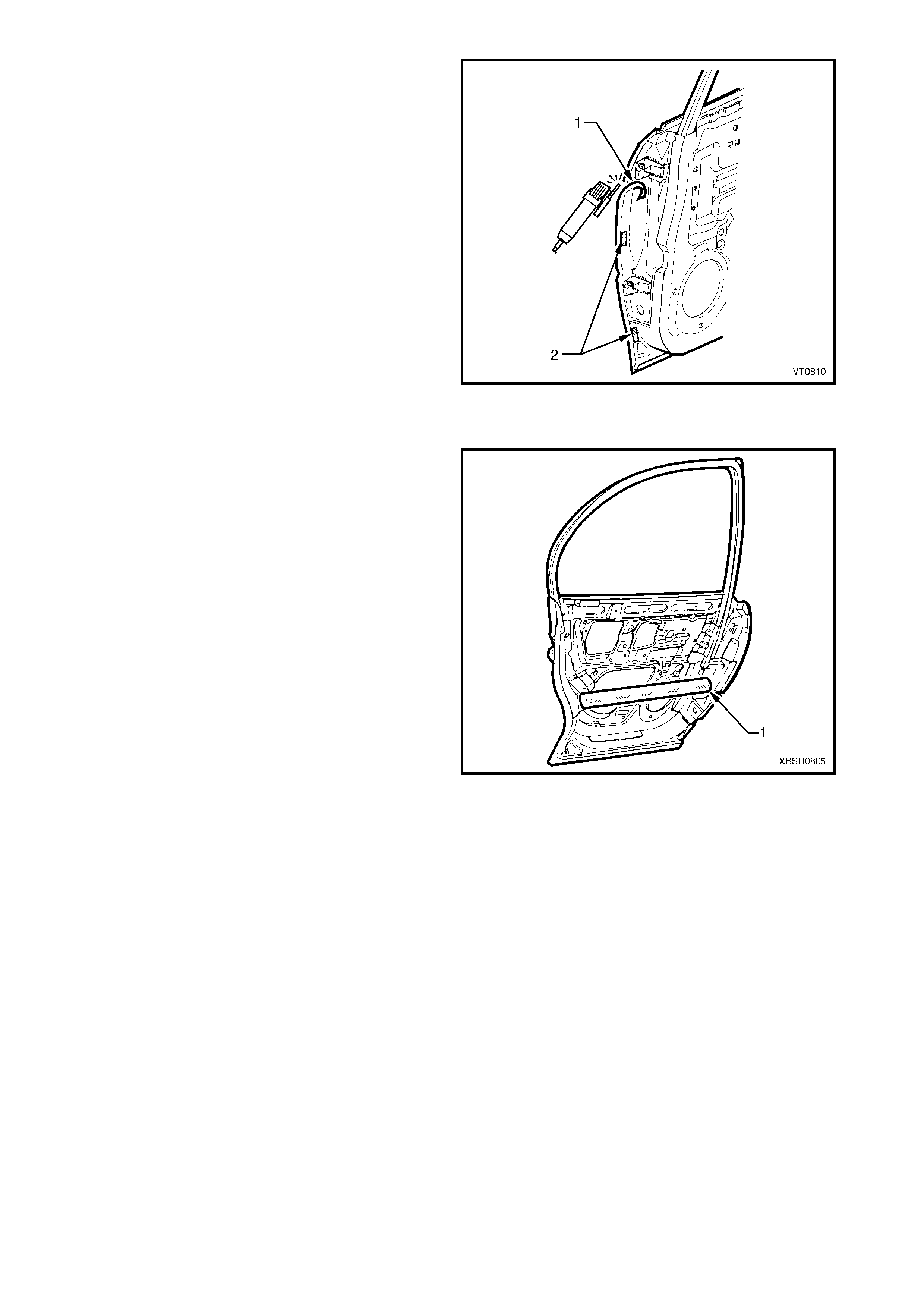

4. Soften the adhesive between the outer panel and

the inner panel support brackets by heating the

areas shaded (1) with a heat gun.

5. Separate the outer panel from the liftgate inner.

Figure 8-36

6. Remove the hemming strip from the liftgate inner

panel by chiselling or grinding away the metal

strip (1) and the adhesive.

7. Repair any damage to the liftgate inner panel

assembly.

8. Clean away sealer from the attaching faces around

the hemming area and clean all remaining

adhesive fr om the outer panel s upport brack ets on

the liftgate inner panel.

9. Prepare and prime any bare metal as required.

Figure 8-37

REPLACE

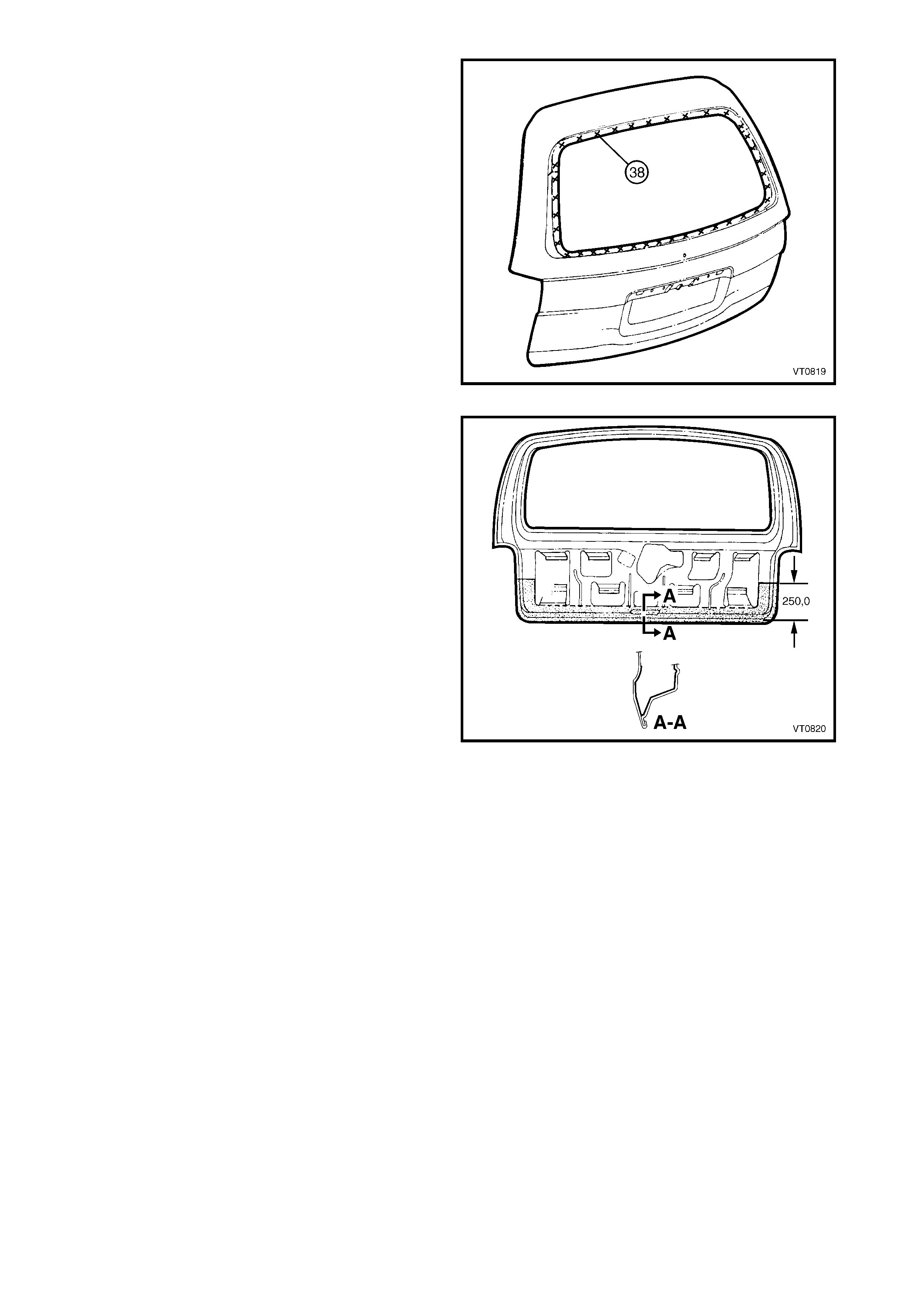

1. Apply beads (1) of Anti-flutter Adhesive (Item 5) in

16 places, each 40 mm long, to the support

brackets, refer to 5. BODY SEALING,

ADHESIVES & DEADENERS in Section 3B.

Figure 8-38

2. Apply structural adhesive (Item 6) to the

mating surfaces of the hem (1), refer to

5. BODY SEALING, ADHESIVES & DEAD ENERS

in Section 3B.

3. Clam p the outer panel in pos ition and fold over the

hem to attach the outer panel firmly to the inner

panel assembly.

NOTE: This procedure must be performed carefully to

avoid damaging the panel surface. The use of body

filler around the outer edges of the outer panel to

rectify hammering damage is considered

unacceptable.

Figure 8-39

4. Spot weld the lif tgate outer panel to the inner panel

assembly around the window flange.

5. Refinish and paint the liftgate as requir ed. Refer to

Section 3, 1.3 PAINT REFINISHING.

6. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3B.

Figure 8-40

7. Apply Cavity Wax (Item 8) as r equired to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3B.

8. Install the liftgate assembly, refer to 2.6 LIFTGATE

ASSEMBLY – REPLACE.

9. Install the liftgate window, refer to Section 1A6

STATIONARY WINDOWS in the MY 2003 VY &

V2 Series II service information.

10. Install the remaining components as required,

refer to Section 1A4 HOOD, REAR

COMPARTMENT LID, LIFTGATE & ENDGATE in

the MY 2003 VY & V2 Series II service information.

Figure 8-41

2.8 ENDGATE ASSEMBLY – REPLACE

NOTE: If only the endgate is damaged, it is best to remove the endgate from the hinges, leaving the hinges

attached to the vehicle. This will avoid disturbing the joint sealer surrounding the hinges.

REMOVE

1. Disassemble the endgate hardware as required. Refer to Section 1A4 HOOD, REAR COMPARTMENT

LID, LIFTGATE & ENDGATE in the MY 2003 VY & V2 Series II service information.

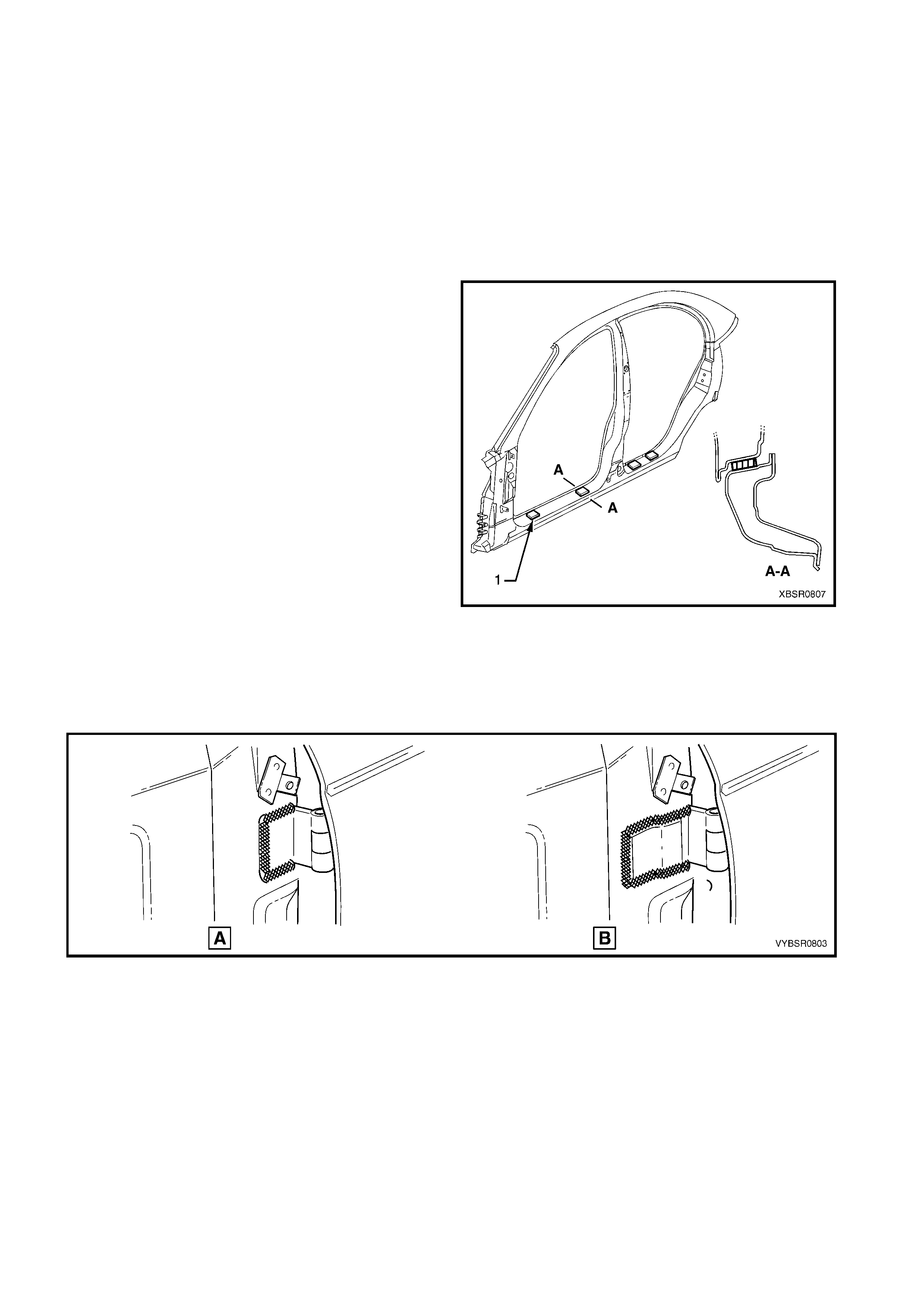

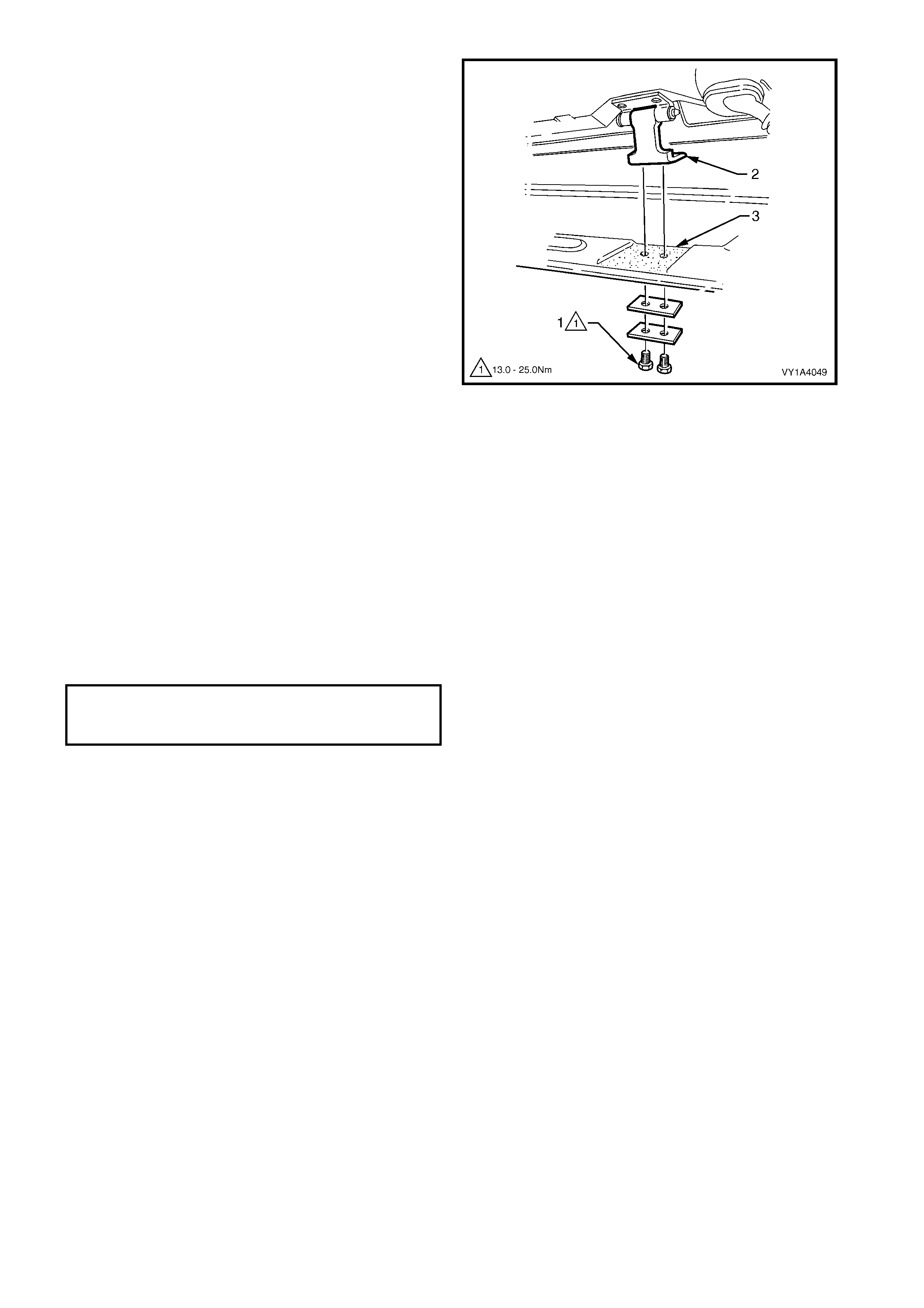

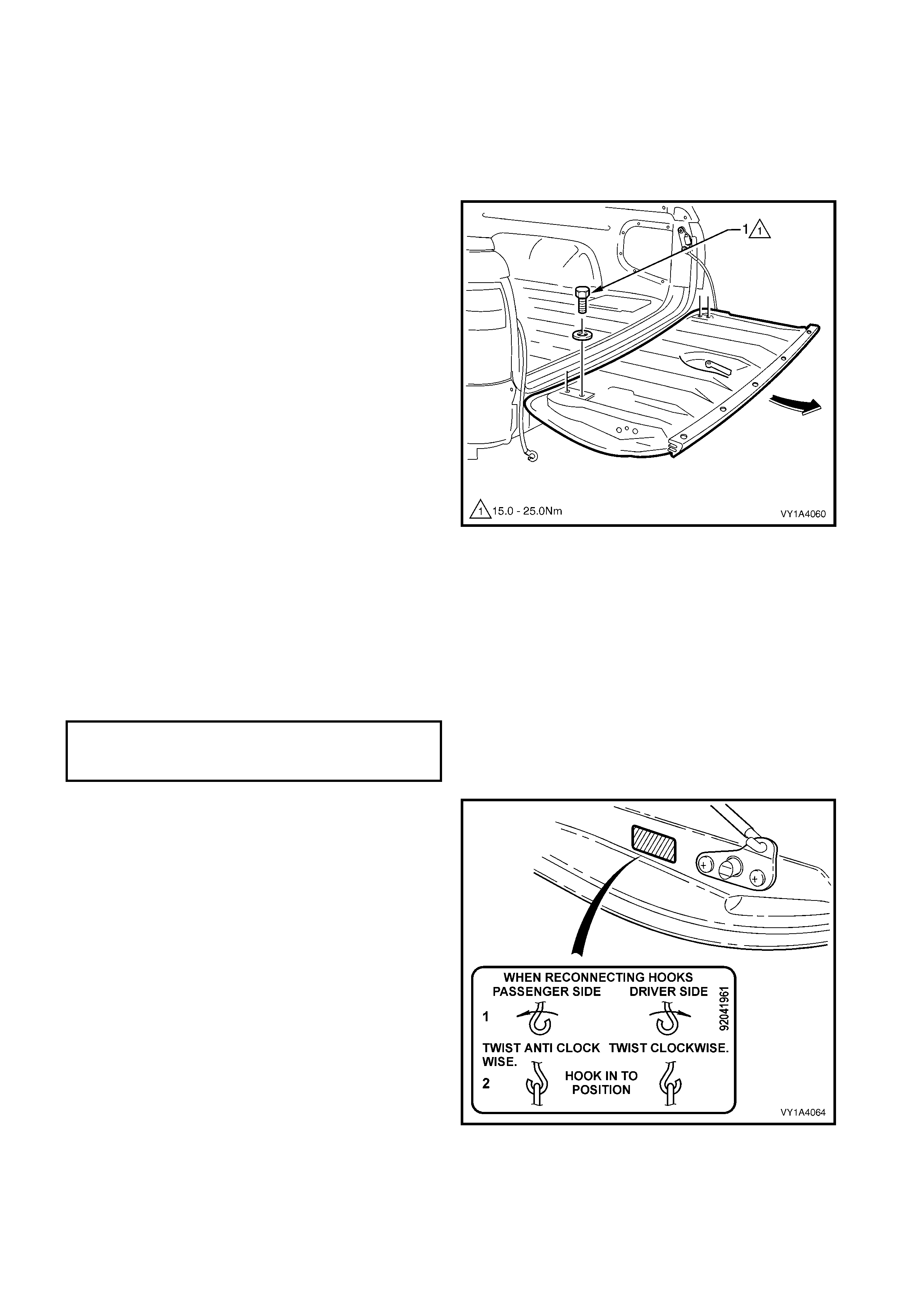

2. Mark the position of the endgate screws with a

marker pen as required.

3. With an assistant supporting the endgate, remove

the four screws (1) and washers attaching the

endgate assembly to the hinge assemblies.

4. Remove the endgate assembly by sliding it

rearwards from the hinge assemblies.

Figure 8-42

REINSTALL

Installation is the reverse of removal noting the

following:

1. Align the endgate screws with the pen marks or

adjust the endgate as described in the following

procedure, ADJUST.

2. Tighten the screws to the specified torque.

3. Install the endgate hook label to the left-hand side

of the endgate inner panel as shown.

Figure 8-43

ENDGATE ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 15.0 – 25.0 Nm

ADJUST

Correct alignment of the endgate assembly is critical to its operation and to the aesthetics of the vehicle. The

following components allow adjustment of the endgate:

• Endgate hinge assembly screws (endgate and body side): Provide vertical, horizontal and skew adjustment.

• Endgate striker latch: Provides adjustment flushness of the endgate assembly to the vehicle.

Whenever alignment is required, perform adjustment in the following order.

1. Remove the endgate striker.

2. Ensure the endgate weatherstrip assembly is installed.

3. Carefully close the endgate, watching each side does not contact the vehicle.

4. Check the alignment of the endgate for height, flushness, width and consistency of gap to the side panel

outer and tail lamps, refer to 4. BODY MARGINS in Section 3C for specifications.

5. As required, loosen the hinge assembly attaching screws and reposition the endgate. If enough adjustment

cannot be obtained, loosen the lower hinge assembly screws.

6. Temporarily tighten the screws.

7. Install the endgate striker, refer to 5.4 ENDGATE STRIKER & ENDGATE CABLE ASSEMBLY in Section

1A4 HOOD, REAR COMPARTMENT LID, LIFTGATE & ENDGATE in the MY 2003 VY & V2 Series II

service information.

8. Close the endgate and adj ust the position of the str iker to provide flus hness of the endgate to the side panel

outer and tail lamps.

9. Check that all screws are tightened to their specified torque.

ENDGATE ASSEMBLY UPPER

ATTACHING SCREW

TORQUE SPECIFICATION 15.0 – 25.0 Nm

ENDGATE ASSEMBLY LOWER

ATTACHING SCREW

TORQUE SPECIFICATION 15.0 – 35.0 Nm

2.9 ENDGATE OUTER PANEL – REPLACE

REMOVE

1. Remove the endgate as s embly from the vehicle as

described in 2.8 ENDGATE ASSEMBLY –

REPLACE.

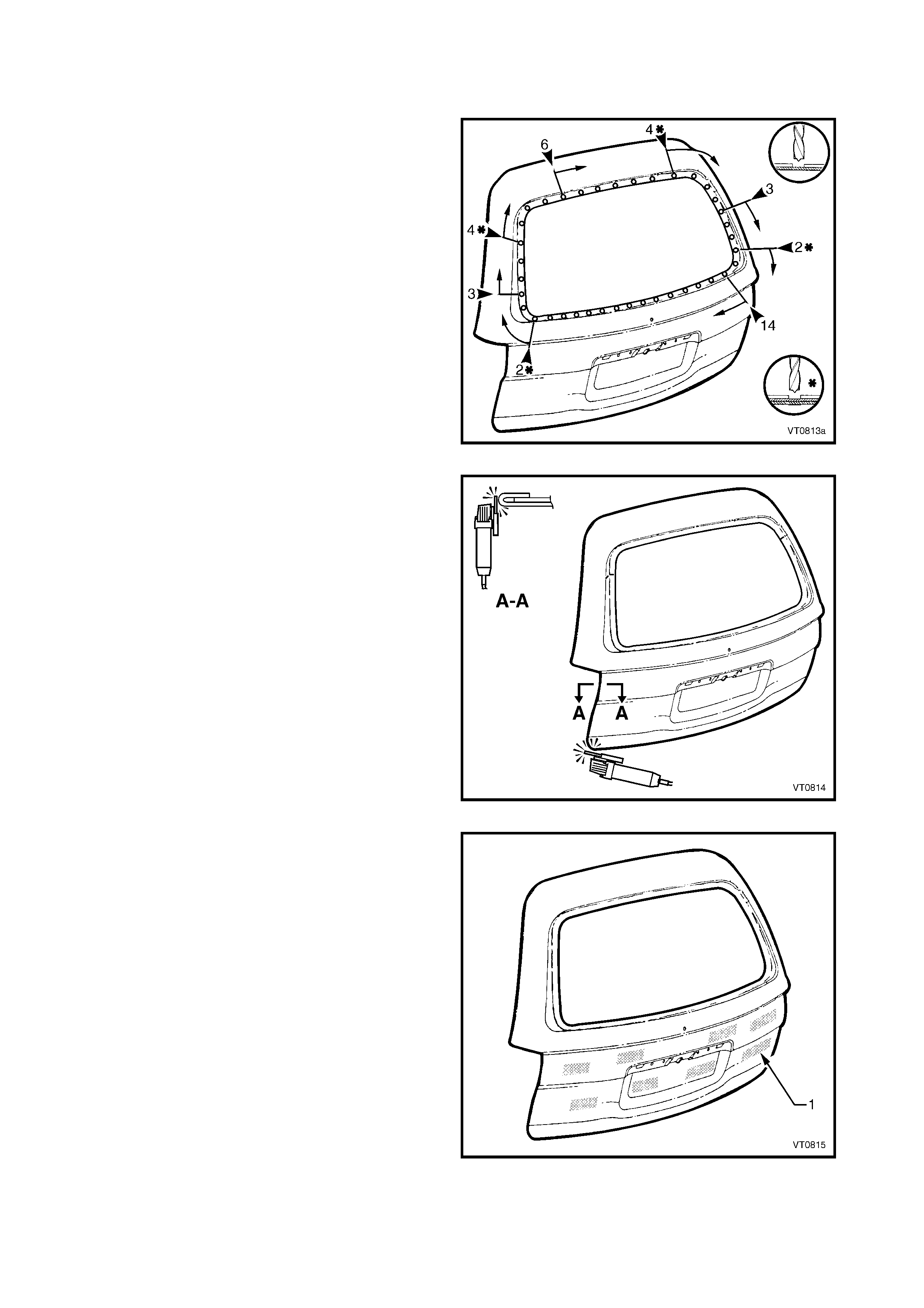

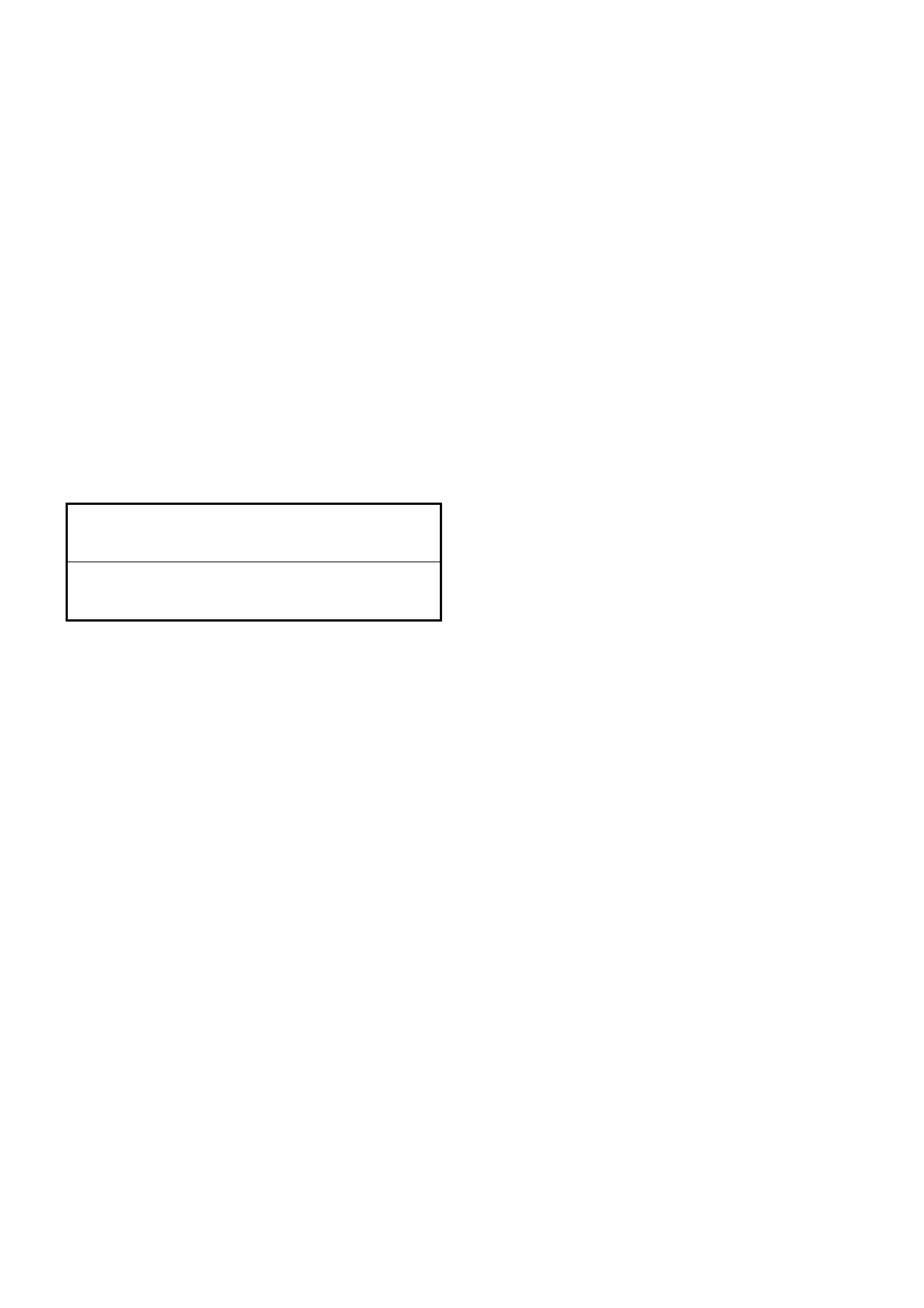

2. From the outer side, spot cut the 14 welds

attaching the upper edge of the endgate outer

panel to the inner panel assembly.

NOTE: Cut through the outer panel only, refer to

Section A-A.

3. From the inner side, spot cut the 15 welds

attaching the endgate outer panel hem to the inner

panel assembly.

NOTE: Cut through the outer panel only, refer to

Section B-B.

Figure 8-44

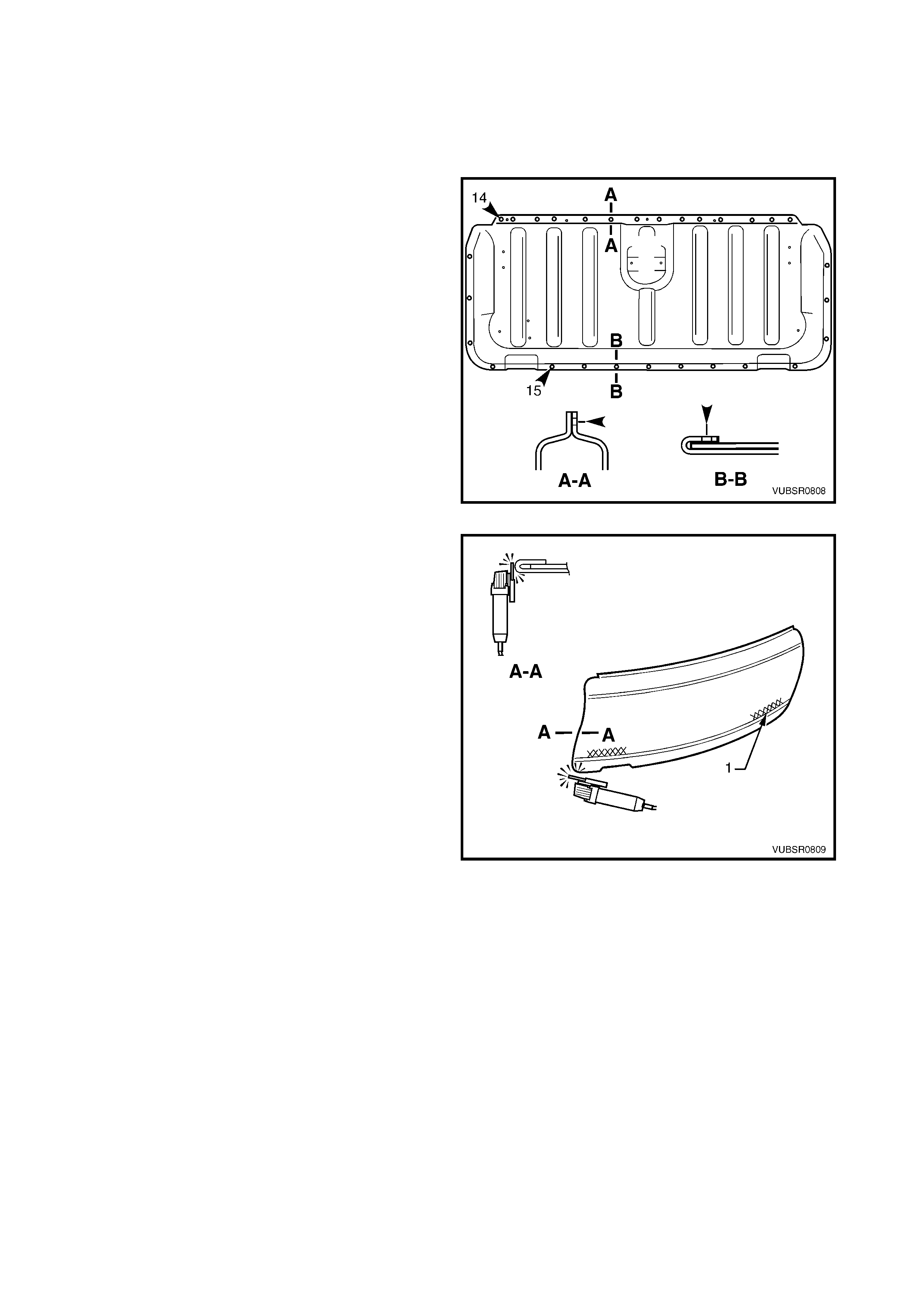

4. Grind or sand the edge of the hem from around

the edges of the endgate.

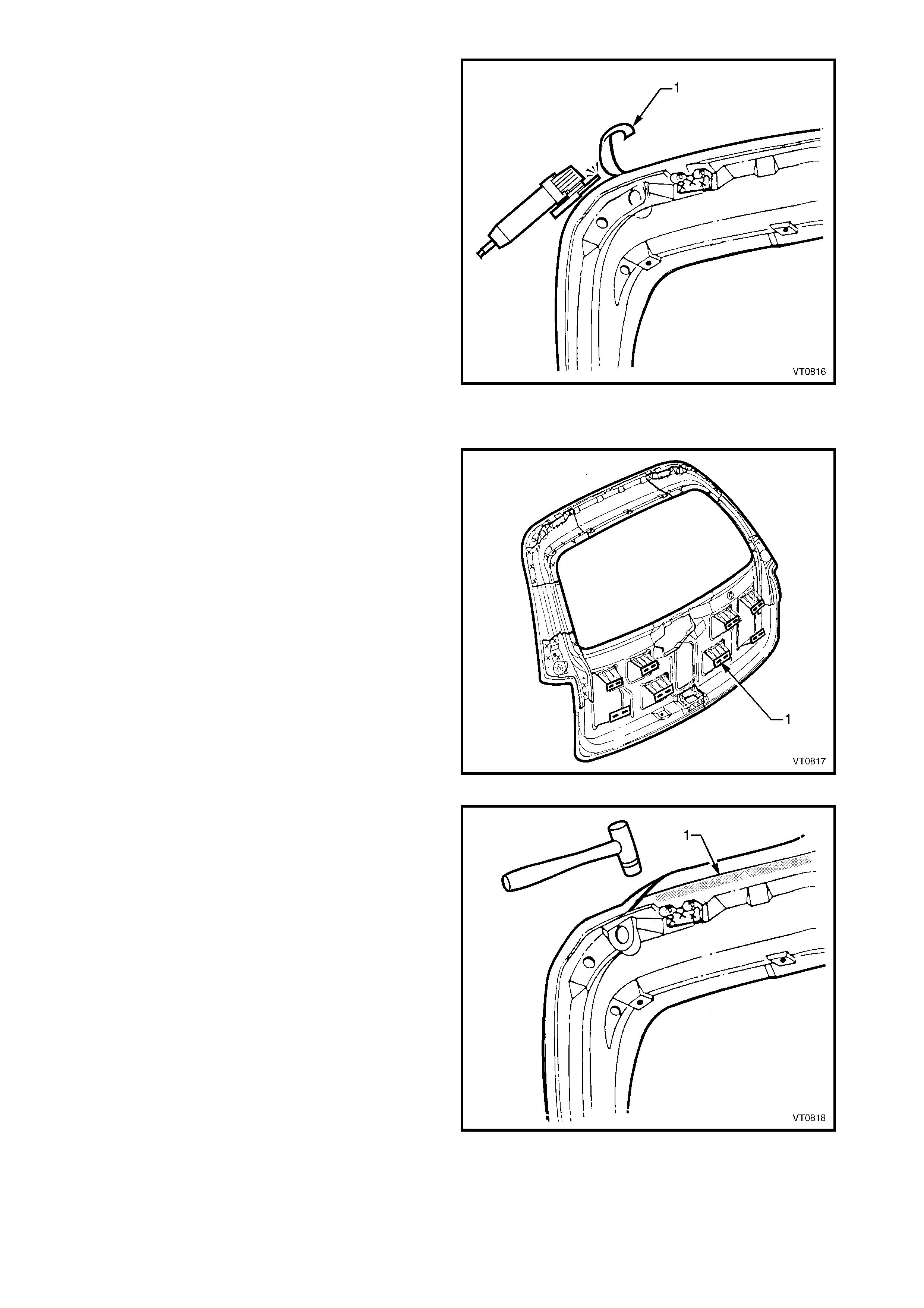

5. Soften the adhesive between the outer panel and

hinge reinfor cement by heating the areas (1) with a

heat gun.

6. Separate the outer panel from the endgate inner.

Figure 8-45

7. Chisel the hemming strip (1) from the endgate

inner panel.

8. Repair any damage to the endgate inner panel

assembly.

9. Clean away sealer or adhesive from the attaching

faces around the hemming area and clean all

remaining anti-flutter adhesive from the hinge

reinforcements on the endgate inner panel.

10. Prepare and prime any bare metal as required.

Figure 8-46

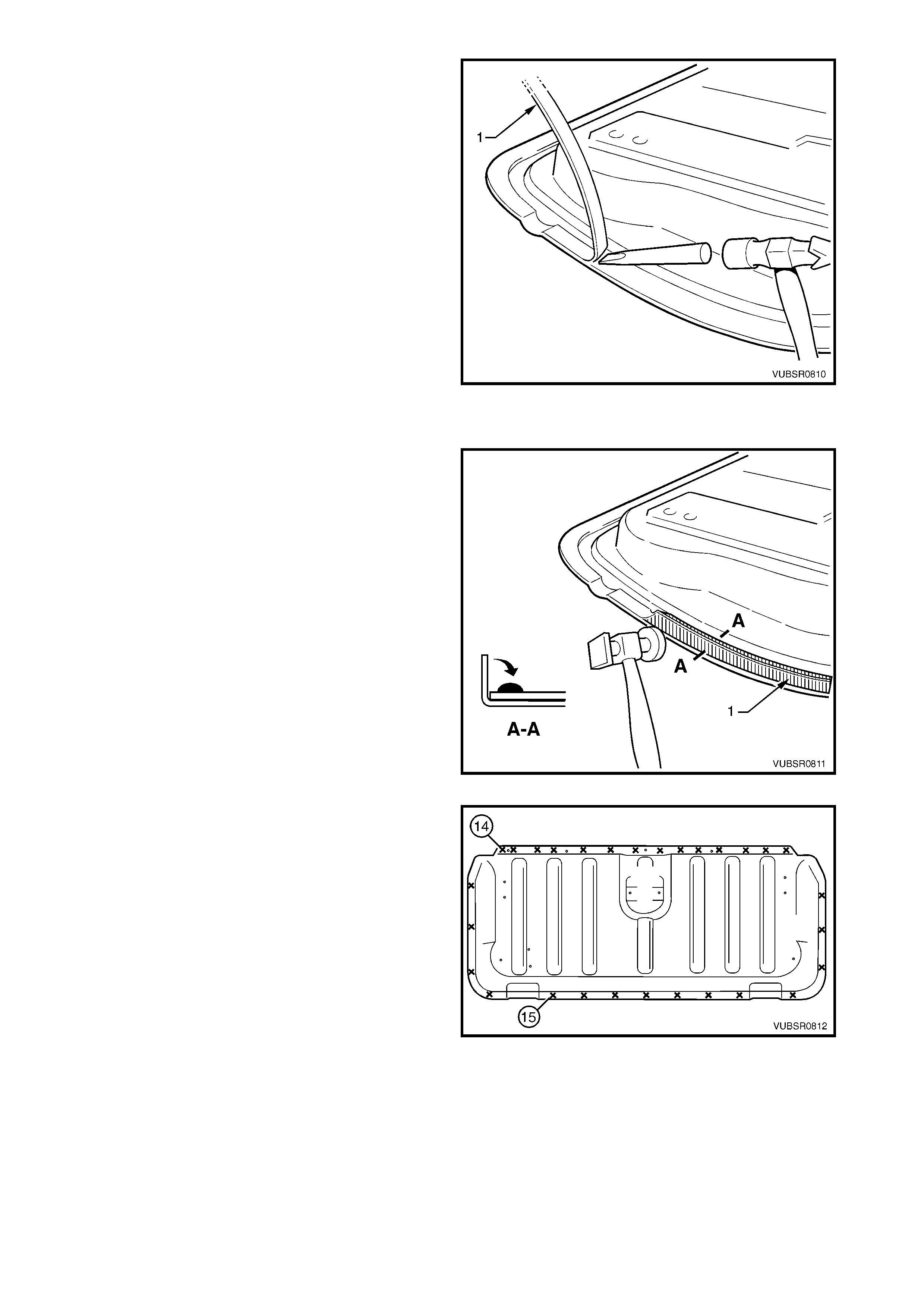

REPLACE

1. Apply structural adhesive (Item 6) to the

mating surfaces of the hem (1), refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

2. Apply anti-flutter adhesive (Item 5) to the

two endgate hinge reinforcements, refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

3. Clam p the outer panel in pos ition and fold the hem

over to attach the outer panel firmly to the inner

panel assembly.

NOTE: This procedure must be performed carefully to

avoid damaging the panel surface. The use of body

filler around the outer edges of the outer panel to

rectify hammering damage is considered

unacceptable.

Figure 8-47

4. Spot or plug weld the endgate outer panel to the

inner panel assembly.

NOTE: Place wet rags against the outer panel around

the weld area to minimise heat distortion.

5. Dress the hem and edges of the outer panel as

required.

6. Refinish and paint the endgate as required. Refer

to Section 3, 1.3 PAINT REFINISHING.

7. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

8. Apply Cavity Wax (Item 8) as r equired to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

9. Install the endgate assembly, refer to

2.8 ENDGATE ASSEMBLY – REPLACE.

10. Install the endgate hardware as required. Refer to

Section 1A4 HOOD, REAR COMPARTMENT

LID, LIFTGATE & ENDGATE in the MY 2003 VY

& V2 Series II service information.

Figure 8-48

3. SPECIAL TOOLS

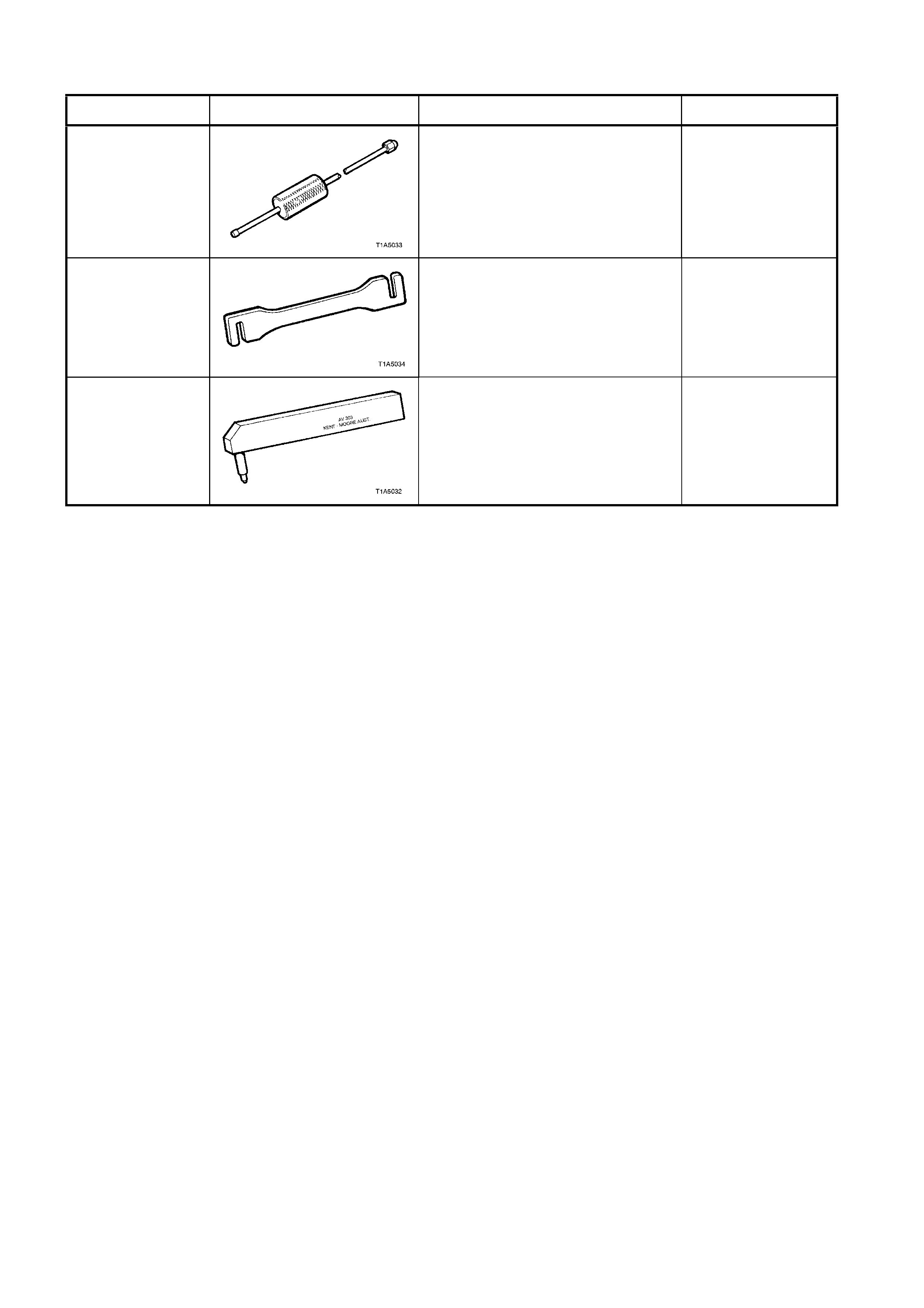

TOOL NUMBER ILLUSTRATION DESCRIPTION CLASSIFICATION

AU170

DOOR HINGE PIN REMOVAL

TOOL

Used for removing door hinge pivot

sleeves

Available

AU184

DOOR HINGE SETTING TOOL

Used to adjust door alignment Desirable

AU303

DOOR HINGE SLEEVE

INSTALLER

Used to install door hinge pivot

sleeves

Available