SECTION 10A – BODY REAR – SEDAN

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to

Section 00 CAUTIONS AND NOTES and Section 2 PRECAUTIONS in this Supplement for correct

workshop practices with regard to safety and/or property damage.

CAUTION

The Structure of the M Y 2003 VY & V2 Series II body shell has been developed using complex design

and development techniques. In addition to meeting all required standards, the v ehicle body is also a

critical part of the overall safety systems. It is therefore imperative the repair procedures described

here are adhered to during all vehicle body repairs.

1. GENERAL DESCRIPTION

1.1 BODY REAR COMPONENTS

2. SERVICE OPERATIONS

2.1 REAR END LOWER PANEL – REPLACE

REMOVE

REPLACE

2.2 REAR END PANEL ASSEMBLY – REPLACE

REMOVE

REPLACE

2.3 REAR END PANEL EXTENSION – REPLACE

REMOVE

REPLACE

2.4 FUEL TANK SUPPORT REINFORCEMENT –

REPLACE

REMOVE

REPLACE

2.5 REAR COMPARTMENT FLOOR PANEL

OUTER EXTENSION – REPLACE

REMOVE

REPLACE

2.6 REAR COMPARTMENT FLOOR PANEL

ASSEMBLY – REPLACE

REMOVE

REPLACE

2.7 REAR WINDOW PANEL ASSEMBLY –

REPLACE

REMOVE

REPLACE

2.8 REAR SEAT BACK PANEL EXTENSION

ASSEMBLY OR REAR WHEELHOUSE

INNER PANEL ASSEMBLY – REPLACE

REMOVE

REPLACE

2.9 REAR COMPARTMENT LID STRUT

BRACKET ASSEMBLY – REPLACE

REMOVE

REPLACE

2.10 CROSSMEMBER ASSEMBLY NO. 2 –

REPLACE

REMOVE

REPLACE

2.11 REAR FLOOR PANEL OUTER EXTENSION –

REPLACE

REMOVE

REPLACE

2.12 REAR TIE DOWN ASSEMBLY – REPLACE

REMOVE

REPLACE

2.13 REAR BUMPER IMPACT BAR BRACE

ASSEMBLY – REPLACE

REMOVE

REPLACE

2.14 REAR SIDE RAIL ASSEMBLY – REPLACE

REMOVE

REPLACE

2.15 REAR FLOOR PANEL ASSEMBLY – REPLACE

REMOVE

REPLACE

2.16 REAR FLOOR PANEL REINFORCEMENT –

REPLACE

LEFT-HAND SIDE

RIGHT-HAND SIDE

1. GENERAL DESCRIPTION

This Section describes replacem ent procedures for the rear section components of the MY 2003 VY Series Sedan

body structure. Removal of bolt-on and mechanical components is not covered. Reference must be made to the

appropriate Sections in the MY 2003 VY & V2 Series II Service Information.

When repairing the rear of the vehicle, care must be taken to ensure the structure is returned to its original

production configuration.

NOTE: It is imperative that the correct body adhesives, sealers, deadeners and cavity waxes are used when

repairing the body structure of MY 2003 VY Series Sedan vehicles. Refer to 5. BODY SEALING, ADHESIVES &

DEADENERS and 6. CAVITY WAX in Section 3A for details of the correct materials and their commercially

available equivalents.

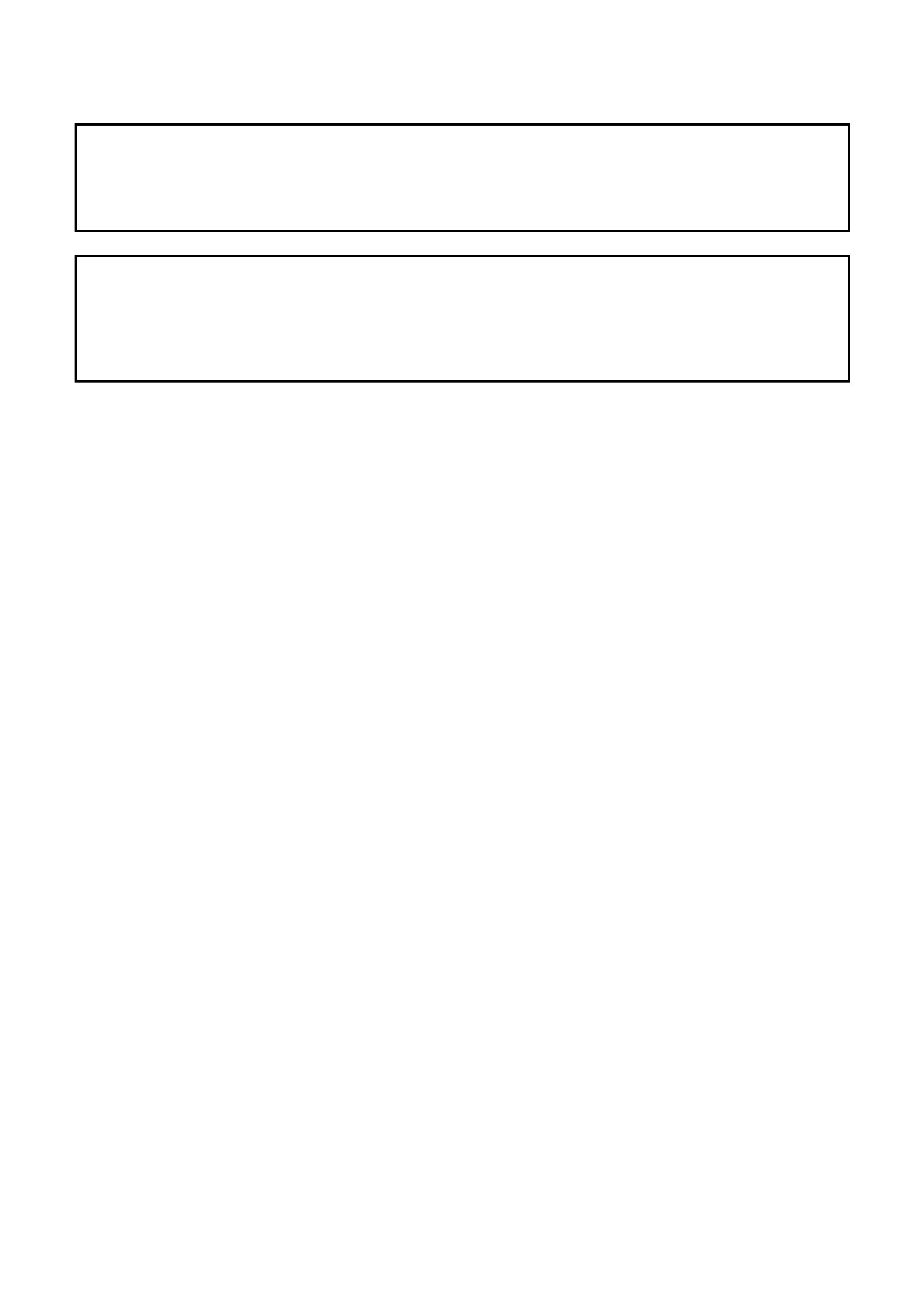

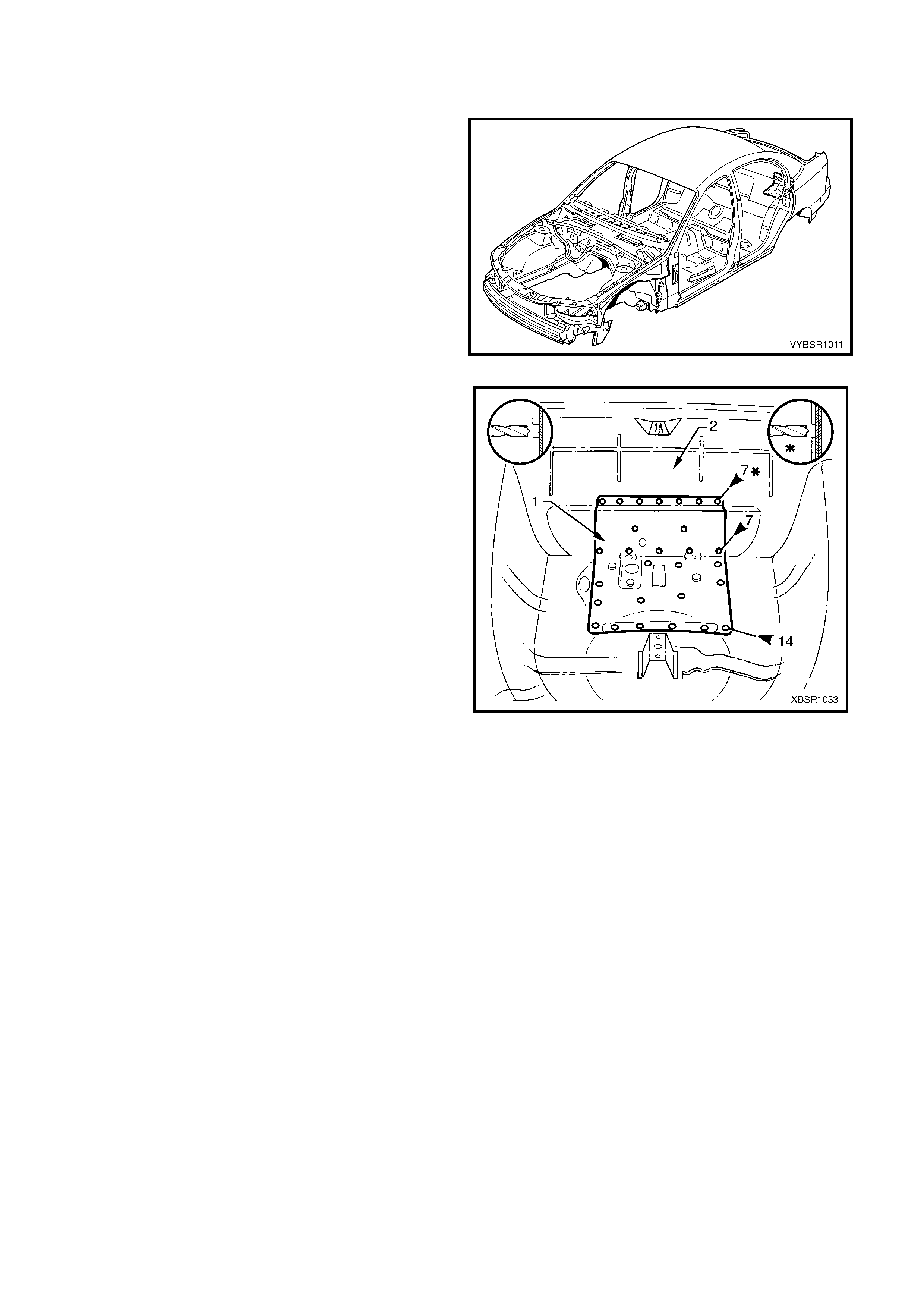

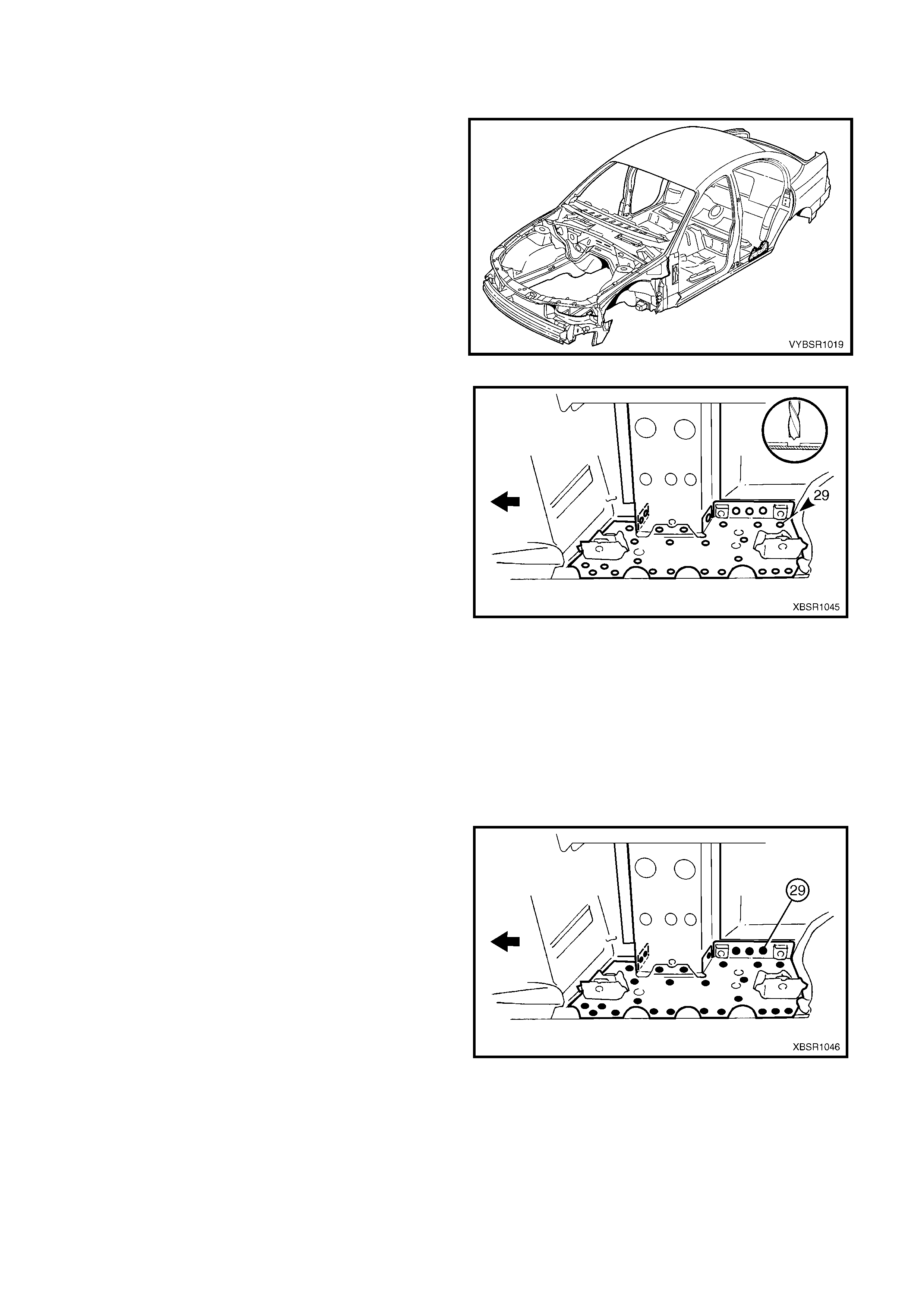

1.1 BODY REAR COMPONENTS

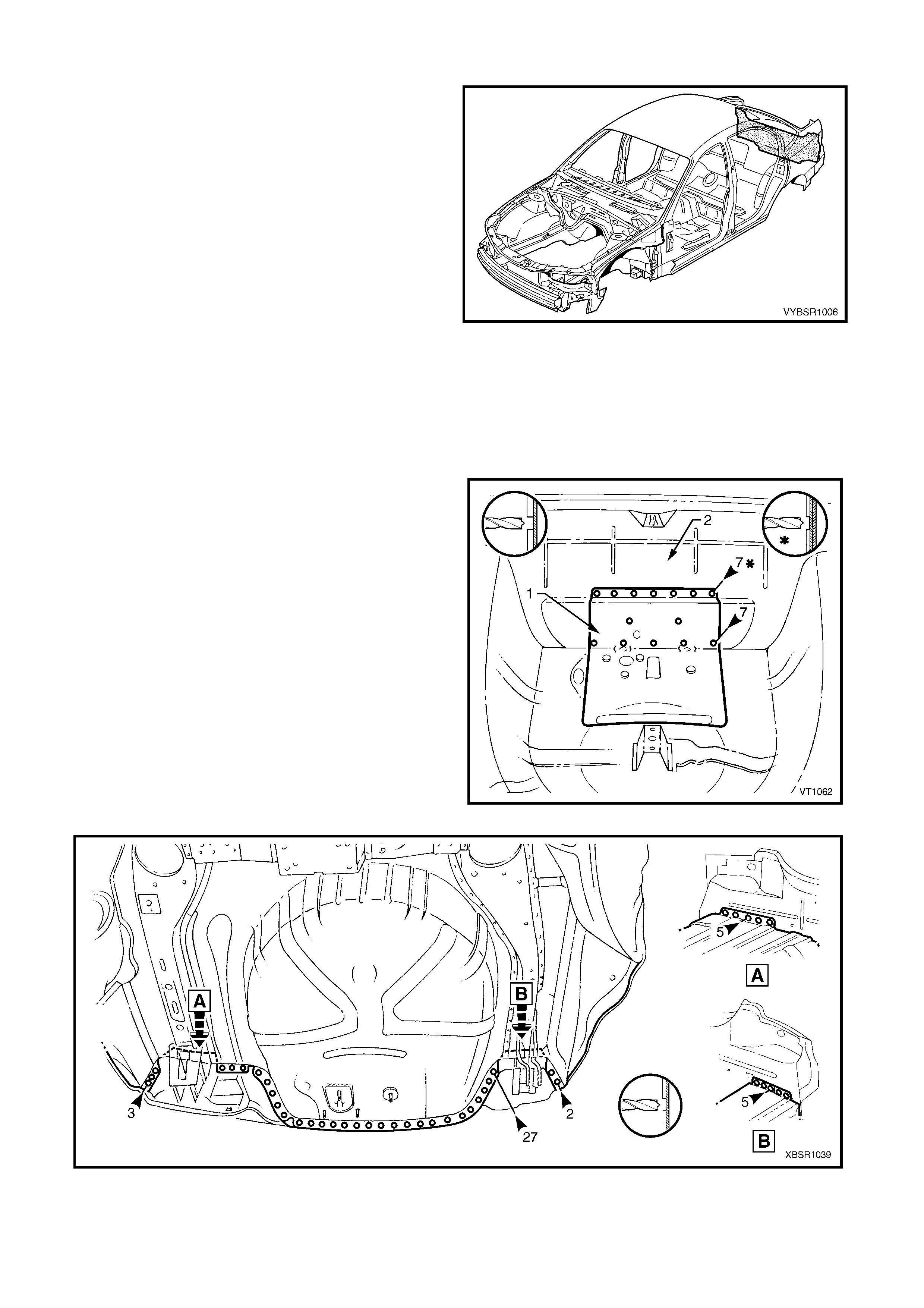

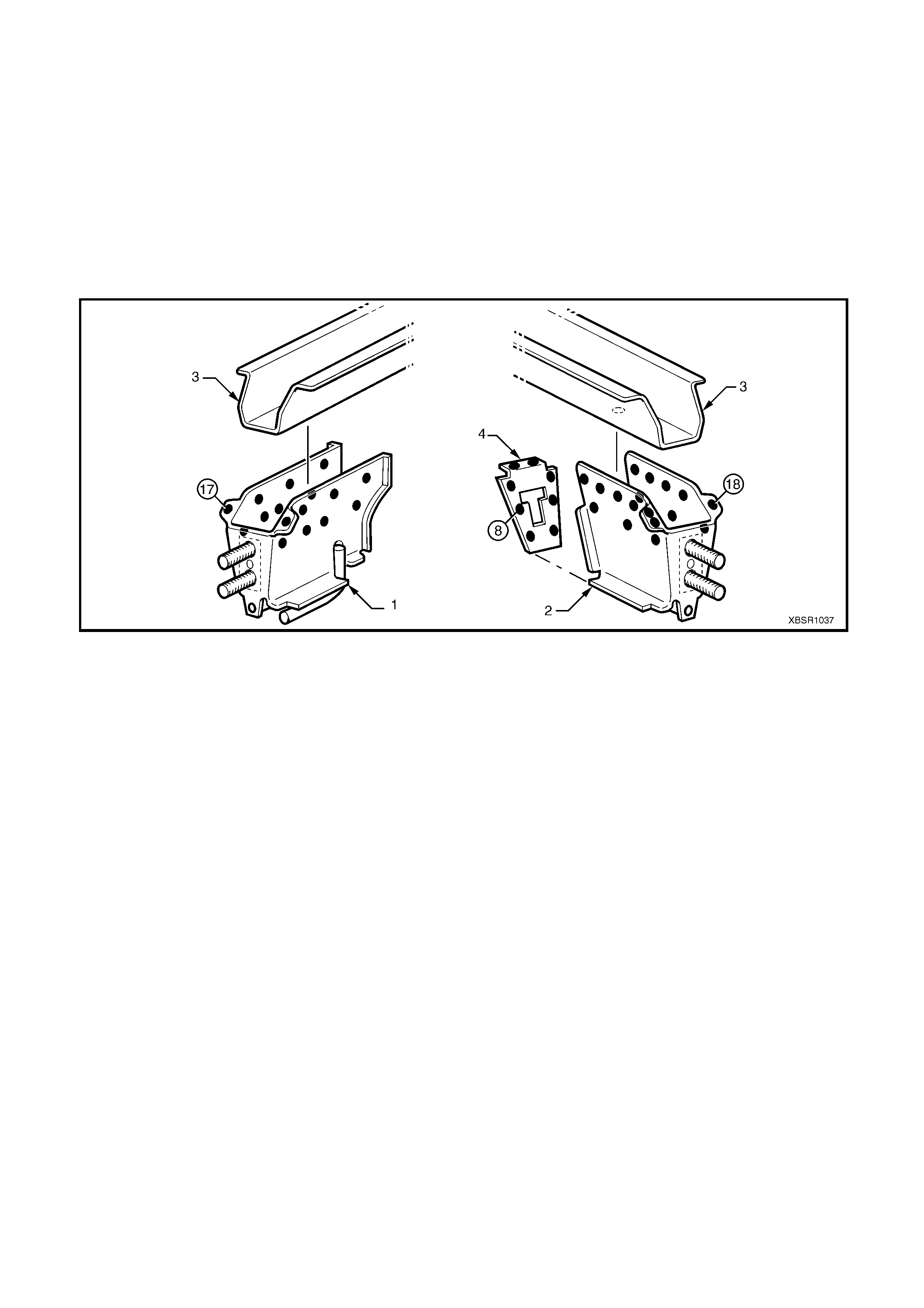

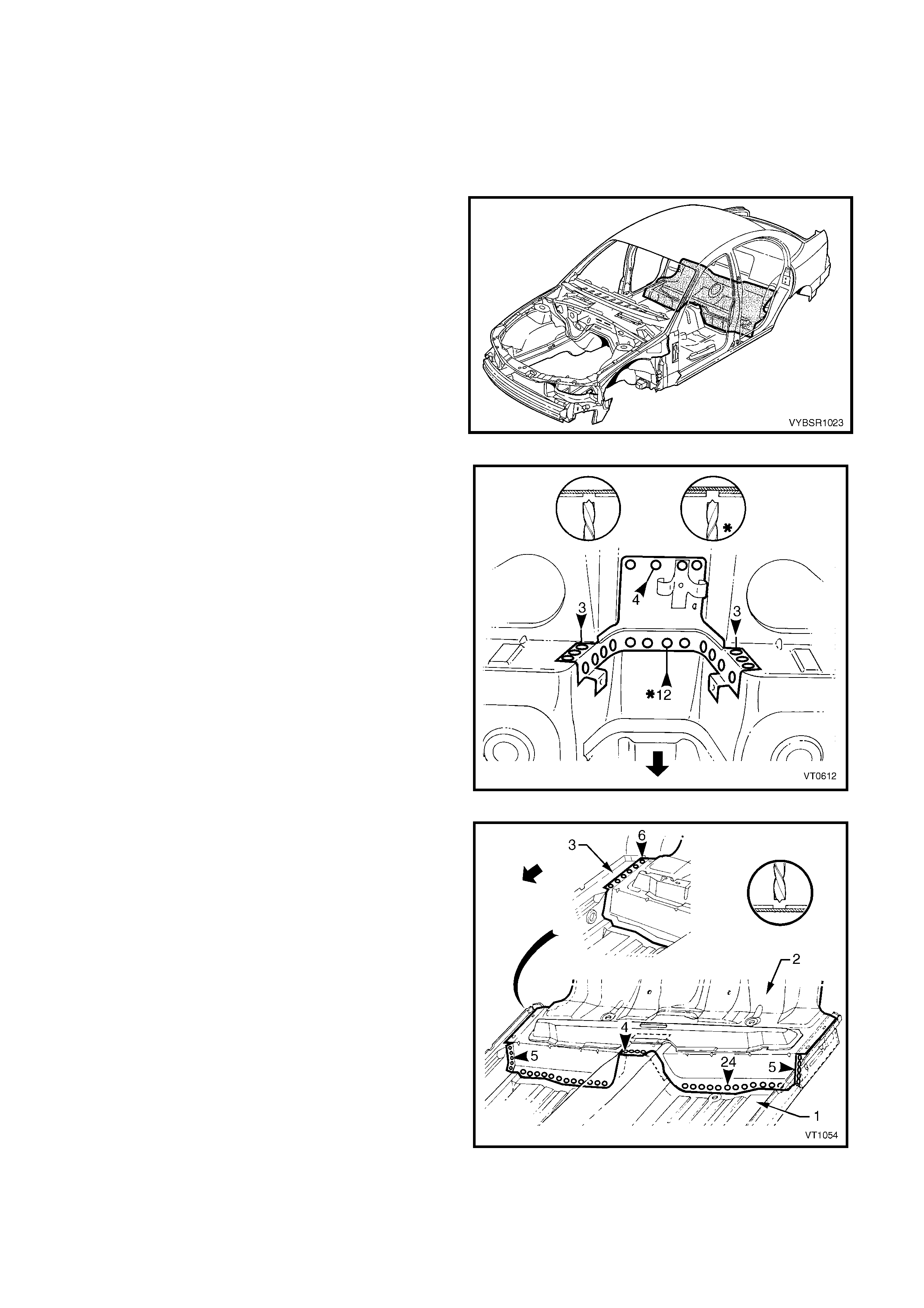

The shaded components in Figure 10A-1 are those

dealt with in this Section.

The components and assemblies shown in Figure

10A-2 are the parts serviced for MY 2003 VY Series

Sedan vehicles which form the basis of the repair

procedures in this Section. For a detailed view of the

body components, refer to Section 3A BODY

CONSTRUCTION – SEDAN.

NOTE: Always refer to your Authorised Retailer for

spare parts availability configurations.

Figure 10A-1

Figure 10A-2

Legend

1. Rear Window Panel Assembly

2. Rear Seat Back Panel Extension Assembly

3. Rear Seat Back Panel Extension

4. Rear Compartment Lid Strut Bracket Assembly

5. Rear Wheelhouse Panel Assembly

6. Rear End Lower Panel

7. Rear End Panel Extension

8. Rear End Panel Assembly

9. Rear Compartment Floor Panel Assembly

10. Rear Compartment Floor Panel Outer Extension,

Left-Hand

11. Rear Floor Panel Reinforcement, Left-Hand

12. Fuel Tank Support Reinforcement Assembly

13. Spare Wheel Anchor Plate Assembly

14. Rear Compartment Floor Panel Outer Extension,

Right-Hand

15. Rear Floor Panel Reinforcement, Right-Hand

16. Rear Floor Panel Assembly

17. Crossmember Assembly No. 2

18. Rear Floor Panel Outer Extension

19. Rear Tie Down Assembly

20. Rear Side Rail Assembly

21. Rear Bumper Impact Bar Brace Assembly

NOTE 1: Rear wheelhouse panel assembly includes part 2, which includes parts 3 & 4.

NOTE 2: Rear compartment floor panel assembly includes parts No. 10, 12, 13 & 14.

NOTE 3: Rear side rail assembly includes parts No. 18, 19 & 21.

2. SERVICE OPERATIONS

2.1 REAR END LOWER PANEL – REPLACE

NOTE: If the rear end panel (inner) is also to be

replaced, remove the rear end panels as an

assembly. Refer to 2.2 REAR END PANEL –

REPLACE.

REMOVE

CAUTION: To avoid the possibility of fire, take

particular care when cu tt ing or welding at the rear

of the vehicle. Remove the fuel tank and plug all

fuel lines.

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Remove the rear bumper impact bar assembly,

refer to Section 3, 2. BUMPER IMPACT BAR

ASSEMBLIES.

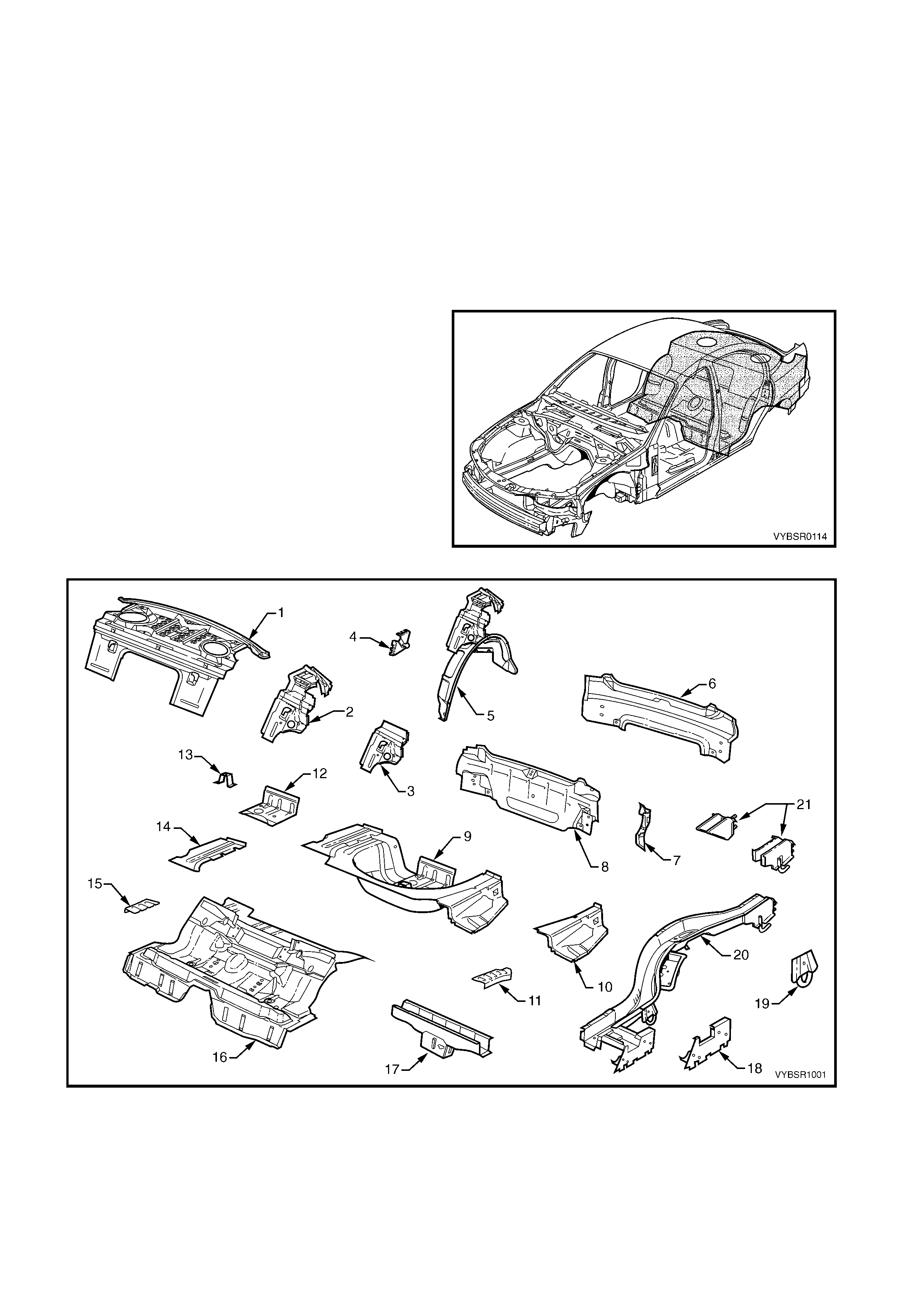

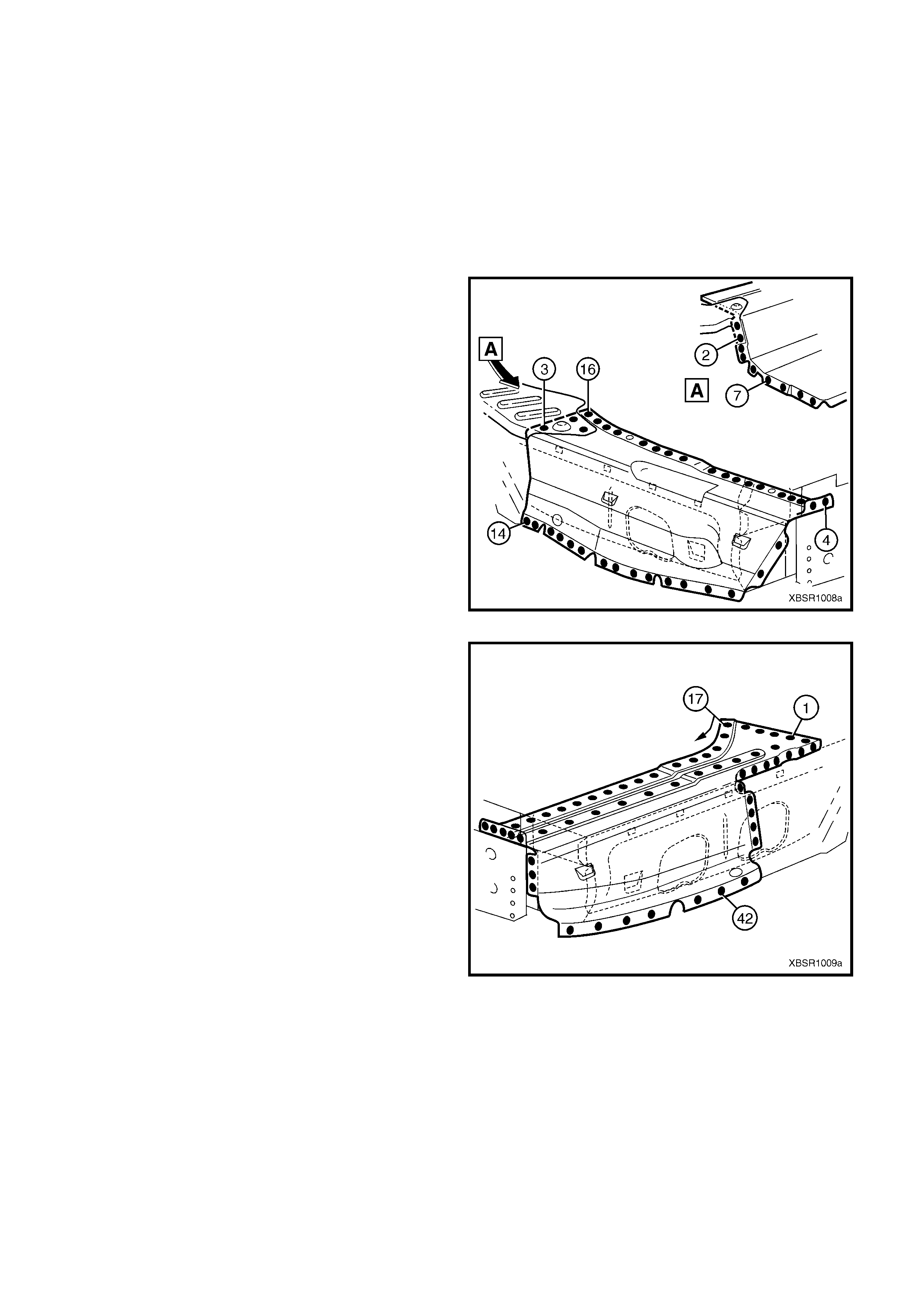

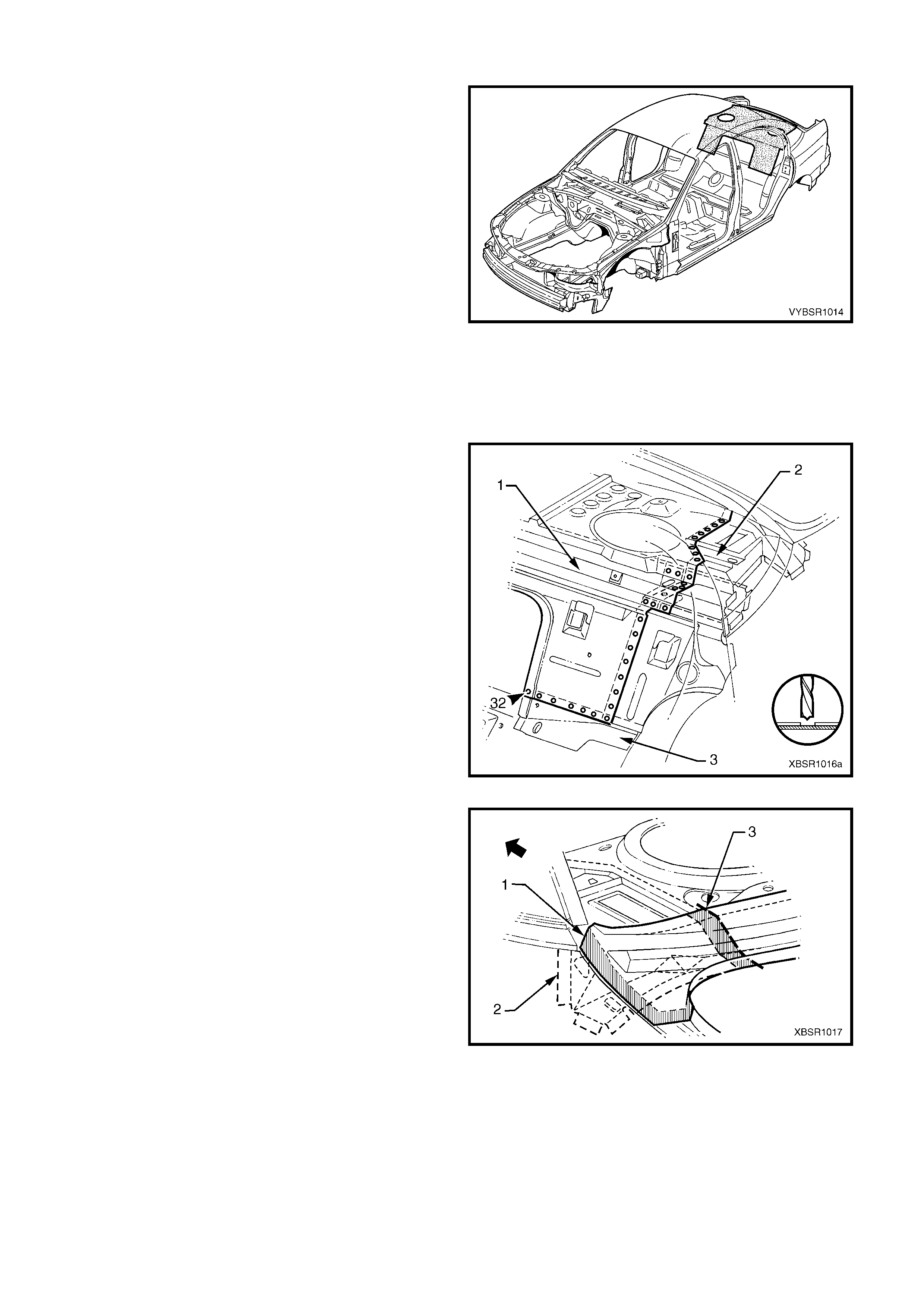

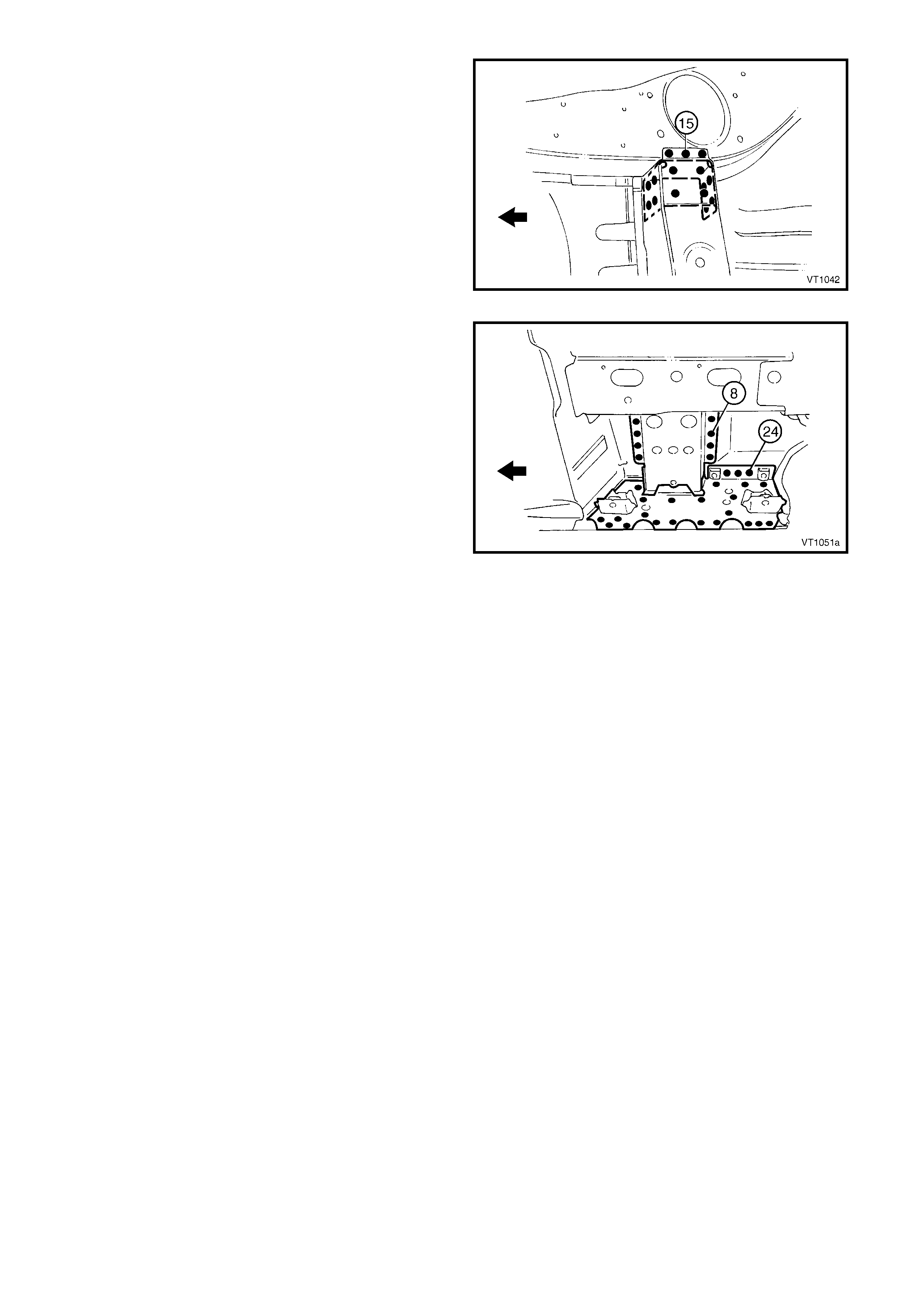

Figure 10A-3

3. Spot cut the welds attaching the rear end lower

panel to the rear quarter panel, web plate, quarter

panel lower extension panel and tail lamp housing.

4. Spot cut the welds attaching the rear end lower

panel to the rear end panel ass em bly and rear end

panel extension, refer to Figure 10A-5.

Figure 10A-4

Figure 10A-5

5. Remove the rear end lower panel from the vehicle and repair any damage to adjacent parts as required.

NOTE: Carefully bend the flange of the rear quarter panel and quarter panel lower extension to allow removal of

the rear end lower panel.

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment available will not access the required weld position, a plug weld should be

performed.

NOTE 2: The same number and position of spot welds ( or plug welds) should be used when replacing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3A.

3. Clamp the rear end lower panel in position on the vehicle ensuring it is seated under the rear quarter panel

and quarter panel lower extension flanges.

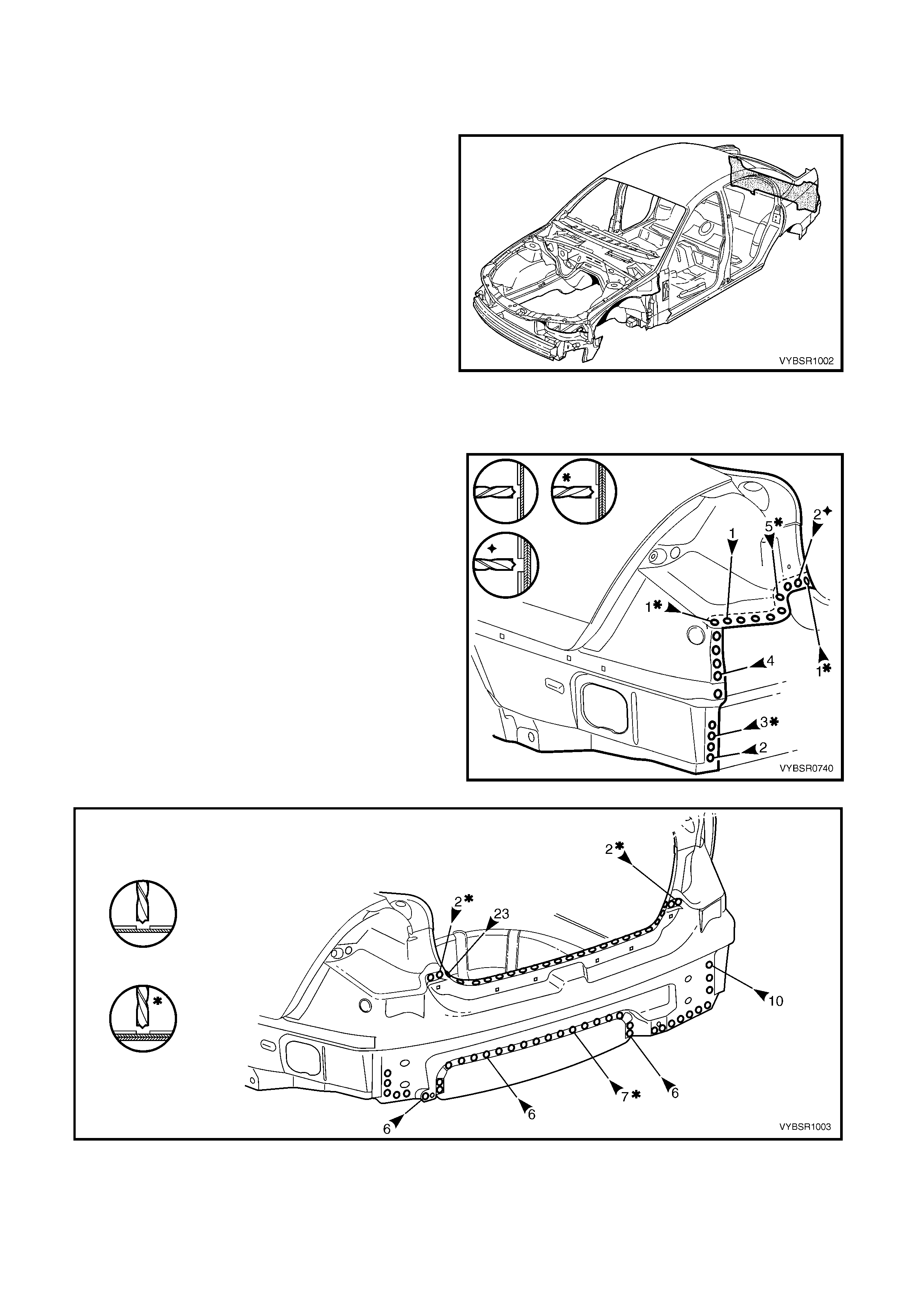

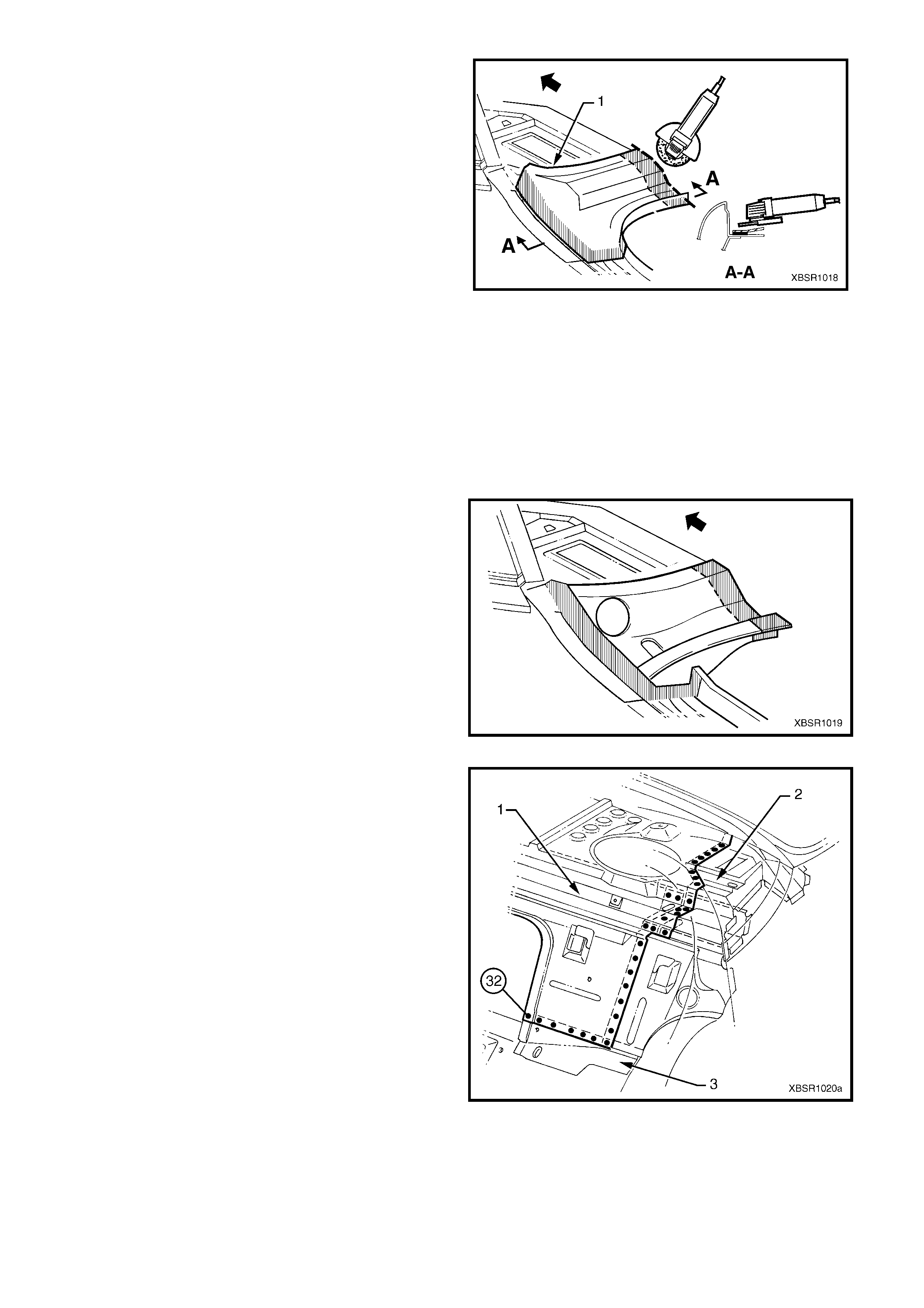

4. Spot cut the welds attaching the rear end lower panel to the rear end panel assembly and rear end panel

extension, refer to Figure 10A-6.

Figure 10A-6

5. Spot or plug weld the rear end lower panel to the

rear quarter panel, web plate, quarter panel lower

extension panel and tail lamp housing.

6. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

7. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3A.

8. Apply Cavity Wax (Item 8) as r equired to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3A.

9. Install the rear bumper impact bar assembly, refer

to Section 3, 2. BUMPER IMPACT BAR

ASSEMBLIES.

10. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10A-7

2.2 REAR END PANEL ASSEMBLY – REPLACE

NOTE: This procedure describes the removal of the

rear end lower panel and rear end panel as an

assembly. As the panels are supplied individually, this

procedure contains the replacement of the rear end

panel only. Reference should be then made to

2.1 REAR END LOWER PANEL – REPLACE for the

relevant replacement procedures of the remaining

panel.

REMOVE

CAUTION: To avoid the possibility of fire, take

particular care when cutting or welding at the rear

of the vehicle. Remove the fuel tank and plug all

fuel lines.

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Remove the rear bumper impact bar assembly,

refer to 2. BUMPER IM PACT BAR ASSEMBLIES

in Section 3.

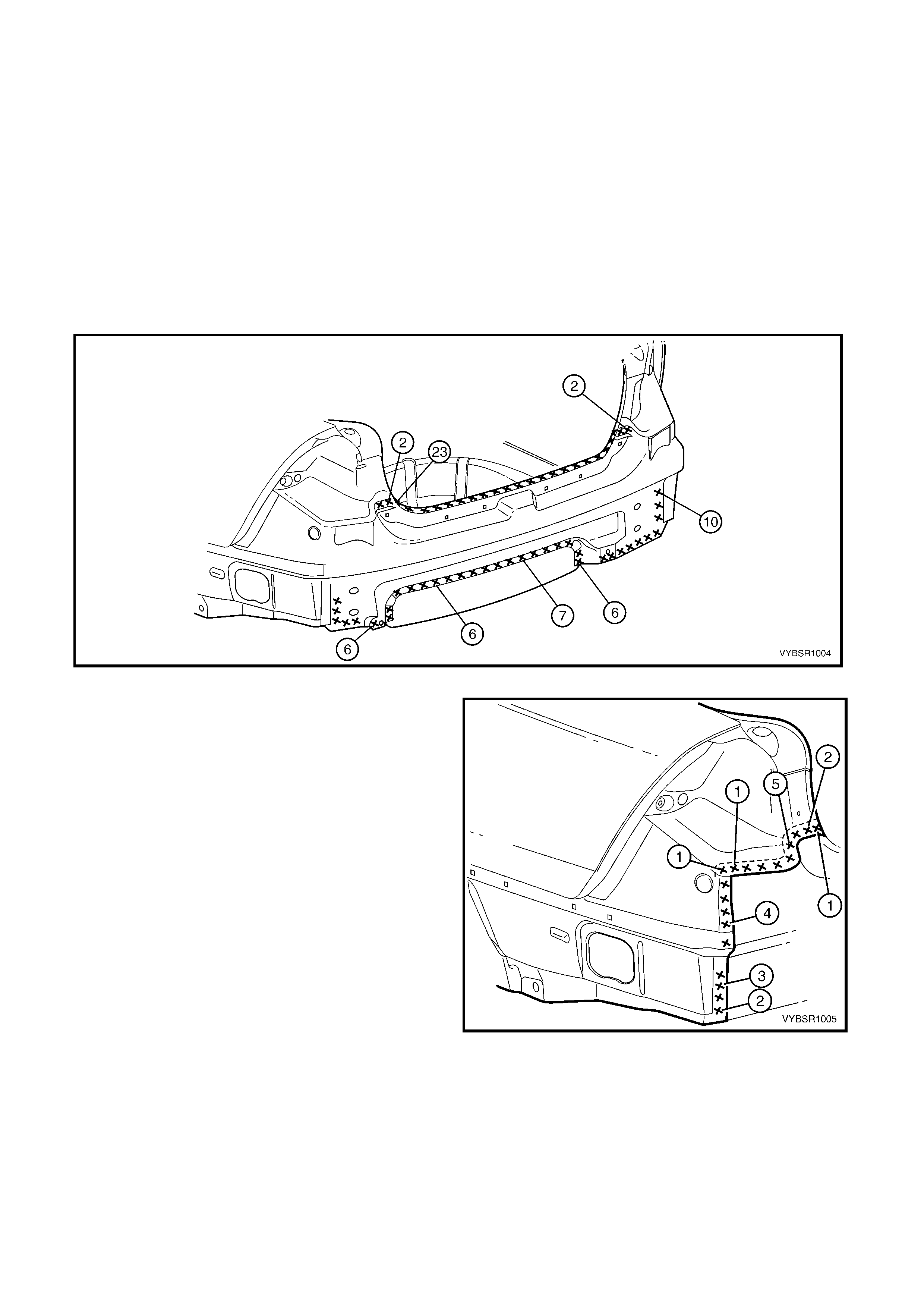

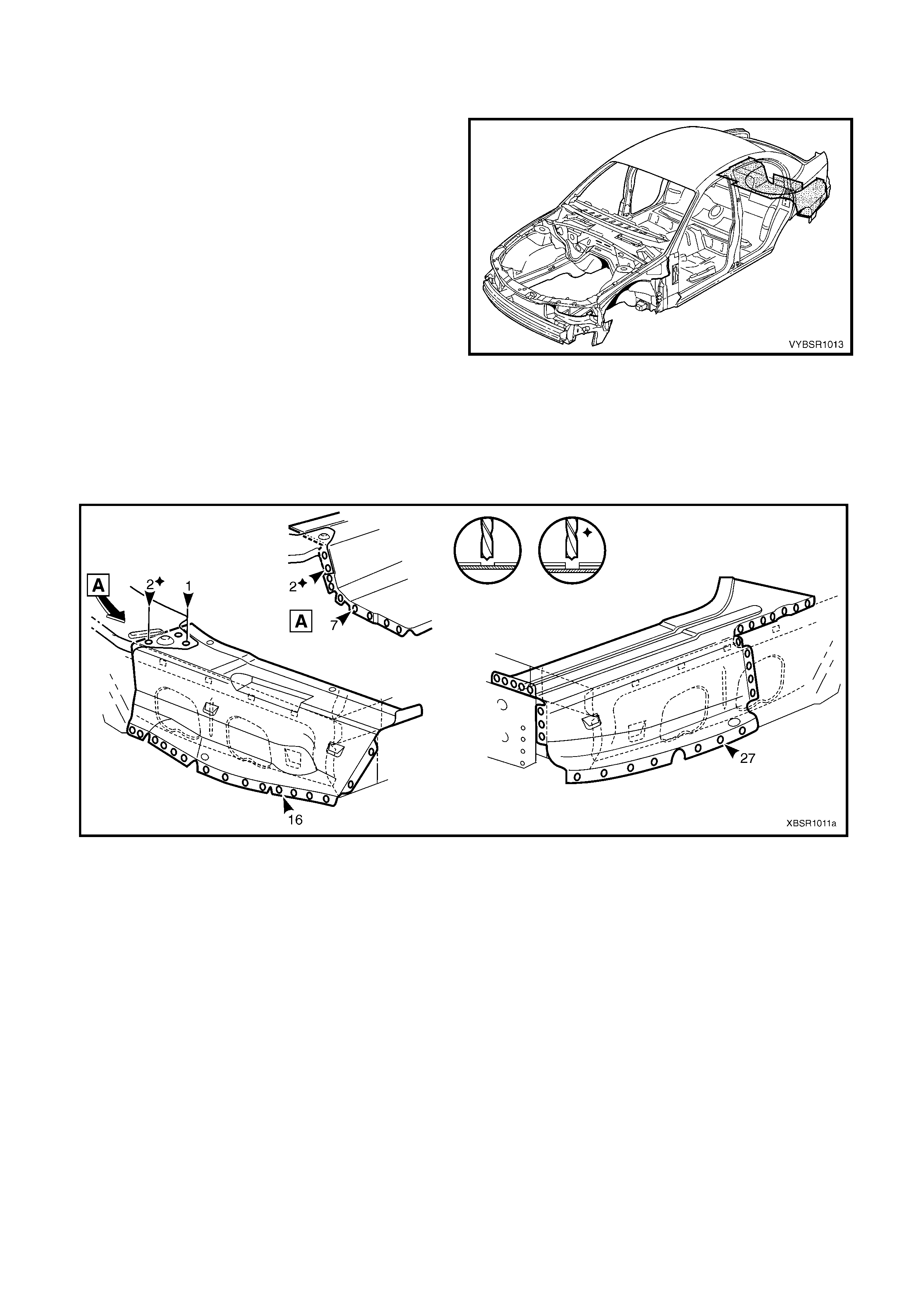

Figure 10A-8

3. Spot cut the welds attaching the fuel tank support

reinforcement (1) to the rear end panel assembly

(2).

NOTE: As an alternative, r emove the f uel tank suppor t

reinforcement from the rear compartment floor panel

assembly, refer to 2.4 FUEL TANK SUPPORT

REINFORCEMENT ASSEMBLY – REPLACE.

4. Spot cut the welds attaching the rear end panel

assem bly to the rear com partment floor assem bly,

refer to Figure 10A-10.

Figure 10A-9

Figure 10A-10

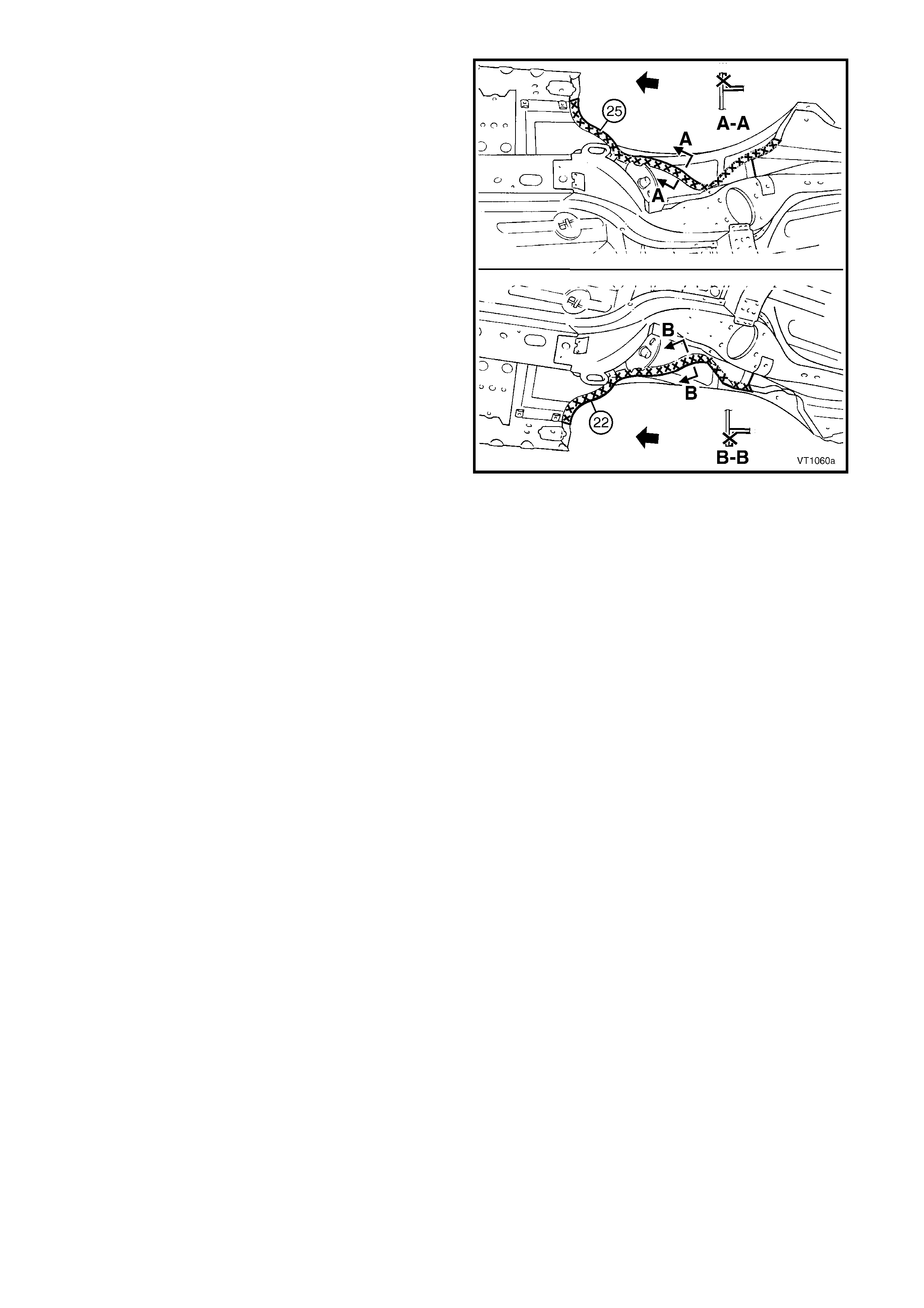

5. Spot cut the welds attaching the rear side rail

assem blies to the rear end panel assem bly. Note

that the left-hand side is different to the right-

hand side.

Figure 10A-11

6. Spot cut the welds attaching the rear end panel

assembly to the rear quarter panel, rear quarter

panel lower extens ion, tail lamp housing and rear

end panel extension as required on each side of

the vehicle.

7. Remove the panels from the vehicle then repair

any damage to adjacent parts as required.

NOTE: Carefully bend the flange of the rear quarter

panel, and quarter panel lower extension to allow

removal of the rear end panel assembly.

8. Check and rectify the alignment of the body as

required, refer to 3. BODY DIMENSIONS in

Section 3A.

Figure 10A-12

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment available will not access the required weld position, a plug weld should be

performed.

NOTE 2: The same number and position of spot welds ( or plug welds) should be used when replacing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3A.

3. Clamp the rear end panel in position on the vehic le

and spot or plug weld to the rear compartment

floor panel assembly.

NOTE: If the r ear quar ter panel, tail lamp hous ing, rear

end panel extension and rear quarter panel extension

were not removed, ensure the rear end panel is

positioned behind the flange of these panels.

Figure 10A-13

4. Spot or plug weld the rear end panel to the rear

side rail ass em bly on each side of the vehicle. T he

left-hand side is different to the right-hand side.

5. If removed, install the fuel tank support

reinforcement and weld to the rear compartment

floor panel assembly ONLY, refer to

2.4 FUEL T ANK SUPPORT REINFORCEM ENT –

REPLACE.

6. In the areas where the rear end lower panel will fit,

grind the welds and prime any bare metal.

7. Install the rear end lower panel, refer to

2.1 REAR END LOWER PANEL – REPLACE.

Figure 10A-14

8. Finish plug welding the fuel tank support

reinforcement to the rear end panel.

9. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

10. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3A.

11. Apply Cavity Wax (Item 8) as r equired to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3A.

12. Install the rear bum per impact bar assembly, refer

to 2. BUMPER IMPACT BAR ASSEMBLIES in

Section 3.

13. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10A-15

2.3 REAR END PANEL EXTENSION – REPLACE

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Remove surrounding panels as required, refer to

the appropriate procedure in this supplement.

Figure 10A-16

3. As required, spot cut the welds attaching the rear

end panel extension to the rear end panel, tail

lamp housing and quarter panel upper extension.

4. Remove the rear end panel extension from the

vehicle and then repair any damage to adjacent

parts as required.

Figure 10A-17

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment available will not access the required weld position, a plug weld should be

performed.

NOTE 2: The s am e num ber and pos ition of s pot welds (or plug welds) s hould be used when replac ing the panel, as

was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3A.

3. As required, spot or plug weld the rear end panel

extension to the surrounding panels.

4. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

5. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3A.

6. Apply Cavity Wax ( Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3A.

7. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10A-18

2.4 FUEL TANK SUPPORT REINFORCEMENT ASSEMBLY – REPLACE

REMOVE

CAUTION: To avoid the possibility of fire, take

particular care when cutting or welding at the rear

of the vehicle. Remove the fuel tank and plug all

fuel lines.

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Remove the deadener panels and j oint s ealer from

around the fuel tank support reinforcement

assembly as required.

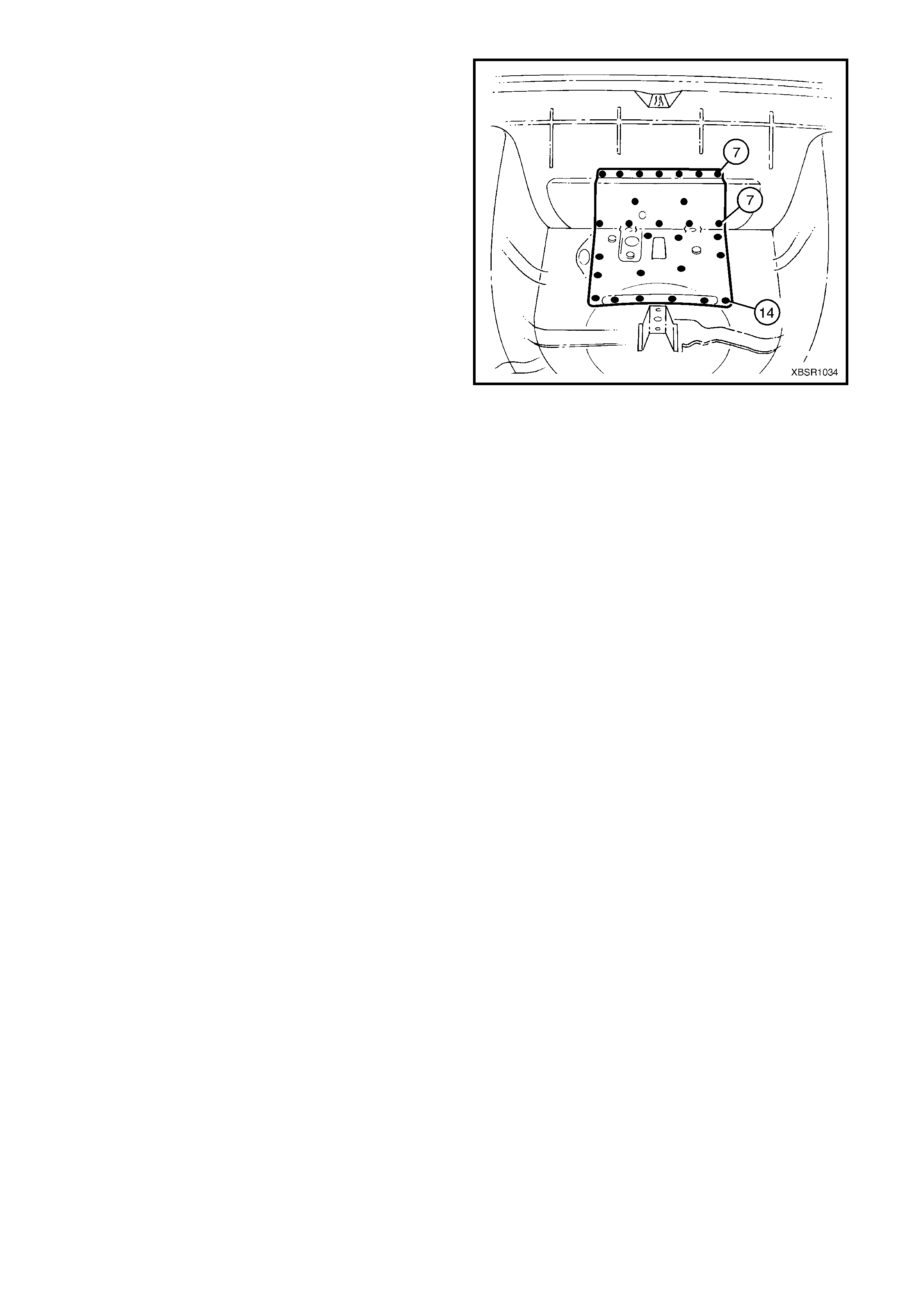

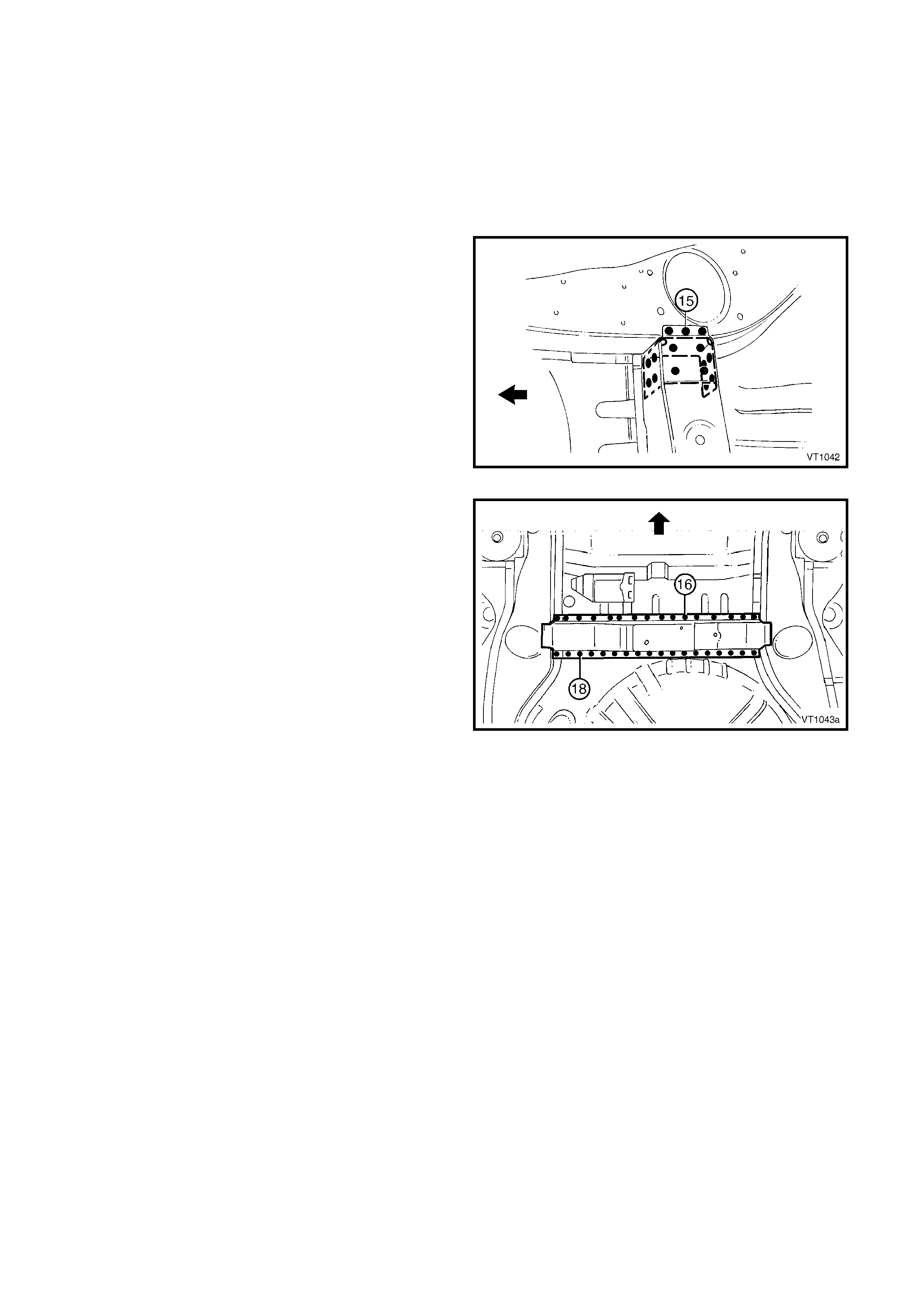

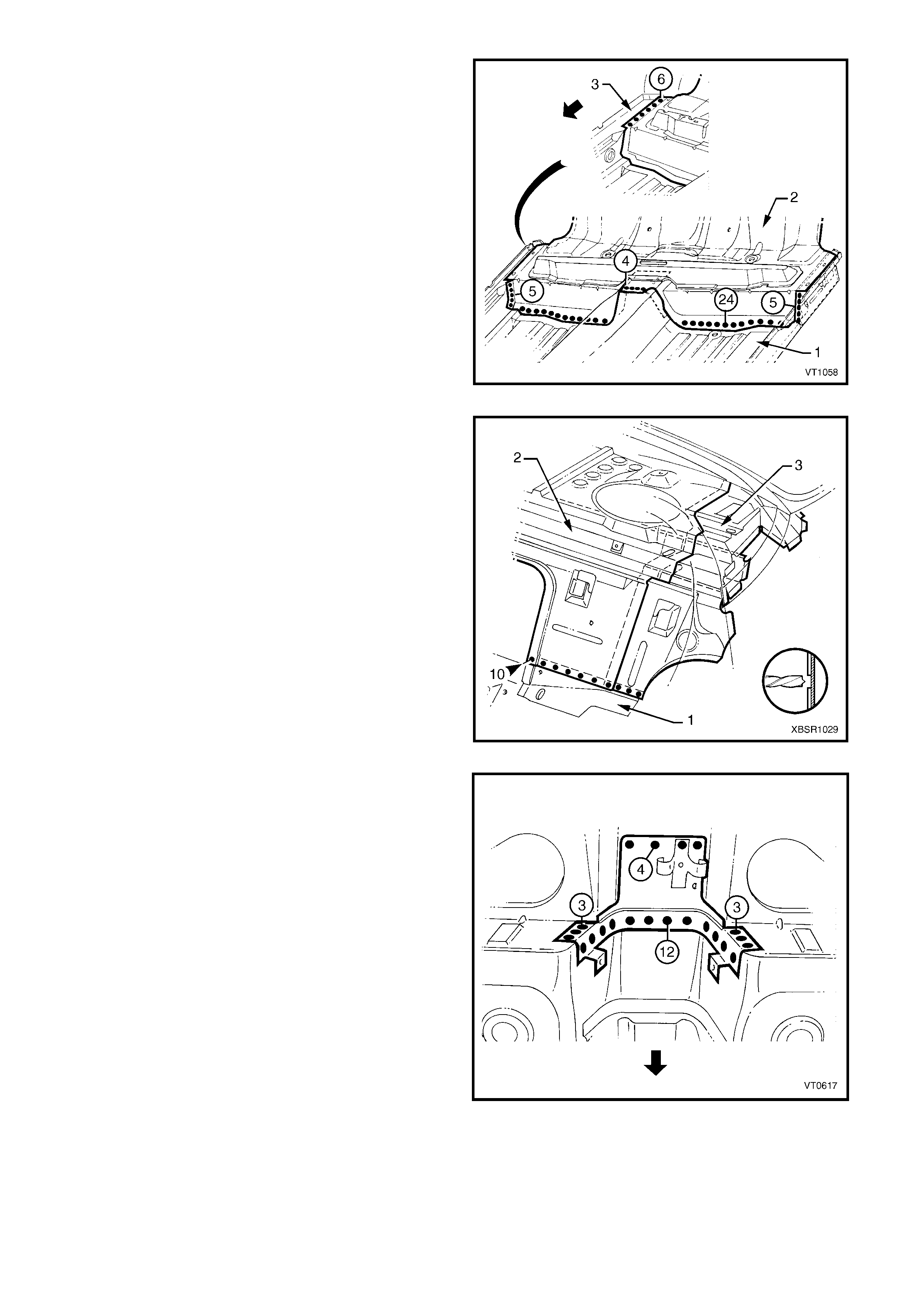

Figure 10A-19

3. Spot cut the 14 welds attaching the reinforcement

to the rear end panel assembly.

4. Spot cut the 14 welds attaching the reinforcement

to the rear compartment floor panel assembly.

5. Remove the fuel tank support reinforcement

assem bly and then repair any damage to adjacent

parts as required.

Figure 10A-20

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment available will not access the required weld position, a plug weld should be

performed.

NOTE 2: The s am e num ber and pos ition of s pot welds (or plug welds) s hould be used when replac ing the panel, as

was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3A.

3. Plug weld the fuel tank support reinforcement

assembly to the rear compartment floor panel

assembly and rear end panel assembly.

4. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

5. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEAD ENERS

in Section 3A.

6. Apply Cavity Wax ( Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3A.

7. Install the deadener panels as required, refer to

5.6 DEADENER PANELS & INSULATORS in

Section 3A.

8. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10A-21

2.5 REAR COMPARTMENT FLOOR PANEL OUTER EXTENSION – REPLACE

REMOVE

CAUTION: To avoid the possibility of fire, take

particular care when cutting or welding at the rear

of the vehicle. Remove the fuel tank and plug all

fuel lines.

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Remove the joint sealer from around the rear

compartment floor panel outer extension joins as

required.

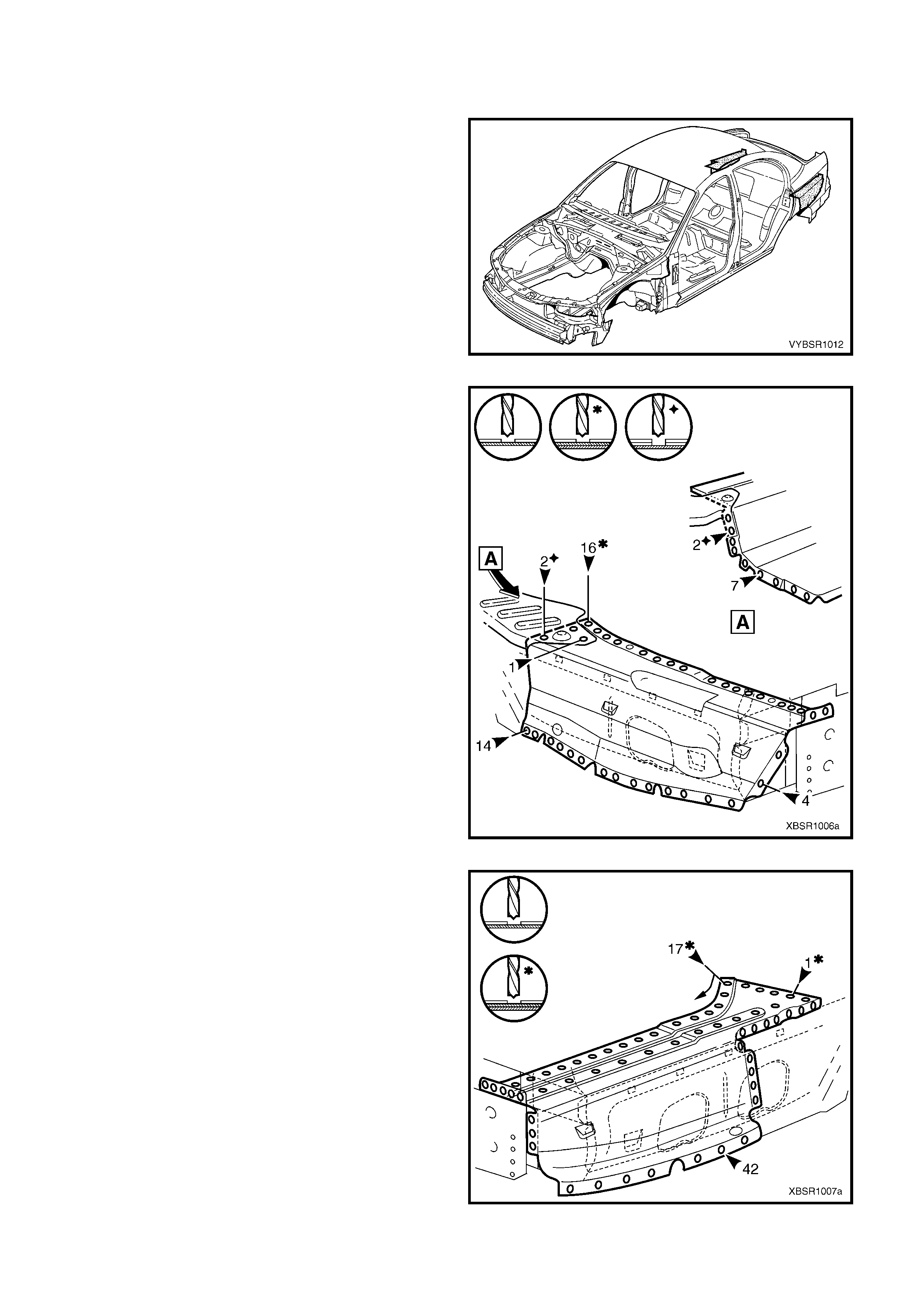

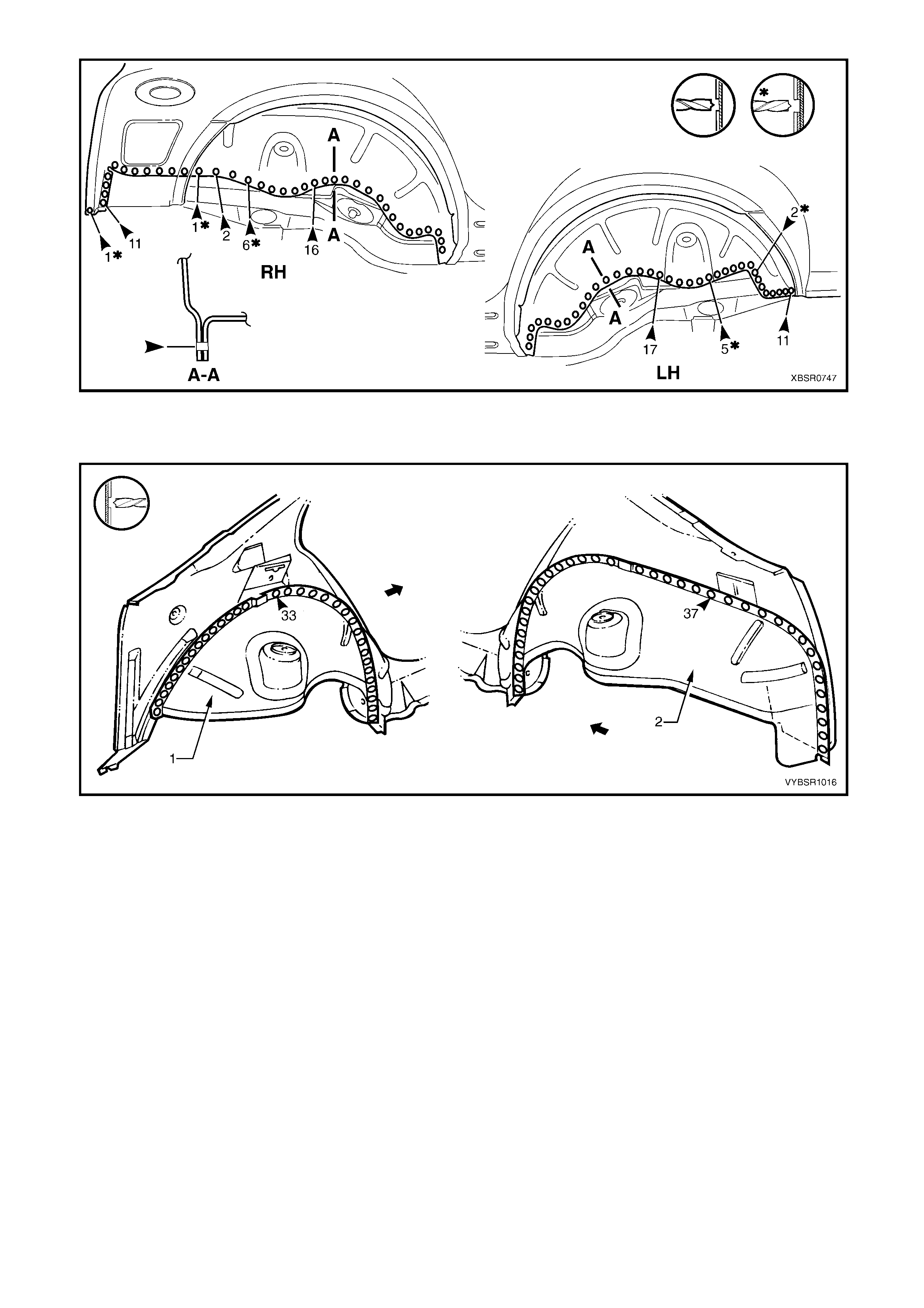

Figure 10A-22

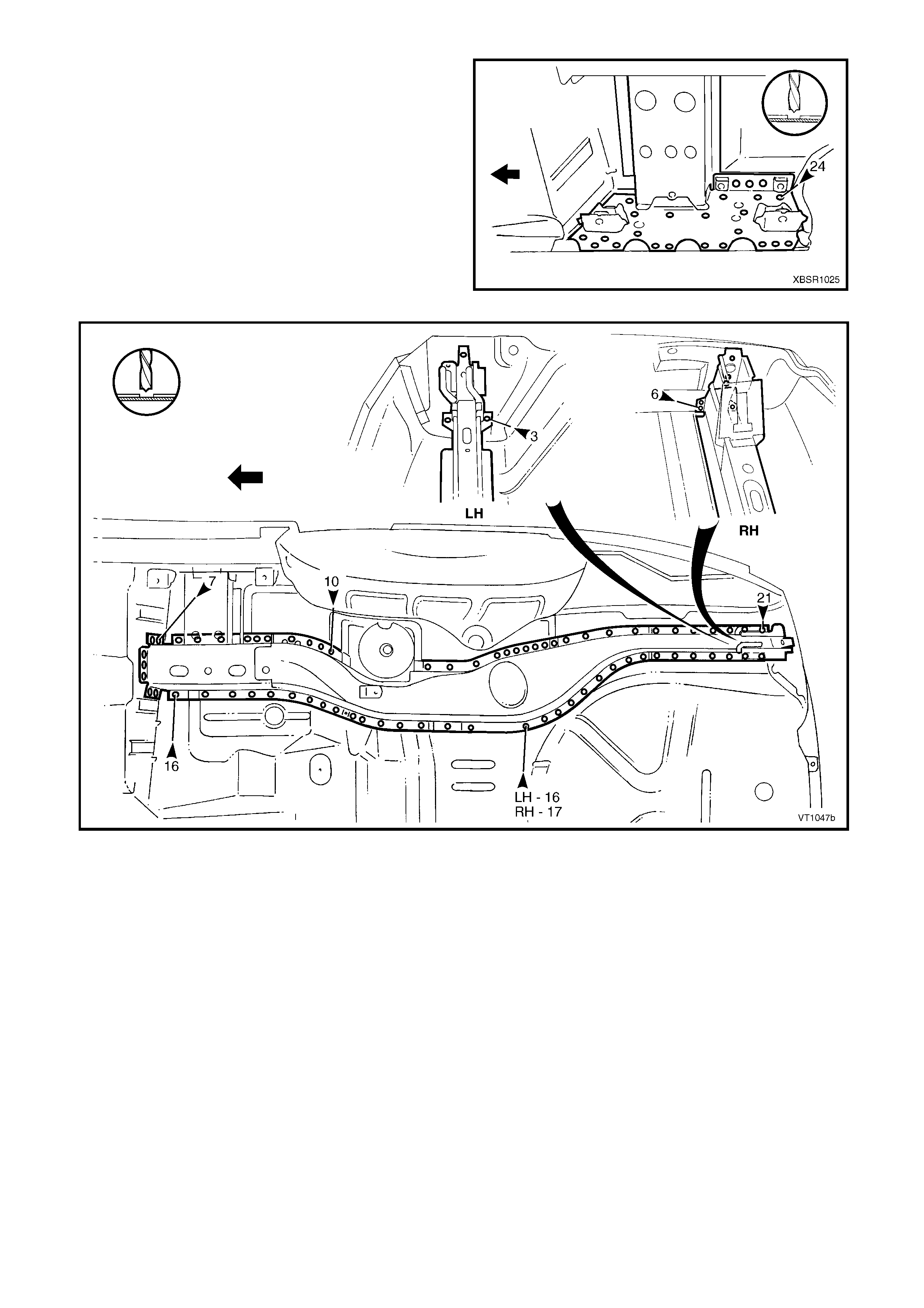

3. Spot cut the welds attaching the rear compar tment

floor panel outer extension to the rear

compartment floor panel, rear side rail assembly,

rear quarter panel and rear wheelhouse panel as

required. Refer to Figure 10A-23 for left-hand or

Figure 10A-24 for right-hand.

NOTE: Also remove several welds from the left-hand

rear floor panel reinforcement as shown.

4. Remove the extension from the vehicle and then

repair any damage to adjacent parts as required.

5. Check and rectify the alignment of the body as

required, refer to 3. BODY DIMENSIONS in

Section 3A.

Figure 10A-23

Figure 10A-24

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s am e num ber and pos ition of s pot welds (or plug welds) s hould be used when replac ing the panel, as

was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3A.

3. Apply Acrylic Spot W eld Sealer (Item 2), refer to 5. BODY SEALING, ADHESIVES & DEADENERS in Section

3A.

4. Fit the left-hand rear compartment floor panel

outer extension in pos ition, ensuring the fr ont edge

is seated under the rear floor panel reinforcement.

5. Spot or plug weld the extension to the rear

compartment floor panel, rear floor panel

reinfor cement, r ear s ide rail as s embly, rear quarter

panel and the rear wheelhouse panel as required.

Figure 10A-25

6. Fit the right-hand rear compartment floor panel

outer ex tension and s pot or plug weld it to the rear

compartment floor panel, rear side rail assembly,

rear quarter panel and the rear wheelhouse panel

as required.

7. Replac e any other rem oved panels as desc r ibed in

this Supplement.

8. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

9. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3A.

10. Apply Cavity Wax (Item 8) as r equired to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3A.

11. Apply Spray-on Deadener (Item 7) where

applicable, refer to 5. BODY SEALING,

ADHESIVES & DEADENERS in Section 3A.

12. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10A-26

2.6 REAR COMPARTMENT FLOOR PANEL ASSEMBLY– REPLACE

REMOVE

CAUTION: To avoid the possibility of fire, take

particular care when cutting or welding at the rear

of the vehicle. Remove the fuel tank and plug all

fuel lines.

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Secure the vehicle on a suitable fixture and use a

suitable brace to maintain the alignment of the rear

side rail assemblies prior to removal of the rear

end panel assembly.

3. Remove the rear end panel assembly, refer to

2.2 REAR END PANEL ASSEMBLY – REPLACE.

4. Remove the j oint sealer f rom the s urrounding area

using a scraper and heat gun.

5. As required, spot cut each rear compartment floor

panel outer extension from the rear wheelhouse

panel and rear quarter panel, refer to Figure

10A-28.

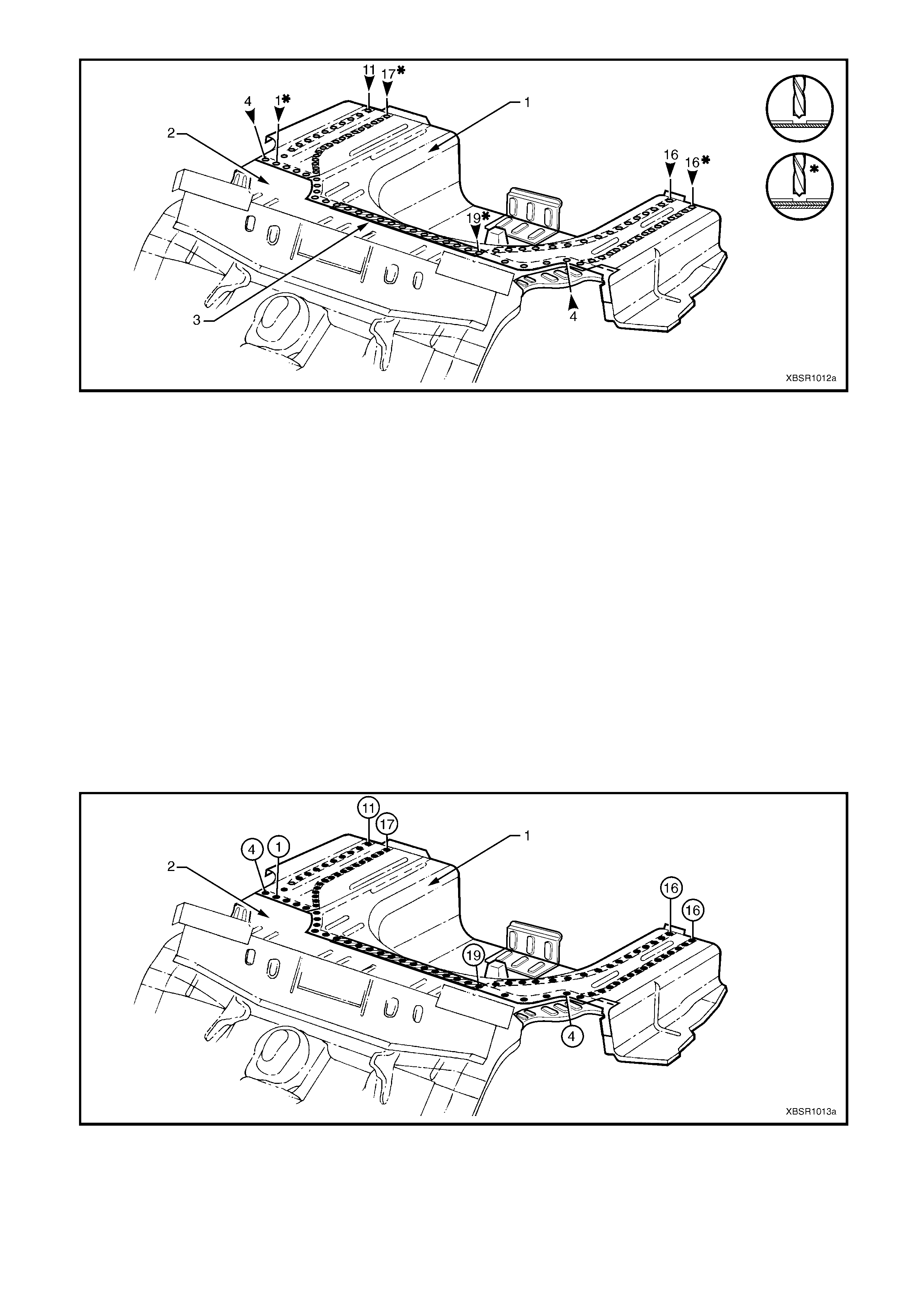

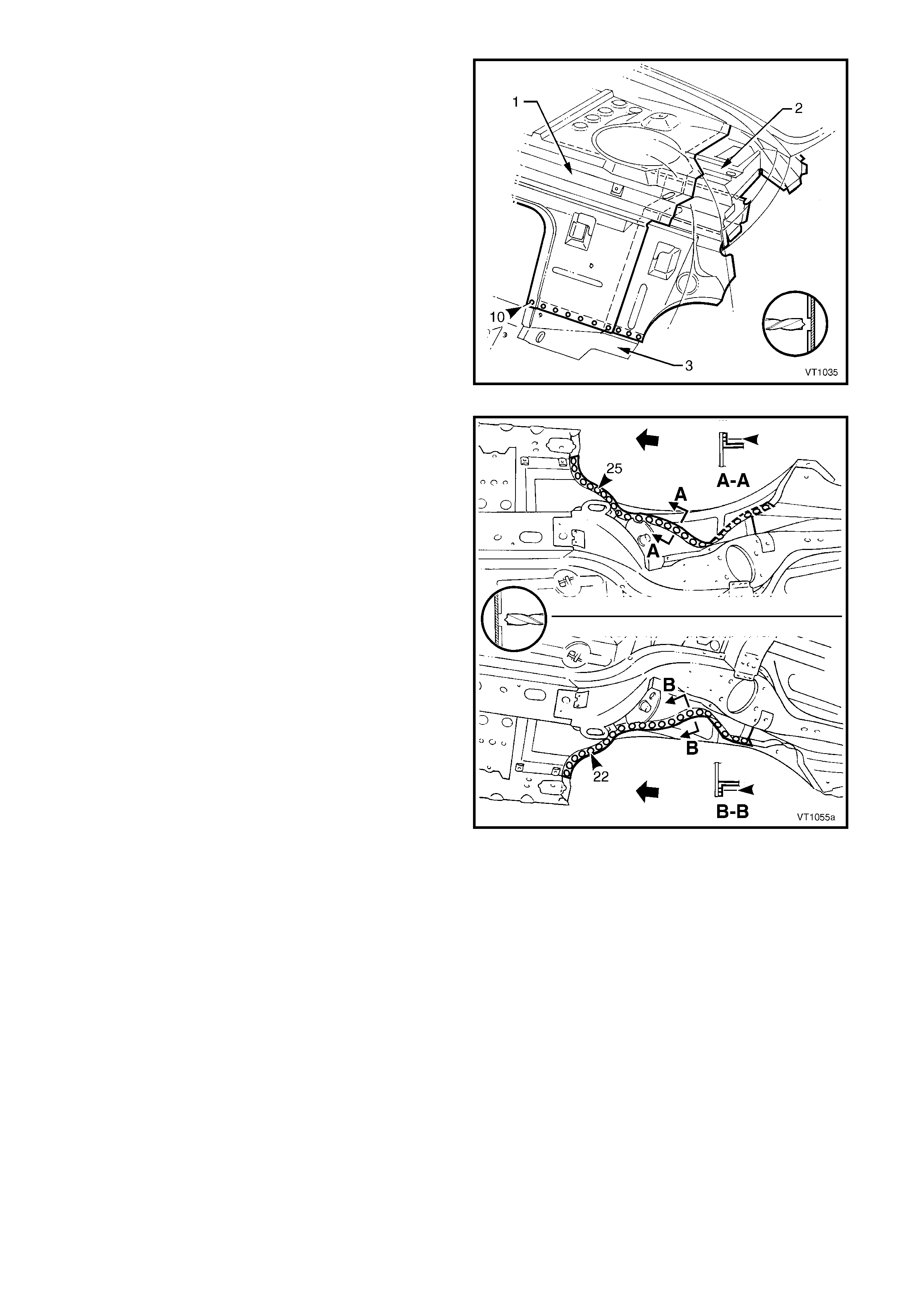

Figure 10A-27

Figure 10A-28

6. Spot cut the welds attaching the rear com partment f loor panel assem bly (1) to the rear floor panel as sem bly (2)

and to the rear side rail assemblies, refer to Figure 10A-29.

NOTE: Structural adhesive is applied in the area shown (3), refer to 5. BODY SEALING, ADHESIVES &

DEADENERS in Section 3A (Sedan).

Figure 10A-29

7. Remove the rear compartment f loor panel assem bly f rom the vehicle and repair any damage to adjacent parts

as required.

8. Check and rectify the alignment of the body as required, refer to 3. BODY DIMENSIONS in Section 3A.

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s am e num ber and pos ition of s pot welds (or plug welds) s hould be used when replac ing the panel, as

was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3A.

3. Apply Acrylic Spot W eld Sealer (Item 2), refer to 5. BODY SEALING, ADHESIVES & DEADENERS in Section

3A.

4. Apply Structural Adhesive (Item 6), refer to 5. BODY SEALING, ADHESIVES & DEADENERS in Section 3A.

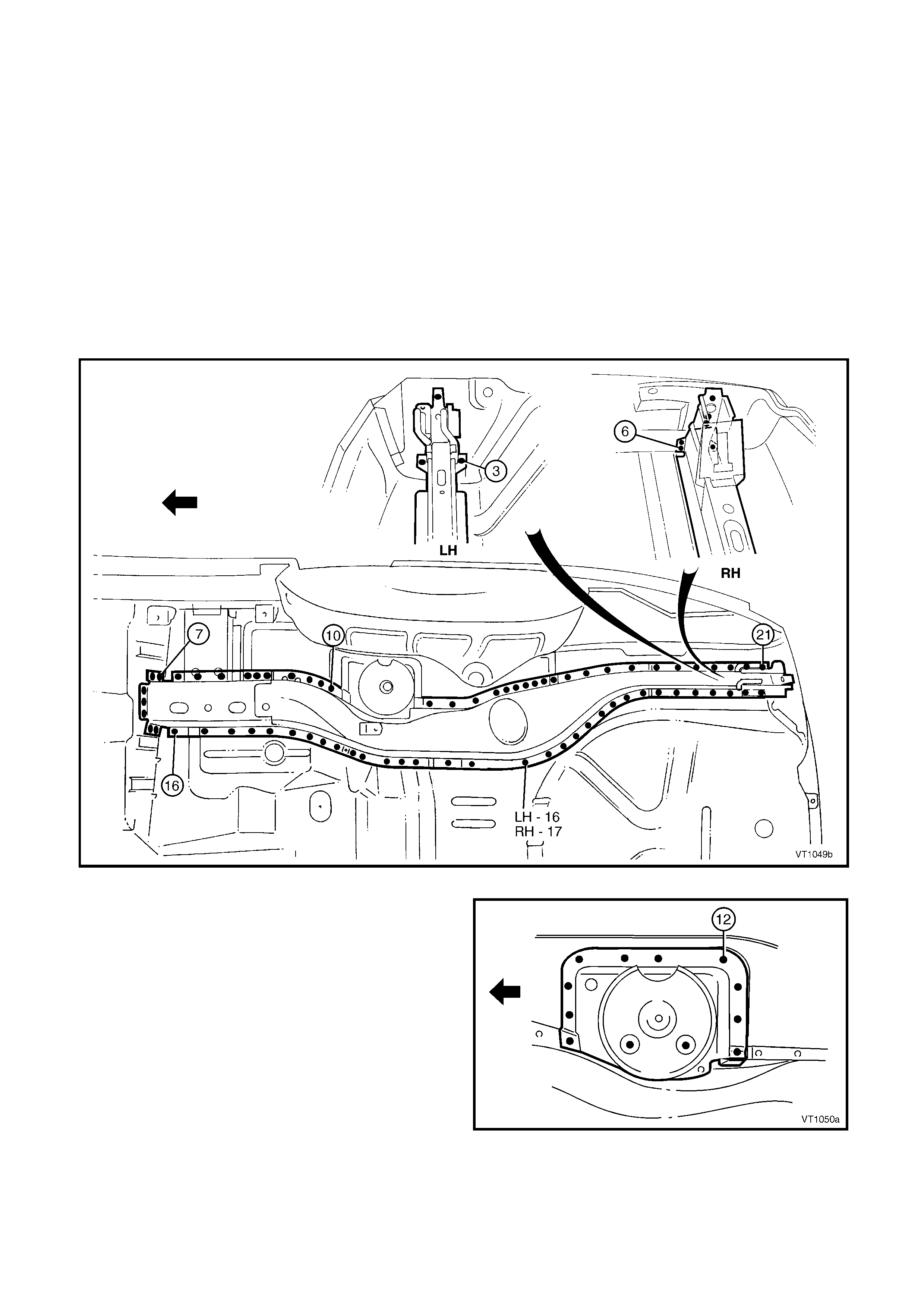

5. Install the rear compartment floor panel assembly (1) ensuring it is seated under the left-hand rear floor panel

reinforcement.

6. Plug weld along the join of the rear floor panel assembly (2) and to the rear side rail assemblies, refer to

Figure 10A-30.

Figure 10A-30

7. As r equired, s pot or plug weld eac h r ear c ompartment f loor panel outer ex tens ion to the rear wheelhouse panel,

rear quar ter panel, rear end panel assem bly and for the lef t-hand side, the rear f loor panel reinforcem ent, refer

to Figure 10A-31.

Figure 10A-31

8. Install the rear end panel and other panels as required, refer to the relevant procedure in this Supplement.

9. Refinish and paint panels and other components as required. Refer to Section 3, 1.3 PAINT REFINISHING.

10. Apply Joint Sealer (Item 3) as required. Refer to 5. BODY SEALING, ADHESIVES & DEADENERS in Section

3A.

11. Apply deadener panels to the r ear c ompartment f loor panel, r ef er to 5.6 DEADENER PANELS & INSULATORS

in Section 3A.

12. Apply Cavity W ax (Item 8) as required to the inside of any box sections or areas inaccessible to paint, refer to

6. CAVITY WAX in Section 3A.

13. Apply Spr ay-on Deadener (Item 7) where applic able, ref er to 5. BO DY SEALING, ADHESIVES & DEADENERS

in Section 3A.

14. Install the remaining components as described in the appropriate Section of the MY 2003 VY & V2 Series II

Service Information.

2.7 REAR WINDOW PANEL ASSEMBLY – REPLACE

Depending on the ar ea of damage, it may be advisable

to include removal of the rear seat back panel

extension assembly or rear wheelhouse inner panel

assembly. Refer to 2.8 REAR SEAT BACK PANEL

EXTENSION ASSEMBLY or REAR WHEELHOUSE

PANEL ASSEMBLY – REPLACE.

REMOVE

CAUTION: To avoid the possibility of fire, take

particular care when cutting or welding at the rear

of the vehicle. Remove the fuel tank and plug all

fuel lines.

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. As required, remove adjoining body structure

panels, refer to the appropriate procedure in this

Supplement.

Figure 10A-32

3. Remove the spot welds attaching the rear window

panel assembly (1) to the rear seat back panel

extension assembly (2) and the rear floor panel

assembly (3).

Figure 10A-33

IMPORTANT: The rear window panel assembly (1) is

attached to the rear seat back panel extension

assembly (2) and rear quarter panel with spot welding

and struc tural adhesive (s hown shaded). The adhesive

bond is not breakable by any normal means, so spot

cutting is not a viable method of removal of the panel.

4. Cut the rear window panel assembly inboard of the

join to the rear seat back panel extension

assembly with a grinder or other cutting tool along

line (3).

5. Remove the r ear window panel ass embly from the

vehicle.

Figure 10A-34

6. Using a grinder, remove the remaining portion of

the rear window panel assembly and the layer of

adhesive below it as required.

7. Repair any damage to adjacent parts as required.

8. Check and rectify the alignment of the body as

required, refer to 3. BODY DIMENSIONS in

Section 3A.

Figure 10A-35

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s am e num ber and pos ition of s pot welds (or plug welds) s hould be used when replac ing the panel, as

was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3A.

3. Apply Structural adhesive (Item 6) to the areas

shown, refer to 5. BODY SEALING, ADHESIVES

& DEADENERS in Section 3A.

4. Clamp the rear window panel assem bly in position

on the vehicle.

Figure 10A-36

5. Spot or plug weld the rear window panel ass embly

(1) to the rear seat back panel extension assembly

(2) and the rear floor panel assembly (3).

Figure 10A-37

6. Spot or plug weld the rear window panel ass embly

(1) to the rear seat back extens ion panel assem bly

(2).

7. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

8. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3A.

9. Apply Cavity Wax ( Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3A.

10. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10A-38

2.8 REAR SEAT BACK PANEL EXTENSION ASSEMBLY or REAR WHEELHOUSE

INNER PANEL ASSEMBLY – REPLACE

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Either remove, or detach the rear window panel

assembly from the rear seat back panel extension

assembly, refer to Section 2.7 REAR WINDOW

PANEL ASSEMBLY – REPLACE.

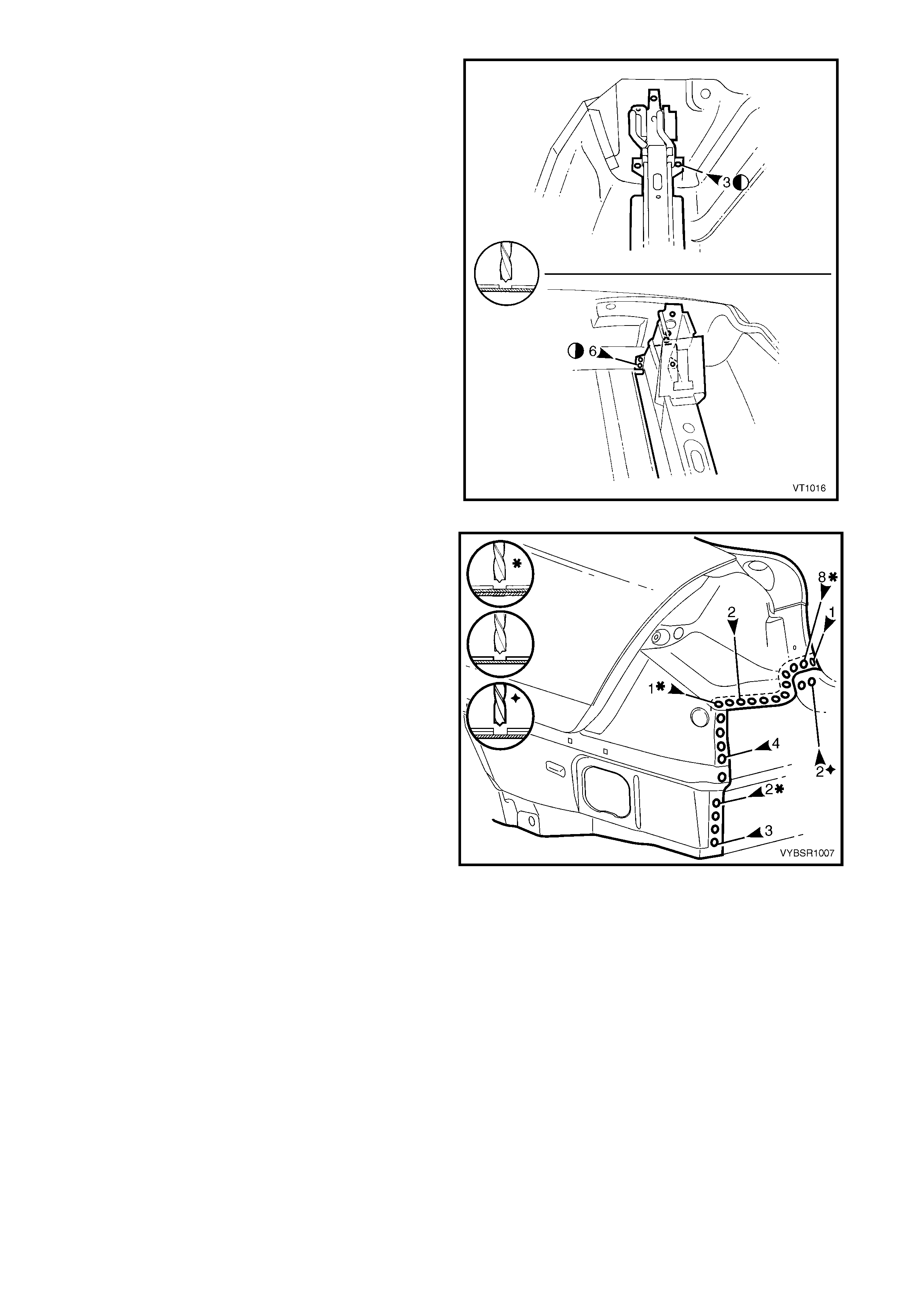

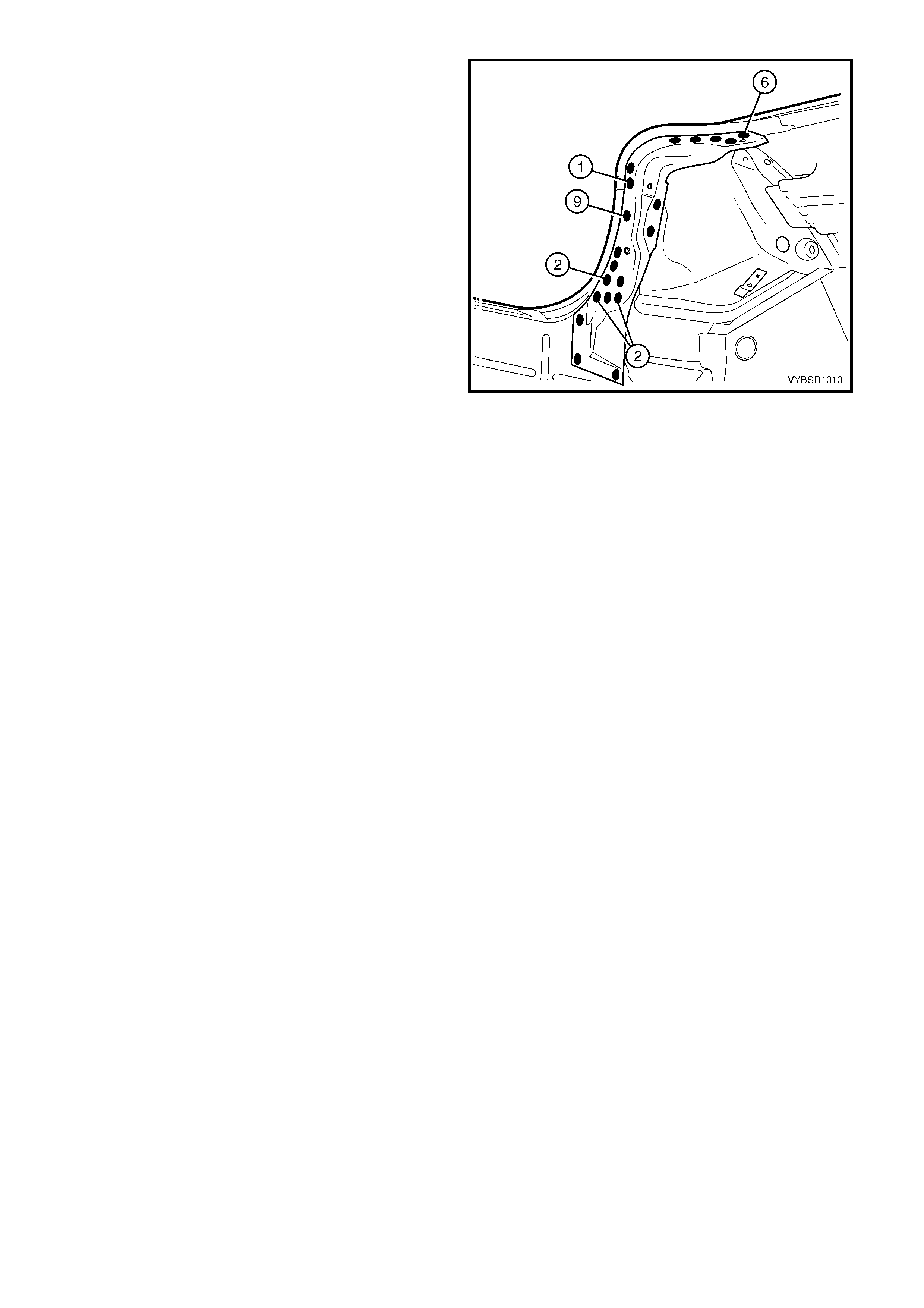

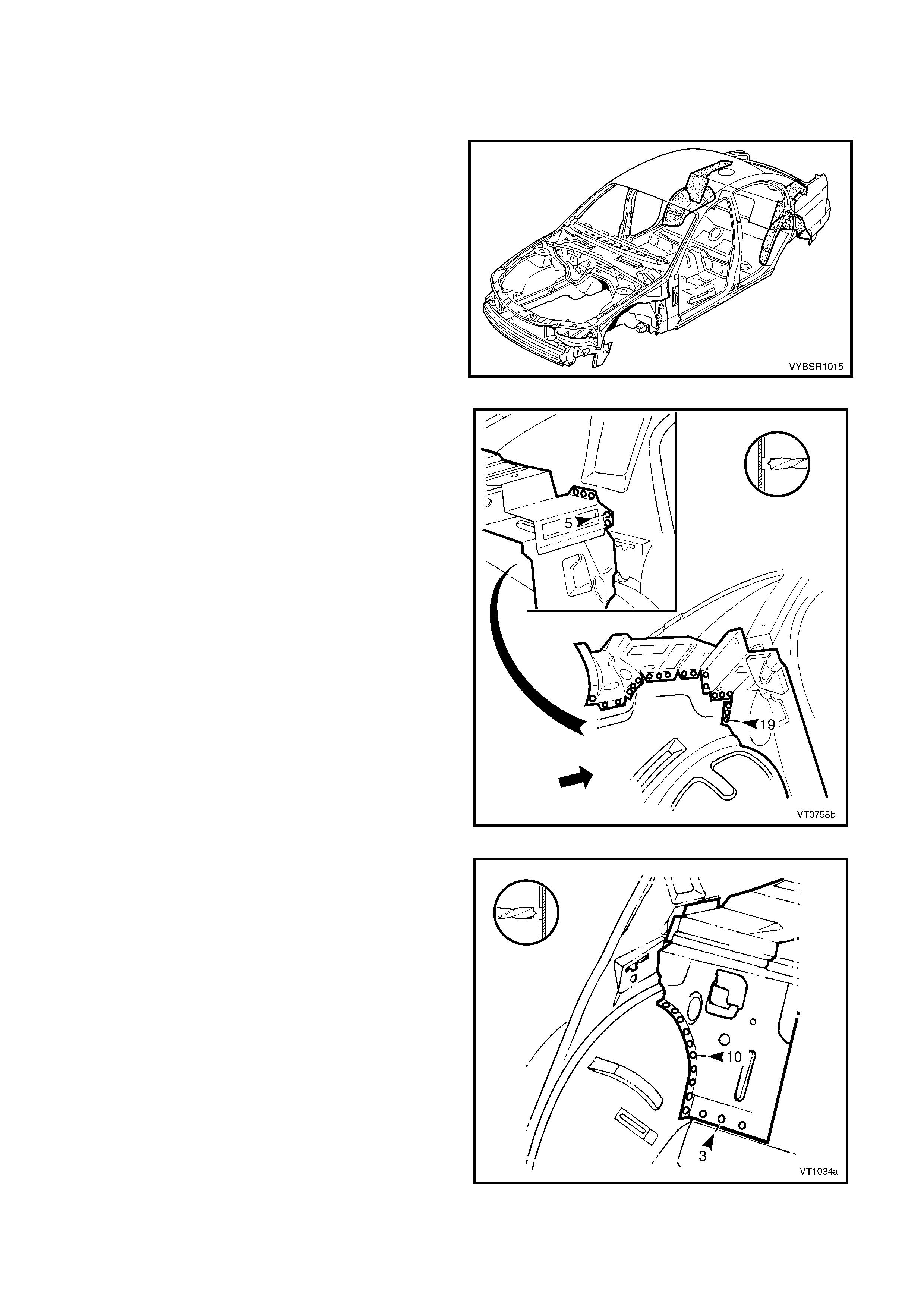

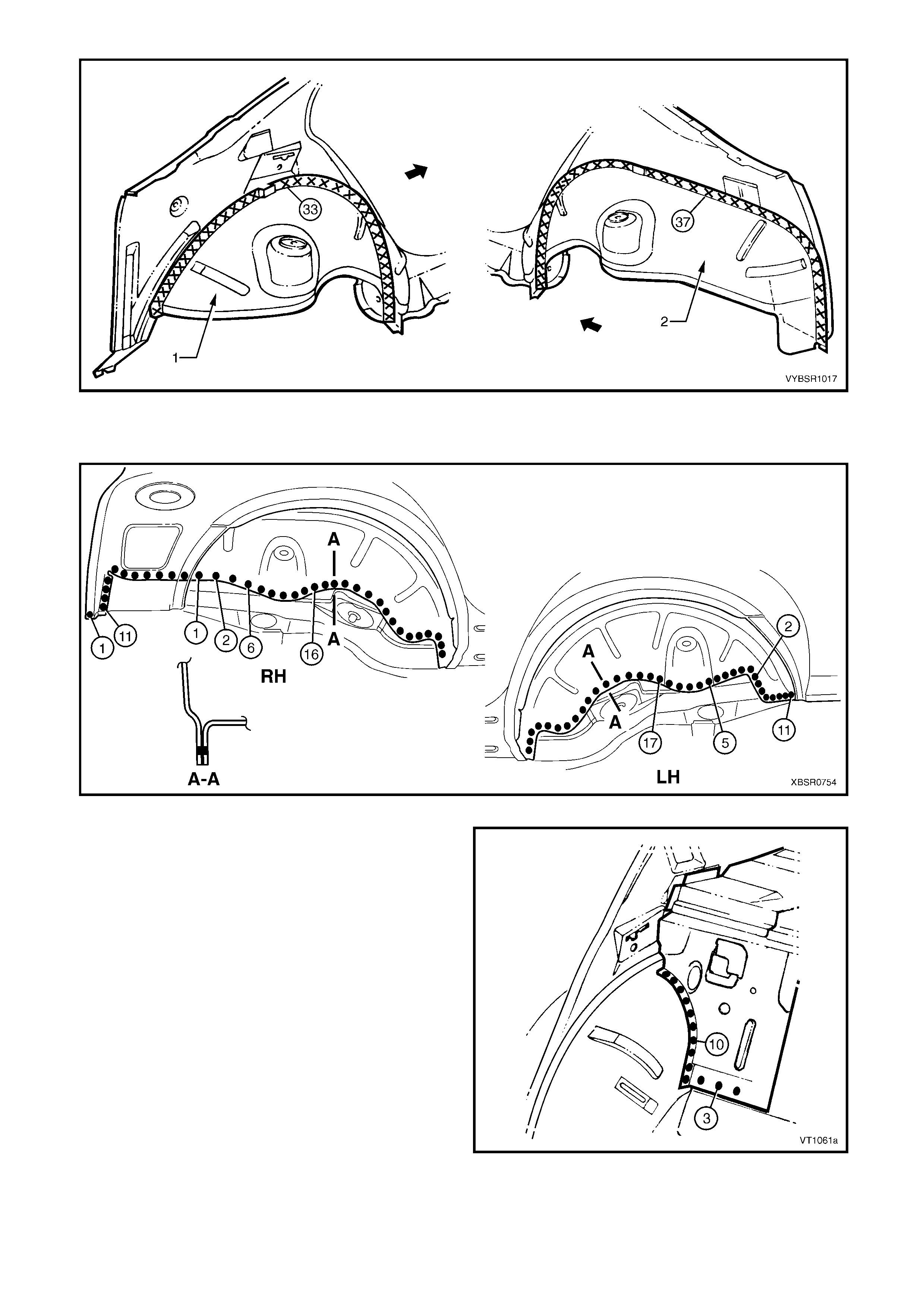

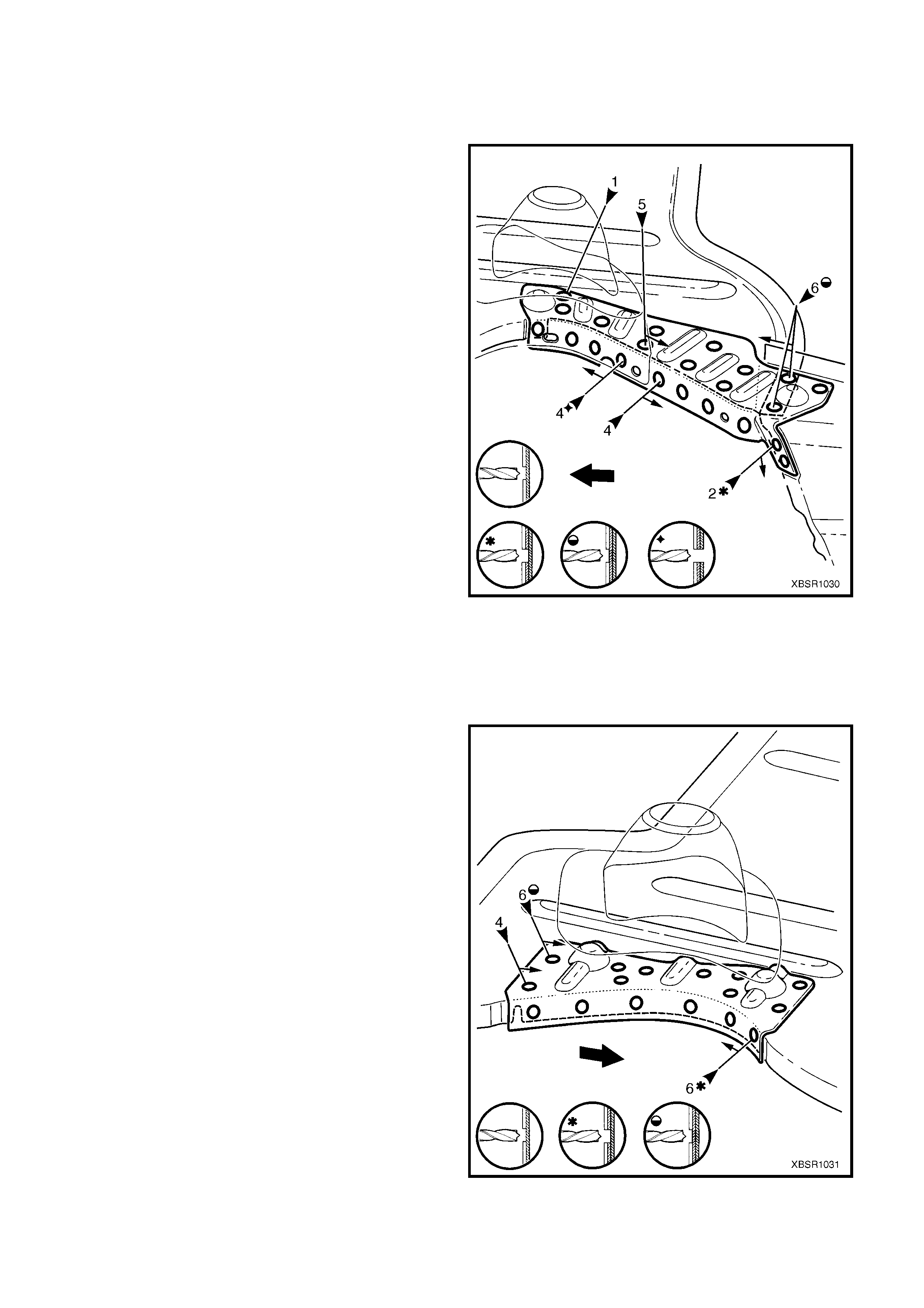

Figure 10A-39

3. Spot cut the welds attaching the rear seat back

panel extension assembly to the quarter panel

inner assembly.

Figure 10A-40

4. Spot cut the three welds attaching the rear seat

back panel extension assembly to the rear floor

panel assembly.

5. If the rear seat back panel extension assembly is

to be replaced without the rear wheelhouse inner

panel, spot cut the ten welds attaching the

extension assembly to the rear wheelhouse inner

panel assembly.

6. Remove the rear seat back panel extension

assembly, if it is being replaced without the rear

wheelhouse inner panel assembly.

7. If the rear wheelhouse inner panel assembly is

being replaced, spot cut the welds attaching it to

the rear floor panel assembly and rear

compartment floor panel outer extension as

required, refer to Figure 10A-42.

Figure 10A-41

Figure 10A-42

8. Spot cut the welds attaching the rear wheelhouse inner assembly to the quarter panel inner assembly, refer to

Figure 10A-43.

Figure 10A-43

9. Remove the rear wheelhouse inner assembly.

10. Repair any damage to adjacent parts as required.

11. Check and rectify the alignment of the body as required, refer to 3. BODY DIMENSIONS in Section 3A.

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s am e num ber and pos ition of s pot welds (or plug welds) s hould be used when replac ing the panel, as

was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3A.

3. If the rear wheelhouse inner assembly is being replaced, spot or plug weld around the rear wheelhouse inner

assembly to the quarter panel inner assembly, refer to Figure 10A-44.

Figure 10A-44

4. Spot or plug weld the rear wheelhouse inner assembly to the rear floor panel assembly and rear compartment

floor panel outer extension, refer to Figure 10A-45.

Figure 10A-45

5. Plug weld three places, rear seat back panel

extension assembly to the rear floor panel

assembly.

6. If the rear seat back panel extension assembly is

being replaced without the rear wheelhouse inner

panel, plug weld ten places.

Figure 10A-46

7. Spot or plug weld the rear seat back panel

extension assembly to the quarter panel inner

assembly.

8. Install, or weld the rear window panel assem bly, to

the rear seat back panel extension, refer to

Section, 2.7 REAR WINDOW PANEL ASSEMBLY

– REPLACE.

9. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

10. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3A.

11. Apply Cavity Wax (Item 8) as r equired to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3A.

12. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10A-47

2.9 REAR COMPARTMENT LID STRUT BRACKET ASSEMBLY – REPLACE

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

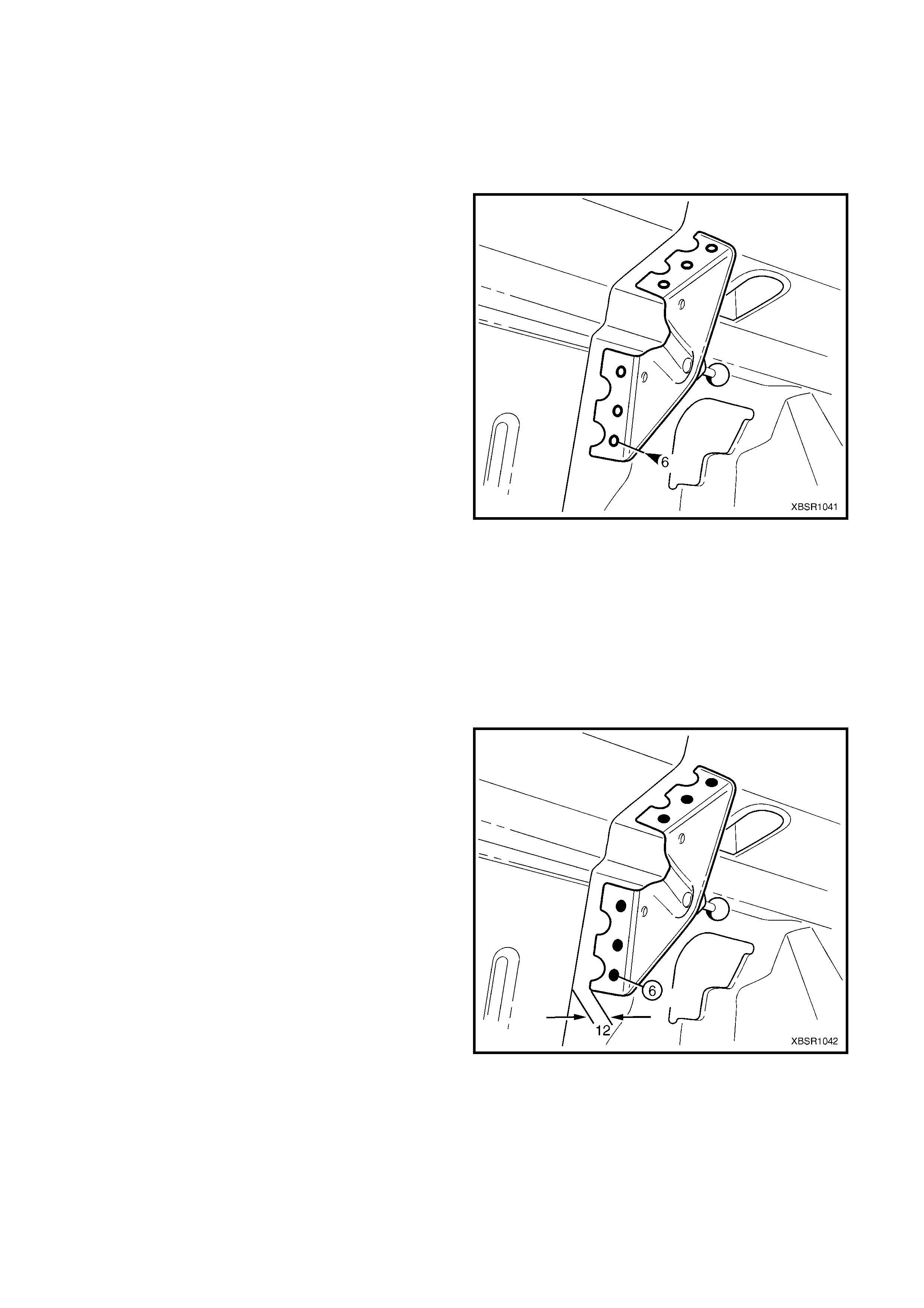

2. Spot cut the welds attaching the rear compar tment

lid strut bracket assembly to the rear seat back

panel extension assembly.

3. Remove the rear compartment lid strut bracket

assembly from the vehicle and repair any damage

to adjacent parts as required.

Figure 10A-48

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s am e num ber and pos ition of s pot welds (or plug welds) s hould be used when replac ing the panel, as

was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3A.

3. Install the rear compartment lid strut bracket

assembly, positioning it approximately 12mm from

the edge of the rear seat back panel extension

assembly.

4. Plug weld the rear compartment lid strut bracket

assembly to the rear seat back panel extension

assembly six places.

5. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

6. Apply Cavity Wax ( Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3A.

7. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10A-49

2.10 CROSSMEMBER ASSEMBLY NO. 2 – REPLACE

REMOVE

CAUTION: To avoid the possibility of fire, take

particular care when cutting or welding at the rear

of the vehicle. Remove the fuel tank and plug all

fuel lines.

1. Remove the adjacent components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

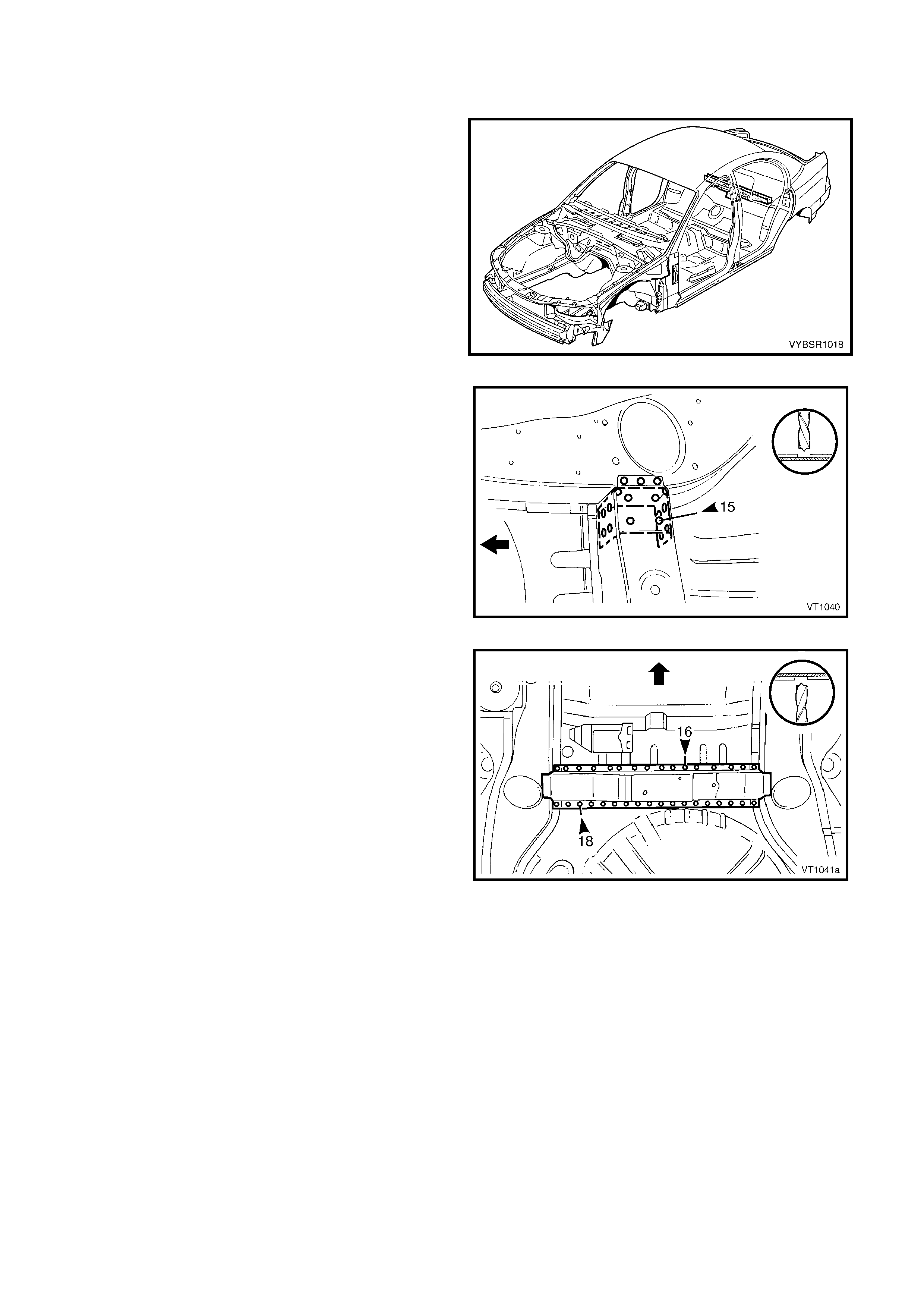

2. Secure the vehicle on a suitable fixture. As a

minimum, support the appropriate structural

sections of the vehicle on safety stands.

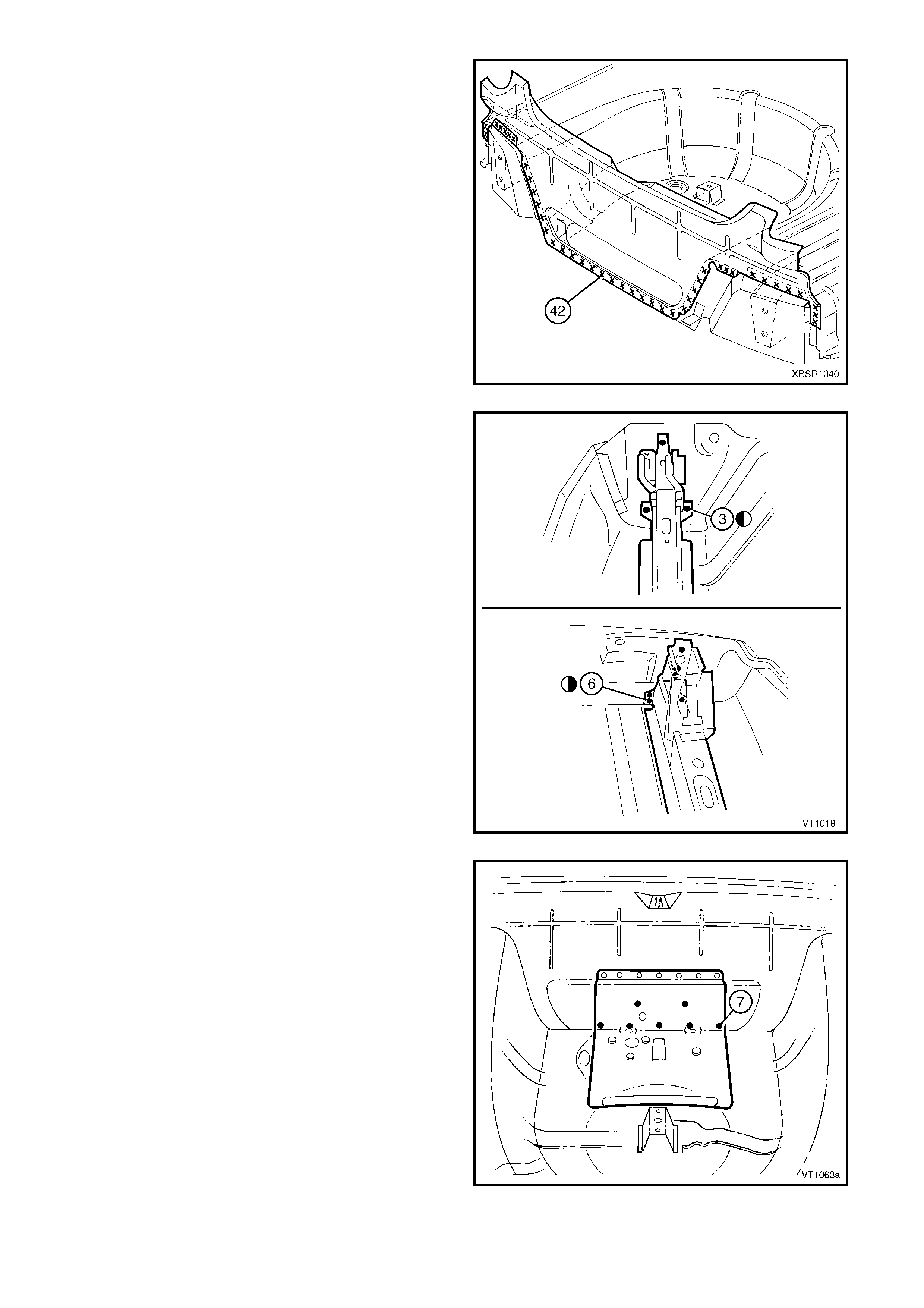

Figure 10A-50

3. Spot cut the welds attaching the crossmember

No.2 to the crossmember bracket and to the rear

side rail, on each side of the vehicle.

NOTE: Take care not to damage the crossmember

brackets when removing the crossmember, as these

parts are only serviced as part of the rear side rail

assemblies.

Figure 10A-51

4. Spot cut the welds attaching the crossmember to

the rear compartment floor panel assembly.

5. Remove the crossmember from the vehicle, and

then repair any damage to adjacent parts as

required.

6. Check and rectify the alignment of the body as

required, refer to 3. BODY DIMENSIONS in

Section 3A.

Figure 10A-52

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s am e num ber and pos ition of s pot welds (or plug welds) s hould be used when replac ing the panel, as

was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3A.

3. Plug weld the crossmember to the crossmember

bracket and rear side rail, on each side of the

vehicle.

Figure 10A-53

4. Plug weld the crossmember to the rear

compartment floor panel assembly.

5. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

6. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3A.

7. Apply Cavity Wax ( Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3A.

8. Apply Spray-on Deadener (Item 7) where

applicable, refer to 5. BODY SEALING,

ADHESIVES & DEADENERS in Section 3A.

9. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10A-54

2.11 REAR FLOOR PANEL OUTER EXTENSION – REPLACE

REMOVE

1. Remove the adjacent components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10A-55

2. Spot cut the welds attaching the rear floor panel

outer extension to the inner rocker panel and rear

side rail assembly and remove.

Figure 10A-56

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s am e num ber and pos ition of s pot welds (or plug welds) s hould be used when replac ing the panel, as

was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3A.

3. Install and plug weld the rear floor panel outer

extension to the inner rocker panel and rear side

rail assembly.

4. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

5. Apply Cavity Wax ( Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3A.

6. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10A-57

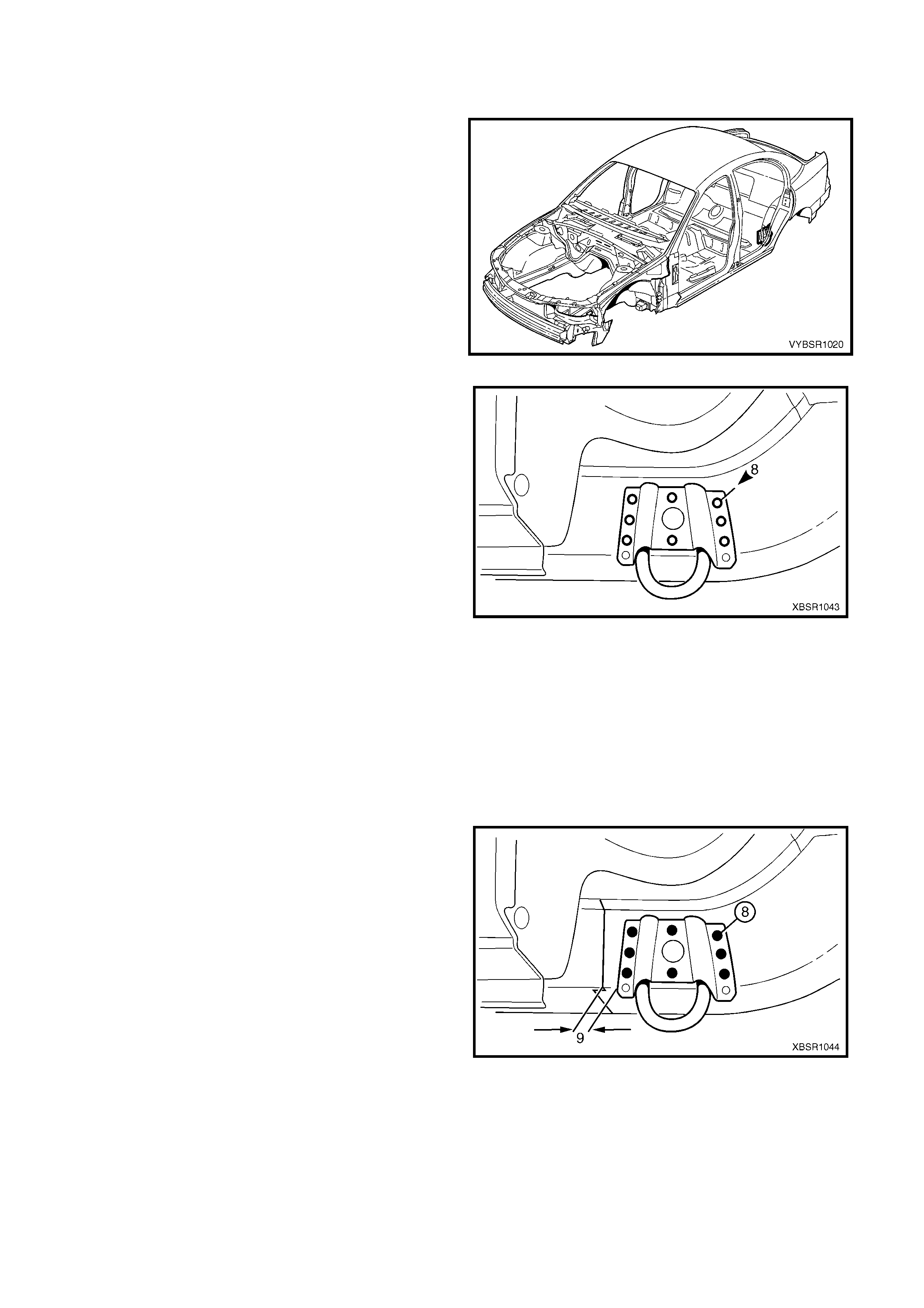

2.12 REAR TIE DOWN ASSEMBLY – REPLACE

REMOVE

1. Remove the adjacent components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10A-58

2. Spot cut the welds attaching the tie down hook

assembly to the rear side rail assembly and

remove.

Figure 10A-59

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s am e num ber and pos ition of s pot welds (or plug welds) s hould be used when replac ing the panel, as

was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3A.

3. Install the tie down hook assembly onto the rear

side rail assembly, approximately 9 mm rearward

of the join.

4. Plug weld the tie down hook assembly to the rear

side rail assembly, eight places.

5. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

6. Apply Cavity Wax ( Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3A.

7. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10A-60

2.13 REAR BUMPER IMPACT BAR BRACE ASSEMBLY – REPLACE

REMOVE

CAUTION: To avoid the possibility of fire, take

particular care when cutting or welding at the rear

of the vehicle. Remove the fuel tank and plug the

fuel lines.

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Secure the vehicle on a suitable fixture. As a

minimum, support the appropriate structural

sections of the vehicle on safety stands. Ensure

that the stands are clear of the sections being

removed.

3. Remove the adjoining panels as required, refer to

the appropriate Section of this Supplement.

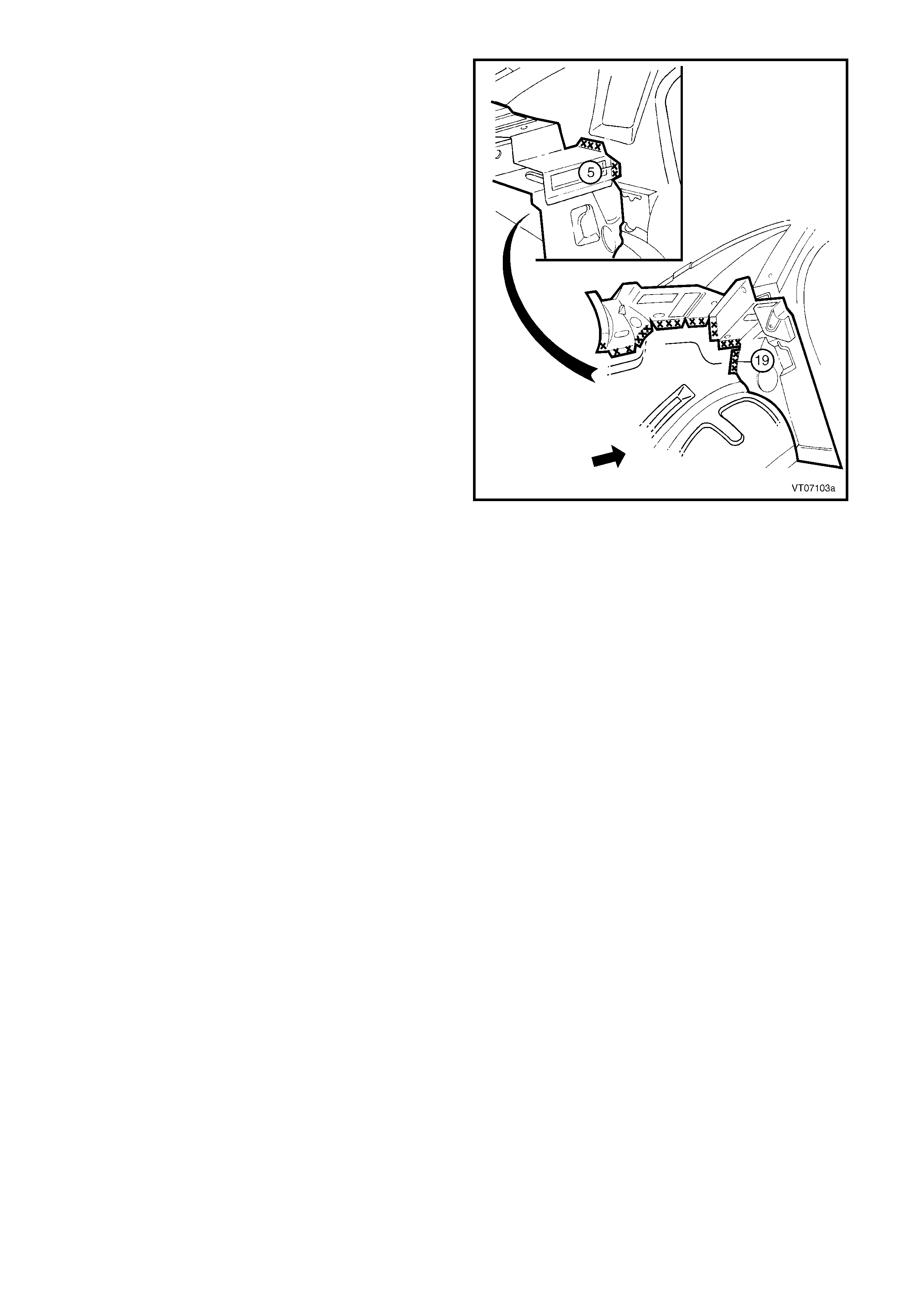

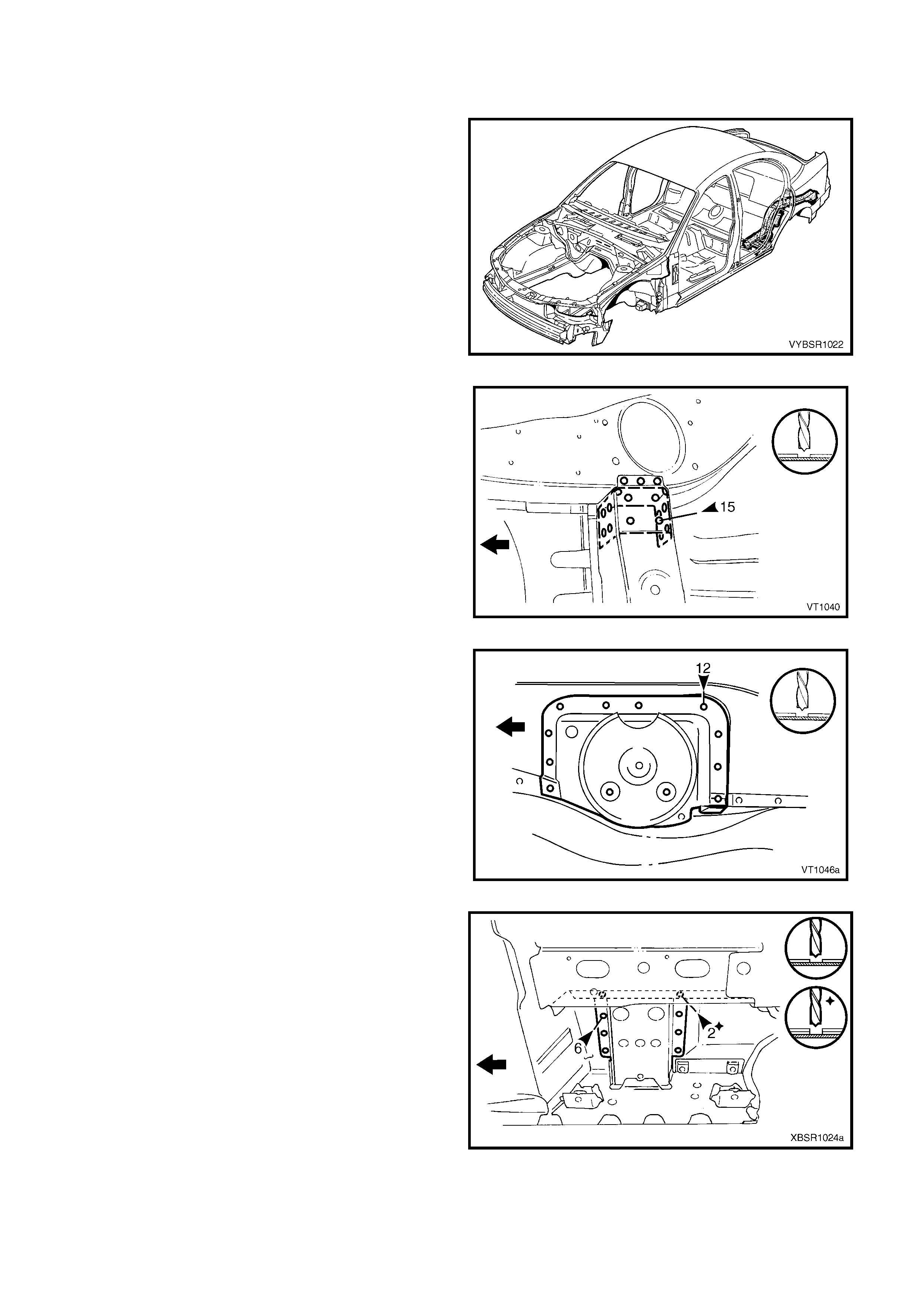

4. Spot cut the welds attaching the left-hand (1) or

right-hand (2) rear bumper impact bar brace

assembly to the rear side rail ass embly (3), refer to

Figure 10A-62.

5. If required, for the right-hand rear bumper impact

bar brace assembly , remove the closing plate (4).

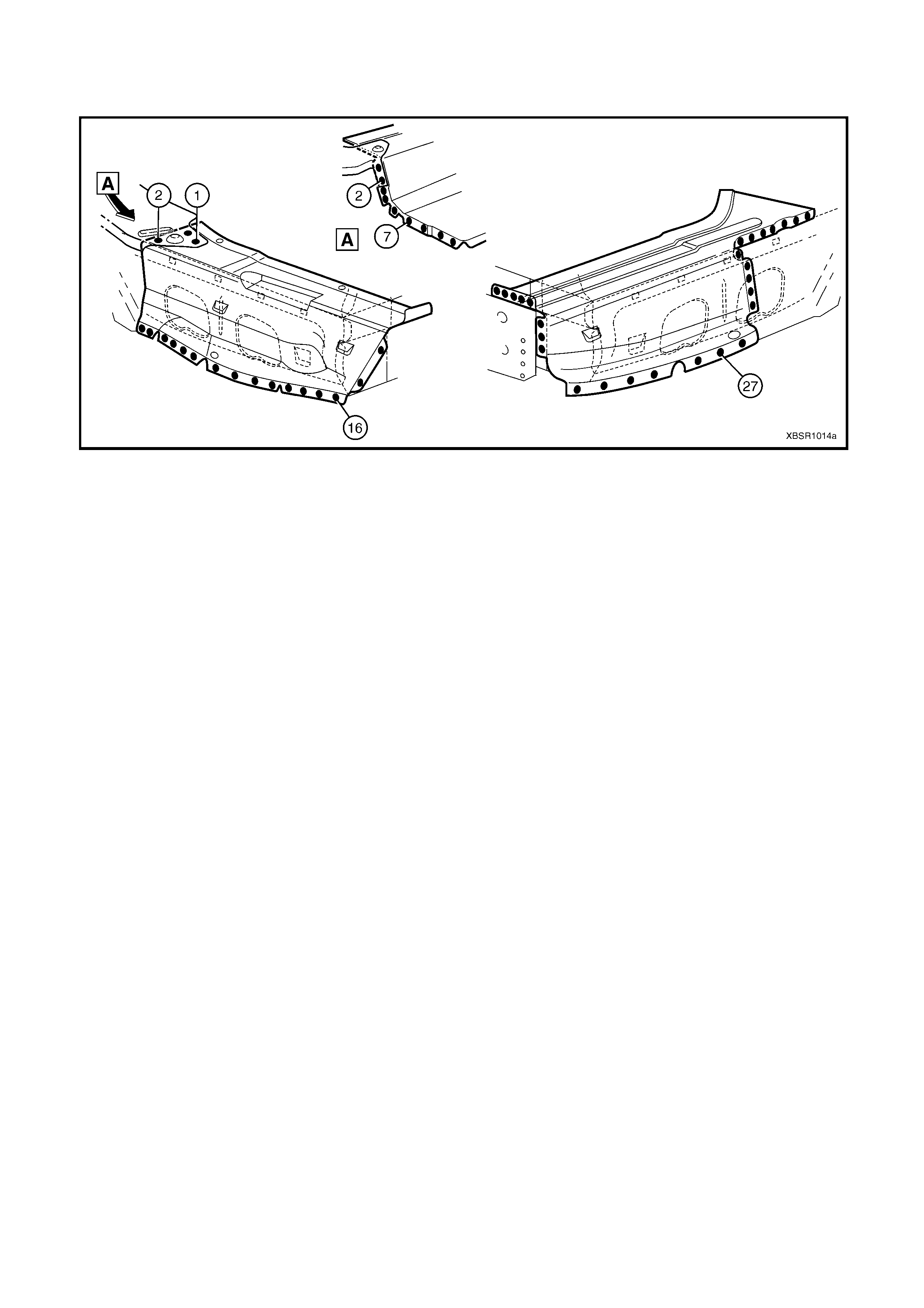

Figure 10A-61

Figure 10A-62

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s am e num ber and pos ition of s pot welds (or plug welds) s hould be used when replac ing the panel, as

was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3A.

3. Clamp and plug weld the rear bumper impact bar brace assembly (1 or 2) in position on the rear side rail

assembly (3).

4. If required, for the right-hand side clamp and plug weld the closing plate (4) in position, refer to Figure 10A-63.

Figure 10A-63

5. Install other panels as required, refer to the appropriate Section in this Supplement.

6. Refinish and paint panels and other components as required. Refer to Section 3, 1.3 PAINT REFINISHING.

7. Apply Joint Sealer (Item 3) as required. Refer to 5. BODY SEALING, ADHESIVES & DEADENERS in Section

3A.

8. Apply Cavity W ax (Item 8) as required to the inside of any box sections or areas inaccessible to paint, refer to

6. CAVITY WAX in Section 3A.

9. Install the remaining components as described in the appropriate Section of the MY 2003 VY & V2 Series II

Service Information.

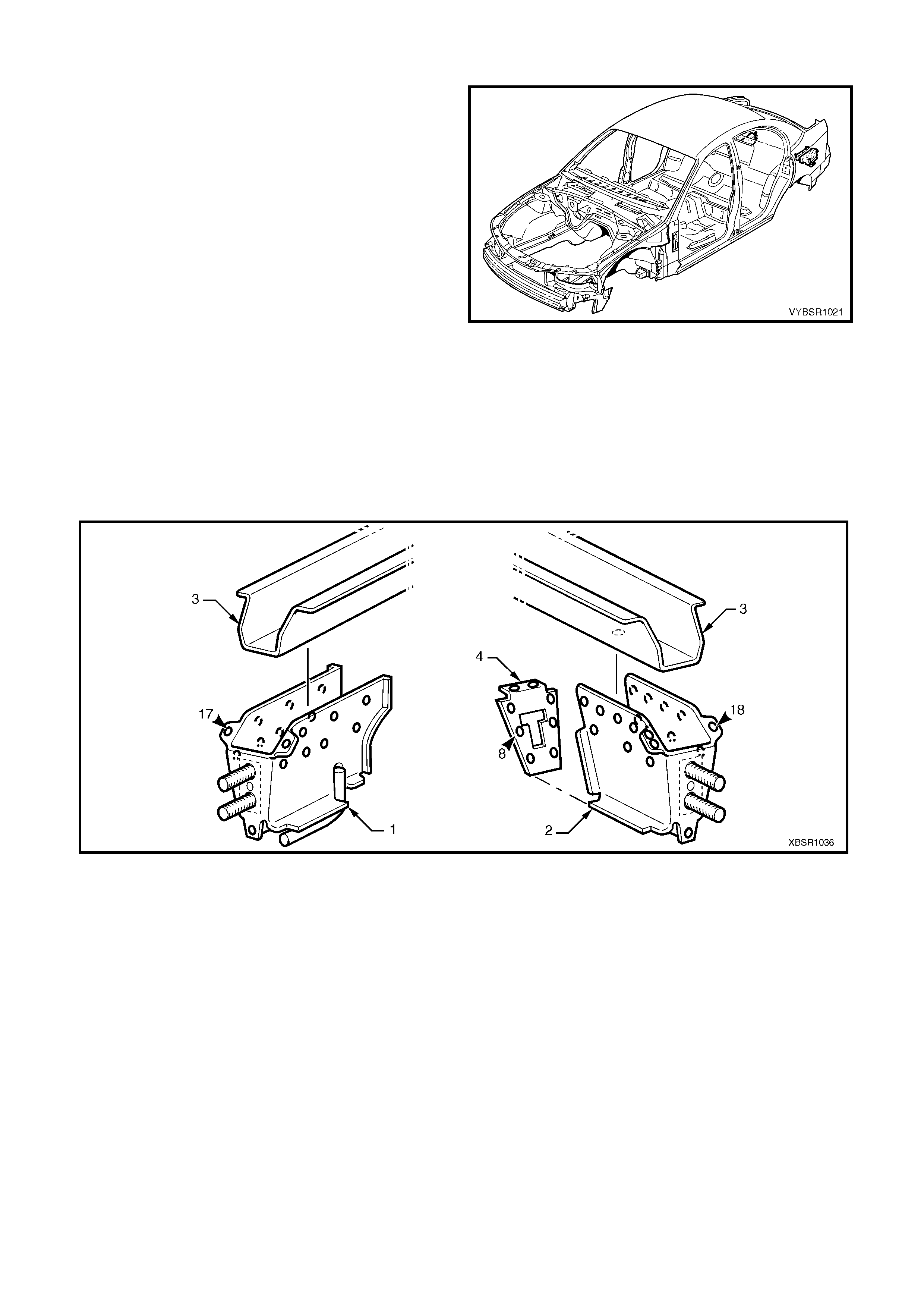

2.14 REAR SIDE RAIL ASSEMBLY – REPLACE

REMOVE

CAUTION: To avoid the possibility of fire, take

particular care when cutting or welding at the rear

of the vehicle. Remove the fuel tank and plug all

fuel lines.

1. Remove the adjacent components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

2. Secure the vehicle on a suitable fixture. As a

minimum, support the appropriate structural

sections of the vehicle on safety stands. Ensure

that the stands are clear of the rear side rail

assembly(s) being removed.

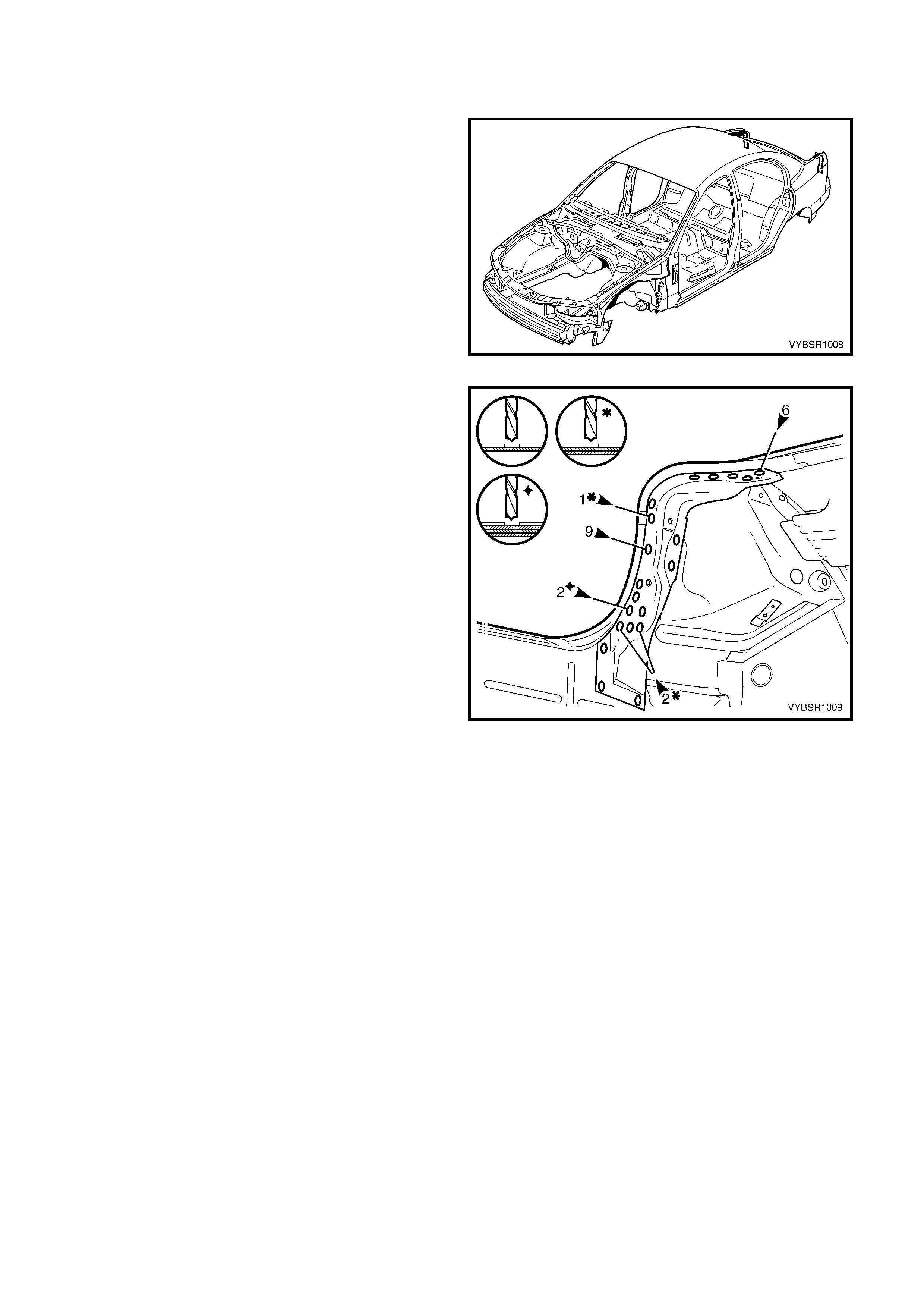

Figure 10A-64

3. Spot cut the welds attaching the crossmember

No.2 to the crossmember bracket and to the rear

side rail, on each side of the vehicle.

Figure 10A-65

4. Spot cut the welds attaching the rear side rail

assembly to the rear floor panel assembly.

Figure 10A-66

5. Spot cut the welds attaching the rear side rail

assembly to the rear floor panel assembly.

Figure 10A-67

6. Spot cut the welds attaching the rear floor panel

outer extension to the inner rocker panel

assembly.

7. Spot cut the rear side rail assembly from the rear

floor panel assembly, rear compartment floor

panel assembly and the rear end panel, refer to

Figure 10A-69.

NOTE: Ther e are a dif f erent num ber of welds between

the left-hand and right-hand sides.

8. Remove the rear side rail assembly from the

vehicle.

Figure 10A-68

Figure 10A-69

9. Repair any damage to adjacent parts as required.

10. Check and rectify the alignment of the body as required, refer to 3. BODY DIMENSIONS in Section 3A.

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s am e num ber and pos ition of s pot welds (or plug welds) s hould be used when replac ing the panel, as

was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3A.

CAUTION: Prior to plug welding in this region, remove the deadener from the inside floor to remove the risk

of fire.

3. Locate and clamp the new rear side rail assembly in position and check and adjust its alignment, refer to

3. BODY DIMENSIONS in Section 3A.

4. Plug weld the rear side rail assembly to the rear floor panel assembly, rear compartm ent floor panel assembly

and the rear end panel, refer to Figure 10A-70.

Figure 10A-70

5. Plug weld the rear side rail assembly to the rear

floor panel assembly.

Figure 10A-71

6. Plug weld the crossm em ber assem bly No. 2 to the

crossmember bracket and rear side rail.

Figure 10A-72

7. Plug weld the rear side rail assembly to the rear

floor panel ass embly and the rear floor panel outer

extension to the inner rocker panel assembly.

8. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

9. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3A.

10. Apply Cavity Wax (Item 8) as r equired to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3A.

11. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10A-73

2.15 REAR FLOOR PANEL ASSEMBLY – REPLACE

REMOVE

CAUTION: To avoid the possibility of fire, take

particular care when cutting or welding at the rear

of the vehicle. Remove the fuel tank and plug the

fuel lines.

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Secure the vehicle on a suitable fixture. As a

minimum, support the appropriate structural

sections of the vehicle on safety stands. Ensure

that the stands are clear of the sections being

removed.

3. Rem ove the sealer and deadener panels from the

relevant areas using a scraper and heat gun.

4. Remove the adjoining panels as required, refer to

the appropriate Section of this Supplement.

Figure 10A-74

5. Spot cut the welds attaching the park brake cable

bracket to the rear floor panel assembly.

Figure 10A-75

6. Spot cut the welds joining the front floor panel

assembly (1) and rear floor panel assembly (2).

7. Spot cut the welds attaching the rear floor panel

assembly to the inner rocker panel (3) each side.

Figure 10A-76

8. Spot cut the welds attaching the rear floor panel

assembly (3), to the rear window panel assembly

(1) and the rear seat back panel extension

assembly (2).

Figure 10A-77

9. Spot cut the welds attaching the rear floor panel

assem bly and rear floor panel reinf orcem ent to the

rear wheelhouse inner panel assembly on each of

the vehicle.

10. Spot cut the welds attaching the crossmember

assembly No. 2 to the rear floor panel assembly,

refer to 2.10 CROSSMEM BER ASSEMBLY NO . 2

– REPLACE.

11. Spot cut the welds attaching each rear side rail

assem bly to the rear floor panel assem bly, refer to

2.14 REAR SIDE RAIL ASSEMBLY – REPLACE.

12. Spot cut the welds attaching the rear floor panel

assembly and rear floor panel reinforcements to

the rear compartment floor panel assembly, refer

to Figure 10A-79.

NOTE 1: Structural adhesive is applied in the area

shown (1), refer to 5. BODY SEALING, ADHESIVES &

DEADENERS in Section 3A (Sedan).

NOTE 2: Also remove the welds attaching the left-

hand rear floor panel reinforcement to the rear

compartment floor panel outer extension.

13. Remove the rear floor panel assembly from the

vehicle and then repair any damage to adjacent

parts as required.

14. Check and rectify the alignment of the body as

required, refer to 3. BODY DIMENSIONS in

Section 3A.

Figure 10A-78

Figure 10A-79

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s am e num ber and pos ition of s pot welds (or plug welds) s hould be used when replac ing the panel, as

was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3A.

3. Apply Structural Adhesive (Item 6), refer to 5. BODY SEALING, ADHESIVES & DEADENERS in Section 3A.

4. Clamp the new panel in position in the vehicle and plug weld to the rear floor rear. Refer to Figure 10A-80.

Figure 10A-80

4. Plug weld the rear floor panel assembly (2) to the

front floor panel assembly (1).

5. Plug weld the rear floor panel assembly to the

inner rocker panel (3) each side.

Figure 10A-81

6. Plug weld the rear floor panel assembly (1) to the

rear window panel assembly (2) and the rear seat

back panel extension assembly (3).

Figure 10A-82

7. Plug weld the park brake cable brack et to the rear

floor panel assembly.

8. Ins tall the r ear floor panel reinforc ement each side,

refer to 2.16 REAR FLOOR PANEL

REINFORCEMENT – REPLACE. Plug weld the

reinfor cem ents on the top s urf ace only, completing

the welds in the next step.

Figure 10A-83

9. Spot or plug weld the rear floor panel assembly

and rear floor panel reinforcement to the rear

wheelhouse inner panel assembly on each of the

vehicle.

10. Plug weld the crossmember assembly No.2 to the

rear floor panel assembly, refer to

2.10 CROSSMEMBER ASSEMBLY NO. 2 –

REPLACE.

11. Plug weld each rear side rail assembly to the rear

floor panel assembly, refer to 2.14 REAR SIDE

RAIL ASSEMBLY – REPLACE.

12. Replace any other rem oved panels as des c ribed in

the appropriate Section of this Supplement.

13. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

14. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3A.

15. Apply Cavity Wax (Item 8) as r equired to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3A.

16. Apply deadener panels to the rear compartment

floor panel, refer to 5.6 DEADENER PANELS &

INSULATORS in Section 3A.

17. Apply Spray-on Deadener (Item 7) where

applicable, refer to 5. BODY SEALING,

ADHESIVES & DEADENERS in Section 3A.

18. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10A-84

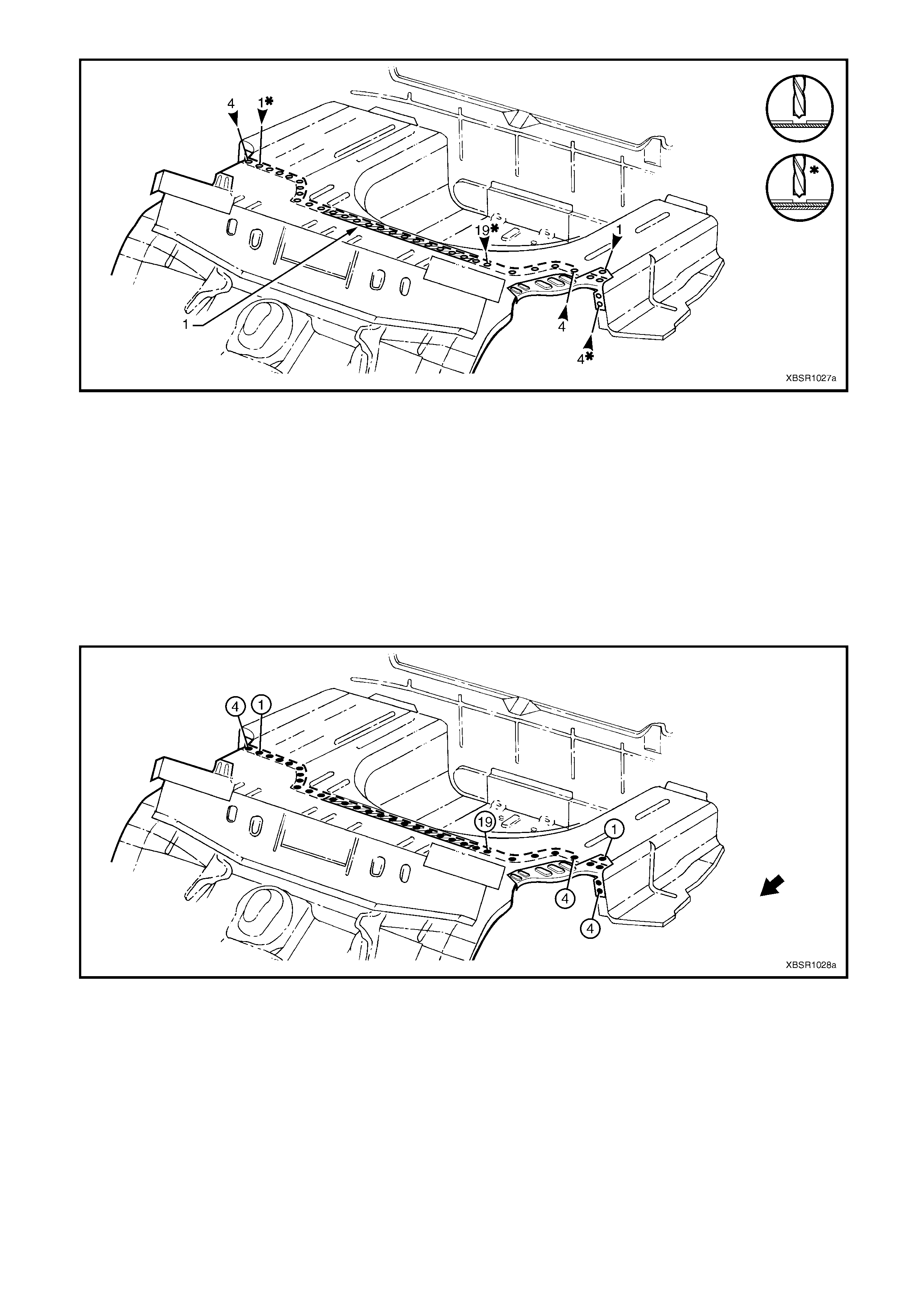

2.16 RE AR FLOOR PANEL REINFORCEMENT – REP LACE

LEFT-HAND SIDE

REMOVE

The left-hand rear floor panel reinforcement is spot

welded to the rear floor panel assembly, rear

wheelhouse panel assembly, rear compartment floor

panel assembly outer extension and rear side rail

assembly.

As required spot cut the welds and remove the

reinforcement.

REPLACE

NOTE 1: Spot welding is the preferred method for

attaching of panels and should be used whenever

possible. W here the spot welding equipment available

to the repairer will not access the required weld

position, a plug weld should be performed.

NOTE 2: T he sam e num ber and position of spot welds

(or plug welds) should be used when replacing the

panel, as was used during manufacture, in order to

maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling

locations in prepar ation f or plug welding. Drill holes

as required.

2. Prepare all mating surfaces and treat with Weld

Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3A.

3. Spot or plug weld the rear floor panel

reinfor c ement to the vehicle, ensur ing it is c orr ec tly

located and welded through the correct panels.

Figure 10A-85

RIGHT-HAND SIDE

REMOVE

The right-hand rear floor panel reinforcement is spot

welded to the rear floor panel assembly, rear

wheelhouse panel assembly and rear side rail

assembly.

As required spot cut the welds and remove the

reinforcement.

REPLACE

NOTE 1: Spot welding is the preferred method for

attaching of panels and should be used whenever

possible. W here the spot welding equipment available

to the repairer will not access the required weld

position, a plug weld should be performed.

NOTE 2: T he sam e num ber and position of spot welds

(or plug welds) should be used when replacing the

panel, as was used during manufacture, in order to

maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling

locations in prepar ation f or plug welding. Drill holes

as required.

2. Prepare all mating surfaces and treat with Weld

Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3A.

3. Spot or plug weld the rear floor panel

reinfor c ement to the vehicle, ensur ing it is c orr ec tly

located and welded through the correct panels.

Figure 10A-86