SECTION 2D - AUTOMATIC AIRCONDITIONING SYSTEM

Automatic Air Conditioning System

General Description

Automatic Air Conditioner Parts

Configuration

Refrigerant Line and Associated Parts

Circuit Diagram

Functions and Features

Automatic Air Conditioner Block Diagram

Control Panel Layout

Air Control Functions

Operation and Functions of Control Panel

Switches

Overview of Construction, Movement

and Control of Major Parts of Automatic

Air Conditioner System

Overview of Automatic Control of

Automatic Air Conditioner

Troubleshooting

Troubleshooting, Its Overview

and Procedures

Auto Air Conditioner Control Unit Power

Supply Diagnosis

Performance and Movement checklist for

Automatic Air Conditioner Related Parts

Troubleshooting With Self-Diagnosis

Function

Inspection By Failed Location

Inspection of the Sensors

Inspection of the Intake Actuator System

Inspection of the Mix Actuator System

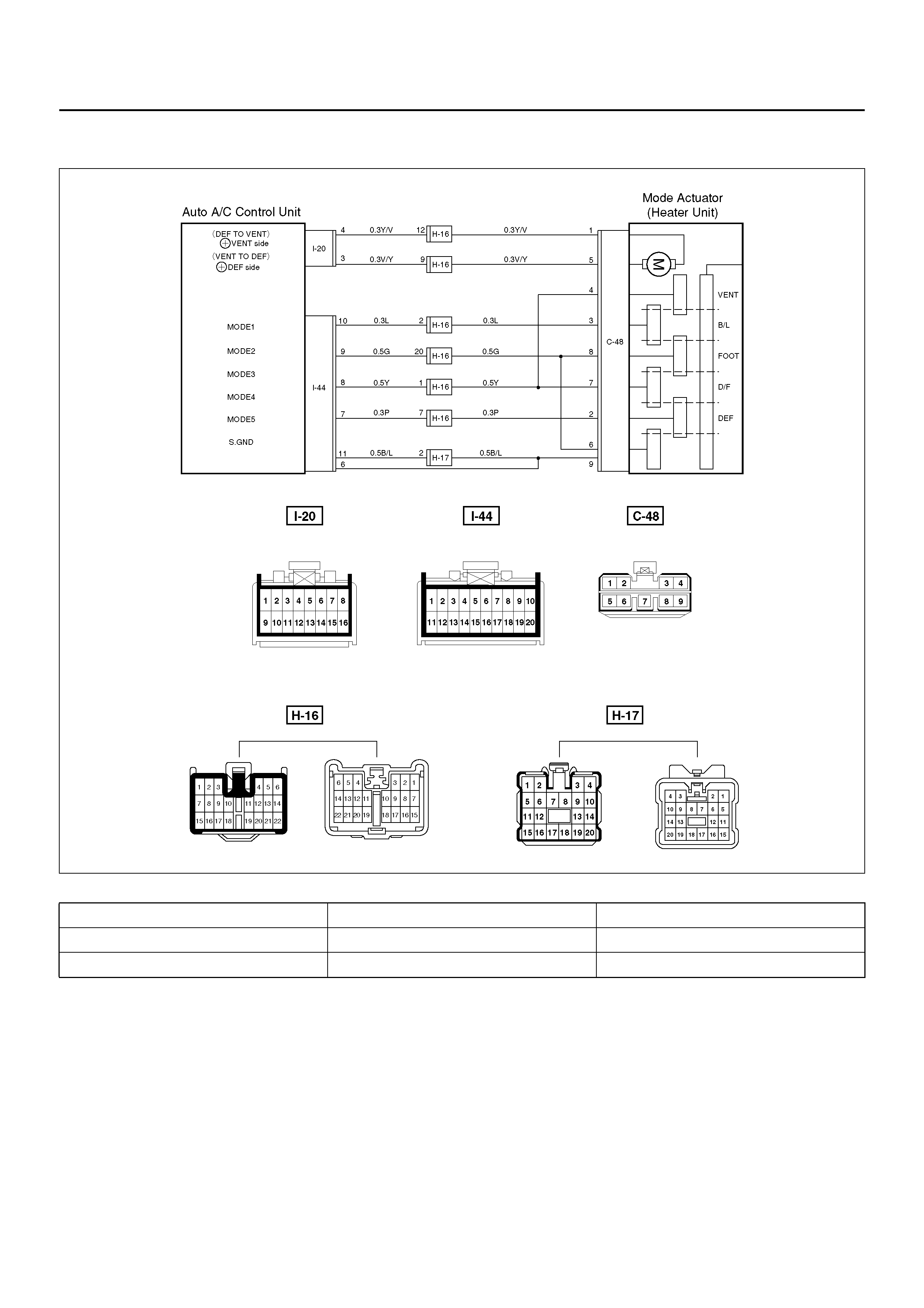

Inspection of the Mode Actuator System

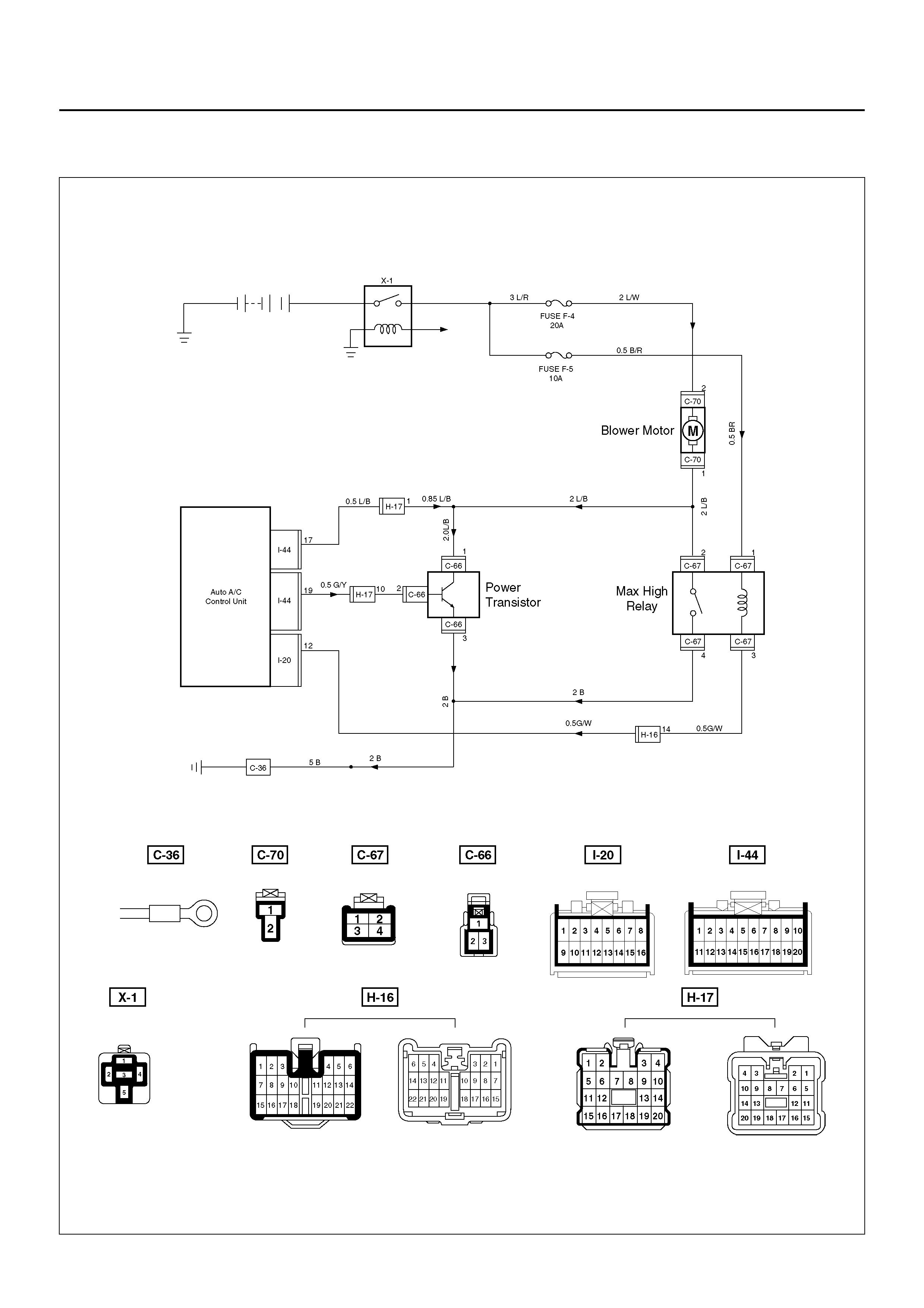

Inspection of the Fan Motor System

Inspection of the Heater Control System

Inspection of the Magnetic Clutch System

Condenser Fan Diagnosis

Individual Inspection

On-Vehicle Service

Power Transistor

Removal

Installation

Automatic Air Conditioner Control Unit

Removal

Installation

In Car Sensor

Removal

Installation

Ambient Sensor

Removal

Installation

Sun Sensor

Removal

Installation

Duct Sensor

Removal

Installation

Mode Actuator

Removal

Installation

Mix Actuator

Removal

Installation

Intake Actuator

Removal

Installation

AUTOMATIC AIR CONDITIONING SYSTEM

GENERAL DESCRIPTION

Using a variety of sensors, this automatic heater and air

conditioner accurately senses outside air temperature,

solar radiation quantity, evaporator's blowing

temperature, and interior temperature, then enters

these data to the automatic heater/air conditioner

control unit (equipped wi th the built- in micro-co mputer).

The data provided to the control unit enables to

automatically control blow temperature and blow air

quantity, turn on or off the compressor and switch the

blow port as well as switching between the fresh air

intake and interior air circulation.

Resetti ng the aut omatic function a llows you to switc h to

the manual control mode.

The self-diagnoisis function of the automatic air

conditioner control unit (with the built-in micro-

computer) allows the unit to access and diagnose a

failed part easier and quicker.

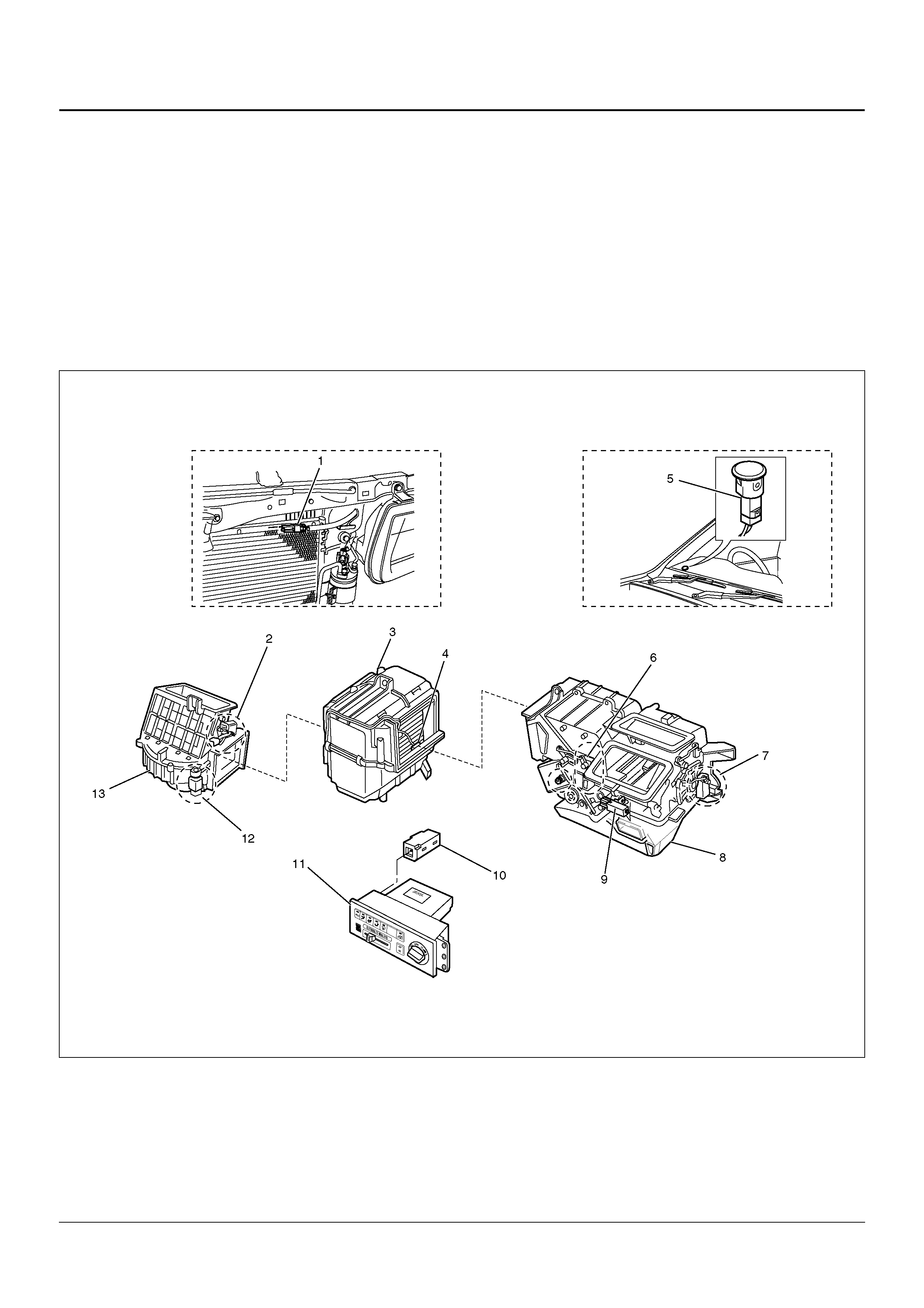

AUTOMATIC AIR CONDITIONER PARTS CONFIGURATION

865R100001

EndOFCallout

Legend

(1) Ambient Sensor

(2) Intake Actuator

(3) Evaporator Assembly

(4) Duct Sensor

(5) Sun Sensor

(6) Mix Actuator

(7) Mode Actuator

(8) Heater Unit

(9) Resistor

(10) In Car Sensor

(11) Automatic Air Conditioner Control Unit

(12) Max – High Relay

(13) Blower Unit

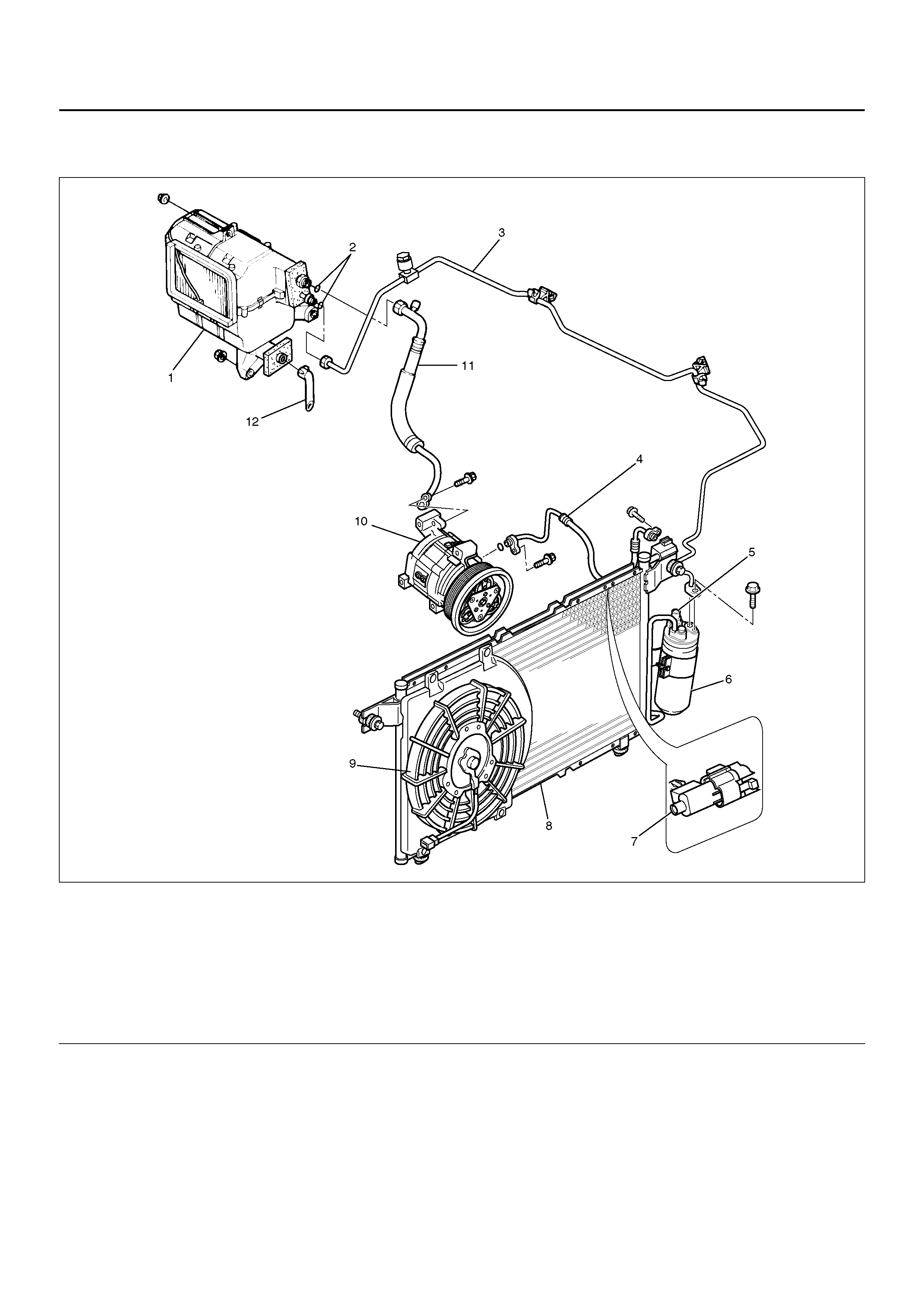

REFRIGERANT LINE AND ASSOCIATED PARTS

852R100009

EndOFCallout

Legend

(1) Eva pol ato r Asse mbl y

(2) O – Ring

(3) Liquid Line (High Pressure Pipe)

(4) High Pressure Hose

(5) Pressure Switch

(6) Receiver Dryer

(7) Ambient Sensor

(8) Con den ser Asse mbl y

(9) Con den se r Fan

(10) Compressor

(11) Suction Line (Low Pressure Hose)

(12) Drain Hose

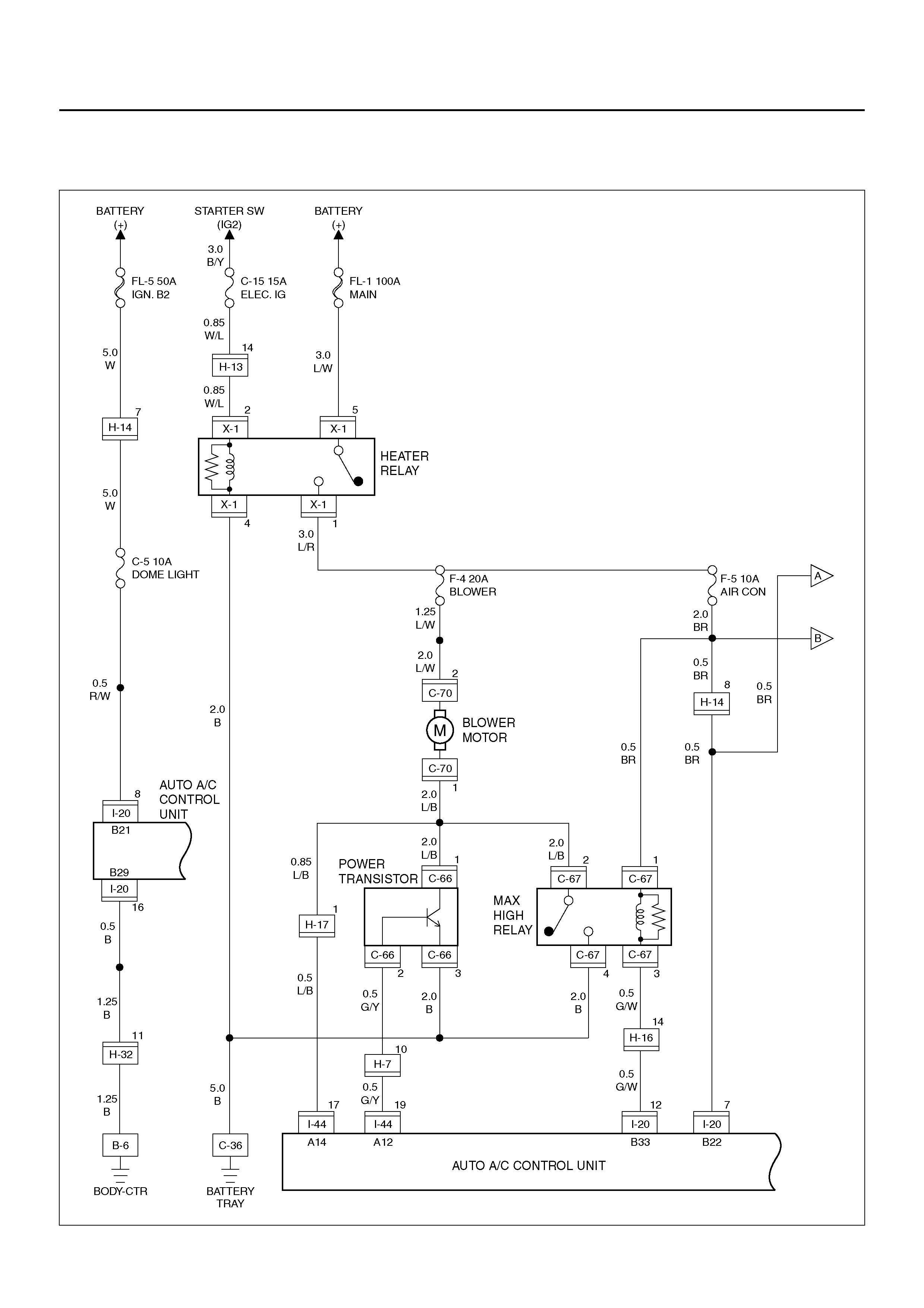

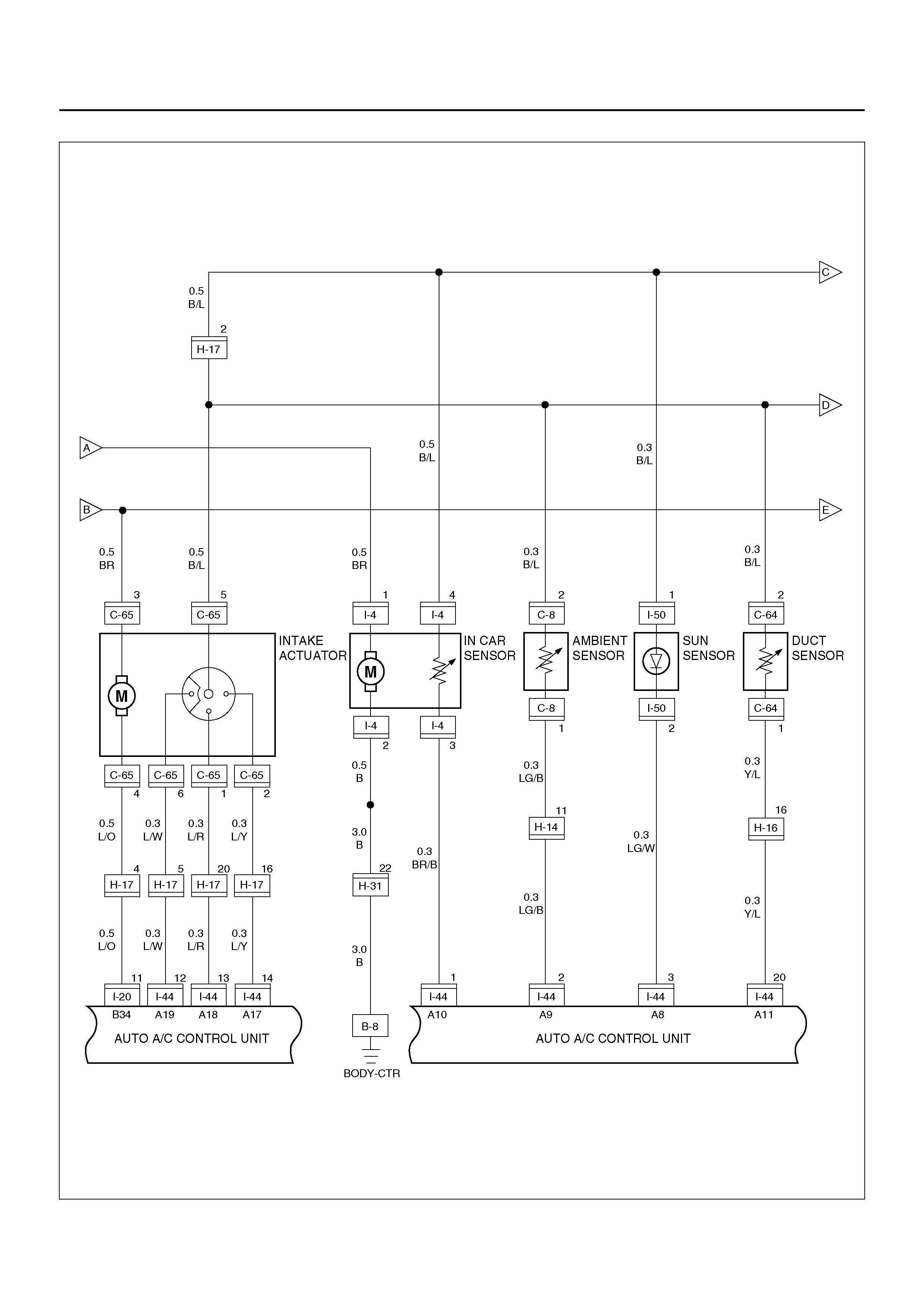

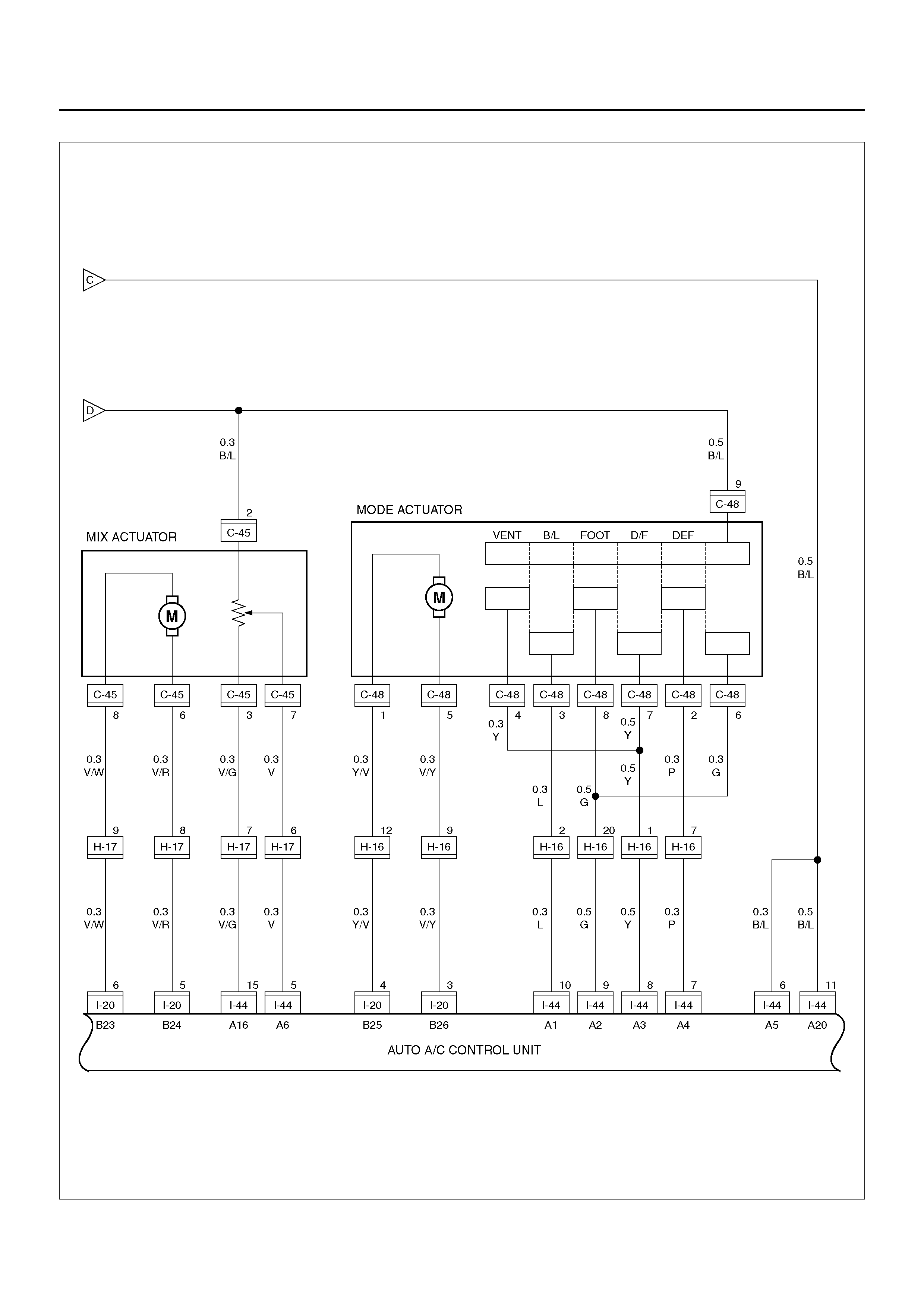

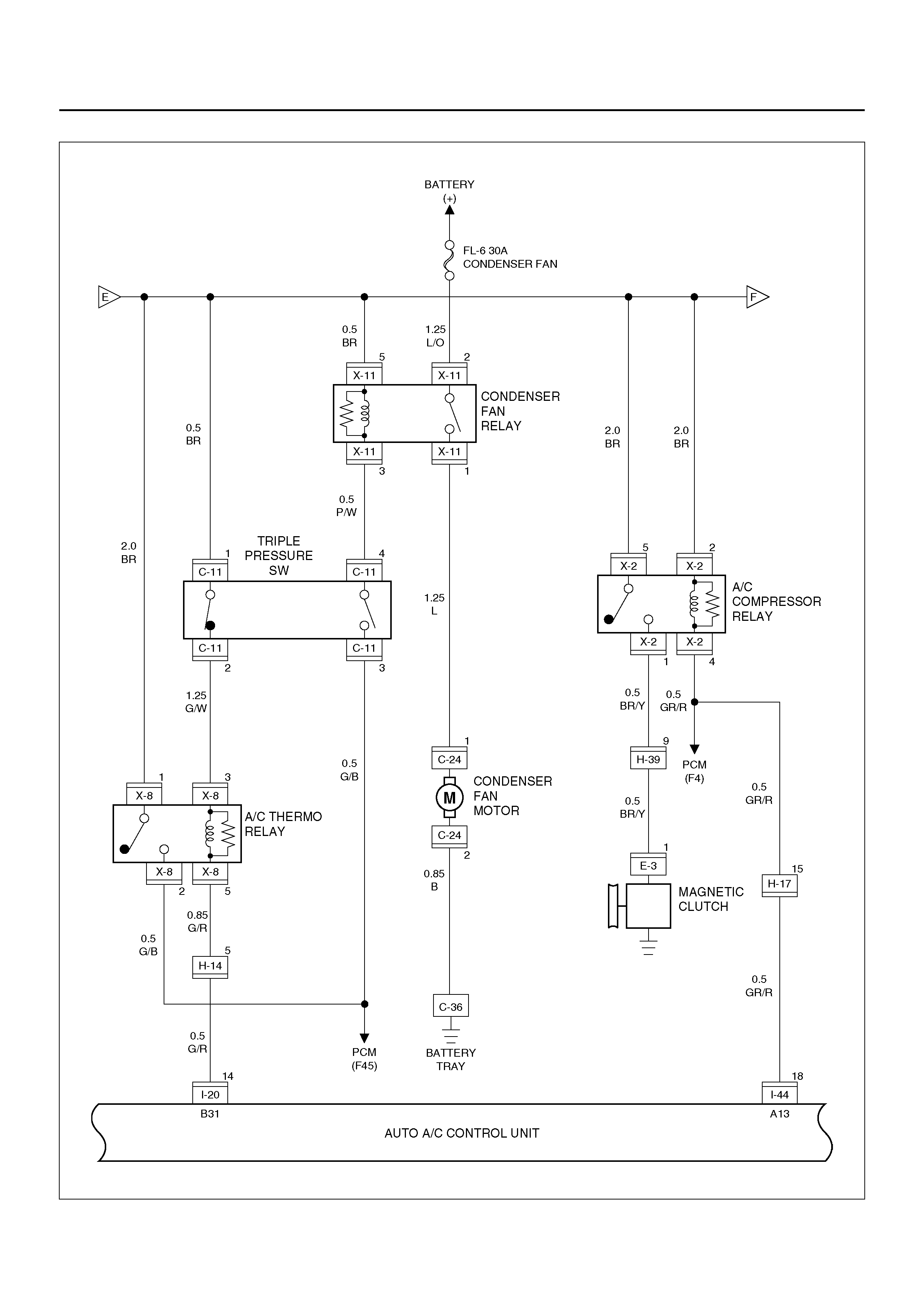

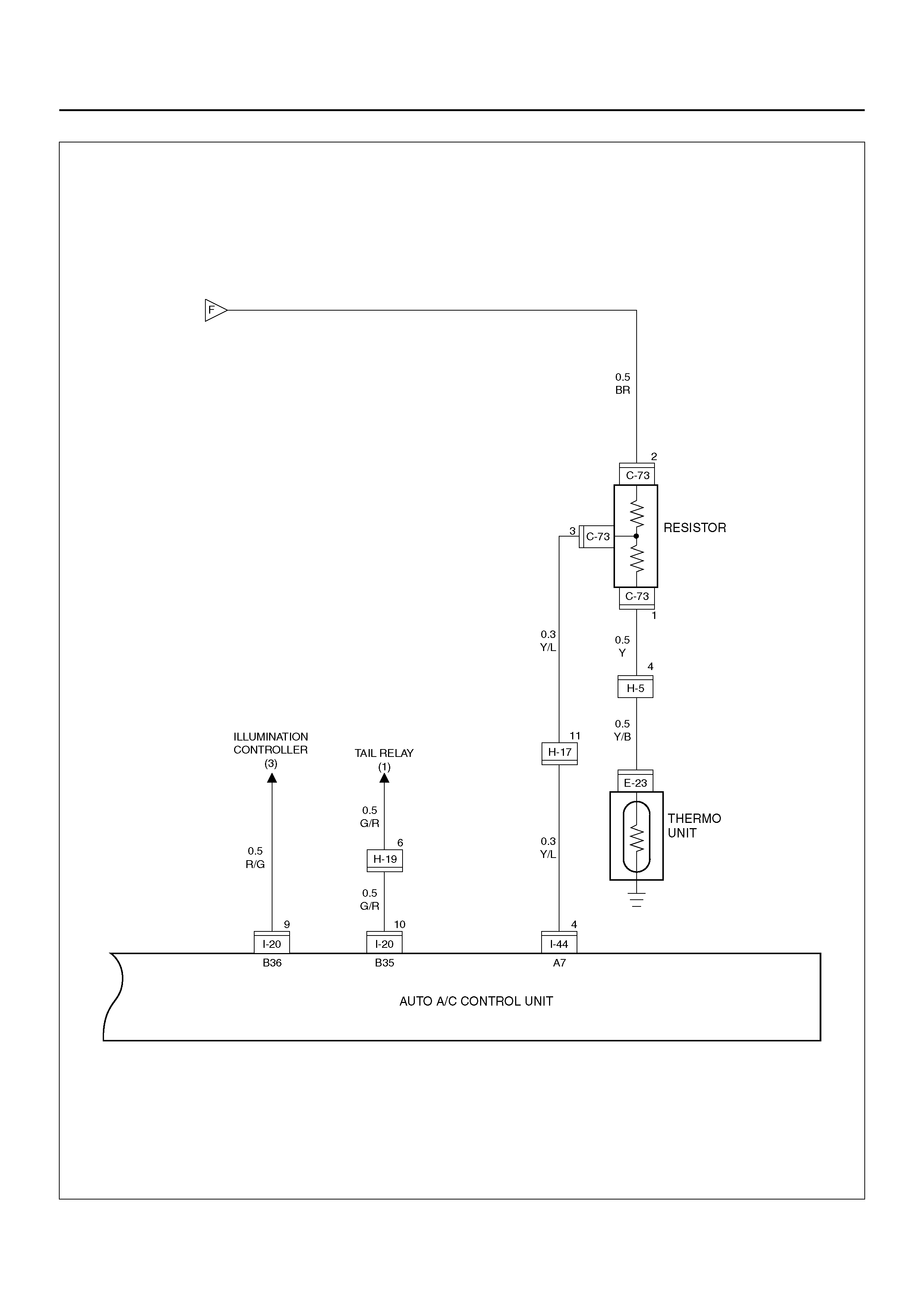

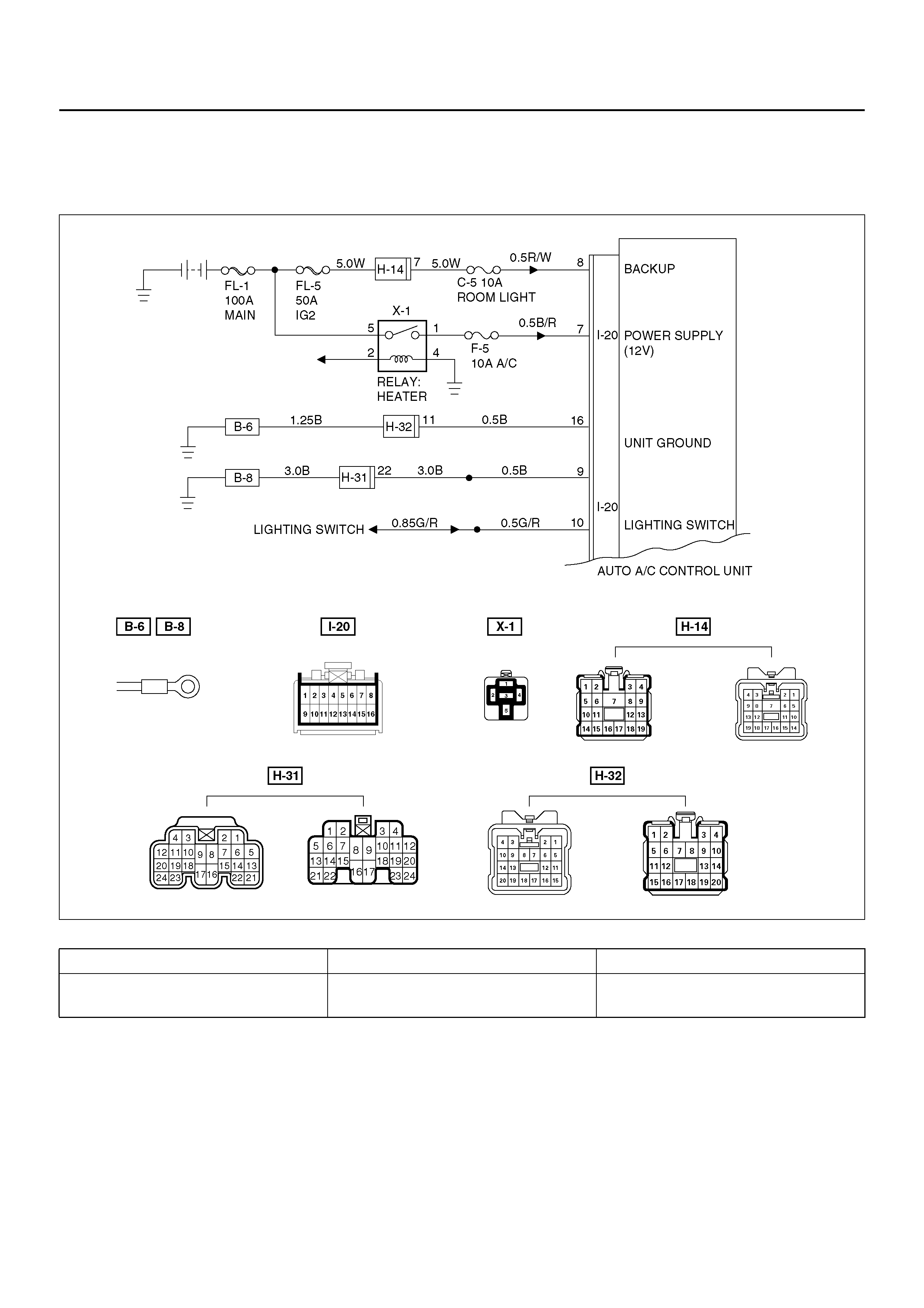

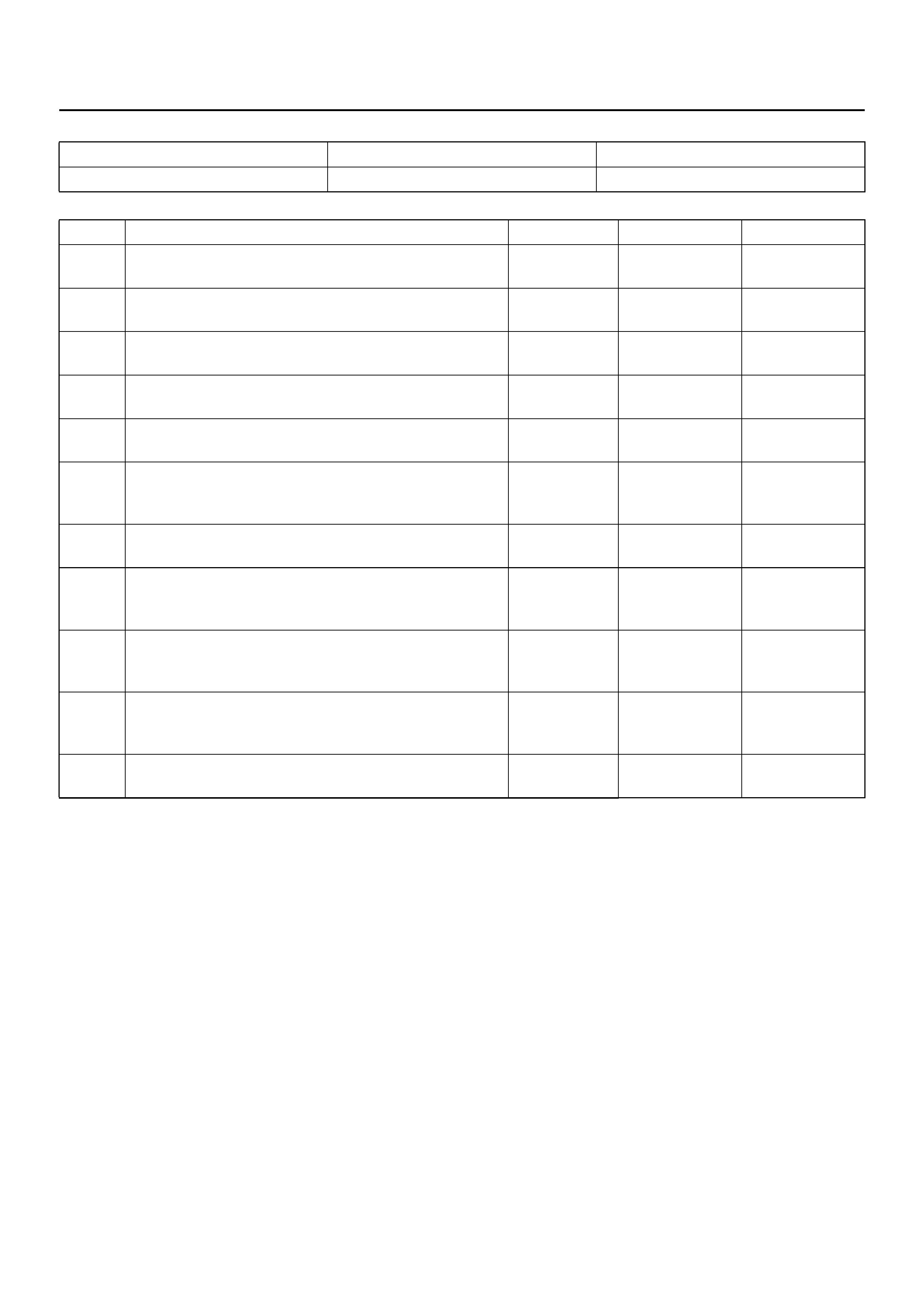

CIRCUIT DIAGRAM

6VD1 Engine

D08R100176

D08R100099

D08R100100

D08R100101

D08R100215

FUNCTIONS AND FEATURES

Automatic interior temperature control

This function enables to maintain the interior

temperature at the level specified from the

temperature control switch despite of changes in

factors such as vehicle speeds, outside air

temperature and number of passengers.

Maximum cooling and heating function

You can select FC (Full cool, namely maximum cooling

temperature) or FH (Full heat, maximum heating

temperature) from the temperature control lever.

Automatic air flow control

Air flow is automatically and consecutively fine tuned

according to the specified interior temperature and

changes in aperture of the heater unit mix door.

Mode (blow port) control

This function automatically selects either one of the

VENT, BI-LEVEL, FOOT or DEF mode for the blow

port according to changes of temperature on the

blow port. Using the mode switch allows you to

select a desired blow port manually.

Intake (switching between the fresh air intake and

circulation of interior air) control

The intake (switching between fresh air intake and

circulation of interior air) mode automatically selects

either FRESH (fresh air intake), MIX or RECIRC

(interior air circulation) according to changes of the

blow port temperature. Using the intake switch

allows you to select a desired intake port manually

(in the manual operation, FRESH and RECIRC

modes alone are available). Pressing the DEF

(defrost) mode switch selects the FRESH (fresh air

intake).

Cooler start-up timing control

This function is used for maintaining the air flow at

“LOW" level until the evaporator is sufficiently cooled

down. It is intended to prevent a large volume of hot

air being blowing into inside of a vehicle when the

cooler is turned on in hot summer season.

Heater start-up timing control

This function is used for maintained the air flow at

“LOW" level and also for maintaining the defrost

mode until temperature of coolant in the heater core

is sufficiently heated. It is intended to prevent a

large volume of cool air being blown into inside of a

vehicle when the heater is turned on in cold winter

season.

Solar radiation quantity offset control

The photodiode on the solar radiation sensor

determines solar radiation quantity accurately to

offset interior temperature quickly.

Switch position storing function

This function is used for storing switch positions being

selected in the immediately preceding operation,

namely the last time the ignition has been turned off.

It simplifies the setup procedures when restarting the

system.

Self-diagnosis function

The self-diagnosis function turned on from the panel

switch makes your troubleshooting easier (for detail

of this function, refer to the section titled

“Self-Diagnosis").

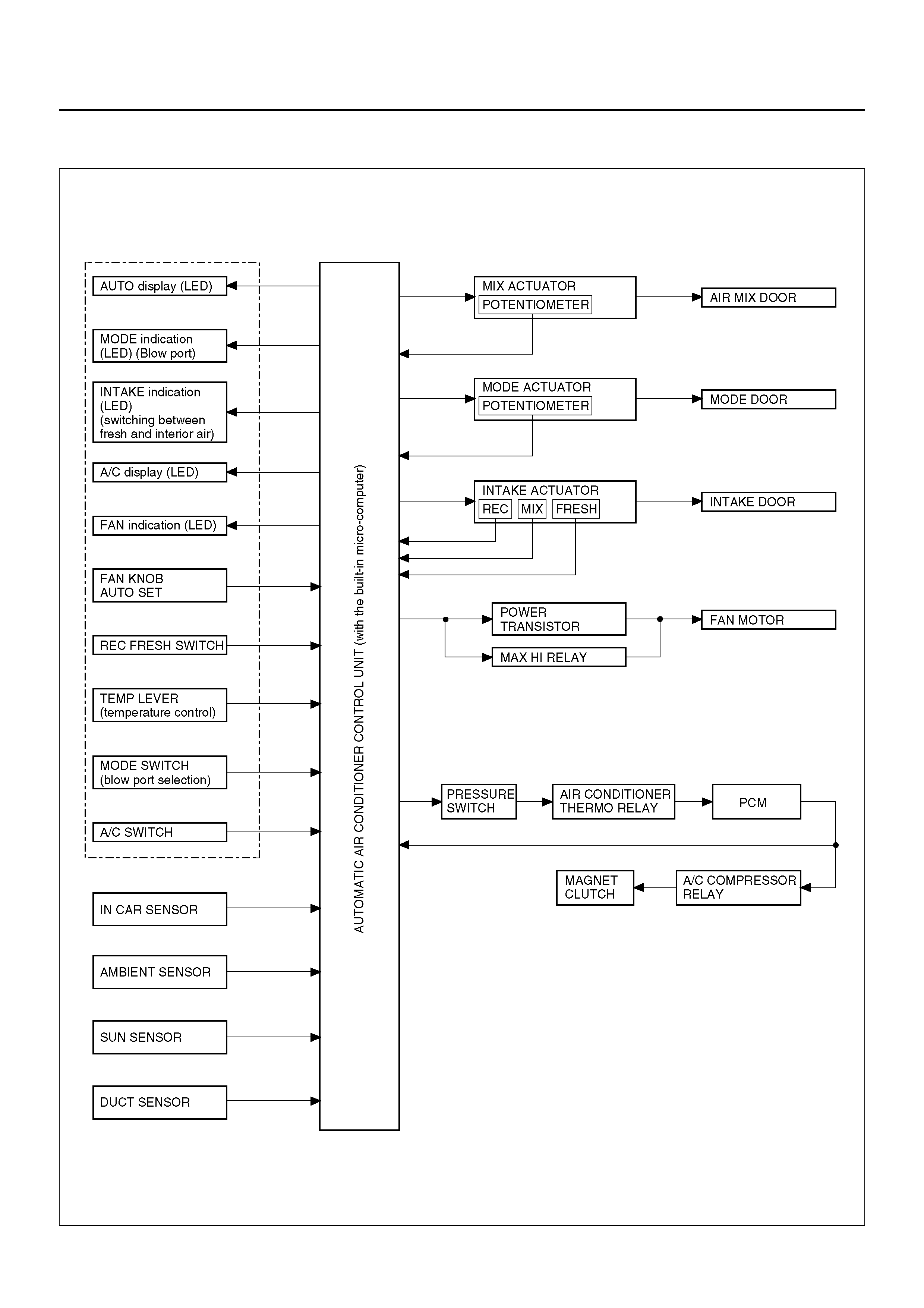

AUTOMATIC AIR CONDITIONER BLOCK DIAGRAM

F01R100001

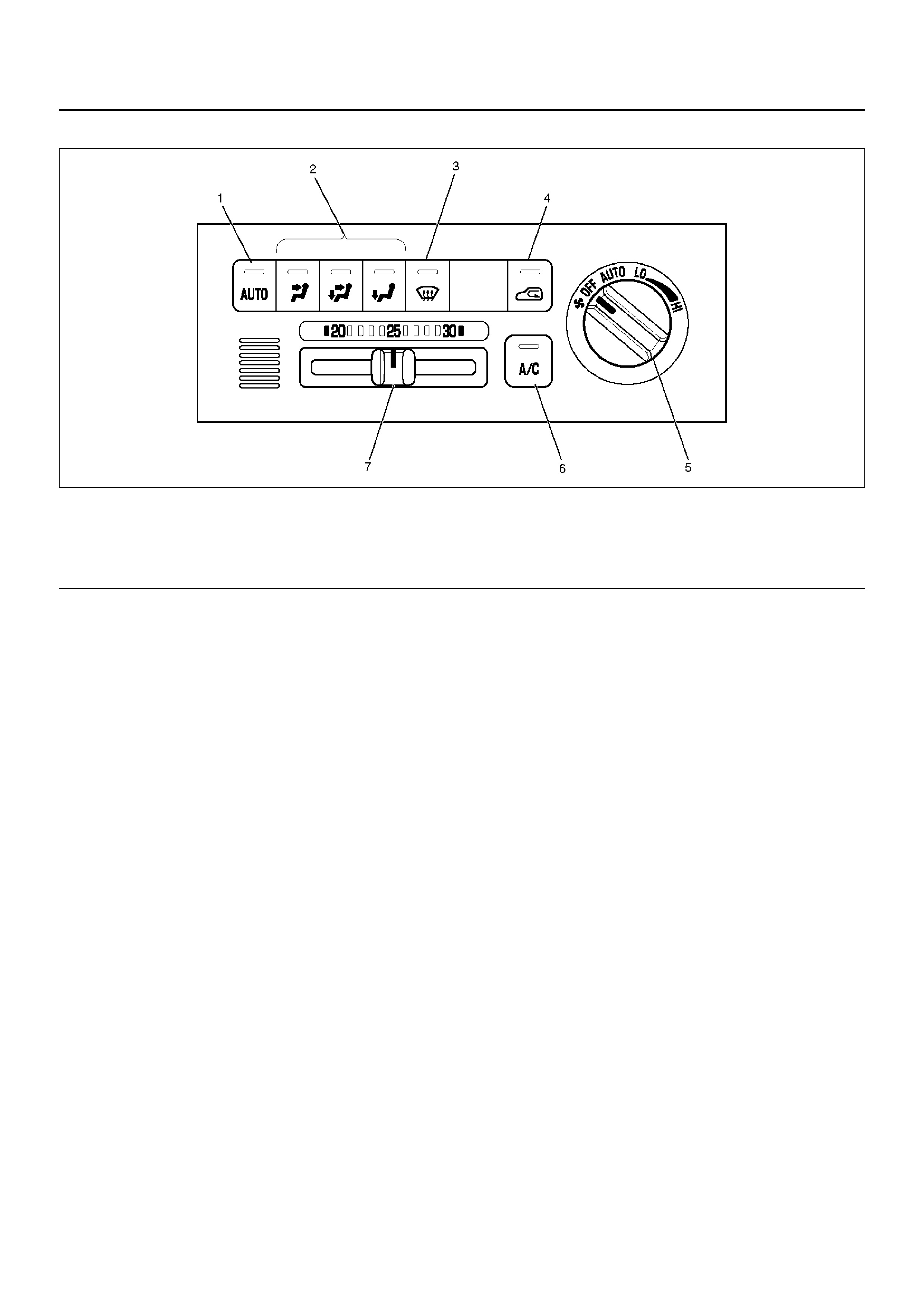

CONTROL PANEL LAYOUT

C01RW007

EndOFCallout

Legend

(1) Auto Switch

(2) Mode Switch

(3) DEF Switch

(4) Int ake Switch

(5) Fan Switch

(6) Air Conditioning Switch

(7) Temperature Control Knob

AIR CONTROL FUNCTIONS

C01RX002

EndOFCallout

Legend

(1) In t er ior Air I ntak e

(2) Fresh Air Intake

(3) Evaporator Core

(4) Air Mix Door

(5) DEF Door

(6) VENT Door

(7) Foot Door

(8) Sub Air Mix Door

(9) Heater Unit

(10) Heater Core

(11) Evapor ato r Unit

(12) Blower Unit

OPERATION AND FUNCTIONS OF CONTROL PANEL SWITCHES

Auto Switch

1. Pressing this switch turns on the automatic control

mode. It resets all manual sw itches except that for

the fan co ntrol. However, when the Manua l REC is

selected for the intake or the Manual Open is

selected, the modes are maintained.

2. It causes the A/C (air conditioner) to the ON mode

(this function, however, available only when the fan

is turned on and also the compressor is turned on

because of the given outside air temperature level).

Indication

• The AUTO LED comes on.

• Currently selec ted mod e for the M ode and Inta ke are

respectively indicated.

• The A/C LED remains turned on even if the

compressor has been turned off because of the given

outside air temperature level. Pressing the air

conditioning switch in this state turns off the A/C LED.

Mode Switch

1. Pressi ng the V ENT, B/L or FO OT s witch selects the

corresponding mode.

2. When the Aut o is select ed for the Mode and Intake ,

pressing the mode switch fixes the Intake to the

immedi atel y prec edi ng status .

Indication

• Turns off the Auto LED.

• Currently selected blow port is indicated.

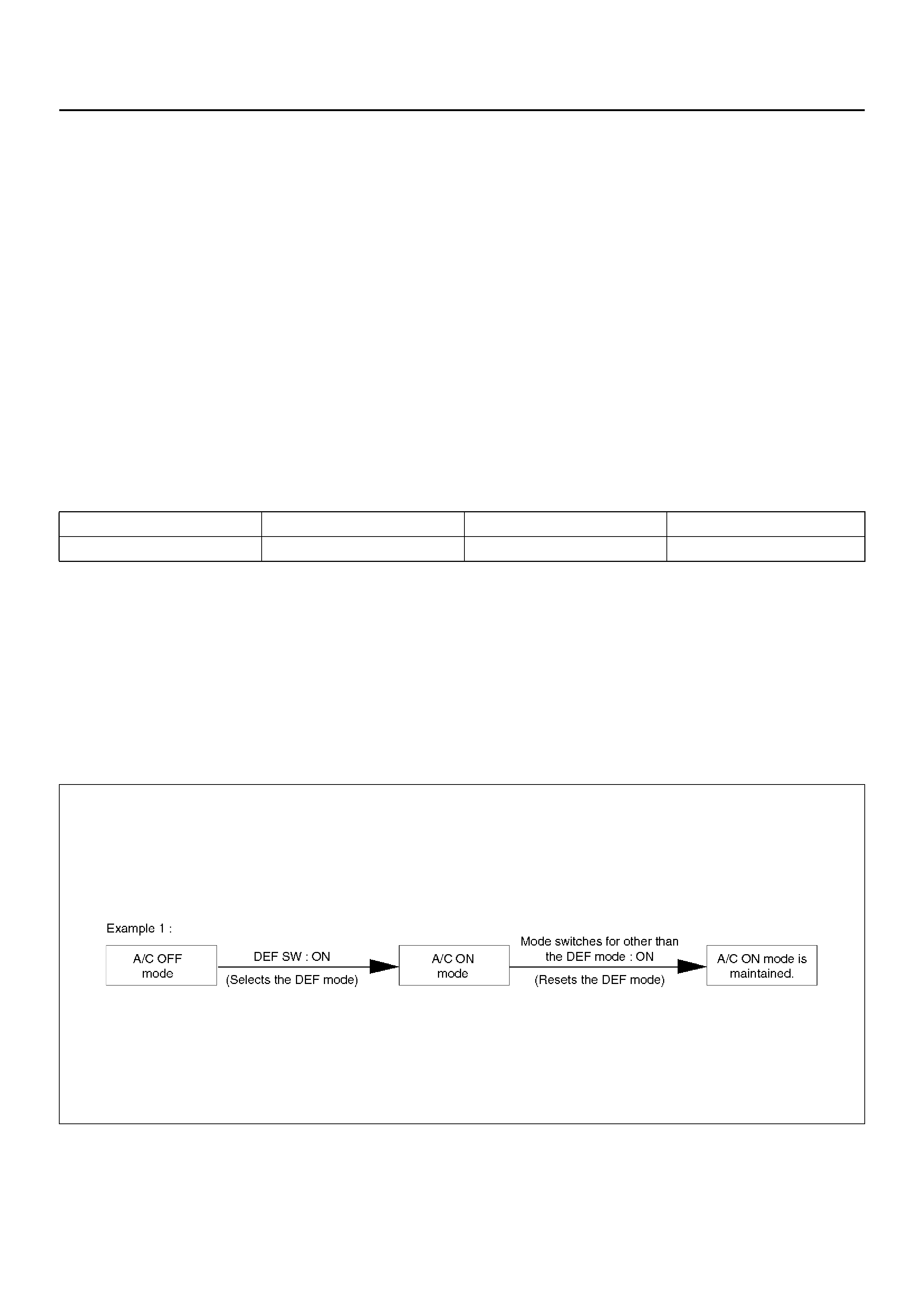

DEF Switch

Press this sw itch to select the DEF mode.

*1: When the manual REC is selected for the Intake, the

manual REC is maintained.

*2: The ON mode is enabled only when the fun is turned

on, and also the compressor is turned on because of

the given outside air temperature level.

Indication

• The Auto LED is turned off.

• DEF is indicated for the blow port, A/C LED comes on

(only when the fan is turned on), and status display is

provided for the Intake and Cold Air Bypass.

F01RX006

Blow port Intake port A/C MIX

DEF Auto FRESH *1 ON mode *2 Auto

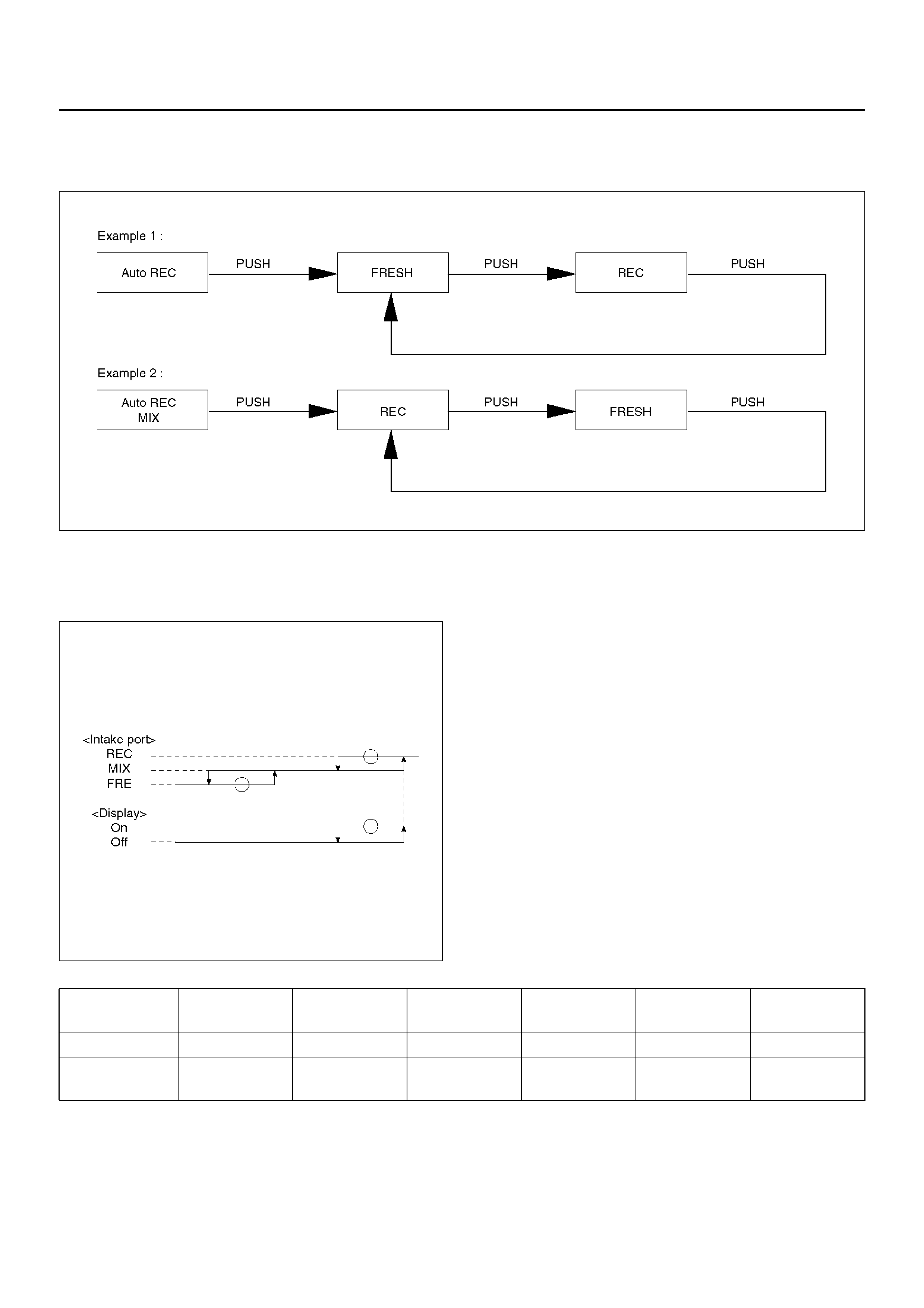

Intake Switch

Pressing this switch sequentially selects a different

intake port in the following order.

F01RX005

Indication

• The Auto LED maintains unaffected.

• Currently selected intake port is indicated.

F01RX007

Fan Switch

1. Sets the fan to the specified mode.

2. Even when the fan switch is turned off, status

displa y for the Mode, Intake an d Cold Air Bypass is

maintained.

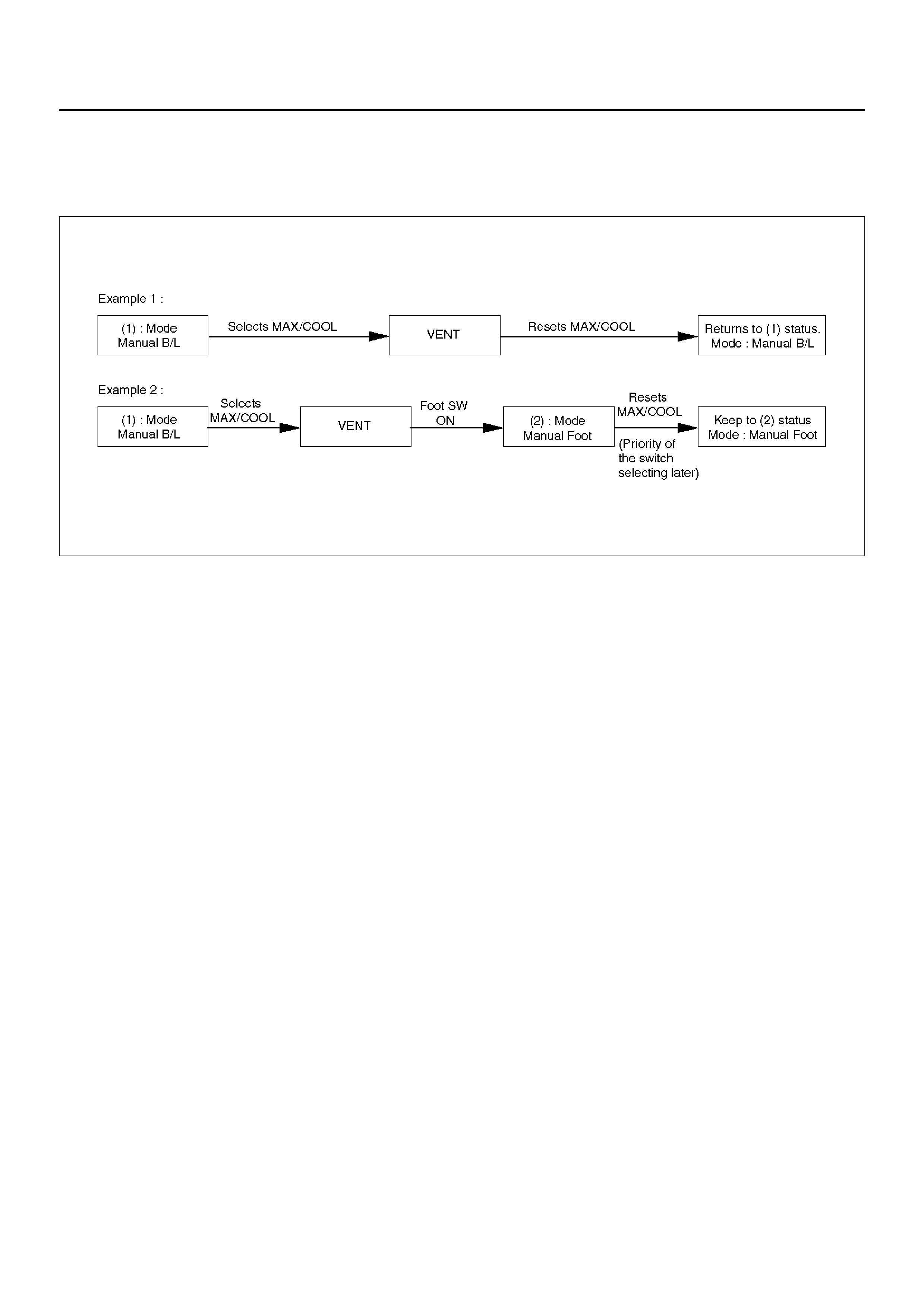

Temperature Control Knob

1. This knob is operable only when the fan is turned

on. It may be used for the MAX control of each

block except the fan.

2. When the manual mode is selected for the fan

control, this manual mode is maintained.

MAX Control Mix Fan Mode Intake Cold air

bypass A/C

MAX/COOL Full cool MAX/HI VENT REC*1 OPEN*2 ON mode*3

MAX/HEAT Full hot AUTO/HI FOOT*4 FRESH CLOSE Current status

is maintained

*1: In the A/C: OFF mode, FRESH shall be selected.

*2: When the fan is turned ON, CLOSE shall be

selected.

*3: The O N m ode is av ai lab le onl y wh en ON i s se lec ted

for the fan as well as for the cold outside air ON/OFF

selection.

*4: When the MAX control is selected from the DEF

mode, this DEF mode shall be maintained.

F01RX008

Indication

• As long as the MAX control is selected, the

immedi ately preced ing indic ation shall be maintained

for the AUTO.

• Status display is provided for others.

Air Conditioning Switch

Pressing this switch turns on or off the A/C (air

conditioning) control. (The compressor remains turned

off if the fan is turned off and also the compressor has

been turned off because of the given outside air

temperature level.)

Indication

1. The A/C LED remains turned on even if the

compressor has been turned off because of the

given outside air temperature level. In this case,

however, the AUTO or DEF switch must be turned

on and the A/C ON mode must also be turned on

(by the MAX/C mode).

2. Pressing the A/C switch from the above state (1)

turns off the A/C LED.

OVERVIEW OF CONSTRUCTION, MOVEMENT AND CONTROL OF MAJOR

PARTS OF AUTOMATIC AIR CONDITIONER SYSTEM

Automatic Air Conditioner Control Unit

Equipped with the built-in micro-computer, this control

unit oper ates on signa ls from sensors an d input si gnals

from switches to offer total control of the blower fan, and

actuators used for the mode door, intake door and air

mix door.

Its self-diagnosis function enables quicker access to a

failed part and its more accurate troubleshooting.

In Car Sensor

It is a sensor used for detecting room temperature of a

vehicle. This sensor converts a given room temperature

into a resistance value before entering the data to the

automatic air conditioner control unit.

This in car sensor unites the power driven aspirator and

the motor fan so that a small amount of room air may be

constantly fed to the sensor.

This sensor is provided on the control panel.

865RX015

EndOFCallout

Ambient Sensor

This sensor is used for detecting temperature outside

the vehicle . It converts a give n outside air temperat ure

into a resistance value before entering the data to the

automatic air conditioner control unit.

Therma l effects from the co ndenser and radiato r during

idling after a run can be measured and offset the

automatic amplifier.

This sensor is provided on the side plate situated at

upper right side of the condenser.

875RY00021

EndOFCallout

Duct Sensor

The duct sensor is the sensor to detect temperature

change of the side of evaporator blower coming by fresh

recirculation of intake door or “on" “off" of compressor.

The temperature is converted to resistant rate.

And it works as thermostat to control to prevent freezing

of evaporator.

This sensor is installed in the upper case of evaporator.

874RX014

Legend

(1) In Car Sensor

(2) Automati c Air Conditi one r Cont rol Unit

Legend

(1) Ambient Sensor

Legend

(1) Eva por ato r Core

(2) Duct Sensor

(3) Lower Case

(4) Upper Case

Sun Sensor

It is a photodiode used for detecting quantity of solar

radiation. This sensor converts the offset signal

generated by changes in the interior temperature (which

results from fluctuations in solar radiation) into

photoelectric current to enter into the automatic air

conditioner control unit.

This sensor is provided at top of the defroster grill.

865RW009

EndOFCallout

Power Transistor

Receiving base current from the automatic air

conditioner control unit, the power transistor implements

stage-less speed chang e of the blower fan motor. Th is

transistor is provided on the evaporator.

874RX031

Max Hi Relay

This relay turned on or off by the signal from the

automatic heater/air conditioner control unit. As the

Max Hi relay is turned on, supply voltage is directly fed

to the blower fan motor to select the Max Hi mode.

860RW028

EndOFCallout

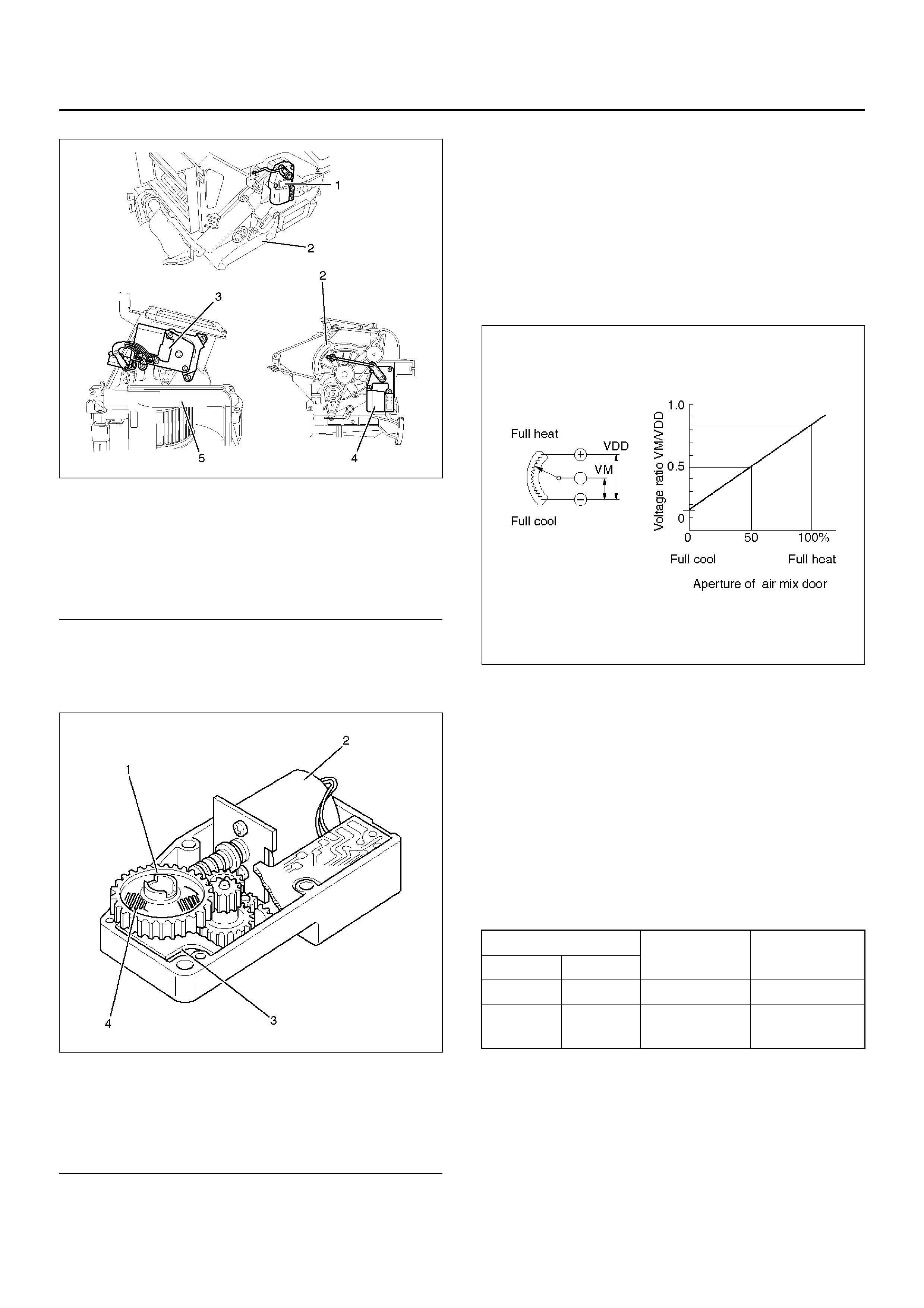

Actuator

The a ctuators are po wer driven type containing a sma ll

motor. Receiving output current from the automatic air

conditioner control unit, actuators drive the heater and

blower unit mode doors.

Actuators consist of the mode actuator used for

switching the mode (blow port selection), the mix

actuato r used f or chang ing apertur e of the ai r mix door,

the intake actuator used for switching the intake

mode(fresh air/interior air) and the cold air bypassing

actuator.

Legend

(1) Sun Sensor

Legend

(1) Evaporator Assembly

(2) Power Transistor

Legend

(1) Blower Unit

(2) Max High Relay

860R100001

EndOFCallout

The actuator changes the motor speed using the gear

and drives each door rotating the output axis united with

the sliding contact.

860RW026

EndOFCallout

The mode and mix actuators are common actuators

with the built-in potentiometer. For the intake actuator,

the contact switch type is selected.

The potentiometer is a register assembled to the printed

circuit board of the mix and mode actuators. It detects

the air mix door position specified by rotation of the

output axis as a ratio of the variable terminal (VM)

voltage against the reference voltage (VDD: 5V), then

signals the value to the automatic air conditioner control

unit.

C01RX016

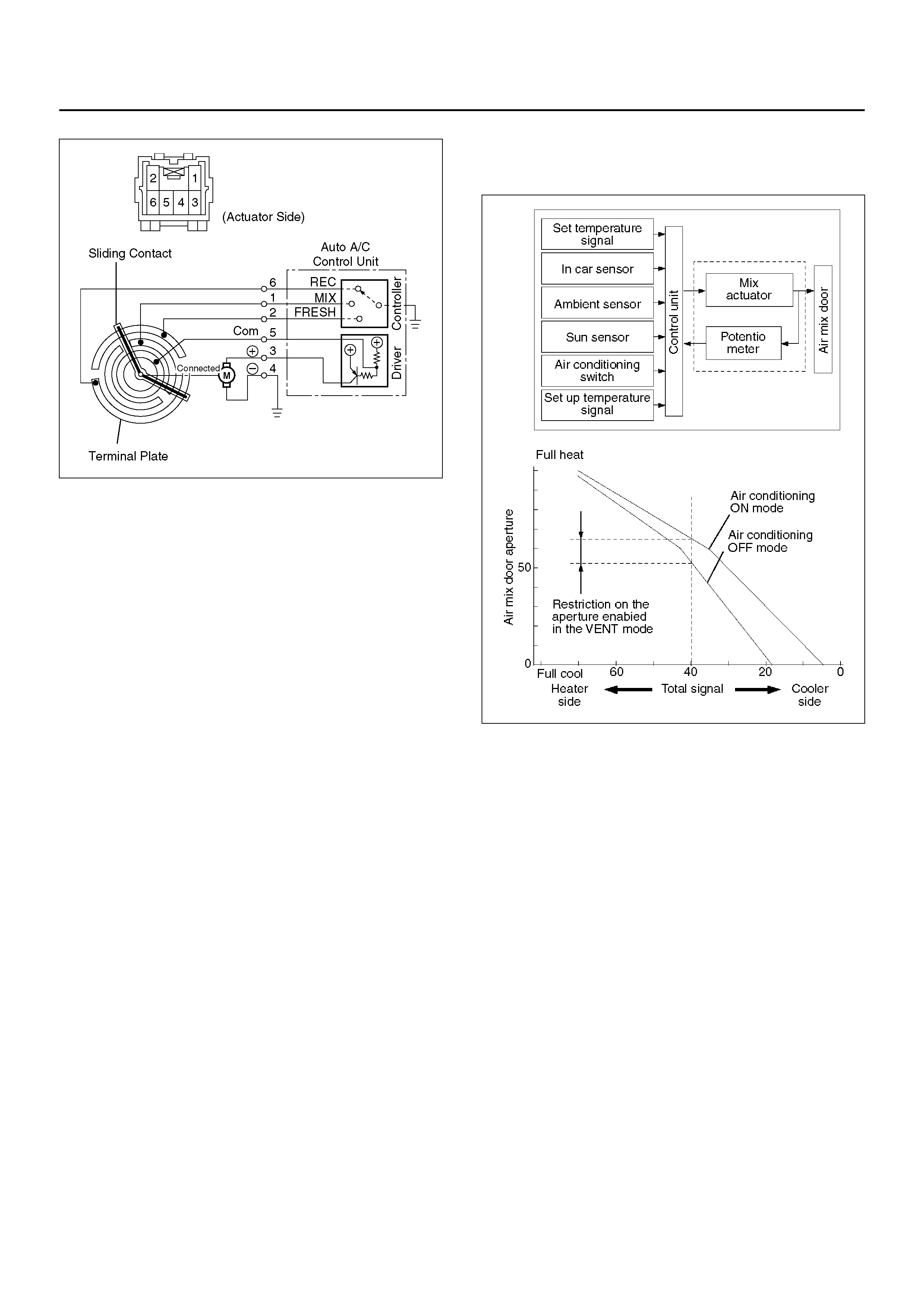

Movement of Mix Actuator

Position of the air mix door is determined by the

controller on the automatic heater/air conditioner control

unit.

As the heat or cool side of the controller is grounded,

the transistor on the driver is activated and, thus, the

motor rotation is turned on. The sliding contact

connected to the motor sends the position detection

signal from the potentiometer to the automatic air

conditioner control unit. As the set temperature and

interior temperature ar e balanced, the con troller retur ns

to the neutral and the motor rotation is stopped.

Legend

(1) Mix Actuator

(2) Heater Unit

(3) Intake Actuator

(4) Mode Actuator

(5) Blower Unit

Legend

(1) Output Axis

(2) Motor

(3) Printed Circuit Board

(4) Sliding Contact

C-45 Rotation

direction Remarks

(+) side (-) side

8 6 Clockwise Full heat side

68Counter

clockwise Full cool side

C01RX005

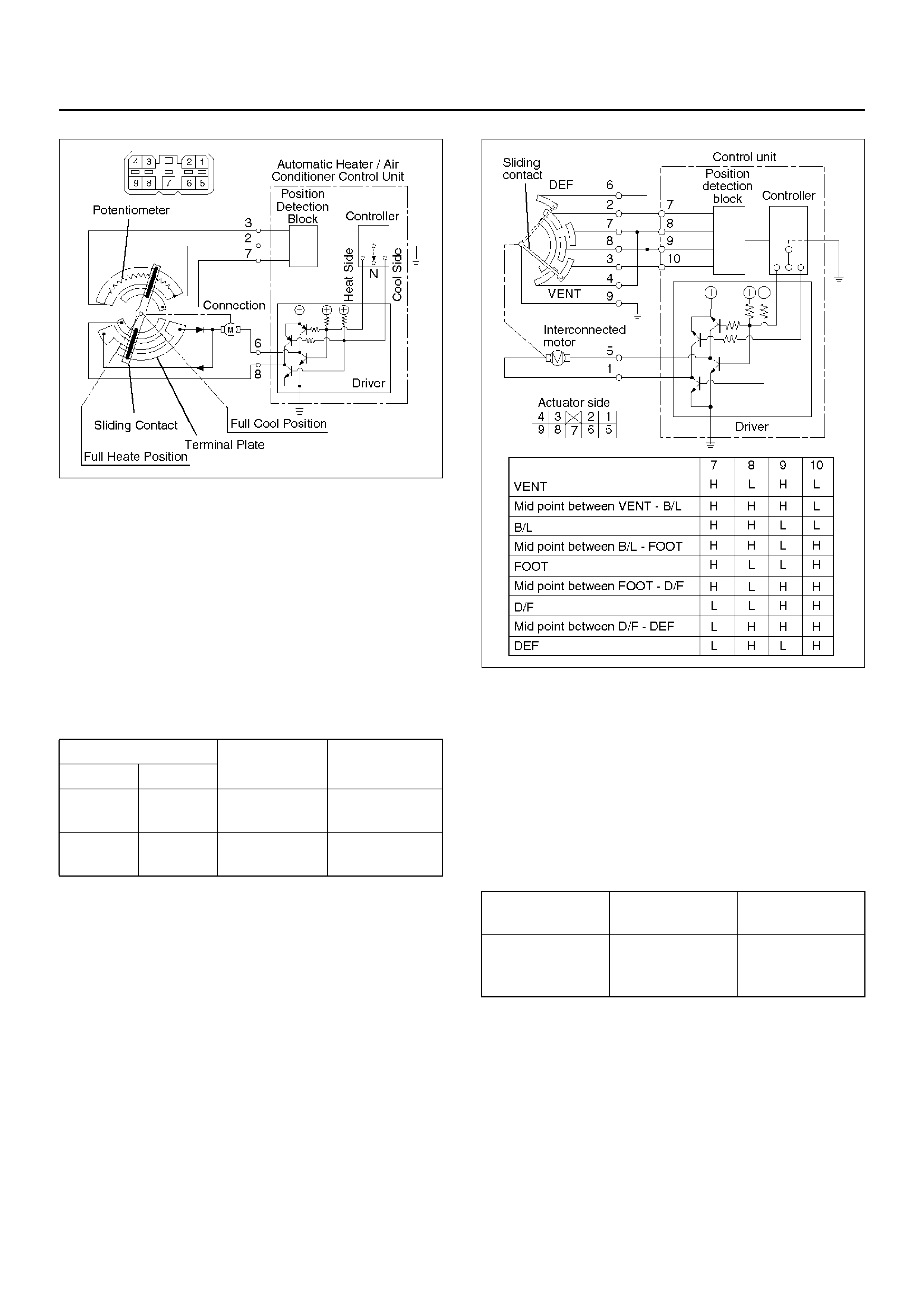

Movement of Mode Actuator

As target position of the mode door is decided on the

controller of the control unit, the control unit reads the

position detectio n signal from the actuator to select the

clockwise or counter clockwise motor rotation direction.

Grounding the controller VENT or DEF side after the

directi on selection a ctivates the trans istor on the dri ver,

thus turning on the motor rotation. Accompanying the

motor rotation, the sliding contact rotates, too. When

the target position is reached, the controller on the

control unit returns to the neutral and the motor stops.

C01RX017

Movement of Intake Actuator

The controller on the automatic air conditioner control

unit selects an intake mode to be used.

As the Terminal No.5 C65 is grounded via the sliding

contact on the terminal plate, the transistor on the driver

is activated, thus turning on the motor rotation. Then,

accompanying move of the motor, the sliding contact

rotates until grounding of the Terminal No.5 C65 is

removed, thus stopping the motor.

Conduction pin Rotation

direction Remarks

(+) side (-) side

5 1 Clockwise VENT to DEF

direction

1 5 Counter

clockwise DEF to VENT

direction

Grounding

terminal Rotation

direction Remarks

No.5 C-65 Clockwise RE-CIRCULATI

ON→MIX→FRE

SH

C01RX006

OVERVIEW OF AUTOMATIC

CONTROL OF AUTOMATIC AIR

CONDITIONER

The auto mati c heater a nd a ir c ond itio n er on thi s ve hic le

has the following features:

• Interior temp er ature contr ol .

• Air flow control.

• Mode (blow port) control.

• Intake (switching between fresh air and interior air)

control.

• Heater start timing control.

• C o ole r start timing control .

• Compressor ON/OFF function according to outside

air temperature level.

• Evaporator anti-freeze control.

Interior Temperature Control

The automatic air conditioner control unit operates on

the setup temperature signal from the temperature

control switch and other sensor signals to derive the

total signal. Then, the cont rol unit c ompares this sig nal

against the signal from the potentiometer to determine

rotation direction of the mix actuator. The mix actuator

moves the air mix door to the aperture specified by the

total signal so that the specified interior temperature is

achieved.

If the compressor is turned off in the A/C (air

conditioning) mode, aperture of the air mix door is offset

according to the outside air temperature or the specified

interior temperature. This function removes the

difference in the blowing temperature in this state and

that of when the compressor is turned on.

When FH or FC is selected for the setup temperature,

the air mix door is accordingly fixed to the Full Heat or

Full Cool mode.

When the VENT mode is selected, aperture of the air

mix door is controlled so that excessively heated air

may not be blown from the VENT blow port.

C01RY00015

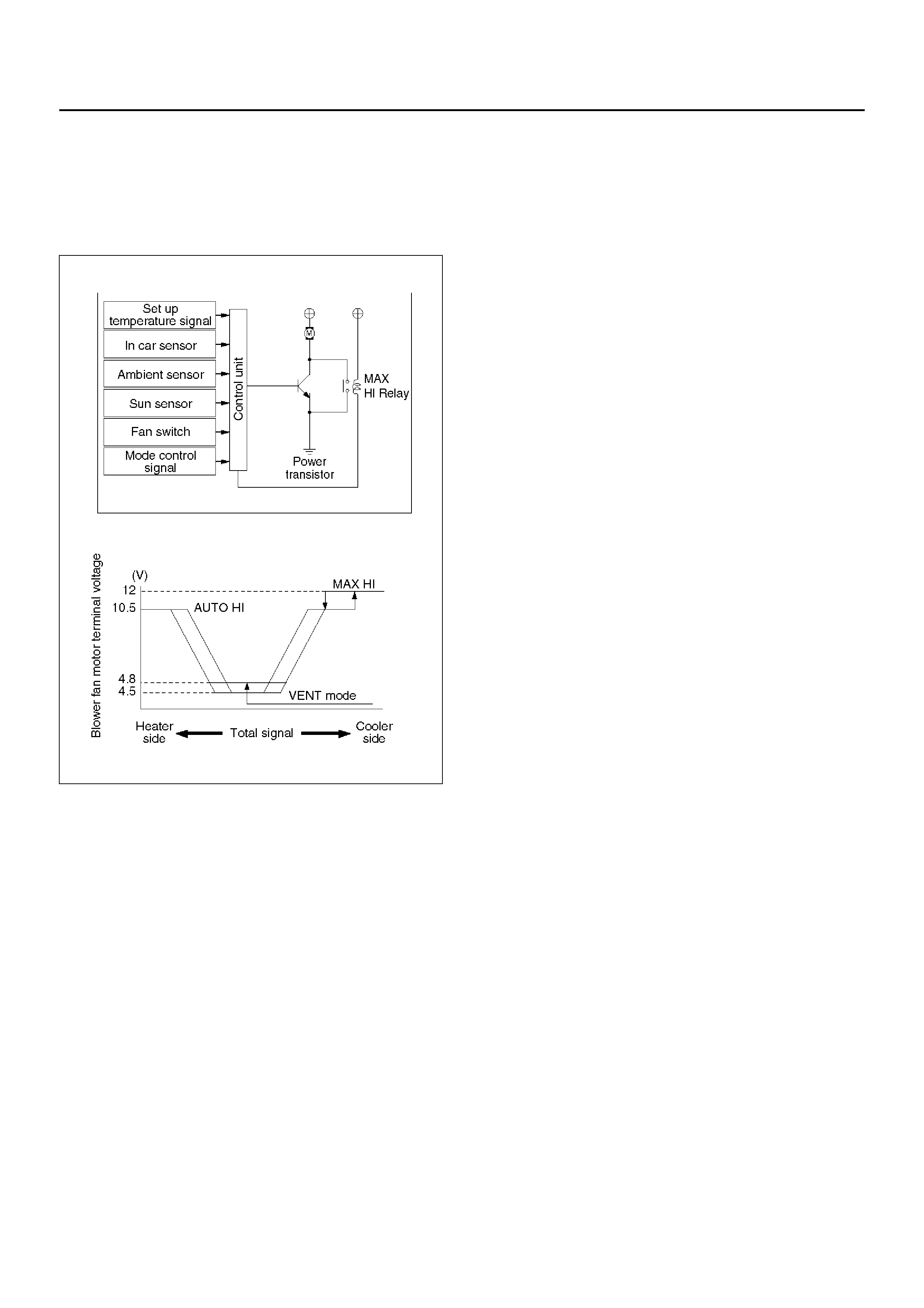

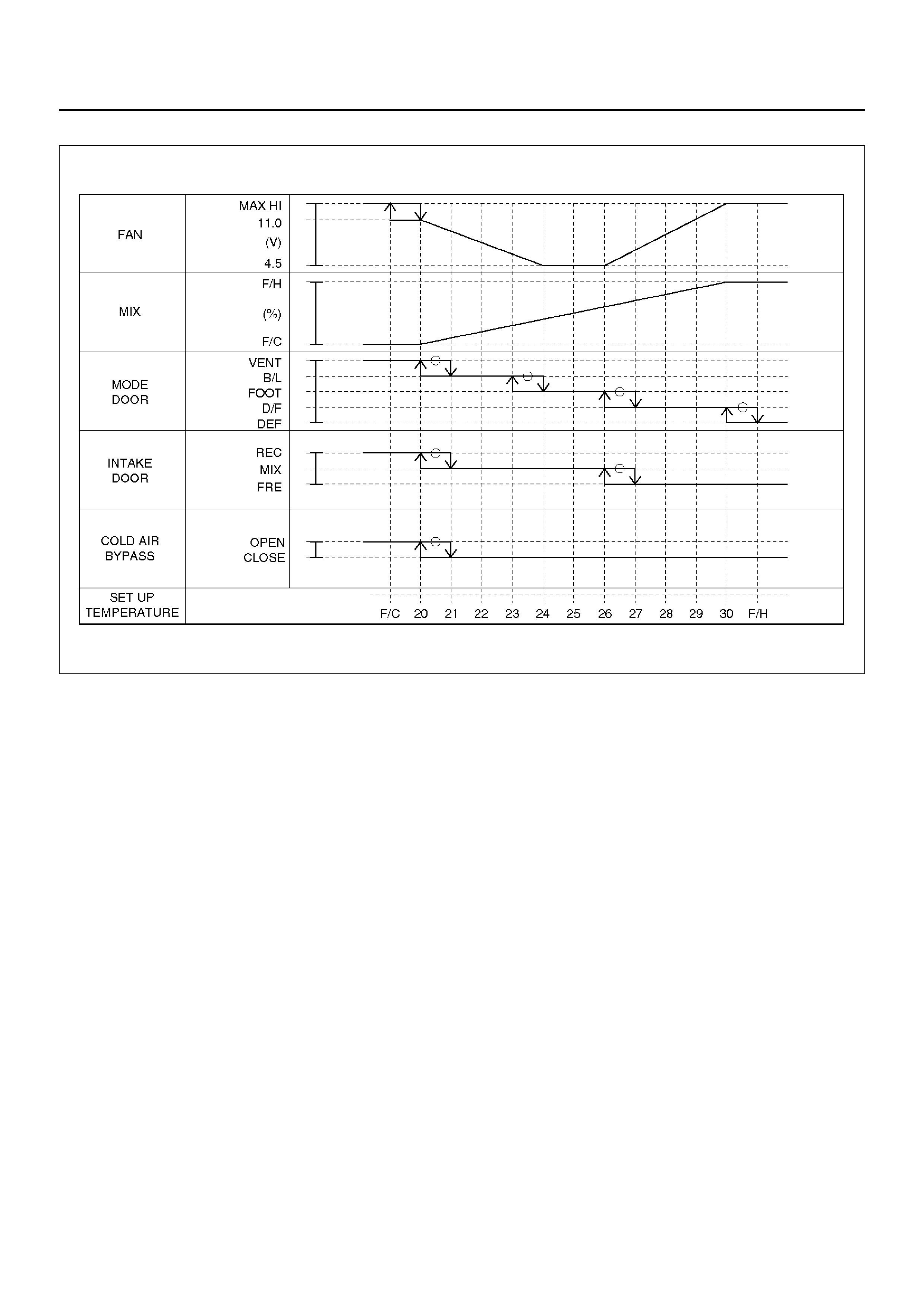

Air Flow Control

In t he Auto Mode

• The automatic air conditioner control unit operates on

the setup temperature signal and other sensor

signals to derive the total signal. Then, the control

unit adjusts base potential of the power transistor to

match it to the voltage pattern of the target fan so that

stage-less fan speed control can be achieved.

When solar radiation quantity is detected in the VENT

or B/L mode, the control unit increases the minimum

fan voltage to offset.

When FH or FC is selected from the temperature

control s witch, a ir flow i s accor dingly f ixed t o MAX H I

or AUTO HI.

In the Manual Mode

• Air flow specified from the fan switch is entered to the

automatic air conditioner control unit as the manual

signal. The signal modifies the air flow to the level

specif ied from t he fan s witch s o that the required fan

voltage is attained.

C01RY00008

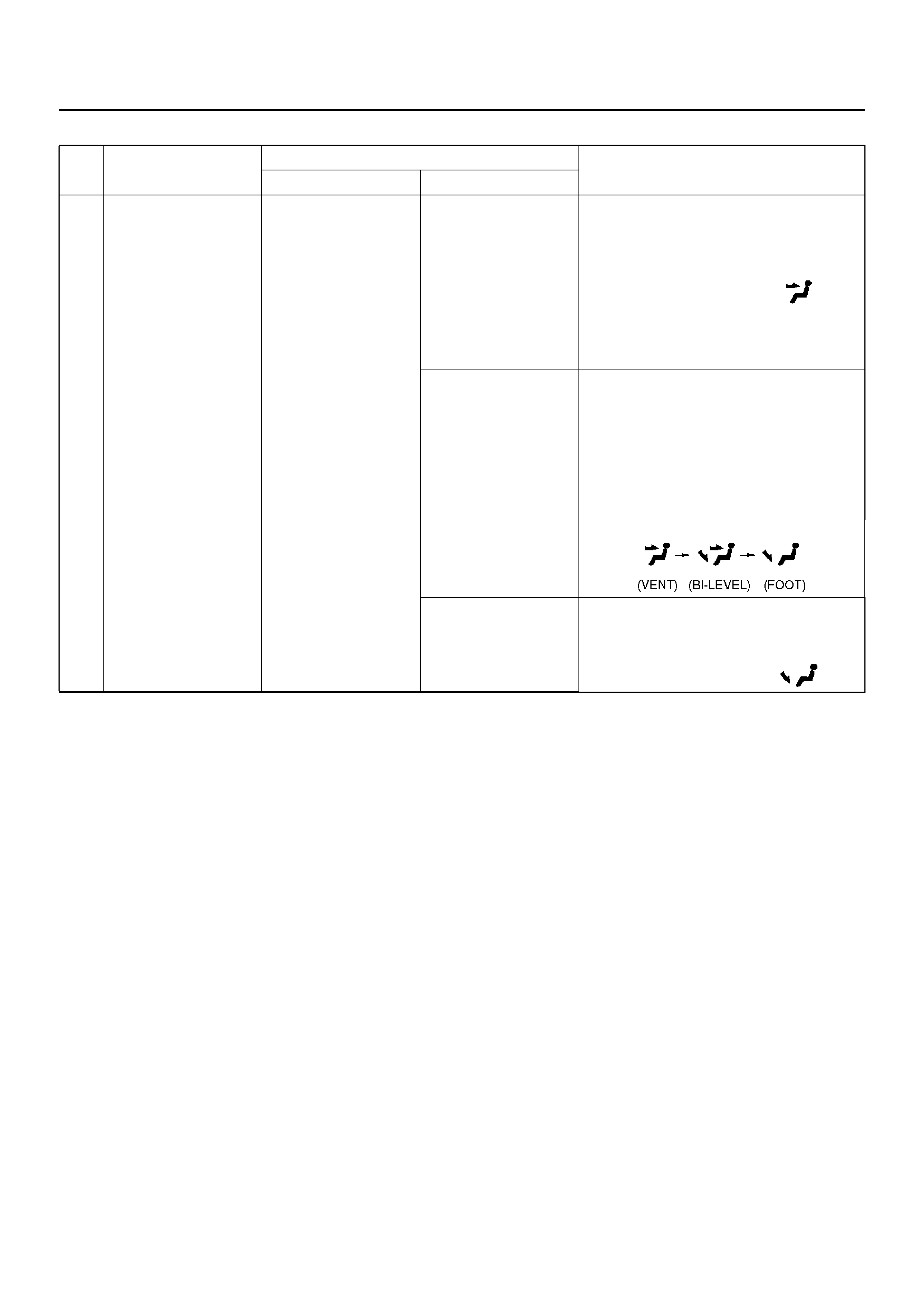

Mode (Blow Po rt) Control

The automatic air conditioner control unit operates on

the setup temperature from the control switch, and

temperature and solar radiation quantify from the

sensors to determine the total mode control signal.

According to the pattern specified by this signal, the

control unit selects either one of the VENT, BI-LEVEL,

FOOT or DEF/FOOT mode.

The mode actuator determines the rotation direction

comparing the target position against the current

position being determined by the position detection

signal.

When FH or FC is selected for the temperature from the

temperature control switch, mode is accordingly fixed to

the VENT or FOOT.

• In the manual oper ation of the mode switc h, you can

select a desired blow port mode pressing the

corresponding mode switch.

• Operating the DEF mode switch selects the DEF for

the blow port mode.

C01RY00009

Intake (Fresh air/interior air switching)

Control

In the Full Auto mode, the automatic heater/air

conditioner control unit operates on the setup

temperature signal and other sensor input signals to

derive the total signal. According to the pattern

specified by this signal, the control unit provides the

intake control.

When the fan is turned off or the A/C (air conditioning) is

turned off, the intake is fixed to the FRESH mode.

When FC or FH is selecte d from the contro l switch, the

intake mode is accordingly fixed to the RECIRC or

FRESH.

In the Manual Operation

• Pressing the FRESH (fresh air intake) or the RECIRC

(room air circulation) accordingly selects t he FRESH

or RECIRC mode.

When the DEF Mode Switch is depressed

• The intake mode is fixed to the FRESH. When the

MANU REC is selected, however, the mode is fixed

the RECIRC.

When the Mode Switch is depressed

• If the automatic intake control is selected, the intake

is fixed to the currently selected mode.

C01RY00012

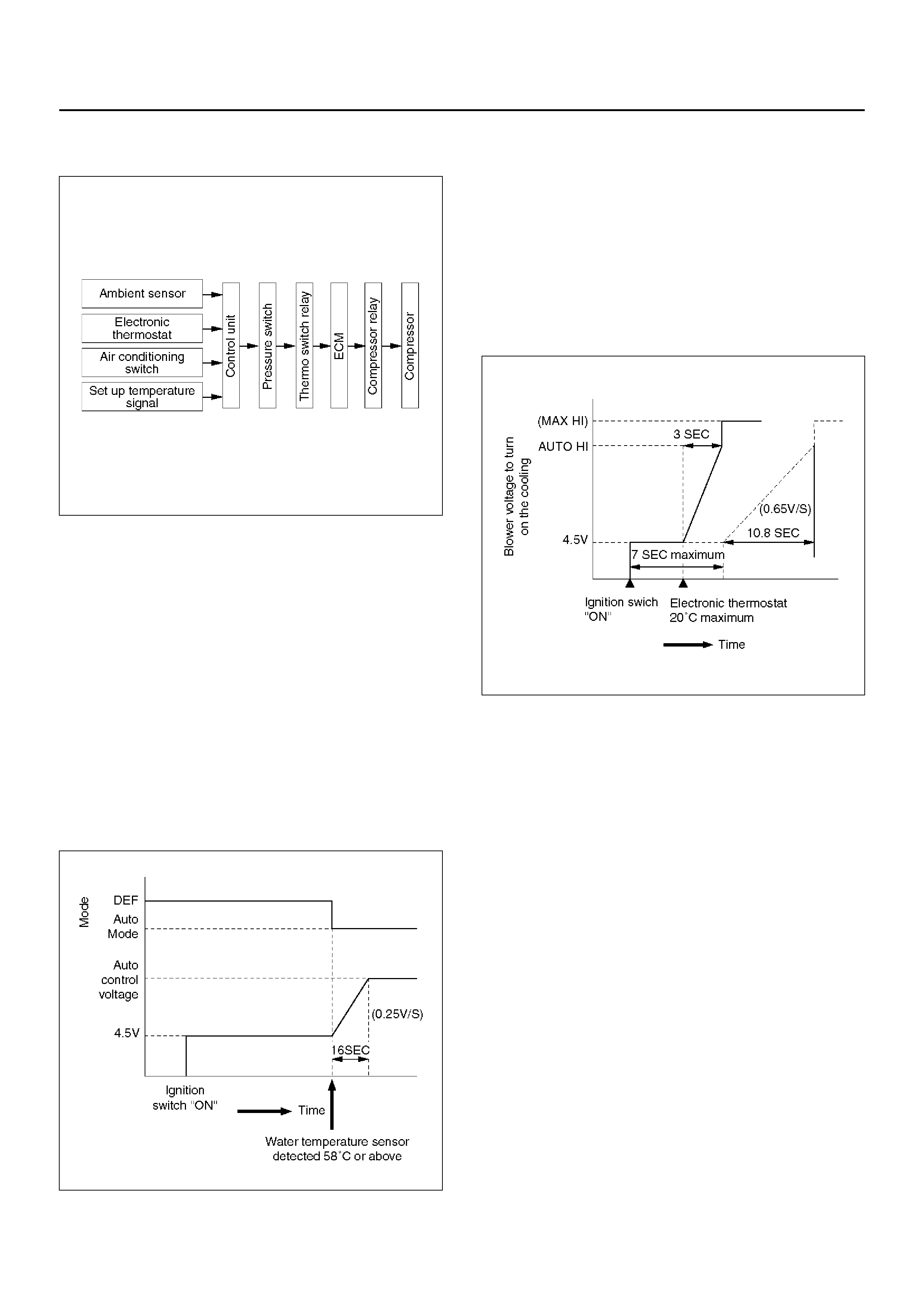

Compressor Control

In the automatic control mode, the automatic air

conditioner control unit turns on or off the compressor

with the evaporator anti-freeze mechanism using the

evaporation sensor. And, when outside air is detected

to be low through the outside air temperature sensor

signal, the control unit turns off the compressor using

the compressor control function.

Manual Control

• In the automatic control mode, pressing the A/C (air

conditioning) switch turns off the compressor.

• Pressing the DEF mode switch automatically turns on

the compressor.

C01RY00010

Heating Start Timing Control

When th e auto mat ic air c ond iti one r is s tarted , hea tin g is

turned on only when the coolant temperature detected

by the coolant temperature sensor is 18°C or less and

total signal derived from the sensor signals has

detected that the heating condition is met.

If the coolant temperature detected by the sensor is

18°C or less, 4.5V is set for the blower fan motor

terminal voltage and the DEF is selected for the blow

port mode.

When the tempe rature detect ed by the sensor is ab ove

18°C, the blow port mode is switched to the Auto

Control and the voltage across the blower fan motor

terminal is linearly increased from 4.5V to auto control

voltage (auto airflow).

840RX015

Cooling Start Timing Control

Whe n the aut omatic air con dit ioner is started, cooli ng is

turned on only when the temperature detected by the

interior temperature sensor is 30°C or above and the

total signal derived from the sensor signals has

detected that the cooling condition is met.

When the cooling condition has been met, the fan

voltage across the blower fan motor terminal is set to

4.5V for 7 seconds maximum, then it is linearly

increased up to the auto airflow level at the rate of 0.6V/

sec.

C06RX003

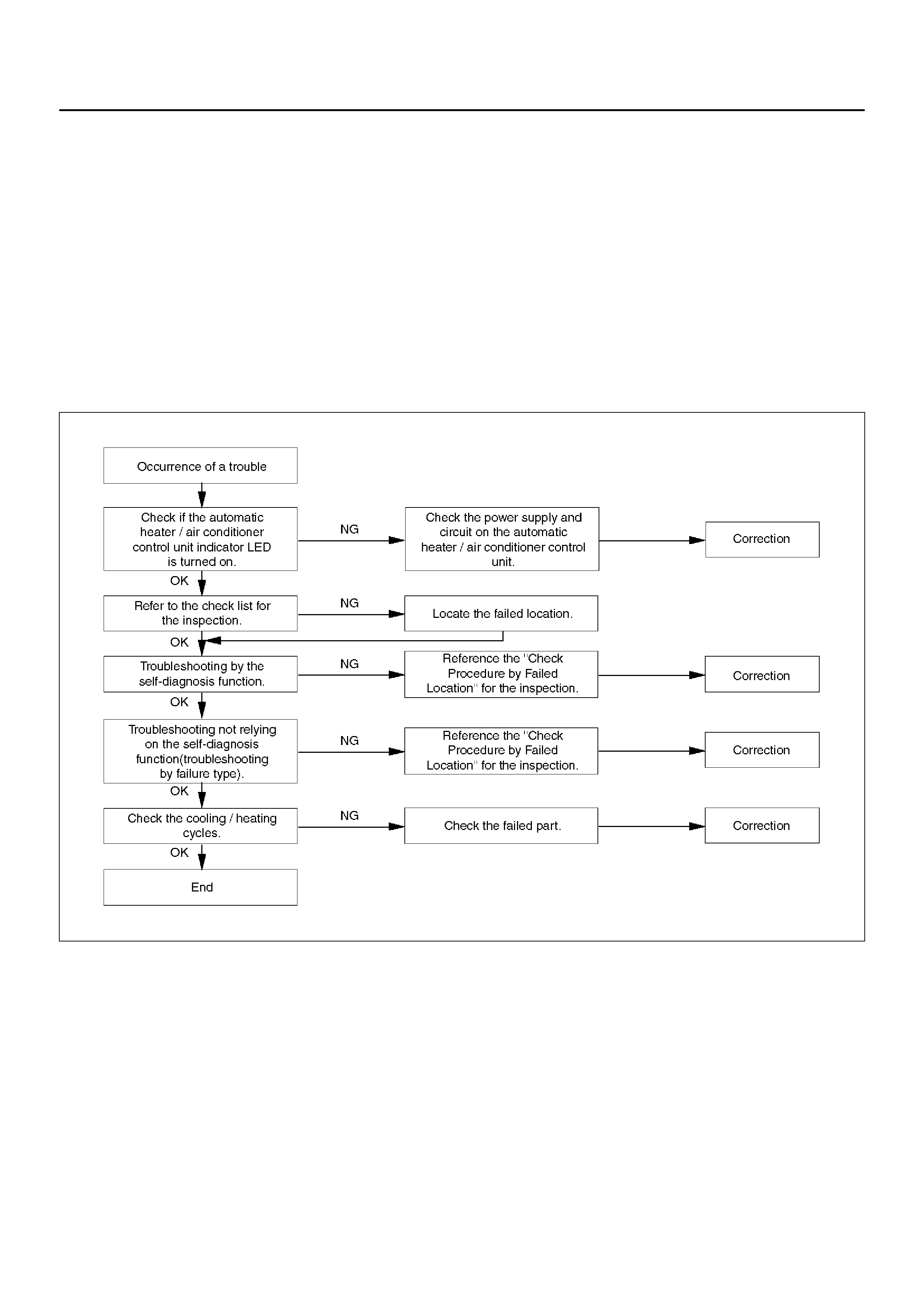

TROUBLESHOOTING

TROUBLESHOOTING, ITS OVERVIEW AND PROCEDURES

The automatic heater and air conditioner equips with the

“Self-Diagnosis Function" to check its major

components.

This function makes access to the sensors, actuators

and blower fan motor system easier when checking

them up and, when a failed part is located, thi s function

restores its original performance.

When implementing the troubleshooting, this

self-diagnosis function narrows the range to be

searche d at th e fi rst s tep, t hen check rele va nt parts one

by one according to the “Checking Procedures by

Failed Location". As for a location this function is

unappreciable, the system accurately determines

characteristics of a given trouble and checks relevant

parts according to the “Checking Procedures by Failed

Location".

The following illustrates basic troubleshooting flow.

Basic Troubleshooting Flow

F01RX009

AUTO AIR CONDITIONER CONTROL UNIT POWER SUPPLY DIAGNOSIS

This check is required because a trouble on the auto

amplifie r (contr ol unit) powe r suppl y circu it or ground ing

circuit prevents accurate troubleshooting.

D08R100120

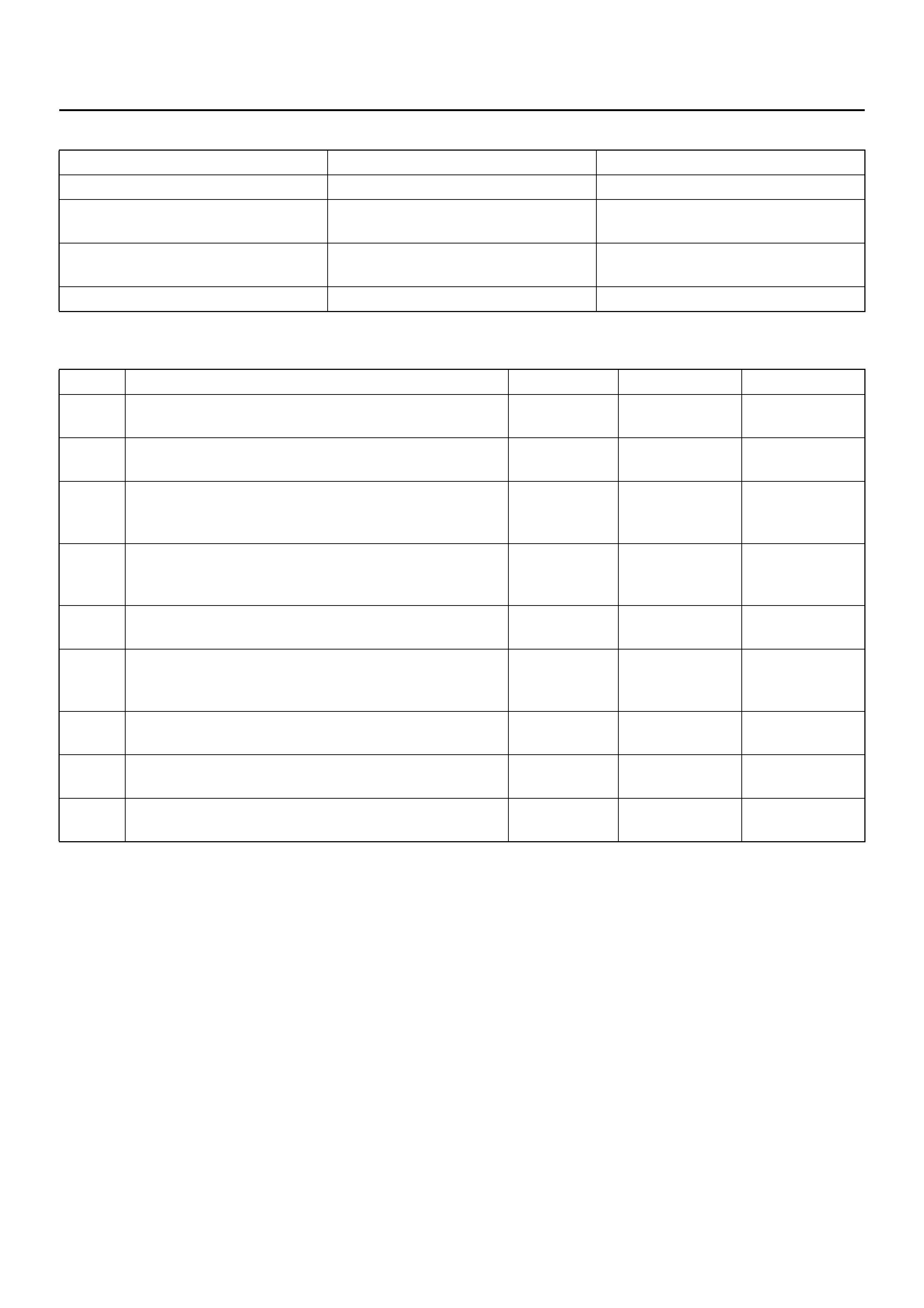

Condition Possible cause Correction

Power source does not supply to

auto air conditioner control unit. — Refer to Chart A

Chart “A": Check of Auto Amplifier Power Supply System

Step Action Value(s) Yes No

1 Is the fuse C–5 normal? — Go to Step 2 Replace the

fuse

2 Is the fuse F–5 normal? — Go to Step 3 Replace the

fuse

3 Disconnect the auto A/C control unit connector I–20.

Is the battery voltage applied between the harness

side connector terminal No.I20–8 and the ground? Approx. 12V Go to Step 5 Go to Step 4

4 Repair an open circuit between the fuse C–5 and

terminal No.I20–8.

Is the action complete? — Go to Step 4 —

5 Is there continuity between the harness side

connector terminal No.I20–16 and the ground? — Go to Step 7 Go to Step 6

6 Repair an open circuit between terminal No.I20–16

and the ground No.B–6.

Is the action complete? — Go to Step 5 —

7 Is there continuity between the harness side

connector terminal No.I20–9 and the ground? — Go to Step 9 Go to Step 8

8 Repair an open circuit between terminal No.I20–9 and

the ground No.B–8.

Is the action complete? — Go to Step 7 —

9 Turn the lighting switch on.

Is the battery voltage applied between the harness

side connector terminal No.I20–10 and the ground? Approx. 12V Go to Step 11 Go to Step 10

10 Repair an open circuit between the lighting switch and

terminal No.I20–10.

Is the action complete? — Go to Step 9 —

11 Turn the starter switch on.

Is the battery voltage applied between the harness

side connector terminal No.I20–7 and the ground? Approx. 12V — Go to Step 12

12 Repair an open circuit between the fuse F–5 and

terminal No.I20–7.

Is the action complete? — Verify repair —

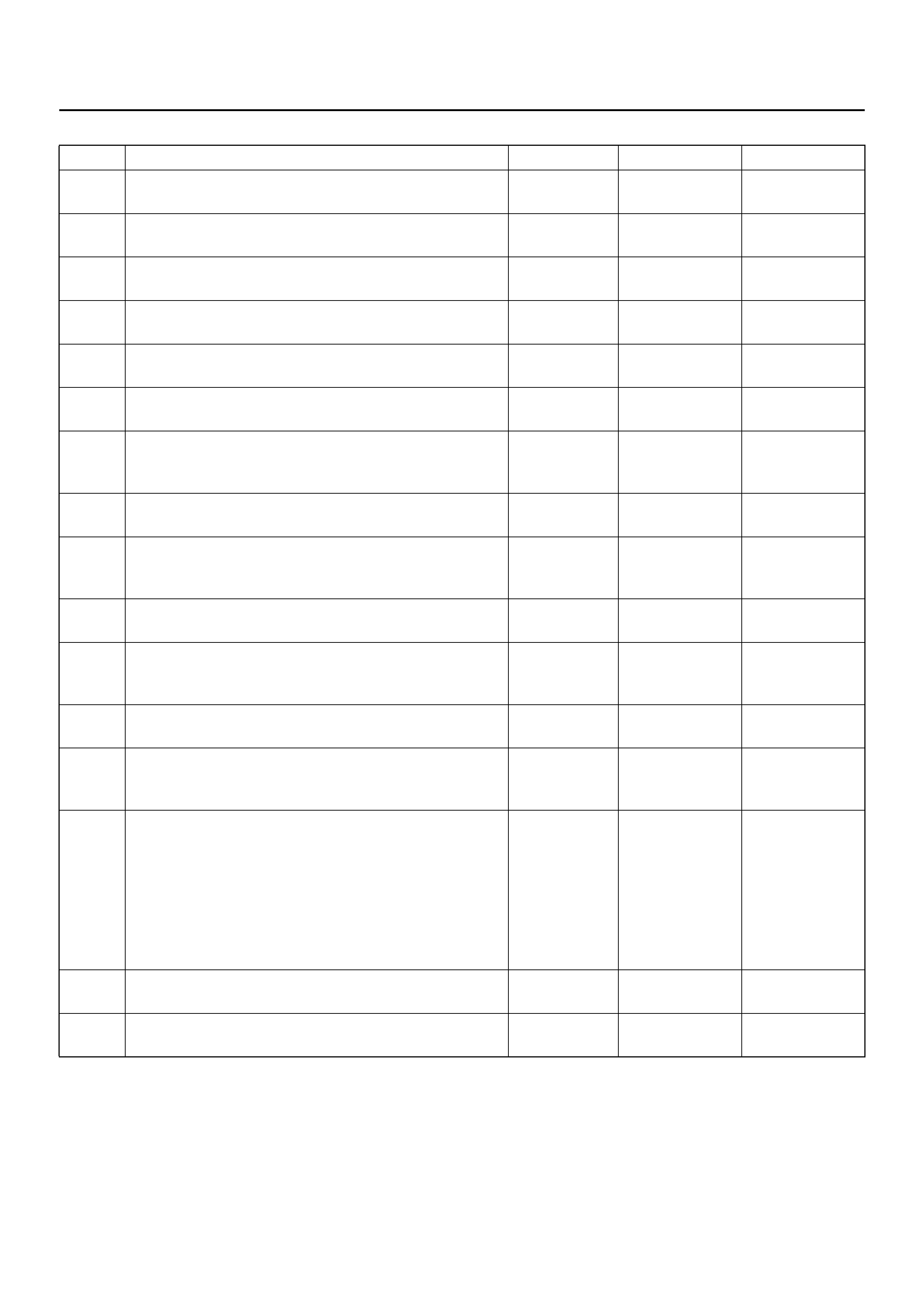

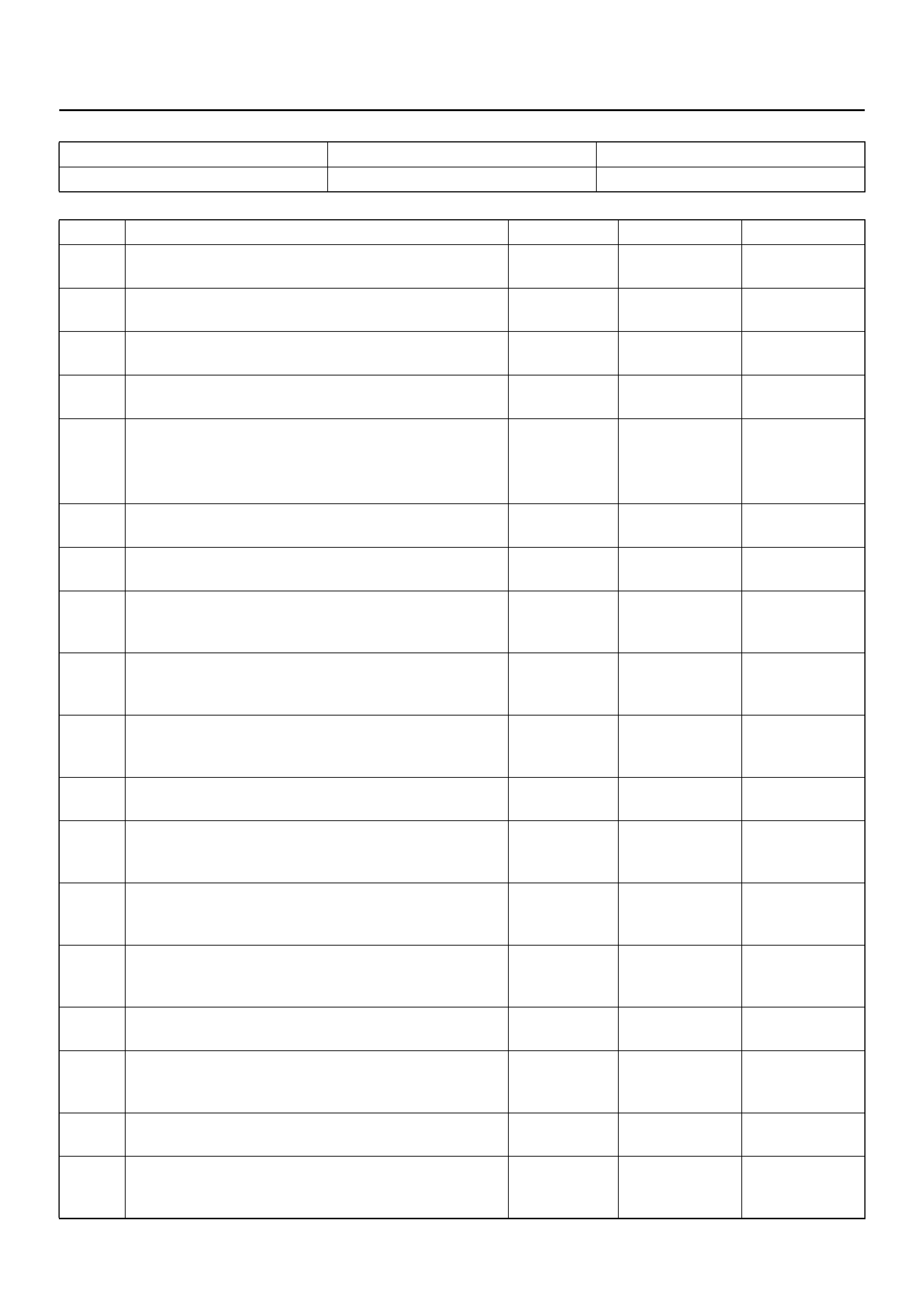

PERFORMANCE AND MOVEMENT CHECKLIST FOR AUTOMATIC AIR

CONDITIONER RELATED PARTS

Start the engine, and when the eng ine coolant reached

50°C check performance and movement of the related

parts accordin g the following checklist.

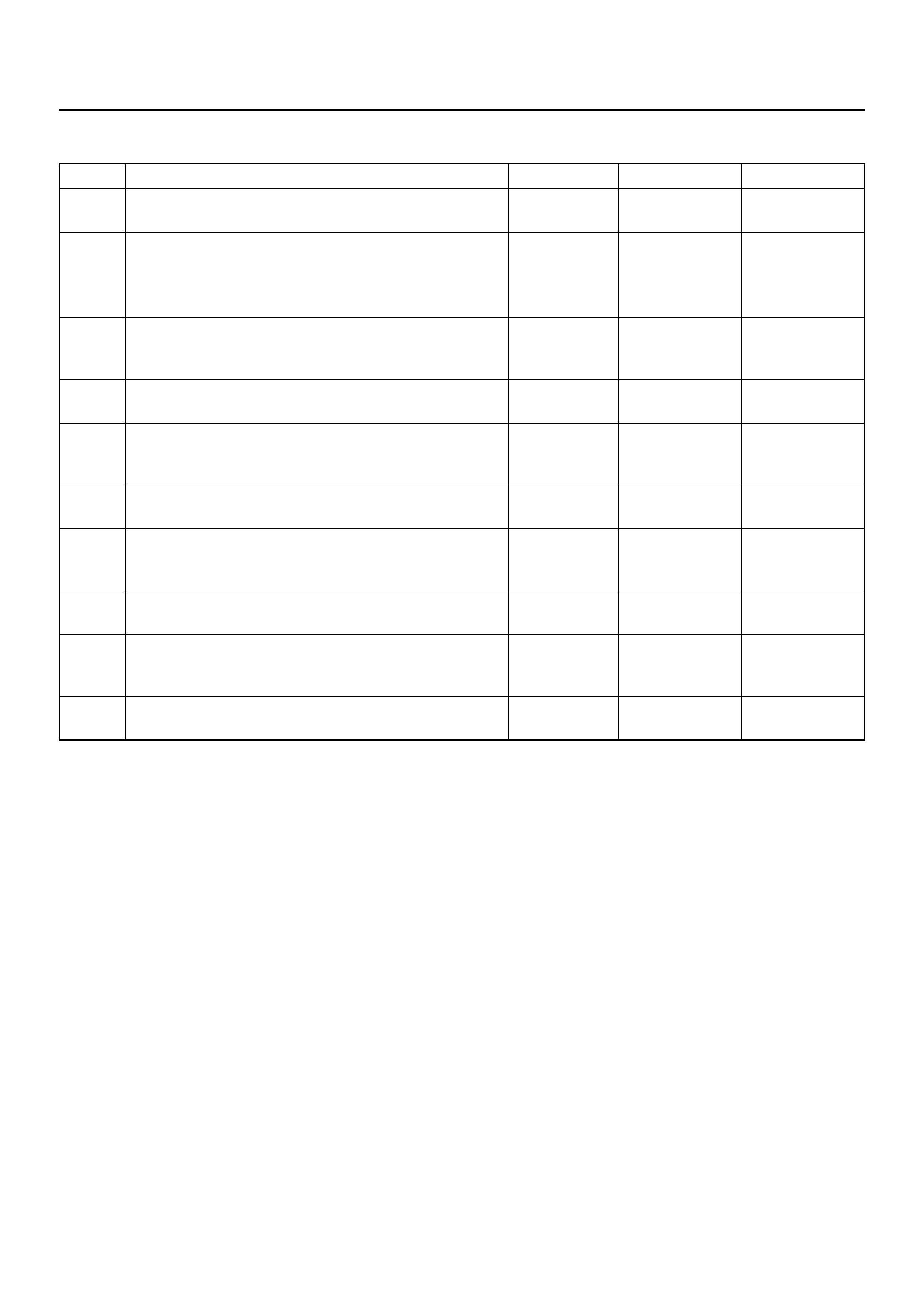

Performance Check Using the Manual Switch

No. Item Checking Approach Acceptance criteria

Condition Operation

1

Blowing

temperature

(check movement

of air mix door)

Auto switch must be

turned on (FAN-

AUTO MODE-AUTO)

1. Select FC for the

setup temperature.

2. Select FH for the

setup temperature.

→ Then, select the

MAX Control.

1. Cold air shall be blown out.

2. Hot air shall be blown out.

2

Airflow volume

(check movement

of the mode door)

Set temperature to

25.0°C. 1. Turn the fan knob

off.

2. Turn the fan knob

from LOW to HI.

1. The fan shall be stopped, thus

stopping air blow, too.

2. Airflow volume shall change

from LOW to HI.

3

Blowing

temperature

(check movement

of the mode door)

Set temperature to

25.0°C. Set the fan

knob to HI.

Press the mode switch

to change the blow p ort

mode sequentially from

the VENT through

BI-LEVEL, FOOT up to

DEF.

LED corresponding to each mode

shall be t urned on and the blow port

mode shall be switched smoothly.

4

The inter i or/outsid e

air switching mode

(check movement

of intake door)

Set temperature to

25.0°C. Turn the LED off using

the interior/outside air

switch (this introduces

the outside air intake

mode). Then, the set

fan knob to HI and

press the interior/

outside switch to turn

on the LED.

The LED indication shall be switched

from OFF to ON accompanying a

change in air blowing sound.

5

Compressor Set the temperature to

18.0°C (FC). (Outside

air temperature is 0°C

or above and interior

temperature at ordinary

temperature.)

Press the “ O FF" switch.

1. Press the Auto

switch.

2. Press the Air

Conditioner switch.

1. As the fan knob is set to the Auto

position, the A/C switch LED

shall come on and the

compr essor shall be turned on.

2. As the A/C LED comes off, the

compr essor shall be turned off.

Check of Auto Function

No. Item Checking Approach Acceptance criteria

Condition Operation

1 Auto function FAN KNOB “AUTO"

MODE SW “AUTO"

Select FC for the

temperature.

The LED shall come on.

Cold air shall be blown out.

The following LEDs shall come on:

• B low por t mode :

• Intake mode

• Fan speed: MAX

Hi

•A/C

Change the

temperature

gradually starting

with 18°C up to

32°C.

The following phenomena shall be

recognized.

• Temperature of blown air: Cold air is

changed to hot air.

• Change in the air flow volume.

• The blow port mode LED indication

changes in the following sequence:

Select FH for the

temperature.

Cold air shall be blown out. The

following LEDs shall come on.

• B low por t mode :

• Fan speed: Max.

TROUBLESHOOTING WITH SELF-DIAGNOSIS FUNCTION

Overview of Self-Diagnosis Function

The self-diagnosis is implemented in 3 steps for each

target. For detail of check procedure contained in each

step, refer to the relevant section of “Check Procedure

by Failed Location" listed in the Self-Diagnosis

Operation Procedure.

For turning on the self-diagnosis function and switching

of the check step, refer to the flow chart given below.

You can reset the self-diagnosis function by turning the

ignition switch off or turning the DEF switch on for 5

seconds.

Self-Diagnosis Operation Procedure

Step Action Value(s) Yes No

1 1. Set the IG to the OFF position.

2. Apply 60W bulb light to the solar radiation sensor.

3. Set the temperature setting lever on the automatic

heater/air conditioner panel to the center position

(25°C).

4. Set the fan switch on the same panel to the Auto

position.

Is the action complete? — Go to Step 2 —

2 While holding both the Auto switch and the DEF

switch on the au tomatic air condi tioner panel, tu rn th e

IG off and then on.

Is the current trouble diagnosing function turned on

approximately in 10 seconds? — Go to Step 3 —

3 Does the A/C LED flash every 0.5 second interval? — Go to Step 4 Refer to *1.

4 Press the A/C switch once.

Does the A/C LED flash every 0.5 second interval? — Go to Step 5 Refer to *2.

5 Refer to *3 chart “Check of Output Equipment".

Does each output equipment function normally

according to operation of the temperature setting

level?

— Go to Step 6

Repair or

replace the

output

equipment or

repair the

harness

6 Press the DEF switch for 5 seconds consecutively or

turn on and off the IG.

Is the action complete? — Go to Step 1 —

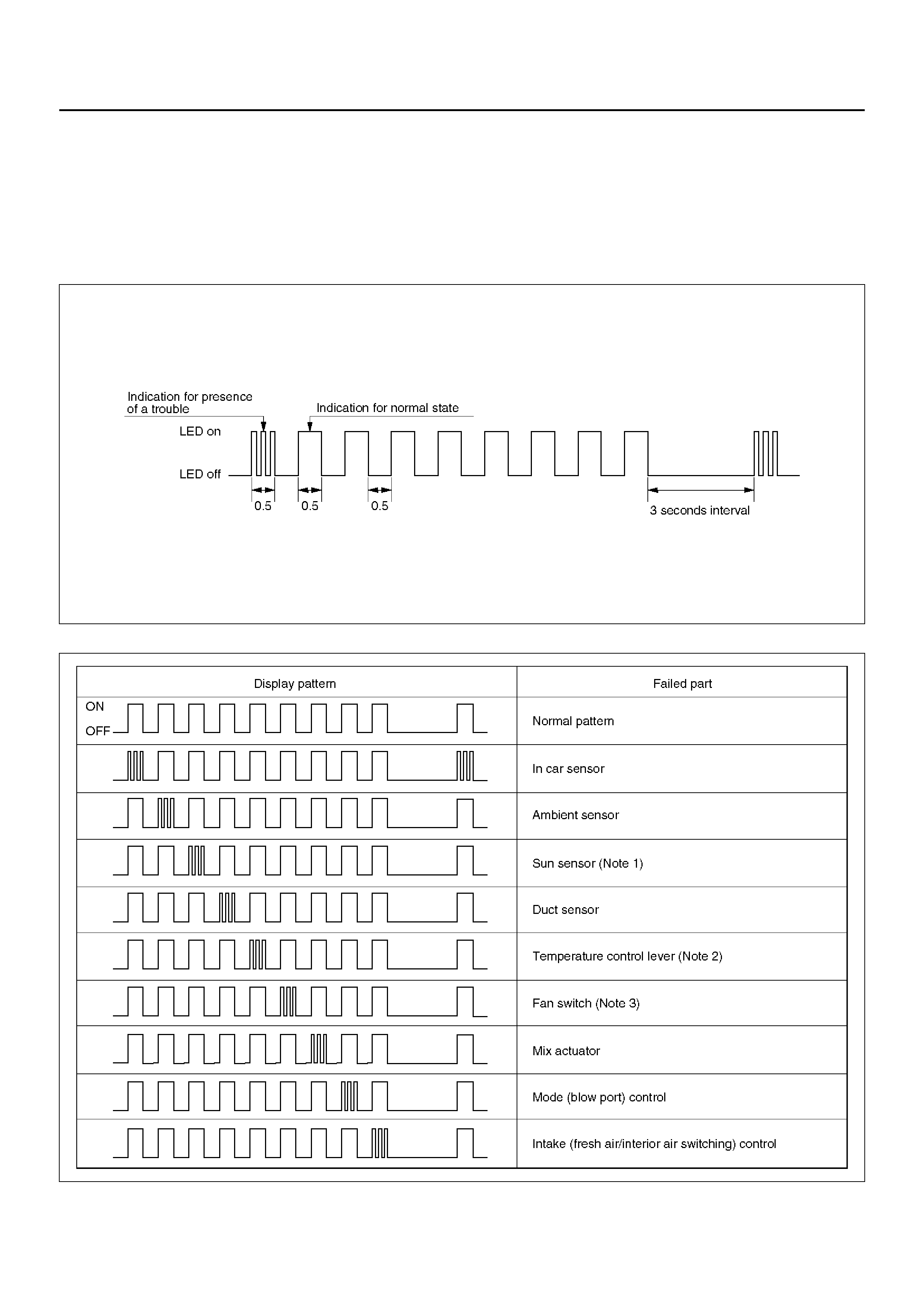

Displaying the Current Trouble Diagnosing Table

Start the engine while holding down both the Auto

switch and the DEF switch on the control panel, and the

table will appear in approximately 10 seconds to the

indicator lamp (LED) of the air conditioning switch.

Result of the diagnosis along the following 9 items will

be shown one by one in 0.5 second in ter v al irre spective

of presence or absence of a trouble for a given item.

When the display 9 items is completed, it is repeated

with 3 seconds of interval in between. A failed item is

indicated by flashing of the LED that is repeated 3 times

within 0.5 seconds. If a trouble is indicated, you can

locate the failed section by knowing when in the total

sequence it has been displayed.

F01RX010

Item for Current Trouble Diagnosis

F01RY00008

As shown above, display of result along nine items is

repeated with 3-second interval in between.

Note 1: When checking the solar radiation sensor , apply

sufficient light using a 60W bulb. Otherwise, it can be

diagnosed as failed.

Note 2: If the temperature setting lever is set on both

ends (one set to 18°C, blue scale = Full cool and the

other to 31°C, red scale = Full hot), they can be

diagnosed as failed.

Note 3: Likewise, the fan switch can be diagnosed as

failed if set on both ends.

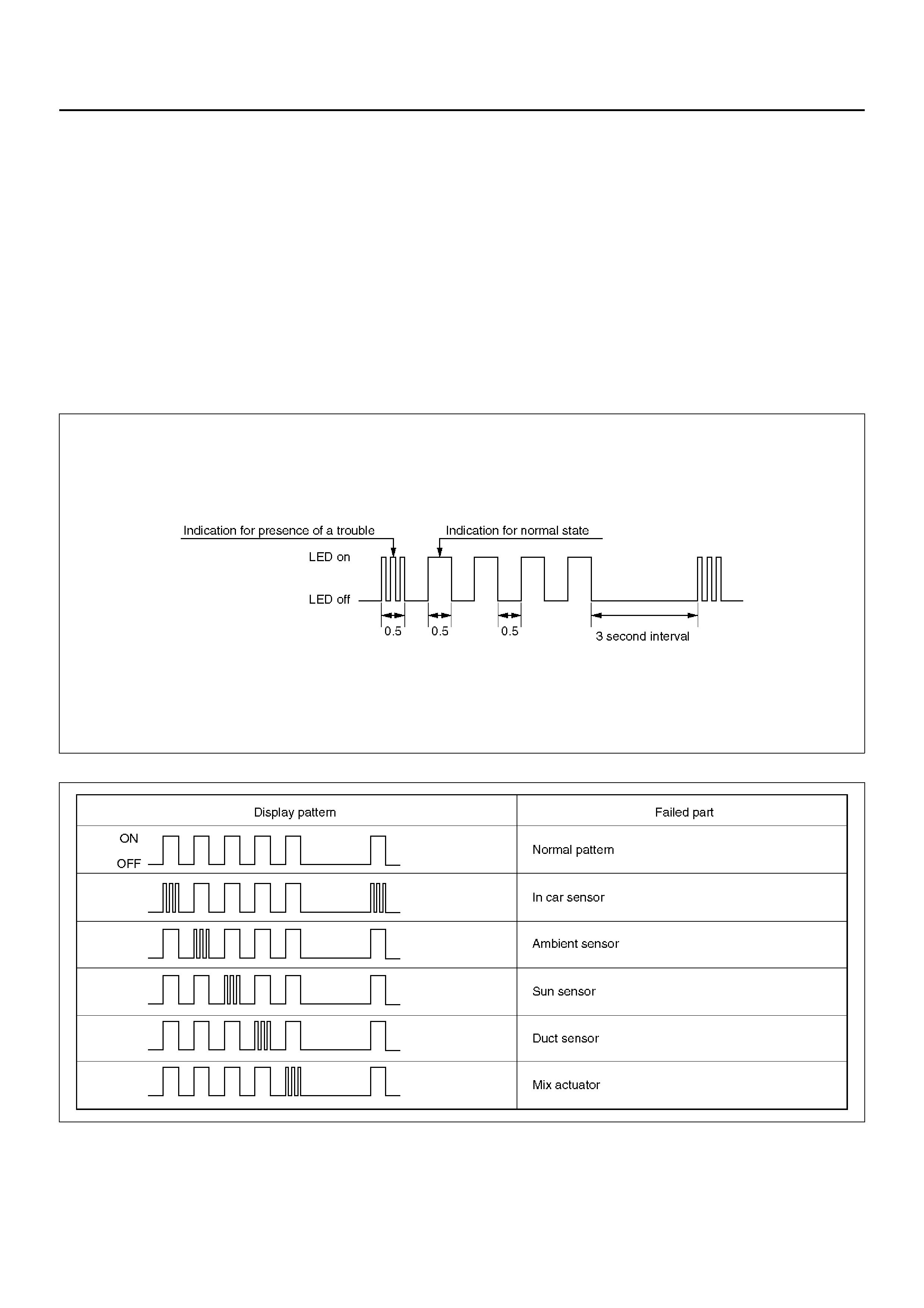

Displaying the Past Trouble Diagnosing Table

The past trouble diagnosis displays only the items on

which trouble has recurred 16 times in the past.

If you press the air conditioning switch once while the

current trouble diagnosis is taking place, display of the

past trouble diagn osis will appear on the indicat or lamp

(LED) of the air conditioning switch.

Results of the diagnosis along the following five items

are displayed one by one in 0.5 second interval

irrespective of presence or absence of a trouble. A

failed item is indicated by flashing of the LED that is

repeated 3 times within 0.5 seconds. You can locate the

fail ed se ction by co unting in wha t seque nce i t has b een

displayed.

F01RX011

F01RY00007

Check of Output Equipment

F01RX015

INSPECTION BY FAILED LOCATION

INSPECTION OF THE SENSORS

When the self-diagnosis function has determined that

trouble is present on the sensors, check them according

to the following flow chart.

F01RY00005

Chart 1: In Car Sensor

D08RY00888

Step Action Value(s) Yes No

1 Disconnect the in car sensor connector. (No.I-4)

Is performance of the sensor normal? (Refer to the

later section on “Individual Inspection") — Go to Step 2 Replace the in

ca r sensor

2 Is there continuity between the harness side

connector No.I44–1 and No.I4–3? — Go to Step 4 Go to Step 3

3 Repair an open circuit between terminal No.I44–1 and

No.I4–3.

Is the action complete? — Go to Step 2 —

4 Is there continuity between the harness side

connector No.I44–11 and No.I4–4? — Go to Step 6 Go to Step 5

5 Repair an open circuit between terminal No.I44–11

and No.I4–4.

Is the action complete? — Go to Step 4 —

6 Replace the auto air conditioner control unit.

Is the action complete? — Verify repair —

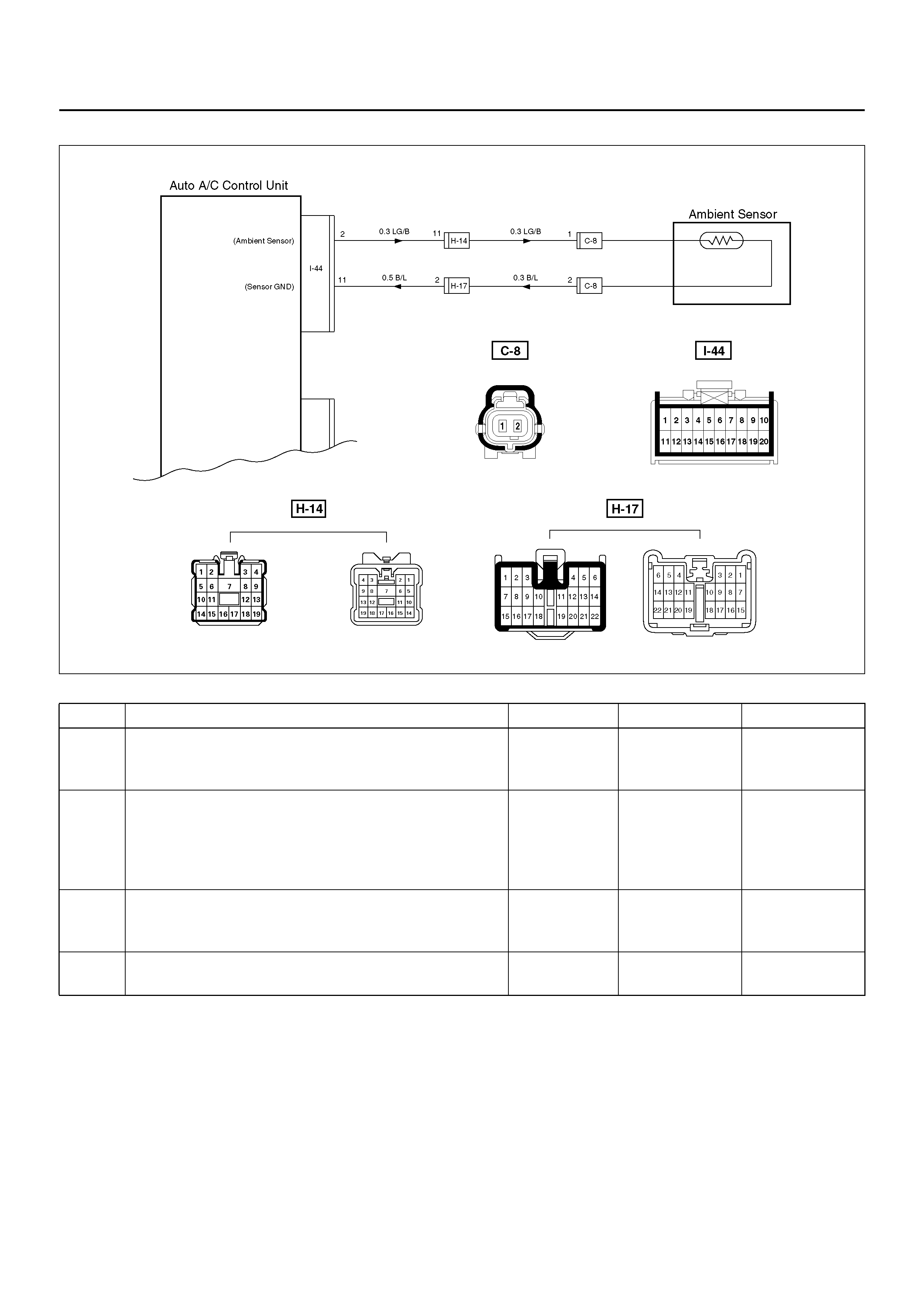

Chart 2: Ambient Sensor

D08R100121

Step Action Value(s) Yes No

1 Disconnect ambient sensor connector. (No.C–8)

Is performance of the ambie nt sensor normal? (Refer

to the later section on “Individual inspection") — Go to Step 2 Replace the

ambient sensor

2 Connect the ambient sensor connector.

Disconnect auto air conditioner control unit

connector.(No.I–44)

Is resistance between the harness side connector

No.I44–2 and No.I44–11 normal?

Refer to the

later section

on “Individual

inspection" Go to Step 4 Go to Step 3

3 Repair an open circuit between terminal No.I44–2 and

No.C8–1 or No.I44–11 and No.C8–2.

Is the action complete? — Go to Step 2 —

4 Replace the auto air conditioner control unit.

Is the action complete? — Verify repair —

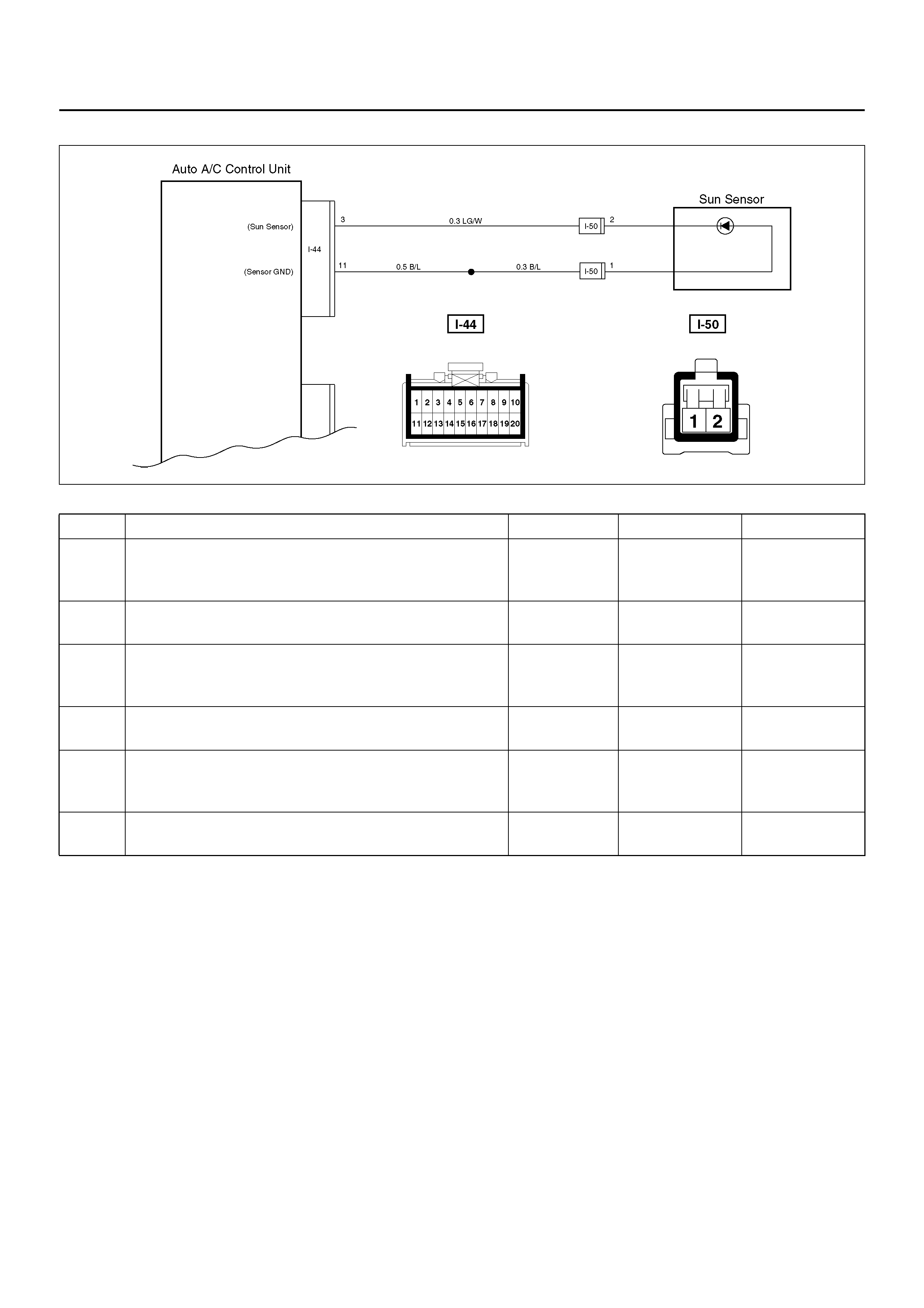

Chart 3: Sun Sensor

D08R100177

Step Action Value(s) Yes No

1 Disconnect the sun sensor connector. (No.I–50)

Is performance of the sun sensor normal? (Refer to

the later section on individual inspection) — Go to Step 2 Replace the

sun sensor.

2 Is there continuity between the harness side

connector terminal No.I44–3 and No.I50–2? — Go to Step 4 Go to Step 4

3 Repair an open circuit between terminal No.I44–3 and

No.I50–2.

Is the action complete? — Go to Step 2 —

4 Is there continuity between the harness side

connector terminal No.I44–11 and No.I50–1? — Go to Step 6 Go to Step 5

5 Repair an open circuit between terminal No.I44–11

and I50–1.

Is the action complete? — Go to Step 4 —

6 Replace the auto air conditioner control unit.

Is the action complete? — Verify repair —

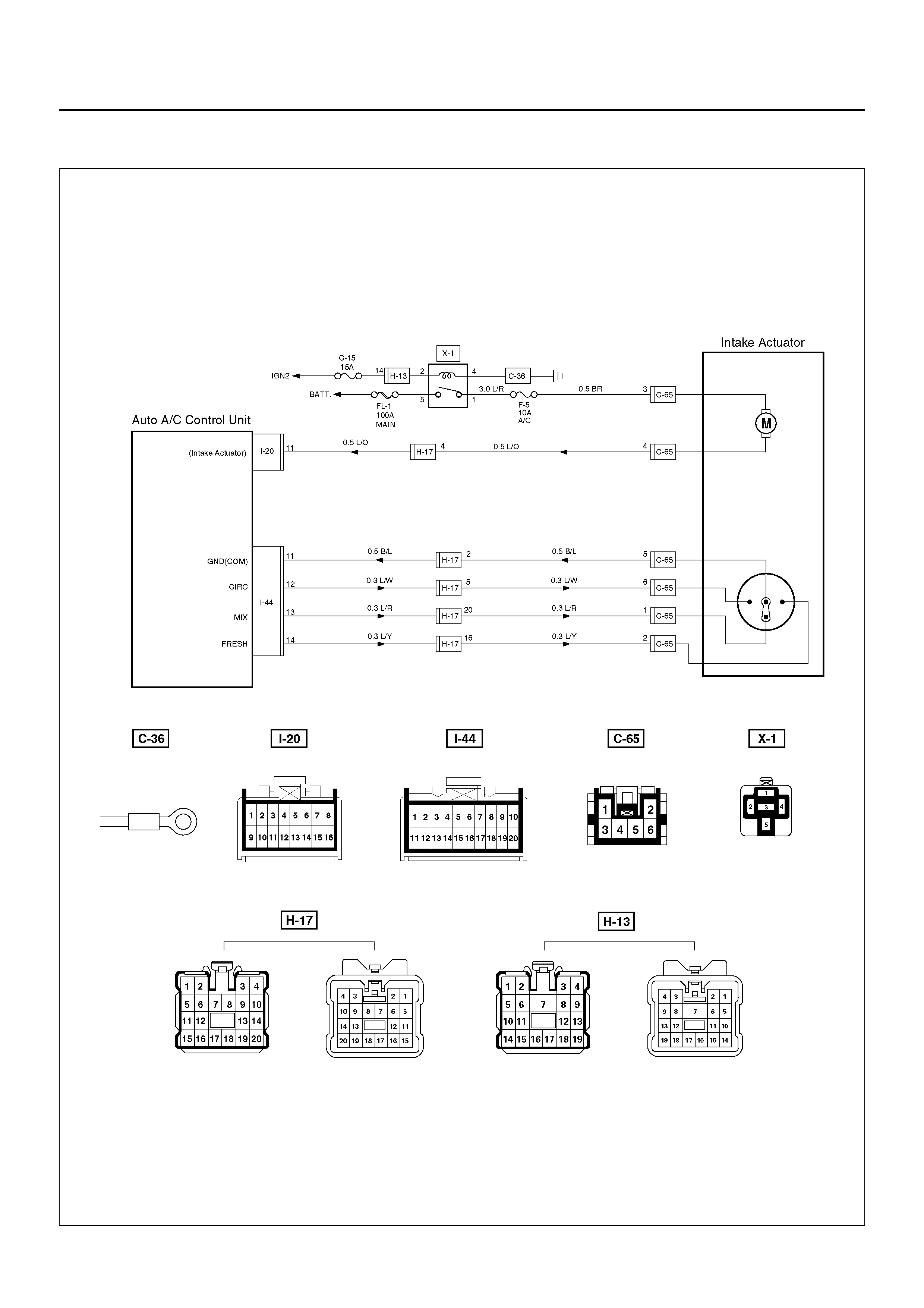

INSPECTION OF THE INTAKE ACTUATOR SYSTEM

D08R100129

Chart A: Does Not Work At All

Condition Possible cause Correction

Does not work at all — Refer to Chart A

Control failure — Refer to Chart B

Step Action Value(s) Yes No

1 Is the fuse C–15 normal? — Go to Step 2 Replace the

fuse

2 Is the fuse F–5 normal? — Go to Step 3 Replace the

fuse

3 Is the relay X–1 normal? — Go to Step 4 Replace the

relay

4 Turn on the ignition switch. (the engine is run.)

Is the battery voltage applied between the harness

side connector terminal No.C65–3 and ground? Approx 12V Go to Step 6 Go to Step 5

5 Repair an open circuit between terminal No.C65–3

and No.X1–1.

Is the action complete? — Go to Step 4 —

6 Is the battery voltage applied between the harness

side connector terminal No.C65–4 and ground? Approx 12V Go to Step 8 Go to Step 7

7 Replace the intake actuator motor.

Is the action complete? — Go to Step 6 —

8 Is there continuity between the harness side

connector terminal No.I20–11 and No.C65–4? — Go to Step 10 Go to Step 9

9 Repair an open circuit between No.I20–11 and C65–4.

Is the action complete? — Go to Step 8 —

10 Replace the auto air conditioner control unit.

Is the action complete? — Verify repair —

Chart B: Failure on the Intake Control

Step Action Value(s) Yes No

1 Is the fuse No.C–15 normal? — Go to Step 2 Replace the

fuse

2 Is the fuse No.F–5 normal? — Go to Step 3 Replace the

fuse

3 Is the relay No.X–1 normal? — Go to Step 4 Replace the

relay

4 Turn on the ignition switch. (the engine is run.)

Is the intake actuator stopped? — Go to Step 6 Go to Step 5

5 Replace or repair the auto air conditioner control unit.

Is the action complete? — Verify repair —

6 Is there continuity between the harness side

connector terminal No.C65–5 and No.I44–11? — Go to Step 8 Go to Step 7

7 Repair an open circuit between terminal No.C65–5

and No.I44–11.

Is the action complete? — Go to Step 6 —

8 Is there continuity between the harness side

connector terminal No.C65–6 and No.I44–12? — Go to Step 10 Go to Step 9

9 Repair an open circuit between terminal No.C65–6

and No.I44–12.

Is the action complete? — Go to Step 8 —

10 Is there continuity between the harness side

connector terminal No.C65–1 and No.I44–13? — Go to Step 12 Go to Step 11

11 Repair an open circuit between terminal No.C65–1

and I44-13.

Is the action complete? — Go to Step 10 –

12 Is there continuity between the harness side

connector terminal No.C65–2 and No.I44–14? — Go to Step 14 Go to Step 13

13 Repair an open circuit between harness No.C65–2

and No.I44–14.

Is the action complete? — Go to Step 12 —

14 1. Disconnect the intake actuator connector No.C–

65.

2. Is the battery voltage applied between harness

side connector terminal

No.C65–6 and ground?

No.C65–2 and ground?

No.C65–1 and ground?

— Go to Step 15 Go to Step 16

15 Replace or repair the intake actuator.

Is the action complete? — Verify repair —

16 Replace or repair the air conditioner control unit.

Is the action complete? — Verify repair —

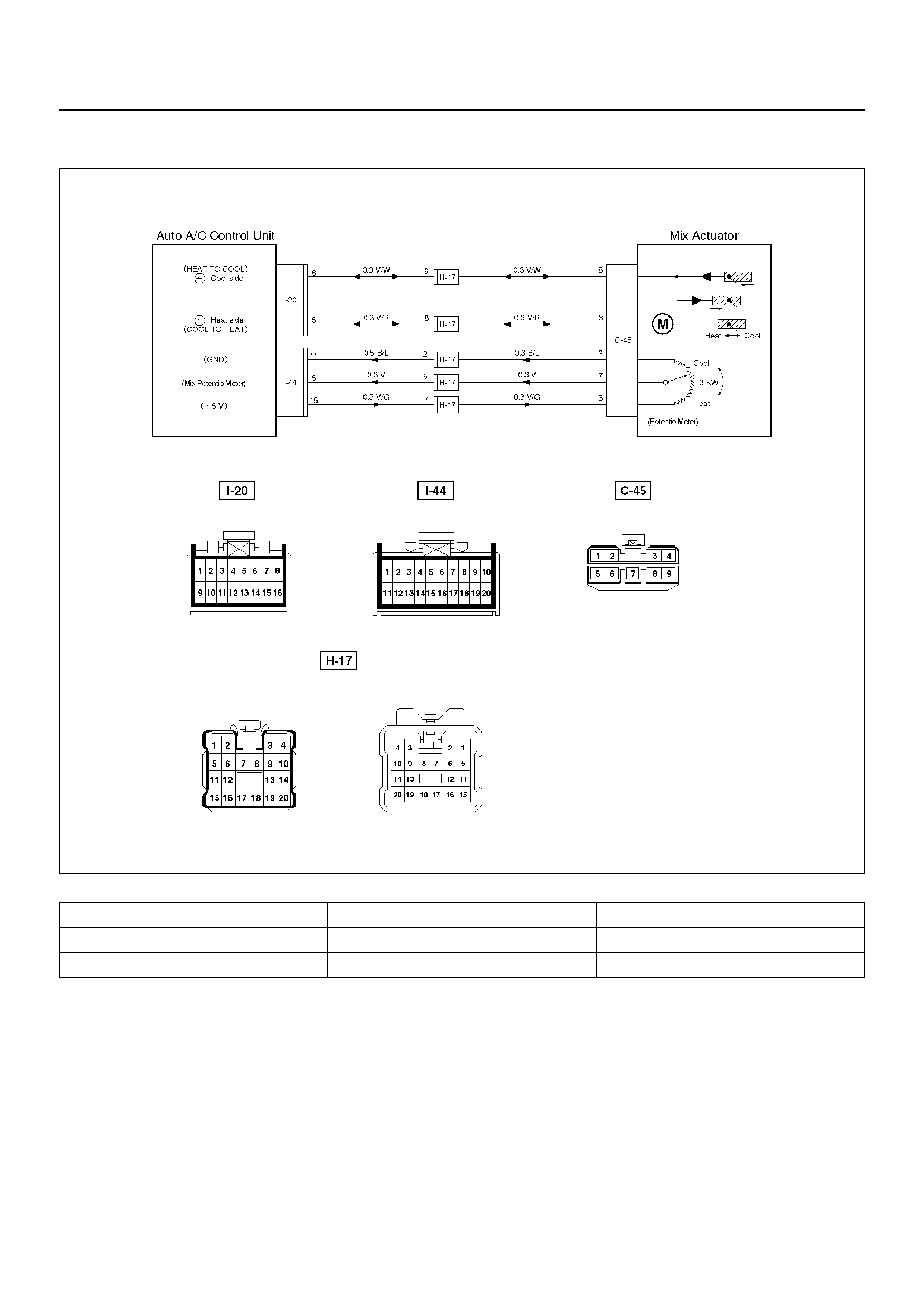

INSPECTION OF THE MIX ACTUATOR SYSTEM

D08RX229

Condition Possible cause Correction

Does not work at all — Refer to Chart A

Control failure — Refer to Chart B

Chart A: Does Not work At All

Step Action Value(s) Yes No

1 1. Turn on the ignition switch (the engine is run).

2. Disconnect the mix actuator connector (C–45).

3. Short-circuit the chassis harness side connector

termina l No.C45 –2 and No.C4 5–7 .

4. Using the temperature control lever, select FH for

the temperature.

Is the battery voltage applied on a regular interval

basis between the harness side connector terminal

No.C45–8 (-) and No.C45–6 (+)? — Go to Step 3 Go to Step 2

2 Replace the auto air conditioner control unit.

—Varify repair —

3 Using the temperature control lever, select FC for the

temperature.

Is the battery voltage applied on a regular interval

basis between the harness side connector terminal

No.C45–8 (+) and No.C45–6 (-)? — Go to Step 5 Go to Step 4

4 Replace the auto air conditioner control unit.

— Verify repair —

5 Is there continuity between the harness side

connector terminal No.I20–6 and No.C45–8? — Go to Step 7 Go to Step 6

6 Repair an open circuit between terminal No.I20–6 and

No.C45–8.

Is the action complete? — Go to Step 5 —

7 Is there continuity between the harness side

connector terminal No.I20–5 and No.C45–6? — Go to Step 9 Go to Step 8

8 Repair an open circuit between terminal No.I20–5 and

No.C45–6.

Is the action complete? — Go to Step 7 —

9 Replace the mix actuator.

Is the action complete? — Verify repair —

Chart B: Mix Actuator Control Failure

Step Action Value(s) Yes No

1 Turn the ignition switch (the engine is run).

Does th e m ix ac tu ator fully st ro ke whe n F H and F C o f

the temperature control lever? — Go to Step 3 Go to Step 2

2 Repair or replace the air mix door or the link unit.

Is the action complete? — Varify repair —

3 Is there continuity between the harness side

connector terminal No.C45–2 and No.I44–11? — Go to Step 5 Go to Step 4

4 Repair an open circuit between terminal No.C45–2

and No.I44–11.

Is the action complete? — Go to Step 3 —

5 Is there continuity between harness side connector

terminal No.C45–7 and No.I44–5? — Go to Step 7 Go to S tep 6

6 Repair an open circuit between terminal No.C45–7

and No.I44–5.

Is the action complete? — Go to Step 5 —

7 Is there continuity between the harness side

connector terminal No.C45–3 and No.I44–15? — Go to Step 9 Go to Step 8

8 Repair an open circuit between terminal No.C45–3

and No.I44–15.

Is the action complete? — Go to Step 7 —

9 Is sum of the voltage between the following chassis

harness side connector terminals approximately 5V?

No.I44–15 and No.I52–5, No.I44–5 and No.I44–11 — Go to Step 11 Go to Step 10

10 Replace the actuator.

Is the action complete? — Go to Step 9 —

11 Replace the auto air conditioner control unit.

Is the action complete? — Verify repair —

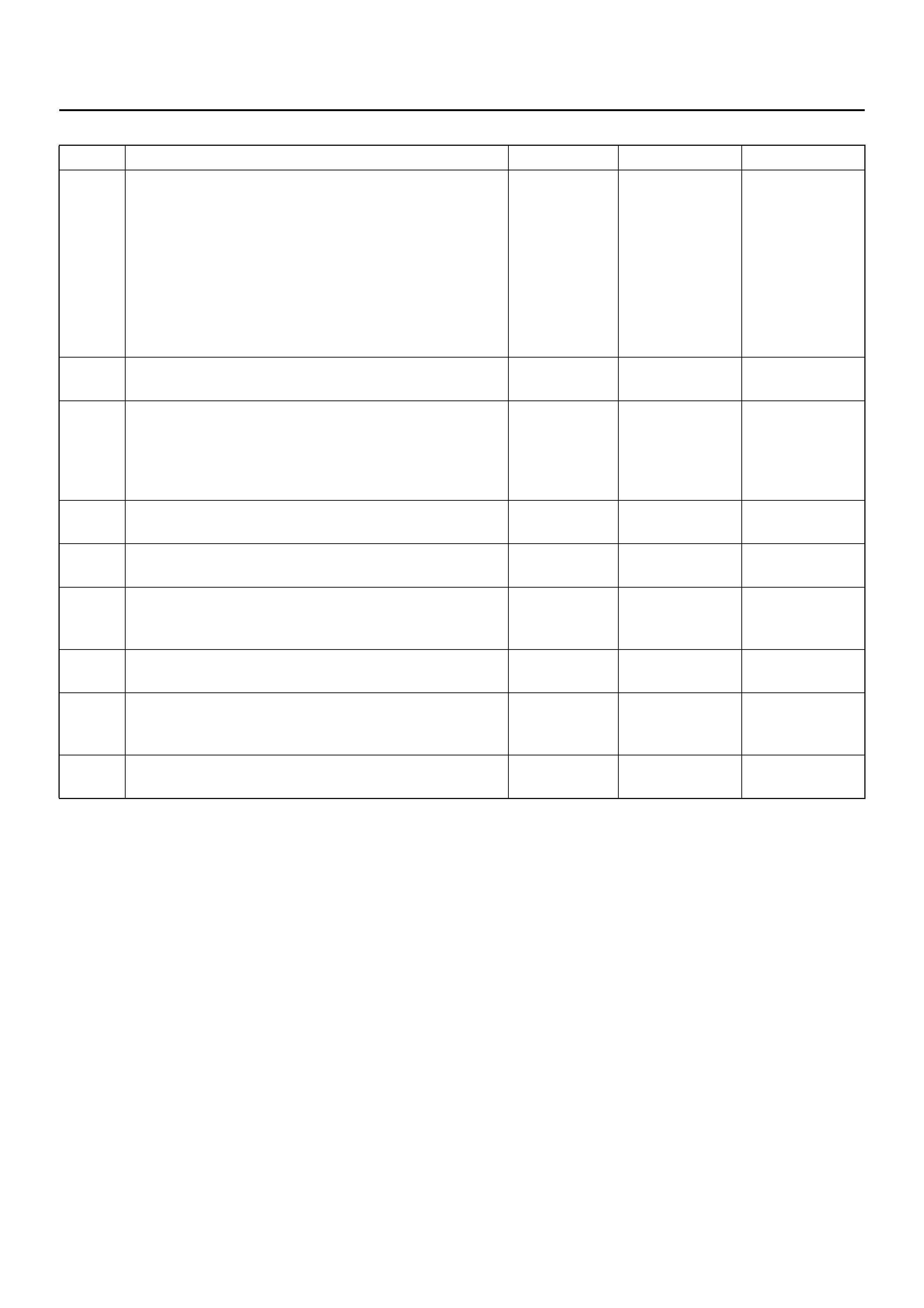

INSPECTION OF THE MODE ACTUATOR SYSTEM

D08R100130

Condition Possible cause Correction

Does not work at all — Refer to Chart A

Control failure — Refer to Chart B

Chart A: Does Not Work At All

Step Action Value(s) Yes No

1 1. Turn on the ignition switch (the engine is run).

2. Disconnect the mode actuator connector (C–48)

3. Select VENT pressing the mode actuator.

Is the battery voltage provided on a regular interval

between the harness side connector terminal

No.C48–1 (+) and No.C48–5 (-)? — Go to Step 3 Go to Step 2

2 Replace the auto air conditioner control unit.

Is the action complete? — Varify repair —

3 Turn on the DEF mode switch.

Is the battery voltage provided on a regular interval

between the chassis side connector terminal No.C48–

5 (+) and No.C48–1 (-)? — Go to Step 5 Go to Step 4

4 Replace the auto air conditioner control unit.

—Varify repair —

5 Is there continuity between the harness side

connector terminal No.C48–1 and No.I20–4? — Go to Step 7 Go to Step 6

6 Repair an open circuit between terminal No.C48–1

and No.I20–4.

Is the action complete? — Go to Step 5 —

7 Is there continuity between the harness side

connector terminal No.C48–5 and No.I20–3? — Go to Step 9 Go to Step 8

8 Repair an open circuit between terminal No.C48–5

and No.I20–3.

Is the action complete? — Go to Step 7 —

9 Replace the mode actuator.

— Verify repair —

Chart B: Mode Actuator Control Failure

Step Action Value(s) Yes No

1 Turn on the ignition switch (the engine is run).

Does the mode actuator fully stroke when the defrost

mode and the vent mode are selected? — Go to Step 3 Go to Step 2

2 Repair or replace the mode door or the link unit.

Is the action complete? — Go to Step 1 —

3 Is there continuity between the harness side

connector terminal No.C48–9 and No.I44–11? — Go to Step 5 Go to Step 4

4 Repair an open circuit between terminal No.C48–9

and No.I44–11.

Is the action complete? — Go to Step 3 —

5 Is there continuity between the harness side

connector terminal No.C48–3 and No.I44–10? — Go to Step 7 Go to Step 6

6 Repair an open circuit between terminal No.C48–3

and No.I44–10.

Is the action complete? — Go to Step 5 —

7 Is there continuity between harness side connector

terminal No.C48–4 and No.I44–8? — Go to Step 9 Go to S tep 8

8 Repair an open circuit between terminal No.C48–4

and No.I44–8.

Is the action complete? — Go to Step 7 —

9 Is sum of the voltage between the following harness

side connector terminal approximately 5V? Voltage

between No.I44–8 and No.I44–10 plus voltage

between No.I44–8 and No.I44–11 5V Go to Step 11 Go to Step 10

10 Replace the actuator.

Is the action complete? — Verify repair —

11 Does the mode actuator work normally through

manual operation? — Go to Step 13 Go to Step 12

12 Replace the sensor.

Is the action complete? — Go to Step 11 —

13 Replace the auto air conditioner control unit.

Is the action complete? — Verify repair —

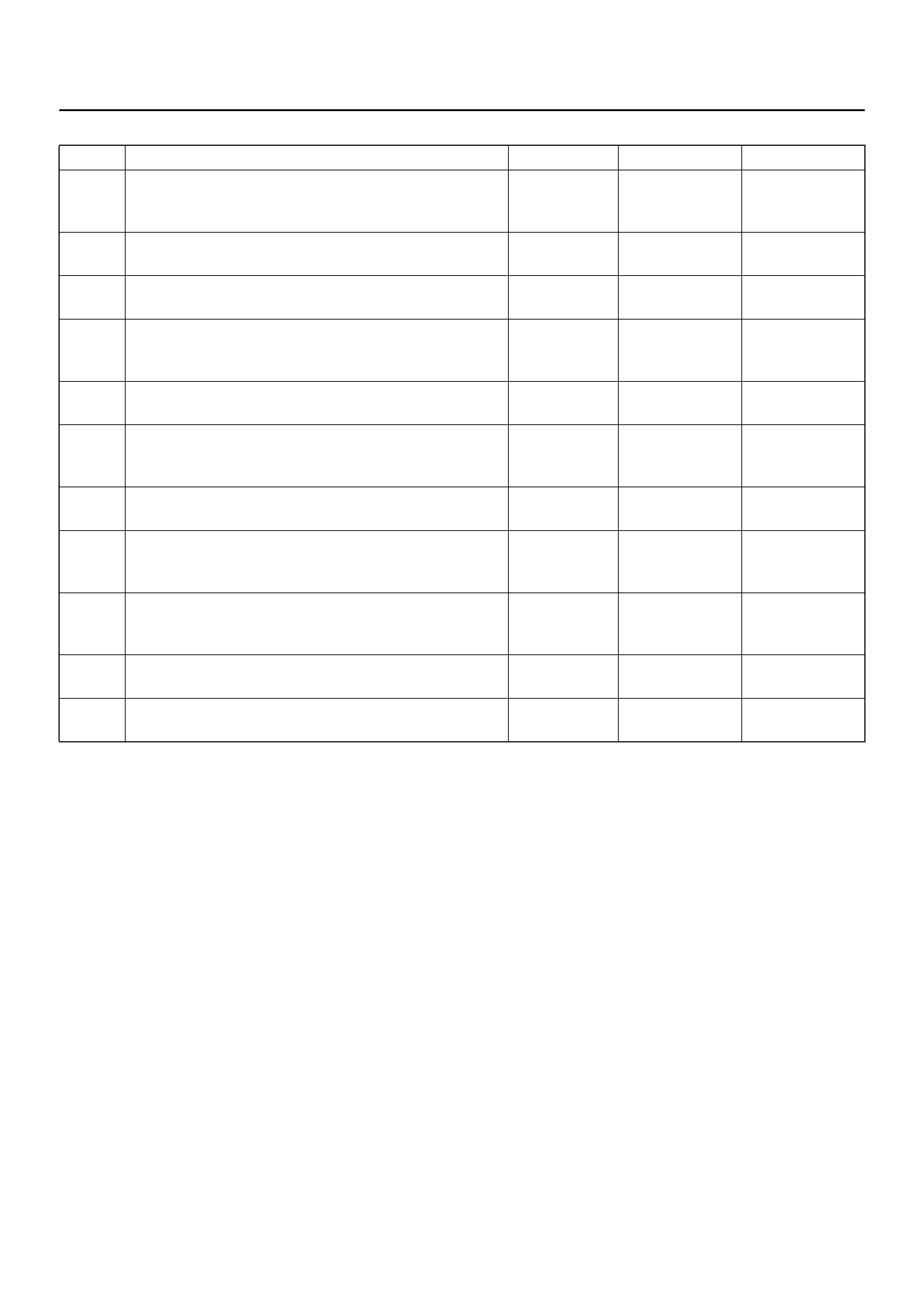

INSPECTION OF THE FAN MOTOR SYSTEM

D08R100131

Chart A: Fan Does Not Rotate At All

Condition Possible cause Correction

The fan does not rotate at all — Refer to Chart A

The fan d oes not rotate in the MAX–

HI mode — Refer to Chart B

The fan does not rotate in any mode

other than MAX–HI — Refer to Chart C

The fan does not stop — Refer to Chart D

Step Action Value(s) Yes No

1 Is the fuse No.F–4 and No.F–5 normal? — Go to Step 2 Replace the

fuse

2 Is the relay No.X–1 and No.C–67 normal? — Go to Step 3 Replace the

relay

3 Turn on the ignition switch (the engine is run).

Is the battery voltage applied between the harness

side connector terminal No.C70–2 and ground? — Go to Step 5 Go to Step 4

4 Repair an open circuit between terminal No.C70–2

and No.F–4 fuse.

Is the action complete? — Go to Step 3 —

5 Is there continuity between the harness side

connector terminal No.C70–1 and ground (No.C–36)? — Go to Step 7 Go to Step 6

6 Repair an open circuit between terminal No.C70–1

and ground.

Is the action complete? —

7 Is the battery voltage applied between the harness

side connector terminal No.C70–1 and No.C70–2? — Go to Step 9 Go to Step 8

8 Replace the blower motor.

Is the action complete? — Verify repair —

9 Refer to chart B and C.

Is the action complete? — Verify repair —

Chart B: Fan Does Not Rotate in MAX HI Mode

Step Action Value(s) Yes No

1 Is the MAX-HI relay (C–67) normal? — Go to Step 2 Replace the

relay

2 1. Turn on the ignition switch (the engine is run).

2. Set the fan switch to the MAX-HI.

Is there continuity between the harness side

connector terminal No.C70–1 and No.C67–2? — Go to Step 4 Go to Step 3

3 Repair an open circuit between terminal No.C70–1

and No.C67–2.

Is the action complete? — Go to Step 2 —

4 Is there continuity between the harness side

connector terminal No.C67–4 and ground (No.C–36)? — Go to Step 6 Go to Step 5

5 Repair an open circuit between terminal No.C67–4

and ground (No.C–36).

Is the action complete? — Go to Step 4 —

6 Is the battery voltage applied between the harness

side connector terminal No.C67–1 and ground? — Go to Step 8 Go to Step 7

7 Repair an open circuit between terminal No.C67–1

and No.F–5 fuse.

Is the action complete? — Go to Step 6 —

8 Is the battery voltage applied between the harness

side connector terminal No.I20–12 and ground? — Go to Step 10 Go to Step 9

9 Repair an open circuit between terminal No.C67–3

and No.I20–12.

Is the action complete? — Go to Step 8 —

10 Replace the auto air conditioner control unit.

Is the action complete? — Verify repair —

Chart C: Fan Does Not Rotate In Any Mode Other Than MAX HI

Chart D: Fan Does Not Stop

Step Action Value(s) Yes No

1 Is t he p ower tra nsi s tor pe rf or man ce norma l? ( Refer t o

the later section on “individual inspection") — Go to Step 2 Replace the

power transistor

2 Is there continuity between the harness side

connector terminal No.C70–1 and No.C66–1,

No.C70–1 and No.I44–17? — Go to Step 4 Go to Step 3

3 Repair an open circuit between terminal.

No.C70–1 and C66–1

No.C70–1 and I44–17

— Go to Step 2 —

4 Is there continuity between the harness side

connector terminal No.C66–3 and ground (No.C–36)? — Go to Step 6 Go to Step 5

5 Repair an open circuit between terminal No.C66–3

and ground.

Is the action complete? — Go to Step 4 —

6 Is there continuity between the harness side

connector terminal No.C66–2 and No.I44–19? — Go to Step 8 Go to Step 7

7 Repair an open circuit between terminal No.C66–2

and No.I44–19.

Is the action complete? — Go to Step 6 —

8 Replace the auto air conditioner control unit.

Is the action complete? — Verify repair —

Step Action Value(s) Yes No

1 1. Disconnect the max high relay, the power

transistor connector C–66 and the auto A/C

control unit connector I–44.

2. Turn on the ignition switch.

Does the blower motor stop? — Go to Step 3 Go to Step 2

2 Repair a short circuit between connector No.C70–1

and No.C67–2, No.C70–1 and No.C66–1, or No.C70–

1 and I44–17.

Is the action complete? — Verify repair —

3 Is the max high relay normal? (Refer to the later

section on “individual inspection".) — Go to Step 4 Replace the

relay

4 Reinstall the max high relay.

Does the blower motor start operating? — Go to Step 6 Go to Step 5

5 Repair a short circuit between connector No.C67–3

and No.I20–12.

Is the action complete? — Go to Step 4 —

6 Is the power transistor normal? (Refer to the later

section on “individual inspection".) — Go to Step 7 Replace the

power transistor

7 Rein stall the power trans istor.

Does the blower motor start operating? —

Replace the

auto A/C control

unit —

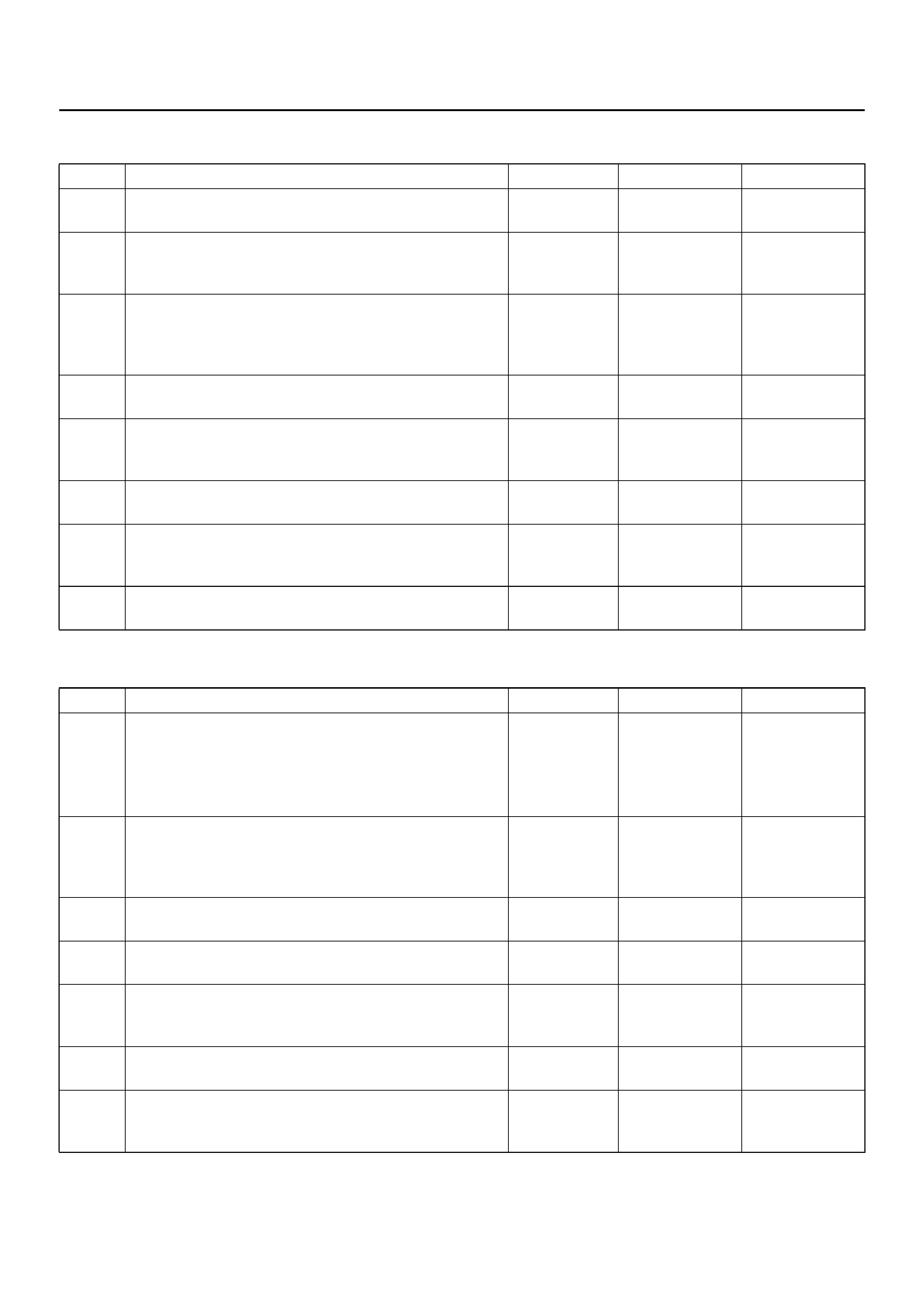

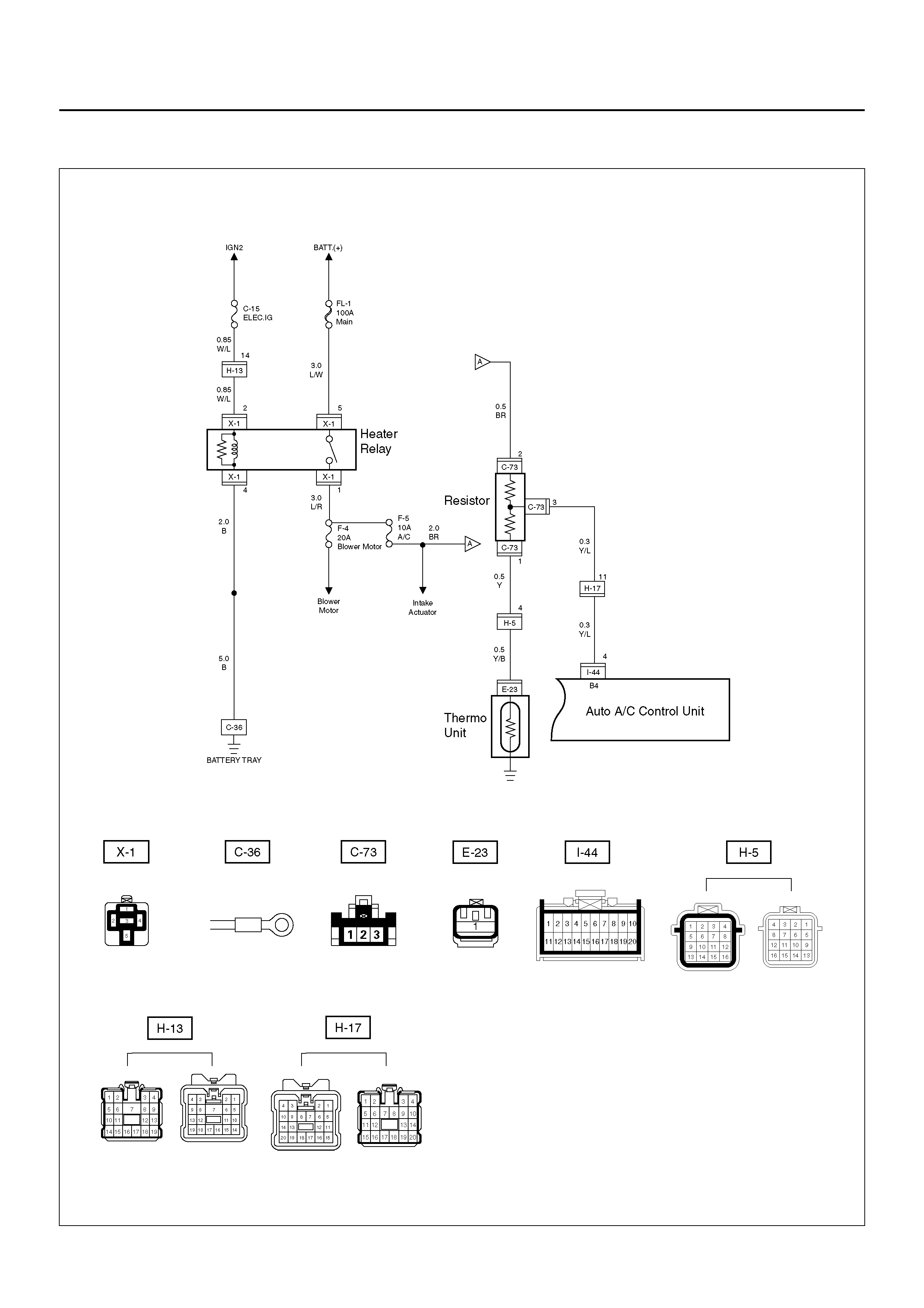

INSPECTION OF THE HEATER CONTROL SYSTEM

D08R100214

Chart A: Heating Start Timing Control Failure

CAUTION: There are conditions which air

conditioner system does not operate except trouble

as follows.

1. The throttle is griater than 90%.

2. The ignition voltage is below 10.5 volts.

3. The engine speed greater than 4500 RPM for 5

seconds or 5400 RPM.

4. The engine coolant temperature (ECT) is greater

than 125°C (257°F).

5. The intake air temperature (IAT) is less than 5°C

(41°F).

6. The power steering pressure switch signals a high

pressure condition.

Condition Possible cause Correction

Heating start timing control failure — Refer to Chart A

Step Action Value(s) Yes No

1 Is the fuse No.F–5 normal? — Go to Step 2 Replace the

fuse

2 Is the relay No.X–1 normal? — Go to Step 3 Replace the

relay

3 Is the thermo unit No.E–23 normal? — Go to Step 4 Replace the

thermo unit

4 Is the resistor No.C–73 normal? — Go to Step 5 Replace the

resistor

5 Is there continuity between the harness side

connector terminal No.C73–1 and No.E23–1? — Go to Step 7 Go to Step 6

6 Repair an open circuit between terminal No.C73–1

and No.E23–1.

Is the action complete? — Go to Step 5 —

7 Is there continuity between the harness side

connector terminal No.C73–3 and No.I44–4? — Go to Step 9 Go to Step 8

8 Repair an open circuit between terminal No.C73–3

and No.I44–4.

Is the action complete? — Go to Step 7 —

9 Turn on the ignition switch (the engine is run).

Is the battery voltage applied between the harness

side connector terminal No.C73–2 and ground? — Go to Step 11 Go to Step 10

10 Repair an open circuit between terminal No.C73–2

and No.F–5 fuse.

Is the action complete? — Go to Step 9 —

11 Replace the auto air conditioner control unit.

Is the action complete? — Verify repair —

INSPECTION OF THE MAGNETIC CLUTCH SYSTEM

6VD1 Engine

D08R100231

Chart A: Magnetic Clutch Does Not work

Condition Possible cause Correction

Magnetic clutch does not work — Refer to Chart A

Step Action Value(s) Yes No

1 Is the fuse No.F–5 normal? — Go to Step 2 Replace the

fuse

2 Is the relay No.X–2 (compressor relay) No.X–8 (A/C

thermo relay) and No.X–1 (heater relay) normal? — Go to Step 3 Replace the

relay

3 Is the pressure switch normal? — Go to Step 4 Replace the

pressure switch

4 Is the duct sensor normal? — Go to Step 5 Replace the

duct sensor

5 1. Turn the ignition switch on. (the engine is run.)

2. Turn the air conditioner switch on.

Is the battery voltage applied between the harness

side connector terminal No.E3–1 and the ground? — Go to Step 6 Go to Step 7

6 Repair or replace the magnetic clutch.

Is the action complete? — Verify repair —

7 Is there continuity between the harness side

connector terminal No.X2–1 and No.E3–1? — Go to Step 9 Go to Step 8

8 Repair an open c ircuit bet ween ter minal No.X 2–1 an d

No.E3–1.

Is the action complete? — Go to Step 7 —

9 Is the battery voltage applied between the harness

side conn ector termina l No.X2 –5 and ground, No .X2–

2 and ground? — Go to Step 11 Go to Step 10

10 Repair an open circ uit bet ween termi nal No.X2– 5 and

fuse No.F–5, No.X2–2 and fuse No.F–5.

Is the action complete? — Go to Step 9 –

11 Is the battery voltage applied between the harness

side connector terminal No.C11–1 and ground? — Go to Step 13 Go to Step 12

12 Repair an open circuit between terminal No.C11–1

and fuse No.F–5.

Is the action complete? — Go to Step 11 —

13 Is the battery voltage applied between the harness

side conn ector termina l No.X8 –3 and ground, No .X8–

1 and ground? — Go to Step 15 Go to Step 14

14 Repair an open circ uit bet ween termi nal No.X8– 3 and

No.C11–2, No.X8–1 and fuse No.F–5.

Is the action complete? — Go to Step 13 —

15 Is the battery voltage applied between the harness

side connector terminal No.I20–14 and ground? — G o to Step 17 Go to Step 16

16 Repair an open circ uit bet ween termi nal No.X8– 5 and

I20–14.

Is the action complete? — Go to Step 15 —

17 Is there continuity between the harness side

connector terminal No.C64–1 and No.I44–20? — Go to Step 19 Go to Step 18

18 Repair an open circuit between terminal No.C64–1

and No.I44–20.

Is the action complete? — Go to Step 17 —

Chart A: Magnetic Clutch Does Not work (Cont’d)

CAUTION: There are conditions which air

conditioner system does not operate except trouble

as follows.

1. The throttle is griater than 90%.

2. The ignition voltage is below 10.5 volts.

3. The engine speed greater than 4500 RPM for 5

seconds or 5400 RPM.

4. The engine coolant temperature (ECT) is greater

than 125°C (257°F).

5. The intake air temperature (IAT) is less than 5°C

(41°F).

6. The power steering pressure switch signals a high

pressure condition.

Step Action Value(s) Yes No

19 Is there continuity between the harness side

connector terminal No.C64–2 and No.I44–11? — Go to Step 21 Go to Step 20

20 Repair an open circuit between terminal No.C64–2

and No.I44–11.

Is the action complete? — Go to Step 19 —

21 Is there continuity between the harness side

connector terminal No.X8–2 and PCM (F45)? — Go to Step 23 Go to Step 22

22 Repair an open circ uit bet ween termi nal No.X8– 2 and

PCM (F45)?

Is the action complete? — Go to Step 21 —

23 Is there continuity between the harness side

connector terminal No.X2–4 and PCM (F4)? — Go to Step 25 Go to Step 24

24 Repair an open circ uit bet ween termi nal No.X2– 4 and

PCM (F4).

Is the action complete? — Go to Step 23 —

25 1. Connect the connector of PCM.

2. Connect the harness side connector terminal

I20–14 to the ground.

Does the magnetic clutch work?

—

Replace the

auto air

conditioner

control unit

Refer to

Powertrain

Control Modul

in ENGINE

DRIVEABILITY

AND

EMISSIONS

section

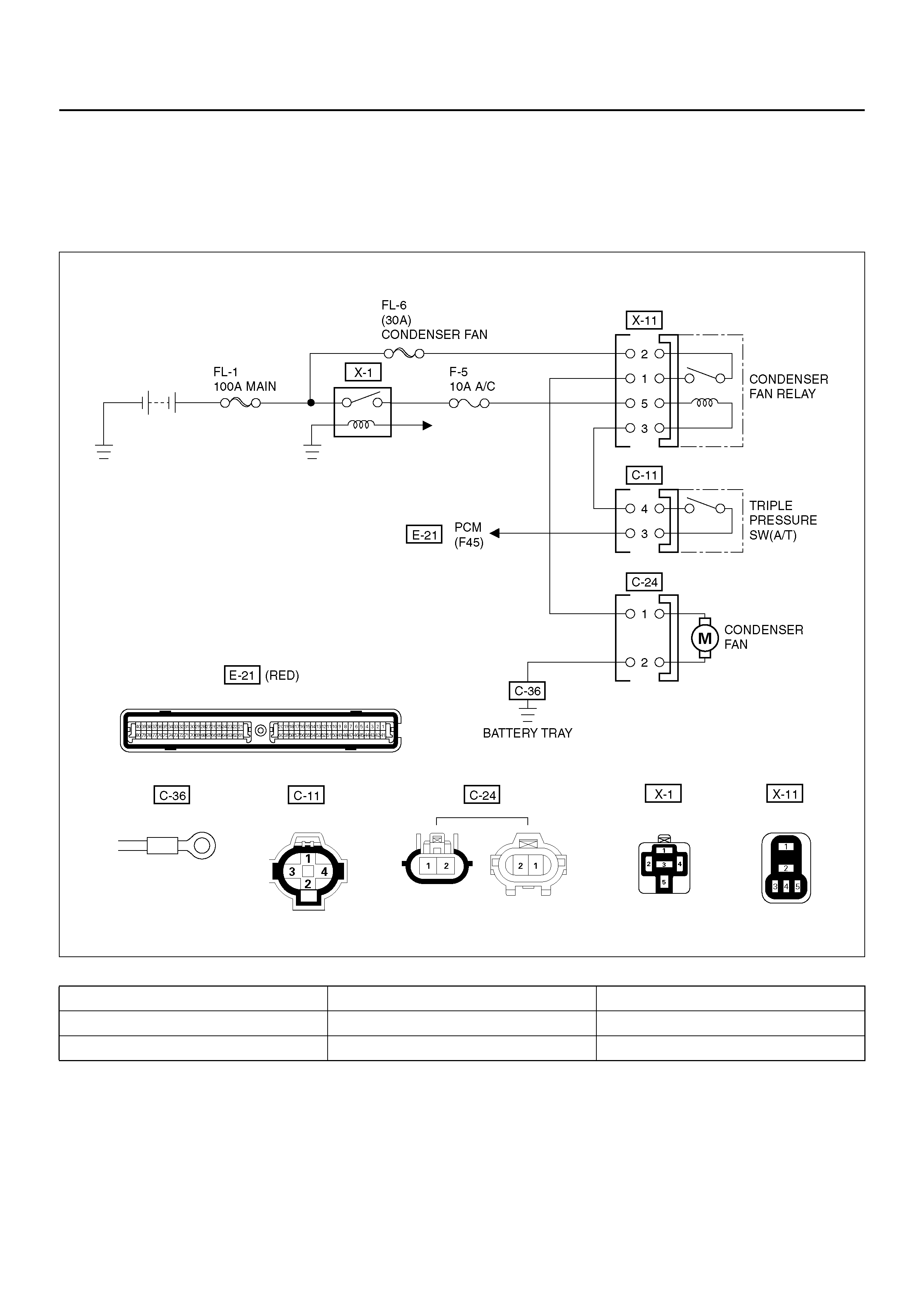

CONDENSER FAN DIAGNOSIS

While the air conditioning is ON, the cycling switch in

the triple pressure switch senses the refrigerant

pressure, and activates the condenser fan to improve

the cooling capacity of the condenser when the

refrigerant pressure exceeds a set pressure value. The

conden ser fan stops when the air conditi oning is turned

“OFF" or when the pressure goes down below the set

pressure value.

D08R100140

Condition Possible cause Correction

Condenser fan does not run. — Refer to Chart A

Condenser fan does not stop. — Refer to Chart B

Chart “A" Condenser Fan Does Not Run

Step Action Value(s) Yes No

1 Is the fusible link No.FL–6 normal? — Go to Step 2 Replace the

fusible link wire

2 Is the fuse No.F–5 normal? — Go to Step 3 Replace the

fuse

3 Is the heater relay (No.X–1) and condenser fan relay

(No.X–11) normal? — Go to Step 4 Replace the

relay

4 1. Disconnect the condenser fan motor connector

No.C–24.

2. Connect the motor side connector terminal

No.C24–1 to the battery positive terminal and

No.C24–2 to the battery negative terminal.

Does the fan operate? — Go to Step 6 Go to Step 5

5 Repair or replace the condenser fan motor.

Is the action complete? — Go to Step 4 —

6 Is there continuity between the harness side

connector terminal No.C24–2 and ground (C–36)? — Go to Step 8 Go to Step 7

7 Repair an open circuit between terminal No.C24–2

and No.C–36.

Is the action complete? — Go to Step 6 —

8 Is there continuity between the harness side

connector terminal No.C24–1 and No.X11–1? — Go to Step 10 Go to Step 9

9 Repair an open circuit between terminal No.C24–1

and No.X11–1.

Is the action complete? — Verify repair —

10 Is the battery voltage applied between the harness

side connector terminal No.X11–2 and ground? — Go to Step 12 Go to Step 11

11 Repair an open circuit between terminal No.X11–2

and No.FL–6.

Is the action complete? — Go to Step 10 —

12 Is the battery voltage applied between the harness

side connector terminal No.C11–4 and ground? — Go to Step 14 Go to Step 13

13 Repair an open circuit between terminal No.X11–3

and No.C11–4.

Is the action complete? — Go to Step 12 —

14 Is there continuity between the harness side

connector terminal No.C11–3 and No.E21–F45? — Go to Step 16 Go to Step 15

15 Repair an open circuit between terminal No.C11–3

and No.E21–F45.

Is the action complete? — Verify repair —

16 Connect the harness side connector terminal

No.C24–1 to the battery terminal and No.C24–2 to the

battery negative terminal.

Is the battery voltage between the pressure switch

side connector terminal No.C24–2 and ground? — G o to Step 18 Go to Step 17

17 Replace the triple pressure switch.

Is the action complete? — Verify repair —

18 Replace the auto air conditioner control unit.

Is the action complete? — Verify repair —

Chart “B" Condenser Fan Does Not Stop

Step Action Value(s) Yes No

1 1. Turn on the ignition switch “ON" (the engine is

run).

2. Air conditioning switch “OFF".

3. Disconnect the triple pressure switch.

Does the condenser fan stop? — Go to Step 2 Go to Step 3

2 Replace the triple pressure switch.

Is the action complete? — Verify repair —

3 Disconnect the relay.

Is there continuity between the harness side

connector terminal No.X11–3 and ground? — Go to Step 4 Go to Step 5

4 Repair short circuit between terminal No.X11–3 and

No.C11–4.

Is the action complete? — Go to Step 3 —

5 Replace the relay condenser fan.

Is the action complete? — Verify repair —

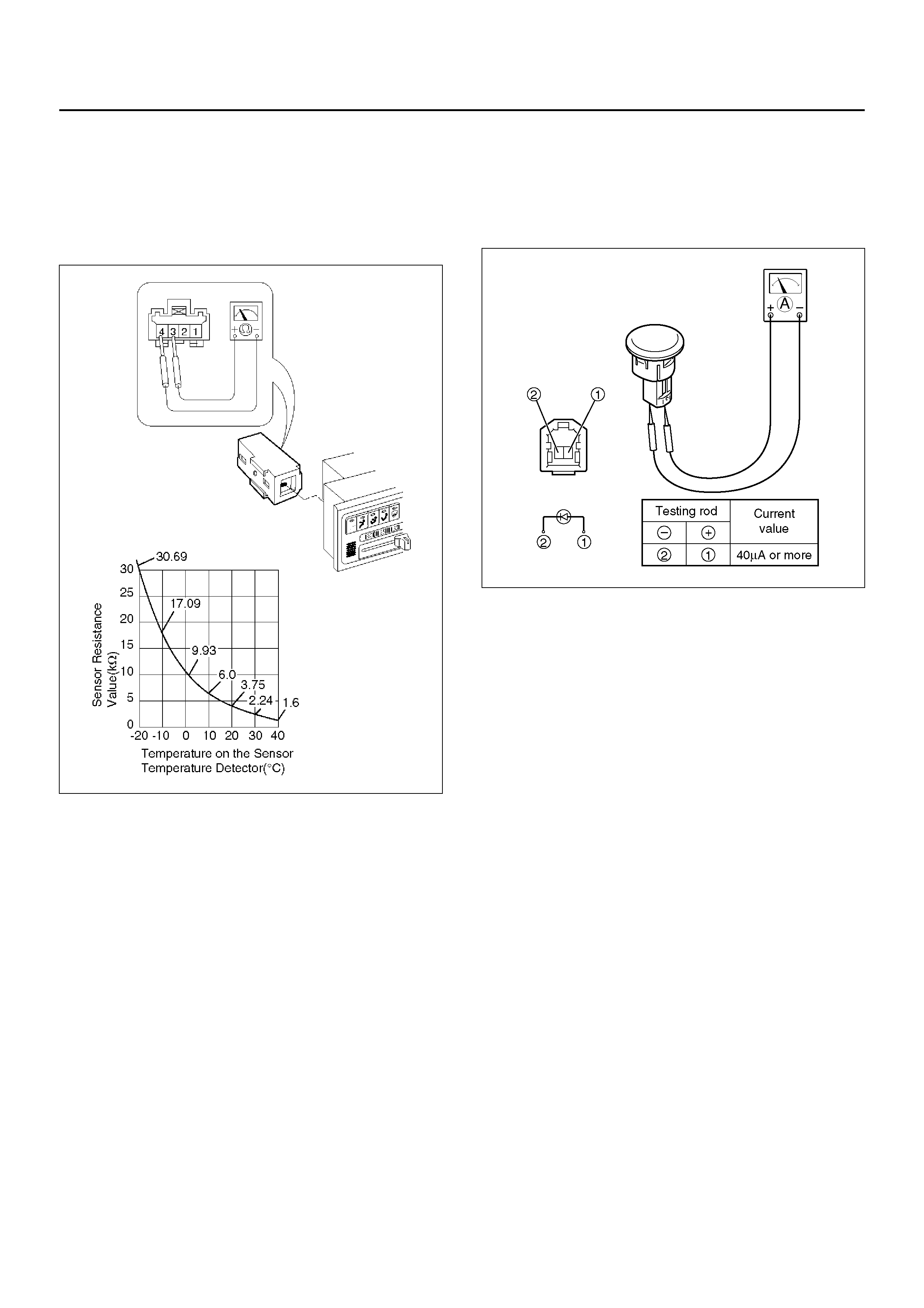

INDIVIDUAL INSPECTION

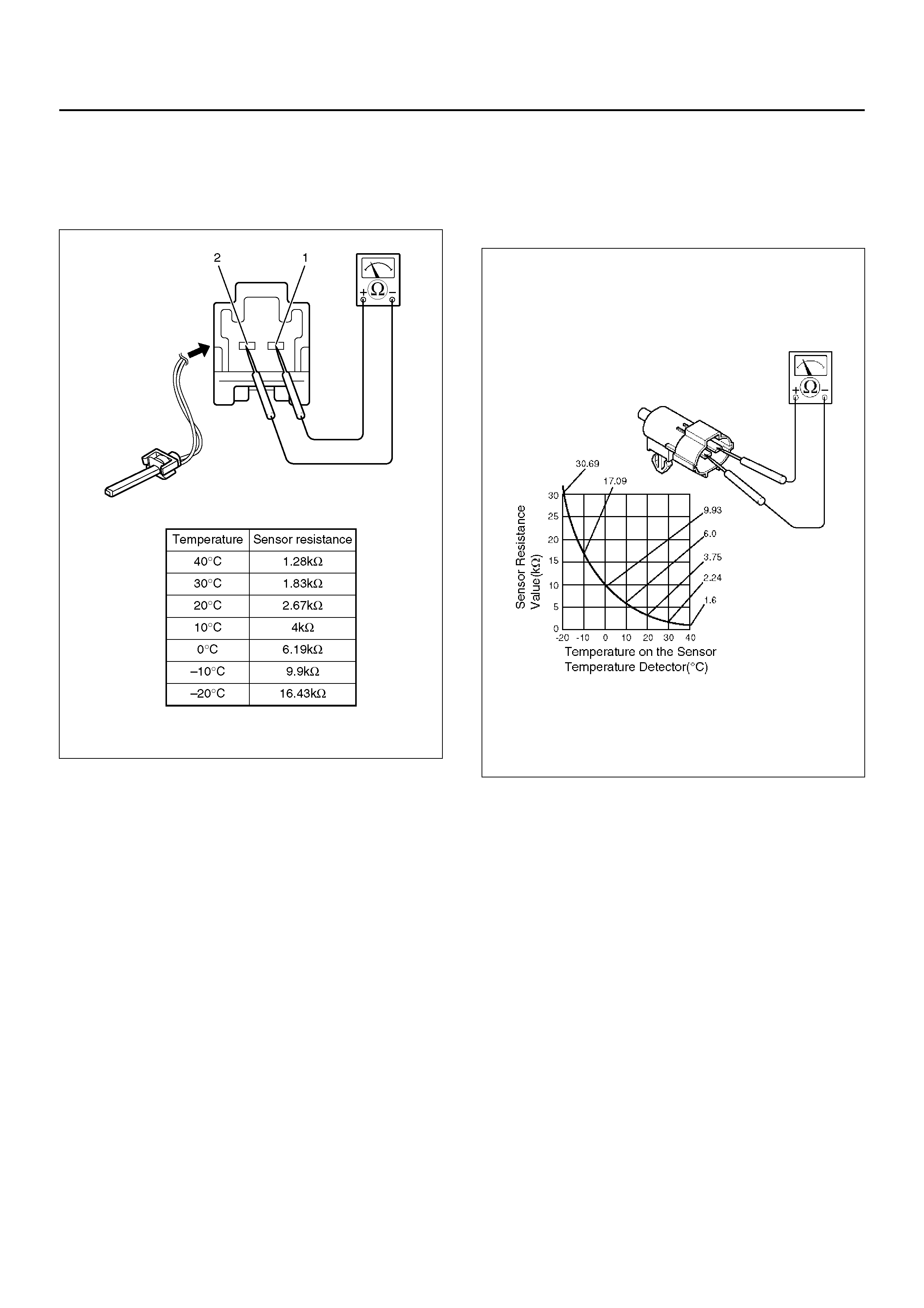

In Car Sensor

1. Disconnect the in car sensor connector (I–4).

2. Measure resistance between the in car sensor side

terminal No.I4–3 and No.I4–4.

865RX007

Sun Sensor

1. Disconnect the sun sensor connector (I–50).

2. Measure th e current value on the sun sensor when

placed it approximately 15 cm away from 60W

incandescent lamp.

D06R200001

Duct Sensor

1. Disconnect the duct sensor connector (C–64).

2. Measure resistance between the duct sensor side

terminal No.C64–1 and No.C64–2.

C01R100006

Ambient Sensor

1. Disconnect the connector (C–8) on the ambient

sensor.

2. Measure resistance between the ambient sensor

side terminals.

C01RX012

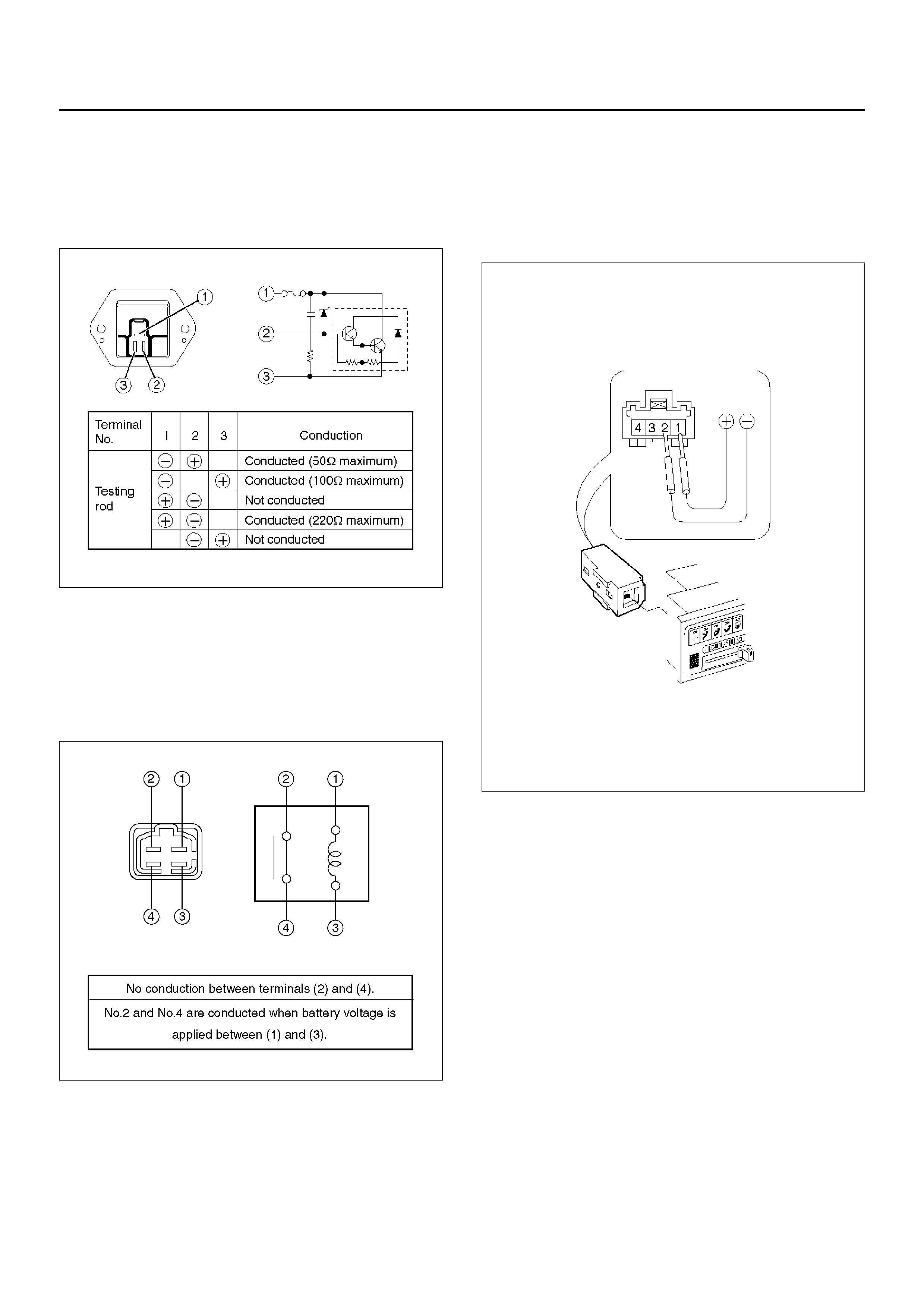

Power Transistor

1. Remove the power transistor connector (C–66) from

the evaporator assembly.

2. Check the cond uction b etween the power tra nsistor

side terminals.

C01RX015

MAX HI Relay

1. Remo ve the MA X – HI rela y connec tor (C–67) from

the blower assembly.

2. Check the conduction between the MAX – HI relay

side terminals.

C01R100001

In Car Sensor

1. Turn on the ignition switch (the engine is started).

St art the air conditioner in “Auto".

2. Make sure that the interior sensor suctions cigarette

smokes and such.

In Car Sensor

1. Dismount the in car sensor from the automatic

heater/air conditioner control unit. Connect (+)

end and (-) end of the battery to the aspirator motor

side terminals No.I4–1 and No.I4–2, respectively,

then check if the motor runs normally.

C01RW020

Thermostat (X-8), Condenser Fan (X-11)

Relay

1. Disconnect relays and check for continuity and

resistance between relay terminals.

• For handling of these relays, refer to Heater

Relay in this section.

C01R100002

Heater (X–1), Compr ess or (X– 2) Relay

1. Disconnect relays and check for continuity and

resistance between relay terminals.

• For handling of these relays, refer to Heater

Relay in this section.

C01R200011

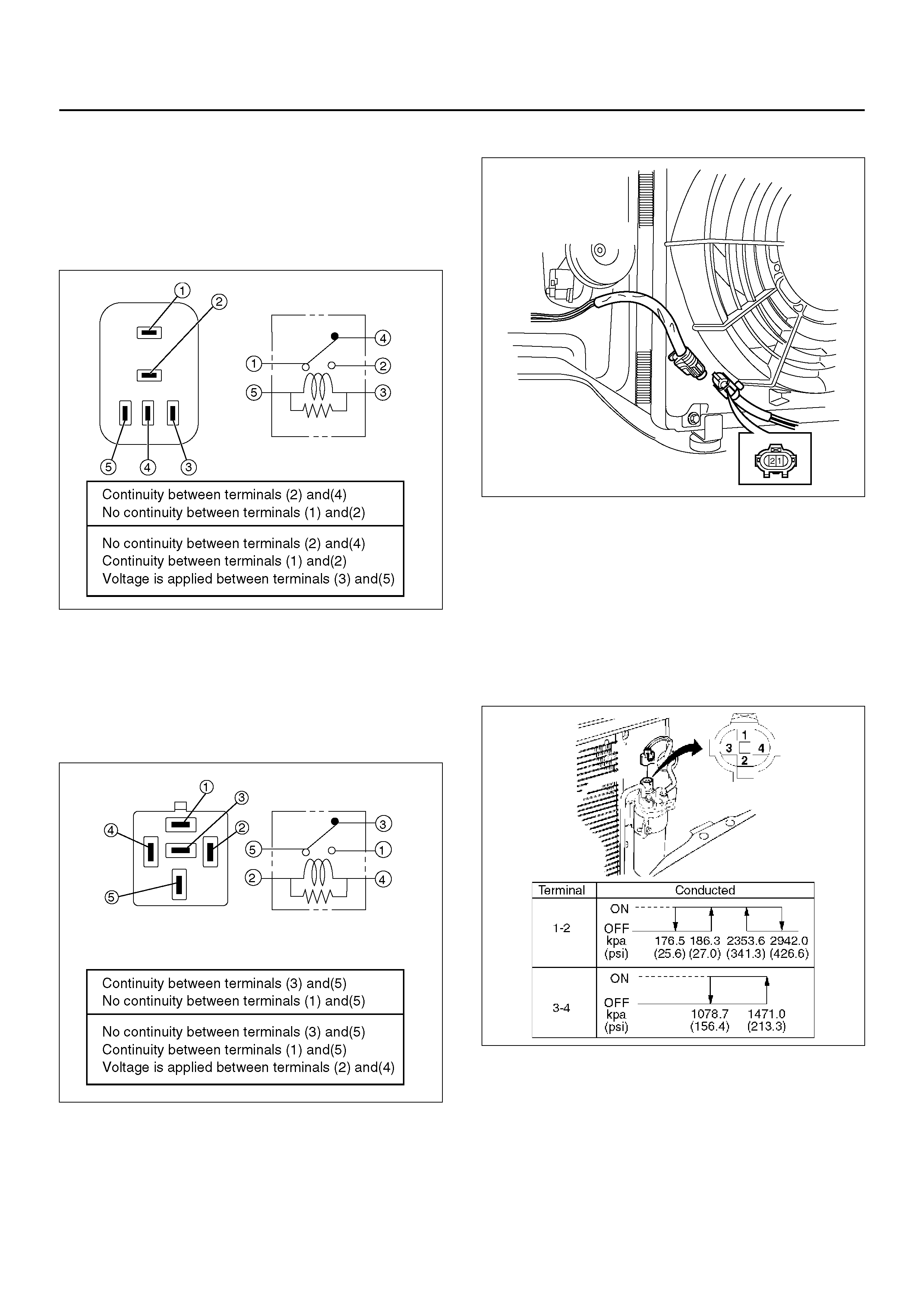

Condenser Fan

1. Disconnect the condenser fan connector.

2. Connect the battery positive terminal to the

conden ser fan side conn ector terminal N o.C24-2

and negative to the No.C24-1.

3. Check that condenser fan is rotating correctly.

875RW010

Triple Pressure Swit ch (V 6, A/T)

1. Disconnect the connector and check for continuity

between pressure switch side connector

terminals (1) and (2).

2. Reconne ct the conn ec tor to a ct iv ate t he A /C s wit ch ,

and check to see if there is continuity between the

chassis side connector terminal (3) and (4) and the

fan operates.

875RX009

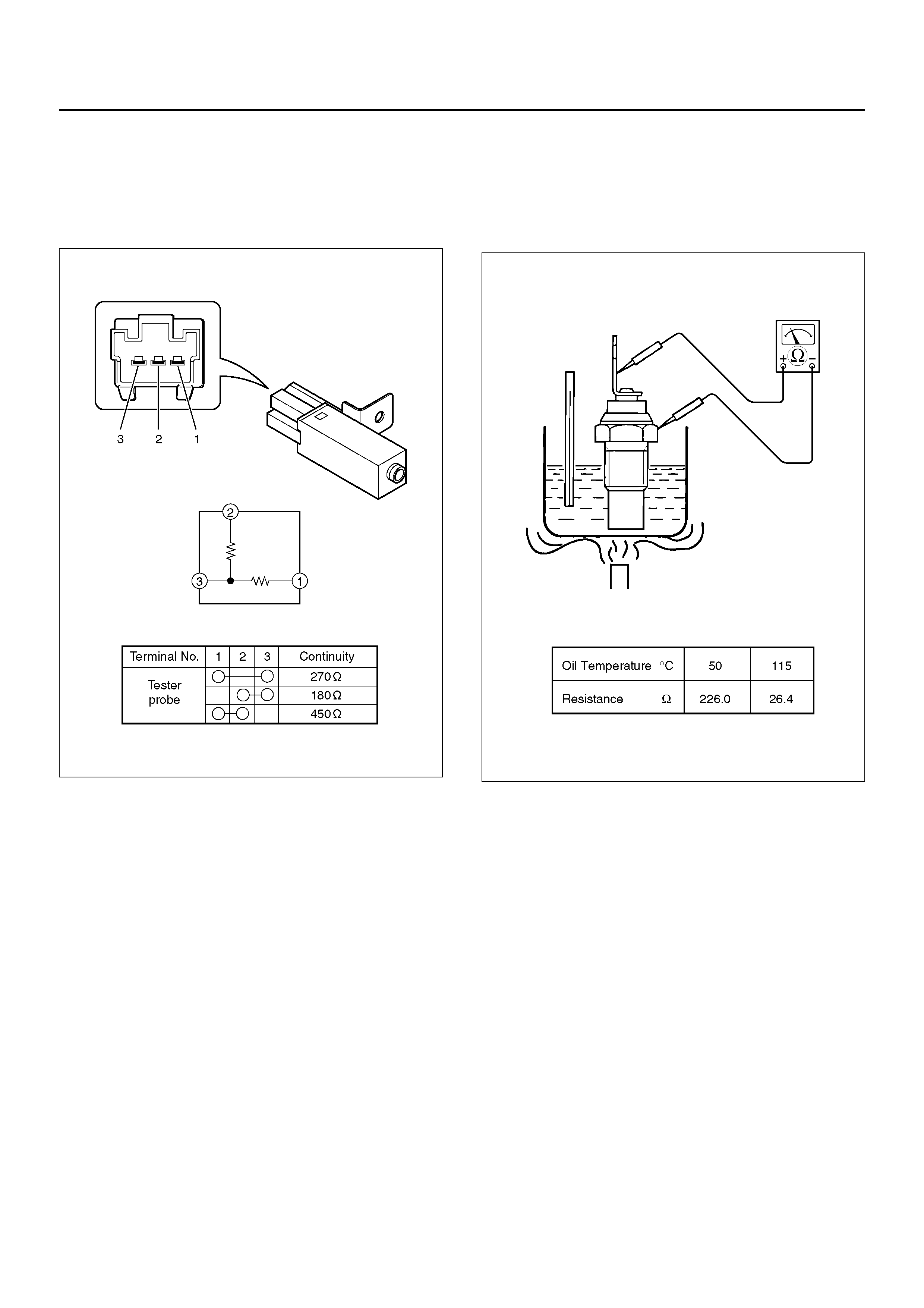

Resistor

1. Disconnect the resistor connector (C-73) from the

heater unit assembly.

2. Check the continuity and resistance value between

the resistor terminals.

C01R100004

Thermo Unit

1. Submerge the sensor portion of the thermo unit in

the oil.

2. Heat the oil.

3. Check the resistance valve of the unit.

C01R100007

ON-VEHICLE SERVICE

POWER TRANSISTOR

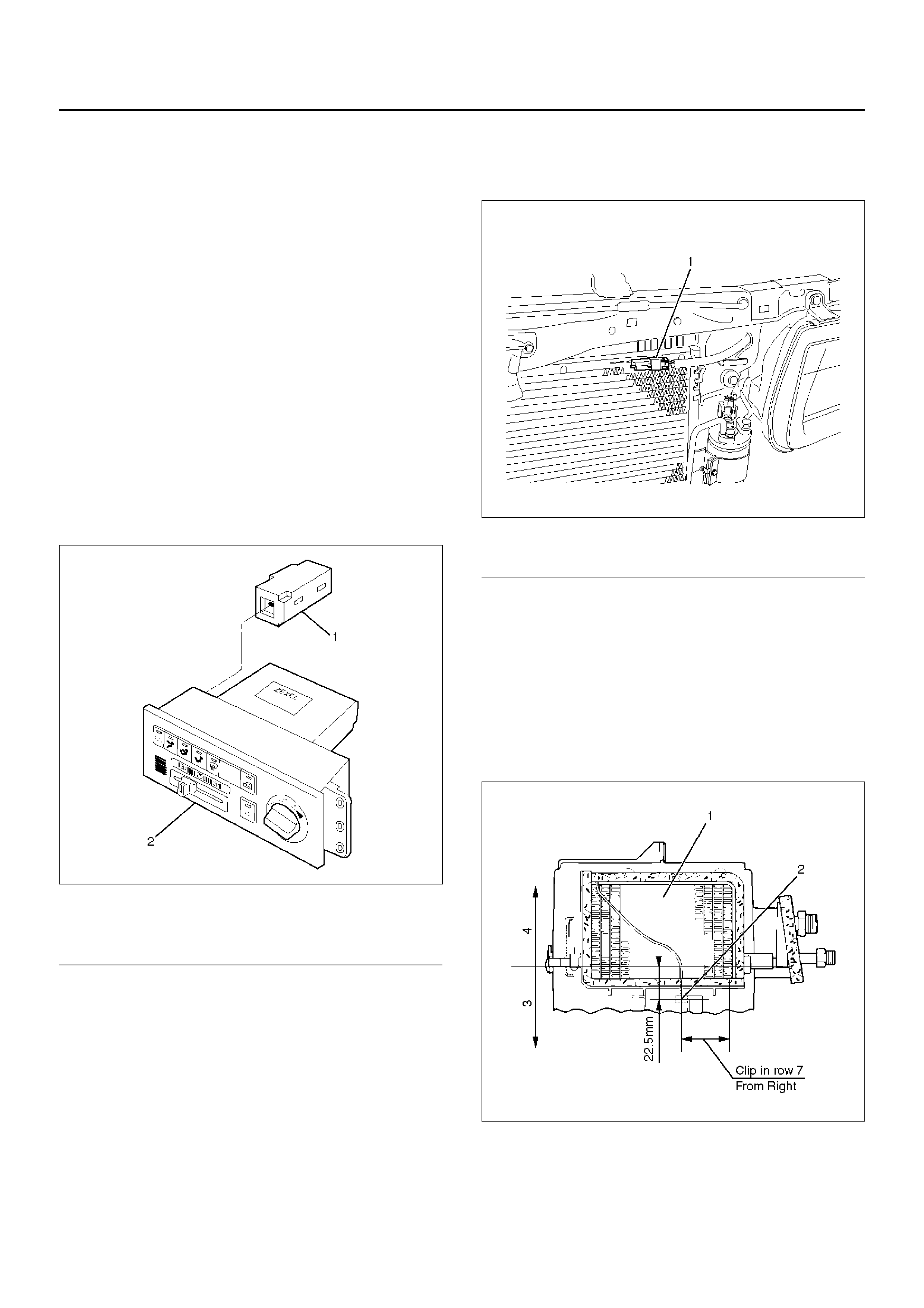

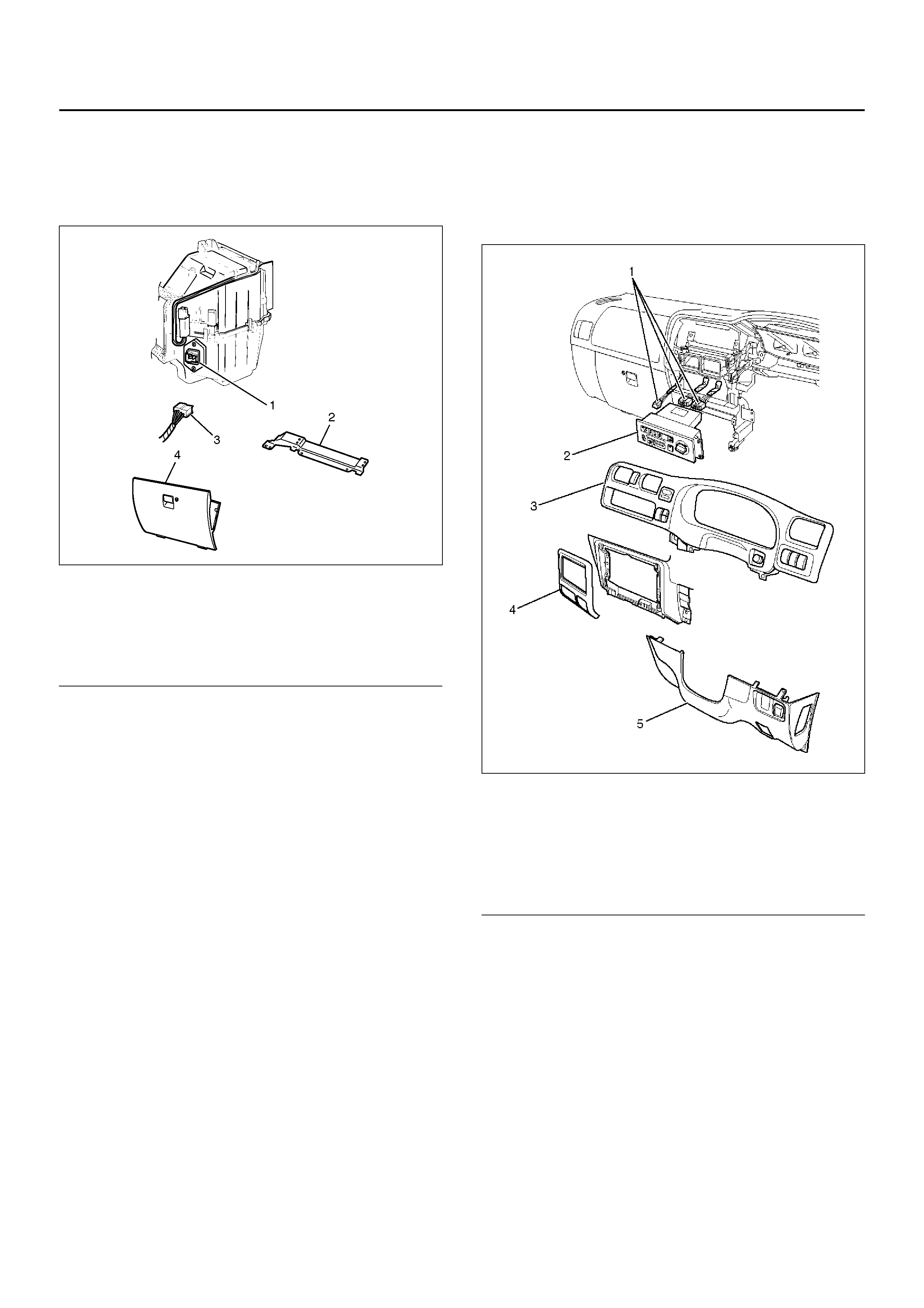

874R100006

EndOFCallout

REMOVAL

1. Remove glove box.

2. Remove passenger knee bolster reinforcement.

3. Disconnect the power transistor connector.

4. Remove power transistor.

INSTALLATION

To install, follow the removal step in the reverse order.

AUTOMATIC AIR CONDITIONER

CONTROL UNIT

865RW016

EndOFCallout

REMOVAL

1. Disconnect the battery ground cable.

2. Remove instrument lower cover.

3. Remove meter cluster assembly.

• Refer to Instrument Panel Assembly in Body

Structure section.

4. Remove the automatic air conditioner control unit

attaching screws.

5. Pull the automatic air conditioner unit out and

disconnect the connectors.

INSTALLATION

To install, follow the removal step in the reverse order.

Legend

(1) Power Transistor

(2) Passenger knee bolster Reinforcement

(3) Power Transistor Connector

(4) Glove Box

Legend

(1) Connector

(2) Automatic Air Control Unit

(3) Meter Cluster Assembly

(4) Instrum ent Center Cluster

(5) Instrum ent Lowe r Cover

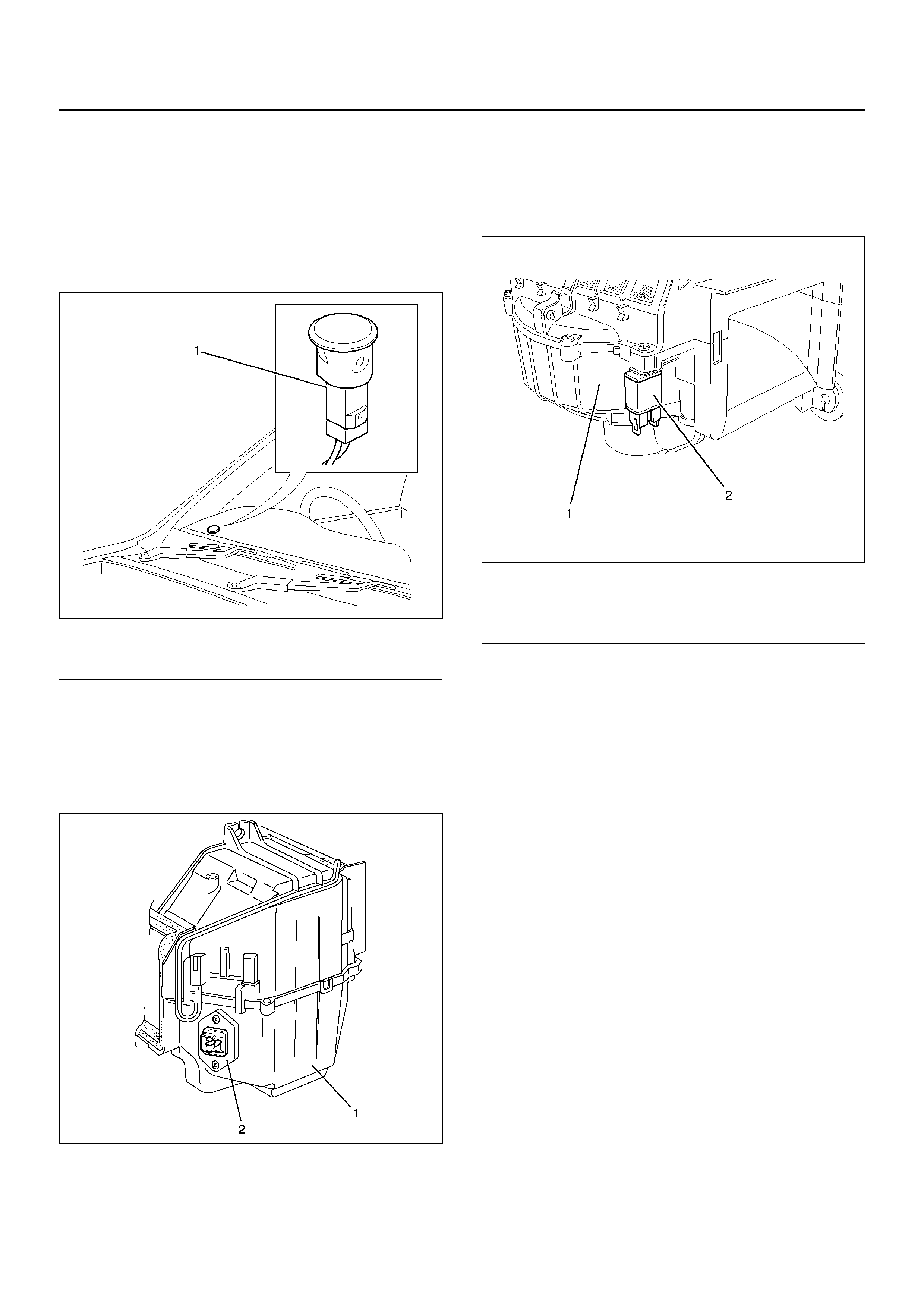

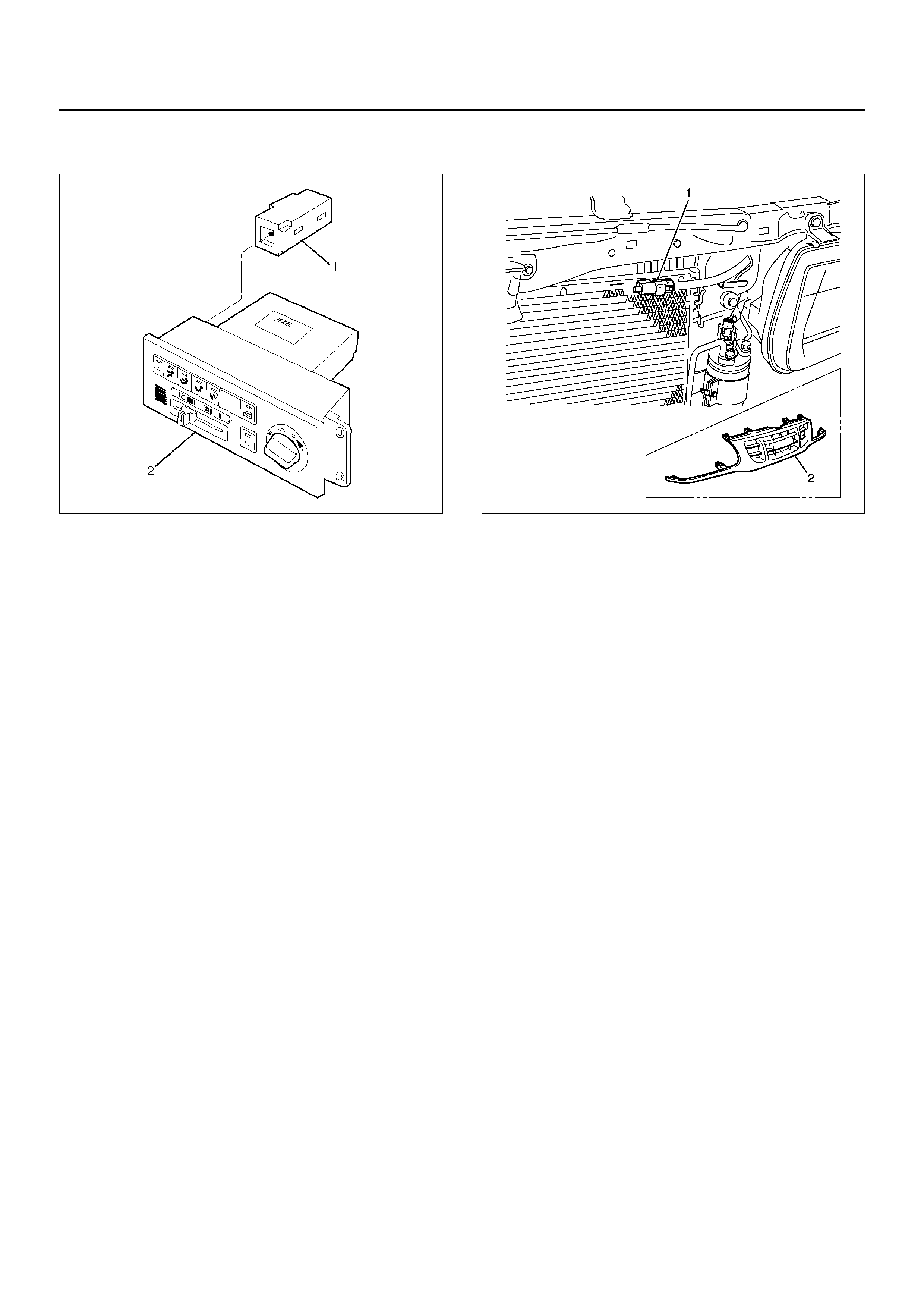

IN CAR SENSOR

865RW014

EndOFCallout

REMOVAL

1. Disconnect the battery ground cable.

2. Remove the automatic air conditioner control unit.

• Refer to the automatic air conditioner control unit

section.

3. Remove in car sensor.

INSTALLATION

To install, follow the removal step in the reverse order.

AMBIENT SENSOR

875R100006

EndOFCallout

REMOVAL

1. Disconnect the battery ground cable.

2. Remove radiator grille.

• Refer to Radiator Grille in Body Structure section.

3. Disconnect the ambient sensor connector.

4. Remove the ambient sensor.

INSTALLATION

To install, follow the removal step in the reverse order.

Legend

(1) In Car Sensor

(2) Automatic Air Control Unit

Legend

(1) Ambient Sensor

(2) Radiator Grille

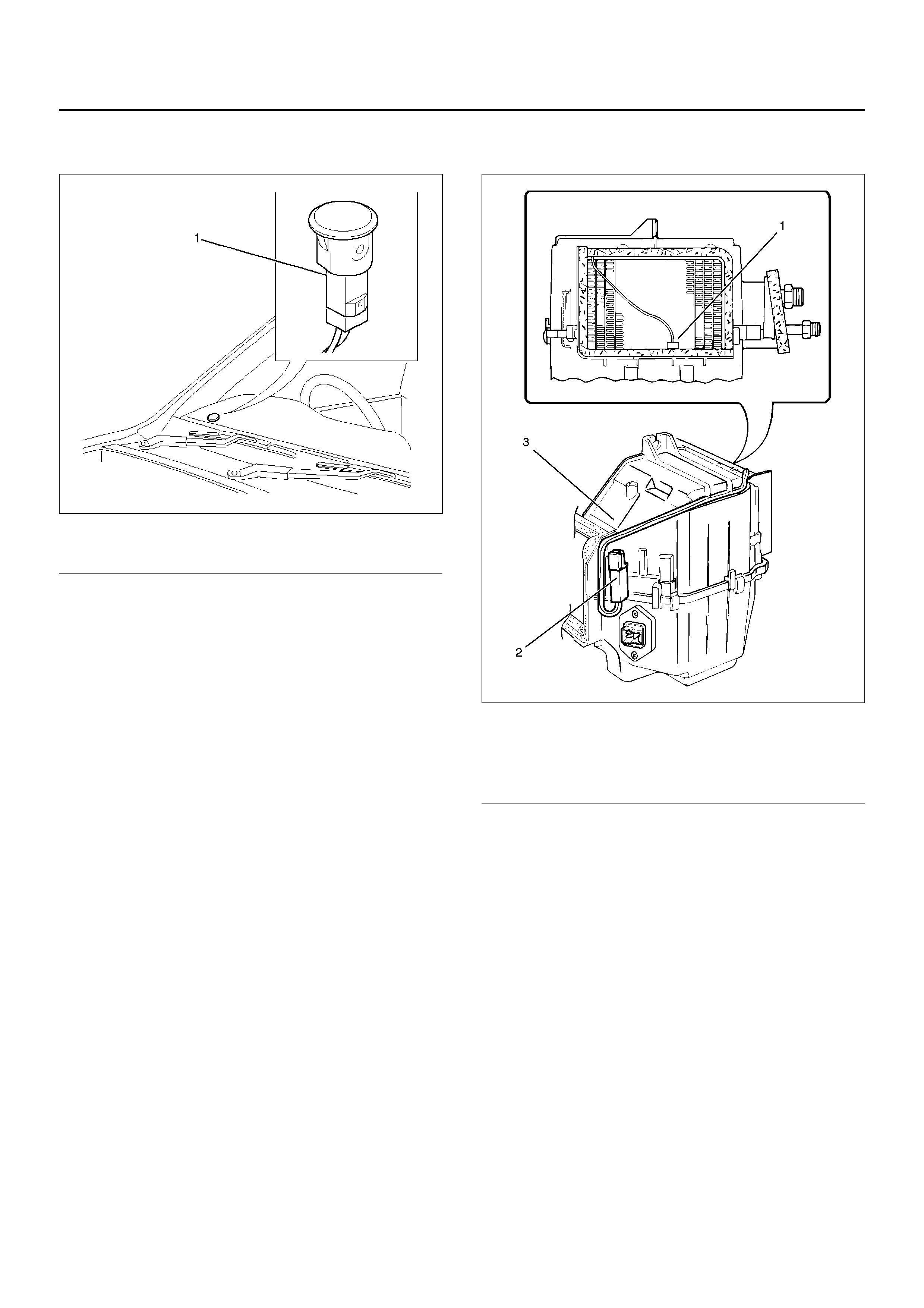

SUN SENSOR

865RW009

EndOFCallout

REMOVAL

1. Disconnect the battery ground cable.

2. Remove the sun sensor.

3. Disconnect the sun sensor connector.

INSTALLATION

To install, follow the removal step in the reverse order.

DUCT SENSOR

874RY00002

EndOFCallout

REMOVAL

1. Disconnect the battery ground cable.

2. Remove the evaporator assembly.

• Refer to Evaporator Assembly section.

3. Remove the duct sensor assembly.

INSTALLATION

To install, follow the removal step in the reverse order.

Legend

(1) Sun Sensor

Legend

(1) Sensor Part

(2) Duct Sensor Assembly

(3) Evapolator Assembly

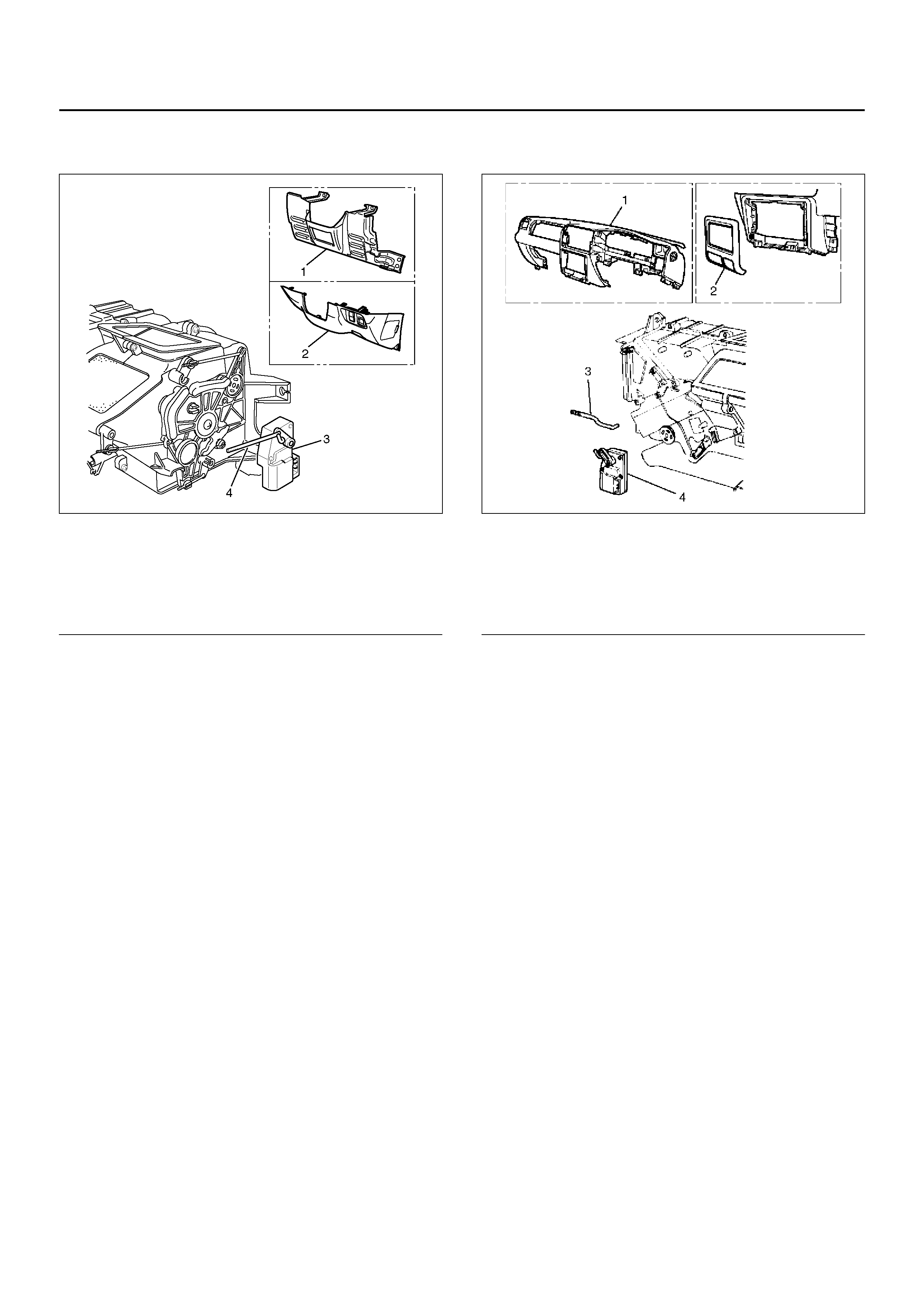

MODE ACTUATOR

860R100002

EndOFCallout

REMOVAL

1. Disconnect the battery ground cable.

2. Remove the instrument panel driver lower cover.

3. Remove the driver knee bolster assembly.

• Refer to the Instrument Panel Assembly in Body

Structure section.

4. Remove the actuator rod.

5. Remove the mode actuator.

INSTALLATION

To install, follow the remove step in the reverse order.

MIX ACTUATOR

860RW033

EndOFCallout

REMOVAL

1. Disconnect the battery ground cable.

2. Remove the instrument panel assembly.

• Refer to the Instrument Panel Assembly in Body

Structure section.

3. Remove the instrument panel center cluster.

4. Remove the actuator rod.

5. Remove the mix actuator.

INSTALLATION

To install, follow the remove step in the reverse order.

Legend

(1) Driver Knee Bolster Assembly

(2) Instrument Panel Driver Lower Cover

(3) Mode Actuator

(4) Actuator Rod

Legend

(1) Instr um ent Pa nel Assemb ly

(2) Instrument Panel Center Cluster

(3) Actuator Rod

(4) Mix Actuator

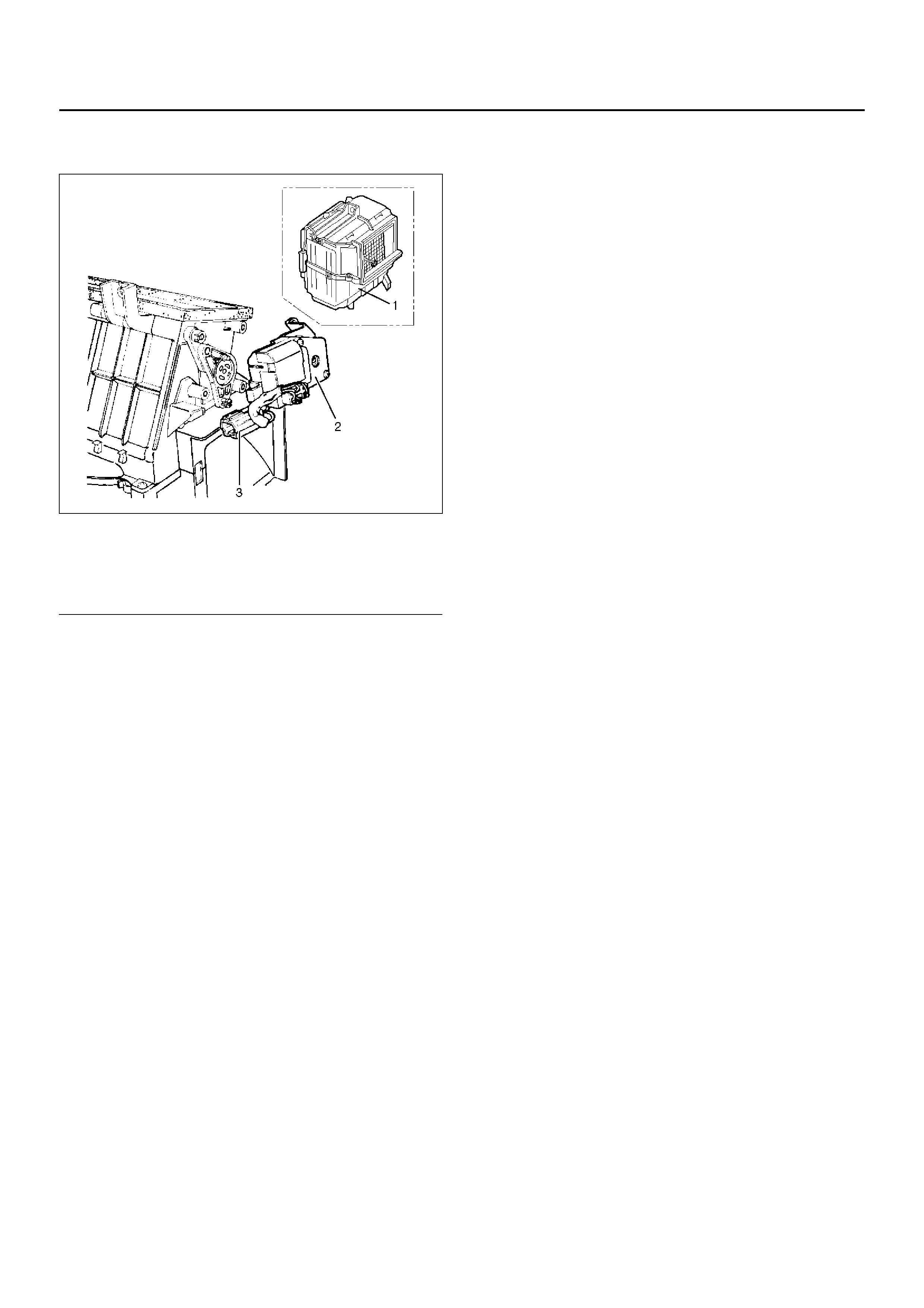

INTAKE ACTUATOR

860RX018

EndOFCallout

REMOVAL

1. Disconnect the battery ground cable.

2. Remove the blower assembly.

• Refer to Blower Assembly section.

3. Disconnect the intake actuator connector.

4. Remove the intake actuator.

INSTALLATION

To install, follow the remove step in the reverse order.

Legend

(1) Evaporator Assembly

(2) Intake Actuator

(3) Intake Actuator Connector