SECTION 12P - WIRING SYSTEM

Service Precaution

General Description

Notes for Working on Electrical Items

Symbols and Abbreviations

Parts for Electrical Circuit

Reading the Circuit Diagram

Main Data and Specifications

Fuse, Fusible Link and Circuit Breaker

Location

Relay & Fuse Box (Engine Bay)

Relay & Fuse Box (Instrument panel)

Fuse Block Circuit

Reference Table of Fuse, Fusible Link

and Circuit Breaker

Relay Location

Diode Location

Grounding Point

Cable Harness Routing

Start and Charging

General Description

Circuit Diagram

Parts Location

Powertrain Control Module (PCM)

General Description

Circuit Diagram

Parts Location

Headlight and Fog Light

General Description

Circuit Diagram

Parts Location

Diagnosis

Clearance Light, Tail Light and License

Plate Light

General Description

Circuit Diagram

Parts Location

Diagnosis

Interior Illumination Light

General Description

Circuit Diagram

Parts Location

Diagnosis

Turn Signal Light, Hazard Warning Light

General Description

Circuit Diagram

Parts Location

Diagnosis

Stoplight

General Description

Circuit Diagram

Parts Location

Diagnosis

Backup Light

General Description

Circuit Diagram

Parts Location

Diagnosis

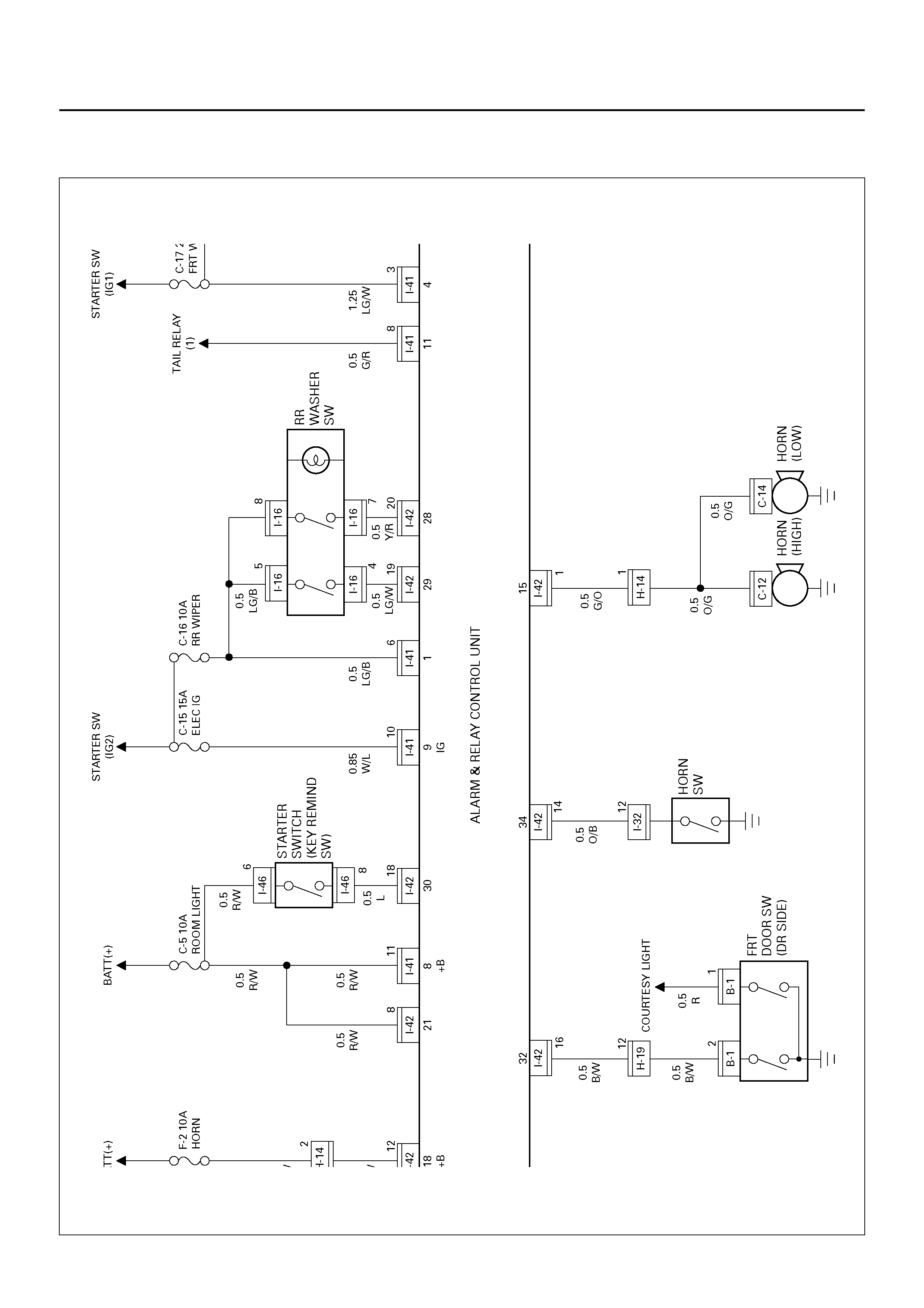

Horn

General Description

Circuit Diagram

Parts Location

Diagnosis

Dome Light, Rear Compartment Light, Courtesy

Light, Map Light, Seat Belt Switch and

Warning Buzzer

General Description

Circuit Diagram

Parts Location

Diagnosis

Power Door Lock

General Description

Circuit Diagram

Parts Location

Diagnosis

Power Window

General Description

Circuit Diagram

Parts Location

Diagnosis

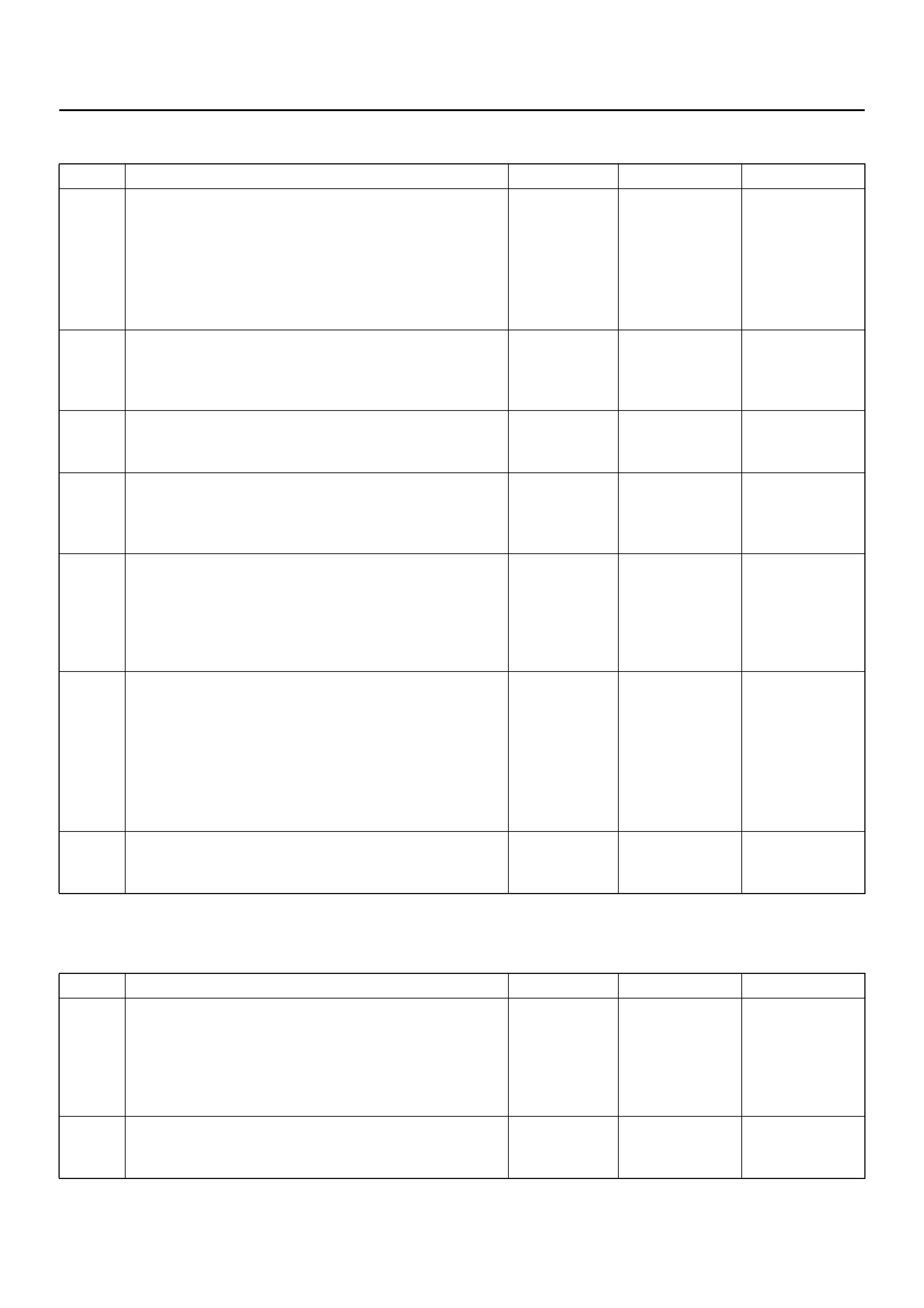

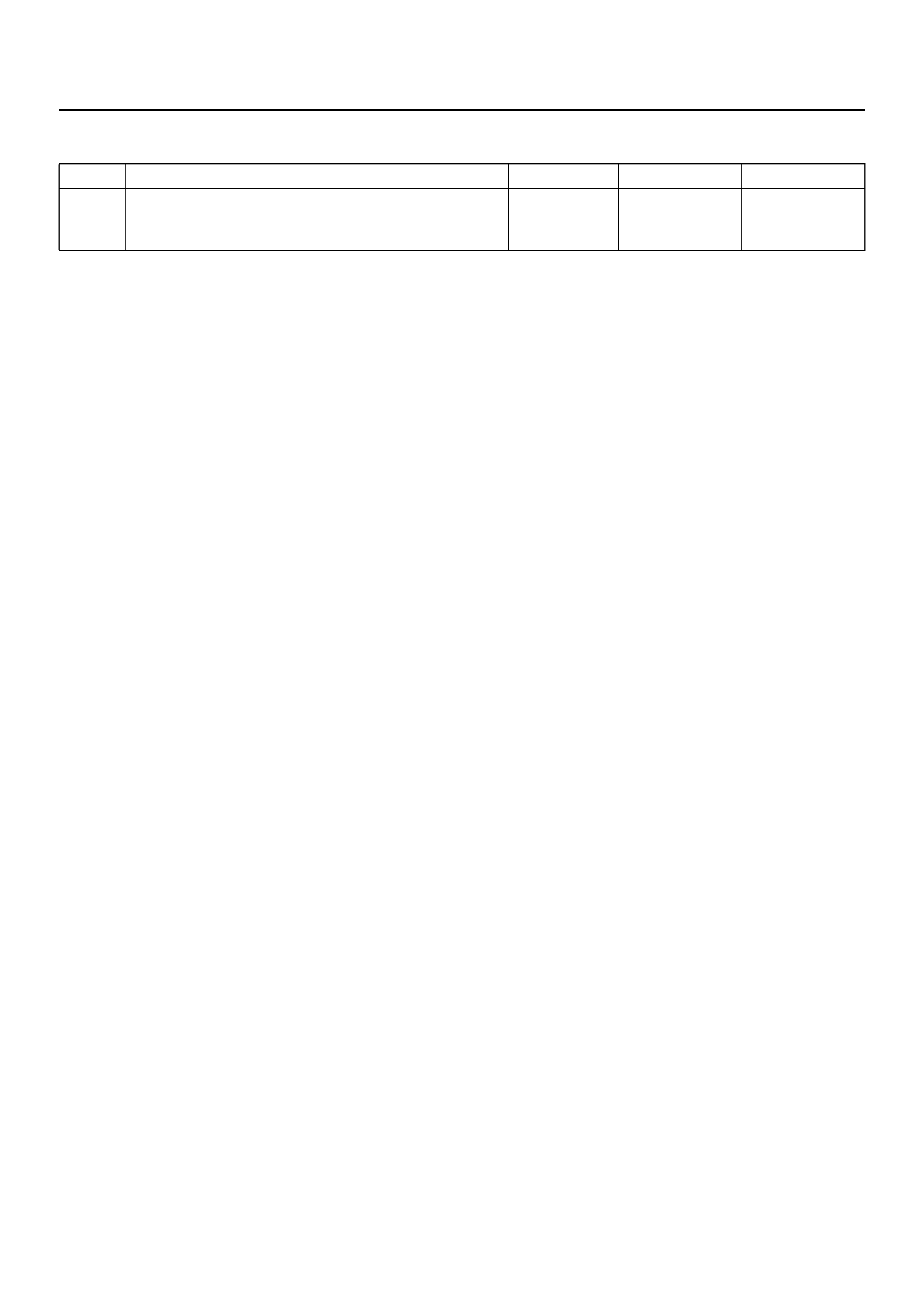

Anti–Lock Brake System (ABS)

General Description

Circuit Diagram

Parts Location

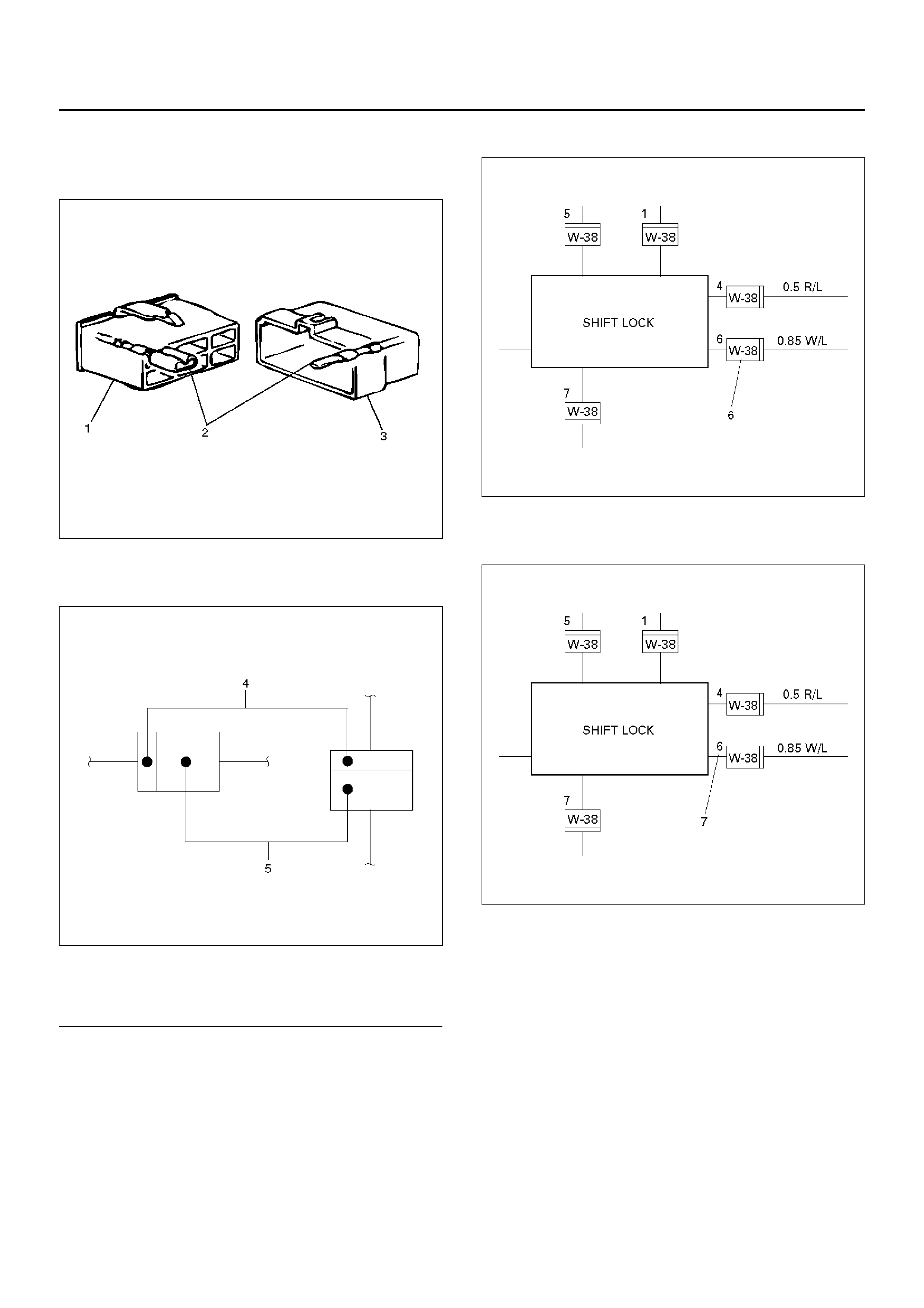

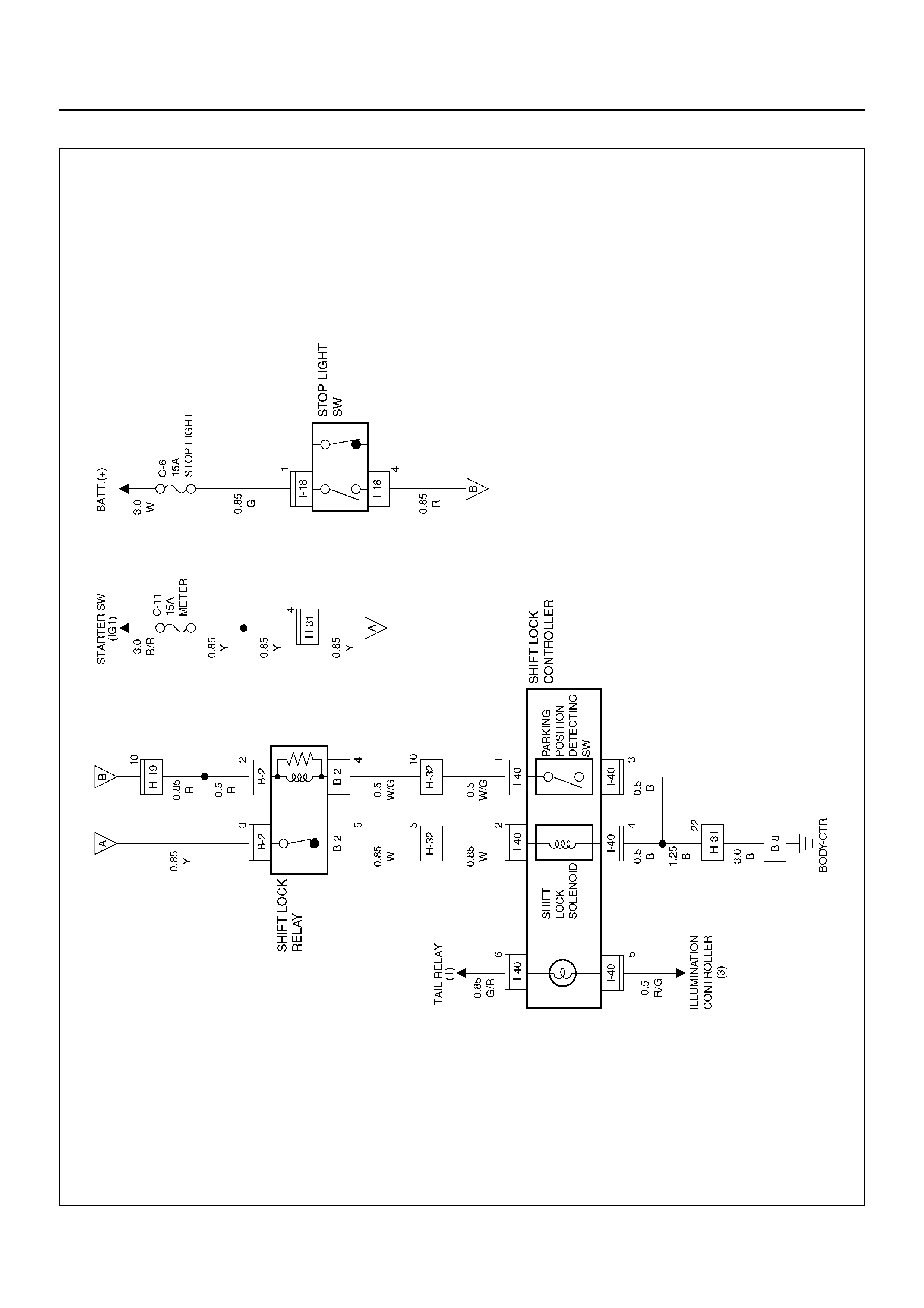

A/T Shift Lock

General Description

Circuit Diagram

Parts Location

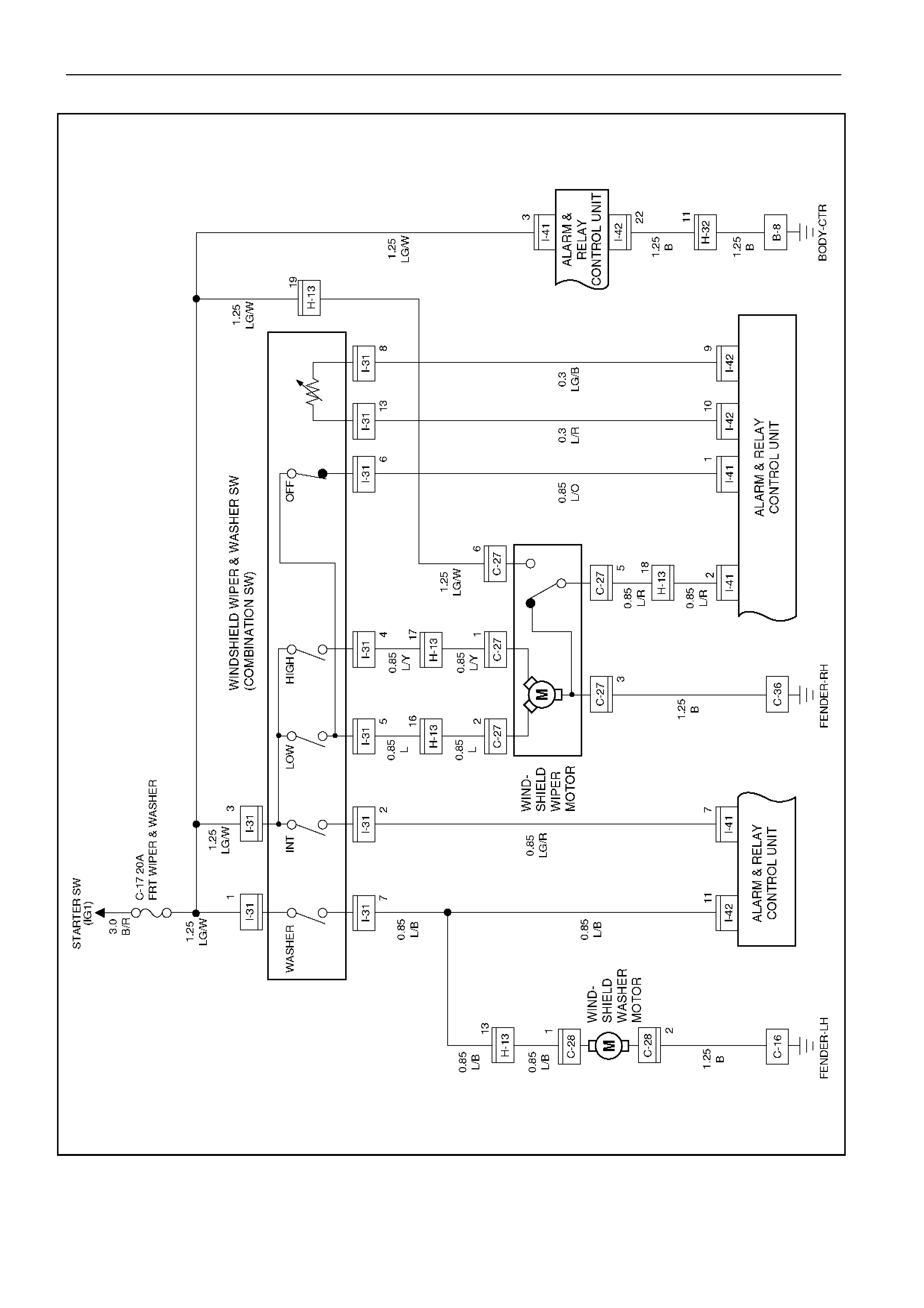

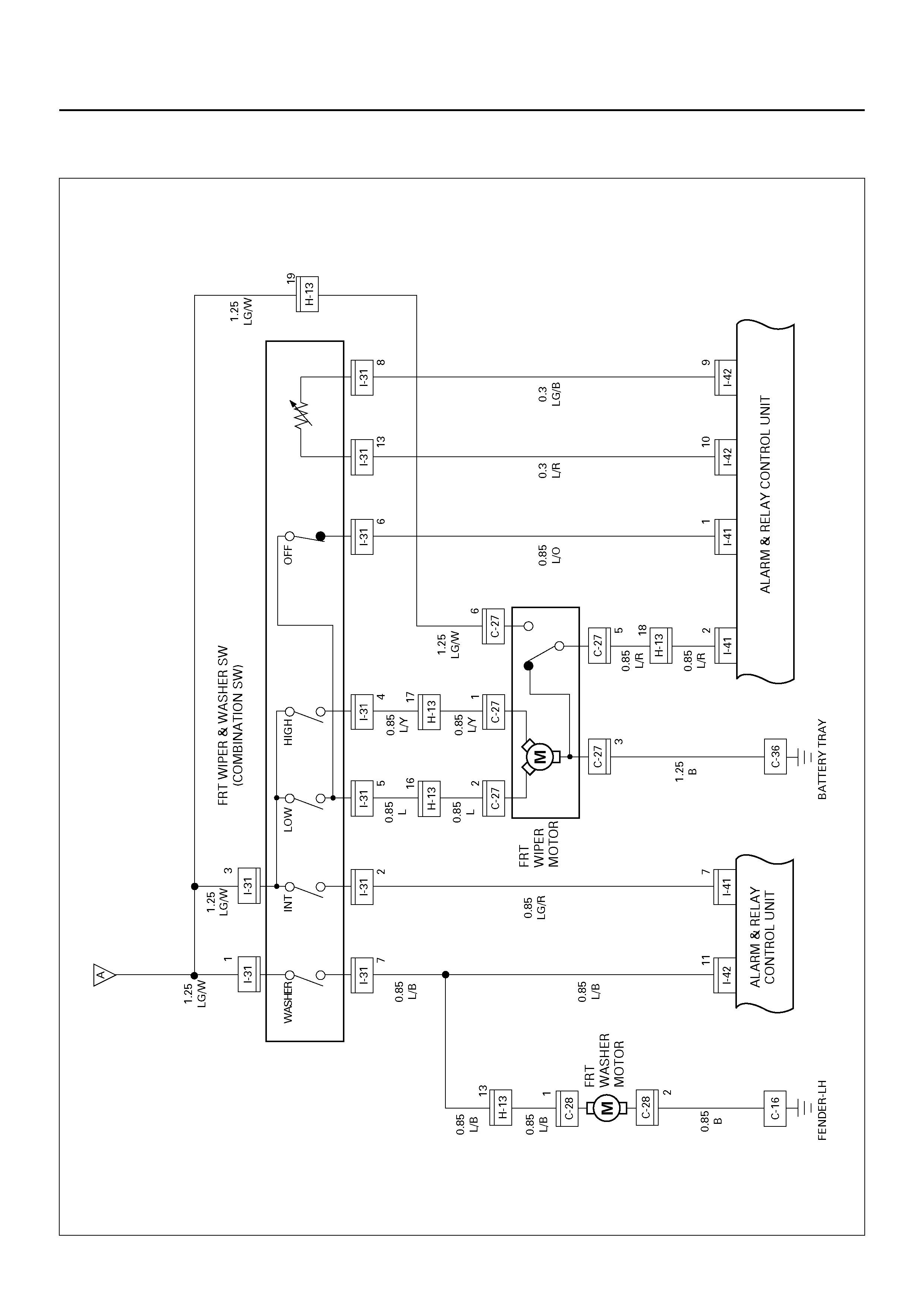

Windshield Wiper and Washer

General Description

Circuit Diagram

Parts Location

Diagnosis

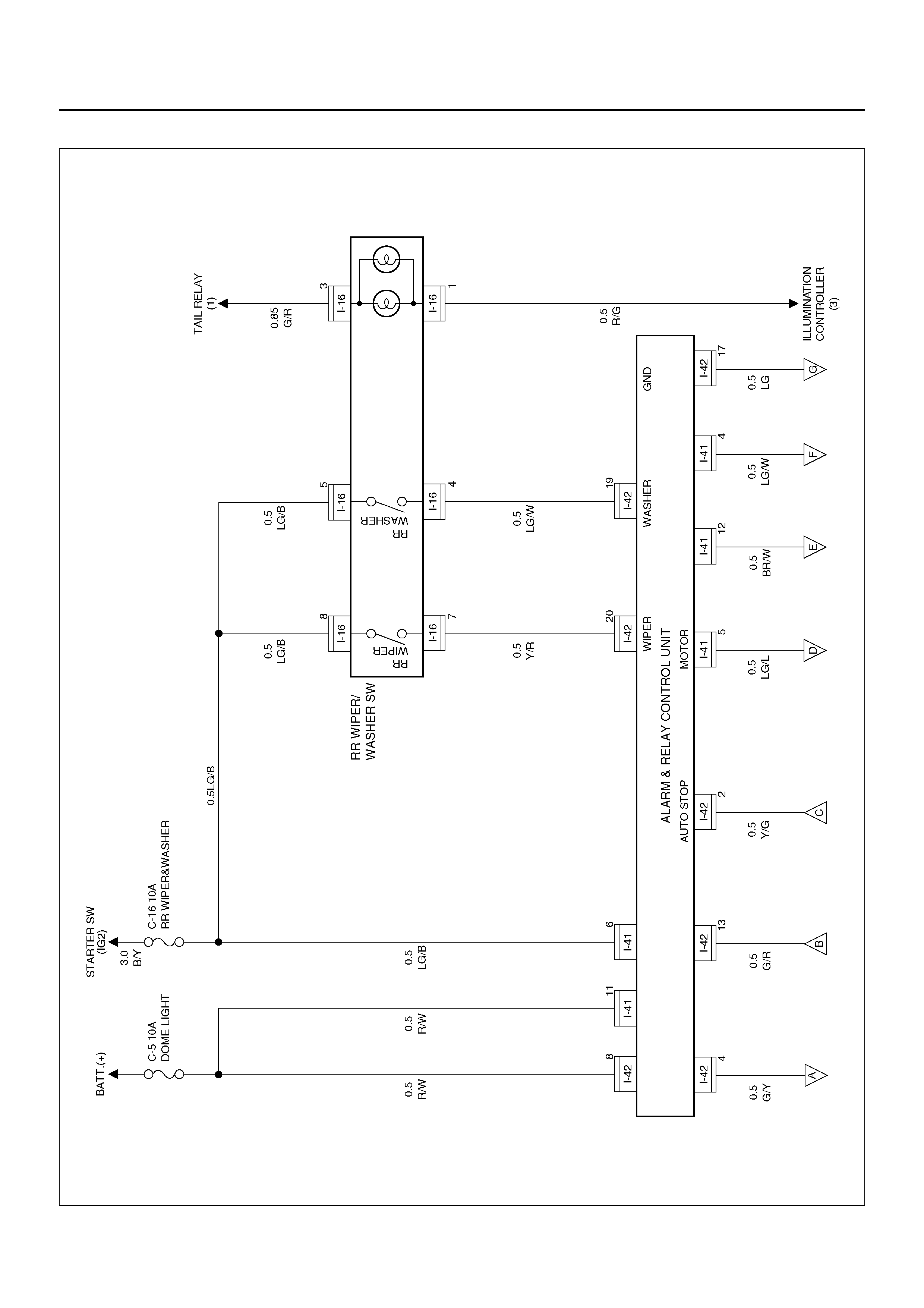

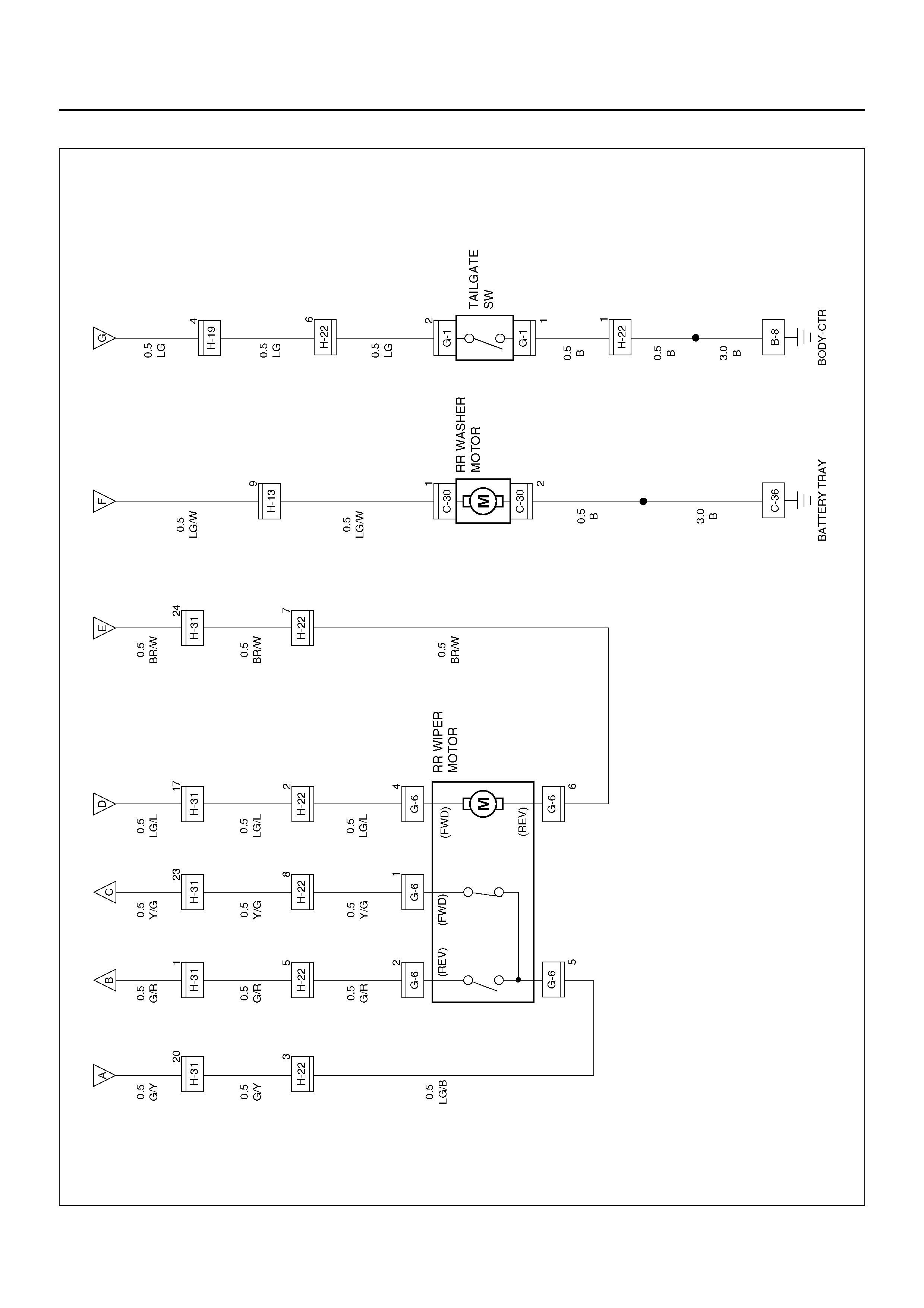

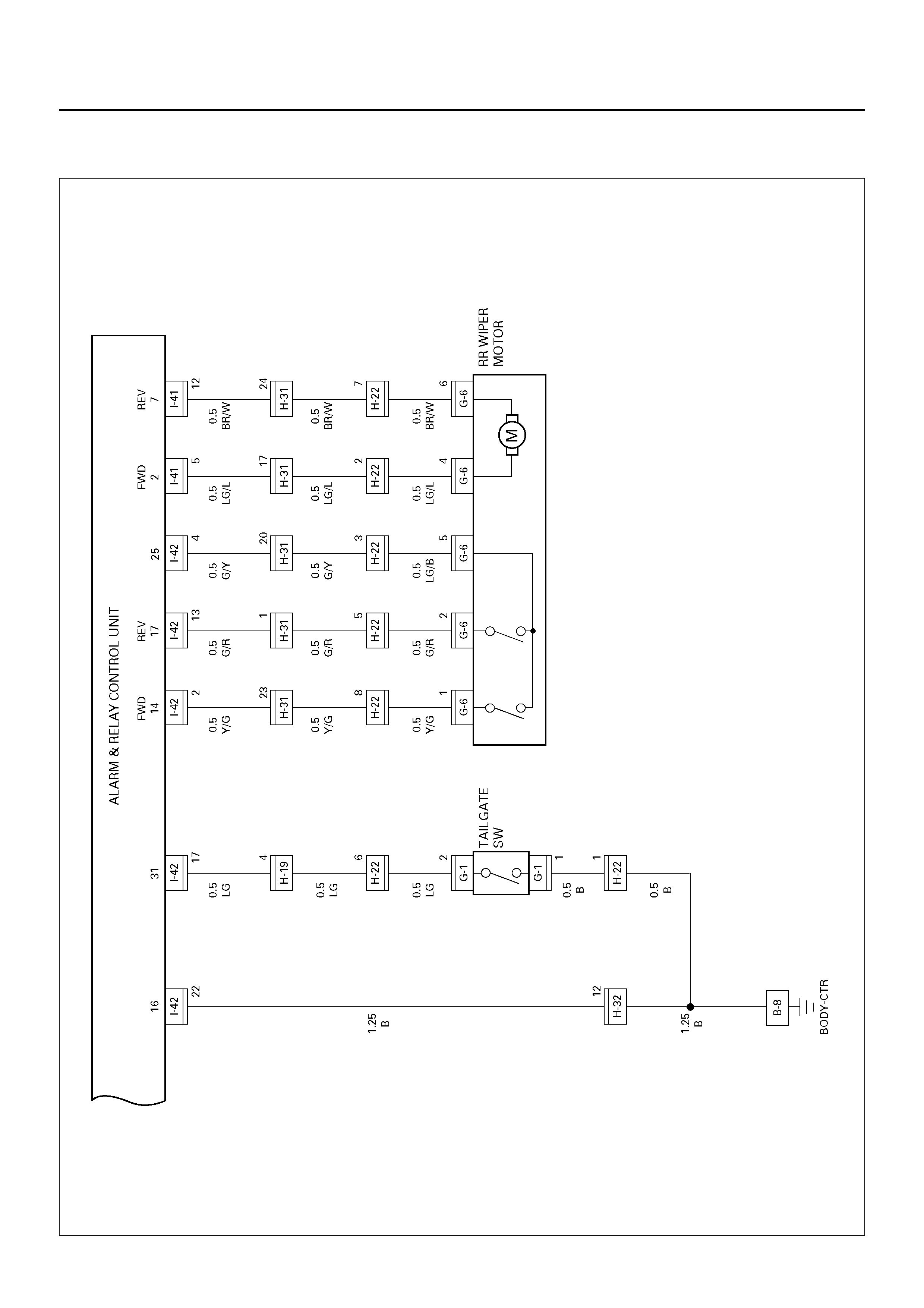

Rear Wiper/Washer

General Description

Circuit Diagram

Parts Location

Diagnosis

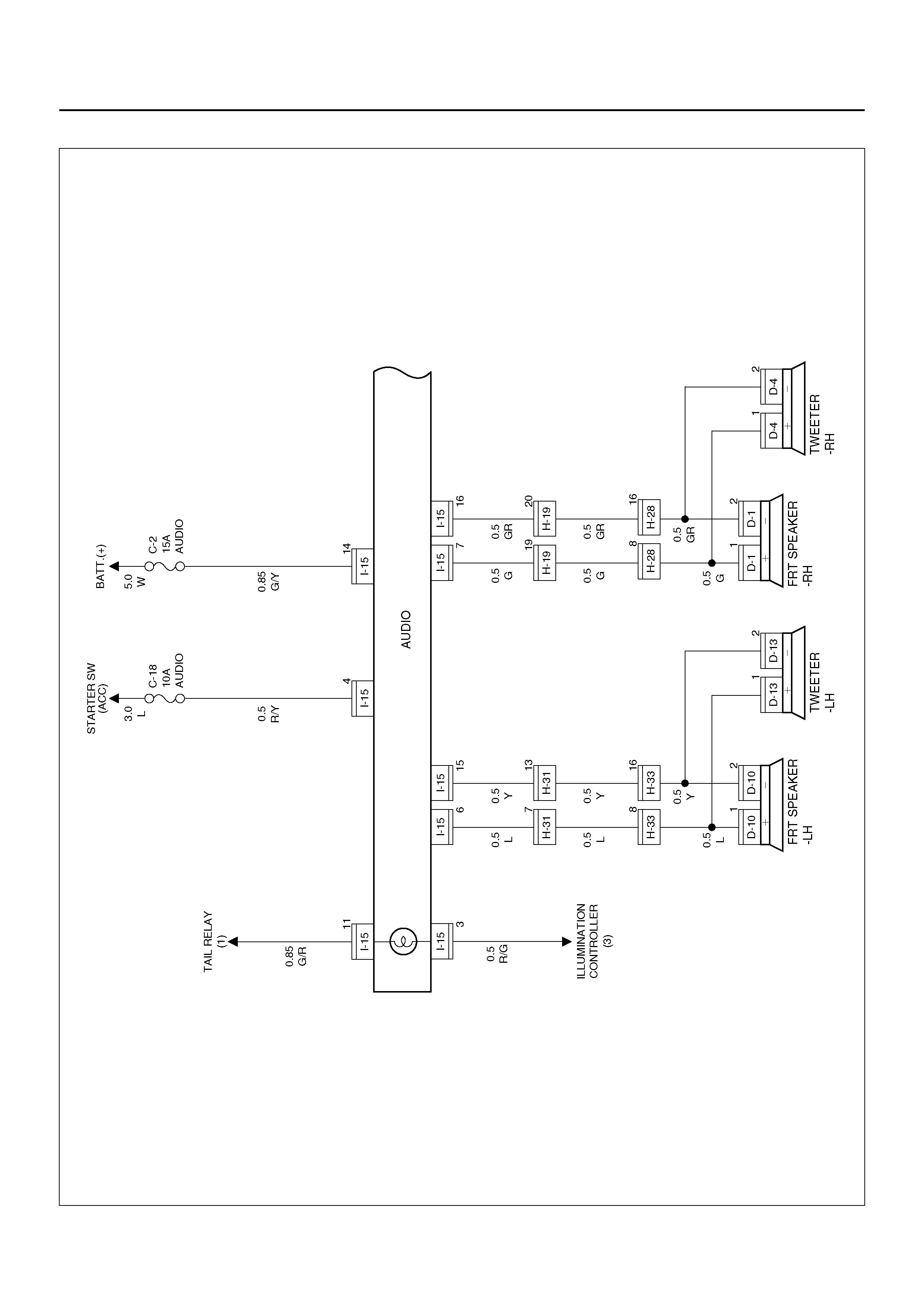

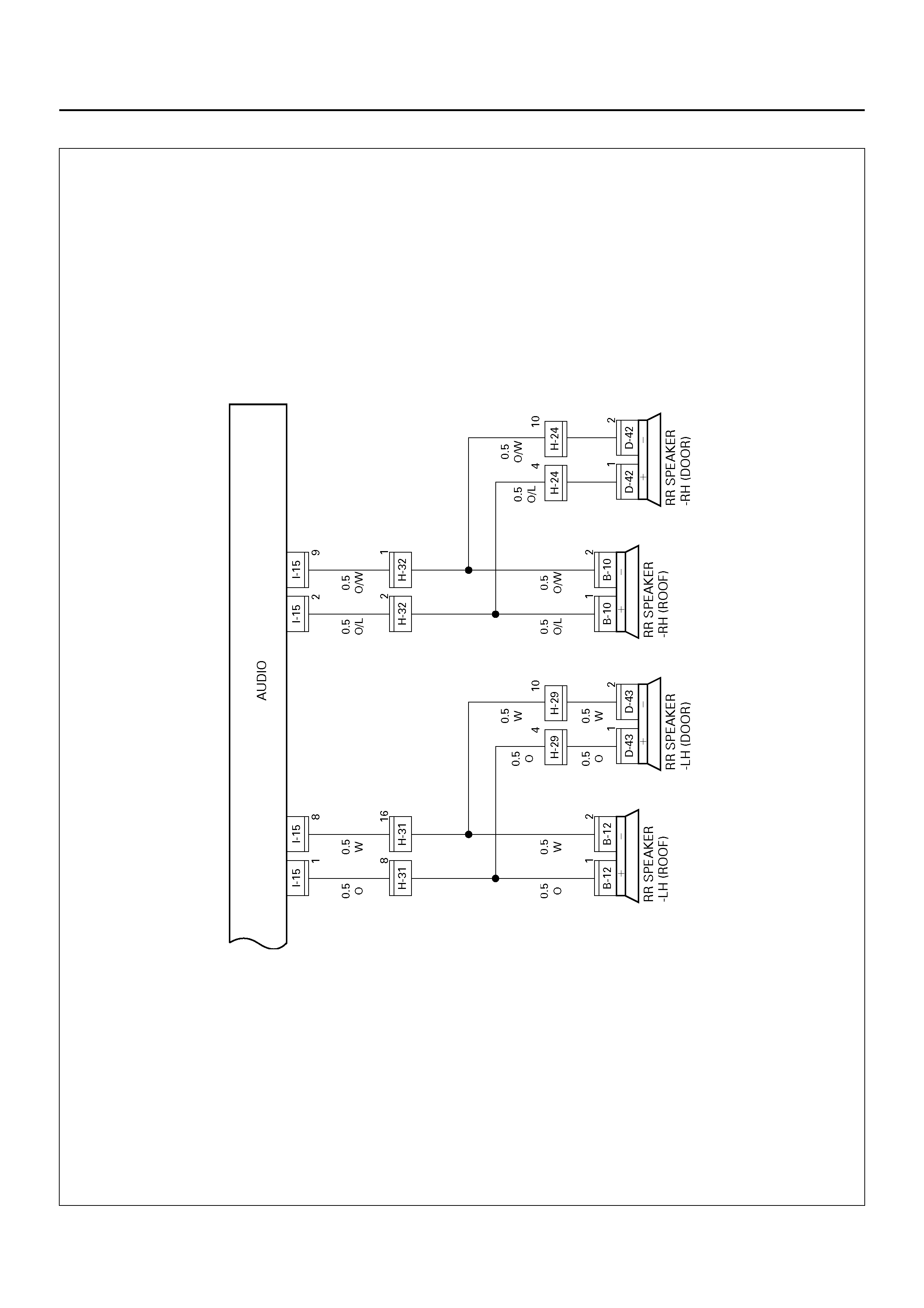

Audio

General Description

Circuit Diagram

Parts Location

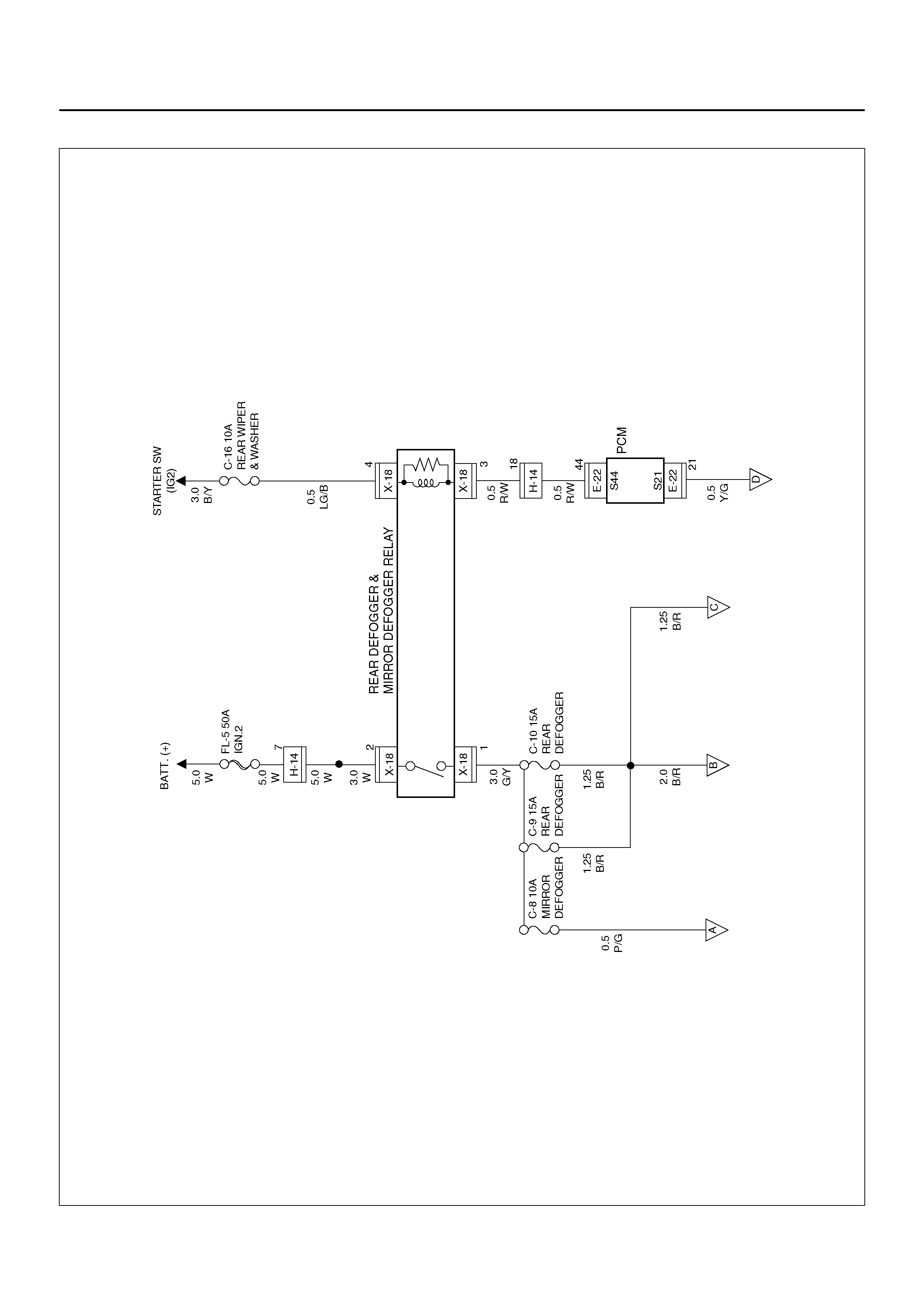

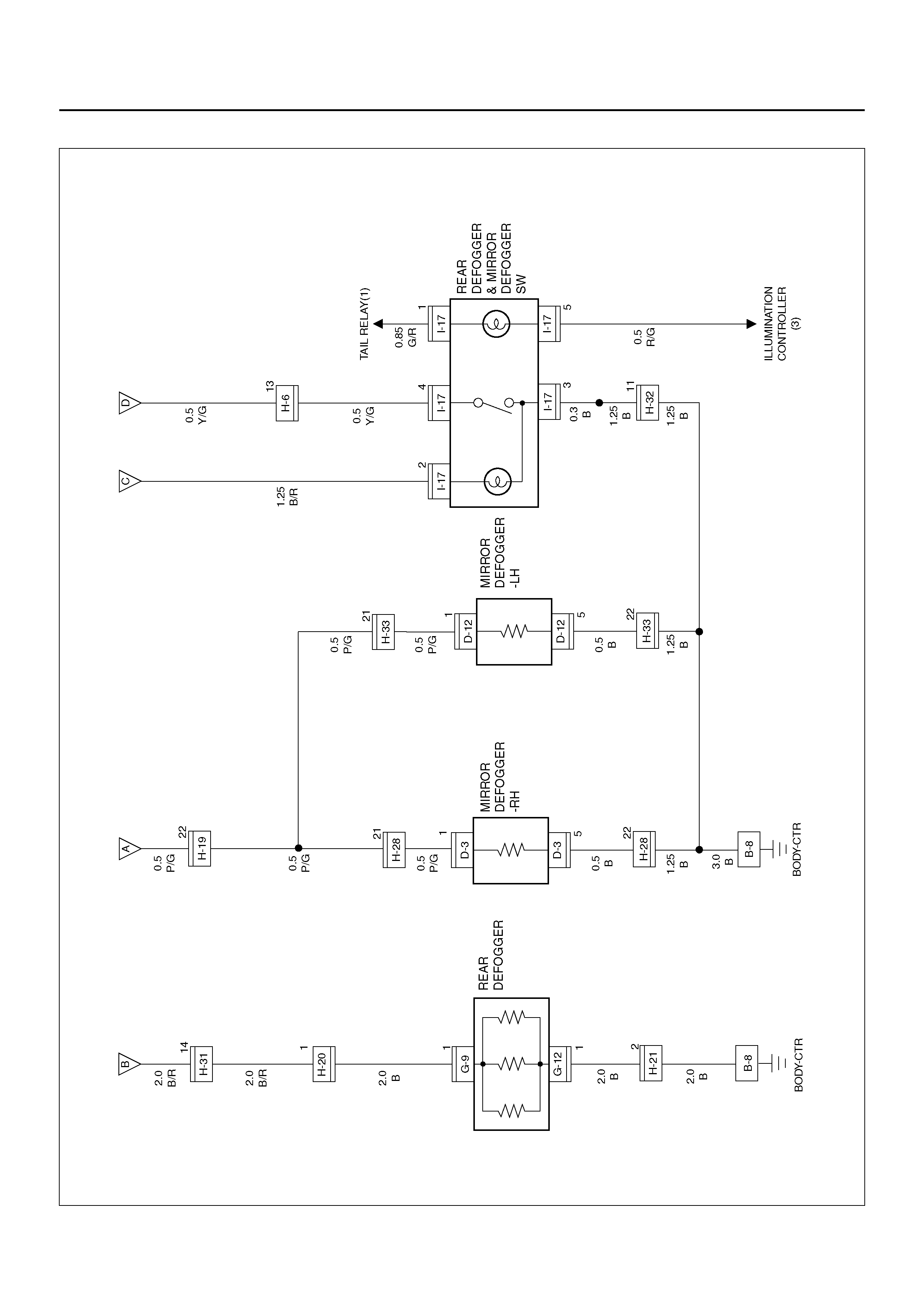

Rear Defogger/Mirror Defogger

General Description

Circuit Diagram

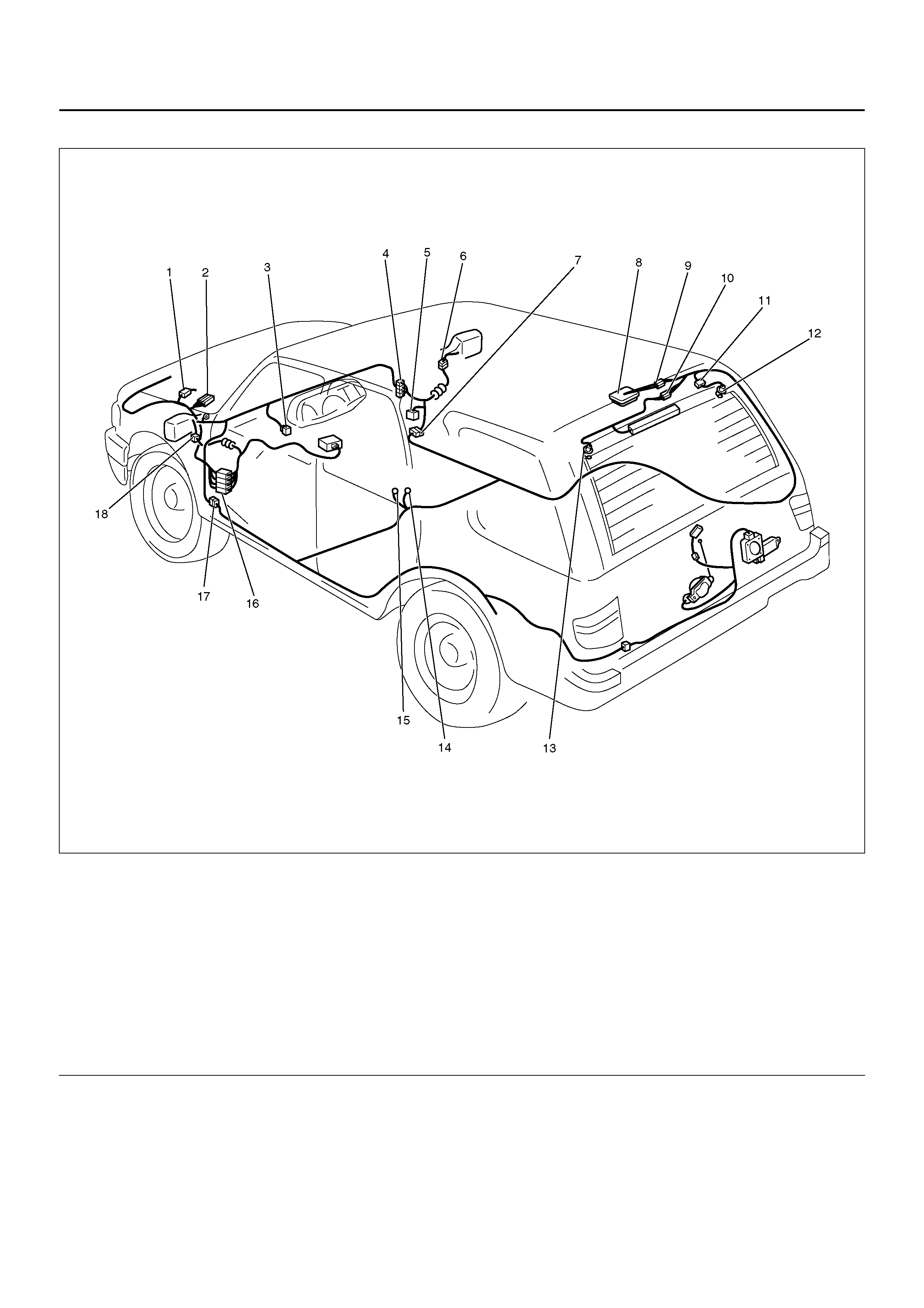

Parts Location

Diagnosis

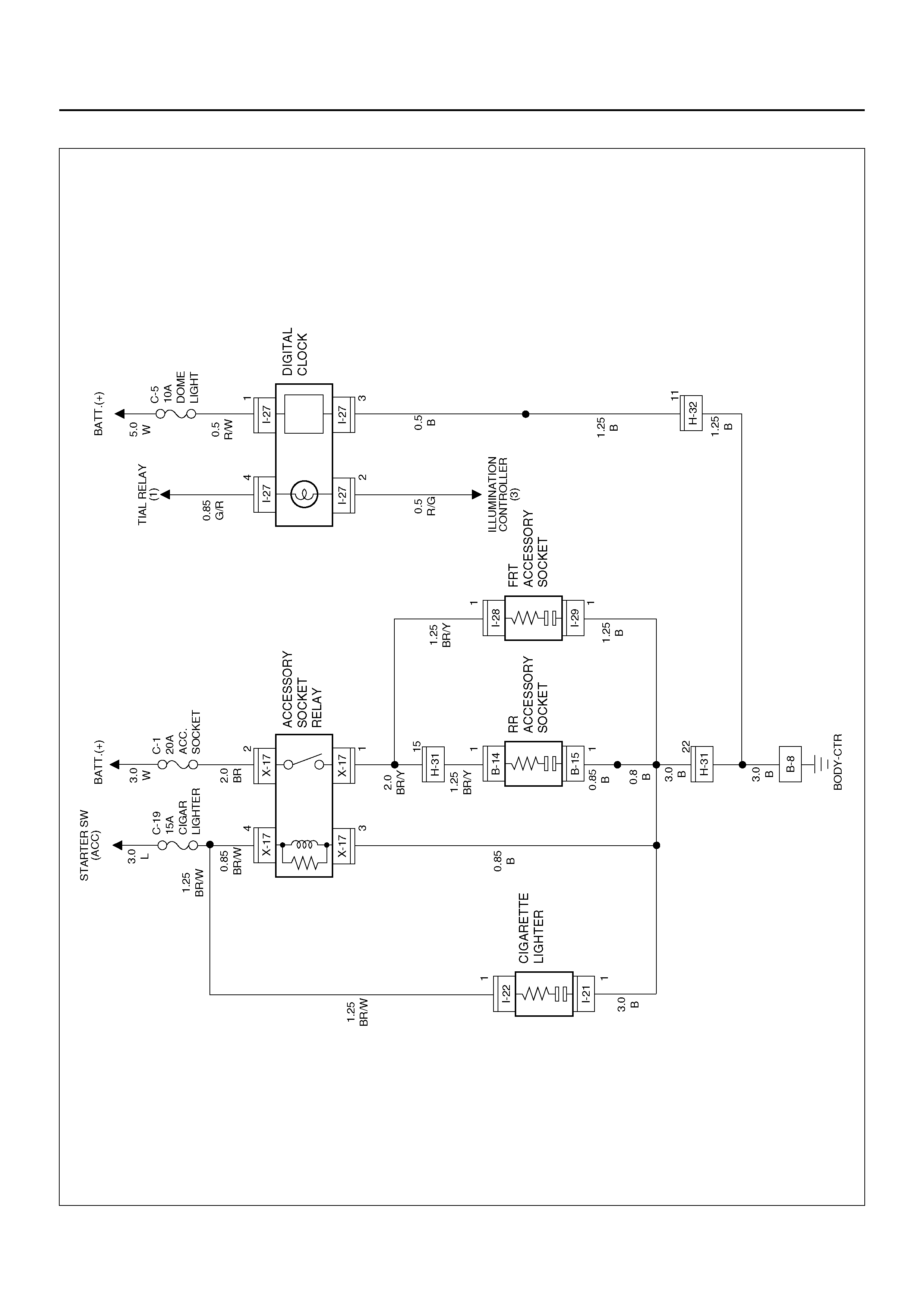

Cigarette Lighter, Digital Clock and

Accessory Socket

General Description

Circuit Diagram

Parts Location

Diagnosis

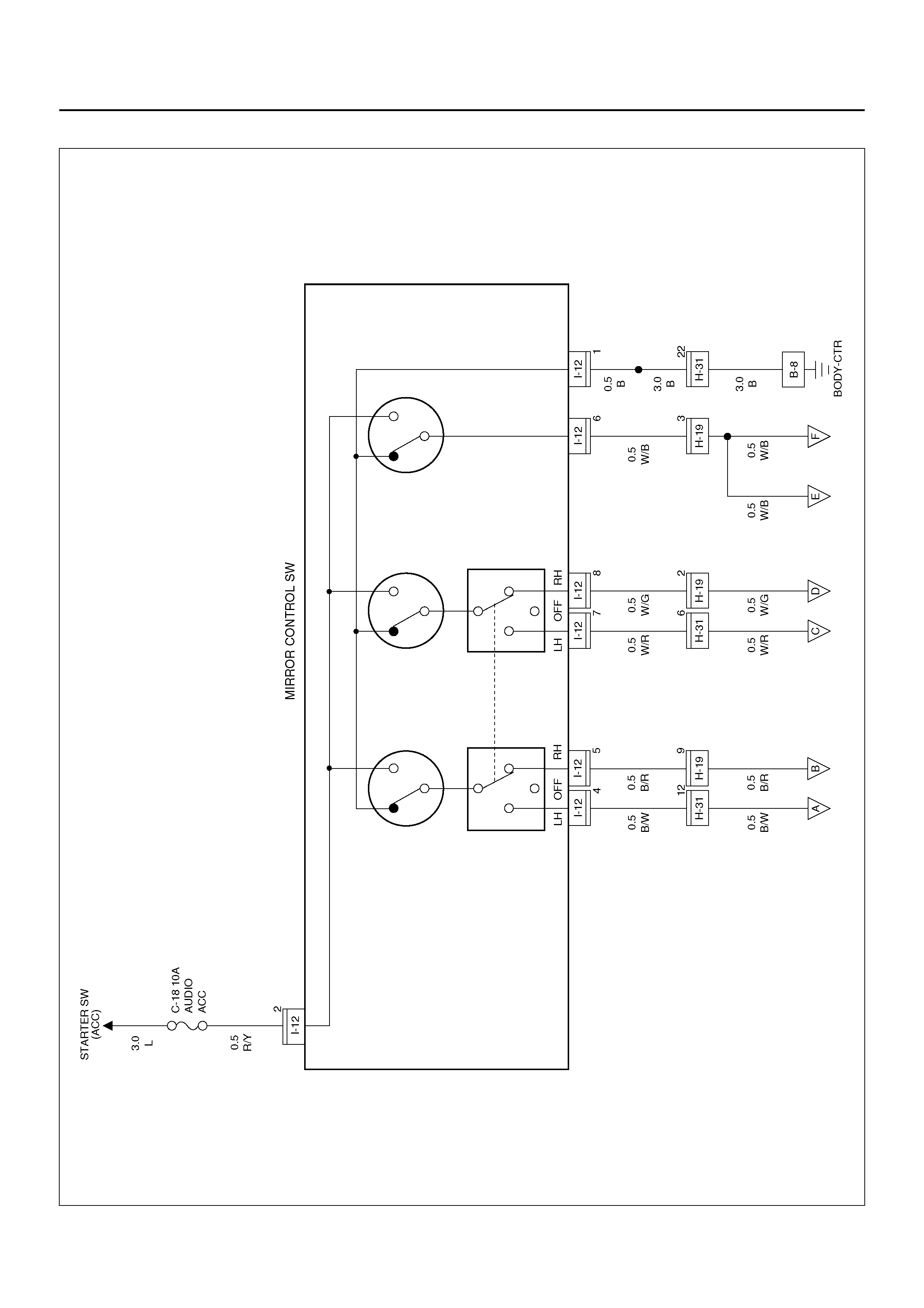

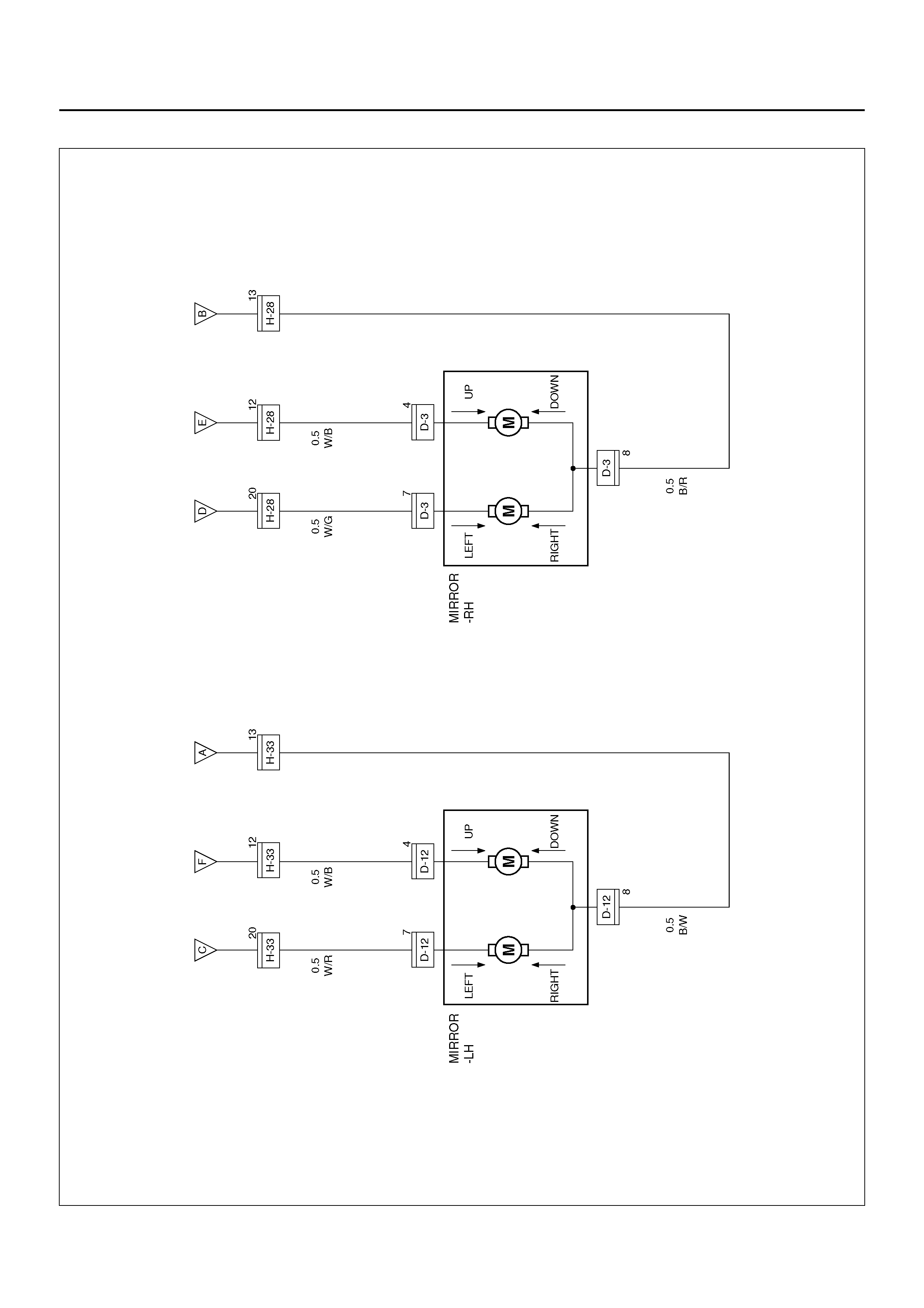

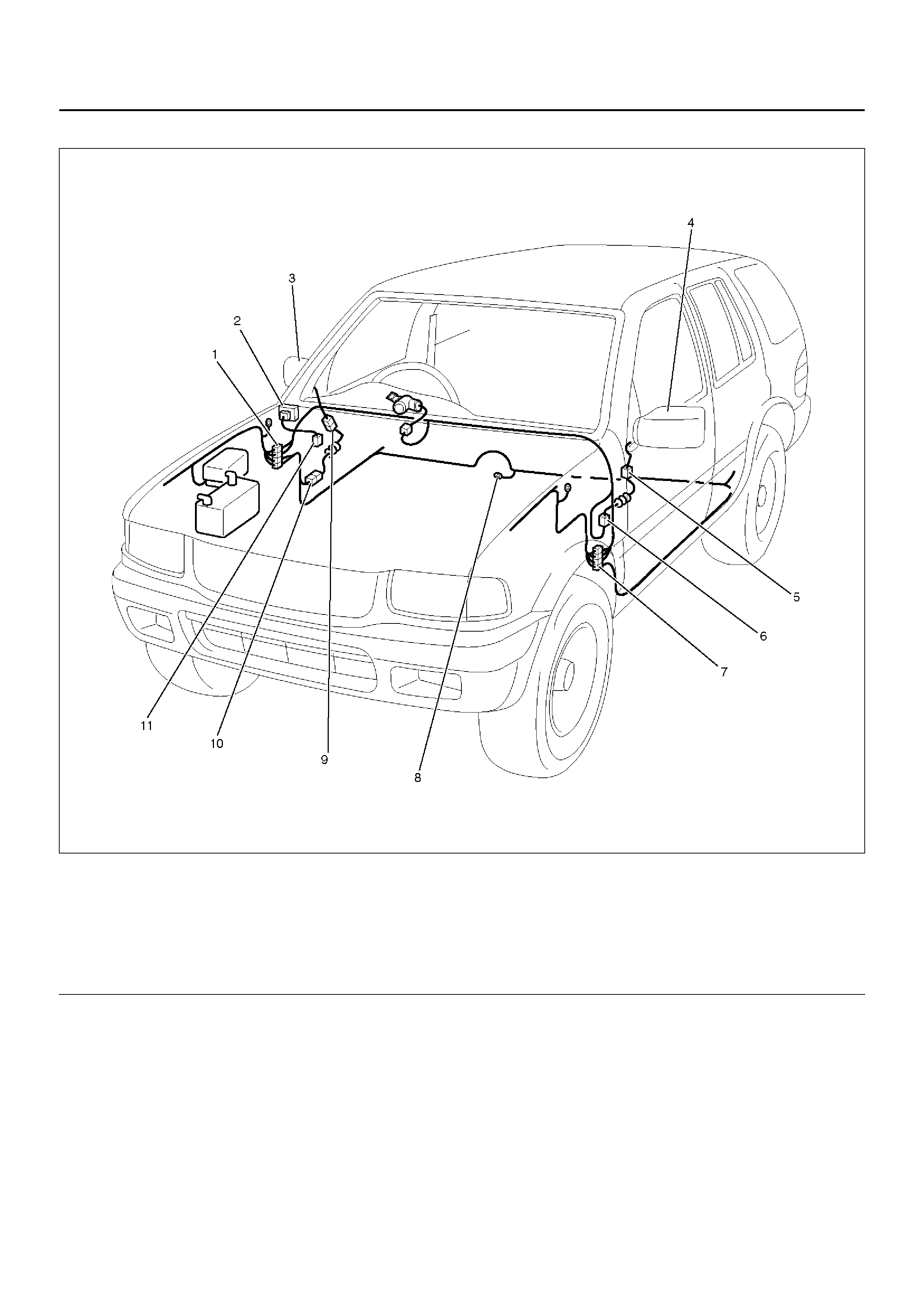

Power Door Mirror

General Description

Circuit Diagram

Parts Location

Diagnosis

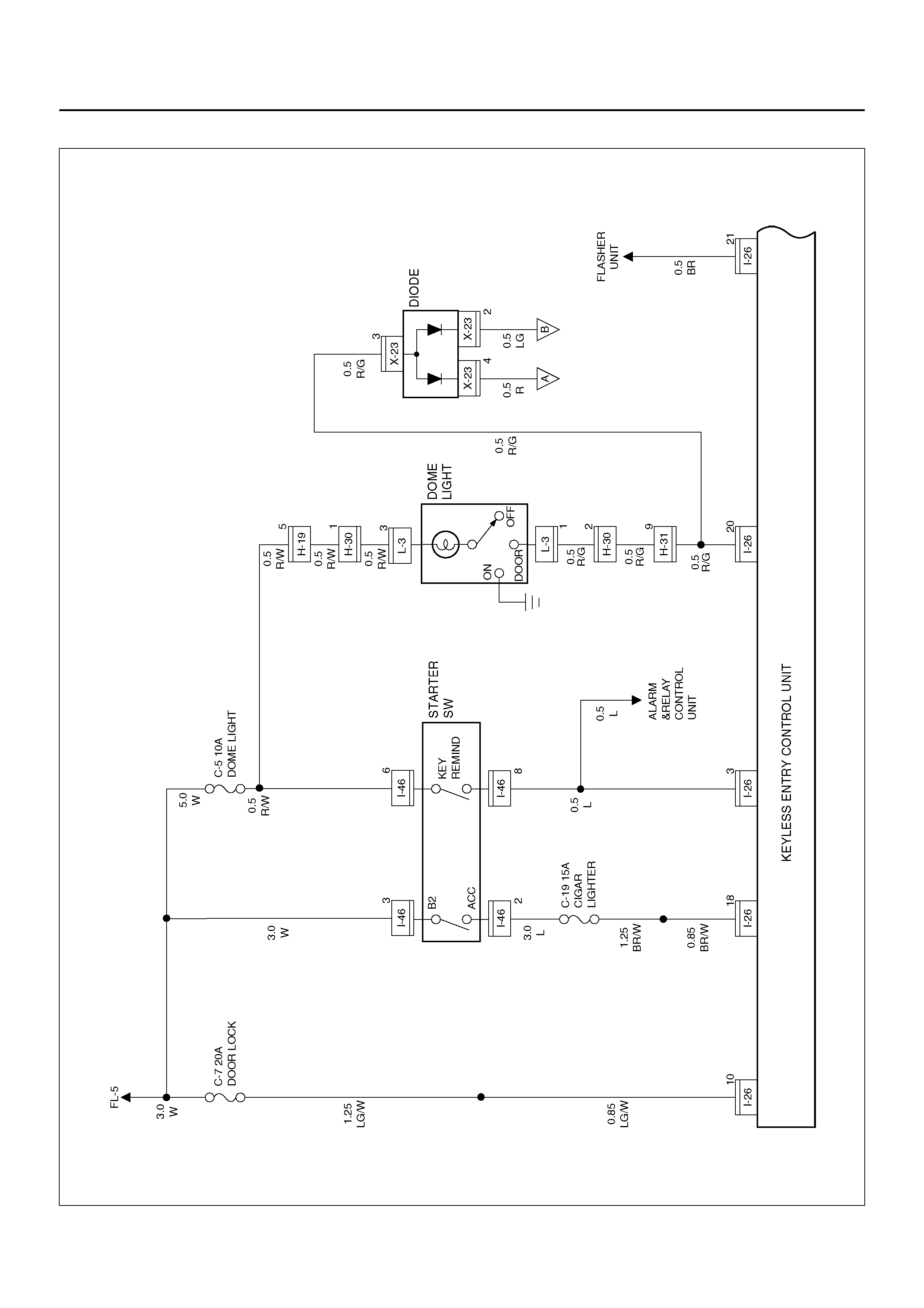

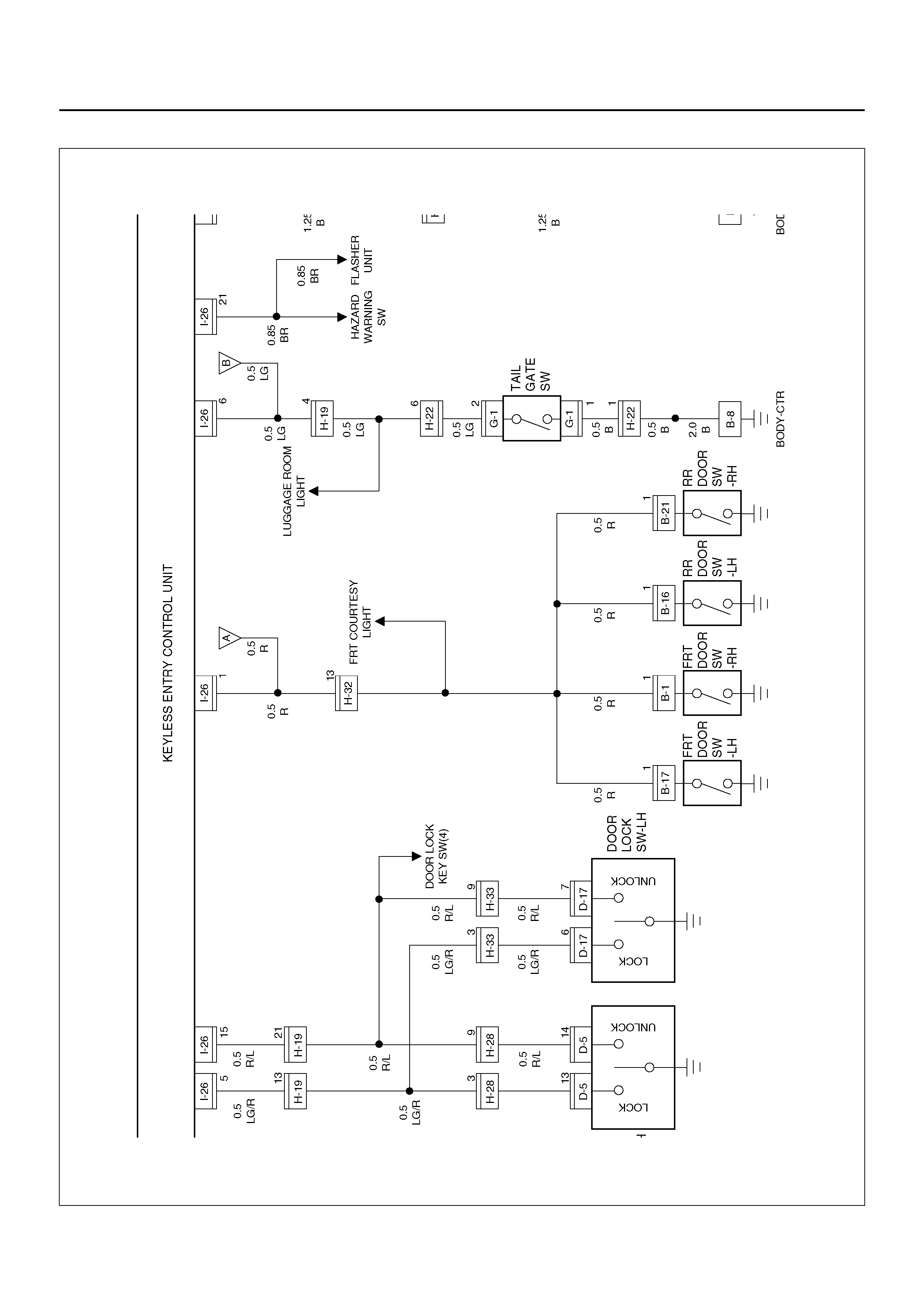

Keyless Entry

General Description

Circuit Diagram

Parts Location

Keyless Entry System

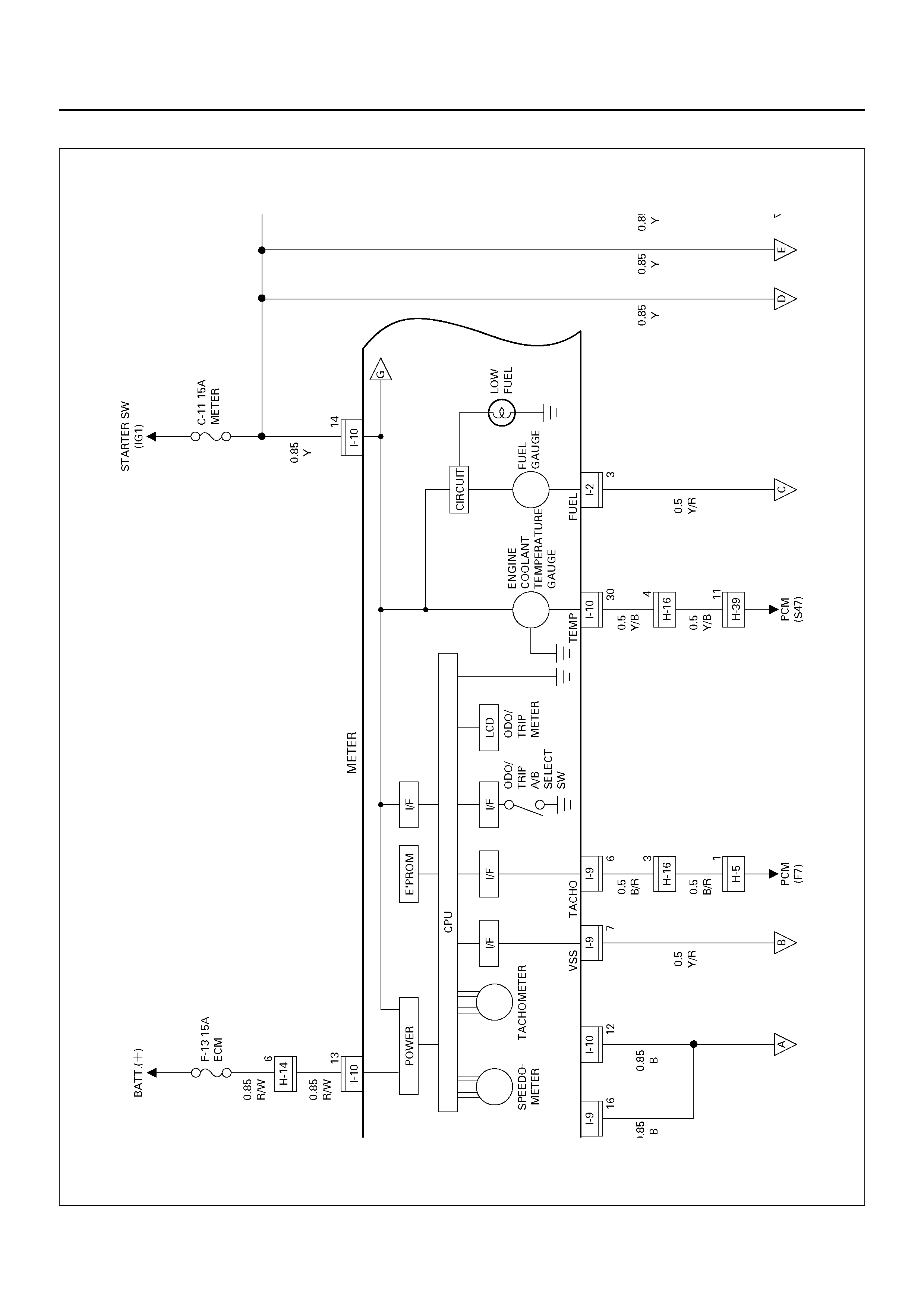

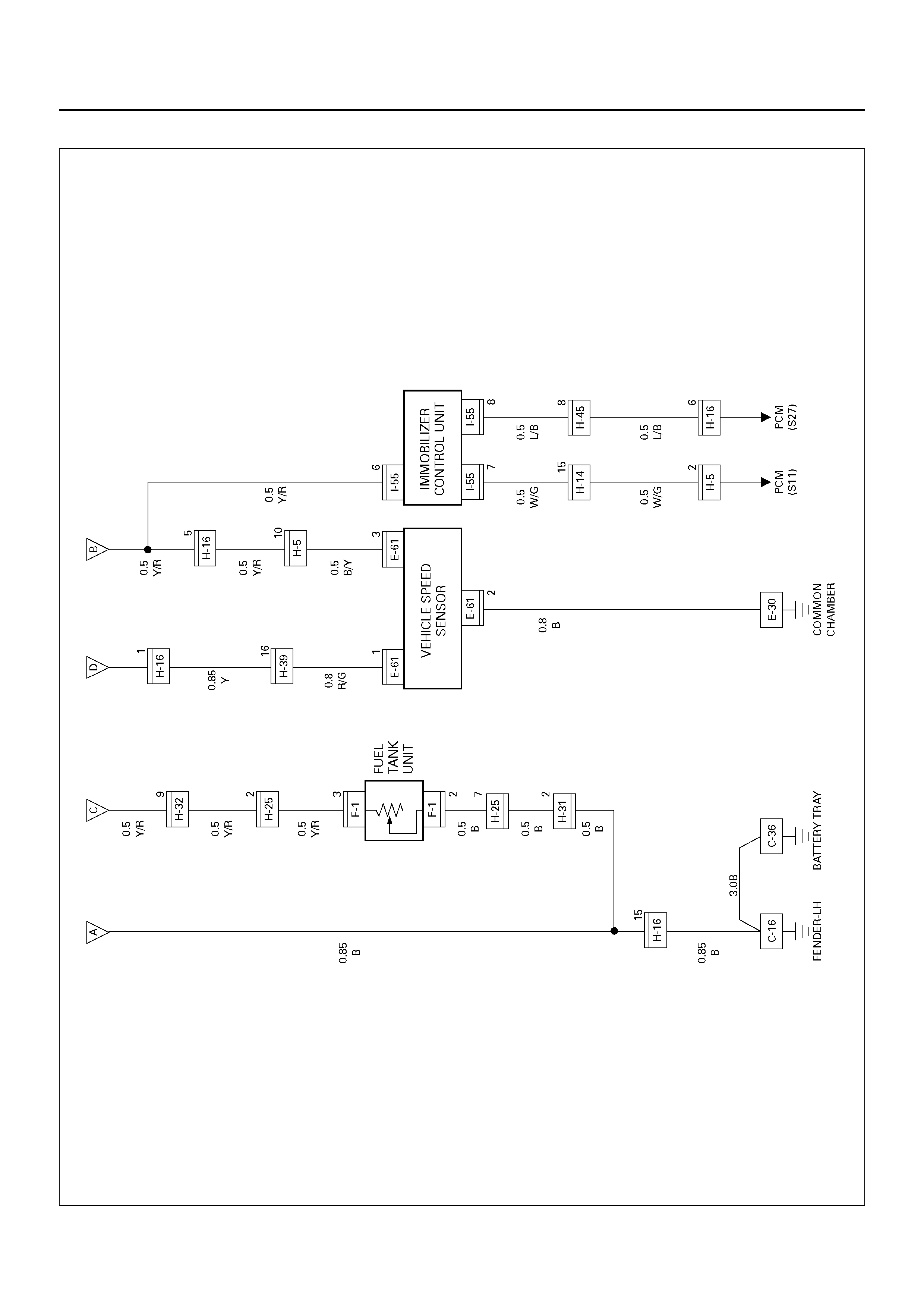

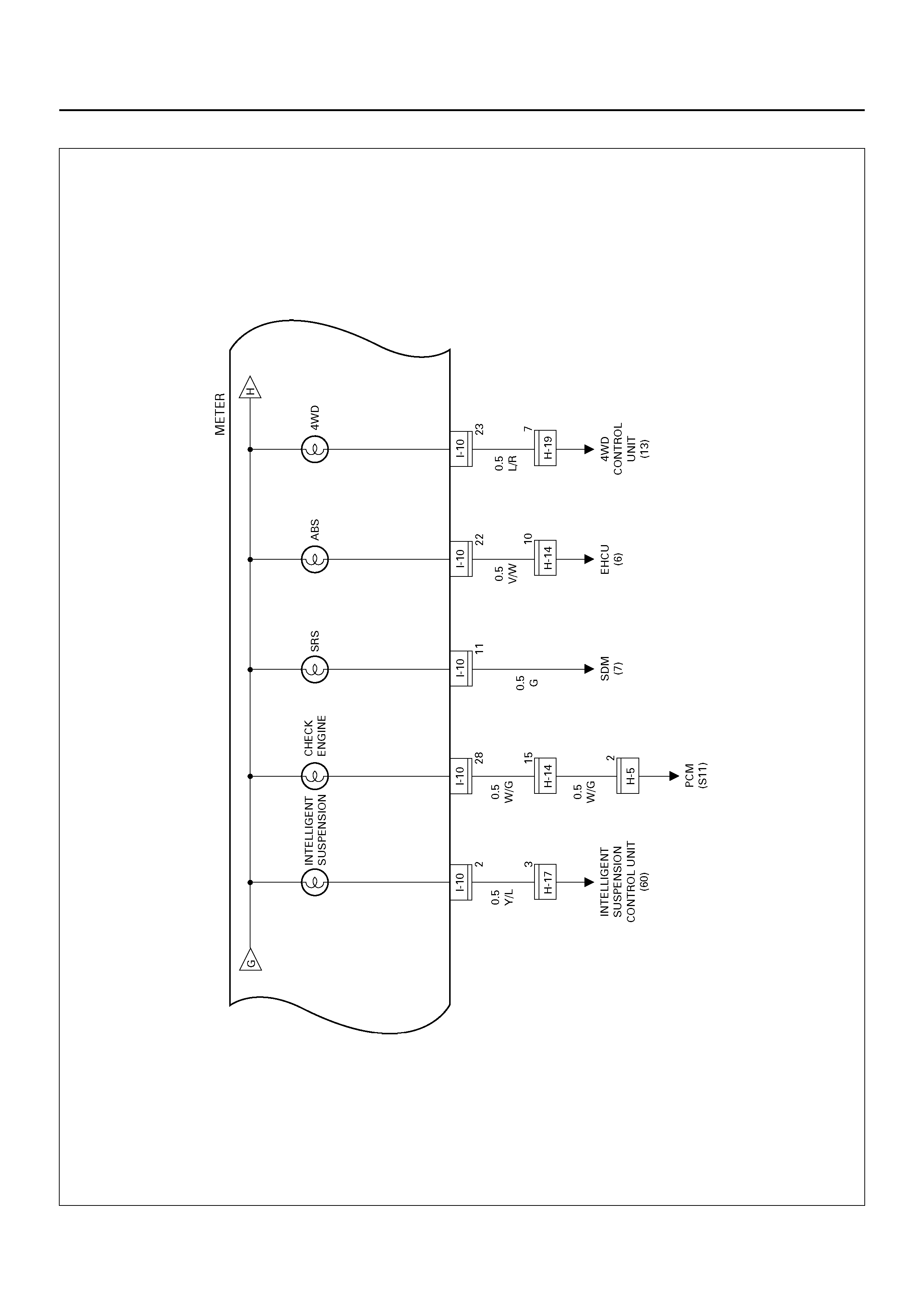

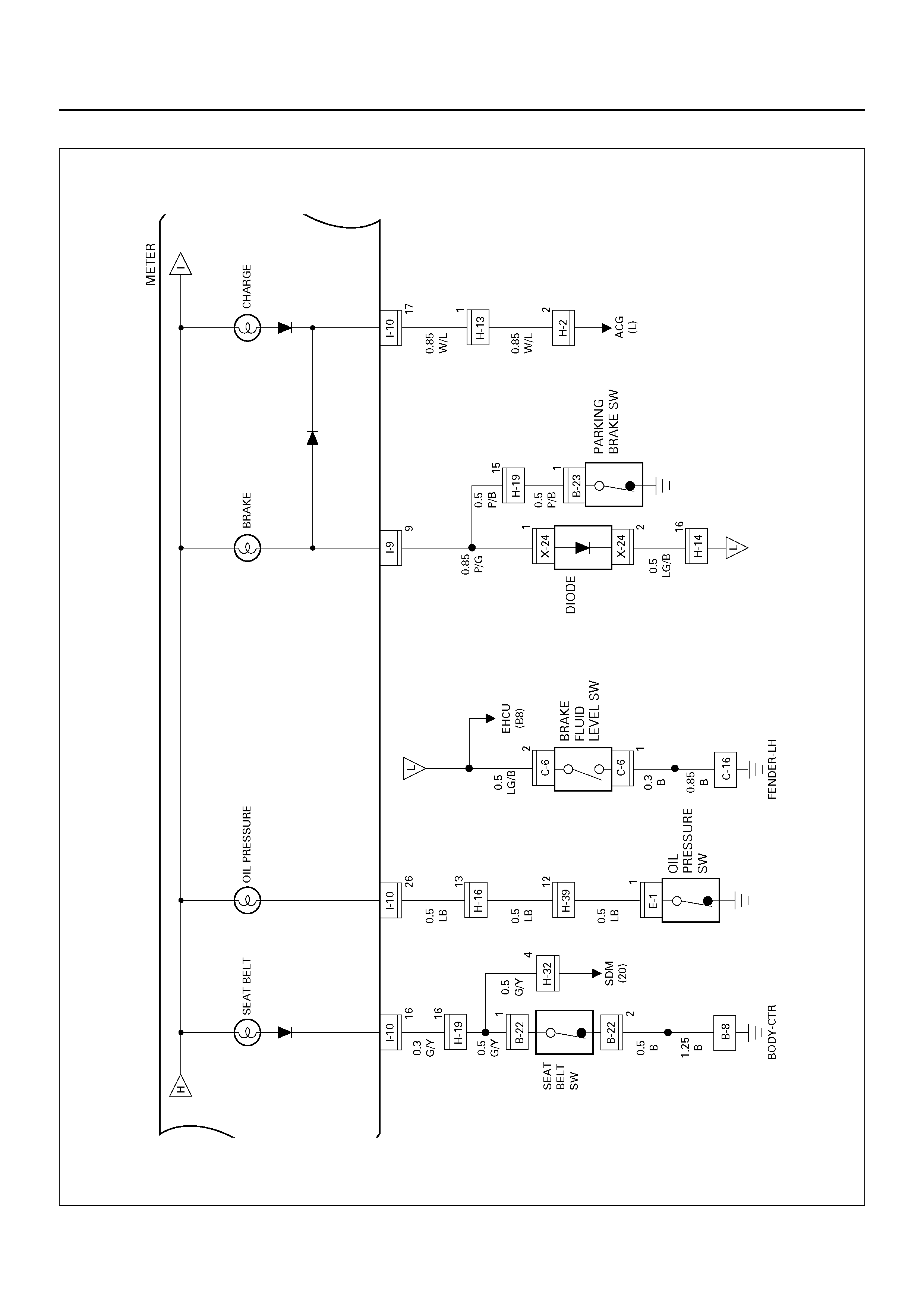

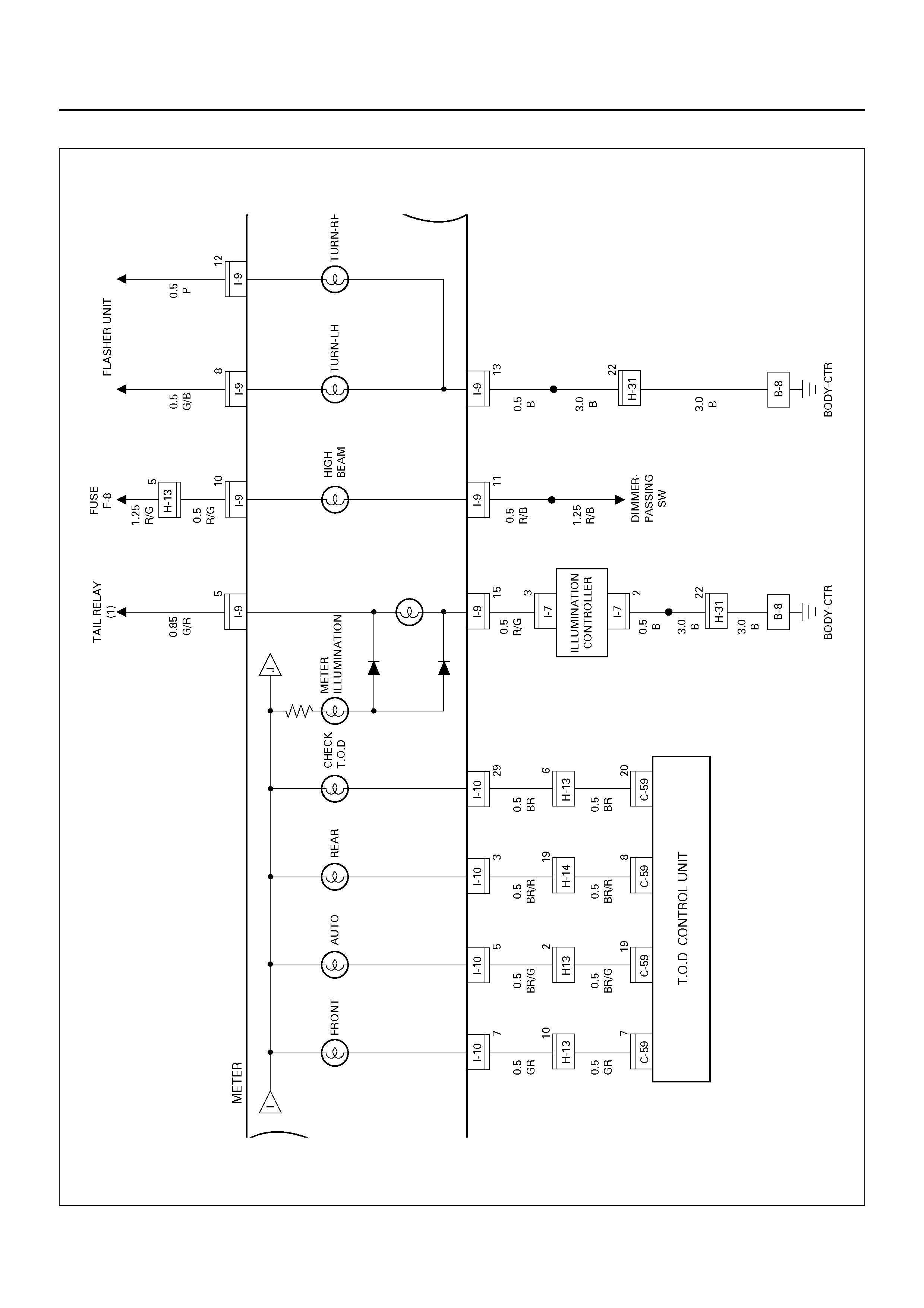

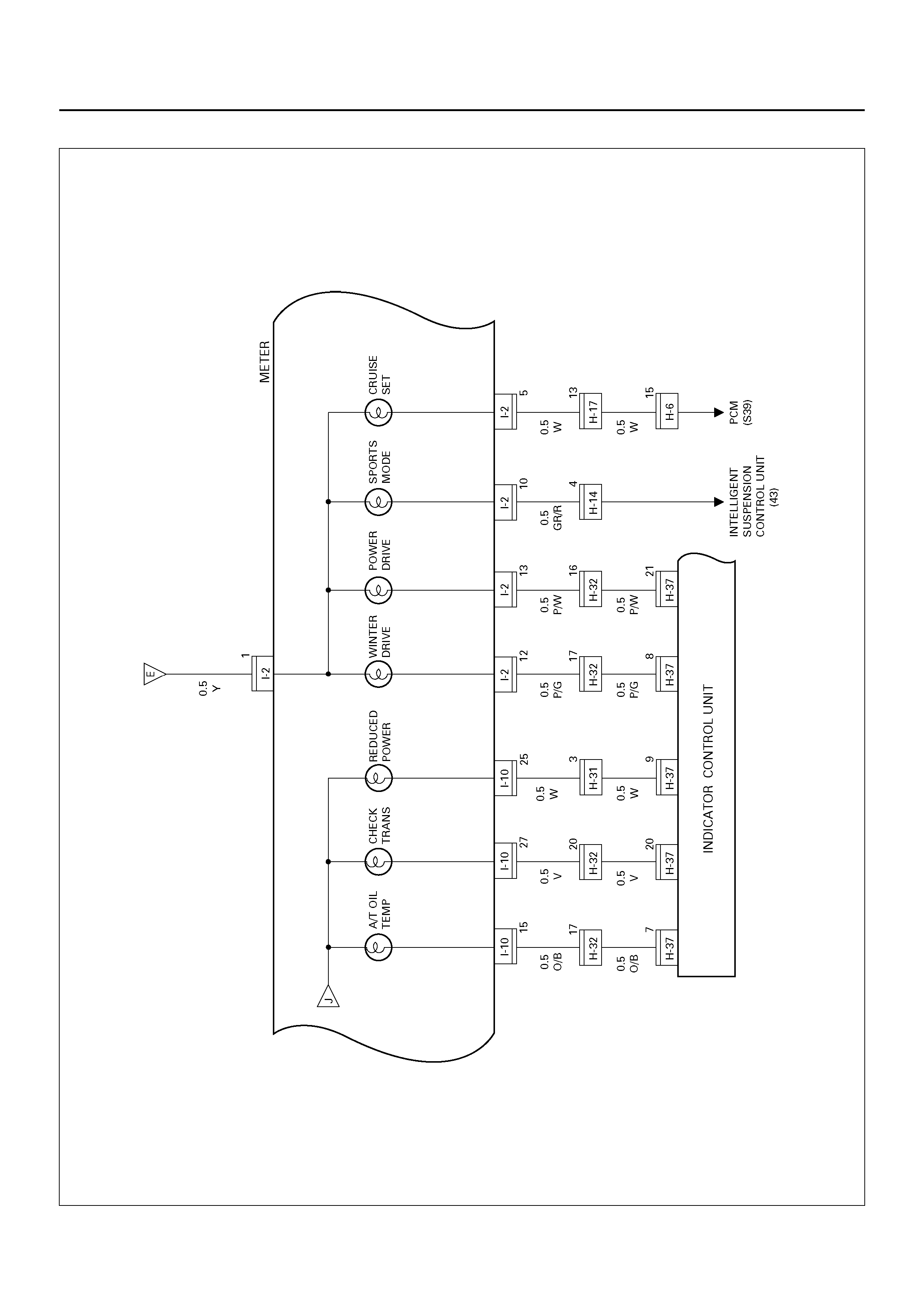

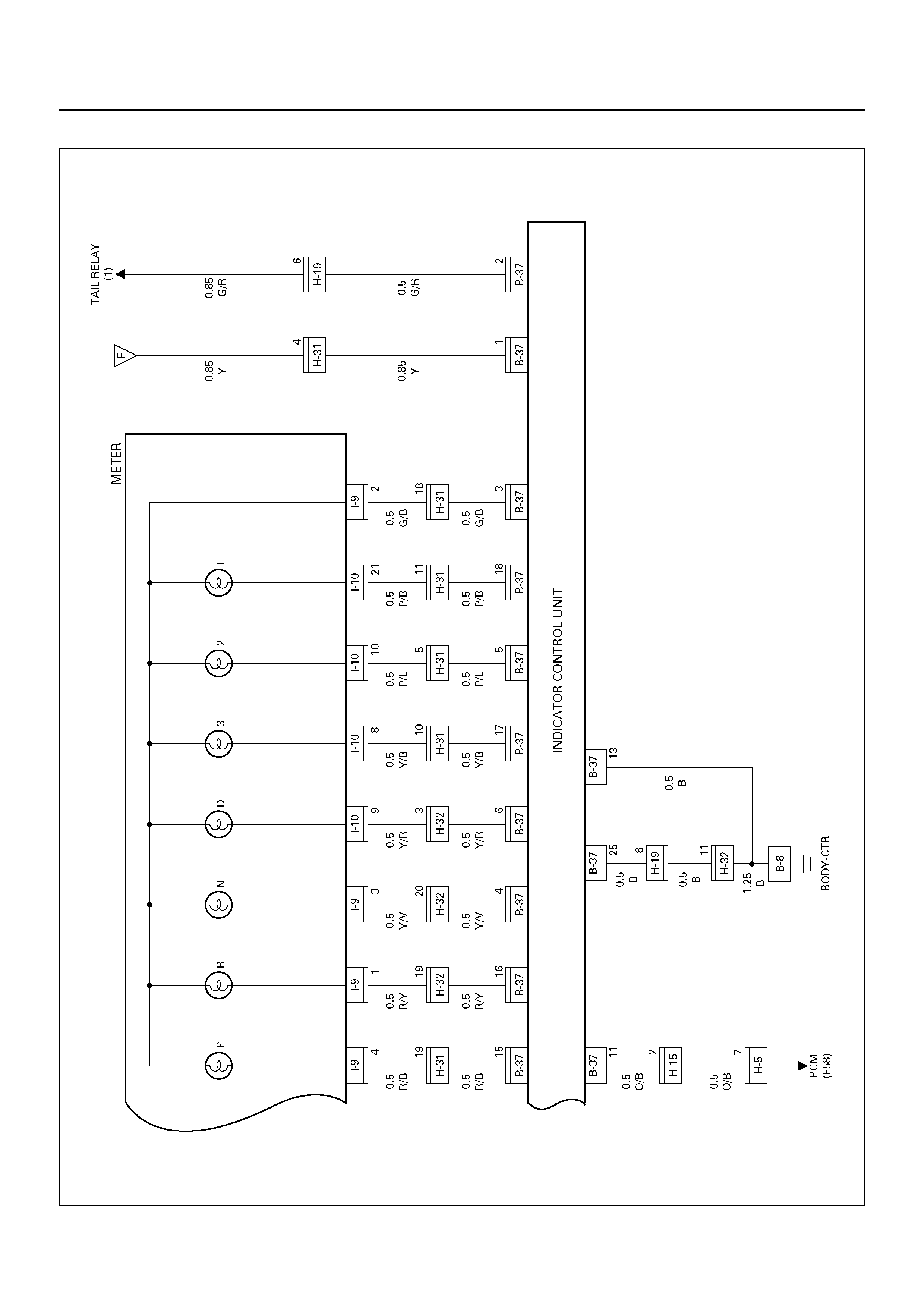

Meter and Warning/Indicator Light

General Description

Circuit Diagram

Parts Location

Diagnosis

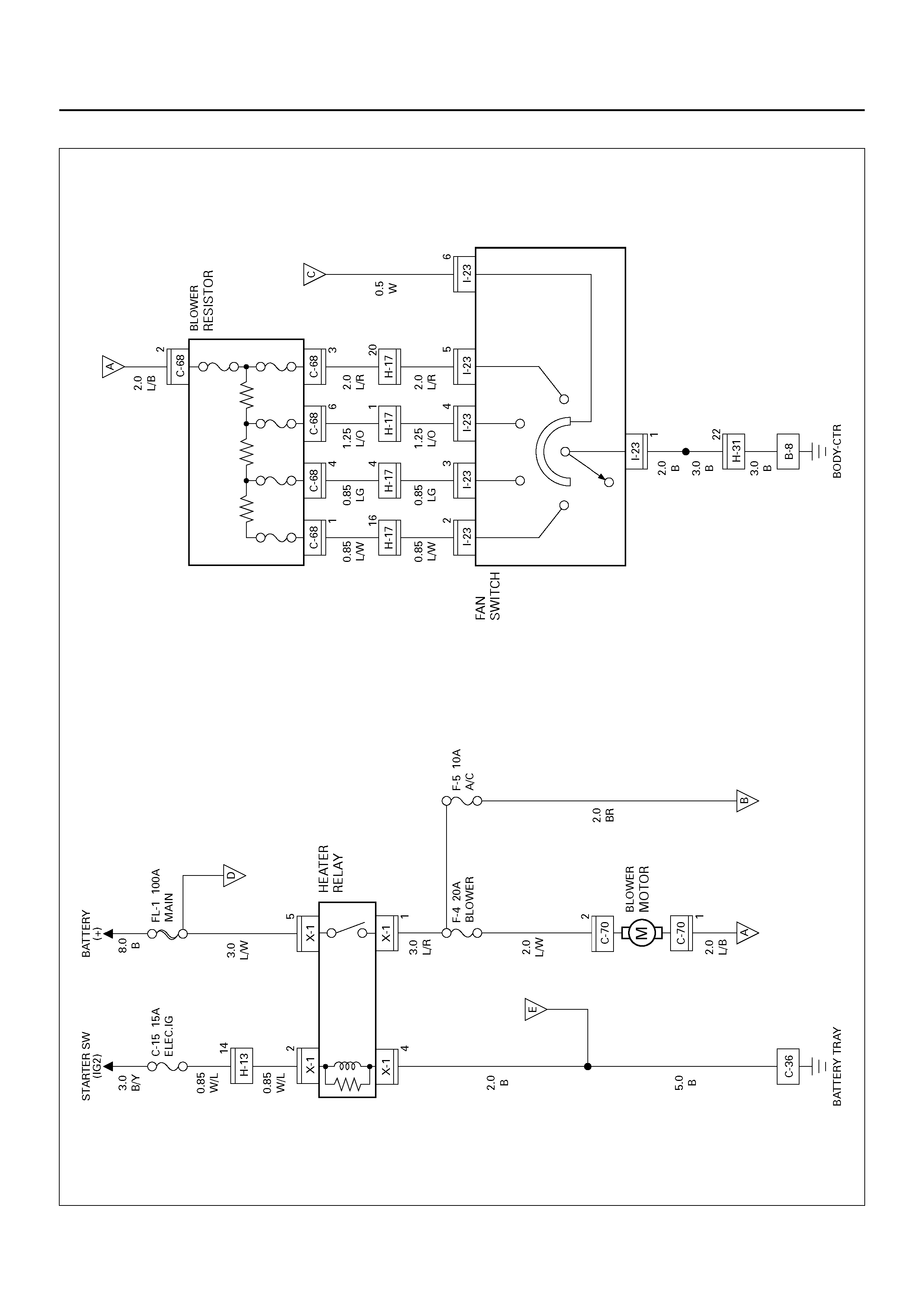

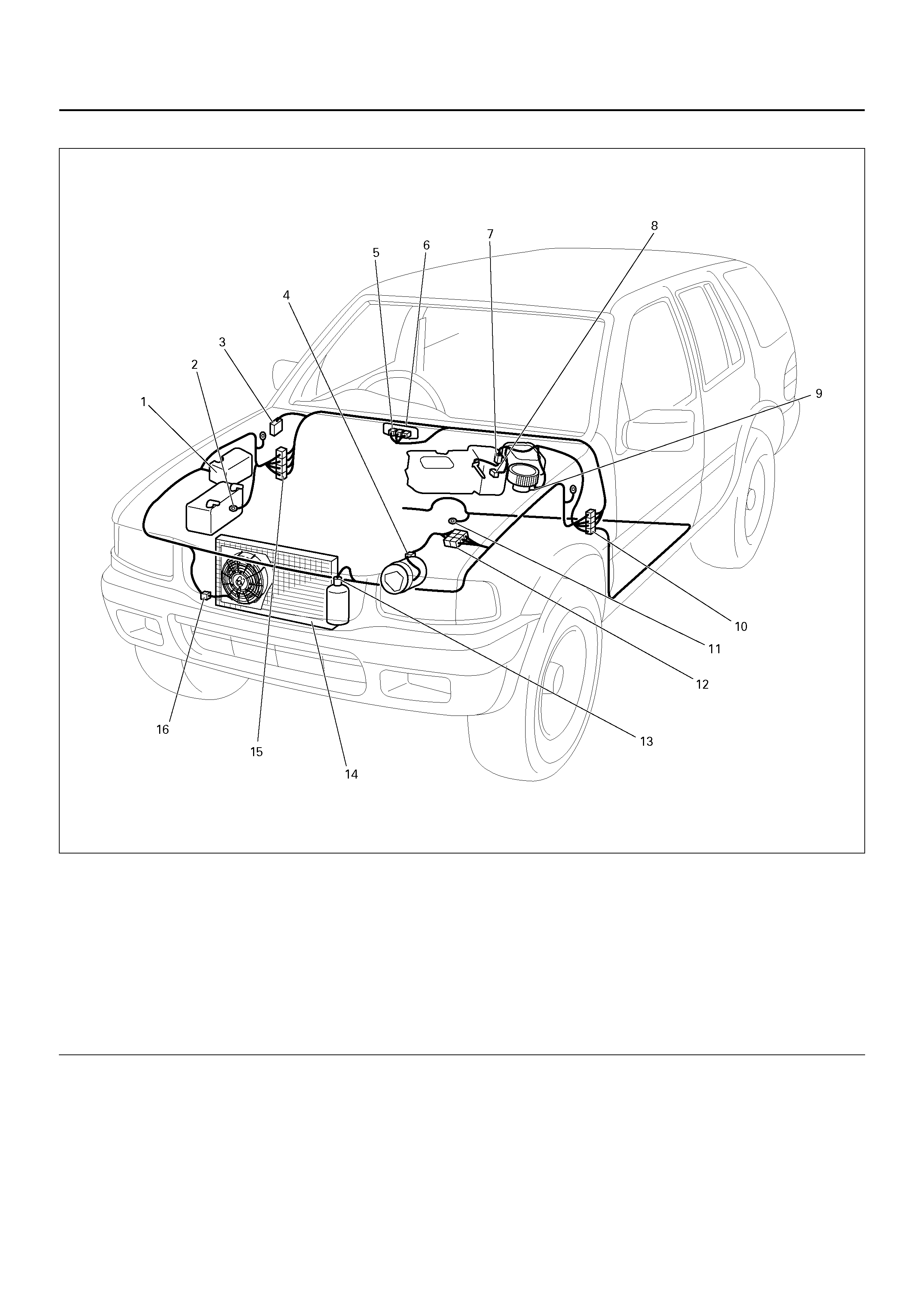

Heater and Air Conditioning (Manual)

General Description

Circuit Diagram

Parts Location

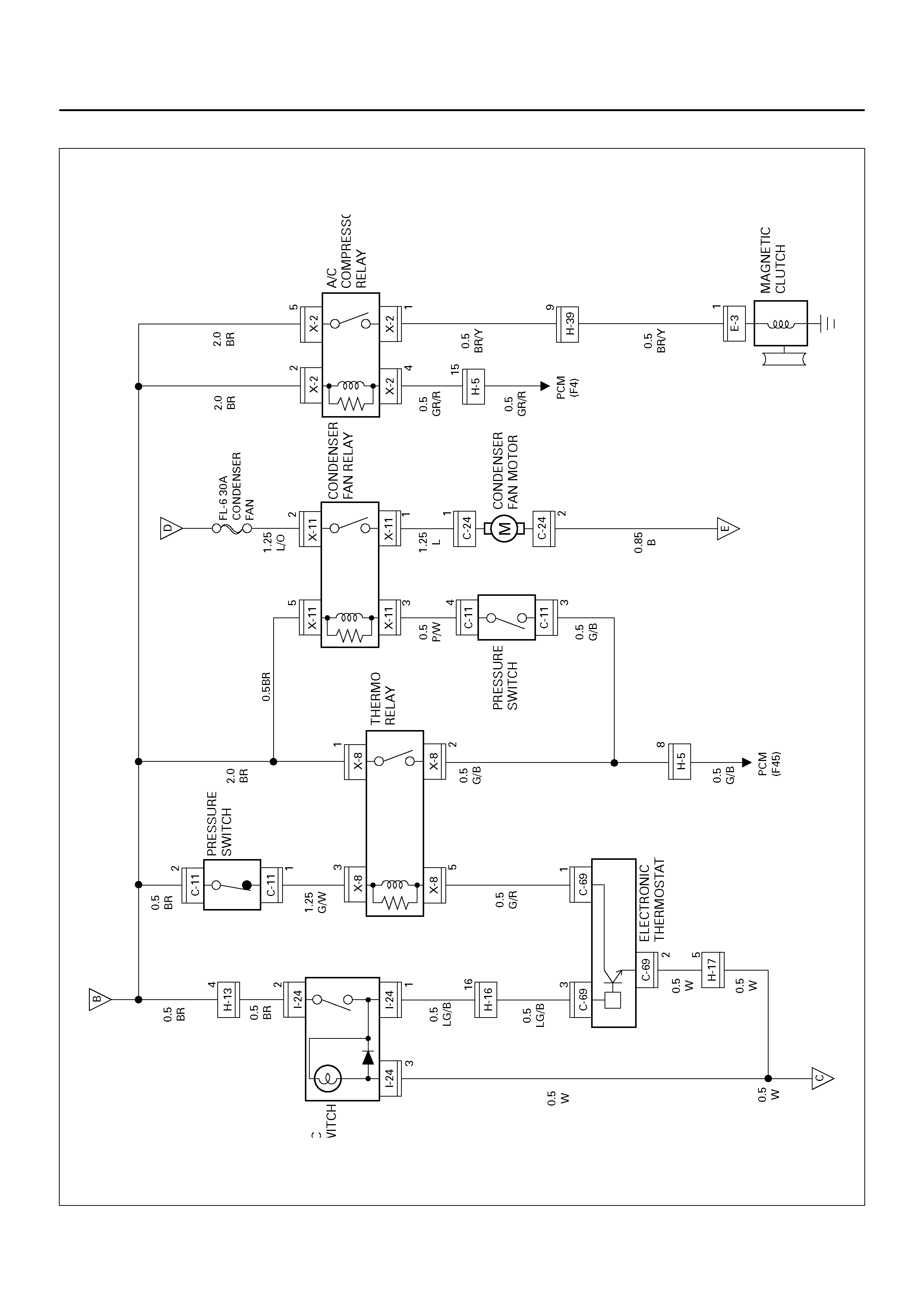

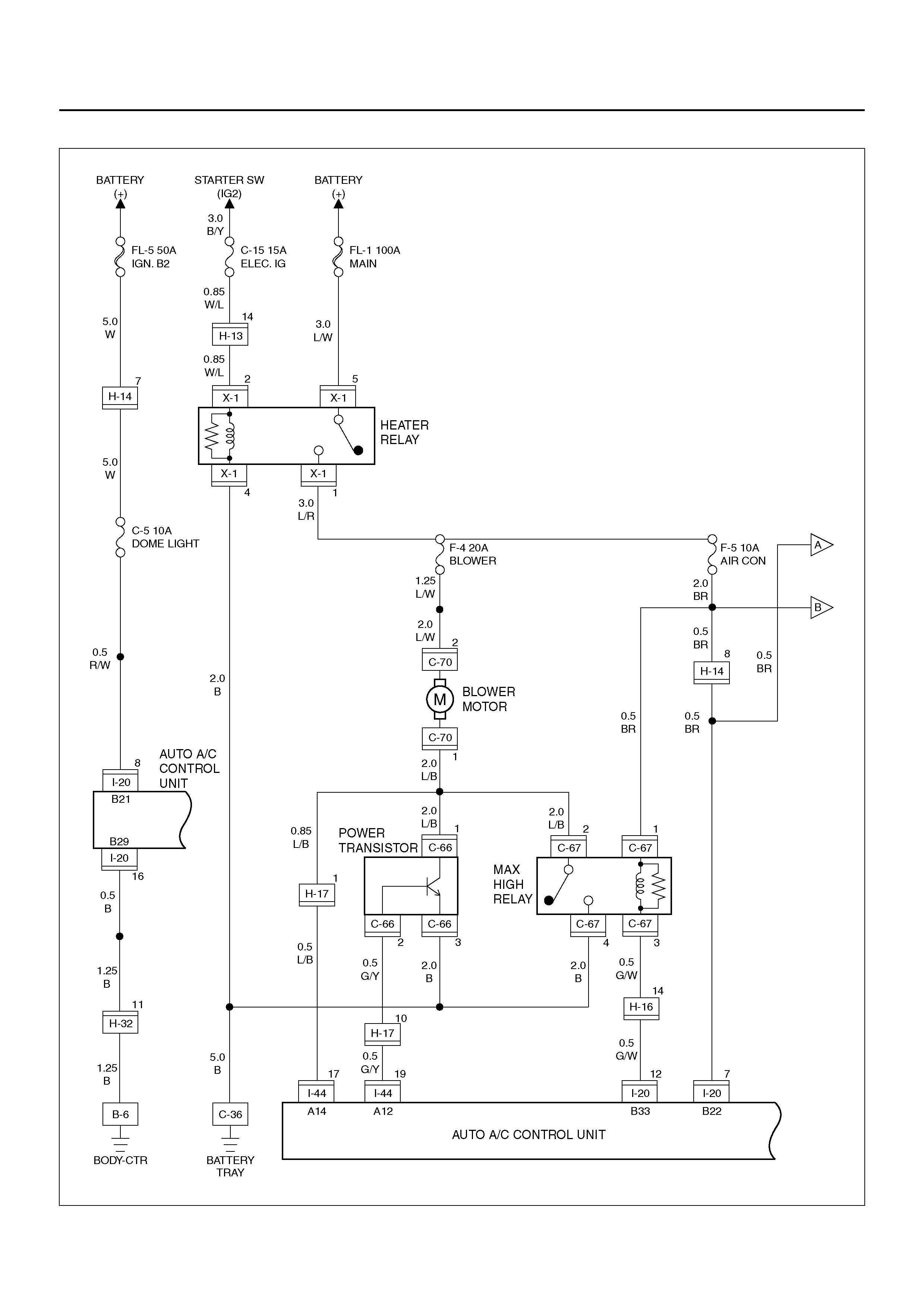

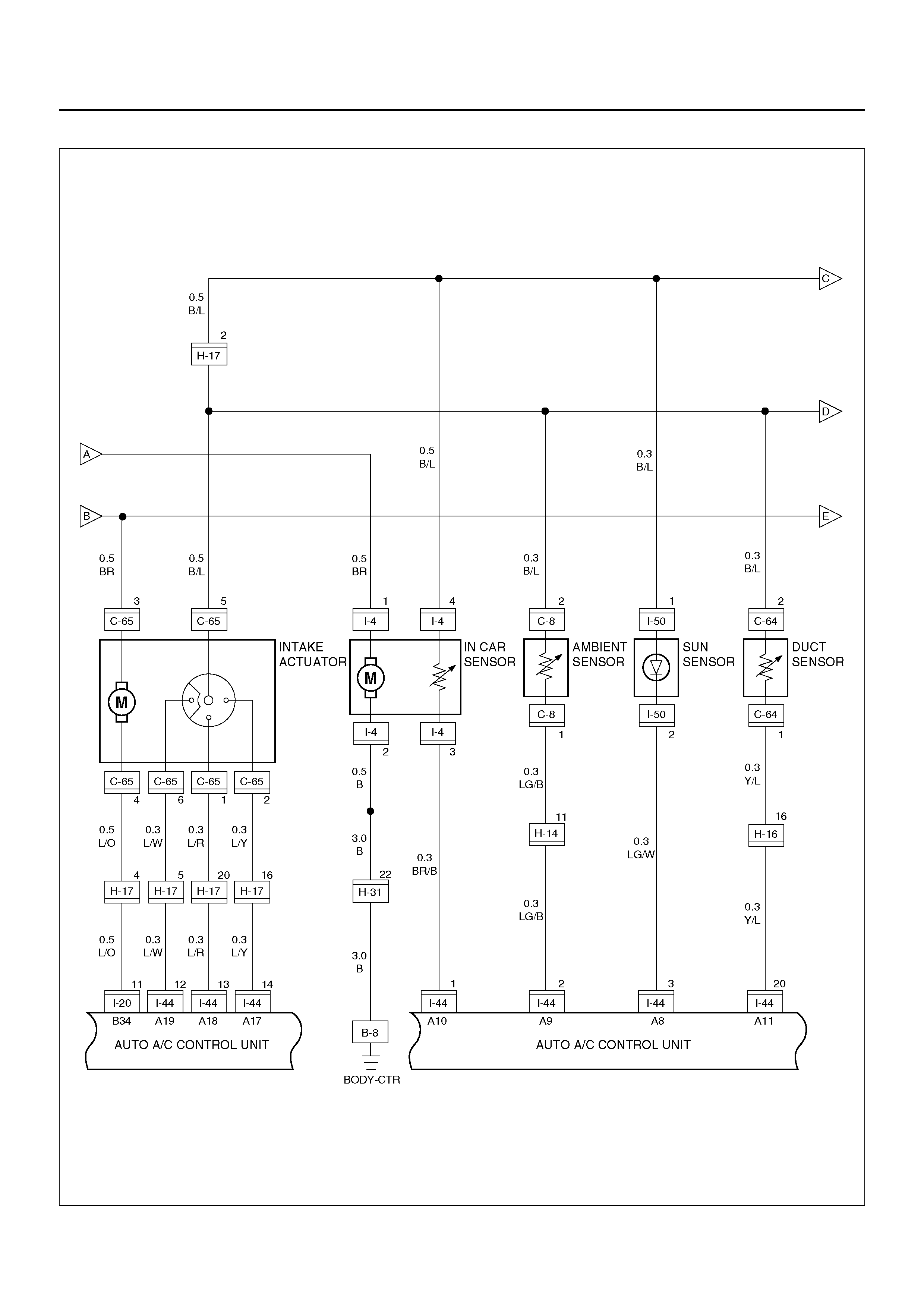

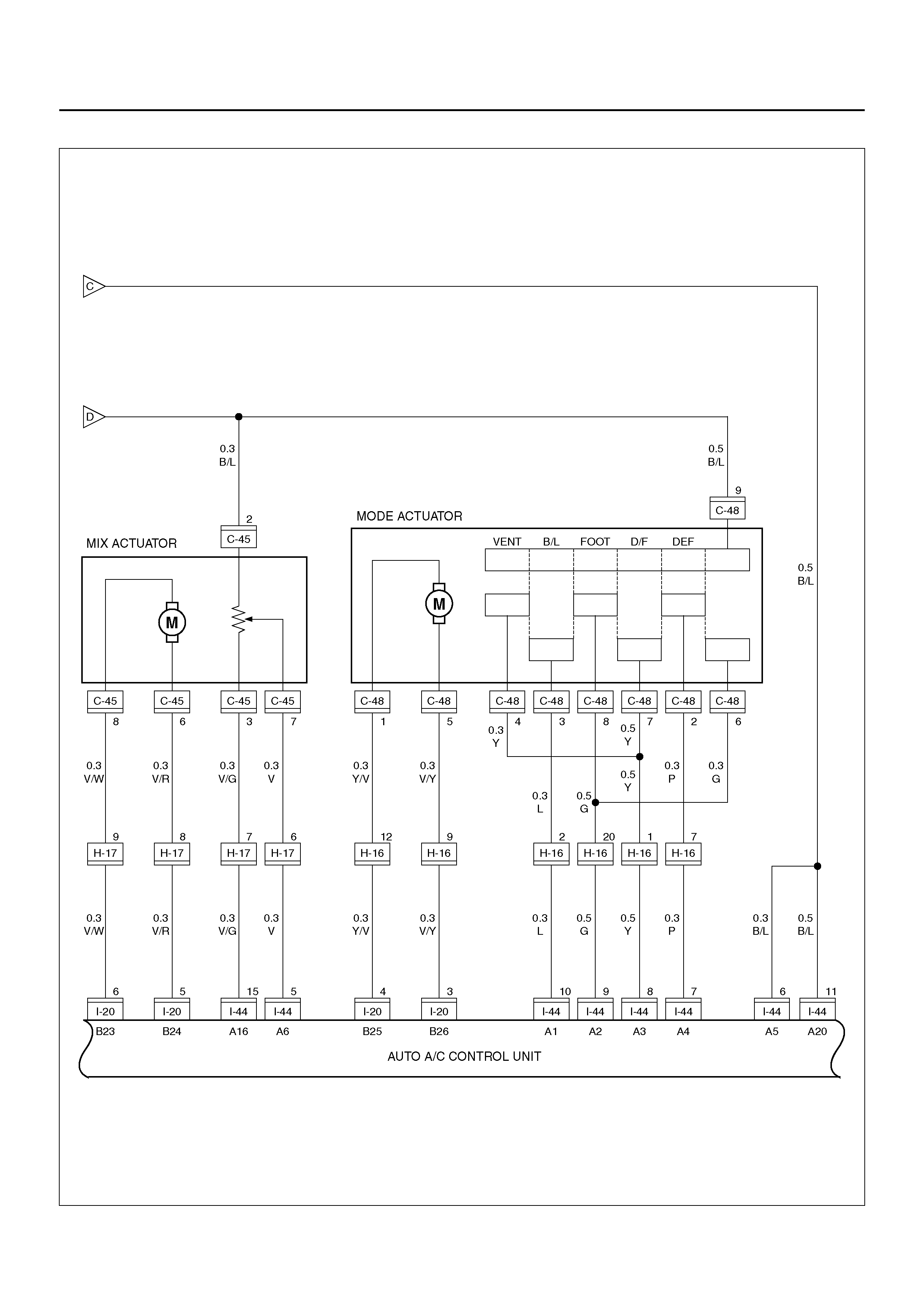

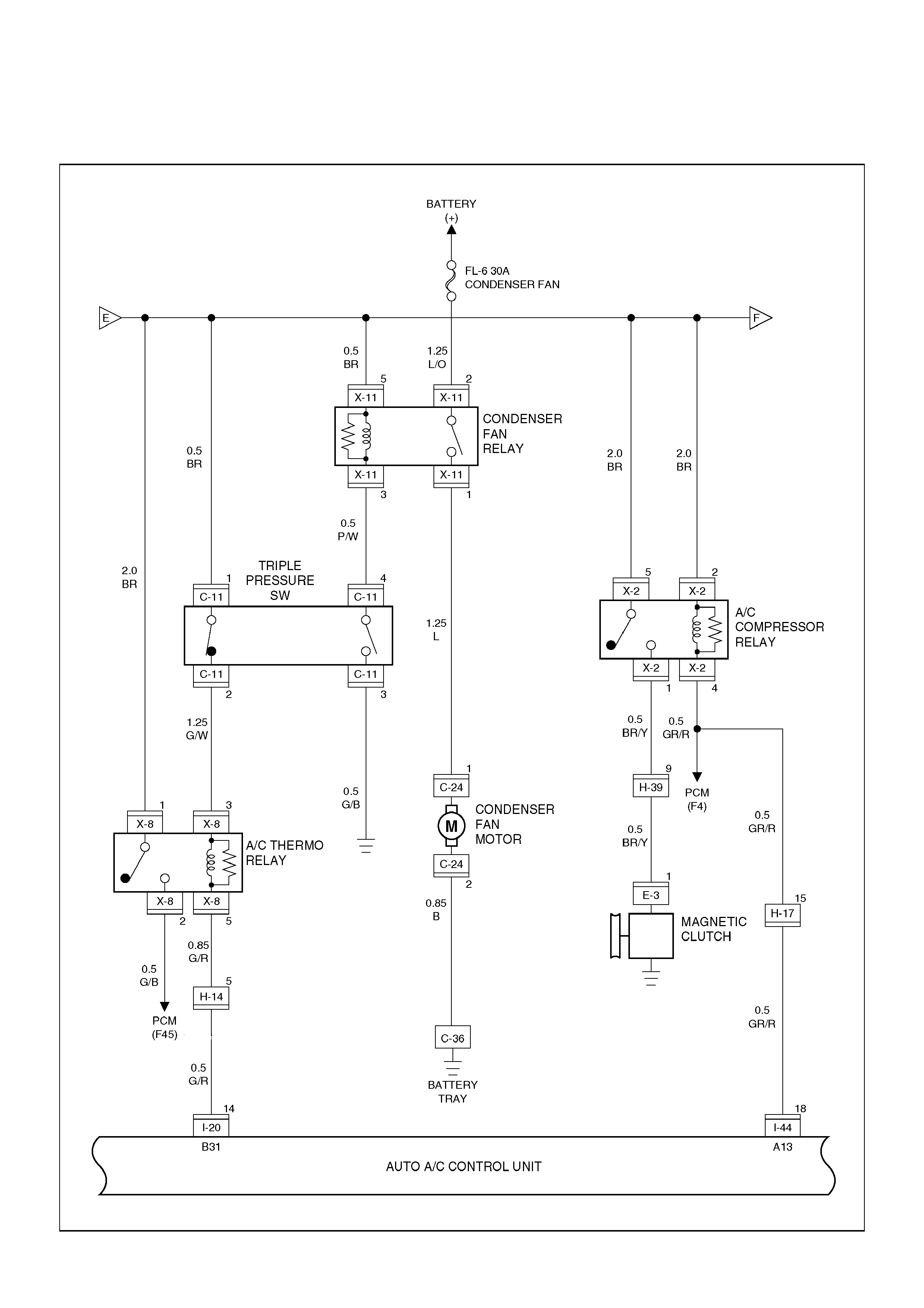

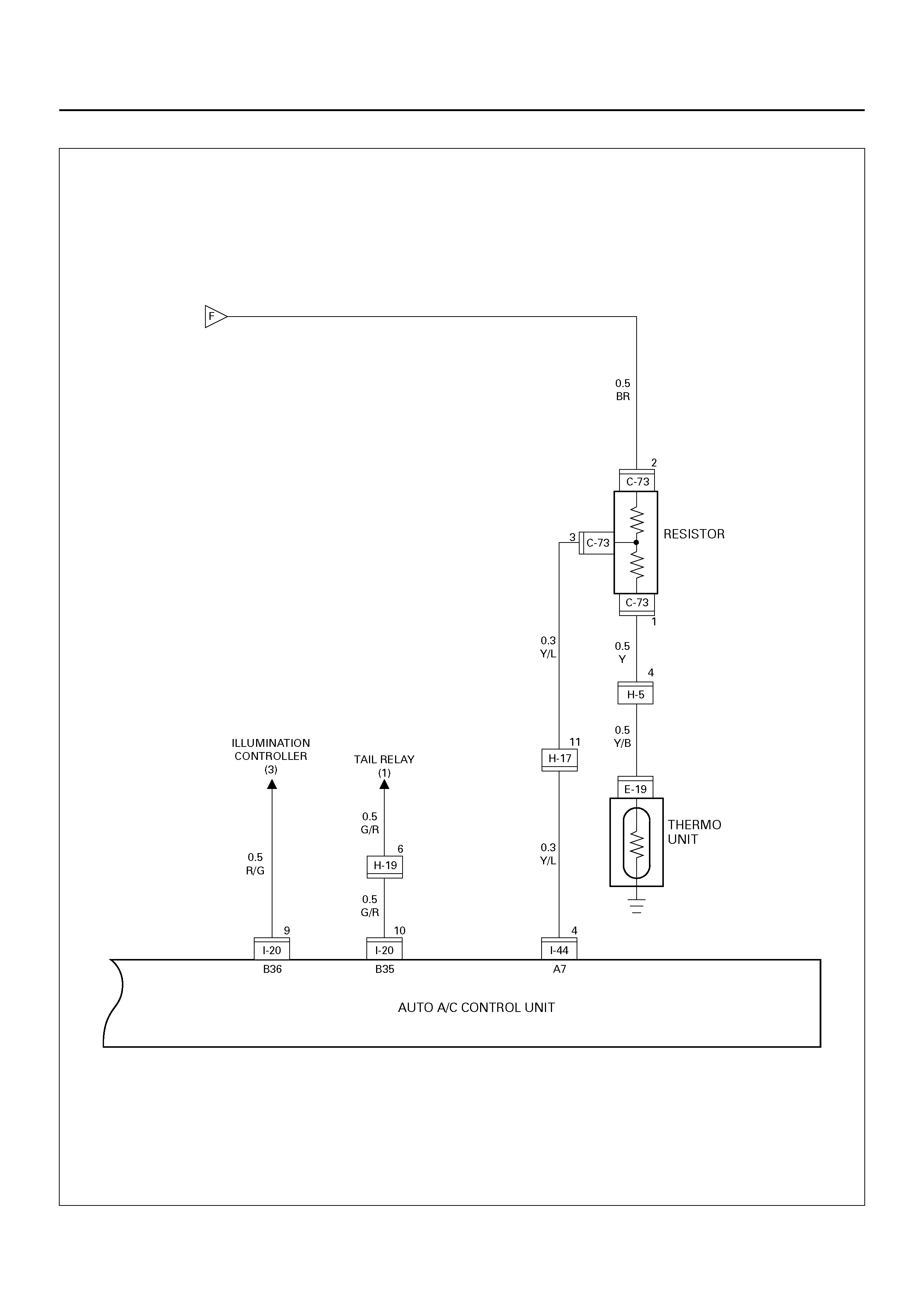

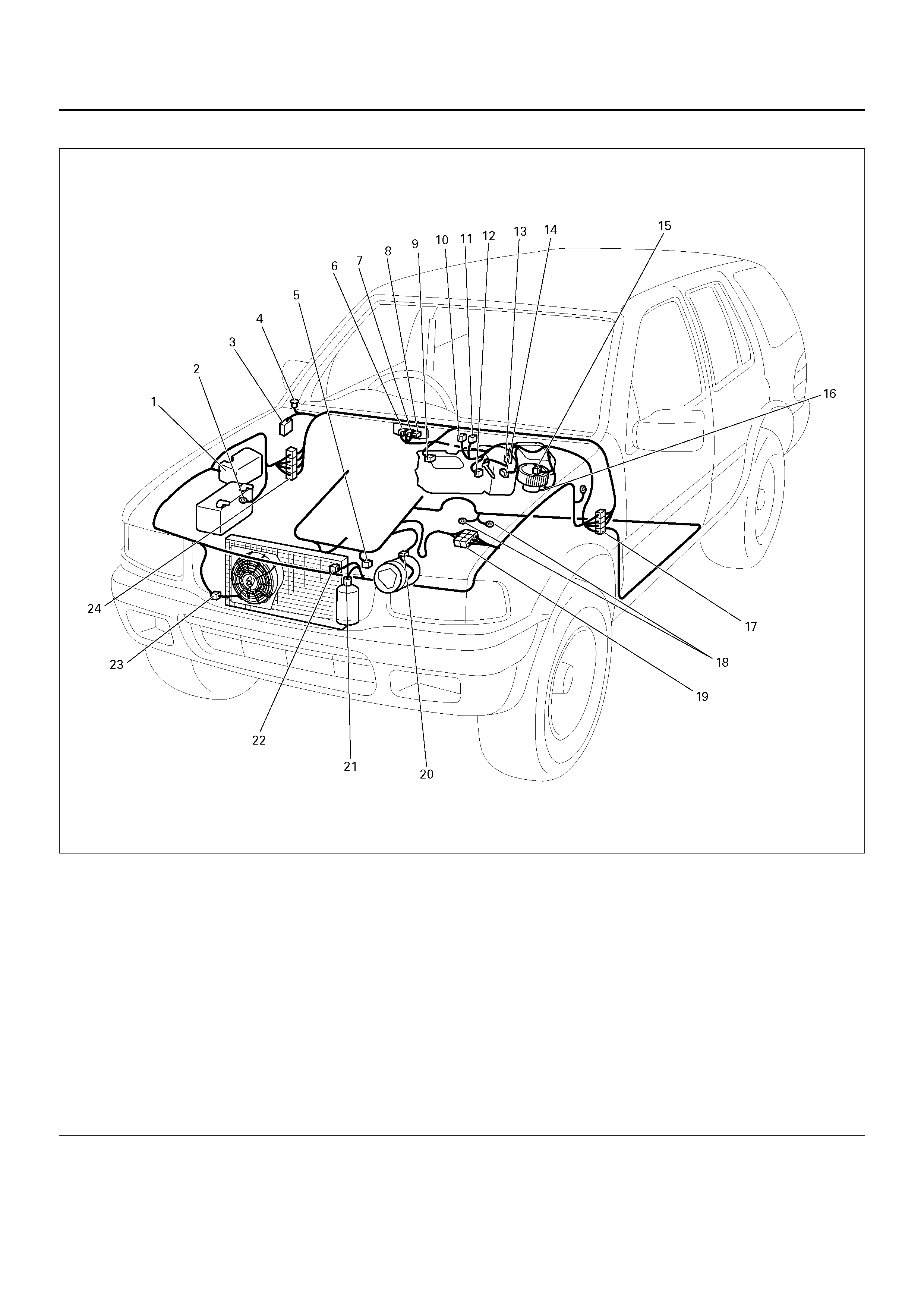

Heater and Air Conditioning (Automatic)

General Description

Circuit Diagram

Parts Location

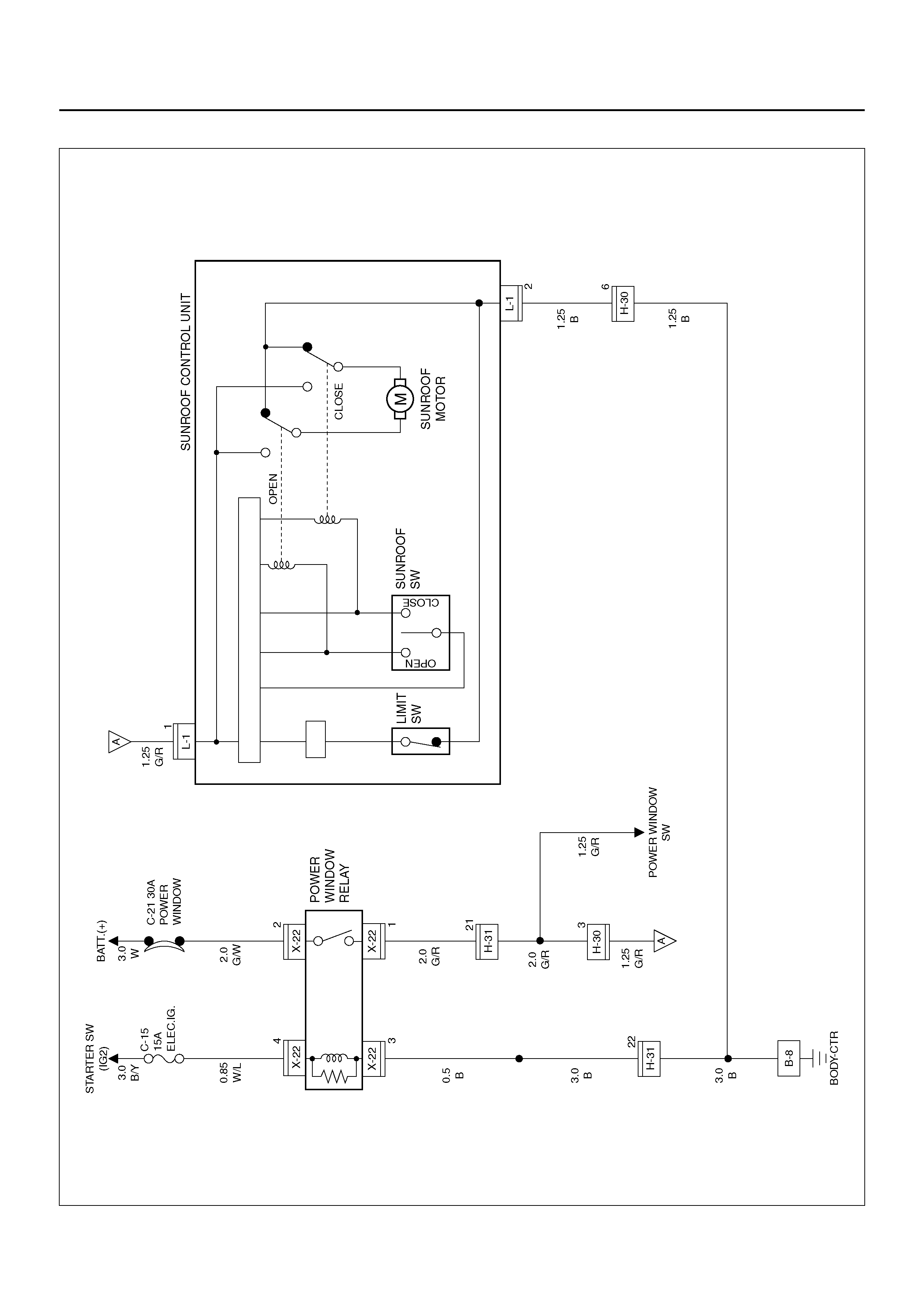

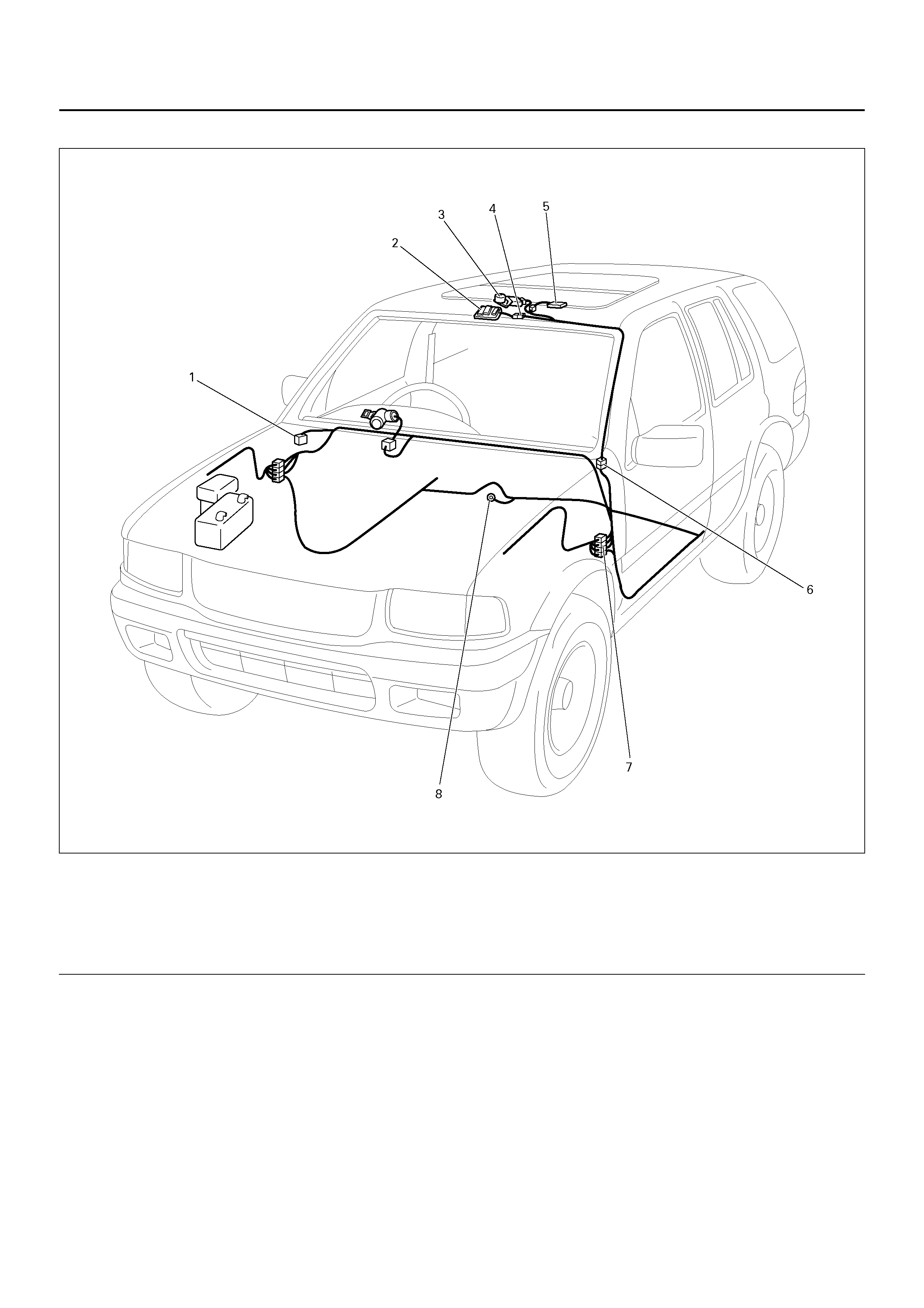

Sunroof

General Description

Circuit Diagram

Parts Location

Diagnosis

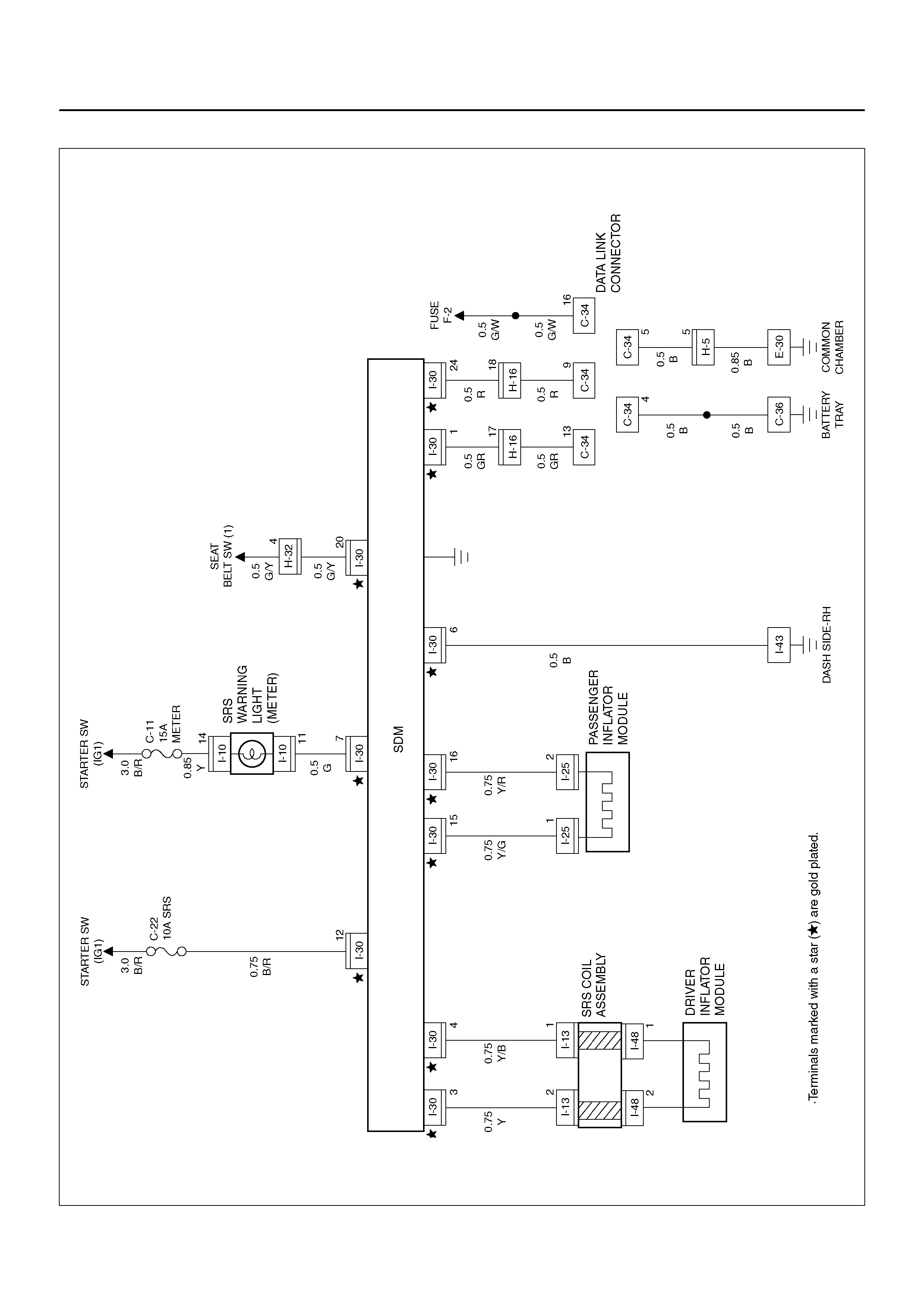

Supplemental Restraint System (SRS)

– Air Bag

General Description

Circuit Diagram

Parts Location

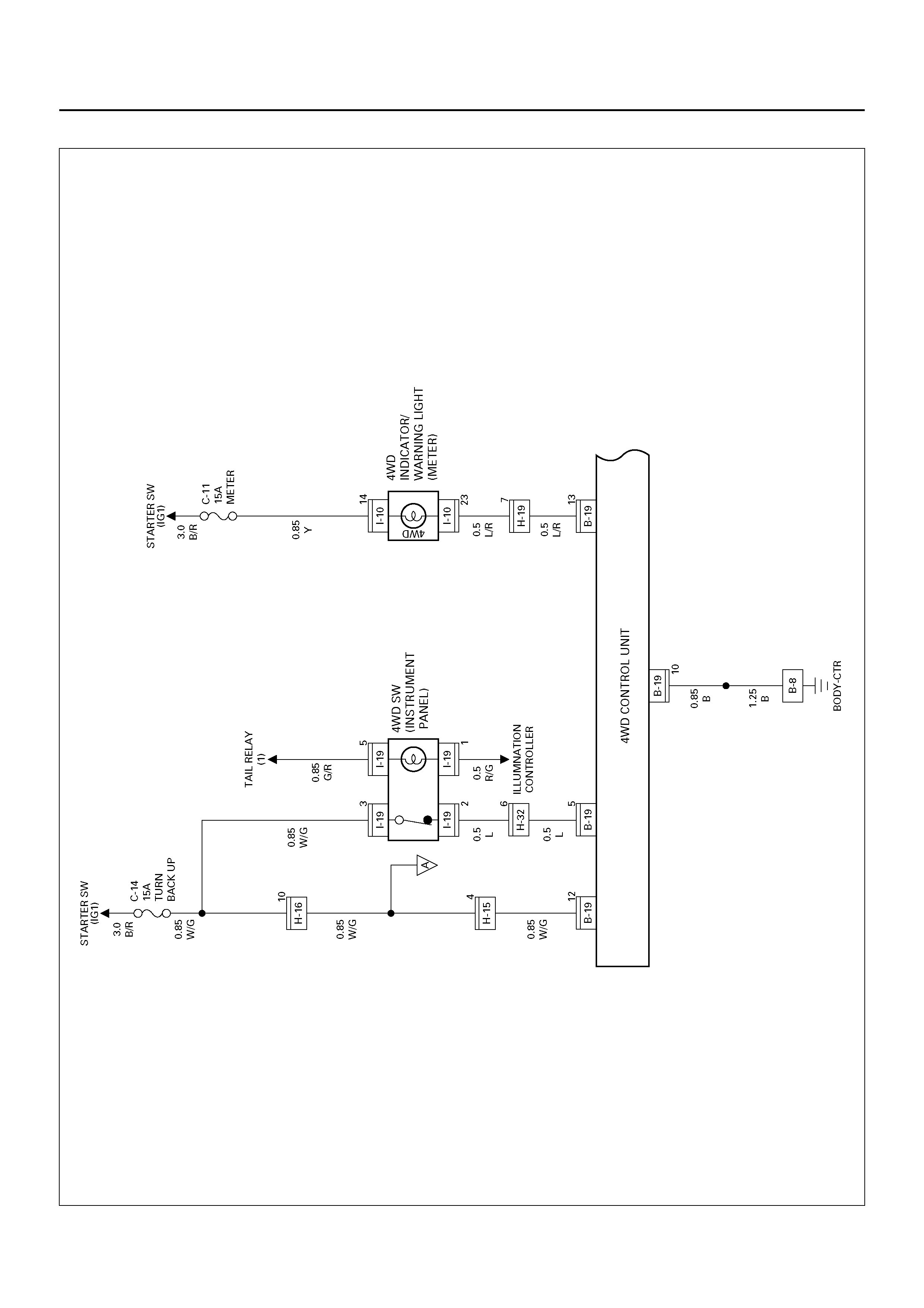

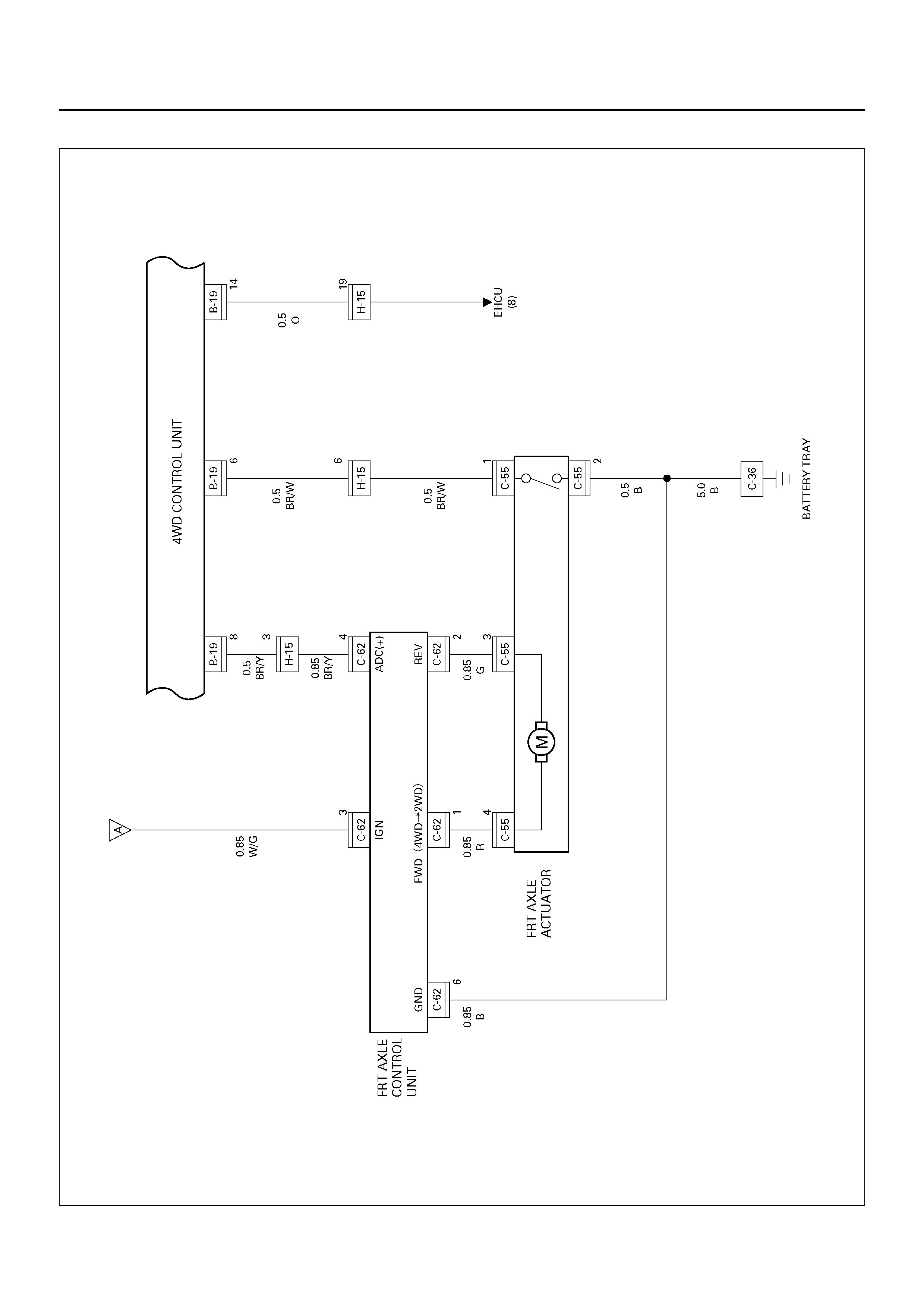

Shift on the Fly System

General Description

Circuit Diagram

Parts Location

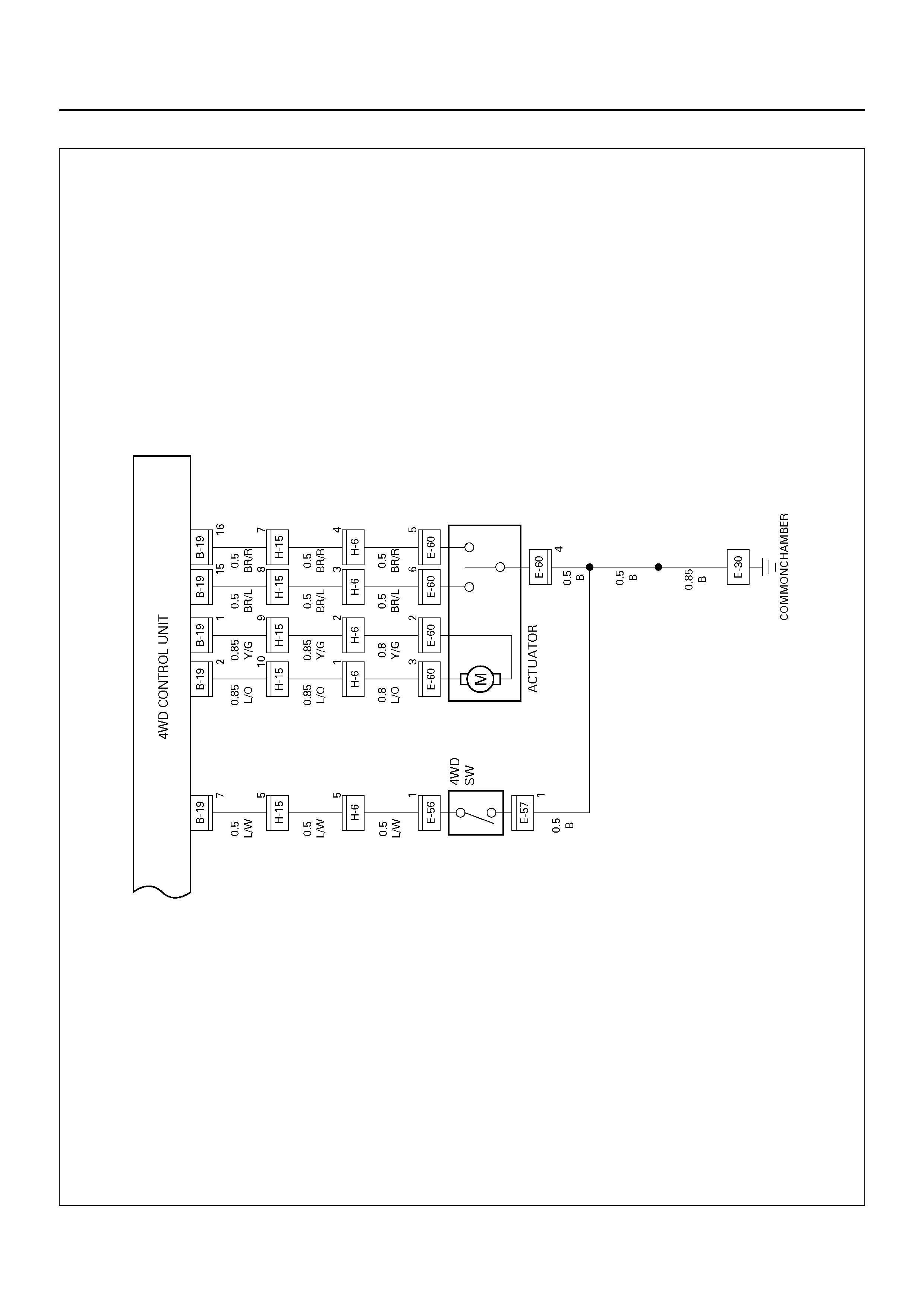

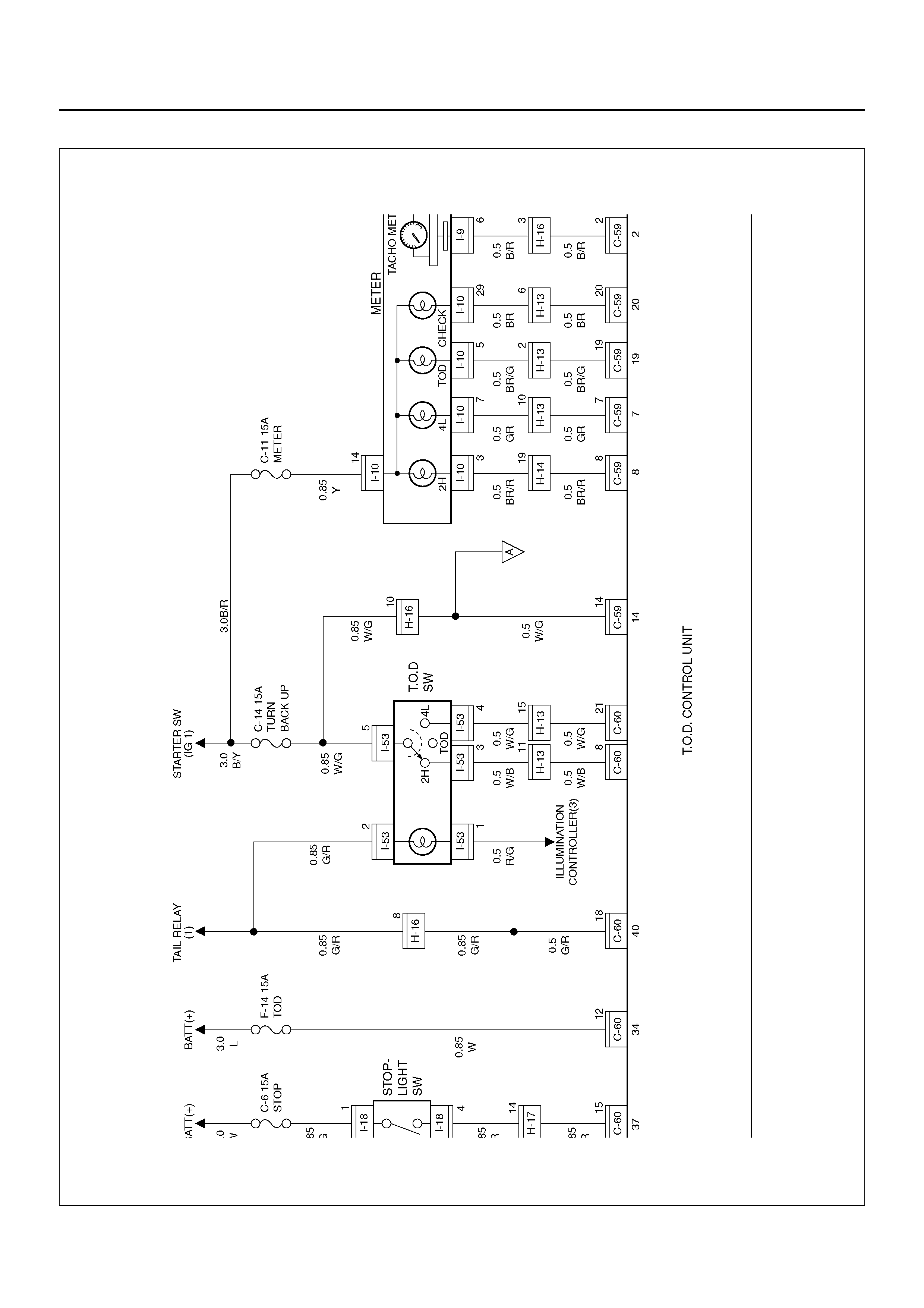

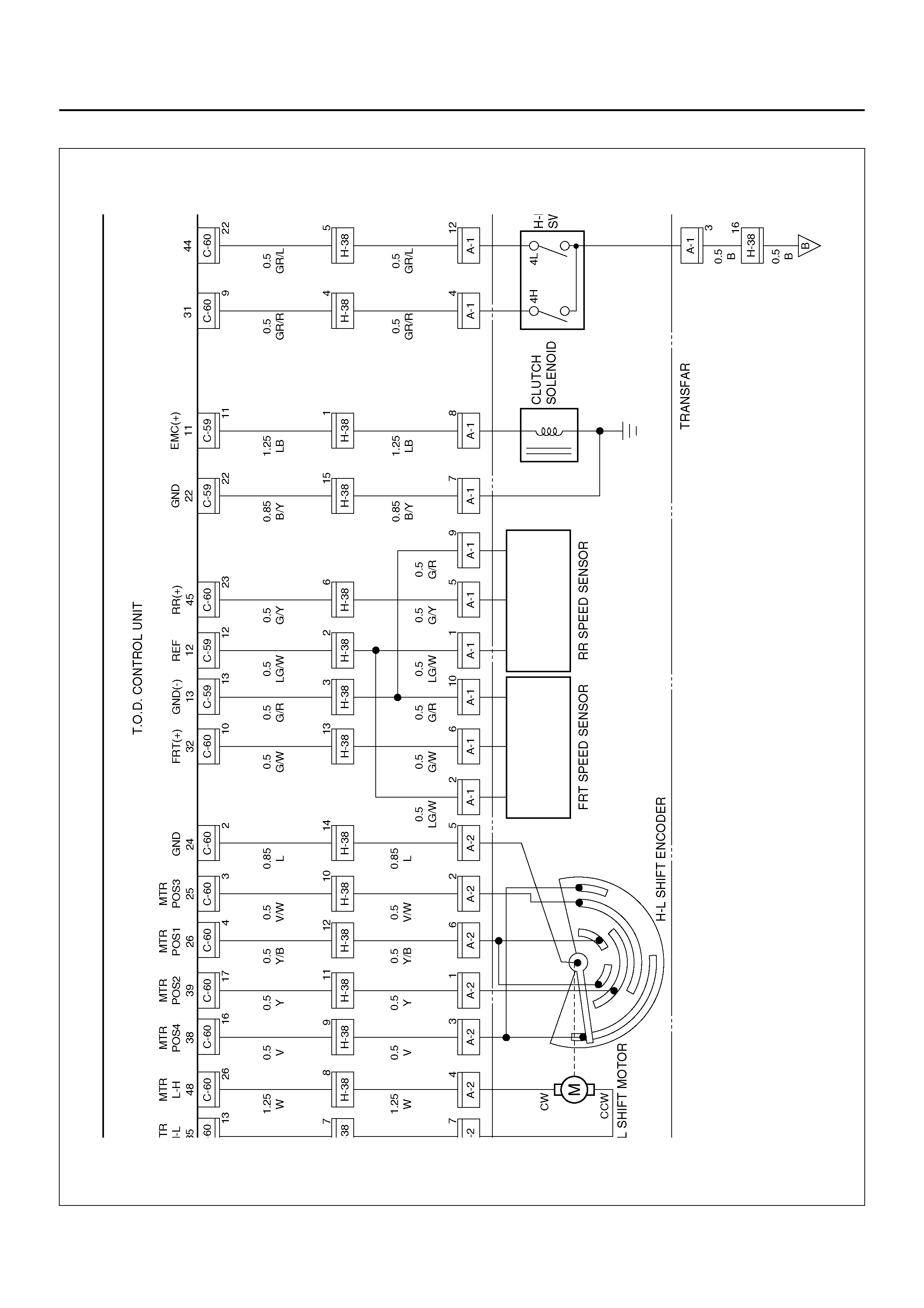

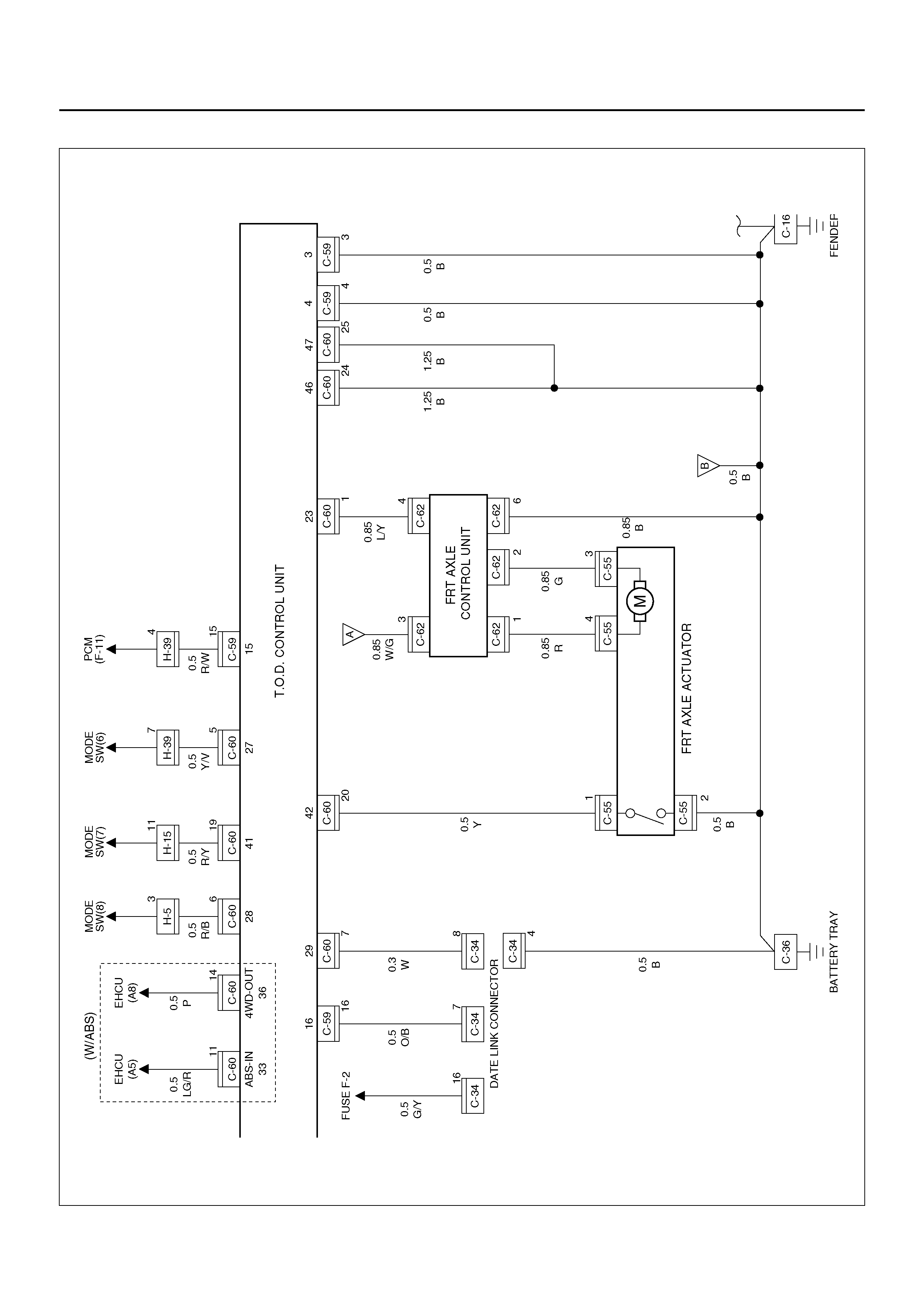

T.O.D.

General Description

Circuit Diagram

Parts Location

Alarm and Relay Control Unit

Circuit Diagram

Parts Location

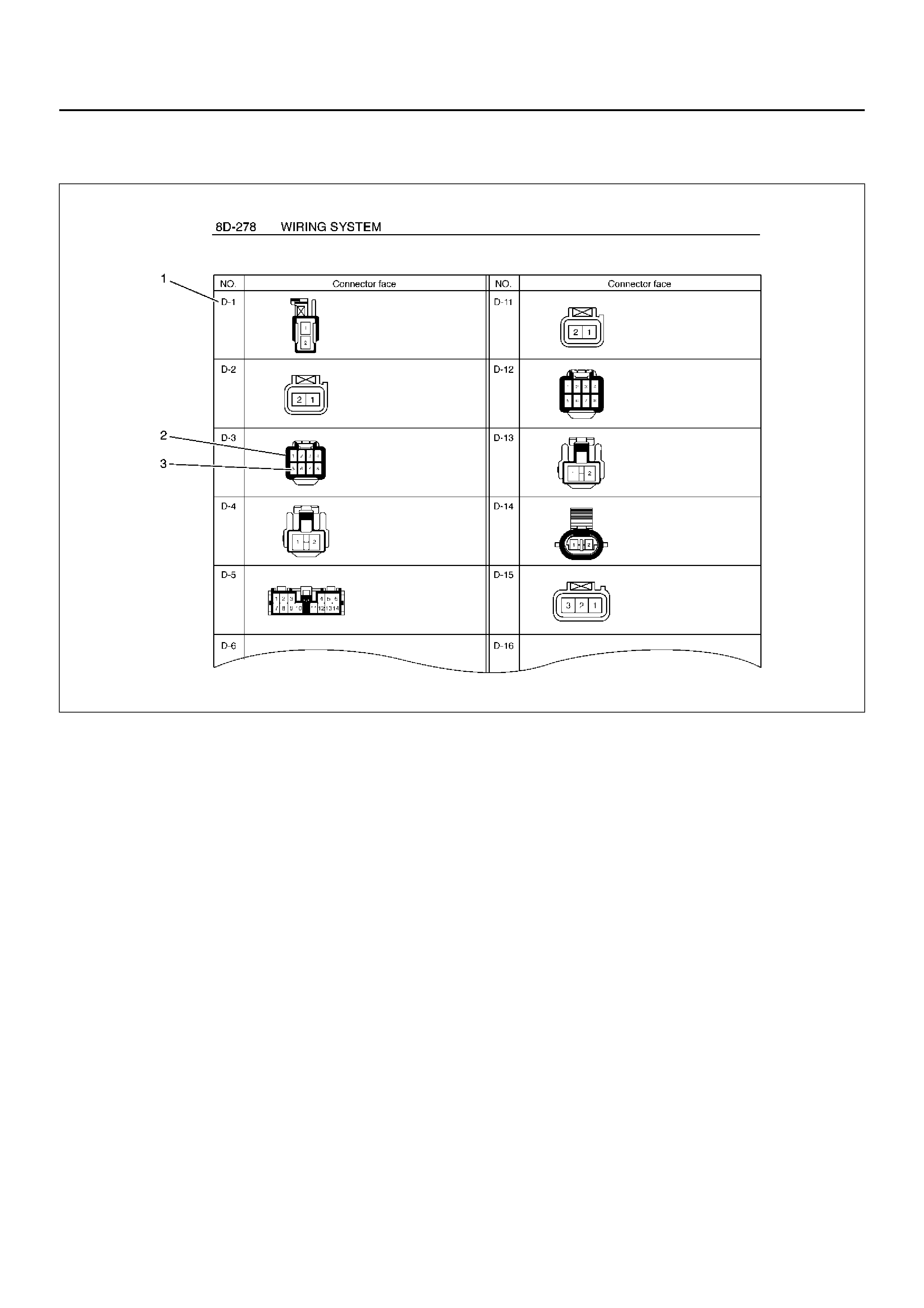

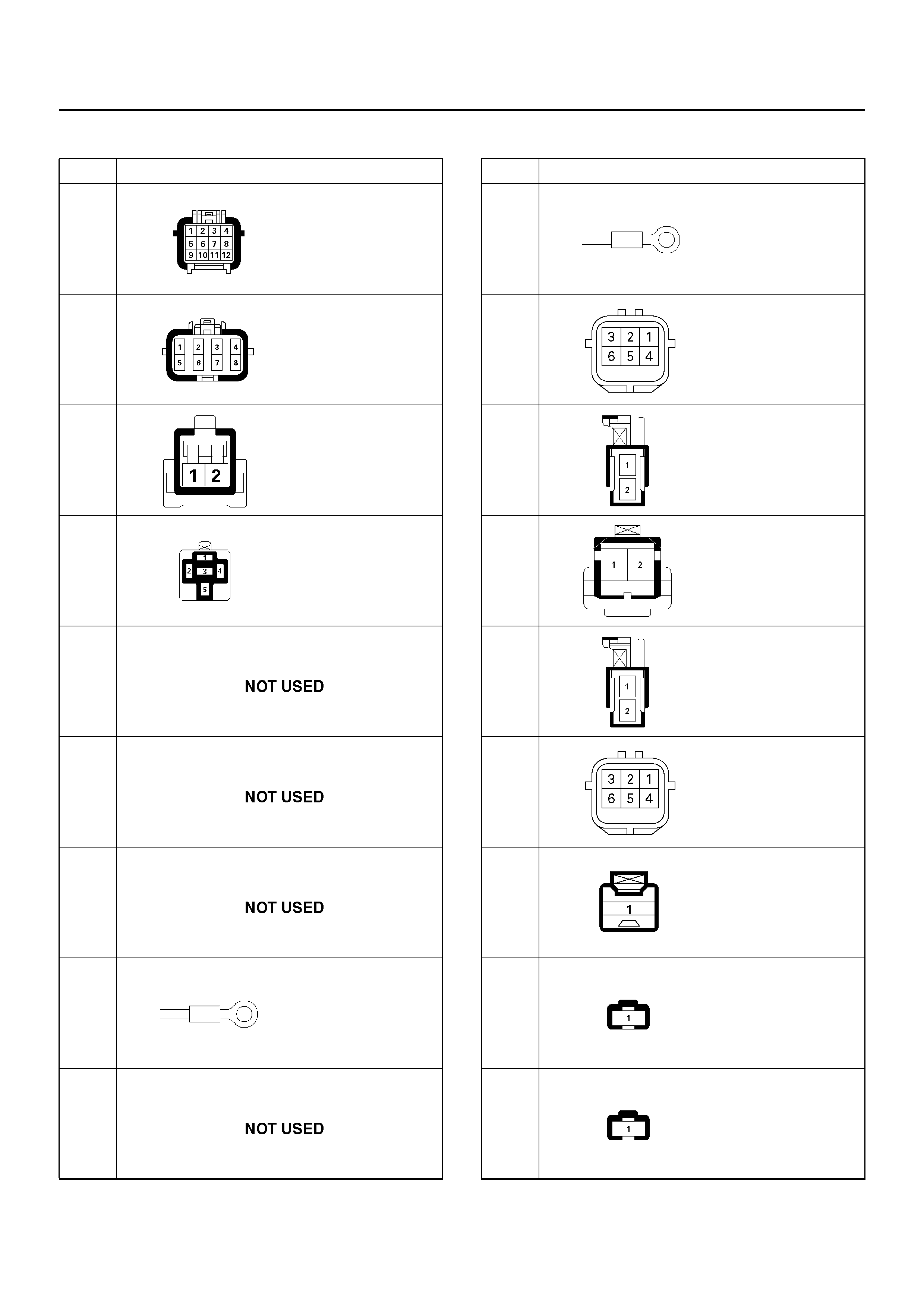

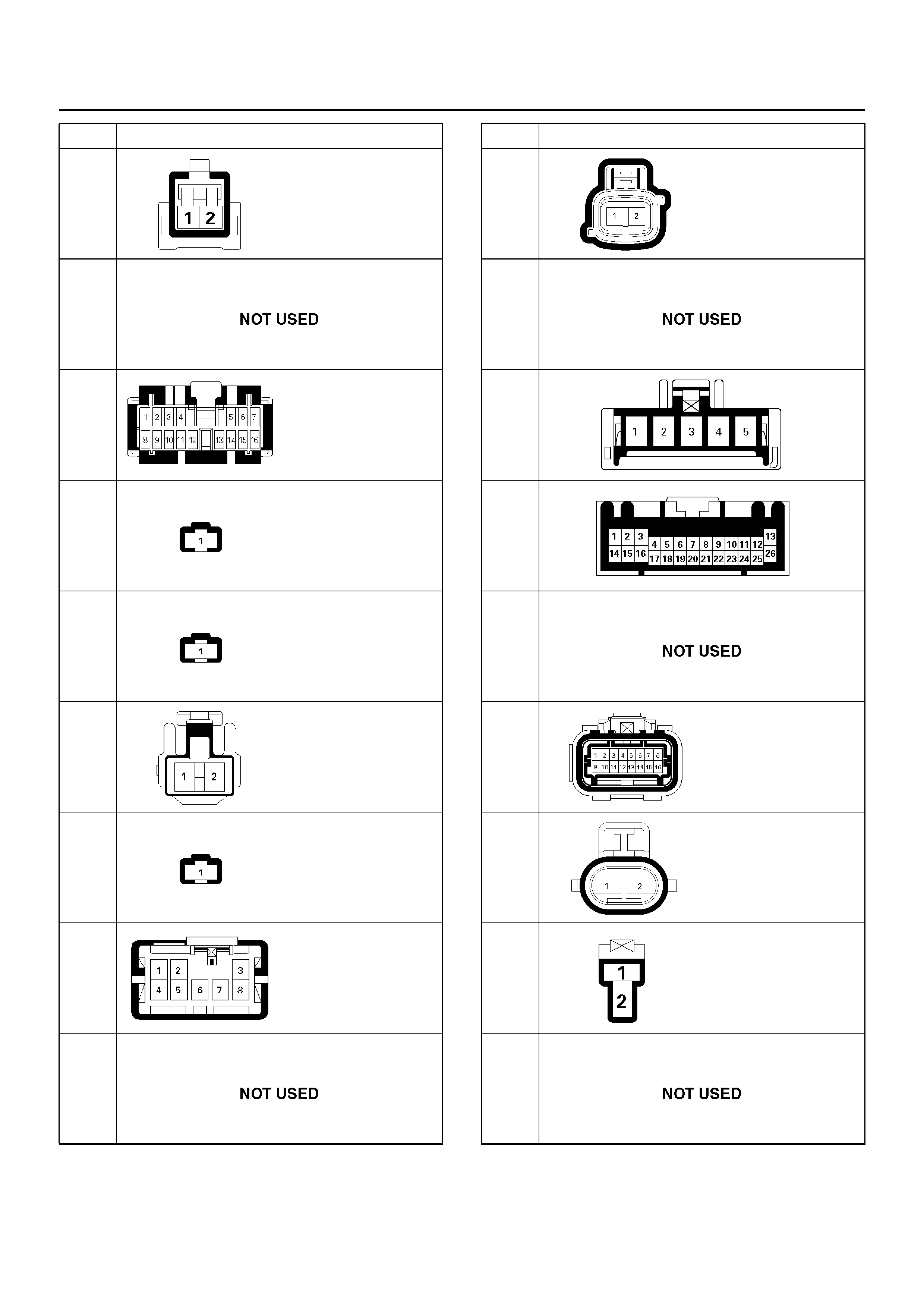

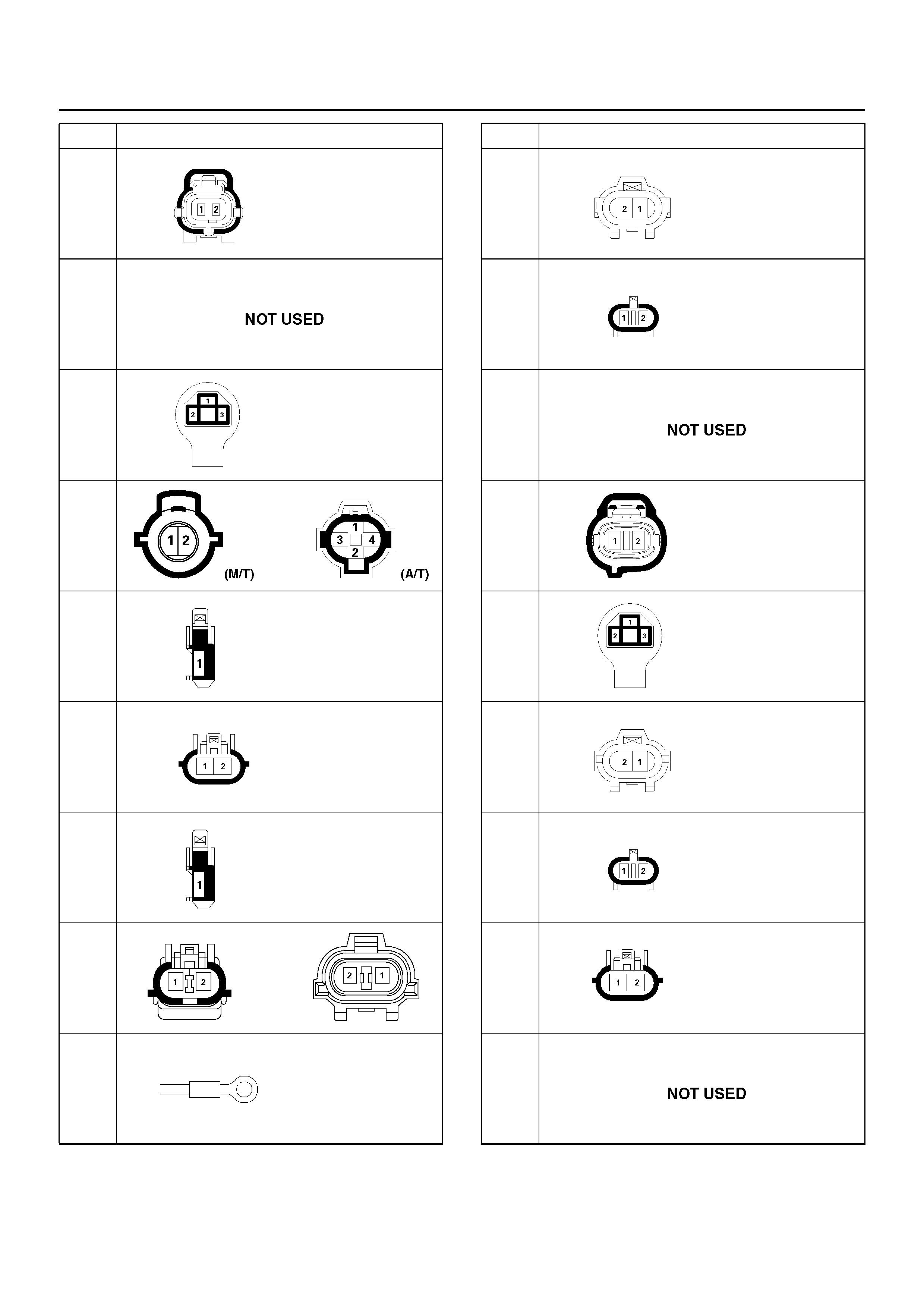

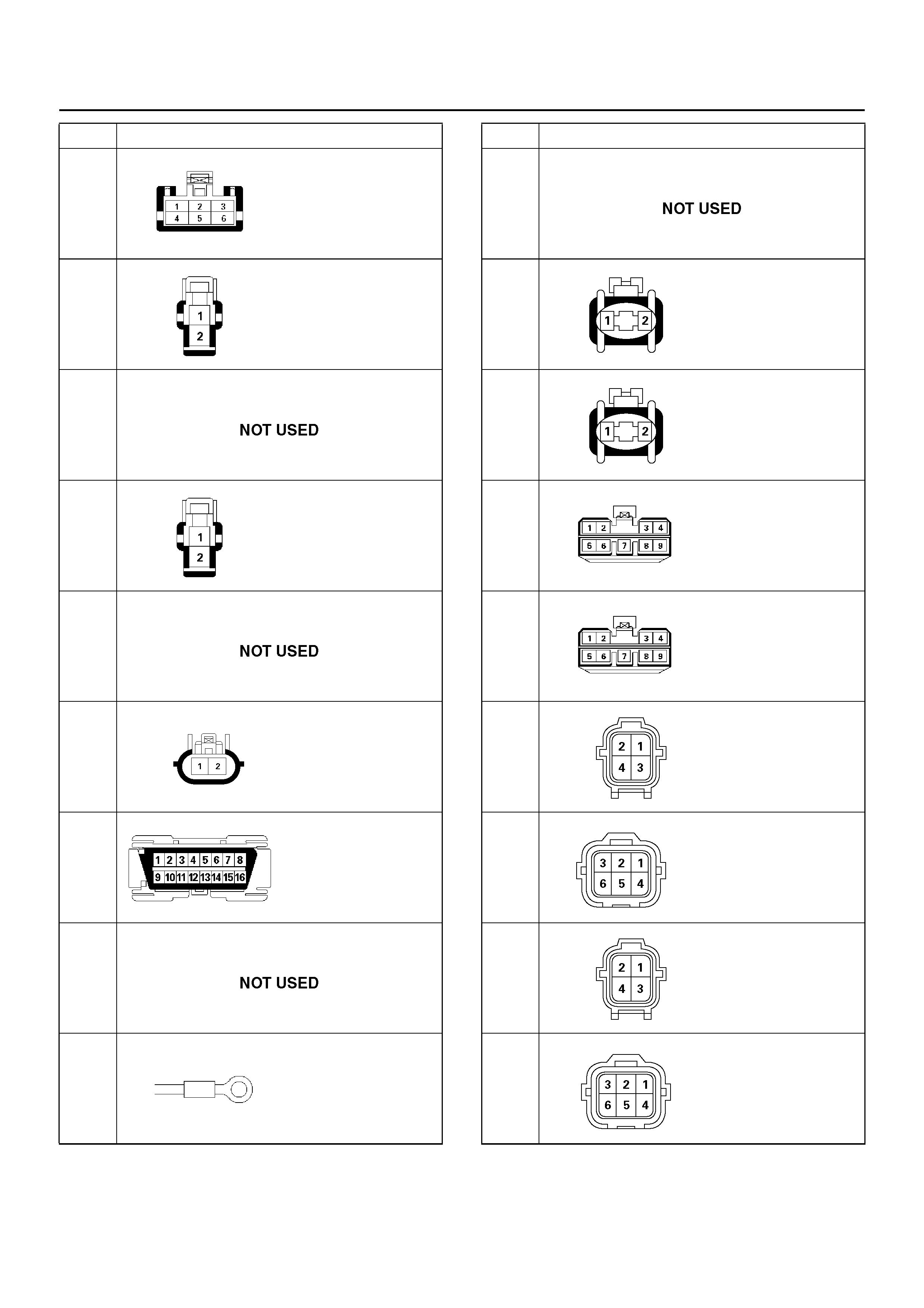

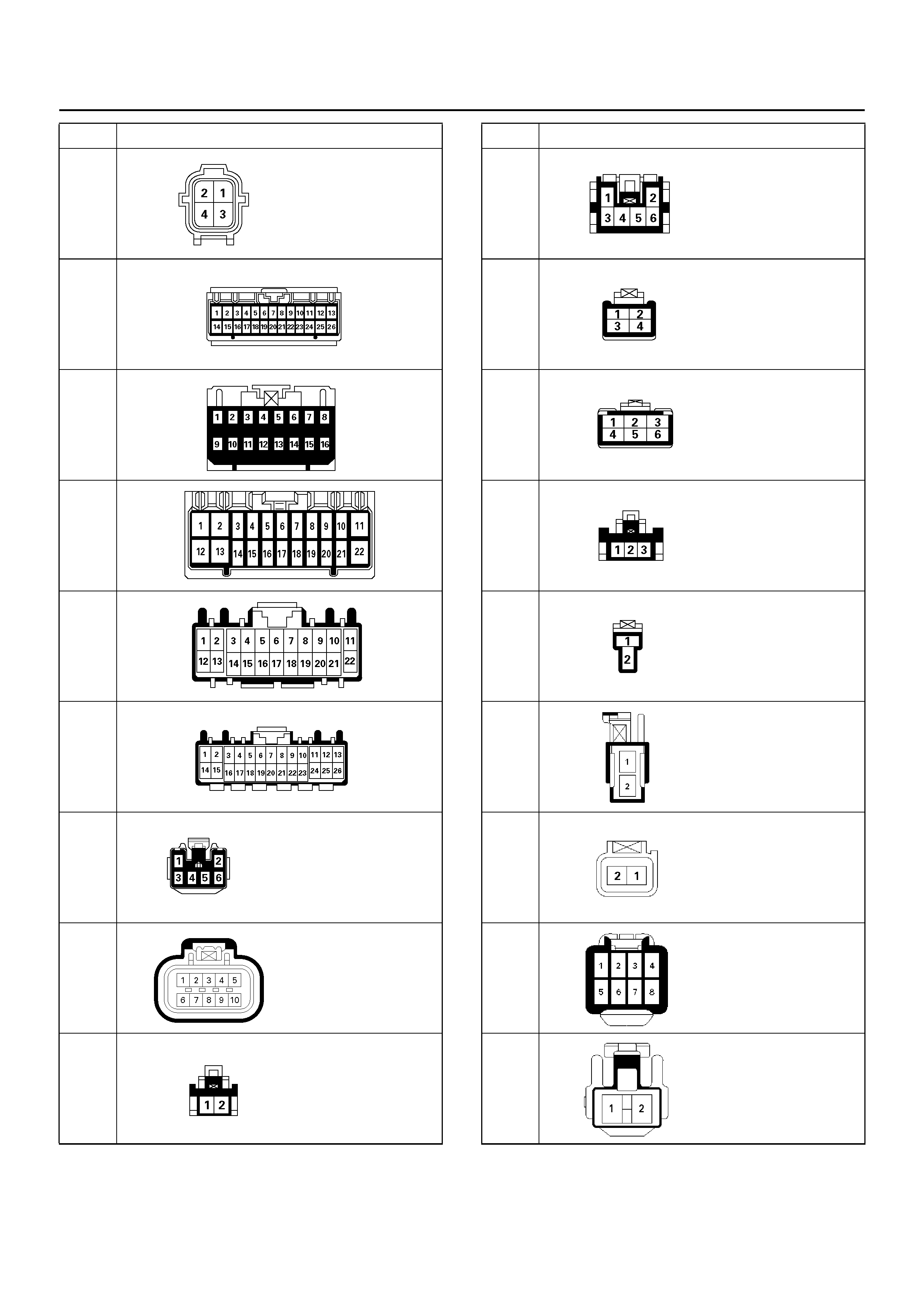

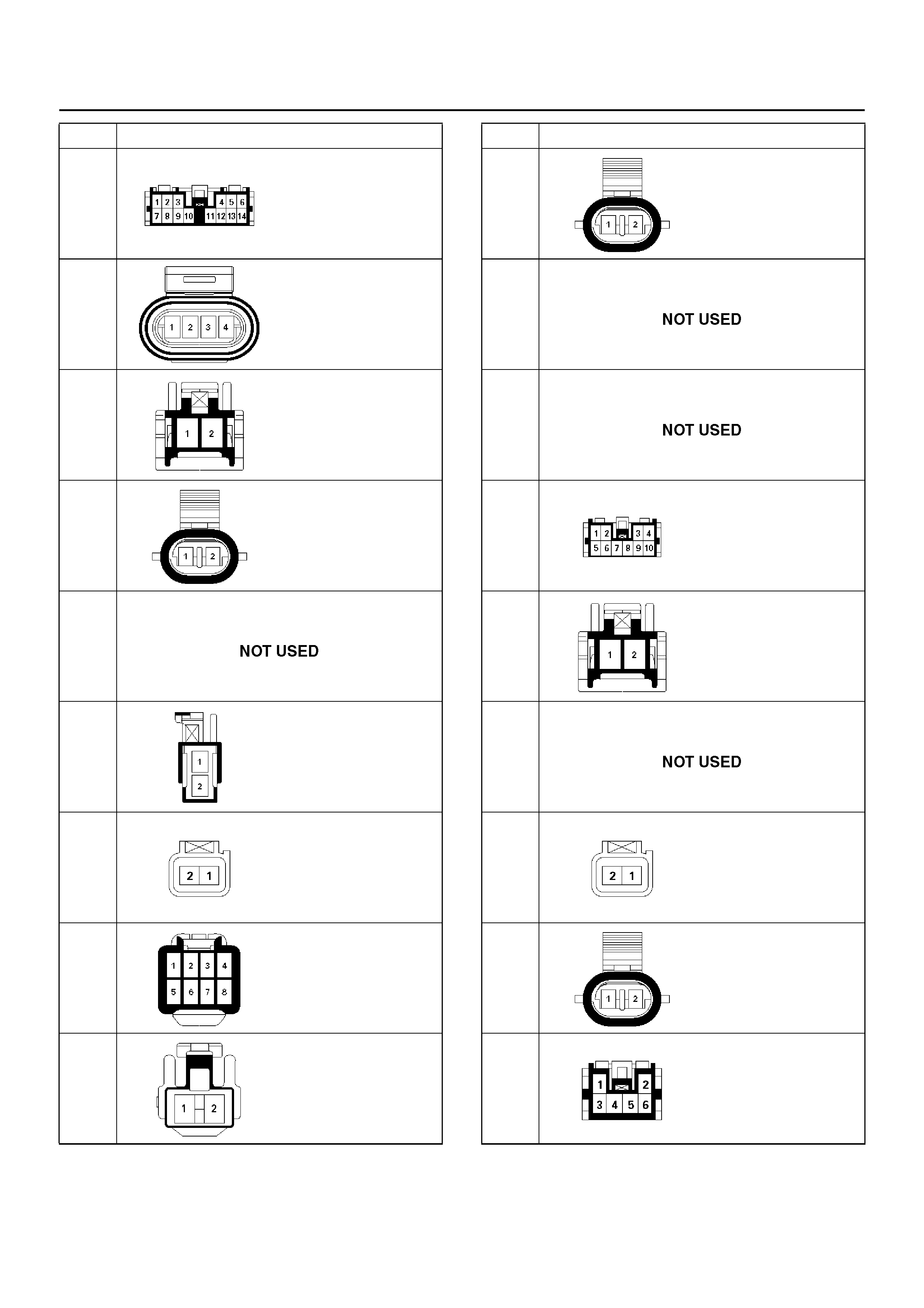

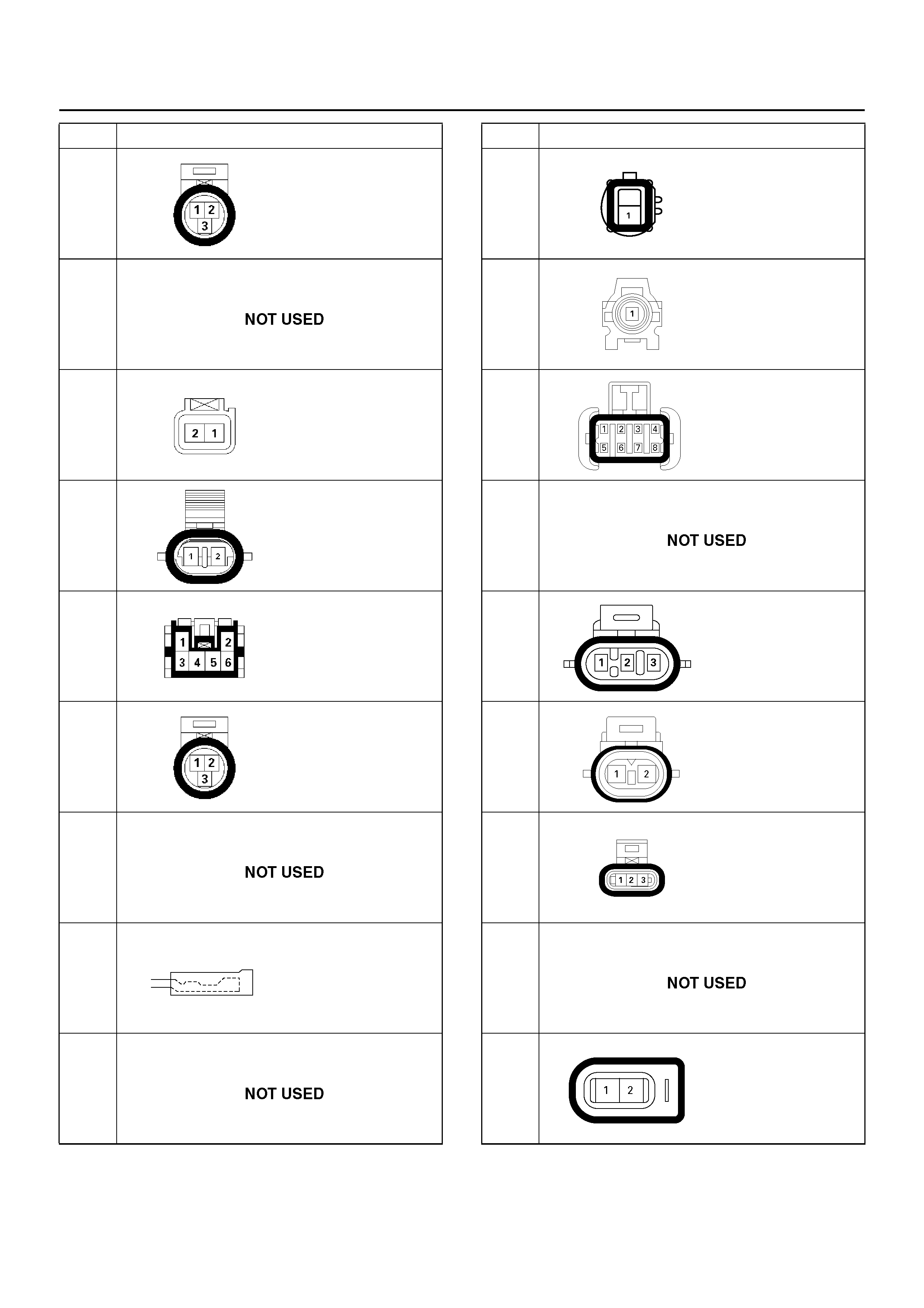

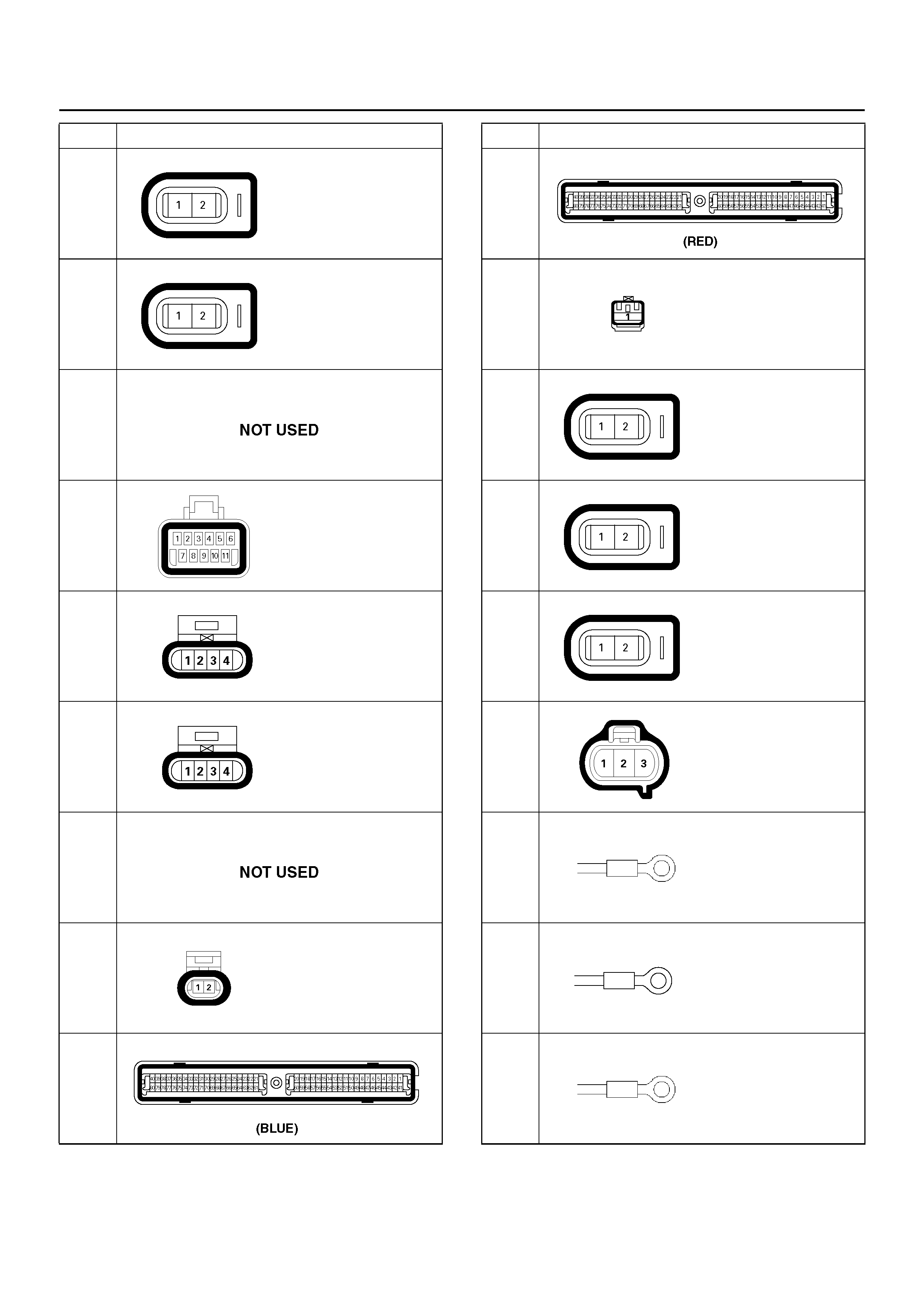

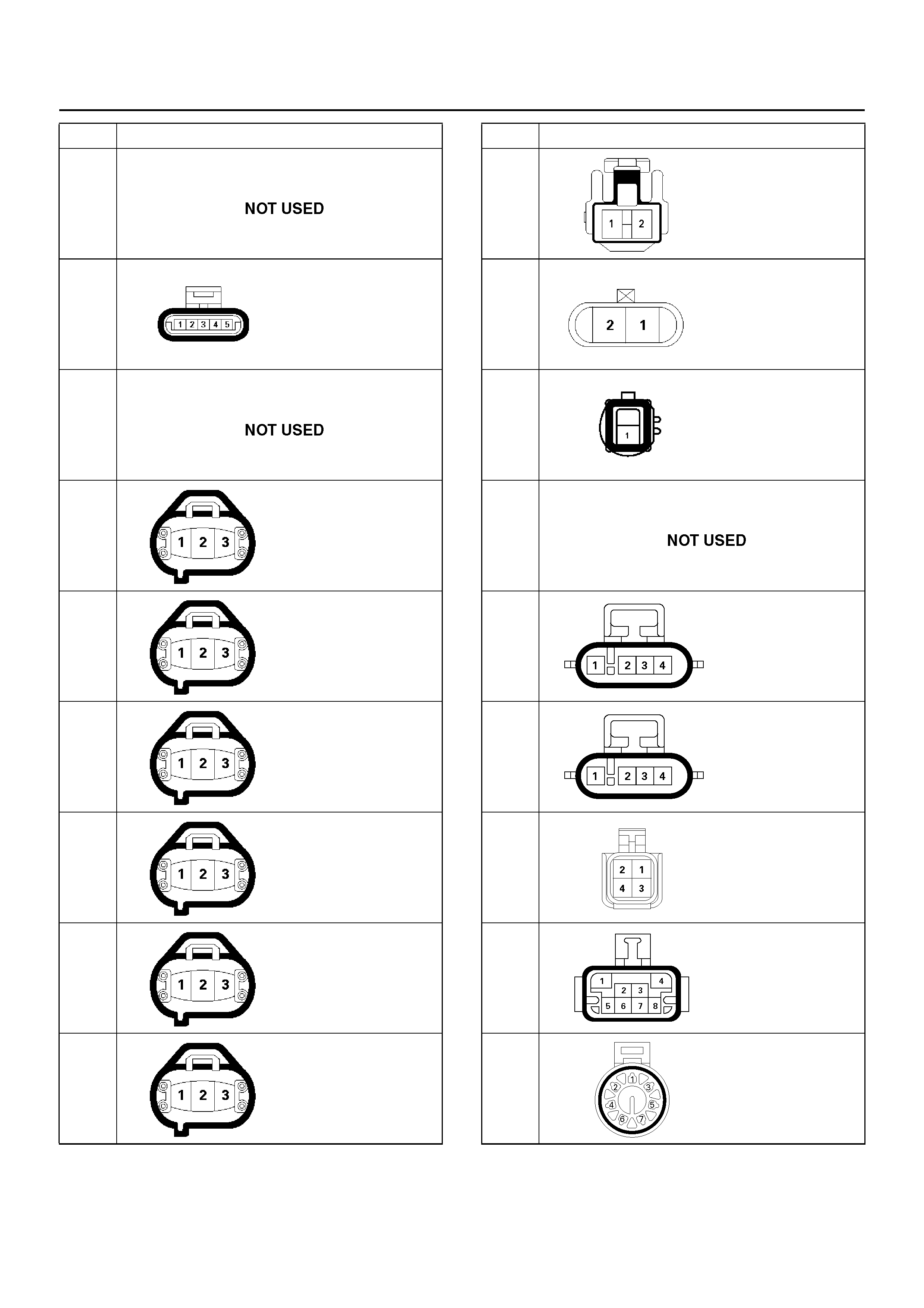

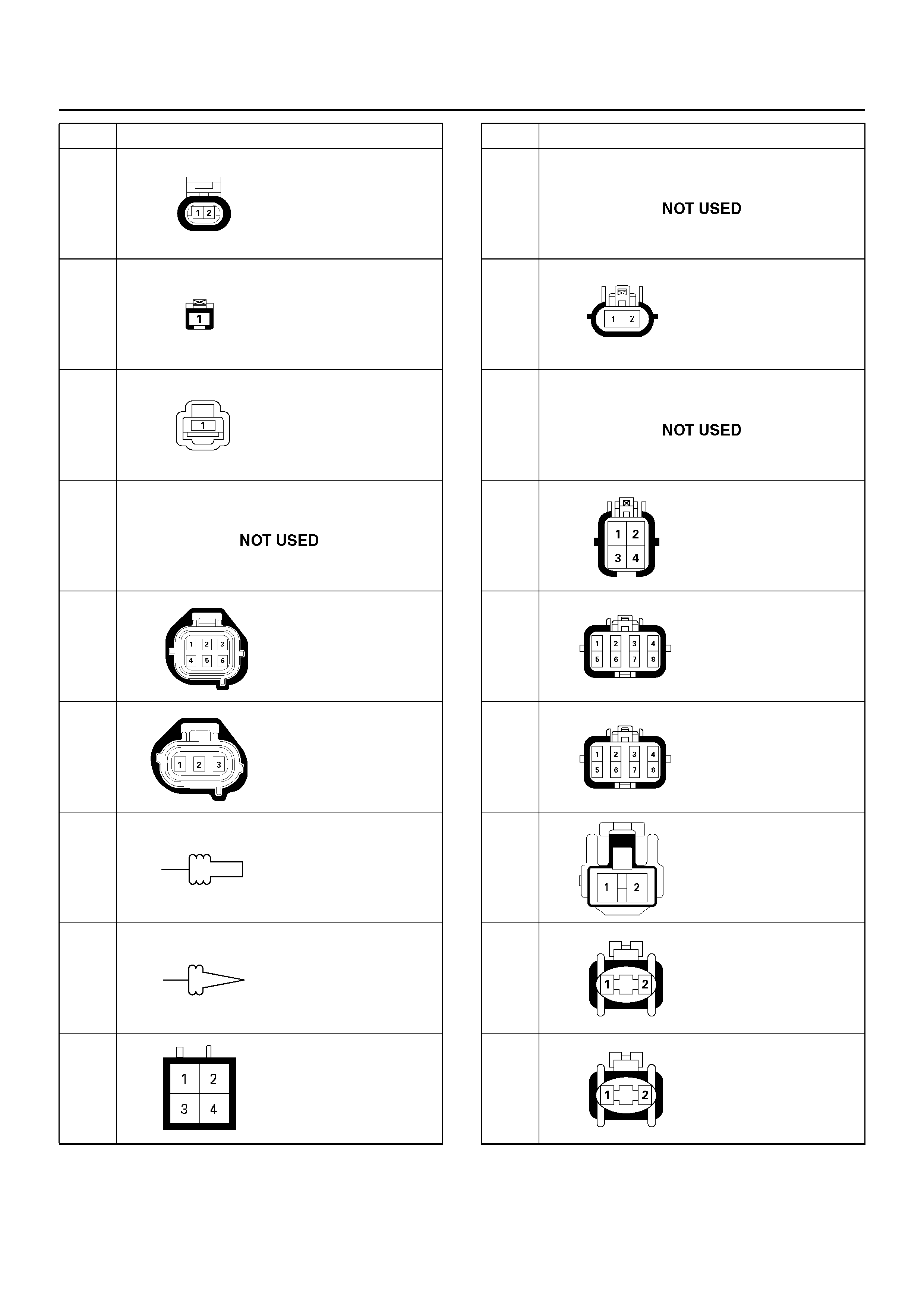

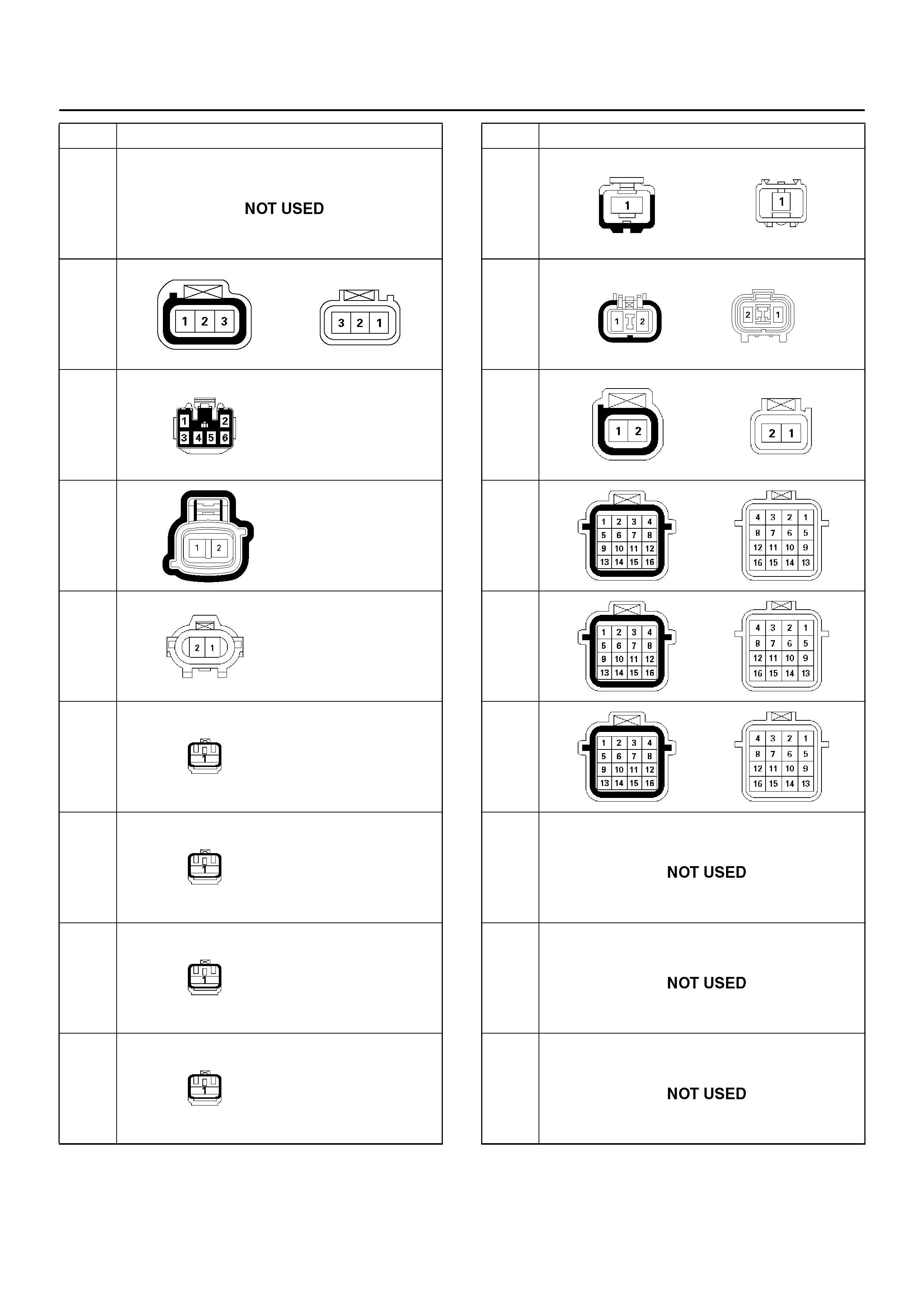

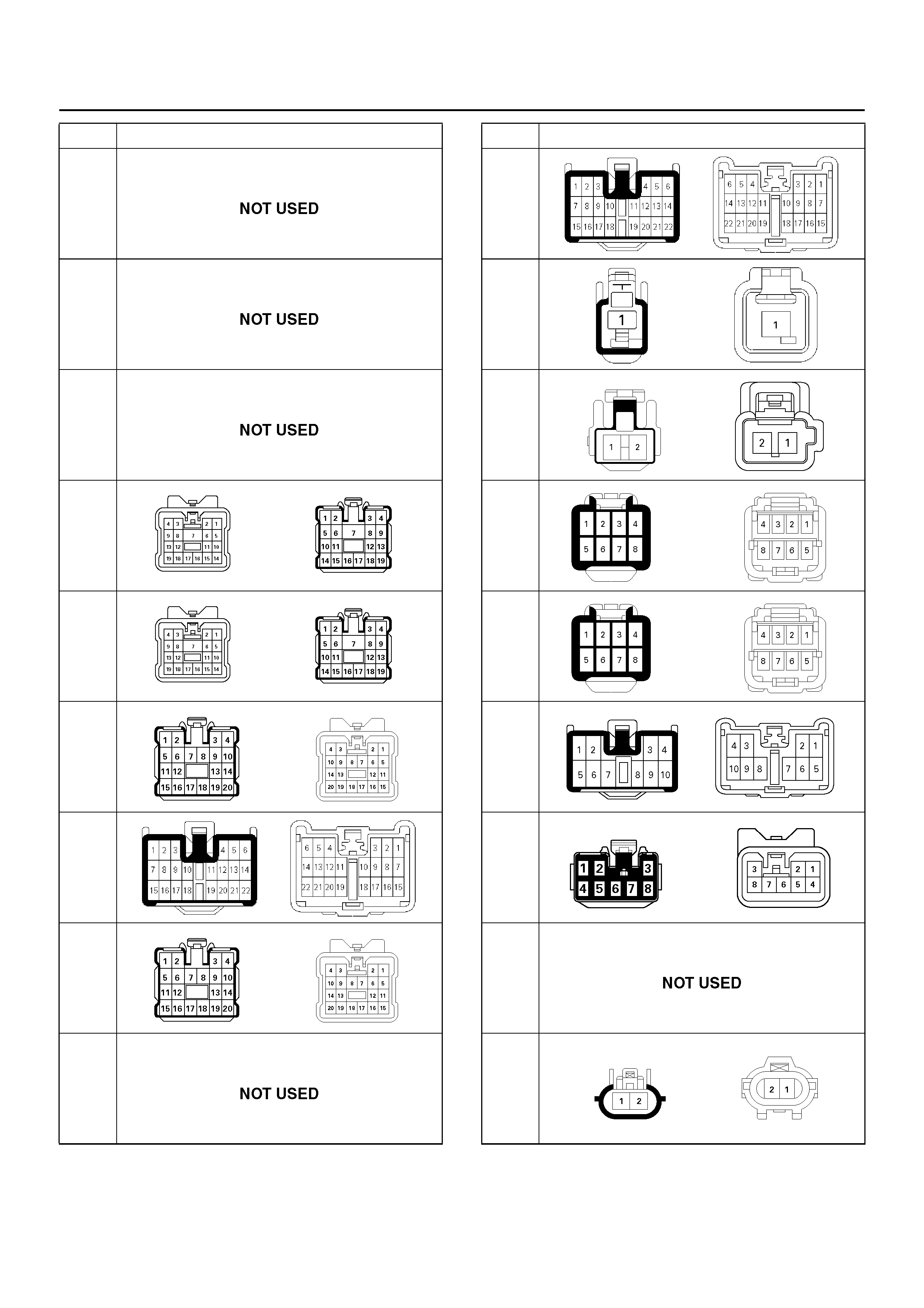

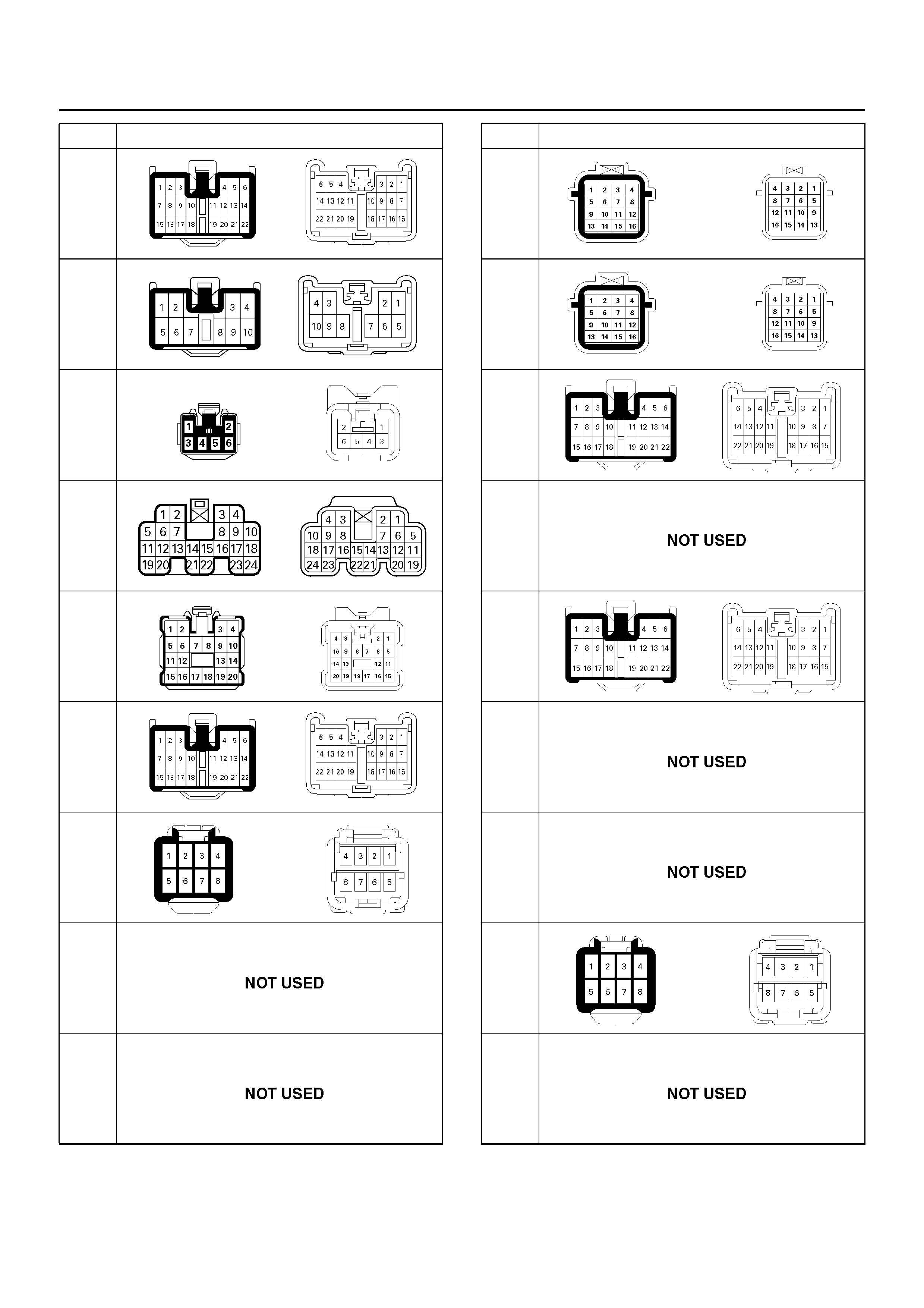

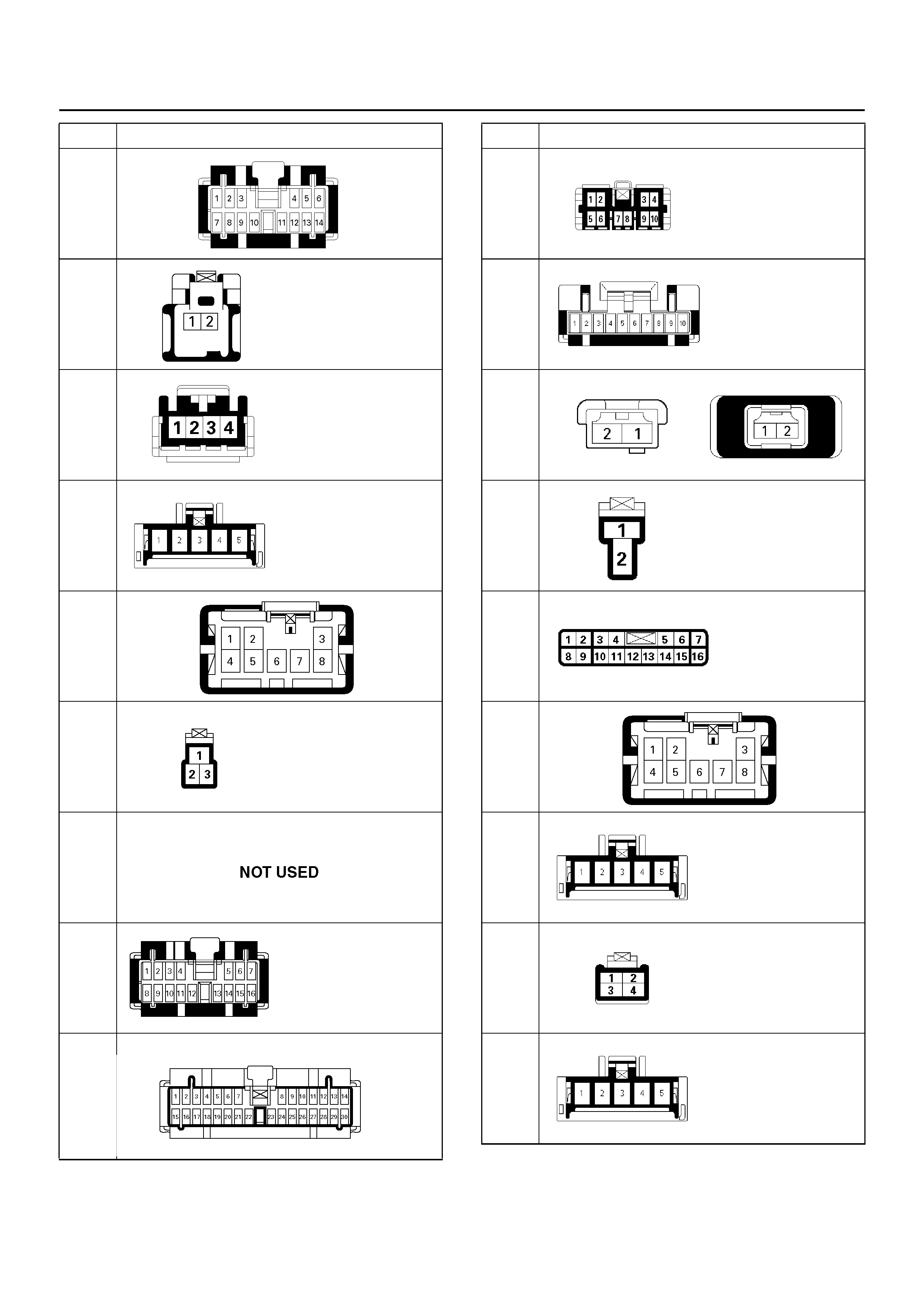

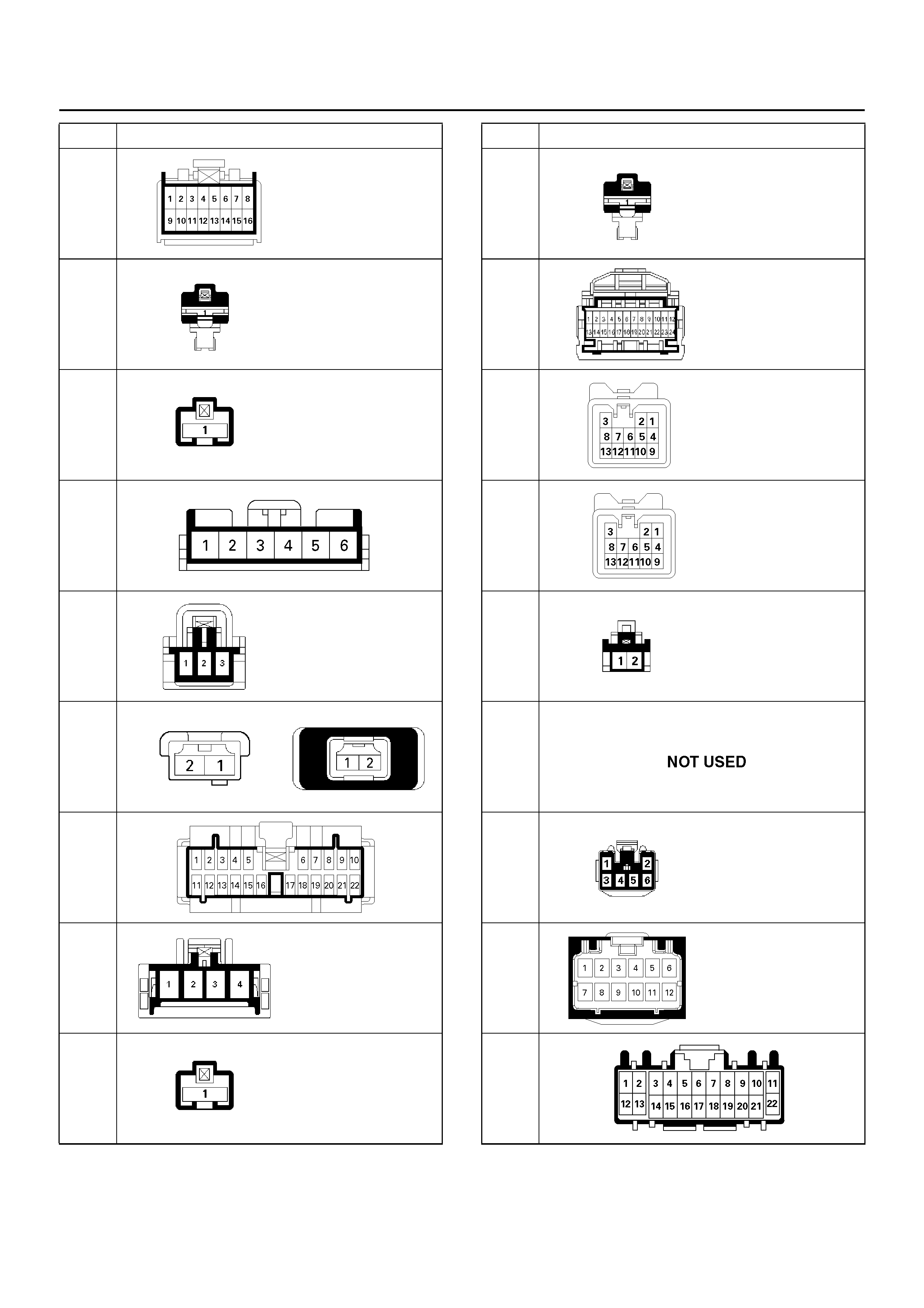

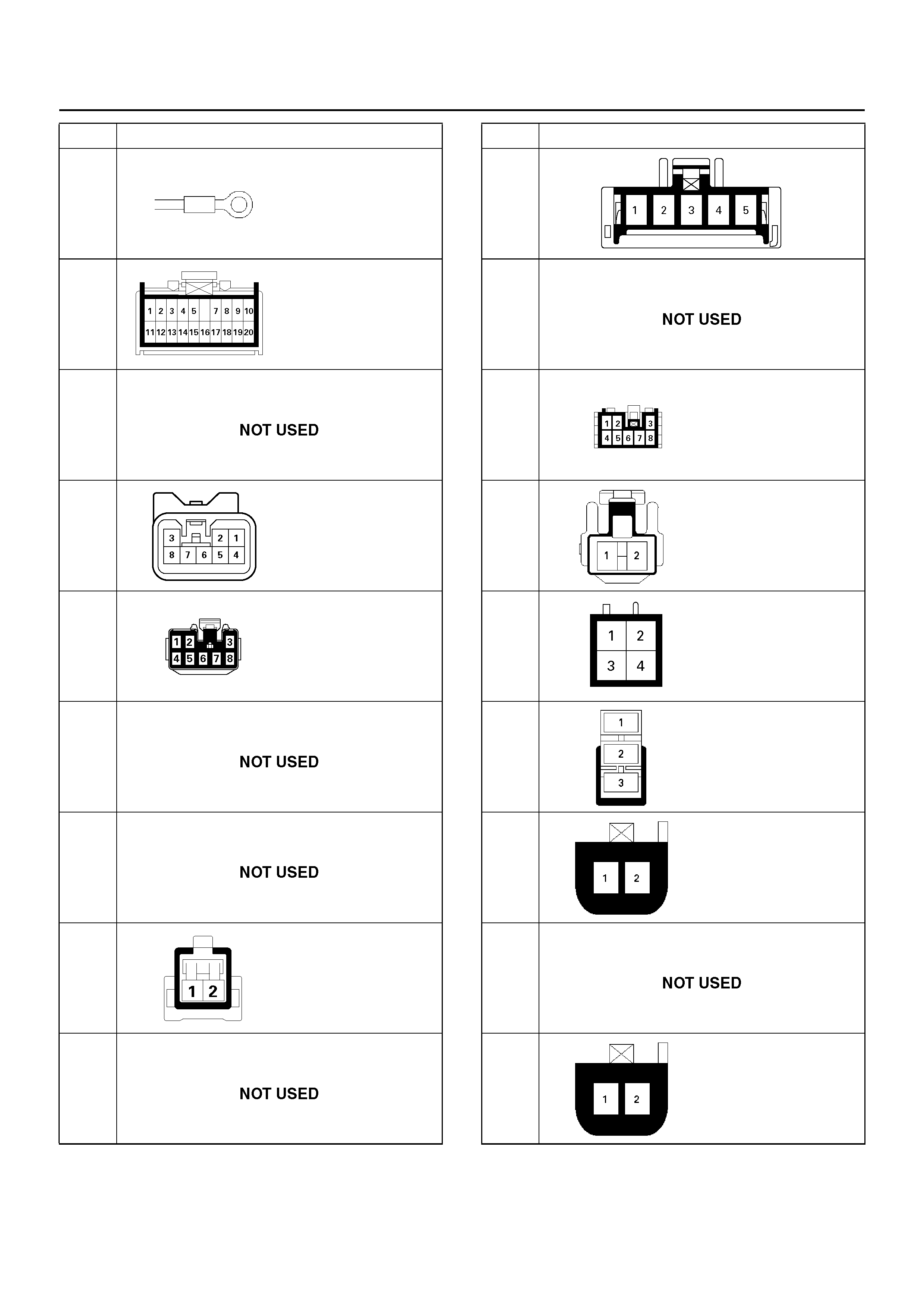

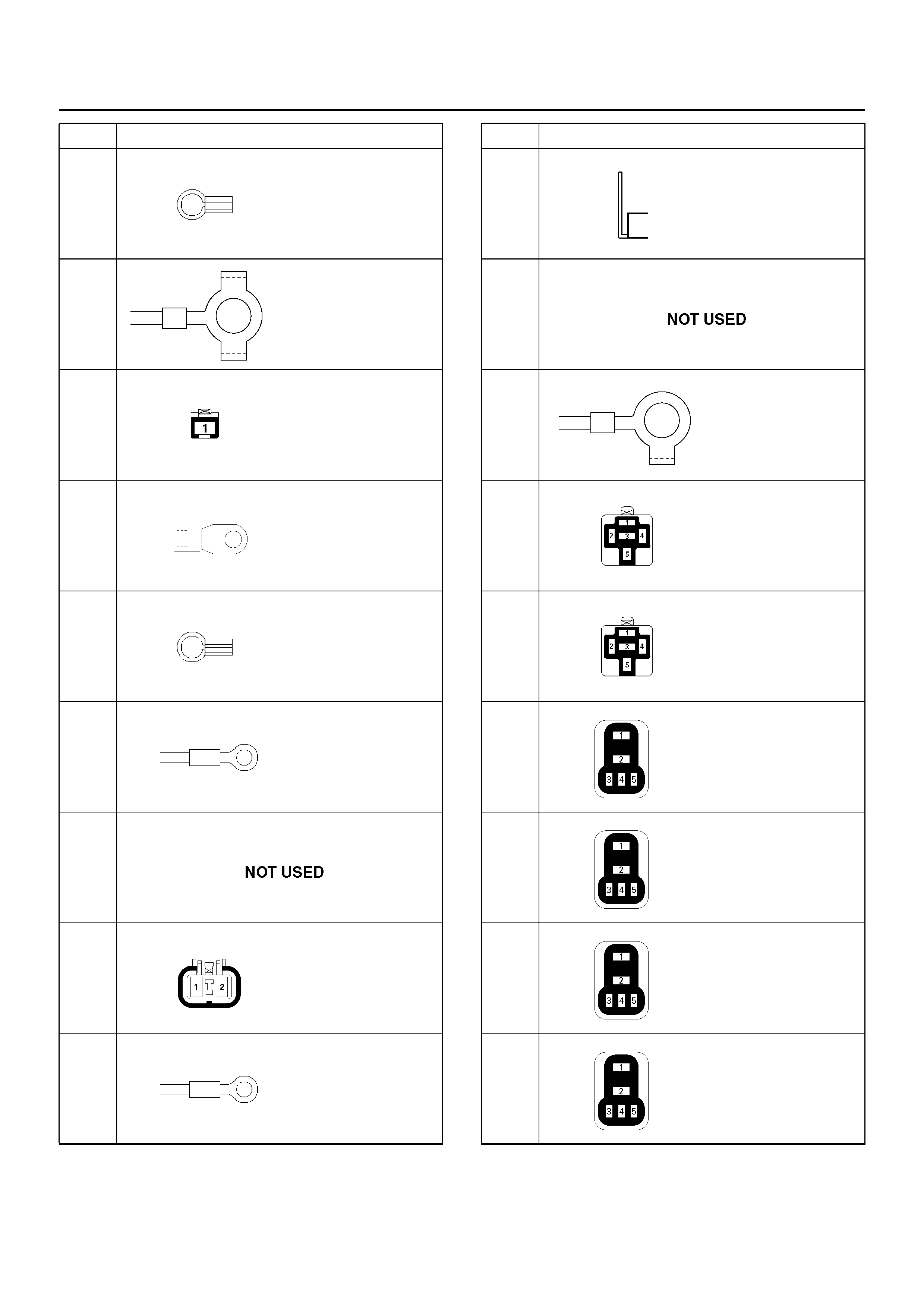

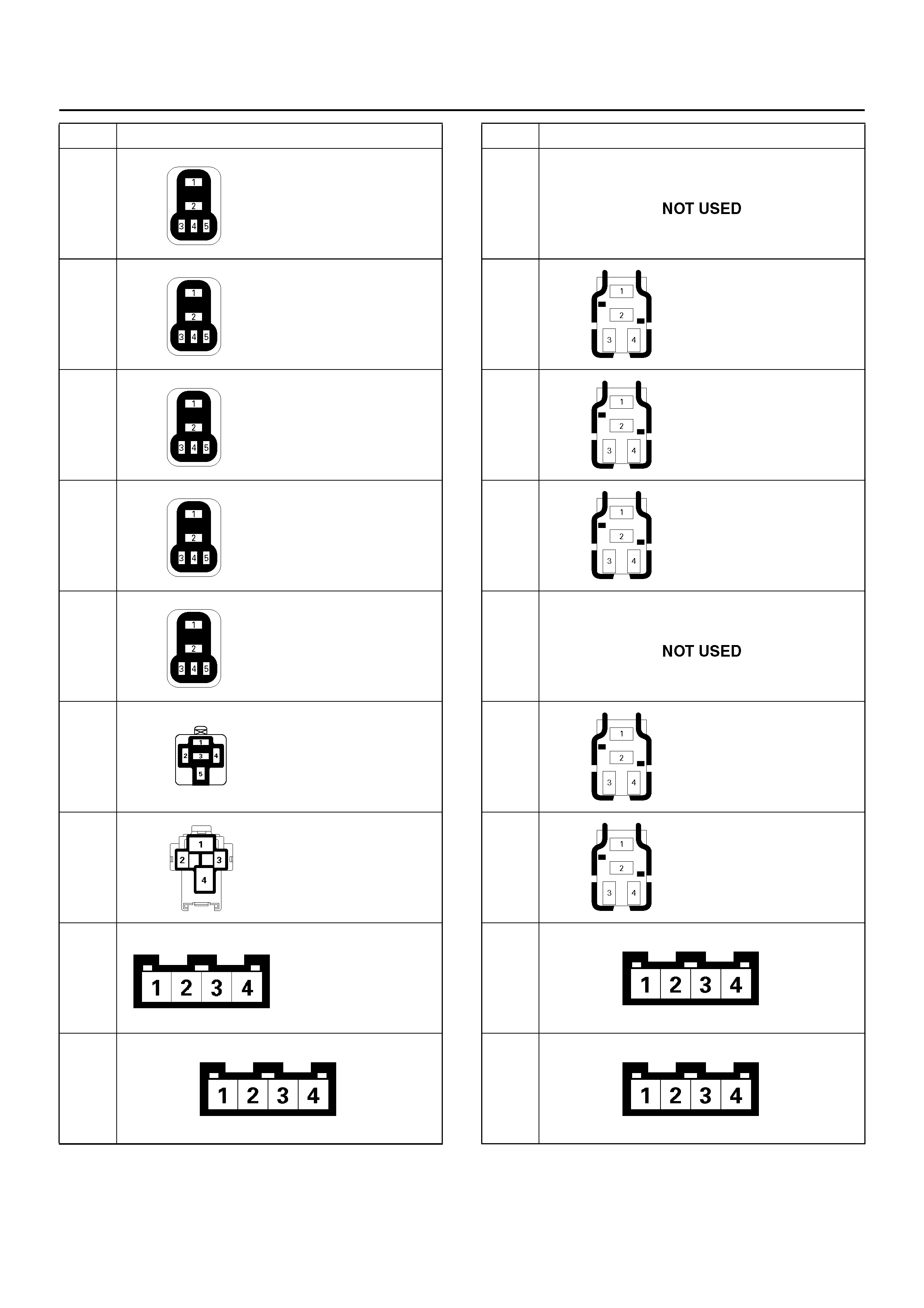

Harness Connector Faces

SERVICE PRECAUTION

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TOFOLLOW WARNINGS COULD RESULT IN POSSIBLEAIR BAG DEPLOYMENT, PERSONAL INJURY, OROTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fasteners joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fasteners. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

GENERAL DESCRIPTION

The chassis electrical system is a 12–volt system with a

negative ground polarity.

Wire sizes are appropriate to respective circuits, and

classified by color. (The classification of harnesses by

color is shown on the circuit diagram for ease of

harness identification.)

The wire size is determined by load capacity and the

length of wire required.

The vehicle harness are: body harness, chassis

harness, engine room harness, instrument harness,

transmission harness, engine ECGI harness, dome light

harness, door harness, rear body harness, tailgate

harness, SRS harness and battery cables.

The harnesses are protected either by tape or

corrugated tube, depending on harness location.

The circuit for each system consists of the power

source, wire, fuse, relay, switch, load parts and ground,

all of which are shown on the circuit diagram.

In this section, each electrical device is classified by

system.

For major parts shown on the circuit based on the circuit

diagram for each system, a summary, diagnosis of

troubles and inspection procedures are detailed.

NOTES FOR WORKING ON ELECTRICAL

ITEMS

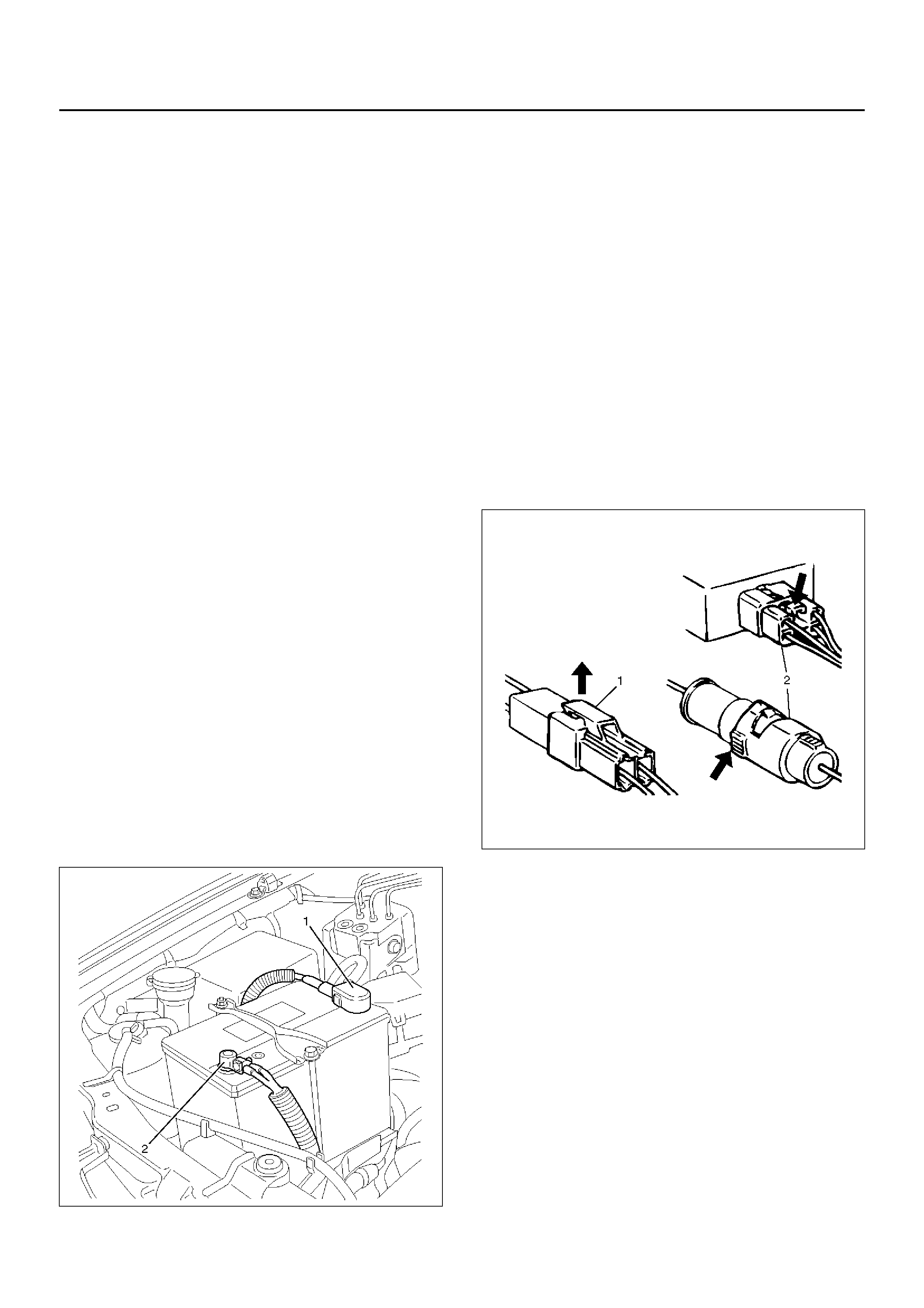

Disconnecting the Battery Cable

1. All switches should be in the “OFF" position.

2. All doors closed.

3. Disconnect the battery NEGATIVE cable (2).

4. Disconnect the battery POSITIVE cable (1).

CAUTION: It is important that the battery negative

cable be disconnected first. Disconnecting the

battery positive cable first can result in a short

circuit.

061RW002

Connecting the Battery Cable

Follow the disconnecting procedure in the reverse

order.

CAUTION: Clean the battery terminal and apply a

light coat of grease to prevent terminal corrosion.

Disconnecting the Connector

Some connectors have a tang lock to hold the

connectors together during vehicle operation.

Some tang locks are released by pulling them towards

you (1).

Other tang lock s are r eleas ed by p re ssin g the m forw a rd

(2).

Determine which type of tang lock is on the connector

being handled.

Firmly grasp both sides (male and female) of the

connector.

Release the tang lock and carefully pull the two halves

of the connector apart.

D08RW128

Never pull on the wires to separate the connectors. This

will result in wire breakage.

D08RW129

When removing the connector for relay (MR5B type) (3),

unfasten the tang lock of the connector by using a

screwdriver, then pull the relay out as shown in the

figure.

D08RW131

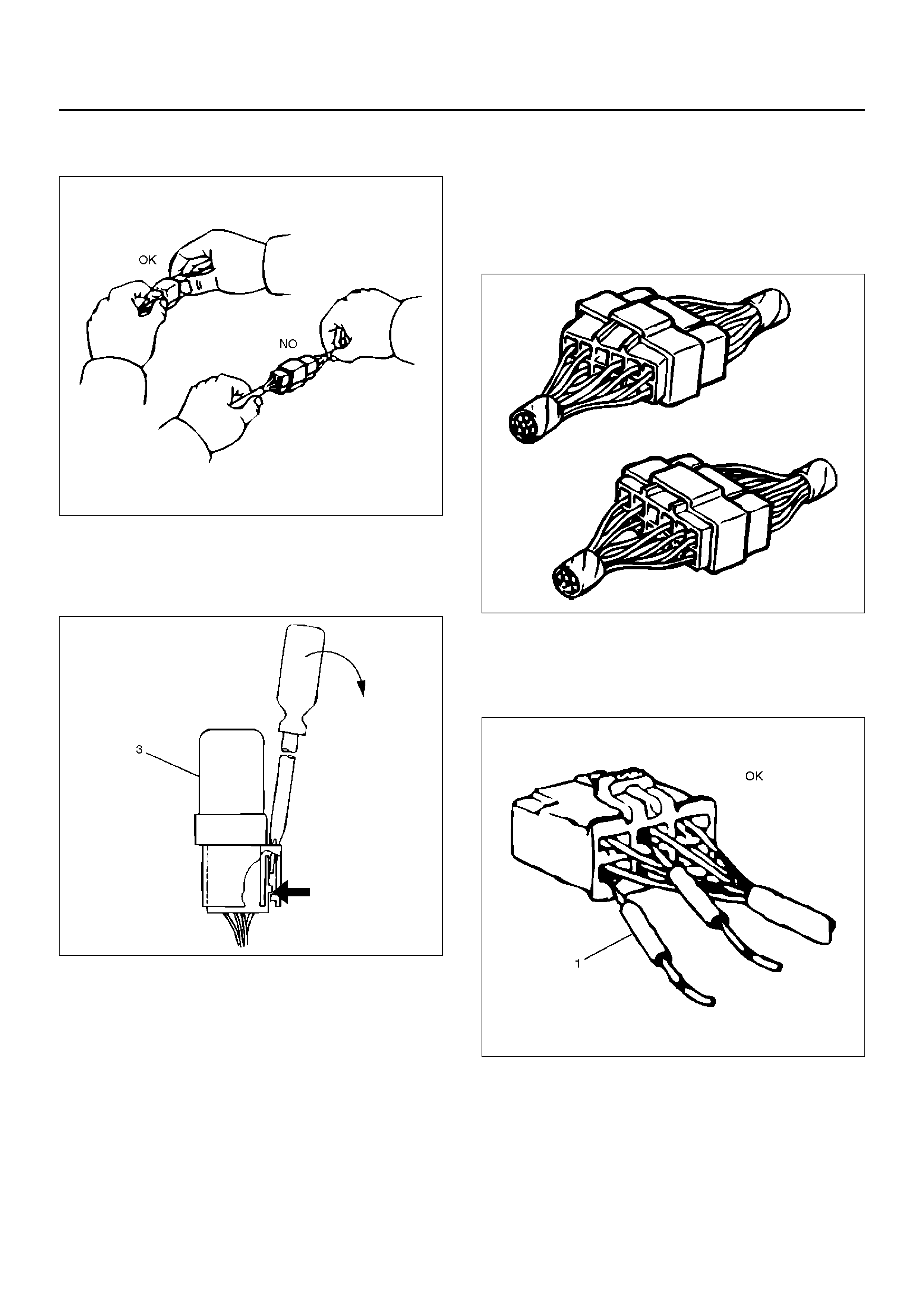

Connecting the Connector

Firmly grasp both sides (male and female) of the

connector. Be sure that the connector pins and pin

holes match, Be sure that both sides of the connector

are aligned with each other.

Firmly but carefu lly push the two sides of the connect or

together until a distinct click is heard.

D08RW130

Connector Inspection

Use a circuit tester to check the connector for continuity.

Insert the test probes (1) from the connector wire side.

D08RW132

Never insert the circuit tester test probes (2) into the

connector open end to test the continuity.

Broken or open connector terminals will result.

D08RW133

Waterproof Connector Inspection

It is not possible to insert the test probes into the

connector wire side of a waterproof connector.

Use one side of a connector (1) with its wires cut to

make the test. Connect the test connector to the

connector (3) to be tested. Connect the test probes (2)

to the cut wires for the electrical test.

D08RW134

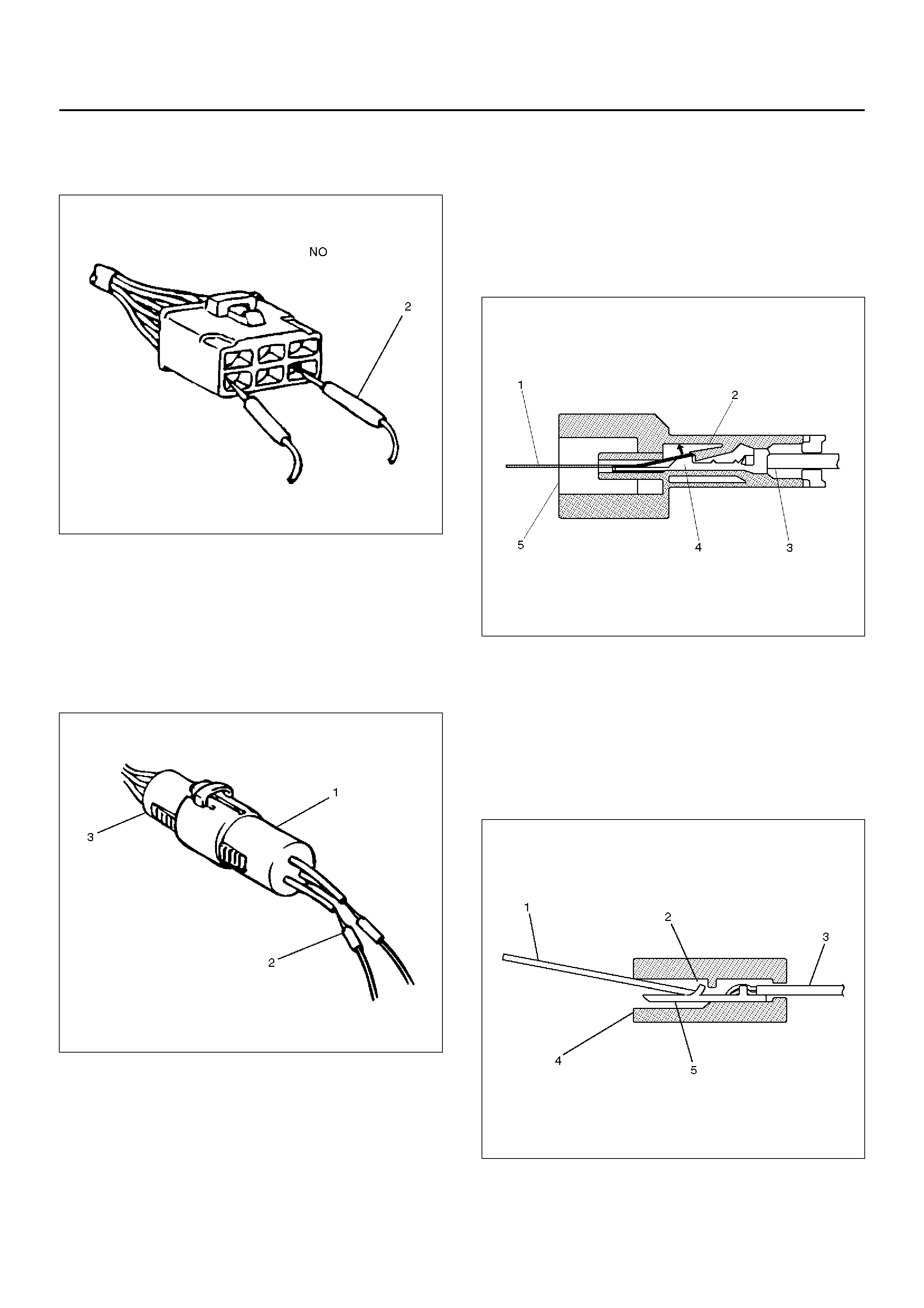

Connector Pin Removal – Connector Housing Tang

Lock Type

1. Inse rt a sl en der s ha ft ( 1 ) in to the connector ho us ing

open end (5).

2. Push the tang lock (2) up (in the direction of the

arrow in the illustrati on) .

Pull the wire (3) with pin (4) free from the wire side

of the connector.

D08RW135

Connector Pin Removal – Pin Tang Lock Type

1. Inse rt a sl en der s ha ft ( 1 ) in to the connector ho us ing

open end (5).

2. Push the tang lock (2) flat (toward the wire (3) side

of the connector.

Pull the wire with pin (4) free from the wire side of

the connector.

D08RW136

Connector Pin Insertion

1. Check that the tang lock (1) is fully up.

2. Insert the pin (3) from the connector wire (2) side.

Push the pin in until the tang lock closes firmly.

3. Gently pull on the wires to make sure that the

connector pin is firmly set in place.

D08RW137

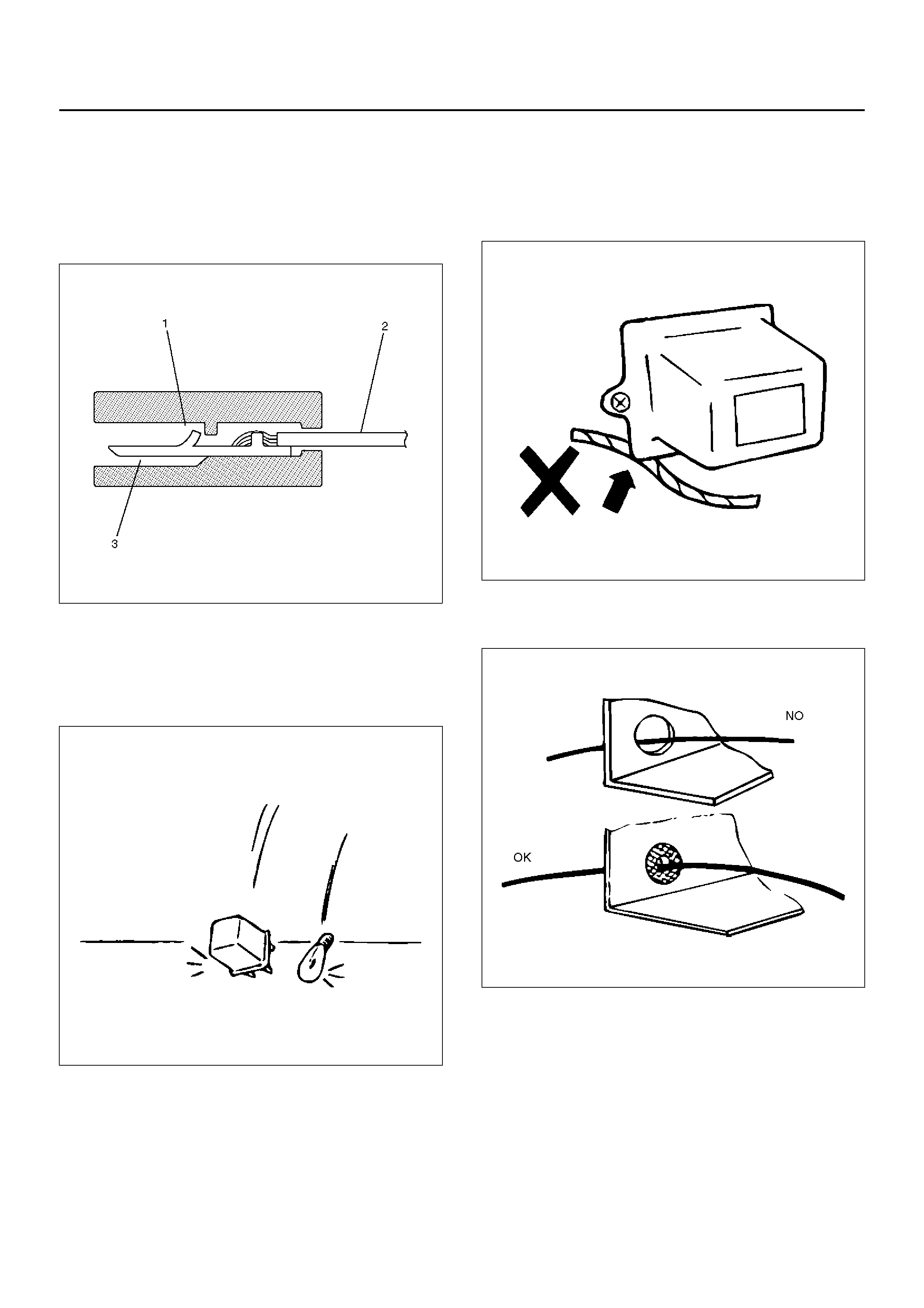

Parts Handling

Be careful when handling electrical parts. They should

not be dropped or thrown, because short circuiting or

other damage may result.

D08RW138

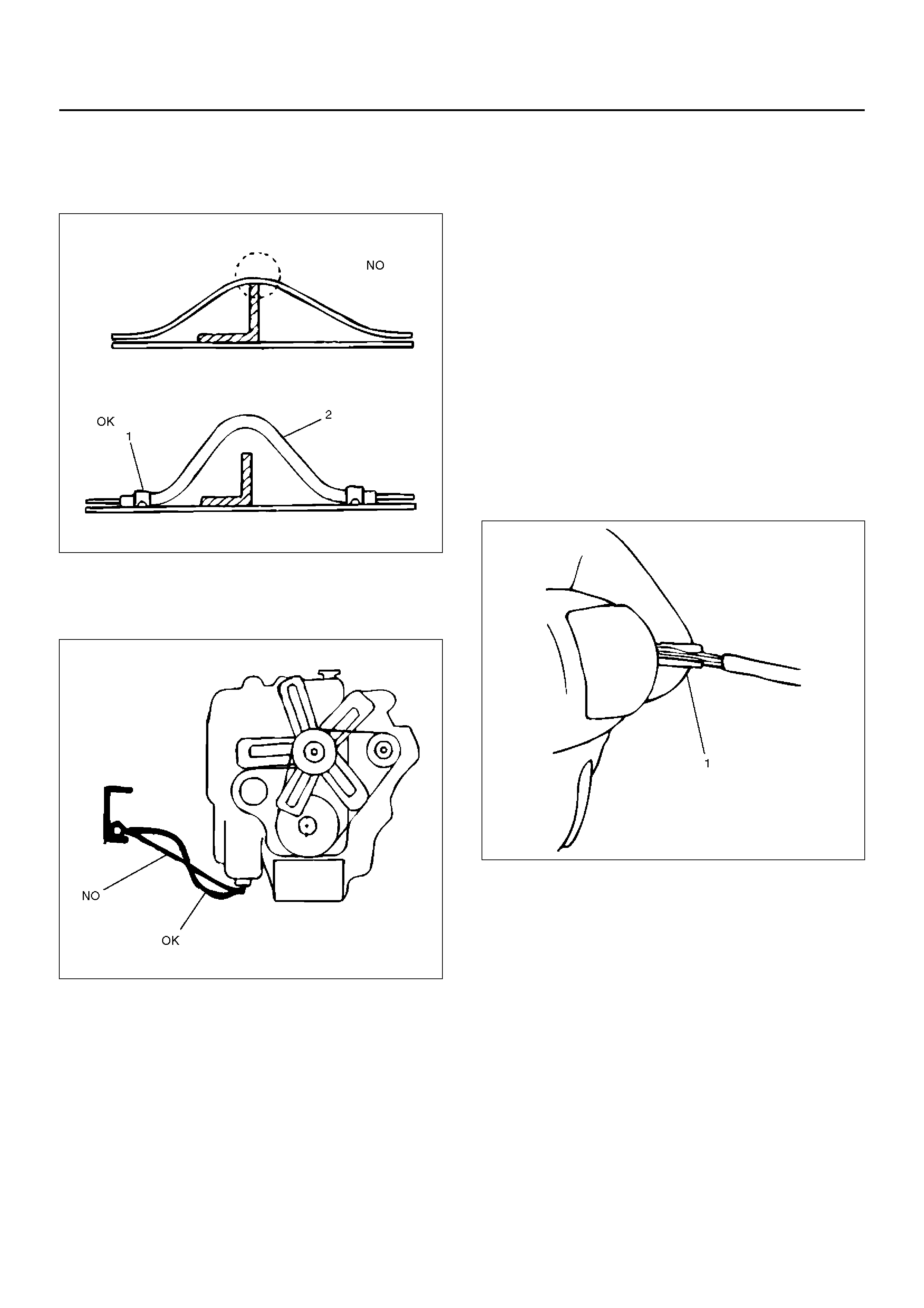

Cable Harness

1. When installing the parts, be careful not to pinch or

wedge the wiring harness.

2. All electrical connections must be kept clean and

tight.

D08RW139

3. Use a grommet or guard tube to protect the wiring

harness from contacting a sharp edge or surface.

D08RW139

4. Position the wiring harness with enough clearance

from the other parts and guard the wiring harness

with a vinyl tube (2) and clips (1) to avoid direct

contact.

D08RW141

5. The wiring harness between engine and chassis

should be long enough to prevent chafing or

damage due to various vibrations.

D08RW142

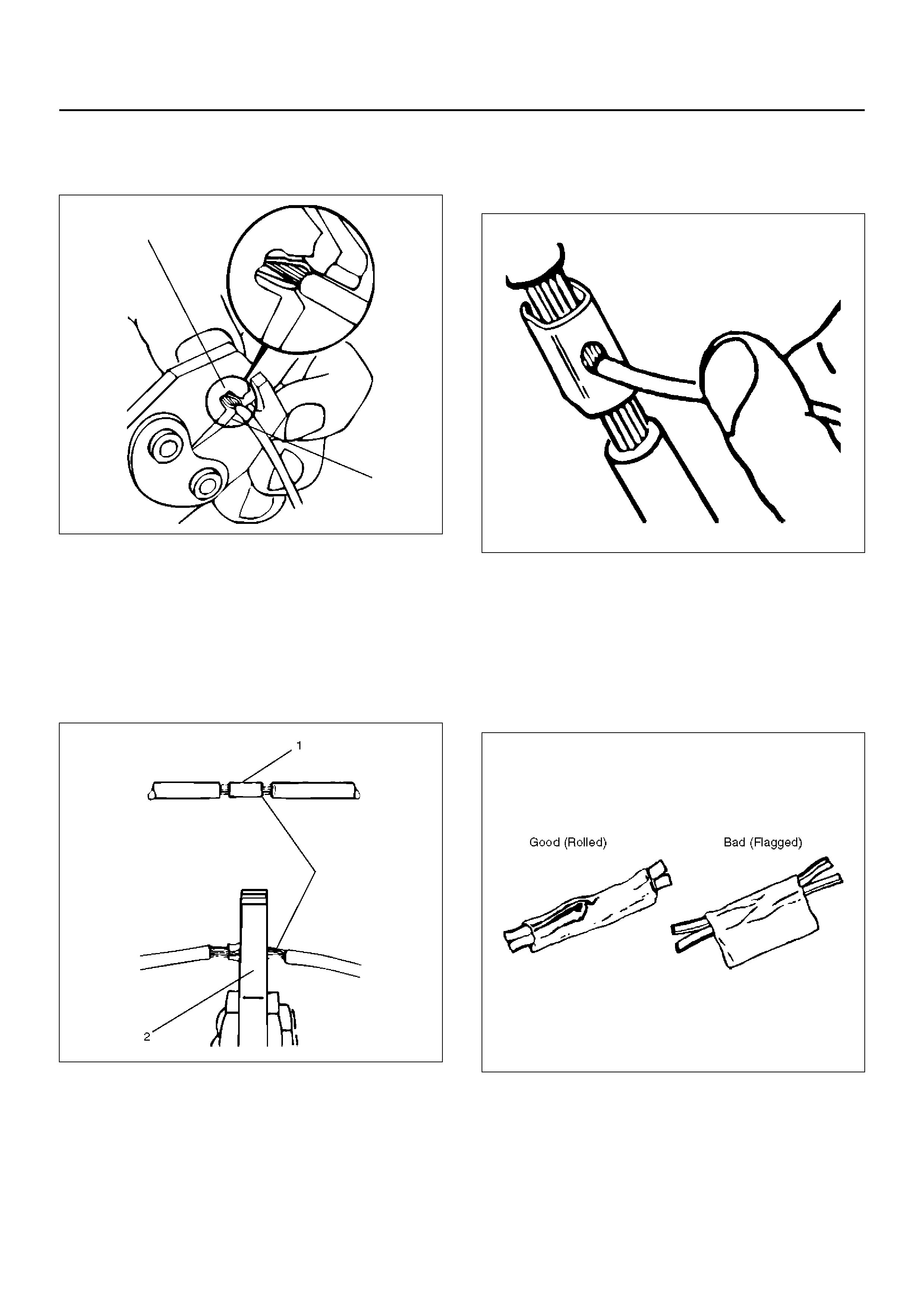

Splicing Wire

1. If the harness is taped, remove the tape. To avoid

wire ins ulation dam age, use a sewing “sea m ripper"

(available from sewing supply stores) to cut open

the harness.

If the harness has a black plastic conduit, simply

pull out the desired wire.

2. Begin by cutting as little wire off the harness as

possib le. You ma y nee d the ext ra l engt h of w ir e late r

if you decide to cut more wire off to change the

location of a splice. You may have to adjust splice

locati ons to mak e certain tha t each s plice i s at le ast

1–1/2" (40 mm) away from other splices, harness

branches, or connectors.

3. When rep lacing a wire, use a wire of the sam e size

as the original wire.

Check the stripped wire for nicks or cut stands. If the

wire is damaged, repeat the procedure on a new

section of wire. The two stripped wire ends should

be equal in length.

4. Select the proper clip to secure the splice.

To determine the proper clip size for the wire being

spliced, follow the directions included with your

clips.

Select the correct anvil on the crimper. (On most

crimpers your choice is limited to either a small or

large anvil .)

Overlap the two stripped wire ends and hold them

between your thumb and fore finger a s s hown in the

figure.

The center the spline clip (1) under the stripped

wires and hold it in place.

D08RW143

• Open the crimping tool to its full width and rest one

handle on a firm flat surface.

• Center t he back o f the spli ce clip on the proper anvil

and close the crimping tool to the point where the

back of the spli ce cl ip touche s the wing s of the cli p.

• Make sure that the clip and wires are still in the

correct position. Then, apply steady pressure until the

crimping tool closes as shown in the figure.

D08RW144

Before crimping the ends of the clip (1), be sure that:

• The wires extend beyond the clip in each direction.

• No strands of wire are cut loose, and

• No insulation is caught under the clip.

Crimp the splice again, once on each end.

Does not let the crimping tool (2) extend beyond the

edge of the clip or you may damage or nick the wires as

shown in the figure.

D08RW145

5. Apply 60/40 resin core solder to the opening in the

back of the clip as shown in the figure.

Follow the manufa cturer 's instr uctions for the sold er

equipment you are using.

D08RW146

6. Center and roll the splicing tape.

The tape should cover the entire splice.

Roll on enough tape to duplicate the thickness of the

insulation on the existing wires.

Does not flag the tape. Flagged tape may not

provide enough insulation, and the flagged ends will

tangle with th e other wires i n the harne ss as shown

in the figure.

D08RW147

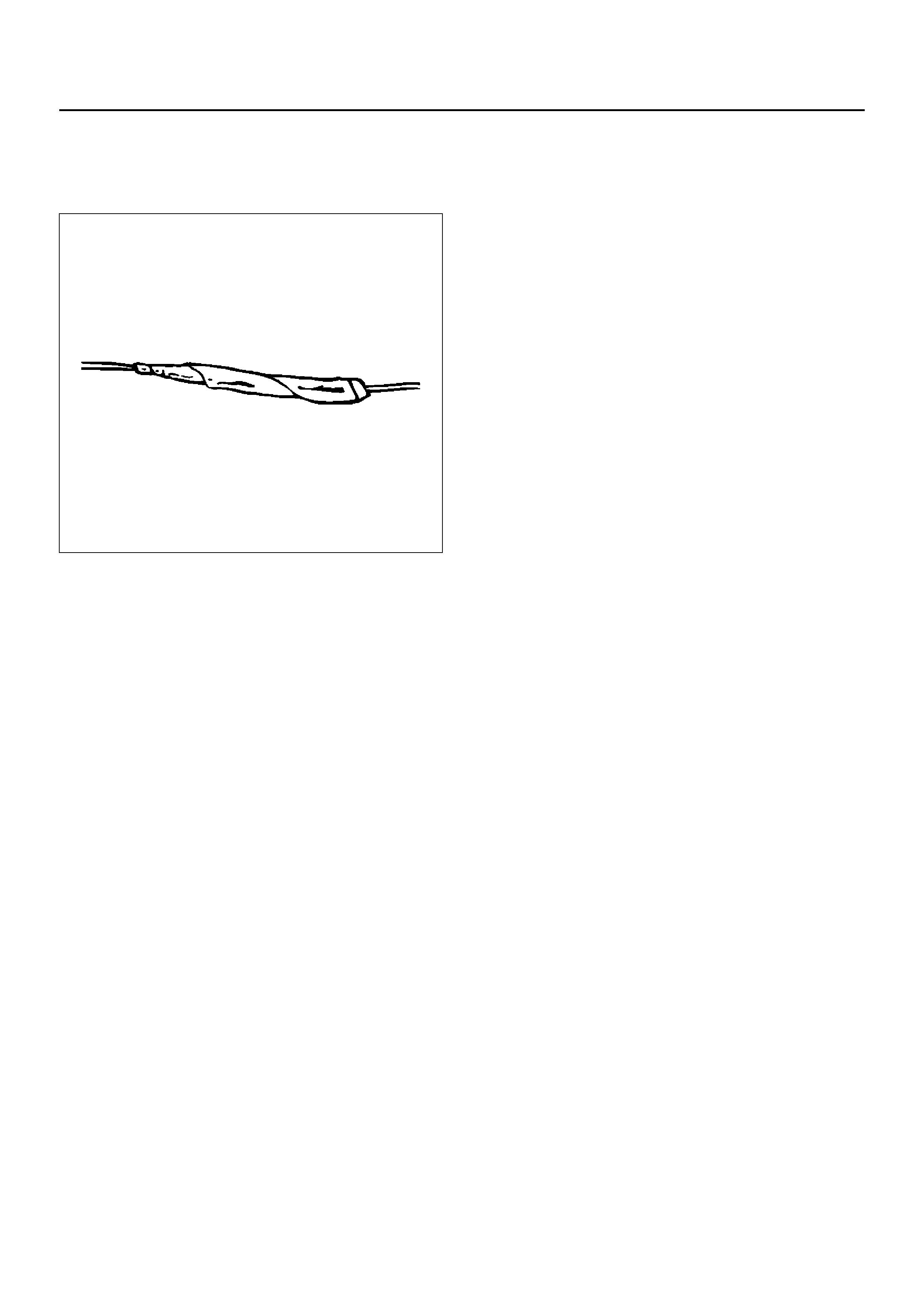

If the wire does not belong in a conduit or other

harness covering, tape the wire again. use a

winding motion to cover the first piece of tape as

shown in the figure.

D08RW148

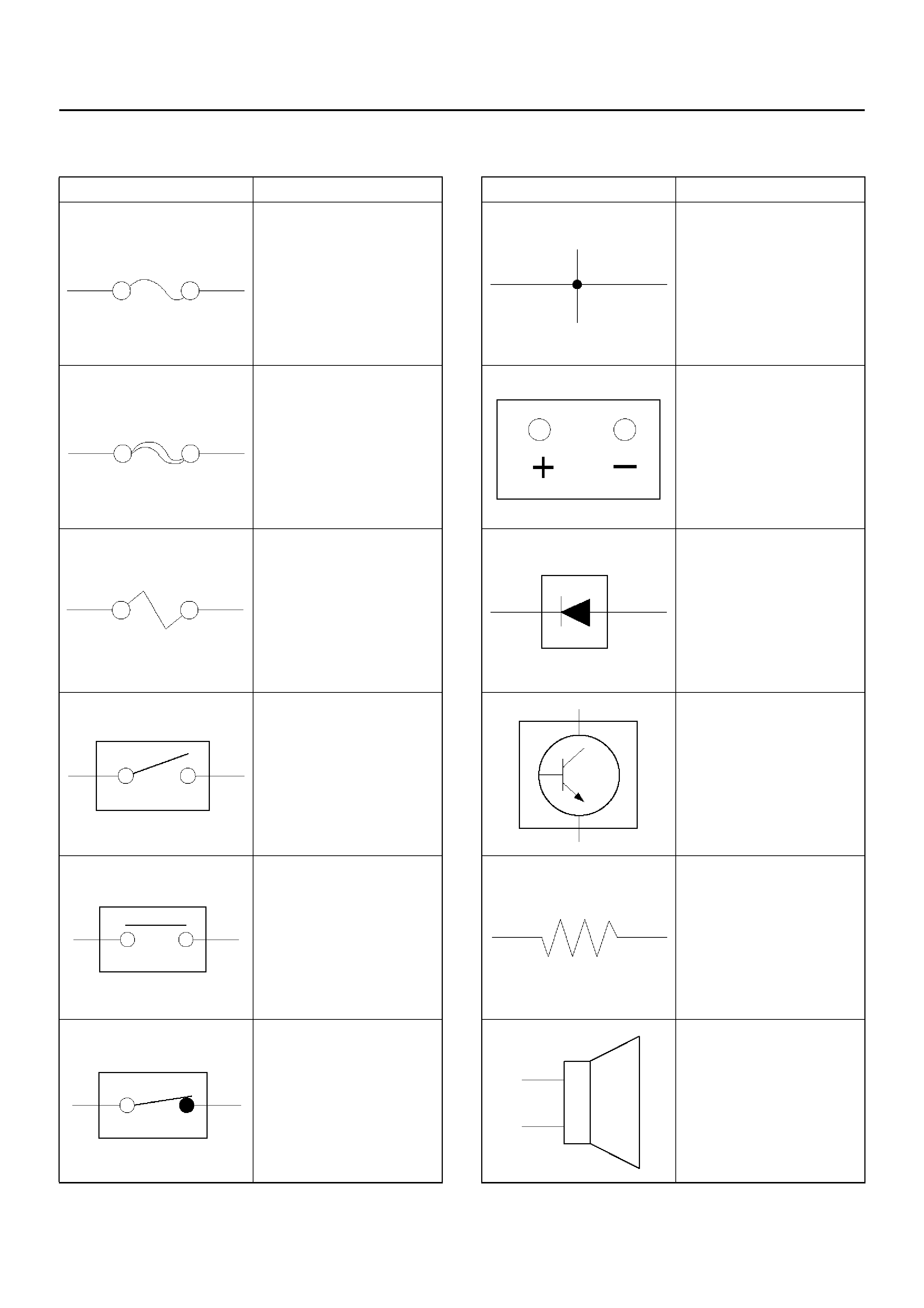

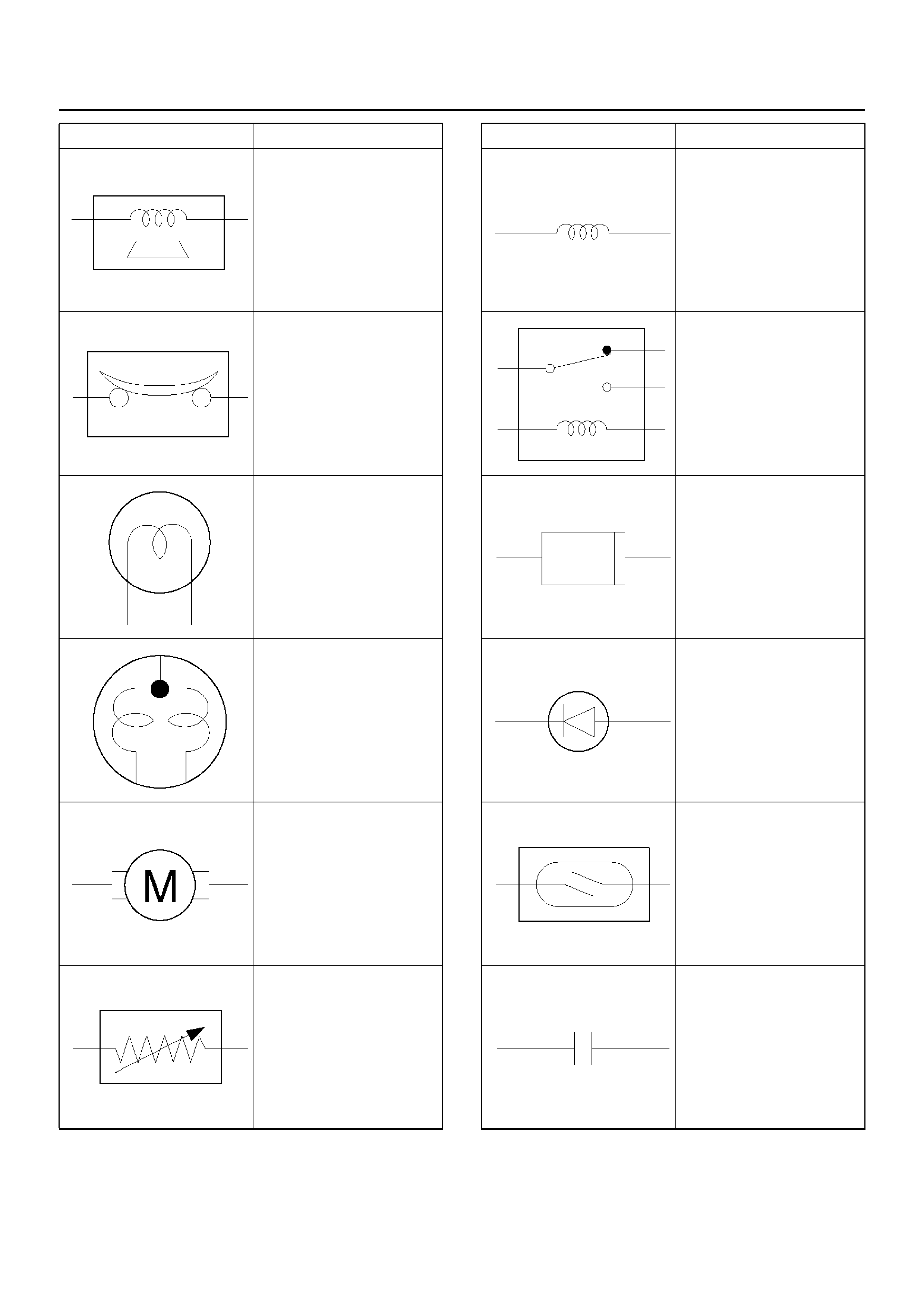

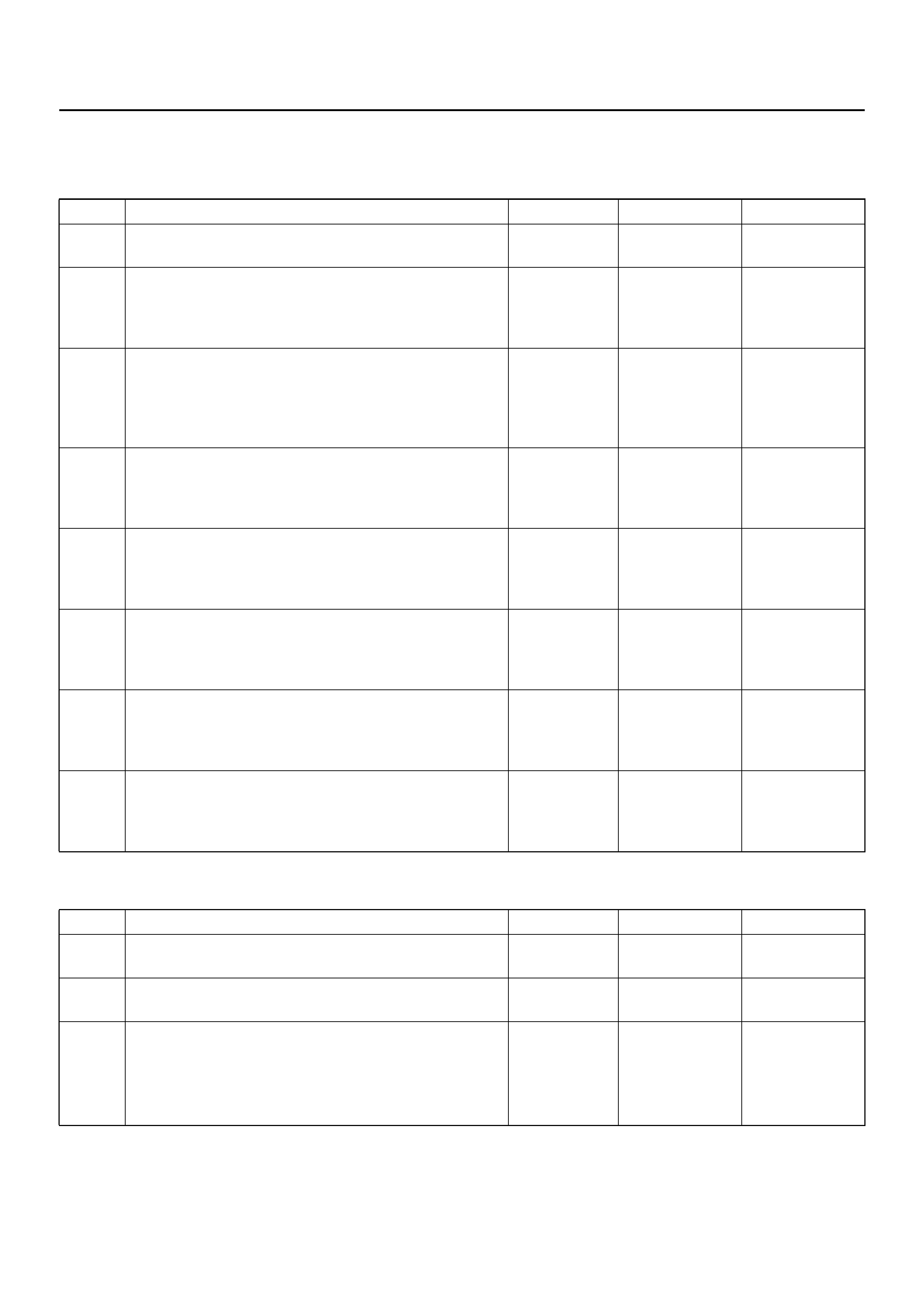

SYMBOLS AND ABBREVIATIONS

Symbols

Symbol Meaning of Symbol

Fuse

Fusible link

Fusible link wire

Switch

Switch

Switch

(Normal close type)

Contact wiring

Battery

Diode

Electronic parts

Resistor

Speaker

Symbol Meaning of Symbol

Buzzer

Circuit br eaker

Bulb

Double filament bulb

Motor

Variable register

Rheostat

Symbol Meaning of Symbol

Coil (inductor), solenoid,

magnetic valve

Relay

Connector

Light emitting diode

Reed switch

Condenser

Symbol Meaning of Symbol

Horn

Vacuum switching valve

Symbol Meaning of Symbol

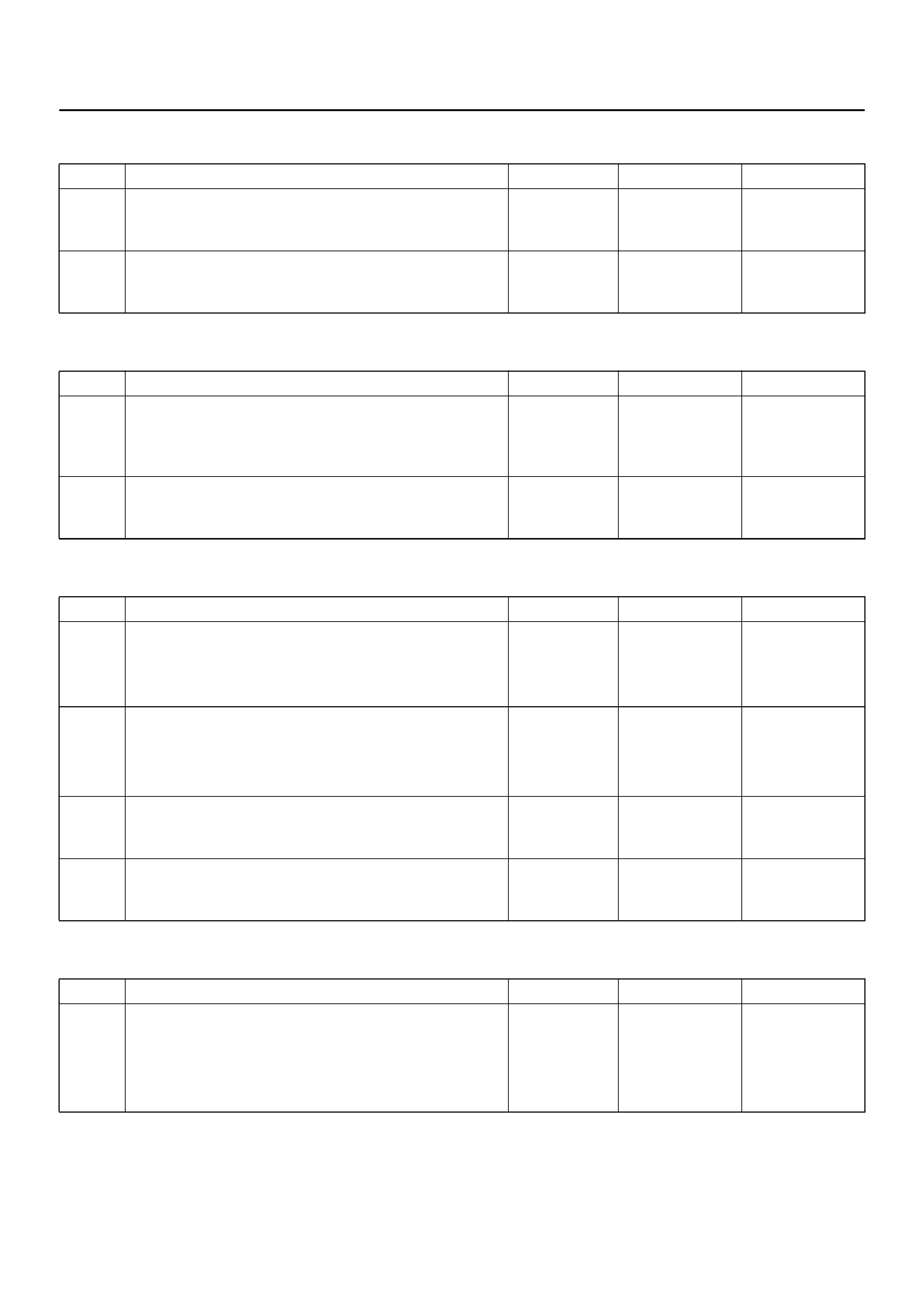

Abbreviations

Abbreviation Meaning

A Ampere (S)

ABS Anti-lock brake system

ASM Assembly

AC Alternating current

A/C Air conditioner

ACC Accessories

A/T Automatic transmission

C/B Circuit breaker

CSD Cold start device

DIS Di re ct igniti on sys tem

EBCM Electronic brake control module

ECGI Electronic control gasoline injection

ECM Engine control module

ECU Electronic control unit

EFE Early fuel evaporation

EGR Exhaust gas recirculation

4A/T 4-speed automatic transmission

4WD Four-w he el driv e

FL Fusib le link

FRT Front

H/L Headlight

IC Integrated circuit

IG Ignition

kW Kilowatt

LH Left hand

LWB Long wheel base

M/T Manual transmission

OD O ver driv e

OPT Option

PCM Powertrain control module

QOS Quick on start

RH Right hand

RR Rear

SDM Sensing and diagnostic module

SRS Supplemental restraint system

ST Start

STD Standard

SW Switch

SWB Short wheel base

3A/T 3-speed automatic transmission

VVolt

VSV Vacuum switching valve

W Watt (S)

WOT Wide open thro ttle

W/ With

W/O Without

Abbreviation Meaning

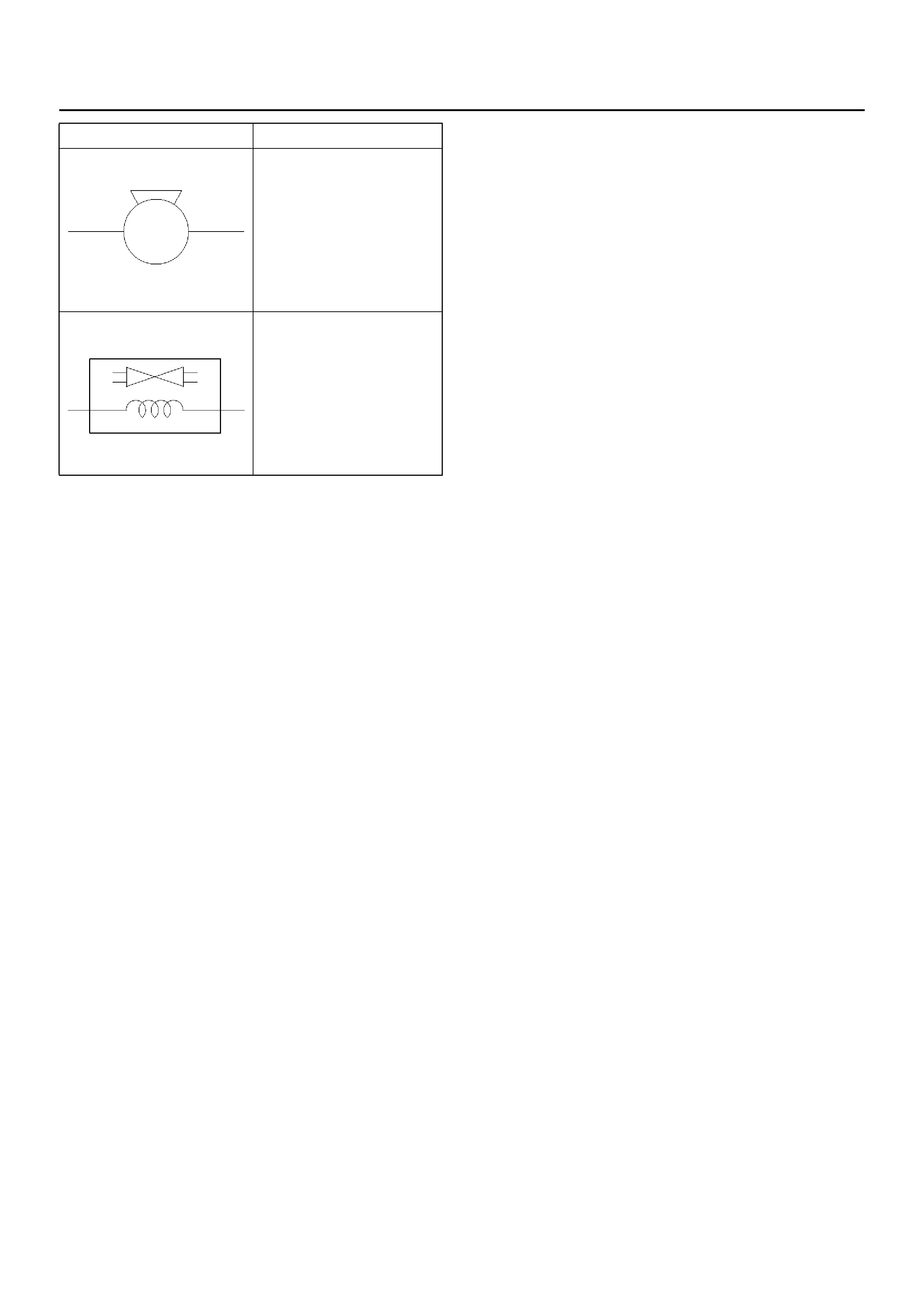

PARTS FOR ELECTRICAL CIRCUIT

Wiring – Wire color

All wires have color–coded insulation.

Wires b elongi ng to a sy stem's main ha rness w ill ha ve a

single color (1). Wires belonging to a system's

subcircuits will have a colored stripe (2). Striped wires

use the following code to show wire size and colors.

F08RW001

D08RW150

Wiring – Wire Color Coding

Abbreviations are used to indicate wire color within a

circuit diagram.

Refer to the following table.

Wiring – Wire Size

The size of wire used in a circuit is determined by the

amount of current (amperage), the length of the circuit,

and the voltage drop allowed. The following wire size

and load capacity, shown below, are specified by AWG

(American Wire Gauge) (Nominal size means

approximate cross sectional area (1).)

D08RW151

Color–coding Meaning

BBlack

WWhite

RRed

GGreen

YYellow

LBlue

O Orange

BR Brown

LG Light green

GR Grey

PPink

LB Light blue

VViolet

Color–coding Meaning

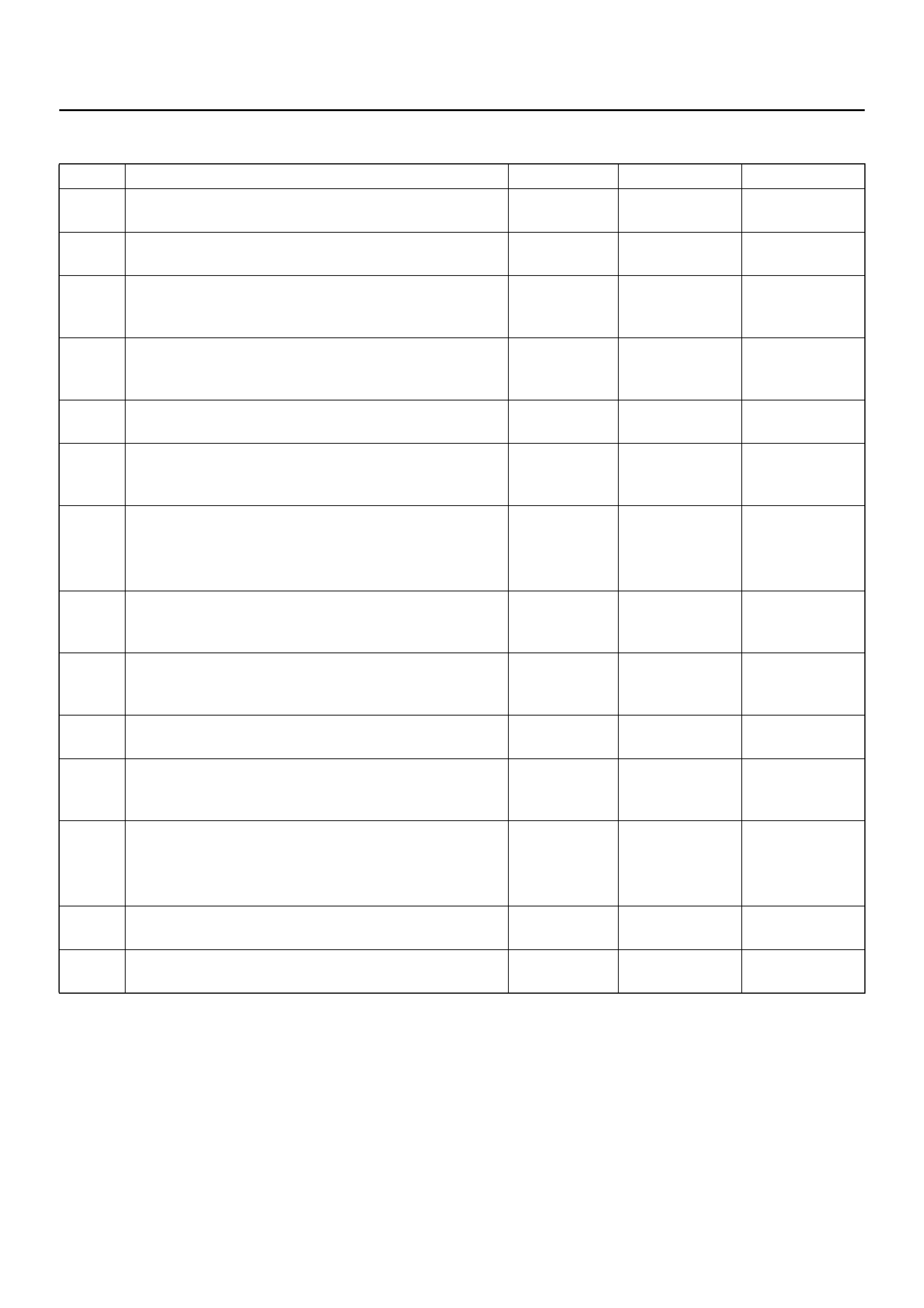

Wiring – Wire Size Table

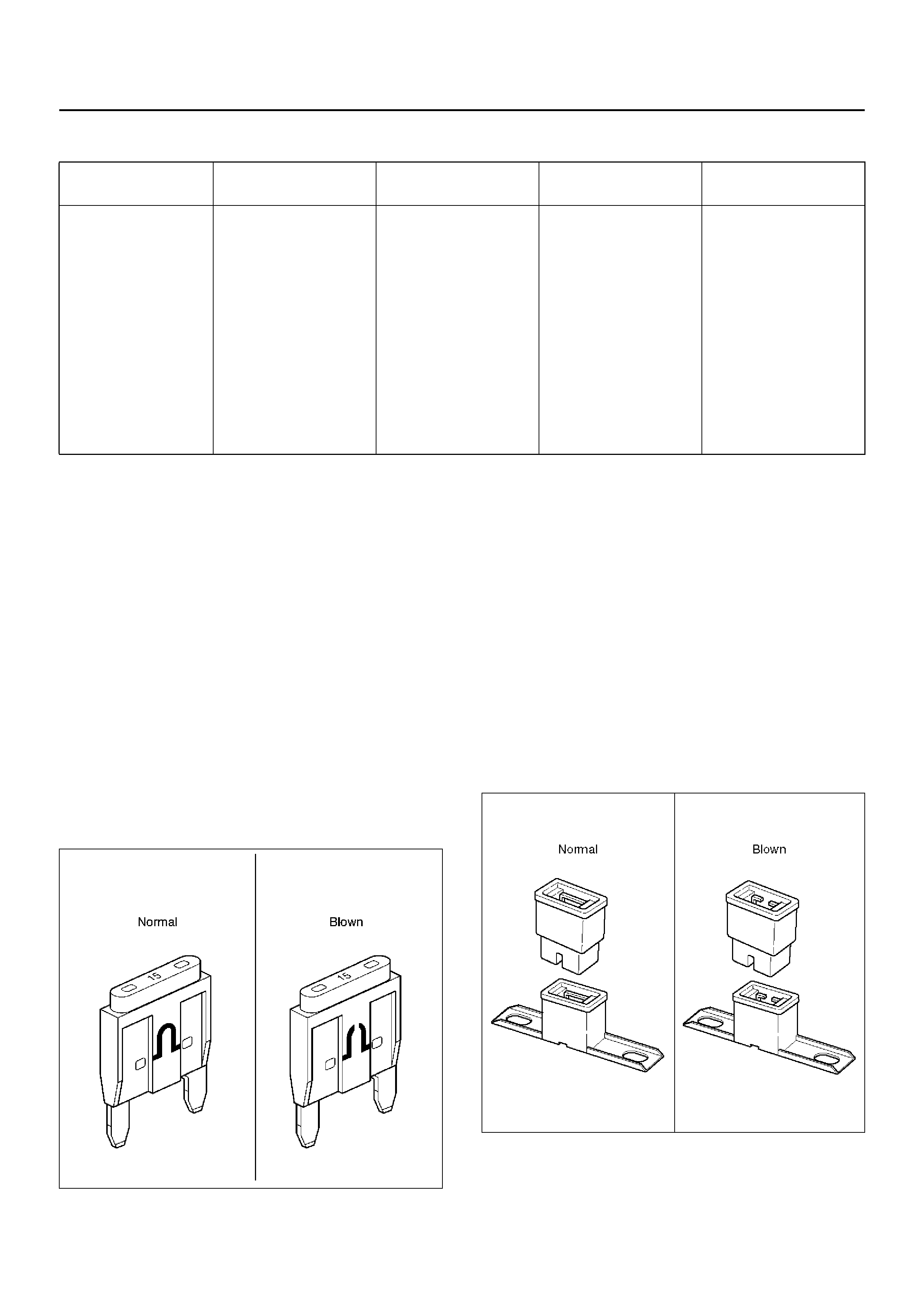

Fuse

Fuses are the most common form of circuit protection

used in vehicle wiring. A fuse is a thin piece of wire or

strip of metal enc ased in a glass it or pla stic housing. It

is wired in se ries with the c irc uit in prote cts. Wh en th ere

is an overload of current in a circuit, such as a short of a

ground, the metal strip is designed to burn out and

interrupt the flow of current. This prevents a surge of

high current from reaching and damaging other

components in the circuit.

Determine the cause of the overloaded before replacing

the fuse.

The replacement fuse must have the same amperage

specification as the original fuse.

Never replace a blown fuse with a fuse of a different

amperage specification.

Doing so can result in an electrical fire or other serious

circuit damage. A blown fuse is easily identified as

shown in the figure.

810RX001

Fusible Link

The fusible link is primarily used to protect circuits

where high amounts of current flow and where it wo uld

not be practical to use a fuse. For example, the starter

circuit. When a current overload occurs, the fusible link

melts open and interrupts the flow of current so as to

prevent the rest of the wiring harness from burning.

Determine the cause of the overload before replacing

the fusible link. the replacement fusible link must have

the sam e amperage s pecification as the original fusible

link. Never replace a blown fusible link with fusible link

of a different amperage specification. Doing so can

result in an electrical fire or other serious circuit

damage.

A blown fusible link is easily identified as shown in the

figure.

D08RW154

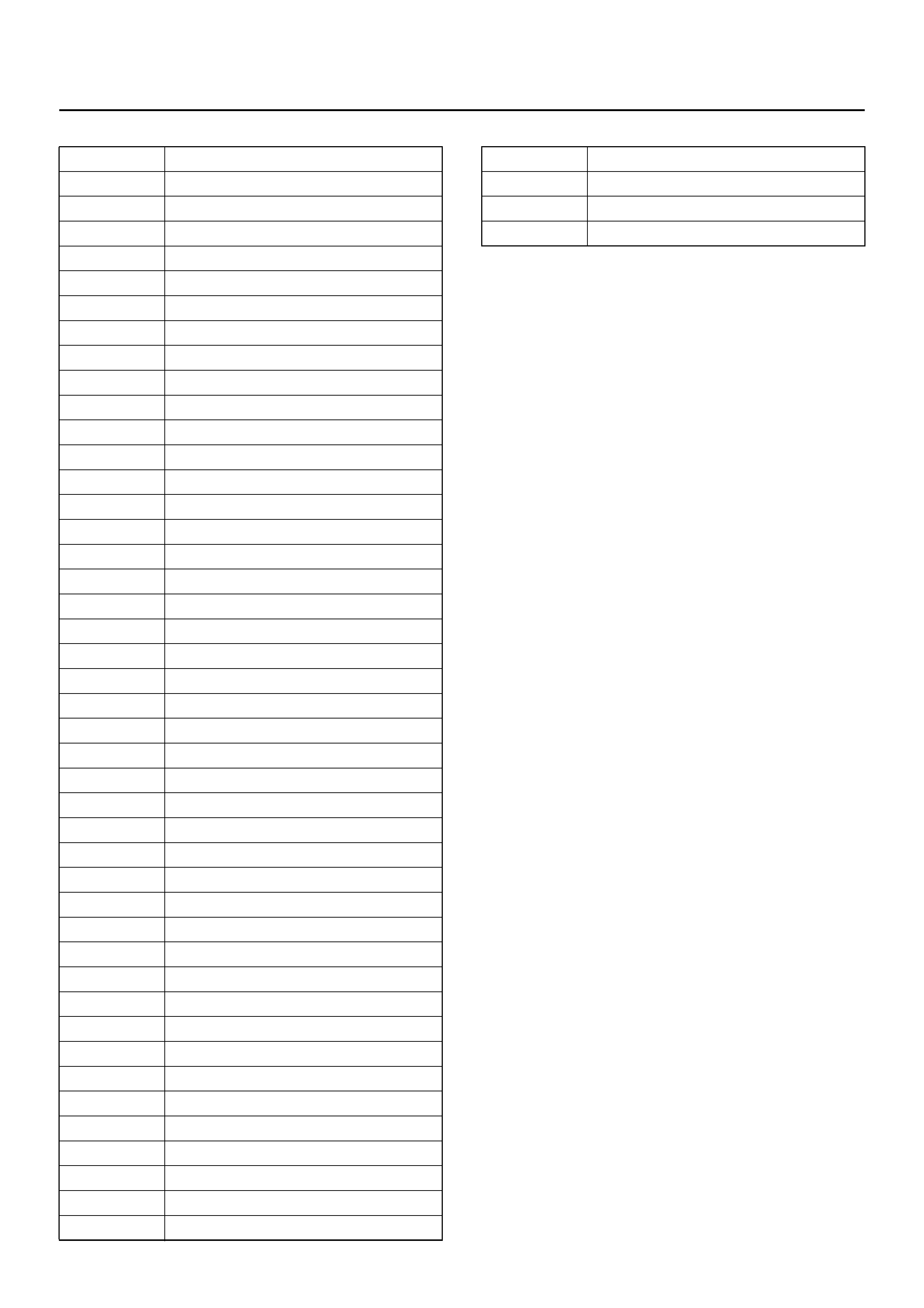

Nominal size Cross section al

area (mm2)Outside diameter

(mm) Allowable current

(A) AWG size (cross

reference)

0.3 0.372 1.5 9 22

0.5 0.563 1.7 12 20

0.85 0.885 1.9 16 18

1.25 1.287 2.2 21 16

2 2.091 2.7 28 14

3 3.296 3.6 37.5 12

5 5.227 4.4 53 10

8 7.952 5.5 67 8

15 13.36 7.0 75 6

20 20.61 8.2 97 4

Fusible Link Specifications

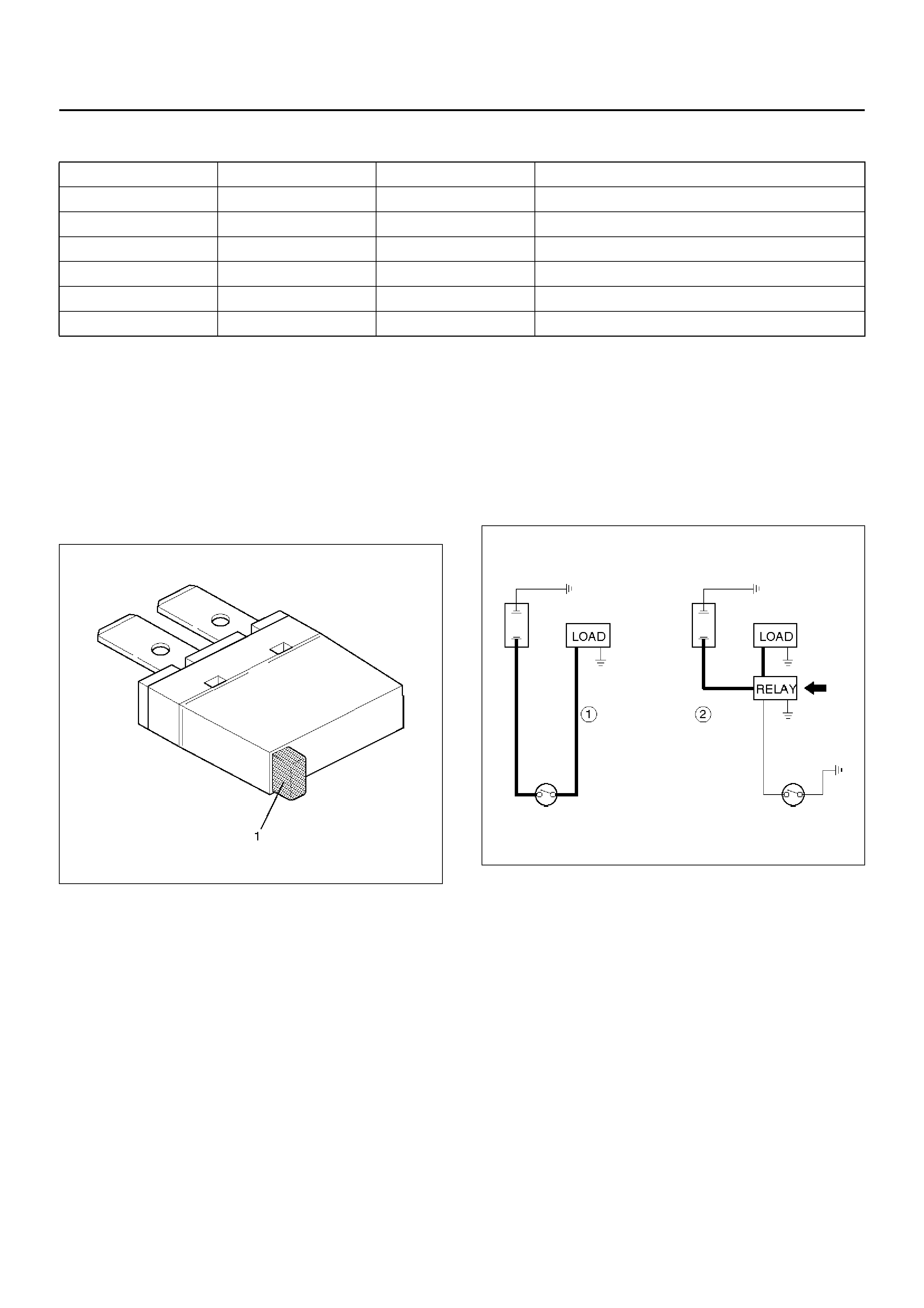

Circuit Breaker

The circuit breaker is a protective device designed to

open the circuit when a current load is in excess of rated

breaker capacity. If there is a short or other type of

overload condition in the circuit, the excessive current

will open the circuit between the circuit breaker

terminals. The reset knob (1) pops out when the circuit

is open. Push the reset knob in place to restore the

circuit after repairing it.

D08RW155

Relay

Battery and load location may require that a switch be

placed some distance from either component. This

means a longer wire and a higher voltage drop (1).

The installation of a relay between the battery and the

load reduces the voltage drop (2).

Because the switch controls the relay, amperage

through the switch can be reduced.

D08RW156

Type Rating Case Color Maximum Circuit Current (A)

Connector 30A Pink 15

Connector 40A Green 20

Bolted 50A Red 25

Bolted/Connector 60A Yellow 30

Bolted 80A Black 40

Bolted 100A Blue 50

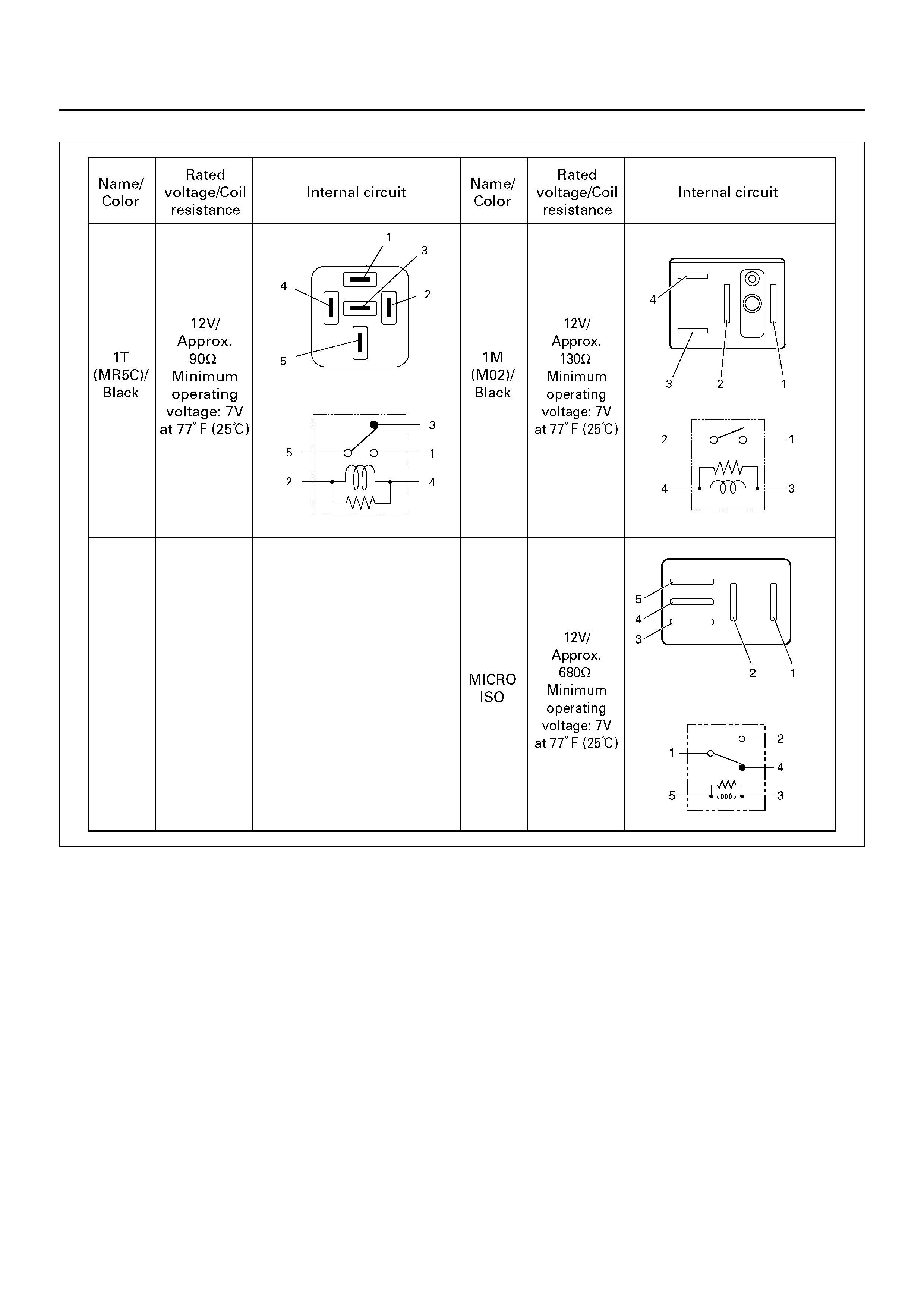

Relay Specifications and Configurations

D08R100212

*Relay contact shown in the wiring diagram indicates

condition before actuation.

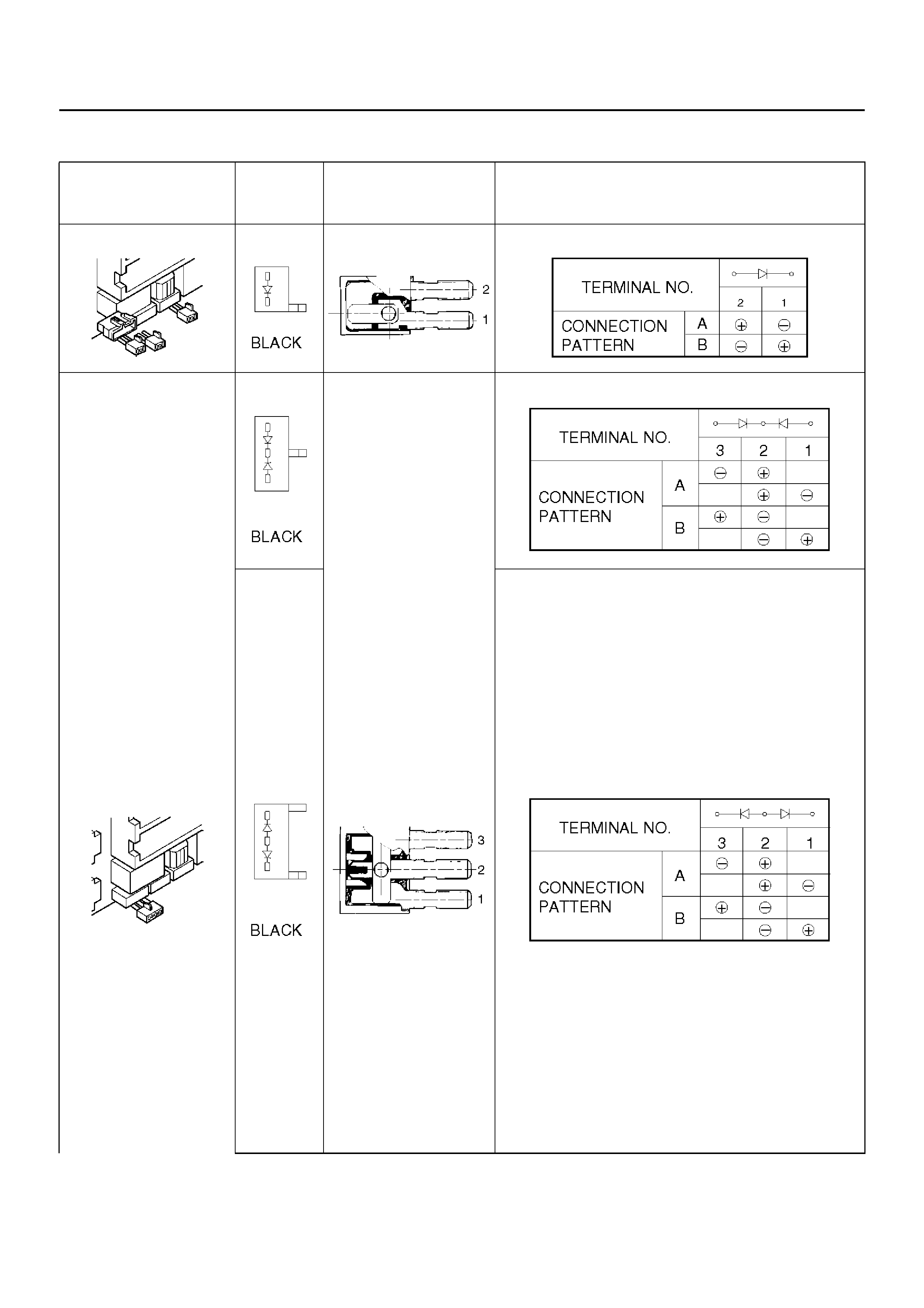

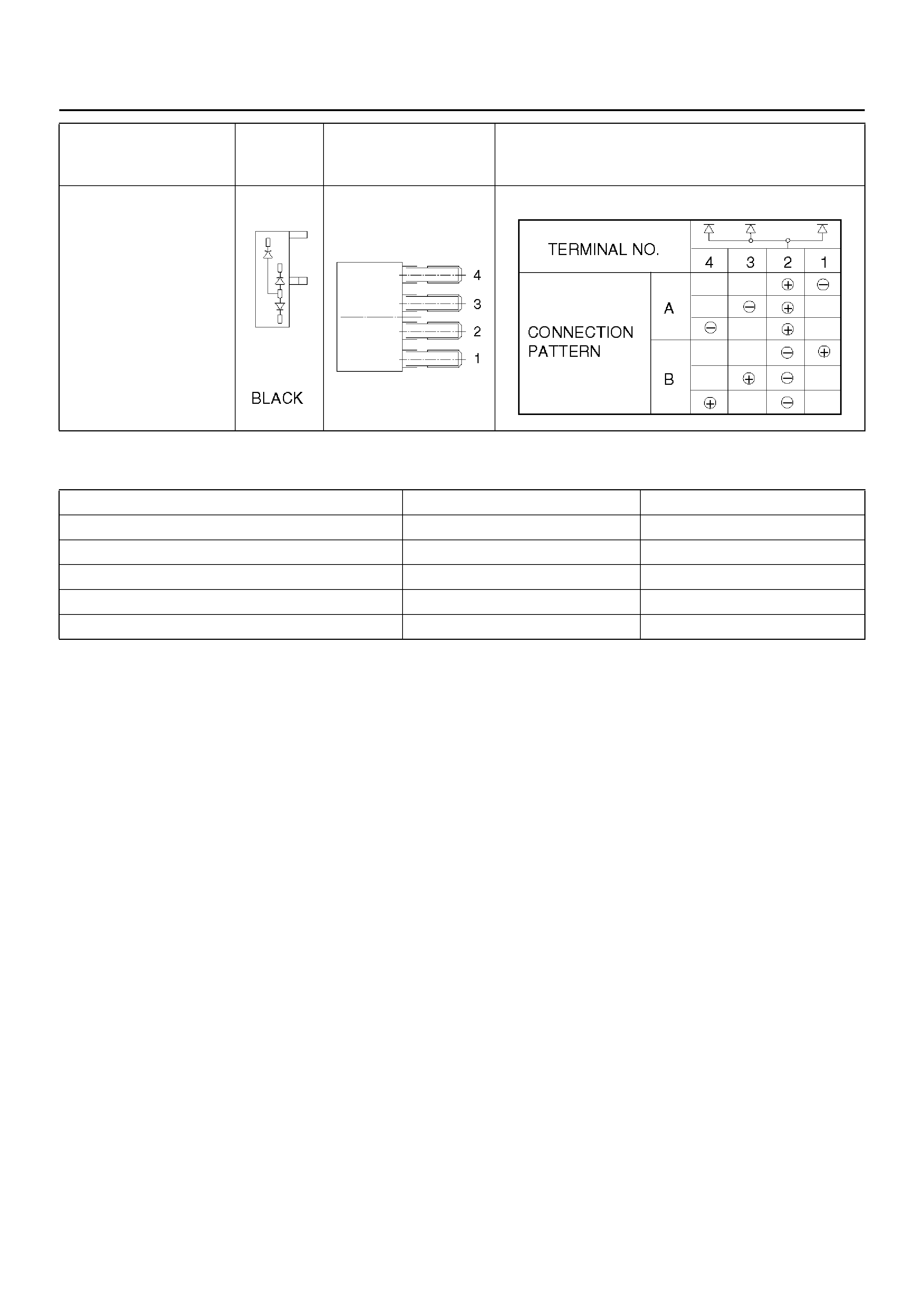

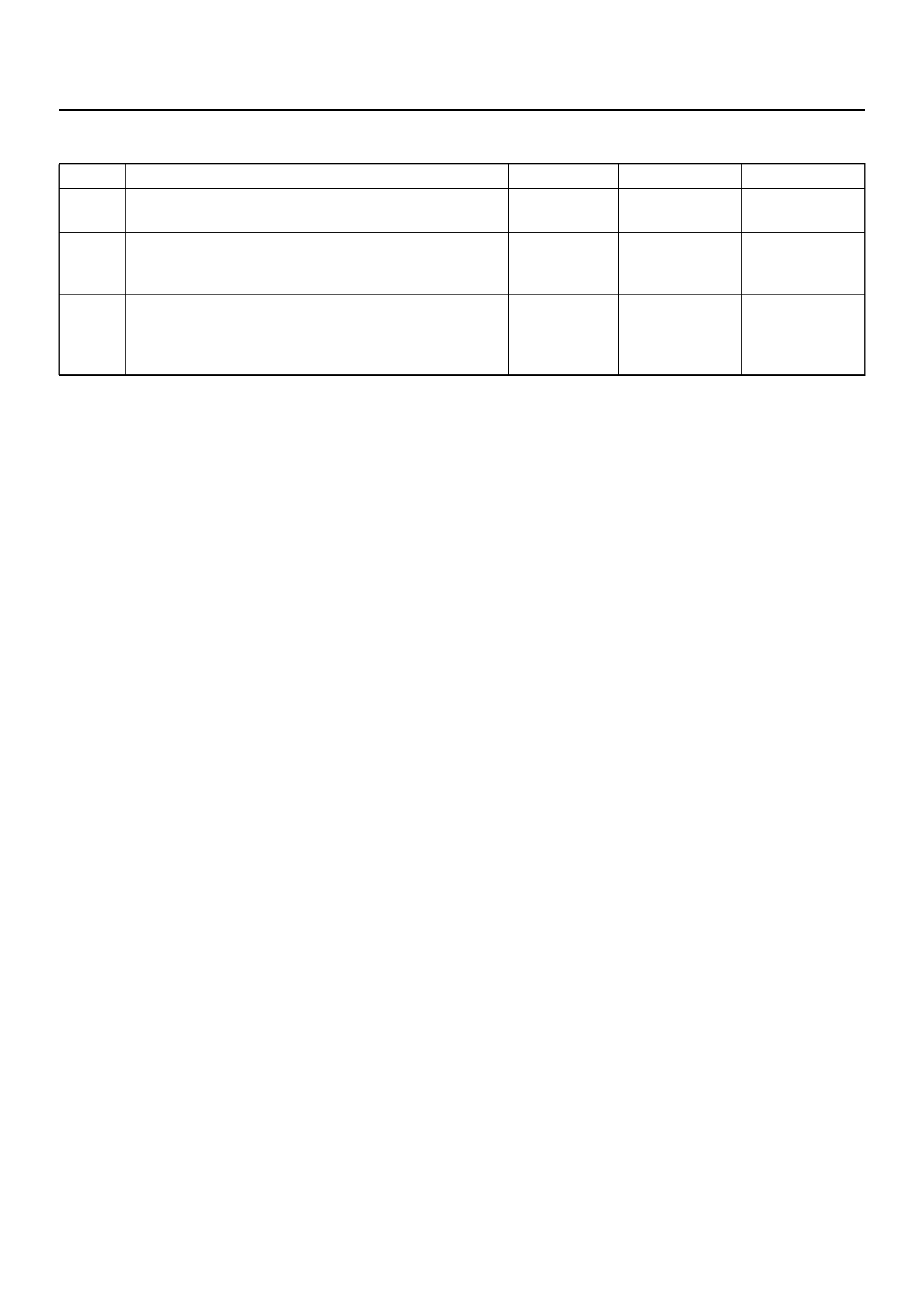

Diode – Diode Specifications and Configurations

SHAPE MARK /

COLOR CONSTRUCTION CHECKING: THERE SHOULD BE CONTINUITY

IN EITHER A OR B WHEN A CIRCUIT TESTER IS

CONNECTED WITH DIODE TERMINAL

Diode – Maximum Rating (Temp. = 77°F (25°C)

SHAPE MARK /

COLOR CONSTRUCTION CHECKING: THERE SHOULD BE CONTINUITY

IN EITHER A OR B WHEN A CIRCUIT TESTER IS

CONNECTED WITH DIODE TERMINAL

Items Rating Remarks

Peak reverse voltage 400V

Transient peak reverse voltage 500V

Average output current 1.5A Temp. = 104°F (40°C)

Working ambient temperature -22°F∼176°F (-30°C∼80°C)

Storage temperature -40°F∼212°F (-40°C∼100°C)

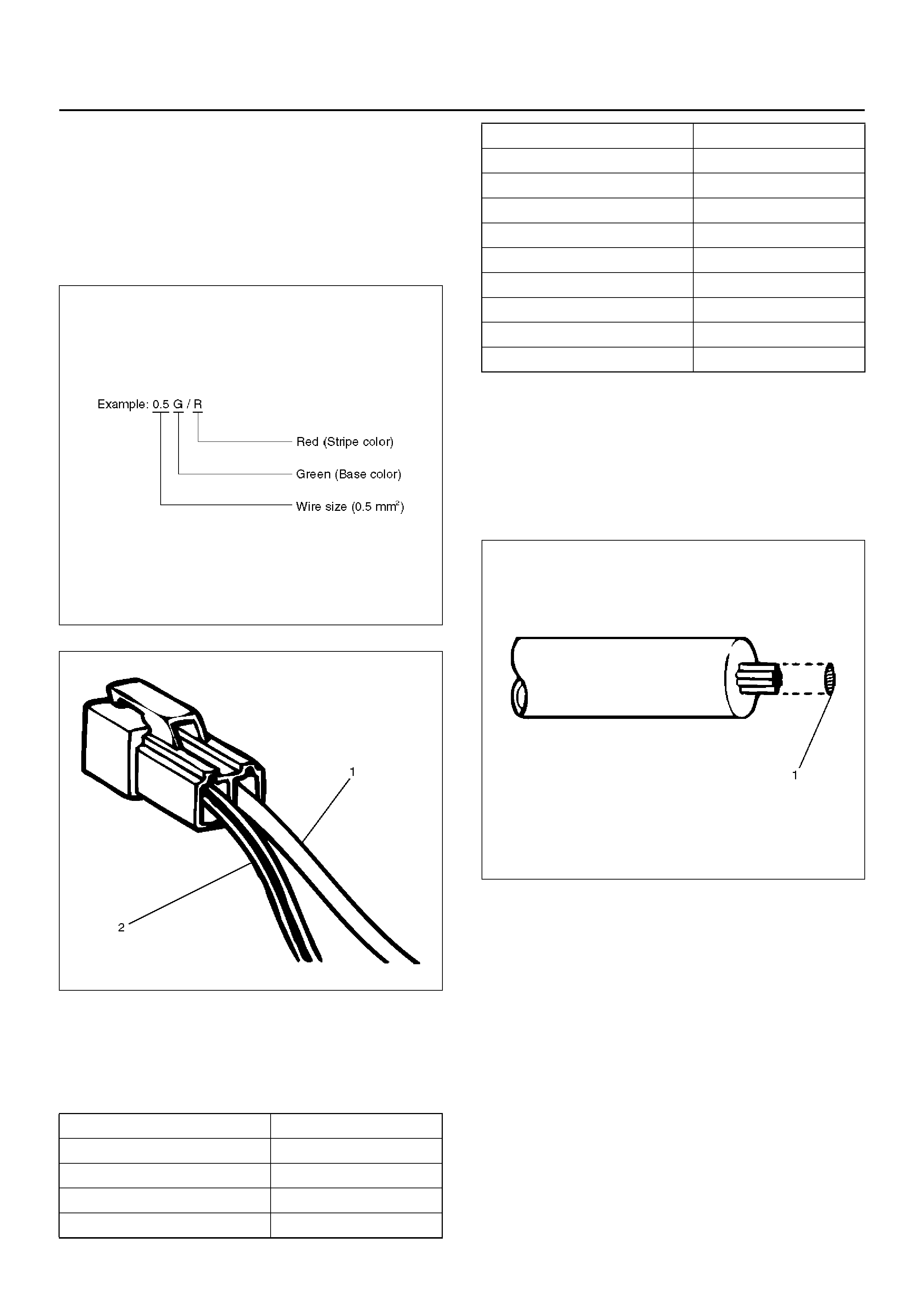

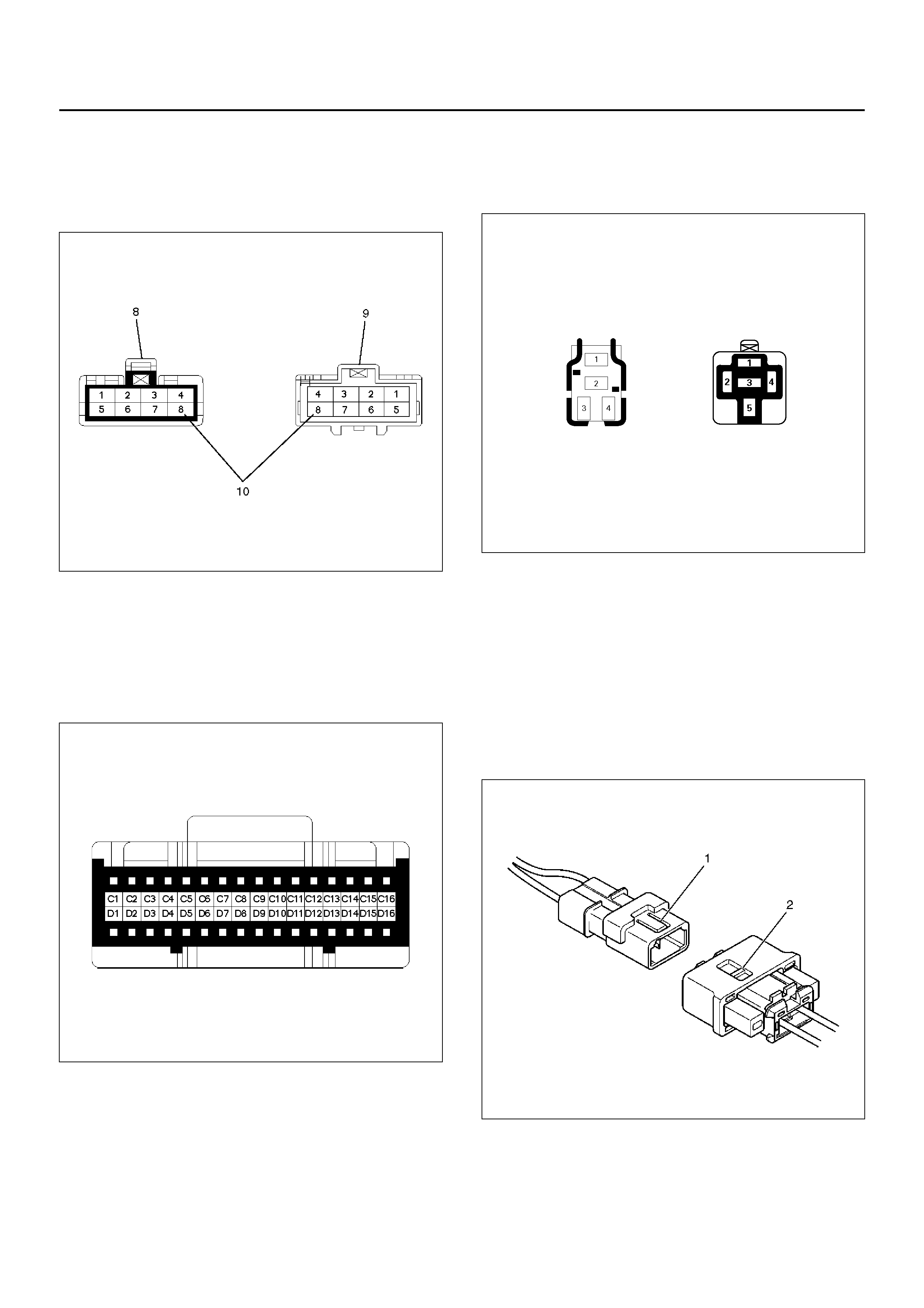

Connector

• The connec tor pin shape (2) d etermines whethe r the

connector is male (3) or female (1).

D08RW159

• The symbol illustrated in the figure is used as

connector, in the circuit of this section.

D08RW160

EndOFCallout

• Connector is identified with a connector number (6)

D08RW161

• The applicable terminal number (7) is shown for each

connector.

D08RW162

Legend

(4) Female Side Connector

(5) Male Side Connector

• Connector terminal numbers (10) are clearly shown.

Make side connector (9) terminal numbers are in

sequence from upper right to lower left.

Female side connector (8) terminal numbers are in

sequence from upper left to lower right.

D08RW163

NOTE:

1. For those connectors on which specific terminal

numb ers or symbol s are shown (such as PCM), th e

termin al numbers o r symbols are us ed in the circuit

diagram, irrespective of the above rule.

Refer to the following figure.

D08RW164

2. The connectors used for relays have their own

terminal number assignment, irrespective of the

above rule.

Refer to the following figure.

Double Lock Type Connector

Doublelock type yellow color connectors are used for

supplemental restraint system–air bag circuit. When

removing the cable harness, disconnect the connector

by unlocking at two places, outside (1) and inside (2). In

such a case, do not pull the cables. Otherwise, cable

disconnection may occur.

When connecting the connector, insert the connector

completely and lock at outside. Imperfect locking may

cause malfunction of SRS system circuit.

F00RX010

READING THE CIRCUIT DIAGRAM

In this section, each system has its own parts location

illustration and circuit diagram. And harness connector

faces used in the circuit diagram are shown at the end

of this section.

Parts Location

The parts locat ion shows th e location of the con nectors

(1) and the harness (2) used in each harness routing.

D08RWD38

Circuit Diagram

The circuit diagram shows the power supply (1) the load

or loads (2) and the grounding point(s) (3).

D08RX124

Harness Connector Faces

The harness connector faces show each connector's

number (1), configuration (2) and the pin number (3).

F00RX011

MAIN DATA AND SPECIFICATIONS

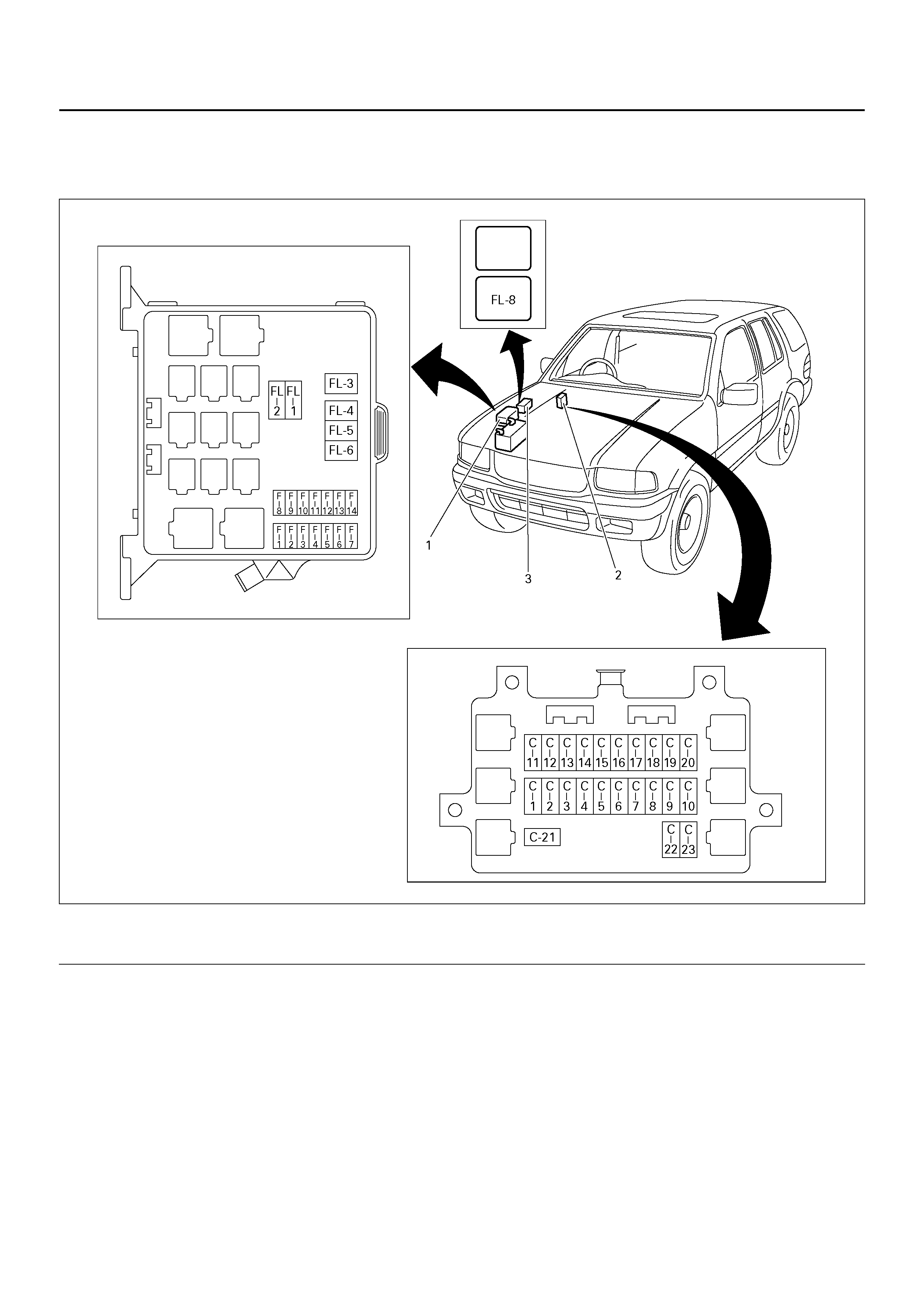

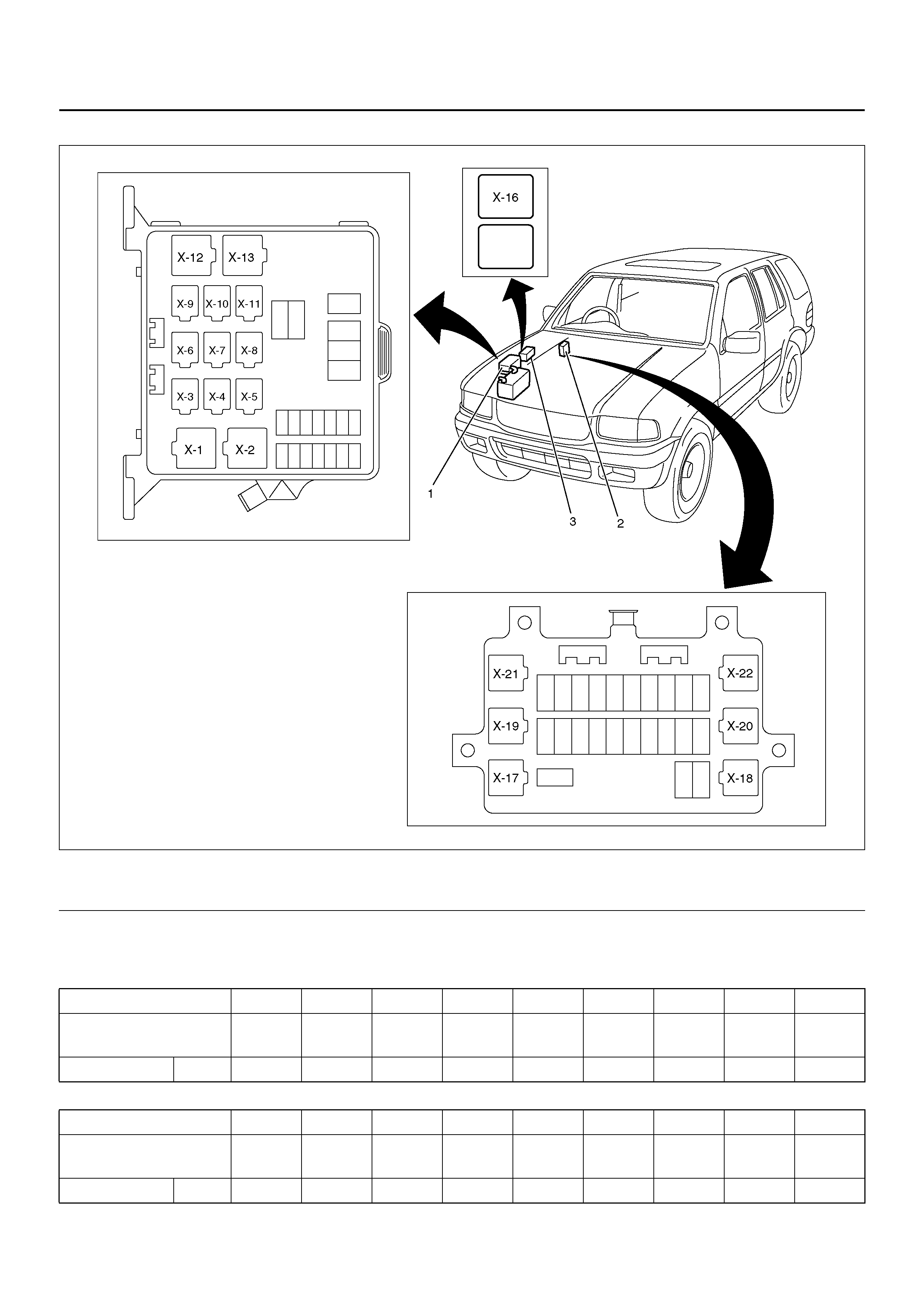

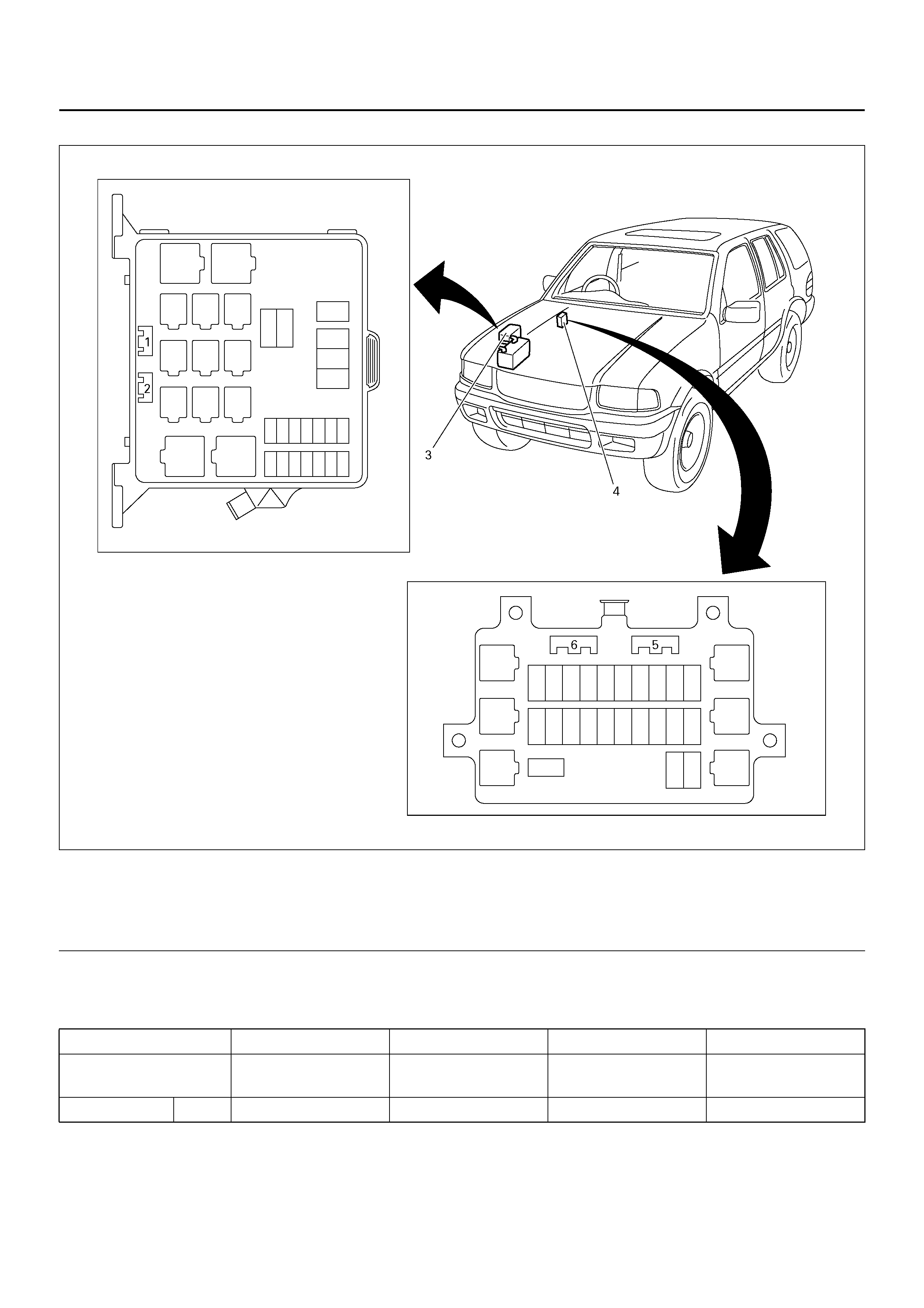

FUSE, FUSIBLE LINK AND CIRCUIT BREAKER LOCATION

810R100009

EndOFCallout

Legend

(1) Relay & Fuse Box (Engine Bay) (2) Relay & Fuse Box (Instrument Panel)

(3) Relay & Fuse Option Box (Engine Bay)

RELAY & FUSE BOX (ENGINE BAY) RELAY & FUSE BOX (INSTRUMENT

PANEL)

Fuse

No. Capacity Indication on label

F-1 15A HAZARD

F-2 10A HORN

F-3 10A ACG-S

F-4 20A BLOWER

F-5 10A A/C

F-6 – –

F-7 – –

F-8 10A H/L LIGHT-LH

F-9 10A H/L LIGHT-RH

F-10 15A (FOG LIGHT)

F-11 10A O2 SENS. HEATER

F-12 20A FUEL PUMP

F-13 15A ECM

F-14 15A (TOD)

FL-1 100A MAIN

FL-2 60A IGN.1

FL-3 30A ECM

FL-4 50A ABS

FL-5 50A IGN.2

FL-6 30A COND. FAN

FL-7 – –

FL-8 – –

Fuse

No. Capacity Indication on label

C-1 20A ACC. SOCKET

C-2 15A (AUDIO) +B

C-3 10A STARTE.

R

C-4 15A TAIL/ILLUMI. LIGHT

C-5 10A DOME LIGHT

C-6 15A STOP LIGHT

C-7 20A POWER DOOR LOCK

C-8 10A MIRROR DEFOG

C-9 15A REAR DEMIST

C-10 15A REAR DEMIST

C-11 15A METER

C-12 15A ENGINE IG.

C-13 15A IG. COIL

C-14 15A BACK UP/TURN LIGHT

C-15 15A ELEC. IG.

C-16 20A REAR WIPER & WASHER

C-17 10A FRONT WIPER & WASHER

C-18 10A ACC (AUDIO)

C-19 15A CIGAR LIGHTER

C-20 10A –

C-21 30A (POWER WINDOW)

C-22 10A SRS

C-23 10A IMMOBILISER

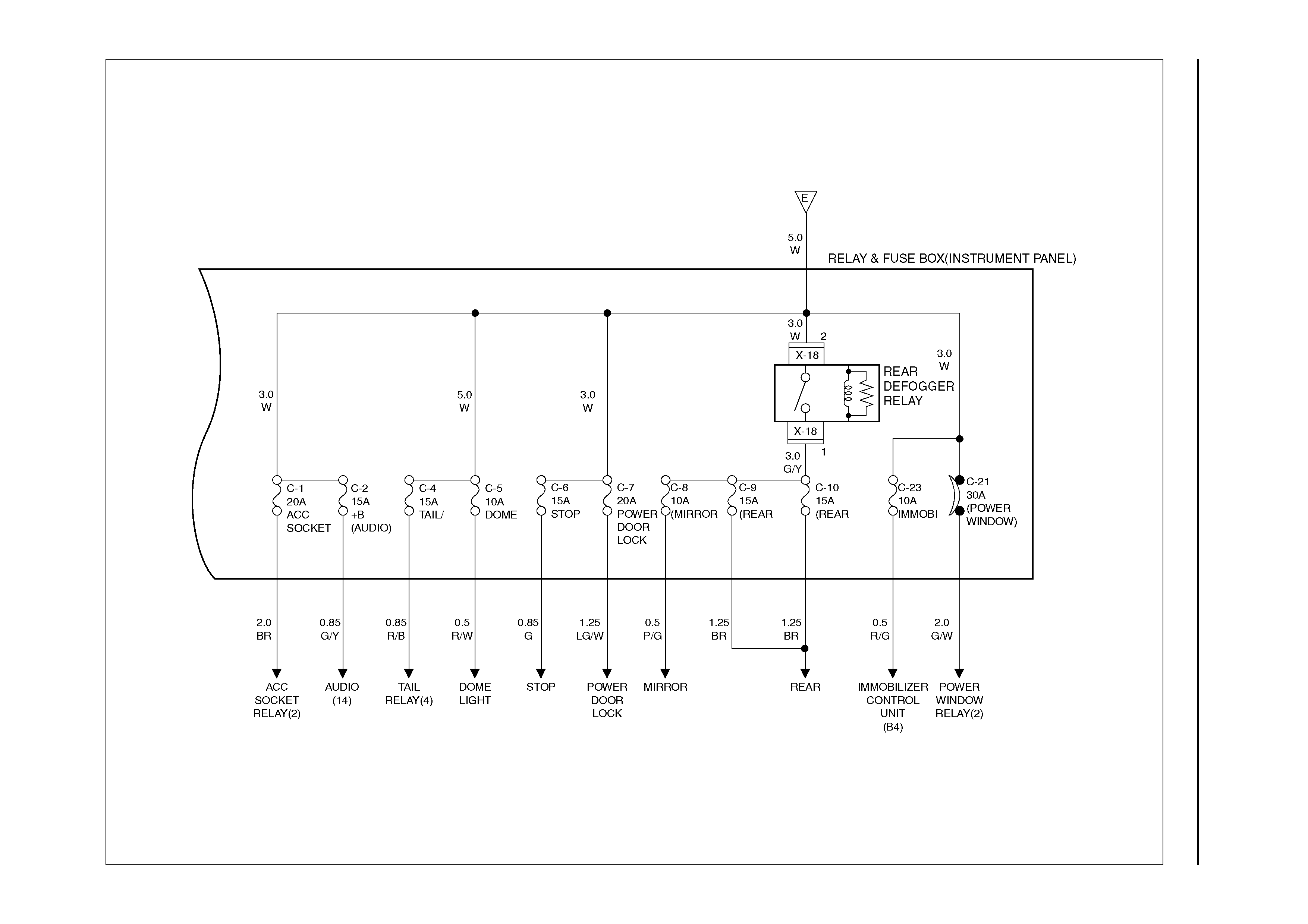

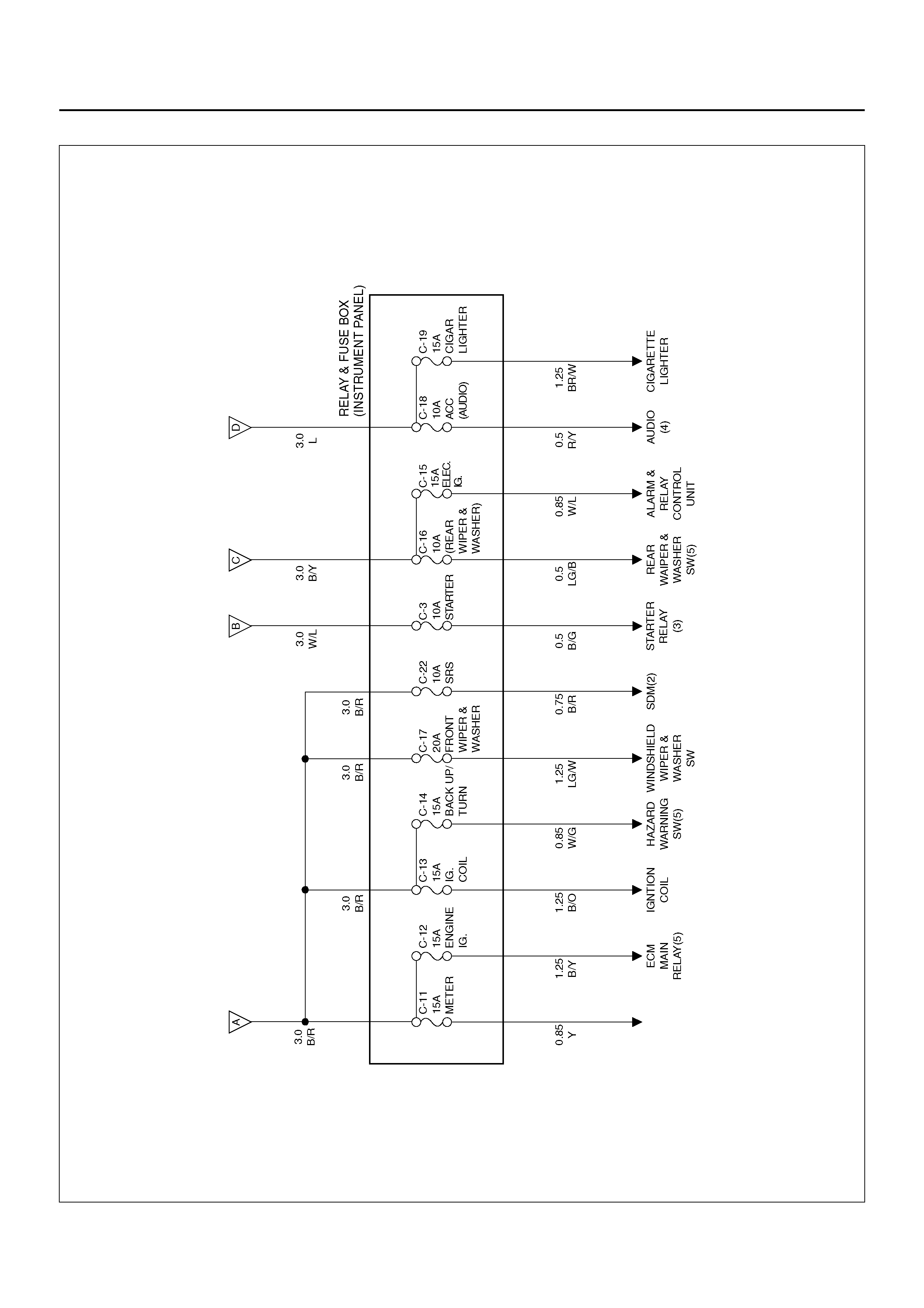

FUSE BLOCK CIRCUIT

Fuse Block Circuit–1

D08R100087

Fuse Block Circuit–2

D08R100222

Fuse Block Circuit–3

D08R100221

Fuse Block Circuit–4

D08R100220

DEMIST) DEMIST)

DEMIST)

DEMIST

DEMIST

LAMP

LAMP

LAMP

Fuse Block Circuit–5

D08R100219

INDIC.

INSTR.

REFERENCE TABLE OF FUSE, FUSIBLE LINK AND CIRCUIT BREAKER

Fuse (Relay and Fuse Box · Engine Bay)

Fuse No. Capacity Indication on label Parts (Load)

F-1 15A HAZARD FRT Turn signal light, RR Turn signal light, Side turn

signal light, Flasher unit

F-2 10A HORN Alarm & relay control unit, Horn

F-4 20A BLOWER Blower motor, Blower resistor, Power transistor

F-5 10A A/C Thermo switch, Blower unit, Intake actuator , In car sensor ,

Resistor, A/C thermostat relay, Electronic thermostat,

Automatic A/C control uni t, A/C compres sor relay,

Magnetic clutch, Condenser fan relay, Max high relay

F-8 10A H/L LIGHT - LH Headlamp - LH, High beam indicator light

F-9 10A H/L LIGHT - RH Headlamp - RH

F-10 15A FOG LIGHT Fog light

F-11 10A O2SENSOR Oxygen sensor

F-12 20A FUEL PUMP Fuel pump

F-13 15A ECM Engine con tr ol mod ule , Instrum ents

F-14 15A TOD TOD control unit

FL-1 100A MAIN Starter

FL-2 60A IGN.1

FL-3 30A ECM Fuel injector

FL-4 50A ABS EHCU

FL-5 50A IGN.2

FL-6 30A COND. FAN Condenser fan

FL-8 N/A N/A

Fuse (Relay & Fuse Box · Instrument Panel)

PCM: Power train module, VSV: Vacuum switching

valve

Fuse No. Capacity Indication on label Parts (Load)

C-1 20A ACC. SOCKET Acc socket

C-2 15A (AUDIO) Audio

C-3 10A STARTER Starter relay

C-4 15A TAIL/ILLUMI. LIGHT Tail relay, Tail lamp, Park Lamp, License plate lamp,

Illumination controller, Illumination light, Fog lamp relay,

Fog lamp SW

C-5 10A DOME LIGHT Dome light, Courtesy light - LH, Courtesy light - RH, Rear

Compartment light, Alarm & relay control unit, Digital

clock, Map light, Automatic A/C control unit

C-6 15A STOP LIGHT Stop lamp switch, Stop lamp - LH, Stop light - RH, High

mounted stop light, A/T shift lock relay

C-7 20A (POWER DOOR

LOCK) FRT door lock & Power window SW, Door lock actuator,

Keyless entry control unit

C-8 1 0A (MIRROR DEFOG) Mirror demist

C-9 15A (REAR DEFOG) Rear demist

C-10 15A (REAR DEFOG) Rear demist

C-11 15A EHCU Indicator and warning lights (meter), Meter gauge,

Generator, Vehicle speed sensor, Shift lock control unit,

Fuel tank unit

C-12 15A ENGINE IG. PCM main relay, VSV; purge solenoid, MAF sensor VSV;

intake air

C-13 15A IG. COIL Ignition coil, Ion sensing module, Condenser

C-14 15A BACKUP/TURN LIGHT Mode SW, Backup light, FRT axle actuator, TOD clutch

solenoid, TOD speed sensor, TOD H-L shift motor,

Indicator control unit, TOD control unit

C-15 15A ELEC. IG. Alarm & relay control unit, Power window relay, 4WD

control unit, Heater relay

C-16 15A REAR WIPER &

WASHER Rear wiper motor, Rear washer motor, Alarm & relay &

control unit, Rear defogger & mirror defogger relay

C-17 20A (FRONT WIPER &

WASHER Windshield wiper motor, Windshield washer motor, Alarm

& relay control unit

C-18 10A (AUDIO) ACC A udi o, Powe r door mirror

C-19 15A CIGAR LIGHTER ACC socket relay cigarette lighter

C-22 10A SRS SRS warning light, SDM

Fusible Link (Relay and Fuse Box · Engine Room)

ABS: Anti - lock Brake System

Circuit Breaker (Relay & Fuse Box · Instrument Panel)

Fuse Link No. Capacity Indication on label

FL-1 100A MAIN

FL-2 60A IGN. 1

FL-3 30A ECM

FL-4 50A ABS

FL-5 50A IGN. 2

FL-6 30A COND. FAN

FL-8 - -

Fuse No. Capacity Indication on label Parts (Load)

C-21 30A (POWER WINDOW) Power window SW, Power window motor.

RELAY LOCATION

810RY00025

EndOFCallout

Relay List

Legend

(1) Relay & Fuse Box (Engine Bay) (2) Relay & Fuse Box (Instrument panel)

(3) Relay & Fuse Option Box (EngineBay)

Connector No. X–1 X–2 X–3 X–4 X–5 X–6 X–7 X–8 X–9

Usage Heater A/C

comp. ECM

Main –Fog

light – – Thermo Head

light

Engine 6VD1 ❍❍❍–❍––❍❍

Connecto r No. X–10 X–11 X–12 X–13 X–1 7 X–18 X–1 9 X–21 I–22

Usage Starter Conden

ser fan Fuel

pump –ACC

socket Rear

demist – Tail light Power

window

Engine 6VD1 ❍❍❍–❍❍–❍❍

DIODE LOCATION

810R100010

EndOFCallout

Diode List

Legend

(1) X–14

(2) X–15

(3) Relay & Fuse Box (Engine Bay)

(4) Relay & Fuse Box (Instrument panel)

(5) X–24

(6) X–23

Connector No . X–14 X–15 X–23 X–24

Usage – – Tailgate SW, Door

SW. Dome light Brake

Engine 6VD1 – – ❍❍

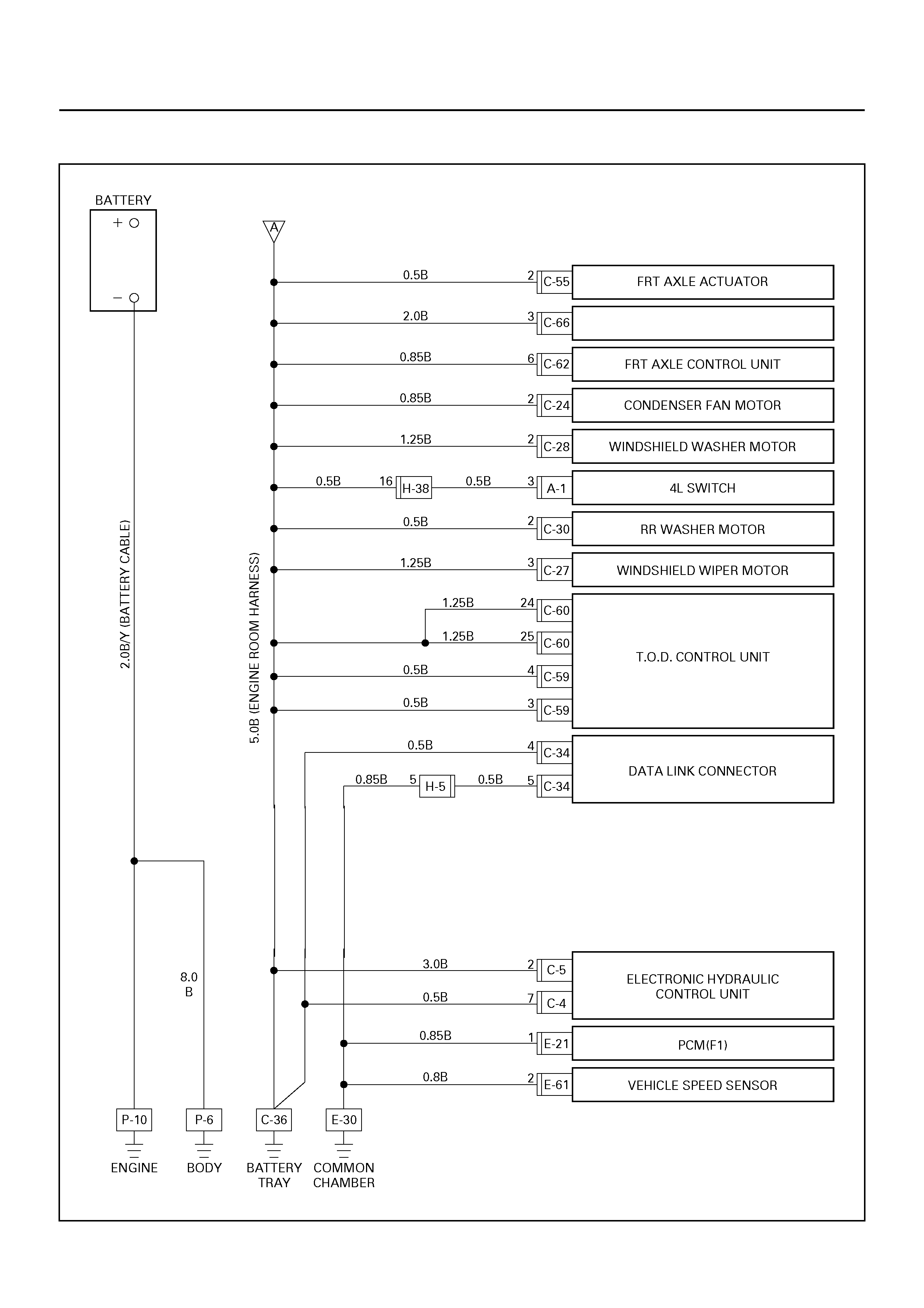

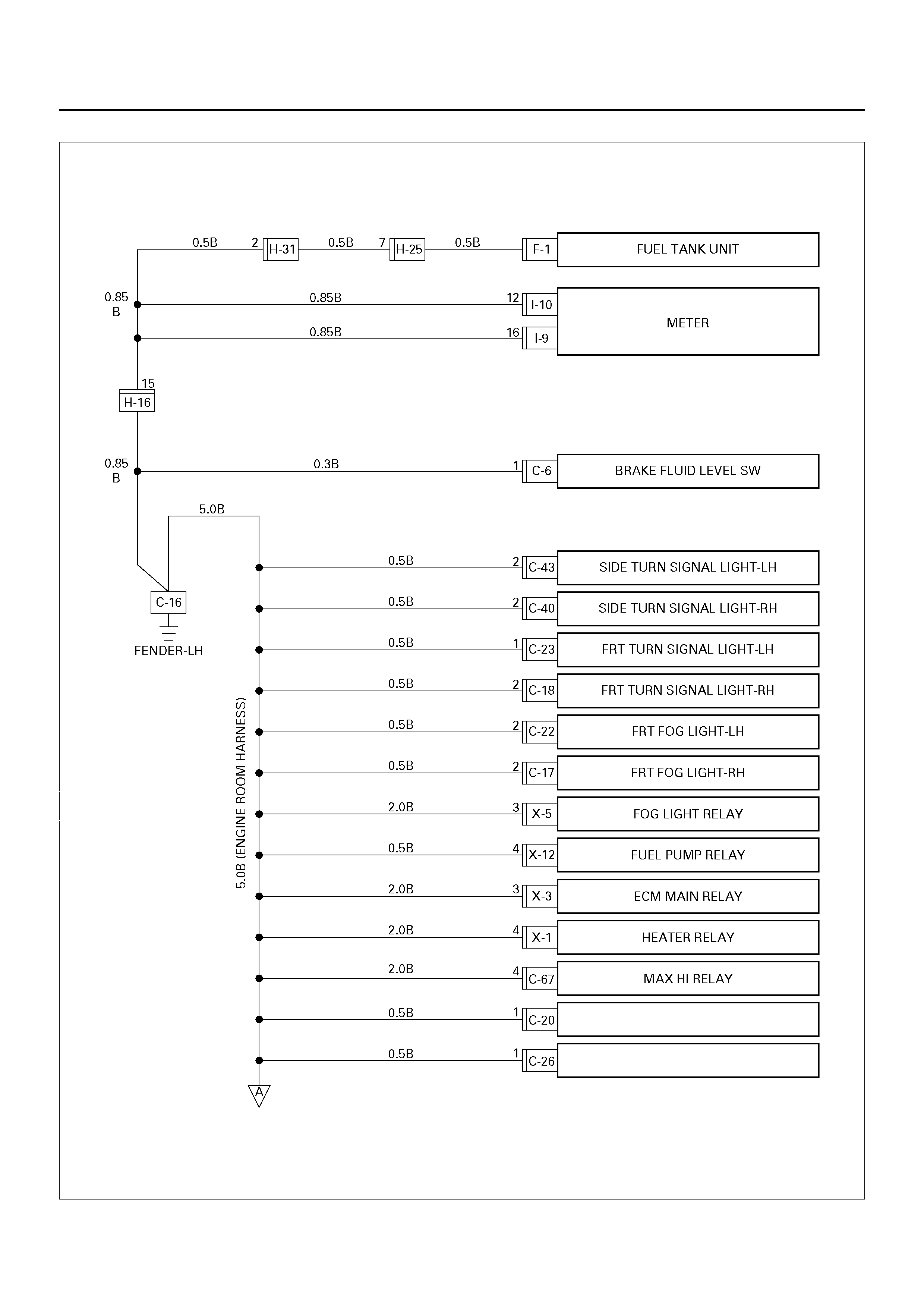

GROUNDING POINT

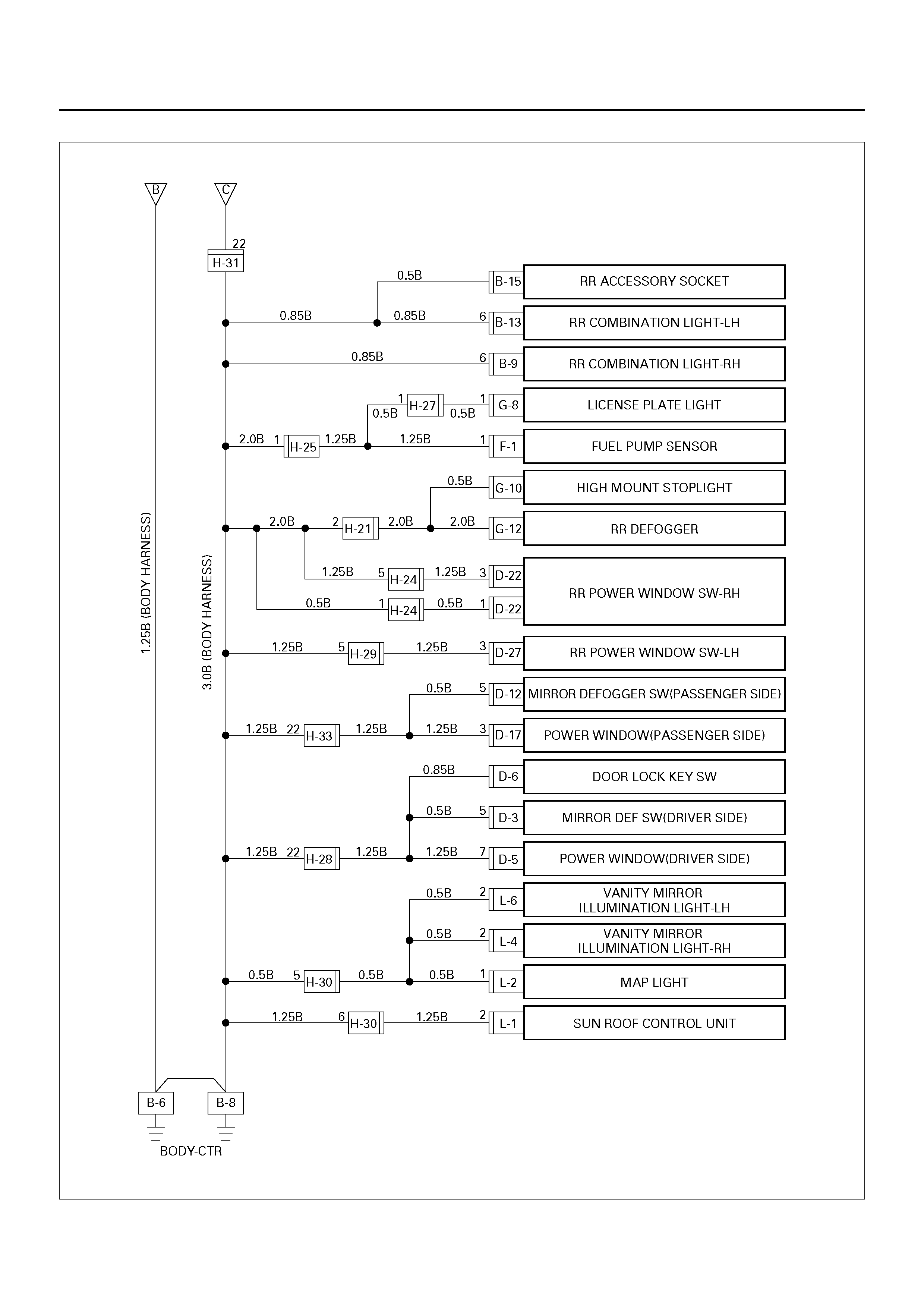

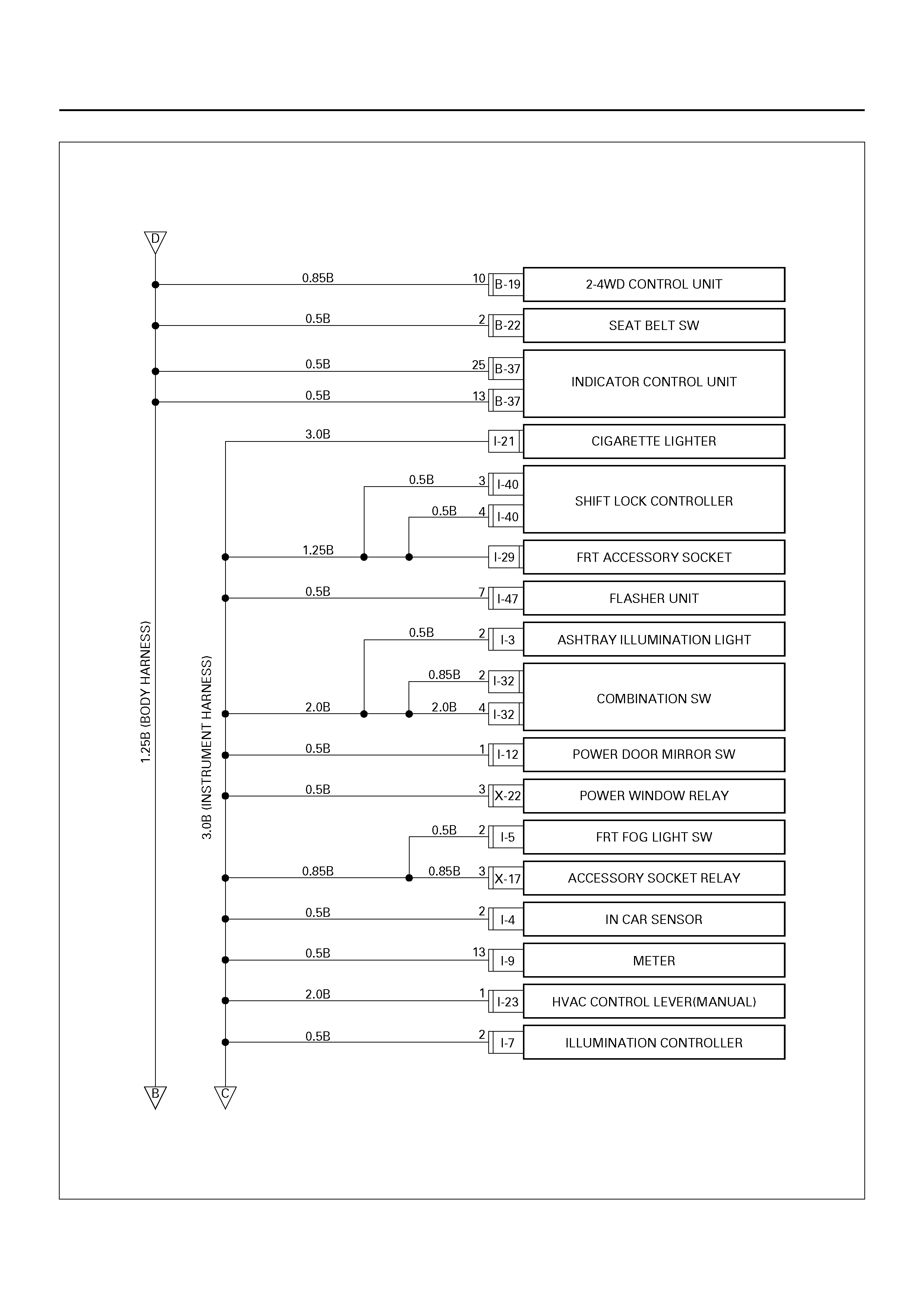

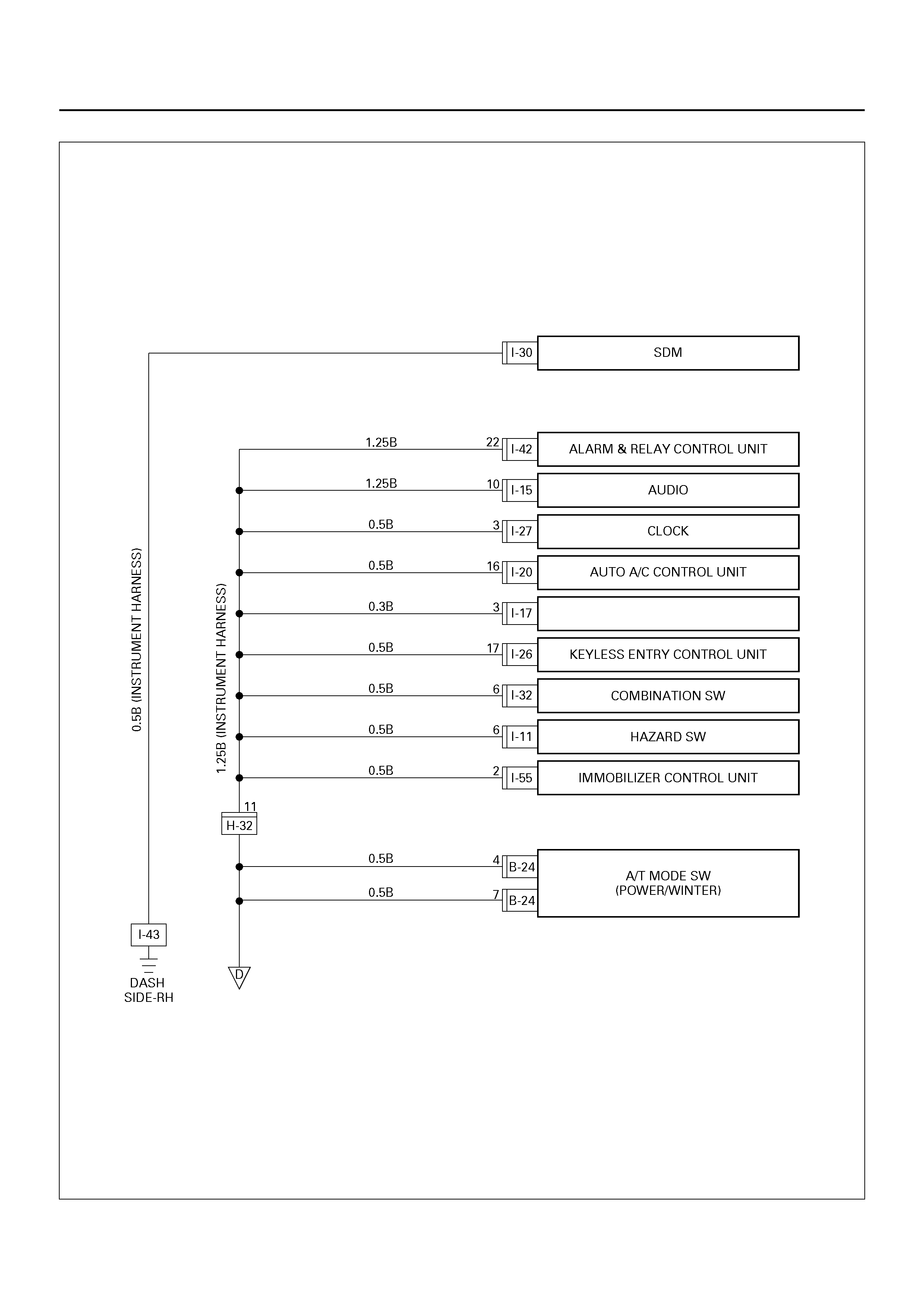

Circuit Diagram – 1

D08R100171

(ABS)

POWER TRANSDUCER

Circuit Diagram – 2

D08R100172

PARK LAMP - RH

PARK LAMP - LH

Circuit Diagram – 3

D08R100173

Circuit Diagram – 4

D08R100228

Circuit Diagram – 5

D08R100175

REAR DEMIST

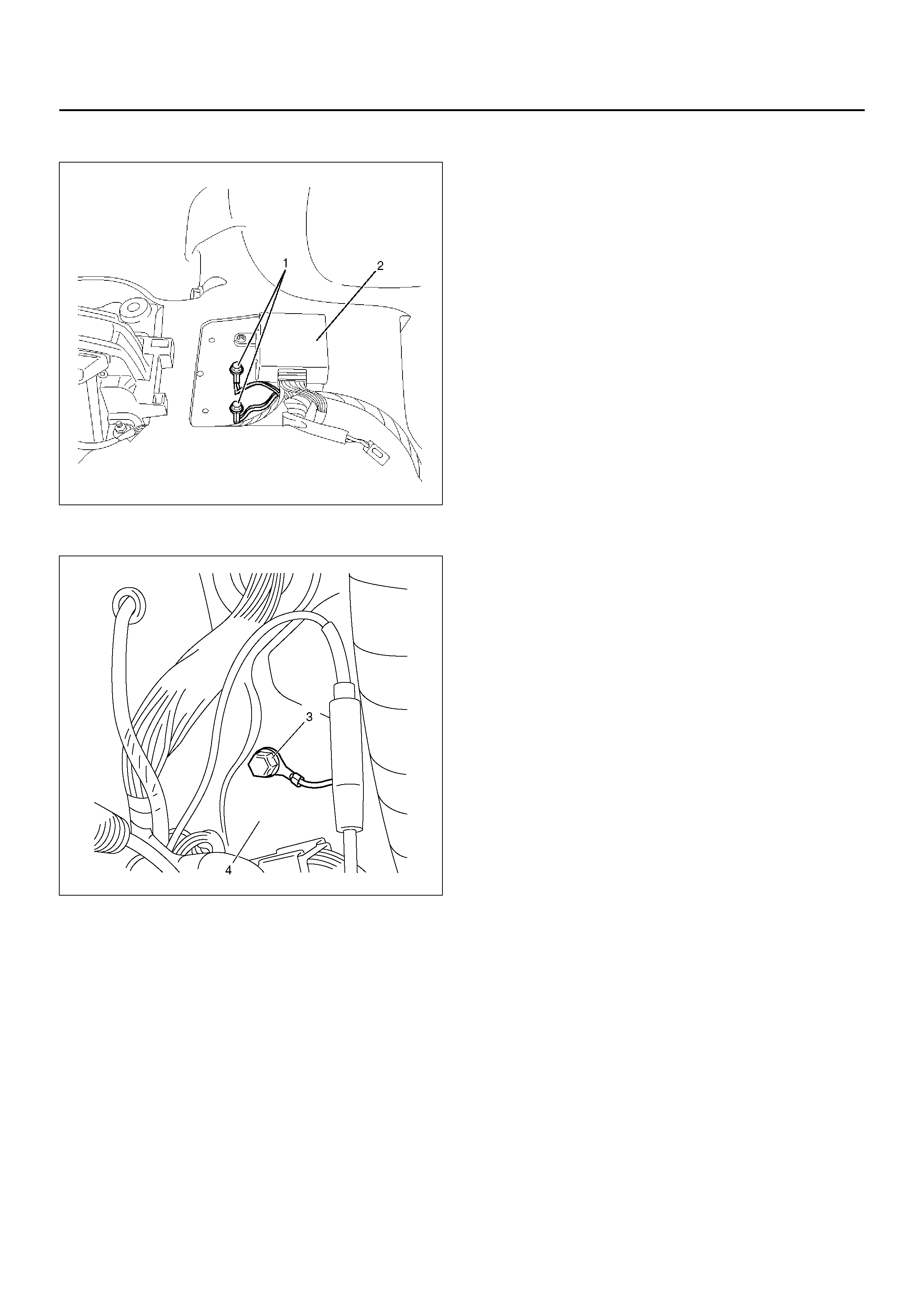

Location – 1

D08RW050

D08R100179

Legend

(1) B–6, B–7, B–8

(2) 2–4WD Control Unit

(3) I–43

(4) Dash Side Panel RH

Location – 2

D08R100180

D08R100182

D08R100181

D08R100183

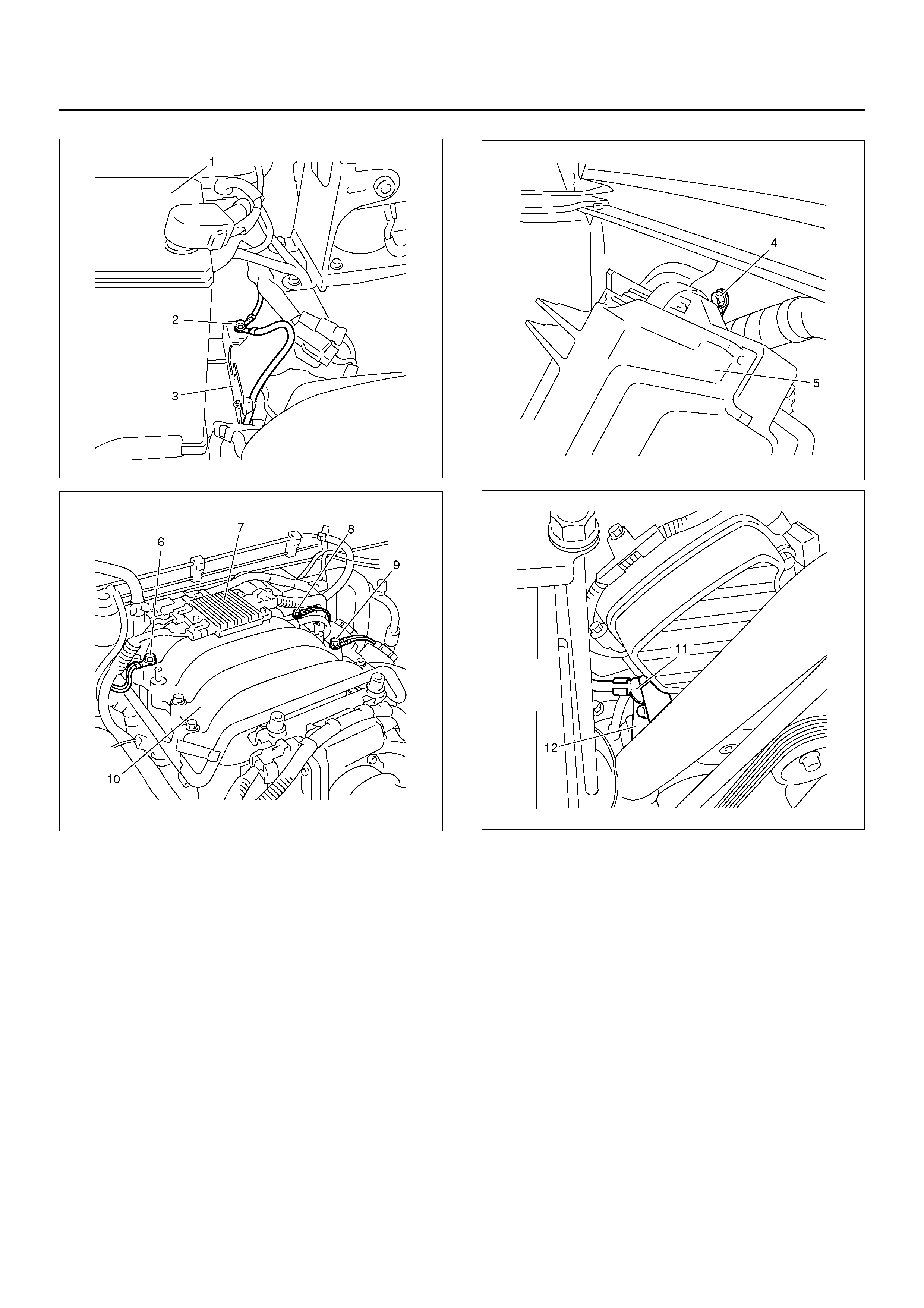

EndOFCallout

Legend

(1) Battery

(2) C– 36, P–6

(3) Battery Tray

(4) C–16

(5) PCM

(6) E–30

(7) Ion Sensor

(8) E–28

(9) E–29

(10) Common Chamber

(11) P–10

(12) ACG

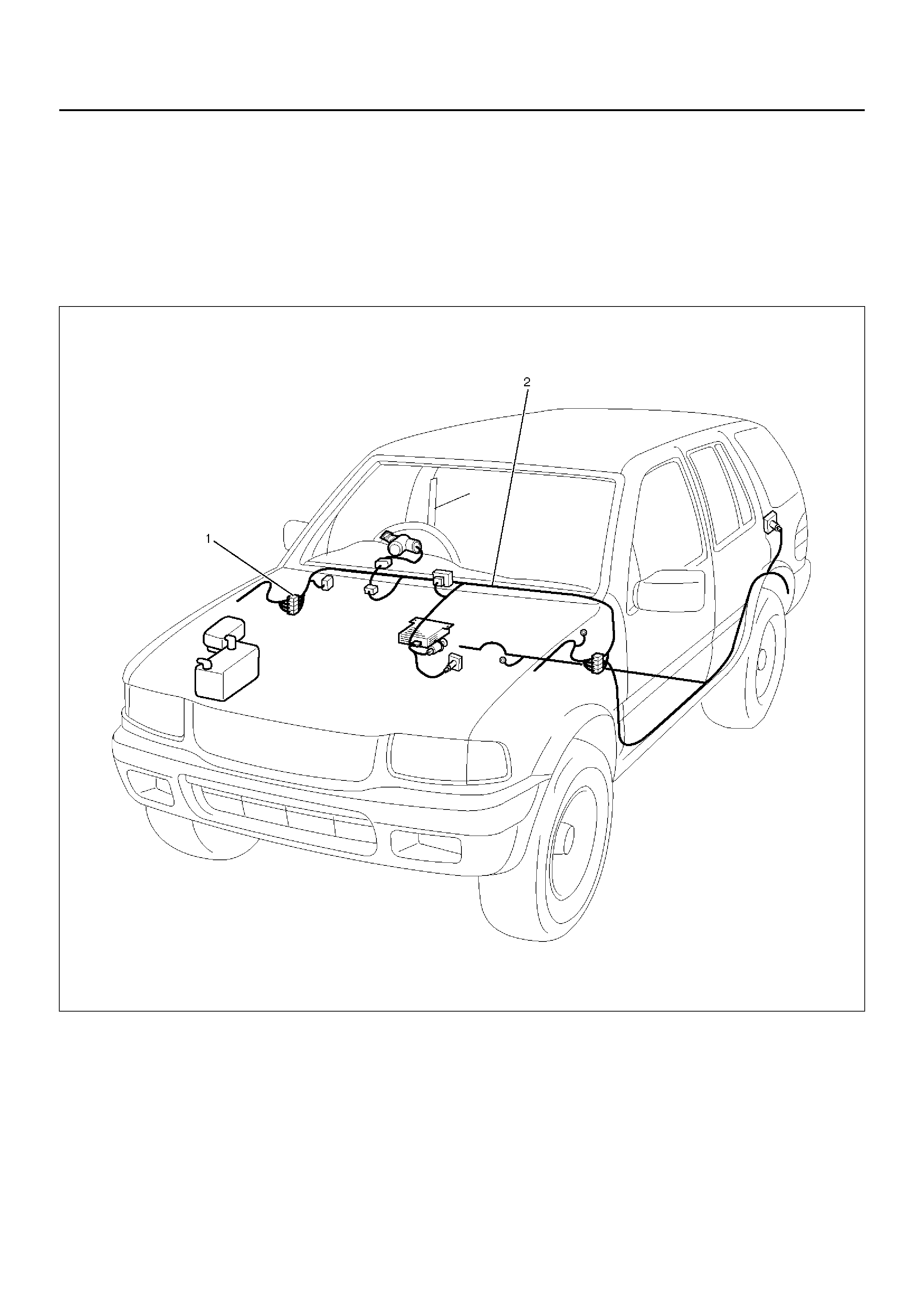

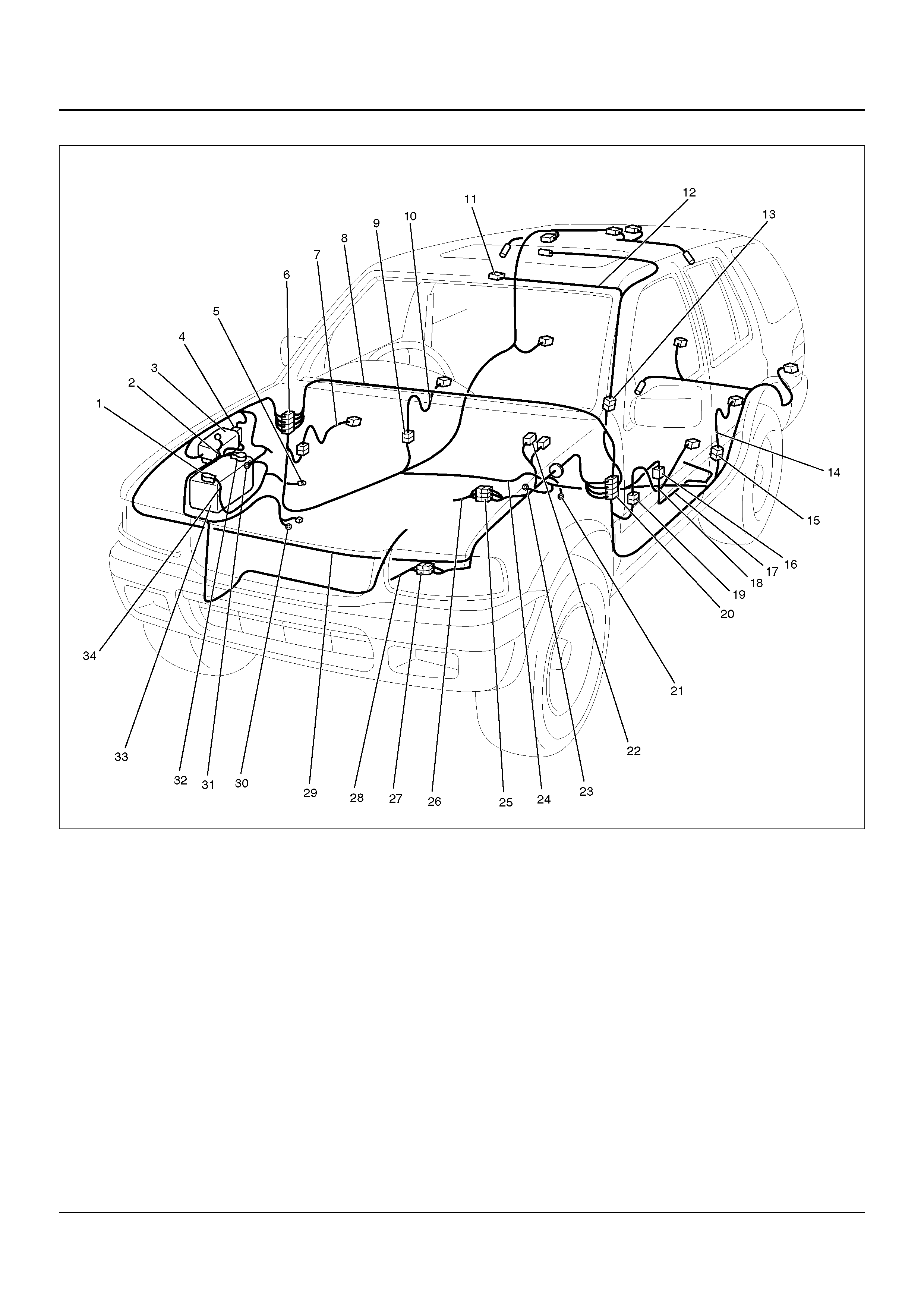

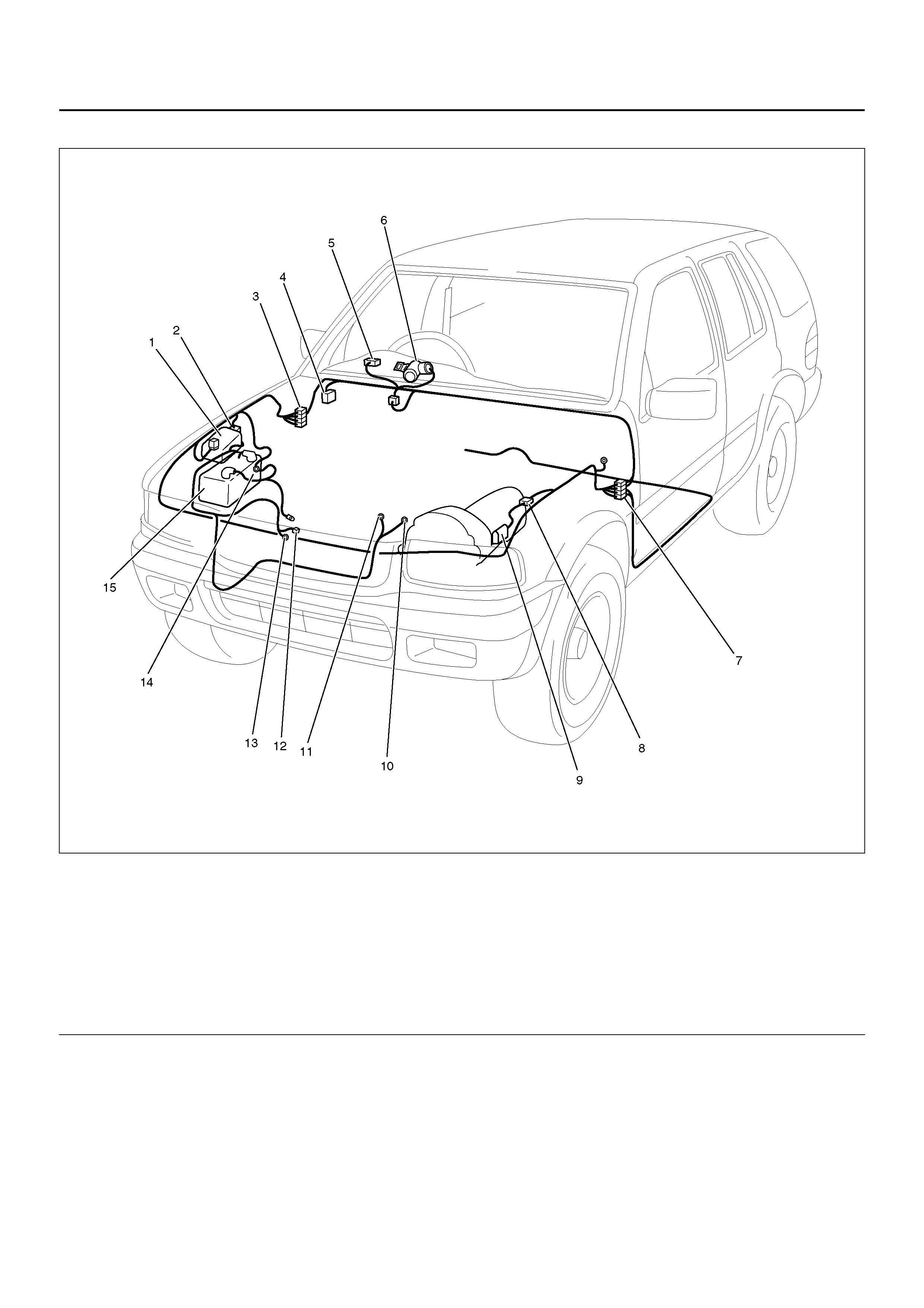

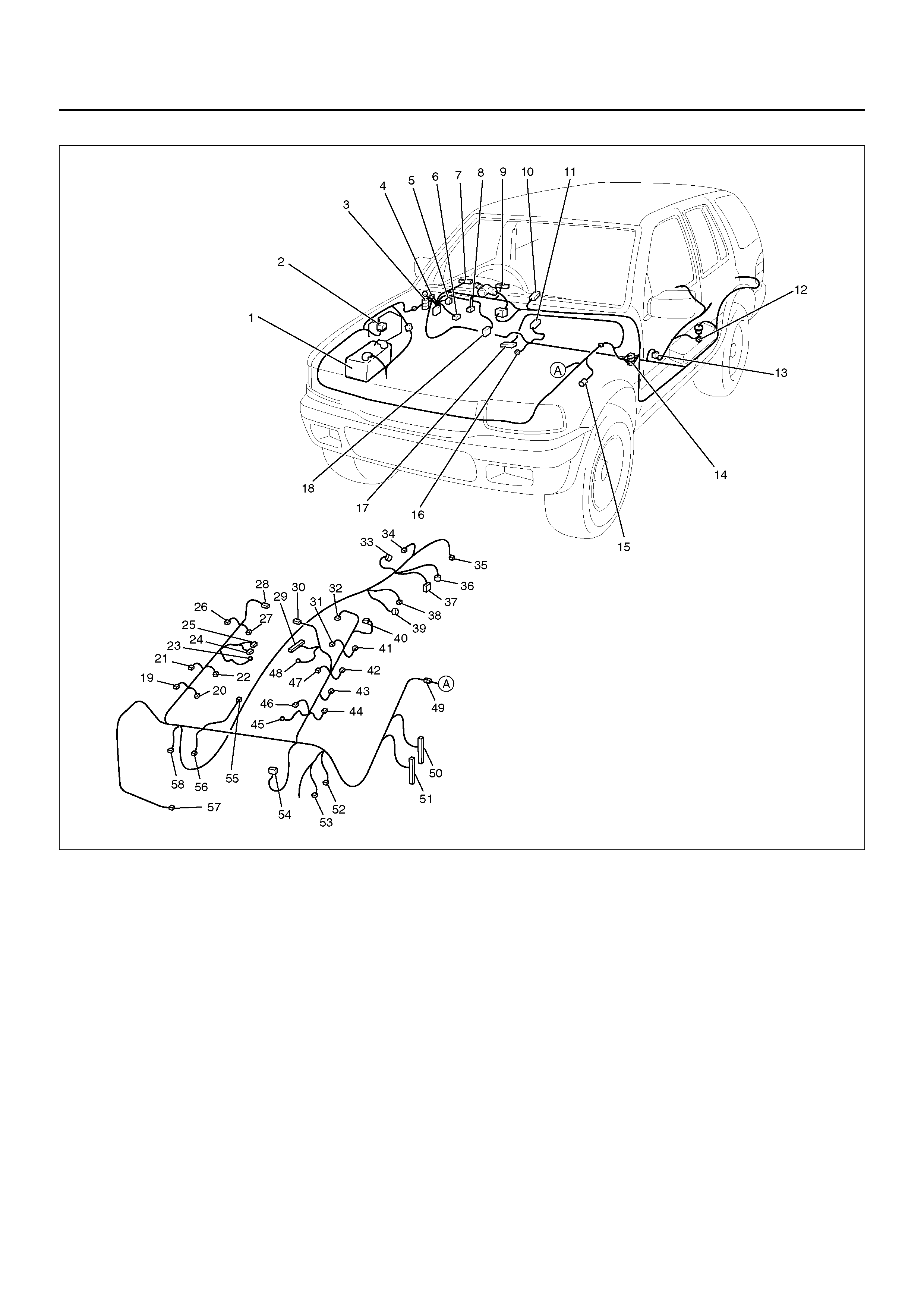

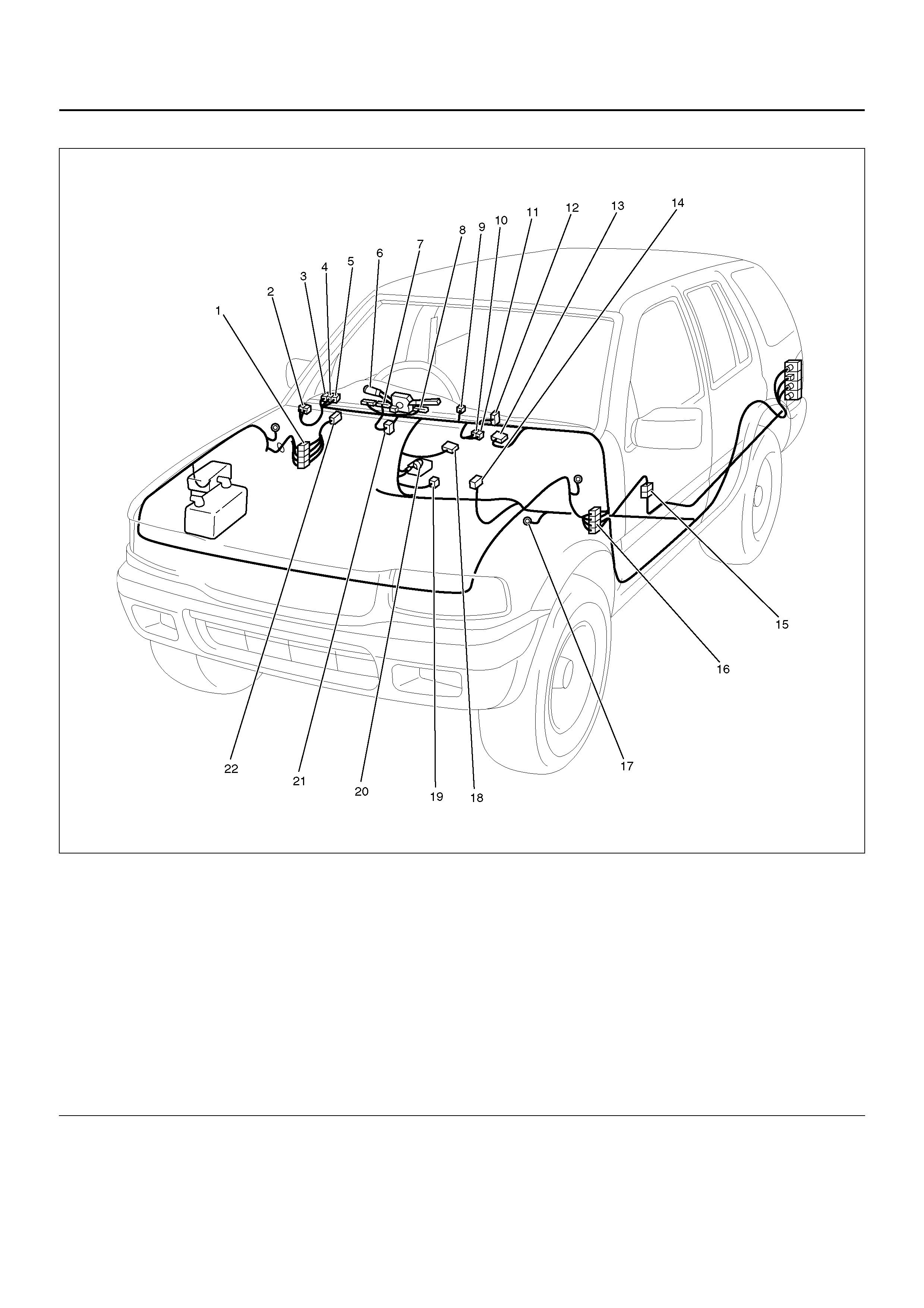

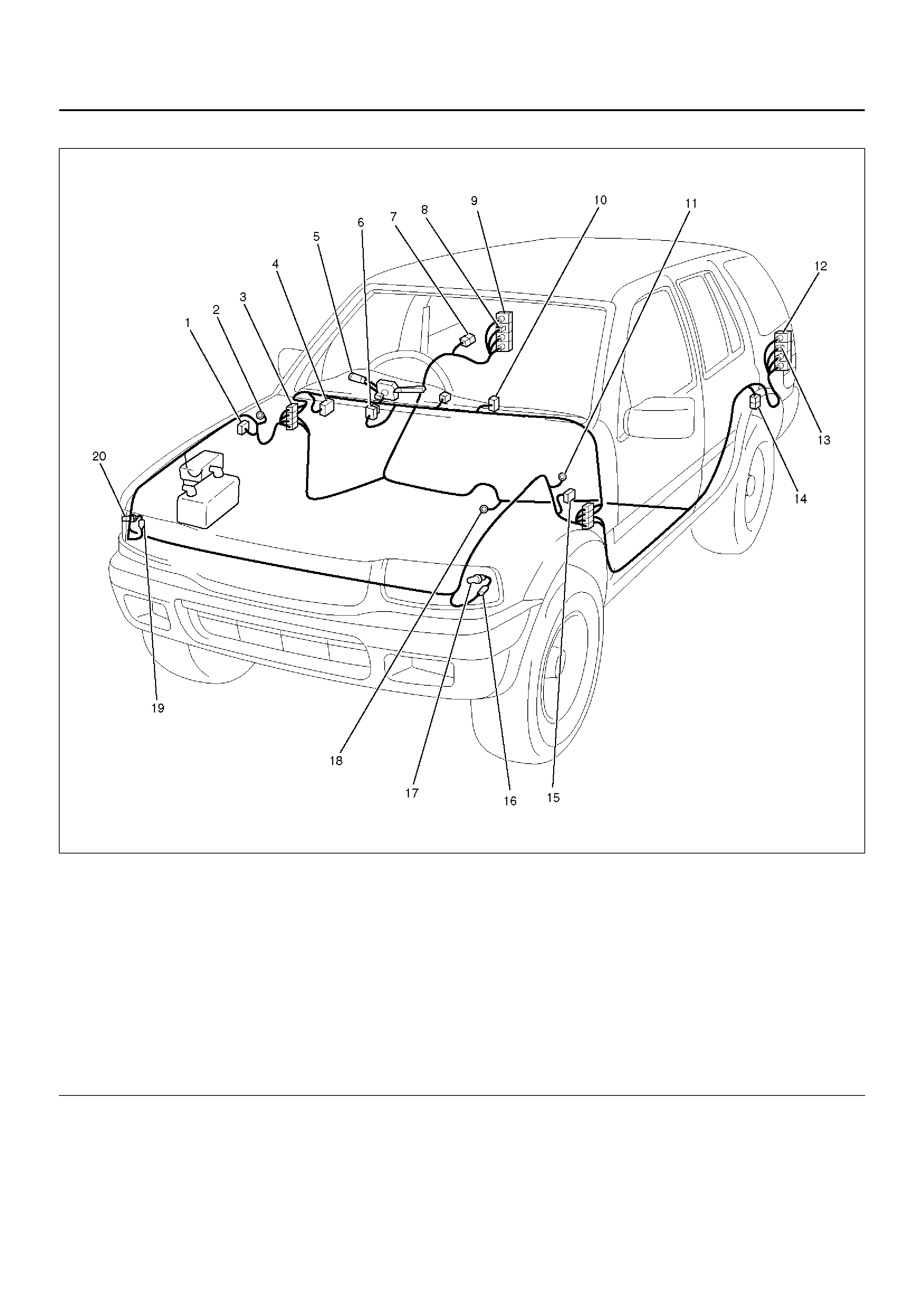

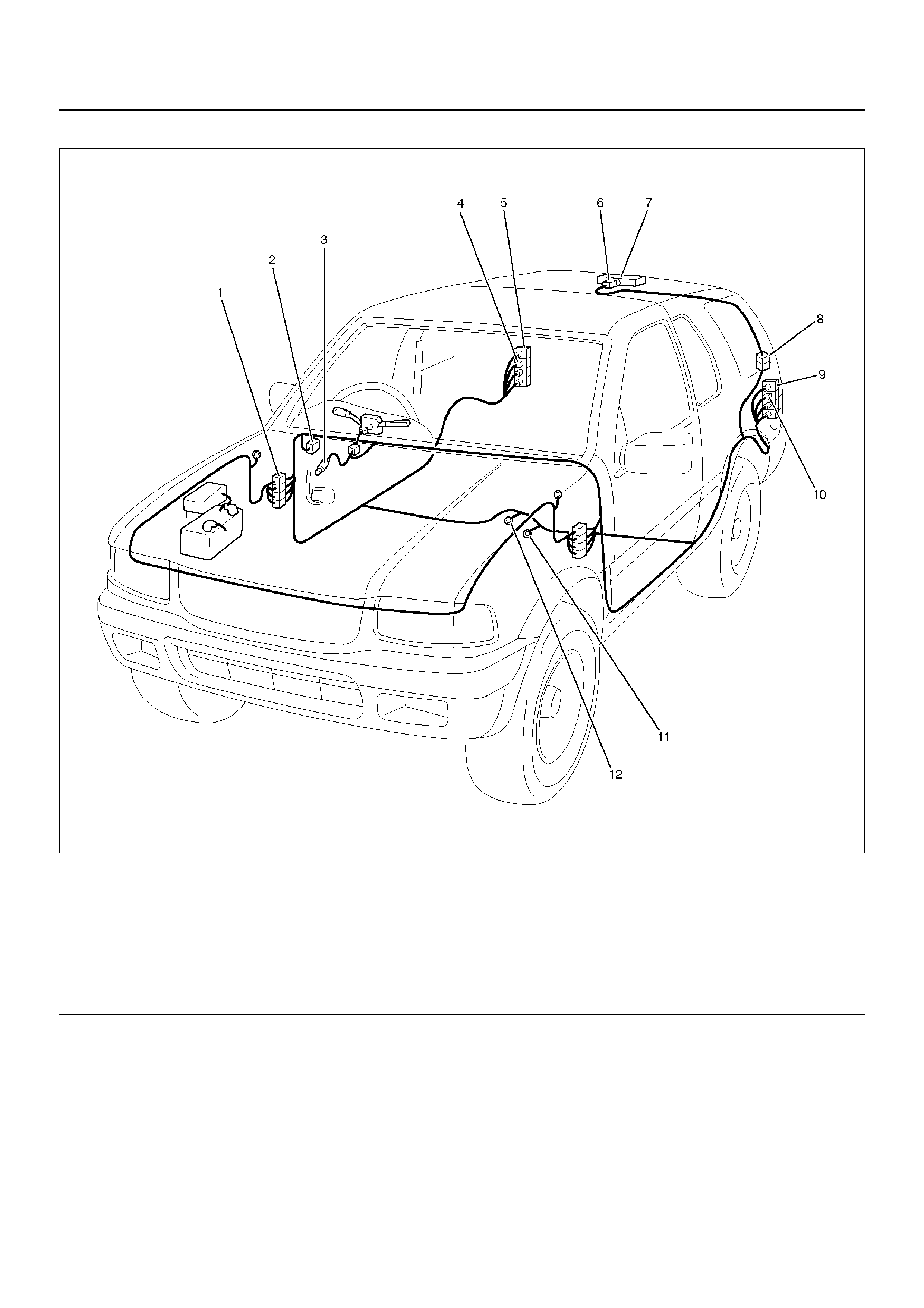

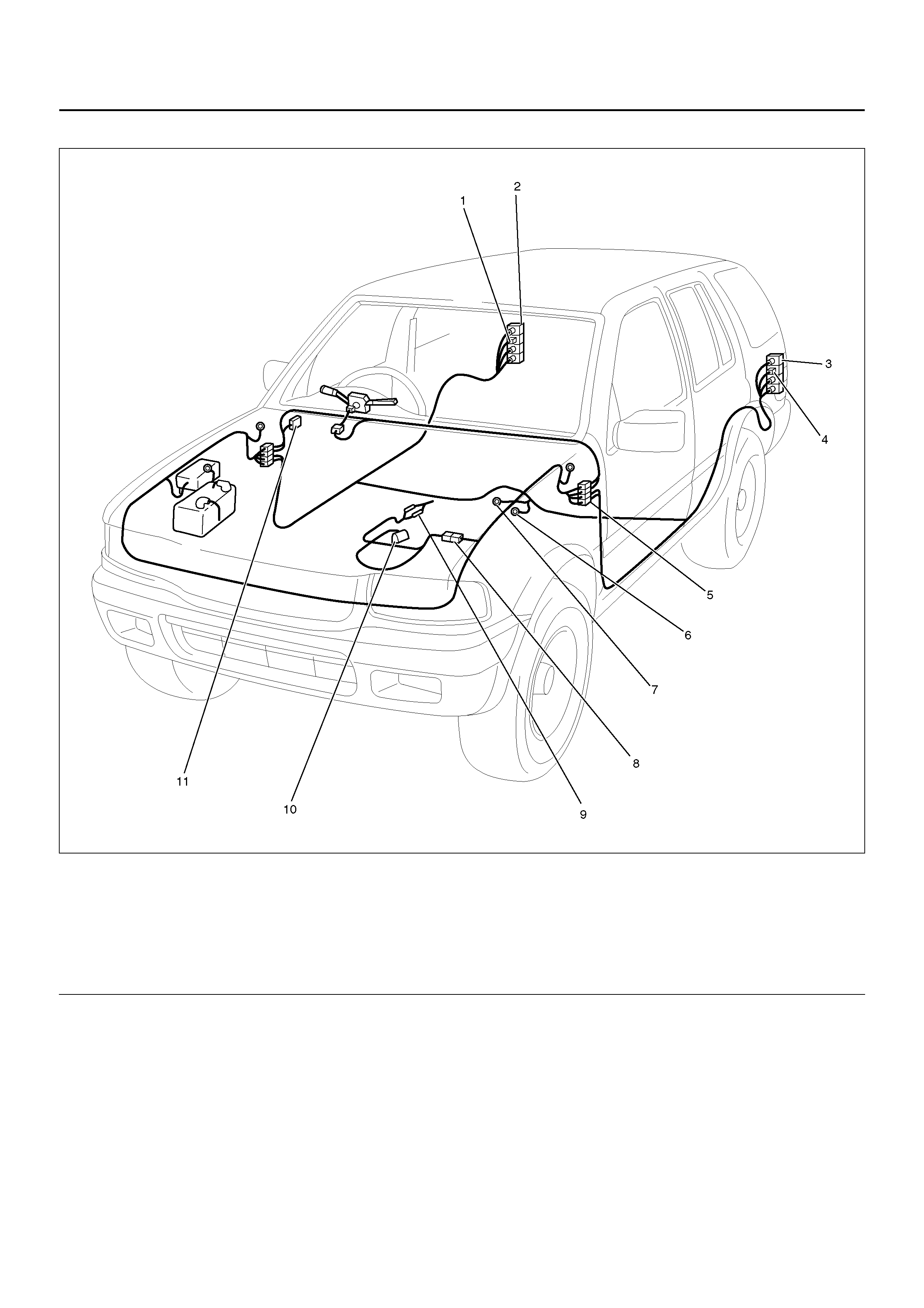

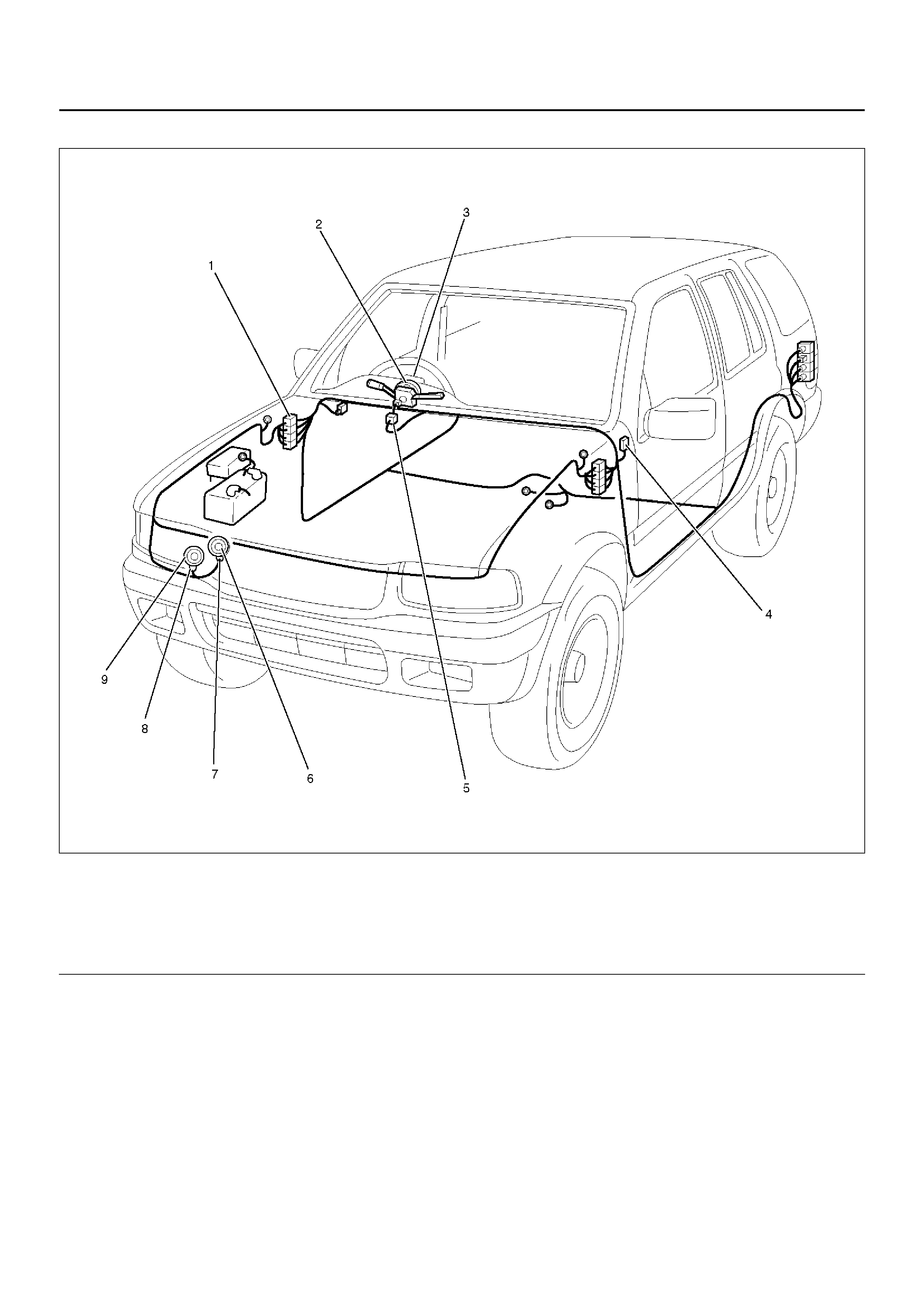

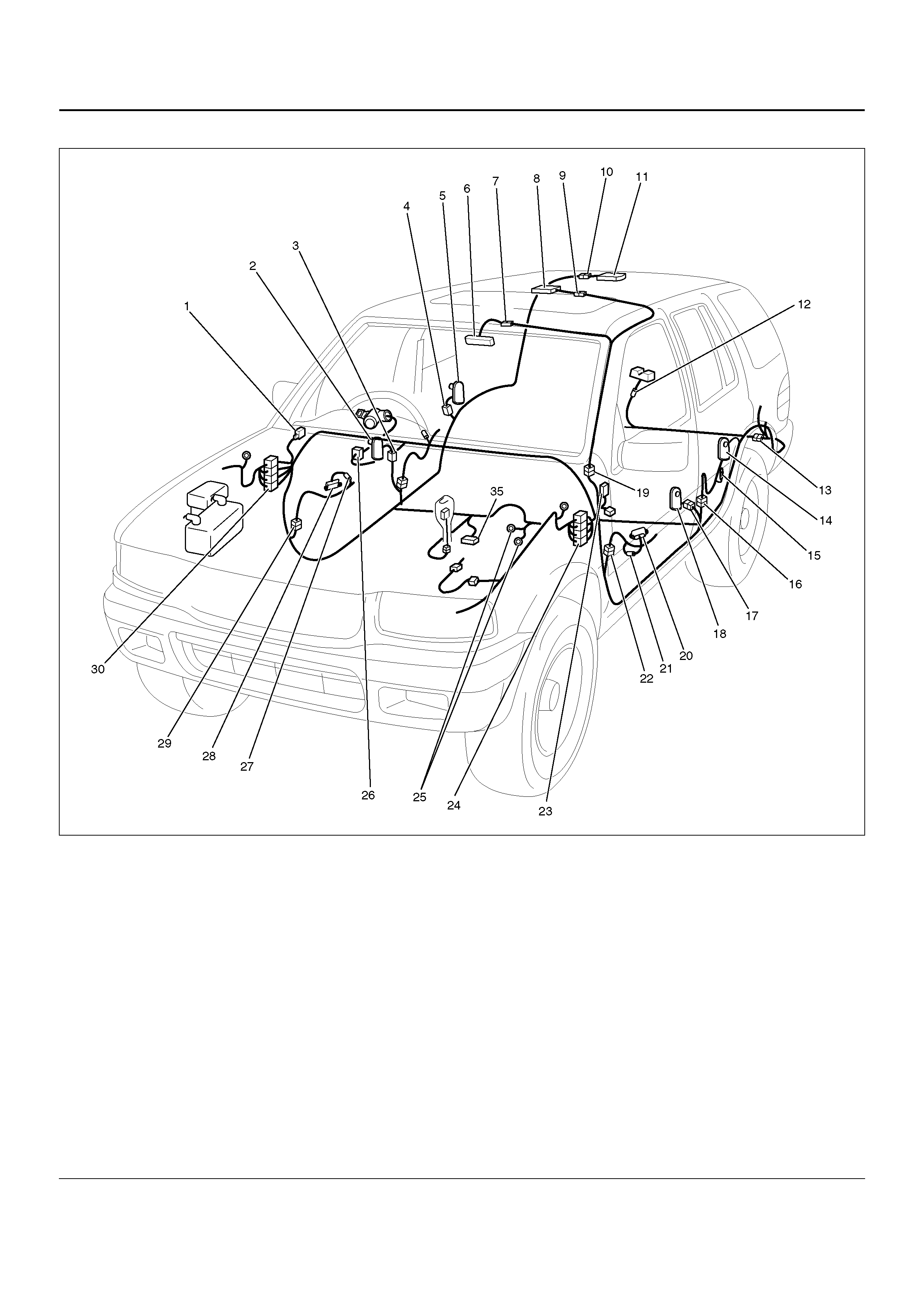

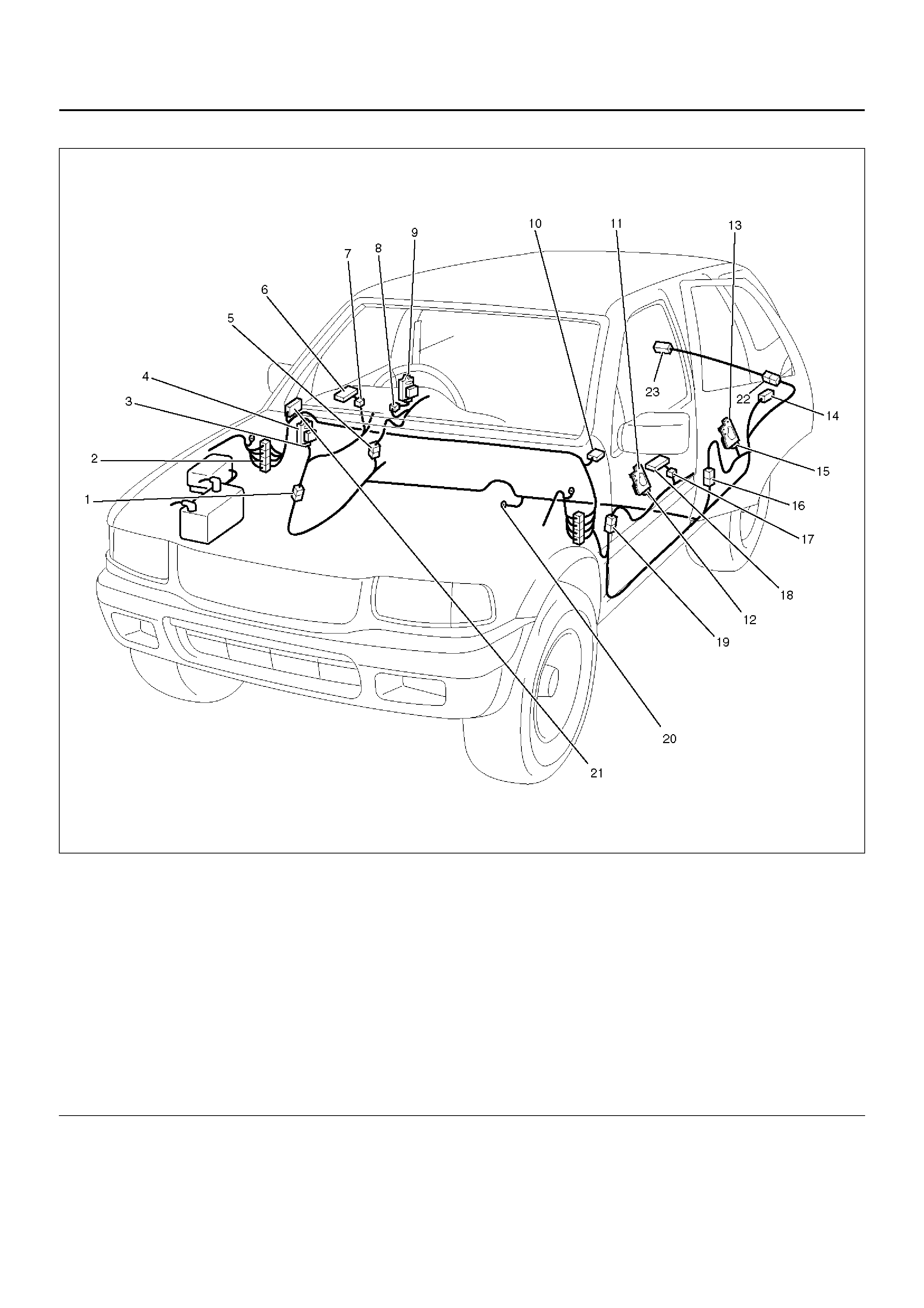

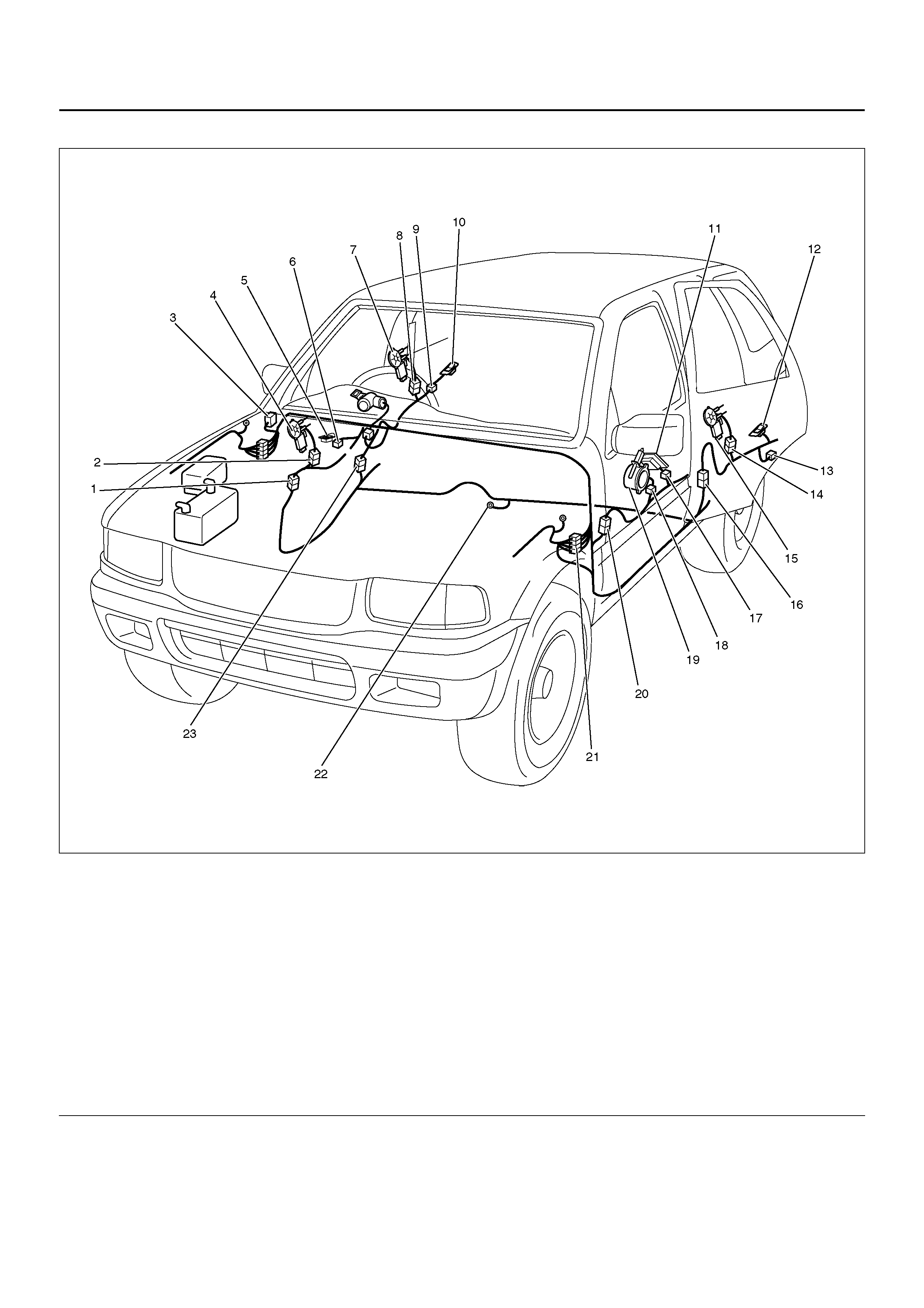

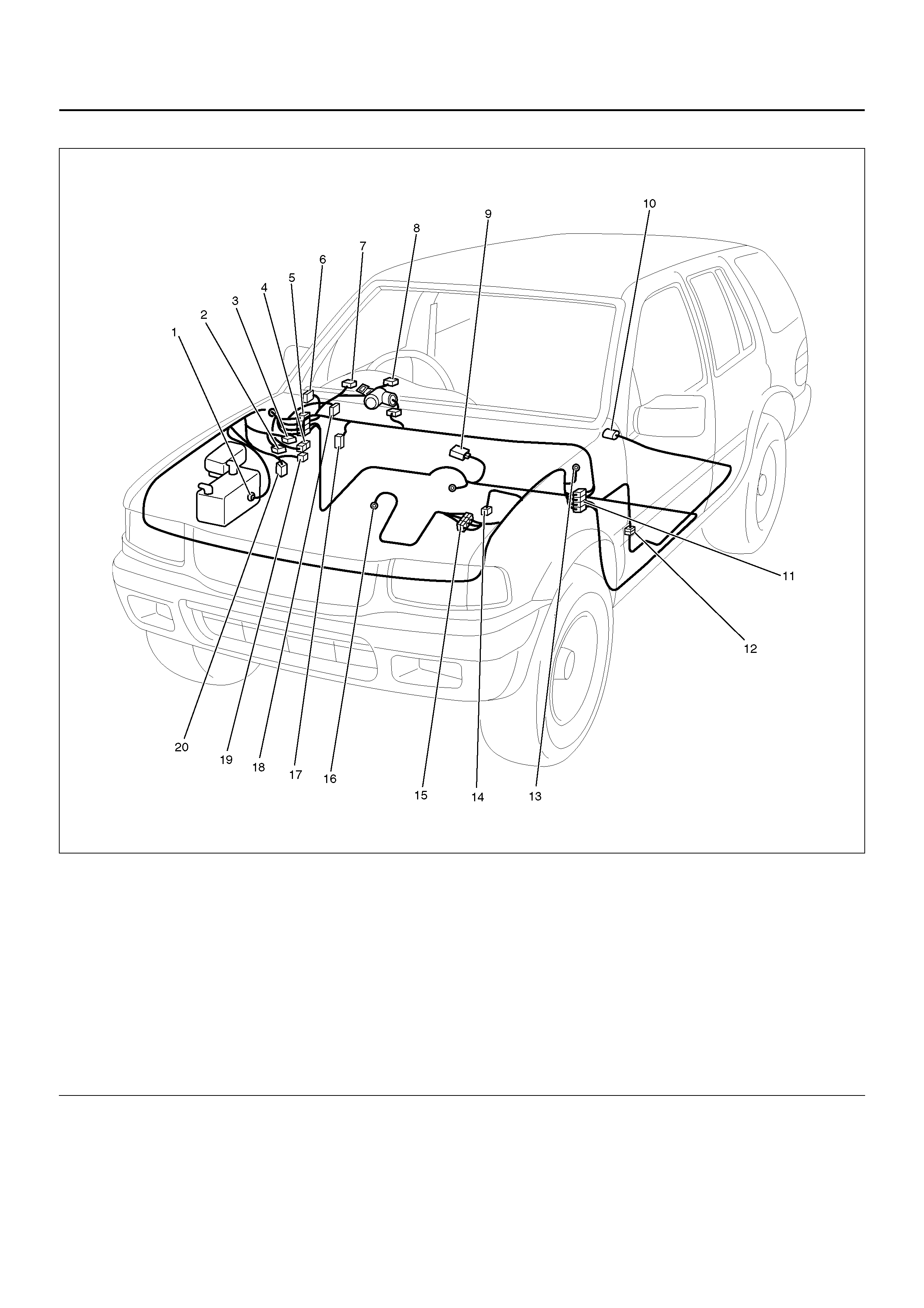

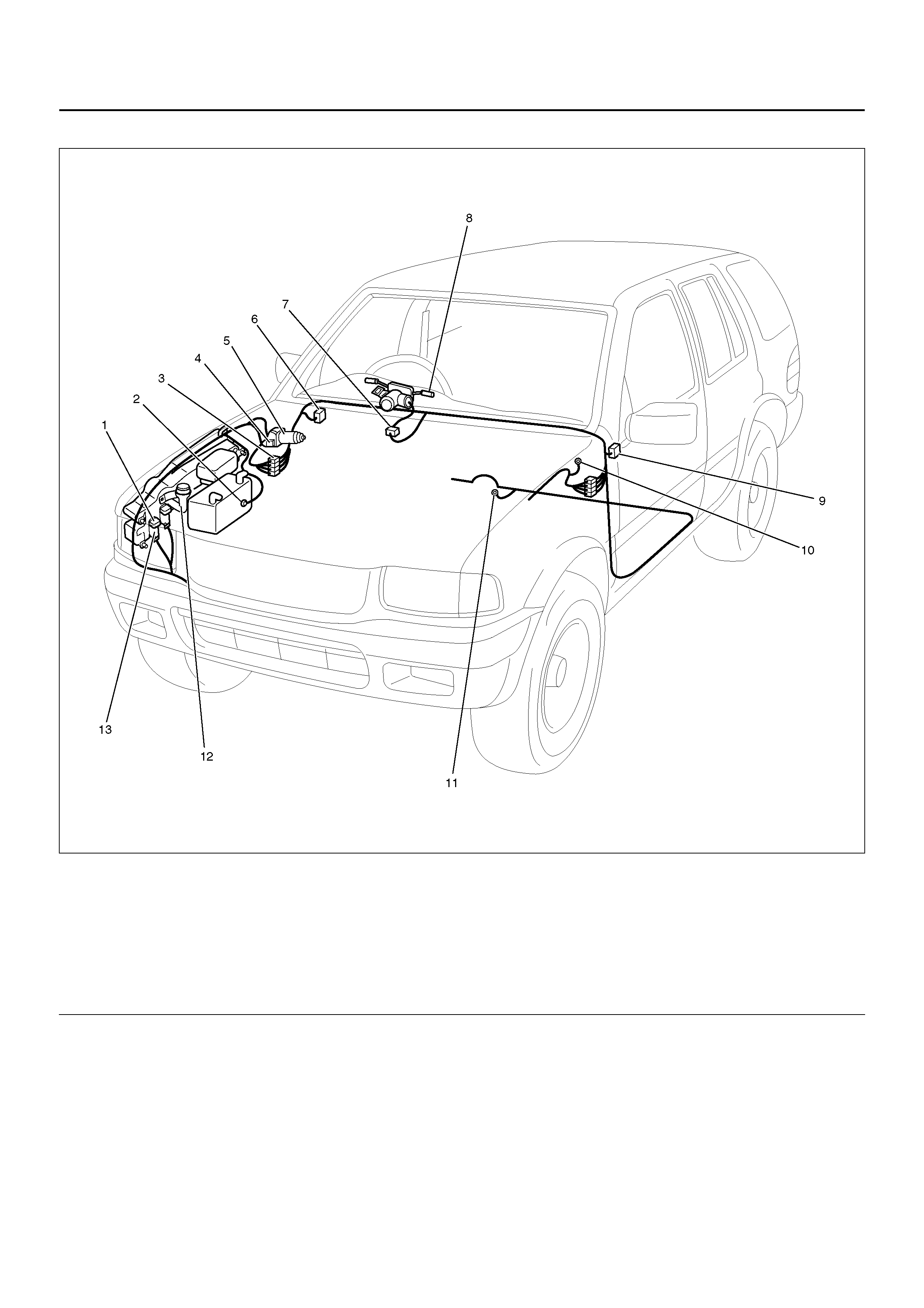

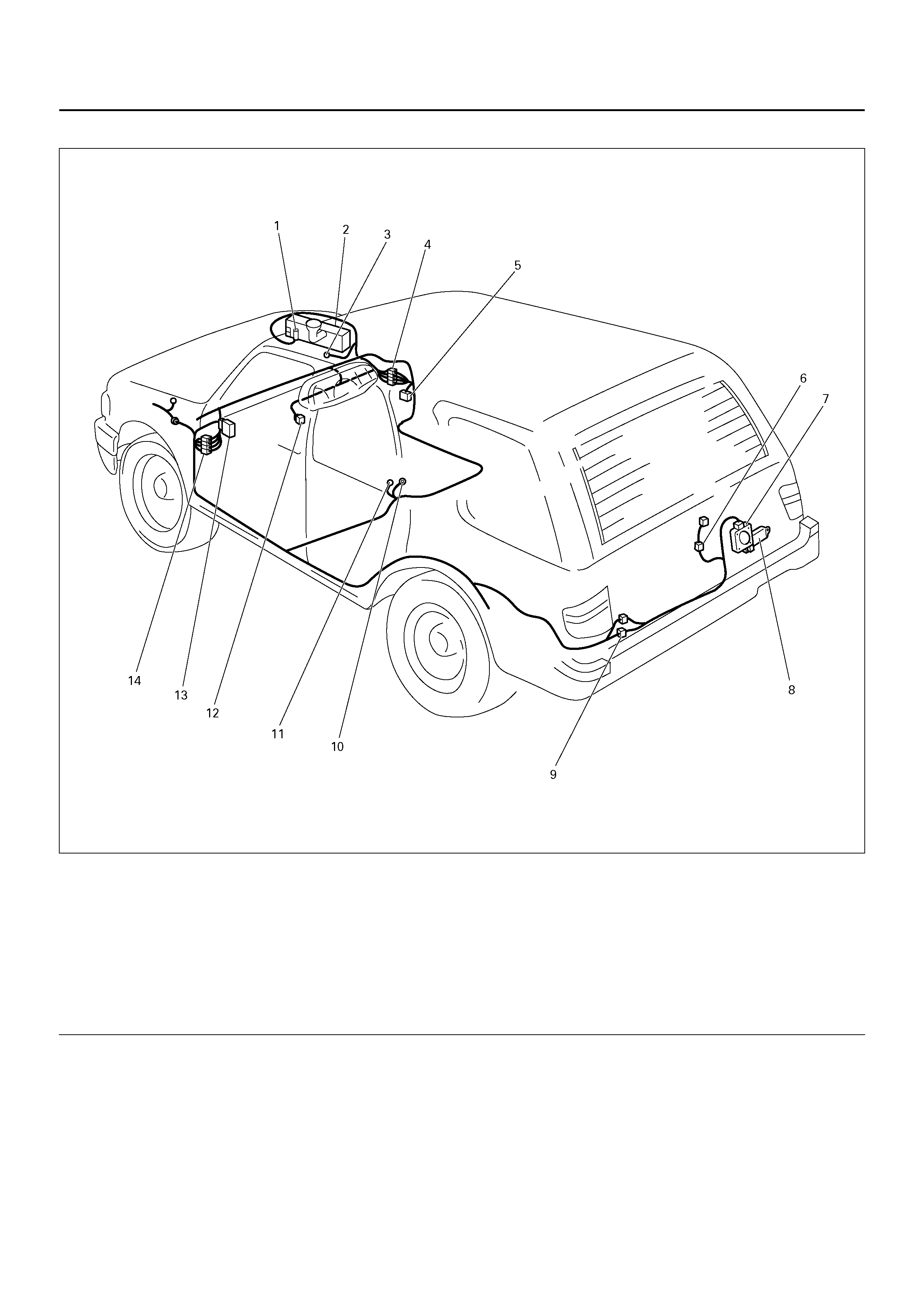

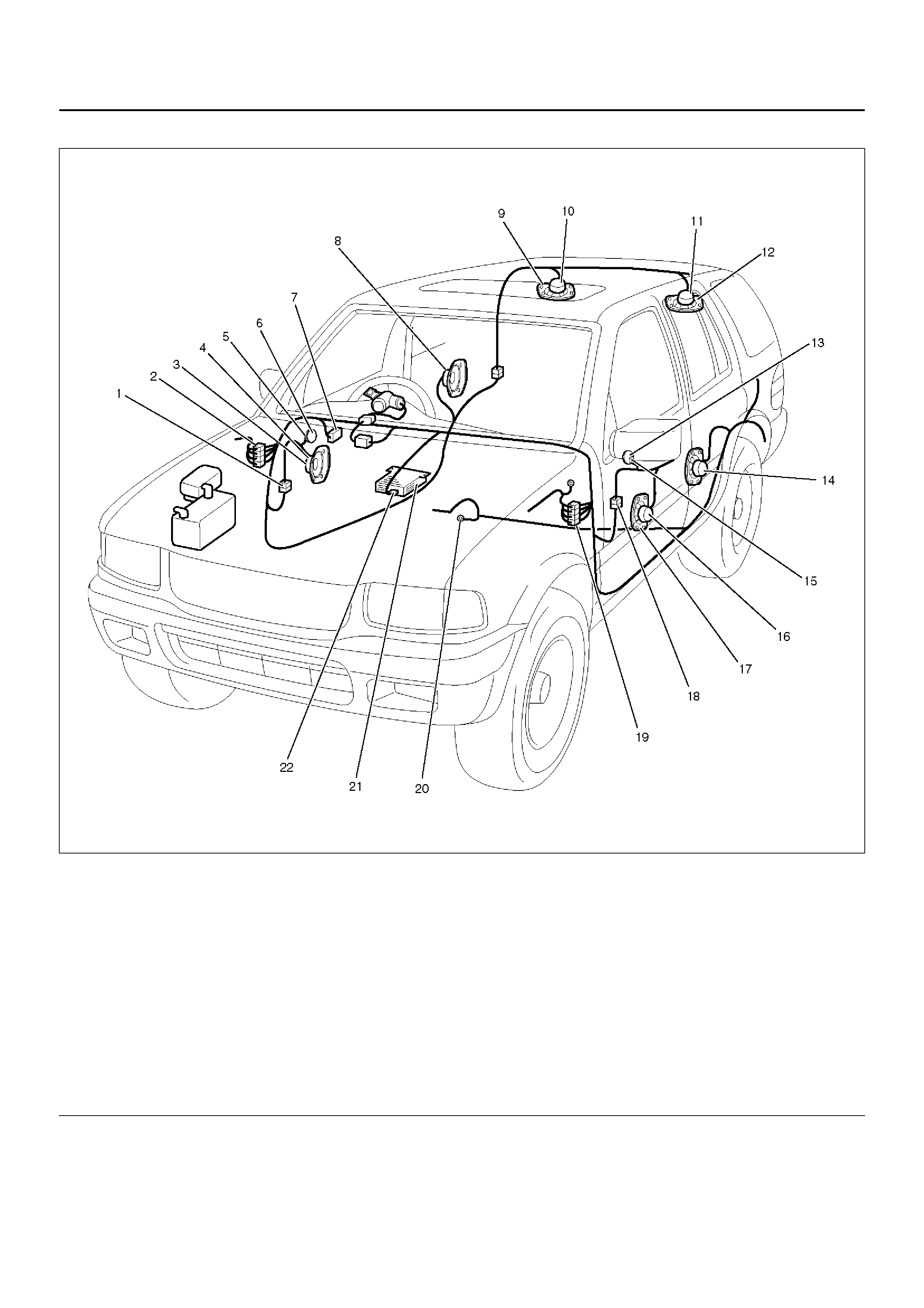

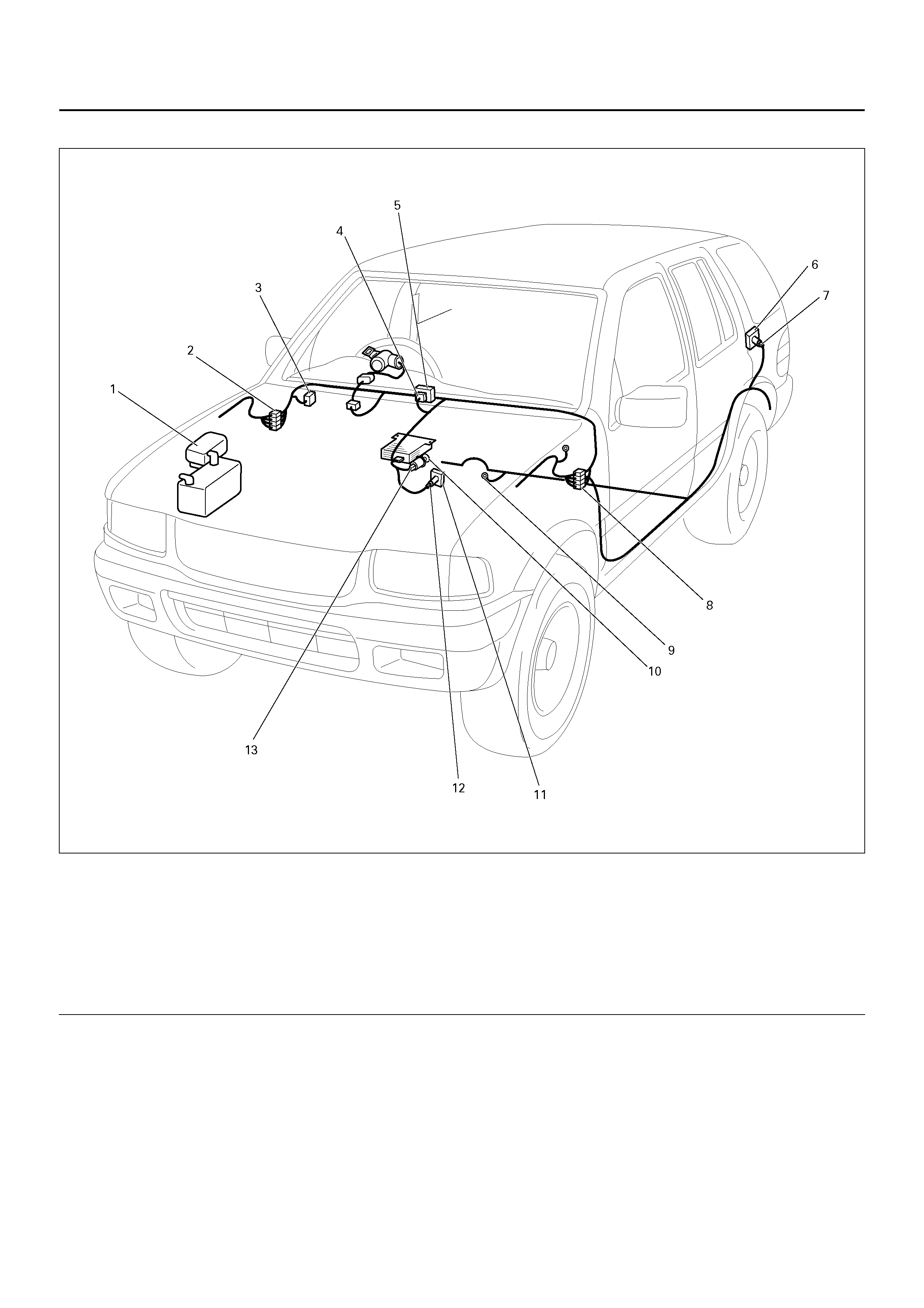

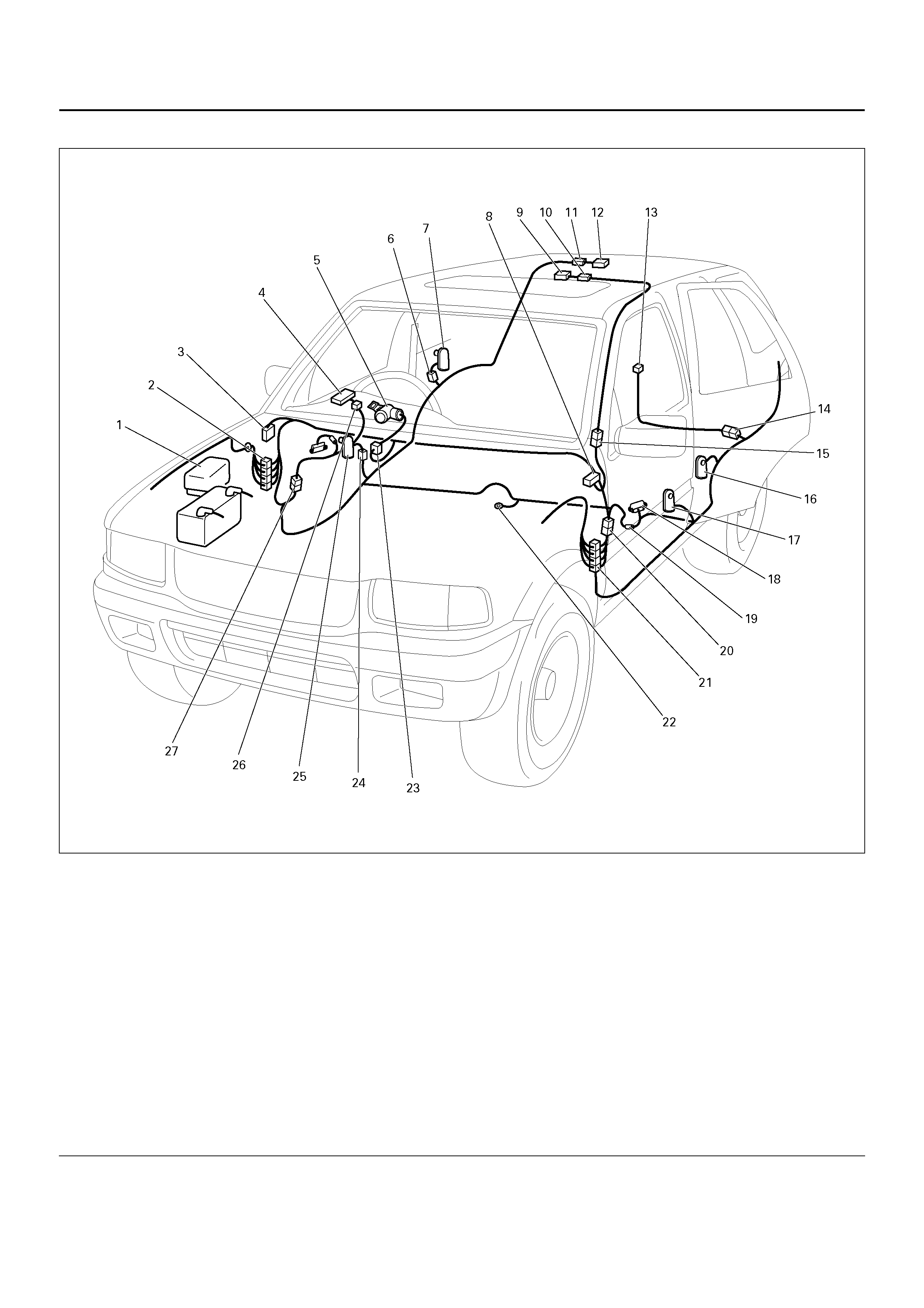

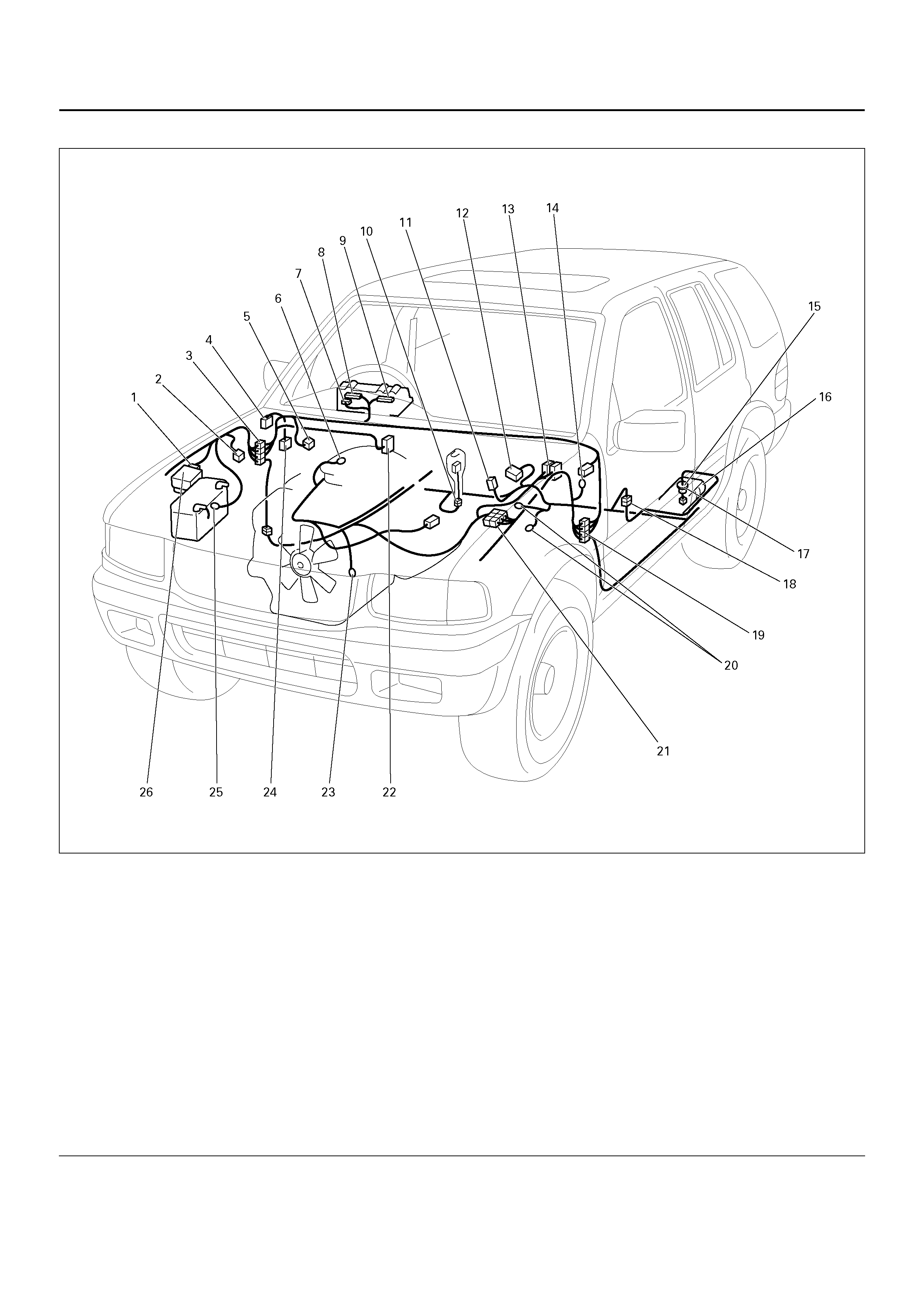

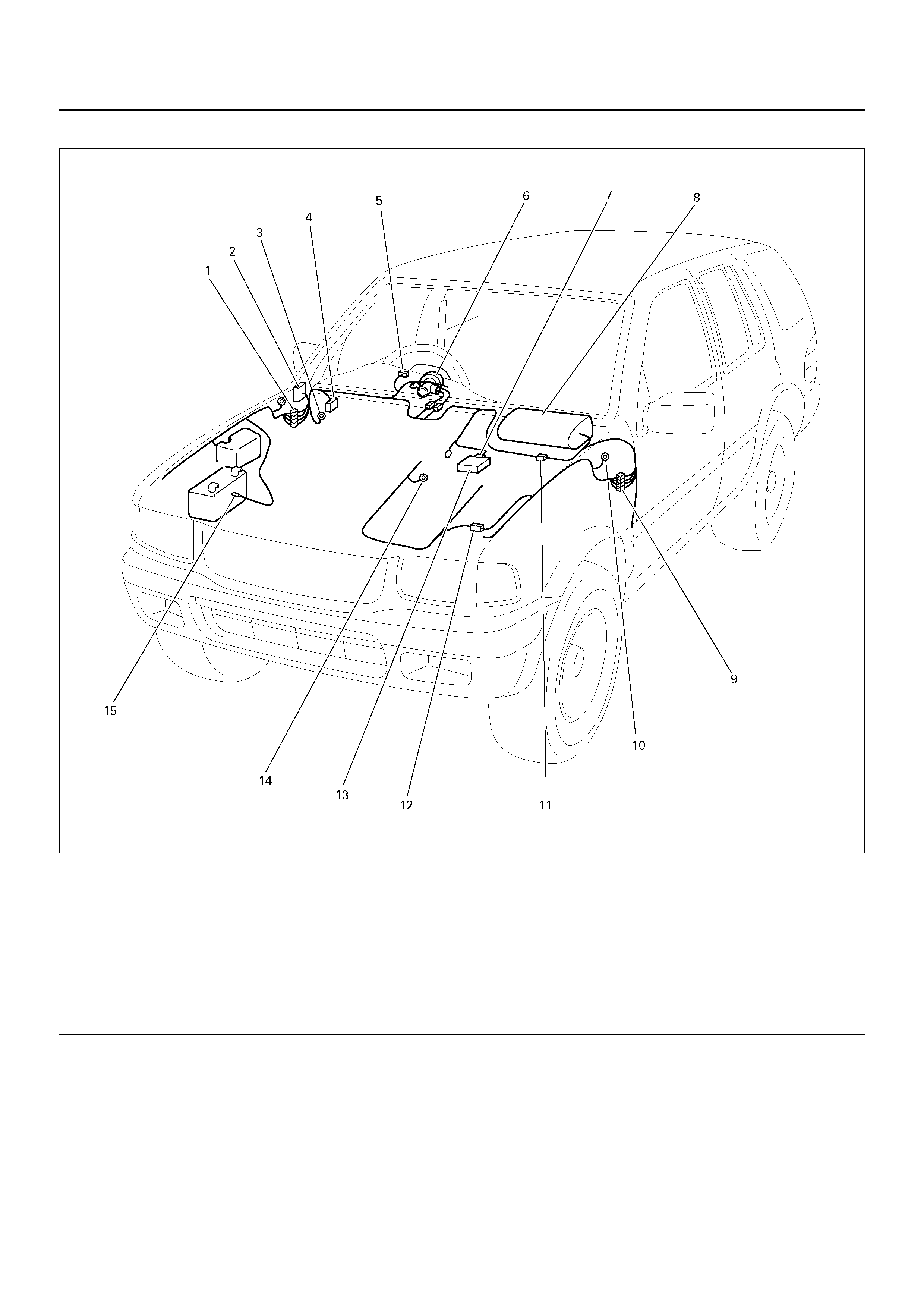

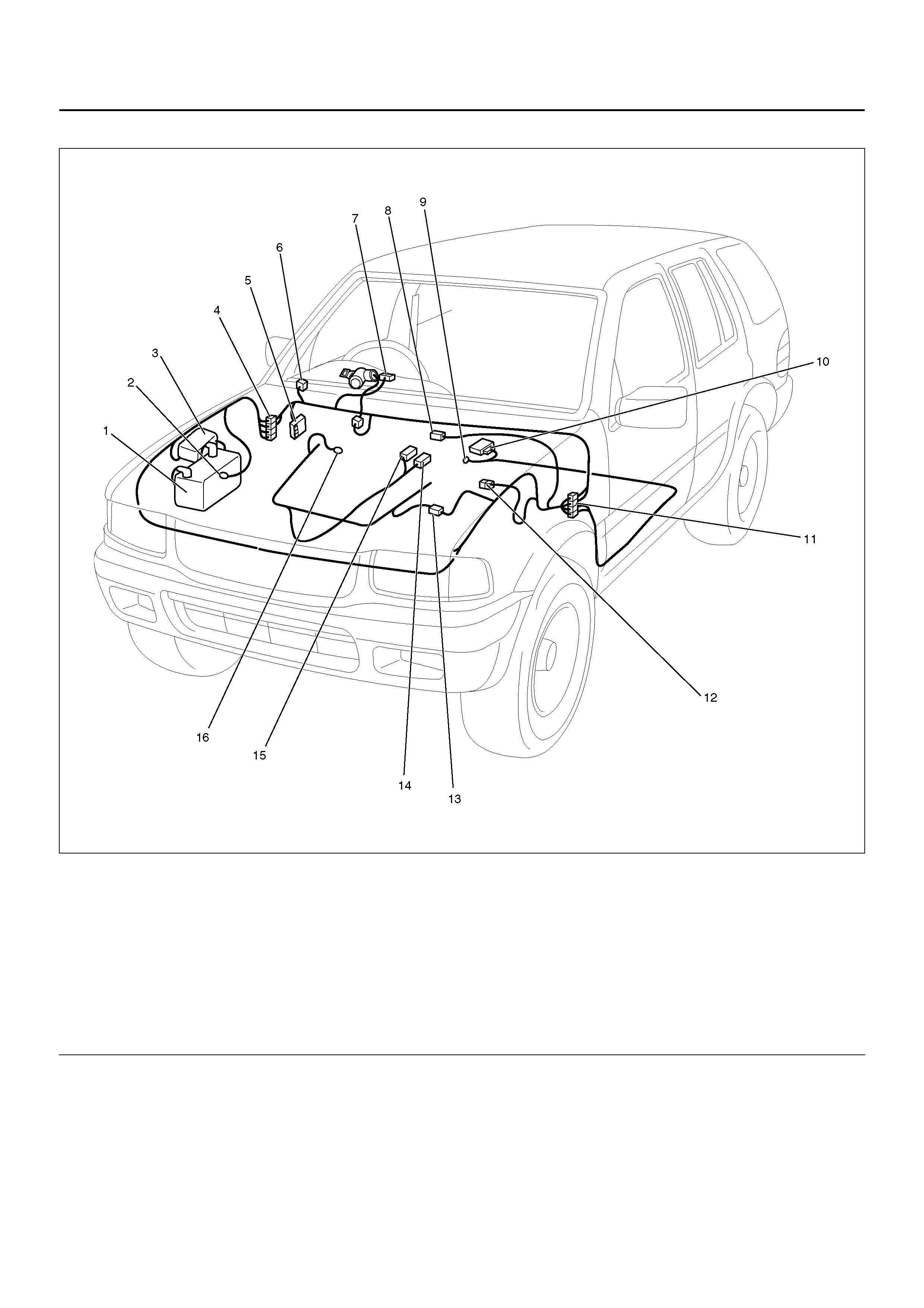

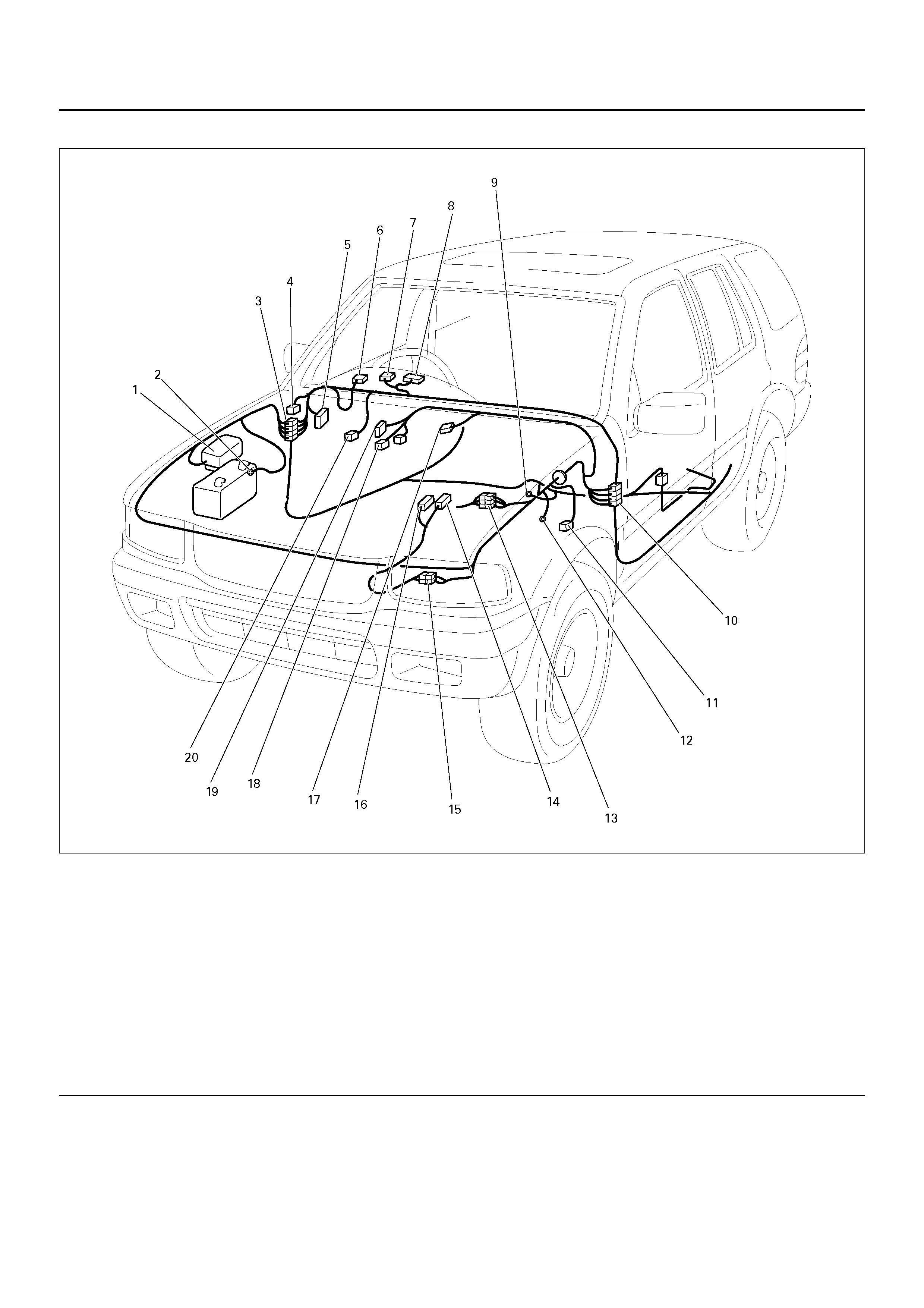

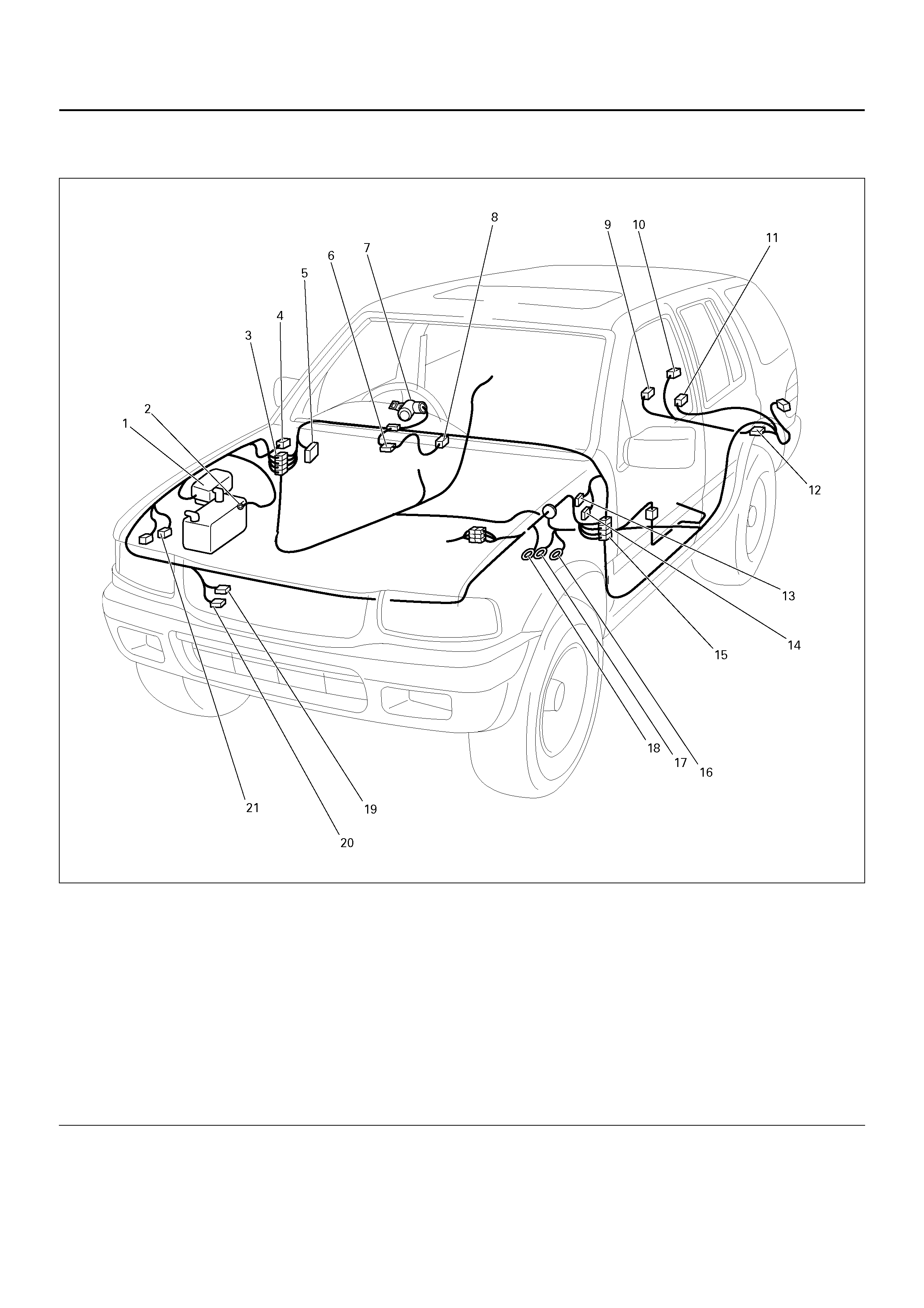

CABLE HARNESS ROUTING

D08R100186

EndOFCallout

Legend

(1) P–5

(2) Battery (+) Cable

(3) H–1

(4) H–2

(5) P–10

(6) H–13, H–14, H–19, H–32, H–45

(7) FRT Door Harness–RH

(8) Instrument Harness

(9) H–24

(10) RR Door Harness–RH

(11) L–2 (Map Light)

(12) Roof Harness

(13) H–30

(14) RR Door Harnes s– LH

(15) H–29

(16) H– 25, H–42

(17) Chassi s Harnes s

(18) FRT Door Harness – LH

(19) H–33

(20) H–15, H–16, H–17, H–31, H–40

(21) C–16

(22) C–53, C–54

(23) B–8

(24) Body Harness

(25) H–4, H–5, H–6, H–39

(26) Engine Harness

(27) H–38

(28) TOD Harness

(29) Engine Room Harness

(30) P–9

(31) P –6, C–36

(32) P–1

(33) Battery

(34) Battery (–) Cable

(4Door Model)

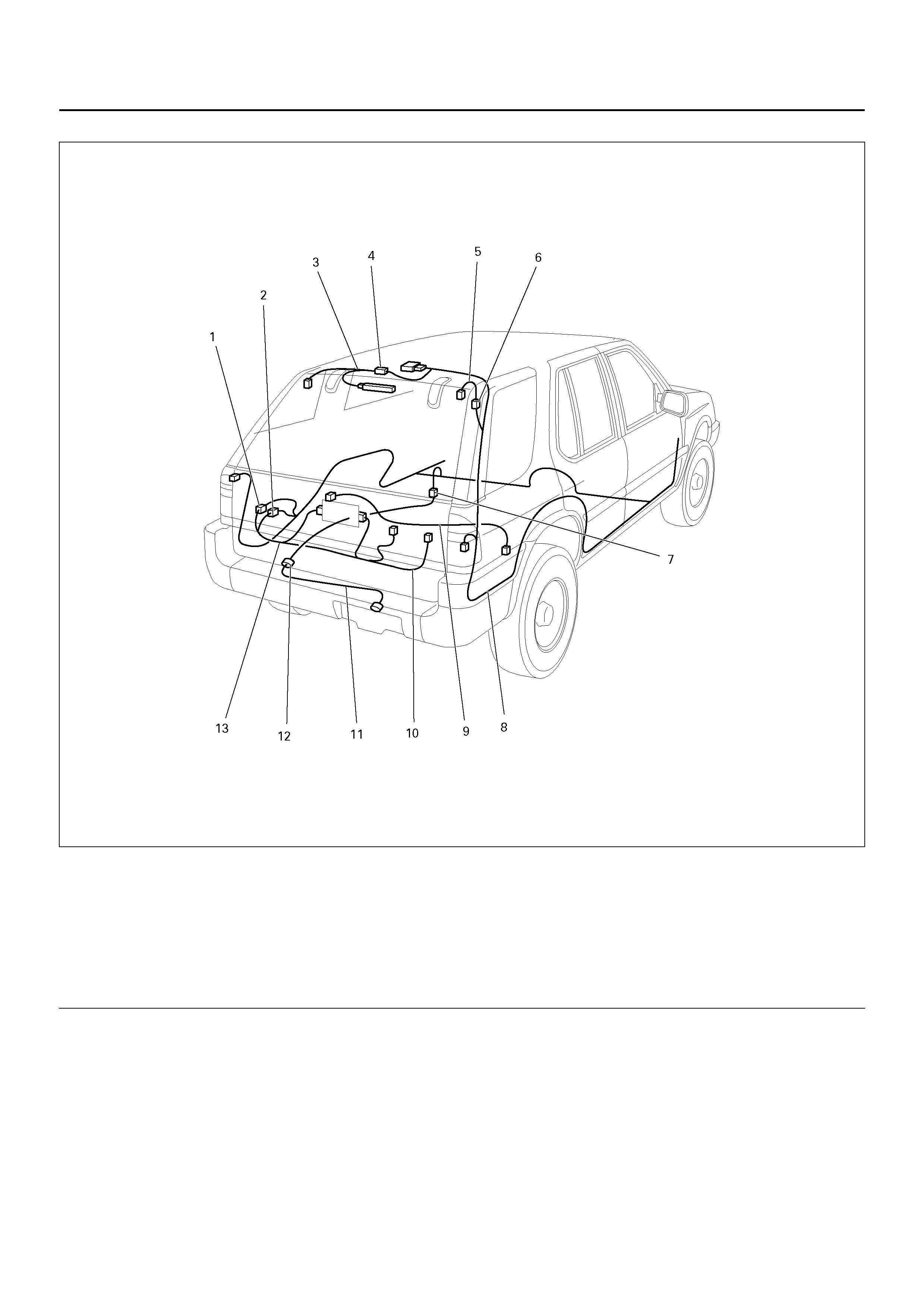

D08R100185

EndOFCallout

Legend

(1) H–22

(2) H–34

(3) Hatch Glass Harness LH

(4) H–21

(5) Hatch Glass Harness RH

(6) H–20

(7) H–25

(8) Body Harness

(9) Chassis Harness

(10) Tailgate Harness

(11) License Plate Light Harness

(12) Trailer Connector

(13) Tailgate Harness

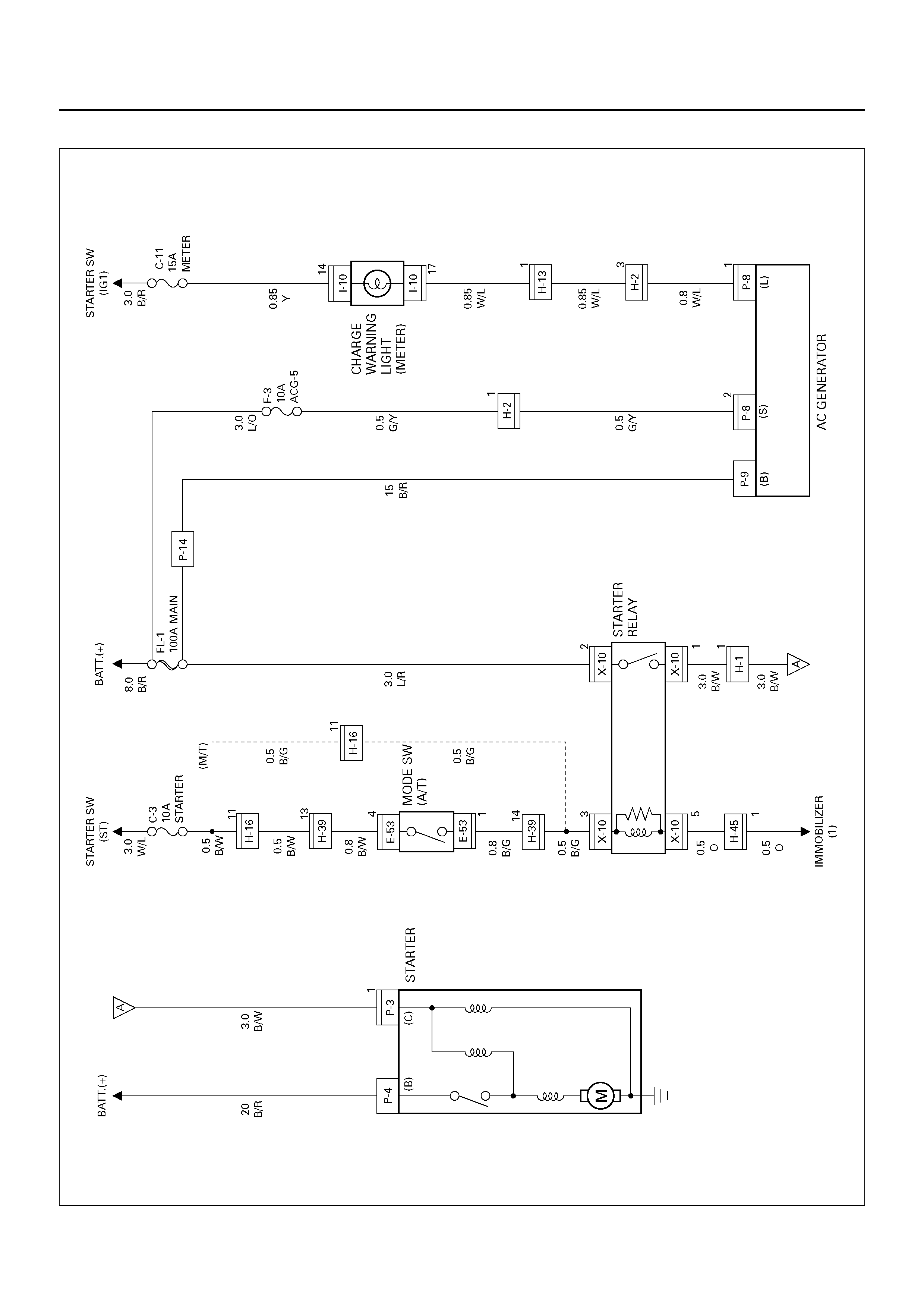

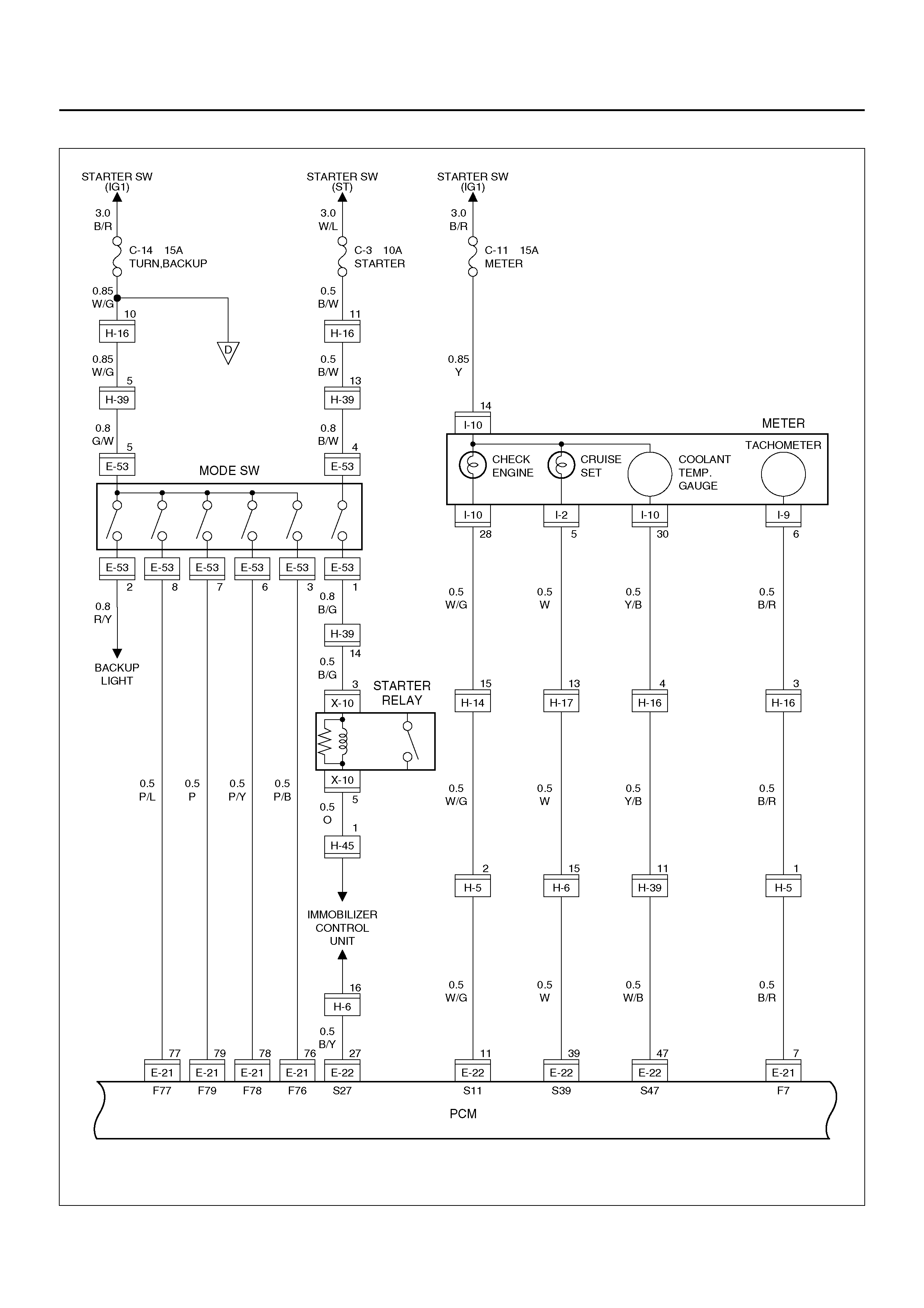

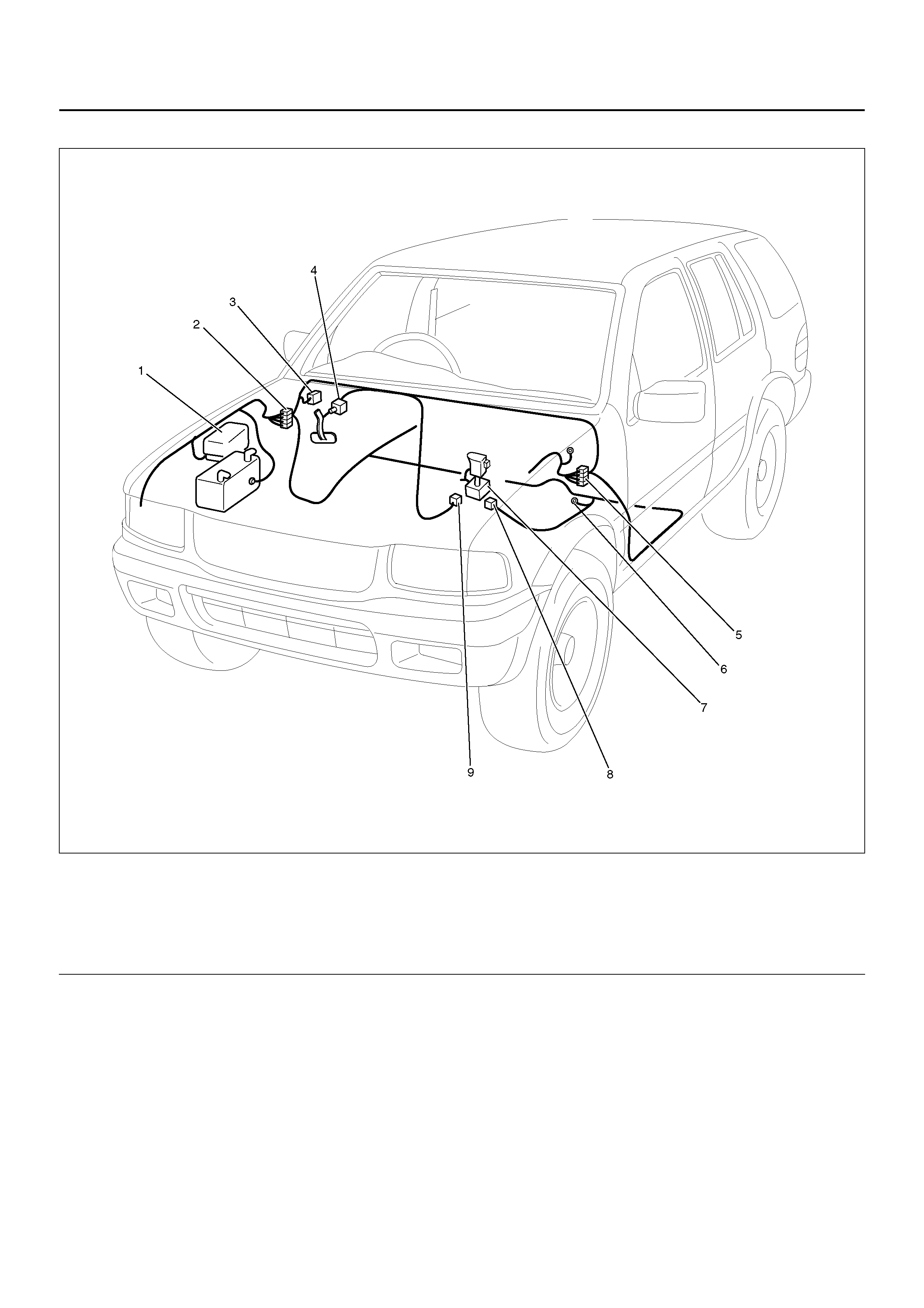

START AND CHARGING

GENERAL DESCRIPTION

This system consists of starter, AC generator, starter

relay, cl utch start SW (M /T), mode SW (A/T) and heater

& A/C relay.

When starter SW is set to “ST" position with A/T select

lever at “P" (Parking) or “N" (Neutral) position (Mode

SW “ON"), or clutch pedal depressed (Clutch start SW

“ON"), battery positive voltage is applied to starter

solen oid coil thro ugh starter re lay to start start er. At th e

some time, starter relay cuts off blower motor and A/C

circuit.

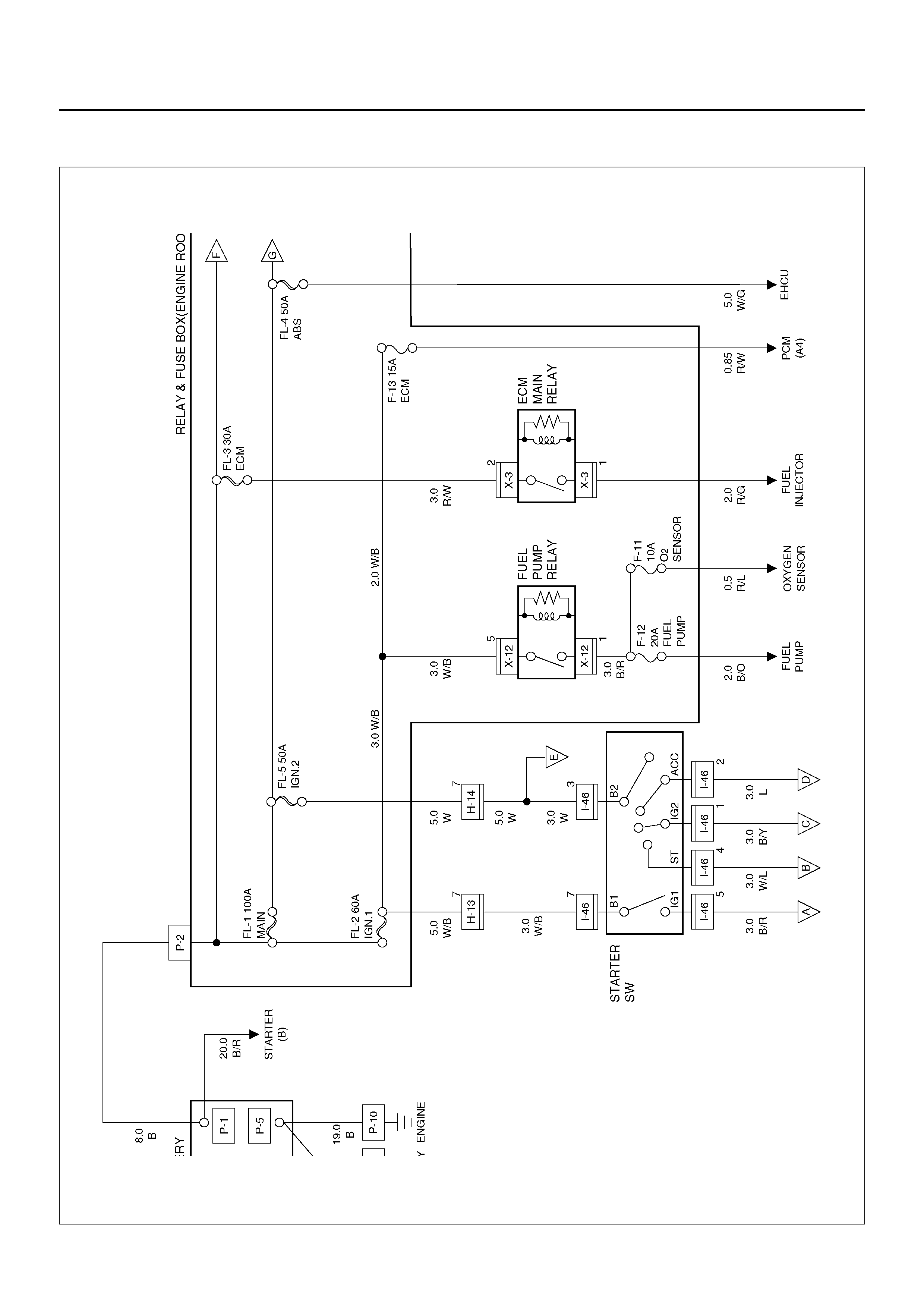

CIRCUIT DIAGRAM–1

D08R100103

PARTS LOCATION

D08R100187

EndOFCallout

Legend

(1) Relay & Fuse Box (X–10, FL–1)

(2) H–2

(3) H–13

(4) Relay & Fuse Box (C–3, C–11)

(5) I–10 (METER)

(6) Starter Switch

(7) H–16

(8) H–39

(9) E–53 (Mode Switch)

(10) P–4

(11) P–3

(12) P–8

(13) P–9

(14) C–36

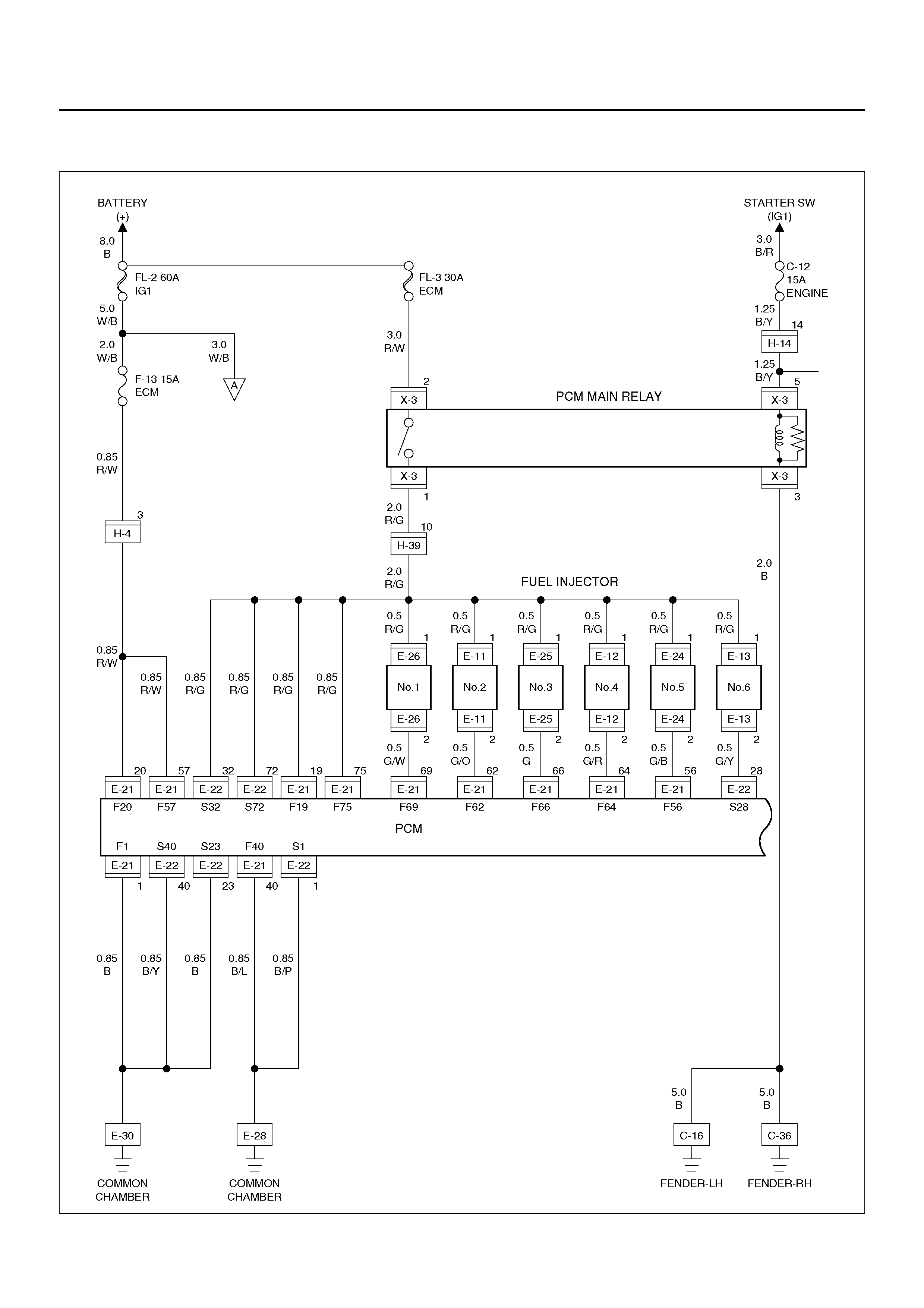

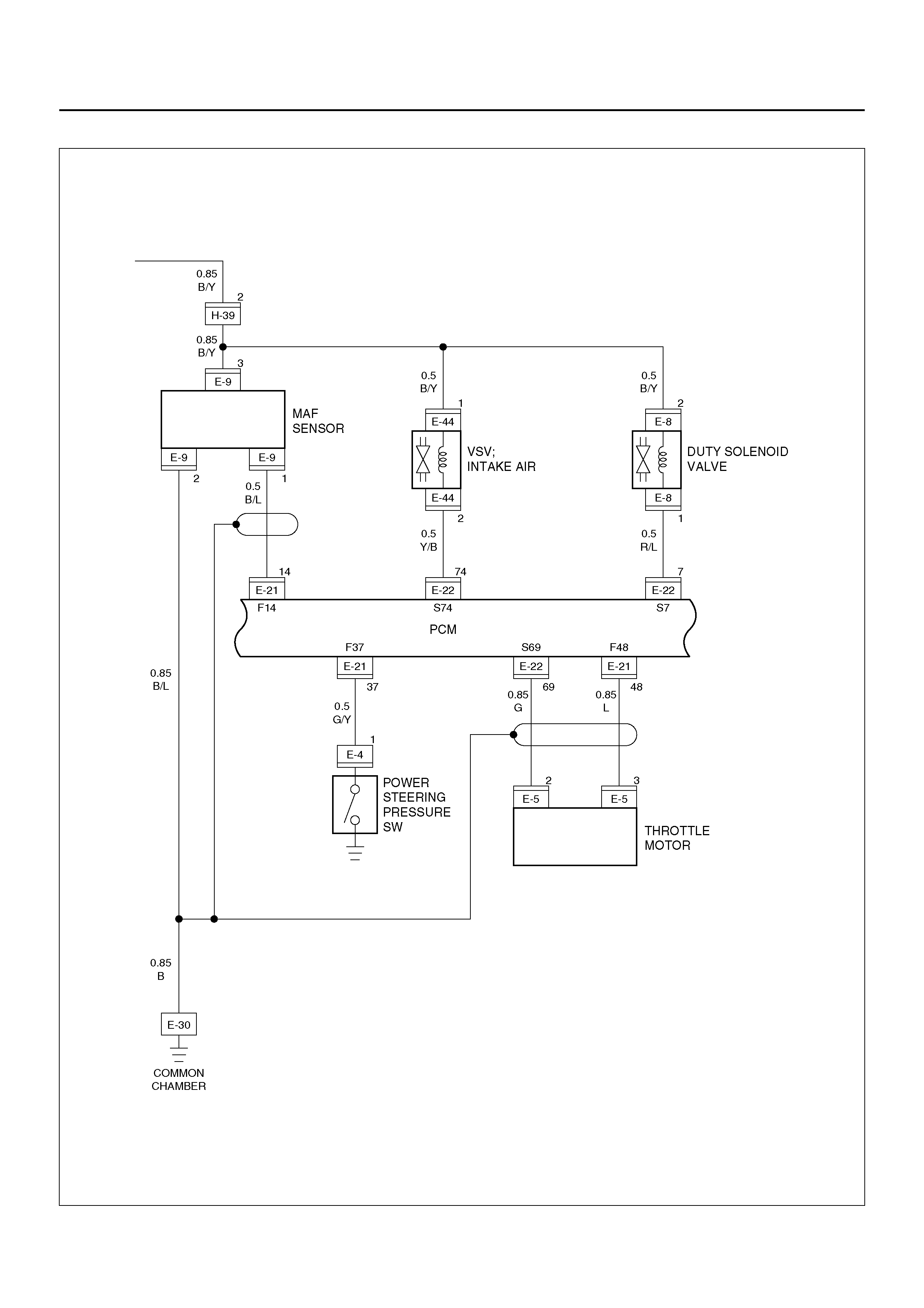

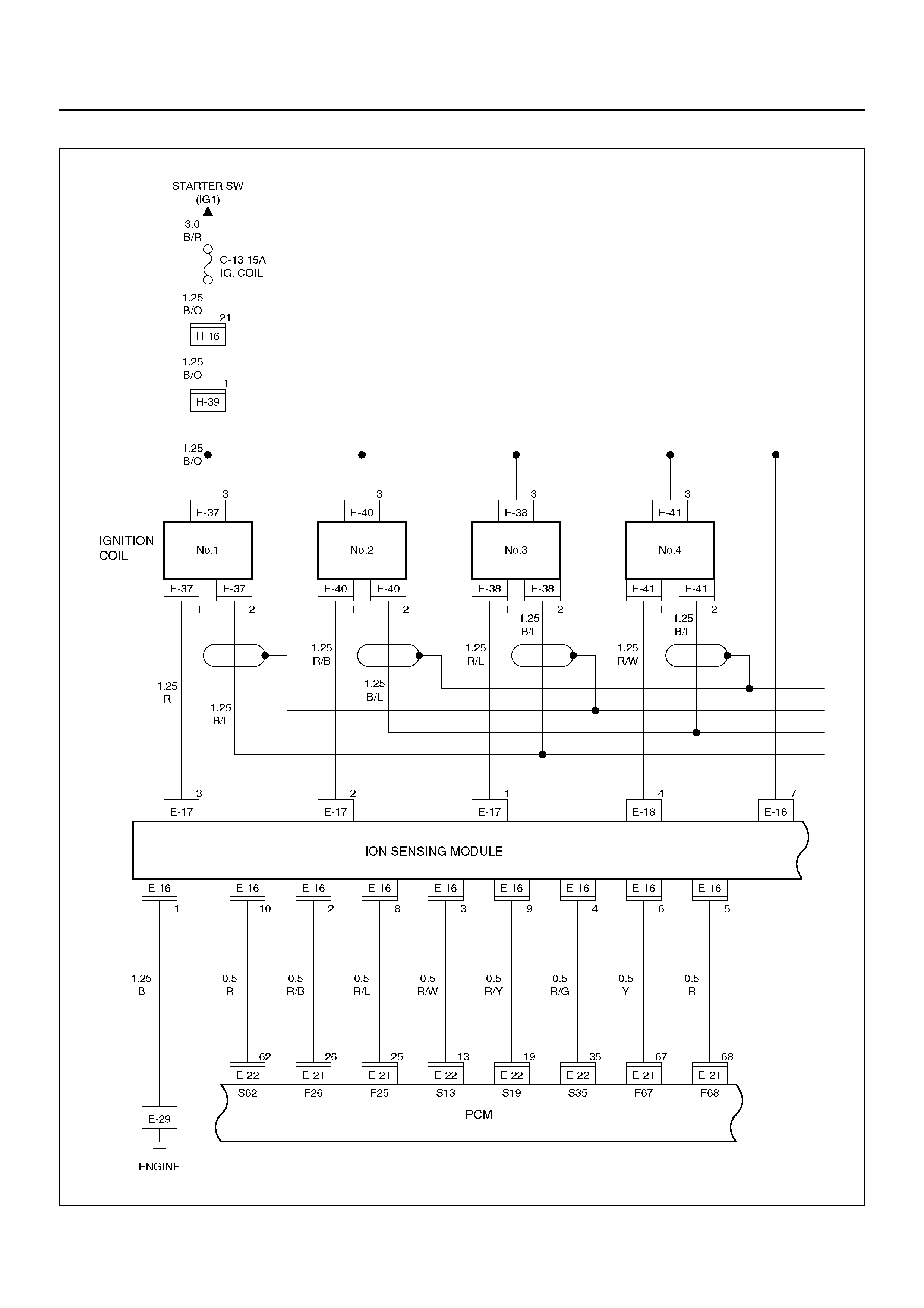

POWERTRAIN CONTROL MODULE (PCM)

GENERAL DESCRIPTION

The Powertrain Control Module (PCM) is located in the

passenger compartment.

The PCM constantly monitors the information from

various sensors, and controls the systems that affect

vehicle performance.

The PCM performs the diagnostic function of the

system. It can recognize operational problems, alert the

driver through the Malfunction Indicator Light (MIL) and

store a Diagnostic Trouble Code (DTC) or DTC(s) which

identify the problem areas to aid the technician in

making repairs. The PCM is designed to process the

various input informations and then send the necessary

electrical responses to control fuel delivery, spark timing

and other emission control systems. The input

information has an interrelation to more than one output

therefore, if the one input failed, it could affect more

than one system operation.

Refer to Driveability and Emission in Engine Section

and Automatic Transmission in Transmission section.

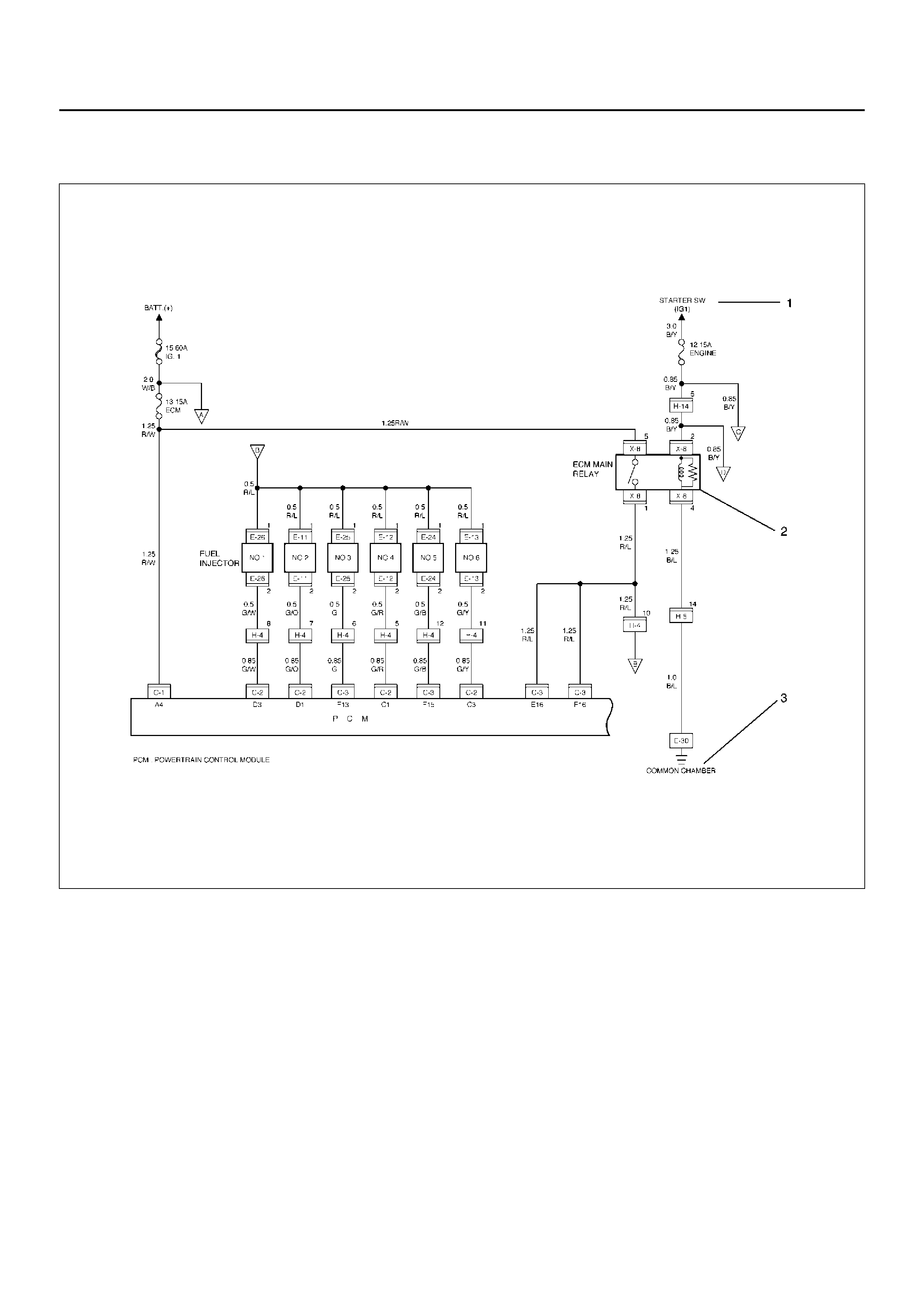

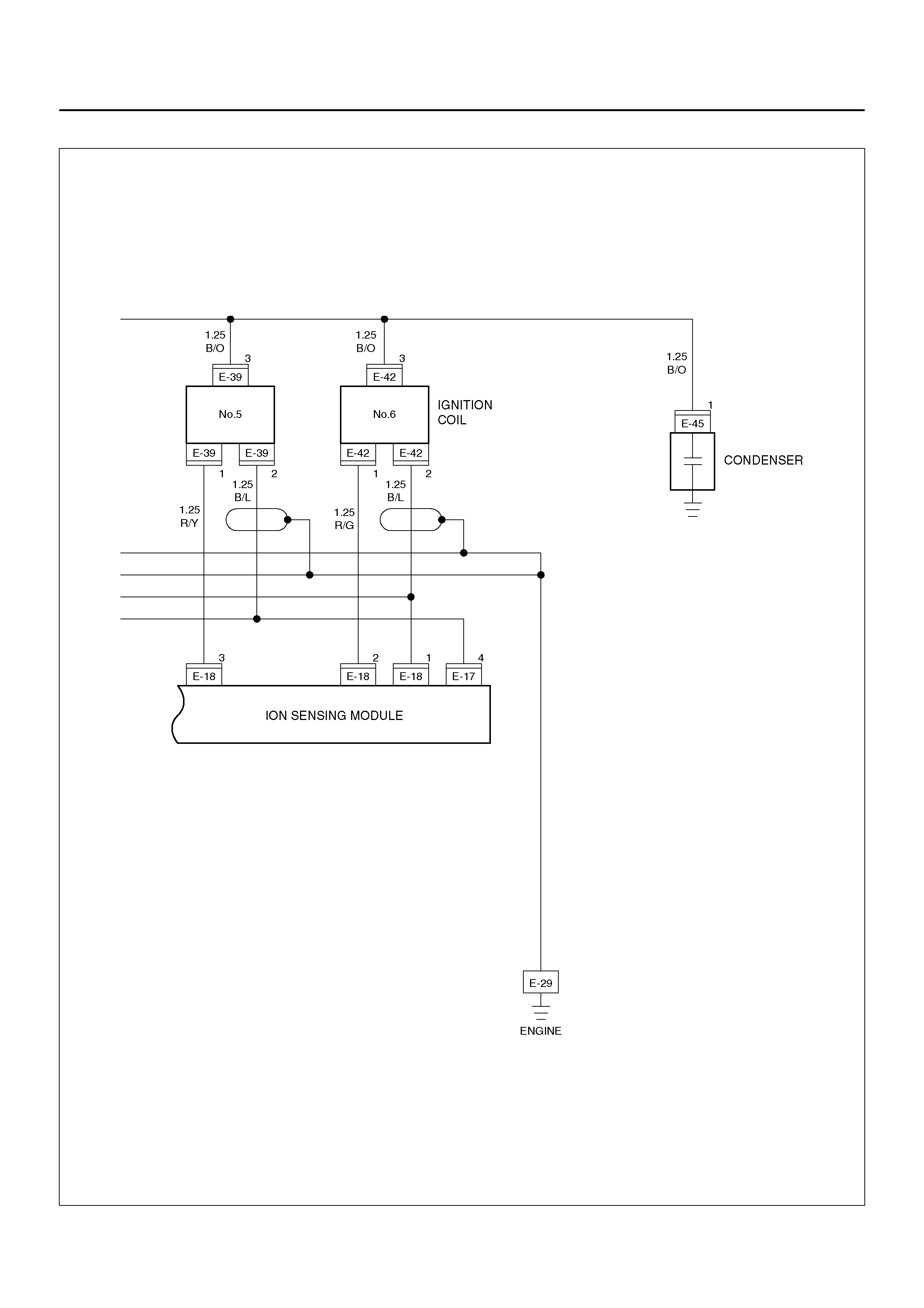

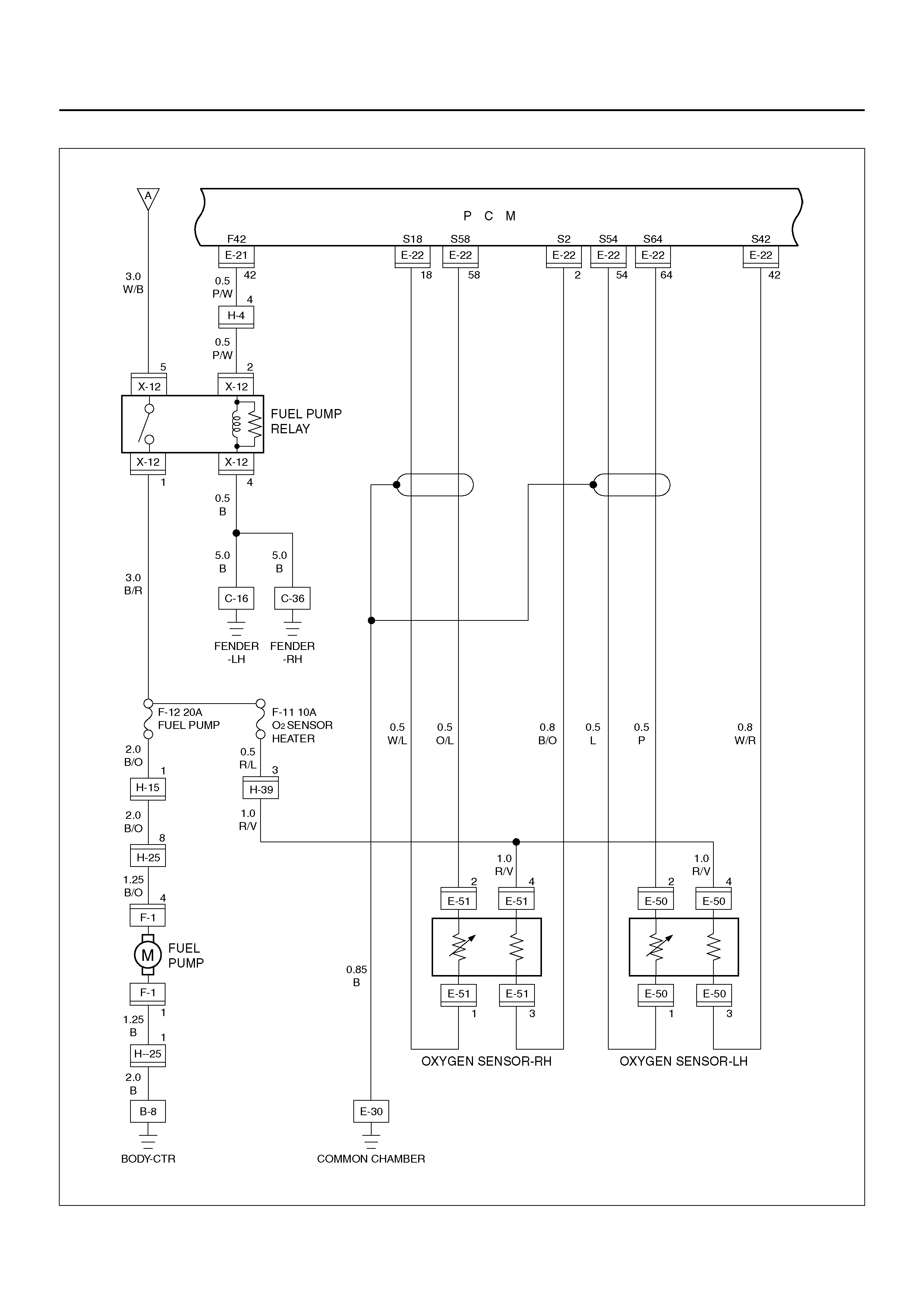

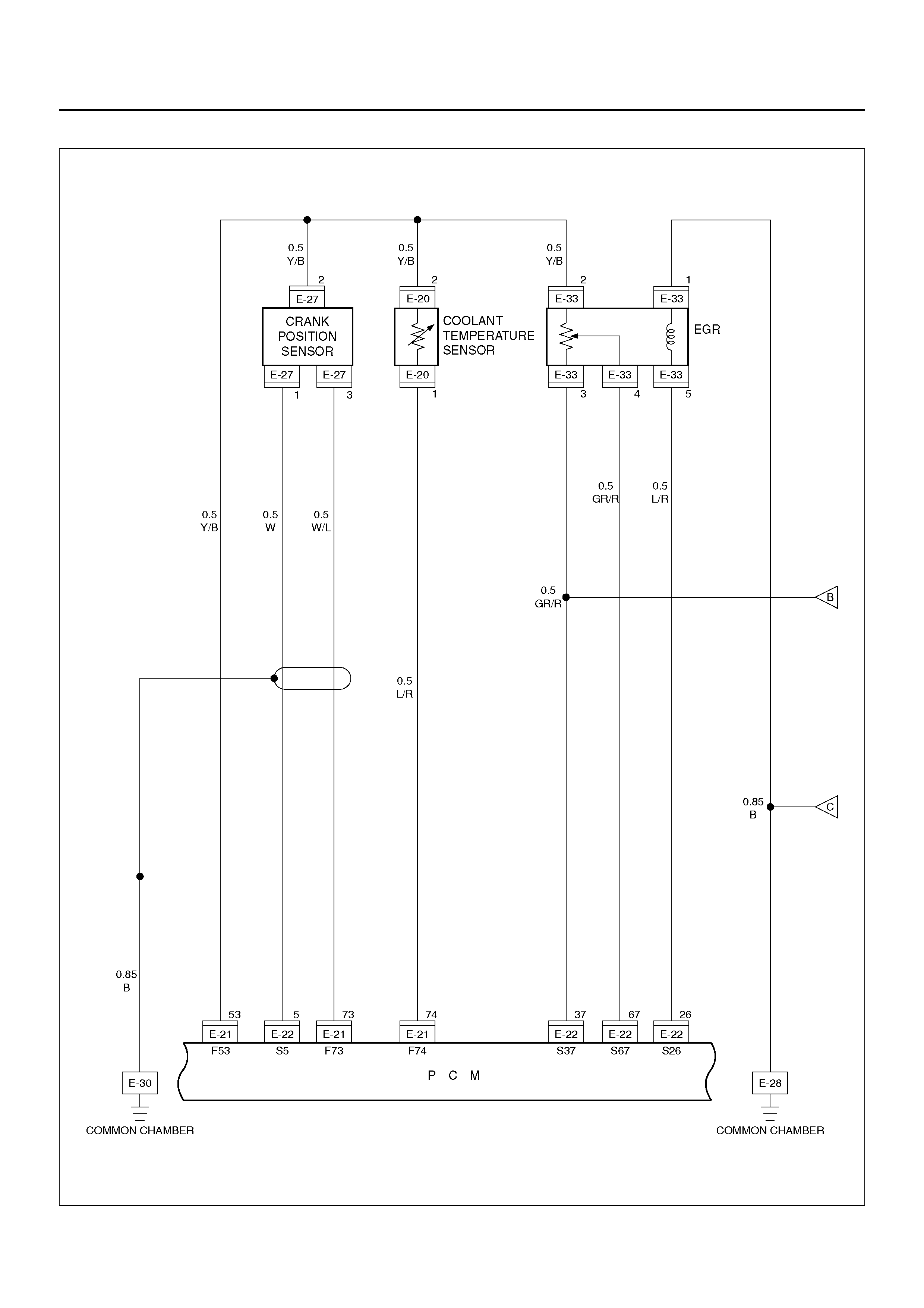

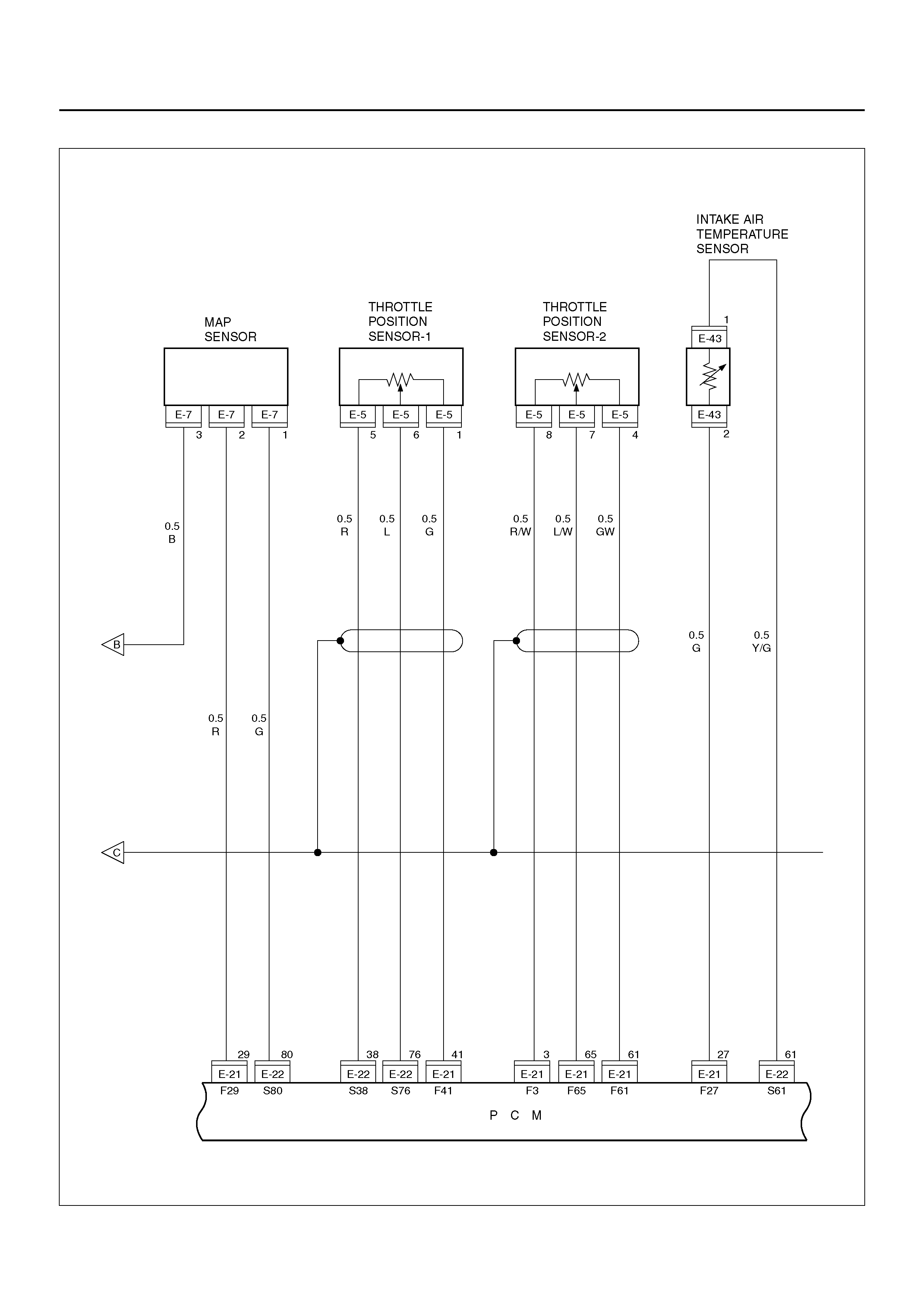

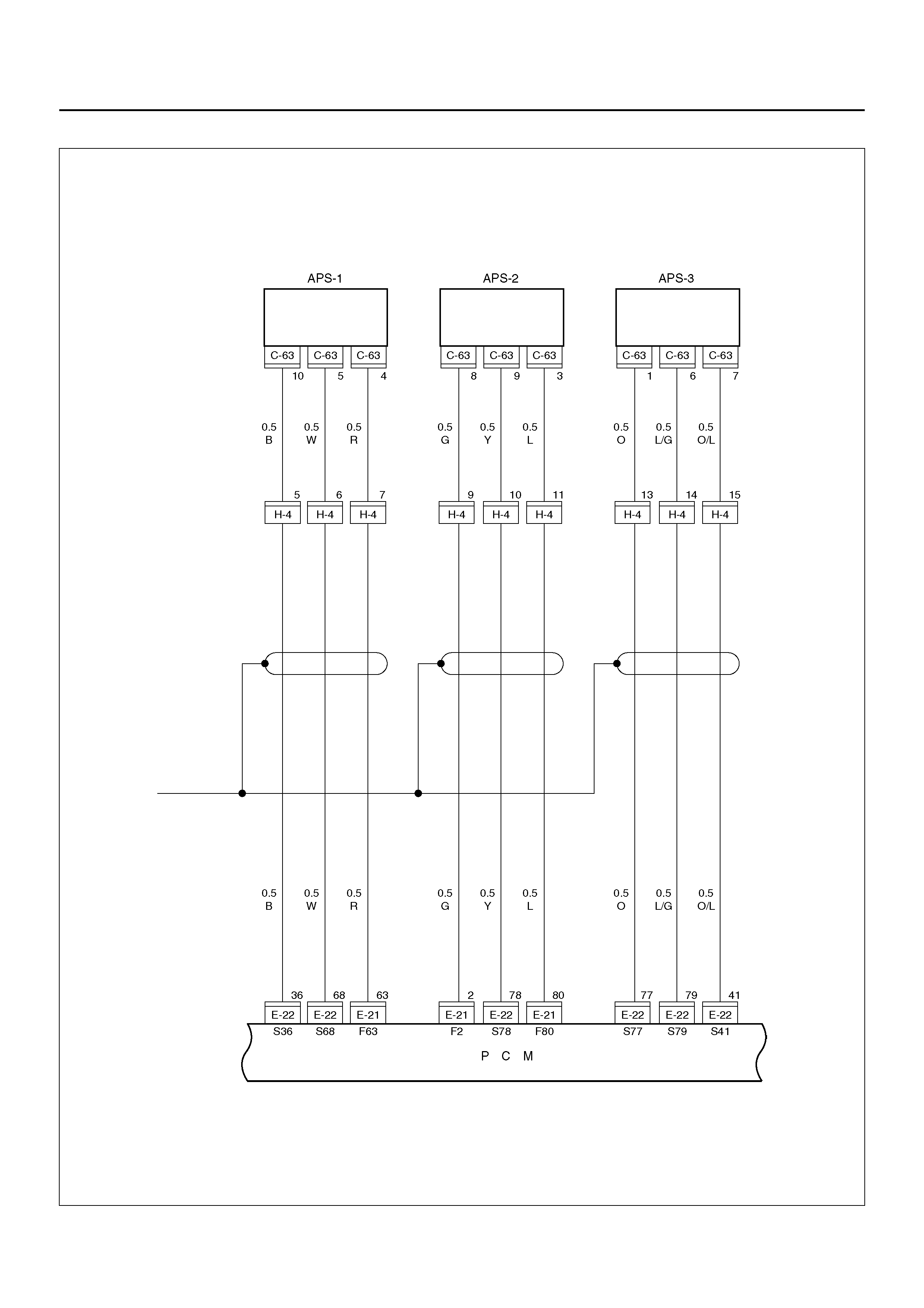

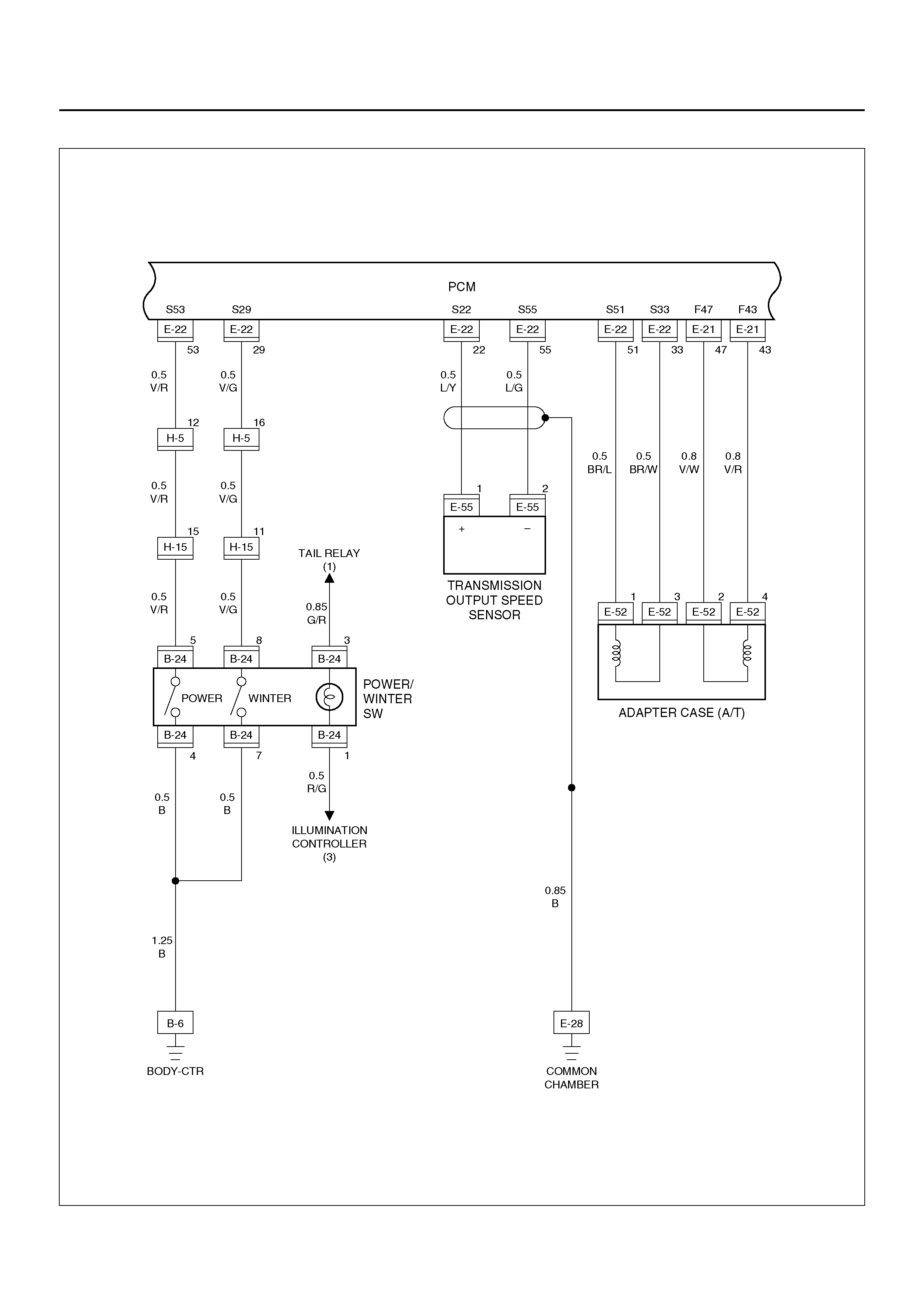

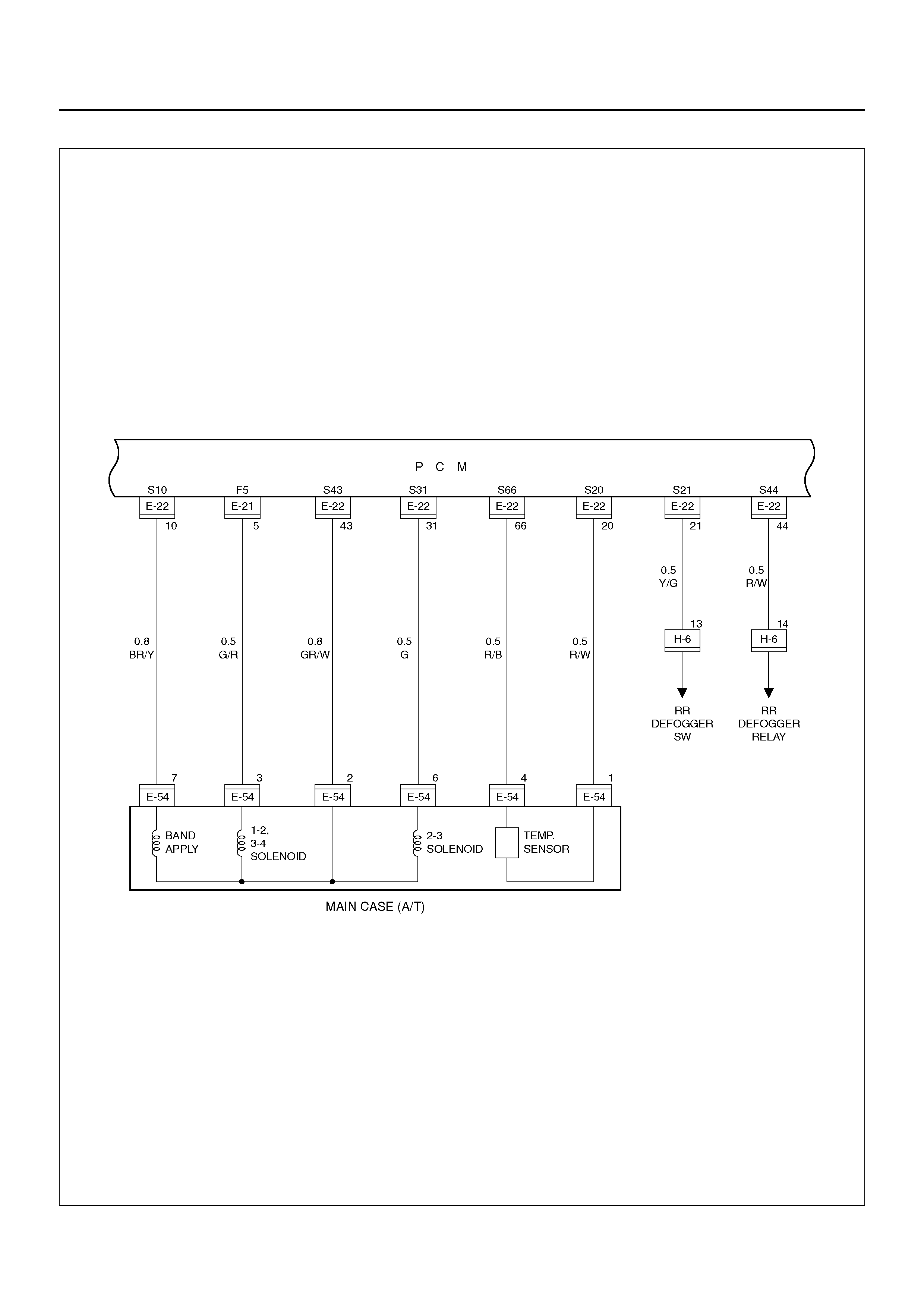

CIRCUIT DIAGRAM

Circuit Diagram–1

D08R100073

Circuit Diagram–2

D08R100188

Circuit Diagram–3

D08R100075

Circuit Diagram–4

D08R100076

Circuit Diagram–5

D08R100189

Circuit Diagram–6

D08R100078

Circuit Diagram–7

D08R100079

Circuit Diagram–8

D08R100080

Circuit Diagram–9

D08R100081

Circuit Diagram–10

D08R100082

Circuit Diagram–11

D08R100083

Circuit Diagram–12

D08R100190

Circuit Diagram–13

D08R100085

Circuit Diagram–14

D08R100086

PARTS LOCATION – 1

Legend

(1) Battery

(2) Fuse & Relay Box

(3) H–14, H–15 , H–45

(4) Relay & Fuse Box

(5) C–34

(6) C–63

(7) I–9

(8) I–18

(9) I–10

(10) I–17

(11) B–24

(12) F–1

(13) H–25

(14) H– 16, H–17

(15) C–16

(16) B–6, B–8

(17) C–58

(18) C–59

(19) E–37

(20) E–26

(21) E–38

(22) E–25

(23) E–30

(24) E–17

(25) E–18

(26) E–39

(27) E–24

(28) E–33

(29) E–16

(30) E–7

(31) E–13

(32) E–44

(33) E–51

(34) E–55

(35) E–61

(36) E–54

(37) E–53

EndOFCallout

(38) E–52

(39) E–50

(40) E–32

(41) E–15

(42) E–42

(43) E–41

(44) E–40

(45) E–29

(46) E–11

(47) E–12

(48) E–28

(49) H–4, H–5, H–6, H–39

(50) E–22

(51) E–21

(52) E–9

(53) E–4

(54) E–5

(55) E–43

(56) E–8

(57) E–27

(58) E–20

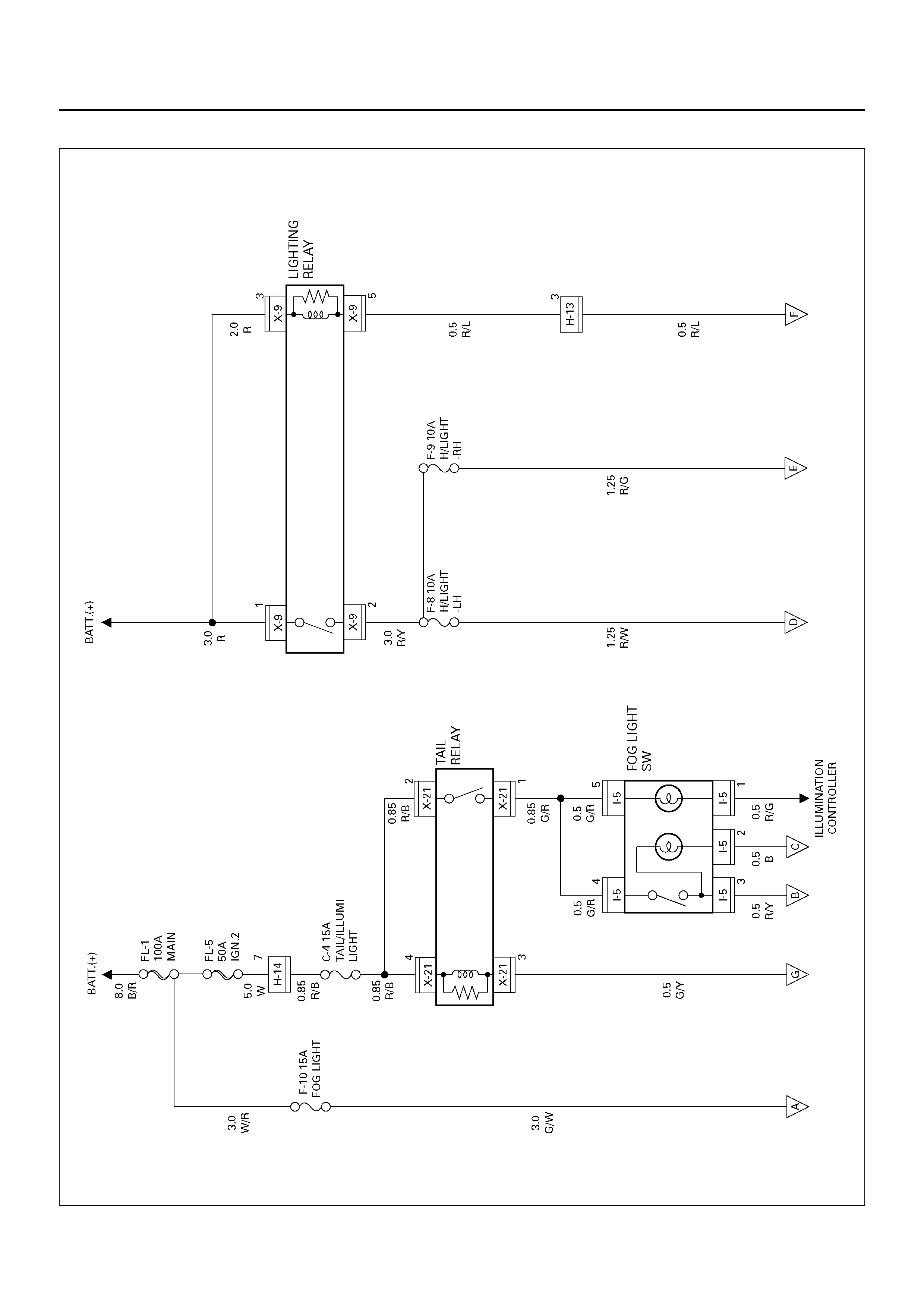

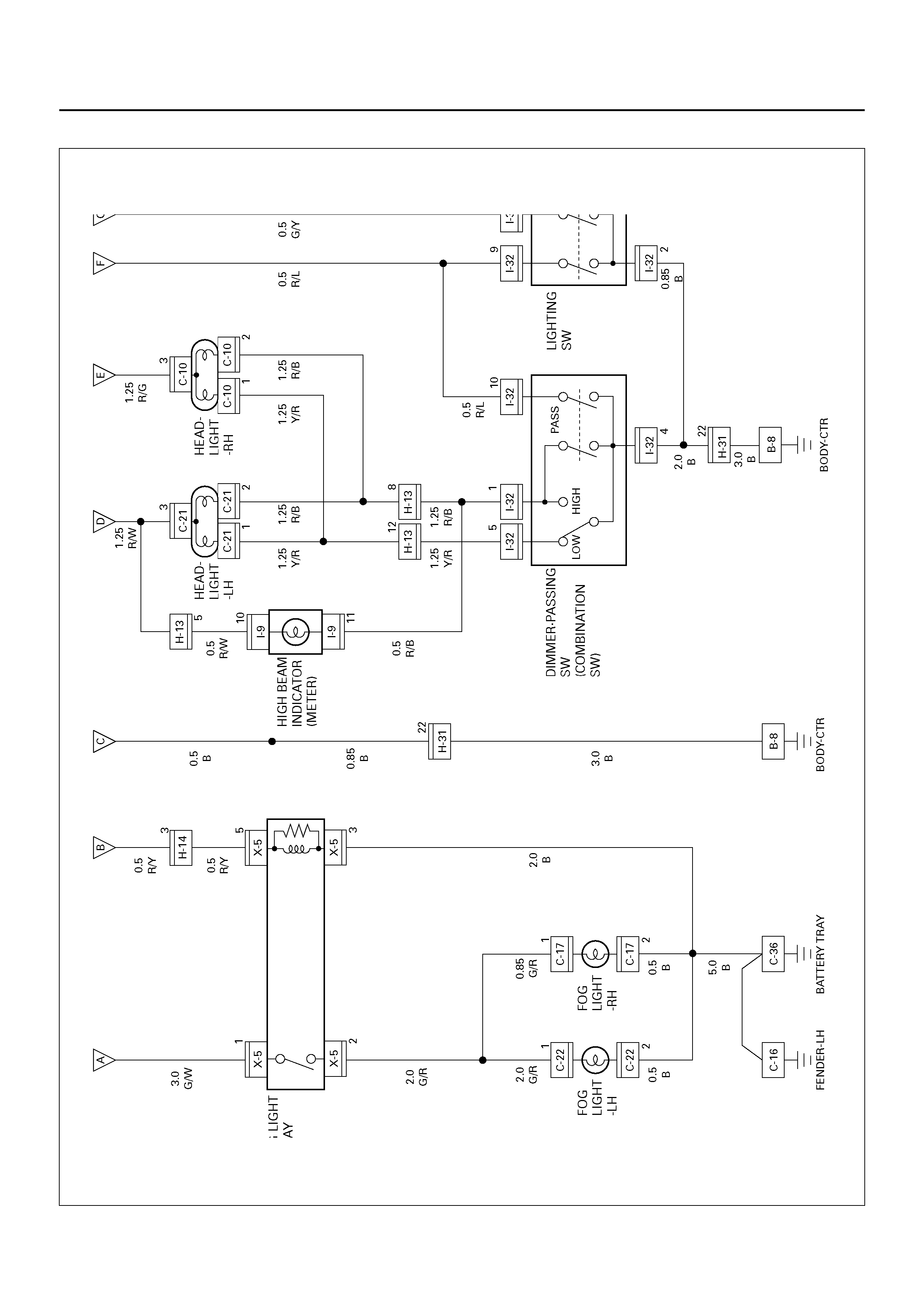

HEADLIGHT AND FOG LIGHT

GENERAL DESCRIPTION

The circuit consists of headlight, fog light, lighting

switch, dimmer·passing switch, fog light switch, high

beam indicator, lighting relay and fog light relay. When

starter switch is turned on by setting it at headlight

position, lighting relay is activated to turn on headlight.

Optical axis of headlight can be turned up or down by

operating dimmer switch wh ile headlight is on. Passing

switch is ind epe nde nt of li gh ting swi tc h, and op tica l ax is

of passing light c an be tu rned up only whi le switch lev er

is pulled up and held in this state.

When fo g light switc h is turne d on while he adlight on at

low–beam, fog light relay is activated to turn on fog light.

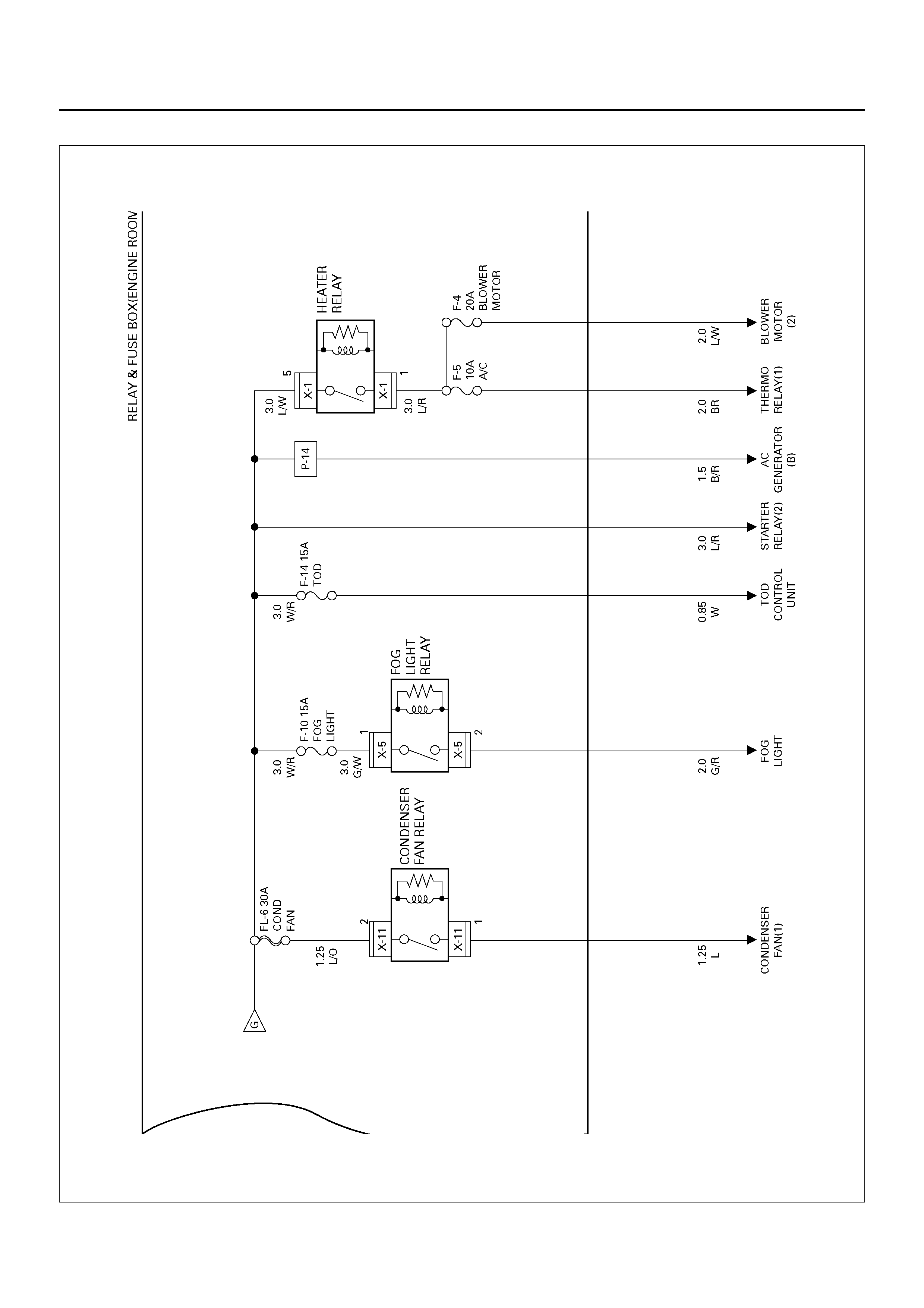

CIRCUIT DIAGRAM–1

D08R100104

Circuit Diagram–2

D08R100105

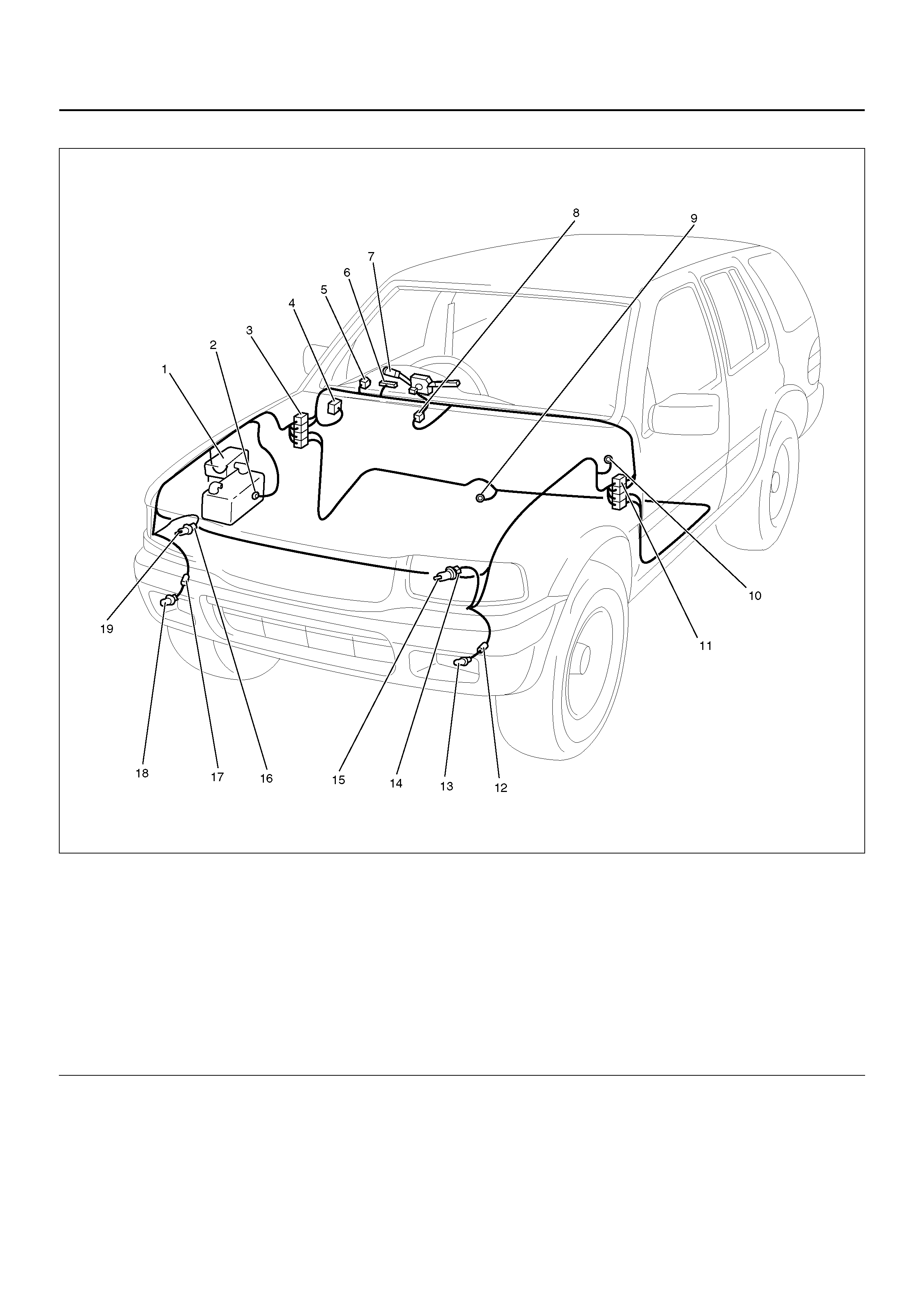

PARTS LOCATION

D08RY00820

EndOFCallout

Legend

(1) Relay & Fuse Box (X–5, X–9)

(2) C–36

(3) H–13, H–14

(4) Relay & Fuse Box (X–21)

(5) I–5

(6) I–9

(7) Lighting Switch

(8) I–32 (Combination Switch)

(9) B–8

(10) C–16

(11) H–31

(12) C–22

(13) Fog Light – LH

(14) C–21

(15) Head Light – LH

(16) C–10

(17) C–17

(18) Fog Light – RH

(19) Head Light – RH

DIAGNOSIS

Both Headlights Inoperative

Headlight On The Left (or Right) Side Inoperative

Step Action Value(s) Yes No

1 Check the ground terminal B–8.

Is B–8 grounded securely? — Go to Step 2 Ground it

securely

2 Disconnect the combination switch connector I–32.

Is there continuity between switch side connector I–32

terminals 9 and 2 with the switch turned to headlight

position?

— Go to Step 2 Replace the

switch

3 Ch ec k con tin ui ty of dimm er -passi ng swi tc h.

Is there continuity between switch side connector I–32

terminal 5 and 4 with the switch turned to low position,

and terminal 1 and 4 with the switch turned to high

position?

— Go to Step 3 Replace the

switch

4 Check continuity between the lighting switch and the

ground B–8.

Is ther e continu ity between h arness si de connec tor I–

32 terminal 2 and the ground?

— Go to Step 5 Repair an open

circuit

5 Remove the lighting relay from the relay and fuse box.

Is the battery voltage applied between harness side

connector X–9 terminal 1 and the ground, X–9

terminal 3 and the ground?

Approx. 12V Go to Step 6 Repair an open

circuit between

battery and the

light ing relay

6 Check continuity between the lighting relay and the

lighting switch.

Is there continuity between harness side connector X–

9 terminal 5 and I–32 terminal 9?

— Go to Step 7 Repair an open

circuit

7 Check continuity between the lighting relay and fuse

F–8 or F–9.

Is there continuity between harness side connector X–

9 terminal 2 and fuse F–8 or F–9?

— Go to Step 8 Repair an open

circuit

8 Check continuity between the dimmer-passing switch

and the ground.

Is there continuity between switch side connector I–32

terminal 4 and the ground B–8?

— Replace the

lighting relay Repair an open

circuit

Step Action Value(s) Yes No

1 Is the fuse F–8 or F–9 normal? — Go to Step 2 Replace the

fuse

2 Remove the headlight bulb on the left or right side.

Is the bulb normal? — Go to Step 3 Replace the

bulb

3 1. Reinstall the bulb.

2. Turn the lighting switch to headlight position.

Is the battery voltage applied between harness side

connector C–21 terminal 3 and the ground or C–10

terminal 3 and the ground?

Approx. 12V Reconnect the

headlight

connector

securely

Repair an open

circuit between

the fuse and

headlight

Headlights In Low–Beam Inoperative

Headlight In High–Beam Inoperative

Headlights Remain On When Lighting Switch Turned Off

Headlight Comes On With Lighting Switch At Parking Light Position

Step Action Value(s) Yes No

1 Disconnect the combination switch connector I–32.

Is there continuity between switch side connector I–32

terminal 5 and 4 with the switch at low-beam position?

— Go to Step 2 Repair or

replace the

switch

2 Repair an open circuit between connector H-13

terminal 12 and connector I-32 terminal 5.

Is the action complete?

— Verify repair —

Step Action Value(s) Yes No

1 Disconnect the combination switch connector I–32.

Is there continuity between switch side connector I–32

terminal 1 and 4 with the switch at high-beam

position?

— Go to Step 2 Repair or

replace the

switch

2 Repair an open circuit between connector H–13

terminal 8 and connector I–32 terminal 1.

Is the action complete?

— Verify repair —

Step Action Value(s) Yes No

1 1. Turn the lighting switch to off position.

2. Disconnect the combination switch connector I–

32.

Do the headlights still remain on?

— Go to Step 3 Go to Step 2

2 Repair or replace the lighting switch.

NOTE: There sh oul d be no co nti nui ty betwee n swi tc h

side connector I–32 terminal 9 and 2.

Is the action complete?

— Go to Step 1 —

3 Re mov e the lig hti ng re lay.

Is there continuity between the relay side connector

X–9 terminal 1 and 2?

— Replace the

relay Go to Step 4

4 Re pair short ci rcuit between the lig hting relay and the

lighting switch.

Is the action complete?

— Verity repair —

Step Action Value(s) Yes No

1 Repair or replace the lighting switch.

NOTE: There sh oul d be no co nti nui ty betwee n swi tc h

side conn ector I–32 ter minal 9 and 2 when the swi tch

is turned to parking light pos iti on .

Is the action complete?

— Verify repair —

(While Headlight Is On In Low–Beam) Both Fog Lights Inoperative

Step Action Value(s) Yes No

1 Are the fuse F–10 and C–4 normal? — Go to Step 2 Replace the

fuse(s)

2 Is C–36 gr ound ed se curely? — Go to Step 3 Gr ou nd it

securely

3 Re mov e the fogl ig ht relay.

Is the battery voltage applied between harness side

connector X–5 terminal 1 and the ground?

Approx. 12V Go to Step 5 Go to Step 4

4 Repair an open circuit between Fuse F–10 and

connector X–5 terminal 1.

Is the action complete?

— Go to Step 3 —

5 Is there continuity between harness side connector X–

5 terminal 3 and the ground? — Go to Step 7 Go to Step 6

6 Repair an open circuit between connector X–5

terminal 3 and the ground C–36.

Is the action complete?

— Go to Step 5 —

7 1. Turn the lighting switch to clearance light position.

2. Turn the fog light switch on.

Is the battery voltage applied between harness side

connector X–5 terminal 5 and the ground?

Approx. 12V Replace the fog

light relay Go to Step 8

8 Disconnect the lighting switch connector I–32.

Is there continuity between the switch side connector

terminal 2 and 3?

— Go to Step 9 Repair or

replace the

switch.

9 Disconnect the tail relay.

Is ther e continu ity between h arness si de connec tor I–

21 terminal 3 and X–32 terminal 3?

— Go to Step 10 Repair an open

circuit

10 Is the battery voltage applied between harness side

connector X–21 terminal 2, 4 and the ground? Approx. 12V Go to Step 12 Go to Step 11

11 Repair an open circuit between the fuse C–4 and

connector X–21 terminal 2 or 4.

Is the action complete?

— Go to Step 10 —

12 1. Disconnect the fog light switch.

2. Turn the switch on.

Is there continuity between the switch terminal 3 and

4?

— Go to Step 13 Repair or

replace the

switch

13 Is there con tinuity b etween har ness side connecto r I–

5 terminal 4 and connector X–21 terminal 1? — Go to Step 14 Repair an open

circuit

14 Is there con tinuity b etween har ness side connecto r I–

5 terminal 3 and connector X–5 terminal 5? — Replace the tail

relay Rep air an open

circuit

(While Headlight Is On In Low–Beam) Fog Light On the Left (or Right) Side Inoperative

Step Action Value(s) Yes No

1 Is the fog light bulb on the left or right side normal? — Go to Step 2 Replace the

bulb

2 Disconnect the fog light connector C–22 or C–17.

Is there continuity between the fog light harness side

connector terminal 2 and the ground?

— Go to Step 3 Repair an open

circuit

3 Repair an open circuit between fog light relay

connector X–5 terminal 2 and fog light connector

terminal 1.

Is the action complete?

— Verify repair —

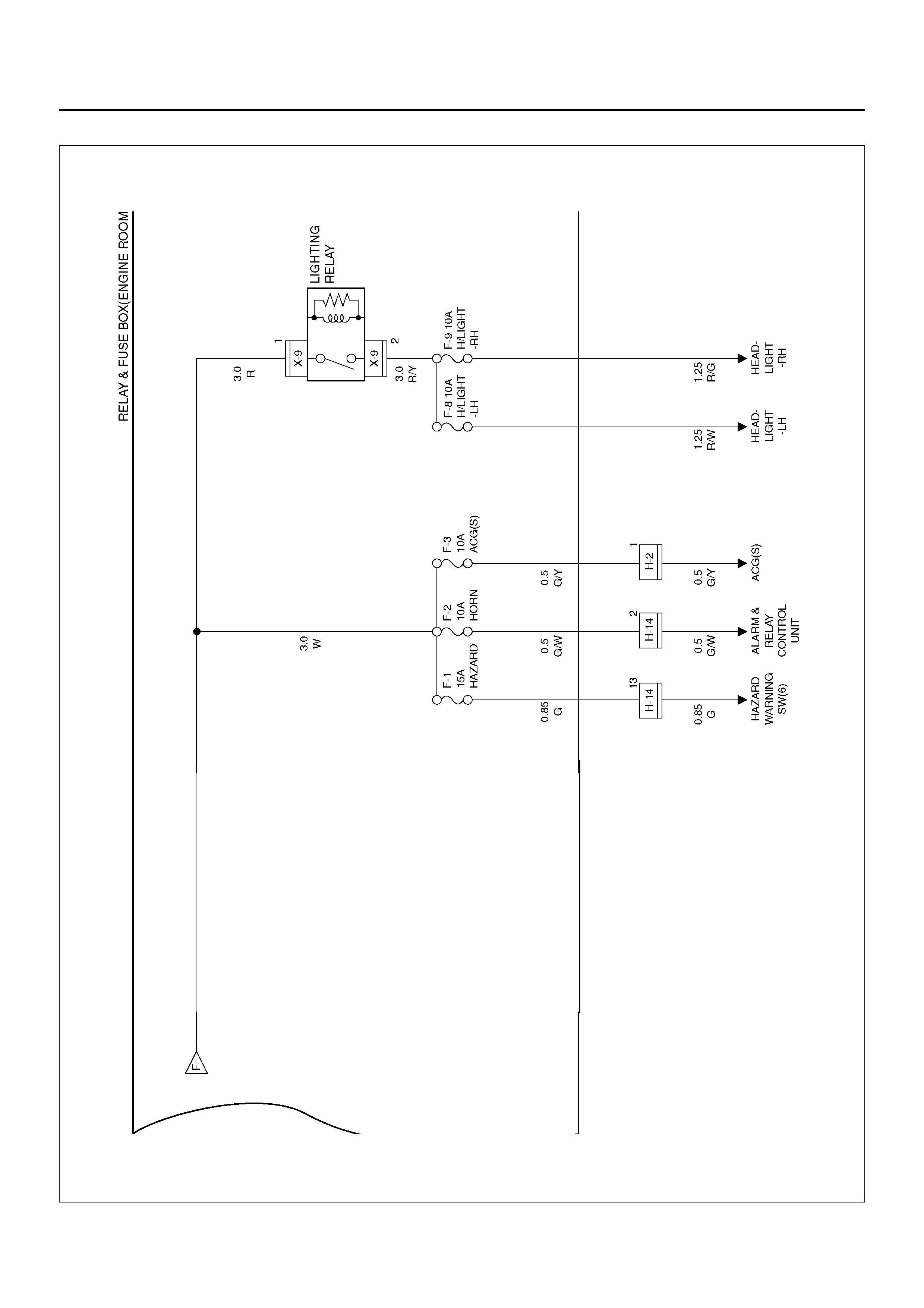

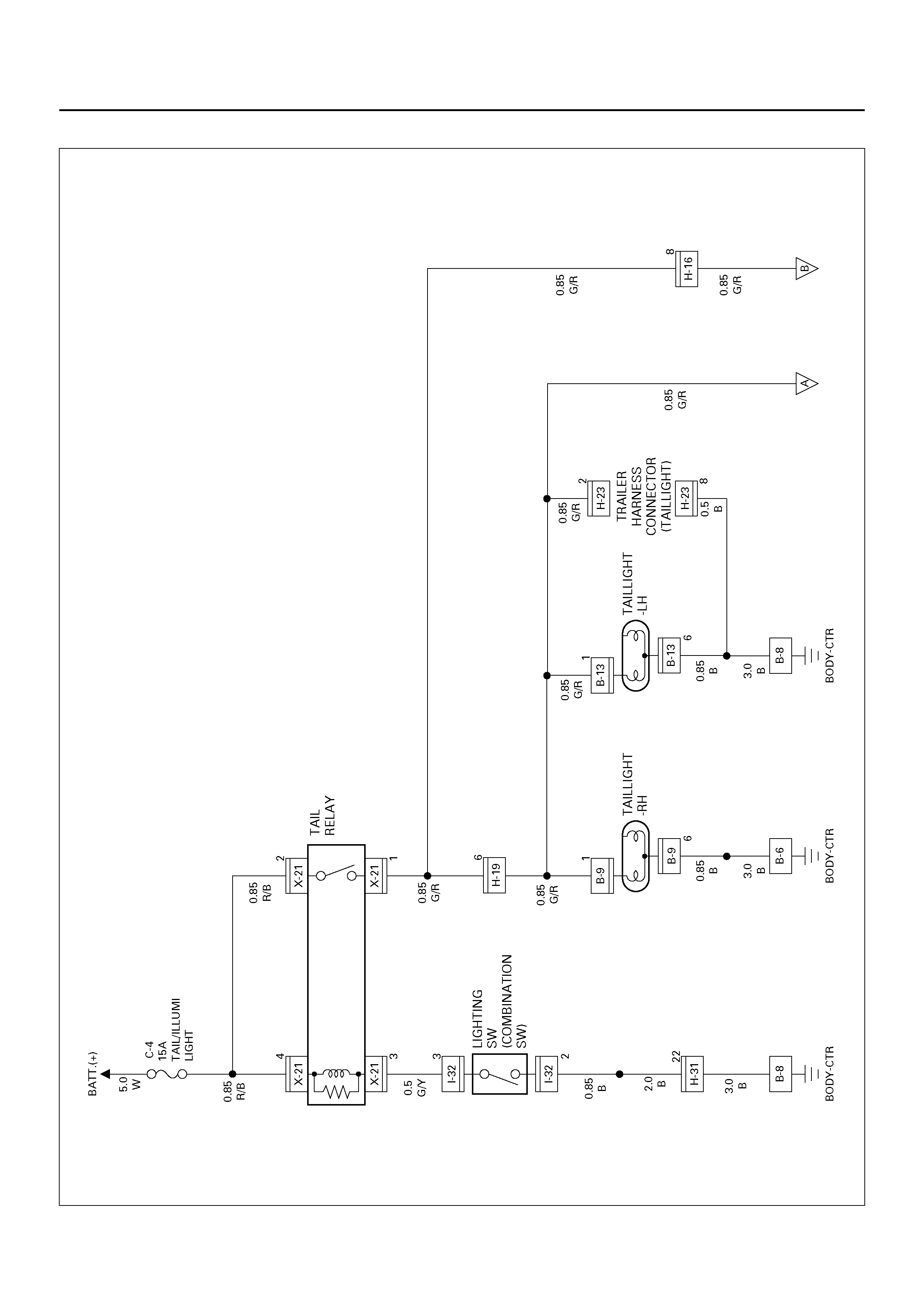

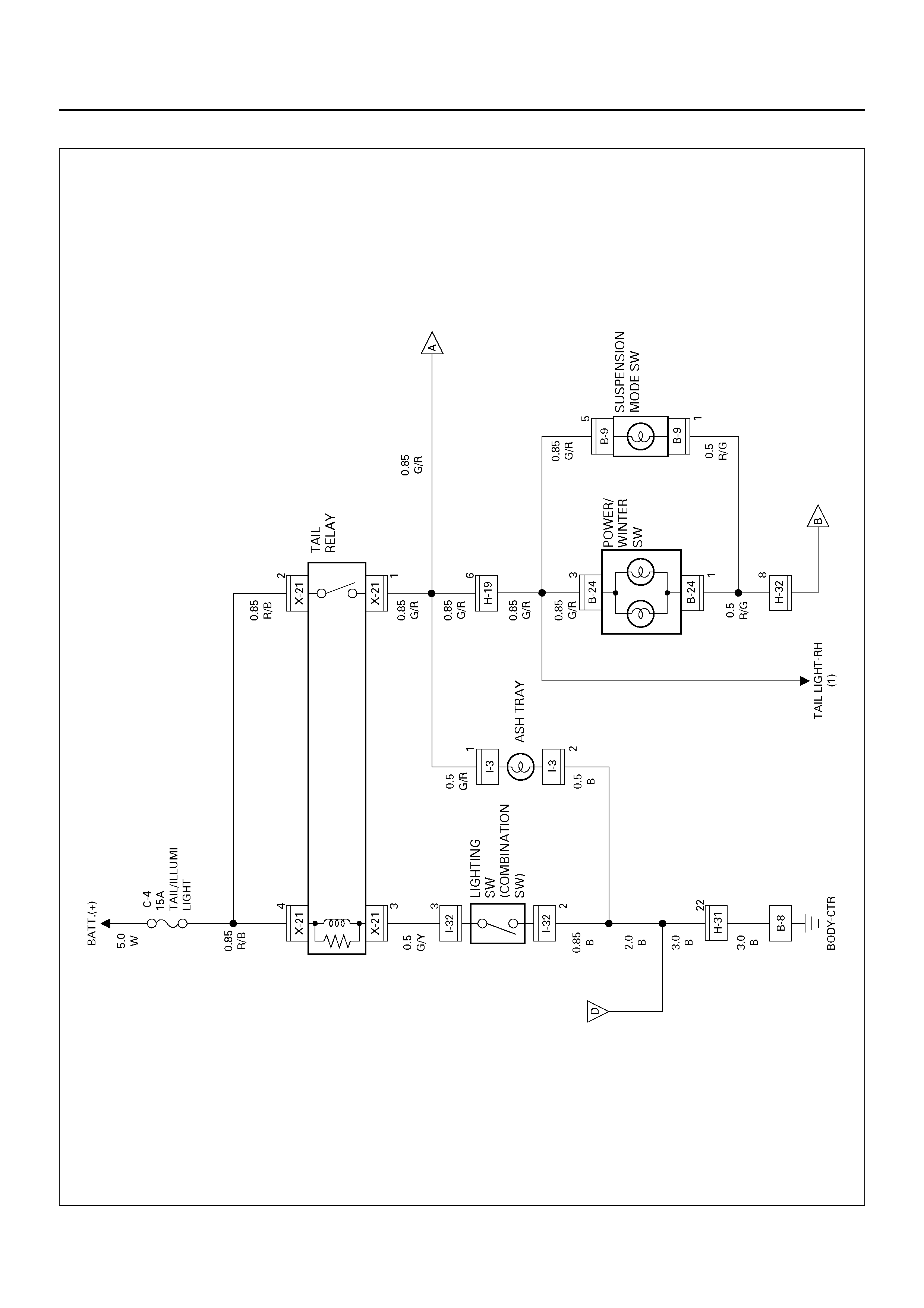

CLEARANCE LIGHT, TAIL LIGHT AND LICENSE PLATE LIGHT

GENERAL DESCRIPTION

The circuit consists of lighting switch, clearance light,

tail light and license plate light.

All these lights come on when lighting switch is turned

on with the switch to either parking or headlight position.

CIRCUIT DIAGRAM–1

D08R100223

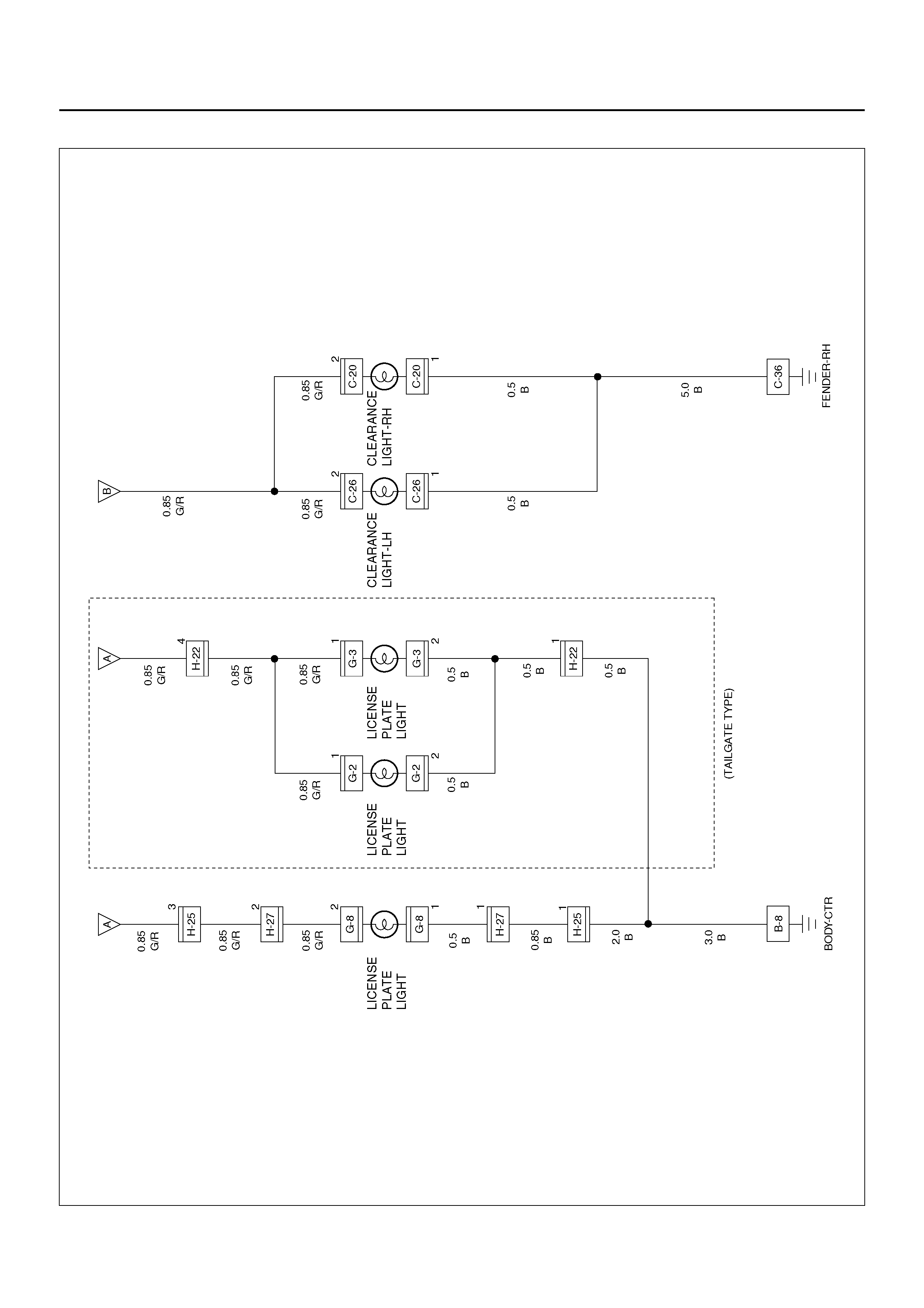

Circuit Diagram–2

D08R100107

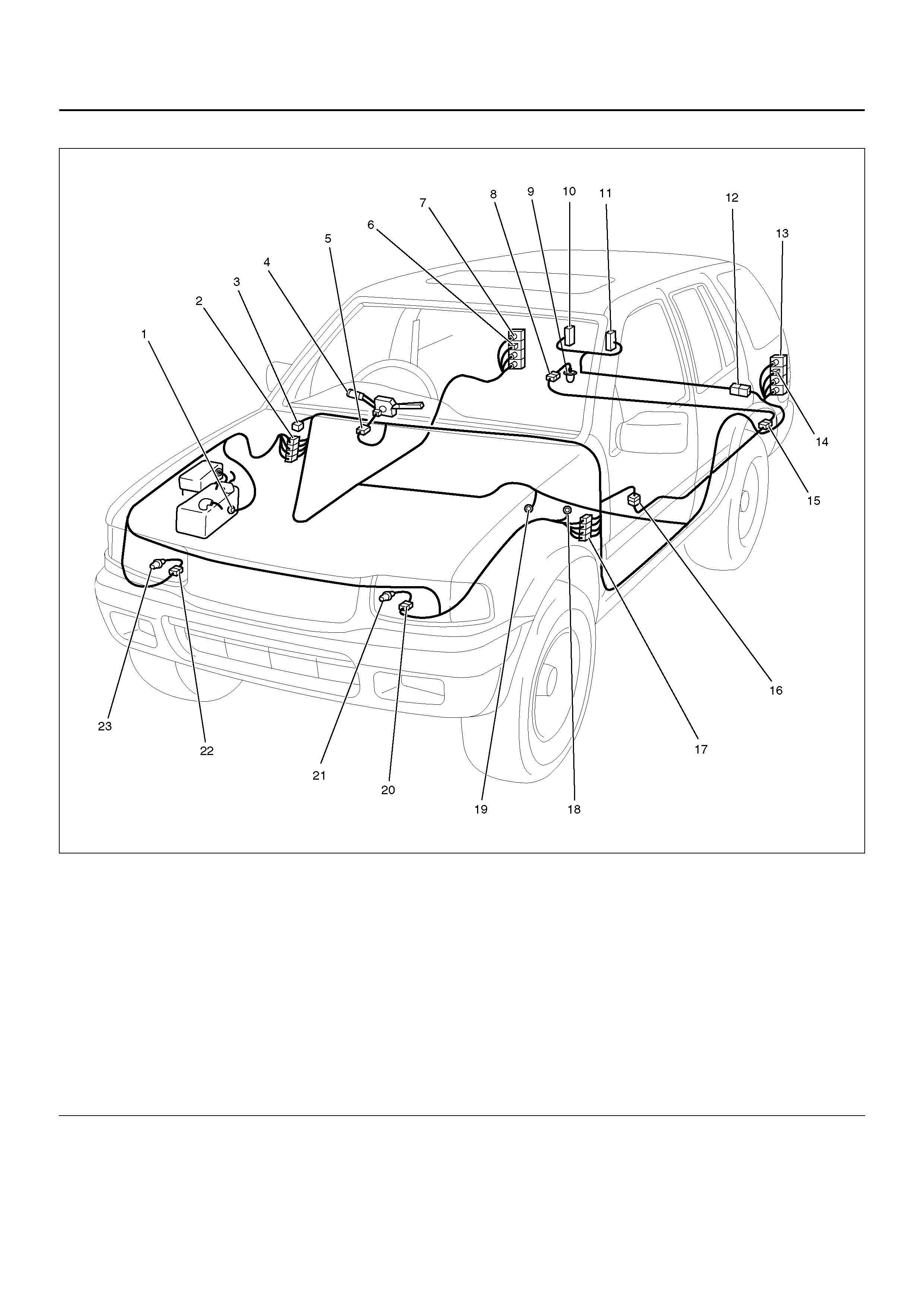

PARTS LOCATION

D08RY00821

EndOFCallout

Legend

(1) C–36

(2) H–19

(3) Relay & Fuse Box (X–21)

(4) Lighting Switch

(5) I–32

(6) B–9

(7) Tail Light–RH

(8) G–8

(9) License Plate Light (Bumper Type)

(10) G–3 (Tailgate Type)

(11) G–2 (Tailgate Type)

(12) H–22

(13) Tail Light – LH

(14) B–13

(15) H–27

(16) H–25

(17) H–31

(18) C–16

(19) B –6, B–8

(20) C–26

(21) Clearance Light–LH

(22) C–20

(23) Clearance Light–RH

DIAGNOSIS

Both Tail Lights Inoperative

Tail Light On The Left (or Right) Side Inoperative

Clearance Light Inoperative

Clearance Light On The Left (or Right) Side Inoperative

Step Action Value(s) Yes No

1 Repair an open circuit between the tail relay and the

taillights.

Is the action complete?

— Verify repair —

Step Action Value(s) Yes No

1 Remove the taillight bulb on the left or right side.

Is the bulb normal? — Go to Step 2 Replace the

bulb

2 Is B–6 or B–8 grounded securely? — Go to Step 3 Ground it

securely

3 Disconnect the taillight connector B–9 or B–13.

Is the battery voltage applied between harness side

connector B–9 or B–13 terminal 1 and the ground?

Approx. 12V Go to Step 5 Go to Step 4

4 Repair an open circuit between the tail relay and the

taillight on the left or right side.

Is the action complete?

— Verify repair —

5 Re pair an ope n circuit between the taillig ht on the left

or right side and the groun d.

Is the action complete?

— Verify repair —

Step Action Value(s) Yes No

1 Repair an open circuit between the tail relay and the

taillights.

Is the action complete?

— Verify repair —

Step Action Value(s) Yes No

1 Remove the clearance light bulb on the left or right

side.

Is the bulb normal?

— Go to Step 2 Replace the

bulb

2 Disconnect the clearance light connector C–20 or C–

26.

Is the battery voltage applied between harness side

connector C–20, or C–26 terminal 2 and the ground?

Approx. 12V Go to Step 4 Go to Step 3

3 Repair an open circuit between the tail relay and the

clearance light on the left or right side.

Is the action complete?

— Verify repair —

4 Repair an open circuit between the clearance light

and the ground?

Is the action complete?

— Verify repair —

License Plate Light Inoperative

Step Action Value(s) Yes No

1 Do the taillights come on? Go to Step 2 Go to Step 6

2 Re mov e the lic en se plate li ght bul b.

Is the bulb normal? Go to S tep 3 Replace bulb

3 1. Disconnect the license plate light connector G–8.

2. Turn the lighting switch on.

Is the battery voltage applied between the license

plate light harness side connector terminal and the

ground?

Approx. 12V Go to Step 5 Go to Step 4

4 Repair an open circuit between connector H–19

terminal 6 and the license plate light.

Is the action complete?

— Verify repair —

5 Repair an open circuit between the license plate light

and the ground.

Is the action complete?

— Verify repair —

6 Refer to the diagnosis procedure for “Both Taillight

Inoperative" in this section.

Is the action complete?

— Verify repair —

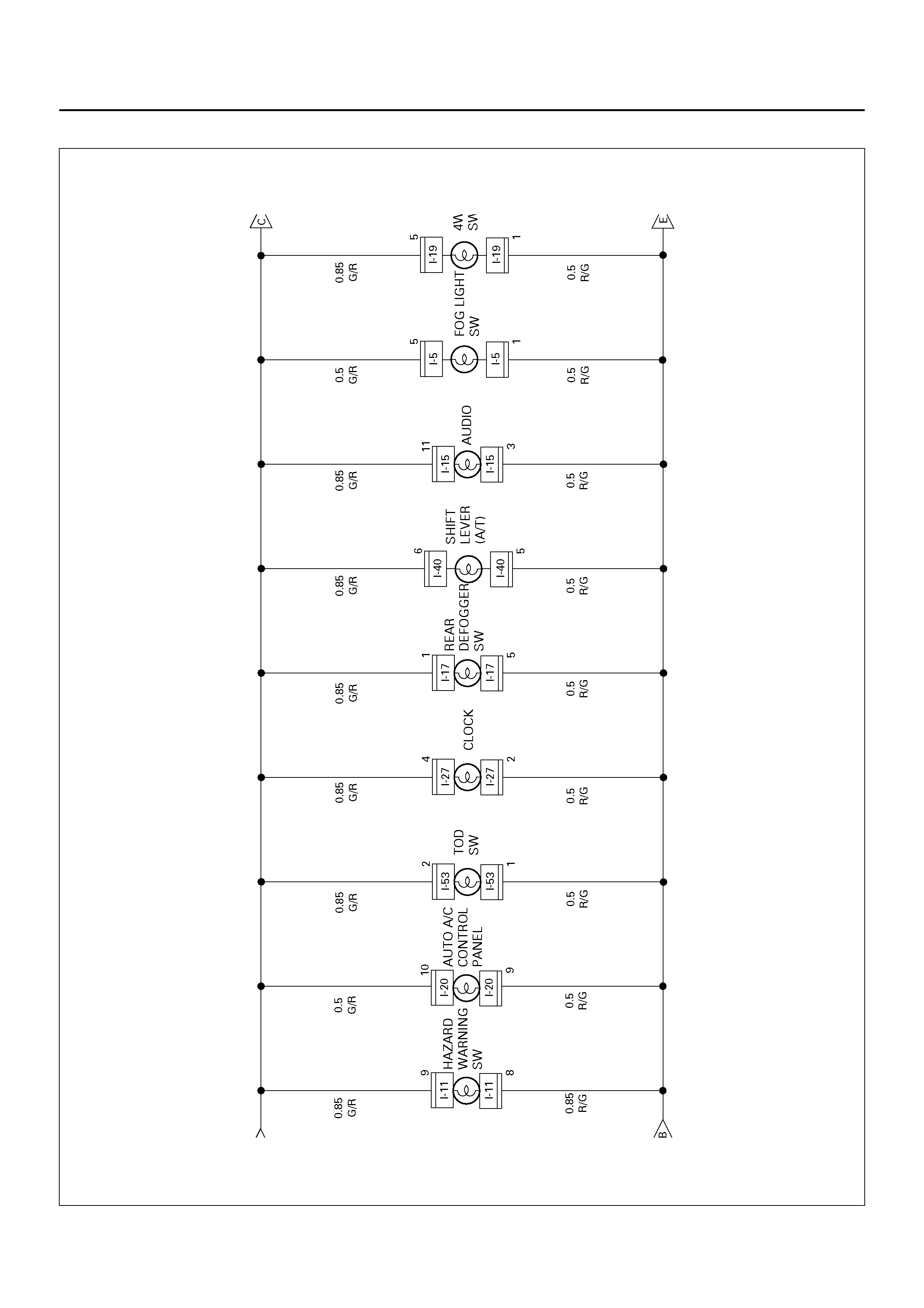

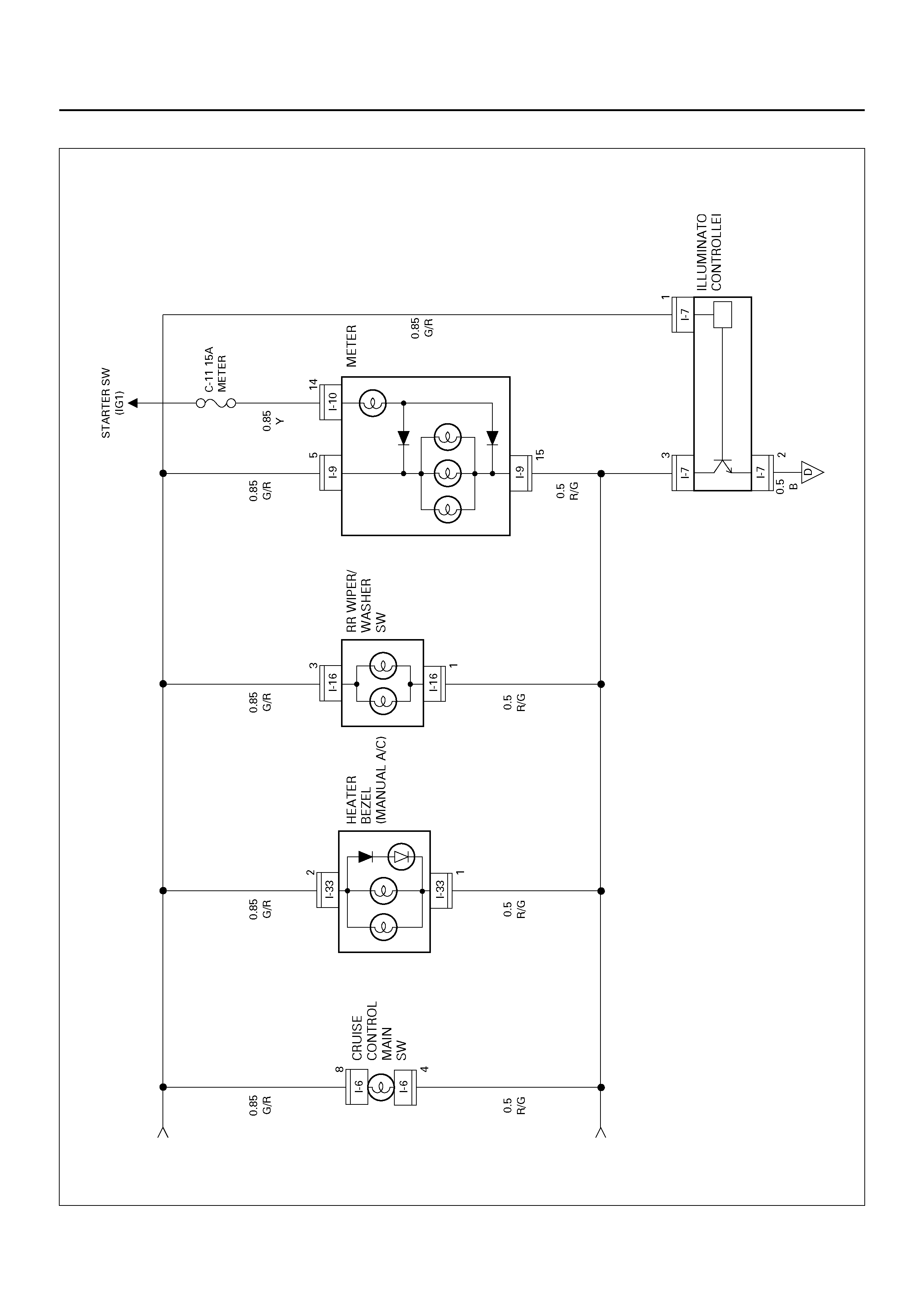

INTERIOR ILLUMINATION LIGHT

GENERAL DESCRIPTION

The circuit consists of lighting switch, tail relay, and

illumination lights.

All these lights come on when lighting switch is turned

on with the switch to either parking or headlight position.

CIRCUIT DIAGRAM–1

D08R100108

Circuit Diagram–2

D08R100109

Circuit Diagram–3

D08R100110

PARTS LOCATION

D08RY00822

EndOFCallout

Legend

(1) H–19, H–32

(2) I–53

(3) I–19

(4) I–7

(5) I–5

(6) Lighting Switch

(7) I–10

(8) I–9

(9) I–27

(10) I–16

(11) I–17

(12) I–11

(13) I–33

(14) B–24

(15) H–25

(16) H–31

(17) B –6, B–8

(18) I–15

(19) I–40

(20) I–3

(21) I–32

(22) Relay & Fuse Box (X–21)

DIAGNOSIS

Interior Illumination Light s Inopera ti ve

Step Action Value(s) Yes No

1 Turn the lighting switch to clearance light position.

Do the exterior lights come on? — Go to Step 3 Go to Step 2

2 Refer to the diagnosis procedure in Clearance Light,

Taillight and License Plate Light section.

Is the action complete?

— Verify repair —

3 Re pair an op en circ uit betwe en tail re lay harn ess sid e

connector X–21 terminal 1 and interior lights.

Is the action complete?

— Verify repair —

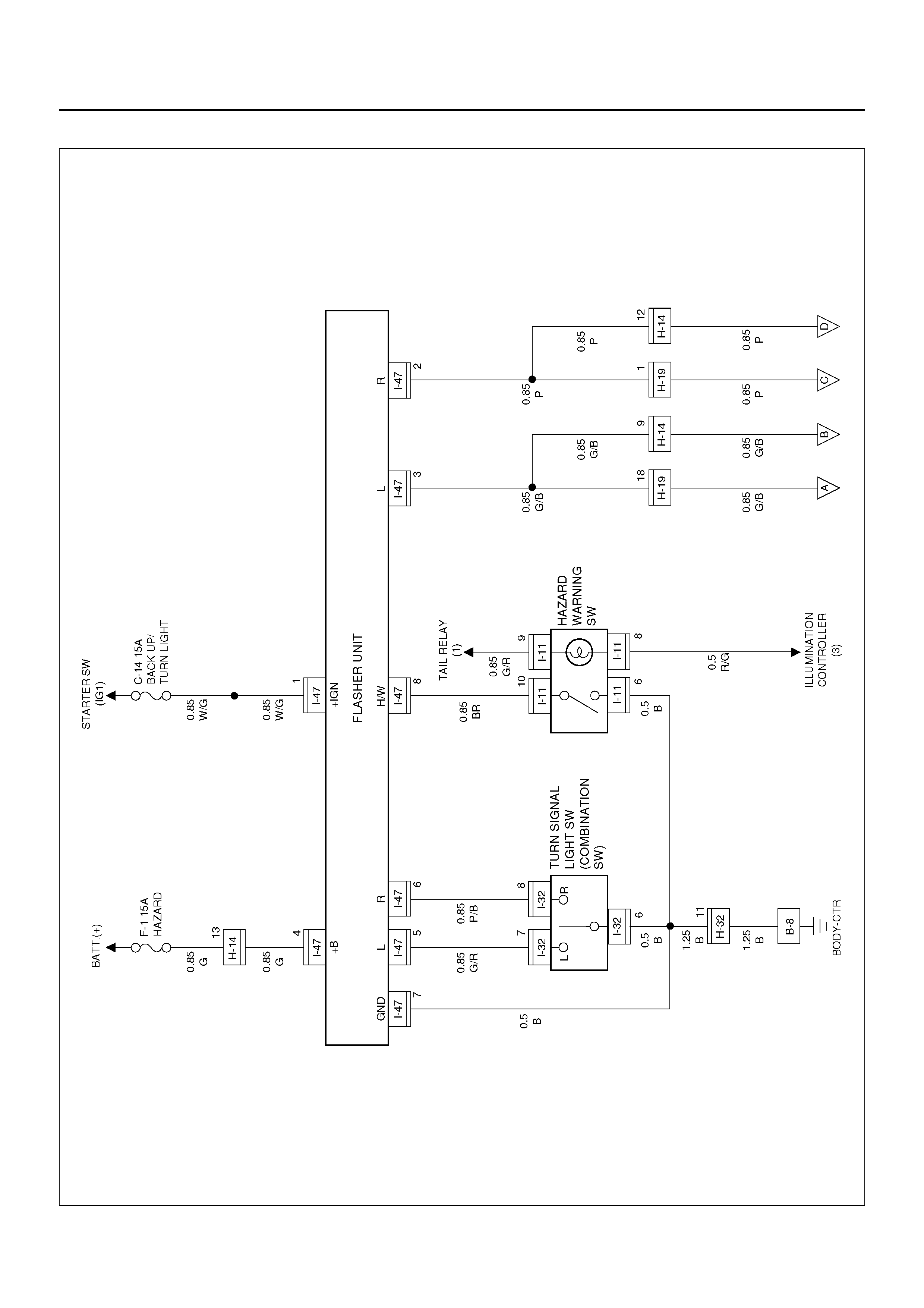

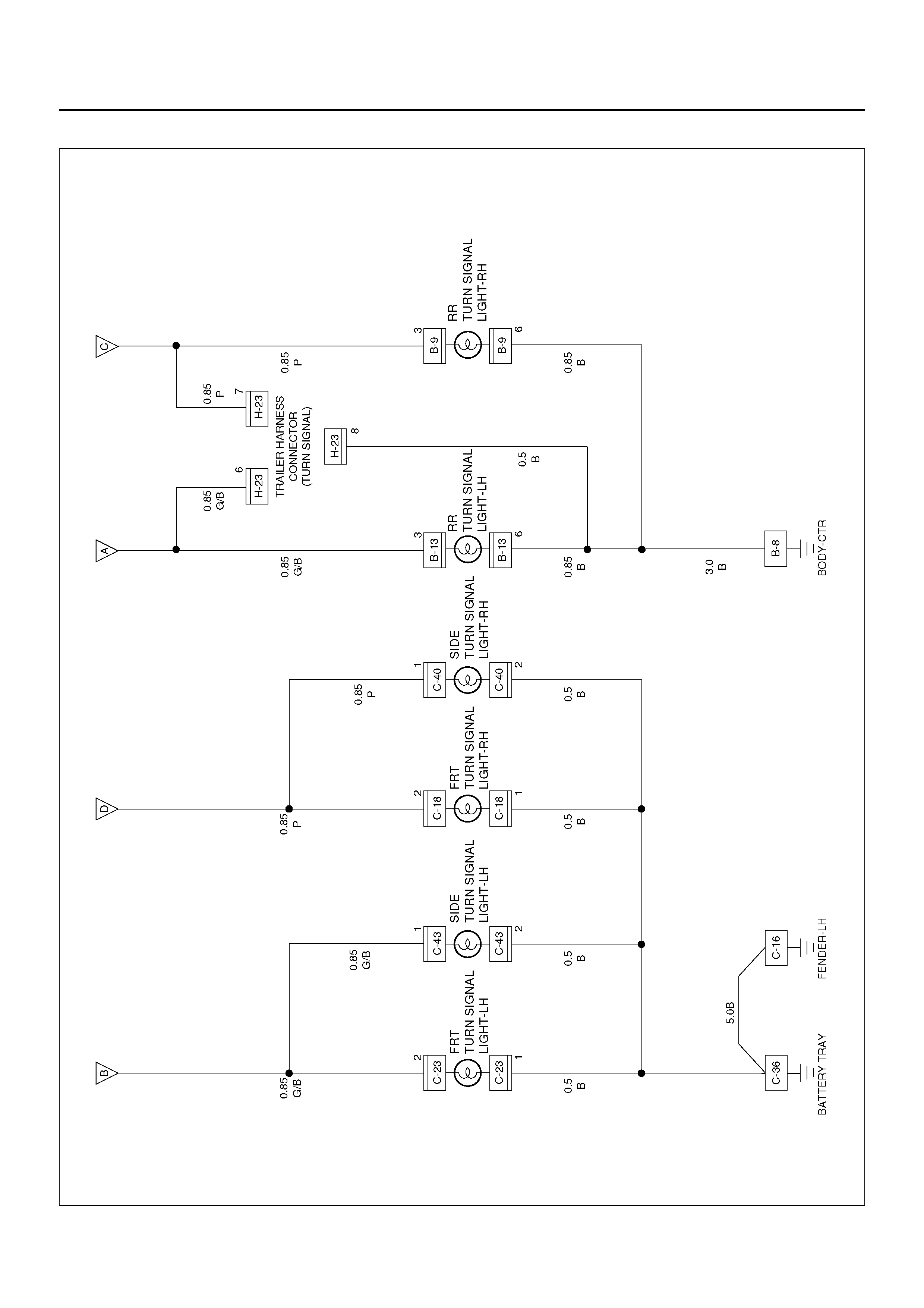

TURN SIGNAL LIGHT, HAZARD WARNING LIGHT

GENERAL DESCRIPTION

The circuit consists of turn signal light switch

(combination switch) turn signal light, hazard warning

switch and flasher unit. When turn signal light switch is

turned on with starter switch on, turn signal light will

operate. When turn signal light is flashing, indicator light

in meter also starts flashing. When hazard warning

switch i s turned on, cu rrent fl ows to flasher unit t hroug h

hazard w arning switch to cause haz ard warning lig ht to

flash independent of position of starter switch. At the

same time, indicator lights in meter also start flashing.

CIRCUIT DIAGRAM–1

D08R100111

Circuit Diagram–2

D08R100112

PARTS LOCATION

D08RX201

EndOFCallout

Legend

(1) C–36

(2) C–40

(3) H–14, H–19 , H–32

(4) Relay & Fuse Box

(5) Turn Signal light Switch

(6) I–32

(7) B–9

(8) Rear Turn Signallight – RH

(9) I–11

(10) C–16

(11) Rear Turn Signalligh t – LH

(12) B–13

(13) H–23

(14) I–47

(15) C– 43

(16) C–23

(17) Front Turn Signallight – LH

(18) B –6, B–8

(19) C–18

(20) Front Turn Signallight – RH

DIAGNOSIS

Turn Signal Light Does Not Flash

Step Action Value(s) Yes No

1 Is fuse C–14 normal? — Go to Step 2 Replace the

fuse

2 1. Disconnect the flasher unit connector I–47.

2. Turn the starter switch on.

Is the battery voltage applied between harness side

connector I–47 terminal 1 and the ground?

Approx. 12V Go to Step 4 Go to Step 3

3 Repair an open circuit between fuse C–14 and

connector I–47 terminal 1.

Is the action complete?

— Go to Step 2 —

4 Is there con tinuity b etween har ness side connecto r I–

47 terminal 7 and the ground? — Go to Step 6 Go to Step 5

5 Repair an open circuit between harness side

connector I–47 terminal 7 and the ground B–8.

Is the action complete?

— Go to Step 4 —

6 Turn the turn signal light SW to the left position.

Is ther e continu ity between h arness si de connec tor I–

47 terminal 5 and the ground?

— Go to Step 12 Go to Step 7

7 Disconnect the turn signal light switch connector I–32.

Is ther e continu ity between h arness si de connec tor I–

32 terminal 7 and I–47 terminal 5?

— Go to Step 9 Go to Step 8

8 Repair an open circuit between connector I–32

terminal 7 and I–47 terminal 5.

Is the action complete?

— Go to Step 7 —

9 Is there con tinuity b etween har ness side connecto r I–

32 terminal 6 and the ground? — Go to Step 11 Go to Step 10

10 Repair an open circuit between connector I–32

terminal 6 and the ground B–8.

Is the action complete?

— Go to Step 9 —

11 Repair or replace the combination switch.

Is the action complete? — Go to Step 5 —

12 Turn the turn signal light to the right position.

Is ther e continu ity between h arness si de connec tor I–

47 terminal 6 and ground?

— Go to Step 18 Go to Step 13

13 Disconnect the turn signal light switch connector I–32.

Is there continuity between the harness side

connector terminal I–32 terminal 8 and I–47 terminal

6?

— Go to Step 15 Go to Step 14

14 Repair an open circuit between connector I–32

terminal 8 and I–47 terminal 6.

Is the action complete?

— Go to Step 13 —

15 Is there con tinuity b etween har ness side connecto r I–

32 terminal 6 and the ground? — G o to Step 17 Go to Step 16

16 Repair an open circuit between connector I–36

terminal 6 and the ground B–8.

Is the action complete?

— Go to Step 15 —

17 Repair or replace the combination switch.

Is the action complete? — Verify repair —

Hazard Warning Light Does Not Flash

Turn Signal Light Flashes Too Quickly

18 Replace the flusher unit.

Is the action complete? — Verify repair —

Step Action Value(s) Yes No

Step Action Value(s) Yes No

1 Is fuse F–1 normal? — Go to Step 2 Replace the

fuse

2 Disconnect the flasher unit connector I–47.

Is the battery voltage applied between harness side

connector I–47 terminal 4 and the ground?

Approx. 12V Go to Step 4 Go to Step 3

3 Repair an open circuit between the fuse F–1 and

connector I–47 terminal 4.

Is the action complete?

— Go to Step 2 —

4 Is there con tinuity b etween har ness side connecto r I–

47 terminal 7 and the ground? — Go to Step 6 Go to Step 5

5 Repair an open circuit between connector I–47

terminal 7 and the ground B–8.

Is the action complete?

— Go to Step 4 —

6 Is B–8 grounded securely? — Go to Step 7 Ground it

securely

7 1. Disconnect the hazard warning switch connector

I–11.

2. Turn the hazard warning switch on.

Is there continuity between the switch side connector

I–11 terminal 6 and 10?

— Go to Step 8 Repair or

replace the

switch

8 Is there continuity between the harness side

connec tor I–11 terminal 6 and the grou nd B–8 or I–11

terminal 10 and I–47 terminal 8?

— Go to Step 10 Go to Step 9

9 Repair an open circuit between connector I–11

terminal 6 and the ground B–8 or I–11 terminal 10 and

I–47 termi nal 8.

Is the action complete?

— Verify repair —

10 Replace the flasher unit.

Is the action complete? — Verify repair —

Step Action Value(s) Yes No

1 Do all of turn signal lights flash? — Go to Step 2 Go to Step 3

2 Replace the flasher unit.

Is the action complete? — Verify repair —

3 Is the bulb of turn signal light that does not work

normal? — Go to Step 4 Replace the

bulb

4 Repair an open circuit between the turn signal light

and the turn signal light.

Is the action complete?

— Verify repair —

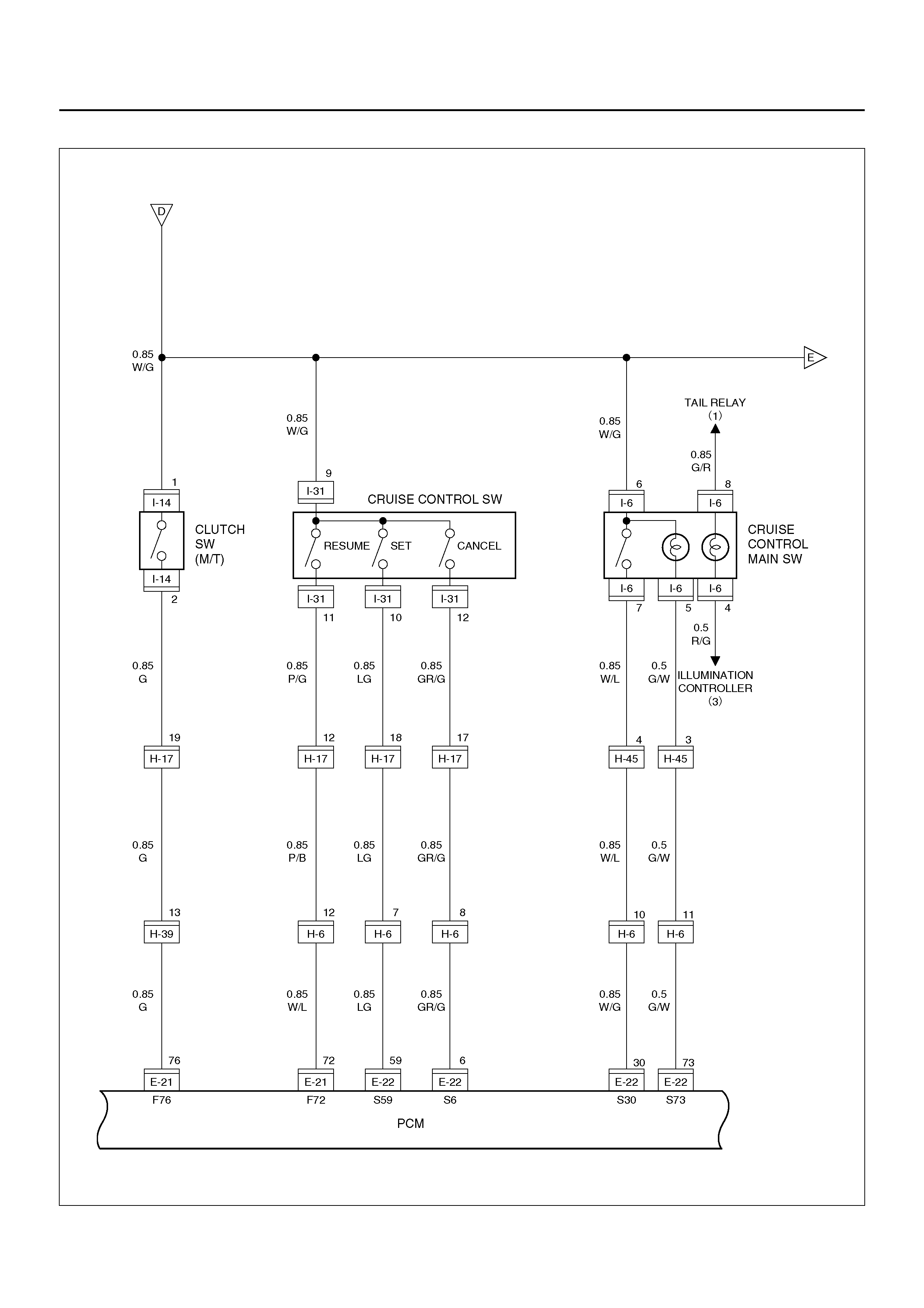

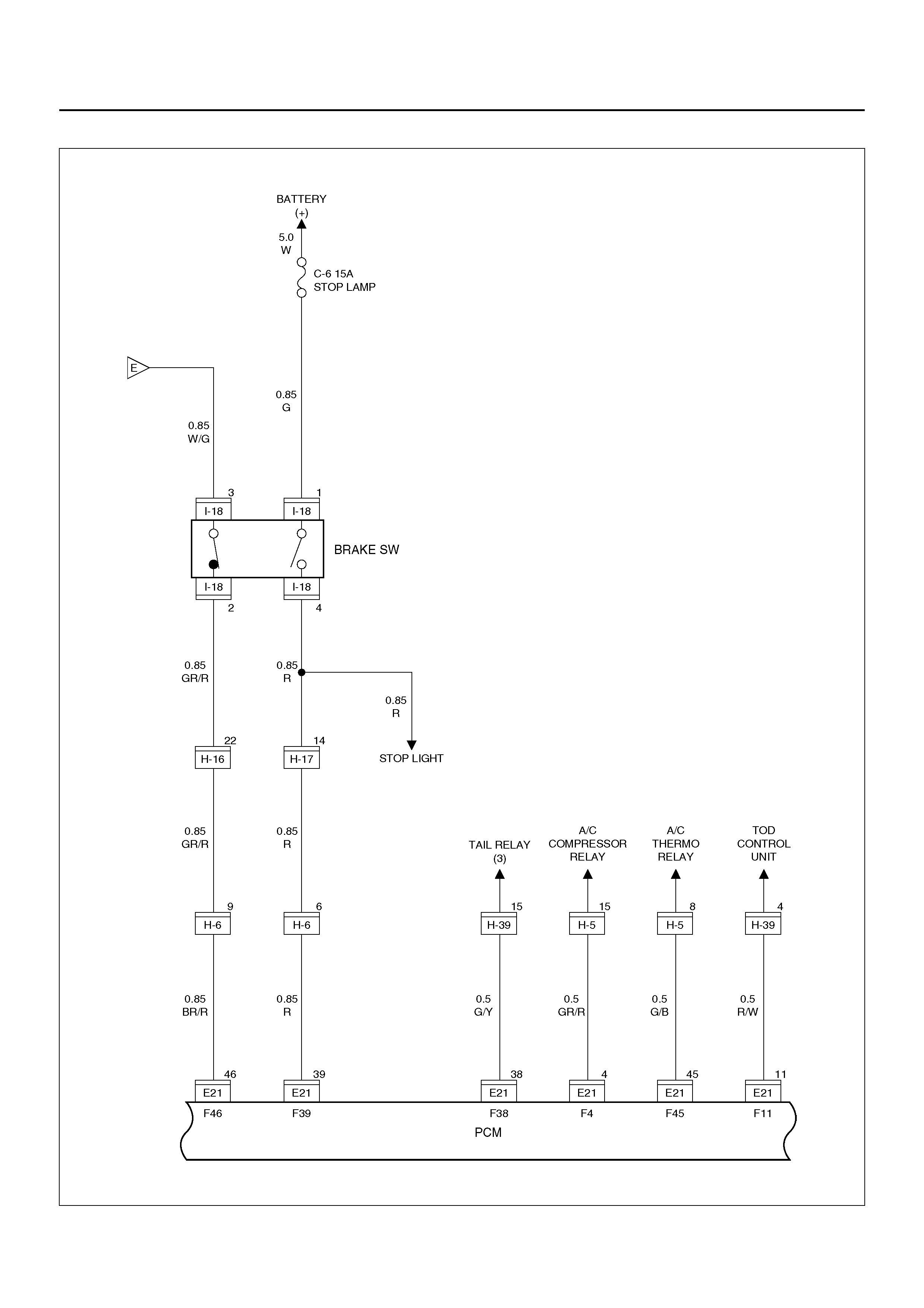

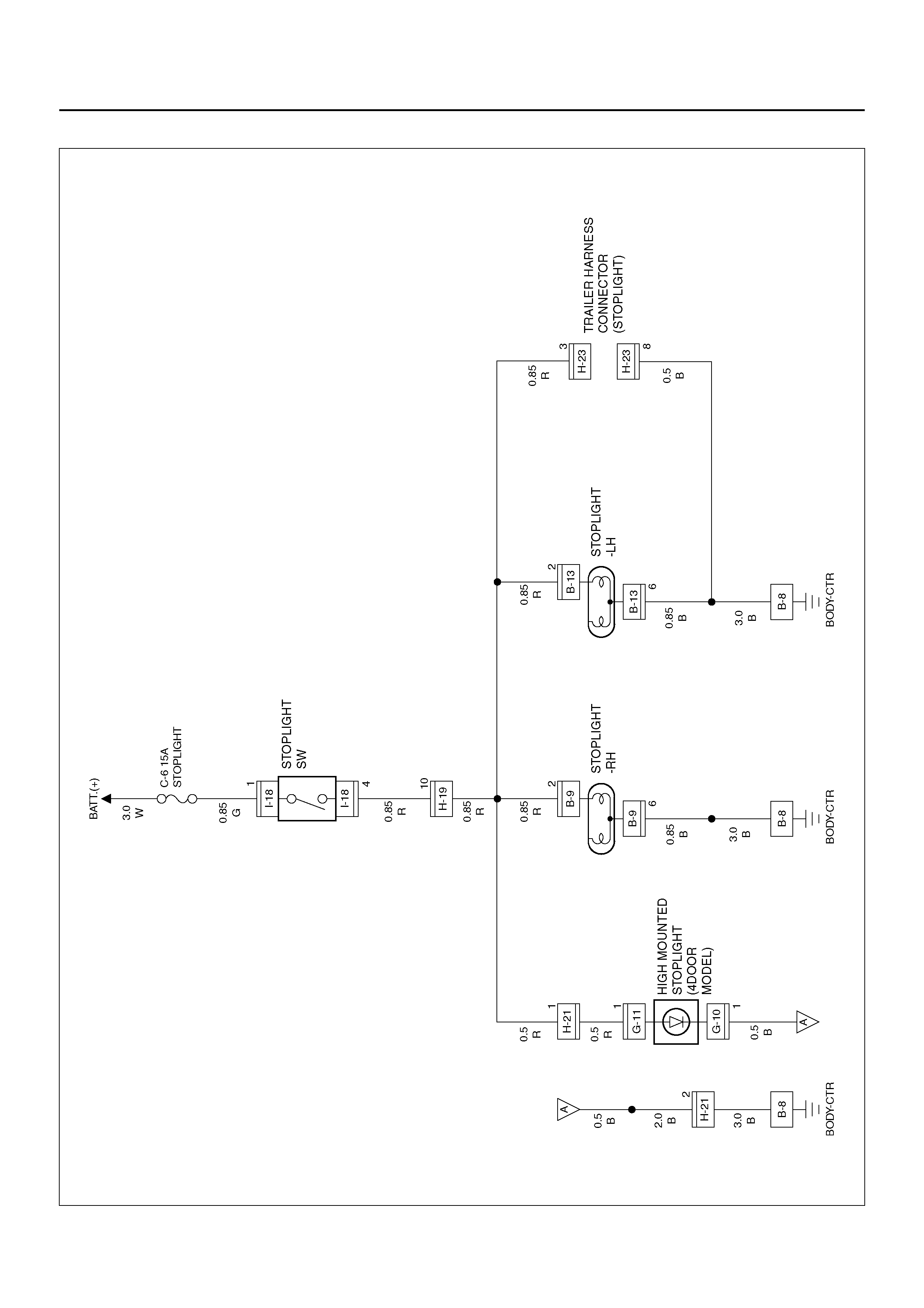

STOPLIGHT

GENERAL DESCRIPTION

The circuit consists of stoplight, high mounted stoplight

and stoplight switch.

With brake pedal depressed, stoplight switch is turned

to on to illuminate stoplight.

Stoplight switch controls not only the operation of

stoplight but also the input of cruise cancel signals to

cruise control unit.

CIRCUIT DIAGRAM

D08R100113

PARTS LOCATION

D08RX203

EndOFCallout

Legend

(1) H–19

(2) Relay & Fuse Box

(3) I–18

(4) B–9

(5) Stoplight – RH

(6) G–10, G–11

(7) High Mounted Stoplight

(8) H–21

(9) Stoplight – LH

(10) B–13

(11) B–8

(12) B–6

DIAGNOSIS

Both Stoplights Inoperative

Stoplight On The Left (or Right) Side Inoperative

High Mounted Stoplight Inoperative

Step Action Value(s) Yes No

1 Is the fuse C–6 normal? — Go to Step 2 Replace the

fuse

2 Dieconnect the stoplight switch connector I–18.

Is there continuity between switch side connector I–18

terminal 1 and 4 with the brake pedal depressed?

— Go to Step 3 Repair or

replace the

switch

3 Is the battery voltage applied between harness side

connector I–18 terminal 1 and the ground? Approx. 12V Go to Step 5 Go to Step 4

4 Repair an open circuit between the fuse C–6 and

connector I–18 terminal 1.

Is the action complete?

— Verify repair —

5 Repair an open circuit between stoplight switch and

the stoplight.

Is the action complete?

— Verify repair —

Step Action Value(s) Yes No

1 1. Disconnect the stoplight connector B–9 or B–13.

2. Depress the brake pedal.

Is the battery voltage applied between stoplight

harness side connector terminal 2 and the ground?

Approx. 12V Go to Step 2 Go to Step 3

2 Repair an open circuit between the stoplight and the

ground.

Is the action complete?

— Verify repair —

3 Repair an open circuit between the stoplight switch

and the stoplight.

Is the action complete?

— Verify repair —

Step Action Value(s) Yes No

1 De pr ess the br ake pedal .

Does the stoplight come on? — Go to Step 3 Go to Step 2

2 Refer to the diagnosis procedure for “Both Stoplights

inoperative" in this section.

Is the action complete?

— Verify repair —

3 Is B–8 grounded securely? — Go to Step 4 Ground it

securely

4 1. Disconnect the high mounted stoplight connector.

2. Depress the brake pedal.

Is the battery voltage applied between harness side

connector G–11 terminal 1 and the ground?

Appprox. 12V Go to Step 6 Go to Step 5

5 Repair an open circuit between connector H–19

terminal 10 and the high mounted stoplight.

Is the action complete?

— Go to Step 4 —

6 Is there continuity between high mounted stoplight

side connector terminals? — Go to Step 7 Repair or

replace the light

7 Repair an open circuit between the high mounted

stoplight and the ground B–8.

Is the action complete?

— Verify repair —

Step Action Value(s) Yes No

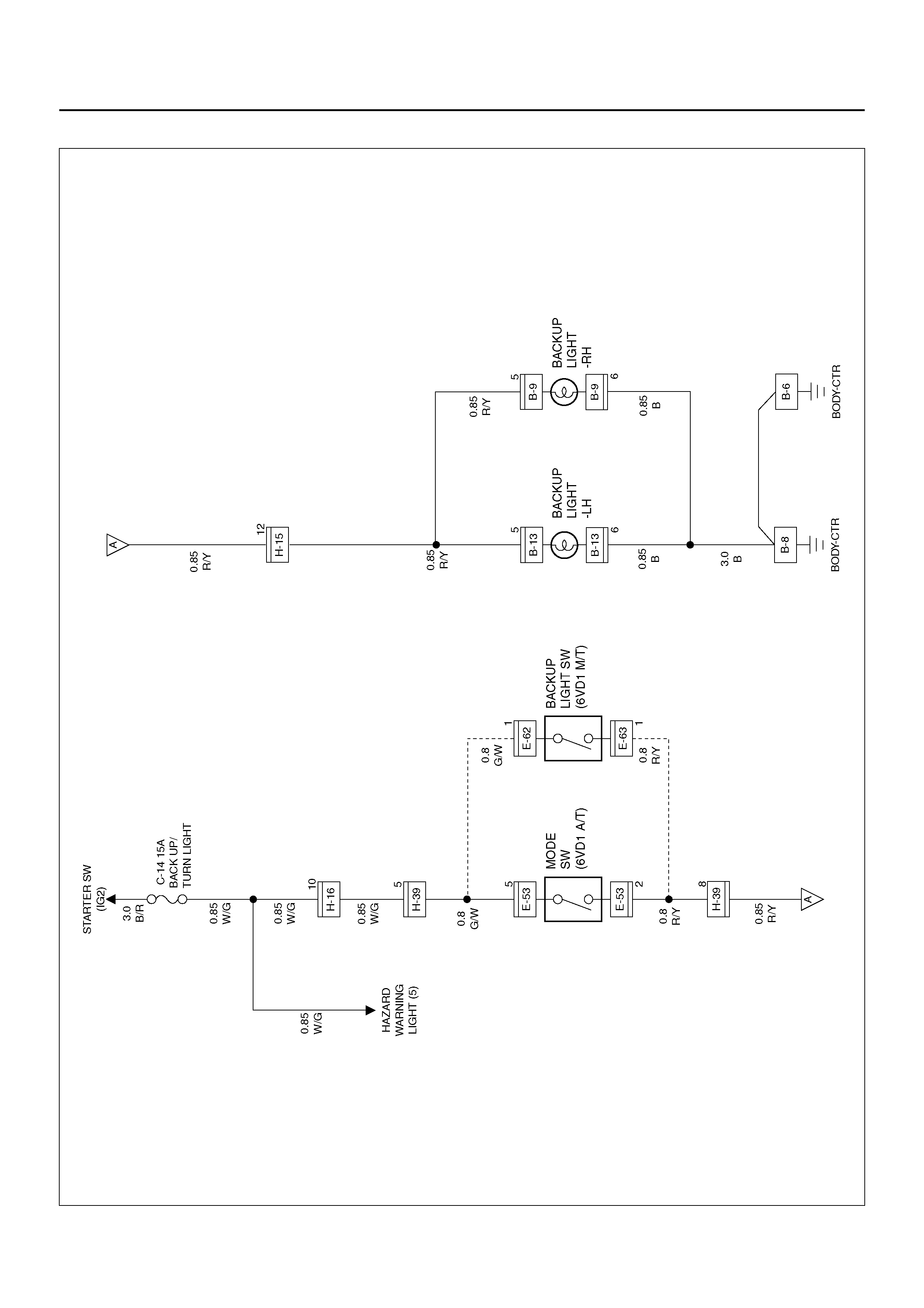

BACKUP LIGHT

GENERAL DESCRIPTION

The circuit consists of backup light switch (M/T), mode

switch (A/T) and backup light.

When shift lever is set to “R" position, backup light

switch (M/T) or mode switch (A/T) is activated to

illumin ate bac ku p lig ht.

CIRCUIT DIAGRAM

D08R100114

PARTS LOCATION

D08RY00824

EndOFCallout

Legend

(1) B–9

(2) Backup Light – RH

(3) Backup Light – LH

(4) B–13

(5) H–15, H–16

(6) B–8

(7) B–6

(8) H–39

(9) E–62

(10) E–53

(11) Relay & Fuse Box

DIAGNOSIS

Both Backup Lights Inoperative

Backup Light On The Left (or Right) Side Inoperative

Step Action Value(s) Yes No

1 Is the fuse C–14 normal? — Go to Step 2 Replace the

fuse

2 Are B–6 and B–8 ground securely? — Go to Step 3 Ground them

securely

3 1. Disconnect the mode switch connector E–53 or

backup light switch connector E–62 and E–63.

2. Turn the starter switch on.

Is the battery voltage applied between harness side

connec tor E-53 termin al 5 and the gr ound, or har ness

side connector E–62 terminal 1 and the ground?

Approx. 12V Go to Step 5 Go to Step 4

4 Repair an open circuit between the fuse C–14 and

connector E–53 terminal 5 or connector E–62 terminal

1.

Is the action complete?

— Go to Step 3 —

5 Set the transmission gear to the reverse position.

Is there continuity between mode switch side

connector terminal 2 and 5, or backup light switch side

connector terminals?

— Go to Step 6 Repair or

replace the

switch

6 1. Reconnect the mode switch connector E–53 or

backup light switch connector E–62 and E–63.

2. Disconnect the backup light connector B–9 or B–

13.

Is the battery voltage applied between the backup

light harness side connector terminal 5 and the

ground?

Approx. 12V Go to Step 8 Go to Step 7

7 Repair an open circuit between the mode switch or

backup light switch and the backup lights.

Is the action complete?

— Verify repair —

8 Re pair an open circuit between backup l ights and the

ground.

Is the action complete?

— Verify repair —

Step Action Value(s) Yes No

1 Remove the backup light bulb on the left or right side.

Is the bulb normal? — Go to Step 2 Replace the

bulb

2 1. Set the transmission gear to the reverse position.

2. Turn the starter switch on.

Is the battery voltage applied between backup light

harness side connector B–9 or B–13 terminal 5 and

the ground?

Approx. 12V Go to Step 4 Go to Step 3

3 Repair an open circuit between connector H–15

terminal 12 and the backup light on the left or right

side.

Is the action complete?

— Verify repair —

4 Repair an open circuit between the backup light on the

left or right side and the ground.

Is the action complete?

— Verify repair —

Backup Lights Remain On

Step Action Value(s) Yes No

1 Re pair or replace the mo de switch or the ba ckup light

switch.

Is the action complete?

— Verify repair —

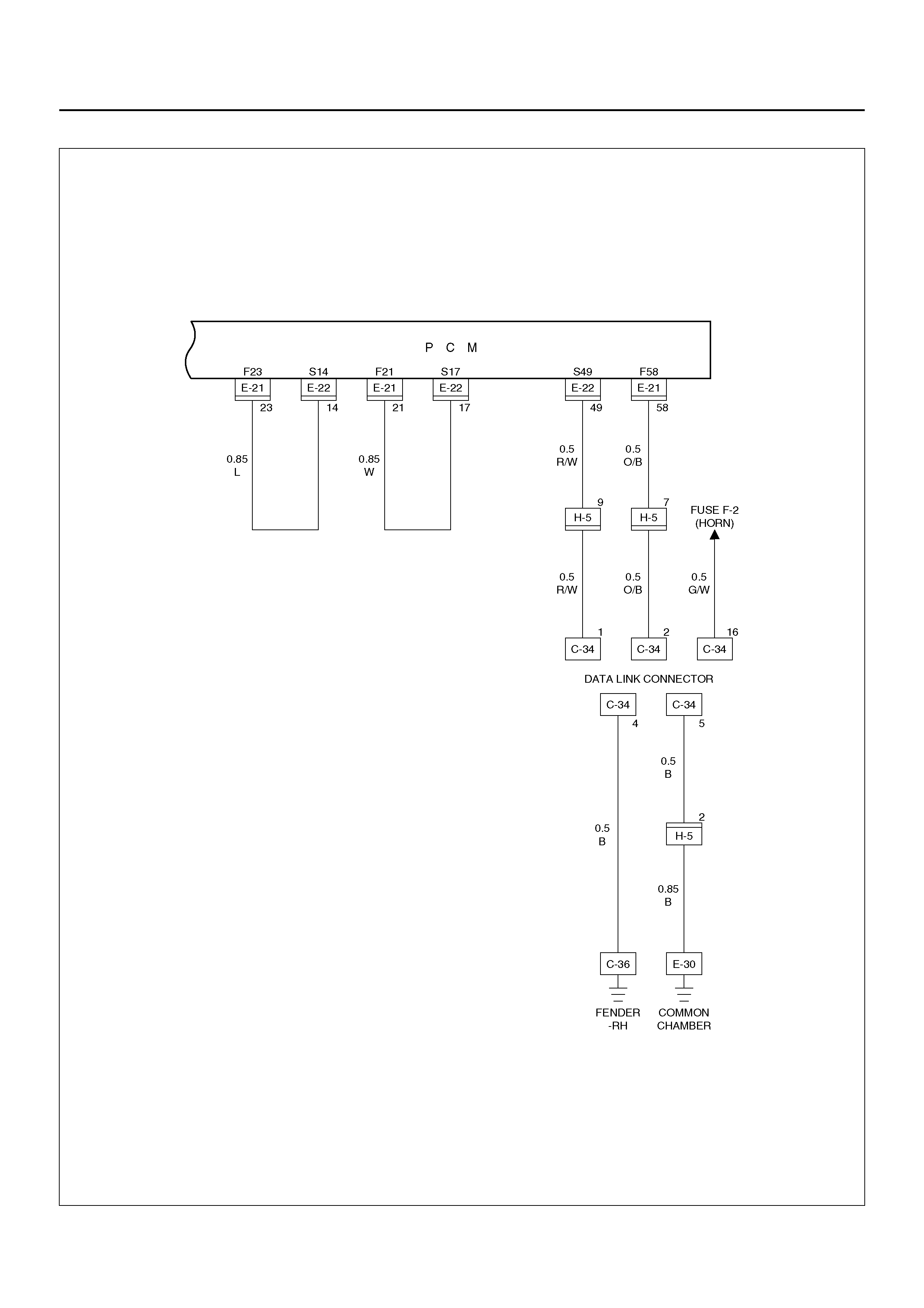

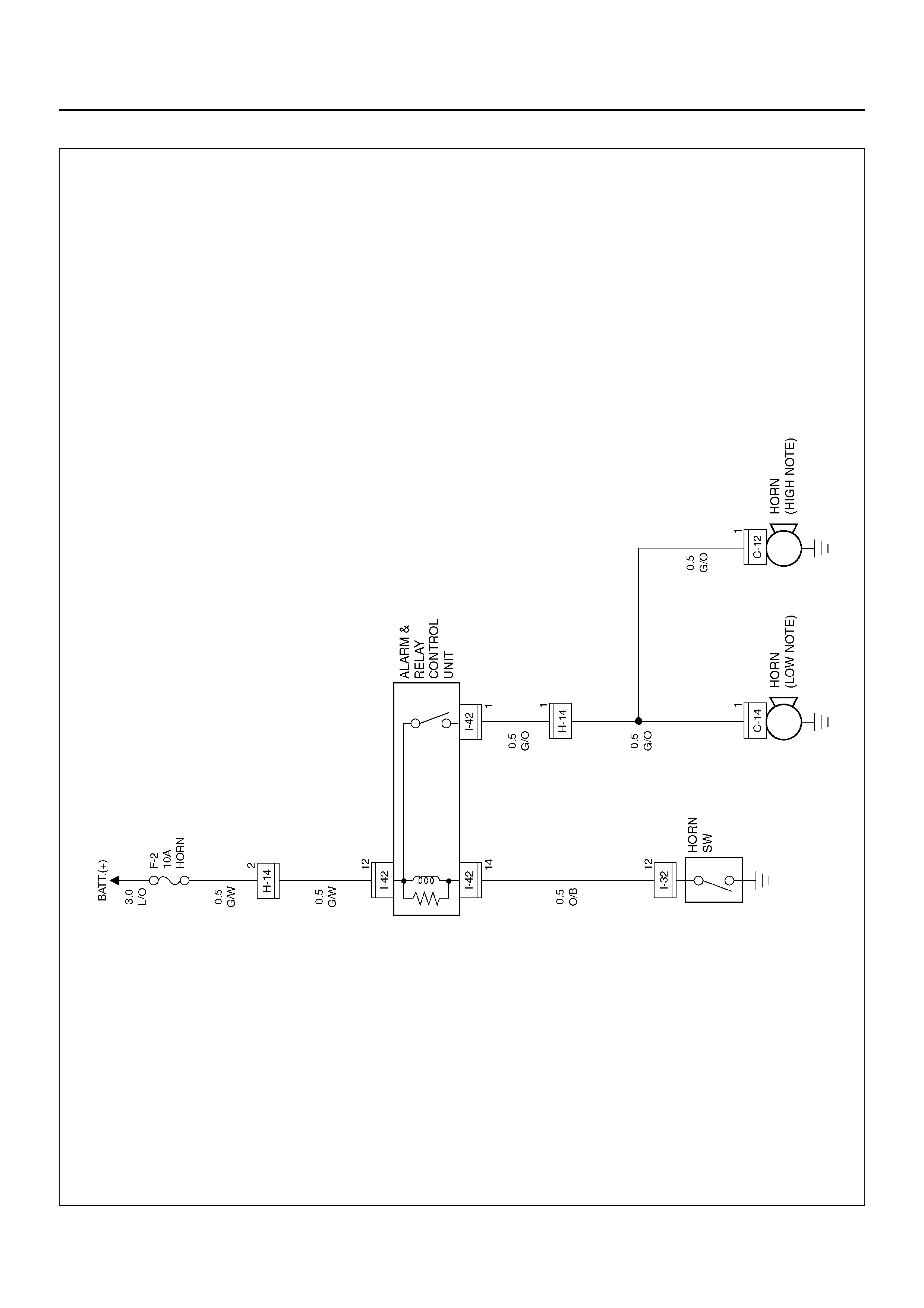

HORN

GENERAL DESCRIPTION

The circuit consists of horn (high note and low note),

horn relay (alarm & relay control unit) and horn switch.

When horn switch is pressed, (independent of position

of starter switch) horn relay is activated to sound horns.

CIRCUIT DIAGRAM

D08R100115

PARTS LOCATION

D08RWD18

EndOFCallout

Legend

(1) H–14

(2) SRS Coil ASM

(3) Horn Switch

(4) I–42

(5) I–32

(6) Horn (Low note)

(7) C–14

(8) C–12

(9) Horn (High note)

DIAGNOSIS

Horn Does Not Sound

Horn Does Not Stop Sounding

Step Action Value(s) Yes No

1 Is the fuse F–2 normal? — Go to Step 2 Replace the

fuse

2 Di sco nnect the alarm & relay contr ol unit c onnec tor I–

42.

Is the battery voltage applied between harness side

connector I–42 terminal 12 and the ground?

Approx. 12V Go to Step 4 Go to Step 3

3 Repair an open circuit between the fuse F–2 and the

alarm & relay control unit.

Is the action complete?

— Verify repair —

4 Disconnect the horn switch connector I–32.

Is there continuity between switch side connector I–32

terminal 12 and the ground with the horn switch

pressed?

— Go to Step 5 Repair or

replace the

switch

5 Is there con tinuity b etween har ness side connecto r I–

32 terminal 12 and connector I–42 terminal 14? — Go to Step 7 Go to Step 6

6 Repair an open circuit between the alarm & relay

control unit and the horn switch.

Is the action complete?

— Verify repair —

7 1. Disconnect the horn connector.

2. Connect the battery positive terminal to the horn

side connector terminal 1.

Does the horn work?

— Go to Step 8 Replace the

horn

8 Is there continuity between harness side connector

terminal between the horn and the alarm & relay

control un it?

— Go to Step 9 Go to Step 10

9 Replace the alarm & relay control unit.

Is the action complete? — Verify repair —

10 Repair an open circuit between the horn and the alarm

& relay control unit.

Is the action complete?

— Verify repair —

Step Action Value(s) Yes No

1 Disconnect the horn switch connector I–32.

Do the horn stop sounding? — Repair or

replace the

horn switch

Go to Step 2

2 Di sco nnect the alarm & relay contr ol unit c onnec tor I–

42.

Is there continuity between harness side connector

terminal 14 and the ground?

— Repair shor t

circuit Replace the

alarm & relay

control unit

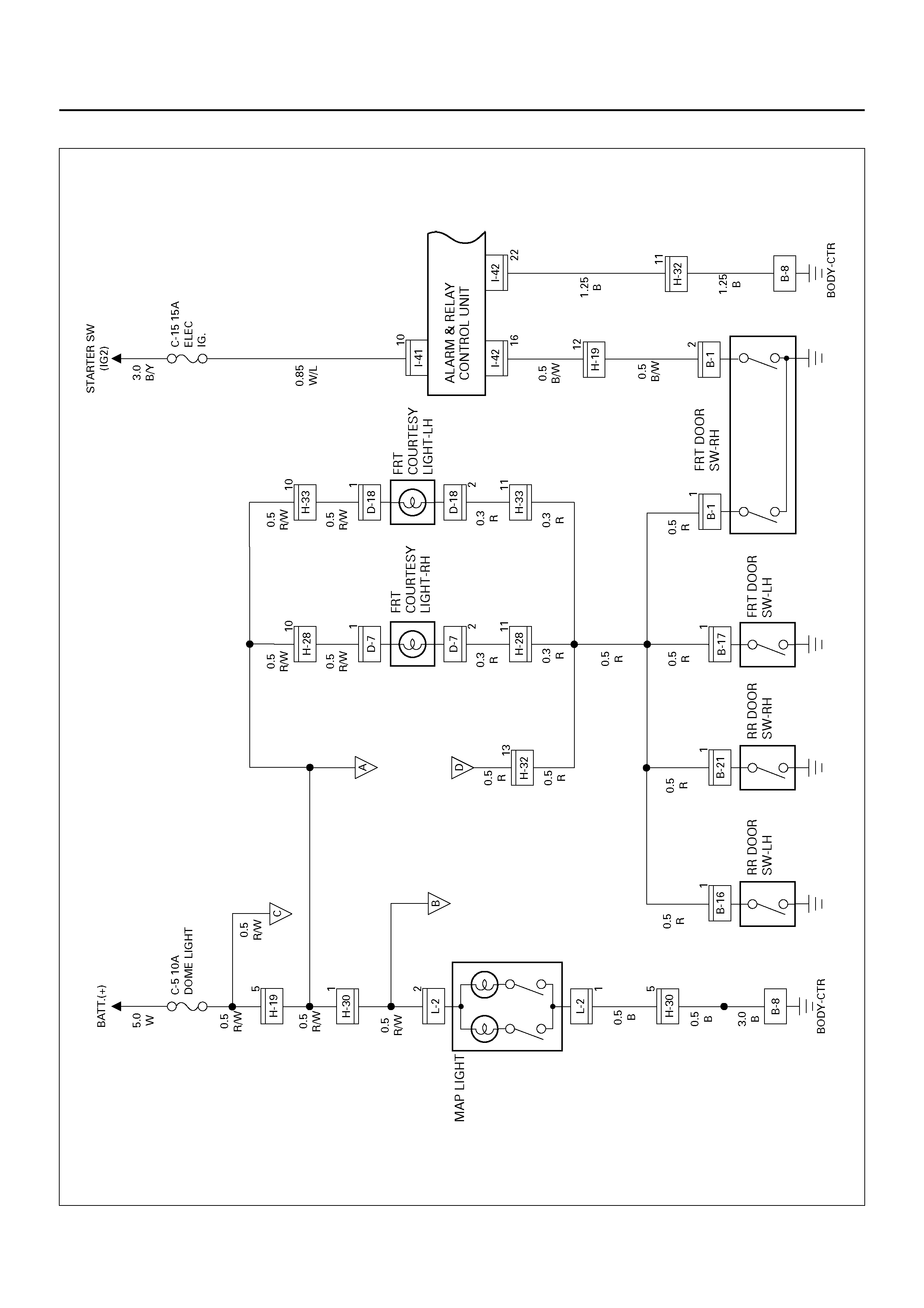

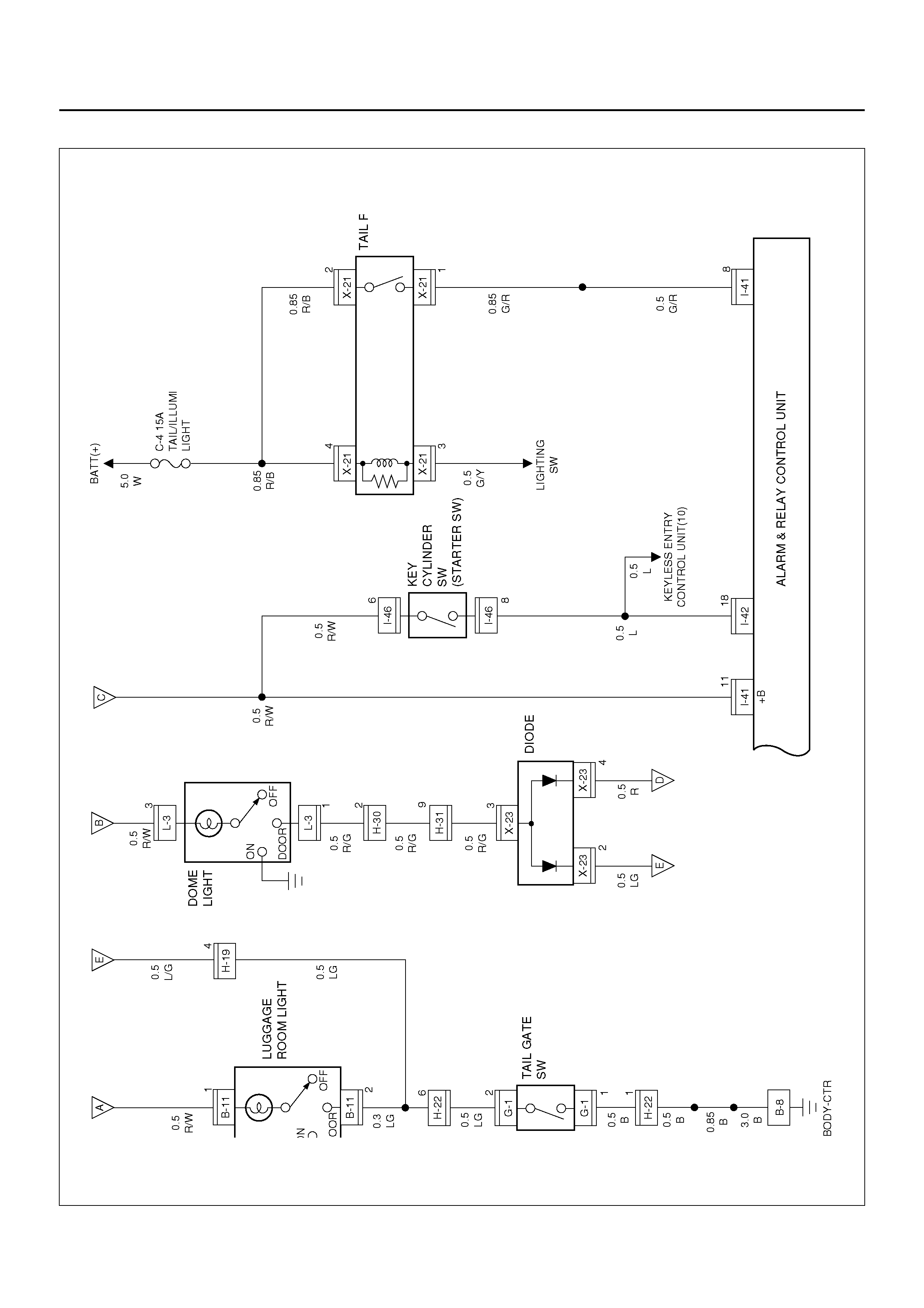

DOME LIGHT, LUGGAGE ROOM LIGHT, COURTESY LIGHT, MAP

LIGHT, SEAT BELT SWITCH AND WARNING BUZZER

GENERAL DESCRIPTION

The circuit consists of door switch, dome light, luggage

room light, courtesy light, map light, tail relay, key

cylinder switch and alarm & relay control unit.

Dome light comes on with dome light switch turned to

door position and any door open.

The buzzer sounds when starter switch is turned to

either “ACC" or “OFF" position and FRT door–RH, is

opened with lighting switch on.

The buzzer also sou nds when FRT door–RH is opene d

with starter key left in starter switch key cylinder.

These functions are controlled by the alarm & relay

control unit.

CIRCUIT DIAGRAM–1

D08R100118

Circuit Diagram–2

D08R100230

PARTS LOCATION

D08R100192

EndOFCallout

Legend

(1) Relay & Fuse Box

(2) FRT Door SW–RH

(3) B–1

(4) B–21

(5) RR Door SW–RH

(6) Map Light

(7) L–2

(8) Do me Lig ht

(9) L–3

(10) B–11

(11) L ugga ge Room Light

(12) G–1

(13) H–22

(14) RR Door SW– LH

(15) B–16

(16) H–29

(17) B–17

(18) FRT Door SW–LH

(19) H–30

(20) F RT Courtesy –Li gh t–LH

(21) D–18

(22) H–33

(23) I–41, I–42

(24) H–31

(25) B –6, B–8

(26) I–46

(27) D–7

(28) F RT Courtesy –Ligh t–RH

(29) H–28

(30) H–19, H–32

DIAGNOSIS

Dome Light Inoperative

Step Action Value(s) Yes No

1 Re mov e the dom e ligh t bulb.

Is the bulb normal? — Go to Step 2 Replace the

bulb

2 1. Reinstall the bulb.

2. Disconnect the dome light connector L–3.

3. Set the dome light switch to door position.

Is there continuity between the dome light side

connector terminal 1 and 3?

— Go to Step 3 Repair or

replace the

dome light

3 Is the battery voltage applied between harness side

connector L–3 terminal 3 and the ground? Approx. 12V Go to Step 5 Go to Step 4

4 Repair an open circuit between the fuse C–5 and th e

dome light.

Is the action complete?

— Verify repair —

5 Repair an open circuit between the dome light and the

door switch or the tail gate switch.

Is the action complete?

— Verify repair —

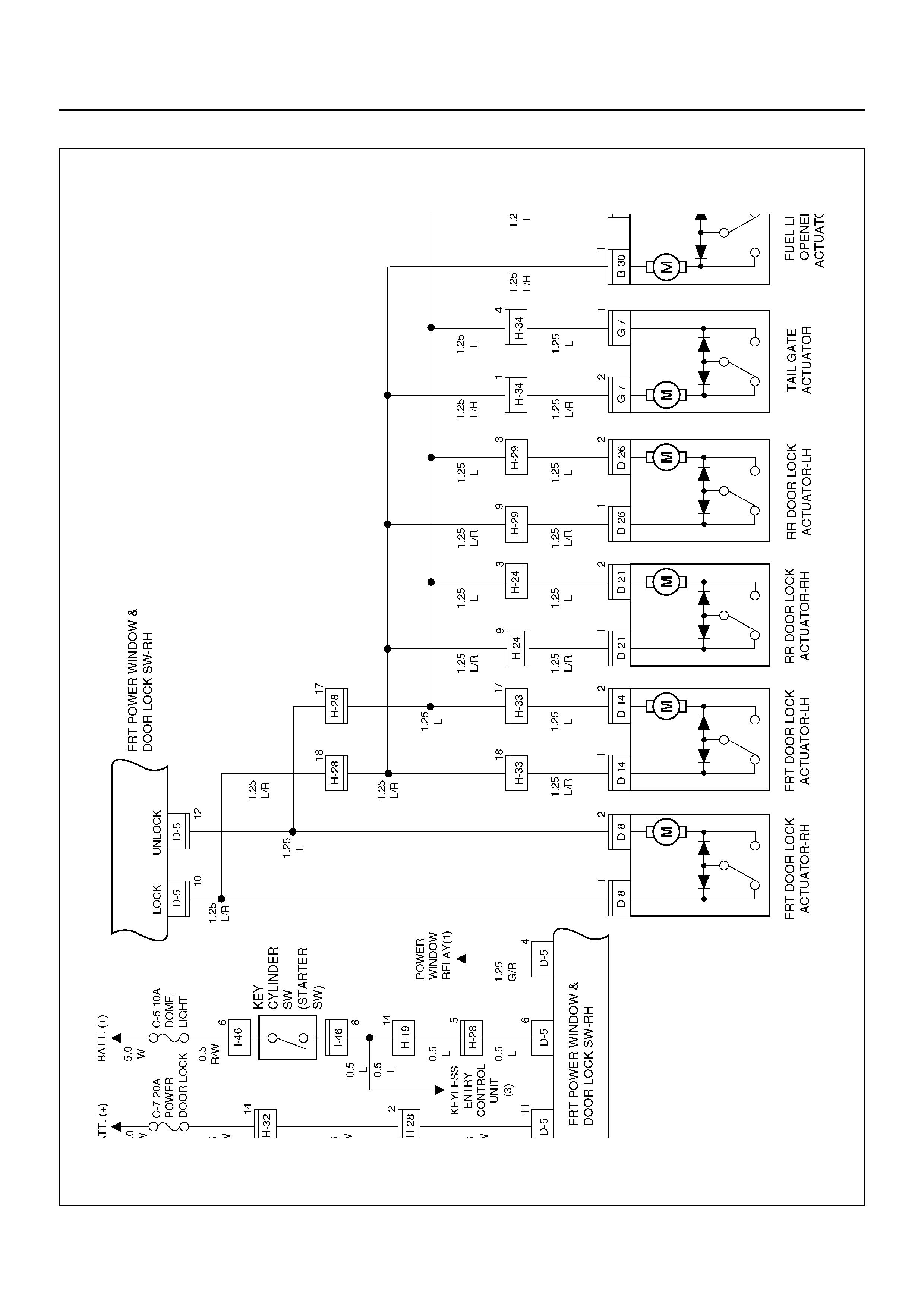

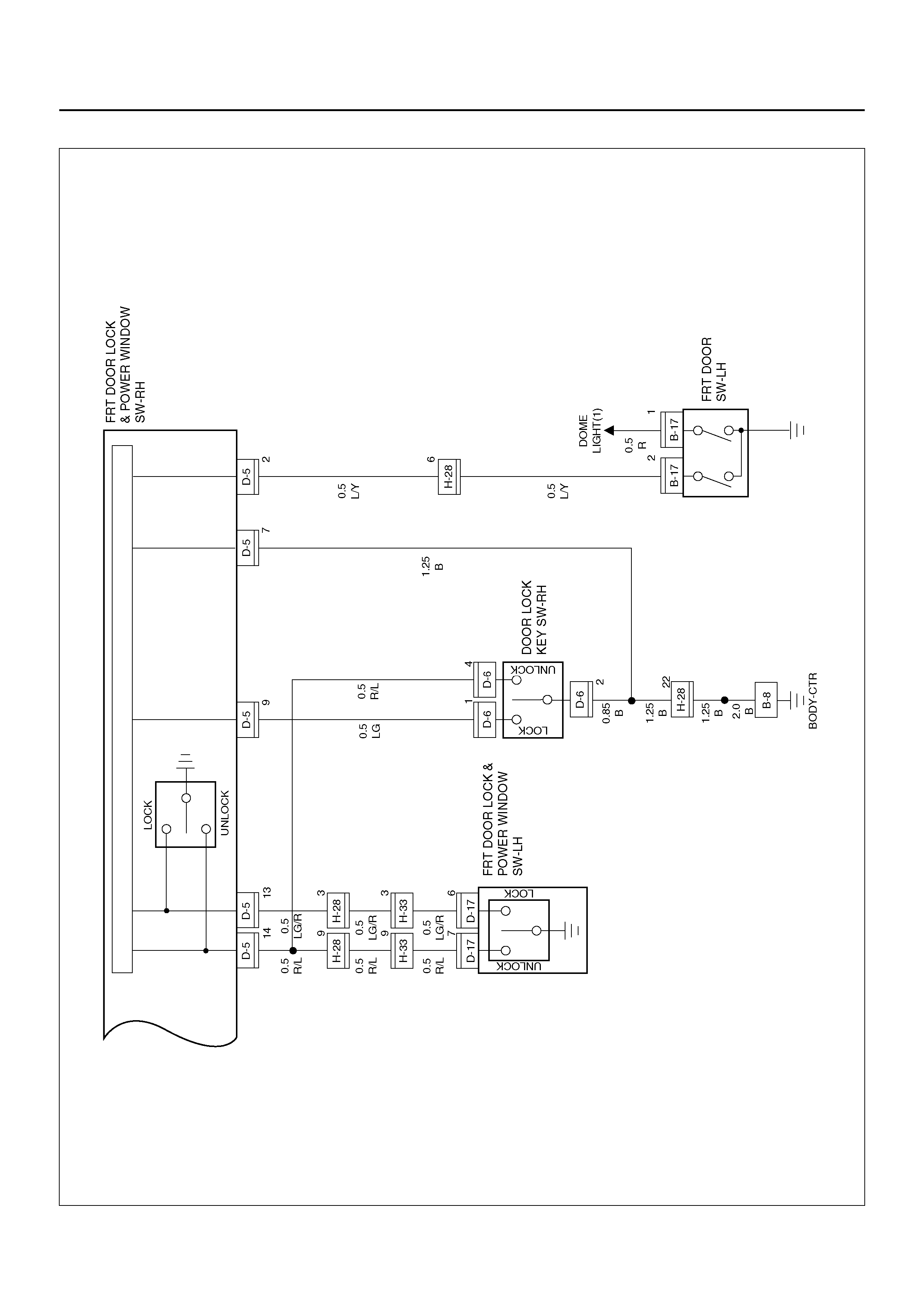

POWER DOOR LOCK

GENERAL DESCRIPTION

The door lock system consists of door lock & power

window switch, key cylinder switch and door lock

actuator. Door lock switch on driver's side can actuate

the door lock mechanism.

Locking or unlocking the lock switch on the driver side

causes the door lock mechanism to be locked or

unlocked.

At this time, the c urr ent fl ows for ap prox . 1 s econd fr om

door lock switch on driv er's side to door lock actuator to

run the motor.

When the key is in the key cylinder, Door Lock can not

be done.

CIRCUIT DIAGRAM–1

D08R100234

Circuit Diagram–2

D08R100124

PARTS LOCATION

D08RWD15

EndOFCallout

Legend

(1) H–28

(2) H–19, H–32

(3) D–8

(4) FRT Door Lock Actuator–RH

(5) H–24

(6) FRT Door Lock Switch–RH

(7) D–6, D–5

(8) D–21

(9) RR Door Lock Actuator–RH

(10) I–26

(11) FRT Door Lock Actuator–LH

(12) D–14

(13) RR Door Lock Actuator–LH

(14) B –30

(15) D–26

(16) H–29

(17) D–17

(18) FRT Door Lock Switch–LH

(19) H–33

(20) B–8

(21) Relay & Fuse Box (Instrument Panel)

(22) H–34, H–22 (2Door Model)

(23) G–7

DIAGNOSIS

All The Doors Do Not Lock And Unlock By Door Lock SW–RH

All The Doors Do Not Lock and Unlock by FRT Door Lock SW–LH

Step Action Value(s) Yes No

1 Is the fuse C–7 normal? — Go to Step 2 Replace the

fuse

2 Disconnect the front power window & door lock SW–

RH connector D–5.

Is the battery voltage applied between harness side

connector D–5 terminal 11 and the ground?

Approx. 12V Go to Step 4 Go to Step 3

3 Repair an open circuit between the fuse C–7 and th e

switch.

Is the action complete?

— Verify repair —

4 Di sconnect the F RT door lo ck actuator–R H connector

D–8.

Is there continuity between harness side connector D–

5 terminal 10 and connector D–8 terminal 1 (or

connector D–5 terminal 12 and connector D–8

terminal 2)?

— Go to Step 5 Go to Step 6

5 Replace the FRT power window & door lock SW–RH.

Is the action complete? — Verify repair —

6 Repair an open circuit between the FRT power

window & door lock SW–RH and door lock actuator.

Is the action complete?

— Verify repair —

Step Action Value(s) Yes No

1 Disconnect the FRT power window & door lock SW–

RH and –LH connector D–5 and D–17.

Is there continuity between harness side connector D–

5 terminal 13 and connector D–17 terminal 6 (or

connector D–5 terminal 14 and connector D–17

terminal 7)?

— Go to Step 2 Go to Step 3

2 Replace the FRT power window & door lock SW–LH.

Is the action complete? — Verify repair —

3 Repair an open circuit between the FRT power

window & door lock SW–RH and –LH.

Is the action complete?

— Verify repair —

All the Doors Do Not Lock and Unlock by Door Lock Key SW

Step Action Value(s) Yes No

1 Is B–8 grounded securely? — Go to Step 2 Ground it

securely

2 Disconnect the door lock key SW connector D–6.

Is there continuity between harness side connector D–

6 terminal 2 and the ground?

— Go to Step 4 Go to Step 3

3 Repair an open circuit between connector D–6

terminal 2 and the ground B–8.

Is the action complete?

— Verify repair —

4 Is there continuity between the switch side connector

terminal 1 and 2 when the switch is turned to lock

position, and terminal 2 and 4 when the switch is

turned to unlock position?

— Go to Step 5 Repair or

replace the

switch

5 Re pair an open circui t between the door lock key SW

and FRT power window & door lock SW–RH.

Is the action complete?

— Verify repair —

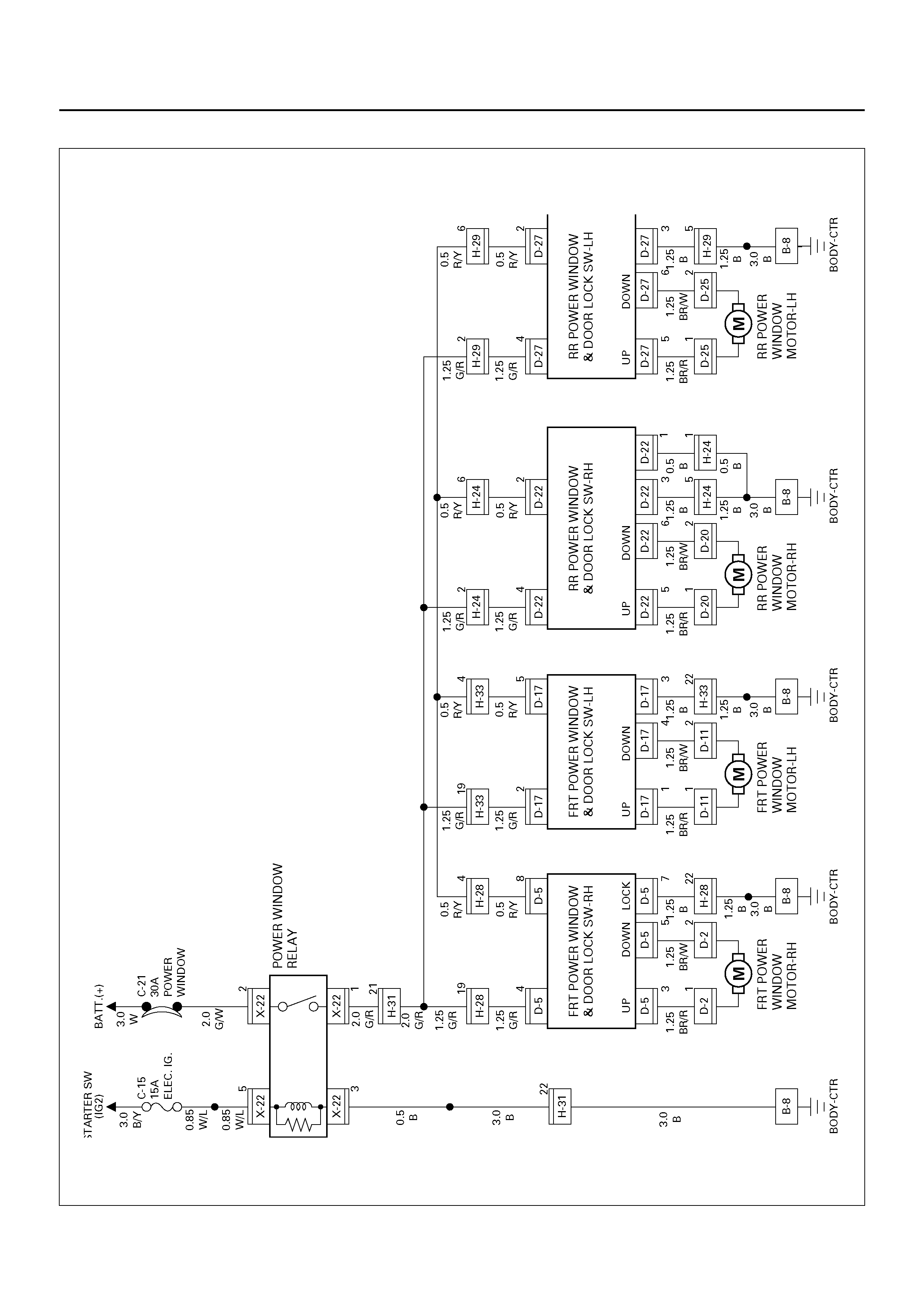

POWER WINDOW

GENERAL DESCRIPTION

The power window system consists of power window

switches, power window motors and power window

relay.

With the starter switch in “ON" position, the battery

voltage is supplied through power window relay to the

power wind ow switche s. Selec tion of up or down swi tch

changes over the motor rotating direction to open or

close the window.

When the lock switch on the switch panel on the driver

side is pressed, the power window switch is in open

state. As a result, the power source to the other

switches are cut off, and the power window motors do

not run.

CIRCUIT DIAGRAM–1

D08R100194

PARTS LOCATION

D08R100195

EndOFCallout

Legend

(1) H–28

(2) D–2

(3) Relay & Fuse Box

(4) Power Window Motor (FRT RH)

(5) Power Window SW (FRT RH)

(6) D–5

(7) Power Window Motor (RR RH)

(8) D–20

(9) D–22

(10) Power Window SW (RR RH)

(11) Power Window SW (FRT LH)

(12) Power Window SW (RR LH)

(13) D–27

(14) D–25

(15) P ower Window Moto r (RR LH)

(16) H–29

(17) D–17

(18) D–11

(19) P ower Window Moto r (FRT LH)

(20) H–33

(21) H–31

(22) B–8

(23) H–24

DIAGNOSIS

All Window Do Not Operate

Step Action Value(s) Yes No

1 Is the fuse C–15 normal? — Go to Step 2 Replace the

fuse

2 Is the circuit breaker C–21 normal? — Go to Step 3 Replace the

circuit breaker

3 Is B–8 grounded securely? — Go to Step 4 Ground it

securely

4 Disconnect the power window relay connector X–22.

Is the battery voltage applied between harness side

connector X–22 terminal 2 and the ground?

Approx. 12V Go to Step 6 Go to Step 5

5 Re pair an open c ircuit between the circui t breaker C–

21 and connector X–22 terminal 2.

Is the action complete?

— Go to Step 4 —

6 Turn the starter switch on.

Is the battery voltage applied between harness side

connector X-22 terminal 5 and the ground?

Approx. 12V Go to Step 8 Go to Step 7

7 Repair an open circuit between the fuse C–15 and

connector X–22 terminal 5.

Is the action complete?

— Go to Step 6 —

8 Is there continuity between harness side connector X–

22 terminal 3 and the ground B–8? — Go to Step 10 Go to Step 9

9 Repair an open circuit between connector harness

side X–22 terminal 3 and the ground B–8.

Is the action complete?

— Go to step 8 —

10 Is there continuity between harness side connector X–

22 terminal 1 and connector D–5 terminal 4? — Replace the

power window

relay

Go to Step 11

11 Repair an open circuit between power window relay

and FRT power window & door lock switch–RH.

Is the action complete?

— Verify repair —

Window On The Driver's Side Does Not Operate

Step Action Value(s) Yes No

1 Turn the starter switch on.

Is the battery voltage applied between harness side

connector D–5 terminal 4 and the ground?

Approx. 12V Go to Step 3 Go to Step 2

2 Repair an open circuit between connector X–22

terminal 1 and connector D–5 terminal 4.

Is the action complete?

— Go to Step 1 —

3 Disconnect the front power window & door lock

switch–RH connector D–5.

Is there continuity between the front power window &

door lock switch–RH harness side connector D–5

terminal 7 and ground B–8?

— Go to Step 5 Go to Step 4

4 Repair an open circuit between connector D–5

terminal 7 an ground B–8.

Is the action complete?

— Go to Step 3 —

5 Connect the battery position terminal with harness

side connector D–5 terminal 3 or 5, and the negative

terminal with harness side connector D–5 terminal 5

or 3.

Does the motor operate?

— Replace the

front power

window & door

lock switch–RH

Go to Step 6

6 1. Disconnect the front power window motor–RH

connector D–2.

2. Connect the battery position terminal with the

motor side connector D–2 terminal 1 or 2, and

connect the battery negative terminal with the

motor side connector D–2 terminal 2 or 1.

Does the motor operate?

— Go to Step 7 Replace the

motor

7 Repair an open circuit between the front power

window and doo r lock switch–RH and the front power

window motor–RH.

Is the action complete?

— Verify repair —

Window On The Front Passenger's Side Does Not Operate

Step Action Value(s) Yes No

1 Turn the starter switch on.

Is the battery voltage applied between harness side

connector D–17 terminal 2 and the ground?

Approx. 12V Go to Step 3 Go to Step 2

2 Repair an open circuit between connector X–22

terminal 1 and connector D–17 terminal 2.

Is the action complete?

— Go to Step 1 —

3 Disconnect the front power window & door lock

switch–RH connector D–17.

Is there continuity between the front power window &

door lock switch–RH harness side connector D–17

terminal 3 and ground B–8?

— Go to Step 5 Go to Step 4

4 Repair an open circuit between connector D–17

terminal 3 an ground B–8.

Is the action complete?

— Go to Step 3 —

5 Connect the battery position terminal with harness

side conn ec tor D–17 termi nal 1 or 4, and th e ne gati v e

termin al with harness si de connector D–17 terminal 4

or 1.

Does the motor operate?

— Replace the