SECTION 10 - WHEELS AND TYRES (MY2002)

Service Precaution

General Description

Diagnosis

Wheel

Wheel and Associated Parts

Removal

Installation

Tyre

Tyre Replacement

General Balance Procedure

Balancing Wheel and Tyre

Main Data and Specifications

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

Techline

General Description

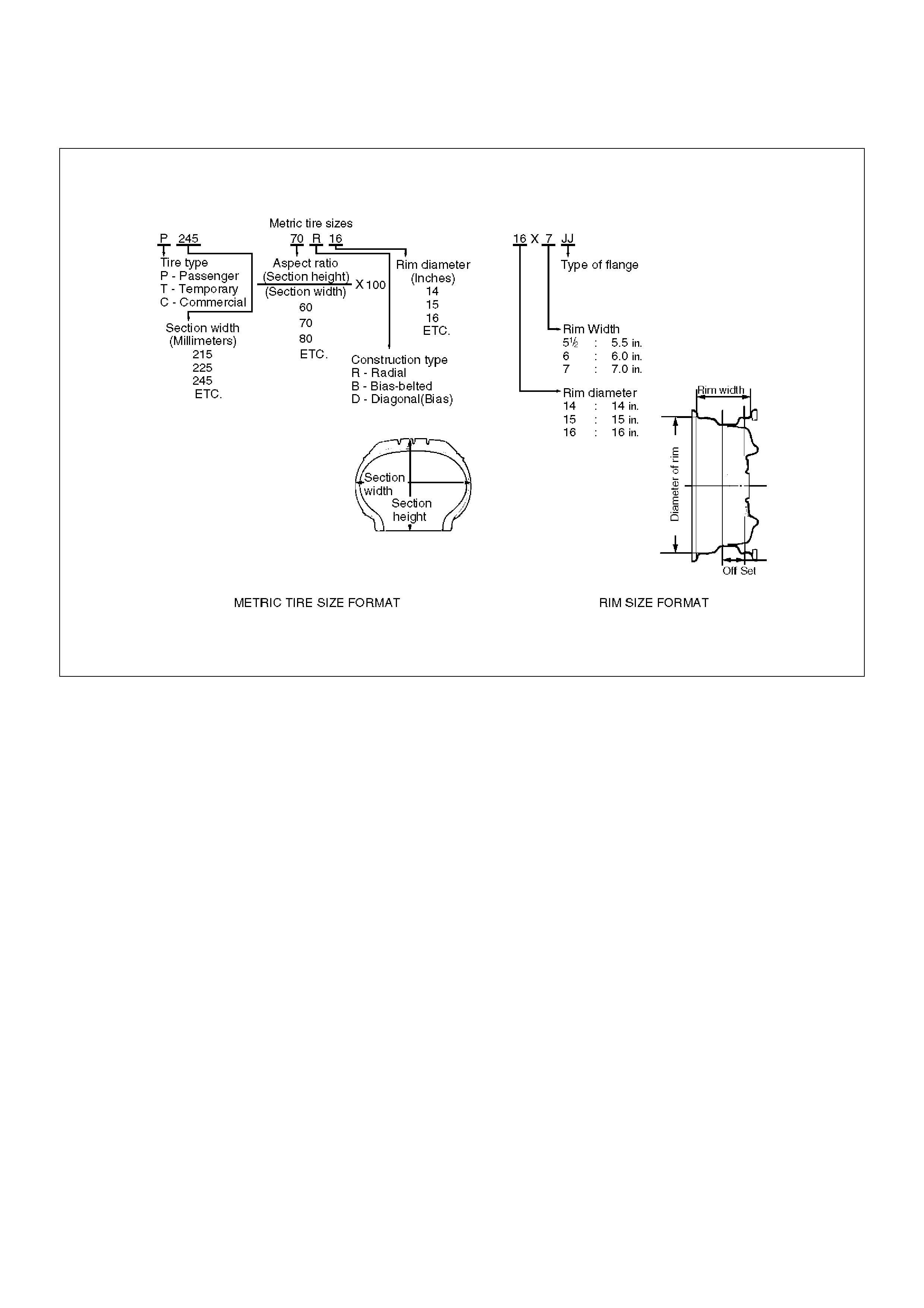

480RS008

Replacement wheels or tyres must be equivalent to the

original equipment in load capacity, specified dimension

and mounting configuration. Improper size or type may

affect bearing life, brake performance, speedometer/

odometer calibration, vehicle ground clearance and tyre

clearance to the body and chassis. All model are

equipped with metric sized tubeless steel belted radial

tyres. Correct tyre pressures and driving habits have an

important influence on tyre life. Heavy cornering,

excessively rapid acceleration and unnecessary sharp

braking increase premature and uneven wear.

Diagnosis

Condition Possible cause Correction

Vehicle Pulls Mismatched or uneven tyres. Replace tyre.

Tyres not adequately inflated. Adjust tyre pressure.

Broken or sagging springs. Replace spring.

Radial tyre lateral force. Replace tyre.

Improper wheel alignment. Adjust wheel alignment.

Brake dragging in one wheel. Repair brake.

Loose, bent or broken front or rear

suspension parts.

Tighten or replace the appropriate

suspension part(s).

Faulty shock absorbers. Replace shock absorber.

Parts in power steering valve

defective.

Replace power steering unit.

Abnormal or Excessive Tyre Wear Sagging or broken spring. Replace spring.

Tyre out of balance. Balance or replace tyre.

Improper wheel alignment. Check front end alignment.

Faulty shock absorber. Replace shock absorber.

Hard driving. Replace tyre.

Overloaded vehicle. Replace tyre and reduce load.

Tyres not rotated periodically. Replace or rotate tyre.

Worn hub unit wheel bearings. Replace hub unit bearing.

Wobbly wheel or tyres. Replace wheel or tyre.

Tyres not adequately inflated. Adjust the pressure.

Wheel Hop Blister or bump on tyre. Replace tyre.

Improper shock absorber operation. Replace shock absorber.

Shimmy, Shake or Vibration Tyre or wheel out of balance. Balance wheels or replace tyre/or

wheel.

Loose hub unit bearings. Replace hub unit bearing.

Worn steering linkage ball joints. Replace ball joints.

Worn upper or lower end ball joints. Replace ball joints.

Excessive wheel runout. Repair or replace wheel and/or tyre.

Blister or bump on tyre. Replace tyre.

Excessive loaded radial runout of

tyre/wheel assembly.

Replace tyre or wheel.

Improper wheel alignment. Check wheel alignment.

Loose or worn steering linkage. Tighten or replace steering linkage.

Loose steering unit. Tighten steering unit.

Tyres not adequately inflated. Adjust tyre pressure.

Loose, bent or broken front or rear

suspension parts.

Tighten or replace the appropriate

suspension parts.

Faulty shock absorber. Replace shock absorber.

Hub bearing preload misadjustment. Adjust preload.

Parts in power steering valve

defective.

Replace power steering unit.

Hard Steering Bind in steering linkage ball studs,

upper or lower ball joint.

Replace ball joint.

Improper wheel alignment. Check wheel alignment.

Tyre not adequately inflated. Inflate tyres to proper pressure.

Bind in steering column or shaft. Repair or replace.

Improper power steering system

operation.

Repair or replace. Refer to Steering

section.

Too Much Play In Steering Hub unit bearings worn. Replace hub unit bearings.

Loose steering unit or linkage. Retighten or repair.

Worn or loose steering shaft

universal joint.

Retighten or replace steering shaft.

Worn steering linkage ball joints. Replace ball joints.

Worn upper or lower end ball joints. Replace ball joints.

Poor Steering Wheel Returnability Bind in steering linkage ball joints. Replace ball joints.

Bind in upper or lower ball joints. Replace ball joints.

Bind in steering column and shaft. Repair or replace.

Bind in steering gear. Check and repair steering gear.

Improper wheel alignment. Adjust wheel alignment.

Tyres not adequately inflated. Adjust pressure.

Loose steering wheel nut. Retighten.

Worn wheel bearing. Replace.

Abnormal Noise Worn, sticky or loose upper or lower

ball joint, steering linkage ball joi nts

or drive axle joints.

Replace.

Faulty shock absorbers. Replace.

Worn upper or lower control arm

bushing.

Replace.

Loose stabilizer bar. Retighten bolts or replace bushings.

Loose wheel nuts. Tighten nuts. Check for elongated

wheel nut holes. Replace wheel if

required.

Loose suspension bolts or nuts. Retighten suspension bolts or nuts.

Broken or otherwise damaged

wheel bearings.

Replace wheel bearing.

Broken suspension springs. Replace spring.

Loose steering unit. Retighten mounting bolt.

Faulty steering unit. Replace steering unit.

Wandering or Poor Steering Stability Mismatched or unevenly worn tyres. Replace tyre or inflate tyres to

proper pressure.

Loose steering linkage ball joints. Replace ball joints.

Faulty shock absorbers. Replace shock absorber.

Loose stabilizer bar. Tighten or replace stabilizer bar or

bushings.

Broken or sagging springs. Replace spring (pairs).

Improper wheel alignment. Adjust wheel alignment.

Condition Possible cause Correction

Erratic Steering When Braking Worn hub unit bearings. Replace hub unit bearings.

Broken or sagging springs. Replace spring (pairs).

Leaking caliper. Repair or replace caliper.

Warped discs. Replace brake disc.

Badly worn brake pads. Replace brake pads.

Tyres are inflated unequally. Inflate tyres to proper pressure.

Low or Uneven Trim Height Broken or sagging springs. Replace springs (In pairs).

Vehicle overloaded. Reduce load.

Incorrect springs. Adjust or replace torsion bar.

Suspension Bottoms Vehicle overloaded. Reduce load.

Faulty shock absorber. Replace shock absorber.

Incorrect, broken or sagging

springs.

Replace springs.

Body Leans Loose stabilizer bar. Tighten stabilizer bar bolts or

replace bushings.

Faulty shock absorber, struts or

mounting.

Replace shock absorber.

Broken or sagging springs. Replace springs (In pairs).

Vehicle overloaded. Reduce load.

Cupped Tyres Worn wheel bearings. Replace wheel bearing.

Excessive tyre or wheel run out. Replace tyre or wheel.

Worn ball joints. Replace ball joints.

Tyre out of balance. Adjust tyre balance.

Condition Possible cause Correction

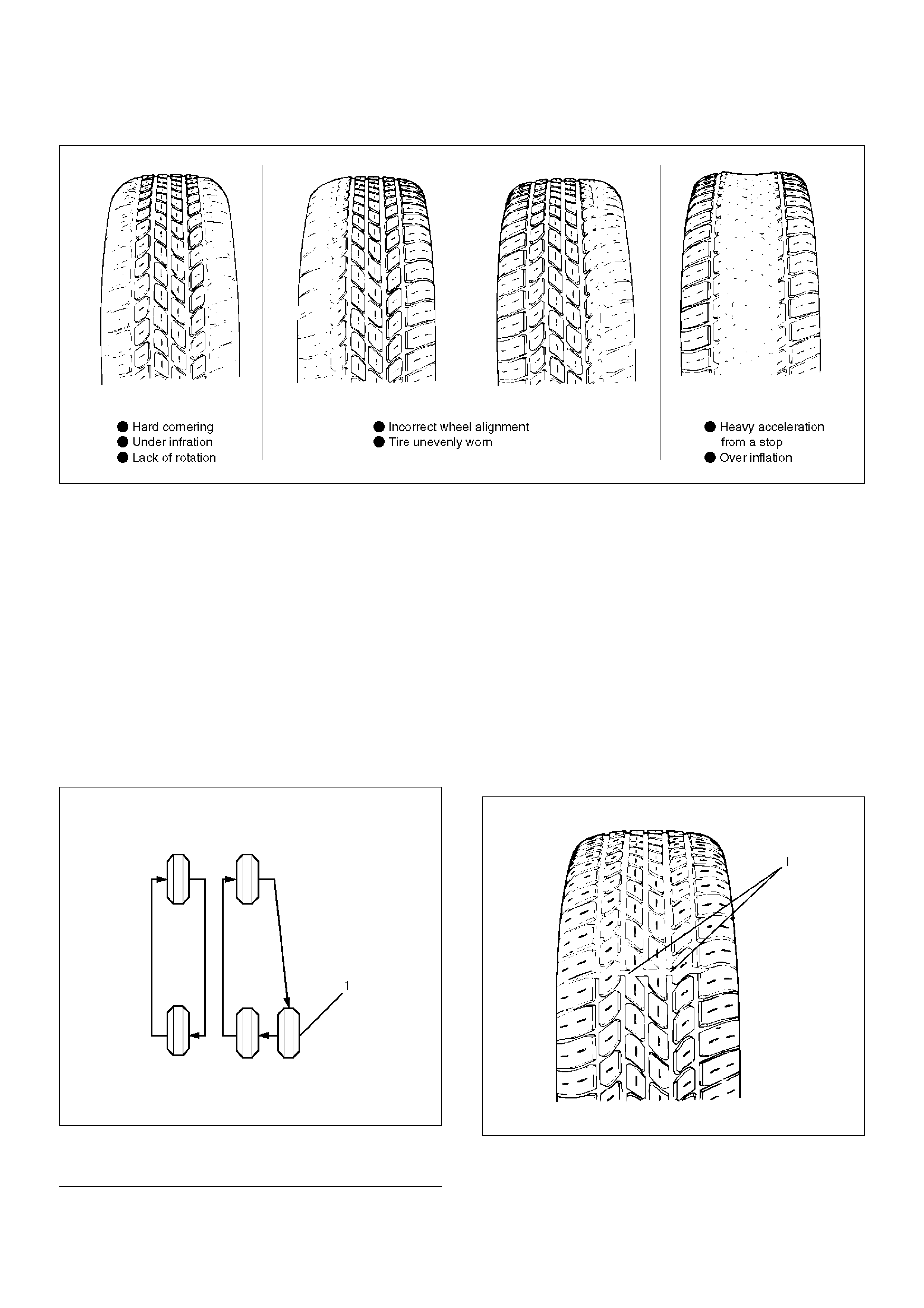

Irregular and Premature Wear

480RS001

Irregular and/or premature wear has many causes.

Some of them are incorrect inflation pressures, lack of

tyre rotation, poor driving habits or improper wheel

alignment. Incorrect inflation is common cause of tyre

premature wear.

NOTE: Due to their design, radial tyres tend to wear

faster in the shoulder area, particularly on the front

tyres. This makes regular rotation especially necessary.

After rotation, be sure to check wheel nut torque, and

set tyre pressures.

Tyre Rotation

Tyre rotation is recommended to balance wear for

longer tyre life.

480RS002

EndOFCallout

If the following conditions are noted, rotate the tyres:

• Front tyre wear is different from rear.

• Uneven wear exists across the tread of any tyre.

• Left and right front tyre wear is unequal.

• Left and right rear tyre wear is unequal.

Check wheel alignment if the following conditions are

noted:

• Left and right front tyre wear is unequal.

• Wear is uneven across the tread of any front tyre.

• Front tyre treads have a scuffed appearance with

“feather" edges on one side of the tread ribs or

blocks.

Tread Wear Indicators

480RS006

The original equipment tyres have built-in tread wear

indicators(1) to show when tyres need replacement.

These indicators may appear as wide bands. When the

indicators appear in two or more grooves at three

locations, tyre replacement is recommended.

Legend

(1) Spare Tyre

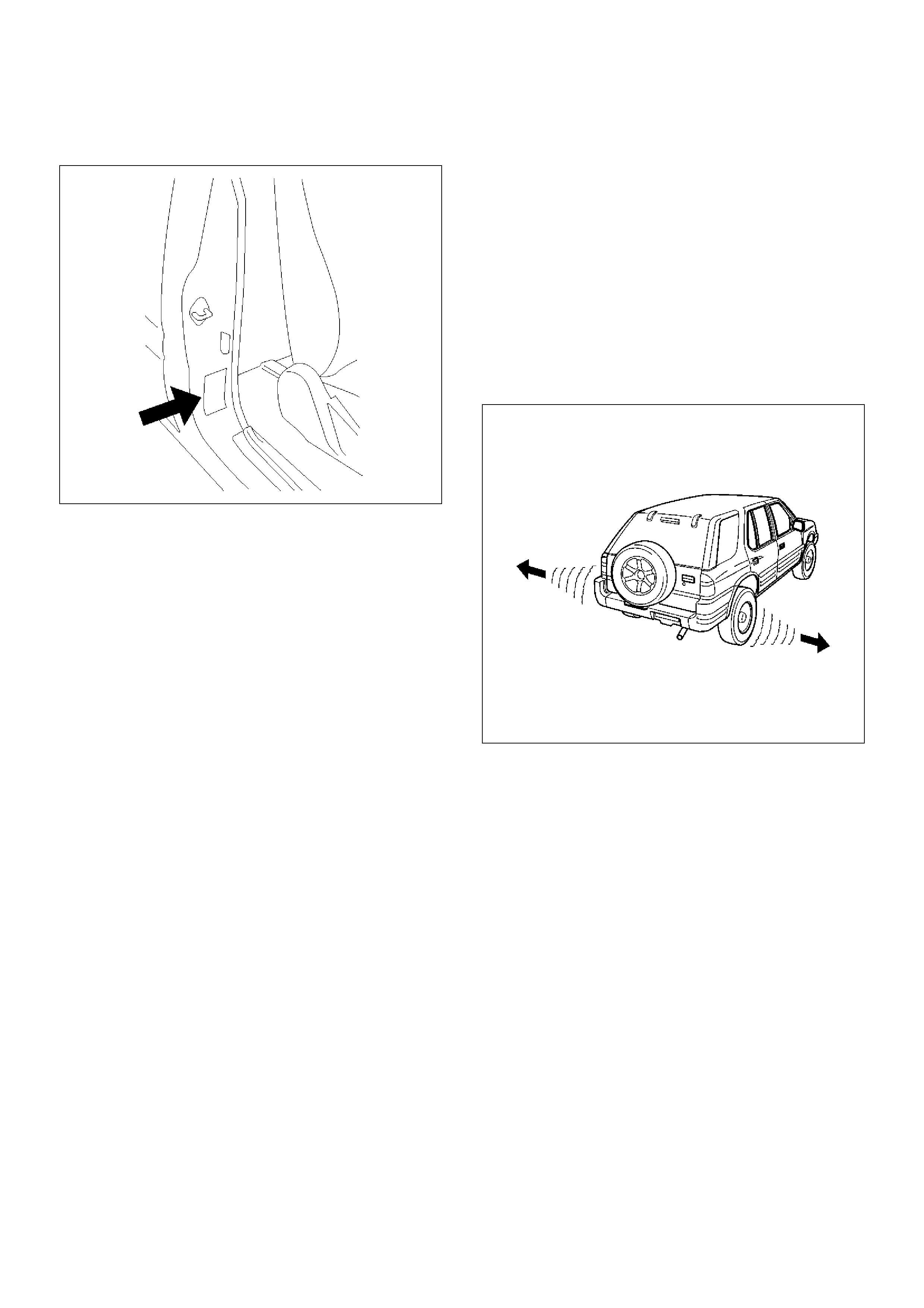

Inflation of Tyres

710RX004

Tyre pressure, in cold condition (after vehicle has set for

three hours or more, and driven less than one mile),

should be checked monthly or before any extended trip.

Tyre pressure increases approximately 15% when the

tyres become hot during driving. Tyre pressure

specification is shown on the label located on the left

door lock pillar.

NOTE: Check the tyre pressure whenever irregular

wear is found. Tyre inflation greatly affects tyre wear. If

the alignment check does not reveal any alignment

problems, check the condition of the shock absorbers

and wheel/tyre balance.

Diagnosis List

If the following conditions are noted, rotation is required.

1. Front tyre wear is different from rear.

2. Uneven wear exists across the tread of any tyre.

3. Left and right front tyre wear is unequal.

4. Left and right rear tyre wear is unequal.

If the following conditions are noted, check the wheel

alignment.

1. Left and right front tyre wear is unequal.

2. Uneven wear exists across the tread of any tyre.

3. Front tyre treads have scuffed appearance with

“feather" edges on one side of tread ribs or blocks.

4. There is cupping, flat spotting etc.

Higher than recommended pressure can cause:

1. Hard ride.

2. Poor steering stability.

3. Rapid and uneven wear at center of the tread.

Lower than recommended pressure can cause:

1. Tyre squeal on turns.

2. Hard steering.

3. Rapid and uneven wear on the edges of the tread.

4. Tyre rim bruises and rupture.

5. Tyre cord breakage.

6. High tyre temperatures.

7. Reduced handling.

8. Reduced fuel economy.

Unequal pressure on same axle can cause:

1. Uneven braking.

2. Steering lead.

3. Reduced handling.

4. Swerve on acceleration.

Radial Tyre Waddle

480RW011

Waddle is side-to-side movement at the front and/or

rear of the car. It can be caused by the steel belt not

being straight within the tyre, or by excessive lateral

runout of the tyre or wheel. It is most noticeable at low

speed, about 8 to 48 km/h (5 to 30 mph). It may also

cause rough ride at 80 to 113 km/h (50 to 70 mph).

The car can be road tested to see which end of the car

has the faulty tyre. If the tyre causing the waddle is on

the rear, the rear end of the car will “waddle". From the

driver's seat, it feels as if someone is pushing on the

side of the car.

If the faulty tyre is on the front, the waddle is more easily

seen. The front sh eet metal appears to be moving back

and forth. It feels as if the driver's seat is the pivot point

in the car.

Another more thorough method of determining the faulty

tyre is substituting tyre and wheel assemblies that are

known to be good. Follow these steps:

1. Drive the car to determine if the waddle is coming

from the front or rear.

2. Install tyre and wheel assemblies known to be good

(from a similar car) in place of those on the end of

the car which is waddling. If the waddle cannot be

isolated to front or rear, start with the rear tyres.

3.Road test again. If improvement is noted, install the

original tyre and wheel assemblies one at a time

until the faulty tyre is found. If no improvement is

noted, install tyres known to be good in place of all

four. Then, install the original tyre assembly one at a

time until the faulty tyre is found.

Radial Tyre Lead/Pull

“Lead/Pull" is vehicle deviation from a straight path, on a

level road with no pressure on the steering wheel.

Lead is usually caused by:

1.Poorly manufactured radial tyres.

2.Uneven brake adjustment.

3.Wheel alignment.

The way in which a tyre is built can produce lead in a

car. An example of this is placement of the belt.

Off-center belts on radial tyres can cause the tyre to

develop a side force while rolling straight down the road

and the tyre will tend to roll like a cone.

The “Radial Tyre Lead/Pull Correction" chart should be

used to make sure that front wheel alignment is not

mistaken for tyre lead.

Rear tyres will not cause lead/pull.

Radial Tyre Lead/Pull Correction Chart

Typical examples of abnormal tyre ahead wear and

major causes:

CAUTION: Similar wear patterns can be caused by

worn suspension parts, misalignment of wheels and

tyres, and other suspension related problems.

Spotty wear – wear localized on shoulder sections, and

in an extreme cases, the tyre becomes polygonal in

shape.

480RW002

Step Action Yes No

1 1. Inflate tyres to recommended pressure.

2. Road test vehicle on level uncrowned road.

Was a problem corrected? End. Go to Step 2

2 Switch front tyres side to side and road test again.

Was a problem corrected?

If roughness

results,replace

tyres. Go to Step 3

3 Did the vehicle lead in same direction? Go to Step 4 Go to Step 5

4 Put tyres back in original position and check alignment.

Was a problem corrected? End. Go to Step 5

5 Install known good tyre on one front side.

Was a problem corrected?

Replace tyre.

Install a known

good tyre in

place of other

front tyre.

If lead

corrected,

replace tyre.

1. Tyre or wheel out of round or distorted.

2. Hub or knuckle out of round or distorted.

3. Play in hub bearings or ball joint.

4. Rotating parts out of balance.

Tread wear one-sided.

480RW003

1. Rotating parts out of balance.

2. Tyre or wheel out of round.

3. Hub or knuckle out of round or distorted.

Localized tread wear.

480RW004

1. Once spotty wear develops in tread due to hard

braking or abrupt starting, localized wear tends to

be promoted.

Shoulder wear (generally wear develops in outer

shoulder):

480RW005

1. Camber or toe-in incorrect.

2. Shoulder wear caused by repeated hard-cornering.

Wear in shoulders at points opposed to each other.

480RW006

1. Tyre or wheel out of round or distorted.

2. Play in bearings or ball joint.

Premature wear in shoulders.

480RW007

1. Flexing of tyre excessive due to under-inflation.

One sided feather edging.

480RW008

1. Wear caused by repeated hard cornering.

2. Camber or toe-in incorrect.

Wheel

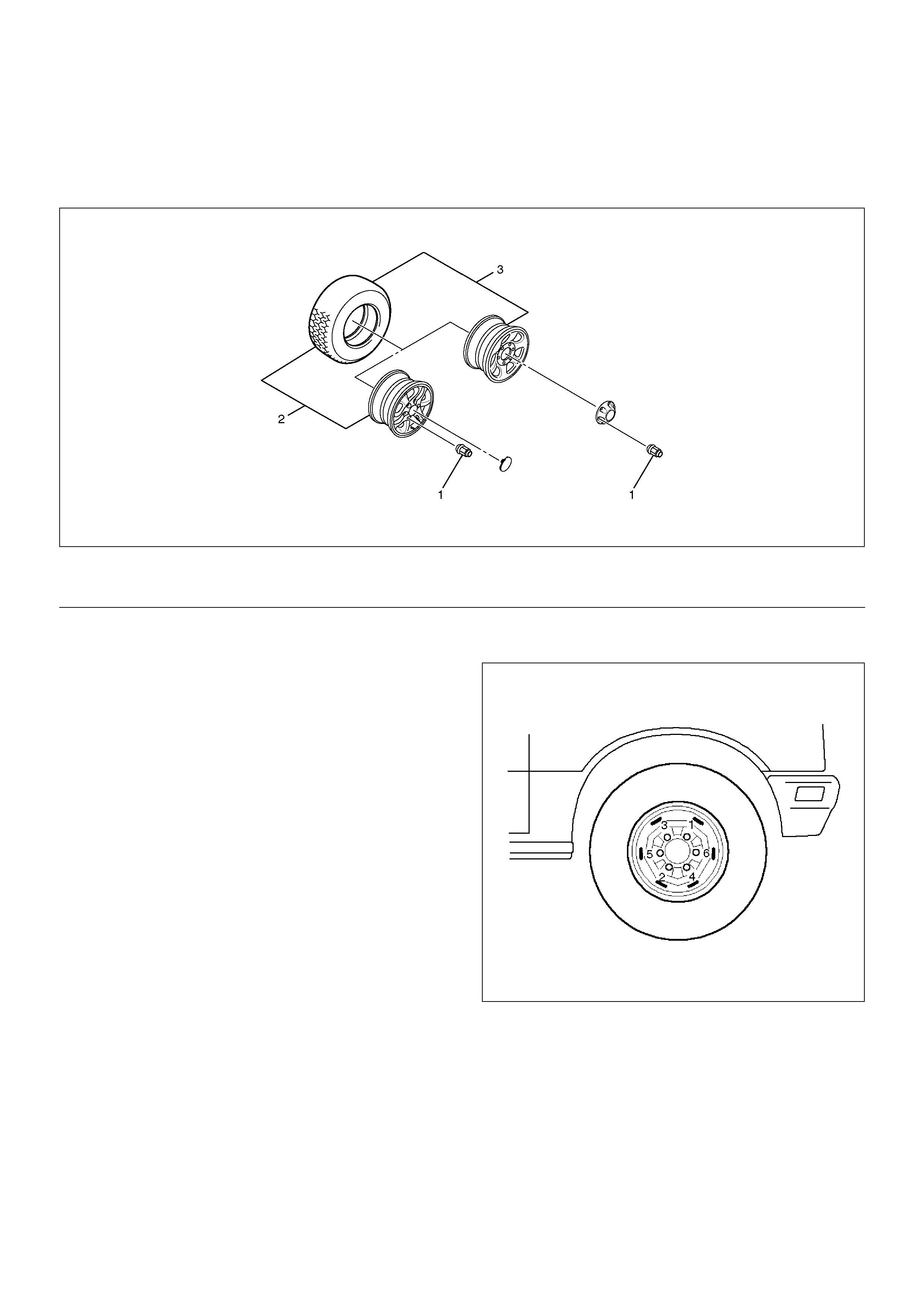

Wheel and Associated Parts

480R200007

EndOFCallout

Removal

1.Loosen wheel lug nuts by by a half turn, then raise

the vehicle and remove the nuts.

2.Remove wheel and tyre.

NOTE: Never use heat to loosen a tight wheel lug nut.

The application of heat to the hub can shorten the life of

the wheel and may cause damage to wheel bearings.

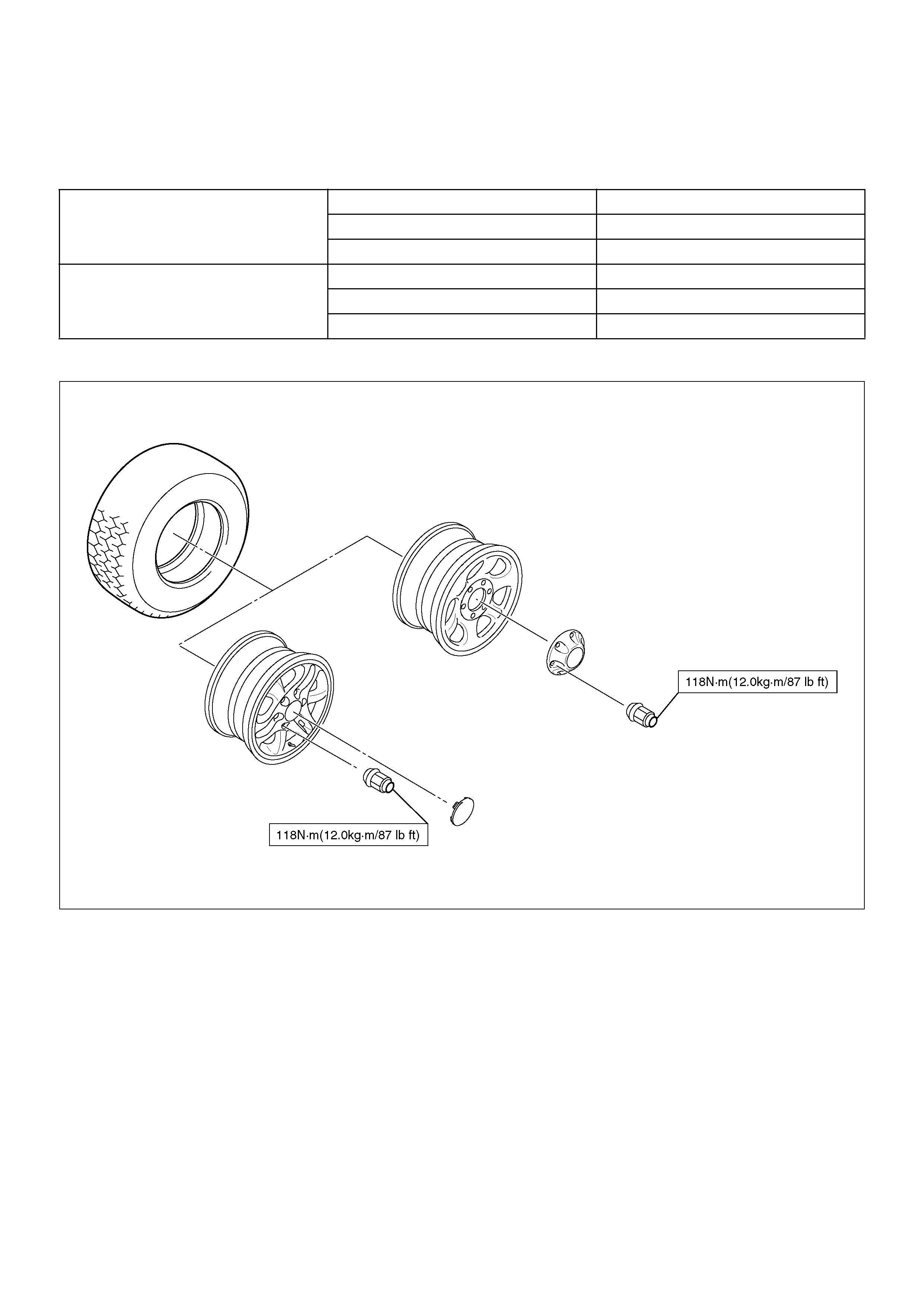

Installation

1.Install wheel and tyre.

2.Install wheel lug nut, and lower the vehicle. Tighten

the wheel lug nuts to the specified torque in the

sequence described in the figure.

Torque: 118N·m (12.0kg·m/87lbft)

CAUTION: Before installing wheels, remove any

build-up of corrosion on the wheel mounting

surface and brake disc mounting surface by

scraping and wire brushing. Installing wheels

without good metal-to-metal contact at mounting

surfaces can cause wheel nuts to loosen, which can

later allow a wheel to come off while the vehicle is

moving.

NOTE: Valve caps should be on the valve stems to

keep dust and water out.

480RS020

Legend

(1) Wheel Lug Nut

(2) Alumi Wheel and Tyre

(3) Steel Wheel and Tyre

Tyre

Tyre Replacement

When replacement is necessary, the original metric the

size should be used. Most metric tyre sizes do not have

exact corresponding alphanumeric tyre sizes. It is

recommended that new tyres be installed in pairs on the

same axle. If necessary to replace only one tyre, it

should be paired with tyre having the most tread, to

balance braking traction.

CAUTION: Do not mix different types of tyres such

as radial, bias and bias-belted tyres except in

emergencies, because vehicle handling may be

seriously affected and may result in loss of control.

Tyre Dismounting

Remove valve cap on valve stem and deflate the tyre.

Then use a tyre changing machine to mount or

dismount tyres.

Follow the equipment manufacturer's instruction. Do not

use hand tools or tyre lever alone to change tyres as

they may damage the tyre beads or wheel rim.

Tyre Mounting

Rim bead seats should be cleaned with a wire brush or

coarse steel wool to remove lubricants, and light rust.

Before mounting a tyre, the bead area should be well

lubricated with an approved tyre lubricant.

After mounting, inflate the tyre to 200kPa (2.0kg/cm2,

28 psi) so that beads are completely seated. Inflate the

air to specified pressure and install valve cap to the

stem.

WARNING: NEVER STAND OVER TYRE WHEN

INFLATING. BEAD MAY BREAK WHEN BEAD

SNAPS OVER RIM'S SAFETY HUMP WHICH CAN

CAUSE SERIOUS PERSONAL INJURY.

NEVER EXCEED 240 KPA (2.4kg/cm2, 35 PSI)

PRESSURE WHEN INFLATING. IF 240 KPA (2.4kg/

cm2, 35 PSI) PRESSURE WILL NOT SEAT BEADS,

DEFLATE, RE-LUBRICATE AND RE-INFLATE. OVER

INFLATION MAY CAUSE THE BEAD TO BREAK AND

CAUSE SERIOUS PERSONAL INJURY.

Tyre Repair

There are many different materials on the market used

to repair tyres.

Manufacturers have published detailed instructions on

how and when to repair tyres. These instructions can be

obtained from the tyre manufacturer if they are not

included with the repair kit.

Wheel Inspection

Damaged wheels and wheels with excessive run-out

must be replaced.

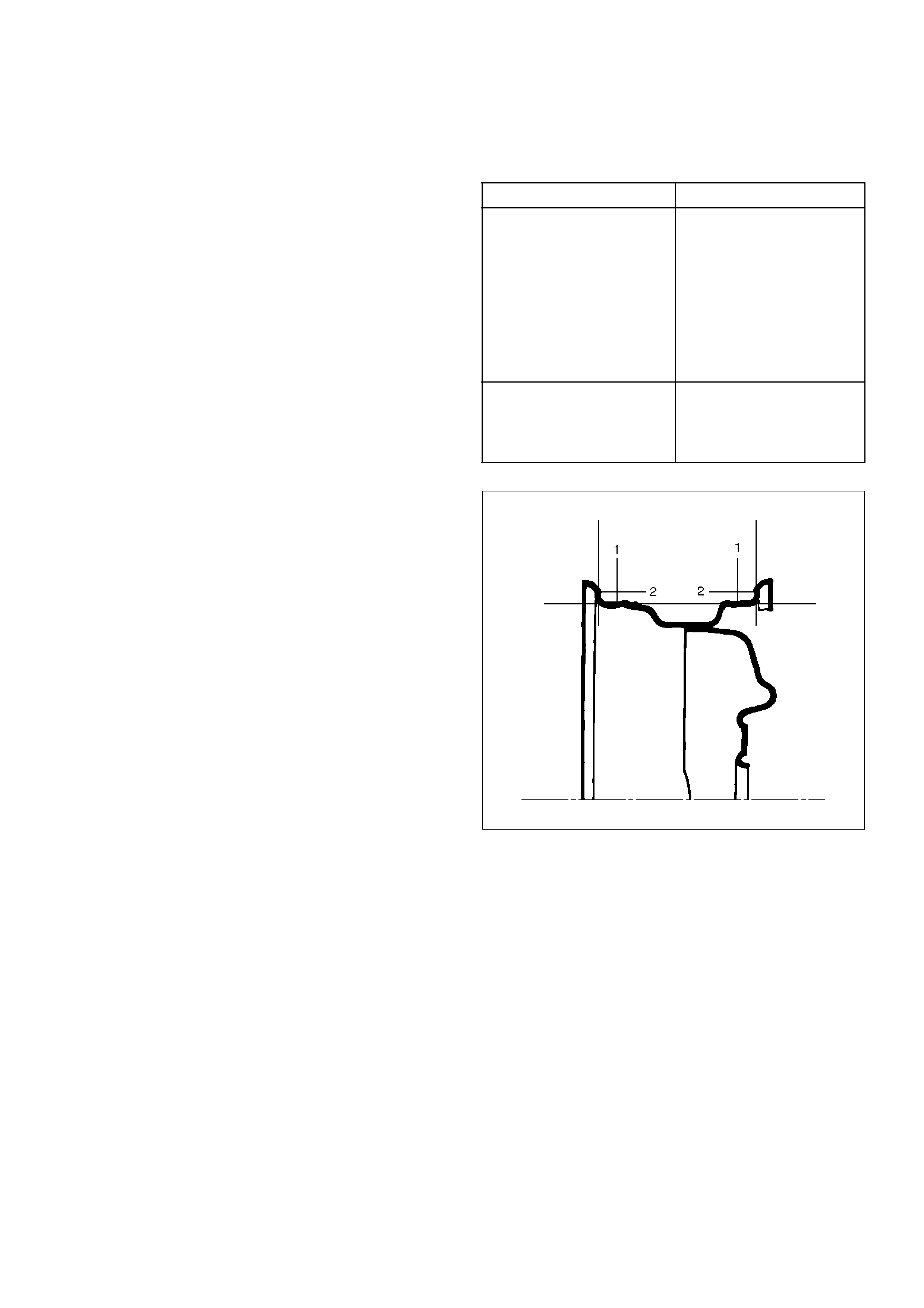

Wheel run out at rim (Base on hub Bore):

480RS012

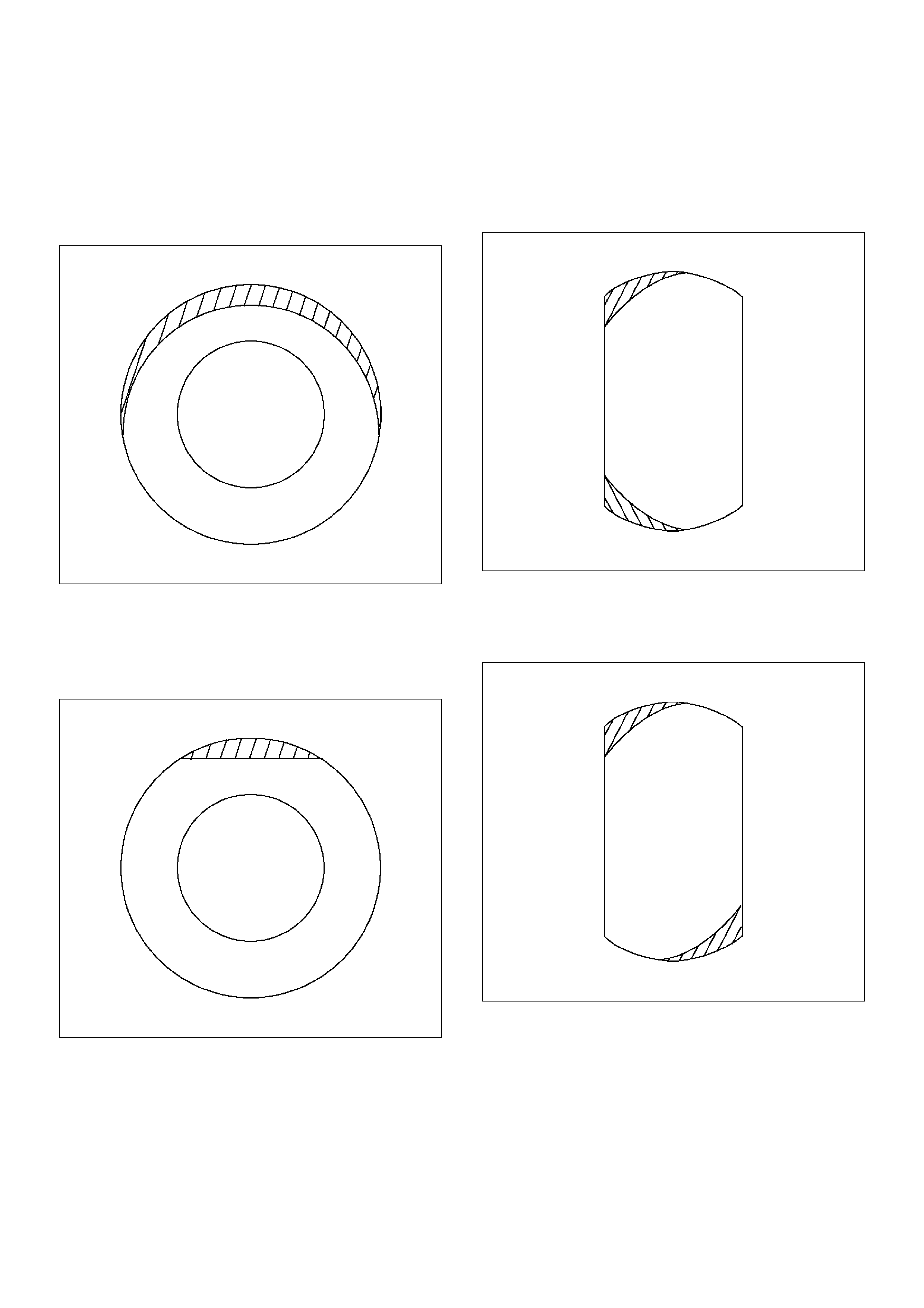

General Balance Procedure

Deposits of mud, etc. must be cleaned from the inside of

the rim.

The tyre should be inspected for the following: match

mount paint marks, bent rims, bulges, irregular tyre

wear, proper wheel size and inflation pressure. Then

balance according to the equipment manufacturer's

recommendations.

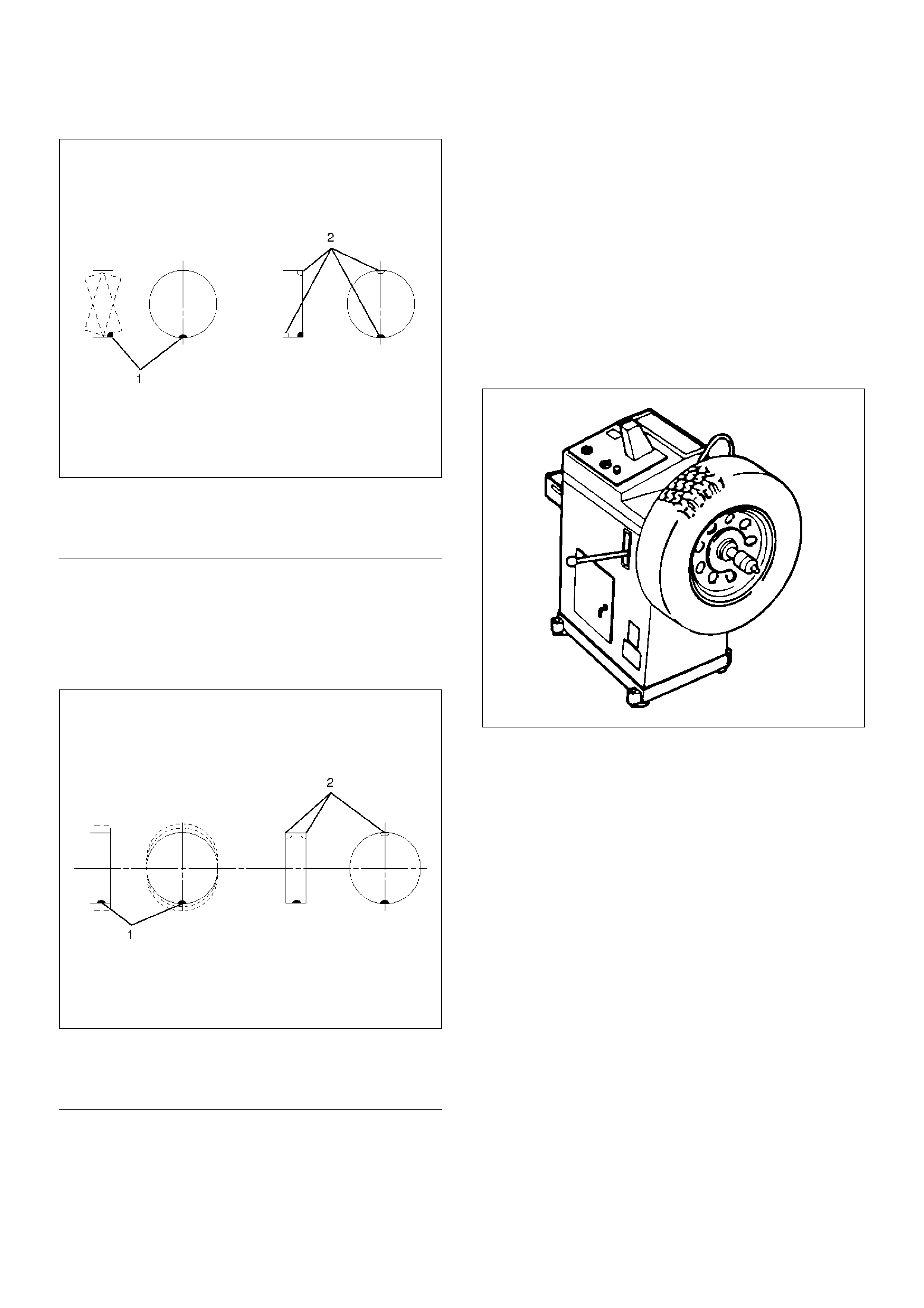

There are two types of wheel and tyre balance.

Static balance is the equal distribution of weight around

the wheel.

Assemblies that are statically unbalanced cause a

bouncing action called tramp. This condition will

eventually cause uneven tyre wear.

Steel Aluminum

1– Vertical play

(AVERAGE OF EACH

SIDE):

Less than

1.5mm (0.059in)

1– Vertical play

(AVERAGE OF EACH

SIDE):

Less than

0.40mm (0.016in)

1-Vertical play

(INDIVIDUAL);

Less than 0.55mm (0.022

in)

2– Horizontal play

(INDIVIDUAL):

Less than

1.5mm (0.059in)

2– Horizontal play

(INDIVIDUAL):

Less than

0.55mm (0.022in)

480RS013

EndOFCallout

Dynamic balance is the equal distribution of weight on

each side of the wheel center-line so that when the tyre

spins there is no tendency for the assembly to move

from side to side. Assemblies that are dynamically

unbalanced may cause shimmy.

480RS014

EndOFCallout

WARNING: STONES SHOULD BE REMOVED FROM

THE TREAD TO AVOID OPERATOR INJURY DURING

SPIN BALANCING AND TO OBTAIN A GOOD

BALANCE.

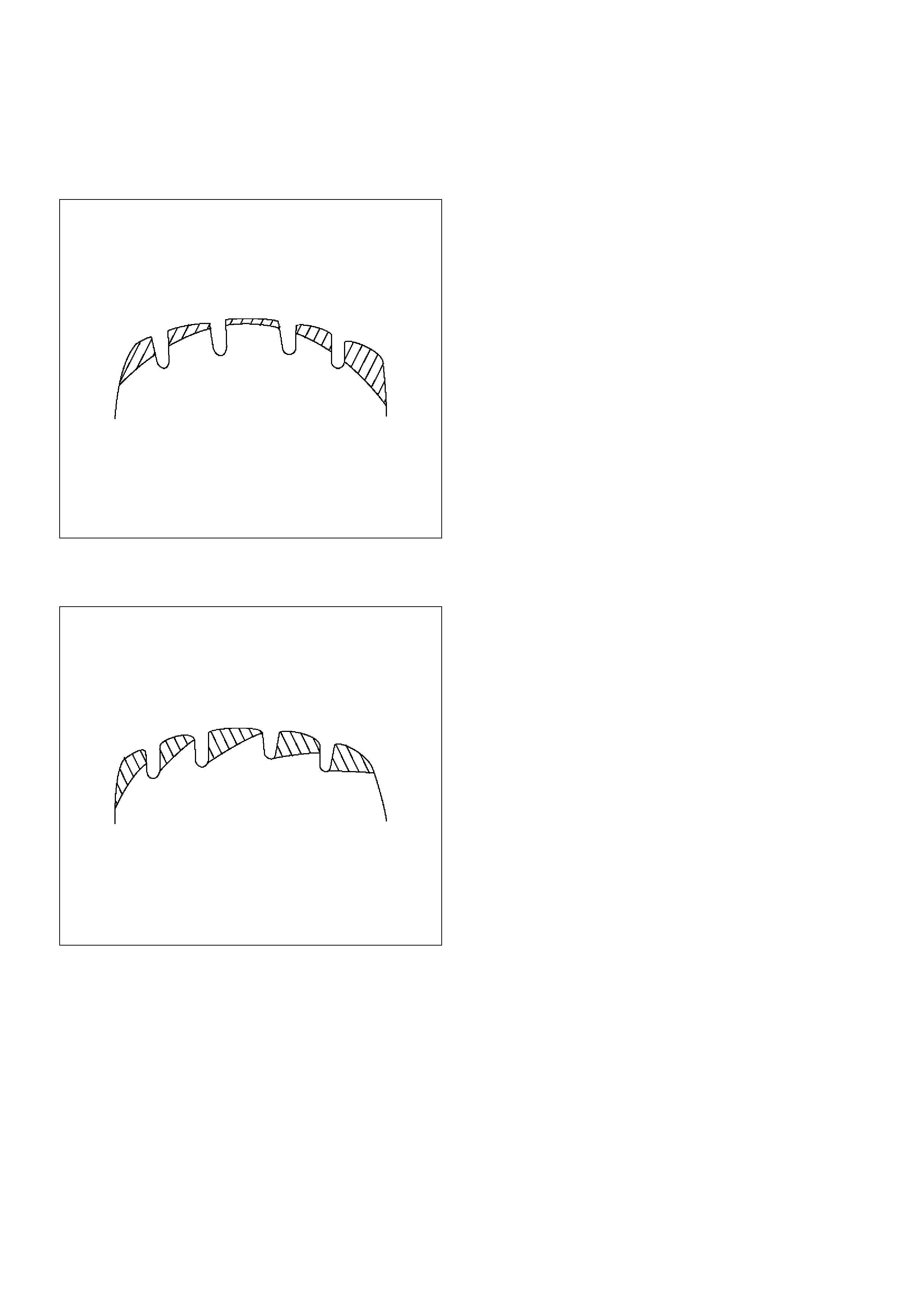

Balancing Wheel and Tyre

On-vehicle Balancing

On-Vehicle balancing methods vary with equipment and

tool manufacturers. Be sure to follow each

manufacturer's instructions during balancing operation.

Off-vehicle Balancing

Most electronic off-vehicle balancers are more accurate

than the on-vehicle spin balancers. They are easy to

use and give a dynamic balance. Although they do not

correct for drum or disc unbalance (as on- vehicle spin

balancing does), they are very accurate.

480RS015

Legend

(1) Heavy Spot Wheel Shimmy

(2) Add Balance Weights Here

Legend

(1) Heavy Spot Wheel Hop

(2) Add Balance Weights Here

Main Data and Specifications

General Specifications

Torque Specifications

480R200019

Wheels Size 16 x 7JJ

Offset 38.0mm (1.50in)

P.C.D., wheel studs 139.7mm (5.50in)

Standard tyre Size P245/70R16

Pressure(Front) 180kPa (1.8kg/cm2, 26psi)

Pressure(Rear) 180kPa (1.8kg/cm2, 26psi)