SECTION 0B - LUBRICATION AND SERVICING - MY2002

Maintenance Schedule List

Maintenance Schedule

Extrem e Op erati ng Cond iti ons

Recommended Fluids and Lubricants

Recommended Liquid Gasket

Recommended Thread Locking Agents

Maintenance Service Data

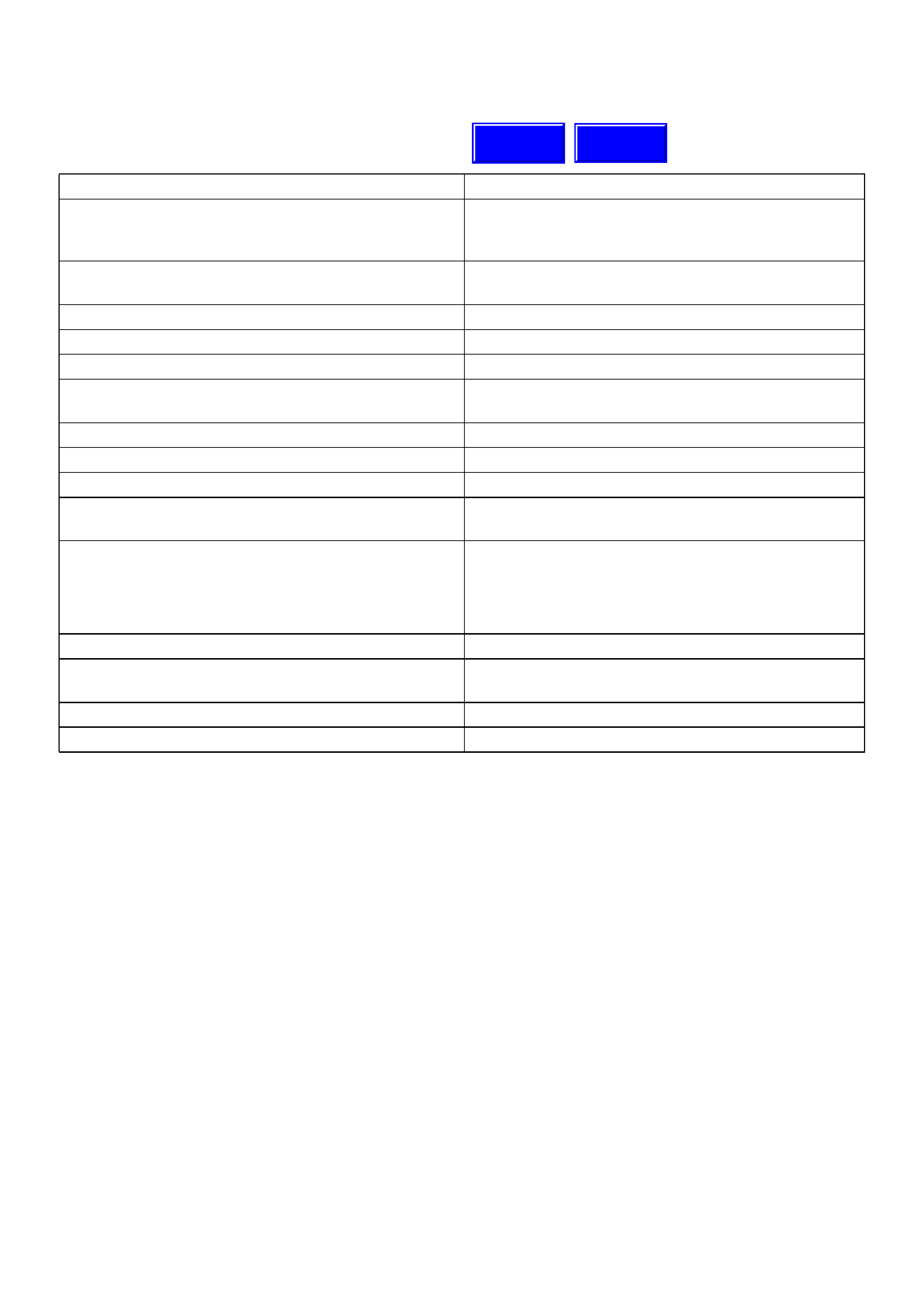

Maintenance Schedule List

Normal Vehicl e Use

The maintenance instructions in this Maintenance Schedule are based on the assumption that the vehicle will be used

as designed:

• to carry passengers and cargo within the limitations specified on the Tyre placard located on the inside of the glove

compartment door;

• to be driven on reasonable road surfaces within legal operating limits;

• to be driven on a daily basis, as a general rule, for at least several miles/kilometers;

• to be driven on unleaded fuel

Unusual or severe operating conditions will require more frequent vehicle maintenance, as specified in the following

sections.

Techline

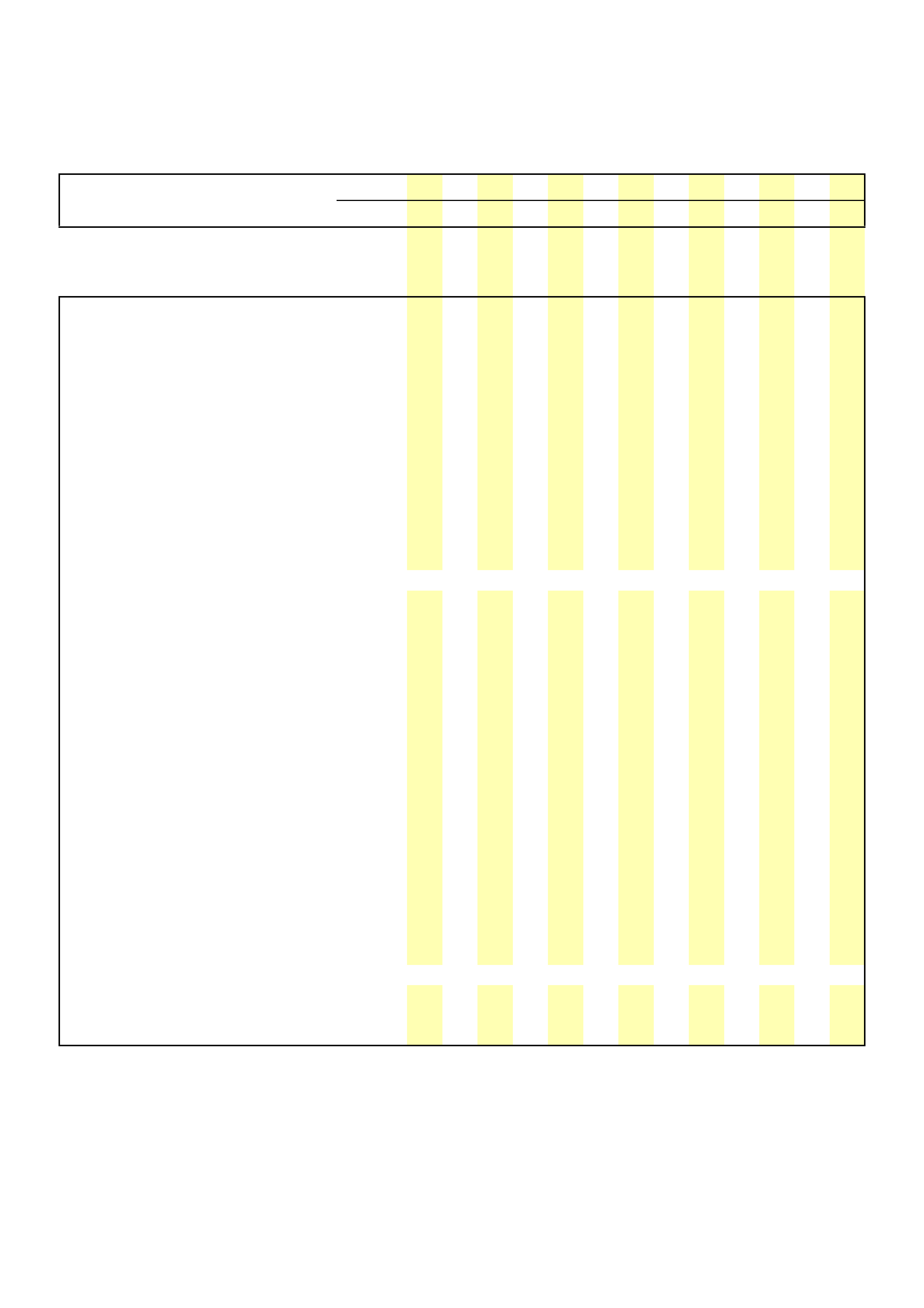

Maintenance Schedule

I: Inspect and correct or replace as necessary

R: Replace or change

T: Tighten to specified torque

L: Lubricate

A: Adjust

Use odometer readings or years, which ever

occurs first.

x1000km 51020 30 40 50 60 70 80 90 100 110 120

or years

.25 .5 11.522.533.544.555.56

UNDERBONNET

Engine oil RRRRRRRRRRRR

Engine oil filter RRRRRR

Oil cont amination IIIIIIIIIIIII

Fluid levels: power steering, brake, clutch,

washer, battery IIIIIIIIIIIII

Coolant Level IIIIIIIIIIIII

Radiator cap and cooling system pressure

test IIIIII

Ti ming belt Replace every 160,000 km or 8 y ears

All hoses and pipes in the engine

compartment for leaks and deterioration IIIIIIIIIIIII

Clean front of radiator core and A/C

condenser IIIIII

Fuel filt er RRRRRR

Air cleaner elem en t I I I I R I I

Pre-air cleaner

Access ory -driv e bel t cond itio n IIIIIIIIIIIII

Valv e clearances A

Spark plugs R

Oxygen Sensors Replace every 150,000 km or 7.5 years

Pow er steering fluid R R R

Maintenance Schedule

I: Inspect and correct or replace as necessary

R: Replace or change

T: Tighten to specified torque

L: Lubricate

A: Adjust

Use odometer readings or years, which ever

occurs first.

x1000km 51020 30 40 50 60 70 80 90 100 110 120

or years

.25 .5 11.522.533.544.555.56

UNDER VEHICLE

Clutch fluid R R R

Brake fluid R R R

Manual tran sm is sion oil IIIIRI IIRI IIR

Automatic transmission fluid IIIIIIIIRI III

Transfer case fluid/oil IIIIIIIIRI III

Universal joints and splines for wear IIIIIIIIIIIII

Universal joints and sliding sleeve LLLLLLLLLLLLL

Differential gear oil (front and rear) IIIIRI IIRI IIR

Disc brake p ad s and dis c wear IIIIIIIIIIII

Wheel nuts TTTTTTTTTTTTT

Front wheel bearing and locking hubs for

axial movement I

Front and rear hubs bearing for looseness IIIIII

Vehicle ride height IIIIIIIIIIIII

Tyre pressure and whee ls for dam age IIIIIIIIIIIII

Tyre rotation Rotate a s necessar y

General underbody check: steering and

suspension components (inc. shock

absorbers, rubber bushes and boots, ball

joints and connections) park brake cables,

fuel sytem, exhaust system, brake system,

bolts, nuts, hoses, pipes and check for

leaks.

IIIIII

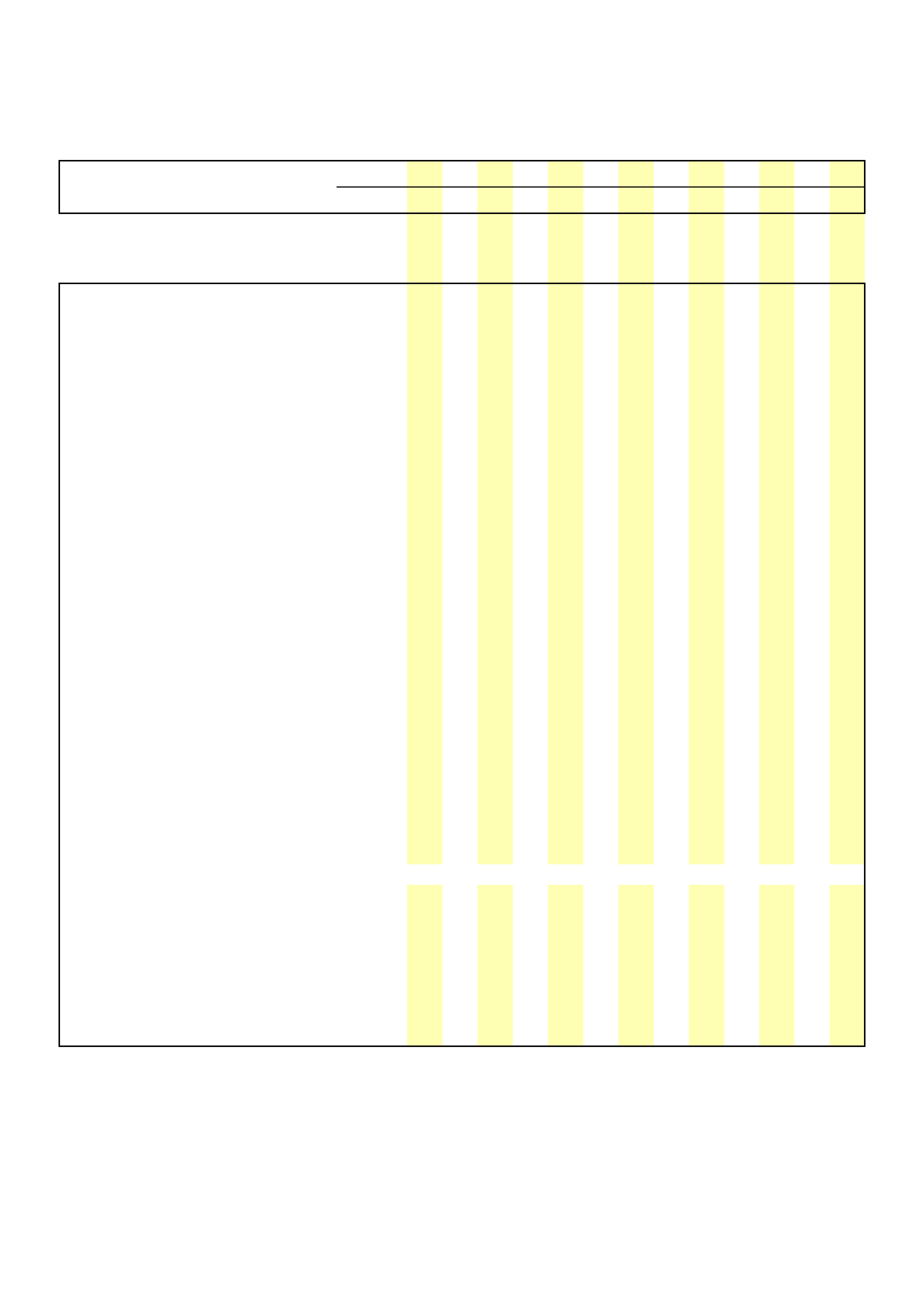

I: Inspect and correct or replace as necessary

R: Replace or change

T: Tighten to specified torque

L: Lubricate

A: Adjust

The owner will be charged for all lubricants and materials plus labour at the times recommended above.

Use odometer readings or years, which ever

occurs first.

x1000km 51020 30 40 50 60 70 80 90 100 110 120

or years

.25 .5 11.522.533.544.555.56

INSIDE VEHICLE

Clutch pedal and free travel IIIIIIIIIIIII

Steering wheel play IIIIIIIIIIIII

Brake pedal and free travel IIIIIIIIIIIII

Park brake lever travel IIIIIII

Park brake ratchet for wear or damage IIIIII

ROAD TEST

Check vehicle on the road for braking,

steering, engine response,and

transmission operation. Check cruise

control, park pawl operation, A/C

performance and neutral start switch.

IIIIIIIIIIIII

SERVICE TIMES

Hours -1.21.4 1.9 2.1 1.2 2.2 1.2 2.1 1.9 61.22.8

- add for automatic transmission 0.2

- add for manual transmission 0.4 0.4 0.4

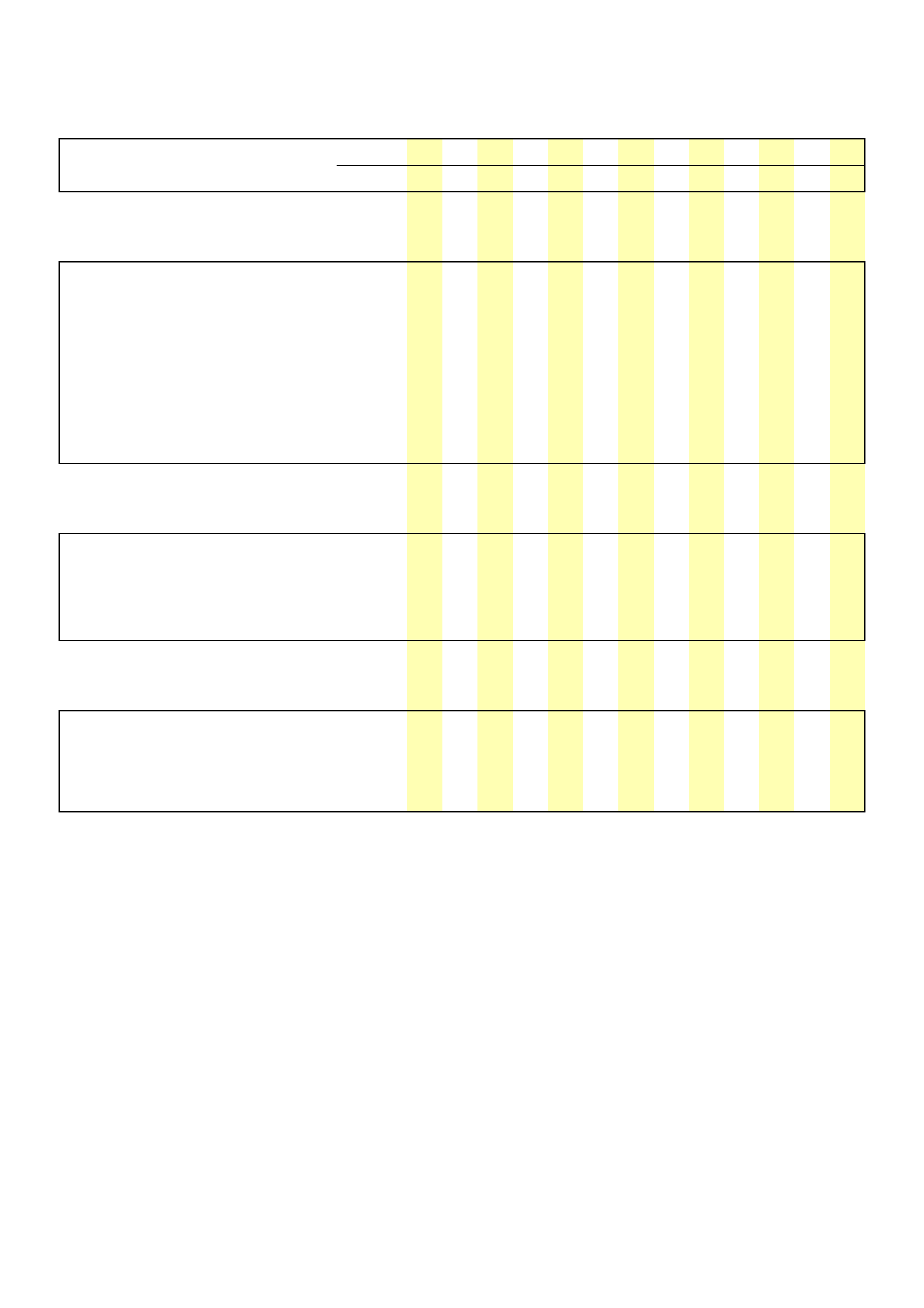

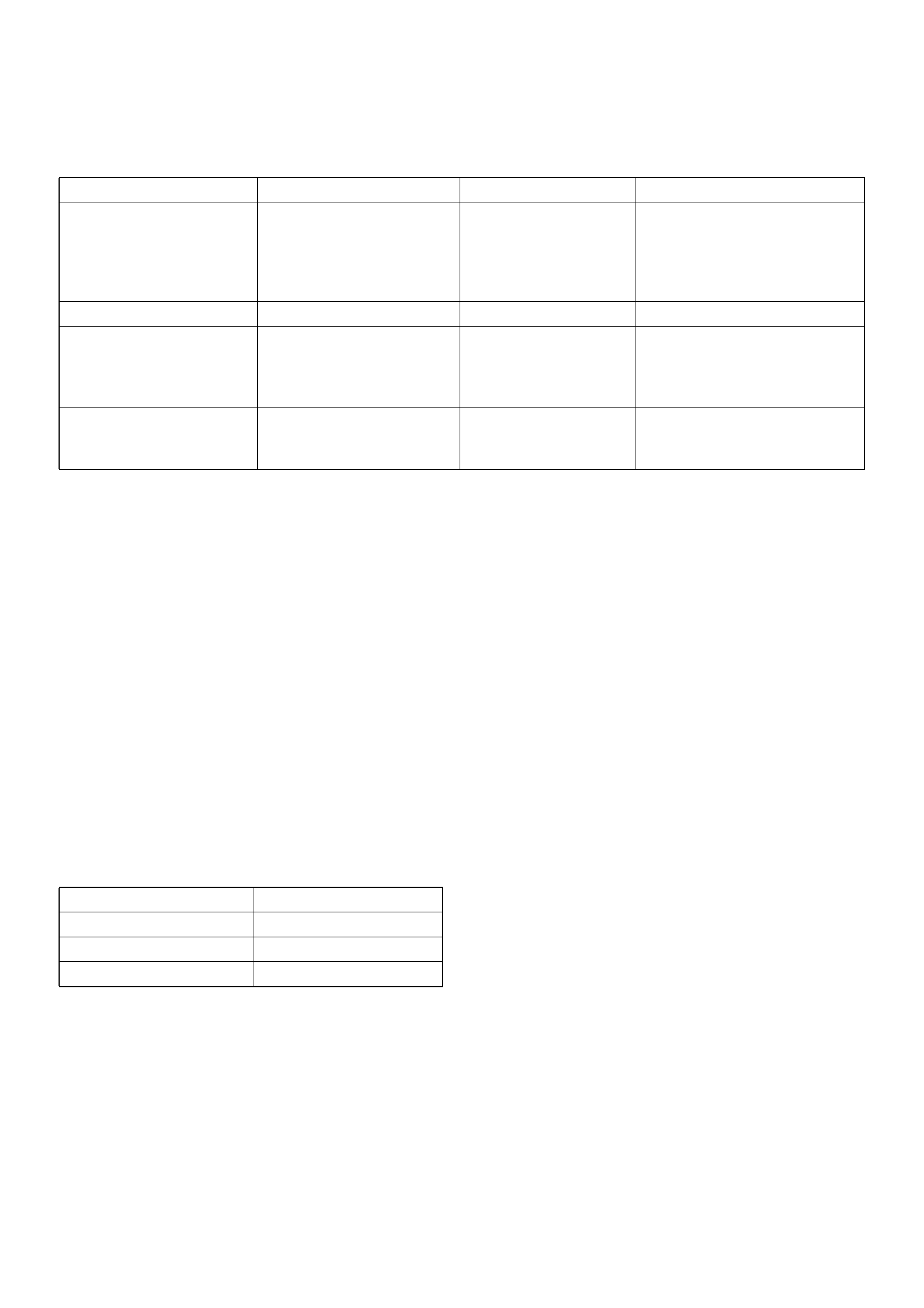

Extreme Operating Conditions

If the vehicle operates under any of the extreme conditions listed below, it is recommended that some items be

serviced more frequently than the intervals specified in the maintenance plan.

The extra services listed below need only be carried out if the vehicle operates continuosly under the conditions

specified.

If the vehicle is operated under any of these conditions on a one-off basis, e.g. a holiday trip, then the extra service

should only be applied for that period of time.

As a guide , if oper ating u nder any o f these ex treme co nditi ons for a pe riod of one m ont h or 1500km , then the vehic le

would qualify for additional services.

A: Repeated short trips

B: Driving on rough roads

C: Driving on dusty roads

D: Drving in extremely cold weather and/or on salted roads.

Change engine oil every 5,000 kms or 3 months

Replace engine oil filter every 10,000km

Inspect exhaust system and mountings every 5000km

Replace aircleaner element every 20,000km

Inspect steer ing sys tem fo r loosenes s or damage ev ery 5,000km

Inspect universal joints and sleeves for wear and lubricate every 5,000km

Change manual transmission oil every 20000km, after an initial 10,000km change

Change transfer case fluid/oil every 20,000km

Change differential oil every 20,000km after an initial 10,000km change.

Inspect f ront brake pads and discs .

ACD

ACD

AB D

C

B

B C

B

B

B

ABC

Recommended Fluids and Lubricant s

B00RW003

USAGE FLUID/LUBRICANT

Engine Oil

Normal use

Prolonged use in snow areas

API SG or SH Engine oil with a viscosity of 20W/50 for

normal use or 15W/40 for prolonged use in snow areas

Engine Coolant 50% water and 50% coolant conforming to Holden

Specific ation HN22 17.

Brake System Heavy Duty Brake Fluid DOT-3, SAE Spec J1703.

Power Steering System DEXRON® -III Automatic transmission fluid.

Automatic Transmission DEXRON® -III Automatic transmission fluid.

MUA T ype Manual transmission & Transfer case

(W/O TOD system) Same oil as engine or 5W/30 synthetic engine oil

Torque On Demand (TOD) Transfer case DEXRON® -III Automatic transmission fluid.

Front Axle API-GL5 80W/90 Gear Oil

Shift On the Fly (SOF) System API-GL5 80W/90 Gear Oil

Rear Axle - Standard Differential

Rear Axle - Limited Slip Differential API-GL5 80W/90 Gear Oil

API-GL5 80W/90 LSD Gear Oil

Clutch System

• Pivot points & Clutch fork joint NLGI No.2 Lithium Grease with 10% Molydenum

Disulphide

• Master cylinder Heavy Duty Brake Fluid DOT-3, SAE Spec J1703.

Parking brake cables Multipurpose grease

Door hinge pins, check straps, fuel door & hood hinges,

hood catch, seat adjusters NLGI No.2 Lithium Grease with 9% Zinc Oxide

Windshield Washer Washer fluid & water

Door and ignition key lock cylinders Powdered Graphite - Do Not Oil

Techline

Techline

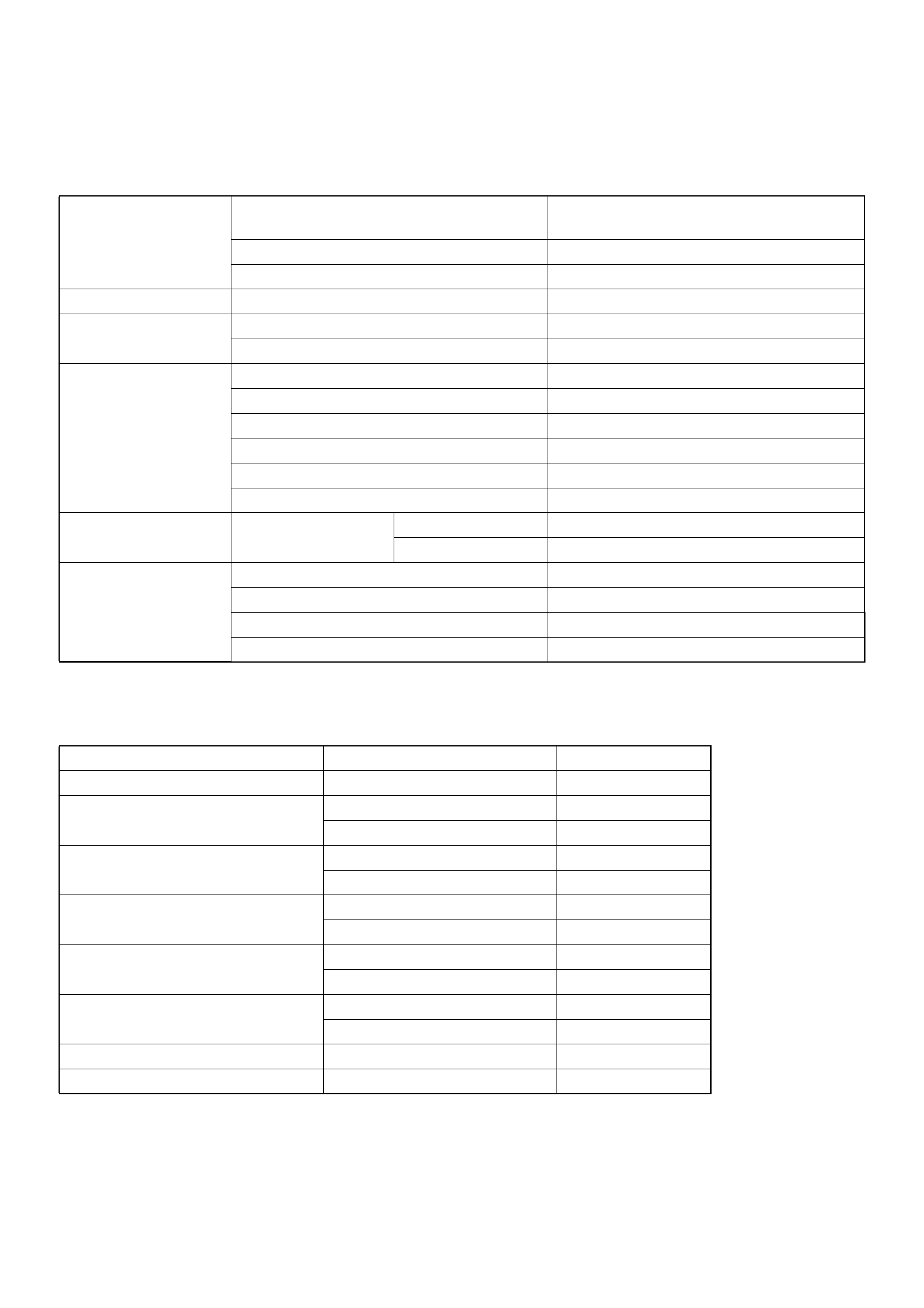

Recommended Liquid Gasket

NOTE:

1. It is very important that the liquid gaskets listed

above or their exact equivalent be used on the

vehicle.

2. Be careful to use the specified amount of liquid

gasket.

Follow the manufacturer's instructions at all times.

3. Be absolutely sure to remove all lubricants and

moistu re from the co nnec ting sur fa ce s before

applying the liquid gasket.

The connecting surfaces must be perfectly dry.

4. Do not apply LOCTITE 17430, LOCTITE 515 and

LOCTITE 518 between two metal surfaces having a

clearance of greater than 0.25 mm (0.01 in). Poor

adhe sion wil l resul t.

* RTV: Room Temperature Vulcanizer

Recommended Thread Locking

Agents

Application Steps

1. Completely remove all lubricant and moisture from

the bolts and the female-threaded surfaces of the

parts to be joined.

The surfaces must be perfectly dry.

2. Apply LOCTITE to the bolts.

3. Tighten the bolts to the specified torque.

After tightening, be sure to keep the bolts free from

vibration and torque for at least an hour until

LOCTITE hardens.

Type Brand Name Manufacturer Remarks

RTV*

Sili con Base

Three Bond 1207B

Three Bond 1207C

Three Bond 1215

Three Bond 1280

Three Bond 1281

Three Bond

Three Bond

Three Bond

Three Bond

Three Bond

For Engine Repairs

For Axle Case

Repairs T/M

Repairs T/M

Water Base Three Bond 1141E Three Bond For Engine Repairs

Solvent

Three Bond 1104

Belco Bond 4

Belco Bond 401

Belco Bond 402

Three Bond

Isuzu

Isuzu

Isuzu

For Engine Repairs

Anaerobic LOCTITE 515

LOCTITE 518

LOCTITE 17430

Loctite

Loctite

Loctite All

LOCTITE Type LOCTITE Color

LOCTITE 242 Blue

LOCTITE 262 Red

LOCTITE 271 Red

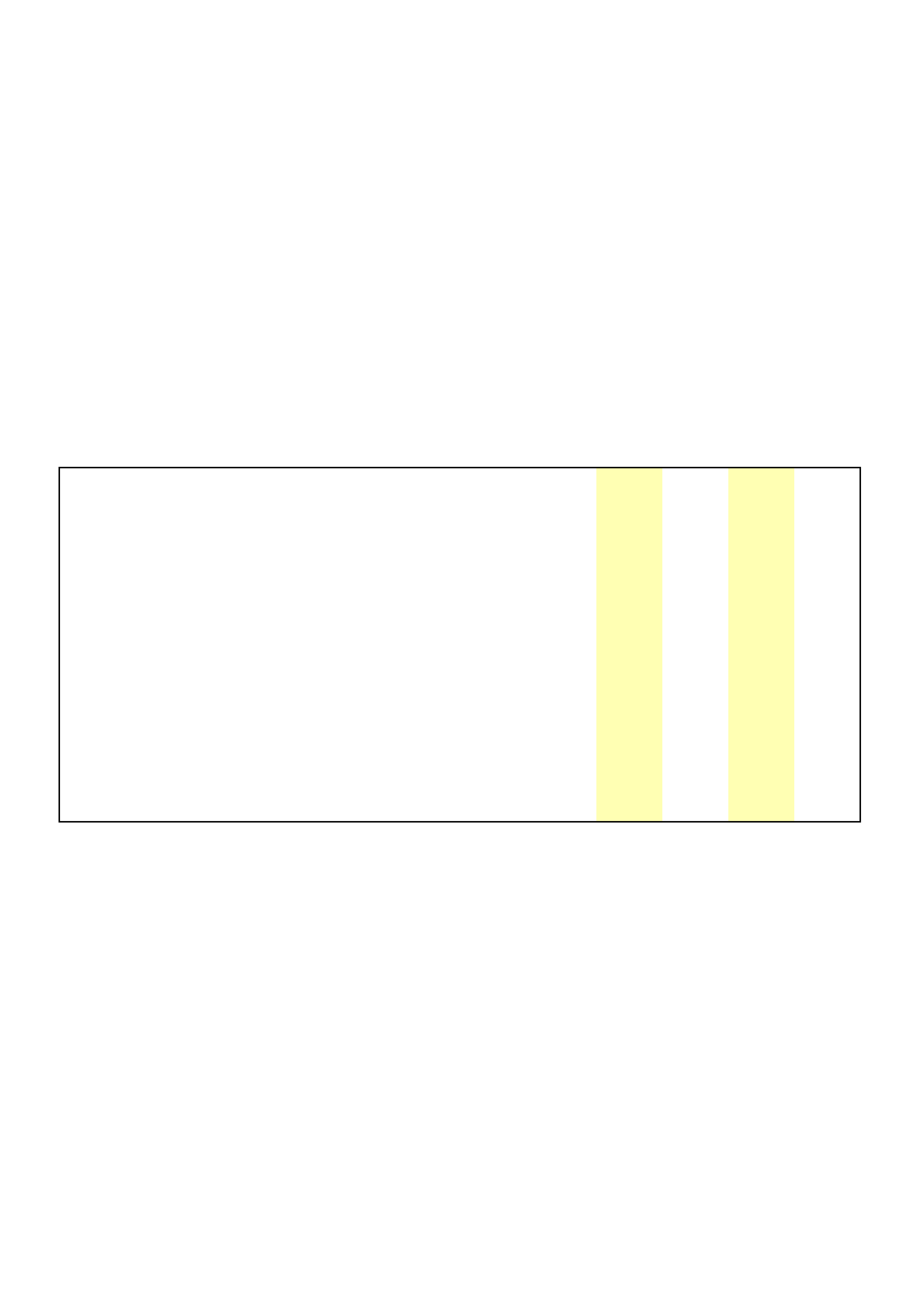

Maintenance Service Data

Service Data and Specifications

* Unless otherwise specified on Tyre information label on the vehicle.

Approximate C apacities

*Crankcase capacities shown are approximate refill capacities. After refill, recheck oil level.

ENGINE Valve clearance (cold) Intake 0.28 ±0.05 mm

Exhaust 0.3 ±0.05 mm

Spark plug type K16PR-P11/PK16PR11/RC10PYP4

Spark plug gap 1.05 mm

CLUTCH Clutch pedal free play 5-15 mm

BRAKE Brake pedal free play 8-11 mm

Parking brake travel 6-8 notches

WHEEL ALIGNMENT Toe-in (Front) 0 to +2 mm

Toe-in (Rear) 0 to +2 mm

Camber (Front) 0×±30'

Camber (Rear) 0×±1×

Caster (Front) 2× 30'±1×

Toe–Axis (Rear) ±1×

PROPELLER SHAFT Flange torque HEX BOLT 63 N·m

INNER HEX BOLT 43 N·m

WHEEL AND TyreS Size P235/75R15

Wheel nut torque 118 N·m

* Tyre inflation pressure (Front) 200 kpa

* Tyre inflation pressure (Rear) 200 kpa

Items Litres

Fuel tank 80

* Crankcase (V6–3.2L ENGINE) Oil Change with Filter 4.5

Oil Change without Filter 4.0

Coolant M/T (V6–3.2L ENG) 11.0

A/T 11.1

Trans miss io n Manu al (V6– 3.2L ENG) 2 .95

Automatic 8.6

Transfer Normal Type 1.45

TOD 1.35

Axle Rear 1.77

Front 1.25

Shift on the fly system 0.12

Air conditioning (R-134a) 0.7