SECTION 5C - POWER-ASSISTED BRAKE SYSTEM (MY2002)

Service Precaution

General Description

Diagnosis

General Diagnosis

Hydraulic Brakes

Filling Master Cylinder Reservoir

Deterioration of Brake Fluid

Leakage of Brake Fluid

Bleeding Brake Hydraulic System

Flushing Brake Hydraulic System

Brake Pipes and Hoses

Brake Hose Inspection

Front Caliper Brake Hose

Front Caliper Brake Hose and

Associated Parts

Removal

Installation

Rear Axle Brake Hose

Rear Axle Brake Hose and Associated Parts

Removal

Installation

Brake Pipe

Removal

Installation

P & B (Proportioning and Bypass) Valve

P & B (Proportioning and Bypass) Valve

Sectional View

Removal

Installation

Main Data and Specifications

Brake Pedal

Checking Pedal Height

Checking Pedal Travel

Brake Pedal and Associated Parts

Removal

Installation

Stoplight Switch

Parts Location

Removal

Installation

Main Data and Specifications

Master Cylinder Assembly

Master Cylinder Assembly and

Associated Parts

Removal

Inspection and Repair

Main Data and Specifications

Master Cylinder Assembly

Master Cylinder Assembly

Disassembled View

Disassembly

Inspection

Reassembly

Installation

Vacuum Booster Assembly

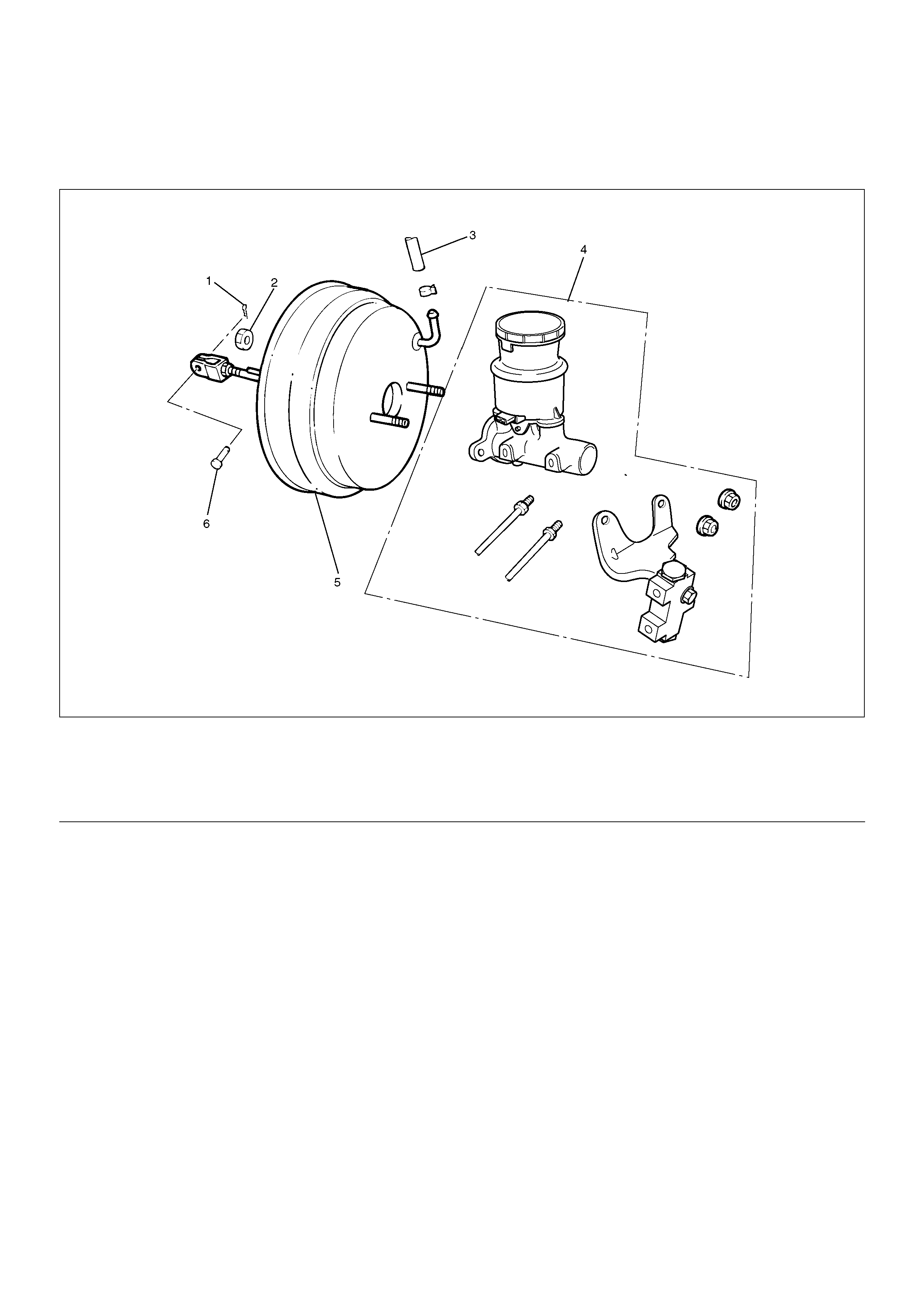

Vacuum Booster Assembly and

Associated Parts

Removal

Inspection and Repair

Installation

Exterior Components

Exterior Components and Associated Parts

Removal

Inspection and Repair

Installation

Vacuum Booster Overhaul

Vacuum Booster

Main Data and Specifications

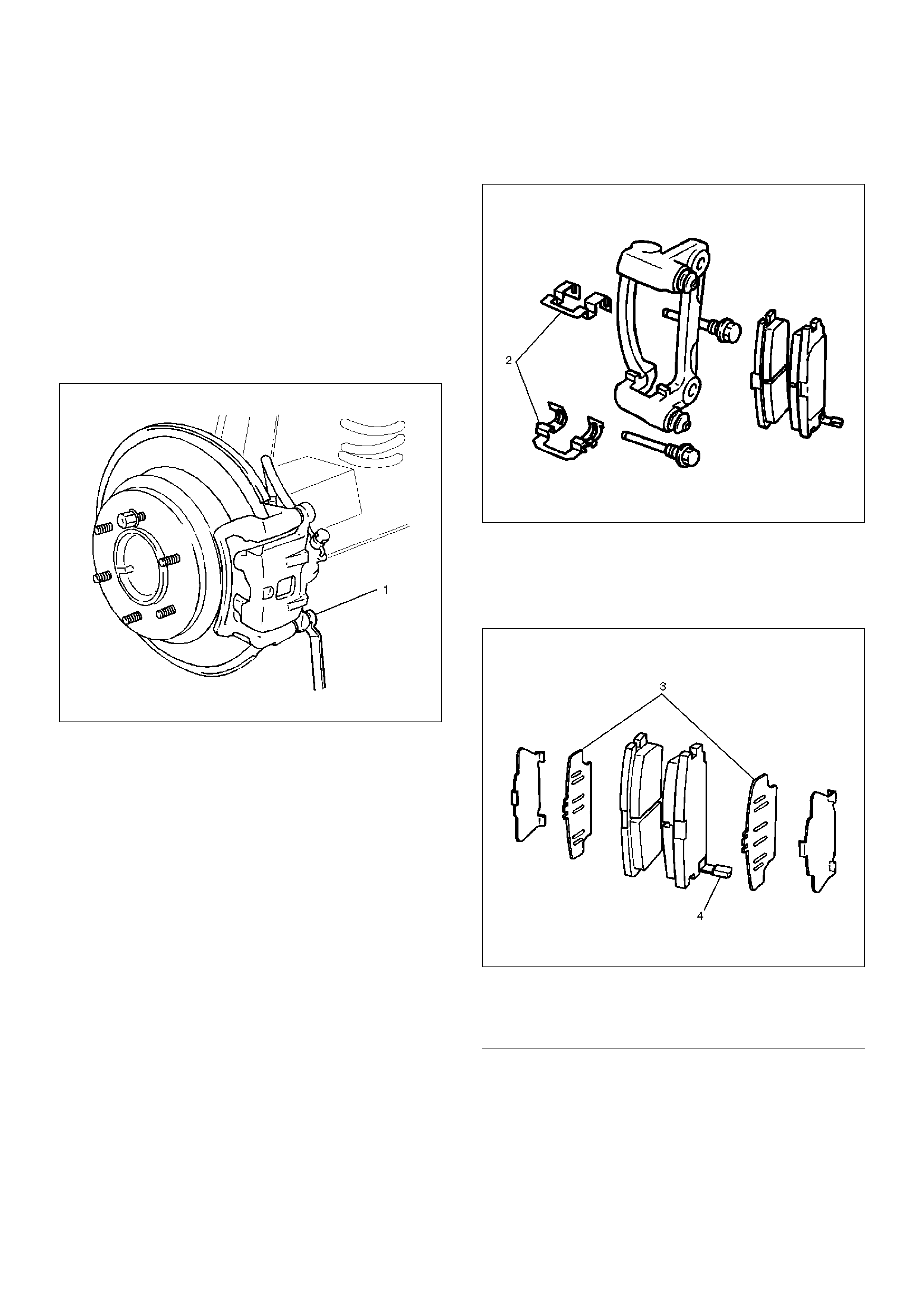

Front Disc Brake Pads

Front Disc Brake Pads Inspection

Front Disc Brake Pads and Associated Parts

Removal

Installation

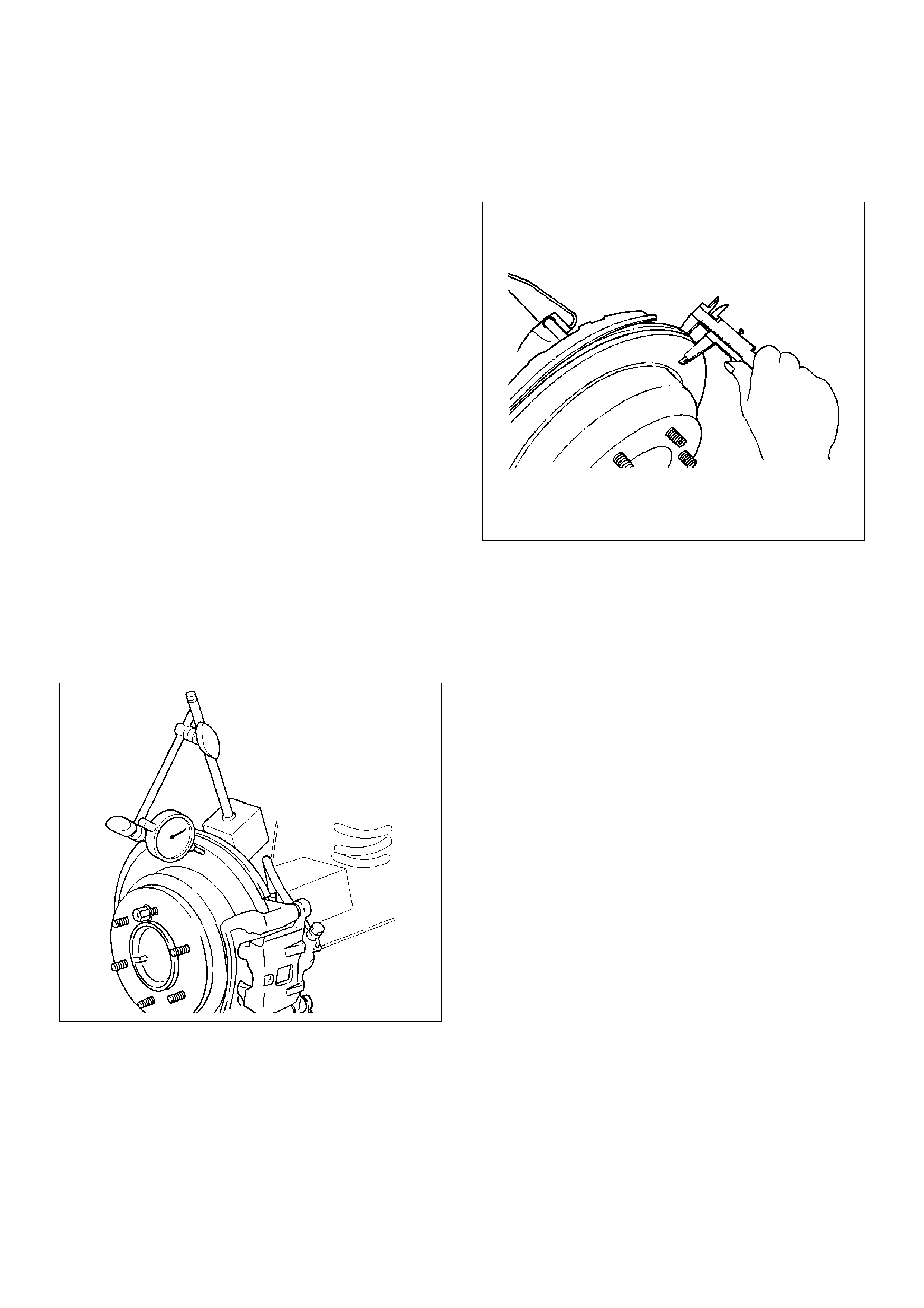

Front Disc Brake Rotor

Inspection

Replacing Brake Rotors

Refinishing Brake Rotors

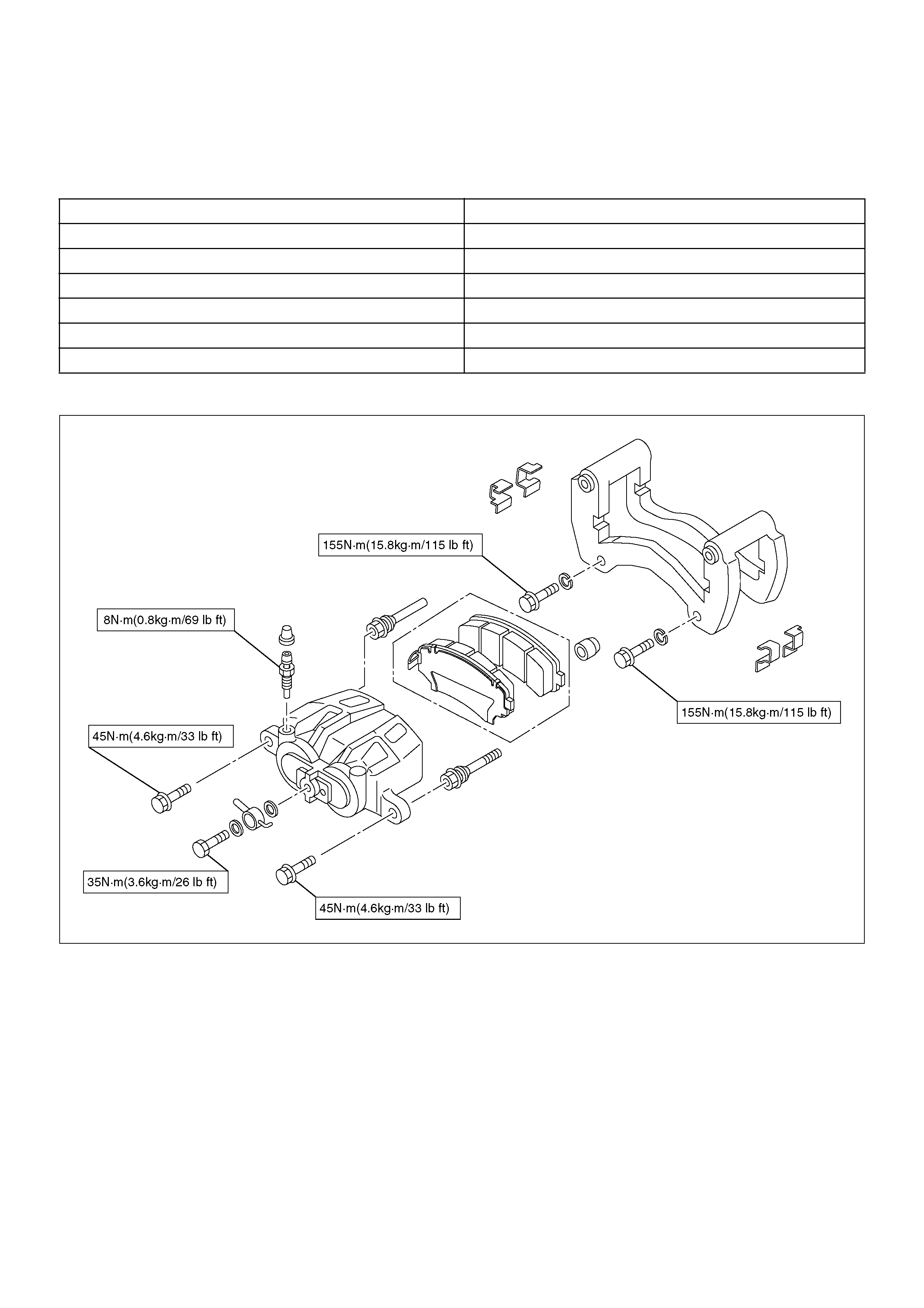

Front Disc Brake Caliper Assembly

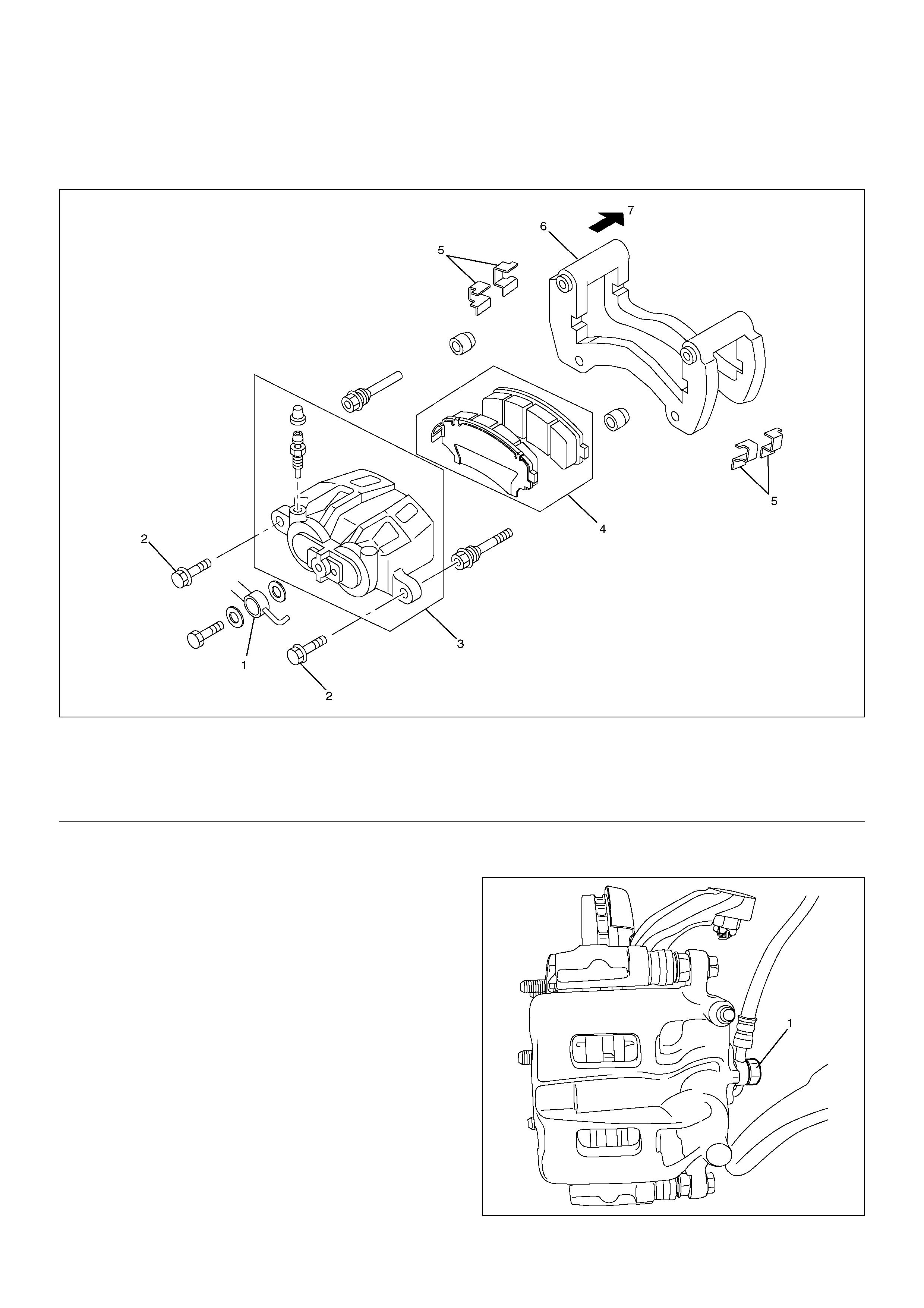

Front Disc Brake Caliper Assembly and

Associated Parts

Removal

Installation

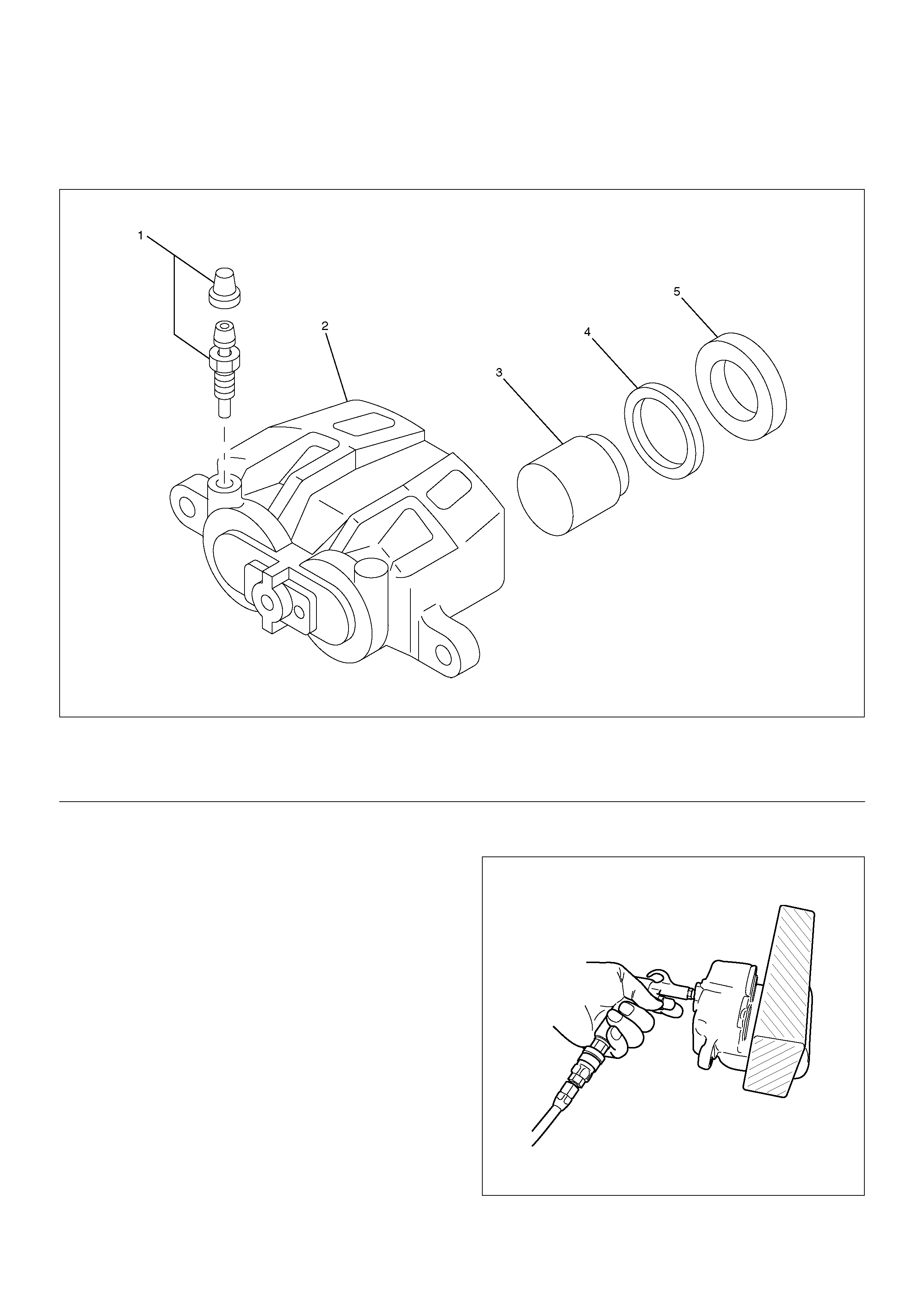

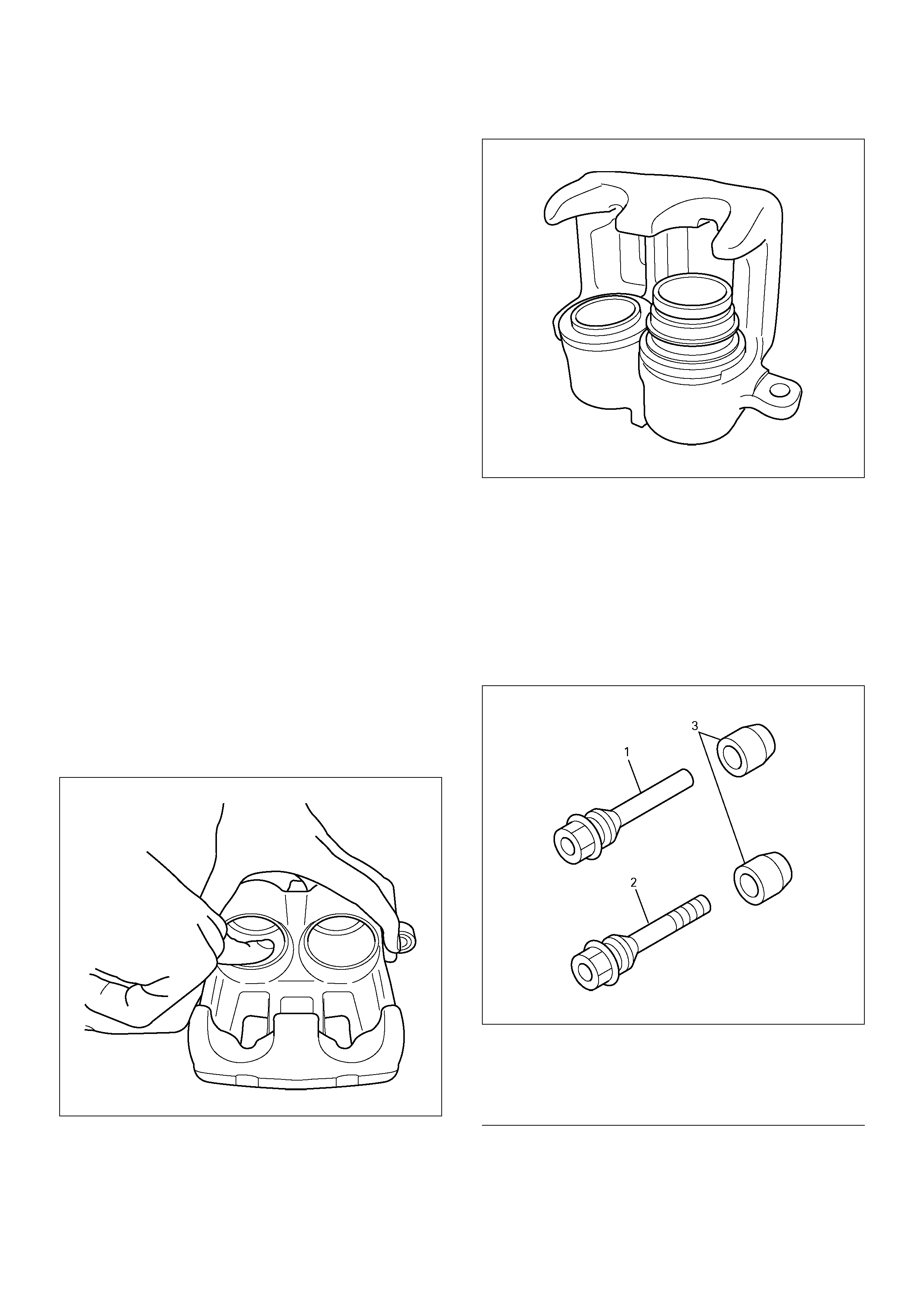

Front Disc Brake Caliper

Front Disc Brake Caliper Disassembled View

Disassembly

Inspection and Repair

Reassembly

Main Data and Specifications

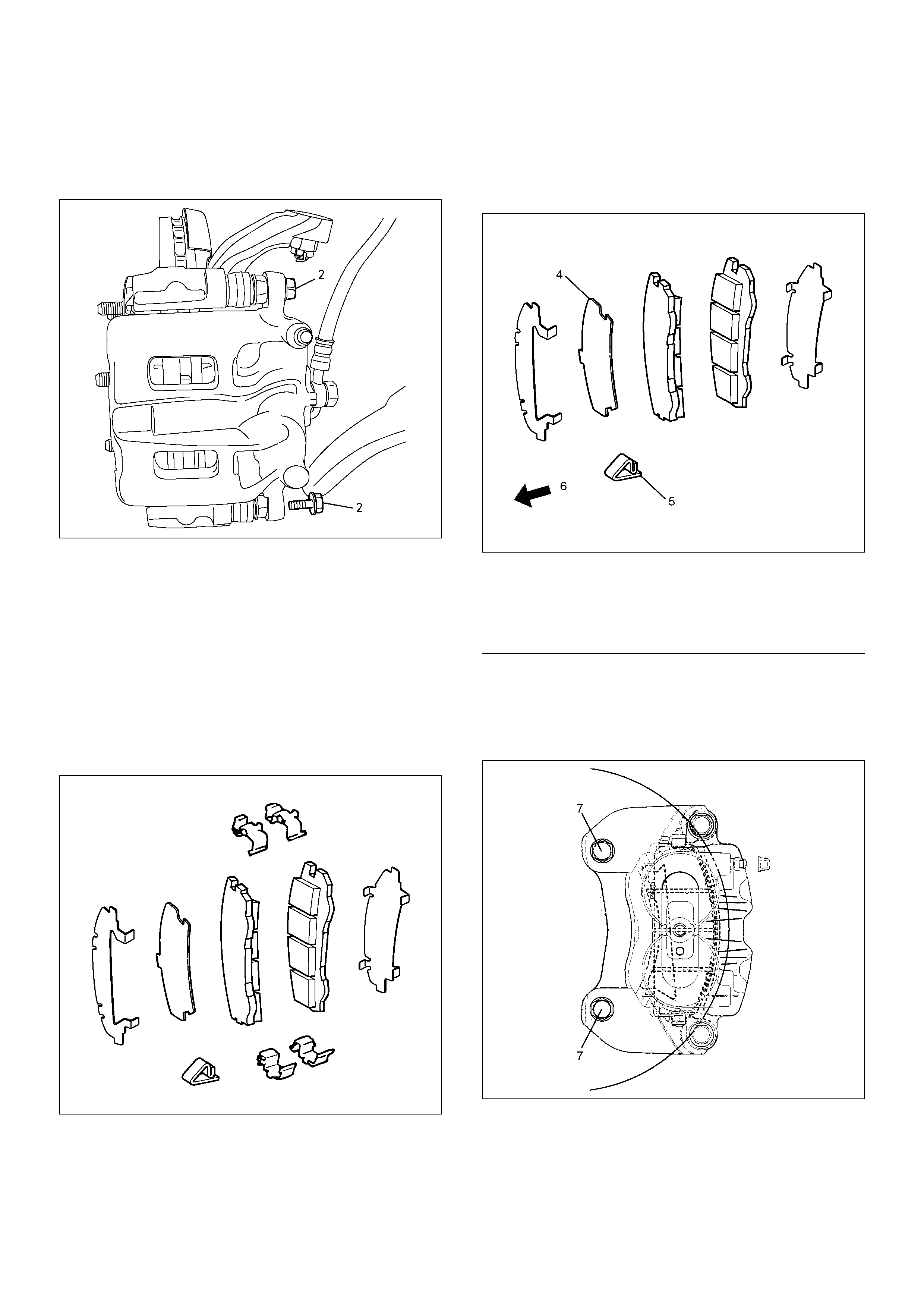

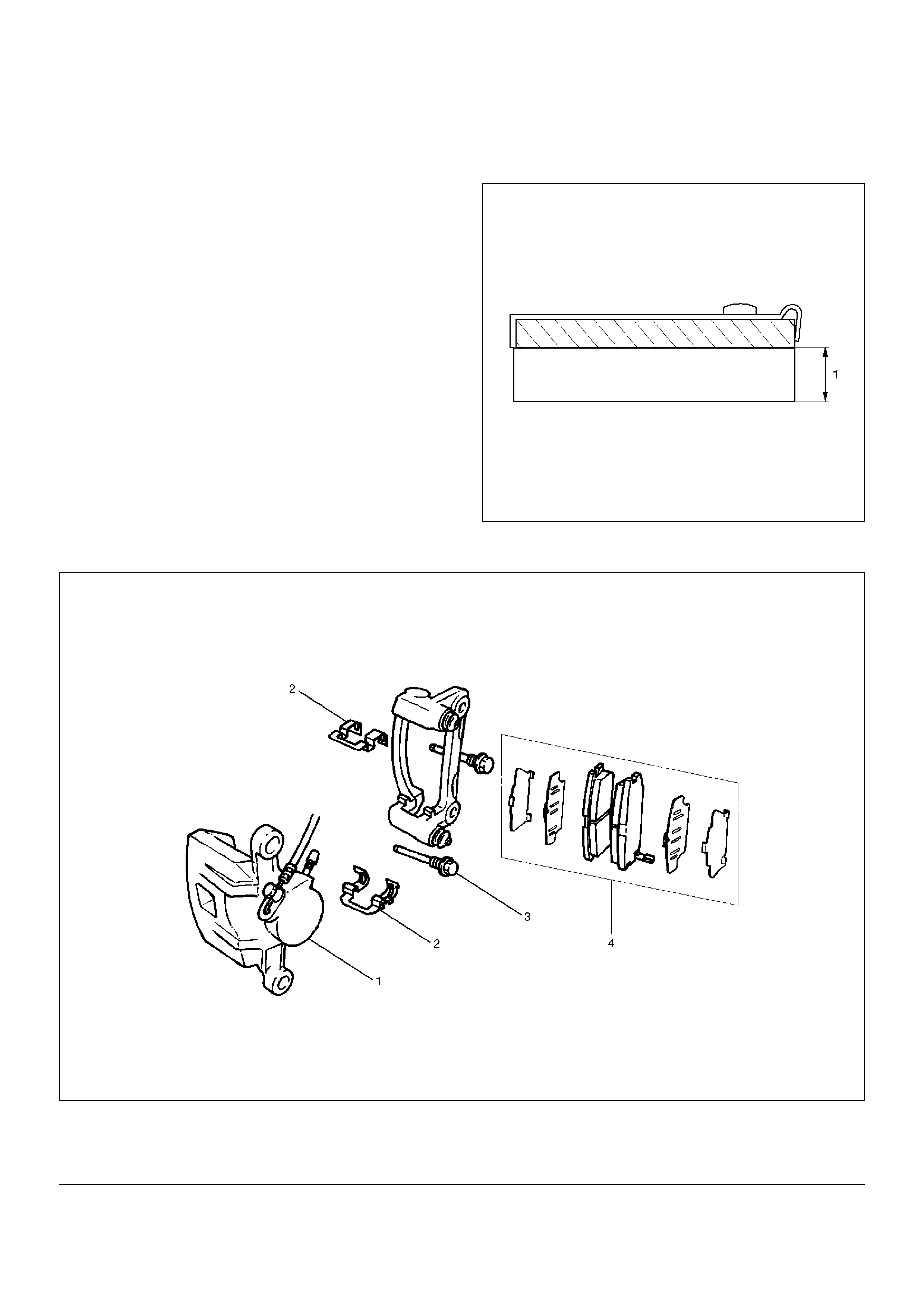

Rear Disc Brake Pads

Brake Pads Inspection

Brake Pads and Associated Parts

Removal

Installation

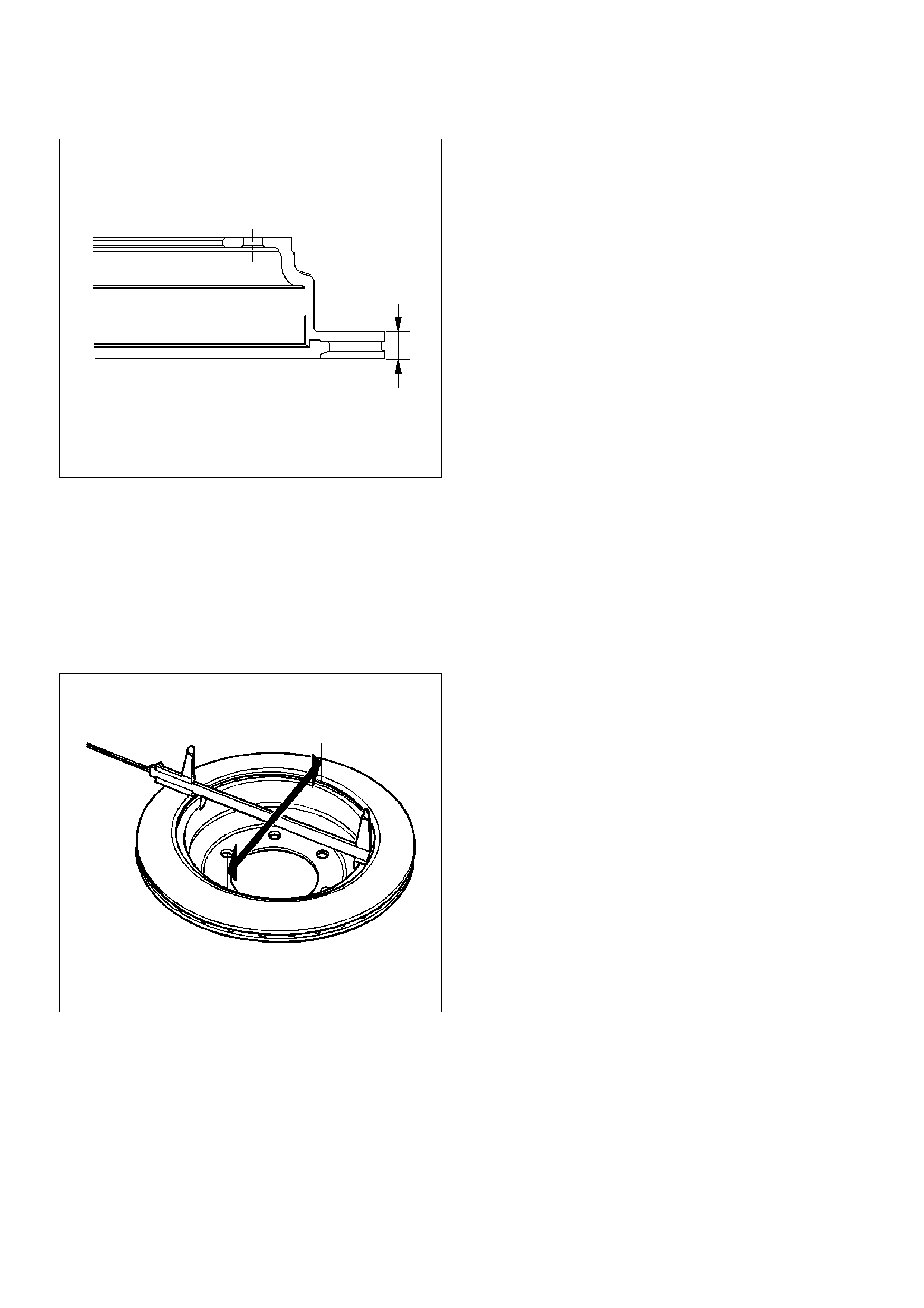

Rear Disc Brake Rotor

Inspection

Replacing Brake Rotors

Refinishing Brake Rotors

Rear Drum (In Disc) Inside Diameter Check

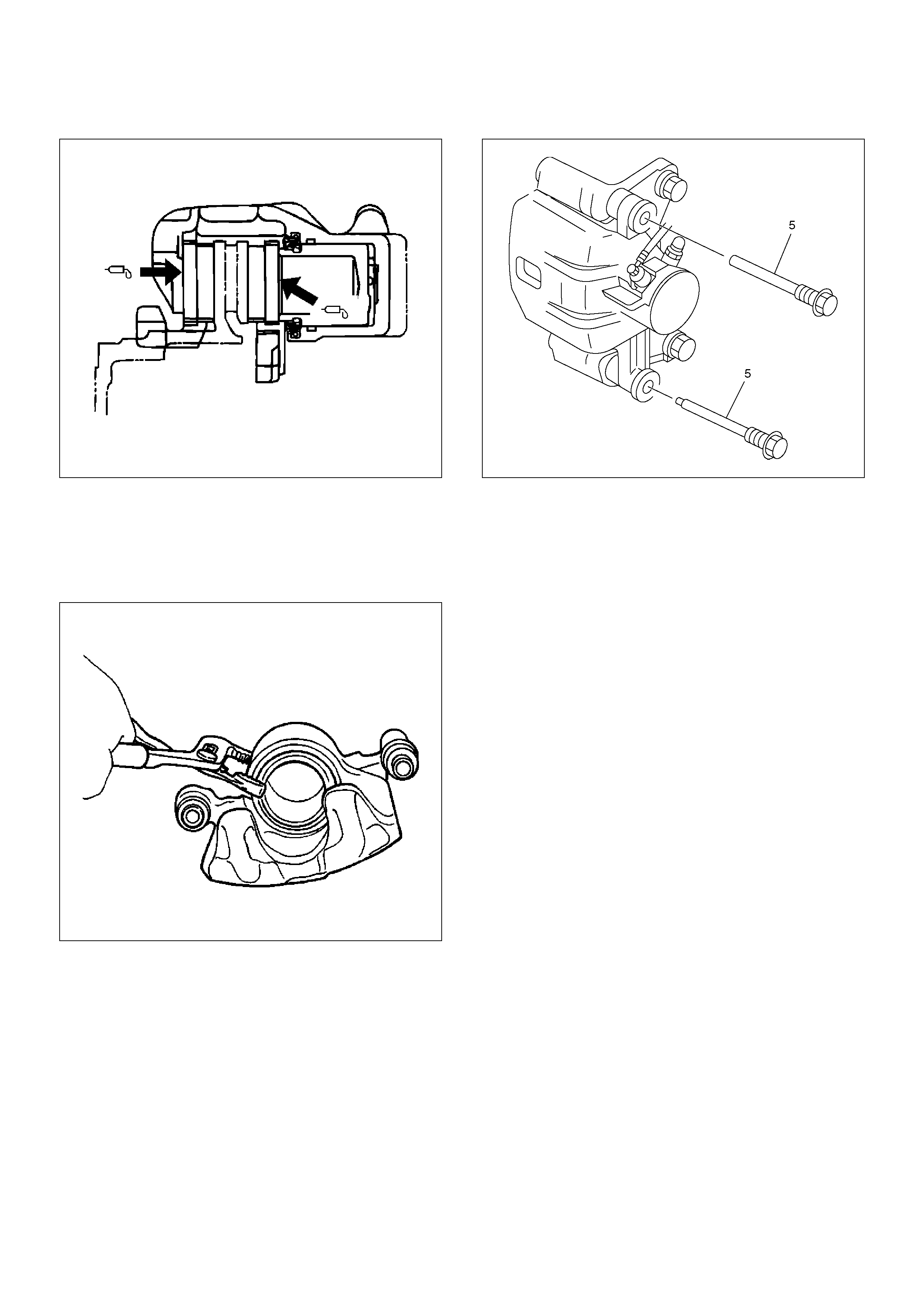

Rear Disc Brake Caliper Assembly

Rear Disc Brake Caliper Assembly and

Associated Parts

Removal

Installation

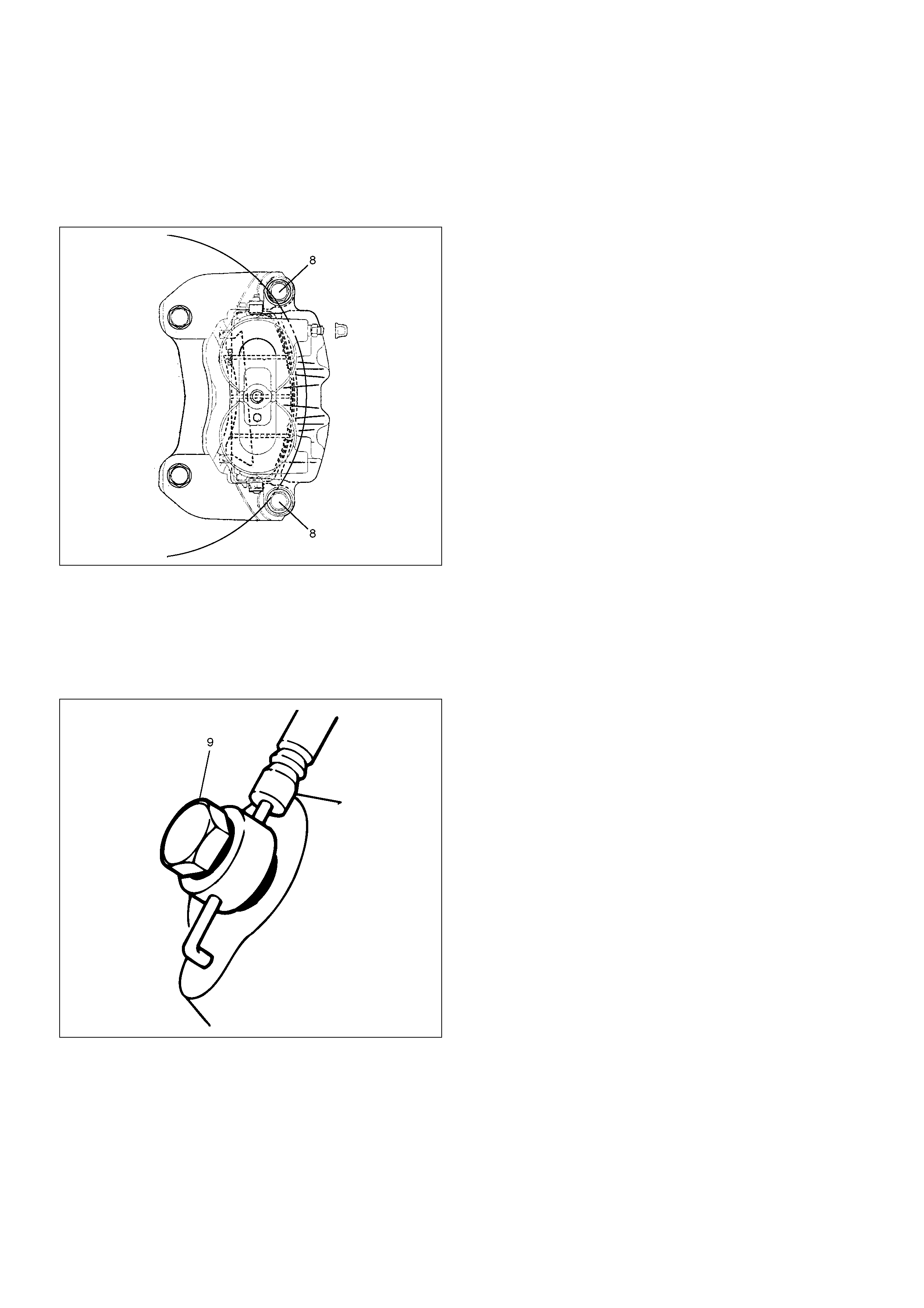

Rear Disc Brake Caliper

Rear Disc Brake Caliper Disassembled View

Disassembly

Inspection and Repair

Reassembly

Main Data and Specifications

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

General Description

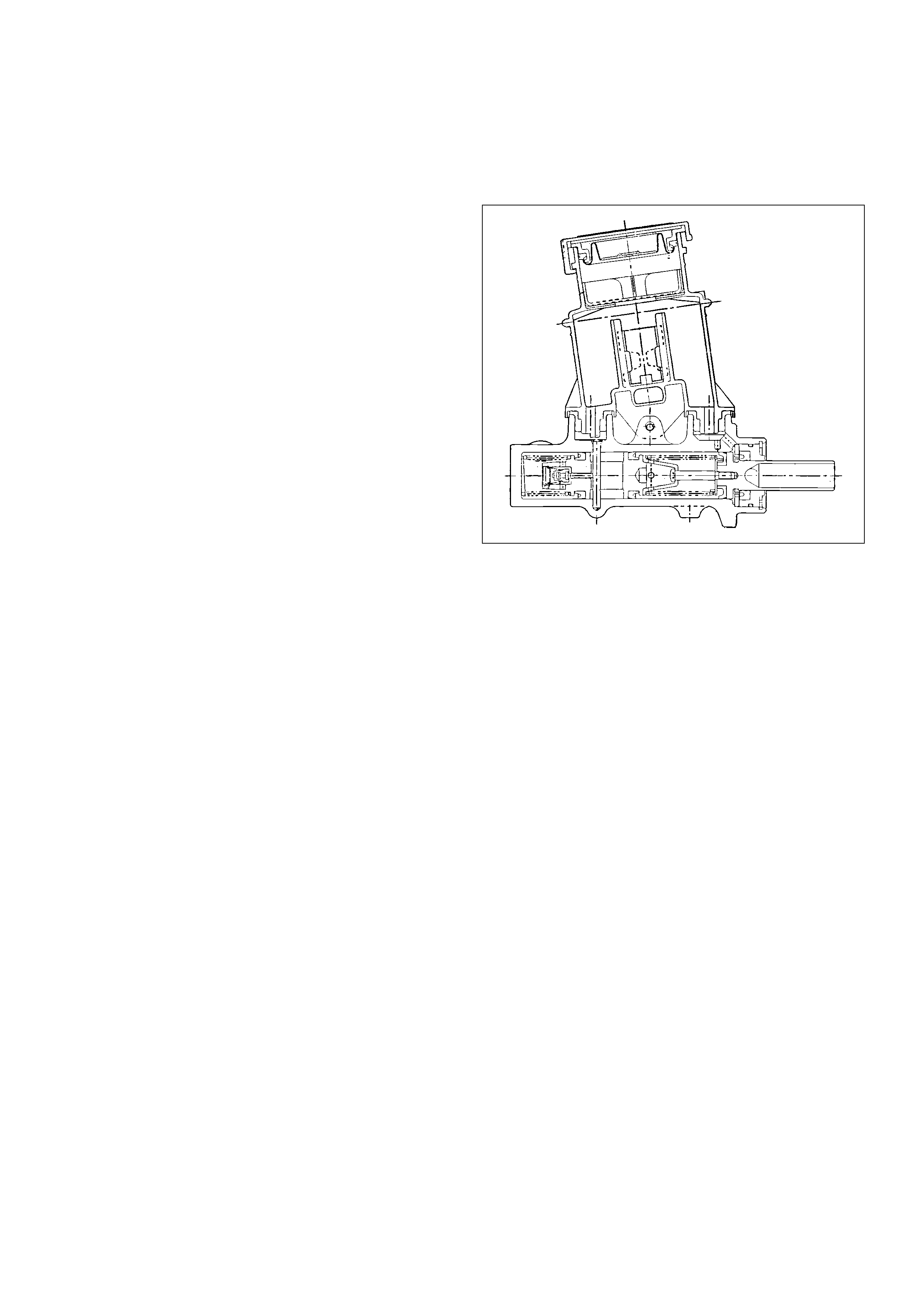

Master Cylinder Assembly

330R200002

The master cylinder contains two pistons that supply the

hydraulic pressure for a dual–circuit braking system.

The primary piston provides the fluid pressure to the

front brakes, while the secondary piston provides the

fluid pressure to the rear brakes. If the pressure is lost

from either system, the remaining system will function to

stop the vehicle.

CAUTION:

1.The master cylinder is not repairable. If found

defective, it must be replaced as a complete

assembly.

2.If any hydraulic component is removed or

disconnected, it may be necessary to bleed all

or part of the brake system. (Refer to “Bleeding

Brake Hydraulic System" in this section.)

3.The torque values specified are for dry,

unlubricated fasteners.

4.Perform service operations on a clean bench

free from all mineral oil materials.

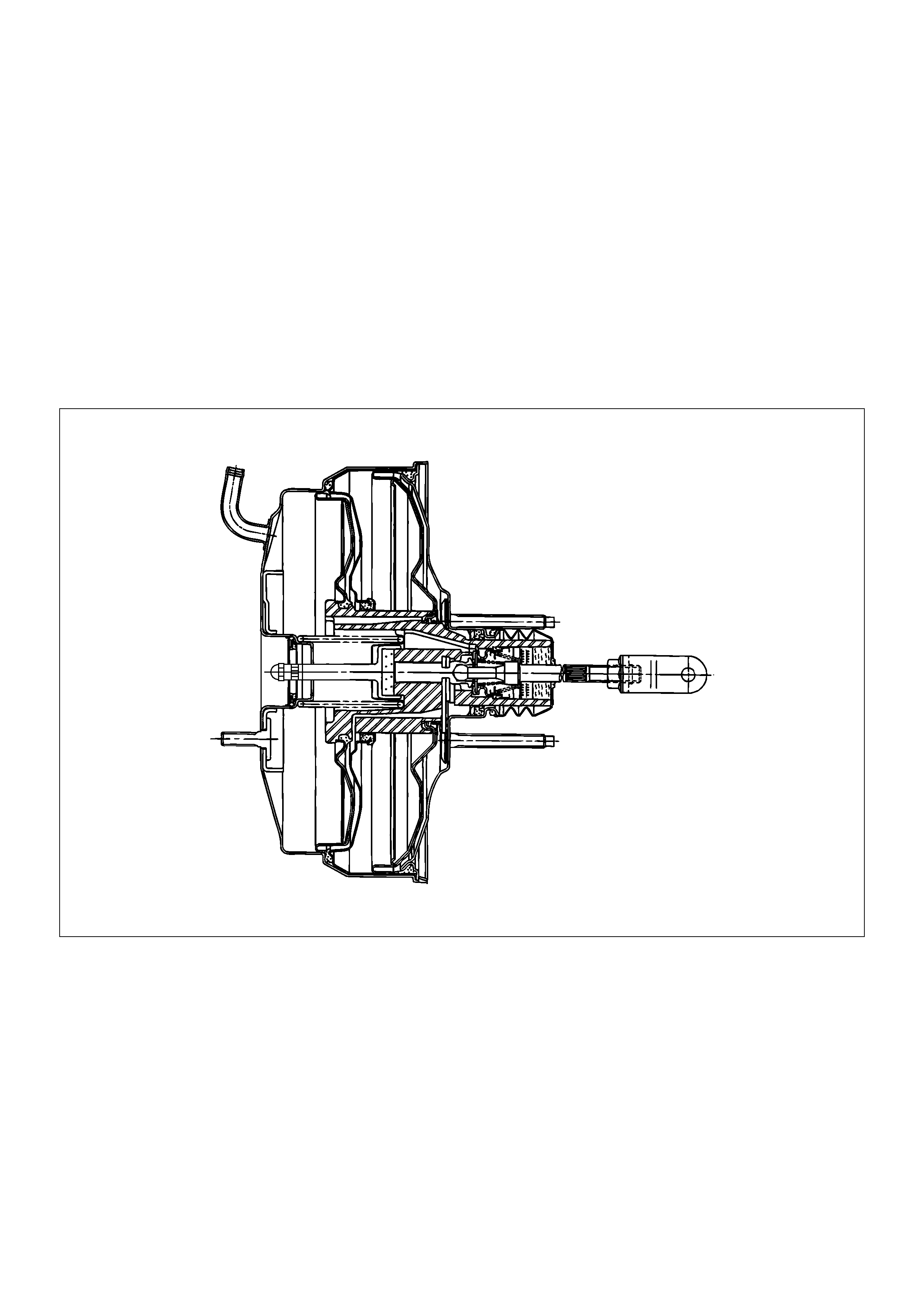

Brake Booster

331R200001

This booster is a tandem vacuum unit with a diaphragm

effective diameter 205mm + 230mm (8.07in + 9.06in). In

normal operating mode, with the service brakes in the

released position, the tandem vacuum booster operates

with vacuum on both sides of its diaphragms. When the

brakes are applied, air at atmospheric pressure is

admitted to one side of each diaphragm to provide the

power assist. When the service brake is released, the

atmospheric air is shut off from the one side of each

diaphragm. The air is then drawn from the booster

through the vacuum check valve to the vacuum source.

CAUTION:

1. If any hydraulic component is removed or

disconnected, it may be necessary to bleed all

or part of the brake system.

2. The torque values specified are for dry,

unlubricated fasteners.

3. The vacuum booster is not repairable and must

be replaced as complete assembly.

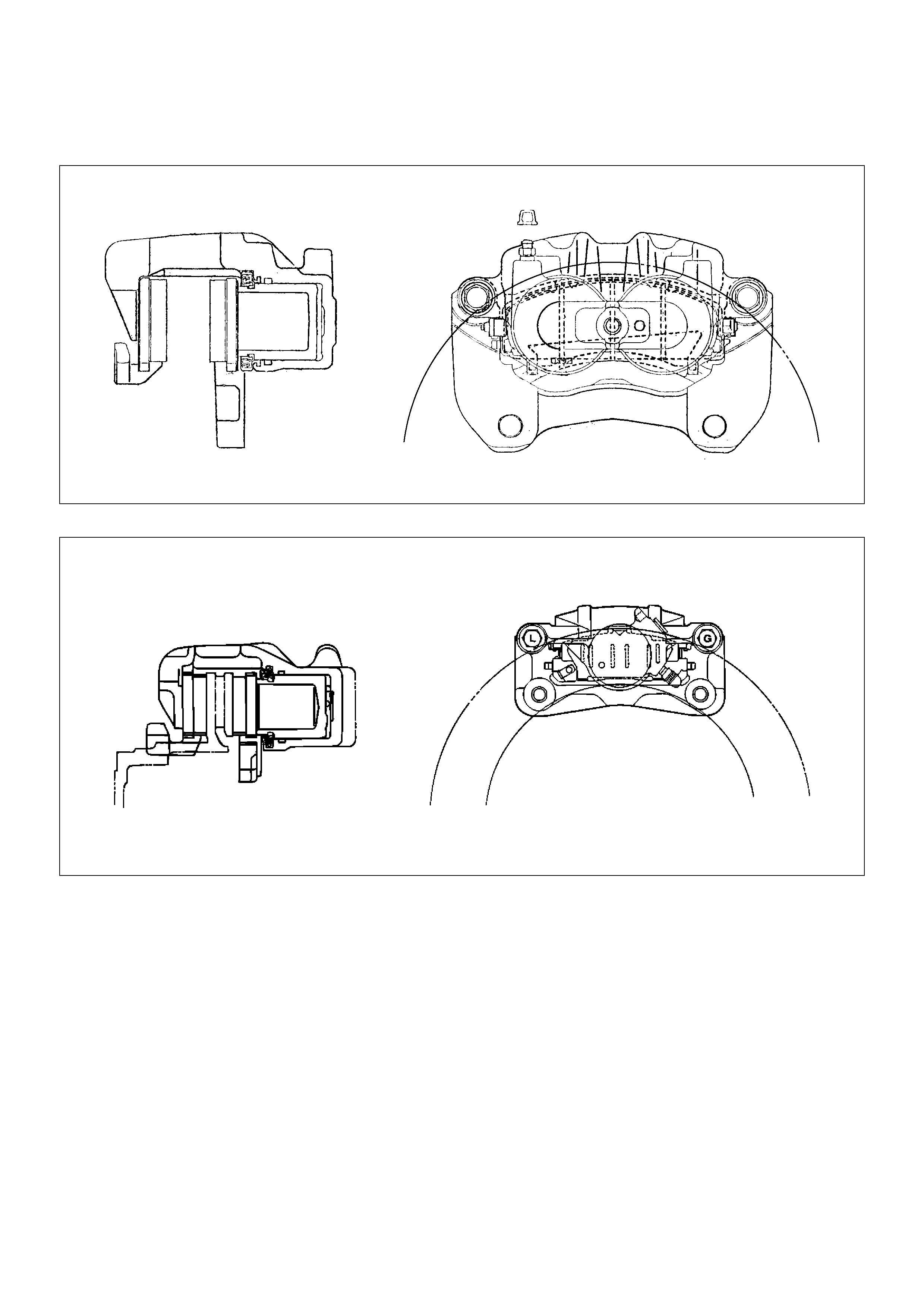

Disc Brake

Front Disc Brake

A05R200001

Rear Disc Brake

A05RW002

The disc brake assembly consists of a caliper, piston,

rotor, pad assembly and support bracket. The caliper

assembly has a single bore and is mounted to the

support bracket with two mounting bolts. The support

bracket allows the caliper to move laterally against the

rotor. The caliper is a one–piece casting with the

inboard side containing the piston bore. A square cut

rubber seal is located in a groove in the piston bore

which provides the hydraulic seal between the piston

and the cylinder wall.

NOTE:

1. Replace all components included in repair kits used

to service this caliper.

2. Lubricate rubber parts with clean brake fluid to ease

assembly.

3. If any hydraulic component is removed or

disconnected, it may be necessary to bleed all or

part of the brake system.

4. Replace pads in axle sets only.

5. The torque values specified are for dry, unlubricated

fasteners.

6. Perform the service operation on a clean bench free

from all mineral oil materials.

Operation

Hydraulic pressure, created by applying the brake

pedal, is converted by the caliper to a stopping force.

This force acts equally against the piston and the

bottom of the caliper bore to move the piston outward

and to move (slide) the caliper inward resulting in a

clamping action on the rotor. This clamping action

forces the linings against the rotor, creating friction to

stop the vehicle.

Diagnosis

Road Testing The Brakes

Brake Test

Brakes should be tested on a dry, clean, reasonably

smooth and level roadway. A true test of brake

performance cannot be made if the roadway is wet,

greasy or covered with loose dirt so that all tyres do not

grip the road equally. Testing will also be adversely

affected if the roadway is crowned so as to throw the

weight of the vehicle toward wheels on one side or if the

roadway is so rough that wheels tend to bounce. Test

the brakes at different vehicle speeds with both light and

heavy pedal pressure; however, avoid locking the

wheels and sliding the tyres. Locked wheels and sliding

tyres do not indicate brake efficiency, since heavily

braked but turning wheels will stop the vehicle in less

distance than locked wheels. More tyre–to–road friction

is present with a heavily braked turning tyre then with a

sliding tyre.

The standard brake system is designed and balanced to

avoid locking the wheels except at very high

deceleration levels.

It is designed this way because the shortest stopping

distance and best control is achieved without brake

lock–up.

Because of high deceleration capability, a firmer pedal

may be felt at higher deceleration levels.

External Conditions That Affect Brake Performance

1.Tyres: Tyres having unequal contact and grip on the

road will cause unequal braking. Tyres must be

equally inflated, identical in size, and the thread

pattern of right and left tyres must be approximately

equal.

2.Vehicle Loading: A heavily loaded vehicle requires

more braking effort.

3.Wheel Alignment: Misalignment of the wheels,

particularly in regard to excessive camber and

caster, will cause the brakes to pull to one side.

Brake Fluid Leaks

With engine running at idle and the transmission in

“Neutral", depress the brake pedal and hold a constant

foot pressure on the pedal. If pedal gradually falls away

with the constant pressure, the hydraulic system may be

leaking.

Check the master cylinder fluid level. While a slight drop

in the reservoir level will result from normal lining wear,

an abnormally low level in reservoir indicates a leak in

the system. The hydraulic system may be leaking

internally as well as externally. Refer to “Master Cylinder

Inspection". Also, the system may appear to pass this

test but still have slight leakage. If fluid level is normal,

check the vacuum booster push rod length. If an

incorrect length push rod is found, adjust or replace the

push rod. Check the brake pedal travel and the parking

brake adjustment.

When checking the fluid level, the master cylinder fluid

level may be low from the “MAX" mark if the front and

rear linings are worn. This is not abnormal.

Warning Light Operation

When the ignition switch is in the START position, the

“BRAKE" warning light should turn on and go off when

the ignition switch returns to the ON position.

The following conditions will activate the “BRAKE" light:

1. Parking brake applied. The light should be on

whenever the parking brake is applied and the

ignition switch is on.

2. Low fluid level. A low fluid level in the master

cylinder will turn the “BRAKE" light on.

3. During engine cranking the “BRAKE" light should

remain on. This notifies the driver that the warning

circuit is operating properly.

General Diagnosis

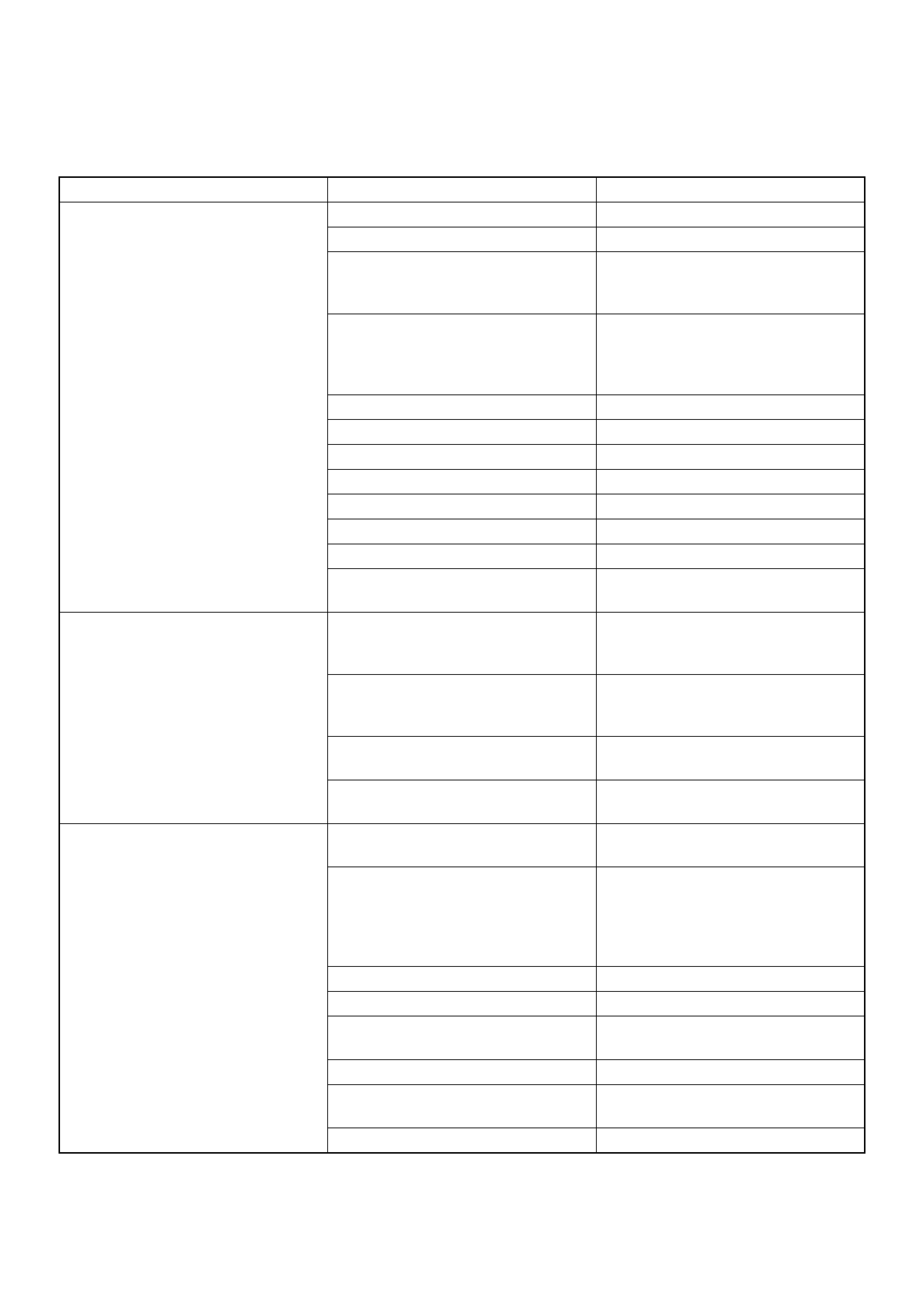

Condition Possible cause Correction

Brake Pull Tyre inflation pressure is unequal. Adjust

Front wheel alignment is incorrect. Adjust

Unmatched tyres on same axle. Tyres with approx. the same amount

of tread should be used on the same

axle.

Restricted brake pipes or hoses. Check for soft hoses and damaged

lines. Replace with new hoses and

new double“walled steel brake

piping.

Water or oil on the brake pads. Clean or replace.

Brake pads hardened. Replace

Brake pads worn excessively. Replace

Brake rotor worn or scored. Grind or replace.

Disc brake caliper malfunctioning. Clean or replace.

Front hub bearing preload incorrect. Adjust or replace.

Loose suspension parts. Check all suspension mountings.

Loose calipers. Check and tighten the bolts to

specifications.

Brake Roughness or Chatter

(Pulsates)

Excessive lateral runout. Check per instructions. If not within

specifications, replace or machine

the rotor.

Parallelism not within specifications. Check per instructions. If not within

specifications, replace or machine

the rotor.

Wheel bearings not adjusted. Adjust wheel bearings to correct

specifications

Pad reversed (steel against iron). Replace the brake pad and machine

rotor to within specifications.

Excessive Pedal Effort Malfunctioning vacuum booster. Check the vacuum booster

operation and repair, if necessary.

Partial system failure. Check the front and rear brake

system for failure and repair. Also,

check the brake warning light. If a

failed system is found, the light

should indicate failure.

Excessively worn pad. Check and replace pads in sets.

Piston in caliper stuck or sluggish. Remove caliper and rebuild.

Fading brakes due to incorrect pad. Remove and replace with original

equipment pad or equivalent.

Vacuum leak to vacuum booster. Check for ruptured or loose hose.

Check the direction of check valve

within vacuum hose.

Correct vacuum hose direction.

Grease on the brake pads. Replace or clean.

Excessive Brake Pedal Travel Air in hydraulic circuit. Bleed the hydraulic circuit.

Level of brake fluid in the reservoir

too low.

Replenish brake fluid reservoir to

specified level and bleed hydraulic

circuit as necessary.

Master cylinder push rod clearance

excessive.

Adjust

Leakage in hydraulic system. Correct or replace defective parts.

Brake Drag Master cylinder pistons not returning

correctly.

Adjust the stop light switch and

vacuum booster push rod. If

necessary, rebuild.

Restricted brake pipes or hoses. Check for soft hoses or damaged

pipes, and replace with new hoses

and new double–walled steel brake

piping.

Parking brake maladjusted. Adjust

Parking brake lining clearance

insufficient.

Adjust

Brake pedal free play insufficient. Adjust the brake pedal height or

power cylinder operating rod.

Piston in the master cylinder

sticking.

Replace

Piston in the disc brake caliper

sticking.

Replace piston seals.

Brake pads sticking in caliper. Clean

Return spring weakened. Replace

Parking brake binding. Overhaul the parking brakes and

correct.

Front hub bearing preload incorrect. Adjust or replace.

Parking brake shoes not returning. Correct or replace the brake back

plate and brake shoe as necessary.

Obstructions in hydraulic circuit. Clean

Rotor warped excessively. Grind or replace.

Rear brake drum distorted. Grind or replace.

Parking cable sticking. Grind or replace.

Grabbing or Uneven Braking Action

(All conditions listed under “Pulls")

Malfunctioning vacuum booster. Check operation and correct as

necessary.

Binding brake pedal mechanism. Check and lubricate, if necessary.

Corroded caliper assembly. Clean and lubricate.

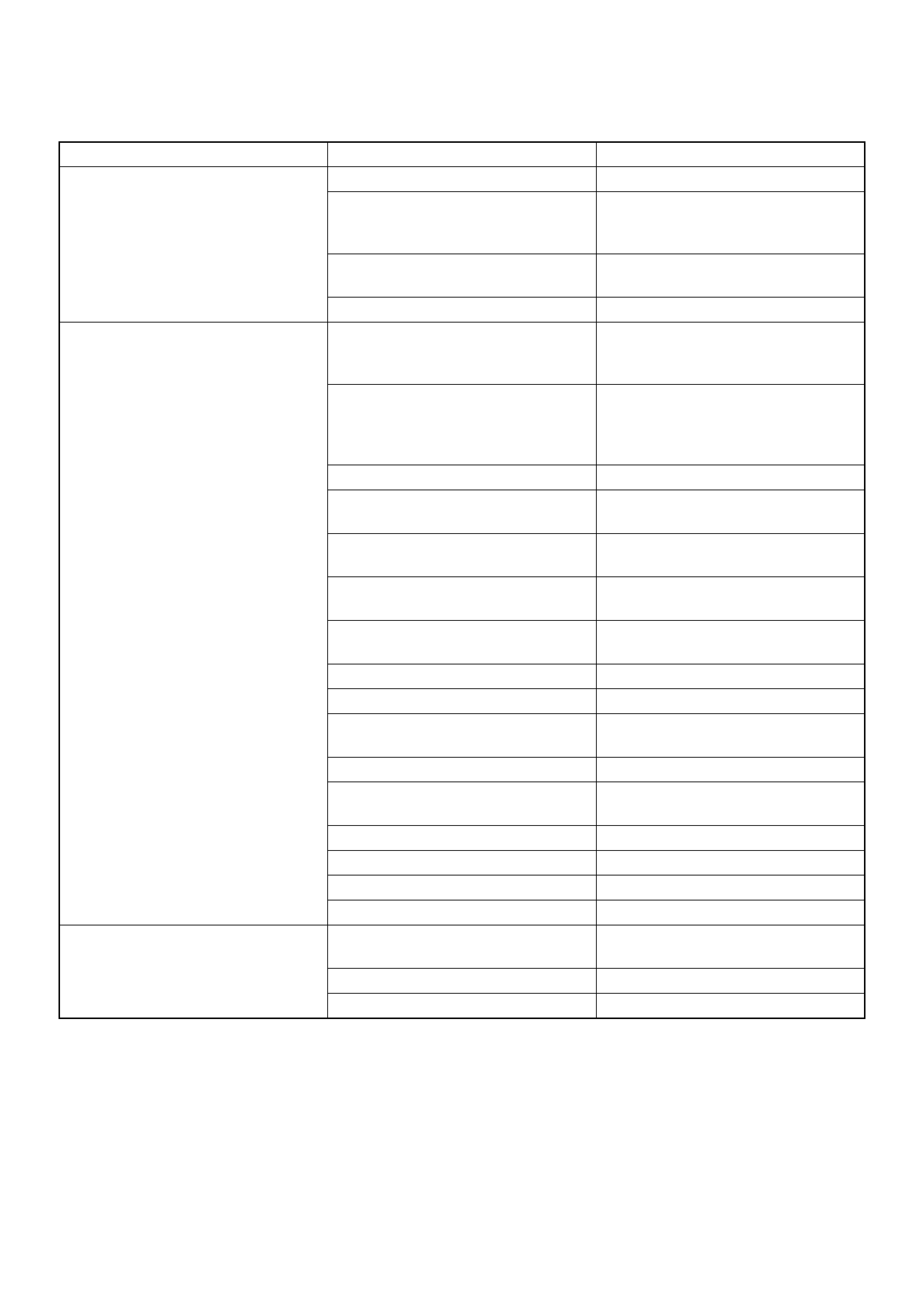

Condition Possible cause Correction

Brake Noisy Brake pads are worn. Replace

Brake pads are hardened. Replace

Brake pads are in poor contact with

rotor.

Correct

Brake disc(s) warped, worn or

damaged.

Grind or replace.

Disc brake anti–squeak shims

fatigued.

Replace

Front hub bearings are loose or

preload is incorrect.

Adjust or replace.

Brake disc is rusted. Grind or replace.

Poor Brake Action Master cylinder faulty. Correct or replace.

Vacuum booster faulty. Correct or replace.

Level of brake fluid in reservoir too

low.

Replenish and bleed.

Air in hydraulic circuit. Bleed

Disc brake caliper faulty. Clean or replace.

Water or oil on brake pads. Clean or replace.

Brake pads in poor contact with the

rotor.

Correct

Brake pads worn. Replace

Brake disc rusted. Grind or replace.

Check valve in vacuum hose faulty. Correct or replace.

Condition Possible cause Correction

Hydraulic Brakes

Filling Master Cylinder Reservoir

CAUTION: Use only specified brake fluid. Do not

use any fluid which contains a petroleum base. Do

not use a container which has been used for

petroleum based fluids or a container which is wet

with water. Petroleum based fluid will cause

swelling and distortion of rubber parts in the

hydraulic brake system. Water mixed with brake

fluid lowers the fluid boiling point. Keep all fluid

containers capped to prevent contamination.

Always fill the master cylinder reservoir when the

engine is cold.

Never allow the brake fluid to come in contact with

the painted surfaces.

The master cylinder reservoir must be kept properly

filled to ensure adequate reserve and to prevent air

and moisture from entering the hydraulic system.

However, because of expansion due to heat

absorbed from the brakes and the engine, the

reservoir must not be overfilled. The brake fluid

reservoir is on the master cylinder, which is located

under the hood on the left side of the cowl.

Thoroughly clean reservoir cap before removal to

avoid getting dirt into reservoir. Remove the

diaphragm. Add fluid as required to bring level to

the “MAX" mark on the reservoir tank. Use “DOT 3"

Hydraulic Brake Fluid. If the fluid cap diaphragm is

stretched, return it to the original position before

installing.

Deterioration of Brake Fluid

Using any other brake fluid than specified or brake fluid

with mineral oil or water mixed in will drop the boiling

point of brake fluid. It may, in turn, result in vapor lock or

deteriorated rubber parts of the hydraulic system. Be

sure to change the brake fluid at specified intervals.

If the rubber parts are deteriorated, remove all the

system parts and clean them with alcohol. Prior to

reassembly, dry the cleaned parts with air to remove the

alcohol. Replace all the hoses and rubber parts of the

system.

Leakage of Brake Fluid

With engine idling, set shift lever in the neutral position

and continue to depress brake pedal at a constant pedal

application force.

Should the pedal stroke become deeper gradually,

leakage from the hydraulic pressure system is possible.

Make sure by visual check that there is no leak.

Bleeding Brake Hydraulic System

A bleeding operation is necessary to remove air from

the hydraulic brake system whenever air is introduced

into the hydraulic system. It may be necessary to bleed

the hydraulic system at all four brakes if air has been

introduced through a low fluid level or by disconnecting

brake pipes at the master cylinder. If a brake pipe is

disconnected at one wheel, only that wheel cylinder/

caliper needs to be bled. If the pipes are disconnected

at any fitting located between the master cylinder and

brakes, then the brake system served by the

disconnected pipe must be bled.

1. For 4–Wheel Antilock Brake System (ABS)

equipped vehicle, be sure to remove the ABS main

fuse 60A located at the relay and fuse box before

bleeding air. If you attempt to bleed air without

removing the main fuse, air cannot be let out

thoroughly, and this may cause damage to the

hydraulic unit. After bleeding air, be sure to replace

the ABS main fuse back to its original position.

2. Set the parking brake completely, then start the

engine.

NOTE: The vacuum booster will be damaged if the

bleeding operation is performed with the engine off.

3. Remove the master cylinder reservoir cap.

4. Fill the master cylinder reservoir with brake fluid.

Keep the reservoir at least half full during the air

bleeding operation

5. Always use new brake fluid for replenishment.

6. In replenishing brake fluid, take care that air bubbles

do not enter the brake fluid.

When the master cylinder is replaced or overhauled,

first bleed the air from the master cylinder, then from

each wheel cylinder and caliper following the

procedures described below.

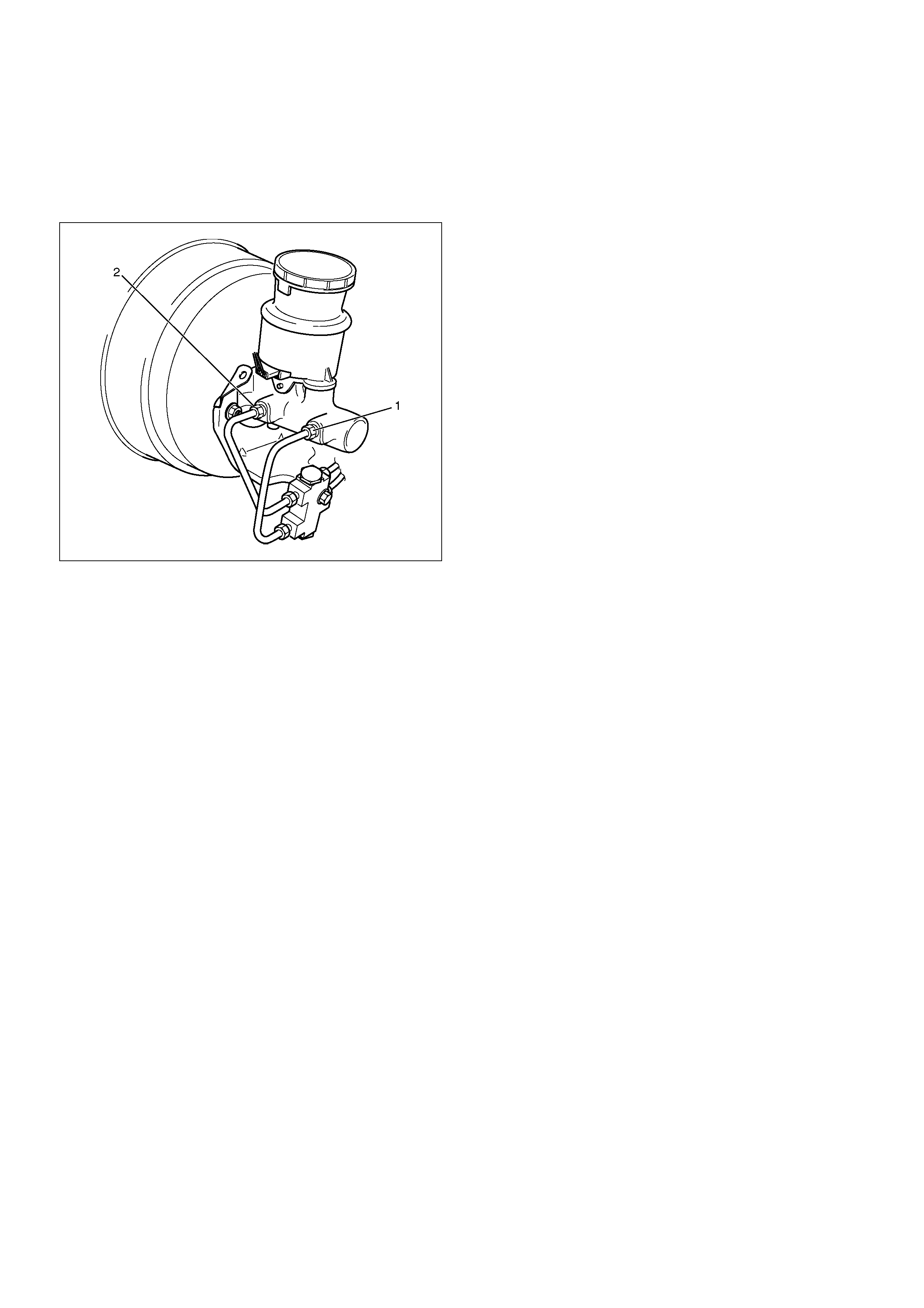

Bleeding the Master Cylinder

7. Disconnect the rear wheel brake pipe (1) from the

master cylinder.

Check the fluid level and replenish as necessary. If

replenished, leave the system for at least one

minute.

8. Depress the brake pedal slowly once and hold it

depressed.

9. Completely seal the delivery port of the master

cylinder with your finger, where the pipe was

disconnected then release the brake pedal slowly.

10. Release your finger from the delivery port when the

brake pedal returns completely.

11. Repeat steps 8 through 10 until the brake fluid

comes out of the delivery port during step 8.

NOTE: Do not allow the fluid level in the reservoir to go

below the half–way mark.

12. Reconnect the brake pipe (1) to the master cylinder

and tighten the pipe.

13. Depress the brake pedal slowly once and hold it

depressed.

14. Loosen the rear wheel brake pipe (1) at the master

cylinder.

15. Retighten the brake pipe, then release the brake

pedal slowly.

16.Repeat steps 13 through 15 until no air comes out of

the port when the brake pipe is loosened

NOTE: Be very careful not to allow the brake fluid to

come in contact with painted surfaces.

330R200004

17.Bleed the air from the front wheel brake pipe

connection (2) by repeating steps 7 through 16.

Bleeding the Caliper

18.Bleed the air from each wheel in the order listed

below:

•Right rear caliper or wheel cylinder

•Left rear caliper or wheel cylinder

•Right front caliper

•Left front caliper

Conduct air bleeding from the wheels in the above

order. If no brake fluid comes out, it suggests that air

is mixed in the master cylinder. In this case, bleed

air from the master cylinder. In this case, bleed air

from the master cylinder in accordance with steps 7

through 17, and then bleed air from the caliper or

wheel cylinder.

19.Place the proper size box end wrench over the

bleeder screw.

20.Cover the bleeder screw with a transparent tube,

and submerge the free end of the transparent tube

in a transparent container containing brake fluid.

21.Pump the brake pedal slowly three (3) times (once/

sec), then hold it depressed.

22.Loosen the bleeder screw until fluid flows through

the tube.

23.Retighten the bleeder screw.

24.Release the brake pedal slowly.

25.Repeat steps 21 through 24 until the air is

completely removed.

It may be necessary to repeat the bleeding

procedure 10 or more times for front wheels and 15

or more times for rear wheels.

26.Go to the next wheel in the sequence after each

wheel is bled.

Be sure to monitor reservoir fluid level.

27.Depress the brake pedal to check if you feel

“sponginess" after the air has been removed from

all wheel cylinders and calipers.

If the pedal feels “spongy", the entyre bleeding

procedure must be repeated.

28.After the bleeding operation is completed on the

each individual wheel, check the level of the brake

fluid in the reservoir and replenish up to the “MAX"

level as necessary.

29.Attach the reservoir cap.

If the diaphragm inside the cap is deformed, reform

it and install.

30.Stop the engine.

Flushing Brake Hydraulic System

It is recommended that the entyre hydraulic system be

thoroughly flushed with clean brake fluid whenever new

parts are installed in the hydraulic system.

Approximately one quart of fluid is required to flush the

hydraulic system.

The system must be flushed if there is any doubt as to

the grade of fluid in the system or if fluid has been used

which contains the slightest trace of mineral oil. All

rubber parts that have been subjected to a

contaminated fluid must be replaced.

Brake Pipes and Hoses

The hydraulic brake system components are

interconnected by special steel piping and flexible

hoses. Flexible hoses are used between the frame and

the front calipers, the frame and rear axle case and the

rear axle and the rear calipers.

When the hydraulic pipes have been disconnected for

any reason, the brake system must be bled after

reconnecting the pipe. Refer to “Bleeding the Brake

Hydraulic System" in this section.

Brake Hose Inspection

The brake hose should be inspected at least twice a

year. The brake hose assembly should be checked for

road hazard, cracks and chafing of the outer cover, and

for leaks and blisters. Inspect for proper routing and

mounting of the hose. A brake hose that rubs on

suspension components will wear and eventually fail. A

light and mirror may be needed for an adequate

inspection. If any of the above conditions are observed

on the brake hose, adjust or replace the hose as

necessary.

CAUTION: Never allow brake components such as

calipers to hang from the brake hoses, as damage

to the hoses may occur.

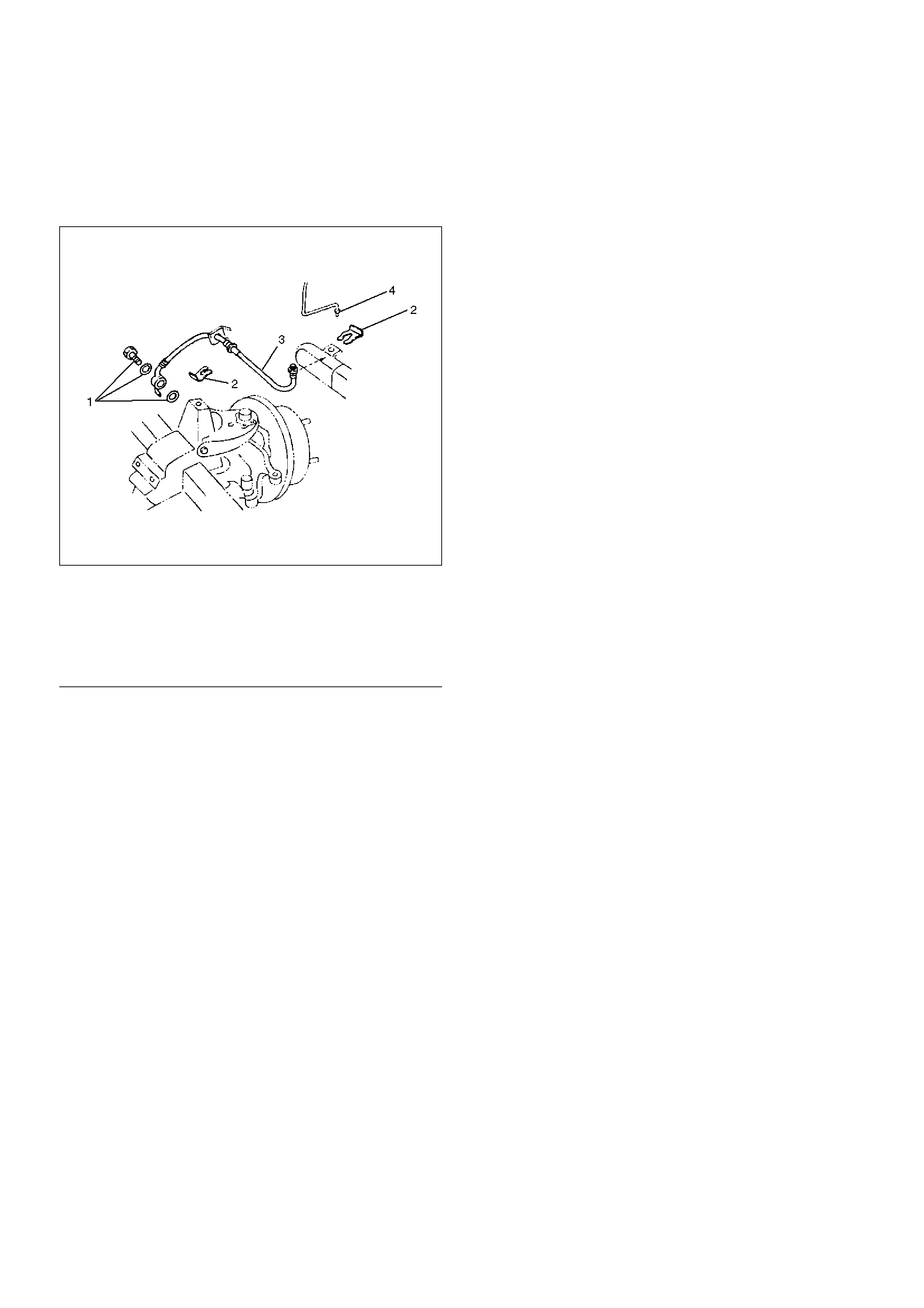

Front Caliper Brake Hose

Front Caliper Brake Hose and Associated

Parts

352RW001

EndOFCallout

Removal

1. Raise the vehicle and support it with suitable safety

stands.

2. Remove the wheel and tyre assembly.

3. Clean dirt, grease, and other foreign material off the

hose fittings at both ends.

4. Disconnect brake pipe.

5. Remove clip.

6. Remove bolt and gasket.

7. Remove hose.

Installation

To install, follow the removal steps in the reverse order,

noting the following points.

1. Tighten the brake pipes to the specified torque

Torque: 19 N·m (1.9 kg·m/14 lbft)

2. Tighten the bolt to the specified torque.

Torque: 34 N·m (3.5 kg·m/25 lbft)

NOTE: Always use new gaskets and be sure to put the

hooked edge of the flexible hose end into the anti–

rotation cavity.

After installing the brake hoses, bleed the brakes as

described in this section.

Legend

(1) Bolt and Gasket

(2) Clip

(3) Hose

(4) Brake Pipe

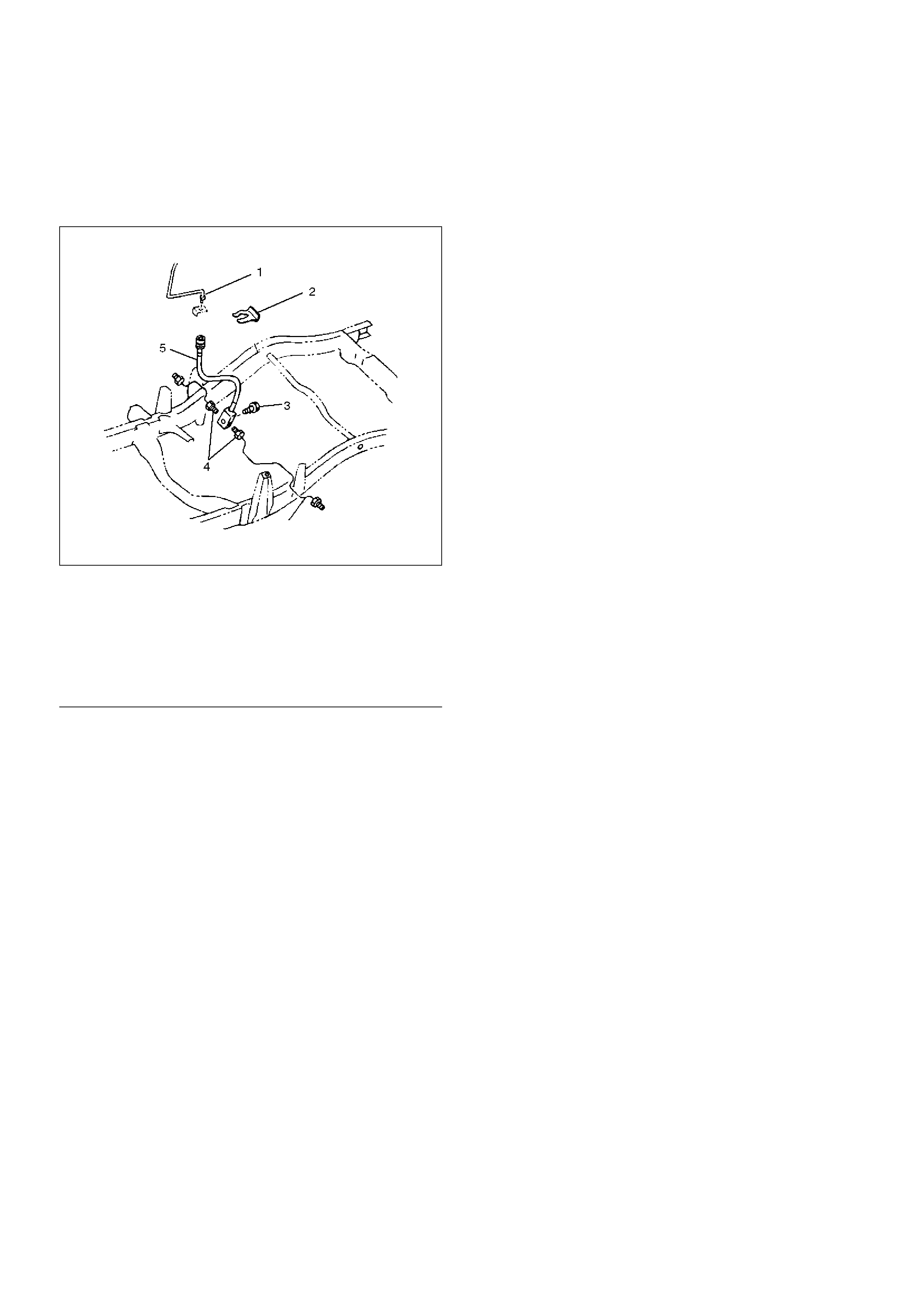

Rear Axle Brake Hose

Rear Axle Brake Hose and Associated

Parts

352RW002

EndOFCallout

Removal

1. Raise the vehicle and support it with suitable safety

stands.

2. Remove wheel and tyre assembly.

3. Clean dirt, grease, and other foreign material off the

hose fittings at both ends.

4. Disconnect brake pipe.

5. Remove clip.

6. Remove brake pipe.

7. Remove bolt.

8. Remove hose.

Installation

To install, follow the removal steps in the reverse order,

noting the following points.

1. Tighten the brake pipes to the specified torque

Torque: 19 N·m (1.9 kg·m/14 lbft)

2. Tighten the bolt to the specified torque.

Torque: 15 N·m (1.5 kg·m/11 lbft)

After installing the brake hoses, bleed the brakes as

described in this section.

Legend

(1) Brake Pipe

(2) Clip

(3) Bolt

(4) Brake Pipe

(5) Hose

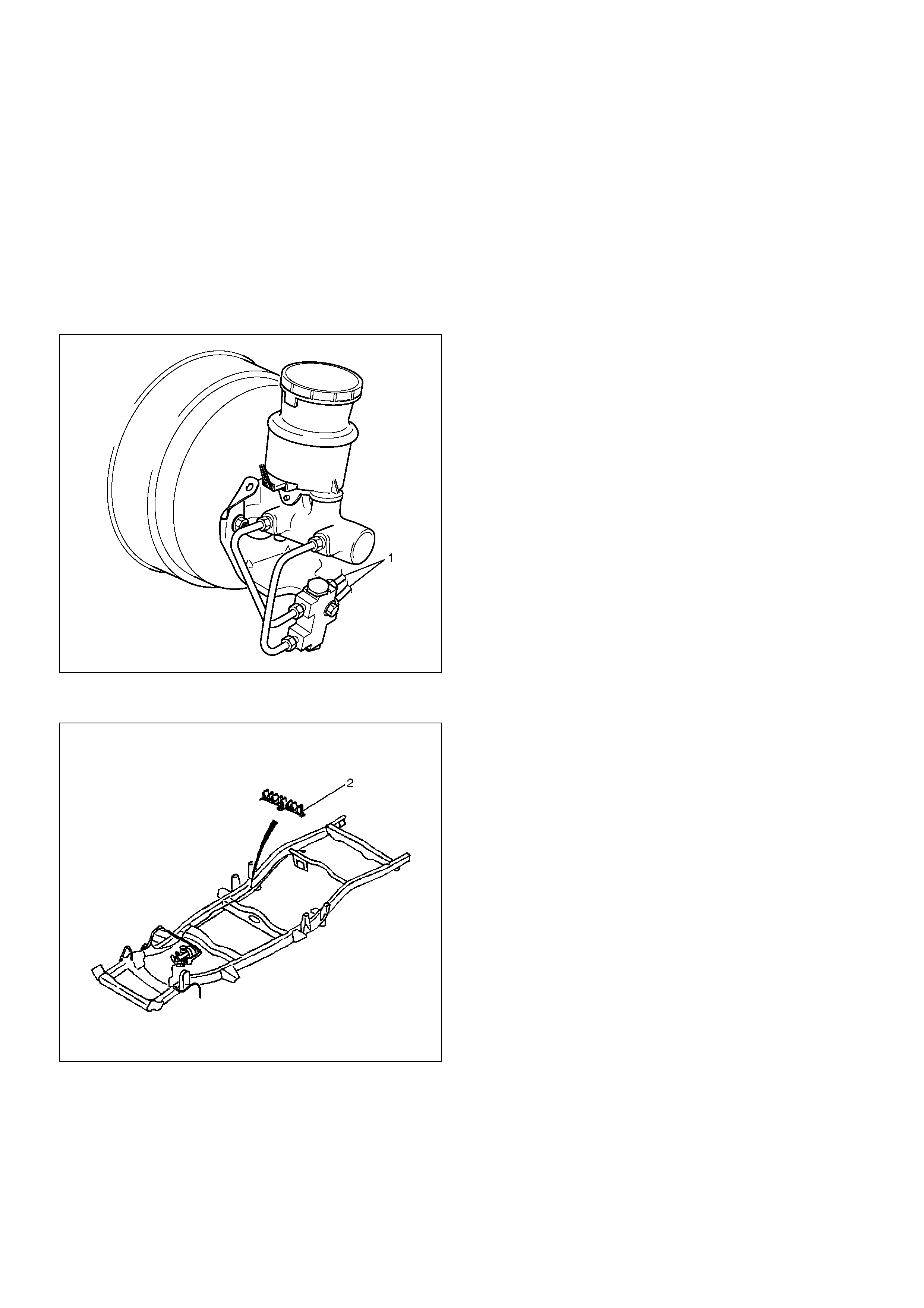

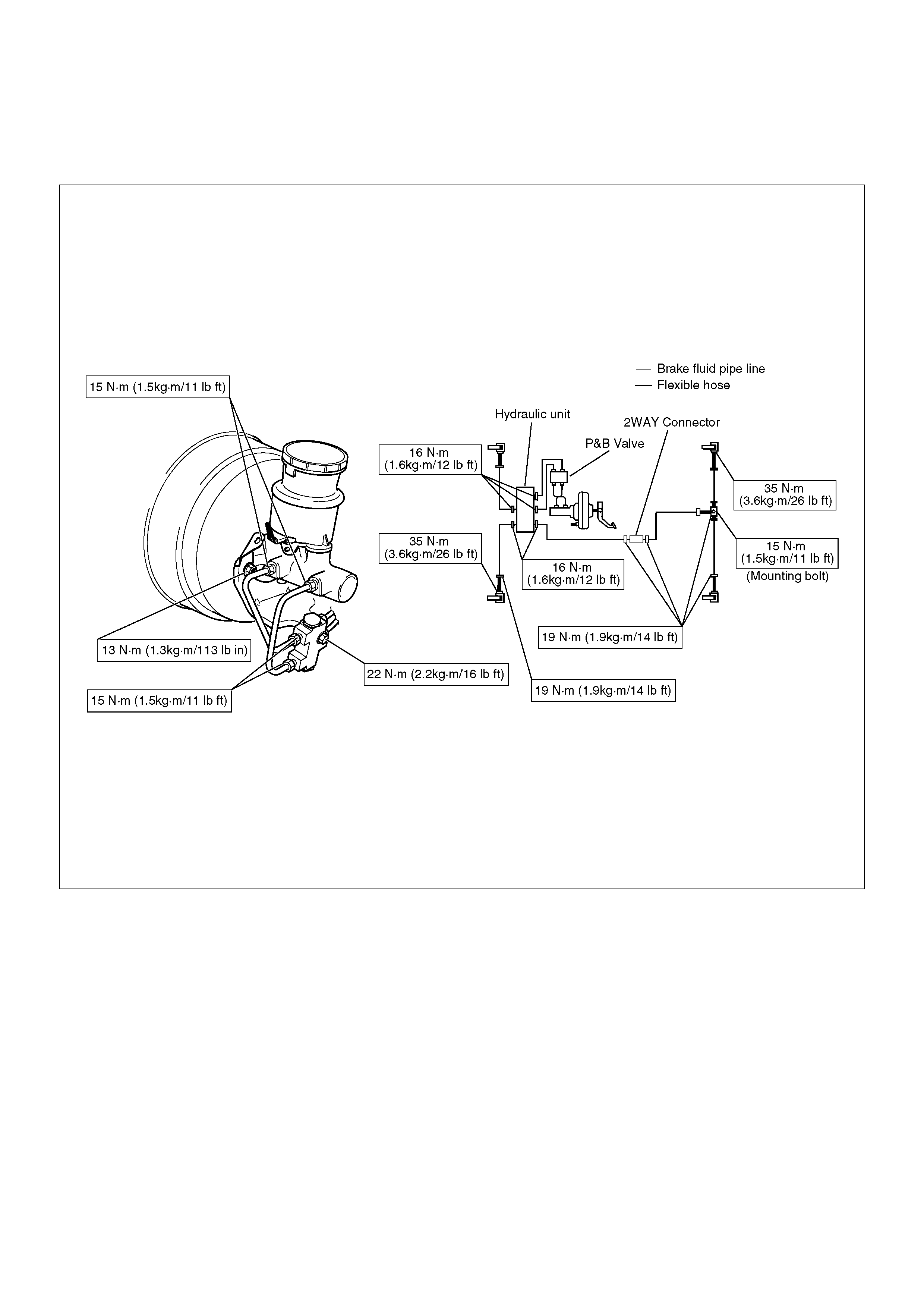

Brake Pipe

Removal

1. Raise the vehicle and support it with suitable safety

stands.

2. Remove wheel and tyre assembly as necessary.

3. Clean dirt, grease, and other foreign material off the

pipe fittings at both ends.

4. Remove brake pipe (1).

330R20000 3

5. Remove plastic clip (2).

330RW002

Installation

To install, follow the removal steps in the reverse order,

noting the following points.

1. Tighten the brake pipes to the specified torque.

Master cylinder and P&B valve sides

Torque: 15 N·m (1.5 kg·m/11 lbft)

Others

Torque: 16 N·m (1.6 kg·m/12 lbft)

After installing the brake pipes, bleed the brakes as

described in this section.

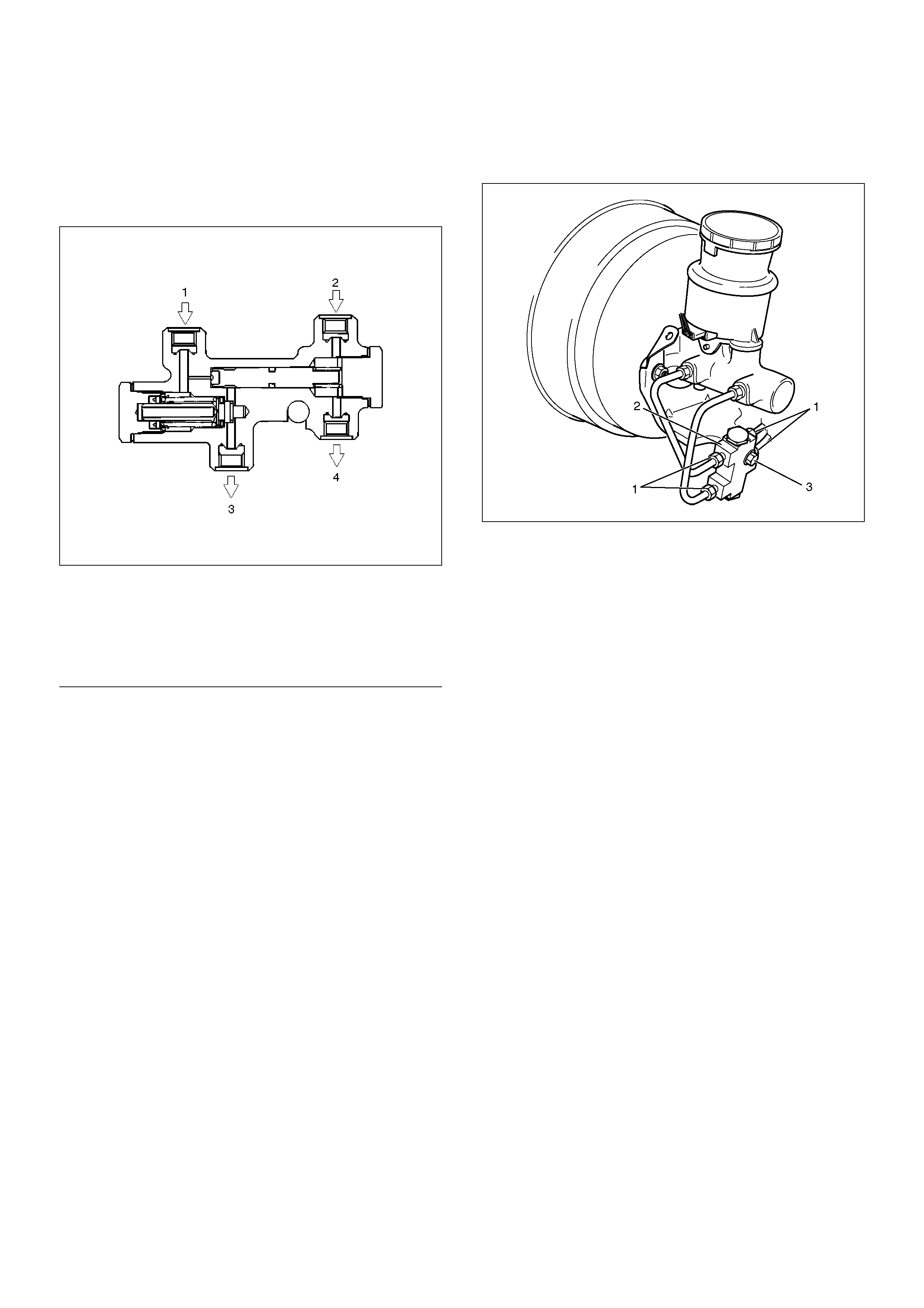

P & B (Proportioning and Bypass) Valve

P & B (Proportioning and Bypass) Valve

Sectional View

350RW014

EndOFCallout

The P&B valve contains two sections, each serving a

different function.

The proportioning section of the P&B valve proportions

outlet pressure to the rear brakes after a predetermined

rear input pressure has been reached. This is done to

prevent rear wheel lock up on the vehicles with light rear

wheel loads. The valve has a by–pass feature which

assures full system pressure to the rear brakes in the

event of front brake system malfunction. Also full front

pressure is retained in the event of rear brake

malfunction.

The P&B valve is not repairable and must be replaced

as complete assembly.

Removal

1. The P&B valve is not repairable and must be

replaced as a complete assembly. Care must be

taken to prevent brake fluid from contacting any

painted surface.

2. Remove hydraulic pipes (1) and plug the pipes (1)

to prevent the loss of fluid or the entrance of dirt.

3. Remove bolt (3).

4. Remove P&B valve (2).

350R200003

Installation

1. Install P&B valve (2).

2. Install bolt (3) and tighten the bolt to the specified

torque.

Torque: 22 N·m (2.2 kg·m/16 lbft)

3. Install hydraulic pipes (1) and tighten the bolt to the

specified torque.

Torque: 15 N·m (1.5 kg·m/11 lbft)

4. After installing the brake pipes, bleed the brakes as

described in Bleeding Brake Hydraulic System in

this section.

Legend

(1) Master Cylinder (Secondary)

(2) Master Cylinder (Primary)

(3) Rear Brake

(4) Front Brake

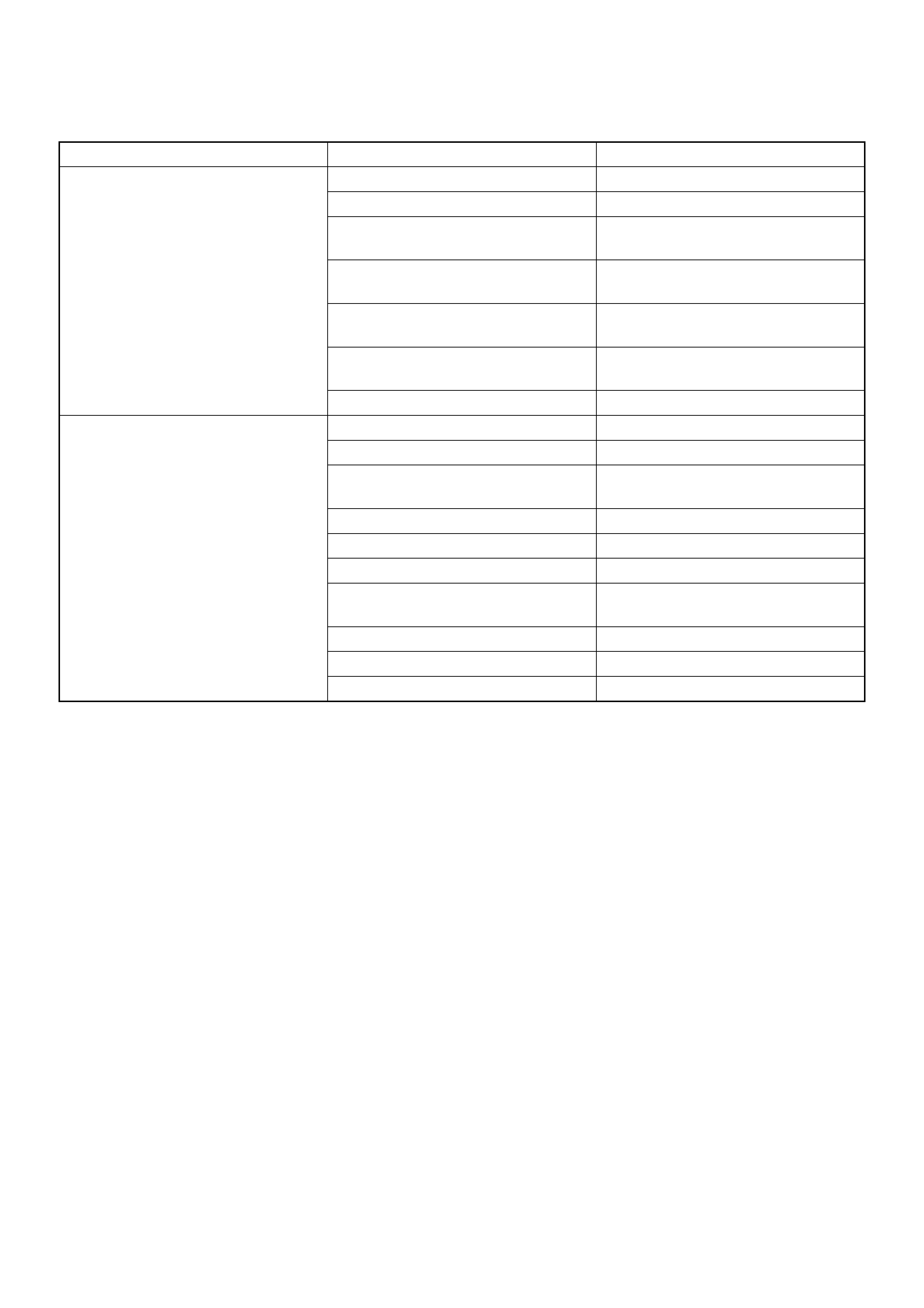

Main Data and Specifications

Torque Specifications

E05R200009

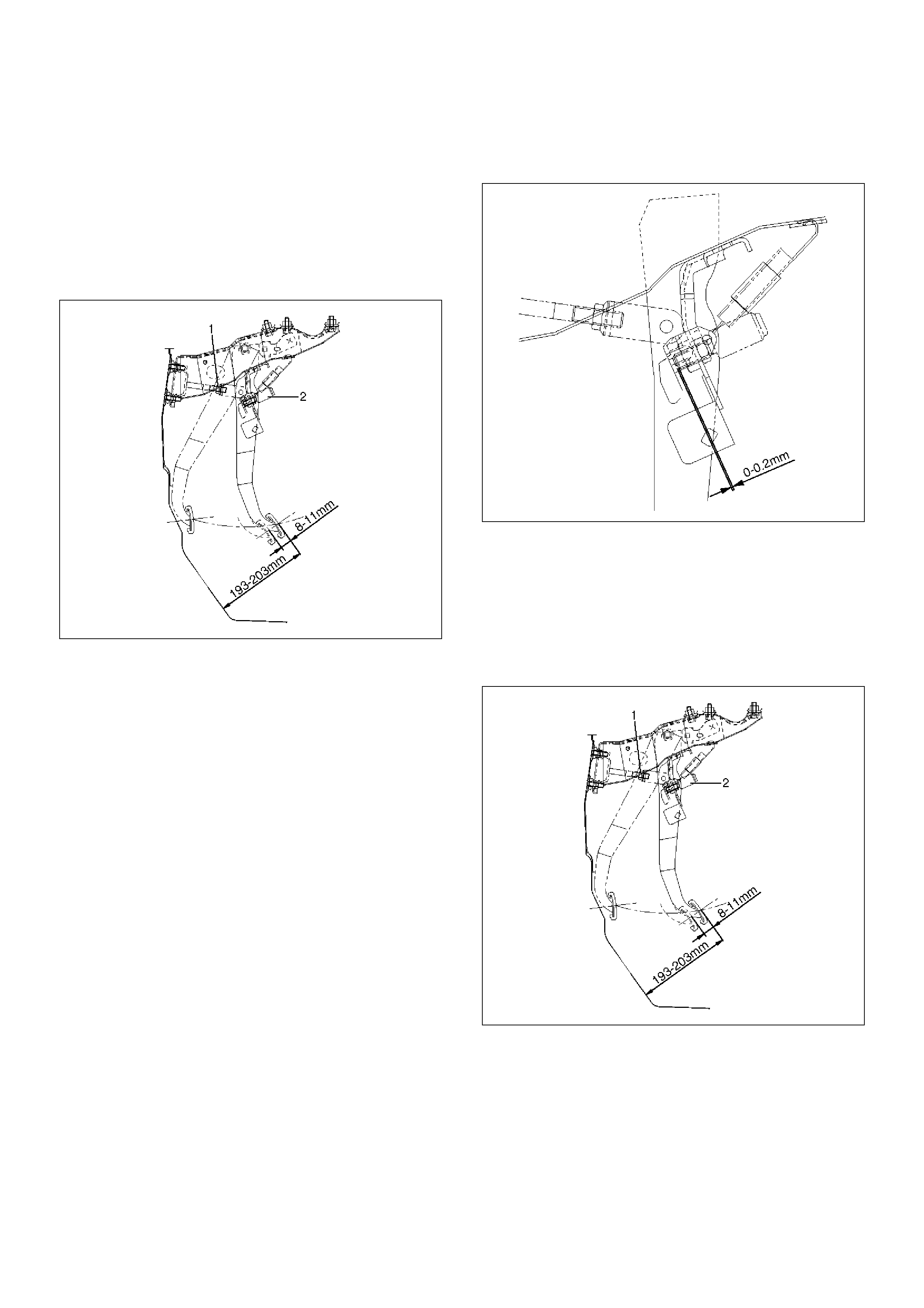

Brake Pedal

Checking Pedal Height

The push rod serves as the brake pedal stopper when

the pedal is fully released. Brake pedal height

adjustment should be performed as follows:

Adjust Brake Pedal

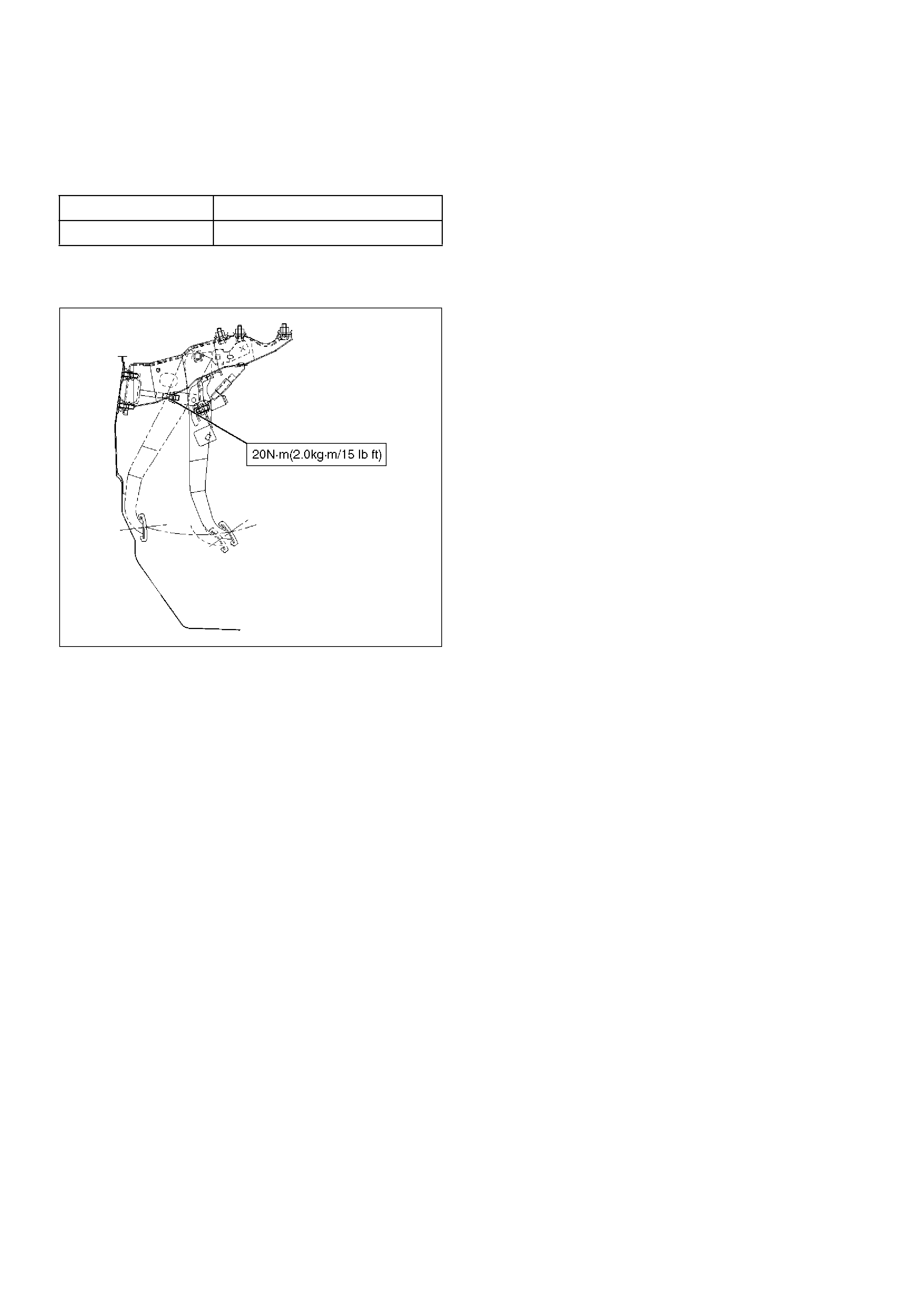

310RW021

1. Measure the brake pedal height after making sure

the pedal is fully returned by the pedal return spring.

Pedal height must be measured after starting the

engine and stepping on it several times.

Pedal Free Play: 8-11 mm (0.31-0.43 in)

Pedal Height: 193-203 mm (7.60-7.99 in)

NOTE: Pedal free play must be measured after turning

off the engine and stepping on the brake pedal firmly

five times or more.

2. If the measured value is not within the above range,

adjust the brake pedal as follows:

a Disconnect the stoplight switch connector.

b Loosen the stoplight switch lock nut.

c Rotate the stoplight switch so that it moves

away from the brake pedal.

d Loosen the lock nut (1) on the push rod.

e Adjust the brake pedal to the specified height by

rotating the push rod in the appropriate

direction.

f Tighten the lock nut to the specified torque.

Torque: 20 N·m(2.0 kg·m/15 lbft)

g Adjust the stoplight switch (2) to the specified

clearance (between the switch housing and the

brake pedal) by rotating the switch housing.

Clearance: 0–0.2 mm (0–0.008 in)

310RW022

NOTE: While adjusting the stoplight switch, make sure

that the threaded part of the stoplight switch does not

push the brake pedal.

h Tighten the stoplight switch lock nut.

i Connect the stoplight switch connector.

Checking Pedal Travel

310RW021

1. Pedal height must be measured after starting the

engine and revving it several times to apply vacuum

to the vacuum booster fully.

NOTE: Pedal height must be 50 mm (1.97 in) or more

when about 490N (50kg/110Ib) of stepping force is

applied.

2. If the measured value is lower than the above

range, air existing in the hydraulic system is

suspected. Perform the bleeding procedure.

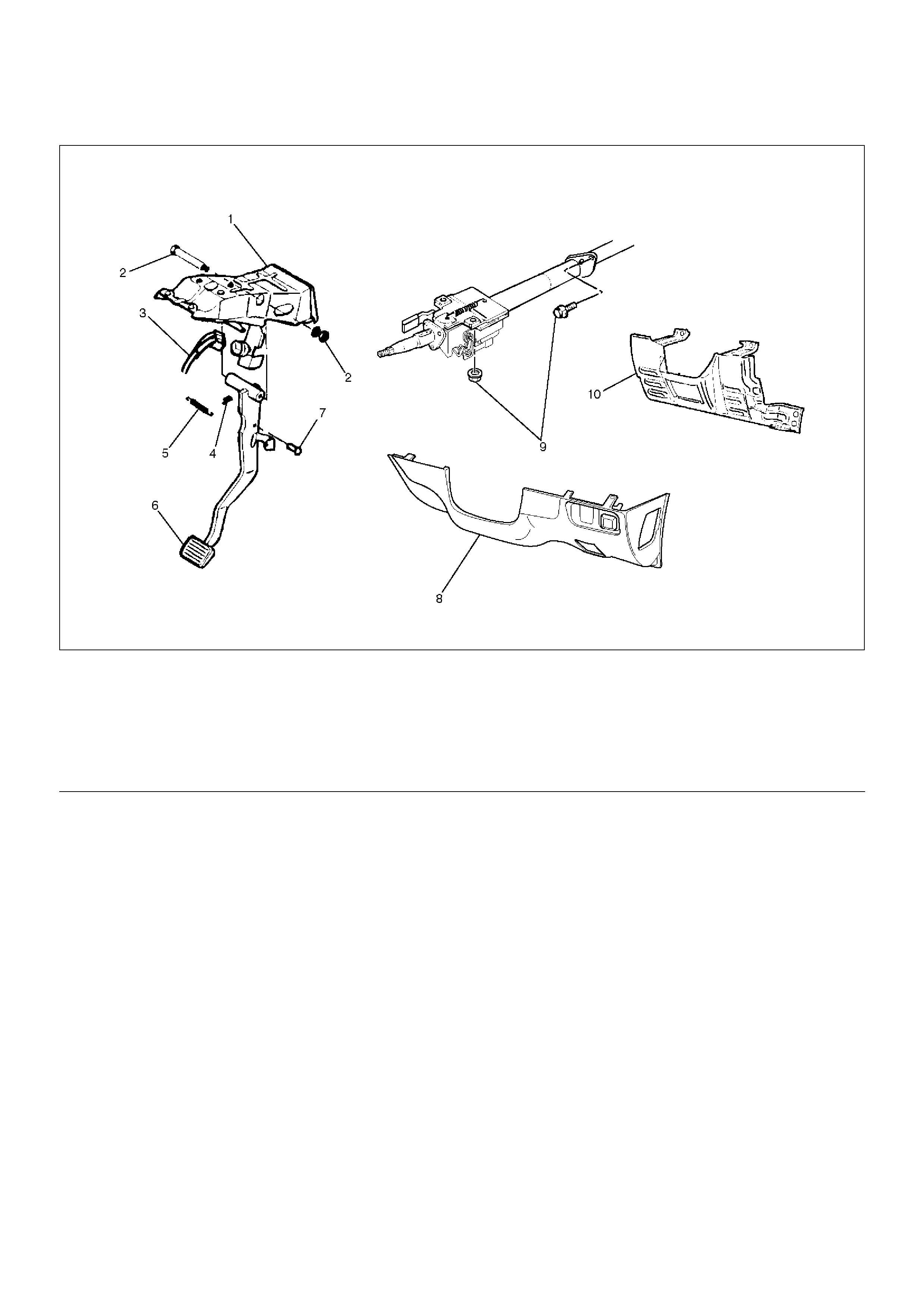

Brake Pedal and Associated Parts

310RY00008

EndOFCallout

Removal

1.Disconnect the battery “–" terminal cable, and wait

at least 5 minutes.

2.Disconnect the yellow 3 way SRS connector located

under the steering column.

3.Remove the engine hood opening lever.

4.Remove lower cover (8).

5.Remove driver knee bolster (10).

6.Disconnect the stop light switch connector (3).

Disconnect the anti-theft control module connector.

f to Body and Accessories section.

7.Remove snap pin (4) and push rod pin (7).

8.Remove the steering column shaft fixing bolt and

nut (9) on the steering wheel side, and lower the

steering column shaft.

9.Remove the brake pedal bracket assembly (1).

10.Remove return spring (5).

11.Remove fulcrum pin and nut (2).

12.Remove pedal assembly (6).

Installation

1.Apply grease to the entyre circumference of the

fulcrum pin.

2.Install pedal assembly (6) and fulcrum pin and nut

(2).

Tighten the nut (2) to the specified torque.

Torque: 35 N·m (3.6 kg·m/26 lbft)

3.Install the brake pedal bracket assembly (1).

Tighten the bolts and nuts soecified torque.

Torque: 15 N·m (1.5 kg·m/11 lbft)

4.Install return spring (5).

5.Adjust pedal free travel.

Refer to Brake Pedal Adjustment in this section.

6. Tighten the steering column fixing bolt (9) (dash

panel) to the specified torque.

Torque: 20 N·m (2.0 kg·m/14 lbft)

7. Tighten the steering column fixing nut (9) (Cross

Beam) to the specified torque.

Torque: 17 N·m (1.7 kg·m/12 lbft)

Legend

(1) Brake Pedal Bracket Assembly

(2) Fulcrum Pin and Nut

(3) Connector

(4) Snap Pin

(5) Return Spring

(6) Pedal Assembly

(7) Push Rod Pin

(8) Lower Cover

(9) Bolts and Nut

(10) Driver Knee Bolster

8.Apply grease to the entyre circumference of the

Push rod pin (7).

9.Install push rod pin (7).

10.Install snap pin (4).

11.Connect the anti-theft control module connector.

Refer to Body and Accessories section.

12. Connect the stop light switch connector (3).

13. Install driver knee bolster (10) and lower cover (8).

14. Install the engine hood opening lever.

15. Connect the yellow 3 way SRS connector located

under the steering column.

16. Connect the battery “–" terminal cable.

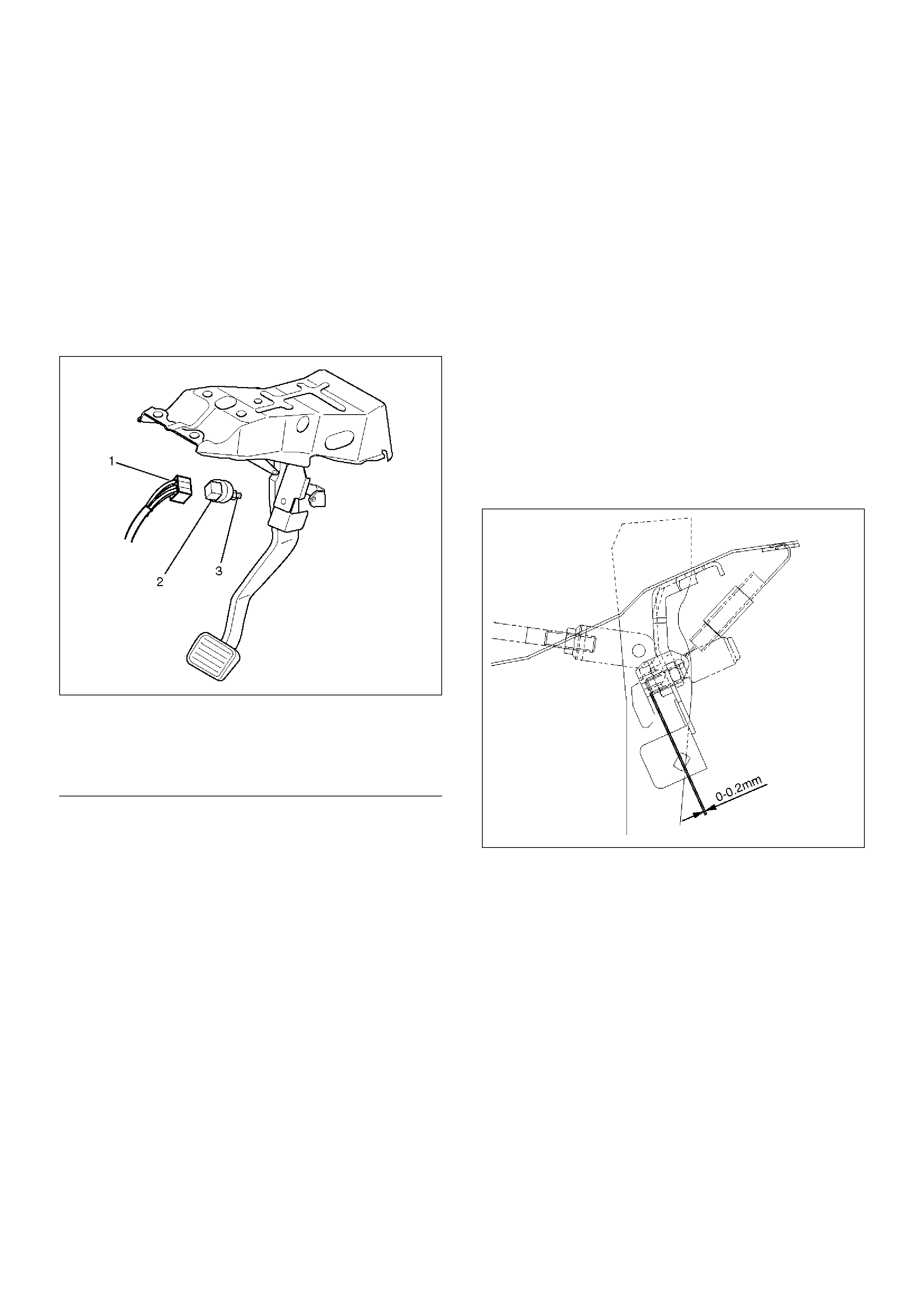

Stoplight Switch

Parts Location

310RW024

EndOFCallout

Removal

1. Disconnect connector (1)

2. Remove lock nut (3).

3. Remove switch (2).

Installation

1. Adjust the stop light switch to the specified

clearance (between switch housing and brake

pedal) by rotating the switch housing.

Clearance : 0-0.2 mm (0-0.008 in)

NOTE: Do not attempt to force the push rod into

position during the stop light switch installation and

adjustment procedure.

310RW022

2. Connect connector (1).

3. Install lock nut (3).

Legend

(1) Connector

(2) Switch

(3) Lock Nut

Main Data and Specifications

General Specifications

Torque Specifications

E05RX006

Pedal free play 6–10 mm (0.23 –0.39 in)

Pedal Height 173–185 mm (6.81–7.28 in)

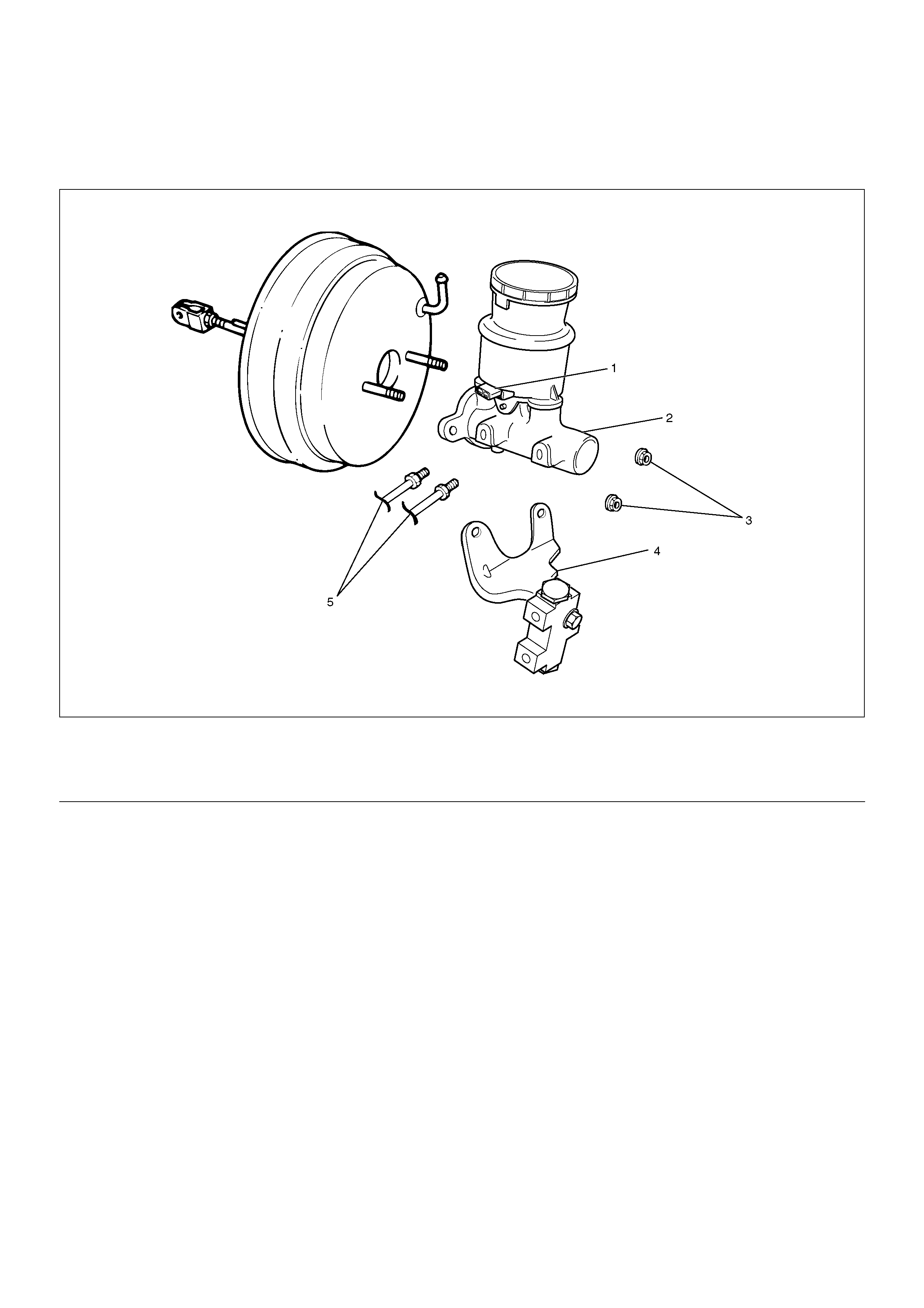

Master Cylinder Assembly

Master Cylinder Assembly and Associated Parts

330R200006

EndOFCallout

Removal

CAUTION: When removing the master cylinder

from the vacuum booster, be sure to get rid of the

internal negative pressure of the vacuum booster

(by, disconnecting the vacuum hose) in advance.

If any negative pressure remains in the vacuum

booster, the piston may possibly come out when the

master cylinder is being removed, letting the brake

fluid run out.

While removing the master cylinder, do not hold the

piston as it can be easily pulled out.

Outside surface of the piston is the surface on

which seals are to slide. Care should be taken to

keep the surface free of cuts and dents.

1. Disconnect electrical connector.

2. Remove brake pipes and after disconnecting the

brake pipe, cap or tape the openings of the brake

pipe to prevent the entry of foreign matter.

3. Remove 2 attaching nuts.

4. Remove P&B valve and bracket.

5. Remove master cylinder.

Inspection and Repair

Master Cylinder

The master cylinder is not repairable and must be

replaced as a complete assembly if found defective.

Inspection

Excessive brake pedal travel, malfunction or dragging

brake suggests that the master cylinder is defective. In

such cases perform the following visual check:

Visual Check

Make parts replacement as required if wear, distortion,

nicks, cuts, corrosion, or other abnormal conditions are

found through the following parts inspection:

• Master cylinder body

• Fluid reservoir

•O–ring

Legend

(1) Electrical Connector

(2) Master Cylinder

(3) 2 attaching Nuts

(4) P&B Valve and Bracket

(5) Brake Pipes

Main Data and Specifications

General Specifications

Torque Specifications

E05R200010

Type Dual–circuit

Piston bore

diameter

25.4 mm (1.000 in)

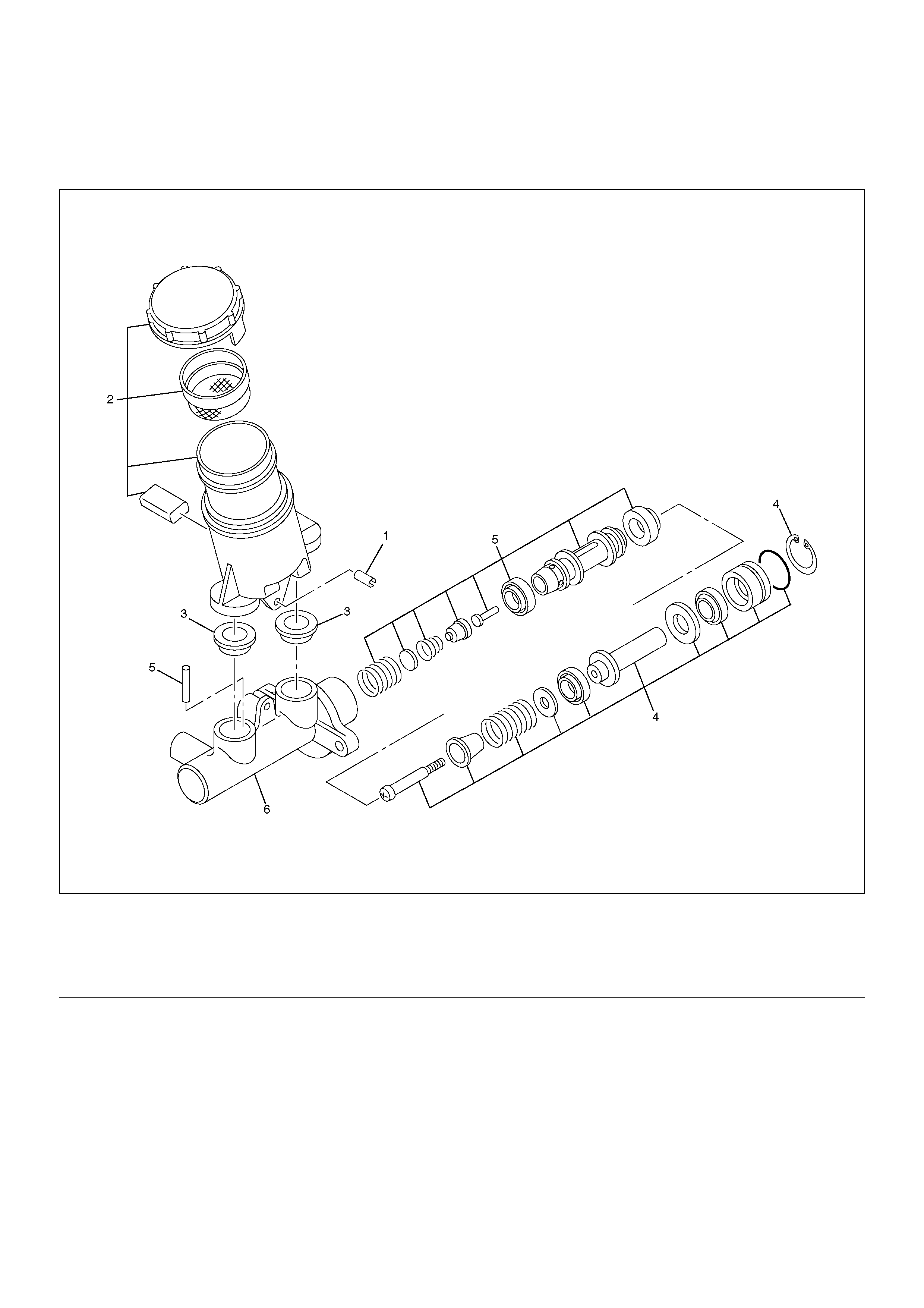

Master Cylinder Assembly

Master Cylinder Assembly Desassembled View

330R200005

EndOFCallout

Disassembly

1. Remove the spring pin.

2. Remove the reserve tank and the reserve tank cap.

The brake fulid level switch is built–in to the reserve

tank and cannot be removed.

3. Remove the O–ring.

4. Remove the snap ring.

5. Remove the primary piston assembly.

6. Invert the cylinder body and push on the secondary

piston until the pin falls free.

7. Remove the secondary piston assembly.

8. Remove the cylinder body.

Inspection

Excessive brake pedal travel, malfunction or dragging

brake suggests that the master cylinder is defective. In

such cases perform the following visual check:

Legend

(1) Spring Pin

(2) Reserve Tank and Reserve Tank Cap

(3) O–ring

(4) Primary Piston Assembly

(5) Secondary Piston Assembly

(6) Cylinder Body

Visual Check

Make parts replacement as required if wear, distortion,

nicks, cuts, corrosion, or other abnormal conditions are

found through the following parts inspection:

•Master cylinder body

•Fluid reservoir

•O–ring

•Wash each part in brake fluid before beginning the

inspection procedure.

•Check the inside surfaces of the master cylinder for

abrasion, corrosion, and other damage. Replace the

cylinder if necessary.

•Check the return port for clogging. Clean the port with

a wire and compressed air if nesessay.

•Check the piston and piston cup for abrasion,

damage, and wear. Replace the piston assembly if

any of these conditions exist.

•Check the return spring. Replace the spring if it is

weak.

•Check the snap ring. Replace the snap ring if it is

stretched or weak.

Reassembly

1.Wash each master cylinder internal part in brake

fluid before beginning installation.

2.Install the cylinder body.

3.Press the secondary piston assembly into the

cylinder body and hold it. Thread the pin through the

long hole of the piston to secure the piston

assembly.

4.Install the primary piston assembly.

5.Install the snap ring.

6.Install the O–ring

7.Install the reserve tank and the reserve tank cap.

8.Install the spring pin.

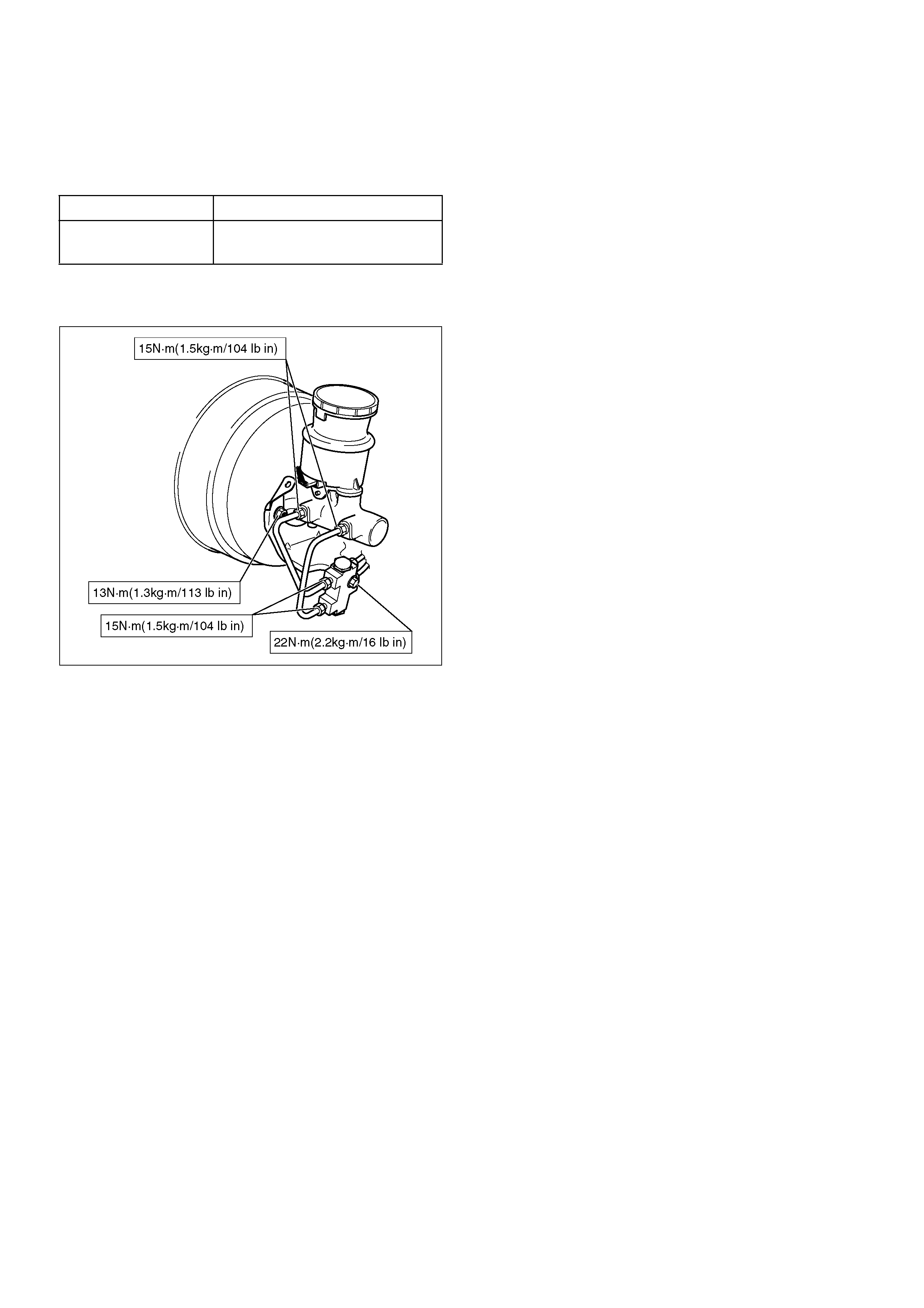

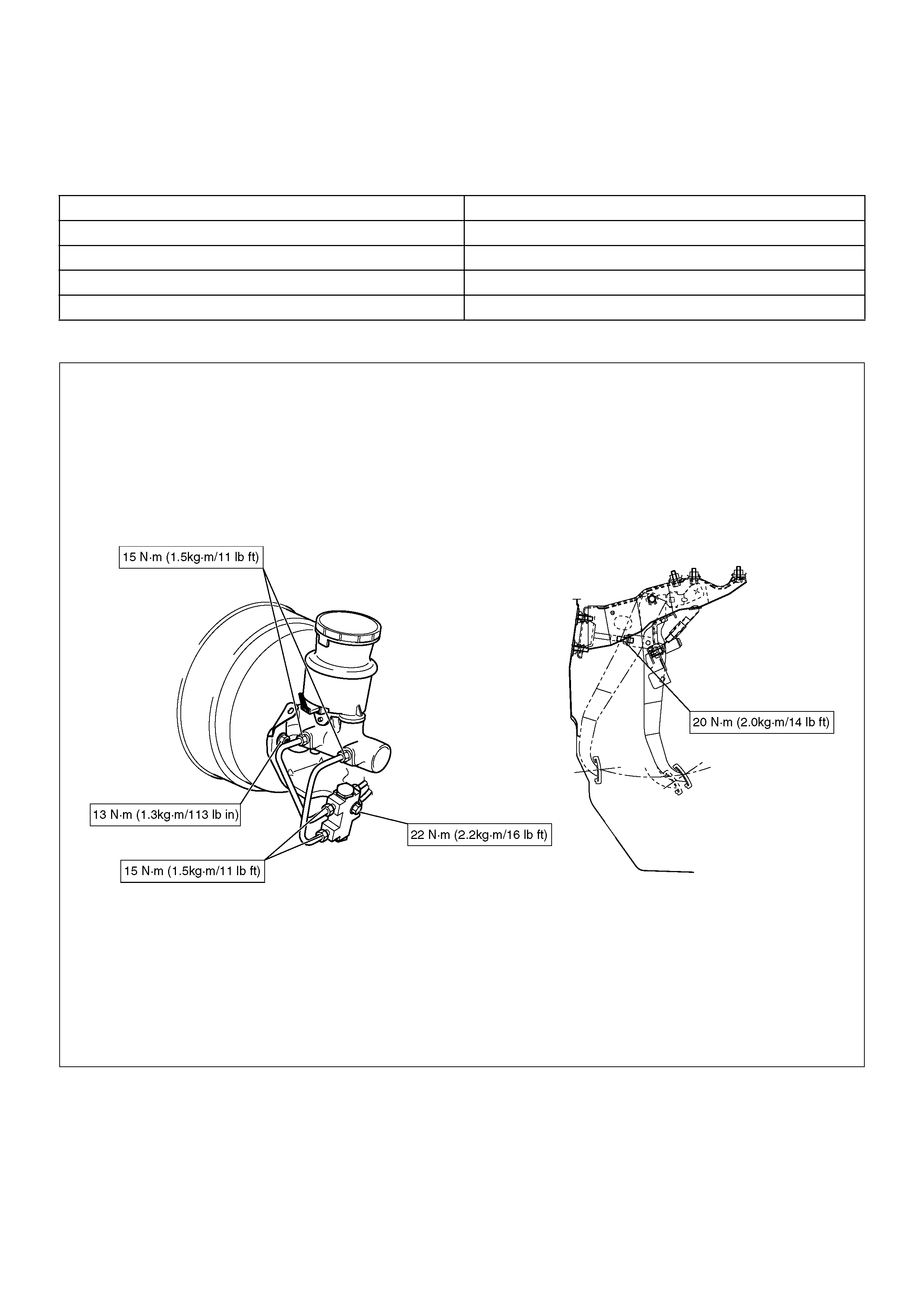

Installation

1.Install master cylinder.

When replacing the master cylinder or vacuum

booster or both, always measure the vacuum

booster push rod protrusion and adjust it as

necessary (Refer to Vacuum Booster in section).

2. Install P&B valve and bracket.

3. Install 2 attaching nuts and tighten the attaching

nuts to the specified torque.

Torque: 13 N·m (1.3 kg·m/113 lbin)

4. Install brake pipes and tighten the brake pipe to the

specified torque.

Master cylinder and P&B valve sides

Torque: 15 N·m (1.5 kg·m/11 lbin)

Others

Torque: 16 N·m (1.6 kg·m/12 lbin)

5. Connect electrical connector.

Vacuum Booster Assembly

Vacuum Booster Assembly and Associated Parts

331R200004

EndOFCallout

Removal

1.Before removing the vacuum booster assembly,

disconnect and remove the brake pipes.

2.Remove master cylinder, refer to “Master Cylinder

Removal" in this section.

CAUTION: When removing the master cylinder

from the vacuum booster, be sure to get rid of the

internal negative pressure of the vacuum booster

(by, disconnecting the vacuum hose) in advance.

If any negative pressure remains in the vacuum

booster, the piston may possibly come out when the

master cylinder is being removed, letting the brake

fluid run out.

Do not hold the piston while removing the master

cylinder, the piston can be easily pulled out.

Outside surface of the piston is the surface on

which seals are to slide. Care should be taken to

keep the surface free of cuts and dents.

3. Remove vacuum hose.

4. Disconnect the yoke clevis from the brake pedal.

5. Remove vacuum booster fixing nut.

6. Remove vacuum booster.

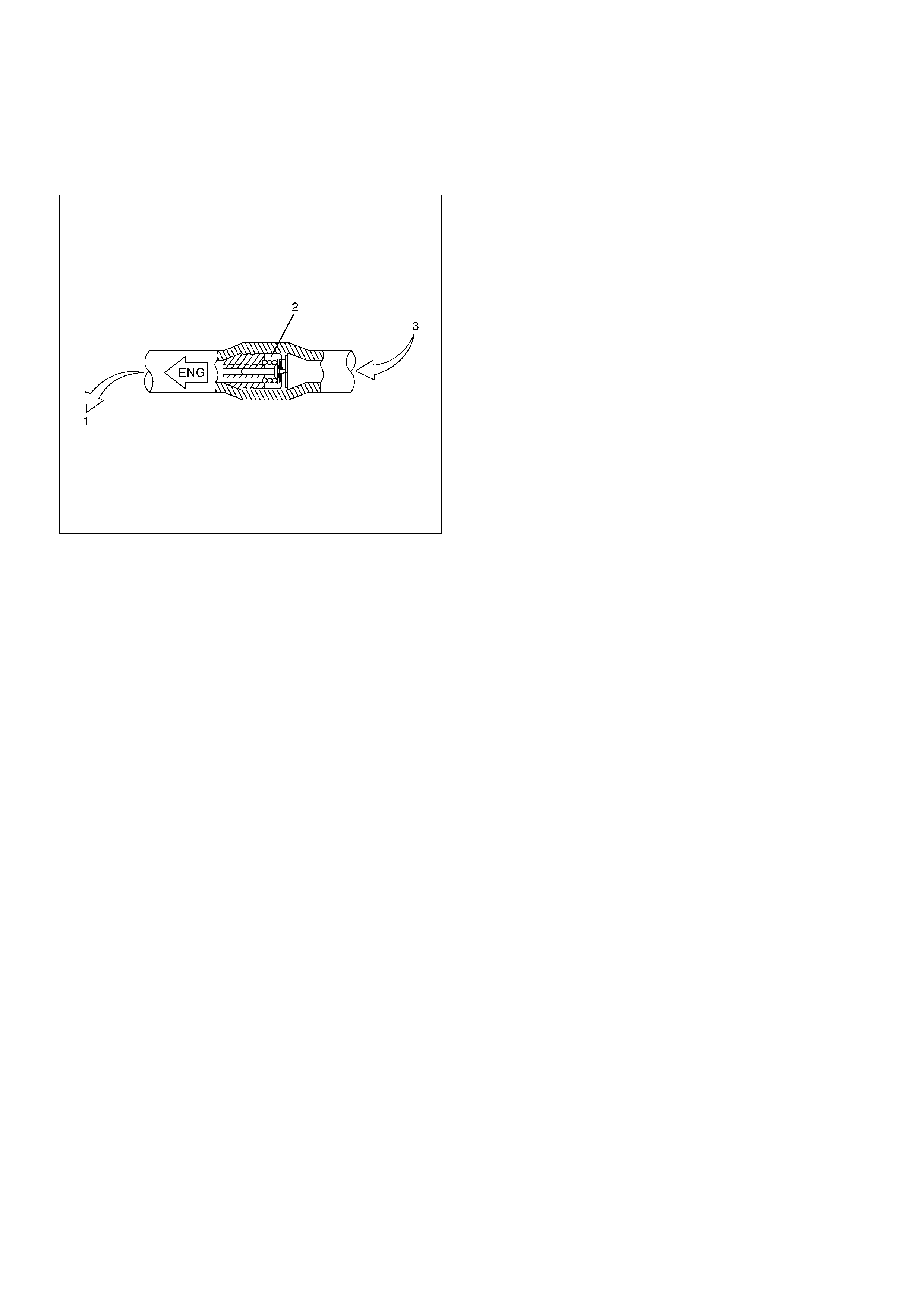

Inspection and Repair

Vacuum Hose

1. Inspect the check valve (2), which is installed inside

the vacuum hose.

2. Air should pass freely from the vacuum booster (3)

to the engine (1).

Legend

(1) Snap Pin

(2) Vacuum Booster Fixing Nut

(3) Vacuum Hose

(4) Master Cylinder

(5) Vacuum Booster

(6) Pin

3.Air should not pass from the engine (1) to the

vacuum booster (3). If it does, the check valve is

inoperative and must be replaced.

360RY00004

Installation

1.Install vacuum booster fixing nut and tighten the

specified torque.

Torque: 15 N·m (1.5 kg·m/11 lbft)

2.Install yoke clevis.

3.Connect vacuum hose and make sure that the

arrow on the hose points in the direction of the

engine.

4.Install master cylinder, refer to “Master Cylinder

Installation" in this section.

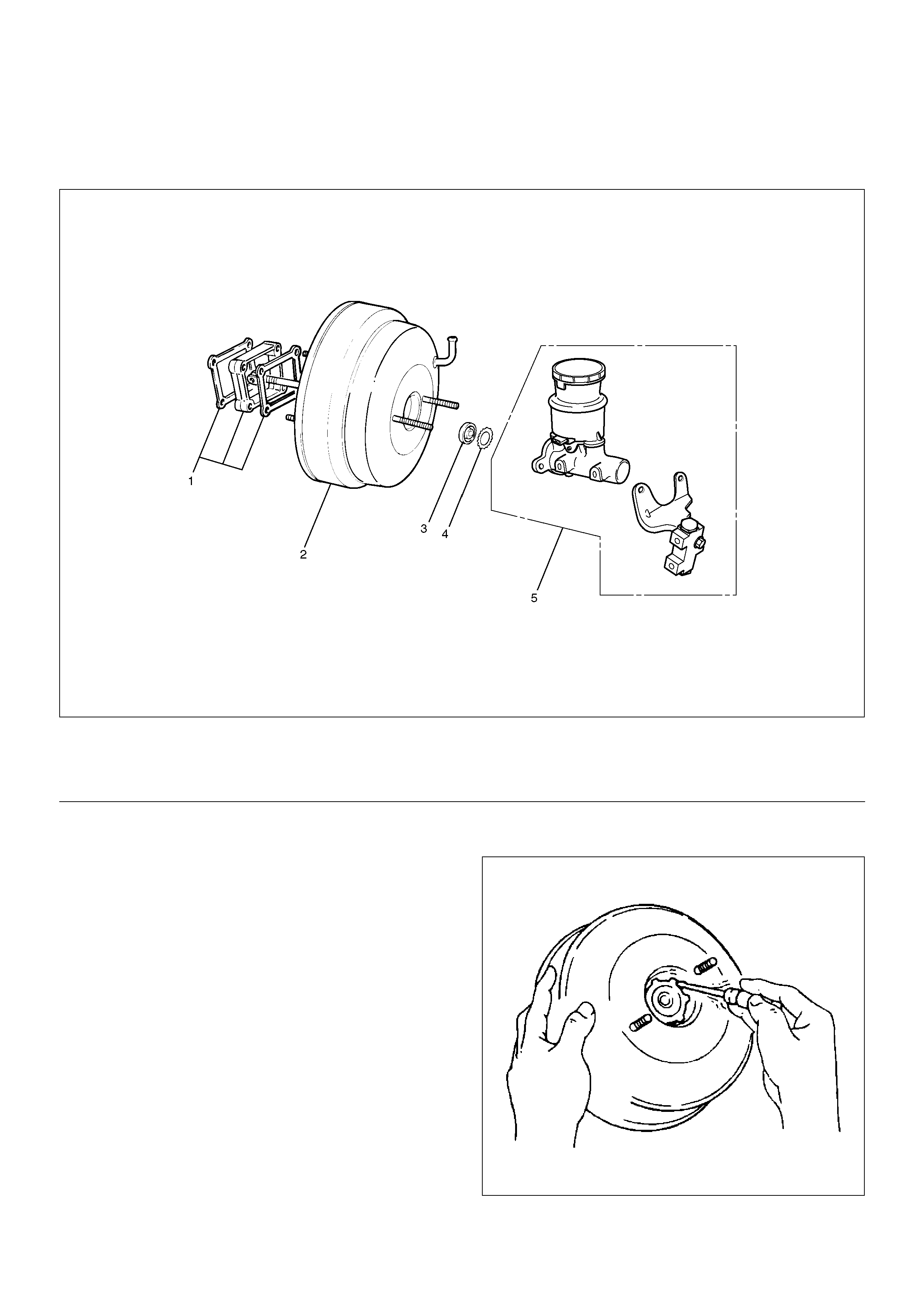

Exterior Components

Exterior Components and Associated Parts

331R200006

EndOFCallout

Removal

1.Remove master cylinder. Refer to “Master Cylinder"

in this section.

2.Remove vacuum booster. Refer to “Vacuum

Booster" in this section.

3. Remove 2 gaskets and spacer.

4. Remove retainer, plate and seal assembly.

331RS003

Legend

(1) 2 Gaskets and Spacer

(2) Vacuum Booster

(3) Plate and Seal Assembly

(4) Retainer

(5) Master Cylinder

Inspection and Repair

Visual Check

Make necessary parts replacement if cuts, nicks,

excessive wear, or other abnormal conditions are found

through inspection.

NOTE: The parts listed below must be replaced with

new ones whenever the master cylinder is removed.

1.Plate and seal assembly

2.Retainer

Installation

1.Install plate and seal assembly.

2.Install retainer.

3.Install vacuum booster, refer to “Vacuum Booster" in

this section.

4.Install master cylinder, refer to “Master Cylinder" in

this section and after installation, perform brake

pedal check and adjustment. Refer to “Brake Pedal"

in this section.

Vacuum Booster Overhaul

Vacuum Booster

The vacuum booster cannot be disassembled for repair.

Replace a defective vacuum booster with a new one.

Main Data and Specifications

General Specifications

Torque Specifications

E05R200011

Vacuum booster diaphragm diameter (Front) 205 mm (8.07 in)

Vacuum booster diaphragm diameter (Rear) 230 mm (9.06 in)

Push rod stroke More than 32.0 mm (1.26 in)

Plunger diameter 10.25 mm (0.40 in)

Push rod diameter 27.4 mm (1.08 in)

Front Disc Brake Pads

Front Disc Brake Pads Inspection

Check the outer pad by looking at each caliper from

above. Check the thickness on the inner pad by looking

down through the inspection hole in the top of the

caliper. Whenever the pad is worn to about the

thickness of the pad base, the pad should be removed

for further measurements. The pad should be replaced

anytime the pad thickness (1) is worn to within 1.00 mm

(0.039 in) of the pad itself.

Wear indicators are installed on disc brake pads, disc

brake pads need replacement when the wear

indicator is heard.

Minimum limit (1): 1.0 mm (0.039 in)

302RS002

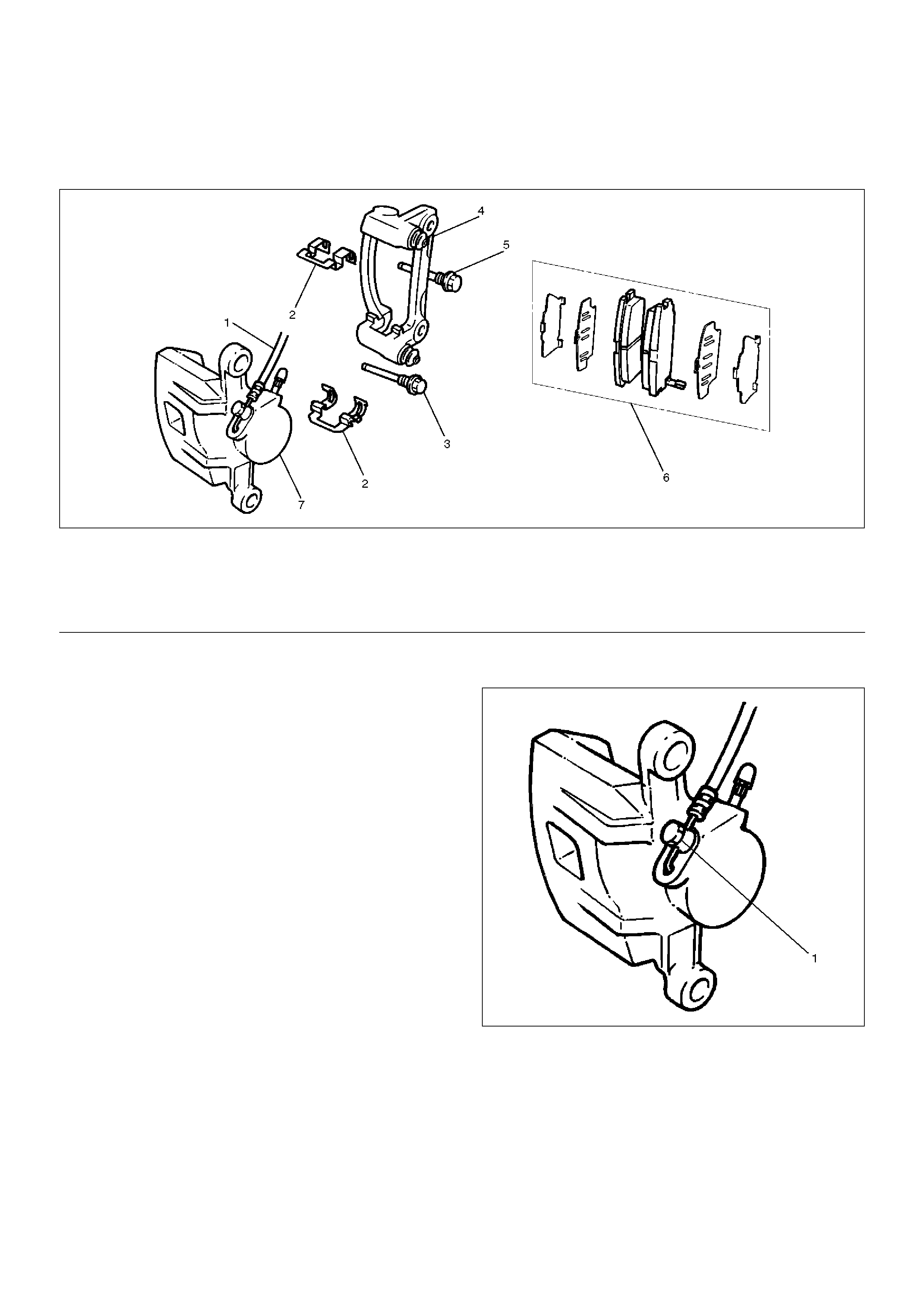

Front Disc Brake Pads and Associated Parts

302R200026

EndOFCallout

Legend

(1) Pin Bolt

(2) Caliper Assembly

(3) Pad Assembly

(4) Clip

(5) Outer Side

Removal

NOTE: If a squealing noise occurs from the front brake

while driving, check the pad wear indicator plate. If the

indicator plate contacts the rotor, the disc pad assembly

should be replaced.

•Draw out two–thirds of the brake fluid from the

reservoir.

•Raise the vehicle and support it with suitable safety

stands.

1.Remove wheel and tyre assembly, refer to Wheels

and Tyres System in Section 10.

2. Remove pin bolt (1).

302R20002 8

3. Rotate caliper assembly and support the caliper

assembly so that the brake hose is not stretched or

damaged.

4. Remove pad assembly with shim.

5. Remove Clip.

Installation

1. Install clip.

302R200023

2. Apply special grease (approximately 0.2g) to both

contacting surfaces of the inner shims (2). Wipe

off extruded grease after installing. Install pad

assembly with shim.

302R200024

EndOFCallout

Legend

(2) Inner Shim

(3) Wear Indicator

(4) Inner Side

3.Carefyully use adjustable pliers to bottom the piston

into the caliper bore. Do not pull or twist the flexible

hose or damage will occur.

Install caliper assembly.

Set caliper assembly in place.

4.Install lock bolt (5) and tighten the bolt to the

specified torque.

Torque: 45 N·m (4.6 kg·m/33 lbft)

302R200008

5.Install wheel and tyre assembly, refer to Wheels and

Tyres System in Section 10.

6. Pump the brake pedal several times to make sure

that the pedal is firm. Check the brake fluid level in

the reservoir after pumping the brakes.

Front Disc Brake Rotor

Inspection

In the manufacturing of the brake rotor, all the

tolerances regarding surface finish, parallelism and

lateral runout are held very closely. Maintaining these

tolerances provides the surface necessary to assure

smooth brake operation.

Lateral Runout

Lateral runout is the movement of the rotor from side to

side as it rotates on the spindle. This could also be

referred to as “rotor wobble".

This movement causes the piston to be knocked back

into its bore. This results in additional pedal travel and a

vibration during braking.

Checking Lateral Runout

1.Adjust the wheel bearing correctly, refer to

Differential in Section 4A.

2. Attach the dial indicator accordingly so that the stem

contacts the rotor surface to approximately

29mm (1.14 in) from the rotor edge.

3. Rotate the rotor one complete turn and inspect for

signs of lateral runout. Lateral runout should

not exceed 0.13 mm (0.005 in).

Maximum runout: 0.13 mm (0.005 in)

411R200008

Parallelism

Parallelism is the measurement of thickness of the rotor

at four or more points around the circumference of the

rotor. All measurement must be made at 29 mm (1.14

in) from the edge of the rotor.

The rotor thickness must not vary more than 0.010 mm

(0.0004 in) from point to point.

Maximum runout: 0.010 mm (0.0004 in)

411R200007

Replacing Brake Rotors

When installing new brake rotors, do not refinish the

surfaces. These parts are at the correct level of surface

finish.

Refinishing Brake Rotors

Accurate control of the rotor tolerances is necessary for

proper performance of the disc brakes. Machining of the

rotor should be done only with precision equipment. All

brake rotors have a minimum thickness dimension cast

into them. This dimension is the minimum wear

dimension and not a refinish dimension. The minimum

wear dimension is 24.60 mm (0.969 in). The minimum

refinish dimension is 26.00 mm (1.024 in).

When refinishing rotors, always use sharp cutting tools

or bits. Dull or worn tools leave a poor surface finish

which will affect initial braking performance. Vibration

dampening attachments should always be used when

refinishing braking surfaces. These attachments

eliminate tool chatter and will result in better surface

finish.

After refinishing, replace any rotor that does not meet

the minimum thickness of 26.00 mm (1.024 in). Do not

use a brake rotor that exceeds the manufacturers

specifications.

Minimum wear dimension: 24.60 mm (1.024 in)

Refinish dimension: 26.00 mm (1.024 in)

411R200009

Front Disc Brake Caliper Assembly

Front Disc Brake Caliper Assembly and Associated Parts

302R200027

EndOFCallout

Removal

1.Raise the vehicle and support with suitable safety

stands.

2.Remove wheel and tyre assembly, refer to Wheels

and Tyres System in Section 10.

3. Remove the bolt and gaskets, then disconnect the

flexible hose from the caliper and after

disconnecting the flexible hose (1), cap or tape the

openings to prevent entry of foreign material.

302R200007

Legend

(1) Brake Flexible Hose

(2) Pin Bolt

(3) Caliper Assembly

(4) Pad Assembly

(5) Clip

(6) Support Bracket with Pad Assembly

(7) Outer Side

4. Since the brake fluid flows out from the connecting

coupler, place a drain pan under the vehicle.

5. Remove pin bolt (2).

302R20002 0

6. Remove caliper assembly.

7. Remove support bracket with pad assembly and

take care not to damage the flexible brake hose

when removing the support bracket.

8. Remove pad assembly with shim and mark the

lining locations if they are to be reinstalled.

9. Remove clip.

Installation

1. Install clip.

302R20002 3

2. Apply special grease (approximately 0.2 g) to both

contacting surfaces of the inner shims (4). Wipe off

extruded grease after installing. Install pad

assembly with shim.

302R200025

EndOFCallout

3. Install support bracket and tighten the bolt (7) to the

specified torque.

Torque: 155 N·m (15.8 kg·m/115 lbft)

302R200009

Legend

(4) Inner Shim

(5) Wear Indicator

(6) Inner Side

4.Install caliper assembly.

5.Install pin bolt (8) and tighten the bolt to the

specified torque.

Torque: 45 N·m (4.6 kg·m/33 lbft)

302R200010

6.Install brake flexible hose, always use new gaskets

and be sure to put the hooked edge of the flexible

hose end into the anti–rotation cavity then tighten

the I–bolt (9) to the specified torque.

Torque: 35 N·m (26 lbft)

302R200021

7.Install wheel and tyre assembly, referring to Wheels

and Tyres System in Section 10.

8.Bleed brakes. Refer to Hydraulic Brakes in this

section.

Front Disc Brake Caliper

Front Disc Brake Caliper Disassembled View

302R200018

EndOFCallout

Disassembly

1.Insert a block of wood into the caliper and force out

the piston by blowing compressed air into the

caliper at the flexible hose attachment. This

procedure must be done prior to removal of the dust

boot.

Remove piston.

WARNING: Do not place your fingers in front of the

piston in an attempt to catch or protect it when

applying compressed air. This could result in

personal injury.

CAUTION: Use just enough air to ease the piston

out of the bore. If the piston is blown out, it may be

damaged.

302R200012

Legend

(1) Bleeder with Cap

(2) Caliper Body

(3) Piston

(4) Piston Seal

(5) Dust Boot: Piston

2. Remove dust boot: piston.

3. Remove piston seal.

4. Remove bleeder with cap.

5. Remove caliper body.

Inspection and Repair

Make necessary parts replacement, if wear, damage,

corrosion or any other abnormal conditions are found

through inspection.

Check the following parts:

• Rotor

• Cylinder body

• Cylinder bore

•Piston

• Guide pin, lock pin

• Support bracket

NOTE: The piston seal, boot ring and dust boot are to

be replaced each time the caliper is overhauled.

Discard these used rubber parts and replace them with

new ones.

Reassembly

1. Install caliper body.

2. Install bleeder with cap and tighten the cap to the

specified torque.

Torque: 8 N·m (0.8 kg·m/69 lbin)

3. Apply special rubber grease to the piston seal and

cylinder wall, then insert the piston seal into the

cylinder. The special rubber grease is included in

the repair kit.

302R20001 3

4. When inserting the piston into the cylinder, use

finger pressure only and do not use a mallet or other

impact tool, since damage to the cylinder wall or

piston seal can result.

Install piston.

302R200015

5. Apply special grease (approximately 1g) to the

piston and attach the dust boot to the piston and

caliper. Insert the dust boot ring into the dust boot.

6. Install guide bolt and lock bolt dust boot.

7. Install the dust boot on the support bracket after

applying special grease (approximately 1 g) onto

the dust boot inner surface. Apply special grease

onto the lock pin and guide pin setting hole of the

support bracket.

302R200022

EndOFCallout

8. Install pin bolt and tighten the bolt to the specified

torque.

Torque: 45 N·m (4.6 kg·m/33 lbft)

Legend

(1) Guide Pin

(2) Lock Pin

(3) Pin Boot

Main Data and Specifications

General Specifications

Torque Specifications

E05R200012

Type Floating, pin slide

Pad dimension 48.7 cm (7.55 in )

Adjusting method Self–adjusting

Piston diameter 45.4 mm (1.79 in) ´2

Disc type Ventilated

Disc thickness 26 mm (1.02 in)

Disc effective diameter 242 mm (9.53 in)

Rear Disc Brake Pads

Brake Pads Inspection

Check the outer pads by looking at each caliper from

above. Check the thickness on the inner pad by looking

down through the inspection hole in the top of the

caliper. Whenever the pad is worn to about the

thickness of the pad base, the pad should be removed

for further measurements. The pad should be replaced

anytime the pad thickness (1) is worn to within 1.0 mm

(0.039 in) of the pad itself.

The disc pads have a wear indicator that makes a noise

when the pad wears to where replacement is required.

Minimum limit (1): 1.0 mm (0.039 in)

302RW016

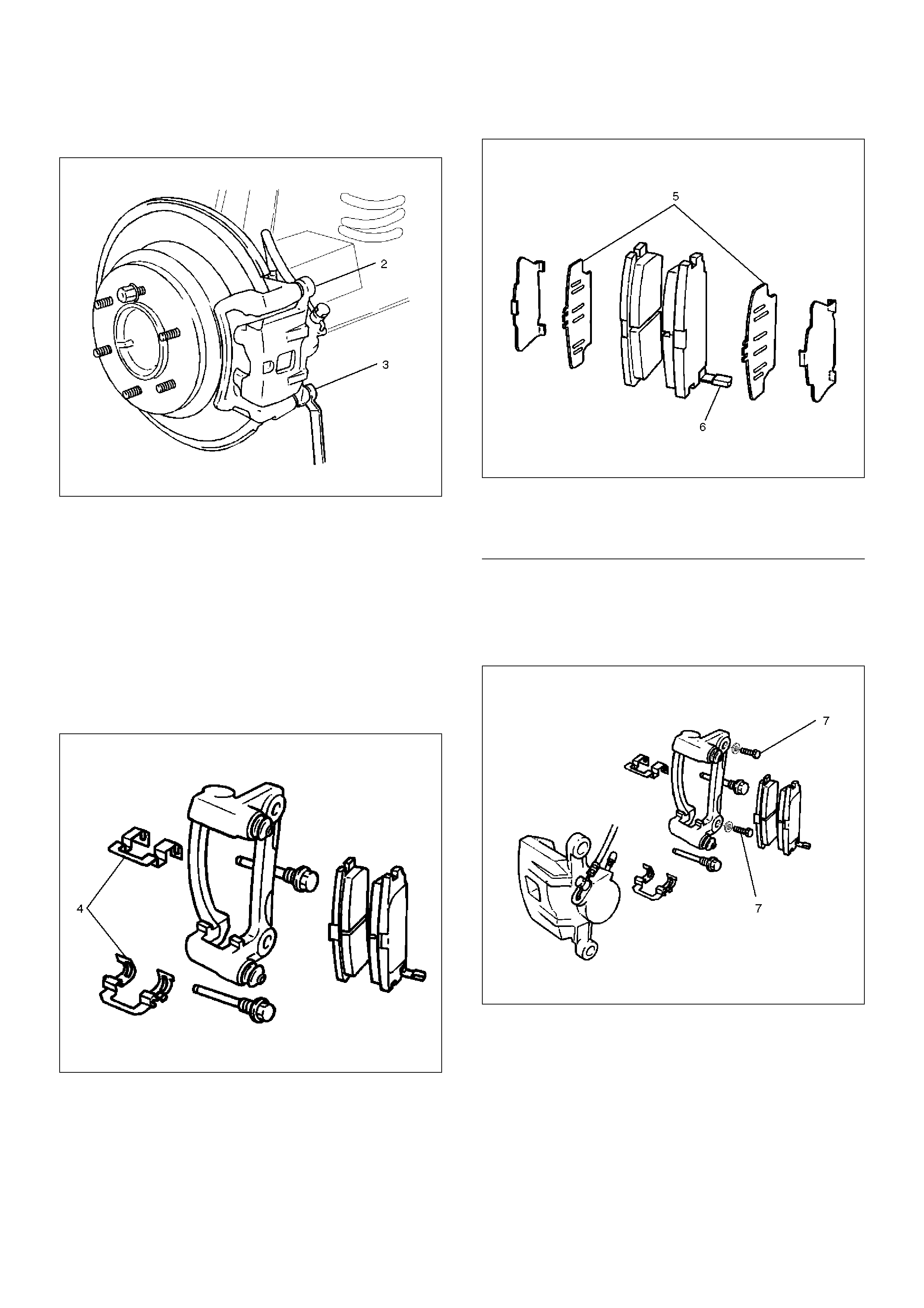

Brake Pads and Associated Parts

306RW001

EndOFCallout

Legend

(1) Caliper Assembly

(2) Clip

(3) Lock Bolt

(4) Pad Assembly

Removal

NOTE: If a squealing noise occurs from the rear brake

while driving, check the pad wear indicator plate. If the

indicator plate contacts the rotor, the disc pad assembly

should be replaced.

•Draw out two–thirds of the brake fluid from the

reservoir.

•Raise the vehicle and support it with suitable safety

stands.

1.Remove wheel and tyre assembly, referring to

“Wheels and Tyres System" in Section 10.

2. Remove lock bolt (1)

306RW002

3. Rotate caliper assembly and support the caliper

assembly so that the brake hose is not stretched or

damaged.

4. Remove pad assembly with shim.

5. Remove clip.

Installation

1. Install clip (2).

306RW003

2. Apply special grease (approximately 0.2g) to both

contacting surfaces of the inner shims. Wipe off

extruded grease after installing. Install pad

assembly with shim.

306RW004

EndOFCallout

Legend

(3) Inner Shim

(4) Wear Indicator

306RW005

3.Use adjustable pliers to bottom the piston into the

caliper bore. Be careful not to damage the piston

dust boot and do not damage the flexible hose by

twisting or pulling it. Install caliper assembly.

Set caliper assembly in place.

302RS008

4.Install lock bolt (5) and tighten the bolt to the

specified torque.

Torque: 43 N·m (4.4 kg·m/32 lbft)

5.Install wheel and tyre assembly, referring to “Wheels

and Tyres System" in Section 10.

6. Pump the brake pedal several times to make sure

that the pedal is firm. Check the brake fluid level in

the reservoir after pumping the brakes.

306R200003

Rear Disc Brake Rotor

Inspection

In the manufacturing of the brake rotor, all the

tolerances regarding surface finish, parallelism and

lateral runout are held very closely. Maintaining these

tolerances provides the surface necessary to assure

smooth brake operation.

Lateral Runout

Lateral runout is the movement of the rotor from side to

side as it rotates on the spindle. This could also be

referred to as “rotor wobble".

This movement causes the piston to be knocked back

into its bore. This results in additional pedal travel and a

vibration during braking.

Checking Lateral Runout

1.Adjust the wheel bearing correctly. Refer to Drive

Shaft System section.

2. Attach a dial indicator to some portion of the

suspension so that the stem contacts the rotor face

about 29 mm (1.14 in) from the rotor edge.

3. Move the rotor one complete rotation.

The lateral runout should not exceed 0.13 mm

(0.005 in)

Maximum runout: 0.13 mm (0.005 in)

306RY00013

Parallelism

Parallelism is the measurement of thickness of the rotor

at four or more points around the circumference of the

rotor. All measurement must be made at 22 mm (0.87

in) from the edge of the rotor.

The rotor thickness must not vary more than 0.010 mm

(0.0004 in) from point to point.

Maximum parallelism: 0.010 mm (0.0004 in)

420RS013

Replacing Brake Rotors

When installing new brake rotors, do not refinish the

surfaces. These parts are at the correct level of surface

finish.

Refinishing Brake Rotors

Accurate control of the rotor tolerances is necessary for

proper performance of the disc brakes. Machining of the

rotor should be done only with precision equipment. All

brake rotors have a minimum thickness dimension cast

into them. This dimension is the minimum wear

dimension and not a refinish dimension. The minimum

wear dimension is 16.6 mm (0.654 in). The minimum

refinish dimension is 16.97 mm (0.668 in).

When refinishing rotors, always use sharp cutting tools

or bits. Dull or worn tools leave a poor surface finish

which will affect initial braking performance. Vibration

dampening attachments should always be used when

refinishing braking surfaces. These attachments

eliminate tool chatter and will result in better surface

finish.

After refinishing, replace any rotor that does not meet

the minimum thickness of 16.97 mm (0.668 in). Do not

use a brake rotor that will not meet the specification.

Minimum wear dimension: 16.6 mm (0.654 in)

Refinish dimension: 16.97 mm (0.668 in)

420RW002

Rear Drum (In Disc) Inside Diameter Check

Check the rear drum inside diameter by measuring at

more than two portions as shown in the illustration.

If the inside diameter is greater than the limit, replace

the rear rotor.

Standard: 210.0 mm (8.27 in)

Limit: 211.4 mm (8.32 in)

420RS035

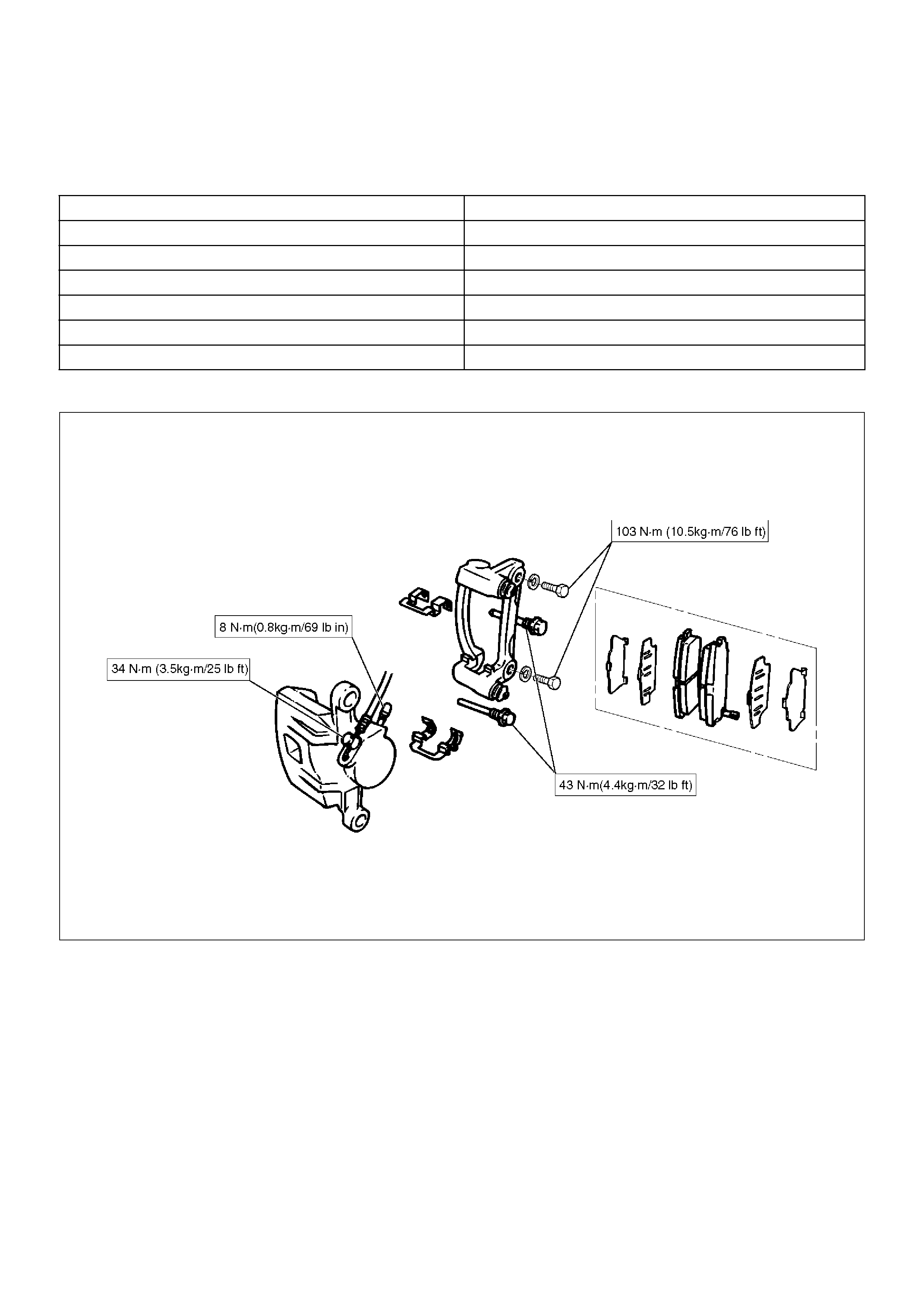

Rear Disc Brake Caliper Assembly

Rear Disc Brake Caliper Assembly and Associated Parts

306RW007

EndOFCallout

Removal

1.Raise the vehicle and support with suitable safety

stands.

2.Remove wheel and tyre assembly, referring to

“Wheels and Tyres System".

3. Remove the bolt and gaskets, then disconnect the

flexible hose from the caliper and after

disconnecting the flexible hose (1), cap or tape the

openings to prevent entry of foreign material.

306RW008

4. Since the brake fluid flows out from the connecting

coupler, place a drain pan under the vehicle.

5. Remove lock bolt (3).

Legend

(1) Brake Flexible Hose

(2) Clip

(3) Lock Bolt

(4) Support Bracket

(5) Guide Bolt

(6) Pad Assembly with Shim

(7) Caliper Assembly

6. Remove guide bolt (2).

306RW009

7. Remove caliper assembly.

8. Remove support bracket with pad assembly and

take care not to damage the flexible brake hose

when removing the support bracket.

9. Remove pad assembly with shim and mark the

lining locations if they are to be reinstalled.

10. Remove clip.

Installation

1. Install clip (4).

306RW010

2. Apply special grease (approximately 0.2g) to both

contacting surfaces of the inner shims (5). Wipe off

extruded grease after installing. Install pad

assembly with shim.

306RW011

EndOFCallout

3. Install support bracket and tighten the bolt (7) to the

specified torque.

Torque: 103 N·m (10.5 kg·m/76 lbft)

306RW012

4. Install caliper assembly.

5. Install lock bolt and guide bolt (8) and tighten the

bolt to the specified torque.

Torque: 43 N·m (4.4 kg·m/33 lbft)

Legend

(5) Inner Shim

(6) Wear indicator

306R200004

6.Install brake flexible hose, always use new gaskets

and be sure to put the hooked edge of the flexible

hose end into the anti–rotation cavity then tighten

the eye–bolt (9) to the specified torque.

Torque: 34 N·m (3.5 kg·m/25 lbft)

302RW017

7.Install the wheel and tyre assembly, referring to

“Wheels and Tyres System" .

8.Bleed brakes. Refer to “Hydraulic Brakes" in this

section.

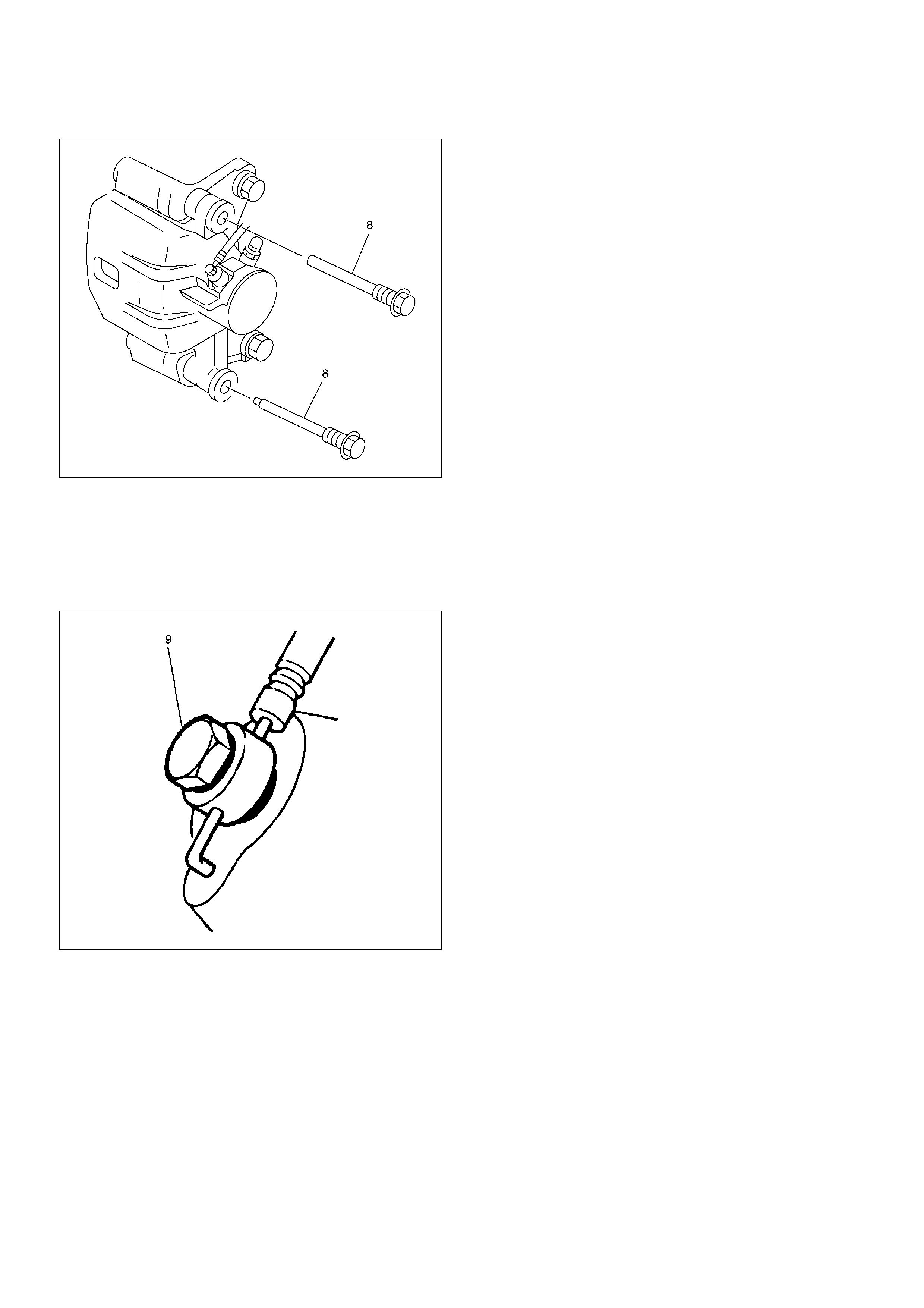

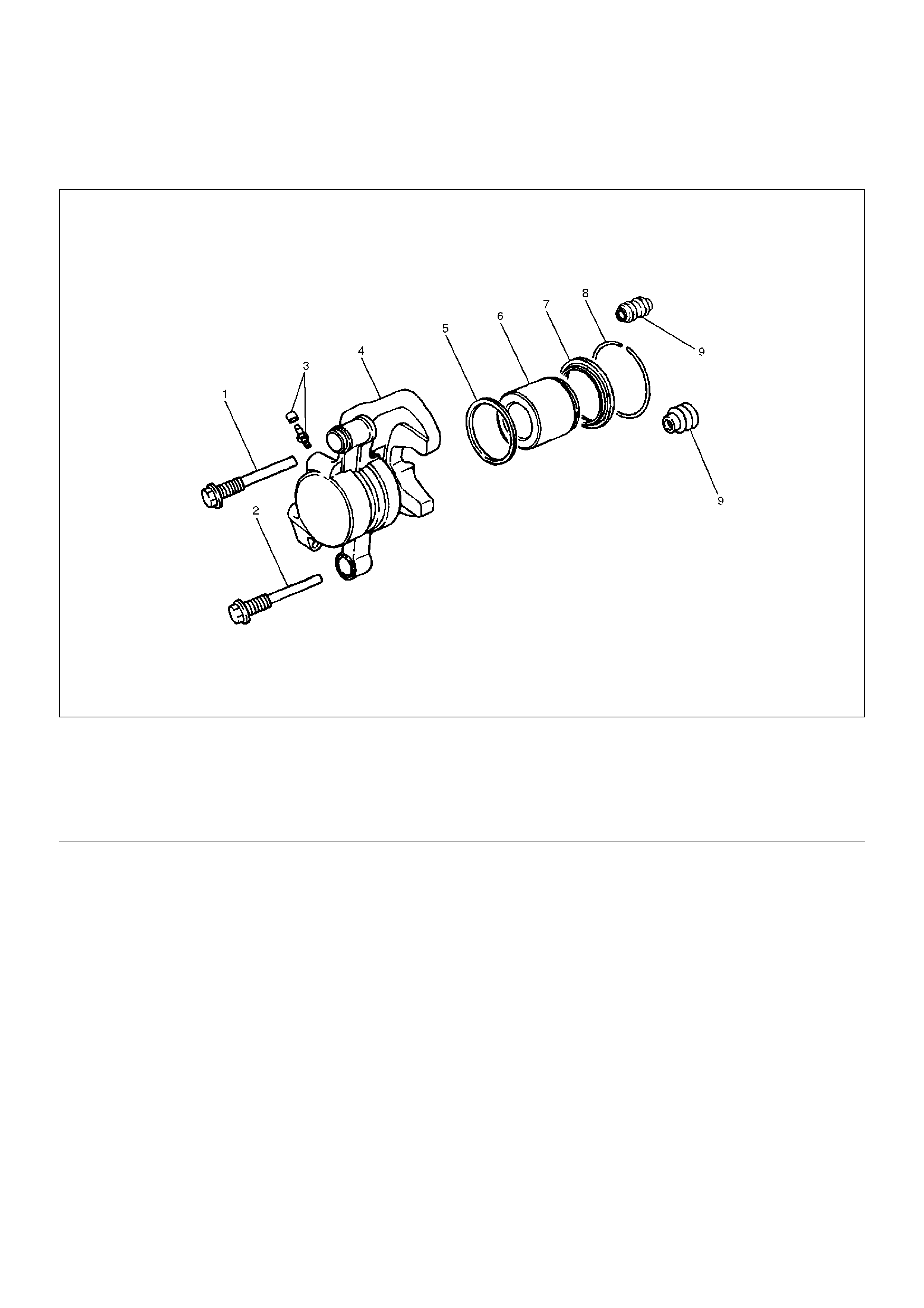

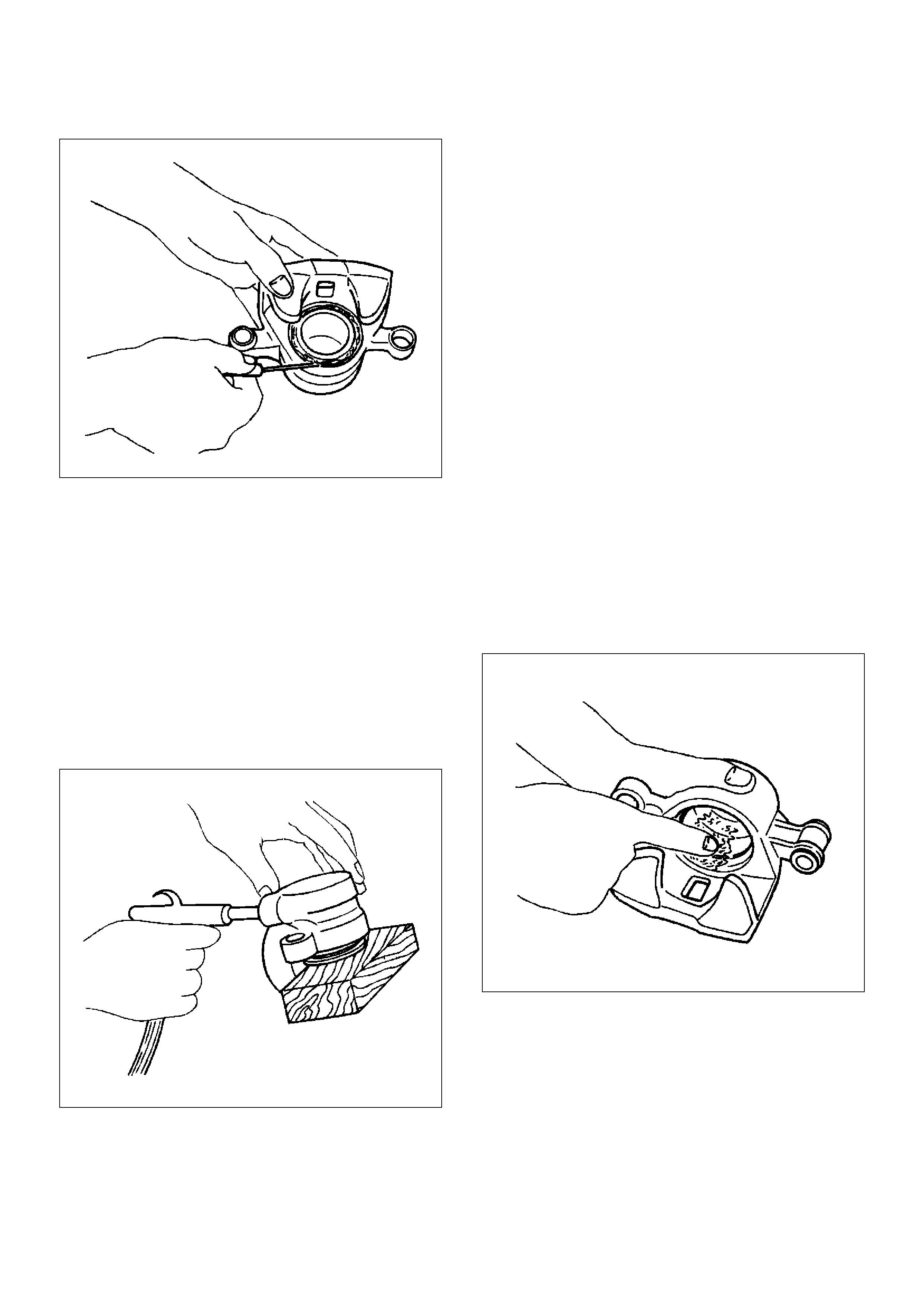

Rear Disc Brake Caliper

Rear Disc Brake Caliper Disassembled View

306RW014

EndOFCallout

Disassembly

1. Remove guide bolt.

2. Remove lock bolt.

3. Remove dust boot; guide bolt and lock bolt.

4. Remove dust boot ring, using a small screwdriver.

Legend

(1) Guide Bolt

(2) Lock Bolt

(3) Bleeder with Cap

(4) Caliper Body

(5) Piston Seal

(6) Piston

(7) Dust Boot: Piston

(8) Dust Boot Ring

(9) Dust Boot: Guide Bolt and Lock Bolt

302RS016

5.Insert a block of wood into the caliper and force out

the piston by blowing compressed air into the

caliper at the flexible hose attachment. This

procedure must be done prior to removal of the dust

boot.

Remove piston.

WARNING: Do not place your fingers in front of the

piston in an attempt to catch or protect it when

applying compressed air. This could result in

personal injury.

CAUTION: Use just enough air to ease the piston

out of the bore. If the piston is blown out, it may be

damaged.

302RS017

6. Remove dust boot: piston.

7. Remove piston seal.

8. Remove bleeder with cap.

9.Remove caliper body.

Inspection and Repair

Make necessary parts replacement, if wear, damage,

corrosion or any other abnormal conditions are found

through inspection.

Check the following parts:

•Rotor

• Cylinder body

• Cylinder bore

•Piston

• Guide bolt, lock bolt

• Support bracket

NOTE: The piston dust seal and dust boot are to be

replaced each time the caliper is overhauled. Discard

these used rubber parts and replace with new ones.

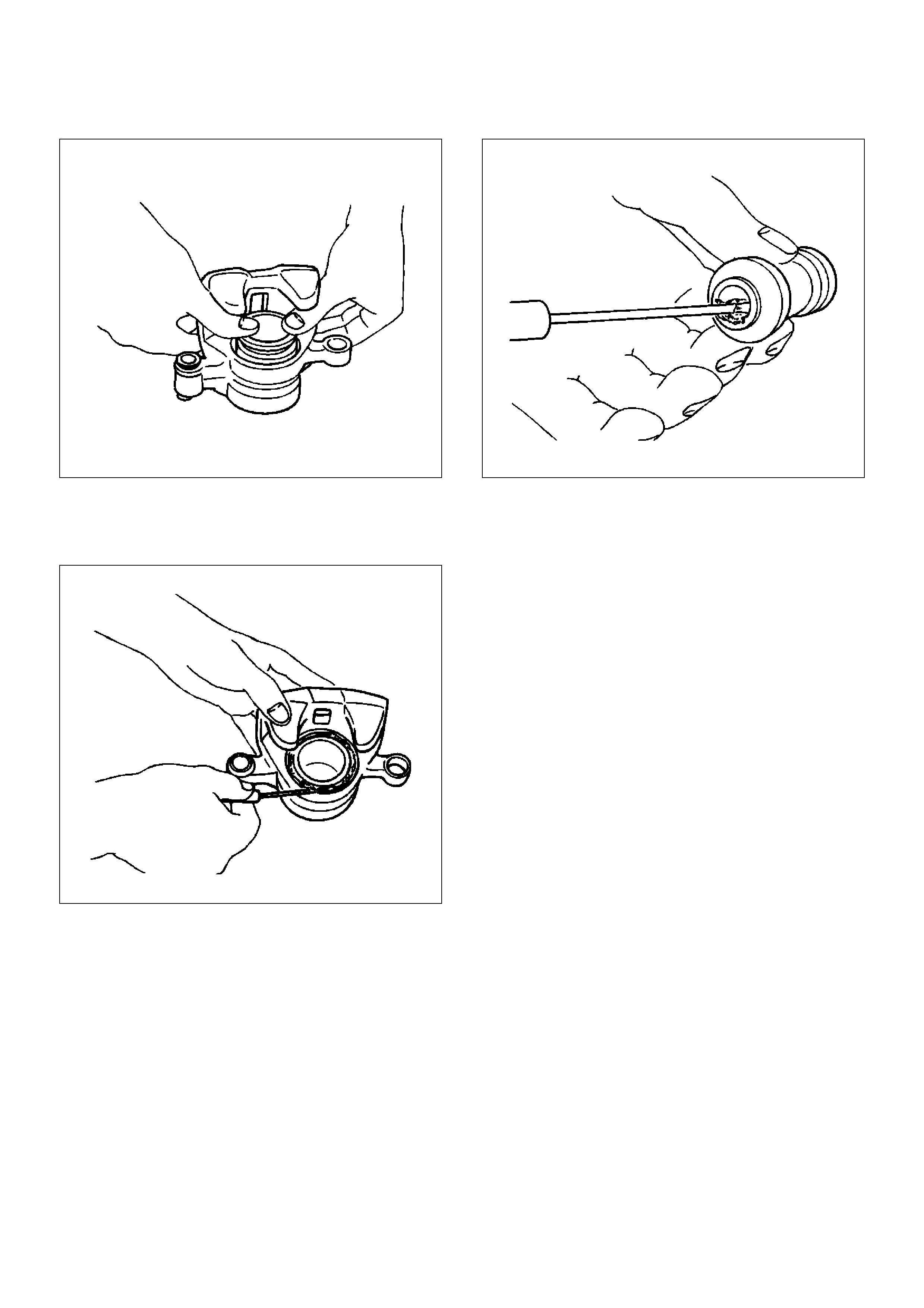

Reassembly

1. Install caliper body.

2. Install bleeder with cap and tighten the cap to the

specified torque.

Torque: 8 N·m (0.8 kg·m/69 lbft)

3. Install piston seal and apply special rubber grease

to the piston seal and cylinder wall, then insert the

piston seal into the cylinder. The special rubber

grease is included in the repair kit.

302RS018

4. When inserting the piston into the cylinder, use

finger pressure only and do not use a mallet or other

impact tool, since damage to the cylinder wall or

piston seal can result.

Install piston.

302RS019

5. Apply special grease (approximately 1g) to the

piston and attach the dust boot to the piston and

caliper. Insert the dust boot ring into the dust boot.

302RS020

6. Install guide bolt and lock bolt dust boot.

7. Install the dust boot on the support bracket after

applying special grease (Approx. 1g) onto the dust

boot inner surface. Also apply special grease onto

the lock bolt and guide bolt setting hole of the

support bracket.

302RS021

8. Install lock bolt and guide bolt and tighten the bolt to

the specified torque.

Torque: 43 N·m (4.4 kg·m/32 lbft)

Main Data and Specifications

General Specifications

Torque Specifications

E05RX010

Type Floating, pin slide

Pad dimension 33 cm2 (5.11 in2)

Adjusting method Self–adjusting

Piston diameter 41.3 mm (1.63 in)

Disc type Ventilated

Disc thickness 18 mm (0.71 in)

Disc effective diameter 269.2 mm (10.60 in)