Roof Panel Page 9–1

Page 9–1

Section 9

Roof Panel

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions And Notes for correct workshop practices with regard to safety and/or property damage.

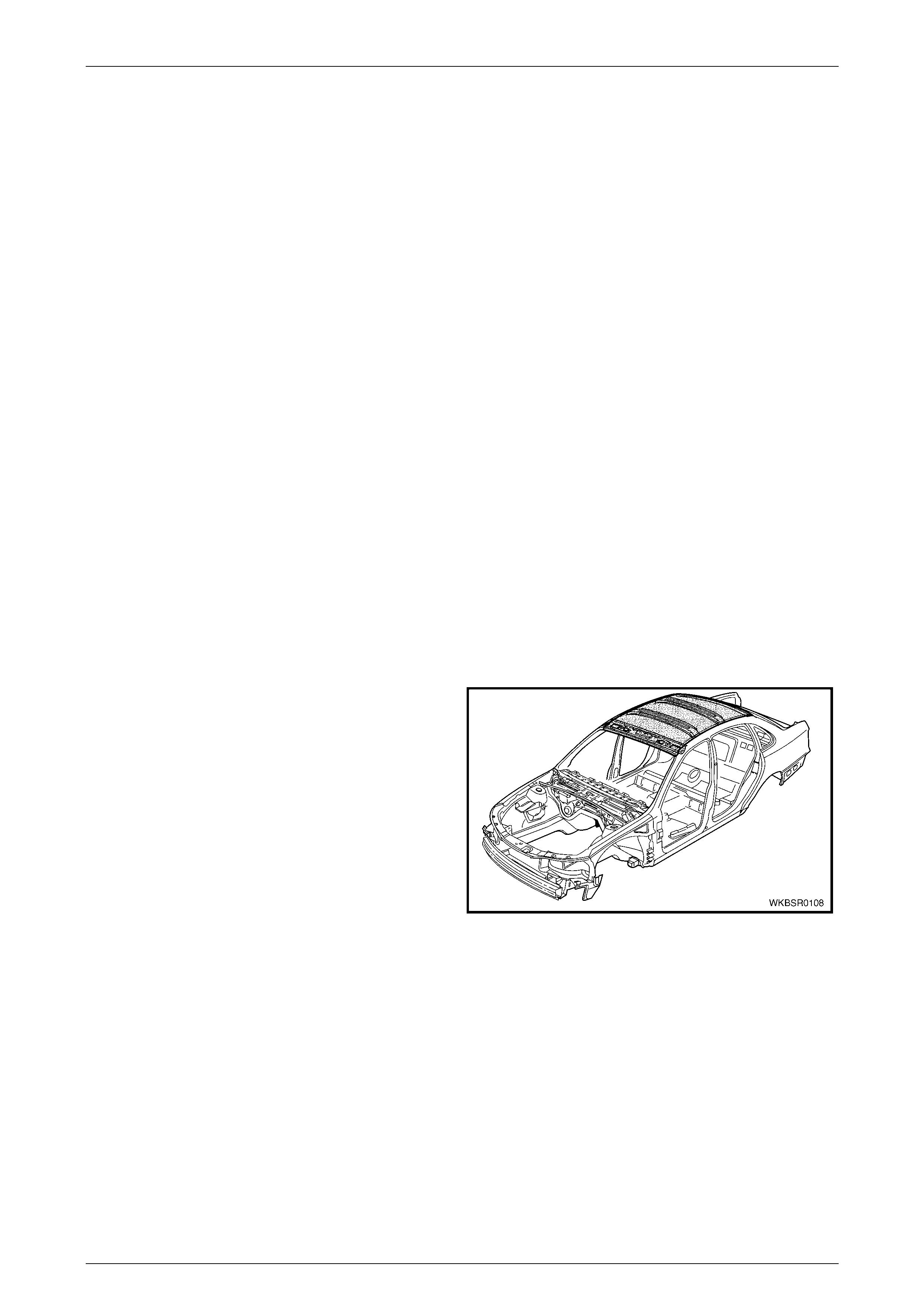

The Structure of the MY 2004 WK Series

vehicle body shell has been developed using

complex design and development techniques.

In addition to meeting all required standards,

the vehicle body is also a critical part of the

overall safety systems. It is therefore

imperative the repair procedures described

here are adhered to during all vehicle body

repairs.

1 General Information............................................................................................................................... 2

1.1 Roof Components..................................................................................................................................................2

2 Service Operations................................................................................................................................ 4

2.1 Roof Panel - Replace Without Sunroof.................................................................................................................4

Remove ...................................................................................................................................................................4

Replace ...................................................................................................................................................................6

2.2 Roof Panel - Replace With Sunroof......................................................................................................................8

Remove ...................................................................................................................................................................8

Replace .................................................................................................................................................................10

Roof Panel Page 9–2

Page 9–2

1 General Information

With the following exceptions, MY 2004 WK Series roof panel information carries over from MY 2003 VY Series vehicles.

For information not contained within this Section, refer to Section 9, Roof Panel, in the MY 2003 VY & V2 Series Service

Information Supplement, Body Structure Repair.

• Roof panel - without sunroof

• Roof panel - with sunroof

This Section describes repairs to the MY 2004 WK Series Vehicles Roof Panel. The repair procedures are limited to the

replacement of this pan el.

The roof panel is both spot welded and glued in place with metal adhesive. This material cannot be softened by heating

or other normal means and the panel can only be removed by cutting and/or grinding.

A sunroof option is available that is fitted on the production line. To cater for this option, a new roof structure has been

introduced which features a housing assembly in place of the roof bow panel. A stainless steel front drain tube is also

fitted within the hinge pillar cavity which effects the service procedures for the hinge pillar, refer to Section 7 Body Side.

When repairing the roof structure, care must be taken to ensure it is returned to its original production configuration.

NOTE

It is imperative that the correct body adhesives,

sealants, deadeners and cavity waxes are

used when repairing the body structure of

WK Series Vehicles. Refer to Section 3,

5 Body Sealing, Adhesives & Deadeners and

Section 3, 6 Cavity Wax for details of the correct

materials and their commercially available

equivalents.

1.1 Roof Components

The shaded components shown are those dealt with in this

Section.

The components and assemblies shown are the parts

serviced for this section of the WK Series Vehicles, refer to

Figure 9 – 2.

These components form the basis of the repair procedures.

Figure 9 – 1

Roof Panel Page 9–3

Page 9–3

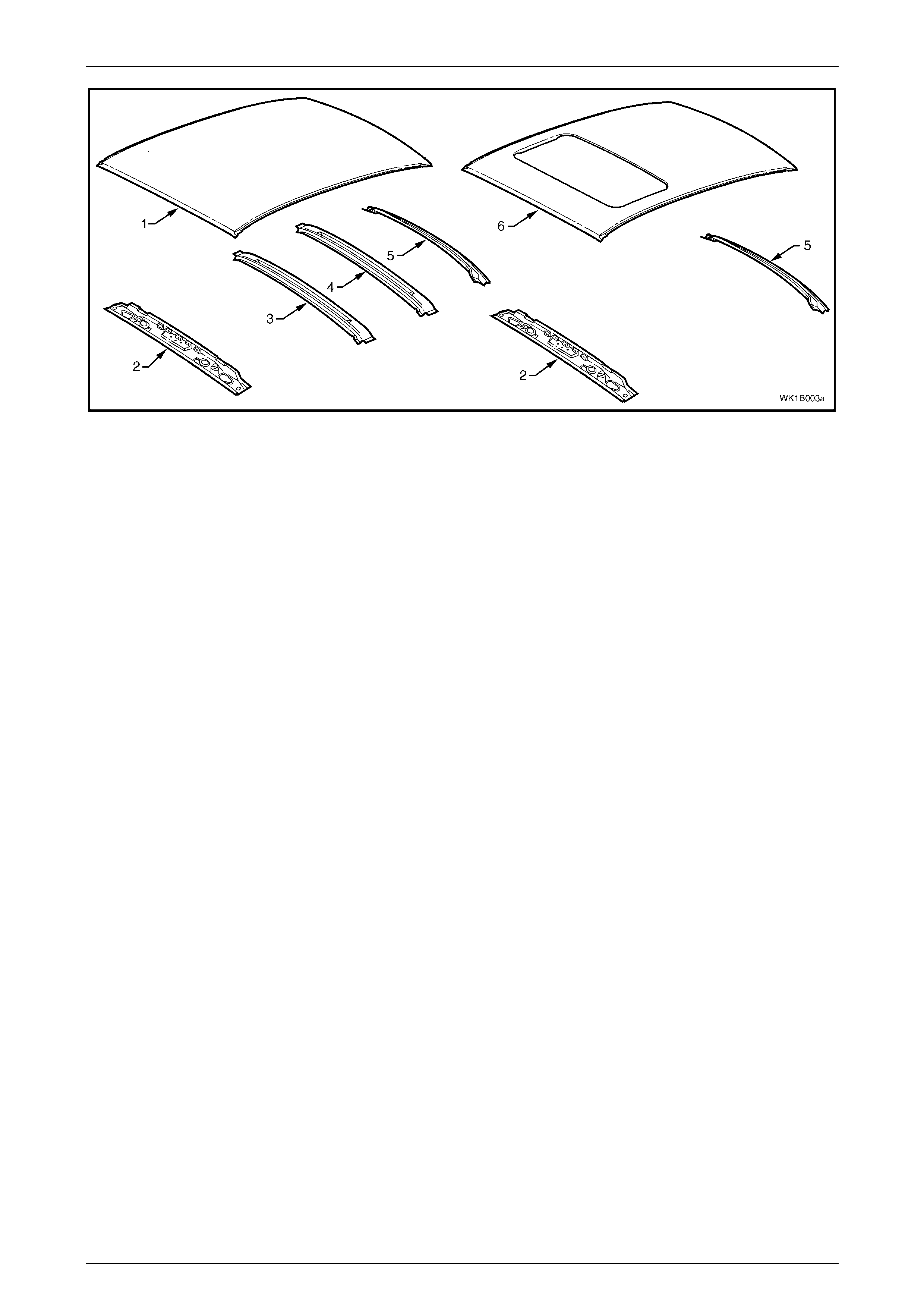

Figure 9 – 2

Legend

1 Roof Panel

2 Roof Front Header Panel

3 Roof Bow Panel

4 Roof Bow Panel No. 2

5 Roof Rear Panel

6 Roof Panel Assembly (With Sunroof)

Roof Panel Page 9–4

Page 9–4

2 Service Operations

2.1 Roof Panel - Replace Without Sunroof

Remove

1 Remove the adjacent trim and components, refer to Section 1A8, Headlining and Interior Trim in the MY 2004 WK

Series Service Information.

2 Remove the front windshield and back window, refer to Section 1A6, Stationary Glass in the MY 2004 WK Series

Service Information.

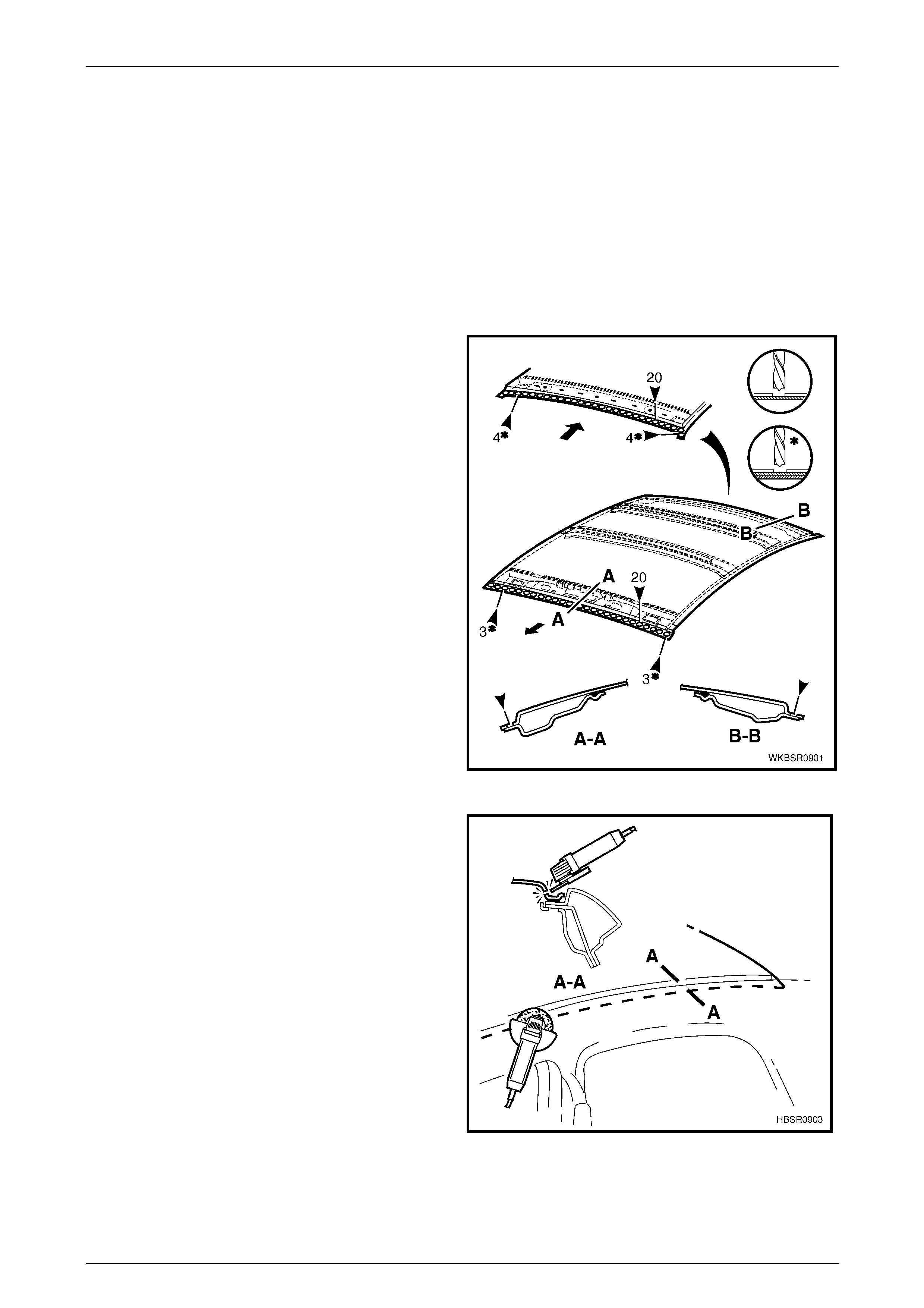

3 Spot cut the welds attaching the roof panel to the

windshield header rail and rear roof frame.

Figure 9 – 3

4 Using a cutting tool such as an air chisel or angle

grinder, cut through the roof panel along the side of

the roof channel.

NOTE

As the roof panel is securely glued to the body

side panel along the channel it cannot be

removed by simply spot cutting the welds.

NOTE

If the header and support panels are to be

retained, take care not to cut them off with the

roof panel. Alternatively, if one or more are to be

replaced, it is easier to cut off those being

replaced along with the roof panel.

Figure 9 – 4

Roof Panel Page 9–5

Page 9–5

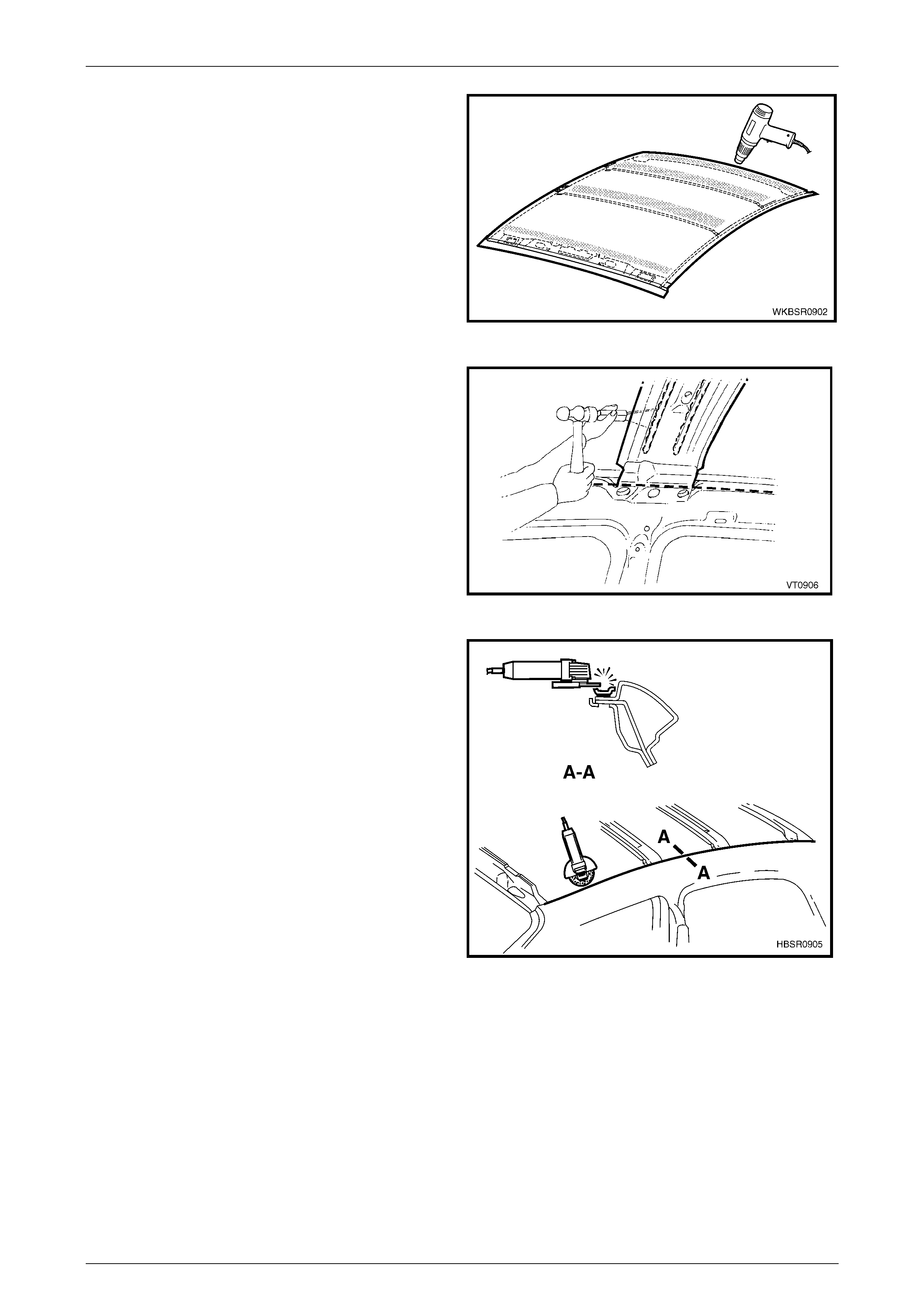

5 Use a heat gun to soften the anti-flutter adhesive

between the roof panel and headers, and roof panel

and support panel, by heating the areas shown.

Figure 9 – 5

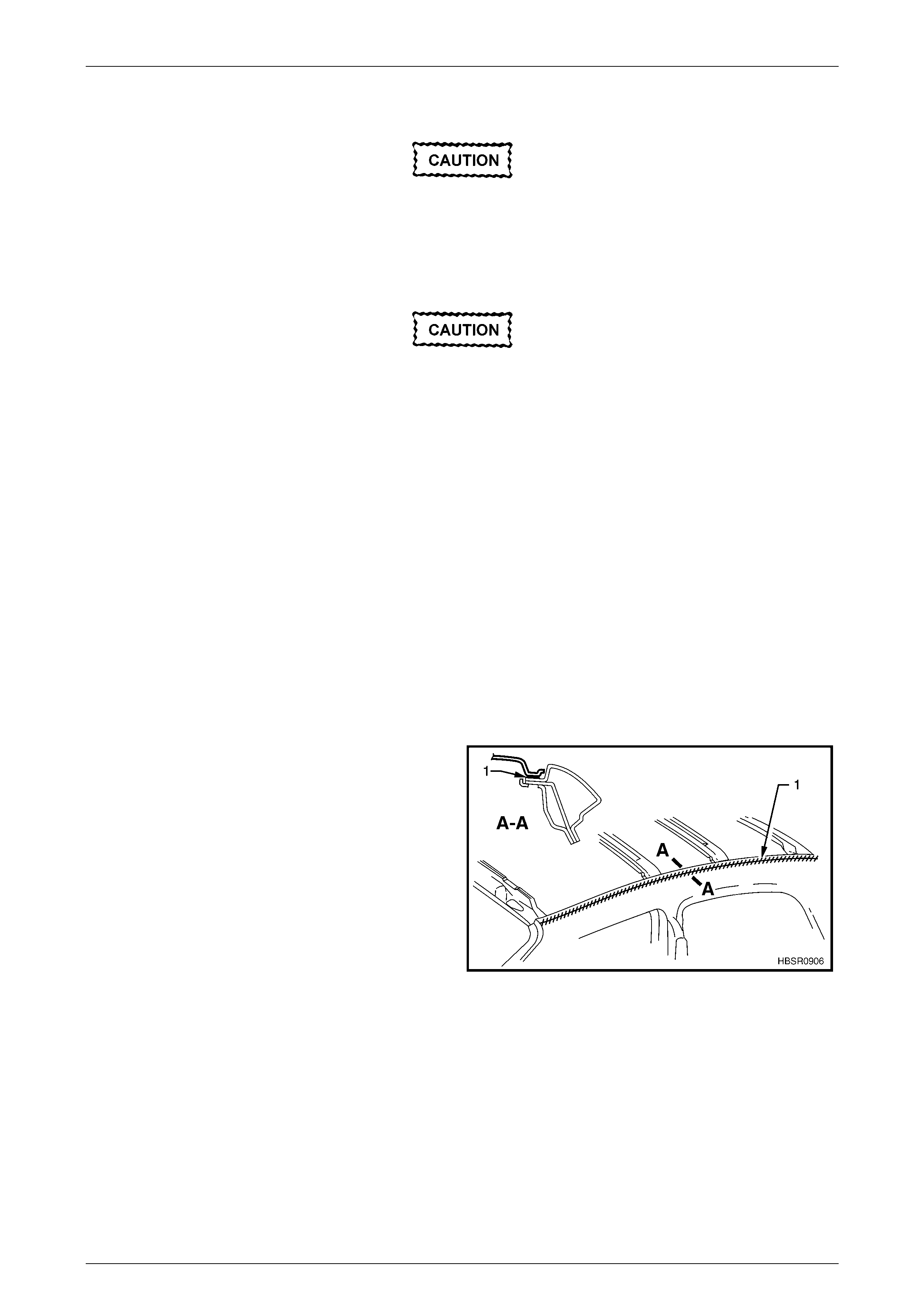

6 Cut through the softened adhesive between the roof

panel and headers, using a suitable tool.

7 Remove the roof panel from the vehicle.

Figure 9 – 6

8 Using an angle grinder, air chisel or other suitable tool,

remove the remaining strip of roof panel from the body

side panel, along with the adhesive beneath the strip.

9 Repair any damage to adjacent parts.

10 Check and repair, if necessary, the alignment of the

body shell. Refer to the dimensions available in

Section 3, Body Construction.

Figure 9 – 7

Roof Panel Page 9–6

Page 9–6

Replace

The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

When welding a relatively flat panel such as

the roof panel, due care must be taken to

minimise the heat absorbed by the panel

which could lead to panel distortion.

NOTE

Spot welding is the preferred method for

attaching of panels and should be used whenever

possible. Where the spot welding equipment

available to the repairer will not access the

required weld position, a plug weld should be

performed.

1 Clean the remaining anti-flutter adhesive from the surfaces of the header rail, roof rear frame and support panel.

2 Prepare the mating surface areas for welding. Dress the channel flange area, the windshield header rail and the

roof rear frame, so they are flat and free from imperfections.

3 Treat the front and rear mating surfaces with Weld Through Primer (Item 1) as required. Refer to Section 3, 5 Body

Sealing, Adhesives & Deadeners.

4 Mark the new roof panel with drilling locations, where plug welding is necessary. Drill holes as required.

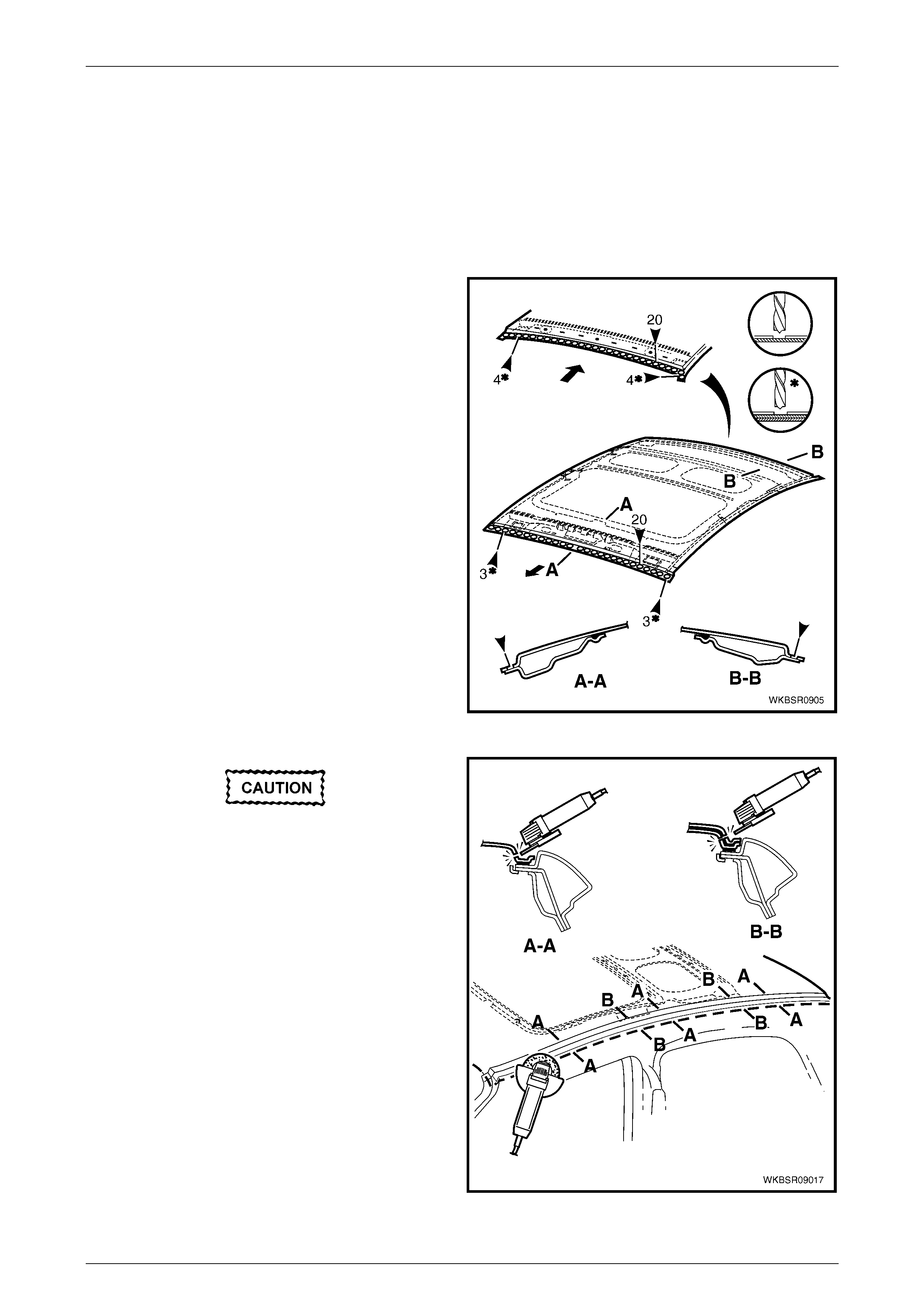

5 Apply Structural adhesive (Item 6) (1) to the mating

surfaces of the roof panel and door opening frame.

Refer to Section 3, 5 Body Sealing, Adhesives &

Deadeners.

6 Apply a bead of Anti-flutter adhesive (Item 5) to the full

length of the groove in the windshield header (section

A-A) and the groove in the rear roof frame (section C-

C), refer to Figure 9 – 9. Refer to Section 3, 5 Body

Sealing, Adhesives & Deadeners.

7 Apply two full length beads of Anti-flutter adhesive to

the grooves in the roof supports (section B-B).

Figure 9 – 8

Roof Panel Page 9–7

Page 9–7

Figure 9 – 9

8 Position the roof panel on the vehicle and clamp in place.

Take care to minimise the heat absorbed by

the panel in order to reduce heat distortion.

In some cases, especially if plug welding, it

may be advantageous to begin welding from

the middle of the run and weld alternatively

to the front and rear. This may reduce panel

distortion.

9 Spot or plug weld the roof panel to the door opening

frame on both sides of the vehicle using the sa me

number of welds as per original build.

Figure 9 – 10

10 Spot or plug weld the roof panel to the windshield

header rail and the rear roof frame using the same

number of welds as per original build.

11 Apply Joint Sealer (Item 3) as required. Refer to

Section 3.5, Body Sealing, Adhesives & Deadeners.

12 Refinish and paint panels and other components as

required. Refer to Sect ion 3, 7 Paint Refini shing in the

MY 2003 VY & V2 Series Service Information

Supplement, Body Structure Repair.

13 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint. Refer

to Sect ion 3, 6 Cavit y Wax.

14 Replace the front and rear windscreens as described

in Section 1A6, Stationary Glass in the MY 2004 WK

Series Service Information.

15 Replace the adjacent trim and components as

described in the appropriate Section of the MY 2004

WK Series Service Information. Figure 9 – 11

Roof Panel Page 9–8

Page 9–8

2.2 Roof Panel - Replace With Sunroof

Remove

1 Remove the adjacent trim and components as described in the appropriate Section of the MY 2004 WK Series

Service Information.

2 Remove the front windshield and back window as described in Section 1A6, Stationary Glass in the MY 2004 WK

Series Service Information.

3 Spot cut the welds attaching the roof panel to the

windshield header rail and rear roof frame.

Figure 9 – 12

If the header and support panels are to be

retained, take care not to cut them off with

the roof panel. Alternatively, if one or more

are to be replaced, it is easier to cut off those

being replaced along with the roof panel.

4 Using a cutting tool such as an air chisel or angle

grinder, cut through the roof panel along the side of

the roof channel.

NOTE

As the roof panel is securely glued to the body

side panel along the channel it cannot be

removed by simply spot cutting the welds.

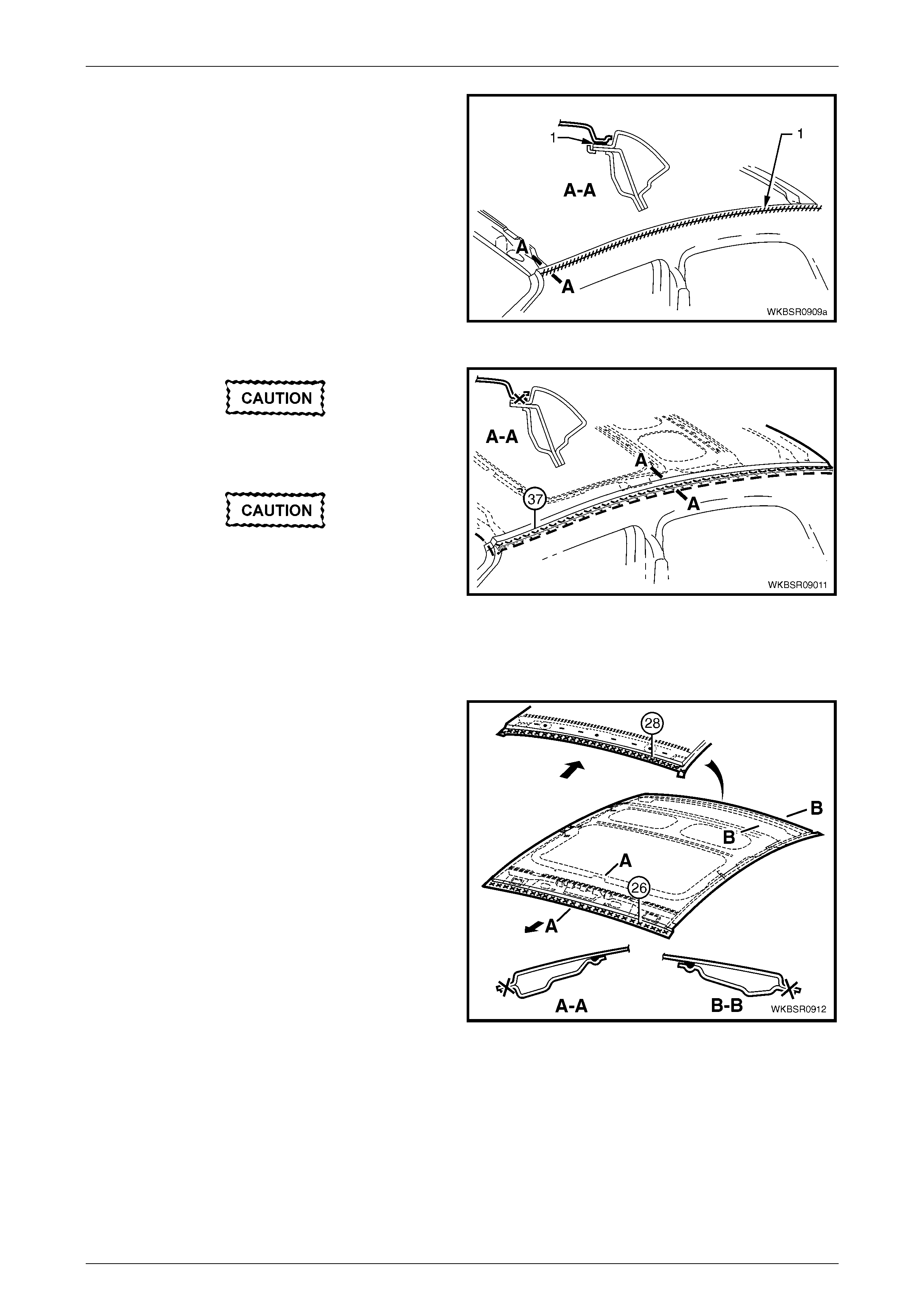

Figure 9 – 13

Roof Panel Page 9–9

Page 9–9

5 Use a heat gun to soften the anti-flutter adhesive

between the roof panel, headers and roof panel

by heating the areas shown.

Figure 9 – 14

6 Cut through the softened adhesive between the roof

panel, roof front header panel and roof rear panel

using a suitable tool.

7 Remove the roof panel from the vehicle.

Figure 9 – 15

8 Using an angle grinder, air chisel or other suitable tool,

remove the remaining strip of roof panel from the body

side panel, along with the adhesive beneath the strip.

9 Repair any damage to adjacent parts.

10 Check and repair, if necessary, the alignment of the

body shell. Refer to the dimensions available in

Section 3, Body Construction.

Figure 9 – 16

Roof Panel Page 9–10

Page 9–10

Replace

The same number and position of spot welds

(or plug welds) should be used when

replacing the panel, as was used during

manufacture, in order to maintain the original

structural strength of the vehicle.

When welding a relatively flat panel such as

the roof panel, due care must be taken to

minimise the heat absorbed by the panel

which could lead to panel distortion.

NOTE

Spot welding is the preferred method for

attaching of panels and should be used whenever

possible. Where the spot welding equipment

available to the repairer will not access the

required weld position, a plug weld should be

performed.

1 Clean the remaining Anti-flutter adhesive from the surfaces of the header rail and the roof rear frame.

2 Prepare the mating surface areas for welding. Dress the windshield header rail and the roof rear frame, so they are

flat and free from imperfections.

3 Treat the front and rear mating surfaces with Weld Through Primer (Item 1) as required. Refer to Section 3, 5 Body

Sealing, Adhesives & Deadeners.

4 Mark the new roof panel with drilling locations, where plug welding is necessary. Drill holes as required.

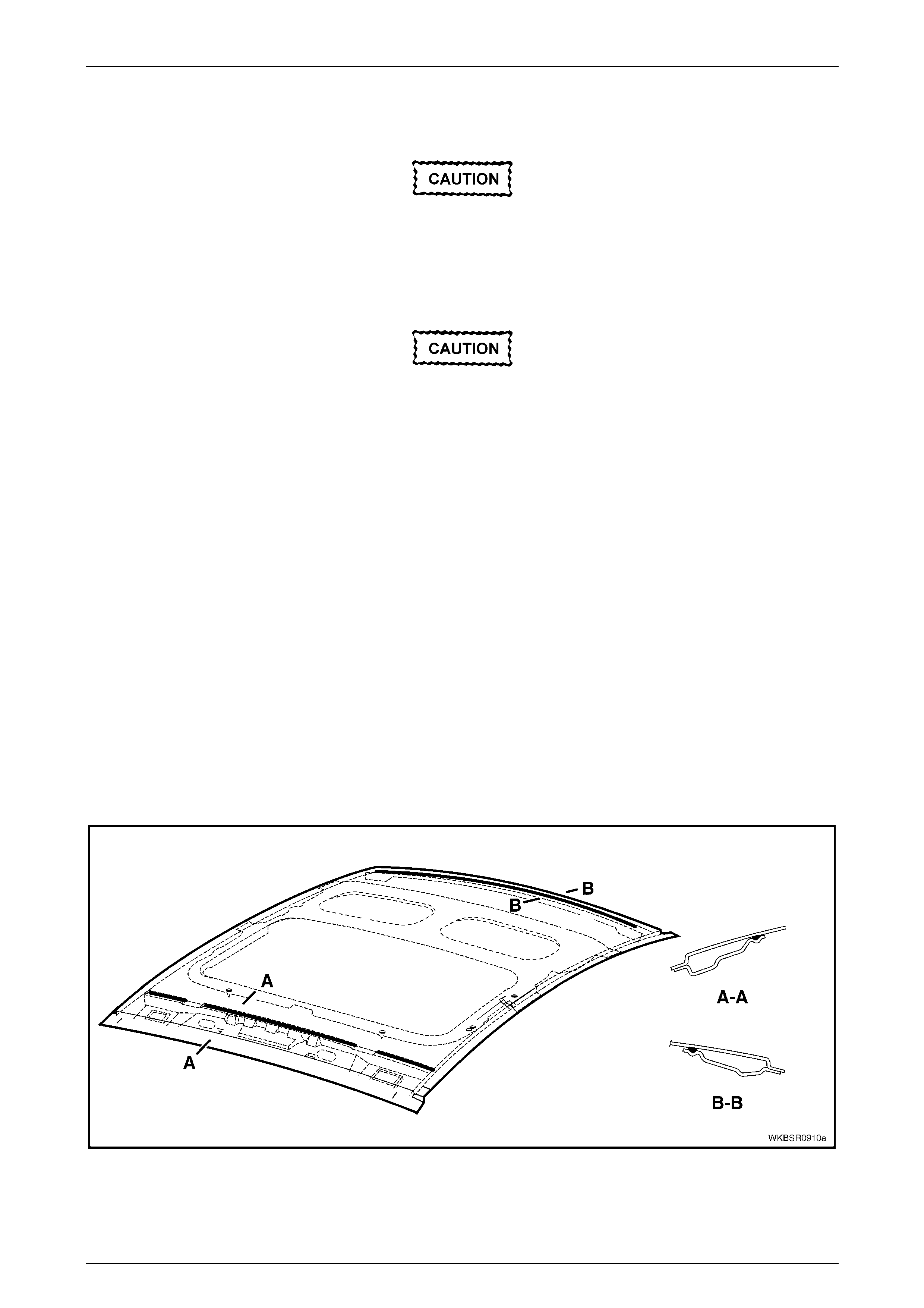

5 Apply a bead of Anti-flutter adhesive (Item 5) to the full length of the groove in the windshield header (section A-A)

and the groove in the rear roof frame (section B-B), refer to Figure 9 - 17. Refer to Section 3, 5 Body Sealing,

Adhesives & Deadeners.

Figure 9 – 17

Roof Panel Page 9–11

Page 9–11

6 Apply Structural adhesive (Item 6) (1) to the mating

surfaces of the roof panel and door opening frame.

Refer to Section 3, 5 Body Sealing, Adhesives &

Deadeners.

7 Position the roof panel on the vehicle and clamp in

place.

Figure 9 – 18

Take care to minimise the heat absorbed by

the panel in order to reduce heat distortion.

In some cases, especially if plug welding, it

may be advantageous to begin welding from

the middle of the run and weld alternatively

to the front and rear. This may reduce panel

distortion.

8 Spot or plug weld the roof panel to the door opening

frame on both sides of the vehicle using the sa me

number of welds as per original build.

Figure 9 – 19

9 Spot or plug weld the roof panel to the windshield

header rail and the rear roof frame using the same

number of welds as per original build.

10 Apply Joint Sealer (Item 3) as required. Refer to

Section 3, 5 Body Sealing, Adhesives & Deadeners.

11 Refinish and paint panels and other components as

required. Refer to Section 3, 1.3 Paint Refinishing in

the MY 2003 VY & V2 Series Service Information

Supplement, Body Structure Repair.

12 Apply Cavity Wax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint. Refer

to Section 3.6, Cavity Wax.

13 Replace the front and rear windscreens as described

in Section 1A6, Stationary Glass in the MY 2004 WK

Series Service Information.

14 Replace the adjacent trim and components as

described in the appropriate Section of the MY 2004

WK Series Service Information.

Figure 9 – 20