SECTION 5A - BRAKE CONTROL SYSTEM (MY2002)

Servic e Prec aut ion

General Description

Functional Description

System Components

Electronic Hydraulic Control Unit (EHCU)

ABS Warning Lamp

Wheel Speed Sensor

G-Sensor

Brake Pedal Travel

Acronyms and Abbreviations

General Diagnosis

General Information

ABS Service Precautio ns

Computer System Service Precautions

General Service Precautions

Note on Intermittents

“ABS" Warning Lamp

Test D riv ing ABS C omp la int Ve hicles

Tech 2 Scan Tool

Using TECH 2 On The Vehicle

Chassis Application Menu - Antilock Braking System

(ABS)

ABS TECH 2 Functions

Data List

Actuator Test

Procedure

Tech 2 Service Bleed

Basic Diagnostic Flow Chart

Basic Inspection Procedure

EHCU Connector Pin-out Checks

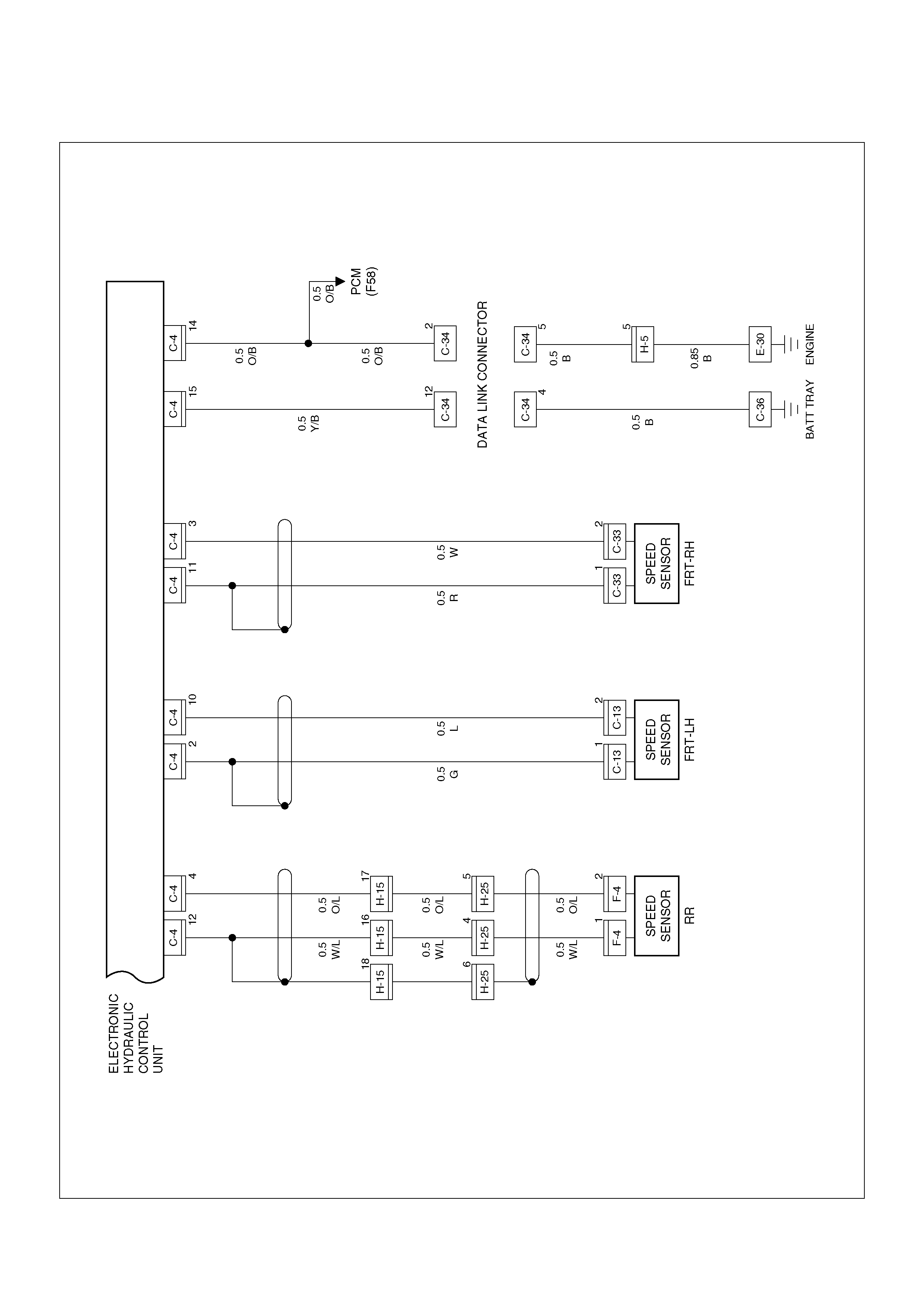

Circuit Diagram

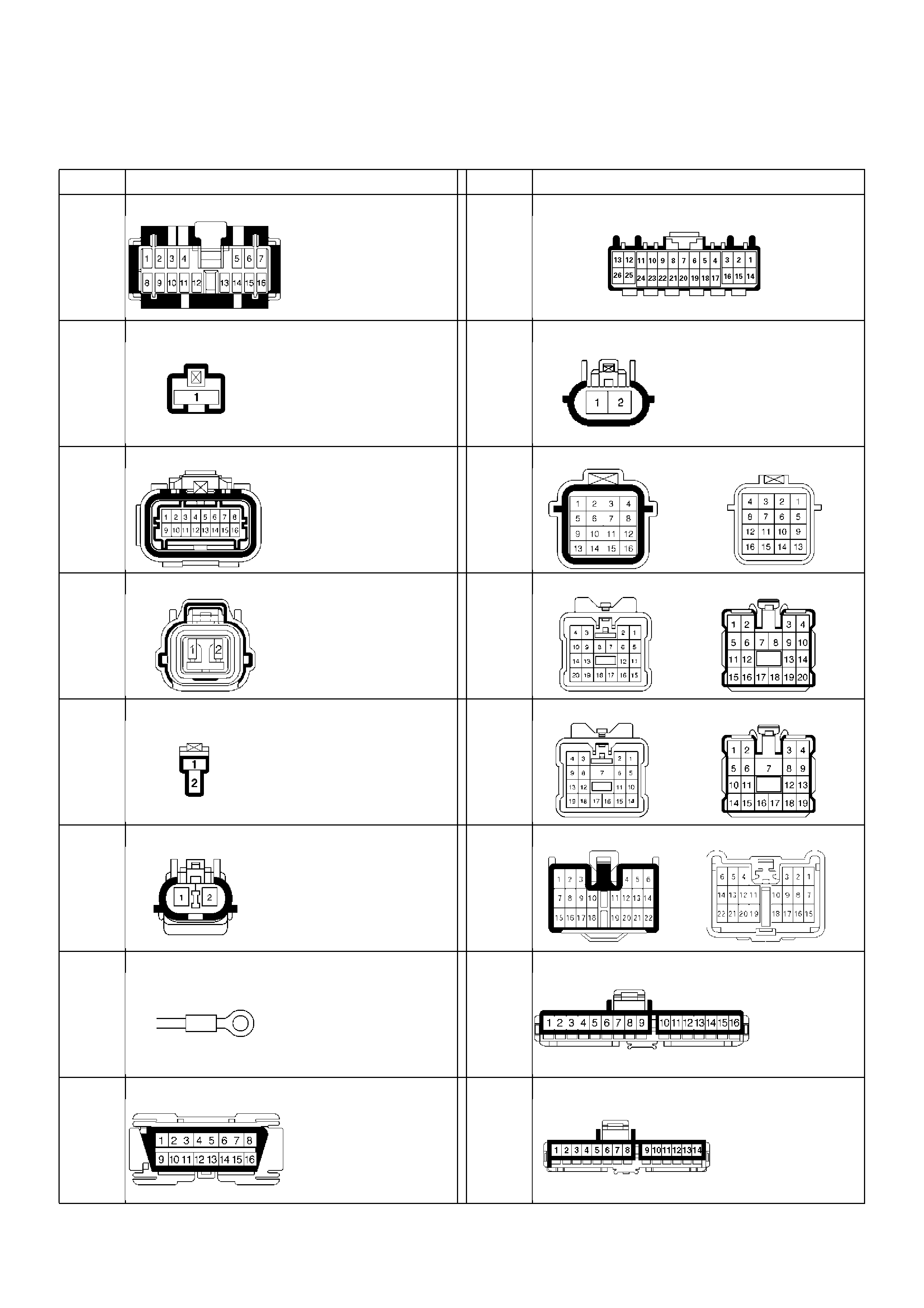

Connector List

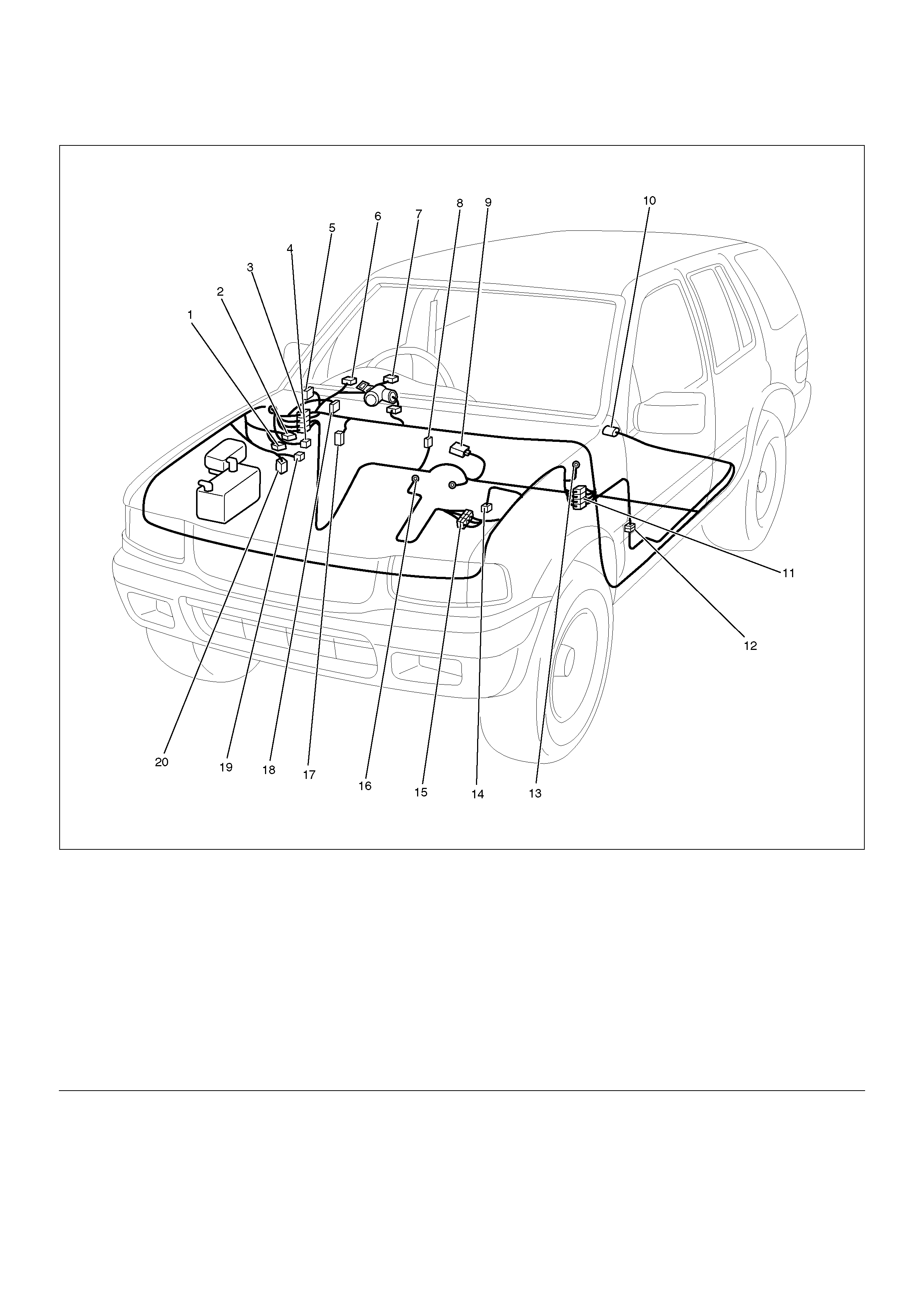

Part Location

Symptom Diag nos i s

Chart A-1 ABS Operates Frequently But The Vehicle

Does Not Decelerate

Chart TA-1 ABS Operates Frequently But The

Vehicle Does Not Decelerate (Use TECH 2)

Chart A-2 Uneven Braking Occurs While ABS

Operates

Char t TA-2 Uneven Braking Occurs While ABS

Operates (Use TECH 2)

Chart A-3, TA-3 The Wheels Are Locked During

Braking

Chart A-4 Abnormal Brake Pedal Feel

Chart A-5, TA-5 EHCU Is Heard Operating While Not

Braking

Diagnosti c Tro uble Codes

Diagnosis By “ABS" Warning Lamp Illumination Pattern

Chart B-1 Warning Lamp (W/L) is not activated when

the ignition is first turned ON .

Chart B-2 CPU Error (DTC C0271, C0272, C0273,

C0284)

Chart B-3 Low or High Ignition Voltage (DTC C0277,

0278 )

Chart B-4 Excessive Dump Time (DTC C0269)

Chart B-5 Excessive Isolation Time (DTC C0274)

Chart B-6 G-Sensor Output Failure (DTC C0276 )

Chart B-7 Brake Switch Failure (DTC C0281)

Chart B-8 4WD/TOD Control Unit Failure( DTC

C0285), 4WD State Input Signal Failure (DTC

C0282)

Chart B-9 Pump Motor Failure (DTC C0267, C0268)

Chart B-10 EHCU Valve Relay Failure (DTC C0265,

C0266 )

Chart B-11 FL Isolation Solenoid Coil Failure (DTC

41 C0245, C0247)

Chart B-12 FL Dump Solenoid Coil Failure (DTC

C0246, C0248)

Chart B-13 FR Isolation Solenoid Coil Failure (DTC

C0241, C0243 )

Chart B-14 FR Dump Solenoid Coil Failure (DTC

C0242, C0244)

Chart B-15 Rear Isolation Solenoid Coil Failure (DTC

C0251, C0253)

Chart B-16 Rear Dump Solenoid Coil Failure (DTC

C0252, C0254)

Chart B-17 FL Speed Sensor Open or Shorted (DTC

C0225)

Chart B-18 FR Speed Sensor Open or Shorted (DTC

C0221

Chart B-19 Rear Speed Sensor Open or Shorted

(DTC C0235)

Chart B-20 FL Speed Sensor Signal Missing (DTC

C0226, C0227)

Chart B-21 FR Speed Sensor Signal Missing (DTC

C0222, C0223)

Chart B-22 Rear Speed Sensor Signal Missing (DTC

C0236, C0237)

Chart B-23 Simultaneous Drop-out of Front Speed

Sensor Signal (DTC C0229)

Chart B-24 Abnormal Wheel Speed Input (DTC

C0238)

Chart B-25 Abnormal TOD Signal (DTC C0287)

Unit Inspection Procedure

Chart C-1-1 FL Sensor Output Inspection Procedure

Chart C-1-2 FR Sensor Output Inspection Procedure

Chart C-1-3 Rear Sensor Output Inspection

Procedure

Chart TC-1 Sensor Output Inspection Procedure

Special Tools

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibi tors) on threaded faste ners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you inst all fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and syst ems.

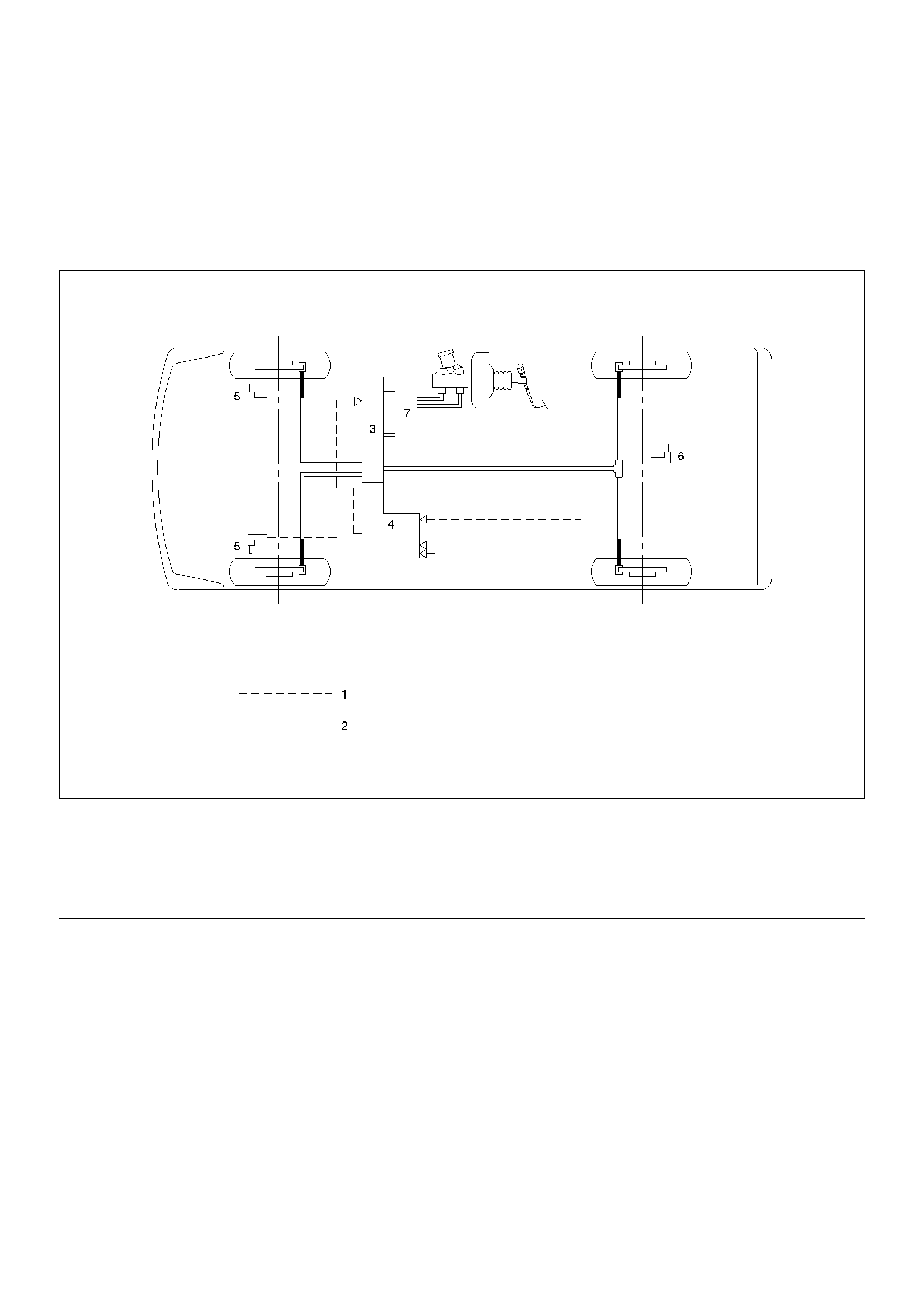

General De scription

The Anti-lock Brake System (ABS) works on all four

wheels. B y mon ito ring whe el sp eed s ens or s i gna ls , th e

Electronic Hydraulic Control Unit (EHCU) can determine

when a road wheel is about to lock and will adjust brake

pressure to maintain optimum braking under most

conditions. By optimisinjg the braking effort without

locking the wheels, the ABS enables the driver to

maintain control of the vehicle under heavy braking

conditions.

NOTE: The Electronic Hydraulic Control Unit (EHCU)

comprises the Hydraulic Unit (H/U) and the coil

Integrated Module.

C05RW004

Legend

EndOFCallout

(1) Electronic

(2) Hydraulic

(3) Hydraulic Unit (H/U)

(4) Coil Integrated Module

(5) Front Wheel Speed Sensor

(6) Rear Wheel Speed Sensor

(7) Proporti oni ng and By pass (P&B) Valve

Functional Description

Hydraulic Unit (H/U)

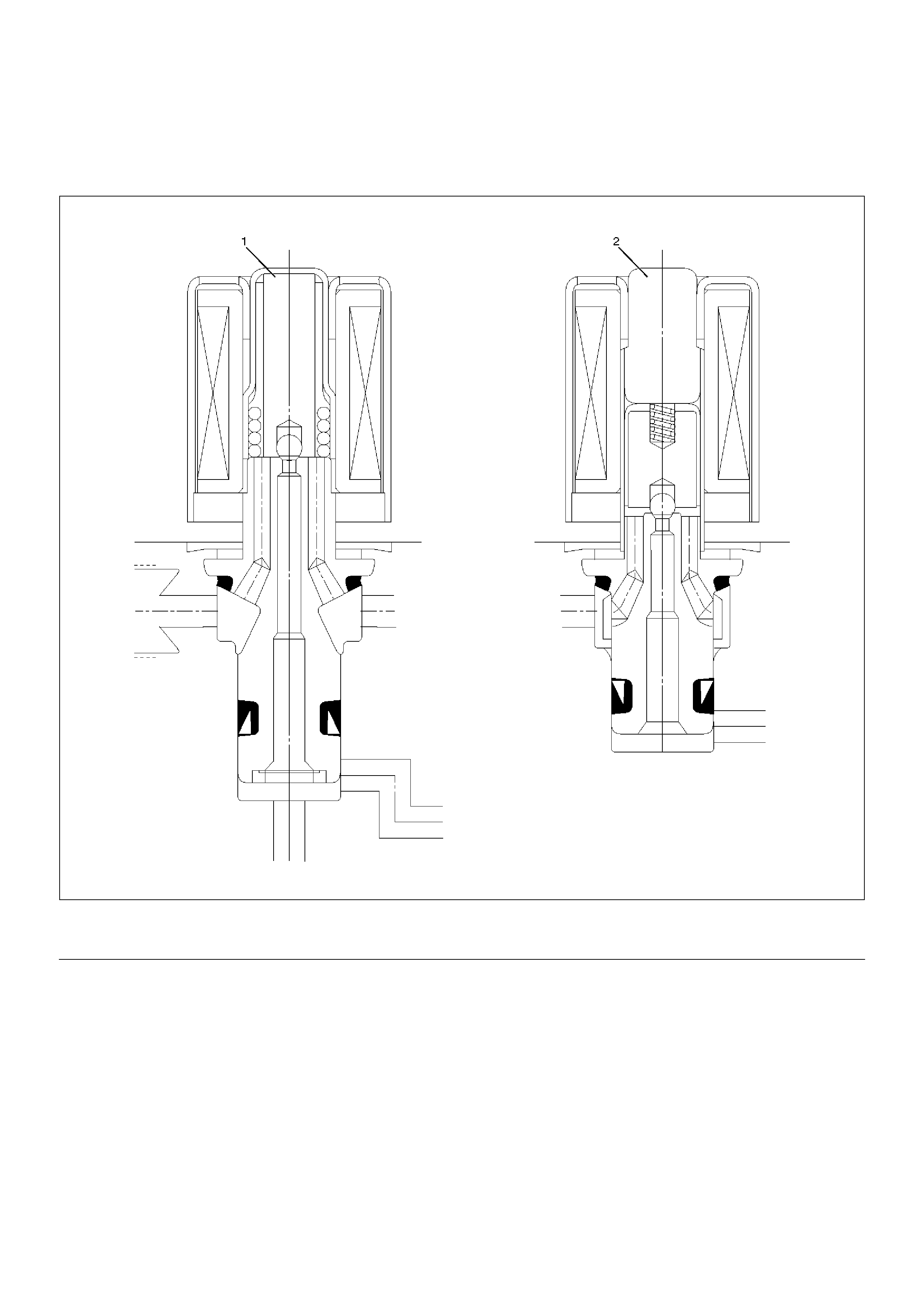

Solenoid Valve

C05RW012

Legend

EndOFCallout

(1) Isolation Valve (2) Dump valve

Normal Braking

During normal (non anti-lock) braking, the solenoid

valves are without current and closed due to spring

force.

Brake fluid travels through the centre of the normally

open isolation valve around the normally closed dump

valve and on to the brake pistons.

C05RW010

Legend

EndOFCallout

(1) Brake (2) Master Cylinder

Pressure Isolation (Pressure Maintain)

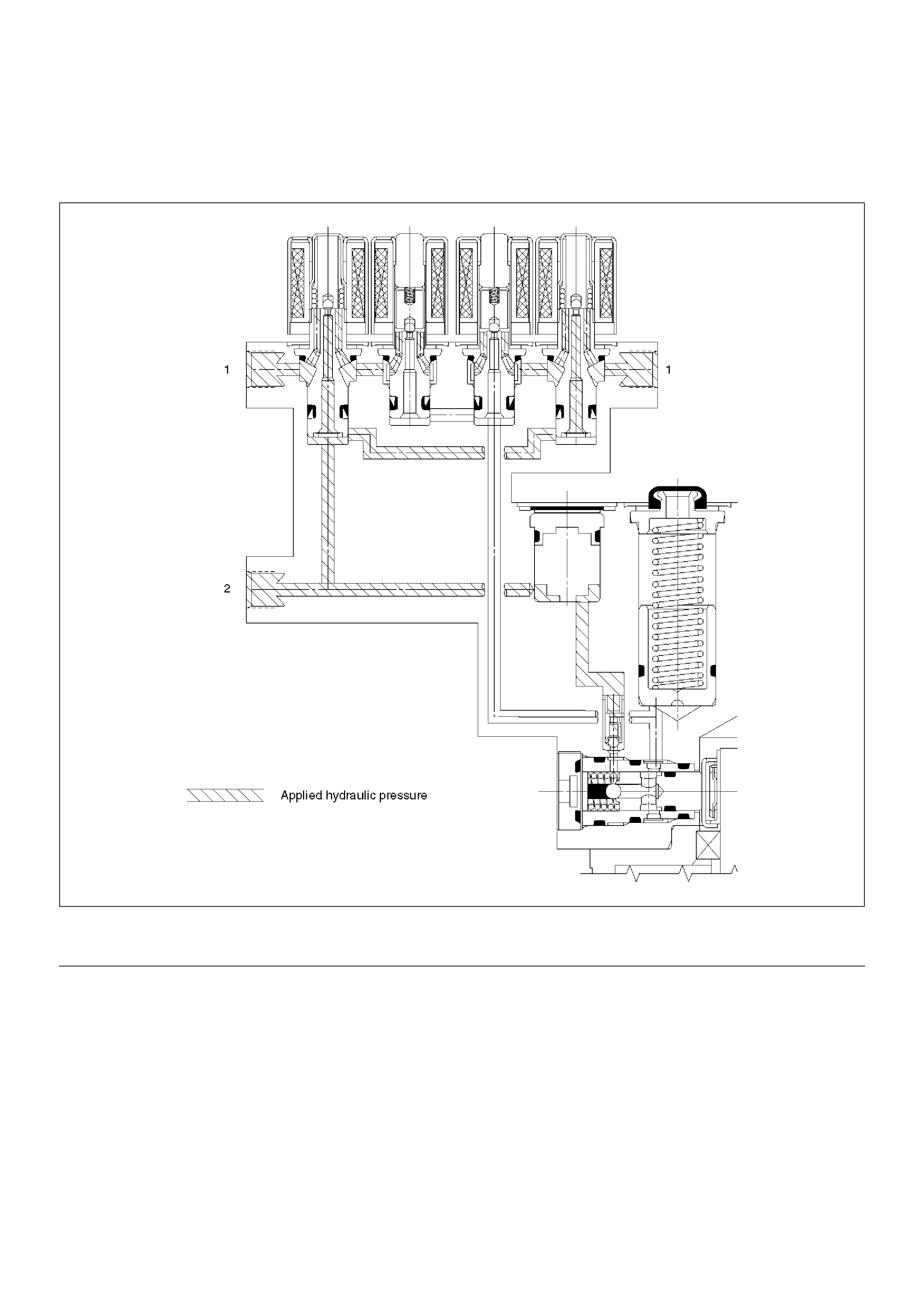

The electro-hydraulic control unit is activated when the

brakes are applied which sends a signal to the coil

integrated module to prepare for a possible anti-lock

stop.

If the information from the wheel speed sensors

indicates excessive wheel deceleration (imminent

lockup), the first step in the anti-lock sequence is to

isolate the brake pressure being applied by the brake

pedal.

The microprocessor in the coil integrated module sends

a voltage to the coil to energize and close the isolation

valve. This prevents any additional fluid pressure

applied by the brake pedal from reaching the wheel.

With the isolation valves closed, further unnecessary

increase in the brake pressure is therefore prevented.

C05RW011

Legend

EndOFCallout

(1) Brake (2) Master Cylinder

Pressure Reduction

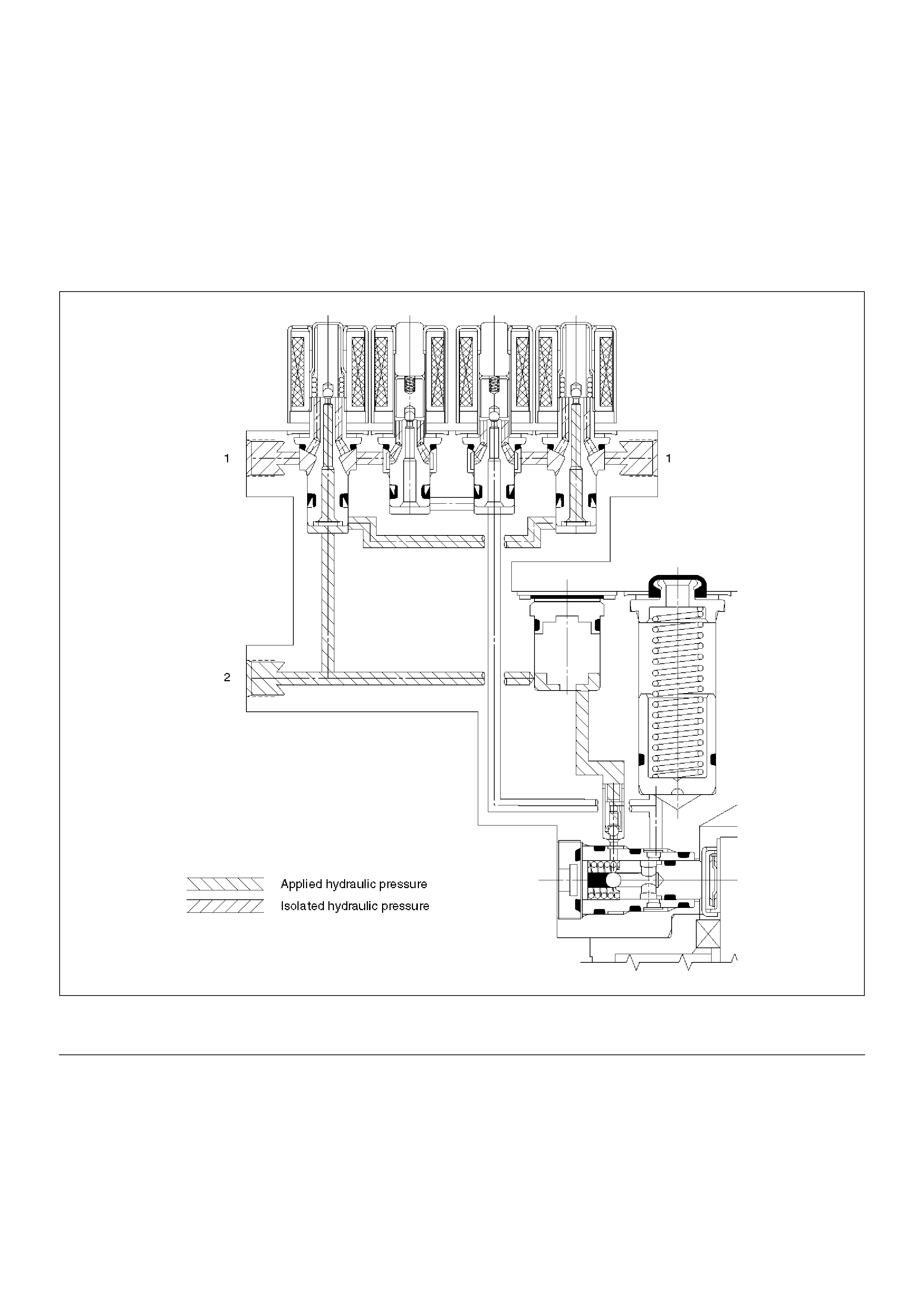

Once the brake pressure is isolated, it must be reduced

to allow the wheels to unlock. This is accomplished by

dumping a portion of the brake fluid pressure into a low

pressure accumulator.

The microprocessor activates the normally closed dump

valve to open, allowing fluid from the wheels to be

dumped into the accumulator. This is done with very

short activation pulses opening and closing the dump

valve passageway. Brake pressure is reduced at the

wheel and allows the wheel to begin rotating again. The

fluid from the brake piston is stored in the accumulator

against spring pressure and a portion of this fluid also

primes the pump.

The dump valves are operated independently to control

the deceleration of the wheel. At this point, the brake

pedal is isolated from the base brake system, the

hydraulic control unit pumps are primed and the

attenuators are ready to pump fluid.

C05RW009

Legend

EndOFCallout

(1) Brake (2) Master Cylinder

Pressure Increase (Re-apply)

The re-apply sequence is initiated to achieve optimum

braking. The isolation valve is momentarily opened to

allow master cylinder and pump pressure to reach the

brakes. This controlled pressure rise continues until the

wheel is at optimum brake output or until the brake

pressure is brought up to the master cylinder output

pressure.

If more pressure is required, more fluid is drawn from

the master cylinder and applied to the brakes. The

driver may feel slight pedal pulsations, or pedal drop,

this is normal and expected.

As fluid is re-applied to the brakes, the wheel speed will

reduce. If the wheels approach imminent lockup again,

the module will isolate, dump and re-apply again. This

cycle occurs in millisecond intervals, allowing several

cycles to occur each second. It is a much faster and

more controlled way of “pumping the pedal".

C05RW014

Legend

EndOFCallout

(1) Brake (2) Master Cylinder

Brake Release

At the end of the anti-lock stop, when the brake pedal is

released, the pump will remain running for a short time

to help drain any fluid from the accumulators. As this

fluid returns into the system, the spring forces the piston

back to its original position.

The isolation valve opens and fluid may return to the

master cylinder. Conventional braking is then resumed.

C05RW013

Legend

EndOFCallout

(1) Brake (2) Master Cylinder

System Components

Electronic Hydraulic Control Unit (EHCU), three Wheel

Speed Sensors, Warning Lamp, and G-sensor.

Electronic Hydraulic Control Unit (EHCU)

The EHCU consists of ABS control circuits, fault

detector, and a fail-safe. It drives the hydraulic unit

according to the signal from each sensor, cancelling

ABS to return to normal braking when a malfunction has

occurred in the ABS.

The EHCU has a self-diagnosing function which can

indicate faulty circuits during diagnosis.

The EHCU is mounted on the engine compartment rear

right side. It consists of a Motor, Plunger Pump,

Solenoid Valves.

Solenoid Valves: Reduces or holds the caliper fluid

pressure for each front disc brake or both rear disc

brakes according to the signal sent from the EHCU.

Rese rv oir: Tempor arily ho l ds t he b r a ke fluid th at re t ur ns

from the front and rear disc brake caliper so that

pressure of front disc brake caliper can be reduced

smoothly.

Plunger Pump: Feeds the brake fluid held in the

reservoir to the master cylinder.

Motor: Drives the pump according to the signal from

EHCU.

Check Valve: Controls the brake fluid flow.

ABS Warning Lamp

825RX048

Vehicles equipped with the Anti-lock Brake System

have an amber “ABS" warning lamp in the instrument

panel. The “ABS" warning lamp will illuminate if a

malfunction in the Anti-lock Brake System is detected

by the Electronic Hydraulic Control Unit (EHCU). In

case of an electronic malfunction, the EHCU will turn

“ON" the “ABS" warning lamp and disable the Anti-lock

braking function.

The “ABS" lamp will turn “ON" for approximately three

seconds after the ignition switch is to the “ON" position.

If the “ABS" lamp stays “ON" after the ignition switch is

the “ON" position, or comes “ON" and stays “ON" while

drivi ng, the Anti-lock Brake System should be inspected

for a malfunction according to the diagnosis procedure.

Wheel Speed Sensor

It consists of a sensor and a rotor. The sensor is

attached to the knuckle on the front wheels and to the

rear axle case on the rear differential.

The rotor is press-fit in the axle shaft.

The flux generated from electrodes magnetized by a

magnet in the sensor varies due to rotation of the rotor ,

and the electromagnetic induction generates alternating

voltage in the coil. This voltage draws a “sine curve"

with the frequency proportional to rotor speed and it

allows detection of wheel speed.

G-Sensor

The G-sensor installed inside the EHCU detects the

vehicle deceleration speed and sends a signal to the

EHCU. In 4WD operation, all four wheels may be

decelerated in almost the same phase, since all wheels

are connected mechanically.

This tendency is noticeable particularly on roads with

low friction coefficient, and the ABS control is adversely

affected.

The G-sensor judges whether the friction coefficient of

road surface is low or high, and changes the EHCU's

operating system to ensure ABS control.

Normal and Anti-lock Braking

Under normal driving conditions, the Anti-lock Brake

System functions the same as a standard power

assisted brake system. However, with the detection of

wheel lock-up, a slight bump or kick-back will be felt in

the brake pedal. This pedal “bump" will be followed by a

series of short pedal pulsations which occurs in rapid

succession. The brake pedal pulsation will continue

until there is no longer a need for the anti-lock function

or until the vehicle is stopped. A slight ticking or popping

noise may be heard during brake applications when the

Anti-lock features is being used.

When the Anti-lock feature is being used, the brake

pedal may rise even as the brakes are being applied.

This is also normal. Maintaining a constant force on the

pedal will provide the shortest stopping distance.

Br ake Pedal Travel

Vehicles equipped with the Anti-lock Brake System may

be stopped by applying normal force to the brake

pedal. Although there is no need to push the pedal

beyond the point where it stops or holds the vehicle, by

applying more force the pedal will continue to travel

toward the floo r.

This extra brake pedal travel is normal.

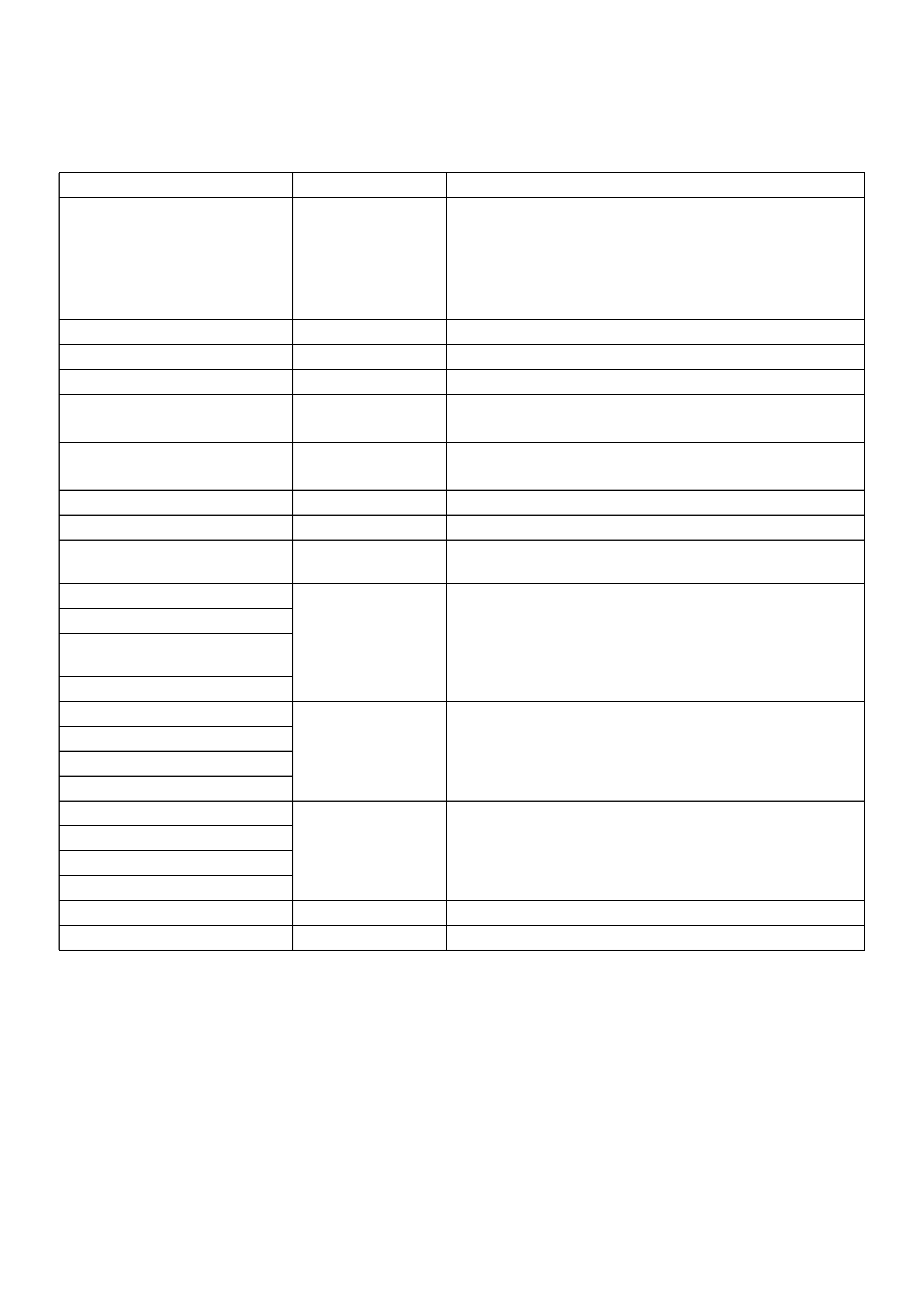

Acronyms and Abbreviations

Several acronyms and abbreviations are commonly

used throughout this section:

ABS

Anti-lock Brake System

CIM

Coil Integrated Module

CKT

Circuit

DLC

Data Link Connect or

EHCU

Electronic Hydraulic Control Unit

FL

Front Left

FR

Front Right

GEN

Generator

H/U

Hydraulic Unit

MV

Millivolts

RR

Rear

RPS

Revolution per Second

VDC

DC Volts

VAC

AC Volts

W/L

Warning Lamp

WSS

Wheel Speed Sensor

General Diagnosis

General Information

ABS troubles can be classified into two types, those

which can be detected by the ABS warning lamp and

those which can be detected as a vehicle abnormality

by the driver.

In either case, locate the fault in accordance with the

“Basic Diagnostic Flowchart" and repair.

Please refer to Section 5C for the diagnosis of

mechanical troubles such as brake noise, brake judder

(brake pedal or vehicle vibration felt when braking),

uneven braking, and parking brake trouble.

ABS Service Precautions

Required Tools and Items:

•Box Wrench

•Brake Fluid

• Special Tool

Some diagnosis procedures in this section require the

installation of a special tool.

5-8840-0366-0 High Impedance Multimeter

When circuit measurements are requested, use a circuit

tester with high impedance.

Computer System Service Precautions

The Anti-lock Brake System interfaces directly with the

Electronic Hydraulic Control Unit (EHCU) which is a

control computer that is similar in some regards to the

Powertrain Control Module. These modules are

designed to withstand normal current draws associated

with vehicle operation. However, care must be taken to

avoid overloading any of the EHCU circuits. In testing

for opens or shorts, do not ground or apply voltage to

any of the circuits unless instructed to do so by the

appropriate diagnostic procedure. These circuits should

only be tested with a high impedance multimeter

5-8840-0366-0 or special tools as described in this

section. Power should never be removed or applied to

any control module with the ignition in the “ON" position.

Before removing or connecting battery cables, fuses or

connectors, always turn the ignition switch to the “OFF"

position.

General Service Preca utions

The following are general precautions which should be

observed when servicing and diagnosing the Anti-lock

Brake System and/or other vehicle systems. Failure to

observe these precautions may result in Anti-lock

Brake System damage.

• If welding work is to be performed on the vehicle

using an electric arc welder, the EHCU and valve

block connectors should be disconnected before the

welding operation begins.

• The EHCU and valve block connectors should never

be connected or disconnected with the ignition “ON" .

• If only rear wheels are rotated using jacks or drum

tester, the system will diagnose a speed sensor

malfunction and the “ABS" warning lamp will

illuminate. But actually no trouble exists. After

inspection stop the engine once and re-start it, then

make sure that the “ABS" warning lamp does not

illuminate.

If the battery has been discharged

The engine may stall if the battery has been completely

discharged and the engine is started via jumper cables.

This is because the Anti-lock Brake System (ABS) self-

test places a high load on the electrical system. In this

case, wait until the battery is recharged, or set the ABS

to a non-operative state by removing the ABS (60A)

fuse. After the battery has been recharged, stop the

engine and reinstall the ABS fuse. Start the engine

again, and confirm that the ABS warning lamp does not

illuminate after the initial self-test has been conducted.

Note on Intermittents

As with virtually any electronic system, it is difficult to

identify an intermittent failure. In such a case duplicating

the system malfunction during a test drive or a good

description of vehicle behavior from the customer may

be helpful in locating a “most likely" failed component or

circuit. The symptom diagnosis chart may also be useful

in isolating the failure. Most intermittent problems are

caused by faulty electrical connections or wiring. When

an intermittent failure is encountered, check suspect

circuits for:

• Suspected harness damage.

• Poor mating of connector halves or terminals not fully

seated in the connector body (backed out).

• Improperly formed or damaged terminals.

“ABS" Warning Lamp

Normal Operation:

The “ABS” warning lamp will illuminate for about three

seconds when the ignition is first turned ON, while the

system performs a self-test.

Upon satisfactory completion of the self-test, the “ABS”

warning lamp will be extinguished. The “ABS” warning

lamp sho uld rema in “O FF " at all othe r tim es .

Fault Detected:

Should a fault be detected during the self-test, or an

ABS failure occur whilst driving, the EHCU will

illuminate the “ABS" warning lamp and log the

appropriate Diagnostic Trouble Code (DTC).

While the “ABS” lamp is illuminated, the anti-lock

braking syatem is disabled, although power assisted

braking is still available.

Should, on the next ignition cycle, the EHCU determine

the fault is no longer present, the “ABS” warning lamp

will extinguish after the self-test, but the DTC will remain

in the EHCU memory until cleared by Tech 2.

Test Driving ABS Complaint Ve hicle s

In case that there has been an abnormality in the

lighting pattern of “ABS" warning lamp, the fault can be

located in accordance with the “Diagnosis By “ABS"

Warning Lamp Illumination Pattern". It is necessary to

drive the vehicle following the test procedure mentioned

below inorder to reproduce the symptom for trouble

diagnosis:

1. Start the engine and make sure that the “ABS"

warning lamp goes OFF. If the warnng lamp

remains ON, it means that the Diagnostic Trouble

Code (DTC) is stored. Therefore, read the code

and locate the fault.

NOTE:After initiating the DTC clearing procedure with

Tech 2, the vehicle MUST be driven above 12 km/h to

finally clear the DTC and extinguish the ”ABS”

warning lamp.

2. Start the vehicle and accelerate to about 30 km/h.

3. Slowly brake and stop the vehicle completely.

4. Then restart the vehicle and accelerate to about 40

km/h.

5. Brake with sufficient pedal force so as to actuate the

ABS and stop the vehicle.

6. Be cautious of any abnormality during the road test.

If the warning lamp is actuated while driving, read

the DTC and locate the fault.

7. If the abnormality is not reproduced by the test,

endeavour to reproduce the situation reported by

the customer.

8. If the abnormality has been detected, carry out

repairs in accordance with the “Symptom Diagnosis"

.

NOTE:

• Be sure to perform the test drive on a wide, even road

with little or no other traffic.

• If any abnormality is detected, immediately suspend

the road test and commence fault diagnosis as soon

as practicable.

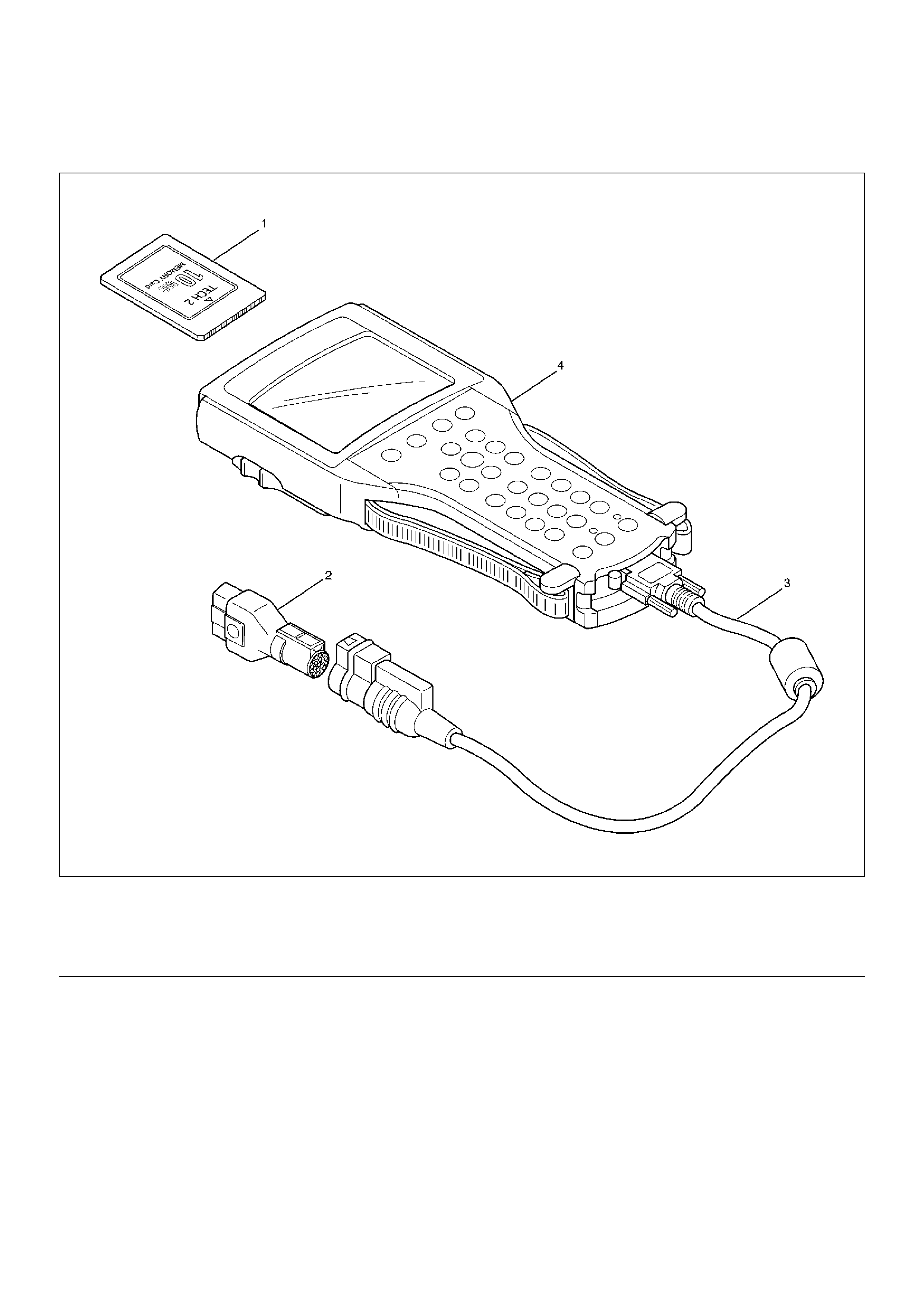

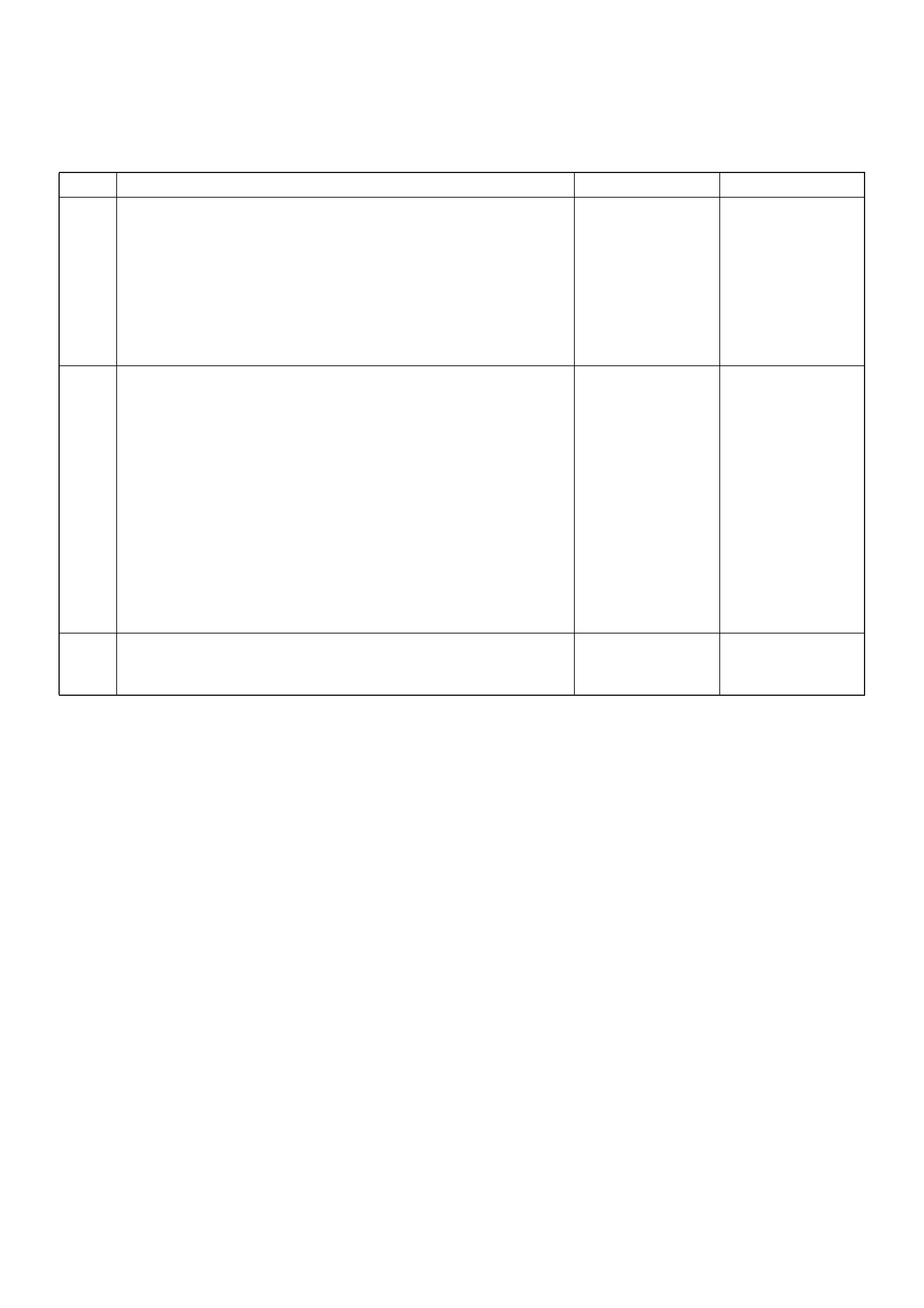

Tech 2 Scan Tool

901RW257

Legend

EndOFCallout

(1) PCMCIA Card

(2) SAE 16/19 Adaptor

(3) DLC Cable

(4) Tech–2

Using TECH 2 On The Vehicle

NOTE: Due to the constant evolution of TECH 2

software, the screens shown in this section may

differ slightly from those displayed for the vehicle

being tested.

Connecting TECH 2 To The Vehicle

1. Connect Tech 2 to the vehicle DLC, with the DLC

cable and the 16/19 pin adapter.

2. Switch the unit on by pressing the power button (2).

A green li ght (1) shoul d come on indi cating that th e

tool is receiving power.

NOTE: At this time the technician should see the Power

On Self Test (POST) run. The POST is a built in

diagnostic self test for the TECH 2 that should find most

common system faults. The POST is run on every

power up to ensure the best operation of the tool. After

the compl etion of the POST, th e TECH 2 uni t will briefly

show the POST results. If POST passes, the tool will

continue onto the title screen. If POST fails, results of all

tests will be d isplayed, an d this should sh ow which test

failed. POST failures may be classified as fatal or non-

fatal. A fatal error will not allow the user to continue

using the tool. Failure of the keypad would be an

example of a fatal error. Non-fatal errors found during

the POST will allow continued use of the TECH 2, but

with some limitations. If either a fatal or non-fatal error

occurs, refer to the Troubleshooting section of the

TECH 2 User's Guide.

1. Power Status Indicator Light

2. PWR (Power) Key

3. SHIFT Key Status Indicator Light

4. SHIFT Key

3. At the Tech 2 title screen press the ENTER key to

continue.

4. A selection can be made from the Main Menu,

either by usi ng a fu nction k ey o r by us ing the arrow

keys to highlight a menu choice and pressing

ENTER.

•NOTE: You will then need to supply some additional

information to the TECH 2. This requires navigation

through a series of lists (called picklists). On some

menus or pi ckl ists, the u se r can us e a fu nc tio n ke y t o

make a menu selection, but most of the picklists

require using the selection and action keys. If a

mistake is made in the selection process, or if a

different application or function is desired, press EXIT

to back up one level. Within an application, there may

be soft keys which are available for use. These soft

keys all ow access to a dditional to ol functi ons without

exitin g a curr ent tool fun ction . Soft keys a re made u p

of sets which will appear together . To see the next set

of soft keys, select the More soft key.

The TECH 2 Main Menu contains the following:

F0: Diagnostics

Contains all functions to test, diagnose, monitor and

program the different vehicle systems.

F1: Service Programming System (SPS)

SPS is used in conjunction with Technical

Information System (TIS) 2000 to program vehicle

control units.

F2: View Capture Data

Contains all functions to work with one or two

previously recorded snapshots on one or two

vehicles. This function is to enable the viewing of

captur ed data without a vehicl e.

F3: Tool Options

Contains the TECH 2 self test, set clock, set units,

set screen contrast and Getting Started.

F4: Download/Upload Help

Contains help information on the downloading and

uploading from the TECH 2 to the TIS 2000 CD-

ROM.

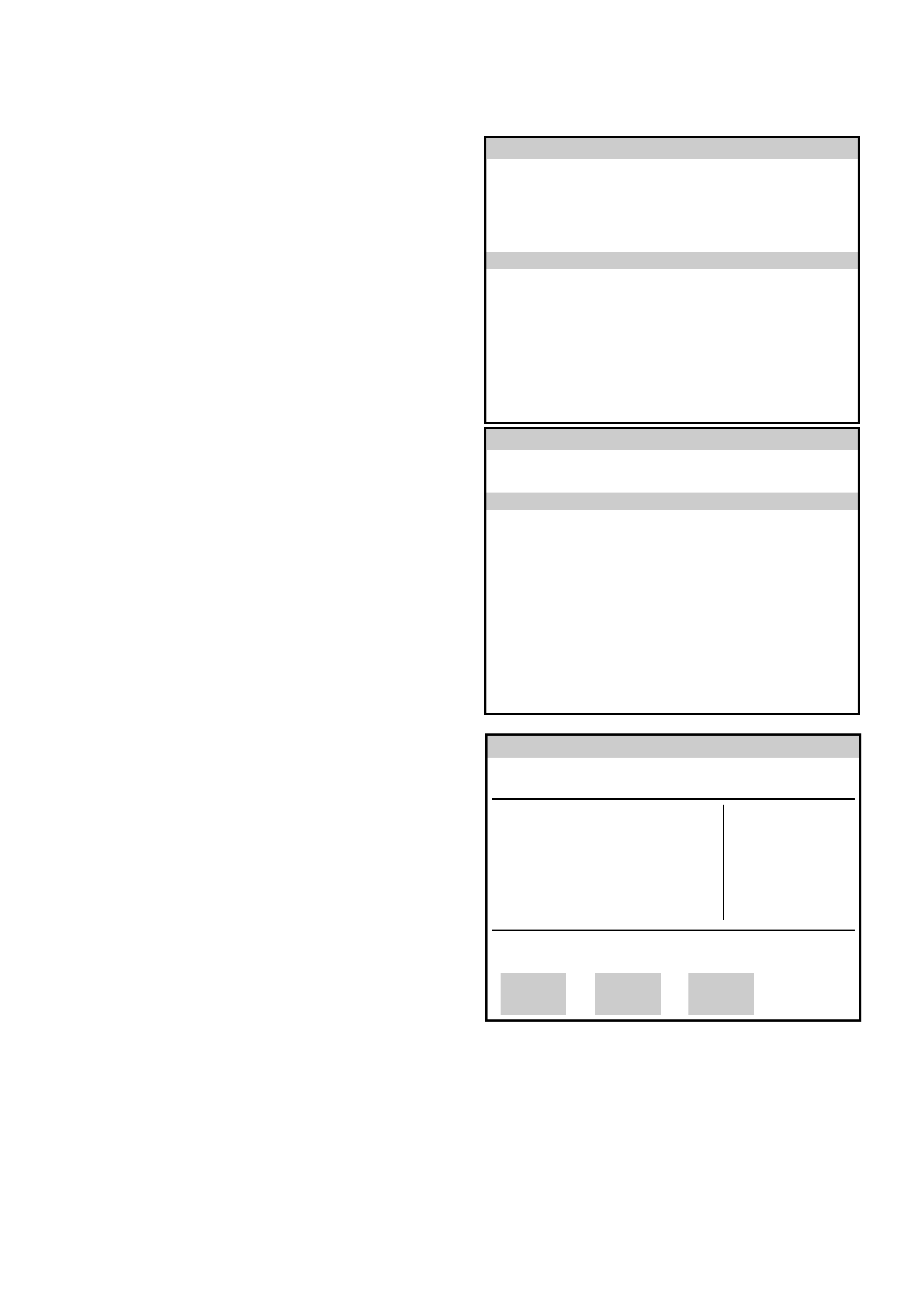

Main Menu

UES2002b

F0: Diagnostics

F1: Service Programming System (SPS)

F2: View Capture Data

F3: Tool Options

F4: Download/Upload Help

5. Select the correct Model Year with the arrow keys

and the press ENTER. The Vehicle identification

screen will then be displayed.

6. Select the correct Vehicle Type with the arrow keys

and the press ENTER. The System Select Menu

will then be displayed.

7. The desired system can be selected from the

System Se lect Menu wi th th e fu nc tio n key s or wit h

arrow keys and then press ENTER.

F0:Powertrain contains all functions to test,

diagnose , and monitor the engine and trans mission

systems that communicate with the Tech 2 via the

Powertrain Control Mod ule (PCM).

F1: Chassis contains all functions to test,

diagnose, monitor the vehicles chassis systems;

TOD and ABS modules.

F2: Body contains all functions to test, diagnose,

monitor the instruments and Supplemental

Restr a int Sy st em.

Main Menu

Select one of the following

Model Year(s)

TF2001a

(2)

(1)

(Y)

(X)

(W)

(V)

(2)

2002

2001

2000

1999

1998

1997

1 / 6

2002

Main Menu

Select one of the following

Vehicle Type(s)

Frontera

Jackaroo

Rodeo

VX Commodore

VU Utility

WH Statesman & Caprice

V2 Monaro

Corsa-C

Astra-F

Astra-G

Frontera 1 / 10

UES2002c

System Select Menu

(2) 2002 Frontera

F0: Powertrain

F1: Chassis

F2: Body

UES2002abs3

Chassis Application Menu - Antilock Braking System (ABS)

1. Select the correct chassis system from the Vehicle

Identification menu with the arrow keys, then

press ENTER and follow the instructions on the

screen.

2. Turn on the ignition and press the Confirm soft key.

3. The System identification screen will t hen displ ay

the control module Part number and System type.

Press the Confirm soft key, and the ABS application

menu will then be displayed.

The following functions are available in the ABS chassis

application menu:

F0: Diagno stic Trouble Codes

F1: Data Display

F2: Snapshot

F3: Actuators

F4: Miscellaneous Tests

System Select Menu

(2) 2002 Frontera

F0: ABS

F1: TOD

UES2002abs4

System Identification

(2) 2002 Frontera

Electronic System: ABS

UE2002abs1

Part number

System 8972874320

ABS

Confirm

Chassis

F0: Diagnostic Trouble Codes

F1: Data Display

F2: Snapshot

F3: Actuator Tests

F4: Miscellaneous Tests

UES2002abs5

ABS TECH 2 Functions

F0: DIAGNOSTIC TROUBLE CODES

In this test mode, DTC(s) stored by the ABS Module can be displayed or cleared. When F0: Diagnostic Trouble Codes

is selected, there are an additional three modes:

F0: Read Current DTC: All current DTC(s) will be displayed.

F1: Clear Current DTC: Clears all current DTC(s) in the PCM memory.

F2: DTC Information: All current DTC(s) will be displayed in numerical order.

F1: DATA DISPLAY

This mode TECH 2 continuously monitors and displays all ABS data parameters.

F2: SNAPSH OT

In this test mo de, the TECH 2 scan to ol captures data be fore and after a snapshot trigger ing condition whic h may or

may not set a DTC.

F3: ACTUATOR TESTS

In this test mode, the TECH 2 performs functional tests on the ABS that will help identify correct operation. Testing and

observing results in this mode can further identify operational errors.

The following tests can be performed:

• Return Pump Relay Test.

• Front Left Solenoid Valve Test

• Front Right Solenoid Valve Test

• Rear Left Solenoid Valve Test

• Rear Right Solenoid Valve Test

F4: MISC ELLA NEOU S TESTS

F0: Brake Bleed: This test prompts the Technician while bleeding the brake system.

The test is divided into two parts; a Primary Brake Bleed - which is a manual bleed of each brake circuit, and a

Secondary Bleed - where the module activates the solenoid and pump motor to expel any air which may be trapped

in the modulator hydraulic circuit .

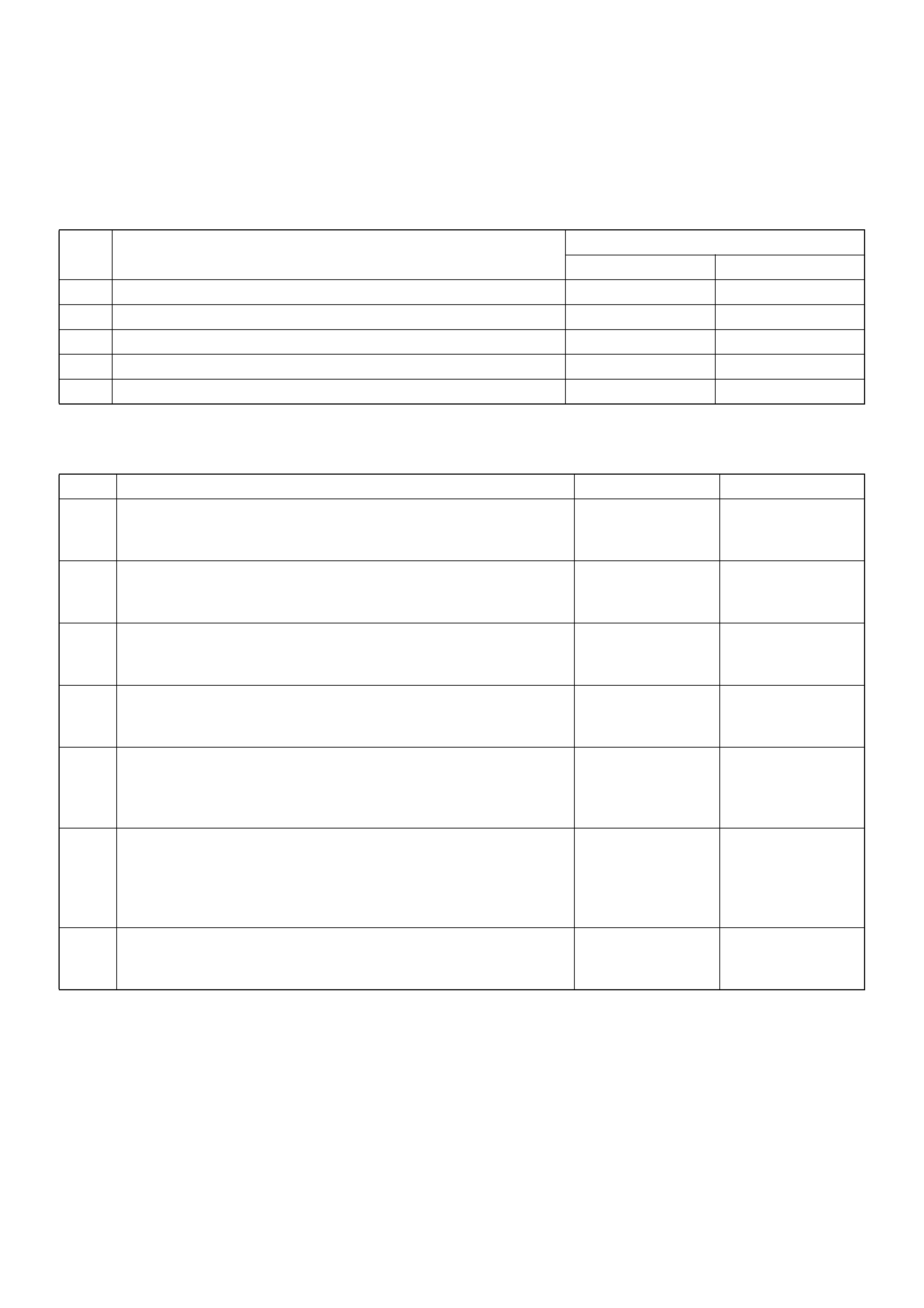

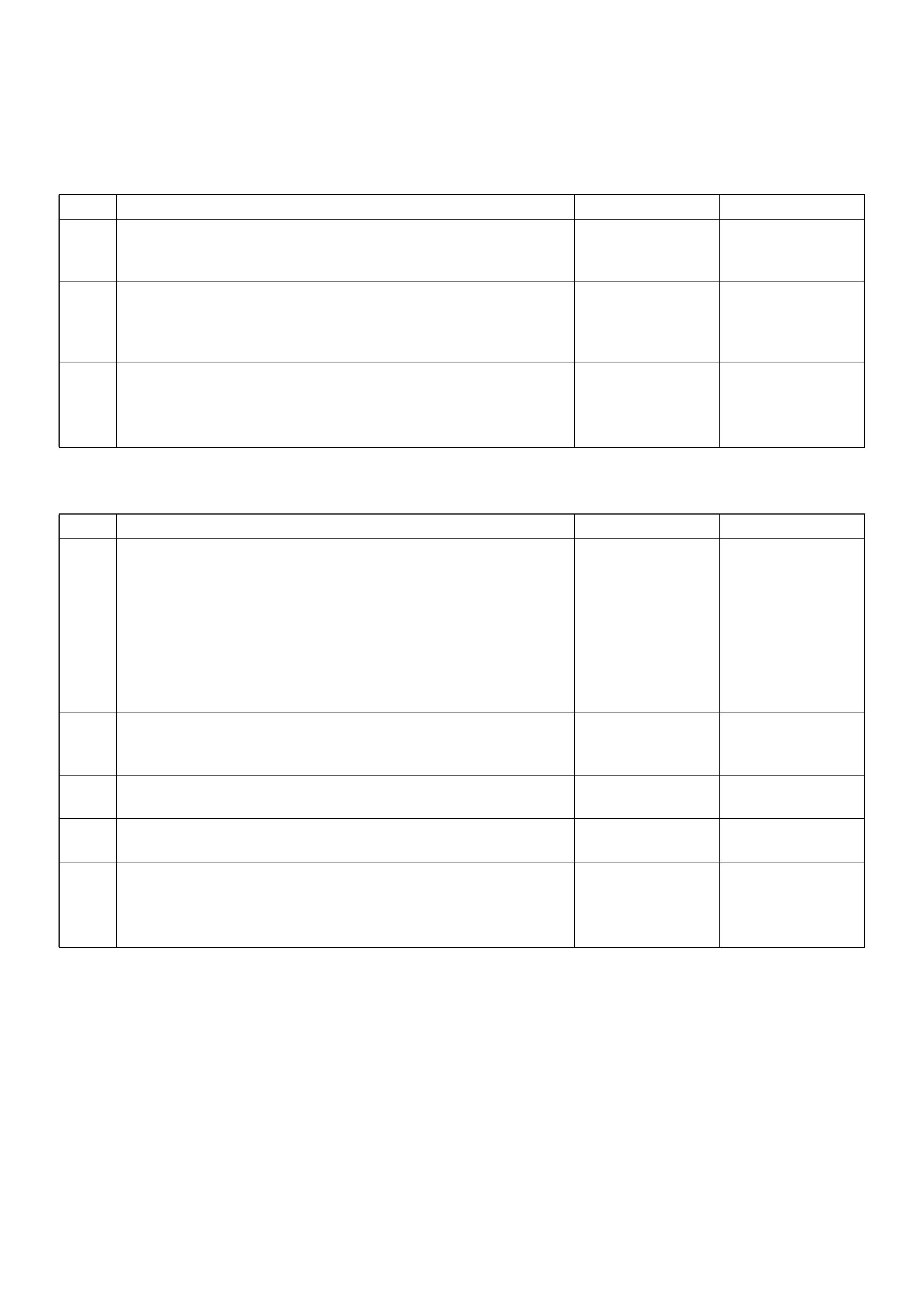

Data List

The data displayed by DATA LIST are as follows:

Display Content Criteria for Data

Front Left Wheel Speed

Front Right Wheel Speed

Rear Wheel Speed

km/h • Start the engine and drive vehicle and check for a linear

change in each wheel speed sensor signal.

OR

• With the vehicle mounted on safety stands, turn the

ignition ON and rotate each wheel by hand and check for

a linear change in each wheel speed sensor signal.

W arning Lamp ON/OFF • Normally OFF

ABS State ON/OFF • Normally OFF

ABS Relay Active/Inactive • Normally Active

4 Wheel Drive Active/Inactive • 2WD: Inactive

•4WD: Active

Brake Switch Active/Inactive • Inactive (Pedal released)

• Active (Pedal depressed)

Brake Fluid Level Normal • Normal

Return Pump Active/Inactive • Normally Inactive

DRP (Dynamic Rear

Proportioning) Active/Inactive • Normally Inactive

Rear Dump Valve Commanded Act ive/Inactive • Normally Inactive

Rear Dump Valve Feedback

Rear Isolation Valve

Commanded

Rear Isolation Valve Feedback

FL Dump Valve Commanded Active/Inactive • Normally Inactive

FL Dump Valve Feedback

FL Isolation Valve Commanded

FL Isolation Valve Feedback

FR Dump Valve Commanded Active/Inactive • Normally Inactive

FR Dump Valve Feedback

FR Isolation Valve Commanded

FR Isolation Valve Feedback

G–Sensor Voltage • 0.00V when vehicle is stopped

Battery Voltage Voltage • Between 10–16.9V

Actuator Test

This mode is used to activate the ABS actuators and confirm correct operation.

Note:

• Before testing, be sure that the service brakes function correctly, and the battery is fully charged.

• Conduct the ACTUATOR TEST with the engine stationary.

• Before testing, make sure that any electrical fault has been rectified. Testing of the ABS solenoids while an

electrical circuit fault is present may result in damage to the ABS control unit.

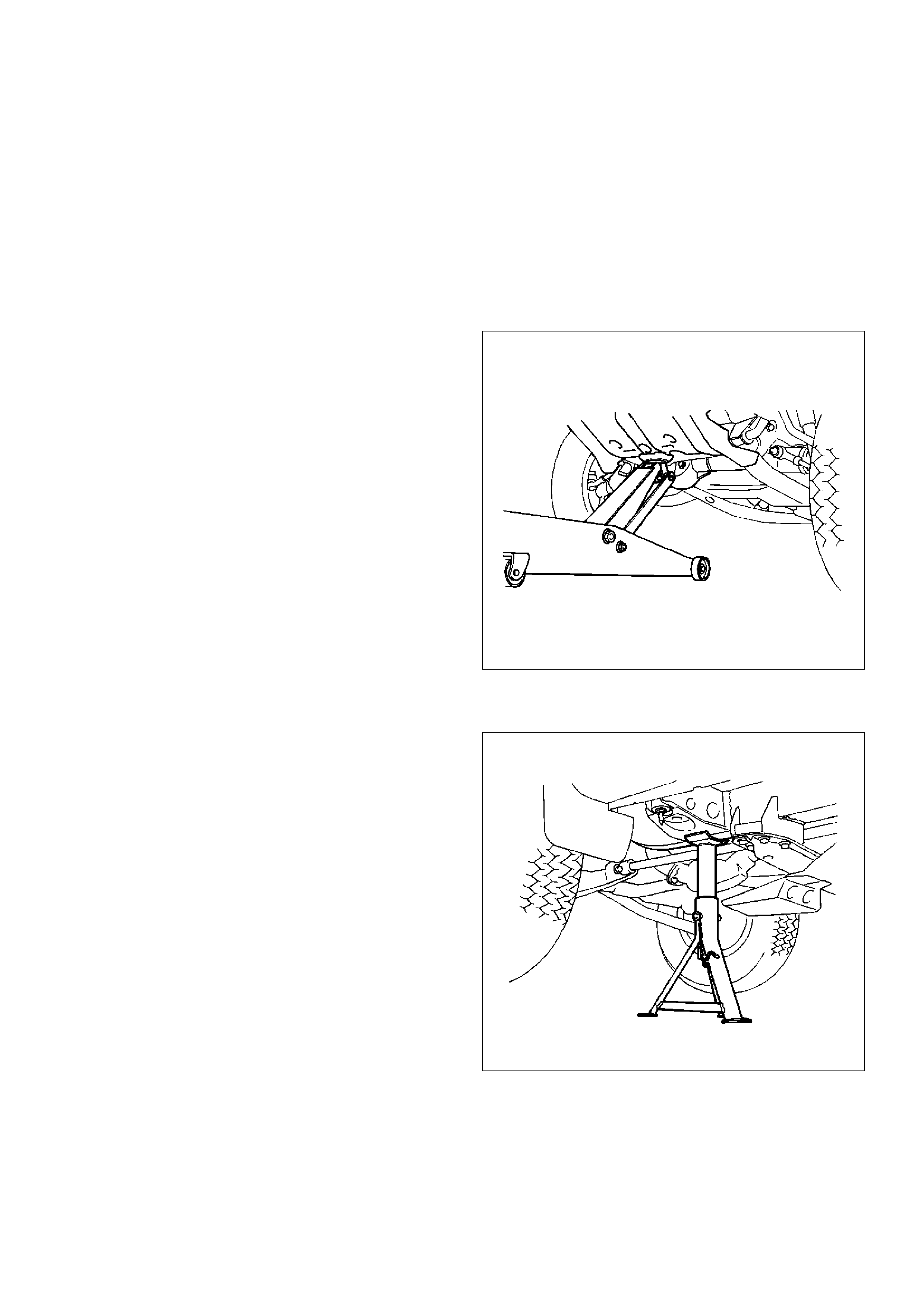

Lifting Point: Front

• When using a floor jack, lift on the Convex portion of

the skid plate.

545RS001

Supportable Point: Front

• Position the chassis stands at the bottom of the frame

sidemember, behind the front wheel.

Procedure

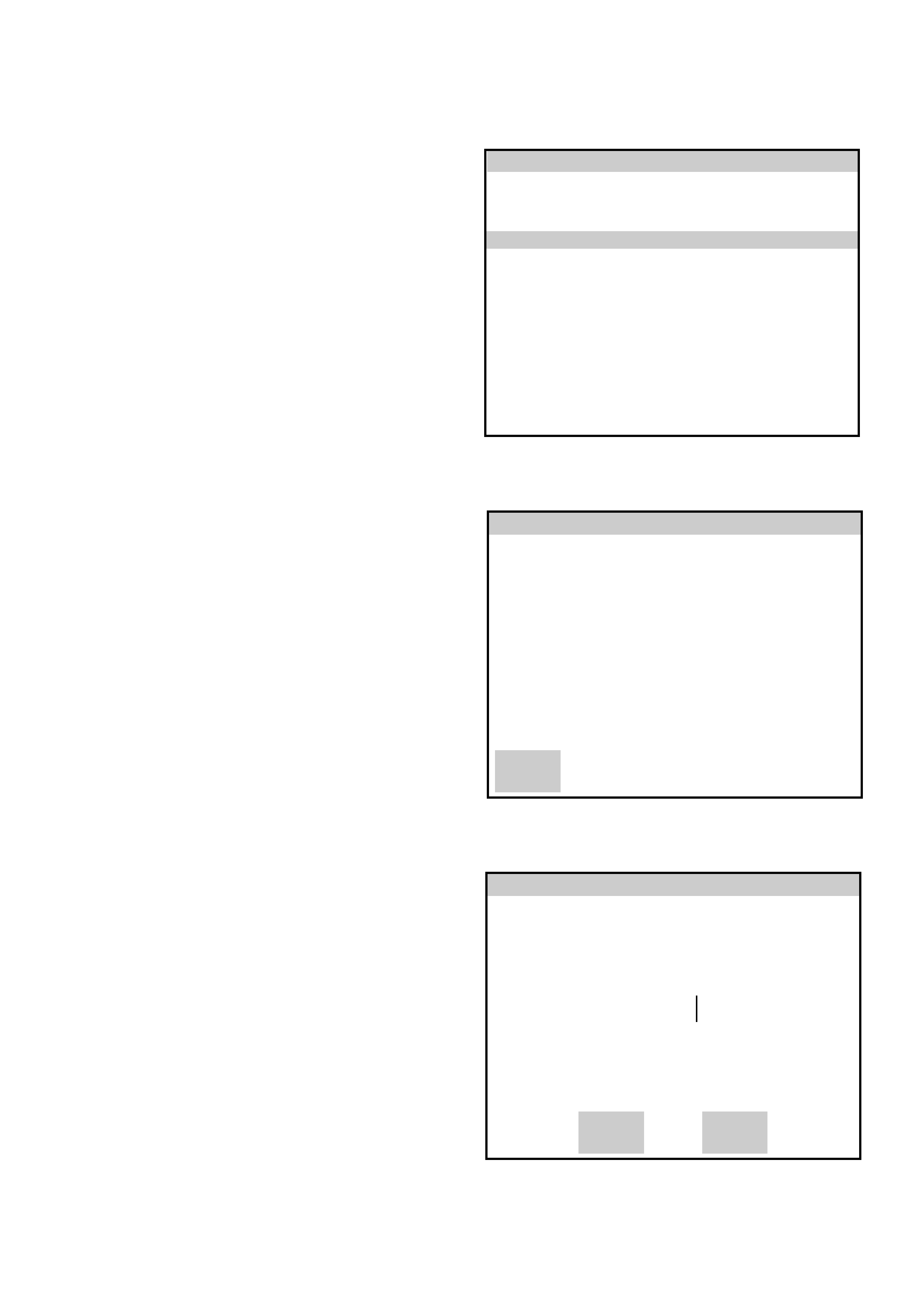

1. Select F3: Actuator Test from the Application

Menu with the arrow keys, then press ENTER.

2. Select F0: Return Pump Relay Test, then press

ENTER

3. Using the softkeys, check the Return Pump

function.

1. Select F3: Actuator Test from the Application

Menu with the arrow keys, then press ENTER.

Application Menu

F0: Diagnostic Trouble Codes

F1: Data Display

F2: Snapsh ot

F3: Actuator Tests

F4: Miscell aneo us Te sts

UES2002abs14

Application Menu

F0: Return Pump Relay Test

F1: Front Left Solenoid Valve Test

F2: Front Right Solenoid Valve Test

F3: Rear Left Solenoid Valve Test

F4: Rear Right Solenoid Valve Test

UES2002abs15

Return Pump Relay Test

(2) 2002 Frontera

Electronic System: ABS

UE2002abs16

On

Return Pump

Off

Front Left Wheel Speed

Front Right Wheel Speed

Rear Wheel Speed

Warning Lamp

ABS State

ABS Relay

4 Wheel Drive

Quit

0 km/h

0 km/h

0 km/h

Off

Off

Active

Inactive

4. Select Solenoid Valve Test from the Application

Menu with the arrow keys, then press ENTER.

5. Press the CONFIRM soft key.

6. Release the brake pedal. Attempt to rotate the

wheel.

Does the wheel rotate?:

YES: Press the YES soft key to go to the next

display.

NO: Press the NO soft key.The test has failed.

Check the hydraulic brake system. Refer to the

Power Assisted Brake Section.

Application Menu

F0: Return Pump Relay Test

F1: Front Left Solenoid Valve Test

F2: Front Right Solenoid Valve Test

F3: Rear Left Solenoid Valve Test

F4: Rear Right Solenoid Valve Test

UES2002abs11

Front Left Solenoid Valve Test

(2) 2002 Frontera

Electronic System: ABS

UE2002abs12

Before Running this Test

See Checking Proce dur e!

Confirm

Front Left Solenoid Valve Test

(2) 2002 Frontera

Electronic System: ABS

UE2002abs13

Normal Funct ion

Brake Switch

Yes

Inactive

Wheel Turnable?

No

7. Depress and hold the brake pedal. Attempt to rotate

the wheel.

Is the wheel blocked?

YES: Press the YES soft key to go to the next

display.

NO: Press the NO soft key.The test has failed.

Check for air in brake system and damaged brake

lines. Refer to the Power Assisted Brake Section.

8. Release the brake pedal. Attempt to rotate the

wheel.

Does the wheel rotate?:

YES: Press the YES soft key to go to the next

display.

NO: Press the NO soft key.The test has failed.

Check the brake disc and caliper. Refer to the

Power Assisted Brake Section.

9. Depress and hold the brake pedal. Attempt to rotate

the wheel.

Does the wheel rotate?:

YES: Press the YES soft key to go to the next

display.

NO: Press the NO soft key.The test has

failed.Check the brake disc and caliper. Refer to the

Power Assisted Brake Section.

Front Left Solenoid Valve Test

(2) 2002 Frontera

Electronic System: ABS

UE2002abs8

Normal Funct ion

Brake Switch

Yes

Active

Wheel Blocked?

No

Front Left Solenoid Valve Test

(2) 2002 Frontera

Electronic System: ABS

UE2002abs9

Normal Function

Brake Switch

Yes

Inactive

Wheel Turn able?

No

Front Left Solenoid Valve Test

(2) 2002 Frontera

Electronic System: ABS

UE2002abs10

Release Function

Brake Switch

Return Pump

Yes

Active

Inactive

Wheel Turn able?

No

10. Depress and hold the brake pedal. Attempt to rotate

the wheel.

Is the wheel blocked?

YES: Press the YES soft key to go to the next

display.

NO: Press the NO soft key.The test has failed.

Check for air in brake system and damaged brake

lines. Refer to the Power Assisted Brake Section.

11. Test is completed. To return to the APPLICATION

MENU, press the CONFIRM soft key

Front Left Solenoid Valve Test

(2) 2002 Frontera

Electronic System: ABS

UE2002abs17

Normal Funct ion

Brake Switch

Yes

Active

Wheel Blocked?

No

Front Left Solenoid Valve Test

(2) 2002 Frontera

Electronic System: ABS

UE2002abs18

Test Passed Successfully!

Confirm

Tech 2 Ser vice Bleed

Procedure

1. Select F4: Miscellaneous Tests from the

Application Menu with the arrow keys, then press

ENTER. Apply the Park Brake. Start the engine and

allow to idle.

2. Select F0: Brake Bleed, then press ENTER

3. Press the CONTINUE soft key

Application Menu

F0: Diagnostic Trouble Codes

F1: Data Display

F2: Snapsh ot

F3: Actuator Tests

F4: Miscell aneo us Te sts

UES2002abs19

Application Menu

F0: Brake Bleed

UES2002abs20

Brake Bleed

(2) 2002 Frontera

Electronic System: ABS

UE2002abs21

1st Time

Perform manual Bleed Procedure Until

Fluid Flows With No Air Present

Continue

Tech 2 Service Bleed

Procedure - Continued

4. Depress and hold the brake pedal. Press the YES

soft key

5. The EHCU will operate the brake bleed function.

6. The first brake bleed cycle is complete.

Brake Bleed

(2) 2002 Frontera

Electronic System: ABS

UE2002abs22

1st Time

Depress And Hold Brake Pedal!

Activate

Yes No

Brake Bleed

(2) 2002 Frontera

Electronic System: ABS

UE2002abs23

1st Time

Depress And Hold Brake Pedal!

Running...

Front Left Solenoid Valve Test

(2) 2002 Frontera

Electronic System: ABS

UE2002abs24

1st Time

Brake Switch Active

Release Brake Pedal!

1st Time Complete

Tech 2 Service Bleed

Procedure - Continued

7. Release the brake pedal. Press the CONTINUE soft

key. The EHCU will repeat the bleed procedure four

times. Brake Bleed

(2) 2002 Frontera

Electronic System: ABS

UE2002abs22

1st Time

1st Time Complete

Continue

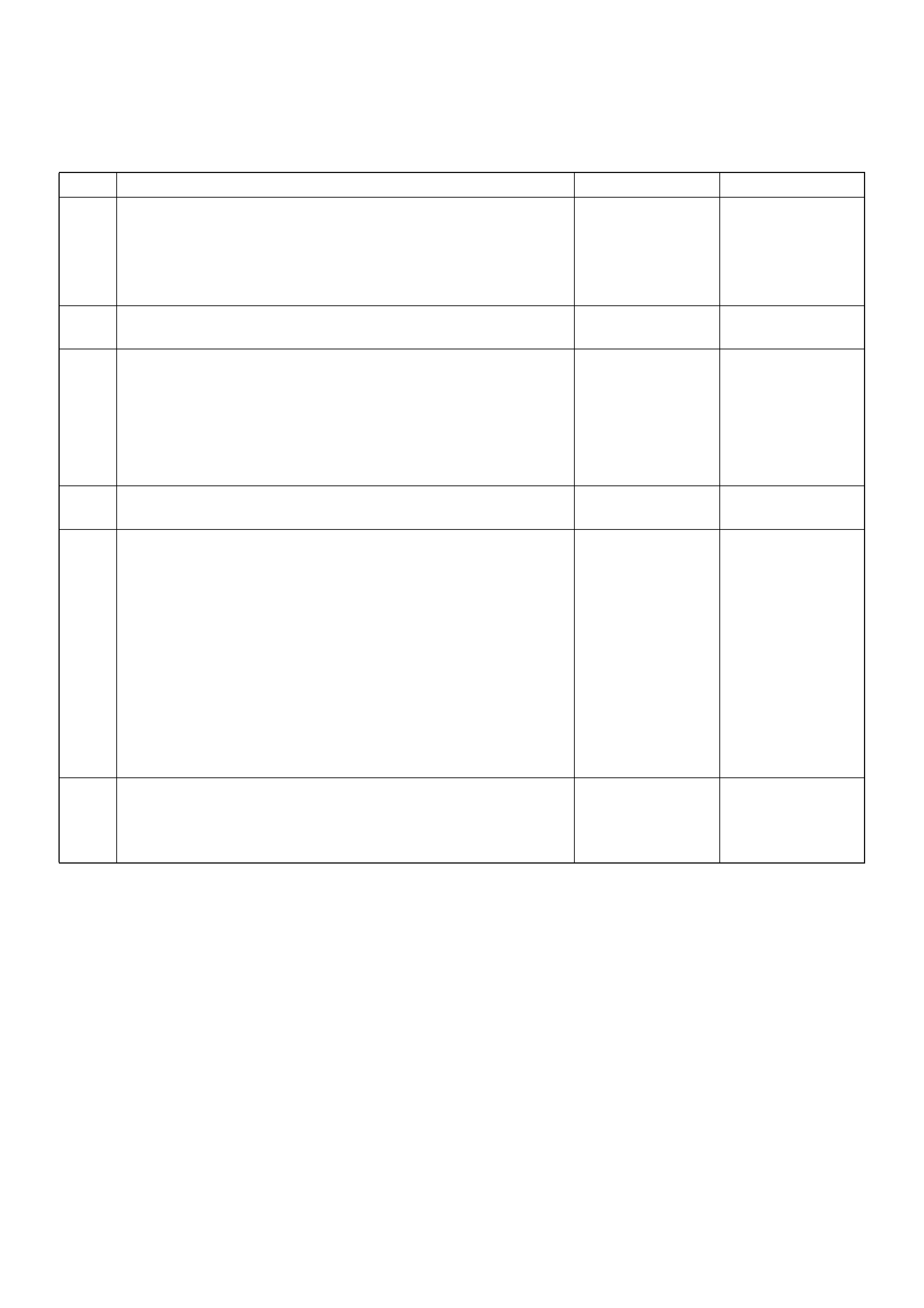

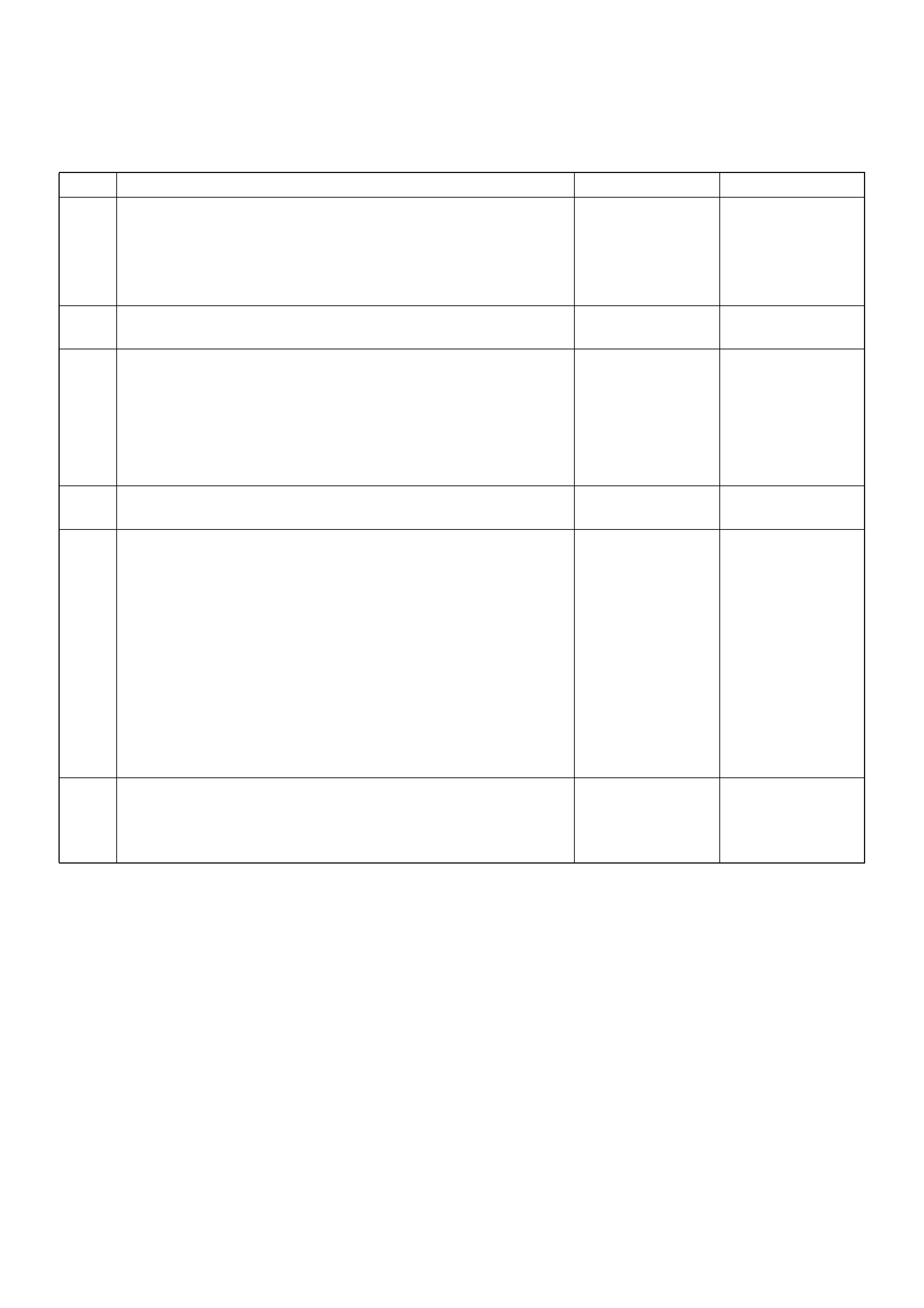

Basic Diagnostic Flow Chart

Basic Inspection Pr ocedure

1. Basic Inspection of Service Brake

2. Ground Inspection

Step Action Yes No

1 1. Customer complaint.

2. Question the customer to illicit exact nature of the complaint.

3. Basic inspection (Refer to “Basic inspection procedure")

Using TECH 2? Go to Step 2 Go to Step 4

2 Check for stored DTC’s with Tech 2 by selecting “F0: Diagnostic

Tr oub le Code s" .

Are any DTC’s stored?

Clear code and

check for

repeatability.

Go to Step 3 Go to Step 5

3 1. Repair of faulty part.

2. Clear the DTC with Tech 2..

3. Inspection of “ABS" W/L Illumination pattern with ignition SW

“ON".

4. Test drive.

Does fault reappe ar ?

Repeat the

diagnosis it the

symptom or

DTC appears

again

Go to Step 1 Go to Step 5

4 Check if the DTC is stored or not.

Is a DTCstored?

Clear code and

check for

repeatability

Go to Step 3

Trouble

diagnosis

based on

symptom (Refer

to “Symptom

Diagnosis")

Go to Step 3

5 1. Reconnect all components. Ensure all component are

properly mounted.

2. Clear diagnostic trouble code.

Was this step completed? Finished Go to Step 5

Step Action Yes No

1 Is the fluid level normal?

Go to Step 2

Repleni sh with

fluid

Go to Step 2

2 Does fluid leak? Repair

Go to Step 3 Go to Step 3

3 Is the booster function normal? Go to Step 4 Repair

Go to Step 4

4 Is the pad and rotor condition normal? Go to Step 5 Repair

Go to Step 5

5 Reconnect all components. Ensure all component are properly

mounted.

Was this step completed? Finished Go to Step 5

Step Action Yes No

1 Do all ABS—related ground points have less than 5 ohms

resistance to the battery negative terminal? Go to Step 2 Repair

Go to Step 2

2 Reconnect all components. Ensure all component are properly

mounted.

Was this step completed? Finished Go to Step 2

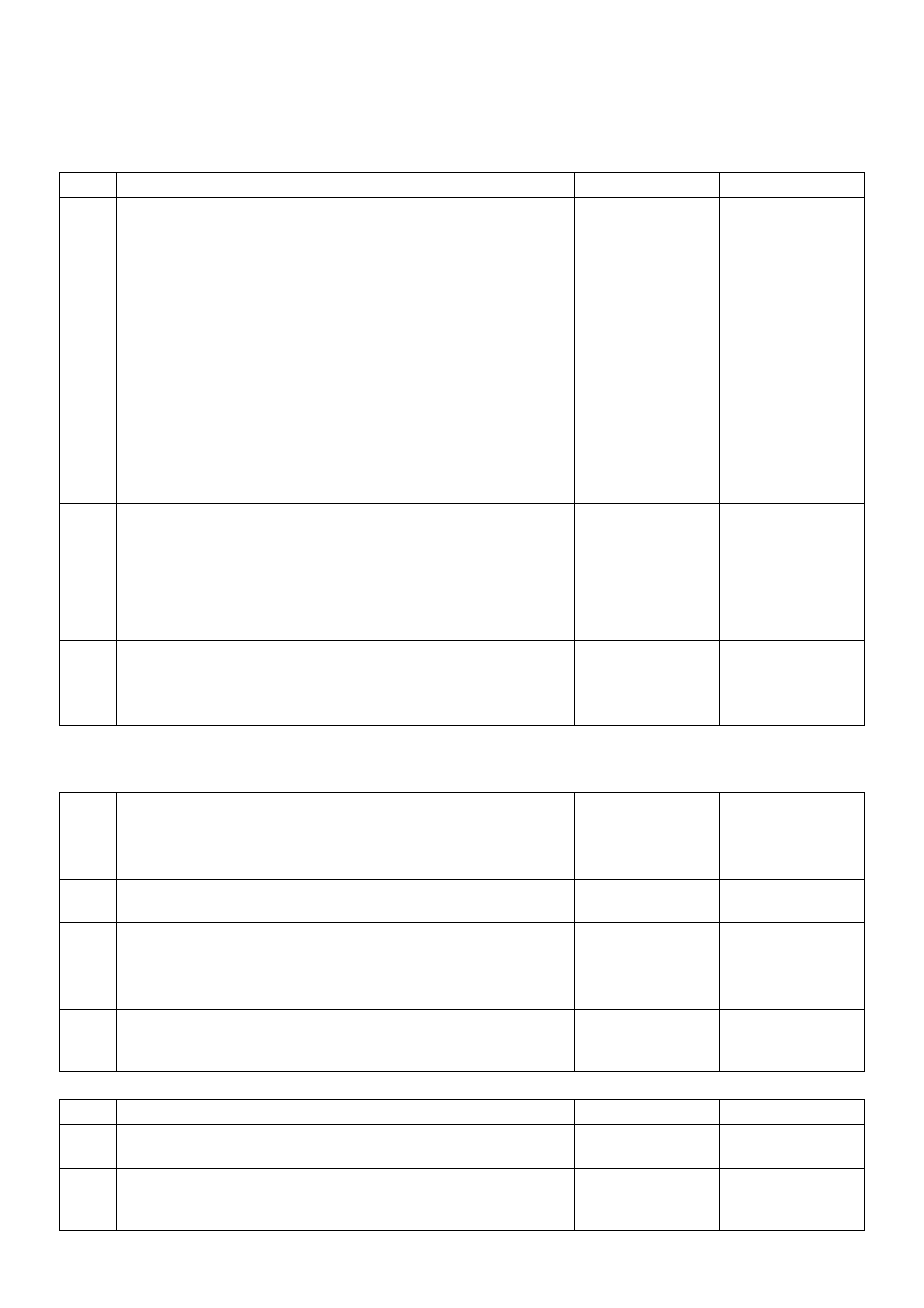

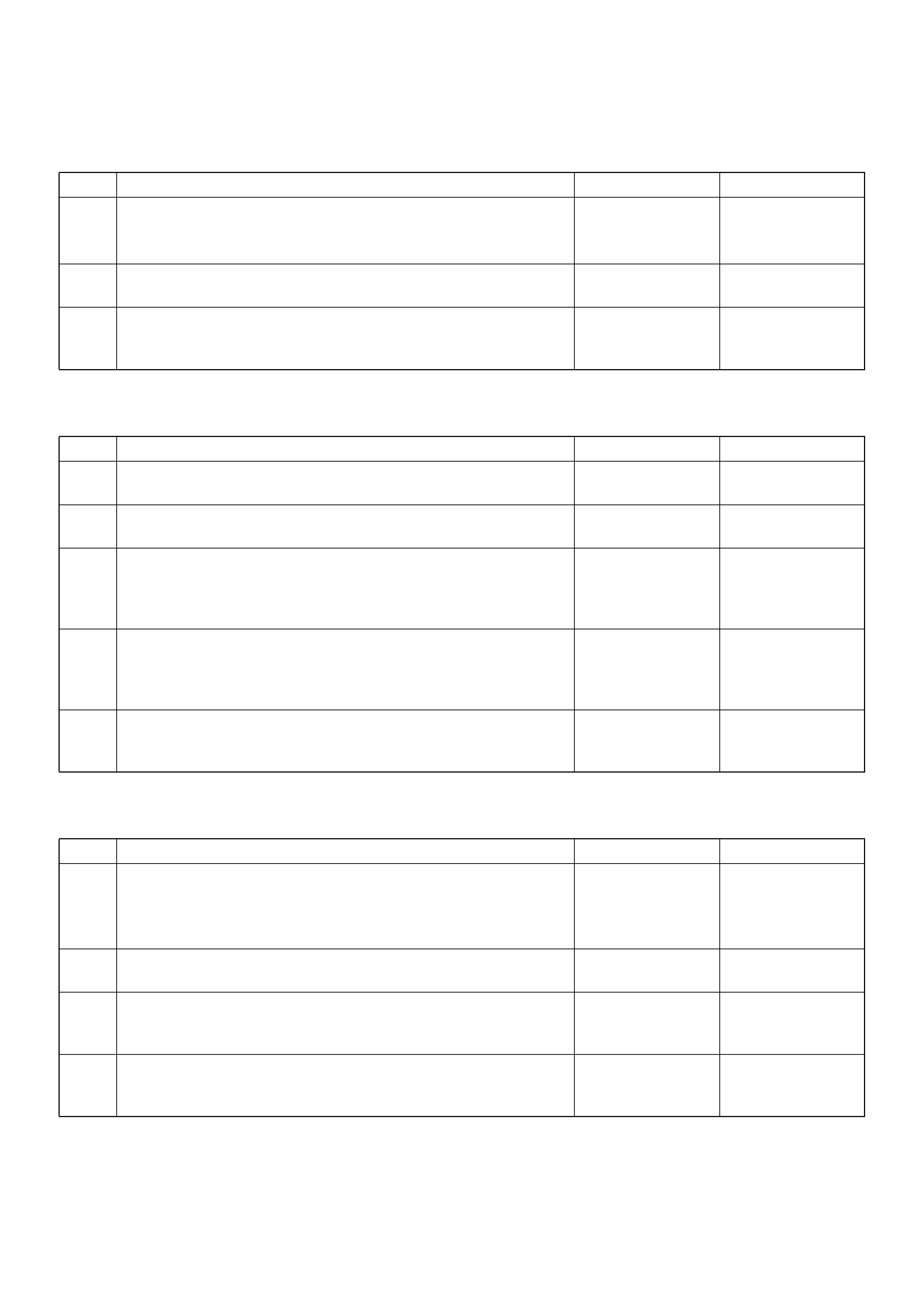

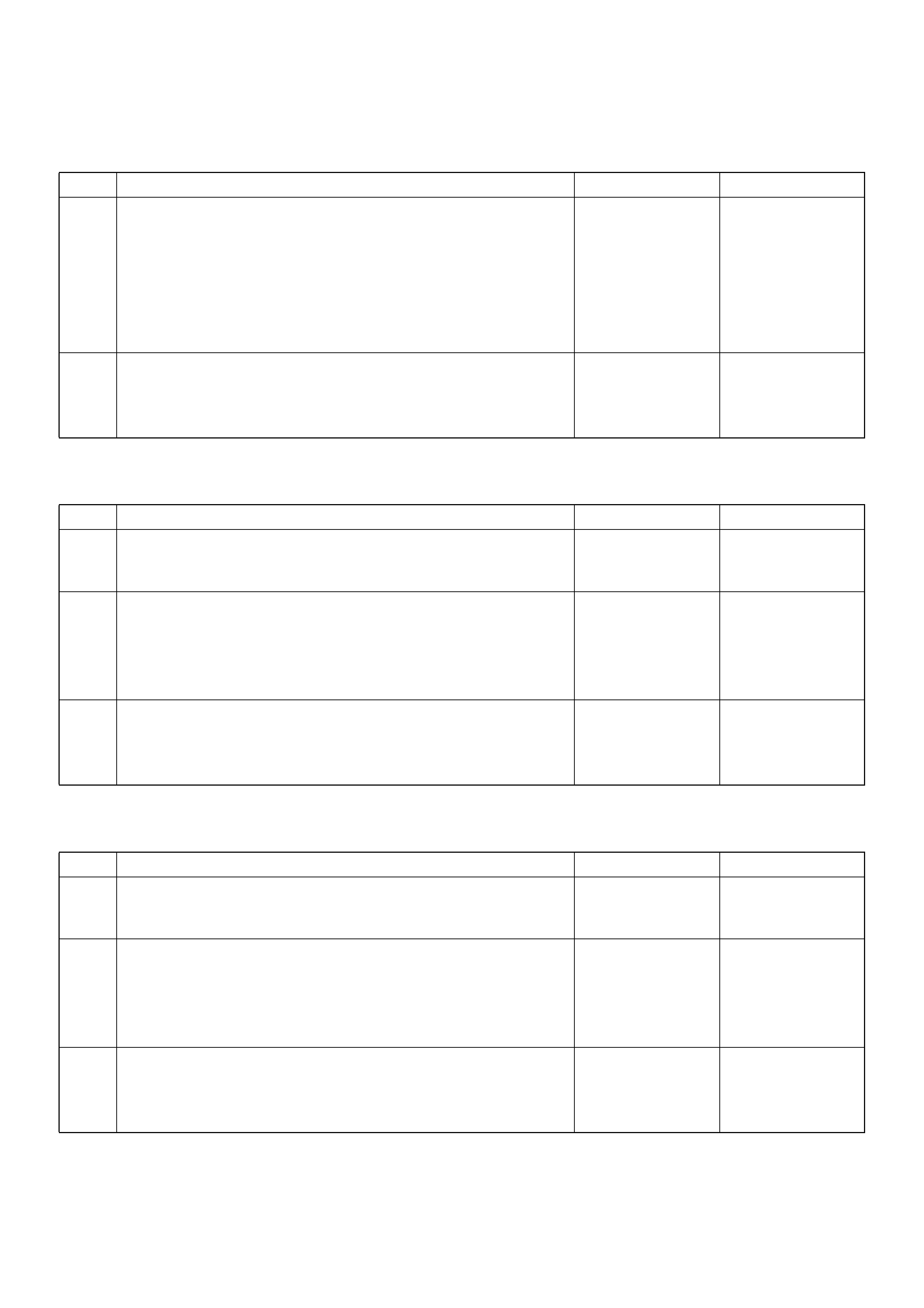

EHCU Connector Pin-out Checks

• Disconnect Electronic Hydraulic Control Module.

• Perform checks with high impedance digital

multimeter 5-8840-0366-0 or equivalent.

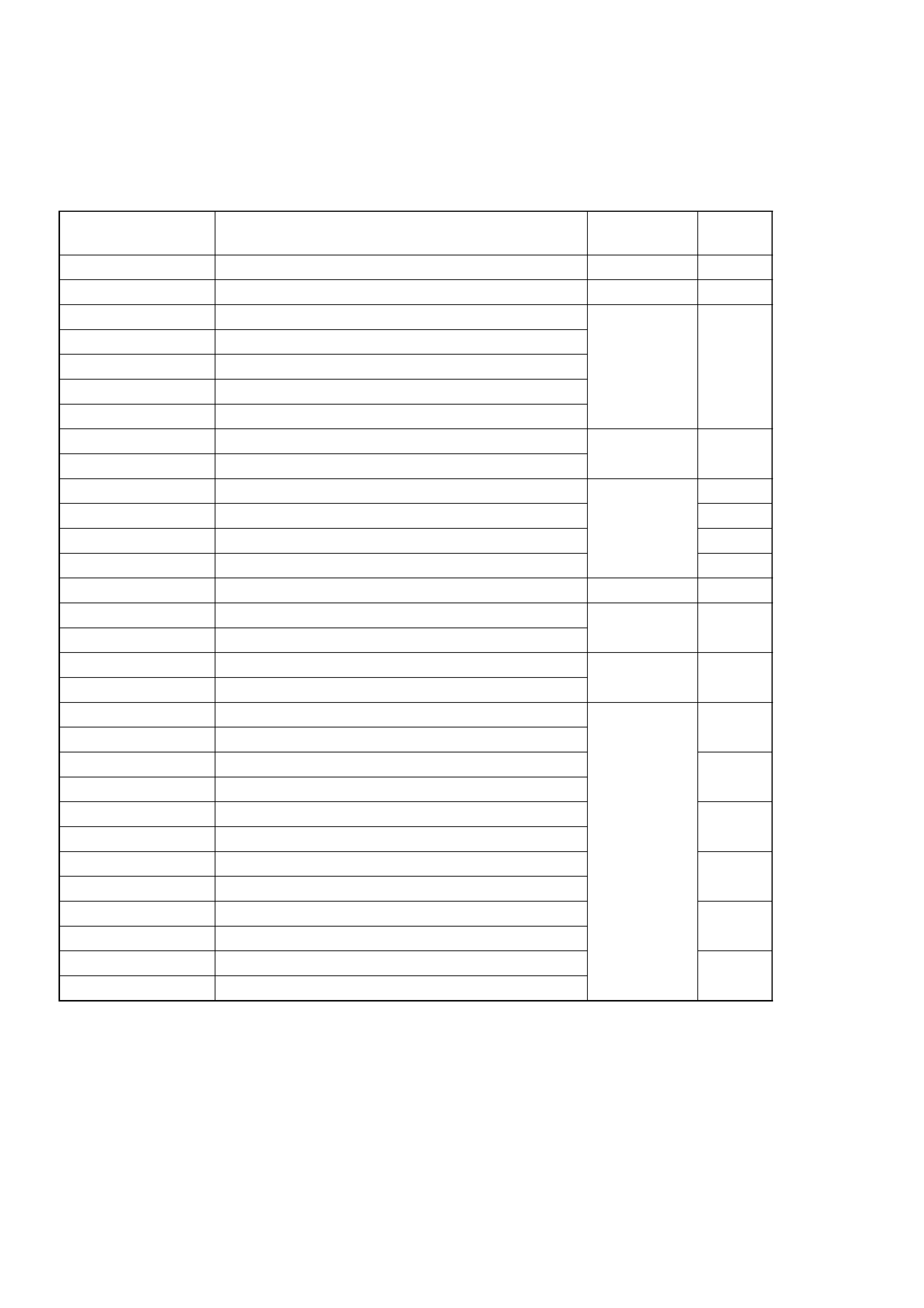

No. Circuit to be Tested Ignition

Switch

Position

Multimeter

Scale/Range Measure

between Pin

Number

Nominal Value Note

1 Power supply OFF 20DCV 1 (C–5)

2 (C–5) 11.5V to 14.5V

2 Ignition enable OFF 20DCV 1 (C–4)

7 (C–4) 0V to 0.1V

ON 20DCV 1 (C–4)

7 (C–4) 11.5V to 14.5V

3 Stoplamp switch OFF 20DCV 13 (C–4)

7 (C–4) 10.5V to 14.5V Press brake pedal

4 Ground connection OFF 200W 7 (C–4)

Ground Less than 2W

OFF 1W 2 (C–5)

Ground Less than 0.2W

5 FL speed se ns or OFF 2kW 2 (C–4)

10 (C–4) 0.7kW to 1.5kW Internal Resistance

OFF 200kW 2 (C–4)

7 (C–4) more than

100kW Insulation Resistance

OFF 200mACV 2 (C–4)

10 (C–4) more than

200mV Turn wheel at 1RPS

6 FR speed sensor OFF 2kW 3 (C–4)

11 (C–4) 0.7kW to 1.5kW Internal Resistance

OFF 200kW 3 (C–4)

7 (C–4) more than

100kW Insulation Resistance

OFF 200mACV 3 (C–4)

11 (C–4) more than

200mV Turn wheel at 1RPS

7 RR speed sensor OFF 2kW 4 (C–4)

12 (C–4) 1.0kW to 1.7kW Internal Resistance

OFF 200kW 4 (C–4)

7 (C–4) more than

100kW Insulation Resistance

OFF 200mACV 4 (C–4)

12 (C–4) more than

200mV Turn wheel at 1RPS

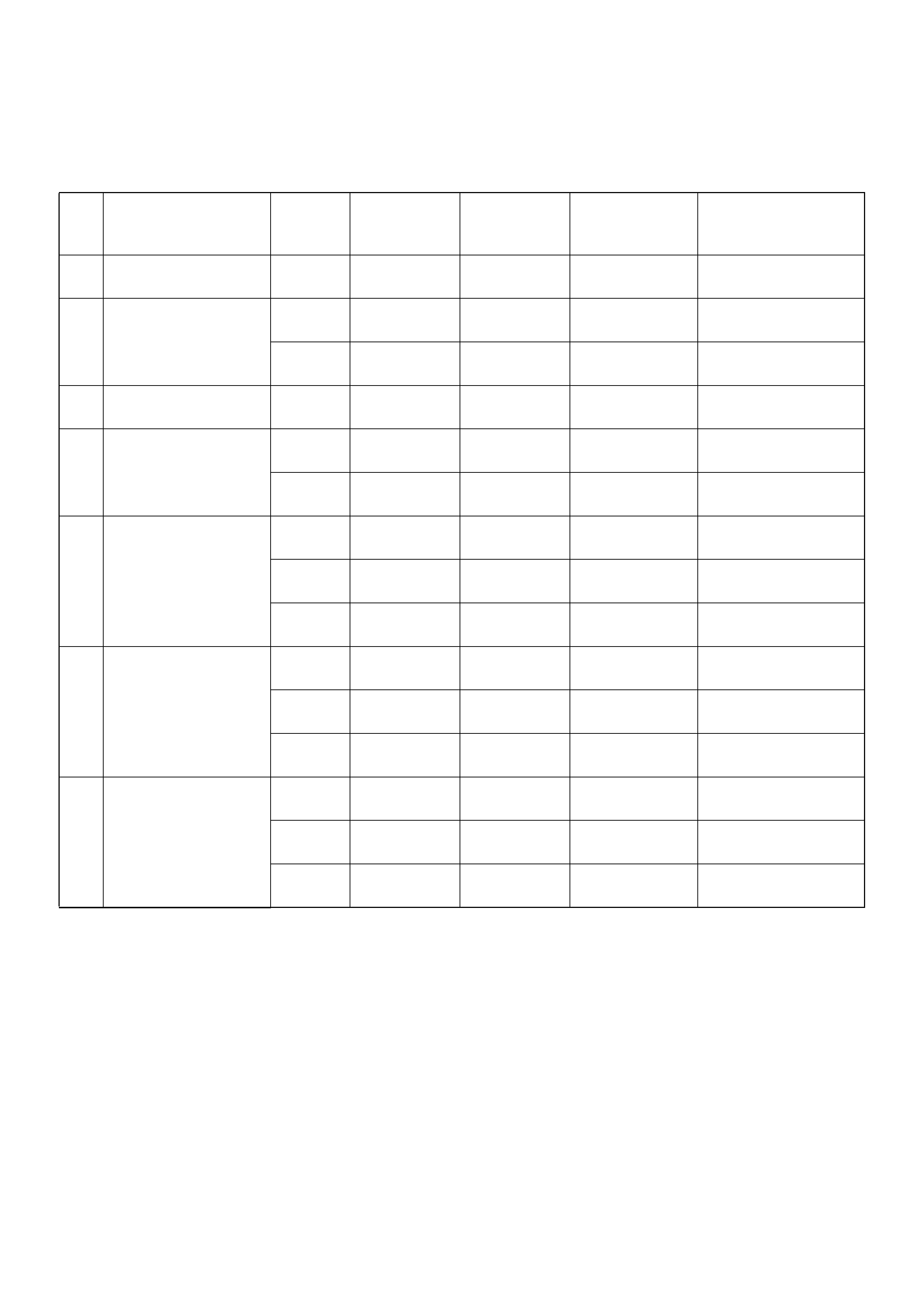

Circuit Diagram

D08R100134

5.0

WHT/GRN

0.85

PNK/

GRN

50A

ABS

INDICATOR

LIGHT(METER)

STOP

LAMP

SW

ELECTRONIC

HYDRAULIC

CONTROL UNIT

1

C-5

0.85

YEL

0.85

YEL

0.85

YEL

0.85

BLK

3.0

BLK/RED

STARTER SW

(IG1)

15A

METER

I-23I-24

14

I-24

10

H-14

19

H-15 18

H-14

9

C-6014

C-6011

22

3.0

WHT 15A

STOP LAMP

BATT.(+)BATT.(+)

STOP LAMP

13

C-4

8

0.85

GRN

0.85

RED

0.85

RED

0.5

RED

0.85

RED

I-31

H-14 15

H-16

1

I-31

4

1

C-4

C-10

H-14

11

C-4

7

6

C-4

0.85

YEL

0.5

PPL/WHT

0.5

PPL/WHT

0.5

O

0.5

O

8

C-4

0.5

P

8

C-4

0.5

LG/R

5

C-4

3.0

BLK

5.0

BLK

C-26

E/ROOM LH

C-5

GROUND GROUND

BATTERY(+) POWER

SUPPLY SILA BRAKE LAMP

SWITCH

2

BATT TRAY

BRAKE

ABS

A

TOD

CONTROL

UNIT

4WD

CONTROL

UNIT

(14)

With TOD

D08R100135

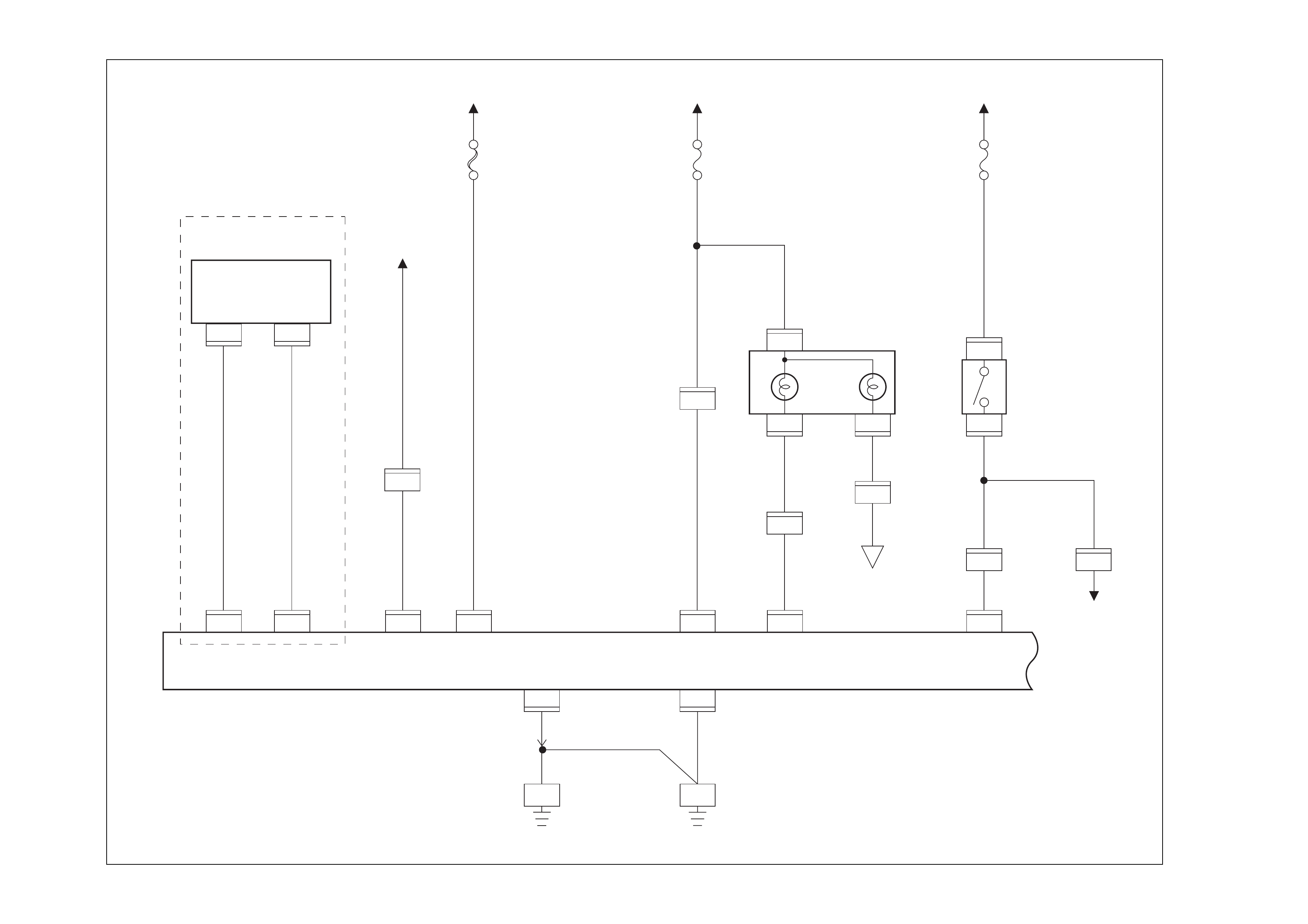

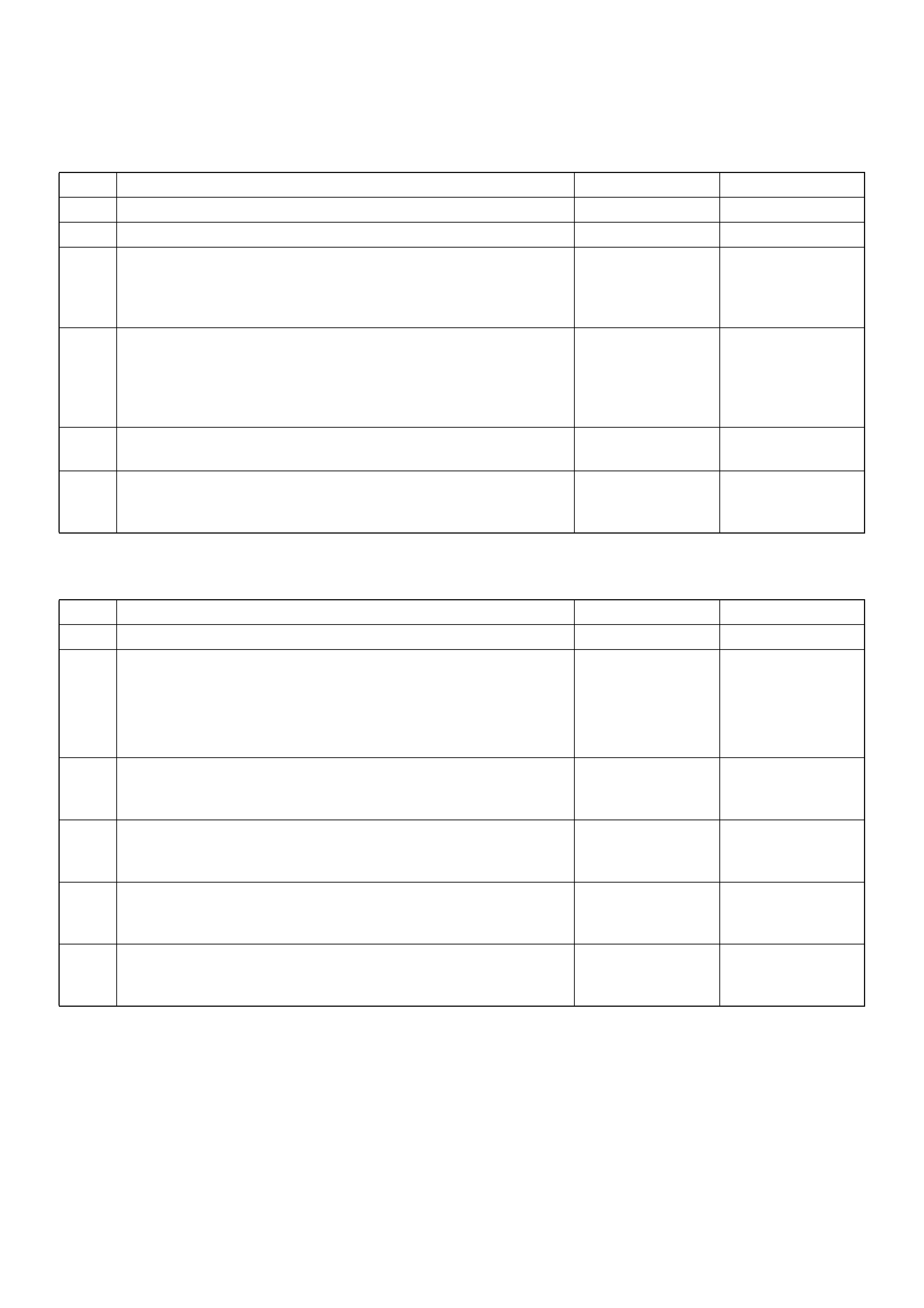

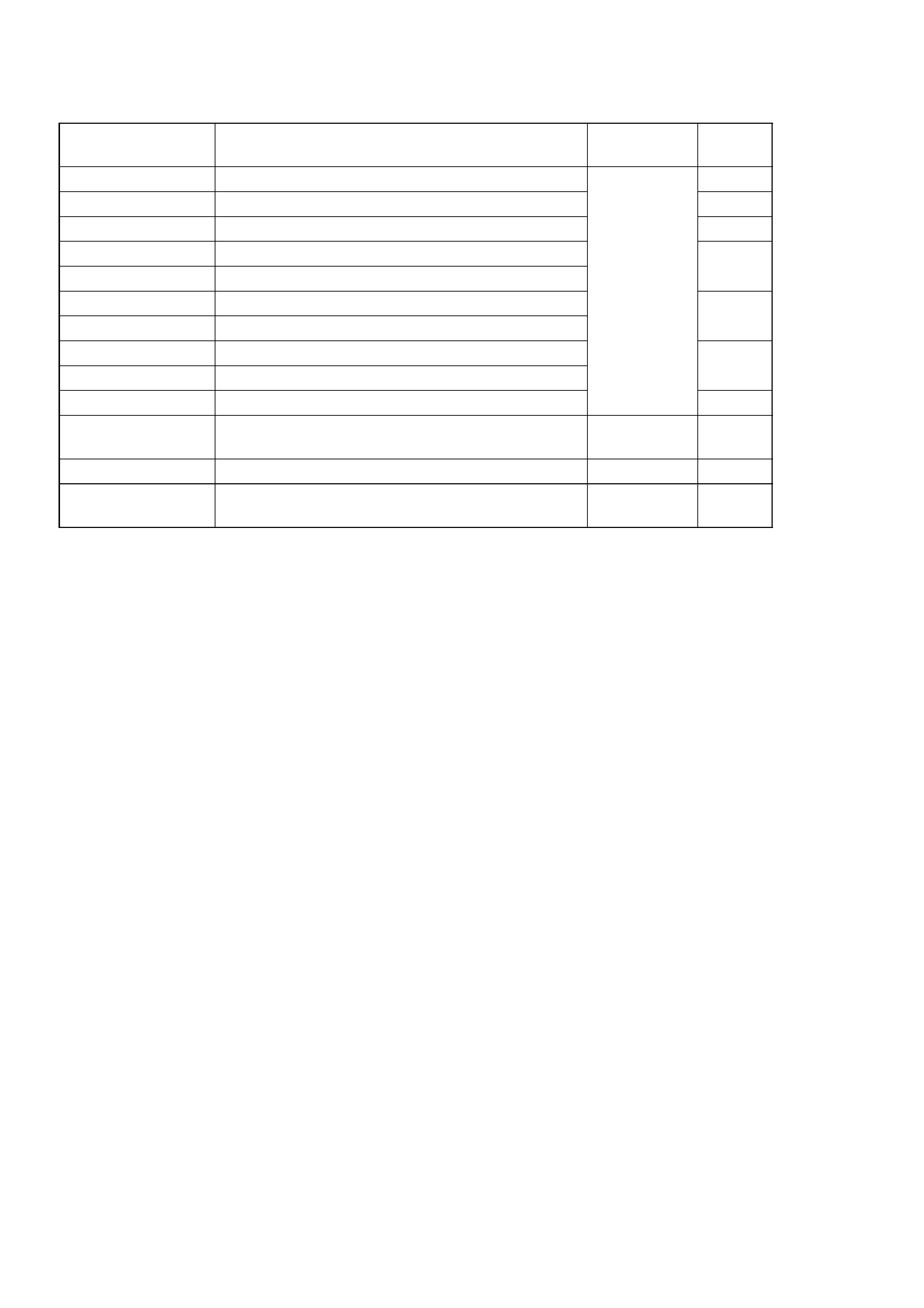

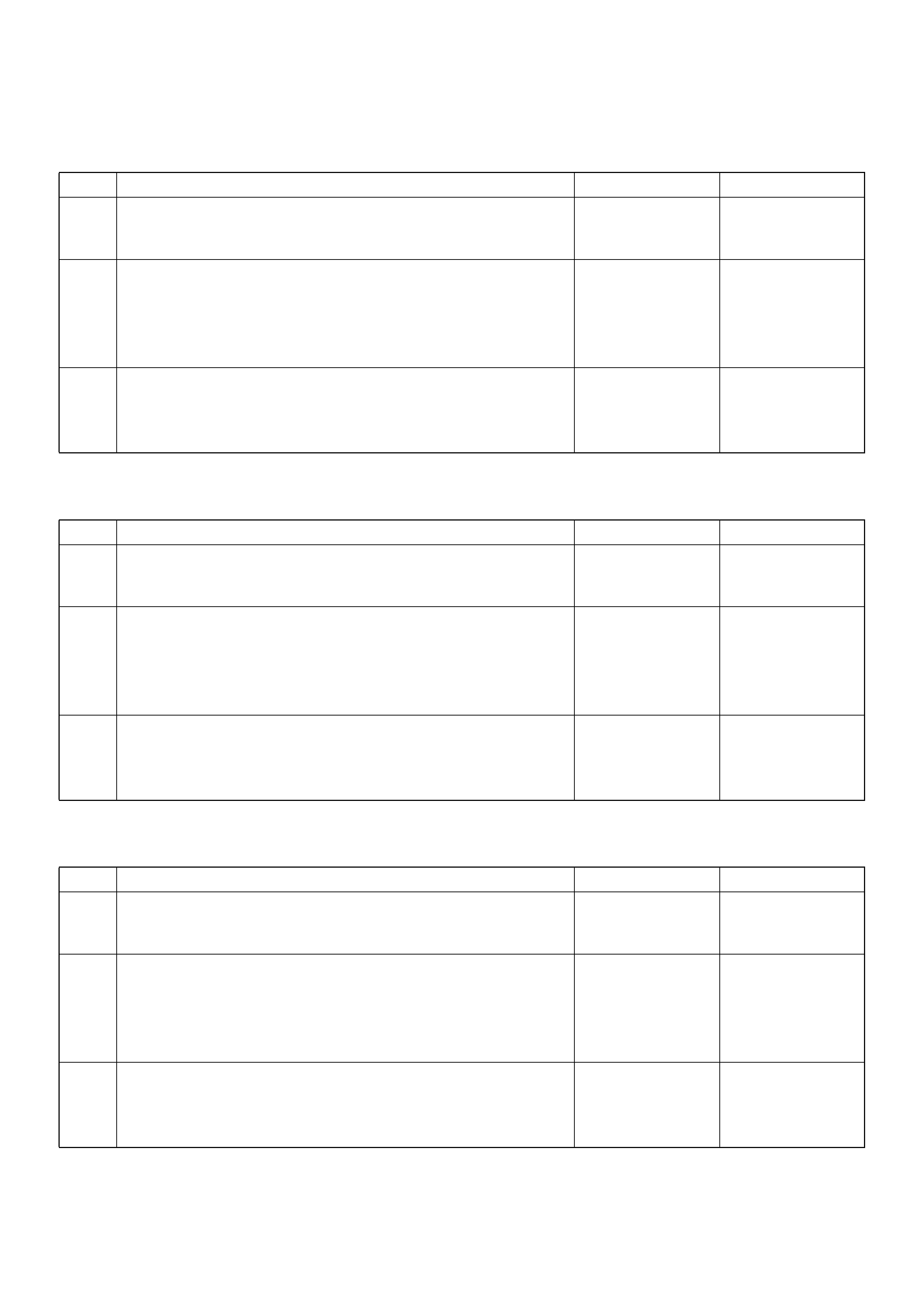

Connector List

No. Connector face No. Connector face

B-19 C-60

B-23 F-4

C-4 H-5

C-5 H-15

H-25

C-6 H-14

C-13

C-33 H-19

C-16

E-30 I-1

C-34 I-2

I-18 I-45

No. Connector face No. Connector face

Part Location

D08R100072

Legend

EndOFCallout

(1) C–5

(2) C–4

(3) H– 14, H–19

(4) C–60

(5) I–45 (Relay & Fuse Box)

(6) I–1

(7) I–2

(8) B–23

(9) B–19

(10) F–4

(11) H–15

(12) H–25

(13) C–16

(14) C–13

(15) H–5

(16) E–30

(17) I–18

(18) C–34

(19) C–6

(20) C–33

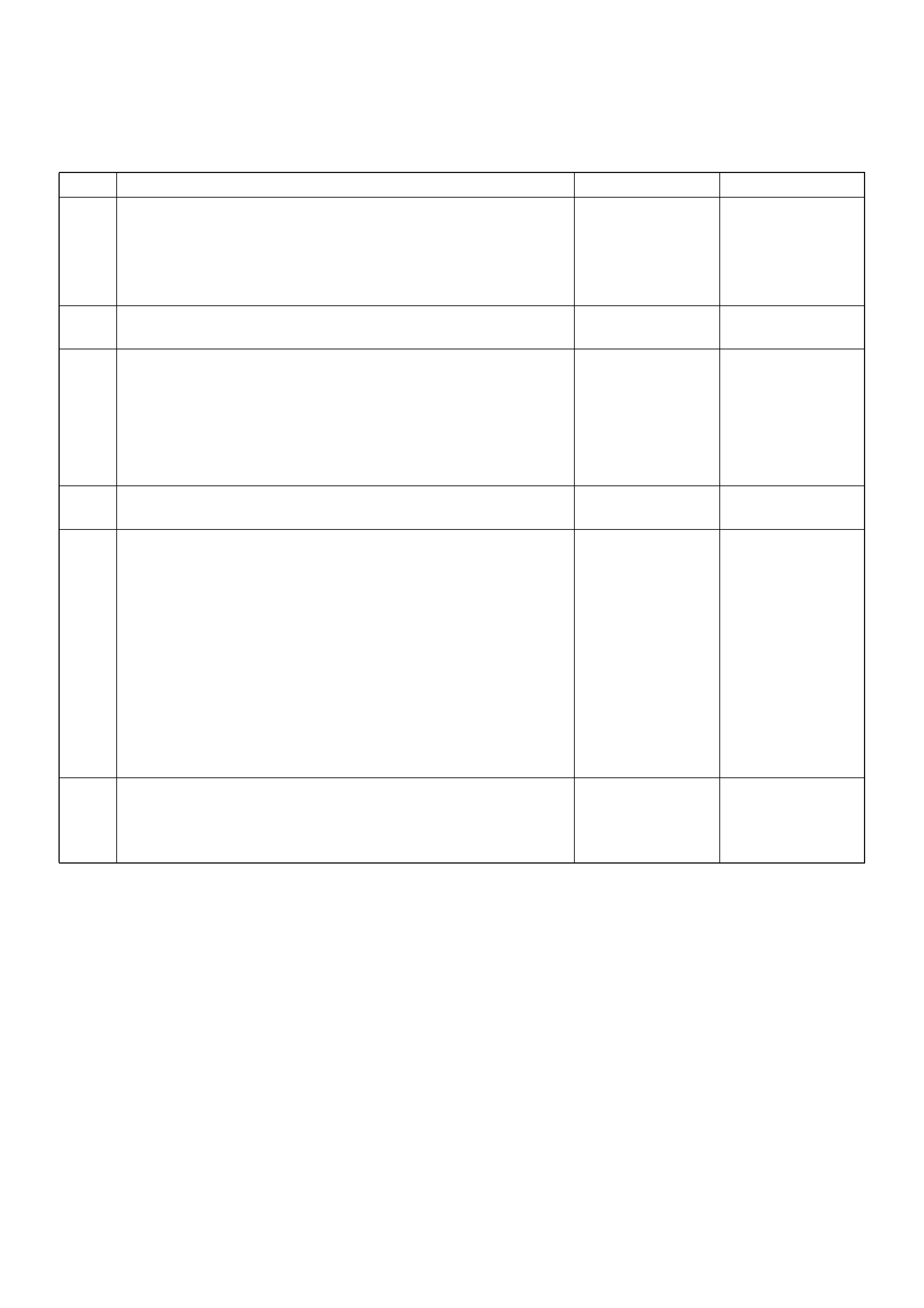

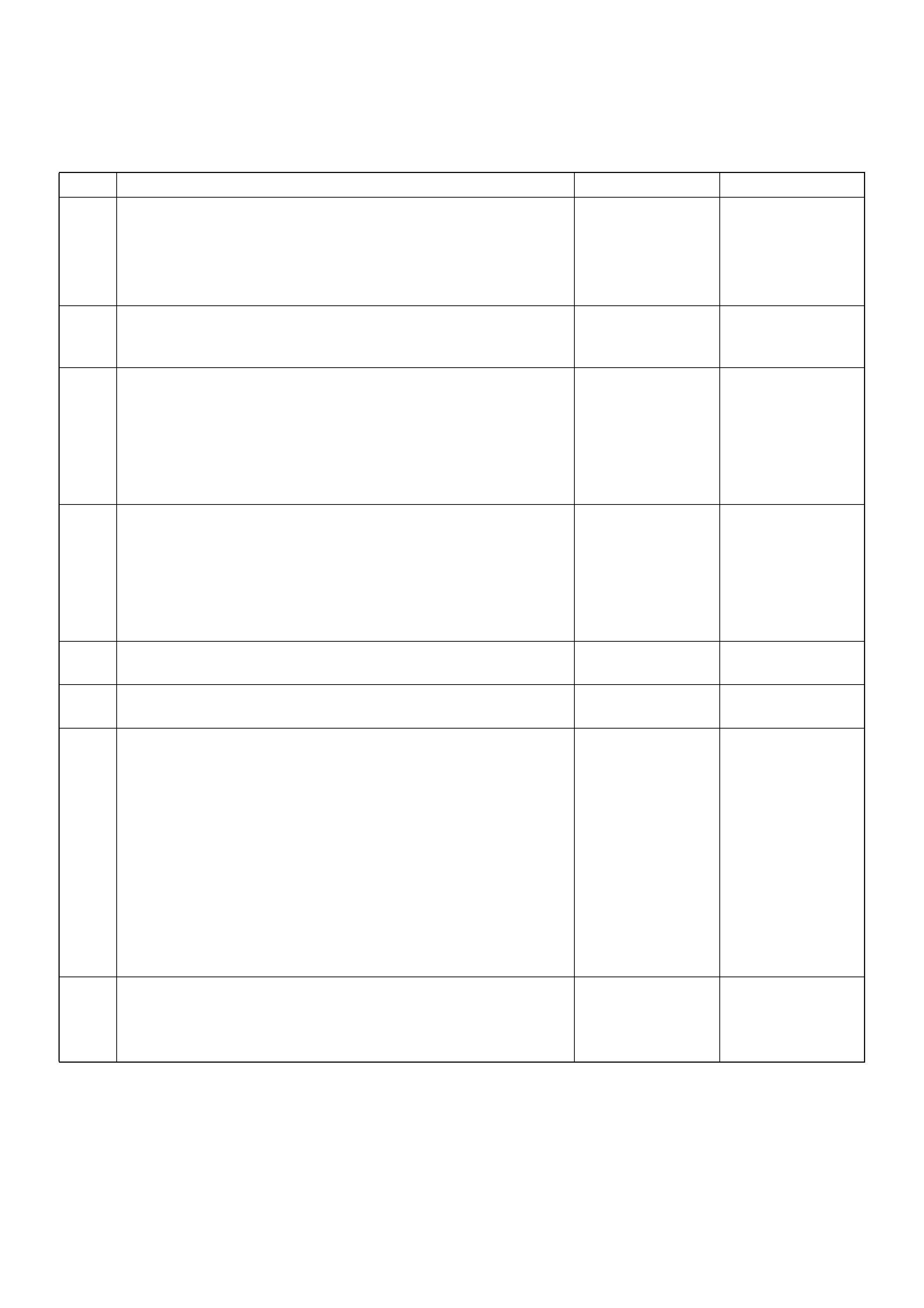

Symp tom Diagnosis

A number of braking system faults may occur that will not illuminate the “ABS” warning lamp. These are all attributable

to probl ems whi ch cannot be detec ted by EHCU sel f-diagno sis. Anal yse the custom er compl aint and conduct a road

test to determine which symptom is present, then follow the appropriate flow chart listed below.

Chart A-1 ABS Operates Frequently But The Vehicle Does Not Decelerate

No. Symptom Diagnostic Flow Charts

Without TECH 2 With TECH 2

1 ABS operates frequently but the vehicle does not decelerate. Chart A-1 Chart TA-1

2 Uneven braking occurs while ABS operates. Chart A-2 Chart TA-2

3 The wheels lock during braking. Chart A-3 Chart TA-3

4 Abnormal brake pedal feel. Chart A-4 —

5 The EHCU is heard operating while not braking. Chart A-5 Chart TA-5

Step Action Yes No

1 Is braking force distributed correctly between front and rear of

vehicle? Go to Step 2

Repair brake

components.

Go to Step 7

2 Are axle and hub components installed correctly?

Go to Step 3

Repair axles

and hubs.

Go to Step 7

3 Is there movement in any wheel speed sensor mounting? Repair wheel

speed sensor.

Go to Step 7 Go to Step 4

4 Is there any damage, or powered iron residue sticking to any

wheel speed sensor/sensor ring? Replace sensor

or sensor ring.

Go to Step 7 Go to Step 5

5 Is the output of each wheel speed sensor normal? (Refer to chart

C-1 or TC-1)

Go to Step 6

Replace wheel

speed sensor or

repair harness.

Go to Step 7

6 Is the 4WD/TOD control unit functioning correctly?

Go to Step 7

Replace 4WD/

TOD control

unit or repair

harness.

Go to Step 7

7 Reconnect all components, ensure all components are properly

mounted.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 7

Chart TA-1 ABS Operates Freque n t ly But The Vehicle Does Not Decelerate (Use TECH 2)

Chart A-2 Uneven Braking Occurs While ABS Operates

Chart TA-2 Uneven Braking Occurs While ABS Operates (Use TECH 2)

Step Action Yes No

1 1. Connect TECH 2.

2. Make sure of the output conditions of each sensor.

Is the output of each sensor correct? Go to Step 2

Replace wheel

speed sensor.

Go to Step 3

2 Return to Chart A-1.

Was the Chart A-1 completed? Go to Step 3 Go to Step 2

3 Reconnect all components, ensure all components are properly

mounted.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 3

Step Action Yes No

1 Is there movement in any sensor mounting? Repair.

Go to Step 5 Go to Step 2

2 Dam age or powdered iron residue sticking to any sensor/sensor

ring? Repair.

Go to Step 5 Go to Step 3

3 Is the output of each wheel speed sensor correct? (Refer to chart

C-1 or TC-1)

Go to Step 4

Replace sensor

or repair

harness.

Go to Step 5

4 Are the brake hydraulic pipes connected to the correct EHCU

ports? Replace H/U.

Go to Step 5

Reconnect

brake pipe

correctly.

Go to Step 5

5 Reconnect all components, ensure all components are properly

mounted.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 5

Step Action Yes No

1 1. Connect TECH 2.

2. Make sure of the output conditions of each wheel speed

sensor.

Is the output of each sensor correct? Go to Step 2 Go to Step 3

2 Check brake pipe connections by TECH 2 ACTUATOR TEST

Are the pipes connected correctly? Replace EHCU.

Go to Step 4 Repair the pipe.

Go to Step 4

3 Repair and check the wheel speed sensor (Refer to chart B-20 to

B-23 , C-1 or TC-1).

Was each chart completed? Go to Step 4 Go to Step 3

4 Reconnect all components, ensure all components are properly

mounted.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 4

Chart A-3, TA-3 The Wheels Are Locked During Braking

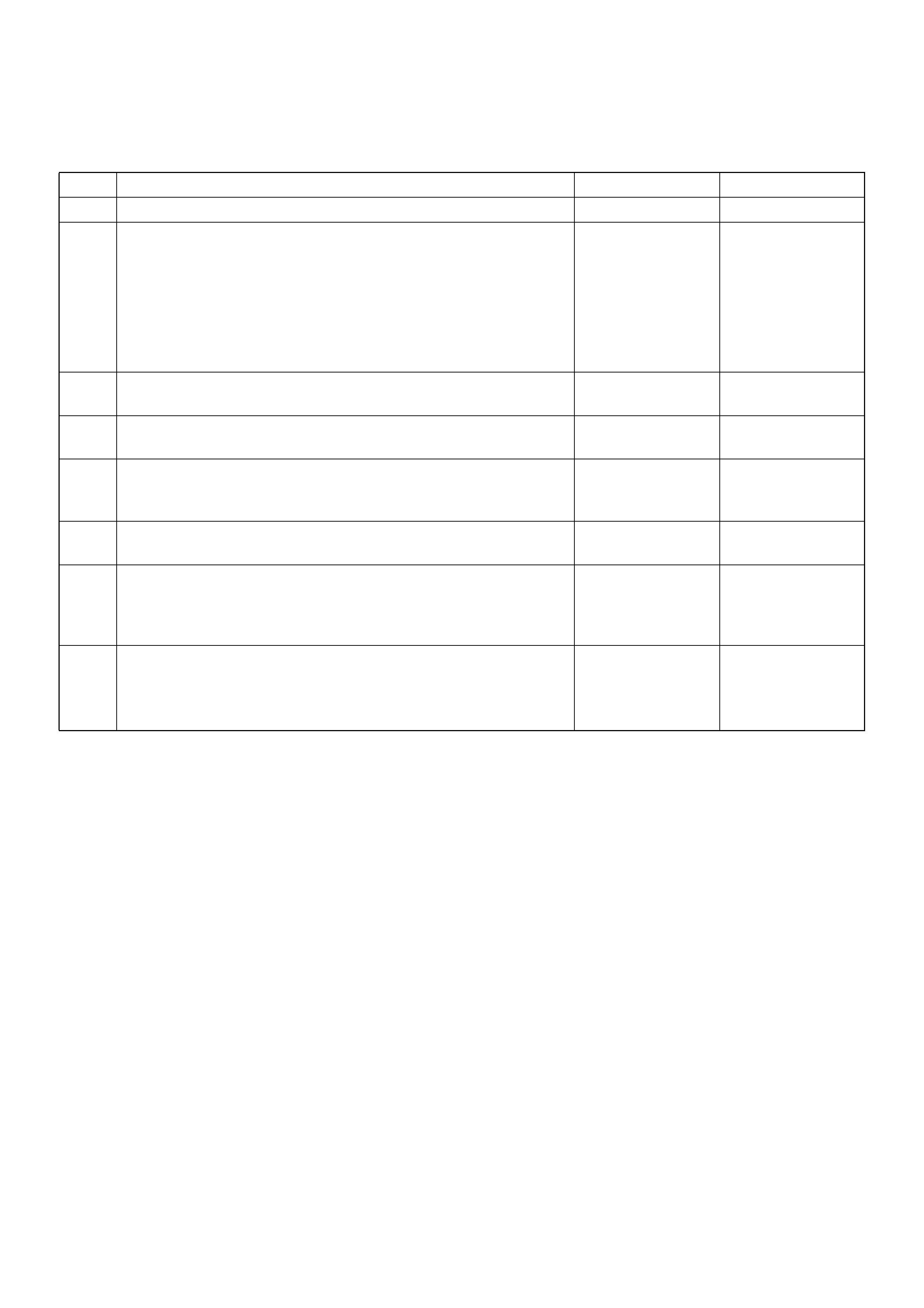

Chart A-4 Abnormal Brake Pedal Feel

Step Action Yes No

1 Is ABS working? Go to Step 2 Go to Step 4

2 Is vehicle speed under 10 km/h? Go to Step 3 Normal.

3 Are the wheel speed sensor outputs correct? (Chart C-1 or TC-1)

Go to Step 4

Replace sensor

or repair

harness.

Go to Step 6

4 Is the 4WD/TOD control unit functioning correctly?

Go to Step 5

Replace 4WD /

TOD control

unit or repair

harness.

Go to Step 6

5 Do the EHCU ground circuits have less than 5 Ohms resistance

to the battery negative terminal? Replace EHCU.

Go to Step 6 Repair.

Go to Step 6

6 Reconnect all components, ensure all components are properly

mounted.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 6

Step Action Yes No

1 Is the stop lamp actuated when the brake pedal is depressed? Go to Step 2 Go to Step 3

2 1. Turn the ignition switch off.

2. Disconnect the EHCU connector.

3. Actuate the stop lamp switch.

Is the voltage between EHCU connector terminals 13 & 7 less

than battery voltage? Go to Step 4

Repair harness

between brake

SW and EHCU.

Go to Step 6

3 Is stop lamp fuse OK?

Go to Step 5

Replace sto p

lamp fuse.

Go to Step 6

4 Is there less than 5 ohms resistance between EHCU connector

terminal 7 and the battery negative terminal? Go to Step 6

Repair ground

circuit

Go to Step 6

5 Is brake SW OK? Repair stop

lamp harness.

Go to Step 6

Replace brake

SW.

Go to Step 6

6 Reconnect all components, ensure all components are properly

mounted.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 6

Chart A-5, TA-5 EHCU Is Heard Operating While Not Braking

Step Action Yes No

1 Is this the first vehicle movement after engine start? System

Self-Test.

Sound is

Normal. Go to Step 2

2 Is vehicle speed under 10 km/h? System

Self-Test.

Sound is

Normal. Go to Step 3

3 Does the noise occur during any of the following conditions:

• Transmission downshift or clutch operation.

• Driving on low road friction roads or rough roads.

• Performing a high-speed turn.

• When operating electrical switches.

• When engine exceeds 5000 rpm.

ABS EHCU may

sometimes be

actuated under

these conditions

even when brake

pedal is not

applied. Go to Step 4

4 Is there play in each or any sensor/wheel speed sensor rings? Repair.

Go to Step 7 Go to Step 5

5 Is there any damage or powdered iron residue sticking to any

sensor/wheel speed sensor ring? Repair.

Go to Step 7 Go to Step 6

6 Is each sensor output correct? (Refer to chart C-1 or TC-1). Check harness/

connector for

suspected open

circuit

If no open

circuit is found,

replace Coil

integrated

module.

Go to Step 7 Repair.

Go to Step 7

7 Reconnect all components, ensure all components are properly

mounted.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 7

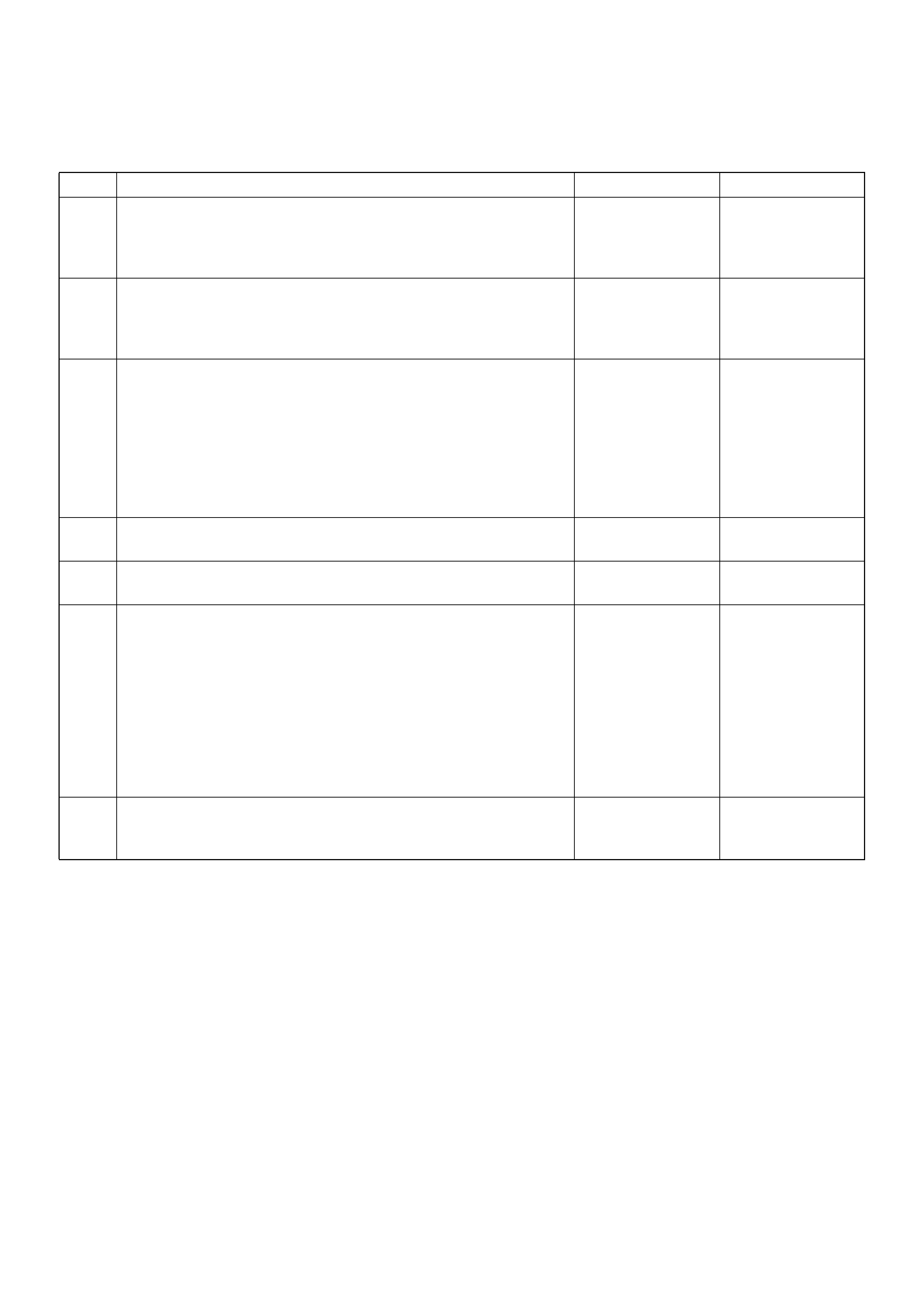

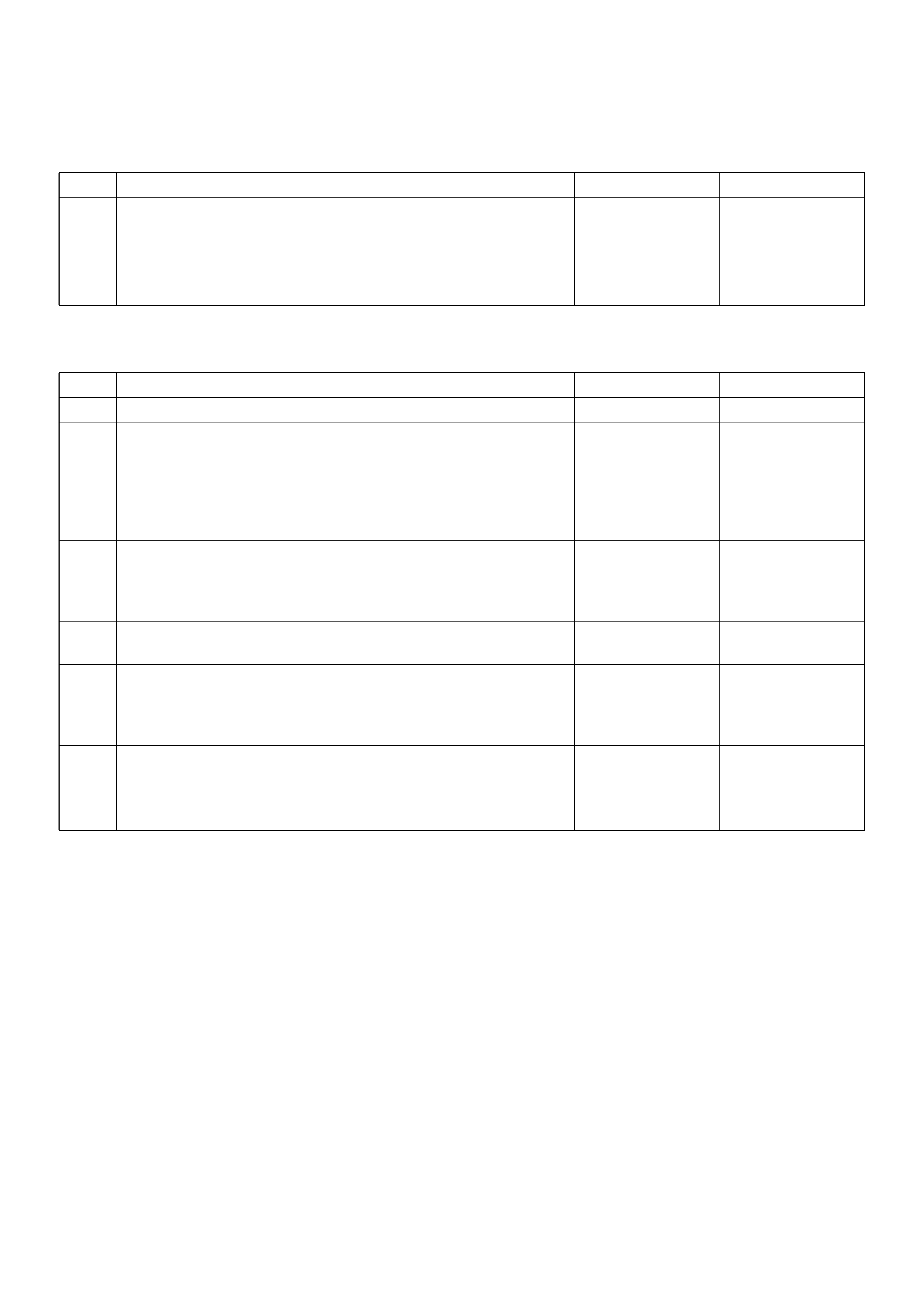

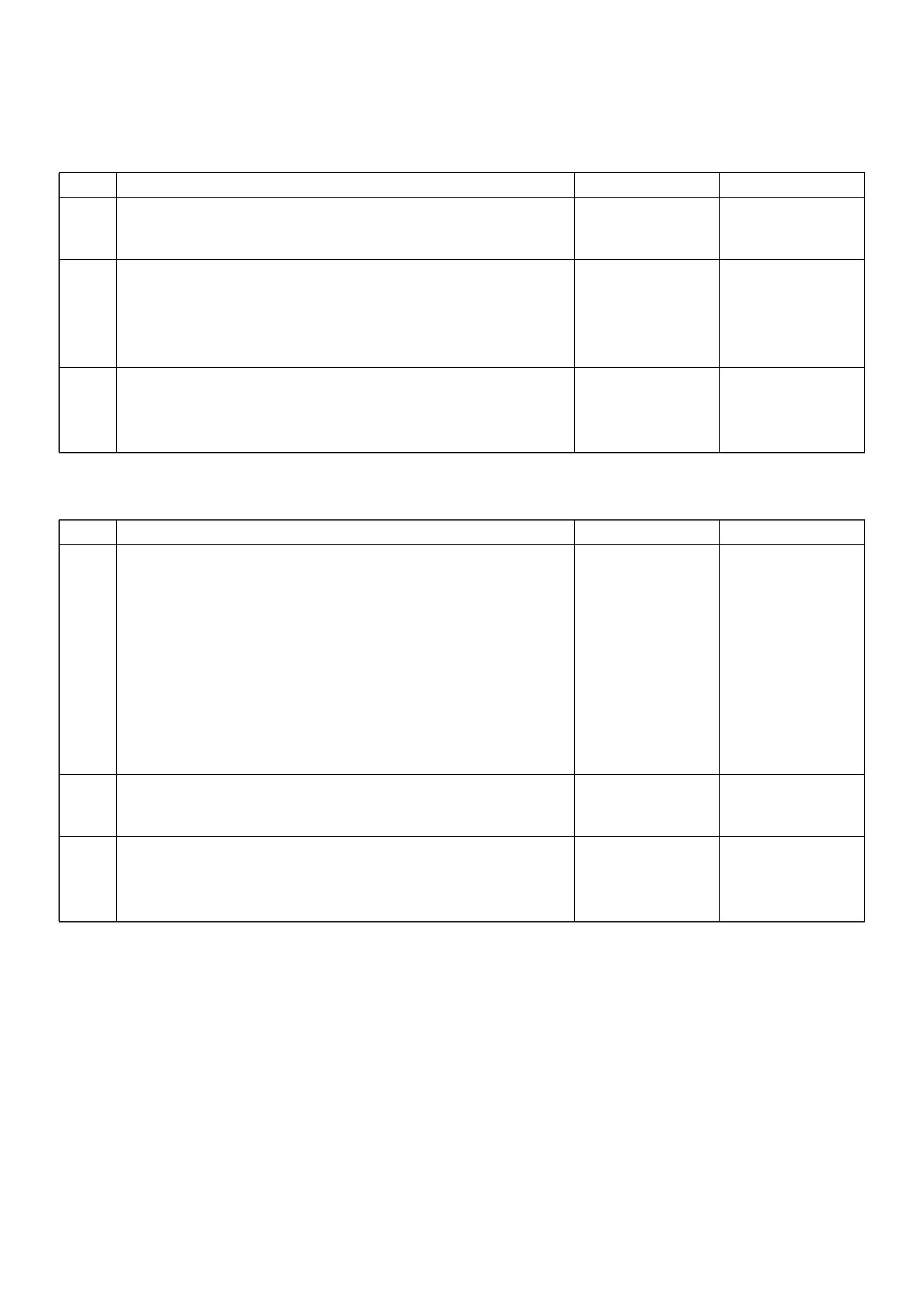

Diagnostic Trouble Codes

Choose and trace an appropriate flowchart by the

numbers listed below to find fault and repair.

Diagnostic Trouble

Code (DTC) Diagnosis Item Chart

No.

————

C0285 4WD/TOD Control Unit 4WD signal failure Wiring B-8

C0271 RAM read/write error

Coil

Integrated

Module B-2

C0272 ROM check sum er ror

C0270 CPU function error

C0273 Inoperative isolation item

C0284 Loop time overrun

C0277 Low ignition voltage Wiring B-3

C0278 High ignition voltage

C0269 Excessive dump time Coil

Integrated

Module

B-4

C0274 Excessive isolation time B-5

C0276 G-Sen so r Fail ur e B-6

C0281 Brake switch Failure B-7

C0282 Open or shorted 4¥4 input signal (Without TOD) Wiring B-8

C0267 Open motor circuit or shorted ECU output Motor B-9

C0268 St a lled motor or open ECU output

C0265 Open relay circuit Relay B-10

C0266 Shorted relay circuit

C0245 FL Open isolation solenoid or shorted ECU output

Solenoid

B-11

C0247 FL Shorted isolation solenoid or open ECU output

C0246 FL Open dump solenoid or shorted ECU output B-12

C0248 FL Shorted dump solenoid or open ECU output

C0241 FR Open isolation solenoid or shorted ECU output B-13

C0243 FR Shorted isolation solenoid or open ECU output

C0242 FR Open dump solenoid or shorted ECU output B-14

C0244 FR Shorted dump solenoid or open ECU output

C0251 Rear Open isolation solenoid or shorted ECU output B-15

C0253 Rear Shorted isolation solenoid or open ECU output

C0252 Rear Open dum p solenoi d or shor ted ECU outp ut B-16

C0254 Rear Shorted dump solenoid or open ECU output

C0225 FL Open or shorted sensor

Sensor or

Wiring

B-17

C0221 FR Open or shorted sensor B-18

C0235 Rear Open or shorted sensor B-19

C0226 FL Missing sensor signal B-20

C0227 FL Sensor signal dropout

C0222 FR Missing sensor signal B-21

C0223 FR Sensor signal dropout

C0236 Rear Missing sensor signal B-22

C0237 Rear Sensor signal dropout

C0229 Simultaneous dropout of front sensor signal B-23

C0238 Wheel speed error Vehicle or

Sensor B-24

C0286 Shorted indicator lamp Wiring —

C0287 Open or Shorted TOD Control Unit Circuit (With

TOD) Wiring B-25

Diagnostic Trouble

Code (DTC) Diagnosis Item Chart

No.

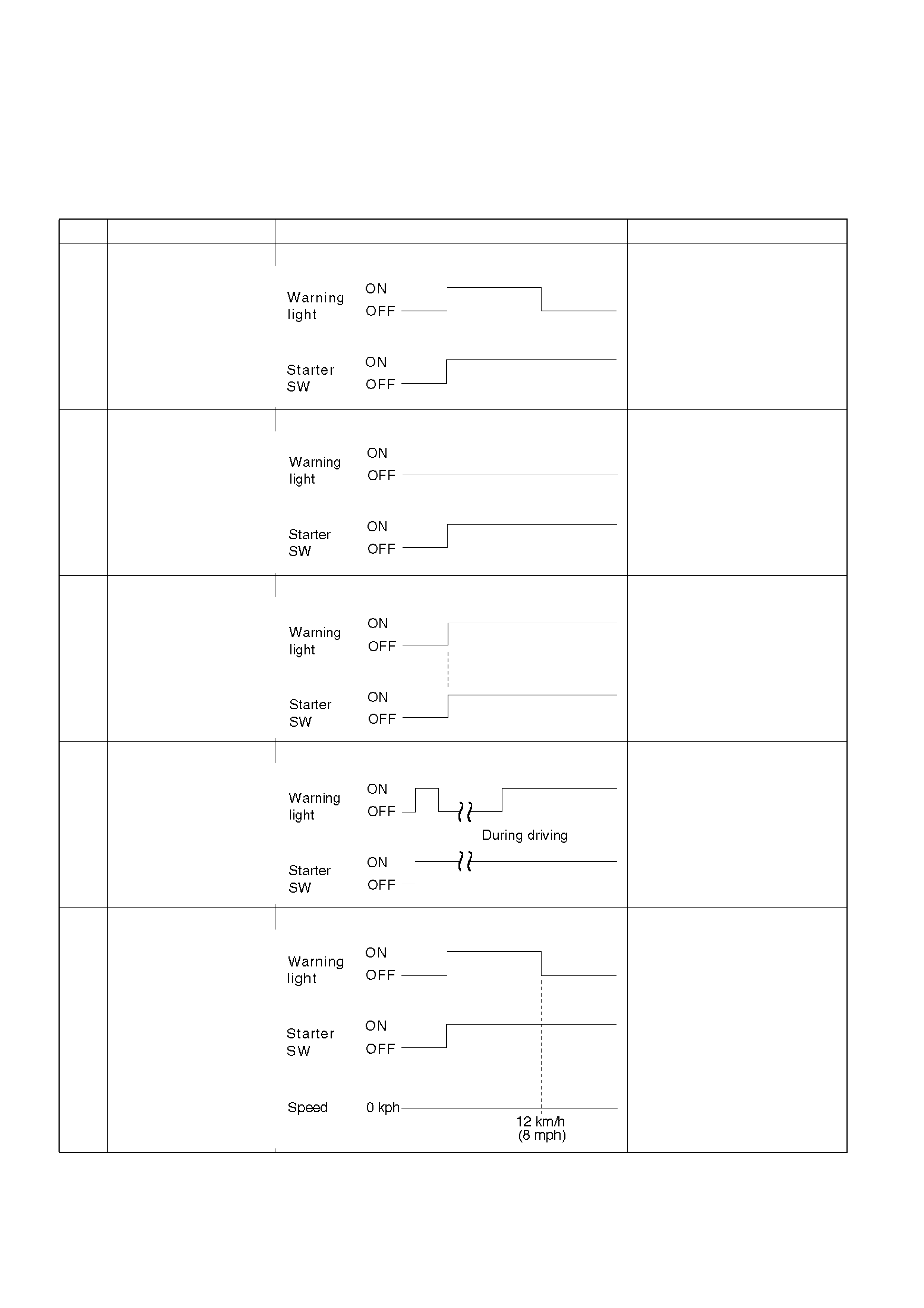

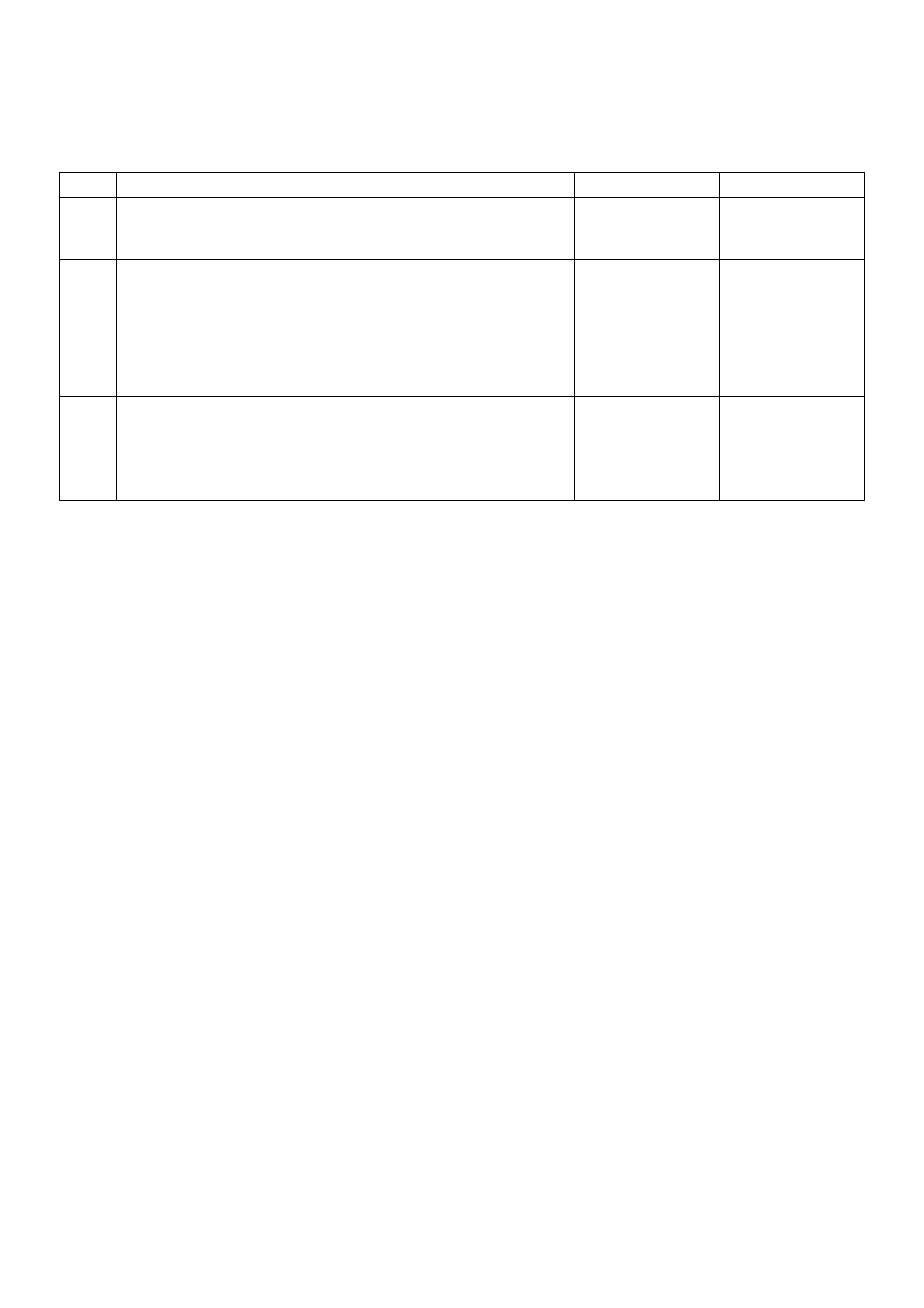

Diagnosis By “ABS" Warning Lamp

Illumination Pattern

In the event that there is abnormality in the “ABS"

warning lamp illumination pattern while the key is in the

ON position or if the warning lamp is actuated during

driving, trouble should be diagnosed on a illumination

pattern basis as follows:

No. Condition “ABS" Warning Lamp Illumination Pattern Diagnostic

1 Normal “ABS” warning

lamp operation Normal - No DTCs stored

2 Warning lamp is not lit Warning lamp circuit failure

ÆGo to Chart B-1

3 W arning lamp remains

ON Diagnostic trouble codes are

stored.

Display diagnostic trouble

codes with Tech 2 and

diagnose on a code basis

according to the flow charts.

4 Warning lamp is

actuated whil e driv ing Diagnostic trouble codes are

stored.

Display diagnostic trouble

codes with Tech 2 and

diagnose on a code basis

according to the flow charts.

5 Warning lamp goes at

12 km/h (8 mph) or

higher (After repairing

the faulty part)

After repairing the fault, the

warning lamp does not

extinguish even though the

DTC/s have been cleared with

Tech 2

Turn the ignition switch to the

ON position and drive the

vehicle at 12 km/h or higher to

extinguish the warning lamp.

Chart B-1 Warning Lamp (W/L) is not activated when the ignition is first turned ON .

Chart B-2 CPU Error (D TC C0271, C0272, C0273, C0284)

Step Action Yes No

1 Has the W/L fuse failed? Replace fuse.

Go to Step 5 Go to Step 2

2 Has the W/L bulb failed? Replace W/L

bulb.

Go to Step 5 Go to Step 3

3 1. Turn the key off.

2. Disconnect coil integrated module connector (C-4).

3. Turn the key ON.

Is the check voltage between coil integrated module connector

(C-4) terminals 6 and 7 less than battery voltage? Go to Step 4

Repair harness

and connector.

Go to Step 5

4 Is there continuity between coil integrated module connector

(C-4) terminals, 1 and 7 and body ground?. No fault found:

Replace EHCU.

Go to Step 5

Repair harness

and connector.

Go to Step 5

5 Reconnect all components, ensure all components are properly

mounted.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 5

Step Action Yes No

1 1. Turn the key off.

2. Disconnect coil integrated module connector.

3. Inspe ct coil int egr ate d module g round .

Is the resistance between the coil integrated module connector

terminals, 2 (C-5) and 7 (C-4) and battery negative terminal less

than 5 Ohms? Go to Step 2

Repair the body

ground

harness.

Go to Step 3

2 1. Turn the key off, connect the coil integrated module

connector.

2. Erase the trouble code.

3. Turn Ignition off, then on, to perform system self-check.

4. If warning lamp remains on, display trouble codes once

again.

Are any of the folowing DTCs set? - C0271, C0272, C0273,

C0284 Replace EHCU.

Go to Step 3

Inspect in

accordance with

the DTC displayed.

3 1. Reconnect all components, ensure all components are

properly mounted.

2. Clear any DTCs.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 3

Chart B-3 Low or High Ignition Voltage (DTC C0277, 0278 )

Char t B-4 Excessive Dump Time (DTC C0269)

Chart B-5 Exc essi ve Isolation Time (DTC C0274)

Step Action Yes No

1 Is battery voltage to specification?

Go to Step 2

Charge or

replace battery.

Go to Step 2

2 1. Turn the key off.

2. Disconnect coil integrated module connector.

3. Turn the key on.

Is the voltage between coil integrated module connector (C-4)

terminals 1 and 7, higher than 10V?

Check harness

connector for

suspected

disconnection

Fault found:

Repair, and

perform system

self-check

No fault found:

replace EHCU.

Go to Step 3

Repair harness

or connector.

Go to Step 3

3 1. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 3

Step Action Yes No

1 Check for anything ca us ing exten ded AB S act ivati on, su ch as

locked brakes or an erratic speed sensor signal.

Was a problem found? Repair or Replace Go to Step 2

2 1. The key turned off.

2. Replace EHCU.

3. Reconnect all components, ensure all components are

properly mounted.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 2

Step Action Yes No

1 Check for anything ca us ing exten ded AB S act ivati on, su ch as

locked brakes or an erratic speed sensor signal.

Was a problem found? Repair or Replace Go to Step 2

2 1. The key turned off.

2. Replace EHCU.

3. Reconnect all components, ensure all components are

properly mounted.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 2

Chart B-6 G-Sensor Output Failure (DTC C0276 )

Chart B-7 Brake Switch Failure (DTC C0281)

Step Action Yes No

1 1. Turn the key off.

2. Replace EHCU.

3. Reconnect all components, ensure all components are

properly mounted.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 1

Step Action Yes No

1 Is the stop lamp actuated when the brake pedal is depressed? Go to Step 2 Go to Step 4

2 1. Turn the key off.

2. Disc onn ec ted co il int egrate d modu le con nector.

Is the voltage at coil integrated module connector (C-4) terminals

13 to 7 when brake pedal is depressed less than battery voltage?

Go to Step 3

Harness

between brake

SW and coil

integrated

module is faulty.

Go to Step 6

3 Do C-5 connector pin 2, and C-4 connector pin 7 have less than

5 ohms resistance to the battery negative terminal? No fault found:

replace EHCU.

Go to Step 6 Repair.

Go to Step 6

4 Is stop lamp fuse OK? Go to Step 5 Replace.

Go to Step 6

5 Is the brake SW functioning correctly? Repair the stop

lampharness.

Go to Step 6 Replace.

Go to Step 6

6 1. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 6

Chart B-8 4WD/TOD Control Unit Failure( DTC C0285), 4WD State Input Signal Failure (DTC

C0282)

Chart B - 9 Pump Motor Failure (DT C C0267, C0268)

Step Action Yes No

1 Remove coil integrated module connector.

Is there continuity between coil integrated module connector

(C-4) terminal 8 and terminal 14 at the 4WD/TOD Control Unit? Go to Step 2 Repair.

Go to Step 3

2 Is the 4WD/TOD control unit OK?

Replace EHCU.

Go to Step 3

Replace 4WD/

TOD control

unit.

Go to Step 3

3 1. Reconnect all components, ensure all components are

properly mounted.

2. Clear DTCs.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 3

Step Action Yes No

1 1. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the voltage between terminal 1 of the coil integrated

module connector (C-5) and body ground.

Is the voltage equal to battery voltage?

Go to Step 2

Repair fuse/

harness

between battery

and coil

integrated

module

connector (C-5)

terminal 1.

Go to Step 5

2 Is the harness from the hydraulic unit connected to the coil

integra ted mod ule conne ct or ? Go to Step 3

Connect to the

connector.

Go to Step 3

3 Is the harness from the hydraulic unit OK? Go to Step 4 Replace EHCU.

Go to Step 5

4 Is the resistance of hydraulic unit connector terminals 1 and 2

between 0.2 and 1.0 ohms? Replace EHCU.

Go to Step 5 Replace EHCU.

Go to Step 5

5 1. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 5

Chart B-10 EHCU Valve Relay Failure (DTC C0265, C0266 )

Chart B-11 FL Isolation Solenoid Coil Failure (DTC 41 C0245, C024 7)

Chart B-12 FL Dump Solenoid Coil Failure (DTC C0246, C0248)

Step Action Yes No

1 1. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the voltage between terminal 1 of the coil integrated

module connector (C-5) and body ground.

Is the voltage equal to battery voltage?

Replace EHCU.

Go to Step 2

Repair fuse and

harness coil

integrated

module

connector (C-5)

terminal 1 and

battery.

Go to Step 2

2 1. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 2

Step Action Yes No

1 Was the “EHCU Connector Pin–out Checks" performed?

Go to Step 2

Go to “EHCU

Connector Pin–out

Checks."

2 1. Turn the key switch to off.

2. Disconnect the 2–way EHCU connector (C–5) from the

EHCU.

3. Inspect the connector for damage or corrosion.

Is the connector free from damage or corrosion? Go to Step 3

Repair the

connector . Repeat

the “Basic

Diagnostic Flow

Chart."

3 1. Replace the Coil Integrated Module.

2. Reconnect all component, ensure all components are

properly mounted.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 3

Step Action Yes No

1 Was the “EHCU Connector Pin–out Checks" performed?

Go to Step 2

Go to “EHCU

Connector Pin–out

Checks."

2 1. Turn the key switch to off.

2. Disconnect the 2–way EHCU connector (C–5) from the

EHCU.

3. Inspect the connector for damage or corrosion.

Is the connector free from damage or corrosion? Go to Step 3

Repair the

connector . Repeat

the “Basic

Diagnostic Flow

Chart."

3 1. Replace the Coil Integrated Module.

2. Reconnect all component, ensure all components are

properly mounted.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 3

Chart B-13 FR Isolation Solenoid Coil Failure (DTC C0241, C0243 )

Chart B-14 FR Dump Solenoid Coil Failure (DTC C0242, C0244)

Chart B-15 Rear Isolation Solenoid Coil Failure (DTC C0251, C0253)

Step Action Yes No

1 Was the “EHCU Connector Pin–out Checks" performed?

Go to Step 2

Go to “EHCU

Connector Pin–out

Checks."

2 1. Turn the key switch to off.

2. Disconnect the 2–way EHCU connector (C–5) from the

EHCU.

3. Inspect the connector for damage or corrosion.

Is the connector free from damage or corrosion? Go to Step 3

Repair the

connector . Repeat

the “Basic

Diagnostic Flow

Chart."

3 1. Replace the Coil Integrated Module.

2. Reconnect all component, ensure all components are

properly mounted.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 3

Step Action Yes No

1 Was the “EHCU Connector Pin–out Checks" performed?

Go to Step 2

Go to “EHCU

Connector Pin–out

Checks."

2 1. Turn the key switch to off.

2. Disconnect the 2–way EHCU connector (C–5) from the

EHCU.

3. Inspect the connector for damage or corrosion.

Is the connector free from damage or corrosion? Go to Step 3

Repair the

connector . Repeat

the “Basic

Diagnostic Flow

Chart."

3 1. Replace the Coil Integrated Module.

2. Reconnect all component, ensure all components are

properly mounted.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 3

Step Action Yes No

1 Was the “EHCU Connector Pin–out Checks" performed?

Go to Step 2

Go to “EHCU

Connector Pin–out

Checks."

2 1. Turn the key switch to off.

2. Disconnect the 2–way EHCU connector (C–5) from the

EHCU.

3. Inspect the connector for damage or corrosion.

Is the connector free from damage or corrosion? Go to Step 3

Repair the

connector . Repeat

the “Basic

Diagnostic Flow

Chart."

3 1. Replace the Coil Integrated Module.

2. Reconnect all component, ensure all components are

properly mounted.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 3

Chart B-16 Rear Dump Solenoid Coil Failure (DTC C0252, C0254)

Chart B-17 FL Speed Sensor Open or Shorted (DTC C0225)

Step Action Yes No

1 Was the “EHCU Connector Pin–out Checks" performed?

Go to Step 2

Go to “EHCU

Connector Pin–out

Checks."

2 1. Turn the key switch to off.

2. Disconnect the 2–way EHCU connector (C–5) from the

EHCU.

3. Inspect the connector for damage or corrosion.

Is the connector free from damage or corrosion? Go to Step 3

Repair the

connector . Repeat

the “Basic

Diagnostic Flow

Chart."

3 1. Replace the Coil Integrated Module.

2. Reconnect all component, ensure all components are

properly mounted.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 3

Step Action Yes No

1 1. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the resistance between coil integrated module

connector (C-4) terminals 2 and 10.

Is the resistance between 0.7k and 1.5k ohms?

Replace coil

integrated

module.

Go to Step 3

Check for faults

in harness

between speed

sensor and coil

integrated

module.

Repair, and

perform system

self-check.

If no fault is found

with harness

Go to Step 2

2 Measure the FL speed sensor resistance at the sensor

connector.

Is the resistance between 0.7k and 1.5k ohms? Go to Step 3

Replace

sensor.

Go to Step 3

3 1. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 3

Chart B-18 FR Speed Sensor Open or Shorted (DTC C0221

Step Action Yes No

1 1. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the resistance between coil integrated module

connector (C-4) terminals 3 and 11.

Is the resistance between 0.7k and 1.5k ohms?

Replace coil

integrated

module.

Go to Step 3

Check for faults

in harness

between speed

sensor and coil

integrated

module.

Repair, and

perform system

self-check.

If no fault is found

with harness

Go to Step 2

2 Measure the FR speed sensor resistance at the sensor

connector.

Is the resistance between 0.7k and 1.5k ohms? Go to Step 3

Replace

sensor.

Go to Step 3

3 1. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 3

Chart B-19 Rear Speed Sensor Open or Shorted (DTC C0235)

Step Action Yes No

1 1. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the resistance between coil integrated module

connector (C-4) terminals 4 and 12.

Is the resistance between 1.0k and 1.7k ohms?

Replace coil

integrated

module.

Go to Step 3

Check for faults

in harness

between speed

sensor and coil

integrated

module.

Repair, and

perform system

self-check.

If no fault is found

with harness

Go to Step 2

2 Measure the Rear speed sensor resistance at the sensor

connector.

Is the resistance between 1.0k and 1.7k ohms? Go to Step 3

Replace

sensor.

Go to Step 3

3 1. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 3

Chart B-20 FL Speed Sensor Signal Missing (DTC C0226, C0227)

NOTE: After clearing the DTCs with Tech 2, drive the

vehicle above 12km/h and ensure the “ABS” warning

lamp goes out.

Step Action Yes No

1 1. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the FL speed sensor resistance between coil

integrated module connector (C-4) terminals 2 and 10.

Is the resistance between 0.7k and 1.5k ohms? Go to Step 2 Go to Step 3

2 Is there any movement in the sensor/sensor rotor? Repair.

Go to Step 6 Go to Step 4

3 Measure the FL speed sensor resistance at the sensor

connector.

Is the resistance between 0.7k and 1.5k ohms?

Repair harness

abnormality

between

sensors and

coil integrated

module.

Go to Step 6

Replace

sensor.

Go to Step 6

4 Is there any damage and powered iron sticking to sensor/sensor

ring? Repair.

Go to Step 6 Go to Step 5

5 Is sensor output normal? (Chart C-1-1 or TC-1) Check for faults

in harness

between speed

sens or an d coi l

integrated

module.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to Step 6

Replace

sensor.

Go to Step 6

6 1. Reconnect all components, ensure all components are

properly mounted.

2. Clear the DTCs.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 6

Chart B-21 FR Speed Sensor Signal Missing (DTC C0222, C0223)

NOTE: After clearing the DTCs with Tech 2, drive the

vehicle above 12km/h and ensure the “ABS” warning

lamp goes out.

Step Action Yes No

1 1. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the FR speed sensor resistance between coil

integrated module connector (C-4) terminals 3 and 11.

Is the resistance between 0.7k and 1.5k ohms? Go to Step 2 Go to Step 3

2 Is there play sensor/sensor rotor? Repair.

Go to Step 6 Go to Step 4

3 Measure the FR speed sensor resistance at the sensor

connector.

Is the resistance between 0.7k and 1.5k ohms?

Repair harness

abnormality

between

sensors and

coil integrated

module.

Go to Step 6

Replace

sensor.

Go to Step 6

4 Damage and powered iron sticking to sensor/sensor ring? Repair.

Go to Step 6 Go to Step 5

5 Is sensor output normal? (Chart C-1-2 or TC-1) Check for faults

in harness

between speed

sens or an d coi l

integrated

module.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to Step 6

Replace

sensor.

Go to Step 6

6 1. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 6

Chart B-22 Rear Speed Sensor Signal Missing (DTC C0236, C0237)

NOTE: After clearing the DTCs with Tech 2, drive the

vehicle above 12km/h and ensure the “ABS” warning

lamp goes out.

Step Action Yes No

1 1. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the Rear speed sensor resistance between coil

integrated module connector (C-4) terminals 4 and 12.

Is the resistance between 1.0k and 1.7k ohms? Go to Step 2 Go to Step 3

2 Is there play sensor/sensor rotor? Repair.

Go to Step 6 Go to Step 4

3 Measure the rear speed sensor resistance at the sensor

connector.

Is the resistance between 1.0k and 1.7k ohms?

Repair harness

abnormality

between

sensors and

coil integrated

module.

Go to Step 6

Replace

sensor.

Go to Step 6

4 Damage and powered iron sticking to sensor/sensor ring? Repair.

Go to Step 6 Go to Step 5

5 Is sensor output normal? (Chart C-1-3 or TC-1) Check for faults

in harness

between speed

sens or an d coi l

integrated

module.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to Step 6

Replace

sensor.

Go to Step 6

6 1. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step complet ed?

Repeat the “Basic

diagnostic flow

chart" Go to Step 6

Chart B-23 Simultaneous Drop-out of Front Speed Sensor Signal (DTC C0229)

NOTE: After clearing the DTCs with Tech 2, drive the

vehicle above 12km/h and ensure the “ABS” warning

lamp goes out.

Step Action Yes No

1 1. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the FL speed sensor resistance between coil

integrated module connector (C-4) terminals 2 and 10.

Is the resistance between 0.7k and 1.5k ohms? Go to Step 2 Go to Step 3

2 Measure the FR speed sensor resistance between coil integrated

module connector (C-4) terminals 3 and 11.

Is the resistance between 0.7k and 1.5k ohms? Go to Step 5 Go to Step 4

3 Measure the FL speed sensor resistance at the sensor

connector.

Is the resistance between 0.7k and 1.5k ohms?

Repair harness

abnormality