SECTION 10C – BODY REAR – UTILITY

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to

Section 00 CAUTIONS AND NOTES and Section 2 PRECAUTIONS in this Supplement for correct

workshop practices with regard to safety and/or property damage.

CAUTION

The Structure of the M Y 2003 VY & V2 Series II body shell has been developed using complex design

and development techniques. In addition to meeting all required standards, the v ehicle body is also a

critical part of the overall safety systems. It is therefore imperative the repair procedures described

here are adhered to during all vehicle body repairs.

1. GENERAL DESCRIPTION

1.1 BODY REAR COMPONENTS

2. SERVICE OPERATIONS

2.1 REAR END LOWER PANEL – REPLACE

REMOVE

REPLACE

2.2 ENDGATE HINGE BRACKET ASSEMBLY –

REPLACE

REMOVE

REPLACE

2.3 REAR END PANEL – REPLACE

REMOVE

REPLACE

2.4 LOAD FLOOR CENTRE RAIL ASSEMBLY –

REPLACE

REMOVE

REPLACE

2.5 LOAD FLOOR REINFORCEMENT RAIL

ASSEMBLY – REPLACE

REMOVE

REPLACE

2.6 CROSSMEMBER ASSEMBLY NO. 2 –

REPLACE

REMOVE

REPLACE

2.7 REAR FLOOR PANEL OUTER

EXTENSION – REPLACE

REMOVE

REPLACE

2.8 REAR TIE DOWN ASSEMBLY – REPLACE

REMOVE

REPLACE

2.9 REAR SIDE RAIL ASSEMBLY – REPLACE

REMOVE

REPLACE

2.10 LOAD FLOOR PANEL ASSEMBLY –

REPLACE

REMOVE

REPLACE

2.11 REAR FLOOR PANEL ASSEMBLY –

REPLACE

REMOVE

REPLACE

1. GENERAL DESCRI PTI O N

This Section describes replacement procedures for the rear section components of the MY 2003 VY Series Utility

body structure. Removal of bolt-on and mechanical components is not covered. Reference must be made to the

appropriate Sections in the MY 2003 VY & V2 Series II Service Information.

When repairing the rear of the vehicle, care must be taken to ensure the structure is returned to its original

production configuration.

NOTE: It is imperative that the correct body adhesives, sealers, deadeners and cavity waxes are used when

repairing the body structure of MY 2003 VY Series Utility vehicles. Refer to 5. BODY SEALING, ADHESIVES &

DEADENERS and 6. CAVITY WAX in Section 3C for details of the correct materials and their commercially

available equivalents.

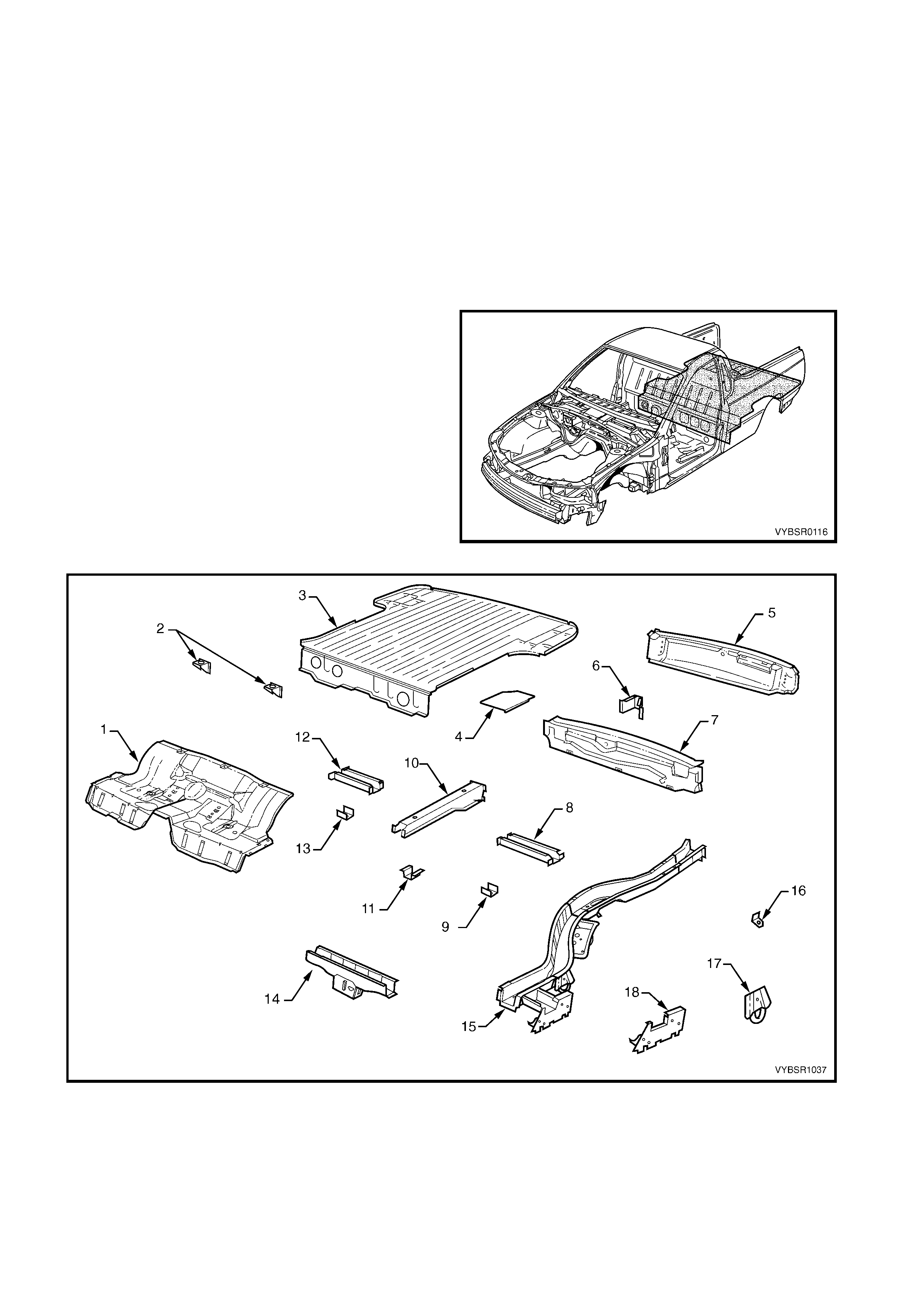

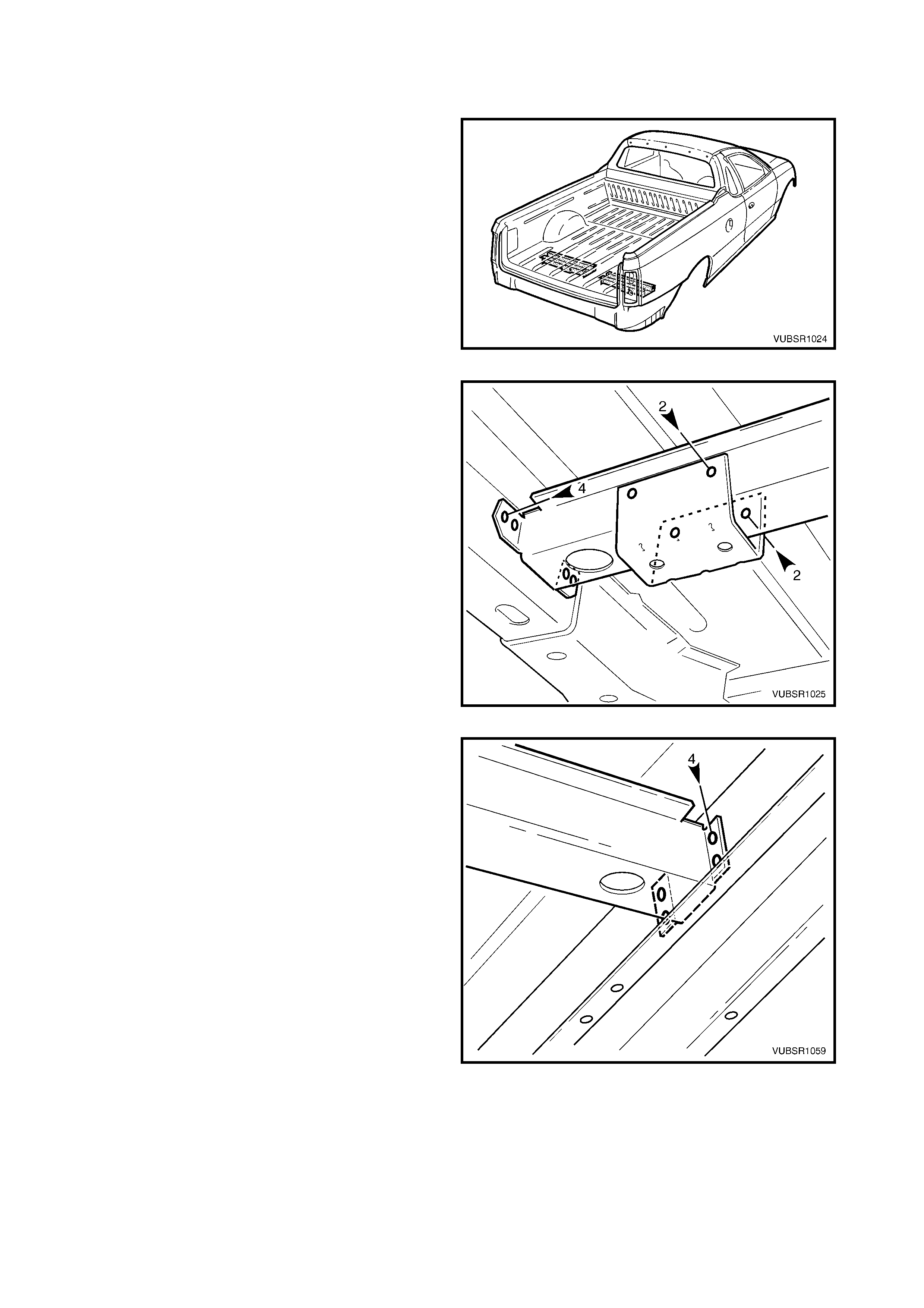

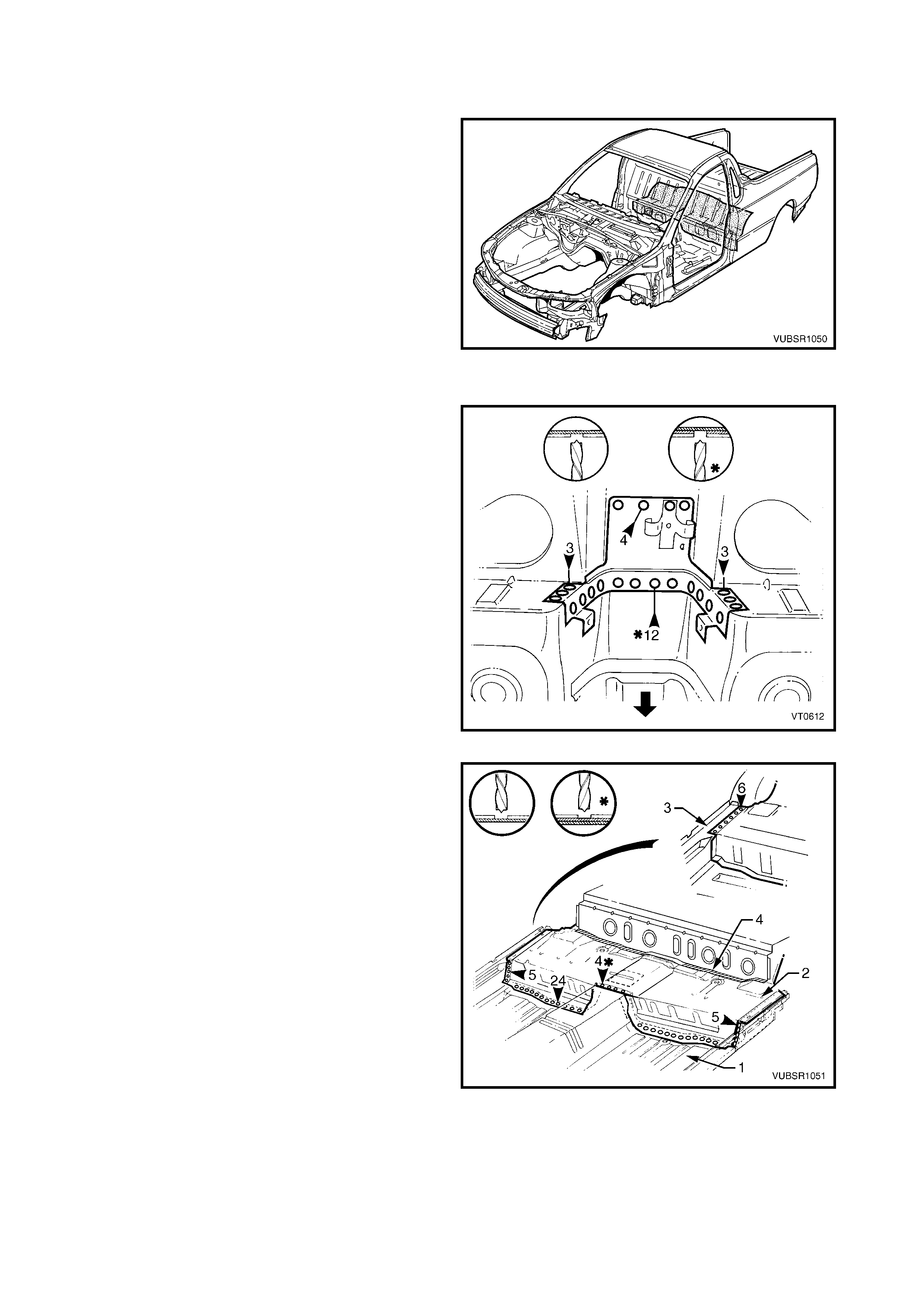

1.1 BODY REAR COMPONENTS

The shaded components in Figure 10C-1 are those

dealt with in this Section.

The components and assemblies shown in Figure

10C-2 are the parts serviced for MY 2003 VY Series

Utility vehicles which form the basis of the repair

procedures in this Section. For a detailed view of the

body components, refer to Section 3C BODY

CONSTRUCTION – UTILITY.

NOTE: Always refer to your Authorised Retailer for

spare parts availability configurations.

Figure 10C-1

Figure 10C-2

Legend (Figure 10C-2)

1. Rear Floor Panel Assembly

2. Fuel Tank Bracket Assembly

3. Load Floor Panel

4. Load Floor Panel Reinforcement

5. Rear End Lower Panel

6. Endgate Hinge Bracket Assembly

7. Rear End Panel

8. Load Floor Reinforcement Rail, Left-Hand

9. Spare Wheel Support, Left-Hand

10. Load Floor Centre Rail

11. Spare Wheel Support

12. Load Floor Reinforcement Rail, Right-Hand

13. Spare Wheel Support, Right-Hand

14. Crossmember Assembly No. 2

15. Rear Side Rail Assembly

16. Rear Brake Hose Bracket

17. Rear Tie Down Assembly

18. Rear Floor Panel Outer Extension

NOTE: Rear Side Rail Assembly includes parts 16, 17 & 18.

2. SERVICE OPERATIONS

2.1 REAR END LOWER PANEL – REPLACE

NOTE: If the rear end panel (inner) is also to be

replaced, rem ove the rear end panels as an assembly.

Refer to 2.3 REAR END PANEL – REPLACE.

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

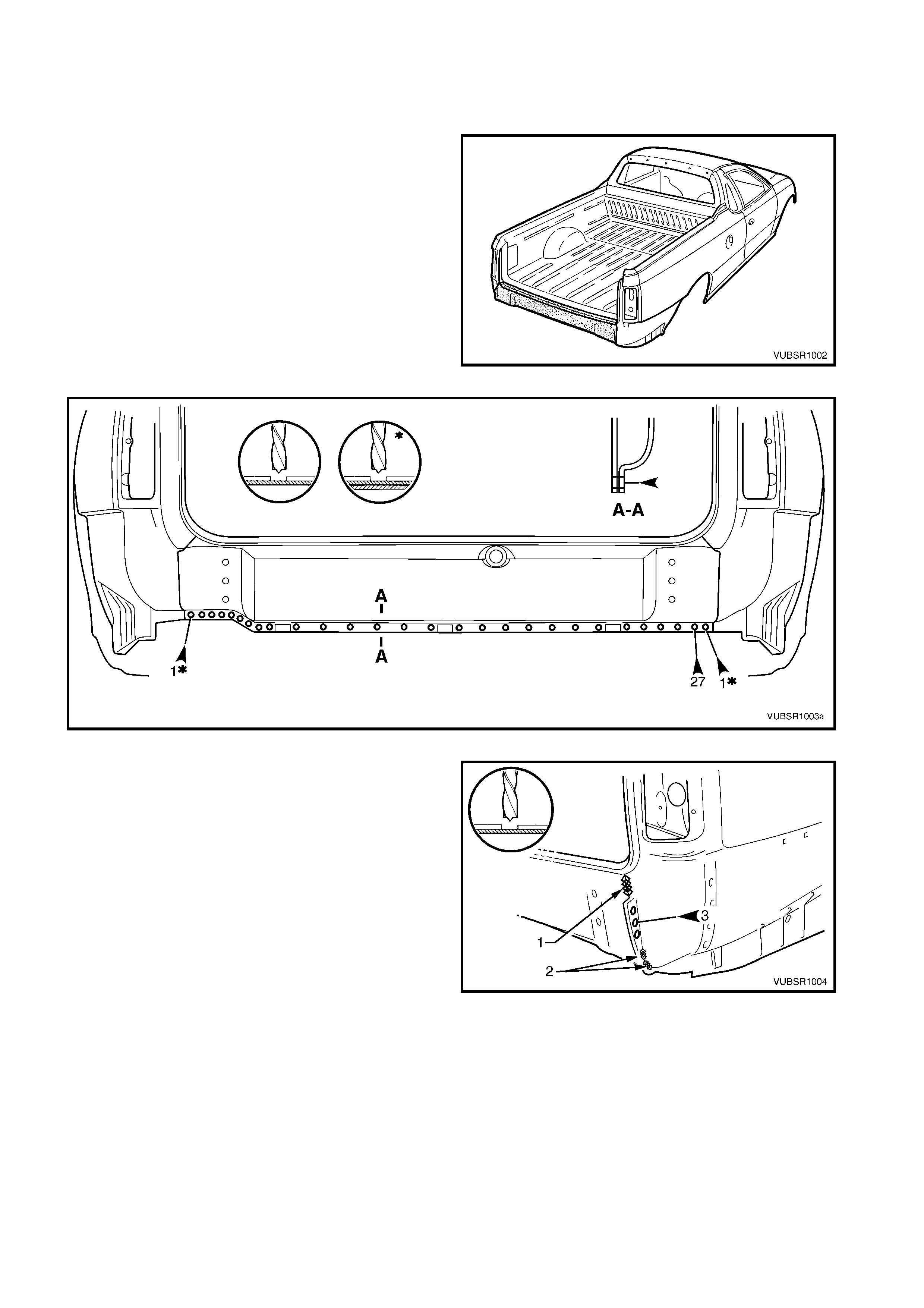

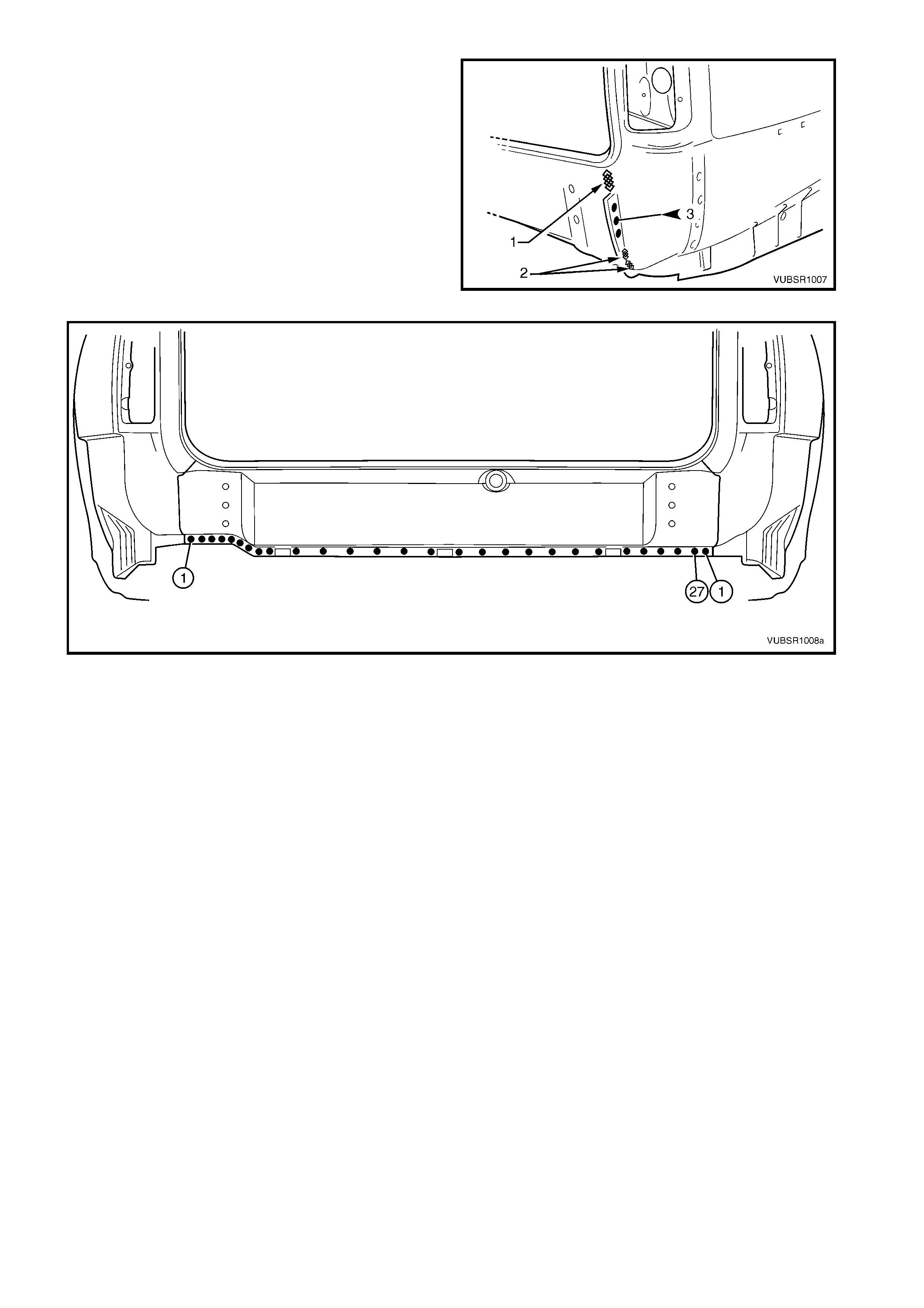

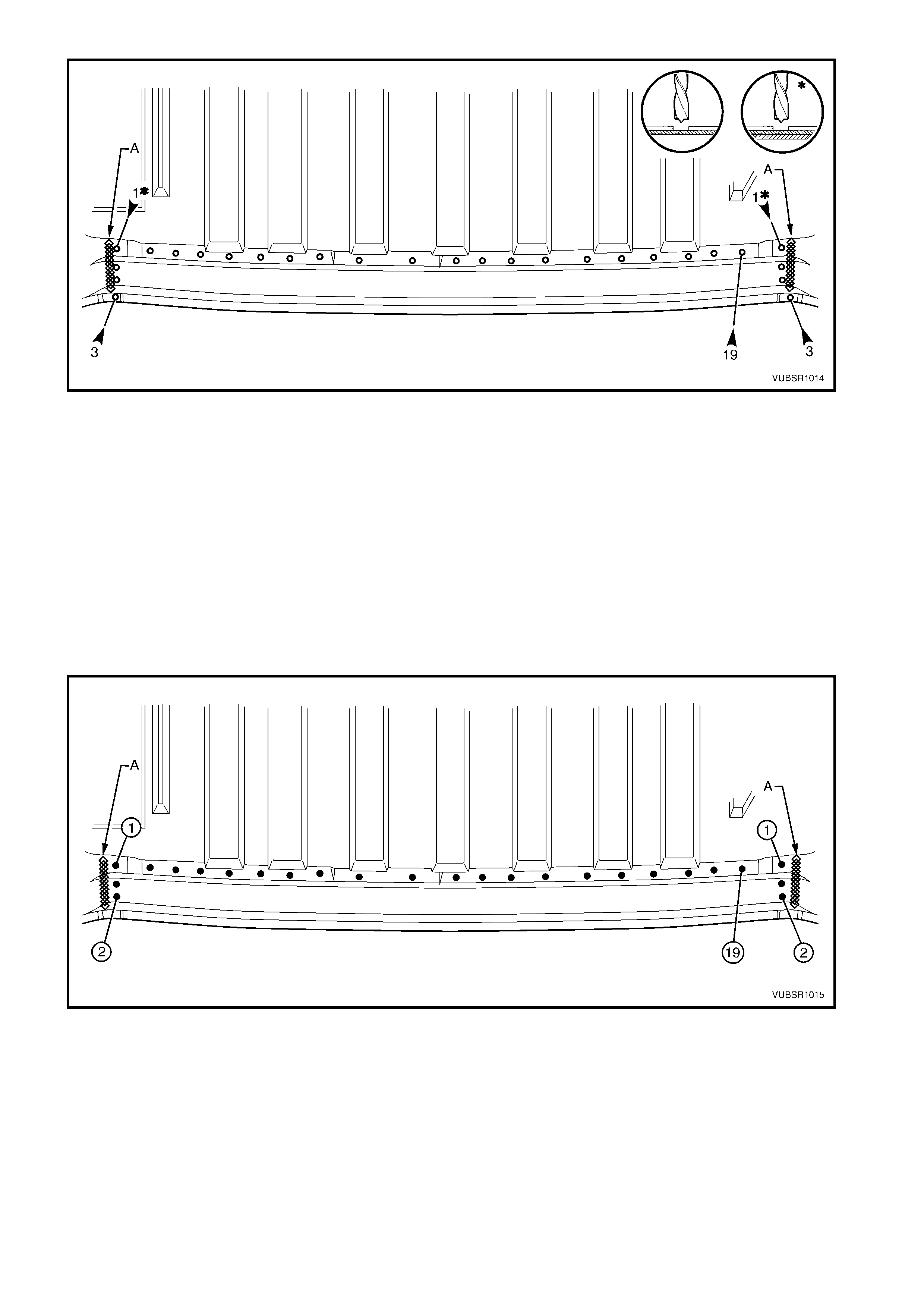

2. Spot cut the welds attaching the rear end lower

panel to the rear end panel and side inner upper

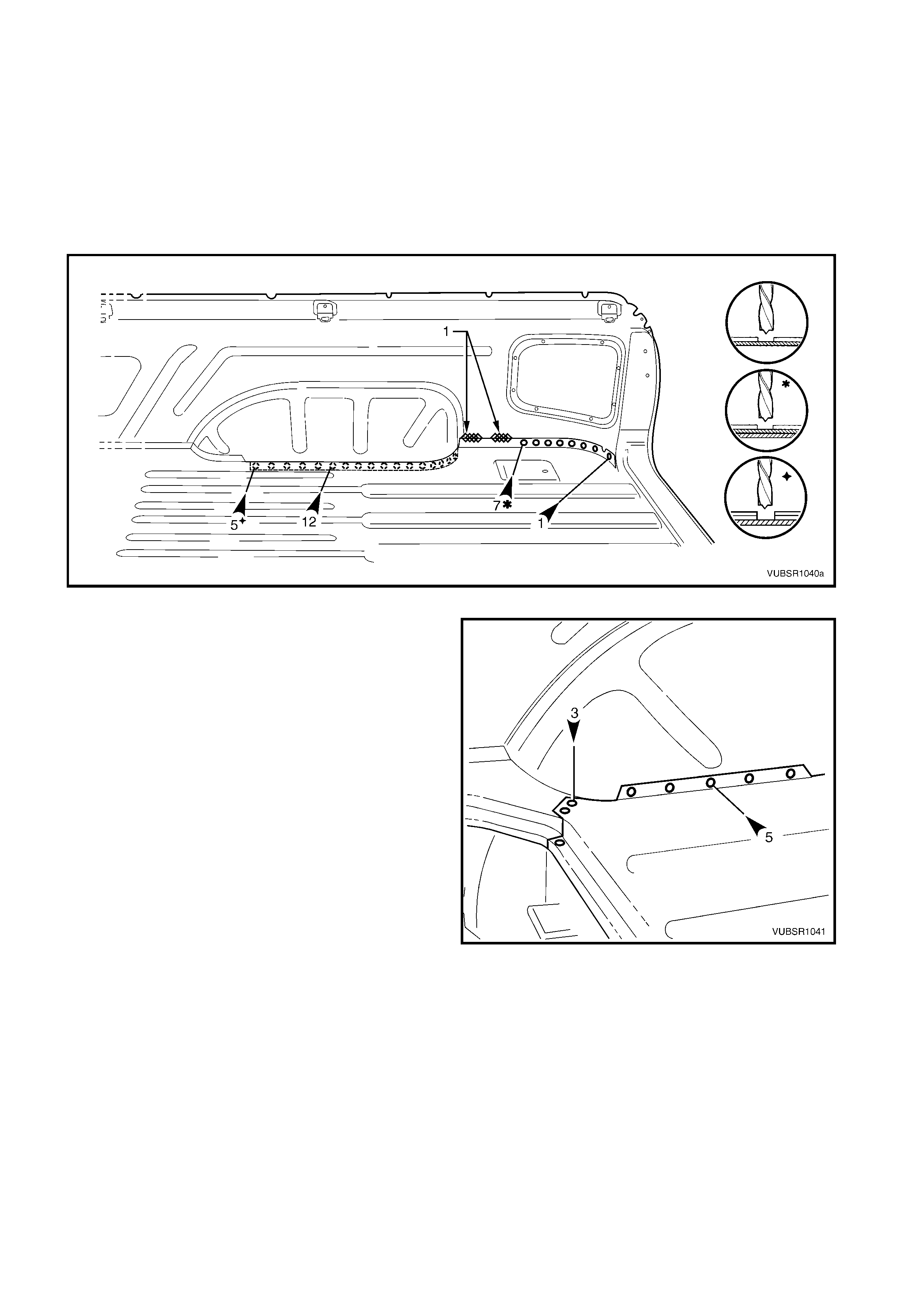

panel, refer to Figure 10C-4.

Figure 10C-3

Figure 10C-4

3. Grind of f the three MIG welds (1 & 2) attac hing the

rear end lower panel to the quarter panel

extension.

4. Spot cut the three welds attaching the rear end

lower panel to the quarter panel extension.

5. Spot cut the welds attaching the rear end lower

panel to the rear end panel and quarter lower rear

panel, refer to Figure 10C-6.

6. Remove the rear end lower panel from the vehicle

and repair any damage to adjacent parts as

required.

Figure 10C-5

Figure 10C-6

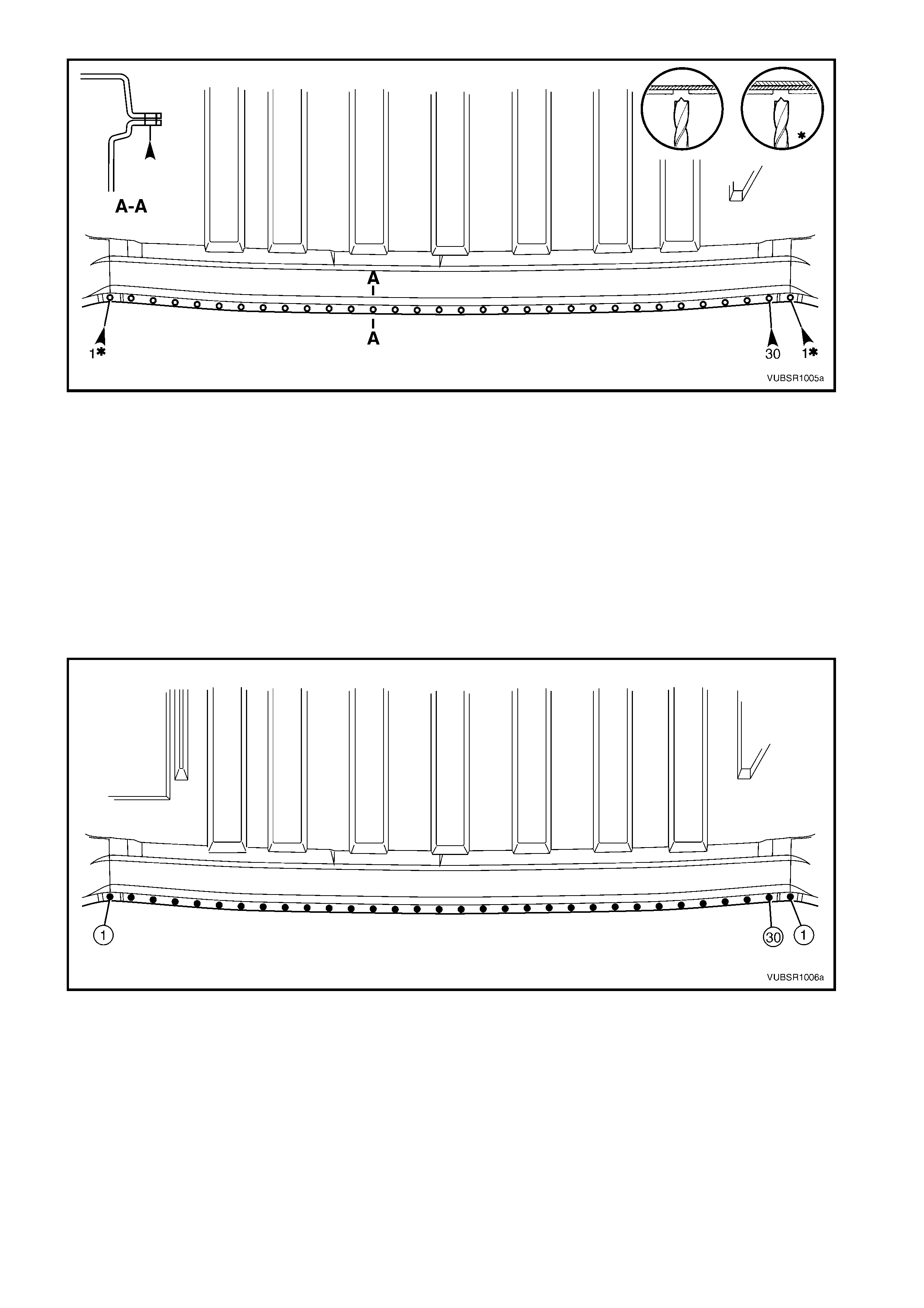

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment available will not access the required weld position, a plug weld should be

performed.

NOTE 2: The s ame number and pos ition of spot welds ( or plug welds) s hould be used when replac ing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. Clamp the rear end lower panel in position on the vehicle and spot or plug weld to the rear end panel and

quarter lower rear panel, refer to Figure 10C-7.

Figure 10C-7

4. Spot or plug weld the rear end lower panel to the

quarter panel extension.

5. MIG weld one place 55 mm (1) and two places 30

mm (2), the rear end lower panel to the quarter

panel extension.

6. Spot or plug weld the rear end lower panel to the

rear end panel and the side inner upper panel,

refer to Figure 10C-9.

Figure 10C-8

Figure 10C-9

7. Refinish and paint panels and other components as required. Refer to Section 3, 1.3 PAINT REFINISHING.

8. Apply Joint Sealer (Item 3) as required. Refer to 5. BODY SEALING, ADHESIVES & DEADENERS in

Section 3C.

9. Apply Cavity W ax ( Item 8) as r equired to the inside of any box sections or areas inacc essible to paint, ref er

to 6. CAVITY WAX in Section 3C.

10. Install the rem aining com ponents as described in the appr opriate Section of the MY 2003 VY & V2 Series II

Service Information.

2.2 ENDGATE HINGE BRACKET ASSEMBLY – REPLACE

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Remove the rear end lower panel, refer to

2.1 REAR END LOWER PANEL.

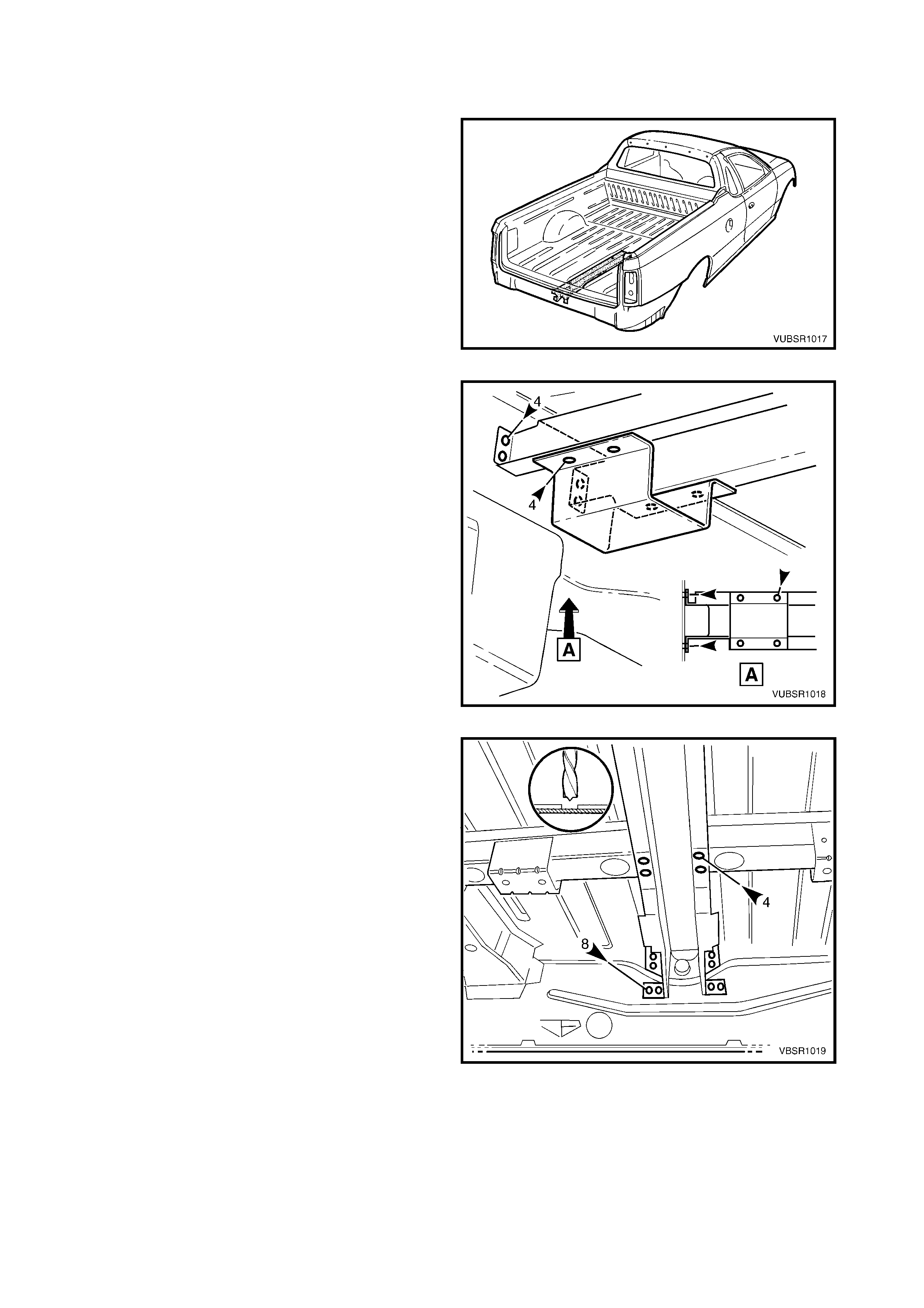

Figure 10C-10

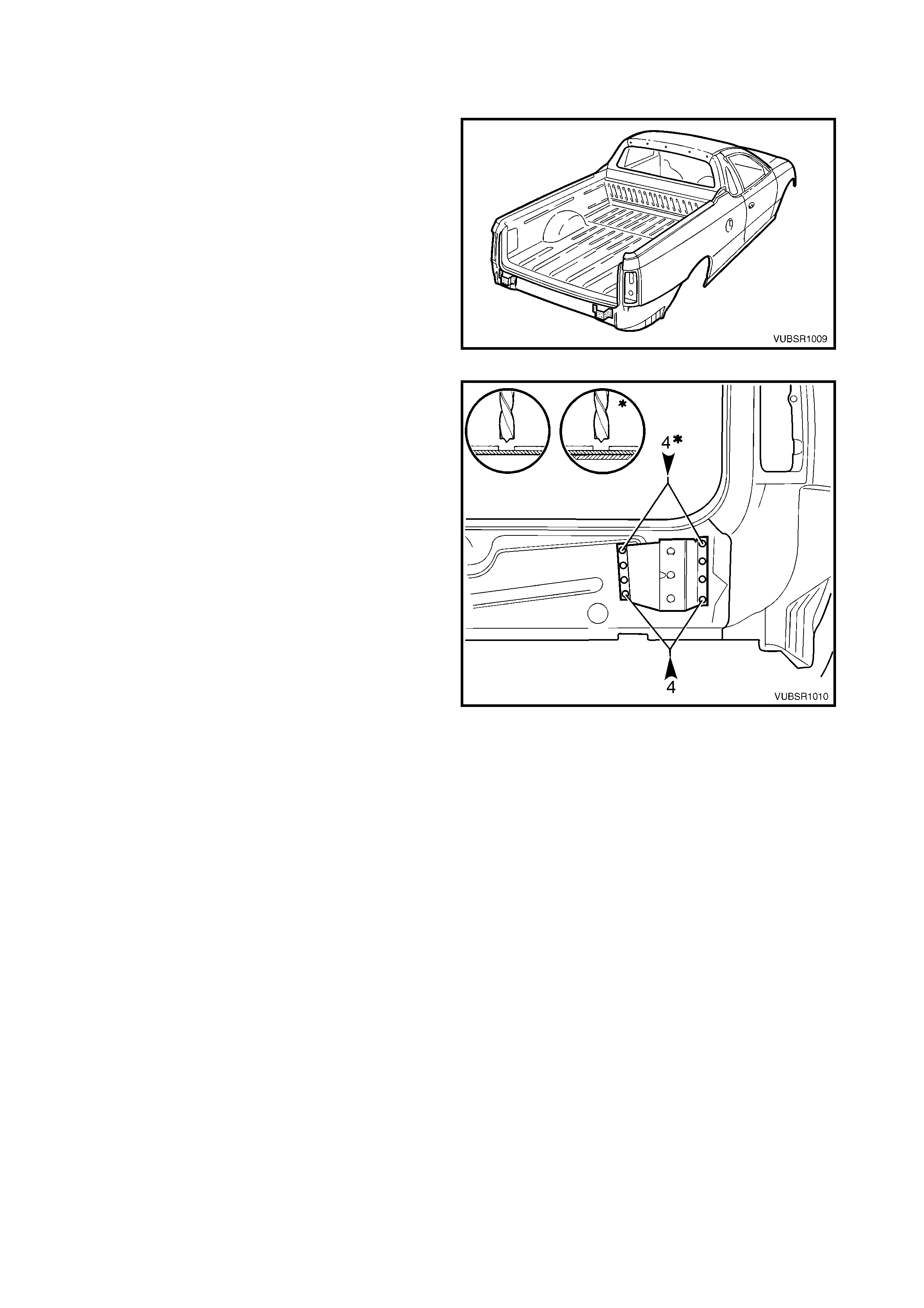

3. Spot cut the four lower welds attaching the

endgate hinge bracket assembly to the rear end

panel.

4. Spot cut the four upper welds attaching the

endgate hinge bracket assembly to the rear end

panel and rear side rail assembly.

NOTE: Cut through the rear end panel as well if it is to

be removed.

5. Rem ove the endgate hinge bracket as sembly then

repair any damage to adjacent parts as required.

Figure 10C-11

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment available will not access the required weld position, a plug weld should be

performed.

NOTE 2: The s ame number and pos ition of spot welds ( or plug welds) s hould be used when replac ing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. Install the endgate hinge bracket assembly in position on the rear end panel.

NOTE: Test fit the rear end lower panel to ensure the endgate hinge mounting holes align.

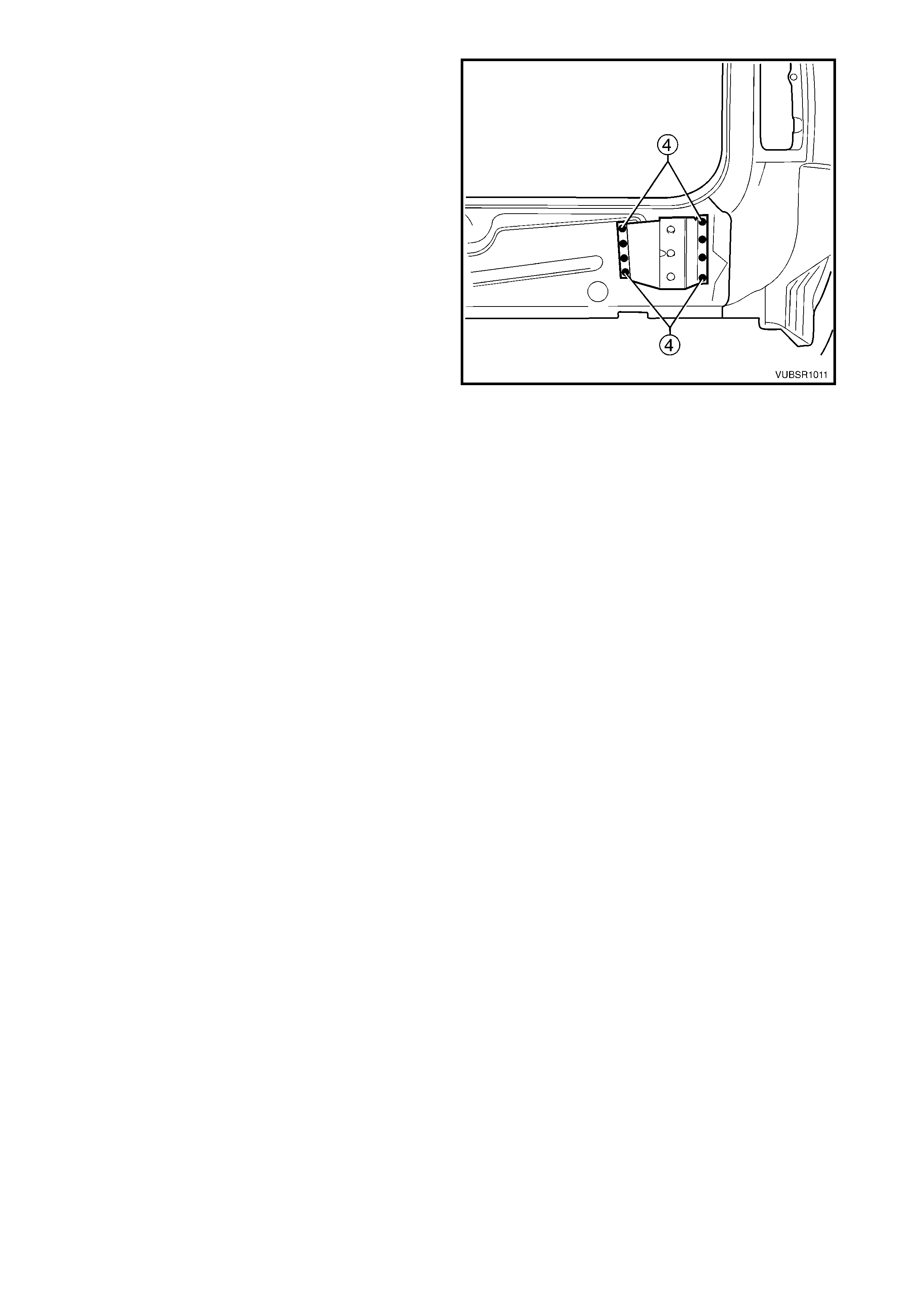

4. Spot or plug weld the four upper welds attaching

the endgate hinge bracket assembly to the rear

end panel and rear side rail assembly.

5. Spot or plug weld the four lower welds attaching

endgate hinge bracket assembly to the rear end

panel.

6. Install the rear end lower panel, r efer to 2.1 REAR

END LOWER PANEL – REPLACE.

7. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

8. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

9. Apply Cavity Wax (Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

10. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10C-12

2.3 REAR END PANEL – REPLACE

NOTE: This procedure describes the removal of

the rear end lower panel, endgate hinge bracket

assembly and rear end panel as an assembly. As

the panels are supplied individually, this procedure

contains the replacement of the rear end panel

only. Reference should be then made to

2.2 ENDGATE HINGE BRACKET ASSEMBLY –

REPLACE and 2.1 REAR END LOWER PANEL –

REPLACE for the relevant replacement procedures of

the remaining panels.

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

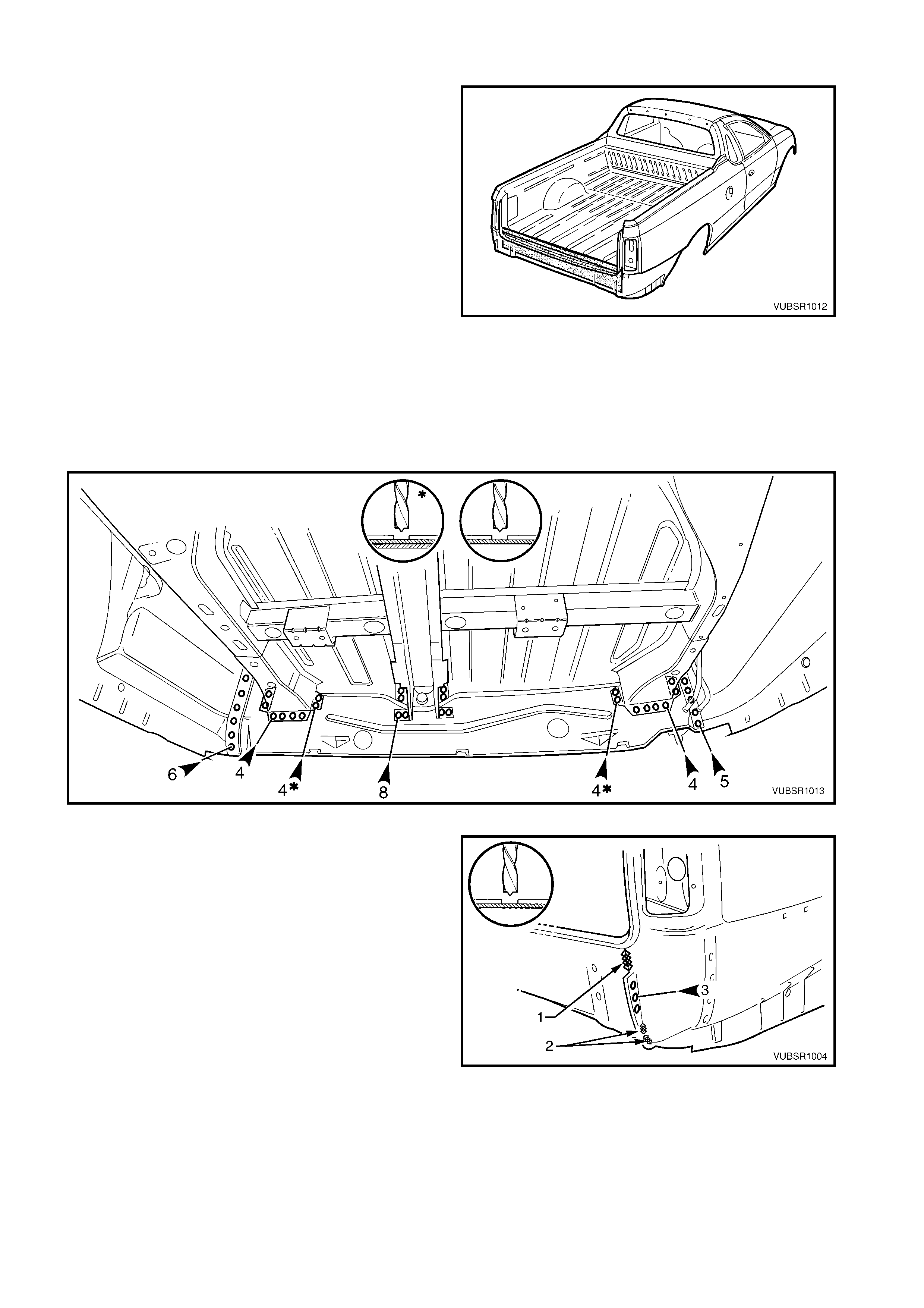

2. From underneath the vehicle, spot cut the welds

attaching the rear end panel assembly to the load

floor centre rail assembly, rear side rail assembly

and side inner upper panel each side, refer to

Figure 10C-14.

Figure 10C-13

Figure 10C-14

3. Grind of f the three MIG welds (1 & 2) attac hing the

rear end lower panel to the quarter panel

extension.

4. Spot cut the welds attaching the rear end lower

panel to the quarter panel extension.

5. Referring to Figure 10C-16:

- Spot cut the three welds each side attaching

the rear end lower panel to the quarter lower

rear panel,

- Spot cut the weld each side attaching the rear

end panel and load floor panel to the quarter

lower rear panel,

- Grind off the MIG weld each side (A) attaching

the rear end panel to the quarter lower rear

panel,

- Spot cut the welds attaching the load floor

panel to the rear end panel.

6. Remove the rear end panel assembly from the

vehicle and repair any damage to adjacent parts

as required.

Figure 10C-15

Figure 10C-16

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment available will not access the required weld position, a plug weld should be

performed.

NOTE 2: The s ame number and pos ition of spot welds ( or plug welds) s hould be used when replac ing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. Clam p the rear end panel in position on the vehicle and spot or plug weld to the load f loor panel, one place

each side to the load floor panel & quarter lower rear panel and two places each side to the quarter lower

rear panel, refer to Figure 10C-17.

Figure 10C-17

4. Referring to Figure 10C-18 Spot or plug weld the rear end panel:

- to the side inner upper panel, six places right-hand and five places left-hand,

- to the load floor centre rail assembly, eight places, and

- to the rear side rail assembly lower flange, four places each side.

NOTE: Do not weld the rear side rail assembly side flanges until the endgate hinge bracket assemblies are

installed.

Figure 10C-18

5. Install the endgate hinge bracket assemblies, refer to 2.2 ENDGATE HINGE BRACKET ASSEMBLY –

REPLACE.

6. Clean up the welds and apply primer to any bare metal.

7. Install the rear end lower panel, refer to 2.1 REAR END LOWER PANEL – REPLACE.

8. Refinish and paint panels and other components as required. Refer to Section 3, 1.3 PAINT REFINISHING.

9. Apply Joint Sealer (Item 3) as required. Refer to 5. BODY SEALING, ADHESIVES & DEADENERS in

Section 3C.

10. Apply Cavity W ax (Item 8) as required to the ins ide of any box s ections or areas inacces sible to paint, refer

to 6. CAVITY WAX in Section 3C.

11. Install the rem aining com ponents as described in the appr opriate Section of the MY 2003 VY & V2 Series II

Service Information.

2.4 LOAD FLOOR CENTRE RAIL ASSEMBLY – REPLACE

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Remove adjacent panels as required, refer to the

appropriate Section in this Supplement.

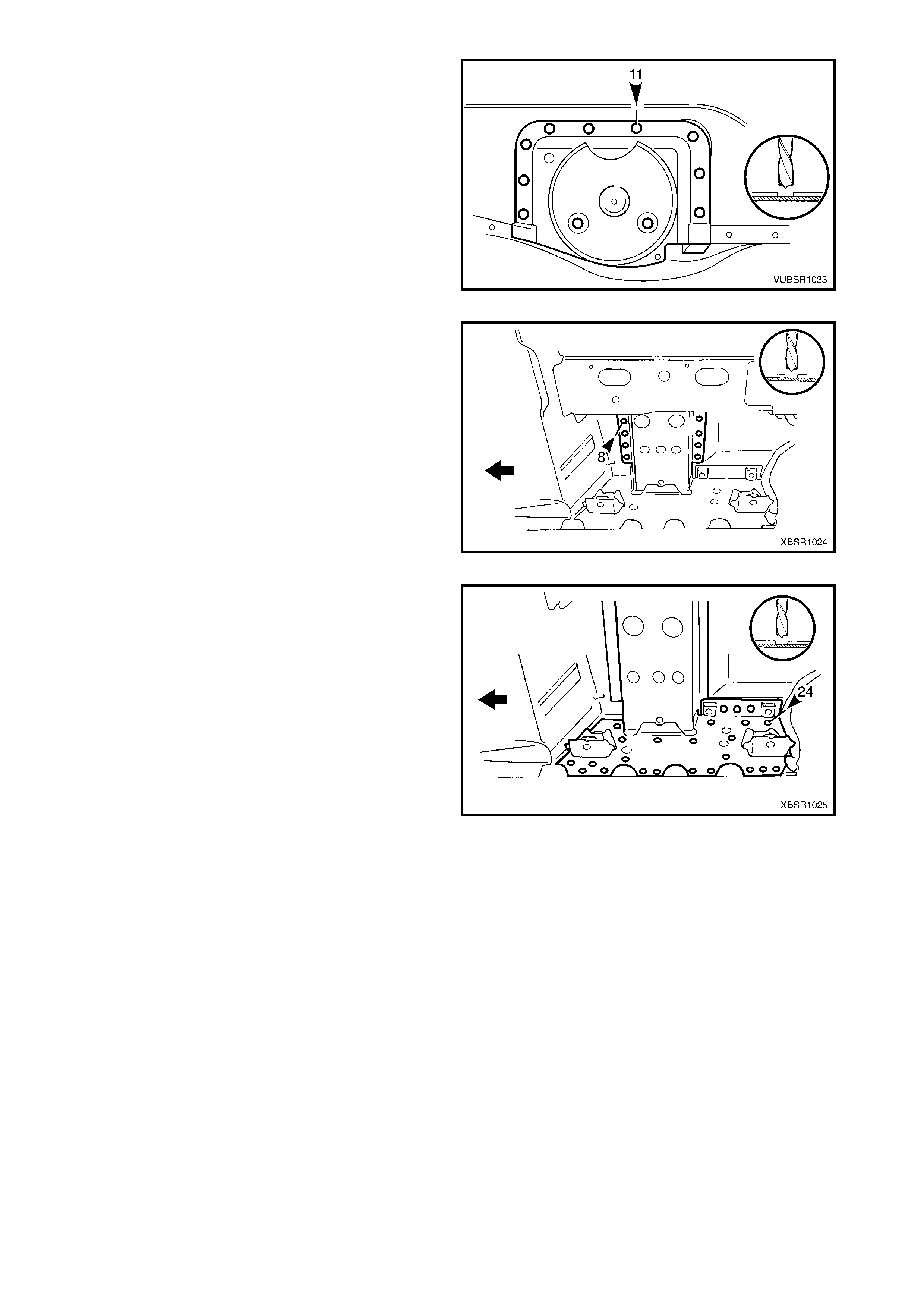

Figure 10C-19

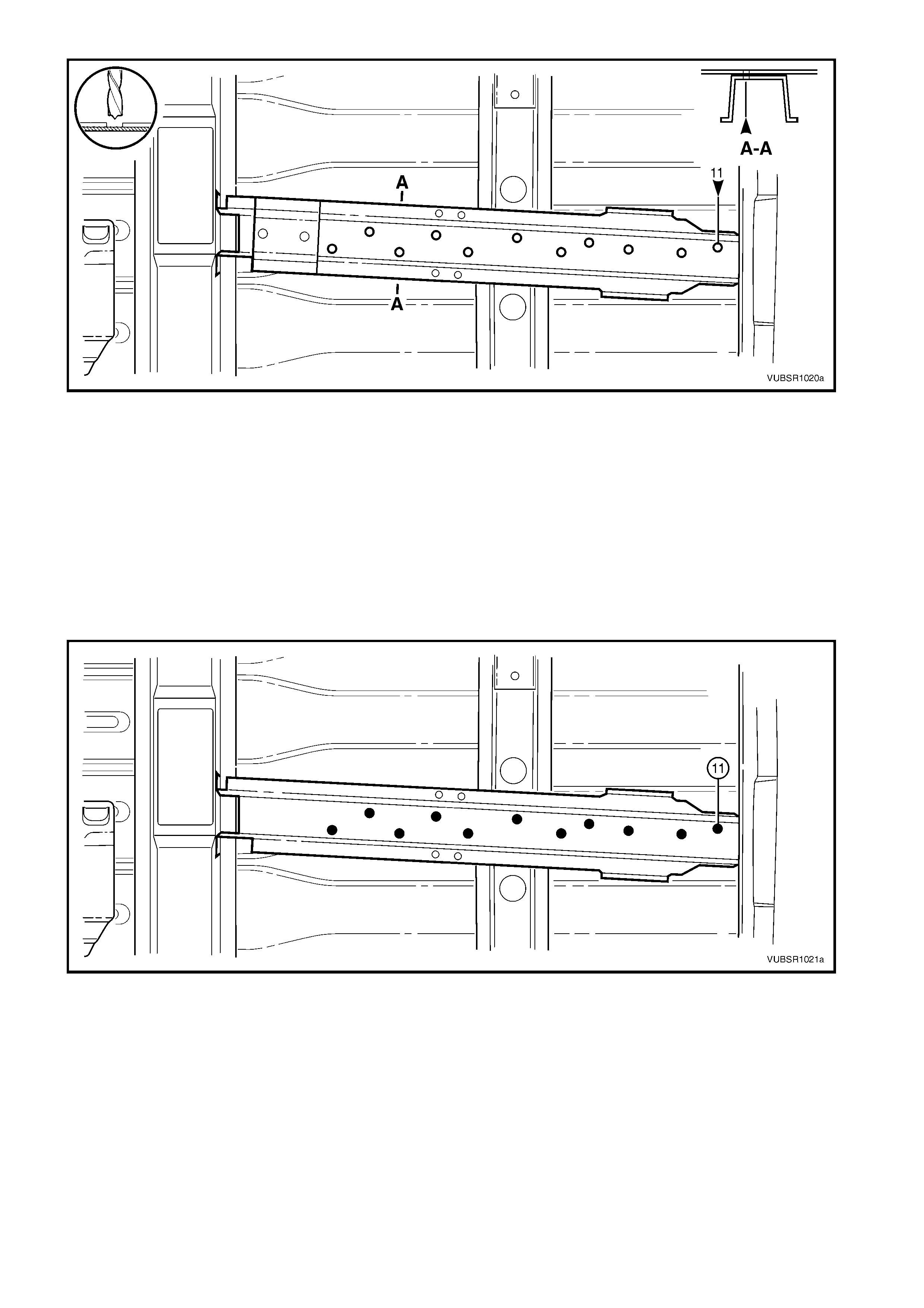

3. If required, from underneath the vehicle spot cut

the welds attaching the spare wheel support to the

load floor centre rail.

4. Spot cut the welds attaching the load floor centre

rail to the crossmember assembly No. 2.

Figure 10C-20

5. Spot cut the welds attaching the load floor centre

rail to the left-hand & right-hand load floor

reinforcement rails.

6. If required, spot cut the welds attaching the load

floor centre rail to the rear end panel.

7. Spot cut the welds attaching the load floor centre

rail to the load floor panel, refer to Figure 10C-22.

8. Remove the load floor centre rail from the vehicle

and repair any damage to adjacent parts as

required.

Figure 10C-21

Figure 10C-22

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment available will not access the required weld position, a plug weld should be

performed.

NOTE 2: The s ame number and pos ition of spot welds ( or plug welds) s hould be used when replac ing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. Spot or plug weld the load floor centre rail to the load floor panel, refer to Figure 10C-23.

Figure 10C-23

4. Spot or plug weld the load floor centre rail to the

left-hand & right-hand load floor reinforcement

rails.

5. If required, spot or plug weld the load floor centre

rail to the rear end panel.

Figure 10C-24

6. Spot or plug weld the load floor centre rail to the

crossmember assembly No. 2.

7. Install the spare wheel support, aligning it to the

front of the right-hand flange (1) of the load floor

centre rail. Spot or plug weld four places.

8. Install any removed panels as required, refer to the

appropriate Section in this Supplement.

9. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

10. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

11. Apply Cavity Wax (Item 8) as r equired to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

12. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10C-25

2.5 LOAD FLOOR REINFORCEMENT RAIL ASSEMBLY – REPLACE

REMOVE

1. Remove the adjacent com ponents as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

2. Secure the vehicle on a suitable fixture. As a

minimum, support the appropriate structural

sections of the vehicle on safety stands.

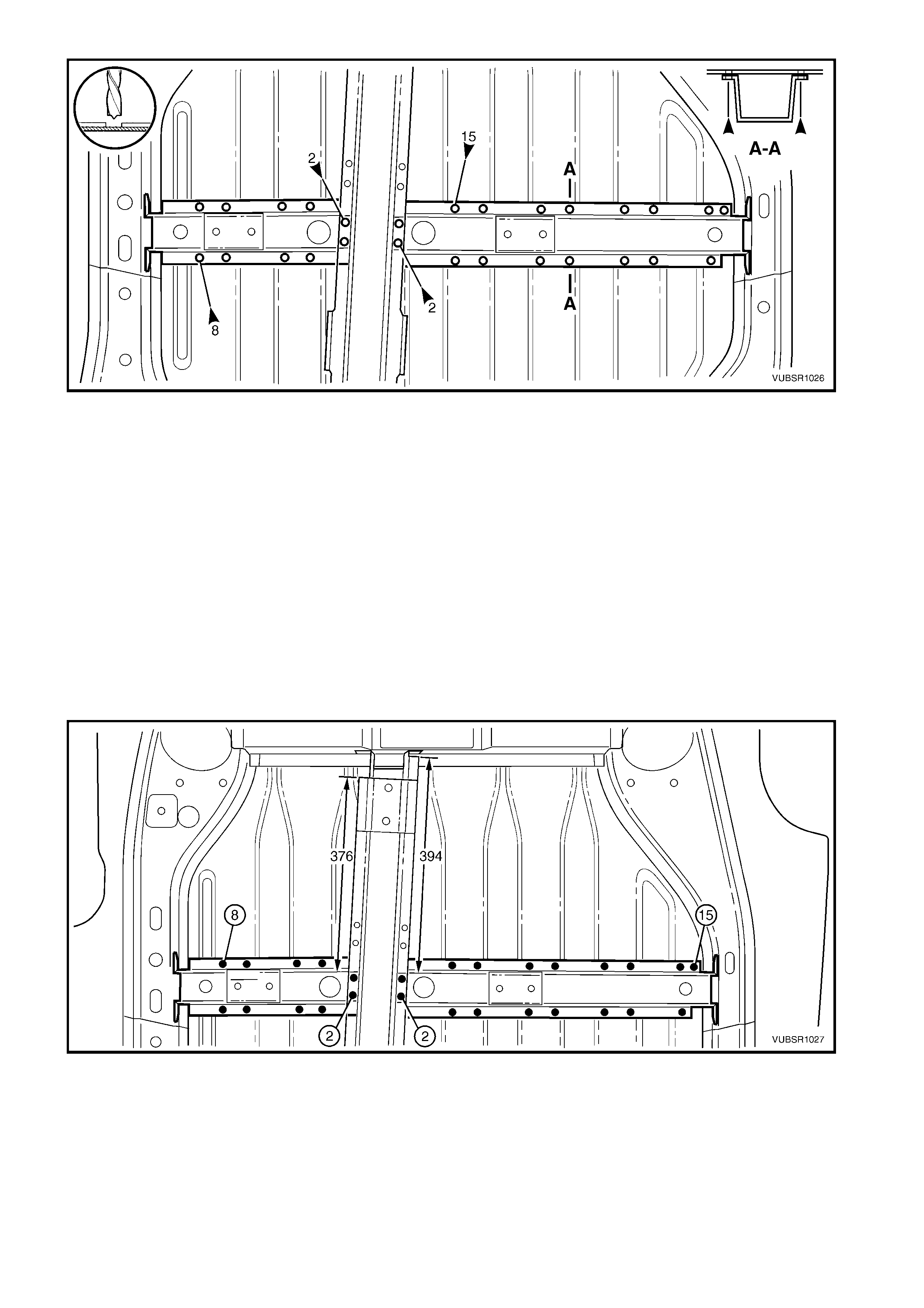

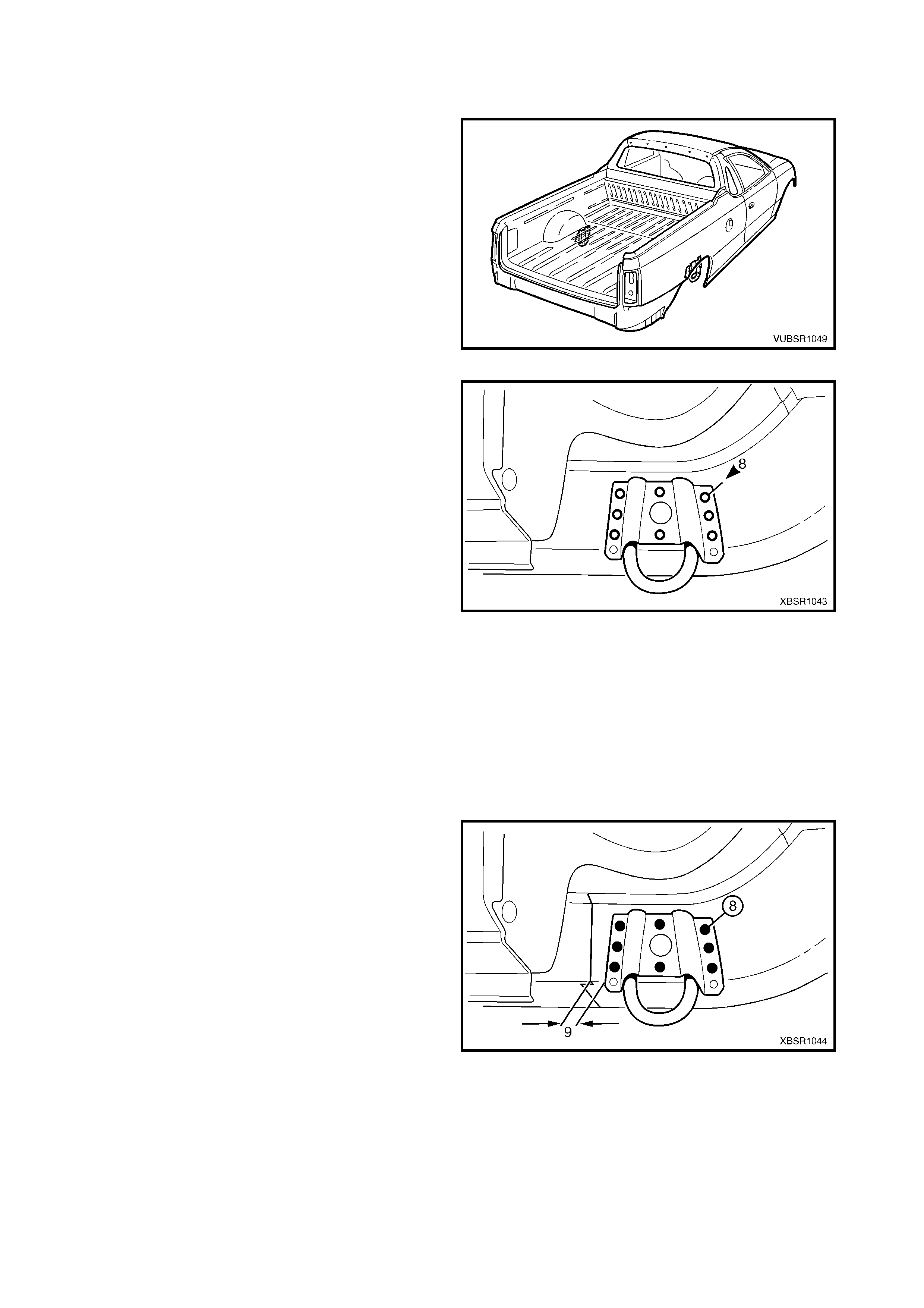

Figure 10C-26

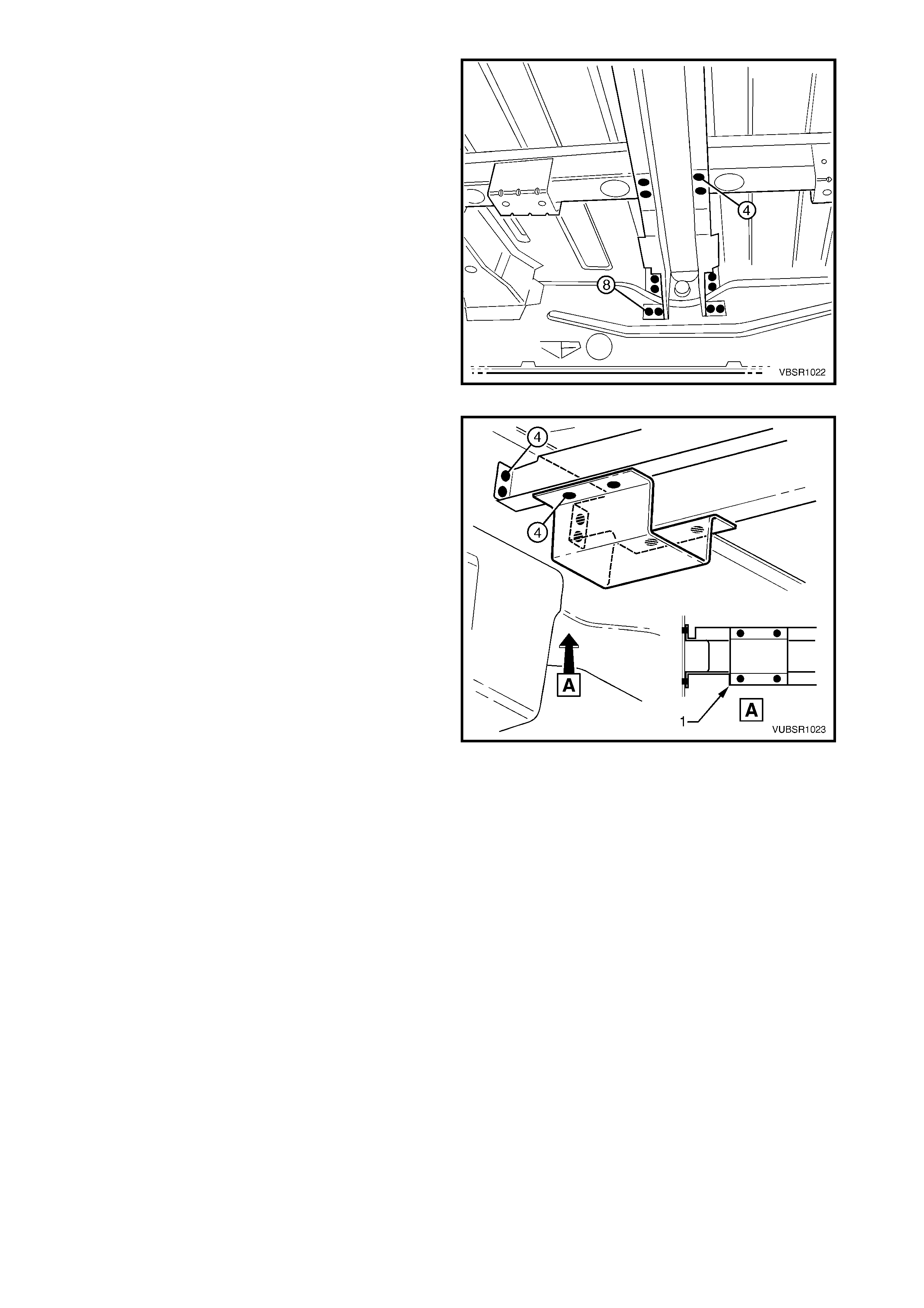

3. If required, from each side remove the spot welds

attaching the spare wheel support to the load floor

reinforcement rail.

4. Spot cut the welds attaching the load floor

reinforcement rail to the rear side rail assembly.

Figure 10C-27

5. Spot cut the welds attaching the load floor

reinforcement rail to the load floor centre rail

assembly.

6. Spot cut the two welds attaching the load floor

reinforcement rail to the load floor centre rail

assembly, refer to Figure 10C-29.

7. Spot cut the eight welds right-hand or 15 welds

left-hand, attaching each load floor reinforcement

rail to the load floor panel, refer to Figure 10C-29.

8. Remove the load floor reinforcement rail from the

vehicle and repair any damage to adjacent parts

as required.

Figure 10C-28

Figure 10C-29

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment available will not access the required weld position, a plug weld should be

performed.

NOTE 2: The s ame number and pos ition of spot welds ( or plug welds) s hould be used when replac ing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. Install the load floor reinforcement rail noting its position from the front of the load floor centre rail flange,

refer to Figure 10C-30.

4. Plug weld two places, the load floor reinforcement rail to the load floor centre rail, refer to Figure 10C-30.

5. Plug weld eight places right-hand or 15 places left-hand, the load floor reinforcement rail to the load floor

panel, refer to Figure10C-30.

Figure 10C-30

6. Plug weld the load floor reinforcement rail to the

rear side rail assembly.

Figure 10C-31

7. Plug weld the load floor reinforcement rail to the

load floor centre rail.

8. Install the left-hand or right-hand spare wheel

support on the load floor reinforcement rail in the

position shown, refer to Figure 10C-33 and plug

weld two places each side.

Figure 10C-32

Figure 10C-33

9. Install any removed panels as required, refer to the appropriate Section in this Supplement.

10. Refinish and paint panels and other components as required. Refer to Section 3, 1.3 PAINT REFINISHING.

11. Apply Joint Sealer (Item 3) as required. Refer to 5. BODY SEALING, ADHESIVES & DEADENERS in

Section 3C.

12. Apply Cavity W ax (Item 8) as required to the ins ide of any box s ections or areas inacces sible to paint, refer

to 6. CAVITY WAX in Section 3C.

13. Install the rem aining com ponents as described in the appr opriate Section of the MY 2003 VY & V2 Series II

Service Information.

2.6 CROSSMEMBER ASSEMBLY NO. 2 – REPLACE

REMOVE

1. Remove the adjacent com ponents as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

2. Secure the vehicle on a suitable fixture. As a

minimum, support the appropriate structural

sections of the vehicle on safety stands.

Figure 10C-34

3. Spot cut the welds attaching the crossmember

No.2 to the crossmember bracket and to the rear

side rail, on each side of the vehicle.

NOTE: Take care not to damage the crossmember

brackets when removing the crossmember, as these

parts are only serviced as part of the rear side rail

assemblies.

Figure 10C-35

4. Spot cut the welds attaching the crossmember to

the load floor panel.

5. Remove the crossmember from the vehicle, and

then repair any damage to adjacent parts as

required.

6. Check and rectify the alignment of the body as

required, refer to 3. BODY DIMENSIONS in

Section 3C.

Figure 10C-36

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The same number and position of spot welds (or plug welds) should be used when replacing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. Plug weld the crossmember to the crossmember

bracket and rear side rail, on each side of the

vehicle.

Figure 10C-37

4. Plug weld the crossmember to the load floor panel.

5. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

6. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

7. Apply Cavity Wax (Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

8. Apply Spray-on Deadener (Item 7) where

applicable, refer to 5. BODY SEALING,

ADHESIVES & DEADENERS in Section 3C.

9. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10C-38

2.7 REAR FLOOR PANEL OUTER EXTENSION – REPLACE

REMOVE

1. Remove the adjacent com ponents as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10C-39

2. Spot cut the welds attaching the rear floor panel

outer extension to the inner rocker panel and rear

side rail assembly and remove.

Figure 10C-40

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s ame number and pos ition of spot welds ( or plug welds) s hould be used when replac ing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. Install and plug weld the rear floor panel outer

extension to the inner rocker panel and rear side

rail assembly.

4. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

5. Apply Cavity Wax (Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

6. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10C-41

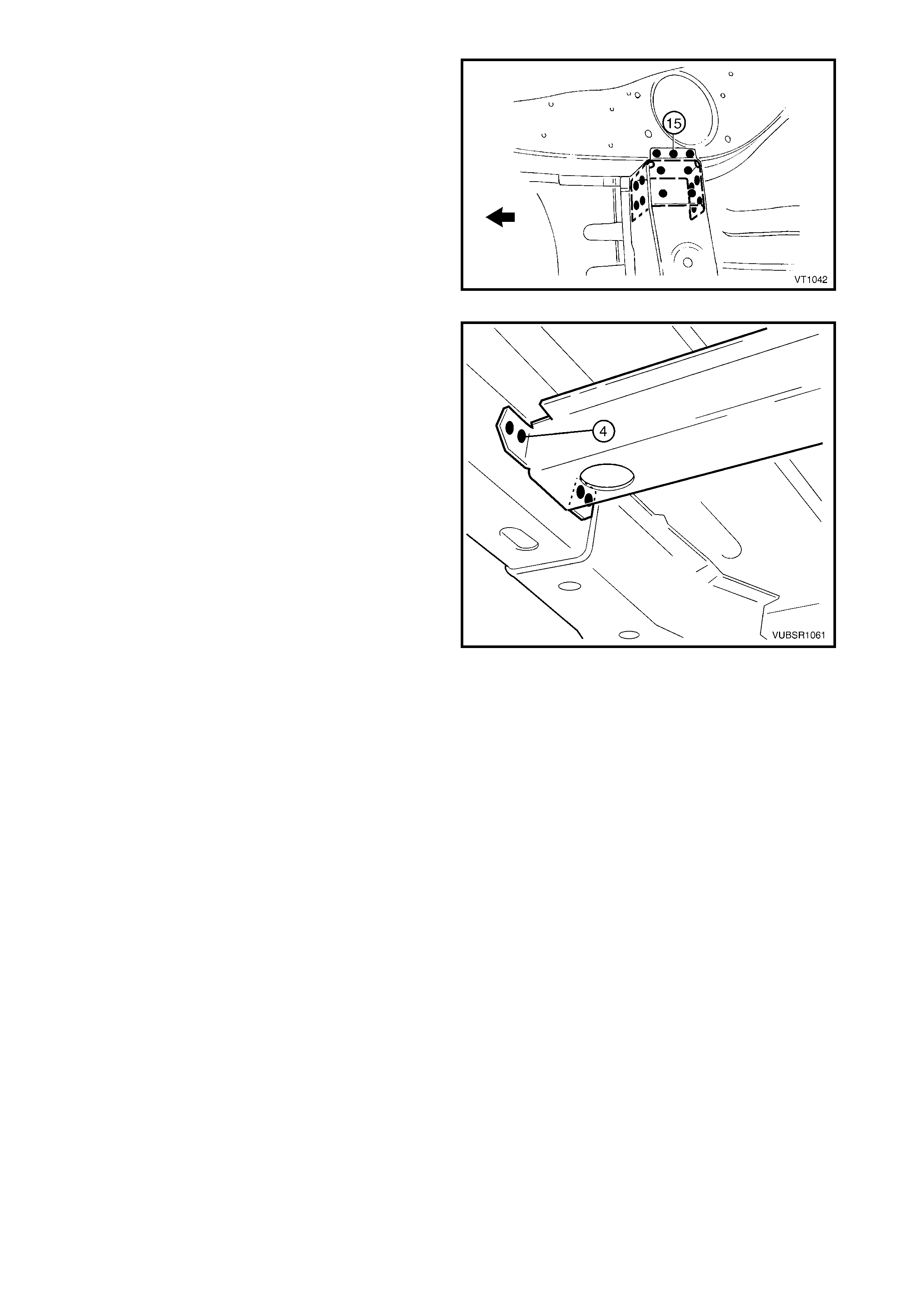

2.8 REAR TIE DOWN ASSEMBLY – REPLACE

REMOVE

1. Remove the adjacent com ponents as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

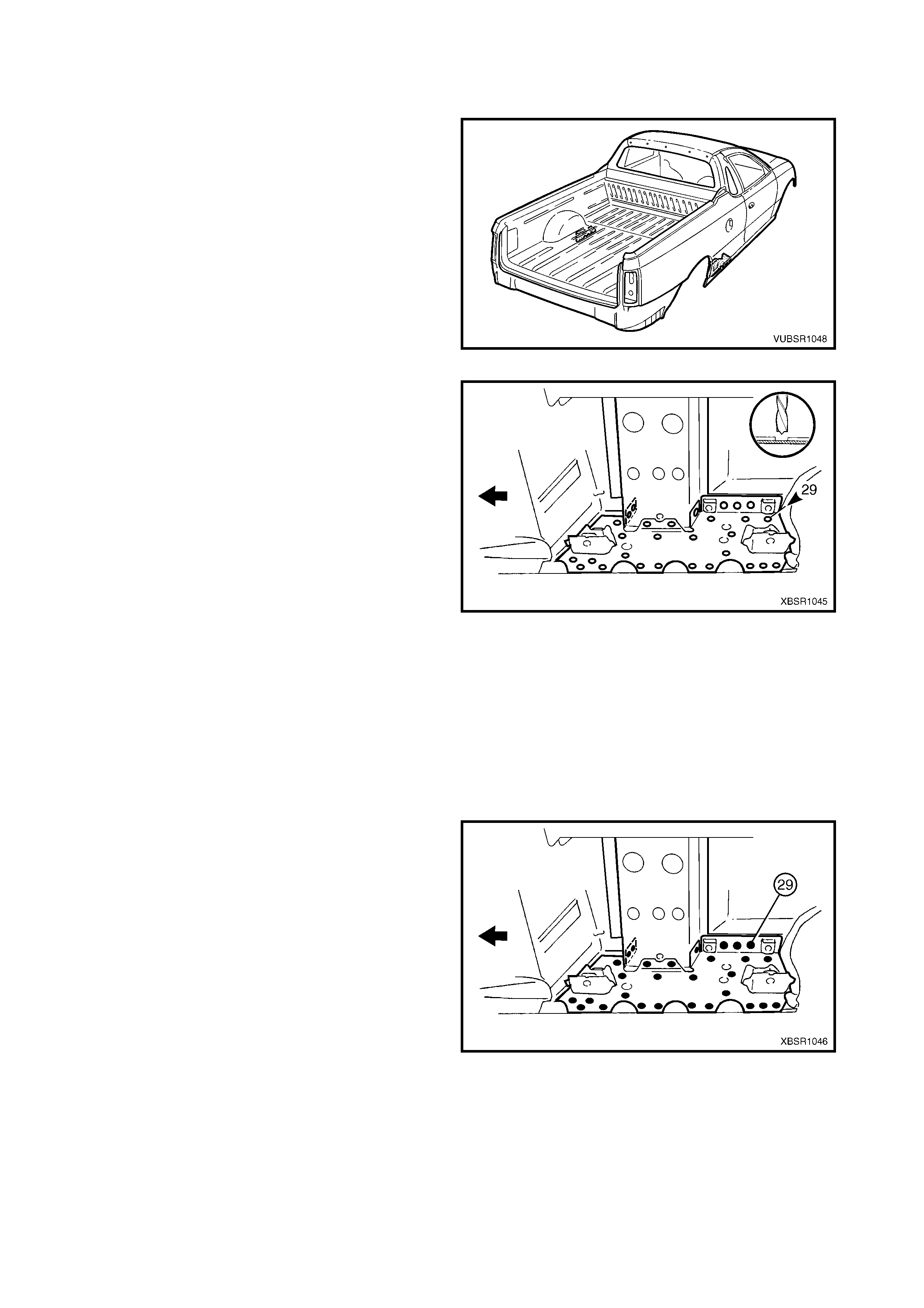

Figure 10C-42

2. Spot cut the welds attaching the tie down hook

assembly to the rear side rail assembly and

remove.

Figure 10C-43

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s ame number and pos ition of spot welds ( or plug welds) s hould be used when replac ing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. Install the tie down hook assembly onto the rear

side rail assembly, approximately 9 mm rearward

of the join.

4. Plug weld the tie down hook assembly to the rear

side rail assembly, eight places.

5. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

6. Apply Cavity Wax (Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

7. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10C-44

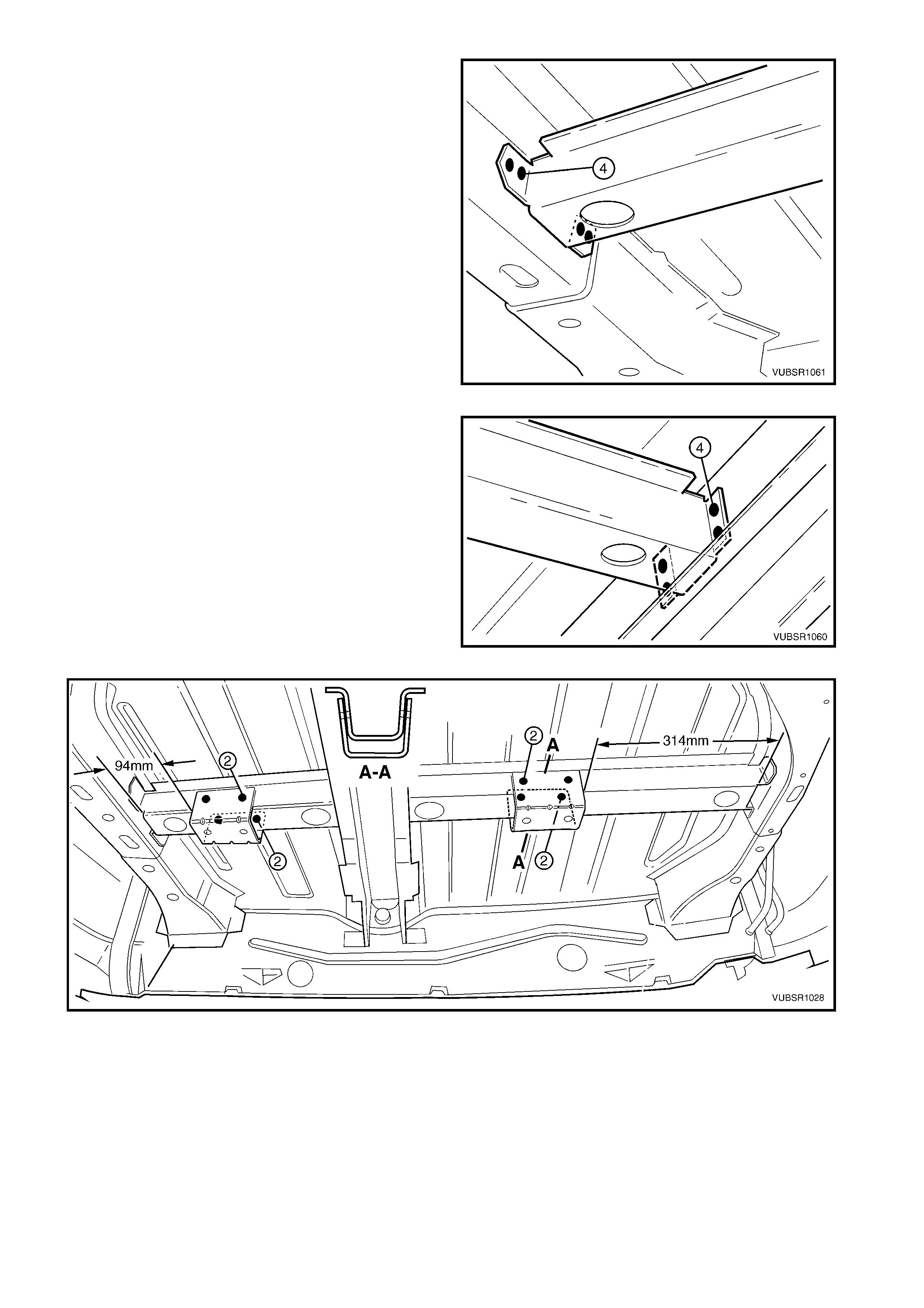

2.9 REAR SIDE RAIL ASSEMBLY – REPLACE

REMOVE

CAUTION: To avoid the possibility of fire, take

particular care when cutting or welding at the rear

of the vehicle. Remove the fuel tank and plug the

fuel lines.

1. Remove the adjacent com ponents as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

2. Secure the vehicle on a suitable fixture. As a

minimum, support the appropriate structural

sections of the vehicle on safety stands. Ensure

that the stands are clear of the rear side rail

assembly(s) being removed.

Figure 10C-45

3. Spot cut the welds attaching the load floor

reinforcement rail to the rear side rail assembly.

Figure 10C-46

4. Spot cut the welds attaching the crossmember

No.2 to the crossmember bracket and to the rear

side rail.

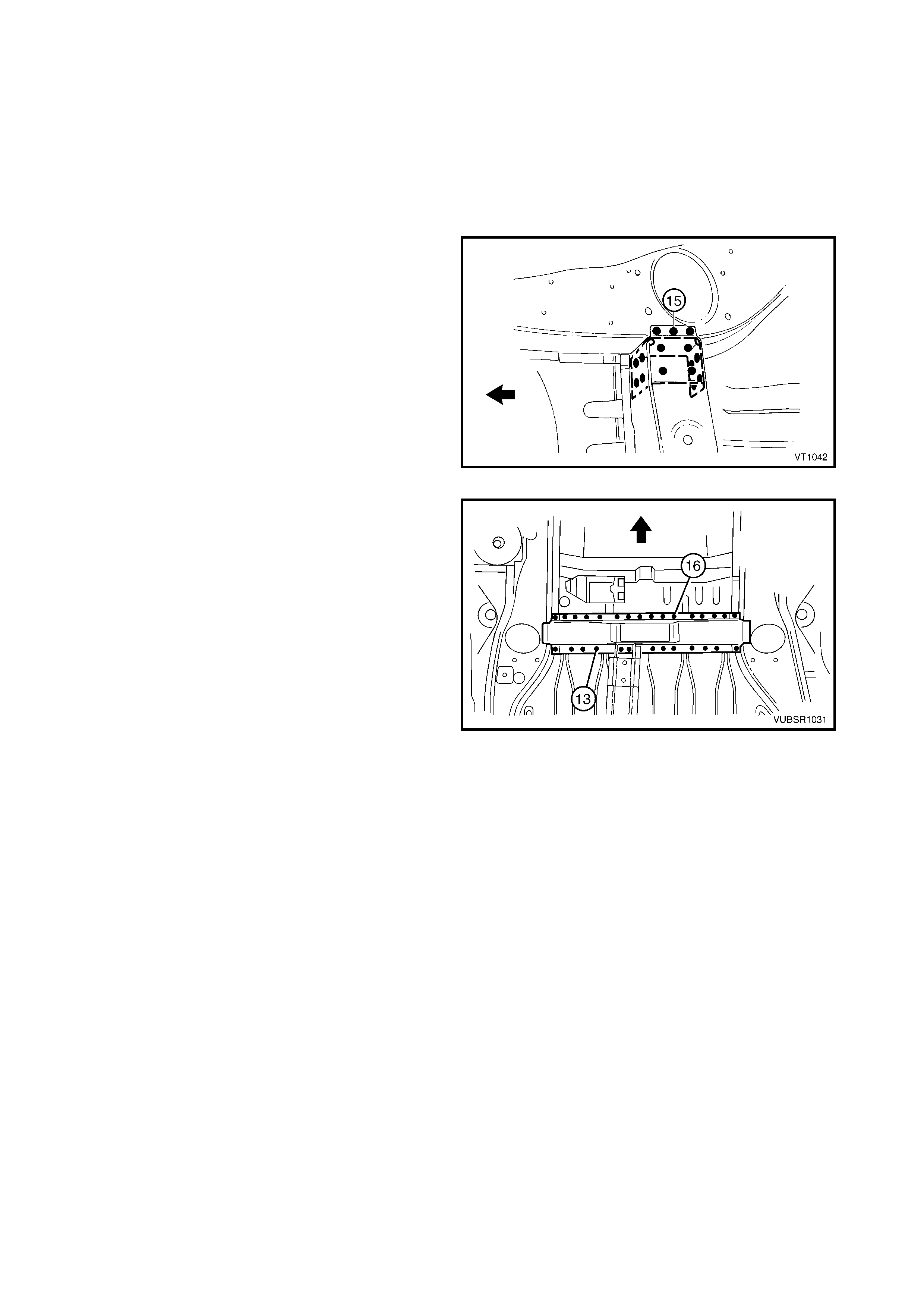

Figure 10C-47

5. Spot cut the welds attaching the rear side rail

assembly to the load floor panel.

Figure 10C-48

6. Spot cut the welds attaching the rear side rail

assembly to the rear floor panel assembly.

Figure 10C-49

7. Spot cut the welds attaching the rear floor panel

outer extension to the inner rocker panel

assembly.

8. Spot cut the rear side rail assembly from the load

floor panel, rear end panel and rear floor panel

assembly, refer to Figure 10C-51.

9. Remove the rear side rail assembly from the

vehicle and repair damage to adjacent parts as

required.

10. Check and rectify the alignment of the body as

required, refer to 3. BODY DIMENSIONS in

Section 3C.

Figure 10C-50

Figure 10C-51

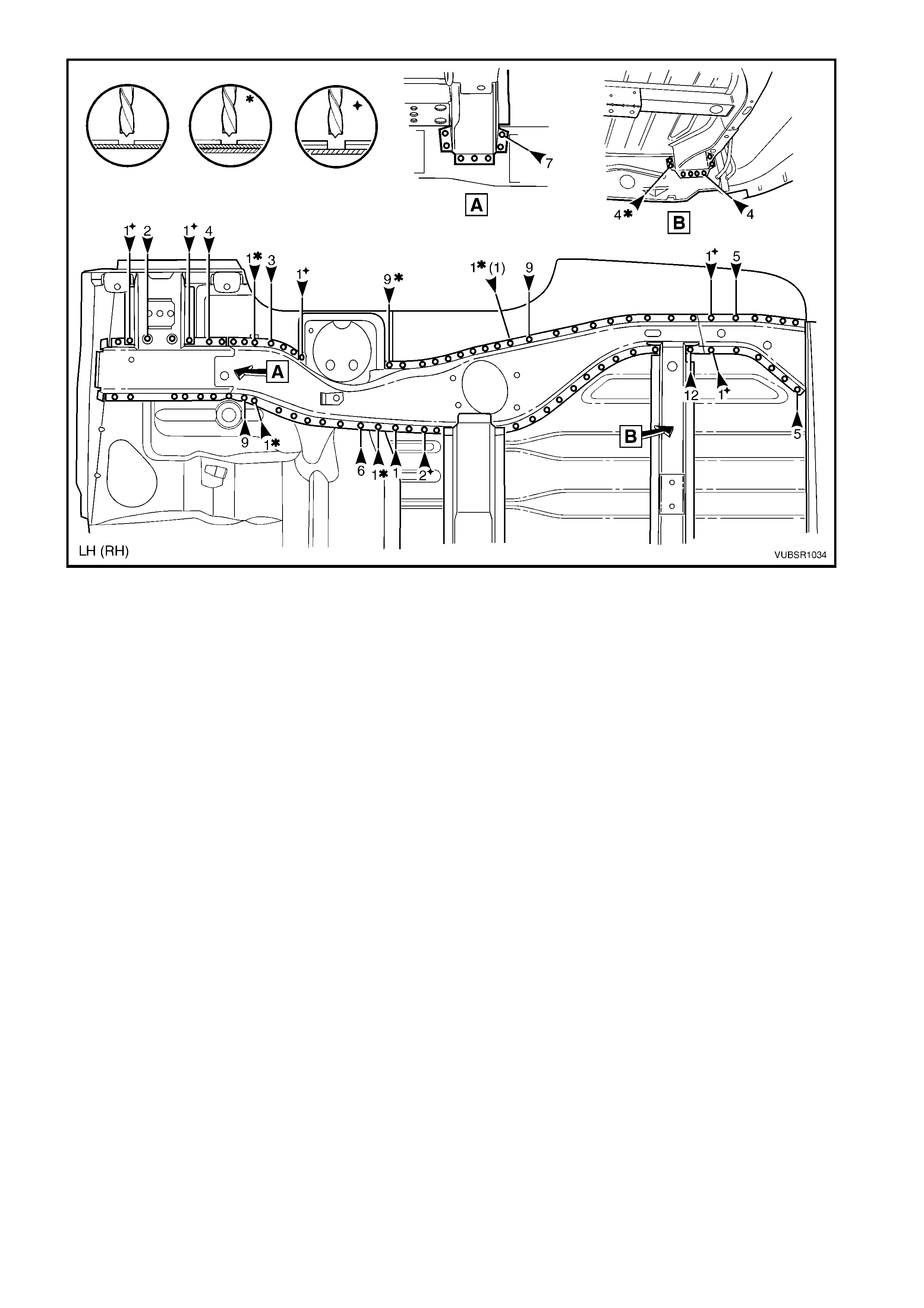

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s ame number and pos ition of spot welds ( or plug welds) s hould be used when replac ing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. Locate and clamp the new rear side rail assembly in position.

4. Check and adjust the alignm ent of the rear side rail assembly as required, refer to 3. BODY DIMENSIONS

in Section 3C.

5. Plug weld the rear side rail assem bly to the load floor panel, rear end panel and rear floor panel assem bly,

refer to Figure 10C-52.

Figure 10C-52

6. Plug weld the rear side rail assembly to the load

floor panel.

Figure 10C-53

7. Plug weld the rear side rail assembly to the rear

floor panel ass embly and the rear floor panel outer

extension to the inner rocker panel assembly.

Figure 10C-54

8. Plug weld the cr ossm ember assem bly No. 2 to the

crossmember bracket and rear side rail.

Figure 10C-55

9. Plug weld the load floor reinforcement rail to the

rear side rail assembly.

10. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

11. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

12. Apply Cavity Wax (Item 8) as r equired to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

13. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10C-56

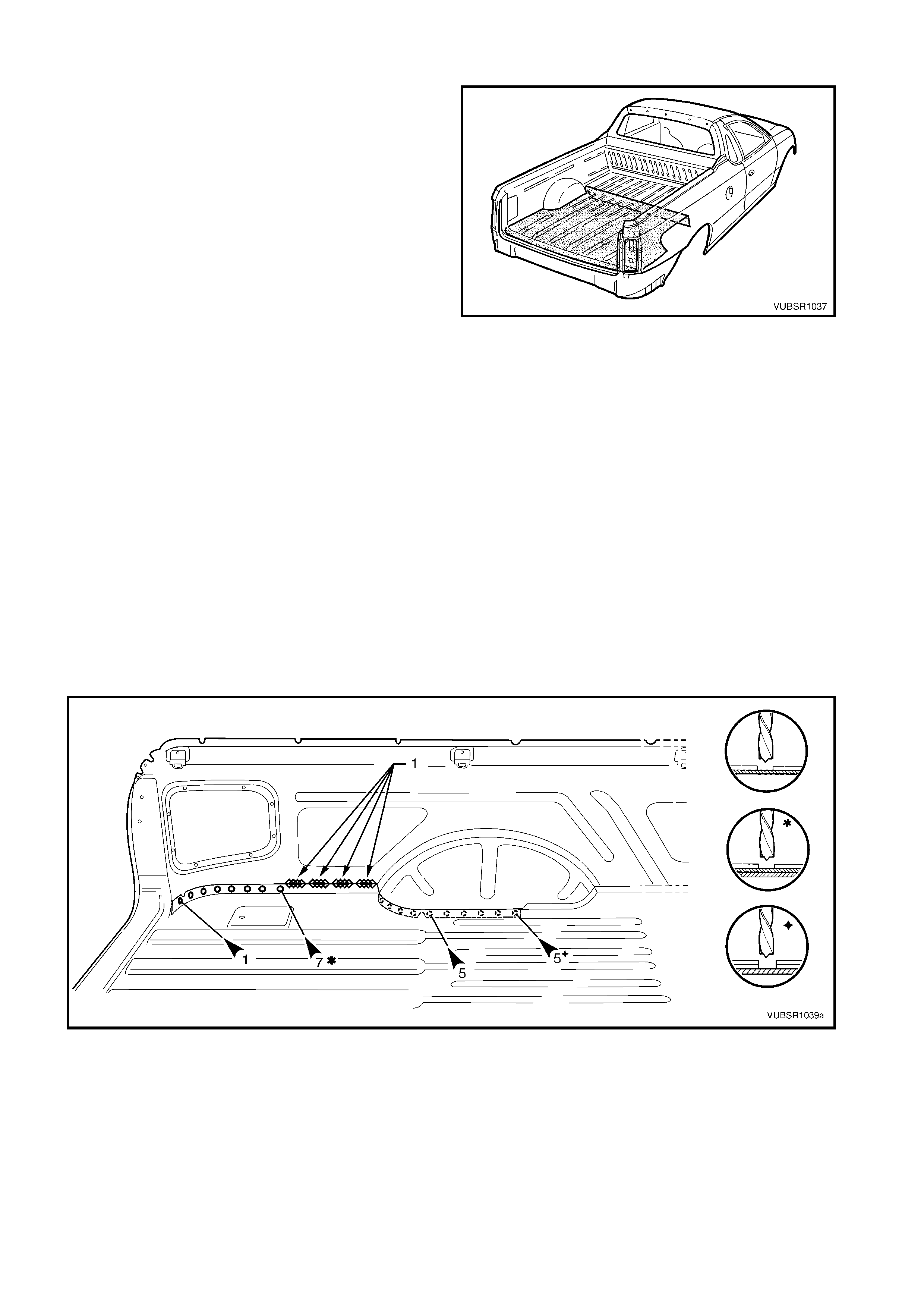

2.10 LOAD FLOOR PANEL ASSEMBLY – REPLACE

NOTE: This procedure describes the removal of the

load floor panel, load floor panel reinforcements and

fuel tank brackets as an assembly. As these

components are serviced separately, their installation

is described as they would be replaced.

CAUTION: To avoid the possibility of fire, take

particular care when cutting or welding at the rear

of the vehicle. Remove the fuel tank and plug the

fuel lines.

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Secure the vehicle on a suitable fixture. As a

minimum, support the appropriate structural

sections of the vehicle on safety stands. Ensure

that the stands are clear of the sections being

removed.

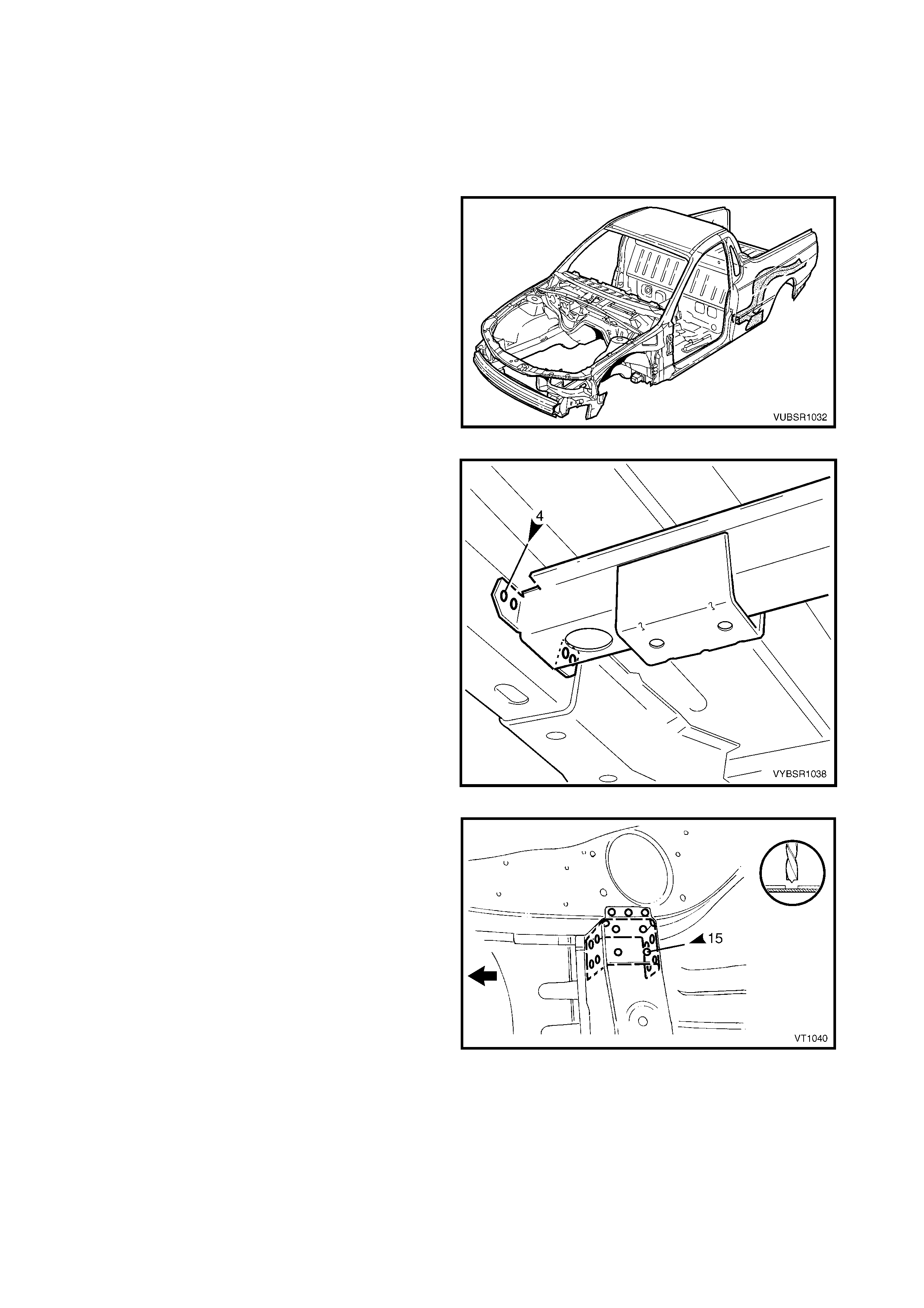

Figure 10C-57

3. Remove the sealer and floor deadener panels from the relevant areas using a scraper and heat gun.

4. Remove the adjoining panels as required, refer to the appropriate Section of this Supplement.

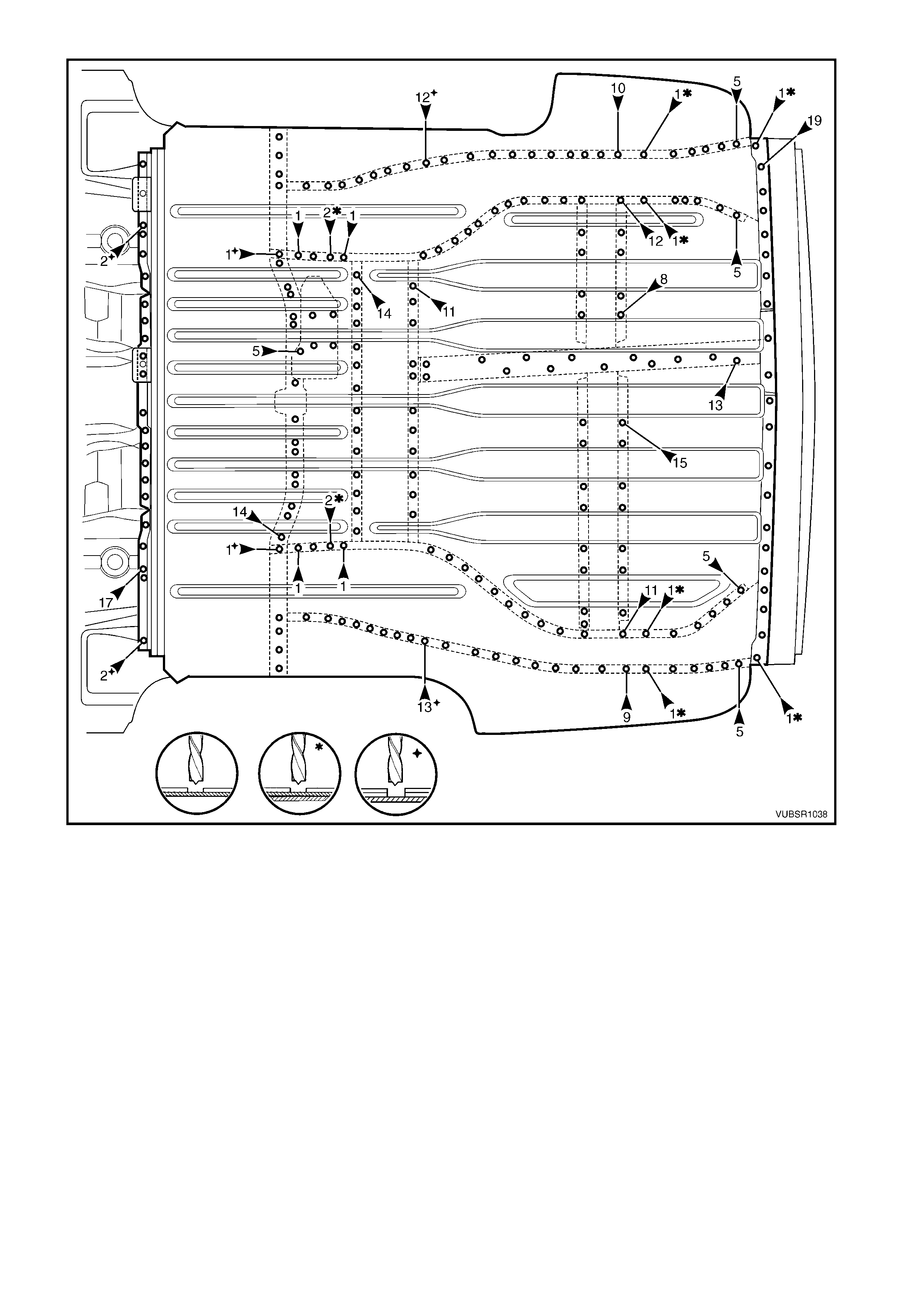

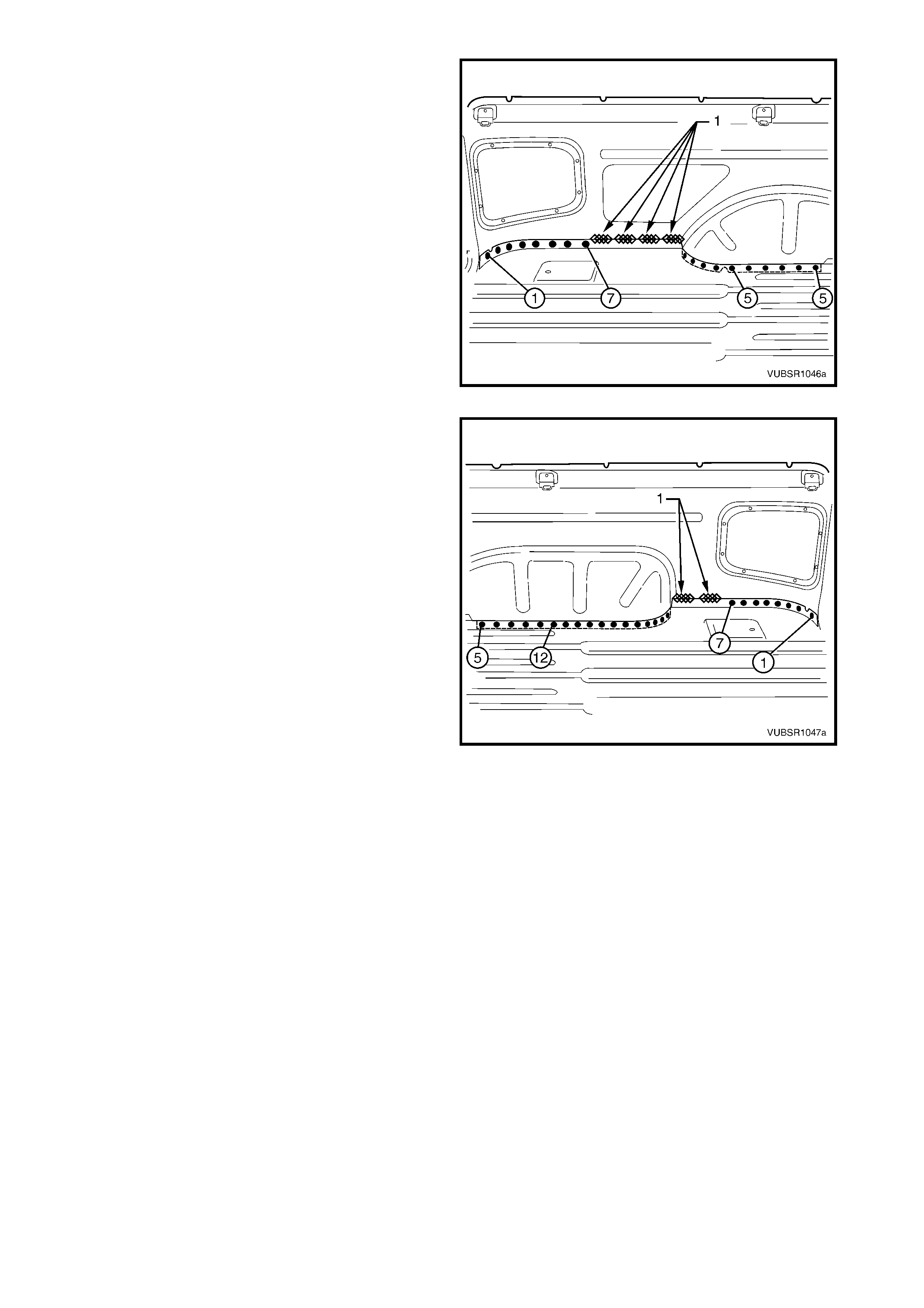

5. Referring to Figure 10C-58:

- Spot cut the weld attaching the load floor panel to the left-hand side inner upper panel, one place,

- Spot cut the welds attaching the load f loor panel to the left- hand side inner upper panel and quarter outer

lower rear panel, seven places,

- Grind off the MIG welds (1) attaching the load floor panel to the left-hand side inner upper panel, four

places,

- From underneath the vehicle, spot cut the welds attaching the load floor panel to the left-hand rear

wheelhouse inner panel, five places,

- From underneath the vehicle, spot cut the welds attaching the load floor panel and load floor panel

reinforcement to the left-hand rear wheelhouse inner panel, five places.

Figure 10C-58

6. Referring to Figure 10C-59:

- Spot cut the weld attaching the load floor panel to the right-hand side inner upper panel, one place,

- Spot cut the welds attaching the load floor panel to the right-hand side inner upper panel and quarter

outer lower rear panel, seven places,

- Grind off the MIG welds (1) attaching the load floor panel to the right-hand side inner upper panel, two

places,

- From underneath the vehicle, spot cut the welds attaching the load floor panel to the right-hand rear

wheelhouse inner panel, five places,

- From underneath the vehicle, spot cut the welds attaching the load floor panel and load floor panel

reinforcement to the right-hand rear wheelhouse inner panel, twelve places.

Figure 10C-59

7. Spot cut the welds attac hing the load floor panel to

the rear wheelhouse inner panel each side of the

vehicle.

8. Spot cut the welds attac hing the load floor panel to

the load floor panel outer extension, each side of

the vehicle.

9. Spot cut the welds attac hing the load floor panel to

the rear side rail assemblies, rear end panel, load

floor centre rail assembly, left-hand & right-hand

load floor reinforcement rails, crossmember

assembly No. 2 and rear floor panel assembly,

refer to Figure 10C-61.

Figure 10C-60

Figure 10C-61

10. Remove the load floor panel and repair any damage to adjacent parts as required.

NOTE: Structural adhesive is applied to the front mating surface of the load floor panel where it attaches the rear

floor – panel assembly, which may require cutting.

11. Check and rectify the alignment of the body as required, refer to 3. BODY DIMENSIONS in Section 3C.

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s ame number and pos ition of spot welds ( or plug welds) s hould be used when replac ing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

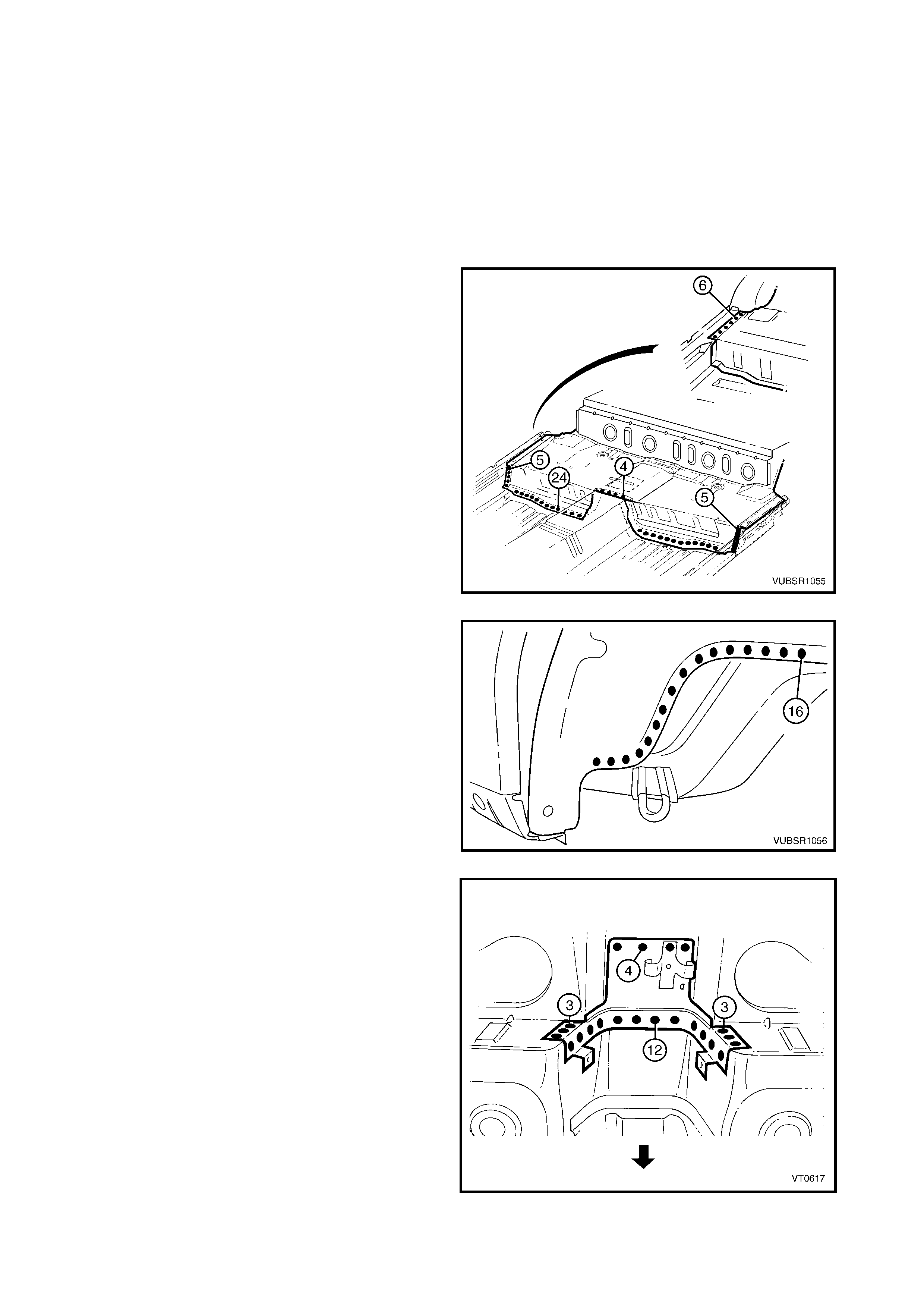

3. Prior to installing the load f loor panel, install the fuel tank mounting brack ets and the left-hand & right-hand

load floor panel reinforcements as described below.

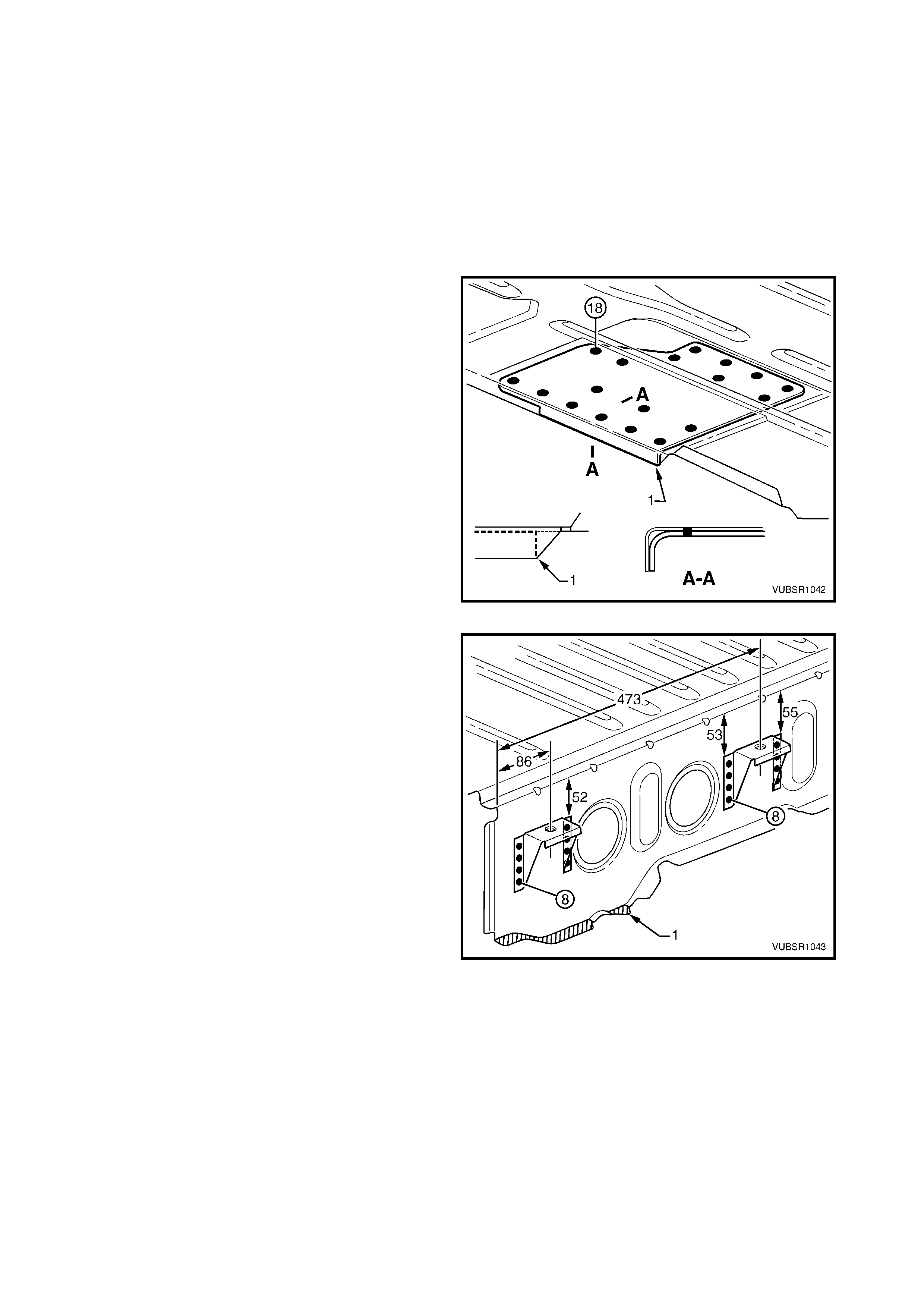

4. Fit the load floor panel reinforcement to the

underside of the load f loor panel, aligning the front

corner as shown (1).

5. Spot or plug weld the reinforcement to the load

floor panel 18 places.

6. Repeat for the opposite side.

Figure 10C-62

7. Position the fuel tank mounting brackets on to the

load floor panel, ensuring they are aligned to the

dimensions shown.

8. Spot or plug weld the brackets to the load floor

panel, eight places each.

9. Apply Structural Adhesive (Item 6), to the front

mating surface of the load floor panel, refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

10. Install the load floor panel and clamp in position.

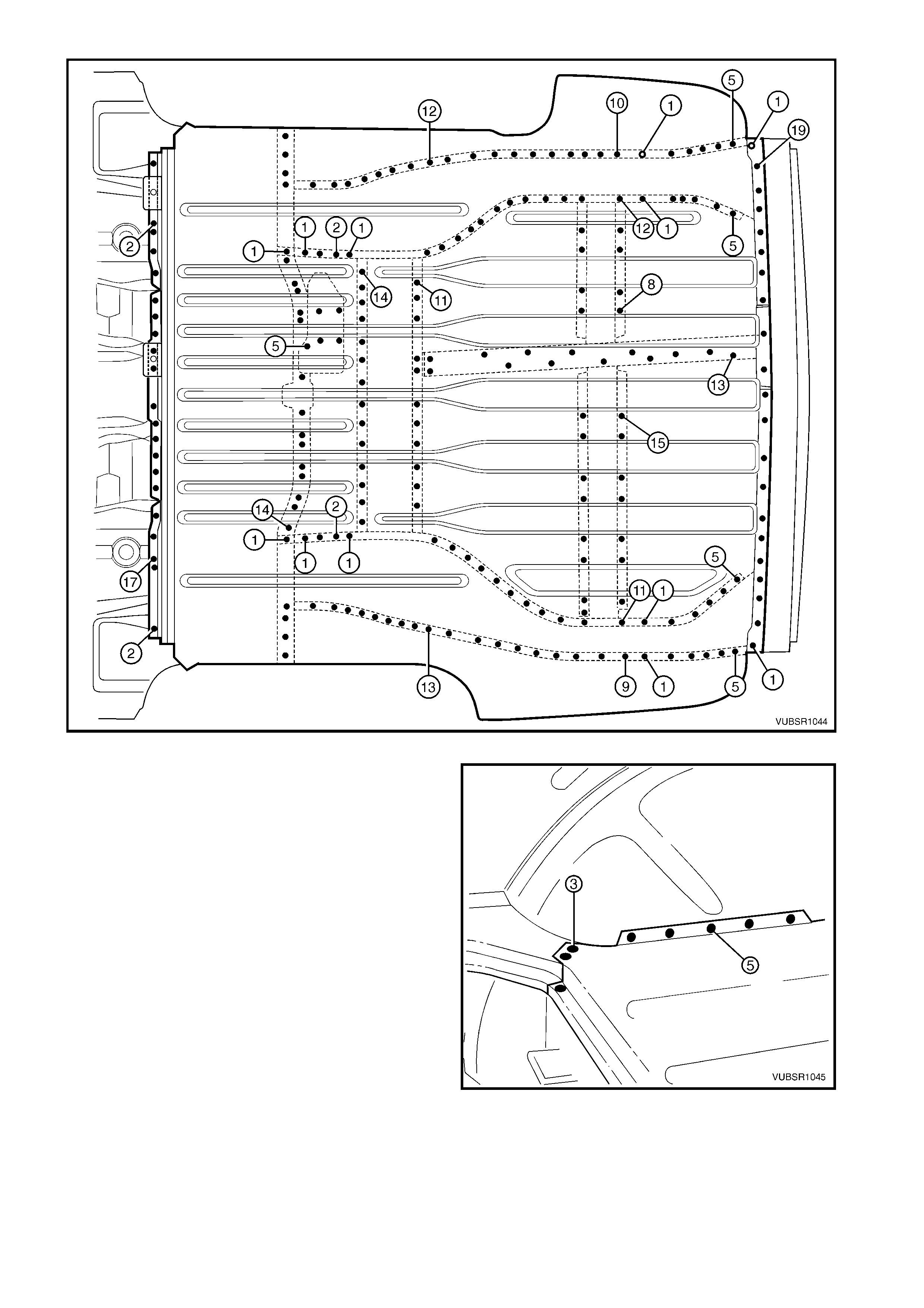

11. Beginning at the front, spot or plug weld the load

floor panel to the rear floor panel assembly,

crossmember assembly No. 2, left-hand & right-

hand load floor reinforcement rails, load floor

centre rail assem bly, rear end panel and rear side

rail assemblies, refer to Figure 10C-64.

Figure 10C-63

Figure 10C-64

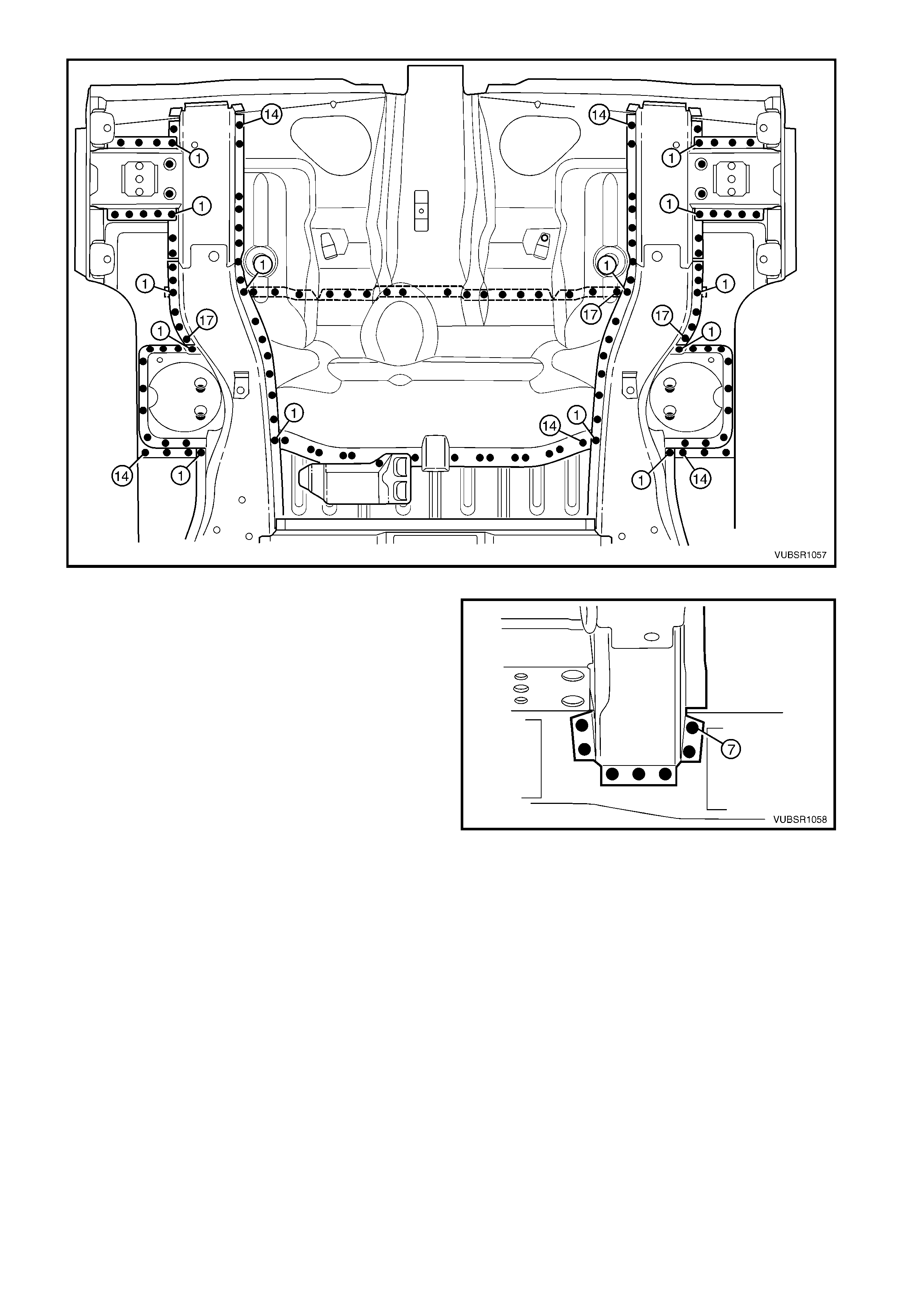

12. Spot or plug weld five places the load floor panel to

the rear wheelhouse inner panel each side of the

vehicle.

13. Spot or plug weld three places the load floor panel

to the load floor panel outer ex tension each side of

the vehicle.

Figure 10C-65

14. Spot or plug weld the load floor panel to the left-

hand side inner upper panel, one place.

15. Spot or plug weld the load floor panel to the left-

hand side inner upper panel and quarter outer

lower rear panel, seven places.

16. MIG weld (1) the load floor panel to the left-hand

side inner upper panel, four places.

17. From underneath the vehic le, spot or plug weld the

load floor panel to the left-hand rear wheelhouse

inner panel, five places.

18. From underneath the vehic le, spot or plug weld the

load f loor panel and load f loor panel reinfor cement

to the left-hand rear wheelhouse inner panel, five

places.

Figure 10C-66

19. Spot or plug weld the load floor panel to the right-

hand side inner upper panel, one place.

20. Spot or plug weld the load floor panel to the right-

hand side inner upper panel and quarter outer

lower rear panel, seven places.

21. MIG weld (1) the load floor panel to the right-hand

side inner upper panel, two places.

22. From underneath the vehic le, spot or plug weld the

load floor panel to the right-hand rear wheelhouse

inner panel, five places.

23. From underneath the vehic le, spot or plug weld the

load f loor panel and load f loor panel reinfor cement

to the right-hand rear wheelhouse inner panel, 12

places.

24. Install any removed panels as required, refer to the

appropriate Section in this Supplement.

25. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

26. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

27. Apply Cavity Wax (Item 8) as r equired to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

28. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10C-67

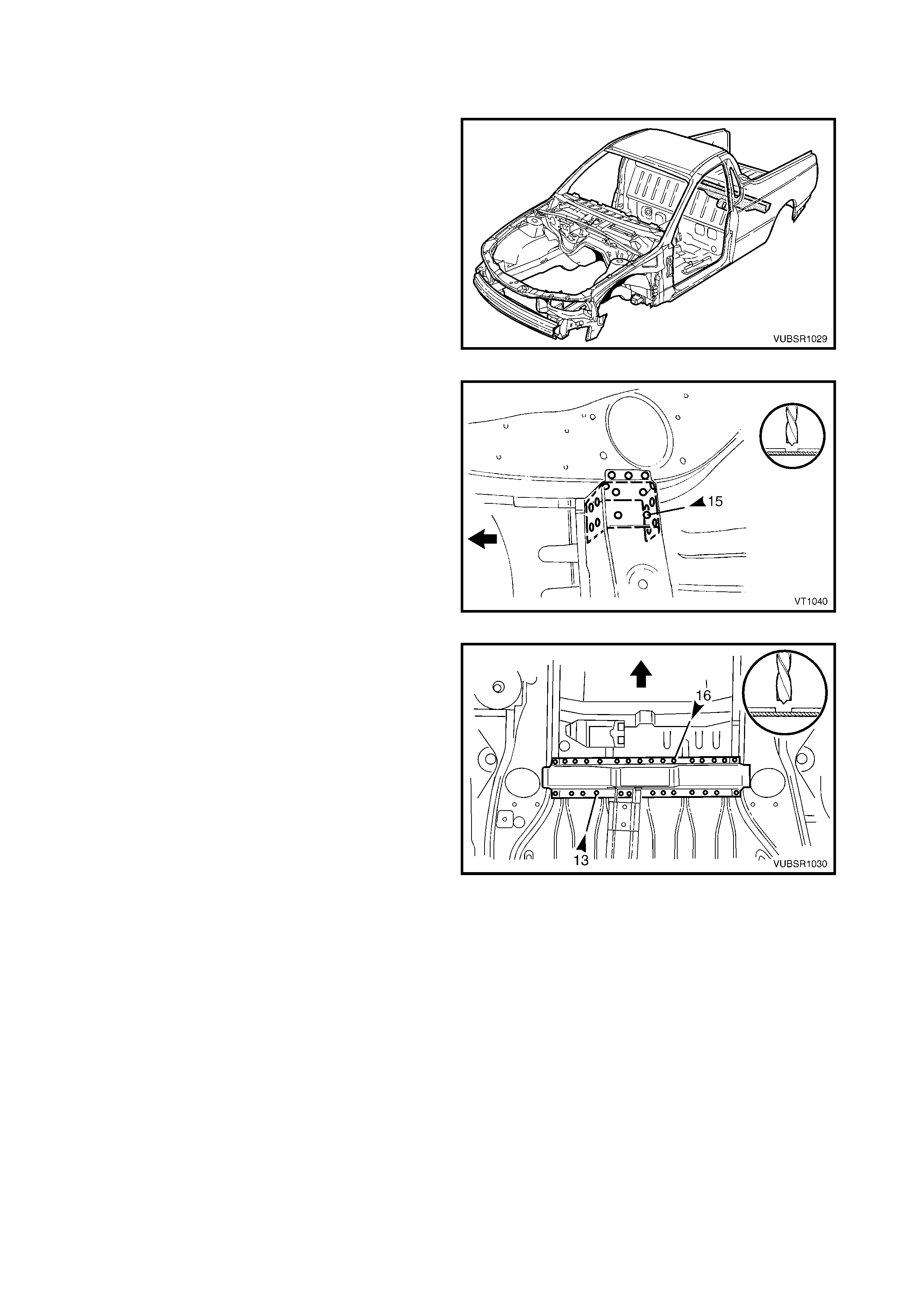

2.11 REAR FLOOR PANEL ASSEMBLY – REPLACE

REMOVE

CAUTION: To avoid the possibility of fire, take

particular care when cutting or welding at the rear

of the vehicle. Remove the fuel tank and plug the

fuel lines.

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Secure the vehicle on a suitable fixture. As a

minimum, support the appropriate structural

sections of the vehicle on safety stands. Ensure

that the stands are clear of the sections being

removed.

3. Remove the adjoining panels as required, refer to

the appropriate Section of this Supplement.

Figure 10C-68

4. Spot cut the welds attaching the park brake cable

bracket to the rear floor panel assembly.

Figure 10C-69

5. Spot cut the welds joining the front floor panel

assembly (1) and rear floor panel assembly (2).

6. Spot cut the welds attaching the rear floor panel

assembly to the inner rocker panel (3) each side.

NOTE: Structural adhesive is applied in the area

shown (4).

Figure 10C-70

7. Spot cut the welds attaching the rear floor panel

assembly to the rear wheelhouse inner panel on

each side of the vehicle.

NOTE: Structural adhesive is applied in the area

shown (1).

Figure 10C-71

8. Spot cut the welds attaching the front of each rear

side rail assembly to the rear floor panel assembly.

9. As required, spot cut the welds attaching the rear

floor panel assembly to the rear side rail

assemblies and load floor panel, refer to Figure

10C-73.

NOTE: Depending on what other panels are removed,

these welds can be cut from above or underneath the

vehicle as required, underside shown.

10. Remove the rear floor panel assembly from the

vehicle and then repair any damage to adjacent

parts as required.

11. Check and rectify the alignment of the body as

required, refer to 3. BODY DIMENSIONS in

Section 3C.

Figure 10C-72

Figure 10C-73

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s ame number and pos ition of spot welds ( or plug welds) s hould be used when replac ing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. Apply Structural Adhesive (Item 6), refer to 5. BODY SEALING, ADHESIVES & DEADENERS in

Section 3C.

4. Clam p the new panel in position in the vehicle and

plug weld to the front floor panel assembly and

inner rocker panel each side.

Figure 10C-74

5. Spot or plug weld the rear floor panel assembly to

the rear wheelhouse inner panel on each side of

the vehicle.

Figure 10C-75

6. Plug weld the park brak e cable bracket to the rear

floor panel assembly.

7. As required, spot or plug weld the rear floor panel

assem bly to the rear s ide rail assem blies and load

floor panel, refer to Figure 10C-77.

NOTE: Depending on what other panels are removed,

these welds can be made from above or underneath

the vehicle as required, underside shown.

Figure 10C-76

Figure 10C-77

8. Plug weld the front of each rear side r ail assembly

to the rear floor panel assembly.

9. Replace any other removed panels, refer to the

appropriate Section of this Supplement.

10. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

11. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

12. Apply Cavity Wax (Item 8) as r equired to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

13. Apply deadener panels in accordance with

the original production condition. Refer to

5.6 DEADENERS & INSULATORS in Section 3C.

14. Apply the fusible reinforcement patch, refer to

5.7 FUSIBLE REINFORCEMENT PATCH in

Section 3C.

15. Apply Spray-on Deadener (Item 7) where

applicable, refer to 5. BODY SEALING,

ADHESIVES & DEADENERS in Section 3C.

16. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 10C-78