SECTION 4A - REAR SUSPENSION (MY2002)

Service Precaution

General Description

Diagnosis

Coil Spring

Coil Spring and Associated Parts

Removal

Inspection and Repair

Installation

Shock Absorber

Shock Absorber and Associated Parts

Removal

Inspection and Repair

Installation

Trailing Link

Trailing Link and Associated Parts

Removal

Inspection and Repair

Installation

Upper Link

Upper Link and Associated Parts

Removal

Inspection and Repair

Installation

Lateral Rod

Lateral Rod and Associated Parts

Removal

Inspection and Repair

Installation

Stabiliser Bar

Stabiliser Bar and Associated Parts

Removal

Inspection and Repair

Installation

Main Data and Specifications

Special Tools

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

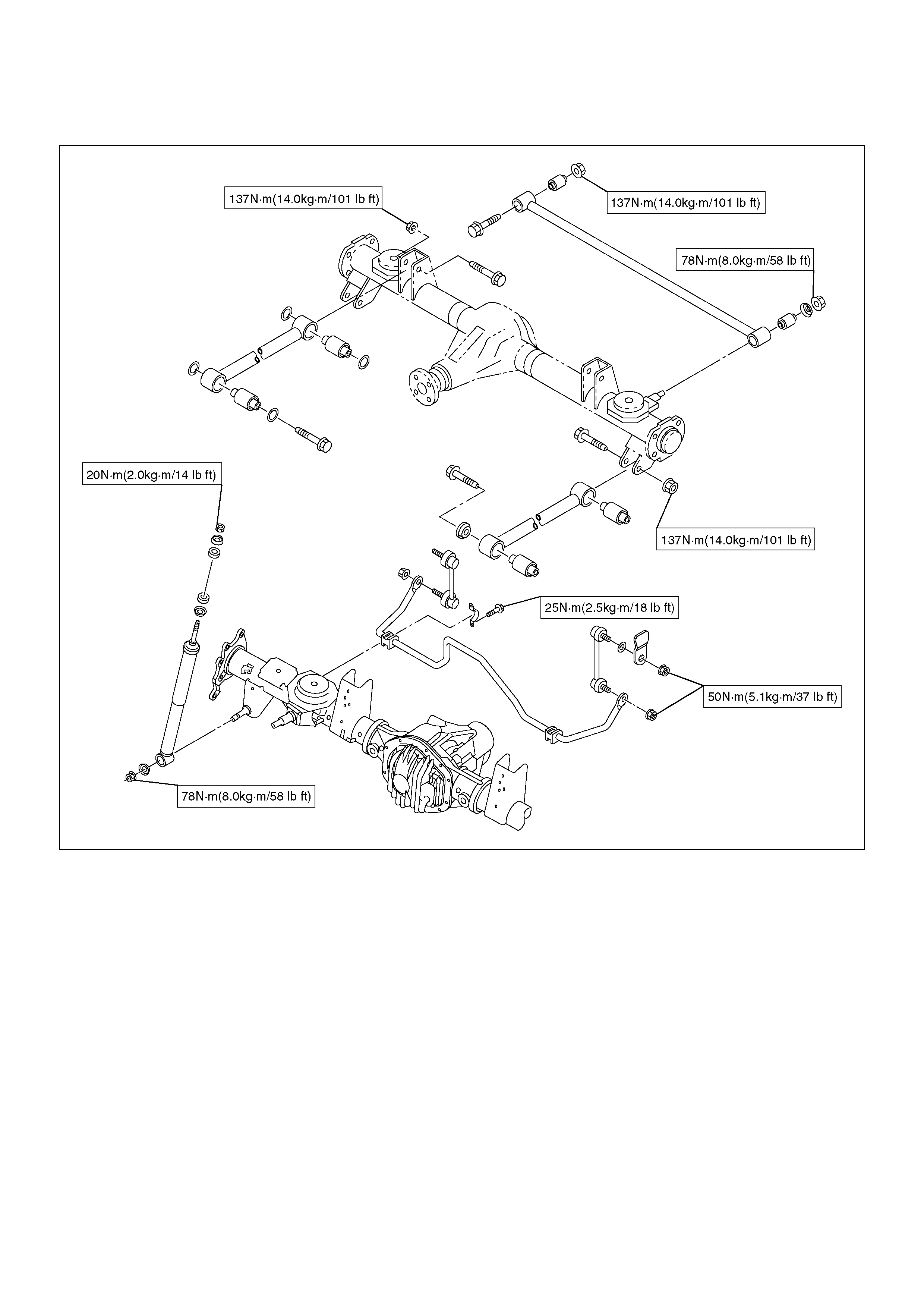

General Description

The rear suspension is a 5-link, coil spring type

suspension with a stabiliser bar, consisting of two

trailing links, two upper links, lateral rod, shock

absorber, and stabiliser. In this suspension, the links are

specially arranged to enable the rear axle to move

freely, thereby expanding suspension stroke, reducing

friction, and improving lateral rigidity and roll control. All

these result in improved stability, riding comfort, and

rough road maneuverability.

Each link connects the axle housing with the frame

through a runner bushing. The axle housing is

supported by the trailing links and upper links

longitudinally and by the lateral rod latitudinally.

Diagnosis

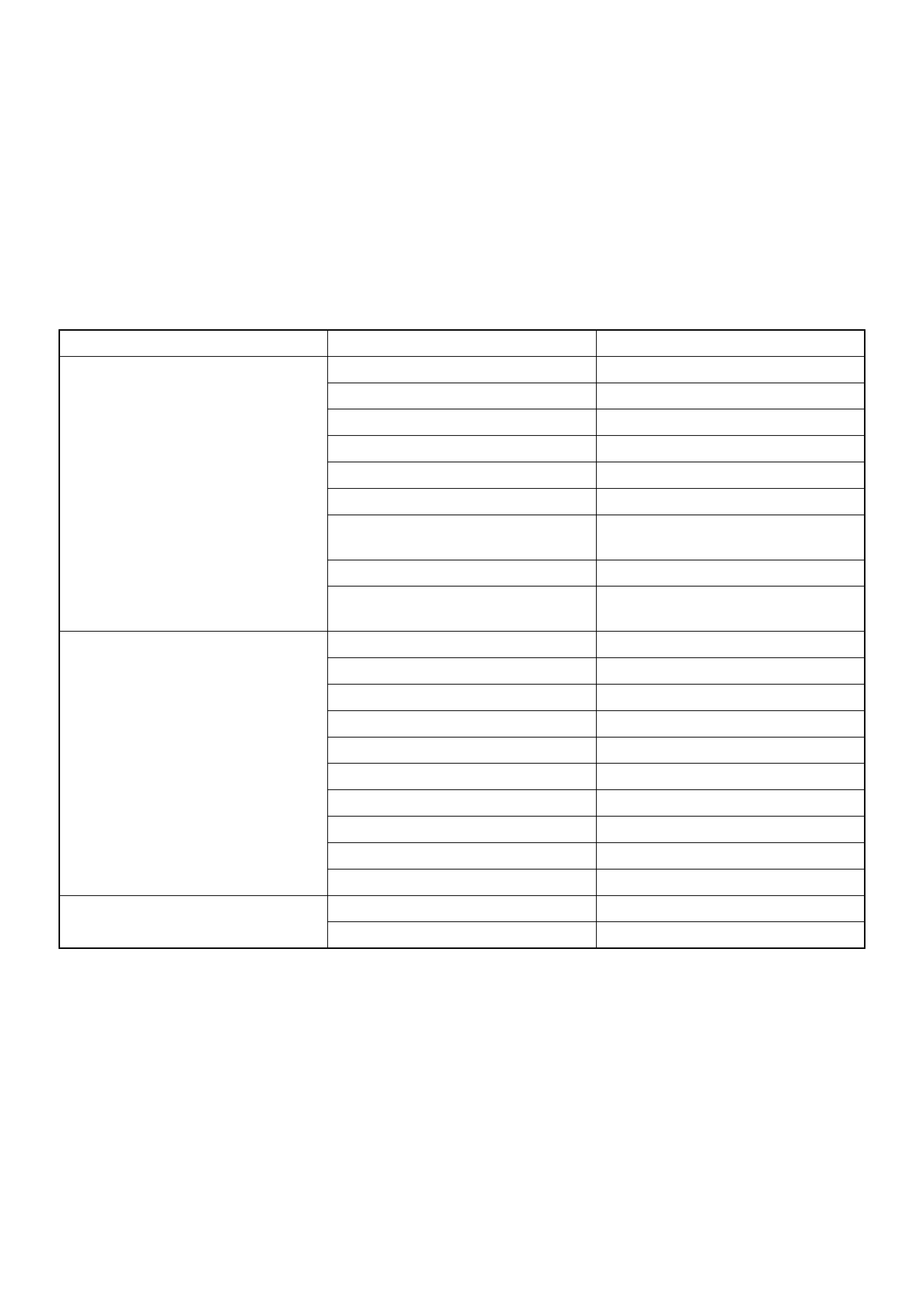

Condition Possible cause Correction

Vehicle Pulls Mismatched or uneven tyres. Replace tyre.

Tyres not adequately inflated. Adjust tyre pressure.

Broken or sagging springs. Replace spring.

Radial tyre lateral force. Replace tyre.

Improper wheel alignment. Adjust wheel alignment.

Brake dragging in one wheel. Repair brake.

Loose, bent or broken front or rear

suspension parts.

Tighten or replace the appropriate

suspension part(s).

Faulty shock absorbers. Replace shock absorber.

Parts in power steering valve

defective.

Replace power steering unit.

Abnormal or Excessive Tyre Wear Sagging or broken spring. Replace spring.

Tyre out of balance. Balance or replace tyre.

Improper wheel alignment. Check front end alignment.

Faulty shock absorber. Replace shock absorber.

Hard driving. Replace tyre.

Overloaded vehicle. Replace tyre and reduce load.

Tyres not rotated periodically. Replace or rotate tyre.

Worn or loose road wheel bearings. Replace wheel bearing.

Wobbly wheel or tyres. Replace wheel or tyre.

Tyres not adequately inflated. Adjust the pressure.

Wheel Hop Blister or bump on tyre. Replace tyre.

Improper shock absorber operation. Replace shock absorber.

Shimmy, Shake or Vibration Tyre or wheel out of balance. Balance wheels or replace tyre/or

wheel.

Loose wheel bearings. Replace wheel bearing.

Worn steering linkage ball joints. Replace ball joints.

Worn upper or lower end ball joints. Replace ball joints.

Excessive wheel runout. Repair or replace wheel and/or tyre.

Blister or bump on tyre. Replace tyre.

Excessive loaded radial runout of

tyre/wheel assembly.

Replace tyre or wheel.

Improper wheel alignment. Check wheel alignment.

Loose or worn steering linkage. Tighten or replace steering linkage.

Loose steering unit. Tighten steering unit.

Tyres not adequately inflated. Adjust tyre pressure.

Loose, bent or broken front or rear

suspension parts.

Tighten or replace the appropriate

suspension parts.

Faulty shock absorber. Replace shock absorber.

Hub bearing preload misadjustment. Adjust preload.

Parts in power steering valve

defective.

Replace power steering unit.

Hard Steering Bind in steering linkage ball studs,

upper or lower ball joint.

Replace ball joint.

Improper wheel alignment. Check wheel alignment.

Tyre not adequately inflated. Inflate tyres to proper pressure.

Bind in steering column or shaft. Repair or replace.

Improper power steering system

operation.

Repair or replace. Refer to Steering

section.

Too Much Play In Steering Hub unit bearings worn. Replace hub unit bearings.

Loose steering unit or linkage. Retighten or repair.

Worn or loose steering shaft

universal joint.

Retighten or replace steering shaft.

Worn steering linkage ball joints. Replace ball joints.

Worn upper or lower end ball joints. Replace ball joints.

Poor Steering Wheel Returnability Bind in steering linkage ball joints. Replace ball joints.

Bind in upper or lower ball joints. Replace ball joints.

Bind in steering column and shaft. Repair or replace.

Bind in steering gear. Check and repair steering gear.

Improper wheel alignment. Adjust wheel alignment.

Tyres not adequately inflated. Adjust pressure.

Loose steering wheel nut. Retighten.

Worn wheel bearing. Replace.

Misassemble Transfer Gear ASM. Reassemble Transfer Gear to

proper portion.

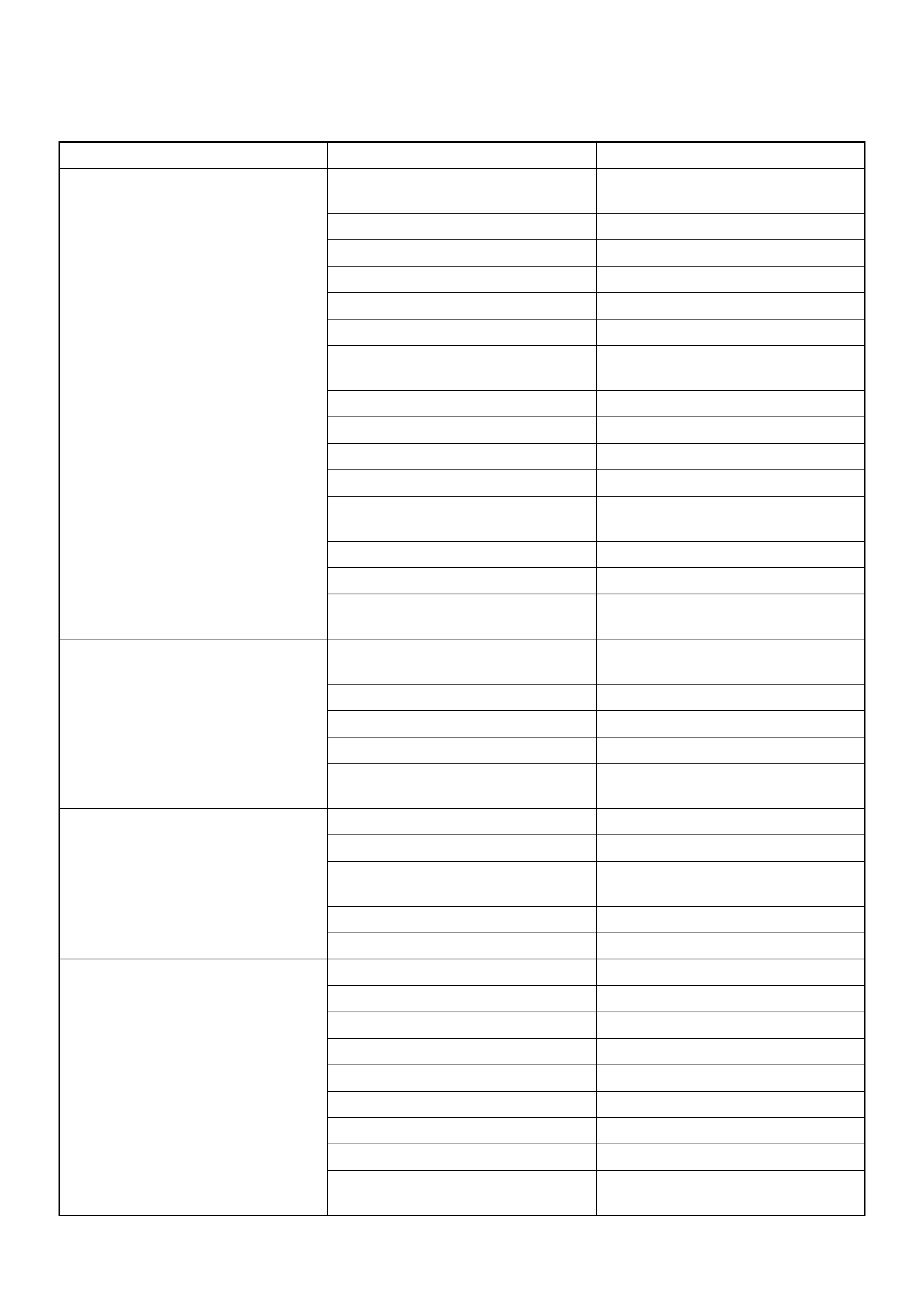

Condition Possible cause Correction

Abnormal Noise Worn, sticky or loose upper or lower

ball joint, steering linkage ball joints

or drive axle joints.

Replace.

Faulty shock absorbers. Replace.

Worn upper or lower control arm

bushing.

Replace.

Loose stabiliser bar. Retighten bolts or replace bushings.

Loose wheel nuts. Tighten nuts. Check for elongated

wheel nut holes. Replace wheel if

required.

Loose suspension bolts or nuts. Retighten suspension bolts or nuts.

Broken or otherwise damaged

wheel bearings.

Replace wheel bearing.

Broken suspension springs. Replace spring.

Loose steering unit. Retighten mounting bolt.

Faulty steering unit. Replace steering unit.

Wandering or Poor Steering Stability Mismatched or unevenly worn tyres. Replace tyre or inflate tyres to

proper pressure.

Loose steering linkage ball joints. Replace ball joints.

Faulty shock absorbers. Replace shock absorber.

Loose stabiliser bar. Tighten or replace stabiliser bar or

bushings.

Broken or sagging springs. Replace spring (pairs).

Improper wheel alignment. Adjust wheel alignment.

Erratic Steering When Braking Worn hub unit bearings. Replace hub unit bearings.

Broken or sagging springs. Replace spring (pairs).

Leaking caliper. Repair or replace caliper.

Warped discs. Replace brake disc.

Badly worn brake pads. Replace brake pads.

Tyres are inflated unequally. Inflate tyres to proper pressure.

Low or Uneven Trim Height Broken or sagging springs. Replace springs (In pairs).

Vehicle overloaded. Reduce load.

Incorrect springs. Adjust or replace torsion bar.

Suspension Bottoms Vehicle overloaded. Reduce load.

Faulty shock absorber. Replace shock absorber.

Incorrect, broken or sagging

springs.

Replace springs.

Trim Height out of spec. Adjust Trim Height.

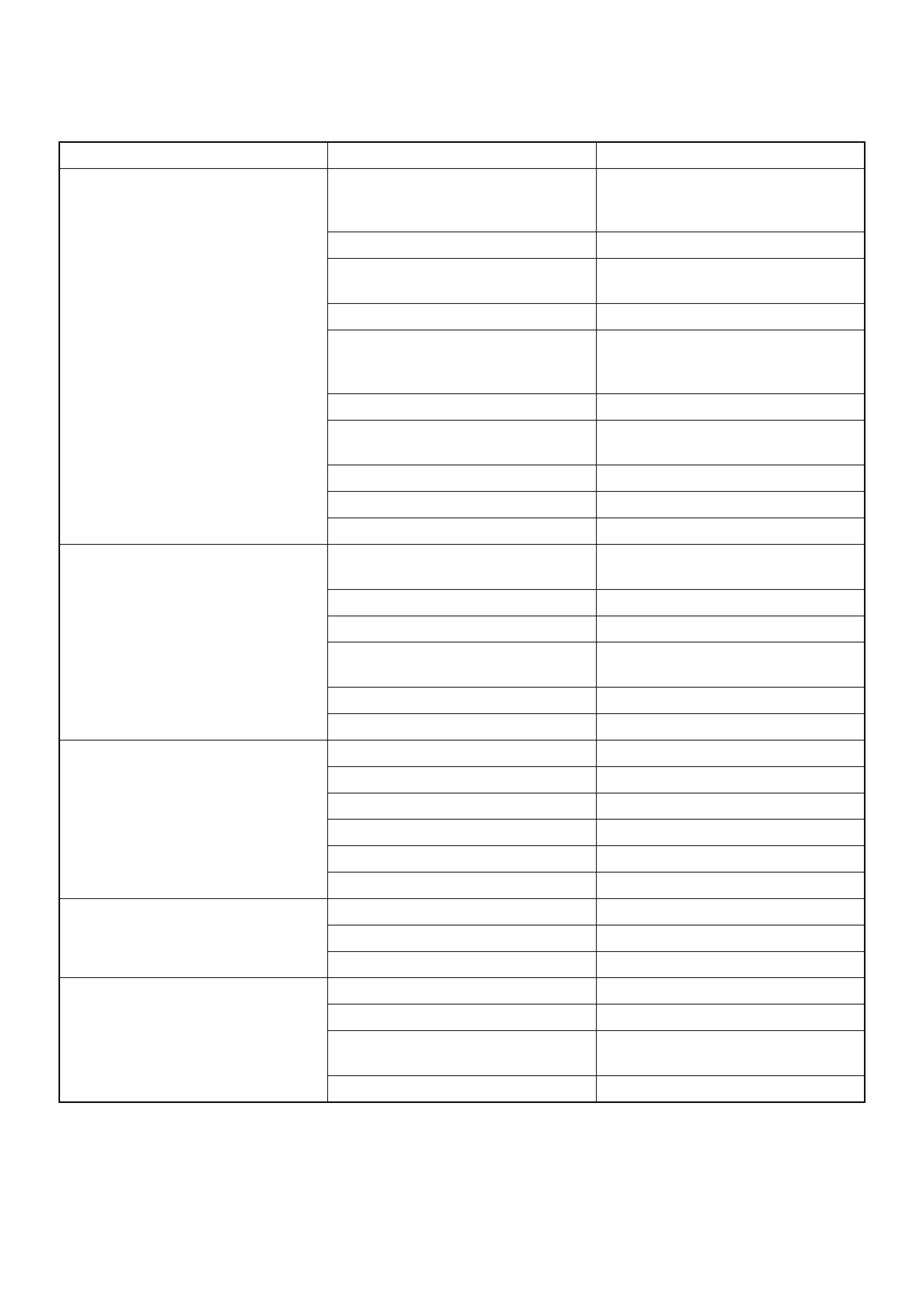

Condition Possible cause Correction

Body Leans Trim Height out of spec. Adjust Trim Height.

Loose stabiliser bar. Tighten stabiliser bar bolts or

replace bushings.

Faulty shock absorber, struts or

mounting.

Replace shock absorber.

Broken or sagging springs. Replace springs (In pairs).

Vehicle overloaded. Reduce load.

Cupped Tyres Worn hub unit bearings. Replace hub unit bearing.

Excessive tyre or wheel run out. Replace tyre or wheel.

Worn ball joints. Replace ball joints.

Tyre out of balance. Adjust tyre balance.

Condition Possible cause Correction

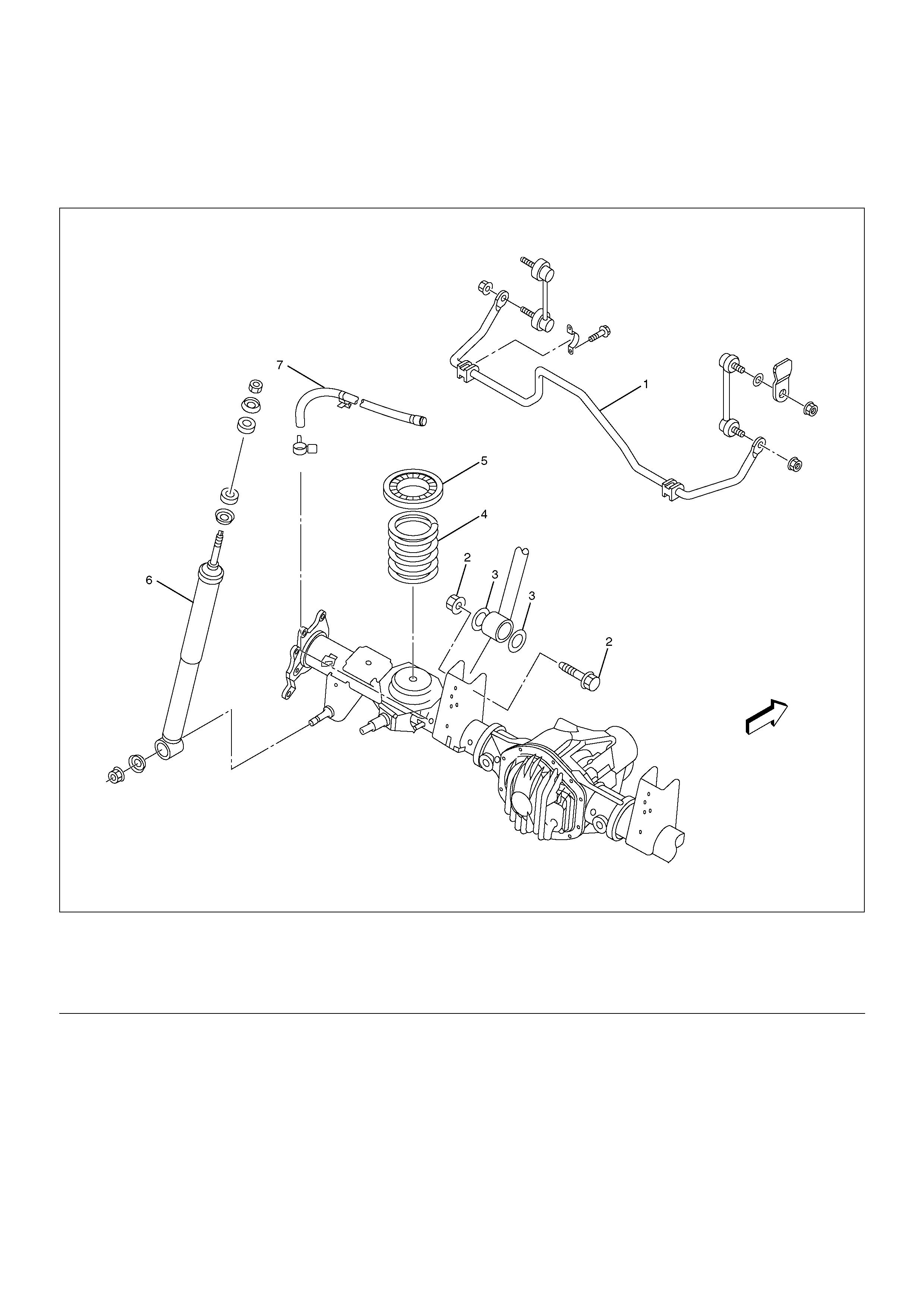

Coil Spring

Coil Spring and Associated Parts

460R200004

EndOFCallout

Removal

1.Raise the vehicle and support the frame with

suitable safety stands.

2.Support the rear axle case with a jack.

3.Disconnect brake hose at the crossmember.

4.Remove breather hose.

5.Remove upper link fixing bolt, nut and rubber plate

on the rear axle case (left-side only).

6.Disconnect the stabiliser bar at the stabiliser link.

7.Remove the shock absorber from the axle case.

8.Remove spring insulator.

9.Remove the insulator and coil spring while lowering

the rear axle case.

CAUTION: Be sure not to let the brake hose,

parking brake cable, and breather hose extend to

their full length.

Legend

(1) Stabiliser Bar

(2) Upper Link Fixing Bolt and Nut

(3) Rubber Plate

(4) Coil Spring

(5) Insulator

(6) Shock Absorbar

(7) Breather Hose

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found through inspection.

Check the following parts:

•Coil spring

•Insulator

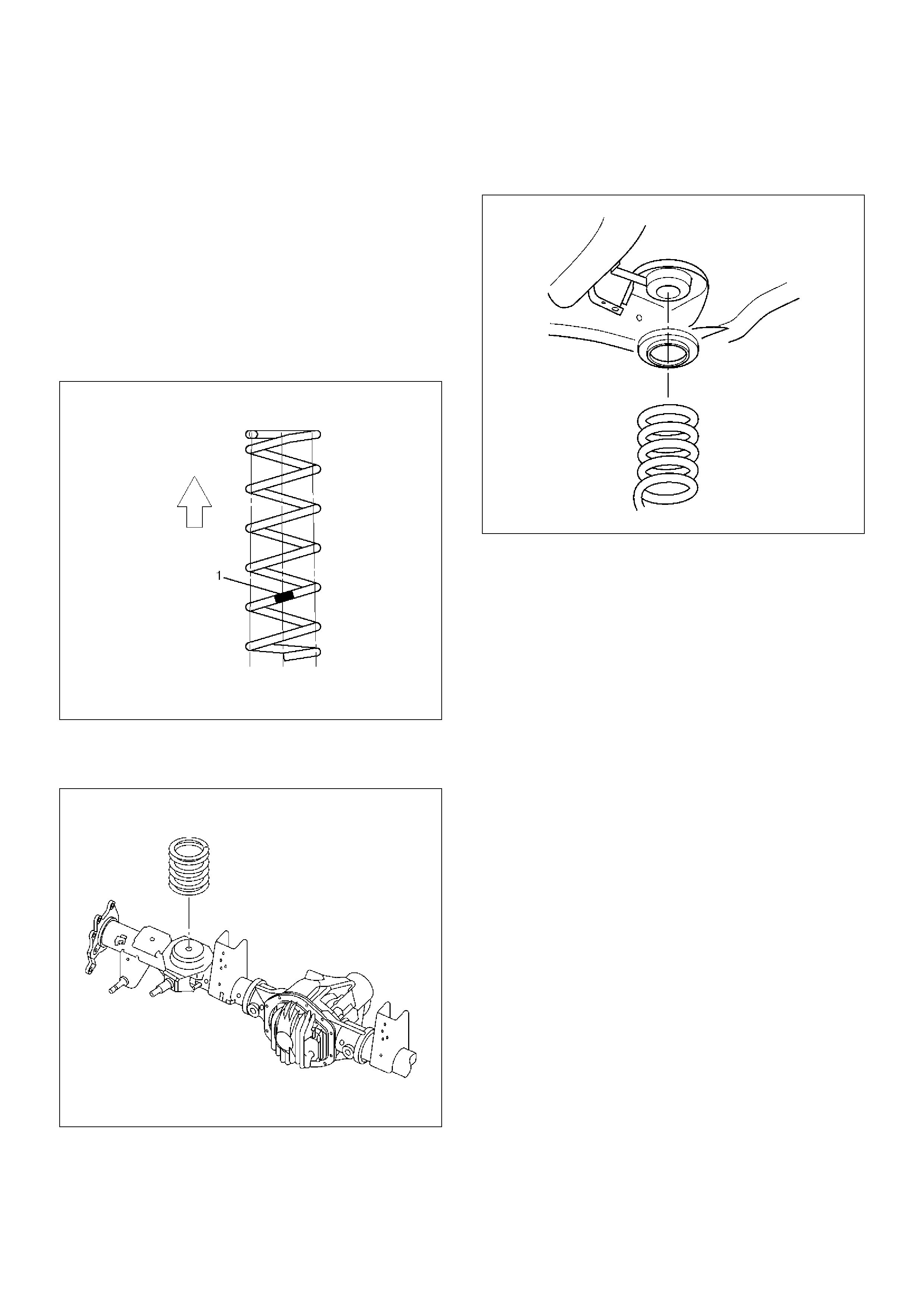

Installation

1.Install coil spring and make sure that the coil spring

is installed in the proper position. Paint mark(1)

should be downward.

460RW001

2.Fit the end of the coil spring to the coil spring seat

and mount the coil spring on the rear axle case.

460RW004

3.Install the insulator on the coil spring. Jack up the

axle case gently with the top of the coil spring set to

the spring seat on the frame side.

460RW013

4.Install shock absorber and tighten the nut lightly,

then retighten it to the specified torque after the

vehicle is at curb height.

NOTE: When mounting shock absorber, be sure not to

use grease on bushings or any other nearby part.

Torque: 78N·m (8.0kg·m/58lbft)

5.Install stabiliser bar at the stabiliser link.

Torque: 31N·m (3.2kg·m/23lbft)

6.Install upper link with rubber plate and tighten fixing

bolt.

Torque: 137N·m (14.0kg·m/101lbft)

7.Install breather hose.

8.Connect brake hose and bleed the brake system.

Refer to Bleeding the Brake Hydraulic System in

Brake section.

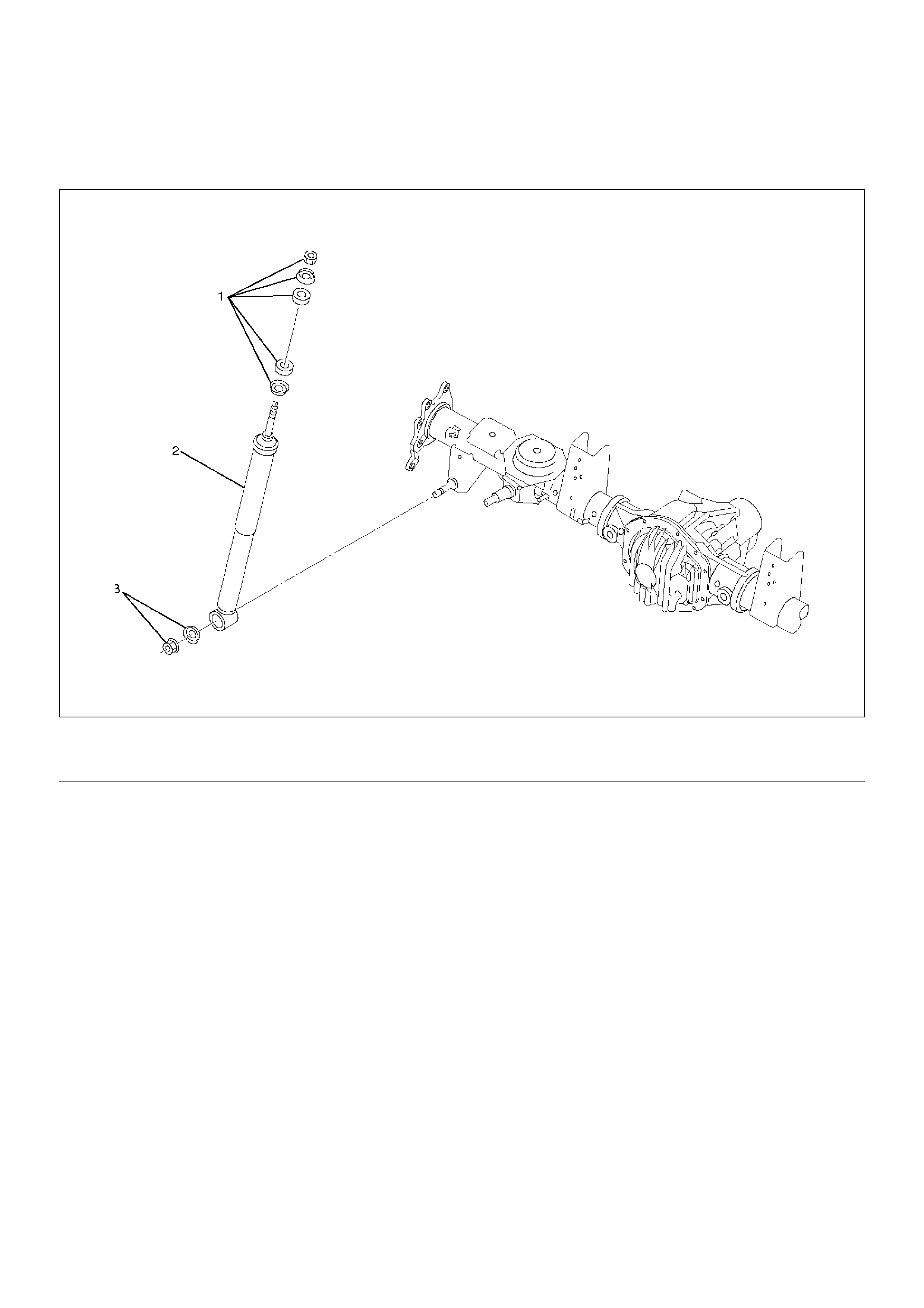

Shock Absorber

Shock Absorber and Associated Parts

461RW001

EndOFCallout

Removal

1. Remove shock absorber fixing nut, bush and

washer (upper side).

2. Remove shock absorber fixing nut and washer

(lower side).

3. Remove shock absorber.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found through inspection.

Check the following parts:

• Shock absorber

• Rubber bushing

NOTE: When mounting rubber bushings, be sure not to

use grease on bushings or any other nearby part.

Installation

1. Install shock absorber. When mounting shock

absorber, be sure not to use grease on bushings or

any other nearby part.

2. Install nut and washer (lower side), then tighten the

nut lightly. Retighten to the bolt and nut specified

torque after the vehicle is at curb height.

Torque: 78N·m (8.0kg·m/58lbft)

3. Install nut, bush and washer (upper side), then

tighten the nut lightly. Retighten to the nut specified

torque after the vehicle is at curb height.

Torque: 20N·m (2.0kg·m/14lbft)

Legend

(1) Nut, Bush and Washer

(2) Shock Absorber

(3) Nut and Washer

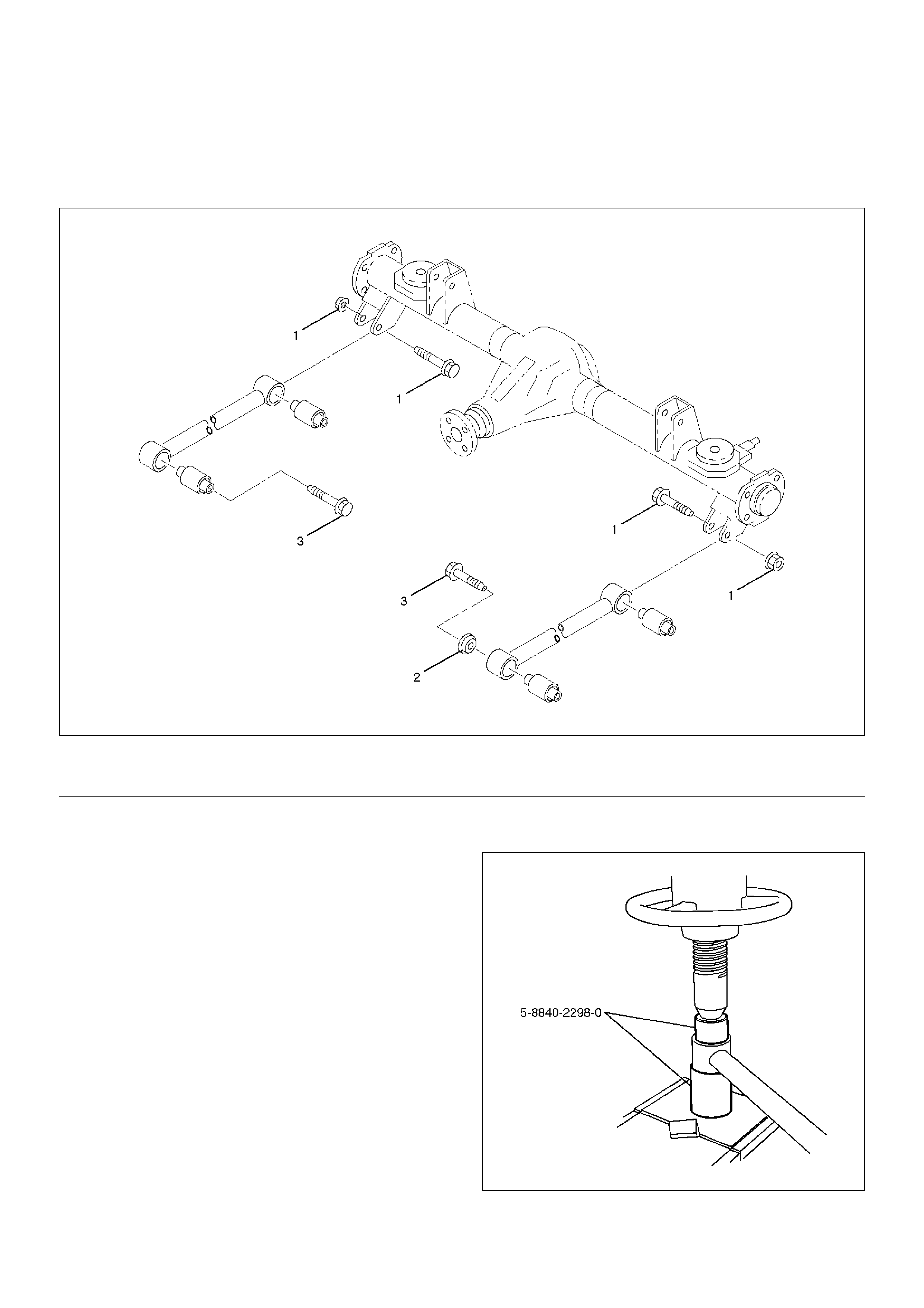

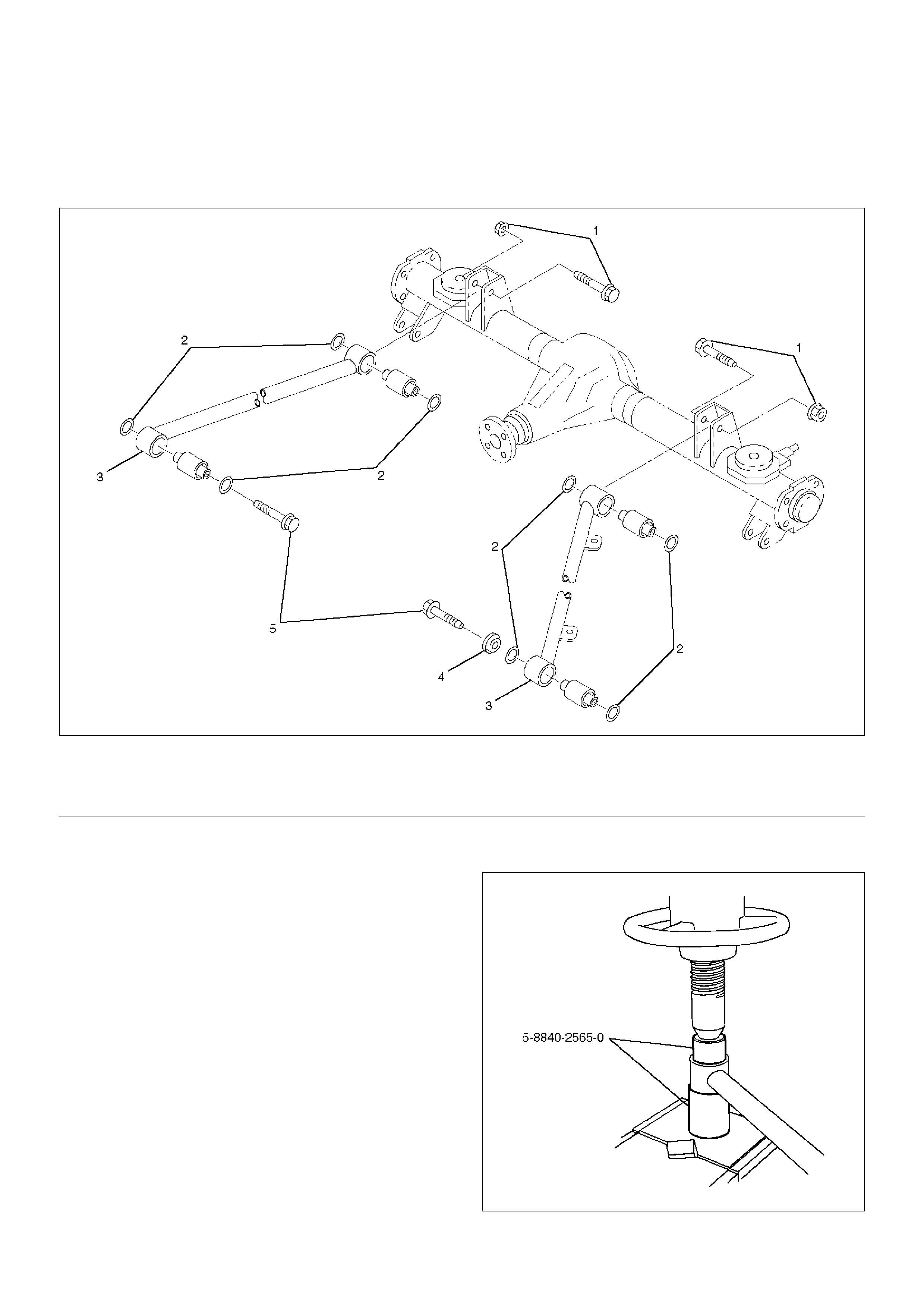

Trailing Link

Trailing Link and Associated Parts

460RW038

EndOFCallout

Removal

1. Remove the parking brake cable from the trailing

link.

2. Remove the trailing link fixing bolt, nut and

protector.

3. Remove trailing link.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found through inspection.

1. Trailing link

2. Rubber bushing

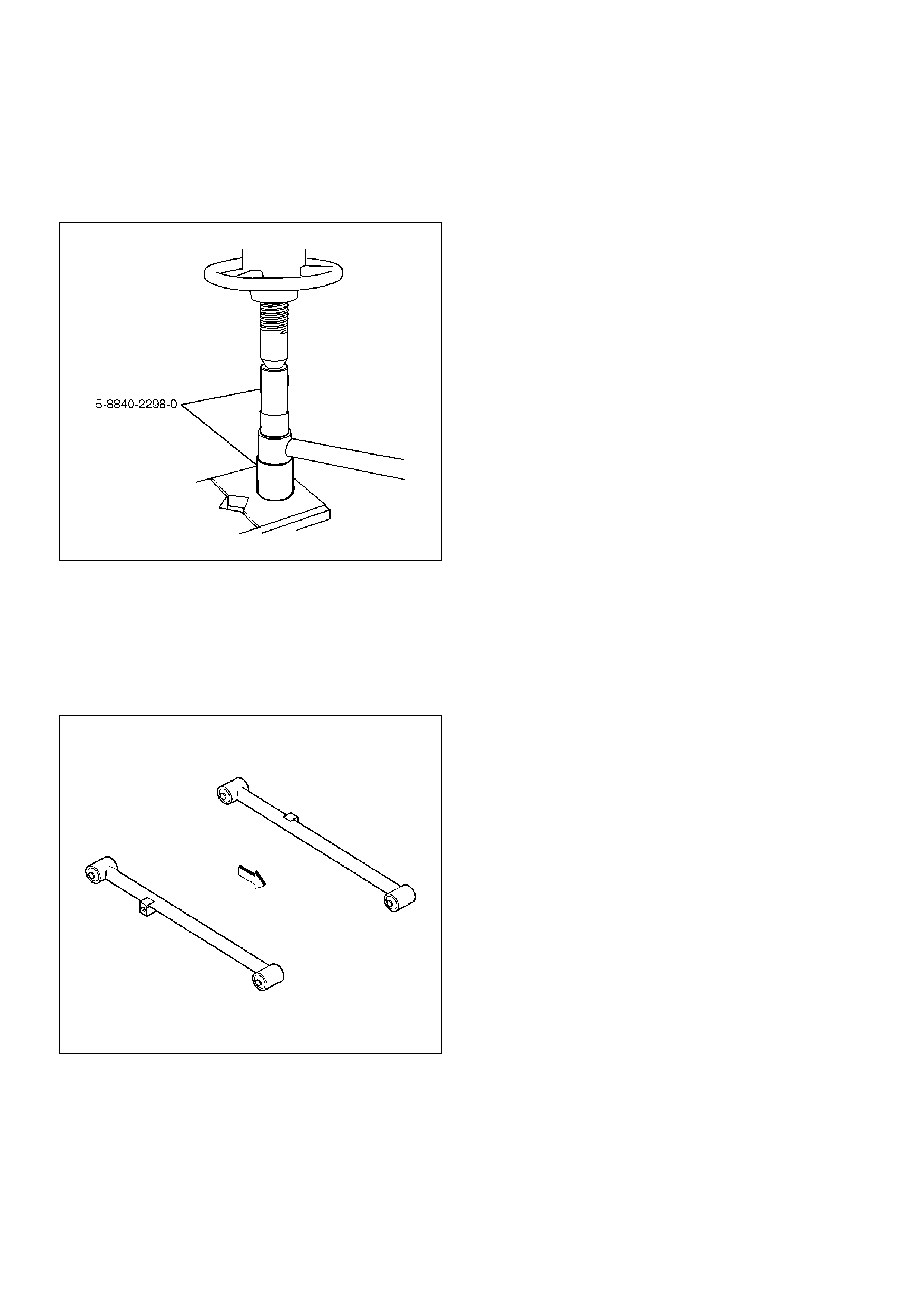

• Remove the rubber bushing by using remover 5–

8840–2298–0.

901RW280

Legend

(1) Bolt and Nut (Axle side)

(2) Protector (Left side only)

(3) Bolt (Frame side)

•Install the rubber bushing by using installer 5–

8840–2298–0.

NOTE: When mounting rubber bushings, be sure not to

use grease on bushings or any other nearby part.

901RW281

Installation

1.Install trailing link. Make sure that the trailing link is

in its correct position.

NOTE: When mounting trailing link, be sure not to use

grease on bushings or any other nearby part.

460RW011

2.Install bolt, nut and protector. Tighten the bolts and

nuts lightly, then retighten them to the specified

torque after the vehicle is at curb height.

Torque: 137N·m (14.0kg·m/101lbft)

3.Install parking brake cable.

CAUTION: The parking brake cable should not be

overstrained or slackened.

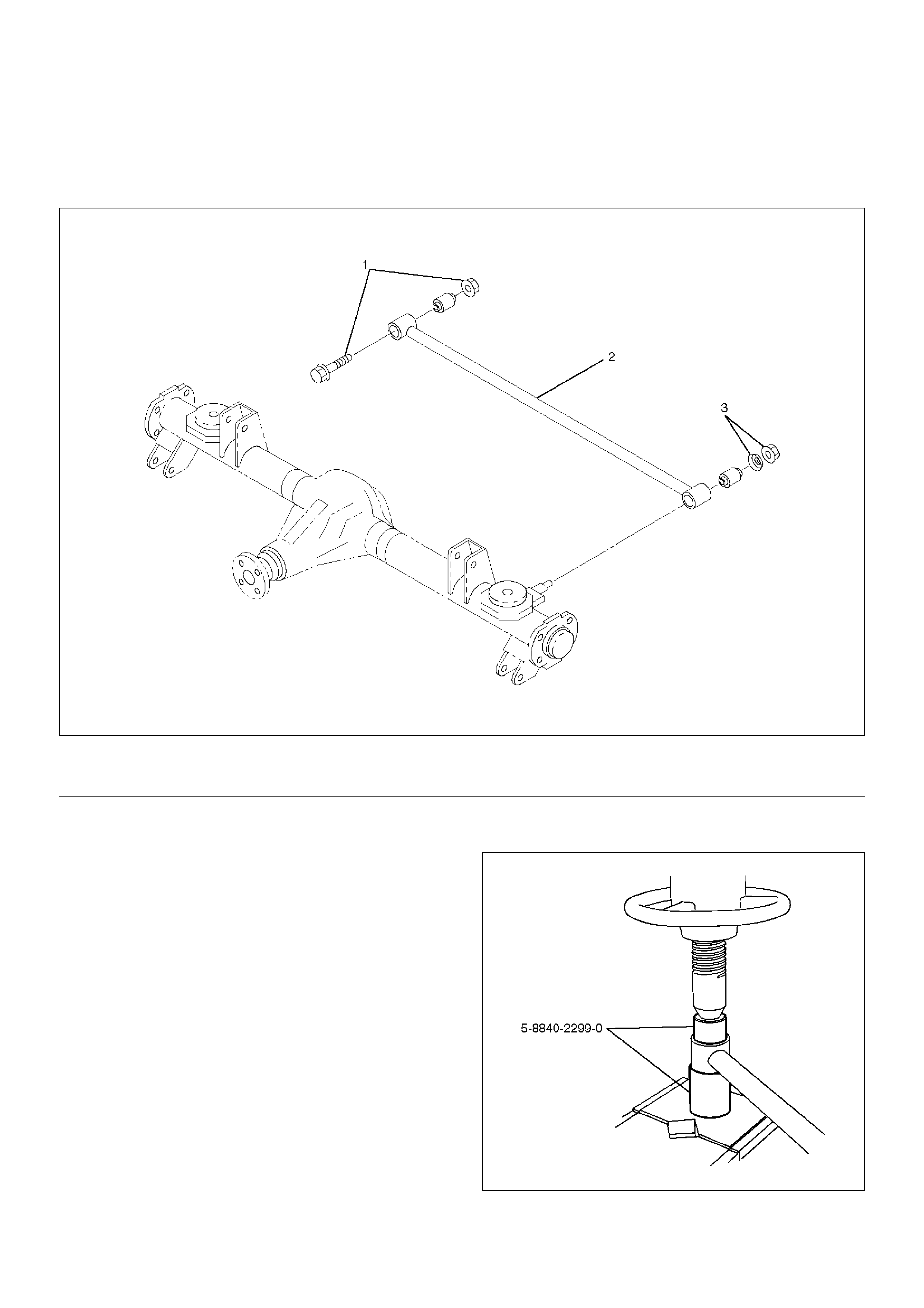

Upper Link

Upper Link and Associated Parts

460RW037-1

EndOFCallout

Removal

1.Remove fuel tank. Refer to Engine Fuel in Engine

section.

2. Remove the speed sensor cable from the upper link.

3. Remove bolt, nut, rubber plate and protector.

4. Remove upper link.

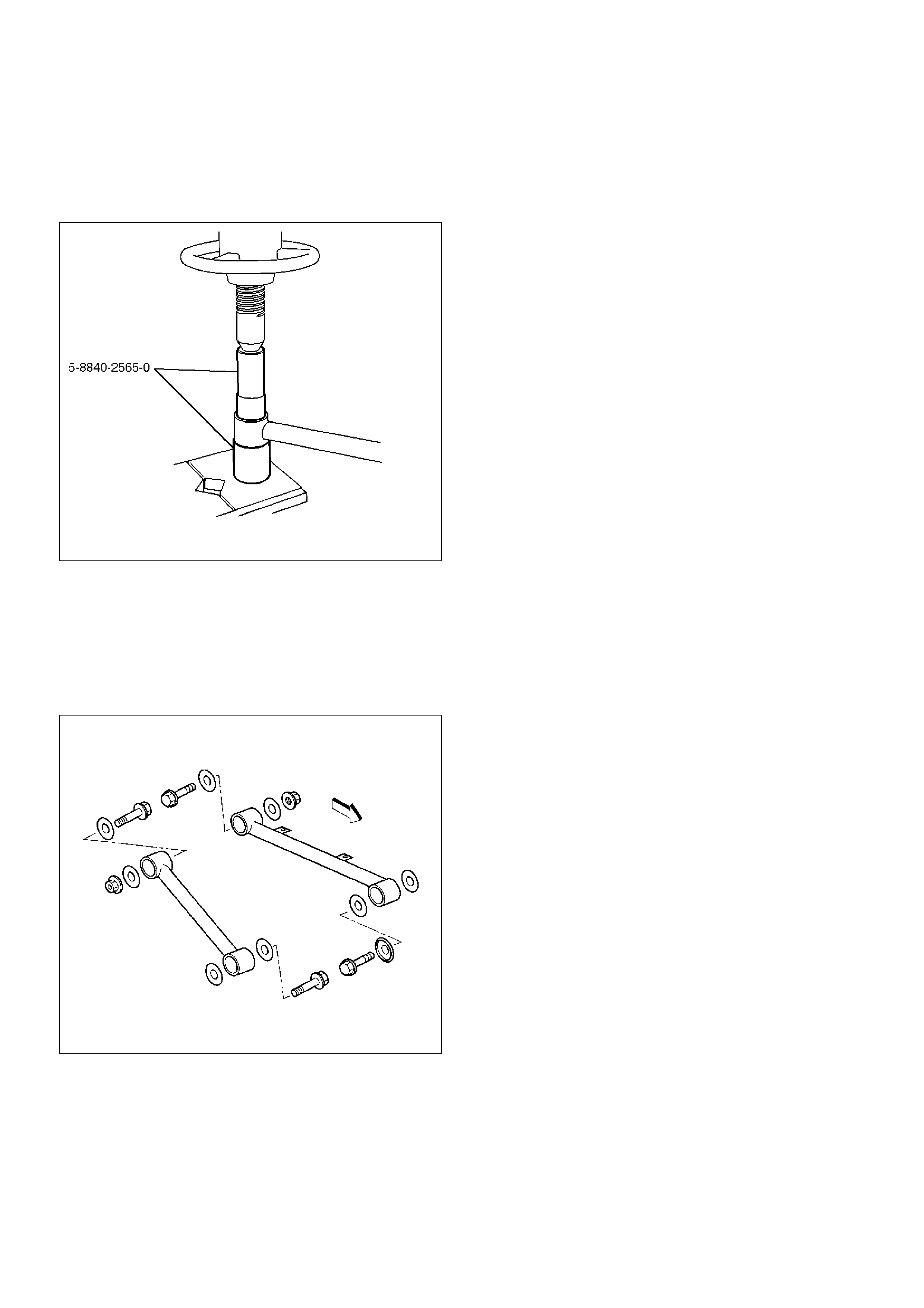

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found through inspection.

1. Upper link

2. Rubber bushing

• Remove the rubber bushing by using remover 5–

8840–2565–0.

901RW282

Legend

(1) Bolt and Nut (Axle side)

(2) Rubber Plate

(3) Upper Link

(4) Protector (Left side only)

(5) Bolt (Frame side)

• Install the rubber bushing by using to installer 5–

8840–2565–0.

NOTE: When mounting rubber bushings, be sure not to

use grease on bushings or any other nearby part.

901RW283

Installation

1. Install upper link. Make sure that the upper link is in

its correct position.

NOTE: When mounting upper link, be sure not to use

grease bushings or any other nearby part.

460RW012

2. Install bolt, nut, rubber plate and protector. Tighten

the bolts and nuts lightly, then retighten them to the

specified torque after the vehicle is at curb height.

Torque: 137N·m (14.0kg·m/101lbft)

3. Install speed sensor cable.

4. Install fuel tank.

Lateral Rod

Lateral Rod and Associated Parts

460RW036

EndOFCallout

Removal

1. Remove nut and washer.

2. Remove bolt and nut.

3. Remove lateral rod.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found through inspection.

1. Lateral rod

2. Rubber bushing (Frame side)

• Remove the rubber bushing (Frame side) by

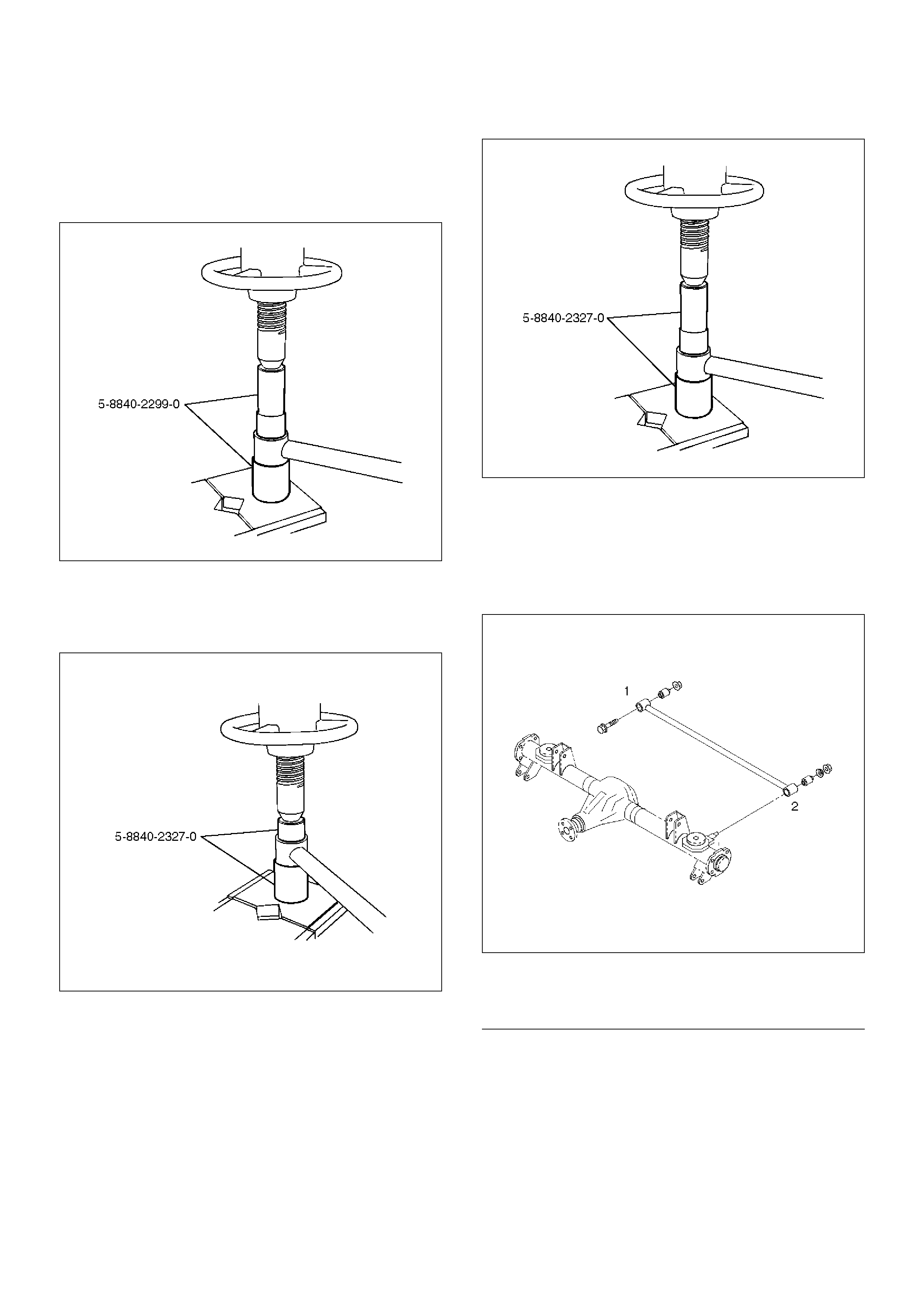

using remover 5–8840–2299–0.

901RW284

Legend

(1) Bolt and Nut (Frame side)

(2) Lateral Rod

(3) Nut and Washer (Axle side)

• Install the rubber bushing (Frame side) by using

Installer 5–8840–2299–0.

NOTE: When mounting rubber bushings, do not use

grease on bushings or any other nearby parts.

901RW285

3. Rubber bushing (Axle side)

• Remove the rubber bushing (Axle side) by using

remover 5–8840–2327–0.

901RW287

• Install the rubber bushing (Axle side) by using

installer 5–8840–2327–0.

901RW286

Installation

1. Install lateral rod and make sure that the lateral rod

is in its correct position.

NOTE: When mounting lateral rod, be sure not to use

grease on bushings or any other nearby part.

460RW035

EndOFCallout

2. Install bolt and nut (Frame side). Tighten the bolt

and nut lightly, then retighten them to the specified

torque after the vehicle is at curb height.

Torque: 137N·m (14.0kg·m/101lbft)

3. Install nut and washer (Axle side). Tighten the nut

lightly, then retighten the nut to the specified torque

after the vehicle is at curb height.

Torque: 78N·m (8.0kg·m/58lbft)

Legend

(1) Frame Side

(2) Axle Side

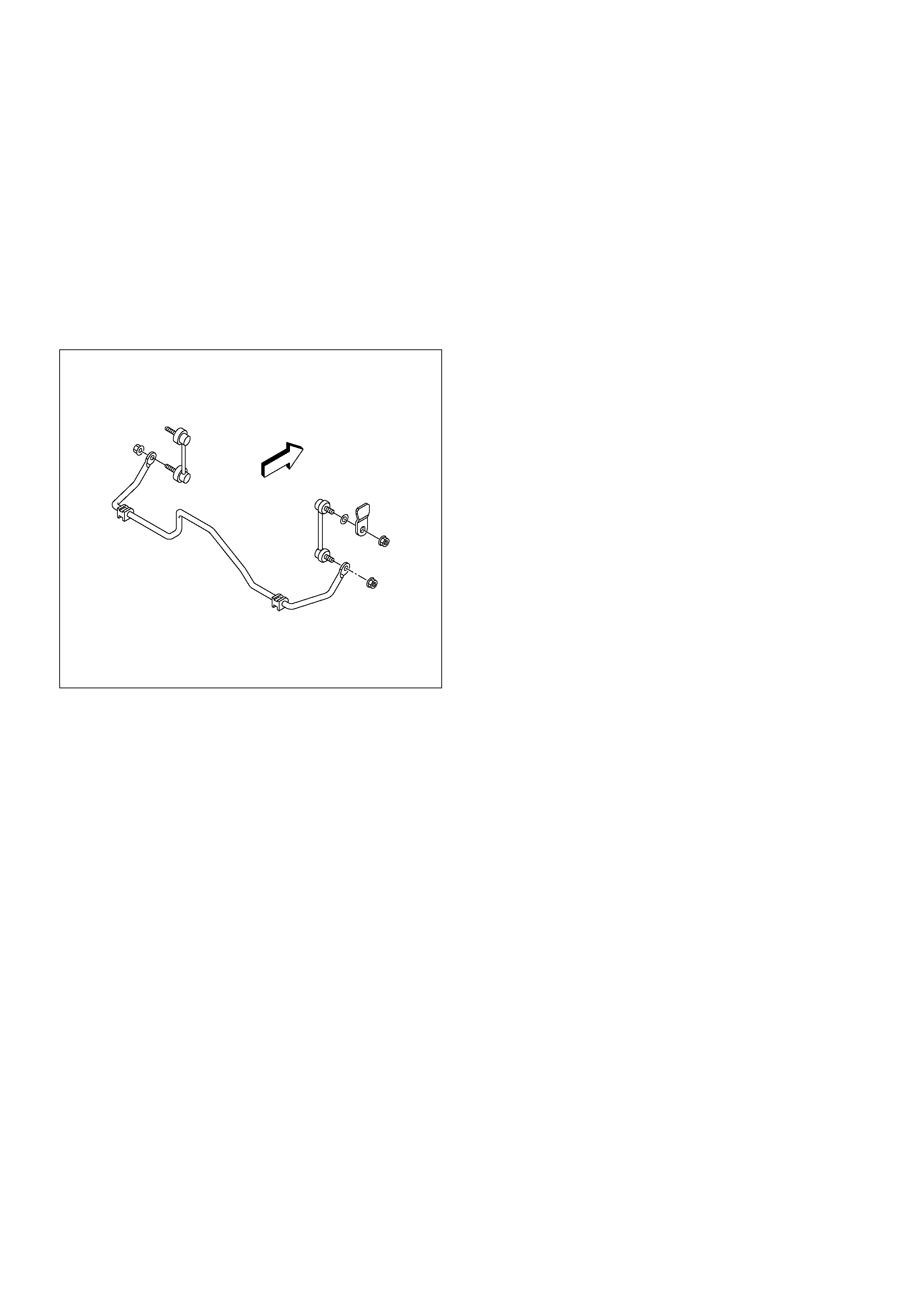

Stabiliser Bar

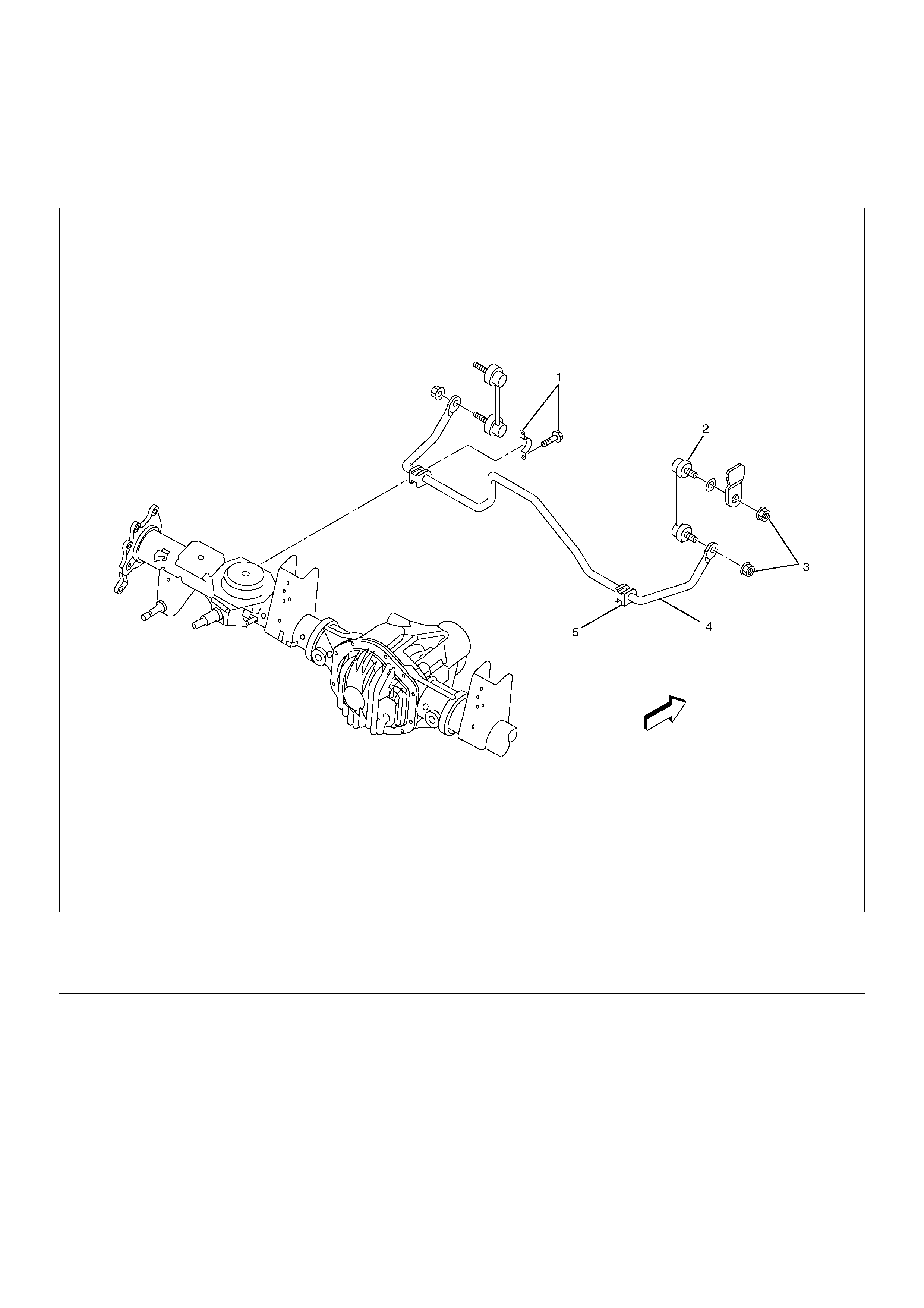

Stabiliser Bar and Associated Parts

460R200003

EndOFCallout

Removal

1.Raise the vehicle and support the frame with

suitable safety stands.

2.Remove wheel and tyre assembly. Refer to Wheel

in this section.

3. Remove nut.

4. Remove link.

5. Remove bracket.

6. Remove rubber bushing.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found through inspection.

Check the following parts:

• Stabiliser bar

• Rubber bushing

•Link

Legend

(1) Bracket and Bolt

(2) Link

(3) Nut

(4) Stabiliser Bar

(5) Rubber Bushing

Installation

1. Install rubber bushing.

2. Install bracket to axle housing and tighten to the

specified torque.

Torque: 25N·m (2.5kg·m/18lbft)

3. Install link.

4. Install nut, then tighten the nut to the specified

torque.

Torque: 50N·m (5.1kg·m/37lbft)

460R200002

Main Data and Specifications

General Specifications

Rear suspension Type 5–Link, coil spring type with stabiliser bar.

Coil spring Free length 378.0mm (14.88in)

Spring diameter 12.8mm (0.5in)

Coil diameter (inner) 105mm (4.13in)

Effective No. of turns 6.00

Total No. of turns 7.50

Shock absorber Type Hydraulic, double acting, telescopic

Piston diameter 30mm (1.18in)

Stroke 175mm (6.89in)

Extended length 473.5mm (18.64in)

Compressed length 298.5mm (11.75in)

Stabiliser bar Diameter 19mm (0.75in)

Torque Specifications

E03R200010

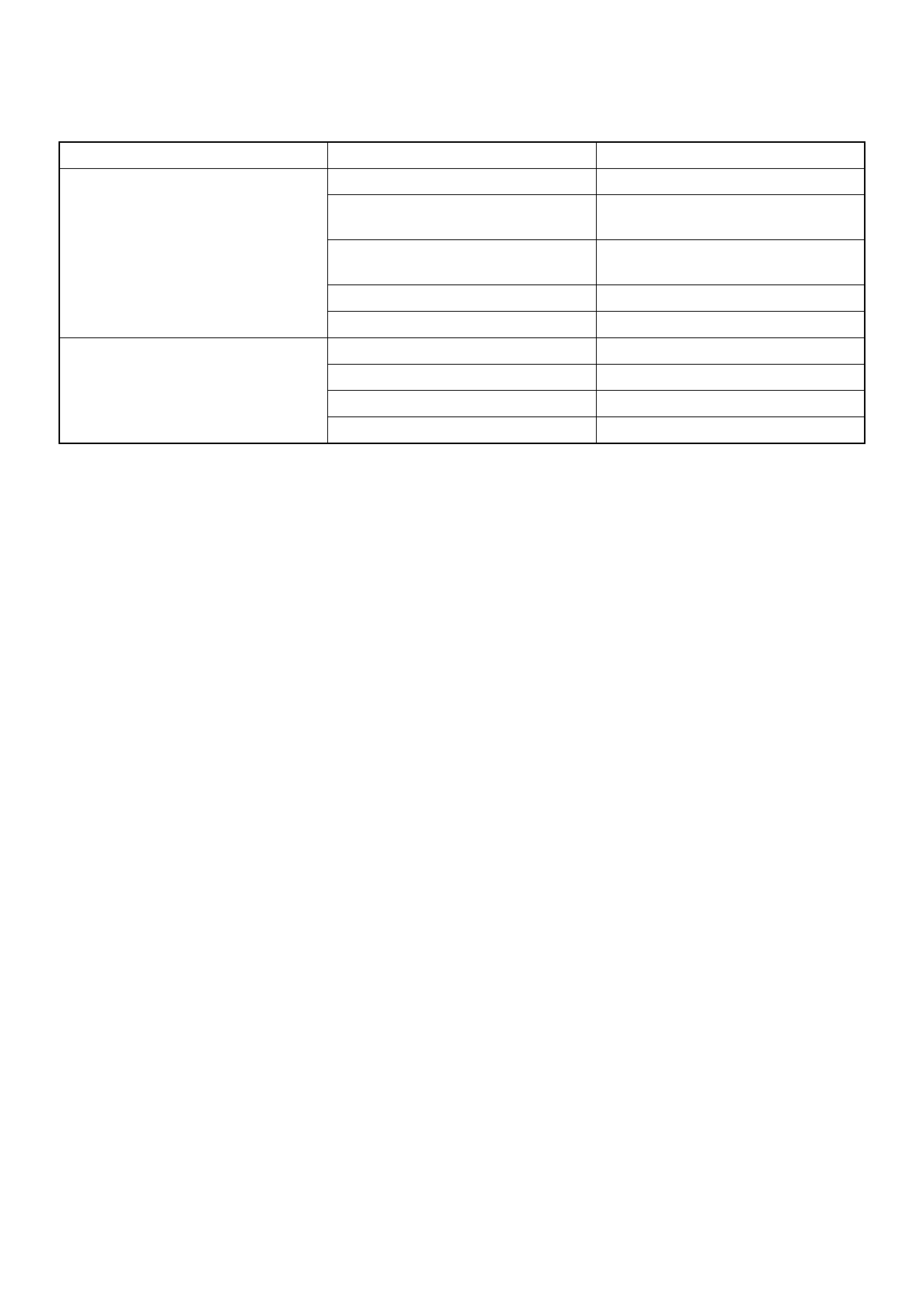

Special Tools

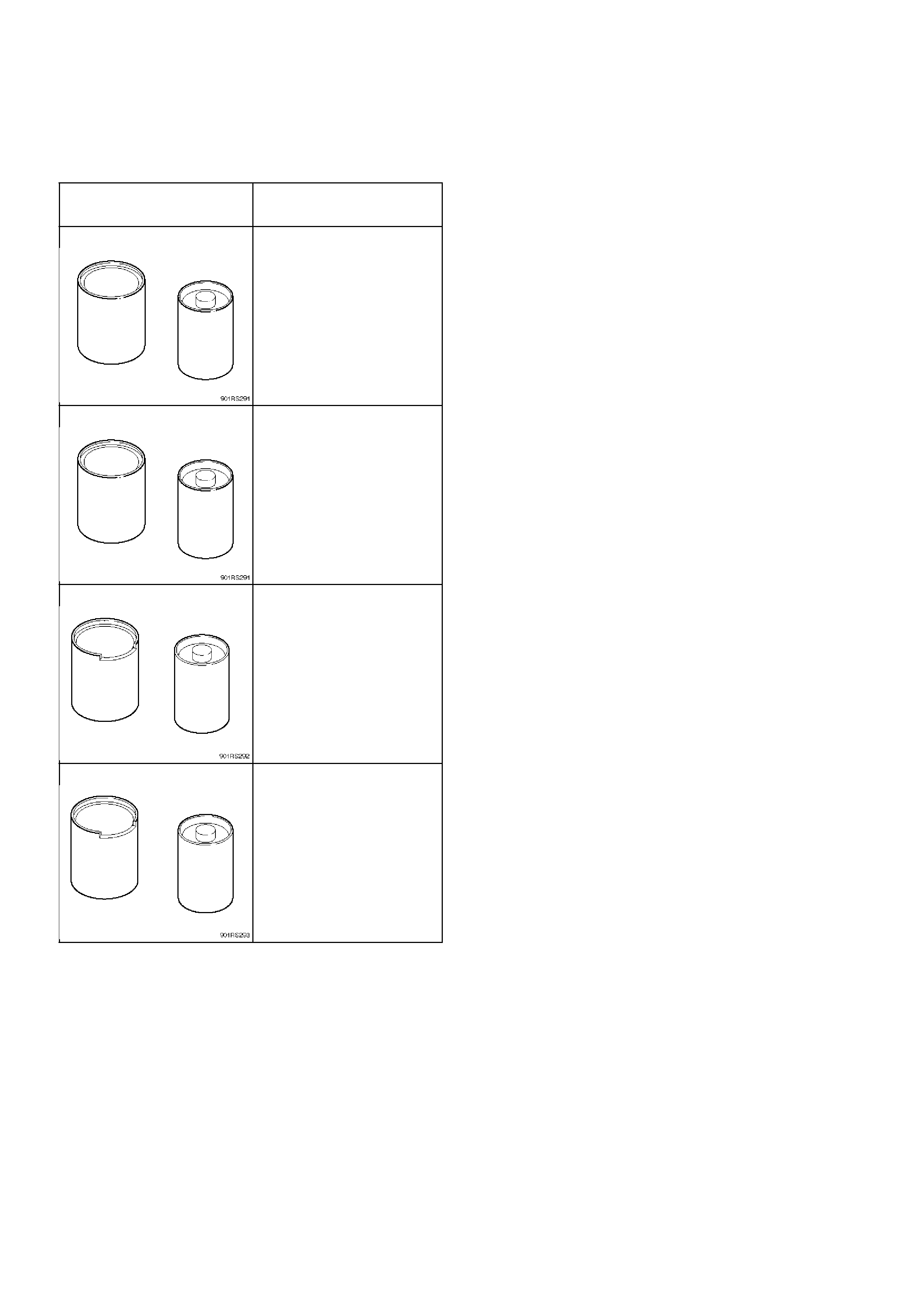

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–2298–0

(J–39214)

Remover and Installer;

Trailing link bushing

5–8840–2565–0

(J–43008)

Remover and Installer;

Upper link bushing

5–8840–2327–0

(J–39792)

Remover and Installer;

Lateral rod bushing (Axle

side)

5–8840–2299–0

(J–3921)

Remover and Installer;

Lateral rod bushing

(Frame side)