SECTION 5B - ANTI-LOCK BRAKE SYSTEM (MY2002)

Service Precaution

Electronic Hydraulic Control Unit

Electronic Hydraulic Control Unit and

Associated Parts

Removal

Disassembled View

Disassembly

Reassembly

Installation

Front Wheel Speed Sensor

Front Wheel Speed Sensor and

Associated Parts

Removal

Inspection and Repair

Installation

Rear Wheel Speed Sensor

Removal

Inspection and Repair

Installation

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

Techline

Electronic Hydraulic Control Unit

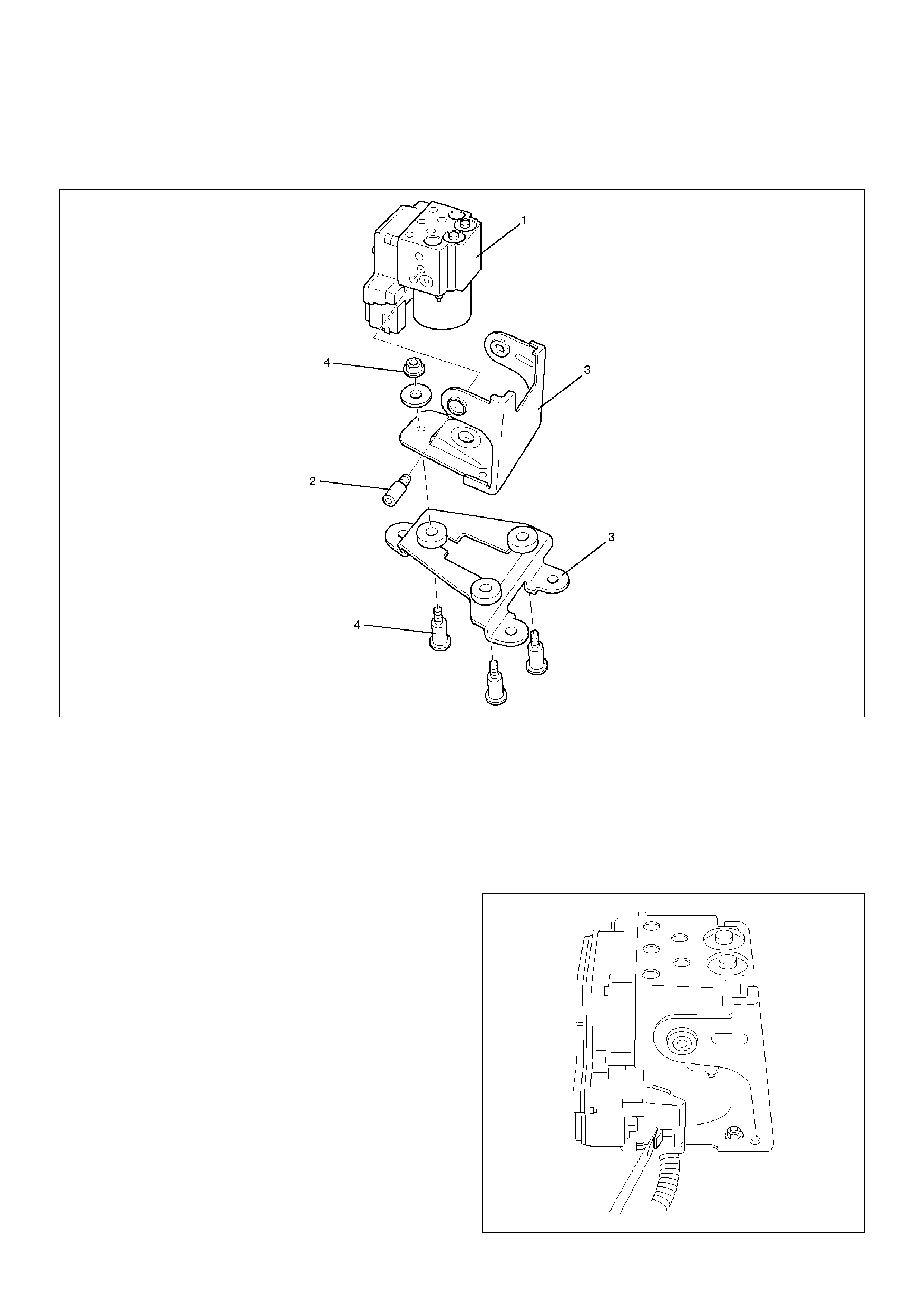

Electronic Hydraulic Control Unit and Associated Parts

350RW017

EndOFCallout

Removal

1. Remove brake pipes.

• After disconnecting brake pipe, cap or tape the

openings of the brake pipe to prevent the entry of

foreign matter.

2. Remove three bracket fixing bolts.

3. Disconnect red clip from harness connector

4. Remove harness connector.

5. Remove EHCU ASM.

6. Remove EHCU.

350RW018

Legend

(1) EHCU

(2) Bolt

(3) Bracket

(4) Bolt and Nut

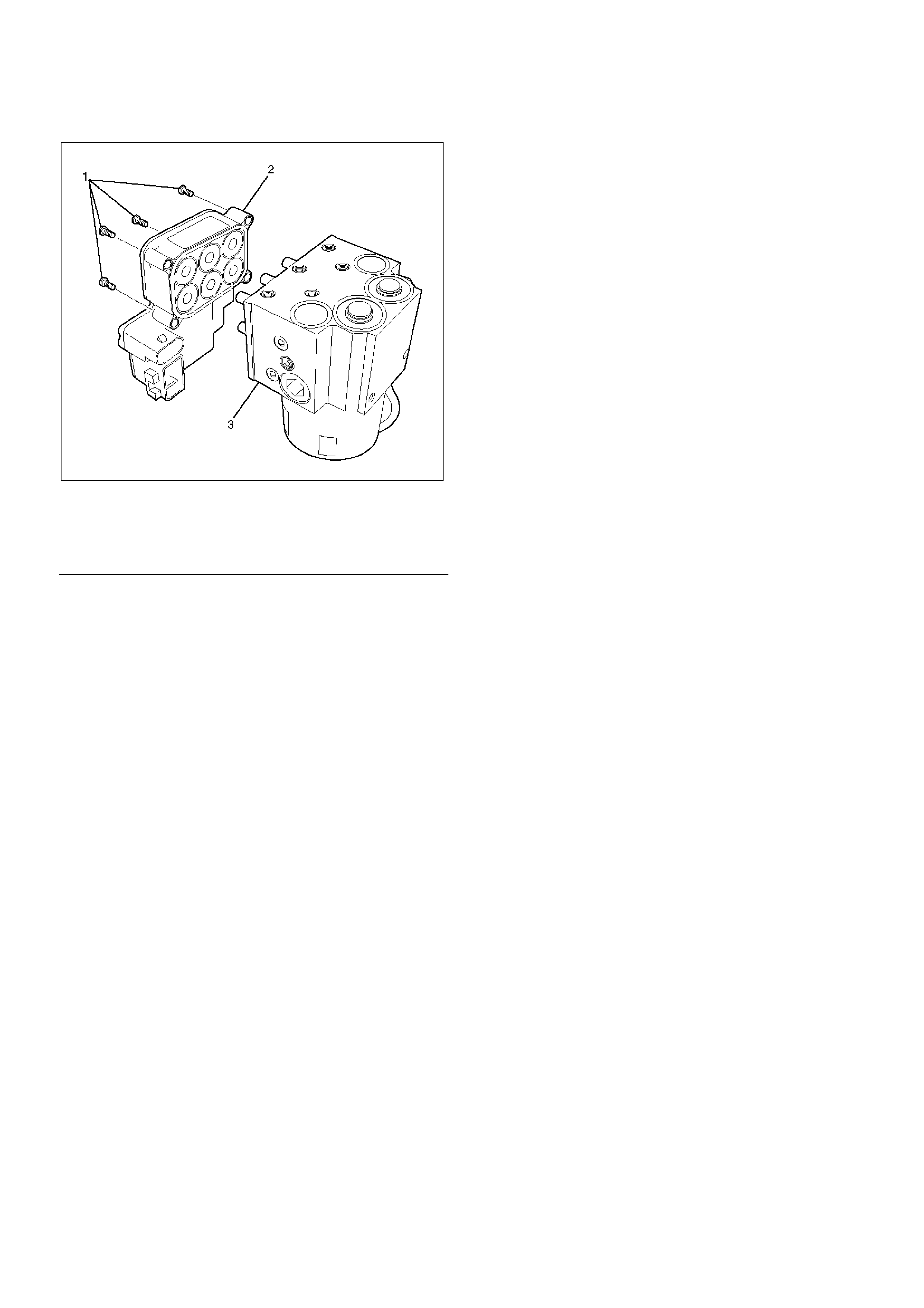

Disassembled View

350RW025

Disassembly

1. Remove fixing bolts from EHCU.

2. Remove coil integrated module from hydraulic unit.

Reassembly

To reassemble, follow the disassembly steps in the

reverse order, noting the following points:

Torque:

1. Fixing bolts: 4.4 N·m (4.5 kg·cm/39 lb in)

Installation

To install, follow the removal steps in the reverse order,

noting the following points:

Torque:

• Hydraulic unit fixing nuts : 22 N·m (2.2 kg·m/16

lbft)

• Ground cable : 14 N·m (1.4 kg·m/10 lbft)

1. Brake pipe (joint bolts) : 16 N·m (1.6 kg·m/12

lbft)

After installing the hydraulic unit, bleed brakes

completely. See Hydraulic Brakes in Power–

assisted brake system section.

Legend

(1) Fixing Bolts

(2) Coil Integrated Module

(3) Hydraulic Unit (H/U)

Front Wheel Speed Sensor

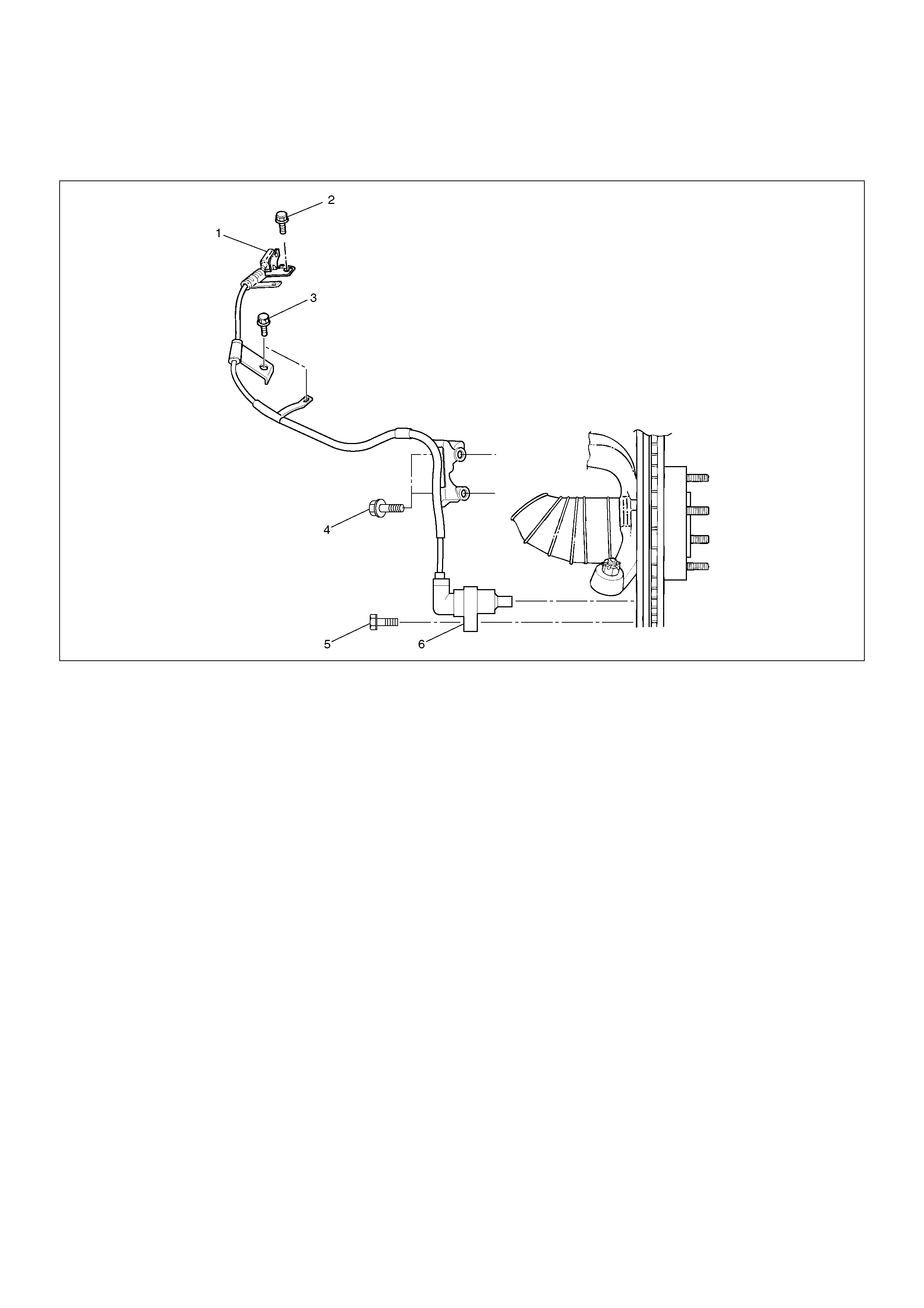

Front Wheel Speed Sensor and Associated Parts

350R200004

EndOFCallout

Removal

1. Remove speed sensor connector.

2. Remove sensor cable fixing bolt (Frame side).

3. Remove sensor cable fixing bolt (Upper arm side).

4. Remove sensor cable fixing bolt (Knuckle side).

5. Remove speed sensor fixing bolt.

6. Remove speed sensor.

Inspection and Repair

1. Check the speed sensor pole for presence of

foreign materials; remove any dirt, etc.

2. Check the pole for damage; replace speed sensor if

necessary.

3. Check the speed sensor cable for short or open

circuit, and replace with a new one if necessary.

To check for cable short or open, bend or stretch the

cable while checking for continuity.

4. Check the sensor ring for damage including tooth

chipping, and if damaged, replace the sensor ring

assembly. Refer to removal of the sensor ring in

Section 4C “Front hub and disc".

Installation

1. Install speed sensor and take care not to hit the

speed sensor pole during installation.

2. Install speed sensor fixing bolt and tighten the fixing

bolt to the specified torque.

Torque: 11 N·m (1.1 kg·m/95 lbin)

3. Install speed sensor cable fixing bolt (Knuckle side

and Upper arm side) and tighten the fixing bolt to

the specified torque.

Torque : 24 N·m (2.4 kg·m/17 lbft)

4. Install speed sensor cable fixing bolt (Frame side)

and tighten the fixing bolt to the specified torque.

Torque : 6 N·m (0.6 kg·m/52 lbft)

1. Confirm that a white line marked on the cable is not

twisted when connecting the speed sensor cable.

5. Install speed sensor connector.

Legend

(1) Speed Sensor Connector

(2) Sensor Cable Fixing Bolt (Frame side)

(3) Sensor Cable Fixing Bolt (Upper Arm side)

(4) Sensor Cable Fixing Bolt (Knuckle side)

(5) Speed Sensor Fixing Bolt

(6) Speed Sensor

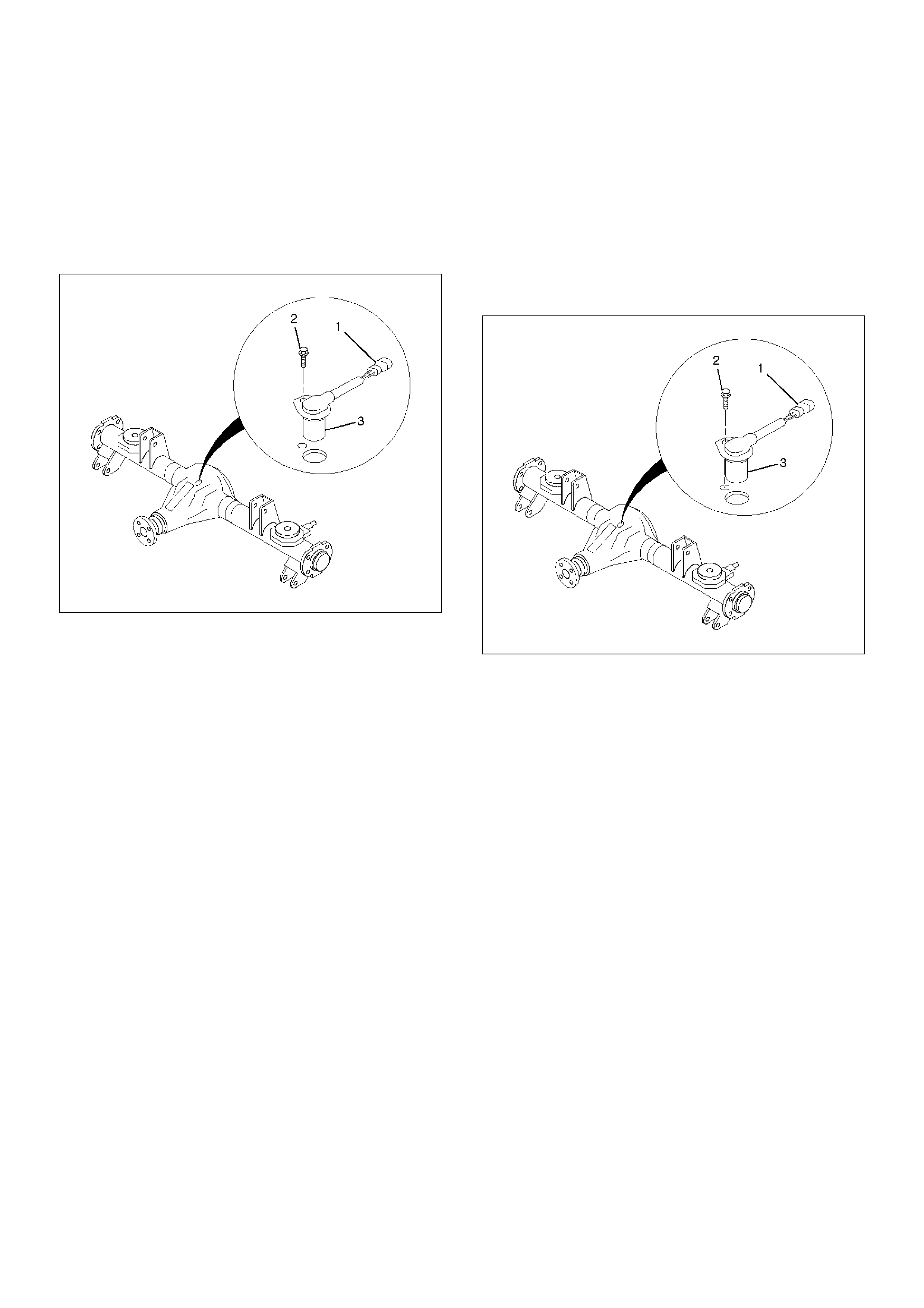

Rear Wheel Speed Sensor

Removal

1.Disconnect harness connector (1).

2.Remove sensor fixing bolt (2) .

3.Remove speed sensor (3).

350RX003

Inspection and Repair

1.Check speed sensor pole for presence of foreign

materials; remove any dirt, etc.

2.Check the pole for damage, and replace speed

sensor if necessary.

3.Check speed sensor cable for short or open, and

replace with a new one if necessary. To check for

cable short or open, bend or stretch the cable while

checking for continuity.

4.Check the sensor ring for damage including tooth

chipping, and if damaged, replace the axle shaft

assembly. Refer to removal of the sensor ring in

Section “Differential (Rear)".

Installation

1. Install speed sensor (3).

2. Tighten the sensor fixing bolt (2) to the specified

torque.

1. Torque : 24 N·m (2.4 kg·m/17 lbft)

3. Connect harness connector (1).

350RX003