SECTION 3C - FRONT SUSPENSION

Service Precaution

General Description

Diagnosis

Shock Absorber

Shock Absorber and Associated Parts

Removal

Inspection and Repair

Installation

Stabilizer Bar

Stabilizer Bar and Associated Parts

Removal

Inspection and Repair

Installation

Torsion Bar

Torsion Bar and Associated Parts

Removal

Inspection and Repair

Installation

Knuckle

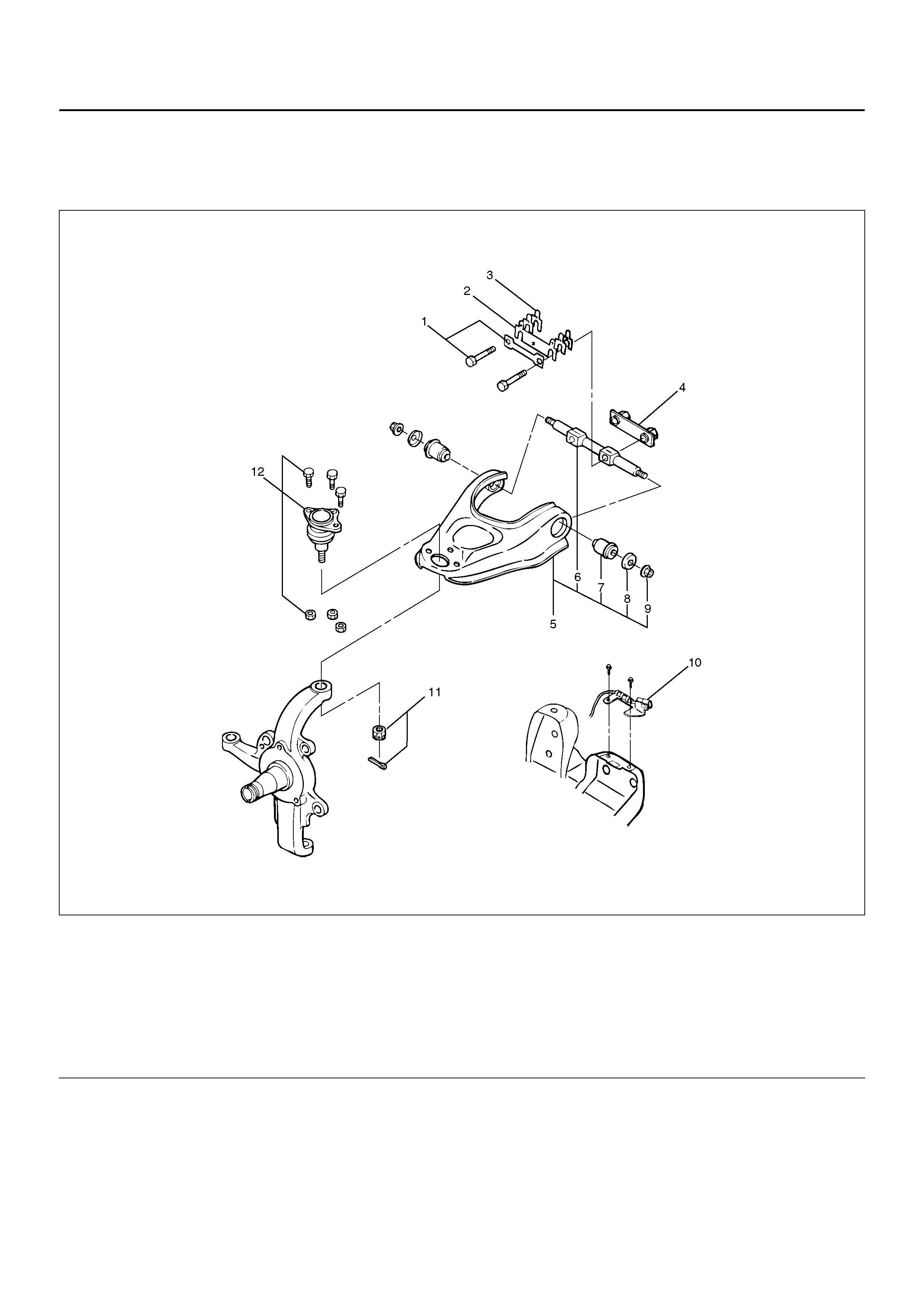

Knuckle and Associated Parts

Removal

Inspection and Repair

Installation

Upper Control Arm

Upper Control Arm and Associated Parts

Removal

Inspection and Repair

Installation

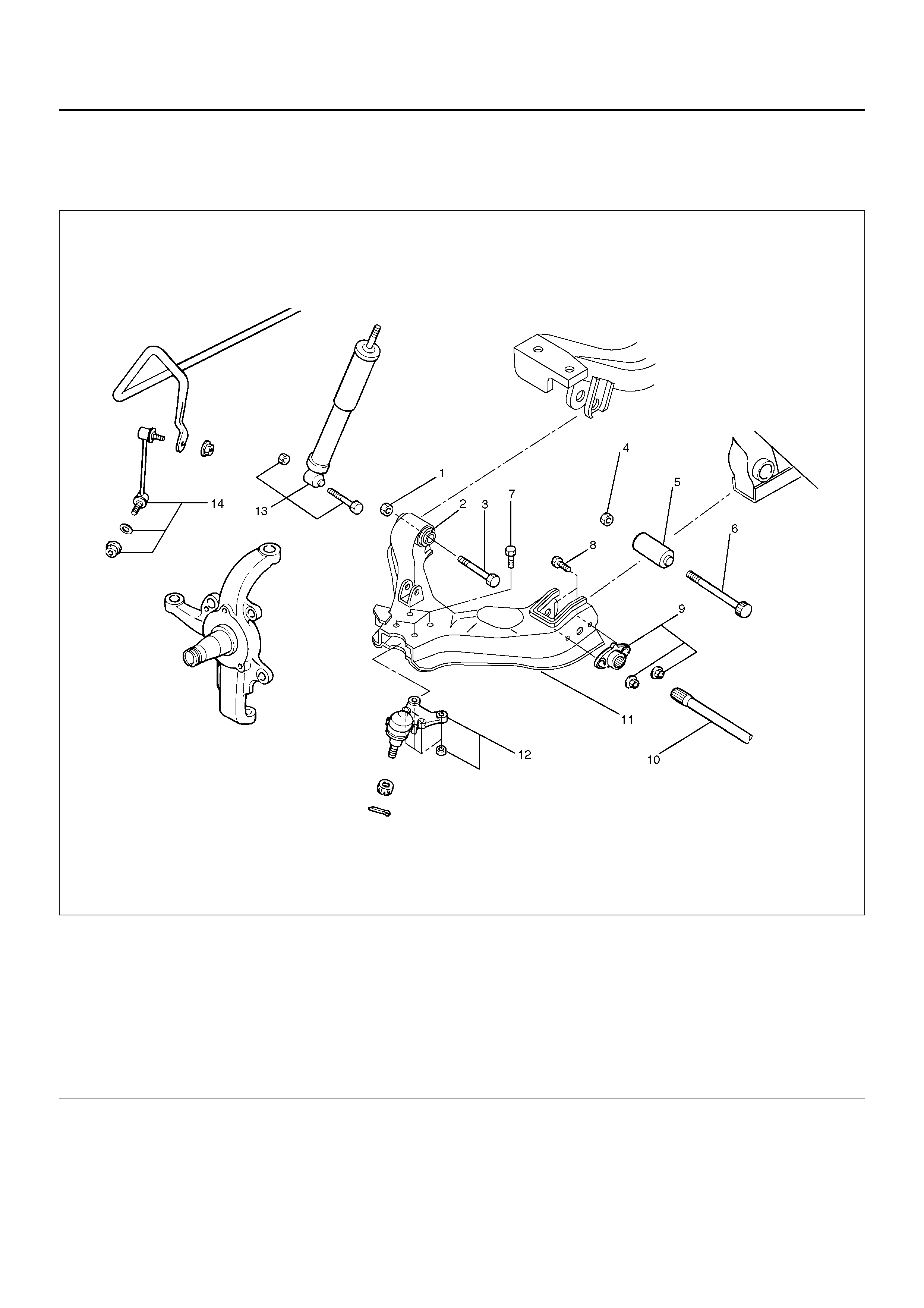

Lower Control Arm

Lower Control Arm and Associated Parts

Removal

Inspection and Repair

Installation

Upper Ball Joint

Upper Ball Joint and Associated Parts

Removal

Inspection and Repair

Installation

Lower Ball Joint

Lower Ball Joint and Associated Parts

Removal

Inspection and Repair

Installation

Main Data and Specifications

Steering Wheel Free Play Inspection

Front End Alignment Inspection and Adjustment

Main Data and Specifications

Special Tools

SERVICE PRECAUTION

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fasteners. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

GENERAL DESCRIPTION

The front suspension is designed to allow each wheel to

compensate for changes in the road surface level

without greatly affecting the opposite wheel. Each

wheel is independently connected to the frame by a

steering knuckle, ball joint assemblies, and upper and

lower control arms. The front wheels are held in proper

relationship to each other by two tie-rods which are

connected to steering arms on the knuckles, and to a

steering unit.

All models have a front suspension system consisting of

control arms, stabilizer bar, shock absorber and a

torsion bar. The front end of the torsion bar is attached

to the lower control arm. The rear of the torsion bar is

mounted into a height control arm at the crossmember.

Vehicle trim height is controlled by adjusting this arm.

Shock absorbers are mounted between the brackets on

the frame and the lower control arms. The lower portion

of each shock absorber is attached to the lower control

arm. The upper portion of each shock absorber extends

through a frame bracket and is secured with two rubber

bushings, two retainers and a nut.

Ball joint assemblies are bolted to the outer end of the

upper and lower control arm and are attached to the

steering knuckle.

The inner ends of the upper control arm have pressed in

bushings. Bolts, passing through the bushing, attach the

control arm to the frame. The inner ends of the lower

control arm are attached to the frame by bolts passing

through the bushings.

Side roll of the front suspension is controlled by a spring

steel stabilizer bar. It is mounted in rubber bushings,

which are held to the frame by brackets. The ends of

the stabilizer bar are connected to the lower control

arms by links.

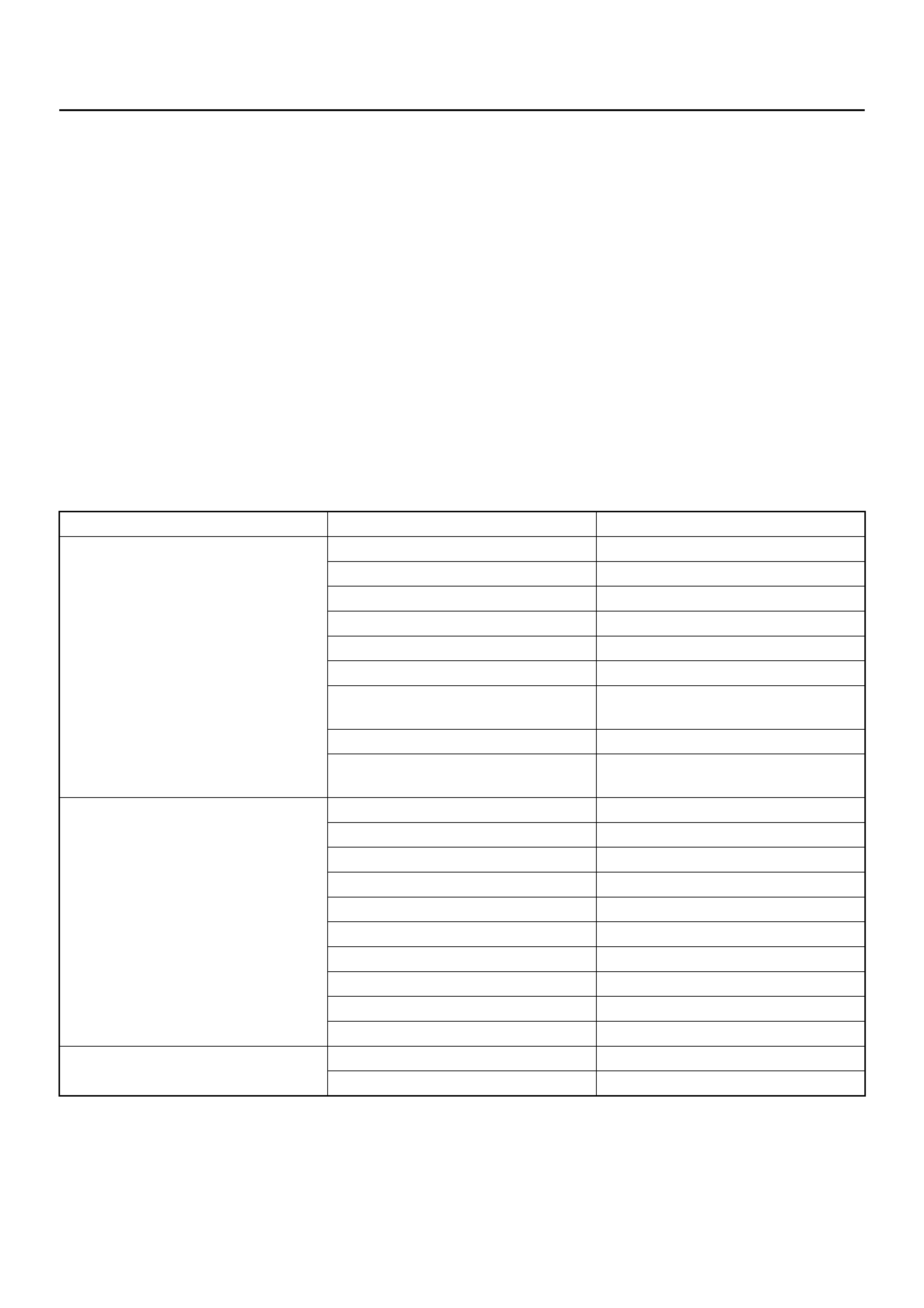

DIAGNOSIS

Condition Possible cause Correcti on

Vehicle Pulls Mismatched or uneven tires. Replace tire.

Tires not adequately inflated. Adjust tire pressure.

Broken or sagging springs. Replace spring.

Radial tire lateral force. Replace tire.

Improper wheel alignment. Adjust wheel alignment.

Brake dragging in one wheel. Repair brake.

Loose, bent or broken front or rear

suspension parts. Tighten or replace the appropriate

suspension part(s).

Faulty shock absorbers. Replace shock absorber.

Parts in power steering valve

defective. Replace power steering unit.

Abnormal or Excessive Tire Wear Sagging or broken spring. Replace spring.

Tire out of balance. Balance or replace tire.

Improper wheel alignment. Check front end alignment.

Faulty shock absorber. Replace shock absorber.

Hard driving. Replace tire.

Overloaded vehicle. Replace tire and reduce load.

Tires not rotated periodically. Replace or rotate tire.

Worn or loose road wheel bearings. Replace wheel bearing.

Wobbly wheel or tires. Replace wheel or tire.

Tires not adequately inflated. Adjust the pressure.

Wheel Hop Blister or bump on tire. Replace tire.

Improper shock absorber operation. Replace shock absorber.

Shimmy, Shake or Vibration Tire or wheel out of balance. Balance wheels or replace tire/or

wheel.

Loose wheel bearings. Replace wheel bearing.

Worn steering linkage ball joints. Replace ball joints.

Worn upper or lower end ball joints. Replace ball joints.

Excessive wheel runout. Repair or replace wheel and/or tire.

Blister or bump on tire. Replace tire.

Excessive loaded radial runout of

tire/wheel assembly. Replace tire or wheel.

Improper wheel alignment. Check wheel alignment.

Loose or worn steering linkage. Tighten or replace steering linkage.

Loose steering unit. Tighten steering unit.

Tires not adequately inflated. Adjust tire pressure.

Loose, bent or broken front or rear

suspension parts. Tighten or replace the appropriate

suspension parts.

Faulty shock absorber. Replace shock absorber.

Hub bearing preload misadjustment. Adjust preload.

Parts in power steering valve

defective. Replace power steering unit.

Hard Steering Bind in steering linkage ball studs,

upper or lower ball joint. Replace ball joint.

Improper wheel alignment. Check wheel alignment.

Tire not adequately inflated. Inflate tires to proper pressure.

Bind in steering column or shaft. Repair or replace.

Improper power steering system

operation. Repair or replace. Refer to Steering

section.

Too Much Play In Steering Wheel bearings worn. Replace wheel bearings.

Loose steering unit or linkage. Retighten or repair.

Worn or loose steering shaft

universal joint. Retighten or replace steering shaft.

Worn steering linkage ball joints. Replace ball joints.

Worn upper or lower end ball joints. Replace ball joints.

Poor Steering Wheel Returnability Bind in steering linkage ball joints. Replace ball joints.

Bind in upper or lower ball joints. Replace ball joints.

Bind in steering column and shaft. Repair or replace.

Bind in steeri ng gear. Check and repair ste ering gear.

Improper wheel alignment. Adjust wheel alignment.

Tires not adequately inflated. Adjust pressure.

Loose steering wheel nut. Retighten.

Worn wheel bearing. Replace.

Misassemble Transfer Gear ASM. Reassemble Transfer Gear to

proper portion.

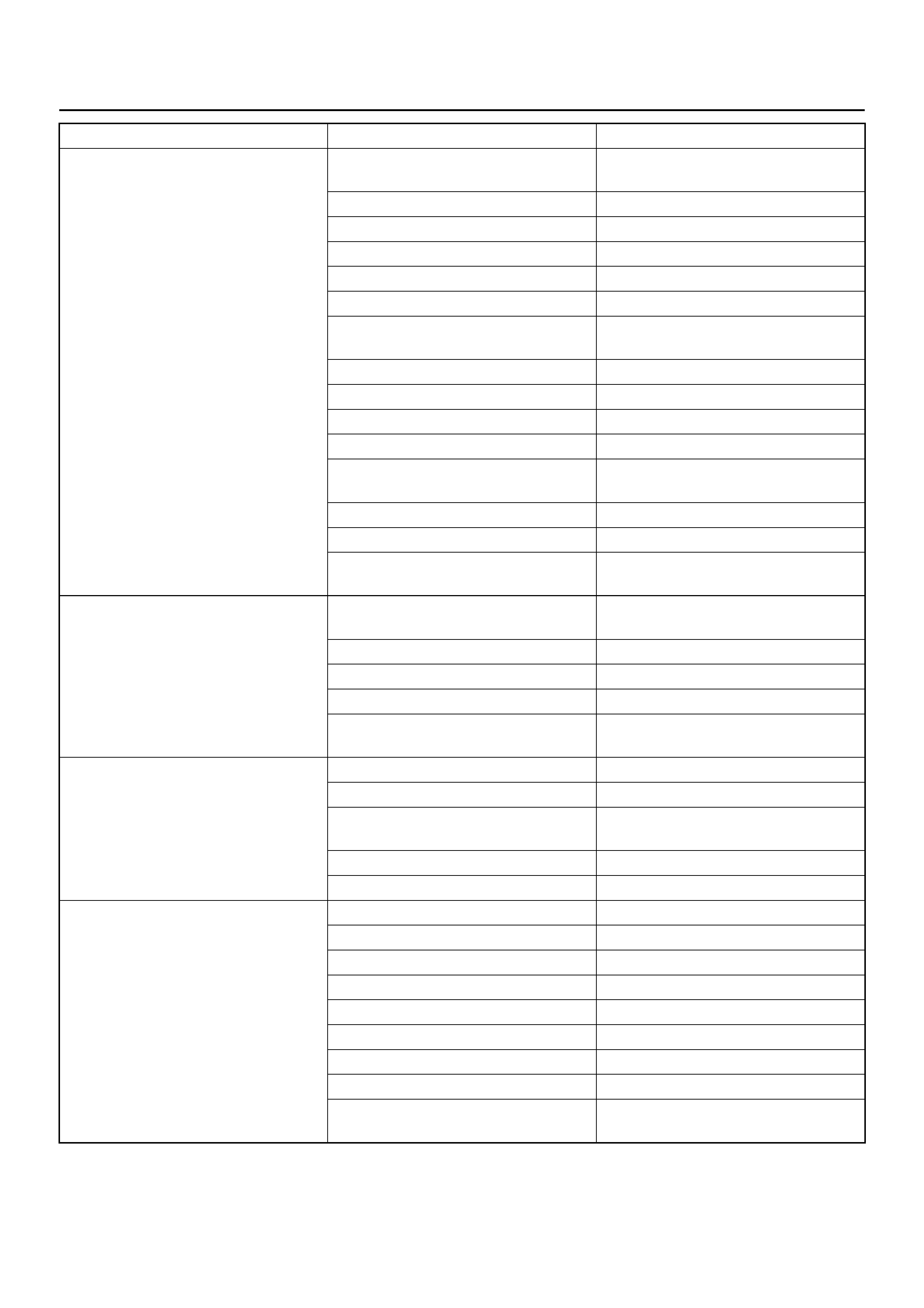

Condition Possible cause Correcti on

Abnormal Noise Worn, sticky or loose upper or lower

ball joint, steering linkage ball joints

or drive axle joints.

Replace.

Faulty shock absorbers. Replace.

Worn upper or lower control arm

bushing. Replace.

Loose stabilizer bar. Retighten bolts or replace bushings.

Loose wheel nuts. Tighten nuts. Check for elongated

wheel nut holes. Replace wheel if

required.

Loose suspension bolts or nuts. Retighten suspension bolts or nuts.

Broken or otherwise damaged

wheel bearings. Replace wheel bearing.

Broken suspension springs. Replace spring.

Loose steering unit. Retighten mounting bolt.

Faulty steering unit. Replace steering unit.

Wandering or Poor Steering Stability Mismatched or unevenly worn tires. Replace tire or inflate tires to proper

pressure.

Loose steering linkage ball joints. Replace ball joints.

Faulty shock absorbers. Replace shock absorber.

Loose stabilizer bar. Tighten or replace stabilizer bar or

bushings.

Broken or sagging springs. Replace spring (pairs).

Improper wheel alignment. Adjust wheel alignment.

Erratic Steering When Braking Worn wheel bearings. Replace wheel bearings.

Broken or sagging springs. Replace spring (pairs).

Leaking caliper. Repair or replace caliper.

Warped discs. Replace brake disc.

Badly worn brake pads. Replace brake pads.

Tires are inflated unequally. Inflate tires to proper pressure.

Low or Uneven Trim Height Broken or sagging springs. Replace springs (In pairs).

Vehicle overloaded. Reduce load.

Incorrect springs. Adjust or replace torsion bar.

Trim Height out of Spec. Adjust Trim Height.

Suspension Bottoms Vehicle overloaded. Reduce load.

Faulty shock absorber. Replace shock absorber.

Incorr e ct, brok en or saggi ng

springs. Replace springs.

Tires are inflated unequally. Inflate tires to proper pressure.

Body Leans Trim Height out of Spec. Adjust Trim Height.

Loose stabilizer bar. Tighten stabilizer bar bolts or

replace bus hi ngs.

Faulty shock absorber, struts or

mounting. Replace shock absorber.

Broken or sagging springs. Replace springs (In pairs).

Vehicle overloaded. Reduce load.

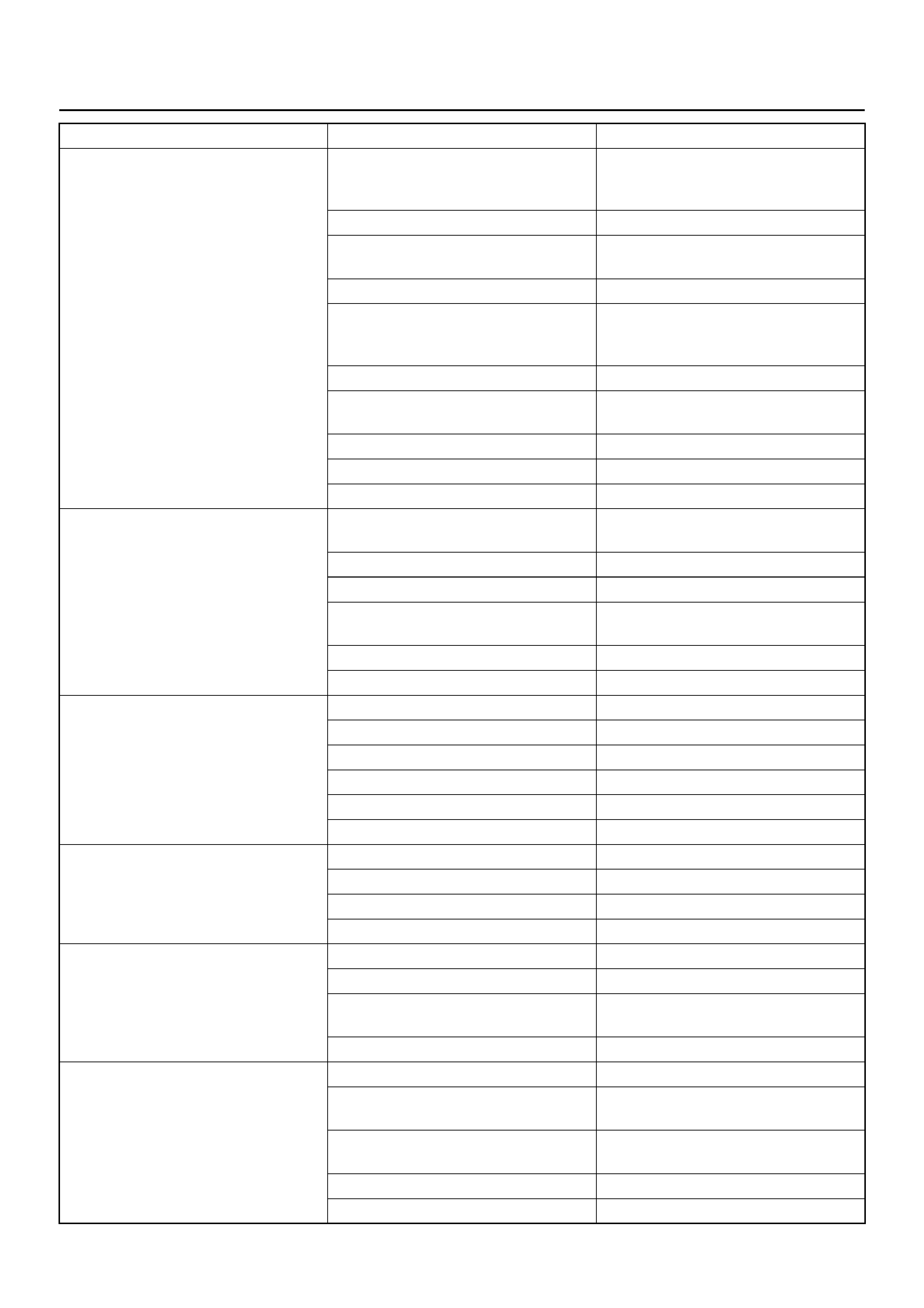

Condition Possible cause Correcti on

Cupped Tires Worn wheel bearings. Replace wheel bearing.

Excessive tire or wheel run out. Replace tire or wheel.

Worn ball joints. Replace ball joints.

Tire out of balance. Adjust tire balance.

Condition Possible cause Correcti on

SHOCK ABSORBER

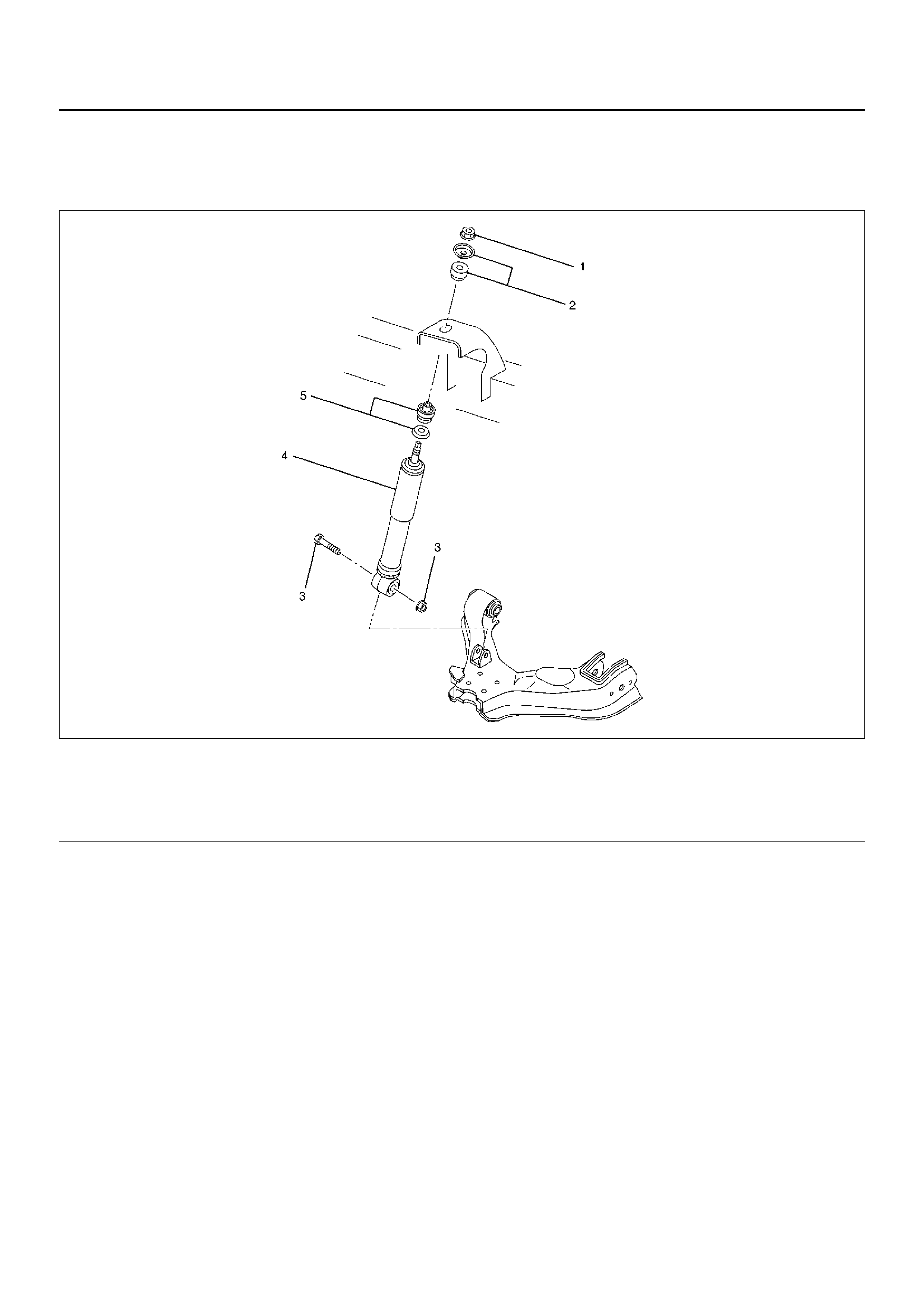

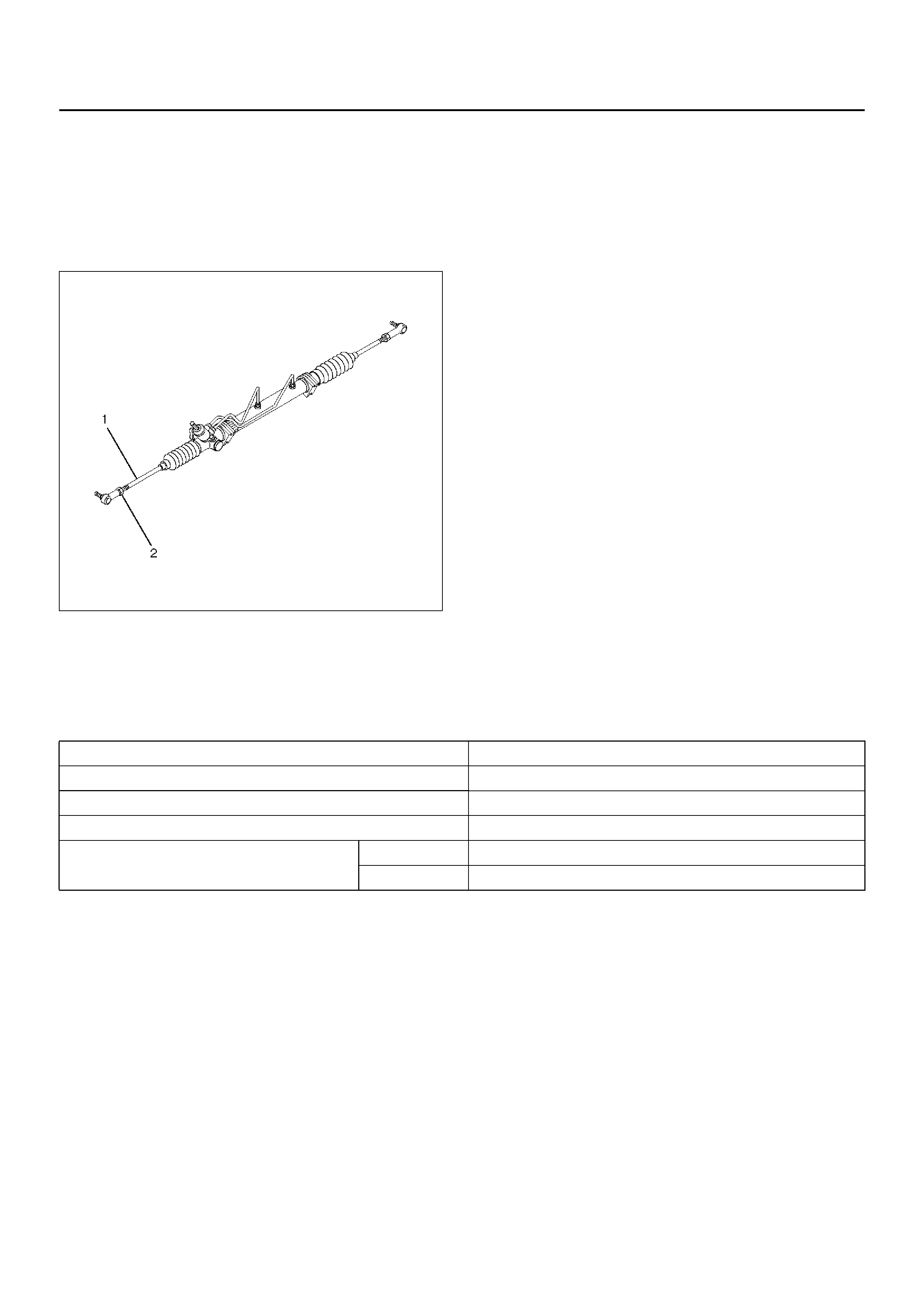

SHOCK ABSORBER AND ASSOCIATED PARTS

450RW009

Legend

EndOFCallout

REMOVAL

1. Raise the vehicle and support it with suitable safety

stands.

2. Remove wheel and tire assembly. Refer to Wheel

Replacement in this section.

3. Remove bolt and nut.

4. Remove nut.

5. Remove rubber bushing and washer.

6. Remove shock absorber.

7. Remove rubber bushing and washer.

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found through inspection.

Check the following parts :

• Shock absorber

• Rubber bushing

INSTALLATION

1. Install rubber bushing and washer.

2. Install shock absorber.

3. Install rubber bushing and washer.

4. Install nut, then tighten it to the specified torque.

Torque: 20N·m (2.0kg·m/14lbft)

5. Install bolt and nut, then tighten to the specified

torque.

Torque: 93N·m (9.5kg·m/69lbft)

(1) Nut

(2) Rubber Bushing and Washer

(3) Bolt and Nut

(4) S hoc k Ab sorber

(5) Rubber Bushing and Washer

STABILIZER BAR

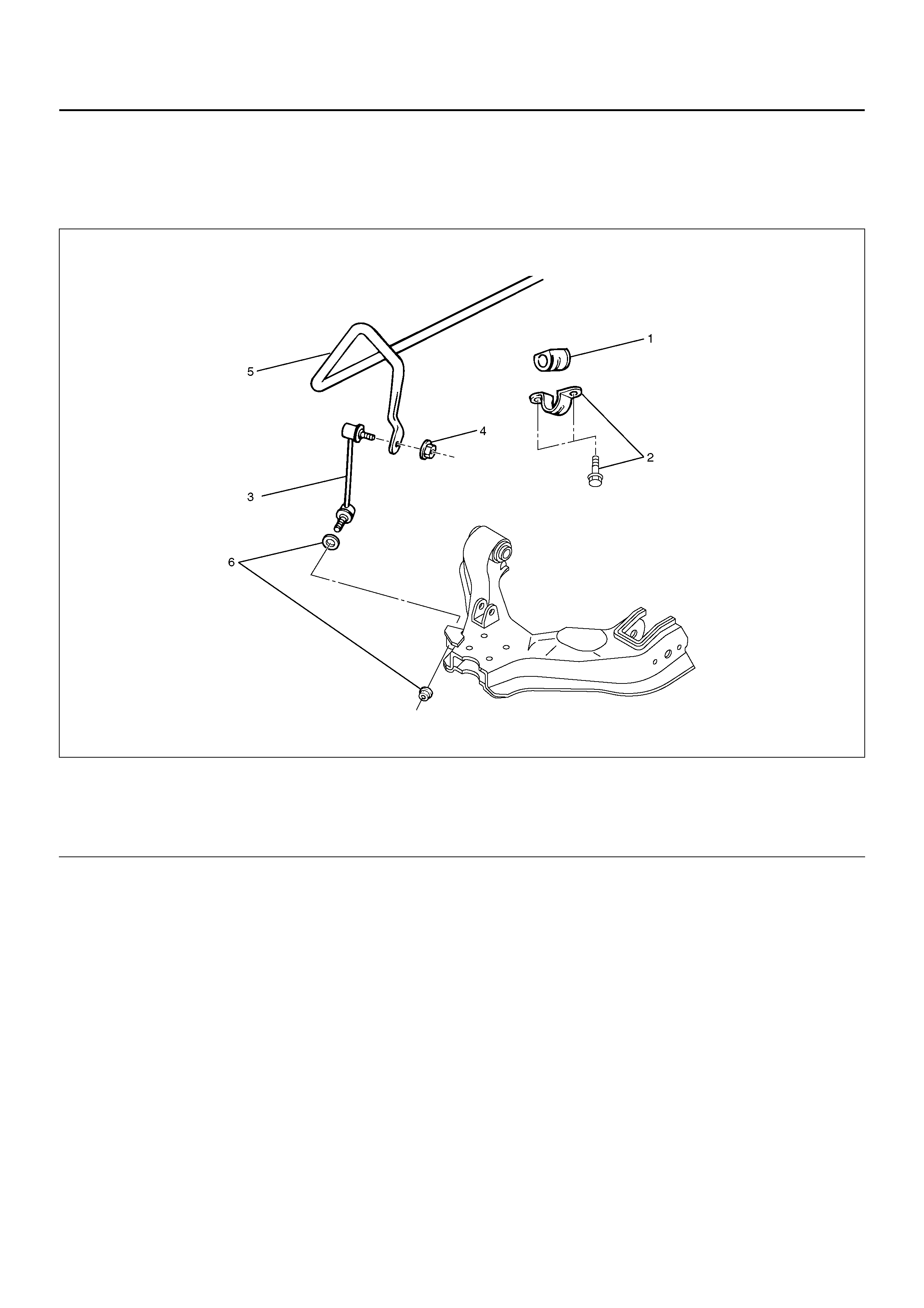

STABILIZER BAR AND ASSOCIATED PARTS

410R100001

Legend

EndOFCallout

REMOVAL

1. Raise the vehicle and support the frame with

suitable safety stands.

2. Remove the stone guard.

3. Remove wheel and tire assembly. Refer to Wheel

Replacement in section 10.

4. Remove nut (4) and (6).

CAUTION: Be careful not to break the ball joint

boot.

5. Remove link.

6. Remove bracket.

7. Remove stabilizer bar.

8. Remove rubber bushing.

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found through inspection.

Check the following parts :

• Stabilizer bar

• Rubber bushing

• Link ball joint

INSTALLATION

1. Install rubber bushing.

2. Install stabi lizer bar.

3. Install bracket and bolt, then tighten it to the

specified torque.

Torque: 25N·m (2.6kg·m/18lbft)

4. Install link.

5. Install nut (4), (6) and washer, then tighten it to the

specified torque.

Torque: 50N·m (5.1kg·m/37lbft)

(1) Rubber Bushing

(2) Bracket and Bolt

(3) Link

(4) Nut

(5) Stabili zer Bar

(6) Nut and Washer

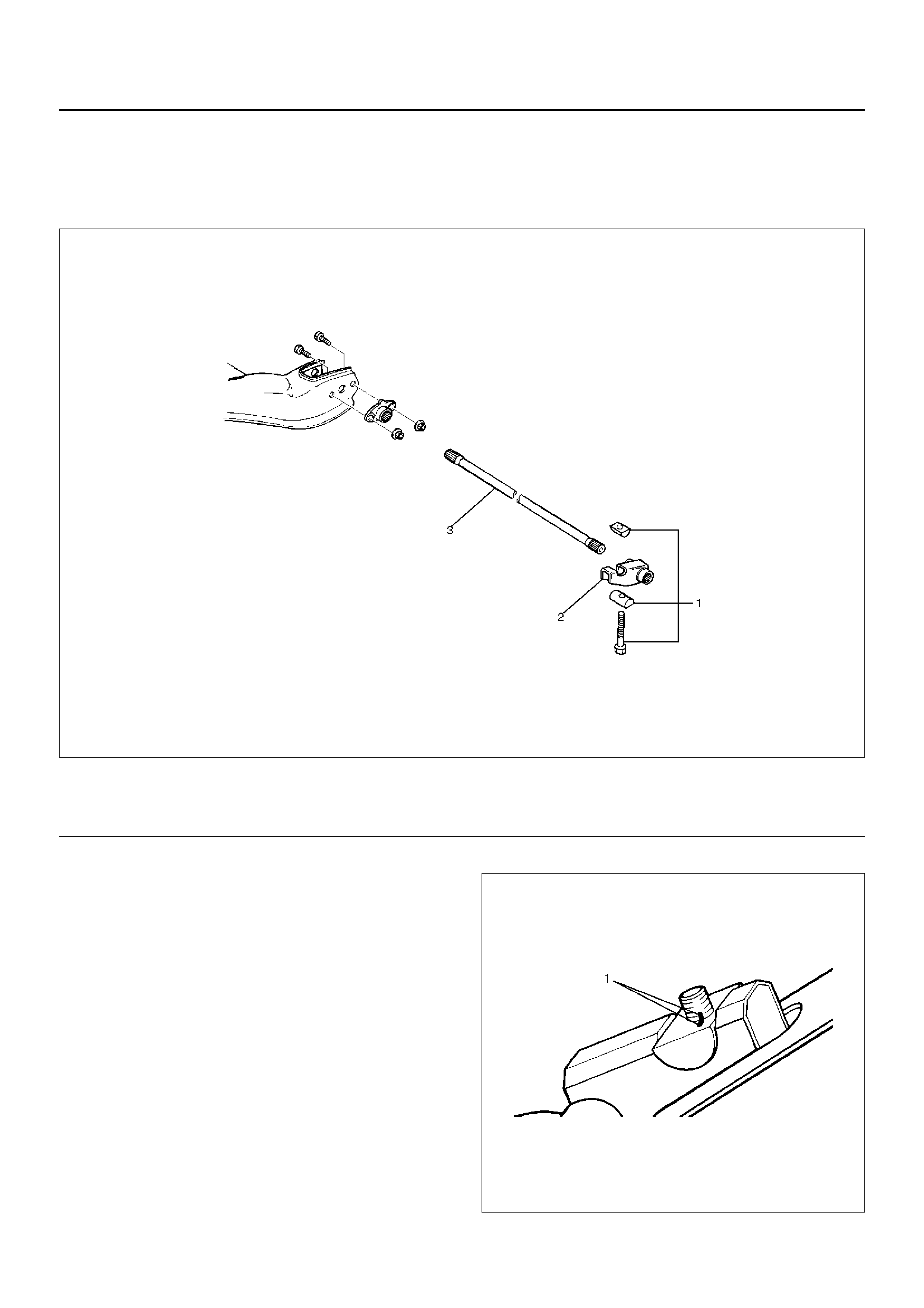

TORSION BAR

TORSION BAR AND ASSOCIATED PARTS

410RS003

Legend

EndOFCallout

REMOVAL

1. Raise the vehicle and support the frame with

suitable safety stands.

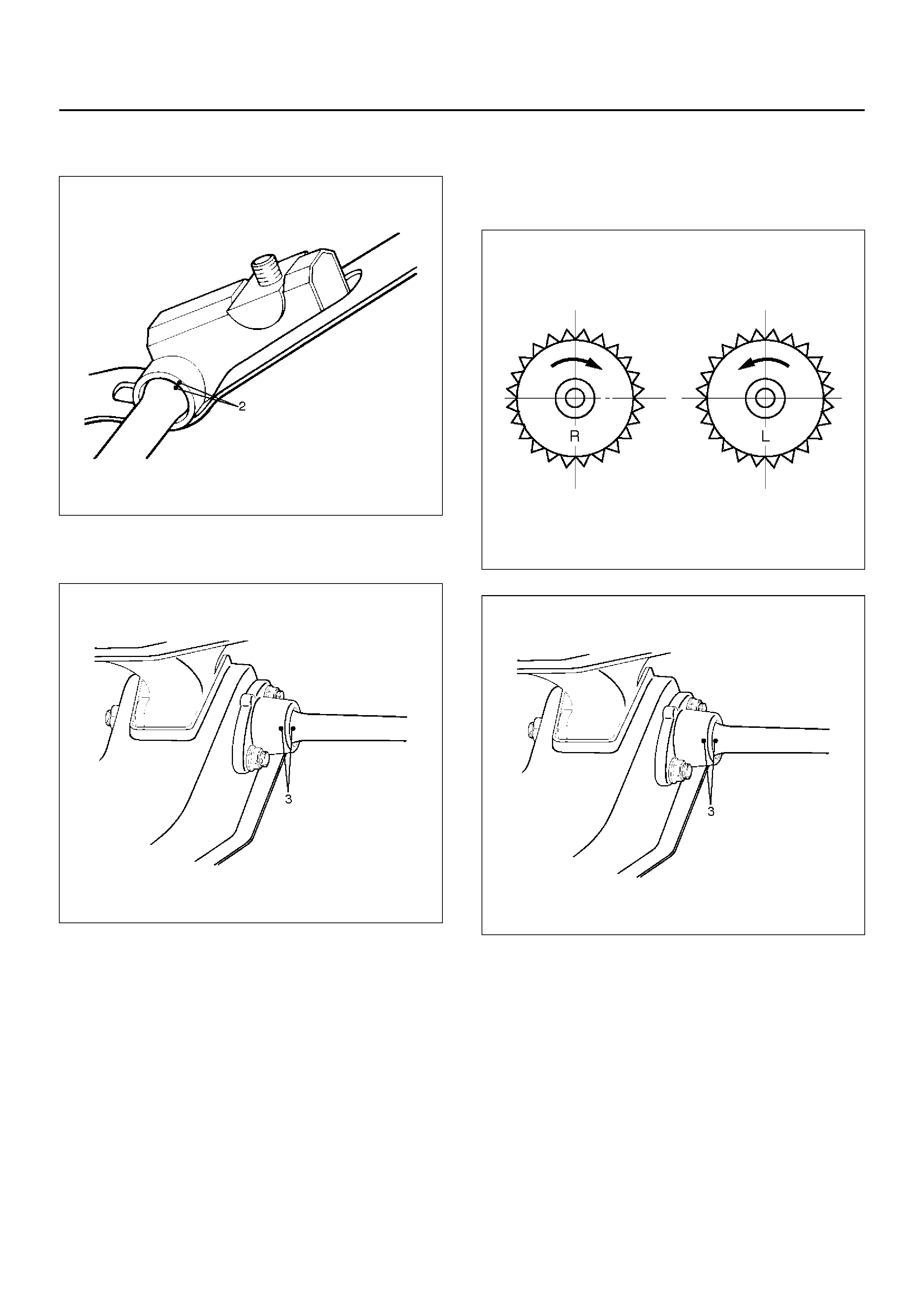

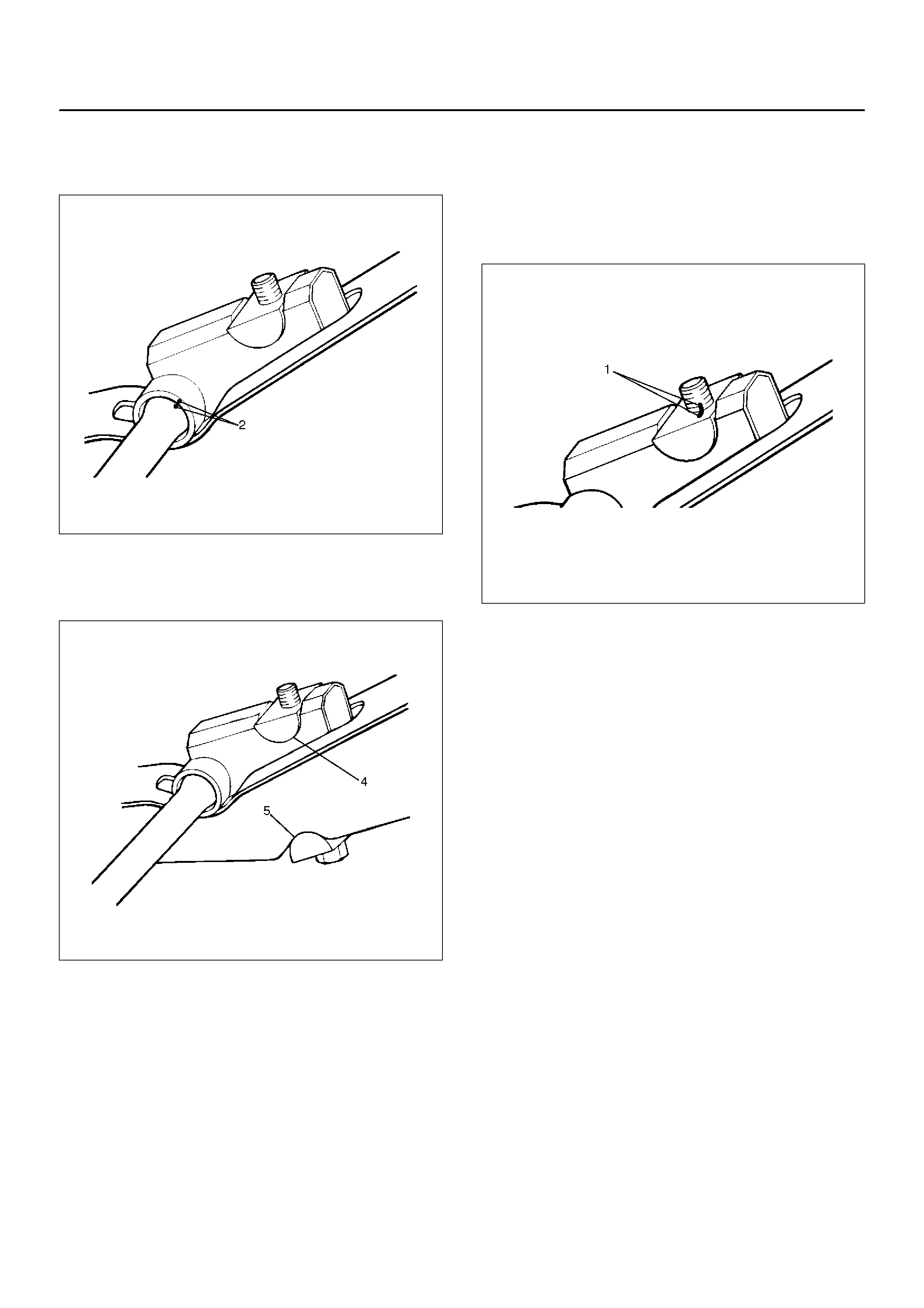

2. Apply the setting marks(1) to the adjust bolt and end

piece, then remove adjust bolt, end piece and seat.

410RS004

(1) Adjust Bolt, End Piece and Seat

(2) Height Control Arm (3) Torsi on Bar

3. Apply the setting marks(2) to the height control arm

and torsion bar, then remove height control arm.

410RS005

4. Apply the setting marks(3) to the torsion bar and

lower control arm, then remove torsion bar.

410RS006

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found through inspection.

Check the following parts:

• Torsion bar

• Height control arm

• Adjust bolt

• Rubber seat

INSTALLATION

1. Apply grease to the serrated portions, then install

torsion bar. Make sure the bars are on their correct

respe ctive sides and ali gn the se ttin g mar ks( 3).

410RS007

410RS006

2. Apply grease to the portion that fits into the bracket

then install height control arm and align the setting

marks(2).

410RS005

3. Apply grease to the bolt portion of the end piece(4).

Apply grease to the portion of the seat(5) that fits

into the bracket.

410RS008

4. Apply grease to the serrated portions.

5. Install adjust bolt and seat, then turn the adjust bolt

to the setting mark(1) applied during disassembly.

NOTE: Adjust the trim height. Refer to Front End

Alignment Inspection and Adjustment in Steering

section.

410RS004

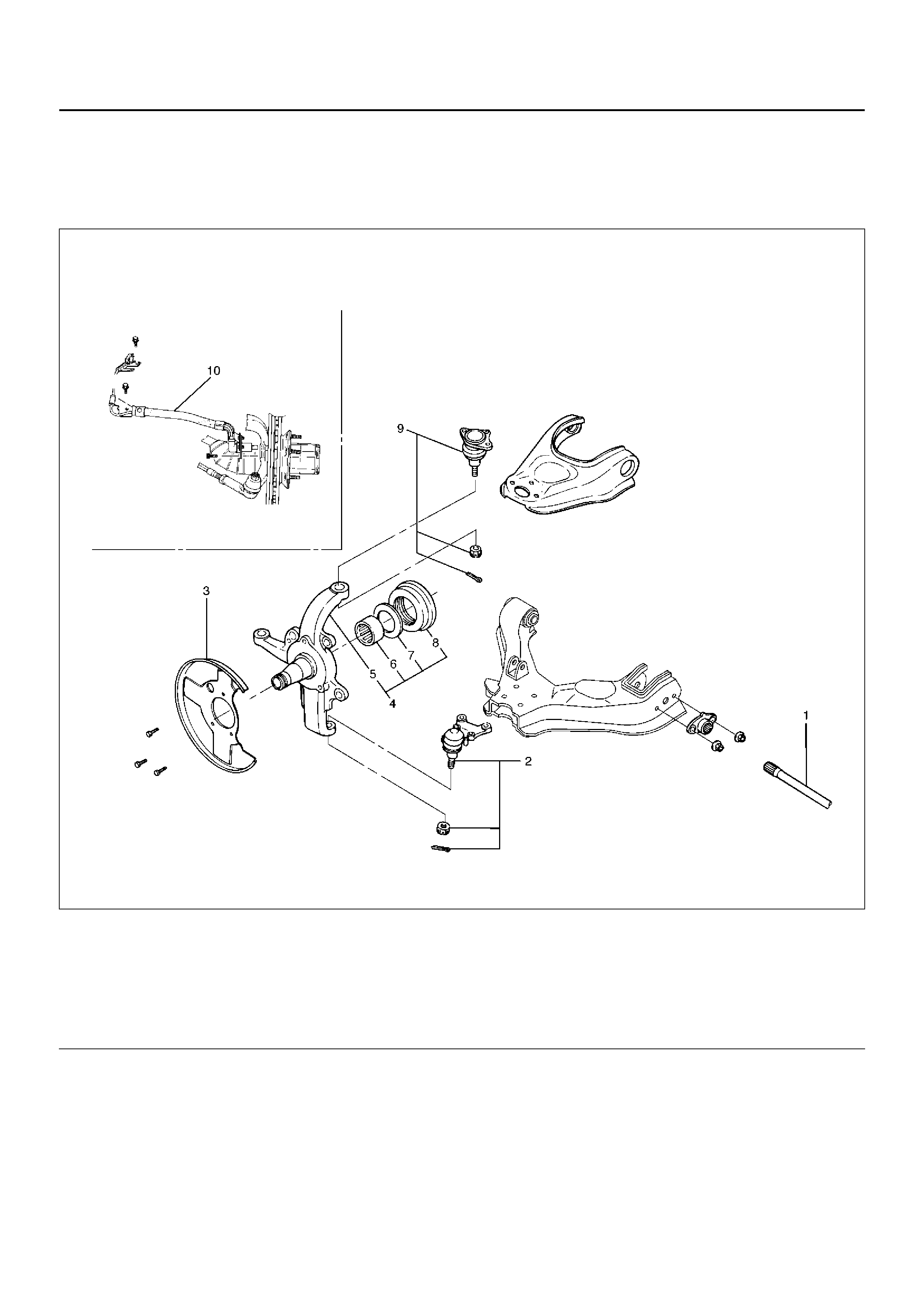

KNUCKLE

KNUCKLE AND ASSOCIATED PARTS

410RW006

Legend

EndOFCallout

REMOVAL

1. Raise the vehicle and support the frame with

suitable safety stands.

2. Remove wheel and tire assembly. Refer to Wheel in

this section.

3. Remove the brake caliper. Refer to Disc Brakes in

Brake section.

4. Remove the hub assembly. Refer to Front Hub and

Disk in this section.

5. Remove tie–rod end from the knuckle. Refer to

Power Steering Unit in Steering section.

6. Remove the speed sensor from the knuckle.

7. Loosen torsion bar by height control arm adjust bolt,

then remove torsion bar. Refer to Torsion Bar in this

section.

(1) Torsion Bar

(2) Lower Ball Joint, Nut and Cotter Pin

(3) Back Pl ate

(4) Knuck le As se mbl y

(5) Knuckle

(6) Needle Bearing

(7) Thrust Washer

(8) Oil Seal

(9) Upper Ball Joint, Nut and Cotter Pin

(10) Wheel Speed Sensor

8. Remove wheel speed sensor.

9. Remove back plate.

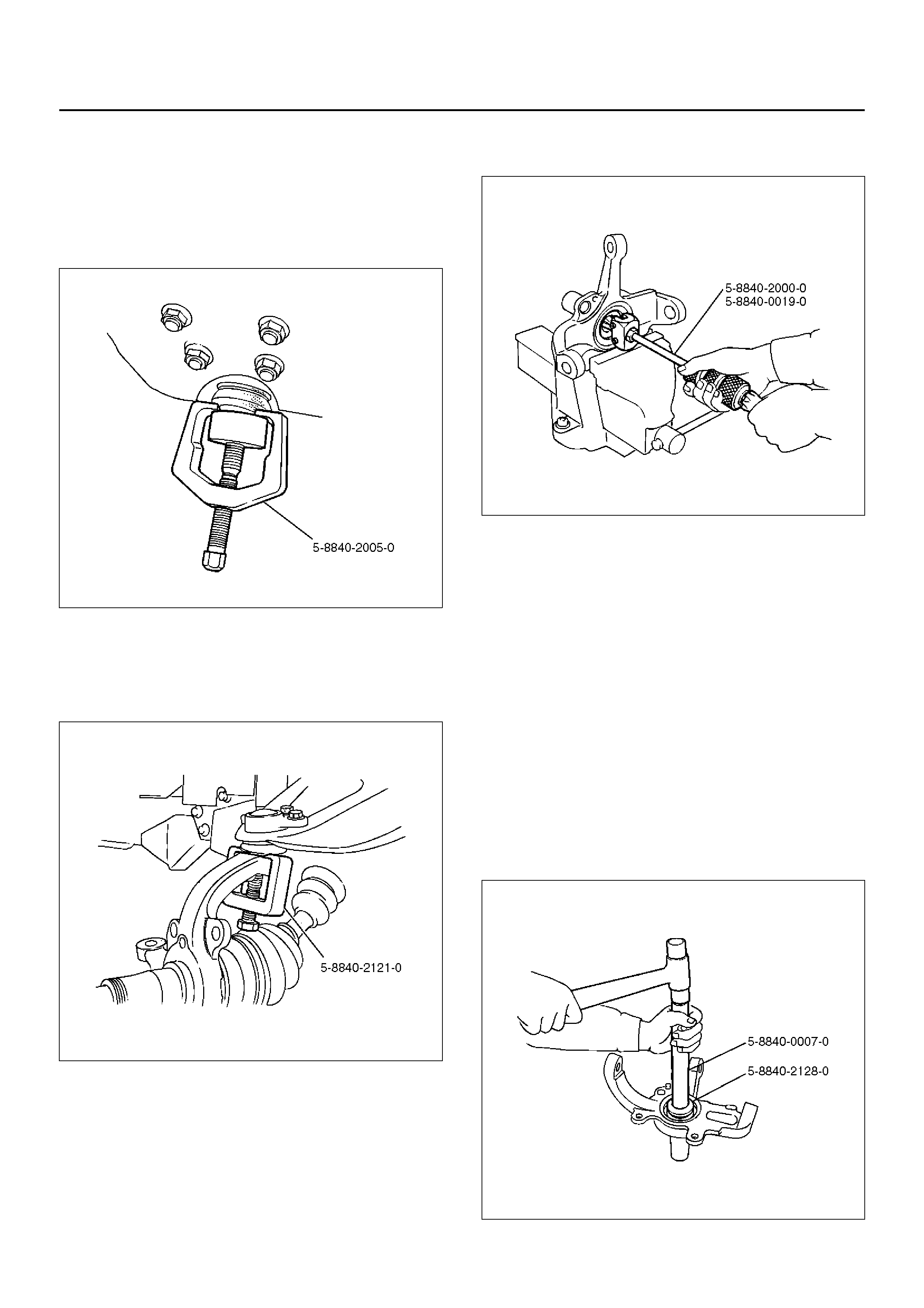

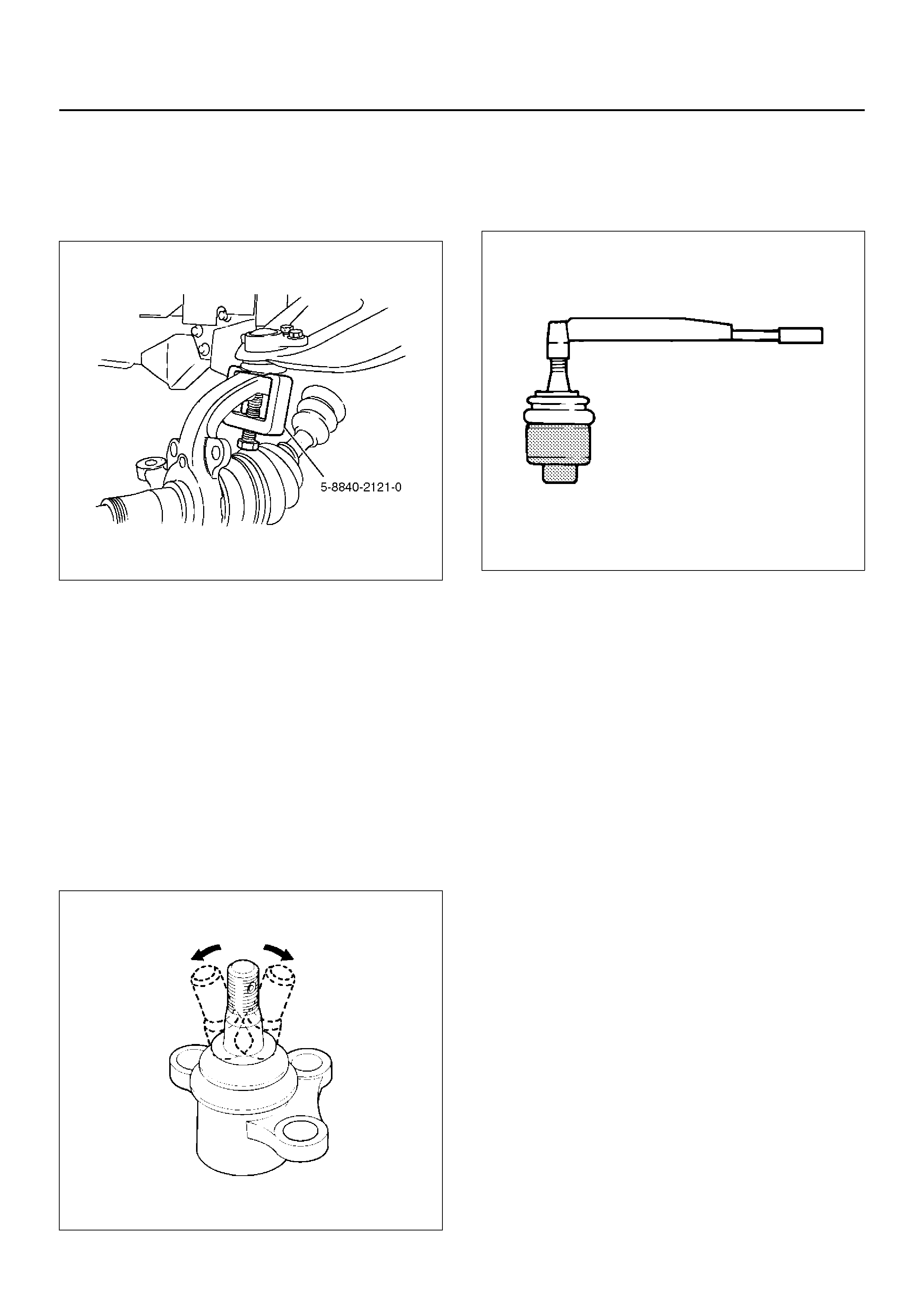

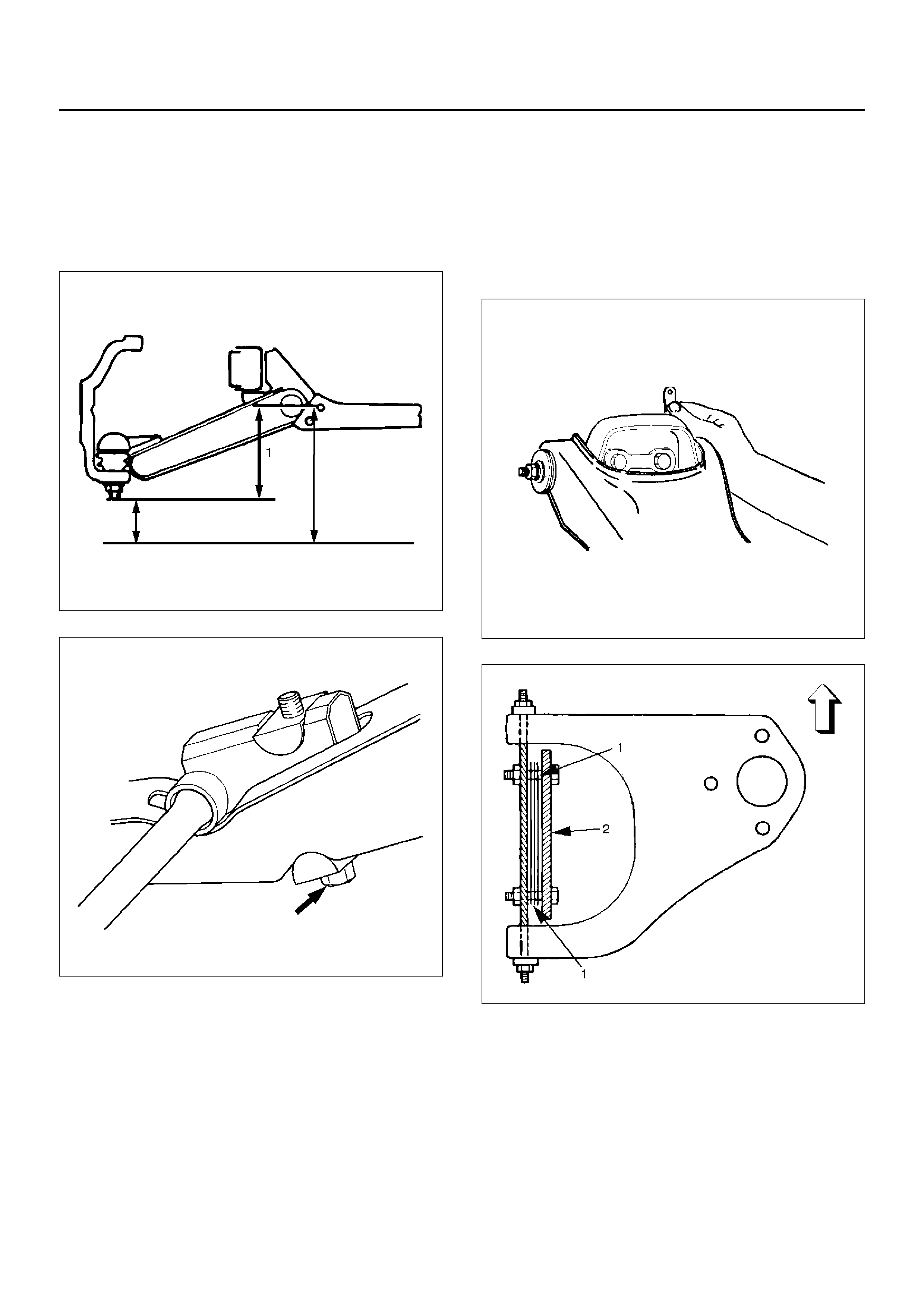

10. Remove lower ball joint by using remover 5–8840–

2005–0.

CAUTION: Be careful not to damage the ball joint

boot.

901RW271

11. Remove upper ball joint by using remover 5–8840–

2121–0.

CAUTION: Be careful not to damage the ball joint

boot.

901RW273

12. Remove knuckle assembly.

13. Remove oil seal.

14. Remove washer.

15. Remove needle bearing by using remover 5–8840–

2000–0 and sliding hammer 5–8840–0019–0.

901RW272

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found through inspection.

Check the following parts:

• Knuckle

• Knuckle arm

• Needle bearing

• Thrust washer

INSTALLATION

1. Apply appropriate amount of multipurpose type

grease to the new bearing (Approx. 5 g) and install

needle bearing by using installer 5–8840–2128–0

and grip 5–8840–0007–0.

901RW275

2. Apply multipurpose type grease to the thrust

washer, and install washer with chamfered side

facing knuckle.

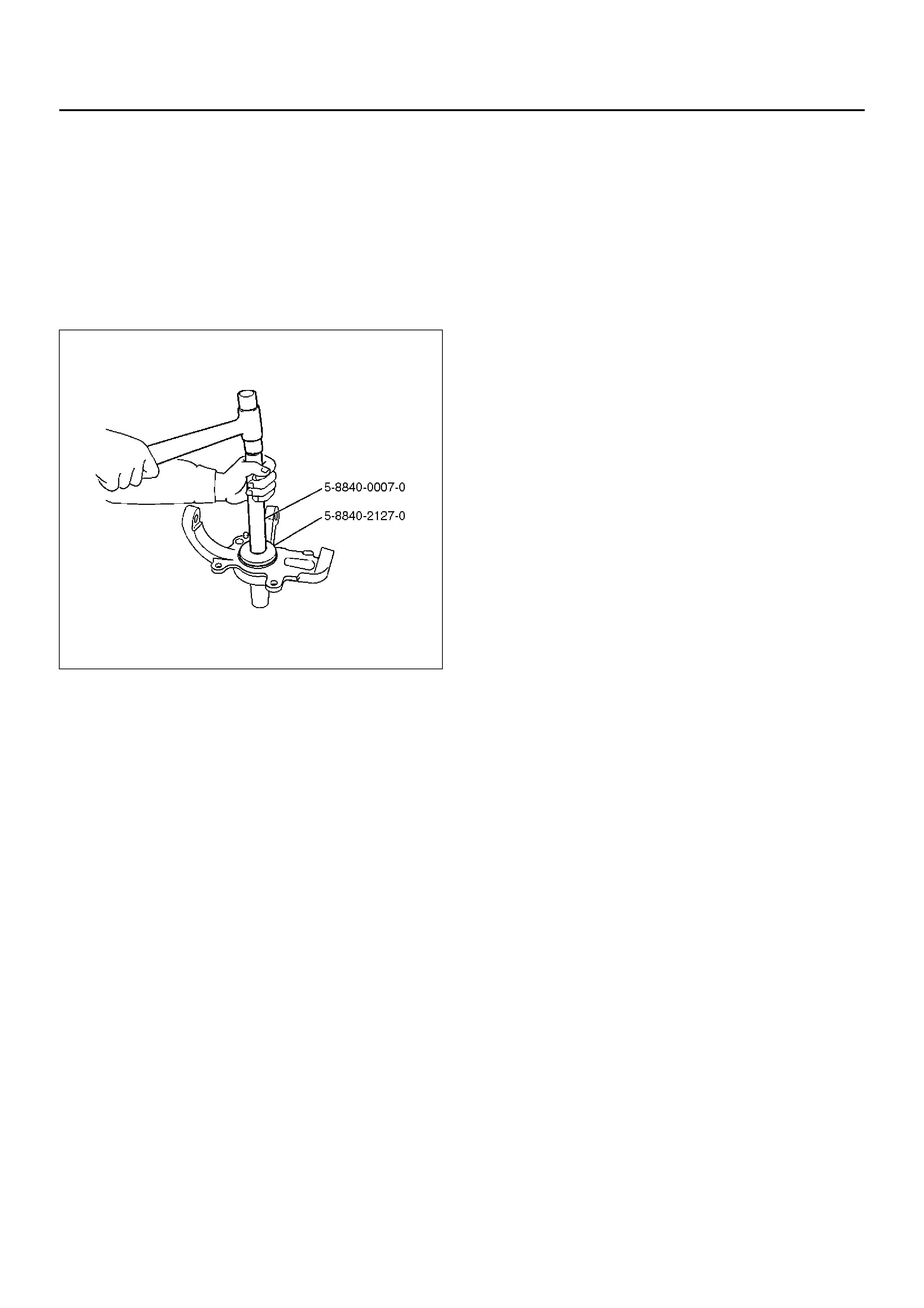

3. Use a new oil seal, and apply multipurpose type

grease to the area surrounded by the lip (approx. 2

g). Then use installer 5–8840–2127–0 and grip 5–

8840–0007–0 to install oil seal. After fitting the oil

seal to the installer, drive it to the knuckle using a

hammer or bench press until the tool front face

contacts with the thrust washer.

901RW274

4. Install knuckle assembly.

5. Install upper ball joint and tighten the nut to the

specified torque, with just enough additional torque

to align cotter pin holes. Install new cotter pin.

Torque: 98N·m (10.0kg·m/72lbft)

6. Install lower ball joint and tighten the nut to the

specified torque, with just enough additional torque

to align cotter pin holes. Install new cotter pin.

Torque: 147N·m (15.0kg·m/108 lbft)

7. Install back plate.

8. Install wheel speed sensor.

9. Install torsion bar, refer to Torsion Bar in this

section.

NOTE: Adjust the trim height. Refer to Front End

Alignment Inspection and Adjustment in Steering.

UPPER CONTROL ARM

UPPER CONTROL ARM AND ASSOCIATED PARTS

450R100001

Legend

EndOFCallout

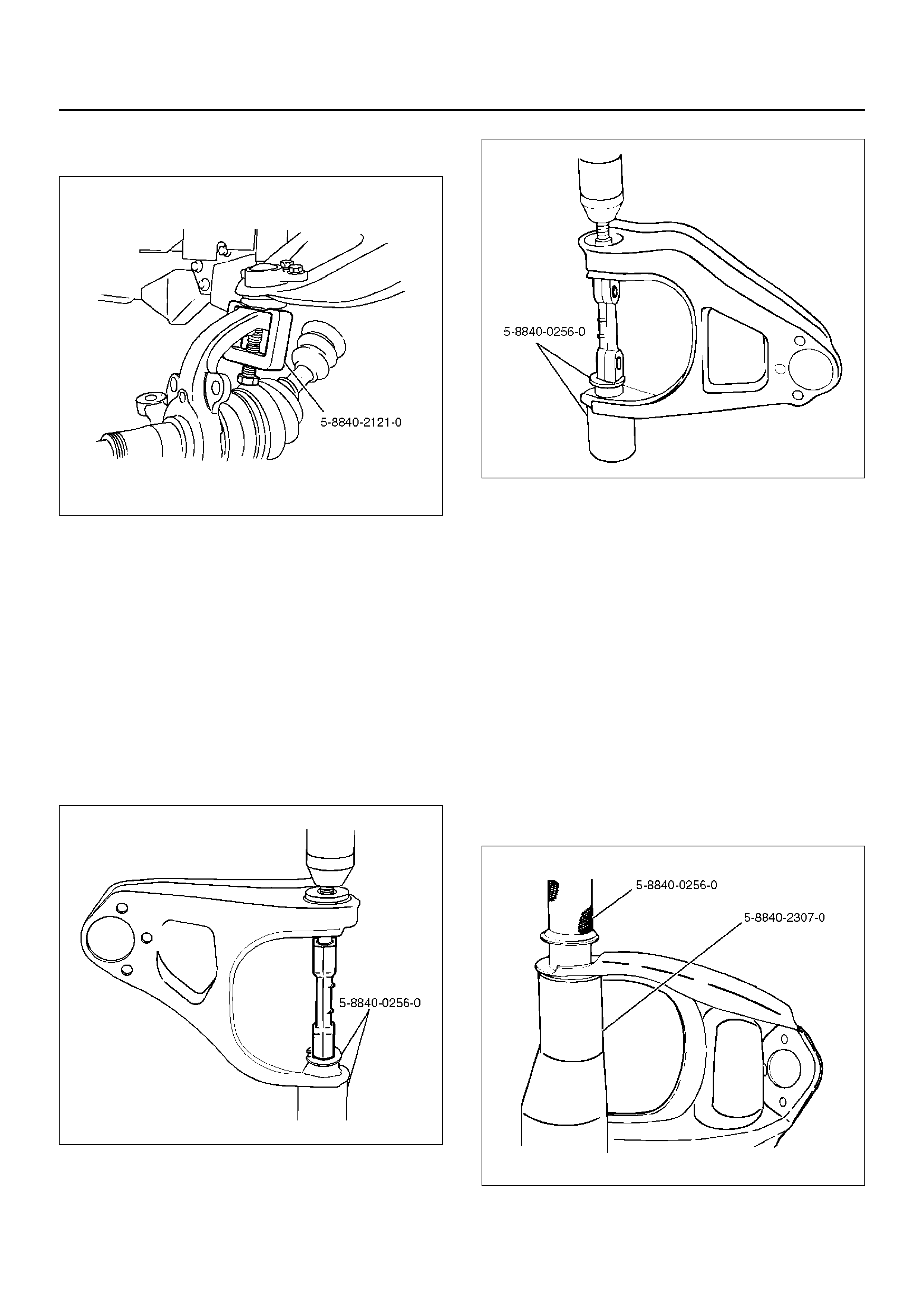

REMOVAL

1. Raise the vehicle and support the frame with

suitable safety stands.

2. Remove wheel and tire assembly. Refer to Wheel in

section 10.

3. Remove the brake caliper and disconnect brake

pipe. Refer to Disc Brakes in section 5.

4. Support lower control arm with a jack.

5. Remove speed sensor cable.

6. Remove nut and cotter pin then remove knuckle

using remover 5–8840–2121–0.

(1) Bolt and Plate

(2) Camber Shims

(3) Caster Shims

(4) Nut Assembly

(5) Upper Control Arm Assembly

(6) Fulcrum Pin

(7) Bushing

(8) Plate

(9) Nut

(10) Speed Sensor Cable

(11) Nut and Cotter Pin

(12) Upper Ball Joint, Bolt and Nut

CAUTION: Be careful not to damage the ball joint

boot.

901RW273

7. Remove upper ball joint.

8. Remove bolt and plate.

9. Remove nut assembly.

10. Remove camber shims and note the positions and

number of shims.

11. Remove caster shims and note the positions and

number of shims.

12. Remove upper control arm assembly.

13. Remove nut (9).

14. Remove plate (8).

15. Remove bushing (7) by using remover 5–8840–

0256–0.

901RW277

901RW276

16. Remove fulcrum pin (6).

INSPECTION AND REPAIR

Make necessary parts replacement if wear, damage,

corrosion or any other abnormal conditions are found

through inspection.

Check the following parts:

• Upper control arm

• Bushing

• Fulcrum pin

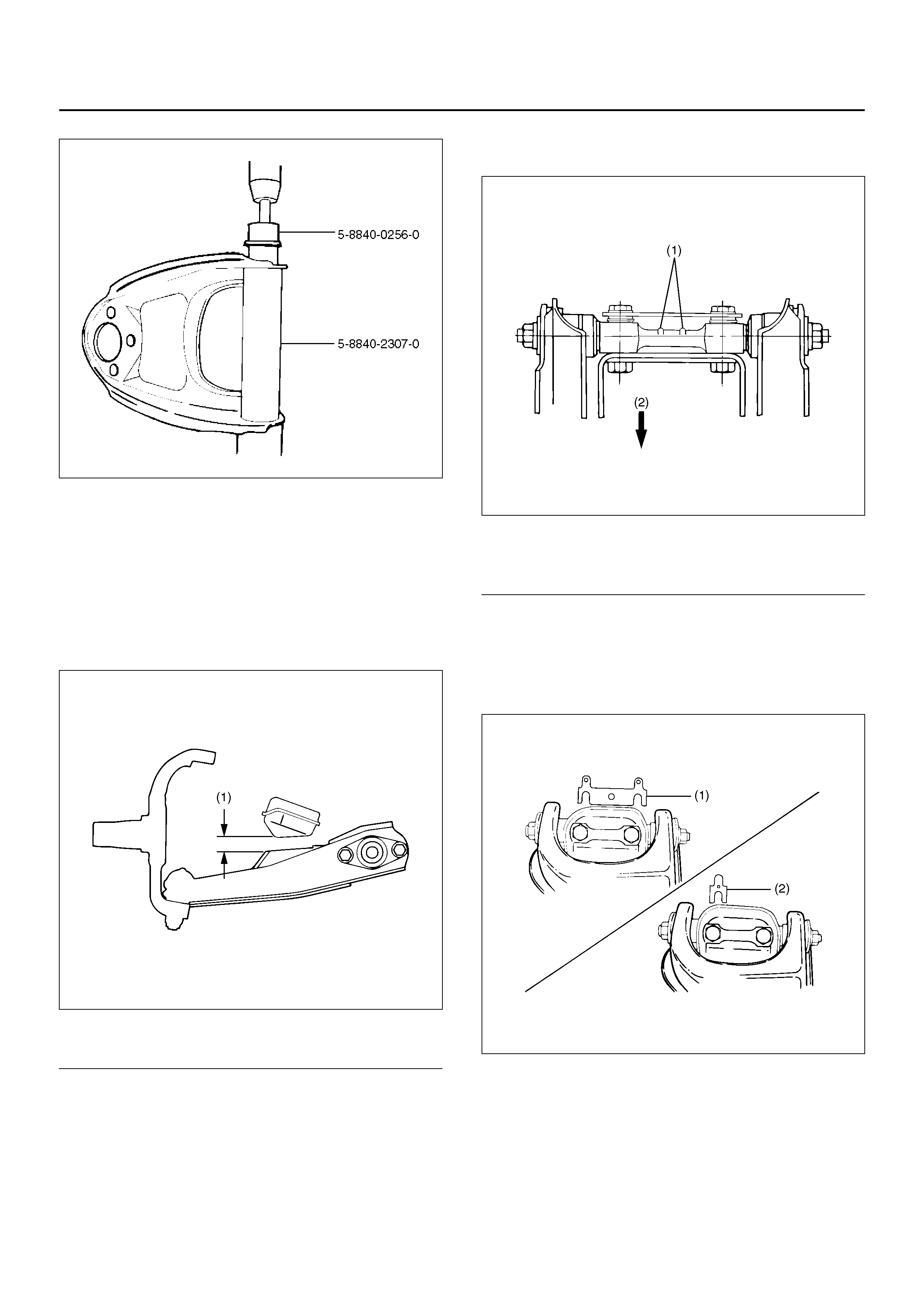

INSTALLATION

1. Install fulcrum pin.

2. Install bushing by using installer 5–8840–0256–0

and 5–8840–2307–0.

901RW278

901RW279

3. Install pla te (8).

4. Install nut (9) and tighten fulcrum pin nut finger–

tight.

NOTE: Torque fulcrum pin nut after adjusting buffer

clearance.

Buffer clearance: 22mm (0.87in)

Torque: 108N·m (11.0kg·m/80lbft)

450R100002

Legend

EndOFCallout

5. Install upper control arm assembly with the fulcrum

pin projections turned inward.

450R100003

Legend

EndOFCallout

6. Install the caster shims(2) between the chassis

frame and fulcrum pin.

7. Install the camber shims(1) between the chassis

frame and fulcrum pin.

450R100004

(1) Buffer Clearance

(1) Projection

(2) Outward

8. Inst all nut assembly.

9. Install bolt and plate, then tighten the bolt to the

specified torque.

Torque: 152N·m (15.5kg·m/112lbft)

10. Install upper ball joint and tighten it to the specified

torque.

Torque: 57N·m (5.8kg·m/42lbft)

11. Install nut and cotter pin then tighten the nut to the

specified torque, with just enough additional torque

to align cotter pin holes. Install new cotter pin.

Torque: 98N·m (10.0kg·m/72lbft)

12. Install speed sensor cable.

LOWER CONTROL ARM

LOWER CONTROL ARM AND ASSOCIATED PARTS

450R100005

Legend

EndOFCallout

REMOVAL

1. Raise the vehicle and support the frame with

suitable safety stands.

2. Remove wheel and tire assembly. Refer to Wheel in

this section.

3. Remove the tie-rod end from the knuckle. Refer to

Power Steering Unit in Steering section.

4. Remove the retaining ring from the front axle driving

shaft to release the shaft from hub. Refer to Front

Hub and Disc in Driveline/Axle section4C.

5. Support lower control arm with a jack.

(1) Nut, Front

(2) Bush, Front

(3) Bolt, Front

(4) Nut, Rear

(5) Bush, Rear

(6) Bolt, Rear

(7) Bolt, Lower Ball Joint

(8) Bolt, Torsion Bar Arm

(9) Torsion Bar Arm Bracket and Nut

(10) Torsion Bar

(11) Lower Control Arm

(12) Lower Ball Joint and Nut

(13) Shock Absorber, Bolt and Nut

(14) Stabili ze r Link, Washer and Nut

6. Remove front nut.

7. Remove rear nut.

8. Remove torsion bar, refer to Torsion Bar in this

section.

9. Remove torsion bar arm bracket.

10. Disconnect the stabilizer link at the lower control

arm.

11. Remove the shock absorber lower end from the

lower control arm.

12. Remove the lower ball joint from the lower control

arm.

13. Remove front bolt.

14. Remove rear bolt.

15. Remove lower control arm.

16. Remove torsion bar arm bolt.

17. Remove lower ball joint bolt.

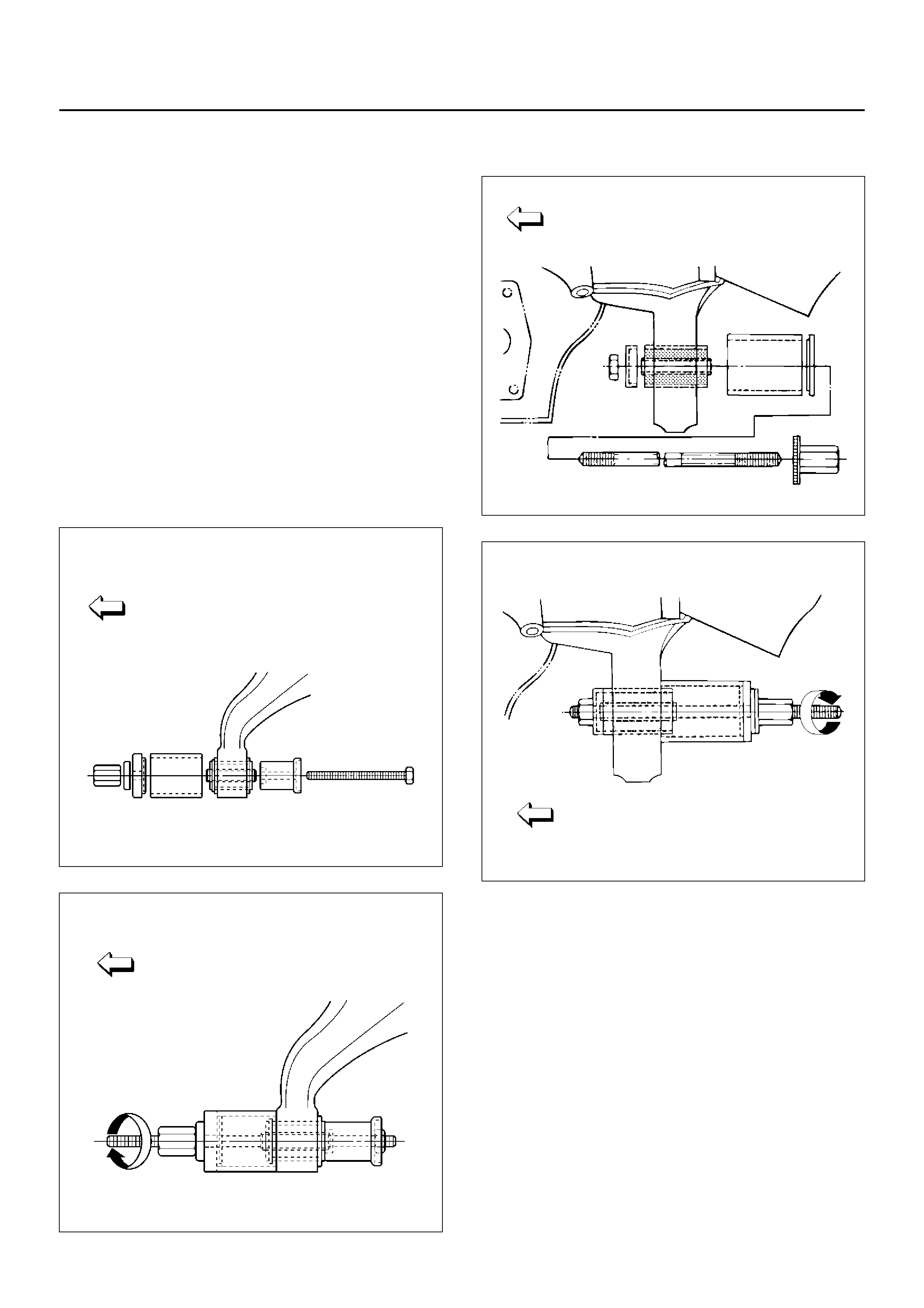

18. Remove front bushing by using remover 5–8840–

2123–0.

901RW154

901RW155

19. Remove rear bushing by using remover 5–8840–

2124–0.

901RW051

901RW052

INSPECTION AND REPAIR

Make the necessary correction or parts replacement if

wear, damage, corrosion or any other abnormal

condition are found through inspection.

Check the following parts:

• Lower control arm

• Bushing

INSTALLATION

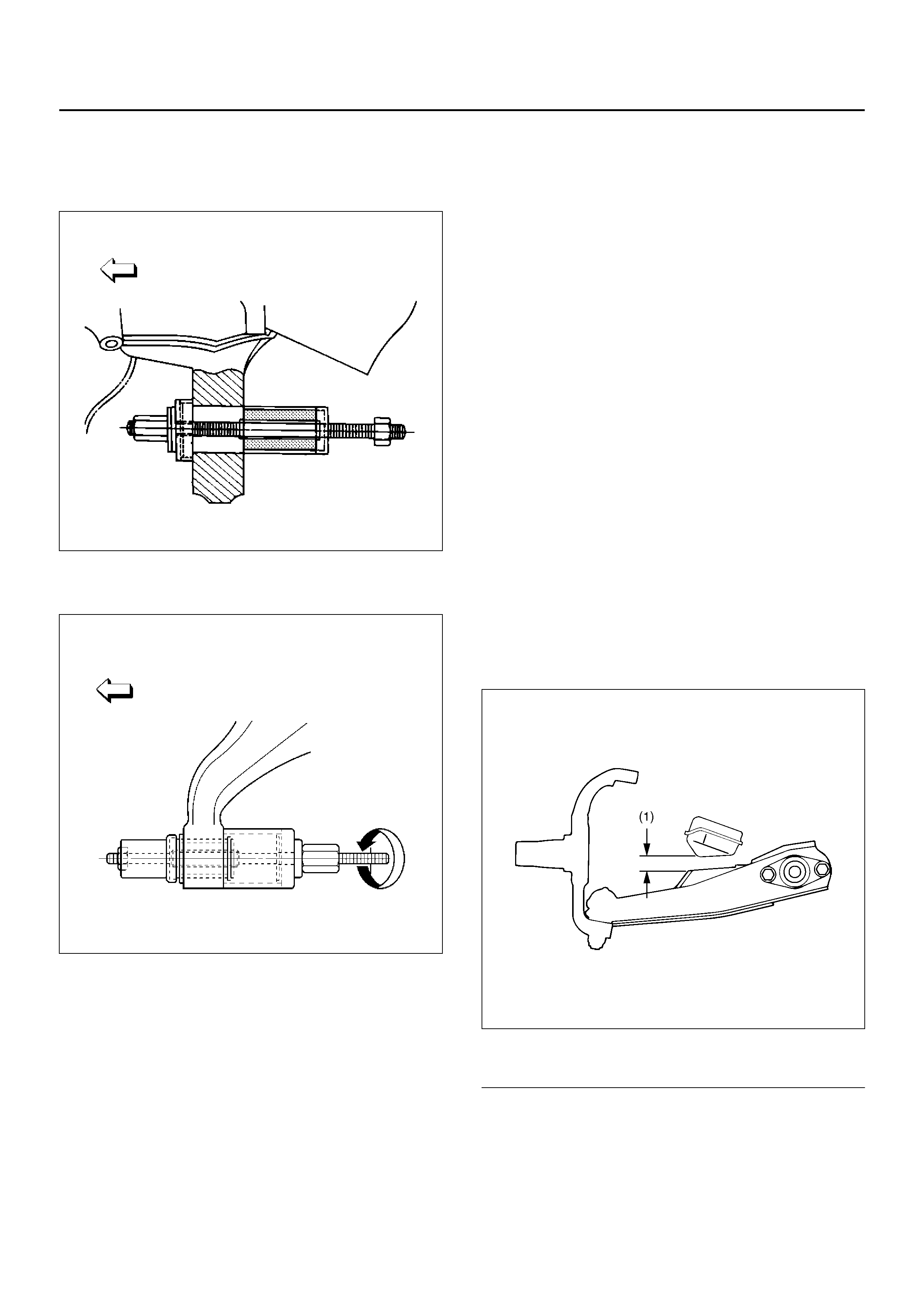

1. Install rear bushing by using installer 5–8840–2124–

0.

901RW053

2. Install front bushing by using installer 5–8840–

2123–0.

901RW156

3. Install lower ball joint bolt.

4. Install torsion bar arm bolt.

5. Install lower control arm.

6. Install rear bolt.

7. Install front bolt.

8. Install lower ball joint and tighten it to the specified

torque.

Torque: 116N·m (11.8kg·m/85lbft)

9. Install shock absorber and tighten it to the specified

torque.

Torque: 93N·m (9.5kg·m/69lbft)

10. Install stabilizer link and tighten it to the specified

torque.

Torque: 50N·m (5.1kg·m/37lbft)

11. Install torsion bar arm bracket and tighten it to the

specified torque.

Torque: 116N·m (11.8kg·m/85lbft)

12. Install Torsion bar, refer to Torsion Bar in this

section.

13. Install rear nut and tighten lower link nut finger–tight.

NOTE: Torque lower control arm nut after adjusting

buffer clearance.

Buffer clearance: 22mm (0.87in)

Torque: 235N·m (24.0kg·m/174lbft)

450R100002

Legend

EndOFCallout

(1) Buffer Clearance

14. Install front nut then tighten lower link nut

finger-tight.

NOTE: Torque lower control arm nut after adjusting

buffer clearance .

Buffer clearance: 22mm (0.87in)

Torque: 186N·m (19.0kg·m/137lbft)

NOTE: Adjust the trim height. Refer to Front End

Alignment Inspection and Adjustment in Steering

section.

450RS012

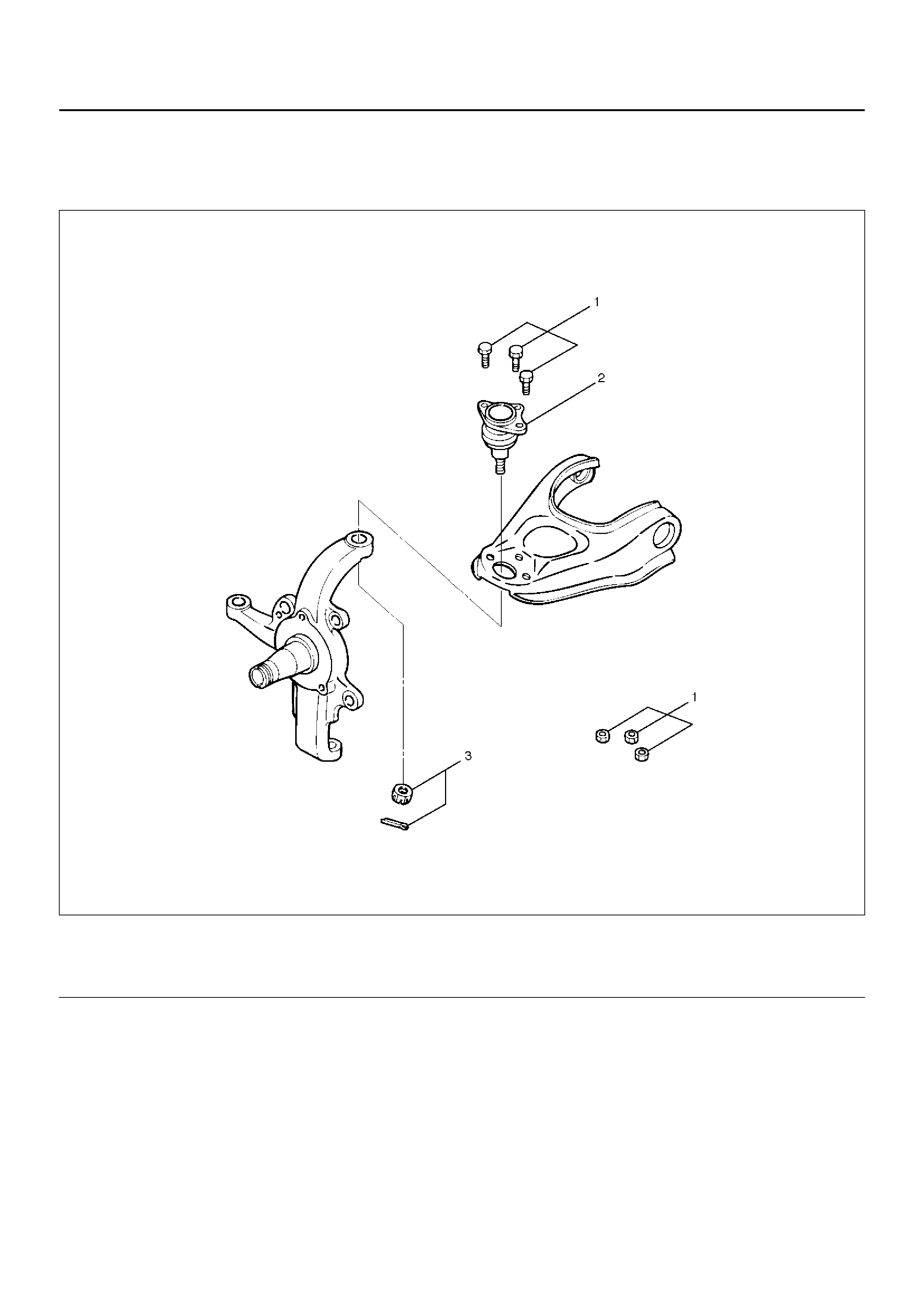

UPPER BALL JOINT

UPPER BALL JOINT AND ASSOCIATED PARTS

450RW004

Legend

EndOFCallout

REMOVAL

1. Raise the vehicle and support the frame with

suitable safety stands.

2. Remo ve the sp eed se ns or from the knu ckle .

(1) Bolt and Nut

(2) Upper Ball Joint (3) Nut and Cotter Pin

3. Remove upper ball joint nut and cotter pin, then use

remover 5–8840–2121–0 to remove the upper ball

joint from the knuckle.

CAUTION: Be careful not to damage the ball joint

boot.

901RW273

4. Remove bolt and nut.

5. Remove upper ball joint.

INSPECTION AND REPAIR

Make necessary parts replacement if wear, damage,

corrosion or any other abnormal conditions are found

through inspection.

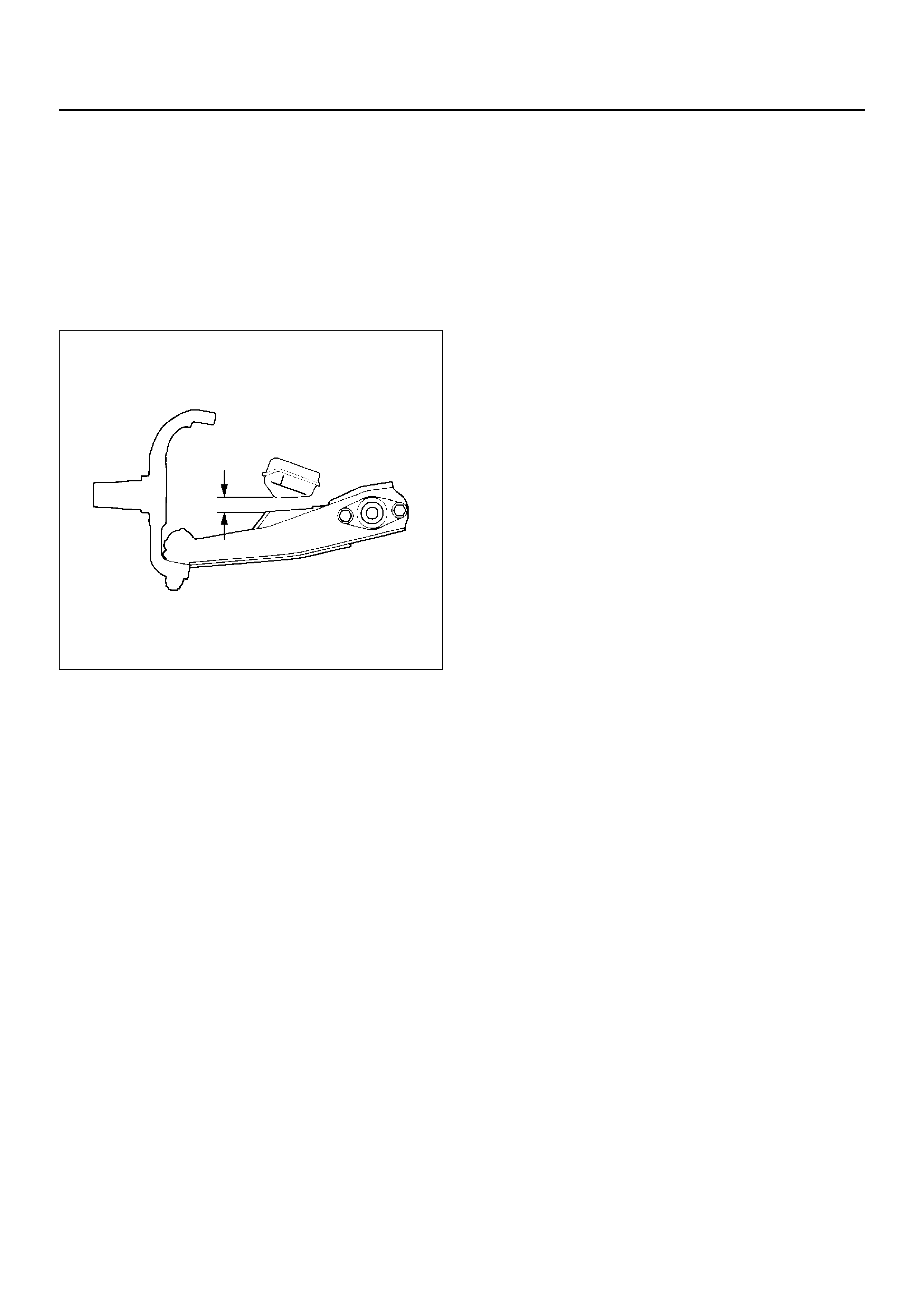

• Inspect the lower end boot for damage or grease

leak. Move the ball joint as shown in the figure to

confirm its normal movement.

• Inspect screw/taper area of ball for damage.

• If any defects are found by the above inspections,

replace the ball joint assembly with new one.

450RS023

• After moving the ball joint 4 or 5 times, attach nut

then measure the preload.

Starting torque: 0.5 –3.2N·m (0.05–0.33kg·m/0.4–

2.4lbft)

450RS024

If the above limits specified are exceeded, replace the

ball joint assembly.

INSTALLATION

1. Install upper ball joint.

2. Install bolt and nut, then tighten them to the

specified torque.

Torque: 57N·m (5.8kg·m/42lbft)

3. Install nut and cotter pin, then tighten the nut to the

specified torque with just enough additional torque

to align cotter pin holes. Install new cotter pin.

Torque: 98N·m (10.0kg·m/72lbft)

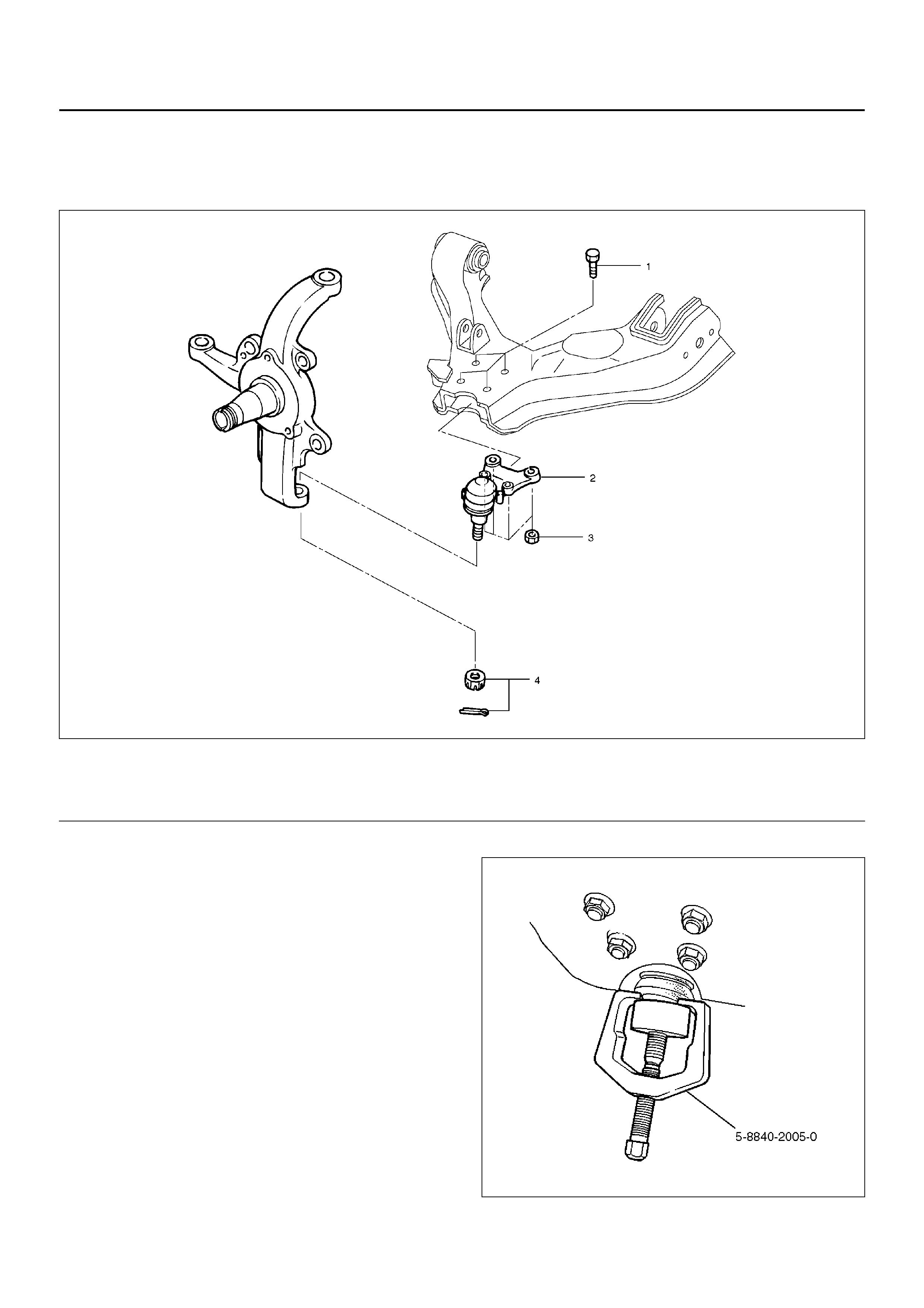

LOWER BALL JOINT

LOWER BALL JOINT AND ASSOCIATED PARTS

450R100006

Legend

EndOFCallout

REMOVAL

1. Raise the vehicle and support the frame with

suitable safety stands.

2. Remove wheel and tire assembly. Refer to Wheel in

this section.

3. Remove the tie-rod end from the knuckle. Refer to

Power Steering Unit in Steering section.

4. Remove the retaining ring from the front axle driving

shaft to release the shaft from hub. Refer to Front

Hub and Disc in Driveline/Axle section4C.

5. Support lower control arm with a jack.

6. Remove lower ball joint nut and cotter pin, then use

remover 5–8840–2005–0 to remove the lower ball

joint from the knuckle.

CAUTION: Be careful not to damage the ball joint

boot.

901RW271

(1) Bolt

(2) Lower Ball Joint (3) Nut

(4) Nut and Cotter Pin

7. Remove nut.

8. Remove bolt.

9. Remove lower ball joint.

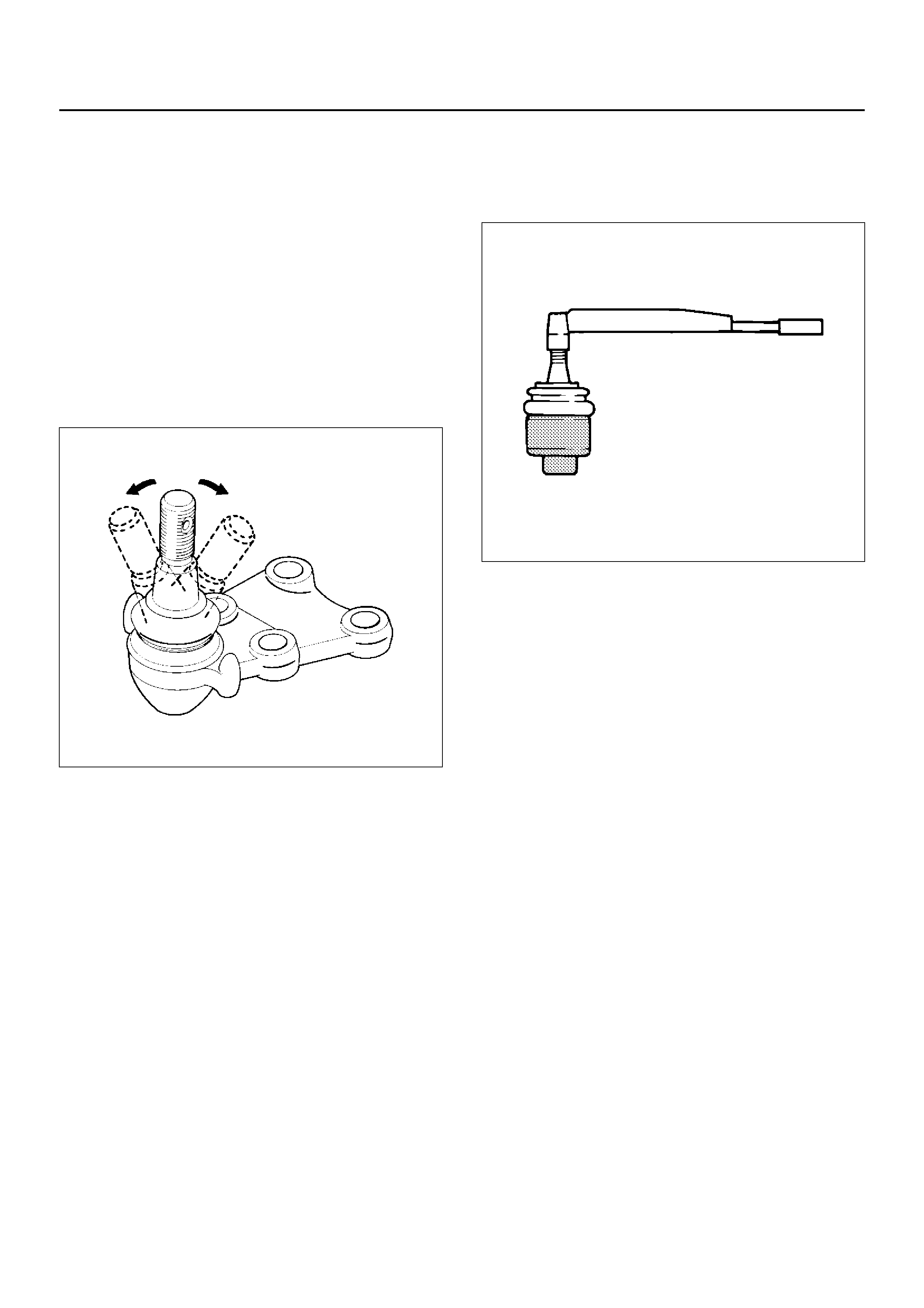

INSPECTION AND REPAIR

Make necessary parts replacement if wear, damage,

corrosion or any other abnormal condition are found

through inspection.

• Inspect the lower end boot for damage or grease

leak. Move the ball joint as shown in the figure to

confirm its normal movement .

• Inspect screw/taper area of ball for damage.

• If any defects are found by the above inspections,

replace the ball joint assembly with new one.

450RS026

• After moving the ball joint 4 or 5 times, attach nut

then measure the preload.

Starting torque: 0.5–6.4N·m (0.05–0.65kg·m/0.4–

4.7lbft)

450RS024

• If the above limits specified are exceeded, replace

the ball joint assembly.

INSTALLATION

1. Install lower ball joint.

2. Install bolt.

3. Install nut and tighten it to the specified torque.

Torque: 116N·m (11.8kg·m/85lbft)

4. Install ball joint nut, then tighten it to the specified

torque with just enough additional torque to align

cotter pin holes. Install new cotter pin.

Torque: 147N·m (15.0kg·m/108lbft)

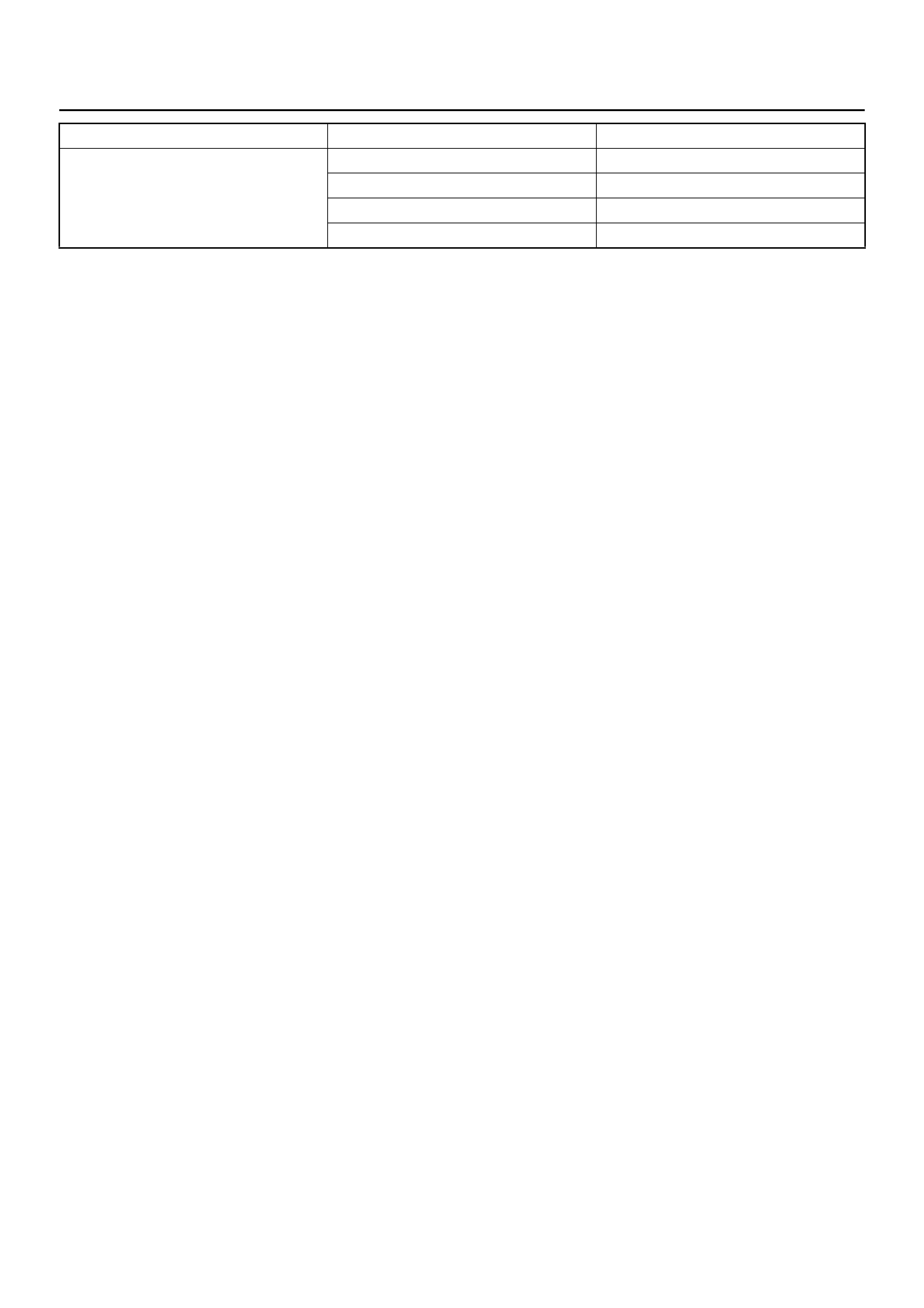

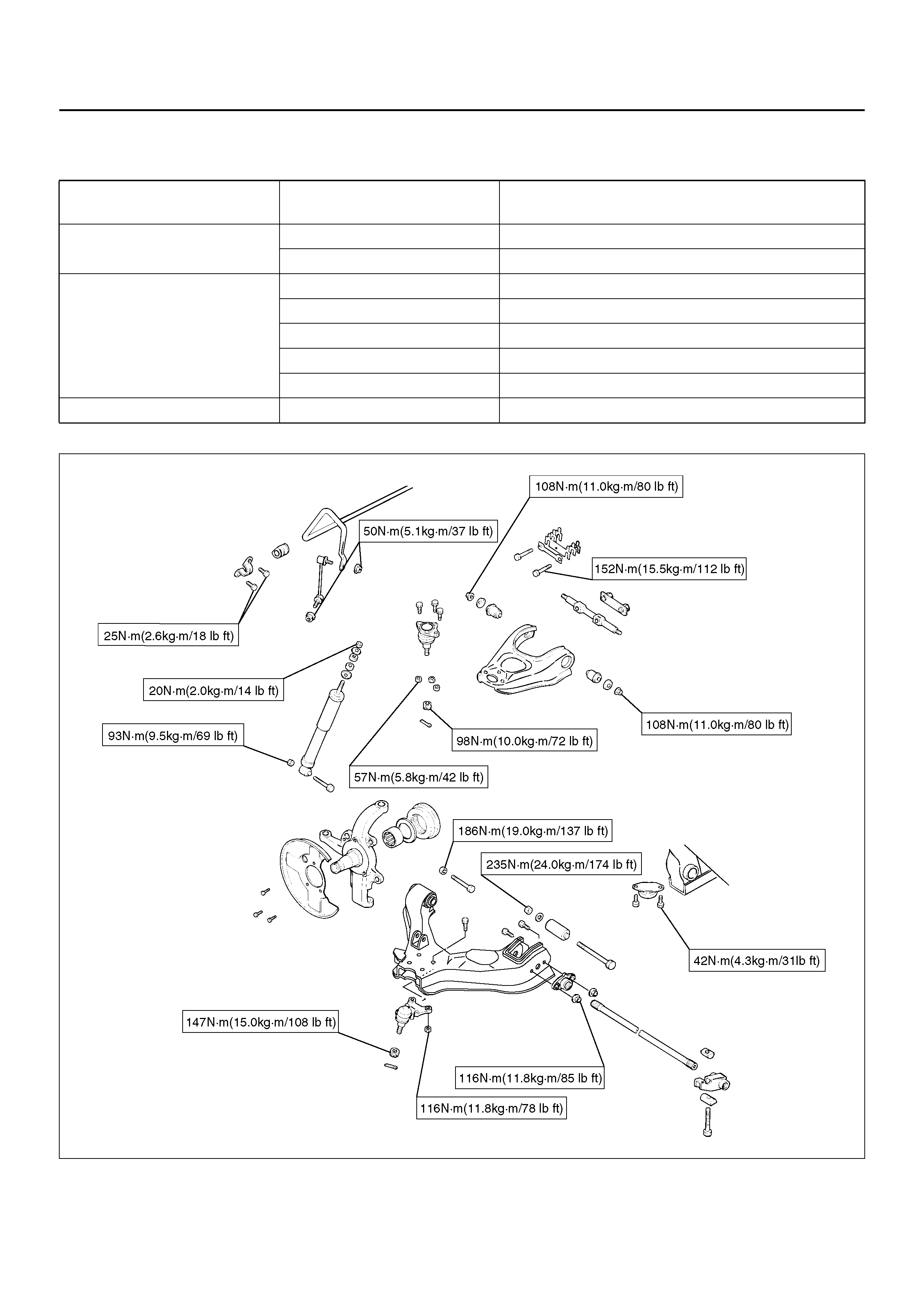

MAIN DATA AND SPECIFICATIONS

General Specifications

Torque Specifications

450R100007

Front suspension T ype Independent wishbone arms, torsion bar spring with

stabilizer bar.

Torsion bar sprin g Length 1142mm (45.0in)

Diameter 28.0 mm (1.10 in)

Front shock absorber Type Hydraulic, double acting, telescopic

Piston diameter 30.0mm (1.18in)

Stroke 125.0mm (4.92in)

Compressed length 255.0mm (10.04in)

Extended length 380.0mm (14.96in)

Stabilizer bar Diameter 24.0 mm (0.94 in)

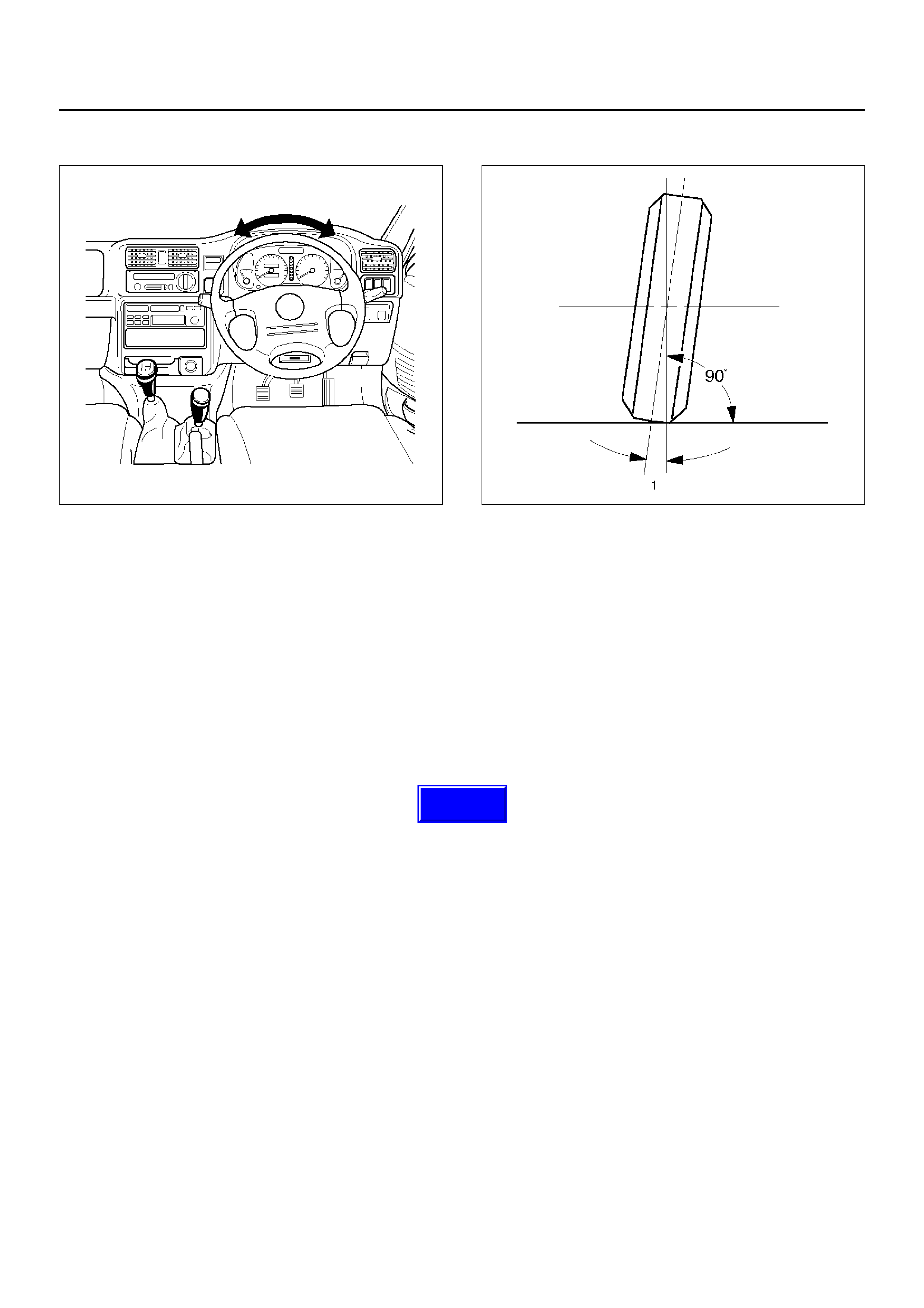

STEERING WHEEL FREE PLAY INSPECTION

430RW020

1. With the tires in the straight-ahead position, check

the amount of steering wheel play by turning the

wheel in both directions until the tires begin to

move.

NOTE: The wheel free play should be checked with the

engine running.

Free play: 0 – 30mm (0 – 1.18in)

2. Also check the steering wheel for play and

looseness in the mount by moving it back and forth

and sideways. When test driving, check for hard

steering, steering shimmy and tendency to pull to

one side.

FRONT END ALIGNMENT

INSPECTION AND ADJUSTMENT

General Description

“Front End Alignment" refers to the angular relationship

between the front wheels, the front suspension

attaching parts and the ground.

Proper front end alignment must be maintained in order

to insure efficient steering, good directional stability and

to prevent abnormal tire wear.

The most important factors of front end alignment are

wheel toe-in, wheel camber and axle caster.

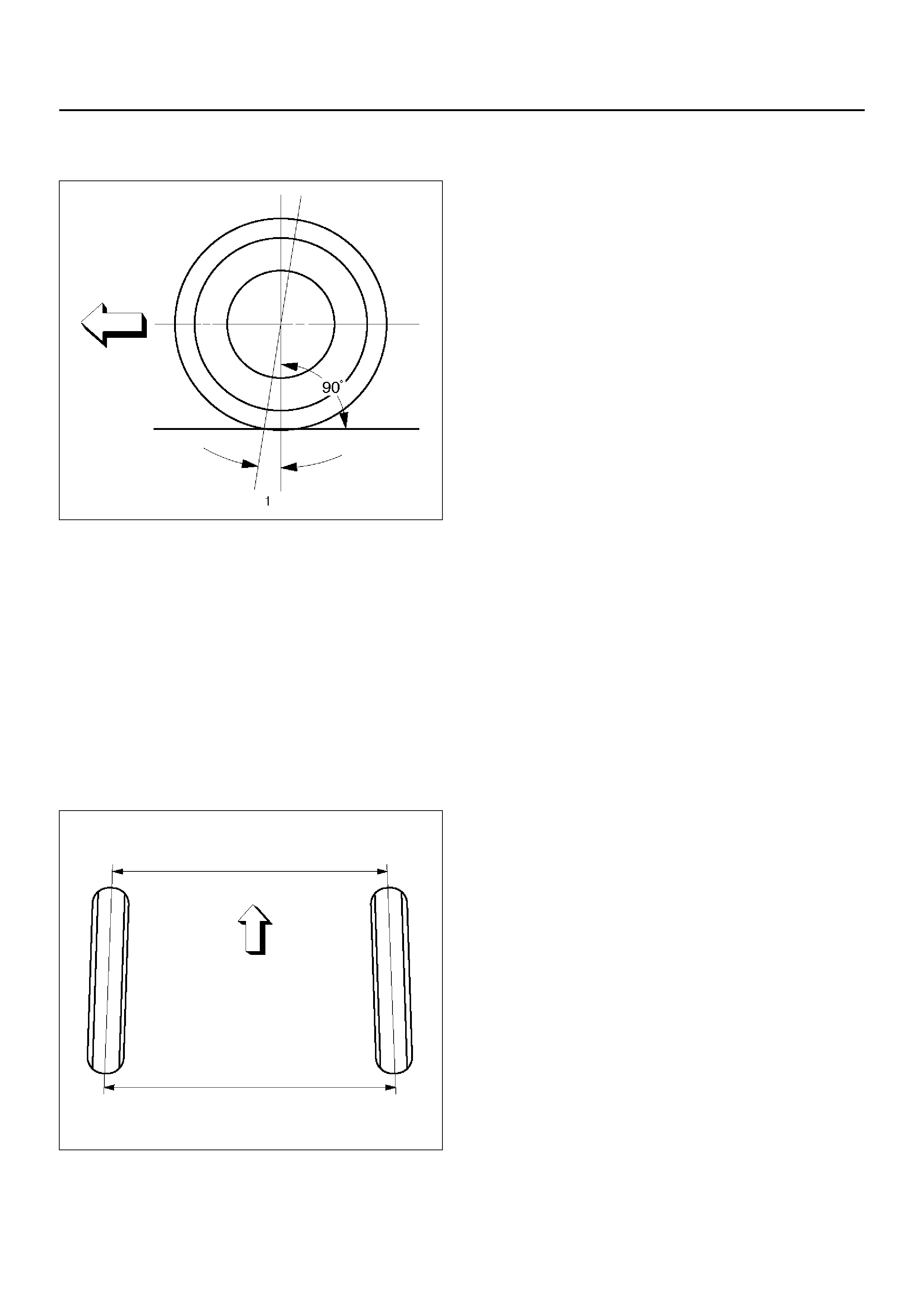

Camber:

This illustration shows view from the front of the vehicle.

480RS004

Camber is the vertical tilting inward or outward of the

front wheels. When the wheels tilt outward at the top,

the camber is positive (+). When the wheels tilt inward

at the top, the camber is negative (-). The amount of tilt

measured in degrees from the vertical is called the

camber angle (1). If camber is extreme or unequal

between the wheels, improper steering and excessive

tire wear will result. Negative camber causes wear on

the inside of the tire, while positive camber causes wear

to the outside.

Techline

Caster:

This illustration shows view from the side of the vehicle.

480RS005

Caster (1) is the vertical tilting of the wheel axis either

forward or backward (when viewed from the side of the

vehicle). A backward tilt is positive (+) and a forward tilt

is negative (-). On the short and long arm type

suspension you cannot see a caster angle without a

special instrument, but if you look straight down from

the top of the upper control arm to the ground, the ball

joints do not line up (fore and aft) when a caster angle

other than 0 degree is present. With a positive angle,

the lower ball joint would be slightly ahead (toward the

front of the vehicle) of the upper ball joint center line.

Toe-in:

This illustration shows view from the top of the vehicle.

480RS003

Toe-in is the measured amount the front wheels are turn

in. The actual amount of toe-in is normally a fraction of

a meter. Toe-in is measured from the center of the tire

treads or from the inside of the tires. The purpose of

toe-in is to insure parallel rolling of the front wheels and

to offset any small deflections of the wheel support

system which occurs when the vehicle is rolling forward.

Incorrect toe-in results in excessive toe-in and unstable

steering. Toe-in is the last alignment to be set in the

front end alignment procedure.

INSPECTION

Before making any adjustments affecting caster,

camber or toe-in, the following front end inspection

should be made.

1. Inspect the tires for proper inflation pressure. Refer

to Main Data and Specifications in Wheel and Tire

System section.

2. Make sure that the vehicle is unladen condition

(With no passenger or loading).

3. Make sure that the spare tire is installed at the

normal position.

4. Inspect the front wheel bearings for proper

adjustment. Refer to Front Hub and Disc in

Driveline section.

5. Inspect the ball joints and tie rod ends. If excessive

looseness is noted, correct before adjusting. Refer

to Steering Linkage in this section.

6. Inspect the wheel and tires for run-out. Refer to

Wheel Replacement in Wheel and Tire System

section.

7. Inspect the trim height. If not within specifications,

the correction must be made before adjusting

caster.

8. Inspect the steering unit for looseness at the frame.

9. Inspect shock absorbers for leaks or any noticeable

noise. Refer to Shock Absorber in Suspension

section.

10. Inspect the control arms or stabilizer bar attachment

for looseness. Refer to Suspension section .

11. Inspect the front end alignment using alignment

equipment. Follow the manufacturer's instructions.

12. Park the veh icle must be on a level sur face.

TRIM HEIGHT ADJUSTMENT

Adjust the trim height (1) by means of the adjusting bolt

on the height control arms.

CAUTION: When adjusting front end alignment, be

sure to begin with trim height first, as it may change

other adjusted alignments.

450RS003

410RS001

1. Check and adjust the tire inflation pressures.

2. Park the vehicle on a level ground and move the

front of the vehicle up and down several times to

settle the suspension.

3. Make necessary adjustment with the adjusting bolt

on the height control arms.

Trim height: 119 ± 5mm (4.69 ± 0.2in)

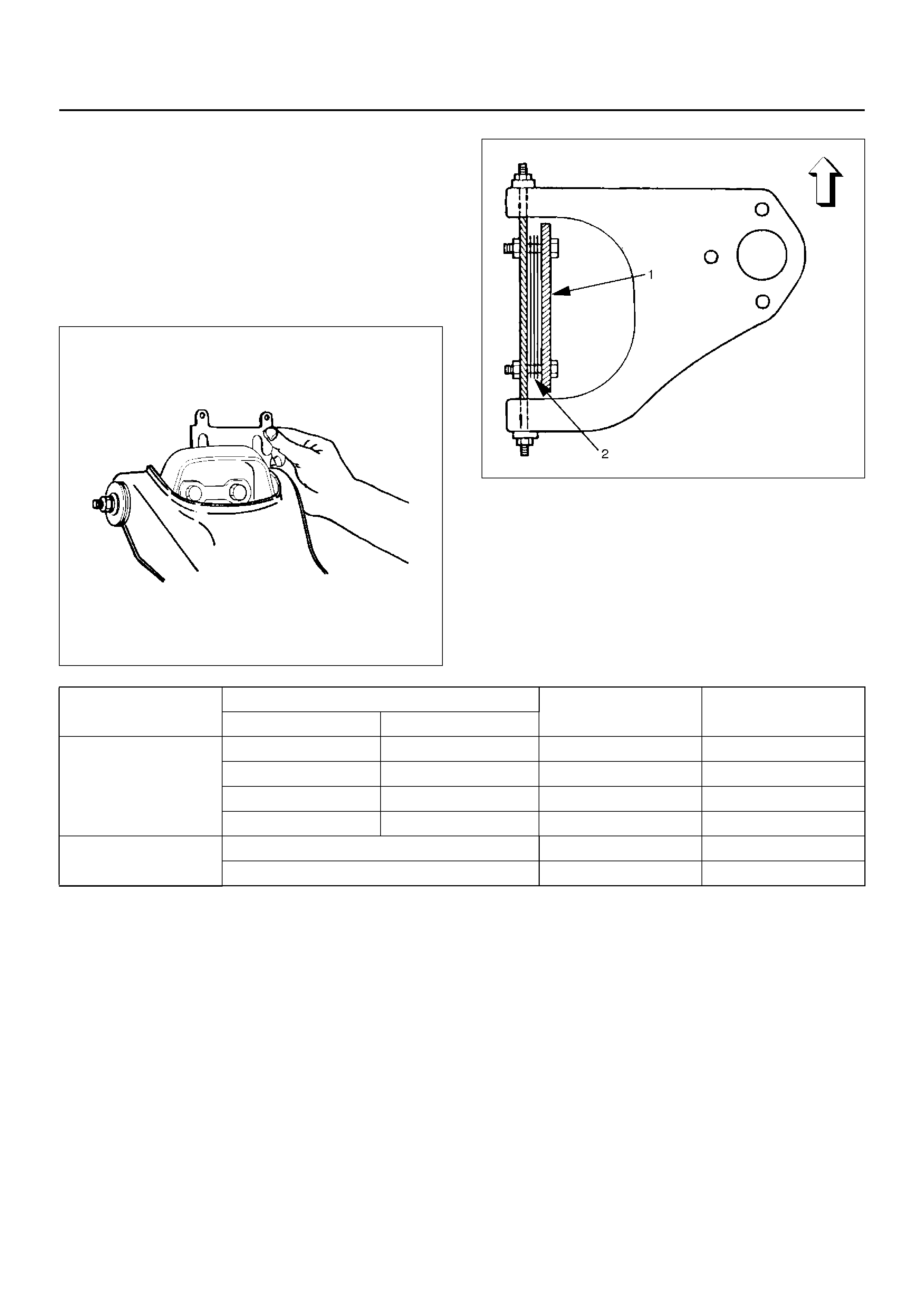

Caster Adjustment

The caster angle can be adjusted by means of the

caster shims (1) installed between the chassis frame

(2) and fulcrum pins.

Caster angle: 2°30' ± 1°

CAUTION: Left and right side must be equal within

30'.

450RW006

450RS002

NOTE: Difference of the caster shim front/rear

thickness should be 3.6mm (0.142in) or less. Overall

thickness of cast er shim and camber shim should be

10.8mm (0.425in) or less.

Tighten the fulcrum pin bolt to the specified torque.

Torque: 152N·m (15.5kg·m/112lbft)

CAMBER ADJUSTMENT

The camber angle can be adjusted by means of the

camber shims (2) installed in position between the

chassis frame (1) and fulcrum pins.

Camber angle: 0° ± 30'

Steering Axis inclination: 12°30' ± 30'

CAUTION: Left and right side must be equal within

30'.

450RW007

450RS005

NOTE: Overall thickness of caster shim and camber

shim should be 10.8mm (0.425in) or less.

Tighten the fulcrum pin bolt to the specified torque.

Torque: 152N·m (15.5kg·m/112lbft)

Position of shims Camber angle Caster angle

Front side Rear side

Caster shim

When added When removed Dec reas es Decreases

When removed When added Increases Increases

— When removed Unchanged Decreases

— When added Unchanged Increases

Camber shim When added Decreases Unchanged

When removed Increases Unchanged

Toe-in Adjustment

1. To adjust the toe-in angle, loosen the lock nuts (2)

on the tie rod (1) and turn the tie rod. Turn both rods

the same amount, to keep the steering wheel

centered .

Toe-in: 0 to +2mm (0 to +0.08in)

433RW006

2. Tighten the lock nut to the specified torque.

Torque: 98N·m (10.0kg·m/72lbft)

MAIN DATA AND SPECIFICATIONS

General Specification

Caster 2°30' ± 1°

Camber 0° ± 30'

Steering Axis Inclination 12°30' ± 30'

Toe-in 1mm ± 1mm

Max. ste erin g angle insid e 32.6° (+0°30' to –2°30' )

outside 31.8°

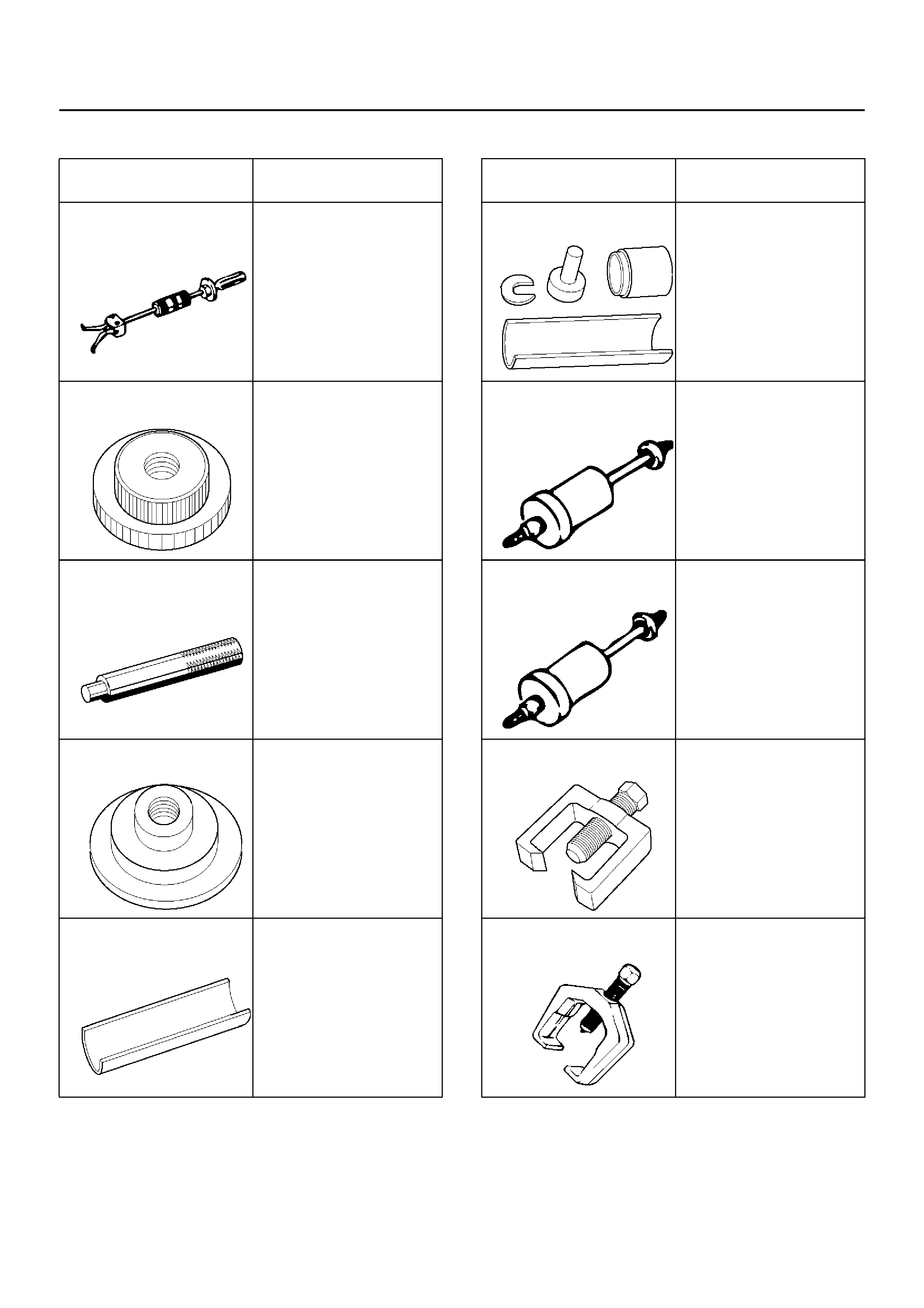

SPECIAL TOOLS

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–2000–0

(J–23907)

Remover;Needle bearing

5–8840–0019–0

Sliding hammer

5–8840–2128–0

(J–36838)

Installer; Needle bearing

5–8840–0007–0

(J–8092)

Grip

5–8840–2127–0

(J–36837)

Installer; Oil seal

5–8840–2307–0

(J–39376)

Installer; Uppe r arm

bushing

5–8840–0256–0

(J–29775)

Remover and Installer

Upper arm bush in g

5–8840–2123–0

(J–36833)

Remover and Installer kit;

Lower arm front bushing

5–8840–2124–0

(J–36834)

Remover and Installer kit;

Lower arm rear bushing

5–8840–2121–0

(J–36831)

Ball joint remover

5–8840–2005–0

(J–29107)

Tie-rod end rem over

ILLUSTRATION TOOL NO.

TOOL NAME