SECTION 2A - HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) SYSTEMS

Service Precaution

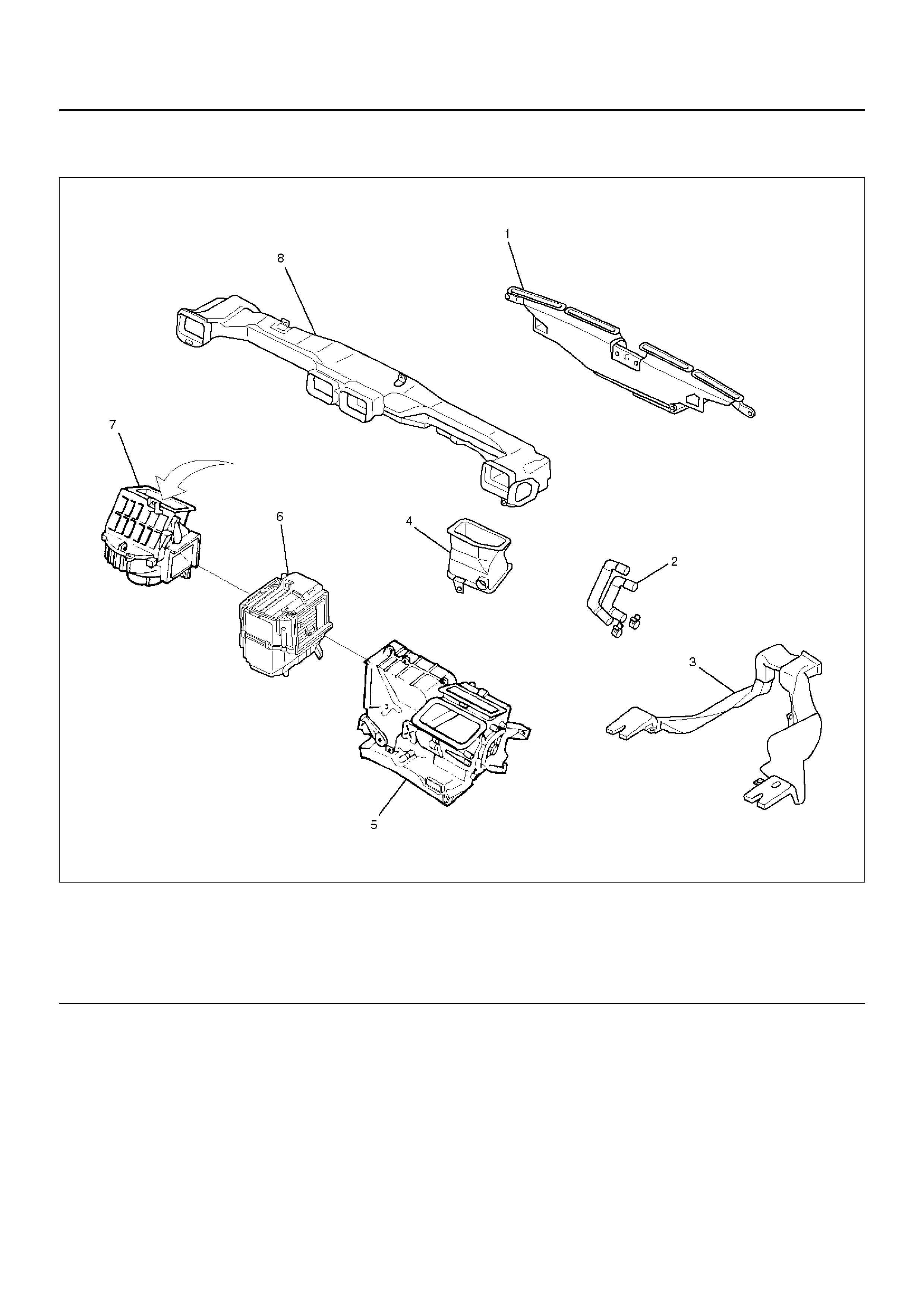

Heating and Ventilation System

General Description

Heater and Ventilation Associated Parts

Ventilation

Circuit Diagram

Diagnosis

Condenser Fan Diagnosis

Individual Inspection

General Repair Procedure

Heater Unit

Heater Unit and Associated Parts

Removal

Installation

Heater Core and / or Mode Door

Disassembled View

Removal

Inspection

Installation

Heater Mode Control Link Unit

Disassembled View

Removal

Installation

Heater Temperature Control Link Unit

Disassembled View

Removal

Installation

Blower Assembly

Blower Assembly and Associated Parts

Removal

Installation

Blower Link Unit and / or Mode door

Disassembled View

Removal

Installation

Blower Motor

Blower Motor and Associated Parts

Removal

Installation

Rear Heater Duct, Defroster Nozzle and

Ventilation Duct

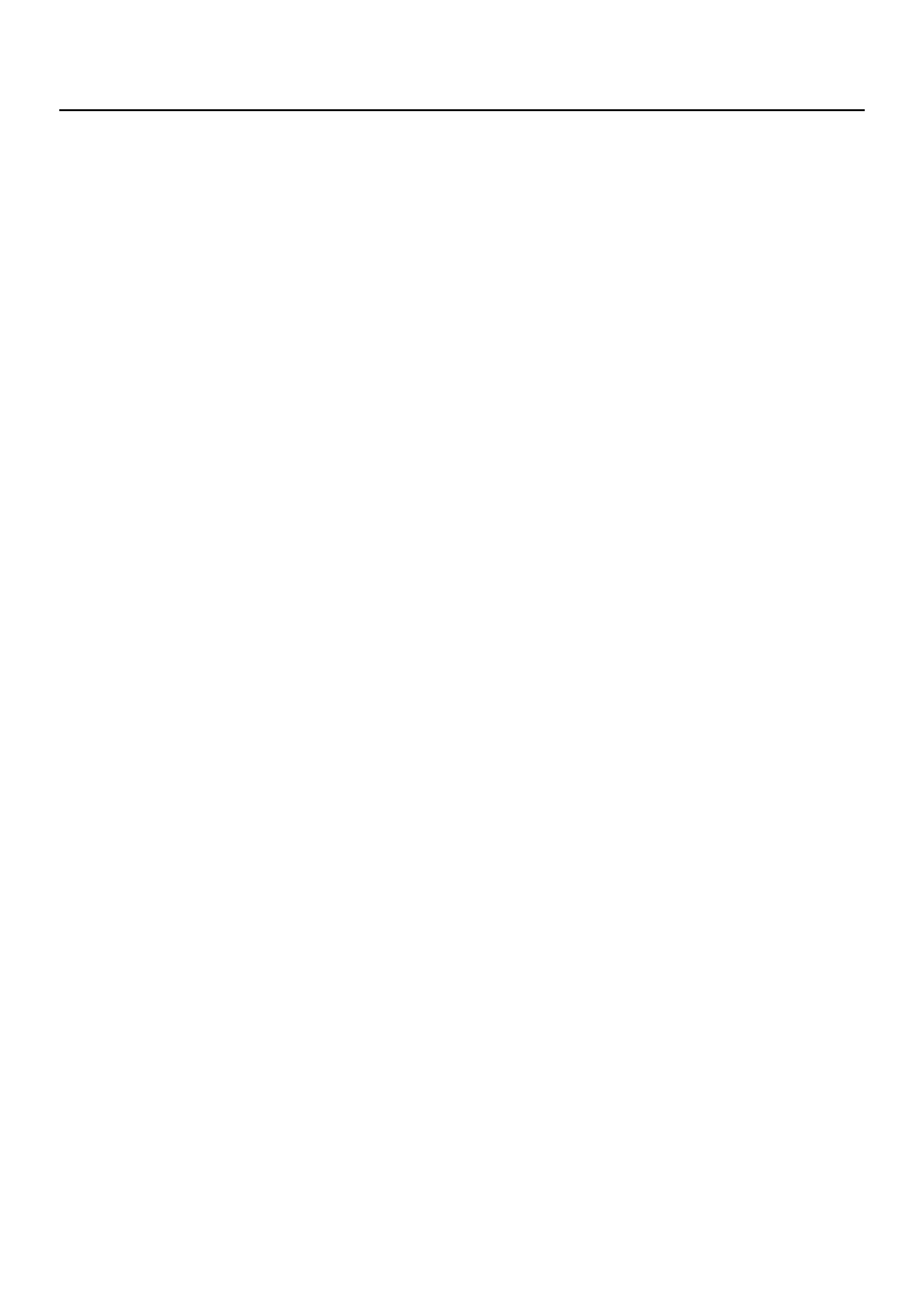

Rear Heater Duct, Defroster Nozzle,

Ventilation Duct and Associated Parts

Removal

Installation

Control Lever Assembly and /

or Control Cable

Control Lever Assembly, Control Cable

and Associated Parts

Removal

Installation

Control Panel Illumination Bulb

Control Panel Illumination Bulb

and Associated Parts

Removal

Installation

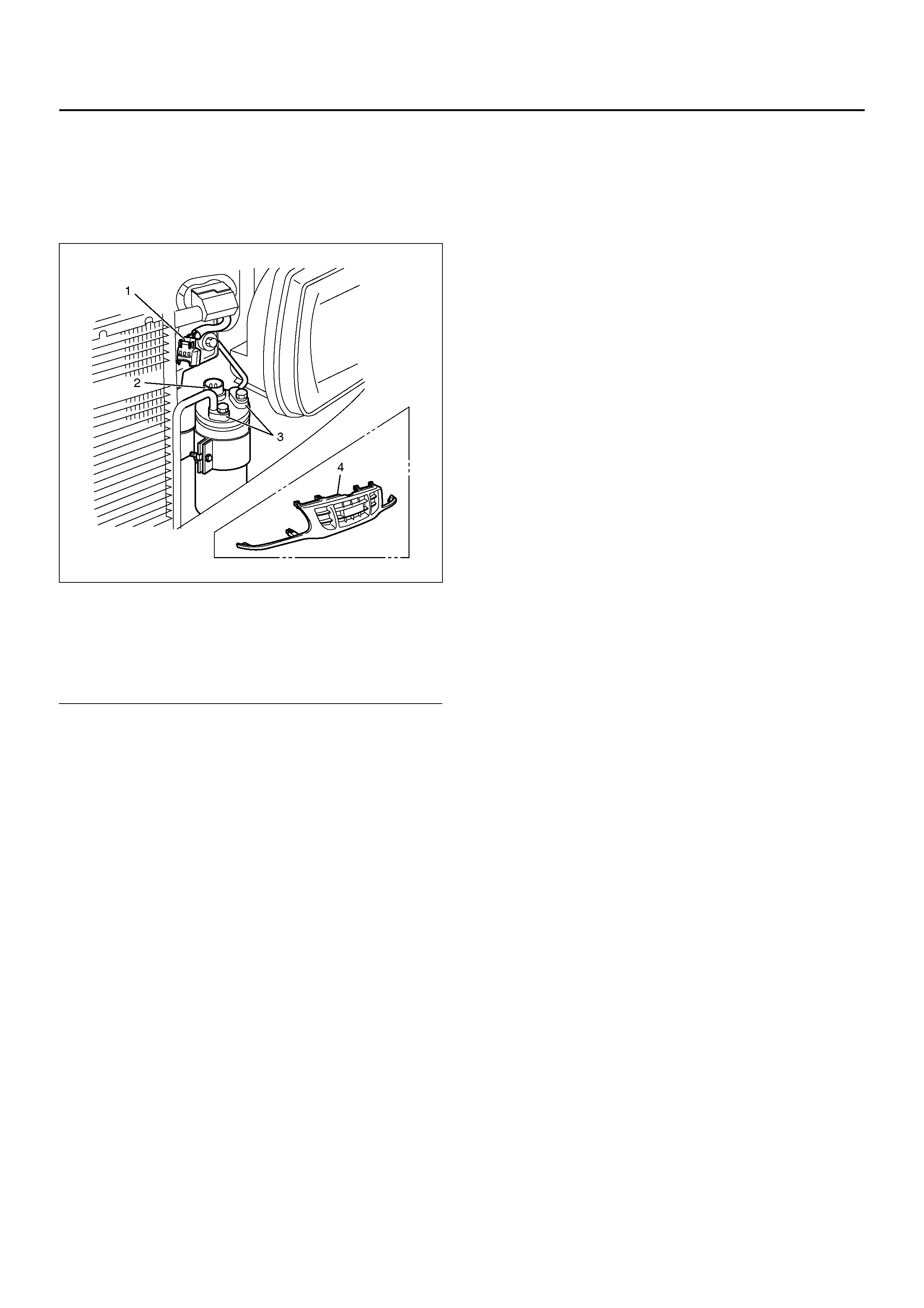

Resistor

Resistor and Associated Parts

Removal

Installation

Air Conditioning System

General Description

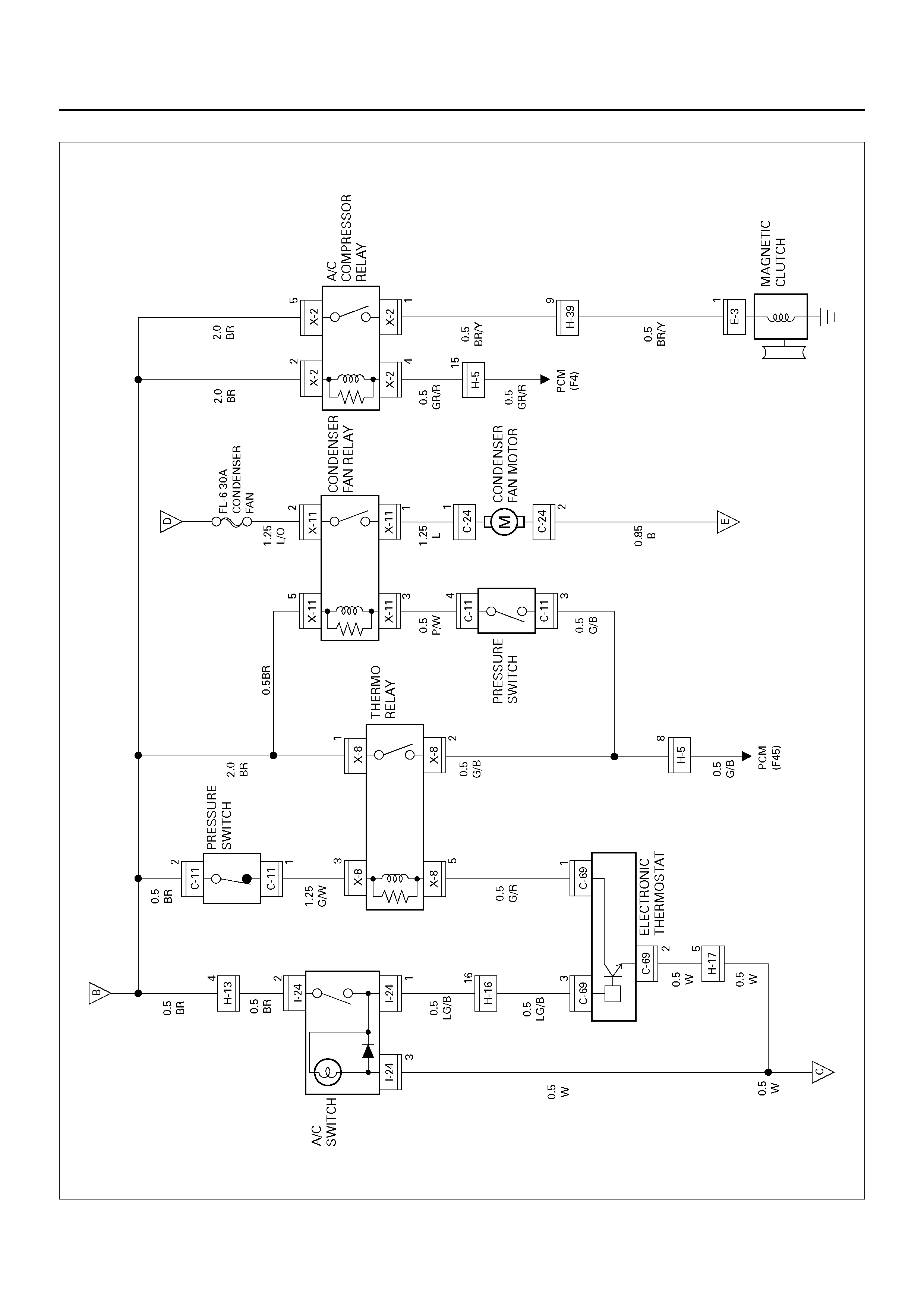

Circuit Diagram

Diagnosis

Individual Inspection

General Repair Procedure

Leak Check

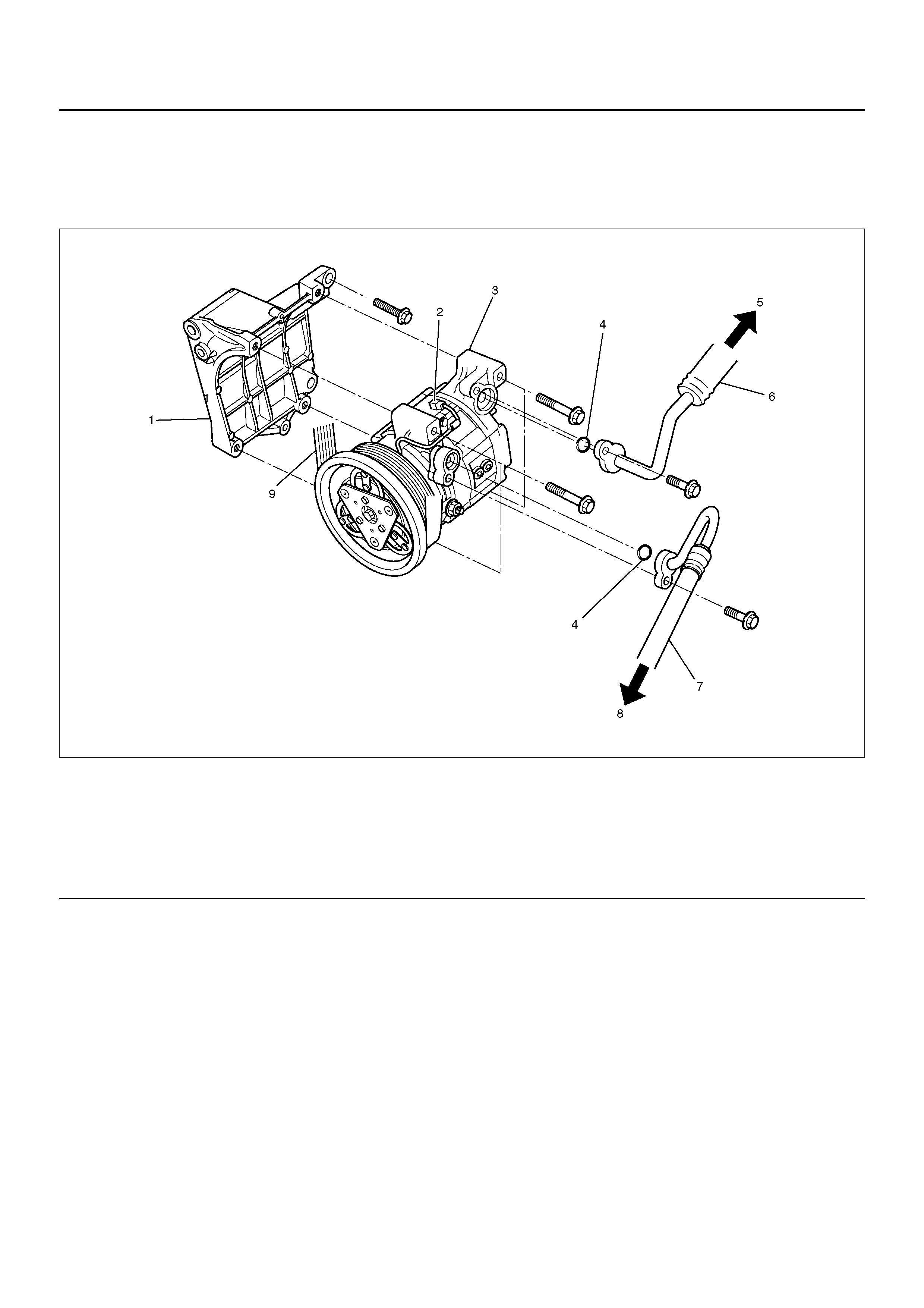

Compressor Assembly

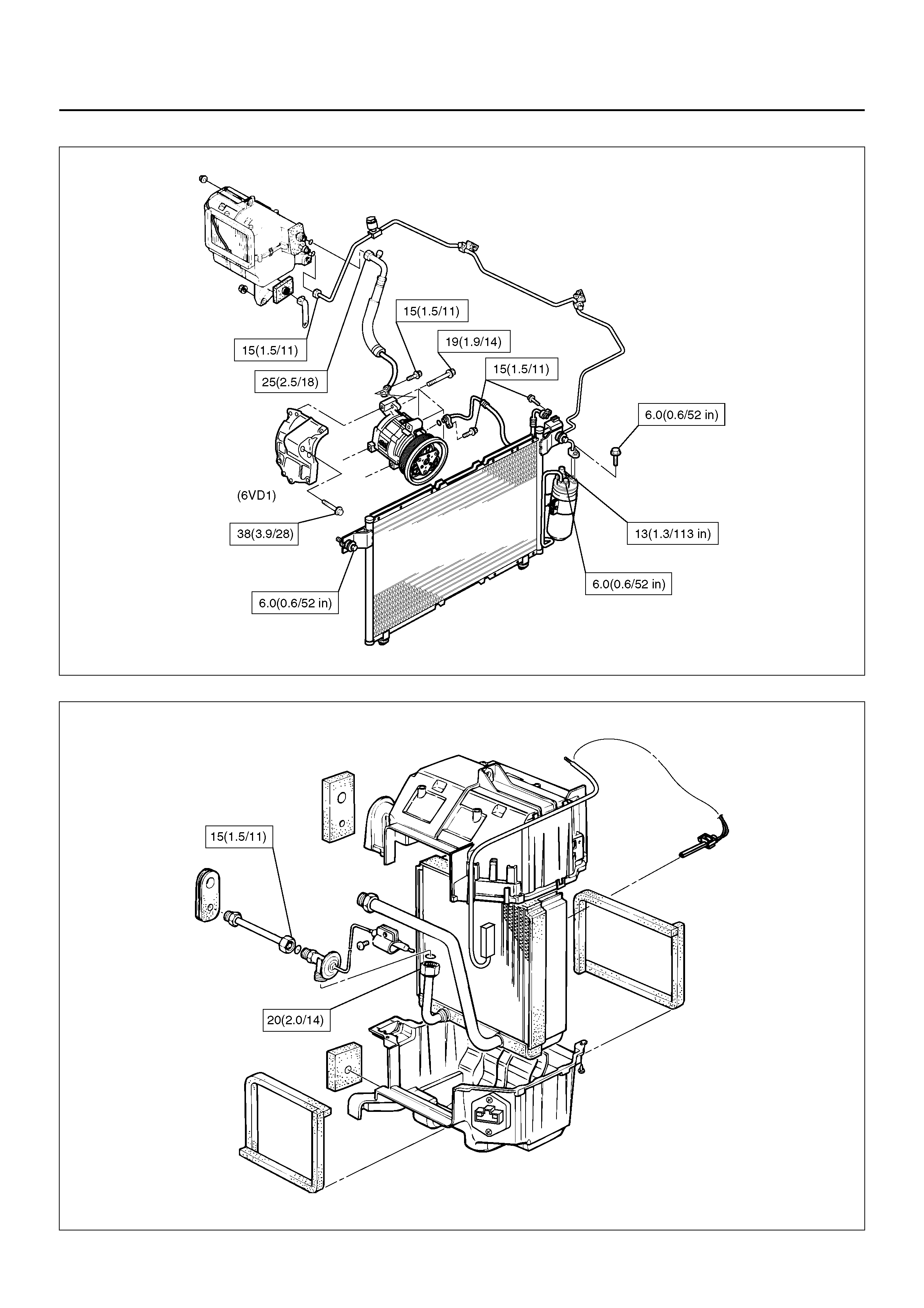

Compressor Assembly and Associated

Parts (6VD1)

Removal

Installation

New Compressor Installation

Condenser Assembly

Condenser Assembly and Associated Parts

Removal

Installation

Condenser Fan Motor

Condenser Fan Motor and Associated Parts

Removal

Installation

Receiver / Drier

Receiver / Drier and Associated Parts

Removal

Installation

Pressure Switch

Pressure Switch and Associated Parts

Removal

Installation

Evaporator Assembly

Evaporator Assembly and Associated

Parts

Removal

Installation

Techline

Electronic Thermostat, Evaporator Core

and/or Expansion Valve

Disassembled View

Removal

Installation

Refrigerant Line

Refrigerant Line and Associated Parts

Removal

Installation

Main Data And Specifications

Compressor

Service Precaution

General Description

Diagnosis

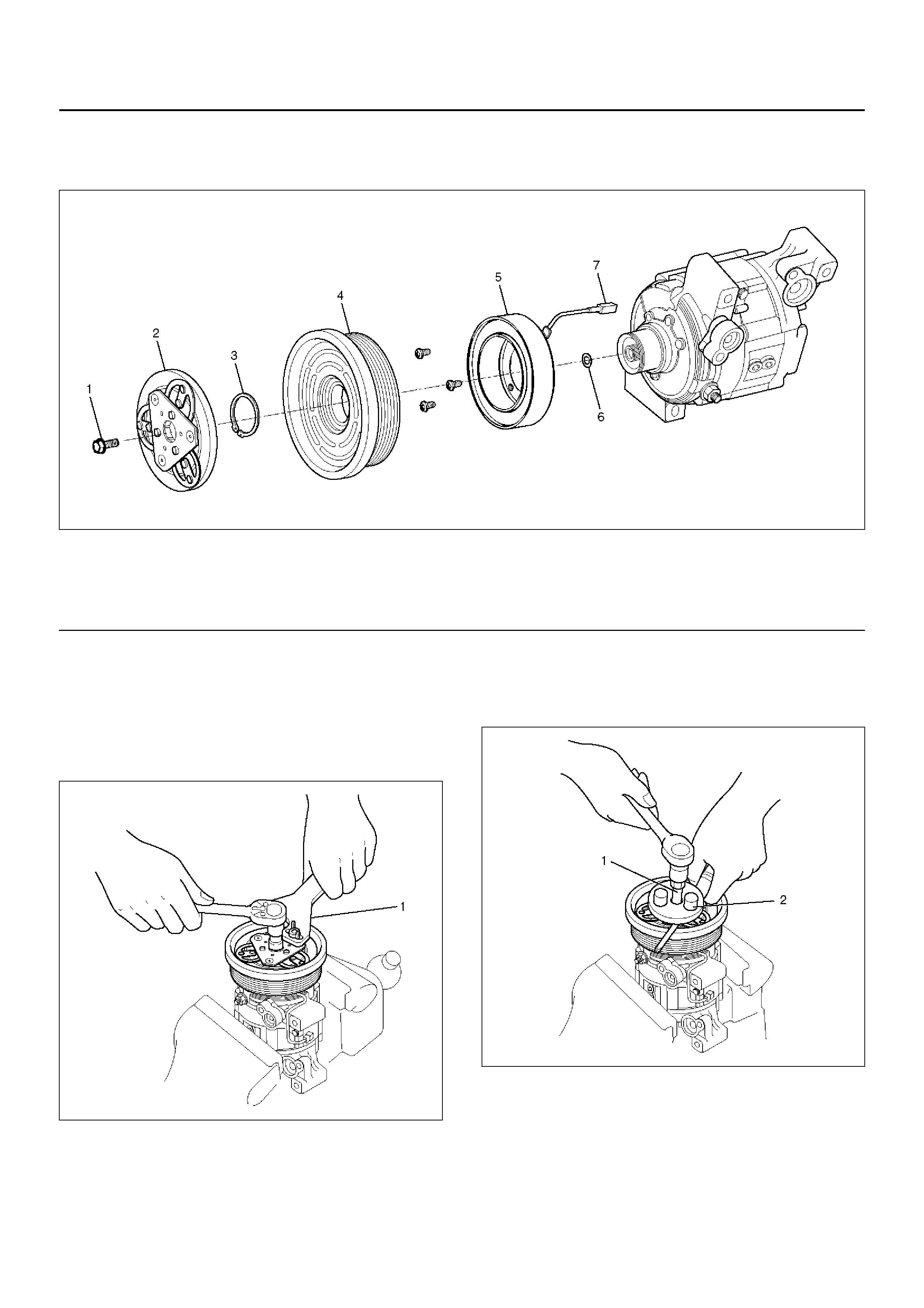

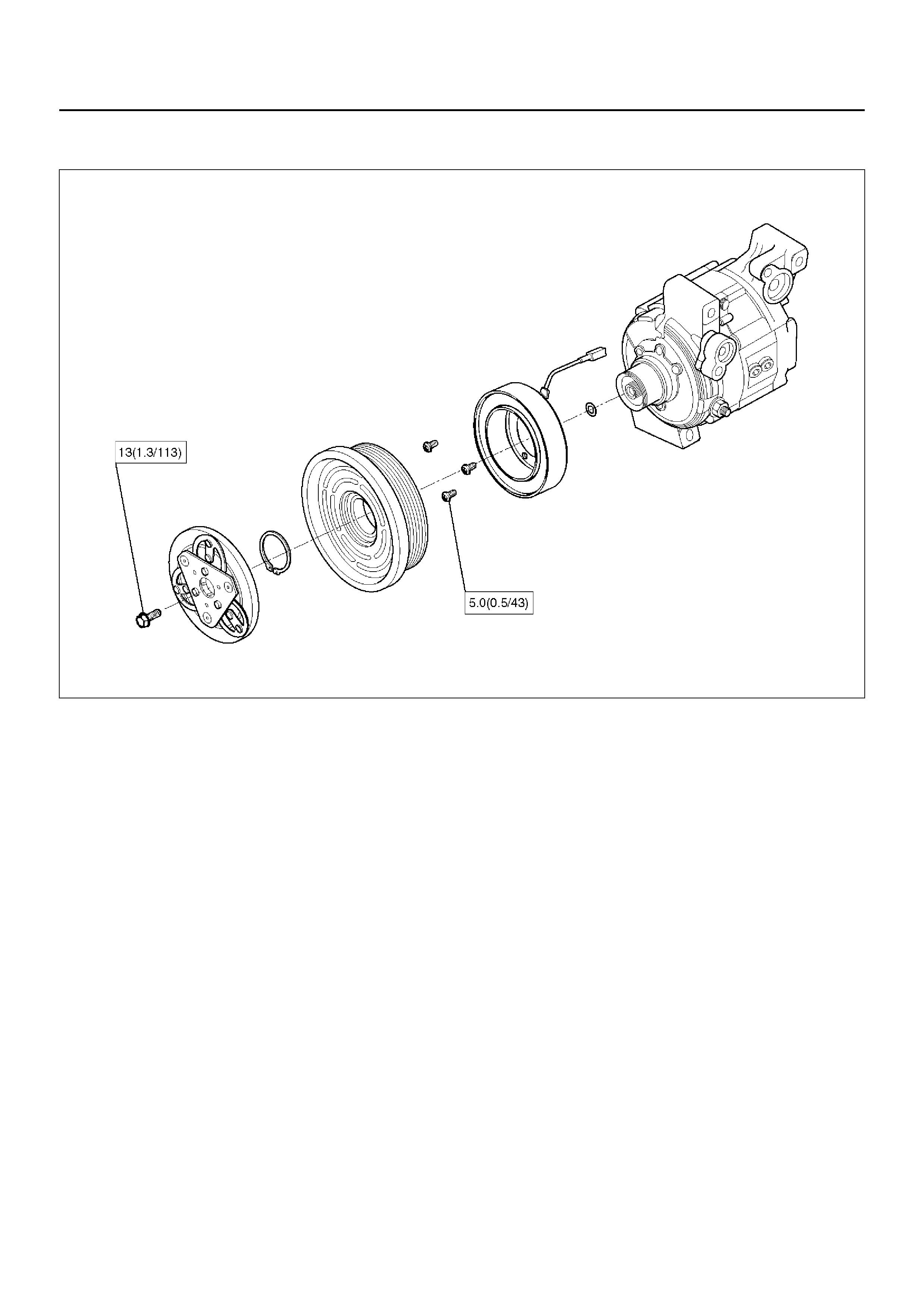

Magnetic Clutch Assembly (DKV-14G Type)

Parts Location View

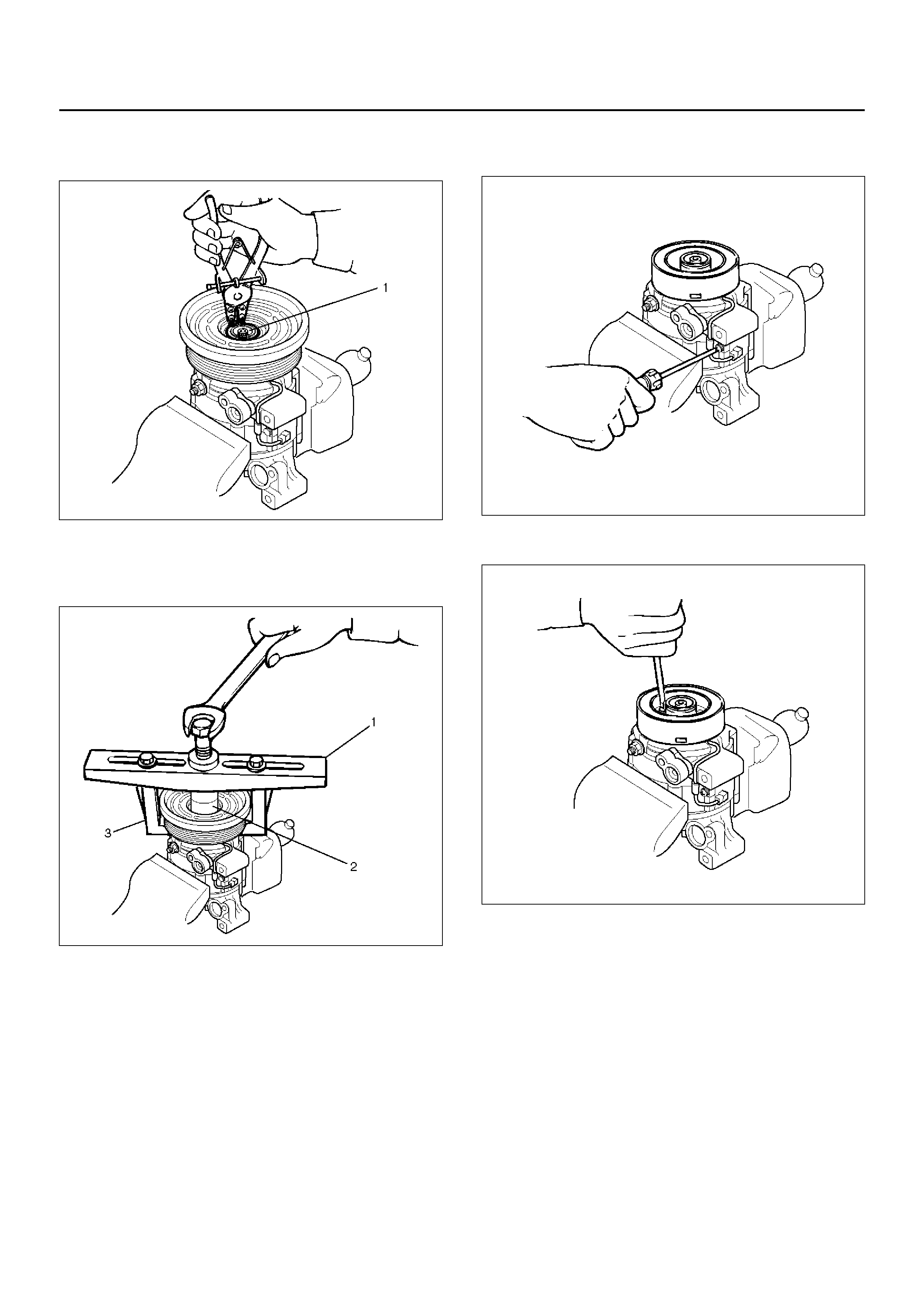

Removal

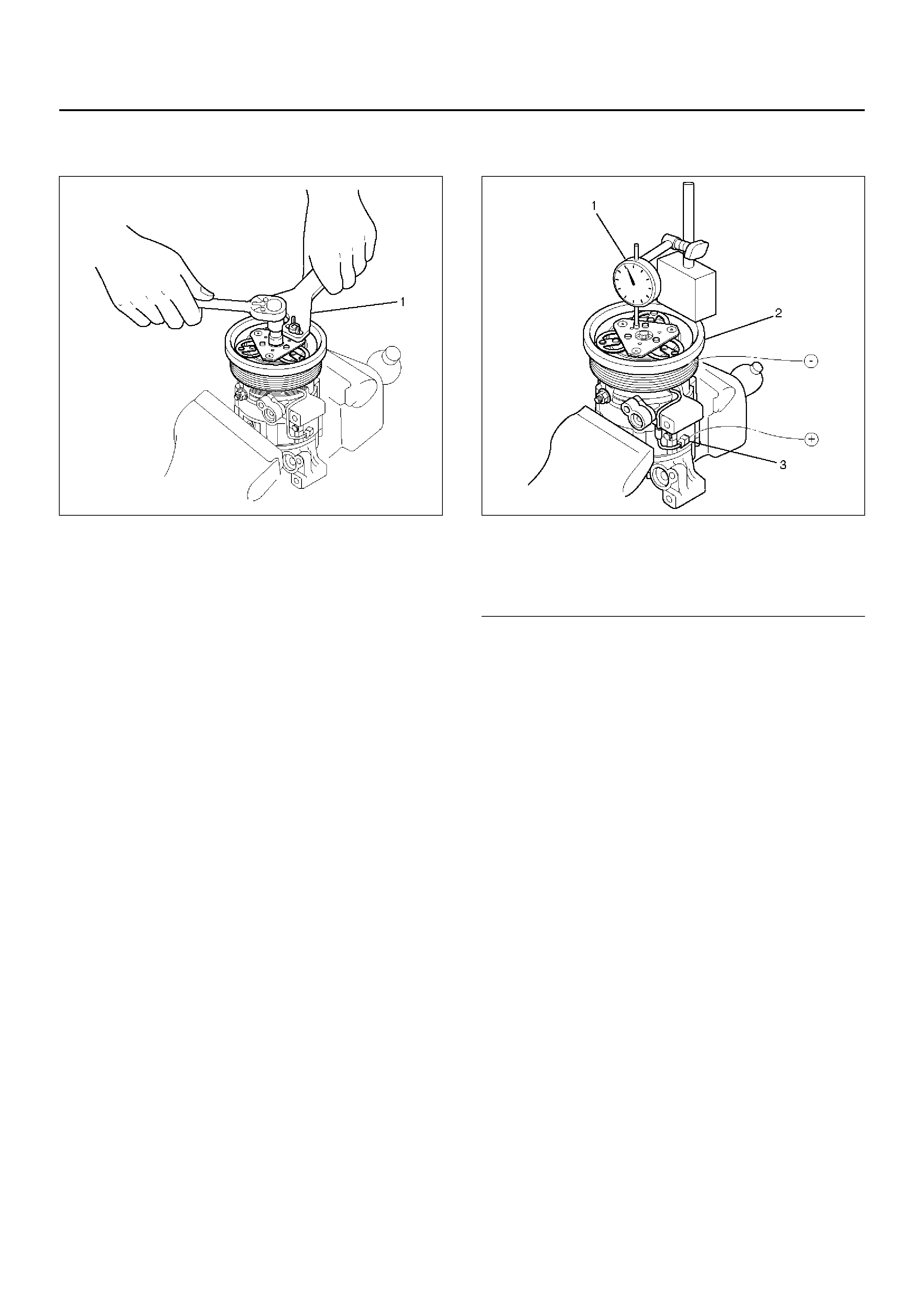

Inspection and Repair

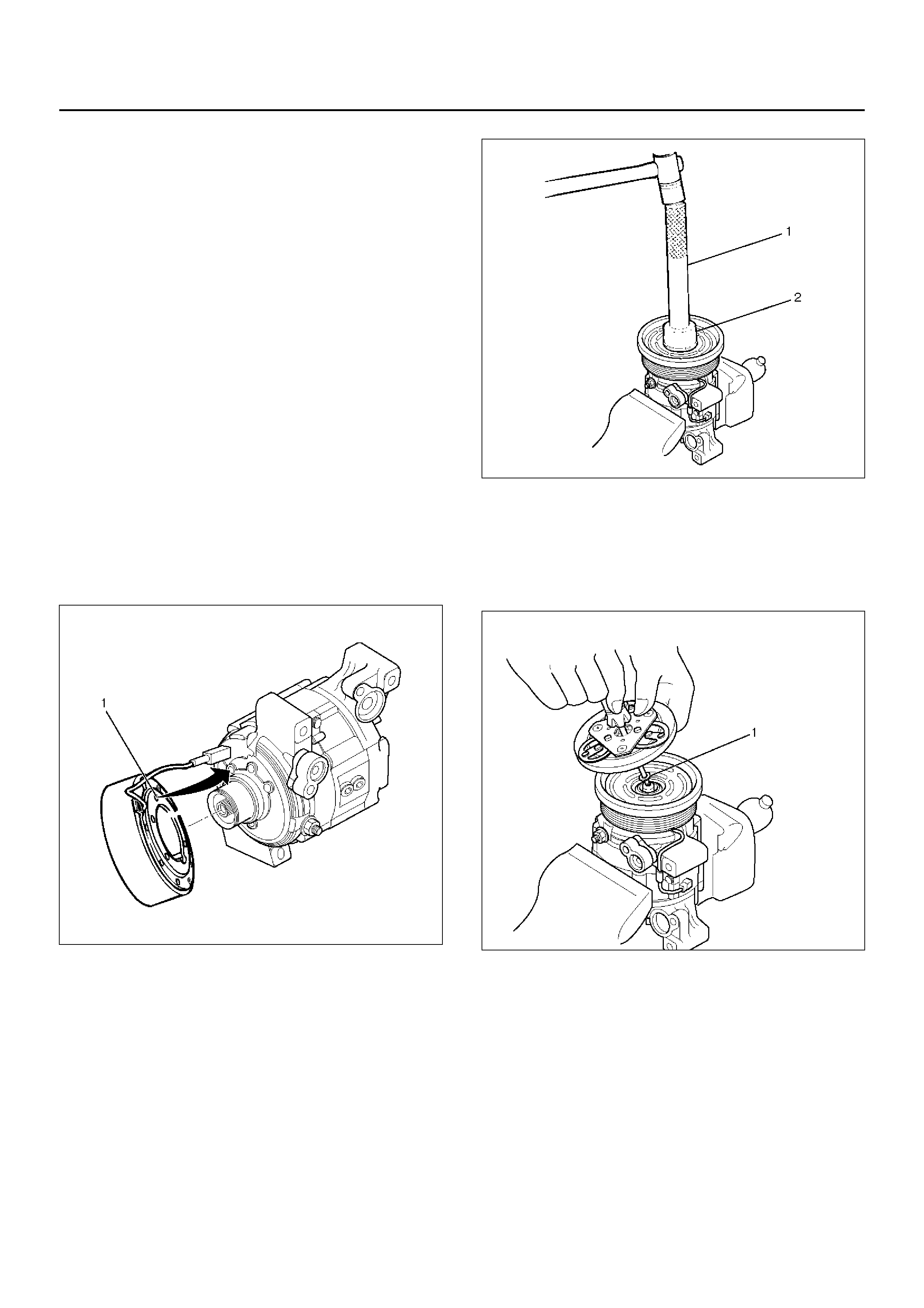

Installation

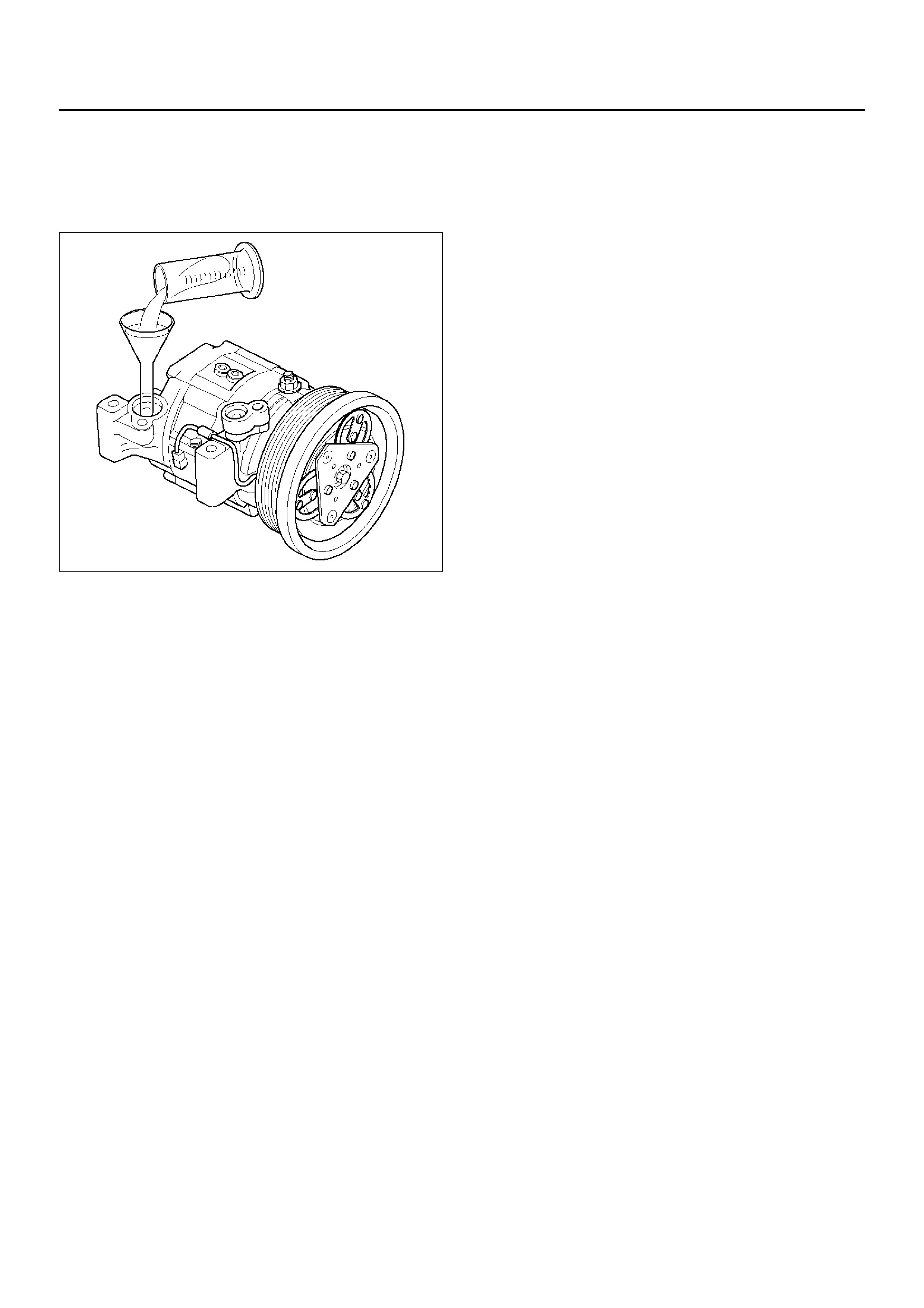

Compressor Oil

Oil Specification

Handling of Oil

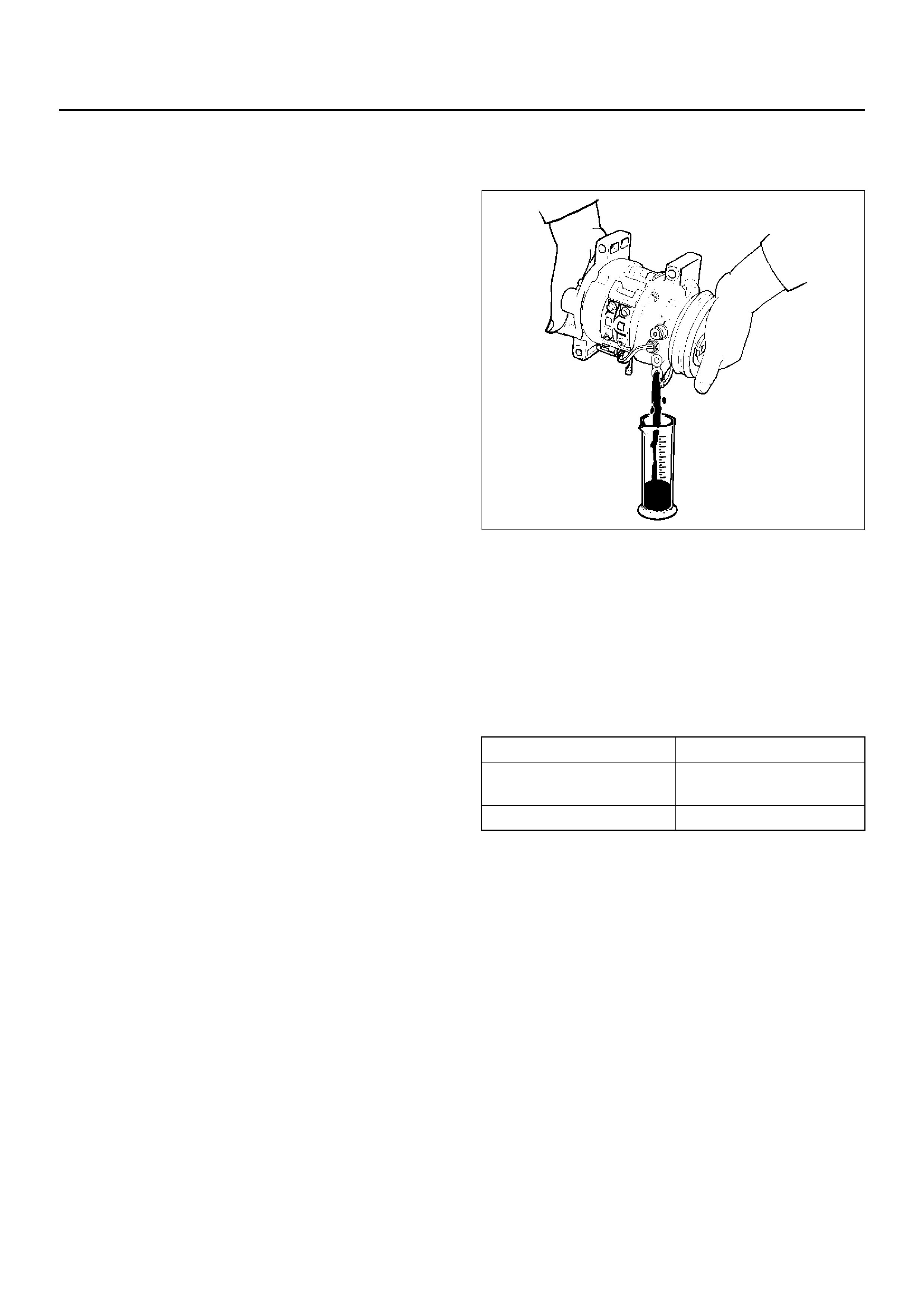

Compressor Oil Check

Checking and Adjusting Oil Quantity for

Used Compressor

Checking and Adjusting for Compressor

Replacement

Contamination of Compressor Oil

Oil Return Operation

Replacement of Component Parts

Main Data and Specifications

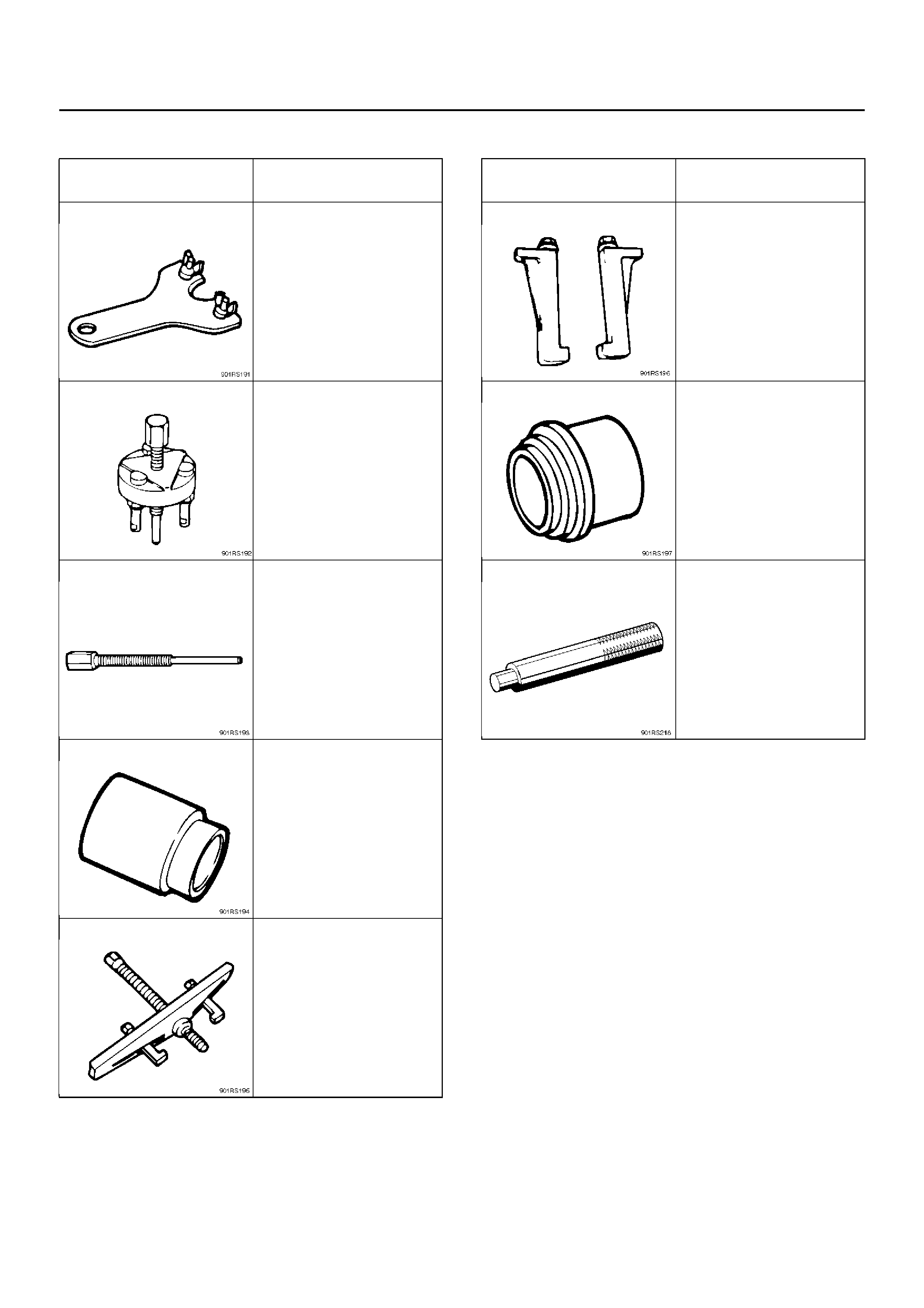

Special Tools

SERVICE PRECAUTION

WARNING: THIS VEHICLE H AS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibi tors) on threaded faste ners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you inst all fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and syst ems.

HEATING AND VENTILATION SYSTEM

GENERAL DESCRIPTION

Heater

The heater system supplies warm air into the passenger

compartment. When the engine is warming up, the

engine coolant is sent into the heater core.

Outside air is circulated through the heater core of the

heater unit and then into the passenger compartment.

By contr olling the mixtu re of outsid e air and he ater cor e

air, the most comfortable passenger compartment

temperature can be selected and maintained.

The temperature of the air sent to the passenger

compartment is controlled by the temperature control

knob. This knob acts to open and close the air mix door ,

thus controlling the amount of air passed through the

heater core.

The air selector knob, with its different modes, also

allows you to sele ct and m aintain the mos t comfortable

temperature.

The air source select lever is used to select either

“FRESH" for the introduction of the outside air, or

“CIRC" for the circulation of the inside air. When the

lever is set to “FRESH", the outside air is always taken

into the passenger compartment. When setting the

lever to “CIRC" position, the circulation of air is

restricted only to the inside air with no introduction of

the outside air and the air in the passenger

compartm ent gets warm quickly. However, the lever is

norma lly set to “FRE SH" to preven t the winds hield fr om

clouding.

HEATER AND VENTILATION ASSOCIATED PARTS

840RY00049

EndOFCallout

Legend

(1) Defroster Nozzle

(2) Heater Hose

(3) Rear Heater Duct

(4) Ventiration Lower Duct

(5) Heater Unit

(6) Evaporato r As se mbl y

(7) Blower Assembly

(8) Ventilation Duct

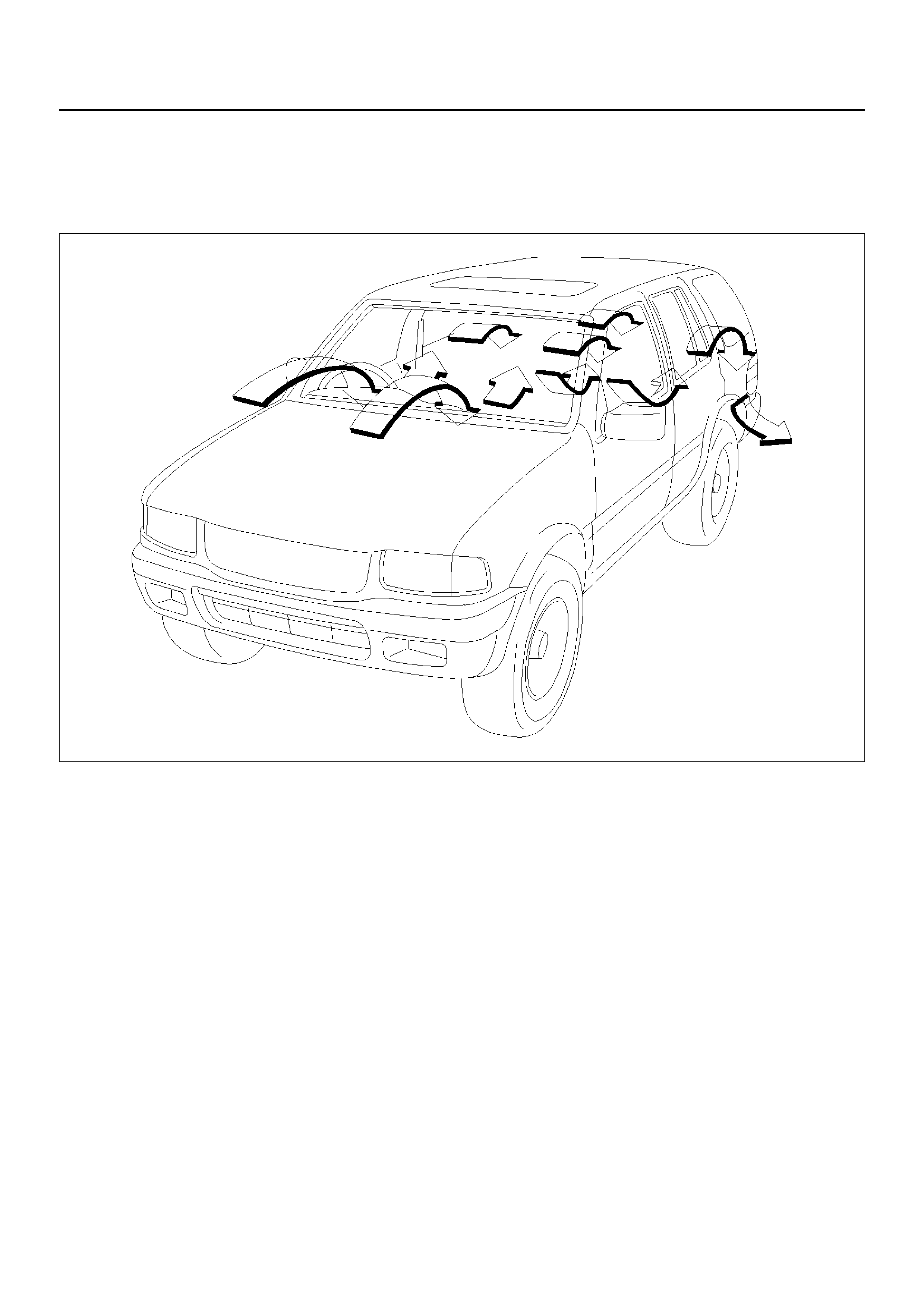

VENTILATION

Setting the air source select lever to “FRESH" position

allows the heating system to work with sending the

fresh air from outside.

The blower fan also serves to deliver fresh outside air to

the passenger compartment to assure adequate

ventilation.

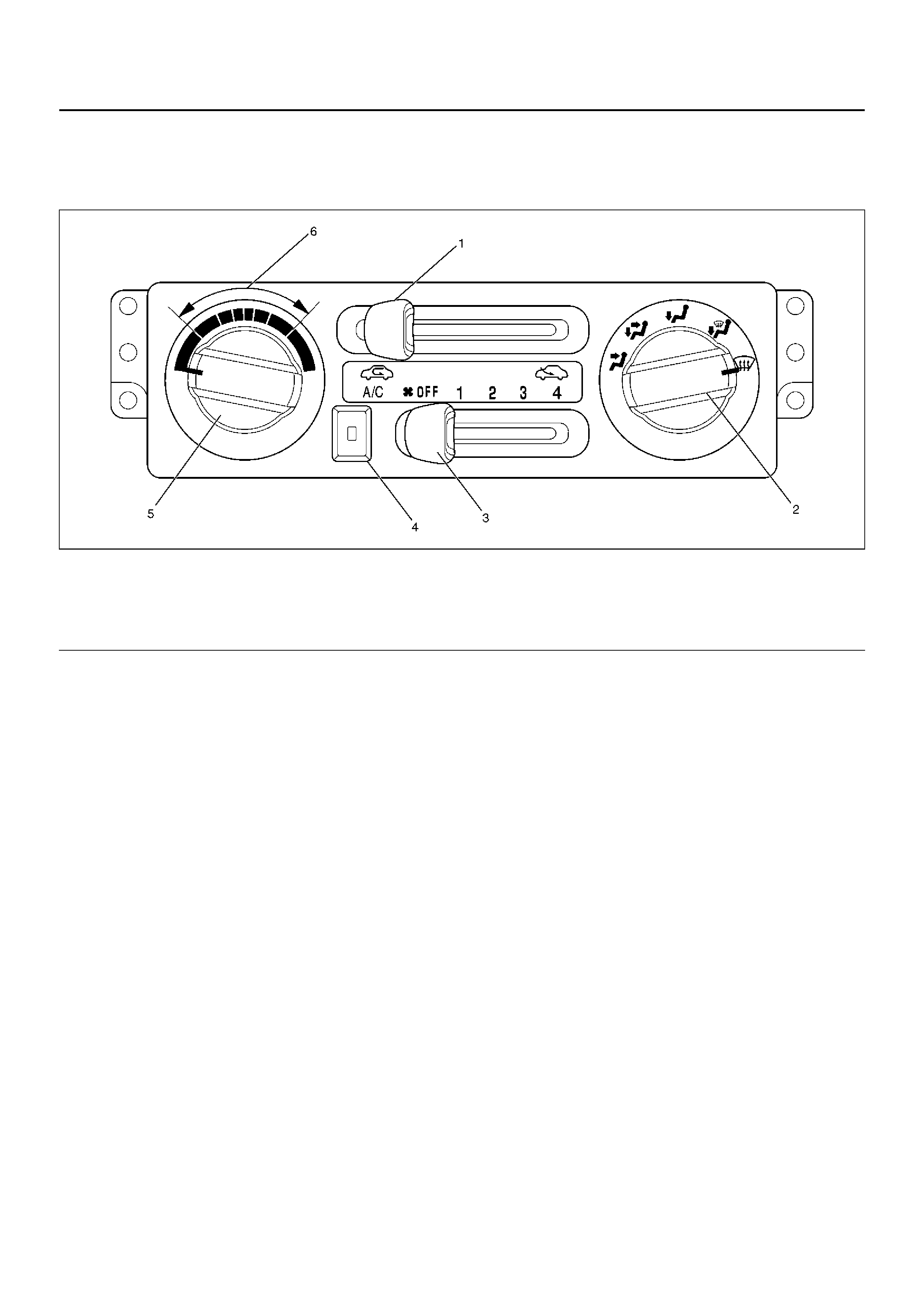

810RW319

Control Lever Assembly

The control lever assembly has some cables to control

the mode and temperature of the heater unit and the

mode door for the air source of the blower assembly.

The fan control i s used to control the amoun t of air sen t

out by the resistor at four levels from “LOW" to “HIGH".

865RW006

EndOFCallout

Air Source Select Lever

The intake of outside air and the ci rculat ion of insid e air

are controlled by sliding this lever left or right.

Fan Control Lever

This lever controls the blower motor speed to regulate

the amount of air delivered to the defrost, foot, and

ventilation ducts:

1. Low

2. Medium Low

3. Medium High

4. High

Temperature Control Knob

When the temperature control knob is in the “COLD"

position, the air mix door closes to block the flow air to

the heater core.

When the temperature control knob is in the “HOT"

position, the air mix door opens to allow air to pass

through the heater core and heat the passenger

compartment.

Placi ng the knob in a intermedi ate position will cause a

lesser or gr eat er amo unt air to re ac h the hea ter c ore. In

this m ode the pass eng er c ompar tmen t te mpe ratur e c an

be regulated.

Legend

(1) Air Source Select Lever

(2) Air Select Knob

(3) Fan Control Lever (Fan Switch)

(4) Air Conditioning (A/C) Sw itch (W/ A/C)

(5) Temperature Control Knob

(6) Middle Position

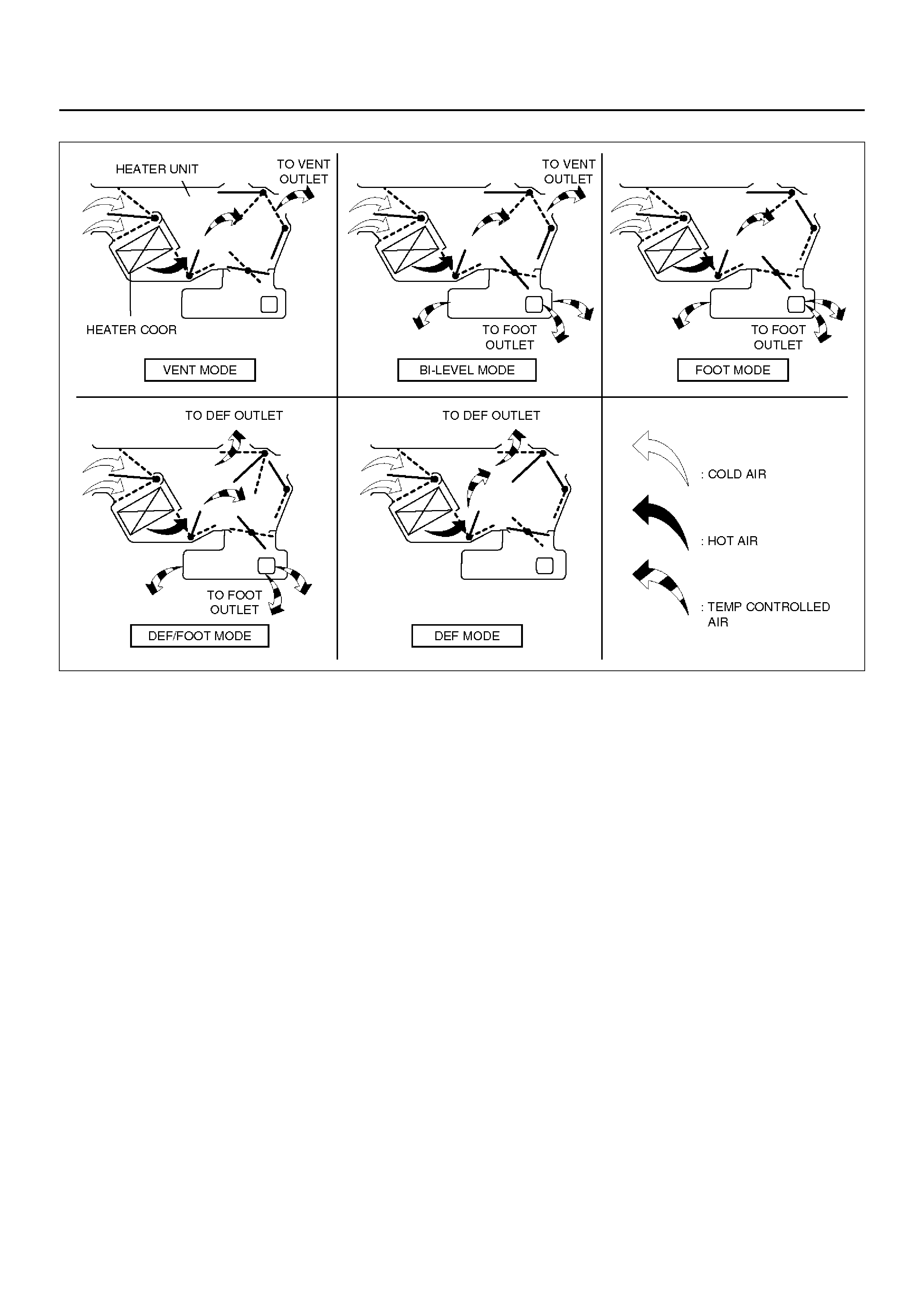

Flow of Each Position of the All Select Dials

C01RX001

Air Select Knob

The air select knob allows you to direct heated air into

the passenger compartment through different outlets.

1. Vent – In this position, air is discharged from the

upper ai r outlet. Ai r quantity is controll ed by the fa n

con tr ol lev er.

2. Bi-Level – In this position, air flow is divided

between the upper air outlets and the floor air

outlets, with warmer air deli vered to th e floor outlets

than the air delivered to the upper air outlets when

the temp lever is in mid dl e posi tio n.

3. Foot – In this position, air flow is delivered to the

foot, while sending a small amount of air to the

windshield.

4. Def/Foot – In this position, air flow is delivered to

the foot, whi le sending app rox. 40% of total am ount

of air to the windshield.

5. Defrost – In this position, most of the air is delivered

to the winds hi eld and a sm al l am ount is del iver ed to

the side windows.

Moving the air source select lever to the “CIRC" position

provides quickest heat delivery by closing the blower

assembly mode door. In this position, outside air is not

delivered to the passenger compartment.

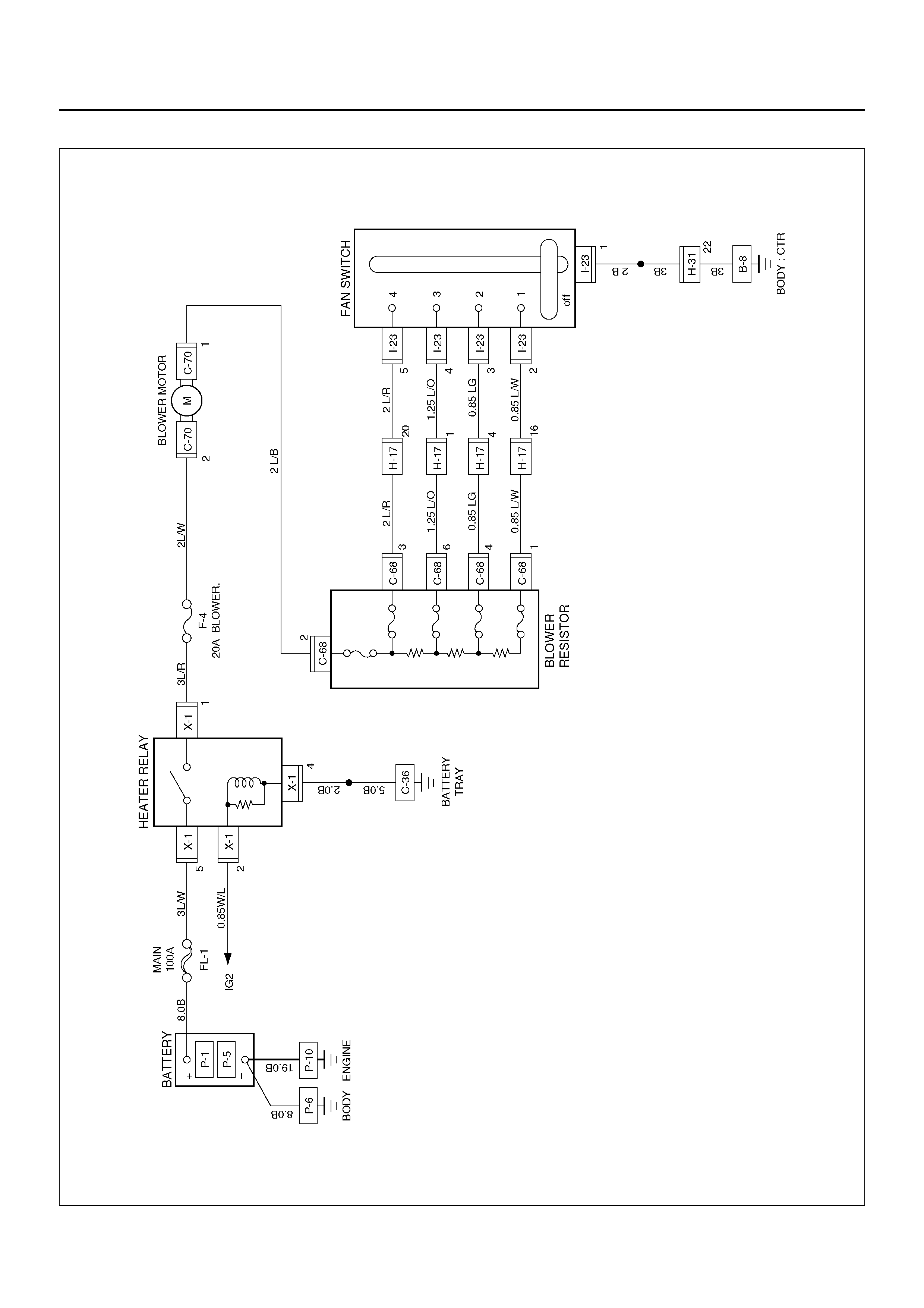

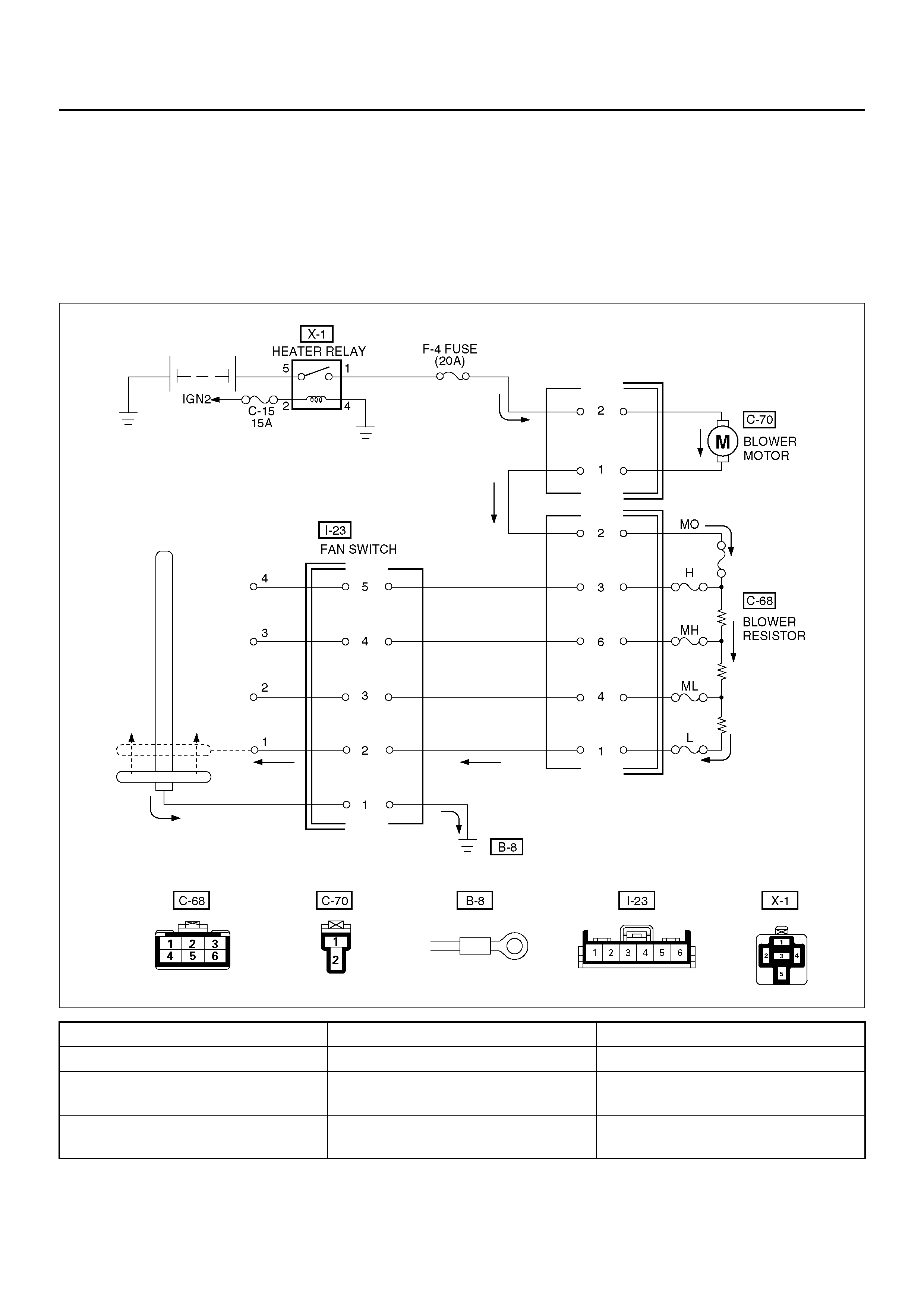

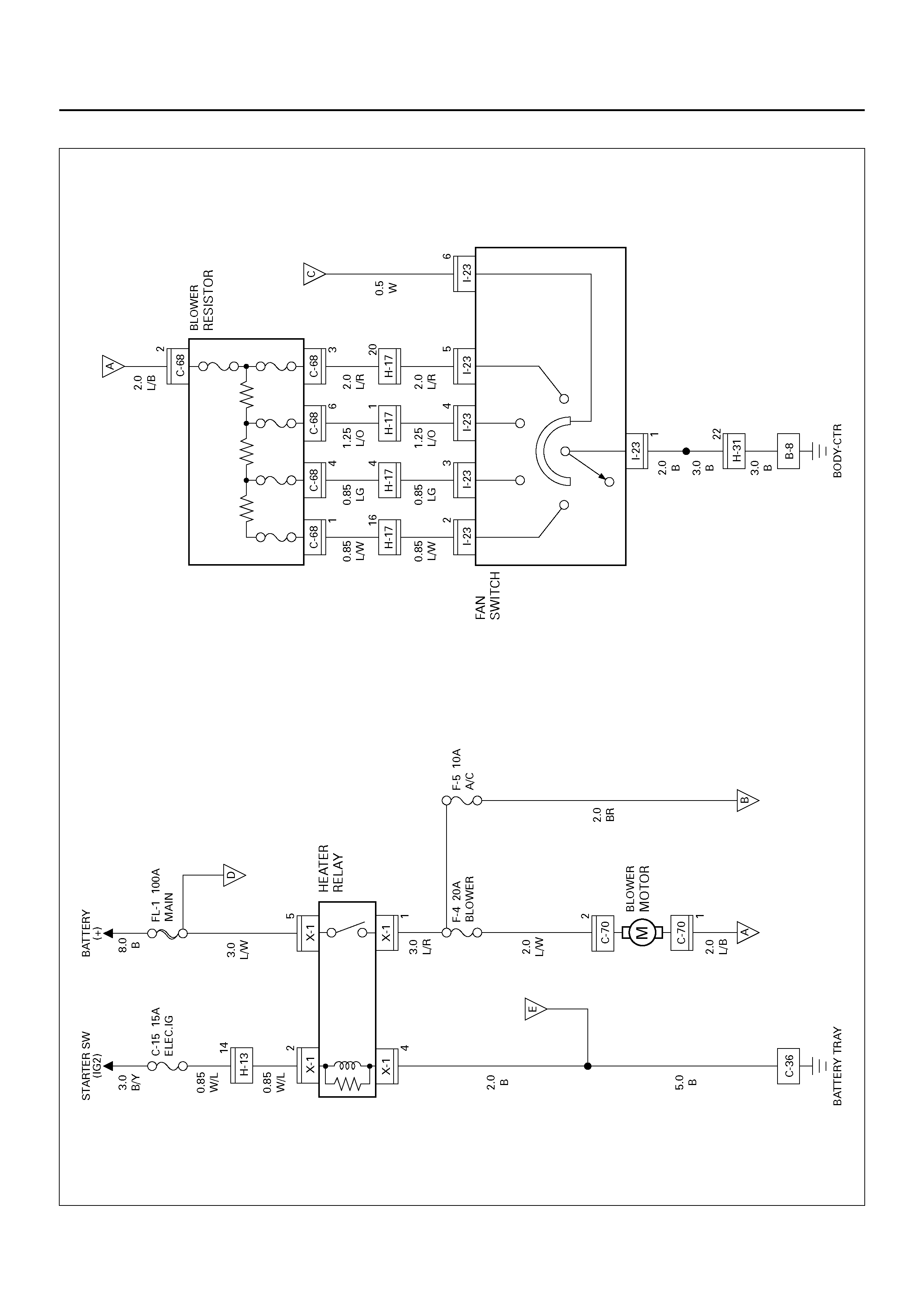

CIRCUIT DIAGRAM

D08R100116

DIAGNOSIS

Heating Cycle diagnosis

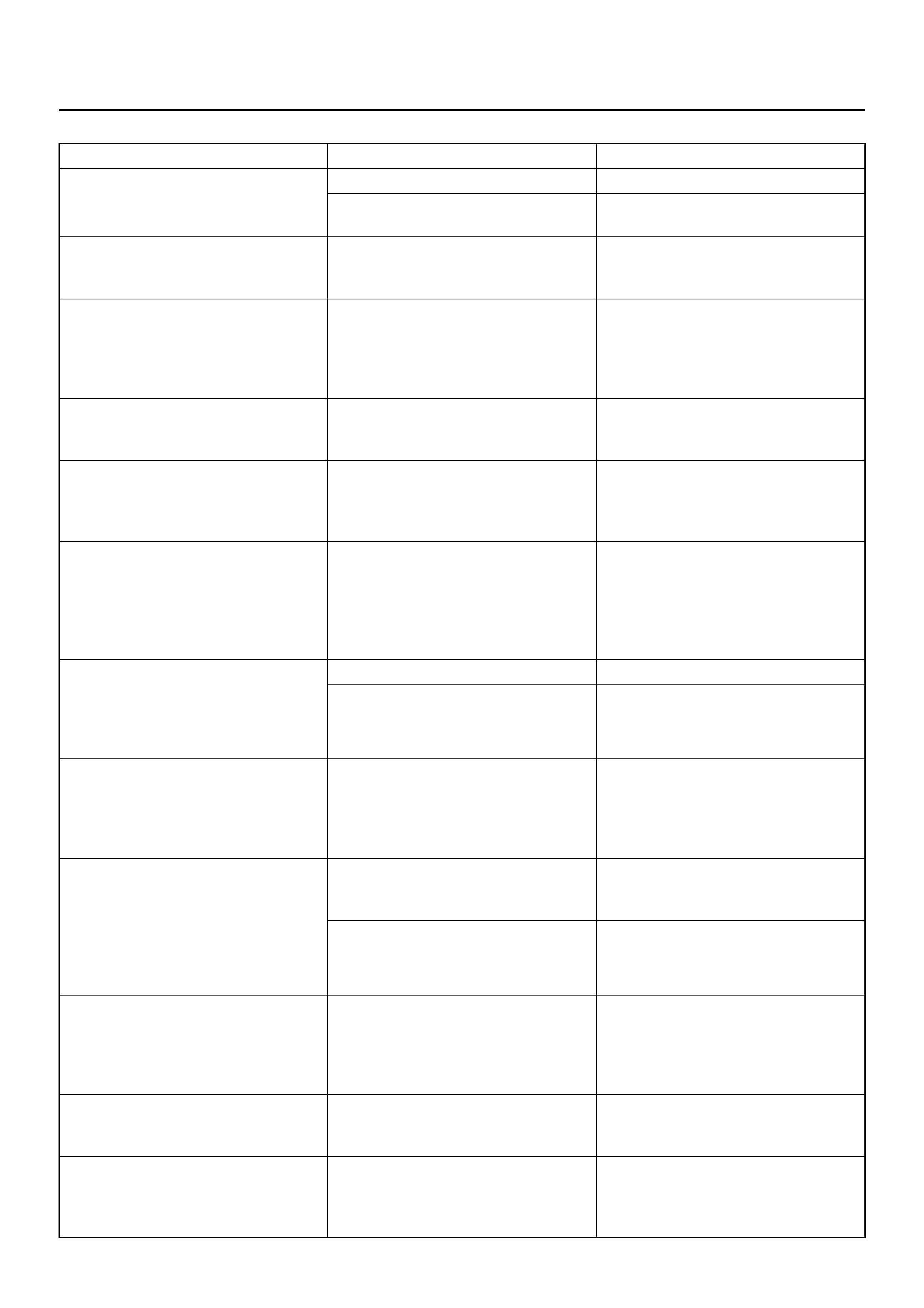

Condition Possible cause Correcti on

No heating or insufficient heating. Blower motor does not run or runs

improperly. Refer to “FAN CONTROL LEVER

(FAN SWITCH) DIAGNOSIS".

Engine coolant temperature is low. Check the engine coolant

temperature after warming up the

engine and c heck th e therm ostat.

Replace as necessary.

Insufficient engine coolant. Add engine coolant as required.

Circulation volume of engine coolant

is insufficient. Check if the water hose to the

heater core is clogged, collapsed or

twisted. Repair or replace as

necessary.

Heater core clogged or collapsed. Clean or replace as necessary.

The heater cores is not provided

with air sent from the blo wer motor. Repair the temperature control link

unit or mode doors.

Duct connections defective or

unsealing. Repair or replace as necessary.

Control lever moves but mode door

does not operate. Cable attaching clip is not correct. Repair

Link unit of heater or blower

assembly defective. Repair

The mode doo r can not be set to the

mode selected. Link unit of heater unit or blower

assembly defective. Repair.

Control cable is not adjusted. Adjust.

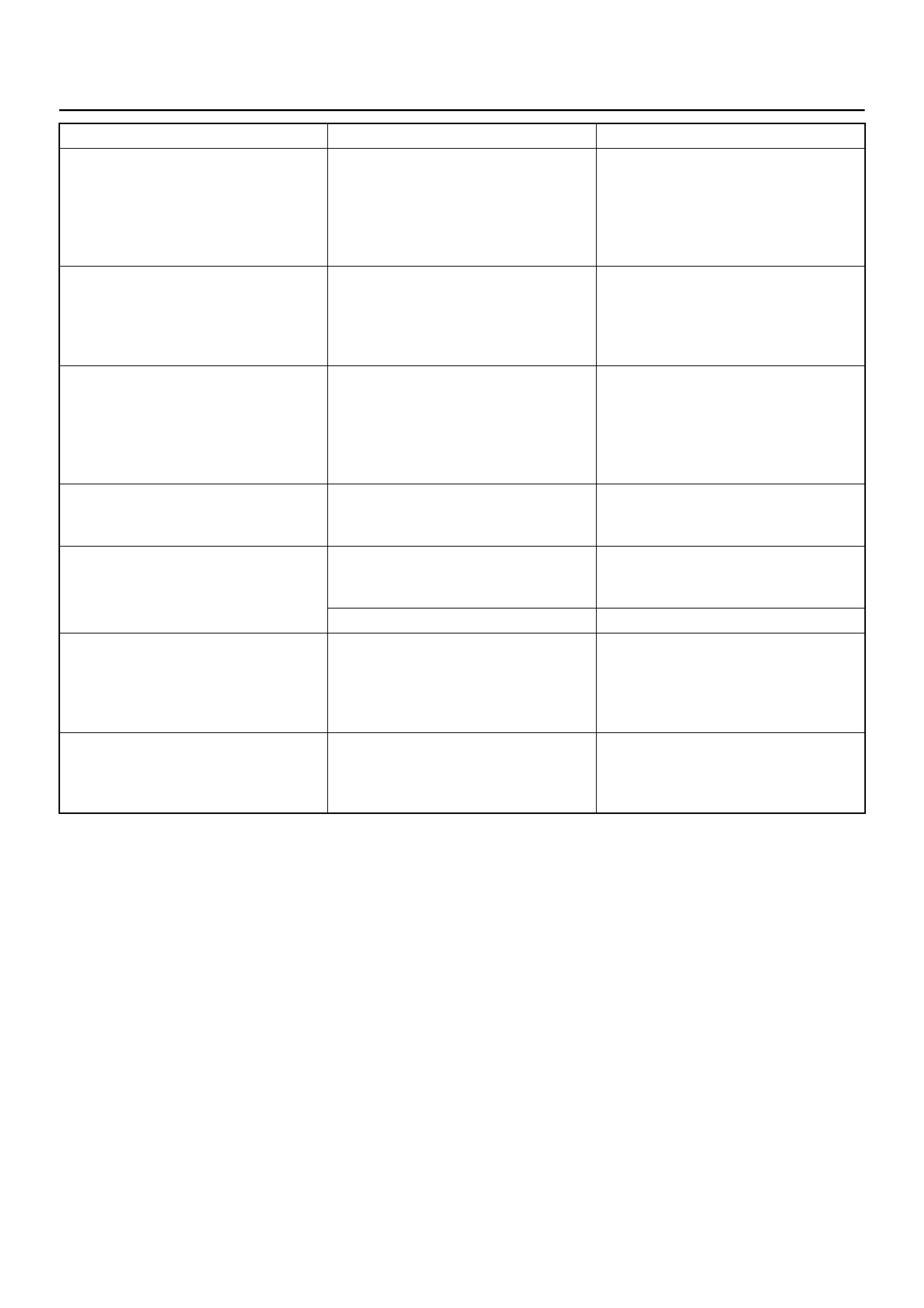

Fan Control Lever (Fan Switch) Diagnosis

Current flows to the blower motor through the heater

relay (X-1) to activate the rotation of the blower motor by

turning “ON" the fan control knob (fan switch). Blower

motor speed is controlled in stages by the resistor, by

operating the switch from “LOW" to “HIGH".

For the inspection of the relays, switches and units in

each table, refer to “INDIVIDUAL INSPECTION" in this

section.

D08R100117

Condition Possible cause Correcti on

Blower motor does not run. — Refer to Chart A

Blower mot or does not run in cer tain

position (s) . — Refer to Chart B, C, D and E

Blower motor does not stop at “OFF"

position. — Refer to Chart F

Chart “A" Blower Motor Does Not Run

Chart “B" Blower Motor Does Not Run At Low Posi tion

Chart “C" Blower Motor Does Not Run At Medium Low Position

Chart “D" Blower Motor Does Not Run At Medium High Position

Step Action Yes No

1 Is relay (X-1) OK? Go to Step 2 Replace

2 Is fuse F-4 (20A) OK? Go to Step 3 Replace

3 Is resistor OK? Go to Step 4 Replace

4 Is fan control lever OK? Go to Step 5 Replace control

lever assembly.

5 Is blower motor OK? Go to Step 6 Replace

6 1. Turn the ignition switch “ON".

2. Turn fan control lever “ON".

3. Check to see if battery voltage is present at chassis side

connector terminal No. C70-2

Is there a battery voltage?

Poor groun d or

open circuit either

between chassis

side connector

terminal No. C70-1

and No. C68-2 or

No. I23-1 and body

ground (No. B-8).

Open circui t

between No. F-4

(20A) fuse and No.

C70-2.

Step Action Yes No

1 Is resistor OK? Go to Step 2 Replace

2 Is fan control lever (Fan Switch) OK? Open circuit

between chassis

side connector

terminal No. C68-1

and No.I23-2. Replace control

lever assembly.

Step Action Yes No

1 Is resistor OK? Go to Step 2 Replace

2 Is fan control lever (Fan Switch) OK? Open circuit

between the

chassis side

connector terminal

No. C68-4 and No.

I23-3. Replace control

lever assembly.

Step Action Yes No

1 Is resistor OK? Go to Step 2 Replace

2 Is fan control lever (Fan Switch) OK? Open circuit

between chassis

side connector

terminal No. C68-6

and No. I23-4. Replace control

lever assembly.

Chart “E" Blower Motor Does Not Run At High Position

Chart “F" Blower Motor Does Not Stop In The “OFF" Position

Step Action Yes No

1 Is resistor OK? Go to Step 2 Replace

2 Is fan control lever (Fan Switch) OK? Open circuit

between Chassis

side connector

terminal No. C68-3

and No. I23-5. Replace control

lever assembly.

Step Action Yes No

1 Is the fan control lever (Fan Switch) OK? Short circuit

between chassis

side connector

terminal No.C70-1

and

No.C68-2,No.C68-

3 and No.I23-5,

No.C68-6 and

No.I23-4,

No.C68-4 and

No.I23-3 or

No.C68-1 and

No.I23-2 Replace control

lever assembly.

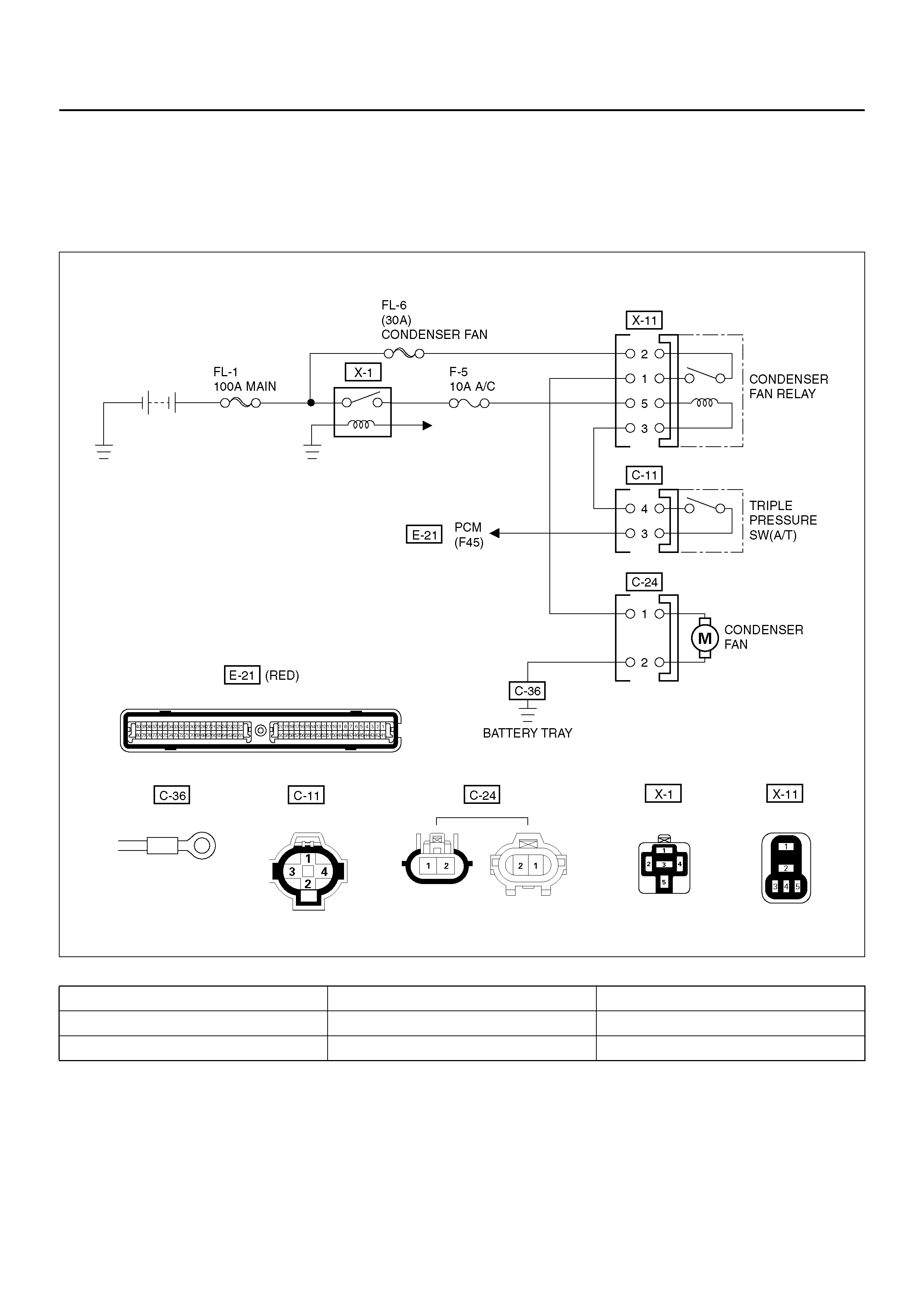

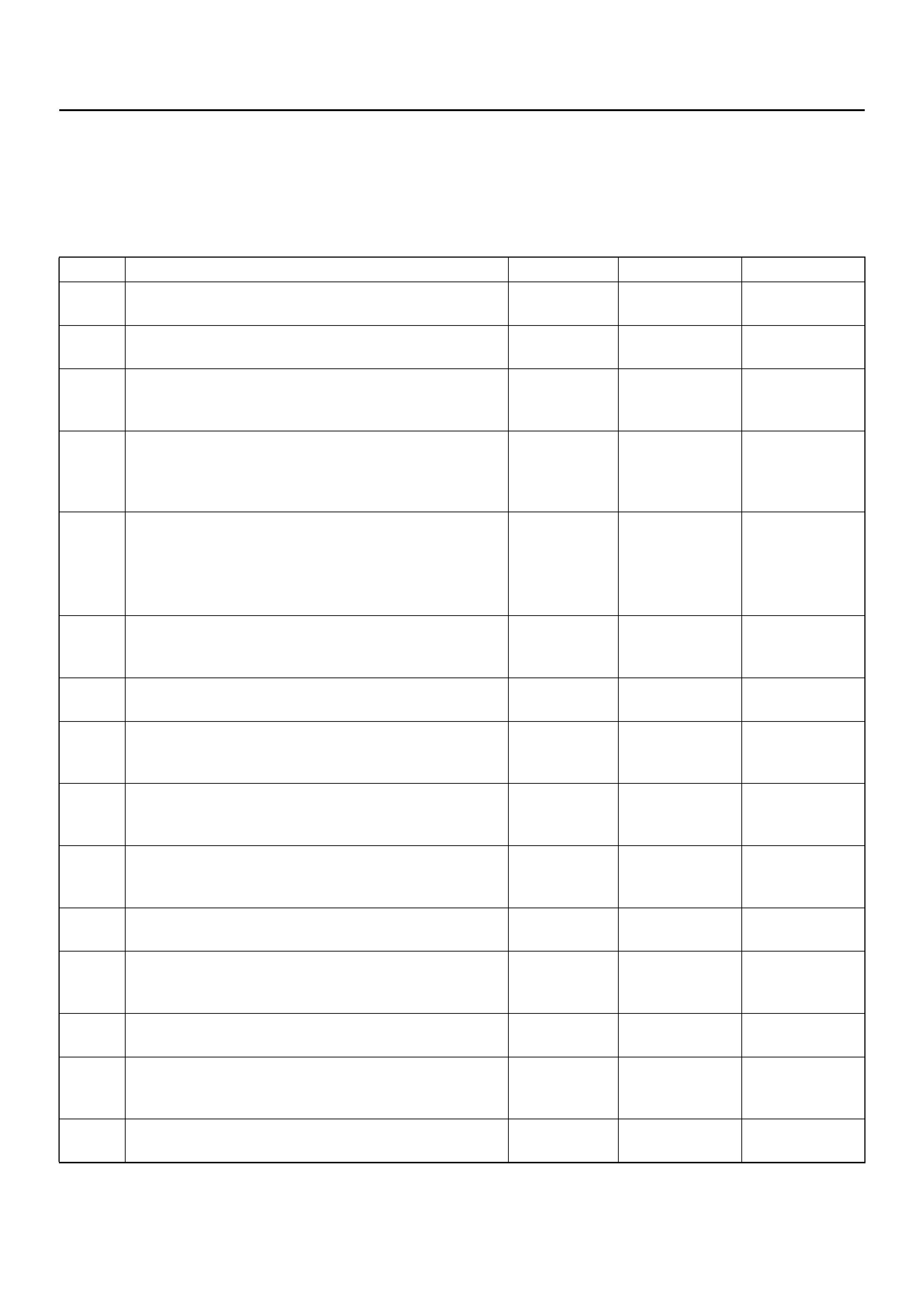

CONDENSER FAN DIAGNOSIS

While the air conditioning is ON, the cycling switch in

the triple pressure switch senses the refrigerant

pressure, and activates the condenser fan to improve

the cooling capacity of the condenser when the

refrigerant pressure exce eds a set pressure value. The

conden ser fan stops when the air conditi oning is turned

“OFF" or when the pressure goes down below the set

pressure value.

D08R100140

Condition Possible cause Correction

Condenser fan does not run. — Refer to Chart A

Condenser fan does not stop. — Refer to Chart B

Chart “A" Condenser Fan Does Not Run

Step Action Value(s) Yes No

1 Is the fusible link No.FL–6 normal? — Go to Step 2 Replace the

fusible link wire

2 Is the fuse No.F–5 normal? — Go to Step 3 Replace the

fuse

3 Is the heater relay (No.X–1) and condenser fan relay

(No.X–11) normal? — Go to Step 4 Replace the

relay

4 1. Disconnect the condenser fan motor connector

No.C–24.

2. Connect the motor side connector terminal

No.C24–1 to the battery positive terminal and

No.C24–2 to the battery negative terminal.

Does the fan operate? — Go to Step 6 Go to Step 5

5 Repair or replace the condenser fan motor.

Is the action complete? — Go to Step 4 —

6 Is there continuity between the harness side

connector terminal No.C24–2 and ground (C–36)? — Go to Step 8 Go to Step 7

7 Repair an open circuit between terminal No.C24–2

and No.C–36.

Is the action complete? — Go to Step 6 —

8 Is there continuity between the harness side

connector terminal No.C24–1 and No.X11–1? — Go to Step 10 Go to Step 9

9 Repair an open circuit between terminal No.C24–1

and No.X11–1.

Is the action complete? — Verify repair —

10 Is the battery voltage applied between the harness

side connector terminal No.X11–2 and ground? — Go to Step 12 Go to Step 11

11 Repair an open circuit between terminal No.X11–2

and No.FL–6.

Is the action complete? — Go to Step 10 —

12 Is the battery voltage applied between the harness

side connector terminal No.C11–4 and ground? — Go to Step 14 Go to Step 13

13 Repair an open circuit between terminal No.X11–3

and No.C11–4.

Is the action complete? — Go to Step 12 —

14 Is there continuity between the harness side

connector terminal No.C11–3 and No.E21–F45? — Go to Step 16 Go to Step 15

15 Repair an open circuit between terminal No.C11–3

and No.E21–F45.

Is the action complete? — Verify repair —

16 Connect the harness side connector terminal

No.C24–1 to the battery terminal and No.C24–2 to the

battery negative terminal.

Is the battery voltage between the pressure switch

side connector terminal No.C24–2 and ground? — Go to Step 18 Go to Step 17

17 Replace the triple pressure switch.

Is the action complete? — Verify repair —

18 Replace the auto air conditioner control unit.

Is the action complete? — Verify repair —

Chart “B" Condenser Fan Does Not Stop

Step Action Value(s) Yes No

1 1. Turn on the ignition switch “ON" (the engine is

run).

2. Air conditioning switch “OFF".

3. Disconnect the triple pressure switch.

Does the condenser fan stop? — Go to Step 2 Go to Step 3

2 Replace the triple pressure switch.

Is the action complete? — Verify repair —

3 Disconnect the relay.

Is there continuity between the harness side

connector terminal No.X11–3 and ground? — Go to Step 4 Go to Step 5

4 Repair short circuit between terminal No.X11–3 and

No.C11–4.

Is the action complete? — Verify repair —

5 Replace the relay condenser fan.

Is the action complete? — Verify repair —

INDIVIDUAL INSPECTION

Blower Motor

1. Dis connect the blower mo tor (C-70 ) connec tor from

the blower motor.

2. Connect the battery positive terminal to the No. 2

termin al of the bl ower m oto r and the ne gati ve to th e

No. 1.

3. Be sure to check to see if the blower motor operates

correctly.

873RW008

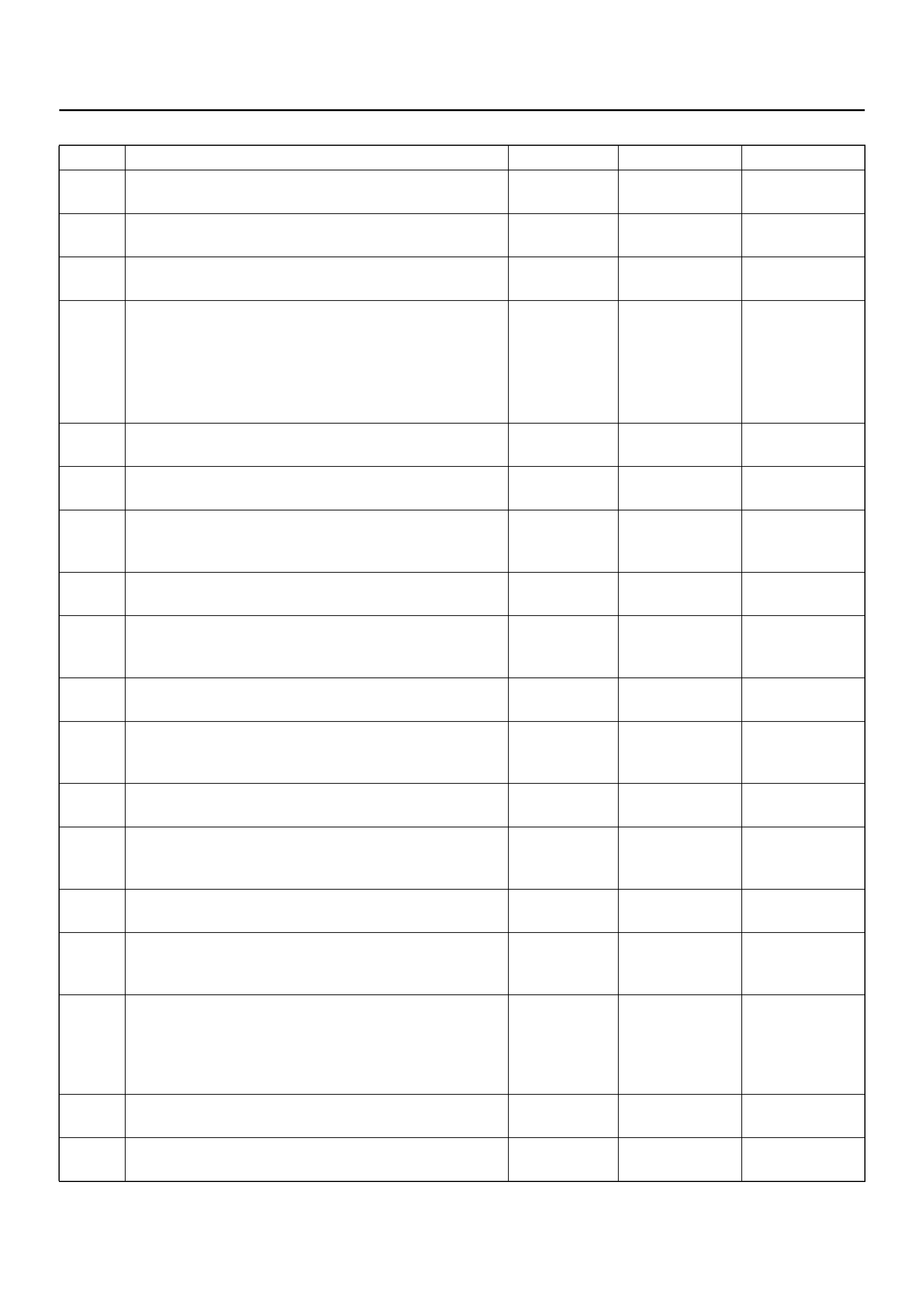

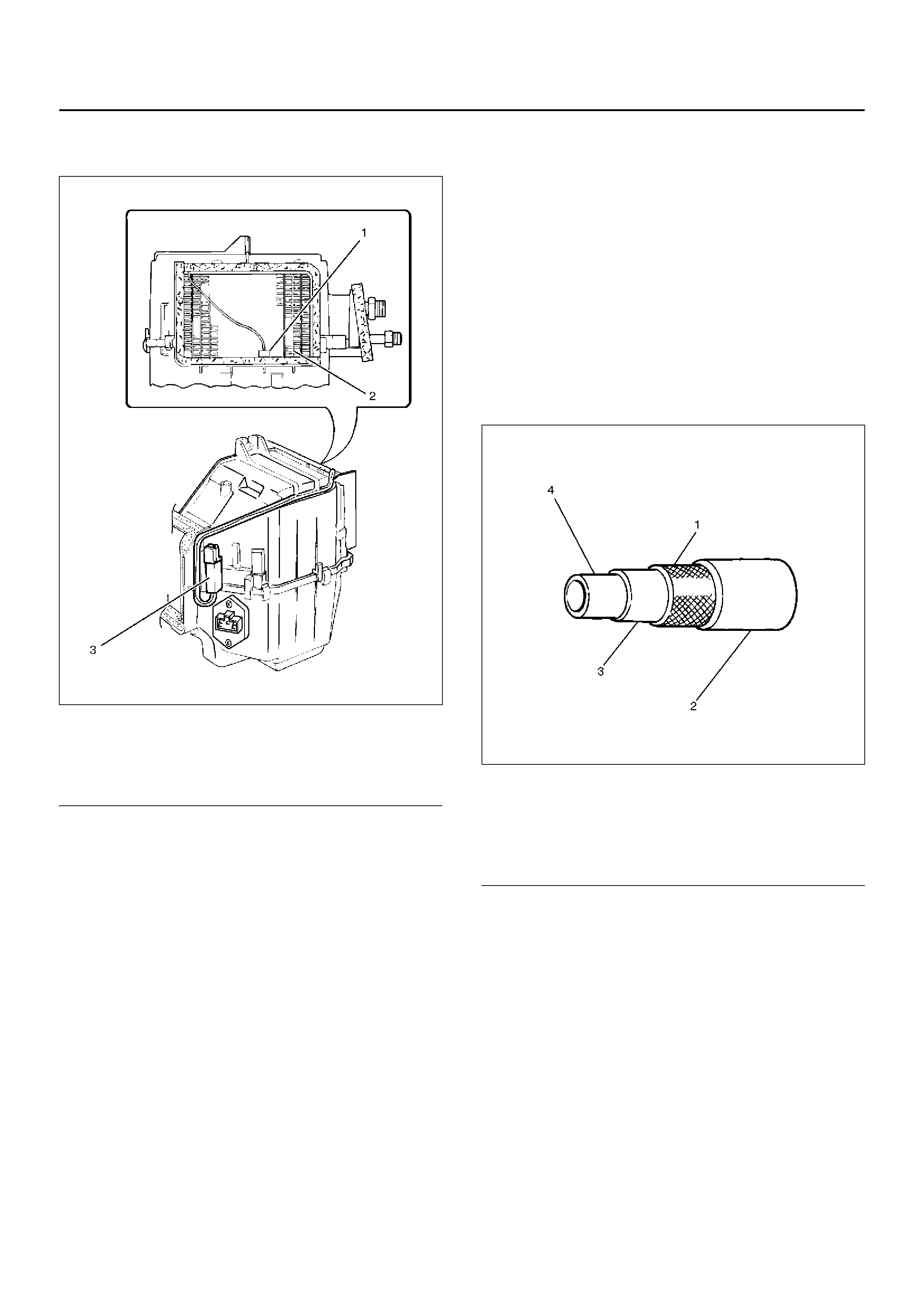

Resistor

1. Disconnect the resistor (C-68) connector.

2. Check for continuity and resistance between the

terminals of the resistor.

840R100006

EndOFCallout

Legend

(1) Resiste r As sembl y

(2) Connector Terminal (Resister Side)

(3) Position Switch

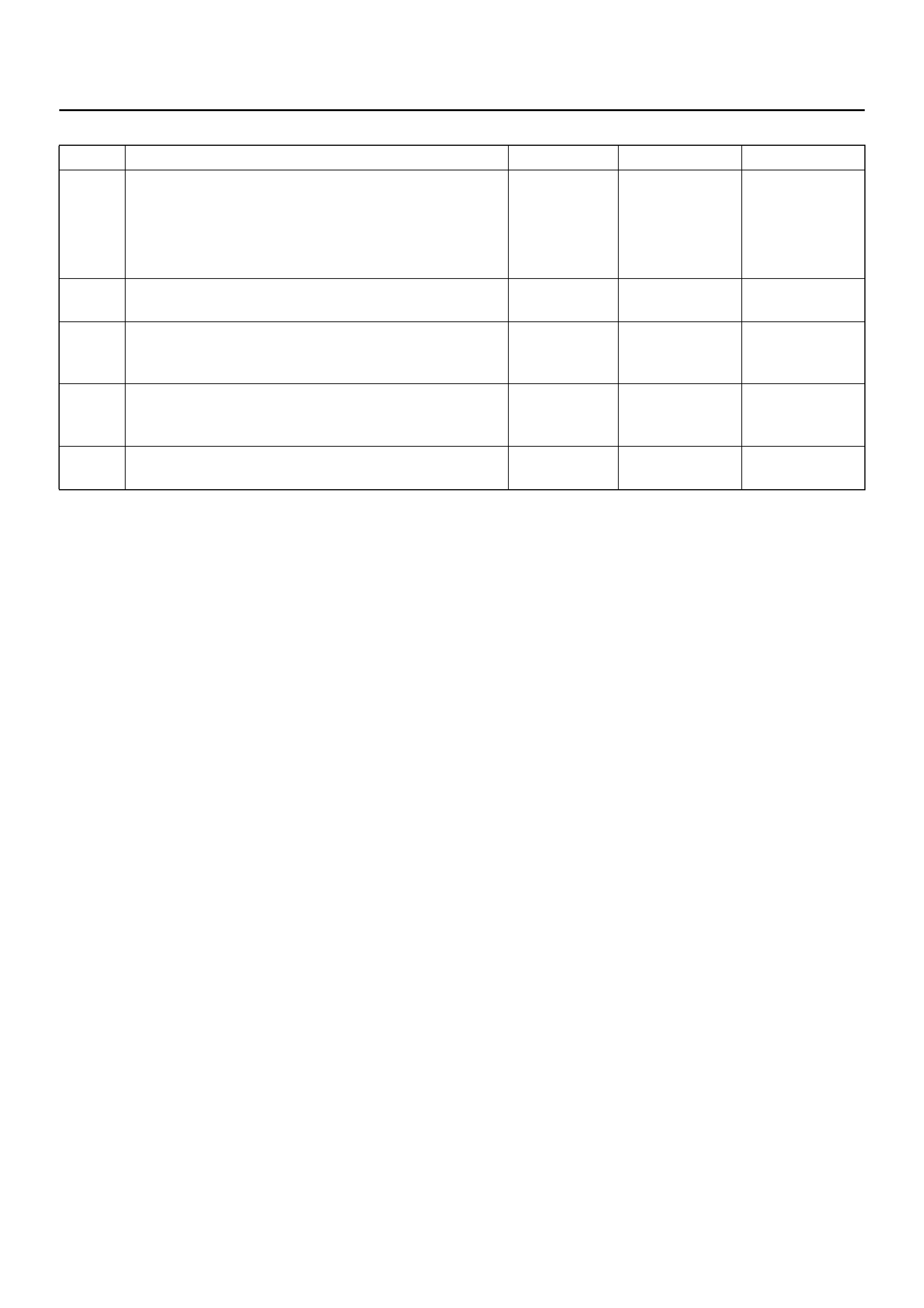

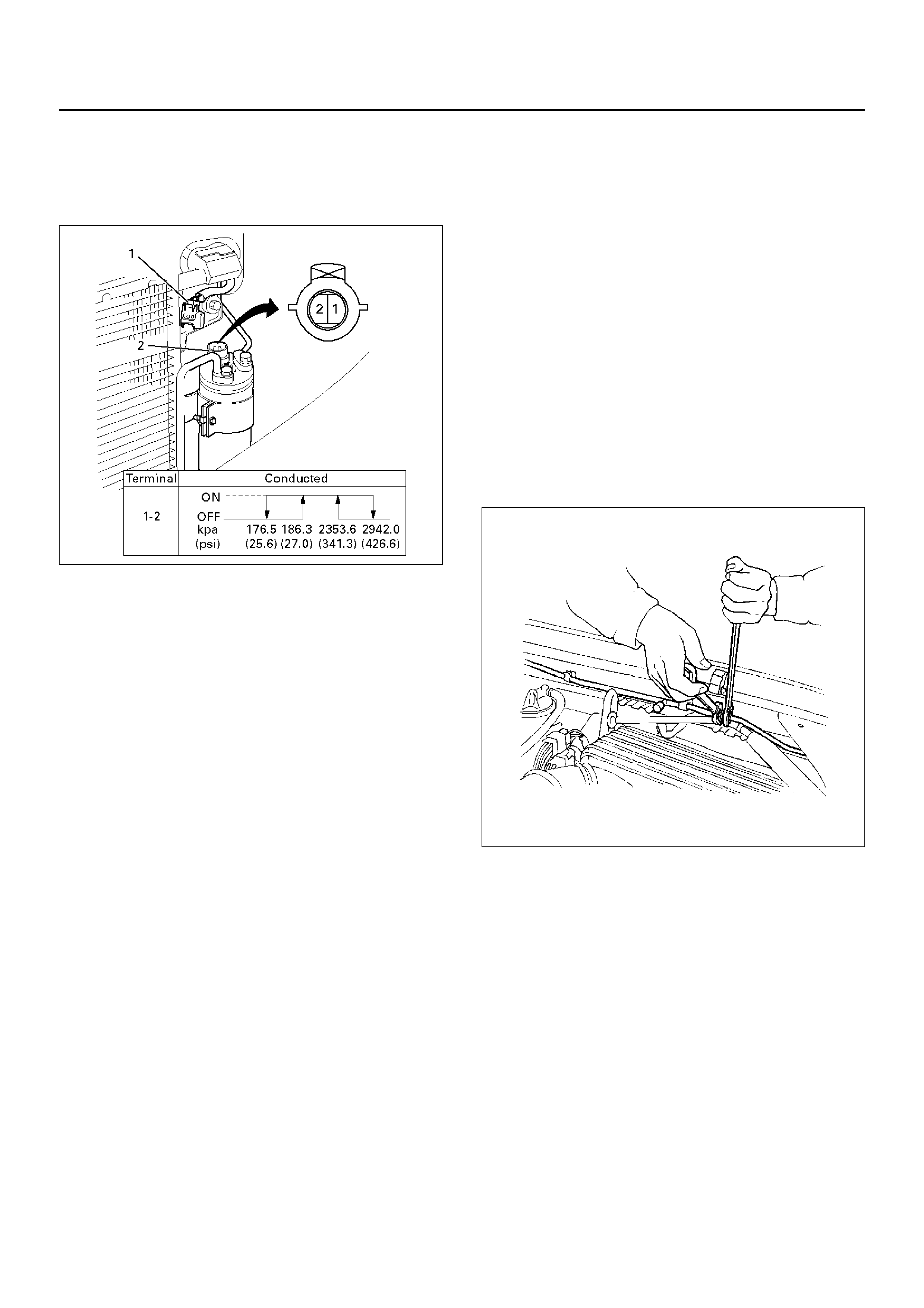

Triple Pressure Switch (V6, A/T)

1. Disconnect the connector and check for continuity

between pressure switch side connector terminals

(1) and (2).

2. Reconnect the connector to activate the A/C switch,

and check to see if there is continuity between the

chassis side connector terminals (3) and (4) and the

fan operates.

875RY00010

Condenser Fan

1. Disconnect the condenser fan connector.

2. Connect the battery positive terminal to the

condenser fan side connector terminal No.C-24-1

and negative to the No.C-24-2.

3. Check that condenser fan is rotating correctly.

875RW010

GENERAL REPAIR PROCEDURE

Precautions For Replacement or Repair of

Air Conditioning Parts

There are certain procedures, practices and precautions

that should be followed when servicing air conditioning

systems:

• Keep your work area clean.

• Always wear safety goggles and protective gloves

when working on refrigerant systems.

• Beware of the danger of carbon monoxide fumes

caused by running the engine.

• Beware of discharged refrigerant in enclosed or

improperly ventilated garages.

• Always disconnect the negative battery cable and

discharge and recover the refrigerant whenever

repairing the air conditioning system.

• When discharging and recovering the refrigerant, do

not allow refrigerant to discharge too fast; it will draw

compressor oil out of the system.

• Keep moisture and contaminants out of the system.

When disconnecting or removing any lines or parts,

use plugs or caps to close the fittings immediately.

Never remove the caps or plugs until the lines or

parts are reconnected or installed.

• When disconnecting or reconnecting the lines, use

two wrenches to support the line fitting, to prevent

from twisting or other damage.

• Alway s install new O-rings wh enever a co nnection is

disassembled.

• Before connecting any hoses or lines, apply new

specified compressor oil to the O-rings.

• When removing and replacing any parts which

require discharging the refrigerant circuit, the

operations described in this section must be

perfor med in the following seque nc e:

1 Use the J-39500 (ACR4: HFC-134a Refrigerant

Recovery / Recycling / Recharging / System) or

equivalent to thoroughly discharge and recover

the refrigerant.

2 Remove and replace the defective part.

3 After evacuation, charge the air conditioning

system and check for leaks.

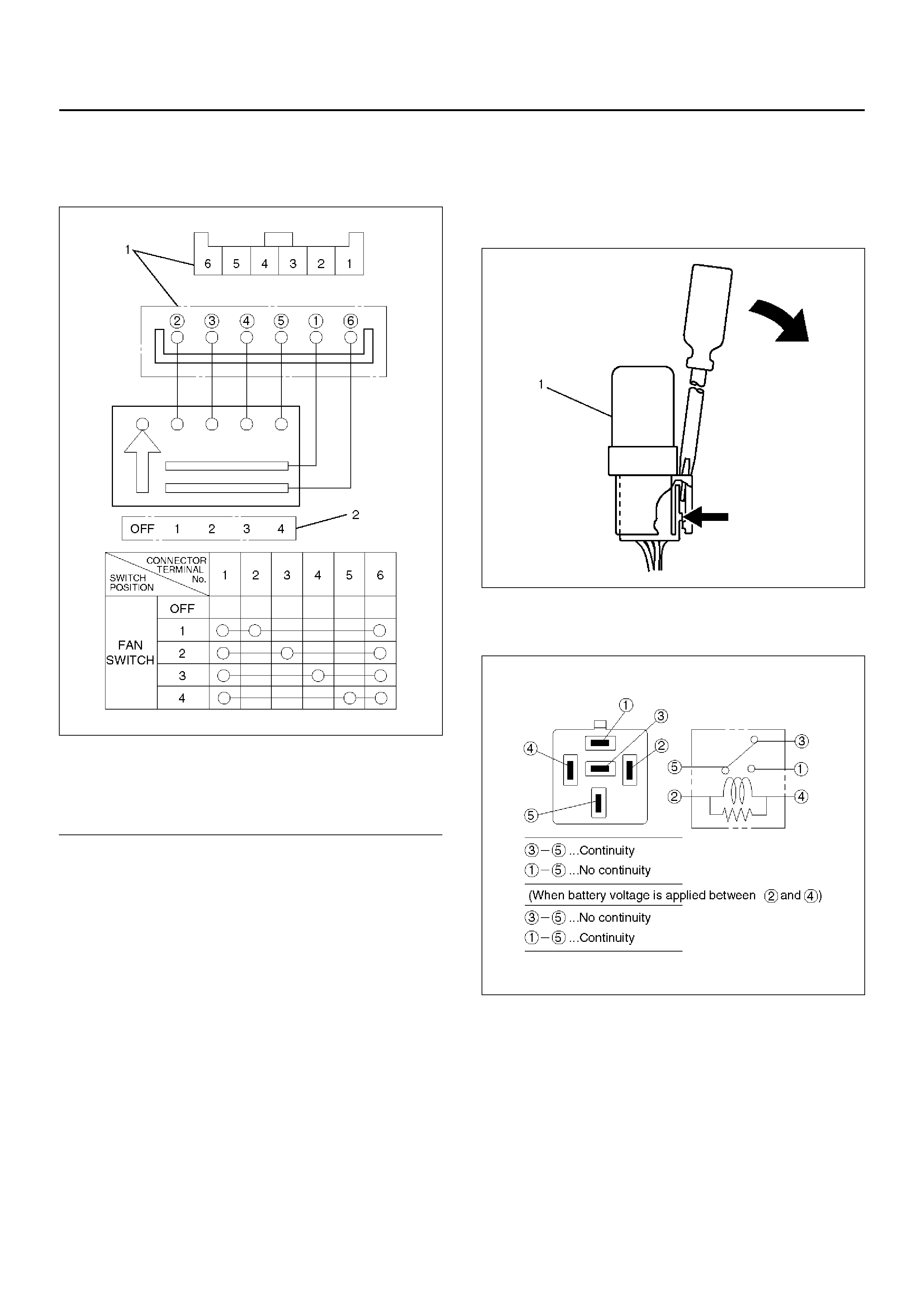

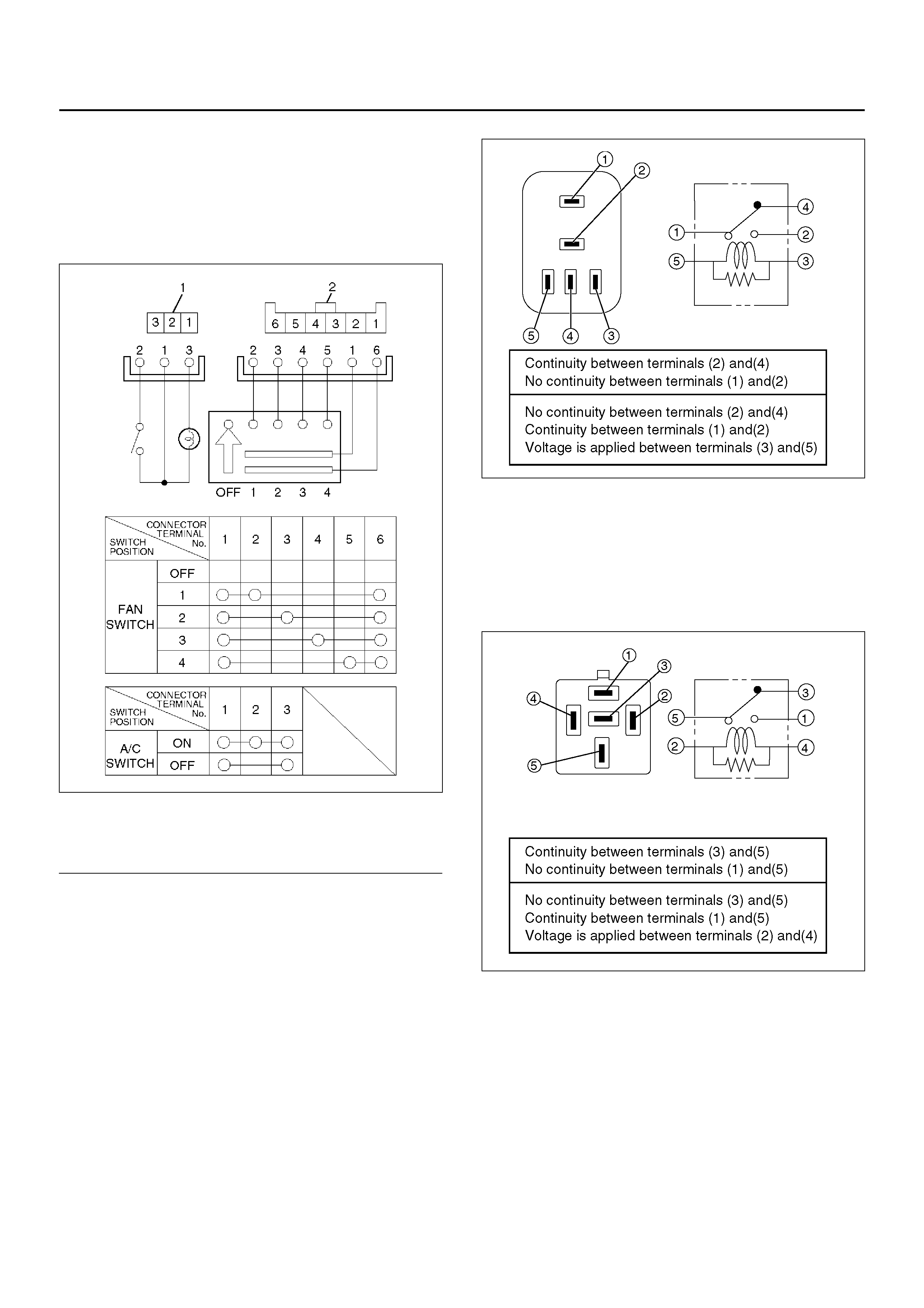

Fan Control Lever (Fan Switch)

1. Check for continuity between the terminals of the

fan switch.

D08RX157

EndOFCallout

Heater R ela y

1. Disconnect the heater relay (X-1).

• When r emoving the c onnector for re lay, unfas ten

the tank lock of the connector by using a

screwdriver, then pull the relay (1) out.

825RX046

2. Check for continuity between th e heater relay (X-1)

terminals.

901RX071

Legend

(1) Control Lever Connector Terminal (Control

Lever Side)

(2) P os iti on Swit ch

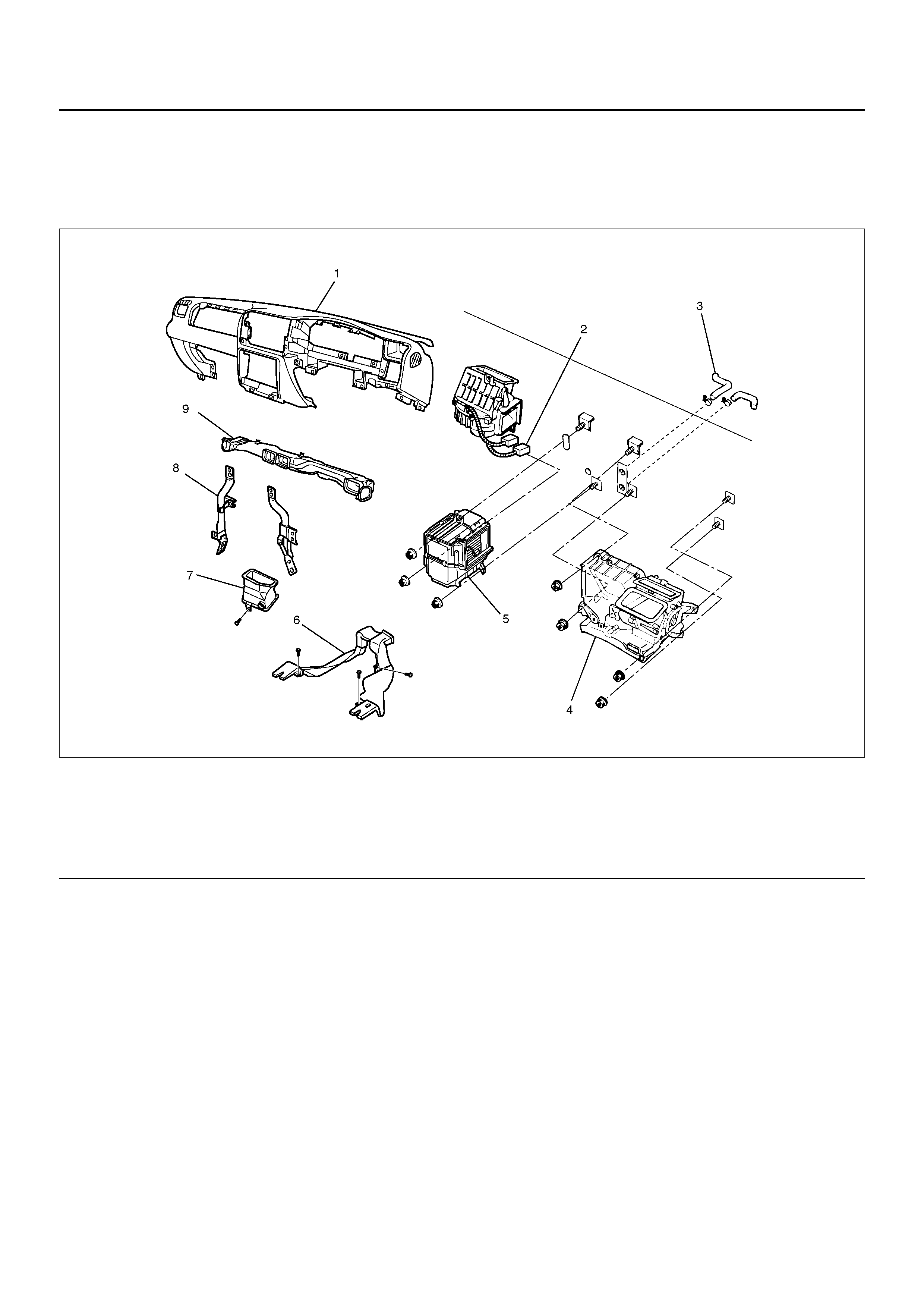

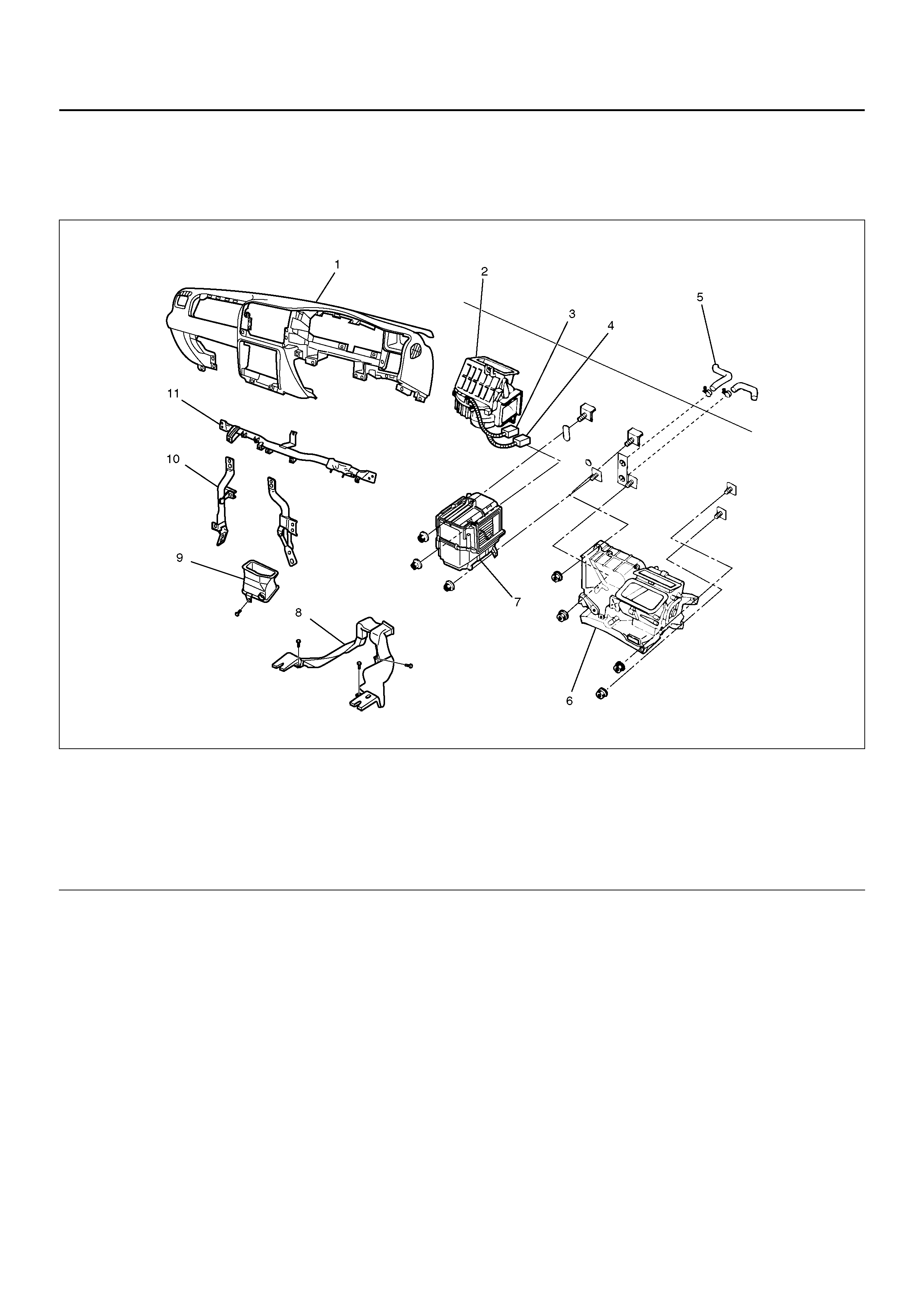

HEATER UNIT

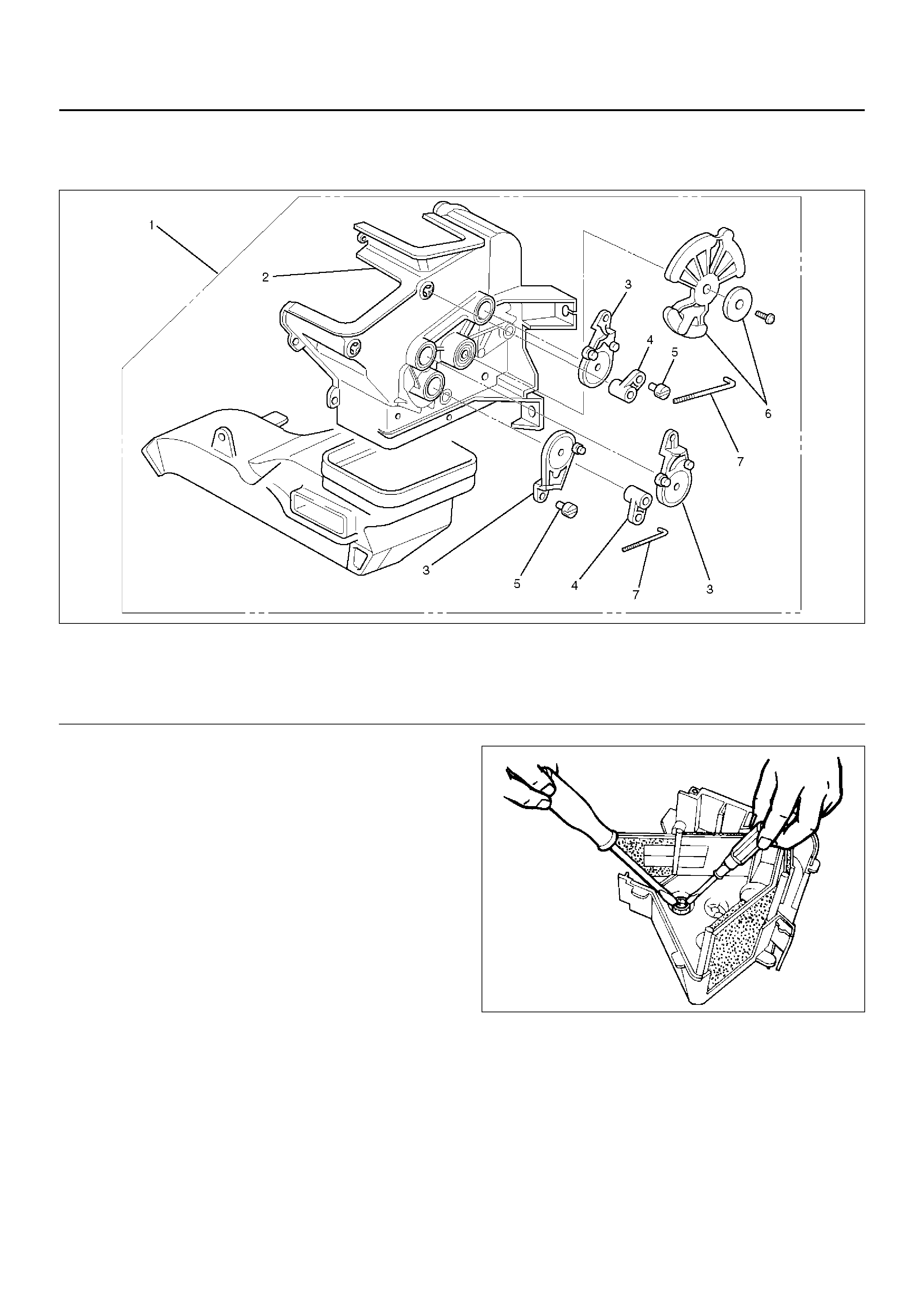

HEATER UNIT AND ASSOCIATED PARTS

840R100003

EndOFCallout

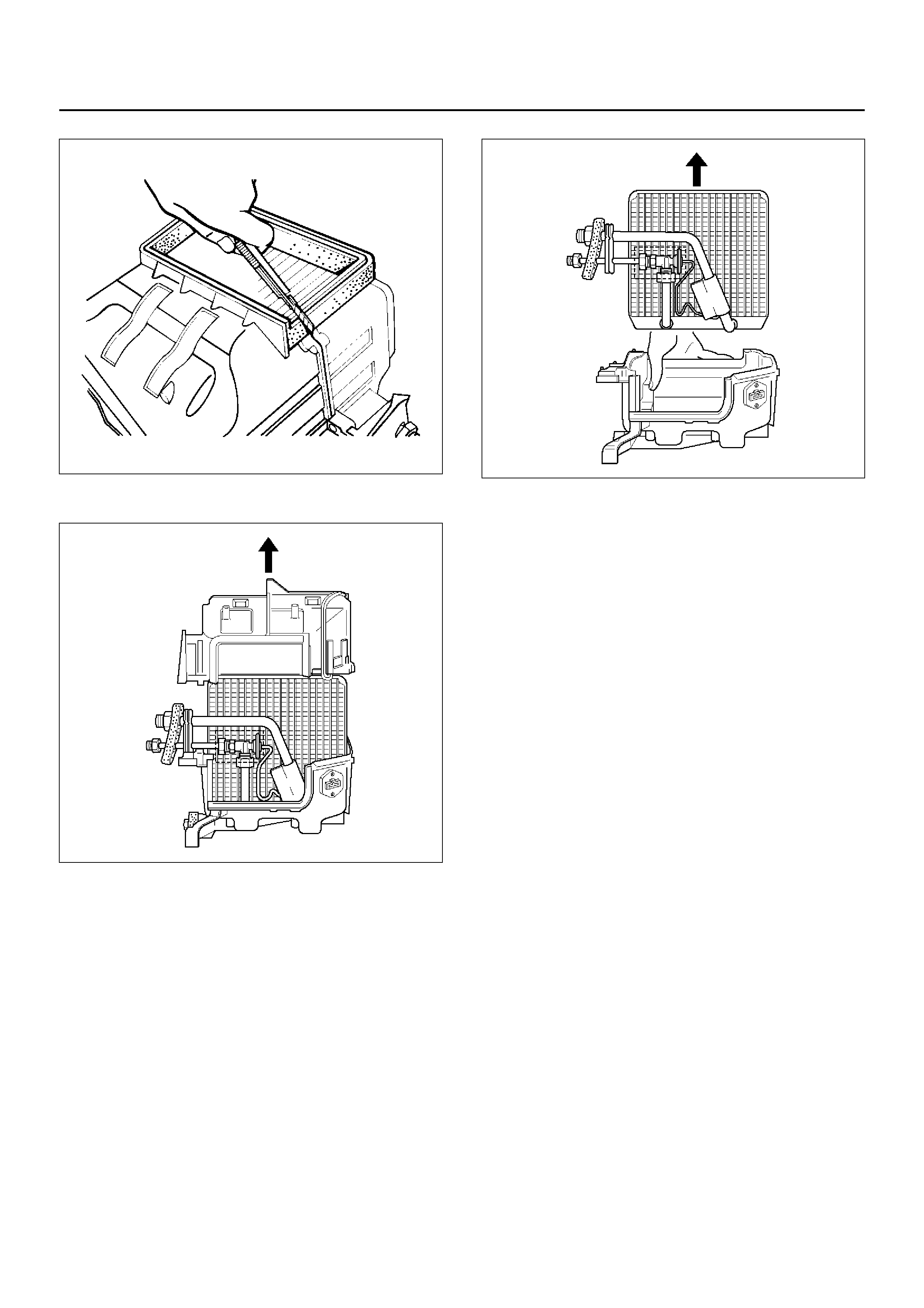

REMOVAL

1. Disconnect the battery ground cable.

2. Drain the engine coolant.

3. Discharge and recover refrigerant (with air

conditioning).

• Refer to Refrigerant Recovery in this section.

4. Remove the Instrument panel assembly.

• Refer to Instrument Panel Assembly in Body and

Accessories section.

5. R emo ve ins trument panel stay.

6. Remove center ventilation duct and side defroster.

7. D is co nnect re si stor connecto r.

8. Re mo ve evaporator ass emb ly.

• Refer to Evaporator Assembly in this section.

9. Remove ventilation lower duct.

10. Remove rear heater duct.

• Remove foot rest, carpet and 3 clips.

11. Remove heater unit assembly.

• Disconnect heater hoses at heater unit.

Legend

(1) Instrument Panel Assembly

(2) Resistor Connector

(3) Heater Hose

(4) Heater Unit Assembly

(5) Evaporato r As se mbl y

(6) Rear Heater Duct

(7) Ventilation Lower Duct

(8) Instrument Panel Stay

(9) Center Ventilation Duct and Side Defroster

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points:

1. When handling the PCM and the control unit, be

careful not to make any improper connection of the

connectors.

2. Adjust the control cables.

• Refer to Control Lever Assembly in this section.

3. When installing the heater unit, defroster nozzle and

center vent duct, be sure that the proper seal is

made, without any gap between them.

4. After putting engine coolant in remove the air well

and confirm the quantity of coolant.

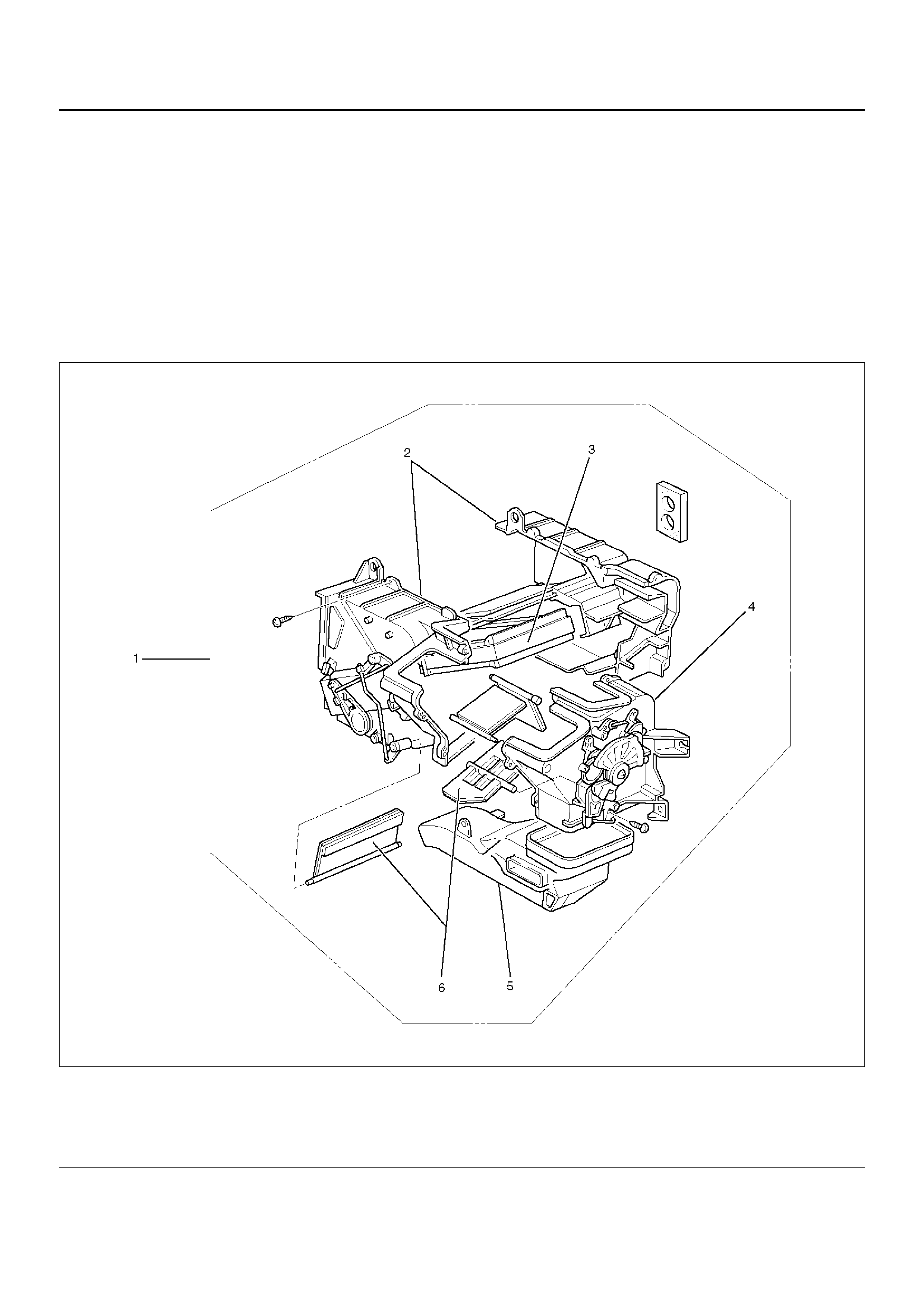

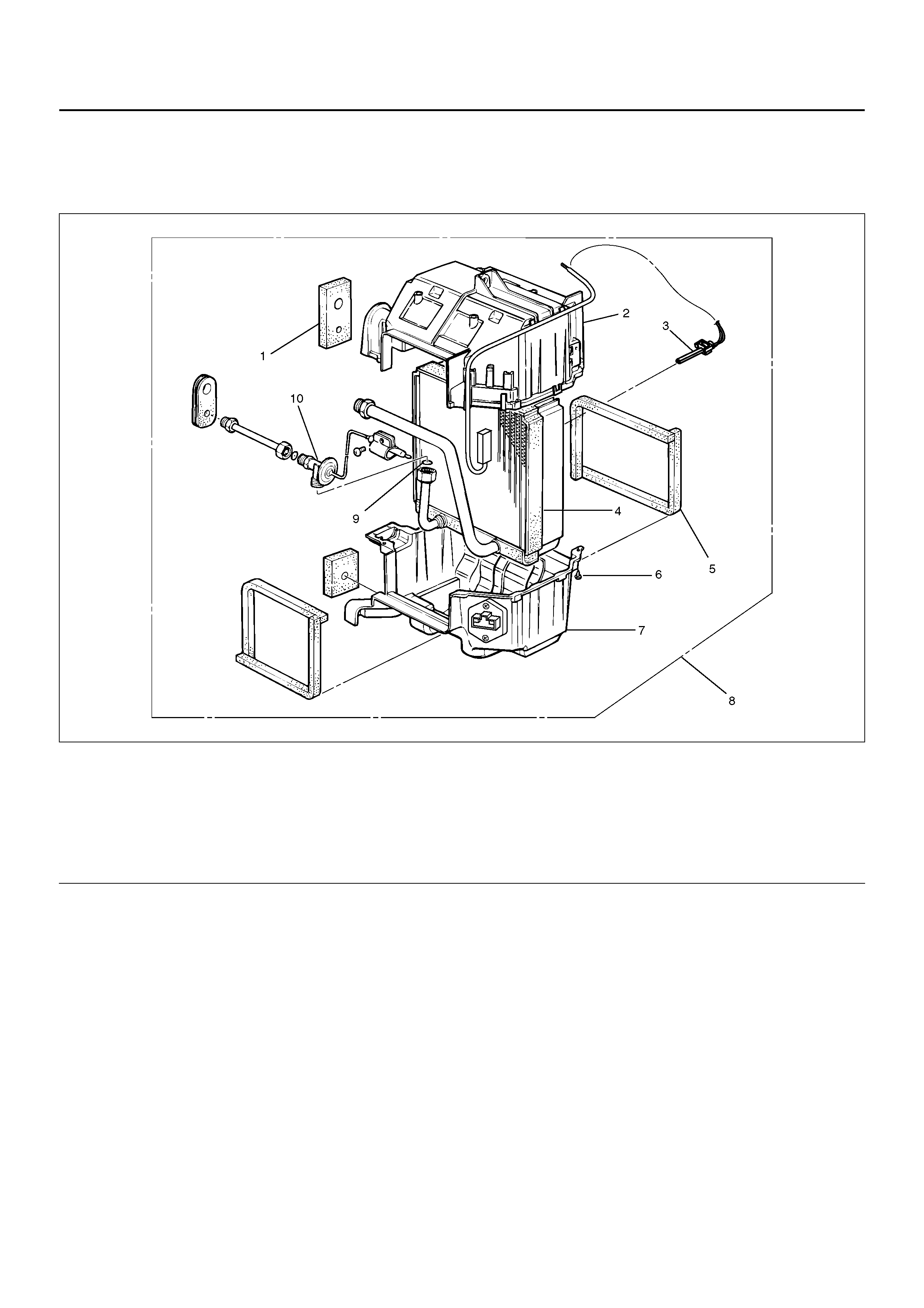

HEATER CORE AND / OR MODE DOOR

DISASSEMBLED VIEW

860RX002

EndOFCallout

Legend

(1) Heater Unit

(2) Case (Temperature Control)

(3) Heater Core

(4) Case (Mode Control)

(5) Duct

(6) Mode Door

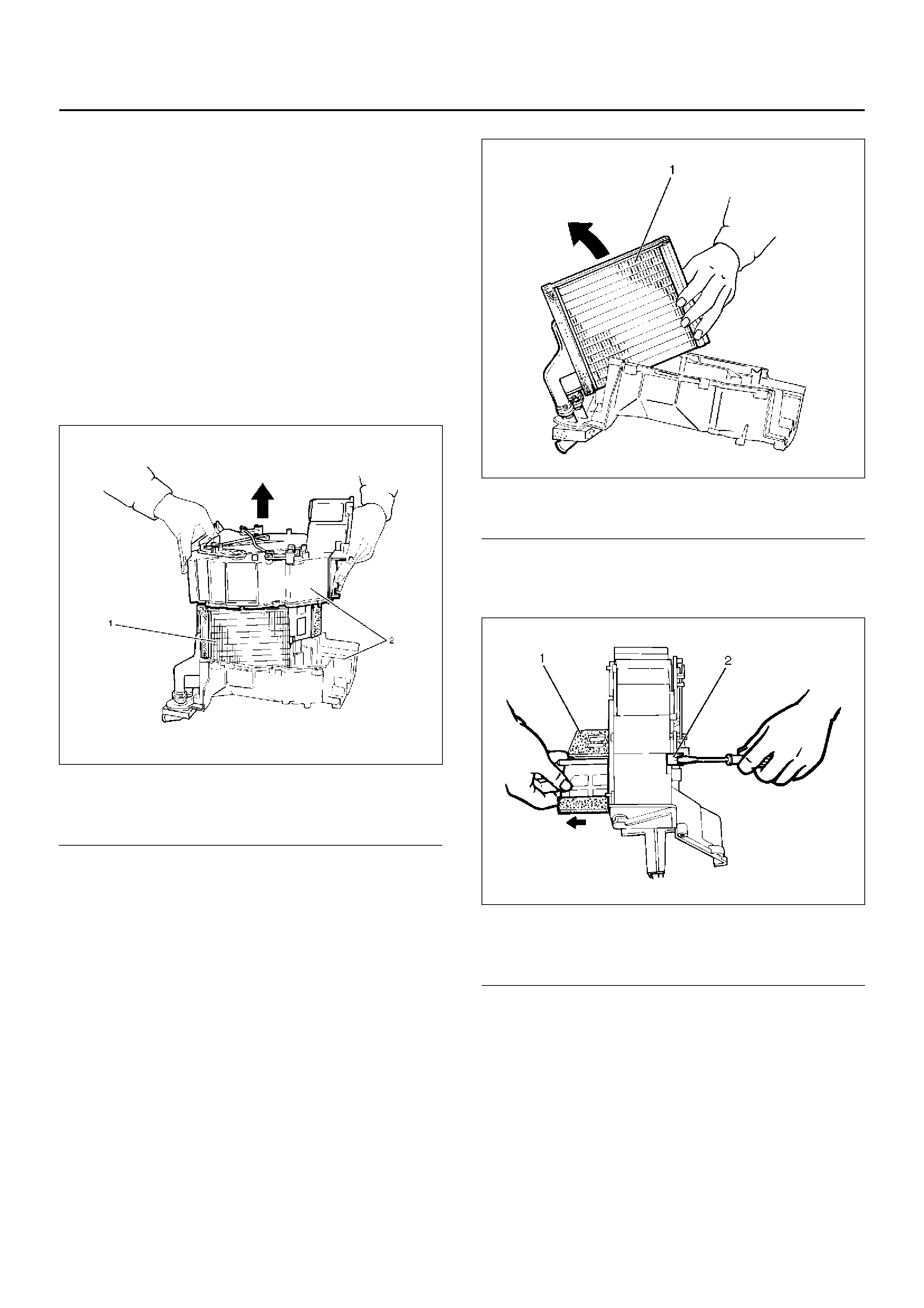

REMOVAL

1. Disconnect the battery ground cable.

2. Drain the engine coolant.

3. Discharge and recover refrigerant (with air

conditioning).

• Refer to Refrigerant Recovery in this section.4. Remove heater unit.• Refer to Heater Unit in this section.

5. Remove duct.

6. Remove case (Mode control) and do not remove

link unit at this step.

7. Remove case (Temperature control) and separate

two halves of core case.

860RW021

EndOFCallout

8. Remove heater core.

860RW020-1

EndOFCallout

9. Pull out the mode door while raising up the catch of

the door lever.

860RX004

EndOFCallout

INSPECTION

Check for foreign matter in the heater core, stain or the

core fin defacement.

INSTALLATION

To install, foll ow the removal ste ps in the reverse or der,

noting the foll owi ng poi nt:

1. Check that each mode door operates properly.

Legend

(1) Heater Core

(2) Core Case

Legend

(1) Heater Core

Legend

(1) Mode Door

(2) Door Lever

HEATER MODE CONTROL LINK UNIT

DISASSEMBLED VIEW

860RY00012

EndOFCallout

REMOVAL

1. Disconnect the battery ground cable.

2. Drain engine coolant.

3. Discharge and recover refrigerant (with air

conditioning)

• Refer to Refrigerant Recovery in this section.

4. Remove heater unit.• Refer to Heater Unit in this section.

5. Remove the case (Mode control) from heater unit.

6. Remove washer and the mode main lever.

7. Remove rod.

8. Press the tab of the sub-lever inward, and take out

the sub-lever.

860RW018

9. Pull out the door lever while raising up the catch of

the door lever.

10. Remove clip.

INSTALLATION

To install, follow the remove steps in the reverse order,

noting the foll owi ng poi nts:

1. Apply grease to the mode sub-lever and to the

abrasive surface of the heater unit.

2. After installing the link unit, check to see if the link

unit operates correctly.

Legend

(1) Heater Unit

(2) Case (Mode Control)

(3) Mode Sub Lever

(4) Door Lever

(5) Clip

(6) Washer and Mode Main Lever

(7) Rod

HEATER TEMPERATURE CONTROL LINK UNIT

DISASSEMBLED VIEW

860RX001

EndOFCallout

REMOVAL

1. Disconnect the battery ground cable.

2. Drain engine coolant.

3. Discharge and recover refrigerant (with air

conditioning).

• Refer to Refrigerant Recovery in this section.

4. Remove heater unit.

• Refer to Heater Unit in this section.

5. Remove the case (Temperature control) from the

heater unit.

6. Remove rod.

7. Remove sub-lever.

8. Pull out the door lever while raising up the catch of

the door lever.

9. Remove clip.

INSTALLATION

To install, foll ow the removal ste ps in the reverse or der,

noting the foll owi ng poi nts:

1. Apply grease to the sub-lever and to the abrasive

surface of the heater unit.

2. After installing the link unit, check to see if the link

unit operates correctly.

Legend

(1) Heater Unit

(2) Case (Temperature control)

(3) Door Lever

(4) Sub Lever

(5) Clip

(6) Rod

(7) Clip

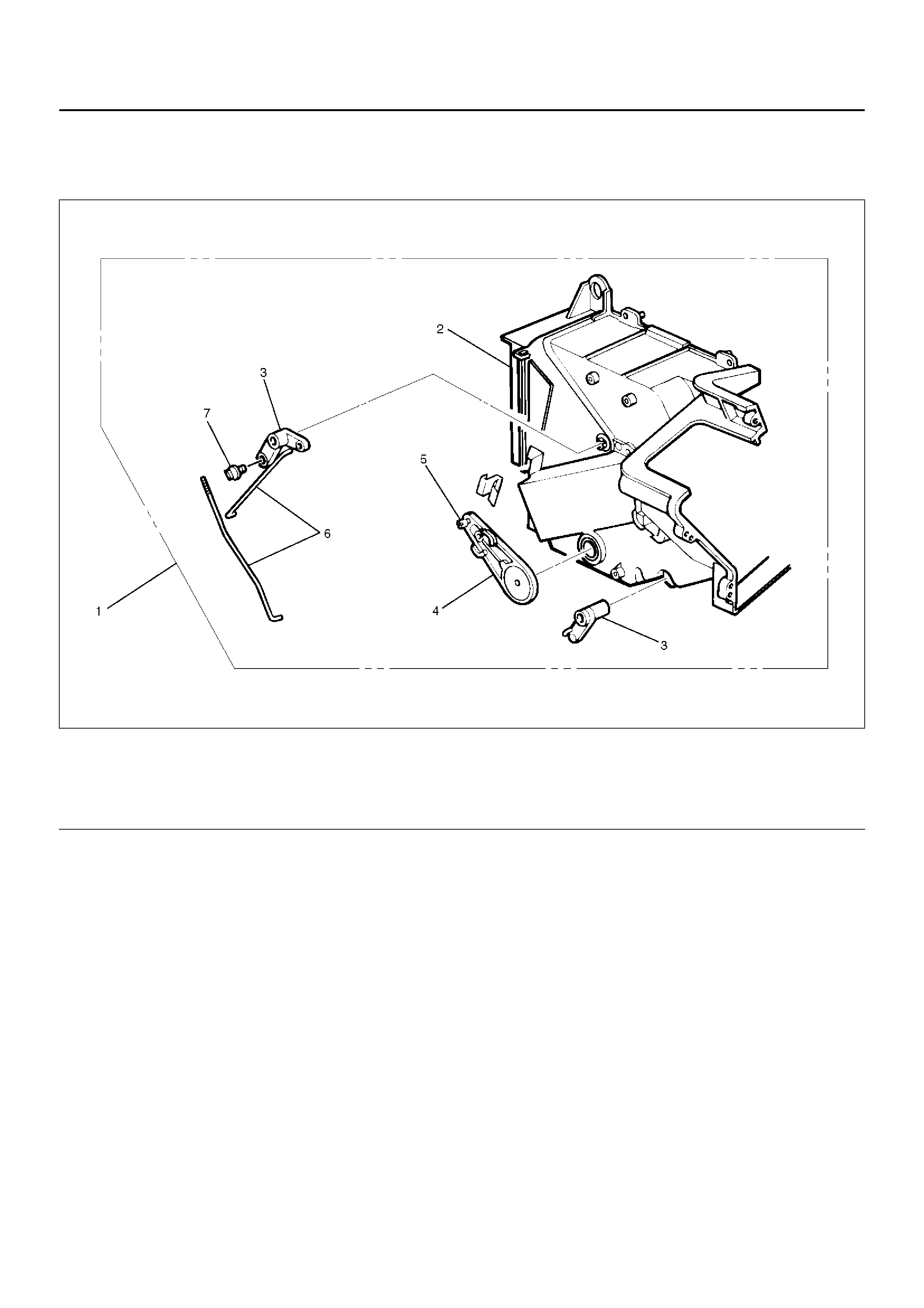

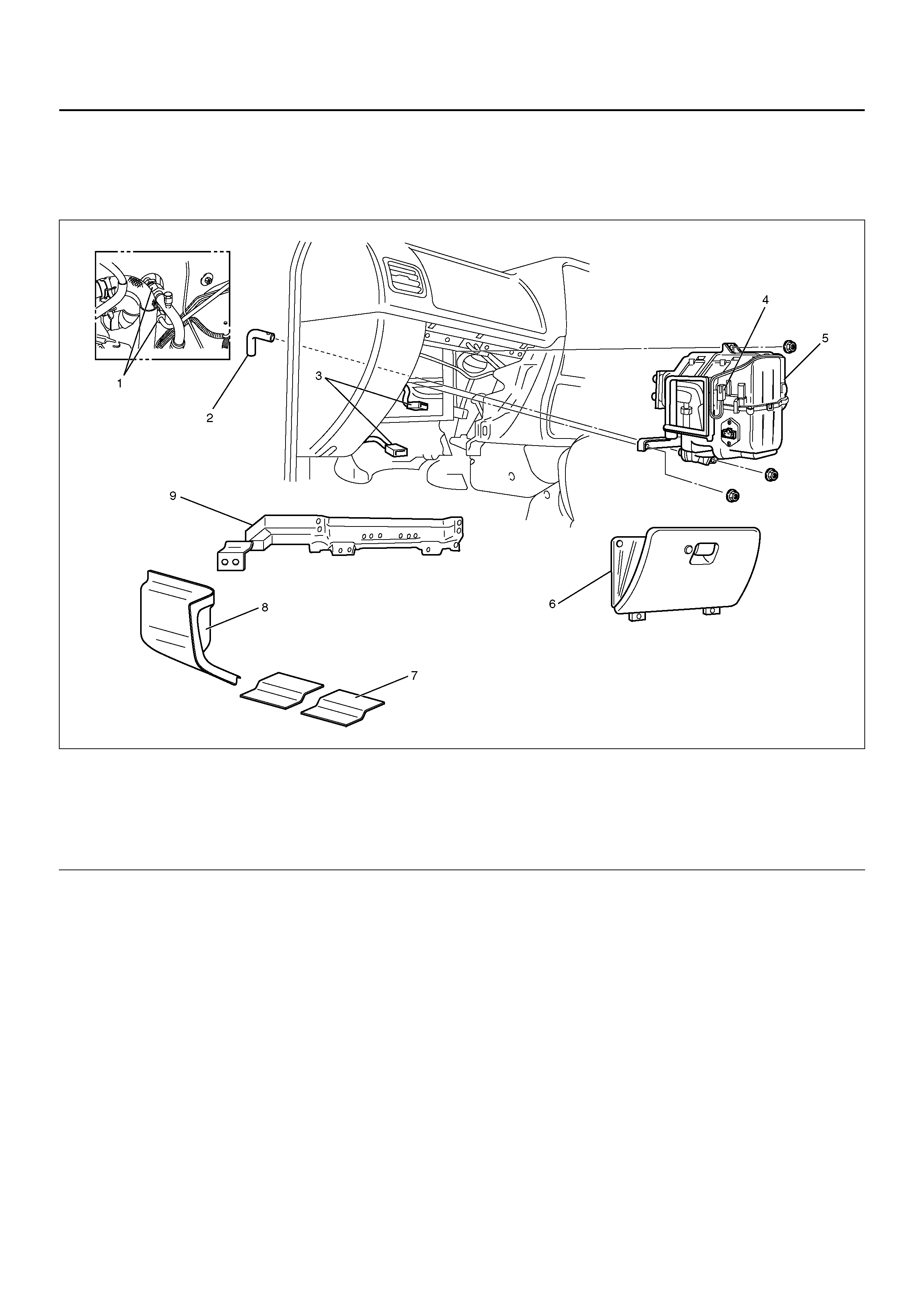

BLOWER ASSEMBLY

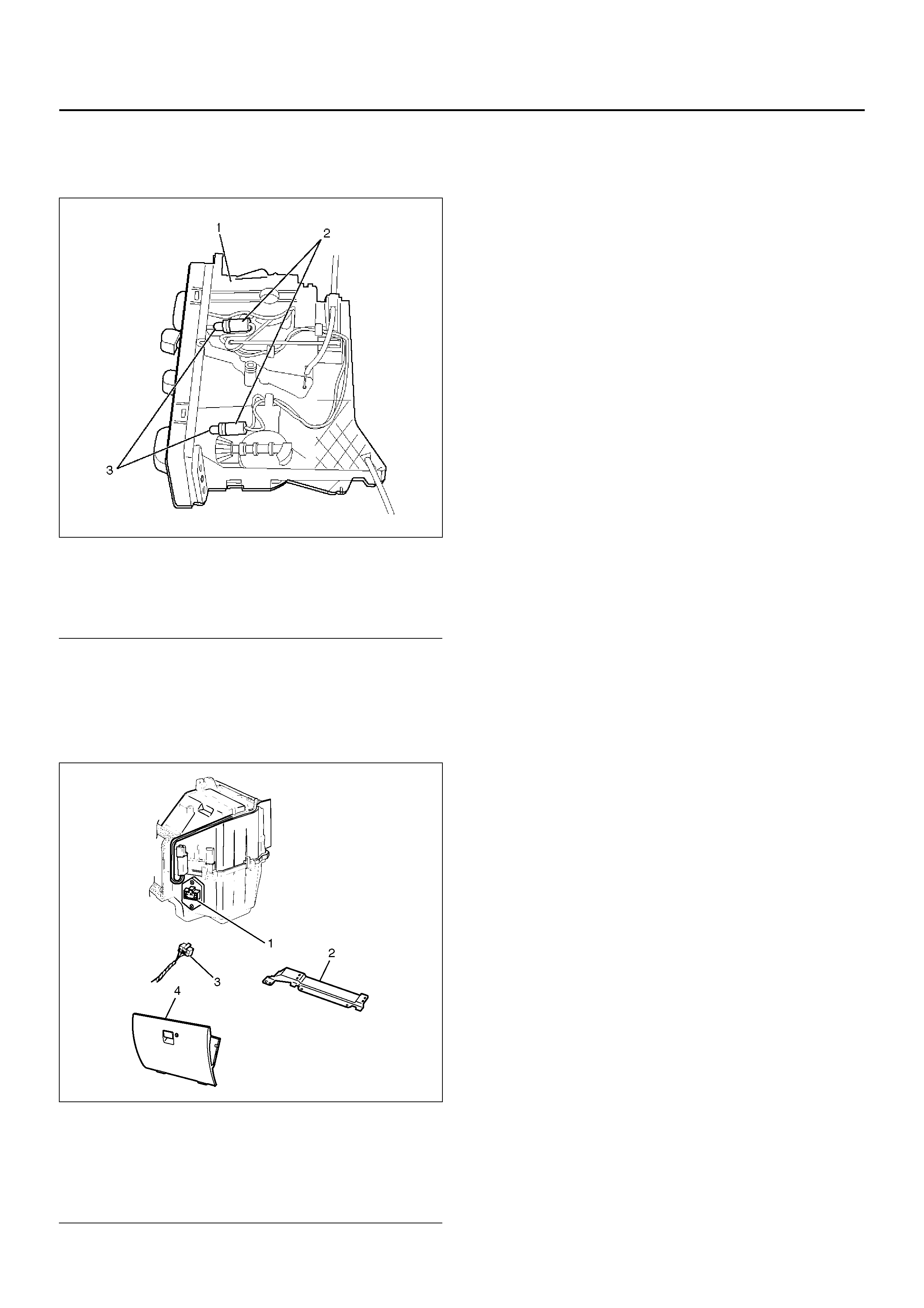

BLOWER ASSEMBLY AND ASSOCIATED PARTS

840R100004

EndOFCallout

REMOVAL

1. Disconnect the battery ground cable.

2. Discharge and recover refrigerant (with air

conditioning).

• Refer to Refrigerant Recovery in this section.

3. Remove instrument panel assembly.• Refer to Instrument Panel Assembly in Body

structure section.

4. Disconnect resistor harness connector.5. Remove evaporator assembly.• Refer to Evaporator Assembly in this section.

6. Disconnect blower motor harness connector.

7. Remove blower assembly.

INSTALLATION

To install, foll ow the removal ste ps in the reverse or der,

noting the foll owi ng poi nt:

1. Adjust the control cables.• Refer to Control Lever Assembly in this section.

Legend

(1) Instrument Panel Assembly

(2) Blower Assembl y

(3) Blower Motor Harness Connector

(4) Resistor Harness Connector

(5) Heater Hose

(6) Heater Unit Assembly

(7) Evaporato r As se mbl y

(8) Rear Heater Duct

(9) Ventilation Lower Duct

(10) Instrument Pa nel Stay

(11) Cross Beam Assembly

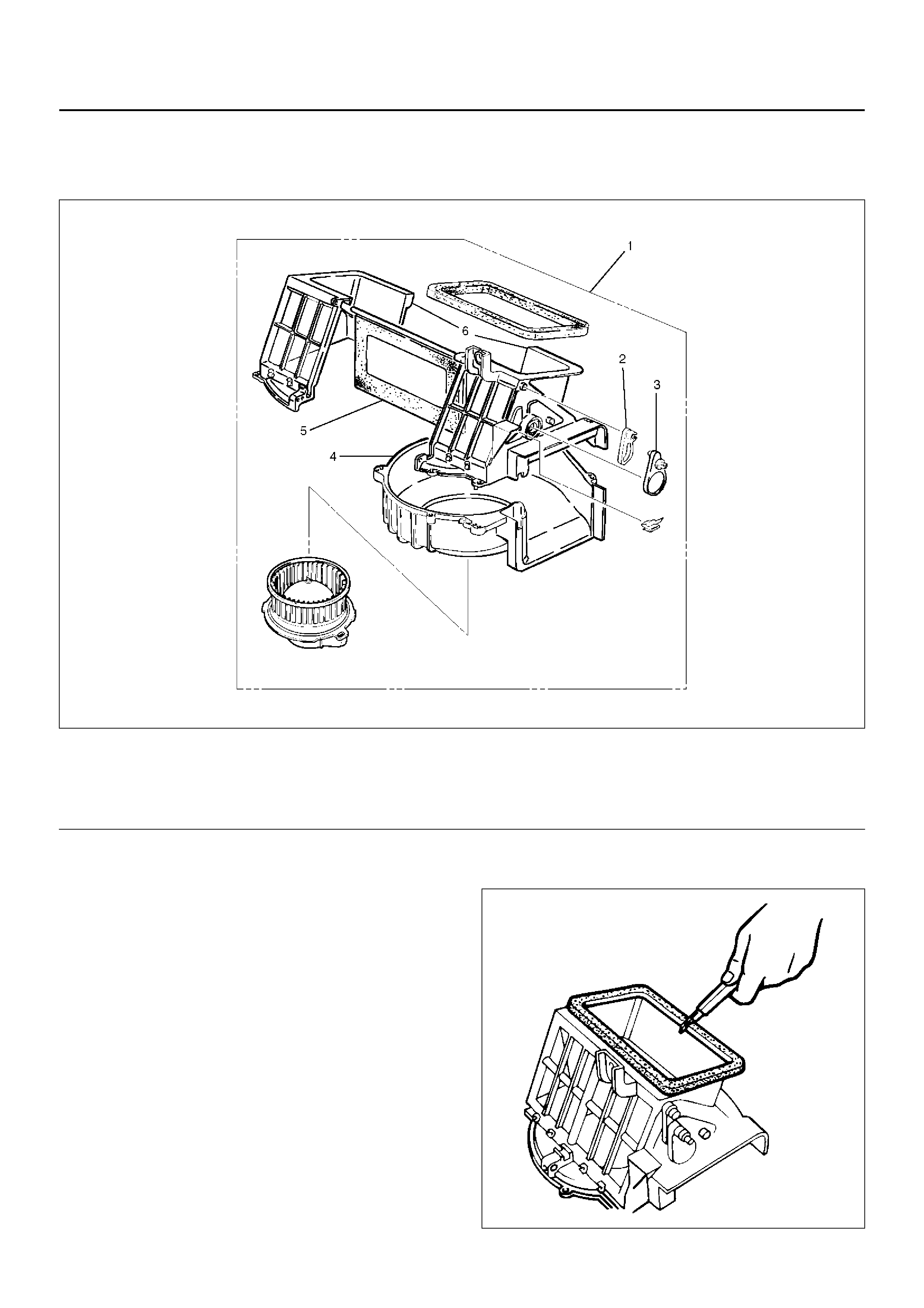

BLOWER LINK UNIT AND / OR MODE DOOR

DISASSEMBLED VIEW

873RX002

EndOFCallout

REMOVAL

1. Disconnect the battery ground cable.

2. Discharge and recover refrigerant (with air

conditioning).

• Refer to Refrigerant Recovery in this section.

3. R emo ve blo wer assembly.

• Refer to Blower Assembly in this section.

4. R emo ve lower case .

5. Separate the upper case and slit the lining parting

face with a knife.

873RW006

Legend

(1) Blower Assembl y

(2) Door Lever

(3) S ub Lev er

(4) Lower Case

(5) Mode Door

(6) Upper Case

6. Pull out the mode door while raising up the catch of

door lever.

7. Remove sub-lever.

8. Remove door lever.

INSTALLATION

To install, f ollow the remova l st eps in the reverse order,

noting the following points:

1. Apply grease to the door lever and to the abrasive

surface of the upper case.

2. Apply an adhesive to the parting face of the lining

when assembling the upper case.

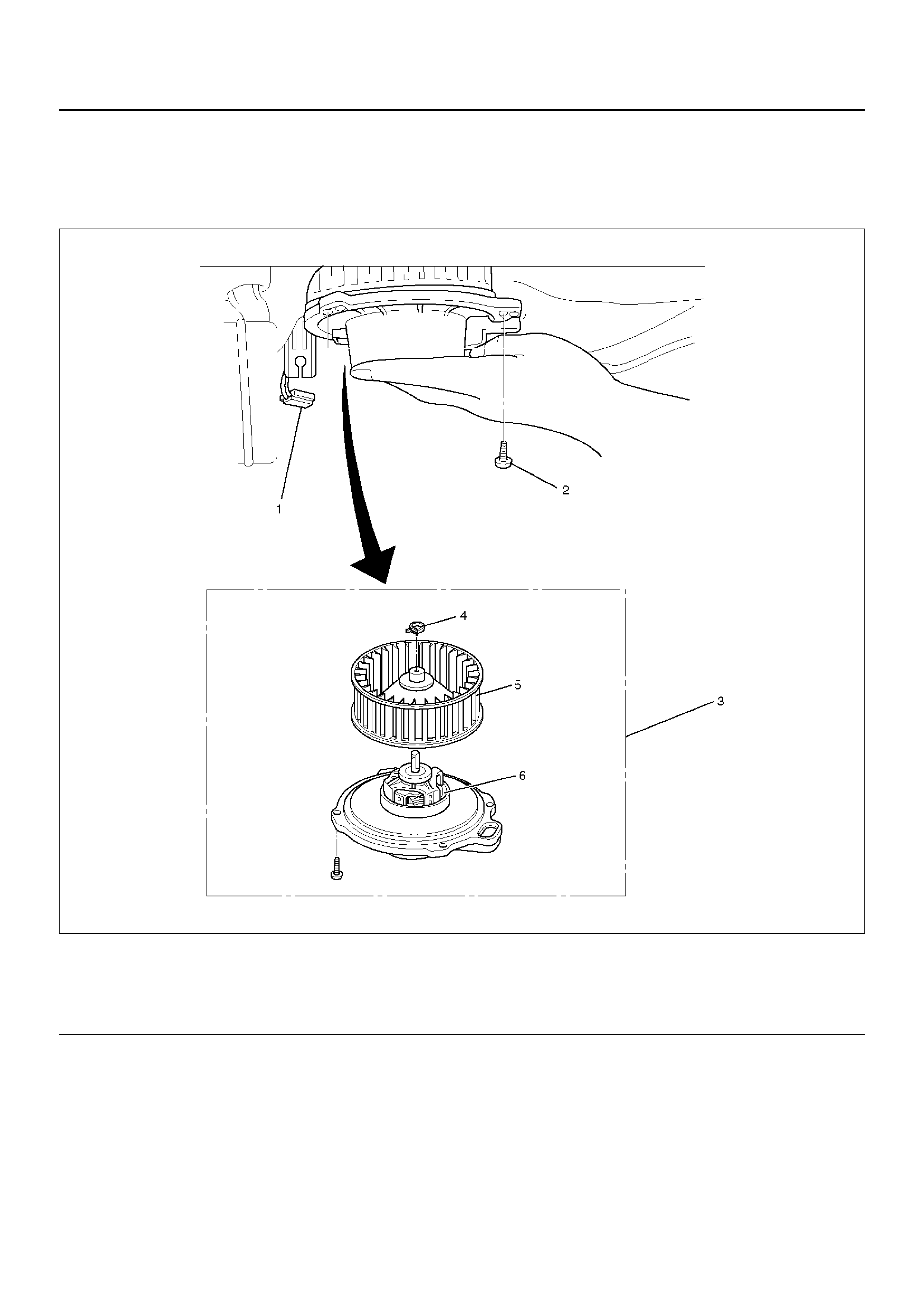

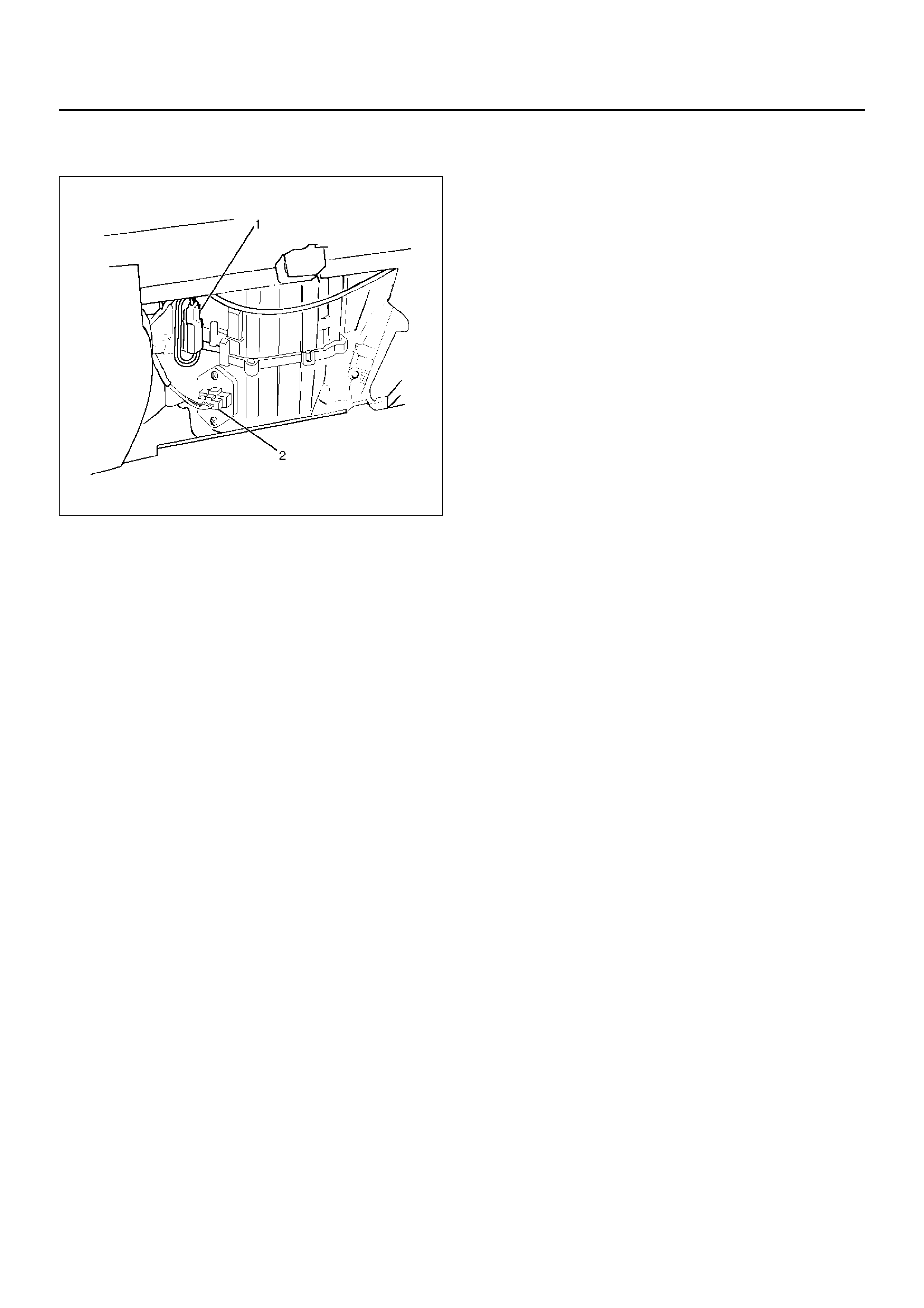

BLOWER MOTOR

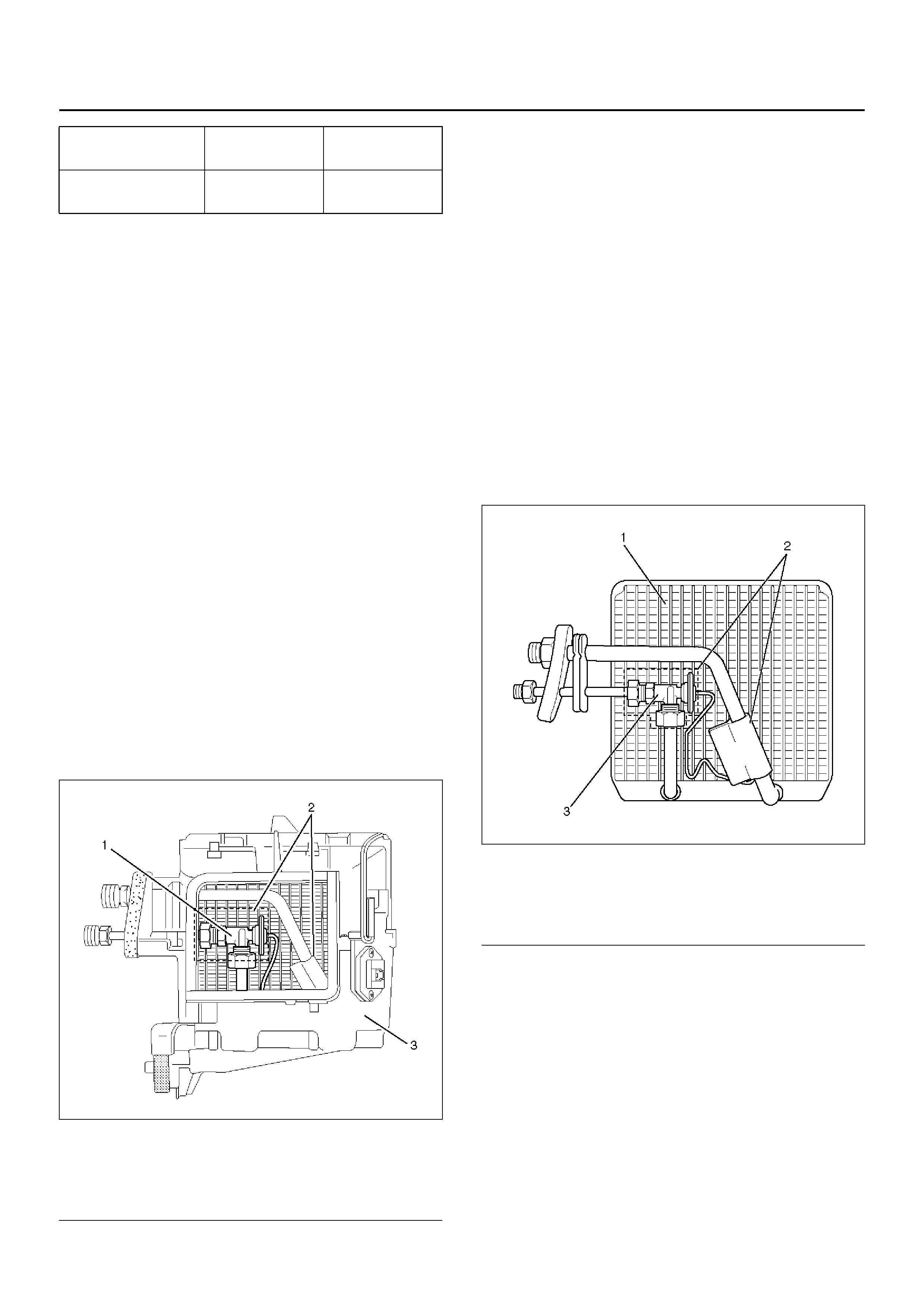

BLOWER MOTOR AND ASSOCIATED PARTS

873RX001

EndOFCallout

REMOVAL

1. Disconnect the battery ground cable.

2. Remove blower motor connector.

3. Remove attaching screw.

4. Remove blower motor assembly.

5. Remove clip.

6. Remove fan.

7. Remove blower motor.

INSTALLATION

To install, follow the removal steps in the reverse order.

Legend

(1) Blower Motor Connector

(2) Attaching Screw

(3) Blower Motor Assembly

(4) Clip

(5) Fan

(6) Blower Motor

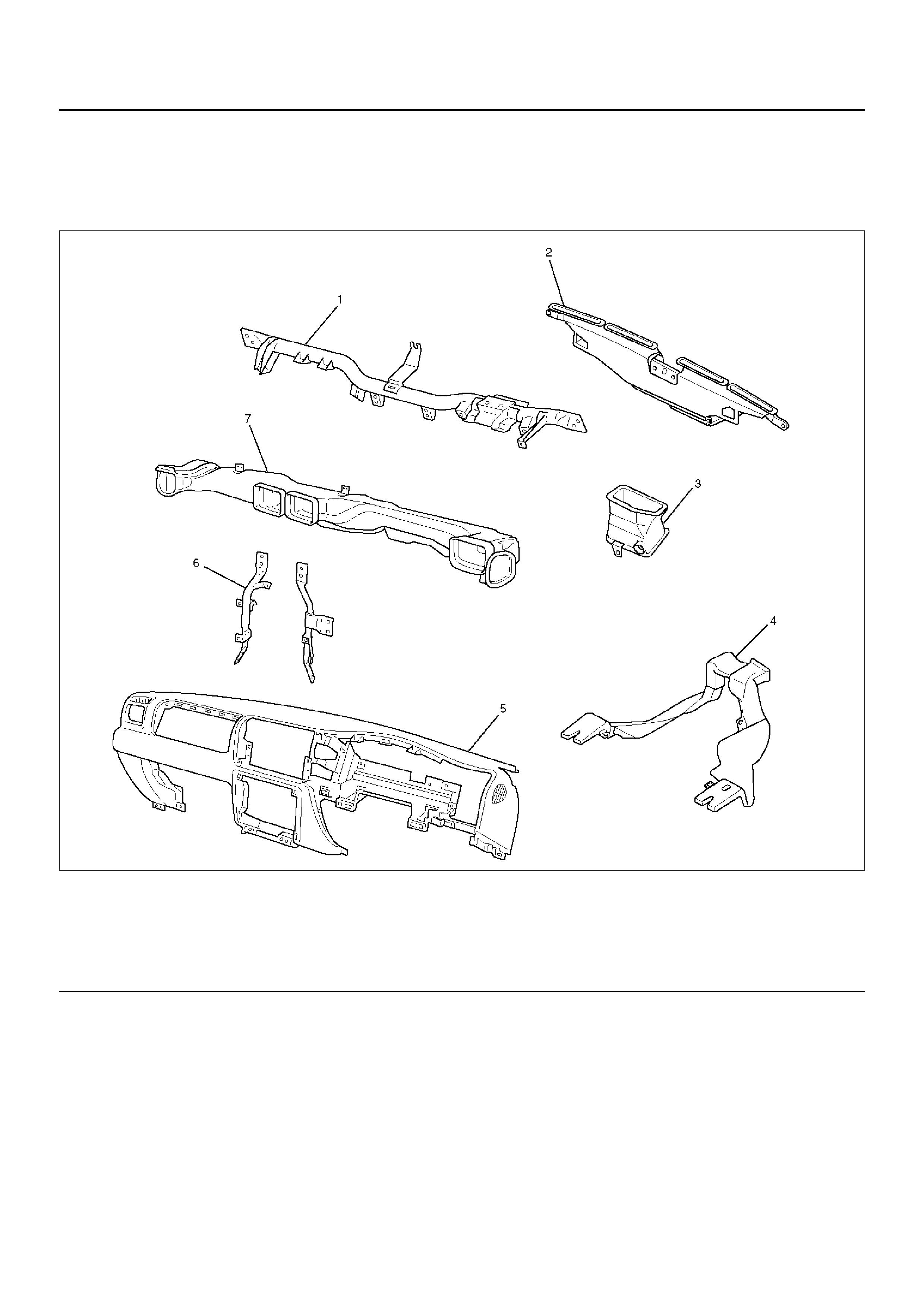

REAR HEATER DUCT, DEFROSTER NOZZLE AND VENTILATION DUCT

REAR HEATER DUCT, DEFROSTER NOZZLE, VENTILATION DUCT AND

ASSOCIATED PARTS

840RY00047

EndOFCallout

REMOVAL

1. Disconnect the battery ground cable.

2. Remove instrument panel assembly.

• Refer to Instrument Panel Assembly in Body

Structure section.

3. Remove center ventilation duct and side defroster

duct.

• Remove 5 screws.

4. Remove instrument panel Stay.

5. Remove cross beam assembly.

6. Remove ventilation lower duct.

7. Remove rear heater duct.

• Remove foot rest carpet and 3 clips.

8. Remove defroster nozzle.

INSTALLATION

To install, foll ow the removal ste ps in the reverse or der,

noting the foll owi ng poi nt:

1. Connect each duct and nozzle securely leaving no

clearance between them and making no improper

matching.

Legend

(1) Cross Beam Assembly

(2) Defroster Nozzle

(3) Ventilation Lower Duct

(4) Rear Heater Duct

(5) Instrument Pa nel Assemb ly

(6) Instrument Panel Stay

(7) Center Ventilation Duct and Side Defroster

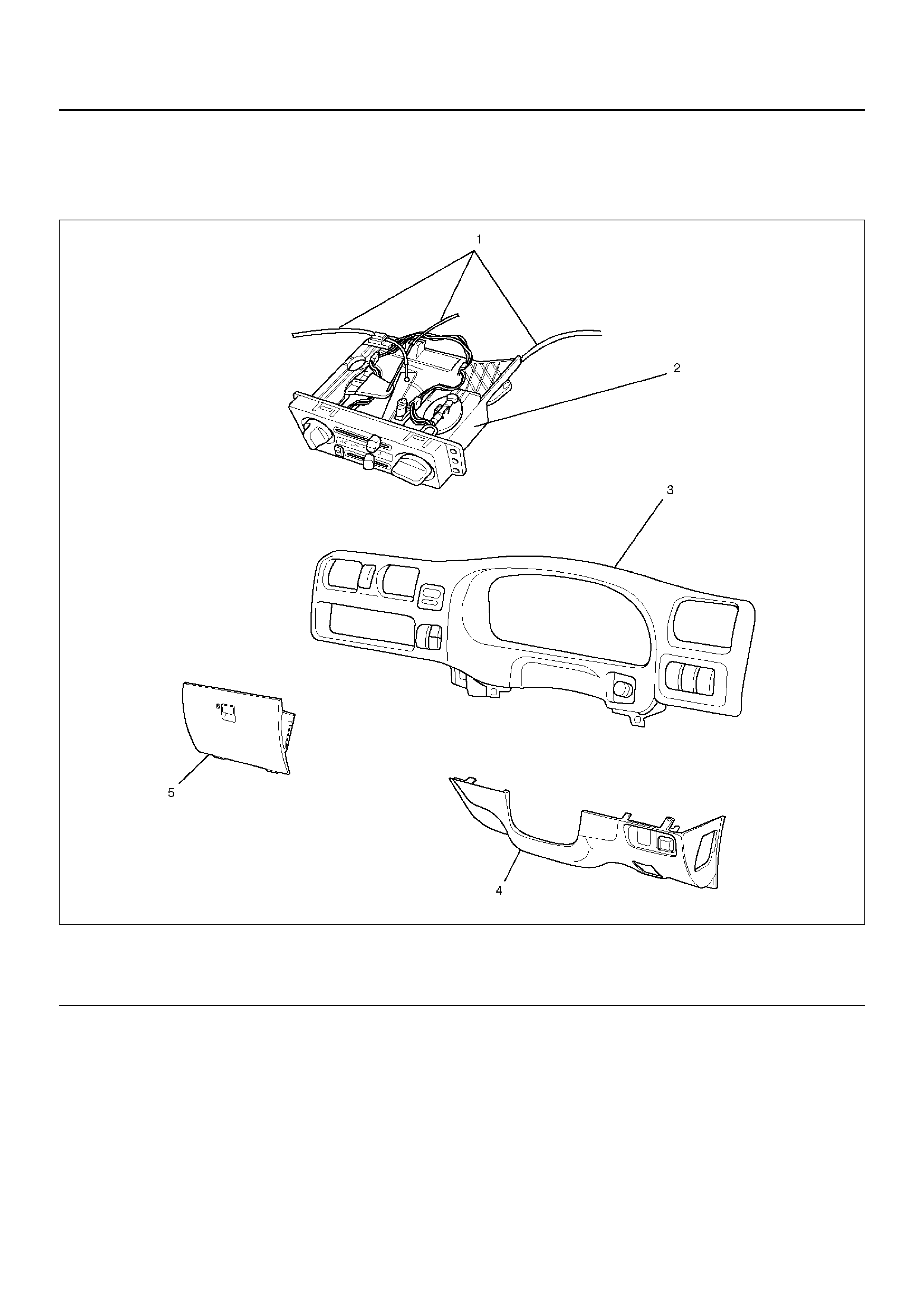

CONTROL LEVER ASSEMBLY AND / OR CONTROL CABLE

CONTROL LEVER ASSEMBLY, CONTROL CABLE AND ASSOCIATED PARTS

865RX009

EndOFCallout

Legend

(1) Control Cable

(2) Control Lever Assembly

(3) Meter Cluster Assembly

(4) Instrument Panel Driver Lower Cover Assembly

(5) Glove Box

REMOVAL

1. Disconnect the battery ground cable.

2. Remove instrument panel driver lower cover

assembly.

3. Remove meter cluster assembly.

• Refer to Instrument Panel Assembly in Body

Structure section.

4. Remove glove box.

5. Remove the control lever attaching screws.

6. Pull the control lever assembly out and disconnect

the fan switch and air conditioning switch

connectors.

865RX012

7. Remove control level assembly.

8. Disconnect control cables at each unit side.

865RX010

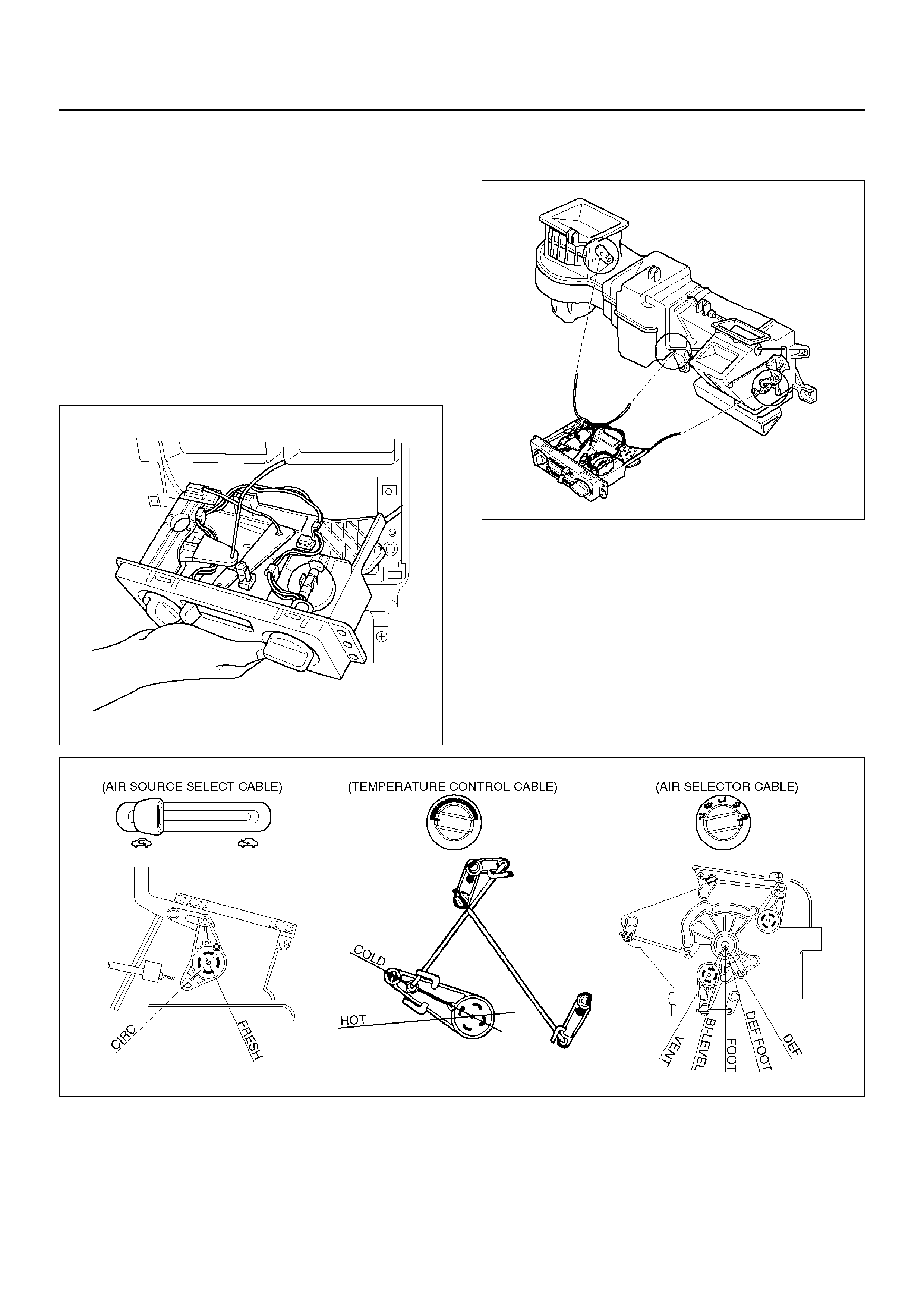

INSTALLATION

To install, foll ow the removal ste ps in the reverse or der,

noting the foll owi ng poi nts:

1. Adjust the control cable.

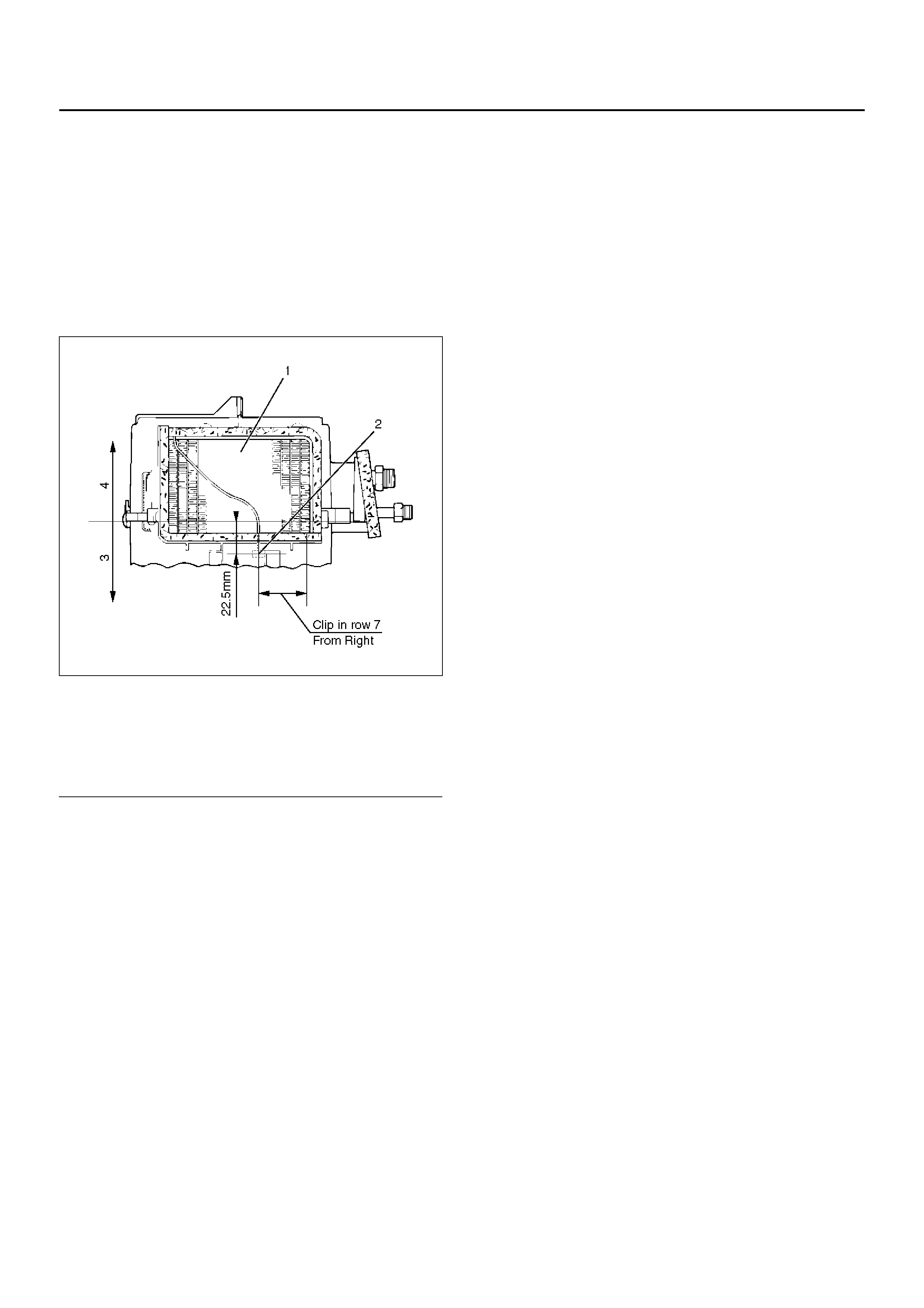

865RX013

• Air source control cable.

1 Slide the control lever to the left (“CIRC"

position).

2 Connect the control cable at the “CIRC"

position of the link unit of the blower

assembl y and se cu re it with the clip .

• Temperature control cable.

1 Turn the control knob to the left (“MAX COLD"

position).

2 Connect the control cable at the “COLD"

position of the temperature control link of the

heater unit and secure it with the clip.

• Ai r sele ct con tr ol cable

1 Turn the control knob to the right

(“DEFROST" position).

2 Connect the control cable at the “DEFROST"

position of the mo de con trol l ink of the hea ter

unit and secure it with the clip.

2. C hec k the con tr ol ca ble oper atio n.

CONTROL PANEL ILLUMINATION BULB

CONTROL PANEL ILLUMINATION BULB AND ASSOCIATED PARTS

865RX011

EndOFCallout

REMOVAL

1. Disconnect the battery ground cable.

2. Remove control lever assembly.

• Refer to Control Lever Assembly in this section.

3. Pull out the bulb socket from the panel by turning it

counterclockwise.

4. Pull the illumination bulb from the socket.

INSTALLATION

To install, follow the removal steps in the reverse order.

RESISTOR

RESISTOR AND ASSOCIATED

PARTS

840R100005

EndOFCallout

REMOVAL

1. Disconnect the battery ground cable.

2. Remove glove box.

• Remove the 2 inside clips.

3. Remove passenger knee bolster reinforcement.

4. Remove resistor harness connector.

5. Remove resistor.

INSTALLATION

To install, follow the removal steps in the reverse order.

Legend

(1) Control Lever Assembly

(2) Bulb Socket

(3) Il lu mi nati on Bulb

Legend

(1) Resistor

(2) P as se nge r Kne e Bol ster Rein for ceme n t

(3) Resistor Harness Connector

(4) Glove Box

AIR CONDITIONING SYSTEM

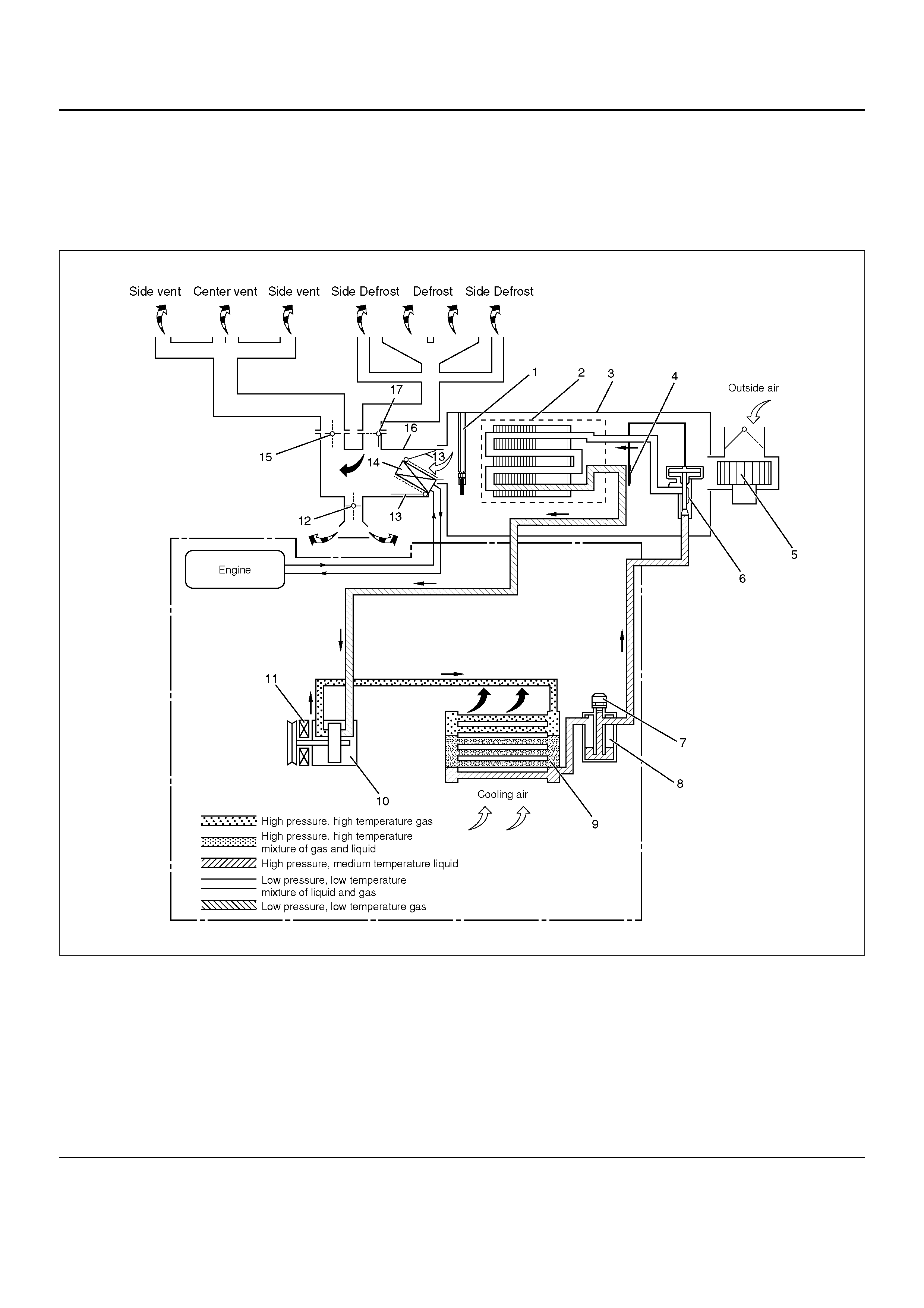

GENERAL DESCRIPTION

Air Conditioning Refrigerant Cycle Construction

C01RY00013

EndOFCallout

The refrigeration cycle includes the following four

processes as the refrigerant changes repeatedly from

liquid to gas and back to liquid while circulating.

Evaporation

The refrigerant is changed from a liquid to a gas inside

Legend

(1) Electronic Thermostat

(2) Evaporator Core

(3) Evaporator Assembly

(4) Temperature Sensor

(5) Blower Motor

(6) Expansion Valve

(7) Pressure Switch or Pressure Sensor

(8) Receiver/Drier

(9) Condenser

(10) Compressor

(11) Magnetic Clutch

(12) Mode (HEAT) Control Door

(13) Temp. Control Door (Air Mix Door)

(14) Heater Core

(15) Mode (VENT) Control Door

(16) Heater Unit

(17) Mode (DEF) Control Door

the evaporator. The refrigerant mist that enters the

evaporator vaporizes readily. The liquid refrigerant

removes the required quantity of heat (latent heat of

vaporization) from the air around the evaporator core

cooling fins and rapidly vaporizes. Removing the heat

cools the air, which is then radiated from the fins and

lowers the temperature of the air inside the vehicle.

The refrigerant liquid sent from the expansion valve and

the vaporized refrigerant gas are both present inside the

evaporator as the liquid is converted to gas.

With this change from liquid to gas, the pressure inside

the evaporator must be kept low enough for

vaporization to occur at a lower temperature. Because

of that, the vaporized refrigerant is sucked into the

compressor.

Compression

The refrigerant is compressed by the compressor until it

is easily liquefied at normal temperature.

The vaporized refrigerant in the evaporator is sucked

into the compressor. This action maintains the

refrigerant inside the evaporator at a low pressure so

that it can easily vaporize, even at low temperatures

close to 0°C (32°Φ).

Also, the refrigerant sucked into the compressor is

compressed inside the cylinder to increase the pressure

and temperature to values such that the refrigerant can

easily liquefy at normal ambient temperatures.

Condensation

The refrigerant inside the condenser is cooled by the

outside air and changes from gas to liquid.

The high temperature, high pressure gas coming from

the compressor is cooled and liquefied by the

condenser with outside air and accumulated in the

receiver/drier. The heat radiated to the outside air by the

high temperature, high pressure gas in the compressor

is called heat of condensation. This is the total quantity

of heat (heat of vaporization) the refrigerant removes

from the vehicle interior via the evaporator and the work

(calculated as the quantity of heat) performed for

compression.

Expansion

The expansion valve lowers the pressure of the

refrigerant liquid so that it can easily vaporize.

The process of lowering the pressure to encourage

vaporization before the liquefied refrigerant is sent to

the evaporator is called expansion. In addition, the

expansion valve controls the flow rate of the refrigerant

liquid while decreasing the pressure.

That is, the quantity of refrigerant liquid vaporized inside

the evaporator is determined by the quantity of heat

which must be removed at a prescribed vaporization

temperature. It is important that the quantity of

refrigerant be controlled to exactly the right value.

Compressor

The compressor performs two main functions:

It compresses low-pressure and low-temperature

refrigerant vapor from the evaporator into high-pressure

and high-temperature refrigerant vapor to the

condenser.

It pumps refrigerant and refrigerant oil through the air

conditioning system.

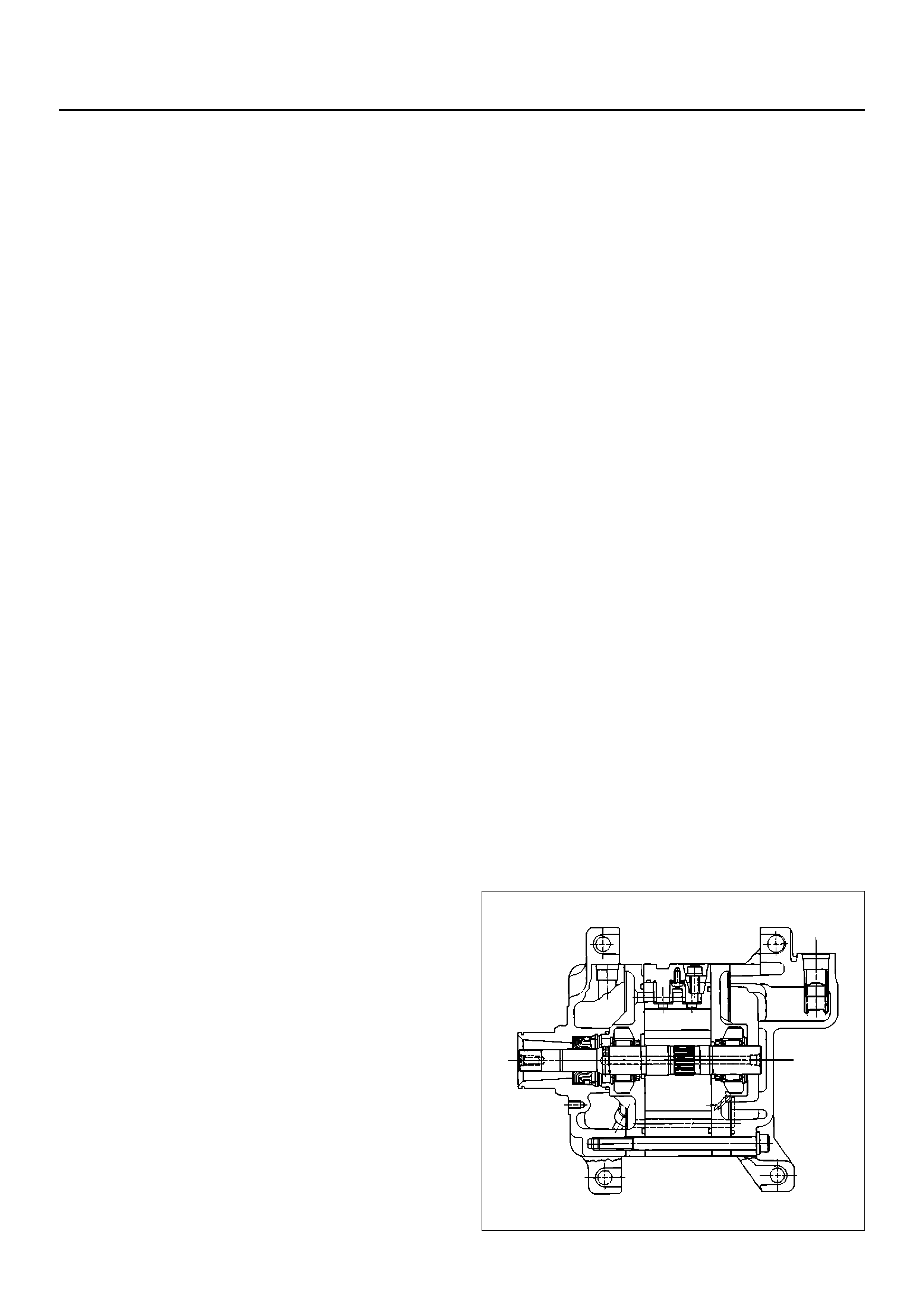

This vehicle is equipped with a five-vane rotary

compressor.

The specified amount of the compressor oil is 150cc

(5.0fl.oz.).

The oil used in the HFC-134a system compressor

differs from that used in R-12 systems.

Also, compressor oil to be used varies according to the

compressor model. Be sure to avoid mixing two or

more different types of oil.

If the wrong oil is used, lubrication will be poor and the

compressor will seize or malfunction.

The magnetic clutch connector is a waterproof type.

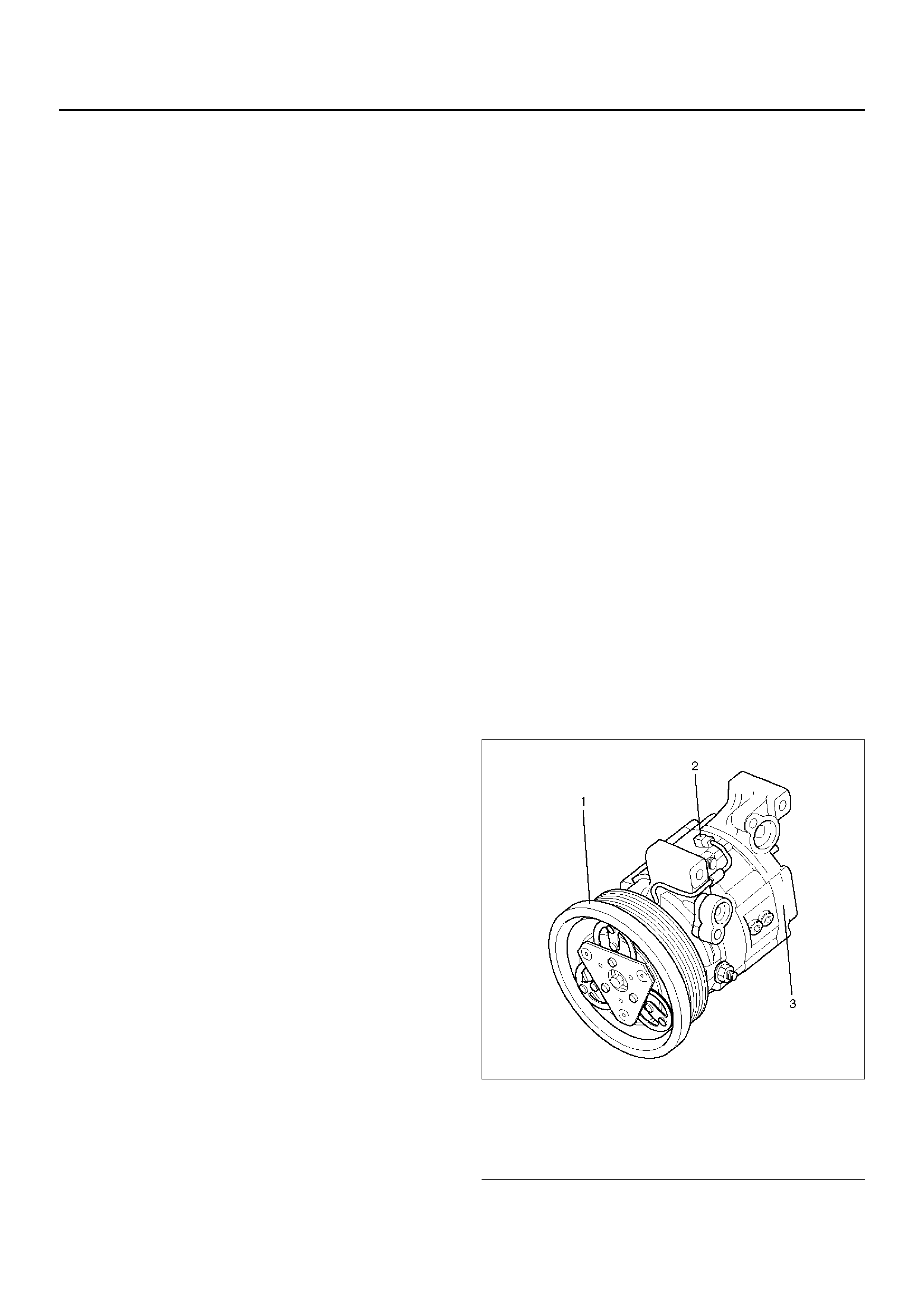

Magnetic Clutch

The compressor is driven by the drive belt from the

crank pulley of the engine. If the compressor is

activated each time the engine is started, this causes

too much load to the engine. The magnetic clutch

transmits the power from the engine to the compressor

and activates it when the air conditioning is ON. Also, it

cuts off the power from the engine to the compressor

when the air conditioning is OFF. Refer to Compressor

in this section for magnetic clutch repair procedure.

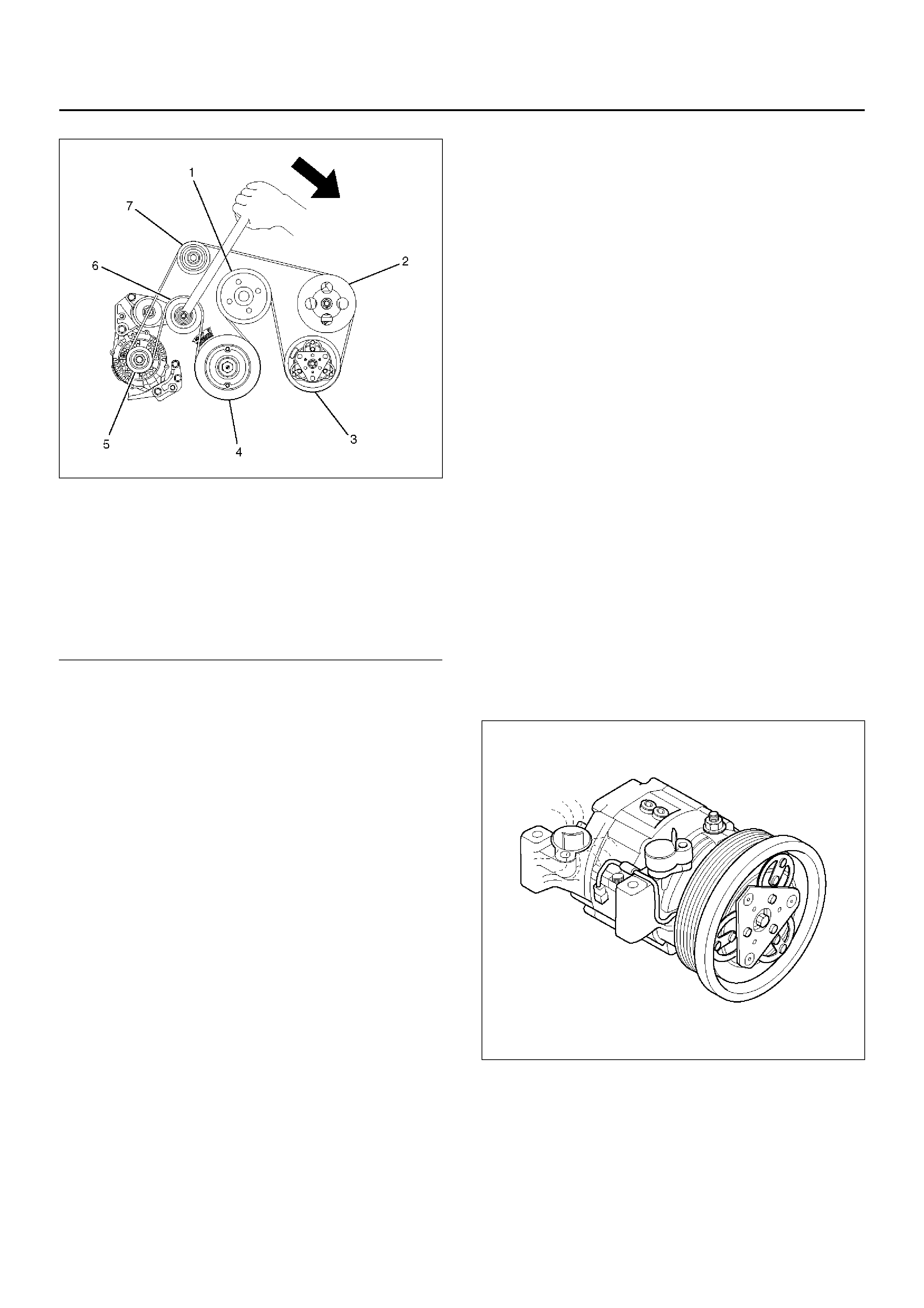

871RX026

EndOFCallout

Legend

(1) Magnetic Clutch

(2) Magnetic Clutch Harness Connector

(3) Compressor

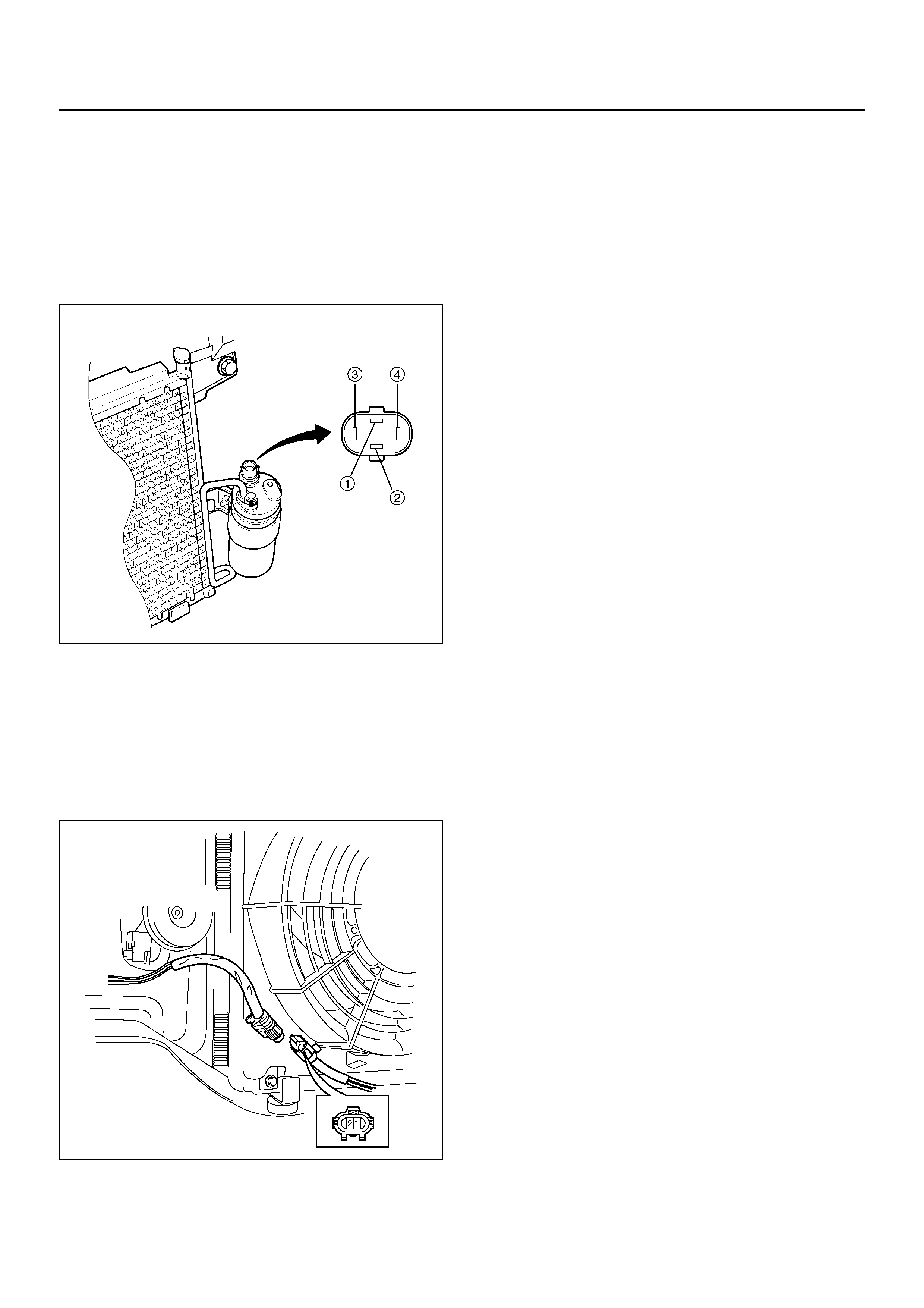

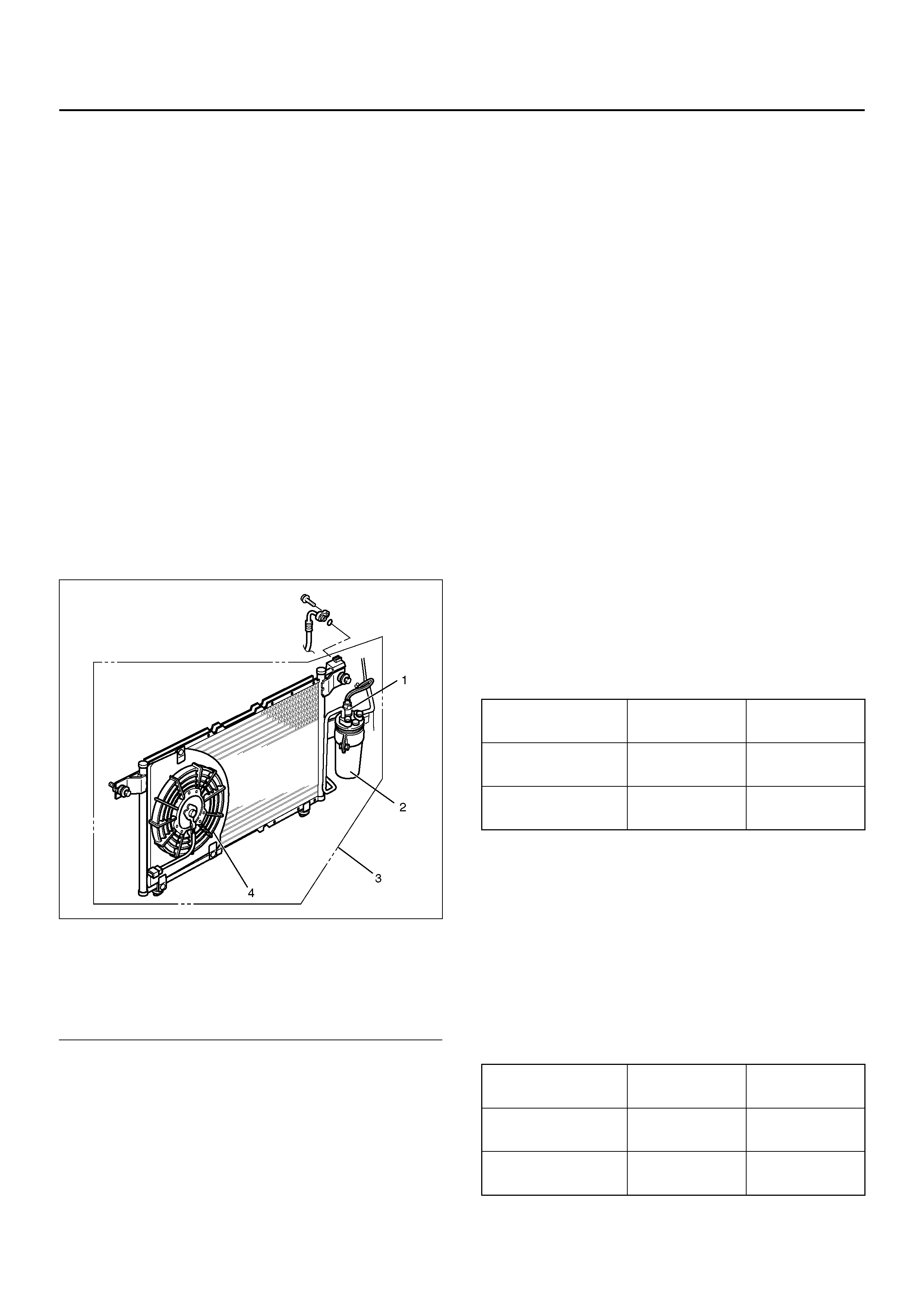

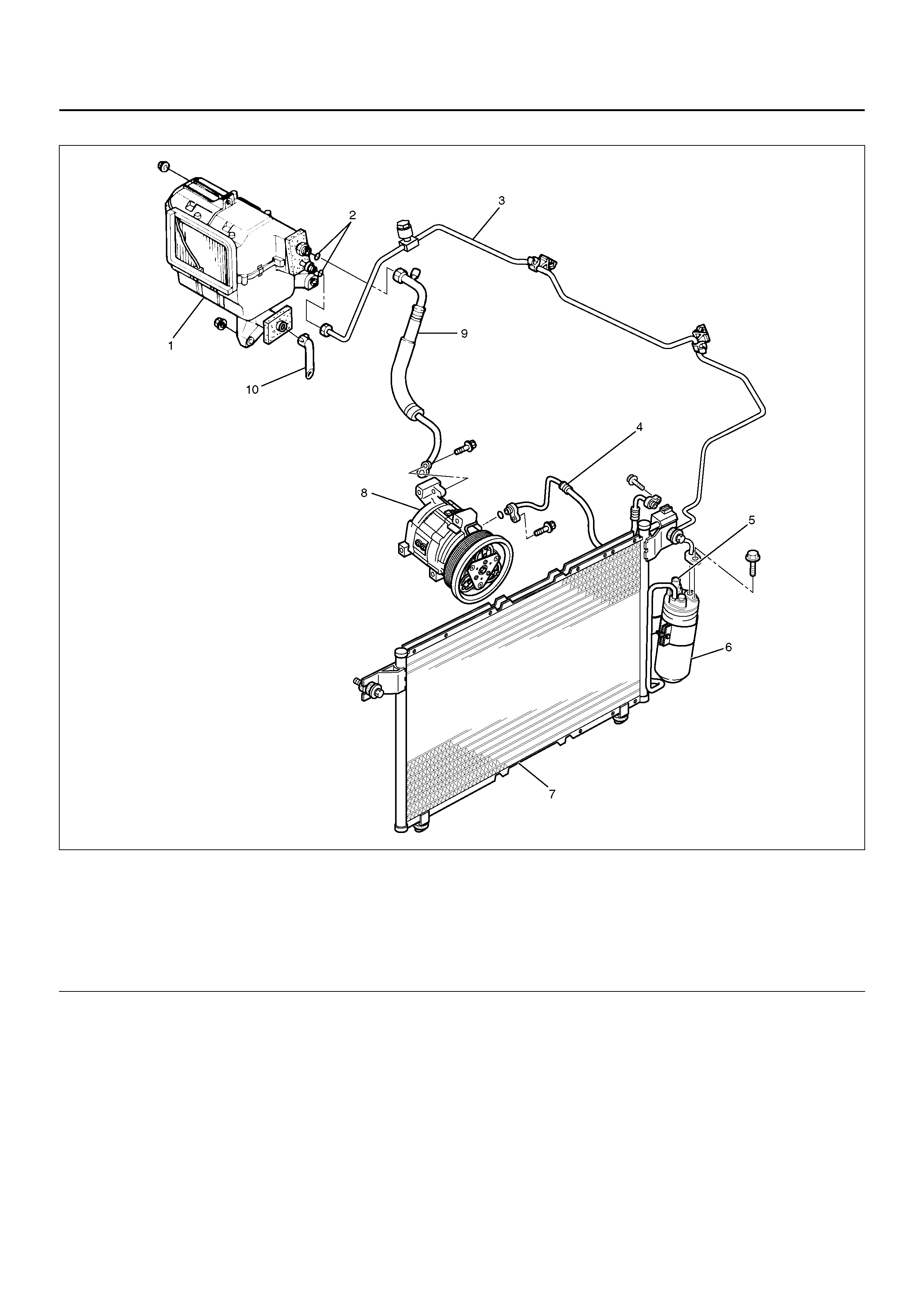

Condenser

The condenser assembly is located in front of the

radiator. It provides rapid heat transfer from the

refrigerant to the cooling fins.

Also, it functions to cool and liquefy the high-pressure

and high-temperature vapor sent from the compressor

by the radiator fan or outside air.

A conden ser may m alfunction i n two ways: i t may leak ,

or it may be restricted. A condenser restriction will

res ult in excessive compressor discharge pressure. If a

partial restriction is present, the refrigerant expands

after passing through the restriction.

Thus, ice or frost may form immediately after the

restriction. If air flow through the condenser or radiator

is blocked, high discharge pressures will result. During

normal condenser operation, the refrigerant outlet line

will be slightly cooler than the inlet line.

The vehicle is equipped with the parallel flow type

condenser. A larger thermal transmission area on the

inner surface of the tube allows the radiant heat to

increase and the ventilation resistance to decrease.

The refrigerant line connection has a bolt at the block

joint, for easy servicing.

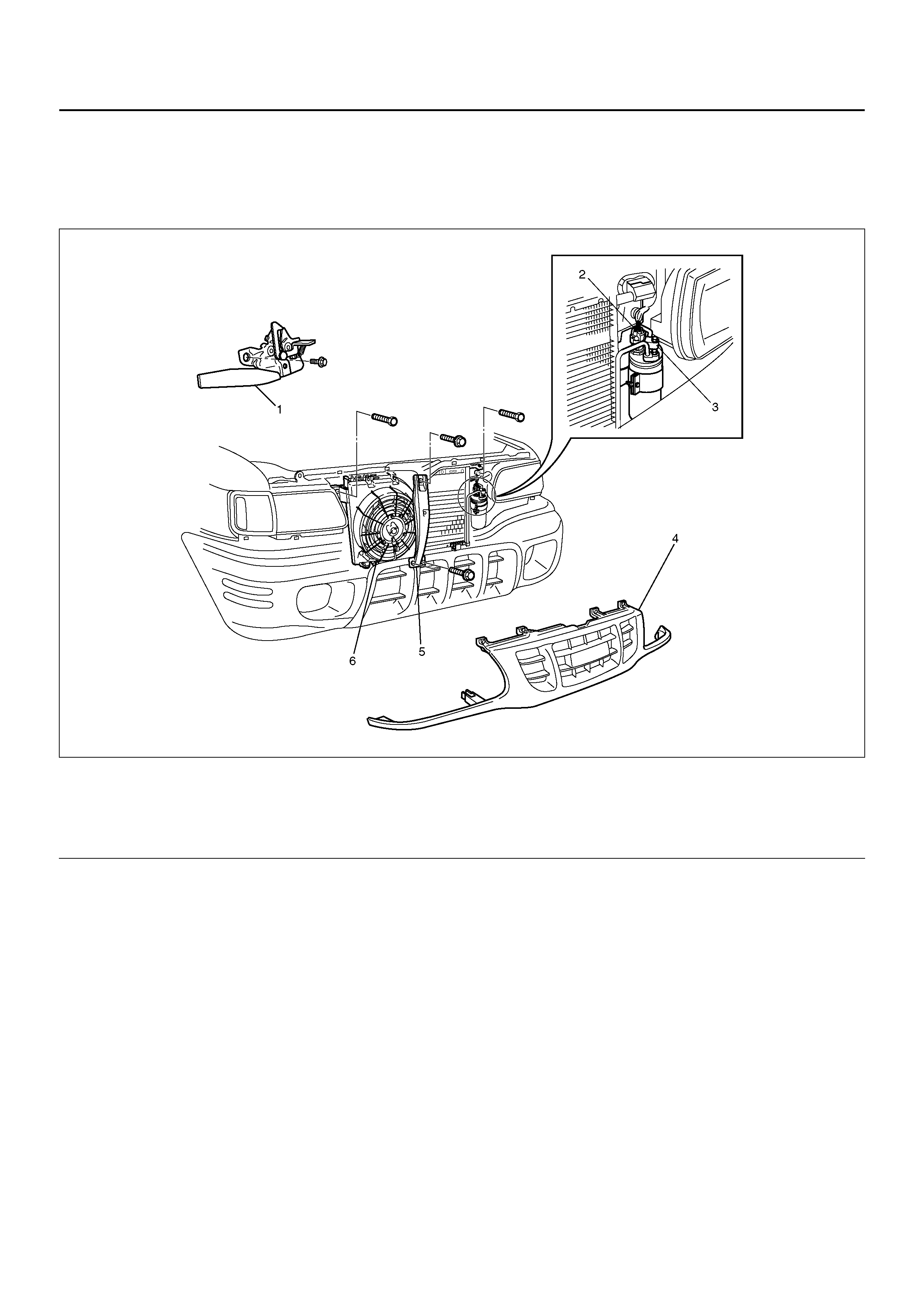

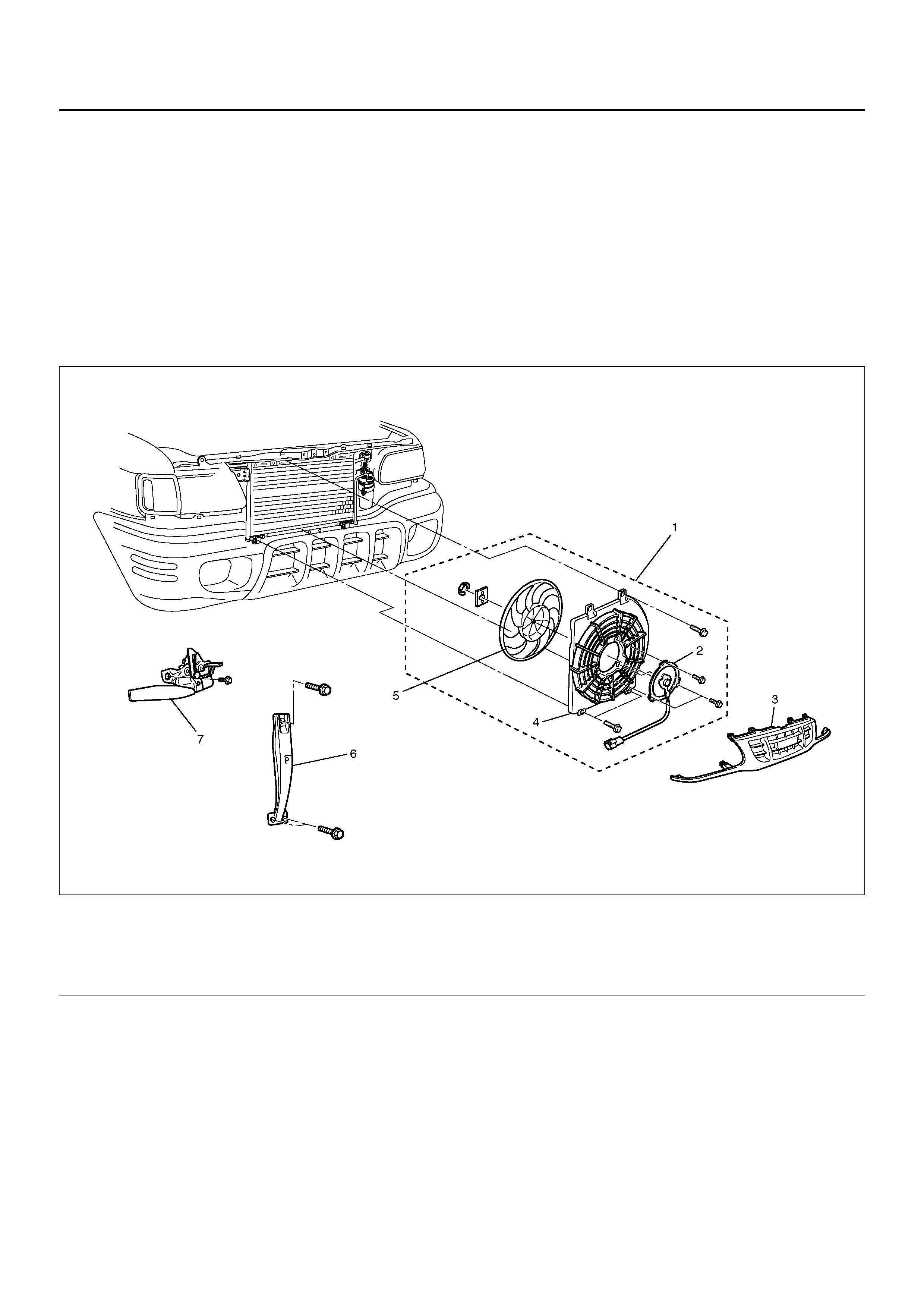

875R100001

EndOFCallout

Receiver / Drier

The receiver/drier performs four functions:

• As the quantity of refrigerant circulated varies

depending on the refrigeration cycle conditions,

sufficient refrigerant is stored for the refrigeration

cycle to operate smoothly in accordance with

fluctua tion s in the quan tit y circul ated .

• The l iquefied r efriger ant from th e conde nser is mixed

with refrigerant gas containing air bubbles. If

refrigerant containing air bubbles. If refrigerant

containing a ir bubble s is sen t to the expansi on valve ,

the cooling capacity will decrease considerably.

Therefore, the liquid and air bubbles are separated

and only the liquid is sent to the expansion valve.

• The receiver/d rier utilizes a filter and drier to remove

the dirt and water mixed in the cycling refrigerant.

• The sight glass, installed atop the receiver/drier,

show the state of the refrigerant.

A receiver/drier may fail due to a restriction inside the

body of th e unit. A res tricti on at the in let to the receive r/

drier will cause high pressure.

Outle t restric tions will be indica ted by low pressur e and

little or no cooling. An excessively cold receiver/drier

outlet may indicate a restriction.

The receiver/drier of this vehicle is made of aluminum

with a smaller tank. It has a 300cc refrigerant capacity.

The refrigerant line connection has a bolt at the block

joint, for easy servicing.

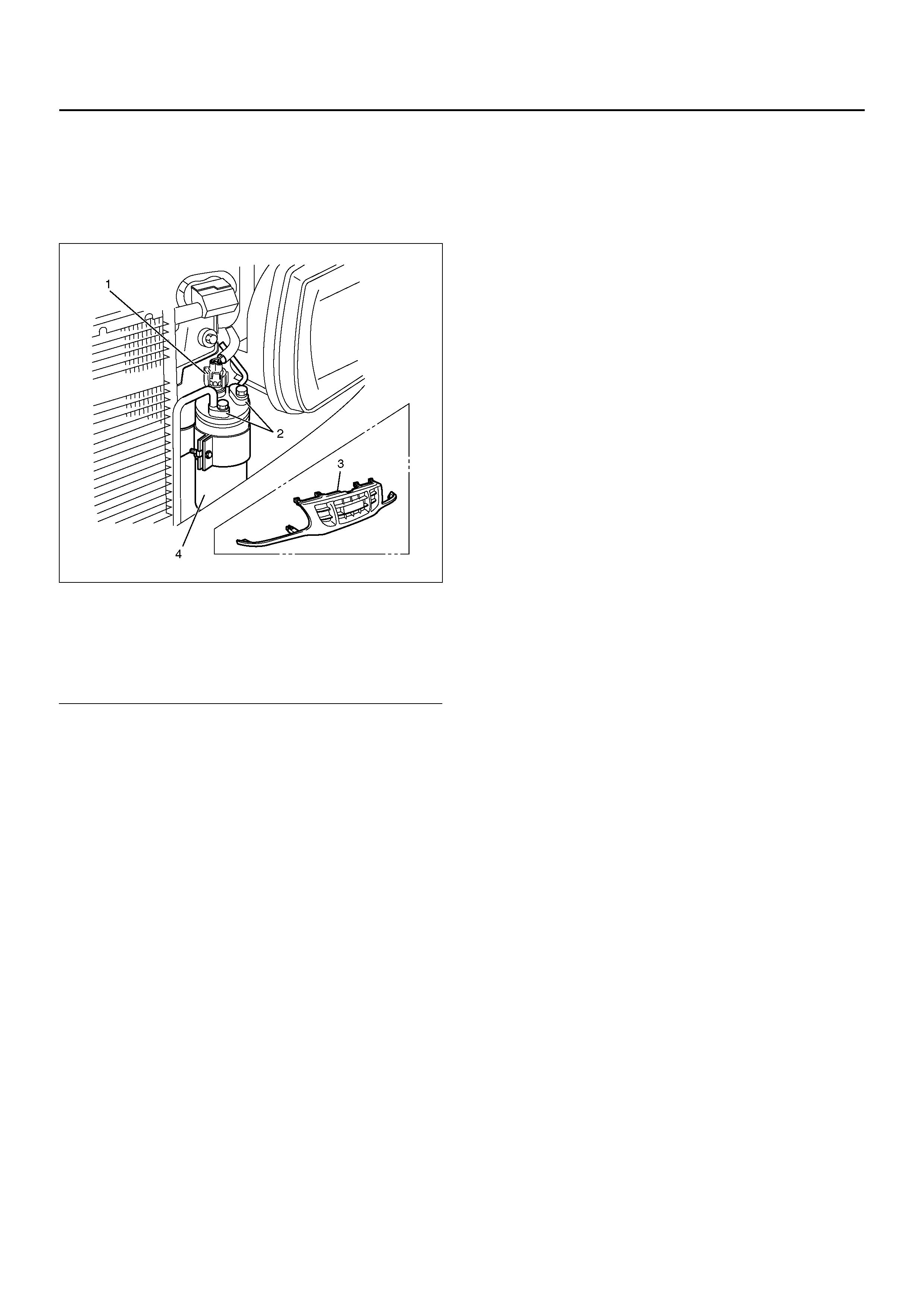

Dual Pressure Swit c h (V 6,M /T)

The pressure switch (Dual pressure switch) is installed

on the upper part of the receiver/drier, to detect

excessively high pressure (high pressure switch) and

prevent compressor seizure due to the refrigerant

leaki ng (low pr es su re sw itch ), so that th e compres sor is

able to be turned “ON" or “OFF".

Triple Pr ess ure Swit ch (V 6, A/T)

Triple pressure switch is installed on the upper part of

the receiver/drier. This switch is constructed with a

unitiz ed type of two switch es. One o f them is a lo w and

high pressure switch (Dual pressure switch) to switch

“ON" or “OFF" the magnetic clutch as a result of

irregularly high-pressure or low pressure of the

refrige ra nt. The other one is a med ium pressure switch

(Cycling switch) to switch “ON" or “OFF" the condenser

fan sensi ng the con den se r hig h side pres sur e.

Legend

(1) Pressure Switch

(2) Receiver/Drier

(3) Condenser & Receiver Tank Assembly

(4) Condenser Fan (6VD1 A/T)

Compressor ON

(kPa/psi) OFF

(kPa/psi)

Low-pressure

control 186.3±29.4

(27.0±4.3) 176.5±19.6

(25.6±2.8)

High-pressure

control 2350.4±196.1

(340.7±28.4) 2942.0±196.1

(426.6±28.4)

Compressor ON

(kPa/psi) OFF

(kPa/psi)

Low-pressure

control 186.3±29.4

(27.0±4.3) 176.5±24.5

(25.6±3.6)

High-pressure

control 2353.6±196.1

(341.3±28.4) 2942.0±196.1

(426.6±28.4)

Expansion Valve

This expansi on v alve i s an ext er nal pres sur e type and i t

is installed at the evaporator intake port.

The expansion valve converts the high pressure liquid

refrigerant sent from the receiver/drier to a low pressure

liquid refrigerant by forcing it through a tiny port before

sending it to the evaporator.

This type of expansion valve consists of a temperature

sensor, diaphragm, ball valve, ball seat, spring

adjustment screw, etc.

The temperature sensor contacts the evaporator outlet

pipe, and co nverts changes in tem perature to pres sure.

It then transmits these to the top chamber of the

diaphragm.

The refrigerant pressure is transmitted to the

diaphragm's bottom chamber through the external

equalizing pressure tube.

The ball valve is connected to the diaphragm. The

opening angle of the expansion valve is determined by

the force acting on the diaphragm and the spring

pressure.

The expansion valve regulates the flow rate of the

refrigerant. Accordingly, when a malfunction occurs to

this expansion valve, both discharge and suction

pressure get low, resulting in insufficient cooling

capacity of the evaporator.

The calibration has been changed to match the

characteristics of HFC-134a.

874RY00023

EndOFCallout

Evaporator

The evaporator cools and dehumidifies the air before

the air enters the passenger compartment.

High-pressure liquid refrigerant flows through the

expansion valve into the low-pressure area of the

evaporator. The heat in the air passing through the

evapor ator core is lost to the coo ler sur face o f the cor e,

thereby cooling the air.

As h eat is l ost bet ween the air a nd the evaporator core

surface, moisture in the vehicle condenses on the

outside surface of the evaporator core and is drained off

as water.

When the evaporator malfunctions, the trouble will show

up as an inadequate supply of cool air. The cause is

typically a partially plugged core due to dirt, or a

malfunc ti oning blo w er motor.

The evaporator core with a laminate louver fin is a

single-sided tank type where only one tank is provided

under the cor e .

874RY00022

EndOFCallout

Electronic Thermostat (With Manual A/C)

The thermostat consists of the thermo sensor and

thermostat unit which functions electrically to reduce the

noises being generated while the system is in operation.

The electronic thermo sensor is mounted at the

evaporator core outlet and senses the surface

temperature of the evaporator core. Temperature

signa ls are in put to the th ermos tat unit . Th is in formation

is compared by the thermo unit and results in the output

to operate the A/C thermostat relay and turn the

magnetic clutch ON or OFF to prevent evaporator

freeze-up.

A characteristic of the sensor is that the resistance

Condenser fan ON

(kPa/psi) OFF

(kPa/psi)

Medium-pressure

control 1471.0±98.1

(213.3±14.2) 1078.7±117.7

(156.4±17.1)

Legend

(1) Expansion Valve

(2) Insulator

(3) Evaporator Assembly

Legend

(1) Evaporato r Core

(2) Insulator

(3) Expansion Valve

decreases as the temperature increases and the

resistance increases as the temperature decreases.

874RX008

EndOFCallout

Refrigerant Line

Restriction in the refrigerant line will be indicated by:

1. Suction line — A restricted suction line will cause

low suction pressure at the compressor, low

discharge pressure and little or no cooling.

2. Discharge line — A restriction in the discharge line

generally will cause the discharge line to leak.

3. Liquid line — A liquid line restriction will be

evidenced by low discharge and suction pressure

and insufficient cooling.

Refrigerant flexible hoses that have a low permeability

to refrigerant and moisture are used. These low

permeability hoses have a special nylon layer on the

inside.

852RS001

EndOFCallout

Legend

(1) Sensor Part

(2) Evaporator Core

(3) Thermostat Assembly Legend

(1) Reinforcement Layer (Polyester)

(2) External Rubber Layer

(3) Internal Rubber Layer

(4) Resin Layer (Nylon)

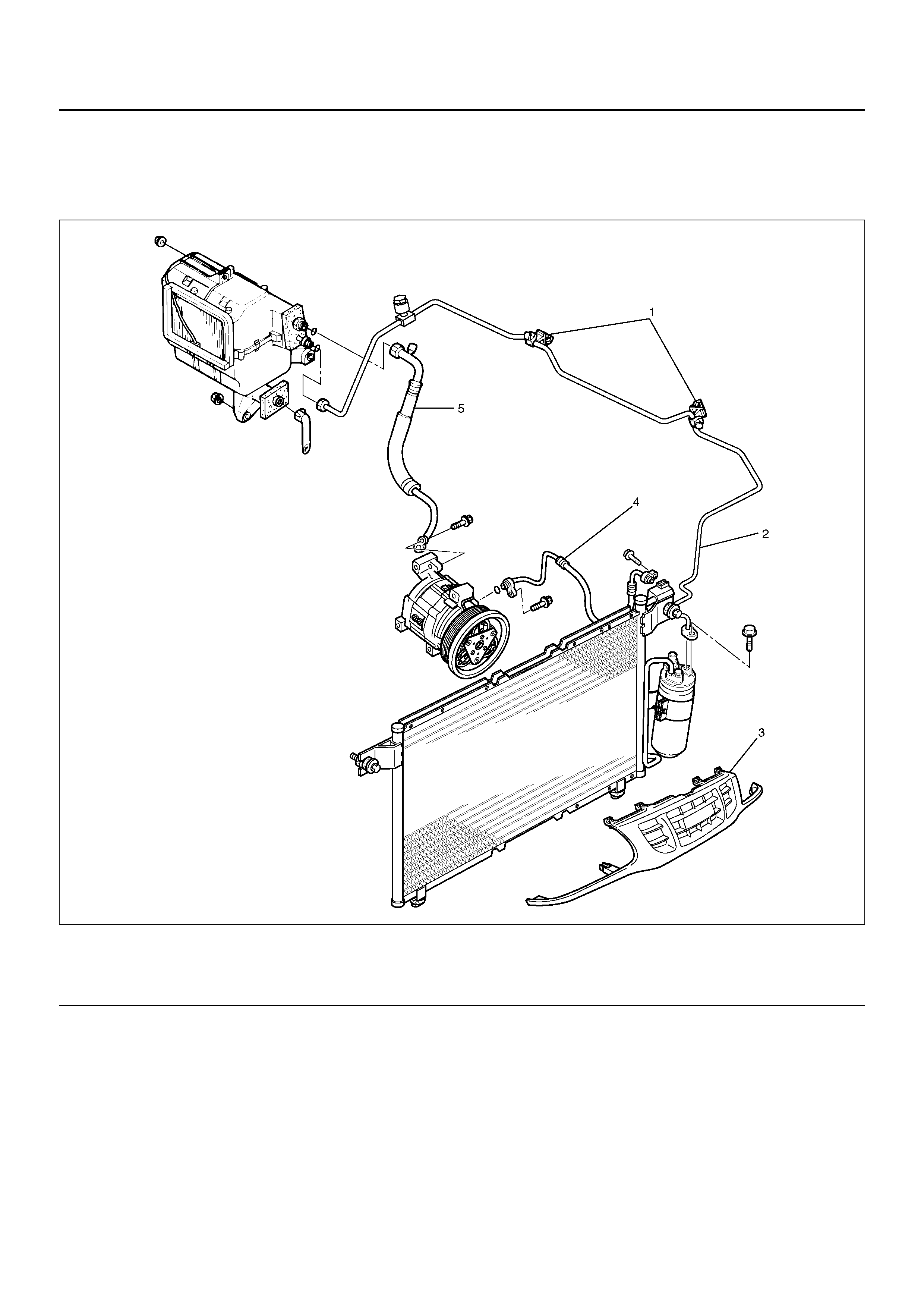

Refrig erant Line Associated Parts

852R100006

EndOFCallout

Legend

(1) Evaporator Assembly

(2) O-Ring

(3) Liquid Line (High Pressure Pipe)

(4) Discharge Line (High Pressure Hose)

(5) Pressure Switch

(6) Receiver Drier

(7) Condense r As se mbl y

(8) Compressor

(9) Suction Line (Low – Pressure Hose)

(10) Drain Hose

CIRCUIT DIAGRAM

D08R100096

D08R100097

DIAGNOSIS

Air Conditioning Cycle Diagnosis

*For the execution of the charging and discharging

operation in the table above, refer to Recovery,

Recycling, Evacuating and Charging in this section.

Condition Possible cause Correction

No cooling or insufficient cooling. Magnetic clutch does not run. Refer to “Magnetic Clutch

Diagnosis" in this section.

Compressor is not rotating properly.

Drive belt is loosened or broken. Adjust the drive belt to the specified

tension or replace the drive belt.

Compressor is not rotating properly.

Magnetic clutch face is not clean

and slips.

Clean the magnetic clutch face or

replace.

Compressor is not rotating properly.

Incorrect clearance between

magnetic drive plate and pulley.

Adjust the clearance. Refer to

Compressor in this section.

Compressor is not rotating properly.

Compressor oil leaks from the shaft

seal or shell.

Replace the compressor

Compressor is not rotating properly.

Compressor is seized.Replace the compressor

Insufficient or excessive charge of

refrigerant. Discharge and recover the

refrigerant. Recharge to the

specified amount.

Leaks in the refrigerant system. Check the refrigerant system for

leaks and repair as necessary.

Discharge and recover the

refrigerant. Recharge to the

specified amount.

Condenser is clogged or insufficient

radiation. Clean the condenser or replace as

necessary.

Temperature control link unit of the

heat unit is defective.Repair the link unit.

Unsteady operation due to a foreign

substance in the expansion valve. Replace the expansion valve.

Poor operation of the electronic

thermostat.Check the electronic thermostat and

replace as necessary.

Insufficient velocity of cooling air. Evaporator clogged or frosted. Check the evaporator core and

replace or clean the core.

Air leaking from the cooling unit or

air duct.Check the evaporator and duct

connection, then repair as

necessary.

Blower motor does not rotate

properly.Refer to Fan Control Lever (Fan

Switch) Diagnosis in this section.

Checking The Refrigerant System Wit h Manifold Gauge

Since R ef riger ant -134a ( HFC -134 a) is use d in the air

conditioning system in this vehicle, be sure to

use manifold gauges, charging hoses and other air

conditioning service tools for HFC-134a when

checking the refrigerant system.

Conditions:

• Run the engine at Idling

• Air conditioning switch is “ON"

• Run the blower motor at “HIGH" position

• Temperature control lever set to “MAX COLD"

• Air source selector lever at “CIRC"

• Open the engine hood

• Clos e all the doo rs

• At ambient temperature: approx. 25–30°C (77–86°F).

Normal Pressure:

• At low-pressure side: approx. 147.1–294.2 kPa

(21.3–4 2.7 psi).

• At high-pressure side: approx. 1372.9–1863.3 kPa

(199.1–270.2 psi).

Refer to the table on the refrigerant

pressu re -t emp era ture re lat ion ship.

HFC-134a Pressure-Temperature Relationship

Pressure Temperature

(kPa) (psi) (°C) (°F)

36 5.3 –20 –4.4

67 9.7 –15 5

104 15 –10 14

147 21 –5 23

196 28 0 32

255 37 5 41

314 45 10 50

392 57 15 59

471 68 20 68

569 82 25 77

677 98 30 86

785 114 35 95

912 132 40 104

1059 154 45 113

1216 176 50 122

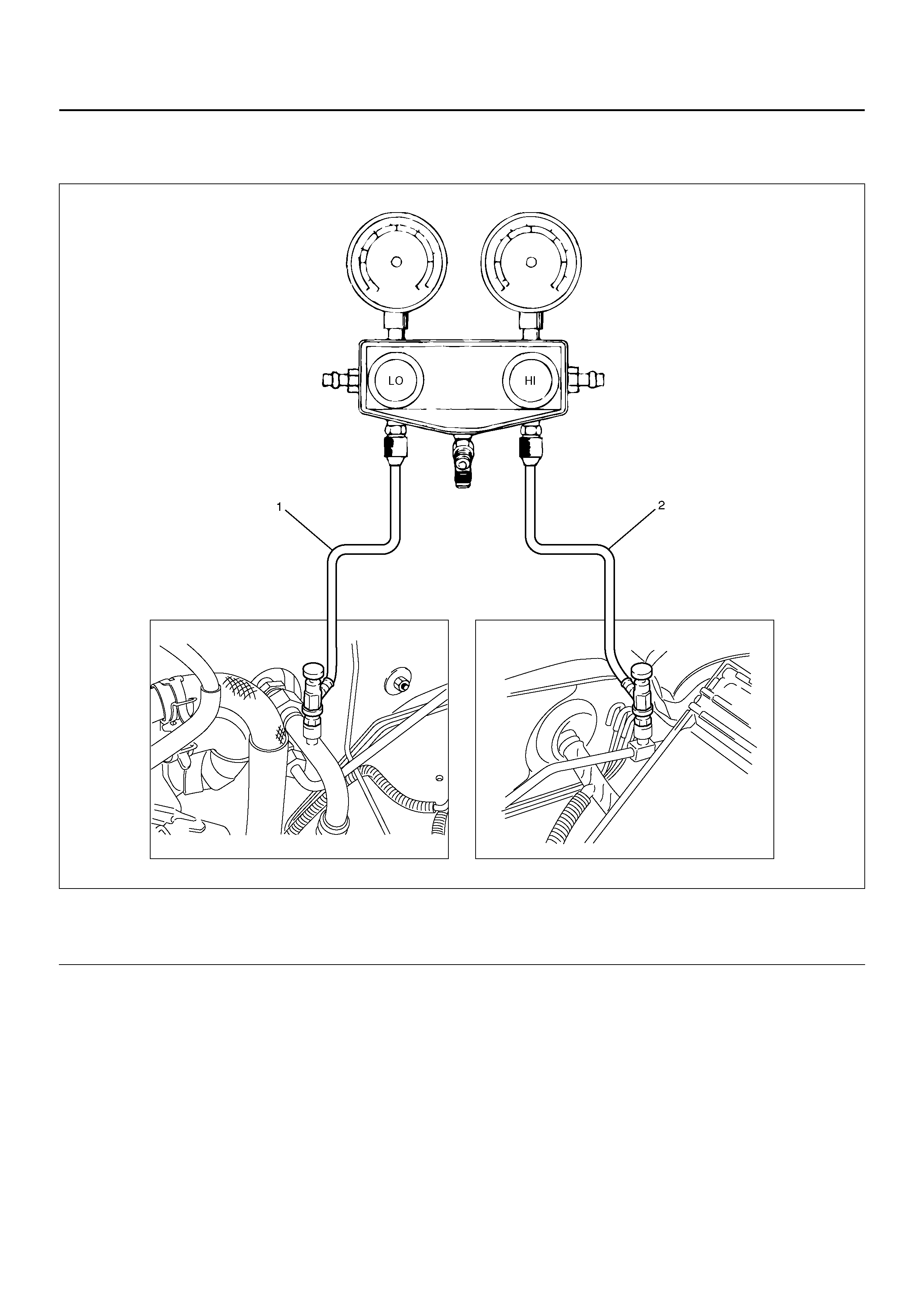

Connect The Manifold Gauge

Low-pressure hose (LOW) — Suction side

High pressure hose (HI) — Discharge side

901R100032

EndOFCallout

Legend

(1) Low Side

(2) H i gh Side

Condition Possible cause Correcti on

Discharge (High Gauge) Pressure

Abnormally High Condenser clogged or dirty. Clean the condenser fins

Cooling fan does not operate

properly. Check the cooling fan operation.

Discharge (High Gauge) Pressure

Abnormally High.

Insufficient cooling.

Excessive refrigerant in system. Discharge and recover refrigerant.

Recharge to specified amount.

Discharge (High Gauge) Pressure

Abnormally High.

High pressure gauge drop . (After

stopping A/C, the pressure drops

approx. 196kPa (28psi) quickly)

Air in system. Evacuate and charge refrigerant

system.

Discharge (High Gauge) Pressure

Abnormally Low.

Insufficient cooling

Insufficient refrigerant in system. Check for leaks. Discharge and

recover the refrigerant. Recharge to

the specified amount.

Discharge (High Gauge) Pressure

Abnormally Low.

Low pressure gauge indicates

vacuum.

Clogged or defective expansion

valve. Replace the expansion valve.

Discharge (High Gauge) Pressure

Abnormally Low.

Frost or dew on refrigerant line

before an d after th e receiv er/dri er or

expansion valve, and low pressure

gauge indicates vacuum.

Restriction caused by debris or

moisture in the receiver/drier. Check system for restriction and

replac e the rece iv er /drie r.

Discharge (High Gauge) Pressure

Abnormally Low.

High and low pressure gauge

bala nced quick ly. (After turned off A/

C)

Compressor seal defective Repair or replace the compressor.

Poor compression due to a defective

compressor gasket. Repair or replace the compressor.

Suction (Low Gauge) Pressure

Abnormally High.

Low pressure gauge (Low pressure

gauge is lowered after condenser is

cooled by water.)

Excessive refrigerant in system. Discharge and recover refrigerant

Recharge to specified amount.

Suction (Low Gauge) Pressure

Abnormally High.

Low pressure hose temperature.

(Low pressure hose temperature

around the compressor refrigerant

line connector is lower than around

evaporator.)

Unsatisfactory valve operation due

to defective temperature sensor of

expansion valve.

Replace the expansion valve.

Expansion valve opens too long. Replace the expansion valve.

Suction (Low Gauge) Pressure

Abnormally High.

High and low pressure gauge

bala nced quick ly. (After turned off A/

C)

Compressor gasket is defective. Repair or replace the compressor.

Suction (Low Gauge) Pressure

Abnormally Low.

Insufficient cooling.

Insufficient refrigerant in system. Check for leaks. Discharge and

recover the refrigerant. Recharge to

specified amount.

Suction (Low Gauge) Pressure

Abnormally Low.

Frost on the expansion valve inlet

line

Expansion valve clogged. Replace the expansion valve.

A/C — Air Conditioning

Suction (Low Gauge) Pressure

Abnormally Low

Receiver/drier inlet and outlet

refrigerant line temperature. (A

distinct difference in temperature

develops.)

Receiver/Drier clogged. Replace the receiver/drier.

Suction (Low Gauge) Pressure

Abnormally Low.

Expansion valve outlet refrigerant

line. (Not cold and low pressure

gauge indicates vacuum.)

Expansion valve temperature

sensor is defective. Replace the expansion valve.

Suction (Low Gauge) Pressure

Abnormally Low.

When the refrigerant line is clogged

or blocked, the low pressure

gauge reading will decrease, or a

vacuum reading may be shown.

Clogged or blocked refrigerant line. Replace refrigerant line.

Suction (Low Gauge) Pressure

Abnormally Low.

Evaporator core is frozen.

Thermo switch defective. Replace thermo switch.

Suction (Low Gauge) and Discharge

(High Gauge) Pressure Abnormally

High.

Insufficient cooling.

Excessive refrigerant in system. Discharge and recover the

refrigerant, the Recharge to the

specified amount.

Condenser clogged or dirty. Clean the condenser fin.

Suction (Low Gauge) and Discharge

(High Gauge) Pressure Abnormally

High.

Suction (Low) pressure hose (Not

cold).

Air in system. Evacuate and charge refrigerant.

Suction (Low Gauge) and Discharge

(High Gauge) Pressure Abnormally

Low.

Insufficient cooling

Insufficient refrigerant in system. Check for leaks. Discharge and

recover refrigerant. Recharge to

specified amount.

Condition Possible cause Correcti on

Magnetic Clutch Diagnosis

D08R100144

When the air conditioning switch and the fan control

knob (fan switch) are turned on with the engine running, current flows through the thermostat and the

compressor relay to activate the magnetic clutch.

The air conditioning can be stopped by turning of the air

conditioning switch or the fan control knob (fan switch).

However, even when the air conditioning is in operation,

the electronic thermostat, the pressure switch or the

Powertrain Control Module (PCM;V6-3.2L) is used to

stop the air conditioning temporarily by turning off the

magnetic clutch in the prearranged conditions to reduce

the engine load which is being caused by the rise in

the engine coolant temperature, and the acceleration of

the vehicle, etc.

For the inspection of the relays, switches and units in

the table, refer to “Individual Inspection" in this section.

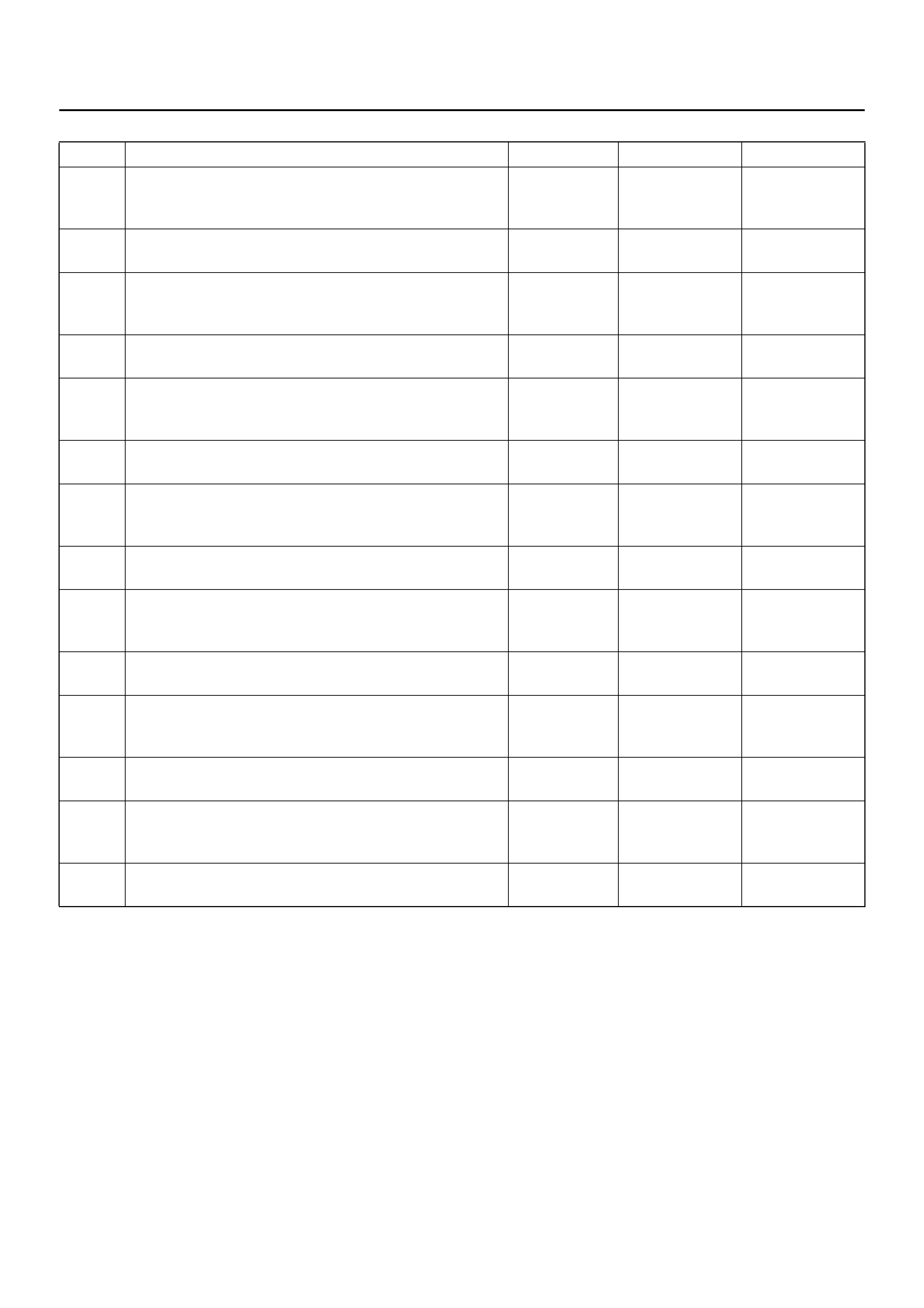

Magnetic Clutch Does Not Run

Step Action Value(s) Yes No

1 Is the fuse No. F-5 normal? — Go to Step 2 Replace the

fuse

2 Is the relay No.X-1 (heater relay). No .X-8 (Thermo stat

relay) and No.X-2 (compressor relay) normal? — Go to Step 3 Replace the

relay

3 Is pressure switch normal? — Go to Step 4 Place the

pressure

switch.

4 Is the air condit ion er sw itch and the fan control switc h

normal? — Go to Step 5 Replace the A/

C switch and

fan control

switch

5 1. Turn the ignition switch “ON" (the engine is run).

2. Turn the air conditioner s witch and the fan control

swit ch on.

Is the battery voltage applied between harness side

connector terminal No.E3-1 and ground?

Approx.12V Go to Step 6 Go to Step 7

6 Repair an open circuit between compressor side

terminal and ground or replace compressor.

Is the action complete?

—Varify repair —

7 Is there continuity between harness side connector

terminal No.X2-1 and No.E3-1? — Go to Step 9 Go to Step 8

8 Repair an open circuit between terminal No.X2-1 and

No.E3-1.

Is the action complete?

— Go to Step 7 —

9 Is the battery voltage applied between harness side

connec tor termina l No.X2-2 and g round, No.X2-5 an d

ground?

Approx.12V Go to Step 11 Go to Step 10

10 Repair and open circuit between terminal No.X2-2 and

No.F-5 fuse, No.X2-5 and No.F-5 fuse.

Is the action complete?

— Go to Step 9 —

11 Is there continuity between harness side connector

terminal No.X2-4 and No.E21-F4? — Go to Step 13 Go to Step 12

12 Repair an open circuit between terminal No.X2-4 an d

No.E21-F4.

Is the action complete?

— Go to Step 11 —

13 Is the battery voltage applied between harness side

connector terminal No.I24-2 and ground? Approx.12V Go to Step 15 Go to Step 14

14 Repair an open circuit between term inal No.I24-2 an d

No.F-5 fuse.

Is the action complete?

— Go to Step 13 —

15 Is the battery voltage applied between harness side

connector terminal No.C69-3 and ground? Approx.12V Go to Step 17 Go to Step 16

Magnetic Clutch Does Not Run (Cont’s)

CAUTION: There are condition whitch air

conditioner system does not operate except trouble

as follows.

1. The throttle is greater than 90%.

2. The ignition voltage is below 10.5 volts.

3. The engine speed is greater than 4500 RPM for 5

seconds or 5400 RPM.

4. The engine coolant temperature (ECT) is greater

than 125°C (257°F).

5. The intake air temperature (IAT) is less than 5°C

(41°F).

6. The power steering pressure switch signals a high

pressure condition.

Step Action Value(s) Yes No

16 Repair an open circuit between terminal No.C69-3

and No.I24-1.

Is the action complete?

— Go to Step 15 —

17 Is there continuity between harness side connector

terminal No.I23-6 and No.C69-2? — Go to Step 19 Go to Step 18

18 Repair an open circuit between term inal No.I23-6 an d

No.C69-2.

Is the action complete?

— Go to Step 17 —

19 Is there continuity between harness side connector

terminal No.I23-1 and ground (No.B-8)? — Go to Step 21 Go to Step 20

20 Repair an open circuit between term inal No.I23-1 an d

No.B-8.

Is the action complete?

— Go to Step 19 —

21 Is the battery voltage applied between harness side

connector terminal No.C11-2 and ground? — Go to Step 23 Go to Step 22

22 Repair an open circuit between terminal No.C11-2 and

No.F-5 fuse.

Is the action complete?

— Go to Step 21 —

23 Is the battery voltage applied between harness side

connector terminal No.X8-3 and ground? — Go to Step 25 Go to Step 24

24 Repair an open circuit between terminal No.X8-3 an d

No.C11-1.

Is the action complete?

— Go to Step 23 —

25 Is the battery voltage applied between harness side

connector terminal No.C69-1 and ground? — Go to Step 27 Go to Step 26

26 Repair an open circuit between terminal No.C69-1

and No.X8-5.

Is the action complete?

— Go to Step 25 —

27 Is there continuity between harness side connector

terminal No.X8-2 and No.E21-F45? — Go to Step 29 Go to Step 28

28 Repair an open circuit between terminal No.X8-2 an d

No.E21-F45.

Is the action complete?

— Verify repair —

29 Replace the PCM.

Is the action complete? — Verify repair —

INDIVIDUAL INSPECTION

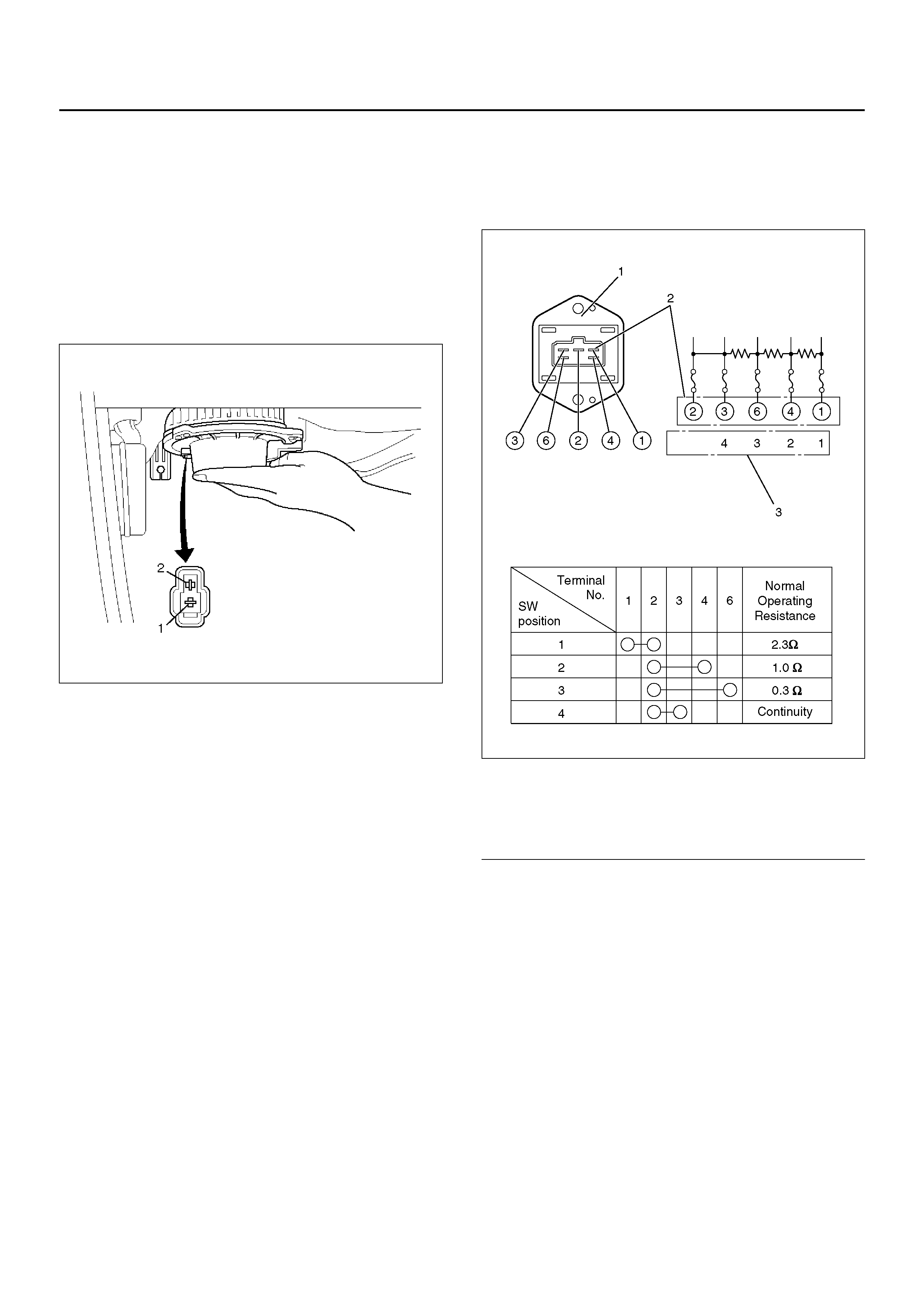

Fan Control Knob (Fan Switch) And Air

Conditioning (A/C) Switch

1. Check for continuity between the fan switch and the

A/C switch side connector terminals.

D08RX254

EndOFCallout

Thermostat (X-8), Condenser Fan (X-11)

Relay

1. Disconnect relays and check for continuity and

resistance between relay terminals.

• For handling of these relays, refer to Heater

Relay in this section.

C01R100002

Heater (X-1), Compressor (X-2) Relay

1. Disconnect relays and check for continuity and

resistance between relay terminals.

• For handling of these relays, refer to Heater

Relay in this section.

C01R200011

Legend

(1) A/C Switch Connector (switch side)

(2) Fan Switch Connector (switch side)

Pressure Switch

1. Disconnect pressure switch connector and check for

continuity between pressure switch side connector

terminals (1) and (2).

875RY00024

GENERAL REPAIR PROCEDURE

Precautions For Replacement or Repair of

Air Conditioning Parts

The re ar e c er tai n proc edu re s, p rac tic es an d pr ec aut ion s

that should be followed when servicing air conditioning

systems:

• Keep your work area clean.

• Always wear safety goggle and protective gloves

when working on refrigerant systems.

• Beware of the danger of carbon monoxide fumes

caused by running the engine.

• Beware of discharged refrigerant in enclosed or

improperly ventilated garages.

• Always disconnect the negative battery cable and

discharge and recover the refrigerant whenever

repairing the air conditioning system.

• When discharging and recovering the refrigerant, do

not allo w refrigerant to discharge too fas t; it will draw

compressor oil out of the system.

• Keep moisture and contaminants out of the system.

When disconnecting or removing any lines or parts,

use plugs or caps to close the fittings immediately.

Never remove the caps or plugs until the lines or

parts are reconnected or installed.

• When disconnecting or reconnecting the lines, use

two wrenches to support the line fitting, to prevent

from twisting or other damage.

• Alwa ys install new O -rings when ever a connect ion is

disassembled.

• Before connecting any hoses or lines, apply new

specified compressor oil to the O-rings.

• When removing and replacing any parts which

require discharging the refrigerant circuit, the

operations described in this section must be

perfor med in the following seque nc e:

1 Use the J-39500 (ACR4: HFC-134a Refrigerant

Recovery / Recycling / Recharging / System) or

equivalent to thoroughly discharge and recover

the refrigerant.

2 Remove and replace the defective part.

3 After evacuation, charge the air conditioning

system and check for leaks.

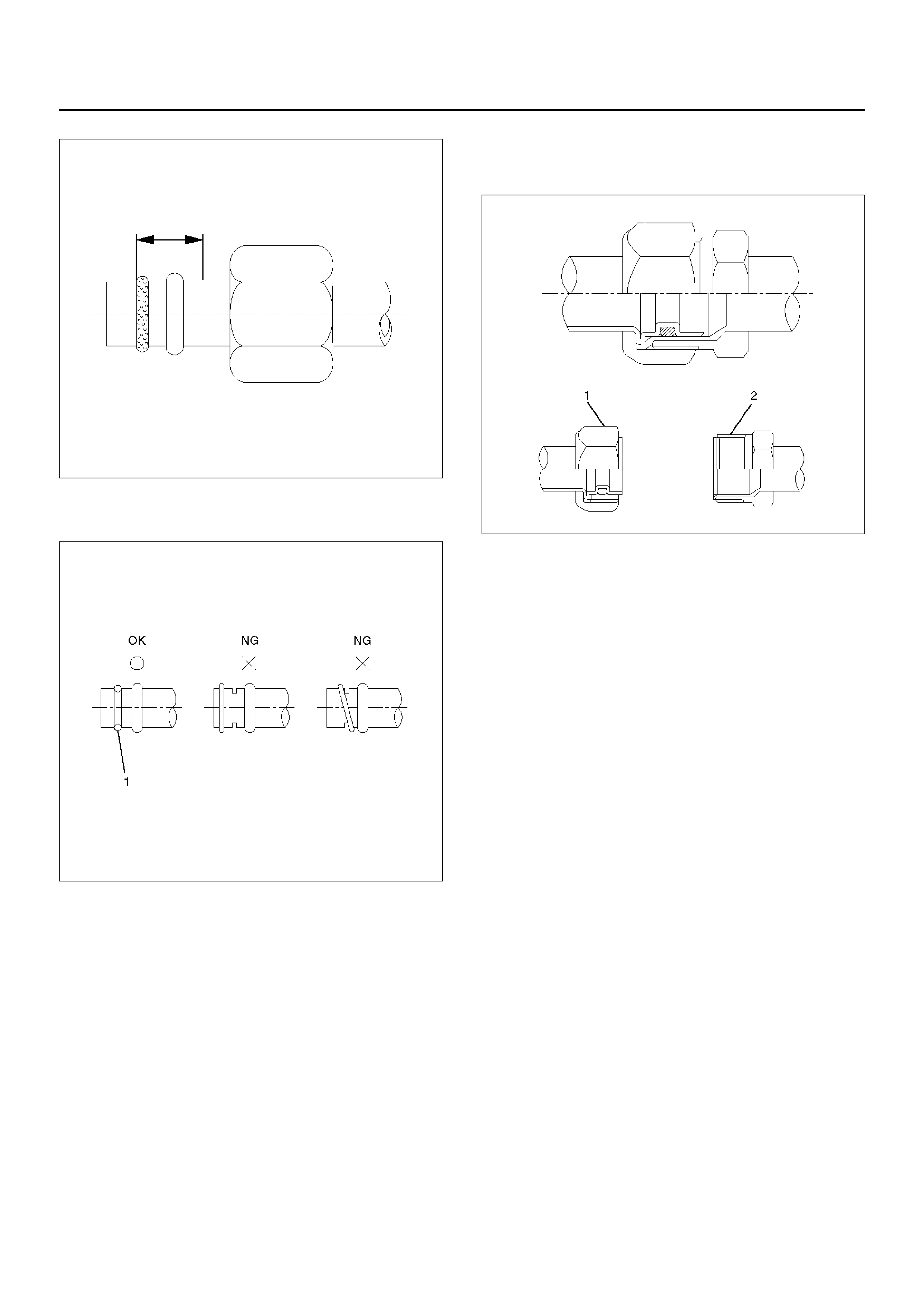

Repair Of Refrigerant Leaks

Refrigerant Line Connections

Install n ew O-rings, if required. W hen discon necting or

connecting lines, use two wrenches to prevent the

connecting portion from twisting or becoming damaged.

852RS003

When connecting the refrigerant line at a block joint,

securel y insert the projecting portion of the j oint portion

into the connecting hole on the unit side and secure with

a bolt. Apply the specified compressor oil to the

O-rings prior to connecting.

CAUTION: Compressor (PAG) oil to be used varies

according to the compressor model. Be sure to

apply oil specified for the model of compressor.

850RW002

O-rings (2) mus t be fi tted in t he g ro ove ( 1) of r ef riger an t

line.

850RW003

Insert the nut into the union.

First, tighten the nut by han d as much as possi ble, then

tighten the nut to the specified torque.

850RW004

LEAK CHECK

Inspec ti on of refrigerant leak

Refrigerant leak may cause an adverse effect not only

on the performance and durability of each component of

the air-conditioner, but also on the global atmosphere.

Therefore, it is most important to repair refrigerant leak

when there is any leak found.

Inspection flow of refrigerant leak

Inspection Steps

Check the components of ai r-cond itioner to see i f there

occurs any refrigerant leak along the flow of refrigerant.

• To avoid an error in the detection of refrigerant leak,

make sure of there being no refrigerant vapor or

cigarette smoke around the vehicle before

conducting the inspection. Also, select a location

where th e refrig erant vapor wi ll no t get bl own off with

wind.

• Inspection should be conducted chiefly on the pipe

connections and sections where a marked oil

contamination is found. When refrigerant is leaking,

oil insi de is also lea king at the same time.

• It is possible to visually check the leak from inside the

cooling unit. Follow the method below when

checking. Remove the drain hose or resistor of the

coolin g unit, and insert a leak de tector to se e if ther e

occurs any leak.

High Pressure Side

1. Discharger section of compressor.

2. In let/out let section of condenser.

3. Inlet/outlet section of receiver driver.

4. Inlet section of cooling unit.

Low Pressure Side

1. Outlet section of cooling unit.

2. Intake section of compressor.

Major Checking Points of Refrigerant Leak

Compressor

• Pipe connection

• Sealing section of shaft

• Mating section or cylinder

Condenser

• Pipe connection

• Welds of condenser body

Receiver driver

• Pipe connection

• Attaching section of pressure switch

• Section around the sight glass

Evaporator unit (cooling unit)

• Pipe connections

• Connections of expansion valve

• Brazed sections of evaporator

• The evaporator and expansion valve are contained in

the case. Remove the drain hose or the resistor of

the cooling unit and insert a leak detector when

checking for any leak.

Flexible hose

• Pipe connection

• Caulking section of the hose

• Hose (cracks, pinholes, flaws)

Pipe

• Pipe connection

• Pipe (cracks, flaws)

Charge valve

• The charge valve, which is used to connect the

gauge manifold, is normally provided with a resin

cap. When the valve inside gets deteriorated,

refrigerant will leak out.

Step Action Yes No

1 1. Evacuate the refrigerant system.

2. Charge the refrigerant.

Is there any refrigerant leak? Repair refrigerant

system. Go to Step 2.

2 1. Operate th e c om pr esso r for m or e t han 5 mi nute s to rais e t he

pressure on the high pressure side.

Is there any refrigerant leak at high pressure components? Repair refrigerant

system.

Compressor

operation to be

confirmed.

Leak at Refrigerant Line Connections

1. Check the torque on the refrigerant line fitting and, if

too loose, tighten to the specified torque.

• Use two wrenches to prevent twisting and

damage to the line.

• Do not over tighten.

2. Perform a leak test on the refrigerant line fitting.

3. If the leak is stil l presen t, disc harg e and re cover th e

refrigerant from the system.

4. Replace the O-rings.

• O-rings cannot be reused. Always replace with

new ones.

• Be sure to apply the specified compressor oil to

the new O-rings.

5. Retighten the refrigerant line fitting to the specified

torque.

• Use two wrenches to prevent twisting and

damage to the line.

6. Evacuate, charge and retest the system.

Leaks In The Hose

If the compressor inlet or outlet hose is leaking, the

entire hose must be replaced. The refrigerant hose

must not be cut or spliced for repair.

1. Locate the leak.

2. Discharge and recover the refrigerant.

3. Re mo ve the hose ass em bly.

• Cap the open connections at once.

4. Connect the new hose assembly.

• Use t wo wrenc hes to pre vent twis ting or damage

to the hose fitting.

• Tighten the hose fitting to the specified torque.

5. Evacuate, charge and test the system.

Compressor Leaks

If leaks are located around the compressor shaft seal or

shell, replace or repair the compressor.

Recovery, Recycling, Evacuation and

Charging of HFC-134a

Air conditioning systems contain HFC-134a. This is a

chemical mixture which requires special handling

procedures to avoid personal injury.

• Always wear safety goggles and protective gloves.

• Alwa ys work in a well-v entilat ed area. Do not wel d or

steam clean on or near any vehicle-installed air

conditioning lines or components.

• If HFC-134a should come in contact with any part of

the body, flush the expos ed area with col d water and

immedi atel y se ek med ic al help.

• If it is necessary to transport or carry any container of

HFC-134a in a vehicle, do not carry it in the

passenger compartment.

• If it is necessary to fill a small HFC-134a container

from a large one, never fill the container completely.

Space shou ld always be al lowed above th e liquid for

expansion.

• HFC-134a and R-12 should never be mixed as their

compos itions are not the same.

• HFC-134a PAG oil tends to absorb moisture more

quickly than R-12 mineral oil and, therefore, should

be handled more carefully.

• Keep HFC-134a containers stored below 40°C

(100°F).

WARNING:

• SHOULD HFC-134A CONTACT YOUR EYE(S),

CONSULT A DOCTOR IMMEDIATELY.

• DO NOT RUB THE AFFECTED EYE(S). INSTEAD,

SPLASH QUANTITIES OF FRESH COLD WATER

OVER THE AFFECTED AREA TO GRA DUALLY

RAISE THE TEMPERATURE OF THE

REFRIGERANT ABOVE THE FREEZING POINT.

• OBTAIN PROPER MEDICAL TREATMENT AS

SOON AS POSSIBLE. SHOULD THE HFC-134A

TOUCH THE SKIN, THE INJURY MUST BE

TREATED THE SAME AS SKIN WHICH HAS BEEN

FROSTBITTEN OR FROZEN.

Refrigerant Recovery

The refrigerant must be discharged and recovered by

using the J-39500 (ACR4:HFC-134a Refrigerant

Recovery/Recycling/Recharging/System) or equivalent

before removing or mounting air conditioning parts.

1. Connect the high and low charging hoses of the

ACR4(or equivalent) as shown below.

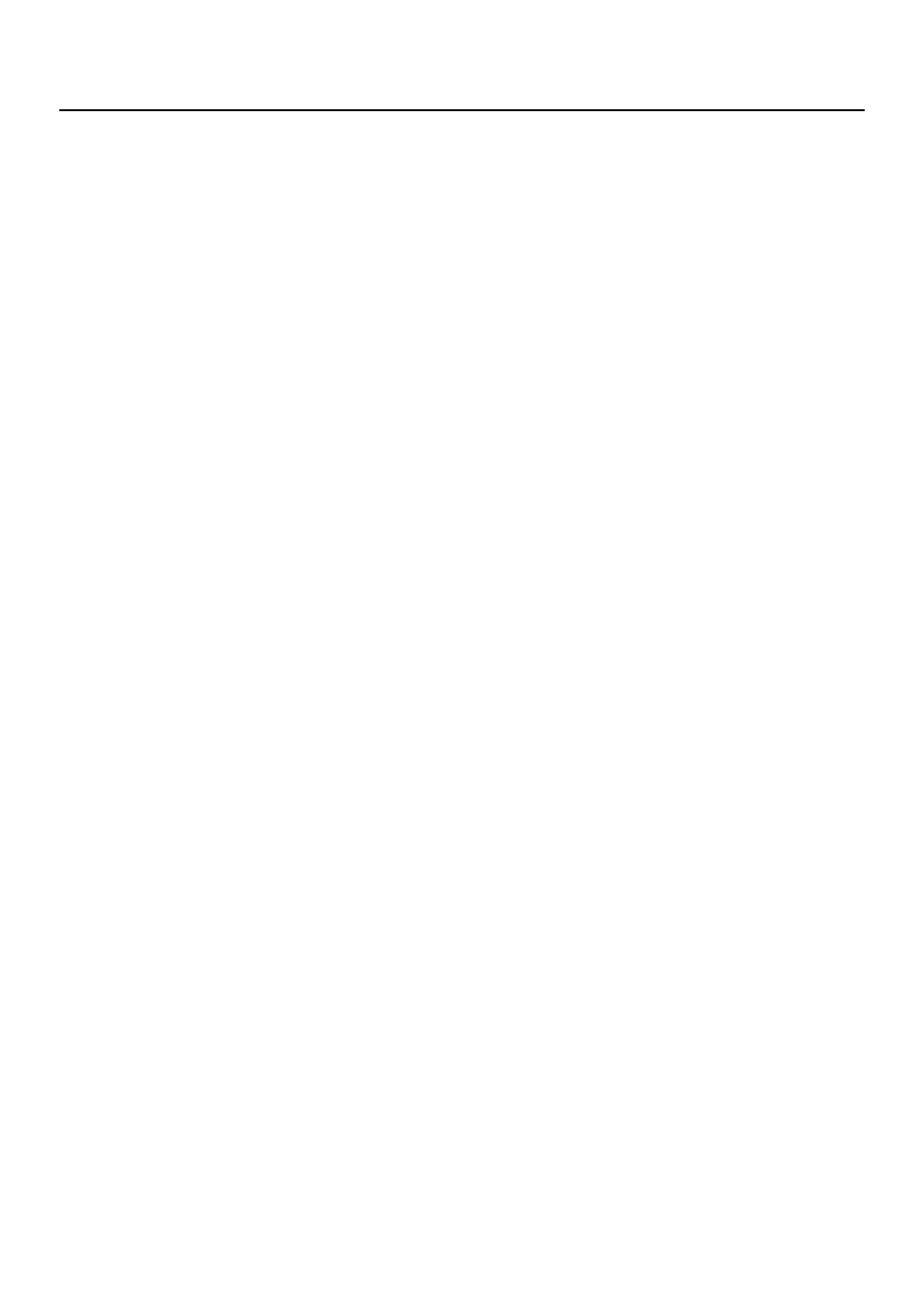

901R100033

EndOFCallout

2. Recover the refrigerant by following the

Manufacturer's Instructions.

3. Whe n a part is removed , put a cap or a pl ug on th e

connecting portion so that dust, dirt or moisture

cannot get into it.

Refrigerant Recycling

Recycle the refrigerant recovered by J-39500

(ACR4:HFC-134a Refrigerant Recovery / Recycling /

Recharging / System) or equivalent.

For the details of the actual operation, follow the steps

in the ACR4(or equivalent) Manufacturer's Instructions.

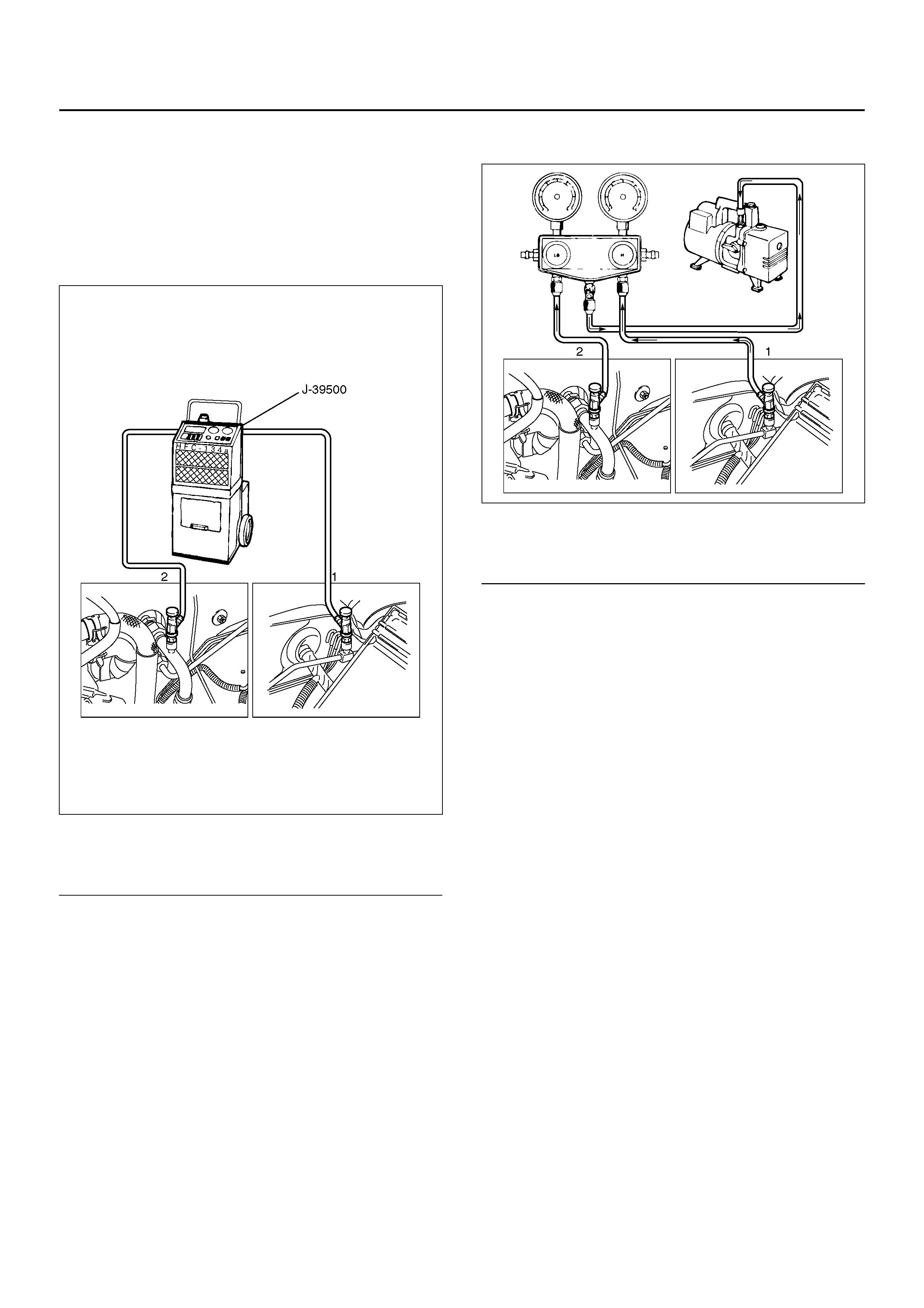

Evacuation of The Refrigerant System

901R100035

EndOFCallout

Explained below is a method using a vacuum pump.

Refer to the ACR4(or equivalent) manufacturer's

instructions when evacuating the system with a

ACR4(or equivalent).

Air and moisture in the refrigerant will cause problems in

the air conditioning system. Therefore, before charging

the refrigerant, be sure to evacuate air and moisture

thoroughly from the system.

1. Connect the gauge manifold.

• High-pressure valve (HI) — Discharge-side.

• Low-pressure valve (LOW) — Suction-side.

2. Discharge and recover the refrigerant.

3. Connect the center hose of the gauge manifold set

to the vacuum pump inlet.

4. Operate the vacuum pump, open shutoff valve and

then open both hand valves.

5. When the low-pressure gauge indicates

approximately 750mmHg (30inHg), continue the

evacuation for 5 minutes or more.

6. Close both hand valves and stop the vacuum pump.

Legend

(1) H i gh Side

(2) Low Side

Legend

(1) High Side

(2) Low Side

7. Chec k to ensu re t hat the pre ssure does not chang e

after 10 minutes or more.

• If the pressure changes, check the system for

leaks.

• If leaks occur, retighten the refrigerant line

connections and repeat the evacuation steps.

8. If no leaks are found, again operate the vacuum

pump fo r 20 mi nutes or m ore. After confirmi ng that

the gauge manifold pressure is at 750mmHg

(30inHg), close both hand valves.

9. C lose p os iti ve s huto ff va lve. Stop the va cu um pum p

and disconnect the center hose from the vacuum

pump.

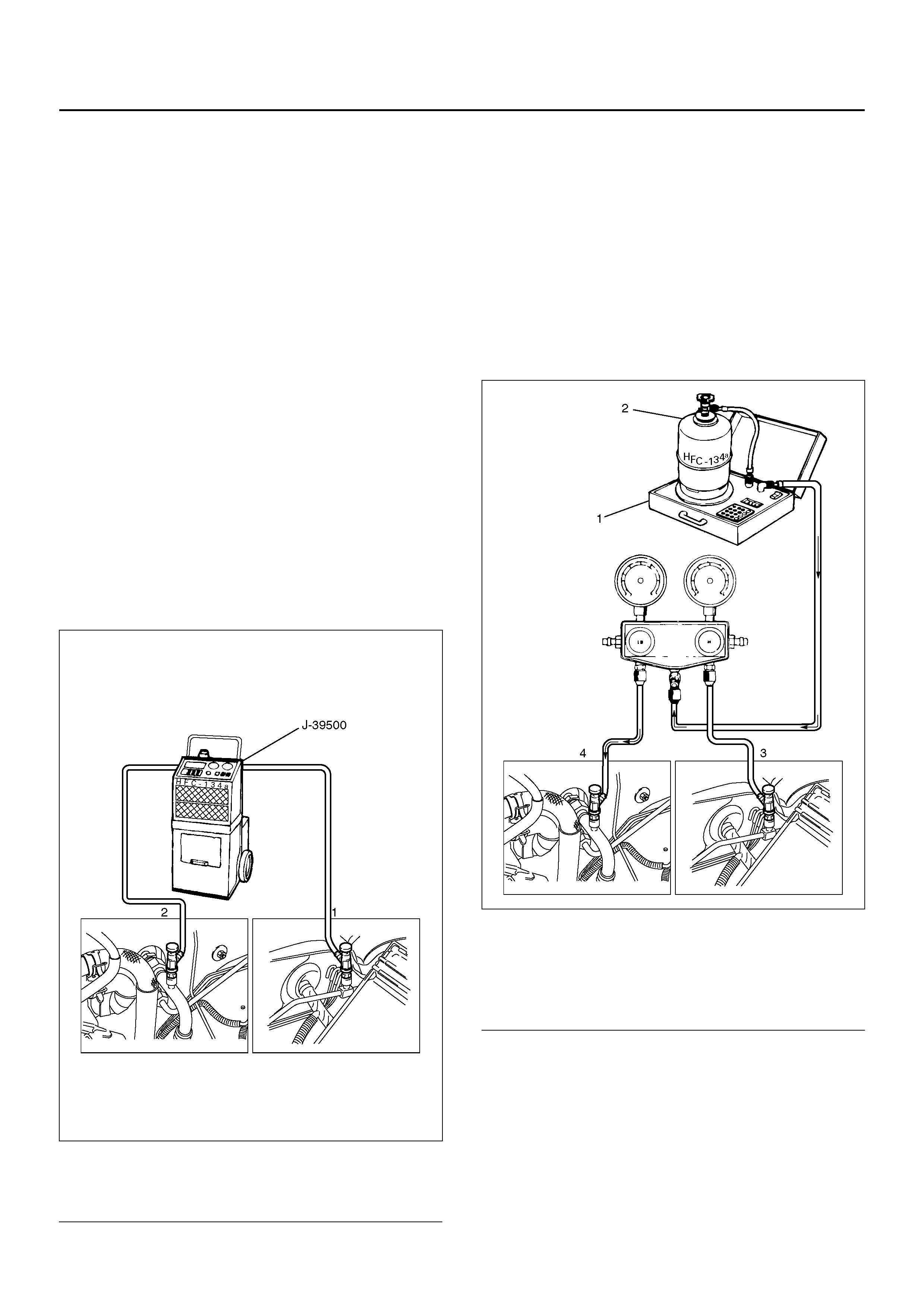

Charging The Refrigerant System

There are various methods of charging refrigerant into

the air conditioning system.

These include using J-39500 (ACR4:HFC-134a

Refriger ant Recover y/Recycling/ Recharging/Sy stem) or

equivalent and direct charging with a weight scale

charging station.

Charging Procedure

•ACR4(or equivalent) Method

For the char ging of refriger ant recovered by ACR4(or

equivalent), follow t he manufacturer's instruction.

901R100033

EndOFCallout

•Direct charging with a weight scale charging

station method

1. Make sure the evacuation process is correctly

completed.

2. Connect the center hose of the manifold gauge to

the weight scale.

3. Connect the low pressure charging hose of the

manifold gauge to the low pressure side service

valve of the vehicle.

4. Connect the high pressure charging hose of the

manifold gauge to the high pressure side service

valve of the vehicle.

901R100034

EndOFCallout

5. Place the refrigerant container up right on a weight

scale.

Note the total weight before charging the refrigerant.

a Open the refrigerant container valve.

b Open the low side vale on the manifold gauge

set. Refer to the manufacturer's instructions for

a weight scale charging station.

Legend

(1) H i gh Side

(2) Low Side

Legend

(1) Weight Scale

(2) Refrigerant Container

(3) High Side

(4) Low Side